Patents

Literature

2280results about How to "Reduce quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

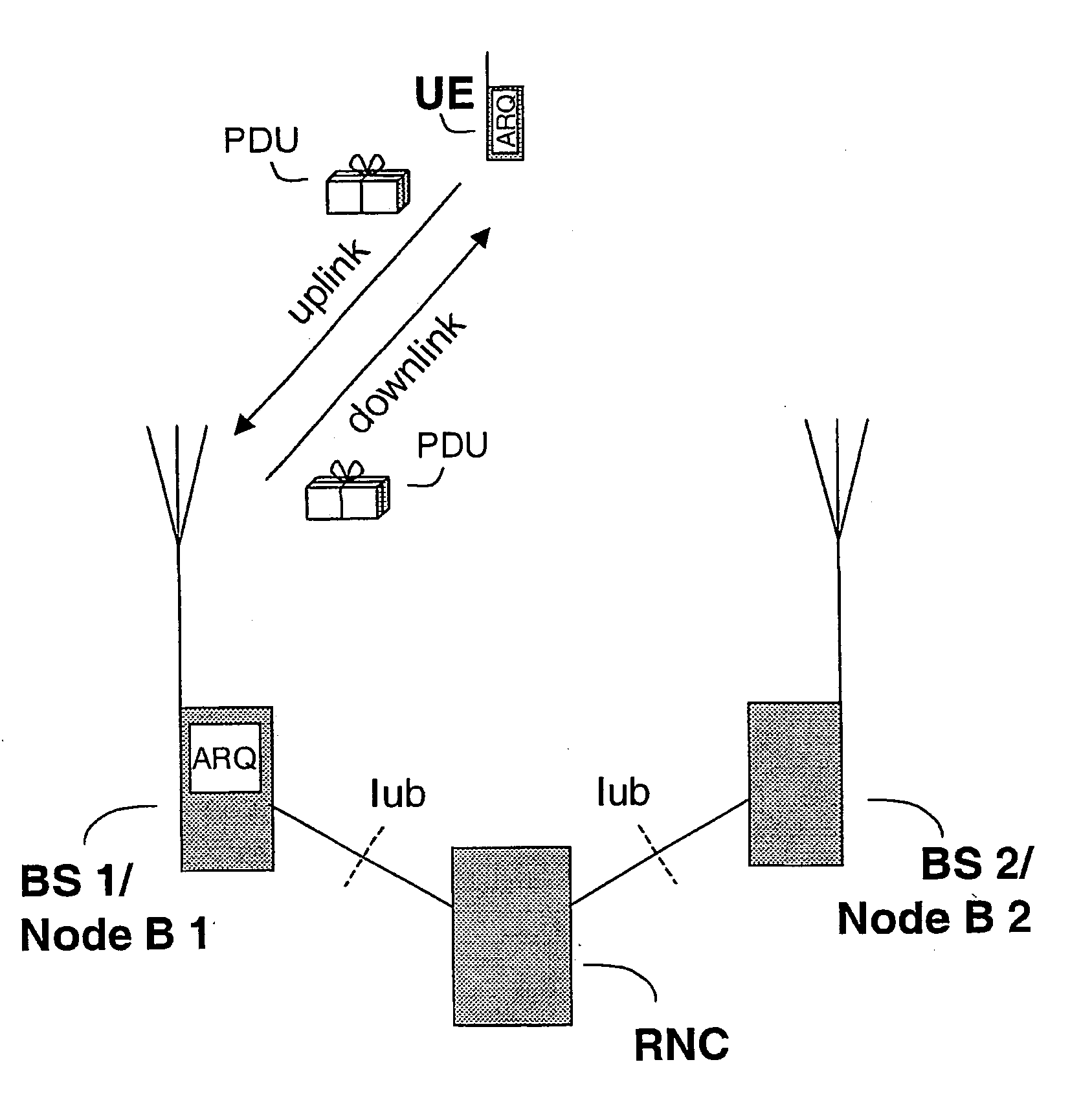

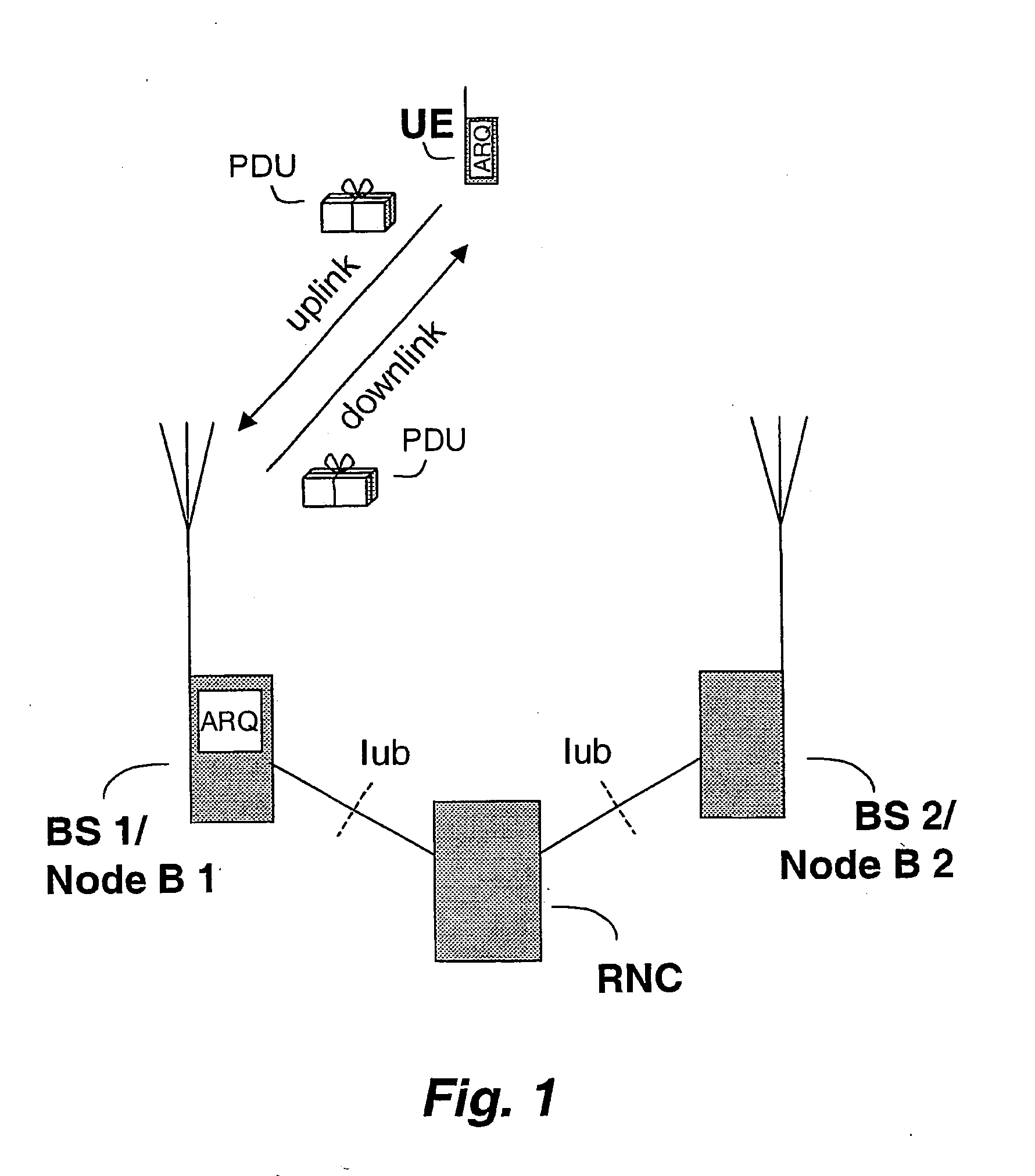

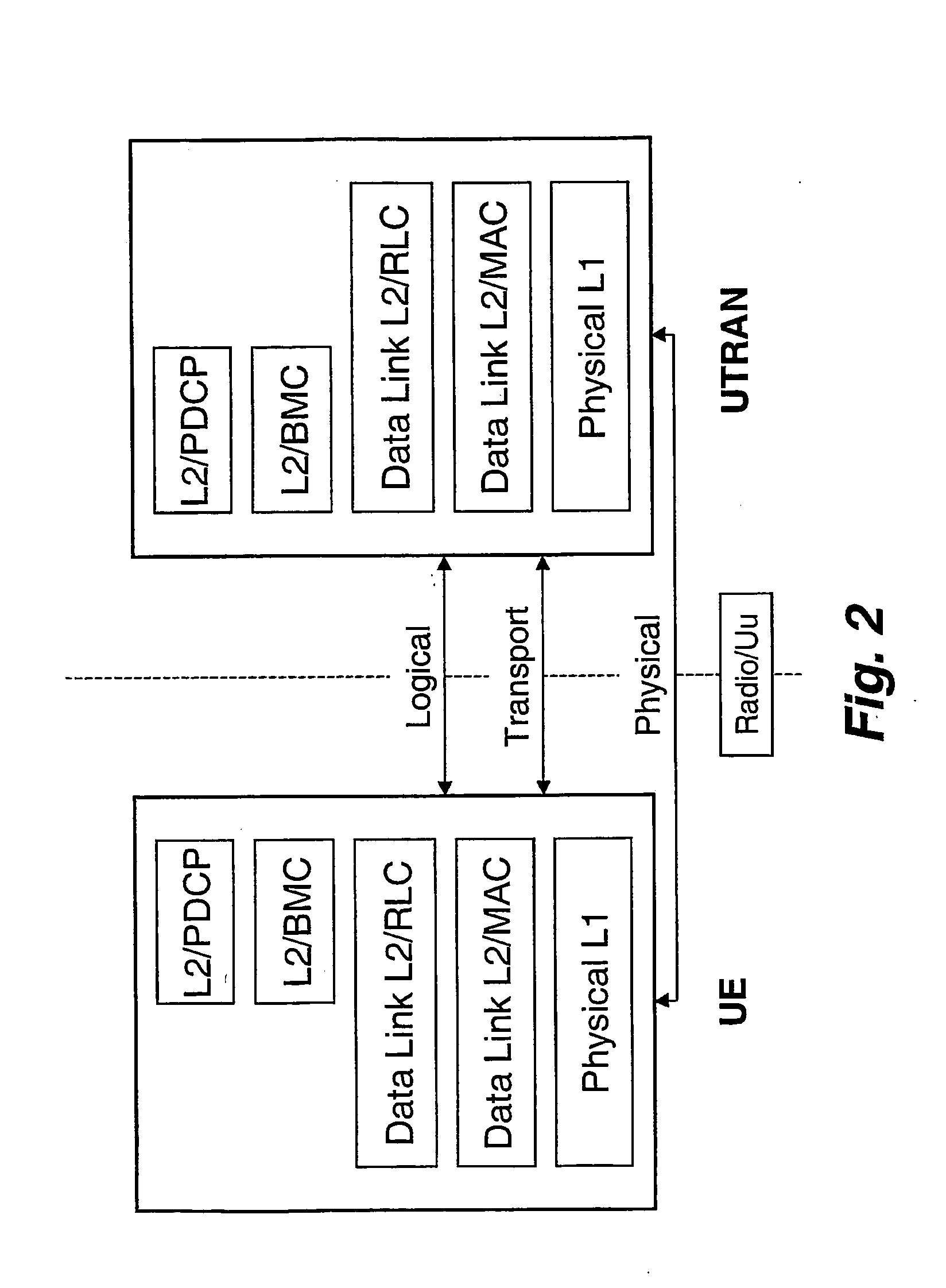

Method and system of retransmission

InactiveUS20050039101A1Reduce qualityImprove system performanceError prevention/detection by using return channelNetwork traffic/resource managementRadio Network ControllerCommunications system

The present invention relates to a method and system of transmissions and retransmissions of packet data in a communications system, introducing concatenated ARQ loops between a radio network controller and a user equipment. Particularly, the invention relates to a Universal Mobile Telecommunications System, UMTS, or WCDMA system.

Owner:TELEFON AB LM ERICSSON (PUBL)

