Patents

Literature

155results about How to "Compact body" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

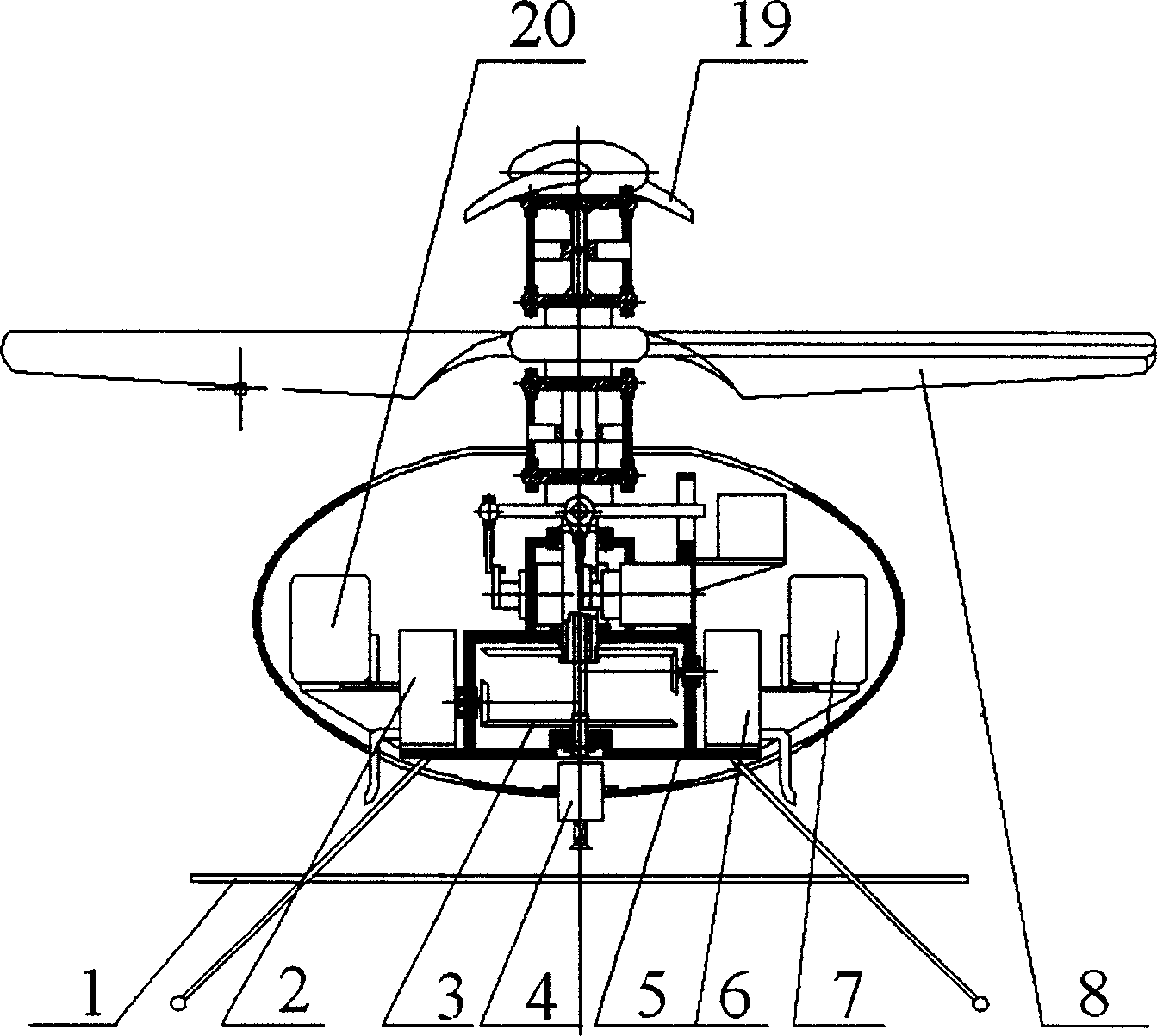

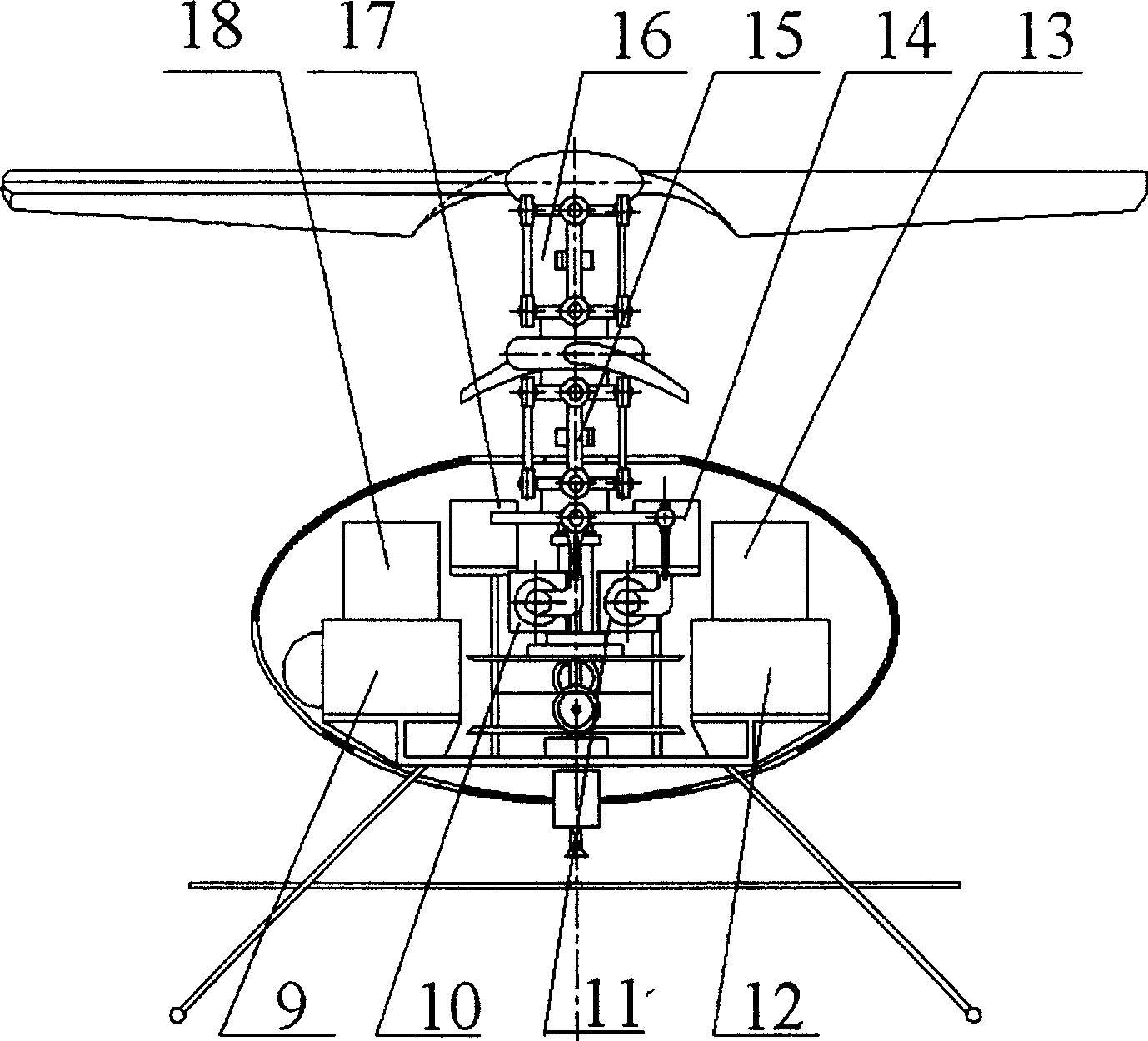

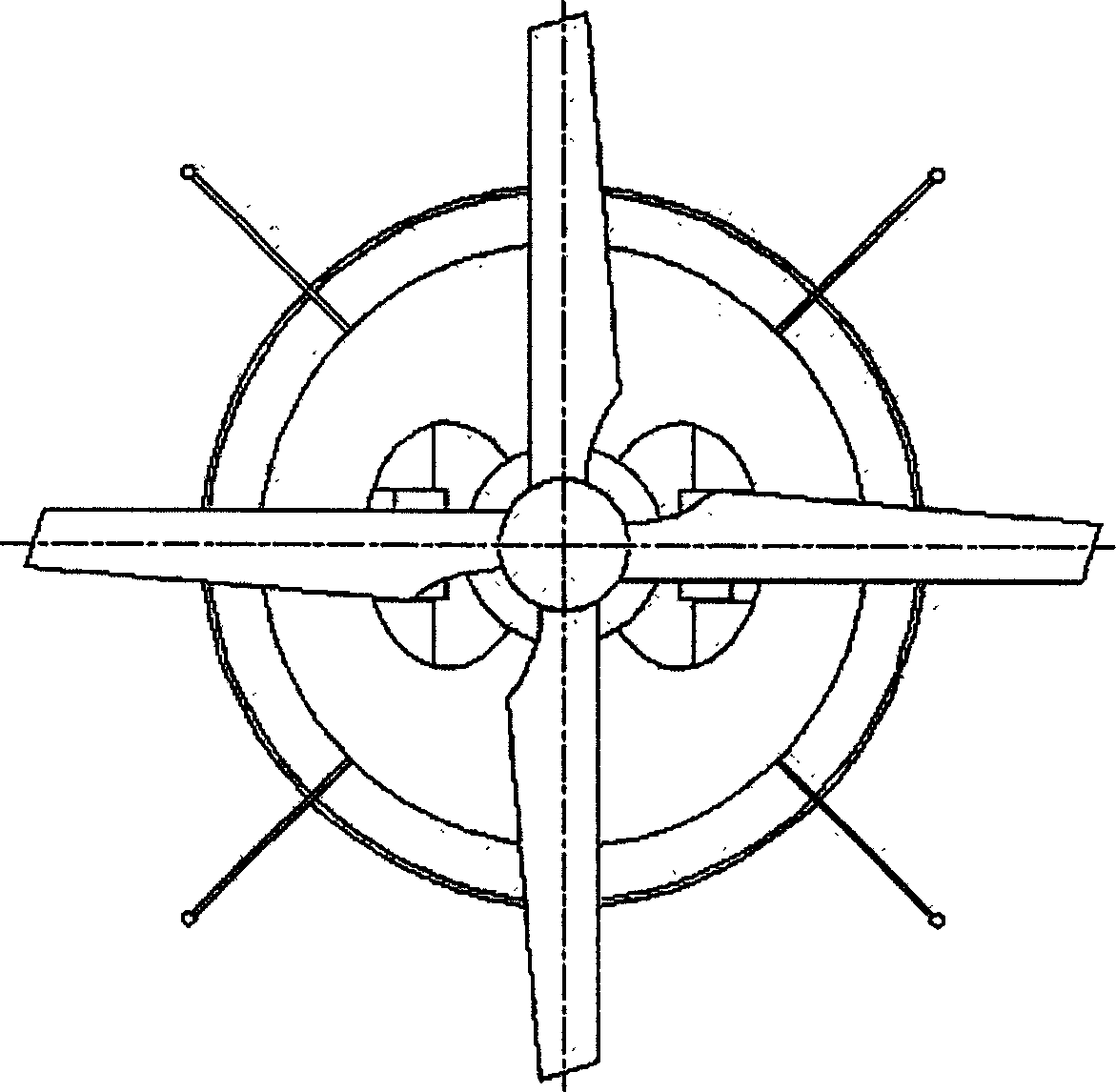

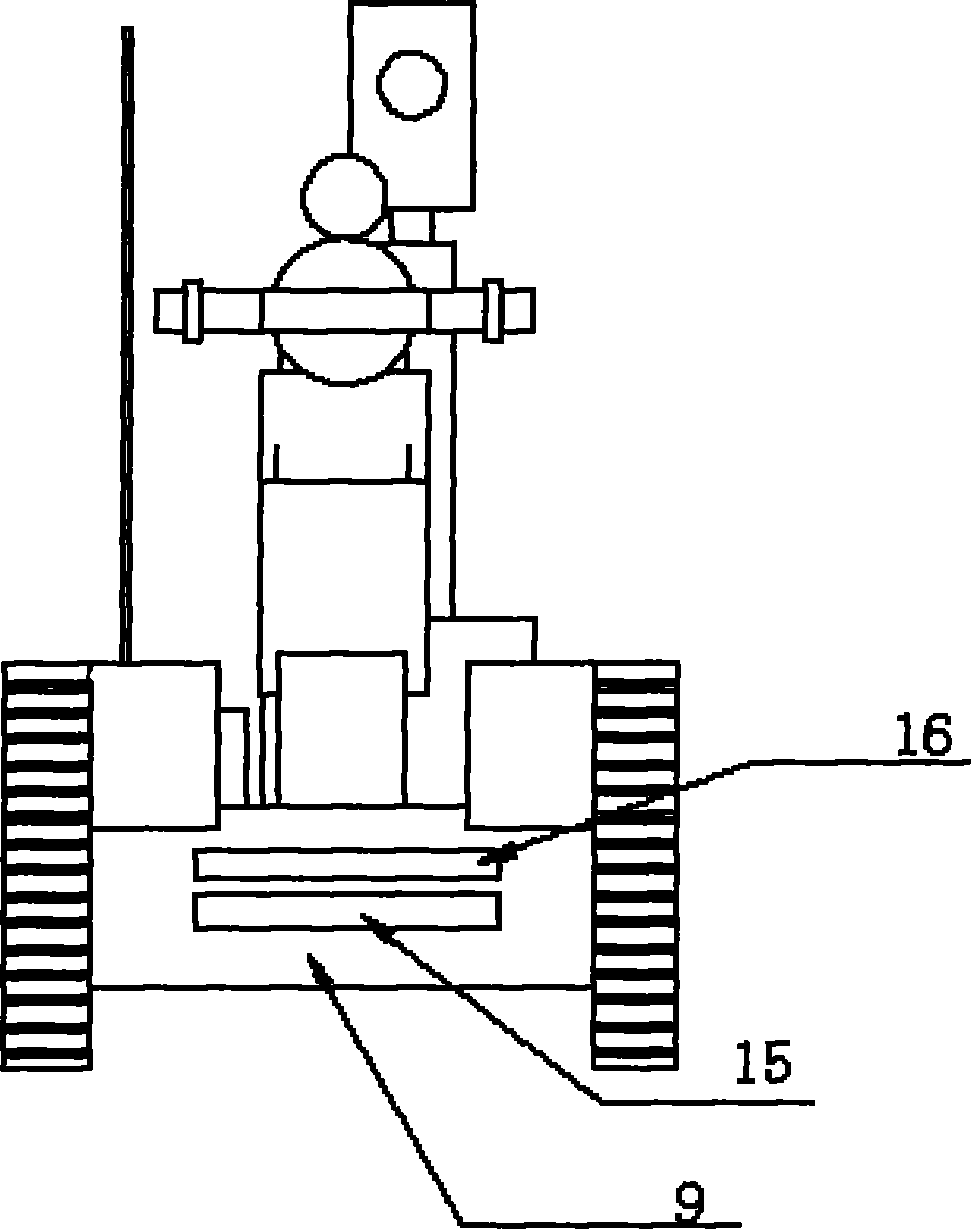

Power circuit scanning test robot airplane and controlling system

InactiveCN1645284ANo casualtiesAvoid lostToy aircraftsCable installation apparatusNavigation systemElectric power

A robot airplane for tour inspection of power line in counterwise driving structure of coxial double propeller uses two engines to control flight stability, GPS and GIS to confirm flight path, computer processor to adjust flight attitute and battery to provide power for motor, transducer and data link system. Its control system consists of navigation system, autonomous planning system, data link system and on line detection system.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

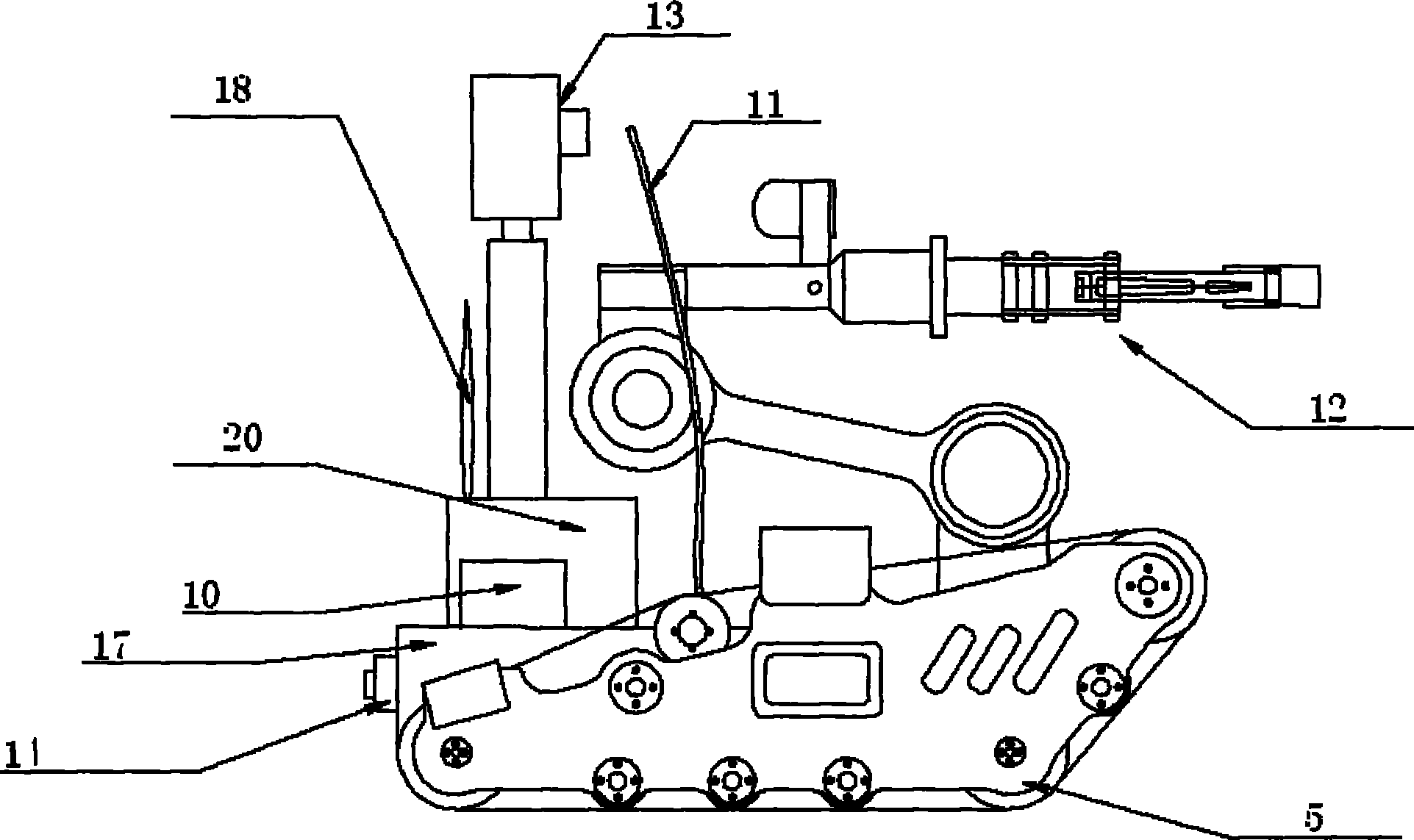

Nuclear power plant working robot and control system thereof

InactiveCN101774170ACapable of autonomous navigationRealize online monitoringEndless track vehiclesManipulatorTerrainOperational costs

The invention relates to a nuclear power plant working robot and a control system thereof, which belong to the fields of robots and automation equipment. The nuclear power plant working robot is a crawler-type mobile manipulator and is composed of a mobile platform driven by double crawlers and a four freedom degree manipulator carried on the mobile platform. The nuclear power plant working robot can move inside a nuclear power plant, has two control modes of manual remote control and autonomous control, and is remotely controlled by a wireless or wired mode. The control system of the nuclear power plant working robot includes a host monitoring and planning control system and a robot control system which are matched to control the operation of the robot. The robot operates autonomously, is safe and reliable, can complete certain dangerous tasks in high radioactivity environment; the robot has small size, stable performance, great maneuverability and low operation cost; a crawler-type chassis has strong gripping force as well as certain climbing and obstacle clearing ability, and is suitable to walking over complex terrains; and the robot has high intelligence degree and can realize autonomous control and manual remote control.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

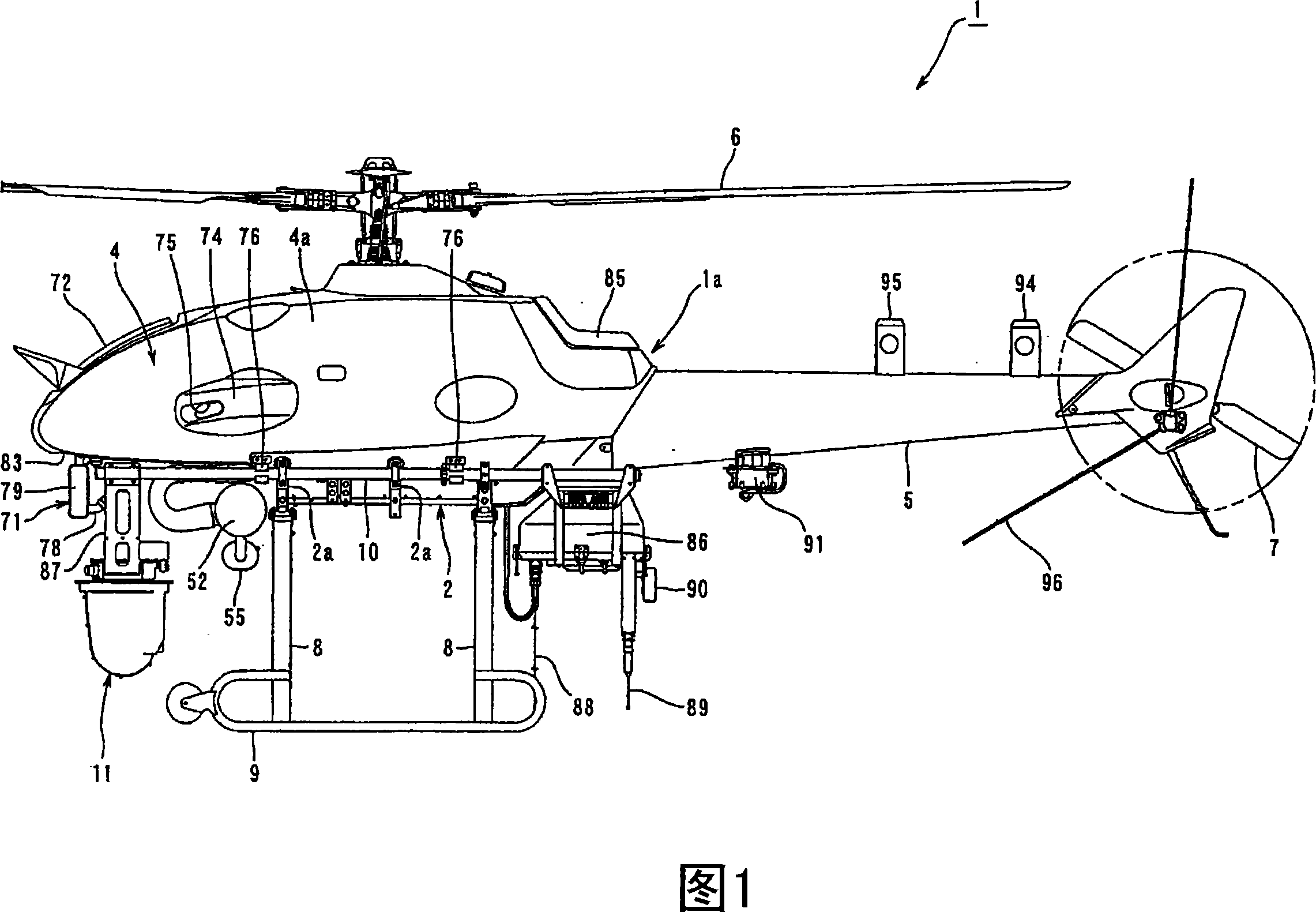

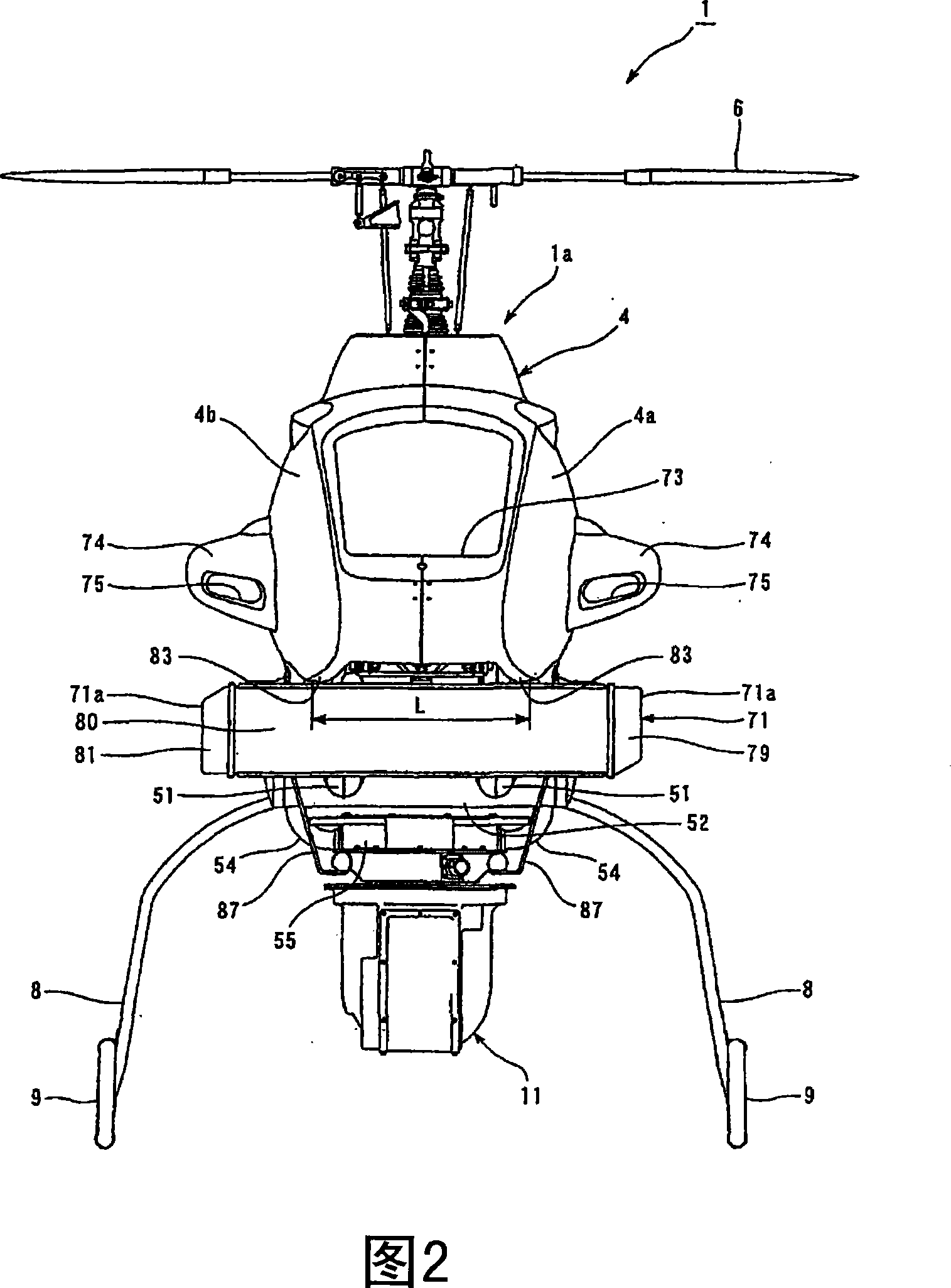

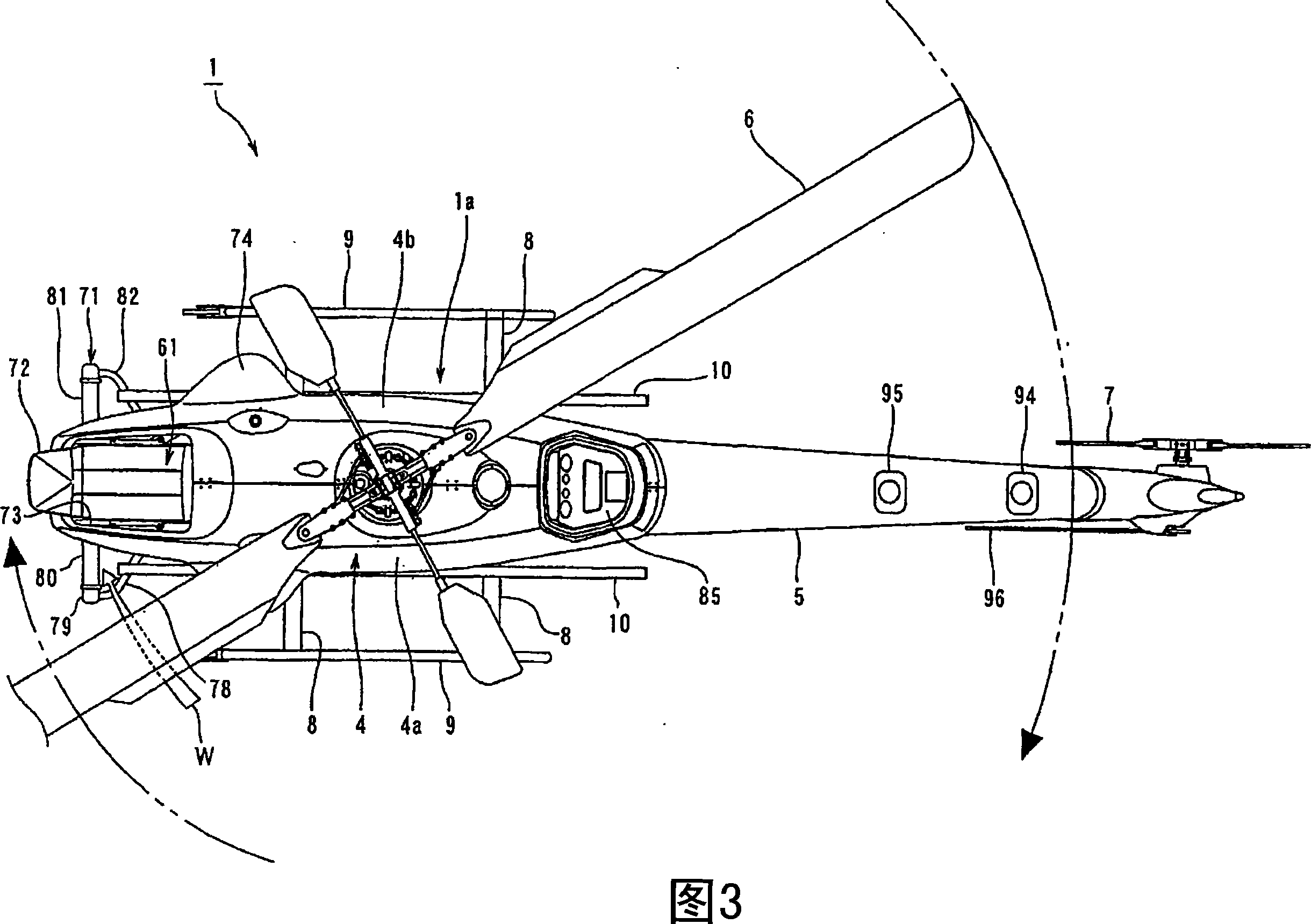

Unmanned helicopter

InactiveCN101238033AImprove cooling effectUnoccupied space expandsPower plant cooling arrangmentsUnmanned aerial vehiclesEngineeringFront edge

