Patents

Literature

277 results about "Mobile manipulator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mobile manipulator is nowadays a widespread term to refer to robot systems built from a robotic manipulator arm mounted on a mobile platform. Such systems combine the advantages of mobile platforms and robotic manipulator arms and reduce their drawbacks. For instance, the mobile platform extends the workspace of the arm, whereas an arm offers several operational functionalities.

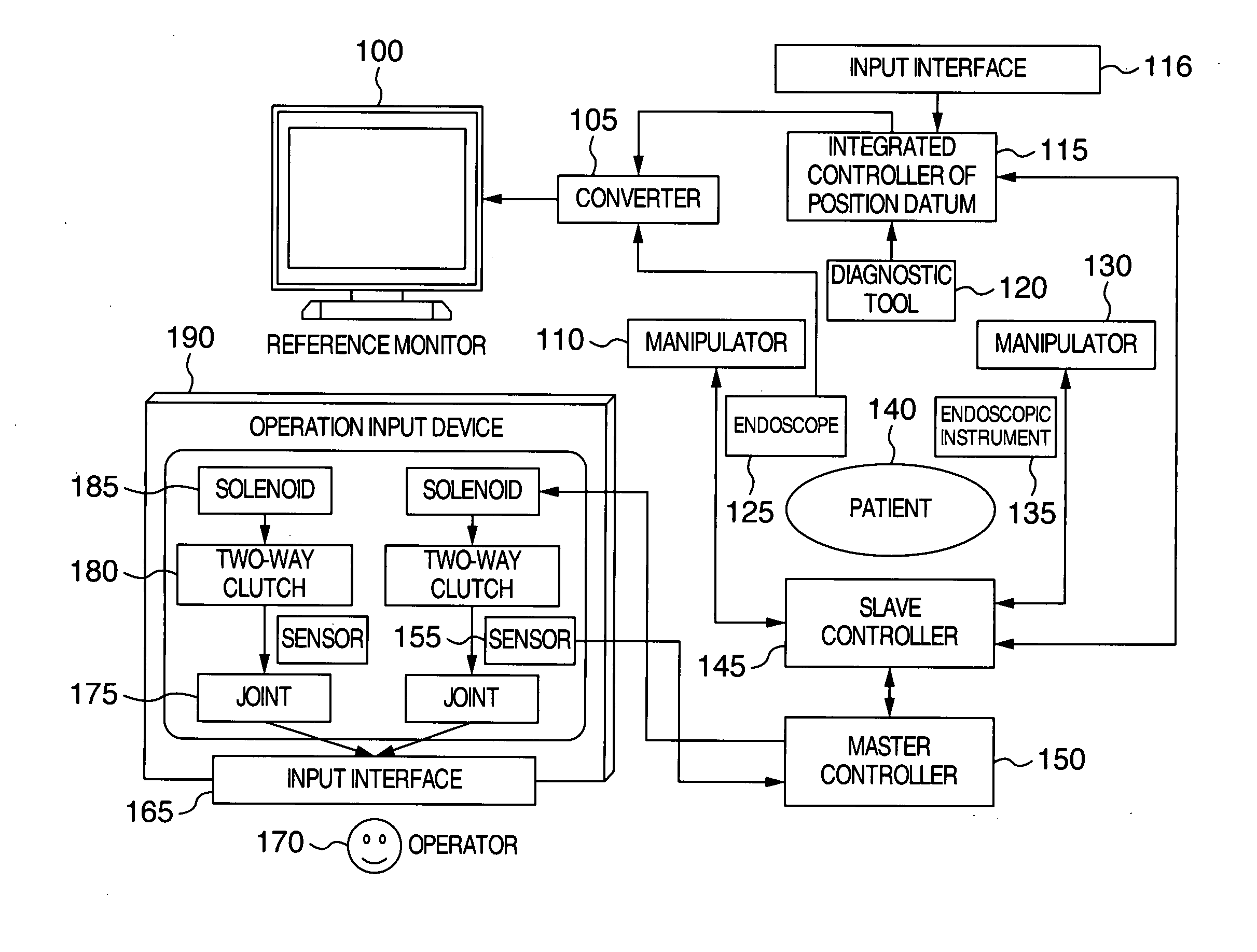

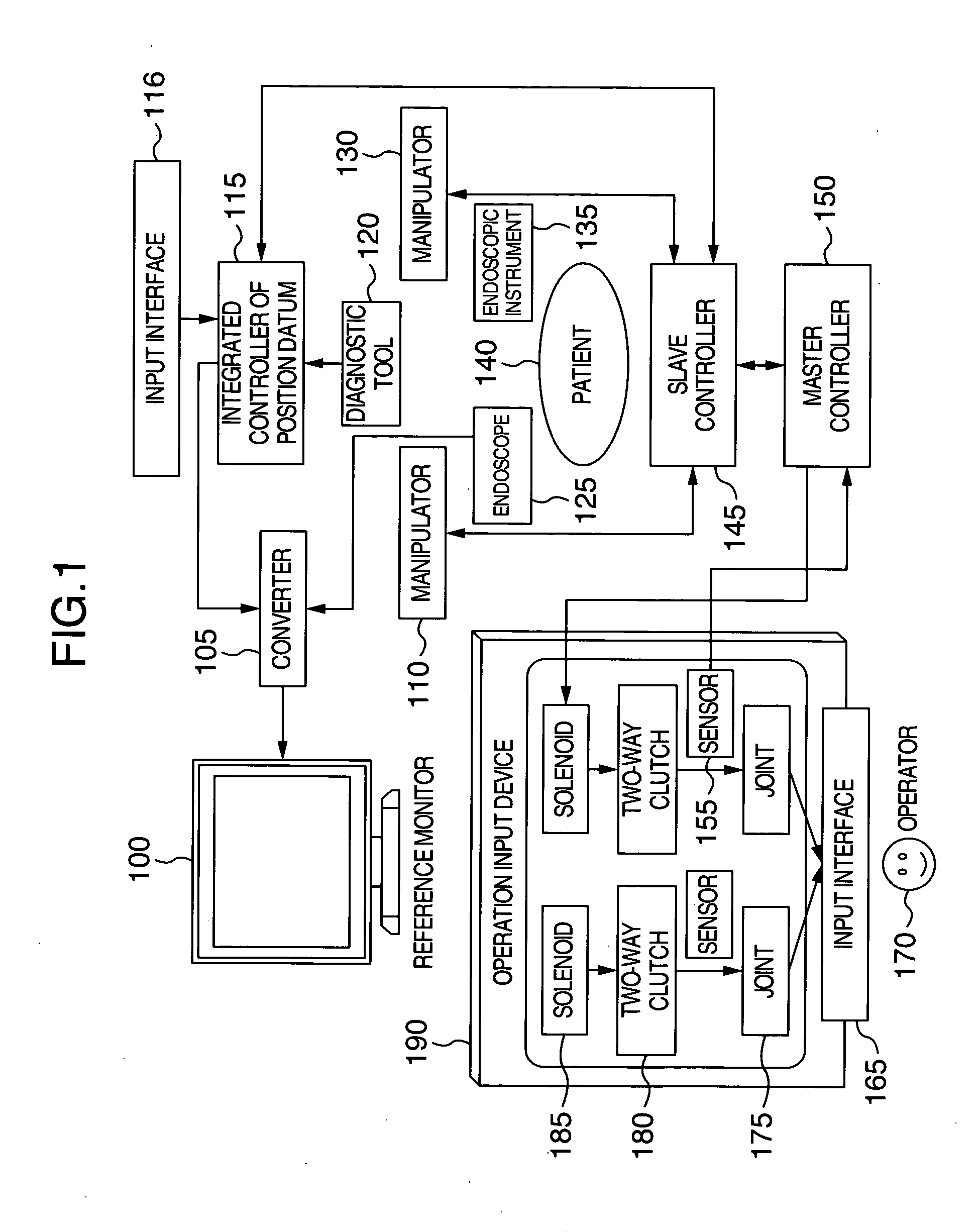

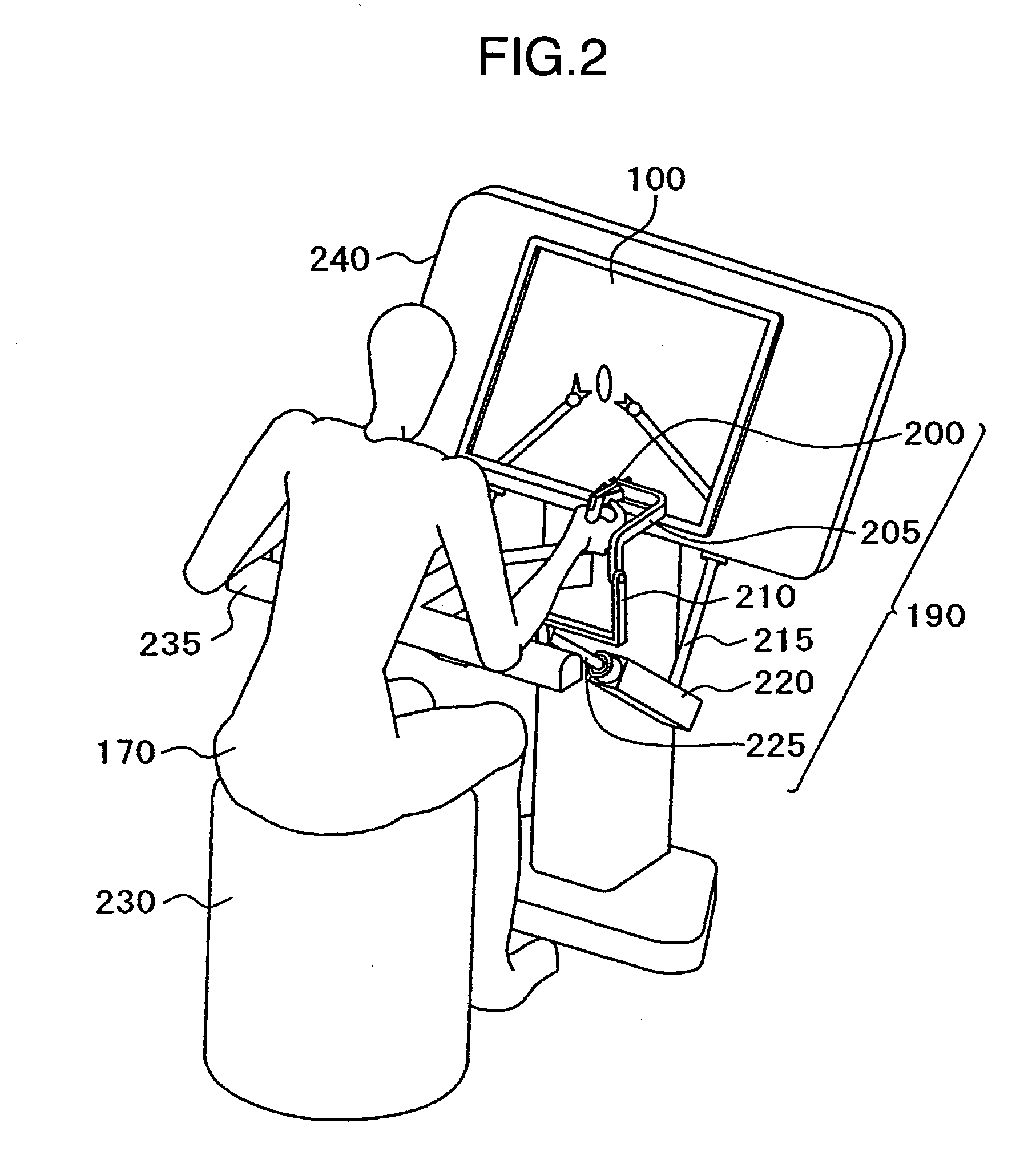

Master-slave manipulator system and this operation input devcies

ActiveUS20060261770A1Improve reliabilityEasy to operateProgramme-controlled manipulatorComputer controlMiniaturizationOperability

In a master-slave manipulator system capable of presenting an obstacle and a limit to an operating range as a force feed-back with no use of a motor in an operation input device and having high reliability, a small size and good operability, the system comprises a manipulator having an arm, an operation input device for moving the arm of the manipulator, and a controller for controlling the manipulator and the operation input device, and the operation input device is provided on joints with a mode change-over mechanism having three modes: of which, in a first mode, power is not transmitted; in a second mode, power is transmitted in one direction and is not transmitted in a reverse direction thereof; and in a third mode, power is transmitted in the reverse direction and is not transmitted in the one direction, selecting one of the above modes and changing over from one mode to the selected mode.

Owner:HITACHI LTD

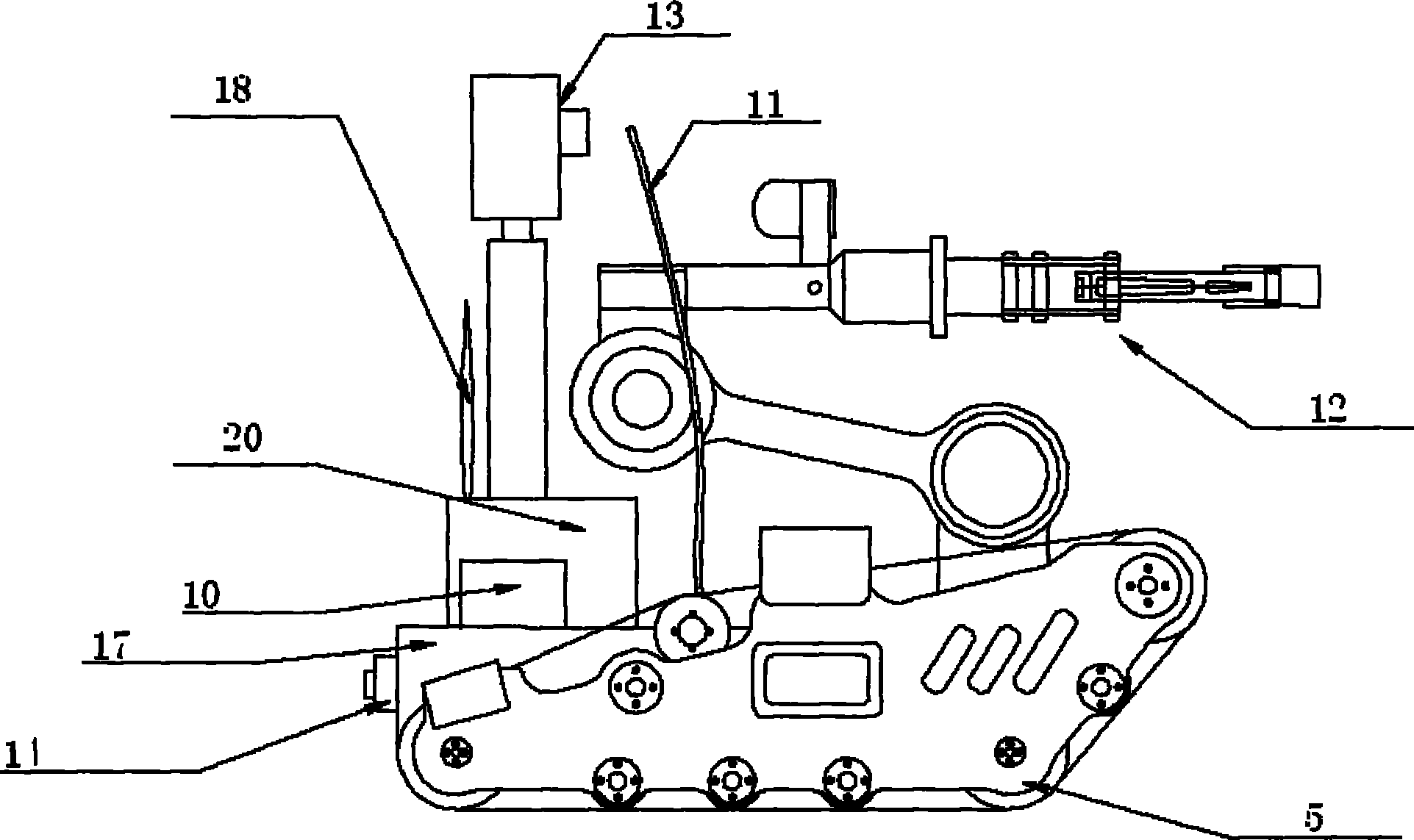

Nuclear power plant working robot and control system thereof

InactiveCN101774170ACapable of autonomous navigationRealize online monitoringEndless track vehiclesManipulatorTerrainOperational costs

The invention relates to a nuclear power plant working robot and a control system thereof, which belong to the fields of robots and automation equipment. The nuclear power plant working robot is a crawler-type mobile manipulator and is composed of a mobile platform driven by double crawlers and a four freedom degree manipulator carried on the mobile platform. The nuclear power plant working robot can move inside a nuclear power plant, has two control modes of manual remote control and autonomous control, and is remotely controlled by a wireless or wired mode. The control system of the nuclear power plant working robot includes a host monitoring and planning control system and a robot control system which are matched to control the operation of the robot. The robot operates autonomously, is safe and reliable, can complete certain dangerous tasks in high radioactivity environment; the robot has small size, stable performance, great maneuverability and low operation cost; a crawler-type chassis has strong gripping force as well as certain climbing and obstacle clearing ability, and is suitable to walking over complex terrains; and the robot has high intelligence degree and can realize autonomous control and manual remote control.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