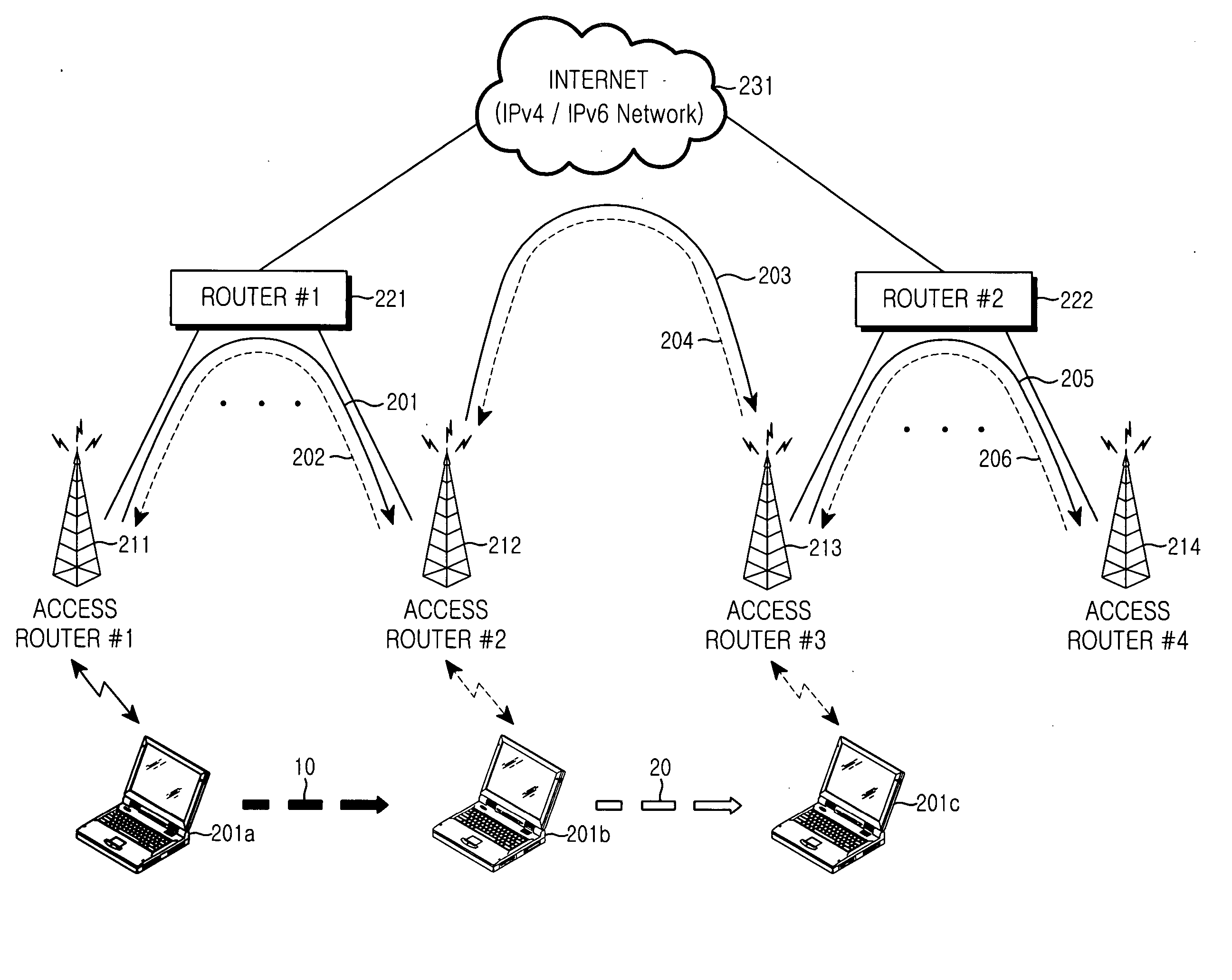

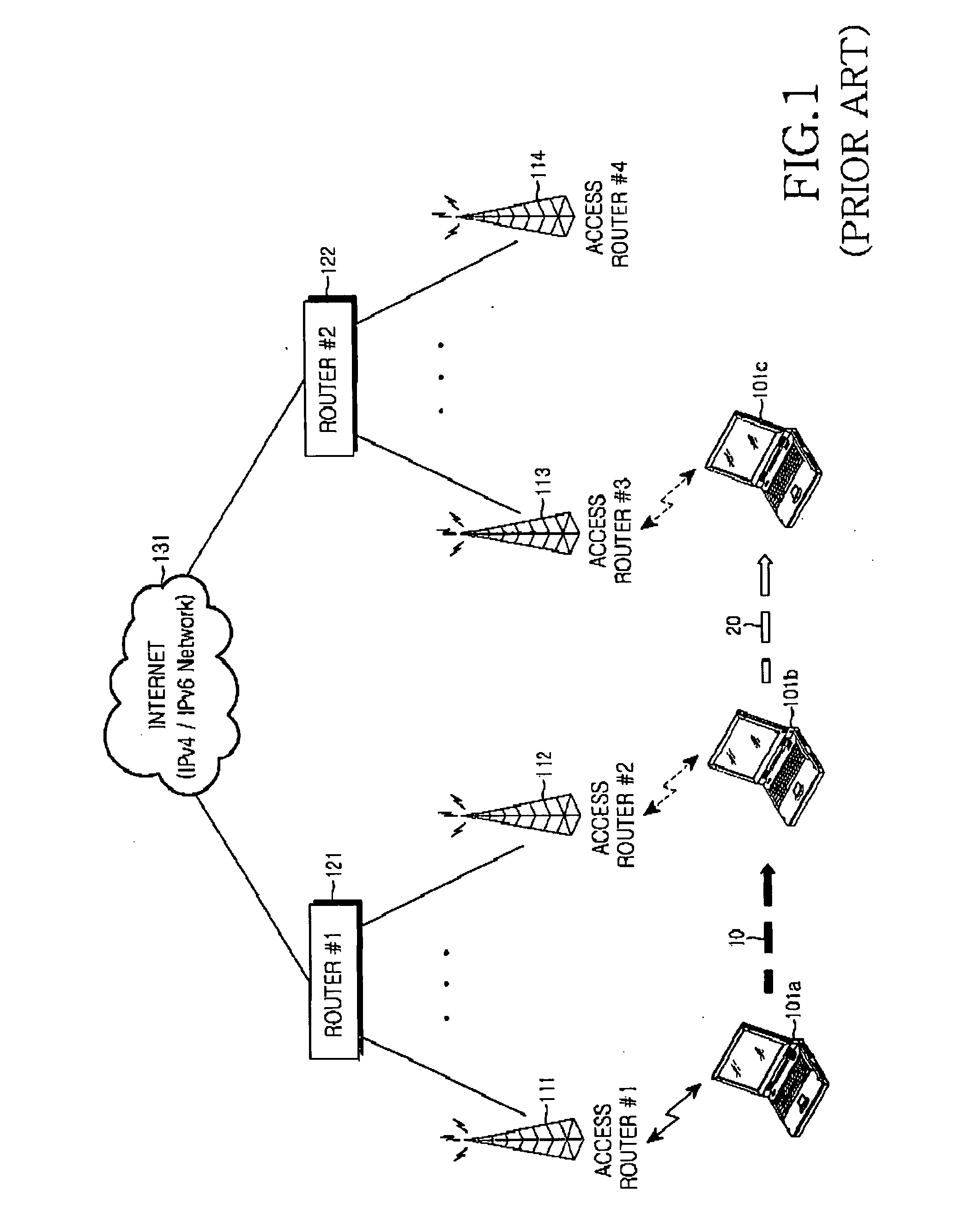

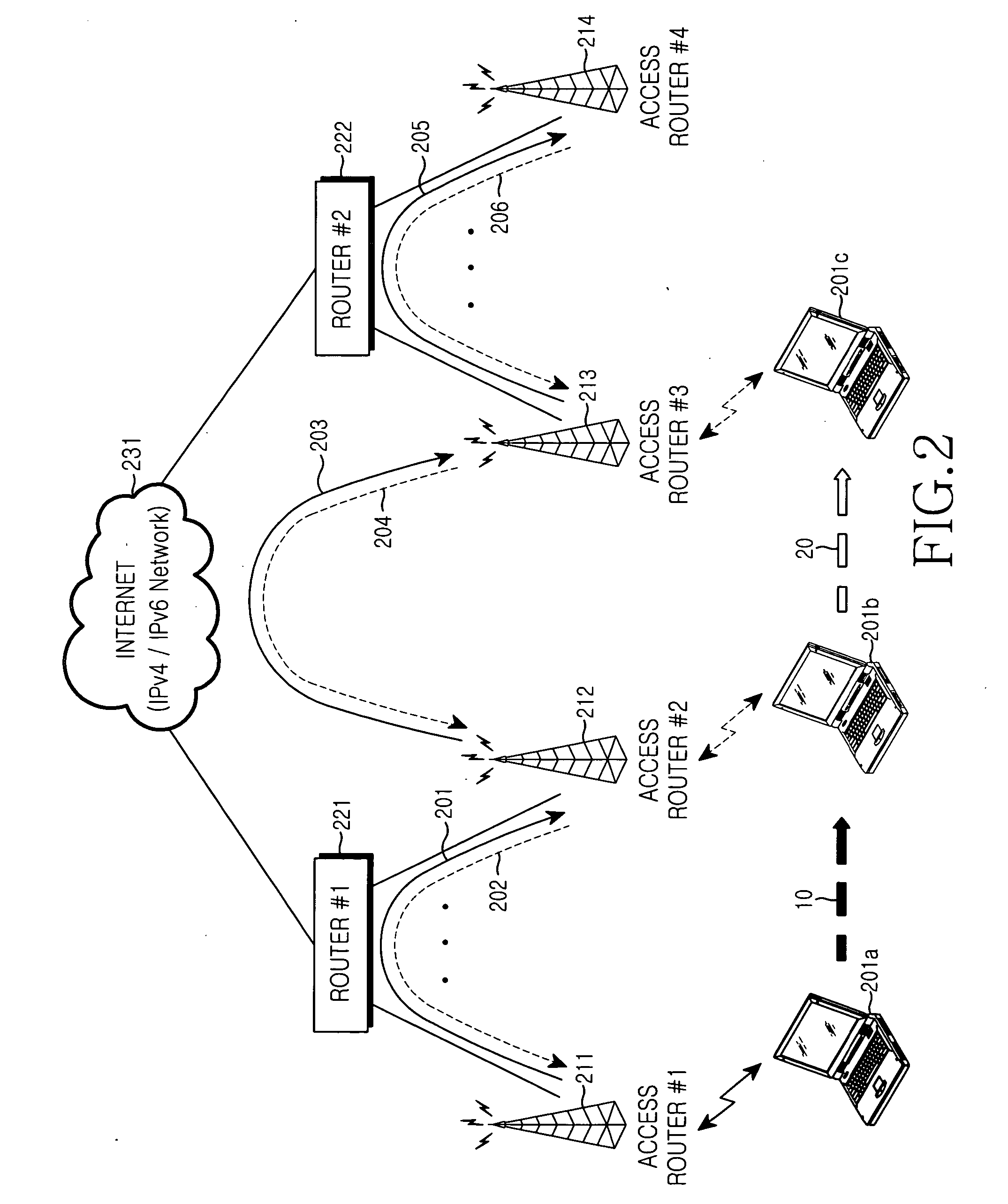

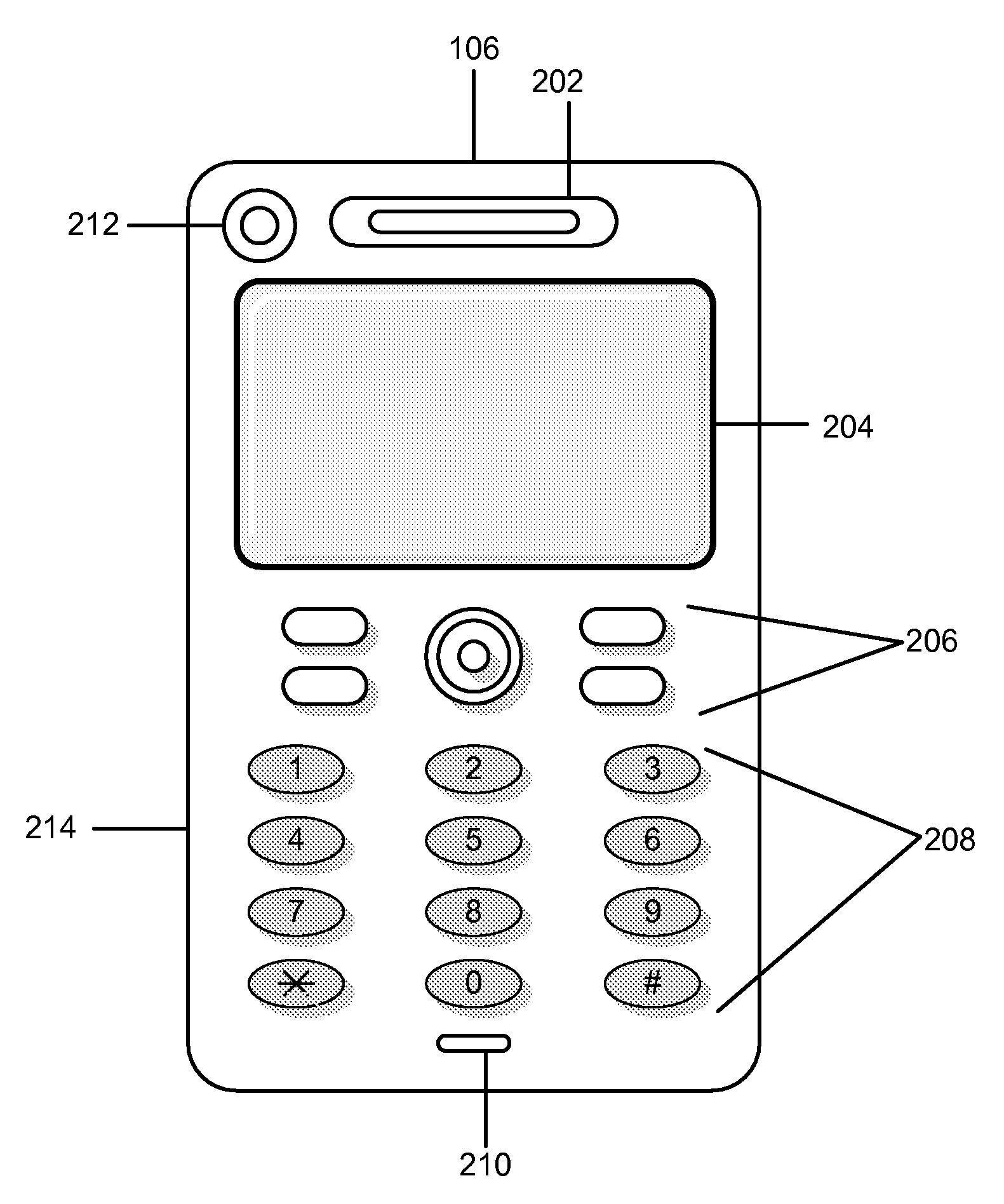

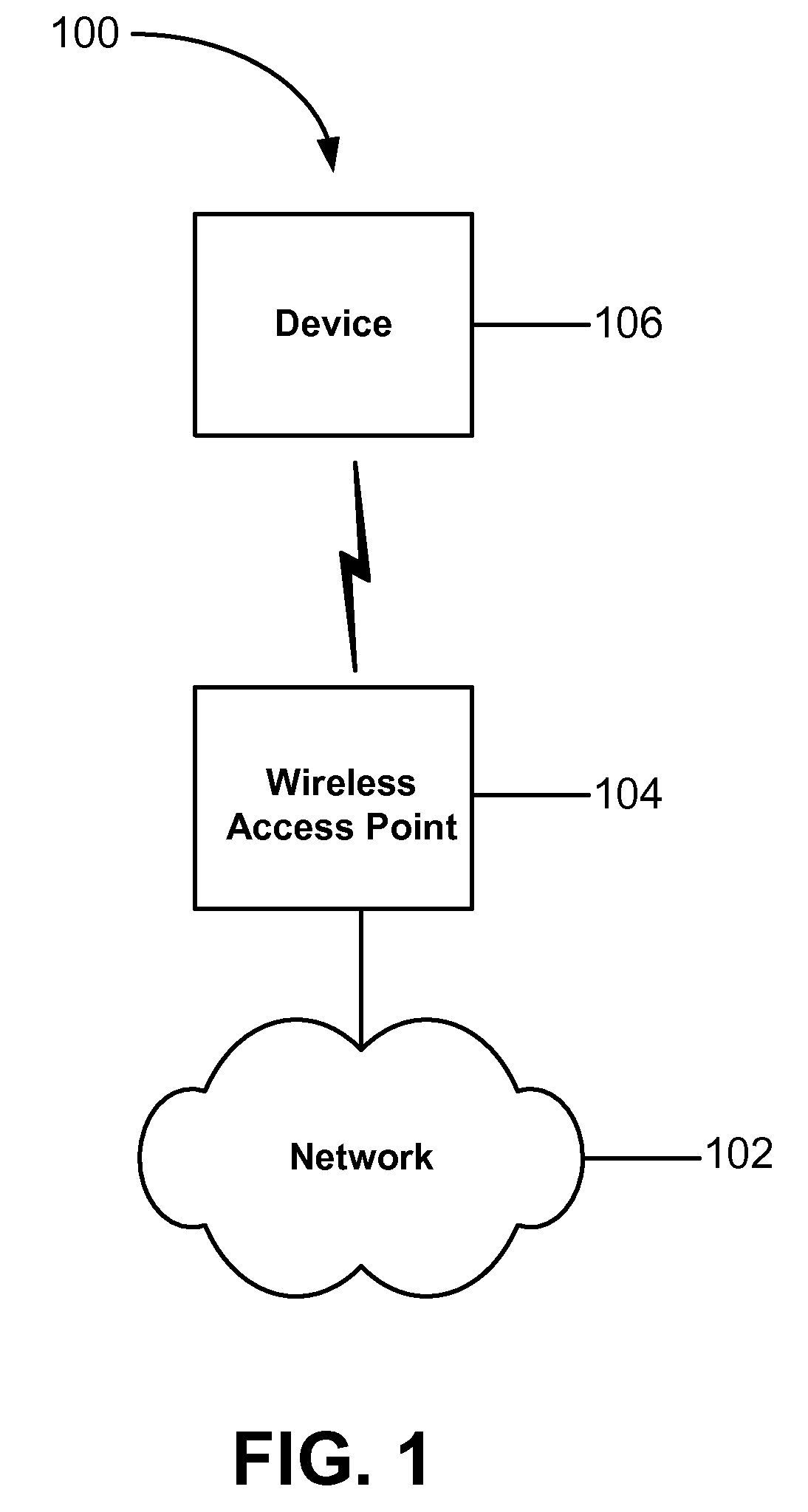

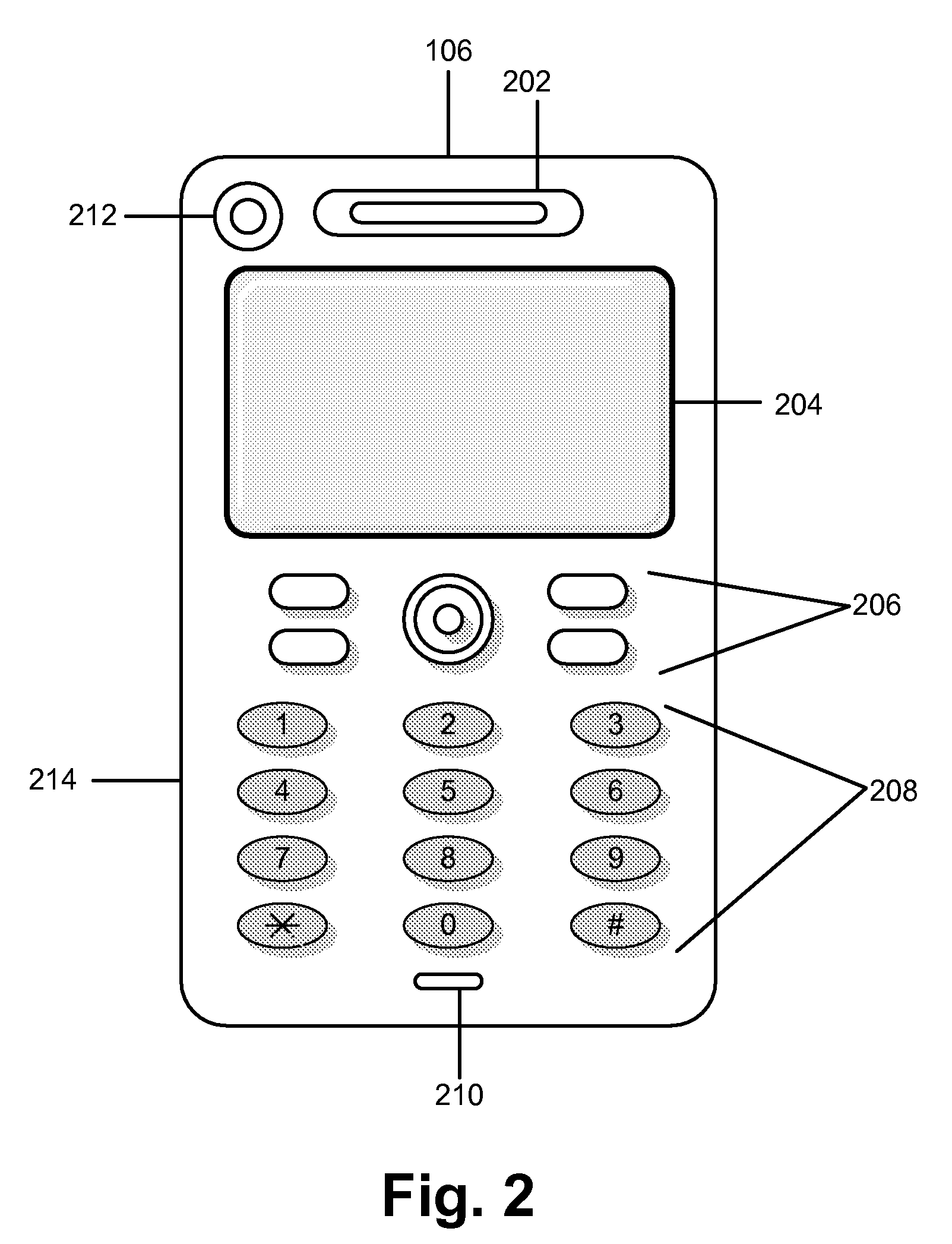

System and method for providing handover of a mobile IP terminal in a wireless network

ActiveUS20050163080A1Longer battery timeReduce qualityAssess restrictionNetwork topologiesMIP protocolMobile internet

Disclosed is a system for providing handover of a mobile node in a wireless network supporting Mobile IP (Internet Protocol). The mobile node sends, when handover is needed, a request for neighbor access router information to a first access router currently communicating with the mobile node, and selects, if the neighbor access router information is received, a second access router serving as a target access router using the received neighbor access router information. The first access router exchanges access router information with a neighbor access router, provides neighbor access router information to the mobile node upon receiving the neighbor access router information request from the mobile node, and redirects data to be delivered to the mobile node to the second access router to which the mobile node will be handed over. The second access router forwards data to be delivered to the mobile node, received from the first access router, to the corresponding mobile node.

Owner:POSTECH ACAD IND FOUND

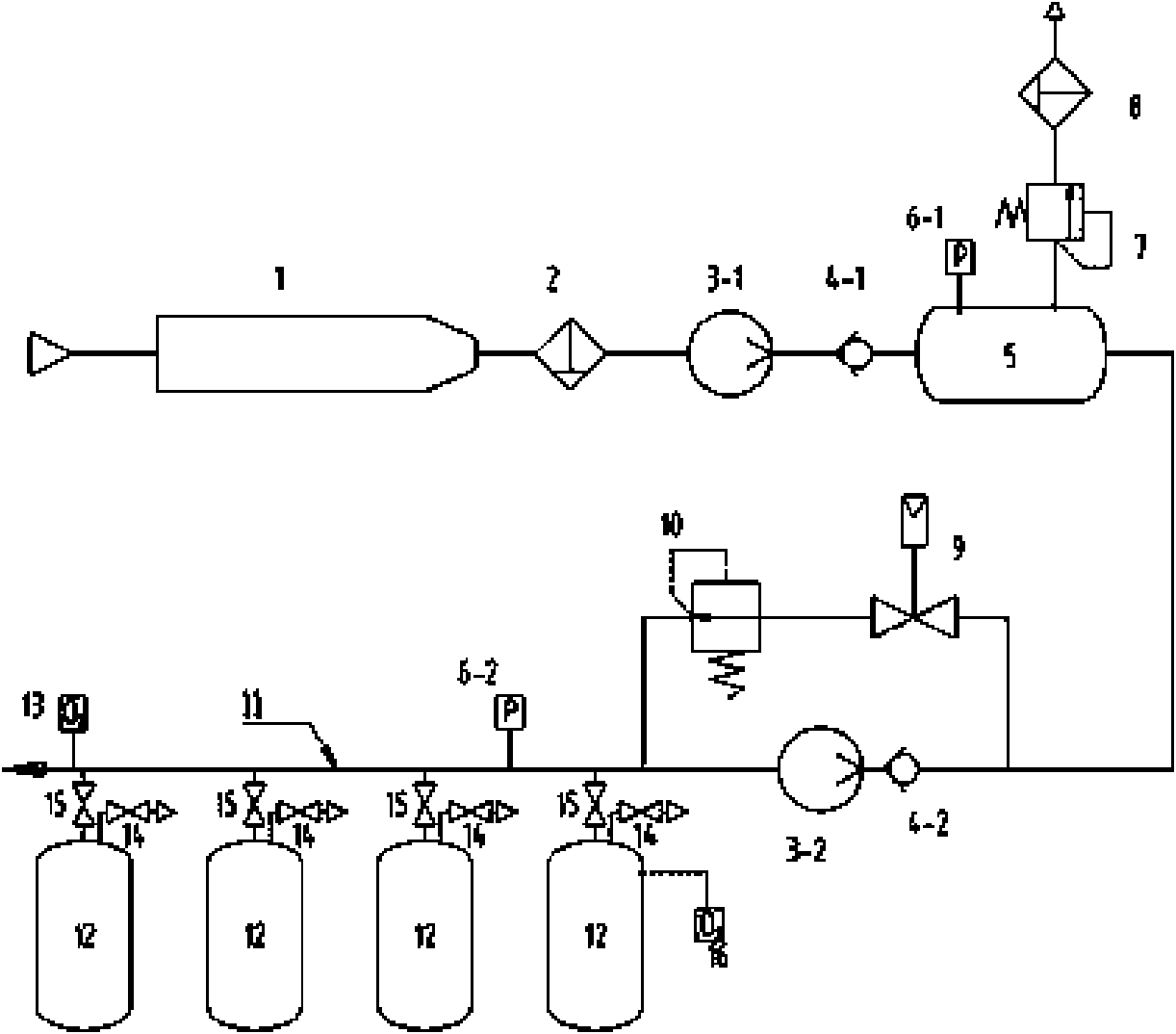

Intrinsically safe inerting protection method and device for oil storage tank

ActiveCN101767697ARealize security protectionImprove real-time performanceLarge containersPipeline systemsEngineeringLimit value

The invention discloses an intrinsically safe inerting protection method and an intrinsically safe inerting protection device for an oil storage tank, relates to a method and a device for active fire and explosion prevention of the oil storage tank, and aims to solve the problem of fire and explosion prevention of the oil storage tank. The method comprises the following steps: a, performing inerting on each oil tank in sequence to ensure that each oil tank achieves an inexplosive condition, namely, the oxygen concentration of gas in the tank is lower than 10 percent; b, detecting the pressure of a pipe network for supplying inert gas to the oil tank, and supplying the inert gas to the pipe network and inputting the inert gas to the oil tank through the pipe network if the pressure is lower than a set lower limit value; c, detecting the pressure of the pipe network for supplying the inert gas to the oil tank, emitting the inert gas in the pipe network if the pressure exceeds a set upper limit value; and d, detecting the oxygen concentration in the pipe network for supplying the inert gas to the oil tank, and repeating the step a if the concentration exceeds the set upper limit value. The device comprises a buffer device, a breathing pipe network, a first pressure transmitter, a second pressure transmitter, an online oxygen analyzer and an electric control device.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA +1

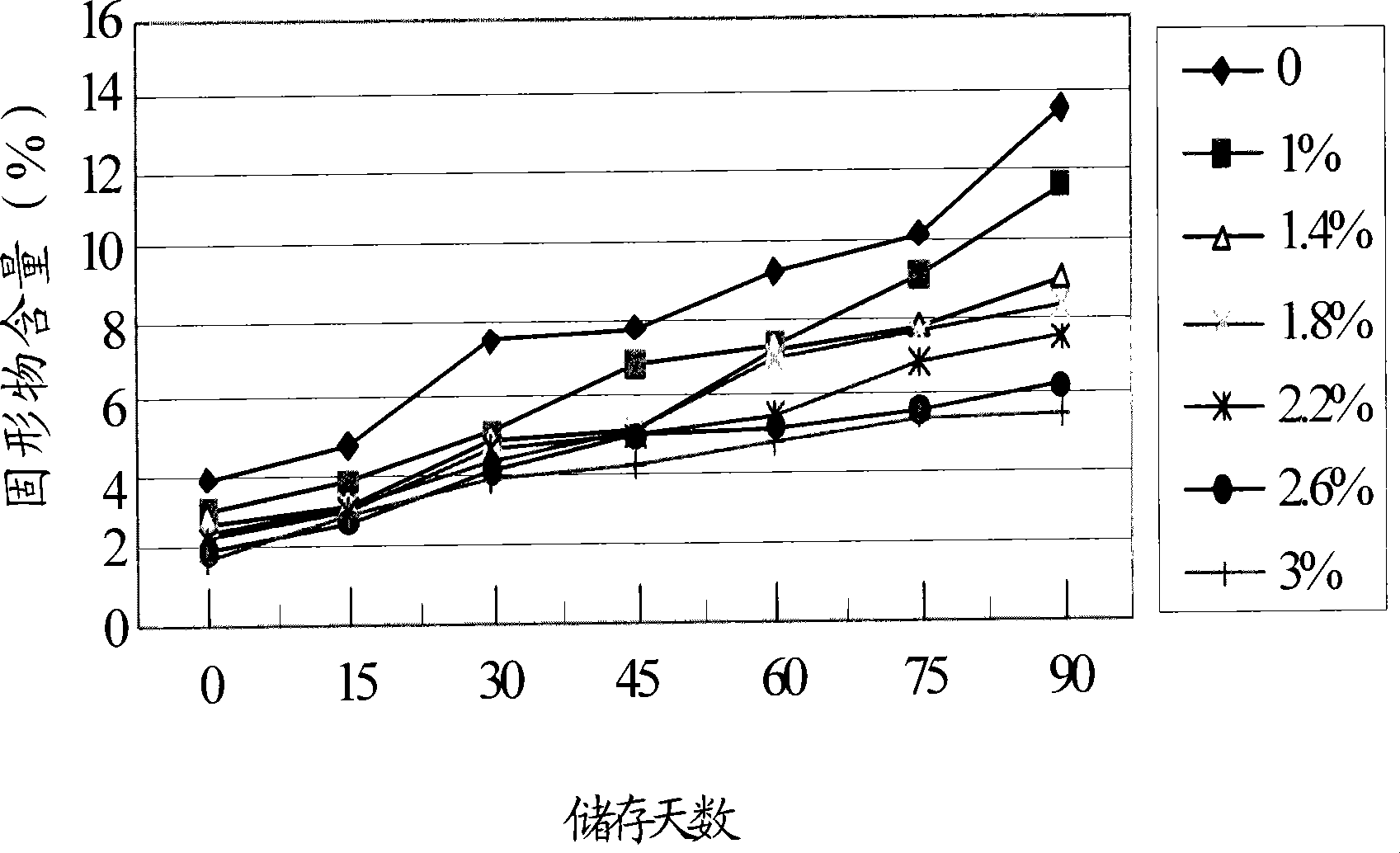

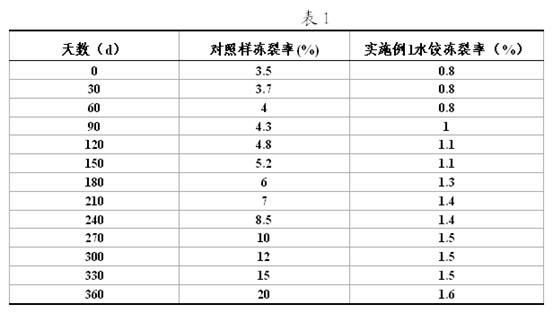

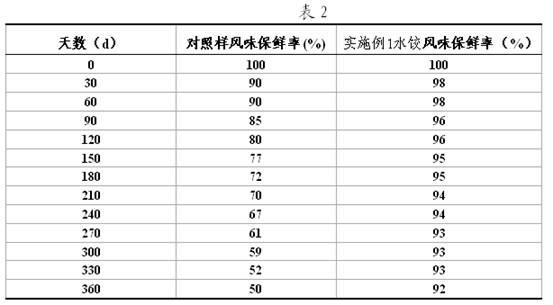

Quick-freezing cooked wheaten food improver and flour, quick-freezing dumpling, noodle and ravioli containing the same

The invention relates to a modifying agent for fast-freezing wheaten food, which contains: (A) 20 to 50 weight portions of sorbierite; (B) at least one kind of 3.5 to 20 weight portions of a thickening agent; (C) at least one kind of 10.2 to 55 weight portions of a flour gluten fortifier; and (D) at least one kind of 10.5 to 38 weight portions of phosphate. A finished product of the fast-freezing wheaten food containing the modifying agent has the skin which is difficult to crack and change color, has good water boiling performance, prolongs freshness period, and has the advantages of bright skin, smooth taste, good elasticity, and no soup turbidness at the same time. And the modifying agent has the advantages of low price and so on.

