Patents

Literature

656results about How to "Promote nucleation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

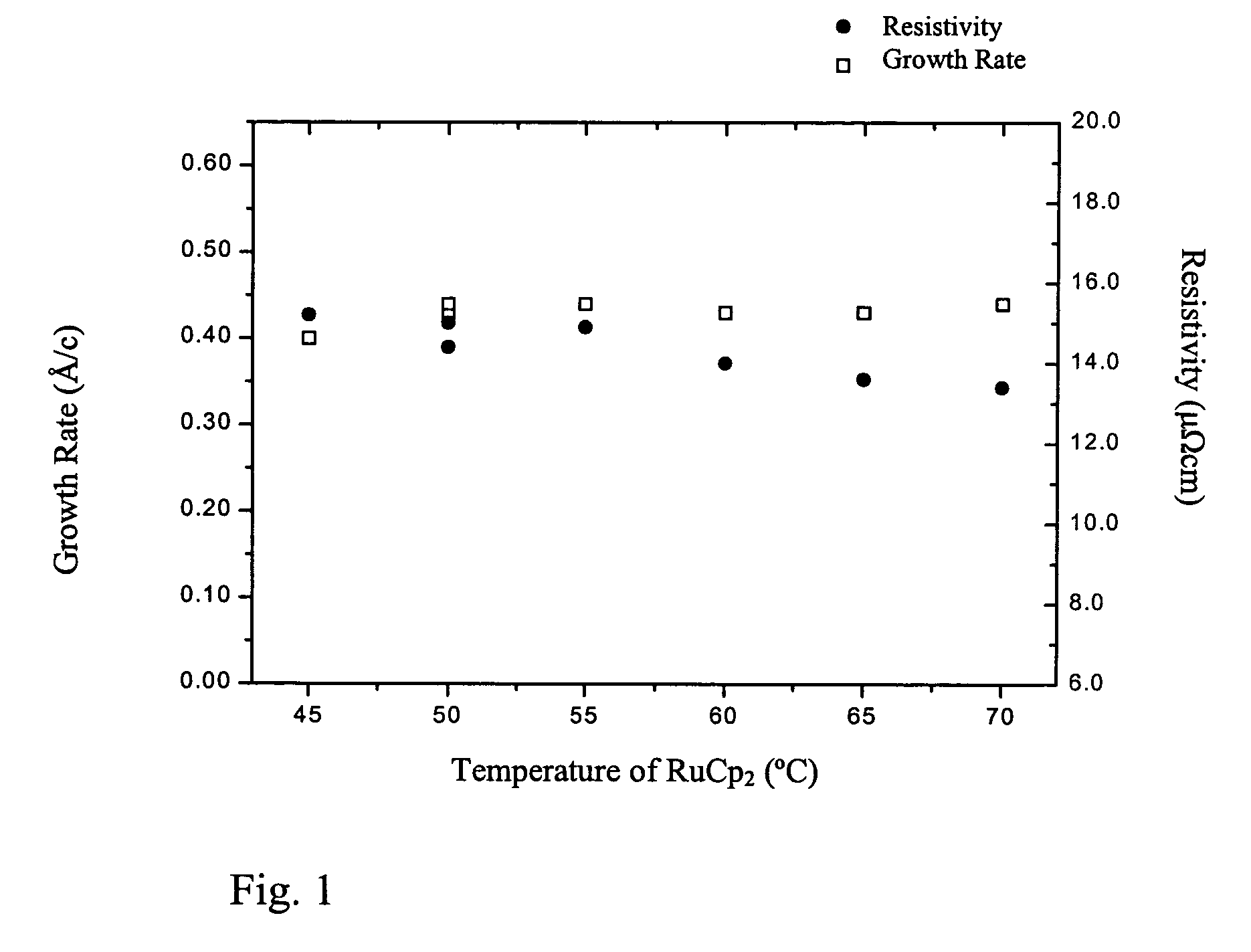

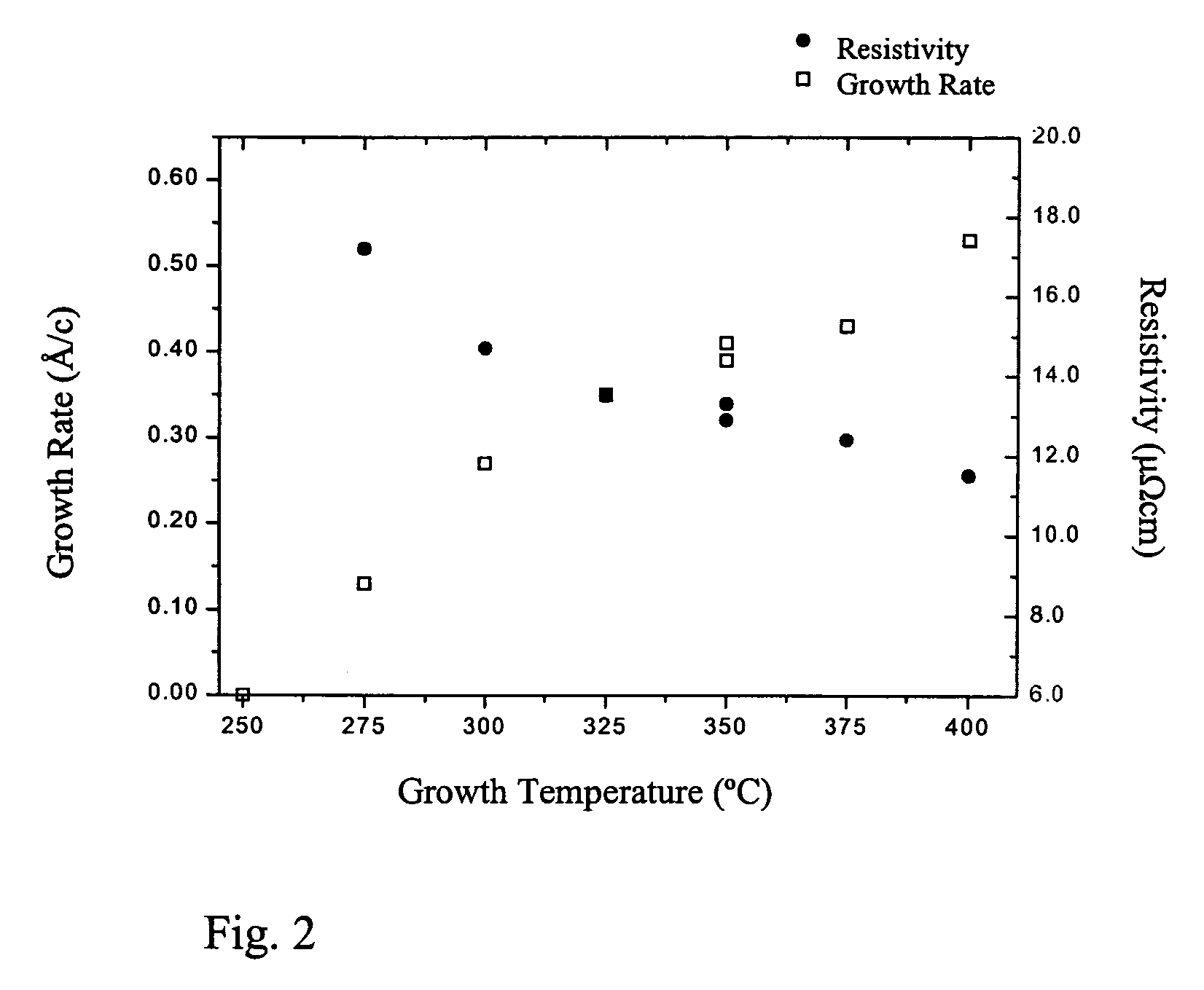

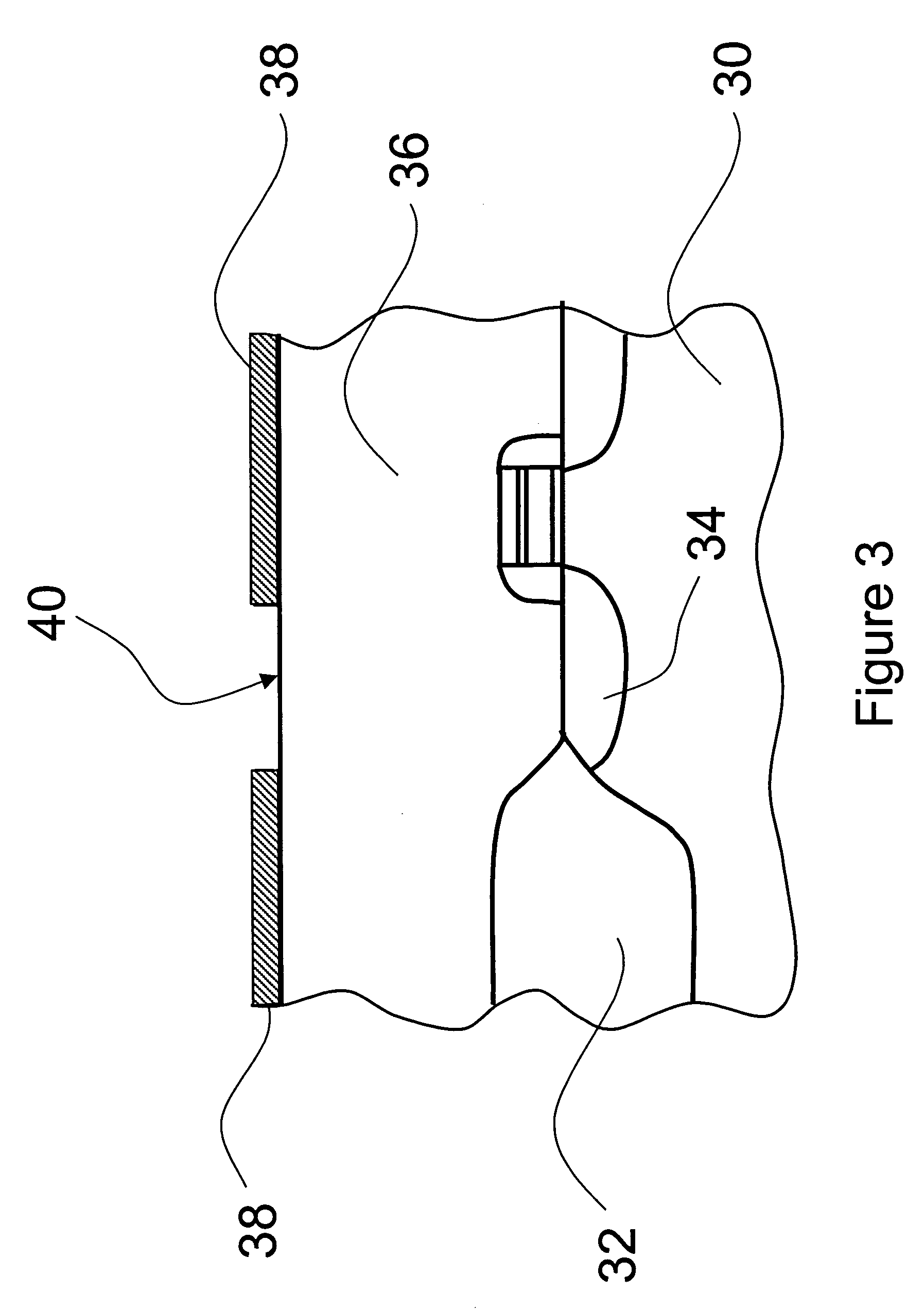

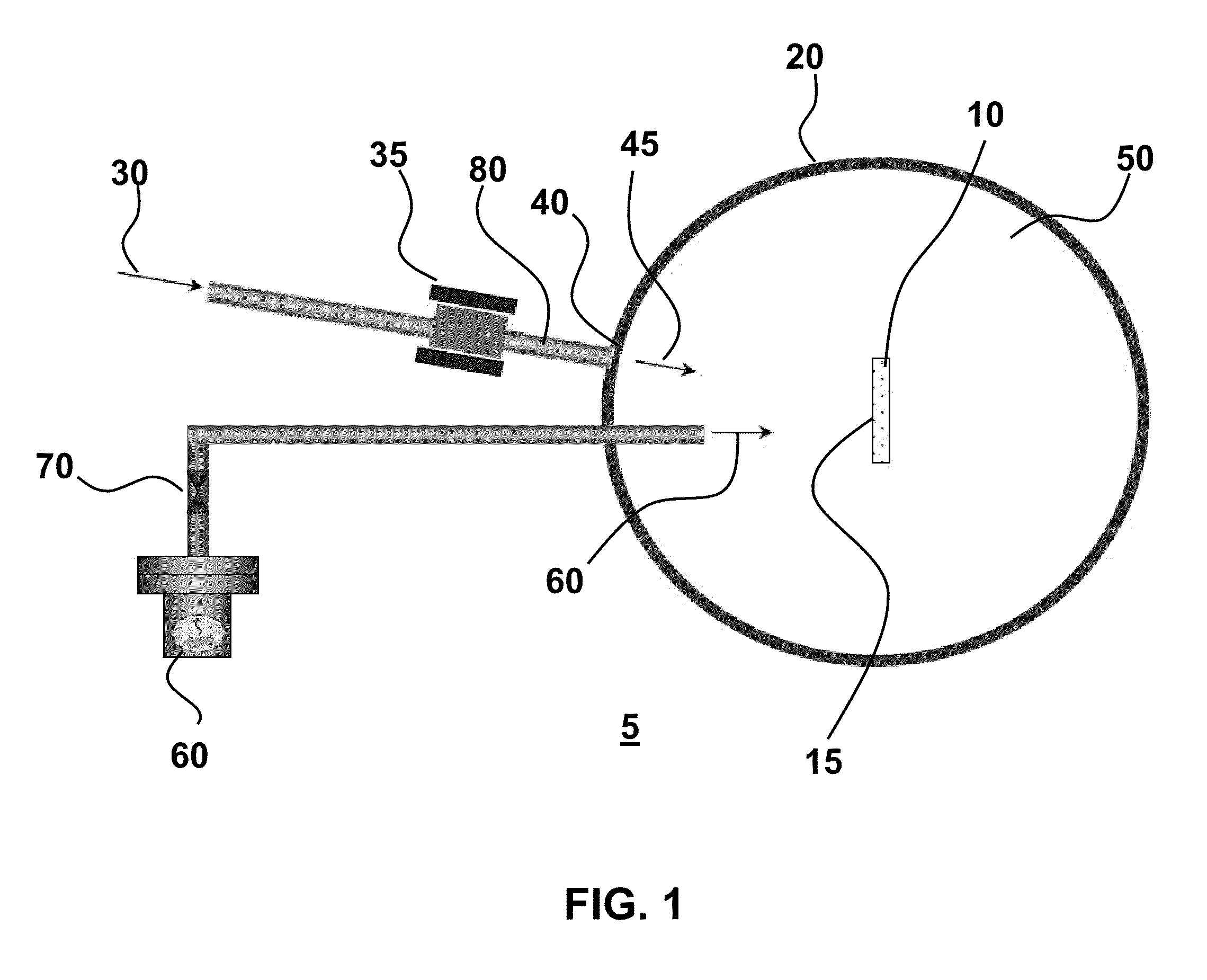

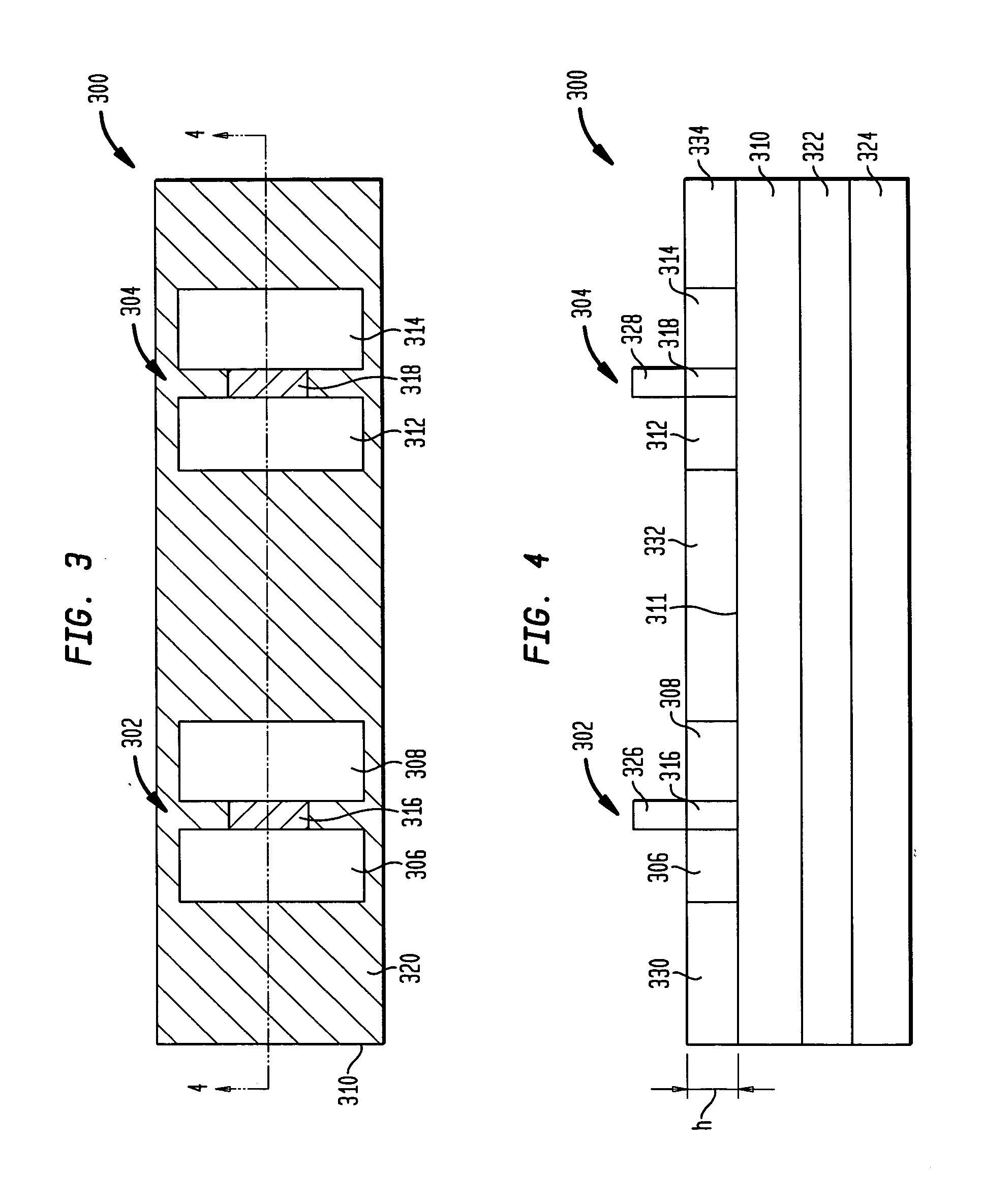

Process for producing metal thin films by ALD

InactiveUS20050020060A1Promote nucleationGood film uniformityNanomagnetismSolid-state devicesHigh elevationSurface structure

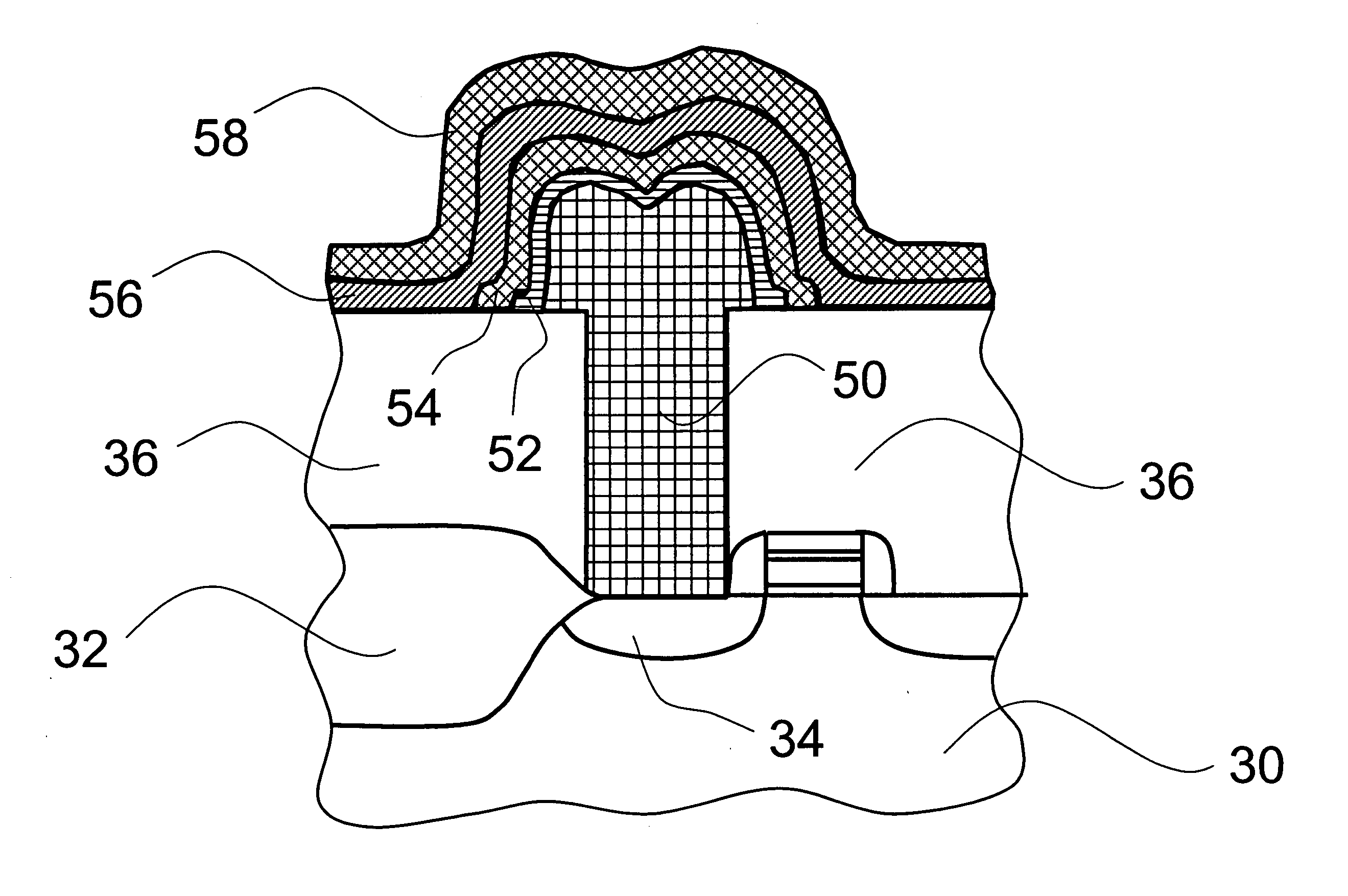

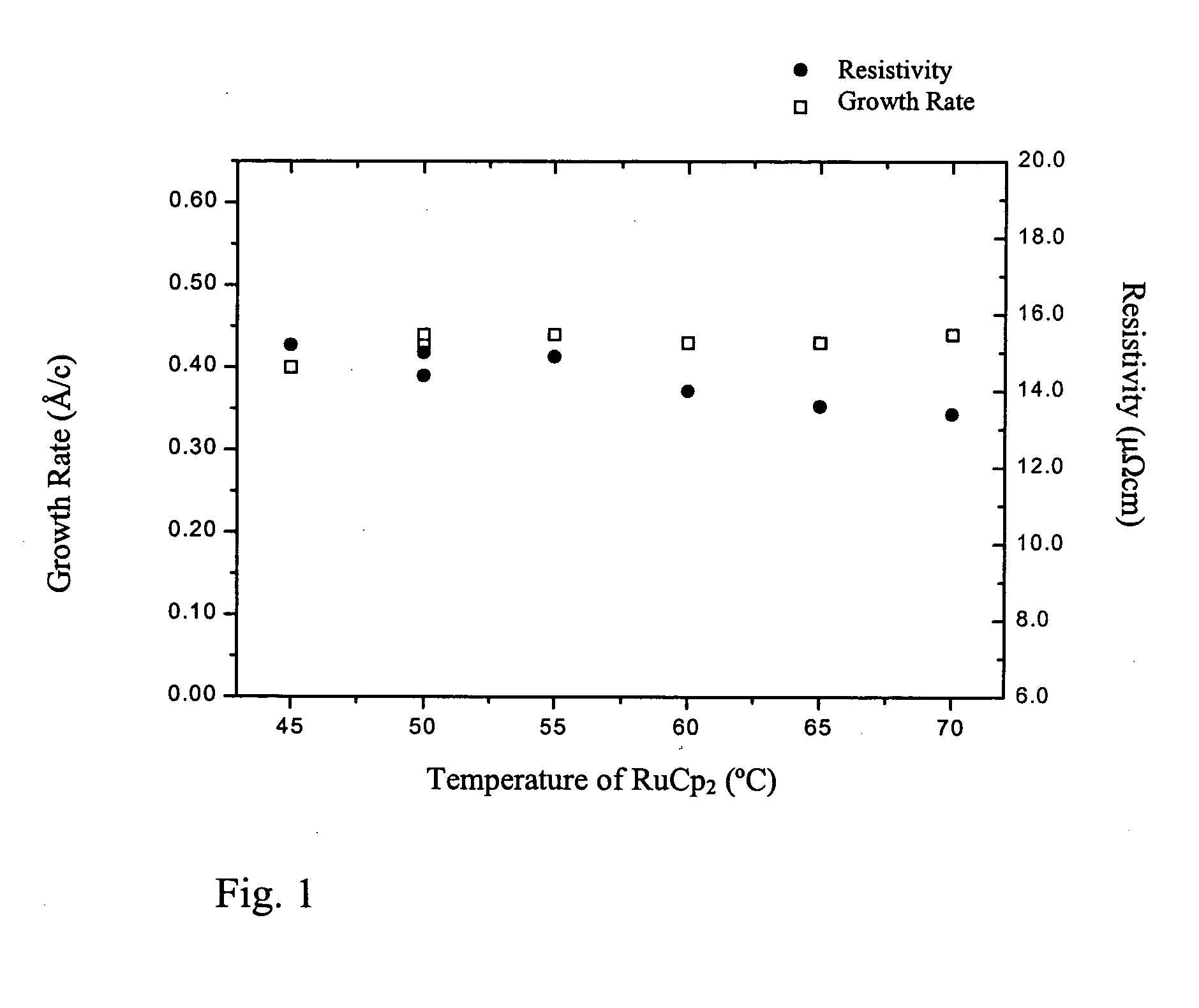

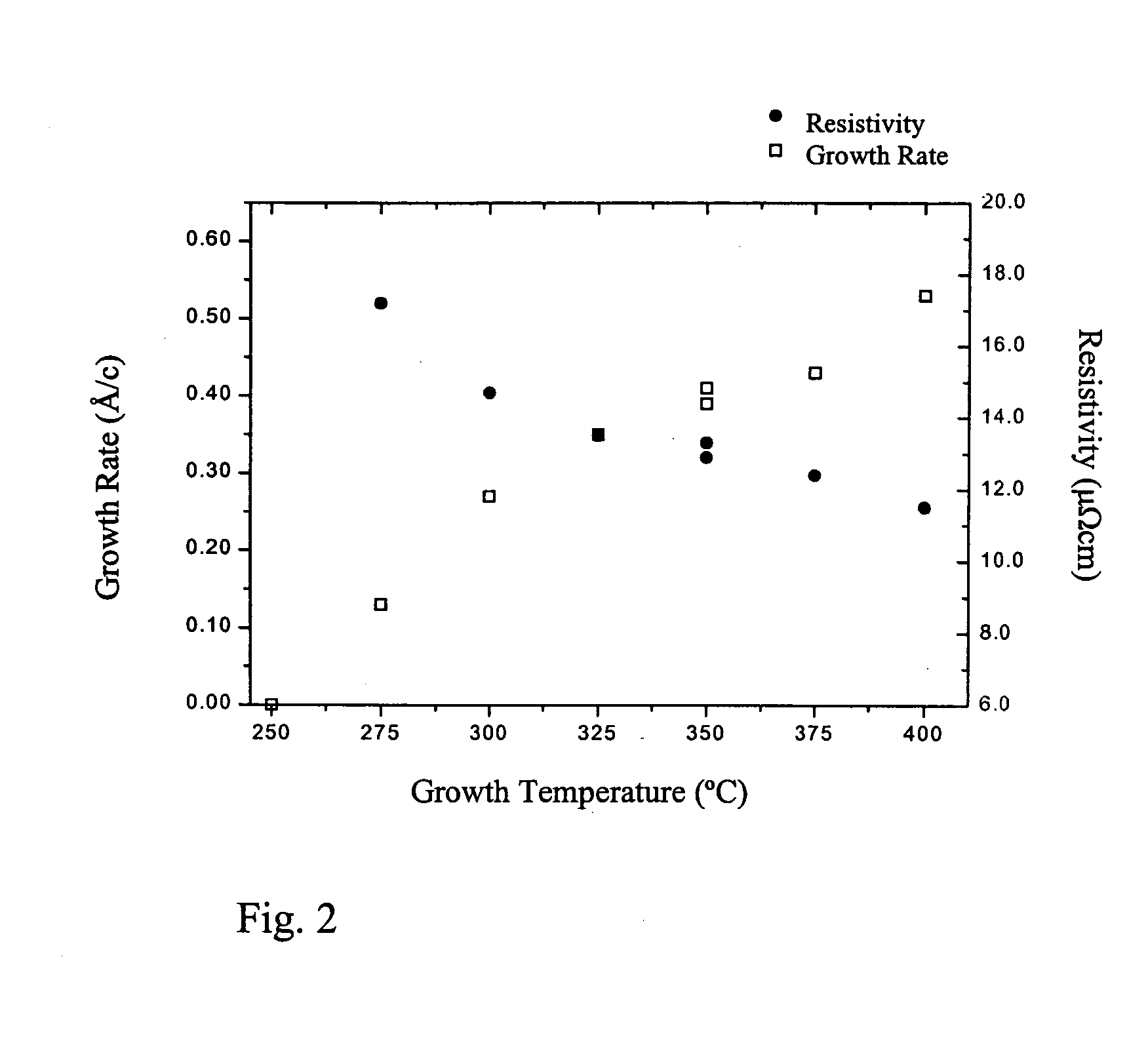

The invention relates generally to processes for producing electrically conductive noble metal thin films on a substrate by atomic layer deposition. According to one embodiment of the invention a substrate with a surface is provided in a reaction chamber and a vaporised precursor of a noble metal is pulsed into the reaction chamber. By contacting the vaporised precursor with the surface of the substrate, no more than about a molecular layer of the metal precursor is formed on the substrate. In a next step, a pulse of molecular oxygen-containing gas is provided in the reaction chamber, where the oxygen reacts with the precursor on the substrate. Thus, high-quality metal thin films can be deposited by utilising reactions between the metal precursor and oxygen. In one embodiment, electrically conductive layers are deposited in structures that have high aspect ratio vias and trenches, local high elevation areas or other similar surface structures that make the surface rough.