Owner:YAMAHA MOTOR CO LTD

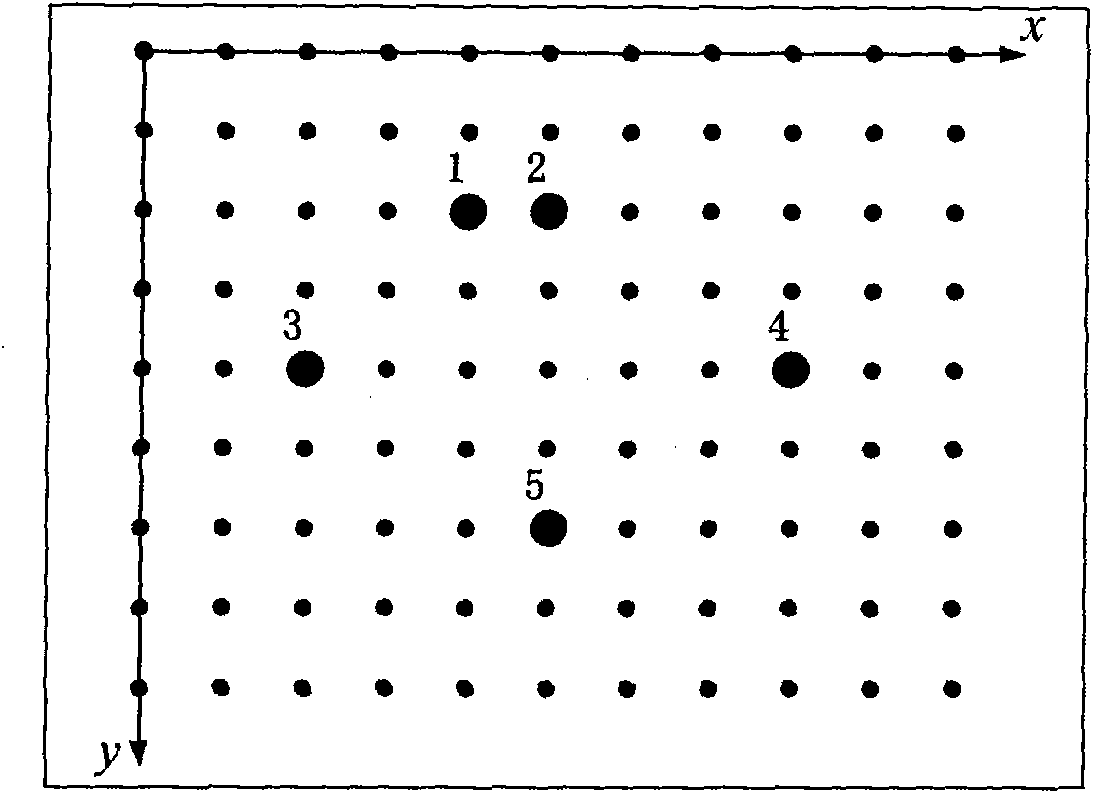

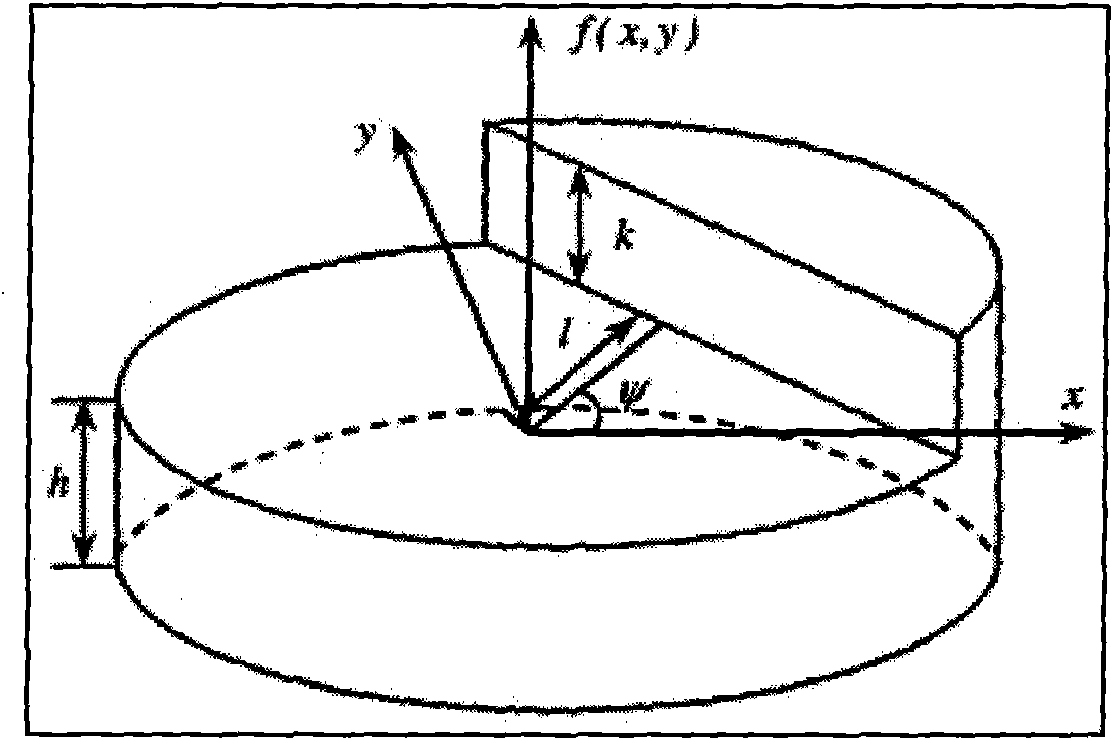

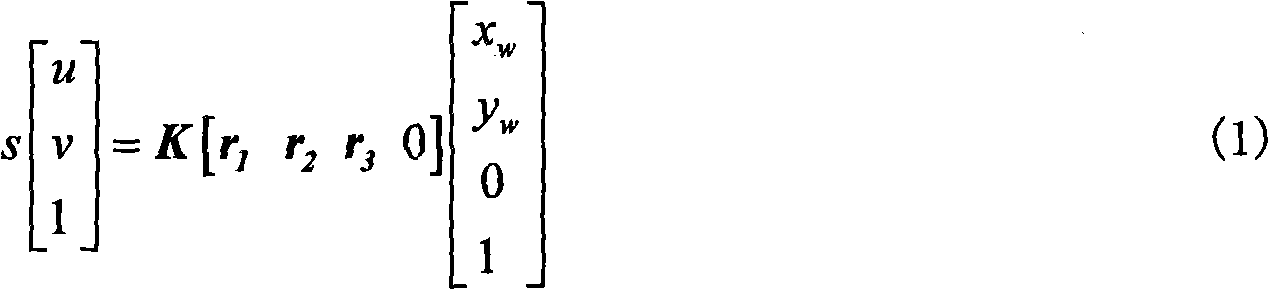

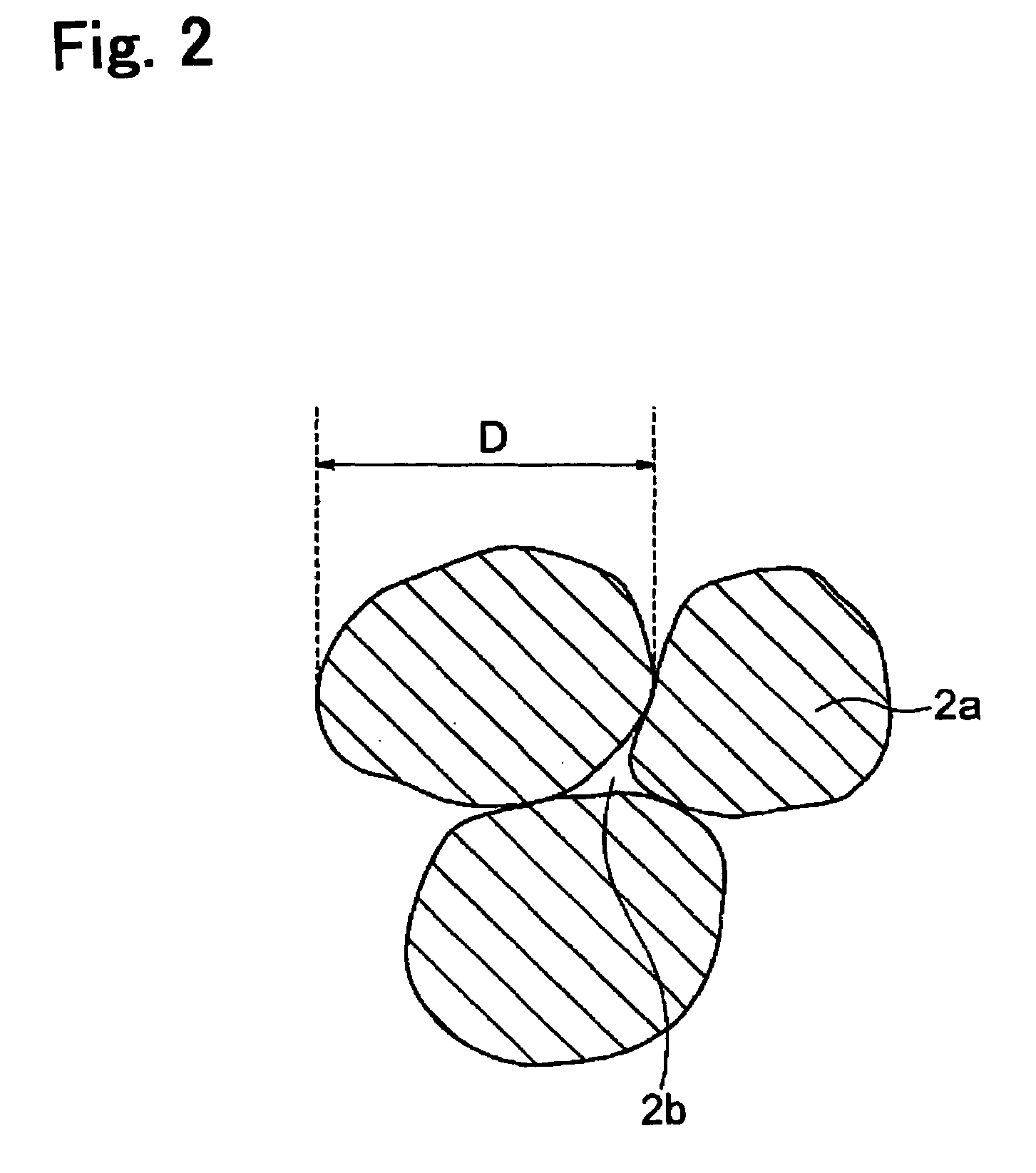

Digital camera nonlinear calibration method based on LCDs

The invention belongs to the technical field of measured calibration, and relates to a calibration process for solving camera inside and outside parameters by using a single digital camera for shooting a group of images based on LCDs, particularly to a digital camera nonlinear calibration method based on the LCDs, which comprises the following steps: designing and drawing a calibration chart through programming, wherein the calibration chart has round marking points in different sizes; displaying the calibration chart on the screen of a liquid crystal display; then shooting images by a digitalcamera in the mode of rotating around an optical axis; and then computing the camera inside and outside parameters by using the shot images; extracting sub-pixel contour edges in the images by usingthe complete pure flatness of the liquid crystal display and easy detection of centralized positioning height and sub-pixel edge contour of the round marked points, and obtaining a calibration resultof digital camera parameters by a nonlinear optimization method. The calibration method has the advantages of simple and easy operation, small and agile use equipment, good calibration precision, goodquality, strong optimization degree and the like.

Owner:QINGDAO UNIV

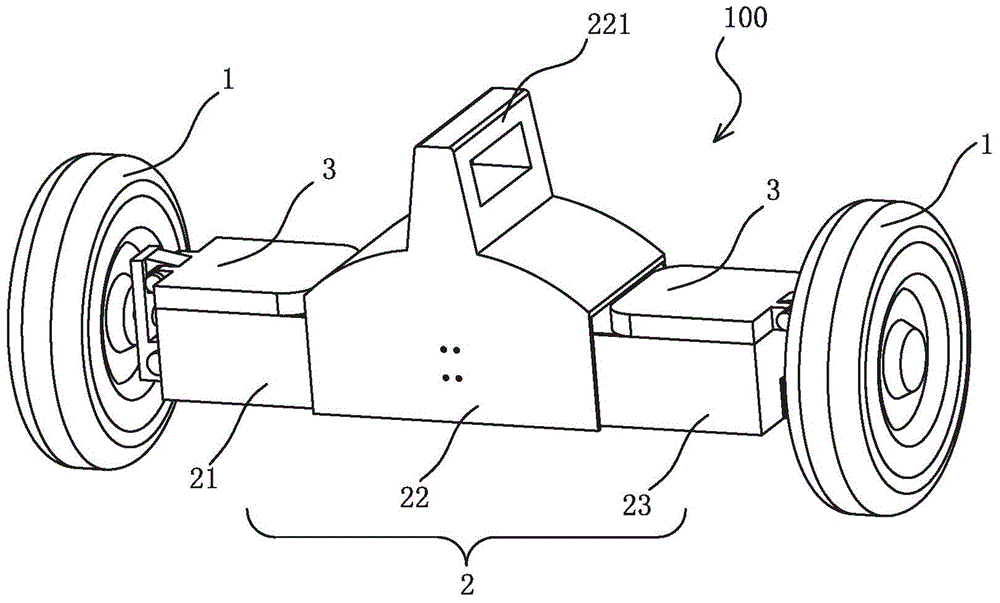

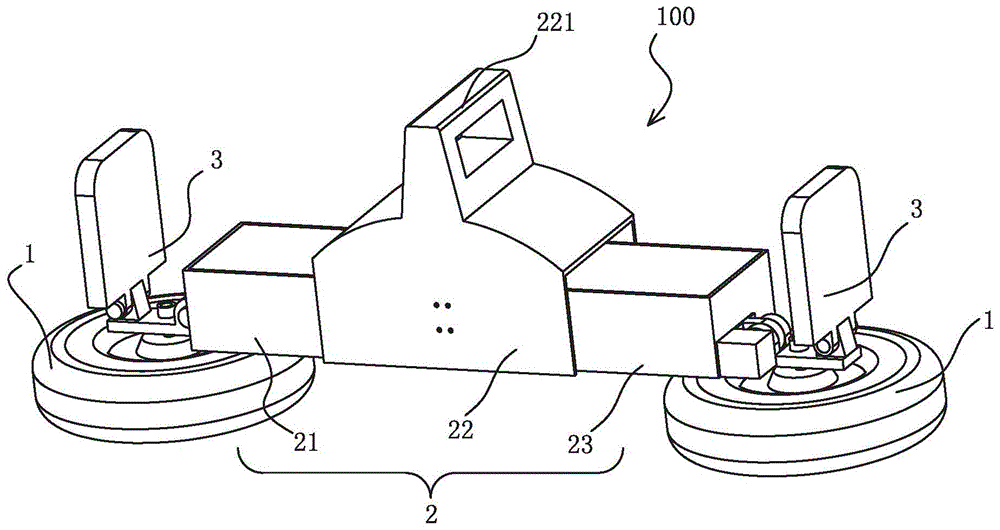

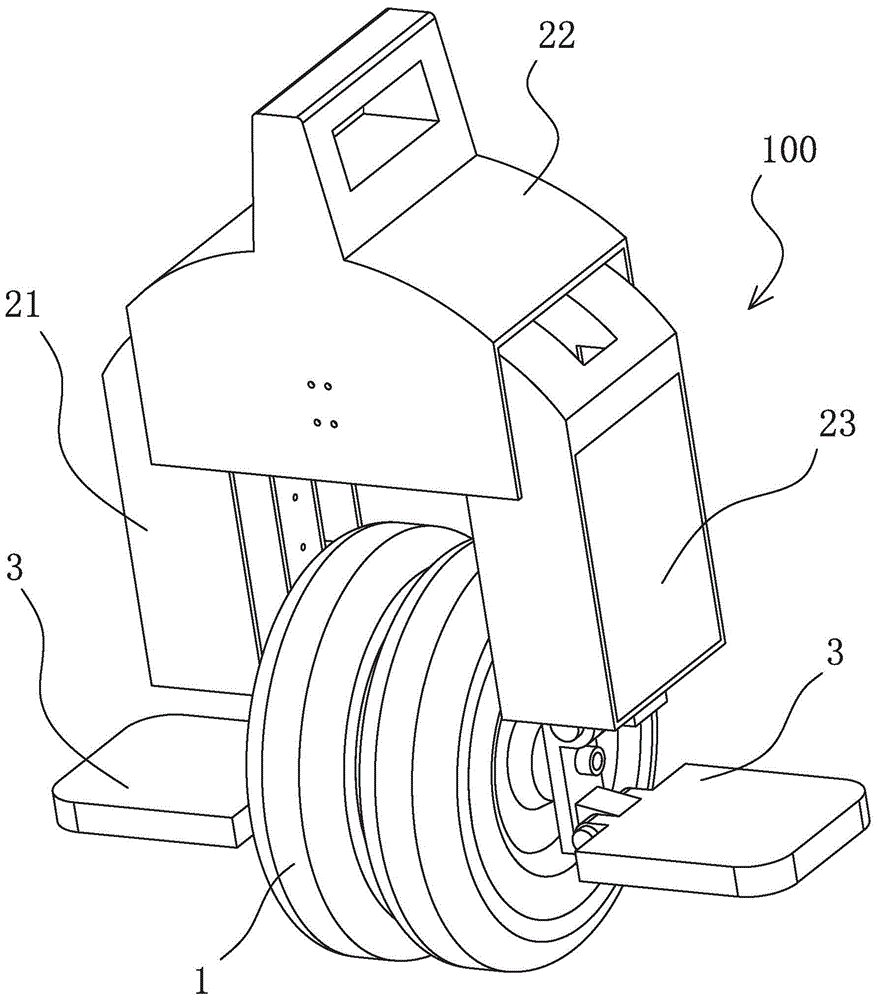

Transformable self-balancing two-wheeled electric vehicle

InactiveCN104859770AIncrease entertainmentCompact bodyFoldable cyclesMotorcyclesElectric machineryElectrical battery

The invention provides a transformable self-balancing two-wheeled electric vehicle which comprises two motor wheels, a self-balancing controller system, a battery, a shell assembly, rotating positioning mechanisms, a steering mechanism and a switching sensing system, wherein the battery supplies operating power to the self-balancing two-wheeled electric vehicle; the self-balancing controller system is arranged in the shell assembly and used for controlling operation of the self-balancing two-wheeled electric vehicle. The self-balancing two-wheeled electric vehicle can be switched between two states, the traveling entertainment is improved, and further, the self-balancing two-wheeled electric vehicle is simple and stable in structure, light in mass, portable, is provided with a compact body and facilitates processing and manufacturing.

Owner:嘉兴斯麦龙电子科技有限公司

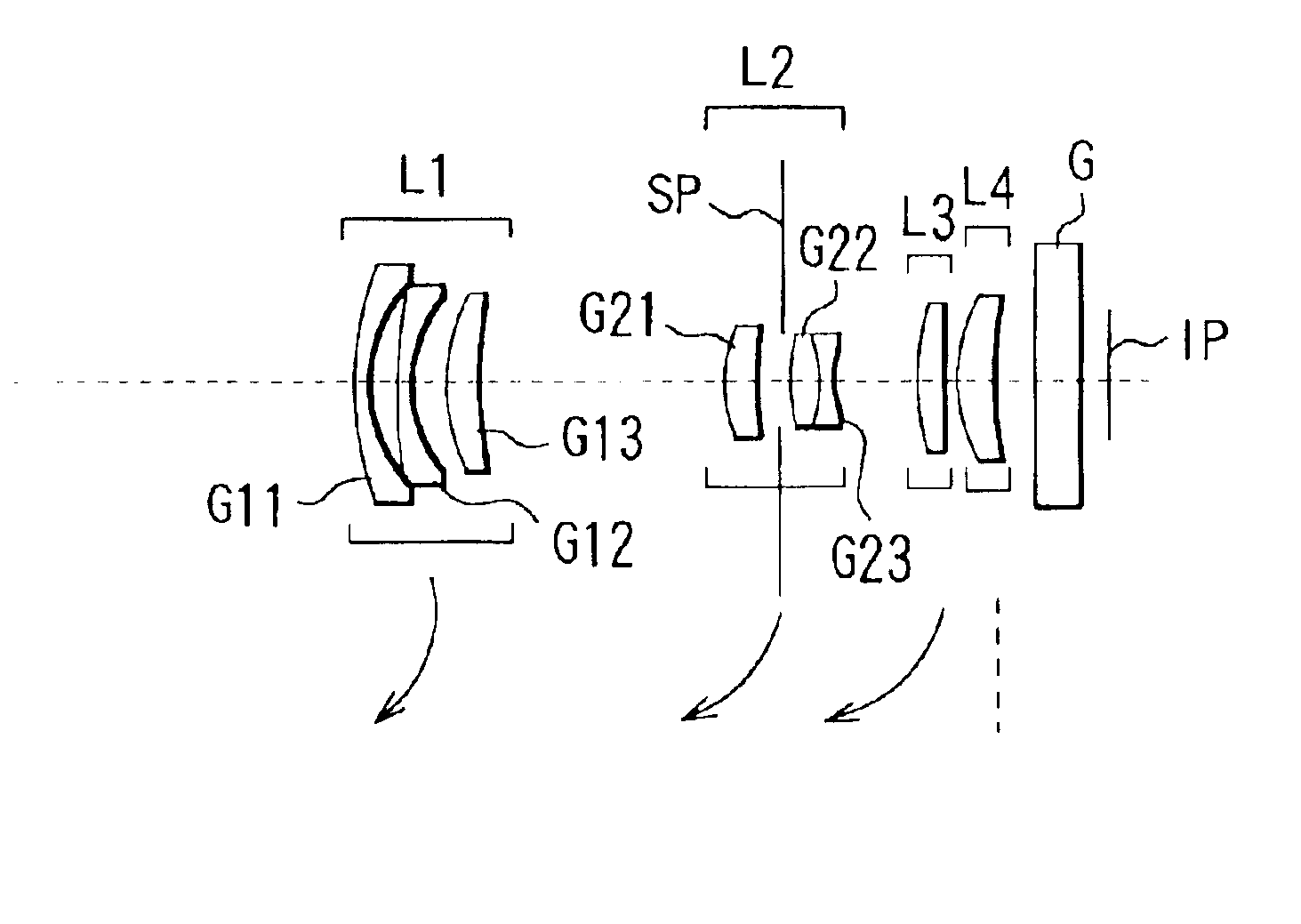

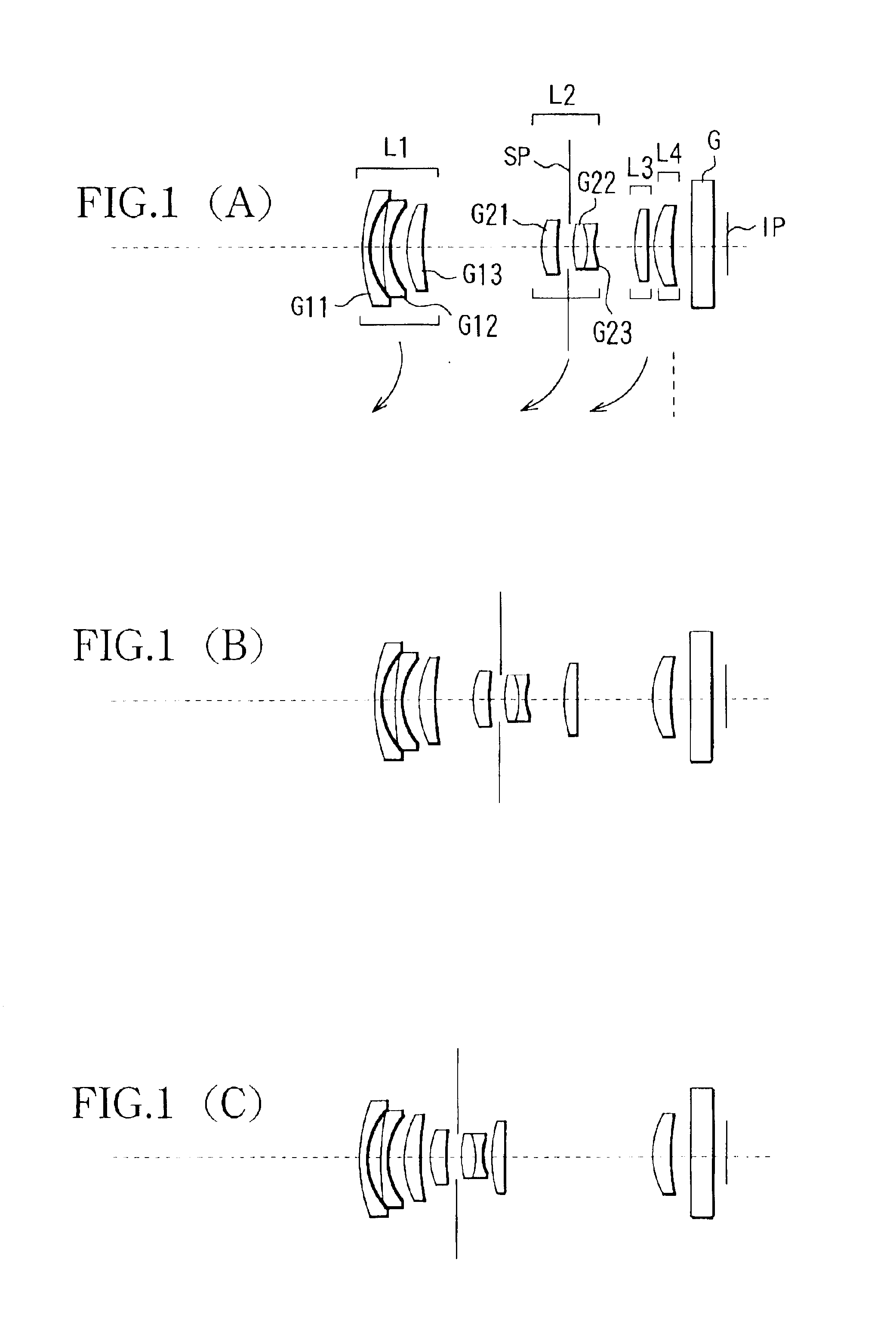

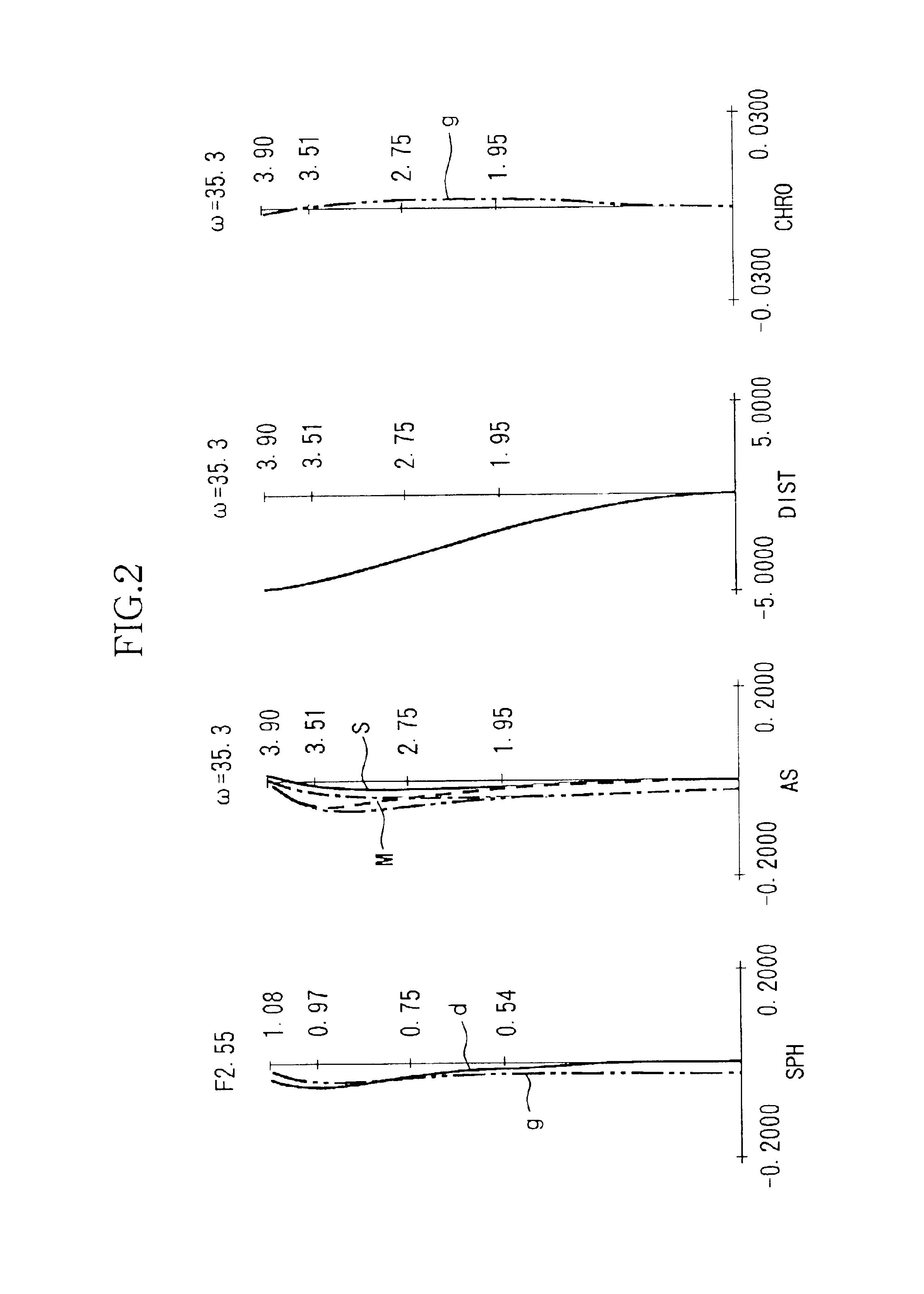

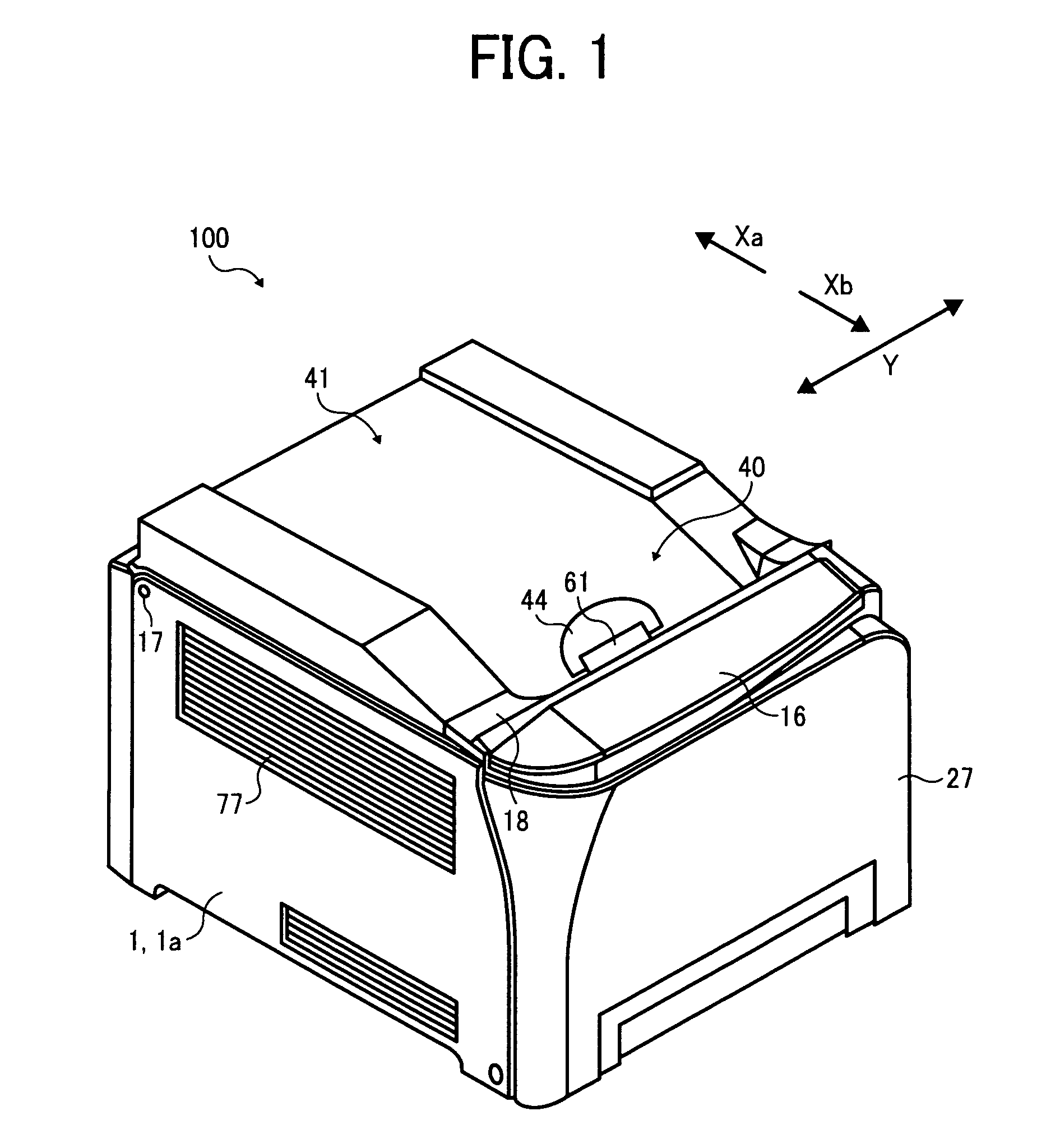

Zoom lens and camera

The present invention discloses a zoom lens including:a first lens unit having negative optical power, the first lens unit having a negative lens element on a closest side to an object;a second lens unit having positive optical power, the second lens unit having two or more positive lens elements;a third lens unit having positive optical power; anda fourth lens unit having positive optical power, the fourth lens unit consisting of one positive lens component, said units arranged in the order presented from an object side to an image side,wherein at least the second lens unit and the third lens unit are moved toward the object for zooming from a wide angle side to a telephoto side such that a space between the first lens unit and the second lens unit is smaller, a space between the second lens unit and the third lens unit is smaller, and a space between the third lens unit and the fourth lens unit is larger at a telephoto end than at a wide angle end.Thus, a zoom lens having fewer lenses, a compact body, and good optical performance, and a camera using the same can be realized.

