Patents

Literature

102 results about "Serpentine channel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

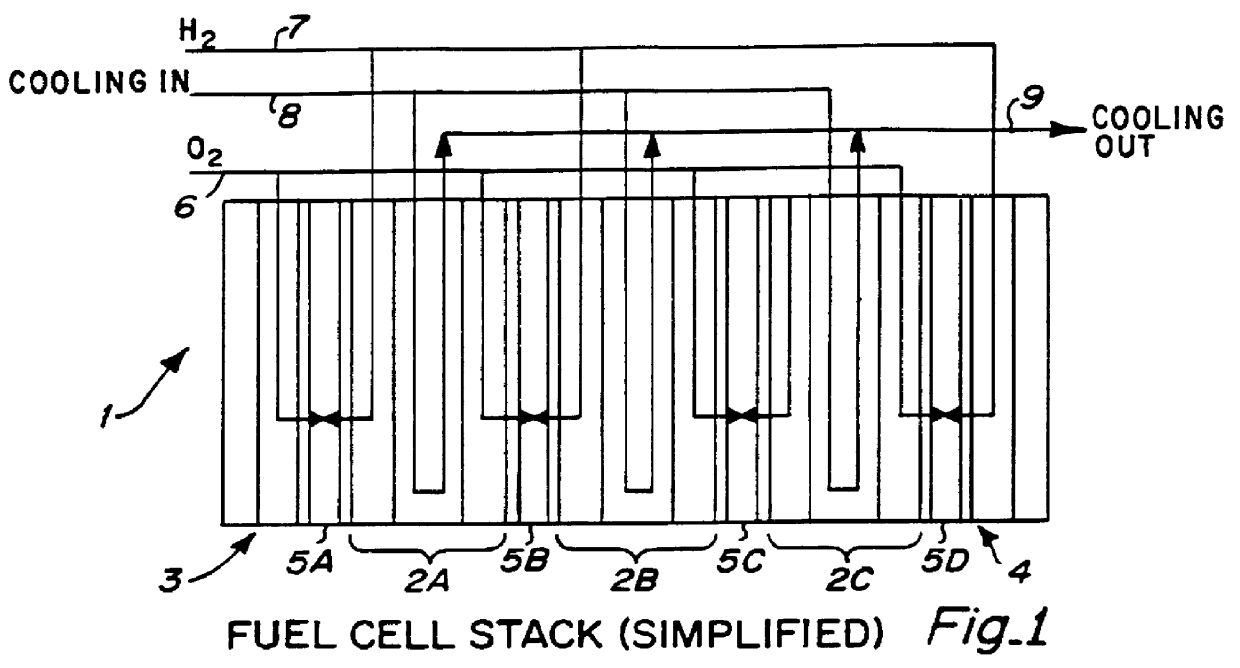

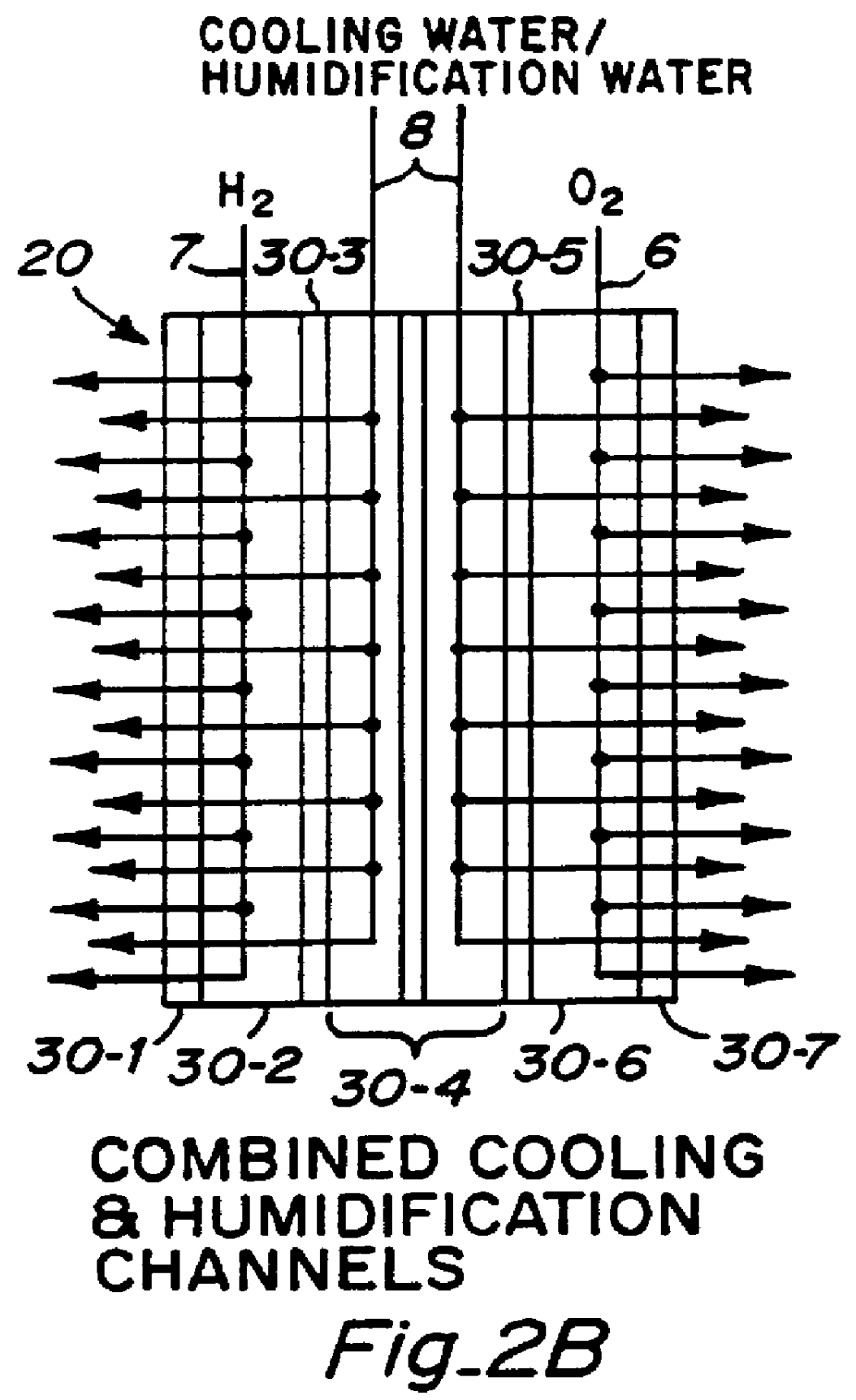

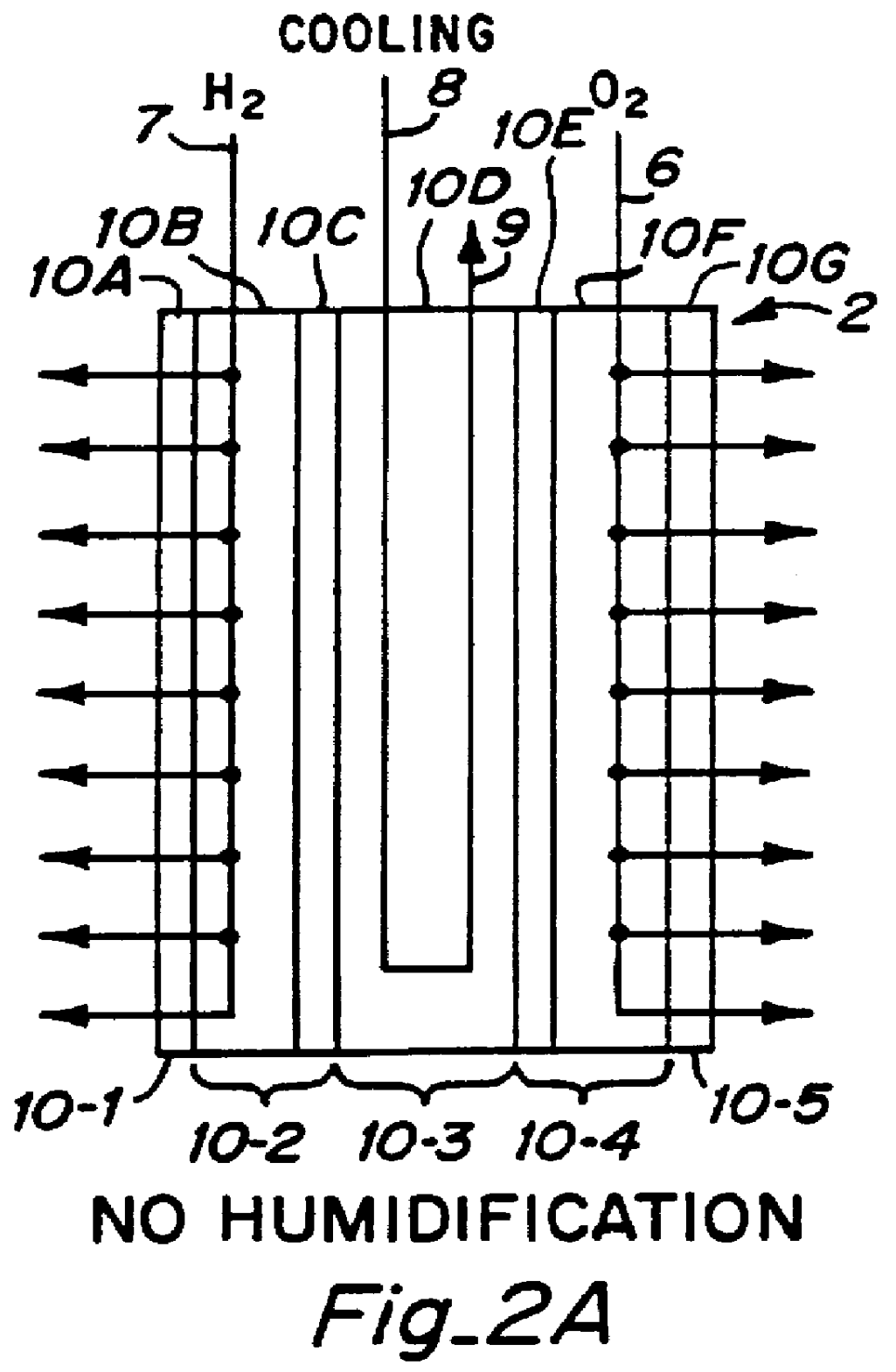

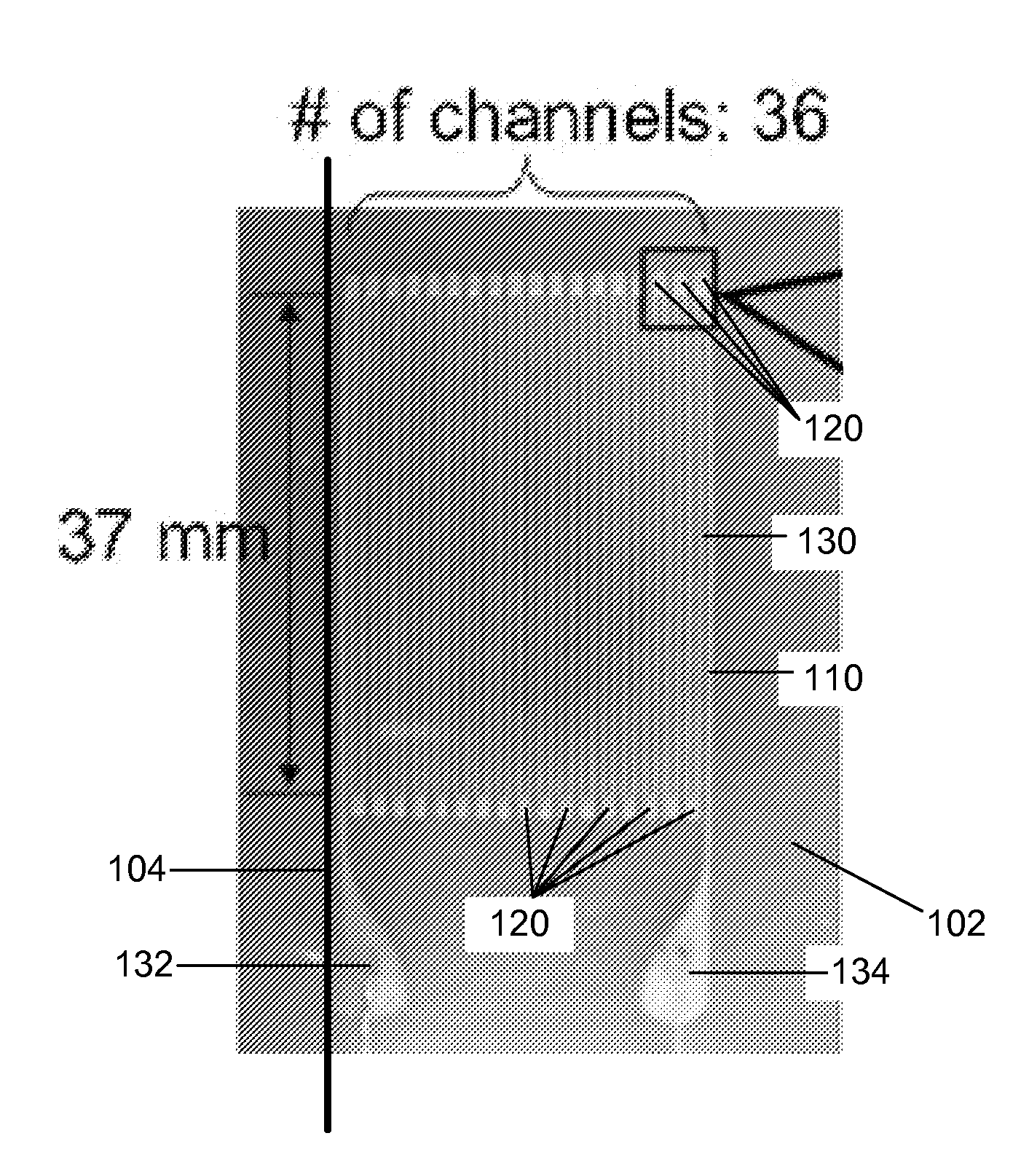

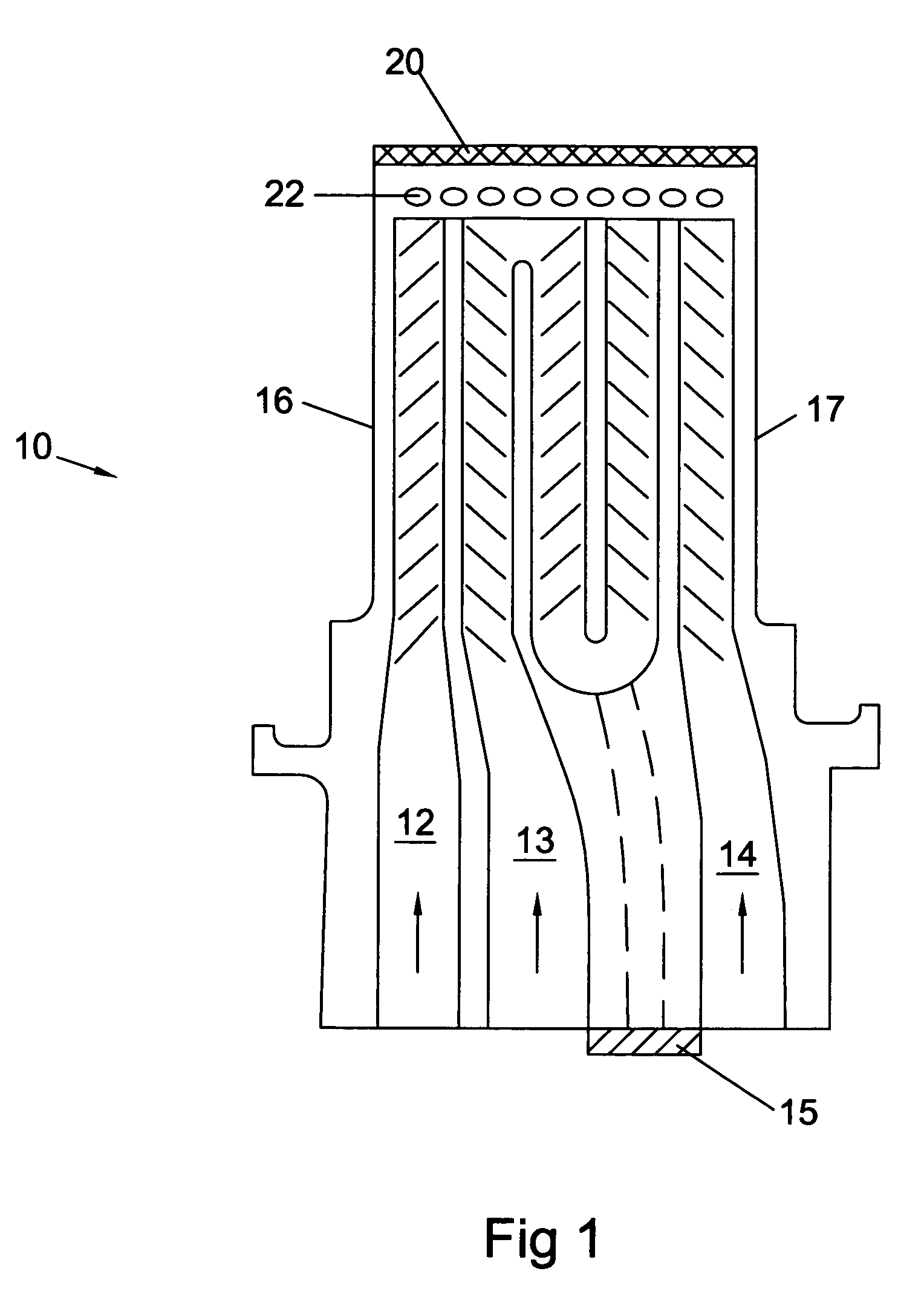

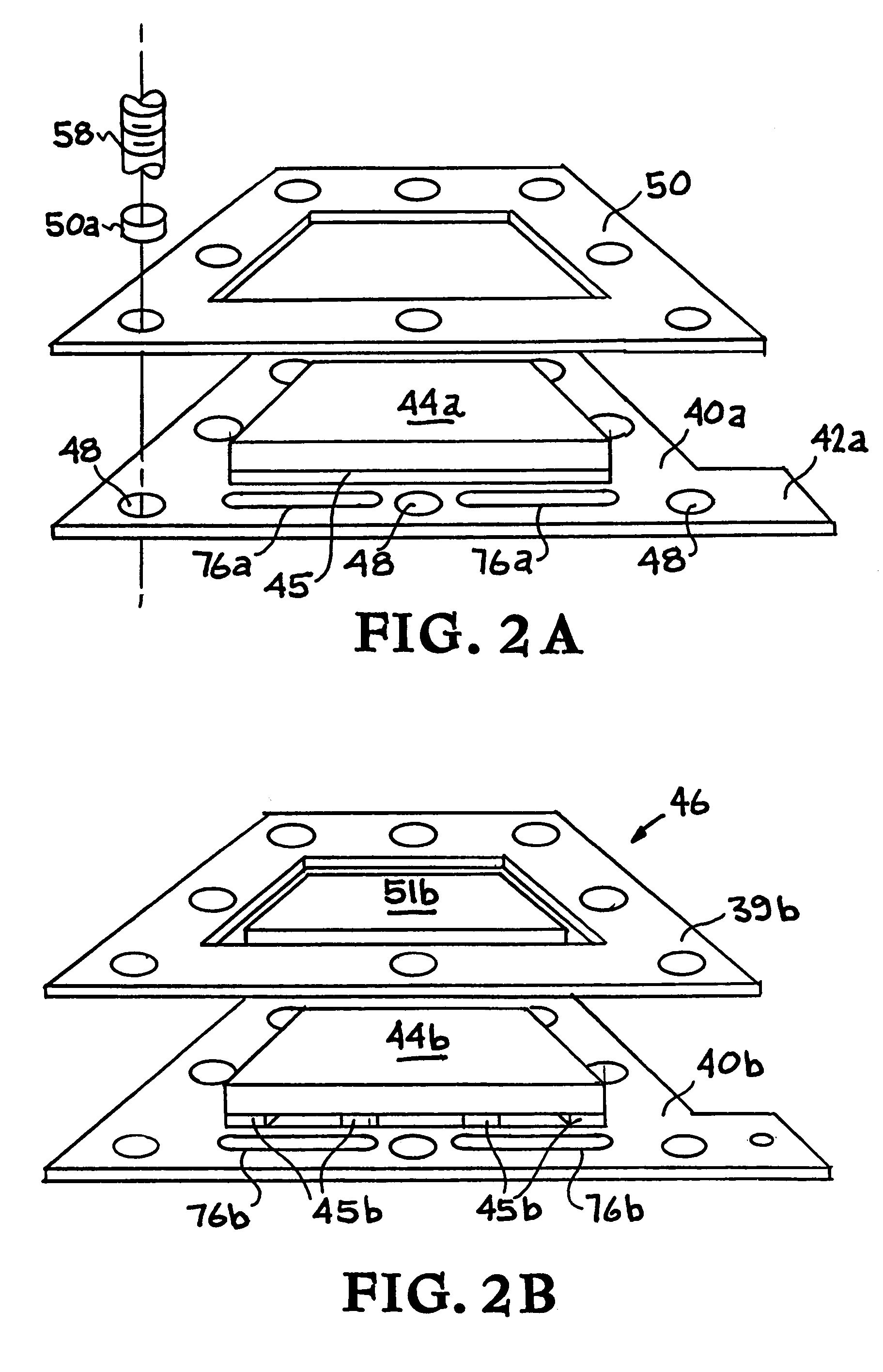

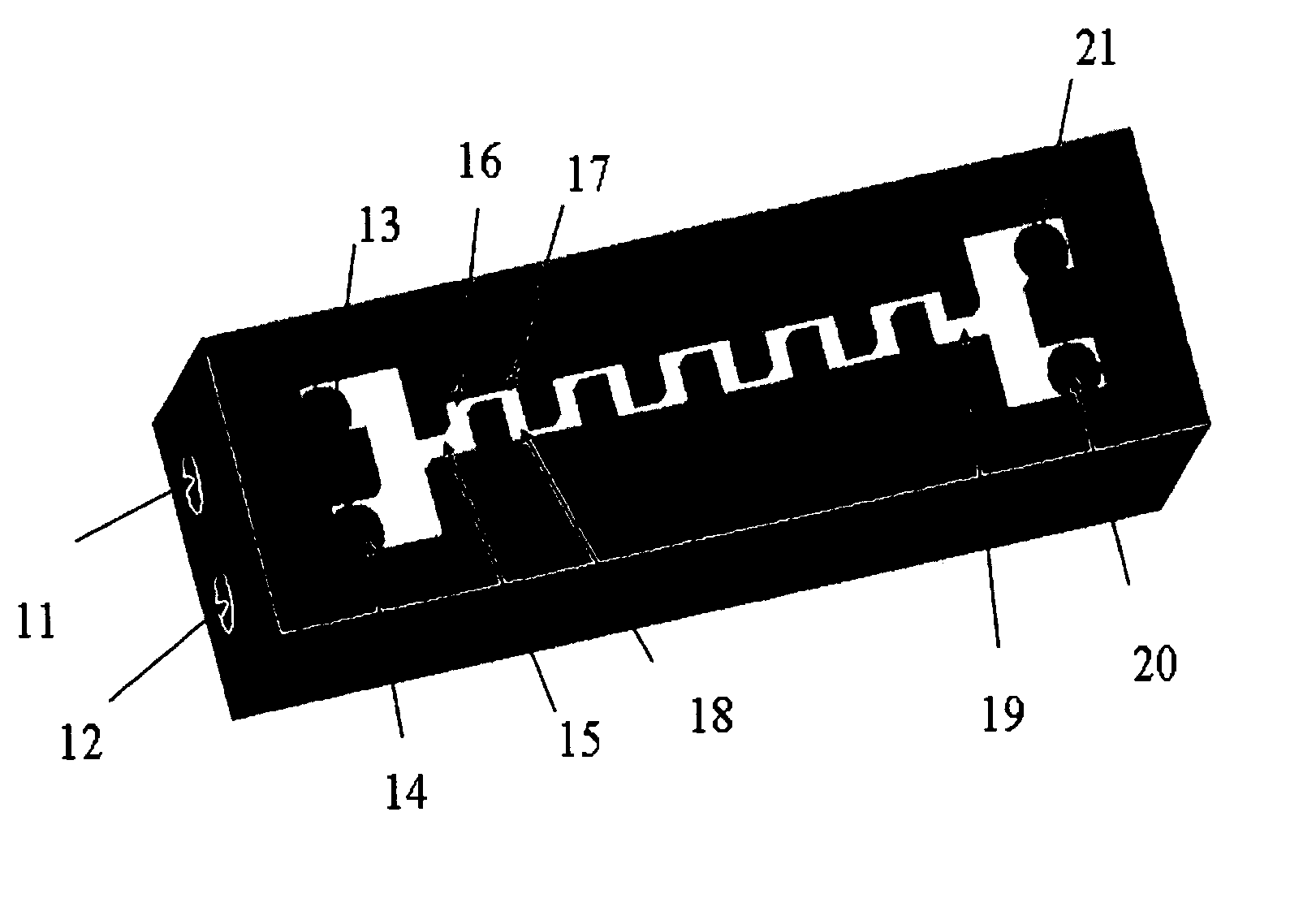

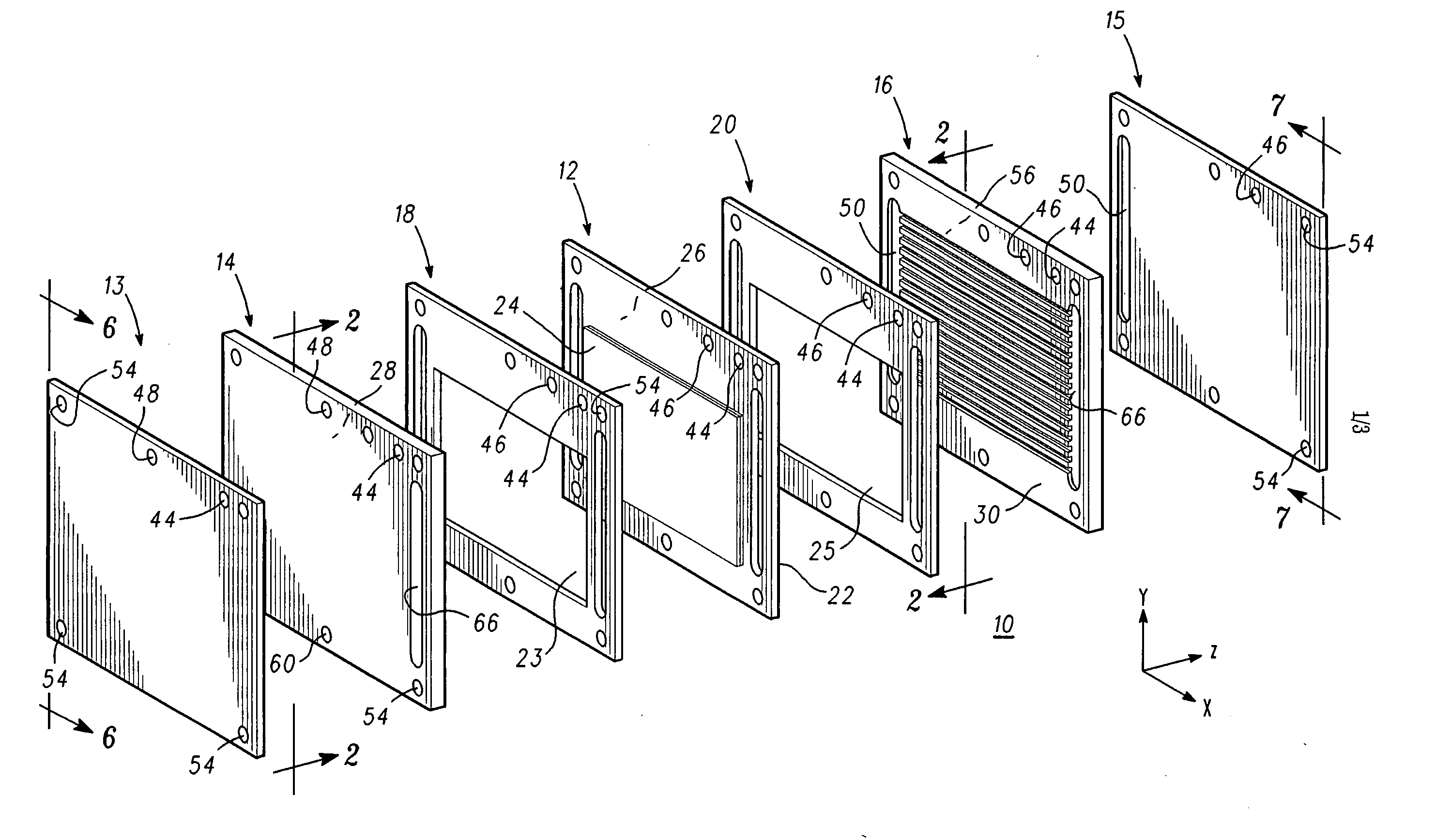

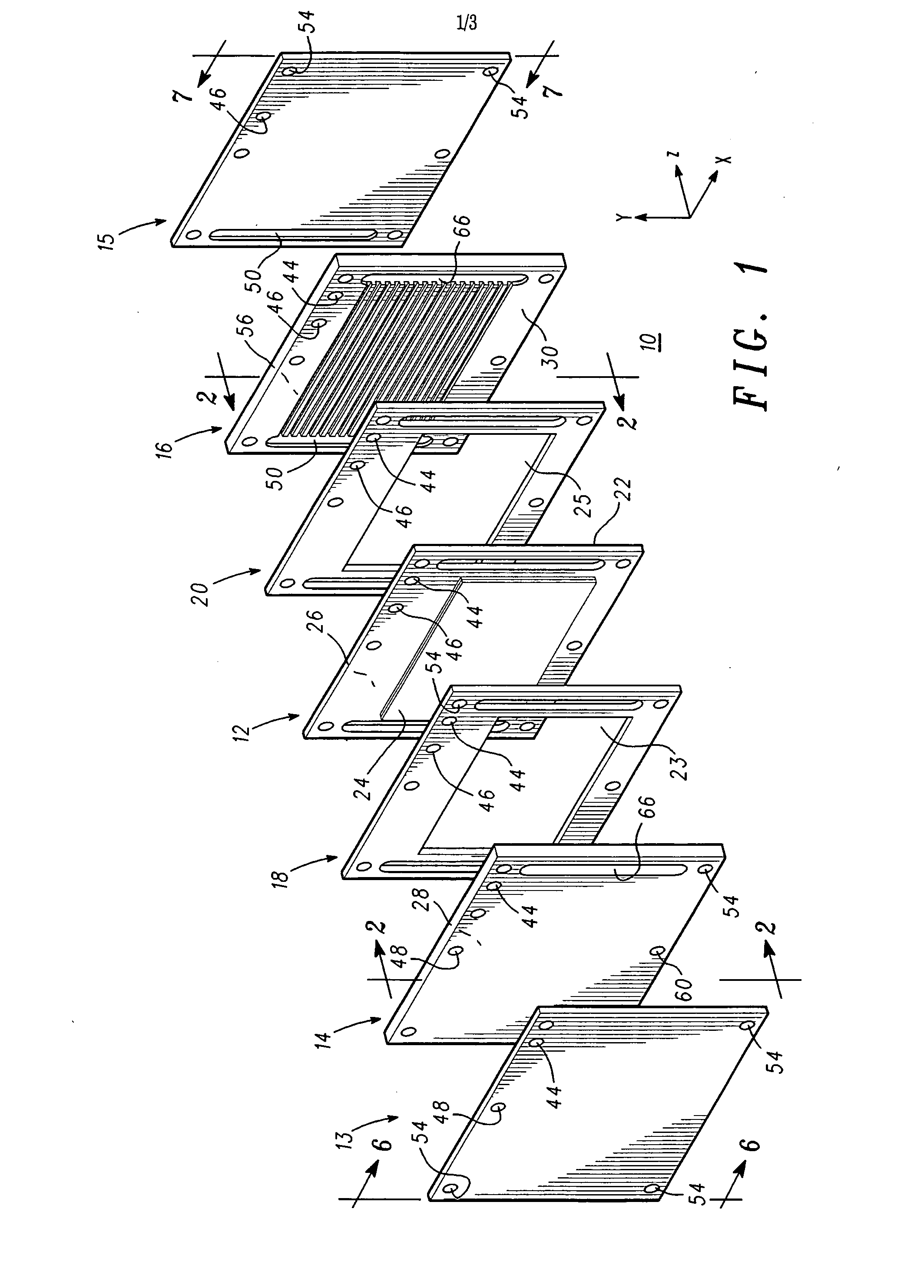

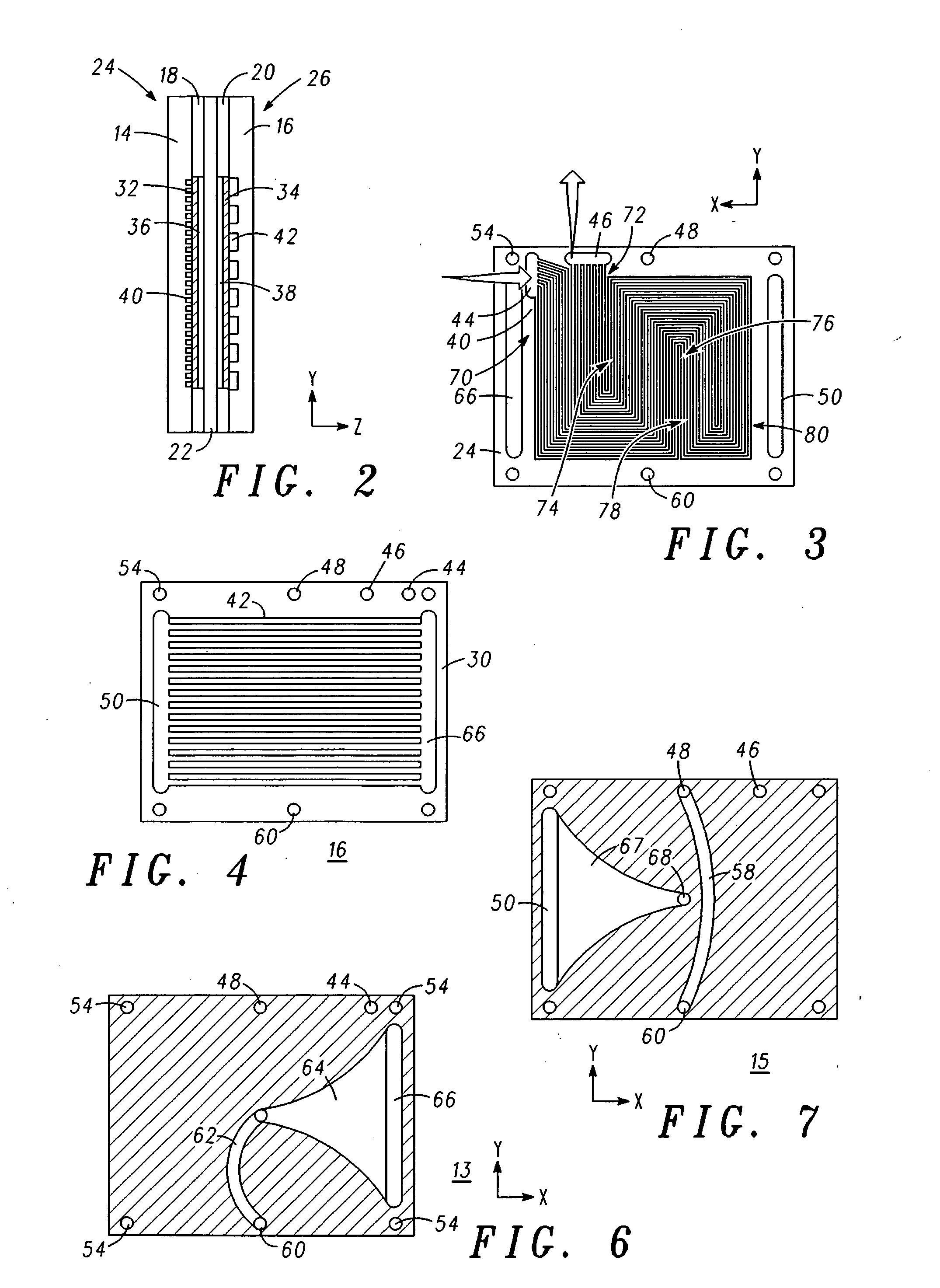

Fuel cell platelet separators having coordinate features

InactiveUS6051331ASimple designEvenly distributedSolid electrolytesFuel cells groupingLaser etchingFuel cells

PCT No. PCT / US95 / 13325 Sec. 371 Date Sep. 28, 1997 Sec. 102(e) Date Sep. 28, 1997 PCT Filed Oct. 10, 1995 PCT Pub. No. WO96 / 12316 PCT Pub. Date Apr. 25, 1996Fuel cell stacks comprising stacked separator / membrane electrode assembly fuel cells in which the separators comprise a series of thin sheet platelets, having individually configured serpentine micro-channel reactant gas humidification active areas and cooling fields therein. The individual platelets are stacked with coordinate features aligned in contact with adjacent platelets and bonded to form a monolithic separator. Post-bonding processing includes passivation, such as nitriding. Preferred platelet material is 4-25 mil Ti, in which the features, serpentine channels, tabs, lands, vias, manifolds and holes, are formed by chemical and laser etching, cutting, pressing or embossing, with combinations of depth and through etching preferred. The platelet manufacturing process is continuous and fast. By employing CAD based platelet design and photolithography, rapid change in feature design can accommodate a wide range of thermal management and humidification techniques. One hundred H2-O2 / PEM fuel cell stacks of this IFMT platelet design will exhibit outputs on the order of 0.75 kW / kg, some 3-6 times greater than the current graphite plate PEM stacks.