Owner:ANGELYEAST CO LTD

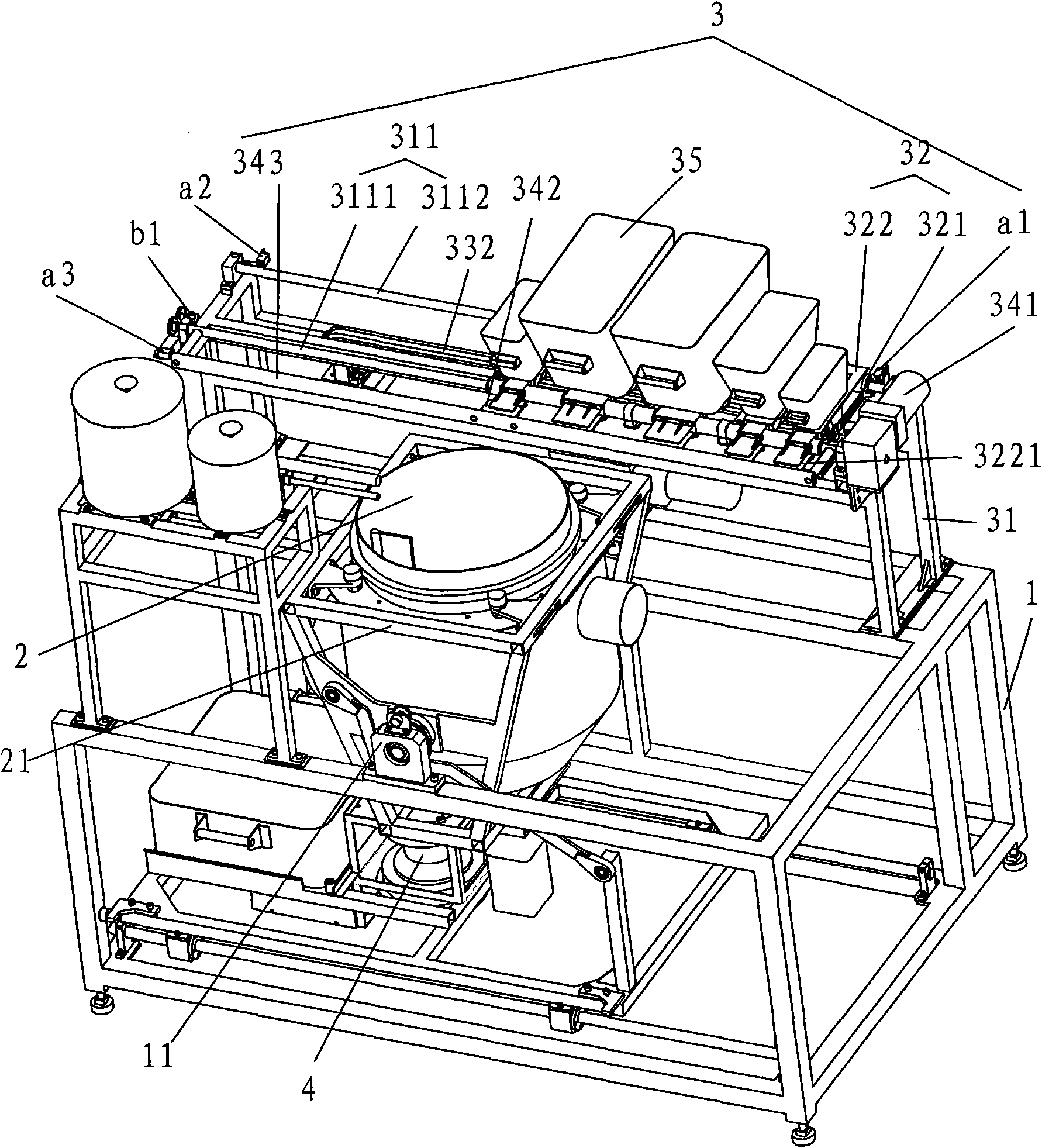

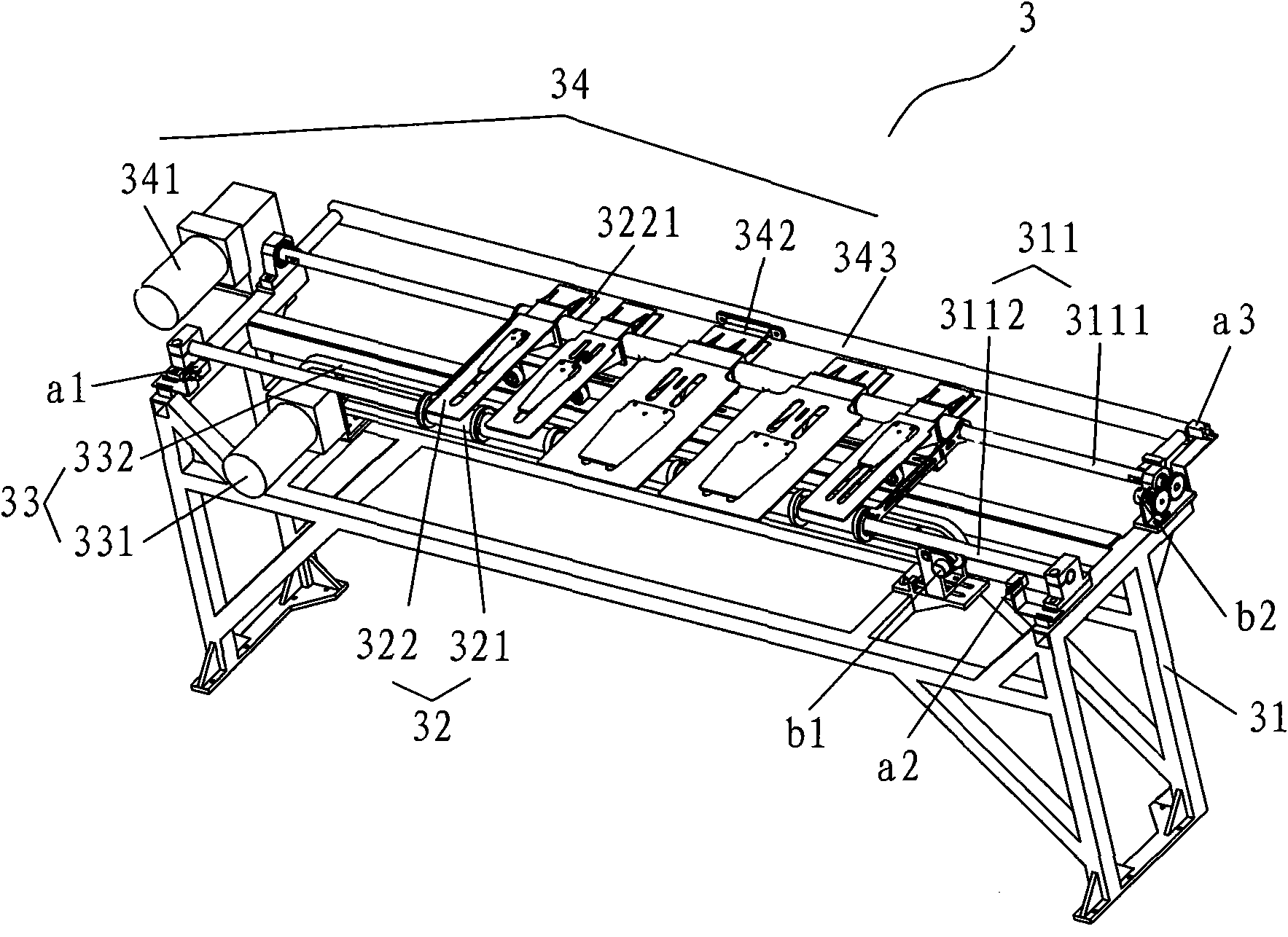

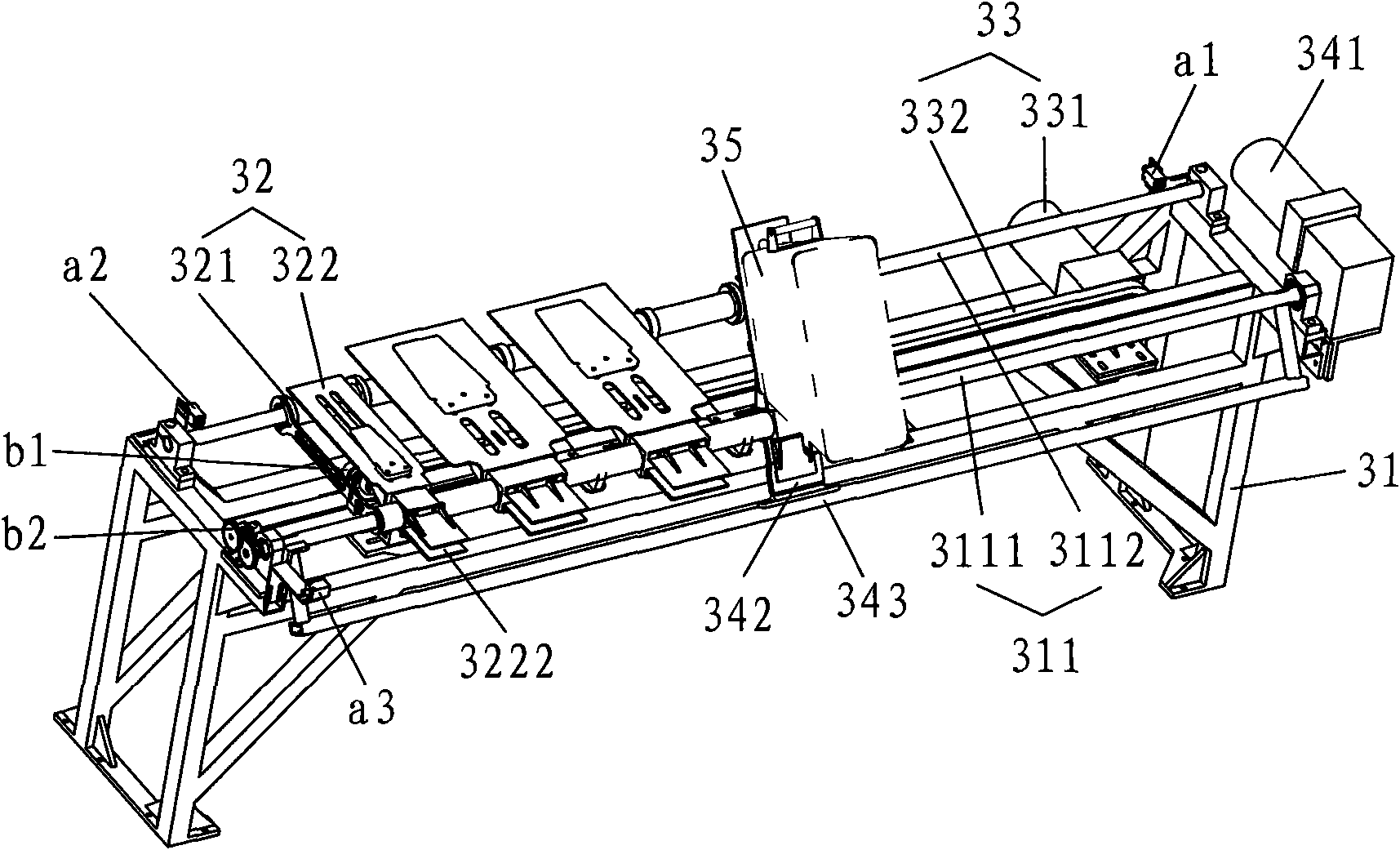

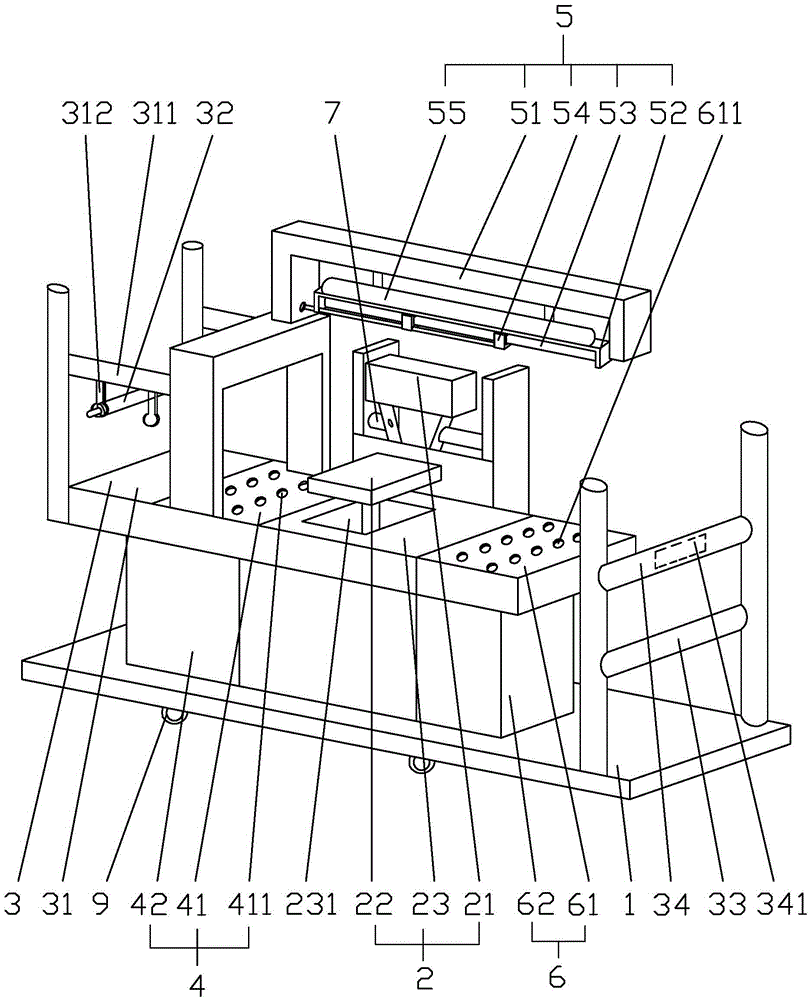

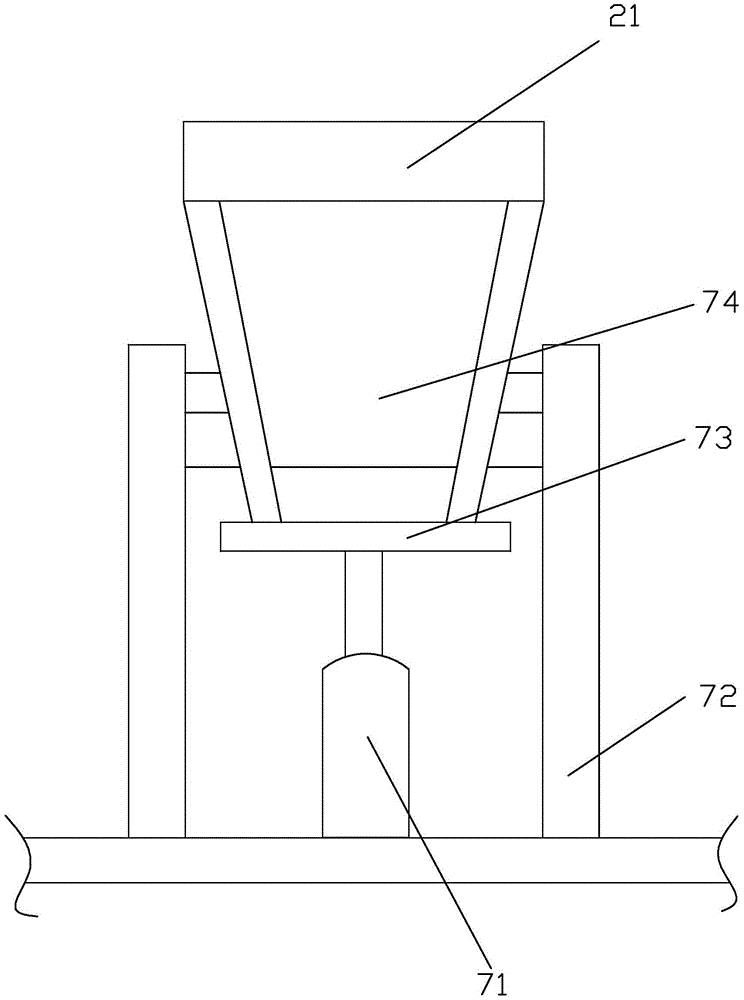

Automatic or semi-automatic cooking equipment and batch charging mechanism thereof

InactiveCN101683236AReasonable structureImprove accuracyBoiling over preventionVessels with intergral heatingEngineeringElectrical and Electronics engineering

The invention relates to automatic or semi-automatic cooking equipment and a batch charging mechanism thereof; the cooking equipment comprises a machine rack, a pot body, a batch charging mechanism, aheating device and a controller; the batch charging mechanism comprises a bracket and a locating mechanism, the locating mechanism is arranged on the bracket for installing a material case; furthermore, a translation mechanism and a turnover mechanism are arranged on the bracket, the translation mechanism carries out moving action of the locating mechanism, and the turnover mechanism carried outrotating and batch charging actions of the material case. The invention has the beneficial effects that: the structure is rational, various materials needed by one dish can be combined together according to the batch charging requirements, and charging is carried out sequentially according to cooing techniques, so as to easily realize intelligent automation or partial automatic charging of the materials for cooking and greatly improve the charging time, position and parts of the materials accurately; the labor intensity is reduced, the efficiency is improved and the quality of dishes can be effectively ensured.

Owner:AIC ROBOTICS TECH

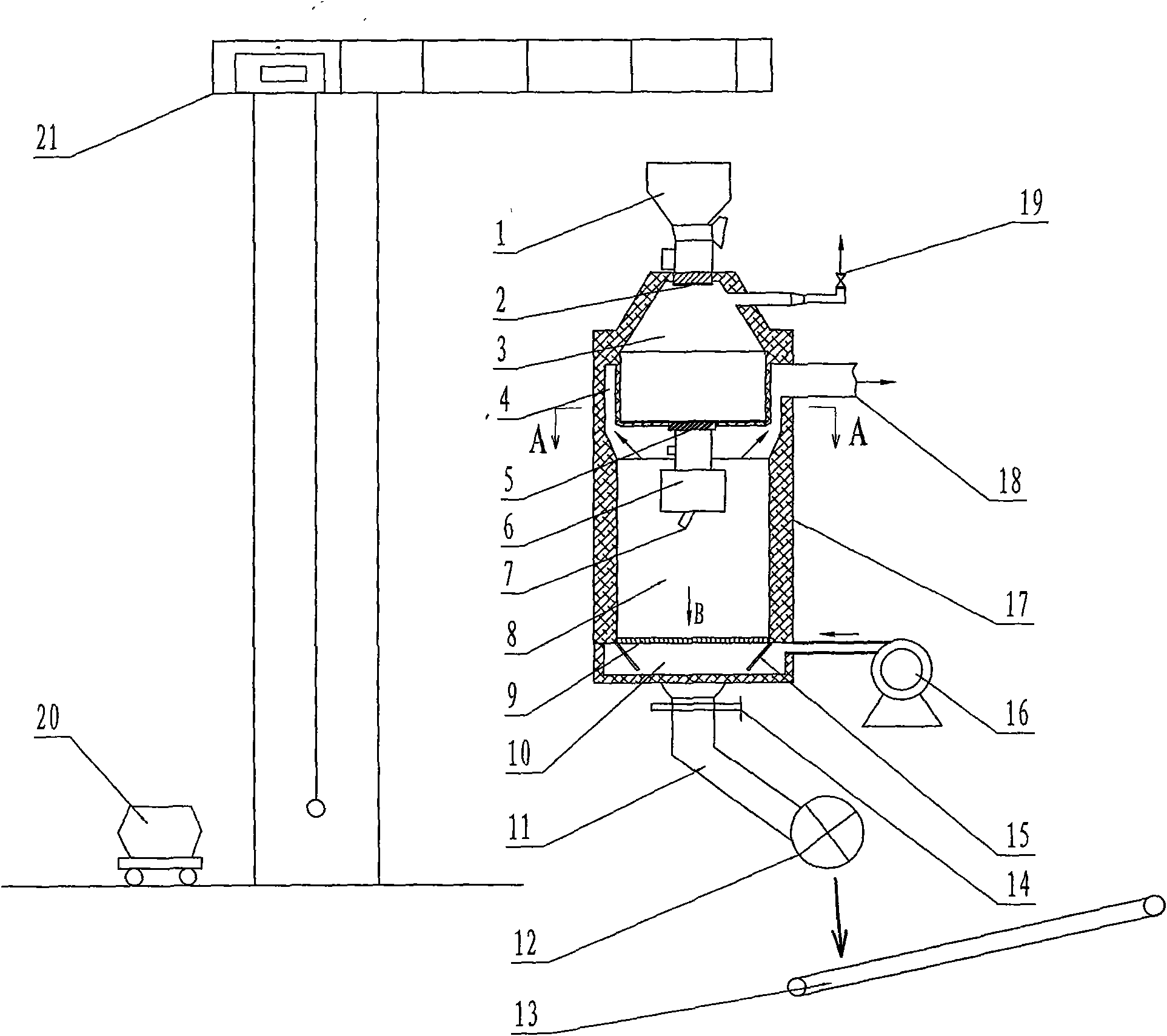

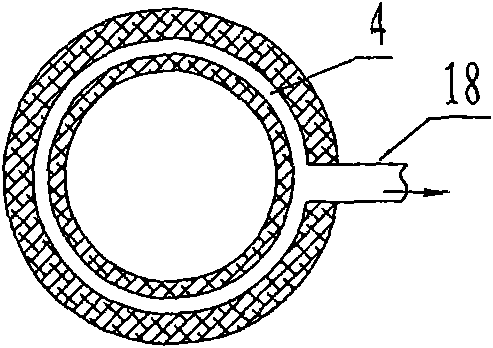

Vertical sinter ore cooling machine capable of efficiently recycling sensible heat of sinter ores

InactiveCN101576351AReduce heat transfer temperature differenceRaise the gradeIncreasing energy efficiencyHandling discharged materialGas solidMaterials science

The invention discloses a vertical sinter ore cooling machine capable of efficiently recycling the sensible heat of sinter ores, which pertains to the technical field of sintering equipment and is used for preventing air leak in the cooling course of sinter ores and effectively recycling the sensible heat of the sinter ores. The technical proposal of the invention is that: the cooling machine consists of a feeding part, a cooling part and a conveying part; the cooling part comprises a vertical closed body, a hot wind pipeline, a blower, as well as a hopper, an upper sealing valve, a pre-storing chamber, a lower sealing valve, a heat exchanging chamber, a wind distributing board, an isopiestic wind chamber and a discharging channel which are in sequence arranged on the body from top to bottom; an annular wind chamber is arranged between the pre-storing chamber and the heat exchanging chamber; the annular wind chamber is communicated with the hot wind pipeline; the isopiestic wind chamber is communicated with the blower; and wind shields and ore falling openings are distributed evenly on the wind distributing board . The vertical sinter ore cooling machine has the following advantages of: 1. an air leak rate near to 0; 2. improved gas-solid heat exchange efficiency of the cooling machine; 3. raised quality of the recycled hot air; and 4. being beneficial to increasing the utilization rate of exhaust-heat boilers. Based on the advantages, the vertical sinter ore cooling machine is expected to be used commonly as an upgraded replacement of the existing sinter cooling machine.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

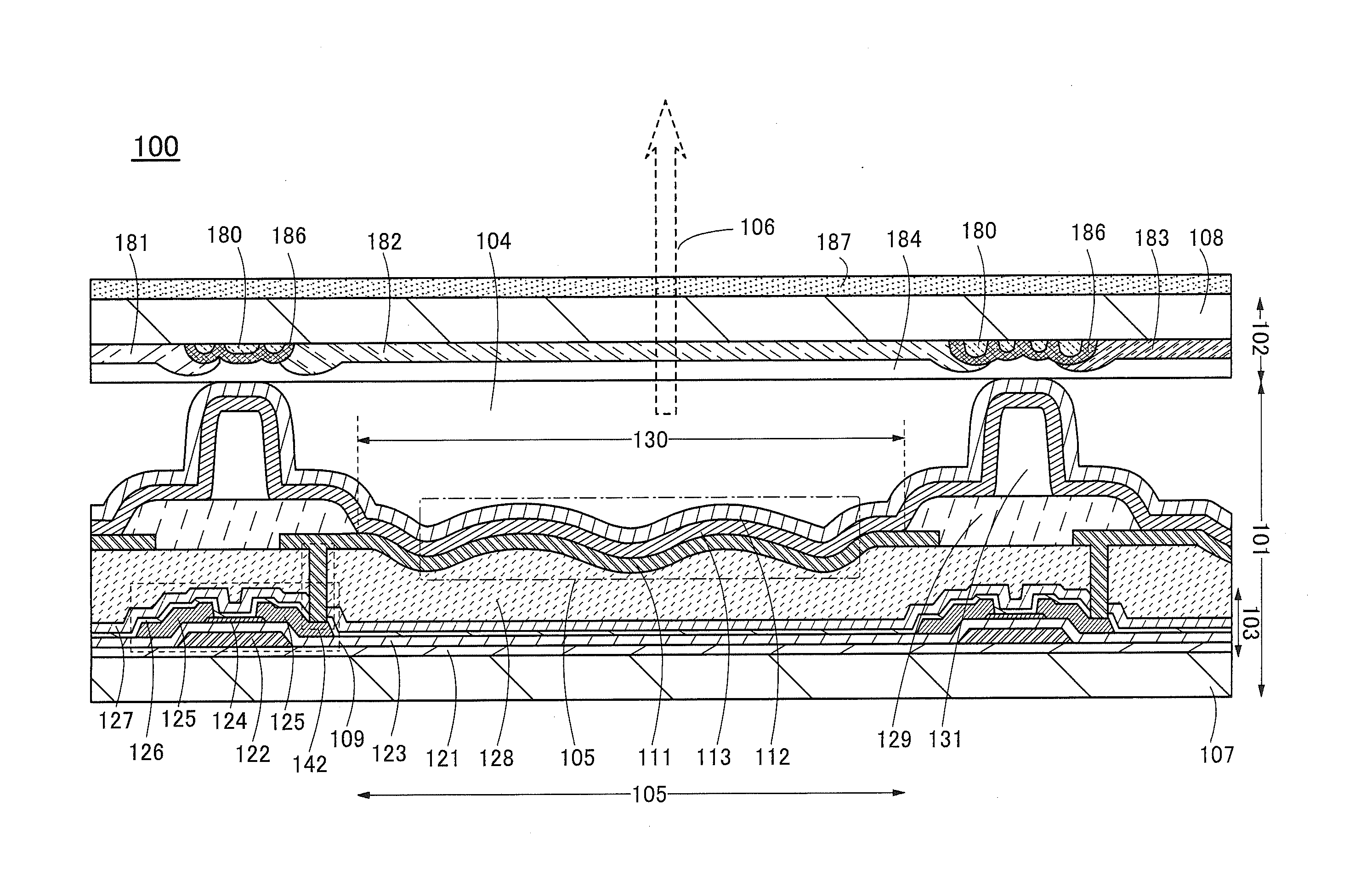

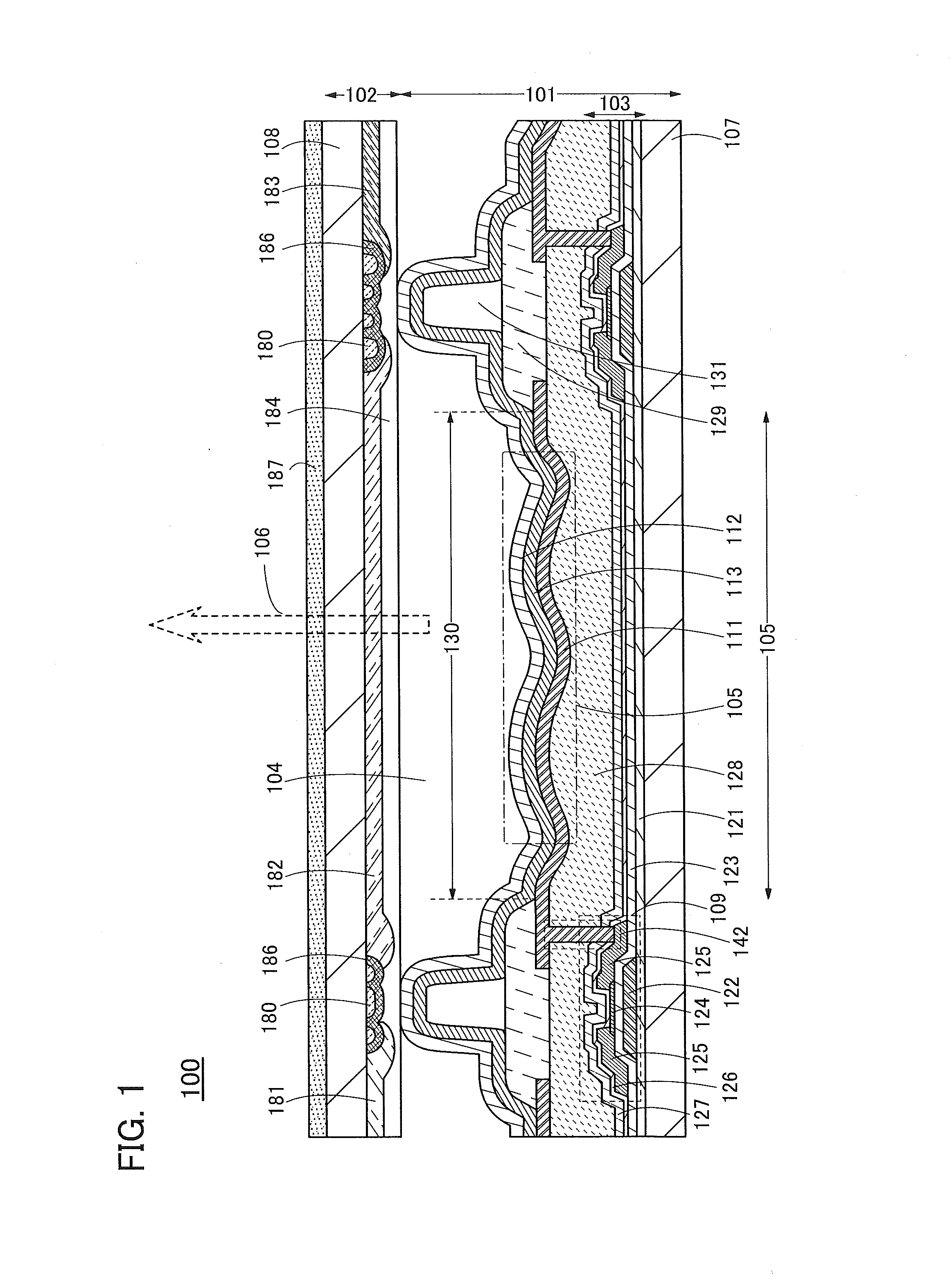

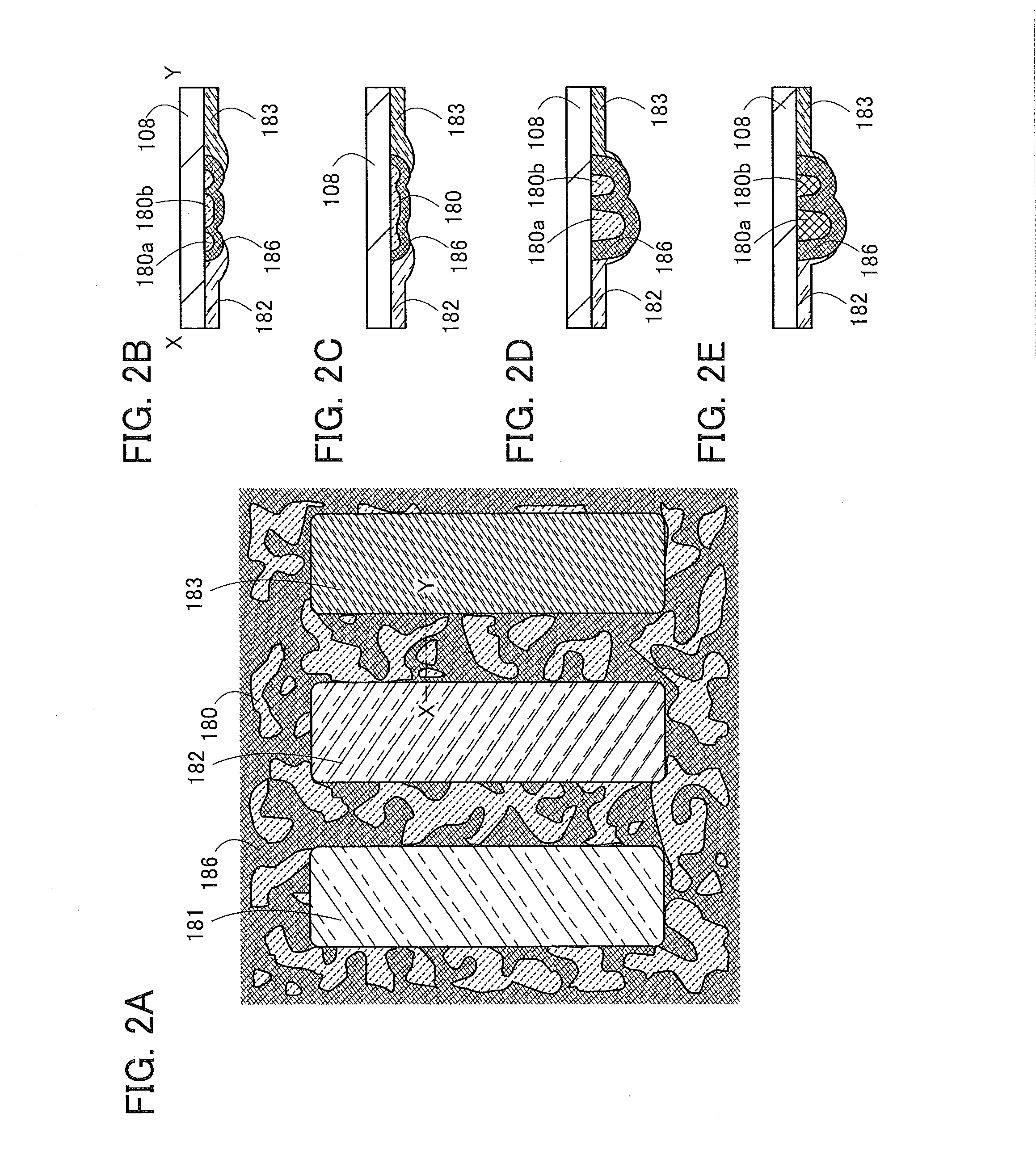

Display Device

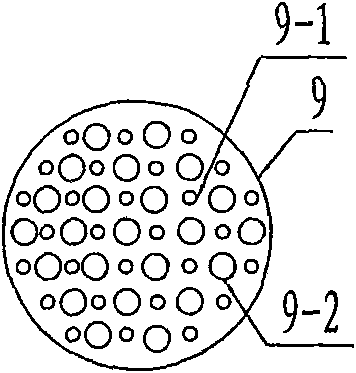

ActiveUS20150362776A1Reduce qualityIncrease of surface irregularityPrinted circuit aspectsSolid-state devicesInput/outputEngineering

Provided is a display device or an input / output device in which reflection of outside light is reduced. The display device includes a first substrate and a second substrate. The first substrate includes a first surface. A transistor is over the first surface. The second substrate includes a second surface. A first structure having a projection, a second structure having a projection, a black matrix covering the first structure and the second structure, and a color filter are over the second surface. The first surface faces the second surface. The black matrix has a plurality of projections reflecting the projection of the first structure and the projection of the second structure. A planar shape of the first structure is different from a planar shape of the second structure.