Owner:CANON KK

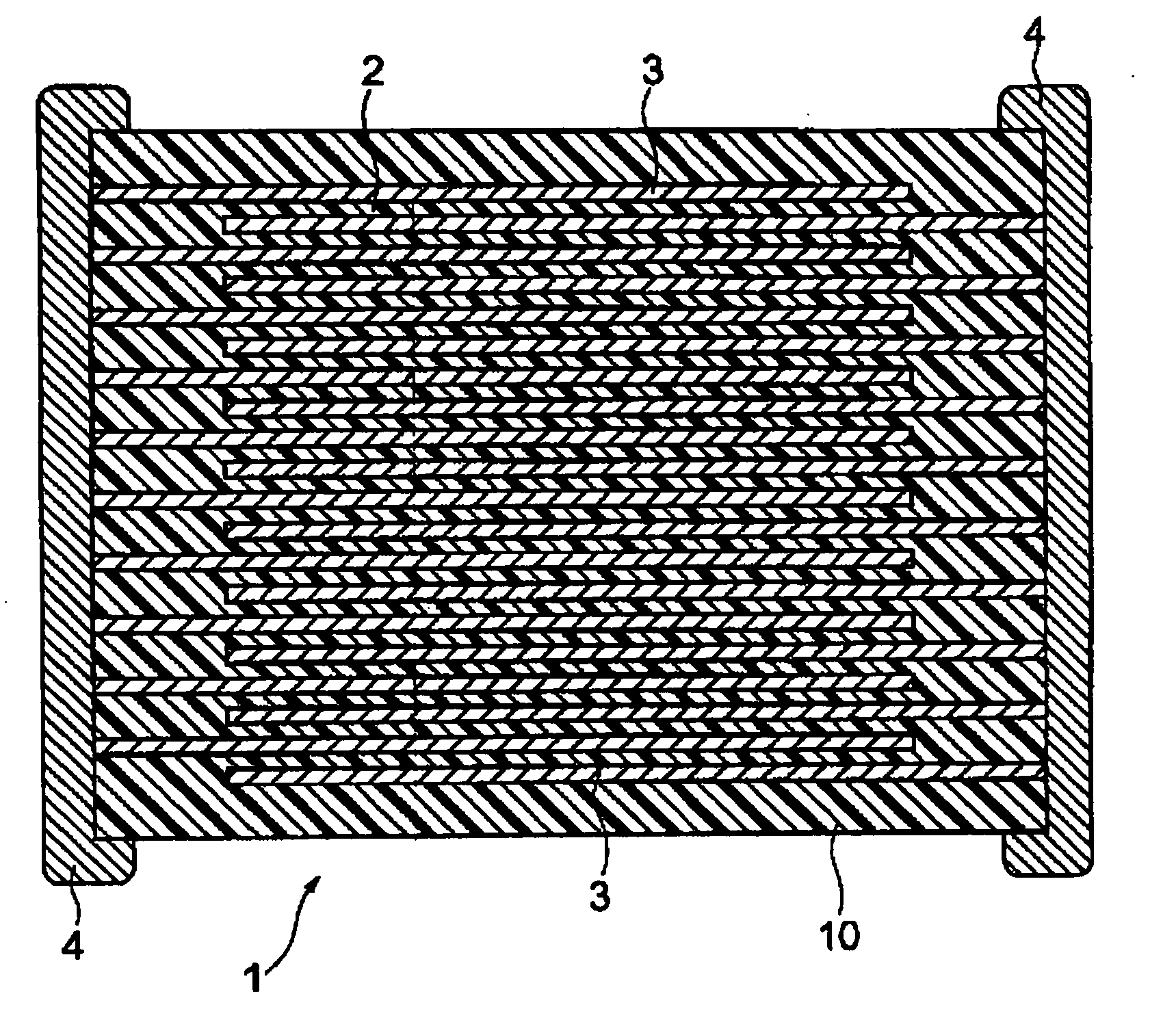

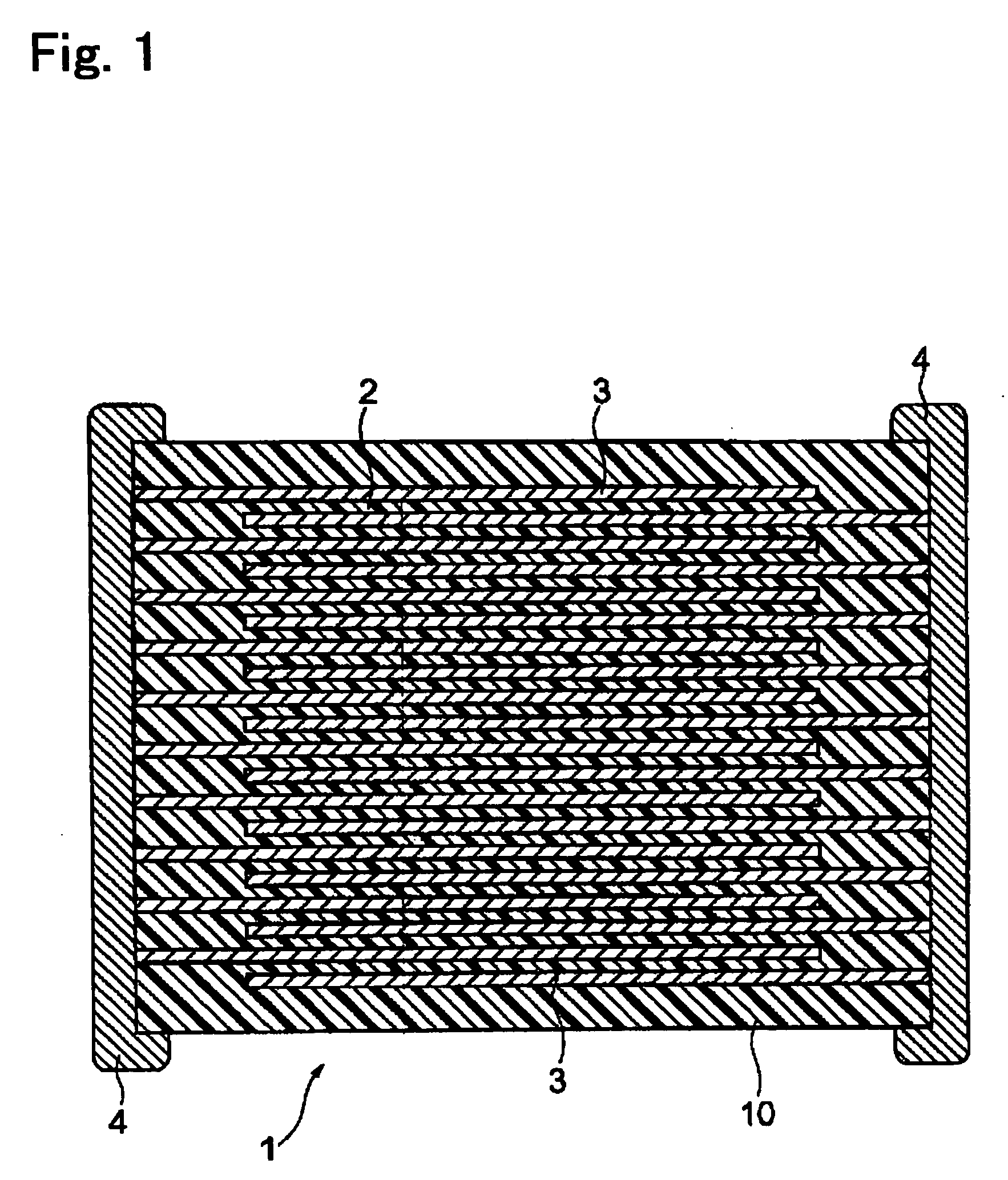

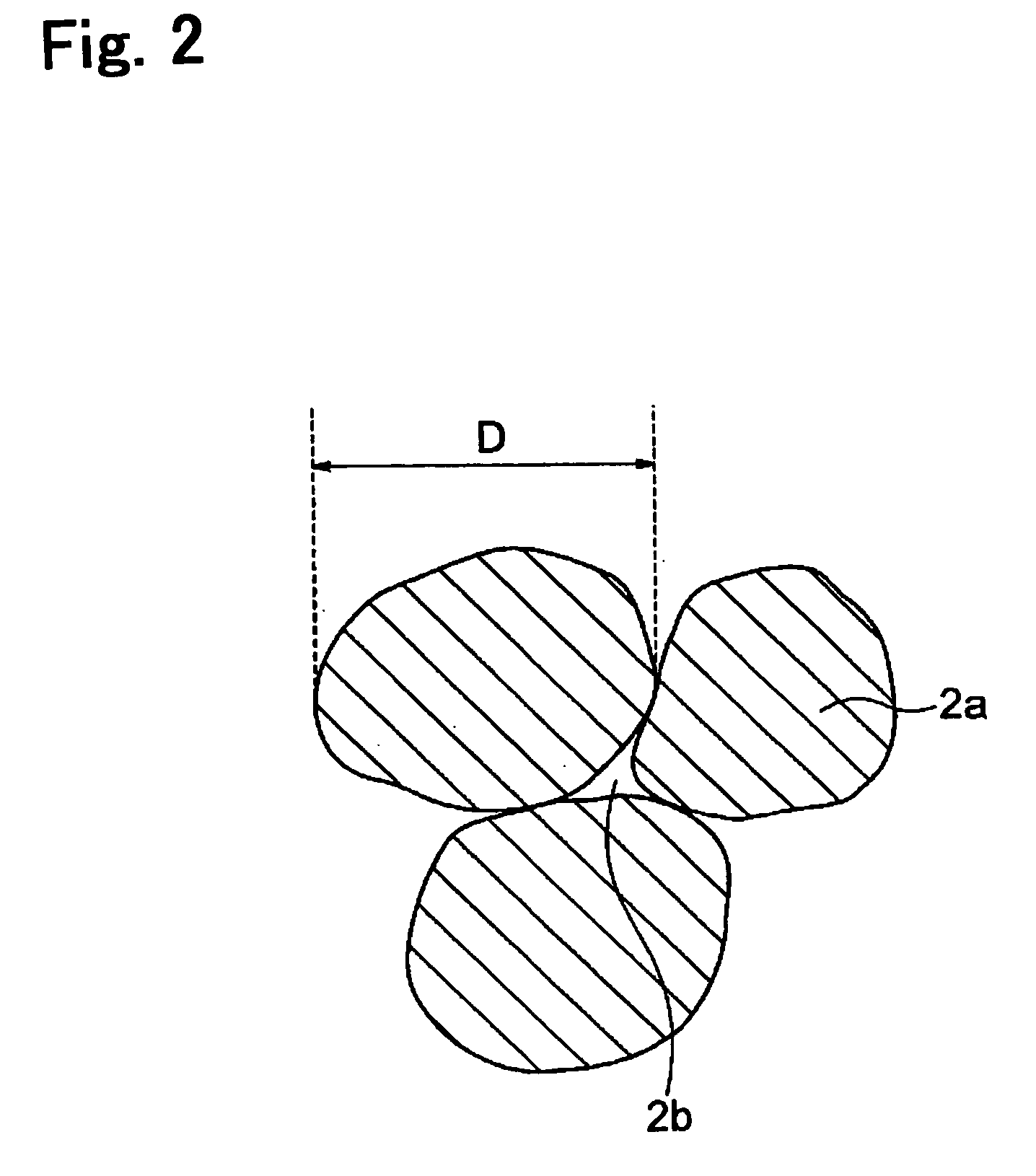

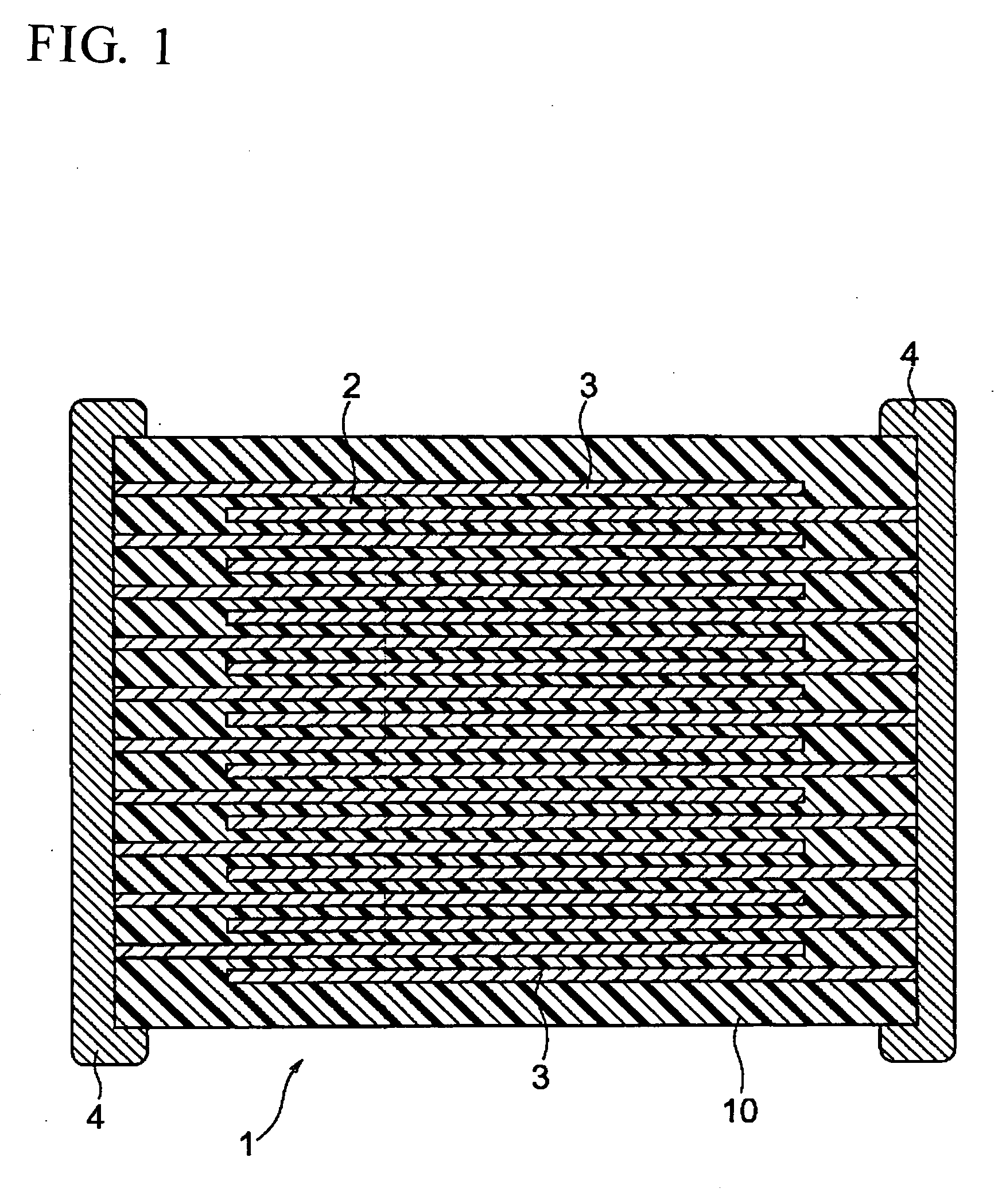

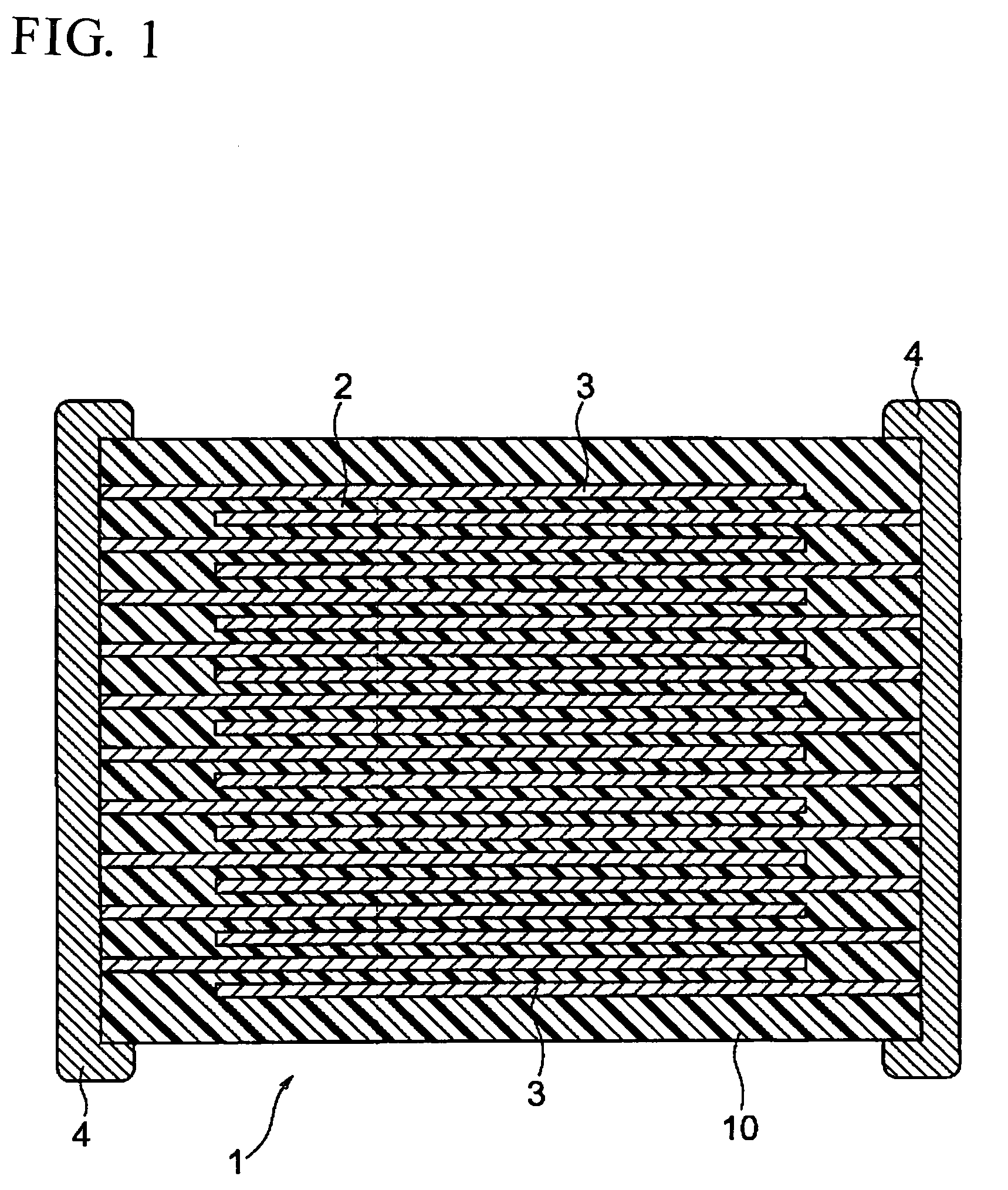

Dielectric ceramic composition and electronic device

ActiveUS7262146B2High specific permittivityReducing atmosphereLayered productsFixed capacitor dielectricBarium titanateMaterials science

A dielectric ceramic composition, comprising a main component including barium titanate; a first subcomponent including at least one kind selected from MgO, CaO, BaO and SrO; a second subcomponent functioning as a sintering auxiliary agent; a third subcomponent including at least one kind selected from V2O5, MoO3 and WO3; a fourth subcomponent including an oxide of R1 (note that R1 is at least one kind selected from Sc, Er, Tm Yb and Lu); a fifth subcomponent including CaZrO3 or CaO+ZrO2; and an eighth subcomponent including an oxide of A (note that A is at least one kind selected from a cation element group having an effective ionic radius at the time of 6 coordination of 0.065 nm to 0.085 nm); wherein a ratio of the eighth subcomponent with respect to 100 moles of the main component is 0 to 4 moles (note that 0 mole and 4 moles are excluded, and the value is in terms of an A oxide).

Owner:TDK CORPARATION

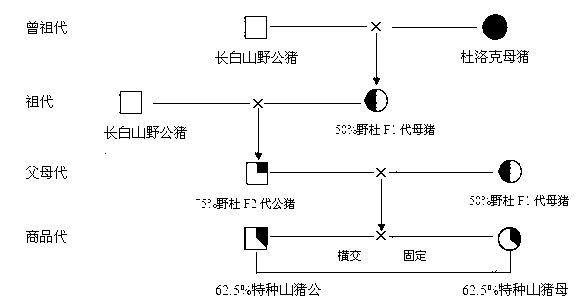

Breeding and feeding method for special wild boars

The invention discloses a breeding and feeding method for special wild boars. According to the method, purebred male wild boars are selected to be used as male parents, American duroc purebred female sows are adopted as female parents, the special wild boars with the wild boar blood relationship content being 62.5 percent can be obtained after the hybridization, and in addition, feeding management such as domestication, coarse fodder addition in different physiological periods is carried out. The technical measures of hybridization, grading hybridization, back crossing, inter-mating, hybridization in strains, hybridization between strains, oriented culture, purification and rejuvenation and the like are adopted, the special wild boars obtained after the treatment have strong breeding power, the annual yield is more than 2.2 boars, the growth speed is high, the body weight of 8-month-old commodity growing and fattening boars can reach 90 to 100kg, the feeding is easy, the disease resistance capability is high, the meat is fresh, tender and delicious, the palatability is good, the color is bright red, the types of amino acids are more, the nutrition is more complete, particularly, the linoleic acid content reaches 17.5 percent, and the nutrition is rich.

