Patents

Literature

80results about How to "Fast melting speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

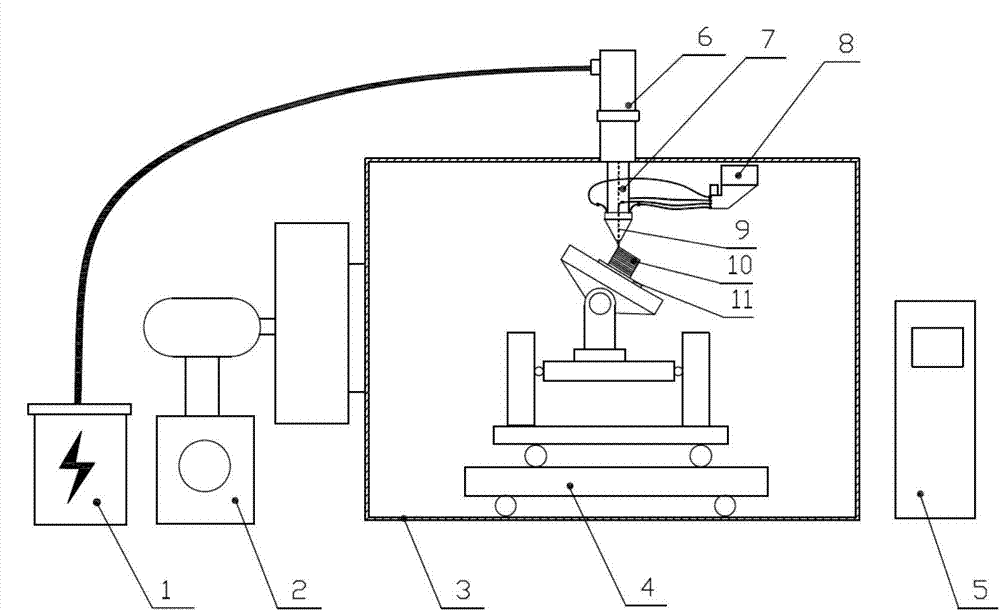

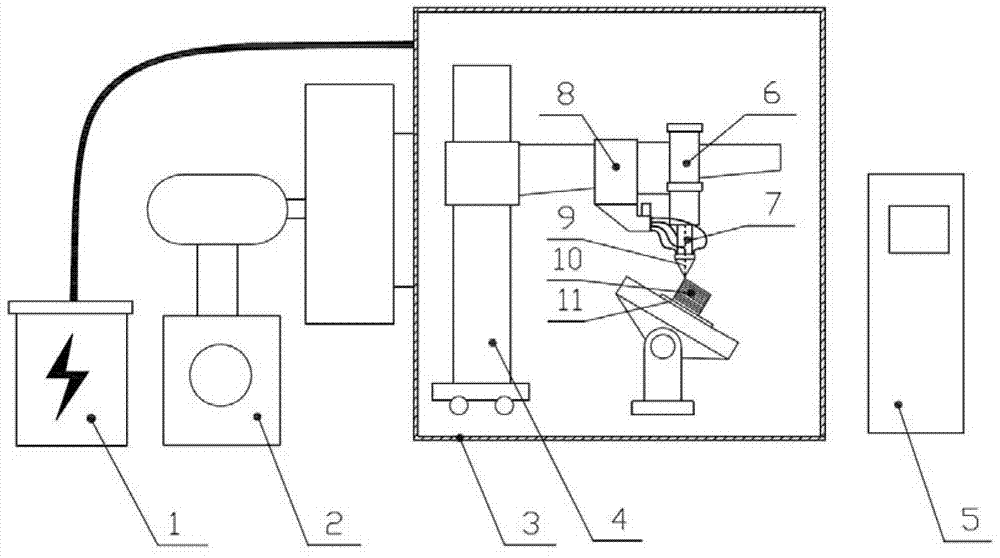

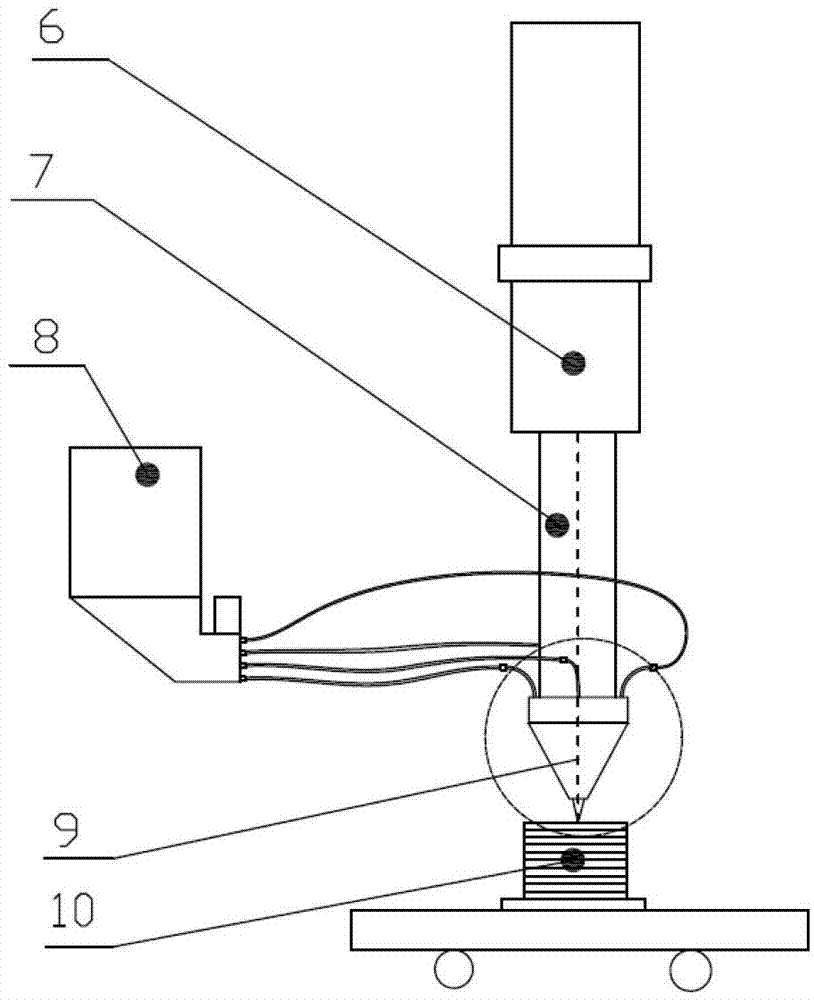

Electron beam synchronous powder feeding and quick forming method

InactiveCN102764889AImprove protectionAvoid mixingAdditive manufacturing apparatusMolten spray coatingMelting tankChemical composition

The invention discloses an electron beam synchronous powder feeding and quick forming method. The method includes that metal powder is fed to a portion, which is intersected with beam current, of a to-be-processed surface, in a coaxial or paraxial manner, and the portion can be positioned in a molten pool or at the front of the molten pool. The electron beam synchronous powder feeding and quick forming method is characterized in that an electron beam bombards a workpiece to form the molten pool, the molten pool moves relative to the surface of the workpiece, the metal powder is simultaneously fed to a thermal action zone to participate in melting, and processing is implemented. As the powder is fed, the synchronous powder feeding and quick forming method has the advantages that speed is fast, quality is good, chemical composition and structure property of a part can be conveniently regulated and controlled, and the method is particularly applicable to preparing high-gradient and multi-step materials and structures and also can be used for processing parts with fine appearances and dimensions. Compared with wire feeding technology, the electron beam synchronous powder feeding and quick forming method has the powder does not interfere with the part, technological difficulty is low, and the method is easy to control.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

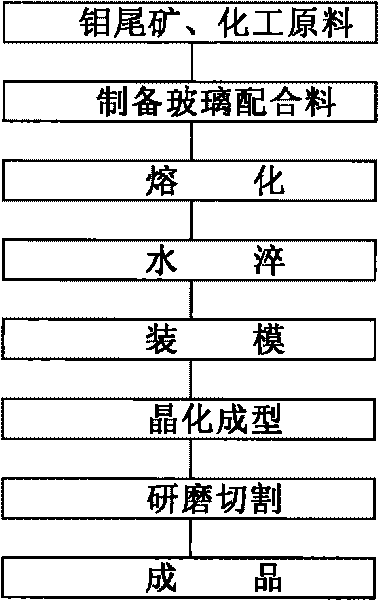

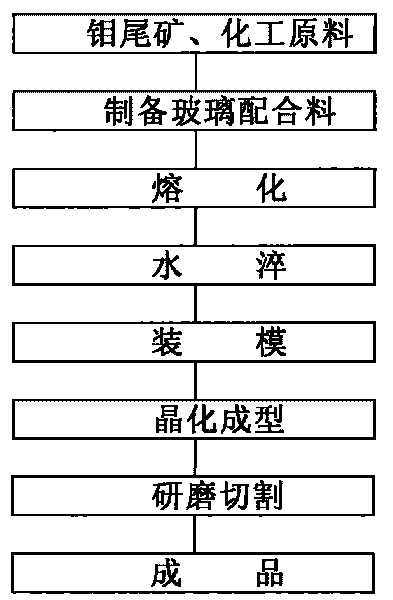

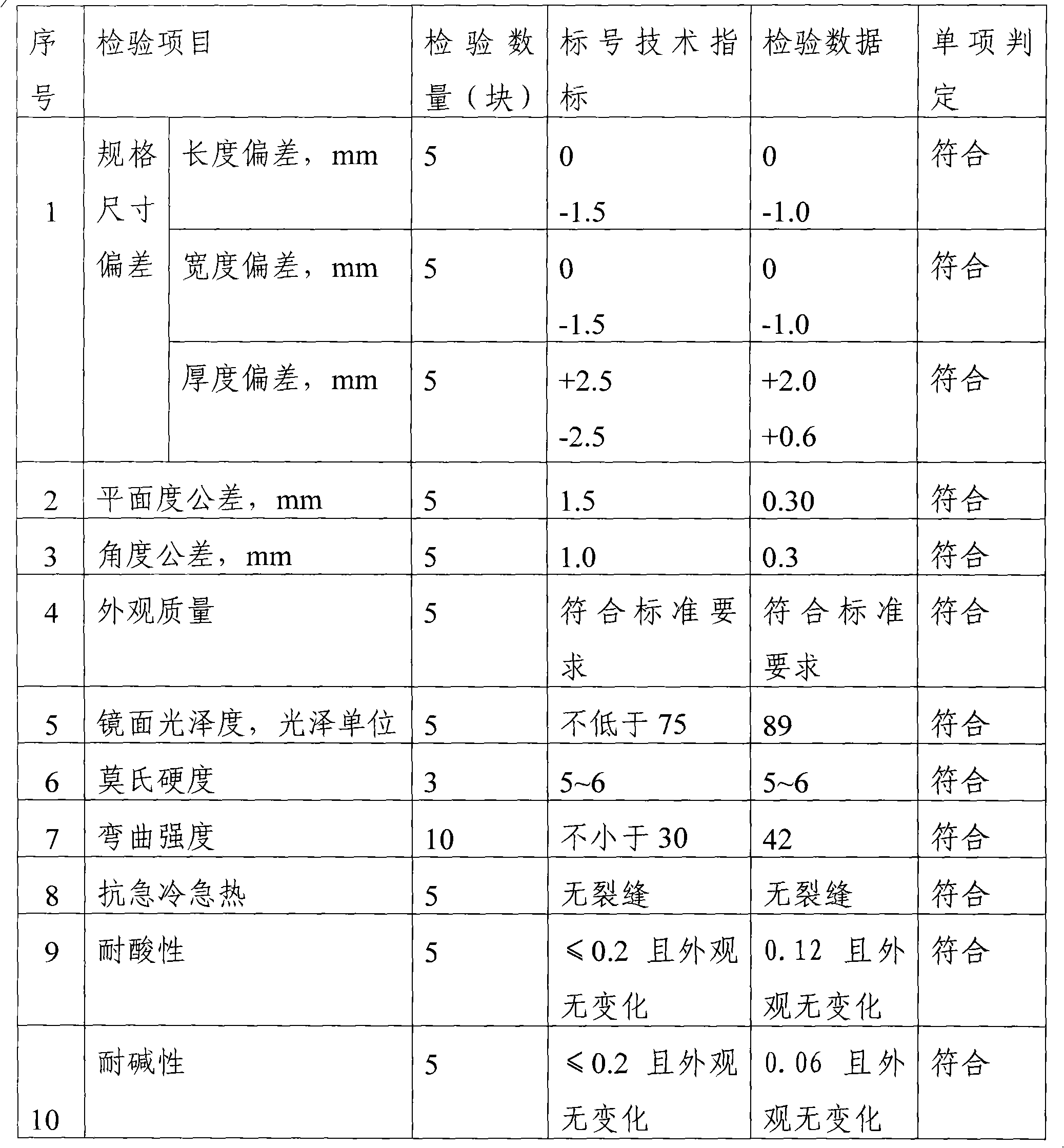

Method for manufacturing black microcrystalline glass plates from molybdenum tailings

The invention discloses a method for manufacturing black microcrystalline glass plates from molybdenum tailings, which comprises the following steps: mixing a certain part by weight of molybdenum tailings, quartz sand, lime stone, sodium carbonate, zinc oxide, barium carbonate, ferric oxide, manganese dioxide, nickel oxide and cobalt oxide to prepare a glass batch; melting the glass batch into molten glass, and then, pouring the molten glass into water to form glass particles; horizontally laying the glass particles in a fire-resistant mold for crystallization heat treatment; and grinding and cutting black microcrystalline glass crude products after crystallization heat treatment to form finished products. By using the molybdenum tailings for manufacturing black microcrystalline glass plates, the invention not only reduces the stockpiling amount of tailings and relieves the environmental pollution, but also can improve the product performance and reduce the production cost, thereby having good social benefit and economic benefit.

Owner:陕西乾盛环保建材工程有限公司

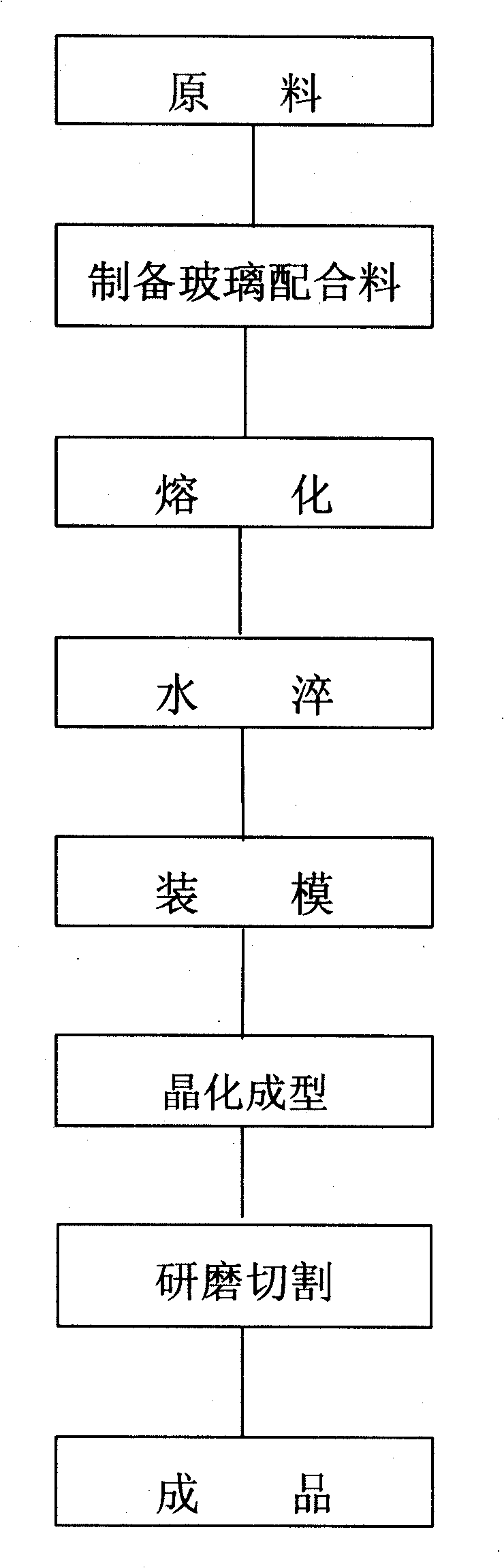

Method for manufacturing microlite by using high-silicon iron tailings

The invention discloses a method for manufacturing microcrystalline glass plates by using iron tailings, which comprises the steps of adding 30 to 70 percents of iron tailings in a glass batch, wherein quartz sand, aluminum oxide, sodium carbonate, calcium carbonate and other raw materials can be partially replaced by the iron tailings; melting the glass batch for four hours in a crucible or an electric box furnace, wherein the melting temperature is 1480-1500 DEG; introducing the molten glass liquid into water directly to form glass particles after the melting process; laying the glass particles in a refractory mould to carry out crystallization heat treatment in a tunnel kiln, a shuttle kiln or an electric box furnace with the crystallization temperature to be 1020-1050 DEG. The invention utilizes castoff microcrystalline glass, thereby not only reducing the stockpiling amount of tailings and relieving the environmental pollution, but also improving the product performance. Meanwhile, the production cost is reduced. Thus, the method for manufacturing microcrystalline glass plates by using iron tailings has good social benefit and economic benefit.