Owner:ASM INTERNATIONAL

Crystallization of sugars

InactiveUS6579375B2Reduce in quantityPromote growthDough treatmentMilk preservationCrystallinitySolvent

A process for preparing crystalline sugar by providing a solution of a solvent and sugar, exposing the solution to a magentic field having a strength which is sufficient to impart improvements in the processing of the sugar or the properties of the resulting crystalline sugar product, and providing conditions suitable for crystallization to obtain a substantially crystalline sugar product. The magnetic field strength is sufficient to influence at least one of morphology, size, nucleation rate or, crystallinity of the crystalline sugar product.

Owner:NESTEC SA

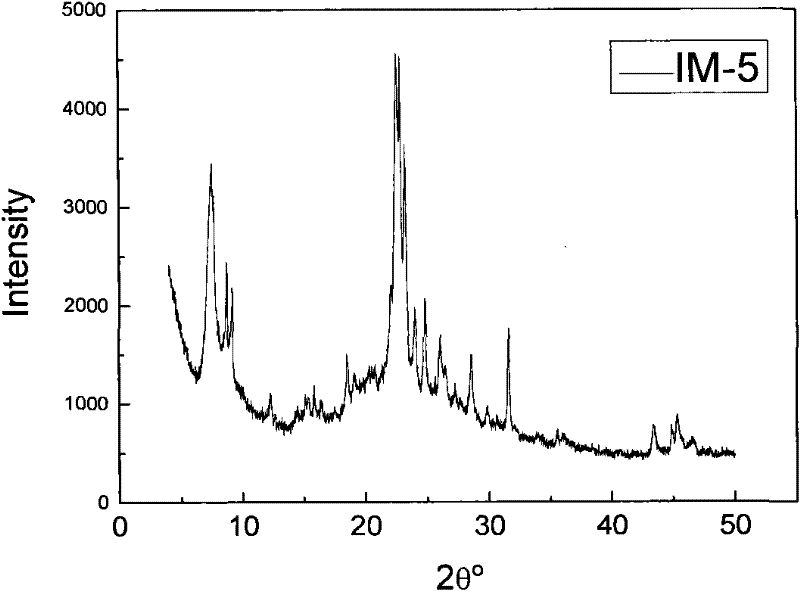

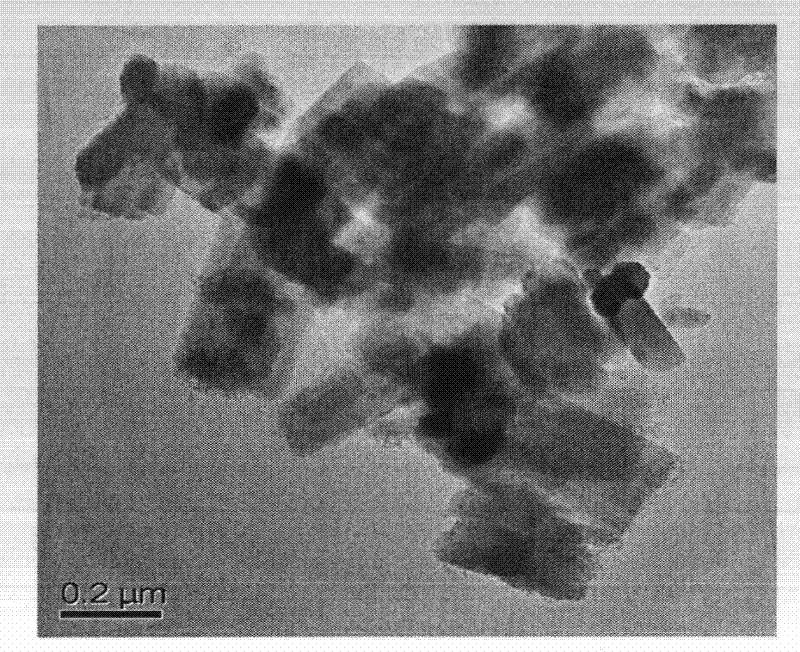

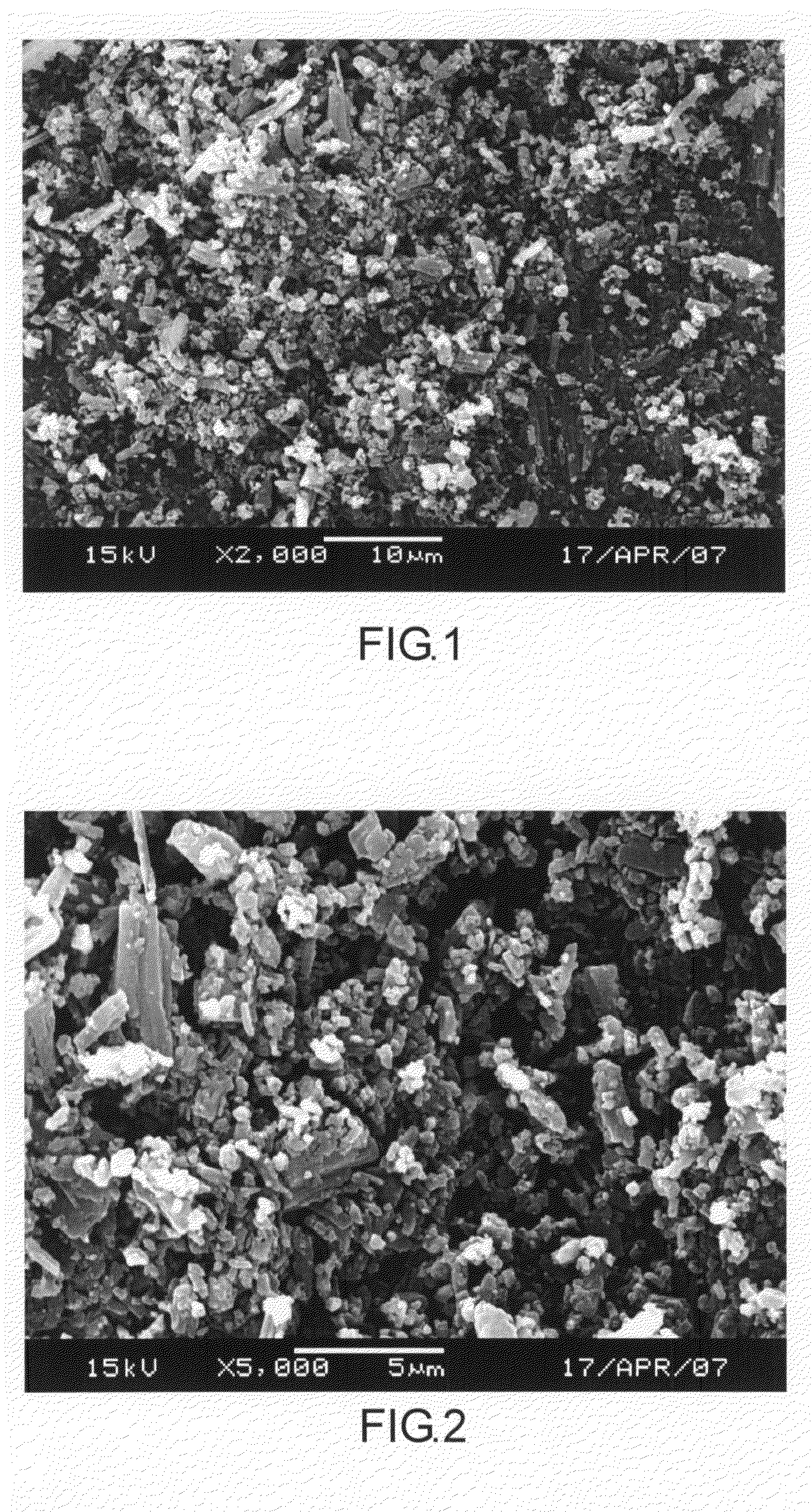

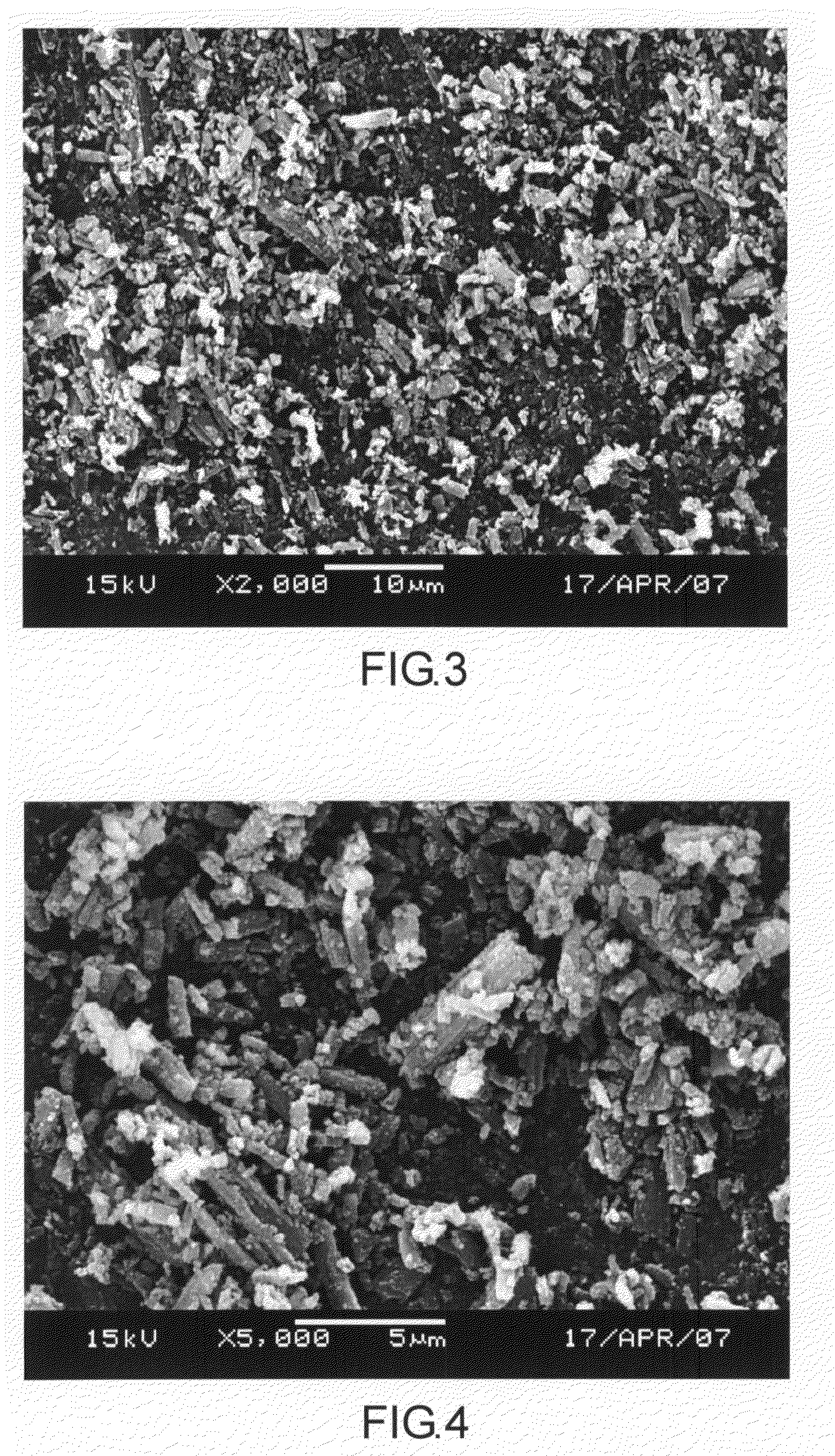

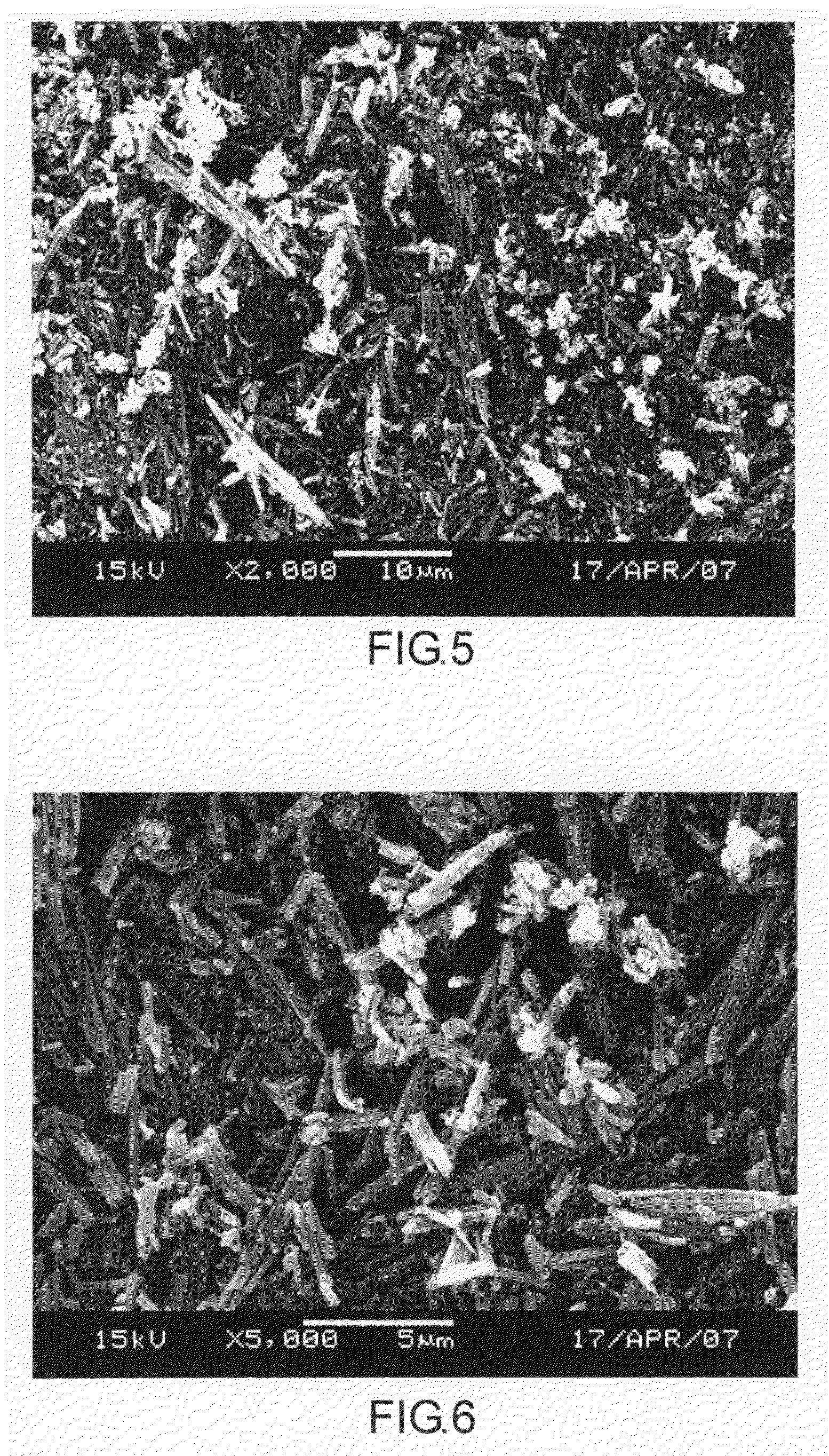

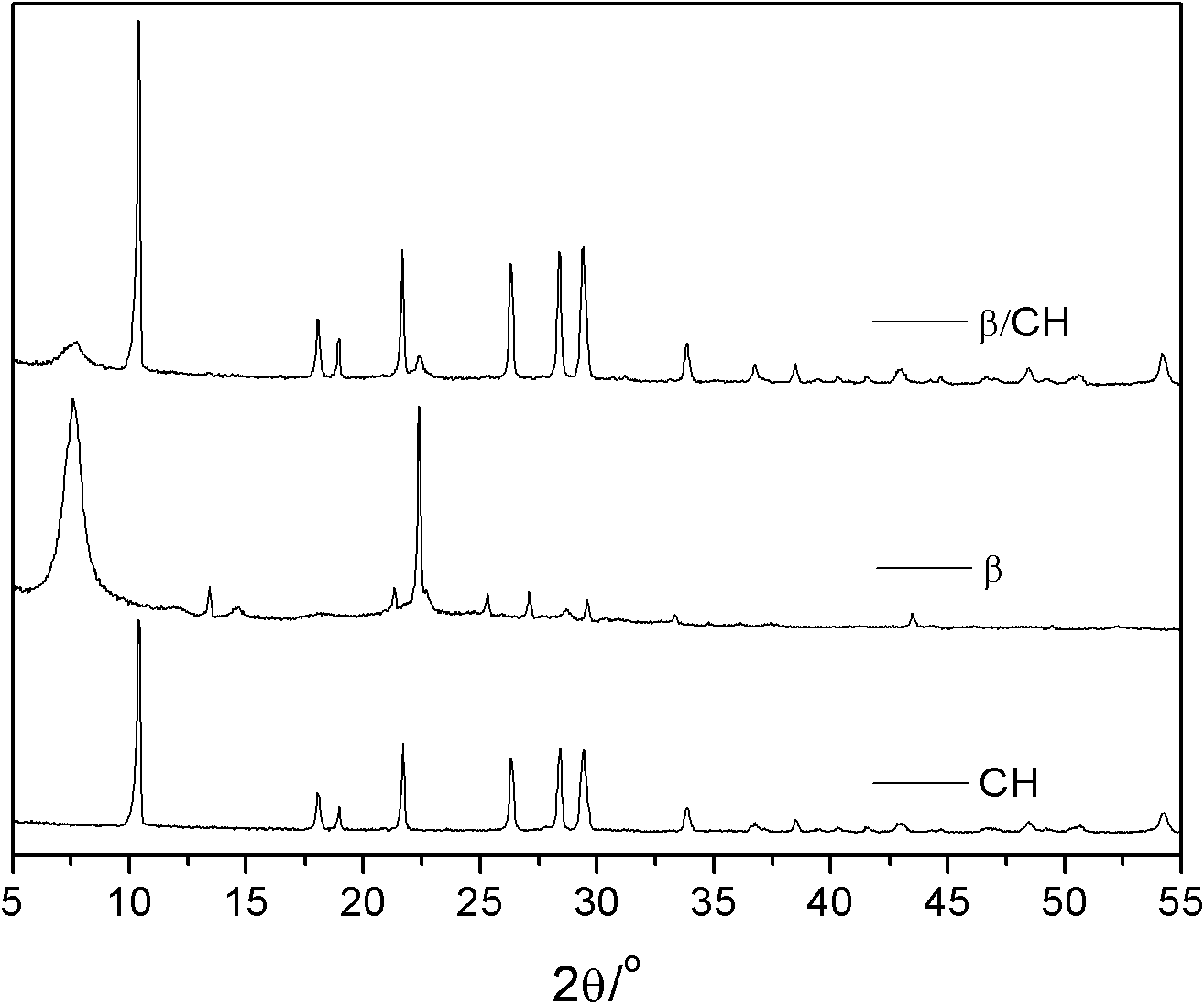

Method of synthesizing IM-5 molecular sieve by using composite template

ActiveCN102452667AReduced nucleation timeShorten crystallization timeCrystalline aluminosilicate zeolitesMolecular sieveAlkali metal oxide

The invention provides a method of synthesizing IM-5 molecular sieve by using a composite template. The method comprises the following steps: (1) dissolving an inorganic base, an aluminum source and two templates in deionized water and carrying out uniform mixing so as to prepare a mixed solution; (2) adding a silicon source into the mixed solution obtained in step (1), optionally adding an additive and carrying out uniform mixing so as to prepare colloid or a solid-liquid mixture; (3) transferring the colloid or the solid-liquid mixture obtained in step (2) to a crystallization kettle, carrying out hydrothermal crystallization at a temperature of 120 to 200 DEG C for 1 to 10 d, carrying out cooling after crystallization and rinsing, filtering and drying the obtained mixed liquor so as to obtain raw powder of the IM-5 molecular sieve. A mole ratio of reactants satisfies the equation of SiO2: Al2O3: M2O: R1: R2: H2O = 60: 0.4-6: 6-21: 0.6-18: 0.6-12: 300-1800, wherein M2O is an alkali metal oxide, R1 is a first template, and R2 is a second template. The method provided in the invention widens the range of mixing ratios of raw materials, improves yield of a single kettle and enables time for crystallization to be further shortened and enlarged production to be easier.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing metal thin films by ALD

InactiveUS7220451B2Good step coverageEasy to controlNanomagnetismSolid-state devicesHigh elevationSurface structure

Electrically conductive noble metal thin films can be deposited on a substrate by atomic layer deposition. According to one embodiment of the invention a substrate with a surface is provided in a reaction chamber and a vaporised precursor of a noble metal is pulsed into the reaction chamber. By contacting the vaporised precursor with the surface of the substrate, no more than about a molecular layer of the metal precursor is formed on the substrate. In a next step, a pulse of molecular oxygen-containing gas is provided in the reaction chamber, where the oxygen reacts with the precursor on the substrate. Thus, high-quality metal thin films can be deposited by utilising reactions between the metal precursor and oxygen. In one embodiment, electrically conductive layers are deposited in structures that have high aspect ratio vias and trenches, local high elevation areas or other similar surface structures that make the surface rough.