Owner:H POWER

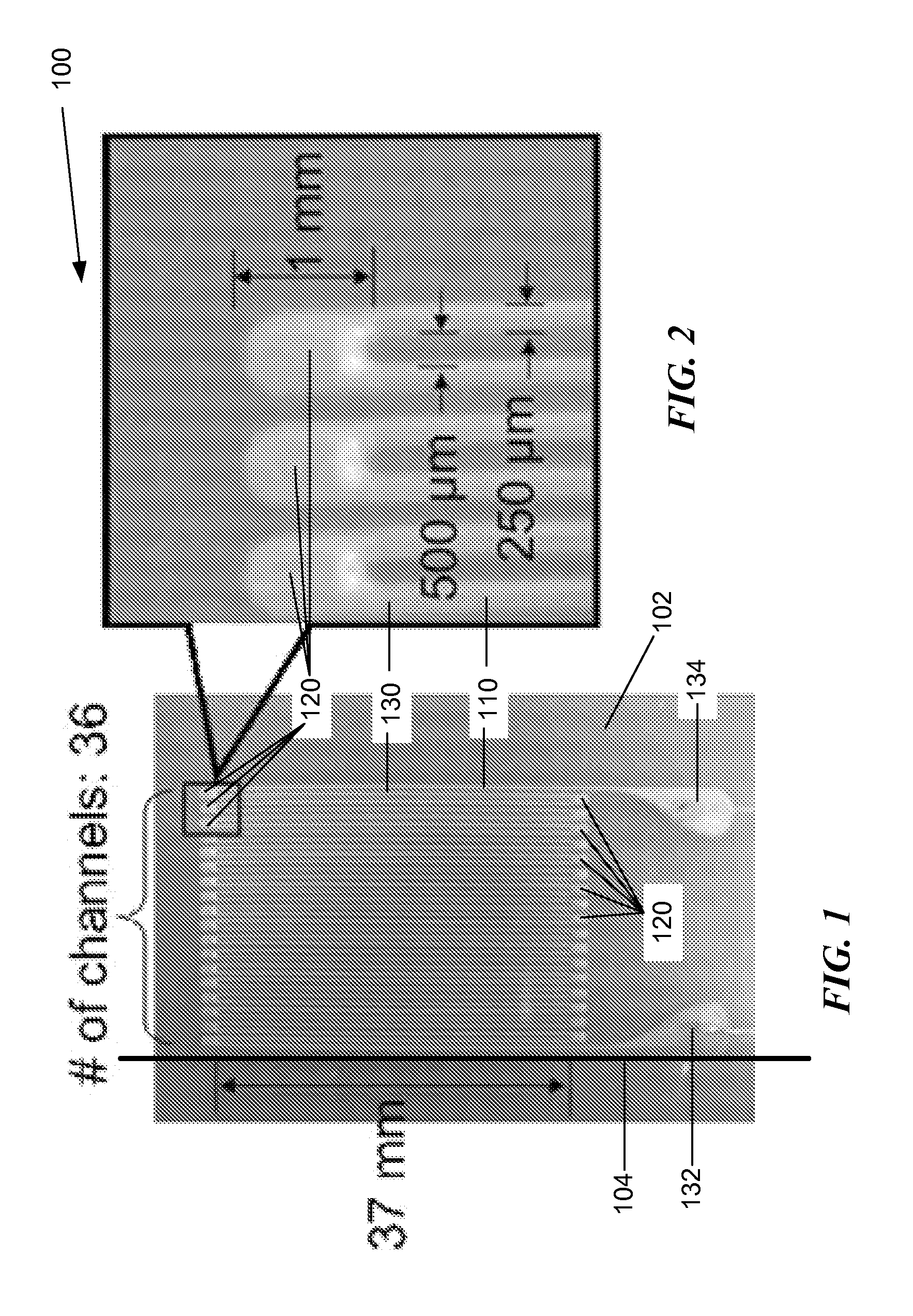

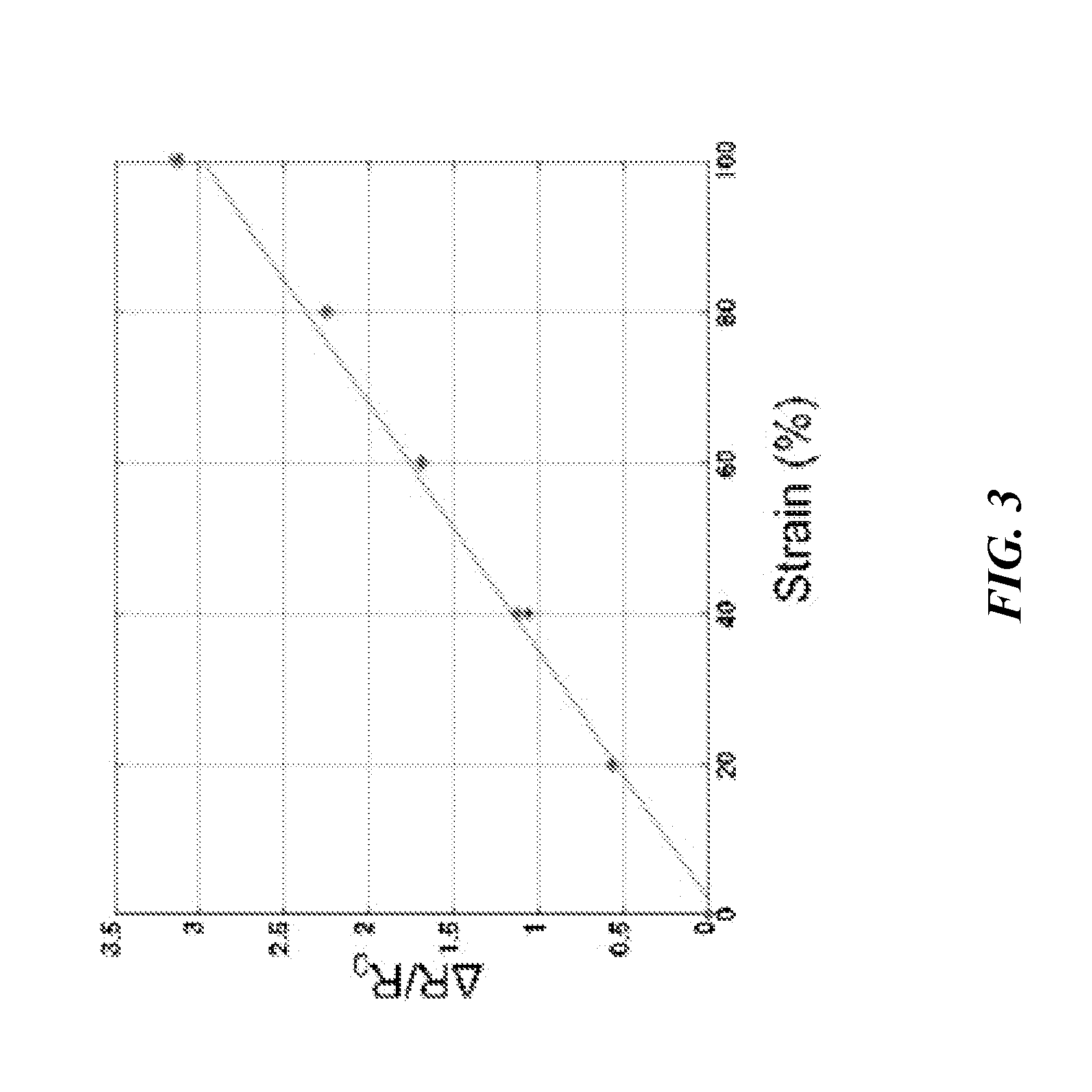

Artificial skin and elastic strain sensor

ActiveUS20140238153A1Sufficient cross-sectional areaHigh sensitivitySkin implantsSolesElectrical resistance and conductanceElastic substrate

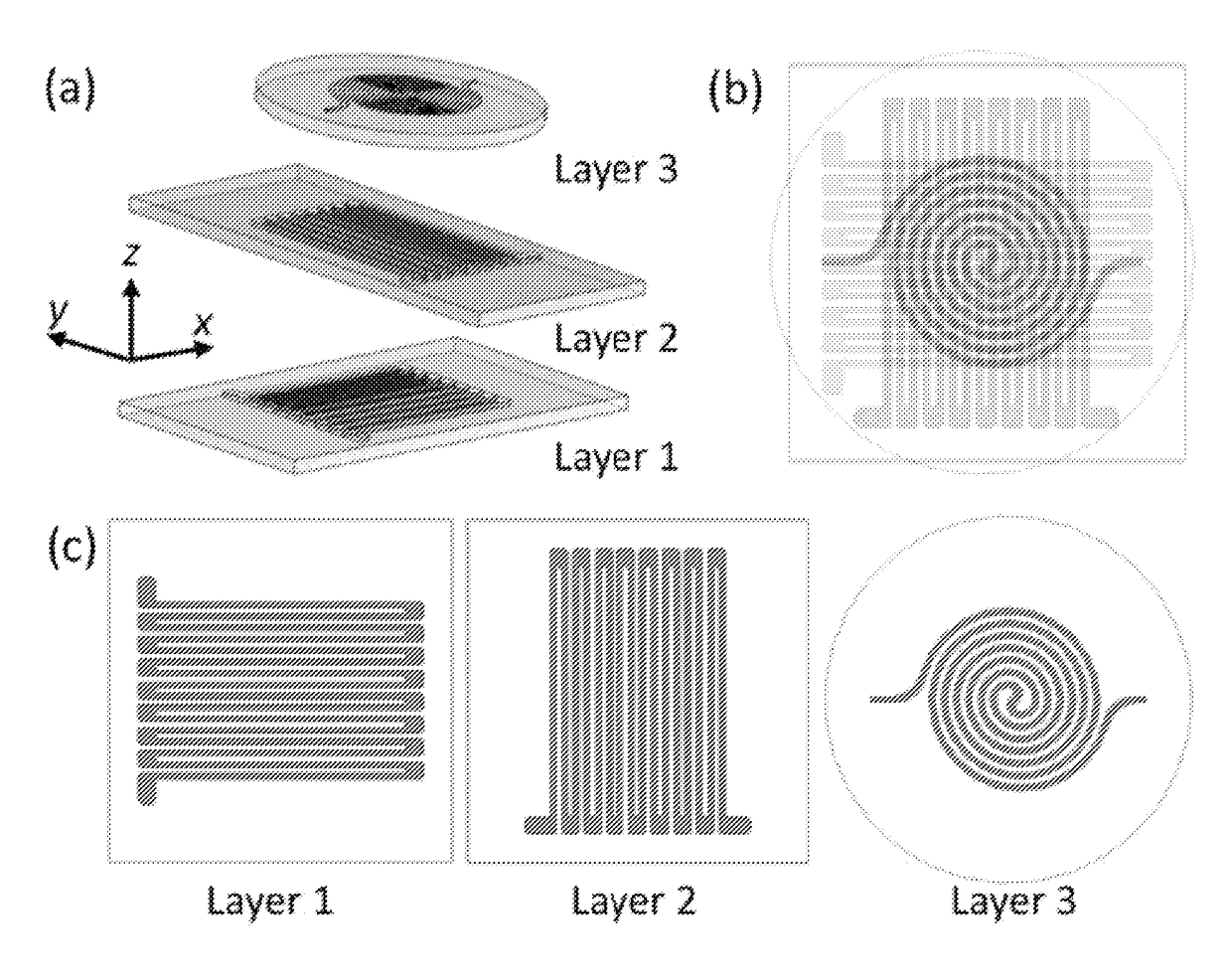

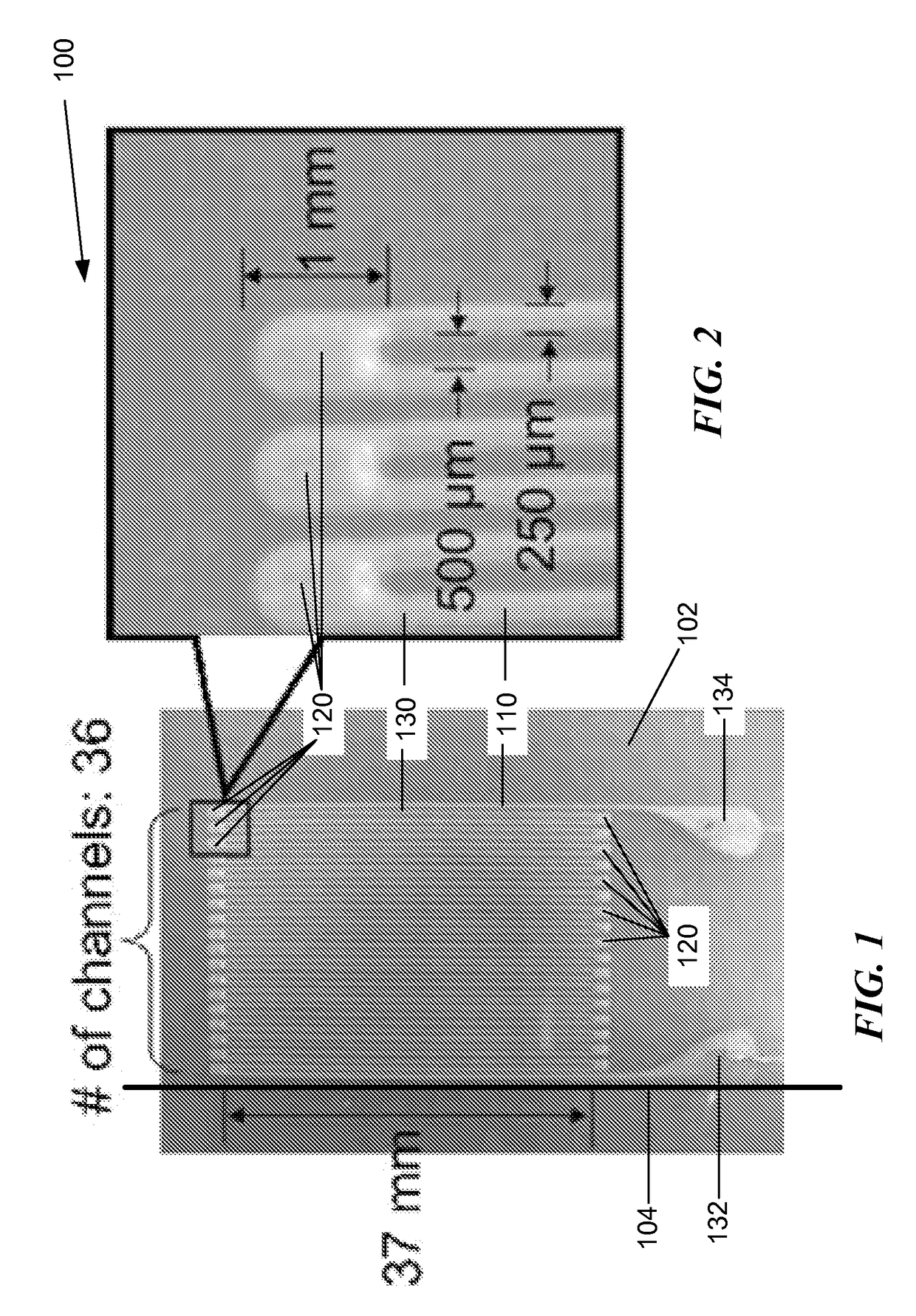

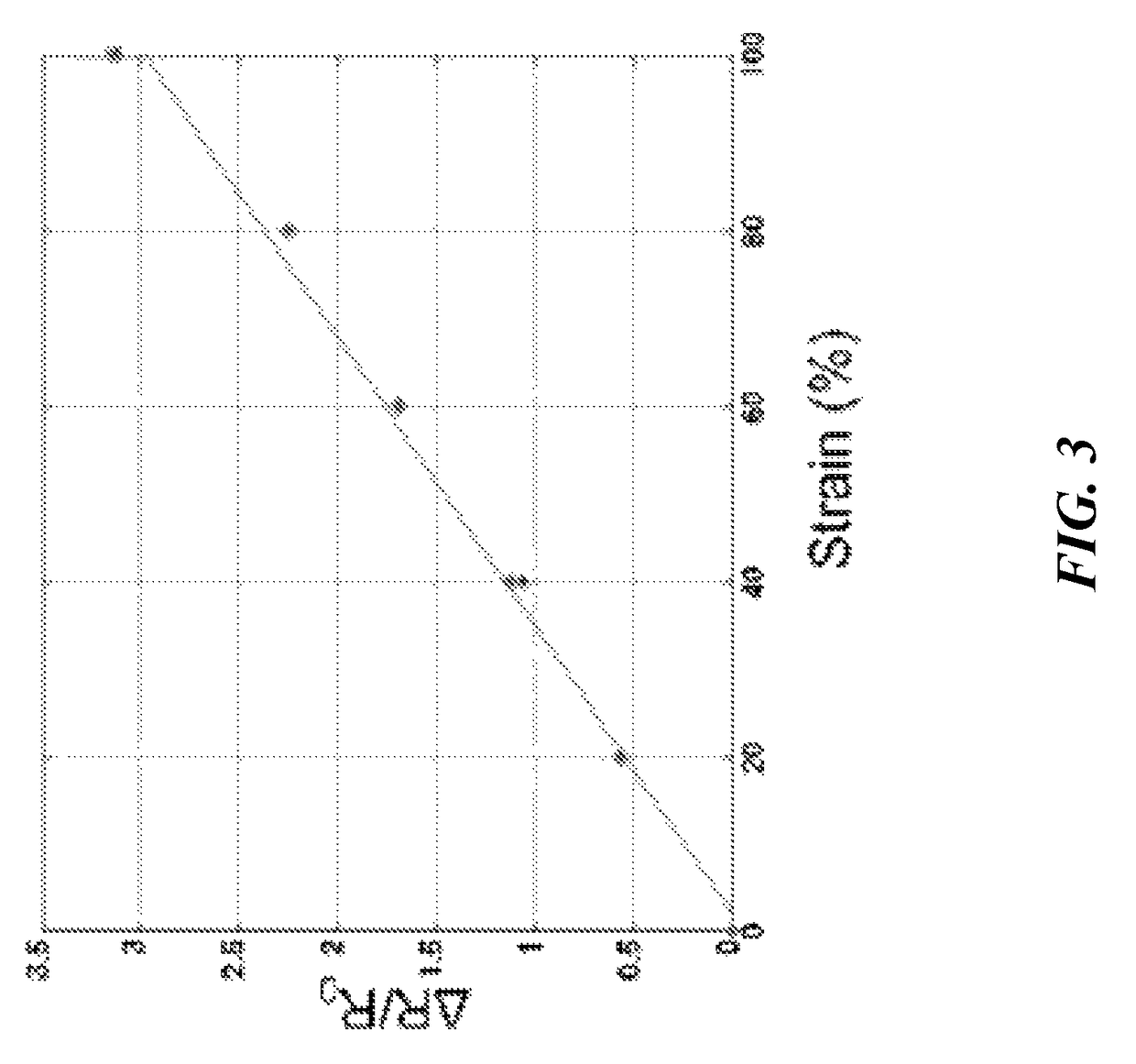

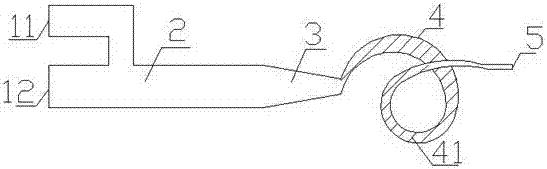

An elastic strain sensor can be incorporated into an artificial skin that can sense flexing by the underlying support structure of the skin to detect and track motion of the support structure. The unidirectional elastic strain sensor can be formed by filling two or more channels in an elastic substrate material with a conductive liquid. At the ends of the channels, a loop port connects the channels to form a serpentine channel. The channels extend along the direction of strain and the loop portions have sufficiently large cross-sectional area in the direction transverse to the direction of strain that the sensor is unidirectional. The resistance is measured at the ends of the serpentine channel and can be used to determine the strain on the sensor. Additional channels can be added to increase the sensitivity of the sensor. The sensors can be stacked on top of each other to increase the sensitivity of the sensor. In other embodiments, two sensors oriented in different directions can be stacked on top of each other and bonded together to form a bidirectional sensor. A third sensor formed by in the shape of a spiral or concentric rings can be stacked on top and used to sense contact or pressure, forming a three dimensional sensor. The three dimensional sensor can be incorporated into an artificial skin to provide advanced sensing.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

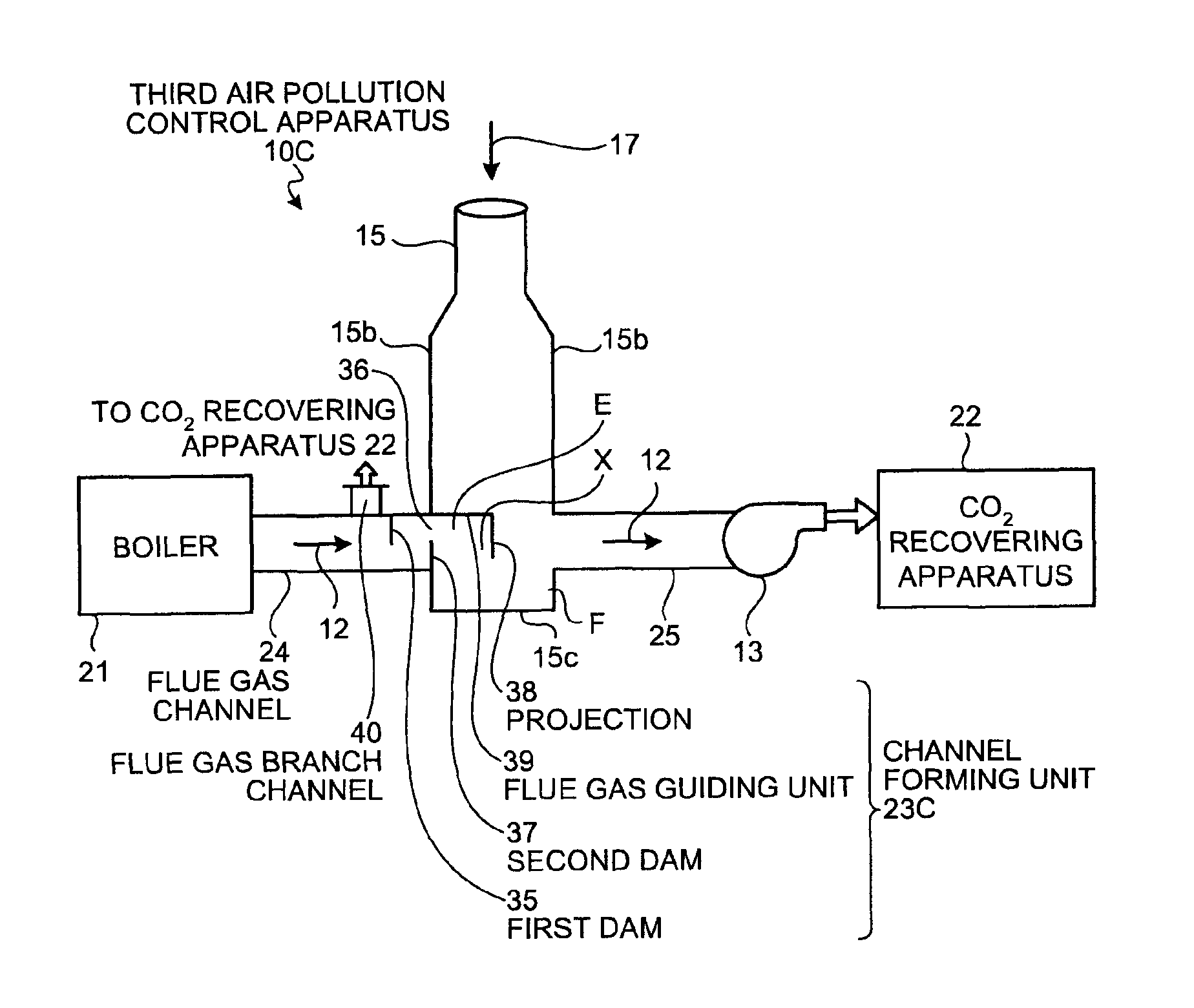

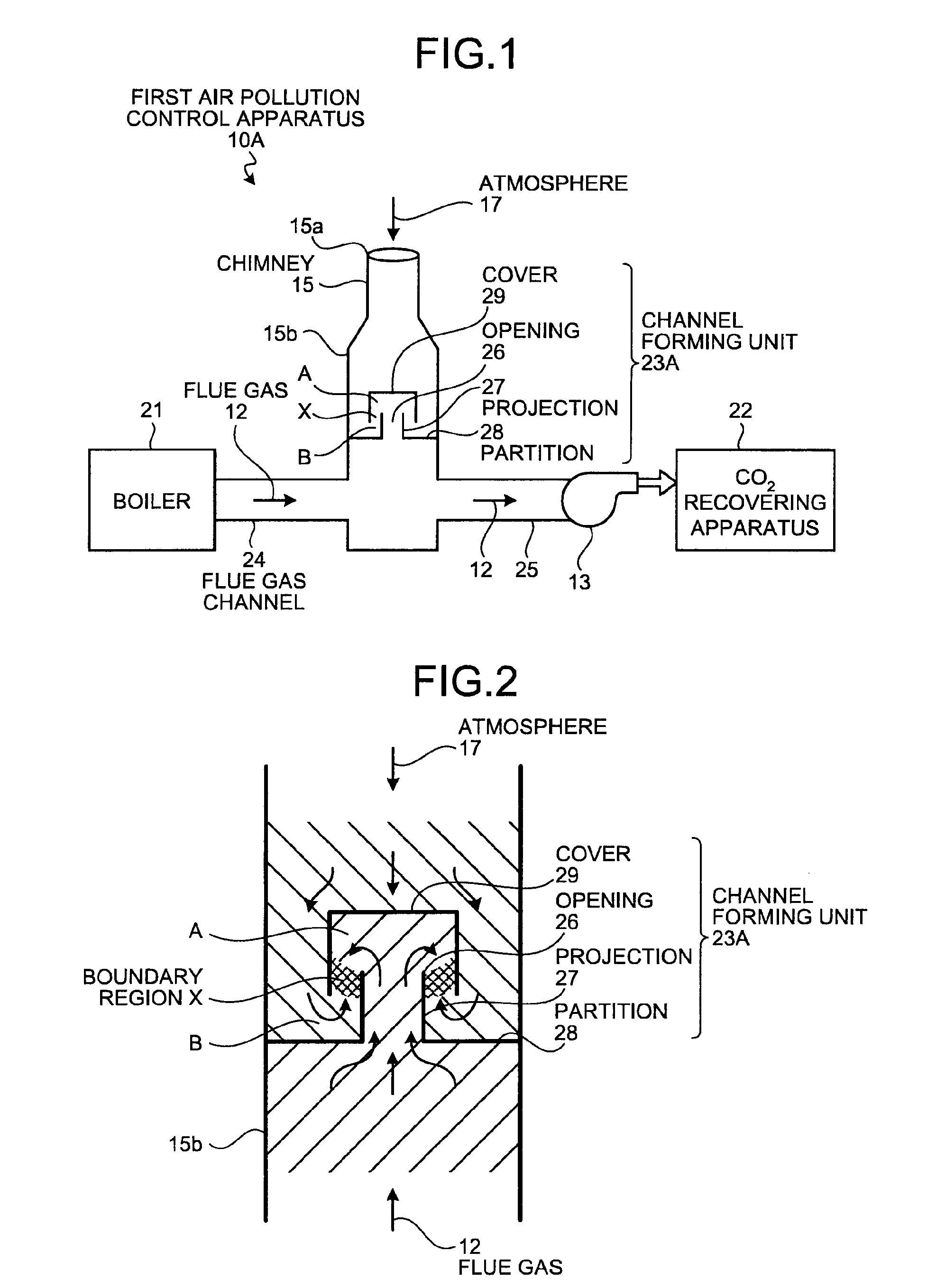

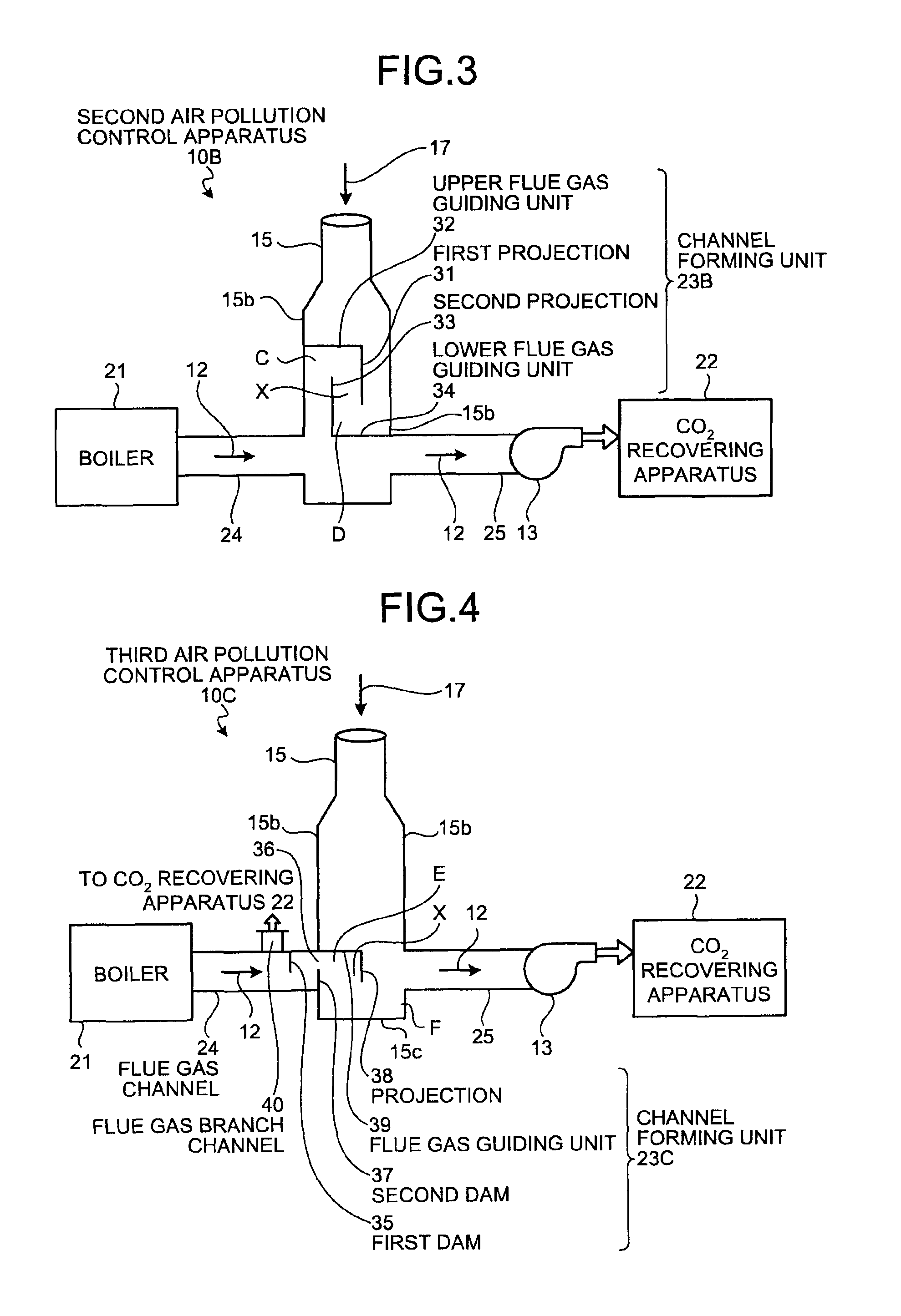

Air pollution control apparatus and air pollution control method

An air pollution control apparatus according to an embodiment of the present invention includes: a stack that discharges flue gas discharged from a boiler outside; a blower that is provided downstream of the stack and draws in the flue gas; and a CO2 recovering apparatus that recovers CO2 in the flue gas drawn in by the blower. The stack includes a controlling unit that suppresses release of the flue gas outside from the stack and suppresses inflow of atmosphere to the stack, and the controlling unit is a channel forming unit that forms a serpentine channel through which the flue gas and the atmosphere in the stack flow.