Owner:BEIJING QING MAI HUA QING HLDG GRP CO LTD

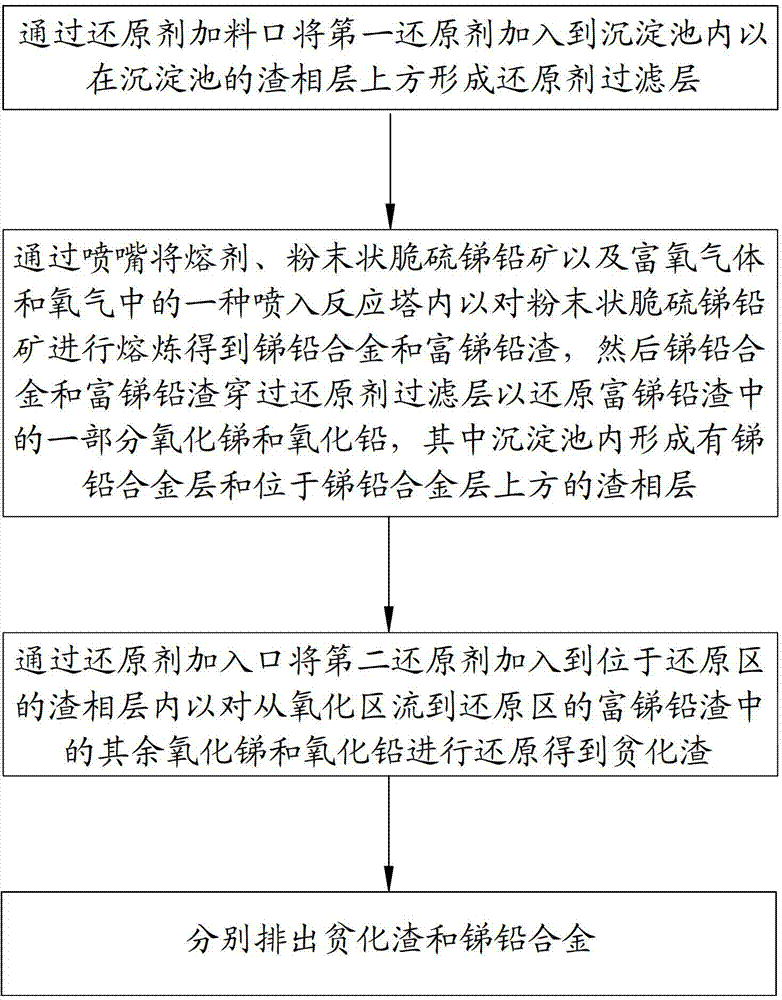

Device and method for smelting antimony

ActiveCN103114212AIncrease productionIncrease productivityLighting and heating apparatusSpray nozzleOxidation zone

The invention discloses a device and a method for smelting antimony. The smelting device comprises a reaction tower and a nozzle, wherein a settling pond is arranged on the lower part of the reaction tower; a separator is arranged in the settling pond and used for separating a furnace chamber of the settling pond into an oxidation zone and a reduction zone which are communicated; the top of the reaction tower is provided with a reducing agent charging hole; the top wall of the oxidation zone is provided with an oxidation zone smoke outlet; one of the side wall and the top wall of the reduction zone is provided with a reducing agent access port; the top wall of the reduction zone is provided with a reduction zone smoke outlet; and the nozzle is arranged on the top of the reaction tower for injecting one of the fluxing agent, powdered jamesonite, enriched oxygen and oxygen in the reaction tower. The smelting device of the antimony has the advantages of high yield and production efficiency, low power consumption and energy consumption, high safety and environment protection, and the like.

Owner:CHINA NERIN ENG +1

Reflective hot-melt marking paint composition

The invention relates to the technical field of paints, specifically to a reflective hot-melt marking paint composition. The paint composition comprises, by weight, 150 to 250 parts of fine powder, 67.5 to 82.5 parts of coarse powder, 63 to 77 parts of C5 petroleum resin, 92 to 108 parts of quartz sand, 12 to 18 parts of pigment, 8 to 12 parts of polyethylene wax, 10 to 15 parts of a plasticizer, 1.5 to 2.5 parts of a leveling agent, 40 to 60 parts of a glass bead and 7 to 9 parts of EVA. The reflective hot-melt marking paint composition contains the fine powder, the coarse powder and the glass bead; and through adjusting the proportion of each component of the marking paint composition, the marking paint composition is allowed to have the beneficial effects of a fast hot melting speed, a fast drying speed, wear resistance and crack resistance.

Owner:WUHAN ZONGHENG TRAFFIC ENG CO LTD

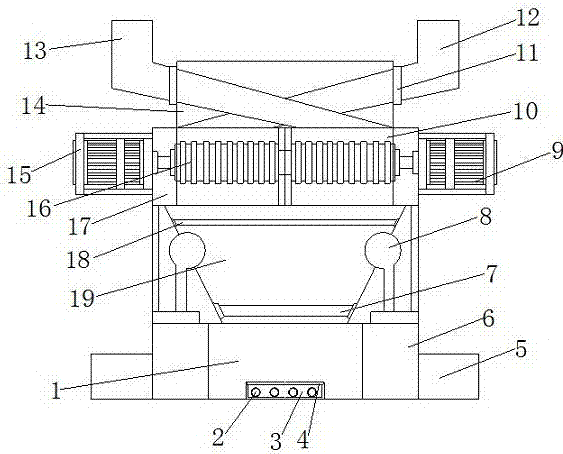

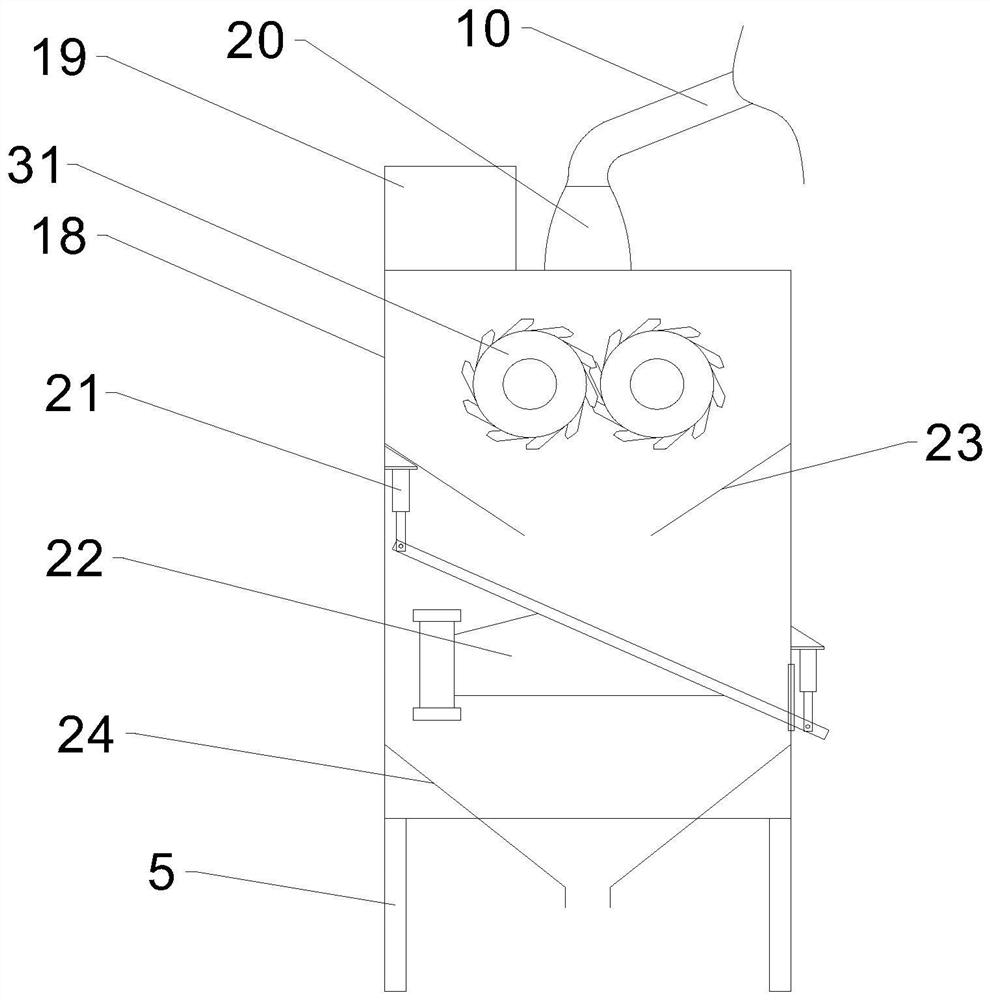

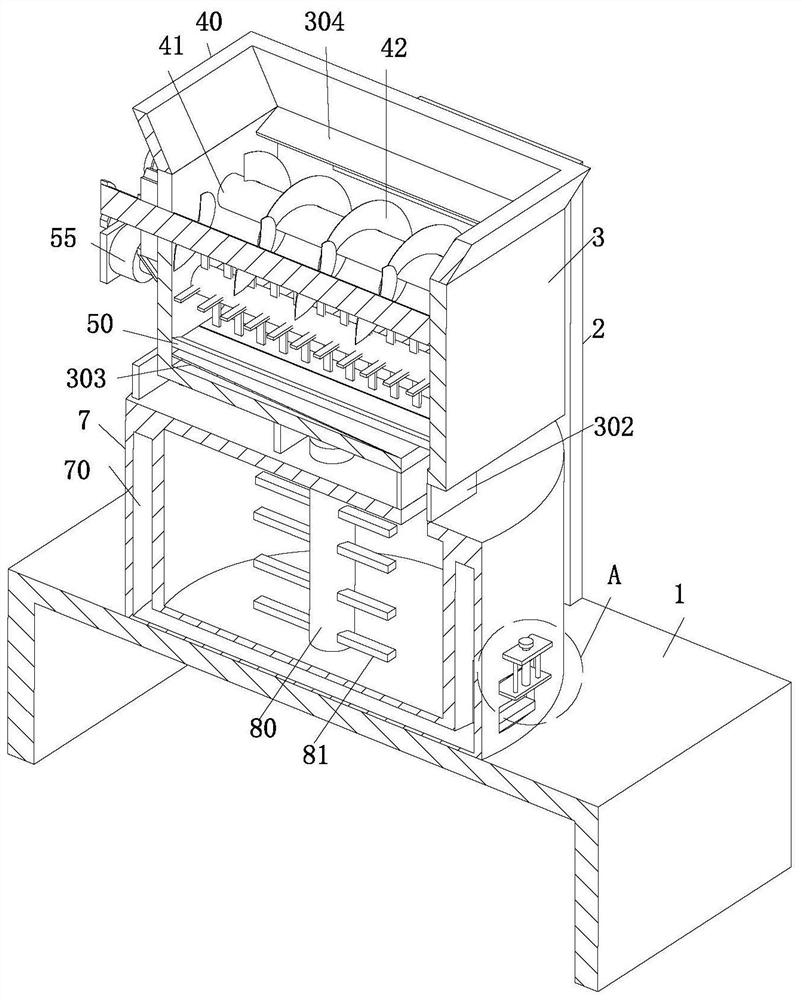

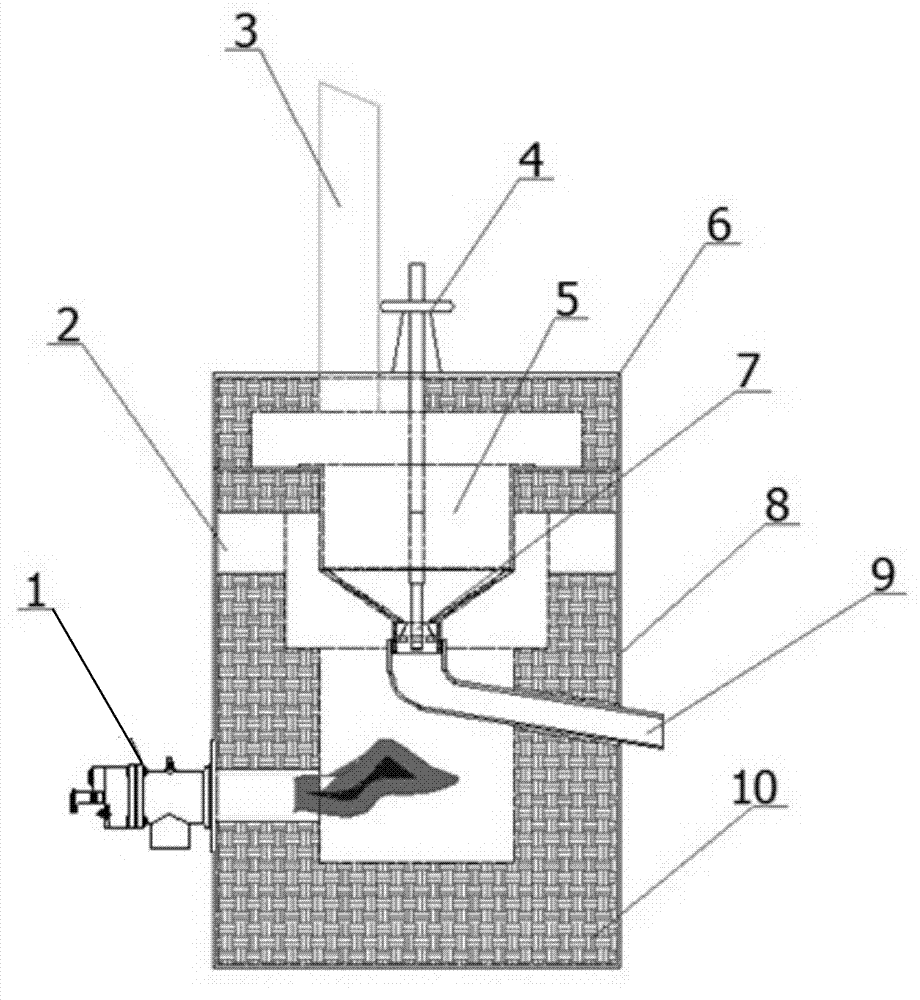

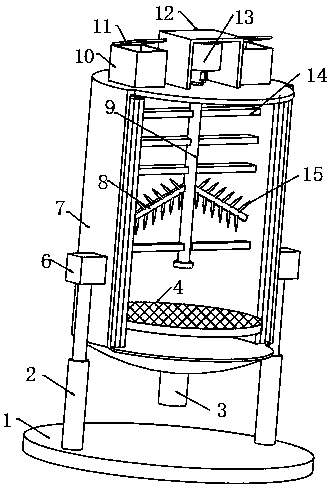

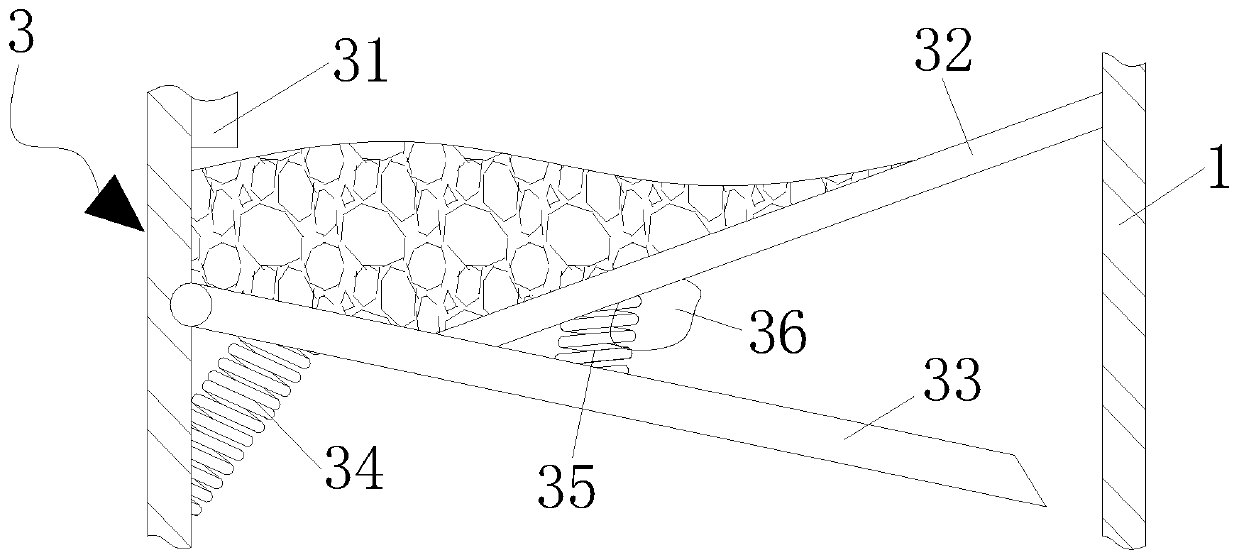

Crushing smelter with better smelting effect

ActiveCN106871644AEasy to reinforcePromote meltingCharge treatment typeFurnace typesCombustorEngineering

The invention discloses a crushing smelter with a better smelting effect. The crushing smelter comprises a smelter body, discharging holes are formed in the obverse side of the smelter body, and burning cavities are formed in the two sides of the smelter body. Burning devices are connected to the outer sides of the burning cavities, a discharging cavity is connected to the top of the smelter body, and a crushing cavity is connected to the top of the discharging cavity. A crushing idler wheel is arranged in an inner cavity body of the crushing cavity and connected with a rotary motor arranged outside the crushing cavity through a wheel shaft, a feeding cavity is connected to the top of the crushing cavity, and a left feeding pipe and a right feeding pipe which are connected with the top of the crushing cavity are installed on an inner cavity of the feeding cavity in a staggered mode. The crushing smelter with the better smelting effect is provided with the crushing cavity and the crushing idler wheel on the whole so that input large metal waste materials can be crushed and pressed, and the large metal waste materials are changed into small metal waste materials, so that smelting operation is convenient to conduct, and the metal waste materials are quickly and conveniently smelted.