Owner:ASM INTERNATIONAL

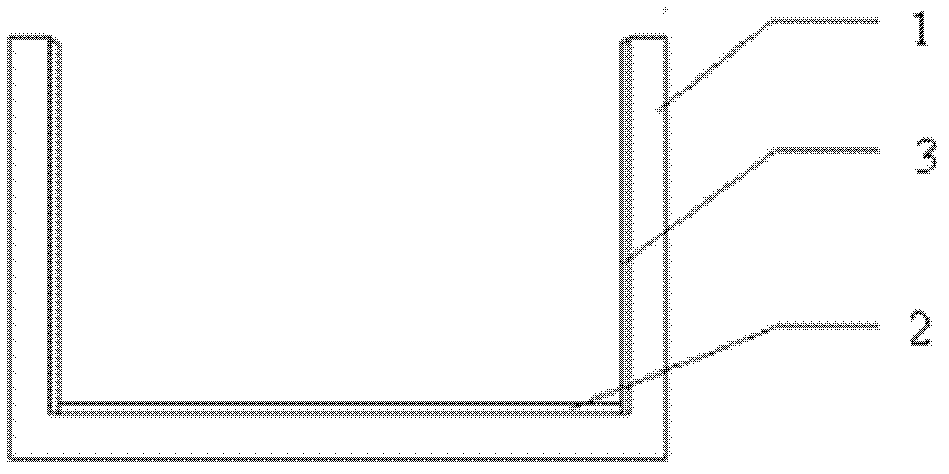

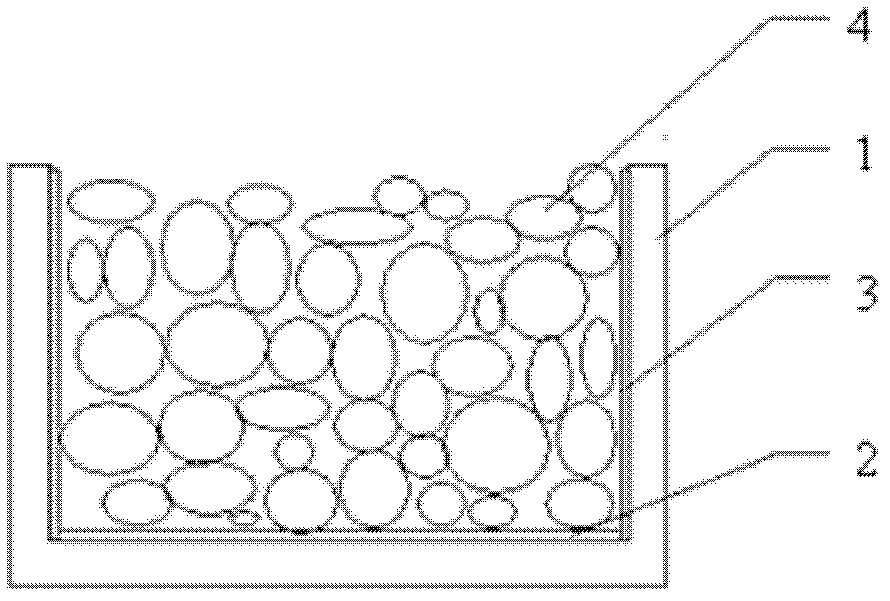

Polycrystalline silicon ingot, preparation method of polycrystalline silicon ingot, polycrystalline silicon slice and crucible for polycrystalline silicon ingot casting

ActiveCN102776561APromote nucleationUniform grainPolycrystalline material growthSingle crystal growth detailsMolten stateCrucible

The invention provides a preparation method of a polycrystalline silicon ingot. The preparation method comprises the following steps that a core source is arranged at the bottom of a crucible, and a core source layer is formed; silicon materials in a molten state are arranged on the core source layer; and the temperature in the crucible is controlled to gradually rise in a direction vertical to the upward direction form the bottom of the crucible, the temperature gradient is formed, the silicon materials in the molten state form core crystallization by utilizing the core source, and the polycrystalline silicon ingot is prepared. The invention also provides high-quality polycrystalline silicon ingot obtained by the preparation method, a polycrystalline silicon slice obtained through the preparation of the polycrystalline silicon ingot and the crucible for polycrystalline silicon ingot casting. The polycrystalline silicon ingot prepared by the preparation method has the advantages that the crystalline size is uniform and regular, the dislocation density is low, and in addition, no obvious pine-tree crystals or twin crystals exist.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

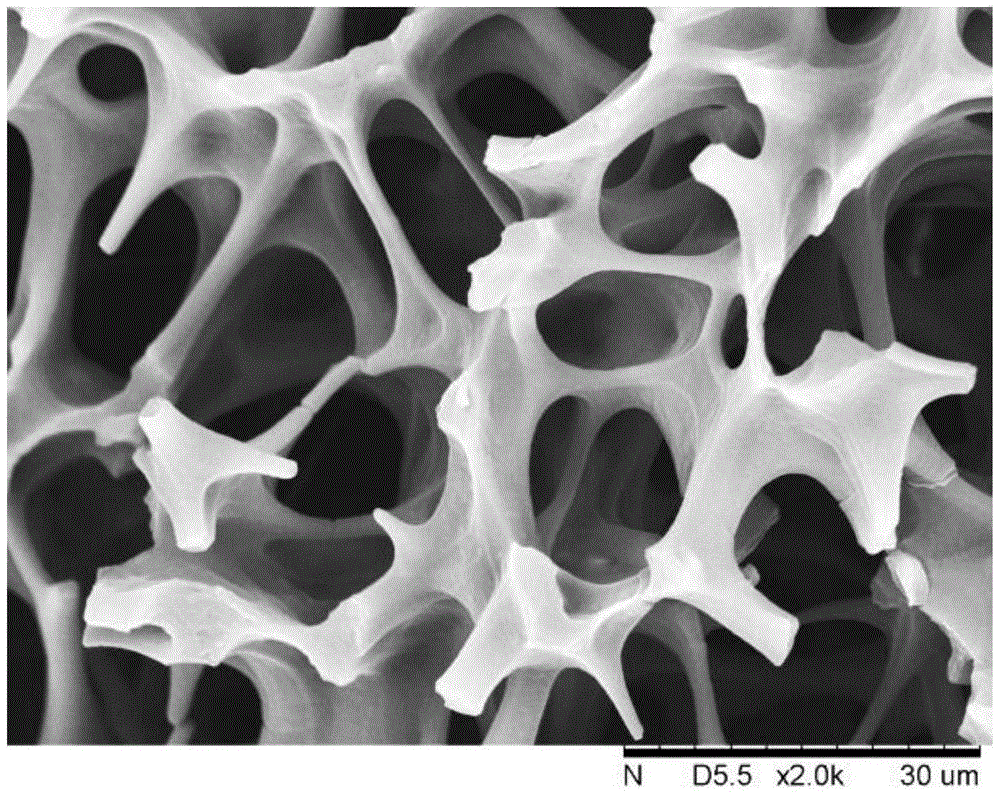

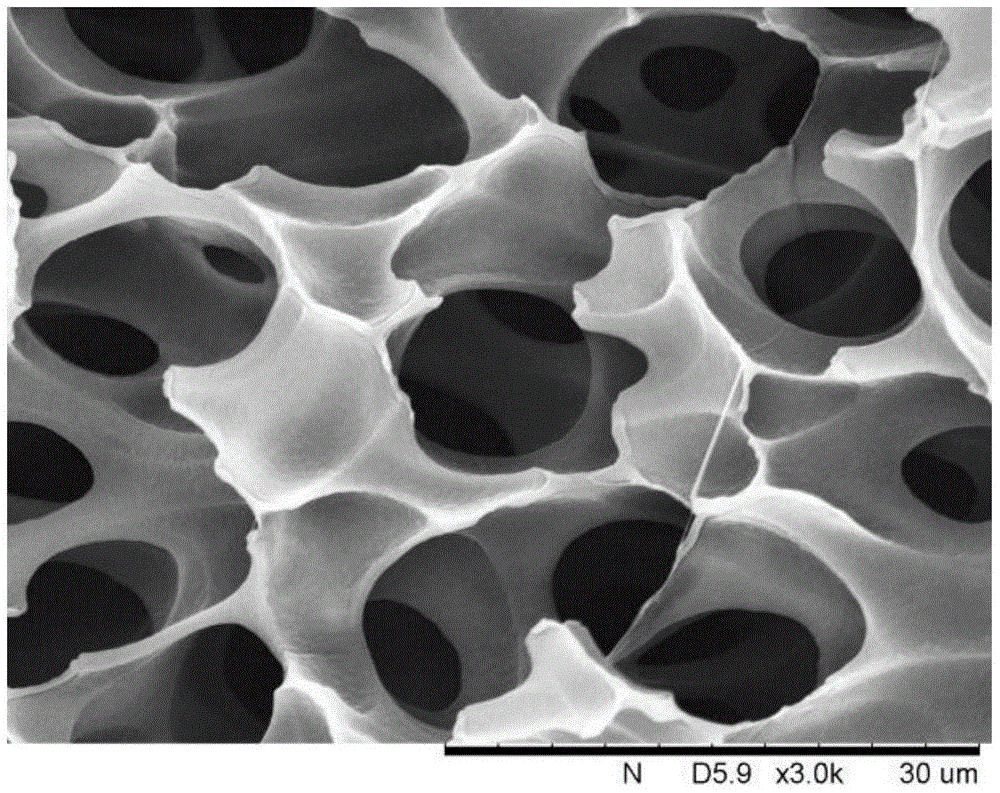

Method for preparing polymeric open cell foam material

The invention relates to a method for preparing a polymeric open cell foam material. By virtue of a supercritical fluid foaming technology, by way of mould foaming, under the premise that other performances of a polymer are not affected, nanoparticles with double effects of a nucleating agent and a cell-opening agent are added, so that the nucleation density and the aperture ratio of the polymer are remarkably improved. By adding a cell-opening auxiliary agent, on the one hand, an effect of a heterogeneous nucleating agent can be exerted to accelerate cells to be nucleated and to increase the cell density; on the other hand, the cell-opening auxiliary agent is a good cell-opening agent which promotes cell walls to break and increases the aperture ratio. The whole process provided by the invention is green and environmental-friendly and free of chemical residues; moreover, the pressure and temperature in a swelling treatment process can be adjusted to prepare the open cell foam material with different cell sizes. The polymer provided by the invention has a lot of open cells and is adjustable in cell size.

Owner:NINGBO UNIV

Clarifying agent composition and manufacturing method thereof

A clarifying agent composition comprises a diacetal powder and an organosilane treated fume silica having a pH value of 5.5 to 8, measured in a 4% w / w dispersion in 1:1 mixture of water-methanol. The diacetal has the general structure formula (I), (II), (III), (IV) or (V),wherein R1 and R2 are independently selected from the group consisting of H, C1-C4 alkyl, C1-C4 carbalkoxy, F, Cl, and Br; a is 0, 1, 2 or 3; b is 0, 1, 2 or 3 and n is 0 or 1. The organosilane treated fume silica is dispersed in the diacetal powder and being 0.05˜50% by weight the clarifying agent composition.This invention also intents to provide a new manufacturing method for preparing superfine powdery diacetal composition with high dispersion characteristic the use of said compositions for preparing polyolefin plastic article without the visible white spots on the surface of the corresponding article.

Owner:SUNKO INK

Crystallization of sugars

InactiveUS20030084898A1Attractive bright and shiny appearanceProduced conveniently and consistentlyMilk preservationDough treatmentNucleationCrystallinity

A process for preparing crystalline sugar by providing a solution of a solvent and sugar, exposing the solution to a magentic field having a strength which is sufficient to impart improvements in the processing of the sugar or the properties of the resulting crystalline sugar product, and providing conditions suitable for crystallization to obtain a substantially crystalline sugar product. The magnetic field strength is sufficient to influence at least one of morphology, size, nucleation rate or, crystallinity of the crystalline sugar product.

Owner:NESTEC SA

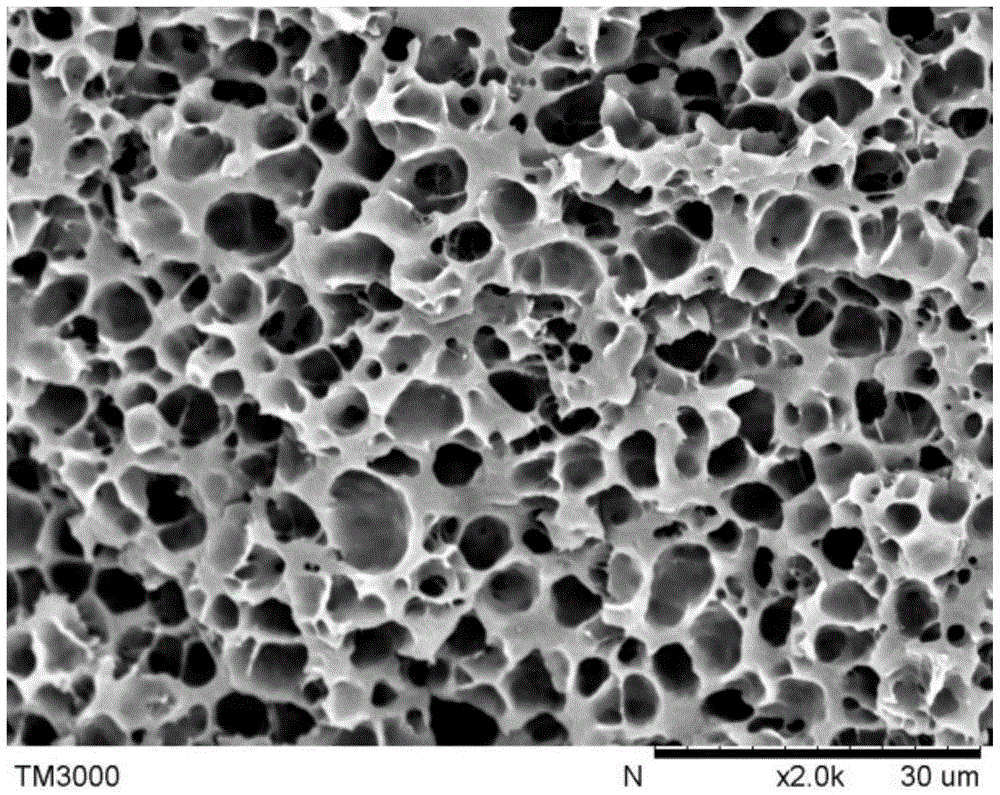

High oil absorption polyurethane foam and preparation method thereof

ActiveCN101987884AHigh oil absorptionFast oil absorptionOther chemical processesChemical recyclingChlorobenzeneKerosene

The invention relates to a high oil absorption polyurethane foam which comprises the following components in parts by weight: 20 to 40 parts of isocyanate, 35 to 60 parts of polyol, 0.5 to 3 parts of catalyst, 0.5 to 3 parts of foam stabilizer, 5 to 10 parts of foaming agent, 2 to 10 parts of opening agent,5 to 20 parts of flame retardant, 5 to 15 parts of silicon rubber spherical micro powder and 0.5 to 2 parts of coupling agent. The preparation method comprises the following technology steps of weighing, prepolymerization, dispersing, polymerization foaming reaction, curing and peeling at room temperature and cutting. The high oil absorption polyurethane foam can be used for the absorption and recycle of various oil products (crude oil, engine oil, diesel fuel, gasoline, kerosene and the like) on water surfaces, ground or surfaces of other objects, and various oil soluble organic compounds (benzene, methylbenzene, dimethylbenzene, chloroform, nitrobenzene, chlorobenzene and the like). The invention has the advantages of simple technology and low cost, obviously improves the dispersing effect of the silicon rubber spherical micro powder in a polymerization system by using ultrasonic technique, and greatly increase the oil absorption quantity and oil absorption rate of the polyurethane foam by adding the silicon rubber spherical micro powder.

Owner:CHINA BLUESTAR CHENGRAND CO LTD +1

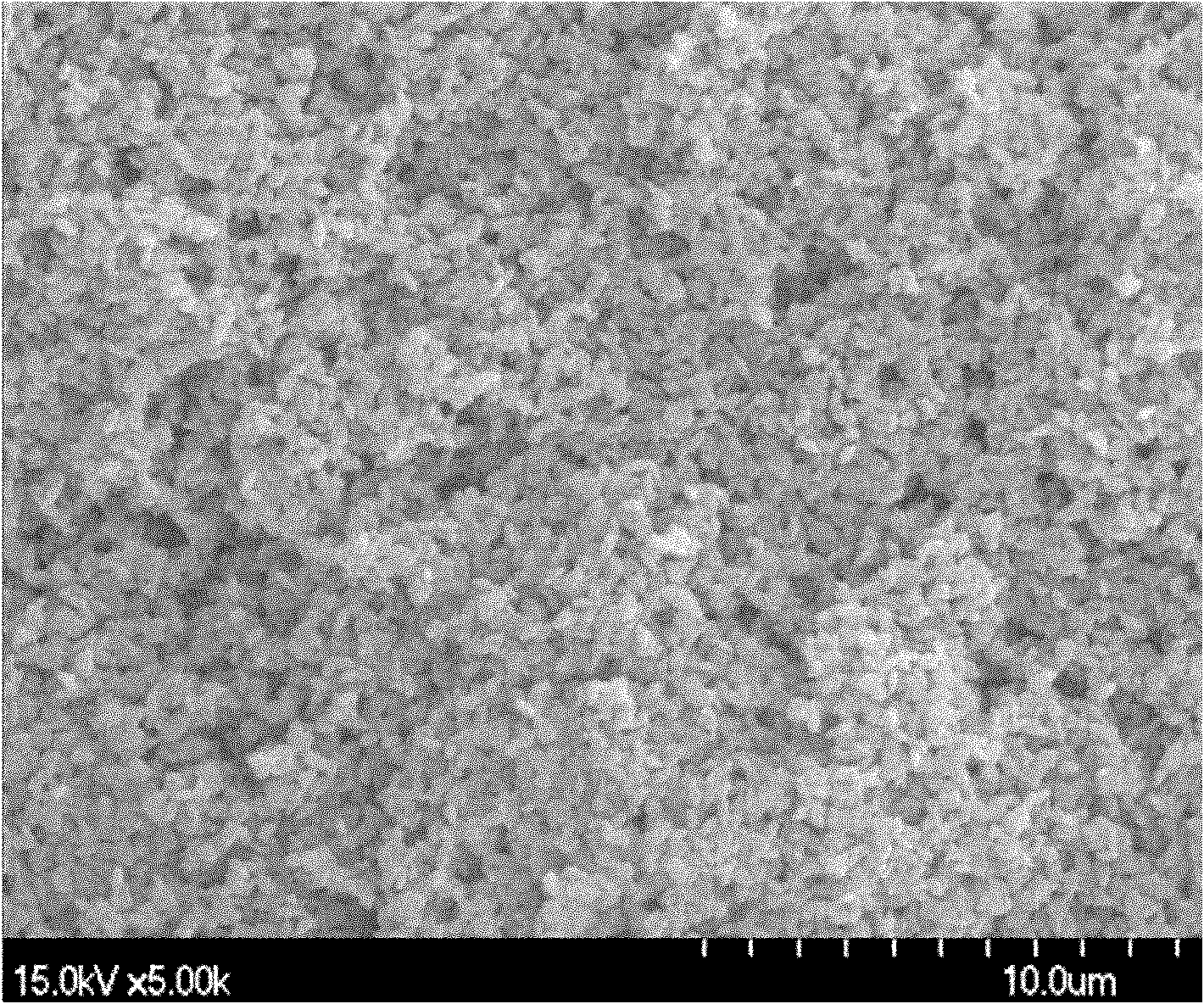

Honeycomb-ceramic-type monolithic catalyst, and preparation method and application thereof

InactiveCN102133537AIncrease roughnessPromote nucleationMolecular sieve catalystsDispersed particle separationMass ratioCordierite

The invention discloses a honeycomb-ceramic-type monolithic catalyst, and preparation method and application thereof. The monolithic catalyst takes honeycomb ceramic as a carrier, a Beta molecular sieve is coated on the surface of the honeycomb ceramic and taken as a coating layer, and then active component, namely precious metal, is loaded on the surface of Beta molecular sieve; the active component of the precious metal is one or two selected from palladium or platinum; in the honeycomb-ceramic-type monolithic catalyst, the mass ratio of the coating layer of the Beta molecular sieve to the honeycomb ceramic is 0.02-0.2:1, the mass ratio of the precious metal to the coating layer of the Beta molecular sieve is 0.02-0.2:1, the honeycomb ceramic is cordierite honeycomb ceramic; and in the invention, the high-silicon or full-silicon Beta molecular sieve is taken as the coating layer of the monolithic catalyst, and has the characteristics of good water resistance, high heat stability andthe like, and the monolithic burning catalyst taking the Beta molecular sieve as the coating layer can keep better activity and stability under high temperature, and suitable for being taken as catalytic combustion catalyst for application.

Owner:ZHEJIANG CENWAY MATERIALS CO LTD

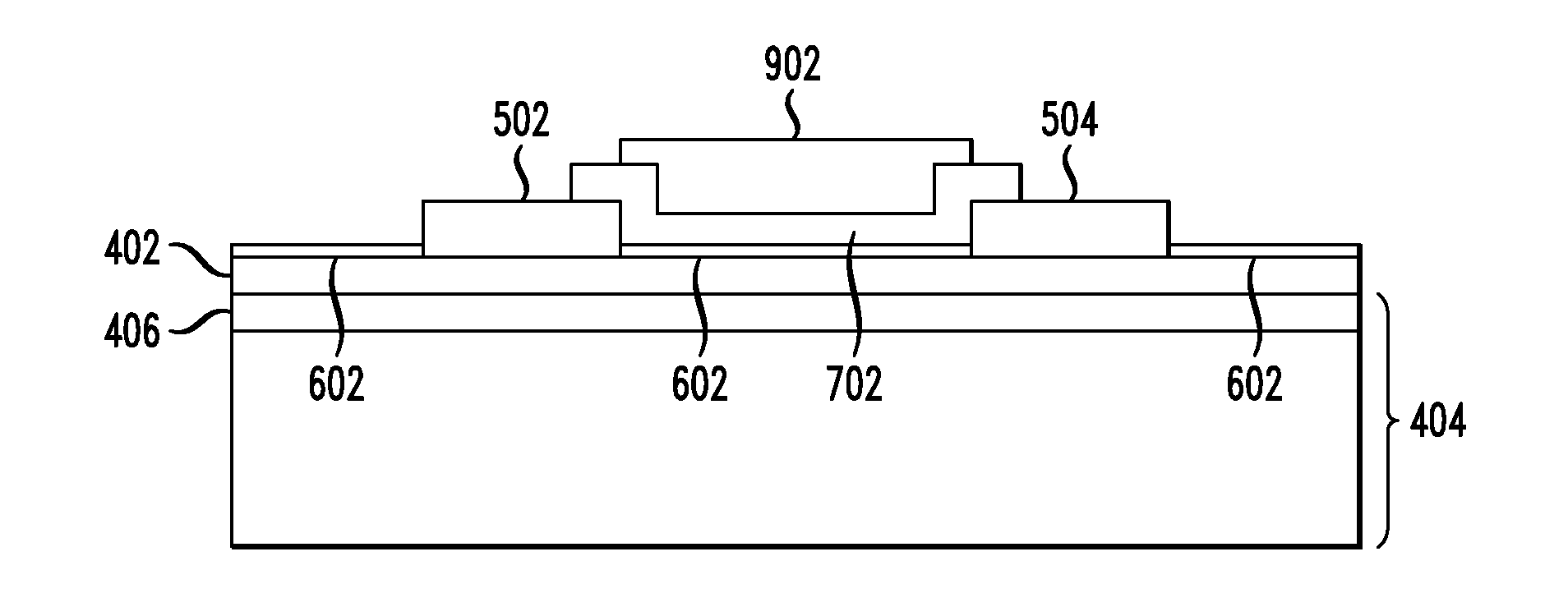

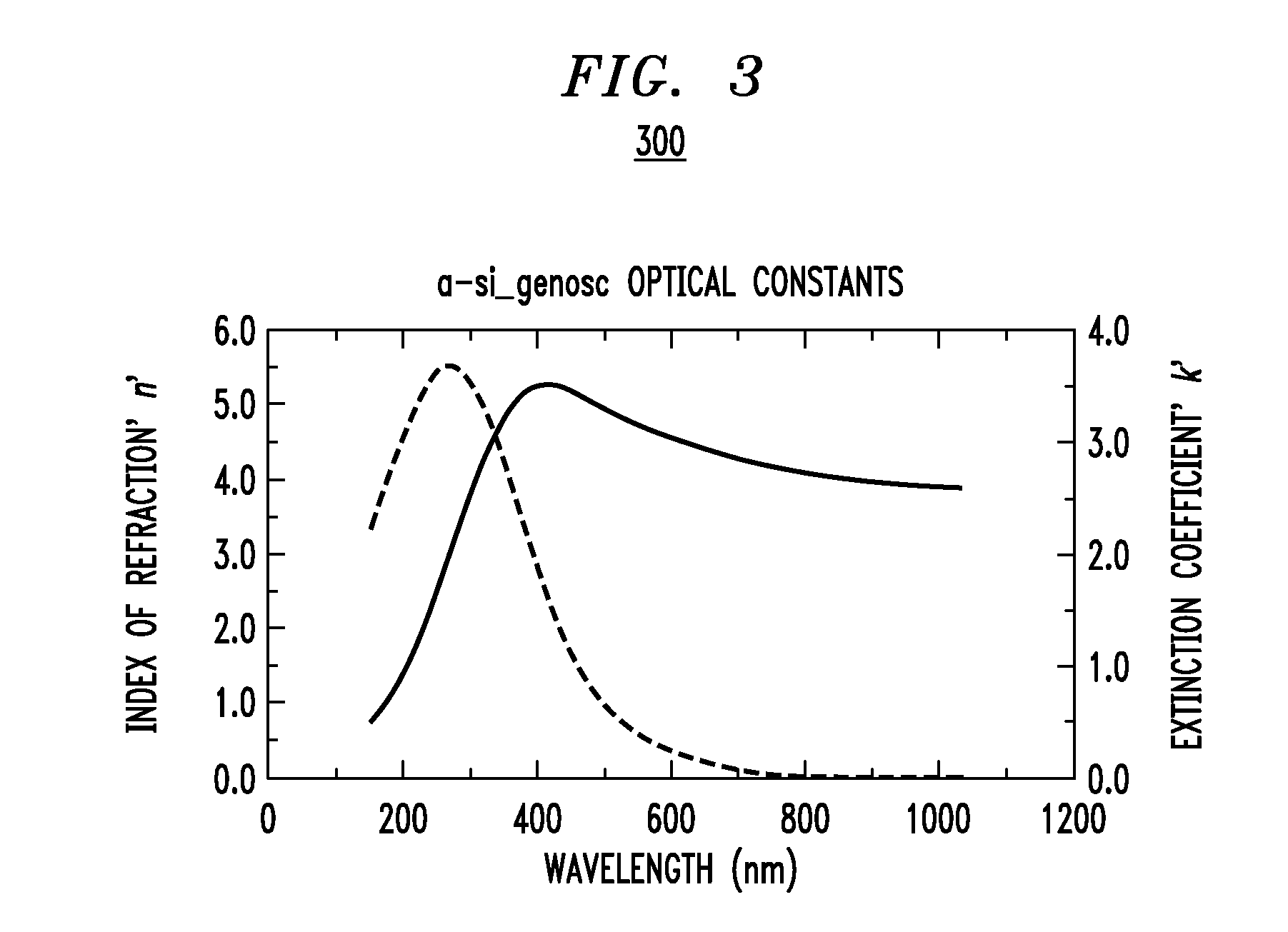

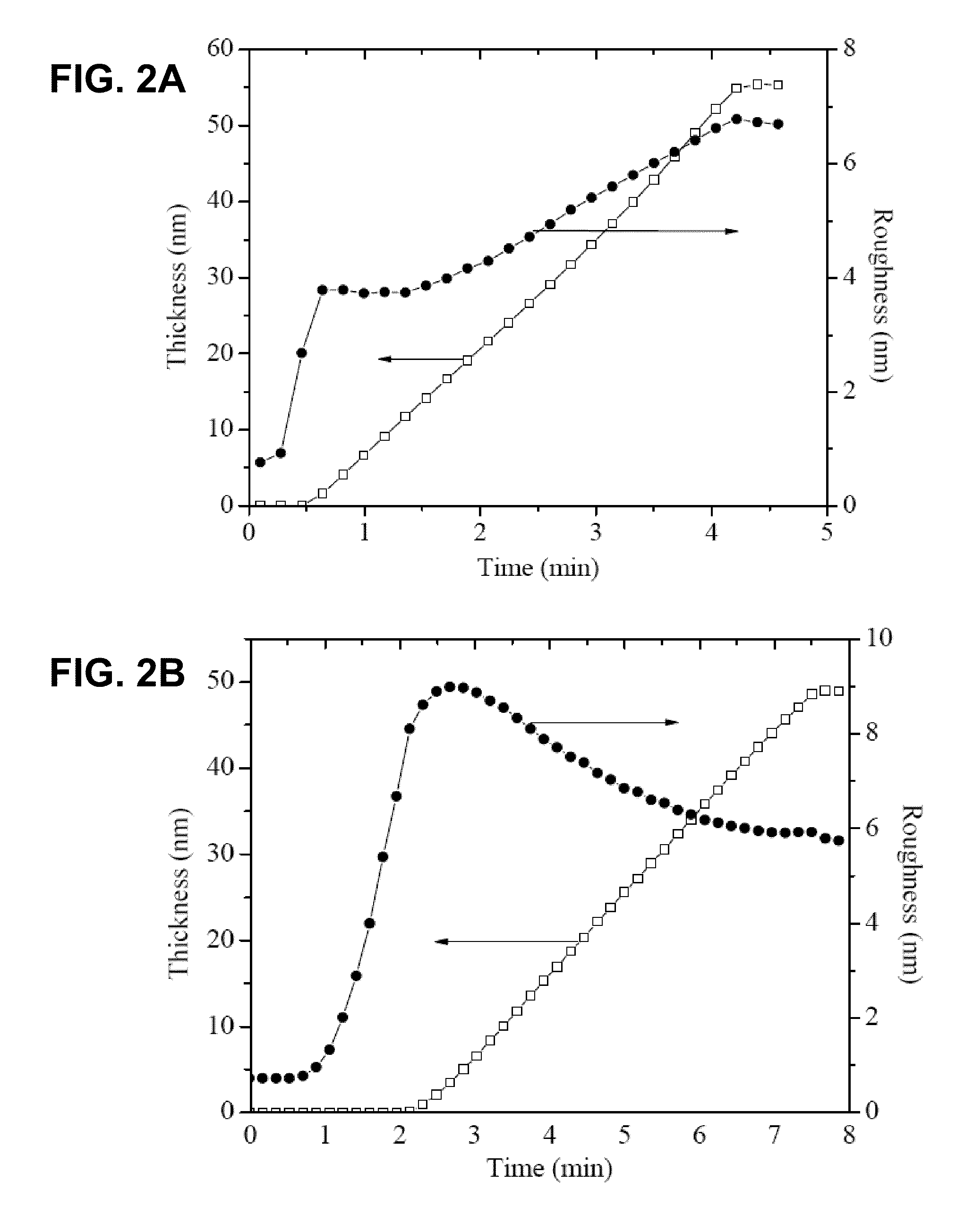

Method to Improve Nucleation of Materials on Graphene and Carbon Nanotubes

ActiveUS20100301336A1Promote nucleationTransistorSemiconductor/solid-state device manufacturingCarbon nanotubeNucleation

Techniques for forming a thin coating of a material on a carbon-based material are provided. In one aspect, a method for forming a thin coating on a surface of a carbon-based material is provided. The method includes the following steps. An ultra thin silicon nucleation layer is deposited to a thickness of from about two angstroms to about 10 angstroms on at least a portion of the surface of the carbon-based material to facilitate nucleation of the coating on the surface of the carbon-based material. The thin coating is deposited to a thickness of from about two angstroms to about 100 angstroms over the ultra thin silicon layer to form the thin coating on the surface of the carbon-based material.

