Electron beam synchronous powder feeding and quick forming method

A technology of synchronous powder feeding and electron beam, applied in metal material coating process, melting spray plating, coating and other directions, can solve the problems of difficult to process large parts, difficult to process shape height, low material deposition speed, etc., to achieve forming The effect of high speed, increased size of forming, and fast melting and accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technology of the present invention will be further described below in conjunction with accompanying drawing and embodiment:

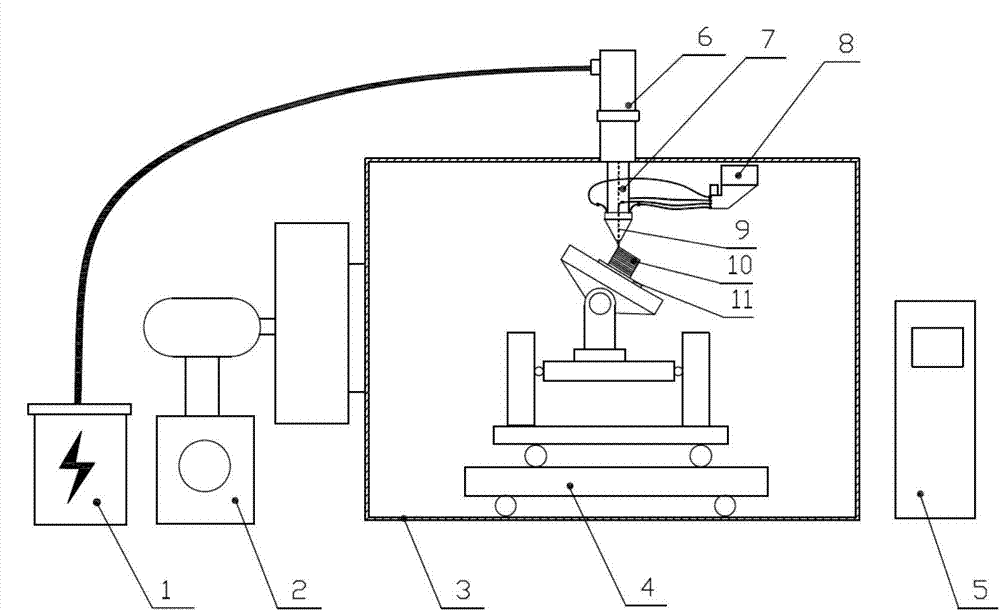

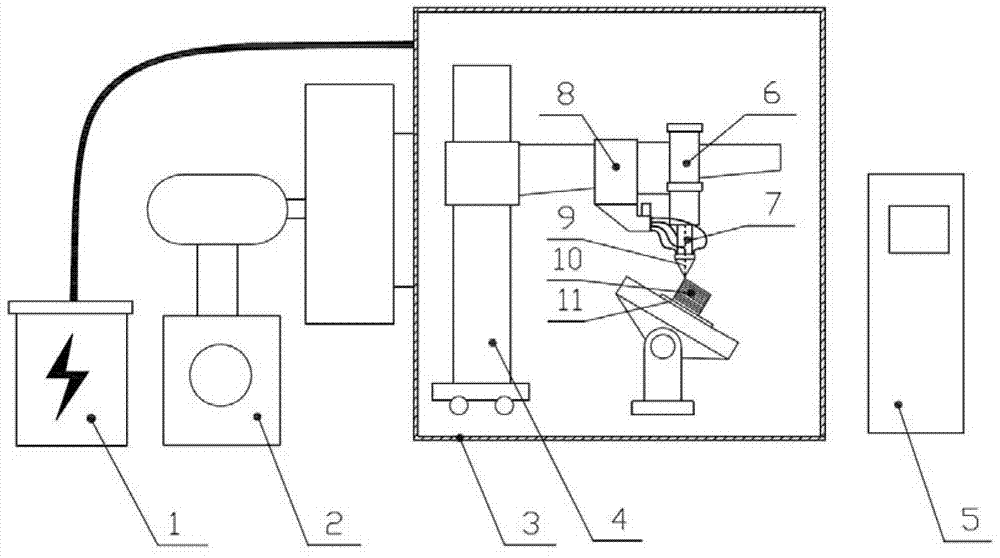

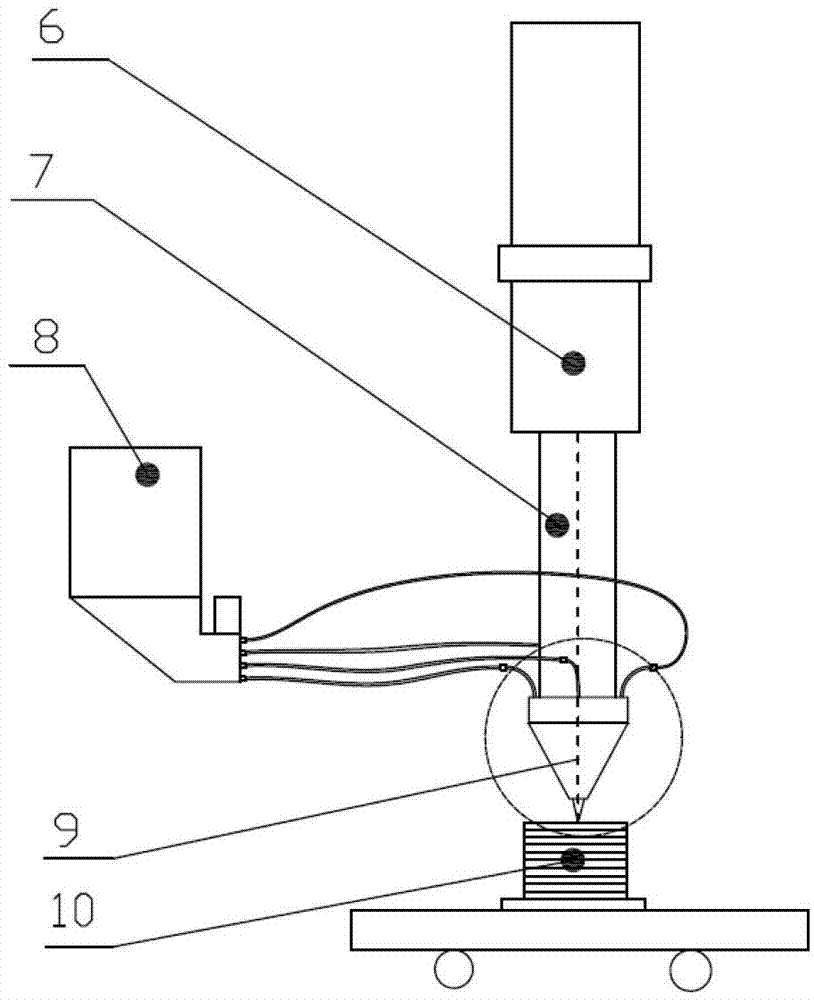

[0036] attached figure 1 Provided is a structural schematic diagram of a fixed-gun synchronous powder-feeding electron beam rapid prototyping equipment implementing the technical solution of the present invention. Powder nozzle 7 produces relative movement. The high-voltage power supply and cable 1 of the equipment are connected to the electron gun 6, the vacuum unit 2 communicates with the main vacuum chamber 3, the electron gun 6 is fixed on the outside of the top of the vacuum chamber 3, the coaxial powder feeding nozzle 7 is fixed on the lower part of the electron gun 6, and the powder feeder 8 passes through the tube The road is connected with the coaxial powder feeding nozzle 7, the multi-axis workbench 4 is placed inside the vacuum chamber 3, and the control cabinet 5 controls the whole equipment. The powder feeder 8 and the workpie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com