Owner:SEMICON ENERGY LAB CO LTD

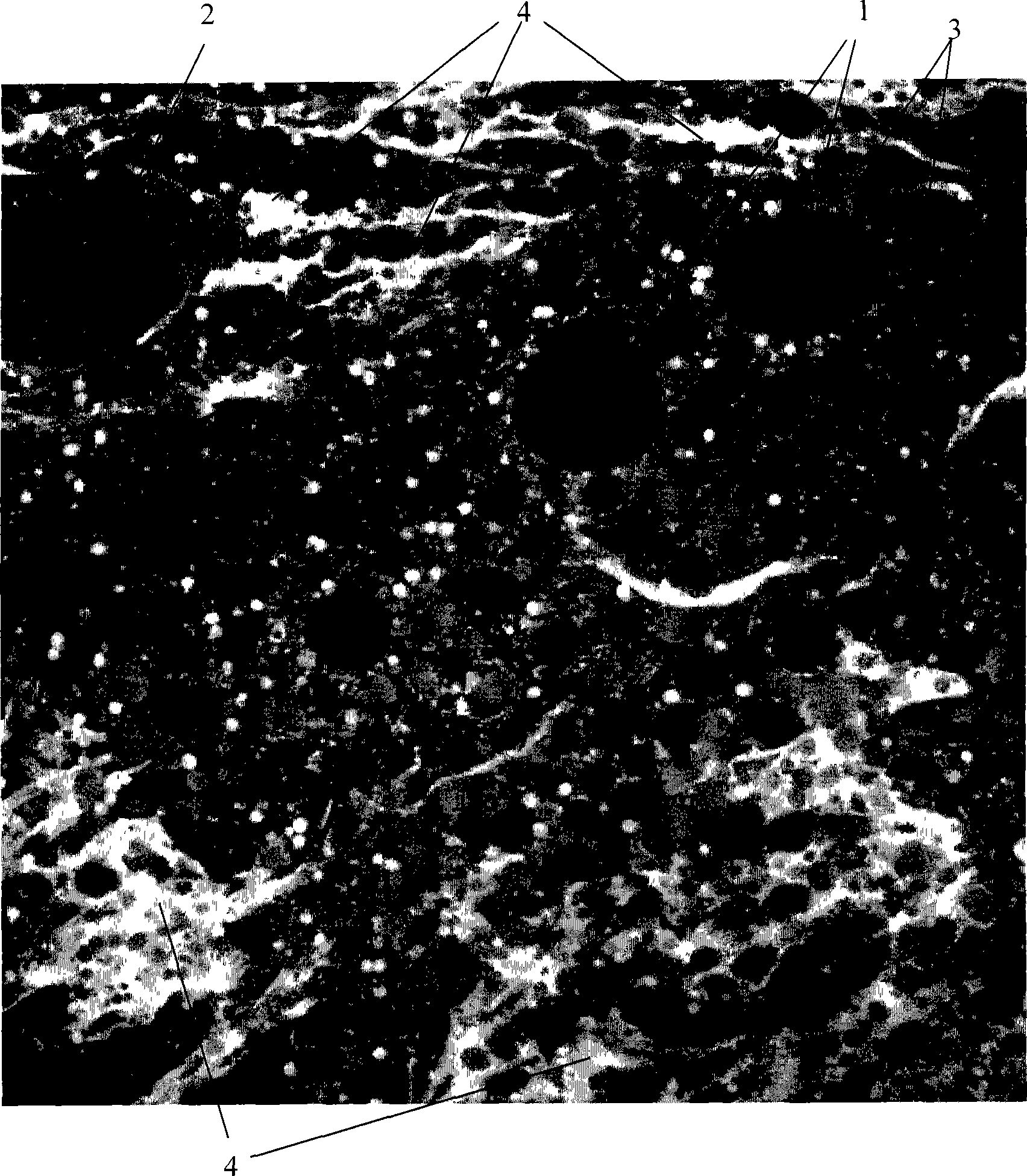

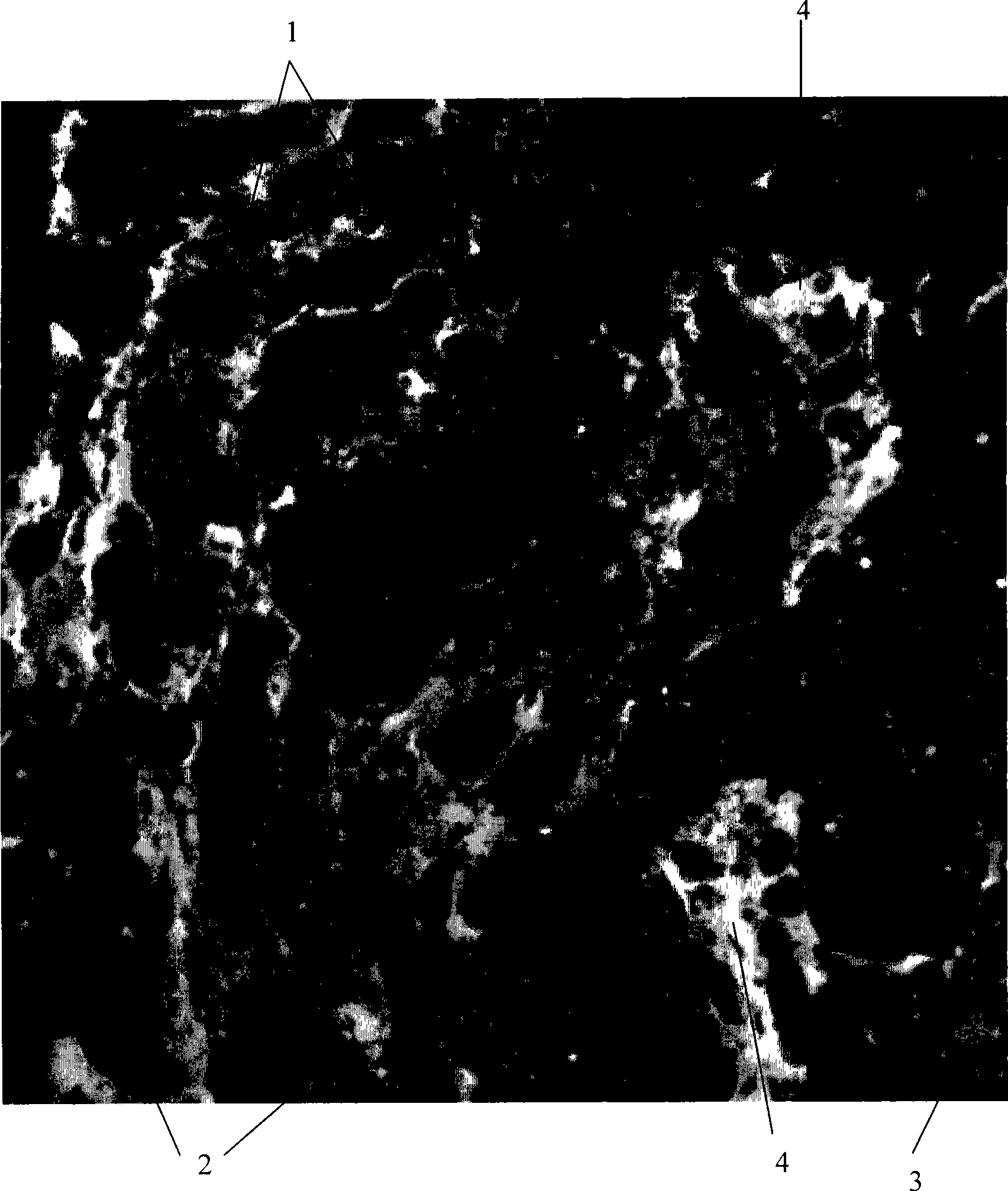

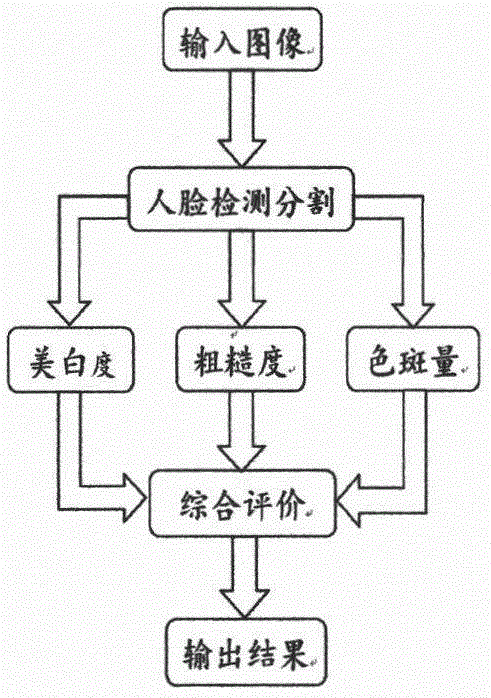

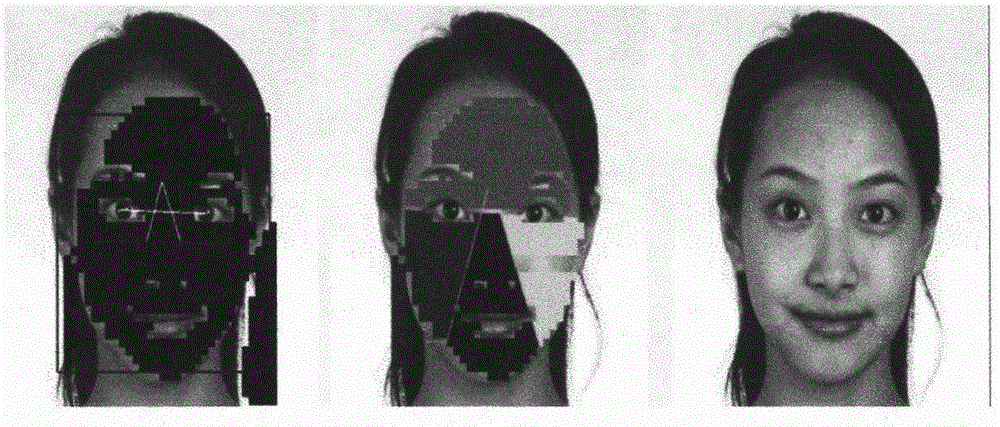

Image recognition-based facial skin analysis system

ActiveCN106529429AShorten the timeImprove efficiencyImage enhancementImage analysisPattern recognitionFacial skin

The present invention discloses an image recognition-based facial skin analysis system. The image recognition-based facial analysis system is capable of conducting a series of evaluation on the condition of the skin to obtain an overall evaluation. The system mainly comprises a face detection and segmentation module, a whitening degree detection module, a roughness detection module, a stain amount detection module and a comprehensive judgment module. Firstly, a detection image is input to be subjected to front face detection, area location and segmentation by a classifier. Secondly, the segmented image is subjected to skin color brightness and ruddy condition analysis, wherein the roughness of a feature index quantification detection area is obtained based on a gray level co-occurrence matrix. Thirdly, the stain amount is analyzed based on the similar watershed method through calculating the sum of sectional areas. Finally, the comprehensive judgment is conducted according to all detection results. Based on the technical means, the application effect of a product is quantified, so that the quality of the product is controlled. The system has great economic value for cosmetic manufacturers. Meanwhile, the system brings more economic benefits.

Owner:CHINA JILIANG UNIV

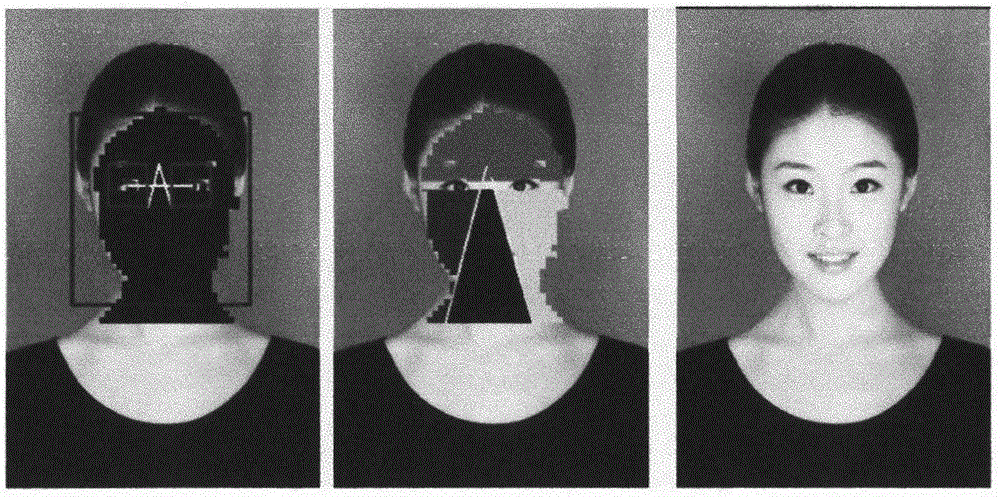

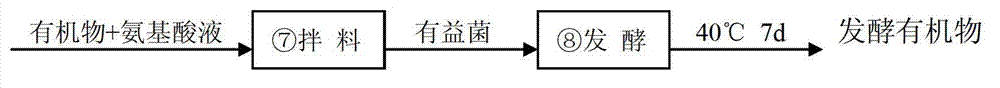

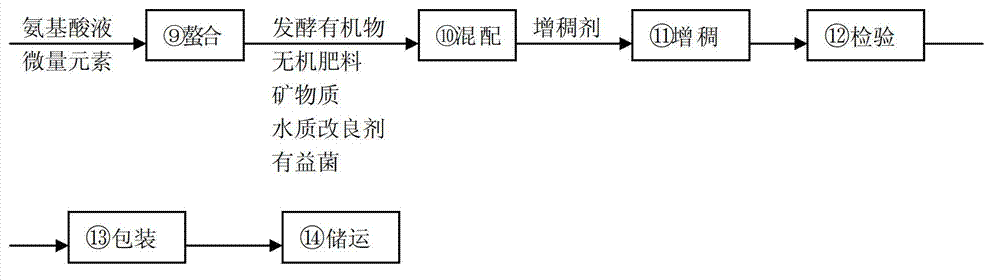

Special amino acid fertilizer-water paste for aquiculture and preparation method thereof

The invention discloses a special amino acid fertilizer-water paste for aquiculture and a preparation method thereof. The special amino acid fertilizer-water paste for aquiculture is prepared from the following raw materials in certain proportion: an amino acid solution, microelements, fermentation organic substances, inorganic fertilizers, minerals, a water quality improver, beneficial bacteria and a thickening agent. The preparation method comprises the following steps: A. production of amino acid solution namely, a. hydrolyzing; b. neutralizing; c. filtering; d. concentrating; B. production of fermentation organic substances: a. mixing: evenly mixing organic raw materials with the amino acid solution; b. inoculation: evenly mixing the organic raw materials with beneficial bacteria; c. fermentation; and C. production of amino acid fertilizer-water paste: a. chelation: heating the amino acid solution, adding microelements while stirring to perform chelation; b. mixing: sequentially adding the fermentation organic substances, inorganic fertilizer, minerals, water quality improver and beneficial bacteria, and evenly mixing; c. thickening: adding a thickening agent, and evenly mixing; d. inspection. The invention enhances the immunity of fish, reduces the occurrence of diseases, increases the culture yield of bighead, lowers the fish culture cost, and improves the fish quality.

Owner:武汉市洪山吕墩氨基酸厂

Cloth ironing machine

InactiveCN105463745AAvoid damageQuality improvementHeating/cooling textile fabricsTextile treatment by spraying/projectingEngineeringEnergy consumption

The invention mainly discloses a cloth ironing machine. The technical scheme is that the cloth ironing machine comprises a rack, an ironing mechanism, a conveying mechanism, a preheating mechanism, a sterilization mechanism and a drying mechanism, wherein the conveying mechanism comprises a putting table, cloth putting rollers and a cloth reeling roller, the putting table is provided with hanging rings, two ends of the cloth putting rollers are respectively hung on the hanging rings, one side of the cloth reeling roller is provided with a cooling roller, the ironing mechanism comprises an upper press mould, a lower press mould and an ironing table, the lower sides of the upper press mould and the lower press mould are respectively provided with a first transmission mechanism and a second transmission mechanism for driving the upper press mould and the lower press mould to be in force fit, the preheating mechanism comprises a preheating plate provided with steam holes and a water tank with an electric heater, the sterilization mechanism comprises a lamp base, a lamp holder and an ultraviolet tube with a cleaning device, the drying mechanism comprises a drying plate provided with air outlets and a warm air chamber provided with a warm air machine, and sliding wheels are arranged below the rack. The cloth ironing machine has the advantages of good ironing effect, shaping in one step, high work efficiency and less energy consumption.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