Owner:XINGHUA SANQIANG MACHINERY MFG CO LTD

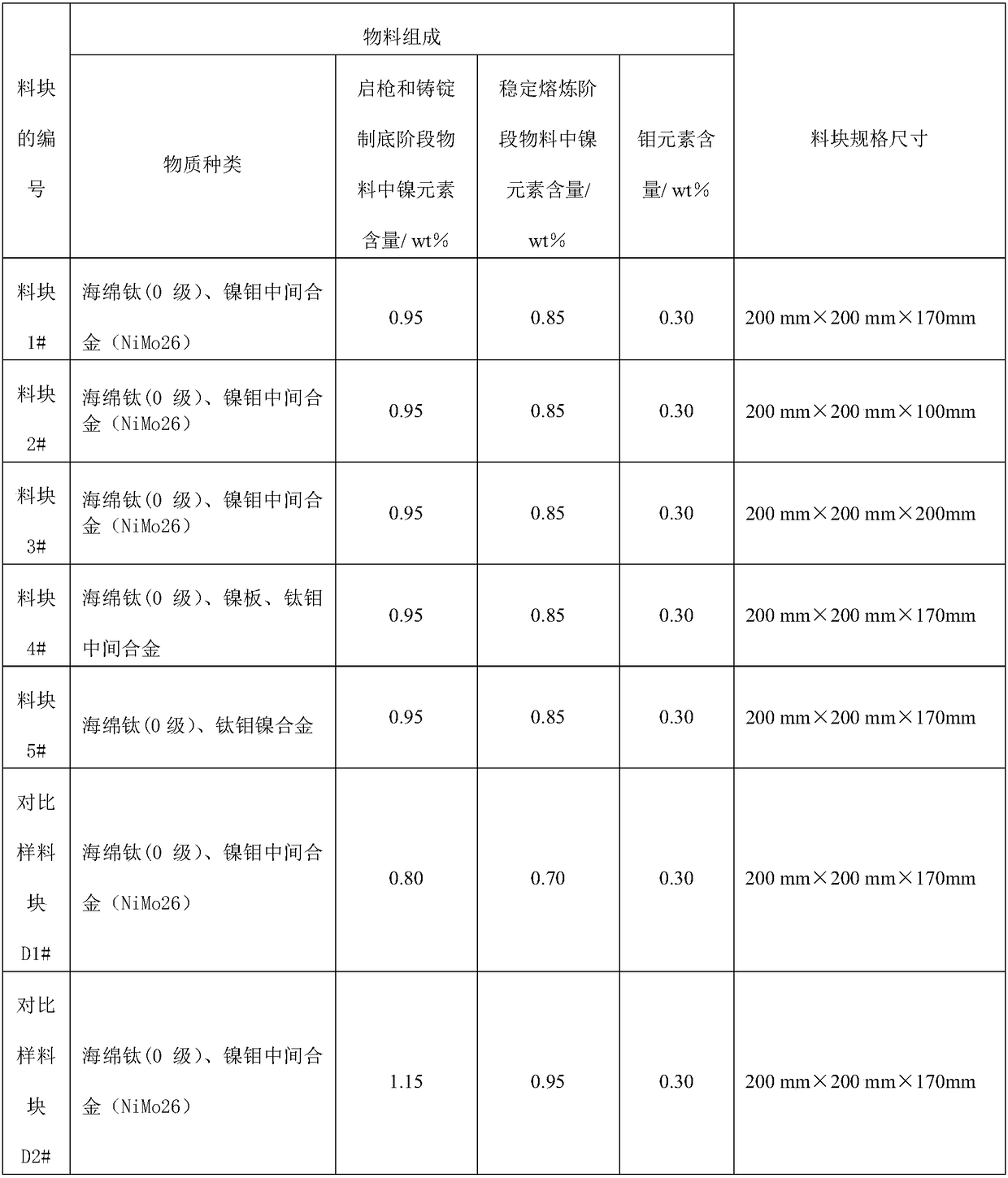

Method for smelting TA10 titanium alloy by using electron beam cold hearth

The invention discloses a method for smelting a TA10 titanium alloy by using an electron beam cold hearth, and belongs to the field of titanium alloys. The method comprises the following steps that (1), materials containing titanium, nickel and molybdenum are mixed and pressed into a material block, and then the material block is dried; and (2) the dried material block is subjected to smelting byusing the electron beam cold hearth, and the TA10 titanium alloy is obtained. Electron beam cold hearth smelting comprises a gun starting stage, a casting ingot bottom making stage, and a stable smelting stage; and the electron beam cold hearth comprises a melting zone, a refining zone and a crystallization zone which are sequentially adjoined, the power of the melting zone in the stable smeltingstage is 800-1100 Kw, the power of the refining zone is 150-180 Kw, and the power of the crystallization zone is 180-210 Kw. The TA10 titanium alloy prepared through the method is good in element distribution uniformity and surface quality.

Owner:QINGHAI JUNENG TITANIUM IND CO LTD

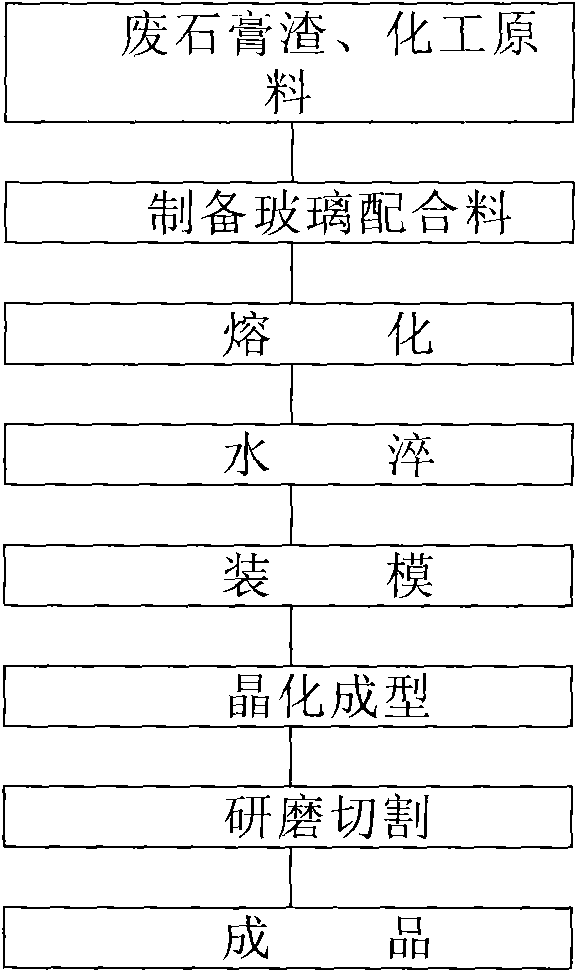

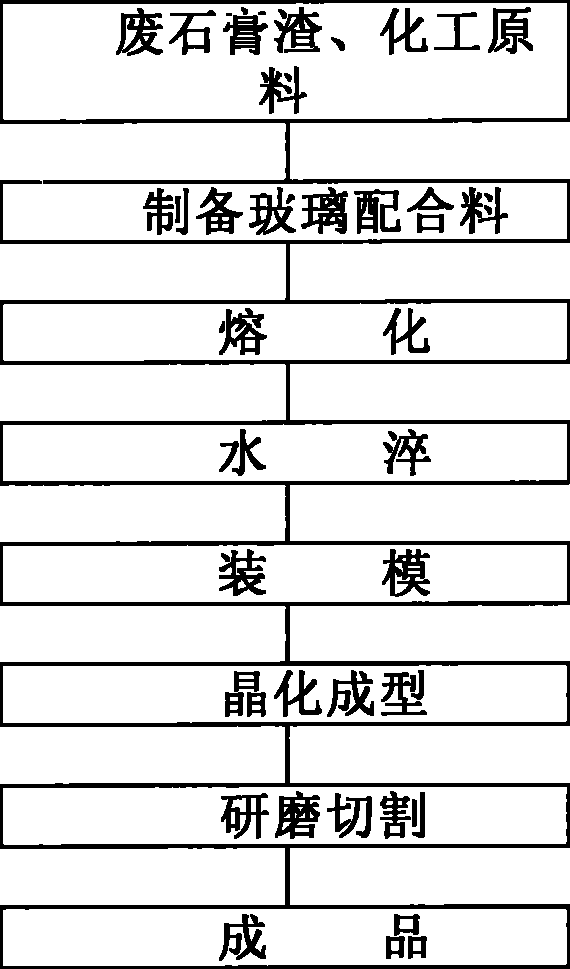

Method utilizing waste gypsum slag to manufacture green microcrystalline glass plate material

The invention discloses a method utilizing waste gypsum slag to manufacture a green microcrystalline glass plate material. The method includes the following steps: the waste gypsum slag, quartz sand, petalite, soda ash, zinc oxide, barium carbonate, chromic oxide, copper oxide and carbon powder are mixed together according to certain parts by weight to prepare a glass batch mixture; the glass batch mixture is molten into liquid glass; the liquid glass is poured into water to obtain glass particles; the glass particles are laid in a fireproof mould to carry out crystallization heat treatment; finally, the rough green microcrystalline glass is ground and cut after the crystallization heat treatment so as to obtain the finished glass. The method in the invention utilizes the waste gypsum slag to manufacture the green microcrystalline glass plate material, which not only reduces the stacking quantity of industrial waste slag and lessens environmental pollution, but also improves the product performance and reduces the production cost. Therefore, the method in the invention has good social and economic benefits.

Owner:陕西乾盛环保建材工程有限公司

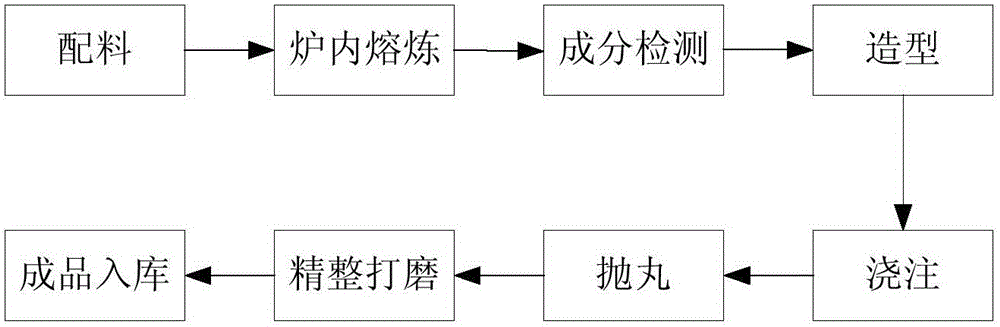

Cast piece processing technology

InactiveCN106311979AQuality improvementExtended service lifeFoundry mouldsFoundry coresIntermediate frequencyThermal efficiency

The invention discloses a cast piece processing technology, and relates to the technical field of casting processing. The cast piece processing technology comprises the steps of material proportioning, furnace melting, component detection, molding, casting, shot blasting, finishing polishing and final product warehousing. An intermediate frequency induction electric furnace is adopted to melt raw materials, so the melting kind can be easily transformed, the melting quality can be conveniently controlled, the operation is flexible and simple, the power density is large, the melting speed is large, the thermal efficiency is high, and initial melting is convenient; foundry returns can be repeatedly used, so the utilization rate of the raw materials is improved, and enterprises' production cost is reduced; exhaust gas obtained after the furnace melting undergoes cloth bag dedusting, so exhaust gas pollution is effectively reduced; and surface shot blasting, polishing treatment and modification of a cast piece formed by casting improve the quality of the cast piece, and surface antirust treatment of the cast piece effectively prolongs the service life of the cast piece.

Owner:ANHUI FENGRUI METAL PROD

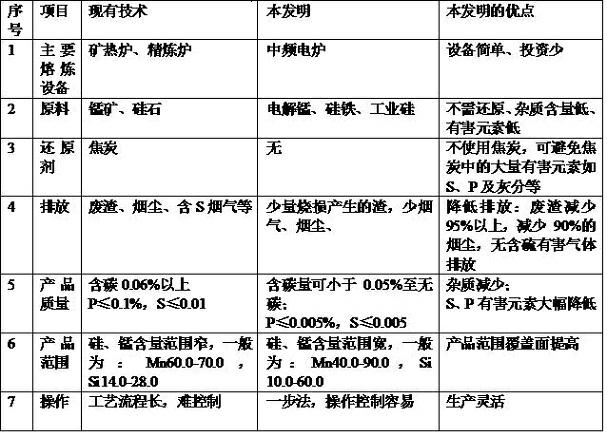

Smelting preparation method of high-purity high-silicon manganese-silicon alloy

InactiveCN102071331ALow elemental contentMeet the requirements of high-purity high-silicon-manganese-silicon alloySilicon alloySmelting process

The invention belongs to the technical field of production of iron alloys and particularly relates to a smelting preparation method of a high-purity high-silicon manganese-silicon alloy, which is used for smelting high-purity steel and other metals. The method is characterized by comprising the following step of: smelting electrolytic manganese, industrial silicon and silicon iron serving as raw materials by using a medium-frequency induction electric furnace. A smelting process comprises the following steps of: mixing the electrolytic manganese and the silicon iron, putting the mixture into the induction electric furnace, electrifying, heating, smelting, measuring alloy components and adding the electrolytic manganese for adjusting manganese amount when the amount of manganese is insufficient; and when the silicon content is insufficient, using silicon iron or industrial silicon to adjust the silicon component and pouring a qualified component into a metal die so as to form a blocky high-silicon manganese-silicon alloy. Due to the adoption of the method, the purity of alloy can be increased remarkably, the carbon content of the alloy can be less than 0.05 percent and even carbon is not produced, P is less than or equal to 0.005 percent and S is less than or equal to 0.005. The alloy is applied to deoxidation alloying of pure steel and used for smelting a reducing agent for high-purity alloy. Moreover, the method has small equipment investment, is easy to operate and realize and has remarkable economic benefit and social benefit.

Owner:JIANGSU UNIV

Tempered sheet glass and preparation method thereof

ActiveCN107056046AEfficient processIncrease the amount of participationGlass furnace apparatusGlass shaping apparatusRoom temperatureMolten salt

The invention relates to tempered sheet glass and a preparation method thereof. The method comprises the steps as follows: step 1, a mixture formed after mixing is accurately weighed according to the mass fraction of the mixture; step 2, cullet accounting for 30%-55% of the mass fraction of the mixture is added and uniformly mixed, and a batch is obtained; step 3, a formed glass sheet is prepared after the batch is molten; step 4, the formed glass sheet is annealed at 700-750 DEG C for 30-60 min and cooled to 450 DEG C, and sheet glass is obtained; step 5, tempering materials are weighed for later use according to the mass fraction; step 6, the tempering materials are kept at the constant temperature of 410-450 DEG C for 1-2 h and uniformly mixed molten salt is formed; step 7, the sheet glass at 450 DEG C is placed in the uniformly mixed molten salt, kept at the constant temperature of 410-450 DEG C for 1-6 h and taken out; step 8, the sheet glass taken out of the molten salt is dried, naturally cooled to the room temperature, washed and dried, and the tempered sheet glass is obtained.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

Glass ceramics made from high silicon iron tailings and manufacturing method thereof

InactiveCN101967043AReduce erosionLower melting temperatureSolid waste disposalOxideResource utilization

The invention relates to the technical field of solid waste resource utilization, in particular to glass ceramics made from high silicon iron tailings, which is characterized by comprising the raw materials in parts by weight: 30-70 parts of the iron tailings, 15-40 parts of quartz, 5-20 parts of calcium carbonate, 3.5-6.5 parts of aluminum oxide, 8.5-9.5 parts of sodium carbonate, 4-5 parts of zinc oxide, 3-6 parts of barium carbonate and 1-3 parts of borax. The manufacturing method of the glass ceramics comprises the following steps: putting the glass ceramics blended materials in a kiln for melting into molten glass; allowing the molten glass to directly flow into water for water quenching to form glass particles; and paving the glass particles in a refractory die, crystallizing the paved particles in a tunnel kiln, a shuttle kiln or a chamber electric furnace, and grinding and cutting the crystallized glass ceramics to finally obtain the finished product of the glass ceramics. The invention can reduce stockpile of the tailings, alleviate environmental pollution, realize comprehensive resource utilization, improve product performances and lower production cost, thus having good social benefit and good economic benefit.