Owner:MITSUBISHI HEAVY IND ENG LTD

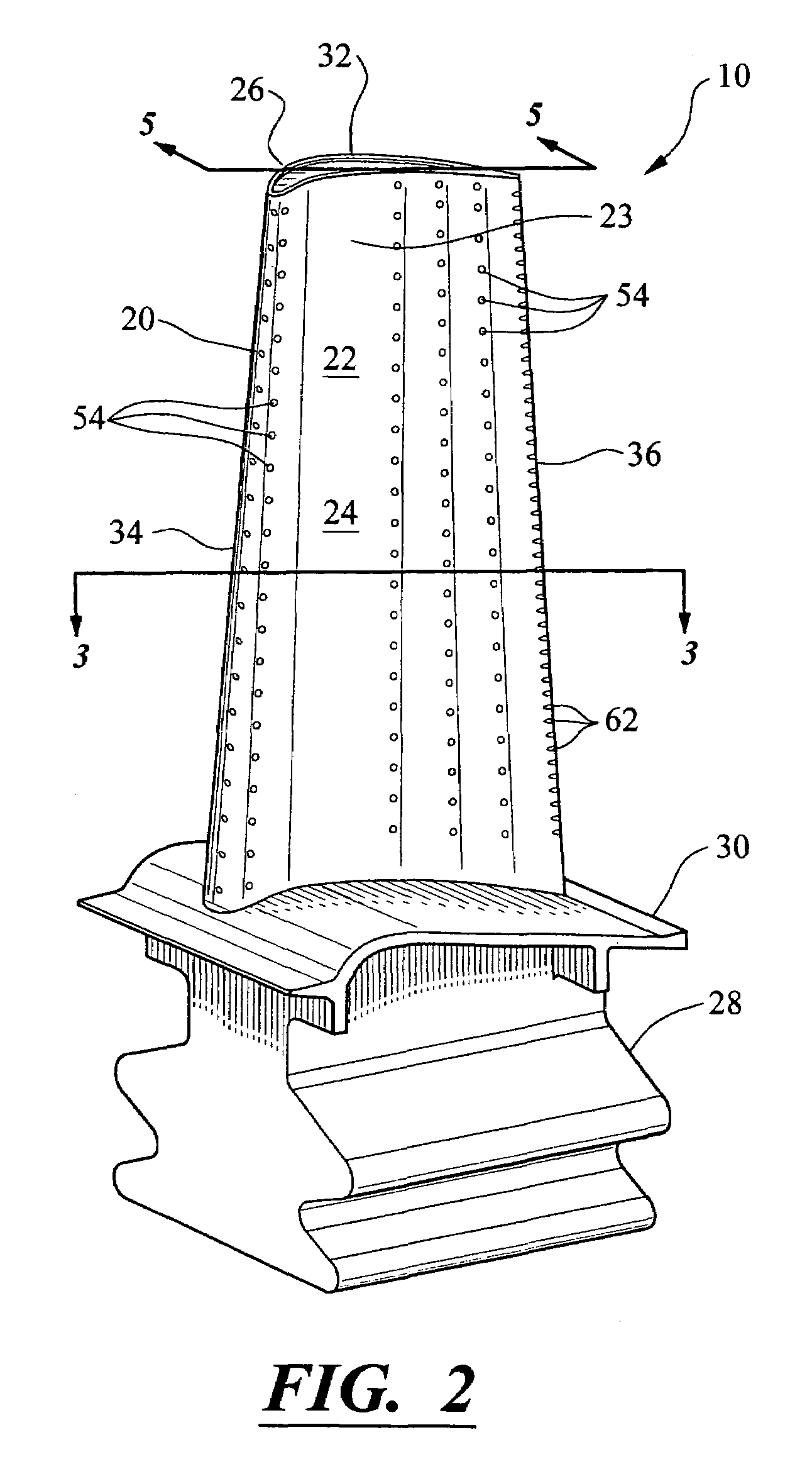

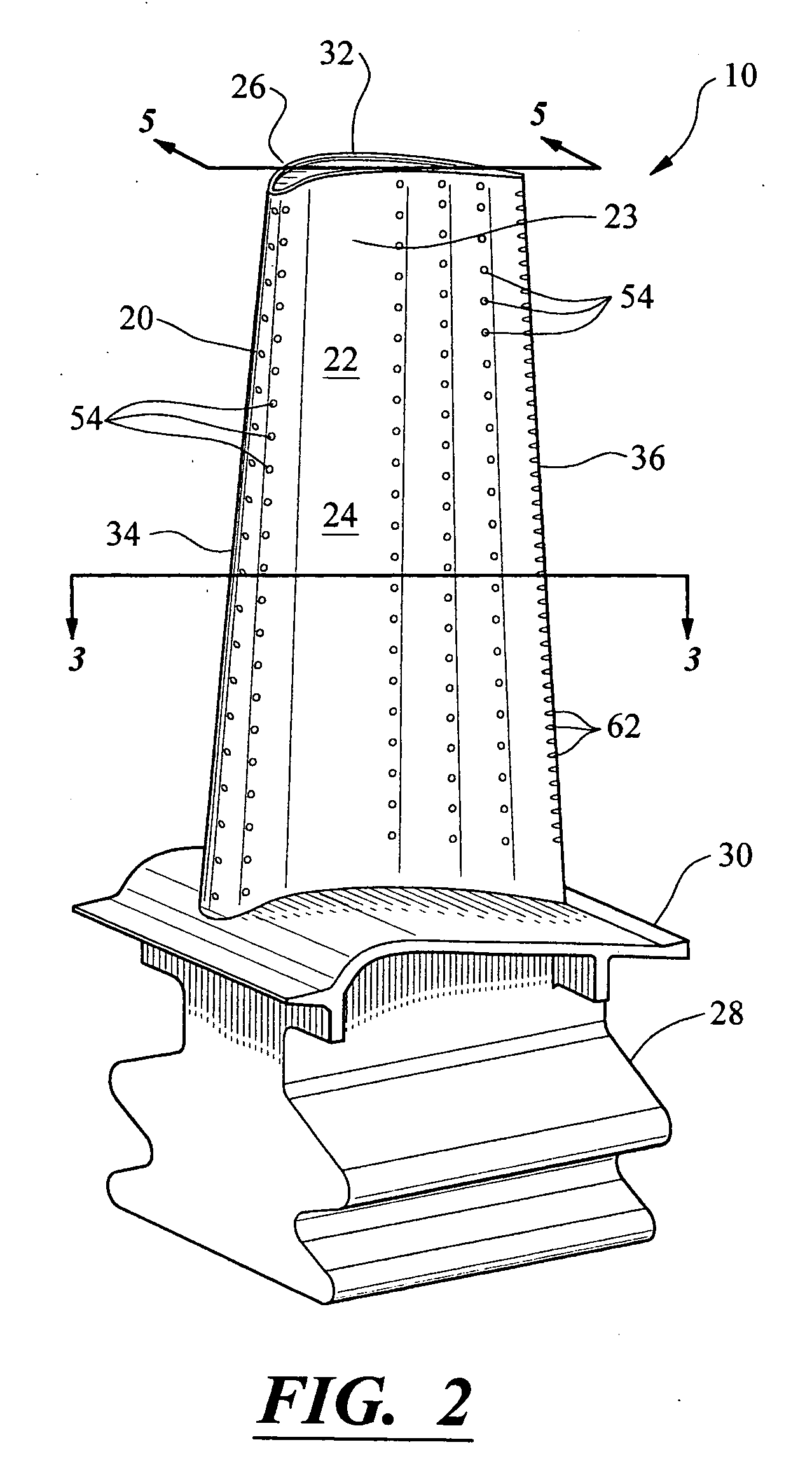

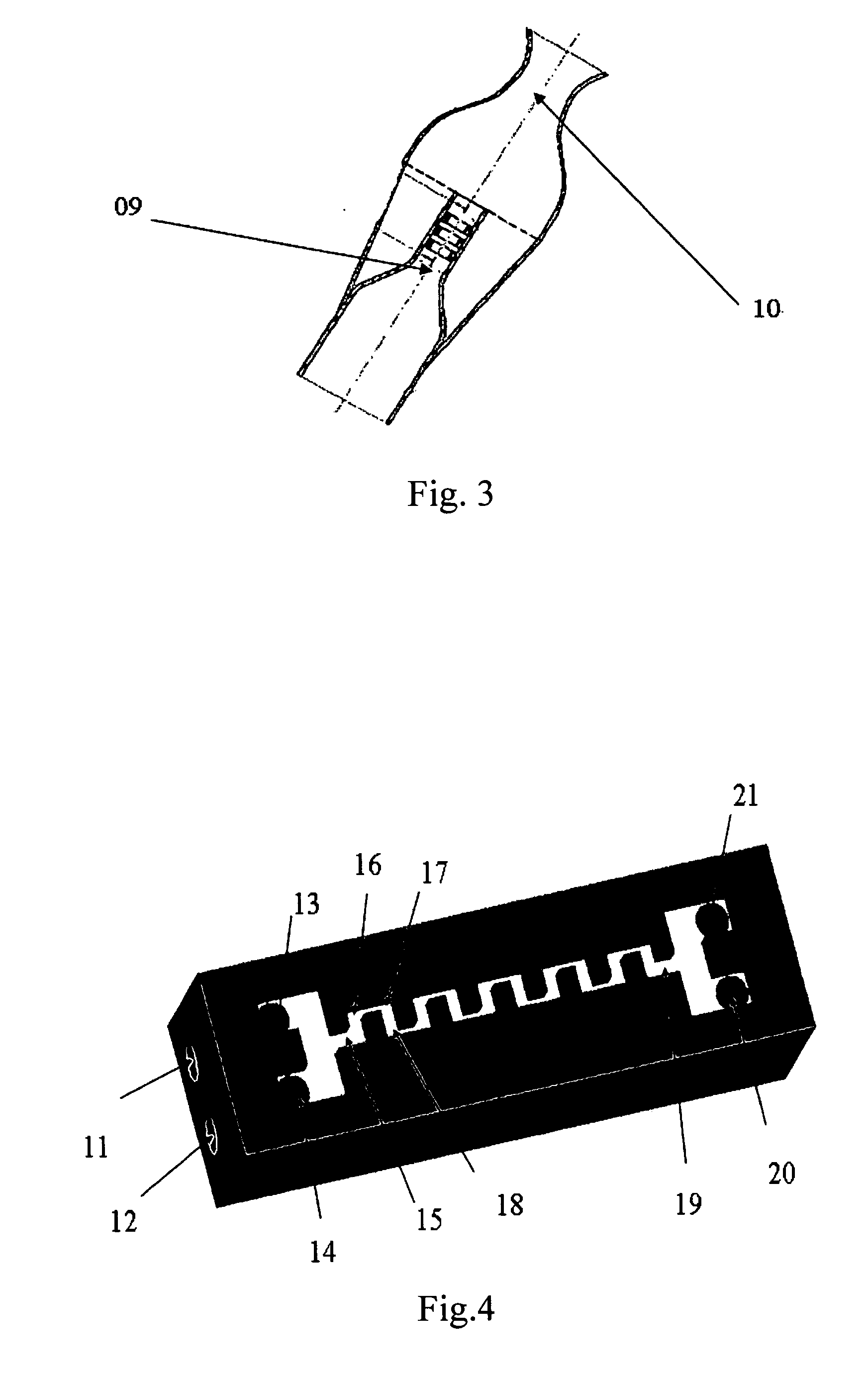

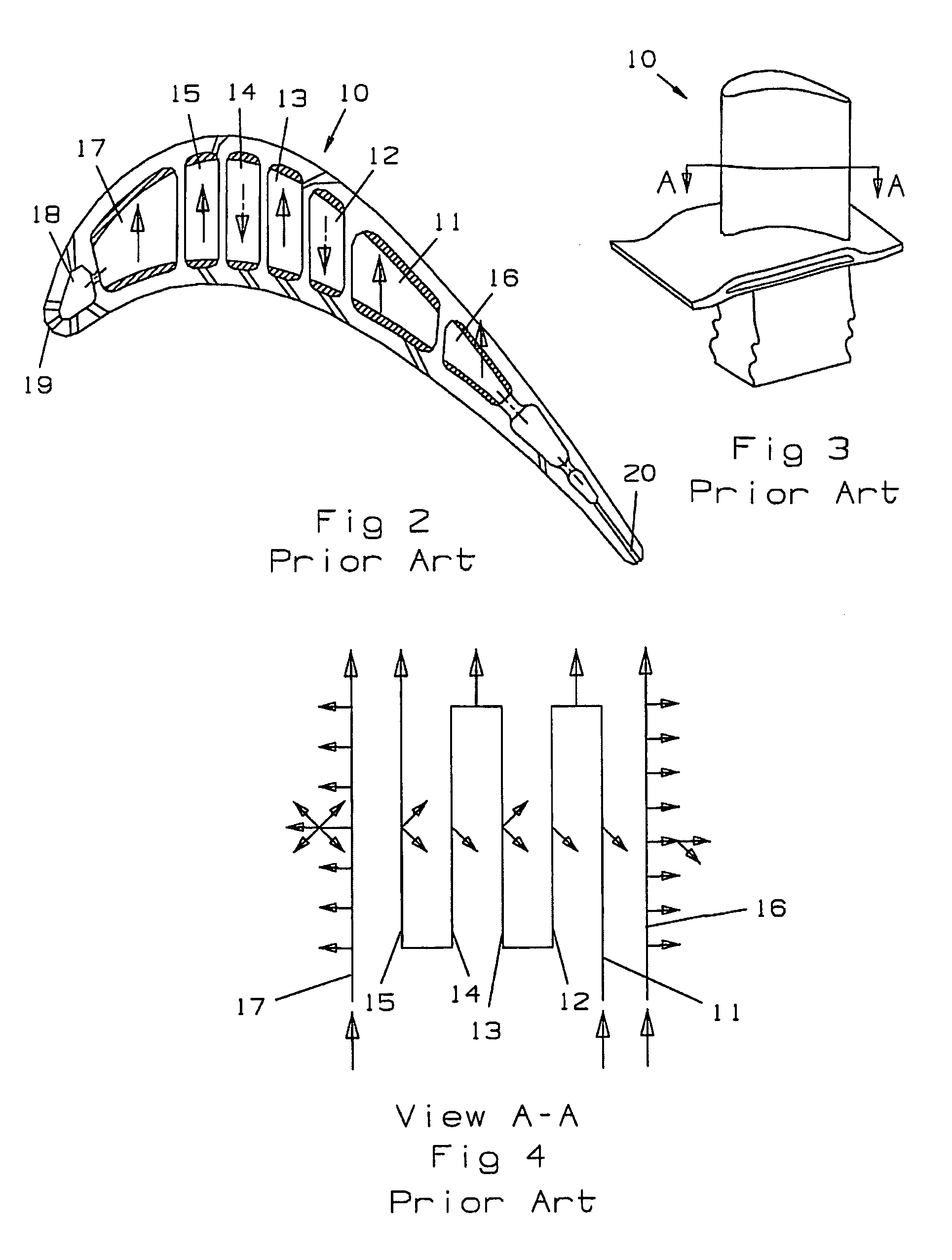

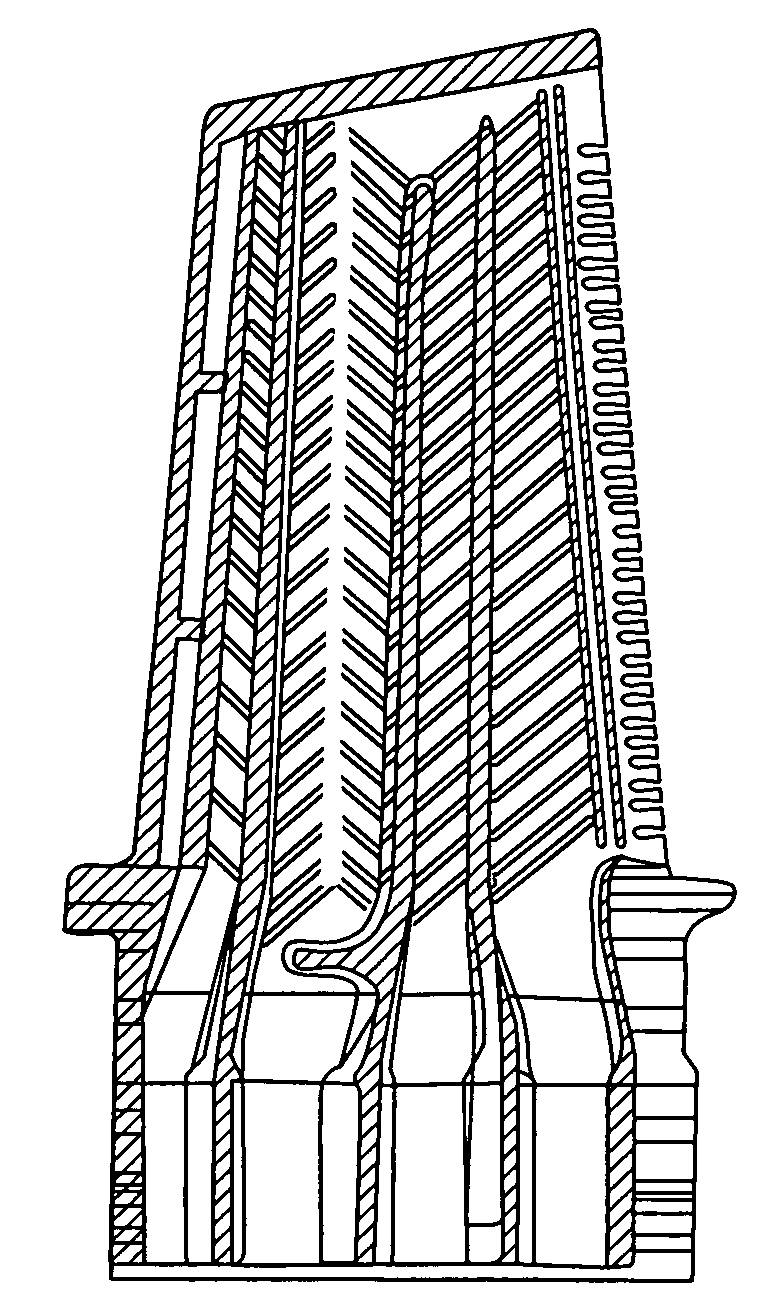

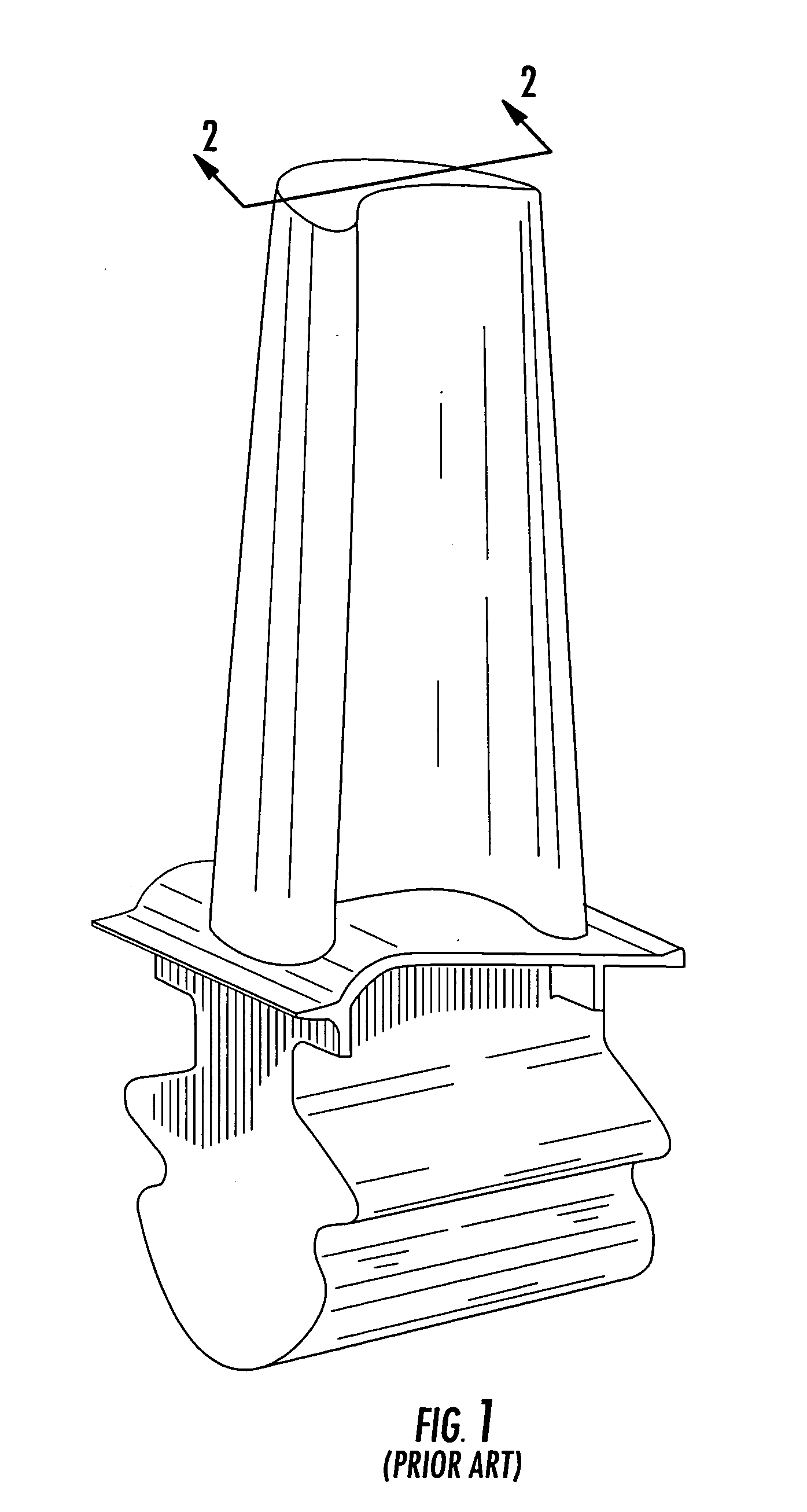

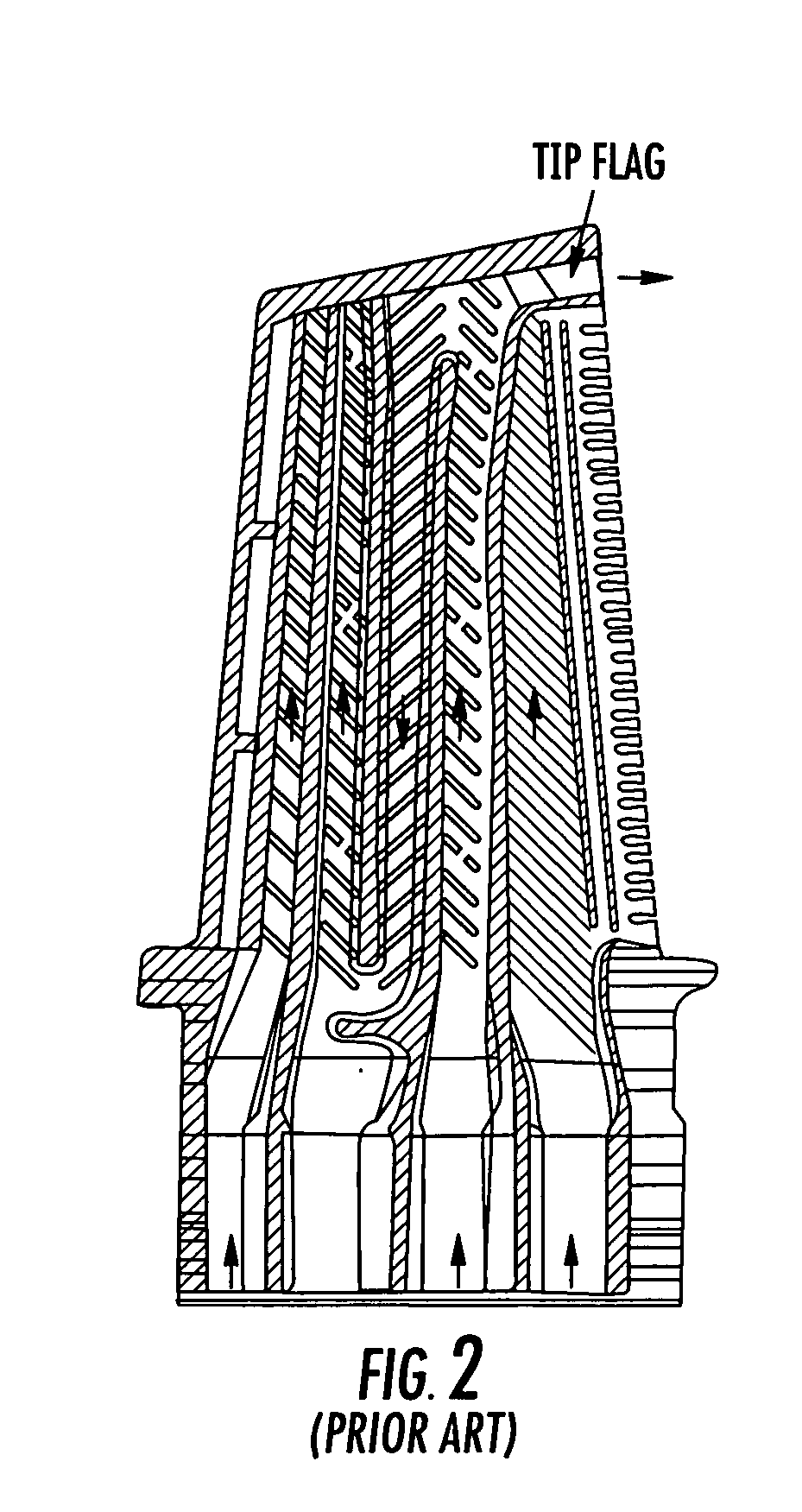

Turbine blade tip with mini-serpentine cooling circuit

InactiveUS7537431B1Increase internal heat transfer coolingImprove cooling effectPropellersEngine manufactureTurbine bladeSerpentine channel

A turbine blade having a cooling supply passage formed within the blade, and a blade tip with a squealer tip formed thereon. The blade tip includes a blade top or cap, and includes a plurality of mini-serpentine cooling channels formed within the tip. The mini-serpentine channels can be 2-pass, 3-pass, 4-pass, or 5-pass serpentine channels, and each includes an inlet hole connected to the internal cooling supply passage to pass cooling air through the channels. Each channel includes an exit hole with a diffuser that opens onto the pressure side of the blade to provide film cooling. The mini-serpentine cooling channels can be arranged to flow substantially from blade side to side or from blade edge to edge.

Owner:FLORIDA TURBINE TECH

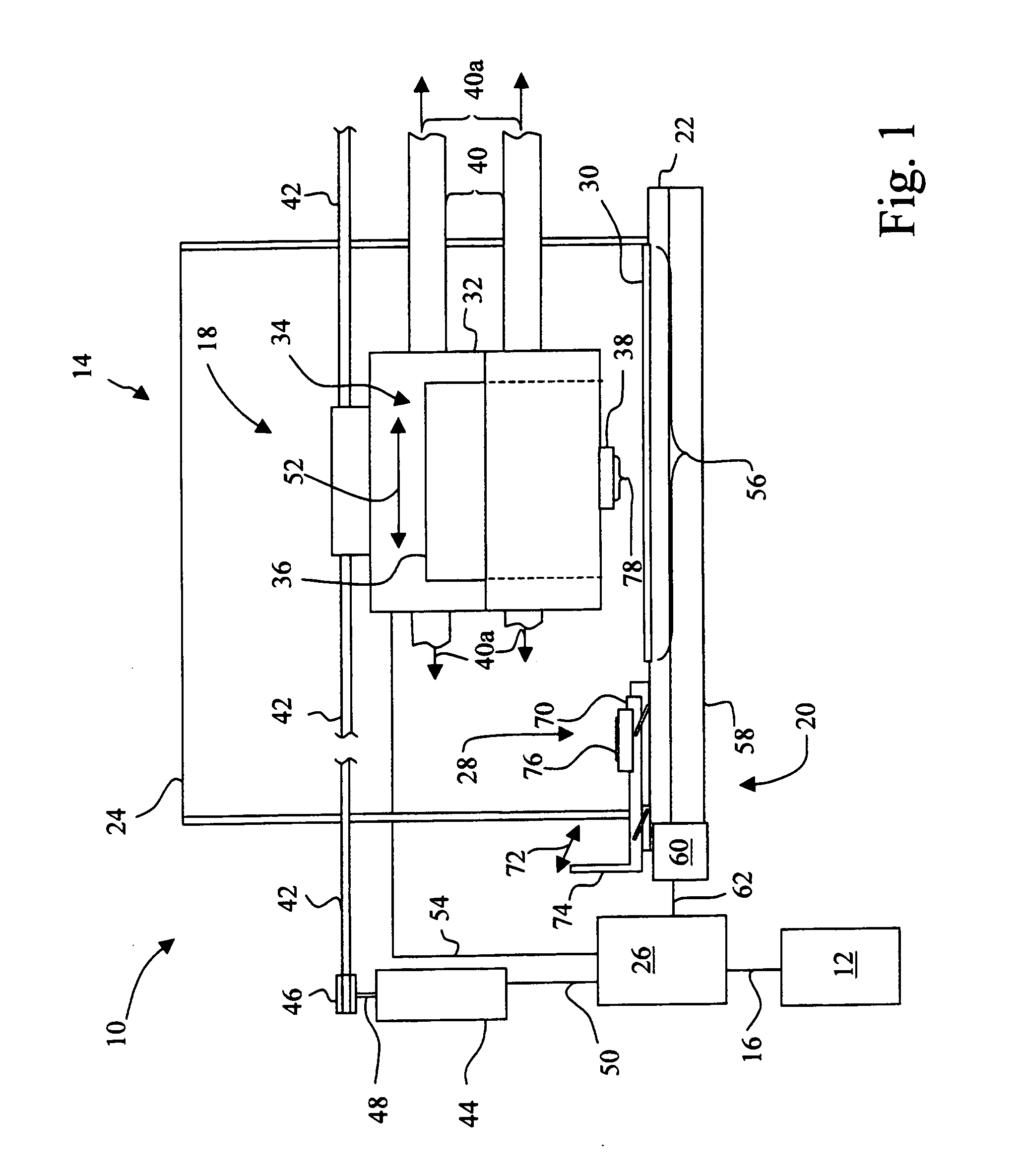

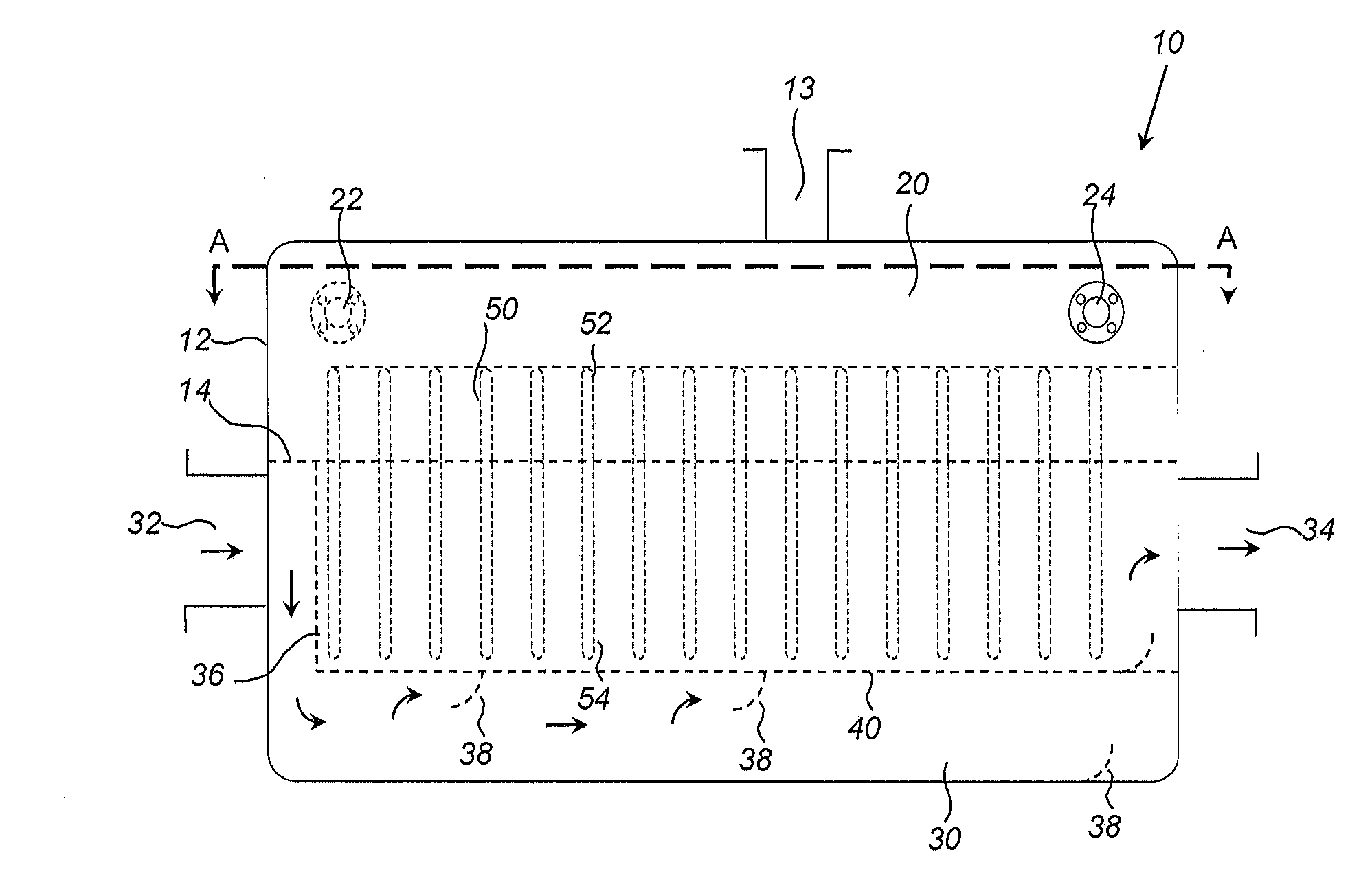

Solder reflow oven

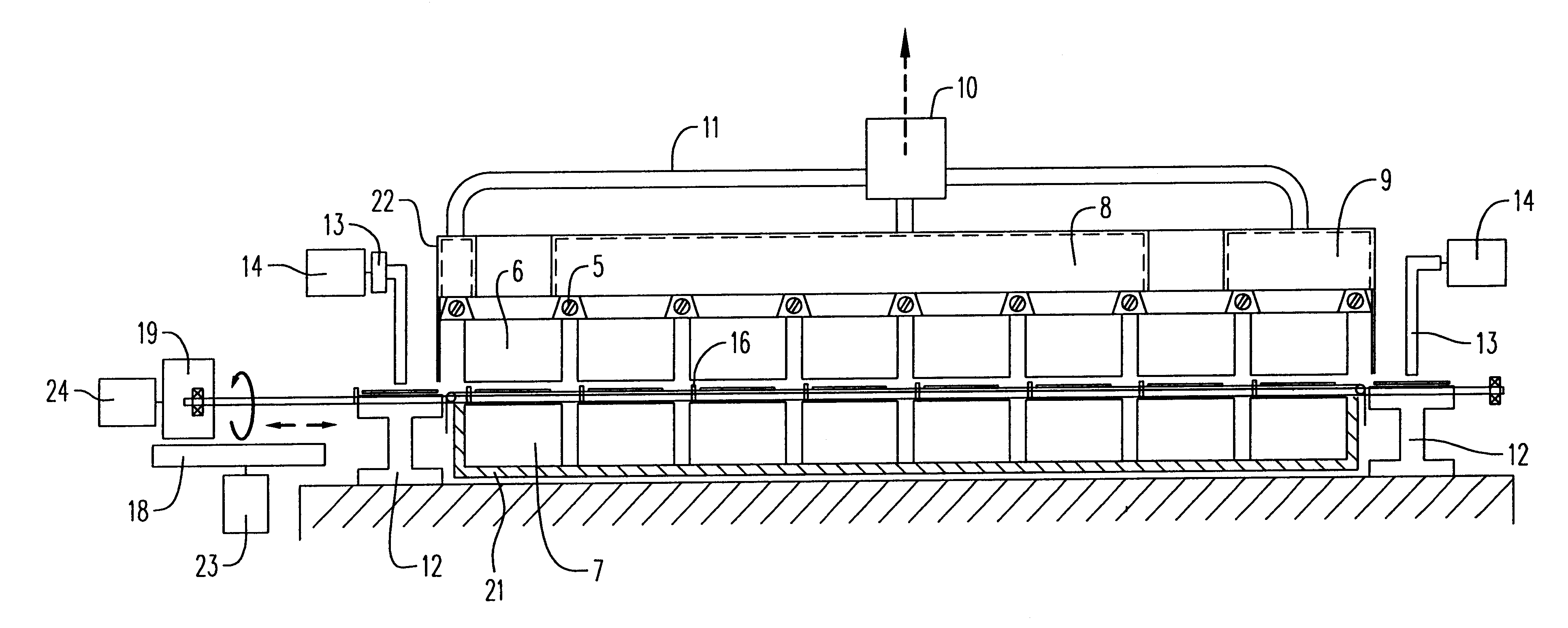

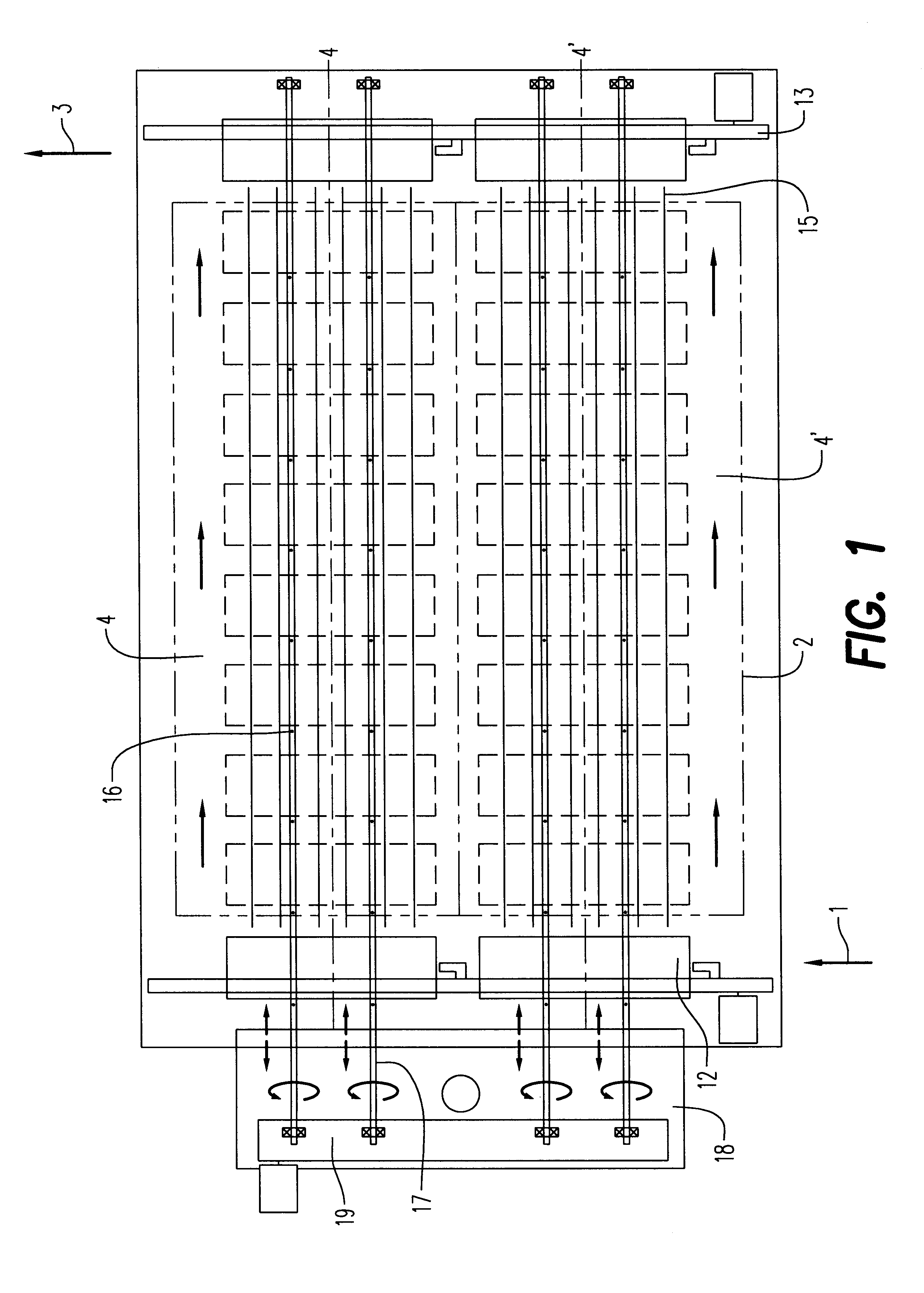

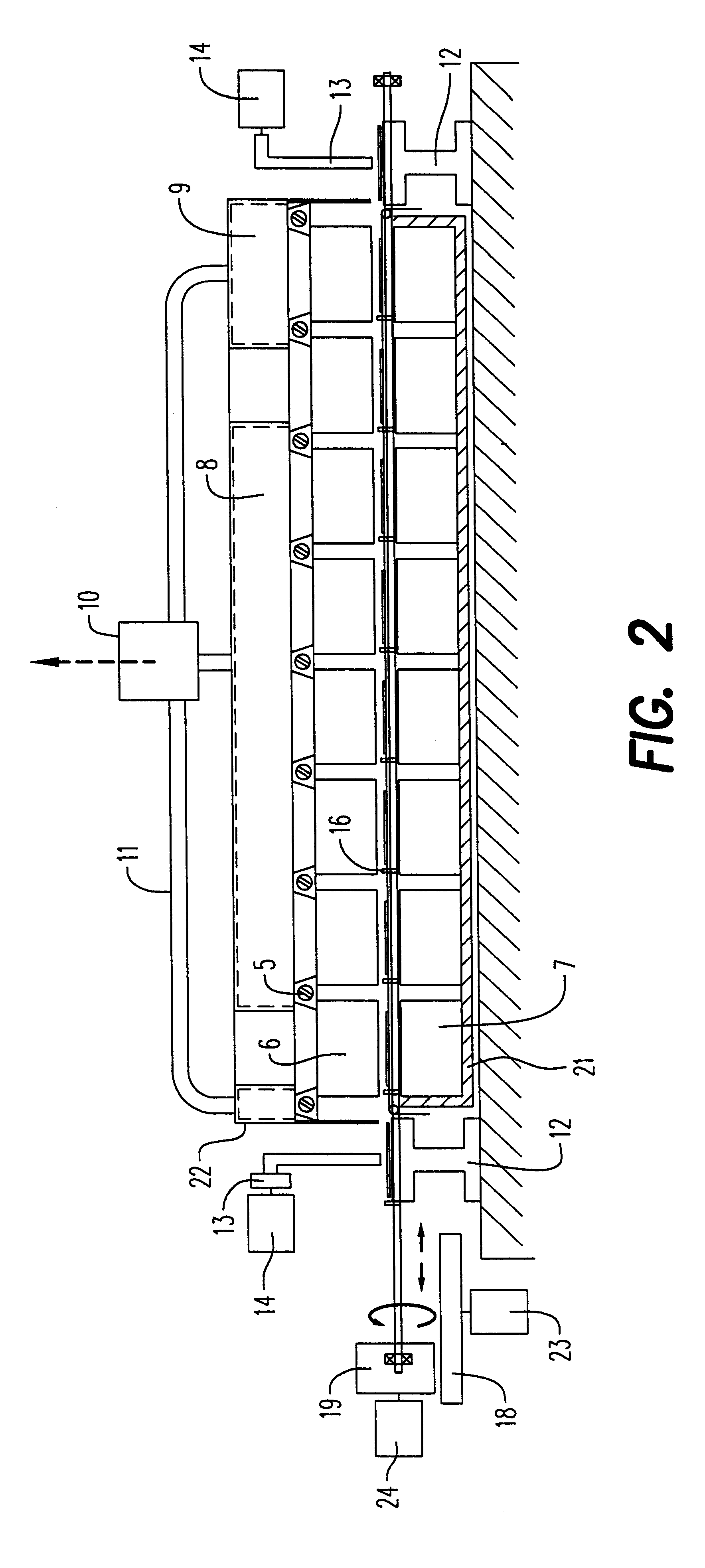

InactiveUS6386422B1Soldering apparatusSemiconductor/solid-state device manufacturingSerpentine channelSolder ball

A solder reflow oven for the processing of ball grid array substrates bearing solder balls is described, comprising: input means for introducing substrates into the oven, a processing chamber within which the substrates are subject to a solder reflow process, and output means for discharging substrates from the oven for further processing or handling, and means for transferring the substrates through the processing chamber in a first direction towards the output means. The processing chamber comprises a plurality of heating and cooling zones arranged with a constant pitch in the first direction, and the transferring means is adapted to move the substrates in the first direction in stages, with each component moving a distance equal to the pitch between two zones in each stage, whereby the components are moved from zone to zone in stages. In addition each block of each heating zone and each block of each cooling zone is connected to a source of fresh gas, and each block of each heating zone is provided with means for heating the gas, and each block of each cooling zone is provided with means for cooling the gas, and each block is formed with a serpentine channel between the source of fresh gas and at least one opening through which the gas is discharged from the block towards a substrate.

