Patents

Literature

1926results about "Handling discharged material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

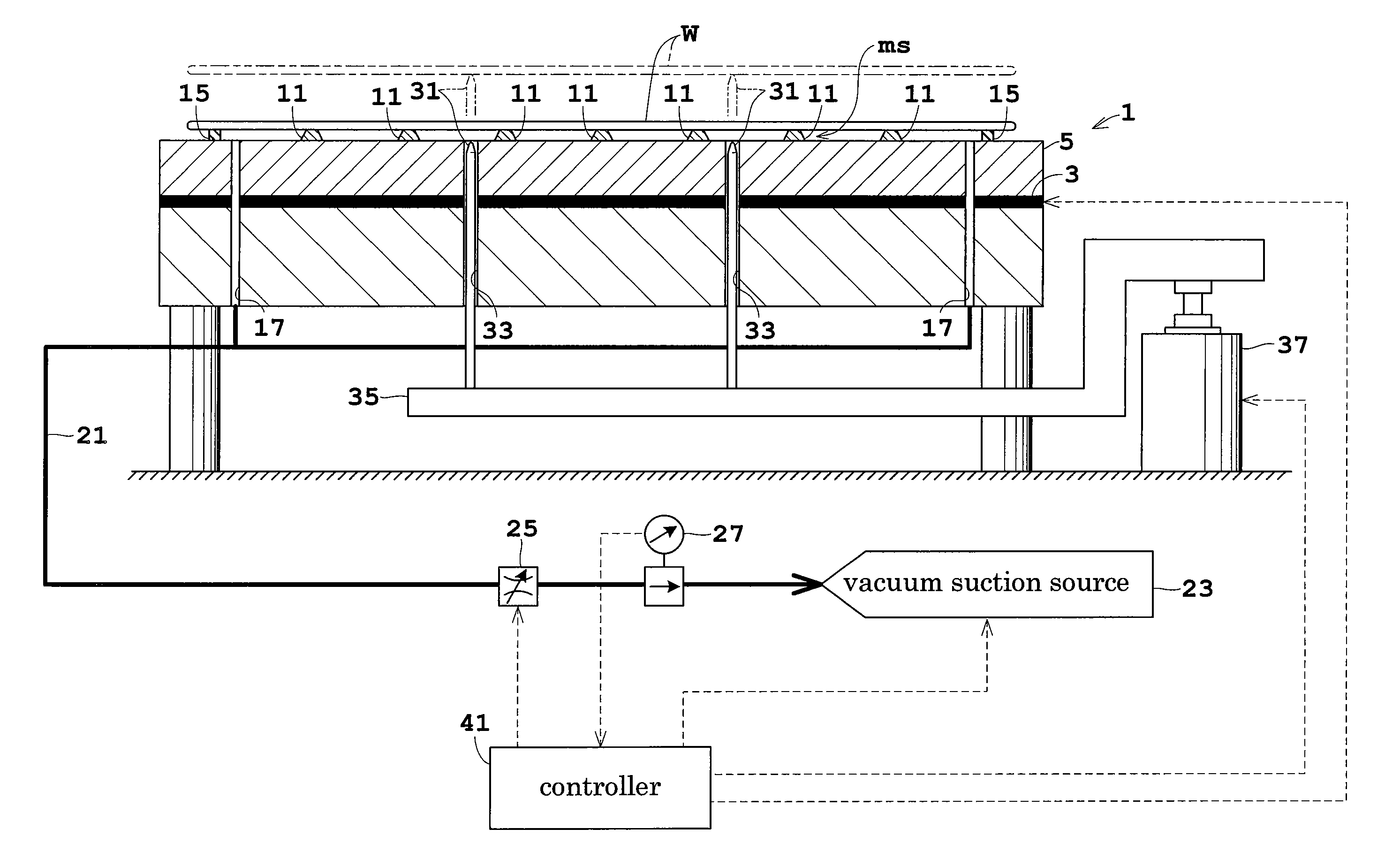

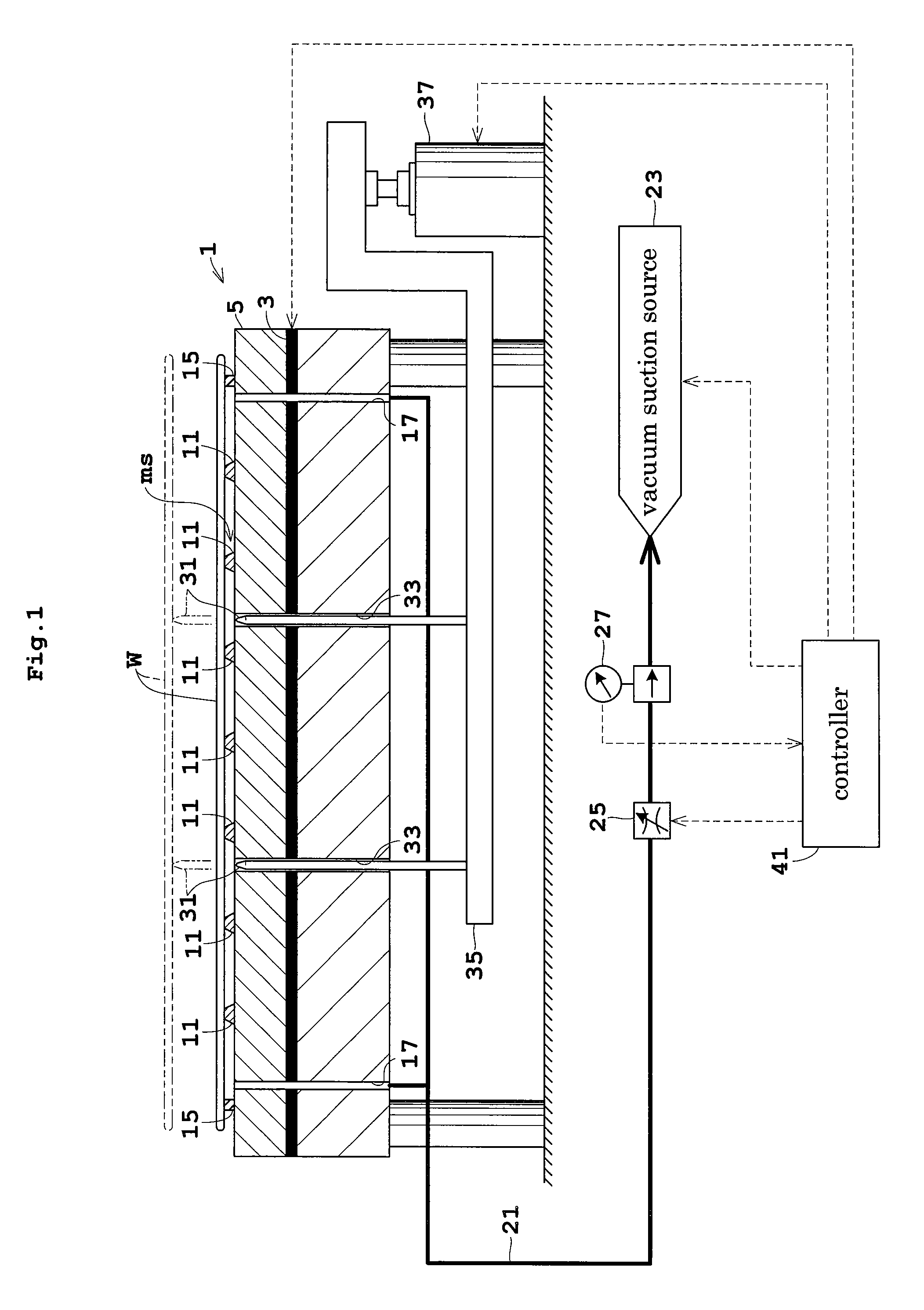

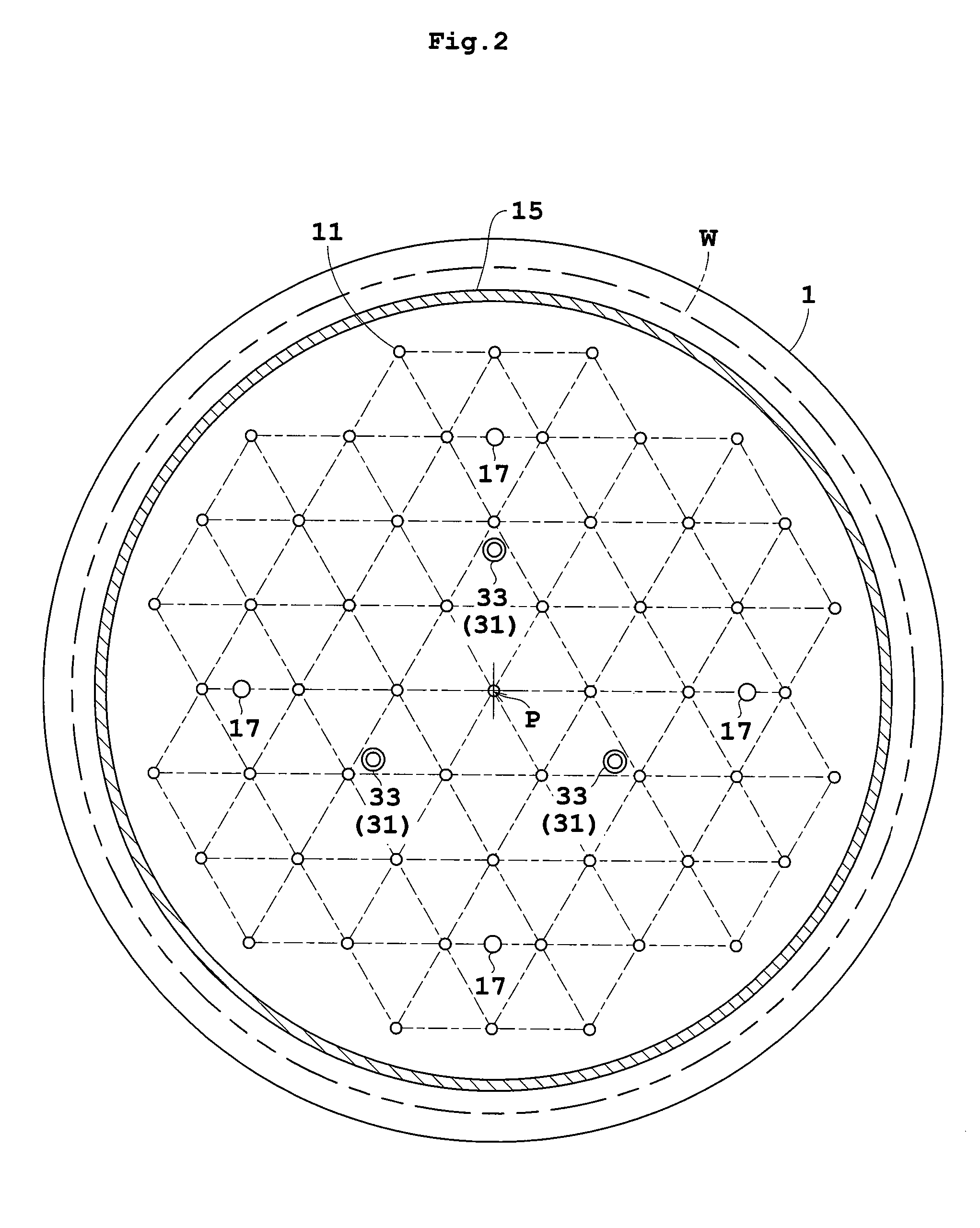

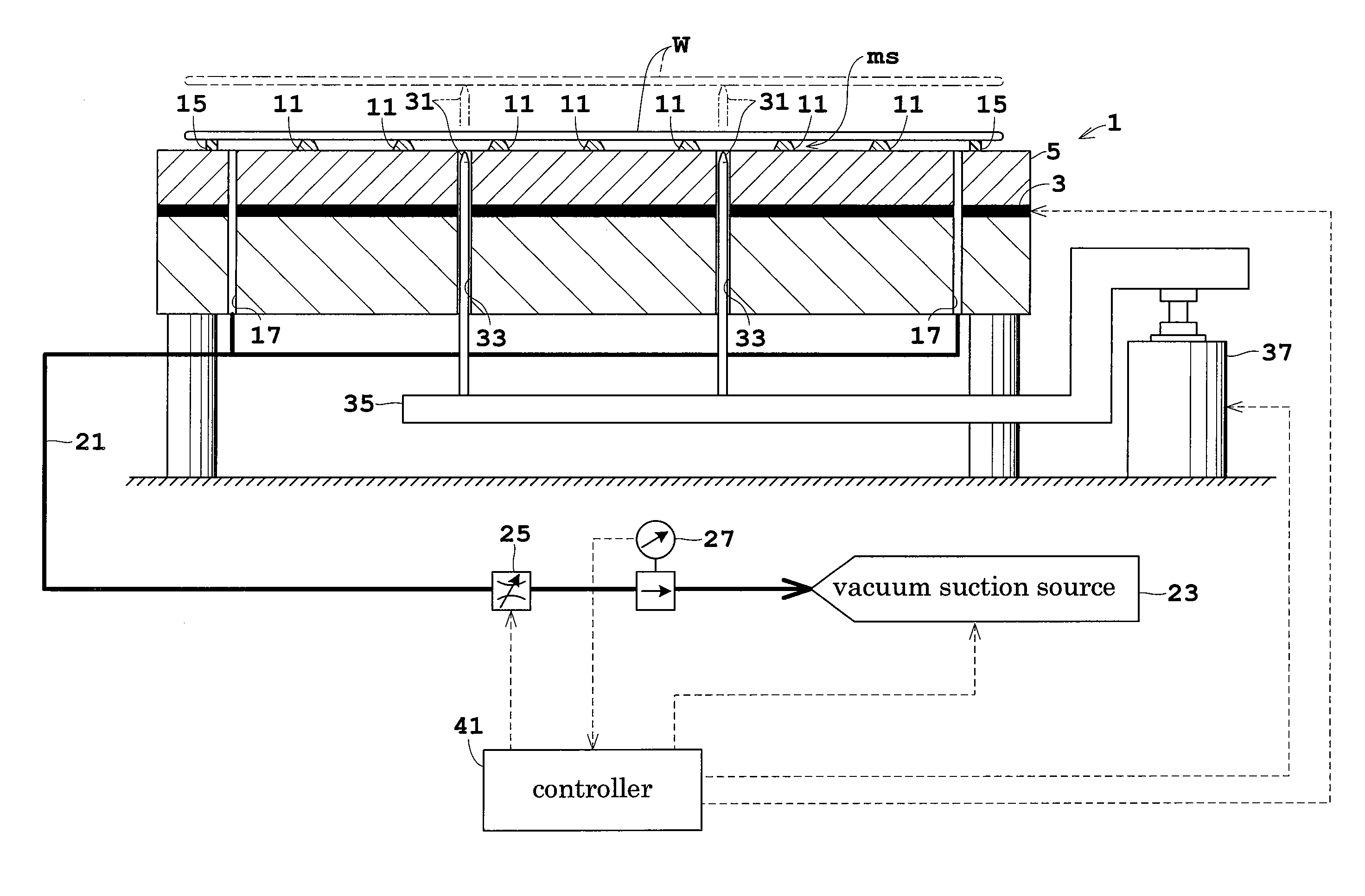

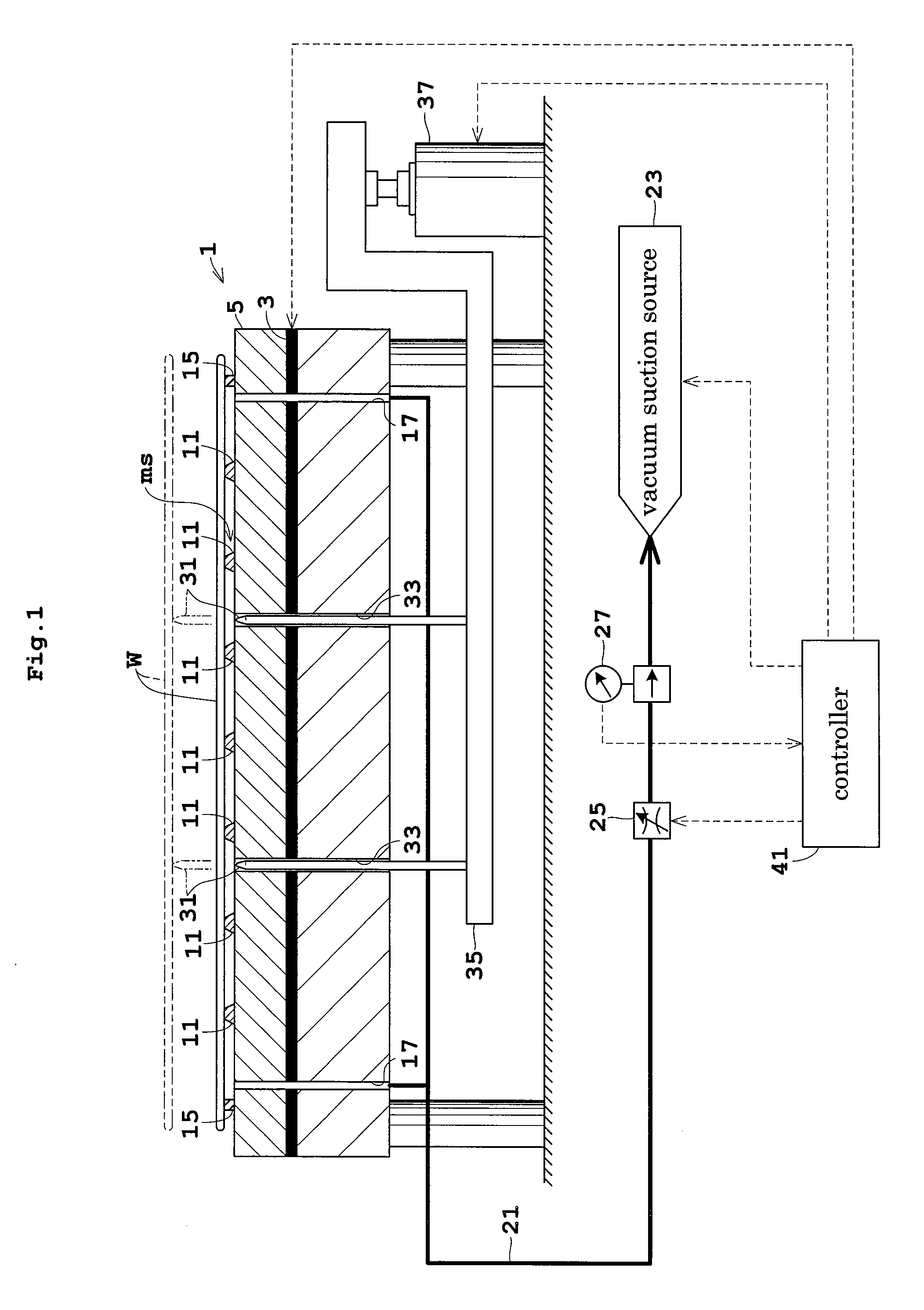

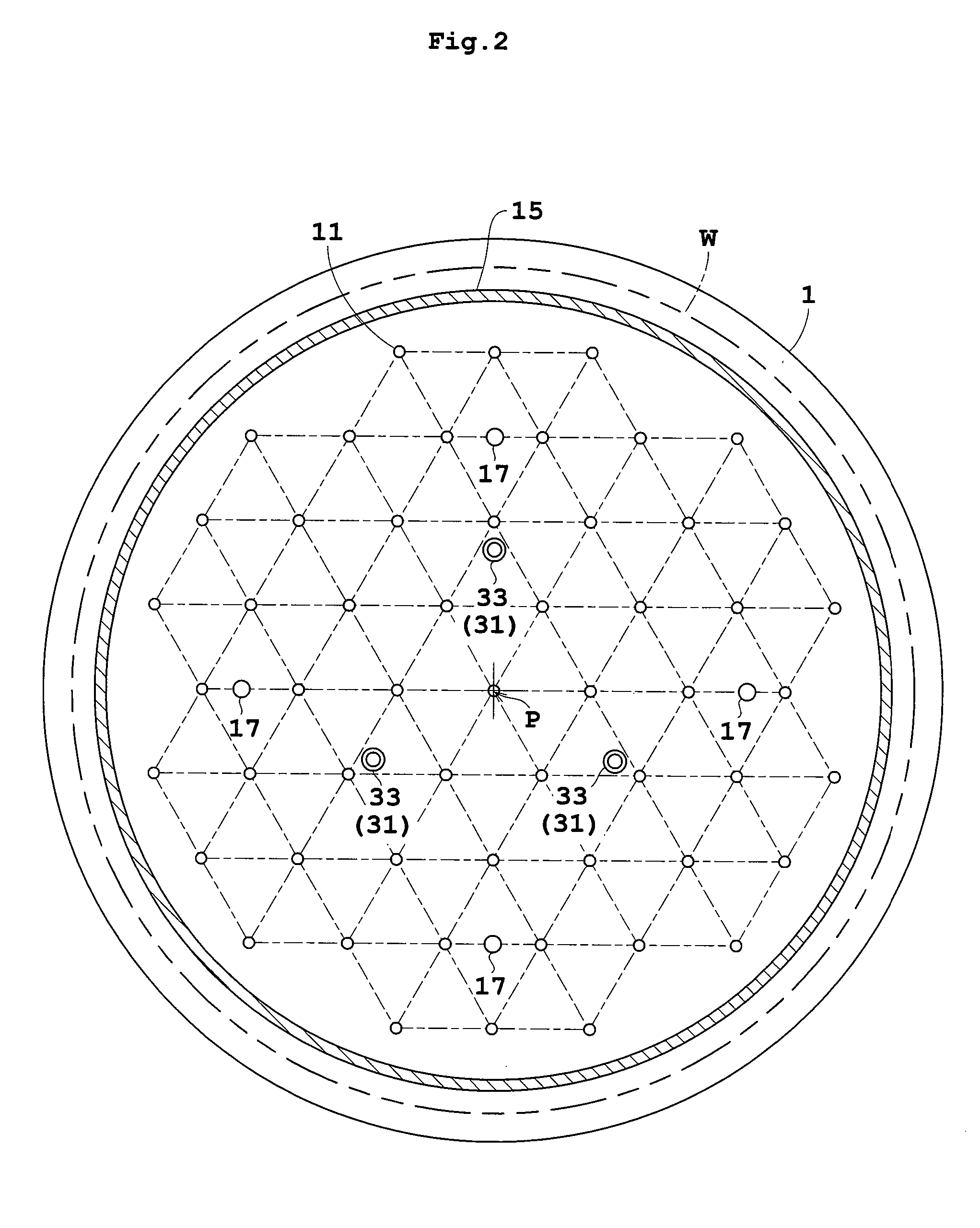

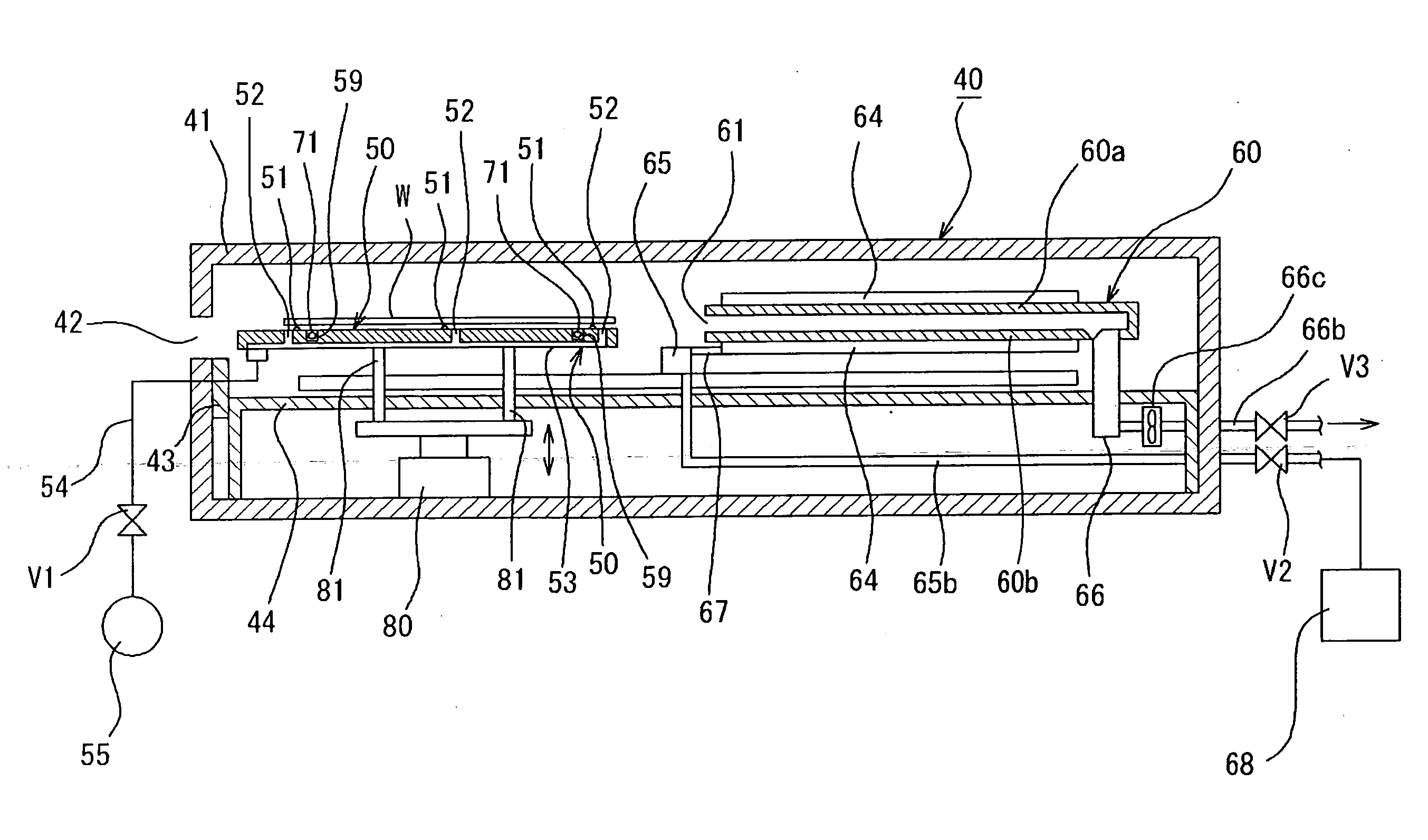

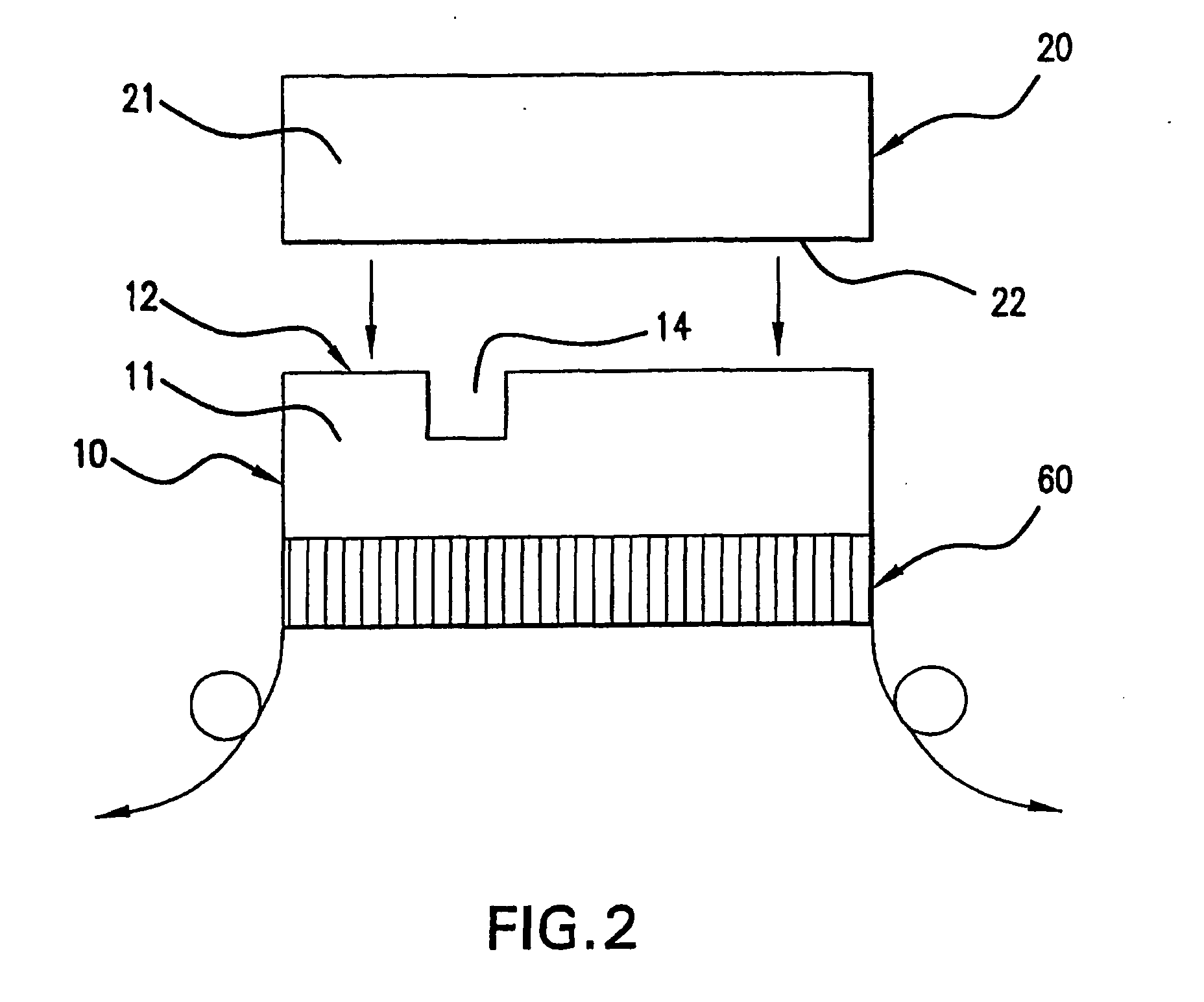

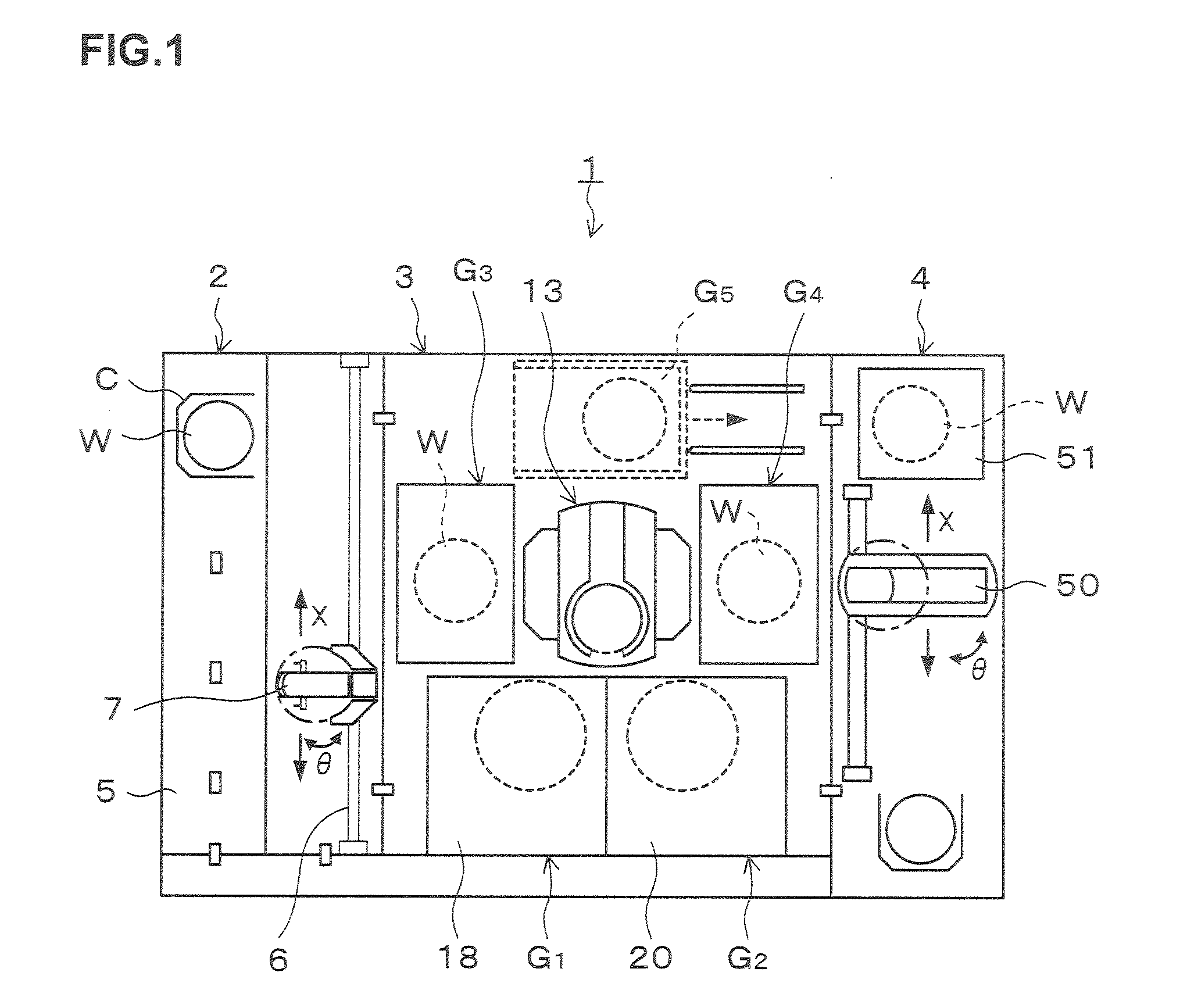

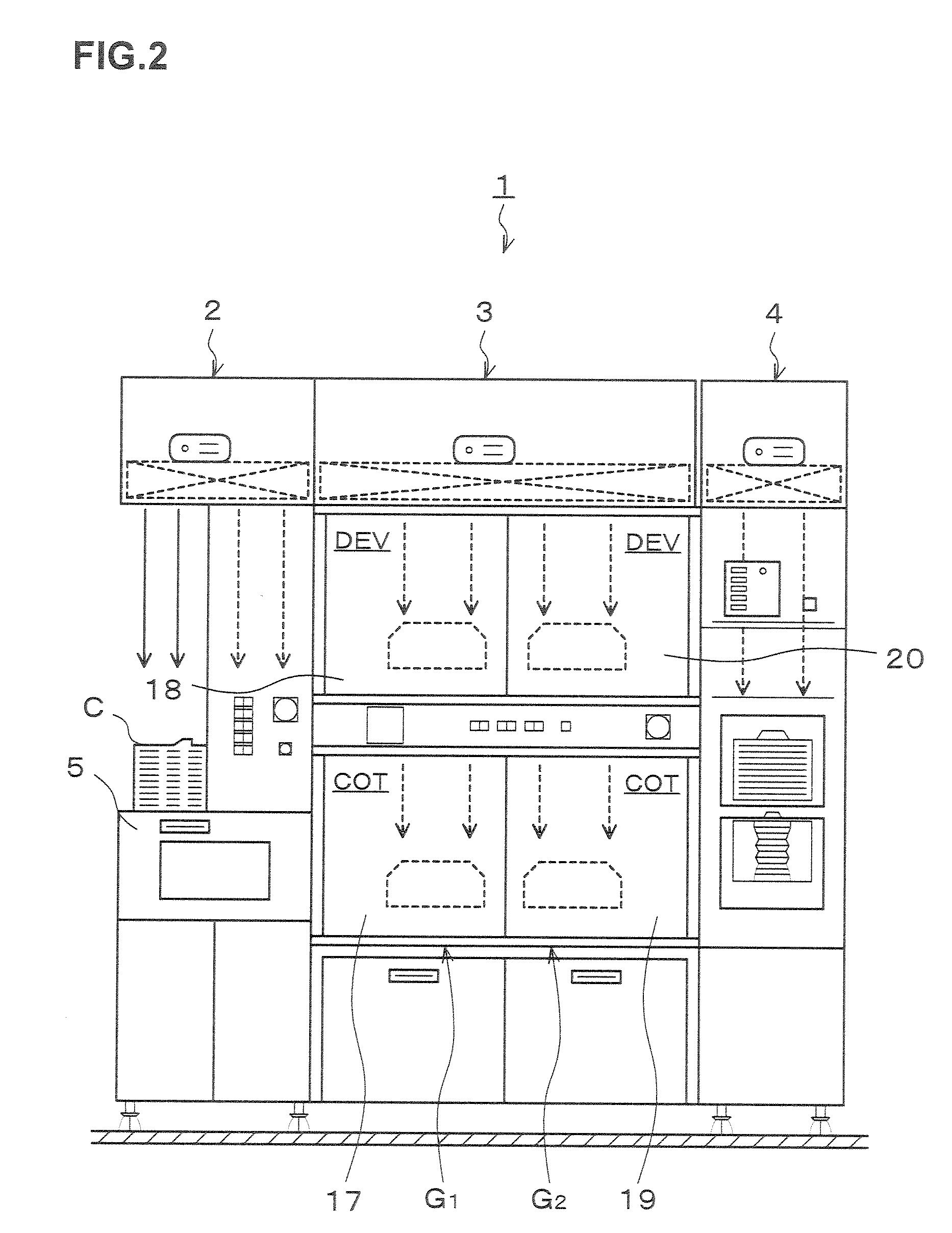

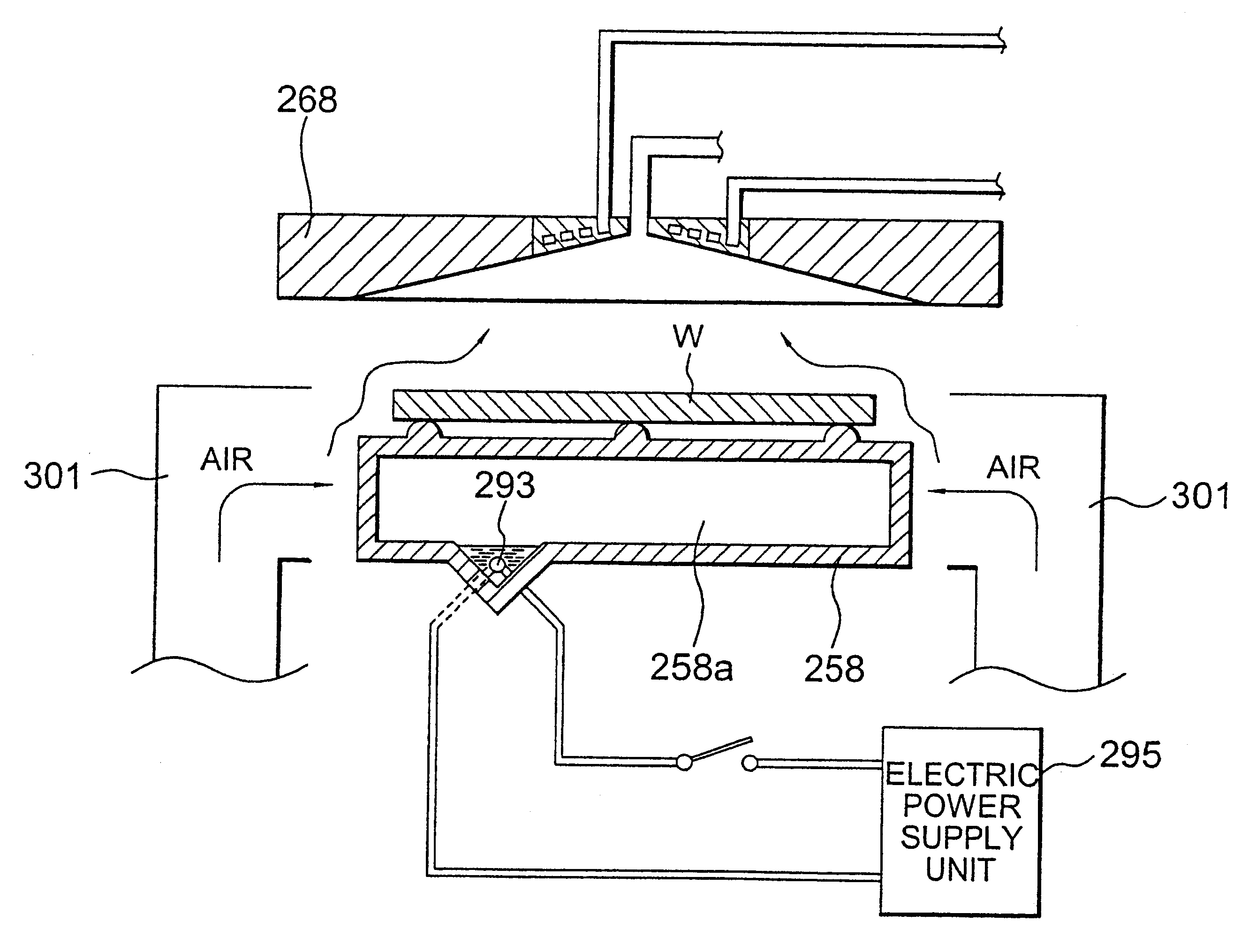

Substrate heat treatment apparatus

A substrate heat treatment apparatus includes a heat-treating plate having a flat upper surface, support devices formed of a heat-resistant resin for contacting and supporting a substrate, a seal device disposed annularly for rendering gastight a space formed between the substrate and heat-treating plate, and exhaust bores for exhausting gas from the space. The support devices are formed of resin, and the upper surface of the heat-treating plate is made flat, whereby a reduced difference in the rate of heat transfer occurs between contact parts and non-contact parts on the surface of the substrate. Consequently, the substrate is heat-treated effectively while suppressing variations in heat history over the surface of the substrate.

Owner:DAINIPPON SCREEN MTG CO LTD