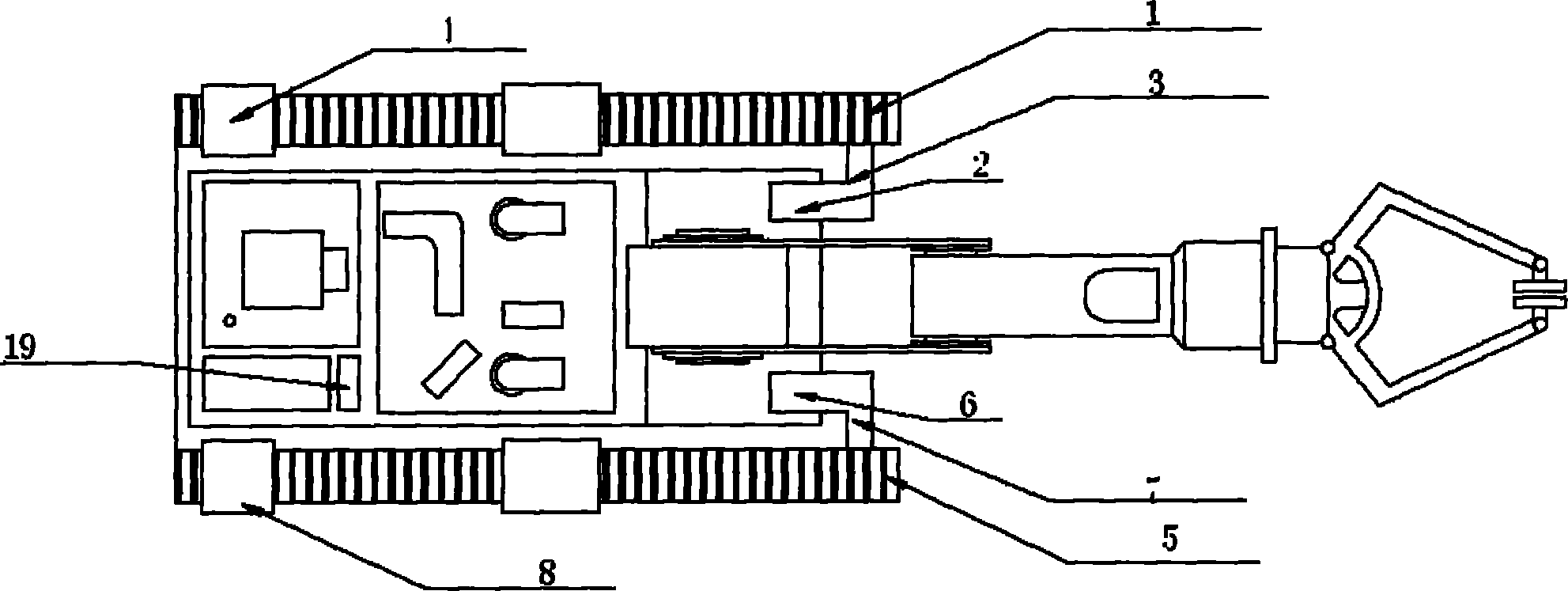

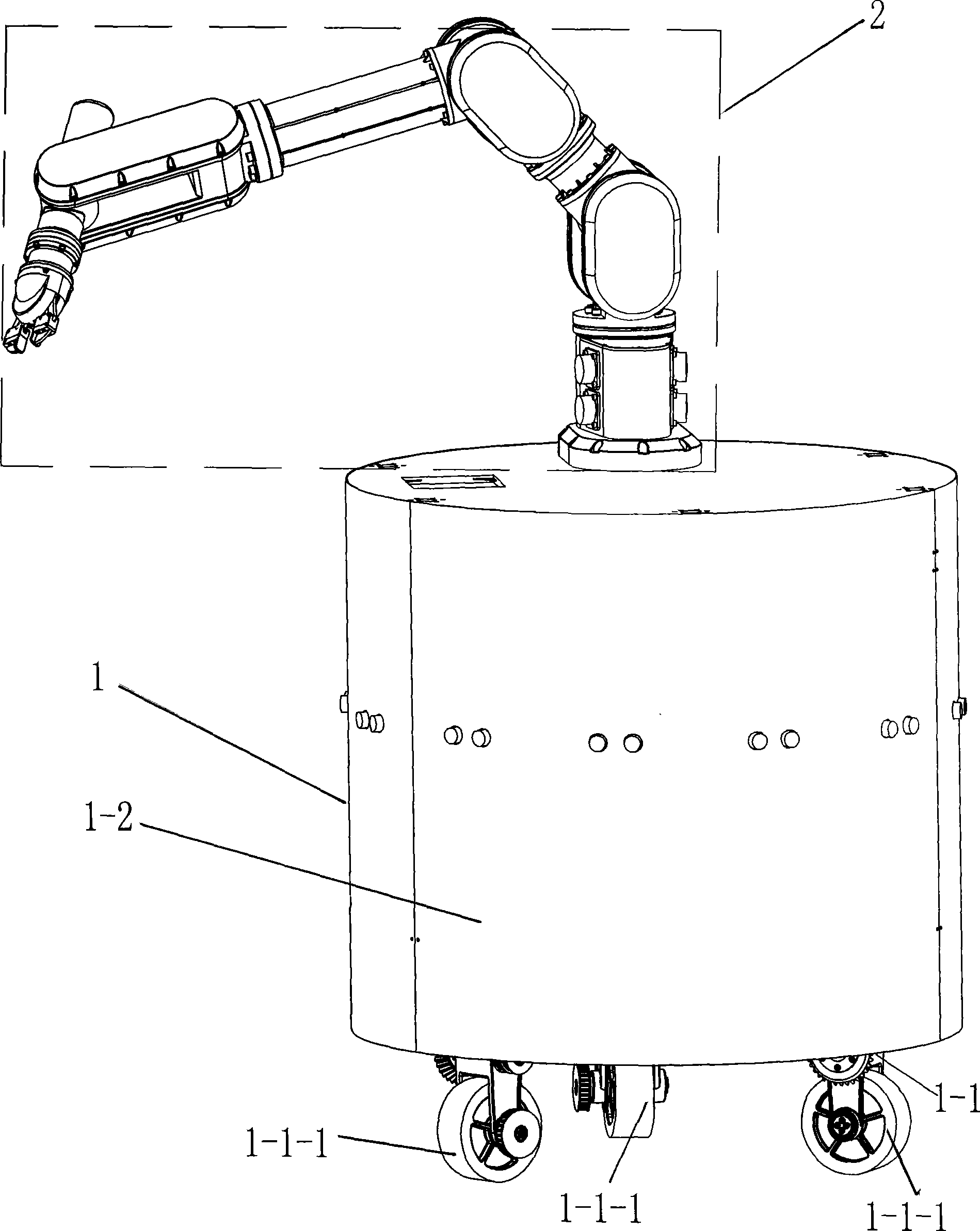

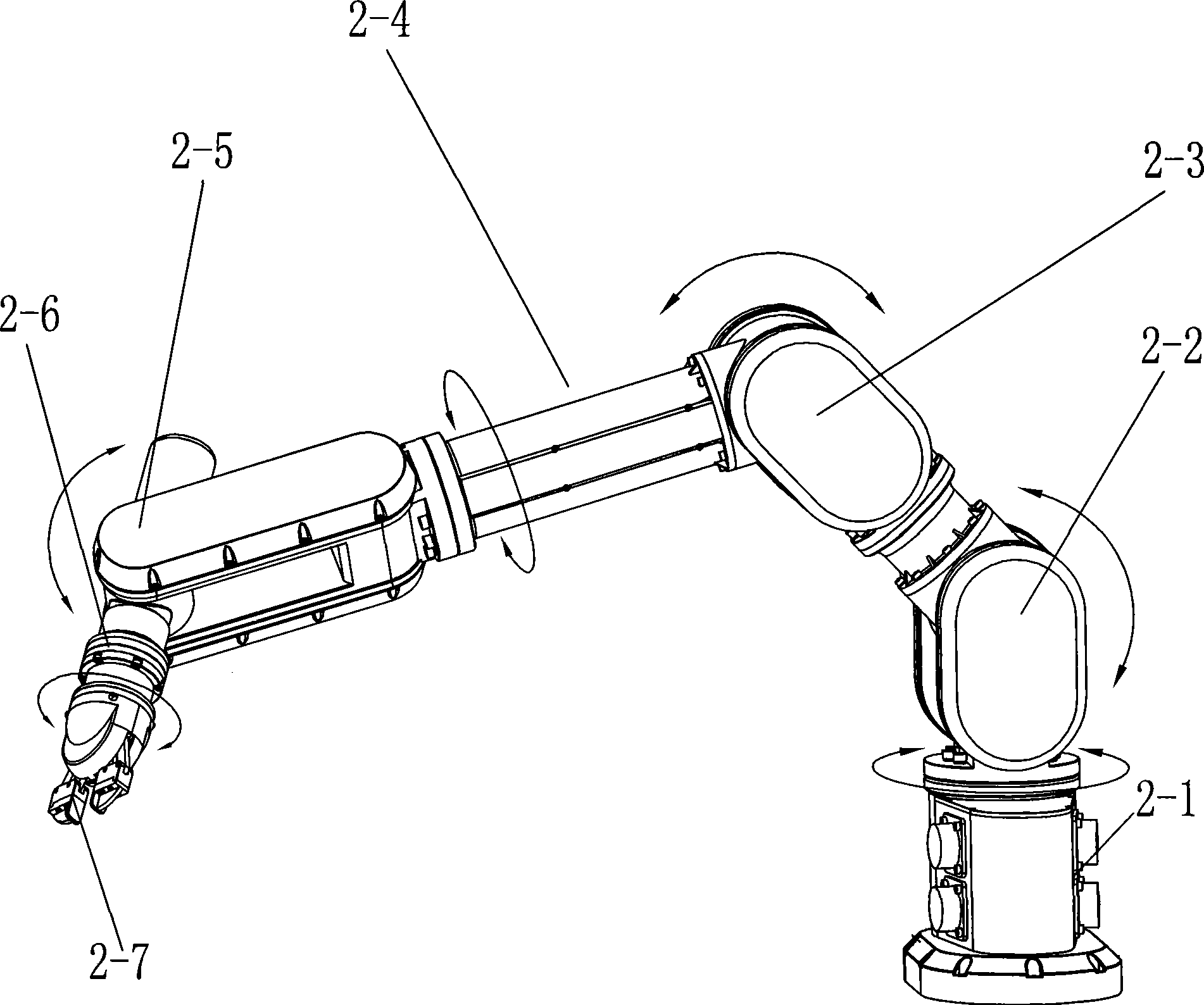

Movable manipulator system

The present invention relates to a mobile robot system, include a 3-freedom mobile platform, a 5-freedom robot, vision system and comptuer control system. Its camera with rotation and pitching function is mounted in the top end of straight-line guideway of robot, the mobile platform can implement forward, backward, leftward, rightward and automatic revolving 3-freedom omnibearing movement, and its 5-freedom robot is consisted of 1 moving joint and 4 turning joints, and its operation is flexible. The movement of said robot can implement large range movement operation function. Besides, said invention also provides the application range and method of said mobile robot system.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

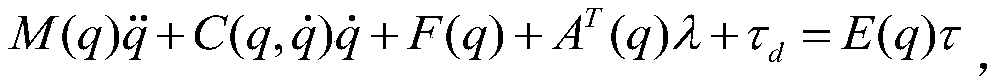

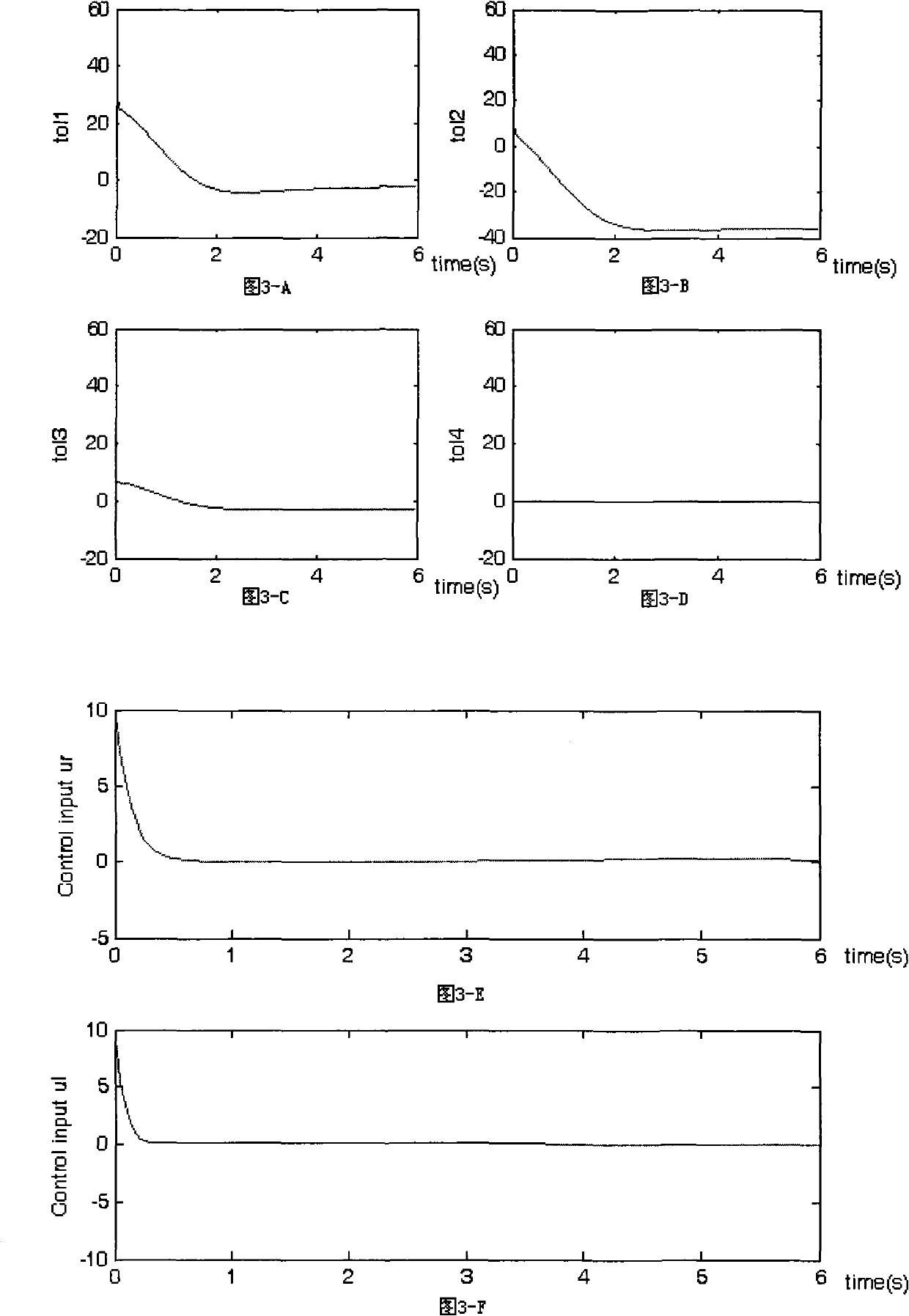

RBF-based mobile manipulator self-adaptive control method

InactiveCN109176525AControl movementImprove robustnessProgramme-controlled manipulatorDynamic modelsClosed loop

The invention discloses an RBF neural network based mobile manipulator self-adaptive control method. The method comprises the following steps of S1, establishing a standard mobile manipulator dynamical model; S2, constructing an RBF neural network of the robot dynamic model; S3, designing a mobile manipulator trajectory tracking method with the adaptive capability through the constructed neural network; S4, automatically identifying unknown mobile platform and manipulator dynamic parameters through online learning, and conducting closed-loop identification and compensation on the unknown dynamic parameters, wherein the parameters of the RBF neural network can be updated on line, and finally, the feasibility and effectiveness of the simulation verification control method are verified. Through the method, output errors caused by the unknown dynamic parameters and external disturbance can be eliminated completely without an accurate robot dynamic model; the deficiency that a model-based robot control scheme cannot be implemented without the accurate dynamic model is made up; and the dynamic performance of a mobile manipulator and the trajectory tracking precision of a joint space areimproved.