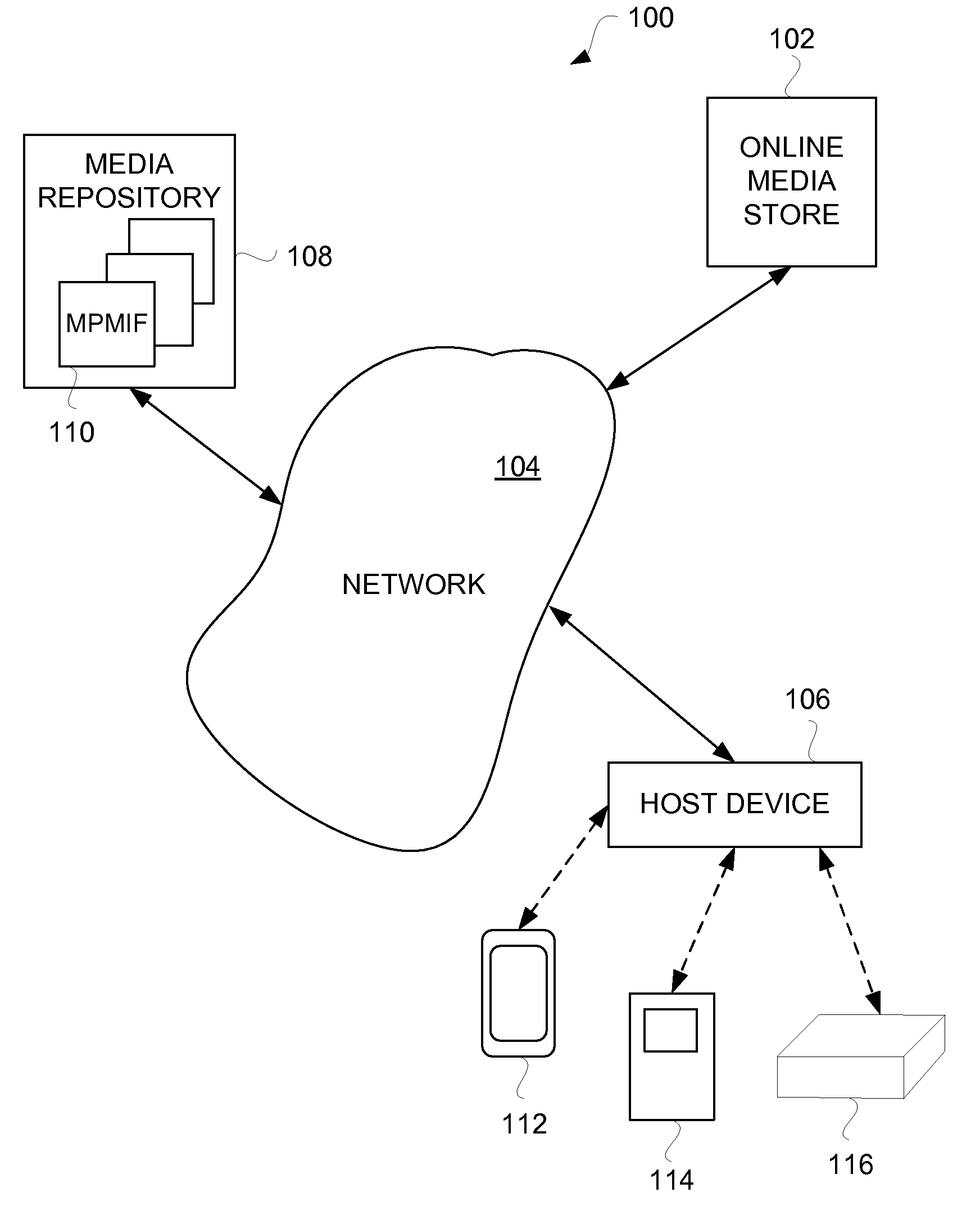

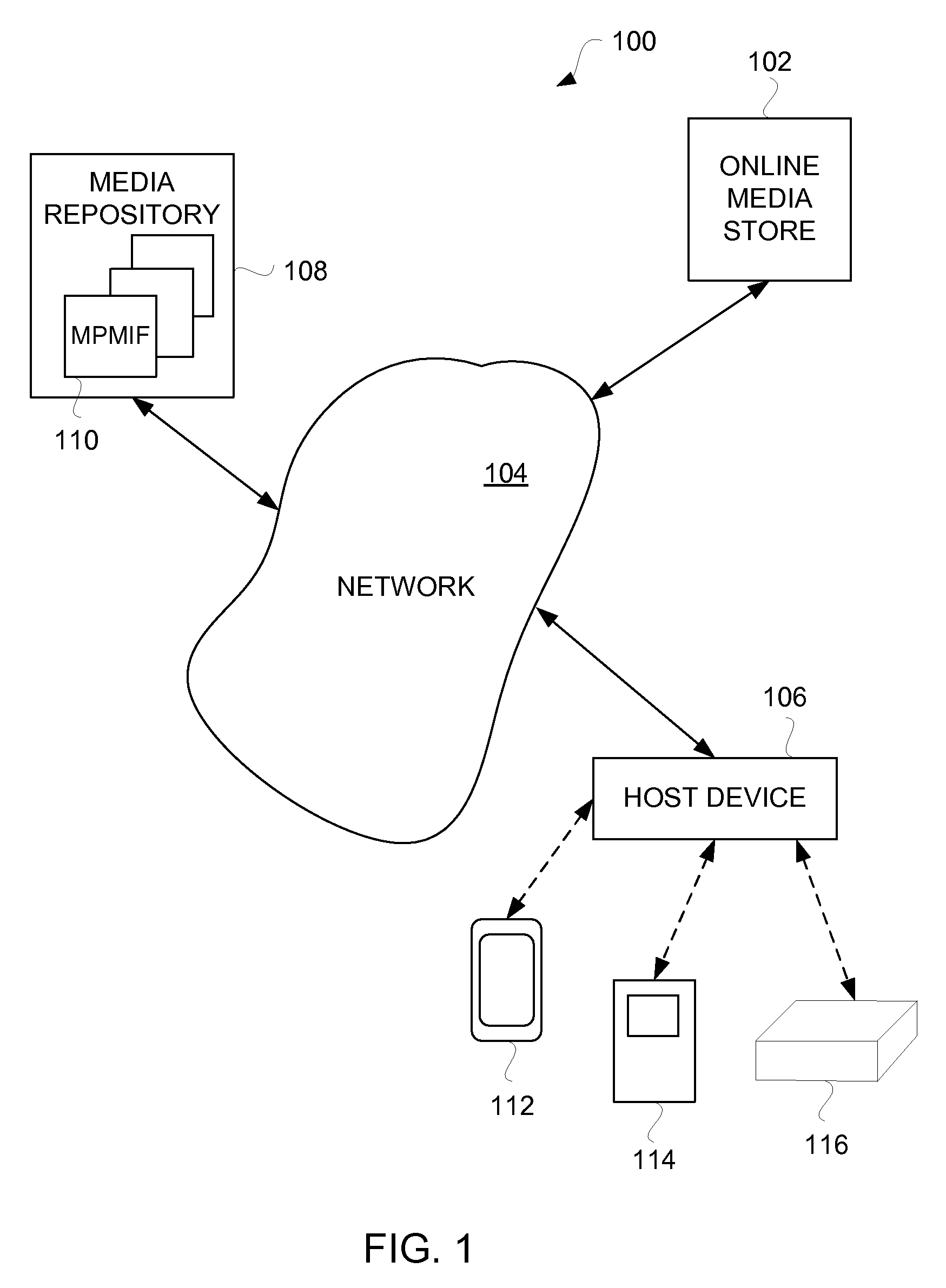

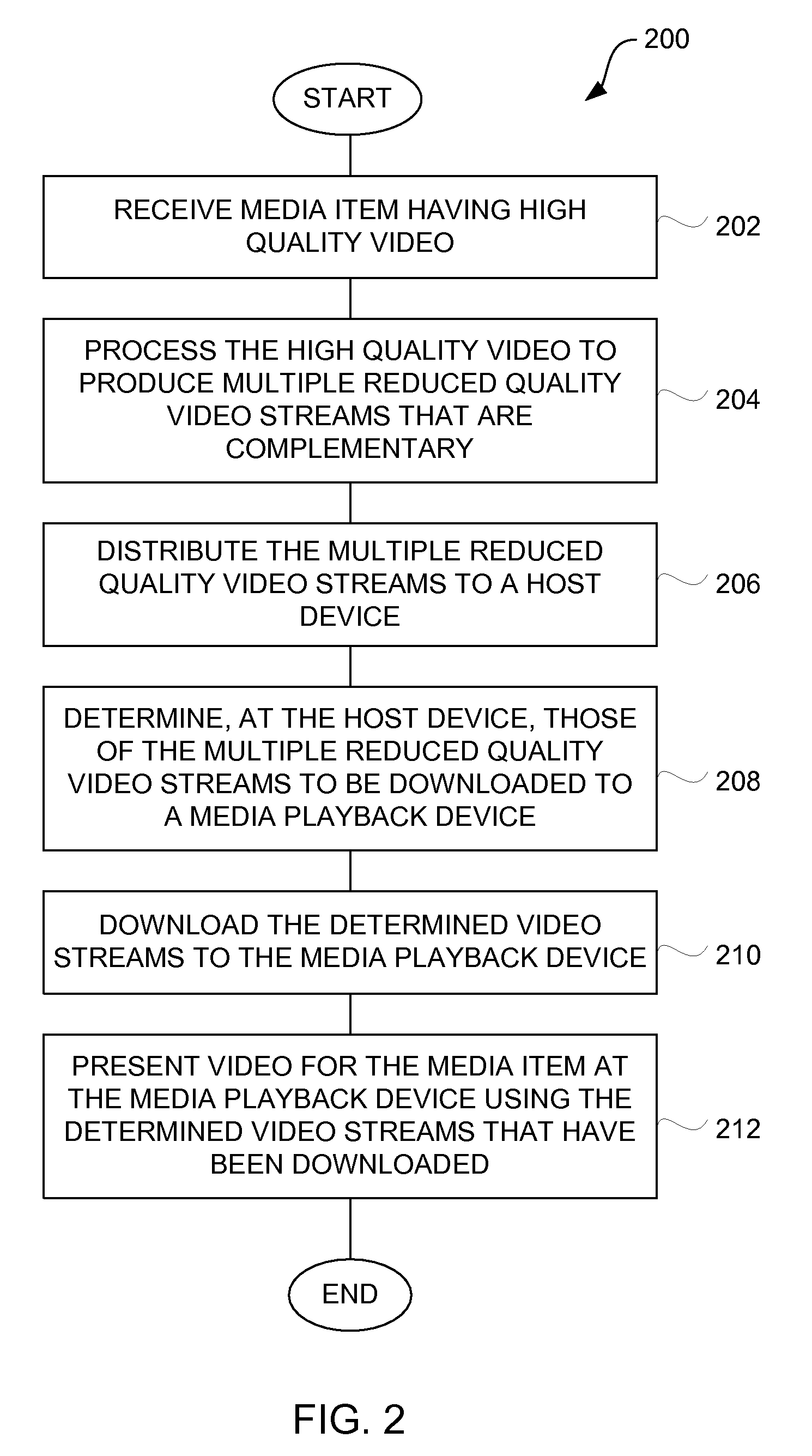

Delivery of Media Assets Having a Multi-Part Media File Format to Media Presentation Devices

InactiveUS20090187957A1Reduce qualityTelevision system detailsTwo-way working systemsElectronic equipmentMultimedia

Owner:APPLE INC

Method for preparing essential oils

InactiveCN102504957AReduce or avoid the use ofEasy to operateEssential-oils/perfumesAlcoholDistillation

The invention relates to a method for preparing essential oils. The method comprises the following steps: taking and smashing raw materials; placing the smashed raw materials in an extraction kettle; carrying out supercritical extraction by taking a supercritical carbon dioxide fluid as an extractive solvent and taking alcohol with the volume concentration of 55 to 65 percent as an entrainer, wherein the extraction temperature is 25 to 38 DEG C, the extraction pressure is 15 to 22 MPa, the extraction time is 1.5 to 3 h, the ratio between the quality (Kg) of the raw materials and the volume (L) of the extraction kettle is 0.2 to 0.5 : 1, and the ratio between dose (L) of the entrainer and the volume (L) of the extraction kettle is 0.05 to 0.07 : 1; separating with a separation kettle to obtain an extract; placing the extract obtained through extraction in a molecular still; carrying out molecular distillation under the conditions of 0.3 to 0.5 Pa, 160 to 180 DEG C; and collecting to obtain a corresponding essential oil. The method can be used for extracting essential oils from various plants, so that compared with the prior art, the invention has the advantages of high essential oil yield and high contents.

Owner:GUILIN NATURAL INGREDIENTS CORP

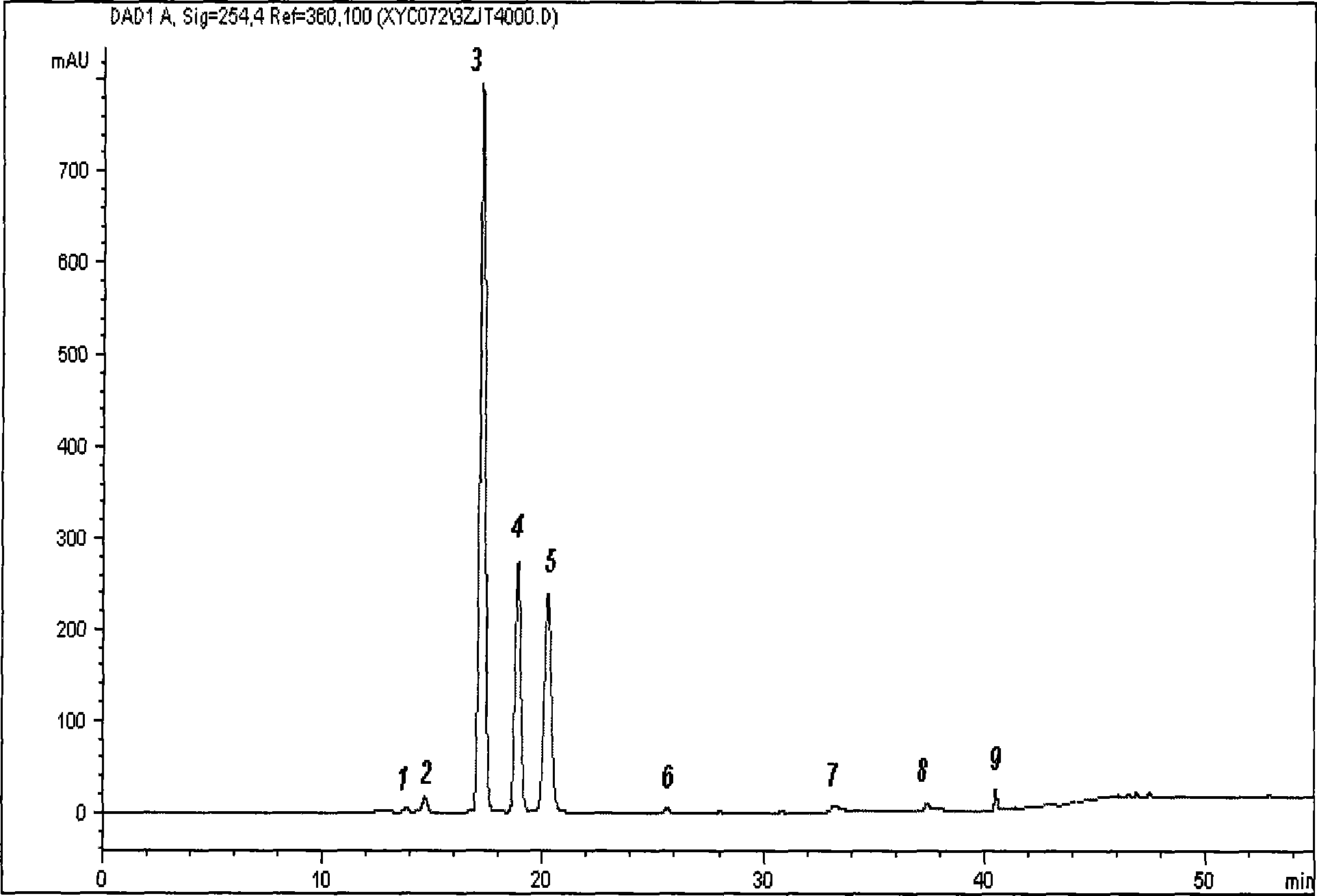

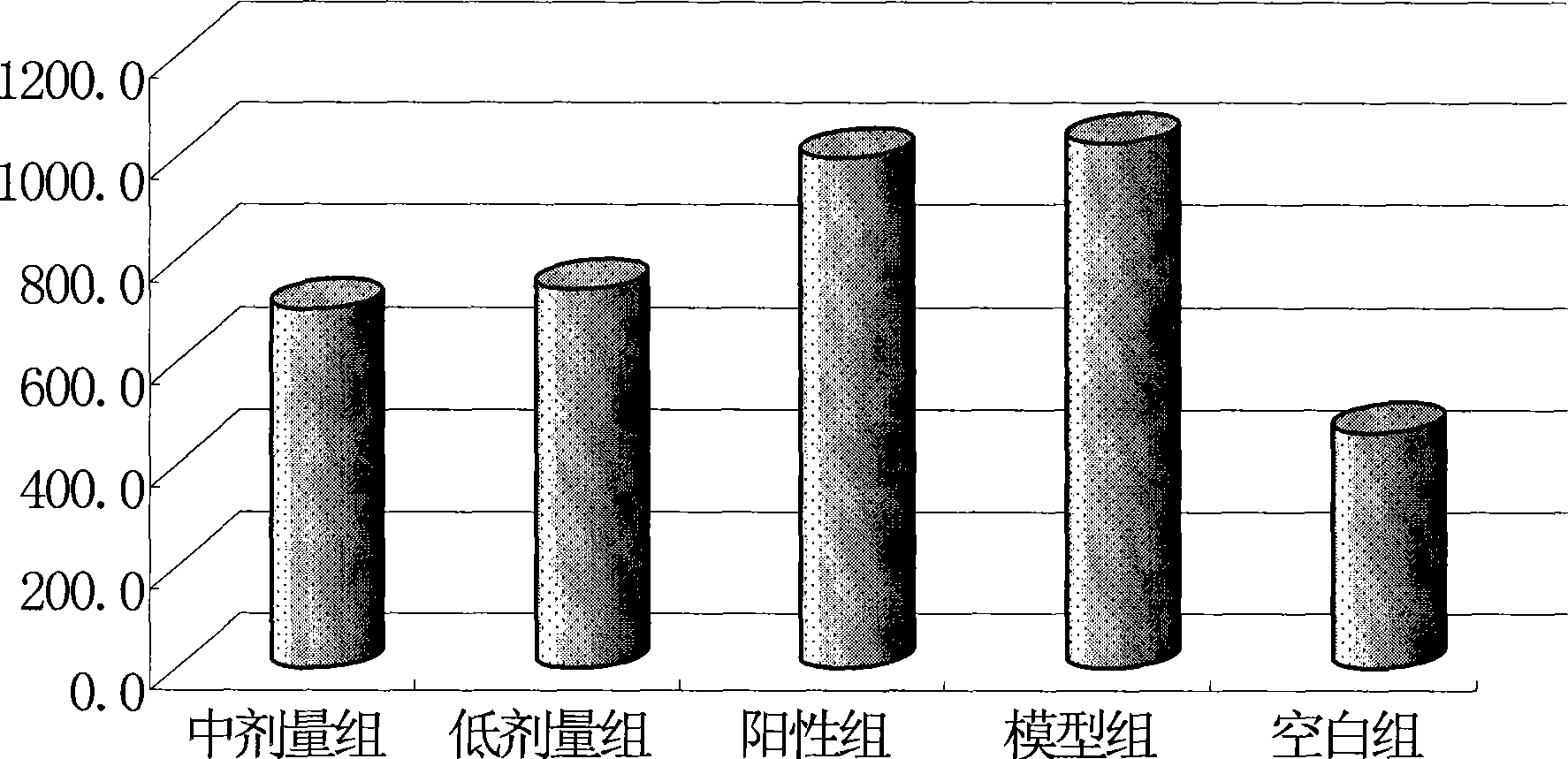

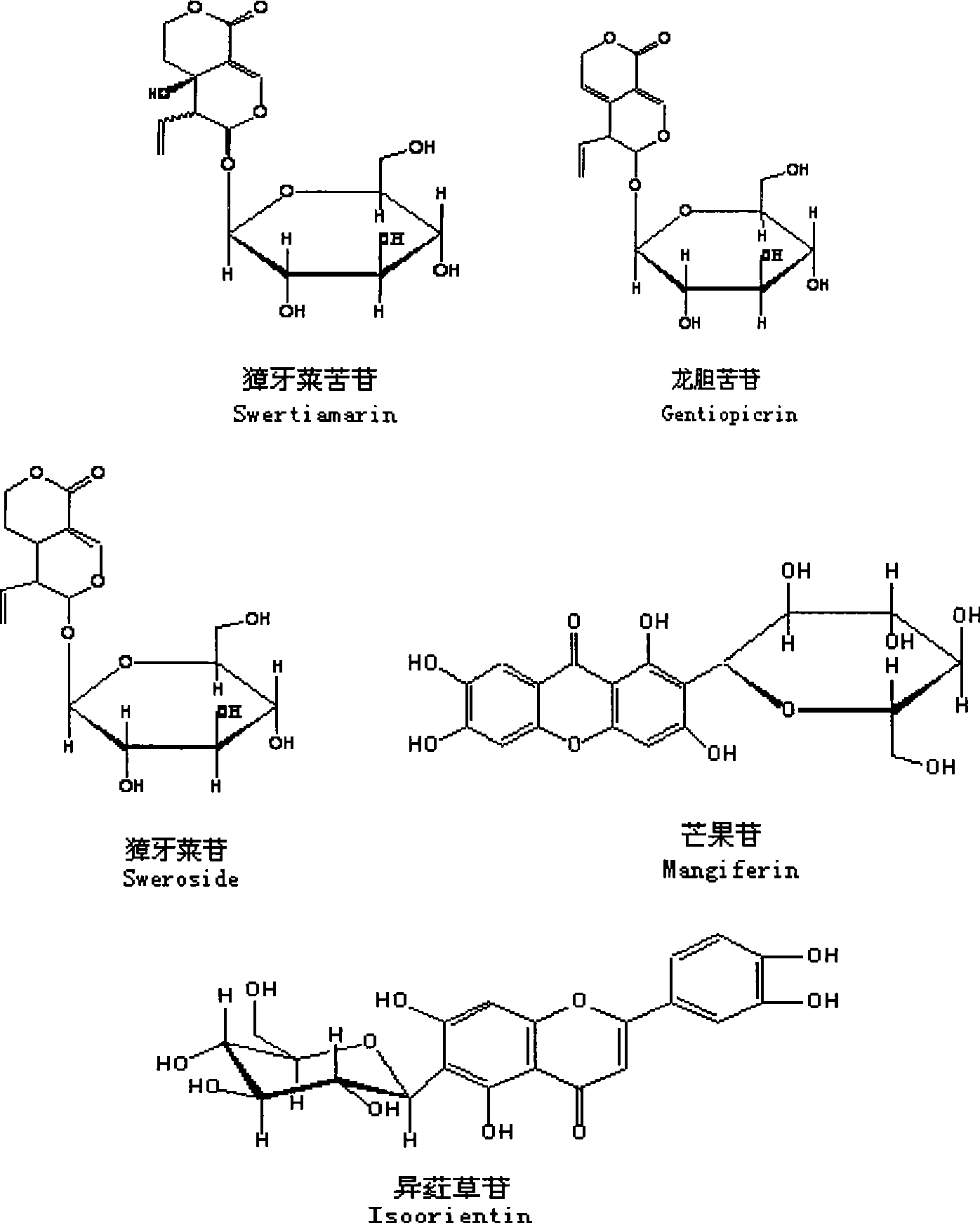

Tibetan capillary extract and preparation method, medicine composition and use thereof

ActiveCN101396428AReduce qualityExcellent indicatorsSugar derivativesDigestive systemAdditive ingredientTraditional medicine

The invention provides a Tibetan virgate wormwood herb extract containing swertiamain, gentiopicroside, sweroside, mangiferin and isoorientin, and the weight ratio of the five ingredients is (0.04-0.71): (20-40): (1-15): (1.6-26): (0.01-0.16). The invention further provides a preparation method of the Tibetan virgate wormwood herb extract, a pharmaceutical composition containing the Tibetan virgate wormwood herb extract and a medical use of the Tibetan virgate wormwood herb extract. The Tibetan virgate wormwood herb extract can improve various indicators caused by liver injury, promote the reversal of the liver fibrosis process and better prevent liver cirrhosis.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST +1

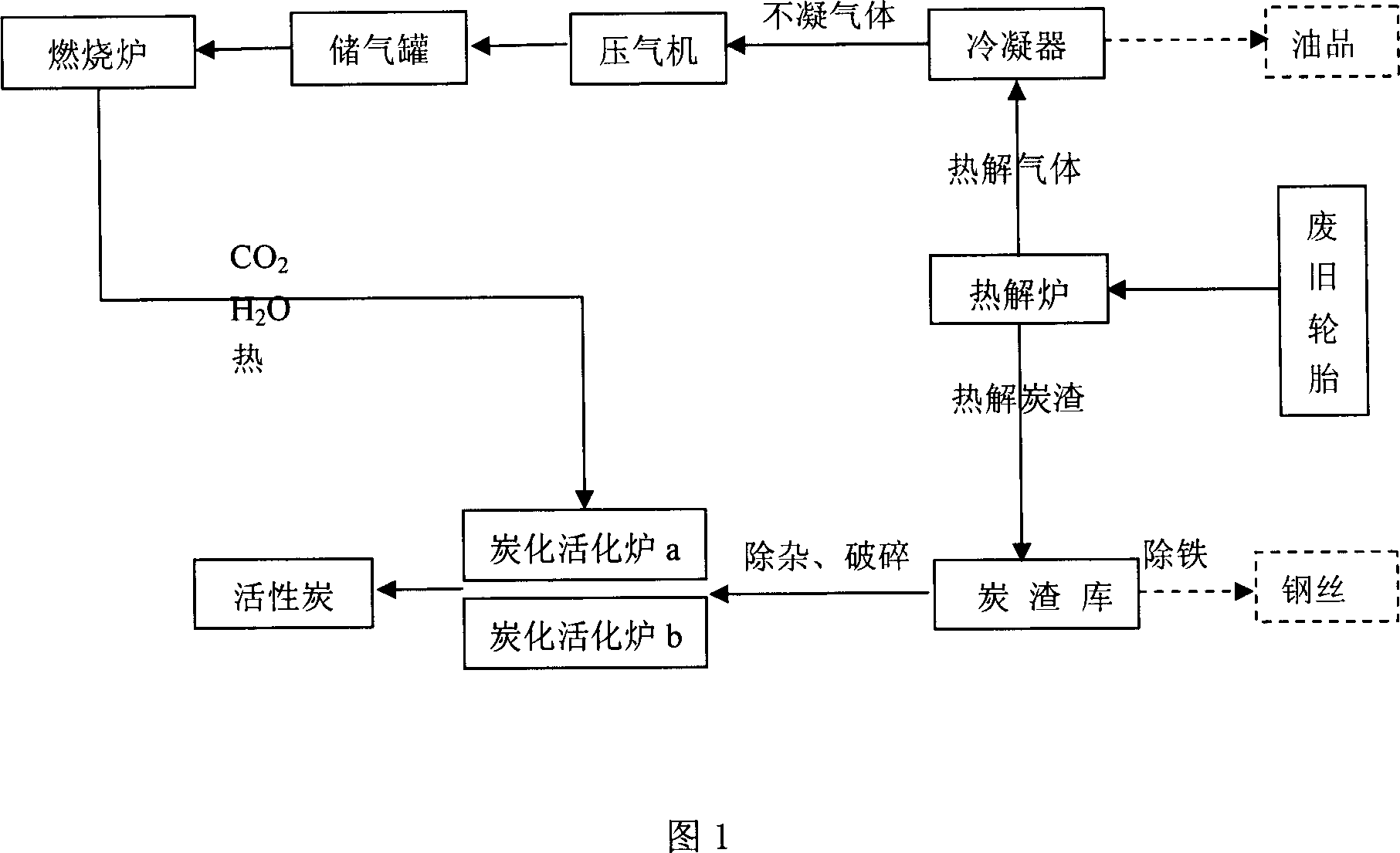

Method of manufacturing active carbon for waste water treatment using waste tyre

InactiveCN101012059AReduce qualityImprove resource utilization efficiencyOther chemical processesWater/sewage treatment by sorptionThermal energyWaste treatment

The invention discloses a making method of wastewater active charcoal through waste tyre in the processing method technical domain of environmental protective solid waste, which is characterized by the following: transmitting entire or broken waste tyre into pyrogenic stove; transmitting carbon waste in the charring activating furnace; sending non-condensed gas into combusting furnace; inducing high-hot CO2 and H2O flow into charring activating furnace to heat charring activating furnace; adopting incomplete combusting carbon black as new additional raw material; insulating the charring activating furnace from air; reducing to below 100 deg.c to obtain the product; alternating two stoves.