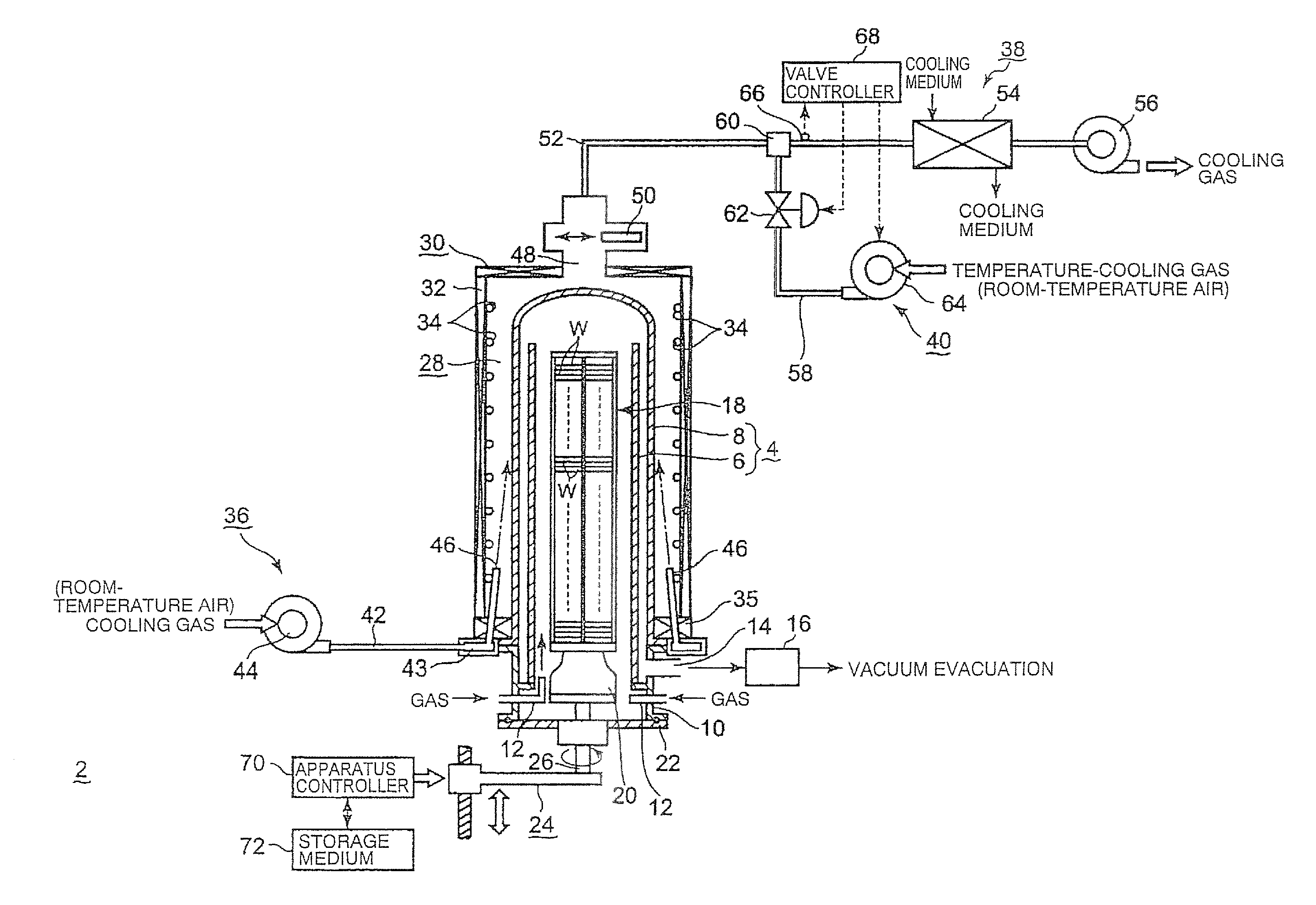

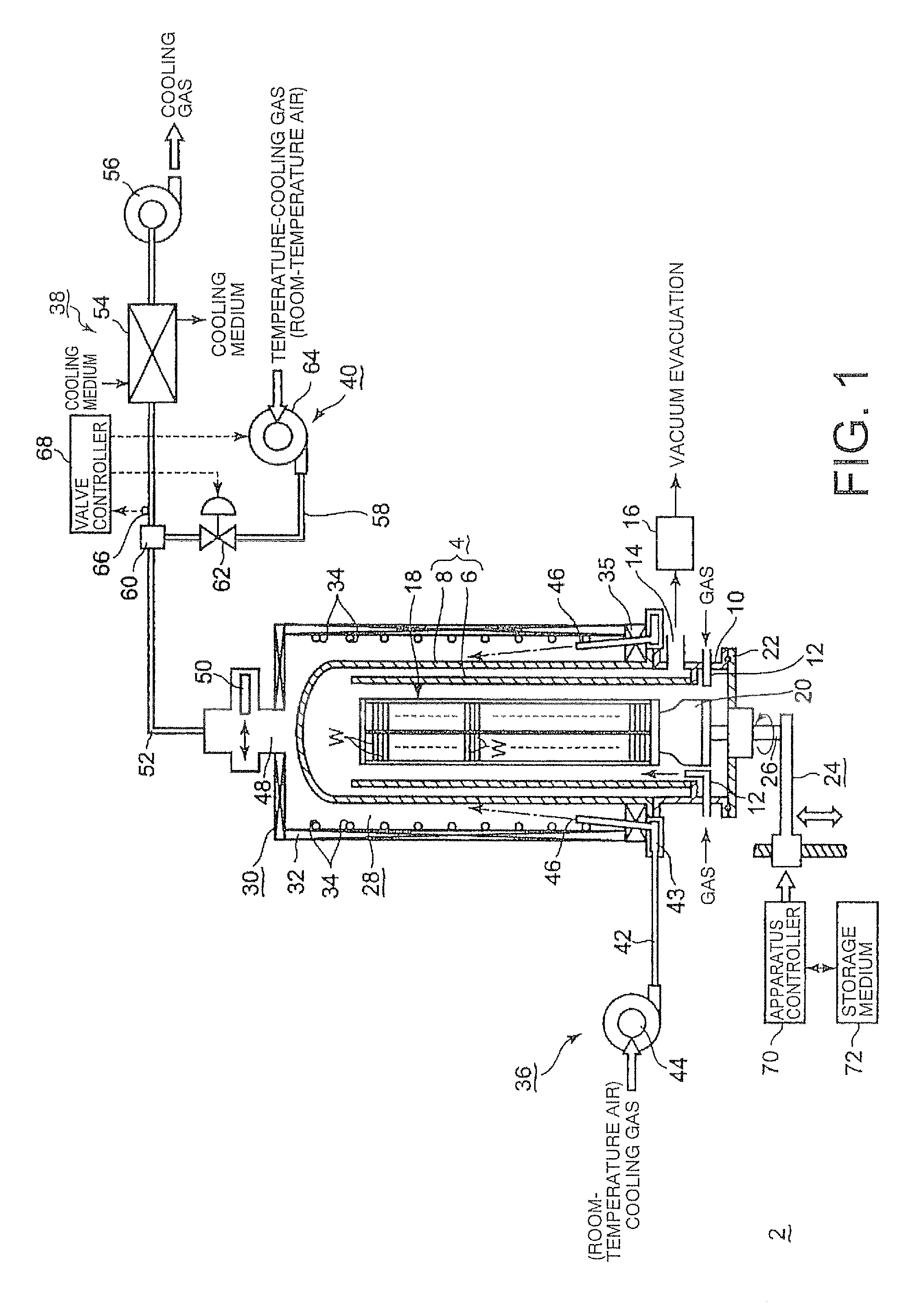

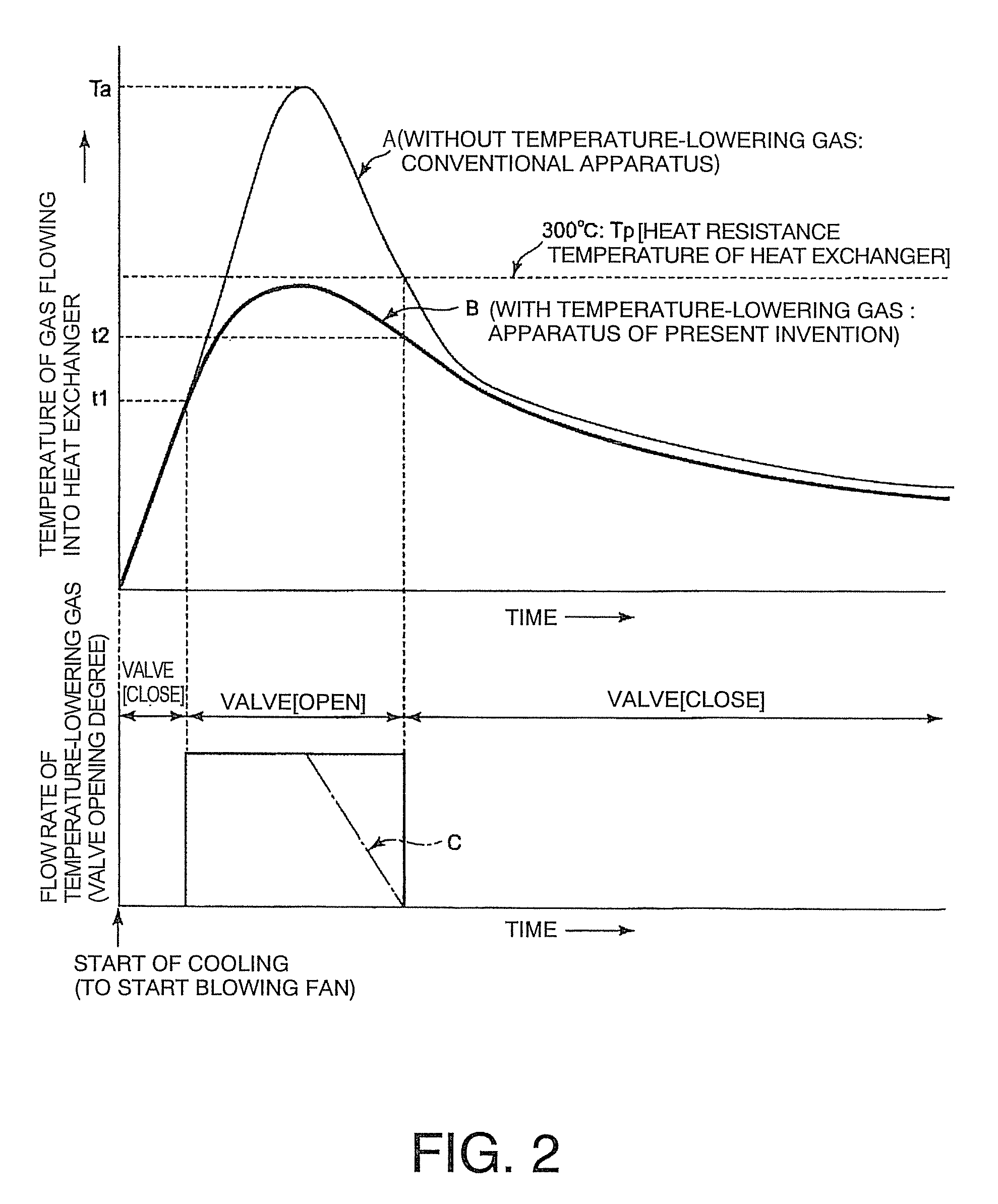

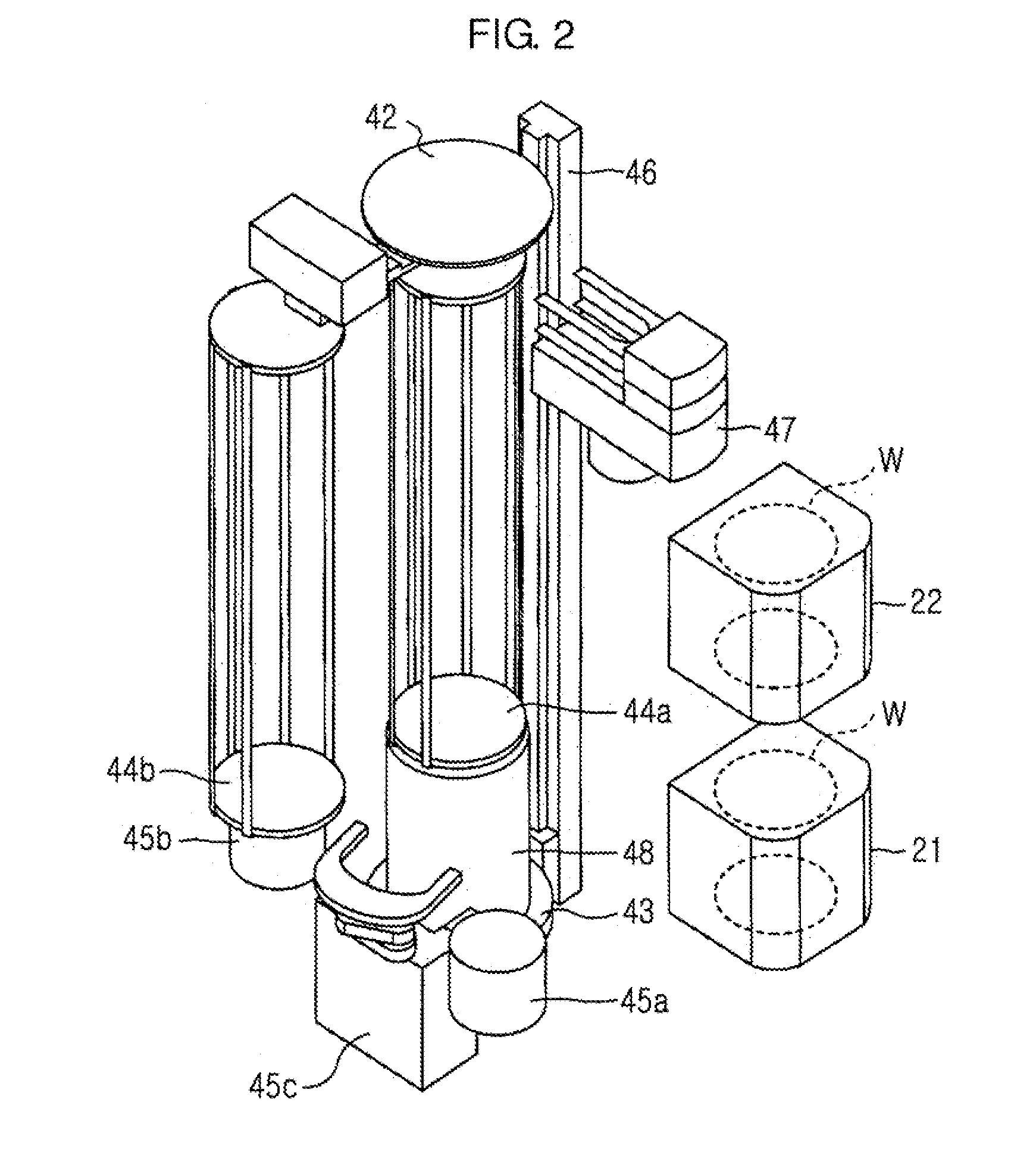

Thermal processing apparatus and cooling method

InactiveUS9099505B2Efficient solutionLow heat resistanceAfter-treatment apparatusSemiconductor/solid-state device manufacturingProcess engineeringHeating furnace

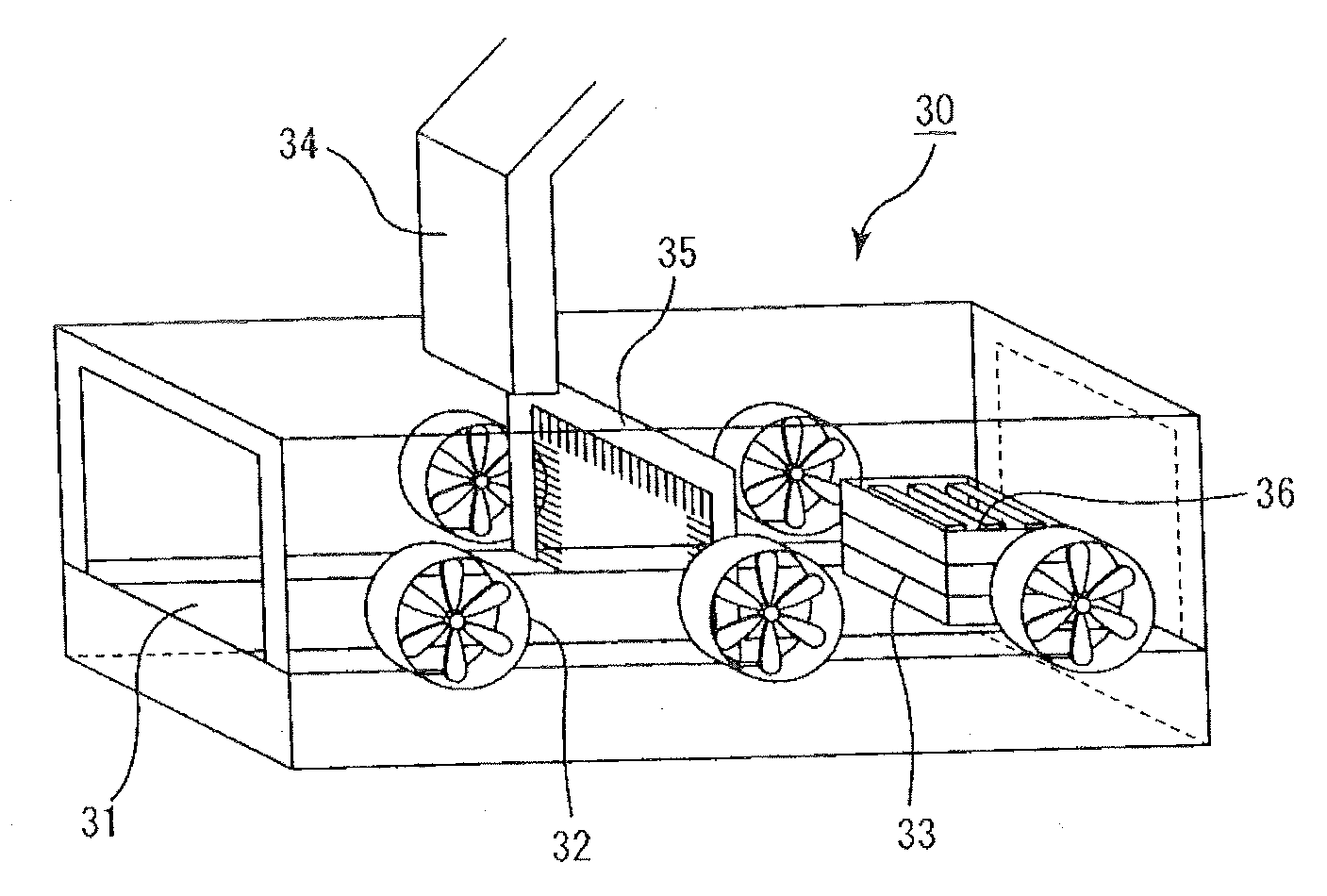

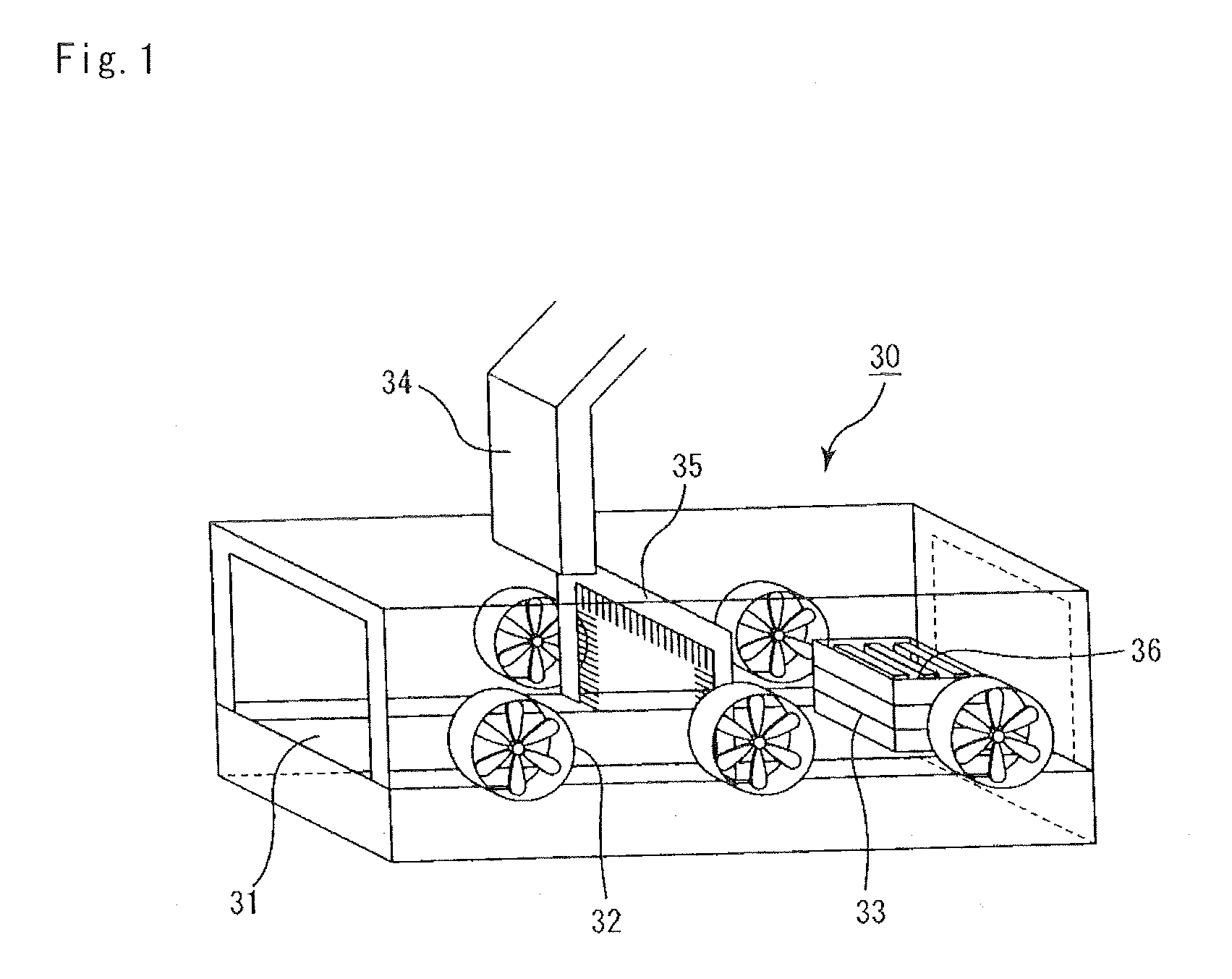

A thermal processing apparatus including: a cylindrical processing vessel; a support unit to be loaded into and unloaded from the vessel; and a heating furnace surrounding an outer periphery of the vessel, with a cooling space therebetween. The furnace is connected to a cooling-gas introduction unit, including a gas introduction passage to which a blowing fan is connected, for introducing a cooling gas into the cooling space during a temperature lowering operation after a thermal process. The furnace is connected to a cooling-gas discharge unit, including a heat exchanger, a suction fan, and a gas discharge passage, for discharging the cooling gas of a raised temperature from the cooling space. Connected to the gas discharge passage at a position upstream of the heat exchanger is a temperature-lowering gas introduction unit for introducing a temperature-lowering gas to the cooling gas of a raised temperature so as to lower its temperature.