Owner:ASM ASSEMBLY AUTOMATION LTD

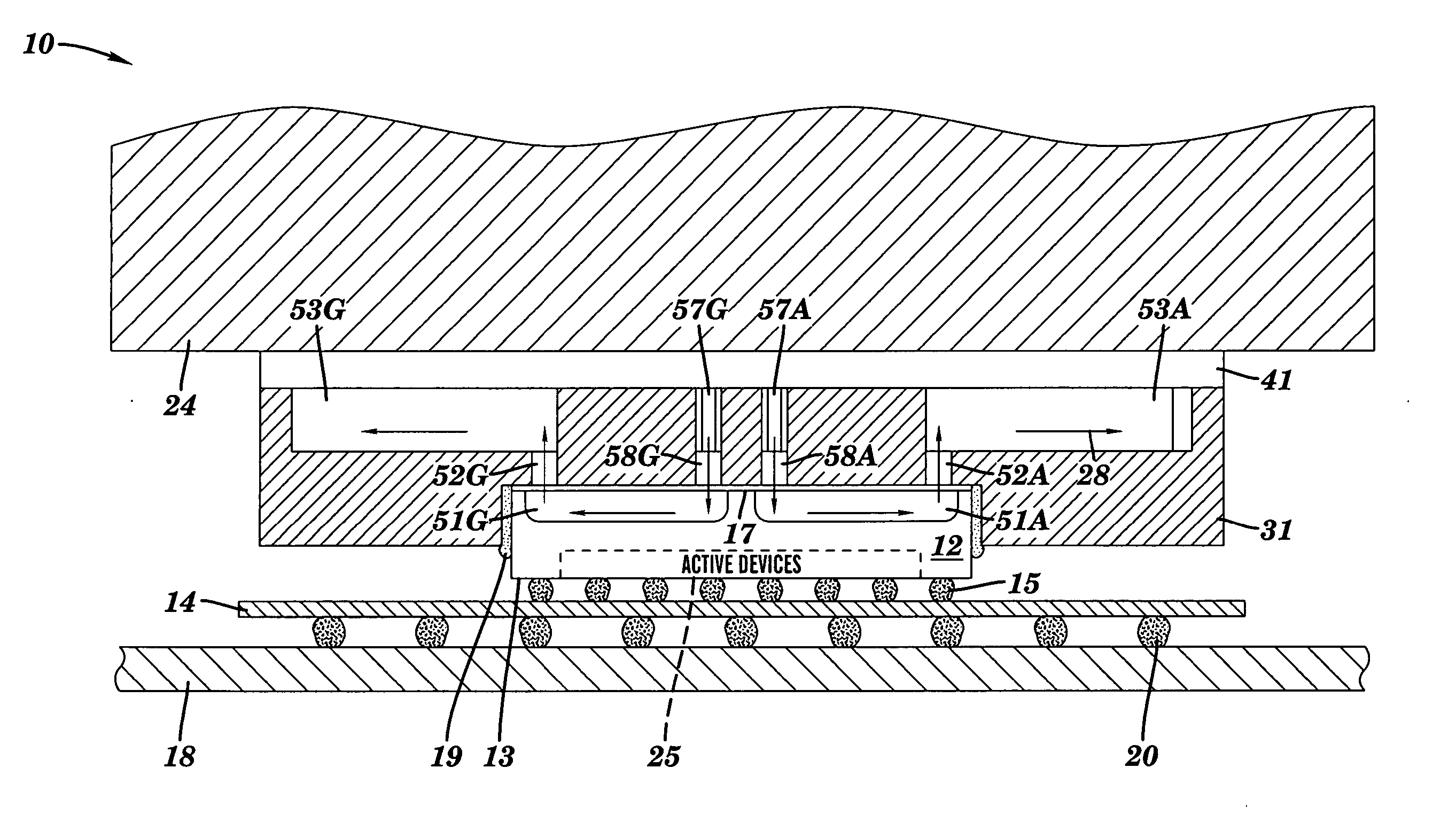

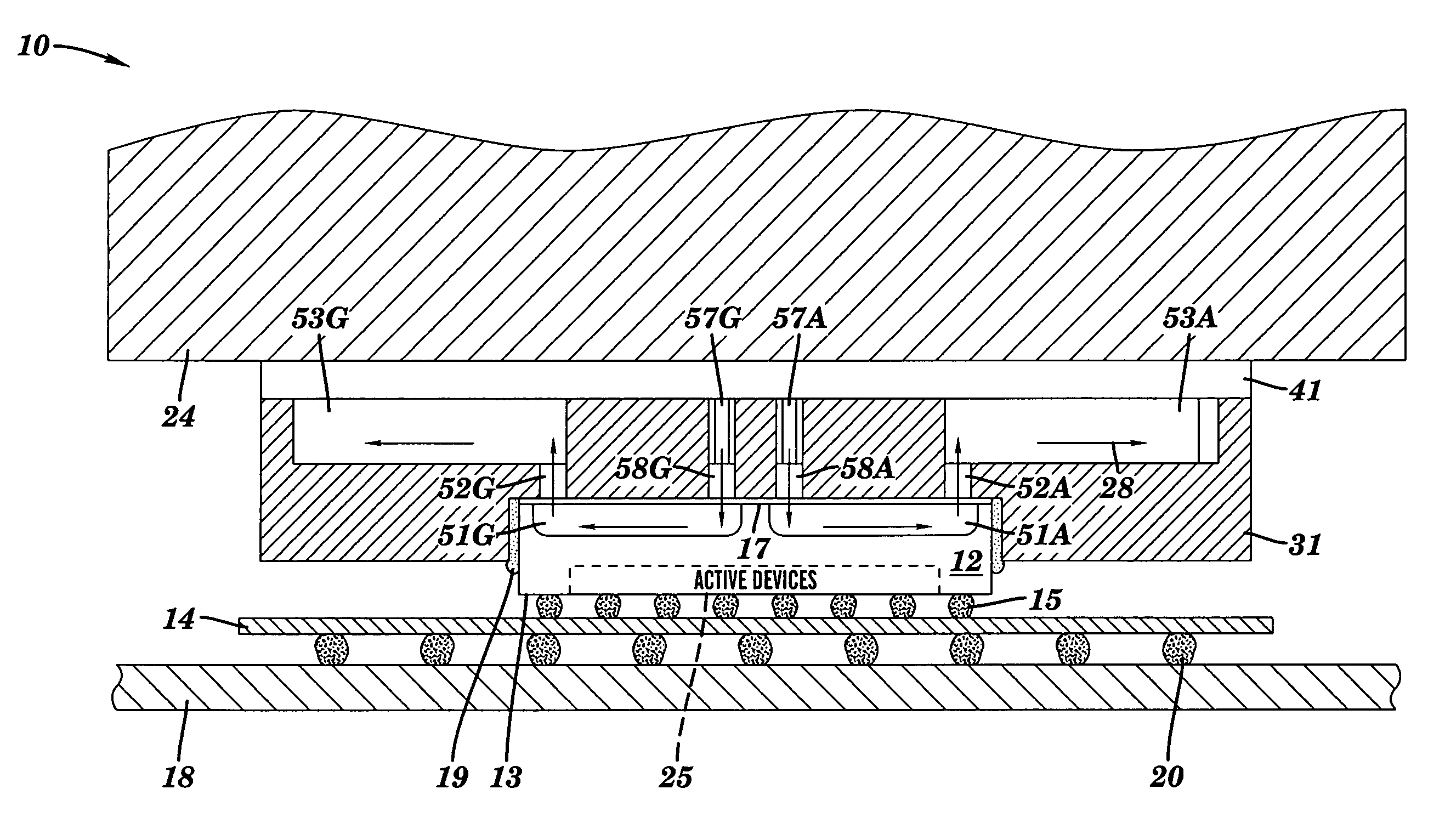

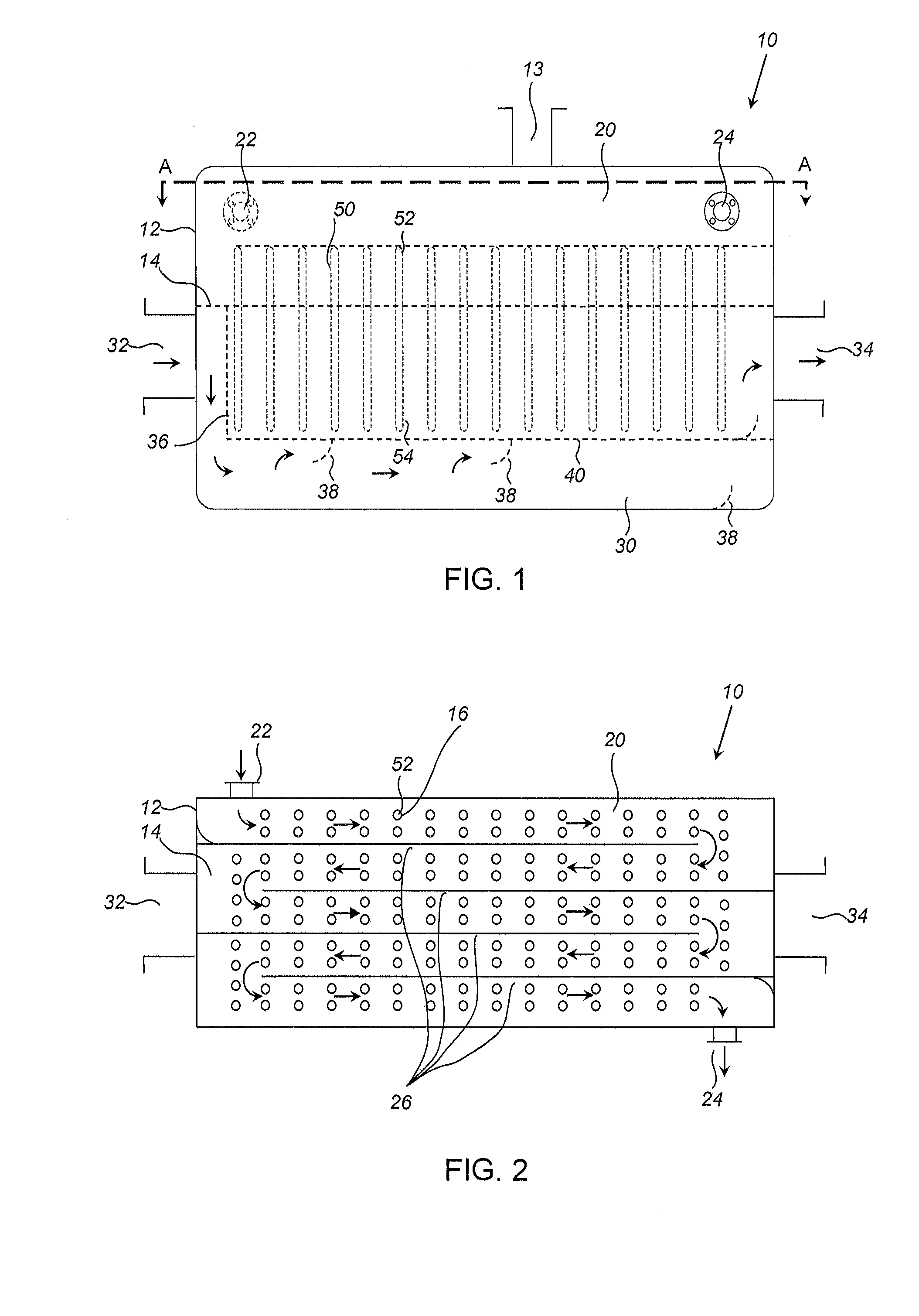

Cooling of substrate using interposer channels

ActiveUS20060042825A1Improve cooling effectPrinted circuit assemblingSemiconductor/solid-state device detailsChannel couplingInterposer

A structure, and method of forming and cooling the structure. The structure may include a substrate (e.g., a semiconductor chip) having N continuous substrate channels and an interposer having N continuous interposer channels (N≧2). The N interposer channels are coupled to the N substrate channels to form M continuous loops (1≦M≦N). The M loops may transfer heat from a heat source within the substrate to the interposer and then to a heat sink thermally coupled to the interposer. The structure may include an interposer having a thermally conductive enclosure surrounding a cavity. The cavity contains a thermally conductive foam material (e.g., graphite foam). The foam material contains a serpentine channel having contiguously connected channel segments. The serpentine channel may transfer heat from a heat source within a substrate (e.g., a semiconductor chip) to the interposer and then to a heat sink thermally coupled to the interposer.

Owner:GLOBALFOUNDRIES US INC

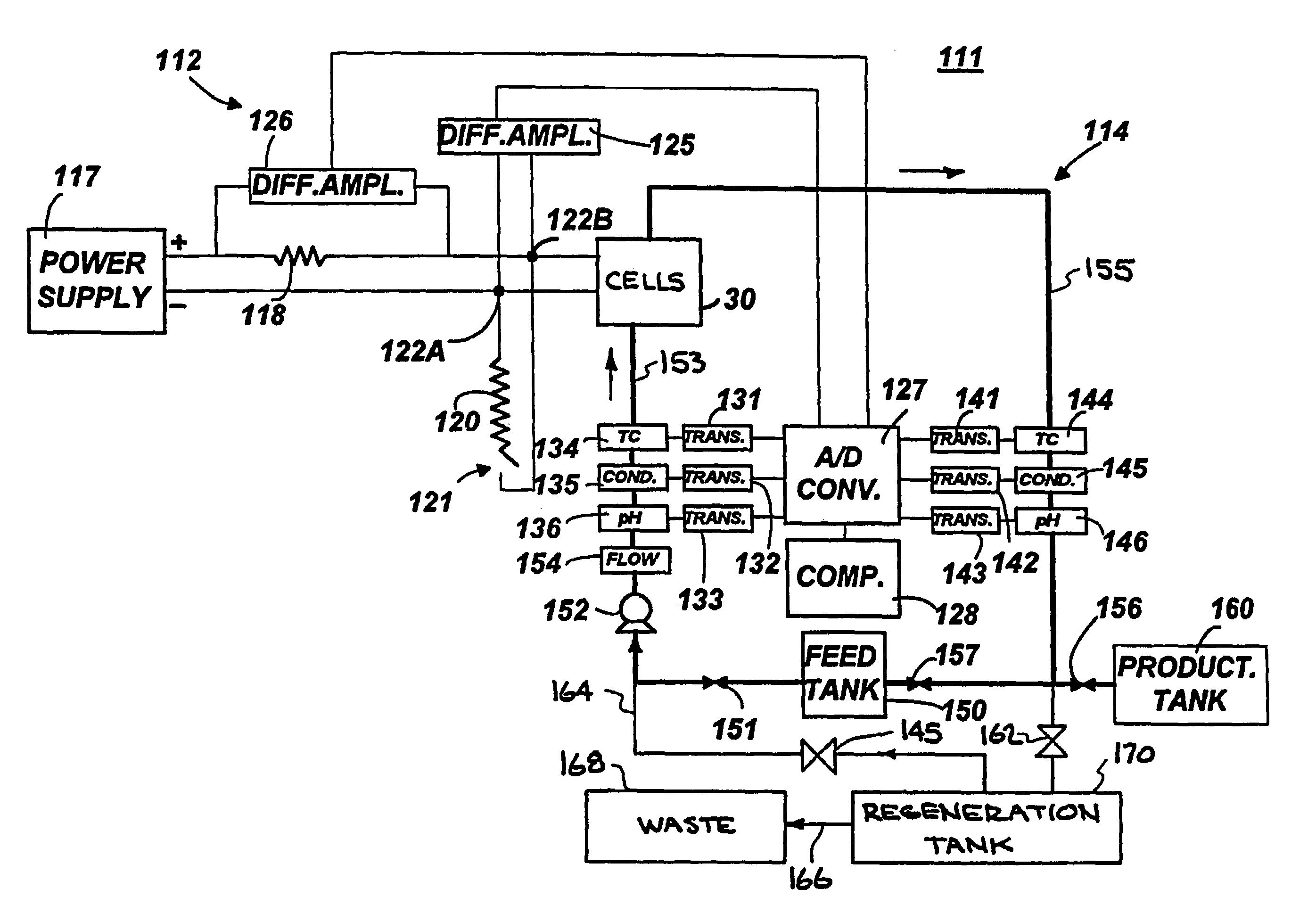

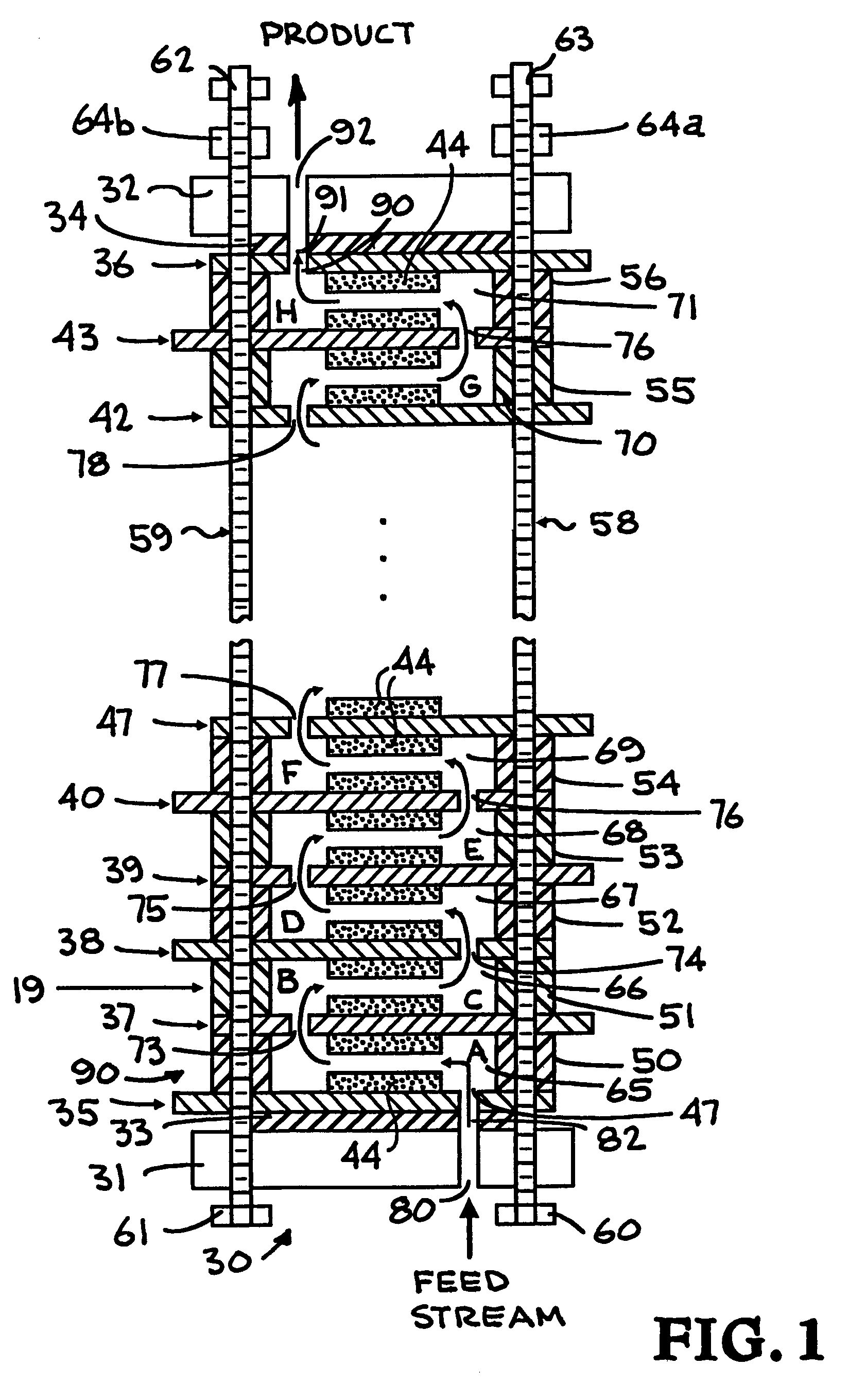

Alternating-polarity operation for complete regeneration of electrochemical deionization system

InactiveUS7138042B2Volume of waste can be minimizedConductivity maximizedCellsMaterial nanotechnologyCapacitanceElectrical battery

An electrically regeneratable battery of electrochemical cells for capacitive deionization (including electrochemical purification) and regeneration of electrodes is operated at alternate polarities during consecutive cycles. In other words, after each regeneration step operated at a given polarity in a deionization-regeneration cycle, the polarity of the deionization step in the next cycle is maintained. In one embodiment, two end electrodes are arranged one at each end of the battery, adjacent to end plates. An insulator layer is interposed between each end plate and the adjacent end electrode. Each end electrode includes a single sheet of conductive material having a high specific surface area and sorption capacity, preferably a sheet formed of carbon aerogel composite. The batter further includes a plurality of generally identical double-sided intermediate electrodes that are equidistally separated from each other, between the two end electrodes. As the electrolyte enters the battery of ells, t flows through a continuous open serpentine channel defined by the electrodes, substantially parallel to the surfaces of the electrodes. By polarizing the cells, ions are removed from the electrolyte and are held in the electric double layers formed at the carbon aerogel surfaces of the electrodes. As the electrodes of each cell of the battery are saturated with the removed ions, the battery is regenerated electrically at a reversed polarity from that during the deionization step of the cycle, thus significantly minimizing secondary wastes.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

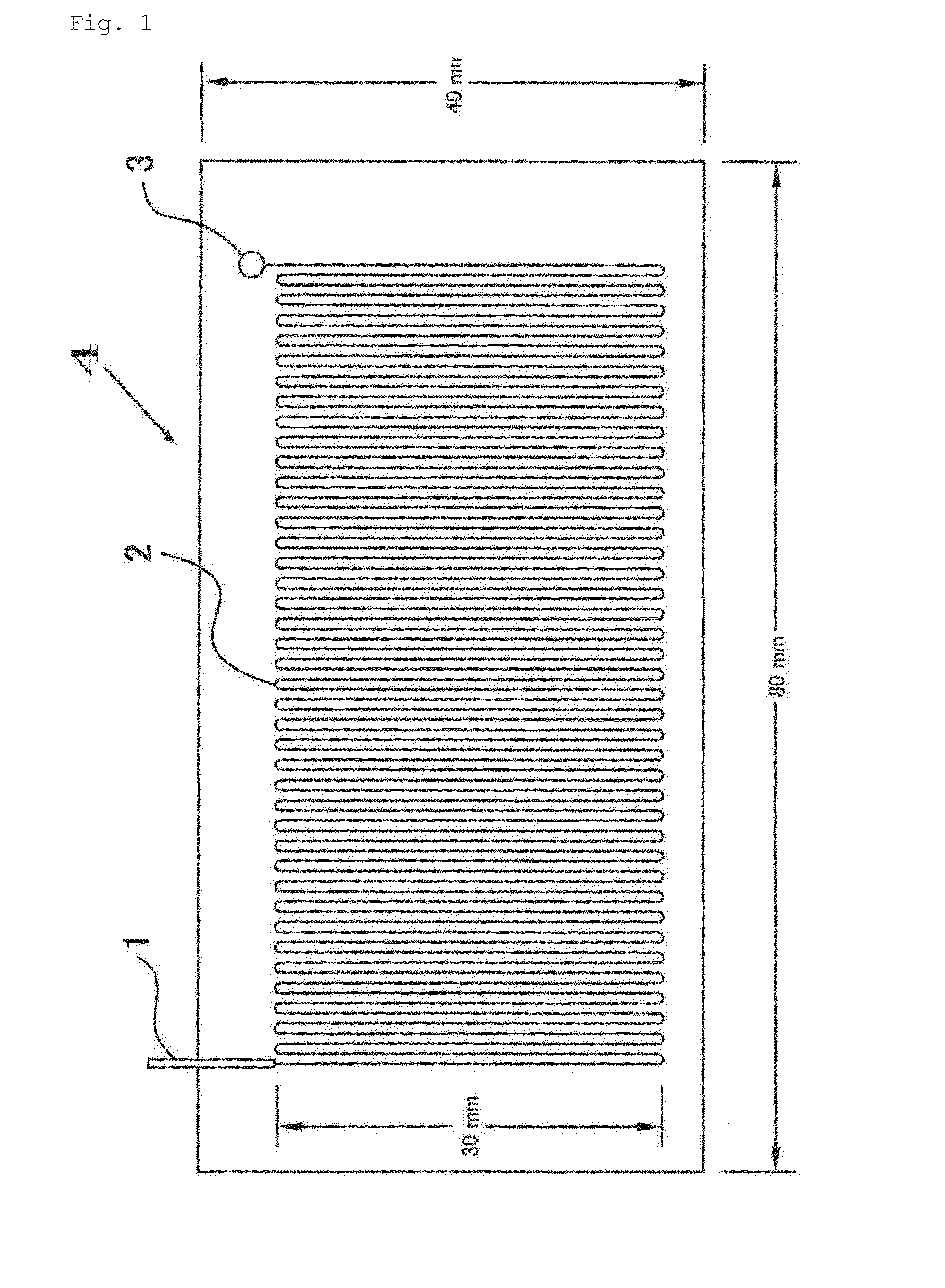

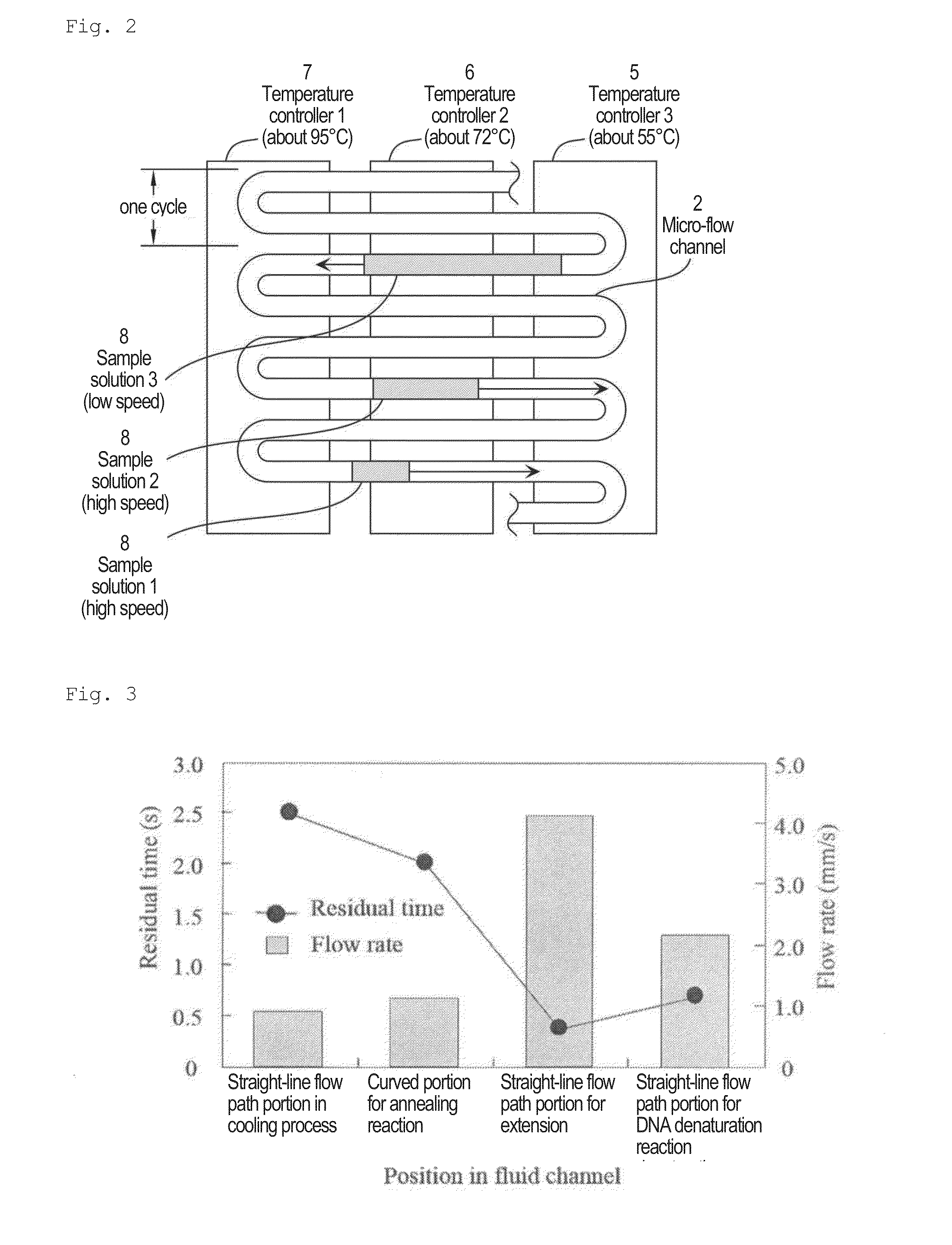

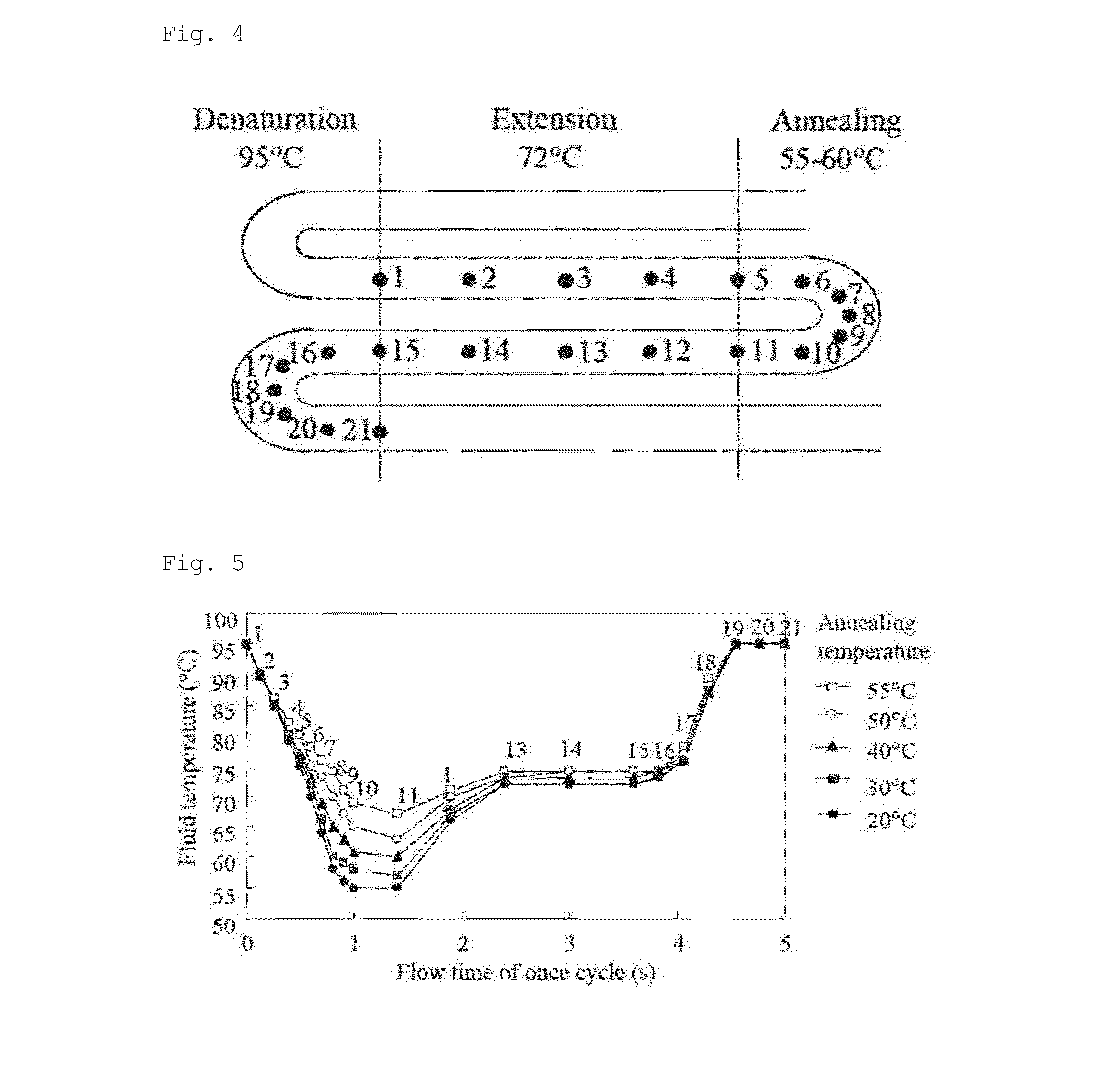

Nucleic acid amplification method

ActiveUS20150031087A1Minimized analytical volumeMaximize heat transfer efficiencyMicrobiological testing/measurementFermentationSerpentine channelBiology

The invention provides an ultra-rapid nucleic acid amplification method performed in a flow channel. Specifically, the invention provides a nucleic acid amplification method for performing a PCR reaction by supplying a PCR sample solution to a nucleic acid amplification device comprising a serpentine channel adapted to perform at least one PCR cycle, the nucleic acid amplification device comprising a DNA denaturation temperature zone corresponding to the curved portions at one side, an annealing temperature zone corresponding to the curved portions at the other side, and an extension temperature zone positioned between the annealing and DNA denaturation temperature zones, wherein the PCR sample solution is introduced in the form of sample plugs separated by gas into the serpentine channel using a pump, the sample solution being supplied into the channel in a state such that the solution is separated by gas into a segment corresponding to one PCR cycle or smaller segments.

Owner:NAT INST OF ADVANCED IND SCI & TECH

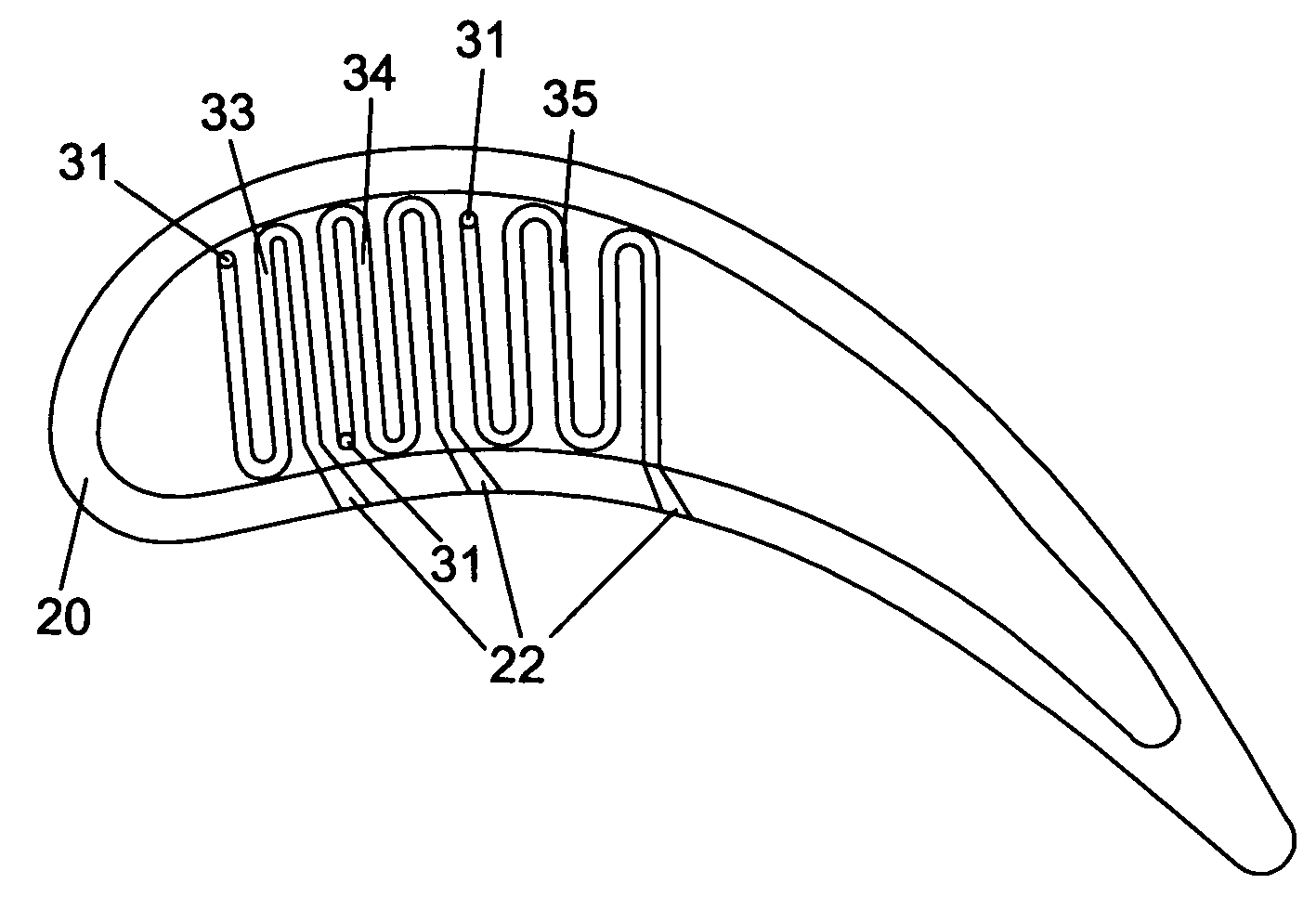

Artificial skin and elastic strain sensor

ActiveUS9841331B2High sensitivityImprove the immunityInput/output for user-computer interactionSolesElectrical resistance and conductanceElastic substrate

An elastic strain sensor can be incorporated into an artificial skin that can sense flexing by the underlying support structure of the skin to detect and track motion of the support structure. The uni-directional elastic strain sensor can be formed by filling two or more channels in an elastic substrate material with a conductive liquid. At the ends of the channels, a loop port connects the channels to form a serpentine channel. The channels extend along the direction of strain and the loop portions have sufficiently large cross-sectional area in the direction transverse to the direction of strain that the sensor is unidirectional. The resistance is measured at the ends of the serpentine channel and can be used to determine the strain on the sensor. Additional channels can be added to increase the sensitivity of the sensor. The sensors can be stacked on top of each other to increase the sensitivity of the sensor. In other embodiments, two sensors oriented in different directions can be stacked on top of each other and bonded together to form a bidirectional sensor. A third sensor formed by in the shape of a spiral or concentric rings can be stacked on top and used to sense contact or pressure, forming a three dimensional sensor. The three dimensional sensor can be incorporated into an artificial skin to provide advanced sensing.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

An ear bud earphone with variable noise isolation, a cushion for an ear bud earphone and a corresponding method

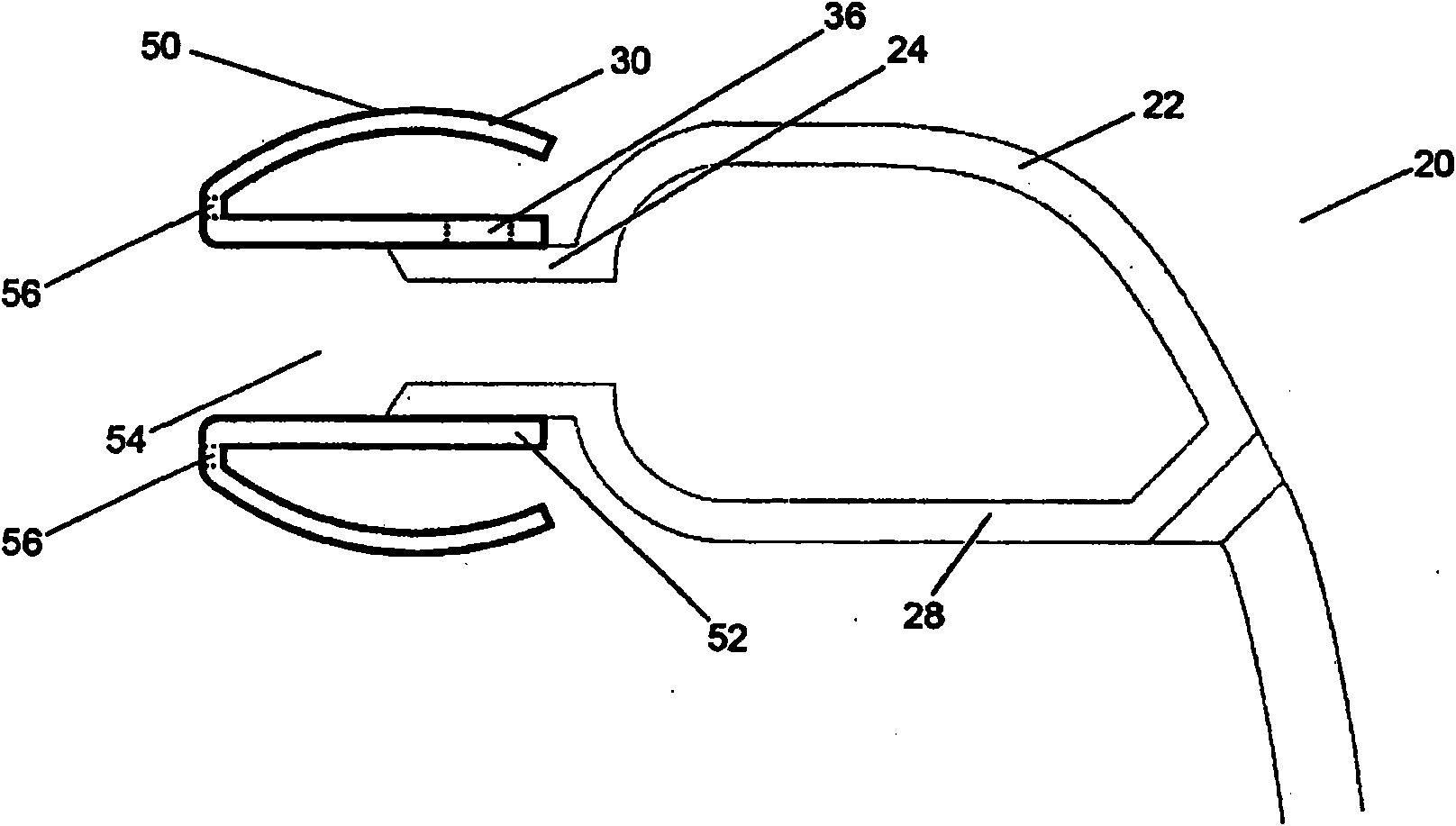

ActiveCN101874410AHeadphones for stereophonic communicationIntra aural earpiecesTransducerSerpentine channel

There is provided an insert ear bud earphone with variable noise isolation. The earphone includes a housing with a serpentine channel which is able to contain at least one transducer in a main body of the housing; and a cushion which contacts a user's ear canal wall, the cushion being mounted on the serpentine channel. There is preferably at least one opening in either the housing or the cushion which causes leakage and allows ambient noise to enter the user's ear canal. There is also provided a cushion for an insert ear bud earphone. Finally, there is provided a method to enable variable noise isolation in an insert ear bud earphone comprising an inclusion of at least one opening in either a housing of the earphone or a cushion mounted on the earphone which causes leakage and allows ambient noise to enter a user's ear canal.