Owner:TSINGHUA UNIV

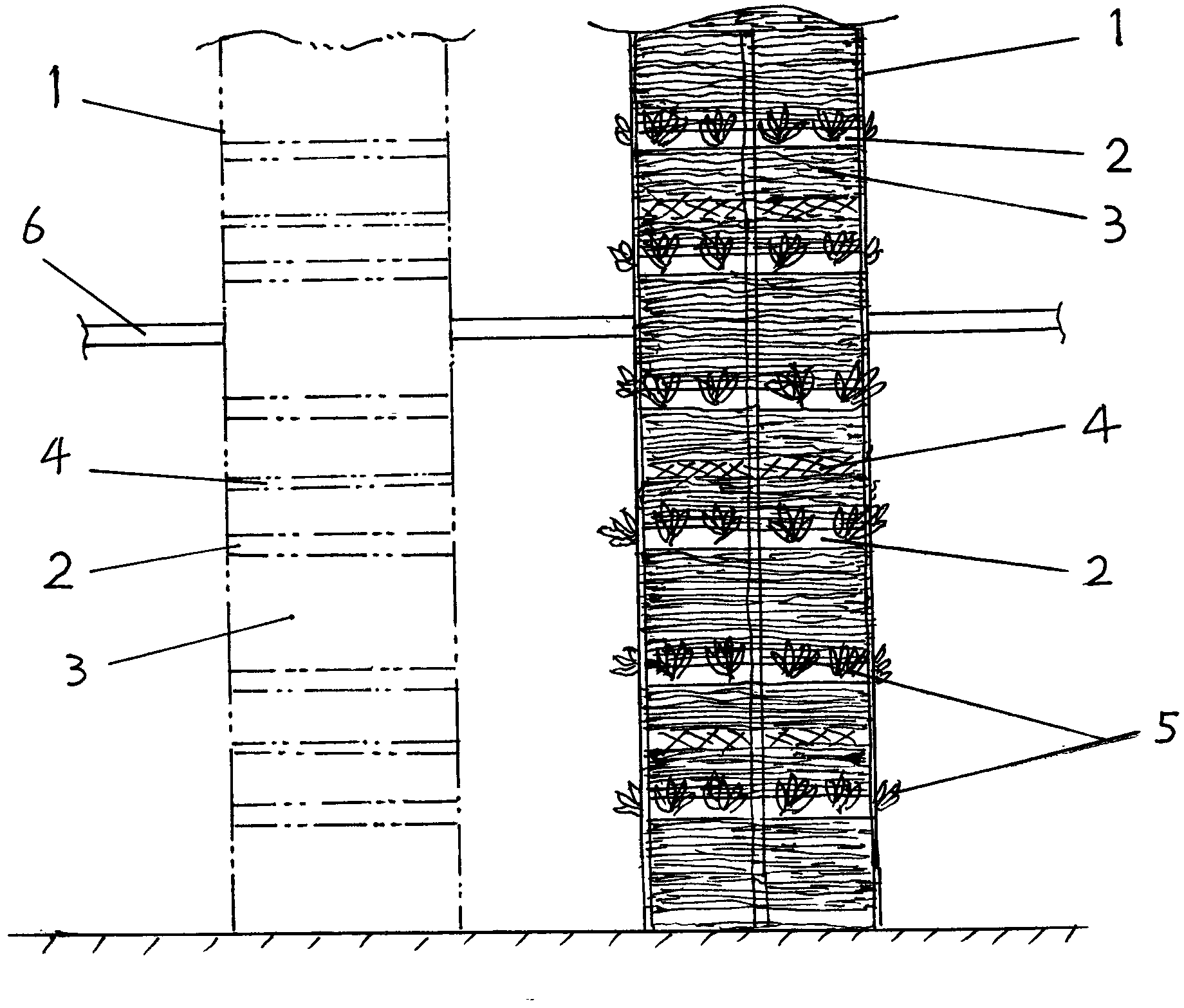

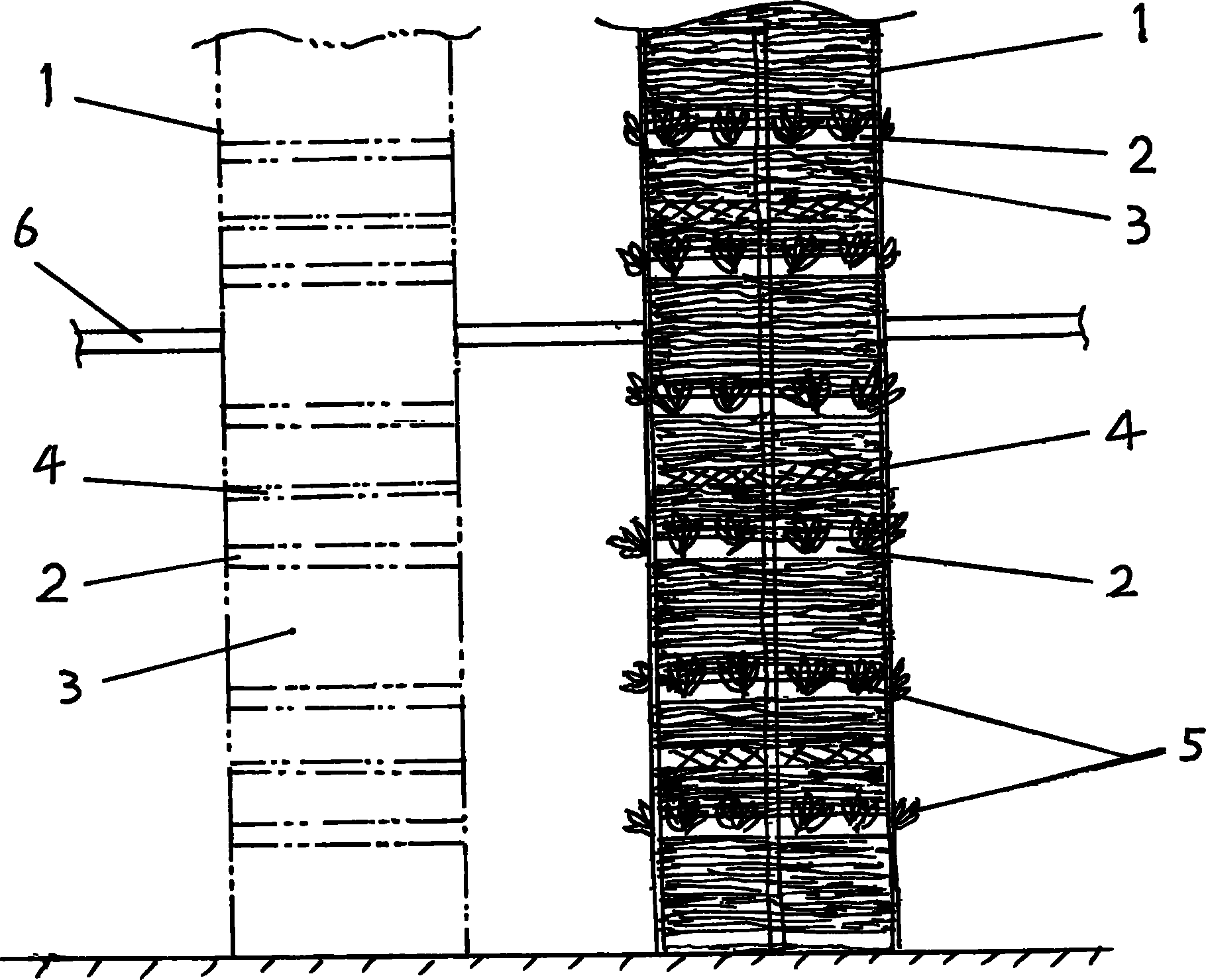

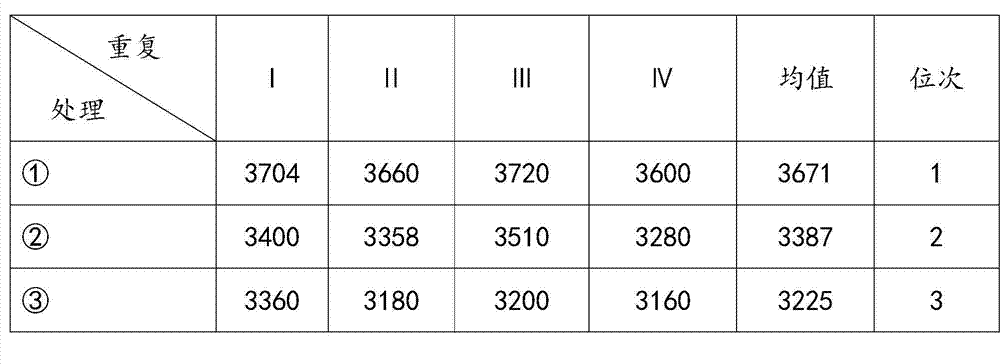

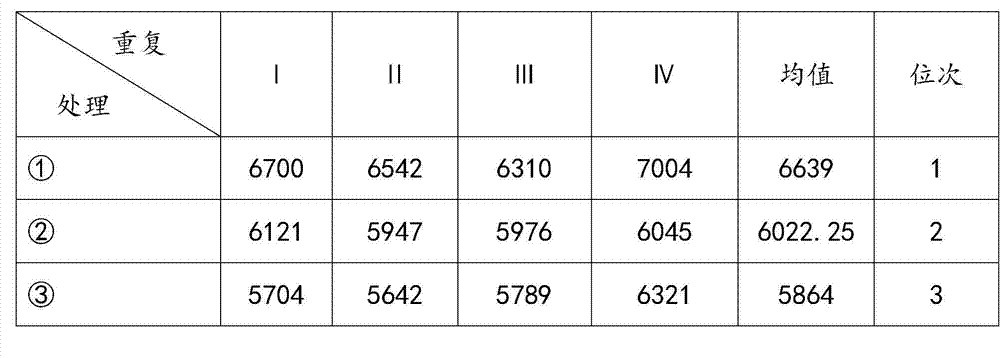

Novel column-shaped three-dimensional cultivation method and device for medical dendrobium

InactiveCN102172205APromote healthy growthEasy to obtainAgriculture gas emission reductionCultivating equipmentsVolumetric Mass DensityHabit

The invention provides a novel column-shaped three-dimensional cultivation method and device for medical dendrobium. The method is characterized by comprising the following steps of making a cultivation device serving as an auxiliary article in a hollow column-shaped body structure; filling a cultivation medium in the interior cavity of the hollow column-shaped body, wherein the hollow column-shaped body is at least 0.5 m in height and at least 8 cm in diameter, the external surface of the hollow column-shaped body is uniformly provided with seedling planting areas, and a cultivation medium composition mainly comprises the following raw materials in parts by volume: 5-15 parts of barks, 10-30 parts of saw dust and 3-10 parts of vermiculite; selecting healthily-growing seedlings to be hardened and then washing the hardened seedlings during cultivating and transplanting the dendrobium seedlings; and after sterilizing by using 800-1000 times of liquid carbendazim, transplanting the seedlings in different plant bunches according to the seedling planting areas, wherein row spaces of the transplanted plants are 4-6 cm*10-15 cm. Compared with the prior art, the cultivation method provided by the invention is very suitable for growth habits of the wild medical dendrobium; and the medical dendrobium cultivated by using the invention has the advantages of easiness for material obtaining, low cost, long service life, good water retention and fertilizer securing effects, high planting density, land utilization rate capable of being increased by 6-7 times, high and stable yield, good product quality and convenience for management.

Owner:杨旺利

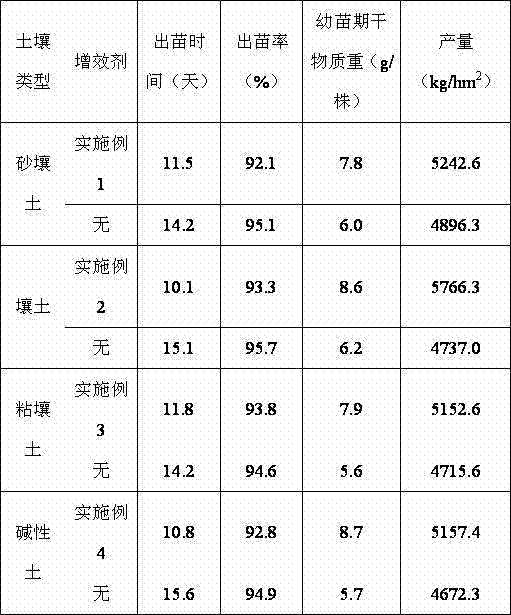

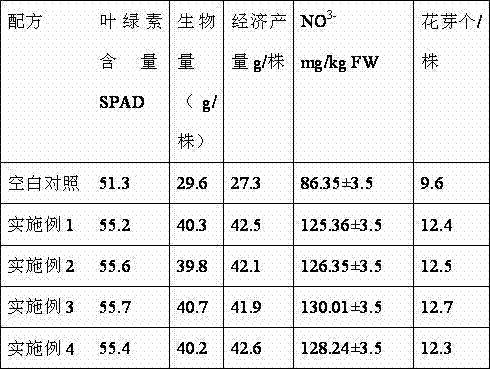

Compound water soluble fertilizer used for citrus crops, preparation method and application method

ActiveCN103073348AAvoid YieldReduce qualityFertilising methodsFertilizer mixturesTrace elementPlant nutrition

The invention discloses a compound water soluble fertilizer used for citrus crops, a preparation method and an application method. The compound water soluble fertilizer used for citrus crops is mainly used in plant nutrition field, and comprises the following components: an amino acid raw material, macroelements P and K, secondary elements Mg and Ca, trace elements Fe, Mn, Zn, B, Mo and Cu, a beneficial element Si, an auxiliary agent, a PH conditioning agent and an aqueous solution. The preparation method is characterized in that composite amino acid chelates Mn, Fe, Cu, Mg, Ca and Zn at normal temperature of 15-35 DEG C and prepares the water soluble fertilizer with six metallic elements, the reasonable fertilizing can be carried out at different growth period of the crops, the balance supplement of a plurality of nutrient elements required by citrus crops can be realized, and the output and quality of the citrus crops can be increased.

Owner:HUBEI GREAT BIOTECH

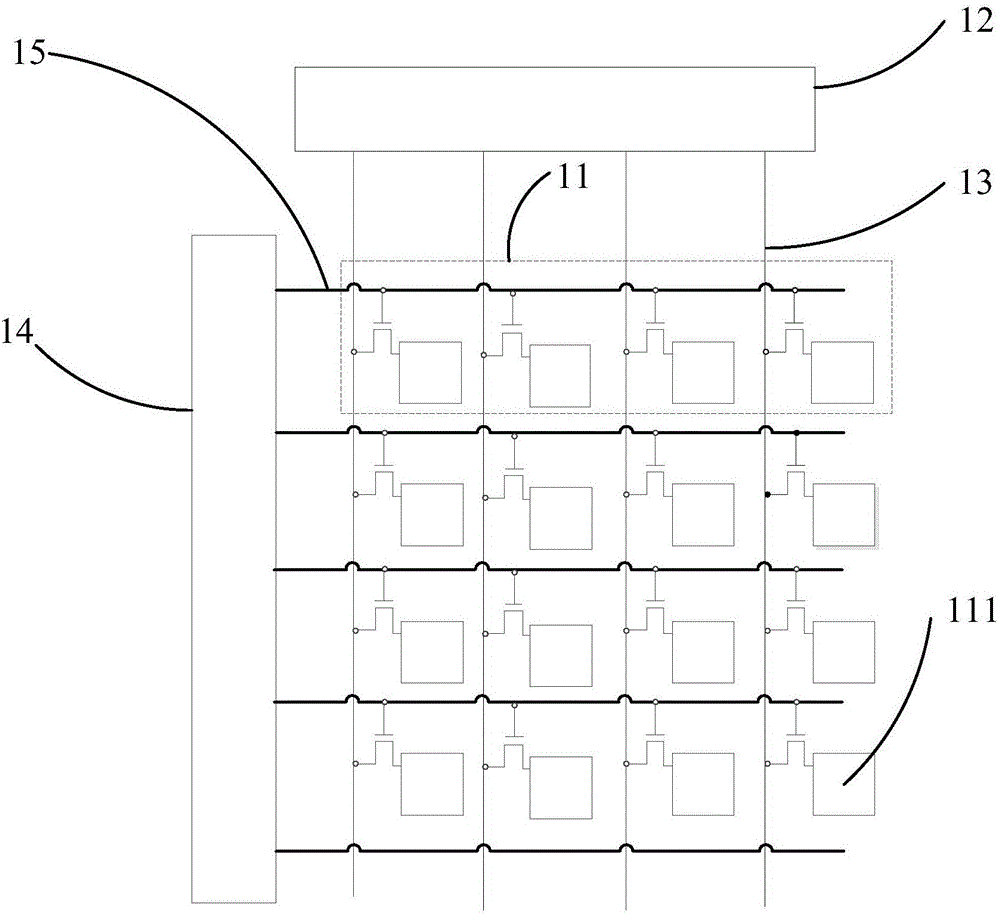

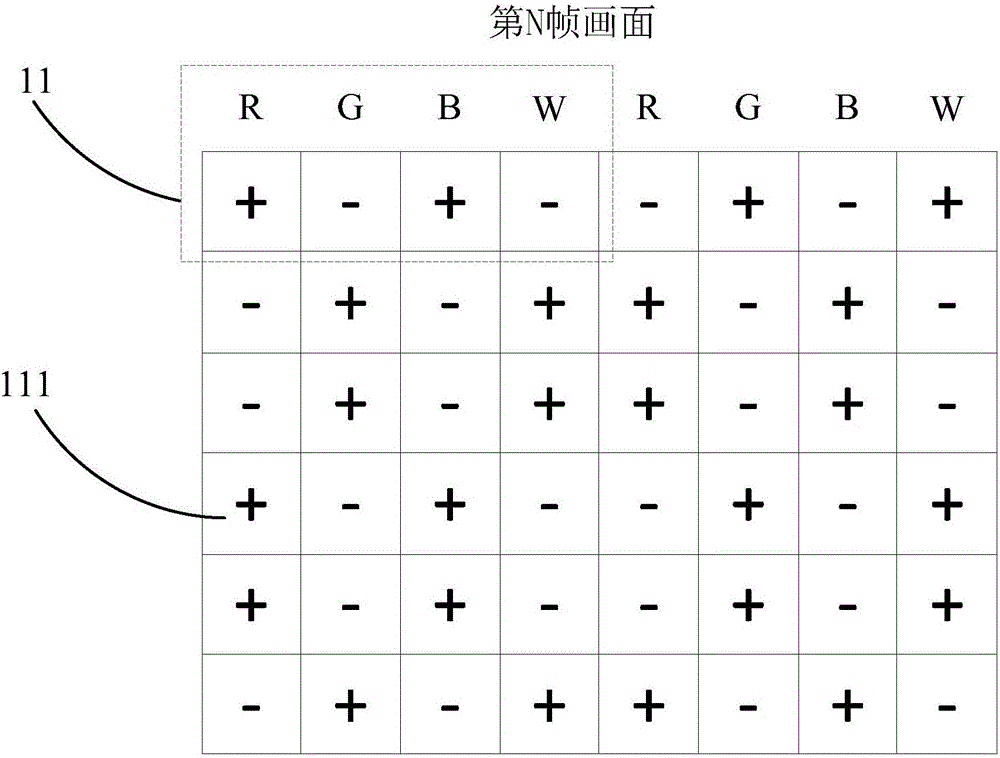

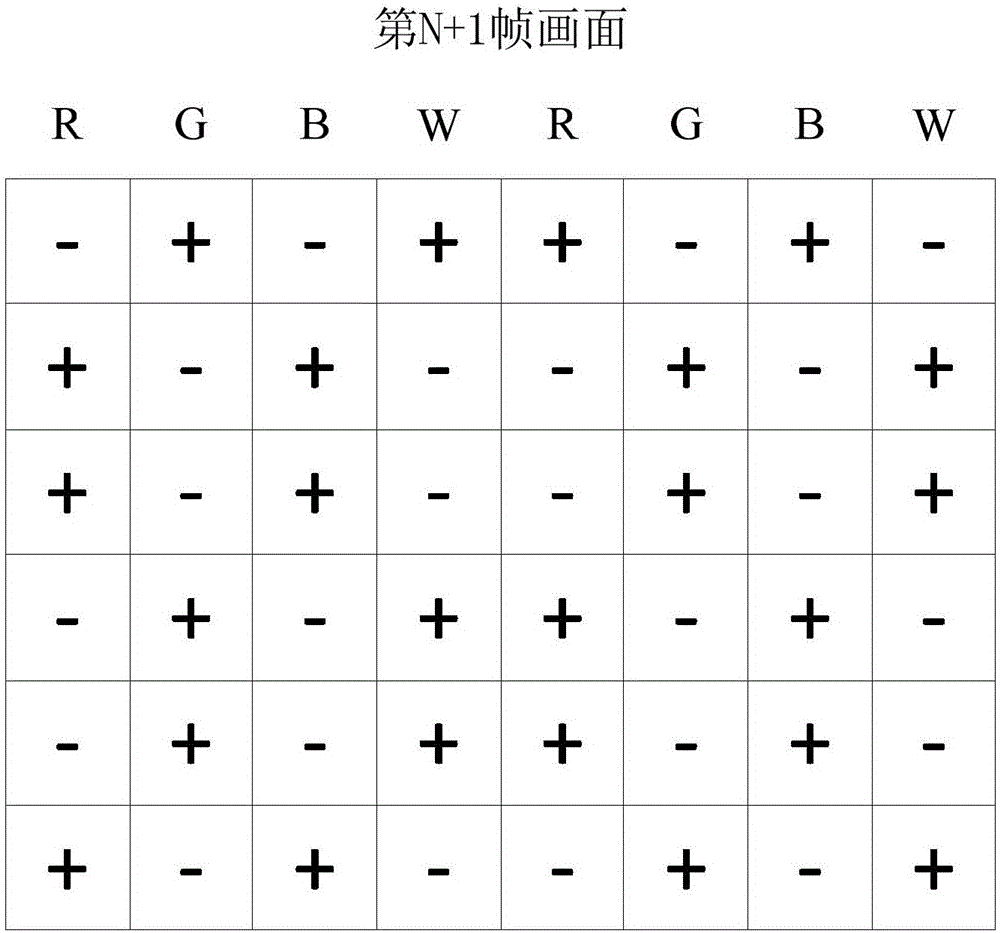

Array substrate and liquid crystal display

ActiveCN106652951AEqualization of light and dark changesAvoid display effectsStatic indicating devicesLiquid-crystal displayEngineering

The invention provides an array substrate and a liquid crystal display. The array substrate comprises a plurality of pixel units arranged in an array manner, a data driver and a plurality of data cables, wherein each pixel unit comprises a plurality of sub-pixels arranged along the row direction and having different colors, and the data driver provides drive voltage for the plurality of sub-pixels through the plurality of data cables. In the same frame of picture, the polarities of driving voltages of the adjacent sub-pixels of the same pixel unit are opposite, and the polarities of driving voltages of the sub-pixels having the same color of each two adjacent pixel units in the same row are opposite. Through the above method, the darkness and brightness change of the array substrate is homogenized, so that the problem that when pure color or special points are displayed, the display is poor, or the quality of the product is reduced, is solved, and the display effect is optimized.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Novel quick-frozen dumpling and preparation method thereof

InactiveCN102125226ASmall volume expansionReduce frost crackingFood preparationAnti freezingAntifreeze protein

The invention belongs to the industrial field of quick-frozen foods, and in particular relates to a quick-frozen dumpling and a preparation method thereof. The novel quick-frozen dumpling comprises a dumpling wrapper and dumpling stuffing, wherein the dumpling wrapper is made from flour, coarse cereals flour, vegetable protein powder, anti-freezing protein, modified starch, an enzyme preparation, vegetable polysaccharide and water; and the dumpling stuffing is made from meat, vegetables, a seasoner, modified starch, vegetable proteins and water. The quick-frozen dumpling is even and reasonable in nutrition collocation, abundant in nutrition, and delicious in taste. The novel quick-frozen dumpling is fresh in taste and good in color and luster under the freezing status, can notbe frozen to be cracked, and can not degrade the dumpling wrapper, the electric energy can be saved by more than 20% during producing, and the multiple effects for improving the high quality, saving the energy, and reducing the consumption are realized.

Owner:河南省食品工业科学研究所

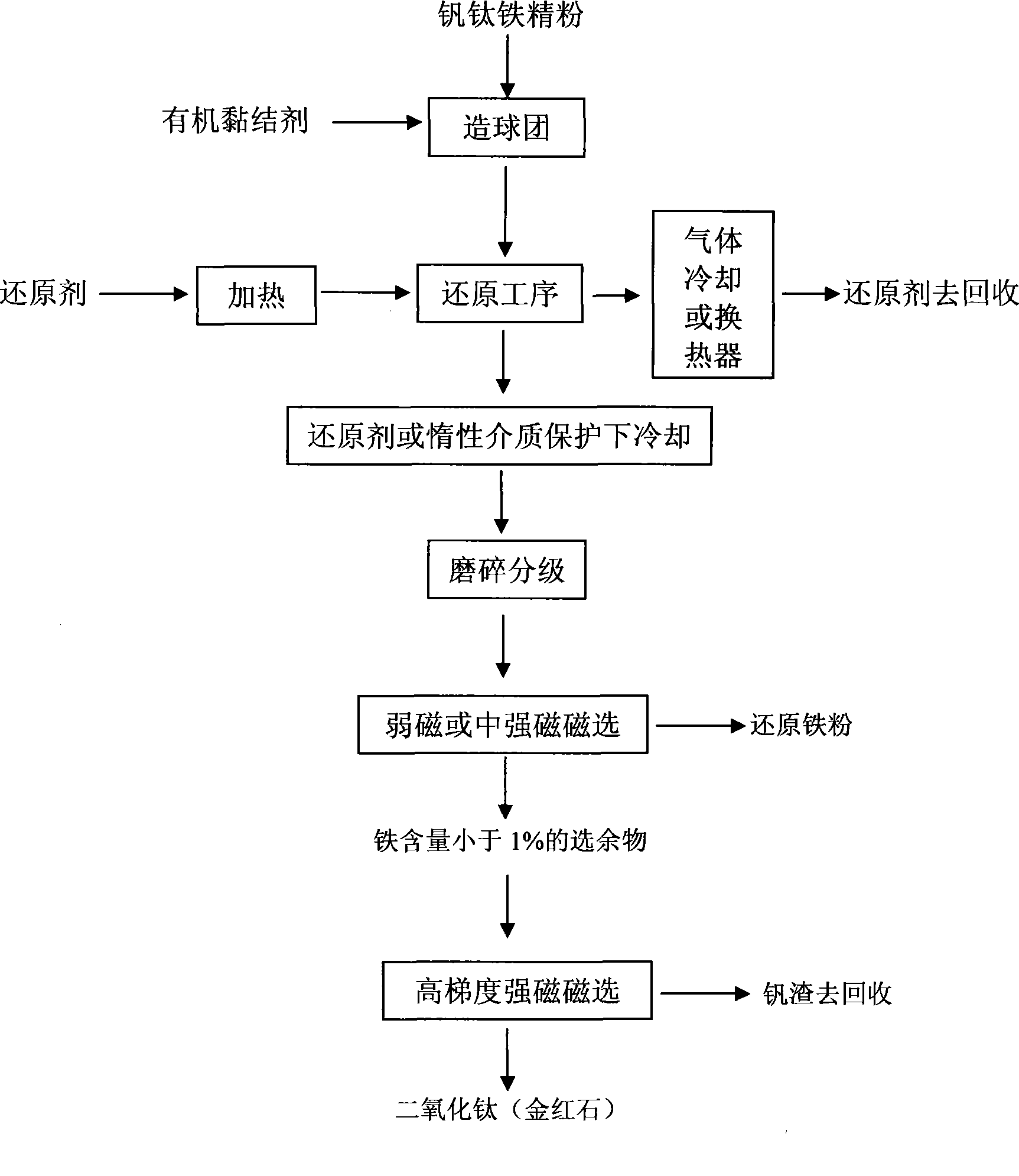

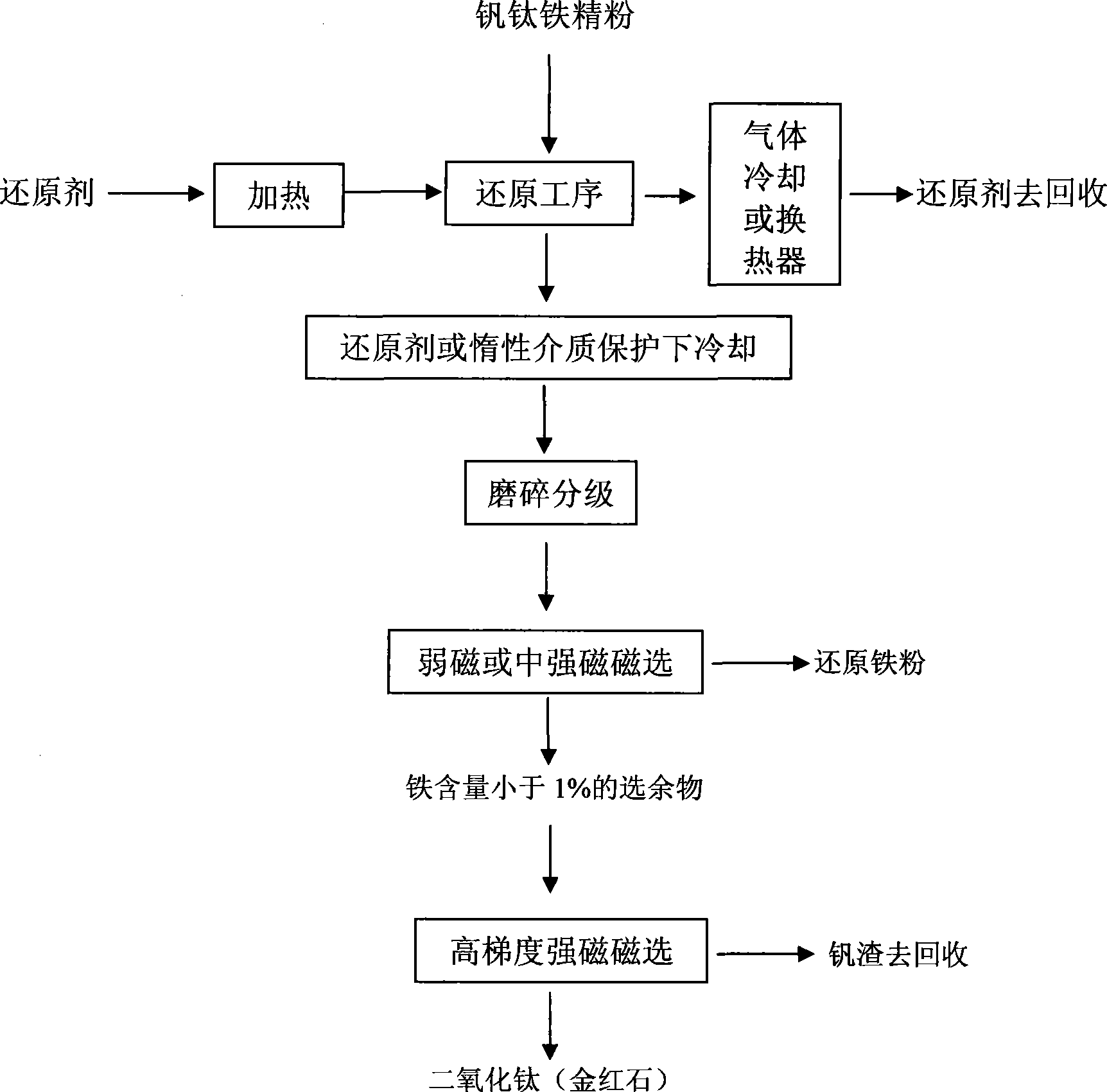

Method for separating V-Ti-Fe concentrate fines

The invention provides a method for separating vanadium-titanium iron fine powder, which comprises the following steps that the vanadium-titanium iron fine powder is sufficiently reduced by a reducing agent under a condition of not less than 500 DEG C, and the reduced vanadium-titanium iron fine powder is grinded and graded; the graded vanadium-titanium iron fine powder is subjected to weak magnetic separation or medium strong magnetic separation, and the magnetic separation object is of high-purity reduced iron powder; the remainders which are subjected to the weak magnetic separation or medium strong magnetic separation are subjected to high-gradient strong magnetic separation; the high-gradient strong magnetic separation object is of titanium dioxide (rutile), and the remainders which are subjected to the high-gradient strong magnetic separation are of high-grade vanadium slag which can be used as raw materials to produce vanadium products; or the remainders which are subjected to the weak magnetic separation or medium strong magnetic separation can also be mixed, roasted and immersed with sodium carbonate, the immersing liquid is acidified by sulfur to produce khaki or read and yellow sedimentation; and the sedimentation is filtered and calcined to obtain vanadium pentoxide products. The method has the characteristics of completely, effectively and economically separating the vanadium-titanium iron fine powder into high-purity reduced iron powder, titanium dioxide and vanadium pentoxide, thereby providing a feasible way for comprehensive utilization of the vanadium-titanium iron fine powder.