Owner:ANSTEEL GRP MINING CO LTD

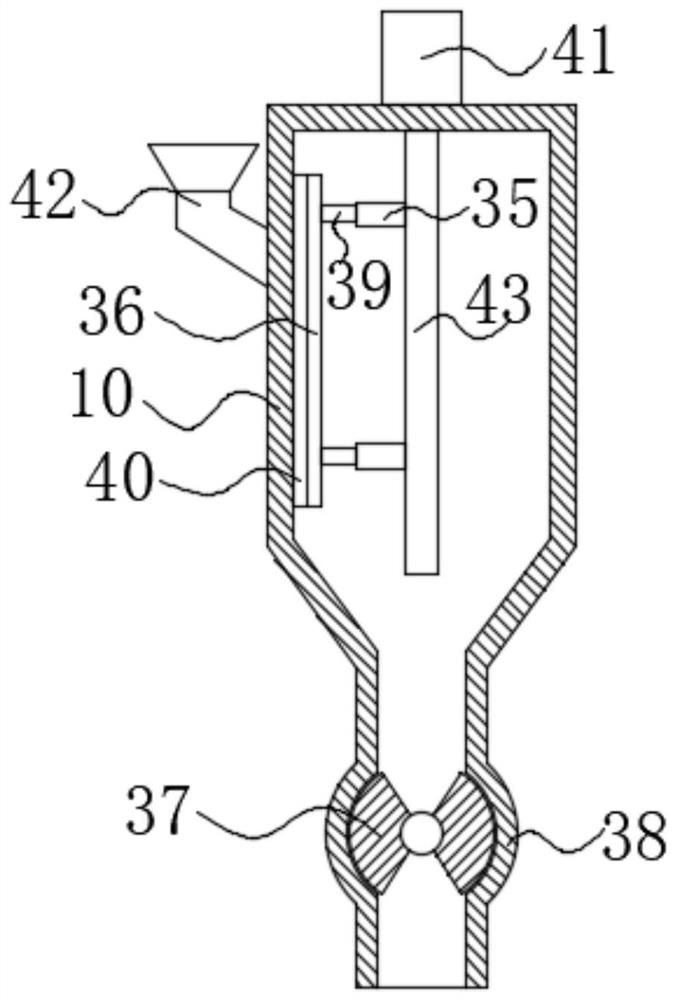

High-toughness halogen-free low-smoke flame-retardant power tube and preparation method thereof

PendingCN113087995ACrushed fullyStir wellGrain treatmentsTubular articlesEthylene glycol monophenyl etherMelting tank

The invention discloses a high-toughness halogen-free low-smoke flame-retardant power tube and a preparation method thereof. Modified resin is prepared from the following raw materials in parts by weight: 75-90 parts of isotactic polyethylene resin, 8-11 parts of ethylene glycol monophenyl ether superfine powder, 4-6 parts of nitrile rubber, 4-6 parts of halogen-free flame retardant powder, 1-4 parts of a synergistic flame retardant and 6-18 parts of ultrahigh molecular weight polyethylene resin. Raw material particles with overlarge particle sizes are conveyed into a material storage box to be crushed again, the screened raw materials are conveyed into a mixing mechanism, the raw materials entering a material mixing tank are mixed uniformly through circular stirring, the raw material particles entering a melting tank are subjected to circular stirring from inside to outside, the melting tank is kept vacuum through a vacuum pump, the melting speed of the raw material particles is increased, and the high-toughness halogen-free low-smoke flame-retardant electric power tube is obtained through extrusion, so that the situation that the performance of the electric power tube is uneven due to uneven raw materials is avoided, and the yield of the electric power tube is greatly increased.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

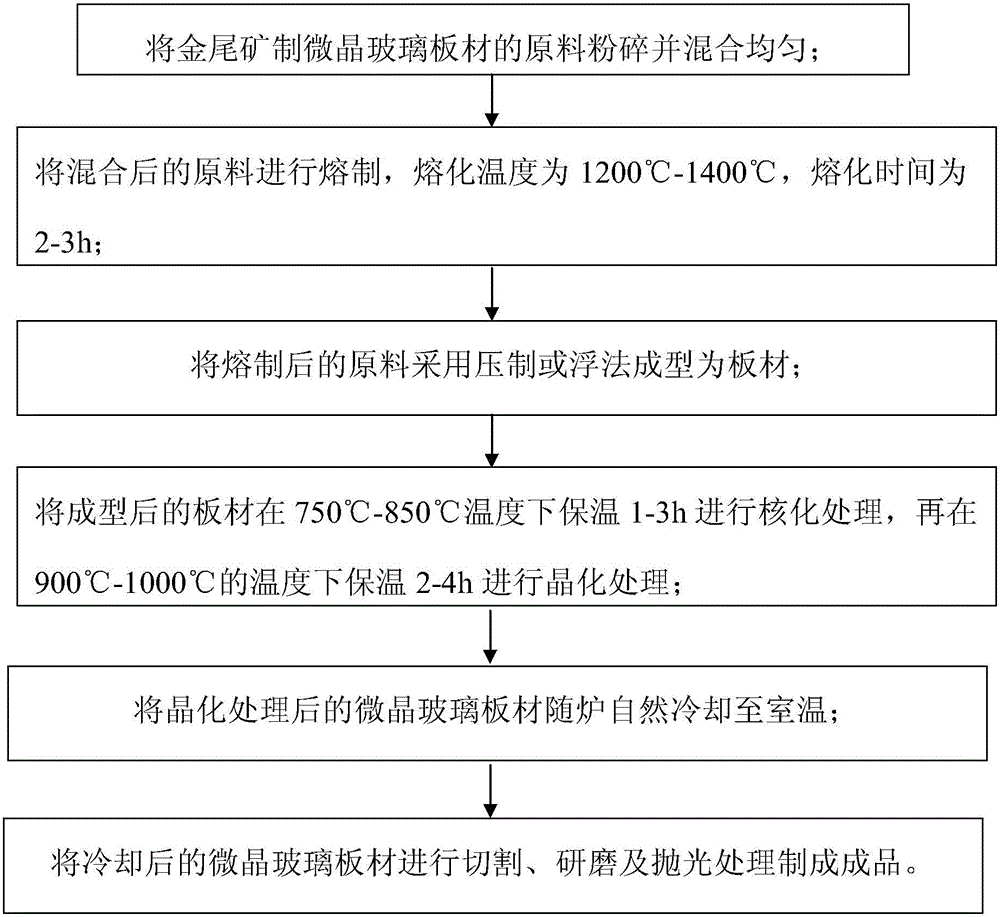

Gold ore tailing manufactured ceramic glass board and manufacturing method thereof

The invention provides a gold ore tailing manufactured ceramic glass board.The gold ore tailing manufactured ceramic glass board is prepared from, by mass, 60-80% of gold ore tailings, 10-30% of limestone, 3-6% of borax, 1.8% of zinc oxide, 1.3% of chromic oxide and 1.4% of sodium fluosilicate.The gold ore tailing manufactured ceramic glass board contain the chemical components including, by mass, 45-60% of SiO2, 5-15% of Al2O3, 15-30% of CaO, 3-10% of K2O+Na2O, 1-5% of B2O3, 1-5% of ZnO and 2-6% of TiO2+Cr2O3.The invention further provides a manufacturing method of the ceramic glass board.The method comprises the steps of mixing, melting, molding to form the board, performing nucleating treatment and crystallization treatment, performing natural cooling to reach room temperature, and performing treatment to obtain the finished gold ore tailing manufactured ceramic glass board.The glass melting temperature is decreased, the glass melting speed is increased, and the melting furnace efficiency is improved.

Owner:DALIAN DEETOP HEAVY IND

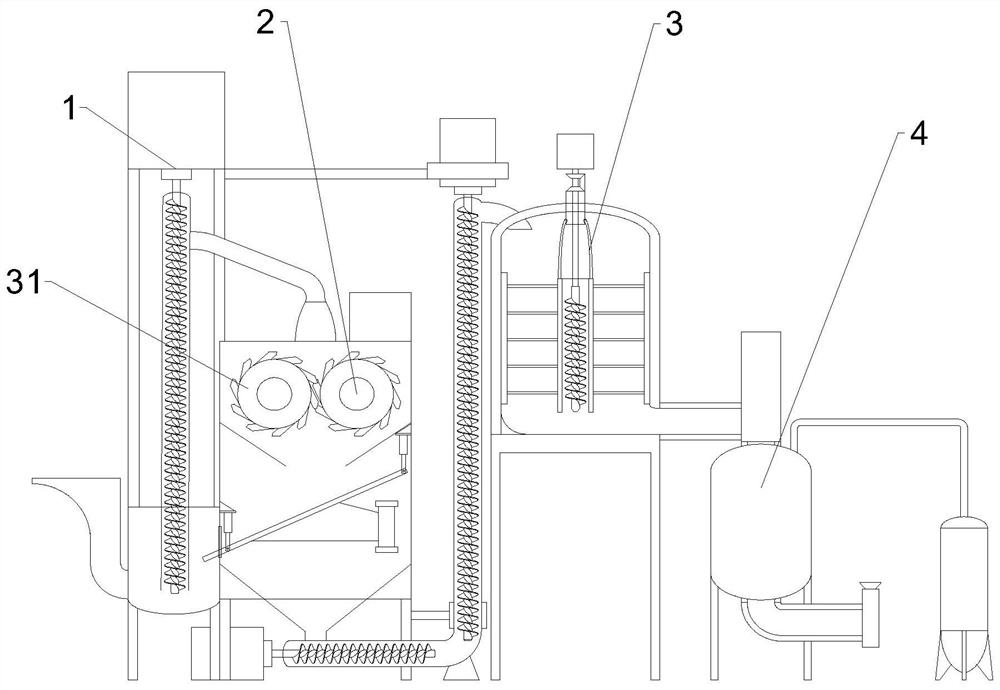

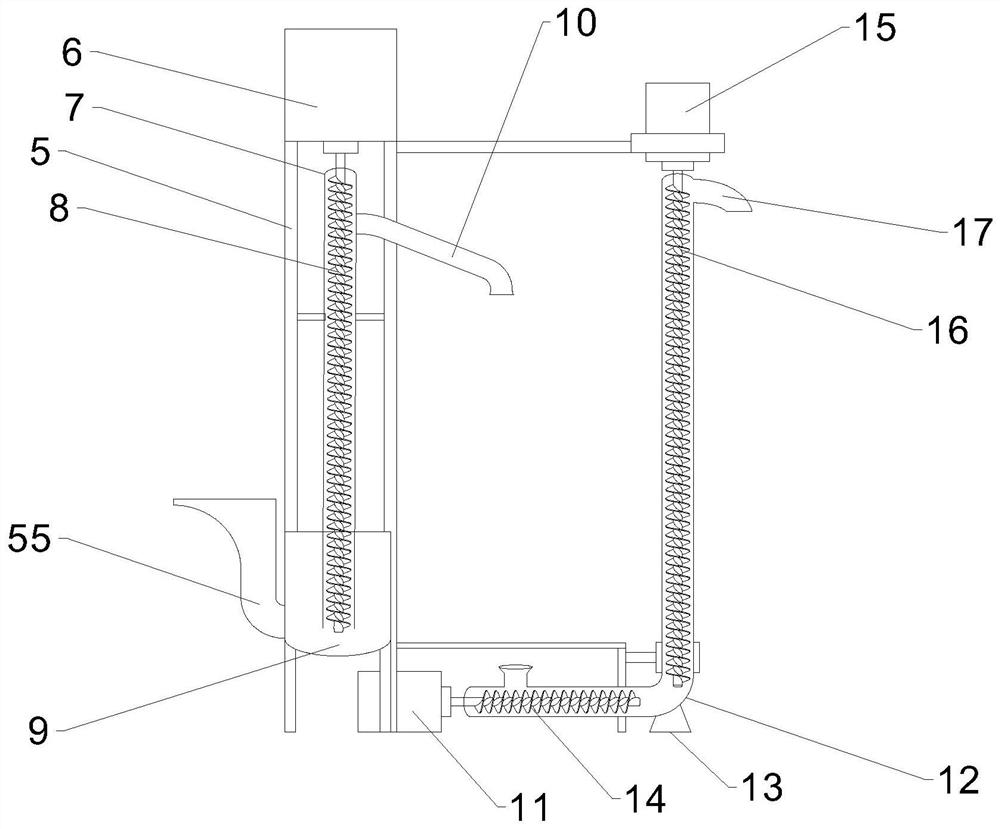

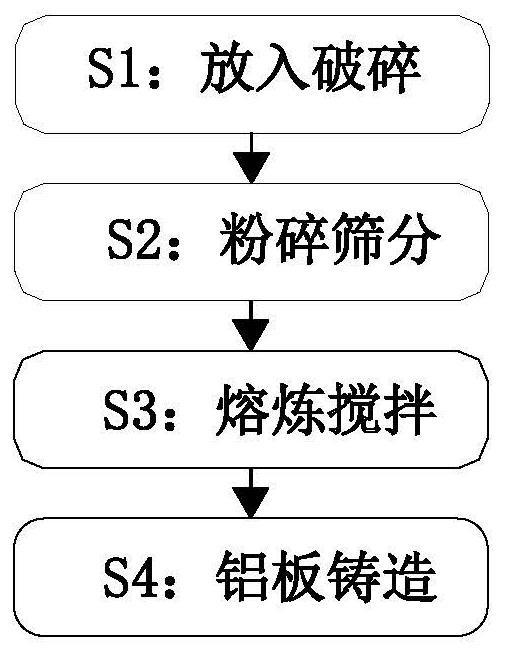

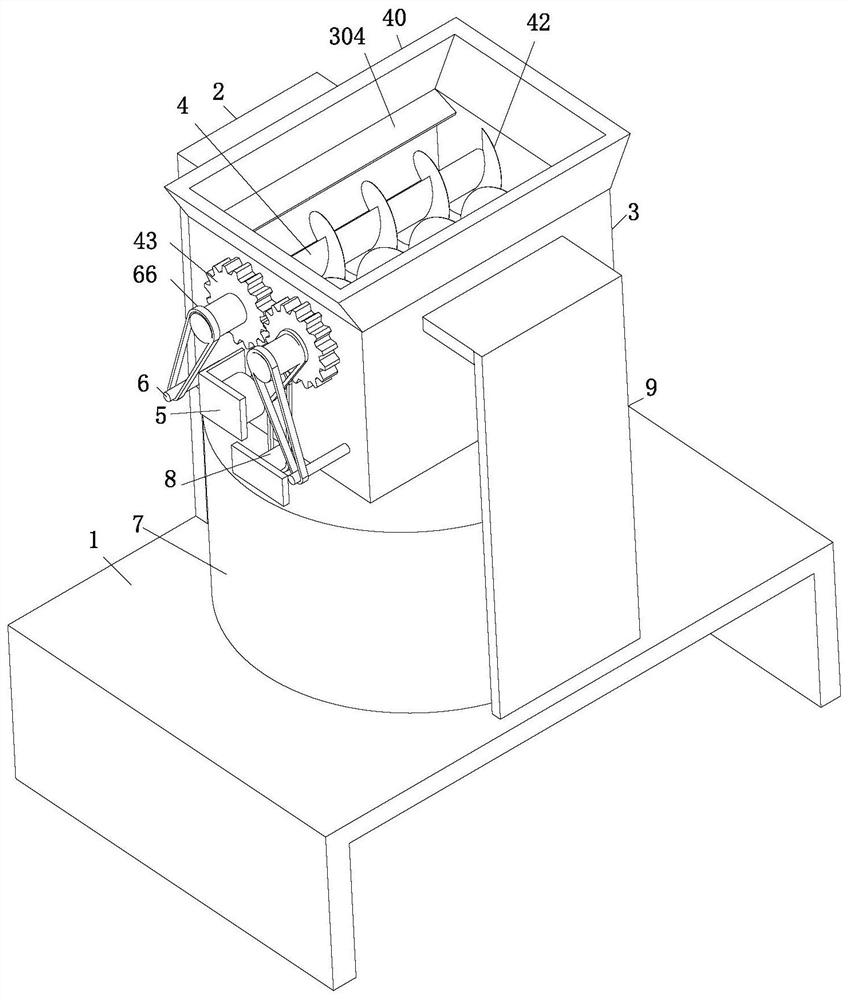

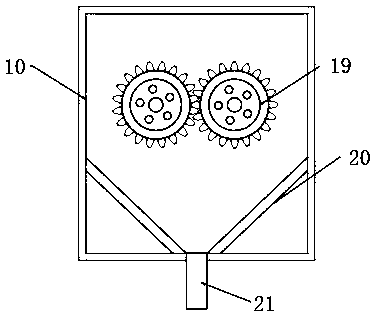

Production method of high-strength and high-toughness aluminum bar

ActiveCN113215422AReduce volumeEasy to transportMolten metal pouring equipmentsGrain treatmentsRaw materialAluminium alloy

The invention relates to a production method of a high-strength and high-toughness aluminum bar. The production method comprises a workbench, an L-shaped frame plate, a crushing box, a crushing mechanism, a smashing mechanism, a screening mechanism, a smelting barrel, a stirring mechanism and an adjusting mechanism. The crushing mechanism, the smashing mechanism and the screening mechanism are combined, so that the size of fed aluminum alloy raw materials is reduced, and the aluminum alloy raw materials are conveniently conveyed and smelted. The small-size aluminum alloy raw materials are conveniently smelted, so that the smelting speed of the aluminum alloy raw materials is increased, and meanwhile the aluminum alloy raw materials are completely smelted. Therefore, the production efficiency of the aluminum bar is improved, and the situation that the production efficiency of the aluminum bar is low is avoided, Meanwhile, the size of a discharge chute is adjusted through the adjusting mechanism, therefore the amount of aluminum alloy raw material liquid injected into an aluminum bar casting cavity mold can be effectively controlled, the raw materials are prevented from spreading out of the aluminum bar mold, and resource waste can be effectively avoided.