Owner:四川惠远农牧科技有限公司

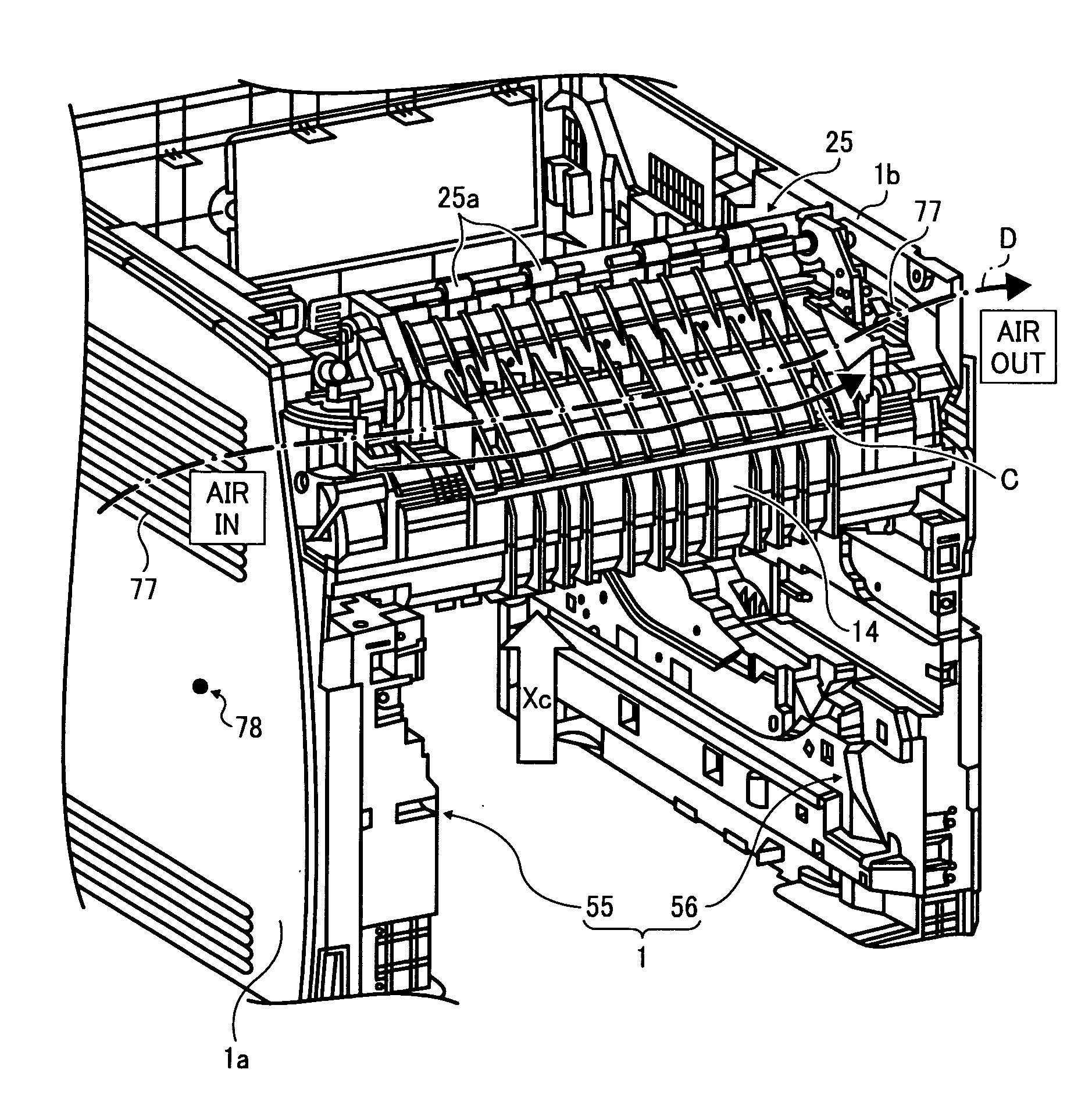

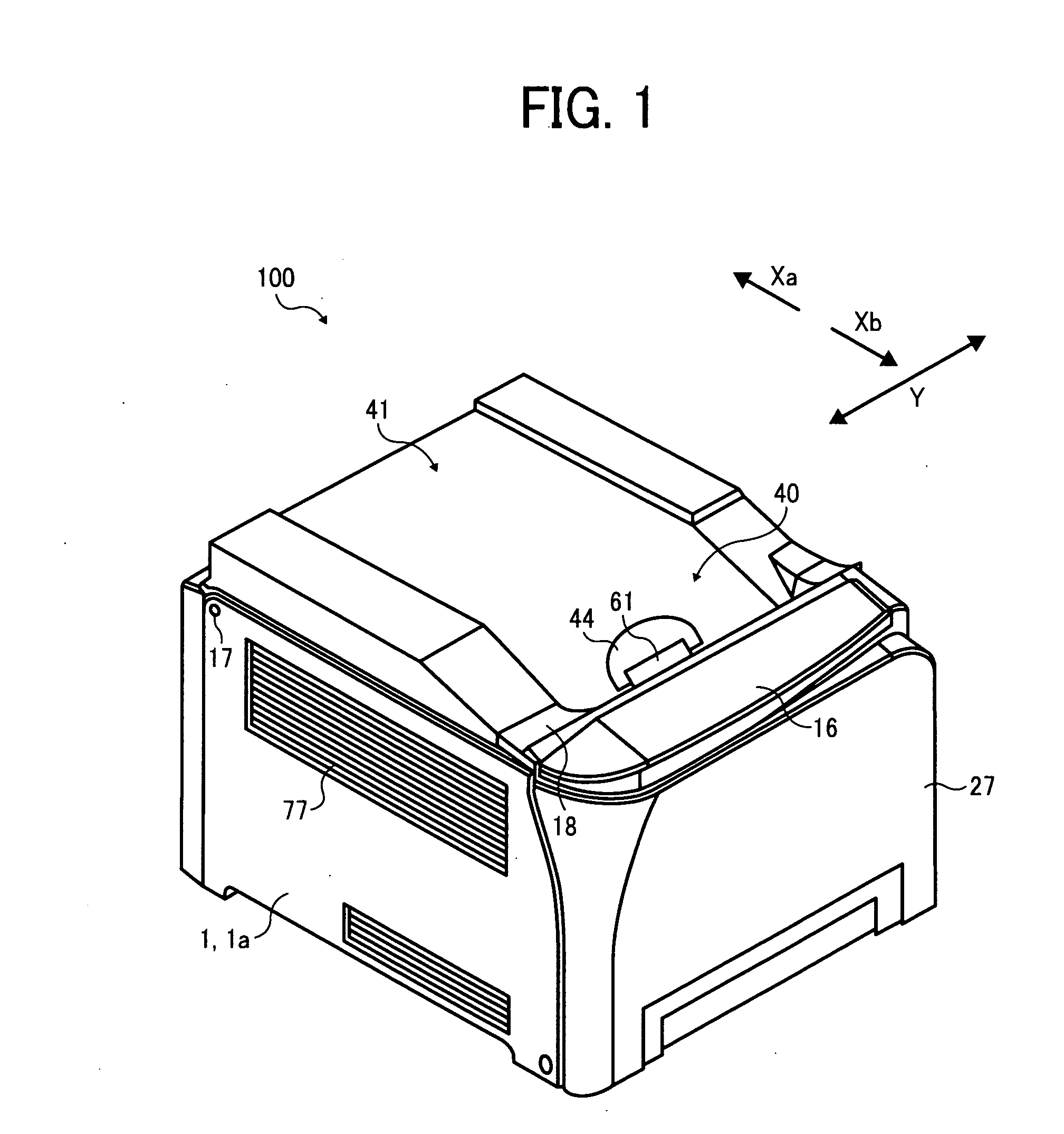

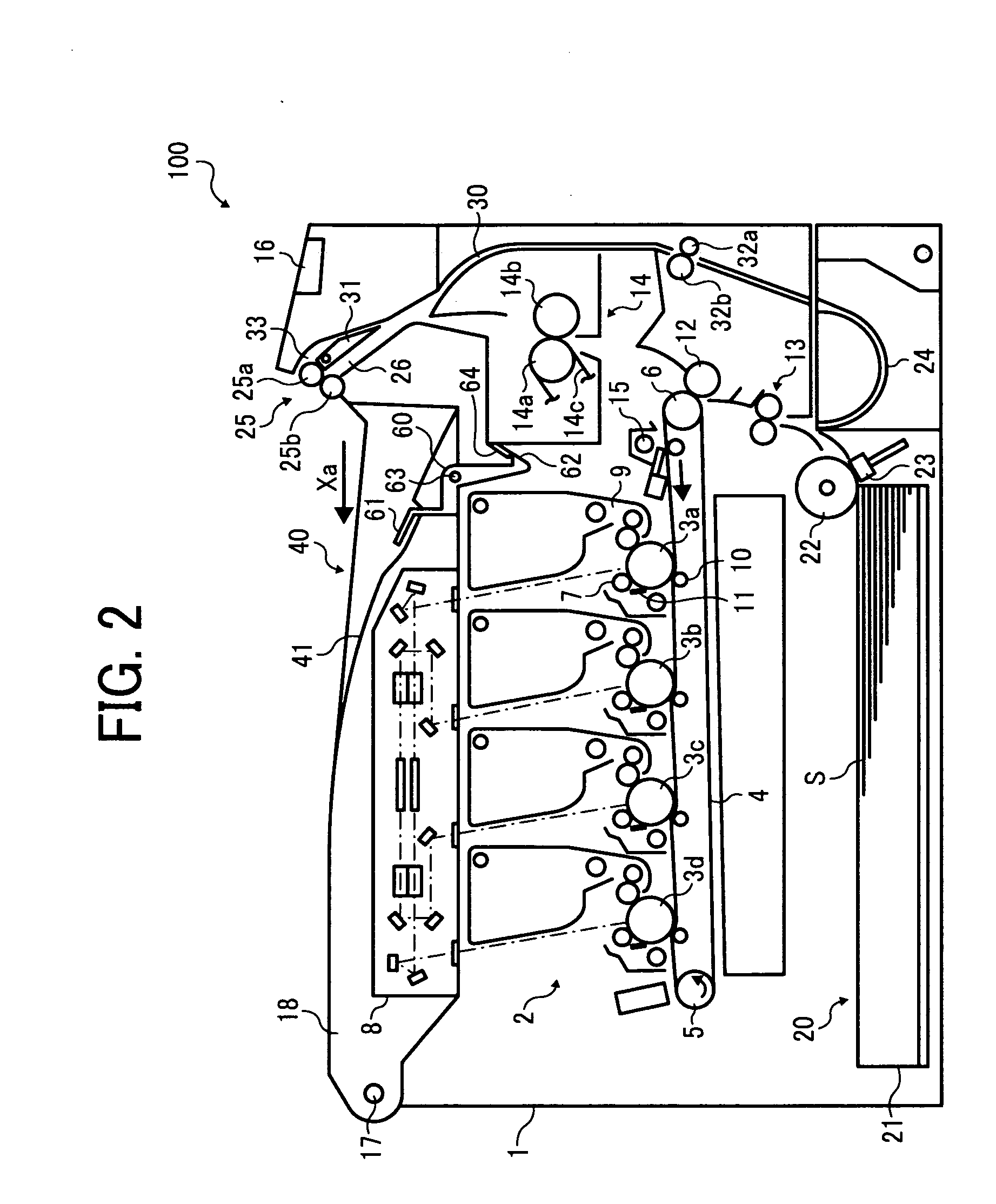

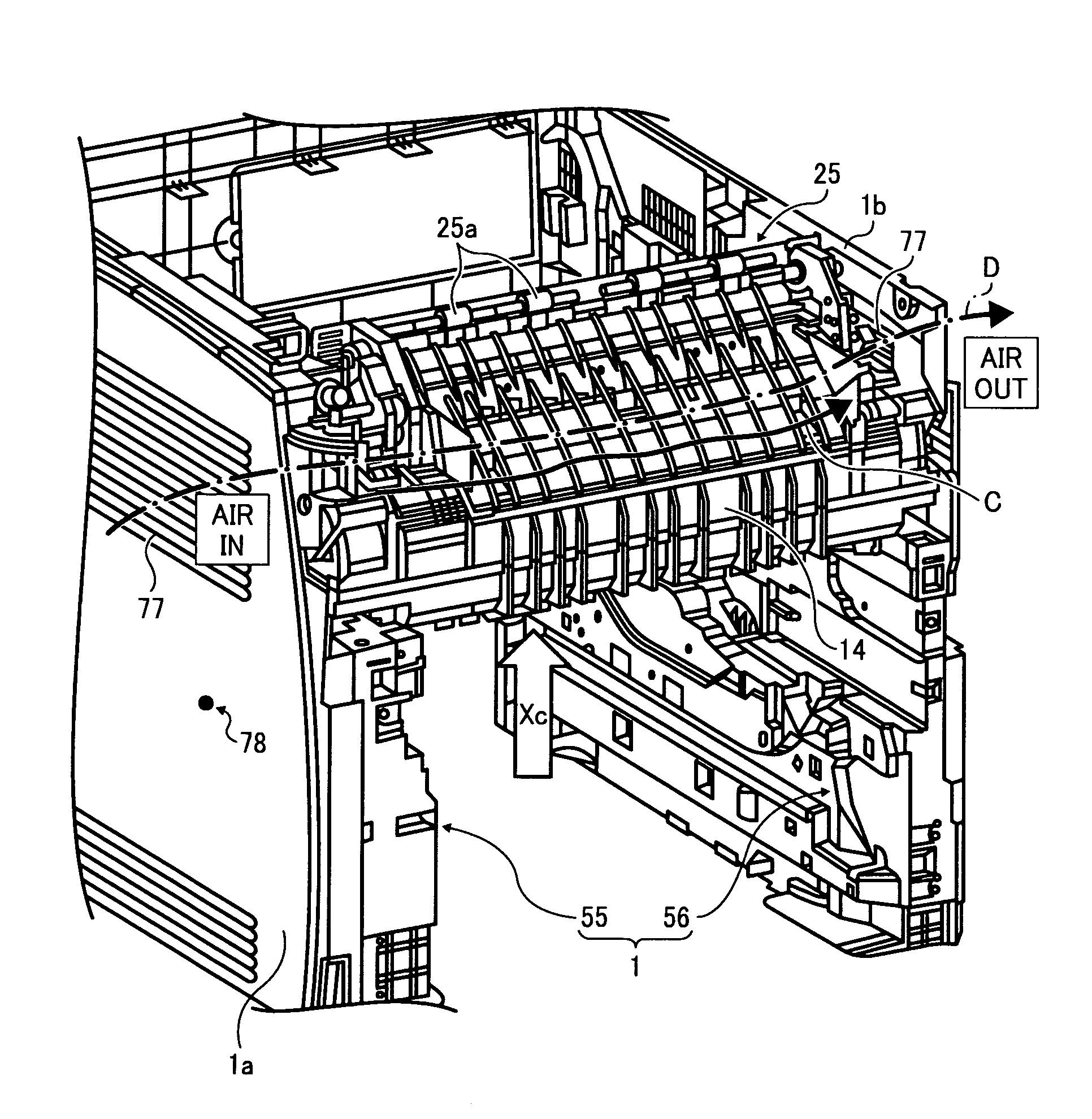

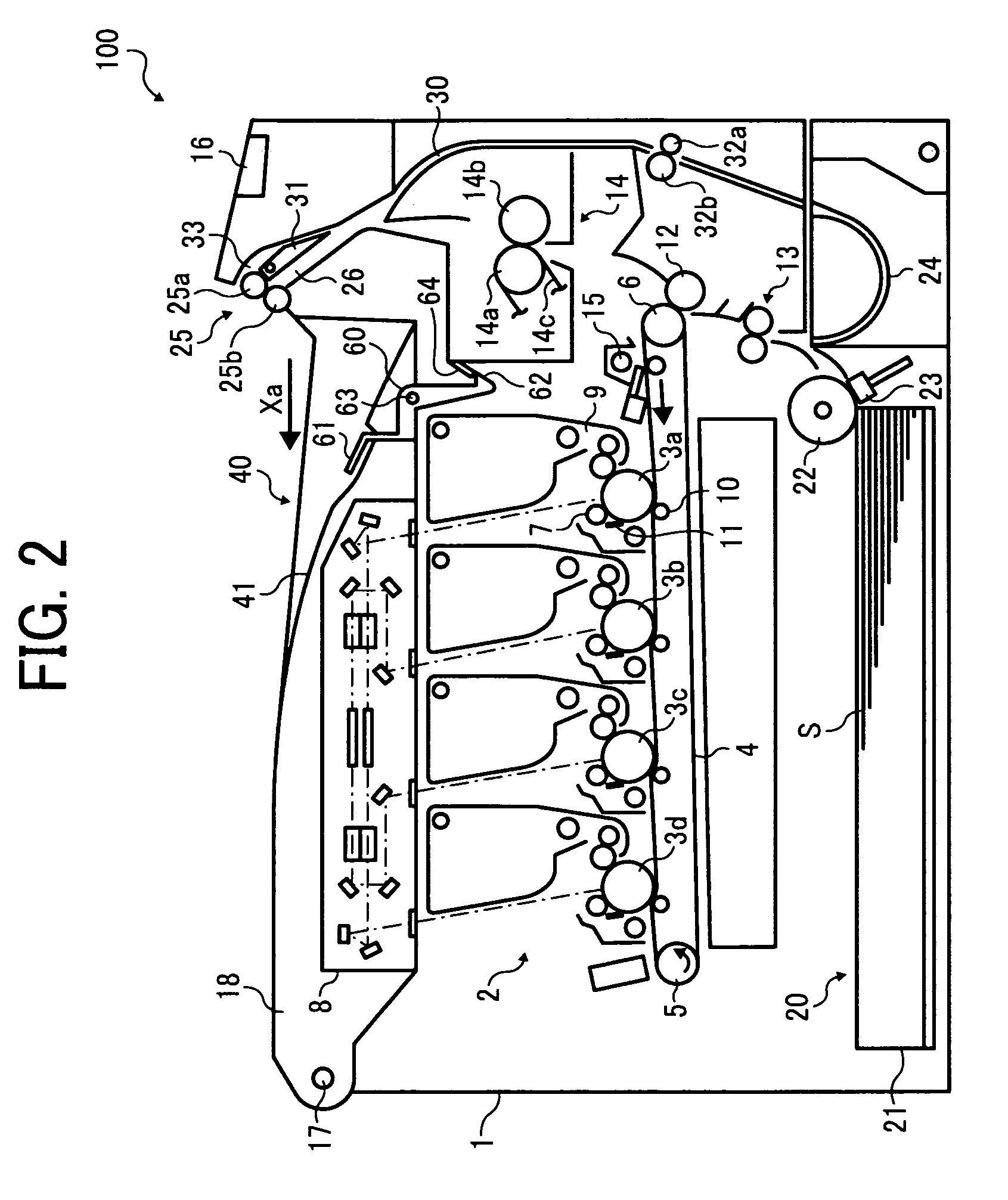

Image forming apparatus

ActiveUS20100003048A1Improve cooling effectInhibit productionElectrographic process apparatusImage formationElectrical and Electronics engineering

An image forming apparatus includes a transfer unit, a fixing unit, a discharging unit, and multiple guide members. The transfer unit transfers an image onto a transfer sheet. The fixing unit fixes the image to the transfer sheet by application of heat and conveys the fixed transfer sheet to a further downstream portion of the image forming apparatus. The discharging unit discharges the transfer sheet to an external portion of the image forming apparatus. The multiple guide members form a sheet conveyance path that has first and second paths including a hollow portion defined by the multiple guide members to enable an air current generated during image forming to pass therethrough.

Owner:RICOH KK

Low dielectric comsumption CaCu3Ti4O12 ceramic preparing method

InactiveCN101070245AExcellent dielectric propertiesCompact bodyPiezoelectric/electrostrictive/magnetostrictive devicesDielectricPolyvinyl alcohol

This invention relates to preparation method of a low electric loss CaCu3Ti4O12 ceramic.Firstly mix the raw material calcium carbonate, titanium dioxide and cupric oxide according to molar ratio of 1:4:3, wet method ball mill to gain mixture powder. Drythe mixture powder, then preburn at 850 to 1000deg. Ball mill the mixture powder after preburning, past at least 80 orders screen mesh, dry, add polyvinyl alcohol and grind, corning, dry pressing and moulding, then cold equal steady pressure for shaping, sintering the body, then furnace cool.

Owner:XIAMEN UNIV

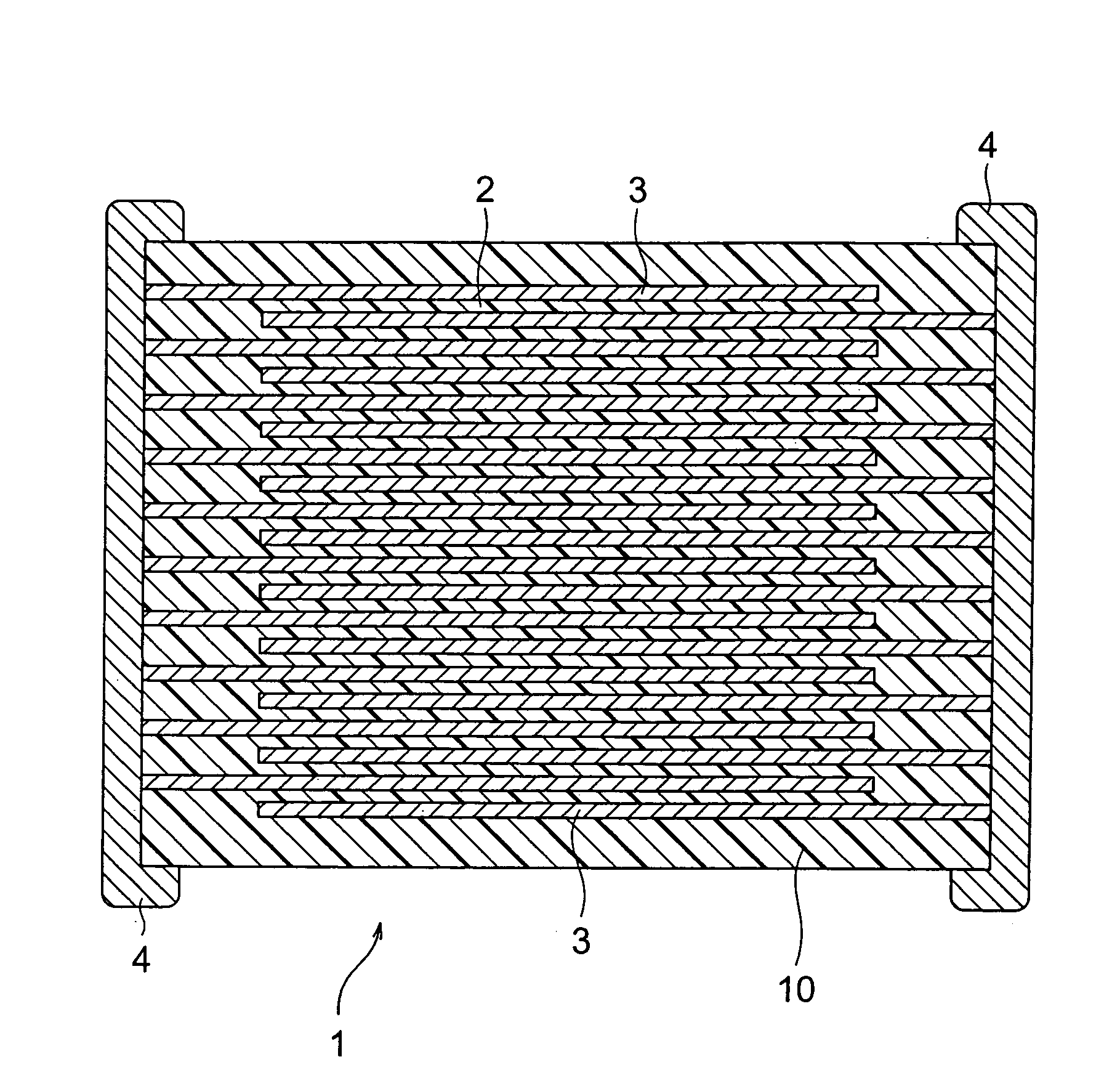

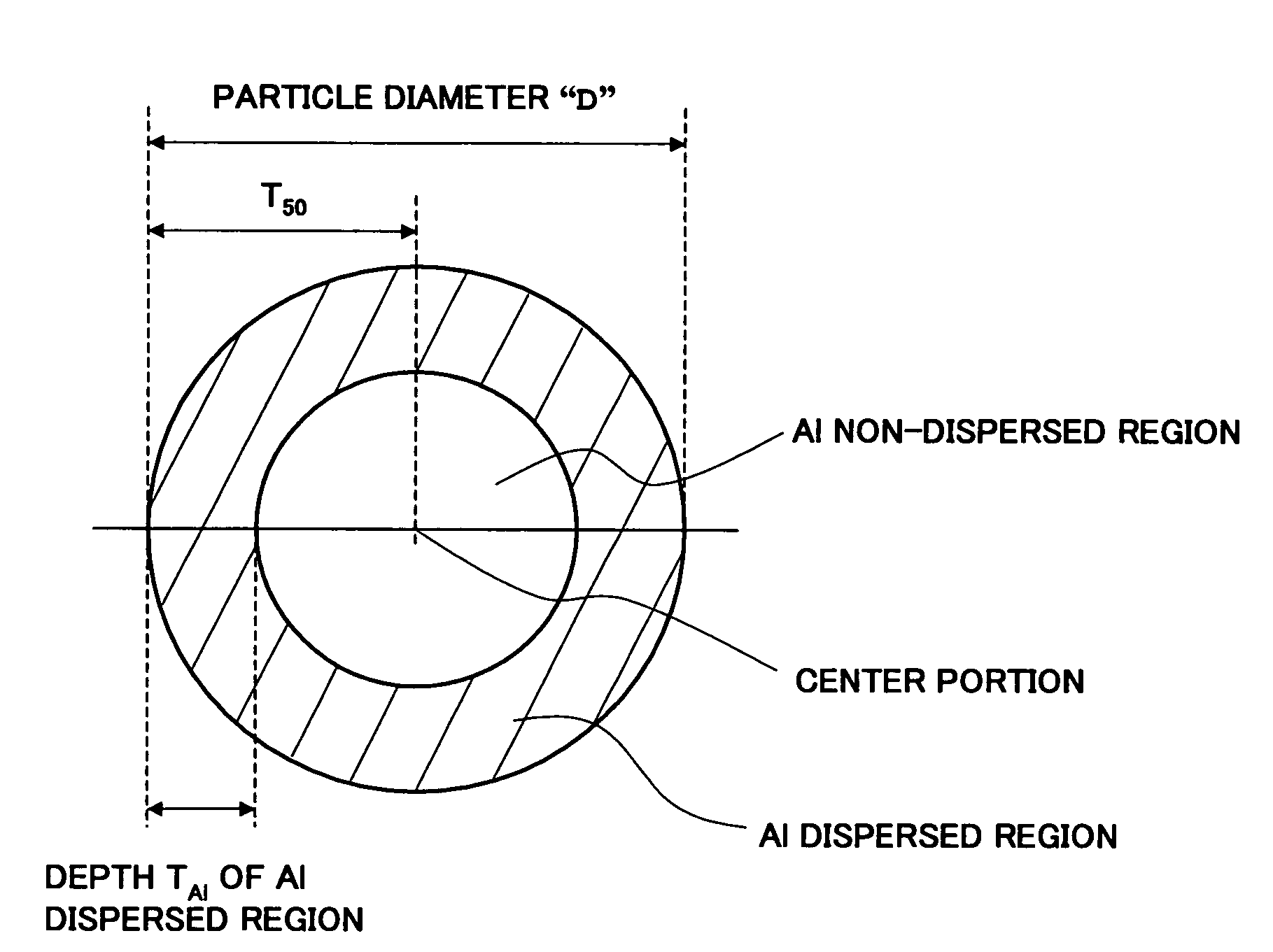

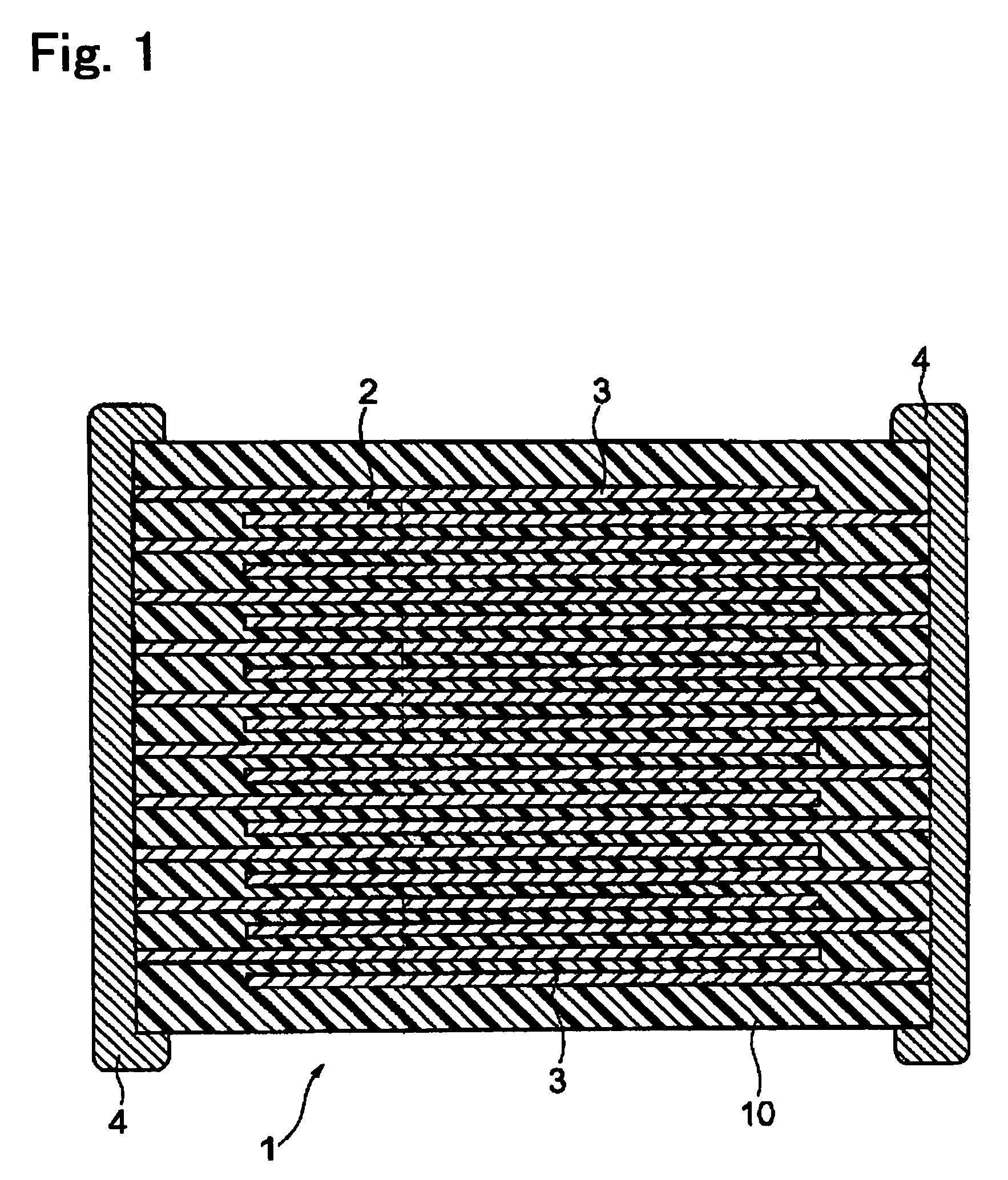

Electronic device, dielectric ceramic composition and the production method

ActiveUS7439203B2Large capacityThin layerFixed capacitor dielectricStacked capacitorsBarium titanateElectron

A dielectric ceramic composition comprising a main component including barium titanate and an oxide of Al, wherein the dielectric ceramic composition includes a plurality of dielectric particles, concentration of Al in each of the dielectric particles becomes lower from a particle surface to inside thereof, and each of the dielectric particles has an Al non-dispersed region substantially not including Al at least at a center portion of the particle.