Owner:BEIJING BOYUAN HENGSHENG HIGH TECH

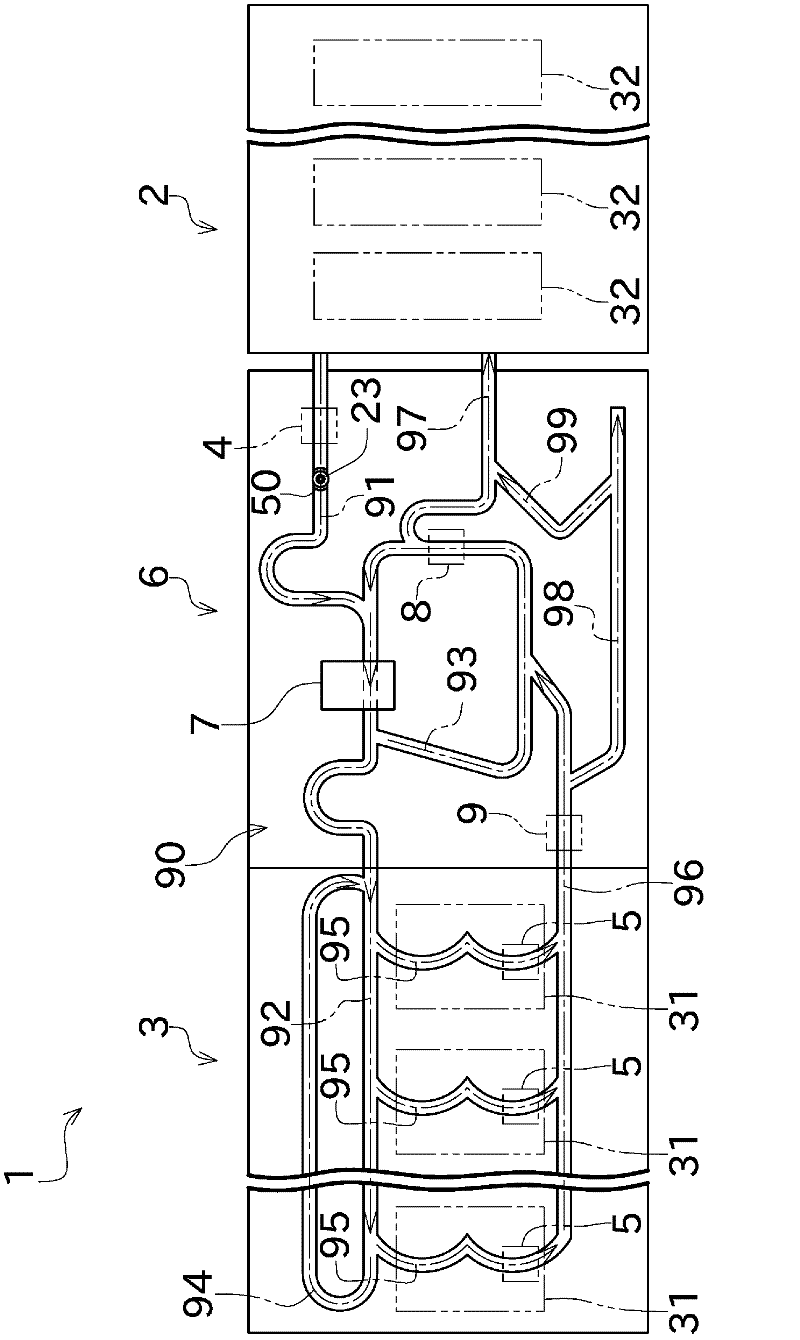

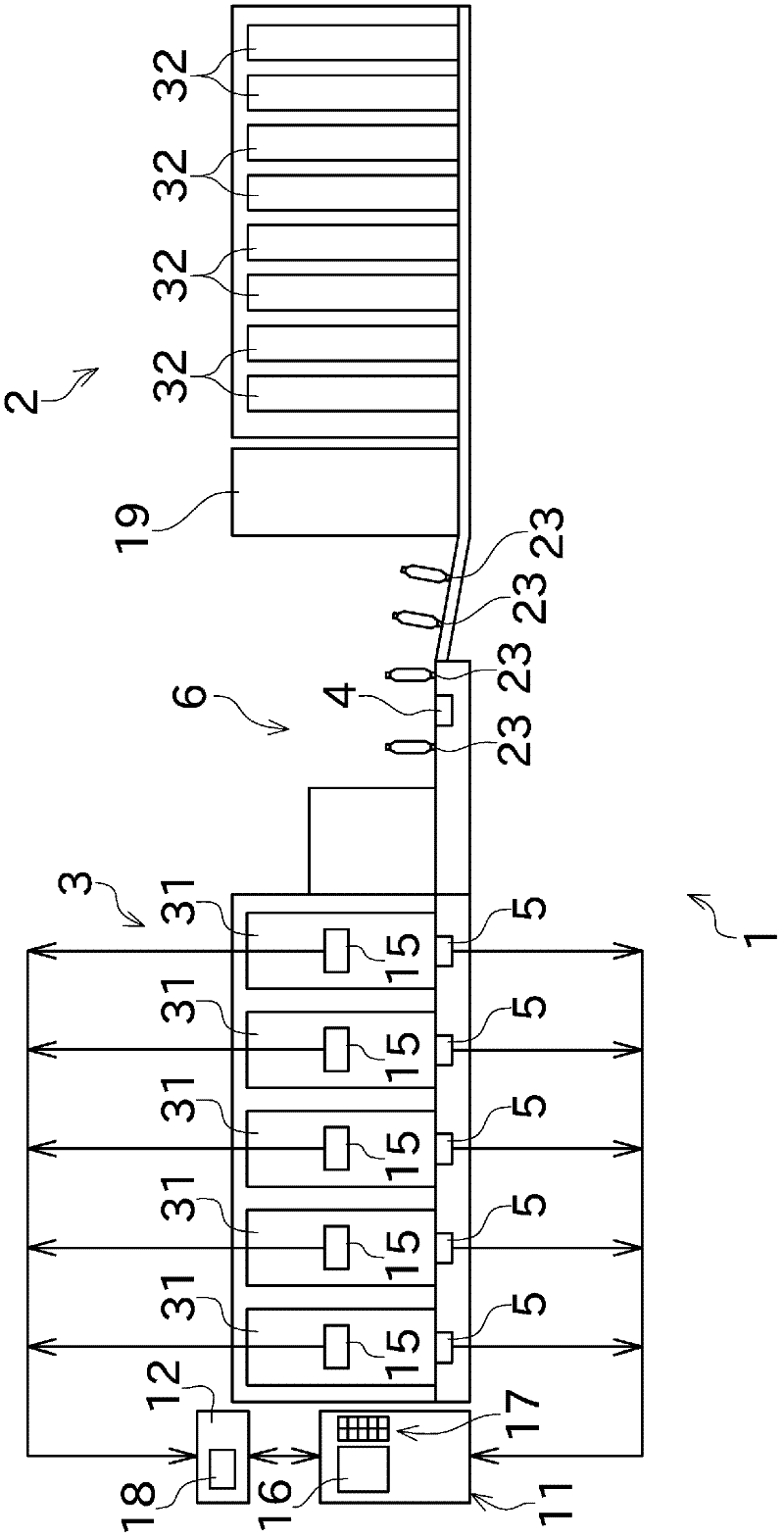

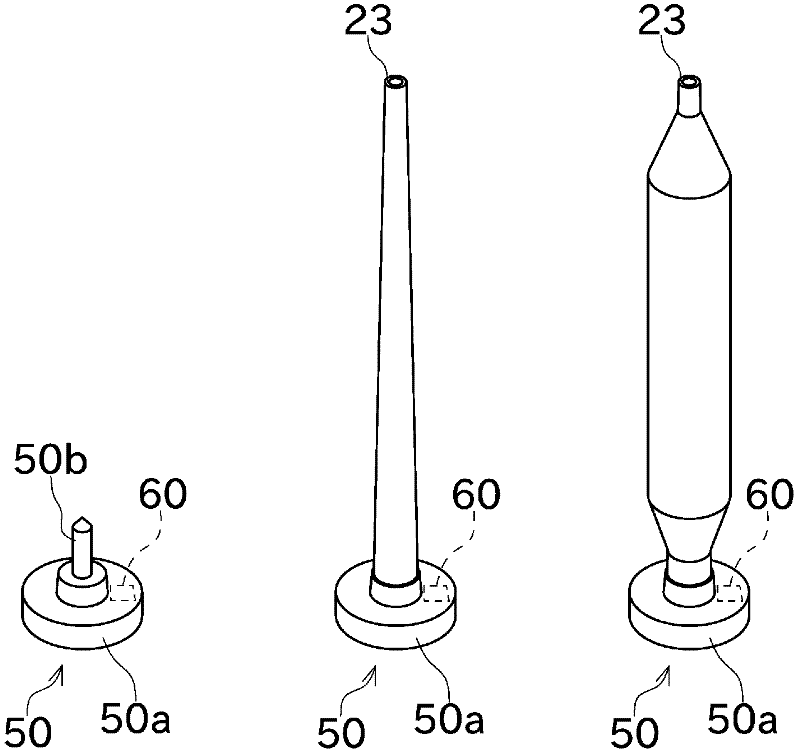

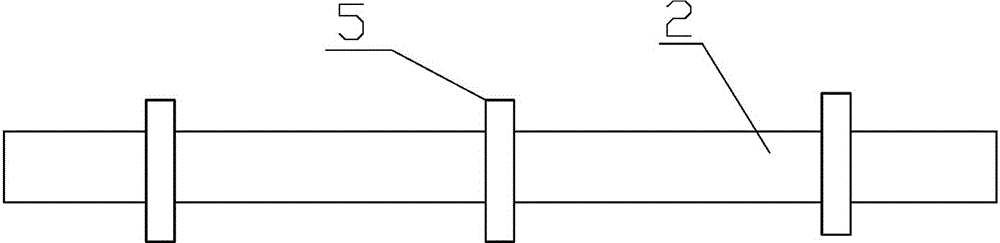

Management system for fine spinning winder and fine spinning winder

Disclosed is a management system for a fine spinning winder, which is capable of automatically analyzing the tendency toward which the fluff of yarn spun by a fine spinning unit is produced in units of bobbins. Trays on which bobbins (23), around which yarn is wound by a spinning frame (2), are set have RF tags capable of recording information for identifying fine spinning units (32) in which theyarn is wound around the bobbins (23) that are set on the trays. Also, winding units (31) have clearers (15), unit control sections, and RF readers (5). A quality inspection section of an automatic winder records the amount of fluff together with the unwound yarn length when the clearers (15) have detected the amount of the fluff, and conducts the quality inspection of the yarn spun by the fine spinning units (32) in units of bobbins (23).

Owner:MURATA MASCH LTD

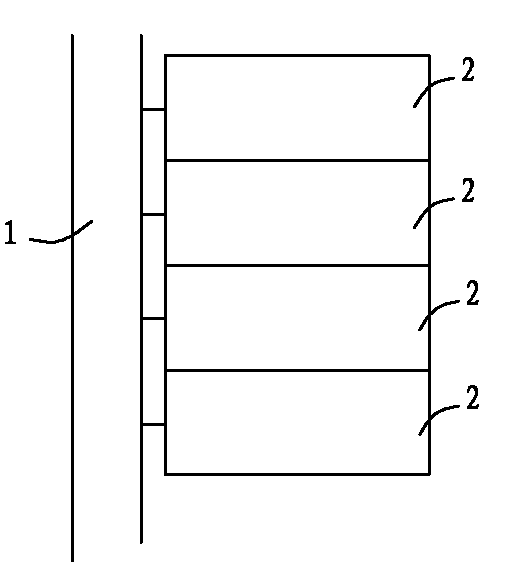

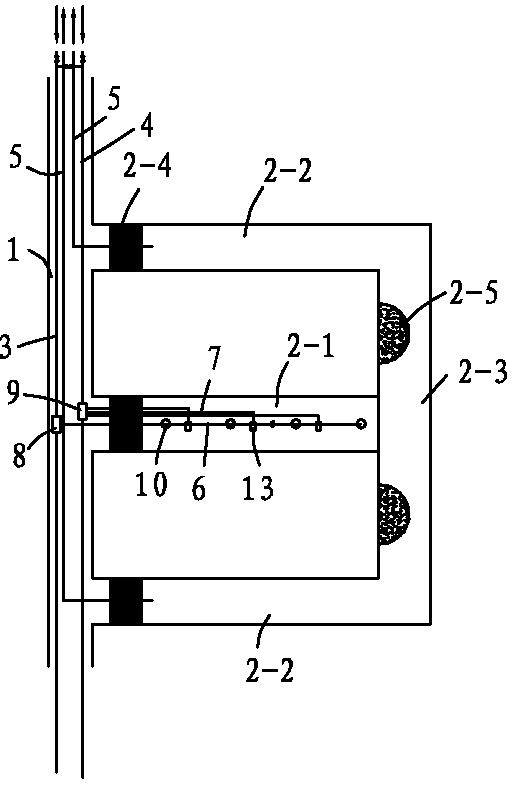

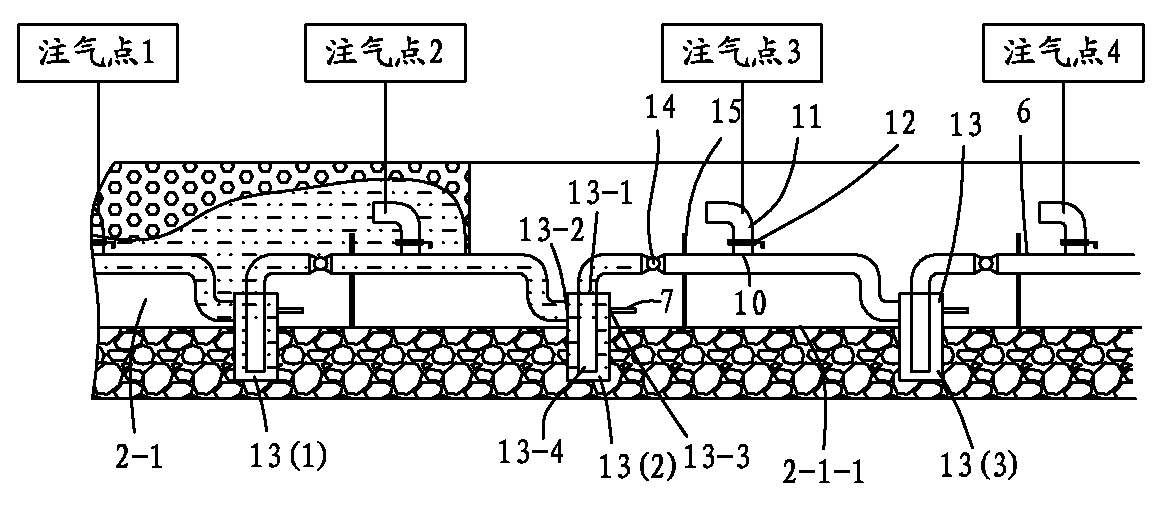

Gas injection point retreating type coal underground gasification system and process

InactiveCN103277082AAvoid cloggingPrevent backflowConstructionsCoal gasificationThermodynamicsCombustion

The invention discloses a gas injection point retreating type coal underground gasification system and process. The gas injection point retreating type coal underground gasification system comprises an airway arranged in a coal layer and multiple coal underground gasification units, wherein the airway is connected to the multiple coal underground gasification units; and the technical steps are sequentially as follows: a step of cold-state testing, a step of ignition on a gasification working surface, a step of debugging of the gasification working surface and a step of gasification normal production process. According to the invention, mud can be prevented from blocking the gas injection point efficiently, and the coal layer can be exploited to the maximum extent, so that possibility of thoroughly cutting off the leakage of a gasification agent to a combustion space area is realized while safe retreating in the coal underground gasification process is realized, filling of the combustion space area is realized, collapse of the ground surface caused by the gasification is removed, stability of the gasification channel structure is guaranteed, problem of the short circuit of the gasification agent caused by a channel which is resulted from collapse of a coal layer plate in the gasification area in the early stage and the gasification channel at the later stage of the underground gasification is solved, the quality of the coal gas is improved, and safe and reliable coal gas production and high gasification rate are achieved.

Owner:HENAN ZHONGKUANG KENENG COAL CHEM

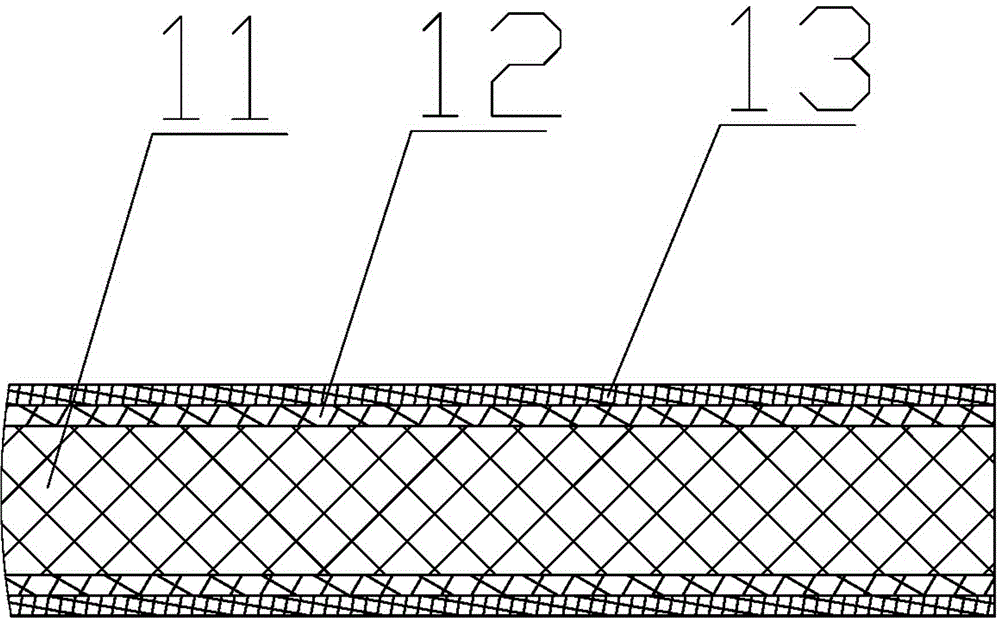

Low-temperature pretreatment process of full-cotton woven fabric

ActiveCN102220684AReduce qualityImprove refining effectBiochemical fibre treatmentDry-cleaning apparatus for textilesPulp and paper industryPre treatment

The invention relates to a continuous type low-temperature boiling-off and bleaching pretreatment process of full-cotton woven fabric. At present, the low-temperature boiling-off and bleaching of pre-treatment process exists, but are only the pre-treatment processing process for cotton and blended knitted fabric; research findings or patent documentation of pre-treatment process taking low-temperature boiling-off and bleaching of full-cotton woven fabric are not found at present. In the invention, hot water pre-treatment processing, biological enzyme processing, hot water washing and enzyme blanching and water washing process are firstly preformed on the full-cotton woven fabric, and then the low-temperature scouring and bleaching processing, the low-temperature steam bleaching processingand the water washing process are then performed to finish the pre-treatment of the cotton woven fabric. In the invention, the cotton woven fabric is pre-treated in combination with biological enzymedesizing and the low-temperature scouring and bleaching; the technology in the invention has a good effect without sizing agent residuals and residual cotton seed hulls, and the brightness achieves the effect of the traditional soda boiling and oxygenation bleaching technology.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +2

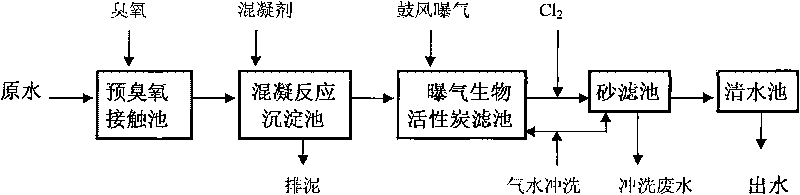

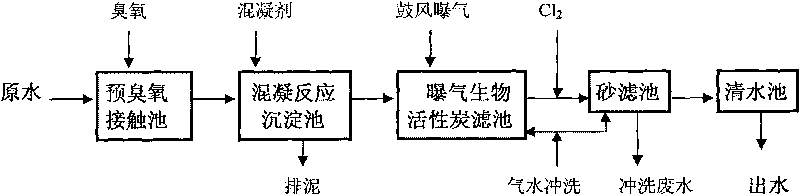

Feedwater treatment method by pre-ozonation and aerated biological activated carbon

InactiveCN101704609AAvoid breedingReduce qualityTreatment using aerobic processesMultistage water/sewage treatmentWater sourceWater quality

The invention discloses a method for applying pre-ozonation and aerated biological activated carbon processes to feedwater treatment. The method combines ozone pre-oxidation, an aerated biological activated carbon filter tank and a coagulation-sedimentation-sand filtering-disinfection conventional feedwater treatment process to produce drinking water, is a feedwater treatment process for improving water quality of feed water aiming at micro-polluted drinking water sources, and integrates the characteristics of an aerated biofilter biological pre-treatment process and an ozone biological activated carbon advanced water-purifying process. Raw water enters a pre-ozonation contact tank, a coagulation sedimentation tank and the aerated biological activated carbon filter tank orderly, is disinfected, enters a sand filtering tank, and finally flows into a clear water tank. Because the pre-ozonation contact tank and the aerated biological activated carbon filter tank are arranged in the conventional feedwater treatment process, the effect of removing organic matters, ammonia nitrogen, pathogenic microorganism, odor, chroma and the like is greatly improved, and the water quality safety of the method is obviously superior to that of the biological pre-treatment process and the ozone biological activated carbon advanced water-purifying process.

Owner:SOUTH CHINA UNIV OF TECH

Method for processing fish collagen oligopeptide

ActiveCN101297673AReduce qualityAvoid environmental pollutionCosmetic preparationsPeptide/protein ingredientsProtein contentPre treatment

The invention discloses a processing method of fish collagen oligopeptide, which comprises the following steps: delimed and degreased dry scales are selected as raw material, after being treated with cleaning, pretreatment, enzymolysis, filtration, decolorization, taste escaping, desalinization, aseptic filtration, concentration, and spray drying, fish collagen oligopeptide powder is obtained; according to dry basis, the fish collagen oligopeptide powder contains: protein content of no less than 95 percent, ash content of less than 0.5 percent, and average molecular weight of 700Dalton. The product processed by the method of the invention has the advantages of high quality, colorlessness, no bitter taste or stink, low salt content, no poisonous or side effect, and short enzymolysis time, the resin filling used during the adsorption process is renewable and can be repeatedly used for a plurality of times, and the problems of wasting of resources and high ash content of the product caused by using the disposable activated charcoal are avoided, thus being widely applied in the fields of food, health products, medicine and cosmetics, etc.

