Film tearing method and film tearing device of film pasting plate in printed circuit board (PCB) production

A technology of membrane device and lamination plate, which is applied in chemical instruments and methods, layered products, lamination auxiliary operations, etc., can solve the problems of product stability and quality that cannot be effectively guaranteed, labor intensity of workers, and high production costs. Eliminate human operation factors, reduce labor intensity, and achieve the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

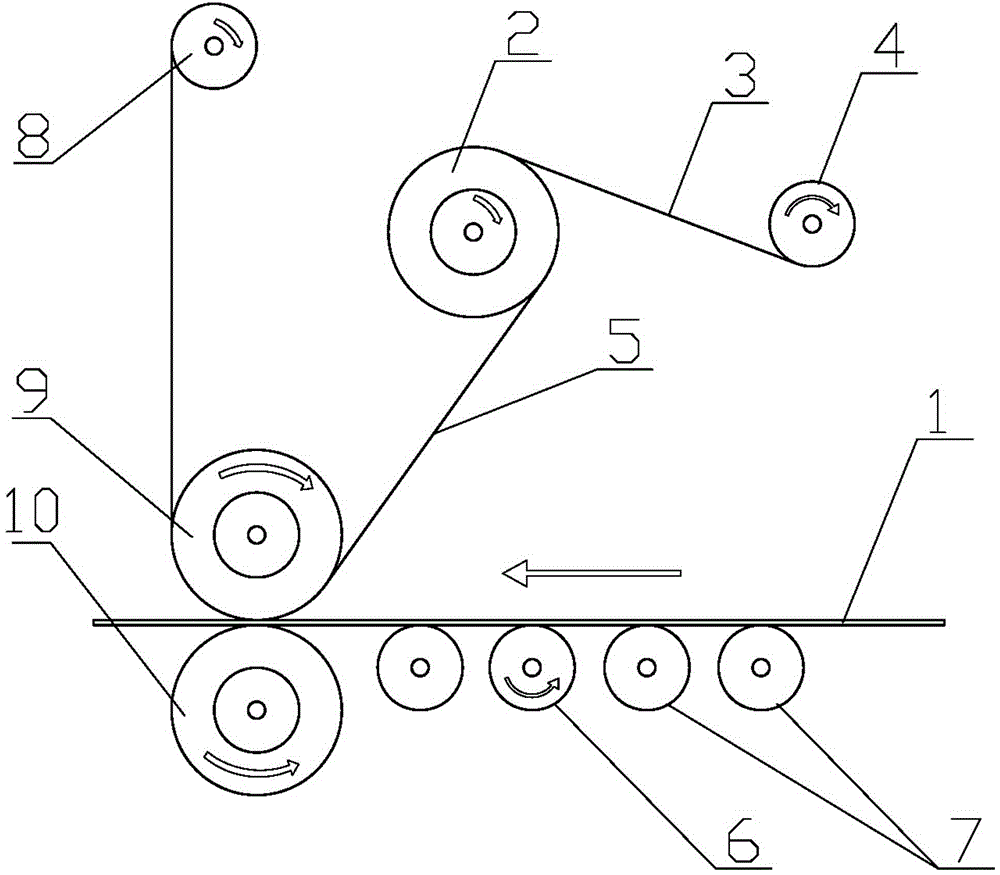

[0023] A film-tearing method for a film board in PCB production, which includes a film board transmission mechanism for conveying a film board, an adhesive tape coated with a layer of adhesive on the surface, an adhesive tape winding mechanism, and a sticking mechanism; the film board is in the process of conveying , The PET protective film on the film-attaching board is stuck up by the adhesive tape through the sticking mechanism and the PET protective film is separated from the film-attaching board. At the same time, the adhesive tape with the PET protective film is rolled up.

[0024] In order to ensure that the adhesive tape sticks to the PET protective film, the conveying speed of the film sticking board in the present invention is 2m / min˜5m / min.

[0025] In order to ensure that the adhesive tape sticks to the PET protective film, the conveying speed of the film sticking board in the present invention is preferably 3m / min˜4m / min.