Owner:安徽佳晟金属科技有限公司

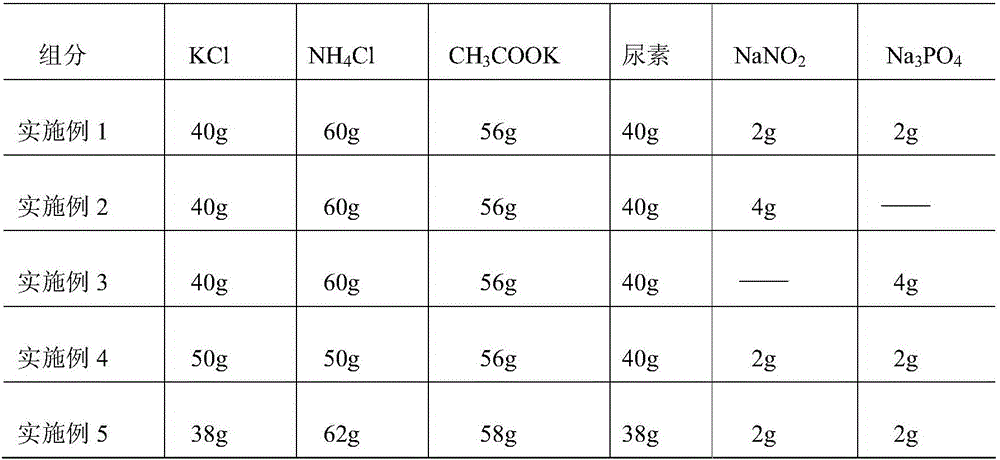

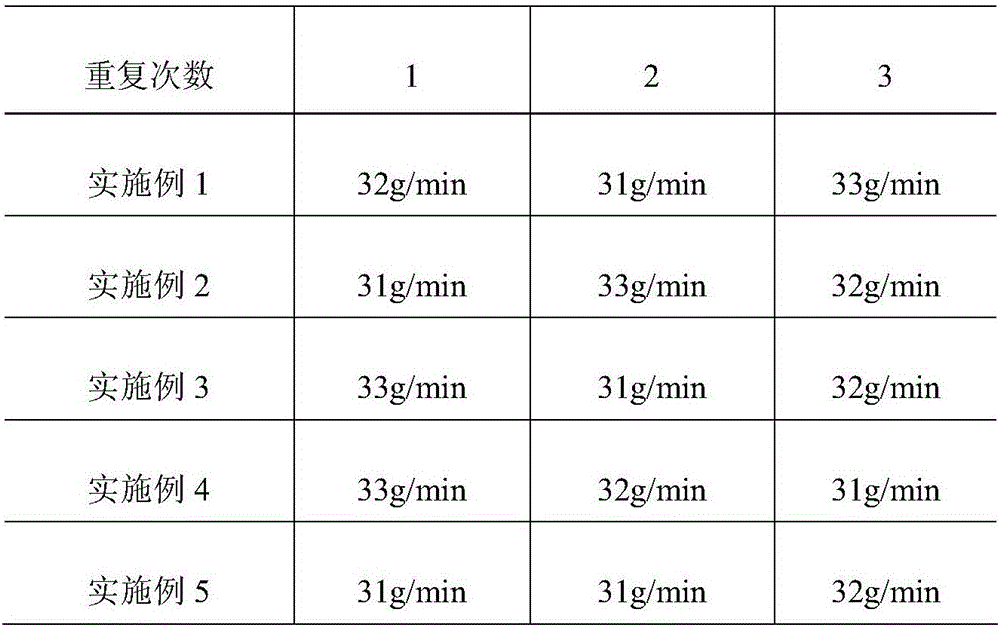

Environmentally-friendly composite type snow-melting agent and preparation method thereof

ActiveCN106634841ARaw materials are easy to getLow costOther chemical processesSodium phosphatesSnow melting

The invention relates to an environmentally-friendly composite type snow-melting agent and a preparation method thereof. The snow-melting agent is prepared from the following raw materials in parts by weight: 40 to 55 parts of chlorine salt, 45 to 55 parts of organic salt and 1 to 2 parts of a corrosion inhibitor, wherein the chlorine salt is prepared from the following raw materials in parts by weight: 15 to 20 parts of potassium chloride and 25 to 35 parts of ammonia chloride; the organic salt is prepared from the following raw materials in parts by weight: 25 to 30 parts of potassium acetate and 20 to 25 parts of urea; the corrosion inhibitor is one of or a mixture of sodium nitrite and sodium phosphate; and the snow-melting agent is prepared from the following raw materials in parts by weight: 50 parts of chlorine salt, 48 parts of organic salt and 2 parts of a corrosion inhibitor. The snow-melting agent is doped with the corrosion inhibitor; and related corrosiveness tests indicate that the snow-melting agent doped with the sodium phosphate has smallest corrosion effect on metal and can protect the surface of the metal, the metal still can maintain the original metal luster when being soaked into a salt solution, and a good metal corrosion-resistant effect is achieved.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Low-expansion micro-crystal glass manufactured from high-silicon iron tailings and preparation method thereof

The invention relates to low-expansion micro-crystal glass manufactured from high-silicon iron tailings and a preparation method thereof. The low-expansion micro-crystal glass provided by the invention is characterized by comprising the following raw materials in parts by weight: 30-35 parts of iron tailings, 40-45 parts of quartz, 16-18 parts of aluminum oxide, 5-10 parts of lithium carbonate, 0.2-2 parts of zinc oxide, 0.1-2 parts of barium carbonate, 0.1-1 part of boracic acid, 1-4 parts of titanium oxide and 1-4 parts of zirconium oxide, wherein the total quantity of the zinc oxide, the barium carbonate and the boracic acid is 1-4 parts; and the total quantity of the titanium oxide and the zirconium oxide is 3-5 parts. The preparation method provided by the invention comprises the following steps: adding micro-crystal glass mixtures to a kiln to be melted into molten glass; after pouring and molding, instantly adding the molten glass after melting to the kiln for annealing; after completing annealing, directly rising the temperature to carry out coring and crystallization processing; and carrying out air cooling to room temperature to obtain finished low-expansion micro-crystal glass. The invention reduces the stacking quantity of tailings, lightens environmental pollution, realizes the comprehensive utilization of resources, can improve the performance of a product and lowers production cost.

Owner:ANSTEEL GRP MINING CO LTD

Method utilizing high-ferrosilicon tailings to manufacture low-expansion microcrystalline glass

The invention provides low-expansion microcrystalline glass. The low-expansion microcrystalline glass is characterized in that the combination of the proportioning ratio according to the weight percent is as follows: iron tailings: 30 to 35; quartz: 40 to 45; alumina: 16 to 18; lithium carbonate: 5 to 10; zinc oxide: 0.2 to 2; barium carbonate: 0.1 to 2; boric acid: 0.1 to 1; the resultant of the zinc oxide, the barium carbonate and the boric acid: 1 to 4; titanium oxide: 1 to 4; zirconia: 1 to 4; and the resultant of the titanium oxide and the zirconia: 3 to 5. With the characteristics of reducing environmental pollution, improving product performance and lowering production cost, the invention solves the problem of utilizing wastes to manufacture the low-expansion microcrystalline glass.

Owner:BEIJING QING MAI HUA QING HLDG GRP CO LTD

Method utilizing high-ferrosilicon tailings to manufacture low-expansion microcrystalline glass

The invention provides low-expansion microcrystalline glass. The low-expansion microcrystalline glass is characterized in that the combination of the proportioning ratio according to the weight percent is as follows: iron tailings: 30 to 35; quartz: 40 to 45; alumina: 16 to 18; lithium carbonate: 5 to 10; zinc oxide: 0.2 to 2; barium carbonate: 0.1 to 2; boric acid: 0.1 to 1; the resultant of thezinc oxide, the barium carbonate and the boric acid: 1 to 4; titanium oxide: 1 to 4; zirconia: 1 to 4; and the resultant of the titanium oxide and the zirconia: 3 to 5. With the characteristics of reducing environmental pollution, improving product performance and lowering production cost, the invention solves the problem of utilizing wastes to manufacture the low-expansion microcrystalline glass.

Owner:BEIJING QING MAI HUA QING HLDG GRP CO LTD

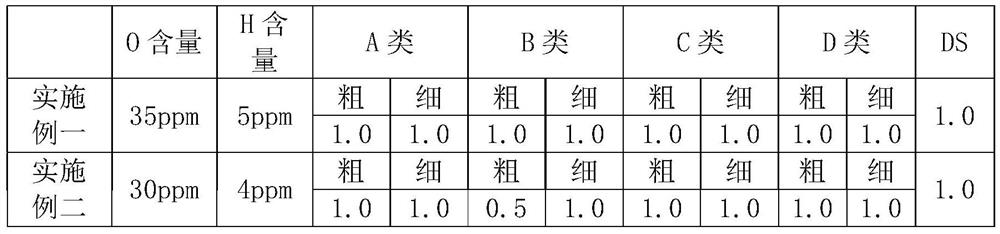

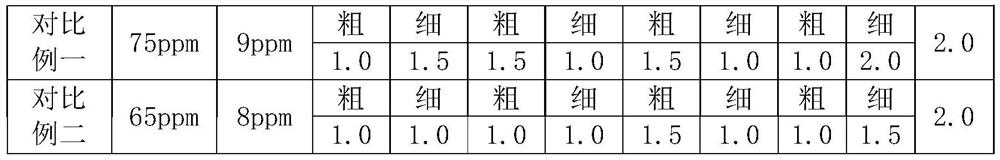

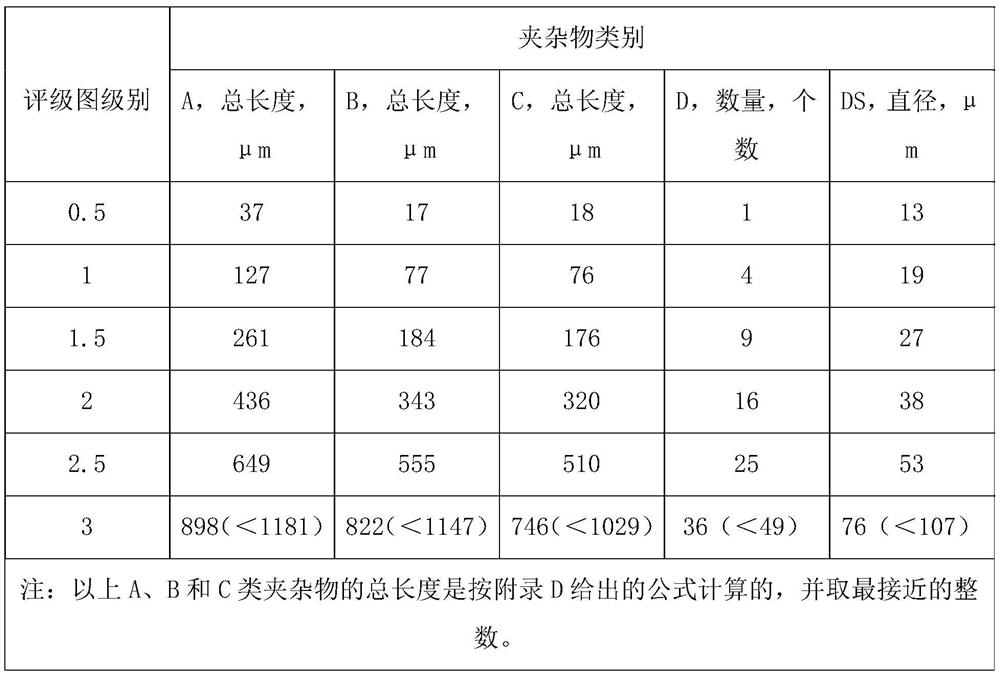

Production method for smelting F55 dual-phase steel in intermediate frequency furnace

The invention provides a production method for smelting F55 dual-phase steel in an intermediate frequency furnace. The production method comprises the following steps that S1, molten steel is prepared in the intermediate frequency furnace according to the following ingredients in percentage by mass: less than or equal to 0.03% of C, less than or equal to 1.00% of Si, less than or equal to 1.00% of Mn, less than or equal to 0.02% of P, less than or equal to 0.015% of S, 24.0%-26.0% of Cr, 6.0%-8.0% of Ni, 3.0%-4.0% of Mo, 0.2%-0.3% of N and the balance of Fe; S2, abottom slag accounting for 2% of the weight of the molten steel is added into the intermediate frequency furnace, and melting is conducted; S3, after melting down, a Si-Ca wire is added for deoxidation; S4, slagging off is conducted after adding Si-Ca wires for 10 minutes, and high-aluminum refractory brick fragments and CaF2 are added to make new slag; S5, a deoxidizing agent is added into the slag layer in batches for first diffusion deoxidation; S6, components in front of the furnace are sampled and analyzed, FeCrNi alloy and alloy elements of Si, Mn, Mo and N are supplemented, and then diffusion deoxidation for the second time is conducted; and S7, the slag amount is adjusted, and tapping is conducted after white slag is kept for 15 minutes. Compared with the prior art, the oxygen content and the inclusion content in the intermediat requency smelting duplex stainless steel are reduced through reasonable intermediate frequency smelting burdening, deoxidation and slagging processes.

Owner:JIANGXI BAOSHUNCHANG SPECIAL ALLOY CO LTD

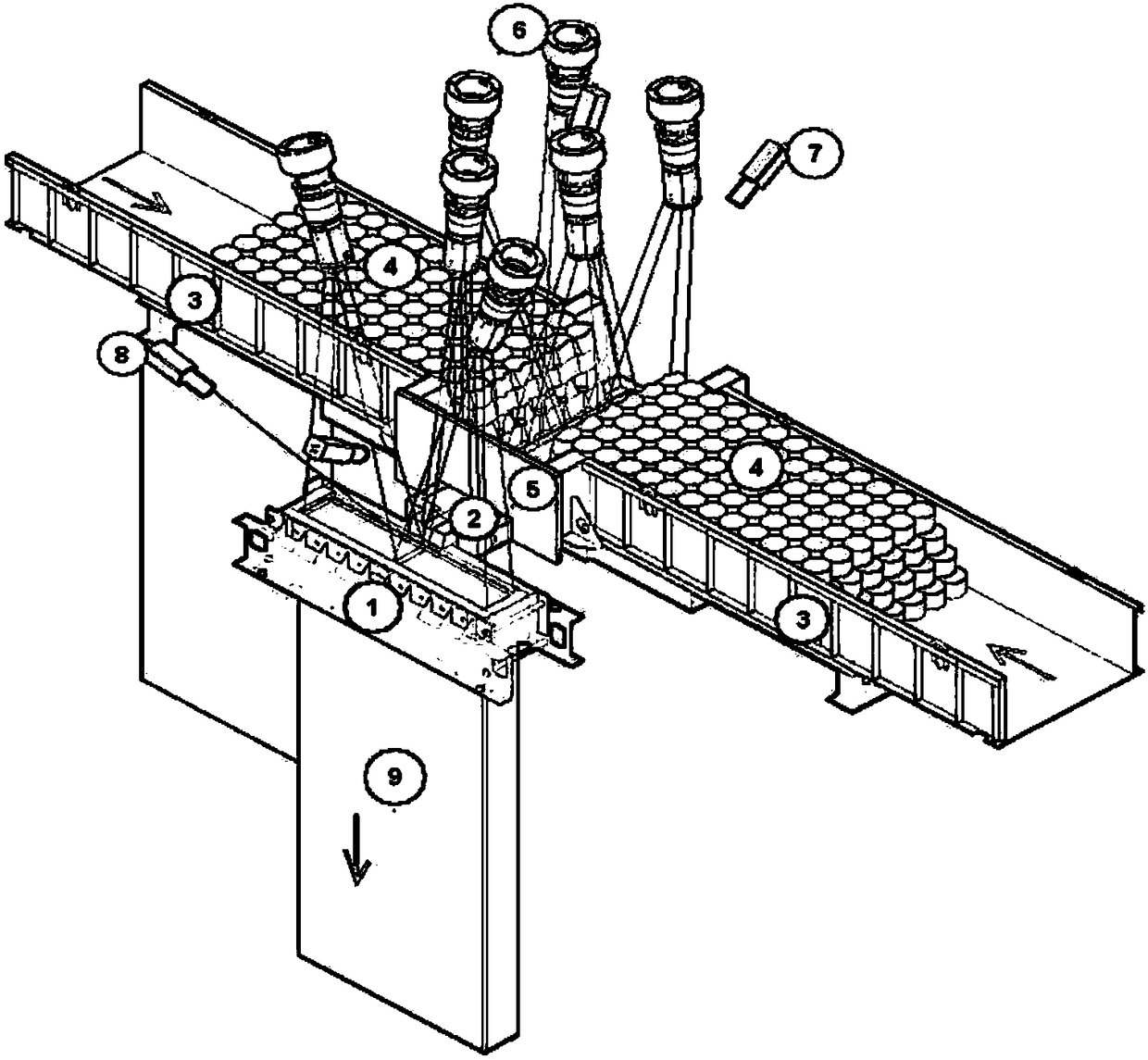

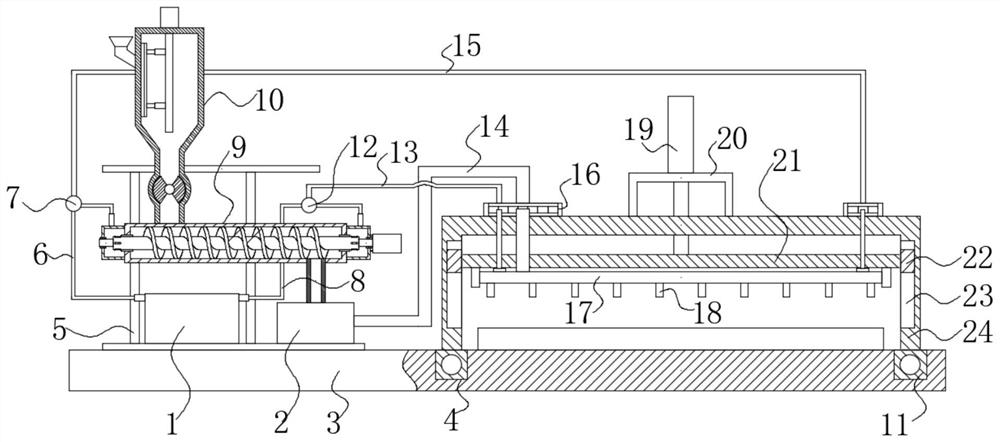

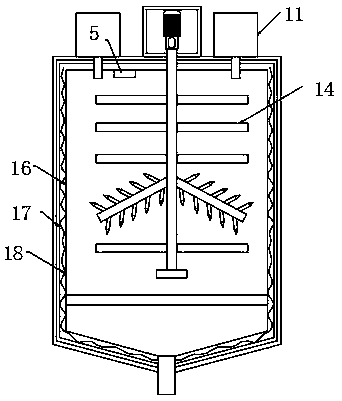

Thermoplastic plastic powder spray fusing device

InactiveCN111889261AReasonable structureInnovative designLiquid spraying apparatusEngineeringPowder Spray

The invention provides a thermoplastic plastic powder spray fusing device. The device comprises a feeding tank, a hot melting drum, a steam furnace, an extruding machine, a rack, a bottom plate and amaterial spraying pipe; the rack is fixedly installed on the bottom plate; the feeding tank, the hot melting drum, the steam furnace and the extruding machine are arranged on the rack; a portal frameis arranged on the bottom plate in a back-and-forth sliding mode; the material spraying pipe is arranged on the portal frame in a vertically sliding mode; an air cylinder is arranged on the portal frame and is used for driving the material spraying pipe to slide vertically; a feeding hopper is arranged on the side wall of the feeding tank; a discharging pipe at the bottom of the feeding tank is connected with a feeding port of the hot melting drum; a quantified discharging device is arranged on the discharging pipe at the bottom of the feeding drum; a shaft sleeve is rotatably installed insidethe hot melting drum in a coaxial sealing mode; a discharging end of the hot melting drum is connected with the extruding machine; hollow spiral plates are distributed on the shaft sleeve along the axial direction; sealing shades are installed at two ends of the hot melting drum in a sealing mode; and the end parts of the shaft sleeve extend into the sealing shades.