Owner:上海神添实业有限公司

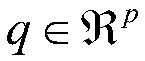

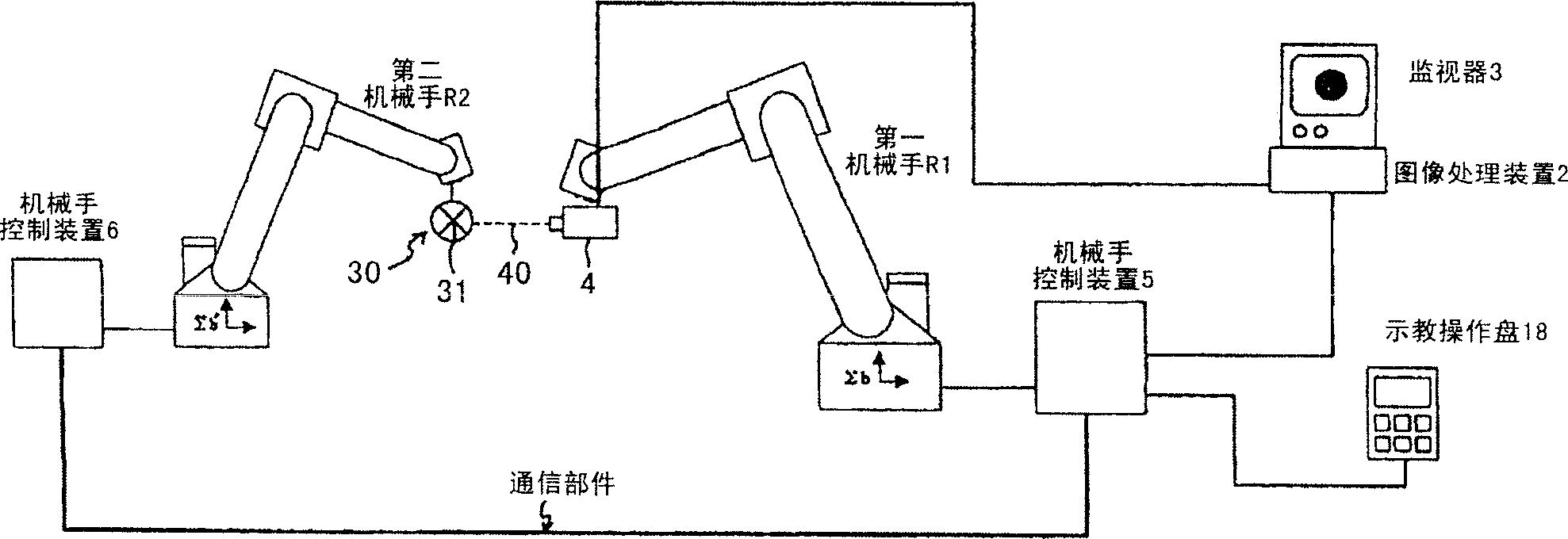

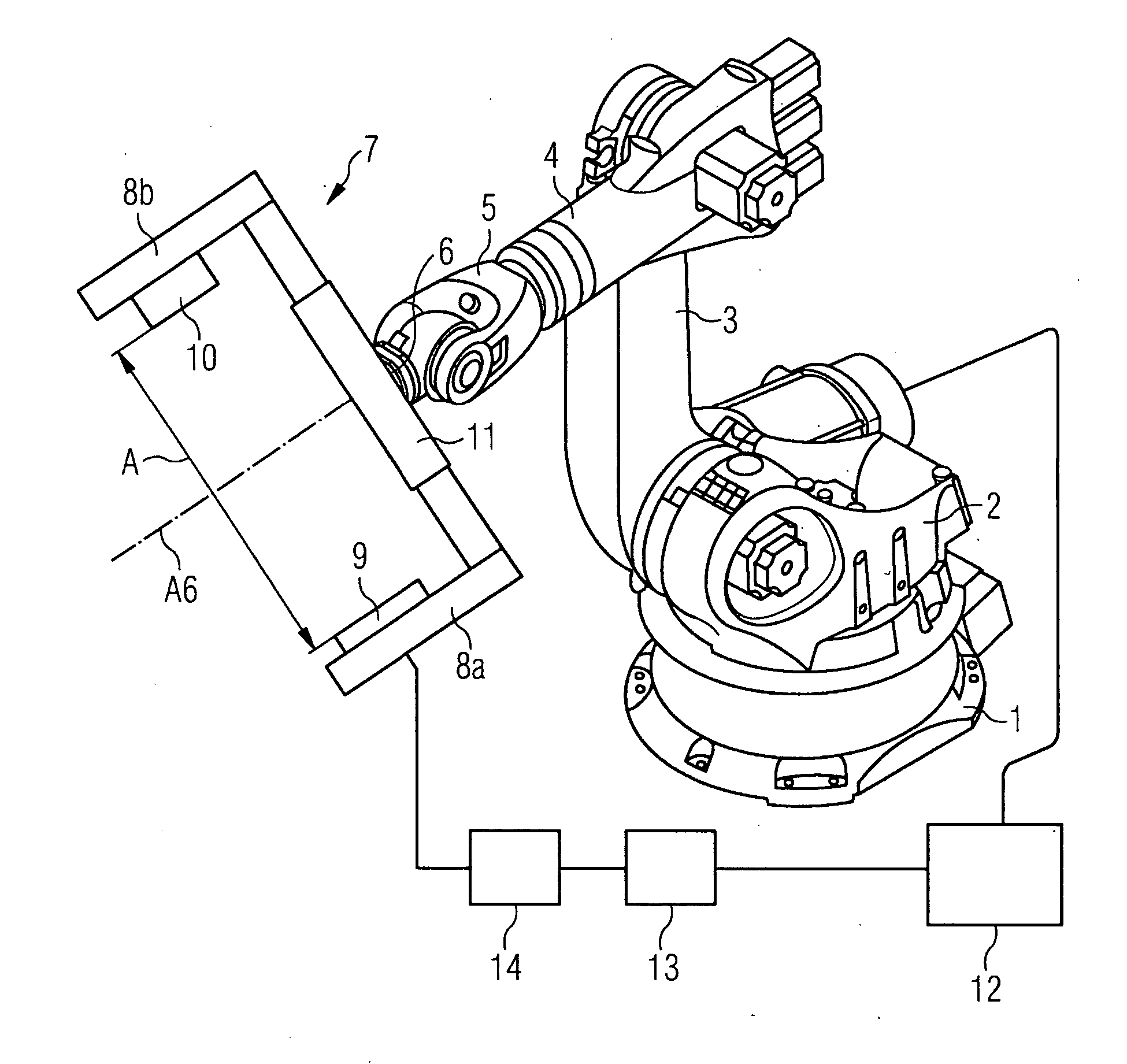

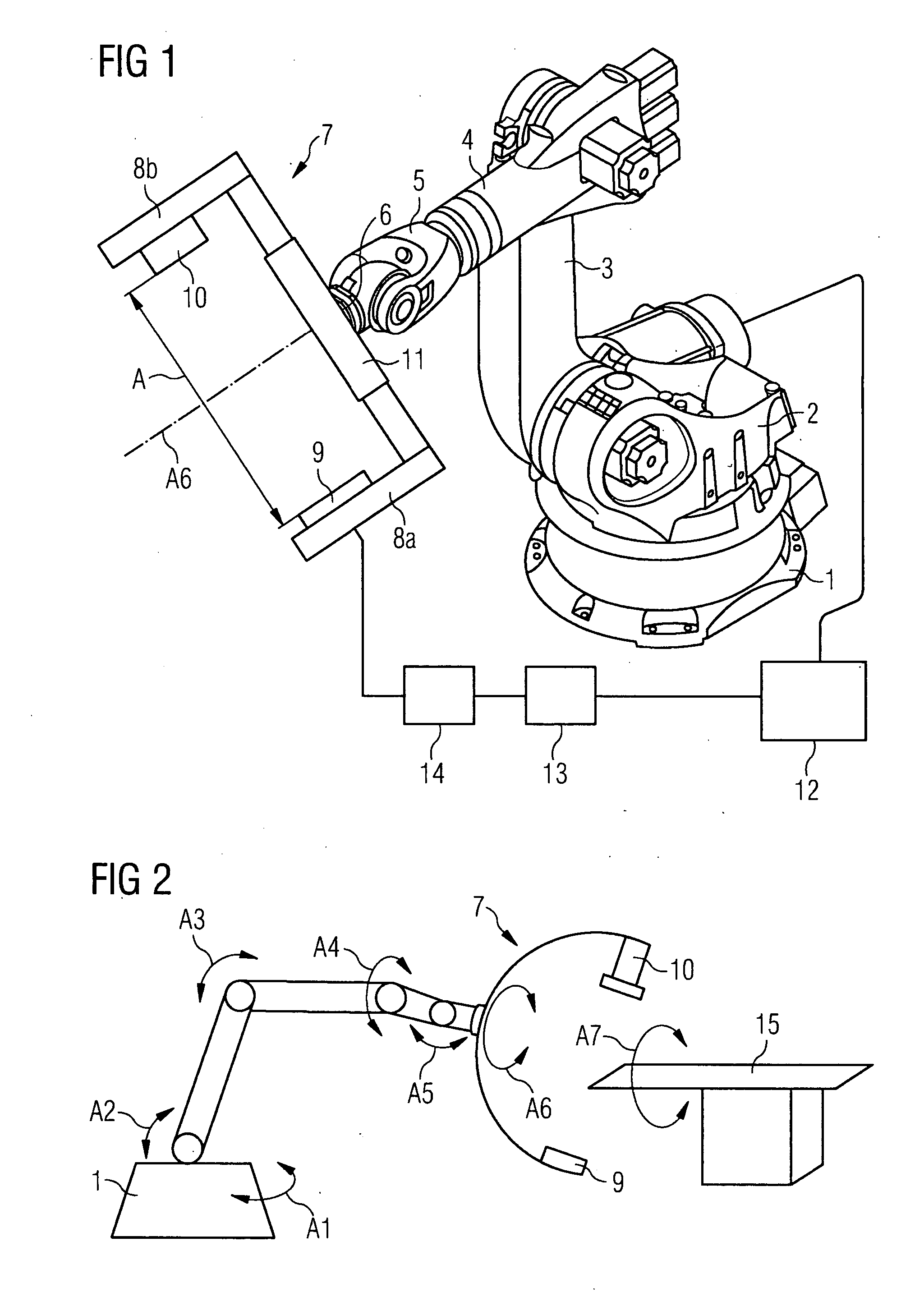

Robot system

ActiveCN1704210AReduce teaching costsLow costProgramme-controlled manipulatorNumerical controlEngineeringRobot control

A robot system comprising a first robot (R1) with a camera of a visual sensor mounted thereon and a second robot (R2) having a feature portion, is disclosed. The robots (R1, R2) are set in the first initial states (G1), from which the first robot (R1) or the second robot (R2) is moved so that the image of the feature portion assumes a target position or size (G2), thereby to store the present positions (P1, Q1) (G3). The same process is repeated N times (N 3) while changing the positions of the initial states of the robots (G4). Based on the positions P1,...., PN and Q1,....., QN obtained by the N repetitive above processes, a matrix T indicating the coordinate conversion from GBP b to GBP b' is determined. One or two robot control units may be provided. As a result, the calibration to determine relative positions between the robots can be carried out easily and with high accuracy, thereby reducing the jig-related cost.

Owner:FANUC LTD

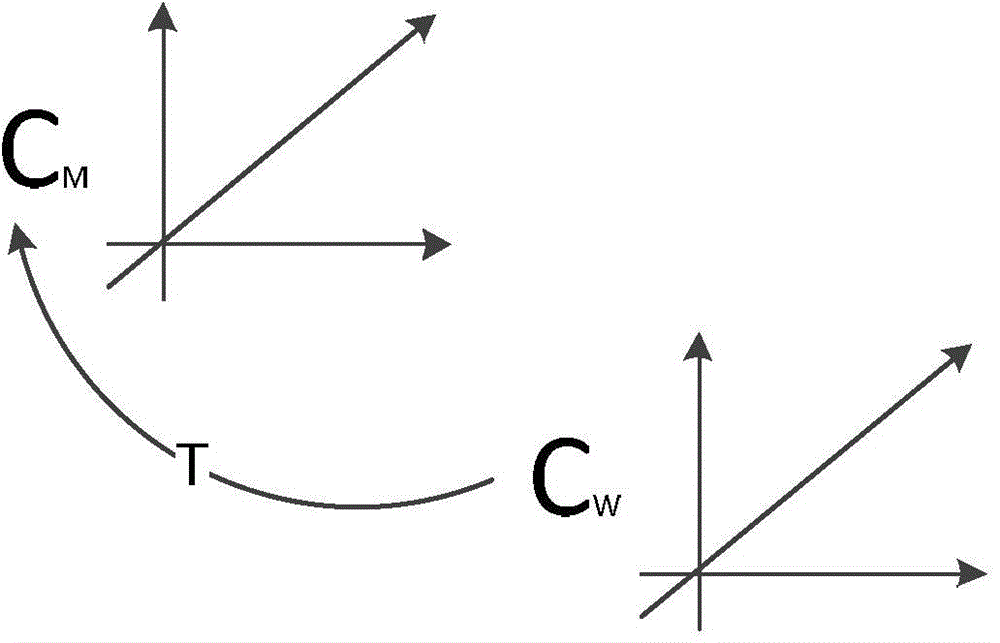

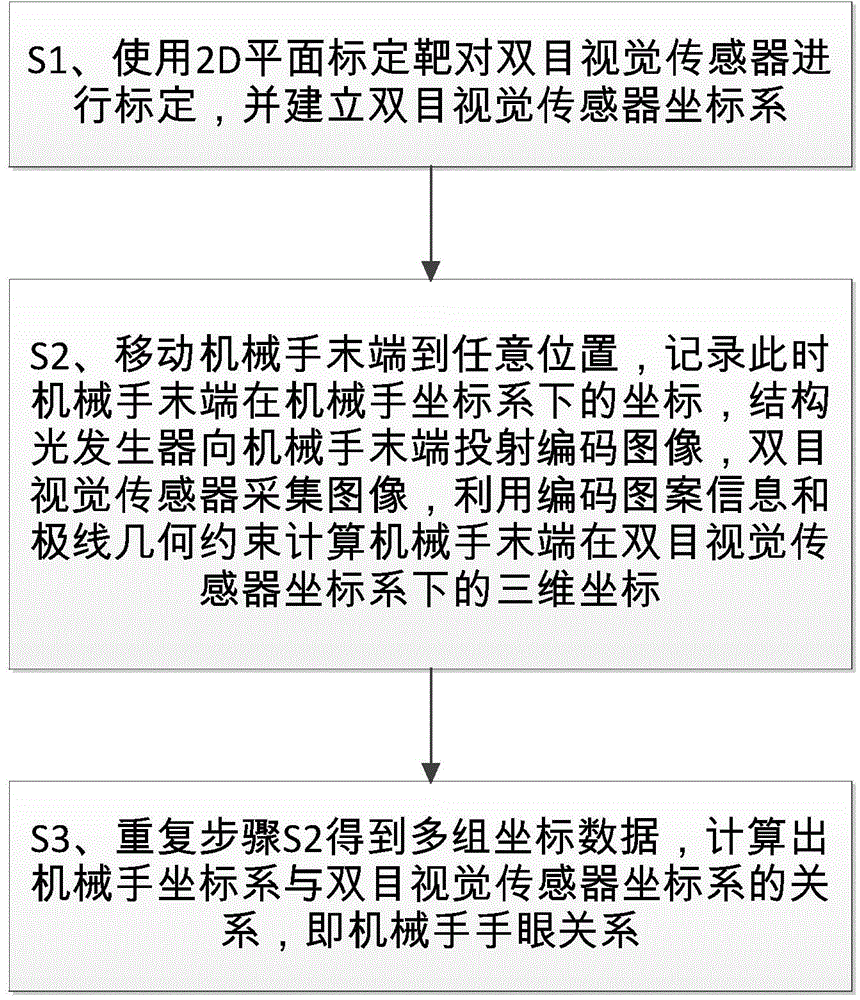

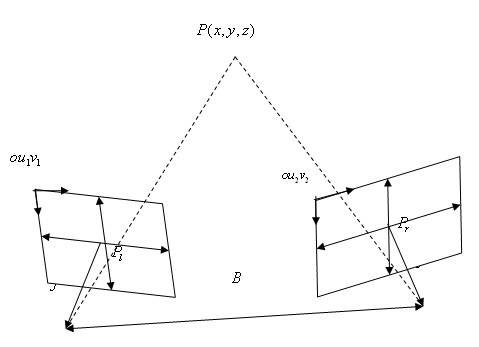

Manipulator hand-eye calibration method based on active binocular vision

ActiveCN104864807AMeet the needs of hand-eye calibrationHigh measurement accuracyUsing optical meansHand eye calibrationEngineering

The invention discloses a manipulator hand-eye calibration method based on active binocular vision. The method comprises the following steps that S1, a binocular vision sensor is calibrated by using a 2D plane calibration target, and a binocular vision sensor coordinate system is established; S2, the tail end of a manipulator is moved to any position, the coordinates of the tail end of the manipulator under a manipulator coordinate system are recorded, coded images are projected to the tail end of the manipulator by a structured light generator, the binocular vision sensor acquires the images, and the three-dimensional coordinates of the tail end of the manipulator under the binocular vision sensor coordinate system are calculated by utilizing coded pattern information and polar geometric constraints; and S3, the step S2 is repeated and multiple sets of coordinate data are obtained, and the relation between the manipulator coordinate system and the binocular vision sensor coordinate system is calculated, i.e. the manipulator hand-eye relation is calculated.