Owner:GLOBALFOUNDRIES US INC

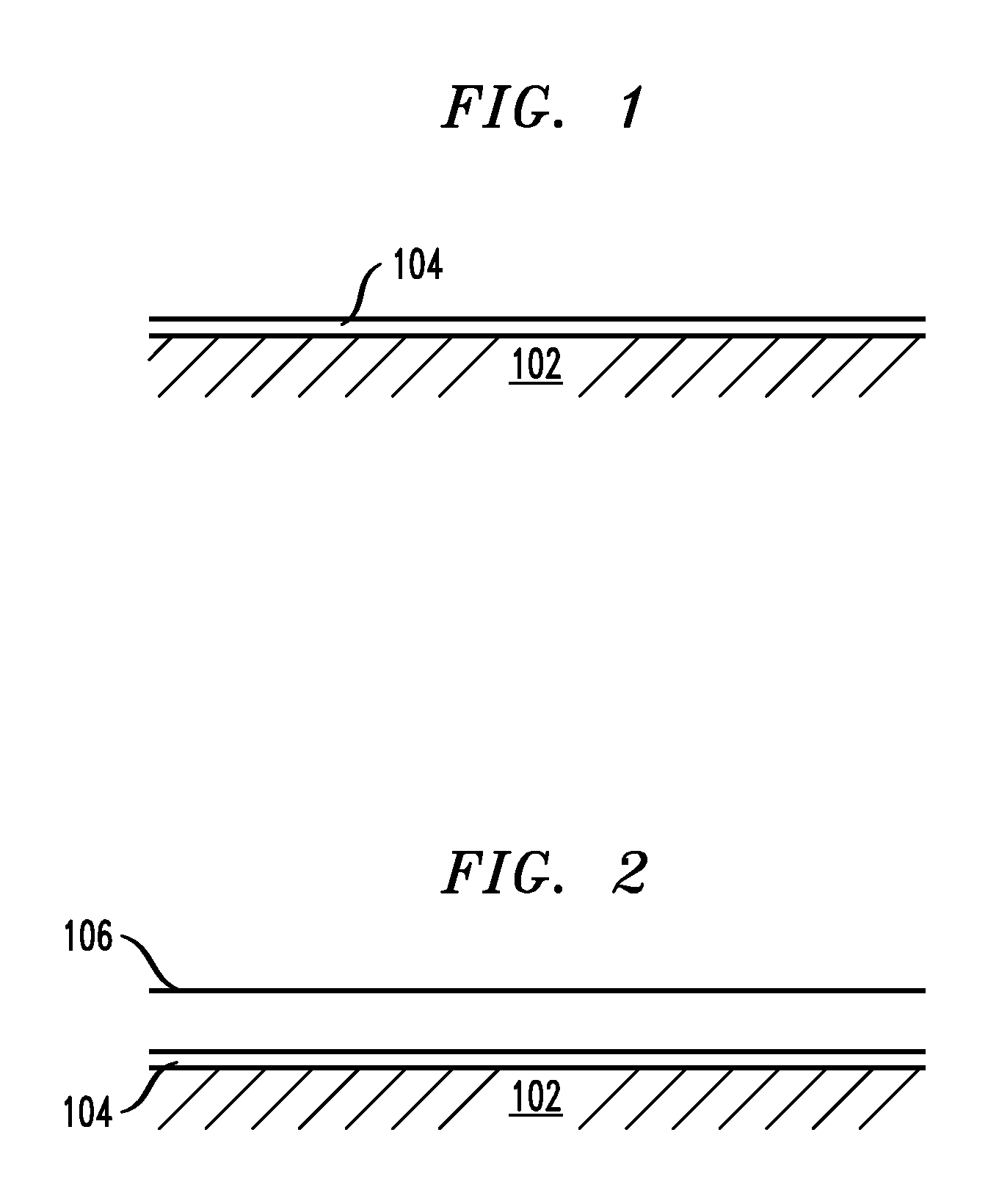

Surface preparation for thin film growth by enhanced nucleation

ActiveUS7943527B2Promote growthEnhanced nucleationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingRemote plasmaOptoelectronics

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

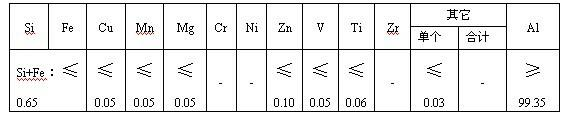

Light gauge aluminum foil woolen produced with AL-Ti-C wire refiner and preparation method

InactiveCN102181754AReduced responseLess rigidRoll mill control devicesMetal rolling arrangementsMaterials preparationFiltration

The invention relates to a light gauge aluminum foil woolen produced with AL-Ti-C wire refiner and a preparation method. The iron-silicon rate of the woolen ranges between 4.3-5.3. The process of the preparation technology is sequentially as follows: material preparation, batching, feeding, melting, stirring, primary refining of a smelting furnace, drossing, sampling, ingredient adjustment, secondary refining of the smelting surface, drossing, converter, primary refining in a holding furnace, intensified refining in the holding furnace, online addition of AL-Ti-C wire intermediate alloy refiner, Ar online degassing, filtration, continuous casting into 7.0-7.5mm cast rolling plates, cold rolling, high-temperature homogenizing annealing of a primary sheet strap, cold rolling, trimming of a rereeling machine, cold rolling, intermediate annealing of a secondary sheet strap, cold rolling to 0.26-0.32mm, trimming of the rereeling machine, and packaging. The cost is low, the quality is stable, the calendaring of the aluminum foil and grain refining are good in effect, and the probability of generating pinholes is low during production.

Owner:江阴新仁铝业科技有限公司

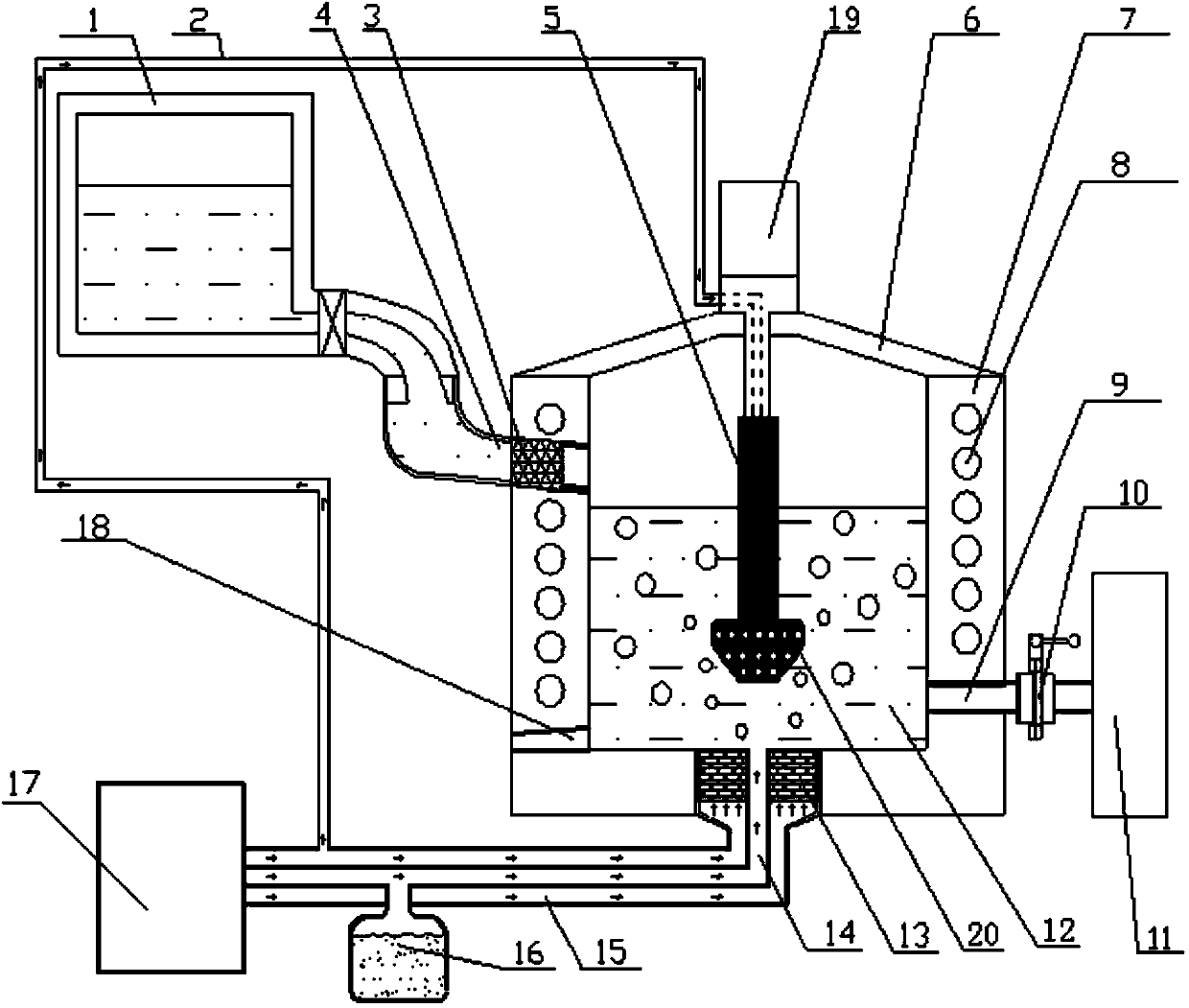

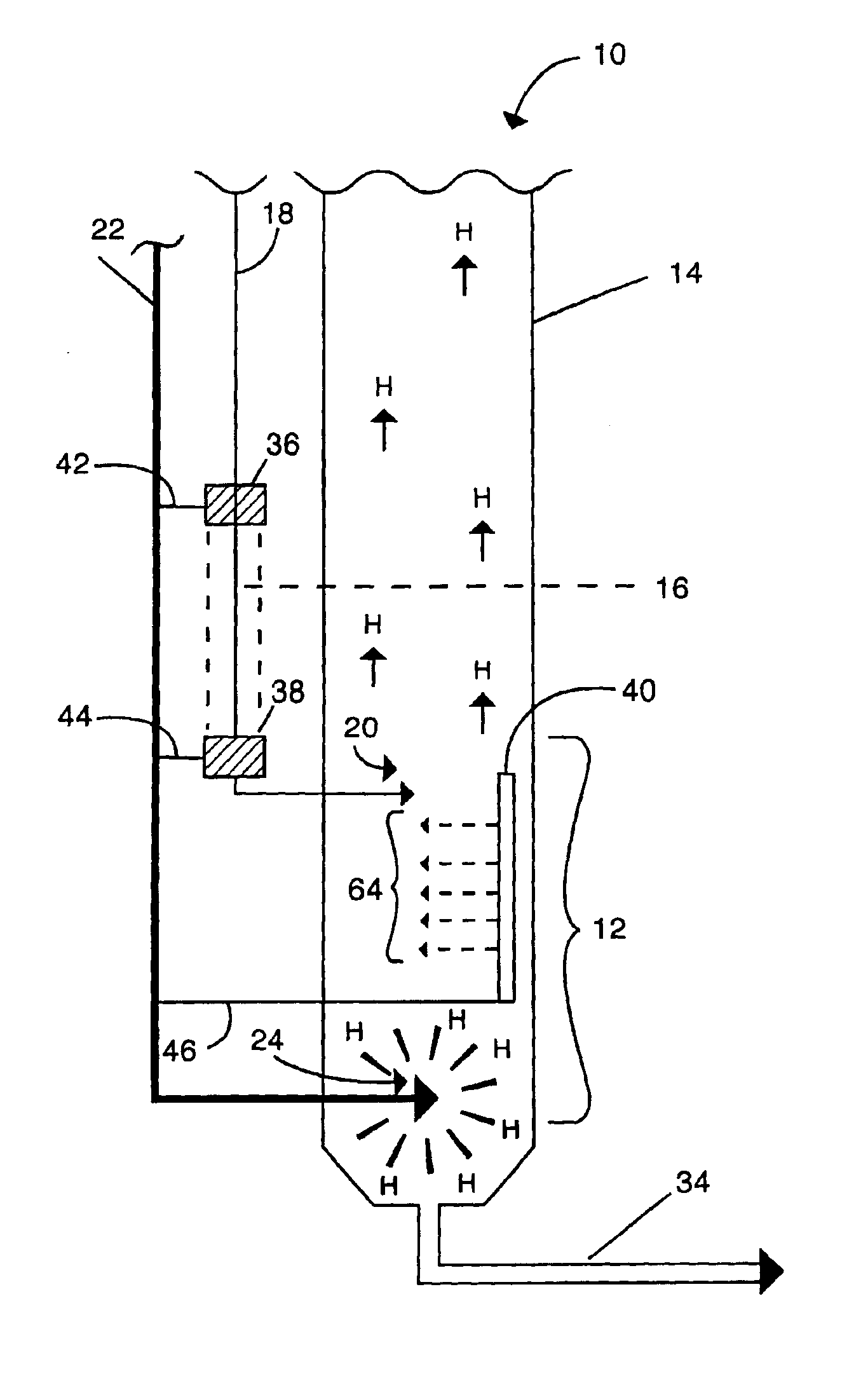

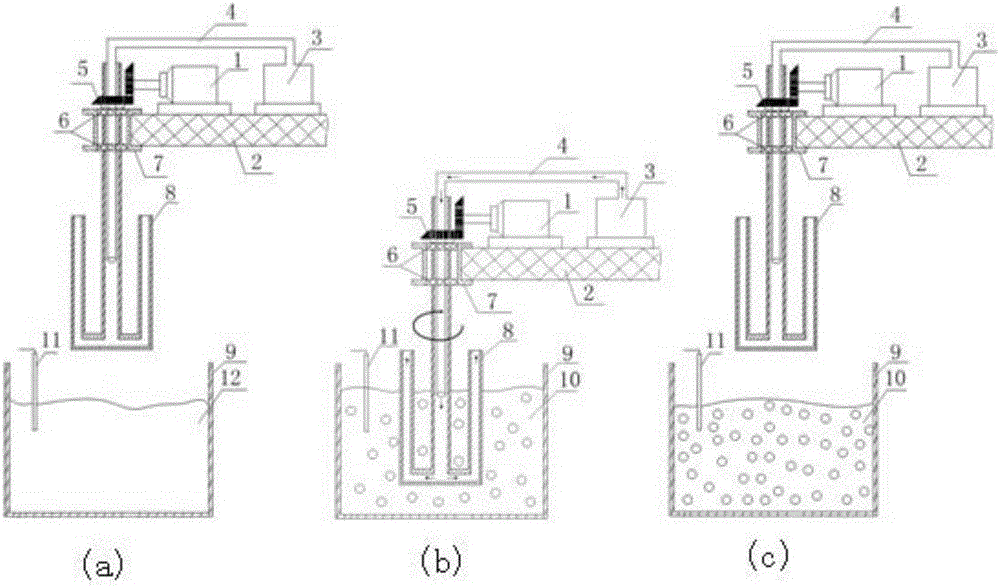

Manufacturing device for light alloy or light metal semi-solid slurry and manufacturing method

The invention discloses a manufacturing device for light alloy or light metal semi-solid slurry and a method for manufacturing the semi-solid slurry through the device. The manufacturing device for the light alloy or light metal semi-solid slurry comprises a smelting furnace, a runner, a mechanical stirring device, an inert gas stirring device, a powder spray device and a heating device. The semi-solid slurry manufacturing device reasonable in structure is designed, continuity for manufacturing the semi-solid slurry is good, and products can be cast industrially and continuously in a large scale by applying a semi-solid pressure casting or squeeze casting forming method. According to the manufacturing method for the semi-solid slurry, efficiency for manufacturing the light alloy or light metal semi-solid slurry is high, energy consumption is less, cost is low, and the manufactured semi-solid slurry cannot generate oxide inclusions, and is even in organization and excellent in quality.

Owner:机械科学研究总院(将乐)半固态技术研究所有限公司

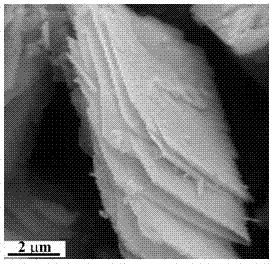

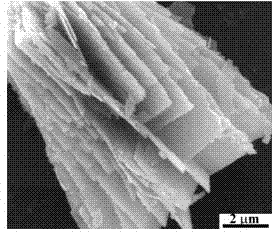

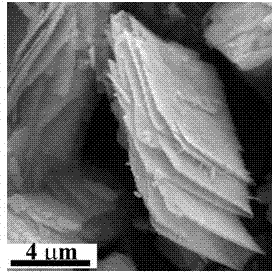

Co3O4 nano lamellar material and preparation method and application thereof

InactiveCN102412397AGood water solubilityPromote nucleationCell electrodesNanotechnologyCobalt saltLithium-ion battery

The invention discloses a Co3O4 nano lamellar material and a preparation method and application thereof. The preparation method comprises the following steps of: mixing cobalt salt, a surfactant, a precipitator and deioned water in stoichiometric ratio; transferring the mixed solution into a reaction kettle and carrying out hydro-thermal reaction for 17.5-18.5 hours at 115-125 DEG C; and then washing and drying to obtain a powdery mixed precursor; and carrying out heat treatment on the powdery mixed precursor in air to finally obtain the Co3O4 nano lamellar material. The prepared Co3O4 material is of a regular nano lamellar structure, and can be applied to the negative electrode of a chargeable lithium ion battery so as to improve the storage capacity of lithium.

Owner:SHANGHAI INST OF TECH

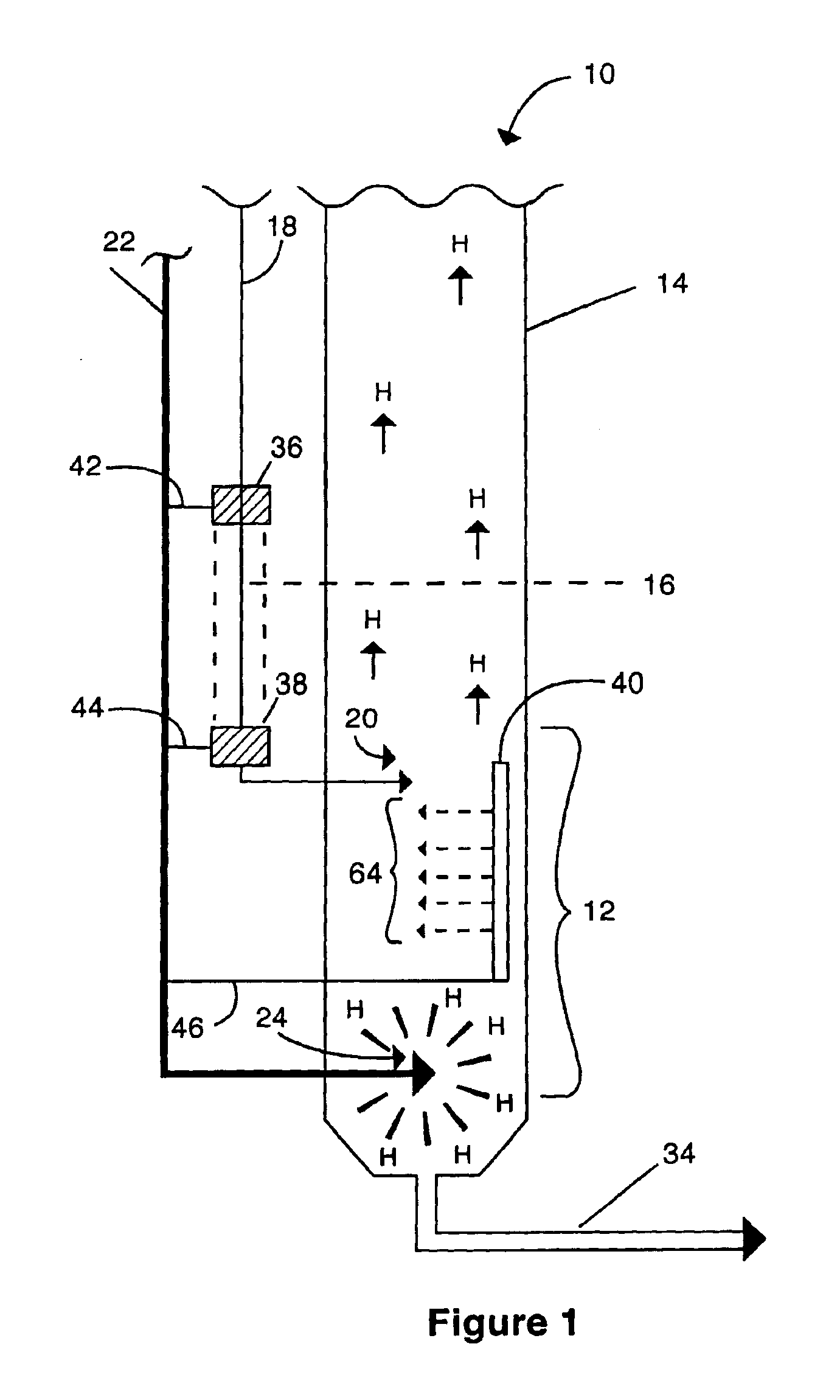

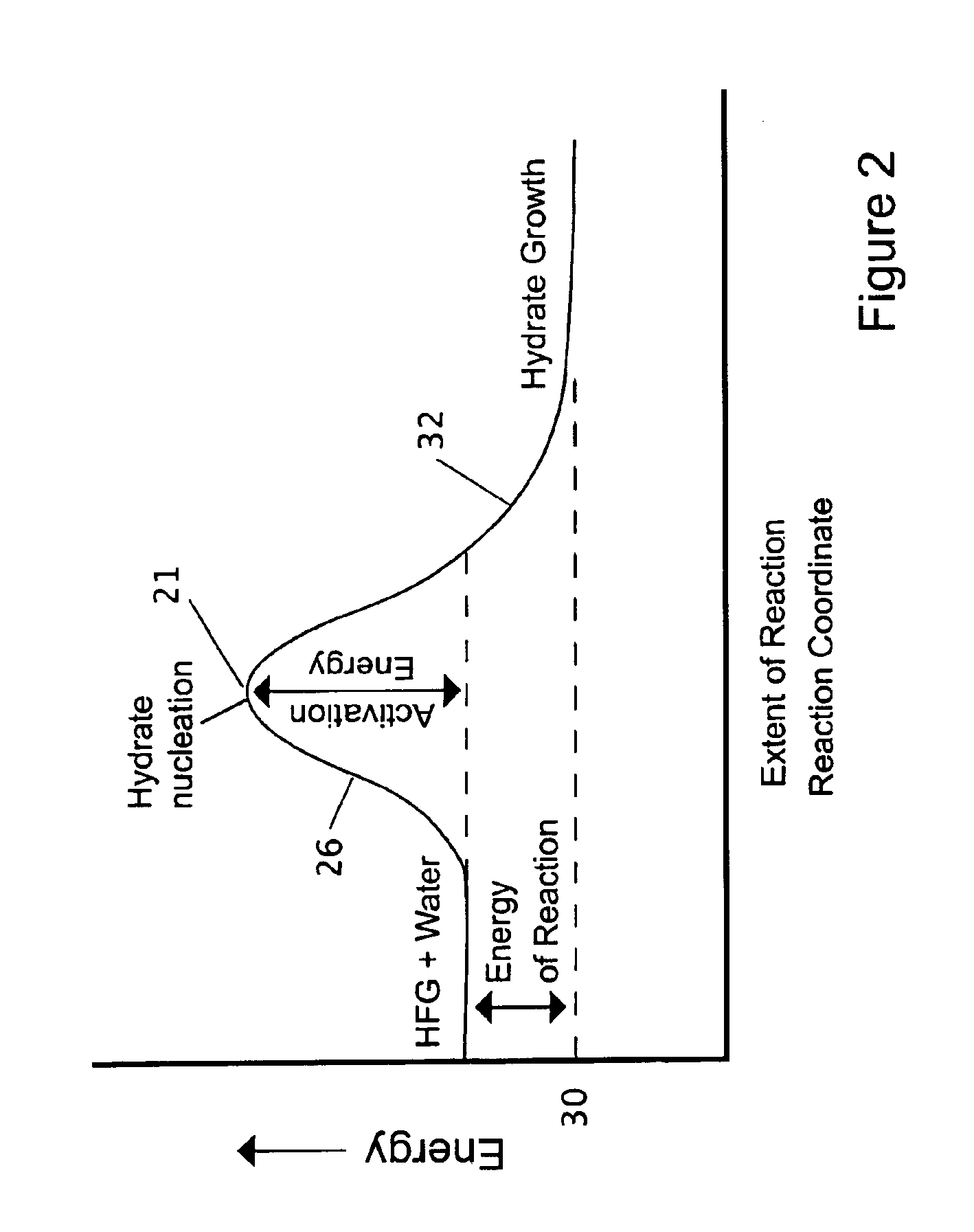

Hydrate formation and growth for hydrate-based desalination by means of enriching water to be treated

InactiveUS6890444B1Saturation pointQuick mergeOrganic chemistryAuxillariesDihydrogen oxideDesalination

Water to be desalinated or otherwise purified is enriched by having hydrate-forming substance dissolved into it, without causing hydrate to form. Hydrate kernels are brought into contact with the enriched water to be treated, and the hydrate kernels grow outwardly into the water to be treated by incorporating dissolved molecules of the hydrate-forming substance and water from the water to be treated. Thus, substantially solid, generally spherical hydrate masses, which are preferred for hydrate-based desalination or purification, can be formed. Hydrate-forming substances can be dissolved into the water to be treated under conditions not conducive to formation of hydrate, such that hydrate does not form, using vigorous means. Hydrate-forming substance is also preferably dissolved into the water to be treated under conditions suitable for hydrate to form, but without causing hydrate to form, e.g., by being infused into the water to be treated using infusion membranes.