Owner:蒙城县虹升塑粉有限公司

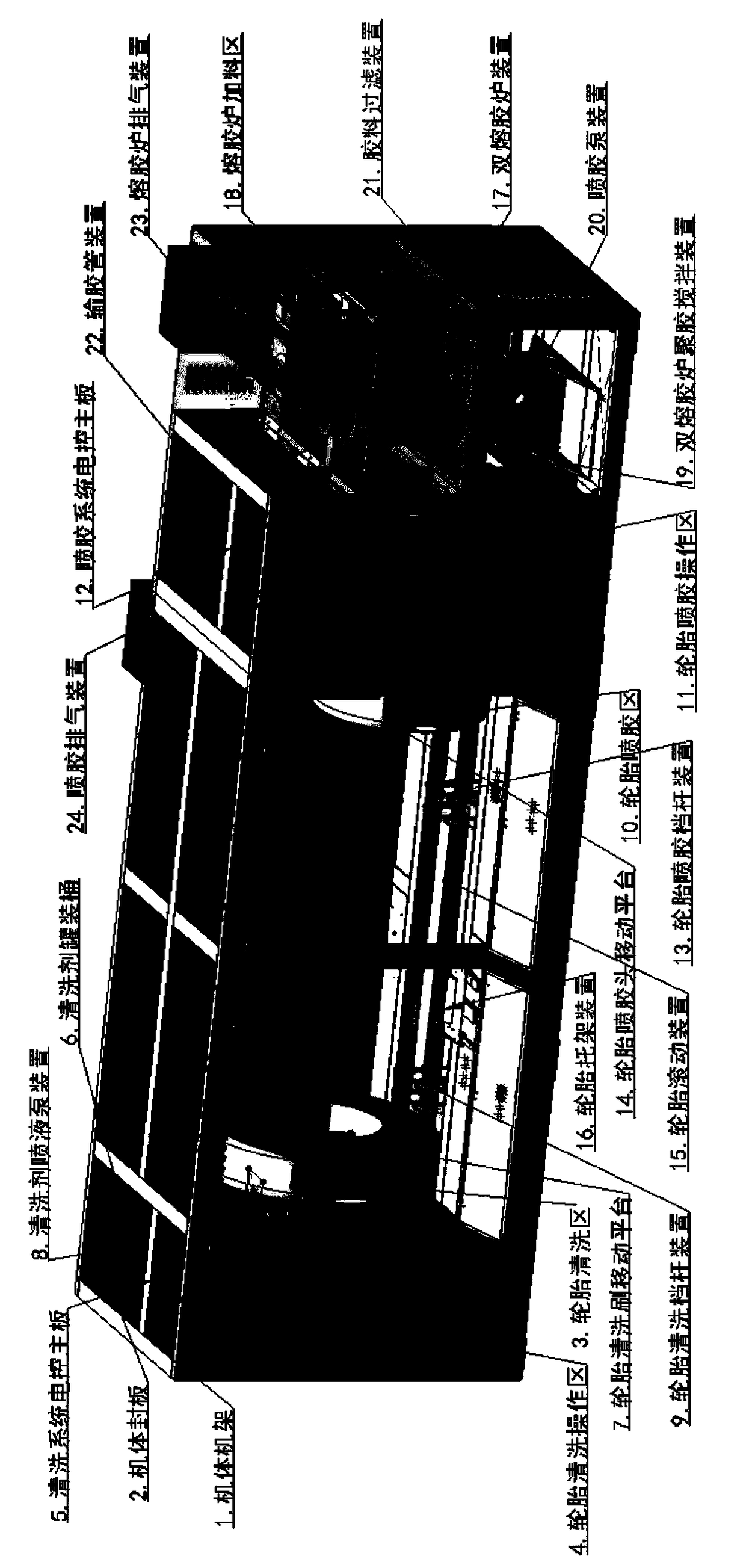

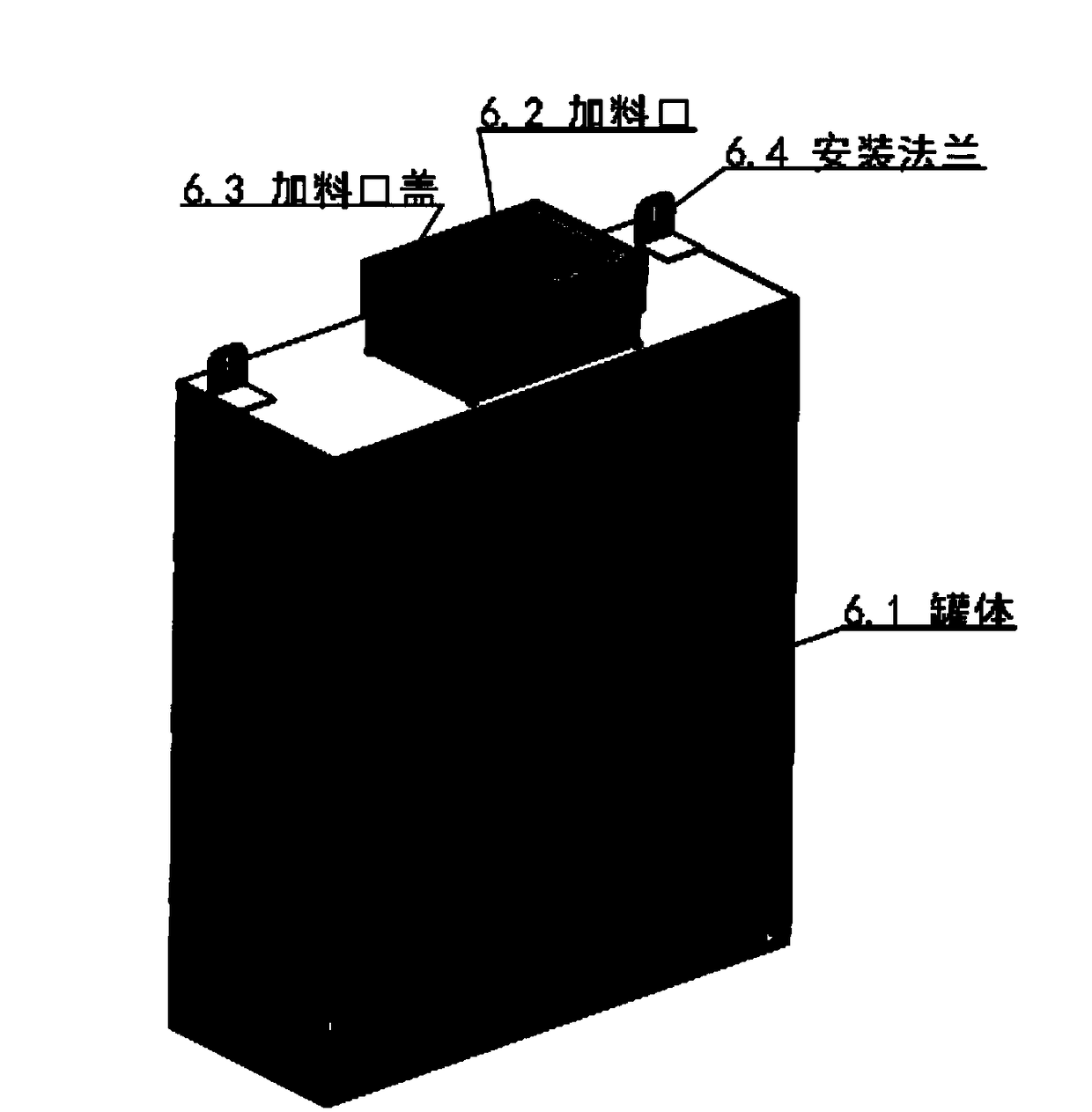

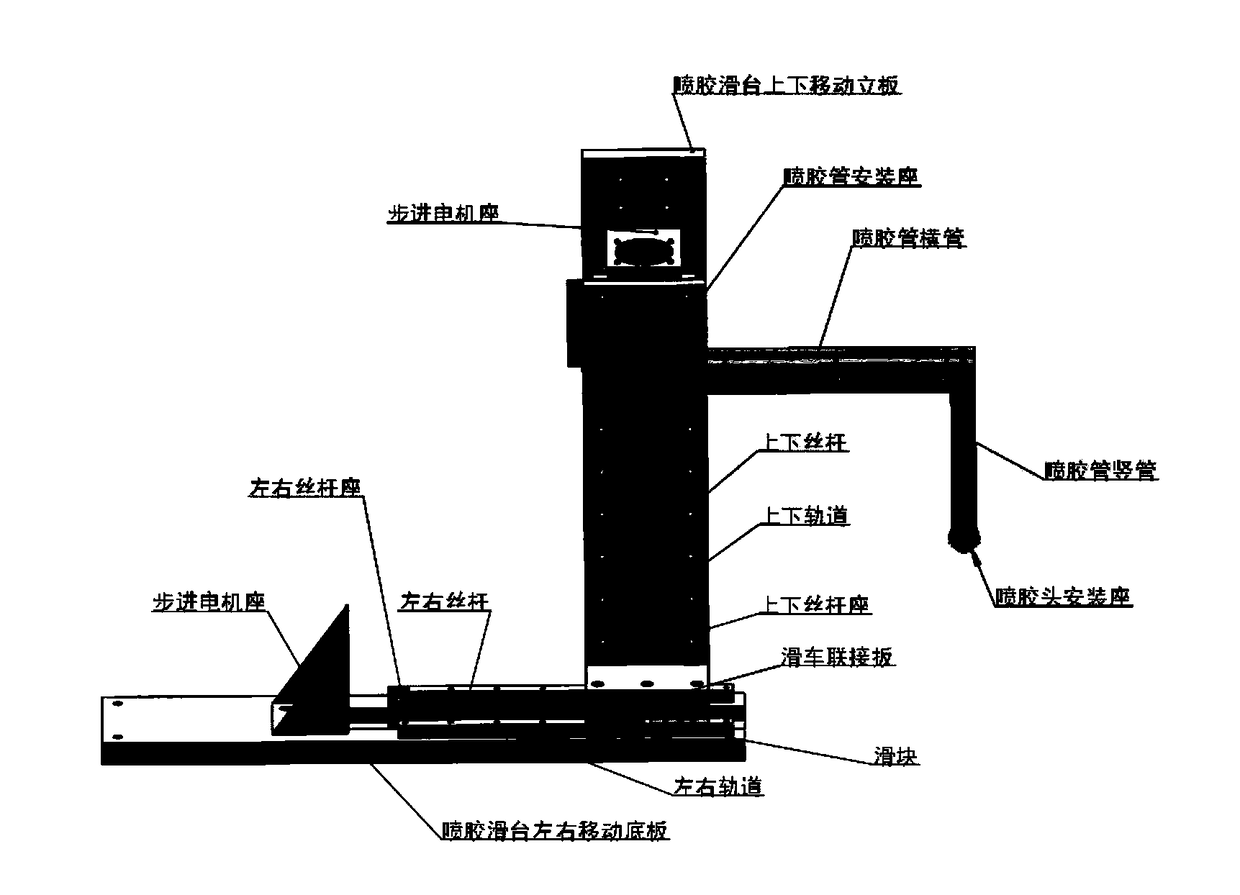

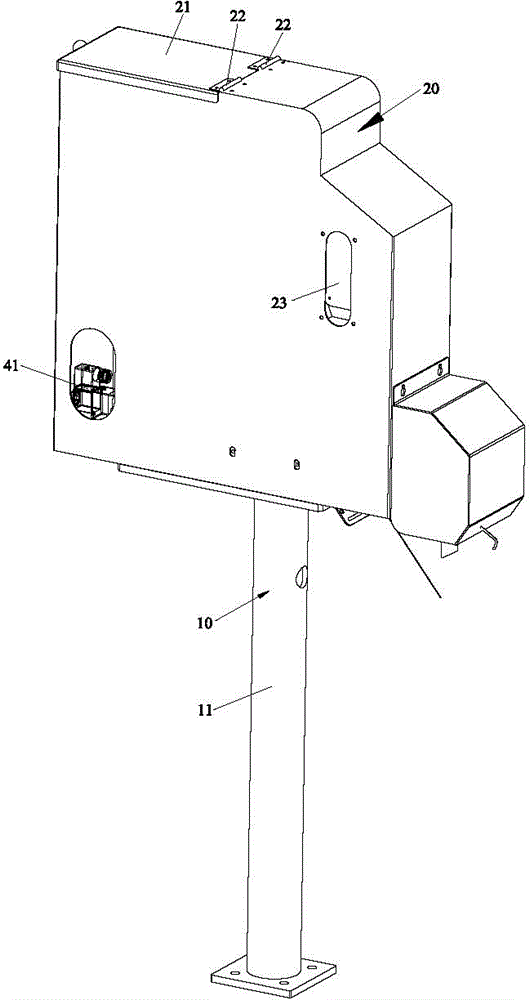

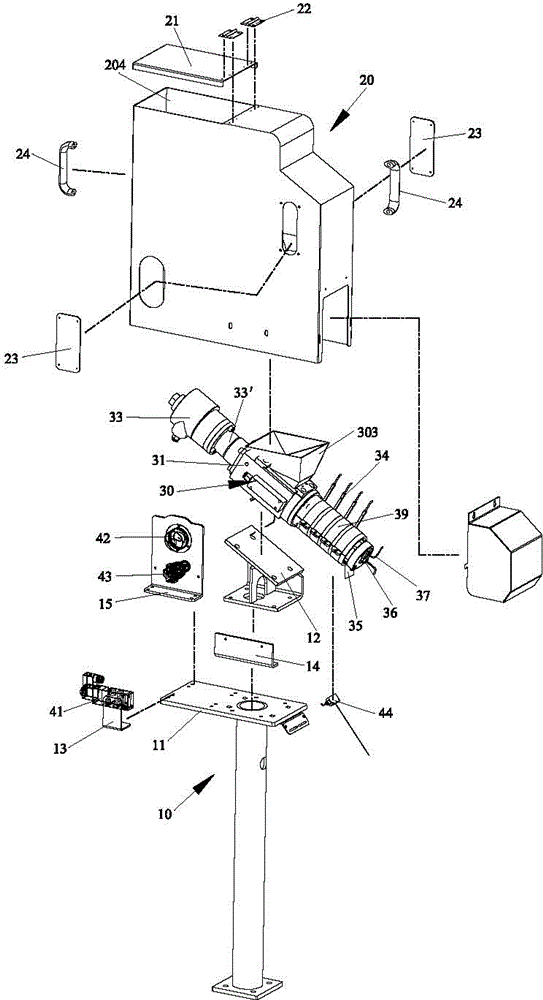

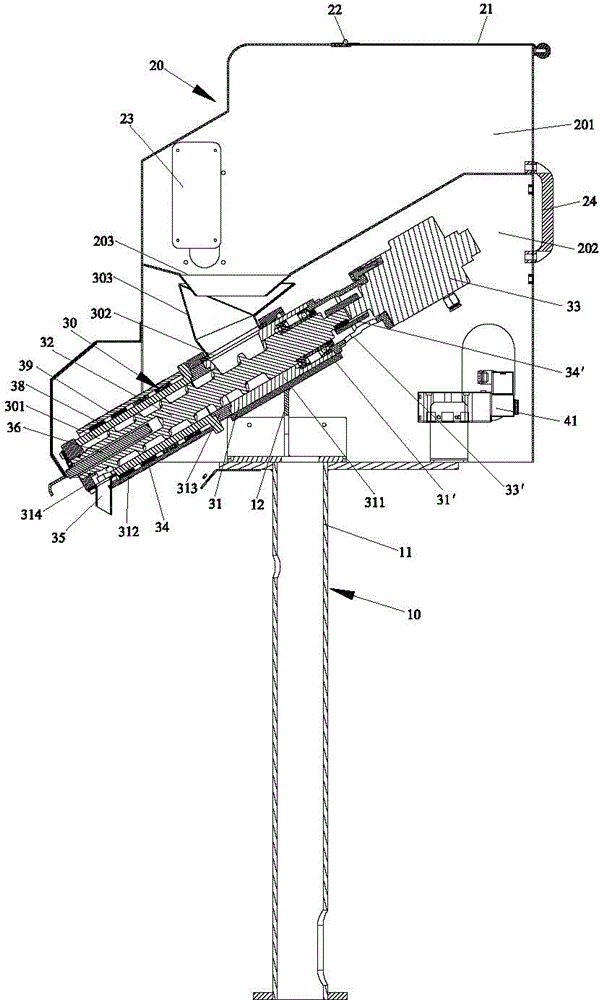

Tire automatic cleaning and rubber spraying all-in-one machine

InactiveCN109367084AInnovative designCompact bodyTyresCleaning using toolsNumerical controlEngineering

The invention discloses a tire automatic cleaning and rubber spraying all-in-one machine. The all-in-one machine comprises a machine body frame. The all-in-one machine is characterized in that heat conduction oil interlayer heating and a multi-separation heating system are adopted in a rubber melting furnace so that the heating area of for rubber heating can be increased, the heat conduction uniformity can be enhanced, the rubber melting speed is increased, and the precision of temperature control is greatly improved; the scientific and reasonable rubber melting heating technical solves the technical problems that due to the fact that the local heating temperature of a traditional rubber spraying machine is not balanced, rubber is prone to be burnt out, and carbon deposit is prone to occurrence; and the rubber melting technology can fully ensure the inherent performance of a high polymer material, and safe tires with higher quality can be produced. According to the all-in-one machine,moving positioning of rubber spraying pipes adopts stepping coding numerical control positioning control, so that the spraying positions of the tires of the same model are consistent, a plurality of nozzles are arranged, so that the sprayed rubber is more balanced, and the effects of being more smooth and bright are achieved; and a computer numerical control metering type high-temperature gear pump rubber spraying technology is adopted, so that the rubber spraying intensity is adjustable, and the rubber spraying quantity is accurate and controllable.