Owner:SHENZHEN UNIV

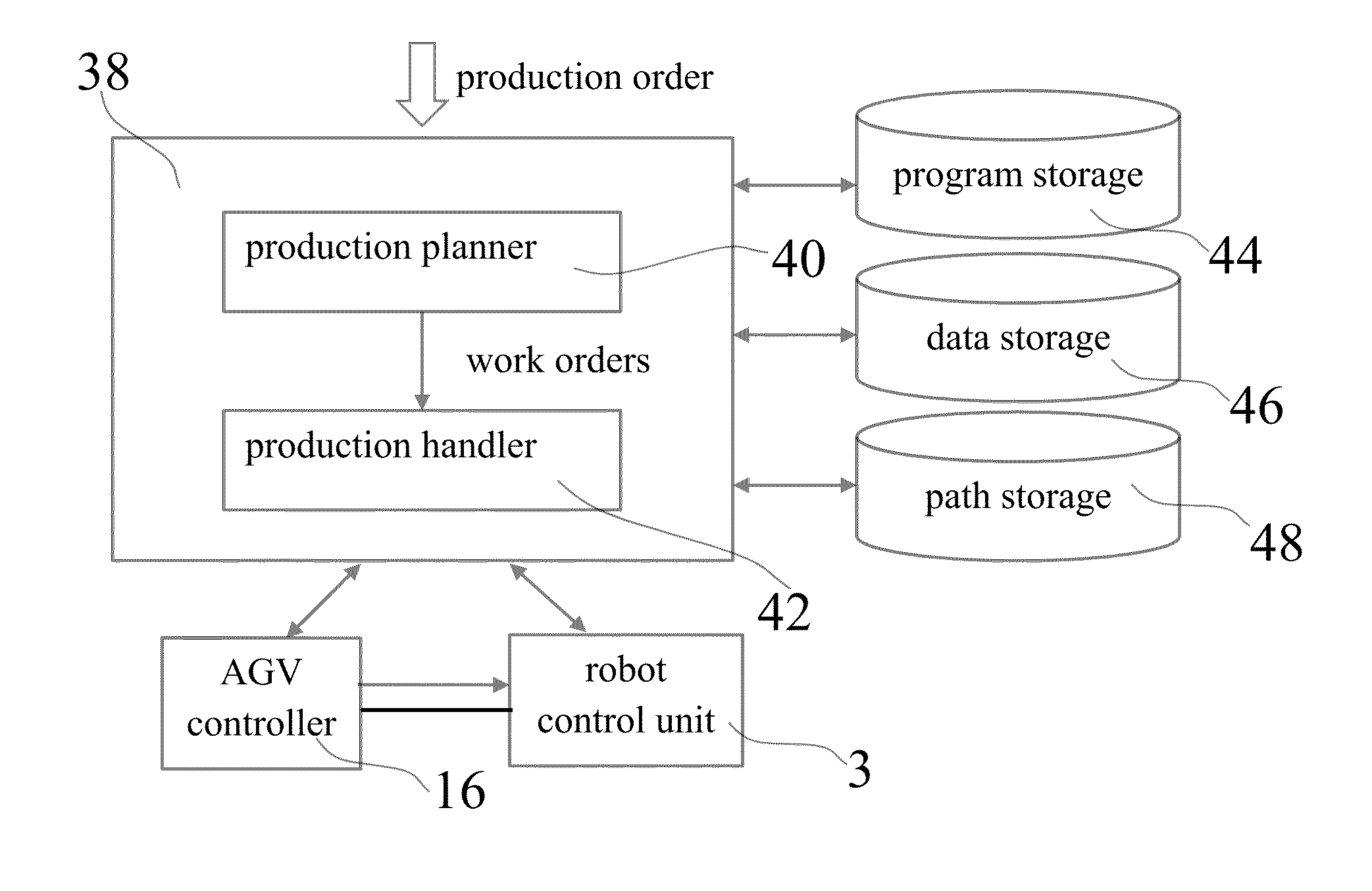

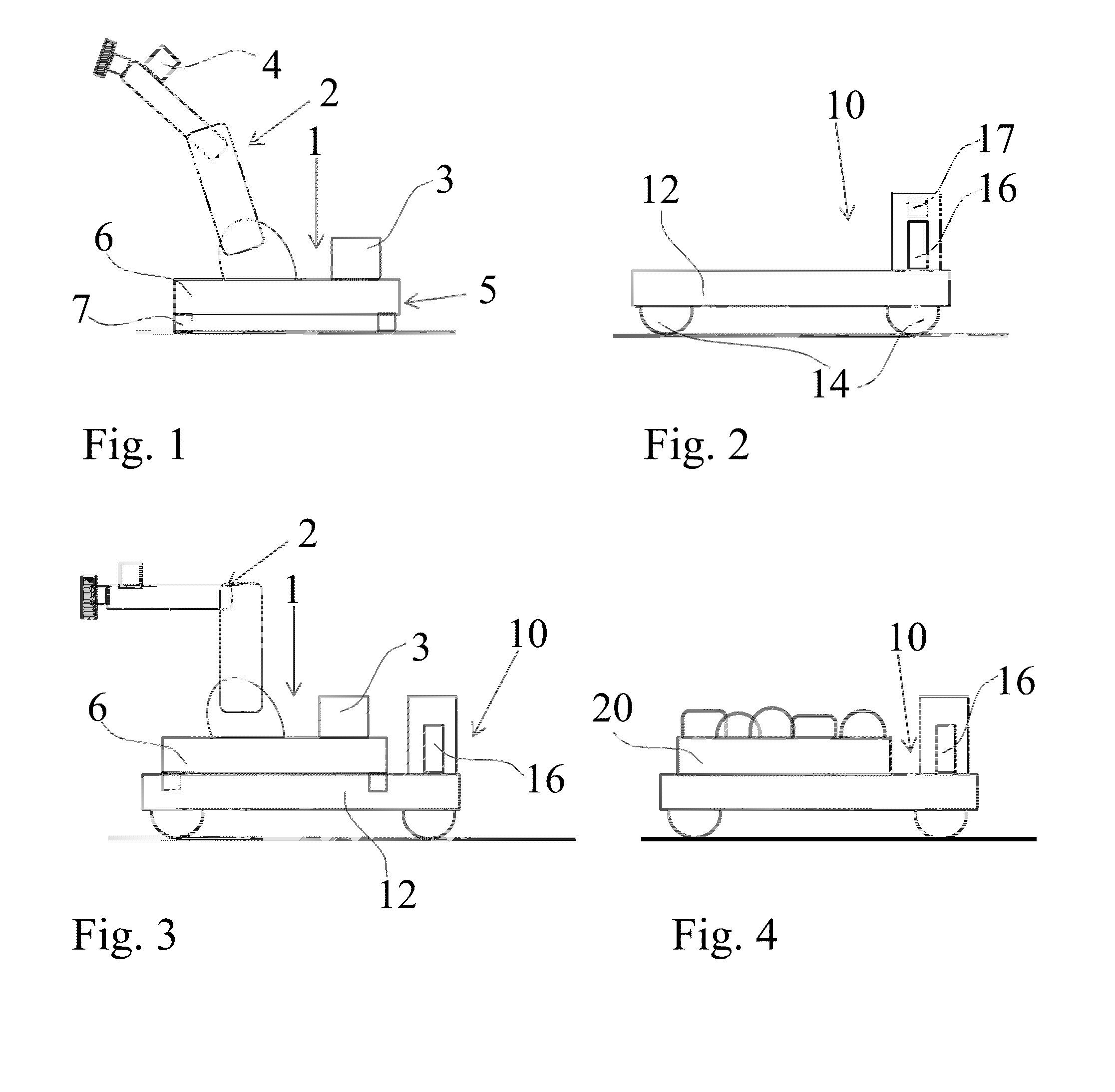

Automation system and a method for tending a production system

InactiveUS20150316925A1Improve efficiencyIncrease profitProgramme-controlled manipulatorElectric/hybrid propulsionWorkstationMobile manipulator

The present invention relates to an automation system for tending a production system comprising a plurality of workstations for producing products. The automation system comprises a mobile manipulator (2) adapted to perform work at the workstations, and an automatic guided vehicle (10), in the following named an AGV, arranged to move the manipulator between the workstations. The AGV and the manipulator are designed as two separate units, which can be positioned and moved independently of each other, and the AGV is arranged to supply the workstations with material needed for producing the products while the manipulator is carrying out work at one of the workstations.