[0026] The conveying speed of the film s...

Embodiment 2

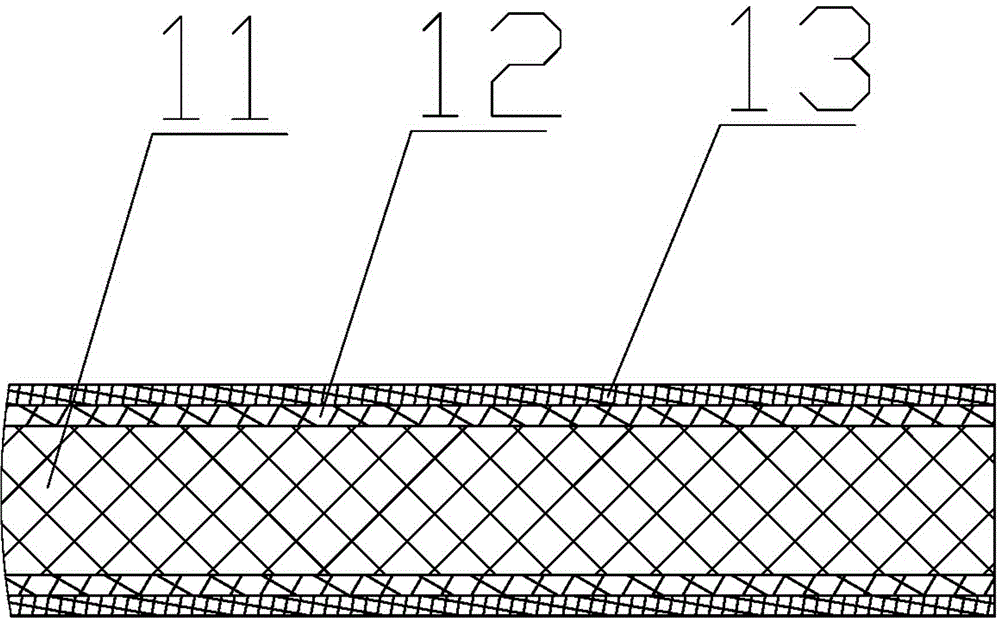

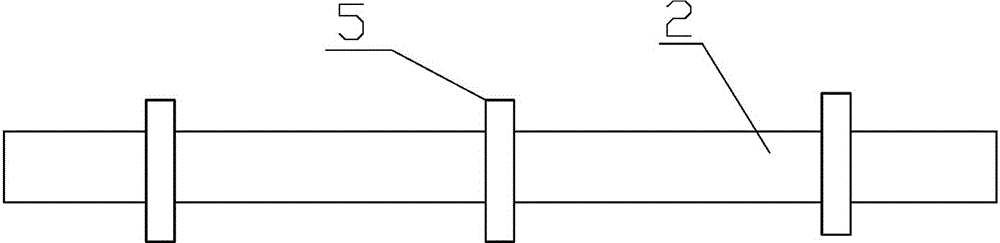

[0038] Depend on Figure 4 It can be seen that, in order to remove the PET protective film 13 on both sides of the film-sticking board 1 at the same time, the adhesive tape winding mechanism of the present invention is divided into two groups, which are respectively arranged on the two sides of the film-sticking board 1. 9; The tape 5 on each group of tape wheels 2 is wound on the corresponding film-receiving rubber wheel 8 through the corresponding film-removing rubber wheel 9, and the pressure between the two film-removing rubber wheels 9 is 1㎏ / ㎝ 2 ~4㎏ / ㎝ 2 (This example is 2㎏ / ㎝ 2 ); during the transmission process of the sticking plate 1 to the sticking mechanism, the PET protective film 13 on the sticking plate 1 that is in contact with the adhesive surface of the sticking tape 5 is respectively stuck up by 2 peeling rubber wheels 9 with the tape 5 wrapped around it. The PET protective film 13 is separated from the film sticking board 1 , and at the same time, each film-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com