Owner:MARINE DESALINATION SYST L L C +1

Method for preparing high-strength high-toughness magnesium alloy plate strip

InactiveCN102127725AImprove ductilityImprove the strengthening effectThermal deformationHigh intensity

The invention relates to a method for preparing a high-strength high-toughness magnesium alloy plate strip by cold deformation and artificial ageing, comprising the following steps of: placing a magnesium alloy in a thermal deformation state or a solid solution magnesium alloy cooled by water quenching after temperature preservation at the temperature of 400-540 DEG C for 1-15 hours into liquid nitrogen to be subjected to subzero treatment and cold deformation, or directly carrying out cold deformation on the original magnesium alloy in the thermal deformation state or the solid solution state, wherein the deformation is controlled to be 5-20%; and finally preserving the temperature of 100-250 DEG C for 5-100 hours and then carrying out artificial ageing, thus the high-strength high-toughness magnesium alloy is obtained. The method provided by the invention is reasonable in design, the equipment requirement is simple, the operation is convenient, and the problems that the cost is high, a large magnesium alloy is difficult to prepare and large-scale application is difficult to realize in the traditional high-strength high-toughness magnesium alloy preparation process can be effectively solved; and magnesium alloy plate strips with excellent comprehensive mechanical properties such as strength, stretchability and the like, thus the method has a good industrial application prospect.

Owner:CENT SOUTH UNIV

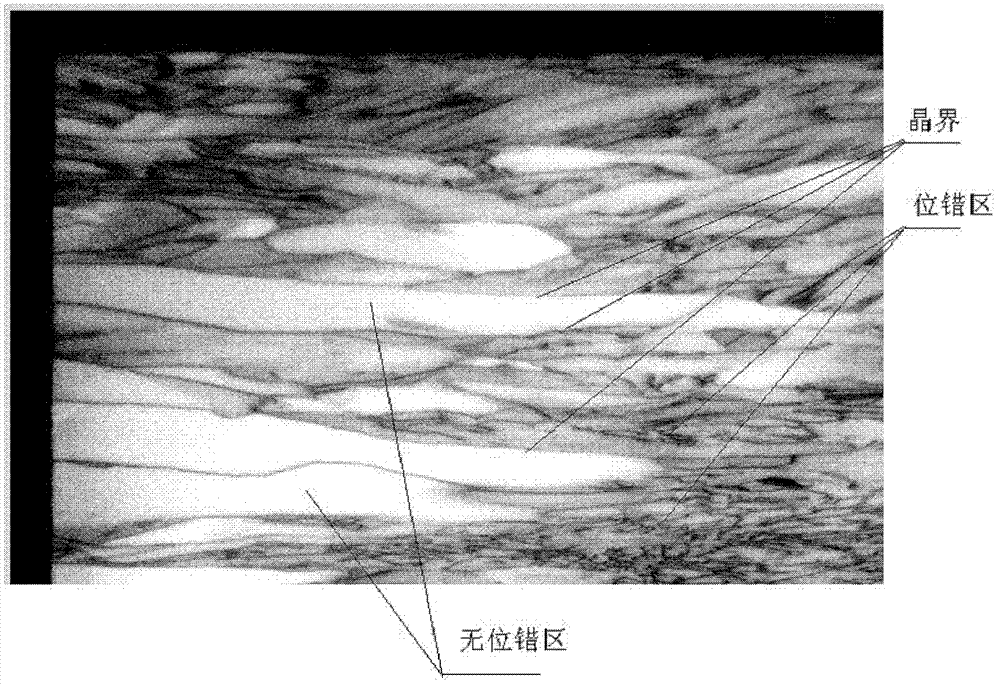

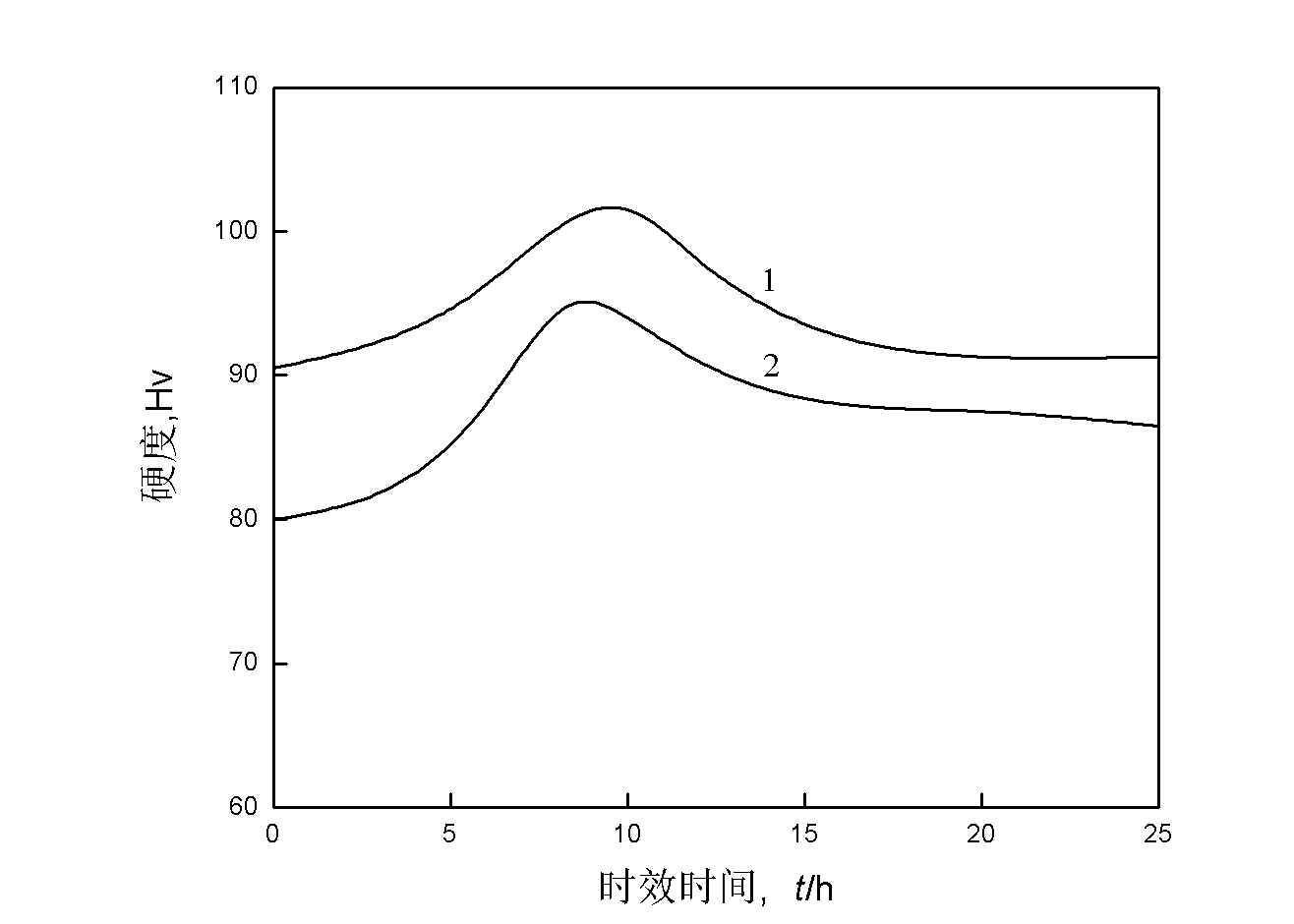

Preparation method for rear-earth magnesium alloy

The invention provides a preparation method for a rear-earth magnesium alloy. The preparation method comprises the following steps of: casting a magnesium melt, extruding and forming after solution treatment, then carrying out cold-rolling and ageing treatment to obtain the rear-earth magnesium alloy, wherein the rear-earth magnesium alloy comprises Mg, Nd, Gd, Y, Zn and Zr. Compared with the prior art, cold-rolling and ageing treatment is carried out after carrying out solution treatment, extruding and forming, so that a great number of beta phases and LPSO phases exist on a crystal boundary, the crystal boundary is pinned to prevent crystalline grains from growing in a transformation process, crystalline grains in the alloy are refined, and therefore, yield strength of the rear-earth magnesium alloy is improved; the rear-earth magnesium alloy has the LPSO phases with 14H structures, and is regularly distributed along extruding direction; stability of the boundary improves strength and toughness of the rear-earth magnesium alloy; moreover, high-density dislocation is introduced in cold-rolling, and nucleation of beta' phases in an ageing process is promoted, so that ageing hardening effect of the alloy is improved; meanwhile, the beta' phases can be more refined by the cold-rolling.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

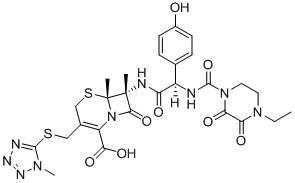

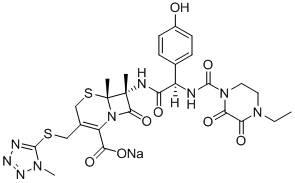

Method for crystallizing cefoperazone sodium

The invention aims to provide a method for crystallizing cefoperazone sodium, which comprises the following steps of: dissolving cefobid in a solvent, and adding a salt forming agent to adjust the pH to between 6.2 and 6.8 until the solid is completely dissolved; and filtering, adding the filtrate into the solvent under the ultrasonic condition to separate out crystals, filtering, washing and leaching the crystals, and performing vacuum drying to obtain the cefoperazone sodium. Aiming at the problems in the industrial crystallization of the cefoperazone sodium, the ultrasonic radiation has strong orienting effect, supplements and enhances the wave action required by the formation of critical crystal nucleus, can accelerate graining process and promote the quick generation of the crystal nucleus, and achieves the effect of quickly graining without seeding by seed crystals; meanwhile, the ultrasonic in the liquid medium can make mass points in the medium obtain high acceleration, has the effect of cavitation, and can prevent the accumulation during crystal growth to make the size distribution of the crystals uniform.

Owner:FUJIAN FUKANG PHARMA

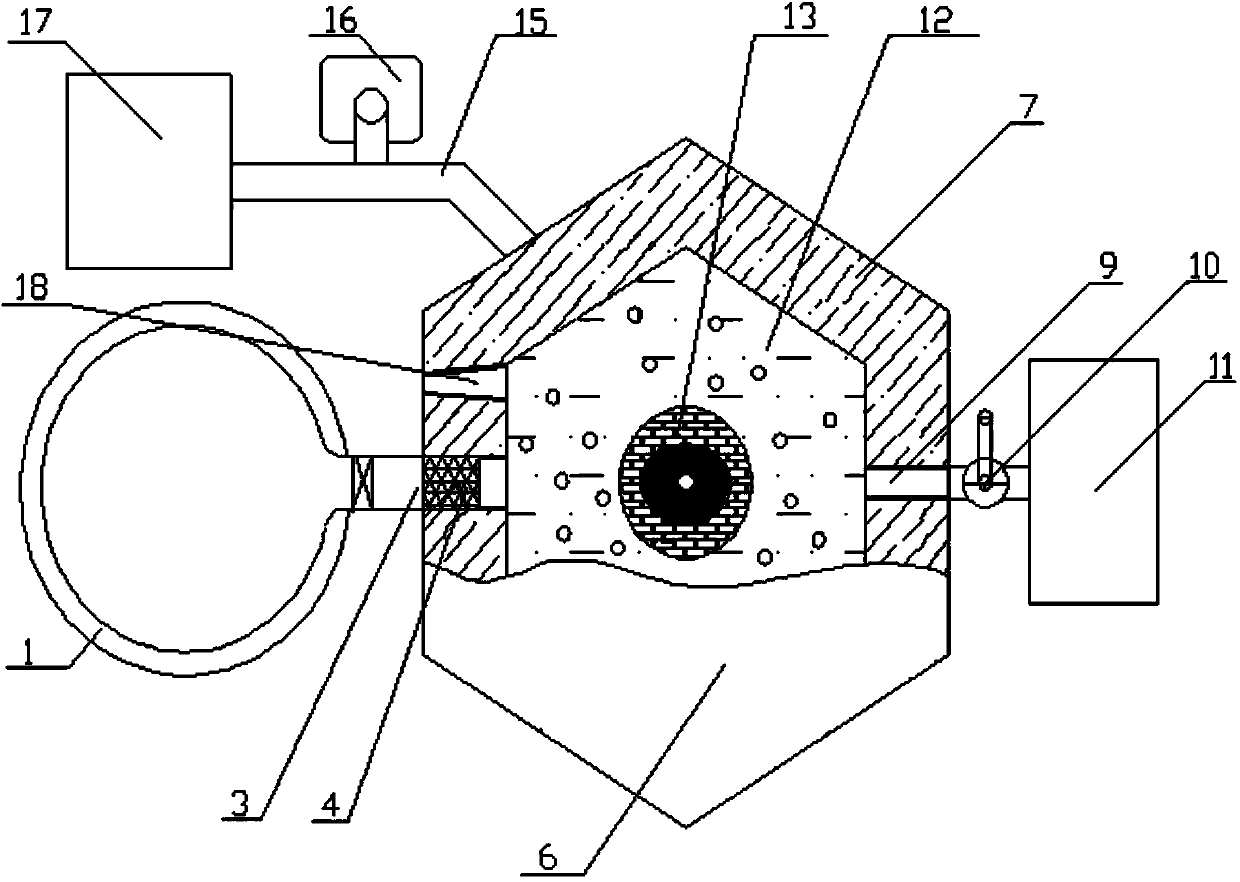

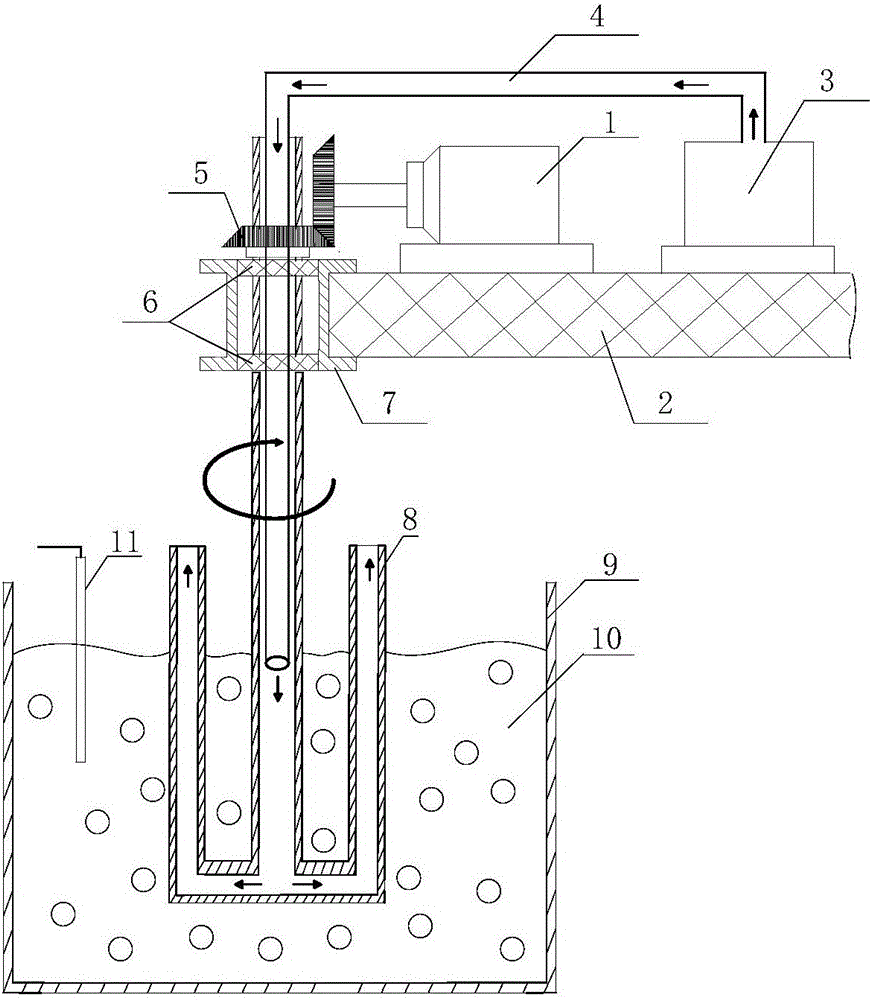

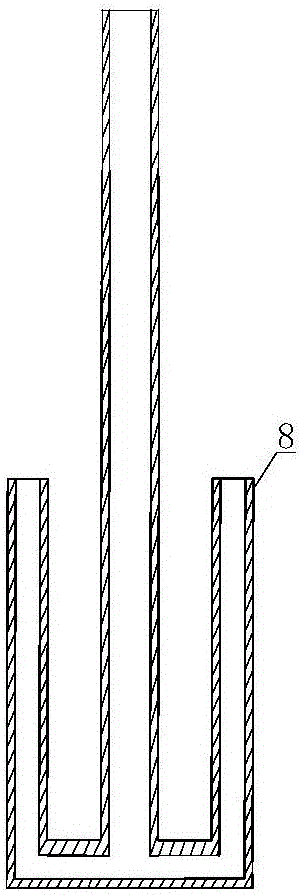

Device and method for preparing light alloy semi-solid slurry through air-cooling multi-tube stirring

The invention provides a device and method for preparing light alloy semi-solid slurry through air-cooling multi-tube stirring. The device comprises a crucible for containing light alloy melt, an air-cooling multi-tube stirring mechanism and a lifting mechanism. The air-cooling multi-tube stirring mechanism comprises a stirring mechanism body and an air supply mechanism. The stirring mechanism body is composed of a stirring motor, a multi-tube stirring rod and a bevel gear drive group which are arranged on a lifting platform. The multi-tube stirring rod is supported and positioned through a bearing. The air supply mechanism is composed of an air guide tube and an air supply device. One end of the air guide tube is combined with the air supply device, and the other end of the air guide tube is inserted into the multi-tube stirring rod. Multiple stirring pipes are filled with air entering the air guide tube. The device is simple in structure, convenient to use, high in efficiency, safe, reliable, wide in applicable scope in alloy and especially suitable for preparing large-volume semi-solid alloy slurry, the melt temperature, the stirring speed, the number of the stirring tubes, the inner diameter, the wall thickness, the stirring time and air ventilation quantity can be accurately controlled, and industrial application and popularization are facilitated.

Owner:UNIV OF SCI & TECH BEIJING

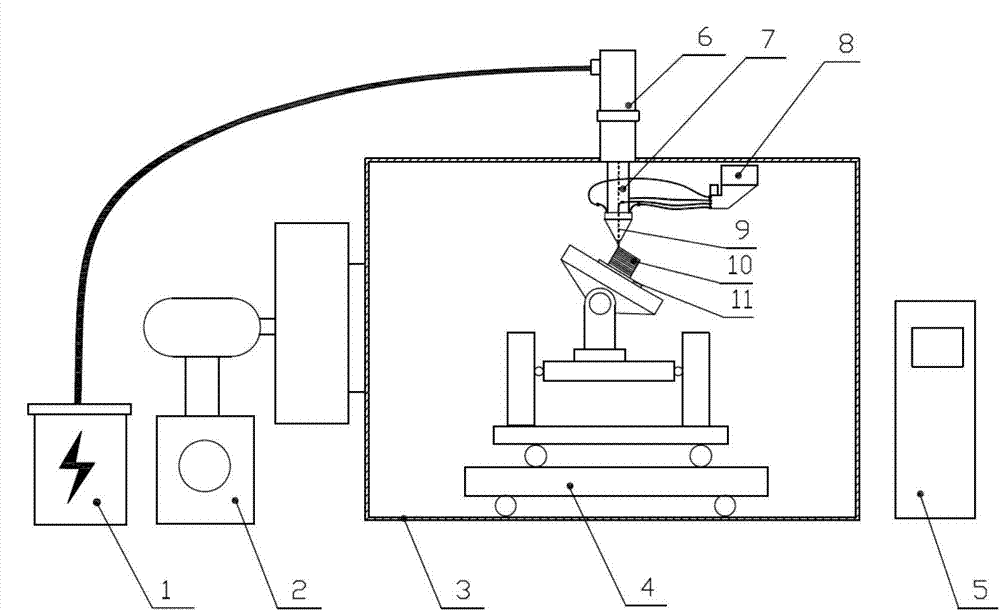

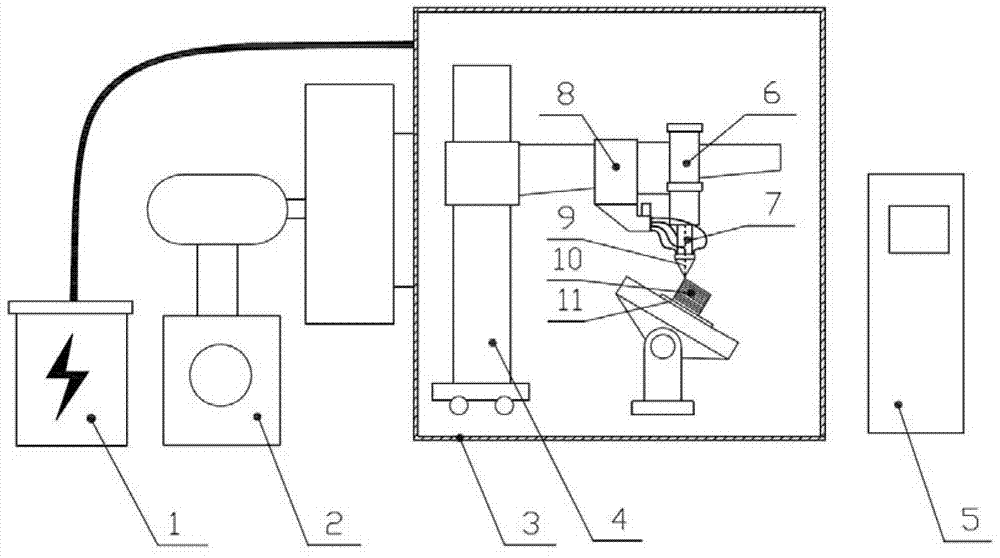

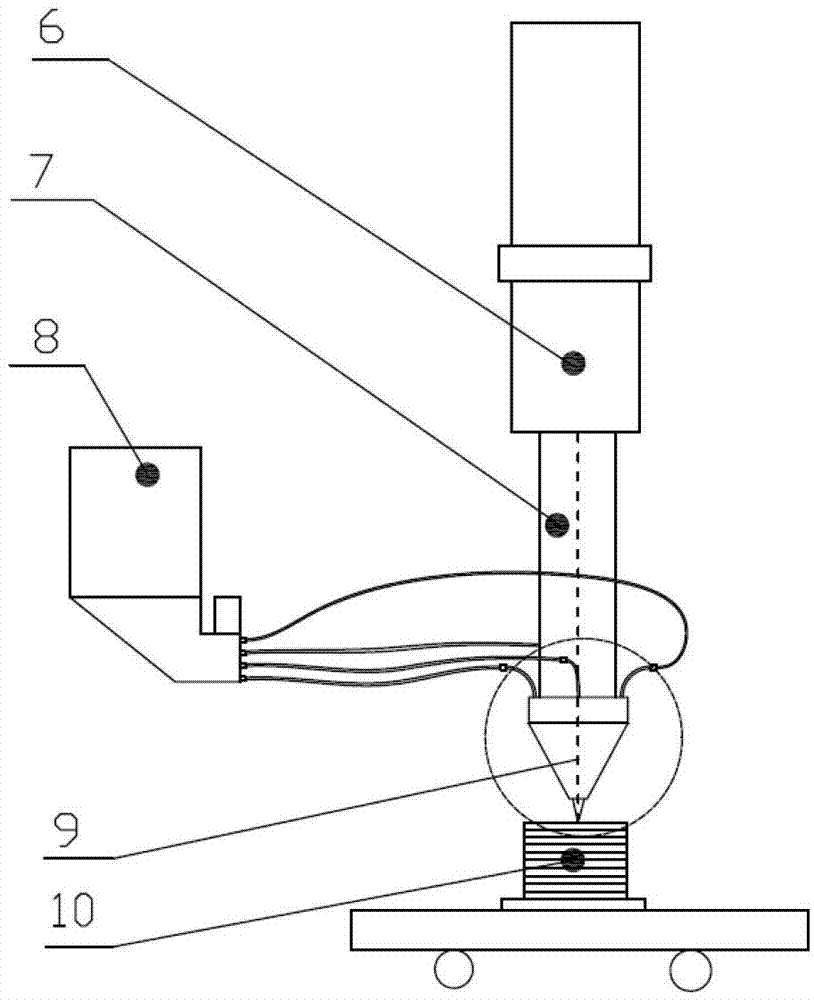

Electron beam synchronous powder feeding and quick forming method

InactiveCN102764889AImprove protectionAvoid mixingAdditive manufacturing apparatusMolten spray coatingMelting tankChemical composition

The invention discloses an electron beam synchronous powder feeding and quick forming method. The method includes that metal powder is fed to a portion, which is intersected with beam current, of a to-be-processed surface, in a coaxial or paraxial manner, and the portion can be positioned in a molten pool or at the front of the molten pool. The electron beam synchronous powder feeding and quick forming method is characterized in that an electron beam bombards a workpiece to form the molten pool, the molten pool moves relative to the surface of the workpiece, the metal powder is simultaneously fed to a thermal action zone to participate in melting, and processing is implemented. As the powder is fed, the synchronous powder feeding and quick forming method has the advantages that speed is fast, quality is good, chemical composition and structure property of a part can be conveniently regulated and controlled, and the method is particularly applicable to preparing high-gradient and multi-step materials and structures and also can be used for processing parts with fine appearances and dimensions. Compared with wire feeding technology, the electron beam synchronous powder feeding and quick forming method has the powder does not interfere with the part, technological difficulty is low, and the method is easy to control.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