Owner:TDK CORPARATION

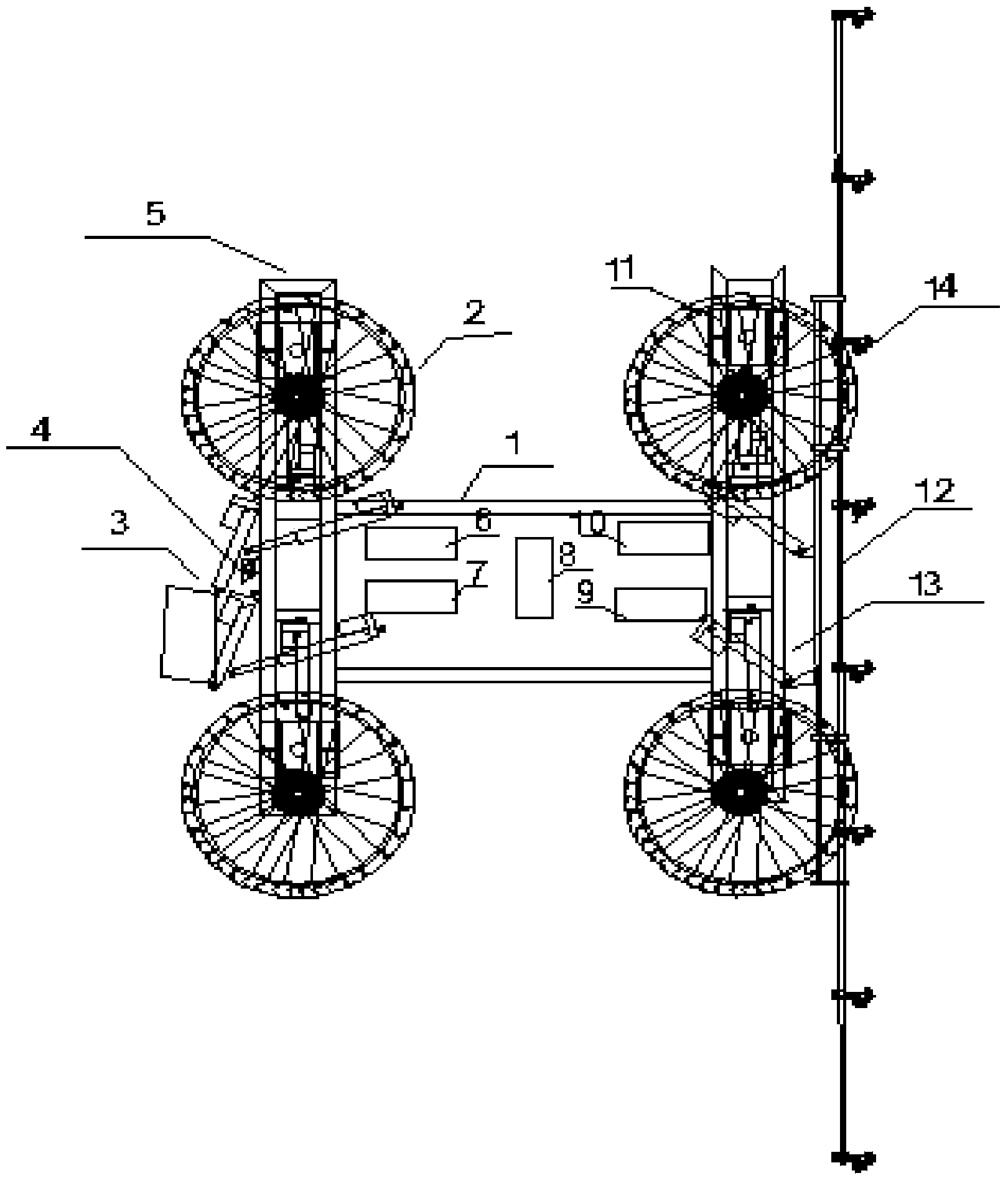

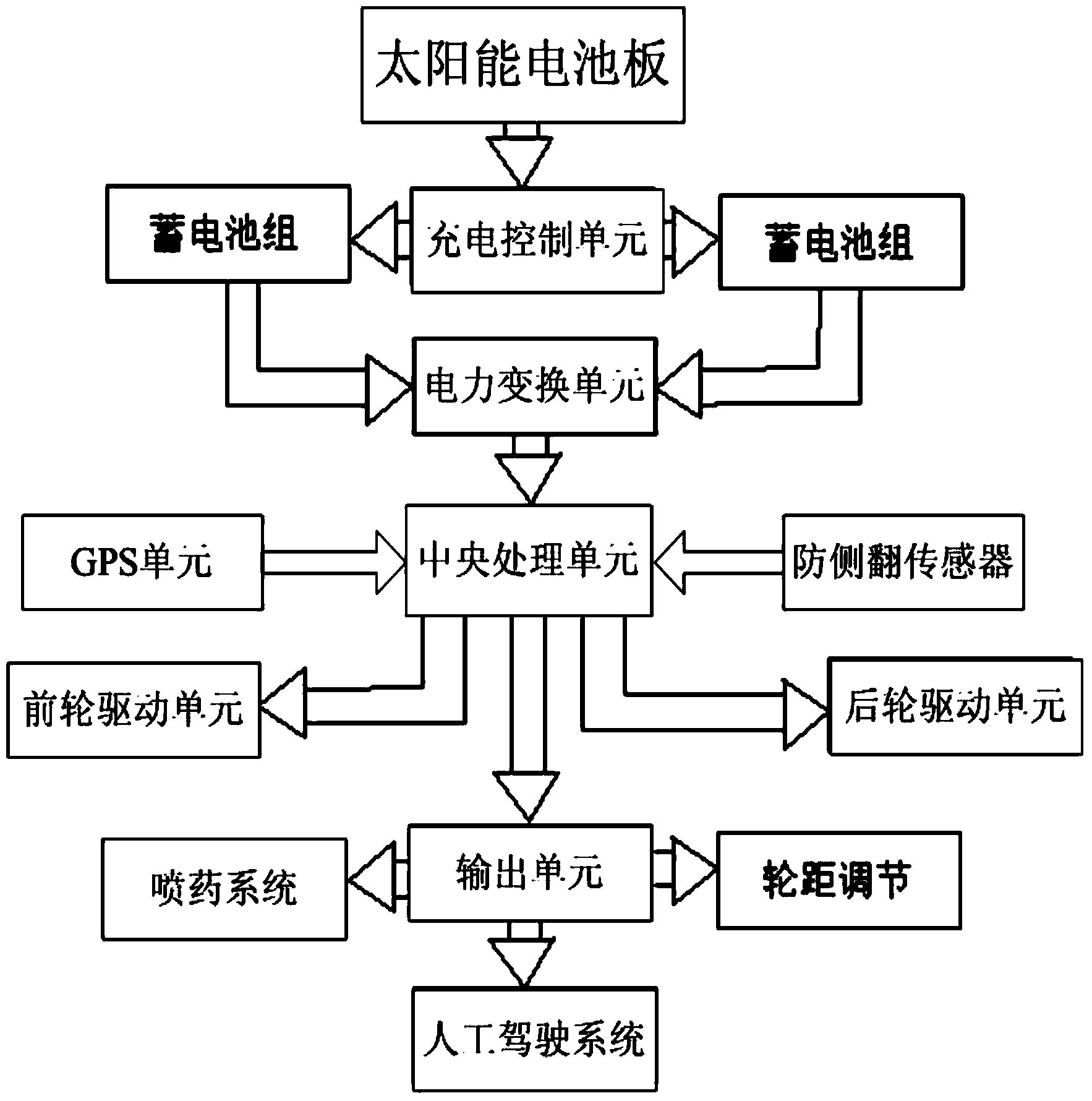

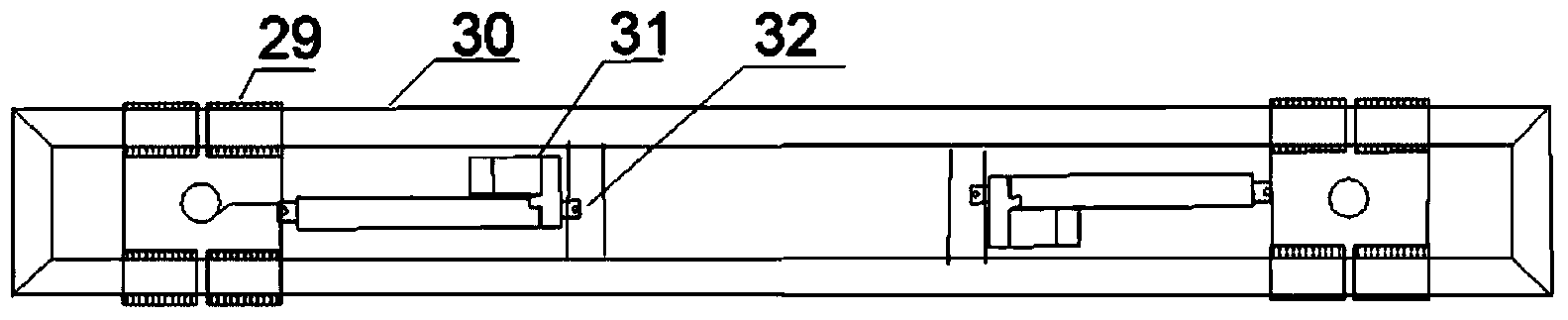

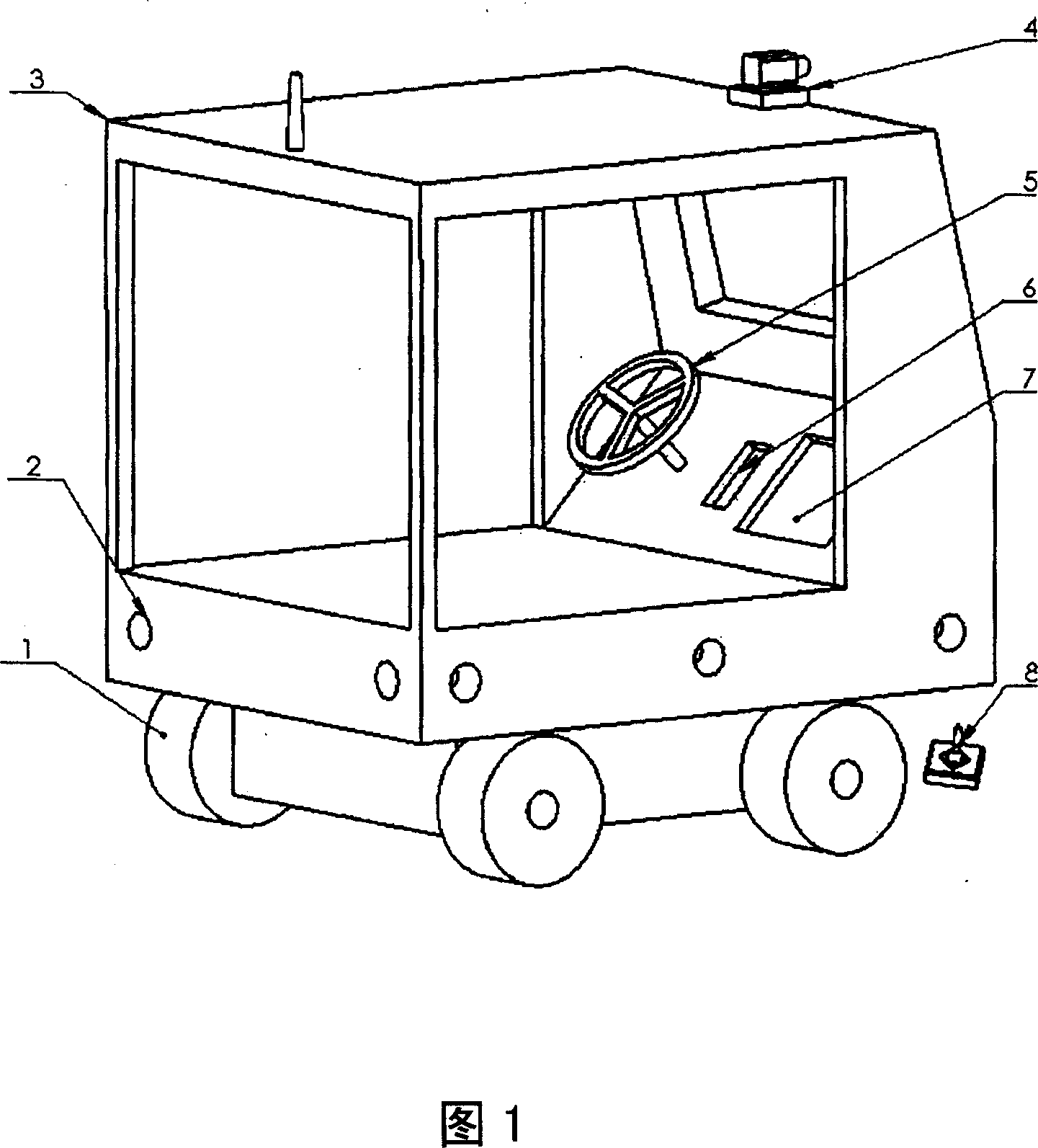

Automatic spraying vehicle

ActiveCN103963889ACompact bodyFew mechanical partsCyclesMotor depositionControl systemCharge control

The invention discloses an automatic spraying vehicle which comprises a frame (1), beams (5) arranged at the front end and the rear end of the frame, a spraying system, an artificial drive system (3) and a control system, wherein the two ends of the beams (5) are provided with wheels (2) and a wheel track adjustment system, and the control system comprises a charging control unit, a power conversion unit, a GPS unit, a front wheel driving unit, a rear wheel driving unit, an output unit and a central processing unit. The automatic spraying vehicle has the advantages of being small in size, large in power, adjustable in wheel track and the like. A spraying rod can be folded automatically.

Owner:HUNAN FENGMAO PLANT PROTECTION MACHINERY CO LTD

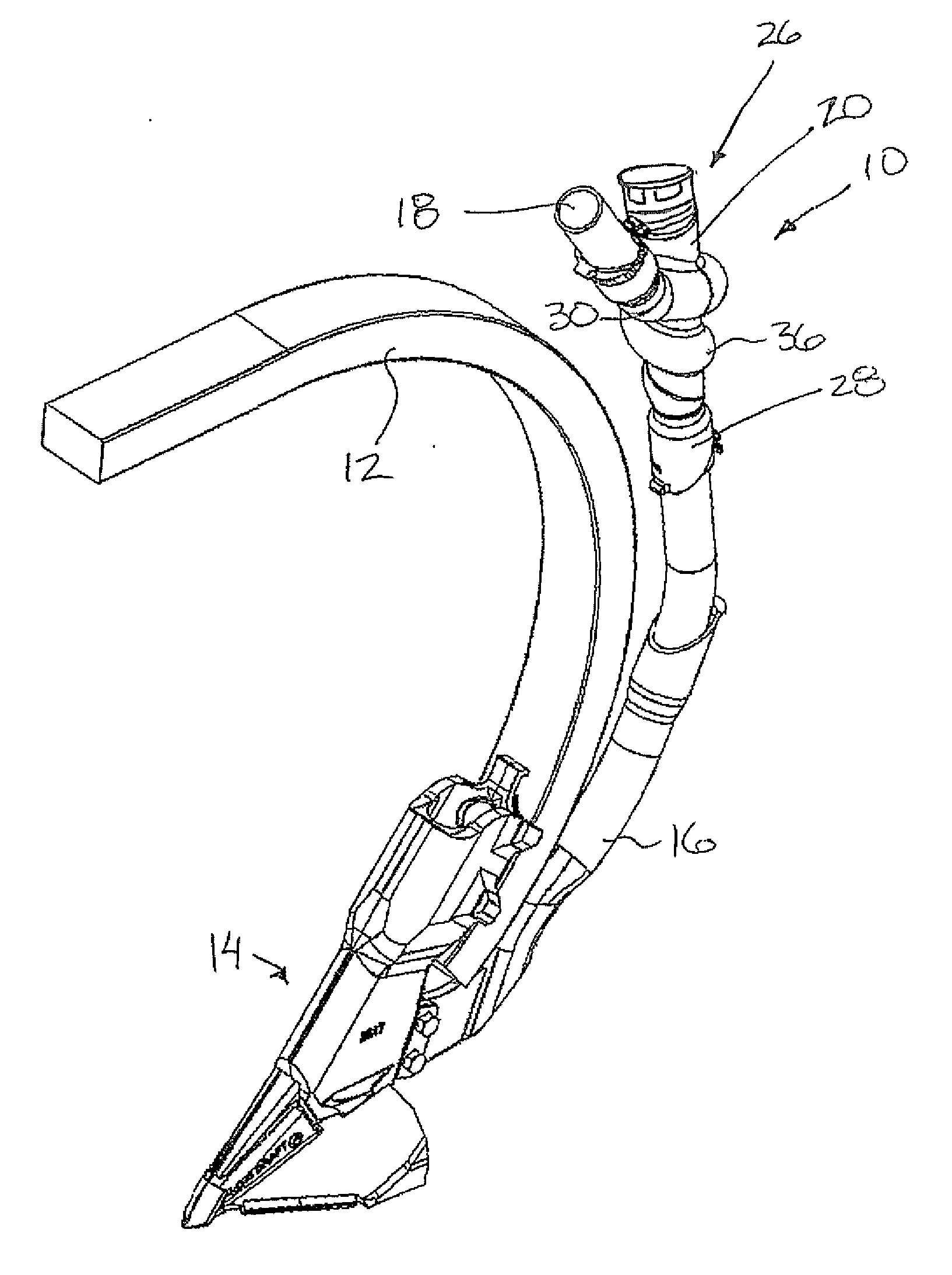

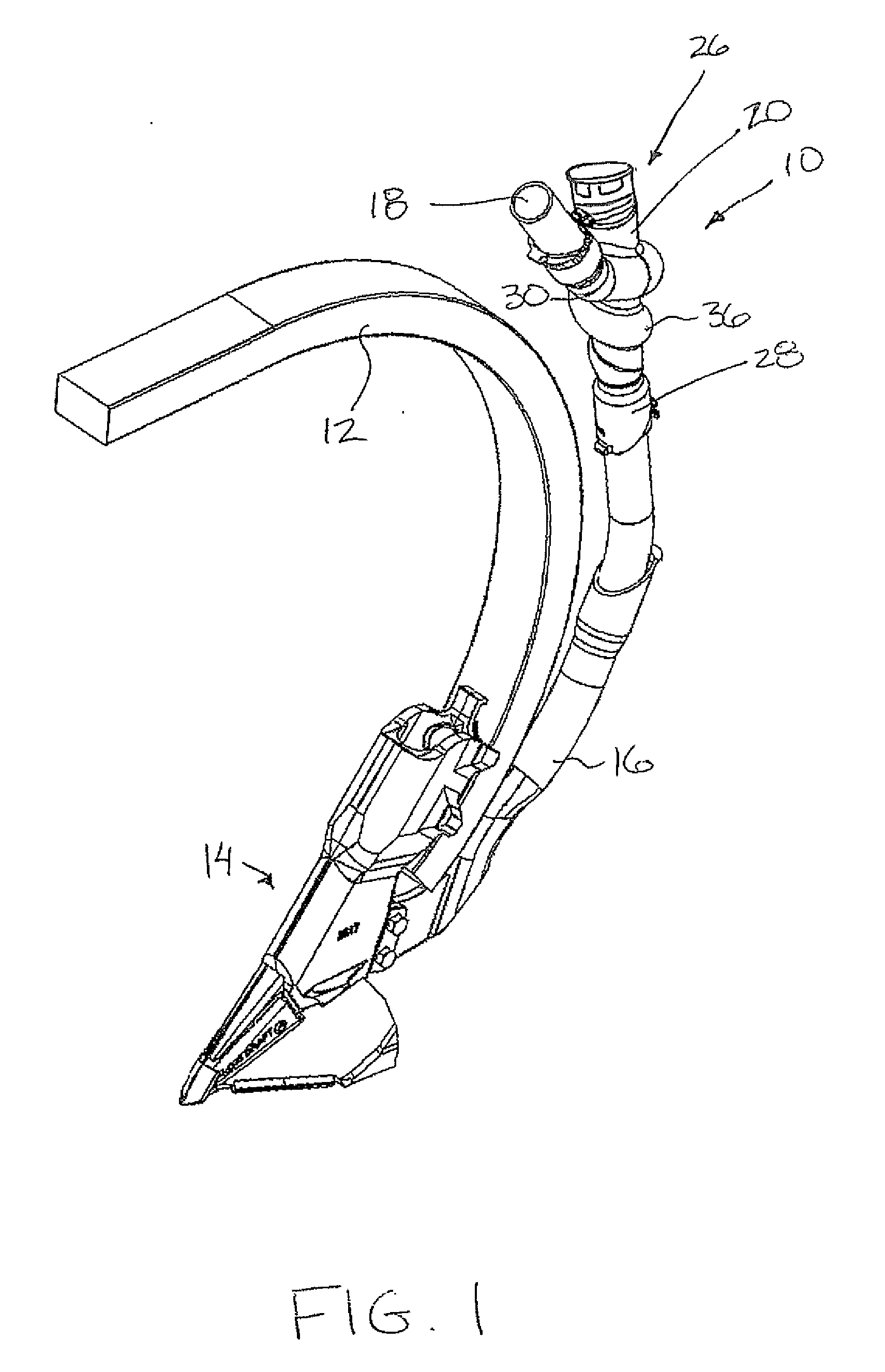

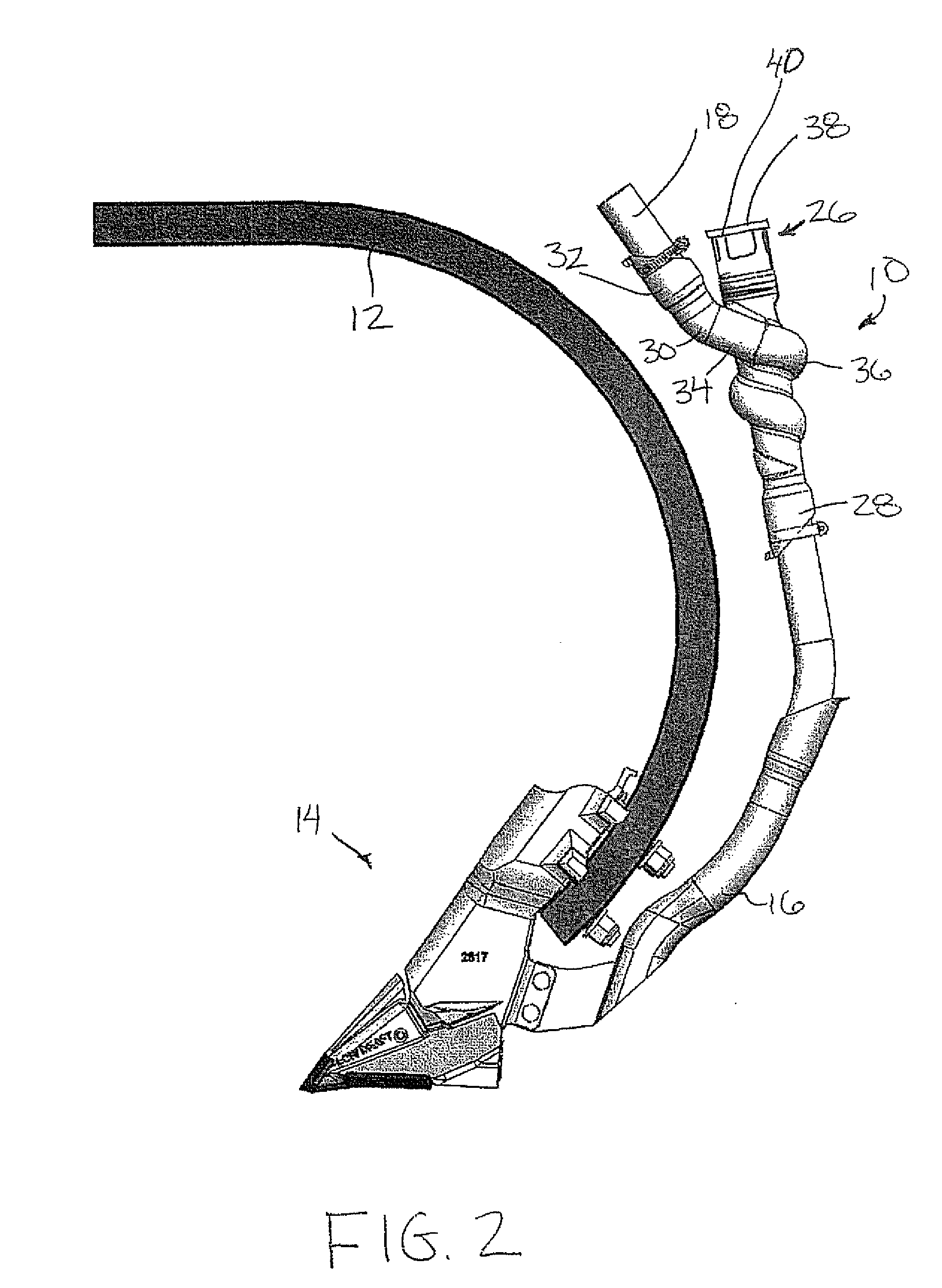

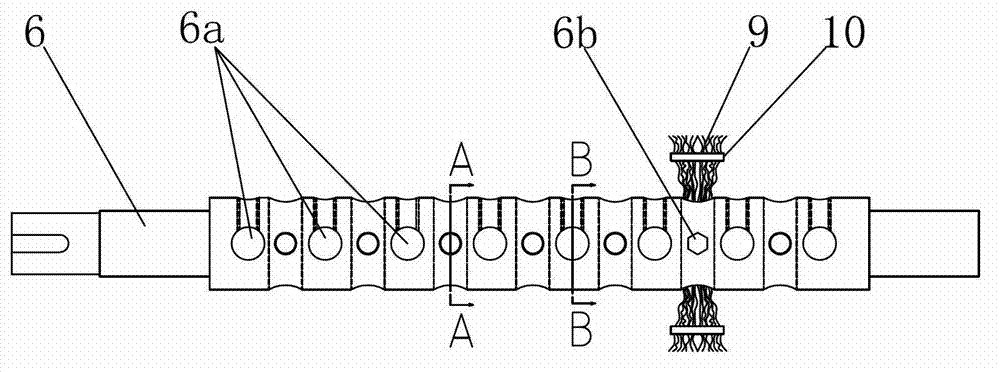

Decelerating Device for Air Conveyed Material

ActiveUS20120312212A1Improve performanceExcessive ratePotato plantersFurrow making/coveringDistribution systemEngineering

A material decelerating device is connected in series with a distribution tube in proximity to a material outlet in an agricultural air distribution system for decelerating conveying air which placing material into a furrow in the ground. The material decelerating includes an inlet tube connected to the distribution tube to receive material and conveying air therefrom. The inlet tube is connected at an intermediate location on a center tube of the device which exhausts the air upwardly to an exhaust opening and deposits the material downwardly through an outlet opening. A cap adjustably spans the exhaust opening to vary the amount of air exhausted. The inlet tube is inclined downwardly in alignment with a helical recessed channel within the center tube to guide material to the outlet.

Owner:TREAD ENTERPRISES

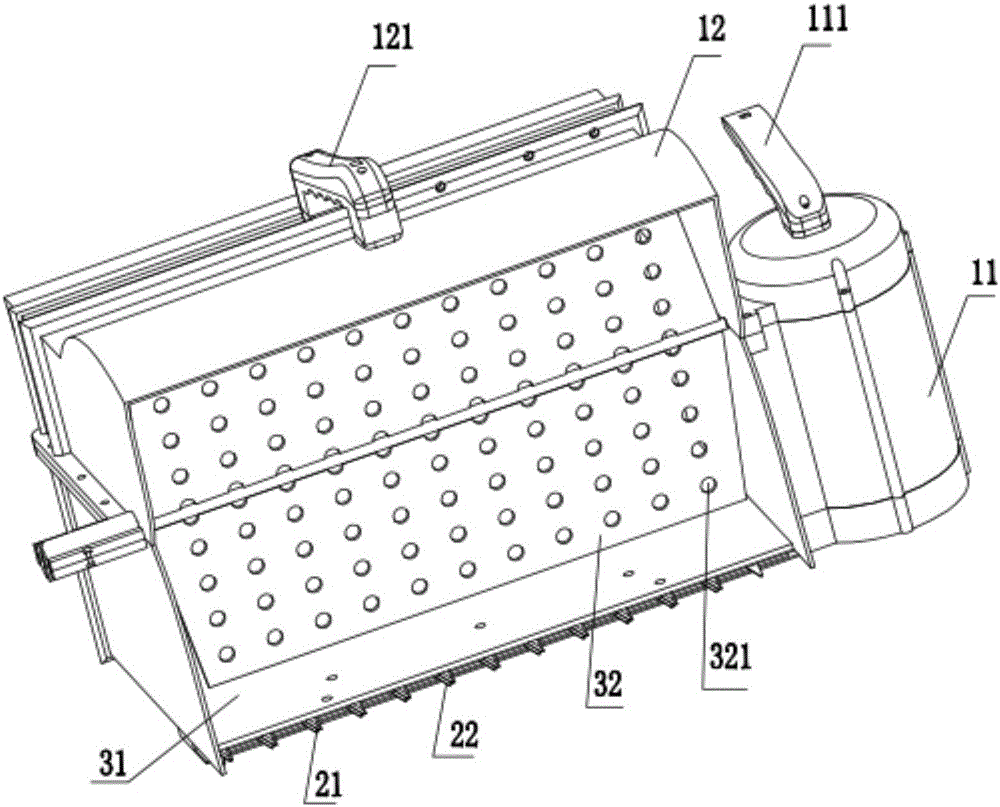

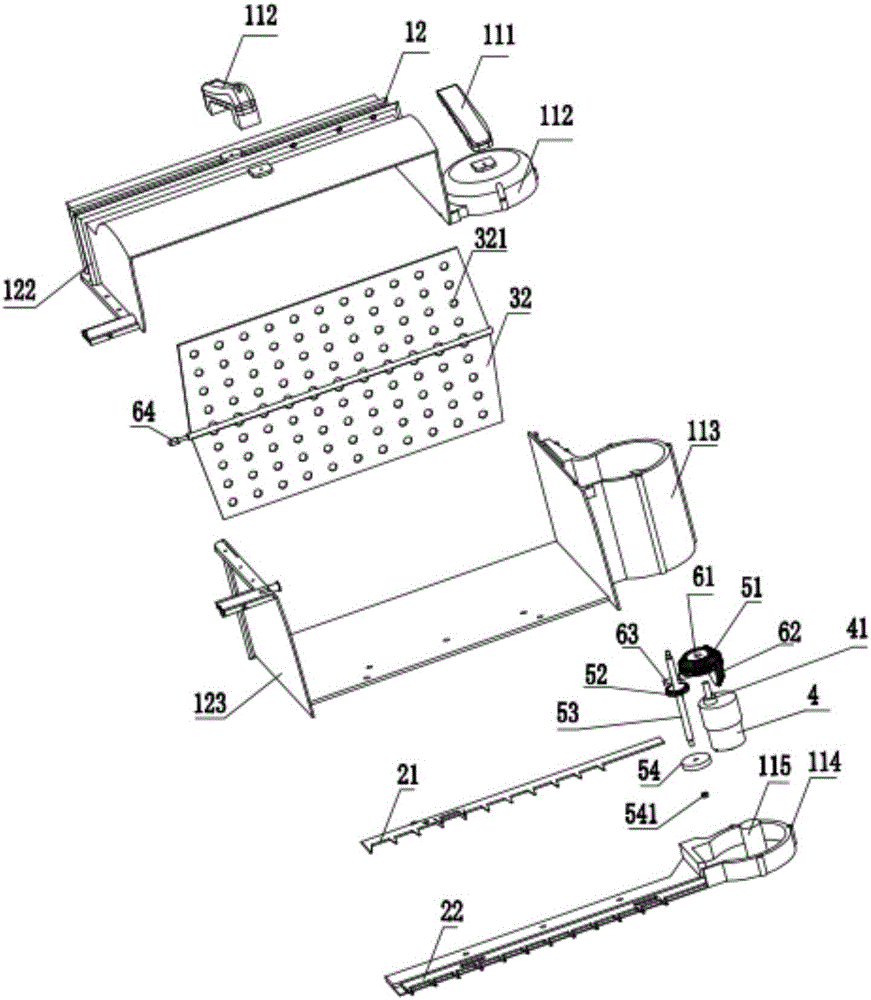

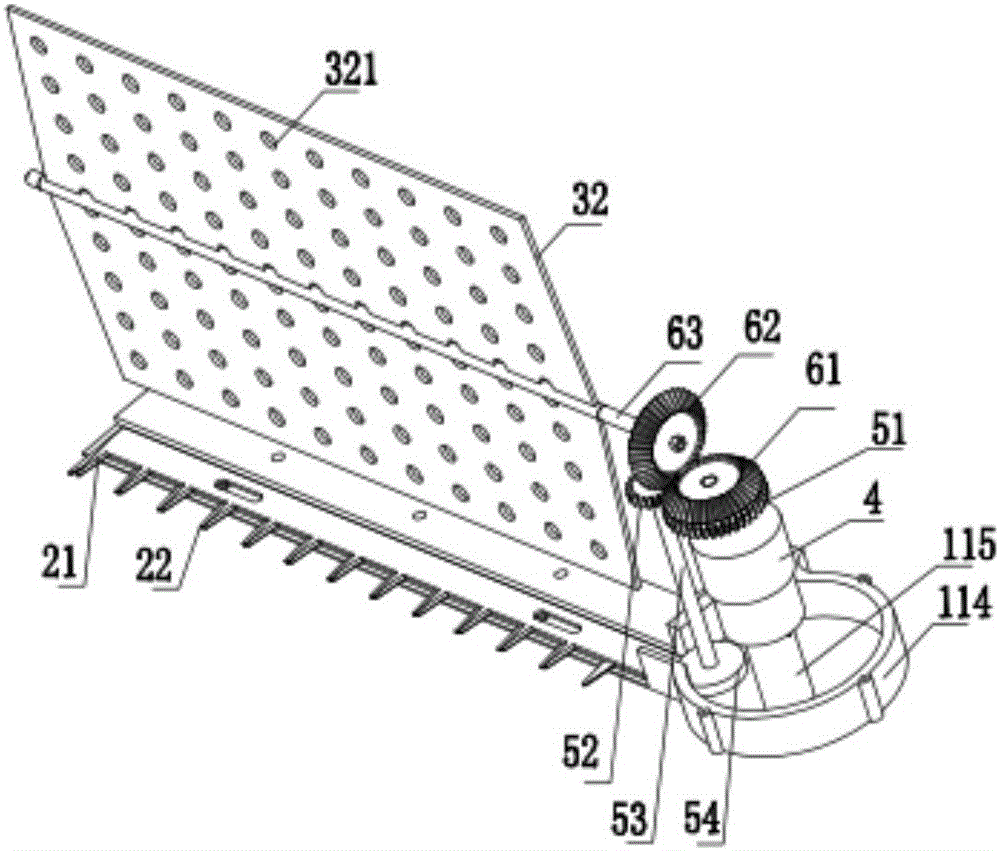

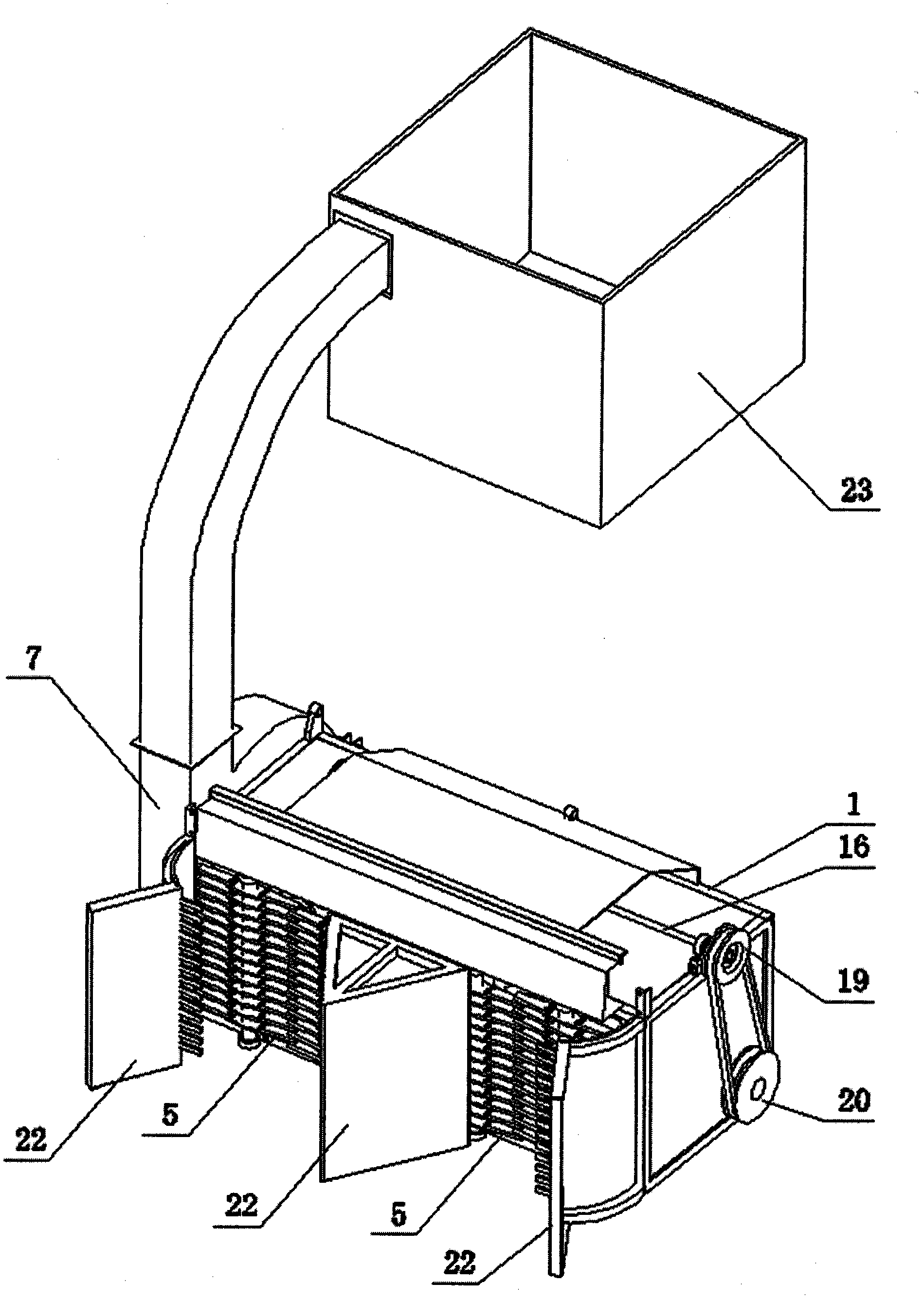

Portable tea-leaf picker

The invention discloses a portable tea-leaf picker. The portable tea-leaf picker comprises a frame, a shearing device, a drive motor and a collecting device, wherein the shearing device comprises an upper shearing blade and a lower shearing blade, which can perform shear motion oppositely; the collecting device comprises a collecting cavity and a leaf sweeping wheel capable of performing rotary motion. The portable tea-leaf picker is characterized in that the shearing device is in transmission connection with the driving motor through a first transmission structure; the leaf sweeping wheel is in transmission connection with the drive motor through a second transmission structure; the drive motor drives the shearing device to perform the shear motion while driving the leaf sweeping wheel to perform the rotary motion. Therefore, the portable tea-leaf picker, disclosed by the invention, adopts one drive motor to drive the shearing motion of the shearing device and the rotary motion of the leaf sweeping wheel synchronously, ensures the shearing efficiency and also enables the sheared green tea leaves to be effectively collected in time.