Owner:南通骏标自密封安全轮胎科技有限公司

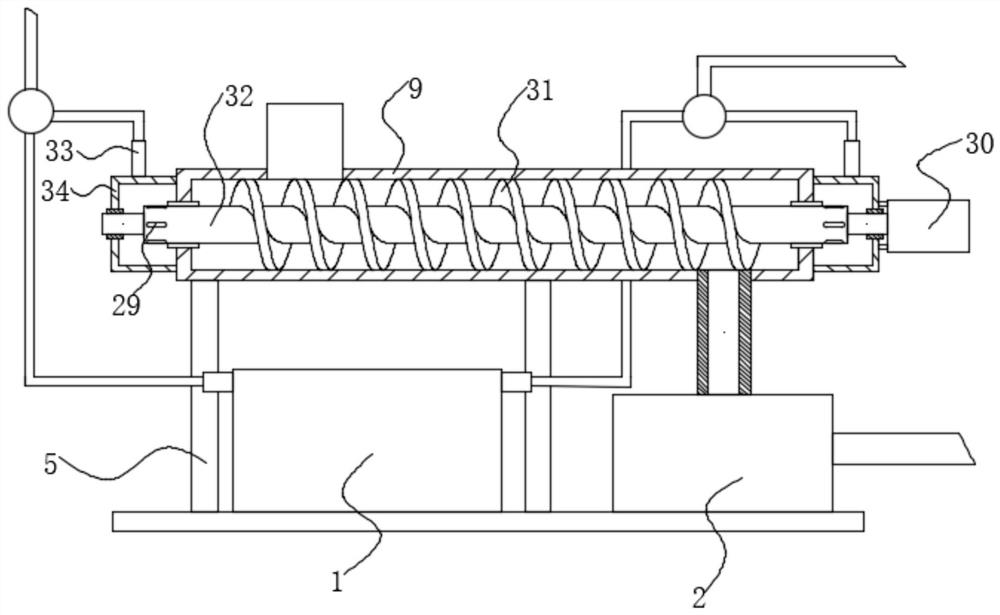

Spiral upper-end glue feeding device of automatic edge bonding machine

ActiveCN104552551AIncrease powerAvoid refractory problemsDomestic articlesGlue gunsDual actionHeat transfer efficiency

The invention discloses a spiral upper-end glue feeding device of an automatic edge bonding machine. The spiral upper-end glue feeding device comprises a frame, a hopper-type housing and a glue core melting component. The glue core melting component comprises a shell, a screw rod and a reducing pneumatic motor. The shell comprises a shaft sleeve seat and a heating cylinder. Heating devices sleeve the heating cylinder. The lower end of the heating cylinder is provided with a diversion pipe communicated with a flow channel. The screw rod is matched with the flow channel and rotatably arranged in the same. A heating pipe is arranged in the lower end of the screw rod. The spiral upper-end glue feeding device has the advantages that the the heaters sleeving the heating cylinder are high in power and heat transferring efficiency, the screw rod extrudes hot melt glue for plasticizing, and glue melting speed is high, besides, by heating in the screw rod and constantly rotary stirring, mixing and extruding under driving of the reducing pneumatic motor, the melt glue is constantly extruded out of the heating cylinder, thus the problems of the traditional cylinder extruding glue of idle running and melting difficulty of solid particles in a cylinder glue extruding cylinder core are solved, and glue melting efficiency and quality is effectively increased.

Owner:NANXING MACHINERY CO LTD

Lysozyme hydrochloride vaginal tablets, and preparation method and application thereof

ActiveCN105749260AImprove curative effectImprove mucopolysaccharide metabolismAntibacterial agentsAntimycoticsFreeze dryActive ingredient

The invention discloses lysozyme hydrochloride vaginal tablets, and a preparation method and application thereof. The vaginal tablets comprise an active ingredient and auxiliary materials; the active ingredient is lysozyme hydrochloride which accounts for 25 to 48 percent by weight in the lysozyme hydrochloride vaginal tablets. The auxiliary materials are any acceptable auxiliary materials required for preparing the lysozyme hydrochloride vaginal tablets, and comprise a freeze-dried powder skeleton agent, a bonding agent, a filling agent, a lubricating agent and / or other additives. The lysozyme hydrochloride vaginal tablets have a good bacterium inhibiting or killing effect, and have a strong killing effect on staphylococcus aureus belonging to gram-positive bacteria and Escherichia coli of the gram-positive bacteria.

Owner:SHANDONG SBOND PHARMA +1

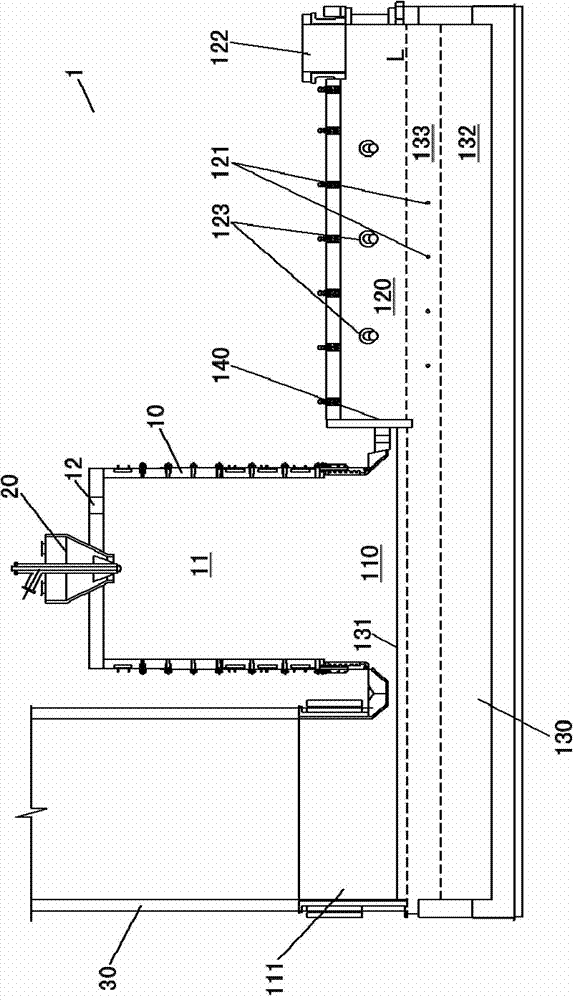

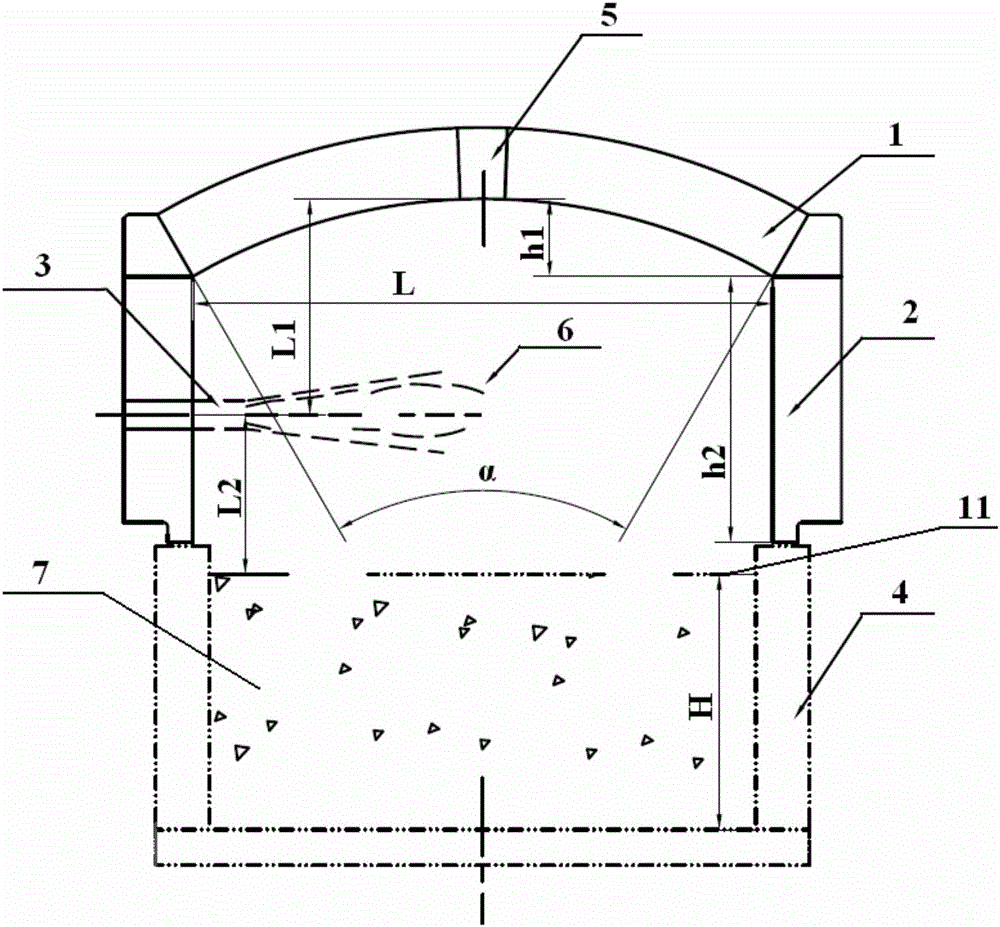

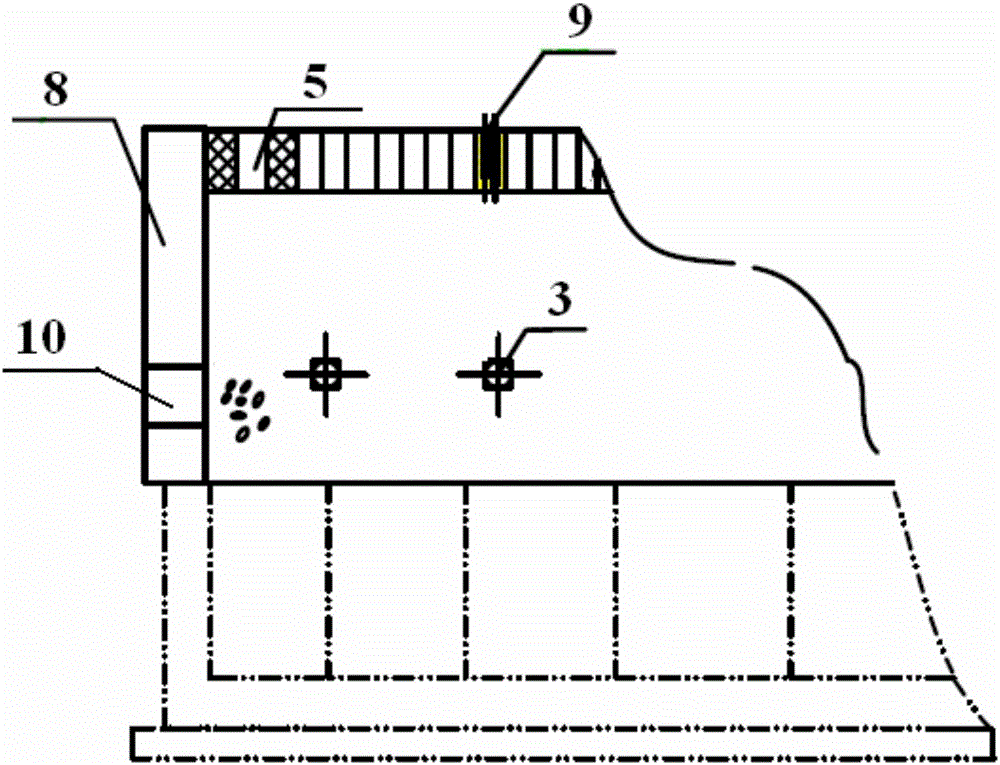

Flame space of pure oxygen combustion kiln, pure oxygen combustion kiln and method for preparing glass liquid

InactiveCN106746500AQuality improvementReduce concentrationTank furnacesGlass furnace apparatusMelting tankCombustor

The invention relates to the field of preparation of glass and discloses a flame space of a pure oxygen combustion kiln, the pure oxygen combustion kiln and a method for preparing a glass liquid. The flame space is a space formed by front and rear gable walls, a breast wall (2) and a crown (1) and is matched with a melting tank (4) located below the flame space; a combustor (3) is arranged in the breast wall; a liquid surface scale mark (11) is arranged on a tank wall of the melting tank; h1 / L=1:(7.5-9), (h1+h2) / H=(1.3-1.8) and L1=90cm-110cm; h1 is the arch height of the crown, L is the arch span of the crown and h2 is the height of the breast wall; H is the vertical height between the liquid surface scale mark and the tank bottom of the melting tank; and L1 is the vertical height between the combustor and a crown top of the crown. The pure oxygen combustion kiln comprising the flame space can be used for preparing high-quality, stable and uniform glass liquid and the melting rate and the yield of the glass are improved; and the service life is obviously prolonged.

Owner:TUNGHSU TECH GRP CO LTD +1

Energy-efficient gas-type borax smelting method and borax smelting furnace

InactiveCN103591800AHigh calorific valueImprove heat utilizationCrucible furnacesGas emission reductionFuel gasFlue

The invention relates to the technical field of borax smelting, and discloses an energy-efficient gas-type borax smelting method and a borax smelting furnace. The smelting furnace adopted in the method comprises a furnace body, a furnace cover, a smelting pool, a circular flue, a chimney outlet, an unloading screw, a discharging guide groove and an efficient natural gas nozzle. The stainless smelting pool arranged at a central position in the upper portion of the furnace body is fixedly connected with the discharging guide groove through a sealing device. The other end of the discharging guide groove is fixed on the wall of the furnace body. The unloading screw is arranged at a central position on the furnace cover above the smelting pool and penetrates the smelting pool to extend out of the discharging guide groove. The chimney outlet arranged on one side of the discharging screw on the furnace cover is communicated with the smelting pool. Due to the efficient gas nozzle and natural gas serving as heating raw materials, heat value is high, smelting speed is high, optionally movable production can be realized, and blank of borax smelting equipment is filled up; the borax smelting furnace has the advantages of low energy consumption, high heat utilization rate, small size, reasonable structure, convenience in maintenance and repairing and low cost.

Owner:LUOYANG ANTUO KILN ENVIRONMENTAL PROTECTION

Sand mould casting process for titanium and titanium alloy castings

ActiveCN102728778AIncrease productivityReduce manufacturing costFoundry mouldsFoundry coresRefractoryTitanium

The invention relates to a sand mould casting process for titanium and titanium alloy castings. The sand mould casting process adopts graphite powders or graphite chippings produced while a graphite casting mould is processed by a production machine as a fire-resistant material, adopts the sand mould casting process to manufacture the casting moulds, and adopts the vacuum self-consuming kish furnace to melt and cast. The sand mould casting process mainly comprises the following processing steps of: 1) manufacturing a casting mould; 2) preparing the manufacturing material; 3) molding; 4) drying and solidifying; 5) performing vacuum degassing and roasting; and 6) melting and casting. The sand mould casting process has the following advantages: with the adoption of the graphite powders or the graphite chippings produced while the graphite casting mould is processed by the production machine, the production cost is reduced and the molding process is simple, so that the utilization rate of the casting material is high; and the sand is convenient to clean.