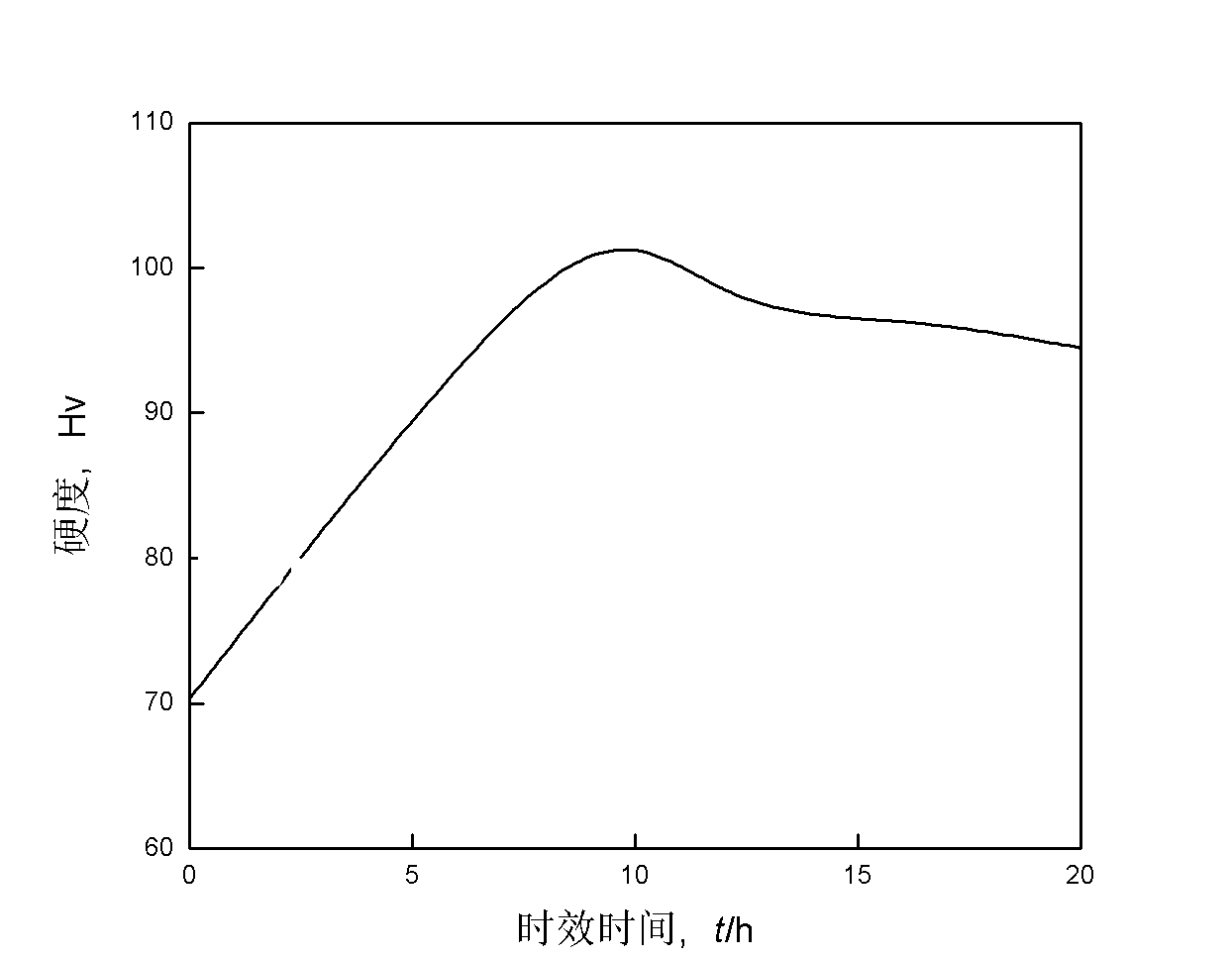

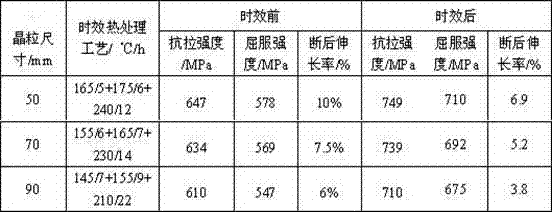

Three-level aging heat treatment process for nanometer magnesium alloy

The invention relates to a three-level aging heat treatment process for nanometer magnesium alloy. The alloy comprises the following components in percentage by mass: 6-13% of gadolinium, 2-6% of yttrium, 0.3-0.8% of zirconium, and the balance of magnesium and inevitable impurities. The nanometer magnesium alloy obtained by extrusion-fast cold forging with average crystallite size of 40-100 nm is subjected to level 1 aging heat treatment at 140-170 DEG C for 4-8 hours, and then the alloy subjected to level 1 aging treatment is subjected to level 2 aging heat treatment at 150-180 DEG C for 5-10 hours, finally the alloy subjected to level 2 aging treatment is subjected to level 3 aging heat treatment at 200-250 DEG C for 10-30 hours. Compared with the nanometer magnesium alloy without aging treatment, the strength and the yield strength of the alloy subjected to three-level aging heat treatment is increased by 100-105 MPa and 123-135 MPa respectively, and the alloy has a strength of extension of 705-750 MPa and yield strength of 670-715 MPa.

Owner:CENT SOUTH UNIV +1

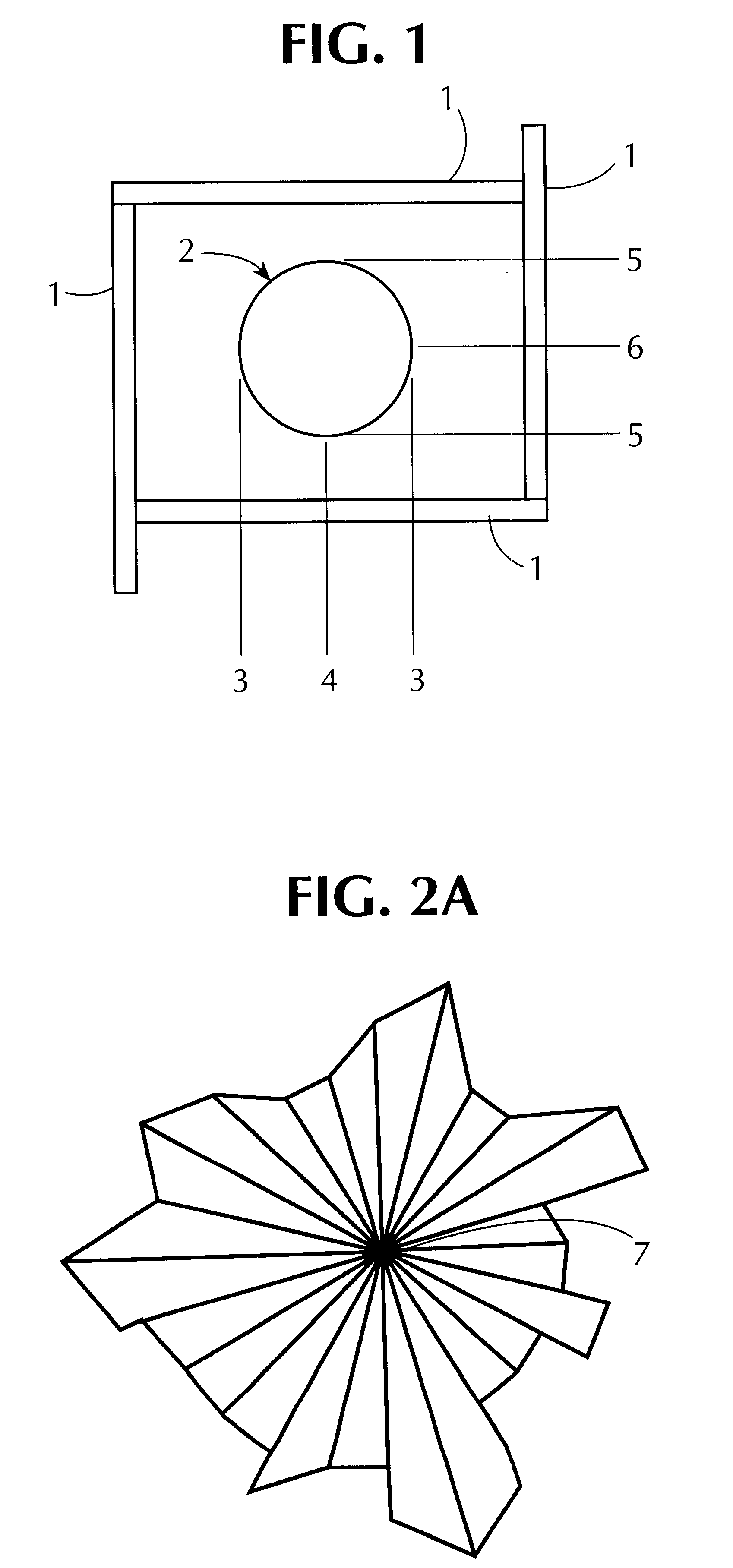

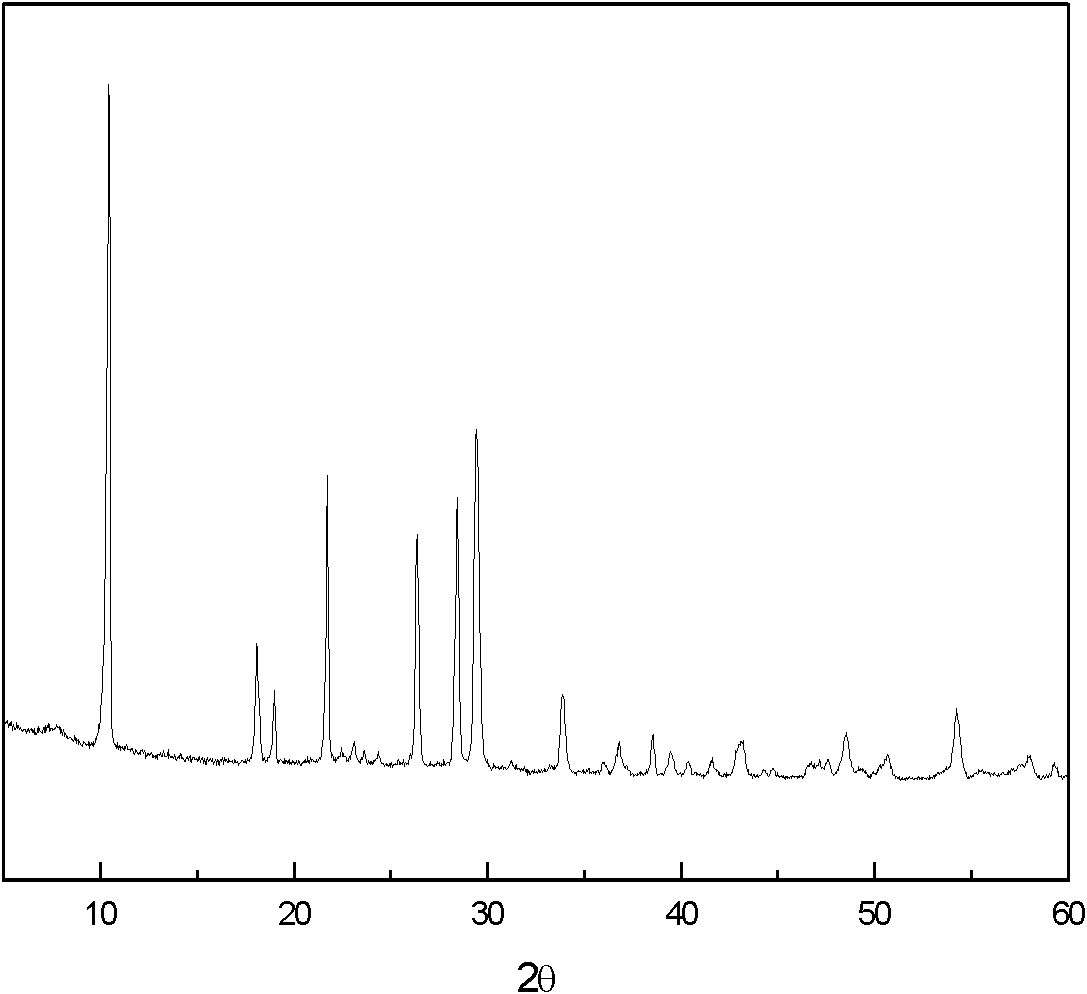

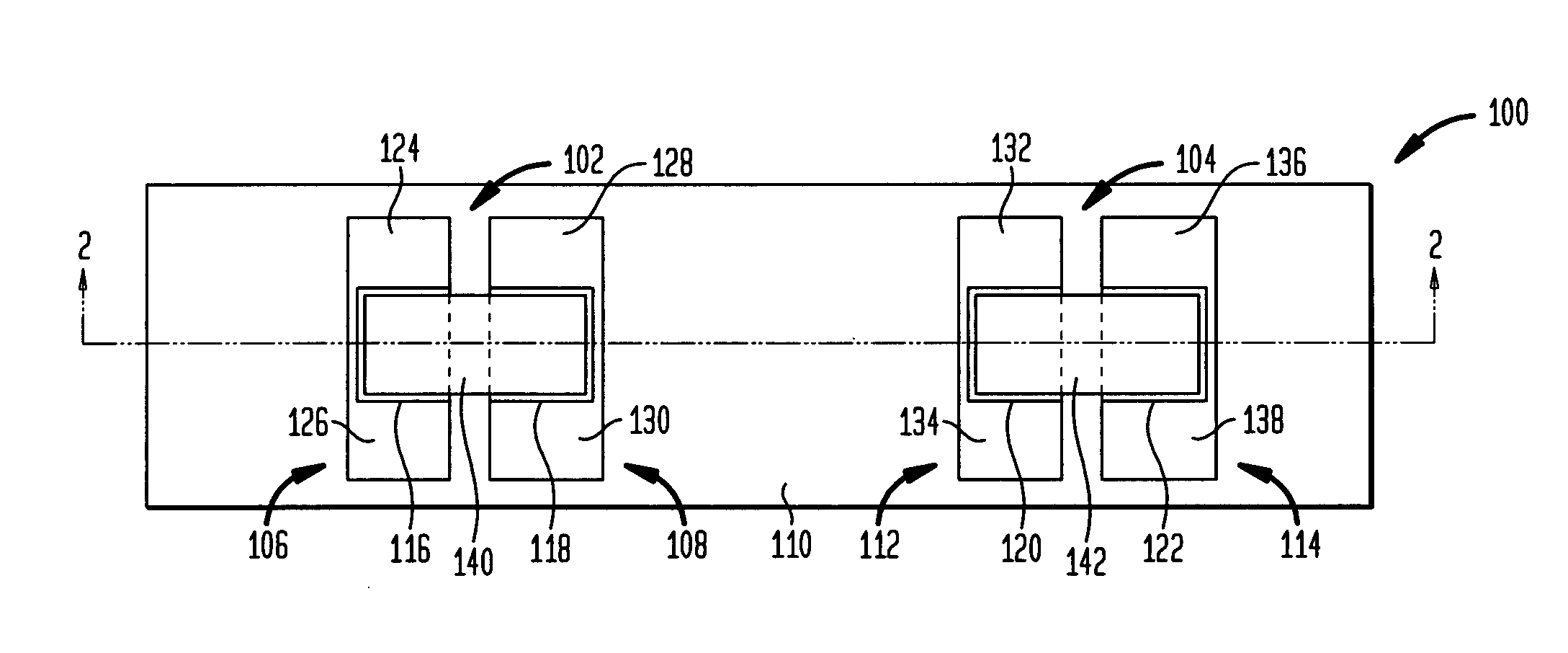

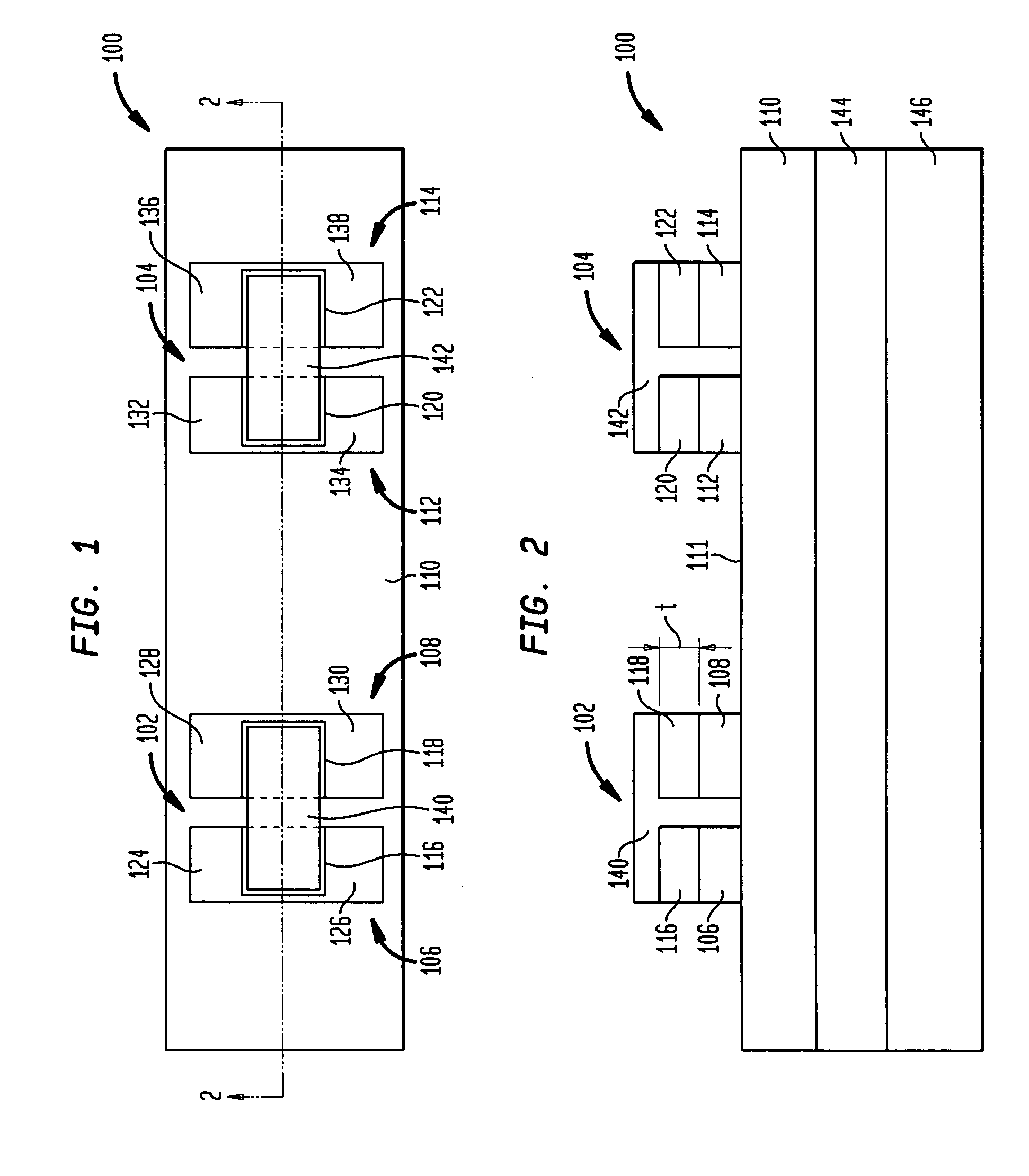

Devices having patterned regions of polycrystalline organic semiconductors, and methods of making the same

InactiveUS20050110006A1Promote and inhibit nucleationInhibition of nucleationTransistorMaterial nanotechnologyCompound (substance)Organic semiconductor

Semiconductor apparatus comprising a substrate having a substrate surface; a first dielectric layer comprising molecules of a first compound, the molecules of the first compound having first ends and second ends, the first ends being covalently bonded to a first region of the substrate surface, the second ends having aromatic regions; and a polycrystalline semiconductor layer comprising organic semiconductor molecules with aromatic portions, the polycrystalline semiconductor layer being on the first region of the substrate. Integrated circuits comprising apparatus, and methods for making apparatus and integrated circuits.