Owner:TOKYO ELECTRON LTD

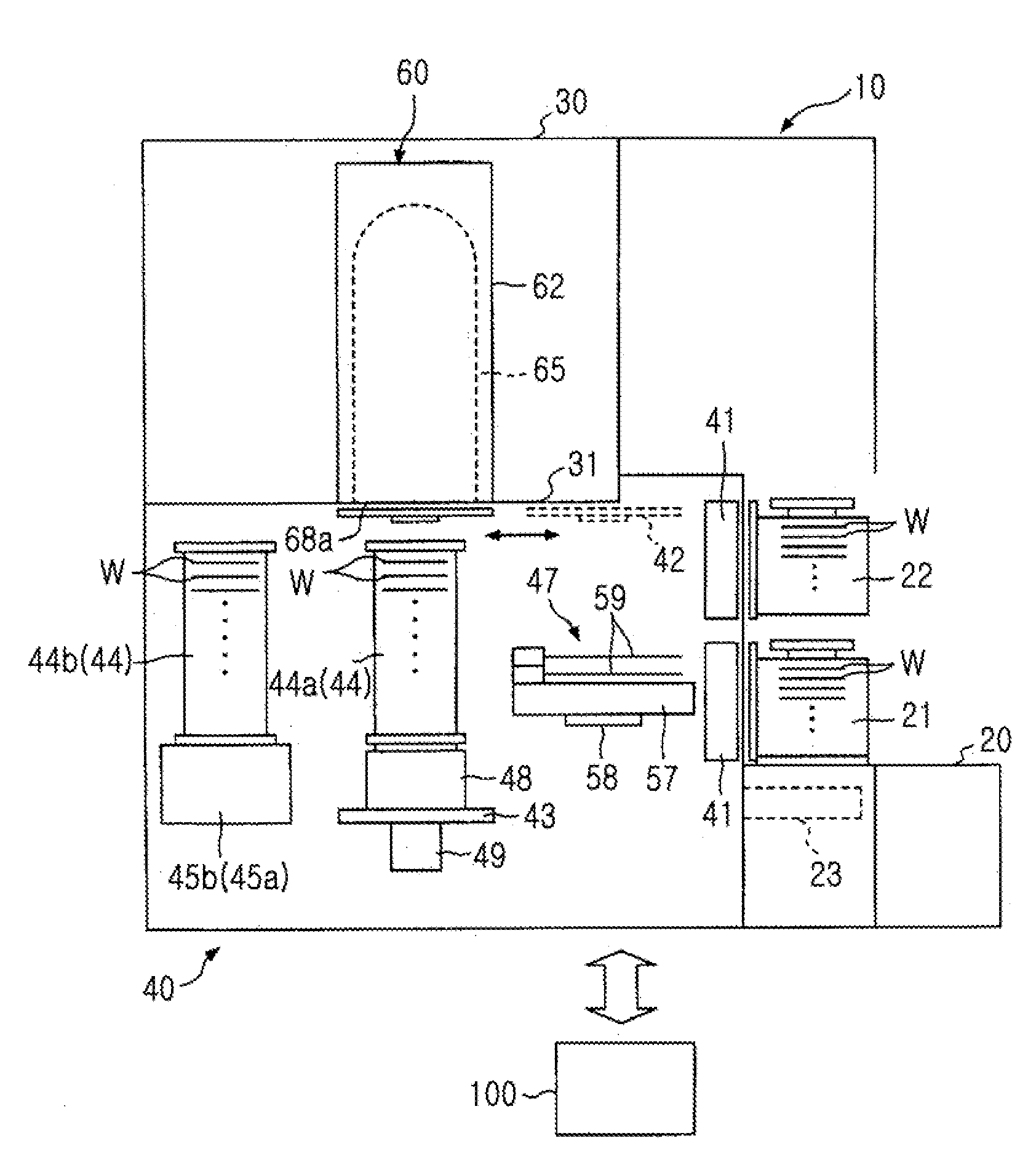

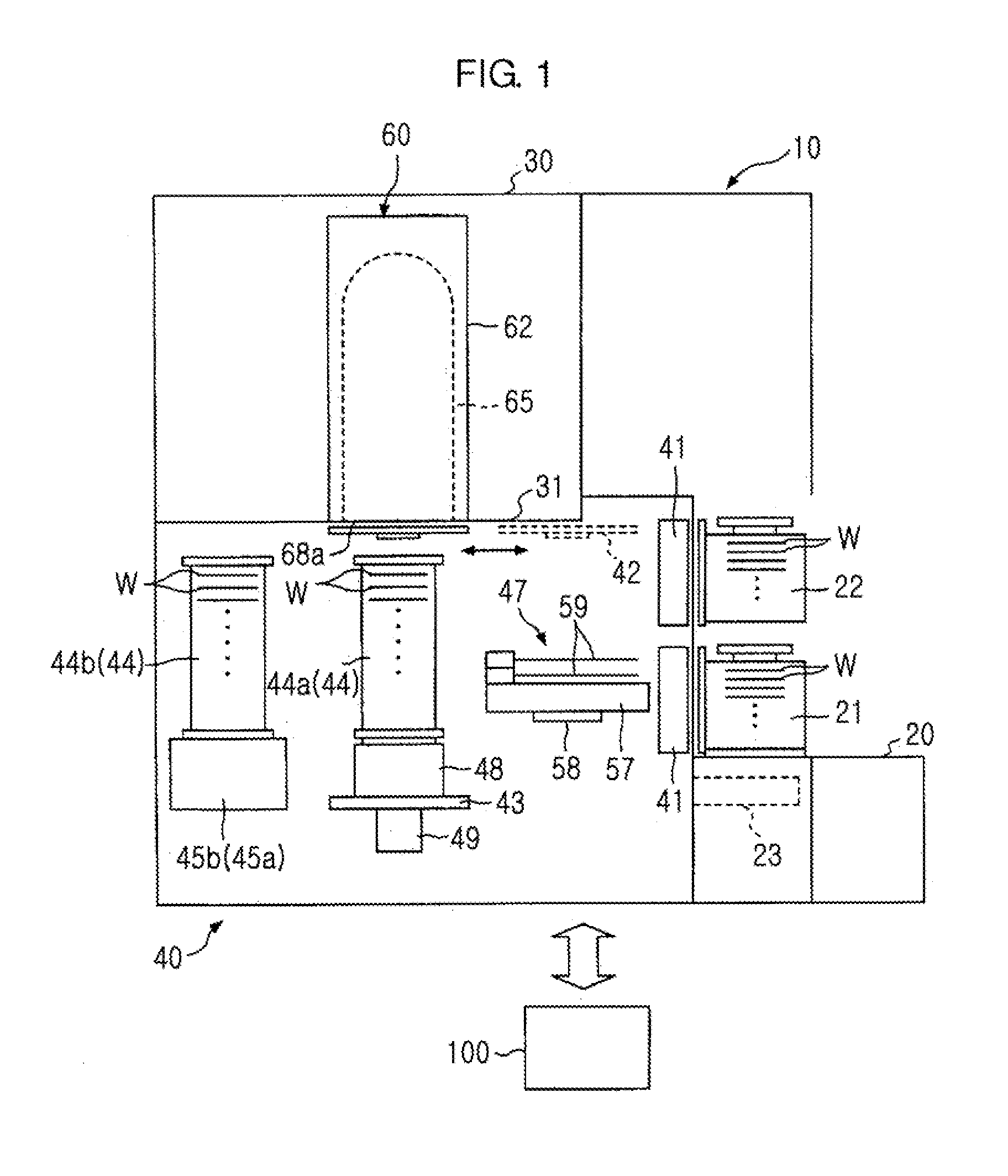

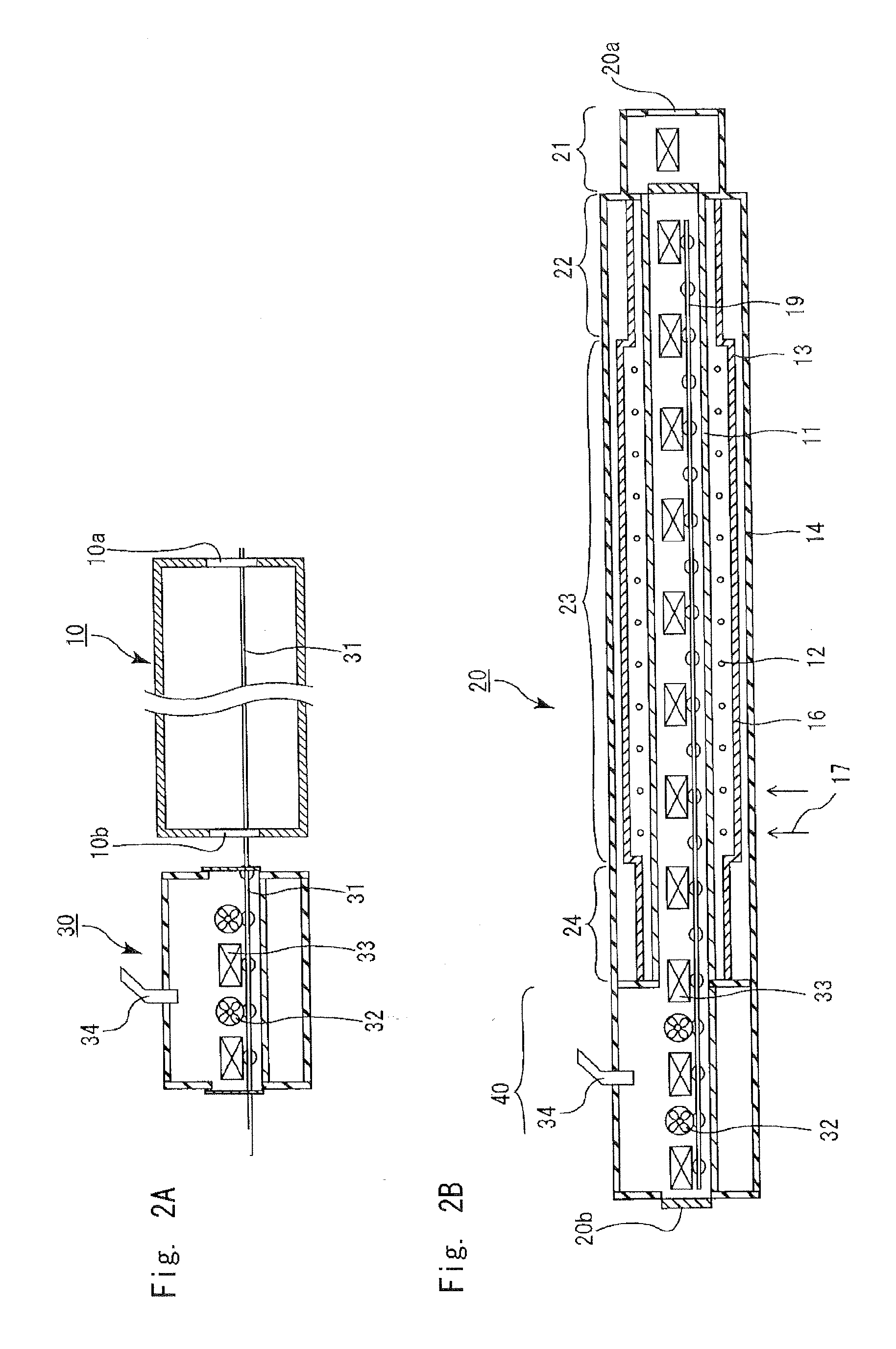

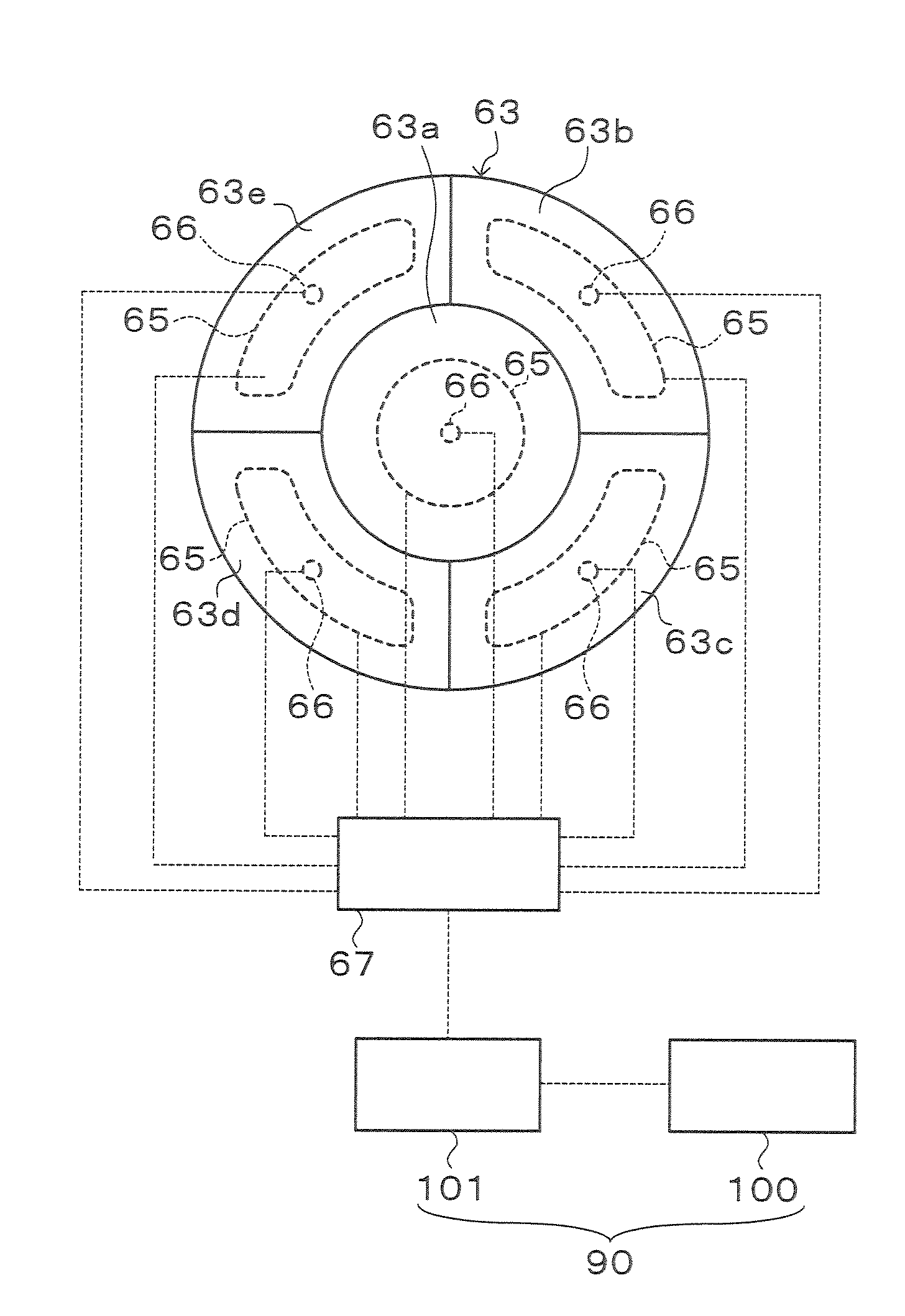

Thermal treatment apparatus, temperature control system, thermal treatment method, temperature control method, and non-transitory computer readable medium embodied with program for executing the thermal treatment method or the temperature control method

InactiveUS20130065189A1Avoid it happening againIncrease power consumptionSemiconductor/solid-state device manufacturingCharge manipulationControl flowTemperature control

A thermal treatment apparatus includes a processing container, a substrate holding unit for holding a plurality of substrates at predetermined intervals in a direction inside the processing container, a heating unit for heating the processing container, a supply unit for supplying gas, a plurality of supply ports provided respectively at different locations in the direction, and a cooling unit for cooling the processing container by supplying the gas into the processing container by the supply unit via each of the supply ports, wherein the supply unit is provided in such a way that the supply unit independently controls flow rates of the gases supplied via each of the supply ports.

Owner:TOKYO ELECTRON LTD

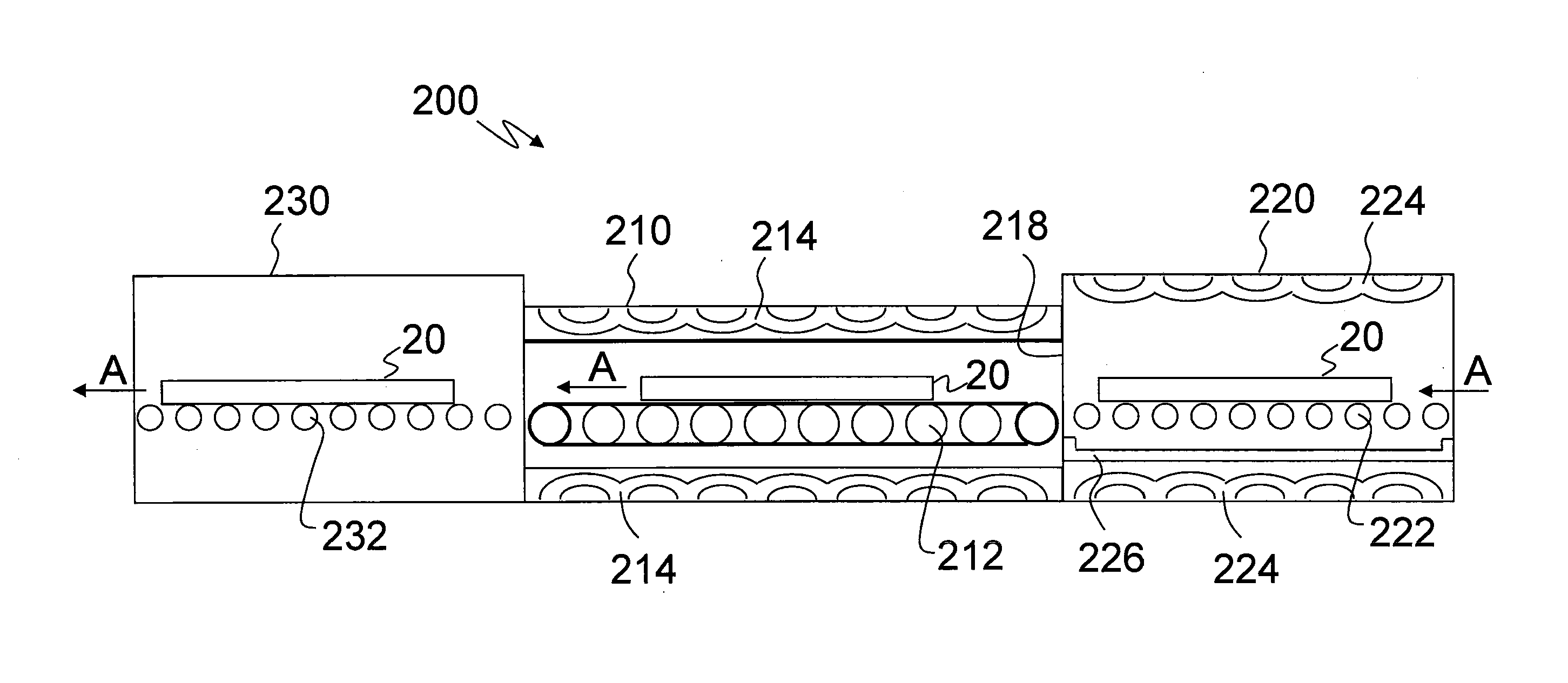

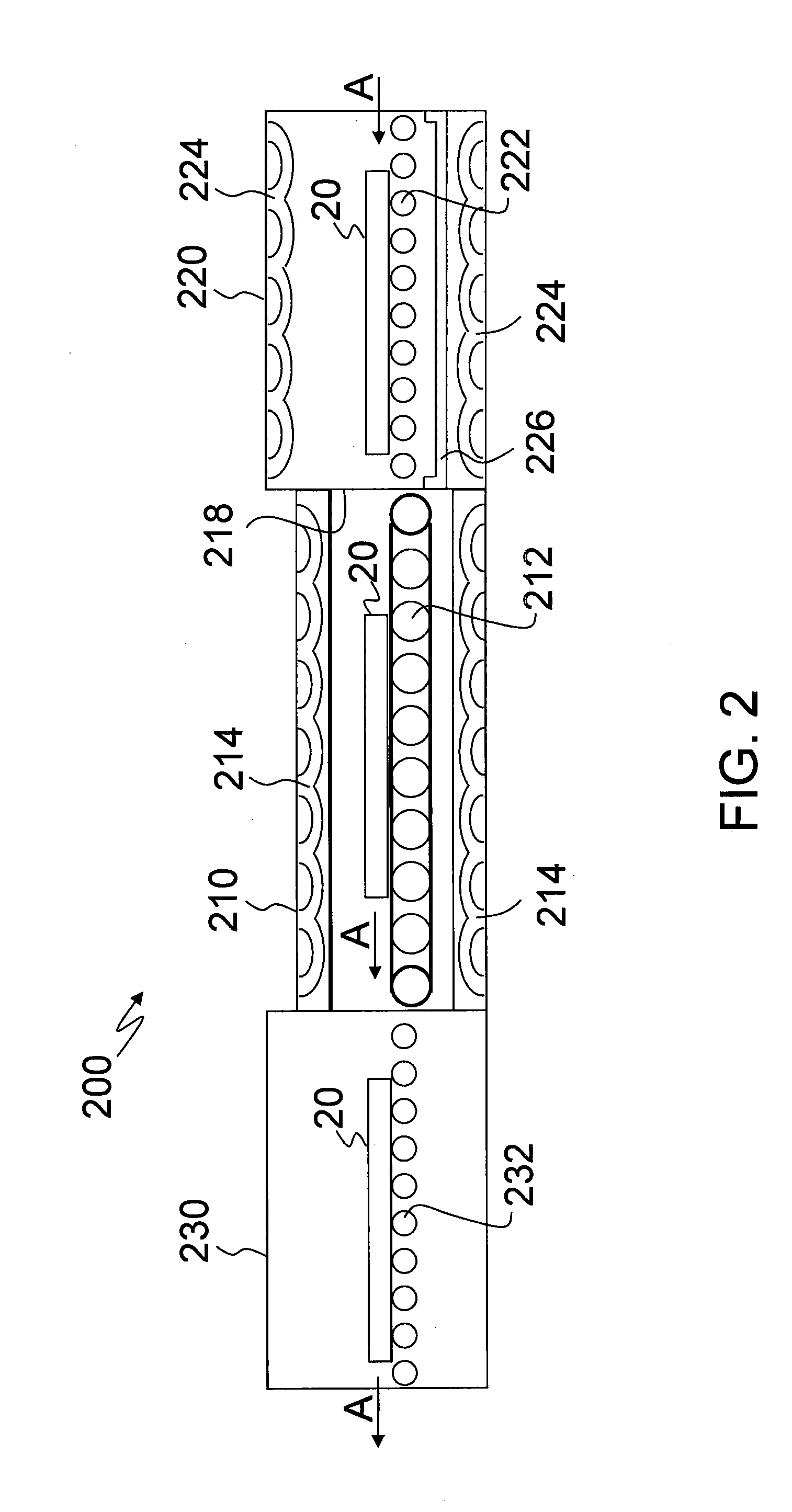

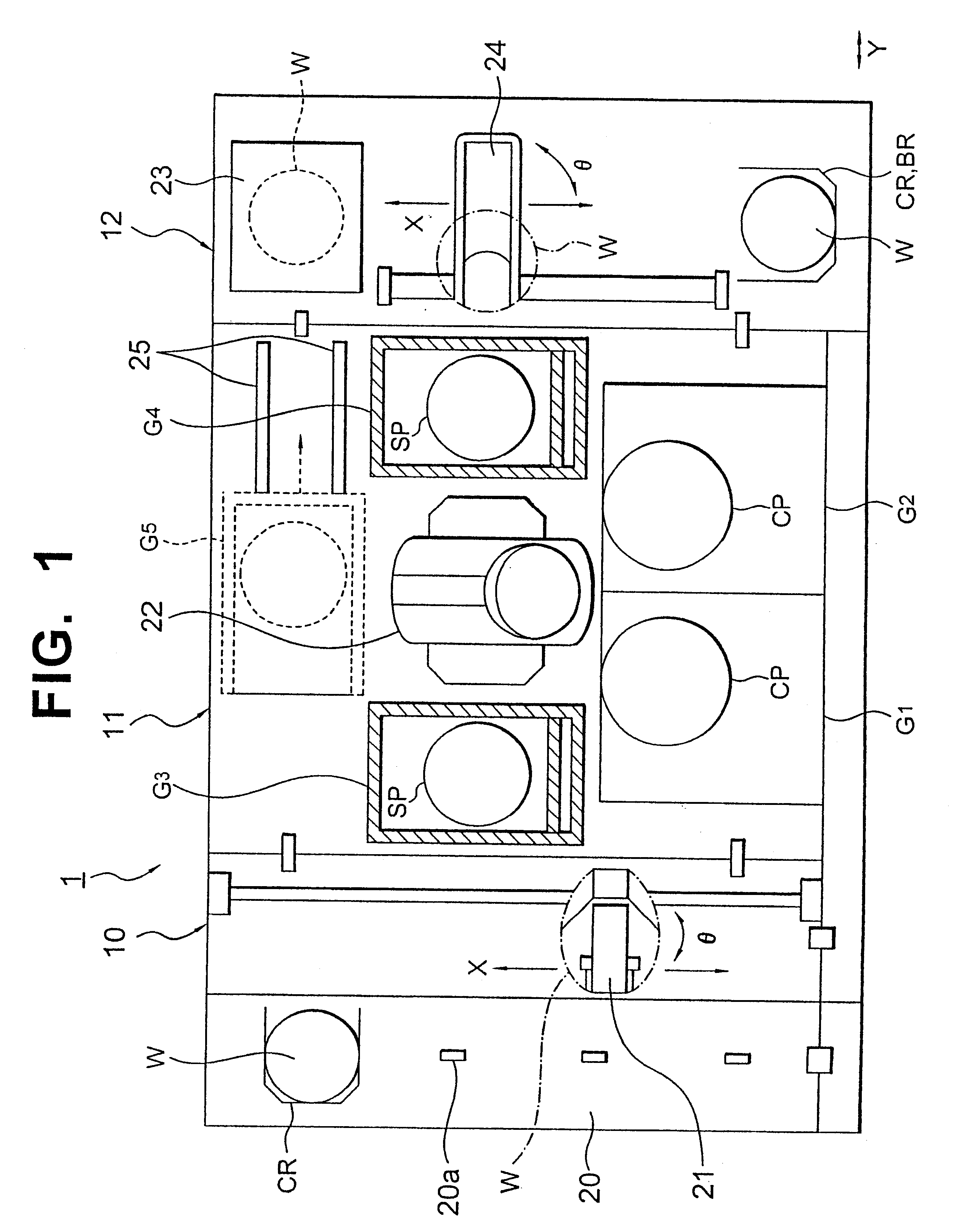

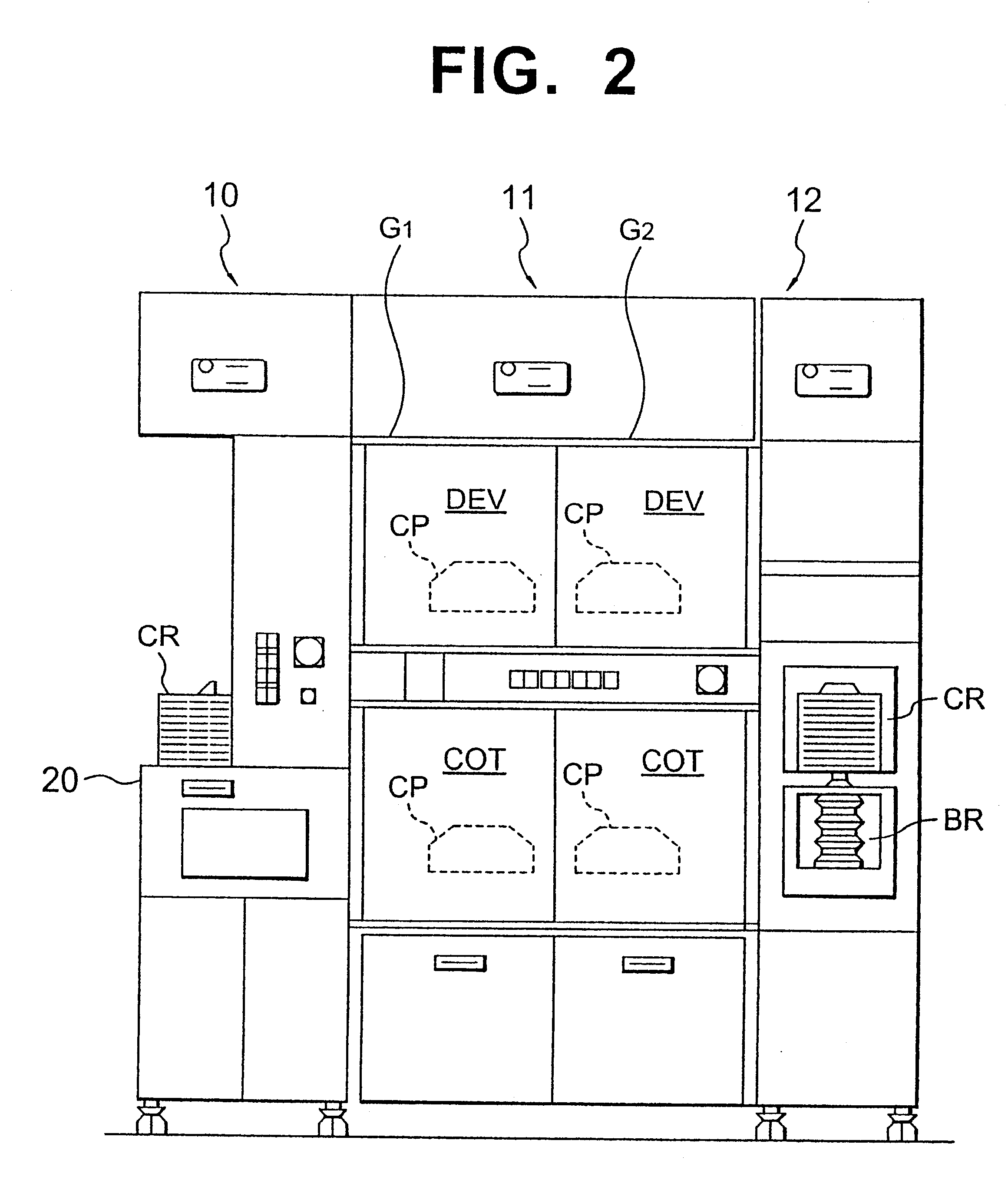

Method and apparatus providing separate modules for processing a substrate

InactiveUS20130189635A1Semiconductor/solid-state device manufacturingCharge manipulationComputer moduleEngineering

A method and apparatus for heat treating a photovoltaic device. The apparatus includes a heating module, a processing module, and a cooling module in which the operating temperatures of the modules may be controlled separately. The heating module is configured to pre-heat a substrate and stabilize the substrate at the desired target temperature, the processing module is configured to thermally process the substrate, and the cooling module is configured for post-treatment cooling of the substrate.

Owner:JPMORGAN CHASE BANK NA

Wafer processing apparatus with heated, rotating substrate support

ActiveUS20130017503A1Easy constructionEasy and economical to constructCharge supportsSemiconductor/solid-state device manufacturingEngineeringSemiconductor

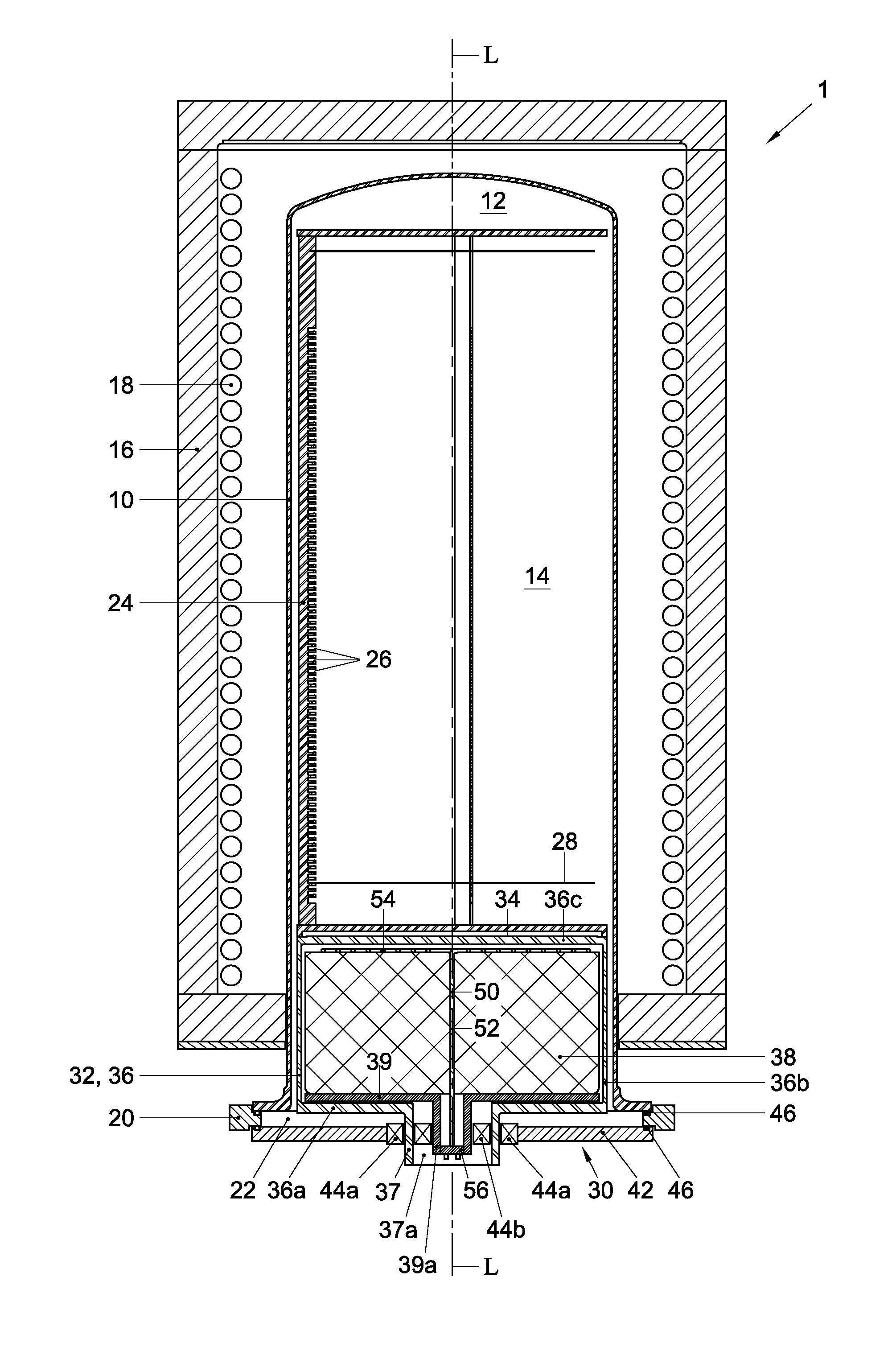

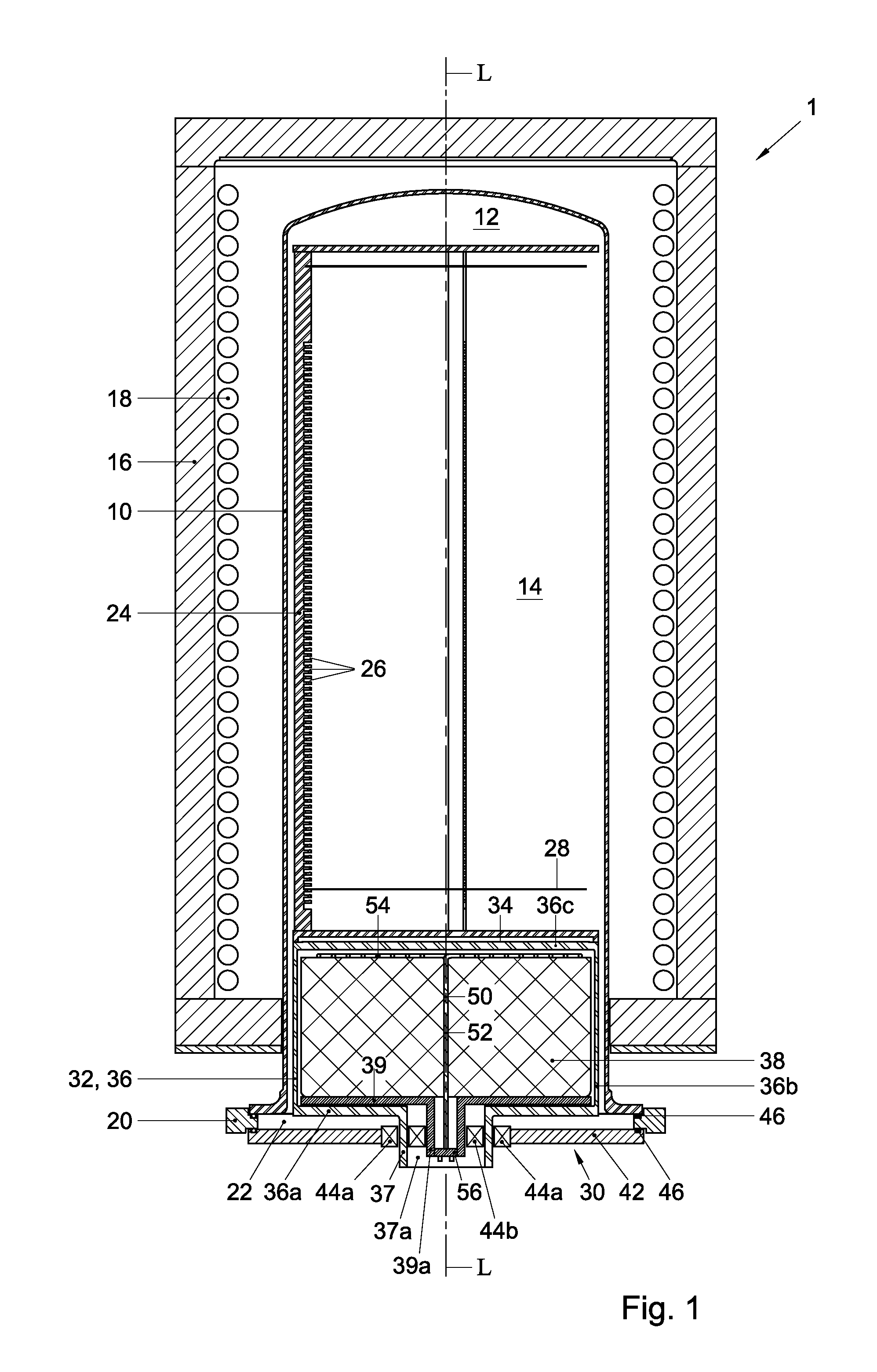

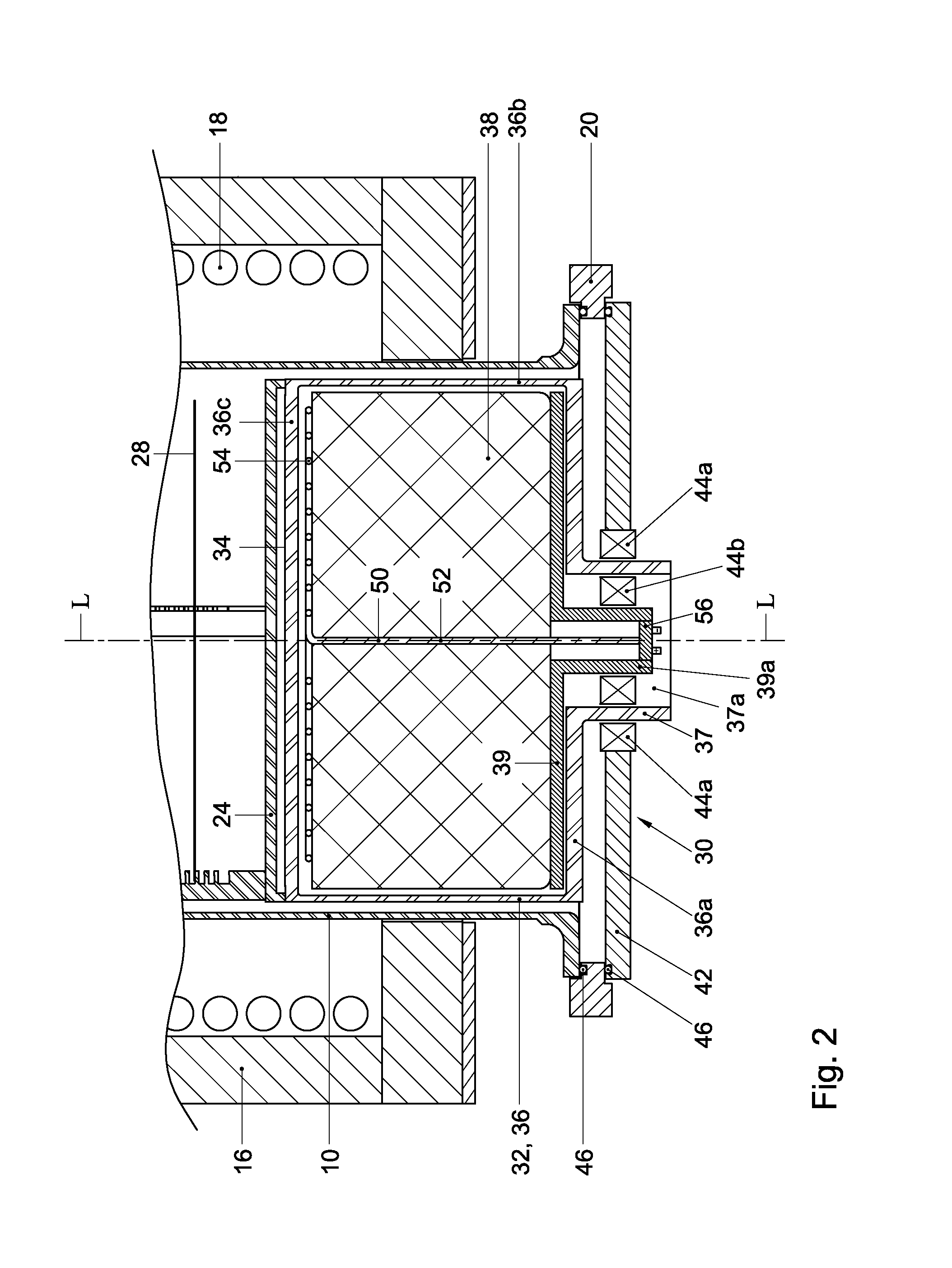

A semiconductor substrate processing apparatus (1), comprising a substrate support assembly (30), including a substrate support (32) defining an outer support surface (34) for supporting a substrate or substrate carrier (24) thereon, and a heater (50) comprising a heat dissipating portion (54) that is disposed within the substrate support (32) and that extends underneath and substantially parallel to the support surface (34), said substrate support (32) being rotatably mounted around a rotation axis (L) that extends through said support surface (34), such that the support surface (34) is rotatable relative to the heat dissipating portion (54) of the heater (50).