Owner:XIAN PUMP & VALVE GENERAL FACTORY CO LTD

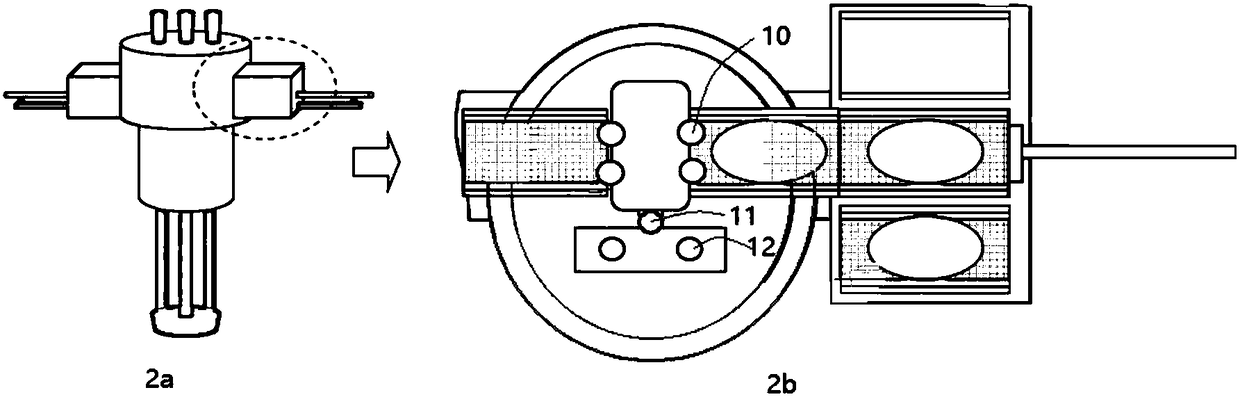

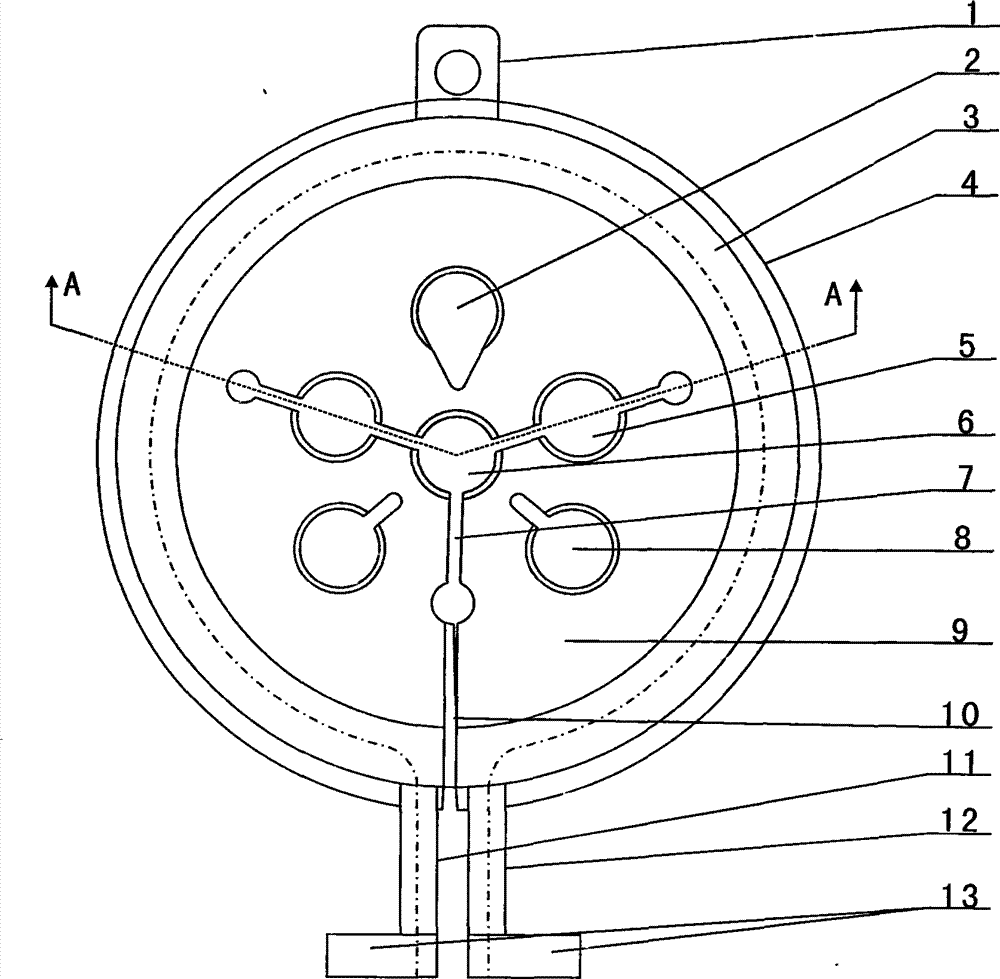

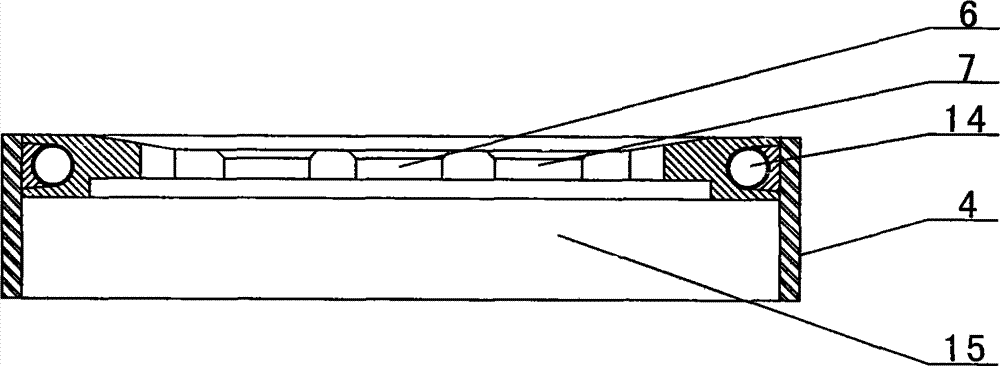

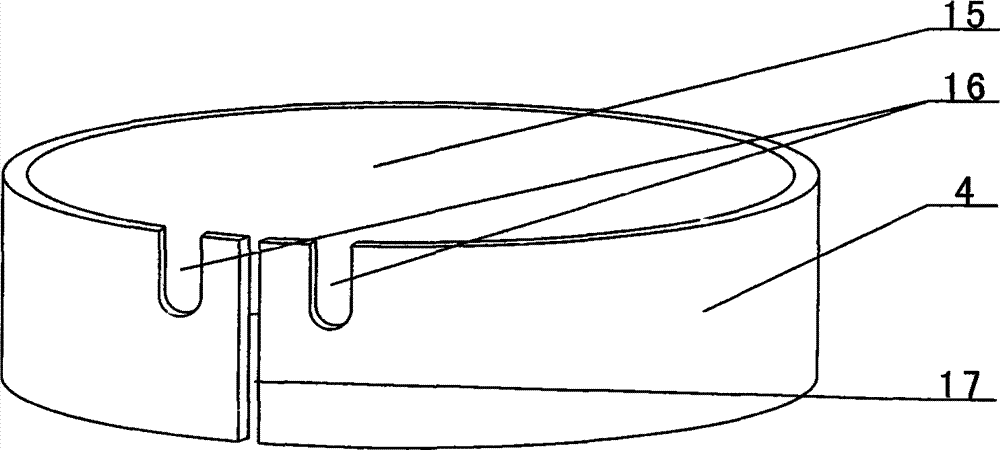

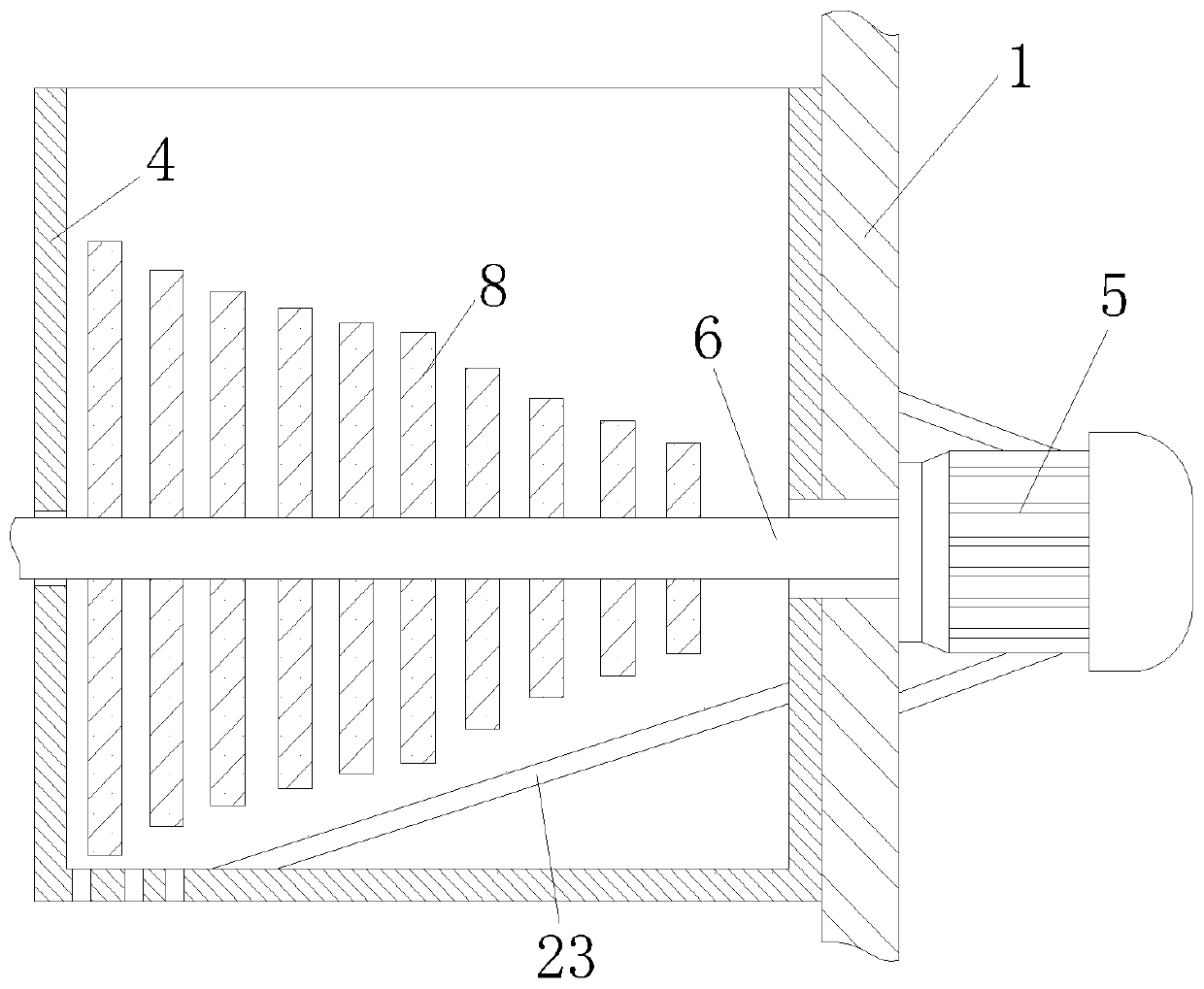

High-frequency coil provided with auxiliary heating cylinder

InactiveCN103046122AFast melting effectFast melting speedAfter-treatment apparatusPolycrystalline material growthEdge surfaceHeat resistance

A high-frequency coil provided with an auxiliary heating cylinder relates to the technical field of artificial lenses. A drawing hole or a chemical material hole (6) is formed in the middle of the high-frequency coil (3); a plurality of surrounding drawing holes (5) are formed outside the high-frequency coil (3); a plurality of drainage grooves (18) are formed in a radial shape from the drawing hole or the chemical material hole; a downwards recessed surface (9) is arranged in the middle of the upper surface of the high-frequency coil; an upwards recessed plane is arranged in the middle of the lower surface of the high-frequency coil; the outer end of one drainage groove (7) is communicated to the outer edge surface of the high-frequency coil through an opening (10); a cooling water way (14) surrounds the external of the high-frequency coil; a ground wire connection mechanism is arranged outside the high-frequency coil; the upper end of a tungsten or molybdenum cylinder (4) is connected with the external surface of the high-frequency coil; and an interval (17) is formed on the tungsten or molybdenum cylinder and corresponds to the opening. Through setting the tungsten or molybdenum cylinder with higher heat resistance at the lower part of the high-frequency coil, the quicker hot melting effect at the upper end of a raw material rod is obtained, and the hot melting speed at the upper end of the raw material rod is effectively quickened.

Owner:LUOYANG JINNUO MECHANICAL ENG

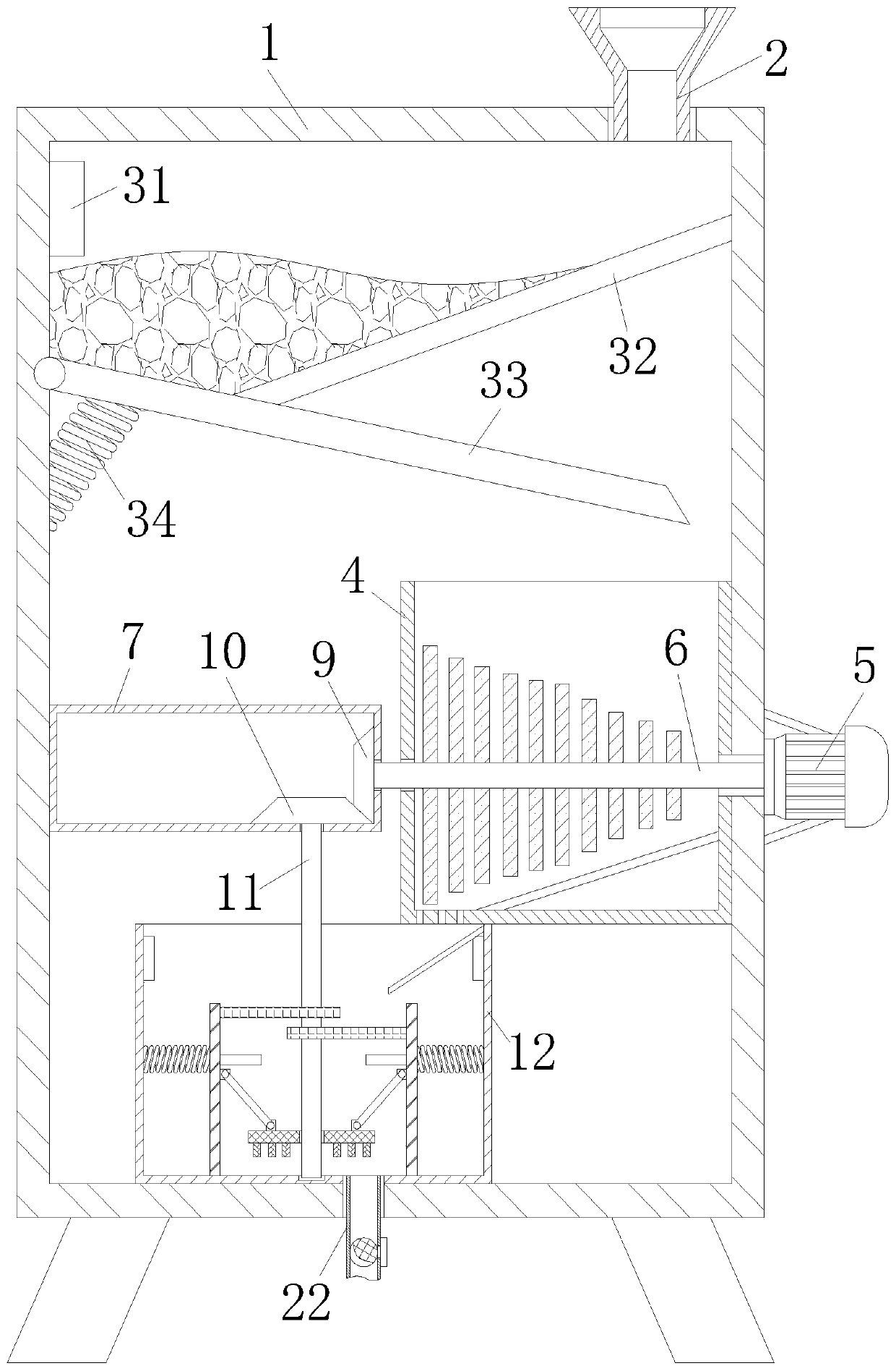

Hot melt device for producing thermoplastic polyurethane elastomers

InactiveCN110757678AIncrease surface areaFast melting speedPolymer scienceThermoplastic polyurethane

The invention relates to the field of hot melt devices, and discloses a hot melt device for producing thermoplastic polyurethane elastomers. The device comprises a bottom plate, wherein hydraulic rodsare arranged on two sides of the top outer wall of the bottom plate, and fixed blocks are arranged on the top outer walls of the hydraulic rods; a hot melt tank body is arranged on the outer walls ofthe fixed blocks, and feed boxes are arranged on the top outer wall of the hot melt tank body; insulation covers are connected to the top outer walls of the feed boxes by hinges; a feed pipe is arranged at the bottom inner wall of each feed box and the top inner wall of the hot melt tank body, and discharge plates are arranged on two sides of the bottom inner walls of the feed boxes. The device has the following advantages and effects: the feed boxes, a second motor and crushing rollers are arranged, after materials enter the feed boxes, the second motor is started, the materials are crushedby the crushing rollers, the surface area of the crushed materials is increased, the hot melting speed of the materials can be effectively improved, and working efficiency is improved.

Owner:NANTONG DE NEW MATERIAL CO LTD

Plastic product machining equipment

The invention provides plastic product machining equipment, and relates to the technical field of plastic product producing and machining. The plastic product machining equipment comprises a work boxand a plurality of supporting legs fixedly connected at the lower end. A feeding hopper is in penetrating connection to the side wall of the work box. A preheating device is arranged below the feedinghopper, a pulverizing box is arranged below the preheating device, a plurality of through holes are formed in the bottom end of the pulverizing box, and the side wall of the pulverizing box is fixedly connected with the inner side wall of the work box. The plastic product machining equipment overcomes the defects in the prior art, design is reasonable, the structure is compact, plastic raw materials are subjected to preheating and crushing treatment, then hot melting treatment is conducted, and the plastic melting speed is greatly increased; meanwhile, during hot melting, raw materials can bestirred and extruded, the plastic raw materials can be heated more evenly, the stirring effect is better, the plastic hot melting uniformity is greatly improved, and the finished product quality of plastic products is improved.

Owner:安徽皖精模具科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com