Owner:CREATIVE TECH CORP

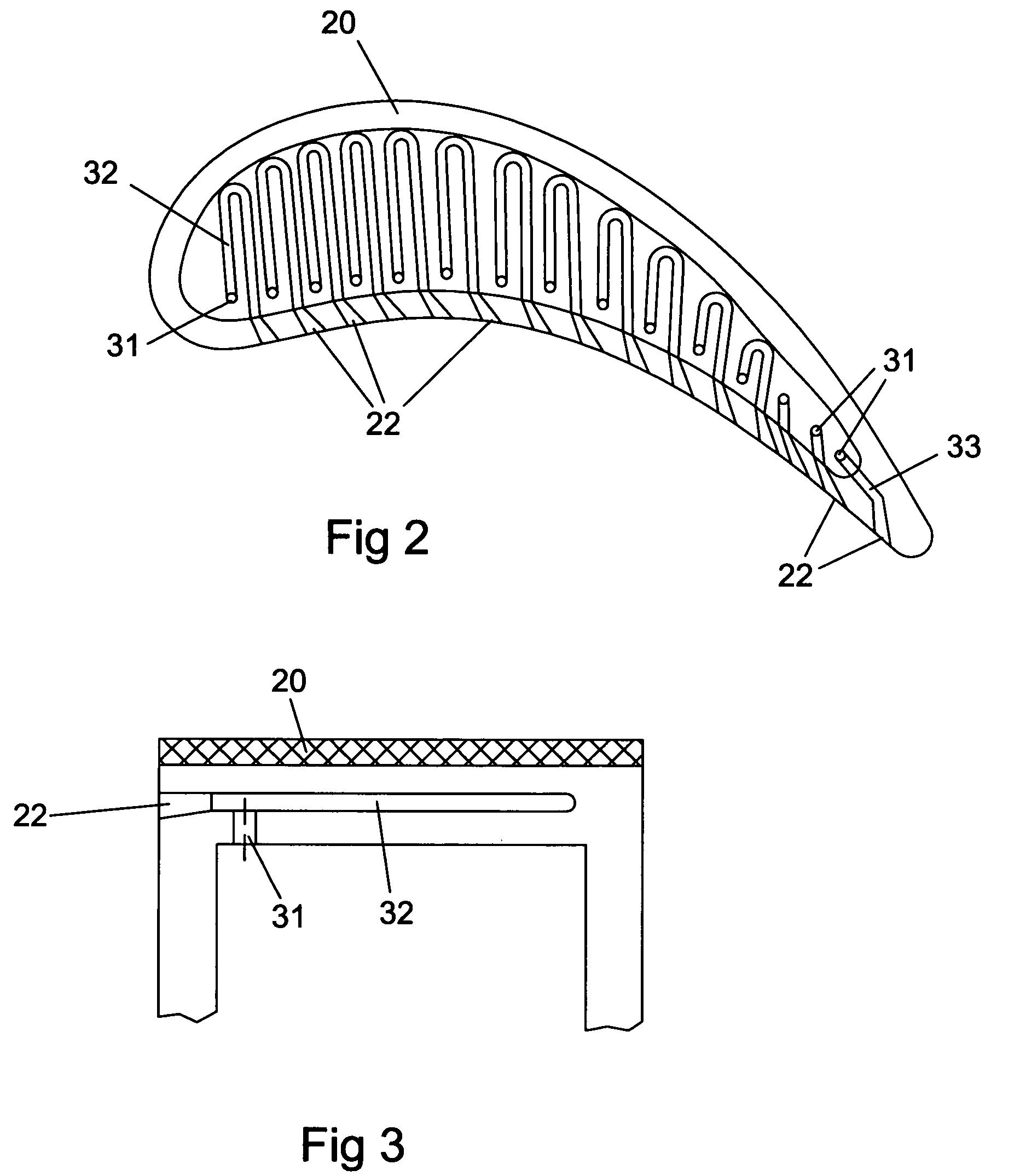

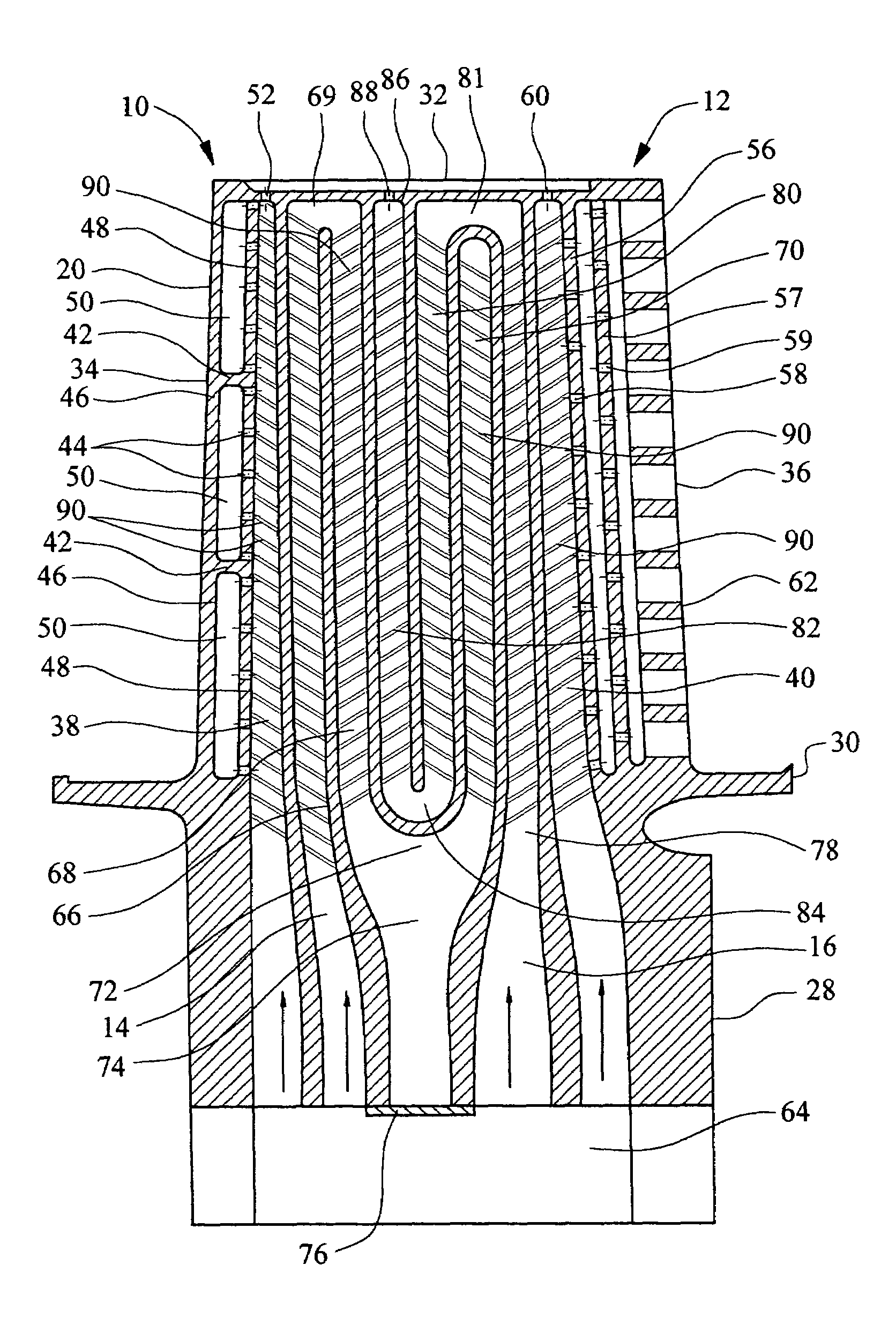

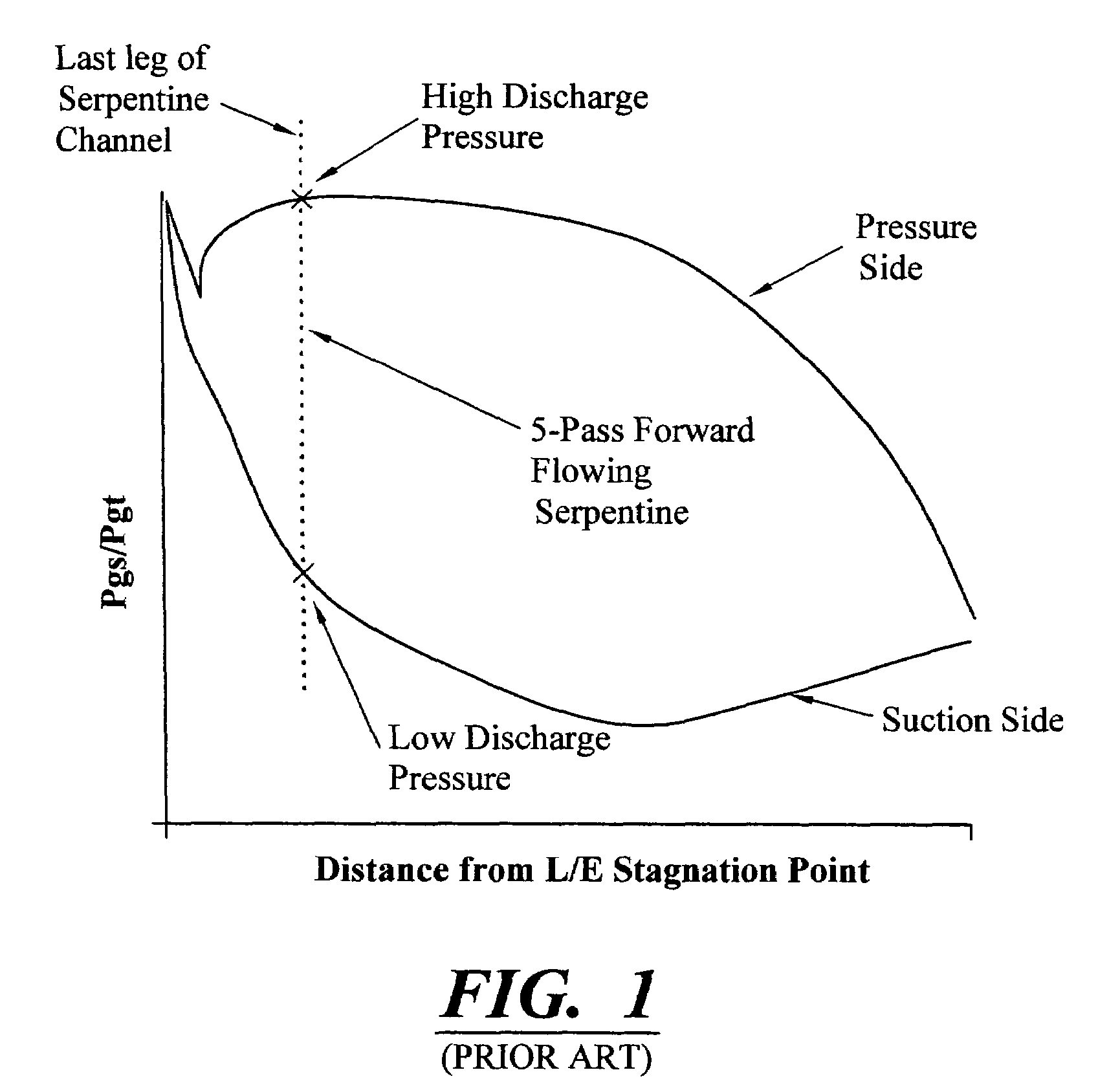

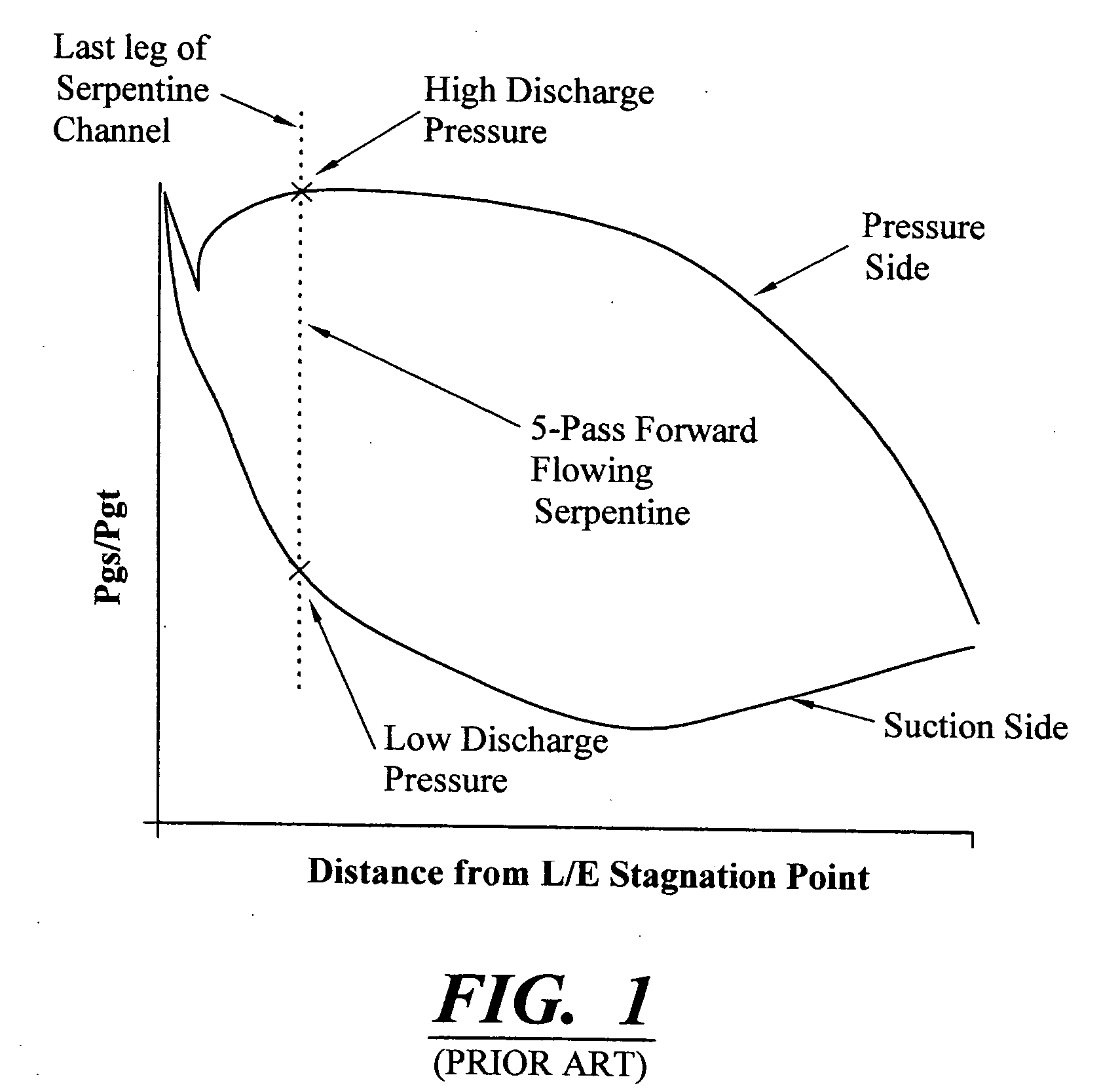

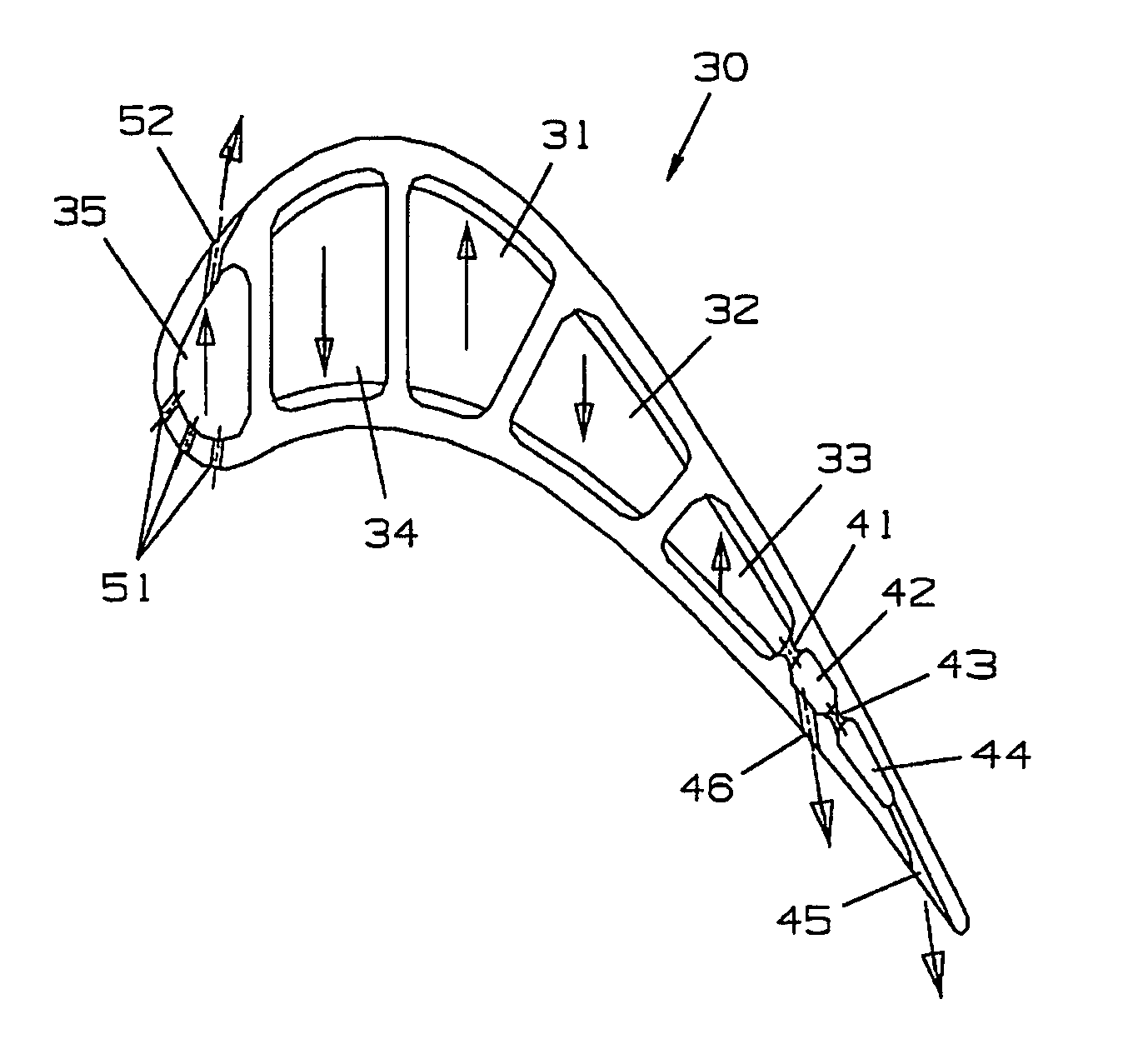

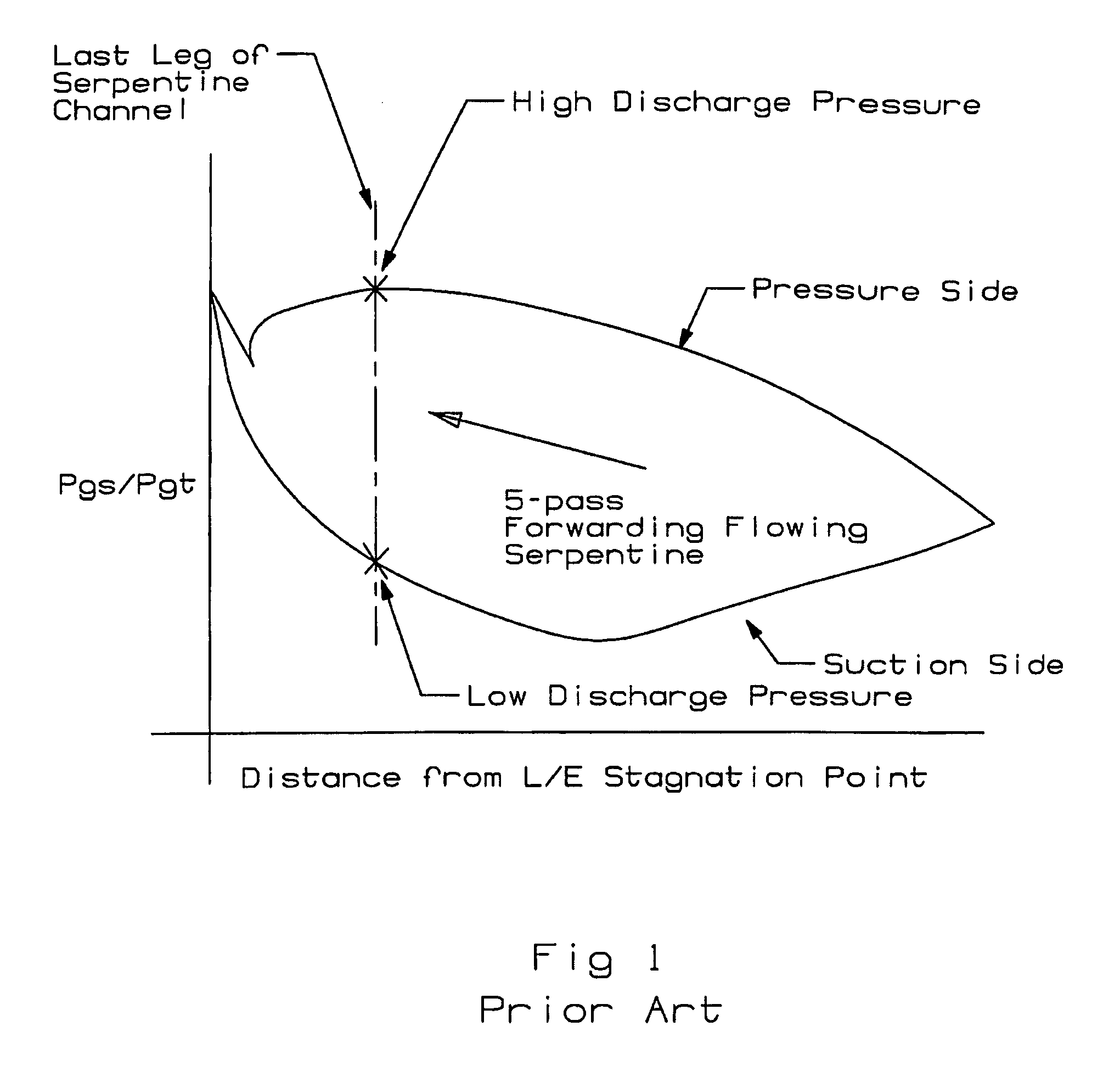

Turbine airfoil with counter-flow serpentine channels

InactiveUS7296972B2Facilitate heat exchangeReduce the amount requiredEngine manufactureEngine fuctionsLeading edgeCounter flow

A turbine airfoil usable in a turbine engine and having at least one cooling system. The cooling system may include a pressure side serpentine cooling channel and a suction side serpentine cooling channel. The cooling channels may be nested within each other to optimize heat exchange between the cooling fluids and the materials forming the airfoil, to reduce the amount of cooling fluids required, to reduce the required pressure of the cooling fluids, and to provide other benefits. The pressure side serpentine cooling channel may pass cooling fluids chordwise towards the trailing edge, and the suction side serpentine cooling channel may pass cooling fluids chordwise towards the leading edge.