Owner:XIAMEN UNIV OF TECH

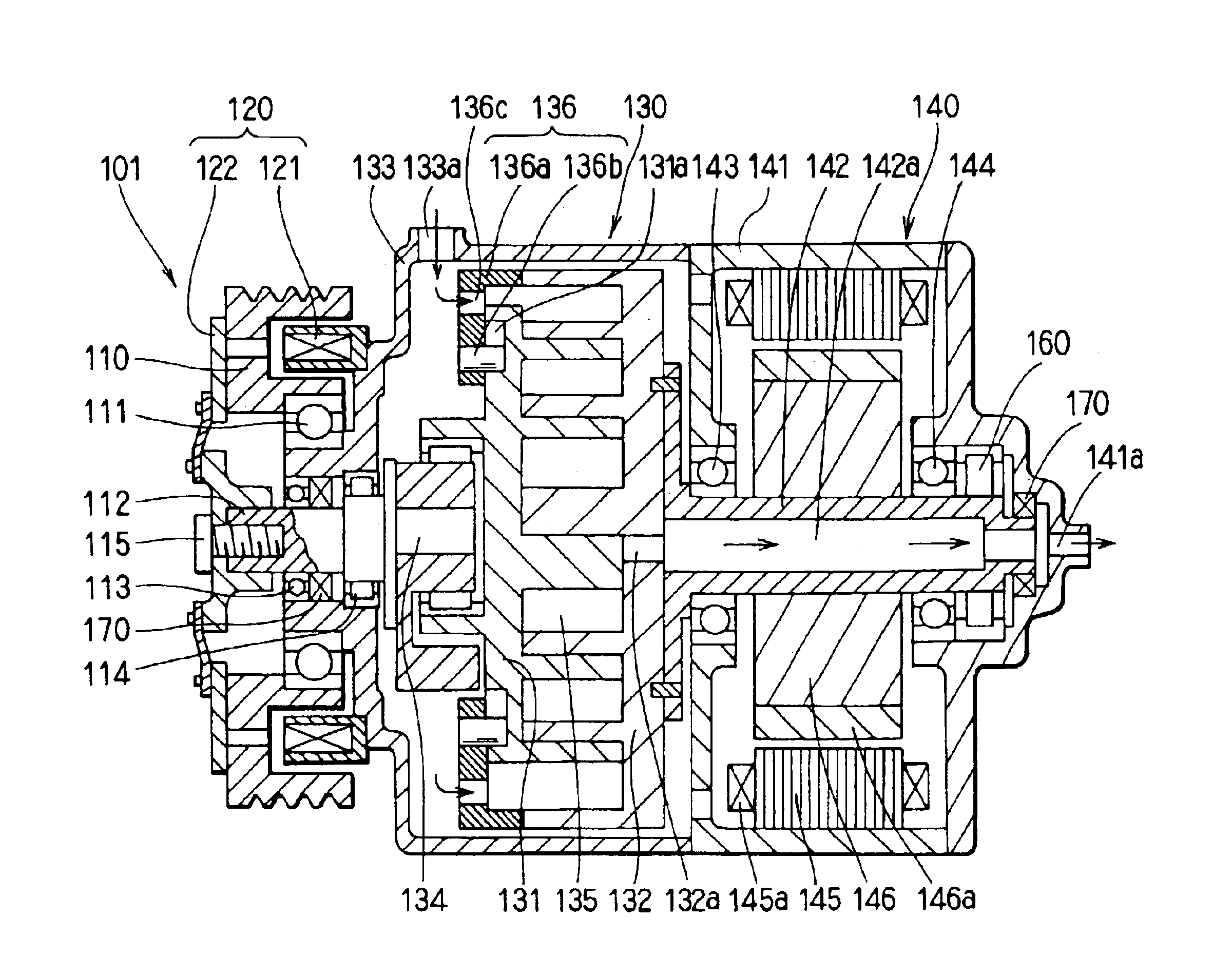

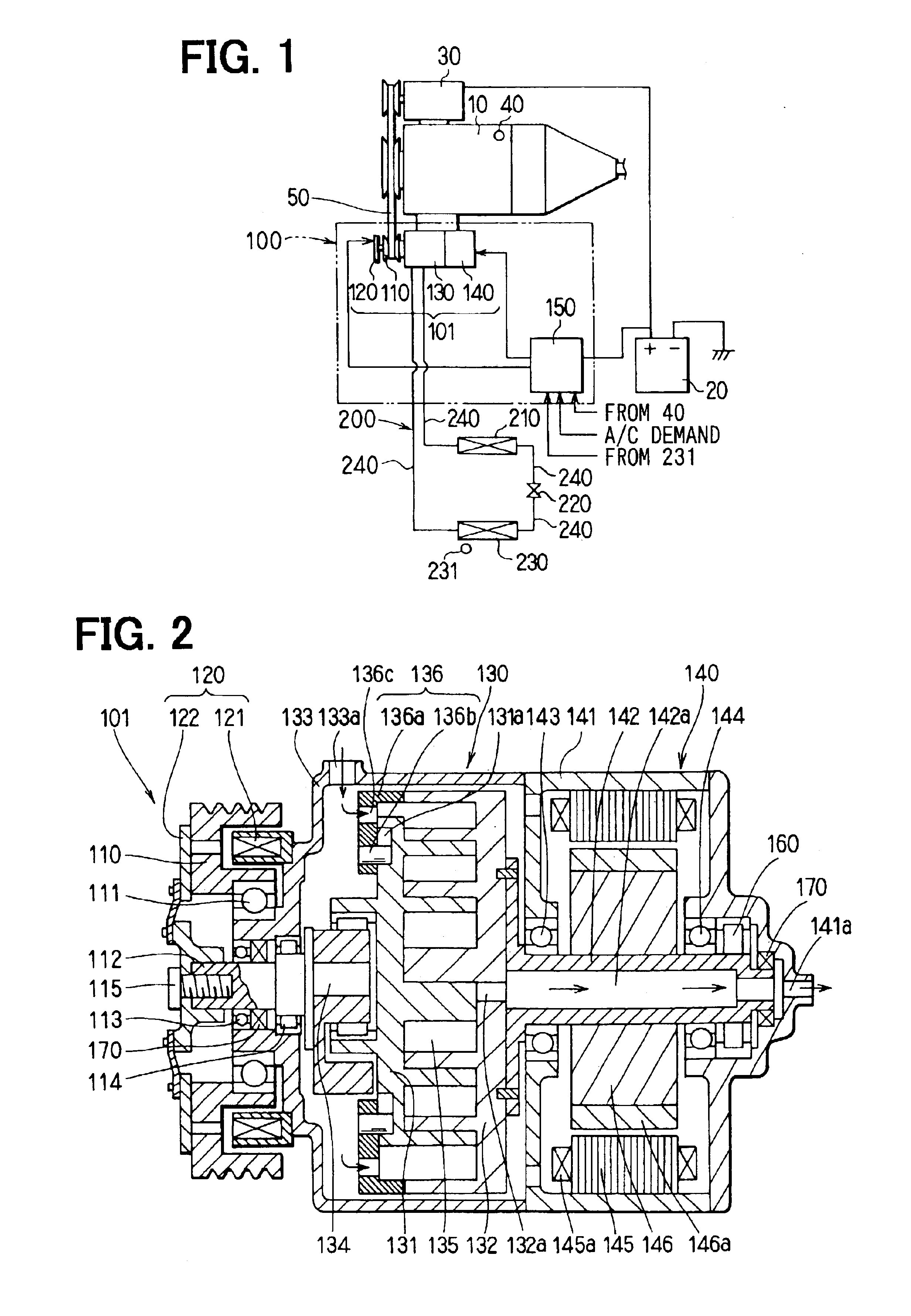

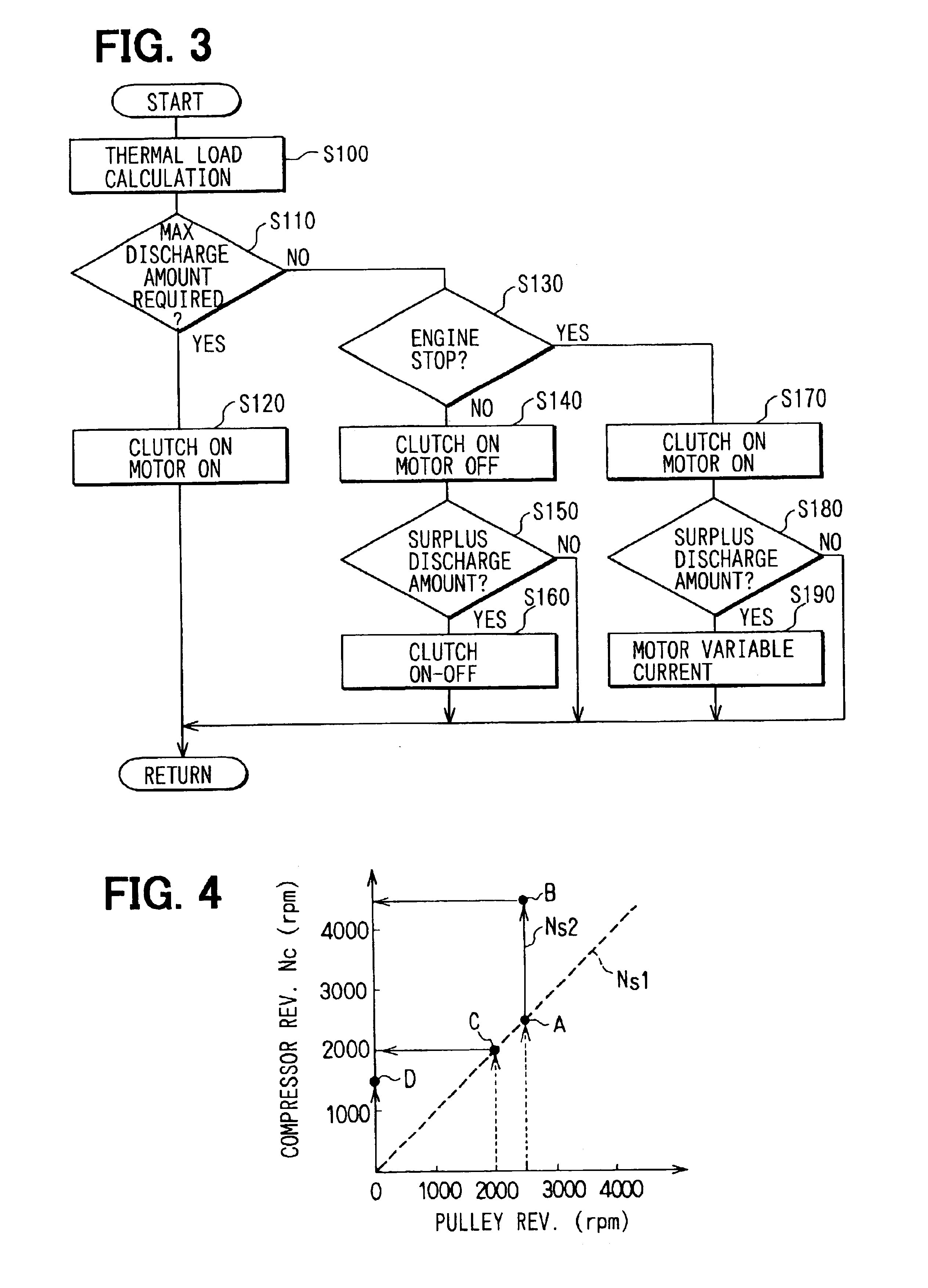

Compressor having independently driven members

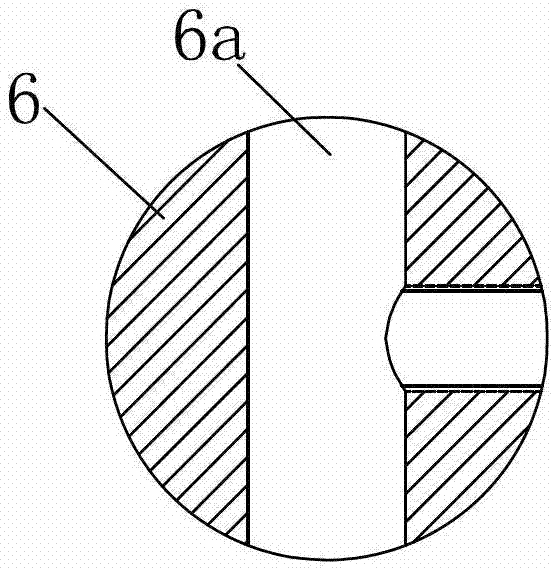

InactiveUS6874996B2Compact bodyEasy to operateRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesEngineeringCompression member

The hybrid compressor apparatus is composed of a compressor in which fluid is compressed by varying a volumetric capacity of a compression space provided between a first compression member and a second compression member, which are movable independently of each other, according to rotation of the first compression member relative to the second compression member, a motor rotatable upon receipt of power of an external electric source, and a driven member rotatably driven by motive force transmitted from an external driving source. The first compression member is connected with the driven member and the second compressor is connected with the motor. If maximum discharge amount is required for the compressor, the motor is driven separately by a control device when the driven member drives the first compression member so that the second compression member is rotated in a direction opposite to that of the first compression member.

Owner:DENSO CORP

Electronic device, dielectric ceramic composition and the production method

ActiveUS20060223692A1Large capacityThin layerFixed capacitor dielectricStacked capacitorsBarium titanateElectron

A dielectric ceramic composition comprising a main component including barium titanate and an oxide of Al, wherein the dielectric ceramic composition includes a plurality of dielectric particles, concentration of Al in each of the dielectric particles becomes lower from a particle surface to inside thereof, and each of the dielectric particles has an Al non-dispersed region substantially not including Al at least at a center portion of the particle.

Owner:TDK CORPARATION

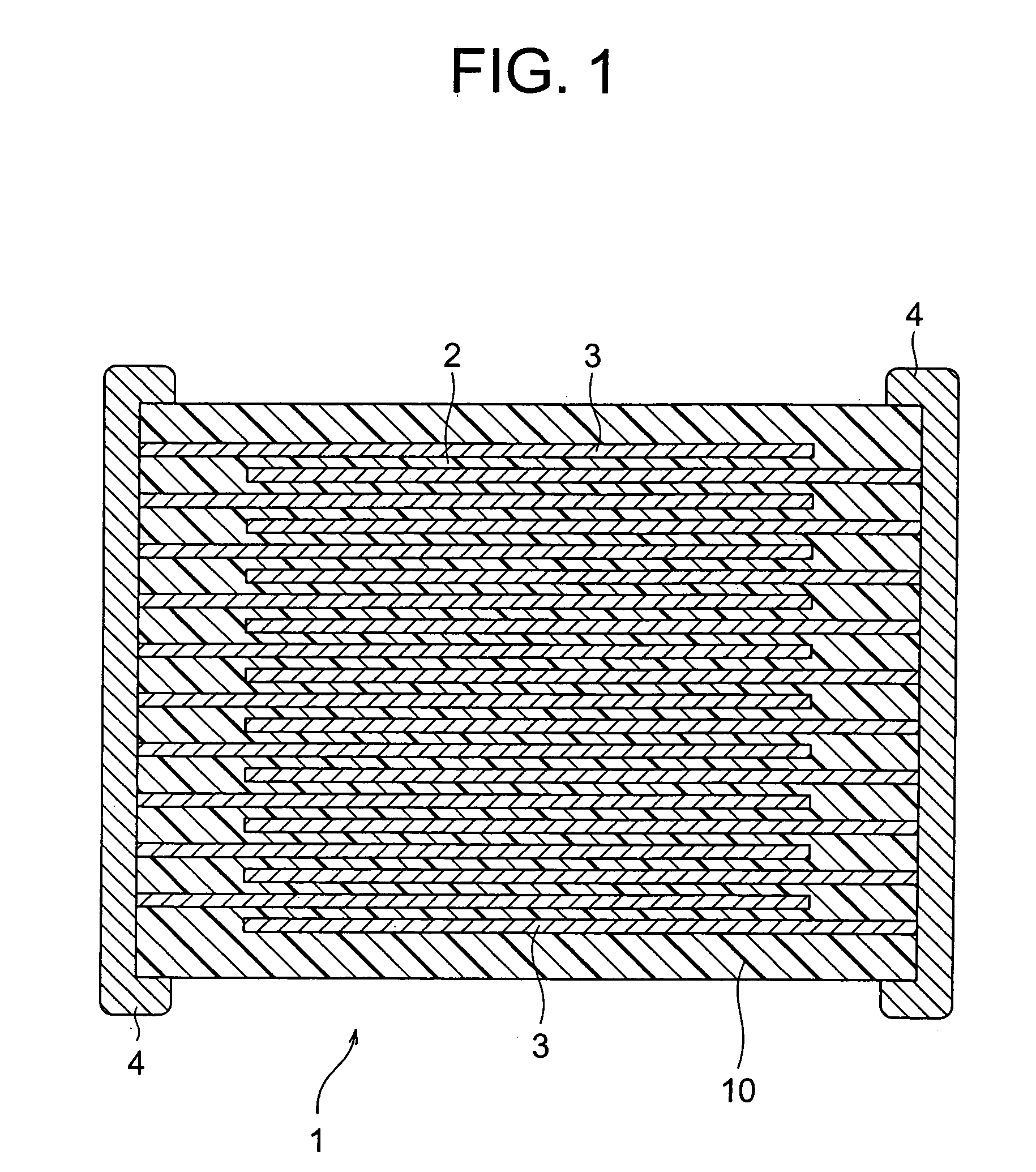

Dielectric ceramic composition and electronic device

ActiveUS20060160693A1High specific permittivityLarge capacityEdge grinding machinesFixed capacitor dielectricDielectricElectron

A dielectric ceramic composition comprising a predetermined main component and a fifth subcomponent including an oxide of A (note that A is at least one king selected from a cation element group having an effective ionic radius of 0.065 nm to 0.085 nm at the time of 6 coordination); and the dielectric ceramic composition comprises a plurality of crystal grains including Ca elements and, when assuming that an average value of a concentration of entire Ca exiting in said respective crystal grains is grain Ca concentration, at least unevenness exists in said grain Ca concentration between said crystal grains and it is 5% or higher in a CV value.

Owner:TDK CORPARATION

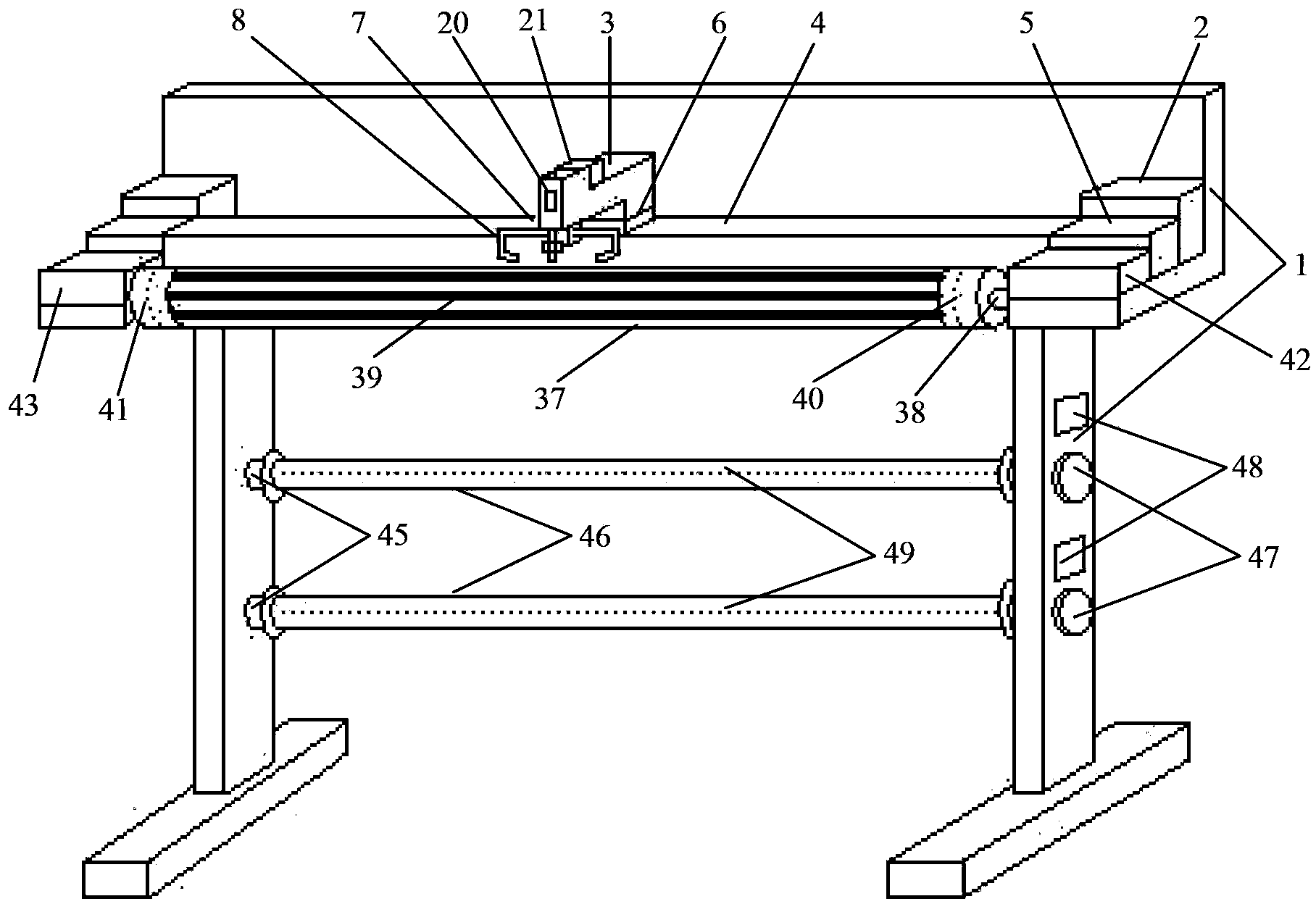

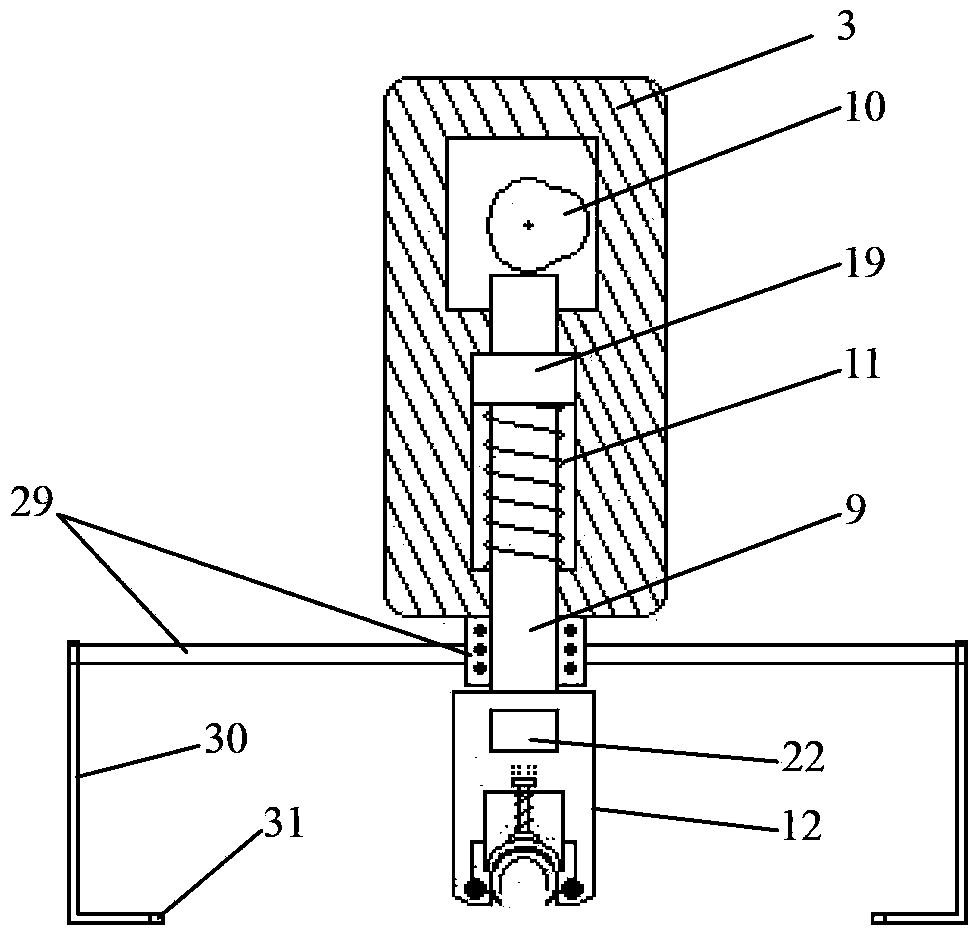

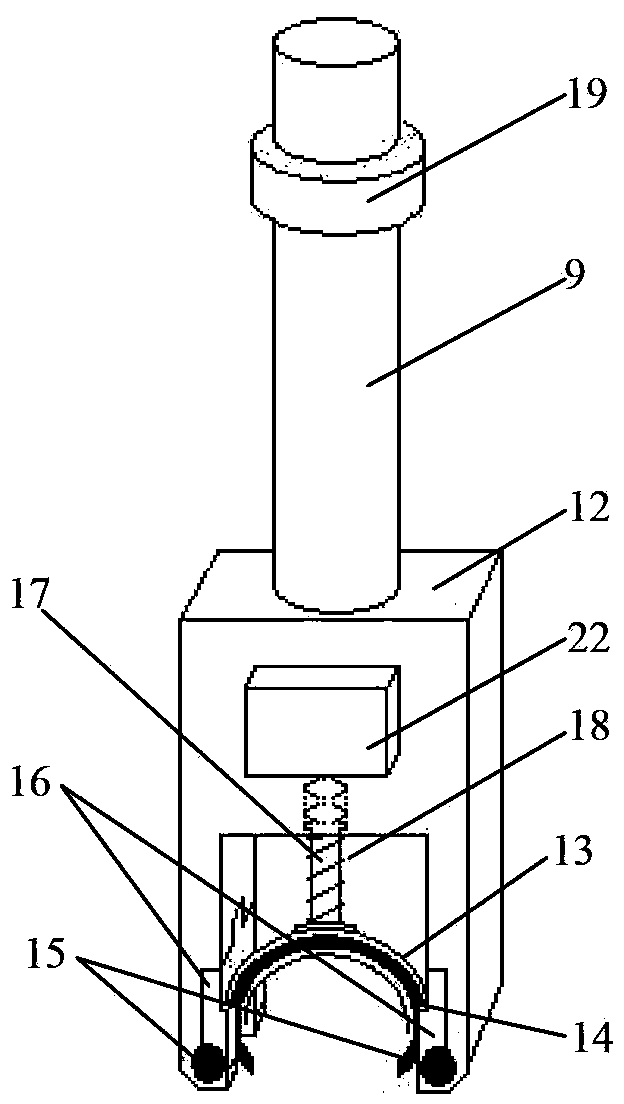

Cross-stitch simulation machine

InactiveCN103510306AMechanizationCompact bodyAutomatic machinesFeedersEngineeringMechanical engineering

The invention relates to a cross-stitch simulation machine which comprises a rack, a programmable controller, a straight-line motion mechanism and a rotating mechanism, wherein the programmable controller is arranged on the rack, the straight-line motion mechanism is connected with the programmable controller, and the rotating mechanism is used for supporting and transmitting stitched cloth and is arranged below the straight-line motion mechanism; the straight-line motion mechanism comprises a seat frame which can be linearly controlled to slide, and a stitching needle device and a thread drawing device are arranged at the front end of the seat frame; the stitching needle device is used for simulating a handmade cross-stitch stitching method, and the thread drawing device is used for being matched with the stitching needle device to draw a thread. The thread pressing direction of embroidery stitched by the cross-stitch simulation machine is consistent, the needle lines on the front surface and the back surface of the embroidery are completely as same as handmade needle lines, and the cross-stitch simulation machine can stitch cross-stitch embroidery comparable with handmade embroidery. The cross-stitch simulation machine has a small and exquisite machine body and small occupied space and can produce large-width and long-width embroidery. Hand work is replaced, the production efficiency is greatly improved, and the real cross-stitch mechanization is realized.