Owner:OPIFLEX AUTOMATION

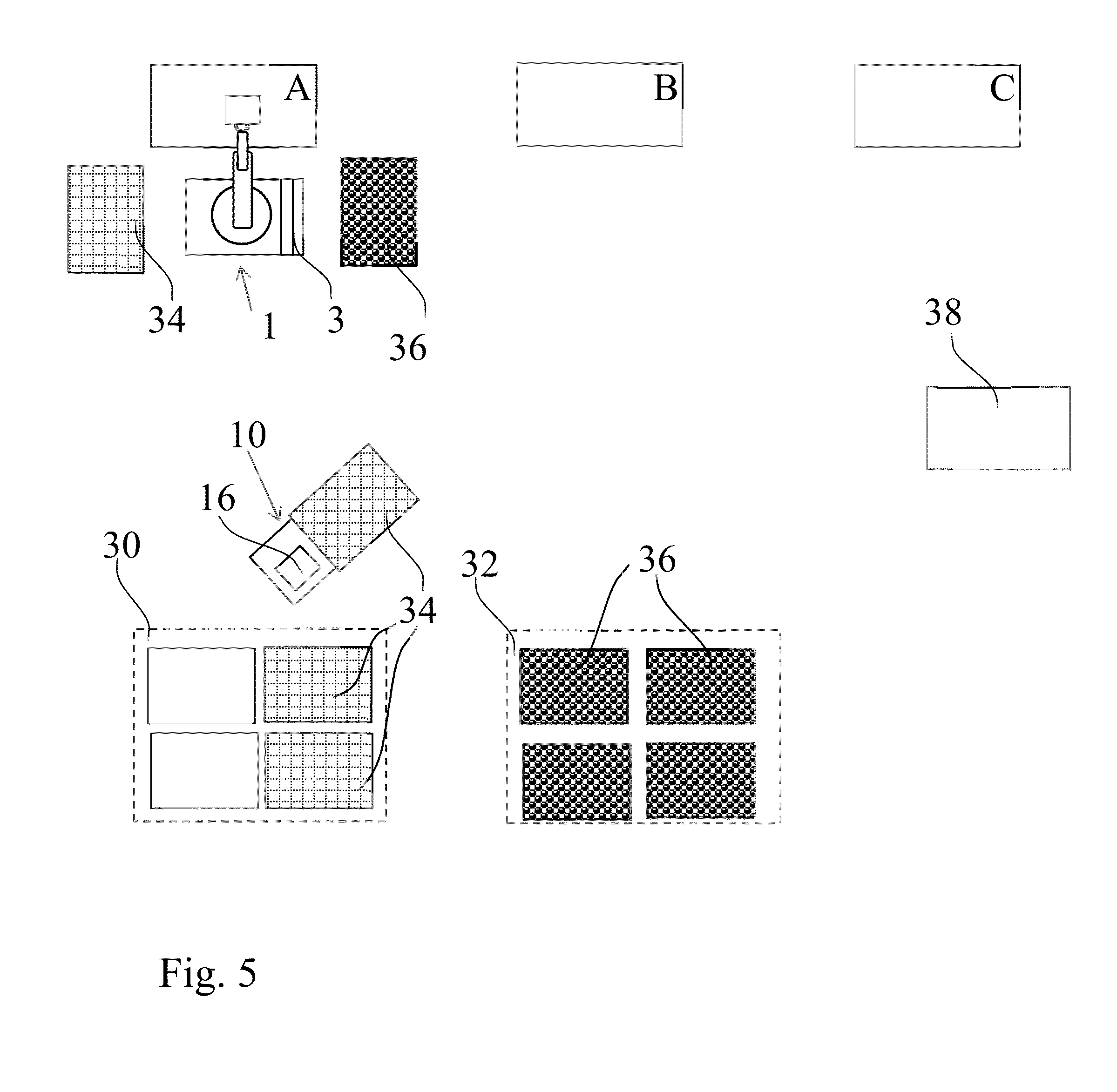

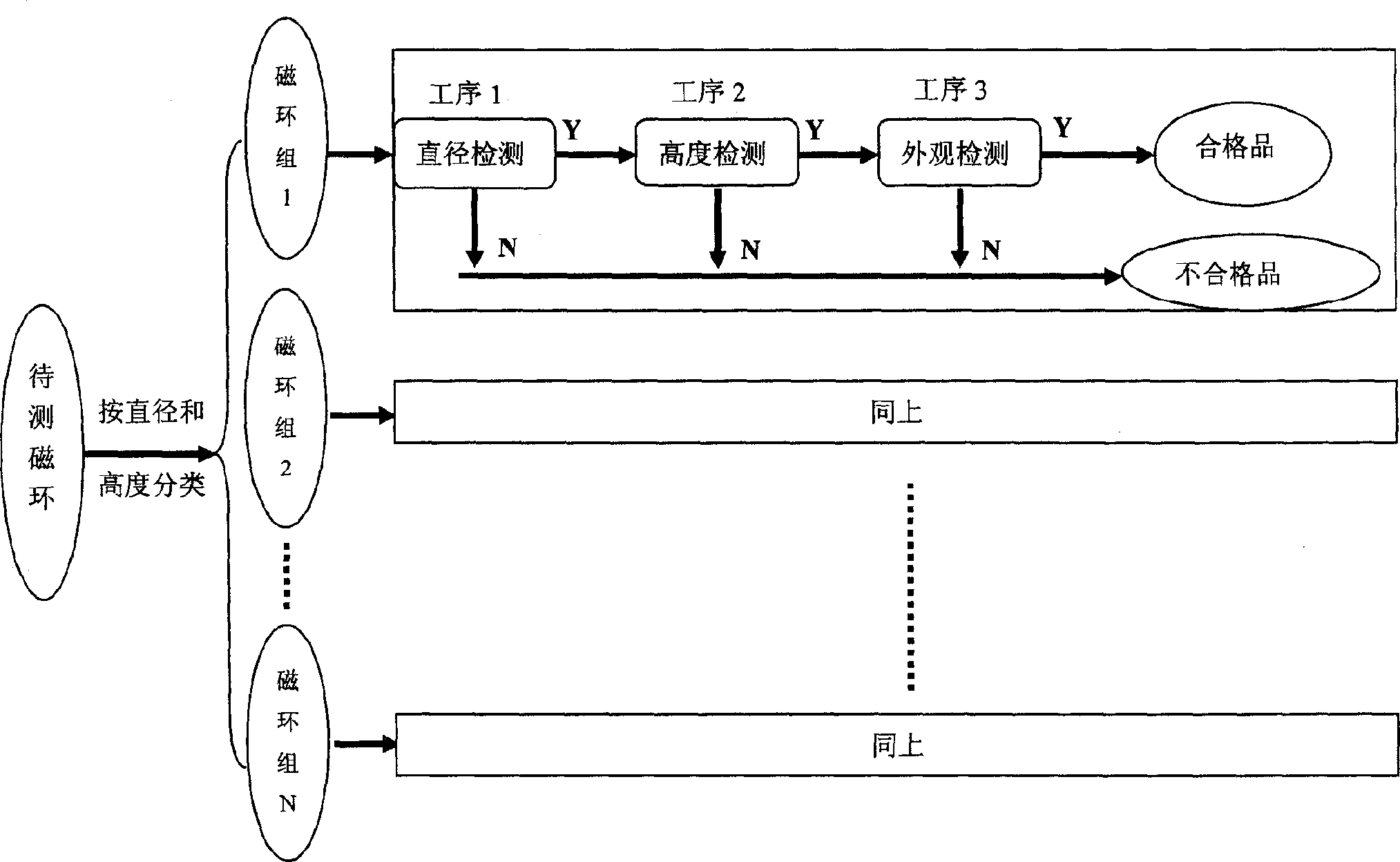

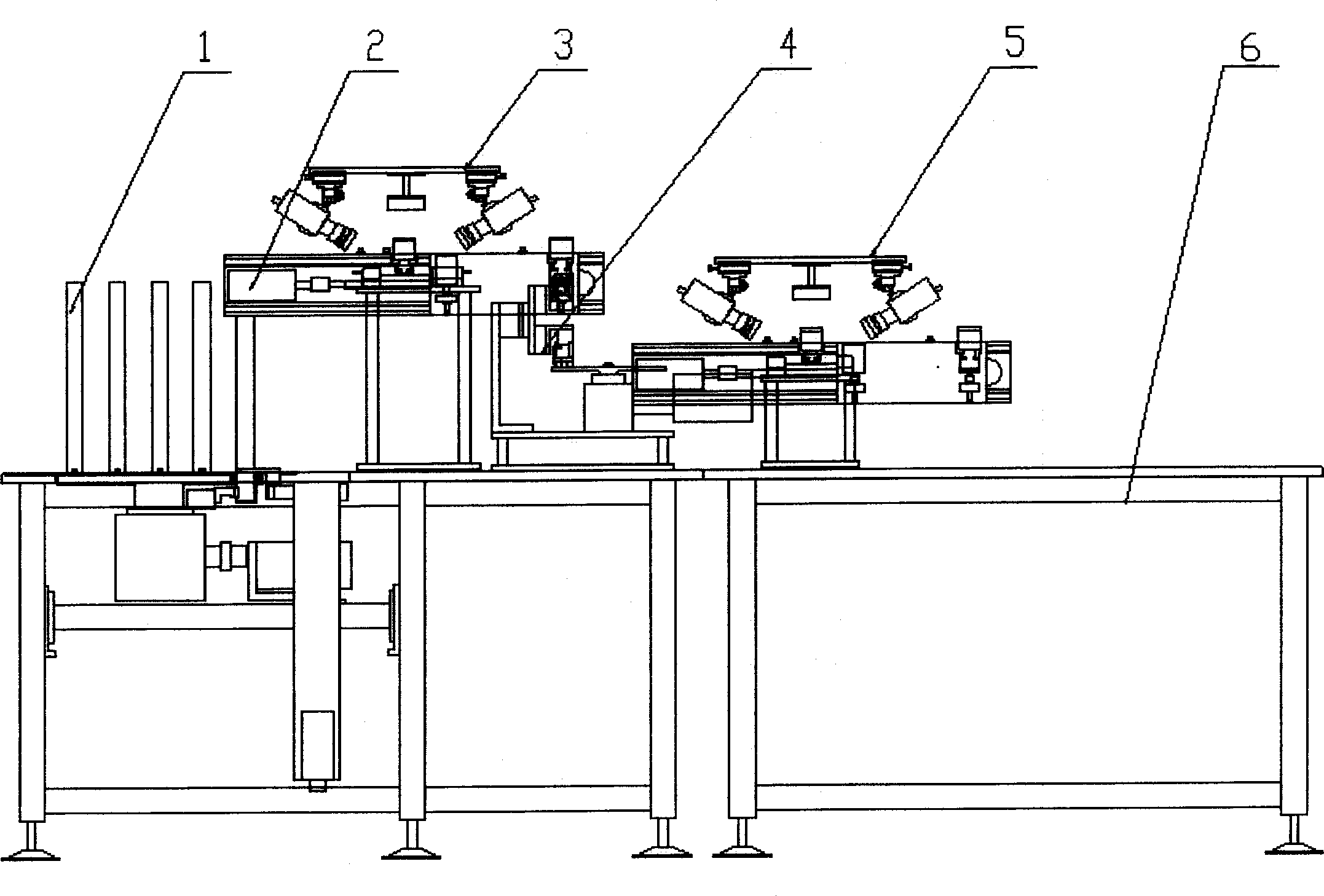

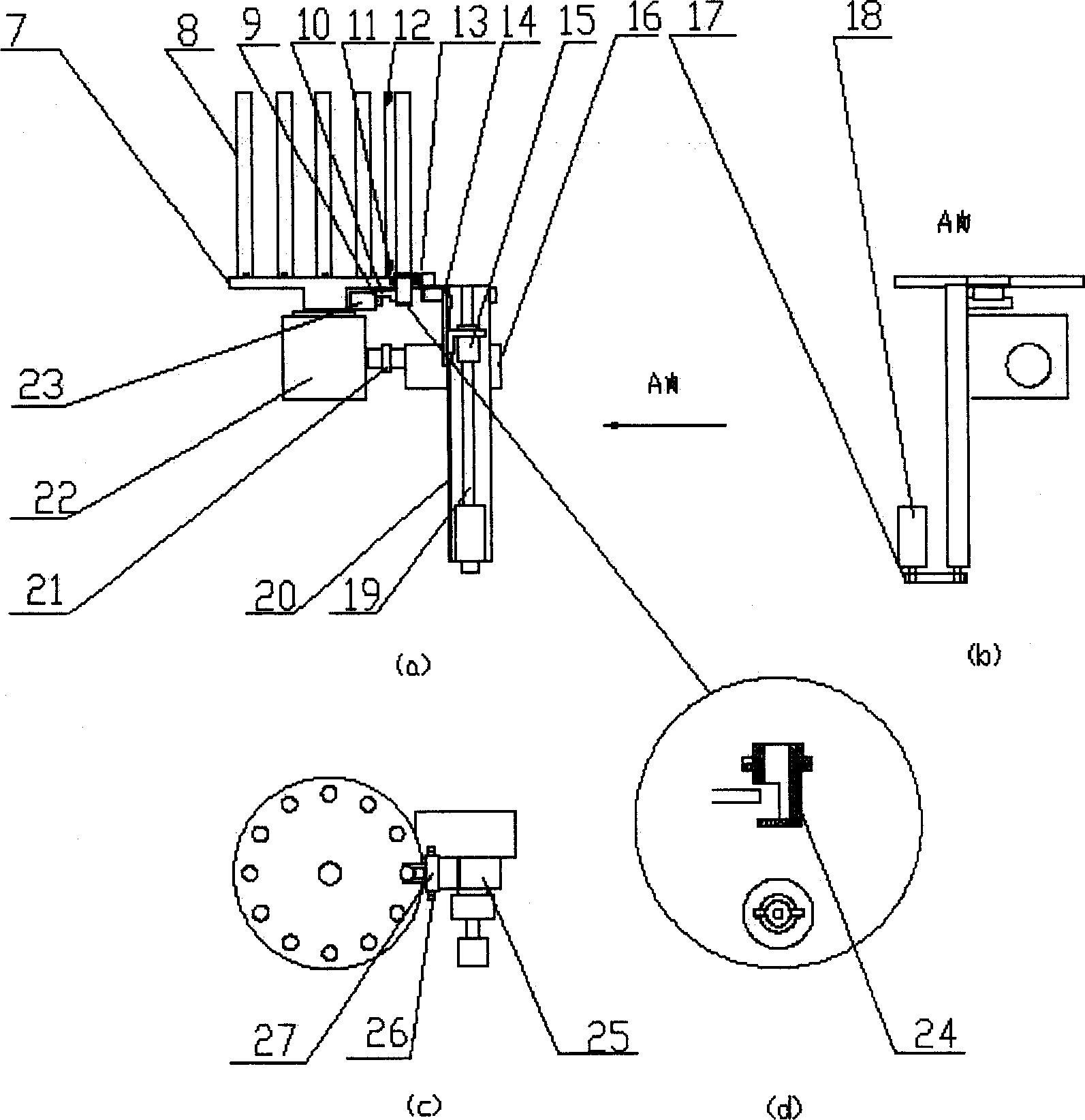

Automatic detection device for magnetic loop image

InactiveCN1865948ARealize fully automatic detectionRealize automated productionInvestigating moving sheetsOptically investigating flaws/contaminationImage detectionManipulator

The related natural detection device for magnet ring image comprises: a frame with an auto feeding pan for magnet ring on front and a first dual-head mobile manipulator on back; arranging a first image detection platform on the manipulator and a second manipulator as well as a ring turning device on back side of the platform; using the first manipulator and platform to detect diameter and top surface, and the second device to detect target thickness and bottom surface. This invention reduces time and cost.

Owner:SHANGHAI UNIV

Robot controlled recording device

ActiveUS20080013690A1Accurate synchronizationSimple to executeX-ray/infra-red processesSurgical robotsRobot handRobot control

The invention relates to a robot-controlled recording device comprising a robot with a number of axes of movement which are able to be controlled via a robot controller for moving a robotic hand and a recording system fitted to the robotic hand which is able to be moved by the robot for recording data of an object supported on a support unit. The robot controller is connected to an additional drive and controls this for moving the robotic hand synchronized to the axes of movement such that the additional drive would create a relative rotation and / or translation movement between the recording system and the support unit created by the movement of the robotic hand solely by a movement of the support unit with a stationary robotic hand. The drive is however connected not to the support unit but to an encoder for creating a synchronization signal for the recording.

Owner:SIEMENS HEALTHCARE GMBH

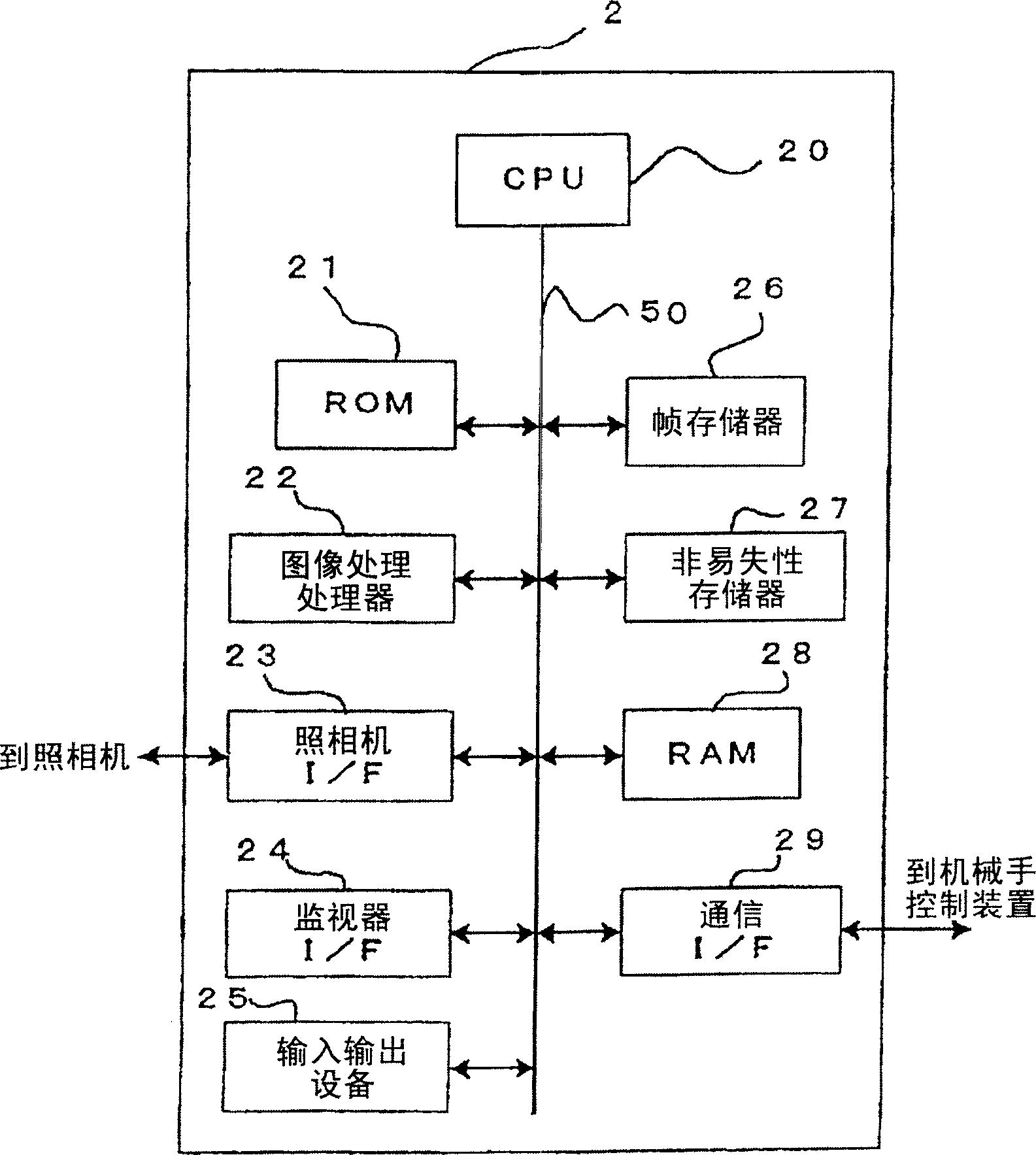

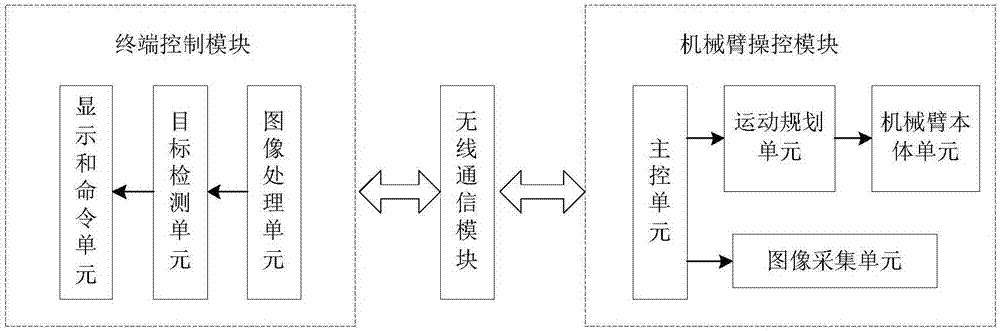

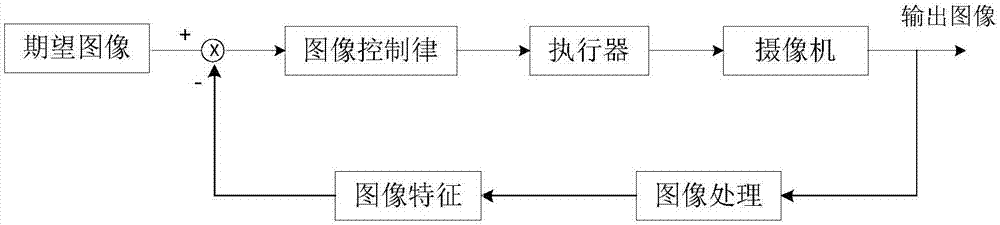

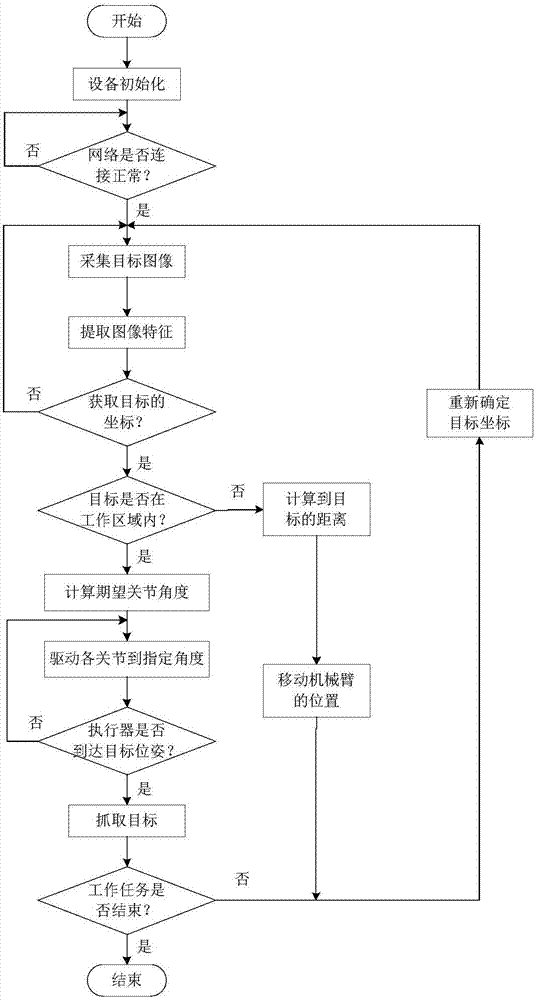

Mobile manipulator grasping control system and method based on machine vision

PendingCN107414832AStrong reliabilityImprove accuracyProgramme-controlled manipulatorImaging processingMachine vision

The invention discloses a mobile manipulator grasping control system and method based on machine vision. The mobile manipulator grasping control system comprises a terminal control module and a manipulator manipulation and control module, wherein the terminal control module comprises an image processing unit, a target object detection unit and a display and command unit; the manipulator manipulation and control module comprises a main control unit, an image acquisition unit, a motion planning unit and a manipulator body unit; the terminal control module carries out communication with the manipulator manipulation and control module through a wireless communication module and receives machine vision information from the image acquisition unit; the image processing unit is connected with the target object detection unit, obtains the position of the target object in the image according to the received data and further displays in real time through the display and command unit; the main control unit is connected with the image acquisition unit, receives data information and further transmits a control command to the motion planning unit, so as to adjust the positions of joints in the manipulator of the manipulator body unit to grasp the target object. According to the mobile manipulator grasping control system and method based on machine vision, long-distance manipulation and control are realized, decisions can be made in real time, and the target object can be grasped stably and reliably.