Owner:SIEMENS ENERGY INC

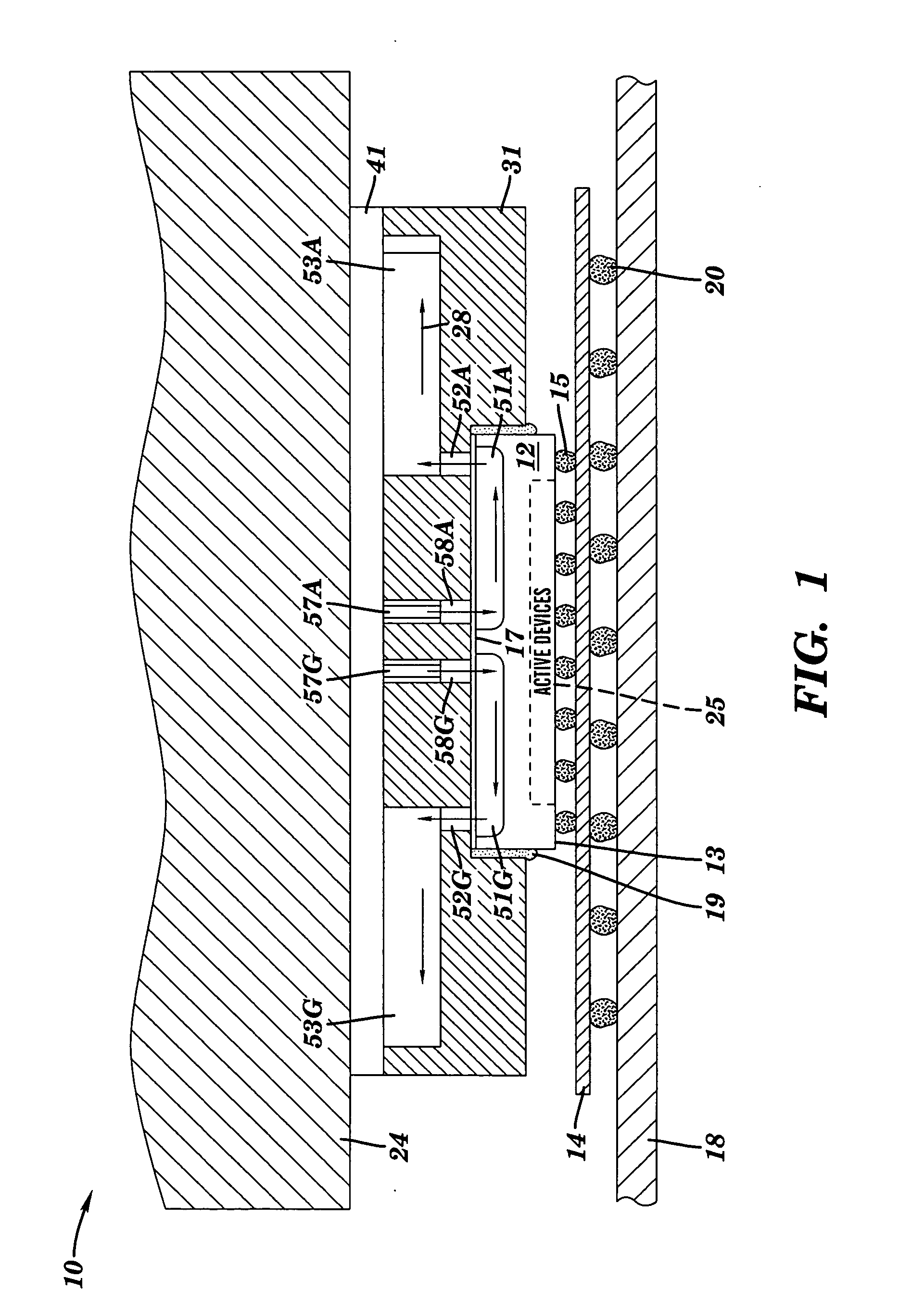

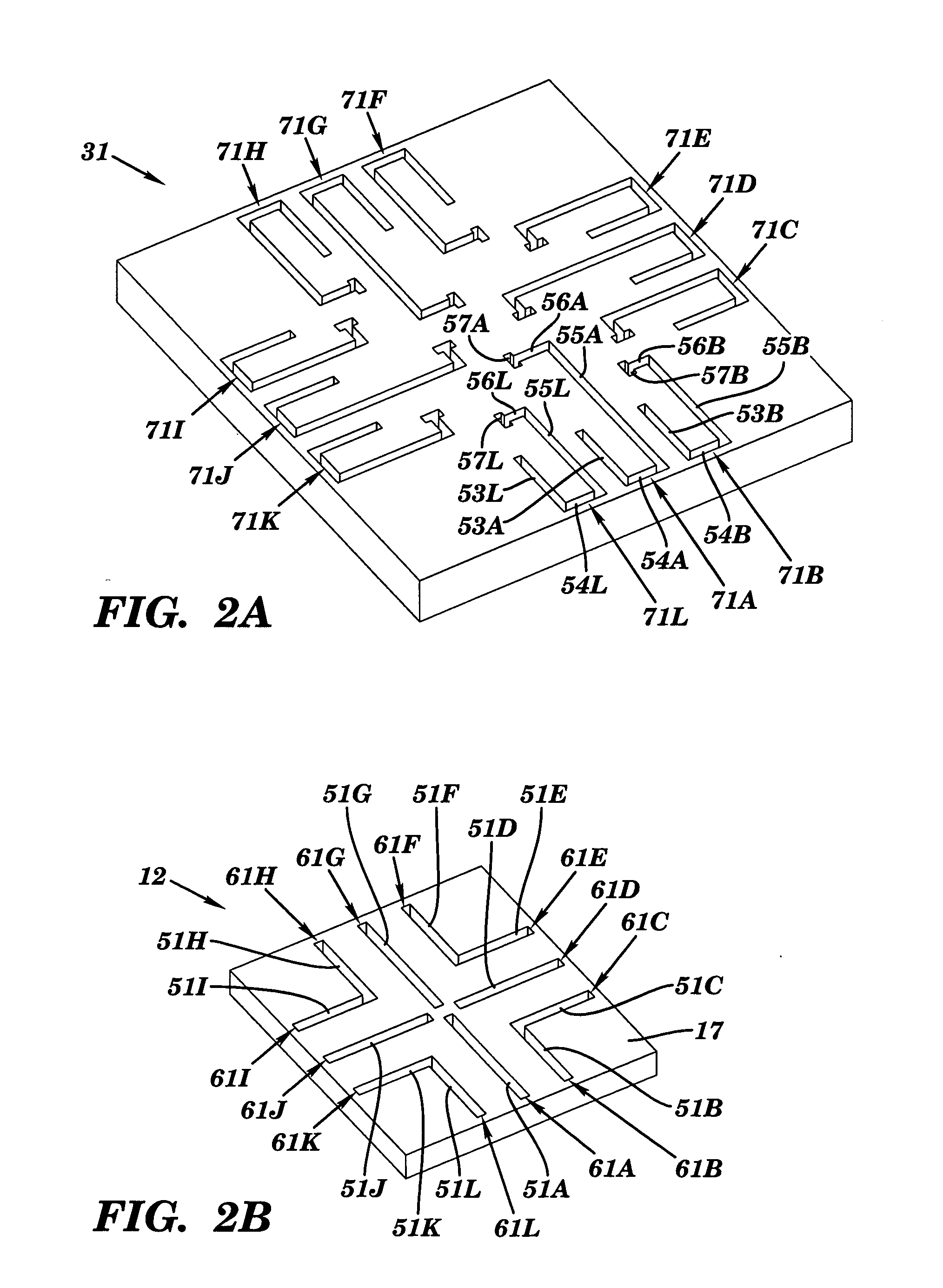

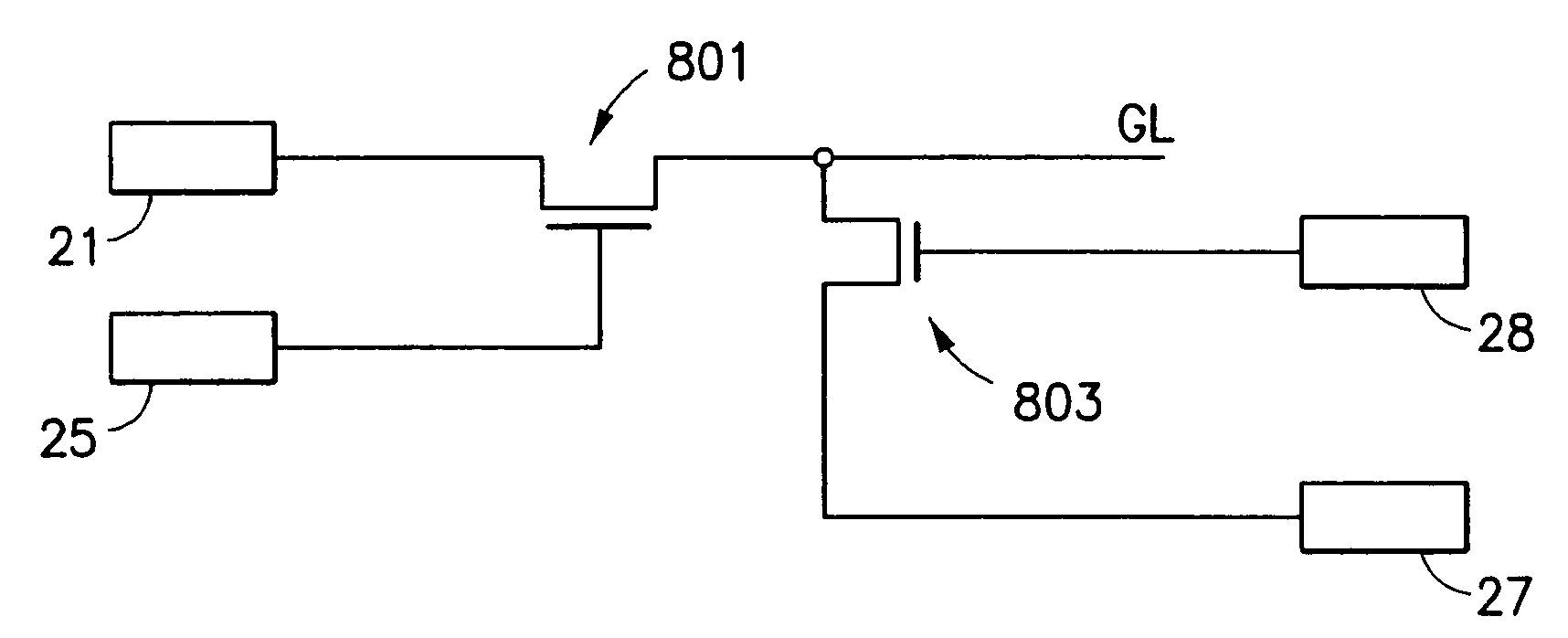

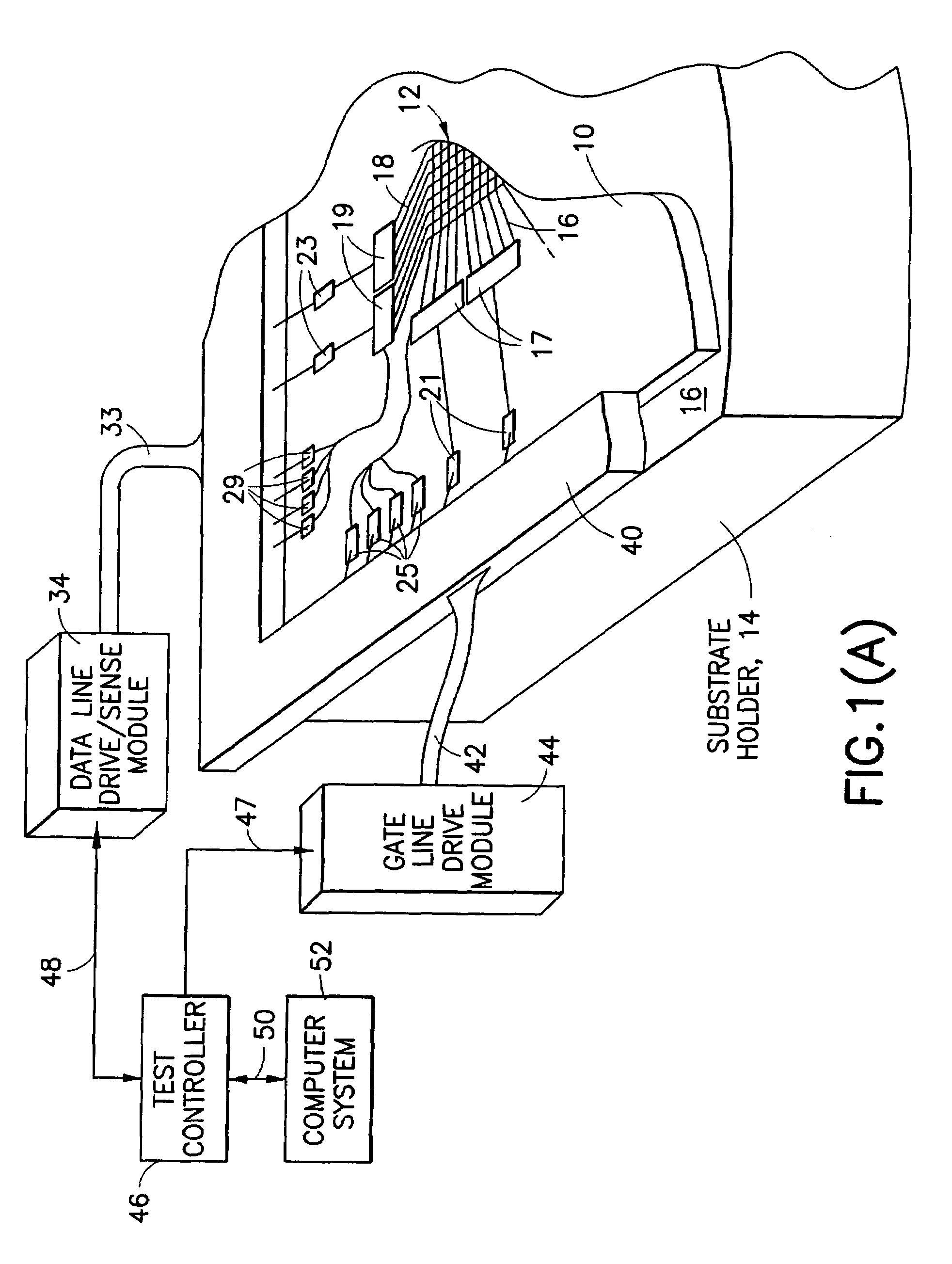

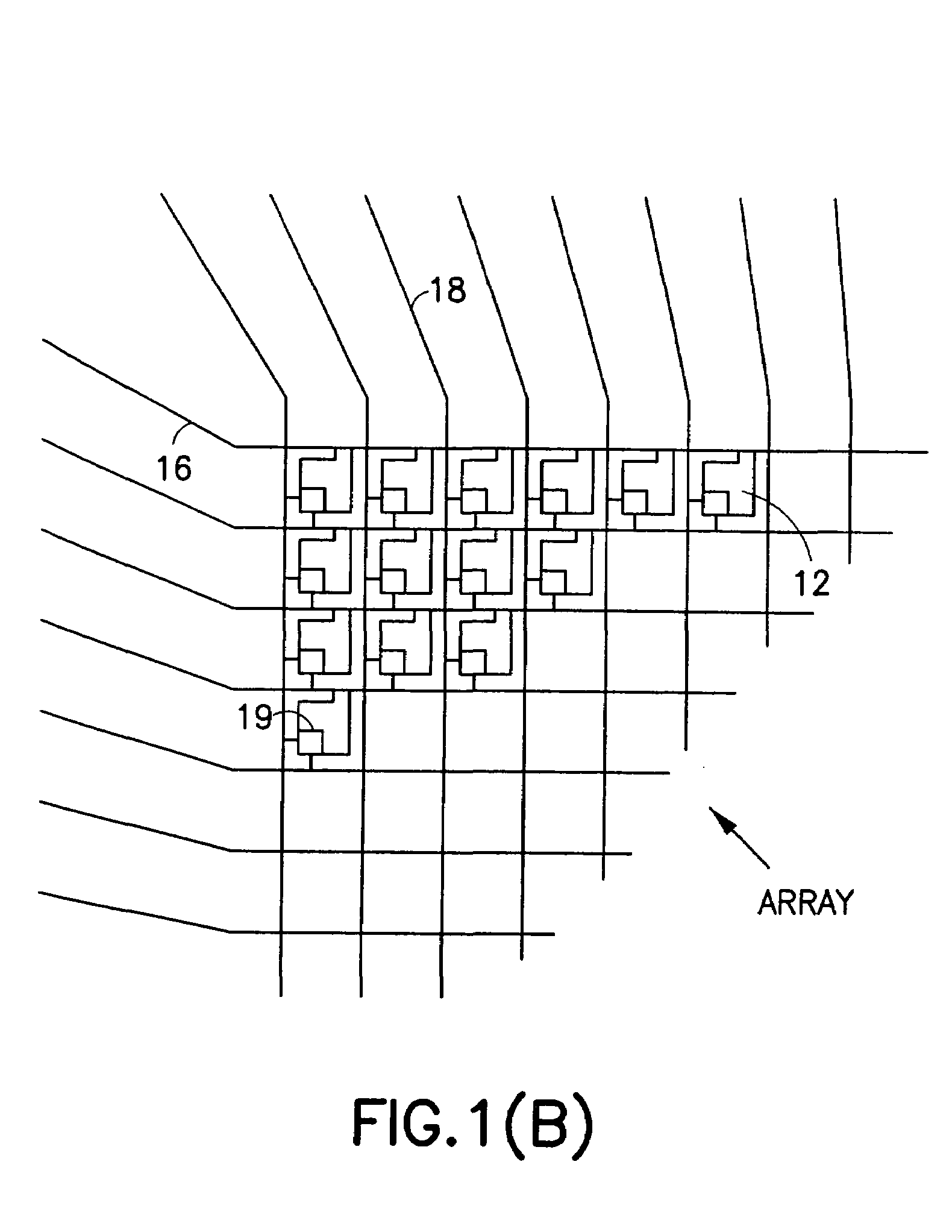

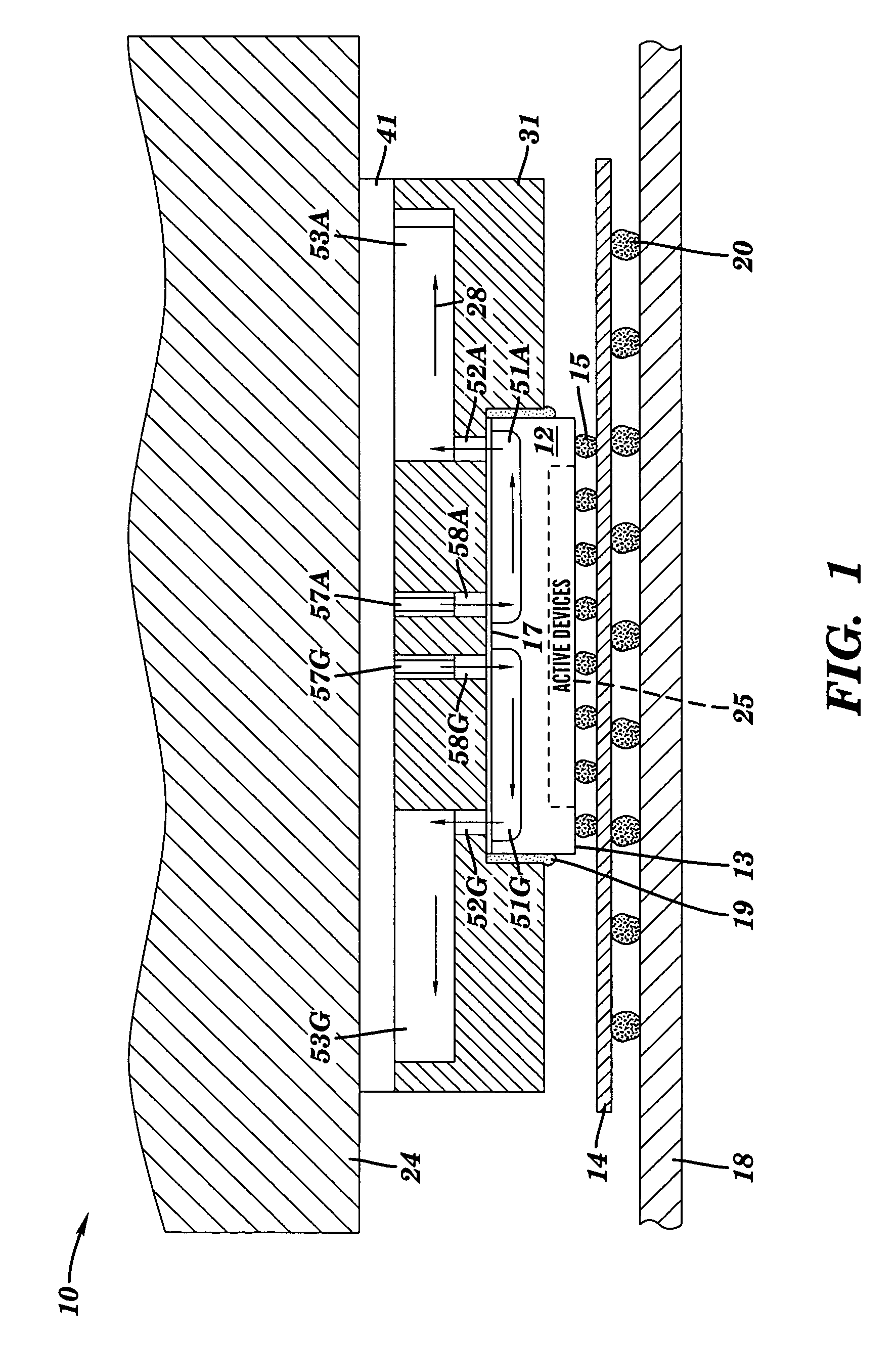

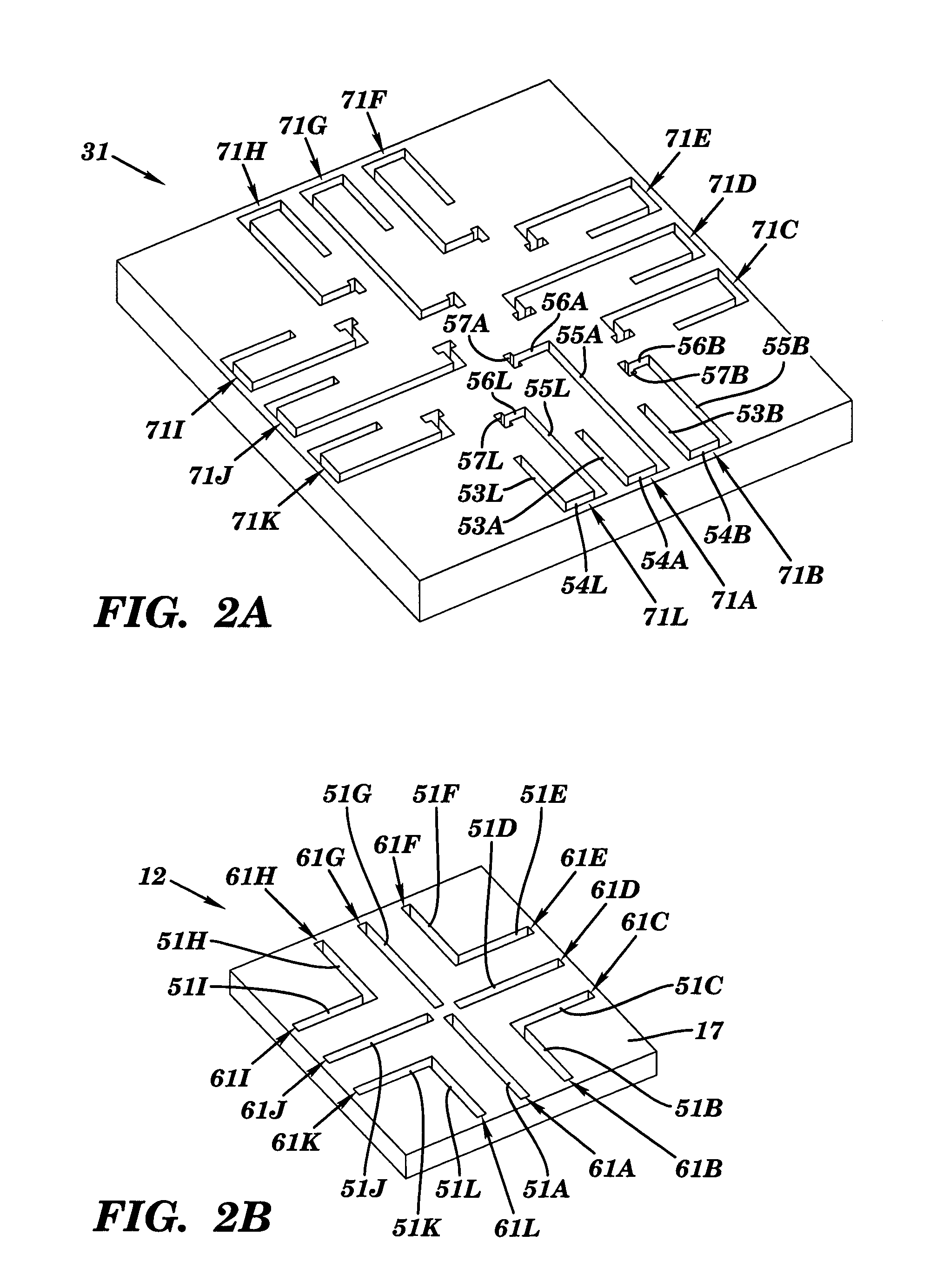

Integrated circuits for testing an active matrix display array

InactiveUS6940300B1Static indicating devicesIndividual semiconductor device testingActive matrixSerpentine channel

A device for use in a display system including an array of pixel cells formed on a substrate. Each pixel cell being coupled to at least one gate line of a plurality of gate lines formed on the substrate and at least one data line of a plurality of data lines being formed on the substrate. The device includes first and second transistors formed on the substrate. Each transistor has a gate electrode and first and second electrodes defining a serpentine channel region there between voltage applied to the gate electrode controls conductivity of the channel region. Preferably, a common electrode includes one of the first and second electrodes of the first transistor and one of the first and second electrodes of the second transistor. The first and second transistors are preferably coupled between a gate line (or data line) and respective probe pads formed on the substrate and selectively couple the respective probe pad to the gate line (or data line) during a test routine whereby charge is written to, stored, and read from the array of pixel cells.

Owner:VIDEOCON GLOBAL

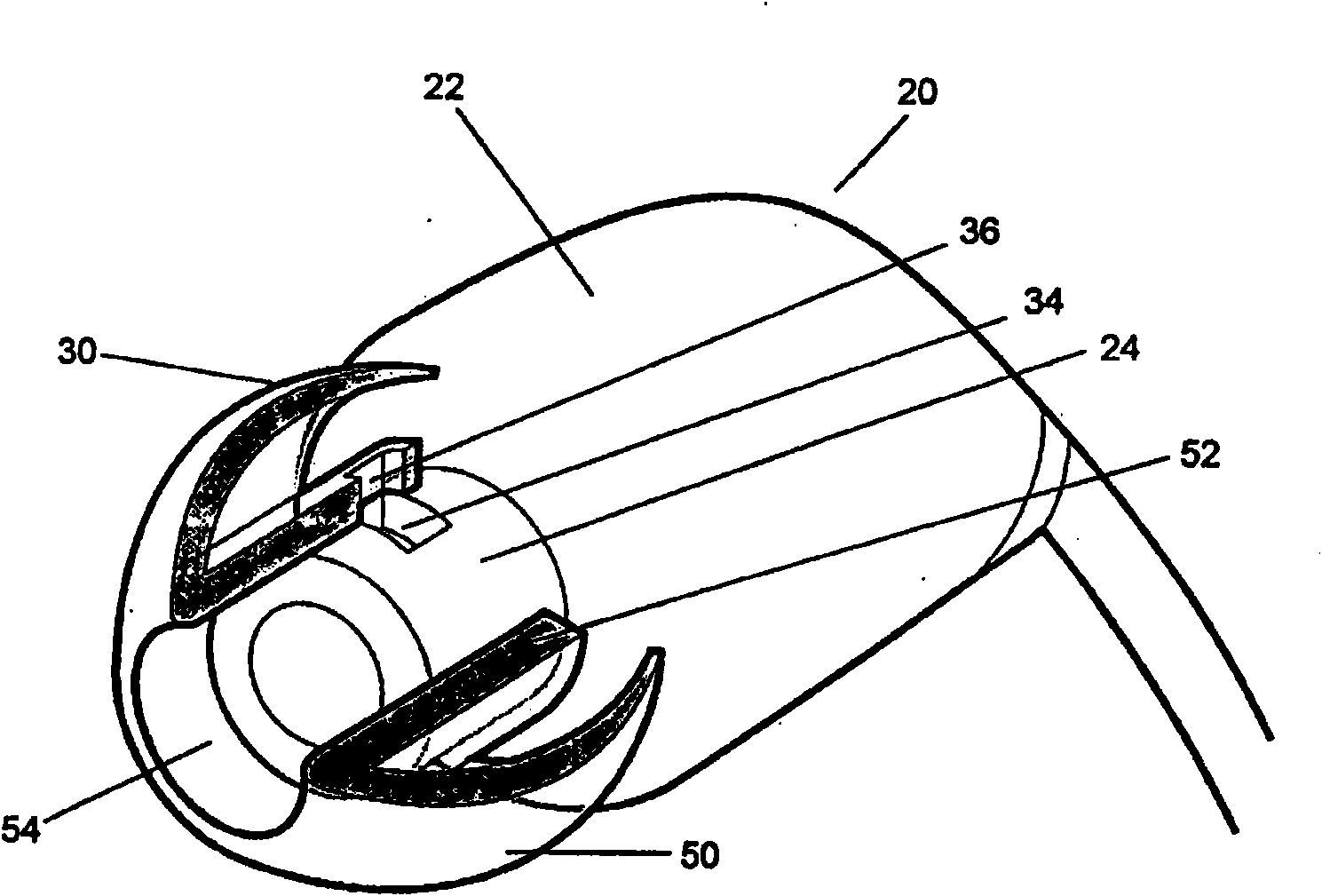

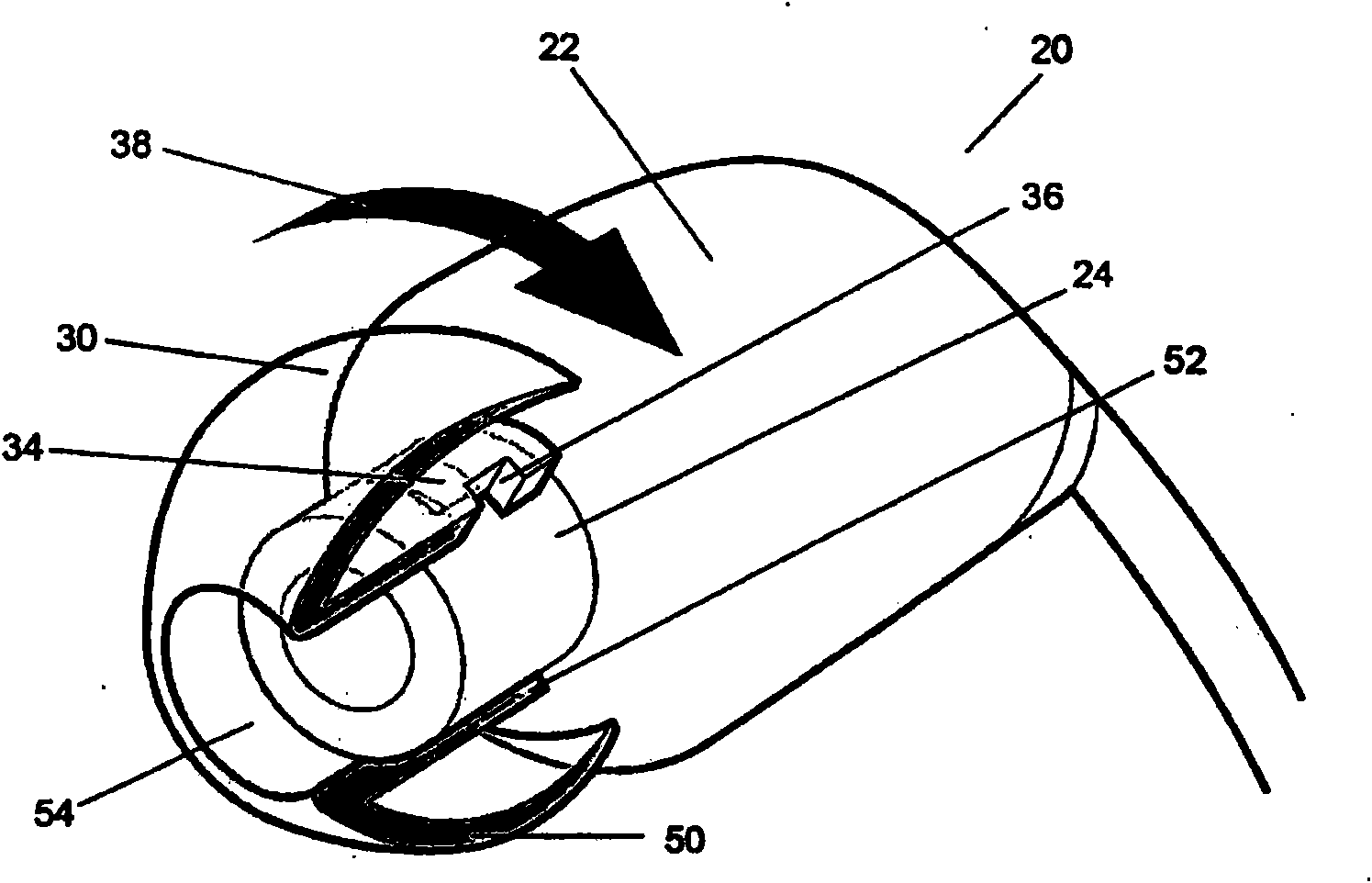

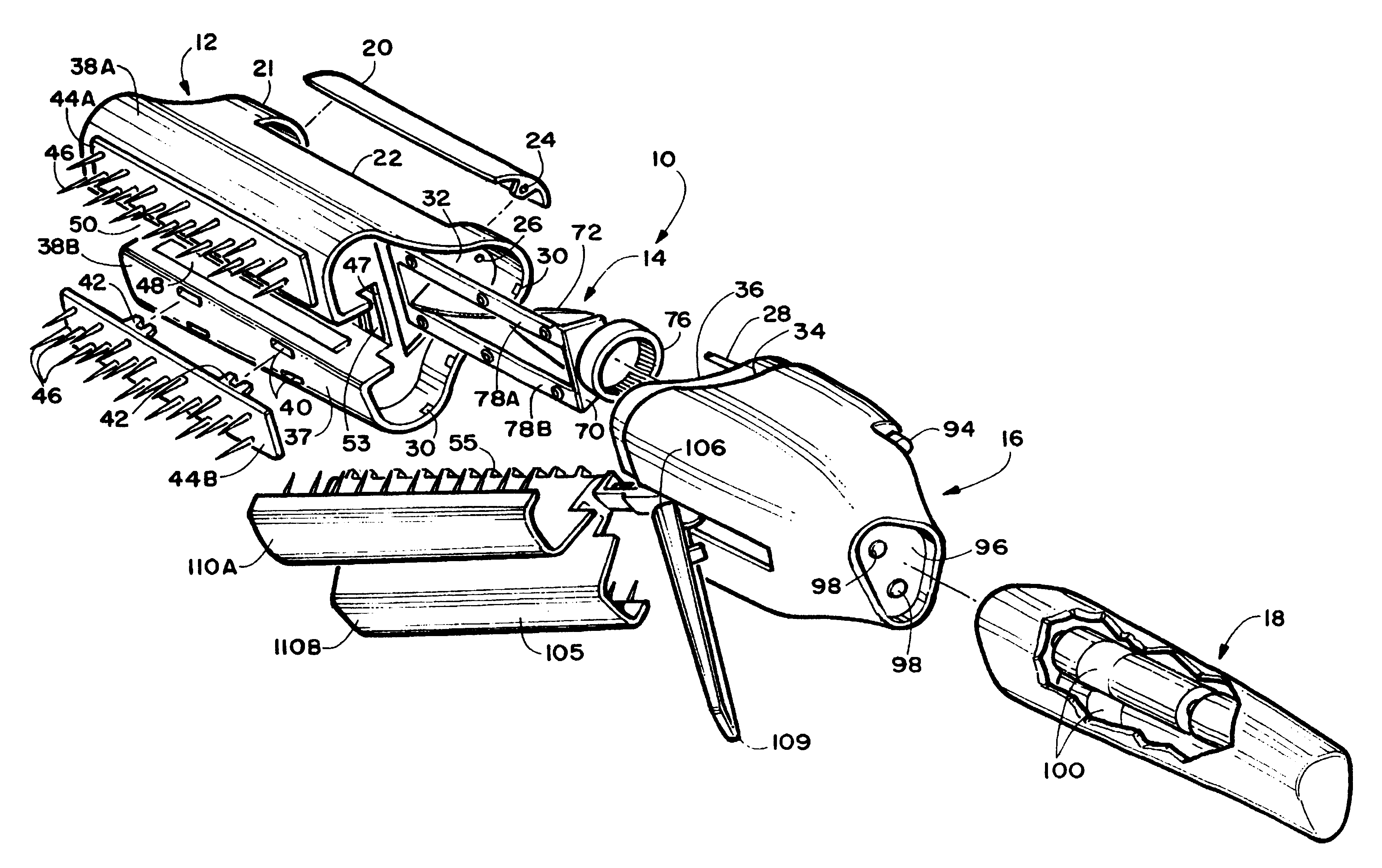

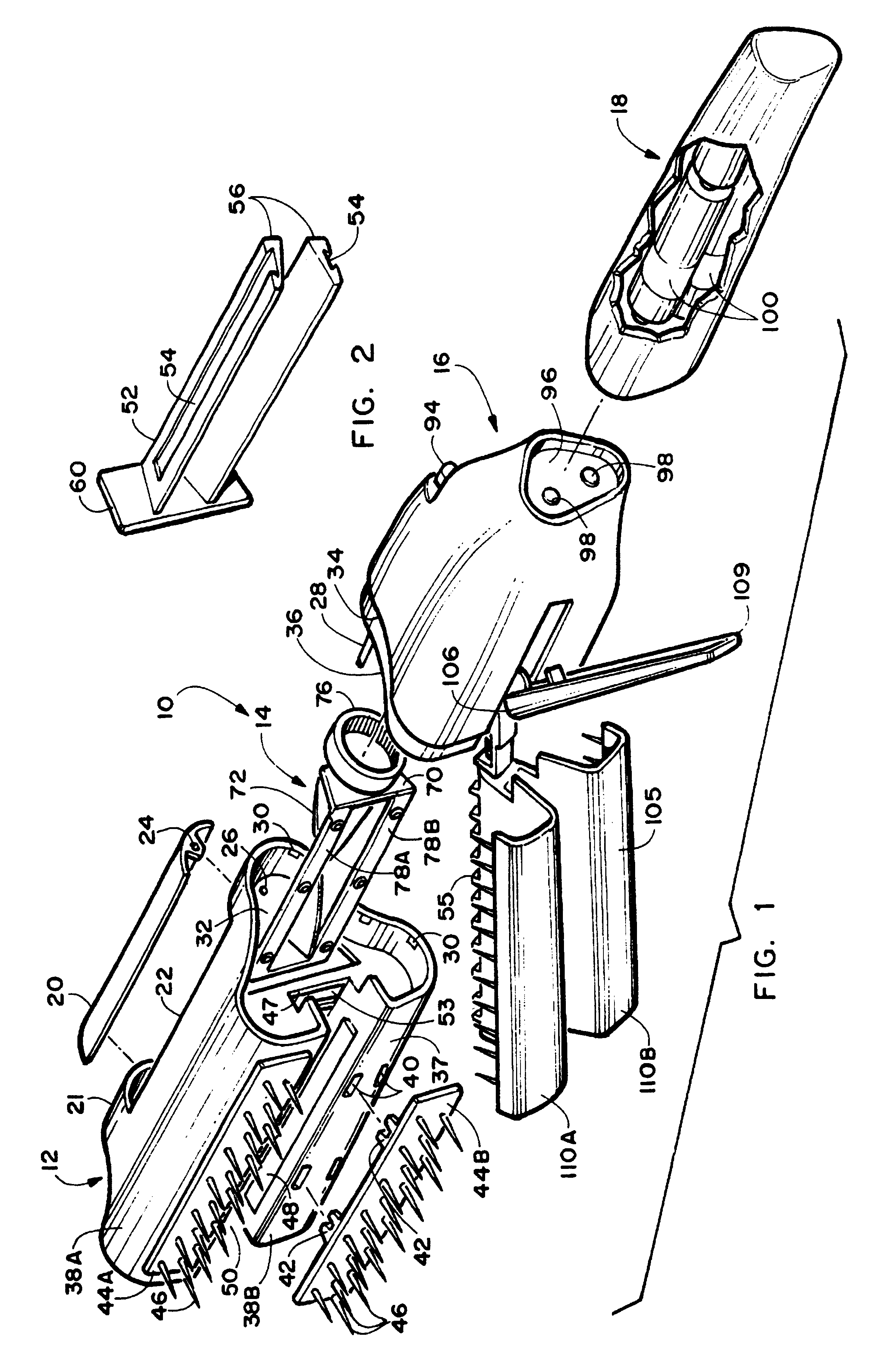

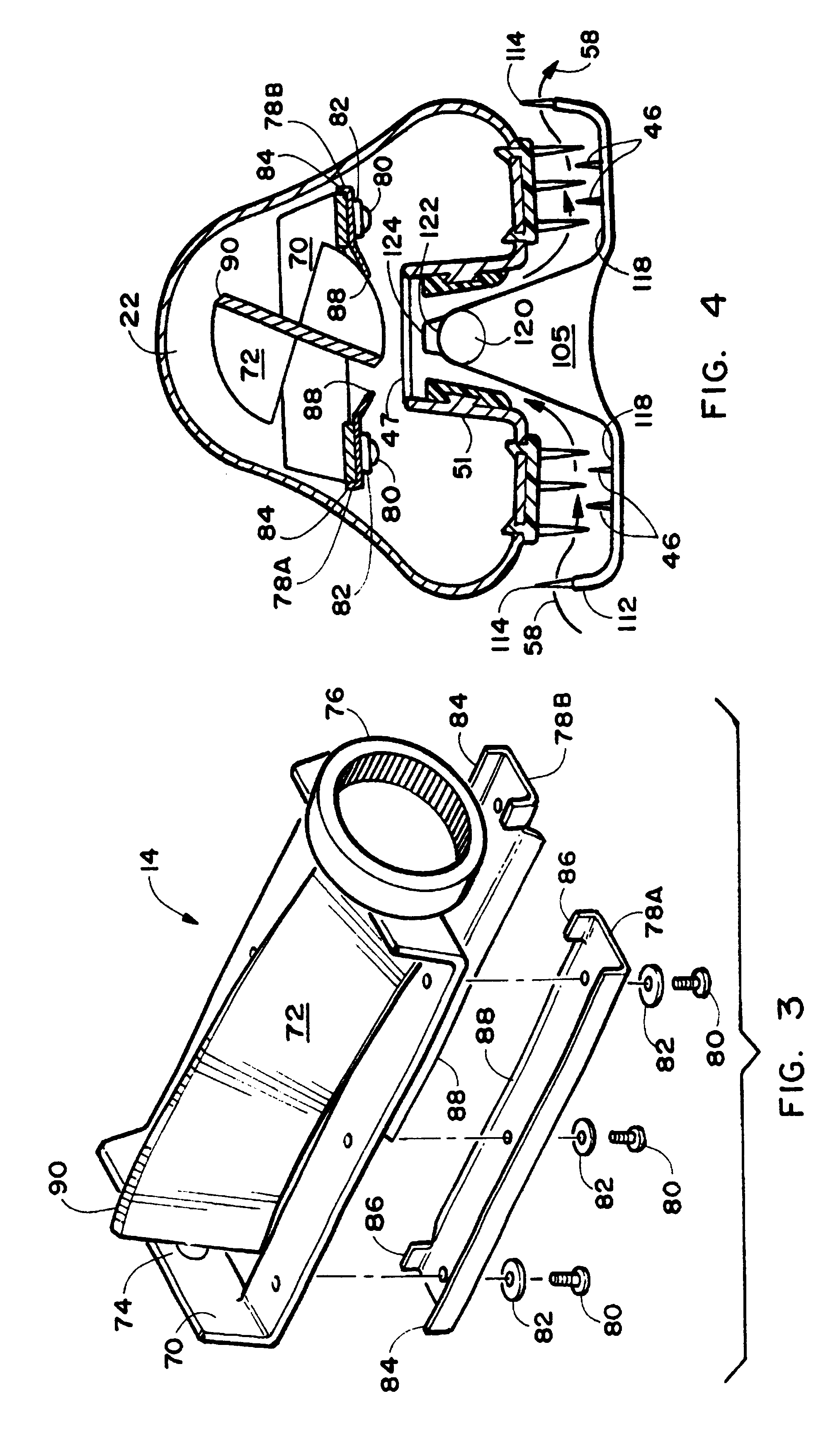

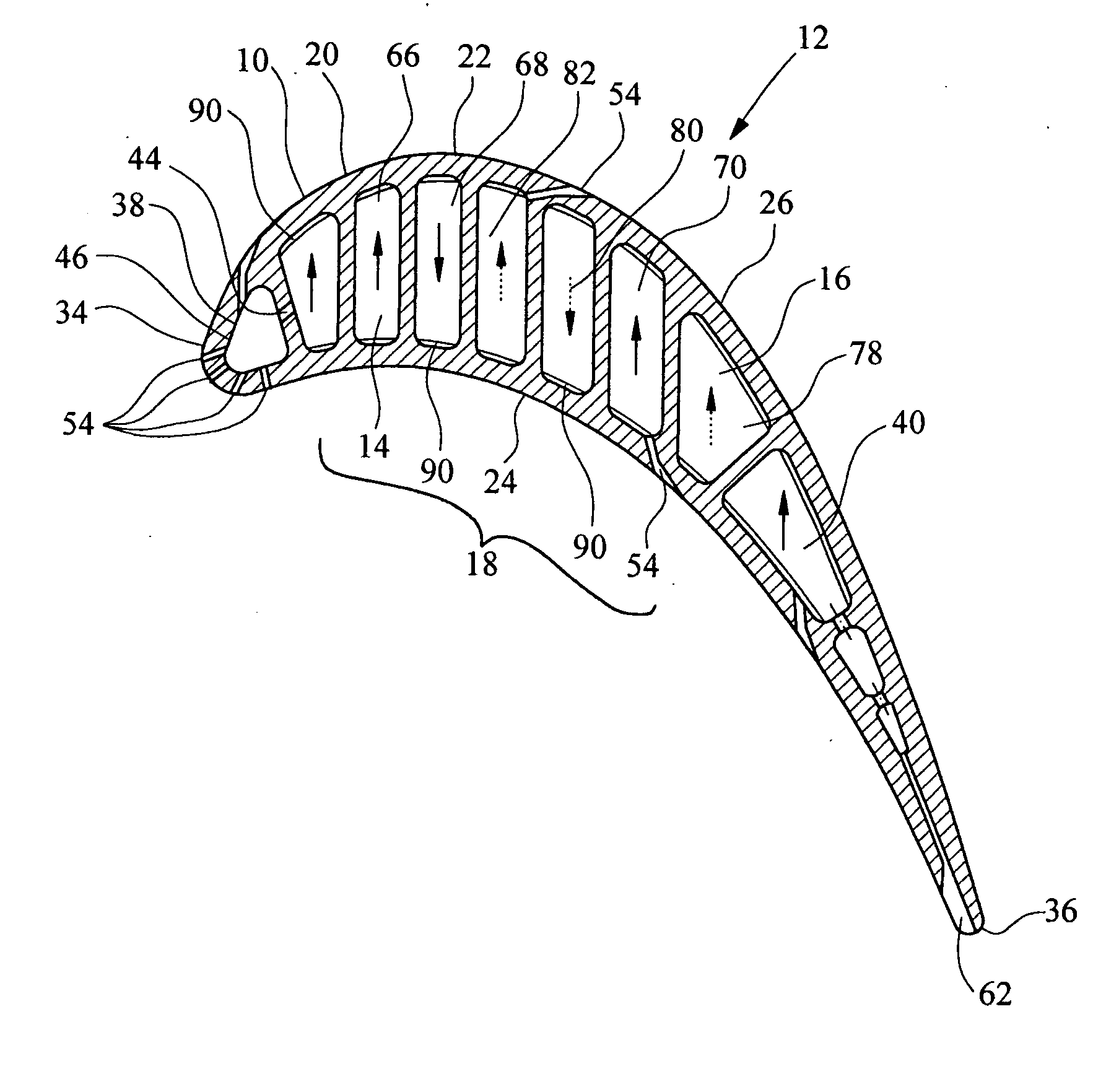

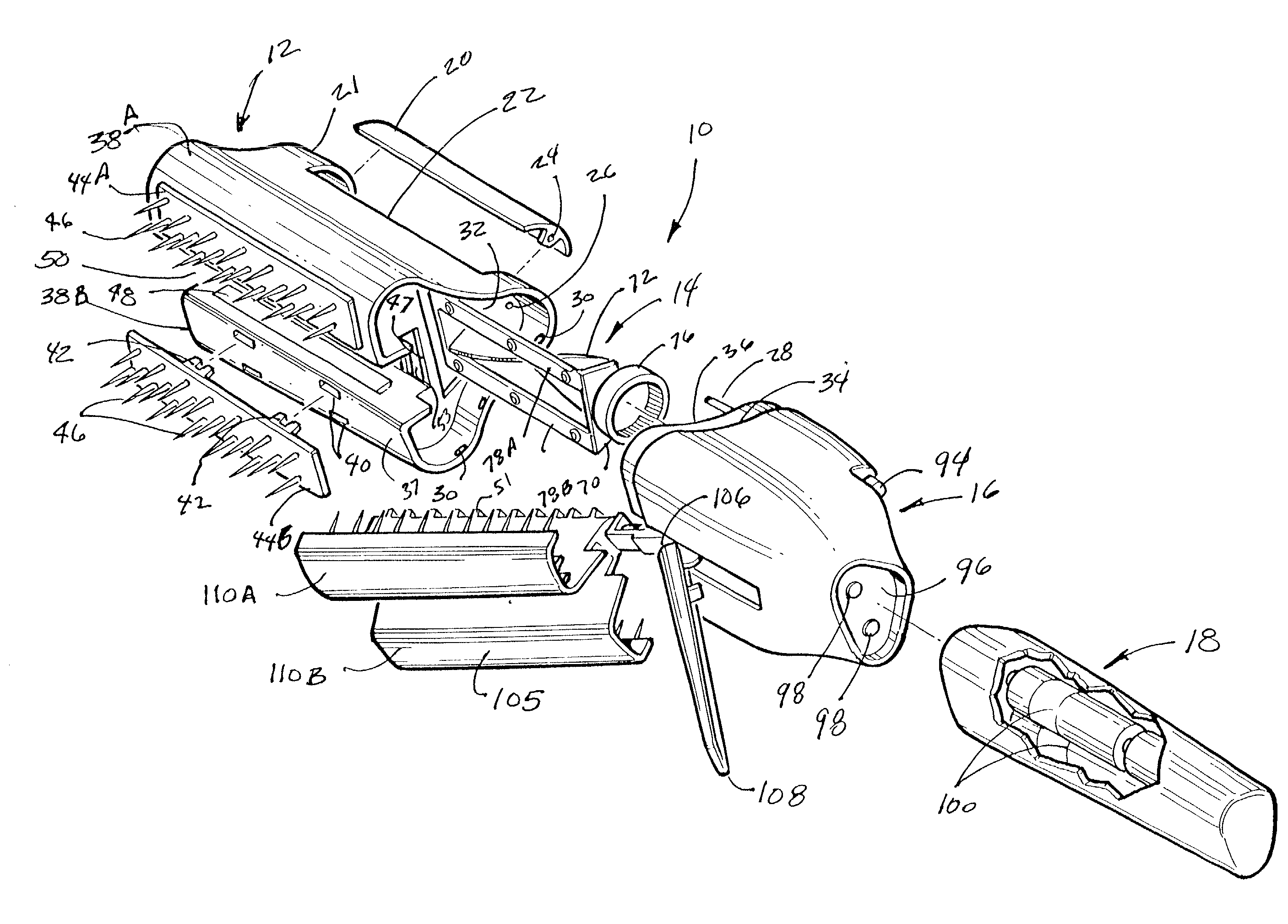

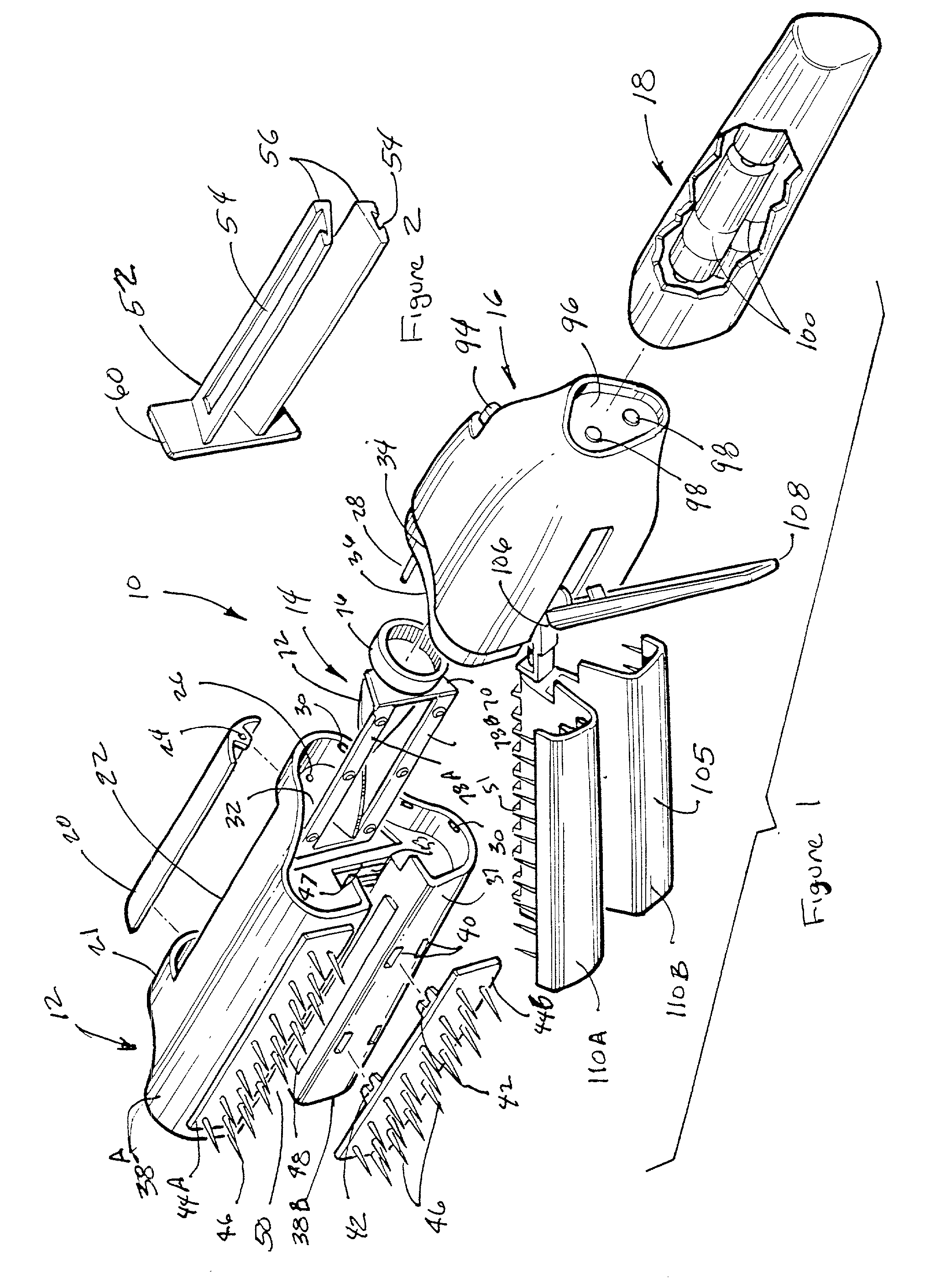

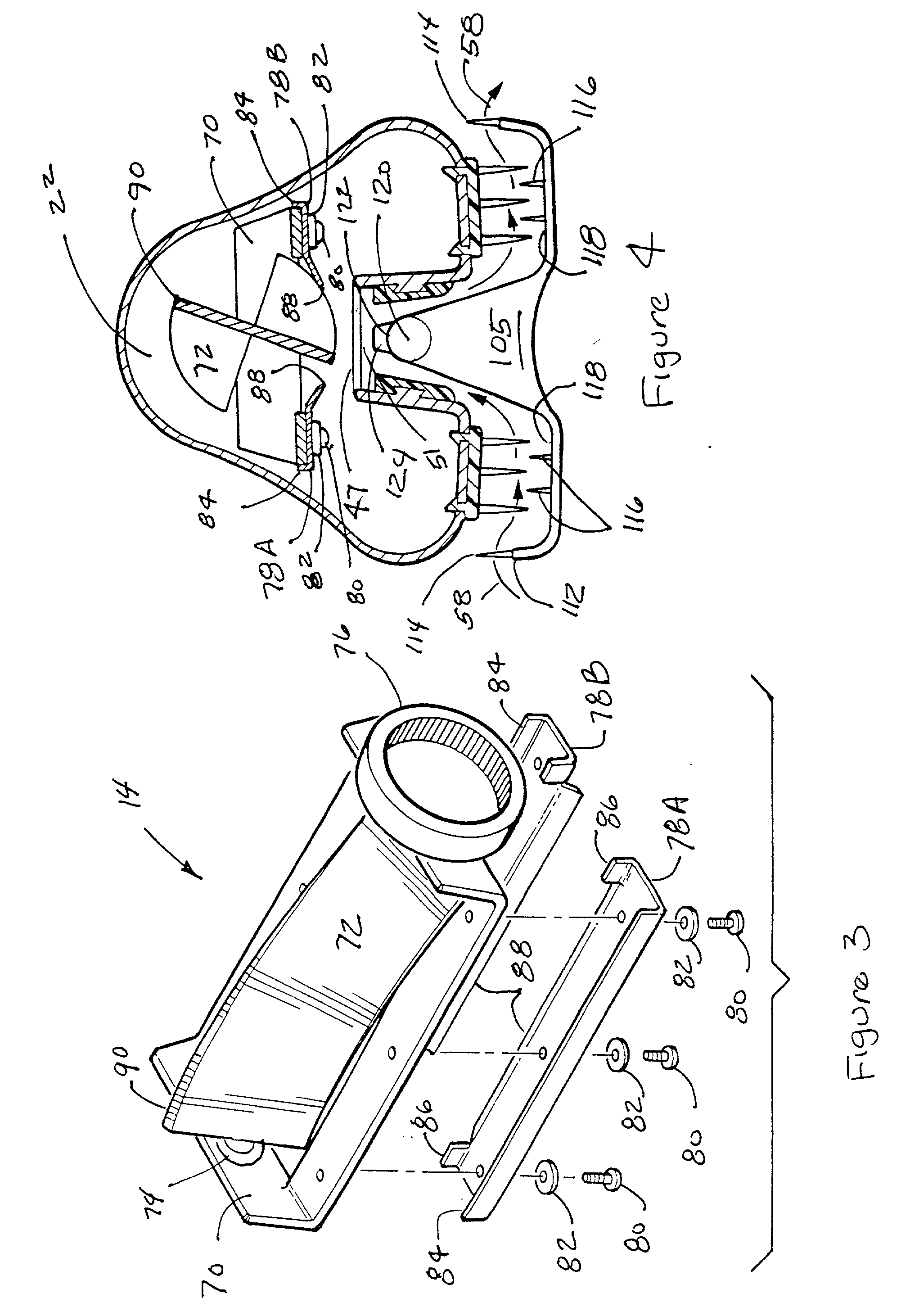

Hair trimming device with removably mountable components for removal of split ends and styling of hair

InactiveUS6588108B2Exact lengthEasy to cutHair combsPortable power-driven toolsHand heldSerpentine channel

A hand held hair trimming device which when pulled through the hair cuts only a determined portion of the ends of hair strands while leaving adjacent hairs uncut. The device will cut a predetermined length off only the distal ends of the hair shafts each time it has the hair drawn through its serpentine channel. Angled encounter of the distal ends with the cutting blade is prevented by ridges and apertures encouraging such contact only at subtantially straight angles. The device may be held in either hand allowing the hair pass through in either direction by merely changing the rotational direction of the motor by moving the thumb switch. The blade section of the device may be adjustable for changing the amount of the determined length to be cut from the hair shafts or may be removable and replaceable with one of a plurality of differently configured blade assemblies thereby allowing for easy adjustment of the trimmed amount.