Owner:吴进明

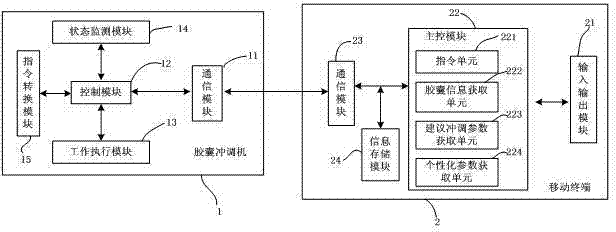

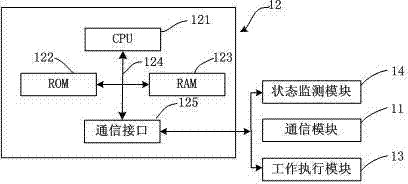

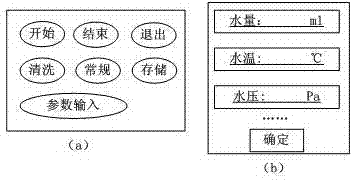

Mixing machine, control device and control method thereof

ActiveCN104777780ASimple operation moduleCompact bodyProgramme controlComputer controlOrder controlControl engineering

The invention provides a mixing machine which is controlled by an external control device. The mixing machine comprises a communication device, a control device and a working and executing mechanism. The communication device is used for receiving an operational order which is set by a user through the control device arranged outside the mixing machine and feeding back local information to the control device. The control device is used for controlling the working and executing mechanism to work according to the operational order and feeding back the local information to the control device through the communication device. The working and executing mechanism is used for executing the corresponding operation under the control of the order control device. The invention further provides the control device used for controlling the capsule mixing machine and a method used for controlling the capsule mixing machine by using the control device.

Owner:苏州益丰粤海同安康大药房连锁有限公司

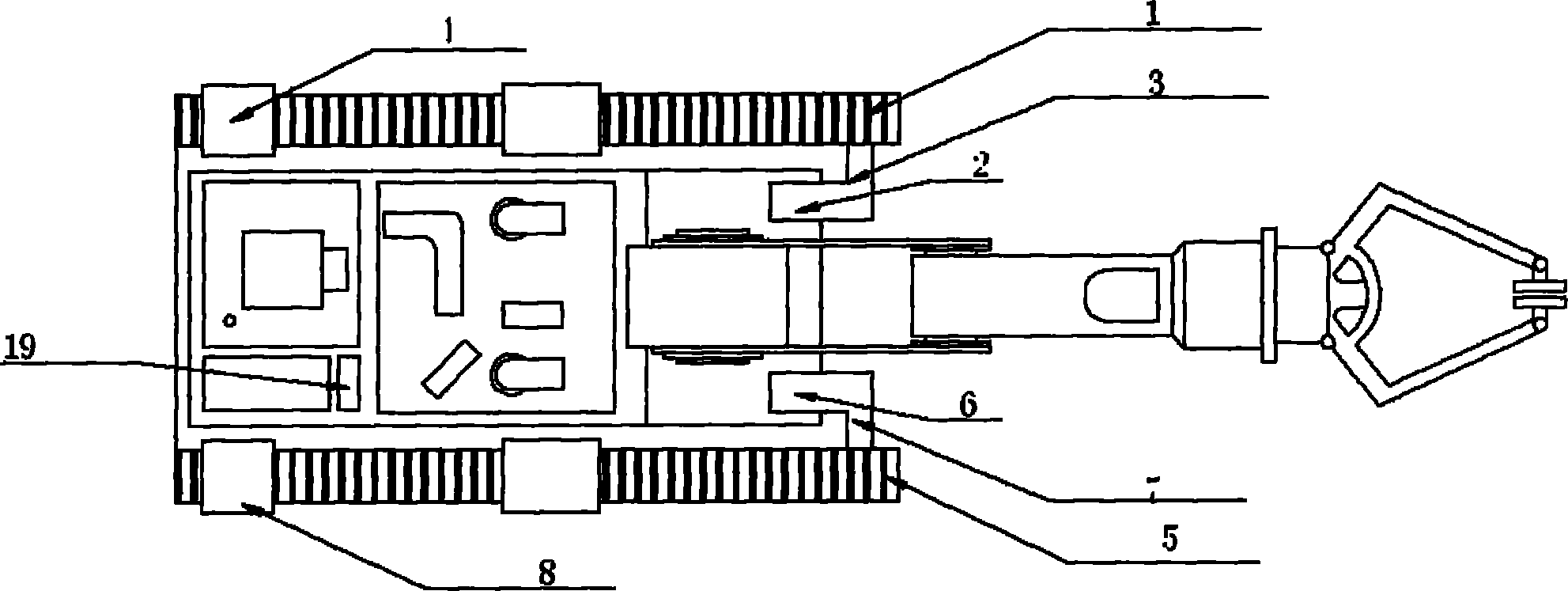

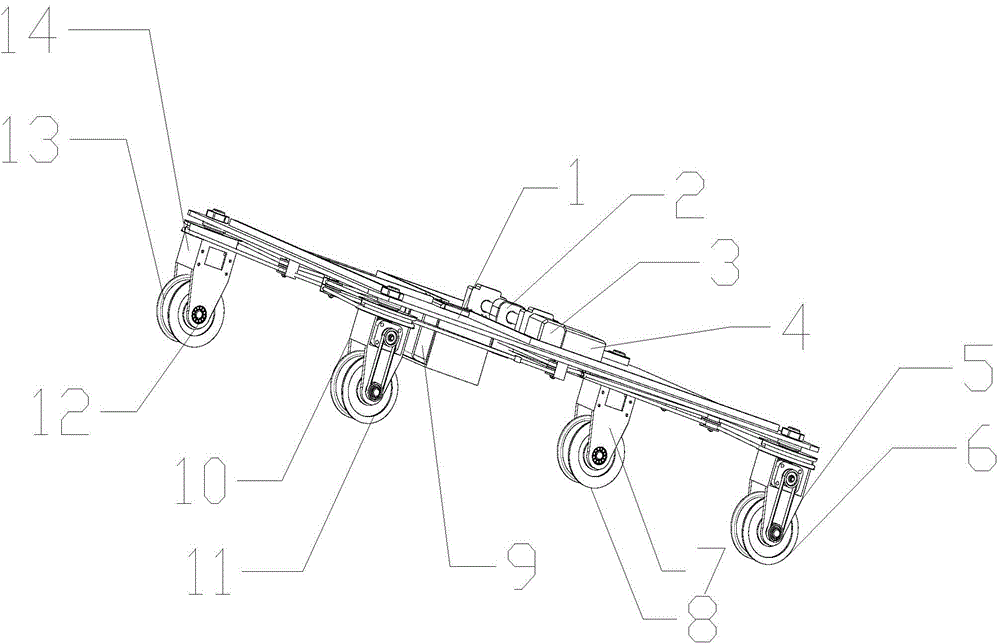

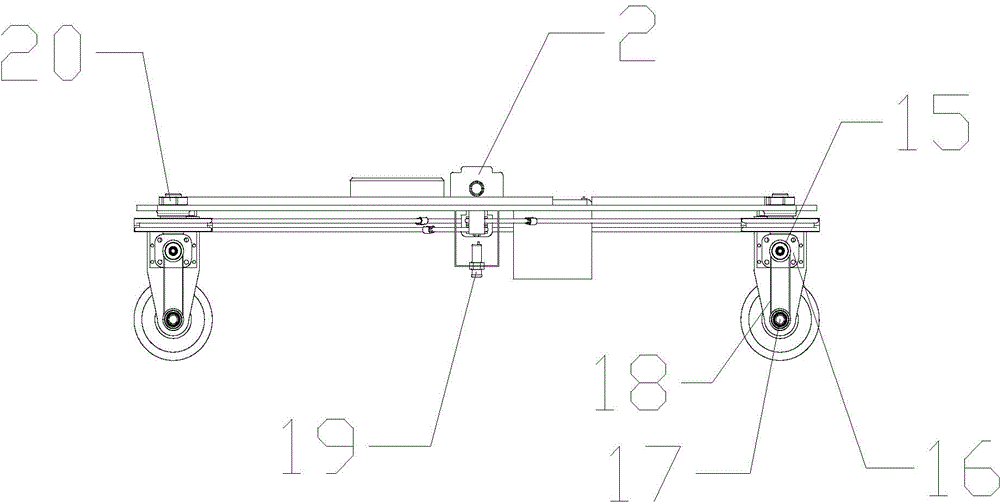

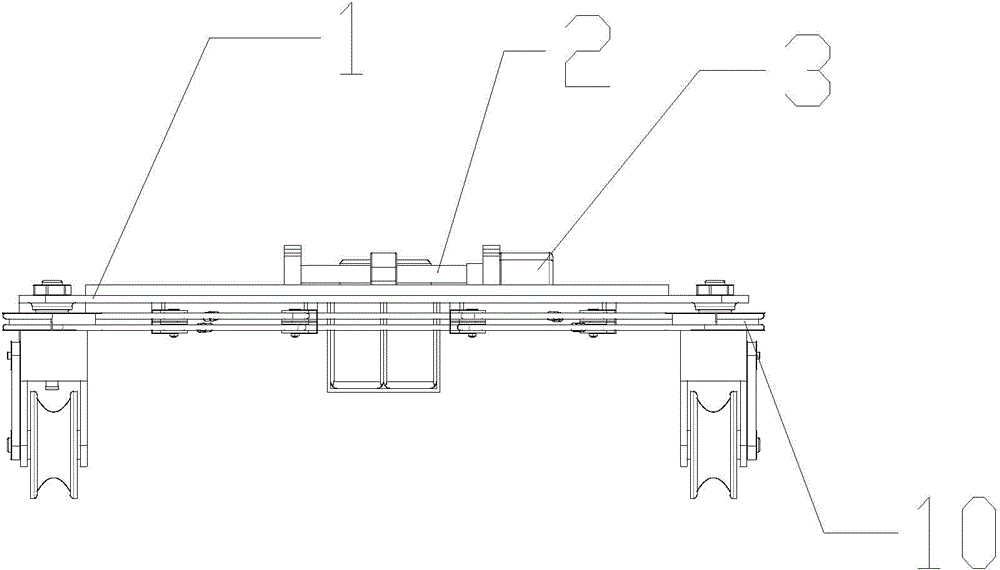

Automatic rail changing walking chassis of facility leaf vegetable harvesting robot and rail changing method

The invention relates to an automatic rail changing walking chassis of a facility leaf vegetable harvesting robot. According to the technical scheme, the automatic rail changing walking chassis comprises a rail car chassis, a movement mechanism, a steering mechanism, a control mechanism and a storage battery. The movement mechanism is used for driving a rail car to move and stop on rails and driving all walking wheels to rotate and walk in the rail changing process. The steering mechanism is used for controlling all the walking wheels to conduct steering work for determining angles three times in the rail changing process. The control mechanism is used for positioning all the working positions of the rail car, controlling the timing sequence matching of the movement mechanism and the steering mechanism and controlling the displacement in all the movement processes. The automatic rail changing walking chassis can be used for bearing other operation machines to complete conveying work and can move along the rails stably and quickly to precisely stop at a set stopping position at the tail ends of the rails, so that various complex functions of parallel rail changing work and the like are achieved autonomously. The automatic rail changing walking chassis is simple in structure, compact in car body, small in occupied area in the rail changing process, free of other auxiliary facilities, high in degree of automation and capable of conducting full-automatic or remote control greenhouse operation.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

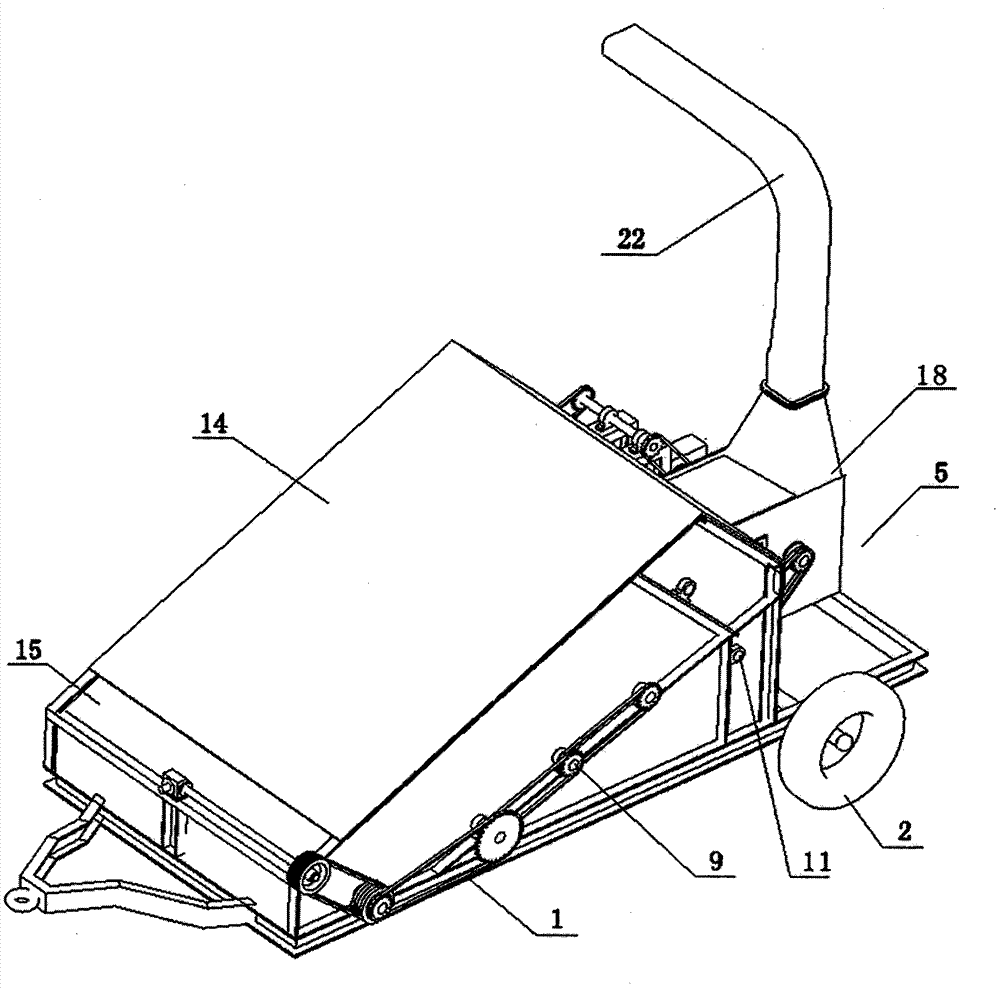

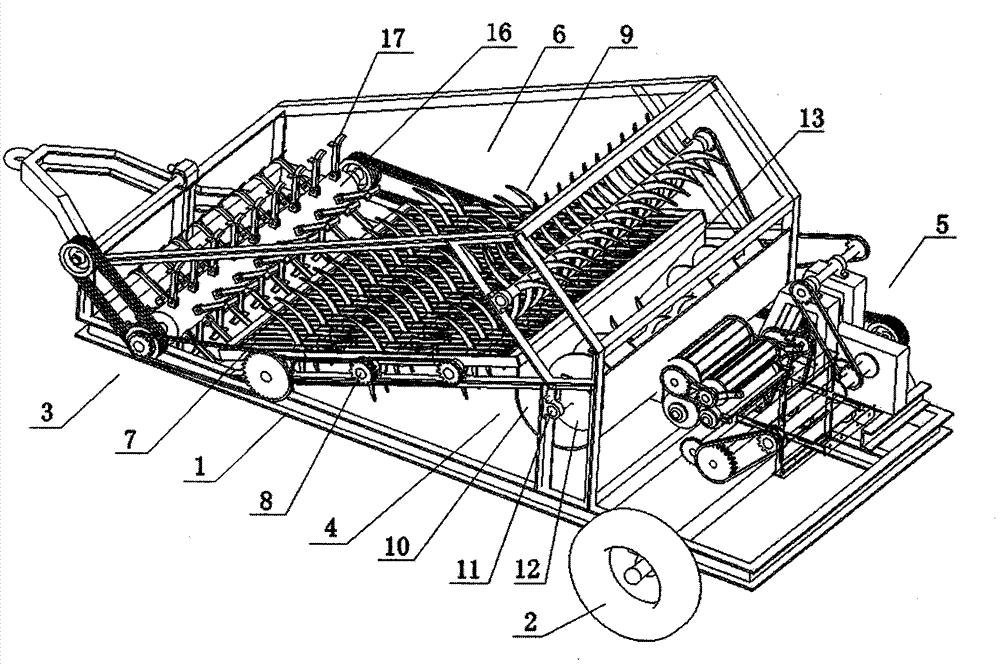

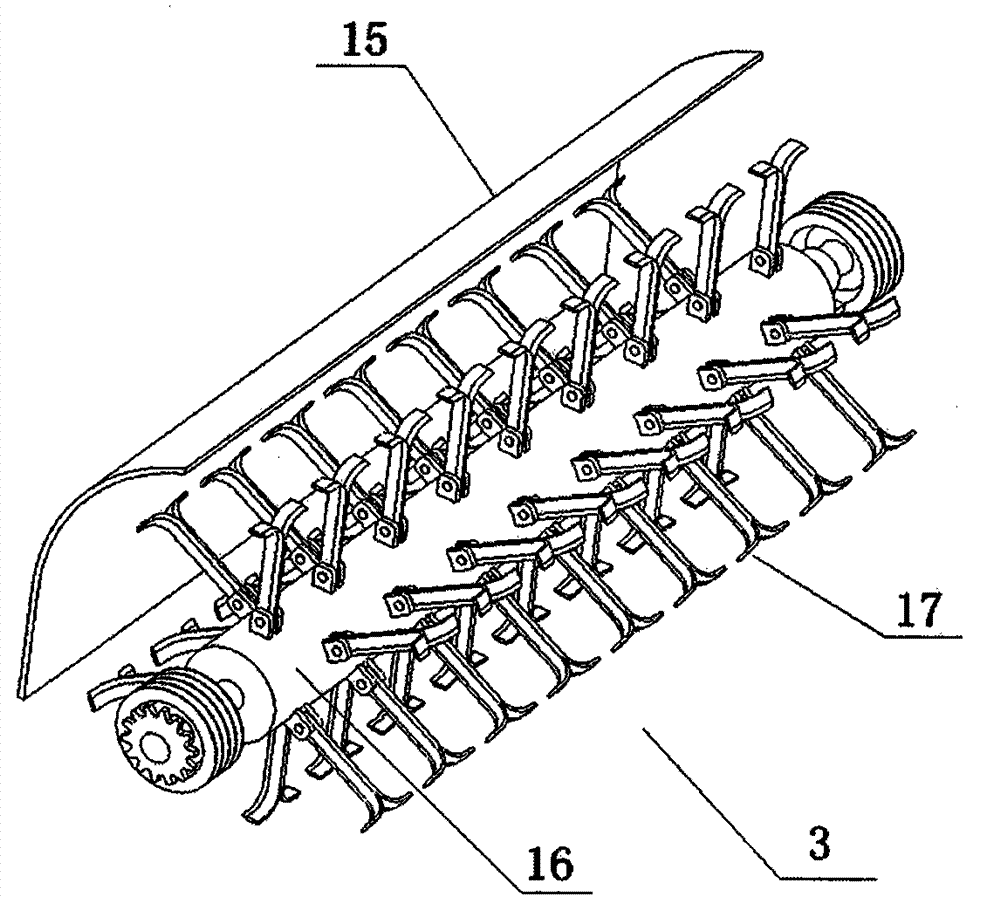

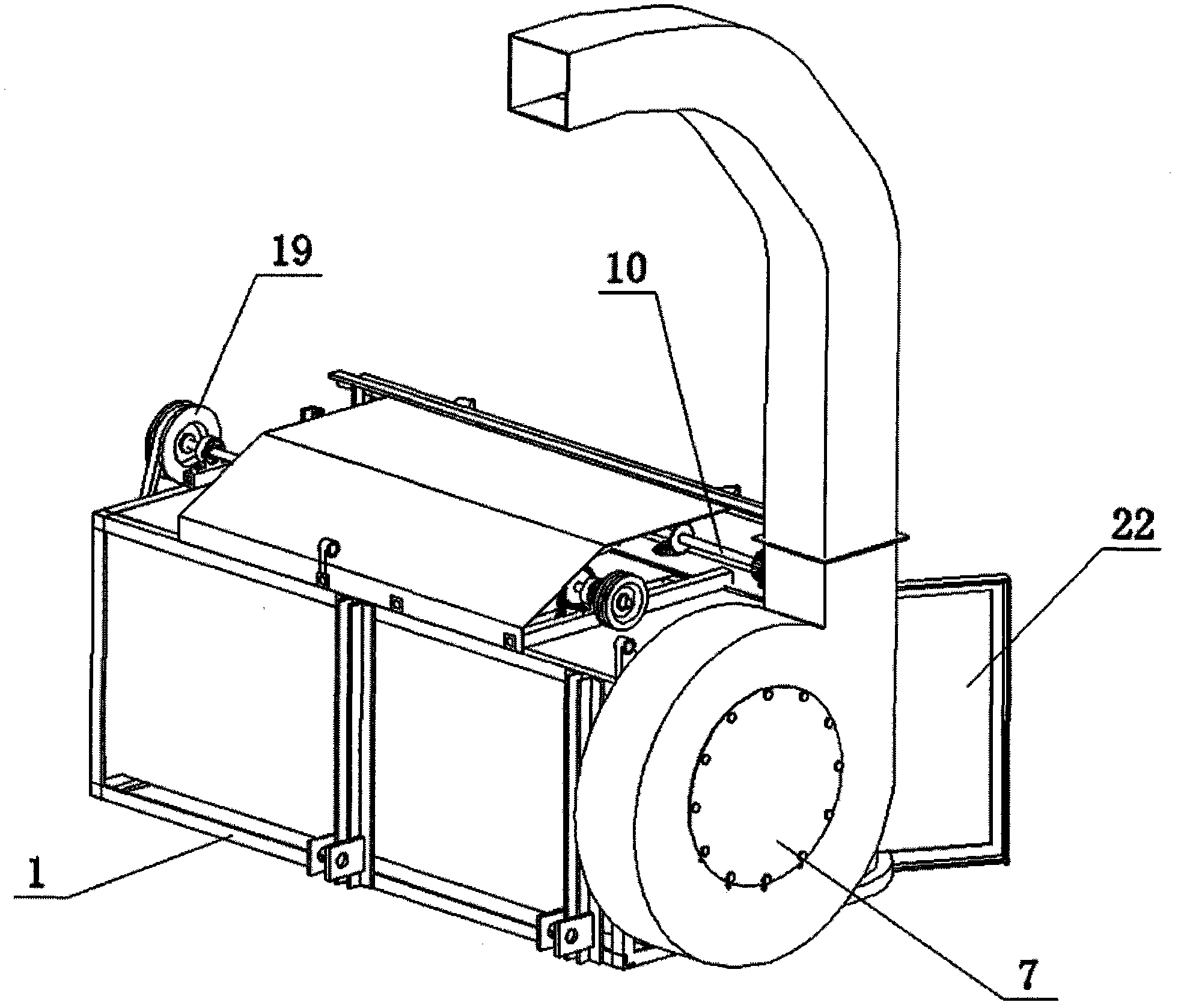

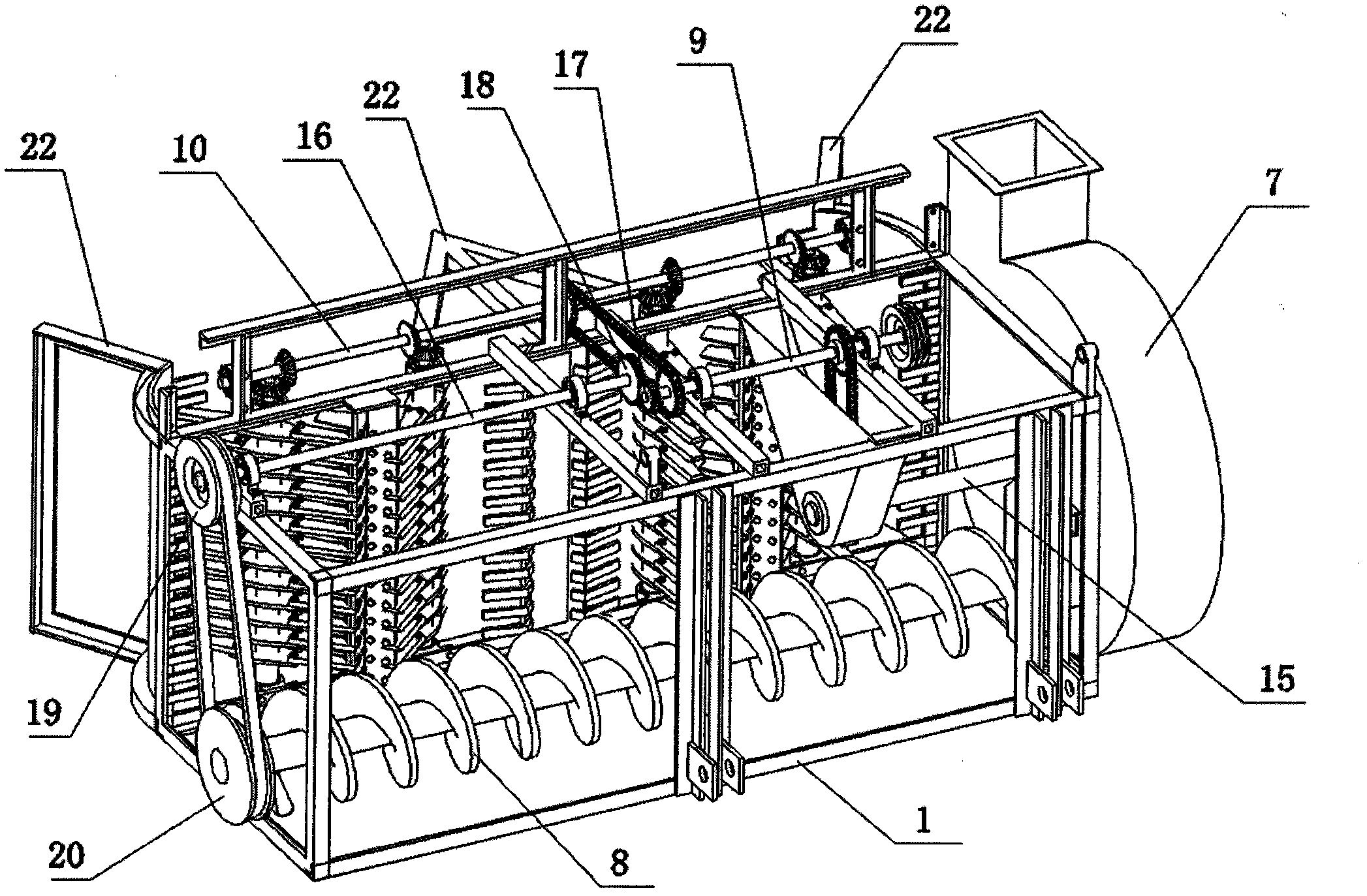

Stalk pickup and chopping machine

InactiveCN104322205AThrown in placeImprove cutting efficiencyLoadersMowersEngineeringMechanical engineering

The invention discloses a stalk pickup and chopping machine. A frame is sequentially provided with a cutting pickup device, a conveying screen, a feeder and a chopping thrower from front to back; the conveying screen comprises a soil screening grate; 2-5 grass poking shafts driven by a transmission mechanism are arranged below the soil screening grate; a grass poking shaft driven by the transmission mechanism is arranged on the back part on the soil screening grate; each grass poking shaft is fixedly provided with a plurality of grass poking wheels; each grass poking wheel is provided with 2 to 4 arc grass poking claws; the feeder comprises a feeding trough; a feeding shaft driven by the transmission mechanism is arranged in the feeding trough; two ends of the feeding shaft are provided with spiral sheets which rotate in opposite directions and gather materials towards the middle; the middle of the feeding shaft is provided with a plurality of feeding claws. The stalk pickup and chopping machine is simple and compact in structure and low in cost, can realize pickup and crushing or harvesting and crushing combined work, the obtained crushed stalks do not have dust, and the working efficiency is high.

Owner:李海龙

Dielectric ceramic composition and electronic device

ActiveUS7358208B2High specific permittivityThin layerEdge grinding machinesFixed capacitor dielectricDielectricElectron

A dielectric ceramic composition comprising a predetermined main component and a fifth subcomponent including an oxide of A (note that A is at least one king selected from a cation element group having an effective ionic radius of 0.065 nm to 0.085 nm at the time of 6 coordination); and the dielectric ceramic composition comprises a plurality of crystal grains including Ca elements and, when assuming that an average value of a concentration of entire Ca exiting in said respective crystal grains is grain Ca concentration, at least unevenness exists in said grain Ca concentration between said crystal grains and it is 5% or higher in a CV value.