Owner:SOUTH CHINA UNIV OF TECH

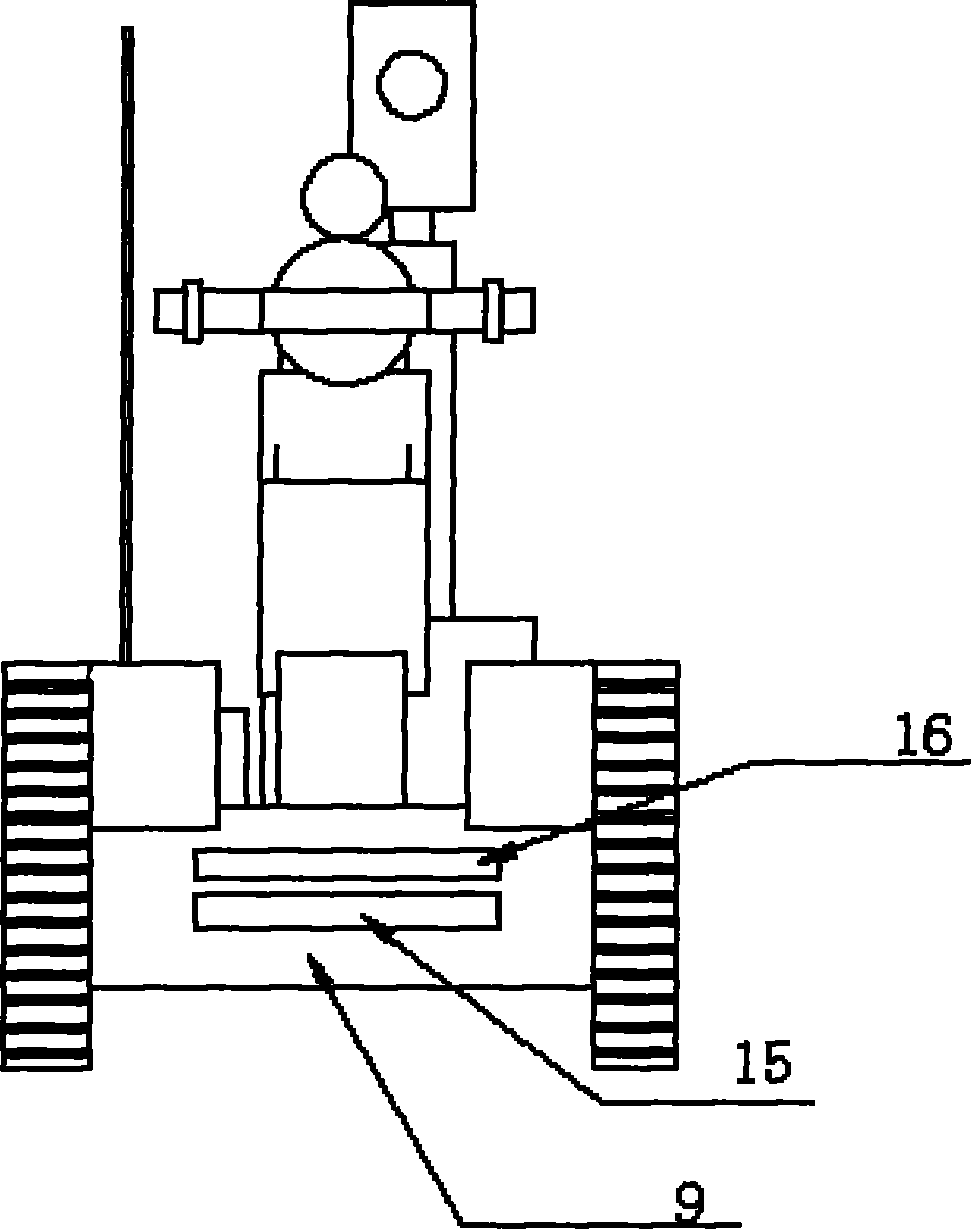

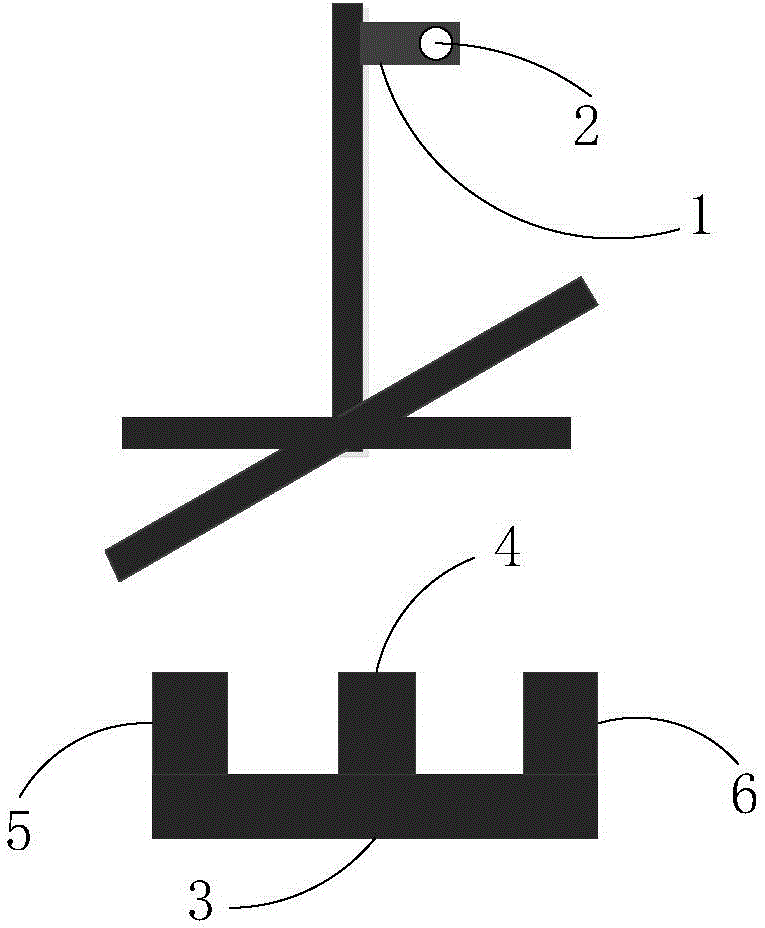

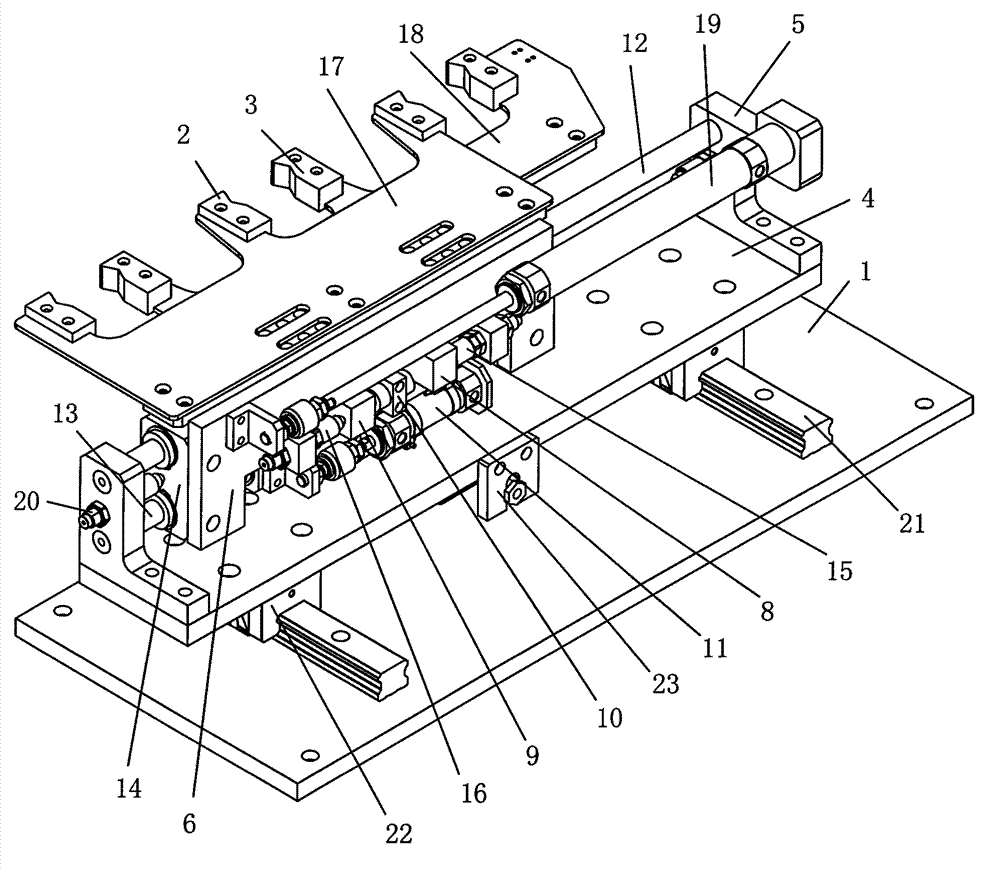

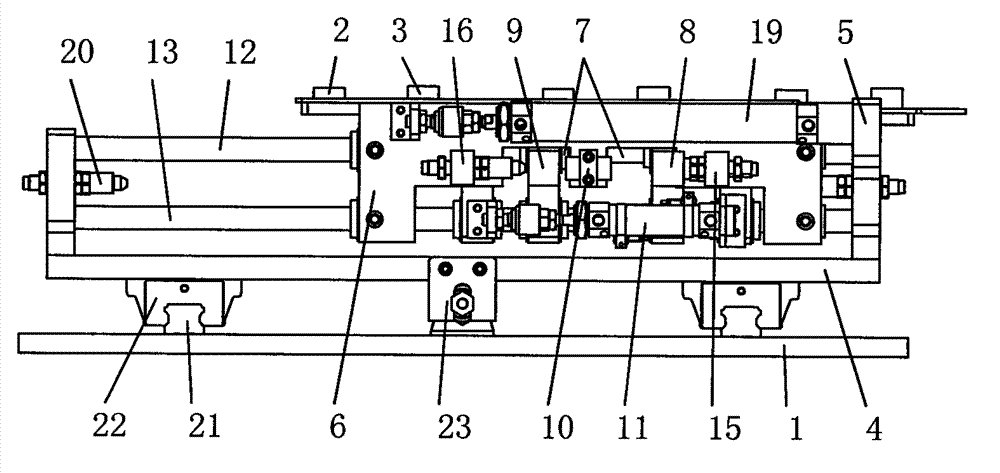

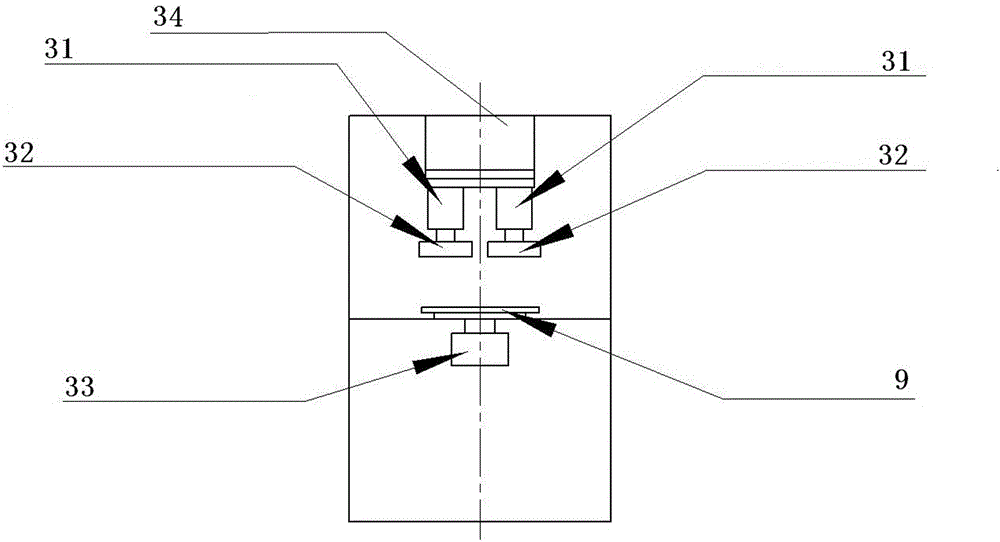

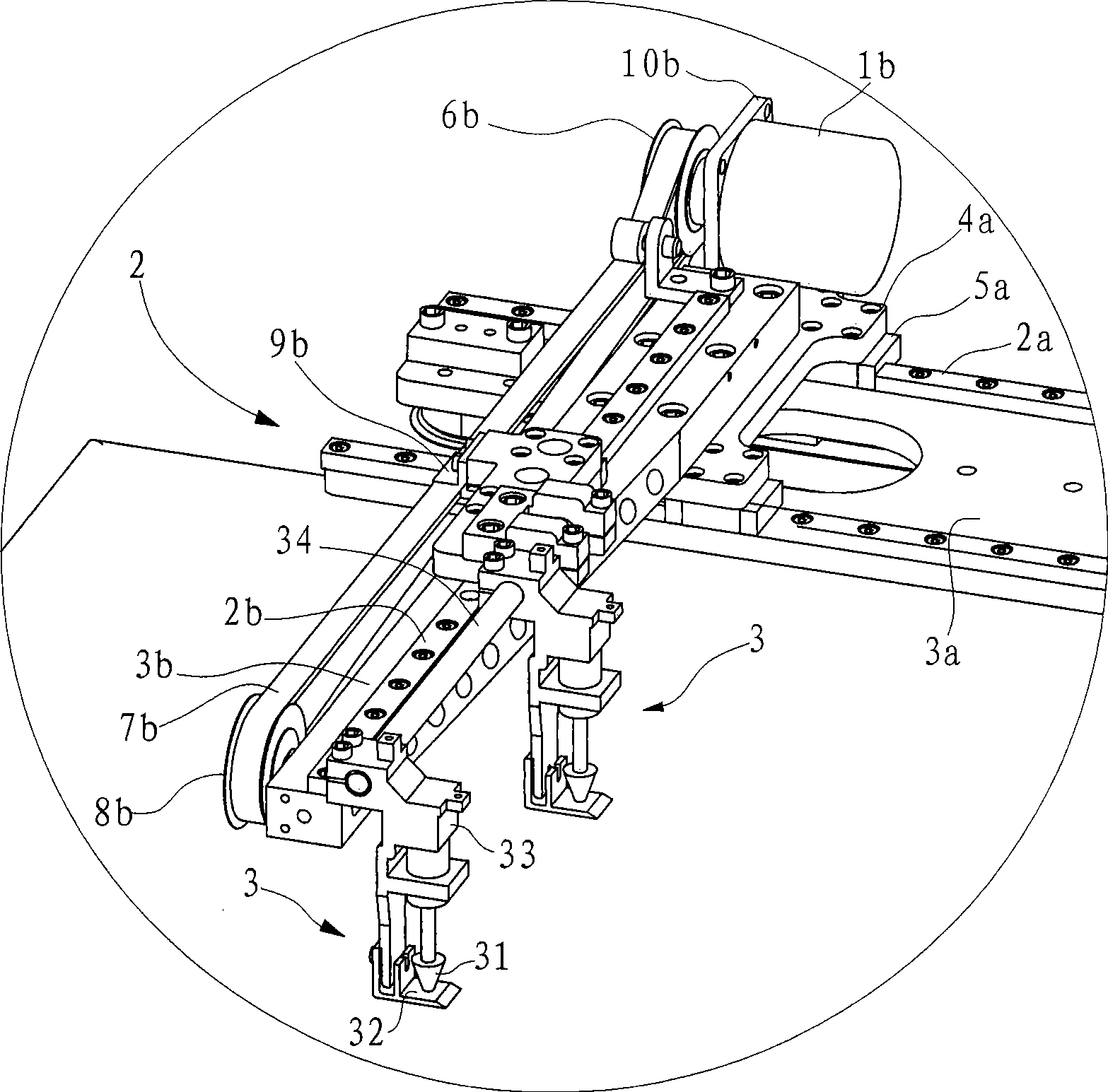

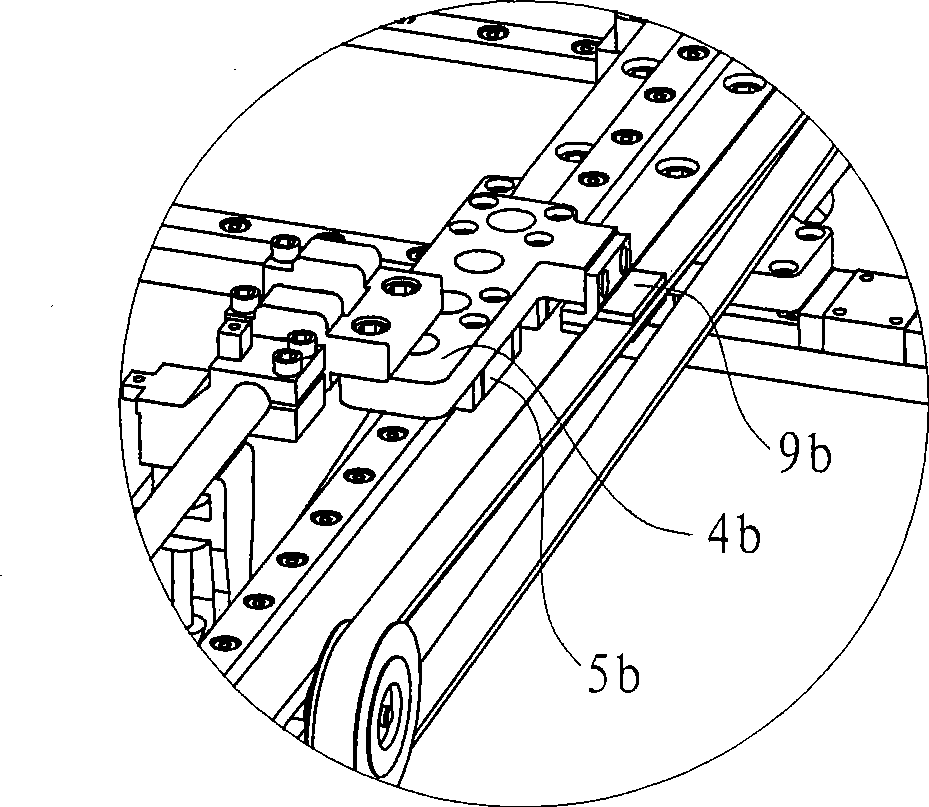

Adjustable clamping mobile manipulator

An adjustable clamping mobile manipulator comprises a worktable, an upper manipulator and a lower manipulator, wherein a support board is arranged on the worktable in a sliding manner, the support board is driven by a vertical driving mechanism, supports are vertically arranged on two sides of the support board, a guide rod is horizontally arranged between the two supports, a sliding plate is arranged on the guide rod in a sliding manner, the sliding plate is driven by a horizontal driving mechanism, a positioning groove is formed at the middle part of the sliding plate, an upper manipulator slider connected with the upper manipulator and a lower manipulator slider connected with the lower manipulator are arranged in the positioning groove, and an opening / closing driving mechanism is arranged between the upper manipulator slider and the lower manipulator slider and is used for driving the upper manipulator slider and the lower manipulator slider to open up or close up, and a positioning block capable of being fixed on the sliding plate and replaceable is arranged between the upper manipulator slider and the lower manipulator slider. Due to the adoption of the structure, the adjustable clamping mobile manipulator has the advantages that the closing stroke of the manipulators can be adjusted through changes of positioning blocks with different sizes, so that products with different sizes can be clamped; moreover, the replacement time is short, shutdown time of the equipment is short, and the utilization efficiency of the equipment is greatly improved.