Owner:ASM IP HLDG BV

Substrate heat treatment apparatus

ActiveUS20070128570A1Stable separationEfficiently suckedCharge supportsSemiconductor/solid-state device manufacturingDevice formHeat treated

A substrate heat treatment apparatus includes a heat-treating plate having a flat upper surface, support devices formed of a heat-resistant resin for contacting and supporting a substrate, a seal device disposed annularly for rendering gastight a space formed between the substrate and heat-treating plate, and exhaust bores for exhausting gas from the space. The support devices are formed of resin, and the upper surface of the heat-treating plate is made flat, whereby a reduced difference in the rate of heat transfer occurs between contact parts and non-contact parts on the surface of the substrate. Consequently, the substrate is heat-treated effectively while suppressing variations in heat history over the surface of the substrate.

Owner:DAINIPPON SCREEN MTG CO LTD

Cooling apparatus for fired body, firing furnace, cooling method of ceramic fired body, and method for manufacturing honeycomb structure

InactiveUS20080136053A1Small distanceCharge manipulationHandling discharged materialAir atmosphereMetallurgy

A cooling apparatus for a fired body includes a transporting member for transporting a firing jig in which a ceramic fired body is housed; a plurality of blowers for cooling the ceramic fired body; and a suction mechanism for changing the atmosphere inside the firing jig from an inert gas atmosphere to an air atmosphere.

Owner:IBIDEN CO LTD

Use of high carbon coal ash

InactiveUS6755905B2Avoid insufficient heatingReduce flowCharge manipulationHandling discharged materialSlagHigh carbon

A synthetic slag is produced by a high temperature combustion reaction between coal ash having a high carbon content, and a source of lime such as cement kiln dust. The carbon content of the coal ash is oxidized by oxygen gas, which typically is derived from air or an air / oxygen combination in an exothermic reaction and the heat generated is exploited in the melting process. In this way the gaseous products will typically comprise nitrogen, unreacted oxygen and carbon dioxide, and heat energy can be readily recovered from the hot off gas products evolving during the combustion reaction. The synthetic slag may be pelletized and employed as lightweight mineral aggregate or milled to cement fineness to provide slag cement.

Owner:LAFARGE CANADA INC

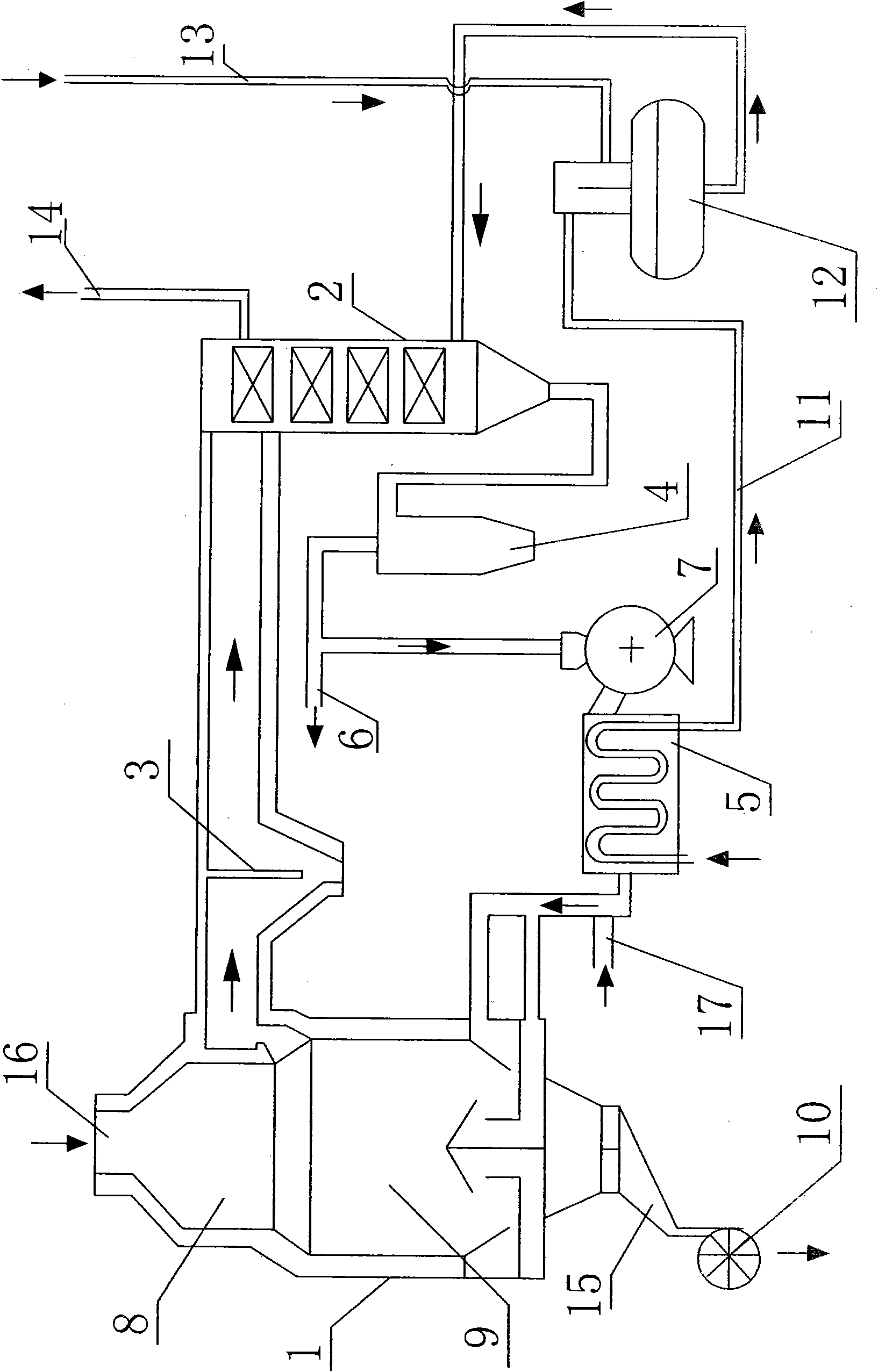

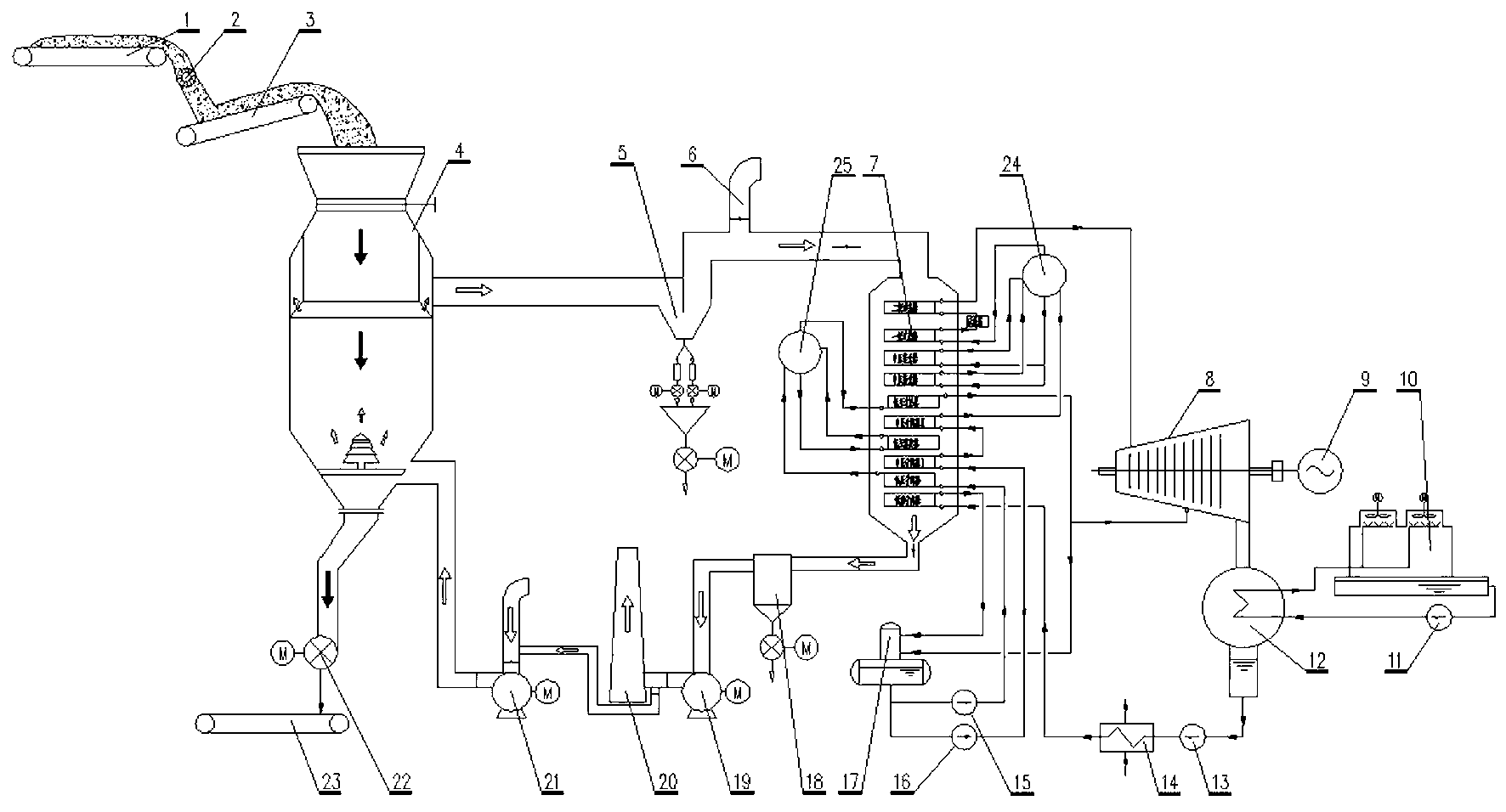

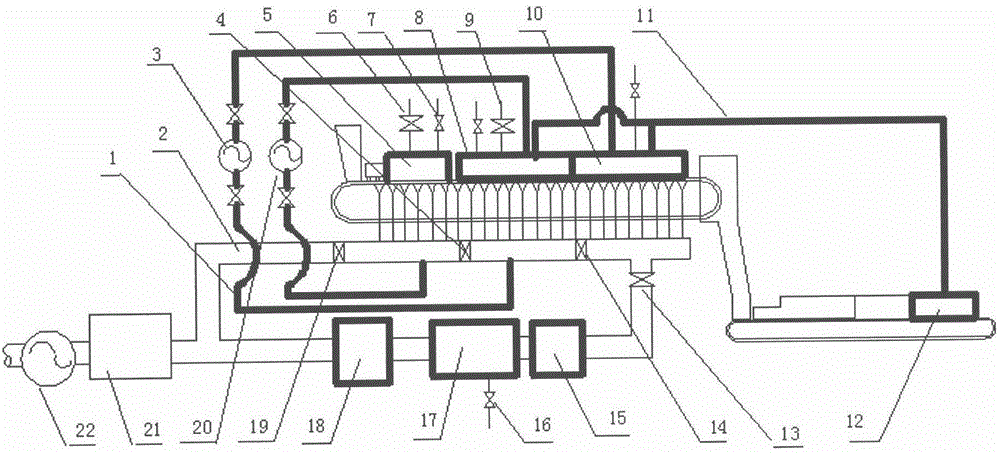

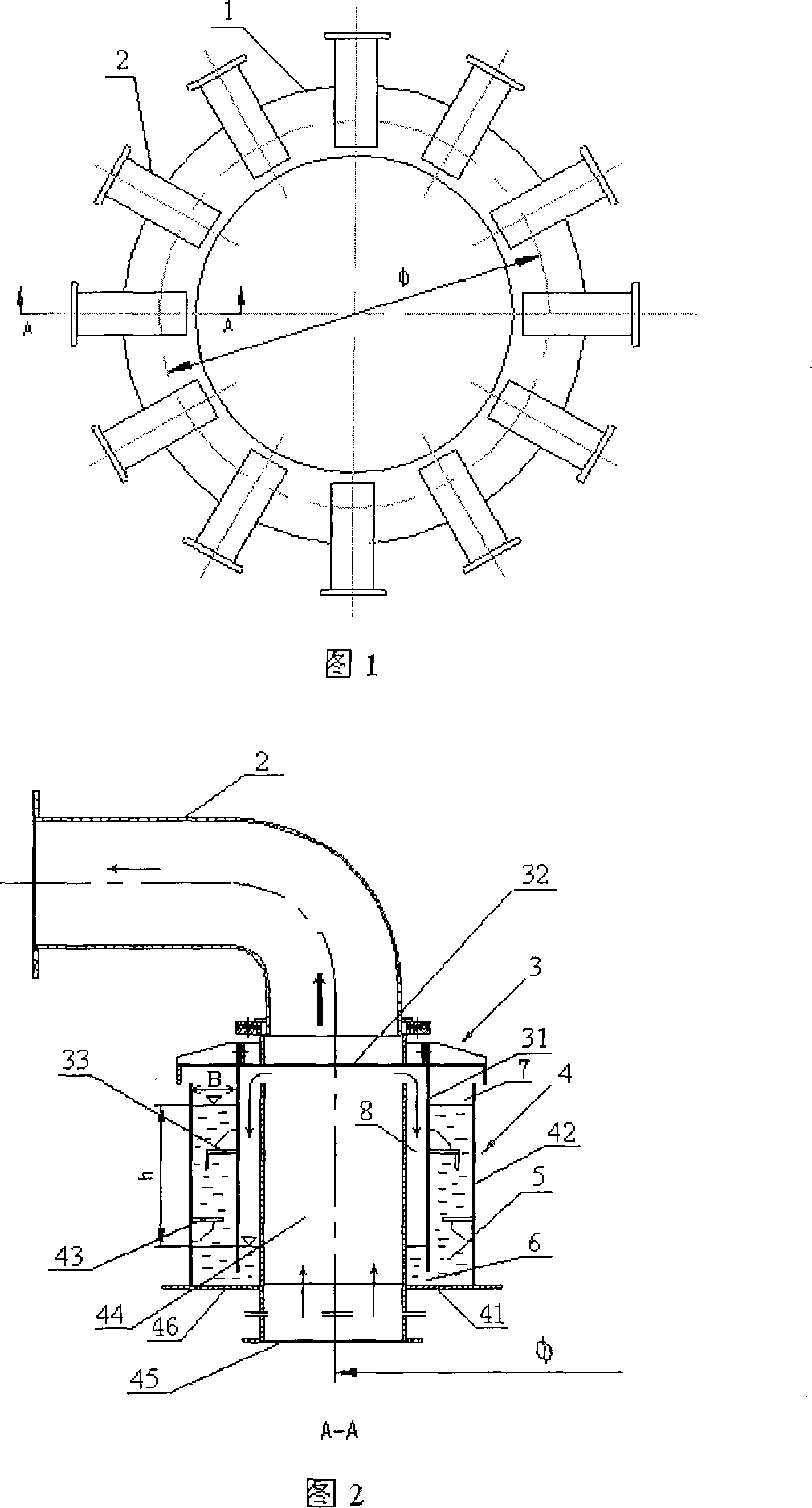

Grading recycling and cascade utilization method of residual heat resources in sintering process and device thereof

ActiveCN101655320AOvercome congenital deficienciesSolve the problem of air leakageLiquid degasificationIncreasing energy efficiencyThermodynamicsEngineering

The invention relates to a method for effectively recycling and utilizing residual heat resources in a sintering process and a device thereof. The invention has the main contents that a fiery sinter ore is filled in a vertical and sealed tank body, air is led from the tank body so as to cool the sinter ore, sensible heat of the sinter ore is almost totally carried by the air and is exhausted fromthe top of the tank body at the same time; and hot air is led into a residual heat boiler to generate steam to synchronously generate power. Compared with the prior sintering residual heat recycling and utilization technology, the invention has higher residual heat recycling utilization ratio, effectively reduces the energy consumption of the sintering procedure with reasonable and effective method, simple apparatus and easy operation, and is relatively favorable for popularization and application in the technical field of residual heat resource recycling and utilization in a metallurgy process.

Owner:NORTHEASTERN UNIV

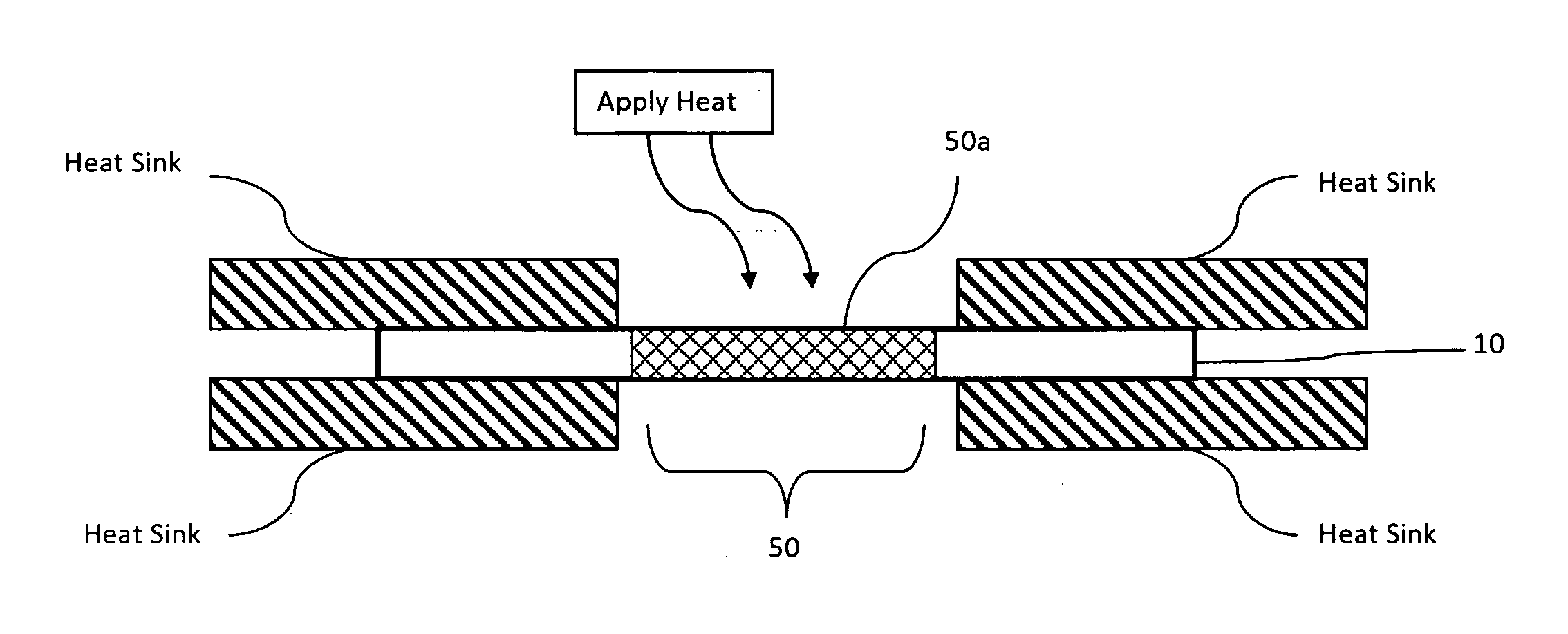

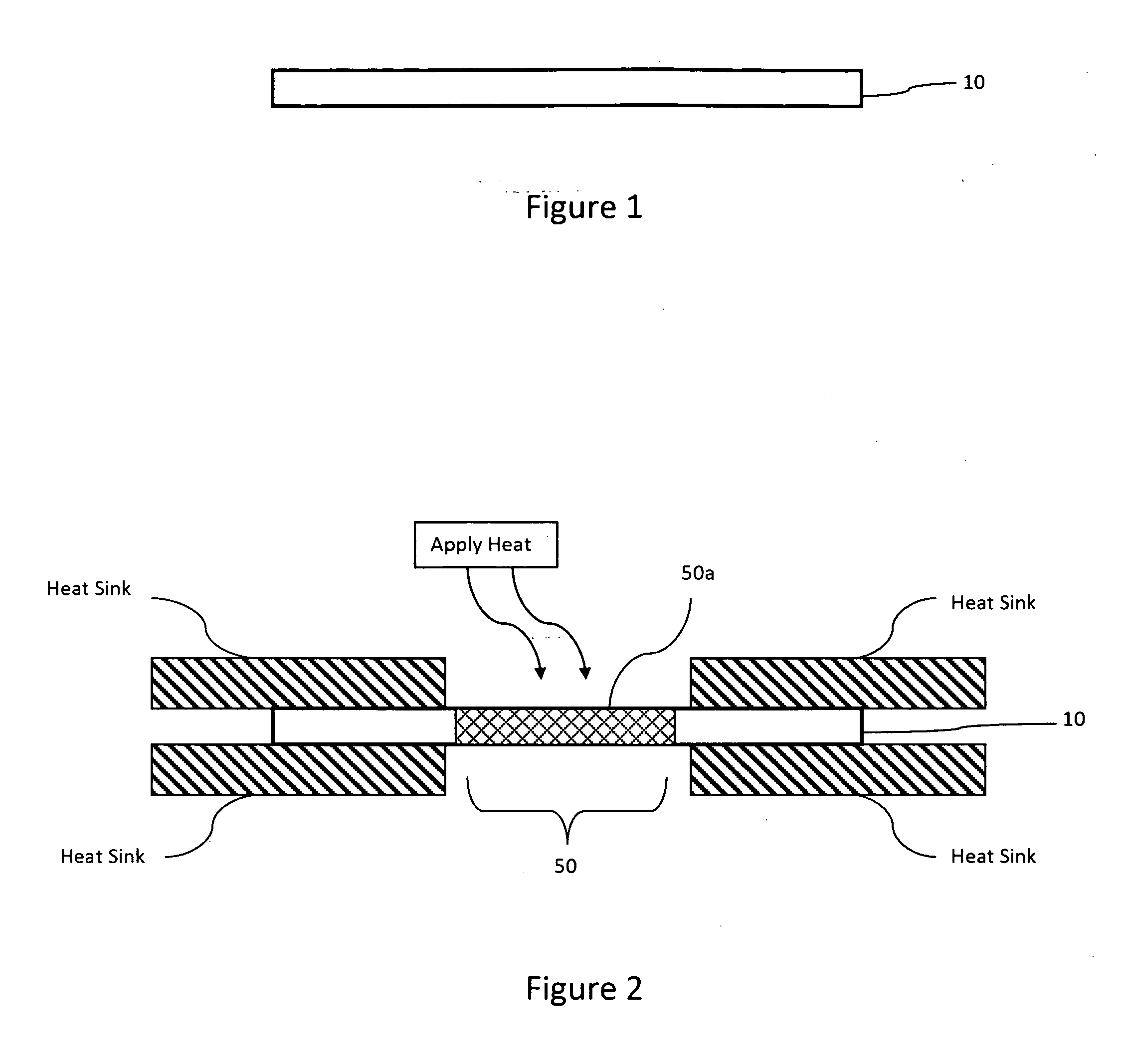

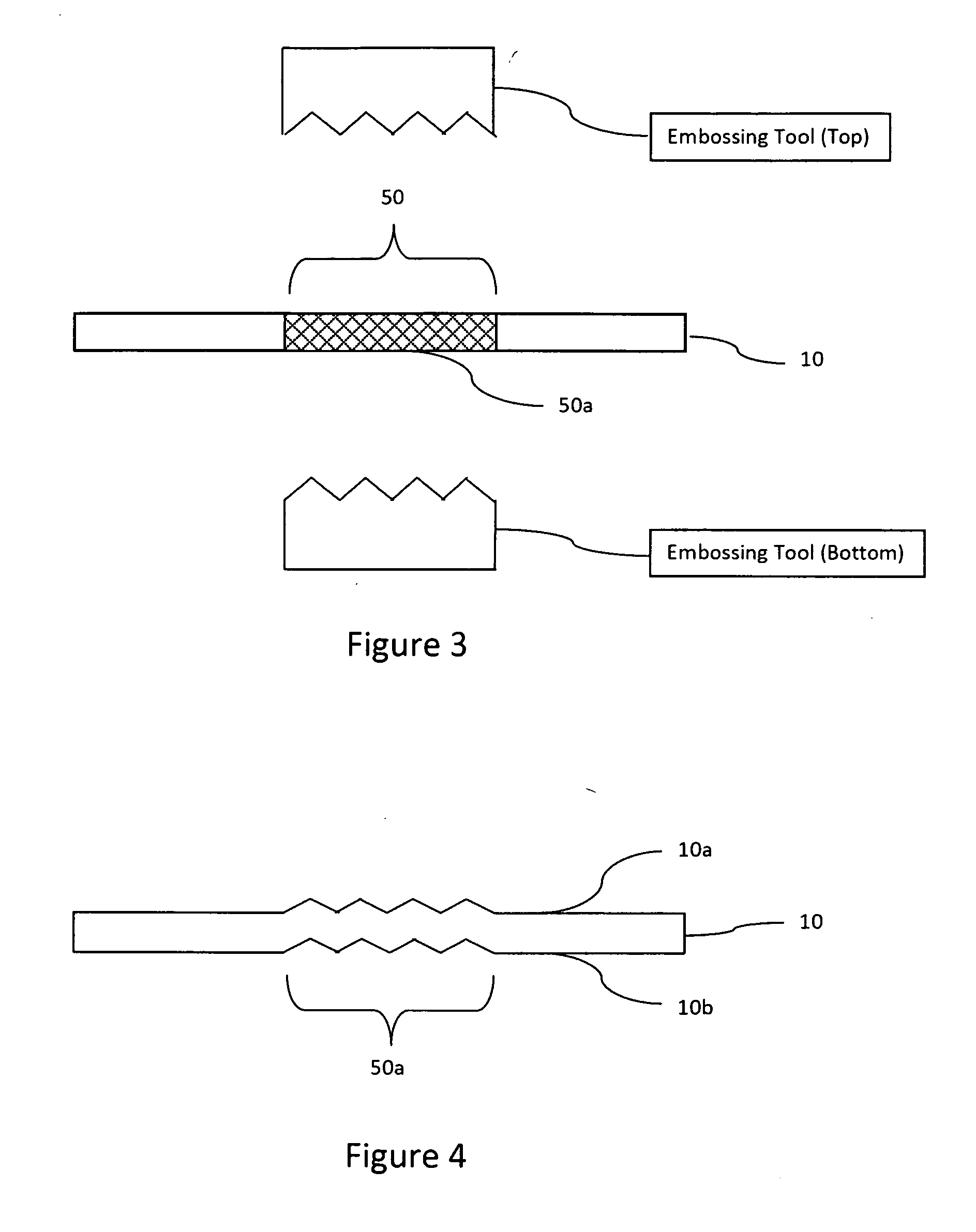

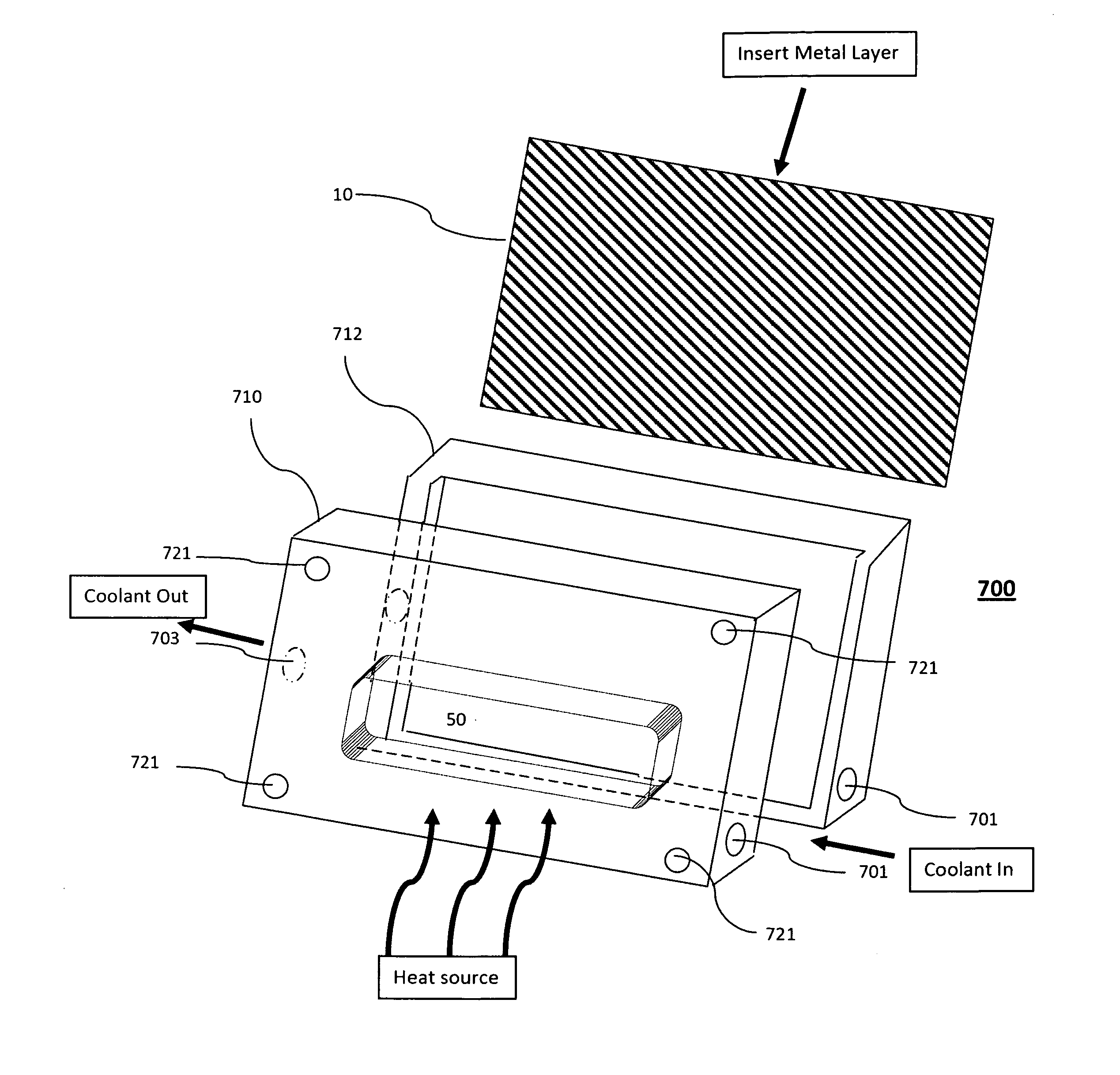

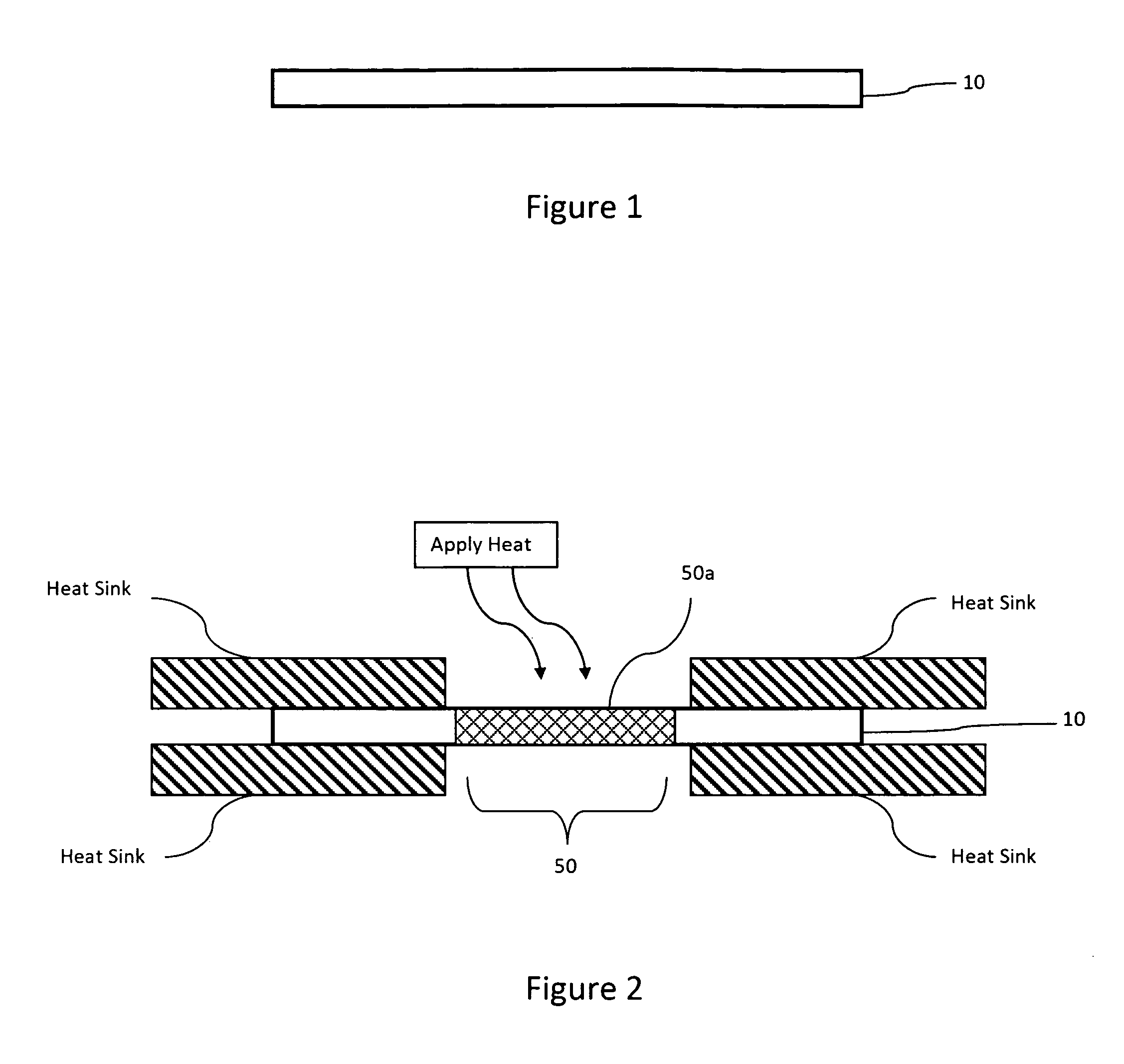

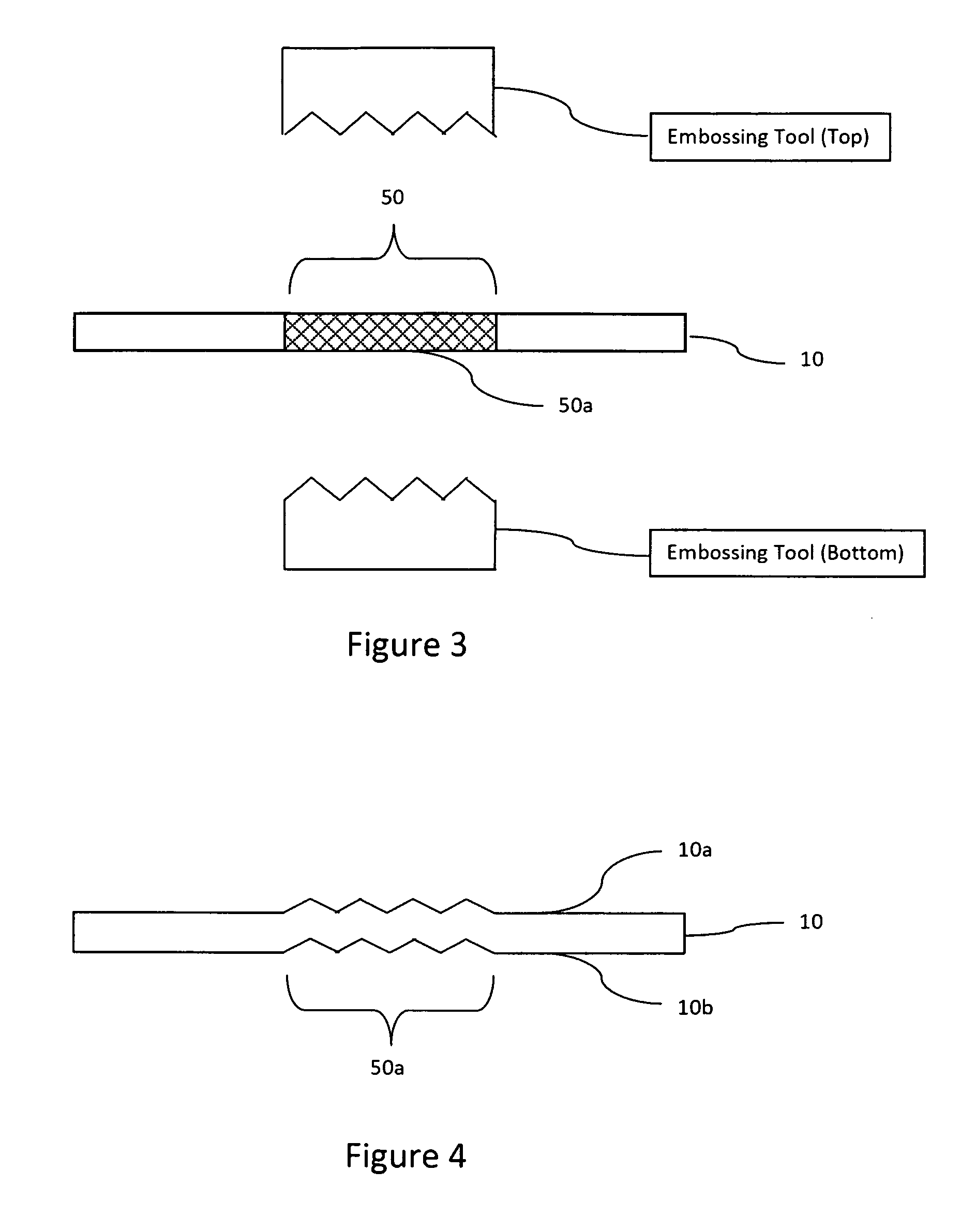

Metal card

ActiveUS20110189620A1Easy embossingSimple equipmentOther heat production devicesCharge manipulationMetalWear and tear

A method and apparatus for treating a selected region of a metal layer, used to form a metal card, by annealing the selected metal region so the selected region becomes soft and ductile, while the rest of the metal layer remains stiff. The softened, ductile, selected metal region can be embossed with reduced power and with reduced wear and tear on the embossing equipment. Alternatively, the annealed metal layer can undergo additional processing steps to form an assembly which can then be embossed. The method may include the use of a fixture for holding the metal layer, with the fixture having a window region for enabling heat to be applied to soften the region of the metal layer within the window region. The fixture includes apparatus for cooling the portion of the metal layer outside of the window region and for preventing the temperature of the metal layer outside the window region from rising above predetermined limits.