Owner:LUCENT TECH INC

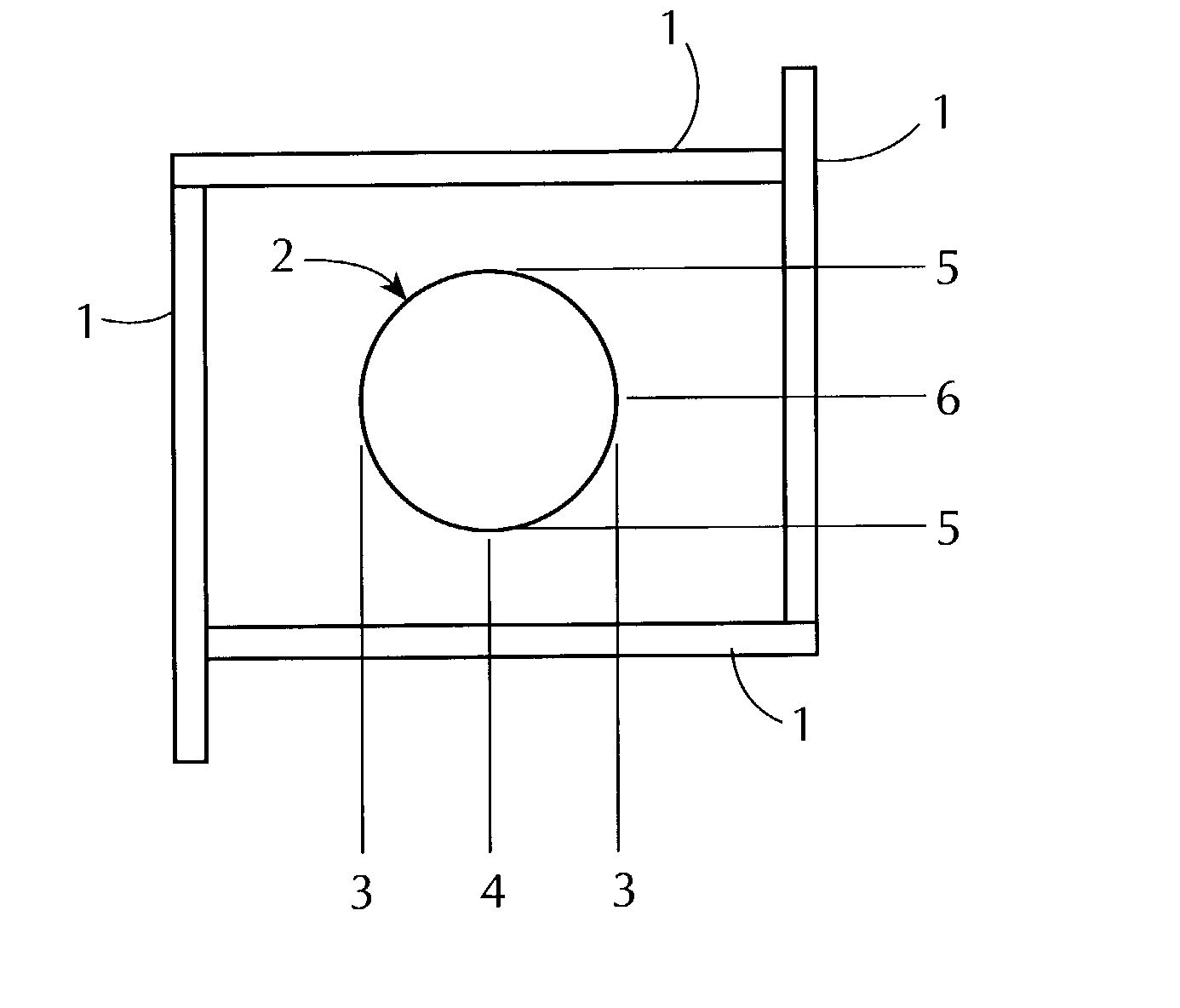

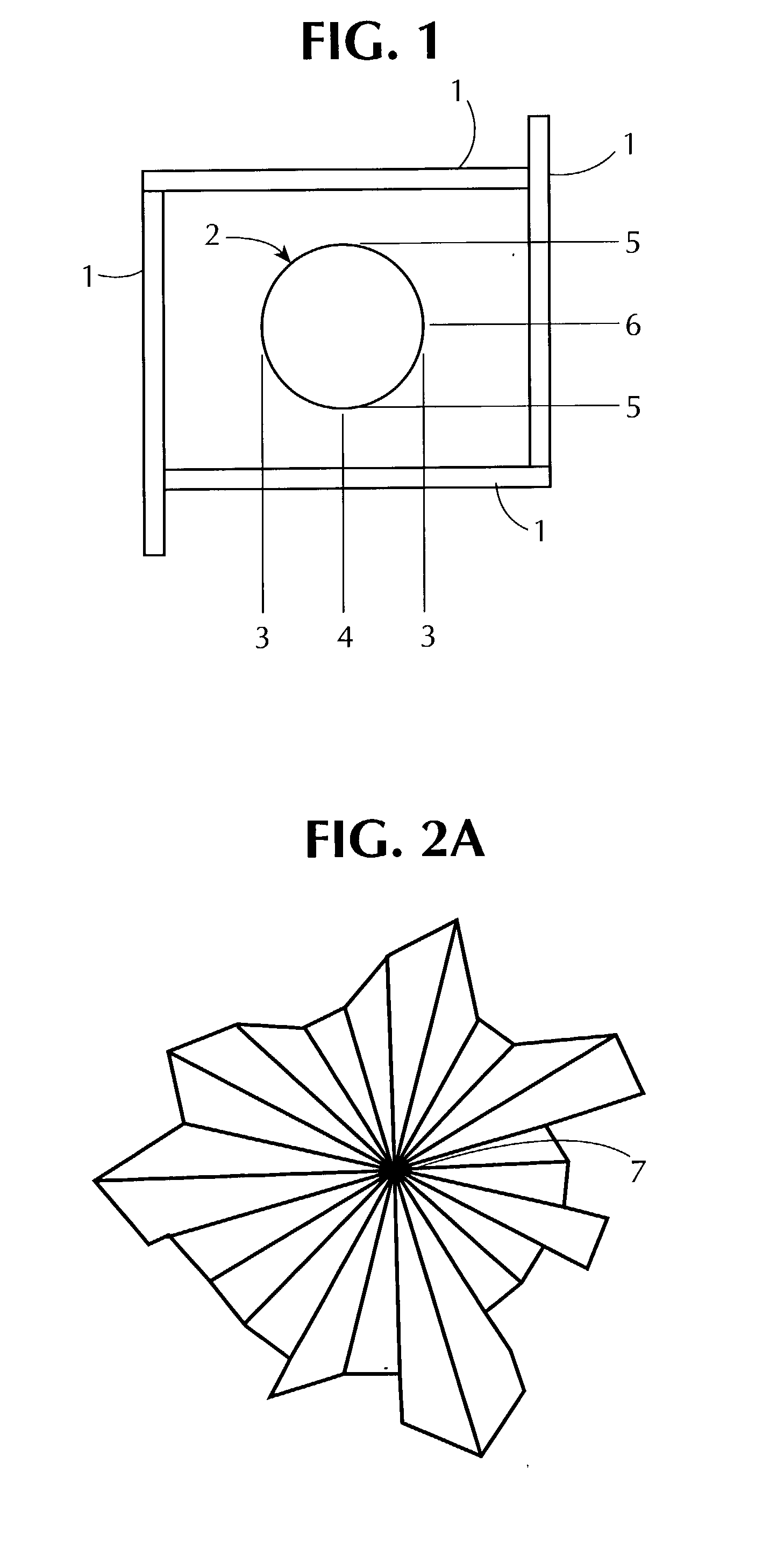

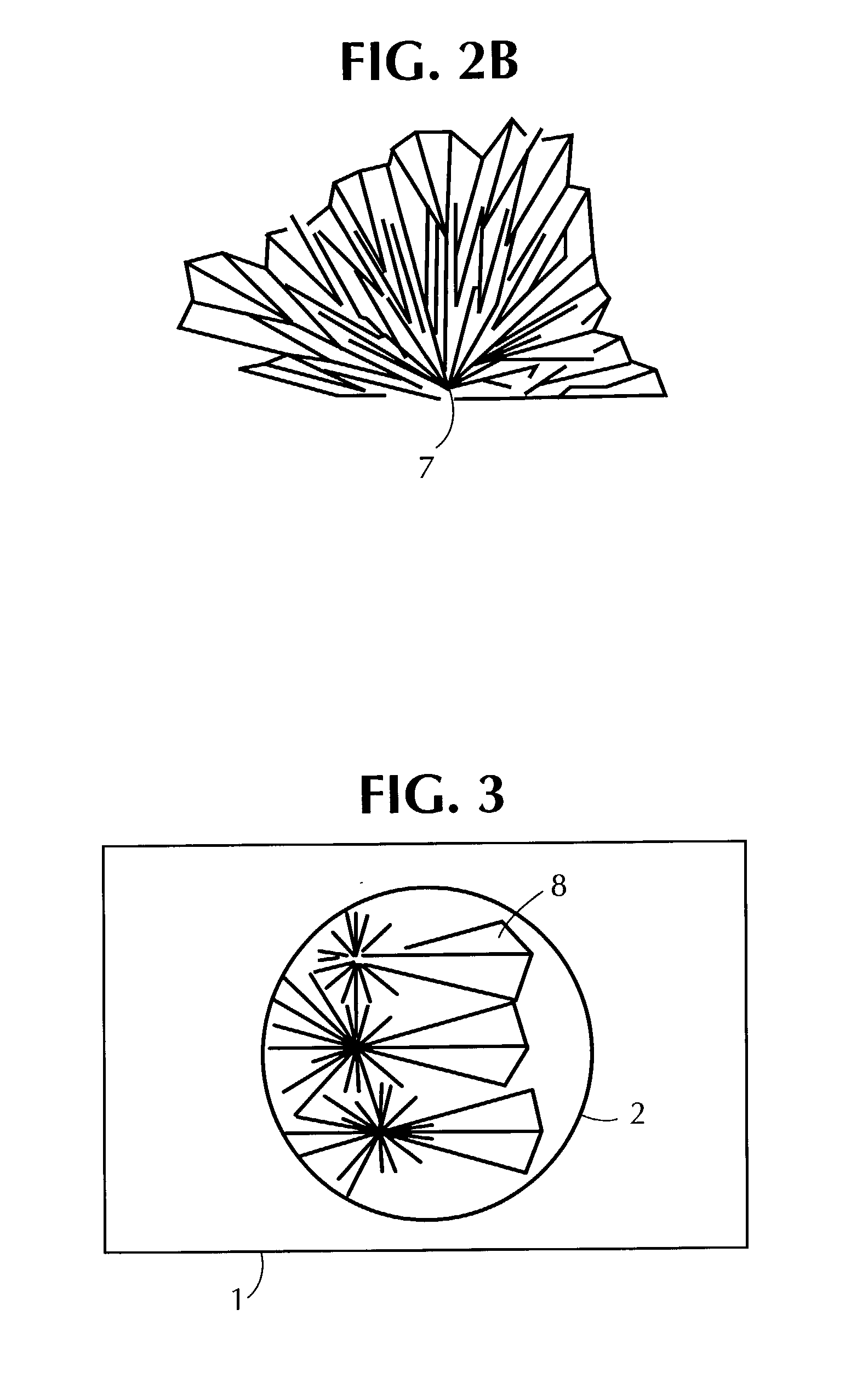

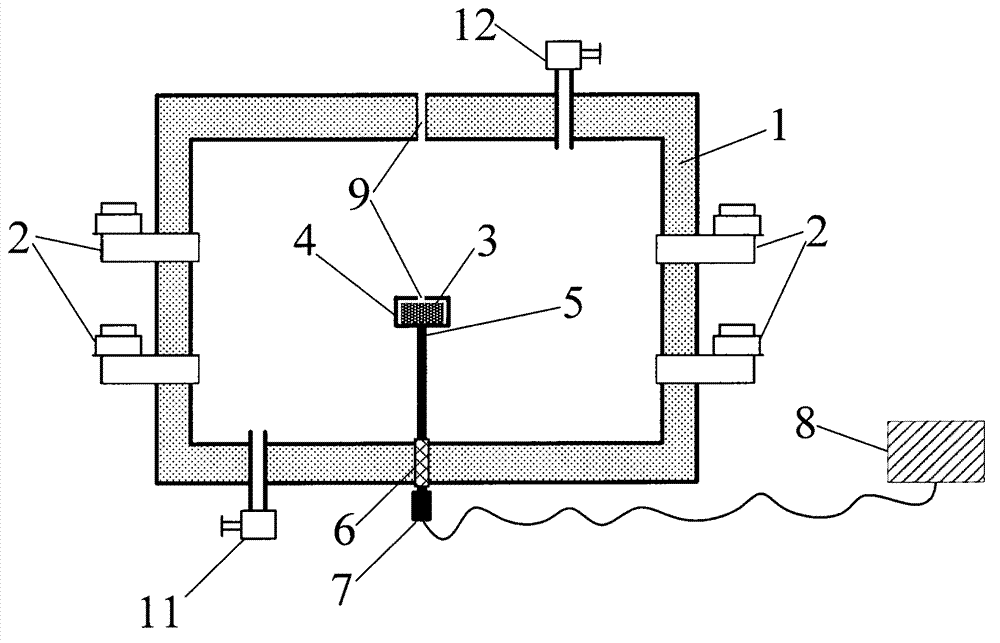

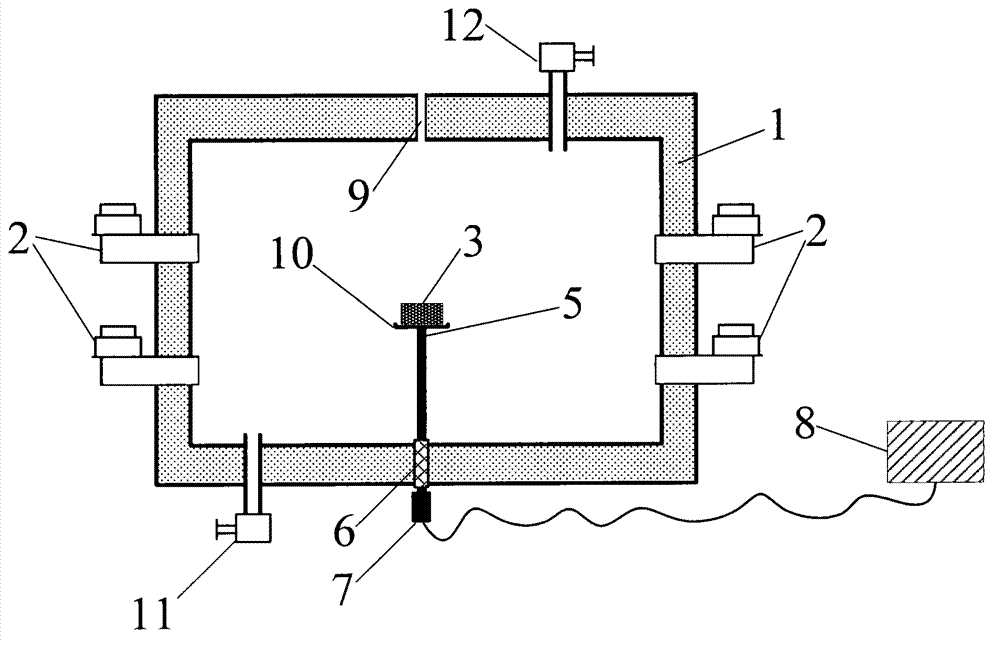

Ultrasonic vibration activation assisted microwave sintering furnace

The invention aims at designing an ultrasonic vibration activation assisted sintering microwave sintering furnace according to the practical needs of new material research and development for the sintering technology and the advantages of the ultrasonic technology. The ultrasonic vibration activation assisted microwave sintering furnace is composed of a microwave source, magnetrons, a waveguide tube, a wave leading crucible or a common high-temperature crucible, an amplitude-change pole, an amplitude-change pole supporting frame, an ultrasonic generator, an ultrasonic transducer and the like. Electric signals generated by the ultrasonic generator are converted into ultrasonic vibration through the ultrasonic transducer, the ultrasonic vibration is transmitted to a sample to be sintered in the wave leading crucible or the common high-temperature crucible through the amplitude-change pole and the crucible, the sample to be sintered is in the ultrasonic vibration state in the microwave sintering process, material particles of the sample to be sintered are vibrated at a high speed under the microwave sintering temperature through the microwave radiation action, crystalline grains of the sample to be sintered are promoted to be quickly and evenly nucleated and grow or part of matter is evenly melted for quickly filling a gap. By means of the ultrasonic vibration activation assisted microwave sintering furnace, the sintered microstructure of a block sample can be more uniform and more compact, and the sample is better in the microstructure.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

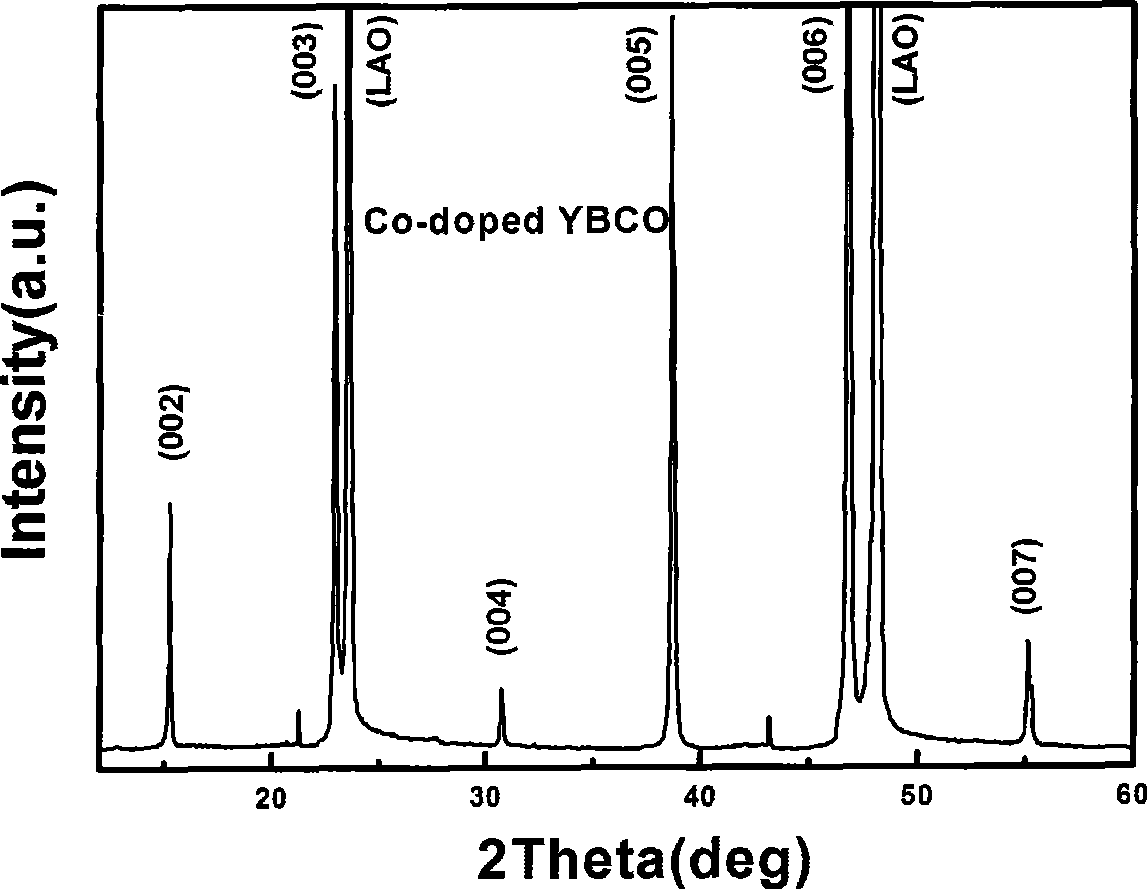

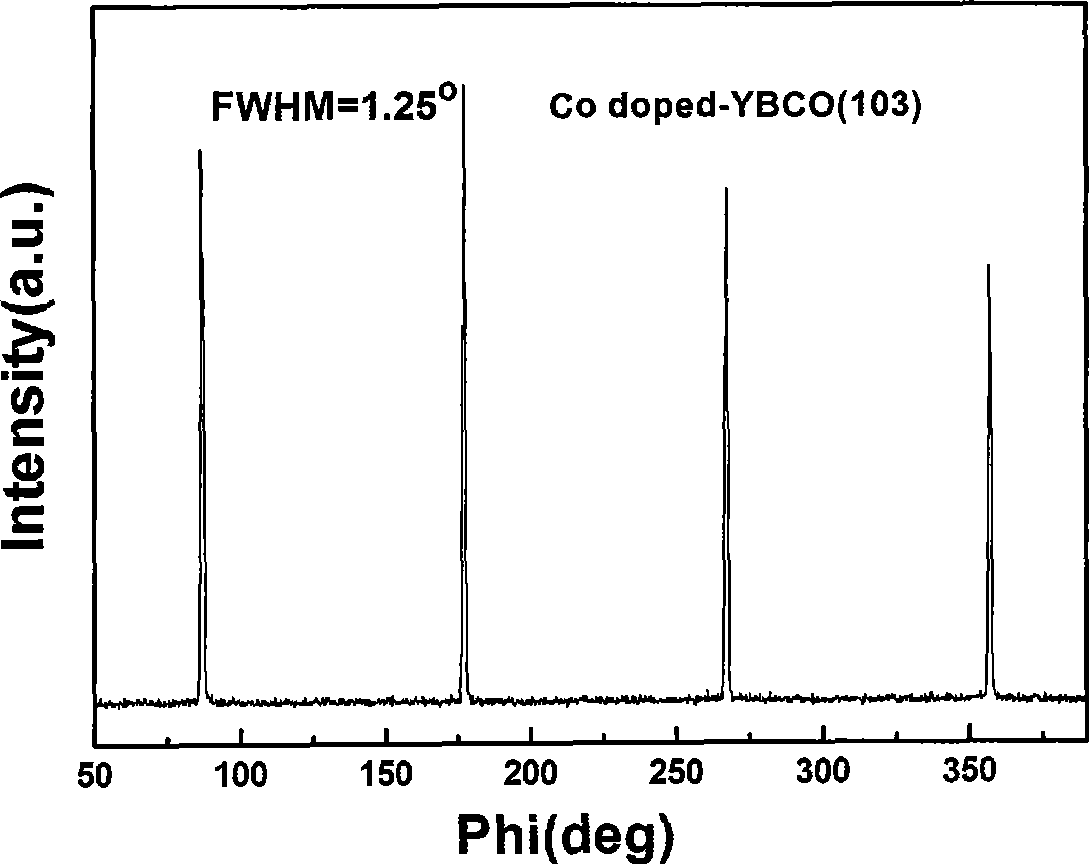

Method for preparing high critical current density yttrium barium copper oxide superconducting film

InactiveCN101456726ASimple processShorten the timeSuperconductors/hyperconductorsSuperconductor devicesPolyvinyl butyralPropanoic acid

The invention discloses a method for preparing a yttrium barium copper oxide superconducting film with high critical current density, which comprises the following concrete steps: a, preparing a precursor solution, which is to dissolve yttrium acetate, barium acetate, copper acetate and acetate of an impurity element into propionic acid according to the proportion that the stoichiometric ratio of yttrium: barium: copper: impurity element is 1: 2: 3-X: X (the X is more than or equal to 0.0002 and less than or equal to 0.008) to obtain the precursor solution, and the impurity element is one of Co, Fe, Zn, Ni, and Li; b, adding a polymer material polyvinyl butyral (PVB) into the precursor solution obtained in a step to obtain a coating colloid; c, coating and drying the coating colloid on a substrate to form a film; and d, performing thermal decomposition treatment on the substrate with the film prepared in c step and then imaging thermal treatment to obtain the YBCO superconducting film. The yttrium barium copper oxide superconducting film prepared by the method has high biaxial texture, smooth and compact surface, high critical current density under a magnetic field, low cost, and simple process, and is suitable for mass industrial production.

Owner:SOUTHWEST JIAOTONG UNIV

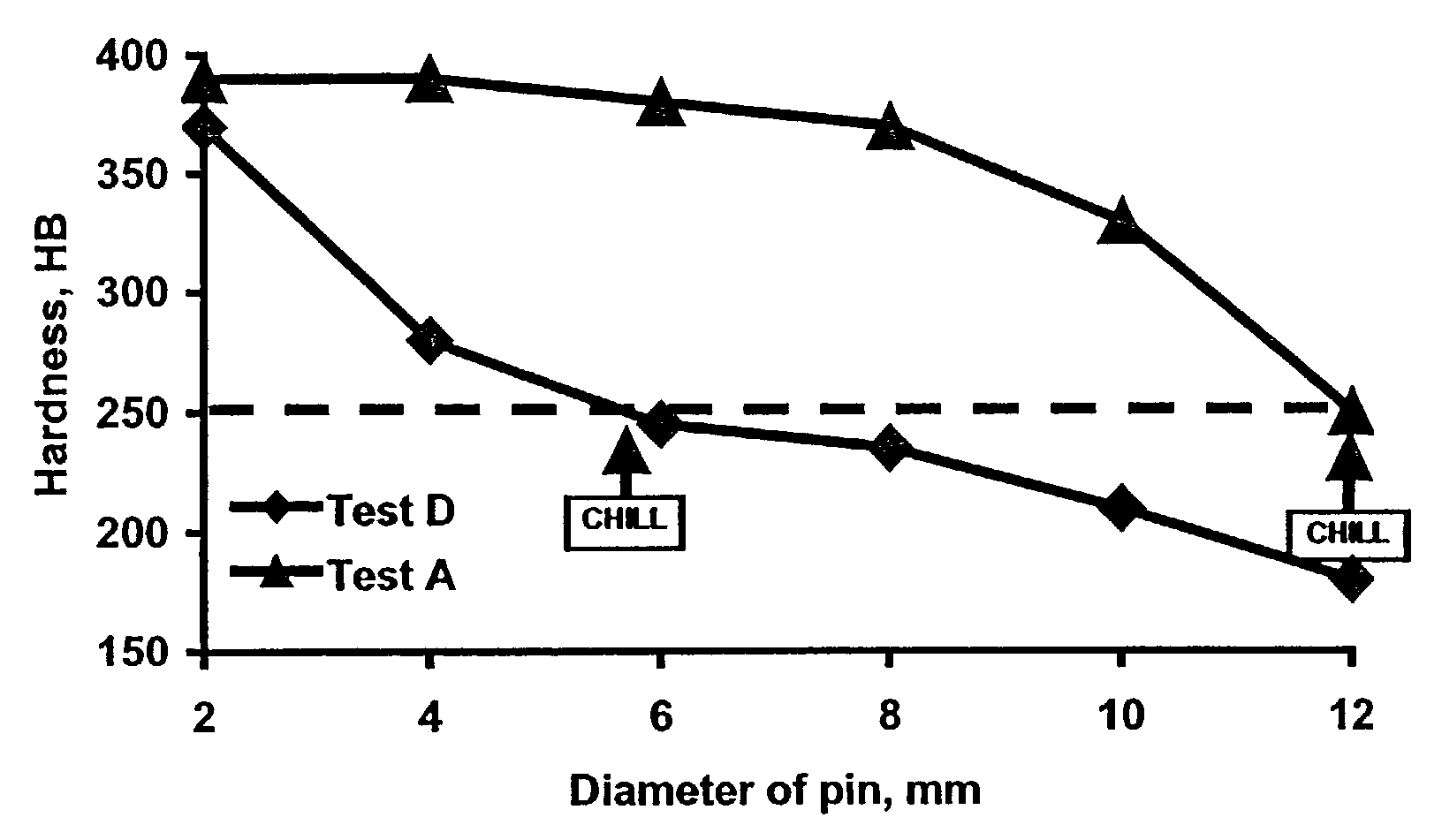

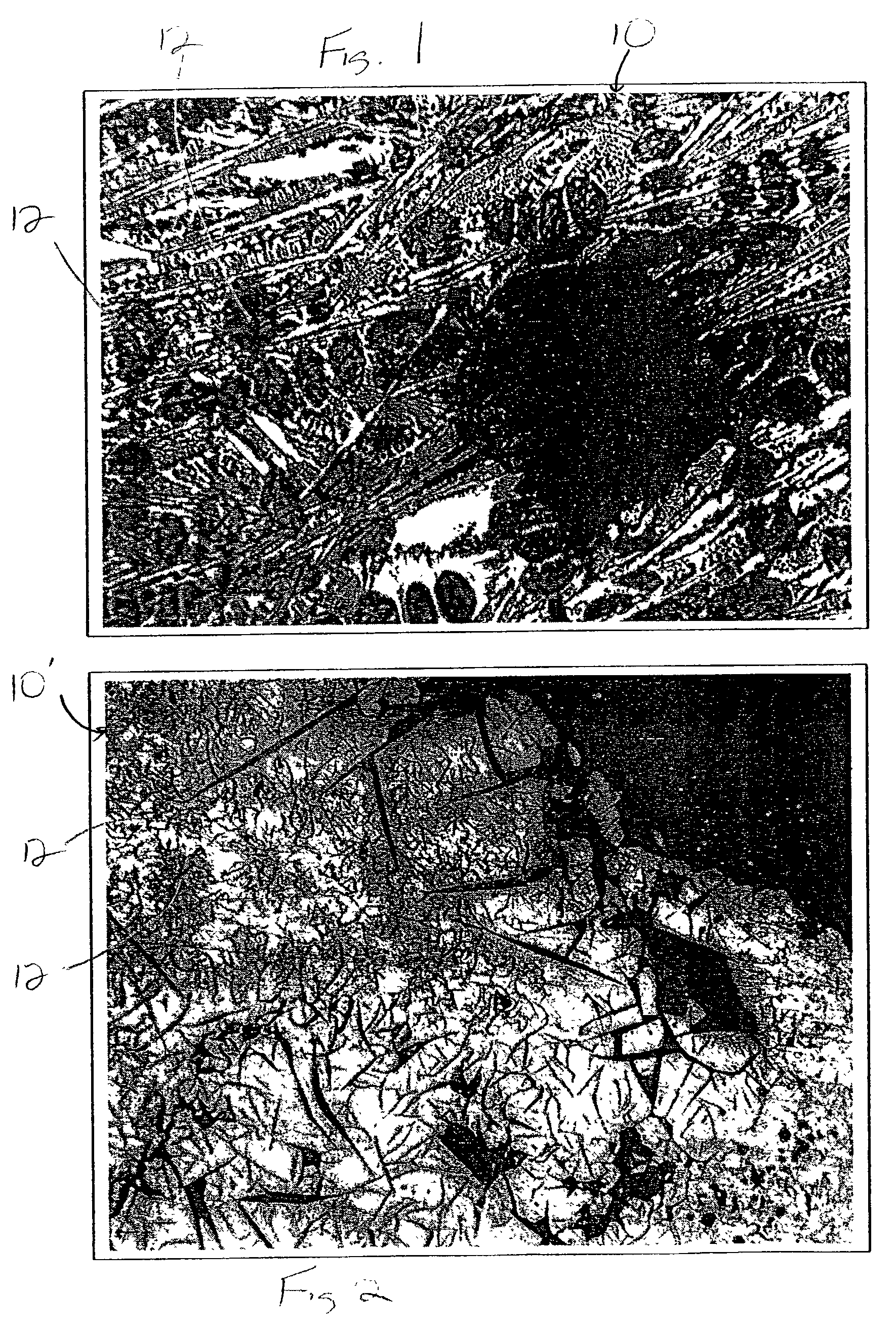

Additive for inoculation of cast iron and method

InactiveUS20050050992A1Increase nucleation numberUniform structureBlast furnace componentsBlast furnace detailsRare earthMetallic sulfide

An additive for increasing the toughness of thin-wall iron castings is provided. The additive includes amounts of a non-ferrous metal oxide and a metal sulfide in which the non-ferrous metal has an affinity for oxygen less than that of iron, and the metal has an affinity for sulfur less than that of magnesium. The metals contained in the oxides and sulfides are also not alkali, alkali earth or rare earth metals to reduce the incidence of defect formation in the castings. The metal oxide and metal sulfide, when added to a cast iron melt react with magnesium added to the melt as a spheroidizing graphite element to form nucleation sites having a core of magnesium oxide surrounded by magnesium sulfide. These nucleation sites allow for increased nucleation of graphite, whether in vermicular or spheroidal form, such that the cross-section of the thin-wall iron casting is more uniform, thereby decreasing the amount of carbide formed in the casting and increasing the toughness of the casting.

Owner:WISCONSIN ALUMNI RES FOUND

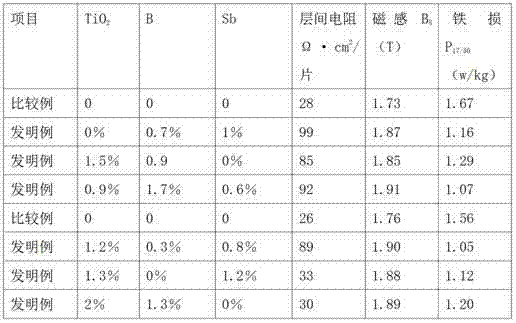

Production method for improving insulating property by adding trace elements in oriented silicon steel barrier-coat

The invention discloses a production method for improving the insulating property by adding trace elements in an oriented silicon steel barrier-coat. The production method comprises the following steps of smelting, processing in vacuum, refining and continuously casting into a blank; carrying out hot rolling; normalizing and acid pickling; carrying out once cold rolling, wherein the reduction rate is greater than or equal to 82%; decarbonizing and annealing, wherein the temperature is 750-890 DEG C, the atmosphere dew-point temperature is 25-75 DEG C, the decarbonization time is 90-350 seconds, and the total oxygen [O] of the surface of a steel belt is greater than or equal to 170 / t and less than or equal to 315 / t; coating a magnesium oxide coating added with trace elements on the surface of the steel belt; carrying out high temperature annealing, wherein the atmosphere dew-point temperature is less than or equal to 30 DEG C, two low thermal insulation steps and one high thermal insulation step are arranged, and the nitridation amount of nitrogen is greater than or equal to 16ppm; stretching and smoothing and annealing, namely, coating, annealing and smoothing. In high temperature annealing stage, silicon dioxide and magnesium oxide on the surface of the steel belt carry out chemical reaction so as to generate a magnesium silicate bottom layer, and additives are added into the magnesium oxide coating so as to help to obtain excellent finished product magnetism and good magnesium silicate bottom layer.