Owner:TALAVERA HAIR PROD INC

Turbine airfoil with counter-flow serpentine channels

InactiveUS20070128028A1Facilitate heat exchangeReduce the amount requiredEngine manufactureEngine fuctionsLeading edgeCounter flow

A turbine airfoil usable in a turbine engine and having at least one cooling system. The cooling system may include a pressure side serpentine cooling channel and a suction side serpentine cooling channel. The cooling channels may be nested within each other to optimize heat exchange between the cooling fluids and the materials forming the airfoil, to reduce the amount of cooling fluids required, to reduce the required pressure of the cooling fluids, and to provide other benefits. The pressure side serpentine cooling channel may pass cooling fluids chordwise towards the trailing edge, and the suction side serpentine cooling channel may pass cooling fluids chordwise towards the leading edge.

Owner:SIEMENS ENERGY INC

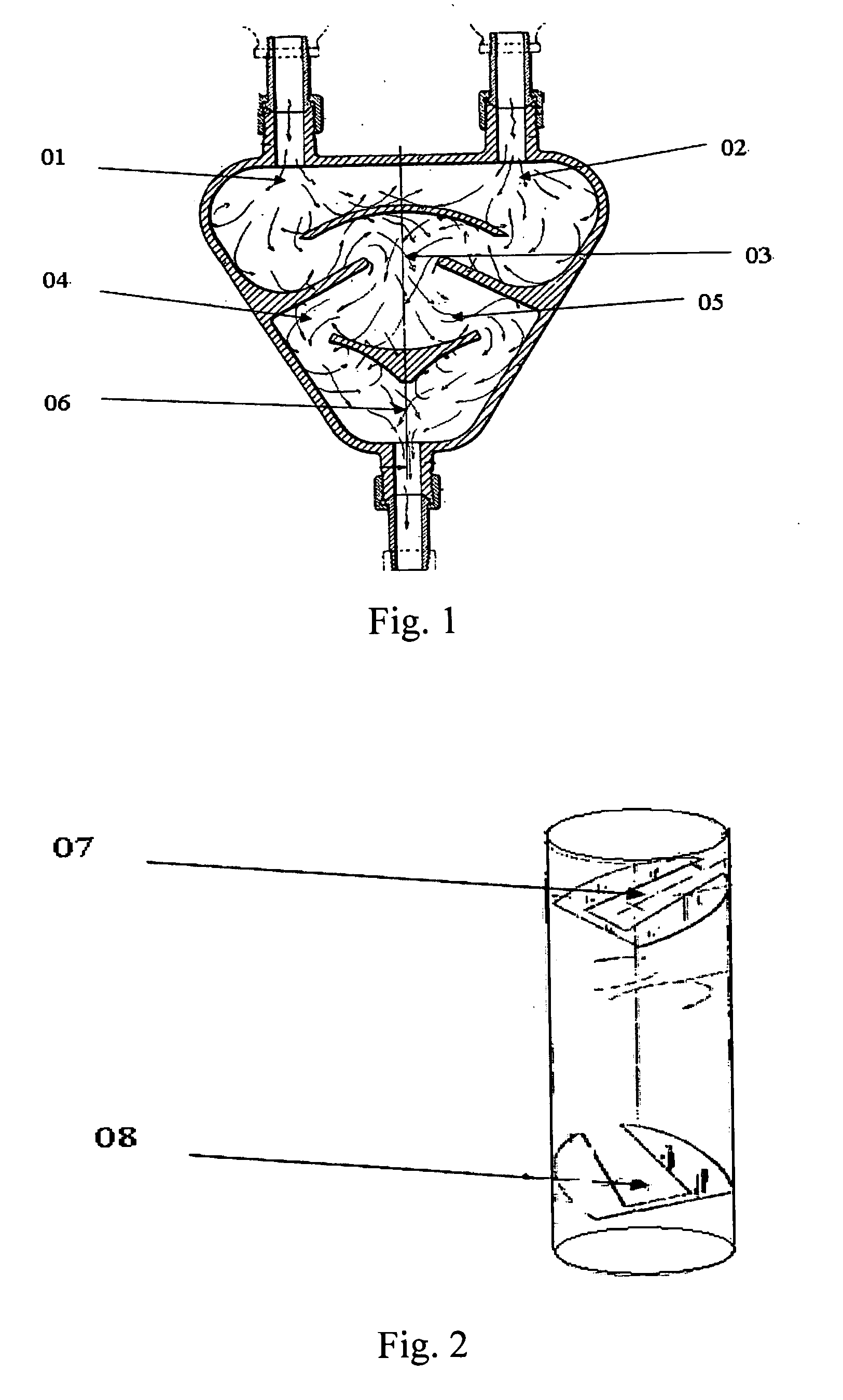

Fluidic mixer of serpentine channel incorporated with staggered sudden-expansion and convergent cross sections

InactiveUS20060285433A1Improve the mixing effectEconomically fabricatedSemi-permeable membranesFlow mixersResidenceWorking fluid

The present invention discloses a fluidic mixer of serpentine channel incorporated with staggered sudden-expansion and convergent cross sections, which comprises a flat cover and a channel body. The channel body further comprises two L-type mixer inlets, a mixing channel, and two L-type mixer outlets. The configuration of the mixing channel is a single serpentine channel incorporated with staggered sudden-expansion and convergent cross sections, wherein the serpentine structure and the sudden-expansion cross sections induces split flows, which further enable the fluid to stretch and fold so that the contact area within the fluid can be increased. The convergence after sudden expansion in cross section is to prepare the next action of sudden expansion, and such an iterative structure can obviously enhance the mixing effect. The present invention has the following characteristics: planar structure, which enables the measurement and fabrication, particularly the fabrication of micro mixing channel, to be easily undertaken; L-type mixer inlets and outlets, which enables the connection between the mixing channel and external channels to be robust so that the linkage and encapsulation of the micro mixing channel will be advantaged thereby; single-channel design, which enables the flow resistance not to increase owing to the mixing action, and which also enables the working fluid to be able to involve two-phase fluids containing suspension solid particles; low pressure drop; and no bulb residence inside the mixing channel.

Owner:NATIONAL TSING HUA UNIVERSITY

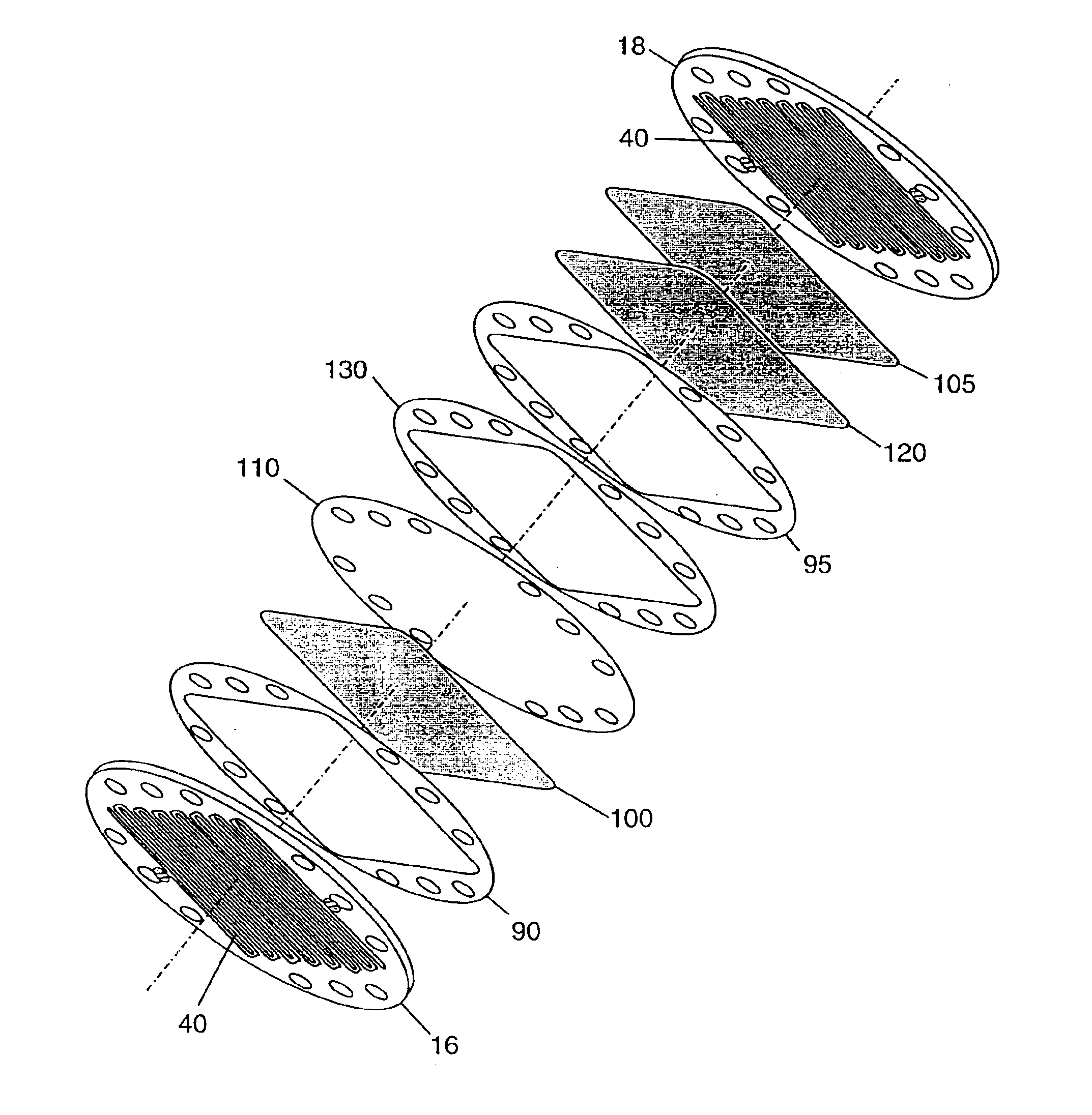

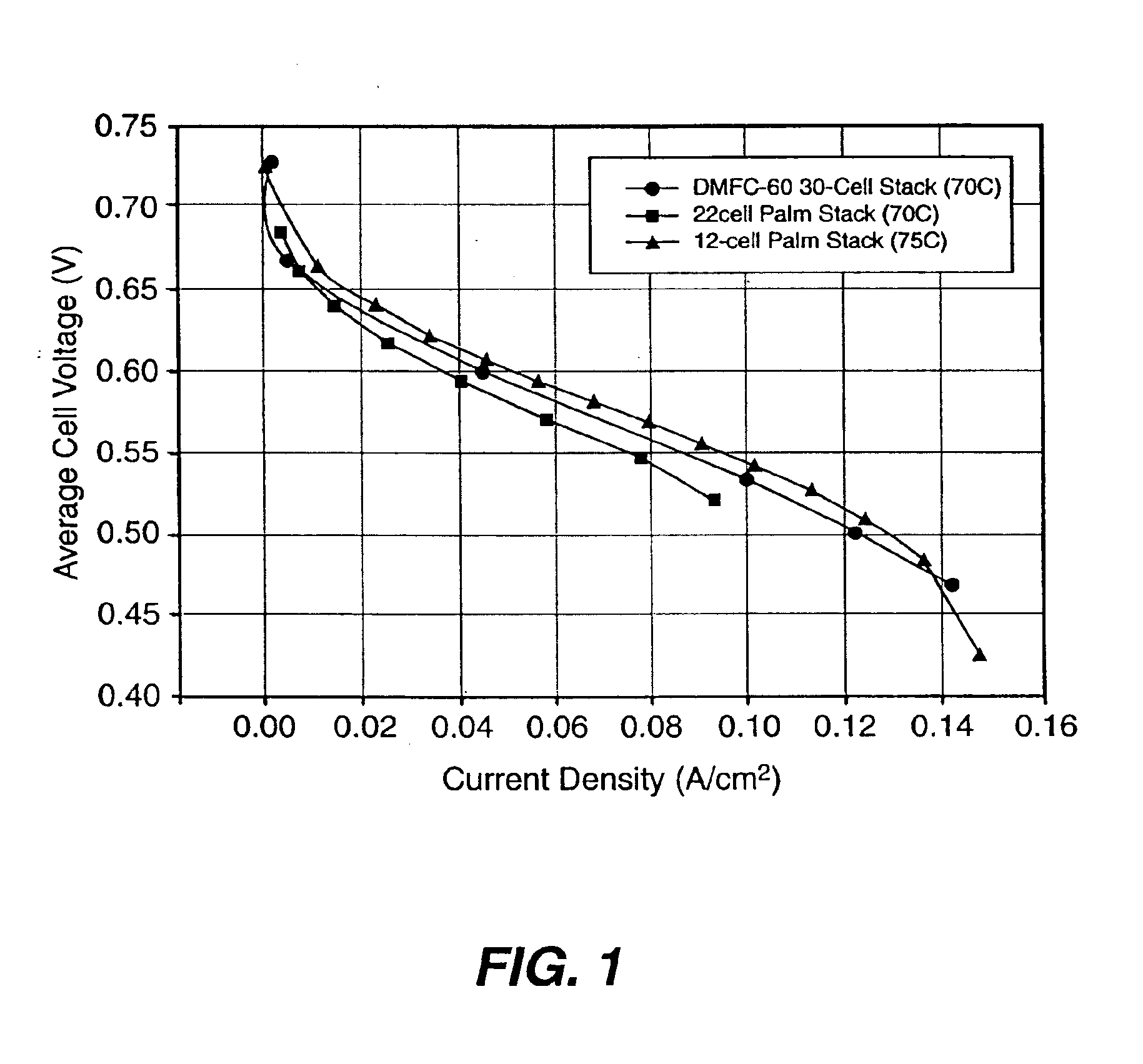

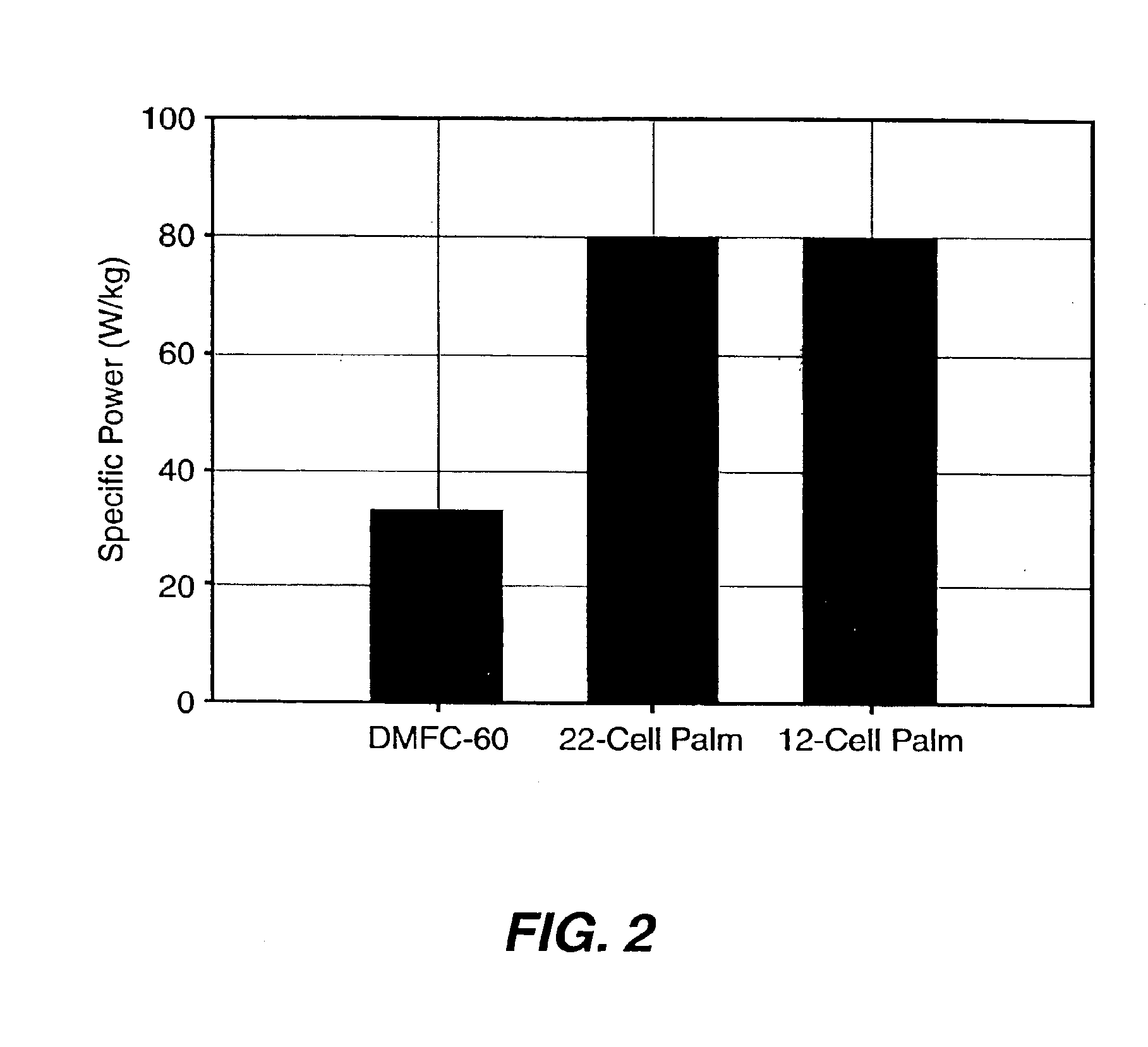

Direct methanol fuel cell stack

A stack of direct methanol fuel cells exhibiting a circular footprint. A cathode and anode manifold, tie-bolt penetrations and tie-bolts are located within the circular footprint. Each fuel cell uses two graphite-based plates. One plate includes a cathode active area that is defined by serpentine channels connecting the inlet and outlet cathode manifold. The other plate includes an anode active area defined by serpentine channels connecting the inlet and outlet of the anode manifold, where the serpentine channels of the anode are orthogonal to the serpentine channels of the cathode. Located between the two plates is the fuel cell active region.

Owner:LOS ALAMOS NATIONAL SECURITY

Turbine blade with dual serpentine cooling

InactiveUS8025482B1Lower temperature conditionsLow cooling flowPropellersEngine manufactureLeading edgeTurbine blade

A turbine rotor blade with a low cooling flow serpentine circuit to provides cooling for the airfoil. The circuit includes a three pass aft flowing serpentine circuit that begins at the airfoil mid-chord region and connects to a series of multiple impingement cooling holes formed within the trailing edge region. A double pass forward flowing serpentine circuit then connects with the triple pass aft flowing serpentine circuit to provide cooling for the leading edge region and is connected to a showerhead arrangement for discharging film cooling air. A blade tip cooling channel connects with the last leg of the double pass forward flowing serpentine to form a 6-pass serpentine flow cooling circuit for the entire blade. Since only the leading edge serpentine channel discharges film cooling air, the serpentine circuit can make use of low cooling flow to provide cooling for the entire blade.

Owner:FLORIDA TURBINE TECH

Cooling of substrate using interposer channels

ActiveUS7434308B2Printed circuit assemblingSemiconductor/solid-state device detailsChannel couplingInterposer

A structure, and method of forming and cooling the structure. The structure may include a substrate (e.g., a semiconductor chip) having N continuous substrate channels and an interposer having N continuous interposer channels (N≧2). The N interposer channels are coupled to the N substrate channels to form M continuous loops (1≦M≦N). The M loops may transfer heat from a heat source within the substrate to the interposer and then to a heat sink thermally coupled to the interposer. The structure may include an interposer having a thermally conductive enclosure surrounding a cavity. The cavity contains a thermally conductive foam material (e.g., graphite foam). The foam material contains a serpentine channel having contiguously connected channel segments. The serpentine channel may transfer heat from a heat source within a substrate (e.g., a semiconductor chip) to the interposer and then to a heat sink thermally coupled to the interposer.

Owner:GLOBALFOUNDRIES US INC

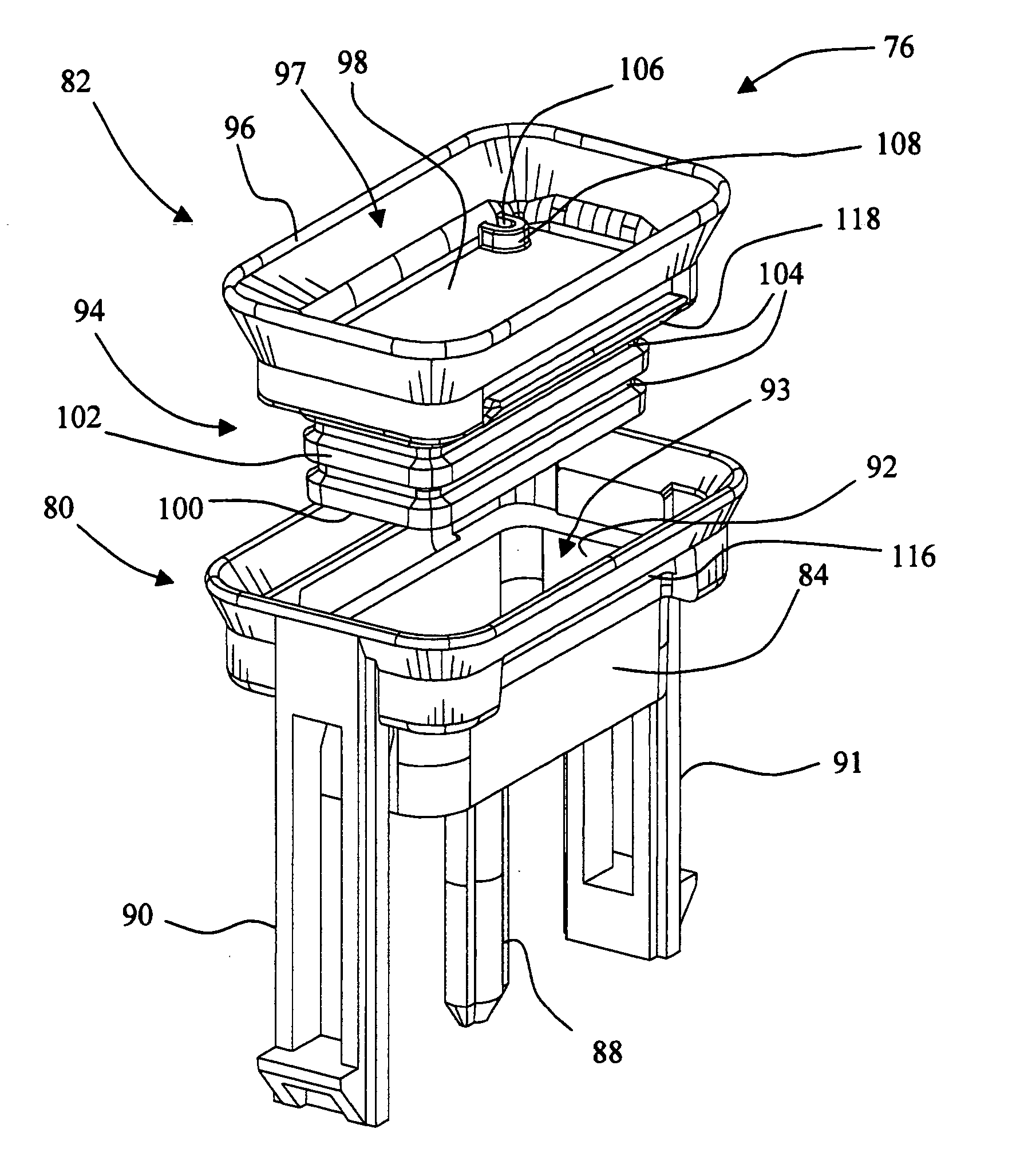

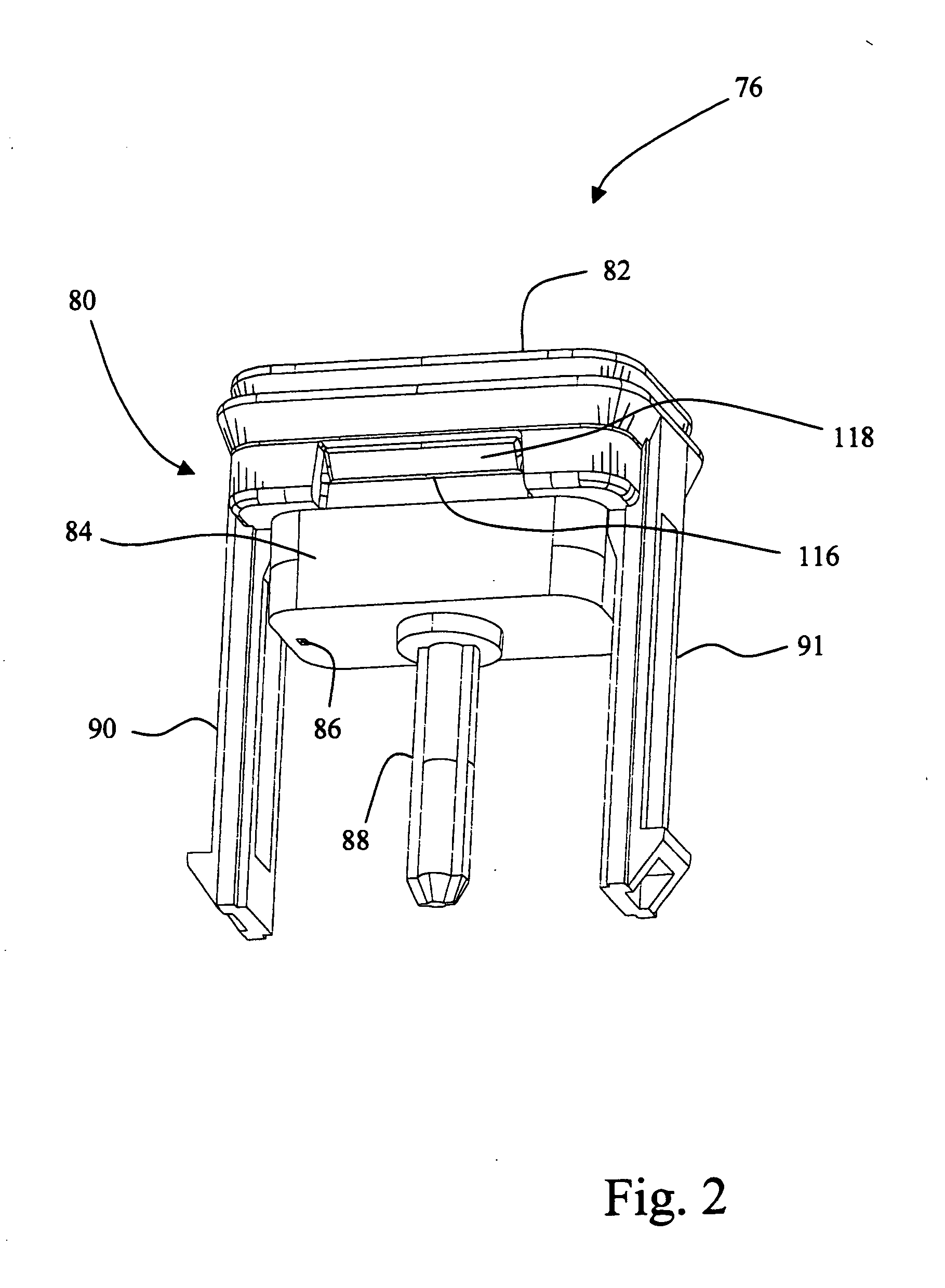

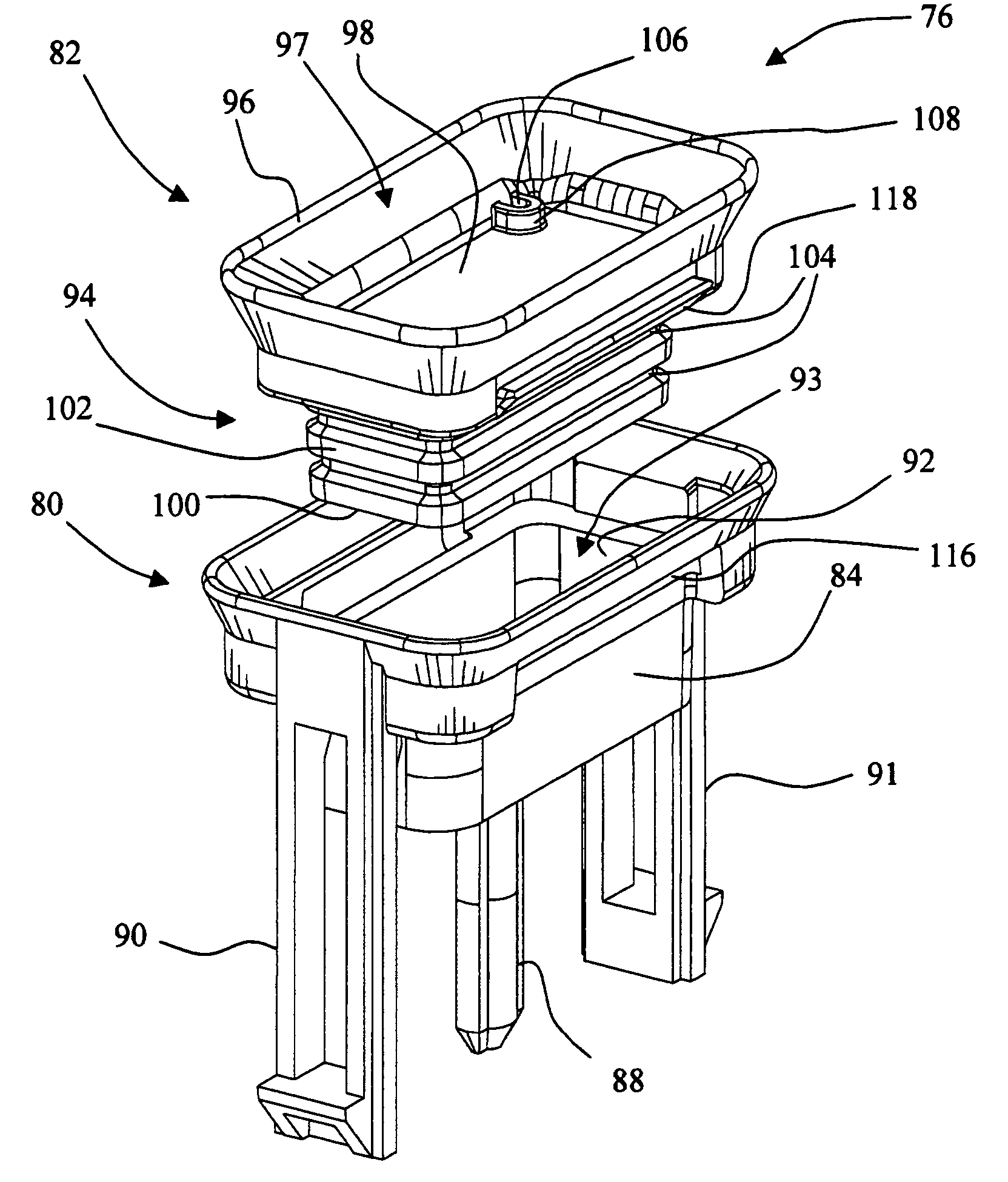

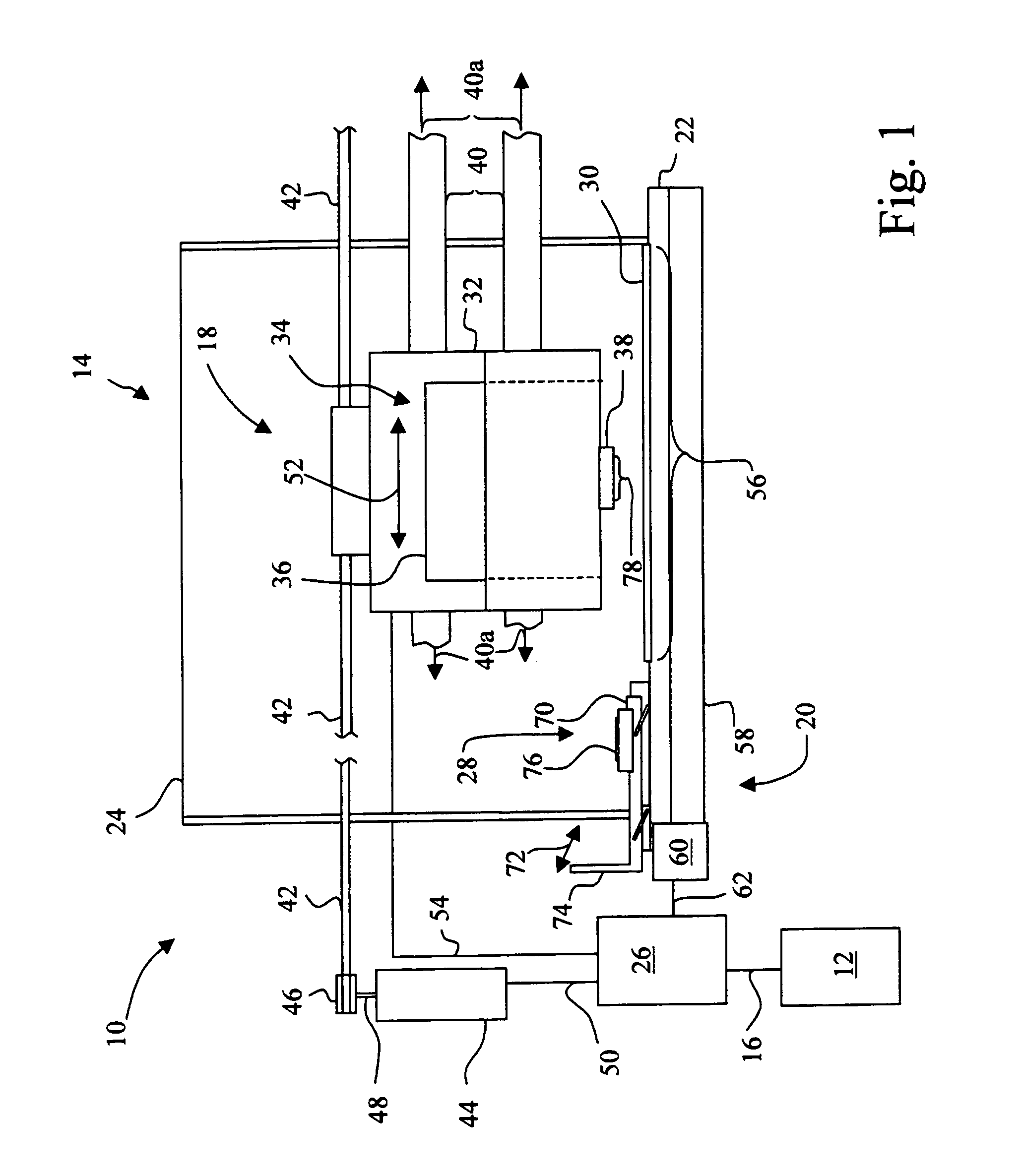

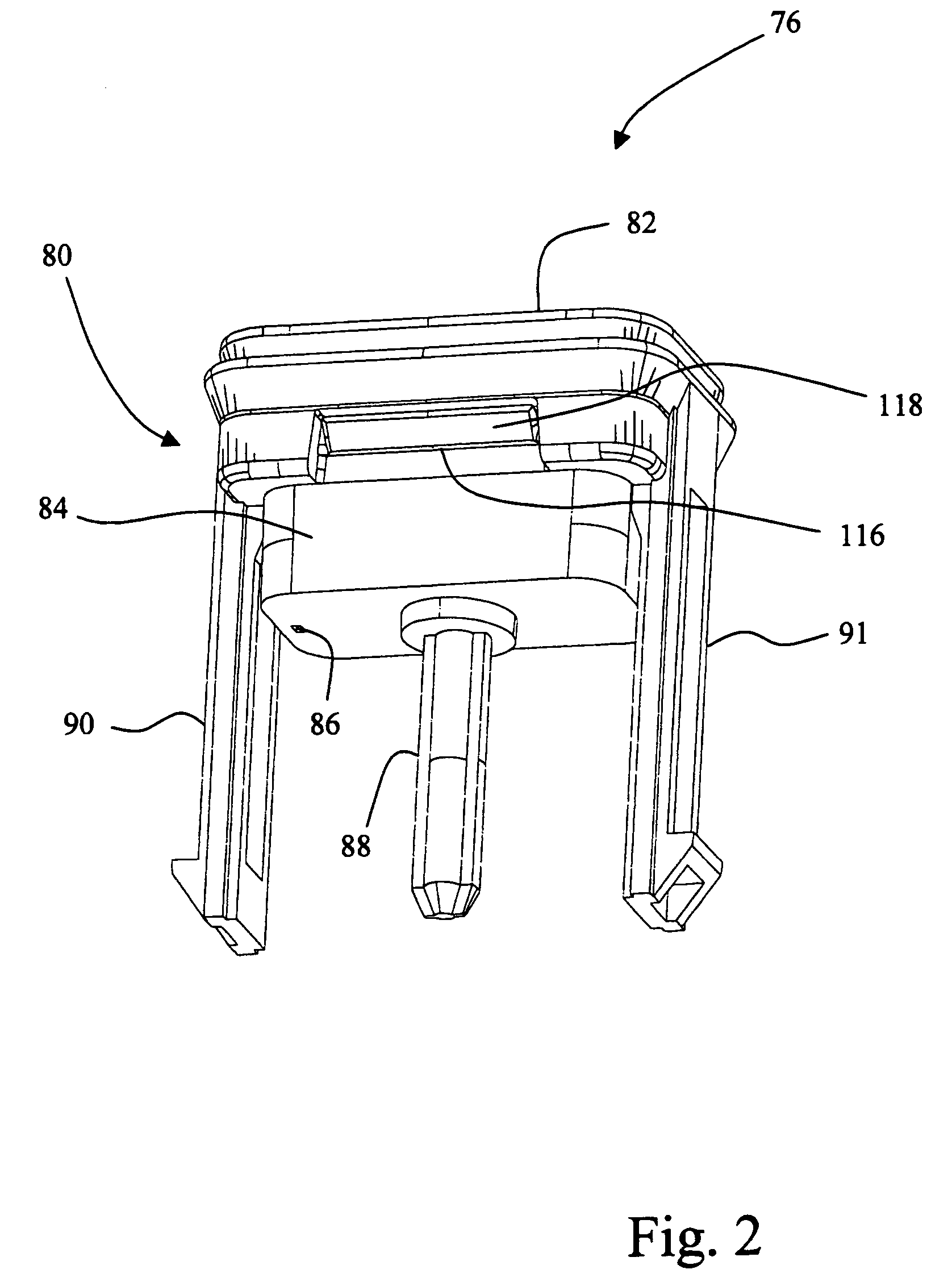

Printhead cap assembly for an ink jet printer

A printhead capping assembly includes a cap holder and a printhead cap. The cap holder defines a cavity and a vent exit. The printhead cap has a base and a lip portion extending from the base. The lip portion defines an open interior region. The base is inserted into the cavity of the cap holder. The base includes a serpentine channel extending from the open interior region to the vent exit of the cap holder.