Owner:COMPOSECURE LLC

Solder reflow oven

InactiveUS6386422B1Soldering apparatusSemiconductor/solid-state device manufacturingSerpentine channelSolder ball

A solder reflow oven for the processing of ball grid array substrates bearing solder balls is described, comprising: input means for introducing substrates into the oven, a processing chamber within which the substrates are subject to a solder reflow process, and output means for discharging substrates from the oven for further processing or handling, and means for transferring the substrates through the processing chamber in a first direction towards the output means. The processing chamber comprises a plurality of heating and cooling zones arranged with a constant pitch in the first direction, and the transferring means is adapted to move the substrates in the first direction in stages, with each component moving a distance equal to the pitch between two zones in each stage, whereby the components are moved from zone to zone in stages. In addition each block of each heating zone and each block of each cooling zone is connected to a source of fresh gas, and each block of each heating zone is provided with means for heating the gas, and each block of each cooling zone is provided with means for cooling the gas, and each block is formed with a serpentine channel between the source of fresh gas and at least one opening through which the gas is discharged from the block towards a substrate.

Owner:ASM ASSEMBLY AUTOMATION LTD

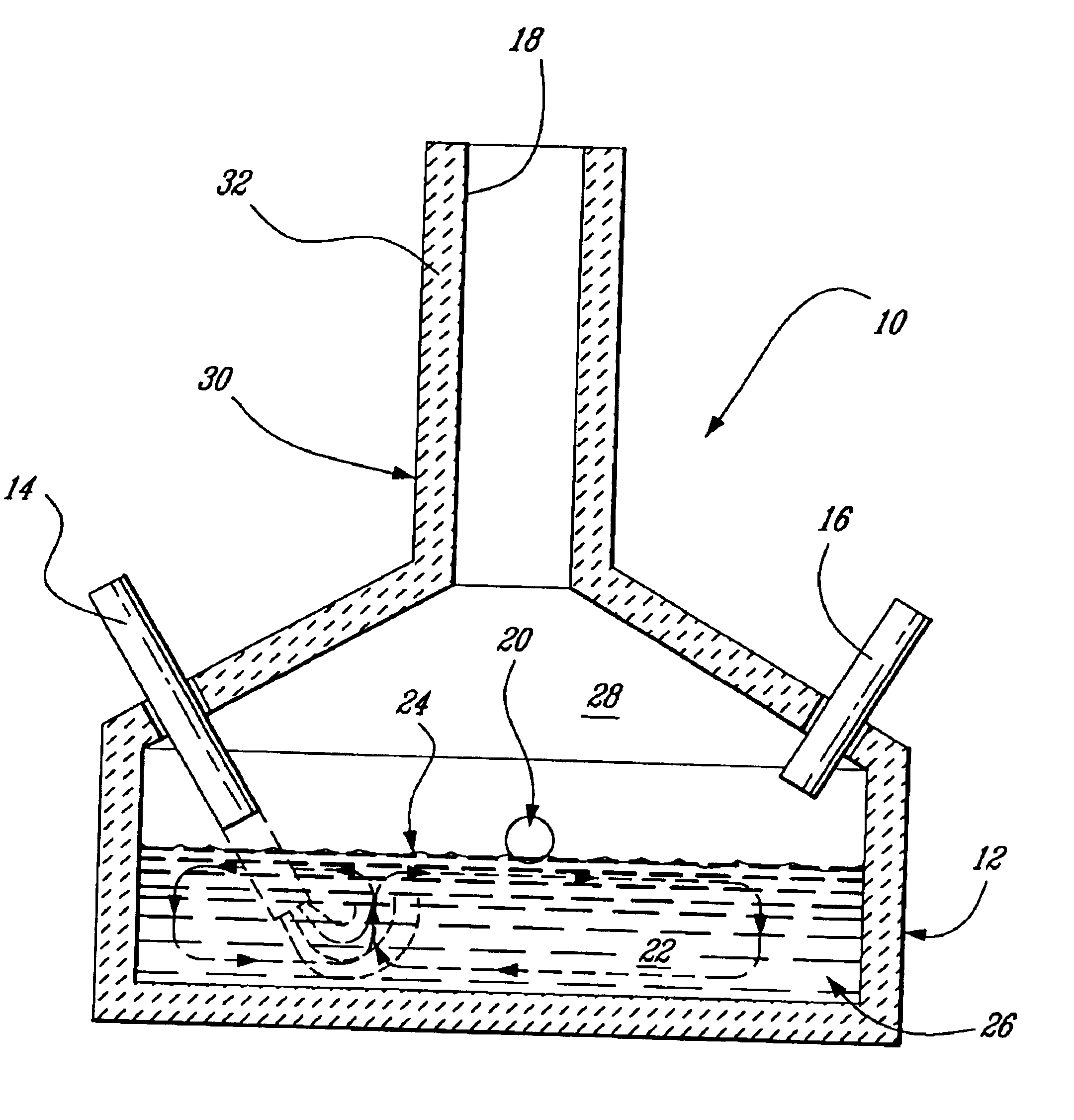

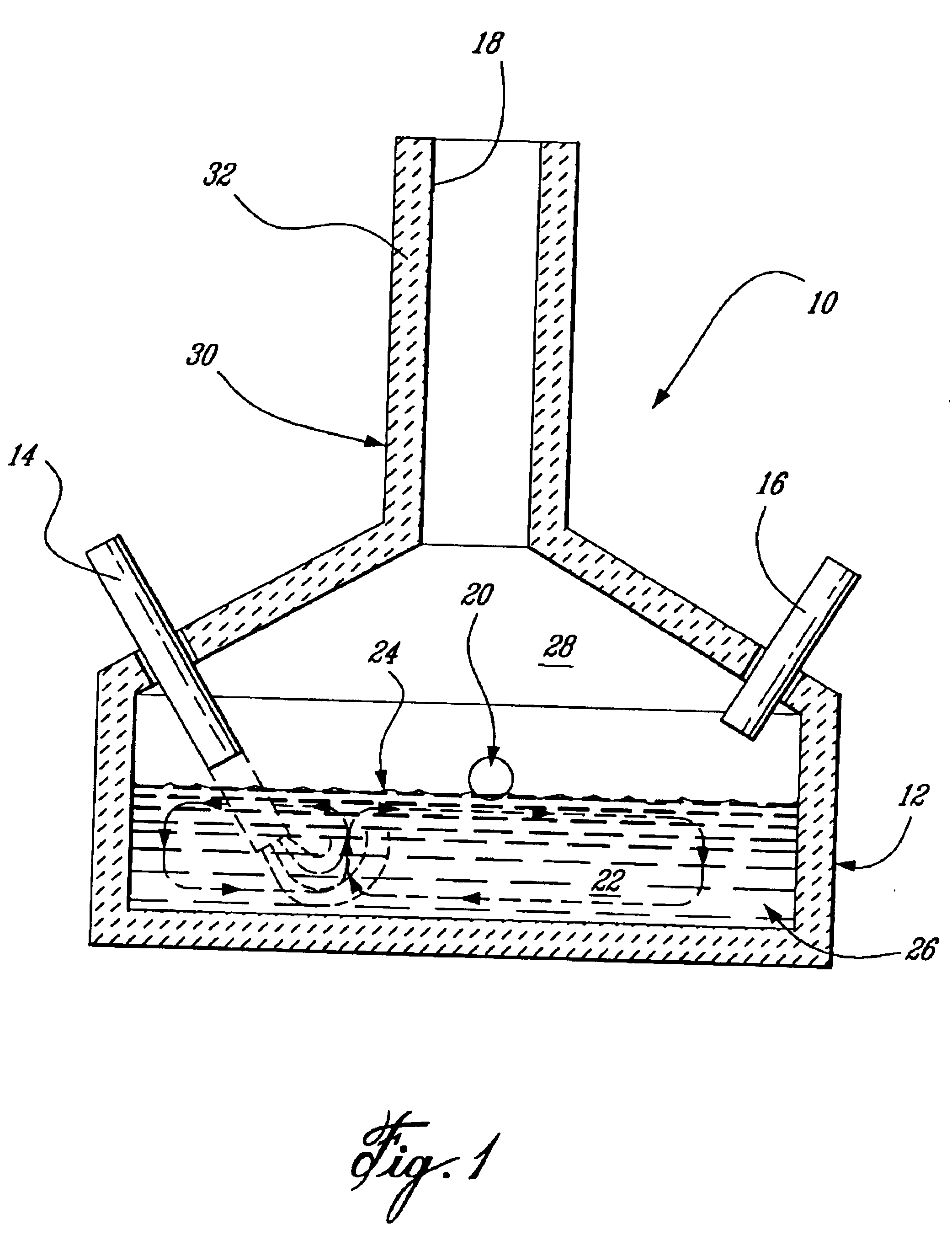

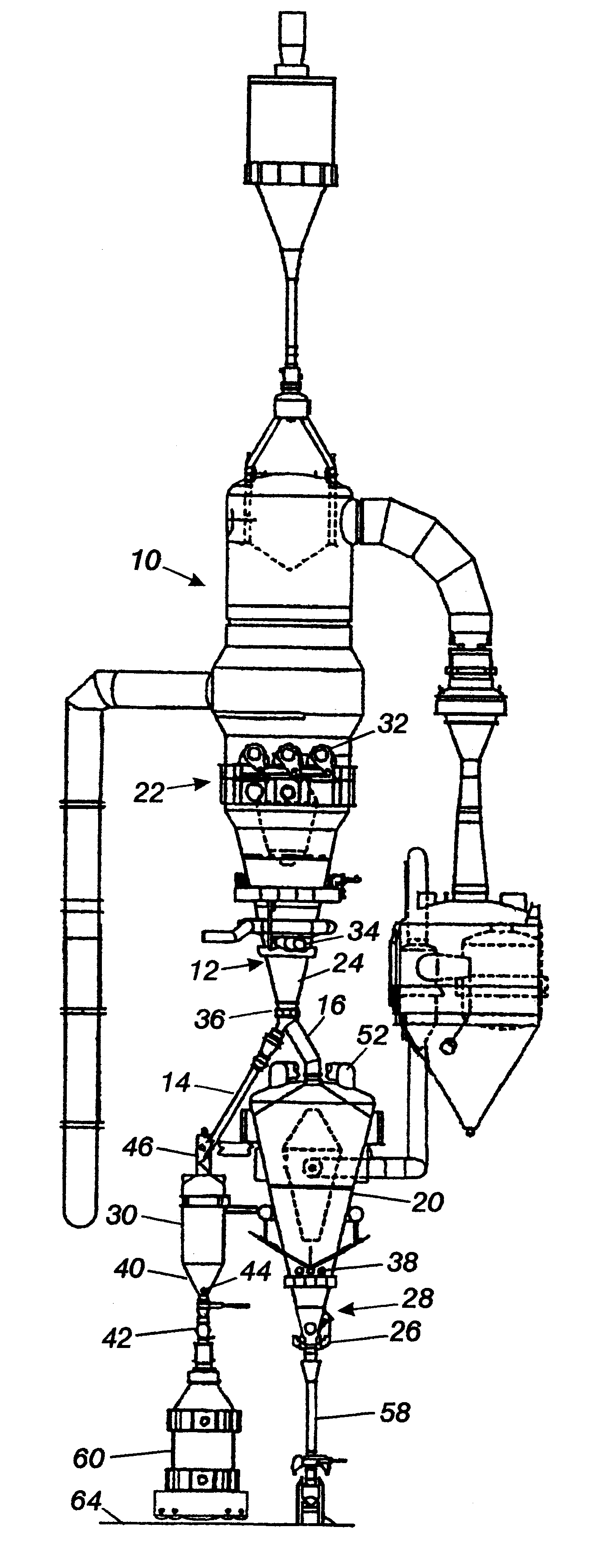

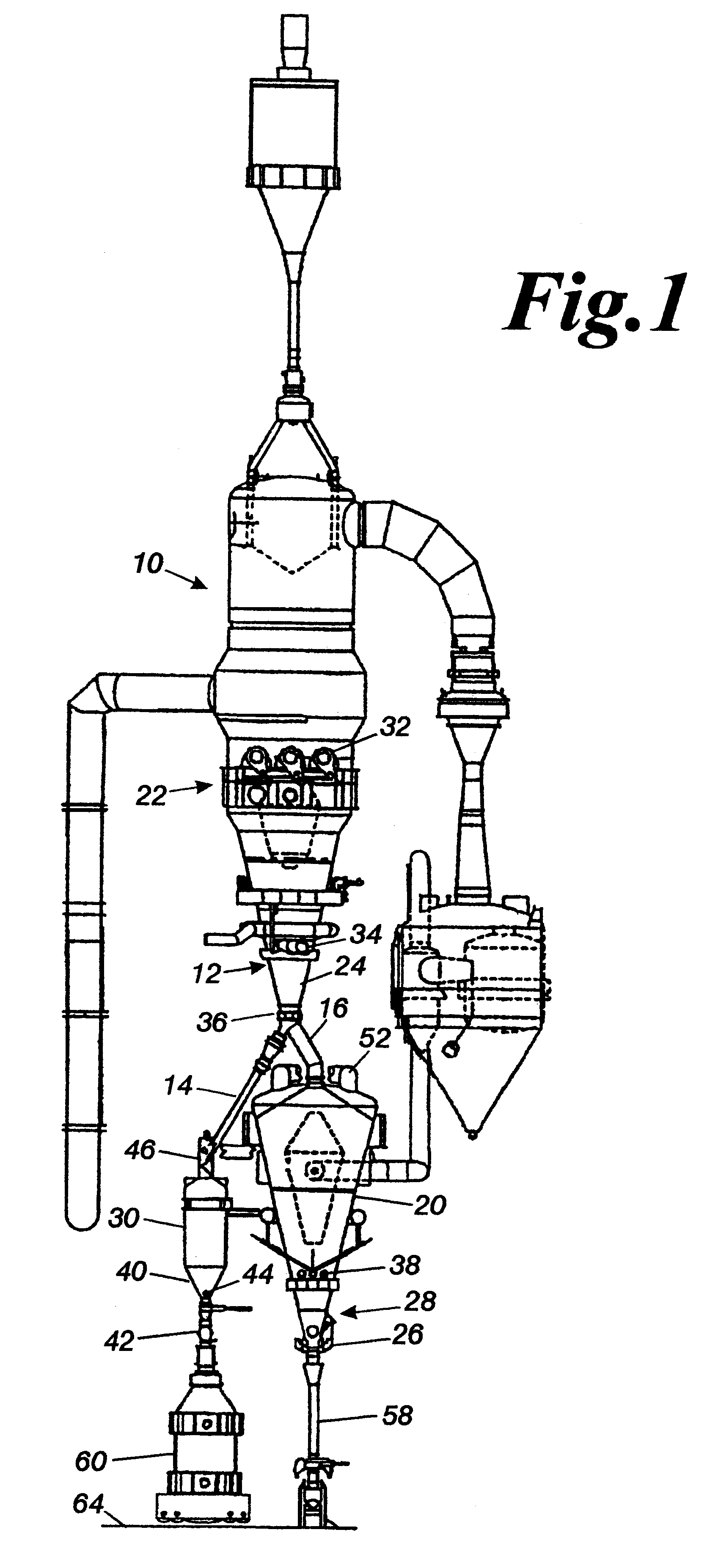

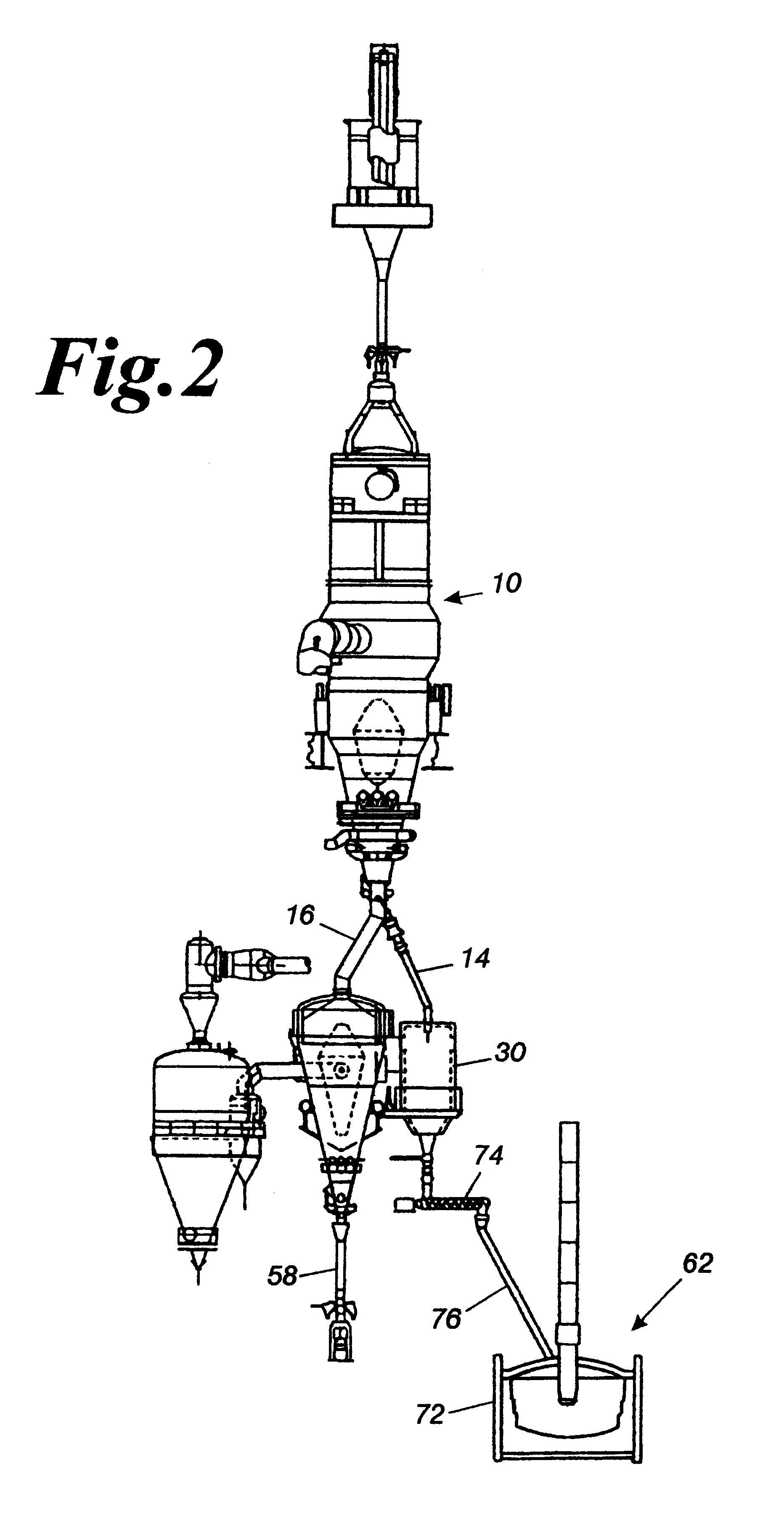

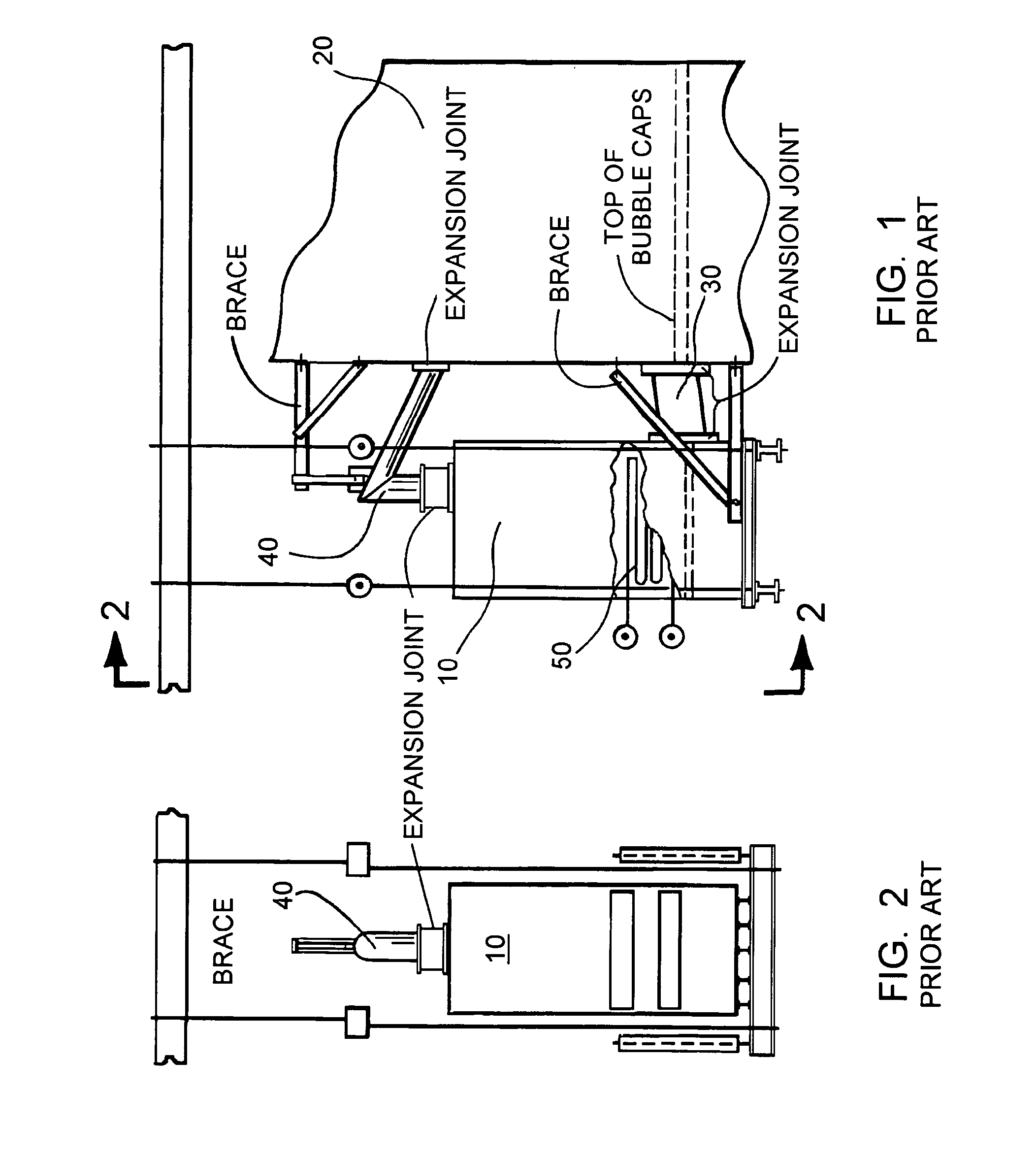

Direct reduced iron discharge system and method

InactiveUS6214086B1No loss in metallizationWide range of sizesMolten spray coatingNuclear energy generationEngineeringDirect reduced iron

A method and apparatus for simultaneously supplying varying proportions of hot and cold direct reduced iron(DRI) material from a source of hot DRI for melting, storage, briquetting, or transport. The system uses gravity to transport hot DRI material from a reduction furnace to a furnace discharge section, which transports desired amounts to a cooling receptacle and to a hot DRI vessel. The cooling section of the apparatus is connected to the furnace discharge section through a dynamic seal leg. The hot section is also connected to the furnace discharge section through separate a dynamic sealing leg and can feed a surge vessel, a briquetter, a storage vessel or a melting furnace. The method of operation is also disclosed.