Owner:TDK CORPARATION

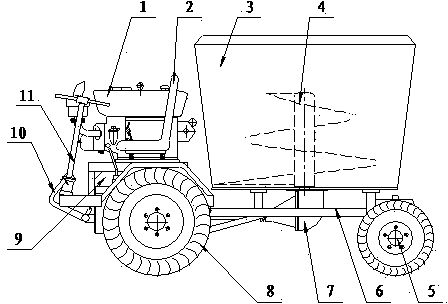

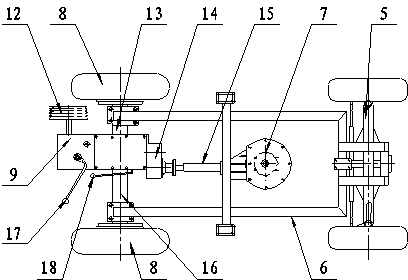

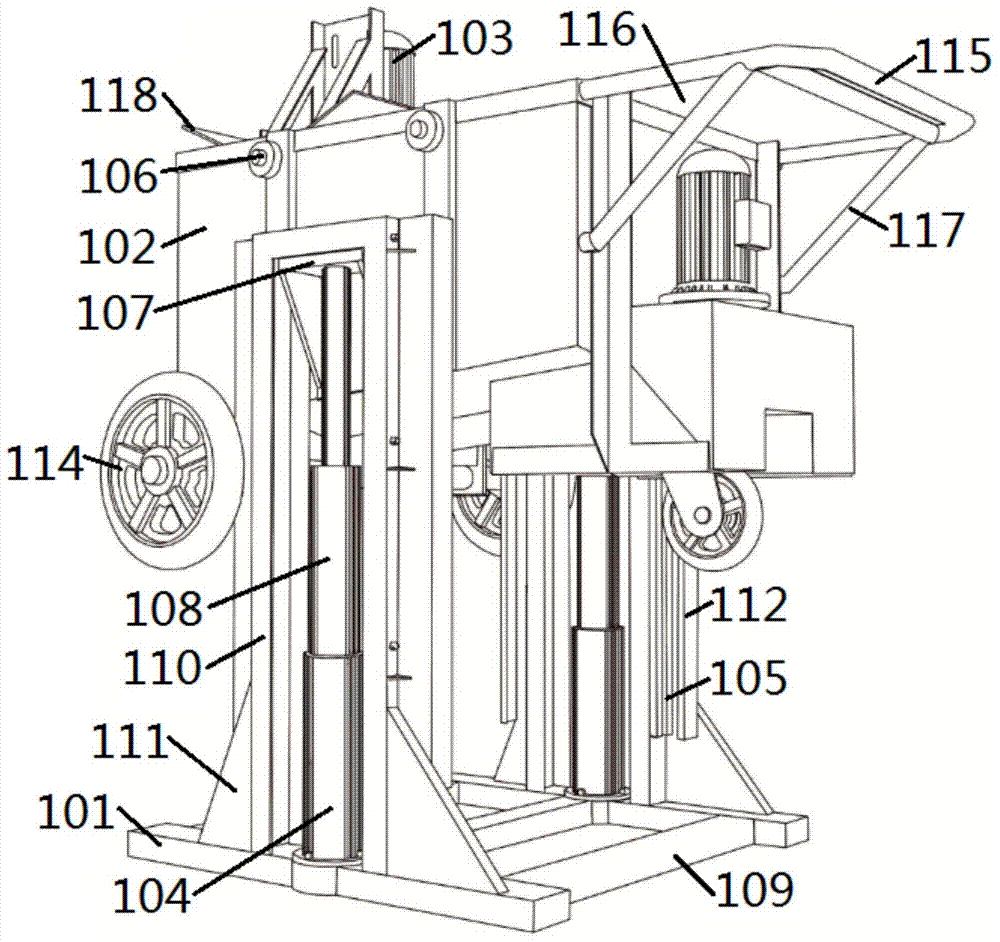

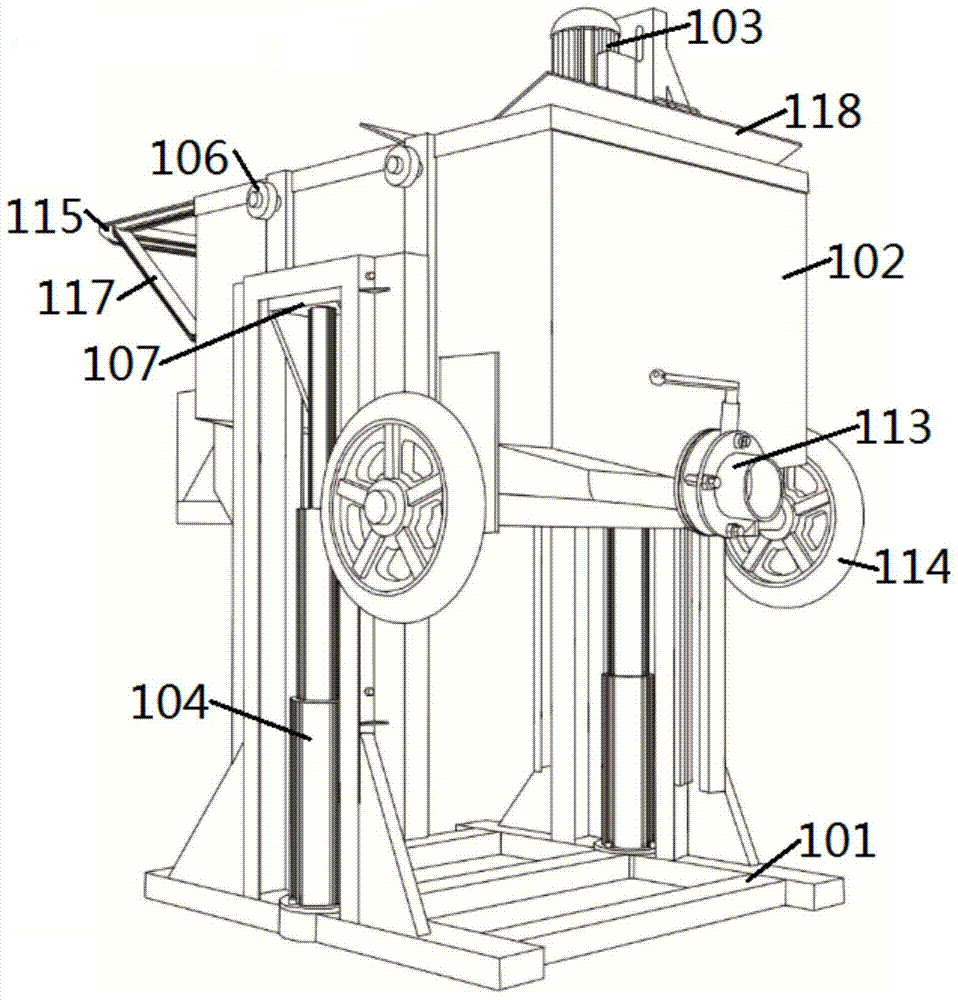

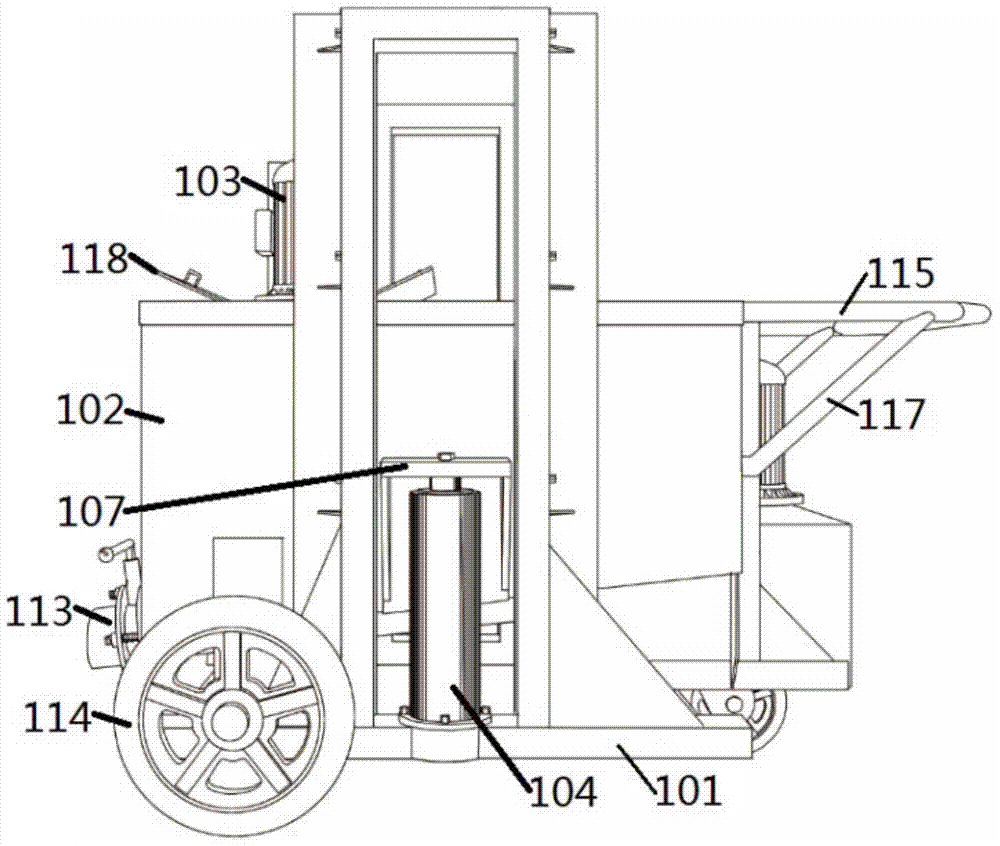

Small self-propelled total-mixed-ration fodder mixing machine

The invention belongs to the field of livestock raising fodder processing equipment, and particularly relates to a small self-propelled total-mixed-ration fodder mixing machine. The small self-propelled total-mixed-ration fodder mixing machine comprises a big frame (6), a power mechanism, a stirring mechanism, a clutch brake mechanism, a traveling mechanism and a seat (2). The small self-propelled total-mixed-ration fodder mixing machine is characterized in that an engine (1) and a gearbox (9) in the power mechanism shift towards a driving wheel on one side of the big frame (6). According to the small self-propelled total-mixed-ration fodder mixing machine, space is fully utilized, a vehicle body is compact, short and small, cost is saved, and the small self-propelled total-mixed-ration fodder mixing machine can move in narrow space of a livestock farm conveniently.

Owner:SHAANXI RUNMU SCI & TECH CO LTD

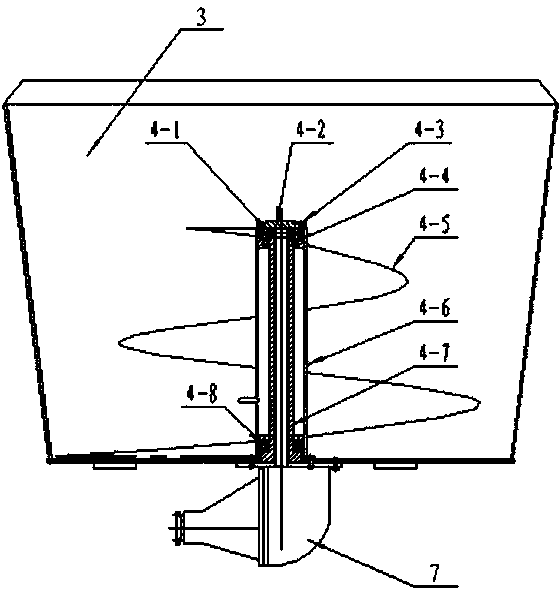

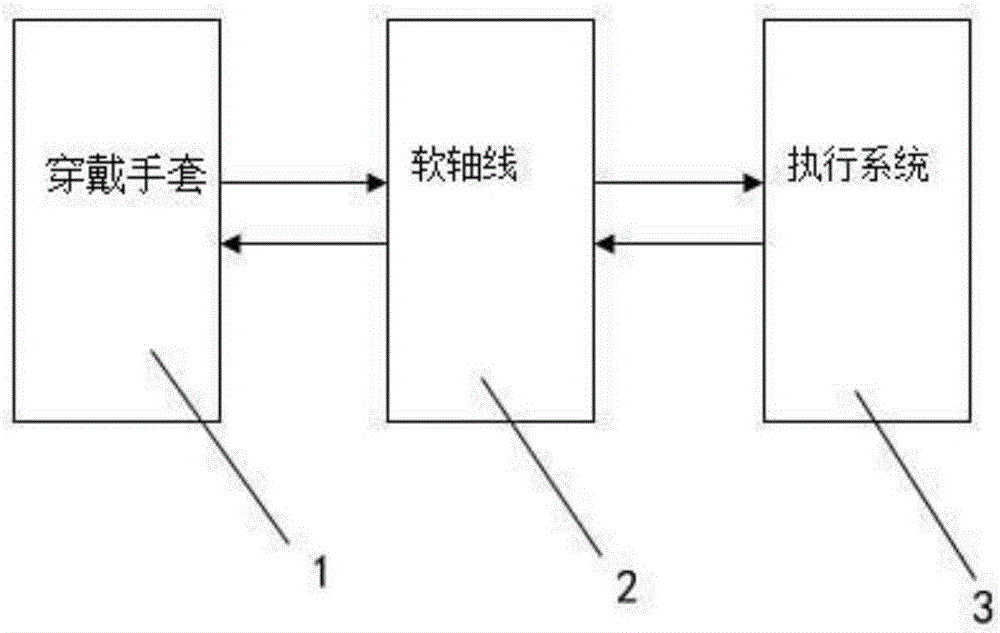

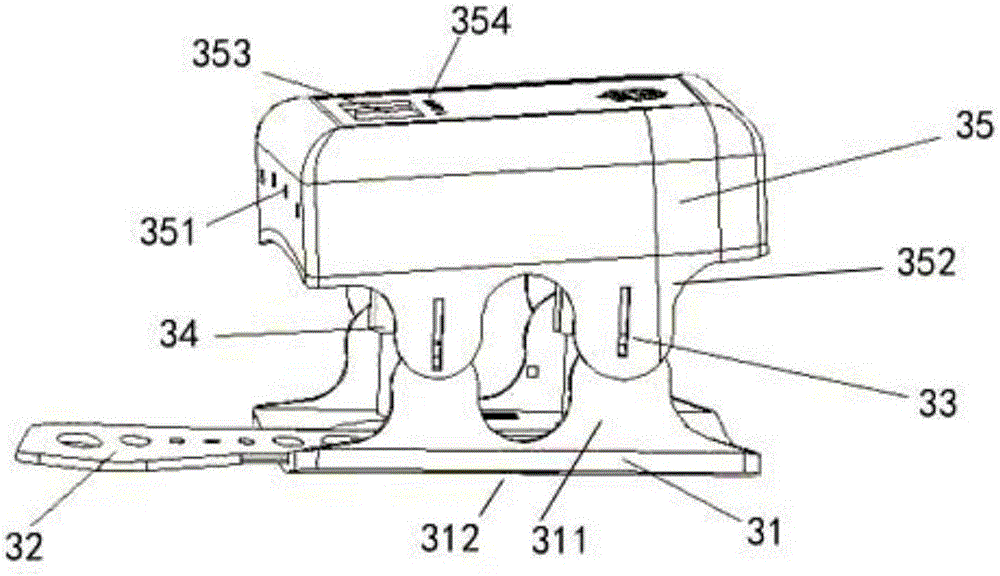

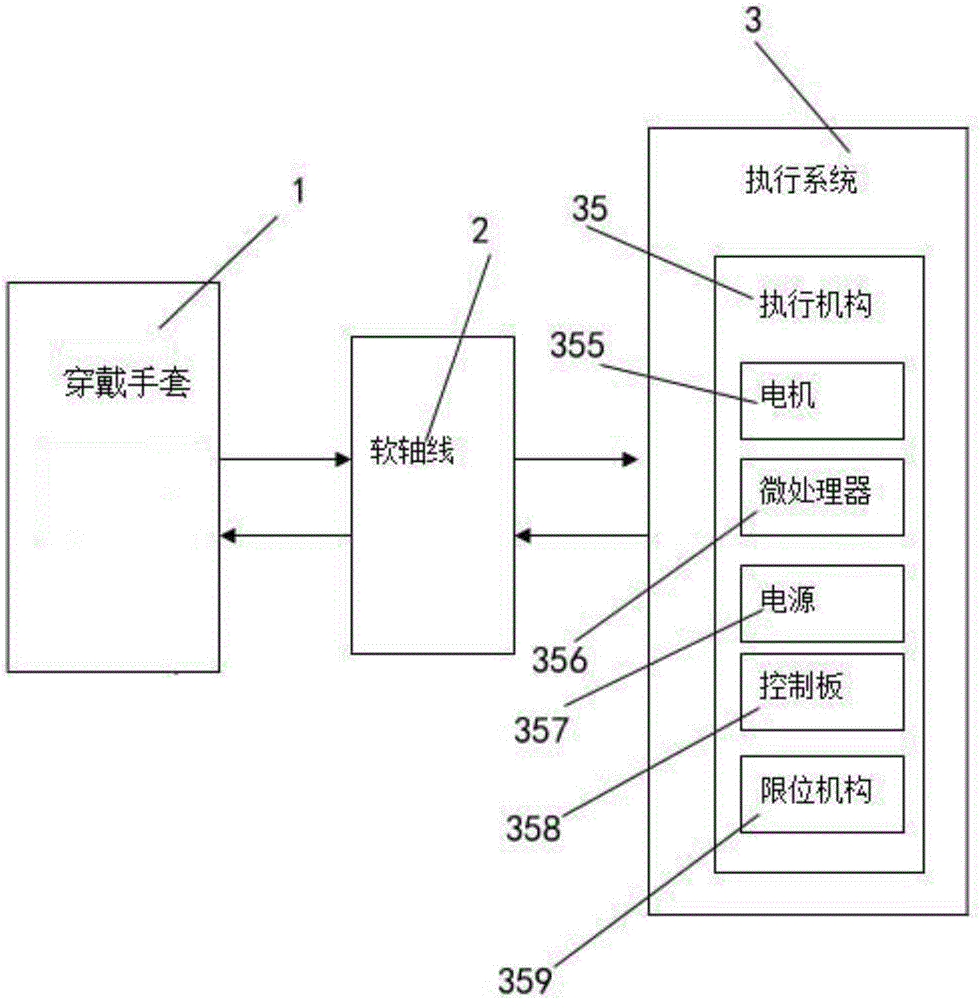

Multi-mode hand function training apparatus

The invention relates to a multi-mode hand function training apparatus. The training apparatus comprises a wearable glove, a soft axis line, and an execution system; the execution system comprises a base support, a palm rest, an elevating mechanism, a locking device, and an execution mechanism; the base support comprises a base plate and a first connection plate; the palm rest is connected with the axial direction of the inner wall of the base plate; a second connection plate is arranged on the execution mechanism, an elevating mechanism is arranged on the outer side of the second connection plate, and the locking device is arranged on the execution mechanism; a WiFi module is arranged on the inner side of the training apparatus, and a motor, a microprocessor, a power supply jack socket, a control plate and a position-limiting mechanism are arranged on the inner side of the execution mechanism. The training apparatus has the advantages that the hand part of a patient is moved by adopting the passive movement method to do the rehabilitation training, the movements of the motor are controlled and executed through the microprocessor, so that the hand part of the patient is moved to do passive movements. The patient can adjust single or multiple finger movement status according to the needs, and the data can be uploaded, so that the nursing staff can give instructional rehabilitation training advices.

Owner:康映科技(上海)有限公司

Stirring machine

InactiveCN104707508AAvoid damageExtended service lifeRotary stirring mixersMixer accessoriesPulp and paper industry

The invention provides a stirring machine and belongs to the field of building appliances. The stirring machine comprises a bracket, a stirring bucket, a stirrer and a hydraulic oil cylinder, wherein the stirring bucket is provided with a cavity with an opening end at the top, a discharging valve communicated with the cavity is arranged at the bottom of one end of the stirring bucket, the stirring bucket is vertically and glidingly arranged on the bracket, and wheels or rollers are arranged at the bottom of the stirring bucket; the stirrer comprises a stirring motor and a stirring head fixed with a rotating end of the stirring motor, a supporting plate is arranged at the opening end of the cavity, the stirring motor is fixedly arranged on the supporting plate, and the stirring head extends into the stirring bucket; one end of the hydraulic oil cylinder is fixed on the bracket, and the other end of the hydraulic oil cylinder is fixedly connected with the stirring bucket. The wheels or the rollers are mounted at the bottom of the stirring bucket, so that the stirring bucket can move on the ground and working personnel can conveniently push the stirring machine to an appointed position and enable the wheels and the like to leave from the ground for performing material stirring and slurry discharging through sliding of the stirring bucket on the bracket; one person is enough to operate the stirring machine, the stirring machine is simple and convenient to move, and the working efficiency is improved.

Owner:赵路航

Plant straw harvesting and smashing machine

The invention discloses a plant straw harvesting and smashing machine. A machine body framework and an iron plate form a material receiving box, and an opening is formed in the front side face of the material receiving box; 2 to 4 sets of cutting and smashing assemblies are arranged on a front side frame of the machine body framework; each set of cutting and smashing assembly comprises a left vertical shaft, a right vertical shaft and a fixed cutter rack which are longitudinally arranged; a plurality of movable cutters are symmetrically arranged on the left vertical shaft and the right vertical shaft respectively at equal intervals; two columns of fixed cutters corresponding to the movable cutters on the left vertical shaft and the right vertical shaft are arranged on the fixed cutter rack; a lifting material conveying fan is arranged on the left side or the right side of the machine body framework; a transverse helical material conveyer is arranged in a material storage box; power is input into a power transmission system through a tractor; and due to transmission connection of a transmission shaft, a gear and a belt wheel, the cutting and smashing assemblies, the transverse helical material conveyer and the lifting material conveying fan are respectively driven. The plant straw harvesting and smashing machine is simple and compact in structure, low in cost and suitable for working together with small-size tractors and can be used for implementing harvesting, smashing and transportation combine work.

Owner:贾志军

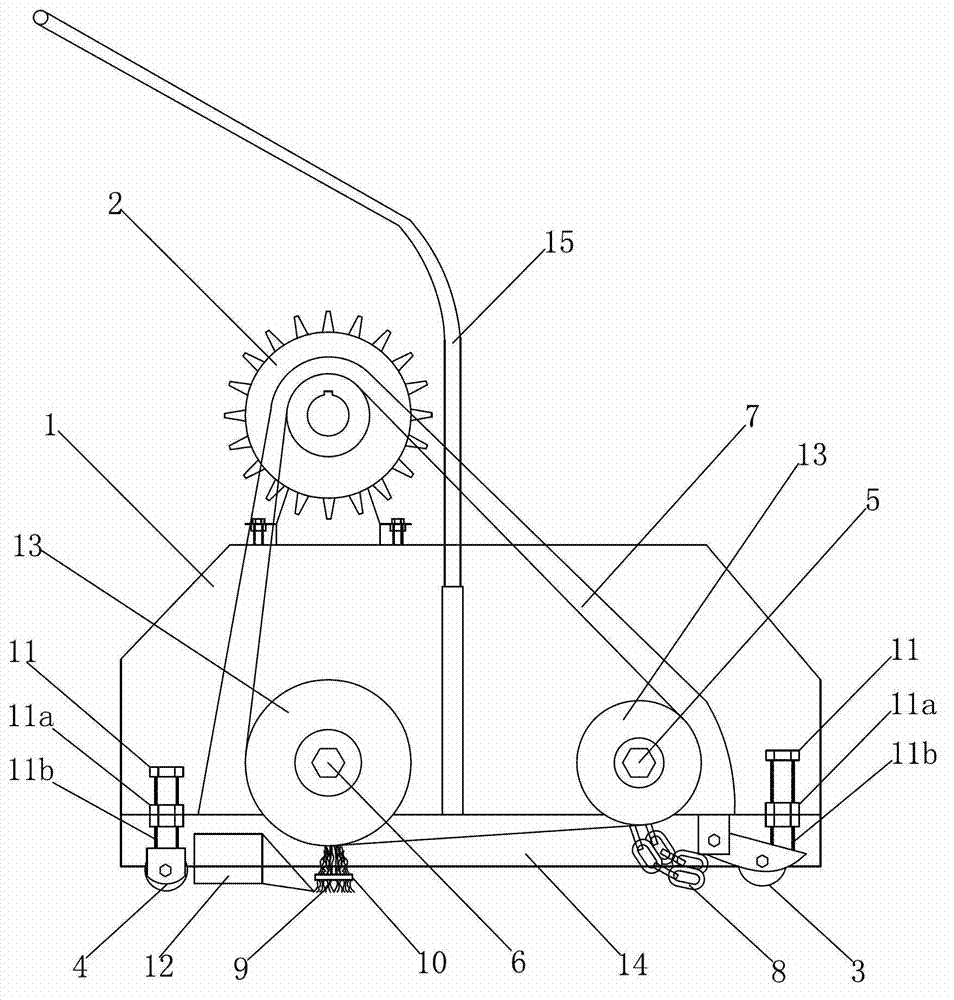

Hand-push type electric rust knocking and removing machine

The invention discloses a hand-push type electric rust knocking and removing machine. The machine comprises a rack, wherein a motor is arranged on the rack, front wheels and rear wheels are arranged on the bottom of the rack, a front shaft and a rear shaft are arranged on the bottom of the rack and are in transmission connection with an output end of a motor through a transmission device, and a rust knocking device and a rust removing device are respectively arranged on the front shaft and the rear shaft. The machine utilizes the front shaft and the rear shaft which are respectively provided with the rust knocking device and the rust removing device to realize the mechanical rust knocking and rust removing work, is convenient to use and has high efficiency; and the system is suitable for the rust removing of iron plates and decks.

Owner:CHANGJIANG WUHAN WATERWAY ENG CO

Rescue robot system for fire-fighting and method thereof

InactiveCN1994495APrevent direct bodily harmAvoid external harmFire rescueMobile vehicleRobotic systems

The invention relates to a fire hazard rescue robot, which comprises movable vehicle, sensor and protective frame, image sound positioning device, driver, intercom, display and wireless controller. Remote operator can use wireless controller to move vehicle into fire site to find and rescue people; and the positioning device will transmit collected data to the remote controller, to find the people position; remote operator controls the vehicle to approach people; and the people can start the protective frame or drive the vehicle by itself, while the vehicle can be controlled by remote operator.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Image forming apparatus including a collecting portion inside guide members to collect and store liquid droplets

ActiveUS8165490B2Inhibit productionLess expensiveElectrographic process apparatusImage formationEngineering

An image forming apparatus includes a transfer unit, a fixing unit, a discharging unit, and multiple guide members. The transfer unit transfers an image onto a transfer sheet. The fixing unit fixes the image to the transfer sheet by application of heat and conveys the fixed transfer sheet to a further downstream portion of the image forming apparatus. The discharging unit discharges the transfer sheet to an external portion of the image forming apparatus. The multiple guide members form a sheet conveyance path that has first and second paths including a hollow portion defined by the multiple guide members to enable an air current generated during image forming to pass therethrough.

Owner:RICOH KK

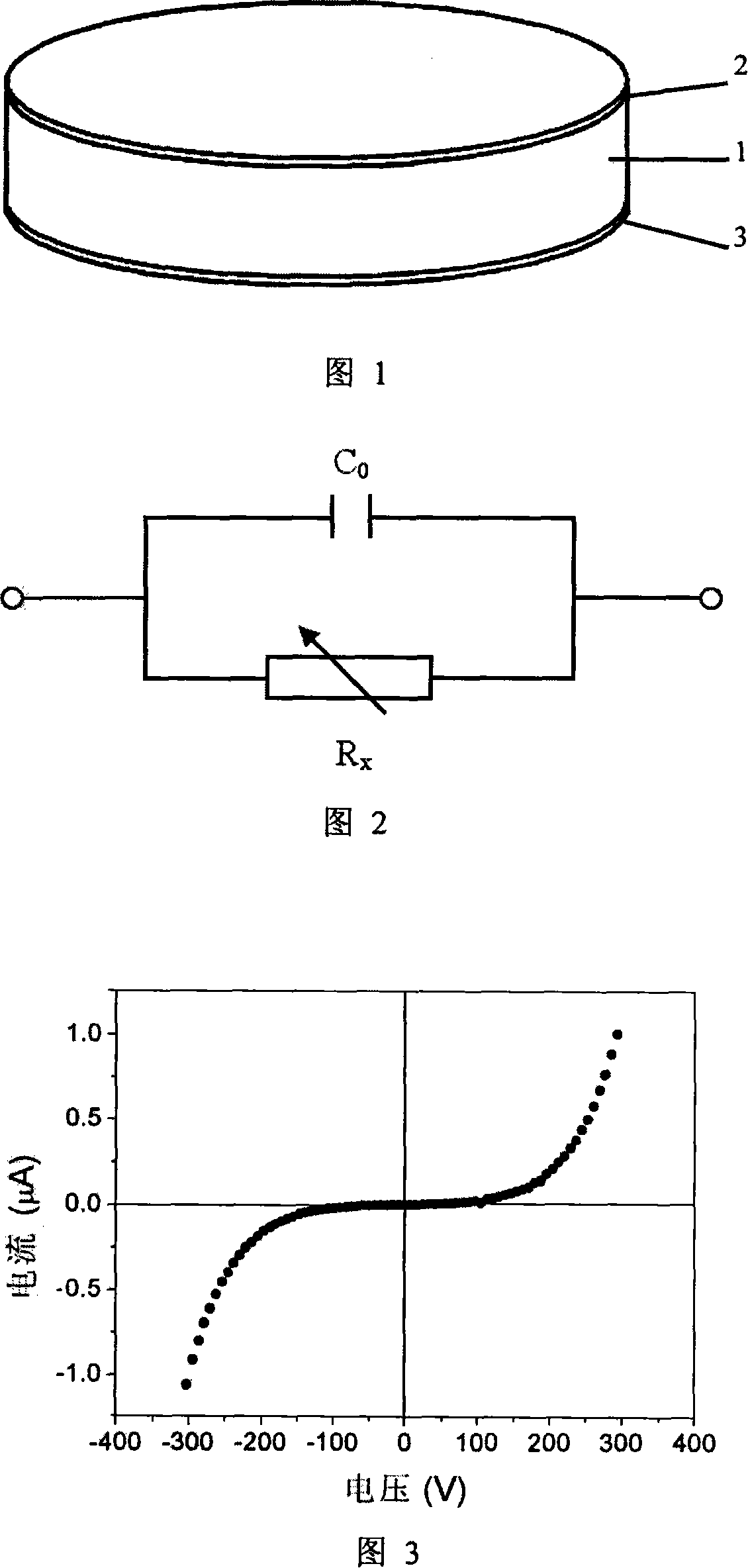

Multifunctional element possessing large electric capacitance and pressure-sensitive character and its preparation method

InactiveCN101150010ACompact bodyReduce the number of poresFixed capacitor electrodesFixed capacitor dielectricPressure sensitiveSolid state reaction method

This invention provides a multifunction element with a large electric volume and voltage-sensitive character and its preparation method, which sets an Ag top electrode and an Ag bottom electrode on the up and down surfaces of a medium wafer of CCTO ceramic material, both of which are wafer electrodes, applies a solid reaction method to synthesize CCTO powder and applies a dry-pressing and cooling static-pressing technology and ceramic sintered technology to prepare CCTO ceramic medium wafer with the synthesized powder to modify its shape and surface of the wafer to be polished and then applies silk-screen printing to prepare Ag top electrode and an Ag bottom electrode on the top and bottom surfaces of the wafer.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com