Owner:宁波江宸智能装备股份有限公司

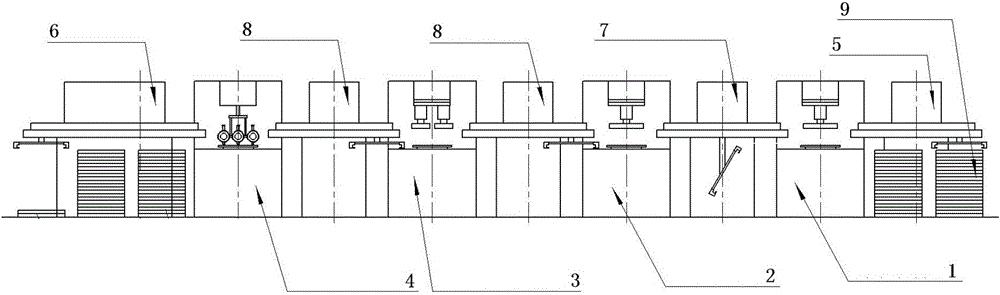

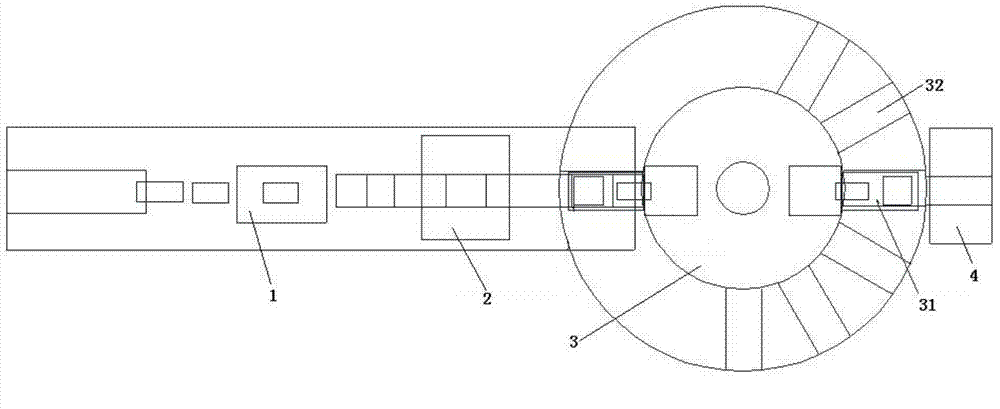

Quality testing system for friction discs

ActiveCN105784716AReduce false detection rateReduce manufacturing costOptically investigating flaws/contaminationMechanical thickness measurementsForeign matterDistance detection

The invention discloses a quality testing system for friction discs. The quality testing system consists of a first defect detection device, a second defect detection device, an internal tooth stick distance detection device, a thickness and flatness detection device, and a controlling and managing machine, wherein the first defect detection device, the second defect detection device, the internal tooth stick distance detection device and the thickness and flatness detection device are sequentially arranged, and the controlling and managing machine is used for controlling the whole testing system to work; a feeding manipulator is arranged at the front end of the first defect detection device; a discharging manipulator is arranged at the tail end of the thickness and flatness detection device; a moving and overturning manipulator which is used for completing the overturning operation of the friction discs in a moving process is arranged between the first defect detection device and the second defect detection device; moving manipulators are arranged between the second defect detection device and the internal tooth stick distance detection device, and between the internal tooth stick distance detection device and the thickness and flatness detection device. The detection of the friction plates on scratches, patches, foreign matters in grooves, broken blocks, grooving traces, center distances of internal tooth sticks, flatness and thickness can be completed at the same time; unmanned automated operation can be realized, a false detection rate generated due to the weariness of staff is reduced, the production efficiency is improved, and the production cost is reduced.

Owner:SUZHOU JIUDIAN INTELLIGENT TECH CO LTD

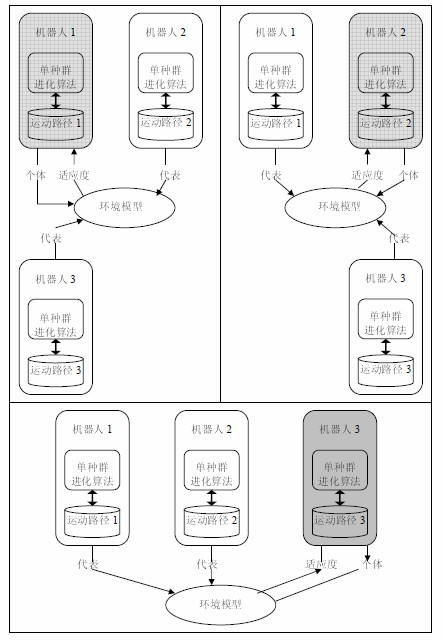

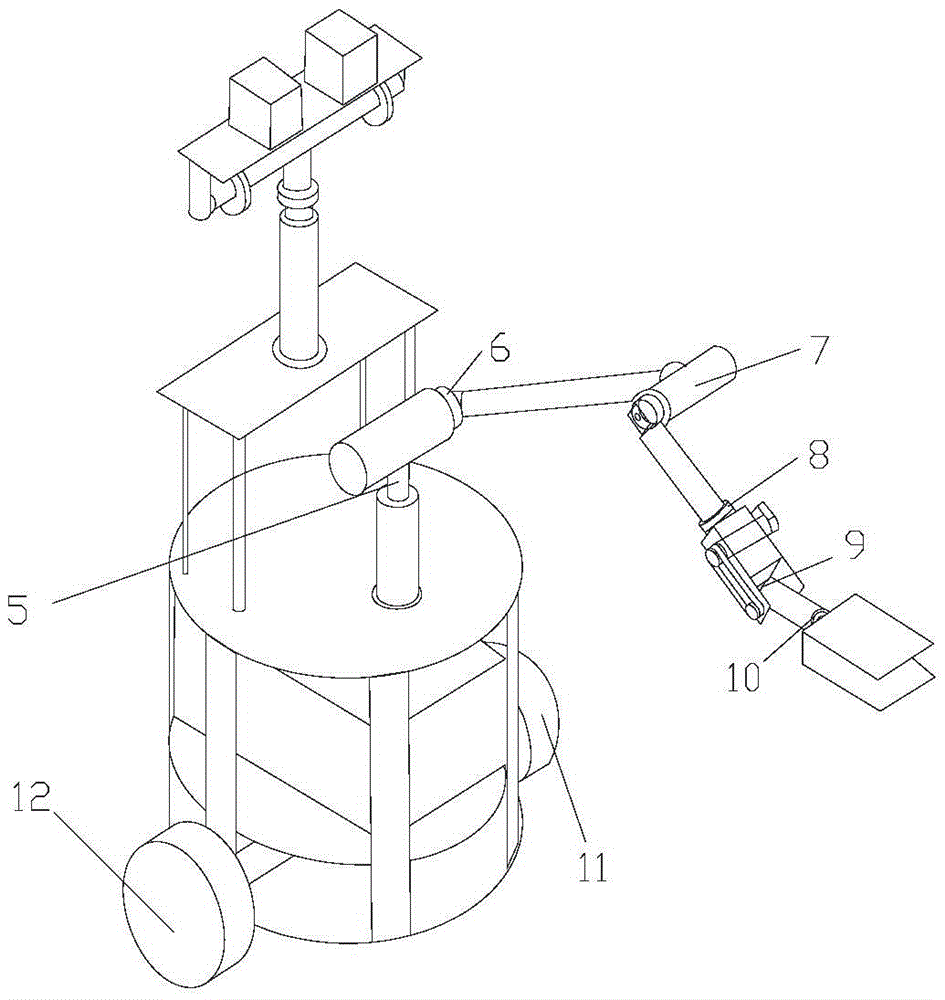

Mater-slave type co-evolution method for path planning of mobile manipulator in three-dimensional space

InactiveCN102161198AImprove performanceEasy to find optimal solutionProgramme-controlled manipulatorGenetic modelsThree-dimensional spaceSimulation

The invention discloses a master-slave type co-evolution method for path planning of mobile manipulators in three-dimensional space. The method can ensure an optimal performance of an integral system instead of the optimal performance of sub-systems. In particular, collision is effectively avoided and a better path is found when both spacial barriers and ground barriers exist.

Owner:ZHEJIANG UNIV

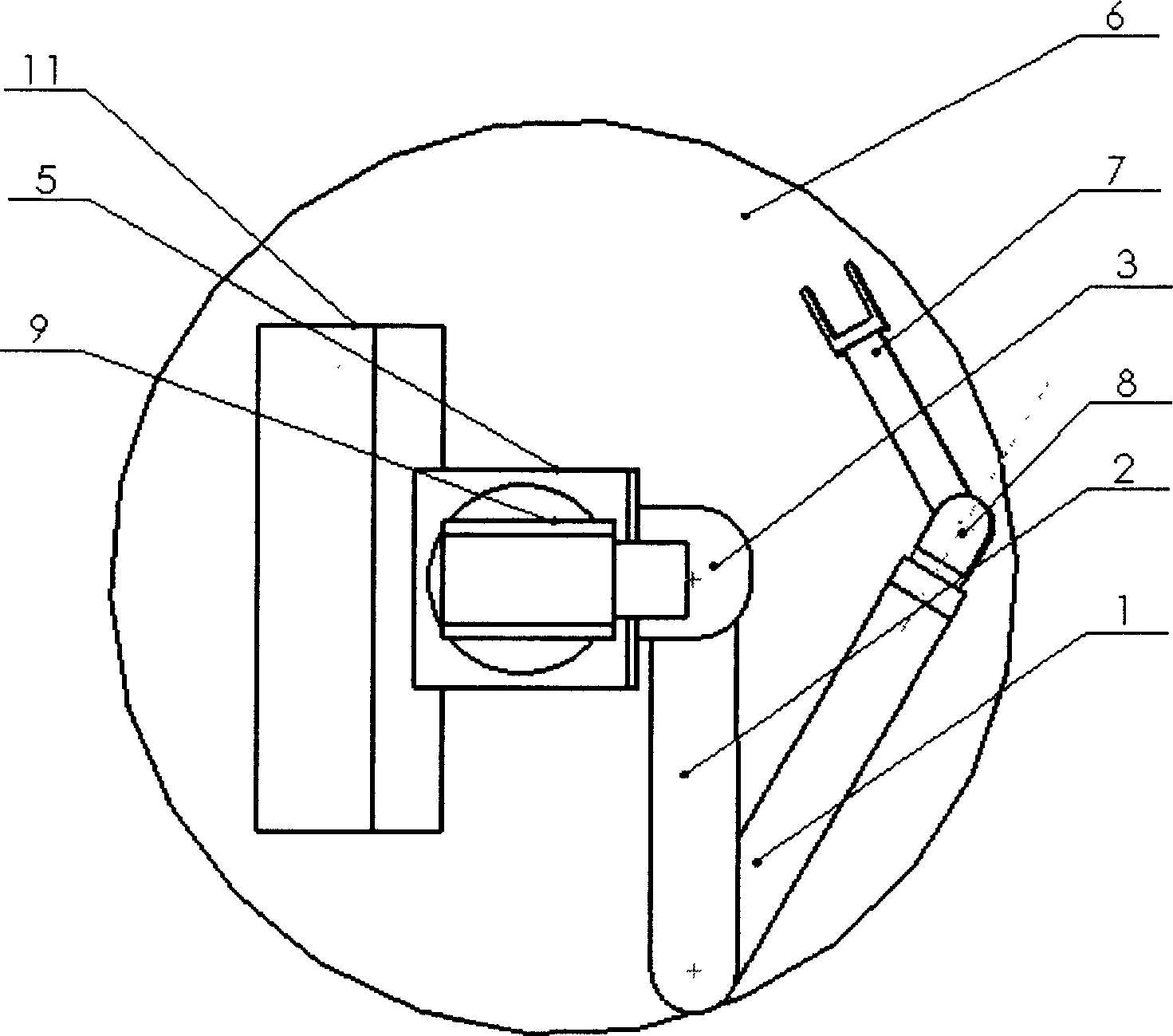

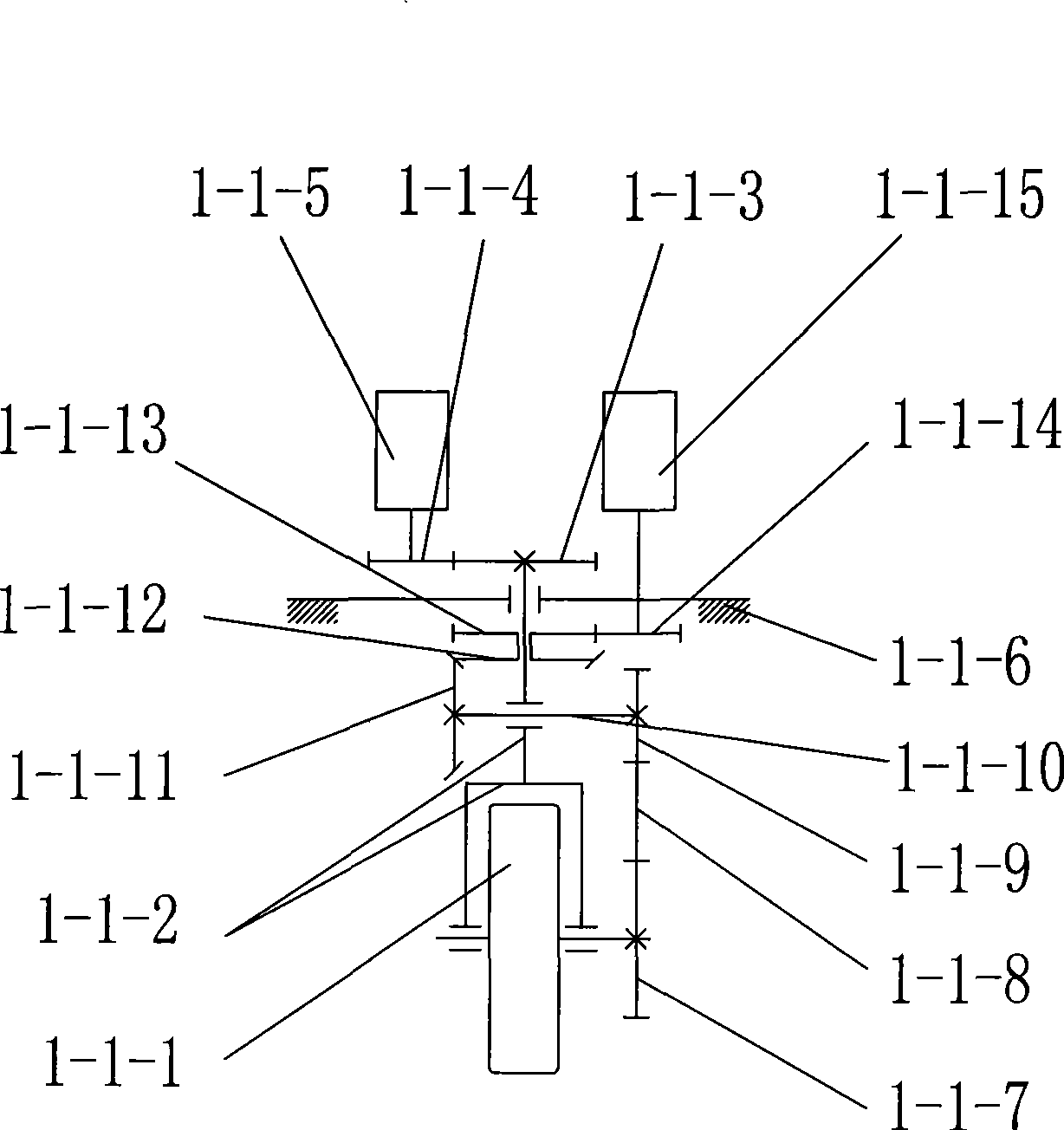

Ultra-redundancy all-directional movable operating arm

A super-redundant all-position mobile manipulator arm relates to manipulator arms, and solves the problem that the operational flexibility of the prior operating robot is poor and the prior operating robot is not capable of all-position walking, so that the working space and the working range thereof are limited to prevent the operating robot from adapting to complex working conditions. The manipulator arm is characterized in that a first steering spur gear is meshed with a second steering spur gear which is connected with the output shaft of a steering motor; a first synchronous belt wheel is connected with a second synchronous belt wheel through a synchronous belt; the second synchronous belt wheel is connected with a first bevel gear through a rotating shaft which is mounted on a steering bracket; the first bevel gear is meshed with a second bevel gear; both the second bevel gear and a first rolling spur gear are mounted on the steering bracket; the first rolling spur gear is meshed with a second rolling spur gear; and the second rolling spur gear is connected with the output shaft of a rolling motor. The manipulator arm has the advantages of higher manipulability, strong task compatibility, large working space and good flexibility, thereby performing the all-position moving function.