Owner:IDREX INT BV ROTTERDAM ZURICH BRANCH

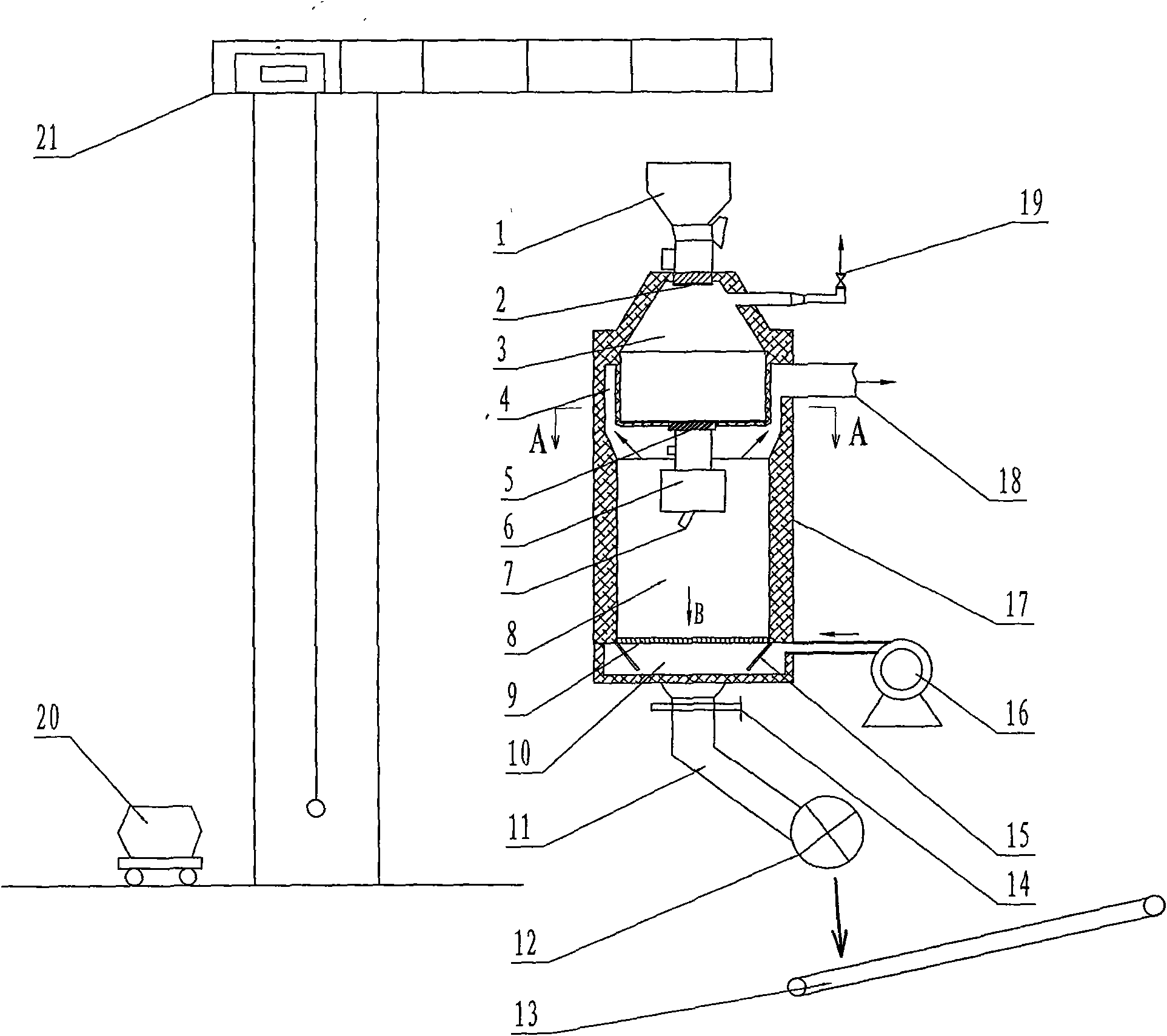

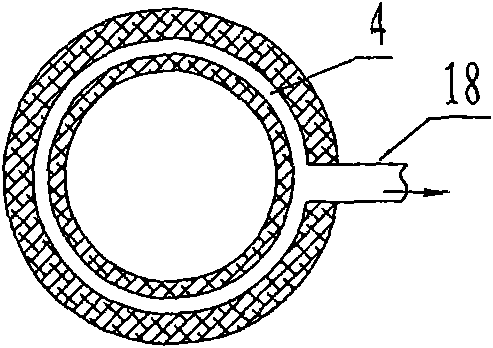

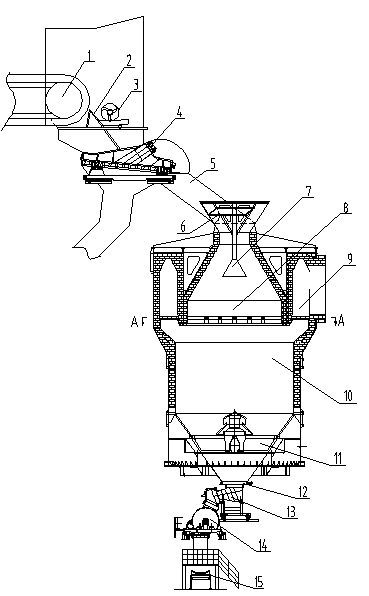

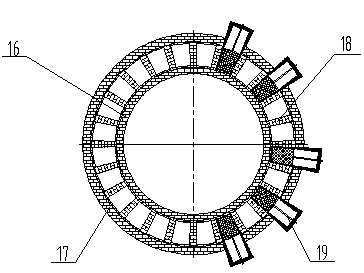

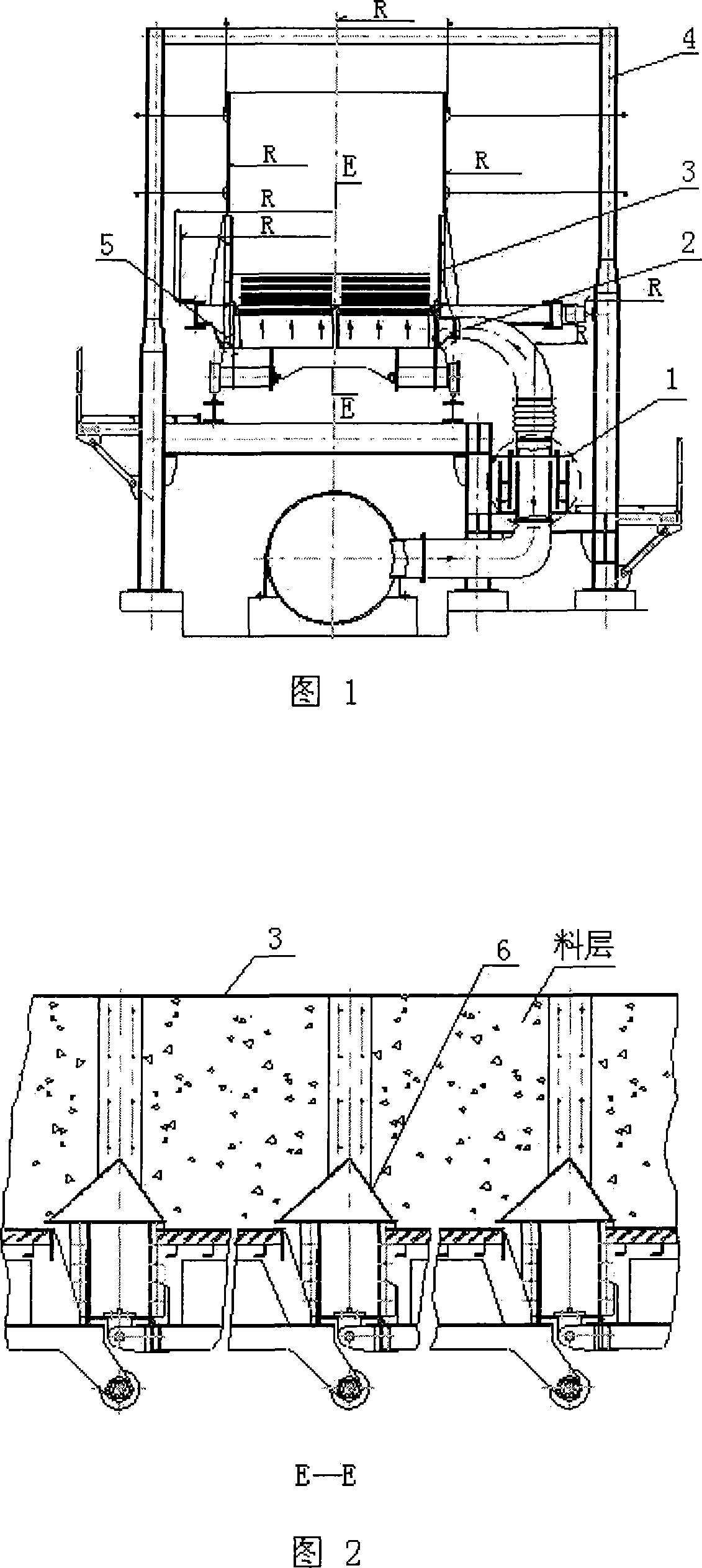

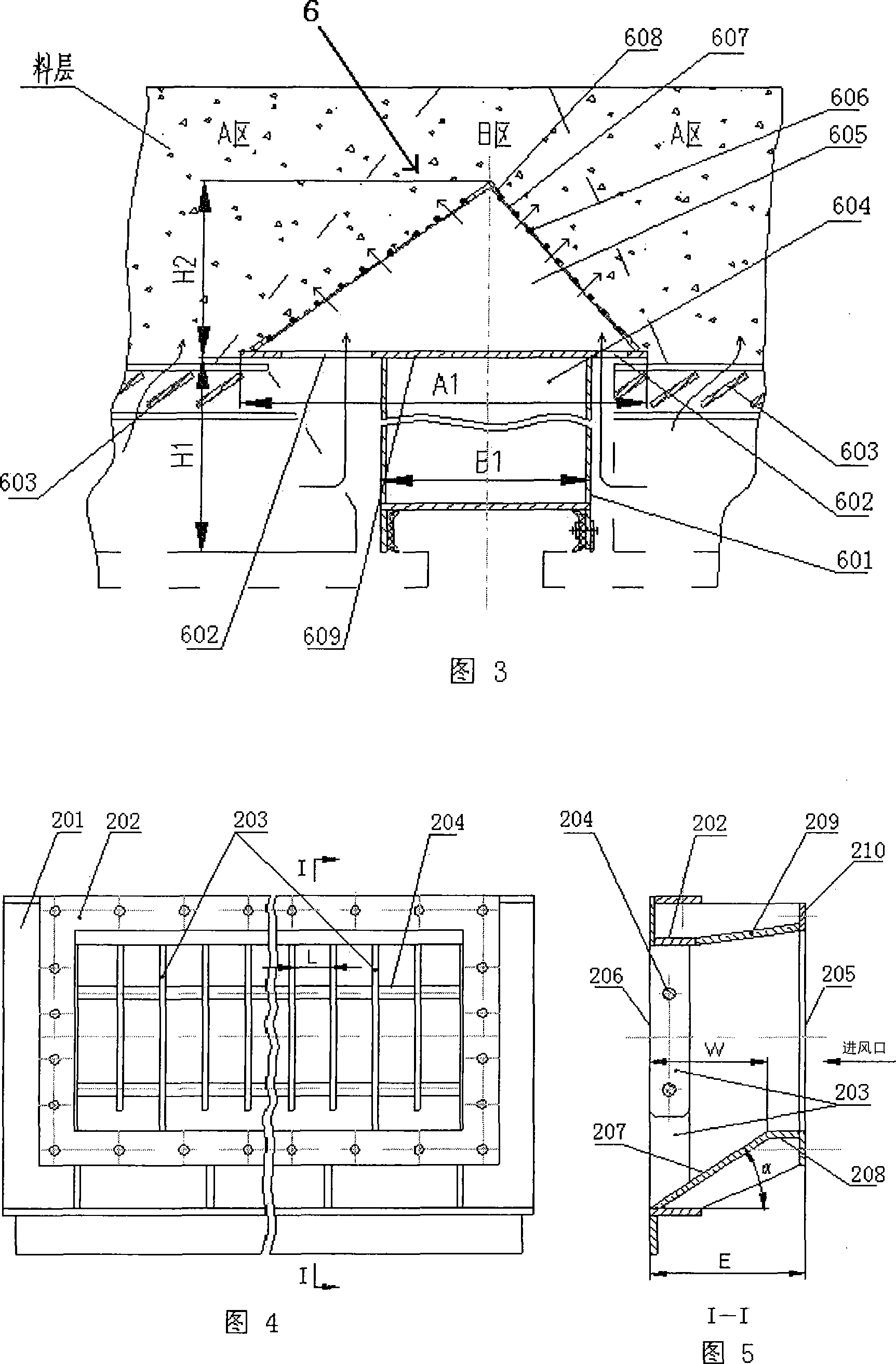

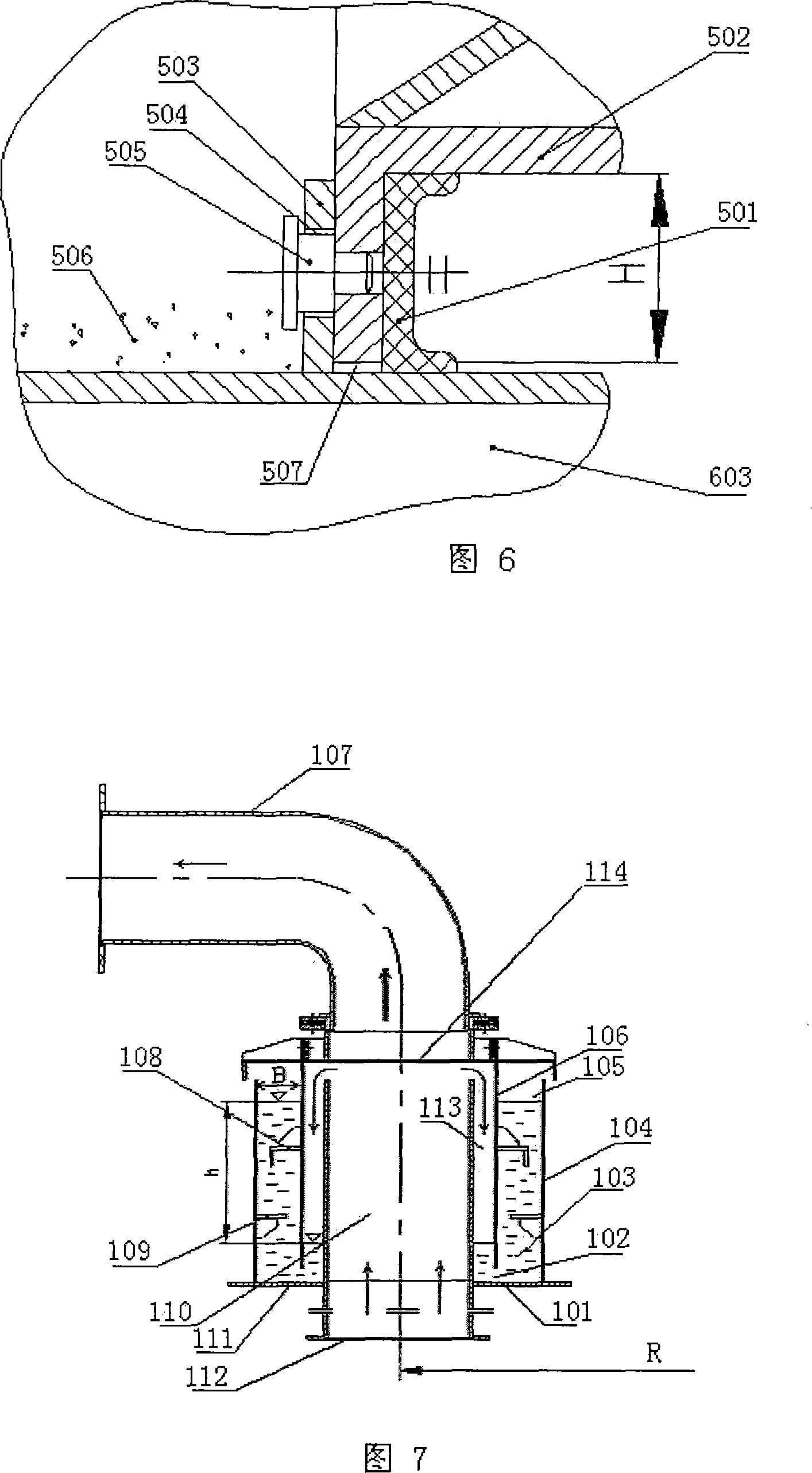

Vertical sinter ore cooling machine capable of efficiently recycling sensible heat of sinter ores

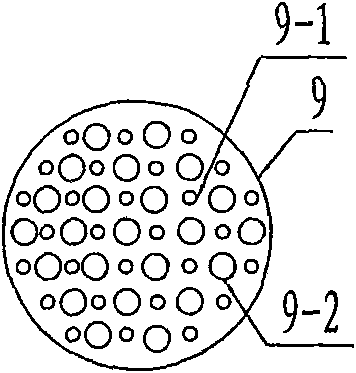

InactiveCN101576351AReduce heat transfer temperature differenceRaise the gradeIncreasing energy efficiencyHandling discharged materialGas solidMaterials science

The invention discloses a vertical sinter ore cooling machine capable of efficiently recycling the sensible heat of sinter ores, which pertains to the technical field of sintering equipment and is used for preventing air leak in the cooling course of sinter ores and effectively recycling the sensible heat of the sinter ores. The technical proposal of the invention is that: the cooling machine consists of a feeding part, a cooling part and a conveying part; the cooling part comprises a vertical closed body, a hot wind pipeline, a blower, as well as a hopper, an upper sealing valve, a pre-storing chamber, a lower sealing valve, a heat exchanging chamber, a wind distributing board, an isopiestic wind chamber and a discharging channel which are in sequence arranged on the body from top to bottom; an annular wind chamber is arranged between the pre-storing chamber and the heat exchanging chamber; the annular wind chamber is communicated with the hot wind pipeline; the isopiestic wind chamber is communicated with the blower; and wind shields and ore falling openings are distributed evenly on the wind distributing board . The vertical sinter ore cooling machine has the following advantages of: 1. an air leak rate near to 0; 2. improved gas-solid heat exchange efficiency of the cooling machine; 3. raised quality of the recycled hot air; and 4. being beneficial to increasing the utilization rate of exhaust-heat boilers. Based on the advantages, the vertical sinter ore cooling machine is expected to be used commonly as an upgraded replacement of the existing sinter cooling machine.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Sintering ore cooling device and waste heat recovery system thereof

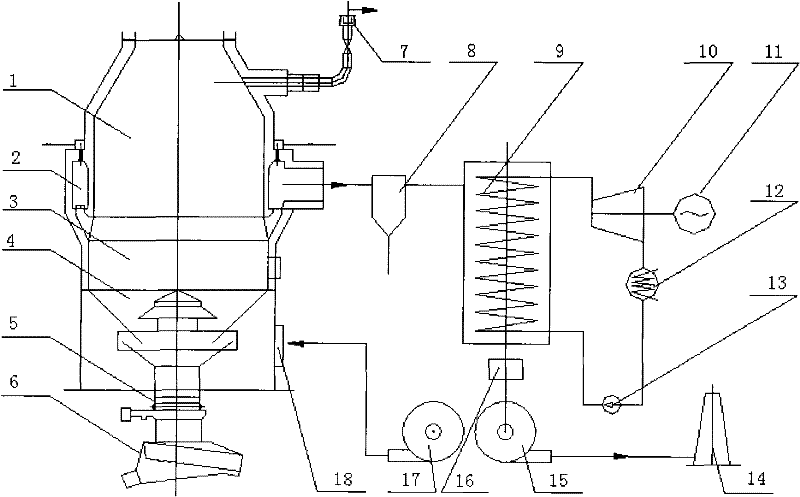

InactiveCN102345981AImprove cooling effectEnsure safe and continuous productionIncreasing energy efficiencyHandling discharged materialCold airAir blower

The invention relates to the physical heat recovery field of solid high temperature materials. The system can be applied in the waste heat recovery of extra-large high-temperature particles such as high-temperature sintering ore and the like and the process is as follows: the high-temperature sintering ore from a sintering machine falls into a cold sinter furnace through a feeding system, gradually falls with ore discharge and enters a cooling section to radiate heat. The cooled sintering ore enters a vibrator feeder discharging system through a blanking hopper and a regulating gate. The process can be adopted to cool the sintering ore from about 700-800 DEG C to about 100 DEG C. Cold air provided by an air blower enters the cold sinter furnace through an air inlet and a blast cap, absorbs heat in the cooling section and then enters an annular channel, the high-temperature gas from the annular channel enters a waste heat boiler through a dust remover, the heat is transferred to a working medium and then pumped by the draft fan through the dust remover, and the gas is discharged in a chimney when reaching the dedusting standard. The heat-absorbing working medium (usually water) is converted to superheated steam with a certain parameter in the waste heat boiler to do work in a turbine and drive a generator to generate power. Dead steam after doing work enters a condenser and is sent back to the waste heat boiler through a circulating water pump, thus, a thermal cycle is completed.

Owner:刘柏谦

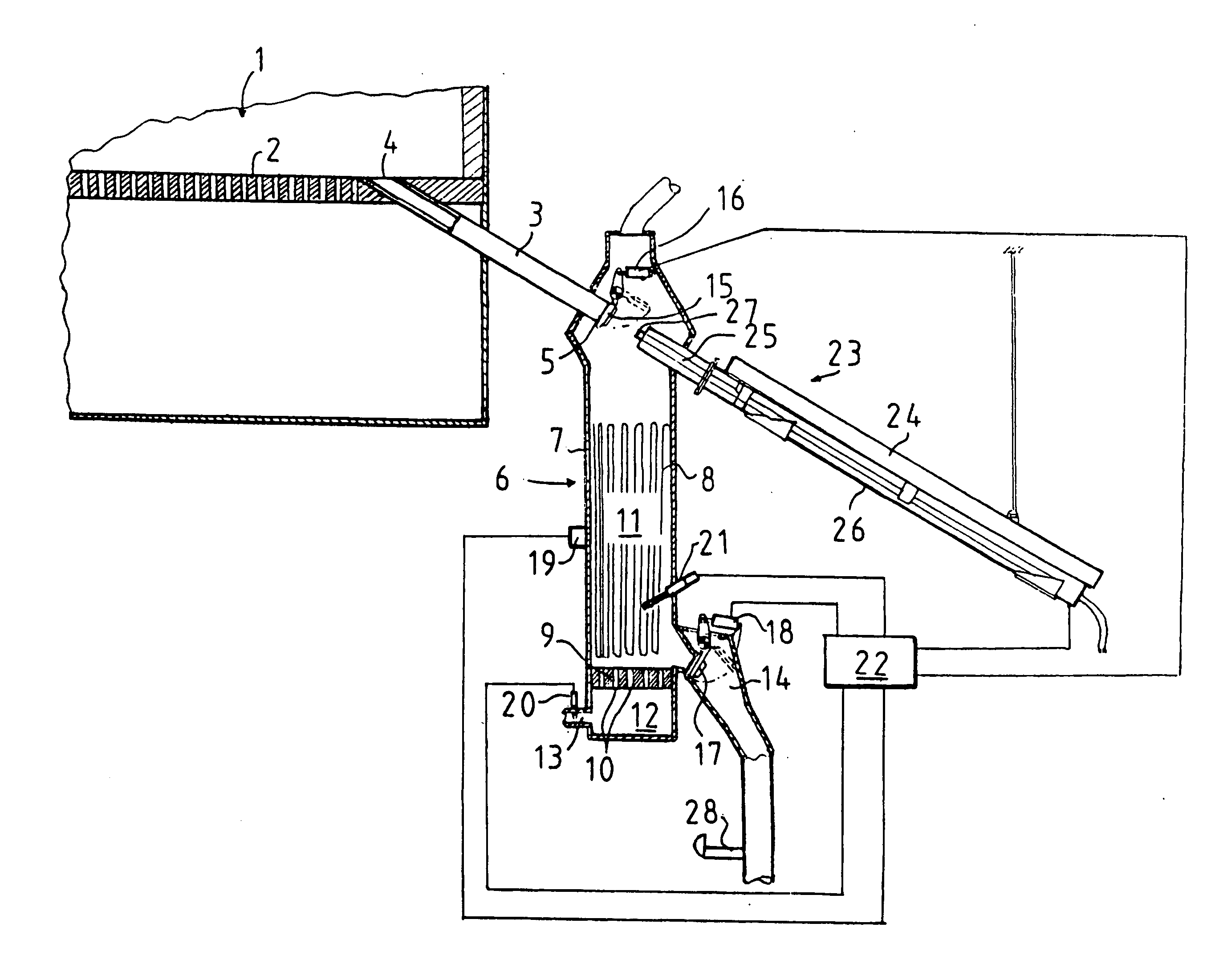

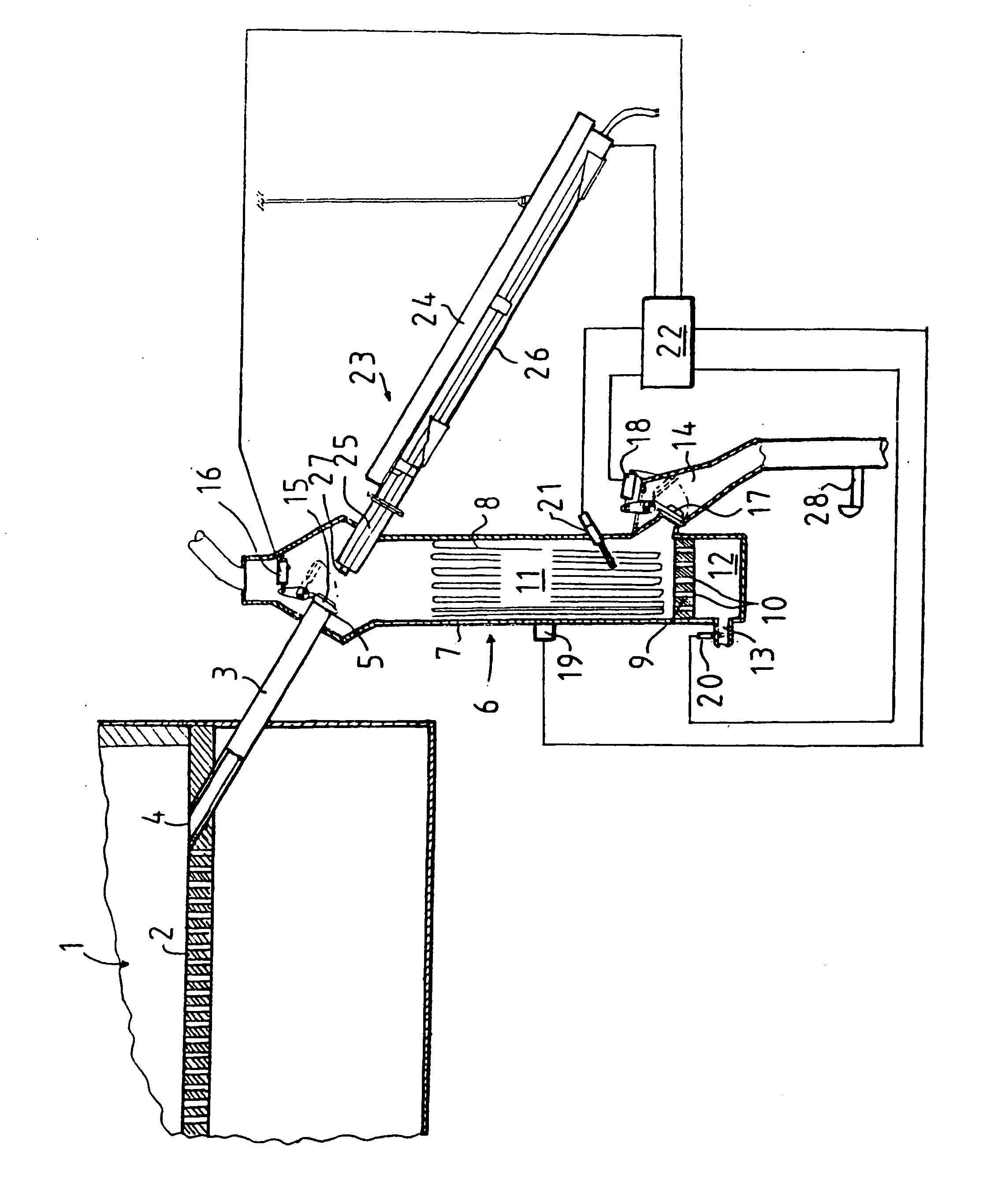

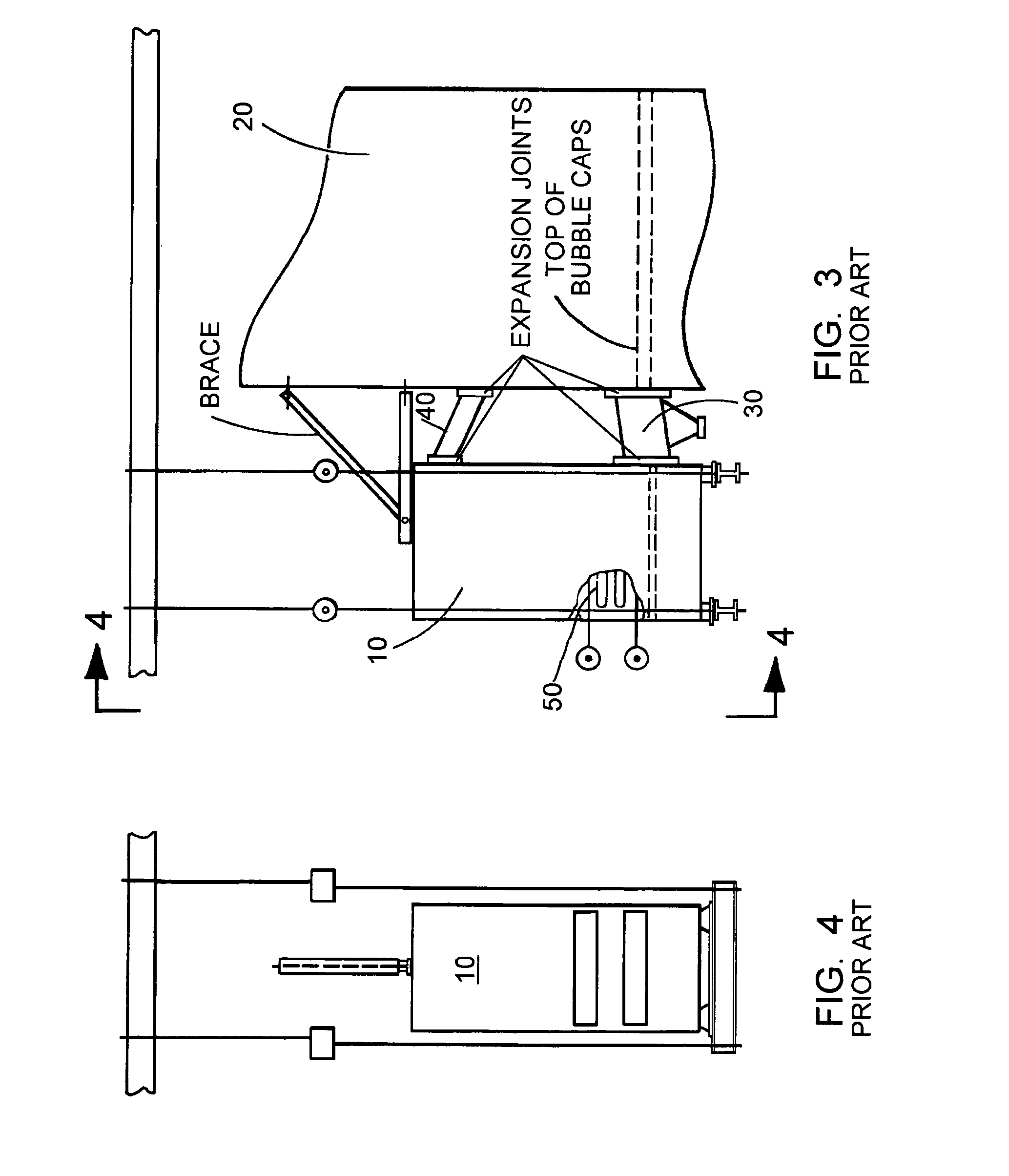

Method And Apparatus For Cooling A Material To Be Removed From The Grate Of A Fluidized Bed Furnace

InactiveUS20080199821A1Improve automationQuantity of charge is controlledFluidized bed combustionGasification processes detailsElectricityLimit value

The invention relates to a method and an apparatus for cooling a material to be removed from the grate of a fluidized bed furnace. Material at a high temperature is passed from the grate of the fluidized bed furnace into a fluidized bed cooler in charges of a given size by measuring the quantity of the material accumulating in the fluidized bed cooler. When the quantity of the material in the cooler has reached a predetermined limit value, the supply of material into the fluidized bed cooler is prevented. The charge is cooled in the fluidized bed cooler by fluidization air and via heat transfer into a cooling liquid circulation system and the temperature of the charge is measured. The charge is removed when the temperature of the charge has fallen to a predetermined limit value. The second end (5) of a supply conduit (3) is provided with a supply valve (15) actuated by a power means (16). A discharge conduit (14) is provided with a discharge valve (17) actuated by a second power means (18). Quantity detection means (19, 20) are provided to produce quantity data regarding the amount of material in a fluidized bed space (11), and temperature measuring means (21) are provided to produce temperature data. A control device (22) controls the first power means (16) to open and close the supply valve (15) and the second power means (18) to open and close the discharge valve (17) on the basis of the quantity data and temperature data and the predetermined limit values of quantity and temperature so that the loading of material into the fluidized bed space and its cooling and removal from the fluidized bed space take place in a charge-by-charge and cyclic manner.

Owner:OUTOTEC OYJ

Sintering furnace type cooling device

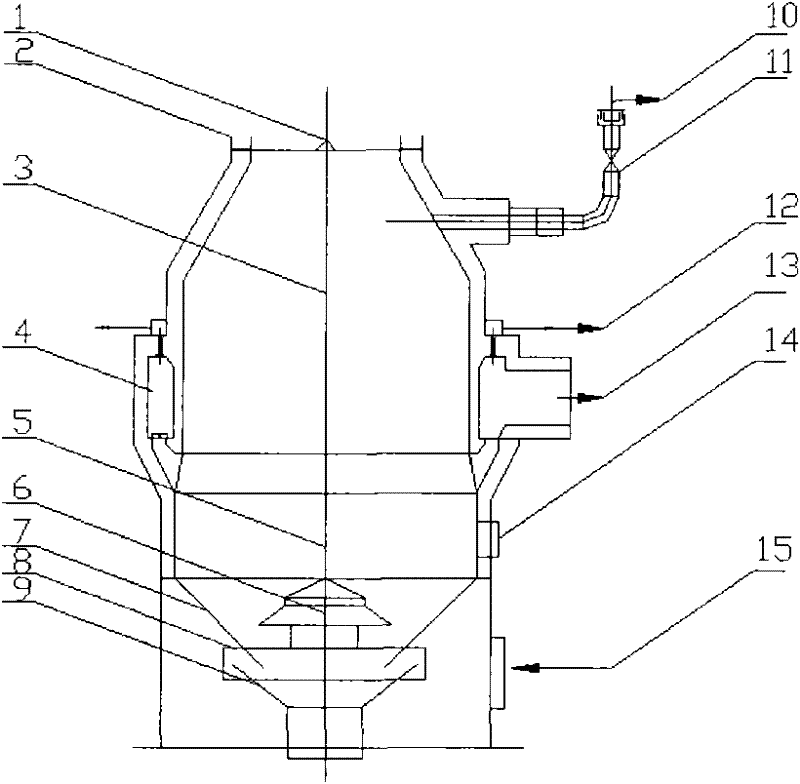

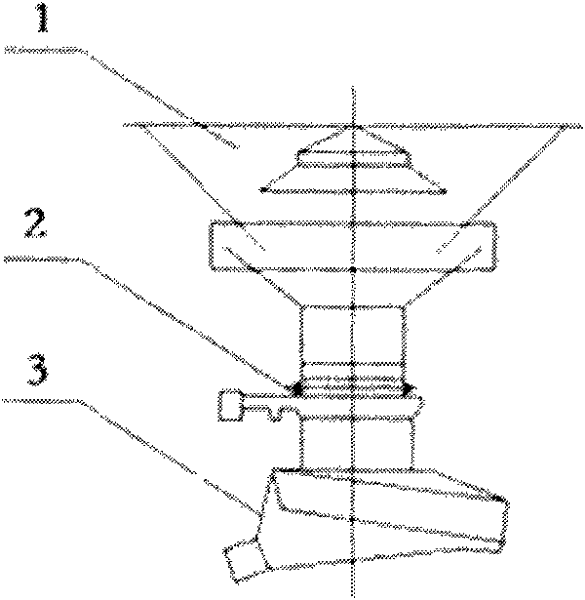

ActiveCN103234359AReduce height differenceImprove qualityHandling discharged materialThermal energyFlue gas

A sintering furnace type cooling device relates to the technology field of sintering cooling devices. An outlet of a sintering machine is provided with a single roll crusher; an outlet of the single roll crusher is provided with a hot sinter screen; the hot sinter screen is connected with an inlet of a chute; an outlet of the chute is connected with a furnace opening of a cooling furnace; a distributing device is arranged inside the furnace opening of the cooling furnace; a ventilation device is arranged at the bottom of the cooling furnace; a discharging device is connected under the ventilation device; a belt conveyer is arranged under the discharging device; the cooling furnace comprises a pre-store area which is arranged on the upper portion, a cooling area which is arranged on the lower portion and an annular flue area which is arranged on the periphery of the pre-store area; radial supporting columns which are integrally and radially distributed are arranged at the bottom of the annular flue area; a high-temperature flue gas adjustment plate is coated on two adjacent radial supporting columns; and the high-temperature flue gas adjustment plate is capable of sliding along a diametrical direction of the annular flue. The sintering furnace type cooling device has the advantages of effectively overcoming the defects that an existing sintering cooling system is serious in air infiltration and low in waste heat utilization rate, achieving efficient heat replacement, improving the temperature of the flue gas and reducing energy consumption in cooling.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Improved blast circular cooling machine

ActiveCN101118118AImprove cooling effectImprove sealingCharge manipulationFurnace typesForced-airEngineering

The present invention discloses an improved rotary forced-air cooler, which comprises a double layer trolley, a supporting beam structure, a material blocking proof air duct sealing plate arranged at the connecting part of the double layer trolley and an air supplying system, a double layer trolley unit static seal device and an air duct device. The supplying system structure is based on a rectangular beam, a triangle beam is arranged on the rectangular beam, and a plurality of ventilation channels are arranged on the bevel edge steel plates at the both waists; an air duct pipe is arranged on the air vent of the material blocking proof air duct sealing plate, an inclined plate inclining upwards from the air vent at the bottom part of the air duct pipe has a transition to a horizontal plate, a stopping ventilation fence is added to the air duct pipe at the side of the trolley; two rubber sealing parts with extended bottom edges are arranged at the outer sides of the lower parts of inner and outer sealing plates of the double layer trolley unit static seal device, an ash baffle plate which can move up and down is hung at the inner side; an air water sealing wave subduing device adopting a damping plate is arranged on the air duct device. The present invention further improves the sealing performance of the equipment, and reduces energy consumption and pollution.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Method of solidifying steel-making slag and material produced by the method

InactiveUS6334885B1Reliably efficiently solidifyingEfficient use ofGlass furnace apparatusSolid waste disposalHydration reactionSlag

A method of solidifying a steel-making slag is performed by subjecting a mixture of a steel-making slag containing at least about 50% by weight of a powdery steel-making slag having a particle size not greater than about 5 mm and a substance containing at least about 30% by weight of SiO2 (e.g., a fly ash and / or the fine powder of a granulated blast furnace slag) to a hydration reaction. The resulting solidified material contains at least about 20% of a tobermorite phase, has high strength and is suitable as an inorganic material useful as a roadbed material, building and civil engineering materials, etc.