Owner:FUNAI ELECTRIC CO LTD +2

Turbine airfoil cooling system with spanwise equalizer rib

InactiveUS20080101961A1Reducing cooling air mass fluxLower turn lossEngine fuctionsBlade accessoriesSerpentine channelTrailing edge

A cooling system for a turbine airfoil of a turbine engine having an inflow mid-chord feed channel and a trailing edge feed channel that are separated by an equalizer rib having a plurality of supply holes. The supply holes enable cooling fluids to be supplied to the trailing edge from the mid-chord feed channel to satisfy the cooling requirements of the entire trailing edge, which is greater than the mid-chord region. A crossover hole may be positioned in the equalizer rib at the tip section to enable the cooling fluids to pass between the mid-chord feed channel and a trailing edge feed channel. The crossover hole may enable cooling fluids to pass from the trailing edge feed channel into the mid-chord feed channel along the tip section to reduce stagnation in the outboard turn of the mid-chord serpentine channel.

Owner:SIEMENS ENERGY INC

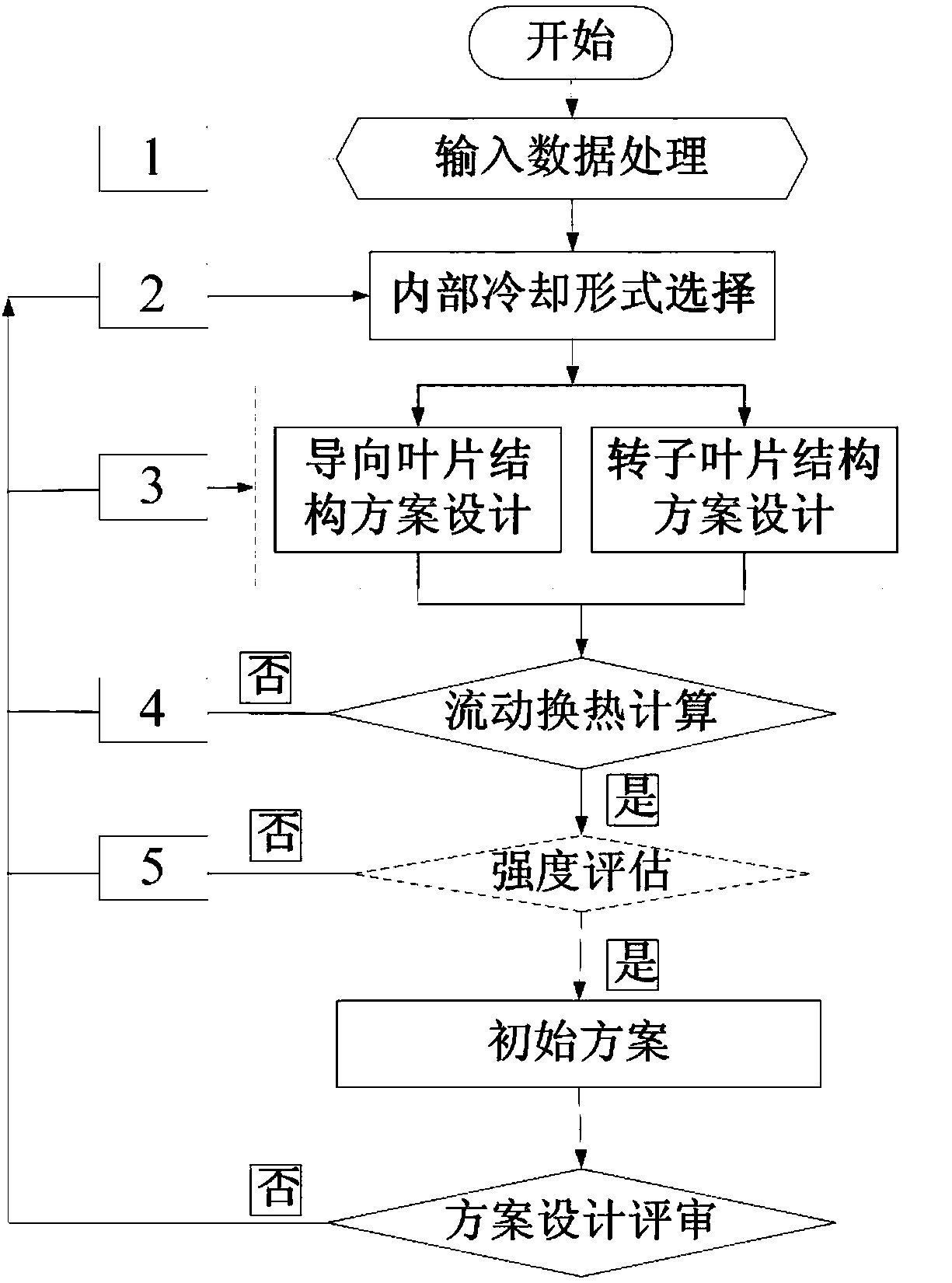

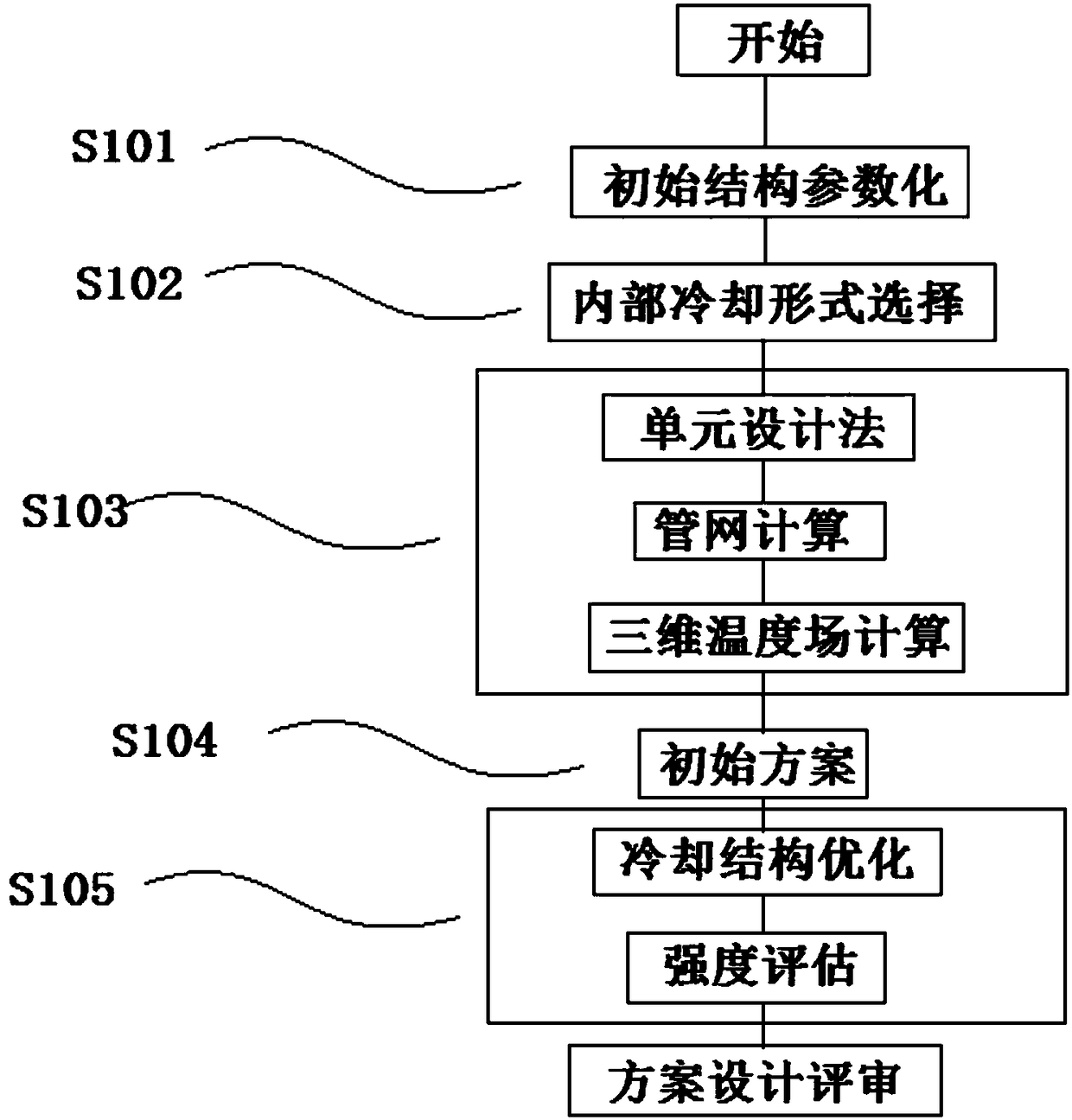

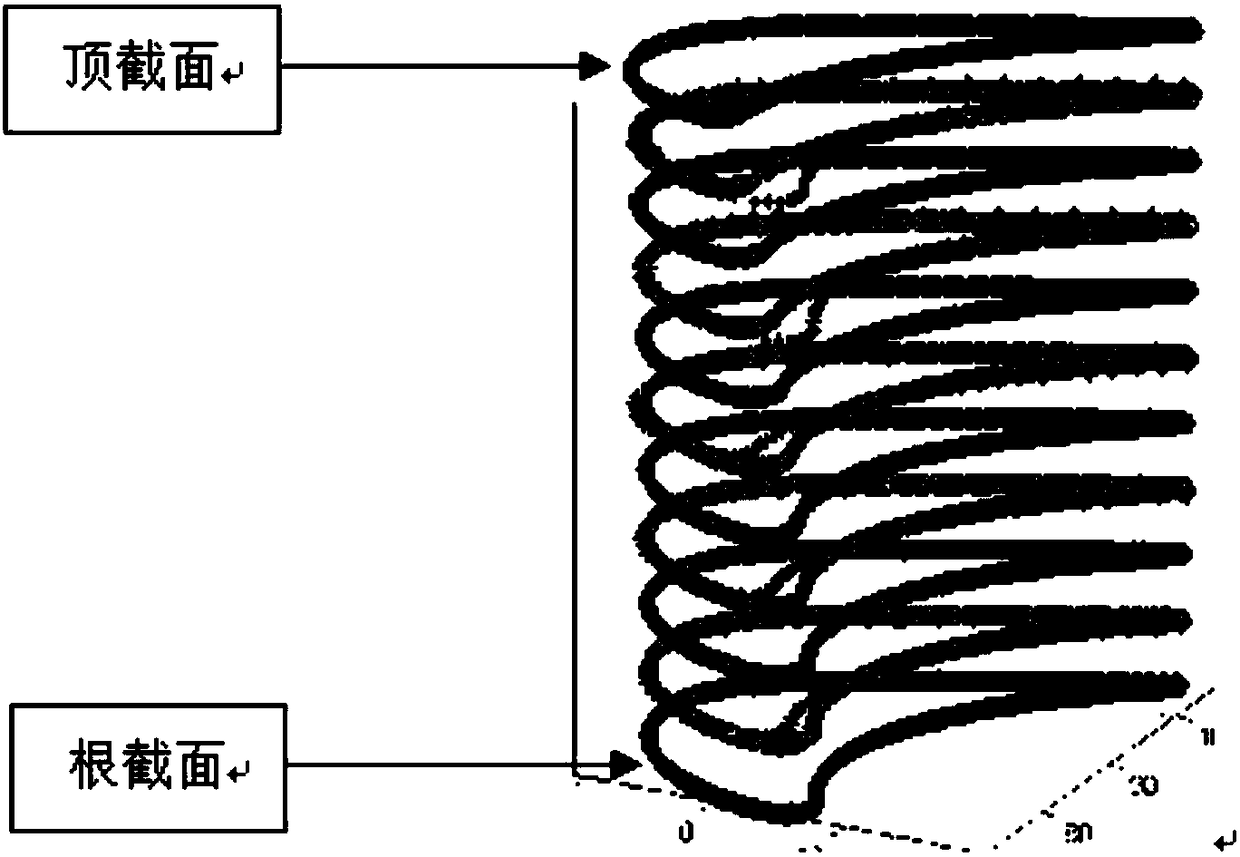

Parametric model-based turbine air-cooled blade configuration method

ActiveCN108090275AEasy to follow upGeometric CADDesign optimisation/simulationLeading edgeSerpentine channel

The invention relates to an aeroengine blade design, in particular to a parametric model-based turbine air-cooled blade configuration method. The method comprises the steps that 1, radial wall thickness of blades is controlled through root and top cross sections, and dorsal side wall thickness of the blades is controlled through positions of a leading edge point, a middle wing chord point and a tailing edge point and wall thickness parameters, so that a variable wall design of the turbine air-cooled blades is achieved to form a blade inner cavity structural frame; 2, based on a predetermined design unit, the inner cavity structural frame formed in step 2 is taken as an object, and topography unit division is conducted on serpentine channels of the blades; 3, a plurality of topography unitsof the serpentine channels of the blades are connected into a pipe network calculation model by setting geometric characteristic parameters of each unit. According to the method, a parametric model modeling method is taken as the basis, a unit design method is taken as a principle, and finally the pipe network calculation model is rapidly obtained to facilitate subsequent processing.

Owner:AECC SHENYANG ENGINE RES INST

Hair trimming device with removably mountable components for removal of split ends and styling of hair

InactiveUS20020157262A1Exact lengthEasy to cutHair combsPortable power-driven toolsSerpentine channelHand held

A hand held hair trimming device which when pulled through the hair cuts only a determined portion of the ends of hair strands while leaving adjacent hairs uncut. The device will cut a predetermined length off only the distal ends of the hair shafts each time it has the hair drawn through its serpentine channel. Angled encounter of the distal ends with the cutting blade is prevented by ridges and apertures encouraging such contact only at subtantially straight angles. The device may be held in either hand allowing the hair pass through in either direction by merely changing the rotational direction of the motor by moving the thumb switch. The blade section of the device may be adjustable for changing the amount of the determined length to be cut from the hair shafts or may be removable and replaceable with one of a plurality of differently configured blade assemblies thereby allowing for easy adjustment of the trimmed amount.

Owner:TALAVERA HAIR PROD INC

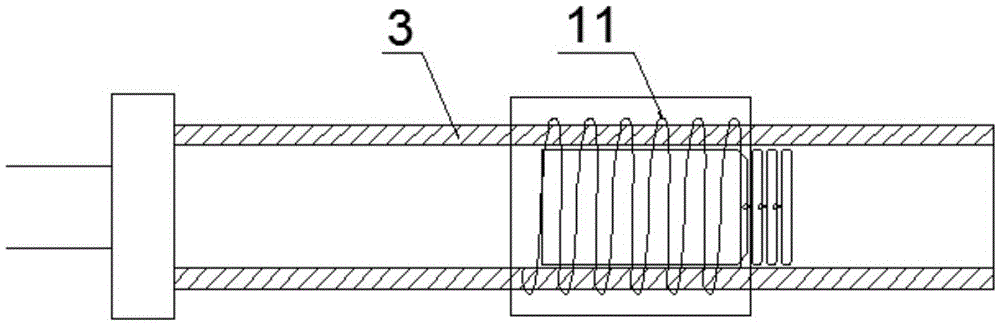

Solid solution-bending-aging forming device and method for vehicle body aluminum alloy pipe

The invention discloses a solid solution-bending-aging forming device and method for a vehicle body aluminum alloy pipe. The device comprises a heating mechanism and a bending mechanism. The heating mechanism comprises an induction coil and a high-frequency power source. The induction coil is arranged on the periphery of a bent part of the pipe in a sleeving mode and connected with the high-frequency power source. The bending mechanism comprises a bending die, a fixed clamp block, a crease-resistant block, movable clamp blocks and a rigid / flexible core die. The bent part of the pipe is placed on the bending die. One end of the pipe is clamped on the bending die through the fixed clamp block and the crease-resistant block, and the other end of the pipe is clamped by the movable clamp blocks. The rigid / flexible core die is arranged in the pipe. The fixed clamp block, the crease-resistant block and the movable clamp block are designed in a split mode, and the bending die is designed in an insert mode, so that water channels are processed conveniently and replacement after abrasion is convenient. The bending die, the fixed clamp block, the crease-resistant block and the movable clamp blocks are all internally provided with serpentine channels used for introducing cooling water. The solid solution-bending-aging forming device and method for the vehicle body aluminum alloy pipe can significantly improve the strength, the hardness and the forming precision of aluminum alloy pipes, and the springback problem of the pipes after bending and quenching is effectively solved.

Owner:WUHAN UNIV OF TECH

Printhead cap assembly for an ink jet printer

A printhead capping assembly includes a cap holder and a printhead cap. The cap holder defines a cavity and a vent exit. The printhead cap has a base and a lip portion extending from the base. The lip portion defines an open interior region. The base is inserted into the cavity of the cap holder. The base includes a serpentine channel extending from the open interior region to the vent exit of the cap holder.

Owner:FUNAI ELECTRIC CO LTD +2

Gas mixer

InactiveCN107398190AImprove the mixing effectSimple structureFlow mixersTransportation and packagingBuffer tankSerpentine channel

The invention discloses a gas mixer. The gas mixer comprises a first gas inlet, a second gas inlet, a mixed gas channel, a spiral pipe and a gas outlet, wherein both the first gas inlet and the second gas inlet are connected with the mixed gas channel; the other end of the mixed gas channel is connected with the spiral pipe; the gas outlet is formed in the other end of the spiral pipe. The gas mixer has the beneficial effects that when two gases enter the mixed gas channel and then flow into the spiral pipe, such a serpentine channel is capable of improving the gas mixing effect, the gas mixer is simple in structure, free of space occupation and free of buffer tanks and can be simply inserted into conventional reaction equipment, and the equipment cost is greatly reduced.

Owner:盐城康鼎机械有限公司

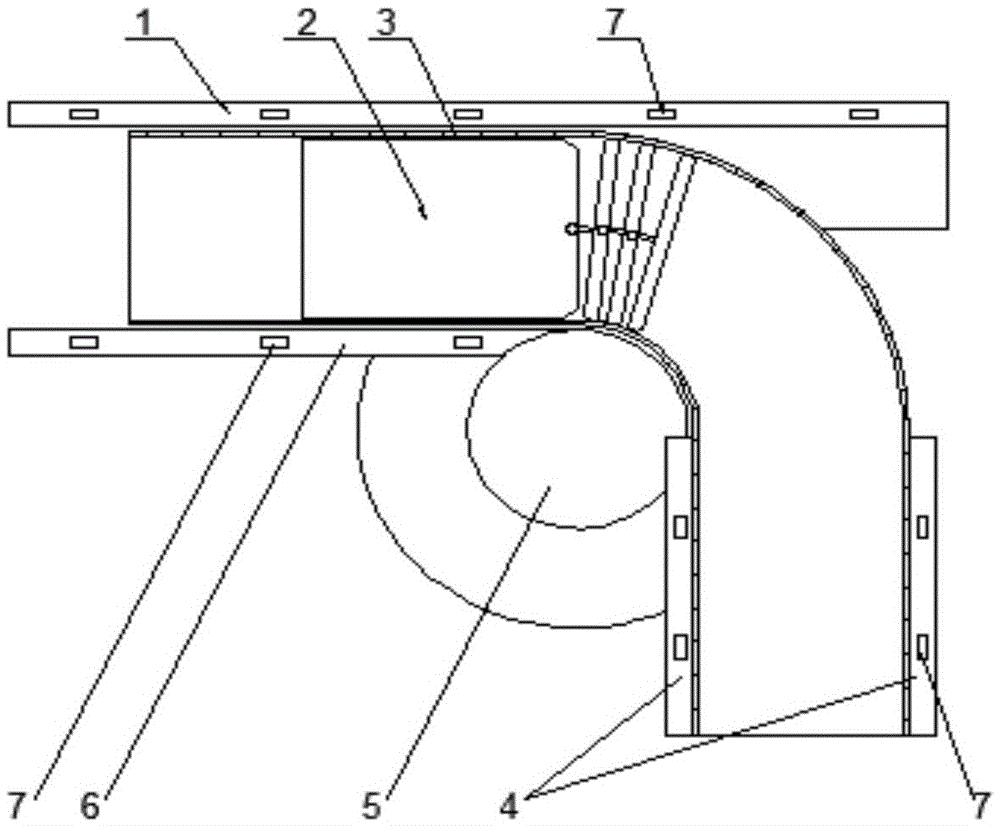

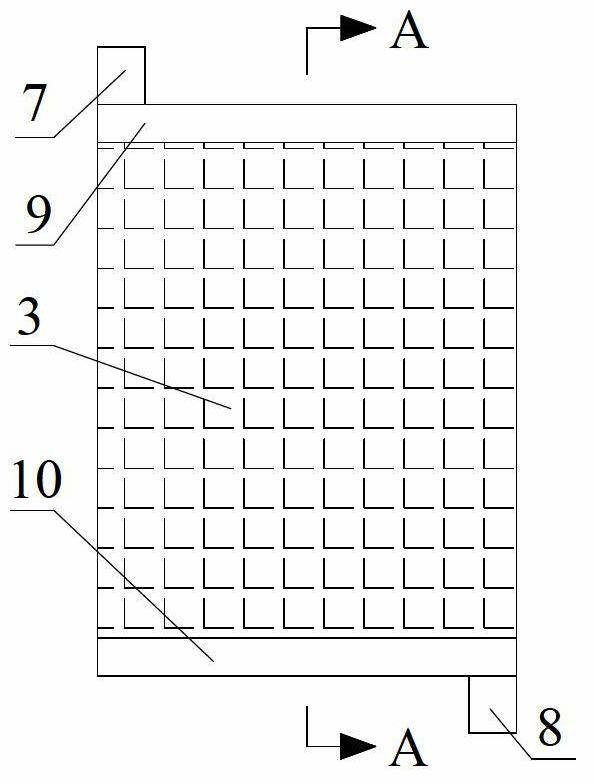

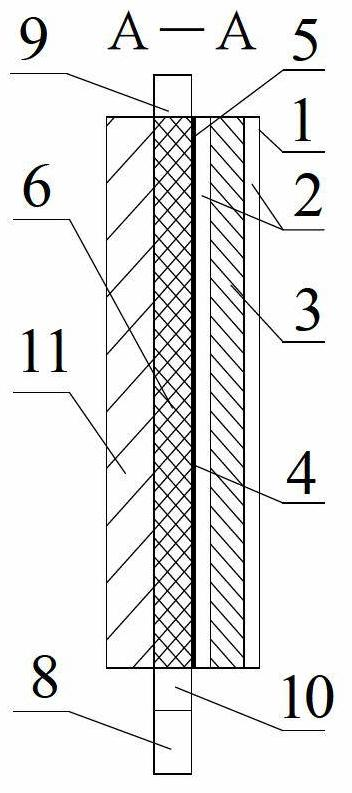

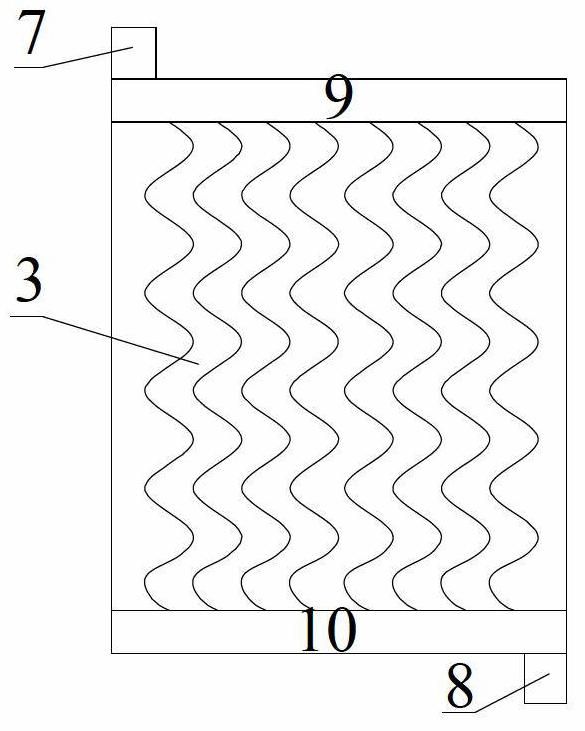

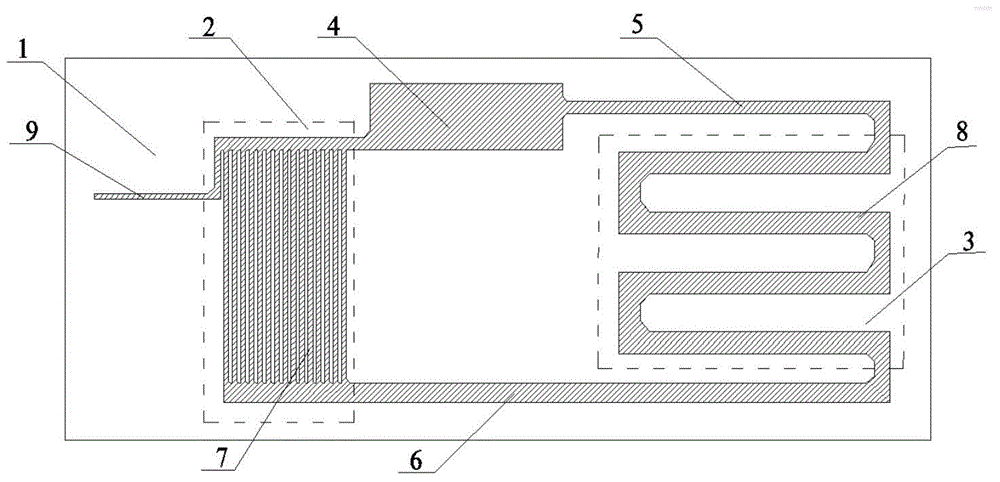

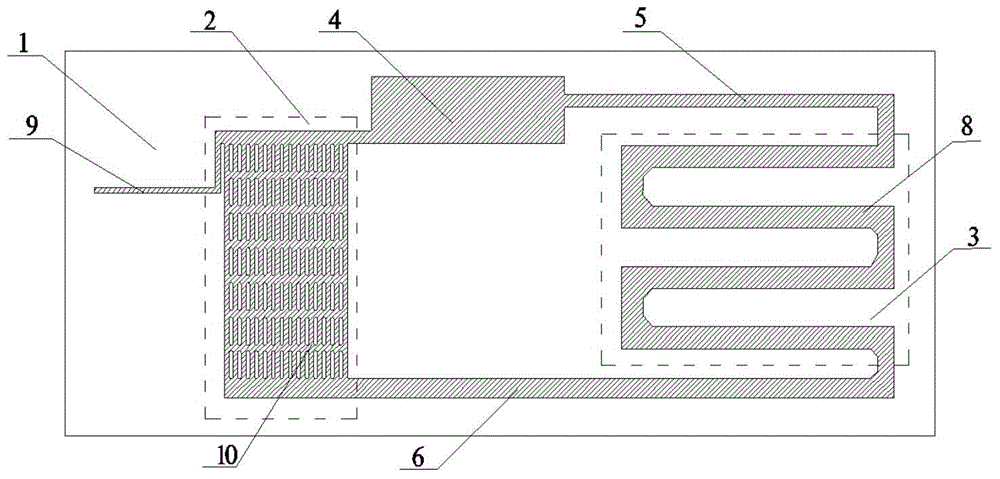

Serpentine channel solar cell waste-heat recovery unit

InactiveCN102664212AReduce the temperatureExtended service lifePhotovoltaic energy generationSemiconductor devicesWaste heat recovery unitInsulation layer

The invention discloses a serpentine channel solar cell waste-heat recovery unit, belonging to the technical field of solar cell preparation. The serpentine channel solar cell waste-heat recovery unit is mainly composed of a photovoltaic template cell system and a waste-heat recovery unit, wherein the photovoltaic template cell system is composed of a front glass cover plate 1, an air layer 2, a solar cell 3 and a back glass cover plate 4; and the waste-heat recovery unit comprises a serpentine water flow channel 6, a water inlet 7, a water outlet 8, a water inlet connection box 9 and a water outlet connection box 10. A transparent silica gel 5 bonds the serpentine water flow channel 6, the water inlet connection box 9 and the water outlet connection box 10 in one group onto the back glass cover plate 4, the components are sequentially welded together, and an upper insulation layer 11 is installed on the other side of the serpentine flat box water flow channel 6. The unit disclosed by the invention does not need additional occupation room, can lower the battery temperature, can enhance the photoelectric conversion efficiency, and can prolong the service life of the cell, thereby satisfying our demands for hypothermal water in daily life and preventing thermal pollution.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Silicon-based miniature loop heat pipe cooler

InactiveCN104406440ASafe and reliable working performanceReduce and balance temperature differencesIndirect heat exchangersClosed loopBorosilicate glass

The invention provides a silicon-based miniature loop heat pipe cooler, which comprises a semiconductor silicon wafer and a heat-resisting borosilicate glass sheet which are bonded together; an evaporator, a condenser, a liquid compensator, a liquid-phase channel, a vapor-phase channel and a vacuumizing / liquid injection micro-channel are etched on the surface, in contact with the borosilicate glass sheet, of the silicon wafer; two ends of the evaporator and two ends of the condenser are connected respectively through the liquid-phase channel and the vapor-phase channel to form a closed loop; a liquid storage cavity is arranged on the liquid-phase channel; the evaporator comprises small conduits; the condenser comprises a condensation serpentine channel; the evaporator is communicated with the vacuumizing / liquid injection micro-channel; a vacuumizing / liquid injection hole which can be communicated with the vacuumizing / liquid injection micro-channel is processed in the borosilicate glass sheet. The silicon-based miniature loop heat pipe cooler provided by the invention can be directly integrated with a semiconductor microelectronic chip, and therefore the temperature and the temperature gradient of the chip are effectively reduced, the 'hotspot' problem caused by local high heat flow is reduced and weakened, and the safe and reliable operation of the chip is ensured.

Owner:JIANGSU UNIV

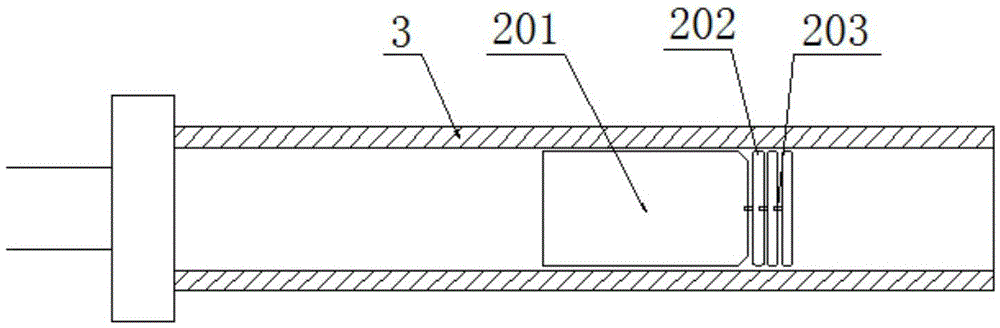

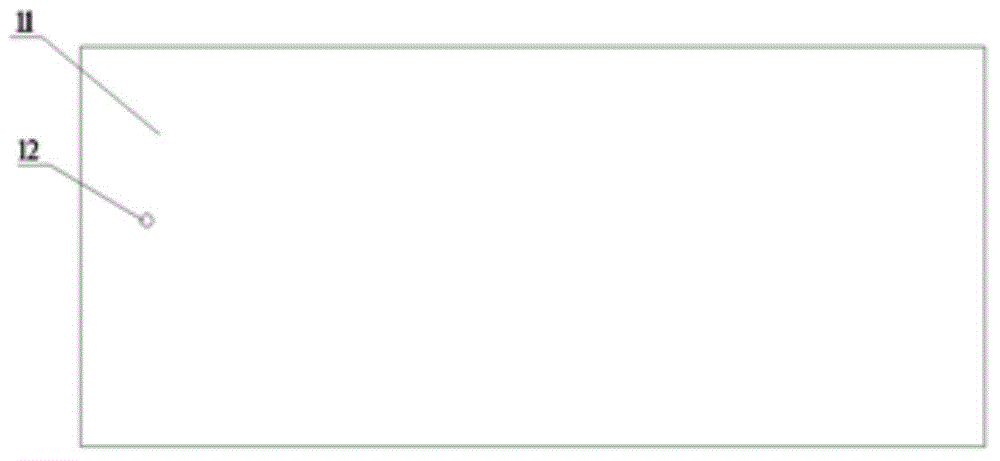

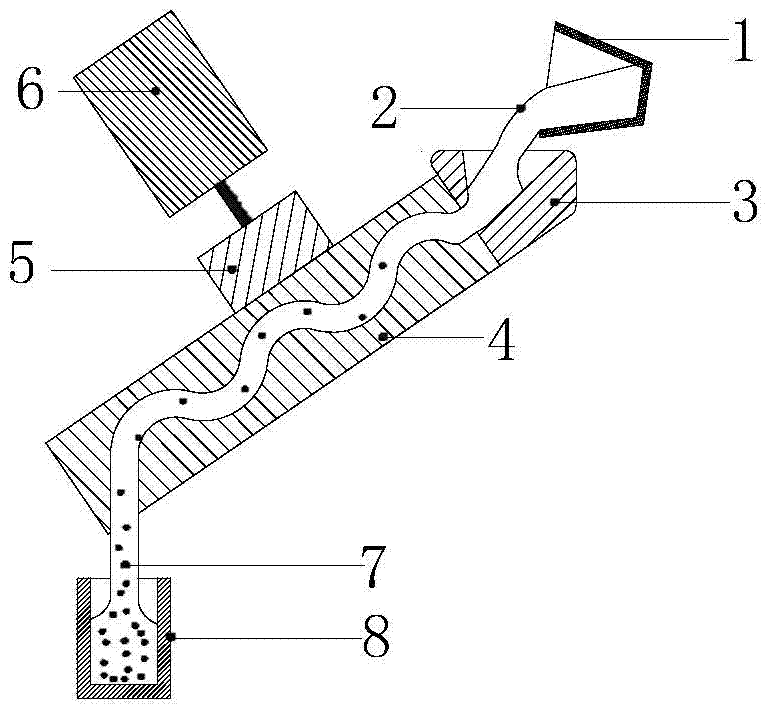

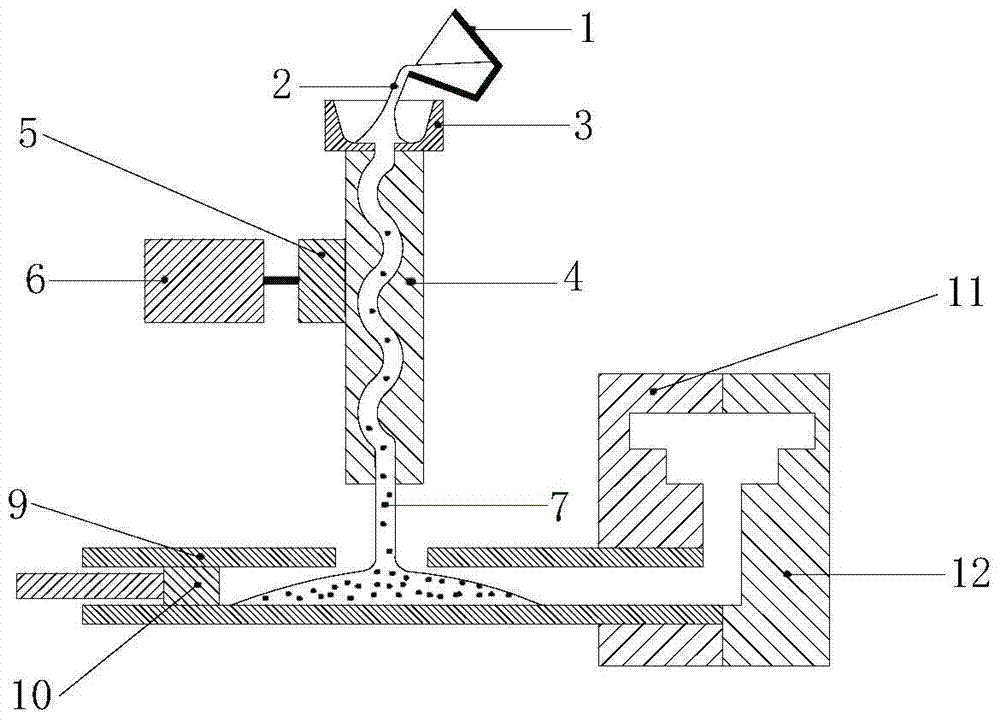

Method and device for manufacturing semi-solid metal by using serpentine vibration channel

The invention belongs to the technical field of semi-solid metal forming and provides a method and a device for manufacturing semi-solid metal by using a serpentine vibration channel. Molten metal with certain superheat degree is poured into an upper opening of the vertical or oblique serpentine channel with a mechanical vibration characteristic, the superheated molten metal downward flows to a lower outlet of the serpentine channel along the inner wall of the serpentine channel under the mechanical vibration effect to form the semi-solid metal. The device comprises a pouring ladle, the superheated molten metal, a pouring cup, the serpentine channel, an electric-excitation mechanical vibrator, an electric-excitation vibrator controller, the semi-solid metal, a collecting container, a pressure chamber, a punch pin and the shaping and ejector die portion. The method and the device have the advantages that cooling, nucleation and crystalline grain dissociation of the molten metal in the serpentine channel are promoted by utilizing the electric-excitation mechanical vibrator, the hanging amount on the inner wall of the serpentine channel is reduced, the cleaning work difficulty is reduced, the metal re-melting amount and the melting energy consumption are reduced, and the device is simple in structure and low in production cost and is suitable for manufacture of the semi-solid metal.

Owner:UNIV OF SCI & TECH BEIJING

Heat exchanger and method for heating a fracturing fluid

A heat exchanger comprises a shell internally divided into a hot fluid vessel and a cold fluid vessel by a pipe retaining plate having a plurality of apertures sealingly retaining a corresponding number of heat pipes, each of which has a hot end in the hot fluid vessel and a cold end in the cold fluid vessel. The hot fluid vessel is internally configured to direct a hot fluid through a porous dispersion plate that distributes the hot fluid amongst the hot ends of the heat pipes. The cold fluid vessel has an internal baffle that defines a serpentine channel that guides a cold fluid through the cold fluid vessel. Fracturing fluid may be heated by streaming flue gas exhausted from an incinerator through the hot fluid vessel while simultaneously streaming the fracturing fluid through the cold fluid vessel.

Owner:MARALTO ENVIRONMENTAL TECH

Polymer electrolyte membrane fuel cell stack

A polymer electrolyte membrane fuel cell stack (52) includes a plurality of membrane electrode assemblies (12) having evenly distributed fuel concentration across an anode (24), and efficient cooling across a cathode (26). A first plate (14) has a fuel side (28) with a plurality of serpentine channels (40) formed therein for distributing fuel across the anode (24), and a second plate (16) has an oxidant side (30) with oxidant channels (42) formed therein for distributing an oxidant across the cathode (26). The membrane electrode assembly (12) has an even fuel concentration thereacross, and the oxidant is routed through the cell (10) at least twice for absorbing heat prior to being distributed across the cathode (26).

Owner:MOTOROLA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com