Owner:新万鑫(福建)精密薄板有限公司

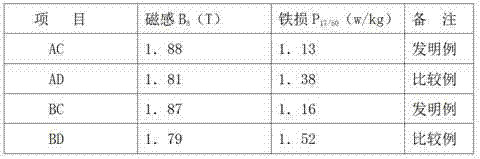

Ferritic stainless steel with good wrinkle resistance and production method thereof

InactiveCN101845595AGood wrinkle effectProduction process is feasibleWrinkle skinTransition temperature

The invention relates to ferritic stainless steel with good wrinkle resistance and a production method thereof. The ferritic stainless steel comprises the following components by weight percentage: less than or equal to 0.02 percent of C, less than or equal to 0.02 percent of N, 0.10-0.50 percent of Si, 0.10-0.50 percent of Mn, less than or equal to 0.03 percent of P, less than or equal to 0.01 percent of S, 16-30 percent of Cr, less than or equal to 1.00 percent of Ni, 0.15-0.40 percent of Nb, less than or equal to 16 percent of Nb / (C+N), less than or equal to 0.010 percent of O, less than or equal to 1.00 percent of Cu and the rest being Fe and inevitable impurity elements. Since the stabilization element Ti which can damage the surface quality of continuous casting and increase the brittle transition temperature is not added, and only the stabilization element Nb is added, the invention can reduce the quantity of casting blank repair and the strip breakage risk, improve the surface quality and overall performance, eliminate the wrinkle of the surface of the ferriticstainless steel cold-rolled plate with a medium and high Cr content, reduce the wear and repair loss during the production process, and decrease the production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

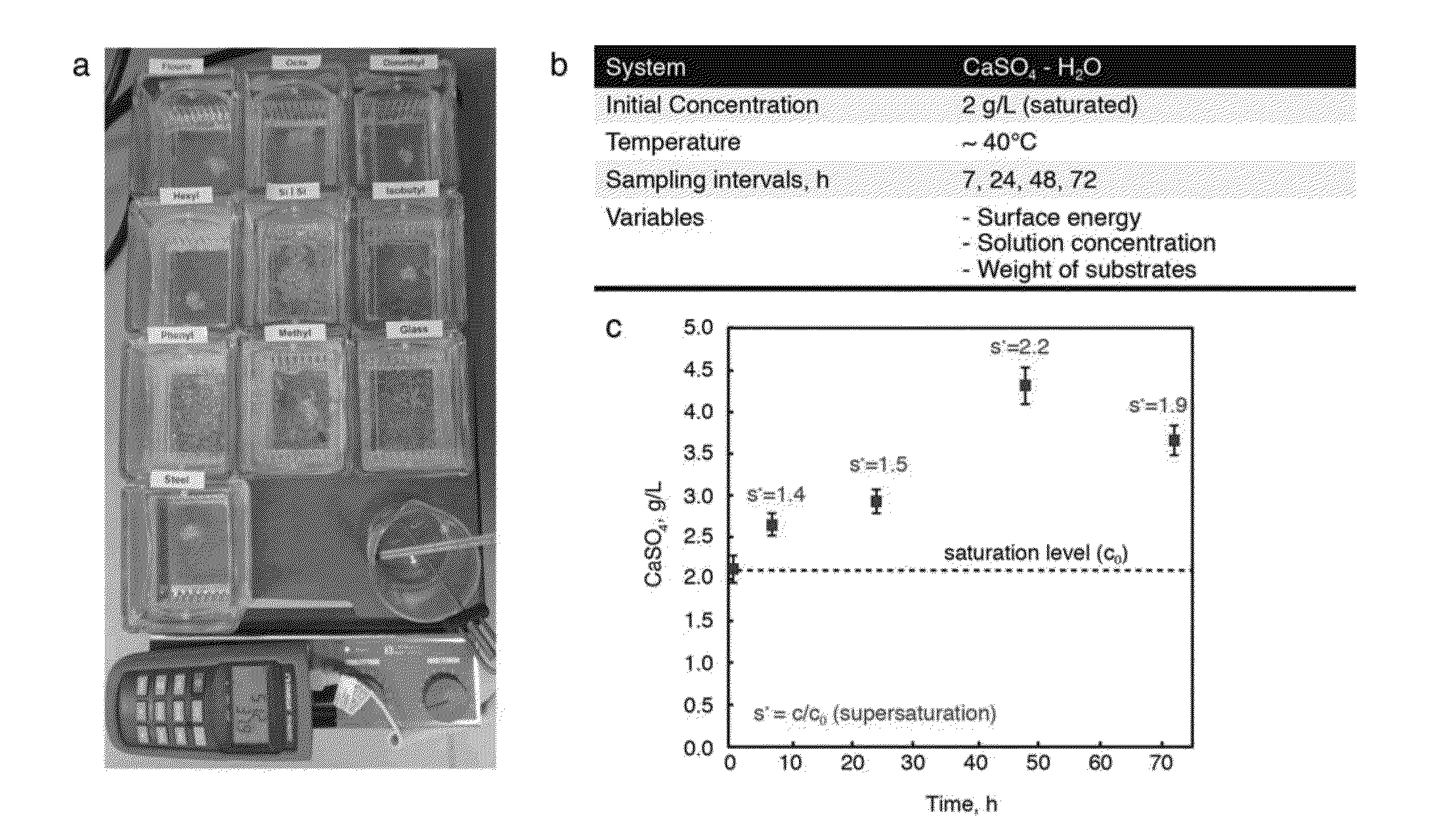

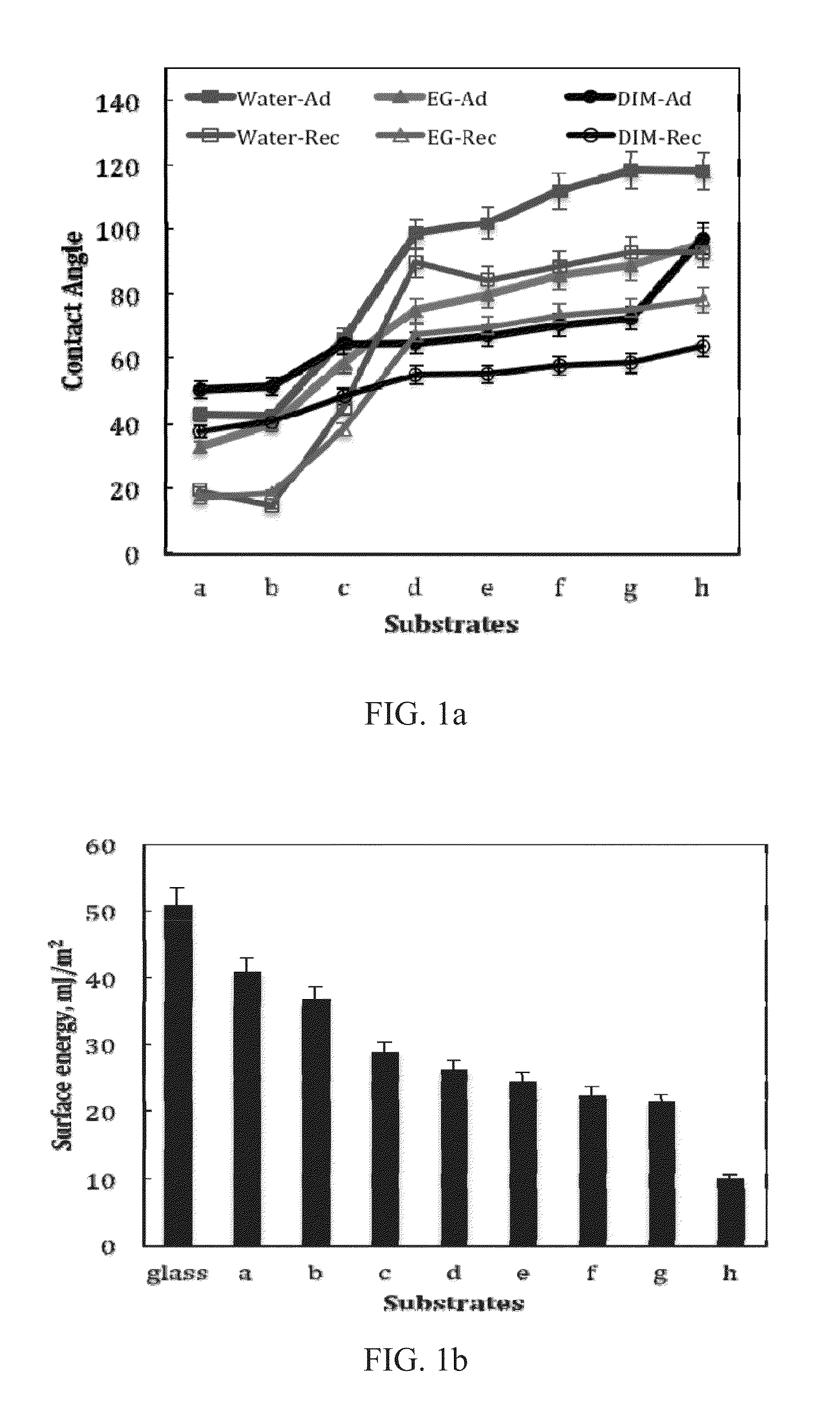

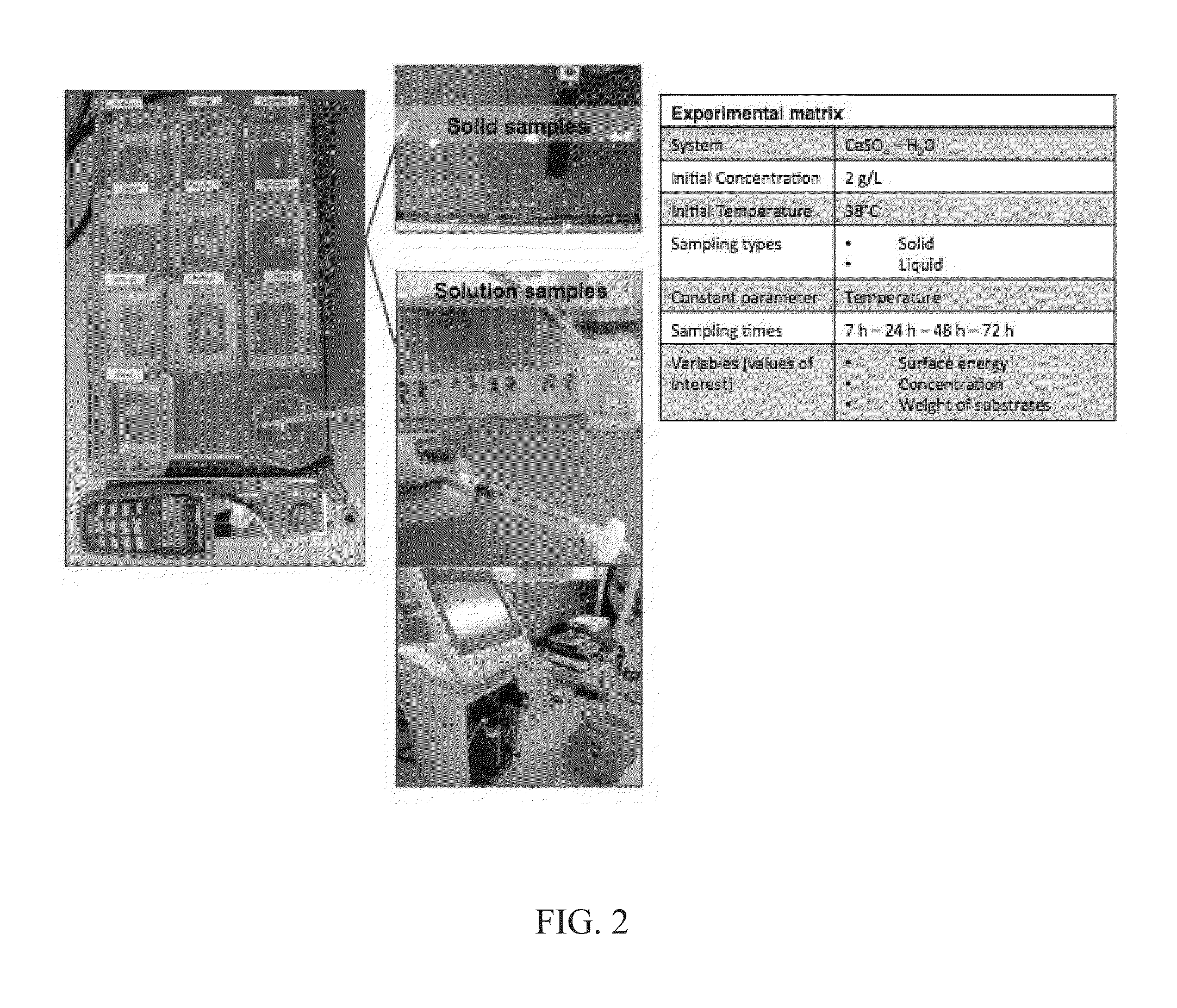

Articles and methods providing scale-phobic surfaces

InactiveUS20130122225A1Promote nucleationReduce scale adhesionEnvelopes/bags making machineryMaterial nanotechnologyChemistrySurface energy

This invention relates generally to articles, devices, and methods for inhibiting or preventing the formation of scale during various industrial processes. In certain embodiments, a vessel is provided for use in an industrial process, the vessel including a surface in contact with a mineral solution, wherein the surface is provided or is modified to have γpolar / γtotal no greater than about 0.2 and / or the surface is provided or is modified to have a surface energy γ no greater than about 32 mJ / m2, thereby providing resistance to mineral scale deposits thereupon.

Owner:MASSACHUSETTS INST OF TECH

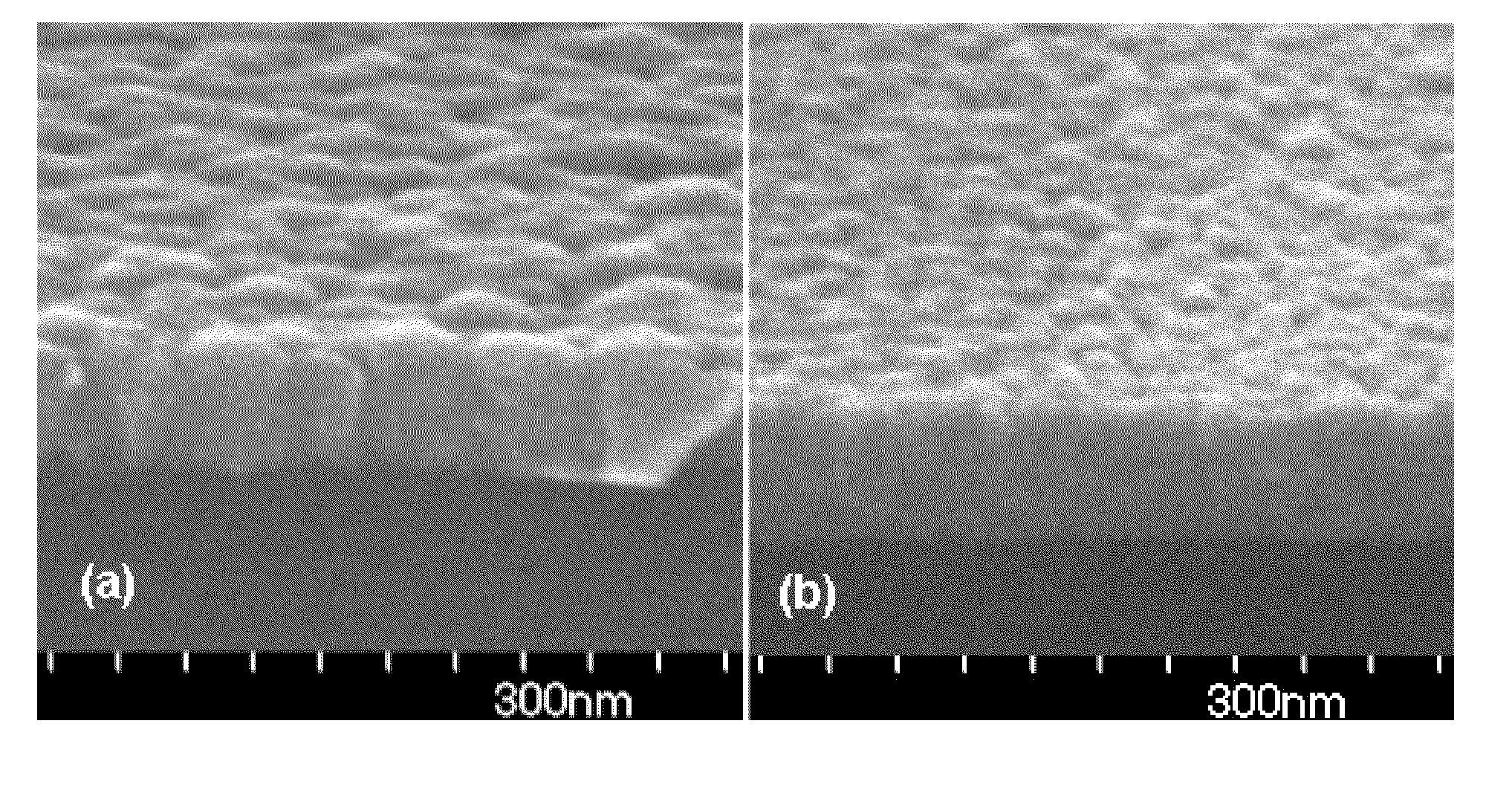

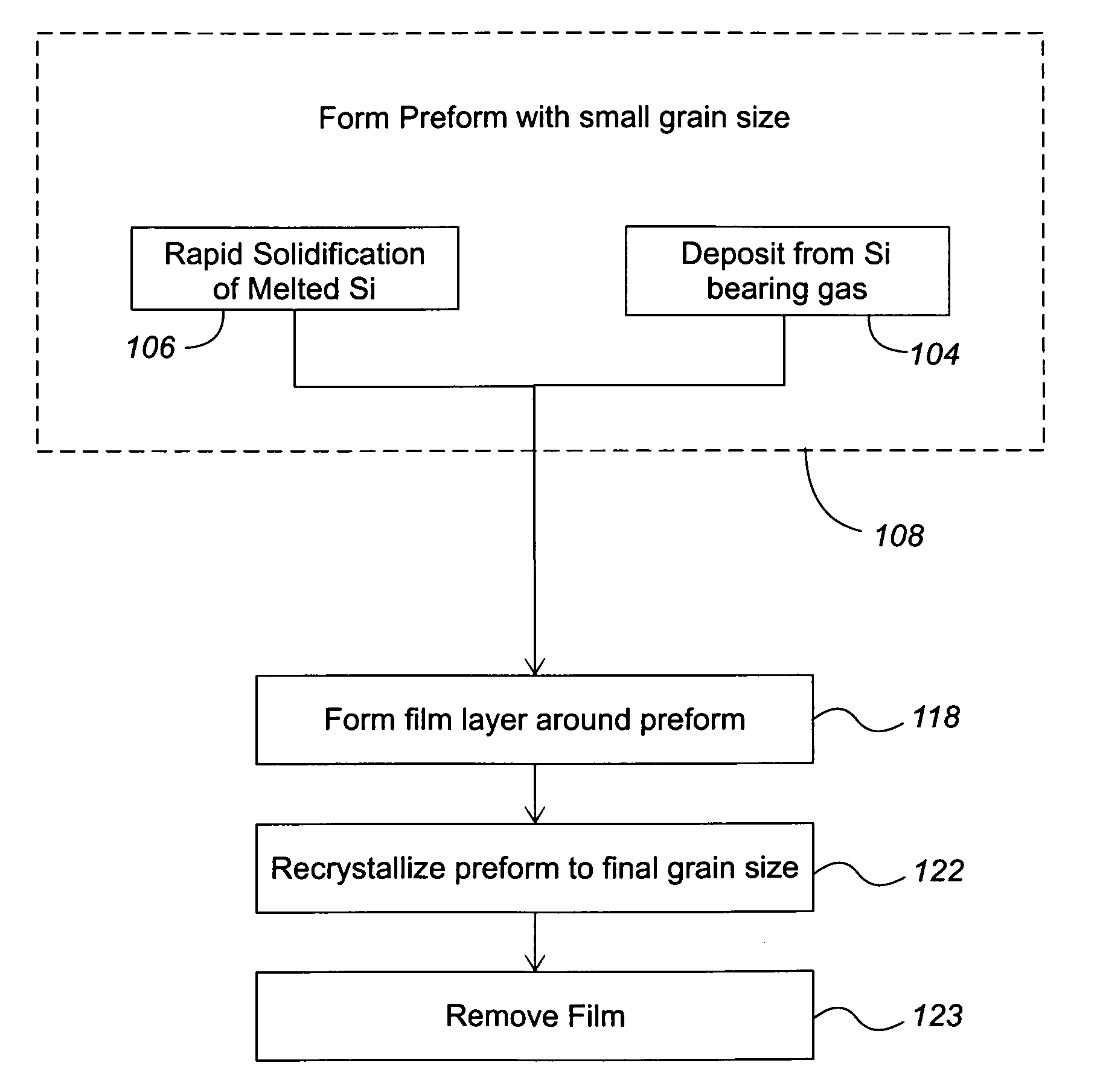

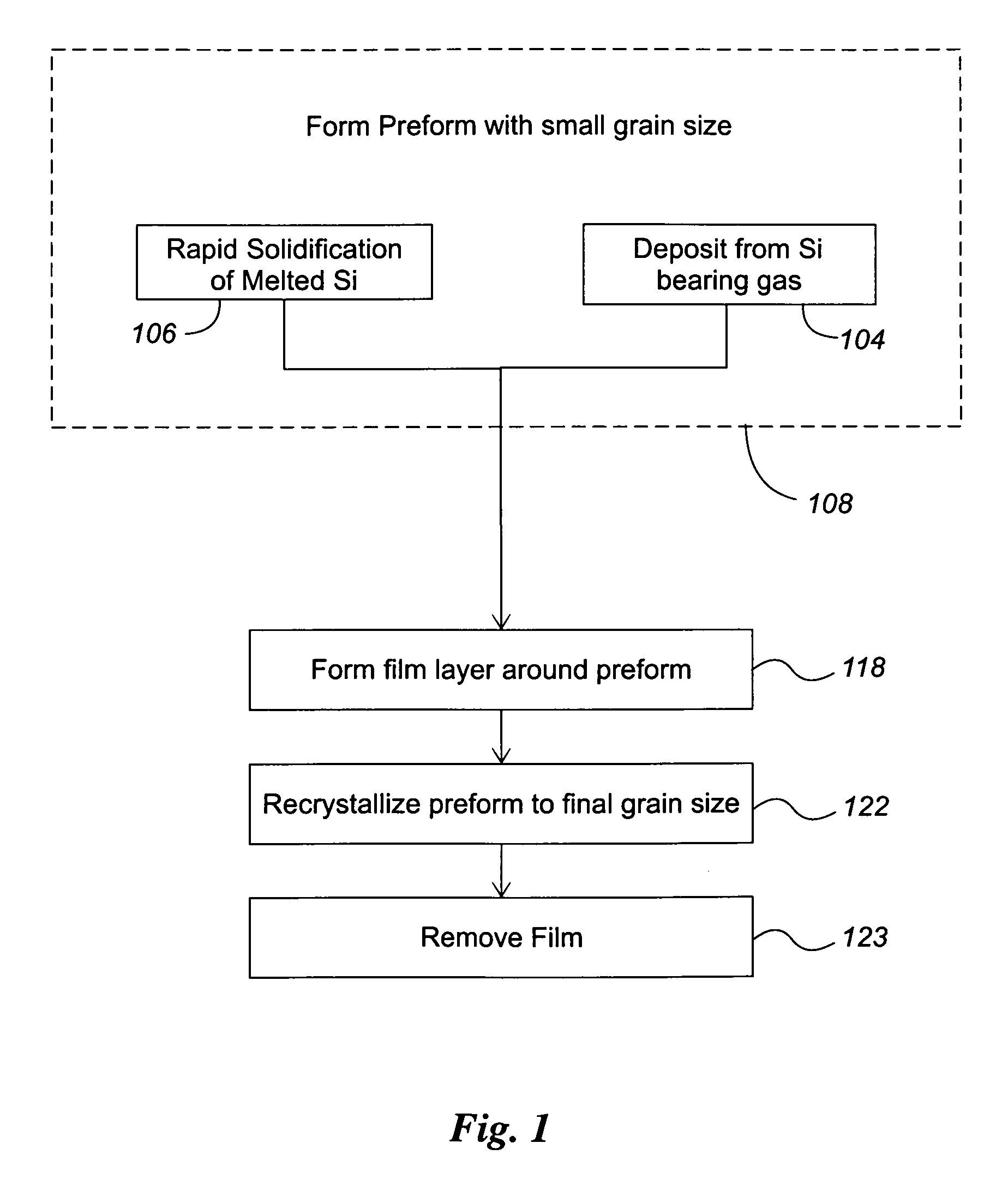

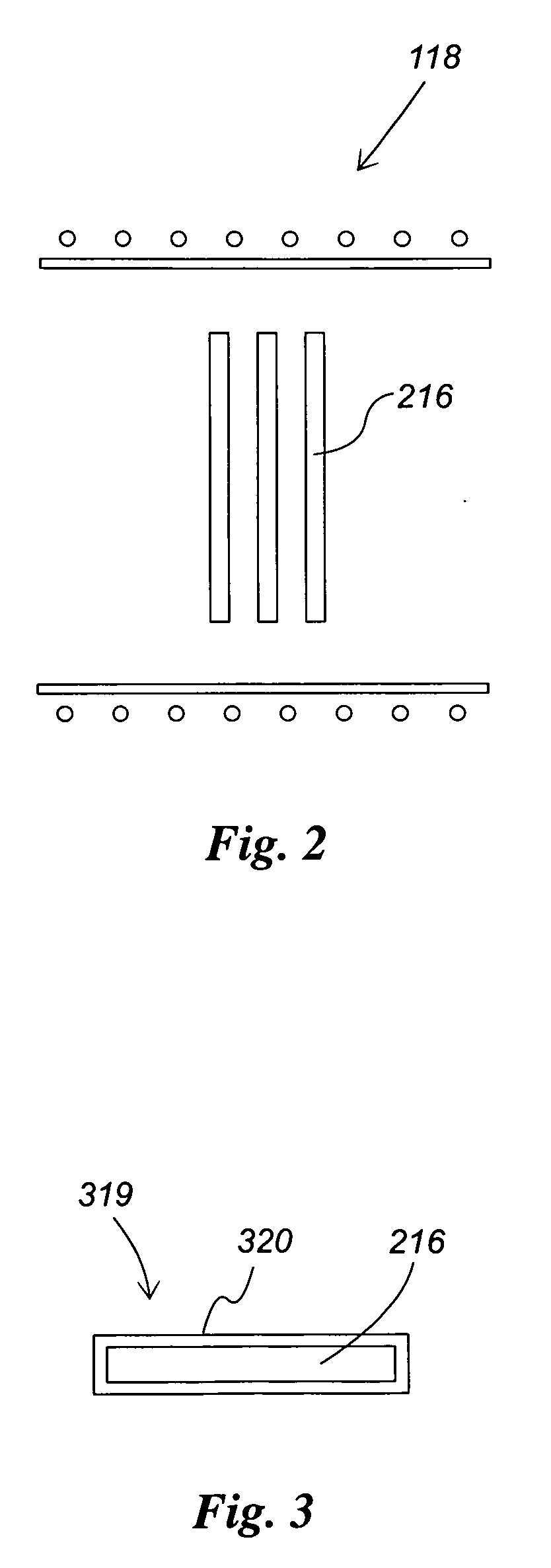

Recrystallization of semiconductor waters in a thin film capsule and related processes

ActiveUS20100295061A1Minimizing thermally induced stressImprove crystal structurePolycrystalline material growthFrom solid stateCrystallitePolymer chemistry

An original wafer, typically silicon, has the form of a desired end PV wafer. The original may be made by rapid solidification or CVD. It has small grains. It is encapsulated in a clean thin film, which contains and protects the silicon when recrystallized to create a larger grain structure. The capsule can be made by heating a wafer in the presence of oxygen, or steam, resulting in silicon dioxide on the outer surface, typically 1-2 microns. Further heating creates a molten zone in space, through which the wafer travels, resulting in recrystallization with a larger grain size. The capsule contains the molten material during recrystallization, and protects against impurities. Recrystallization may be in air. Thermal transfer through backing plates minimizes stresses and defects. After recrystallization, the capsule is removed.

Owner:MASSACHUSETTS INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com