Owner:BEIJING SEMNL BIOTECHNOLOGY CO LTD +2

Alginic acid fertilizer synergist with ammonia volatilization inhibiting effect and preparation method of alginic acid fertilizer synergist

The invention discloses an alginic acid fertilizer synergist with an ammonia volatilization inhibiting effect. The alginic acid fertilizer synergist is characterized by being prepared from the following ingredients in parts by weight: 60-80 parts of seaweed, 2-5 parts of strains, 5-10 parts of carbon sources, 3-5 parts of nitrogen sources, 30-50 parts of water, 1.2-1.5 parts of medium trace elements, 0.4-0.6 parts of soil loosening agent, 2-4 parts of acid soil conditioners and 0.8-1.2 parts of plant growth regulators. The prepared alginic acid fertilizer synergist adopts the pure natural ingredients, so that the alginic acid fertilizer synergist is excellent in environmental protection property, can be degraded completely, and can facilitate a plant to absorb nutrients in soil; an ammonia volatilization inhibiting rate reaches up to 34-45%; the soil loosening agent can loosen the soil; the acid soil conditioner can improve a micro ecological environment of the soil and promote yield increasing of crops; the plant growth regulator accelerates germination and can increase the stress resistance of the crops; and the chelating state medium trace elements can increase the utilization ratio of nutrients and improve the quality of the crops.

Owner:QINGDAO HAILIYUAN BIOTECH

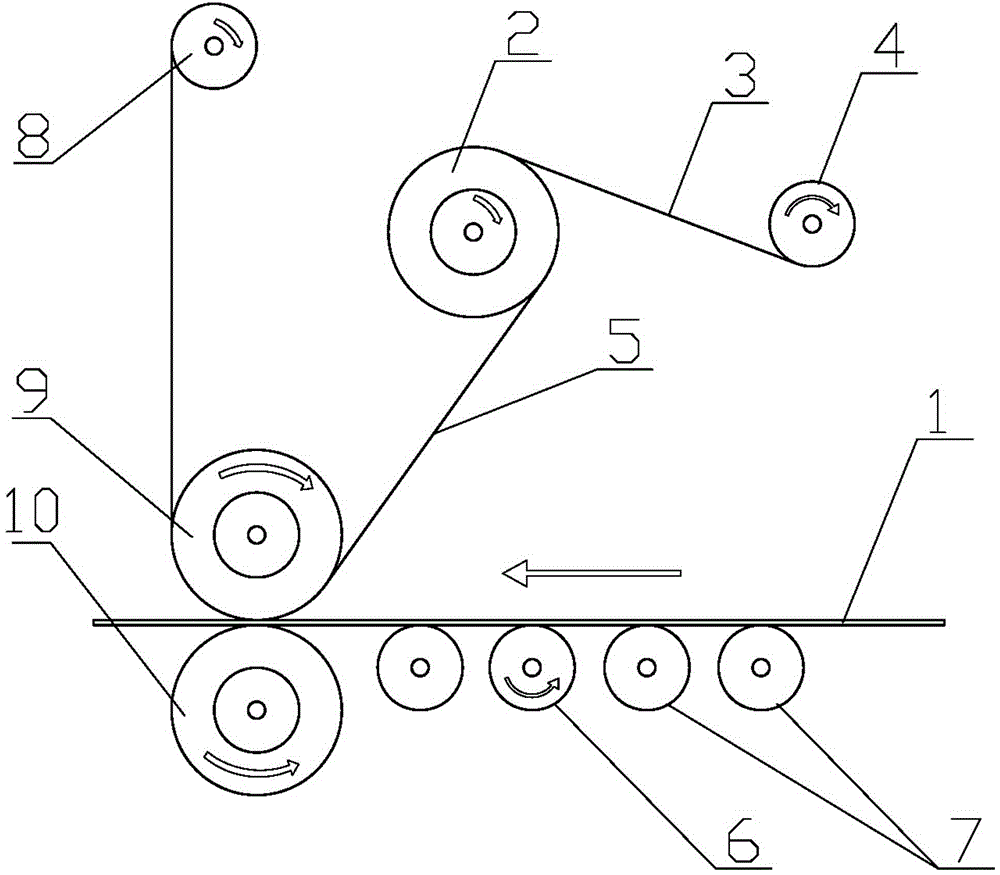

Film tearing method and film tearing device of film pasting plate in printed circuit board (PCB) production

InactiveCN104827748AFully automatedReduce labor intensityLamination ancillary operationsLaminationPolyethylene glycolEngineering

The invention discloses a mechanical automatic film tearing method of a film pasting plate in printed circuit board (PCB) production, the mechanical automatic film tearing method is characterized in that: in the process of transmission of the film pasting plate, a PET (polyethylene glycol terephthalate) protective film is pasted by an adhesive tape, the PET protective film is separated from the film pasting plate, and the adhesive tape stuck with the PET protective film is rolled; a film tearing device comprises a frame, an adhesive tape rolling mechanism and a sticking mechanism; a film pasting plate delivery mechanism comprising a driving wheel is arranged on the frame, the adhesive tape rolling mechanism comprises the adhesive tape, an adhesive tape wheel and a film collecting adhesive wheel, the sticking mechanism comprises a film uncovering rubber wheel, the adhesive tape on the adhesive tape wheel is winded on the film collecting adhesive wheel by the film uncovering rubber wheel, in the process of transmission of the film pasting plate, the PET protective film on the film pasting plate is stuck up by the film uncovering rubber wheel for separation of the PET protective film and the film pasting plate, at the same time, the adhesive tape stuck with the PET protective film is rolled by the film collecting adhesive wheel, the method is simple, the automation of artificial film tearing is realized, the production efficiency and product stability can be improved, artificial operation factors can be eliminated, product quality can be better controlled, the labor intensity of workers can be reduced, and the production cost can be reduced.

Owner:AOSHIKANG TECH CO LTD

Dry type manufacturing method of animal specimen

InactiveCN1971663AImprove qualityAdequate perfusionDead animal preservationEducational modelsHigh concentrationGlycerol

The invention relates to a dry type making method for animal specimen that includes six steps: collecting material, reshaping antisepsis fix and tube cavity cast, alcohol dewatering fix, glycerol process, turpentine impregnation and air drying, material repairing tinction preservation or seal up for keeping. Thereinto, in step 1, the animal material is bleed and killed via health quarantine, in step 2, potting it with the formalin with colorless glycerin and phenol or alcohol solution, in step 3, controlling the concentration of every step and fixed time, in step 4, marinating it with glycerol moisture absorption soften liquid, and transfer it from low concentration to high concentration of glycerin, and the time is prolonged gradually, in step 5, treating it with turpentine continually, in step 6, printing it. The invention improves the present technique, the quality of specimen is improved greatly, and that can keep the original state of material, the color and the luster. The dried specimen is sanitation without peculiar smell, and good at handle and quality.

Owner:王荣林

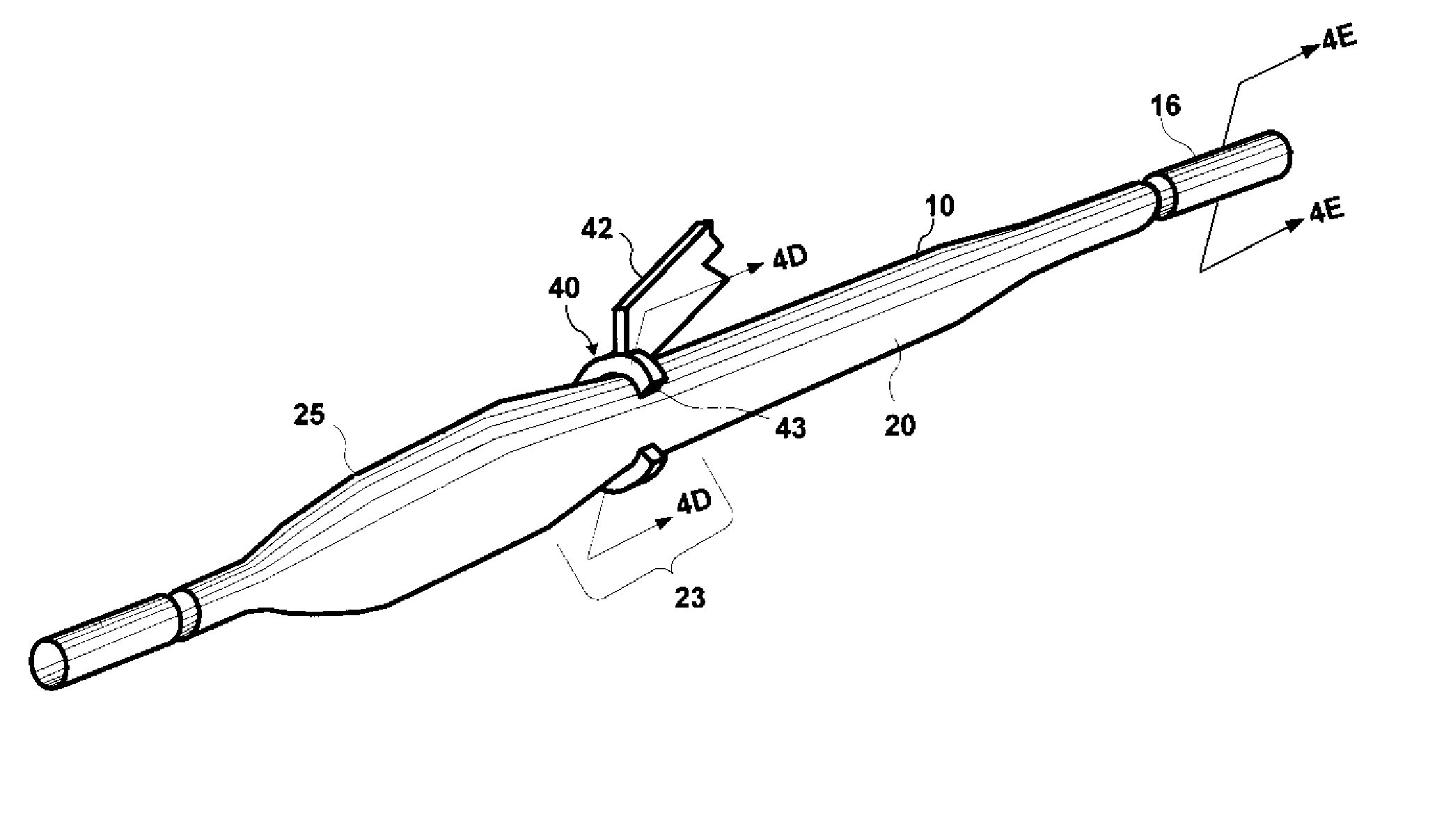

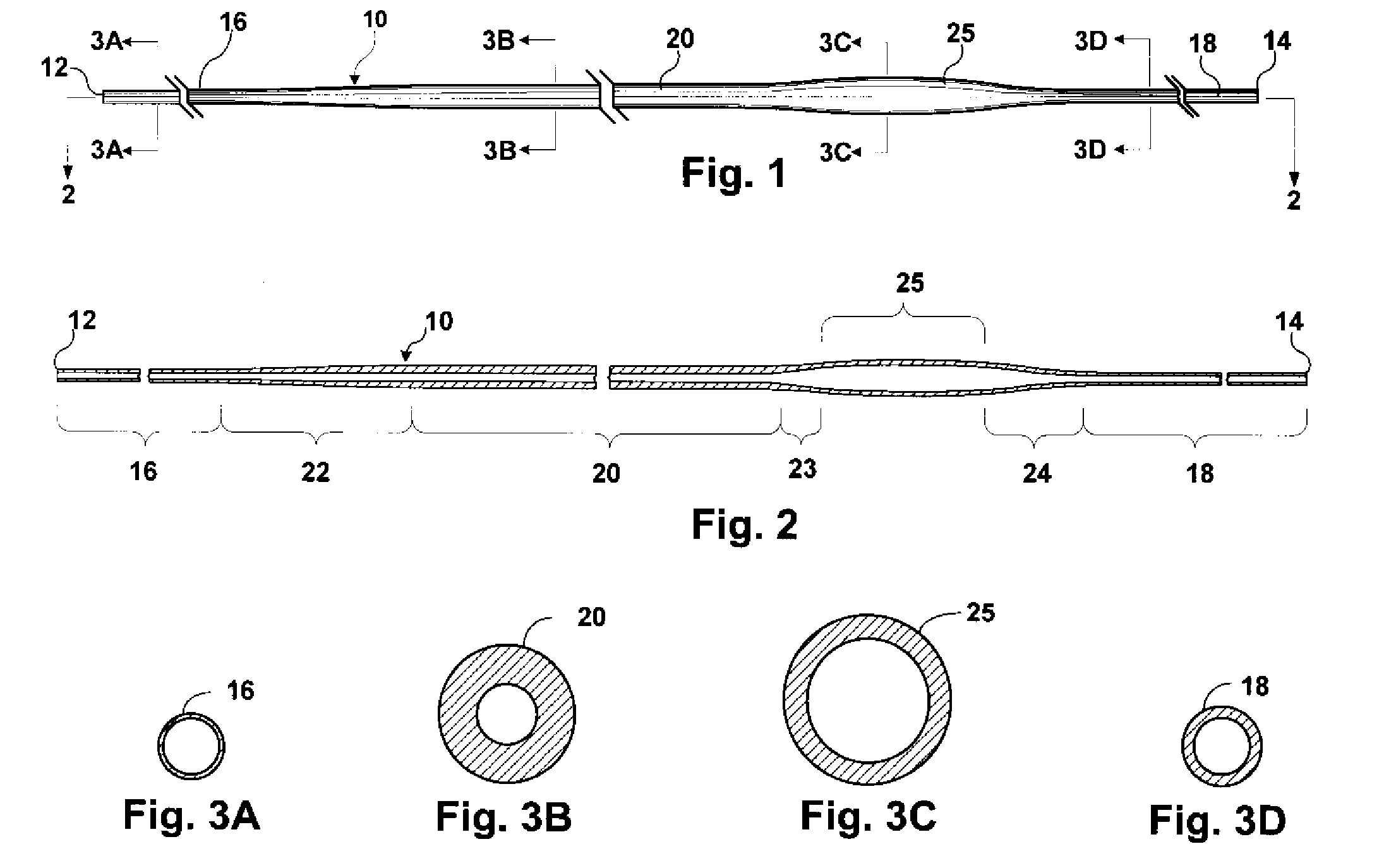

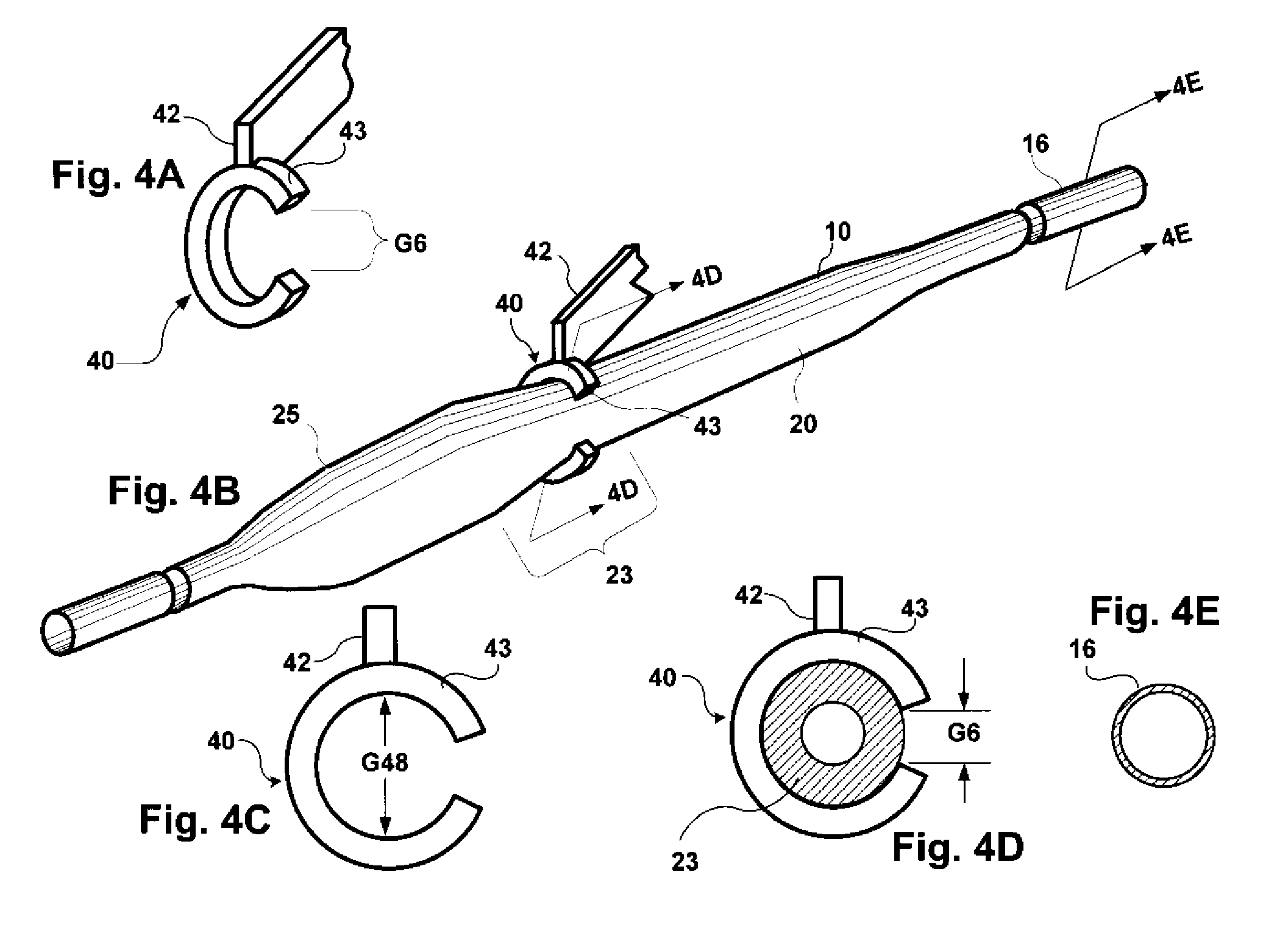

Roller pump and peristaltic tubing with atrium

InactiveUS20090053084A1Reduce qualityIncrease effective surface areaAnaesthesiaFlexible member pumpsArterial segmentMoving parts

A single piece of extruded peristaltic roller pump tubing may have an inside diameter and outside diameter and wall thickness that may vary from one segment to next along its length. The tube may be formed with an atrial segment having an OD that is larger than the ventricular OD. Also, the arterial segment wall can be distensible and may be fluted. A peristaltic pump head assembly may have a C-shaped tube-holder which has no moving parts; secures the tubing 10 in pump assembly without the clamps, flanges or other tube-attaching devices; and provides a safer method for inserting the tubing into the pump head assembly. The inner diameter of the C-shaped tube-holder may be smaller than the OD of the atrial segment such that the atrial segment becomes snuggly wedged in the holder and prevents the incremental migration of the tubing through the roller raceway in the direction of the pump roller assembly rotation.

Owner:KLEIN JEFFREY A

High-efficiency compound microbial inoculum for fermenting beds, and preparation method and application thereof

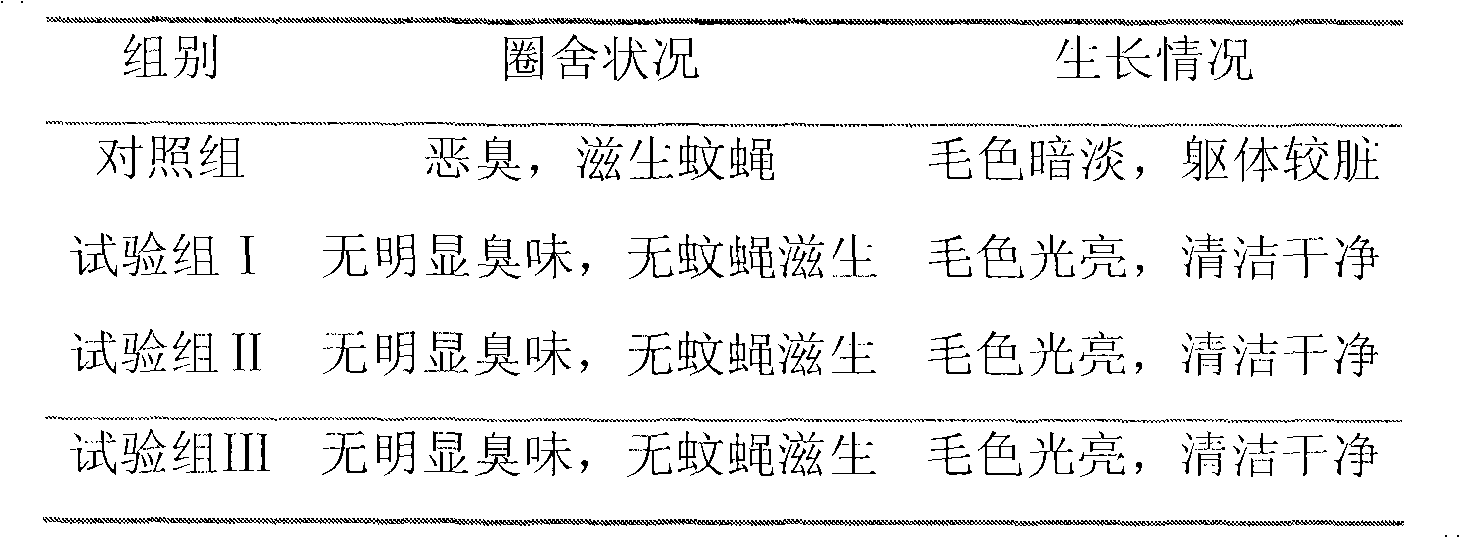

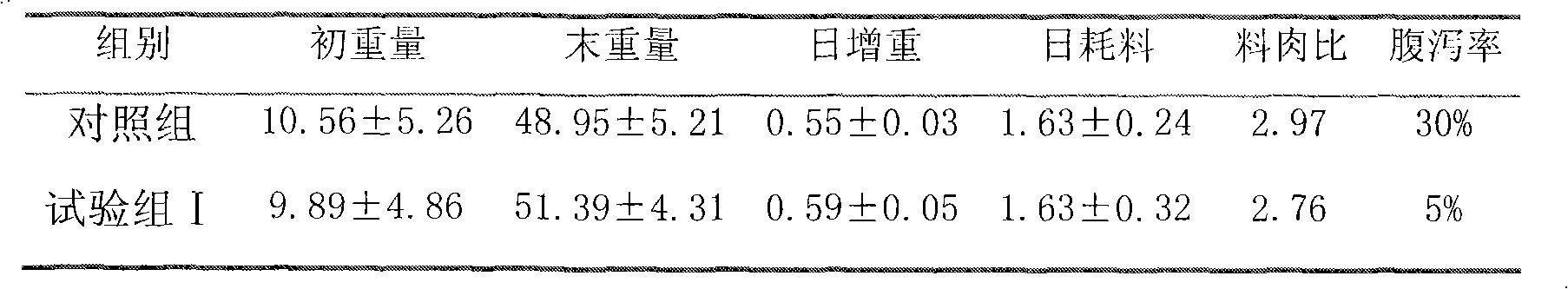

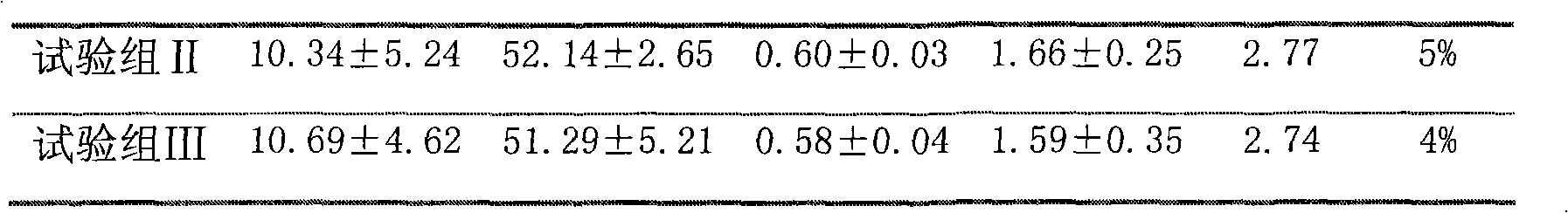

The invention provides a high-efficiency compound microbial inoculum for fermenting beds, particularly relates to a compound microbial inoculum for the fermenting beds, and a preparation method and application thereof. The compound microbial inoculum is composed of five beneficial bacterium strains (Bacillus subtilis CGMCC1.769 and CGMCC1.210, lactobacillus plantarum CICC6073, Candida tropicalis CGMCC2.587 and Trichoderma koningii CGMCC3.4290) and metabolites thereof (amylase, protease, lipase, cellulase, organic acid, bacteriophage and the like). The compound microbial inoculum is prepared by using a submerged liquid mixed fermentation technique. The method comprises the following steps: carrying out liquid submerged fermentation on the lactobacillus plantarum at 35 DEG C for 12 hours, respectively inoculating Candida tropicalis and Trichoderma koningii, carrying out mixed fermentation at 30 DEG C for 12 hours, inoculating Bacillus subtilis, carrying out liquid submerged mixed fermentation for 24 hours, respectively controlling the fermented viable count at 1-2*10<9> cfu / mL, 5-8*10<8> cfu / mL, 3-5*10<8> cfu / mL, 3-5*10<9> cfu / mL and 2-5*10<9> cfu / mL, finishing fermentation, packaging and sealing to obtain the high-efficiency compound microbial inoculum for the fermenting beds. The invention also provides application of the high-efficiency compound microbial inoculum-a preparation method of padding material. The compound microbial inoculum has the advantages of high viable count, high biological activity and low impurity bacterium pollution; the compound microbial inoculum can obviously reduce the odor of pigsties and reduce the living possibility of mosquitoes and flies, thereby achieving the ecological culture goals of no pollution and zero discharge; and the process for manufacturing the ferment bed is simple, thereby saving the padding material, human power and the like.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

Copy protected information distribution

ActiveUS20080199040A1Reduce image qualityReduce qualityCharacter and pattern recognitionSubstation equipmentComputer hardware

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com