Owner:KAWASAKI STEEL CORP

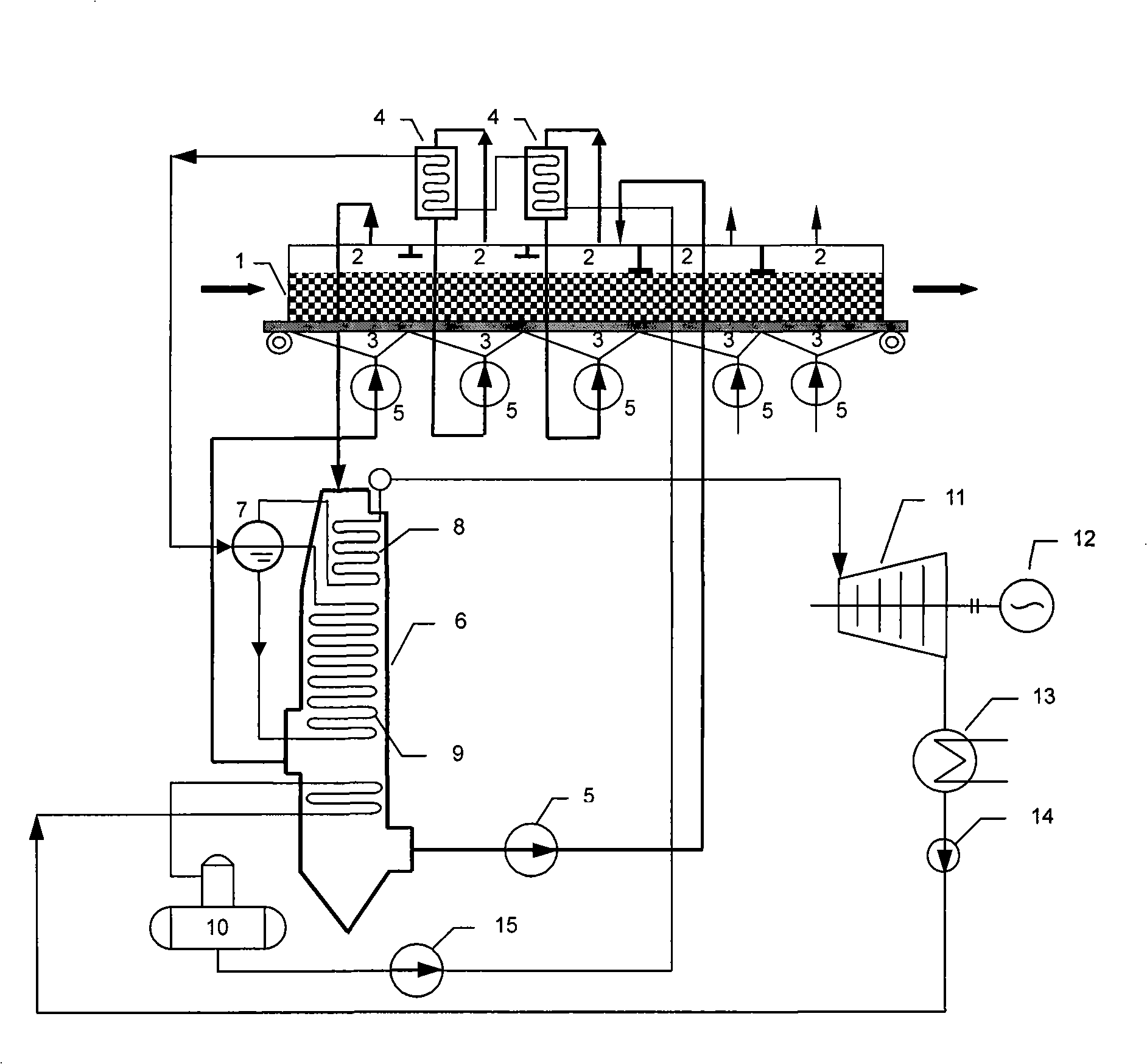

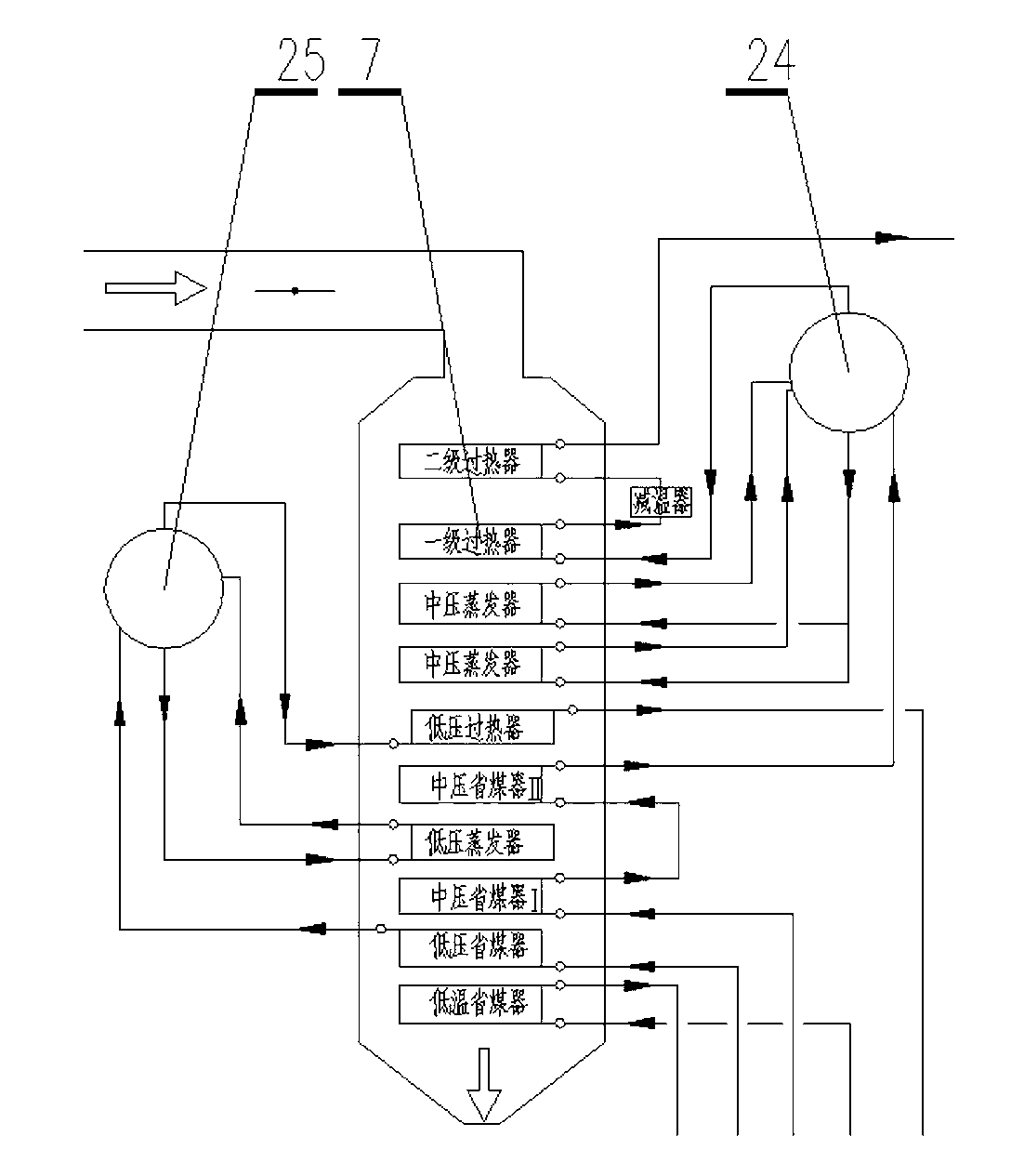

Sintered ring cold exhaust heat stepped recovery power generation system and technique

ActiveCN101344359AGuaranteed cycleImprove parametersFurnace typesIncreasing energy efficiencyAir volumeCooling effect

A sintering circulating cooling waste heat cascade recovery power generation system and a process thereof belong to the sintering waste heat utilization technology field. The system comprises a sintering circulating cooling machine, a windward chamber, a leeward chamber, a heat exchanger, a fan, a waste heat boiler, a steam bag, a superheater, an evaporator, an oxygen remover, a steam turbine, a generator, a condenser, a condensate pump and a water supply pump. The totally closed system is adopted to carry out subsection cooling and cascade recovery of waste heat of sinter, thereby recovering the sensible heat of the sinter to the maximum extent; the gradual increase of the temperature of cooling air can reduce the heat exchange temperature difference with the sinter; in order to not affect the cooling effect of the sinter, the system adopts the combined mode of the sub-cycle of the cooling air and the major cycle to absorb the sensible heat of the sinter, thereby improving the waste heat recovery efficiency. Compared with the prior art, the system and the process can extremely recover the waste heat of the sinter, improve the temperature of steam which is used for power generation under the premise of not increasing the total circulating air volume, increase the waste heat power generation amount and have great economic effects.

Owner:SHOUGANG CORPORATION +1

Heat treatment device

ActiveUS20080135207A1Warpage suppressionCool evenlySemiconductor/solid-state device manufacturingHot plates heating arrangementsEngineeringSemiconductor

In a heat treatment device including a heating chamber having a heating plate heating a semiconductor wafer, a cooling plate cooling the wafer heated by the heating chamber, and a transporting device transporting the wafer into and from the heating chamber, the cooling plate is provided with a coolant passage, a plurality of projections carrying the wafer with a space between the wafer and the surface of the cooling plate, and suction holes neighboring to the respective projections and connected to a suction device.

Owner:TOKYO ELECTRON LTD

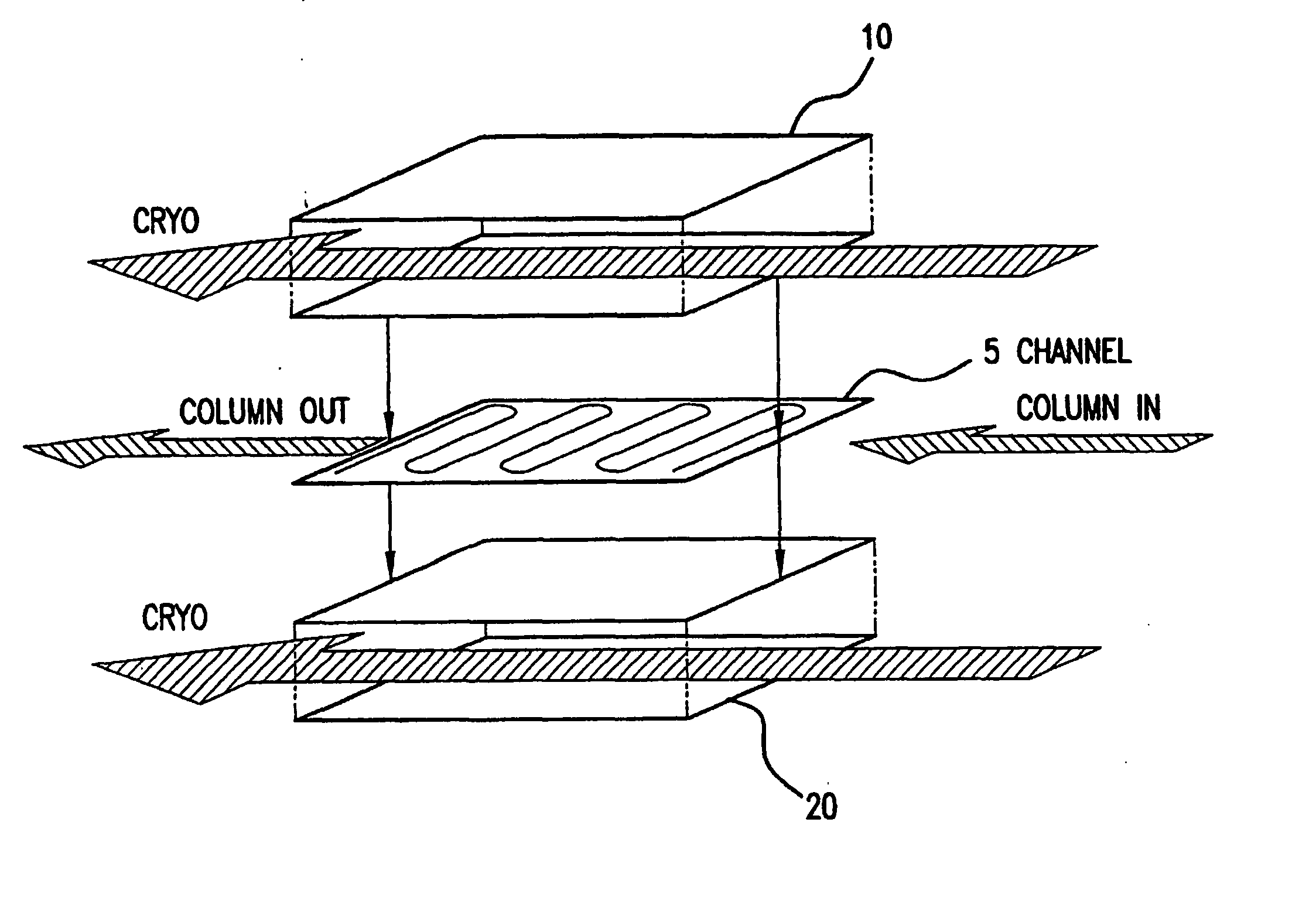

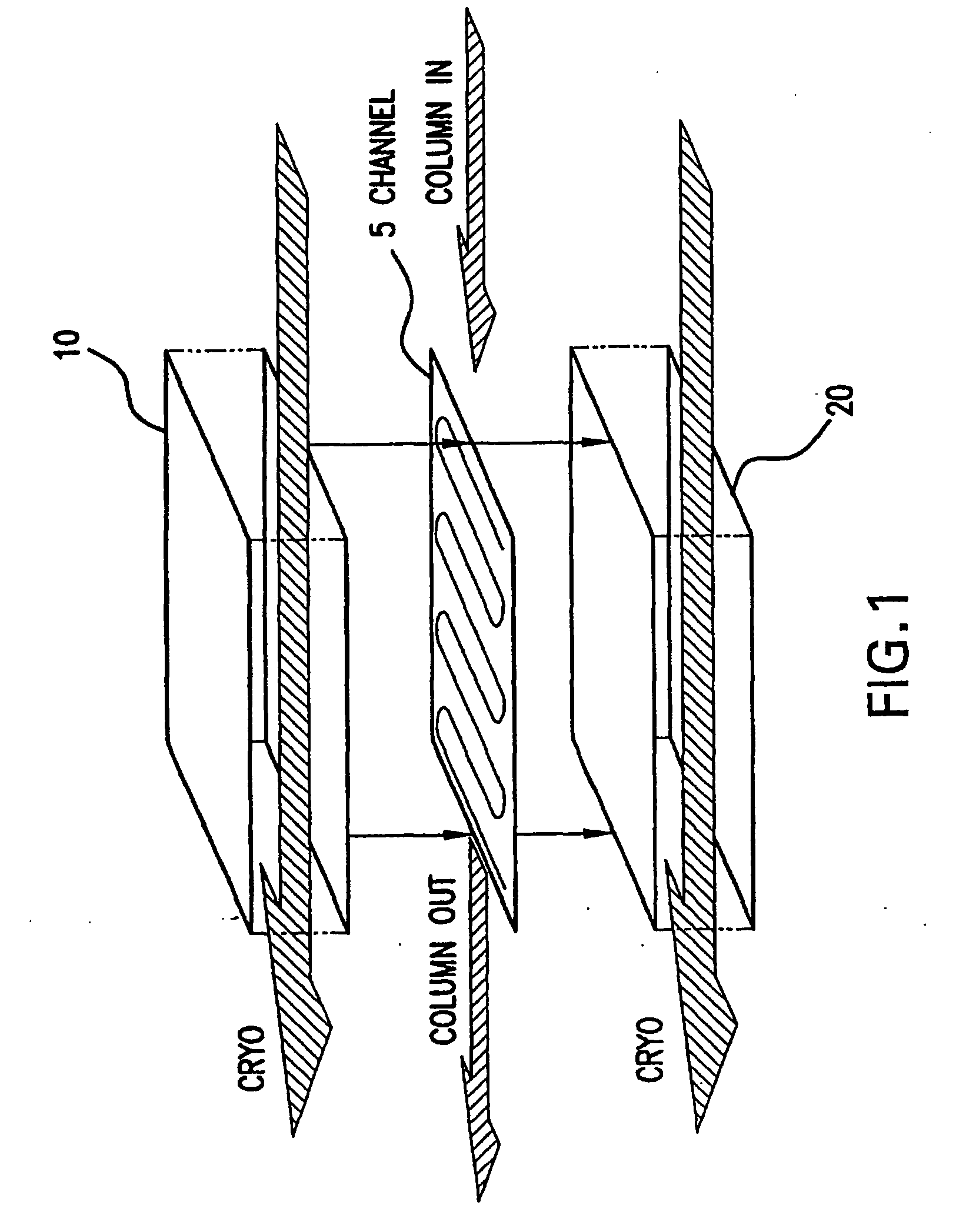

Focusing device based on bonded plate structures

The invention provides a low mass and size thermal focusing device for a gas phase analytical device. The device has two or more plates bonded together. The device also has at least one channel with an entrance and exit is formed within allowing ingress and egress of a gas stream. The device also has a temperature reduction module in thermal contact with at least one plate of the device. Thermal focusing devices with additional plates and / or channels are also disclosed.

Owner:AGILENT TECH INC

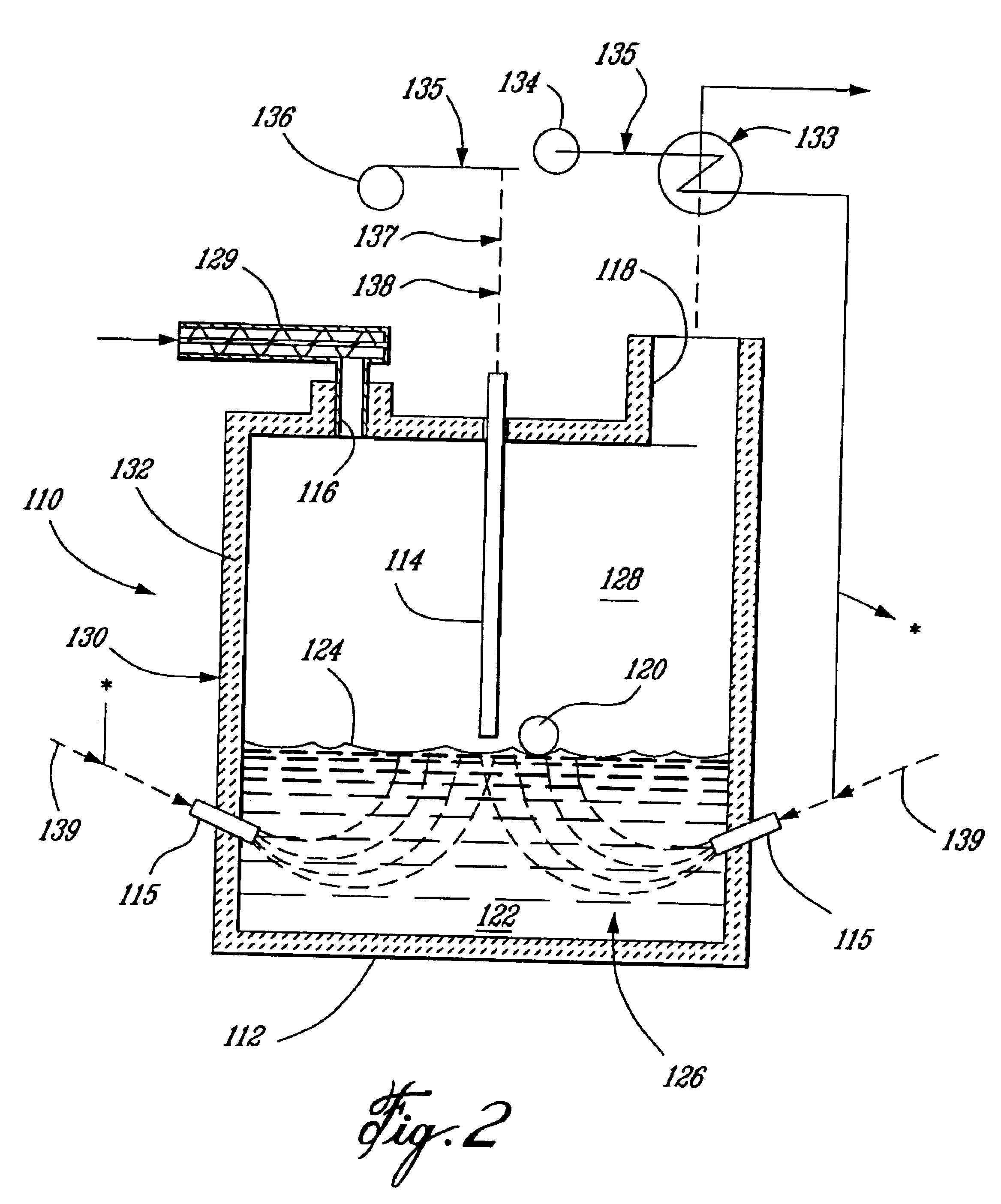

Integrated fluidized bed ash cooler

ActiveUS20070283902A1Reduction in size and weight and costSimple designFluidized bed combustionFluidised-bed furnacesHigh elevationFluidized bed

An integrated fluidized bed ash cooler for a fluidized bed boiler, particularly a circulating fluidized bed (CFB) boiler, employs at least two fluidized bed sections positioned in series along a solids flow path. Each section contains fluidizing means, the first section along the solids path being separated from a following section with a threshold. The first section contains means for measuring a bed temperature in the vicinity of the fluidizing means and at a higher elevation within the fluidized bed. Means are provided for removing oversized bed material from the first section to facilitate the removal of ash while minimizing the possibility of ash plugging during operation.

Owner:THE BABCOCK & WILCOX CO

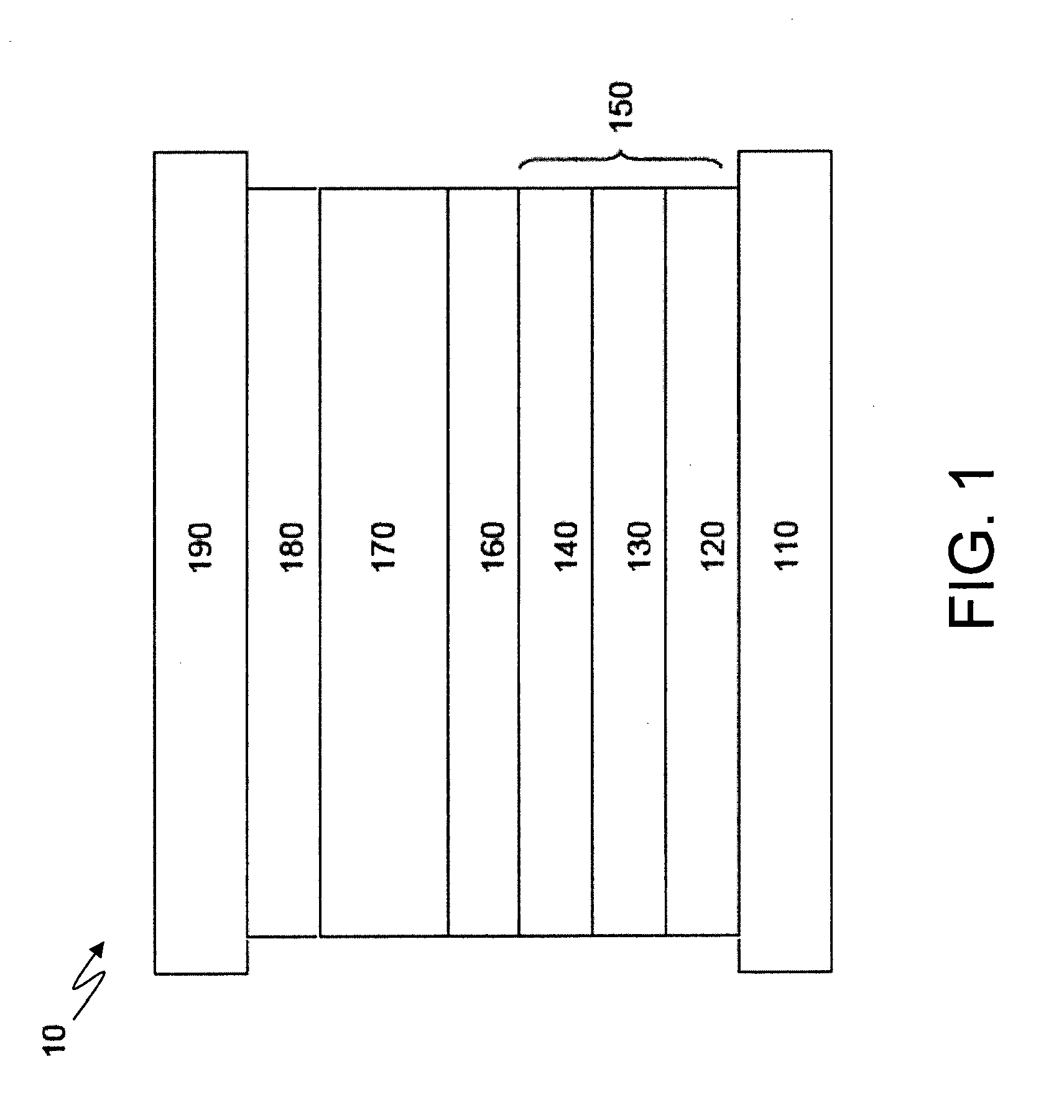

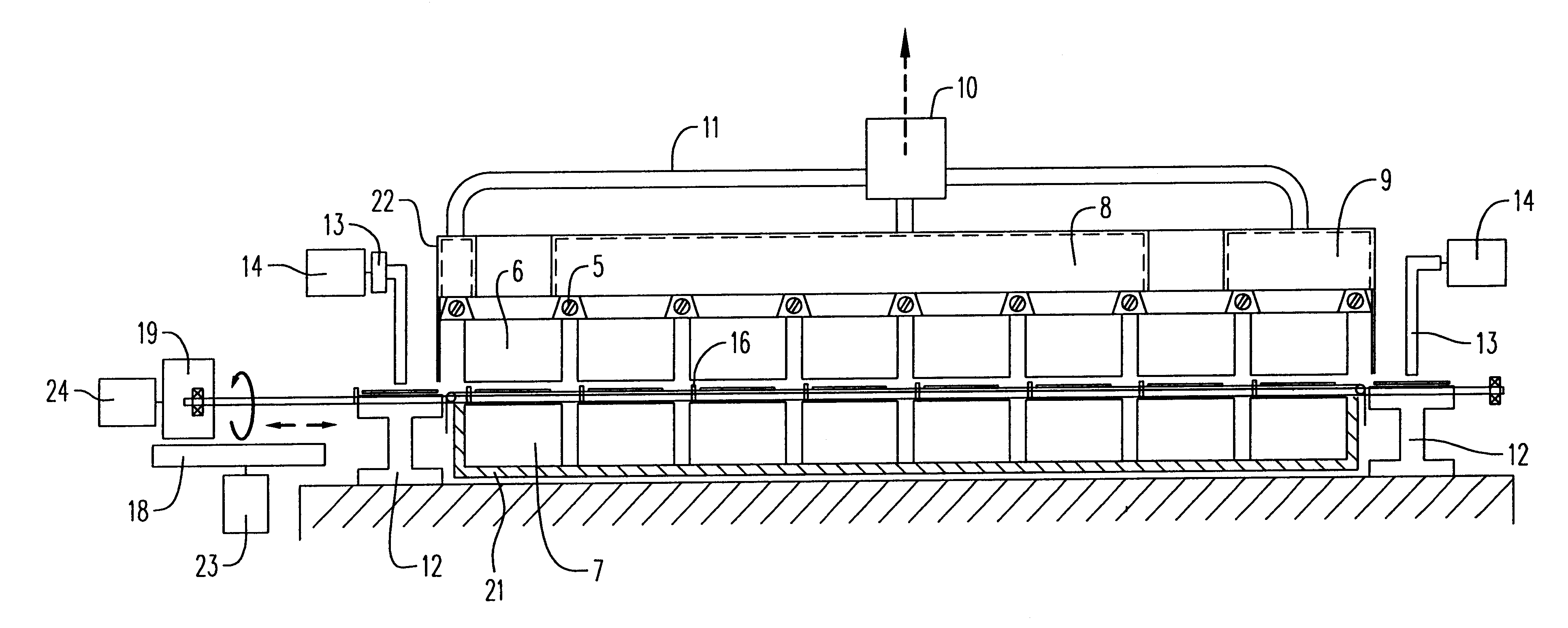

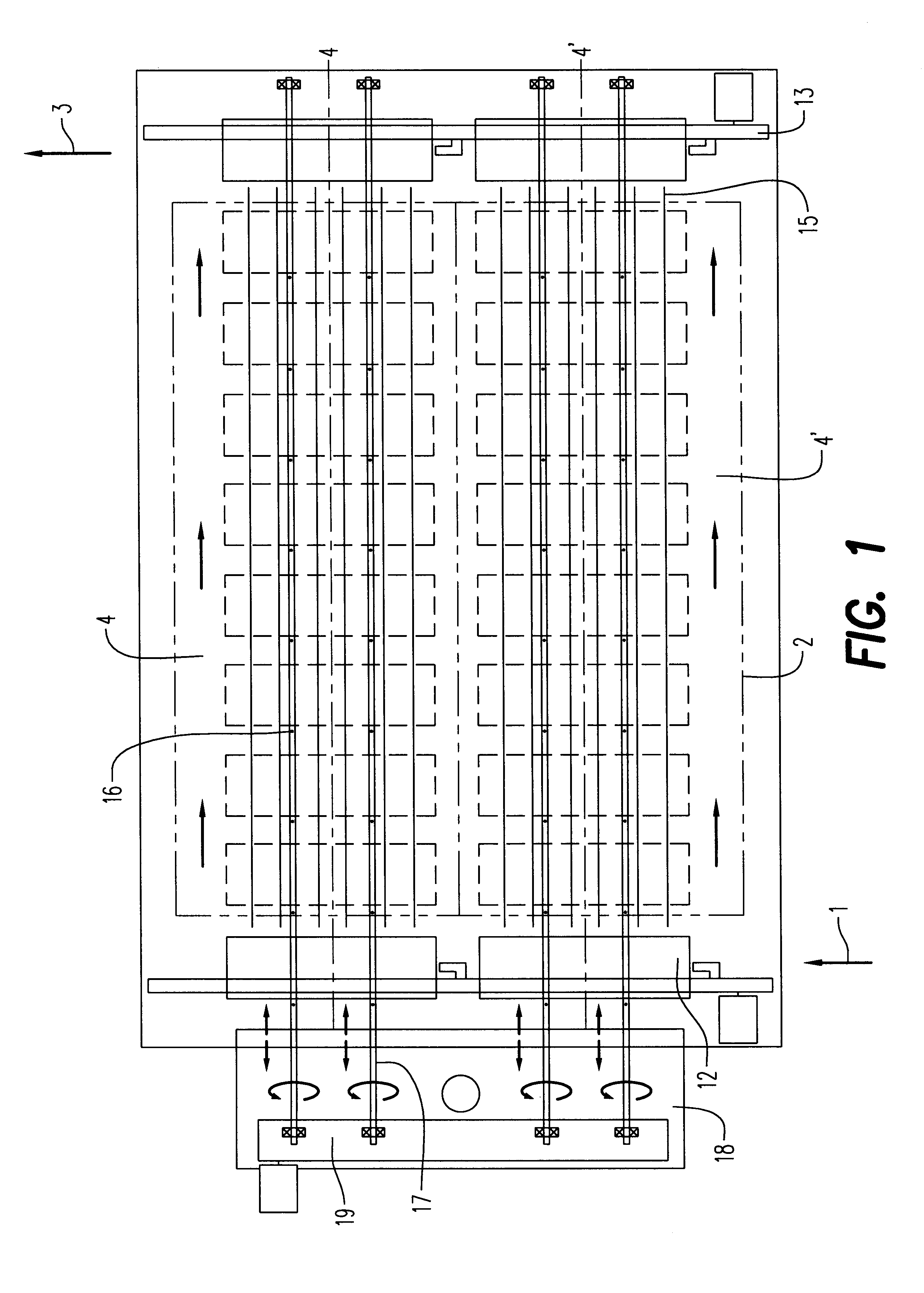

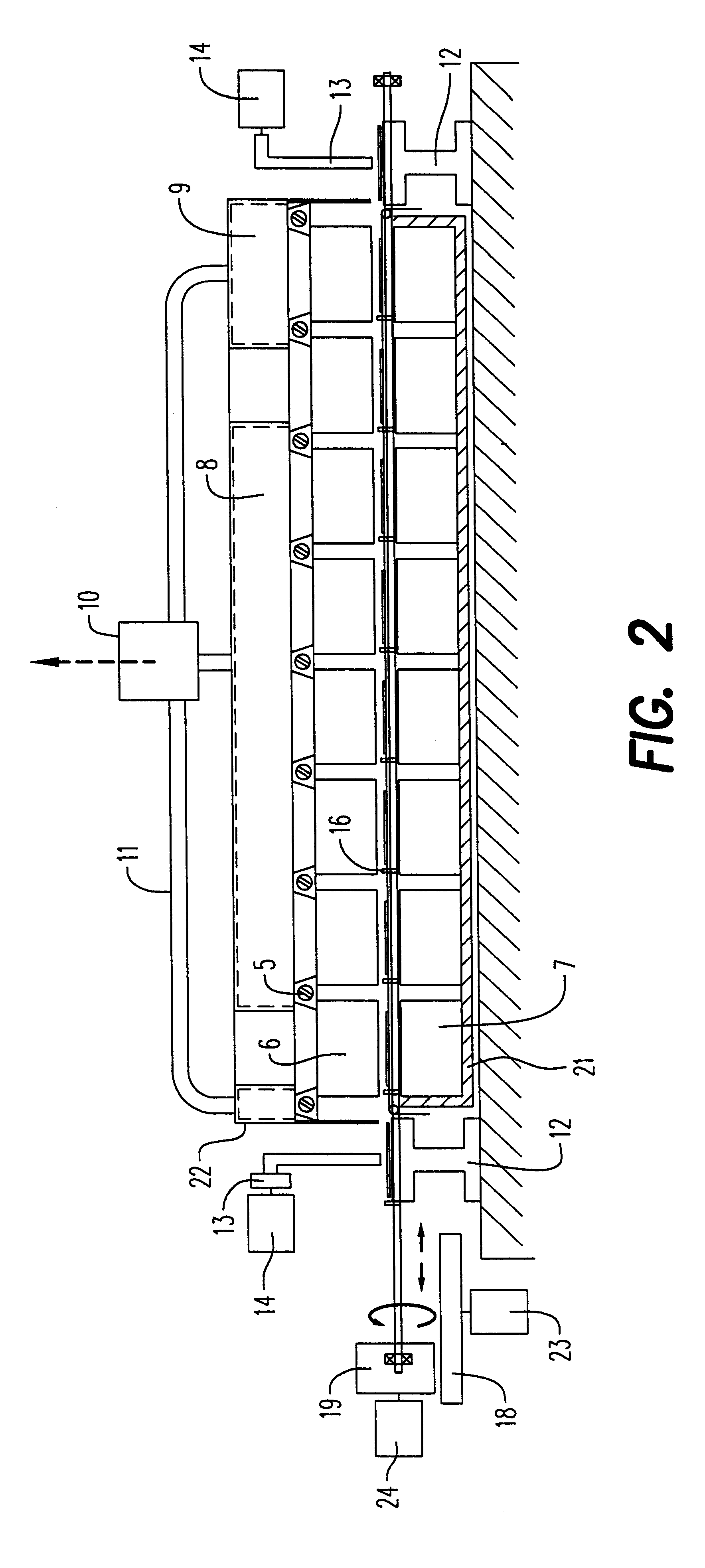

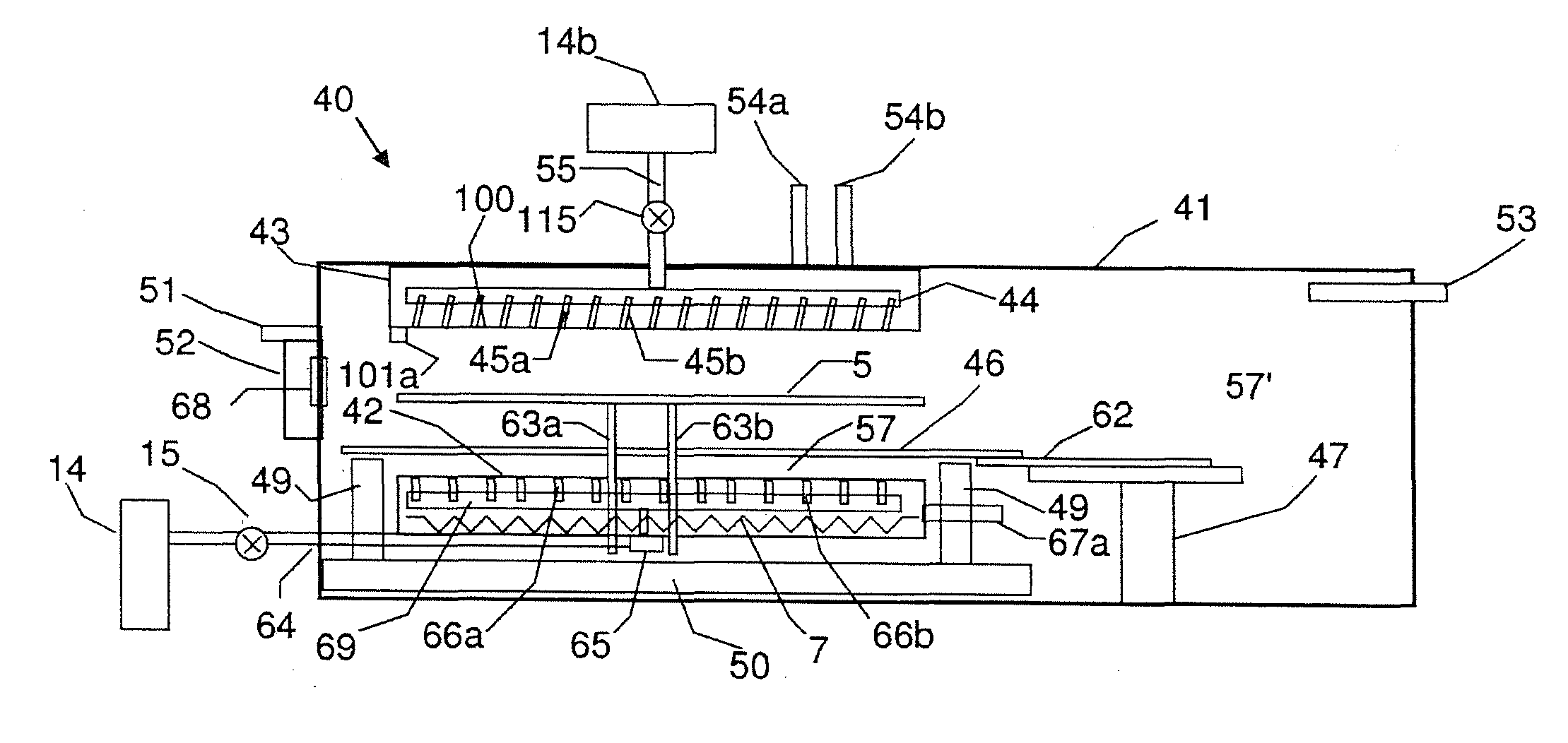

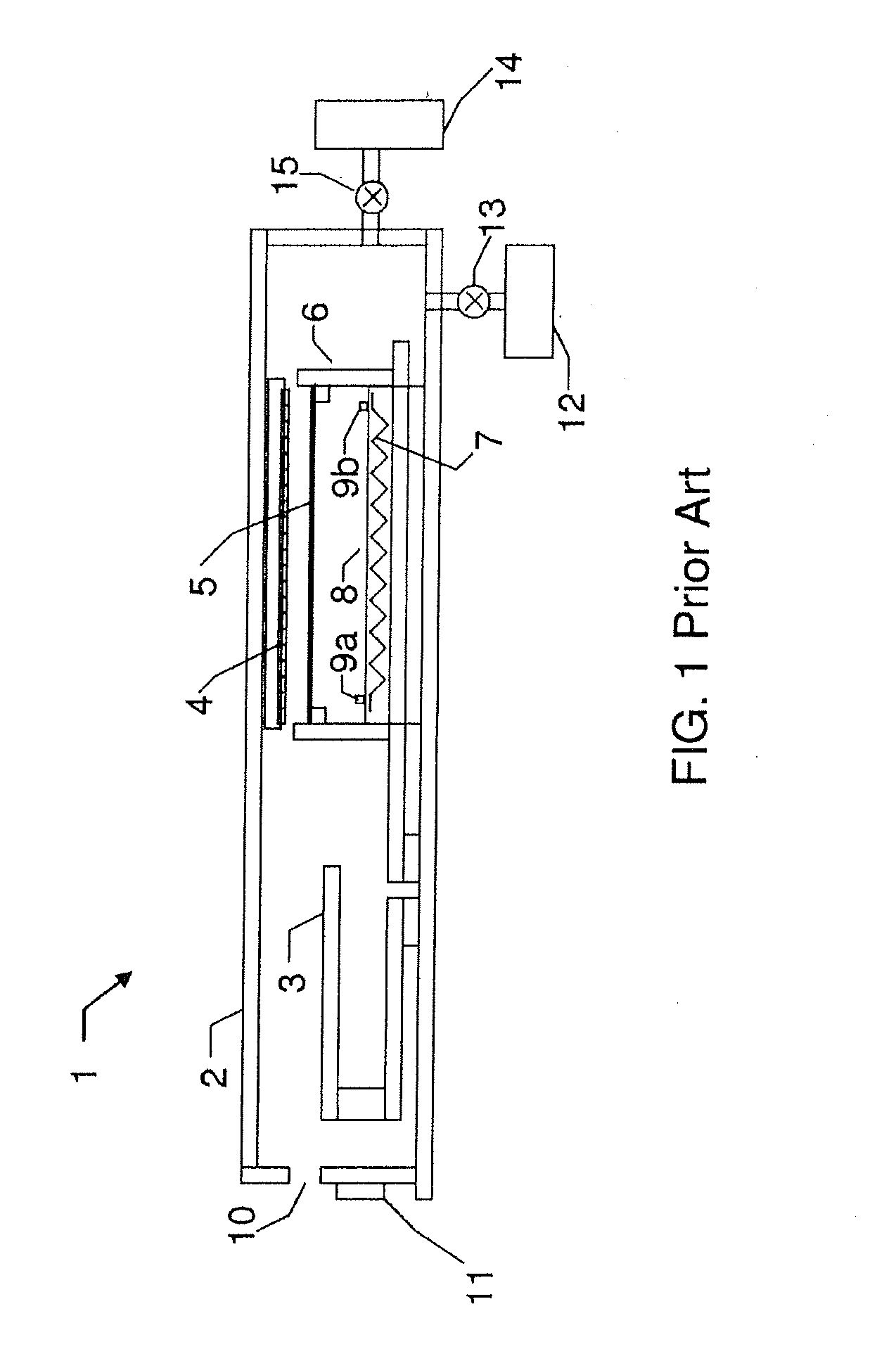

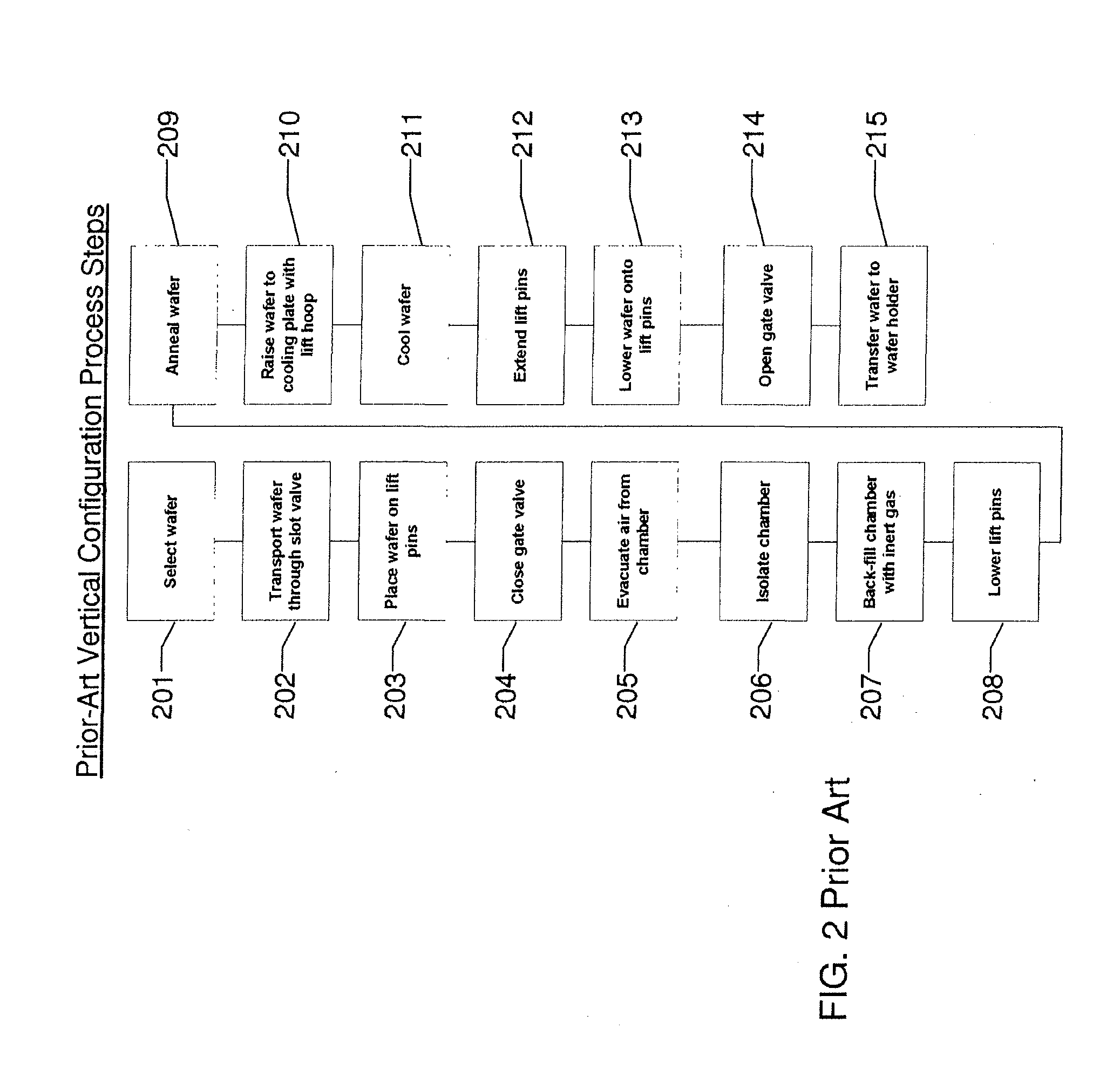

Apparatus for thermal processing with micro-environment

InactiveUS20110114623A1Reduce gas flowRestricting flow of gasSemiconductor/solid-state device manufacturingHandling discharged materialEngineeringIsolated environment

A substrate thermal processing system. The system has at least one substrate holding module having a housing configured for holding an isolated environment therein. A substrate heater is located in the housing and has a substrate heating surface. A substrate cooler is located in the housing and having a substrate cooling surface. A gas feed opening into the housing and feeding inert or reducing gas into the housing when the substrate is heated by the heating surface. A gas restrictor is within the housing restricting the fed gas between the substrate heating surface and a surrounding atmospheric region substantially surrounding the substrate heating surface in the housing and forming an aperture through which the fed gas communicates with the atmospheric region.

Owner:TEL NEXX INC

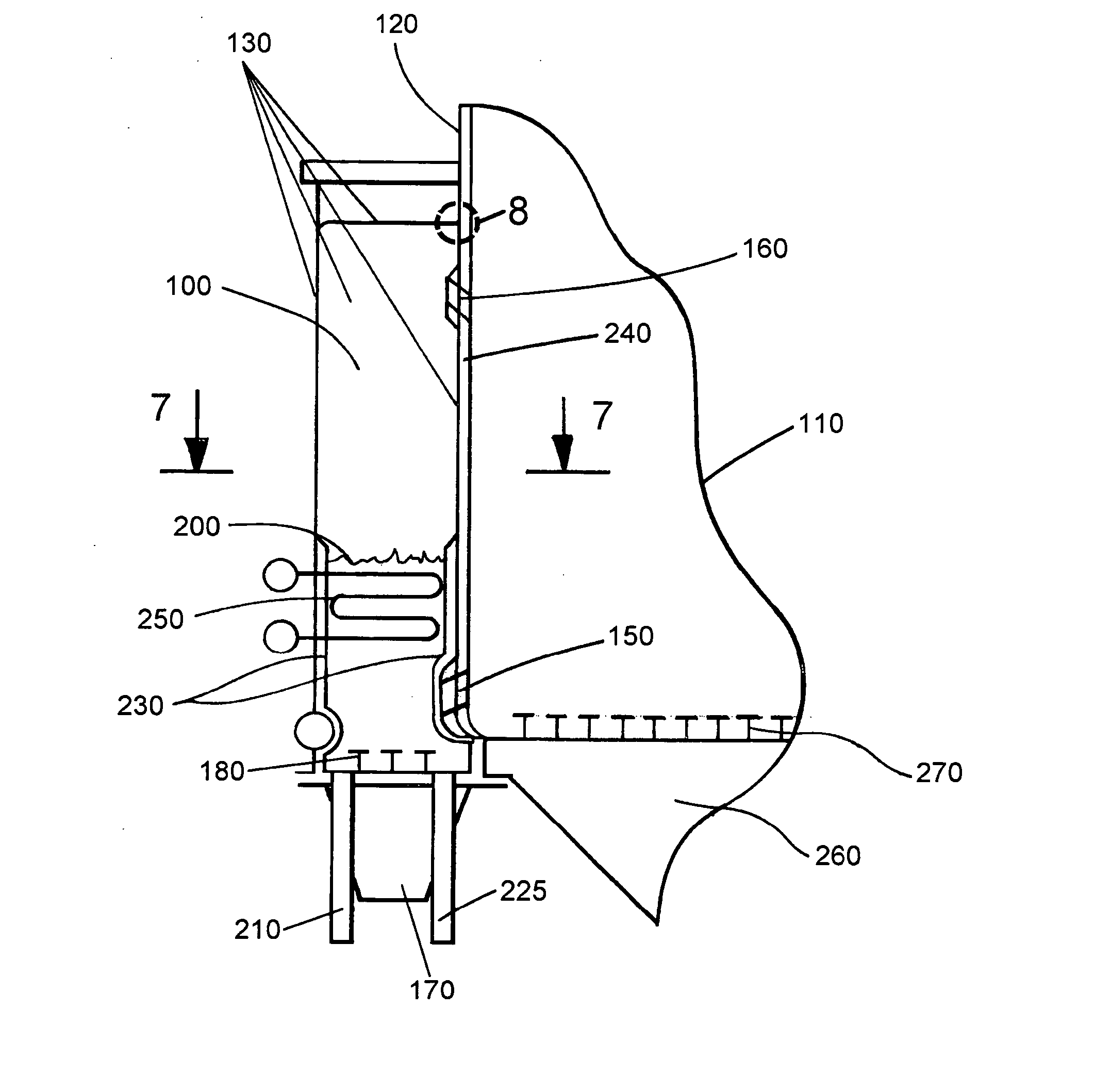

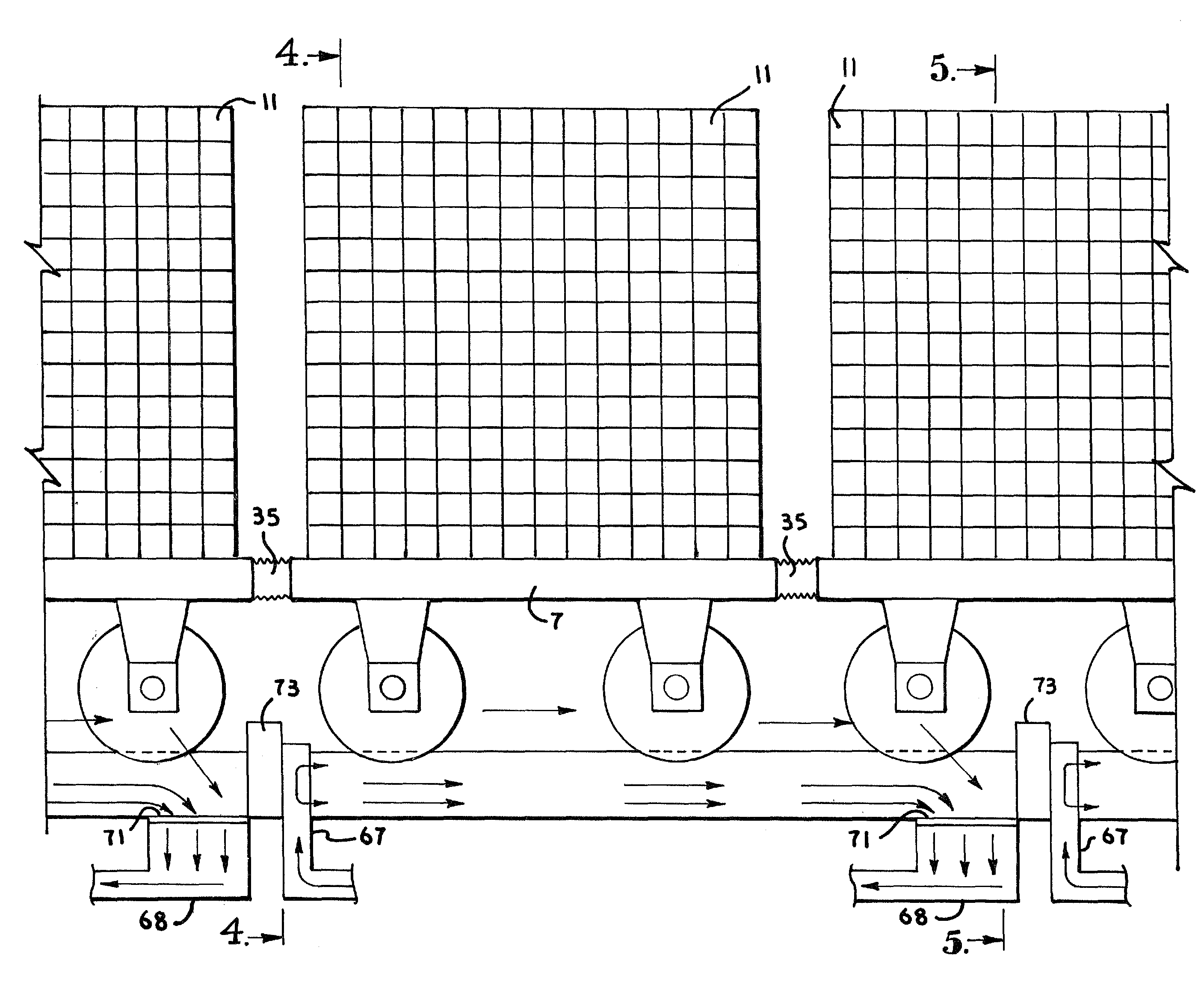

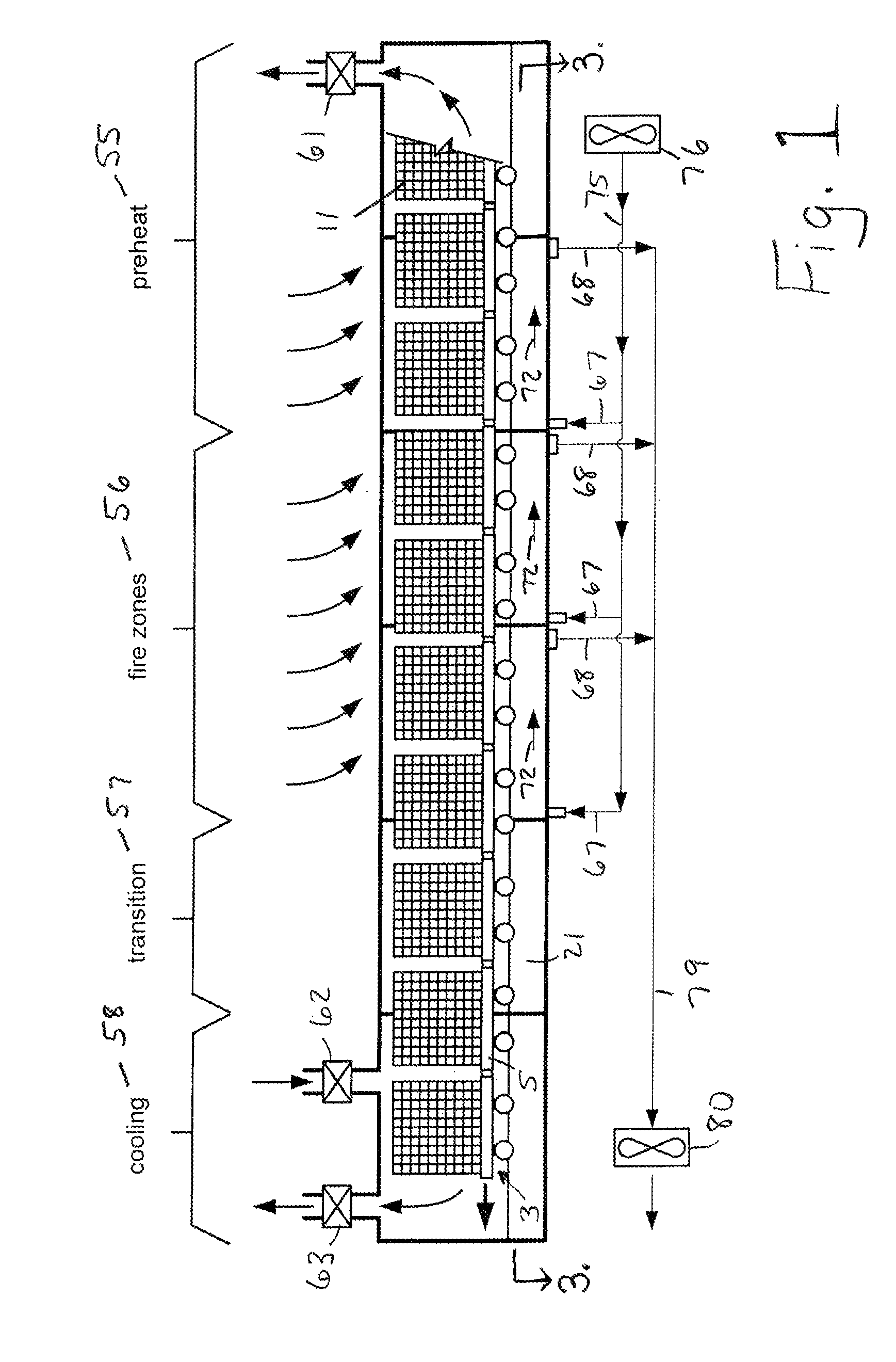

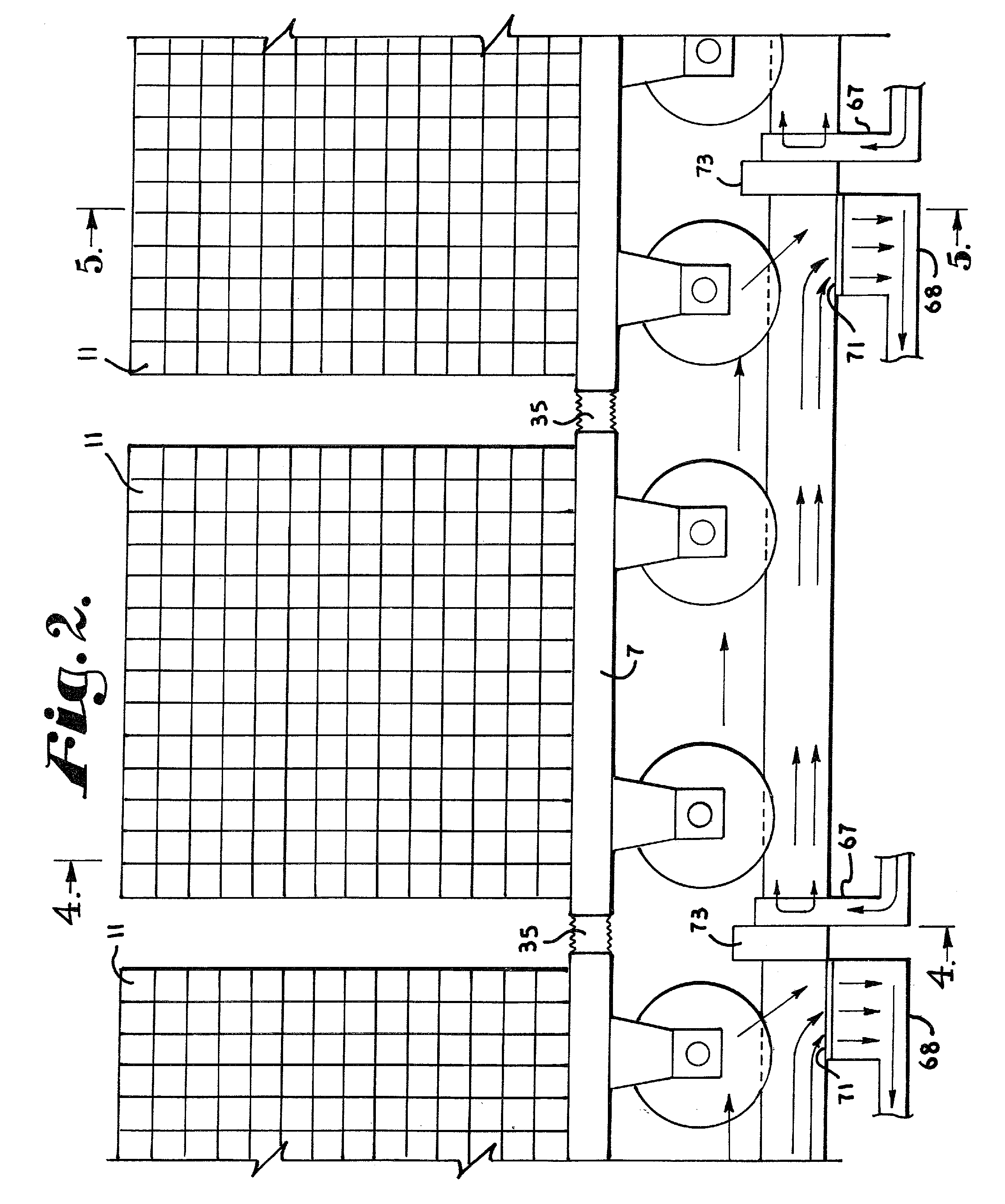

Method and apparatus for cooling the underside of kiln cars

InactiveUS7950921B1Minimize migrationFacilitates movement and circulationCharge manipulationFurnace typesTunnel kilnEngineering

An improved method and apparatus for cooling the under-car channel of a tunnel kiln while minimizing migration of air between the above-car and under-car channels involves controlling or equalizing the mass flow of cooling air directed through the under-car channel and in particular through individual undercarriage cooling zones which can match individual heating zones of the tunnel kiln.

Owner:SOLUTION DYNAMICS

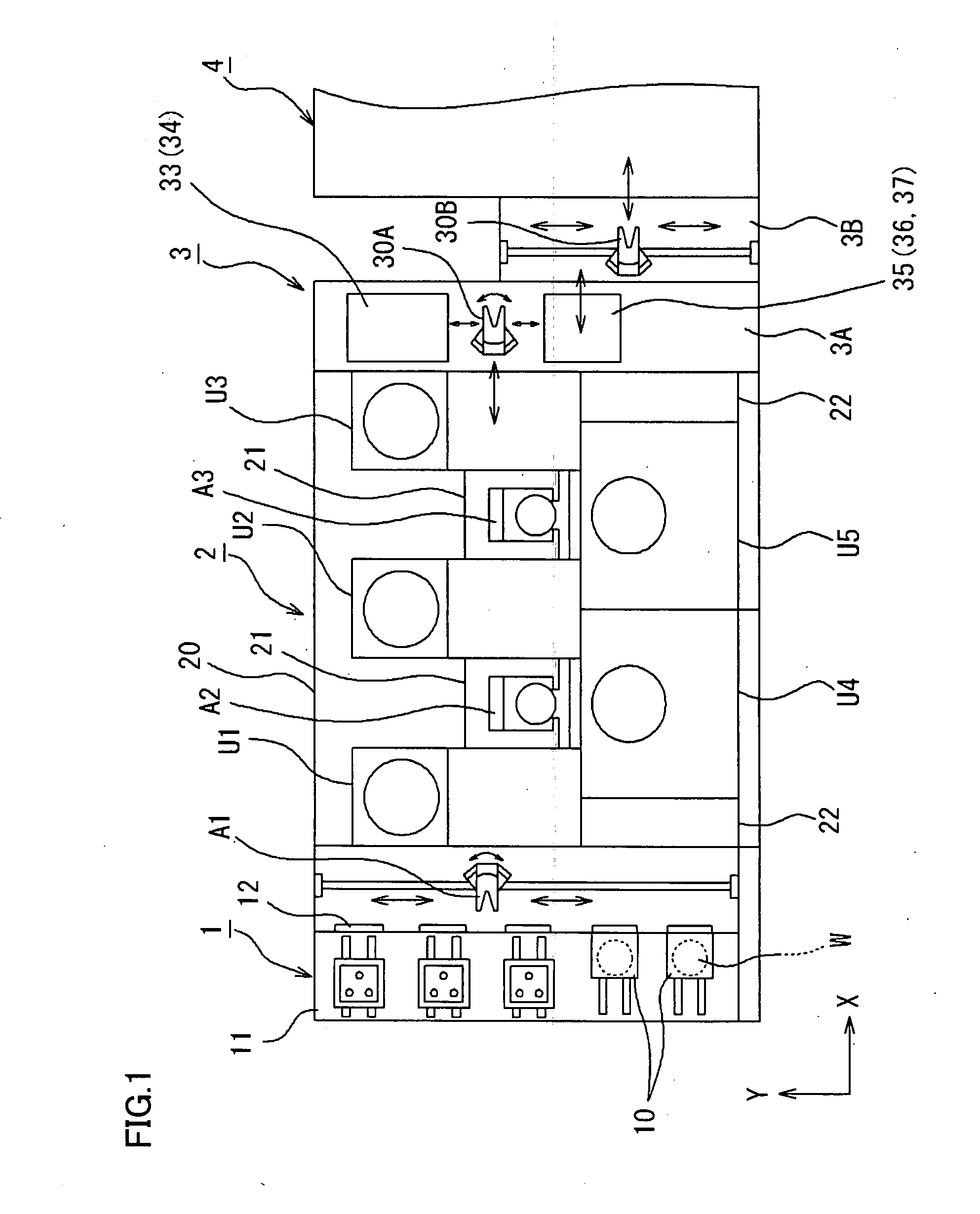

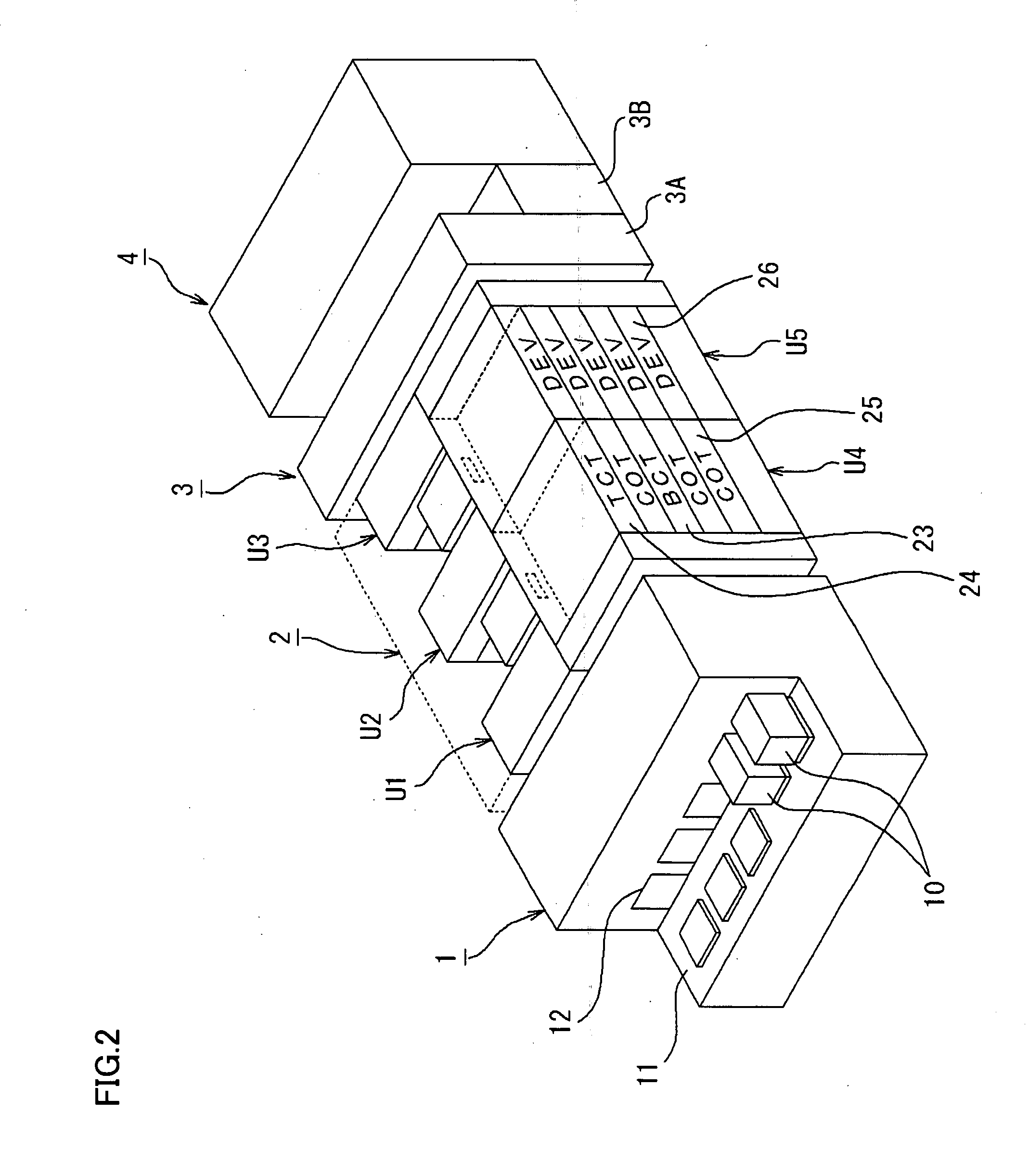

Temperature setting method of heat processing plate, temperature setting apparatus of heat processing plate, program, and computer-readable recording medium recording program thereon

ActiveUS20090254226A1Increase productionUnified performanceCombustible gas coke oven heatingSpace heating and ventilationEngineeringHeat treated

An object of the present invention is to perform temperature setting of a heating plate so that a wafer is uniformly heated in an actual heat processing time. The temperature of a wafer is measured during a heat processing period from immediately after a temperature measuring wafer is mounted on the heating plate to the time when the actual heat processing time elapses. Whether the uniformity in temperature within the wafer is allowable or not is determined from the temperature of the wafer in the heat processing period, and if the determination result is negative, a correction value for a temperature setting parameter of the heating plate is calculated using a correction value calculation model from the measurement result, and the temperature setting parameter is changed.

Owner:TOKYO ELECTRON LTD

Device and process for generating power through efficient recovery of waste heat of sintered ores

ActiveCN103234362AIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialCogenerationMaterials science

The invention discloses a device and a process for generating power through efficient recovery of waste heat of sintered ores and belongs to the technical field of cogeneration. The device comprises a sintered ore cooling system, a waste heat power generating system and a smoke system, wherein the sintered ore cooling system and the waste heat cycling power generating system are connected through the smoke system to form a loop. The process comprises the steps of 1), cooling of sintered ores; 2) the smoke system; and 3) waste heat power generating. The device and the process for generating power through waste heat have the advantages that discharged waste heat is used fully during cooling of sintered ores, the electric energy production is improved significantly, the power rate of the system is reduced significantly, and the energy-saving effect is significant.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Sintering flue gas energy-saving type denitrification system

ActiveCN104792186AIncrease waste heat recoveryRealize joint denitrification processEnergy industryIncreasing energy efficiencyWaste heat recovery unitFlue gas

The invention discloses a sintering flue gas energy-saving type denitrification system. The sintering flue gas energy-saving type denitrification system comprises a denitrification device, a heat exchanger, a circulating fan and an ammonification device. The sintering flue gas energy-saving type denitrification system fully uses waste heat of a sintering process, the sintering flue gas efficient denitrification is achieved, and the flue gas waste heat is recovered. The sintering flue gas energy-saving type denitrification system can greatly reduce nitrogen oxide discharge amount of sintering flue gas and improve the waste heat recovery level of the sintering process.

Owner:孙慕文

Metal card

ActiveUS8944810B2Easy embossingReduce the amount requiredExothermal chemical reaction heat productionOther heat production devicesMetalWear and tear

A method and apparatus for treating a selected region of a metal layer, used to form a metal card, by annealing the selected metal region so the selected region becomes soft and ductile, while the rest of the metal layer remains stiff. The softened, ductile, selected metal region can be embossed with reduced power and with reduced wear and tear on the embossing equipment. Alternatively, the annealed metal layer can undergo additional processing steps to form an assembly which can then be embossed. The method may include the use of a fixture for holding the metal layer, with the fixture having a window region for enabling heat to be applied to soften the region of the metal layer within the window region. The fixture includes apparatus for cooling the portion of the metal layer outside of the window region and for preventing the temperature of the metal layer outside the window region from rising above predetermined limits.

Owner:COMPOSECURE LLC

Air duct water sealing shock wave device used for ring cold machine

ActiveCN101118120AAvoid vibrationAvoid resonanceFurnace typesHandling discharged materialResonanceAtmospheric air

The present invention discloses an air water seal wave subduing device for a circular cooling machine, which comprises an inner ring-shape fluid bath, an outer ring-shaped fluid bath, and an inner water seal and an outer water seal composed of sealing plate devices with the radial cross section being in a door shape supported by a suspension. The inner water seal and the outer water seal are both composed of outer ring grooves connected with atmosphere and inner ring grooves connected with the air duct, a plurality of damping plates are fixed and arranged on the groove walls which form the water seal outer ring groove. Because damping plates are arranged in the water seal, under the good sealing effect of the ring-shape air duct, the vibration or resonance of the water in the water seal caused by wind in the air duct can be avoided, thus the circular cooling machine normal operation is ensured.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Heat treatment apparatus

InactiveUS6450803B2Uniform heat treatmentEasy to controlSpadesMuffle furnacesEngineeringHeat treated

A heat treatment table is divided into two or more regions, a heater is disposed for each region. On a predetermined portion of the heat treatment table, a plurality of sensors are disposed separately each other. A relation between temperatures of the respective portions on the heat treatment table and temperatures detected by the sensors is grasped in advance, thereby enables to surmise a temperature of the respective portion of the heat treatment table from the temperature detected by the sensors. In the case of an wafer being actually treated by placing on the heat treatment table, the temperatures detected by the sensors are observed, from these detected temperatures, the temperatures of the respective portions on the heat treatment table, that is, temperatures affecting the wafer, are surmised.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com