Owner:HARBIN INST OF TECH

Storage Systems and Methods for Robotic Picking

PendingUS20210032034A1Programme controlProgramme-controlled manipulatorComputer hardwareOperator interface

A mobile manipulator robot for retrieving inventory items from a storage system. The robot includes a body, a wheel assembly, a sensor to locate a position of the robot within the storage system, an interface configured to send processor readable data to a remote processor and to an operator interface, and receive processor executable instructions from the remote processor and from the operator interface, an imaging device to capture images of the inventory items, a picking manipulator, first and second pneumatic gripping elements for grasping the inventory items, and a coupler configured to mate with a valve to access a pneumatic supply for operating at least one of the first or second pneumatic gripping elements. The robot is configured to transition the valve from a closed condition to an open condition and selectively place one of the first or the second pneumatic gripping elements in communication with the pneumatic supply.

Owner:NIMBLE ROBOTICS INC

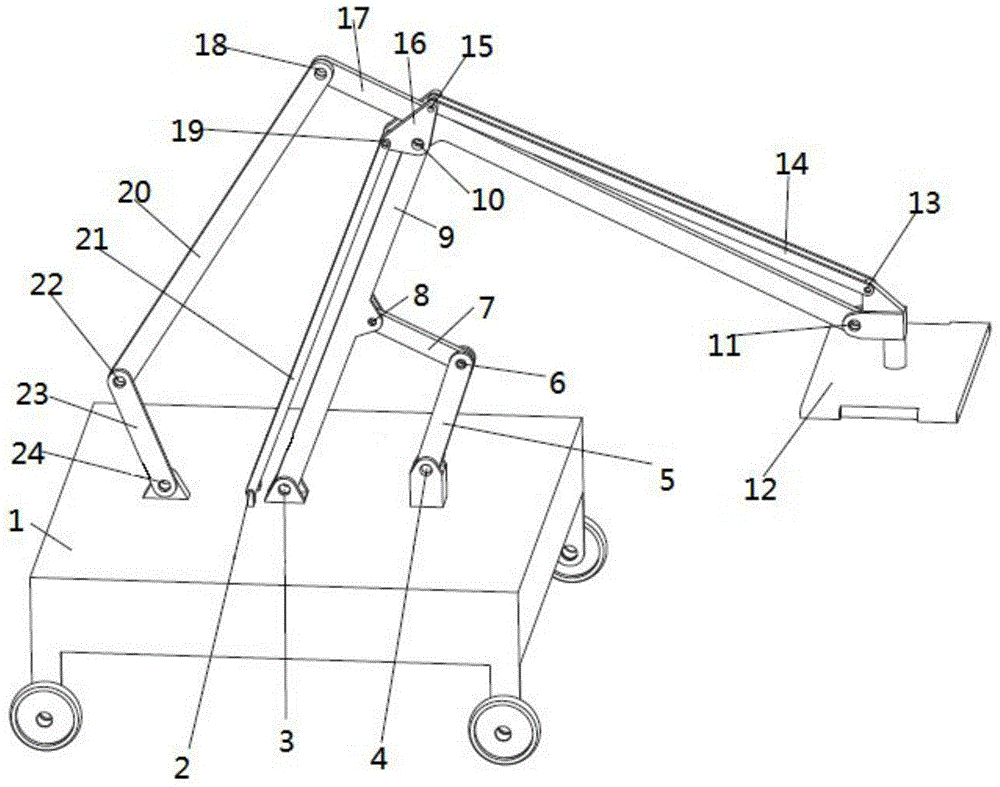

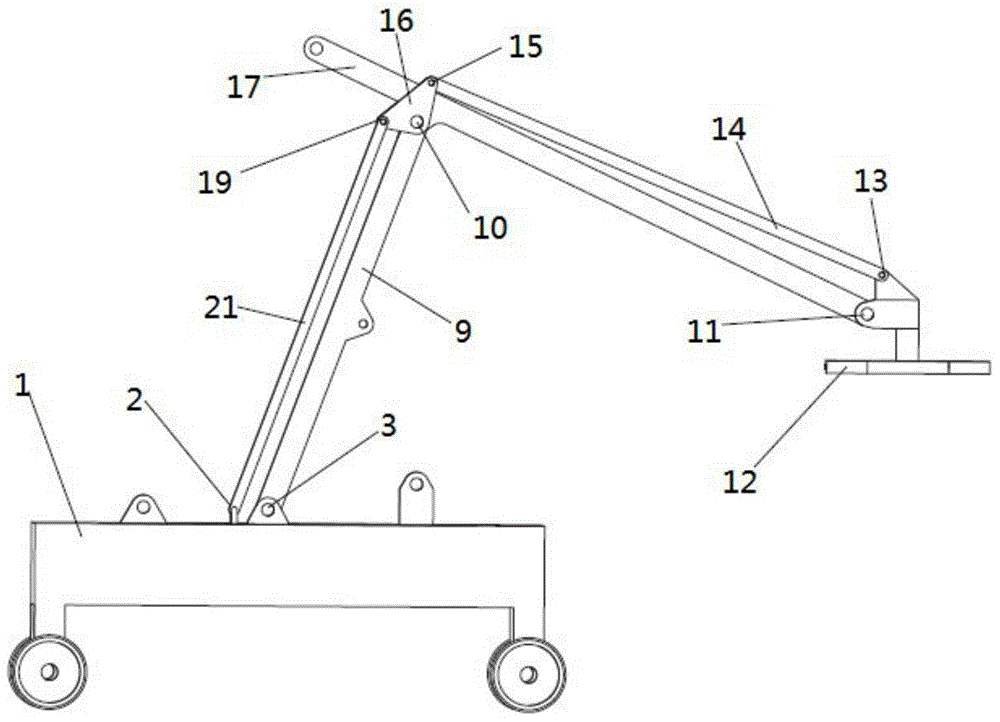

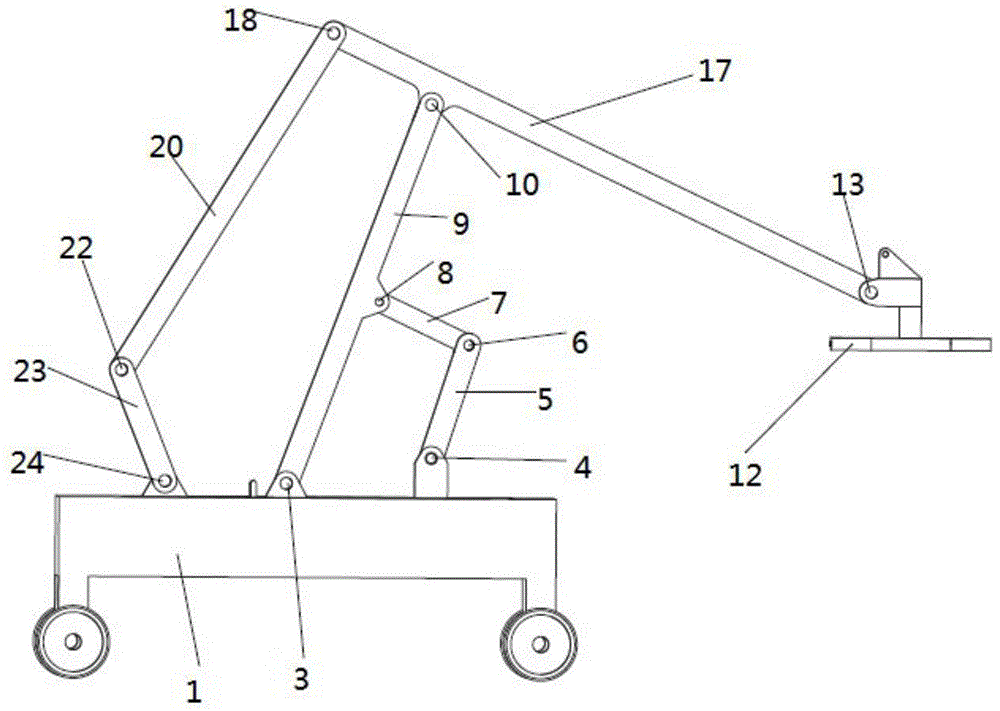

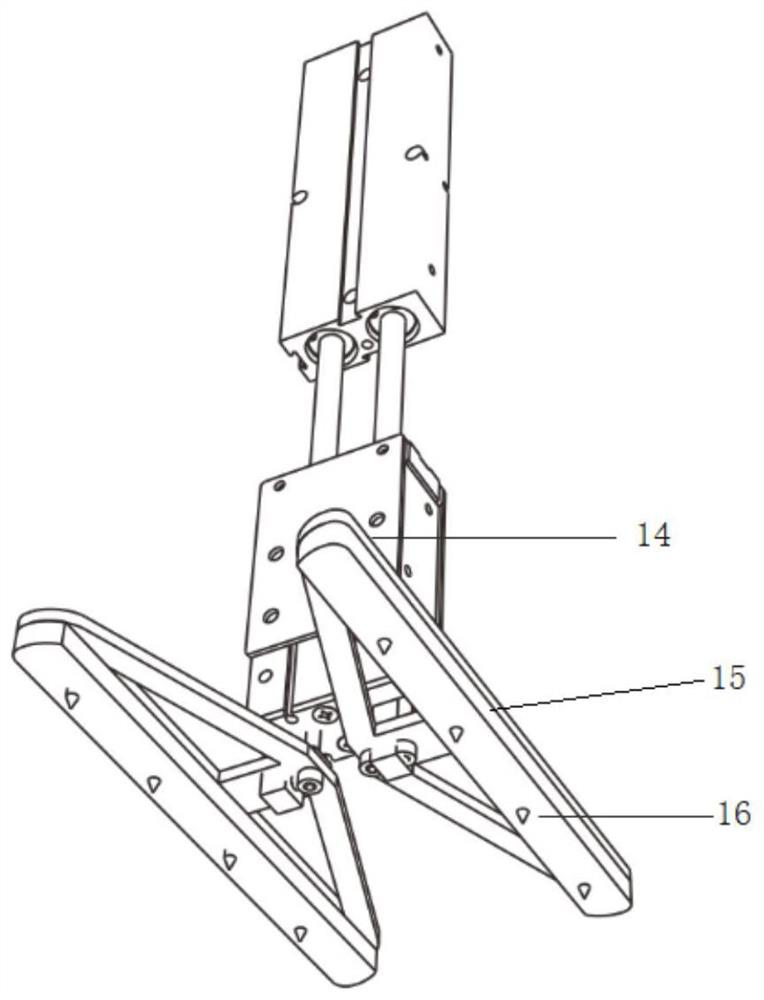

Controllable mechanism type two-degrees-of-freedom mobile manipulator

InactiveCN104647336ALarge working spaceImprove stress conditionsManipulatorStress conditionsResidual vibration

The invention relates to a controllable mechanism type two-degrees-of-freedom mobile manipulator. A fourth connecting rod of the manipulator is of a triangular shape; the lower end of a first driving part is connected to a mobile platform and the upper end of the first driving part is connected with one end of a first connecting rod; the other end of the first connecting rod is connected with one end of a second connecting rod; the other end of the second connecting rod is connected with an operation platform; the lower end of a big arm is connected to the mobile platform and the upper end of the big arm is connected with the first end of a fourth connecting rod and simultaneously, the upper end of the big arm is connected to the second connecting rod by a compound hinge; the lower end of the third connecting rod is connected to the mobile platform and the upper end of the third connecting rod is connected with the second end of a fourth connecting rod; one end of a fifth connecting rod is connected with the third end of the fourth connecting rod and the other end of the fifth connecting rod is connected with the operation platform; the lower end of a second driving part is connected to the mobile platform and the upper end of the second driving part is connected with one end of a sixth connecting rod; the other end of the sixth connecting rod is connected to the big arm. According to the invention, the stress condition of the manipulator is improved; the defects of rotational inertia, residual vibration intensity and the like of the manipulator are reduced; moreover, the controllable mechanism type two-degrees-of-freedom mobile manipulator has the advantages of easiness for implementing remote control, reduction of labor intensity of workers and the like.

Owner:GUANGXI UNIV

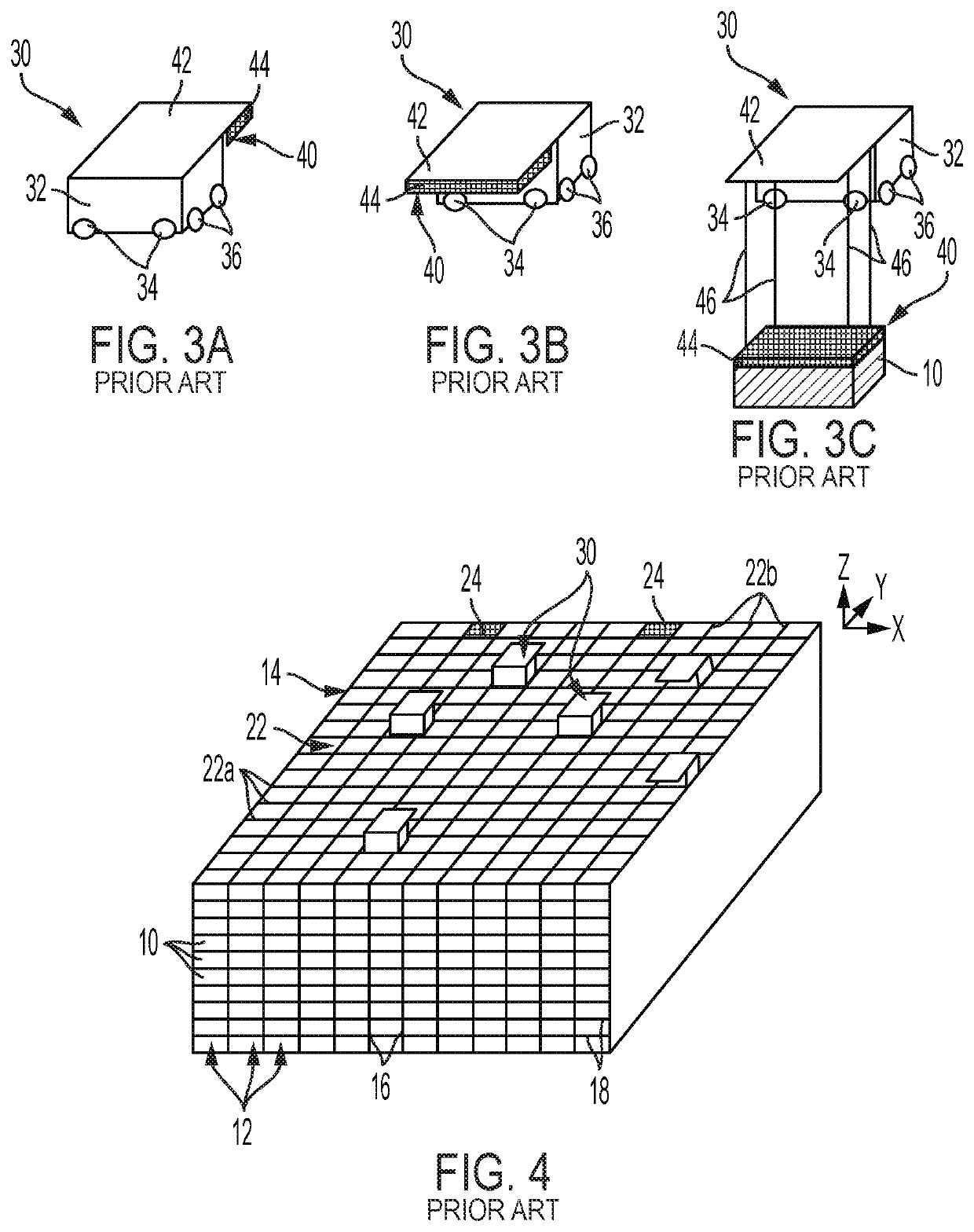

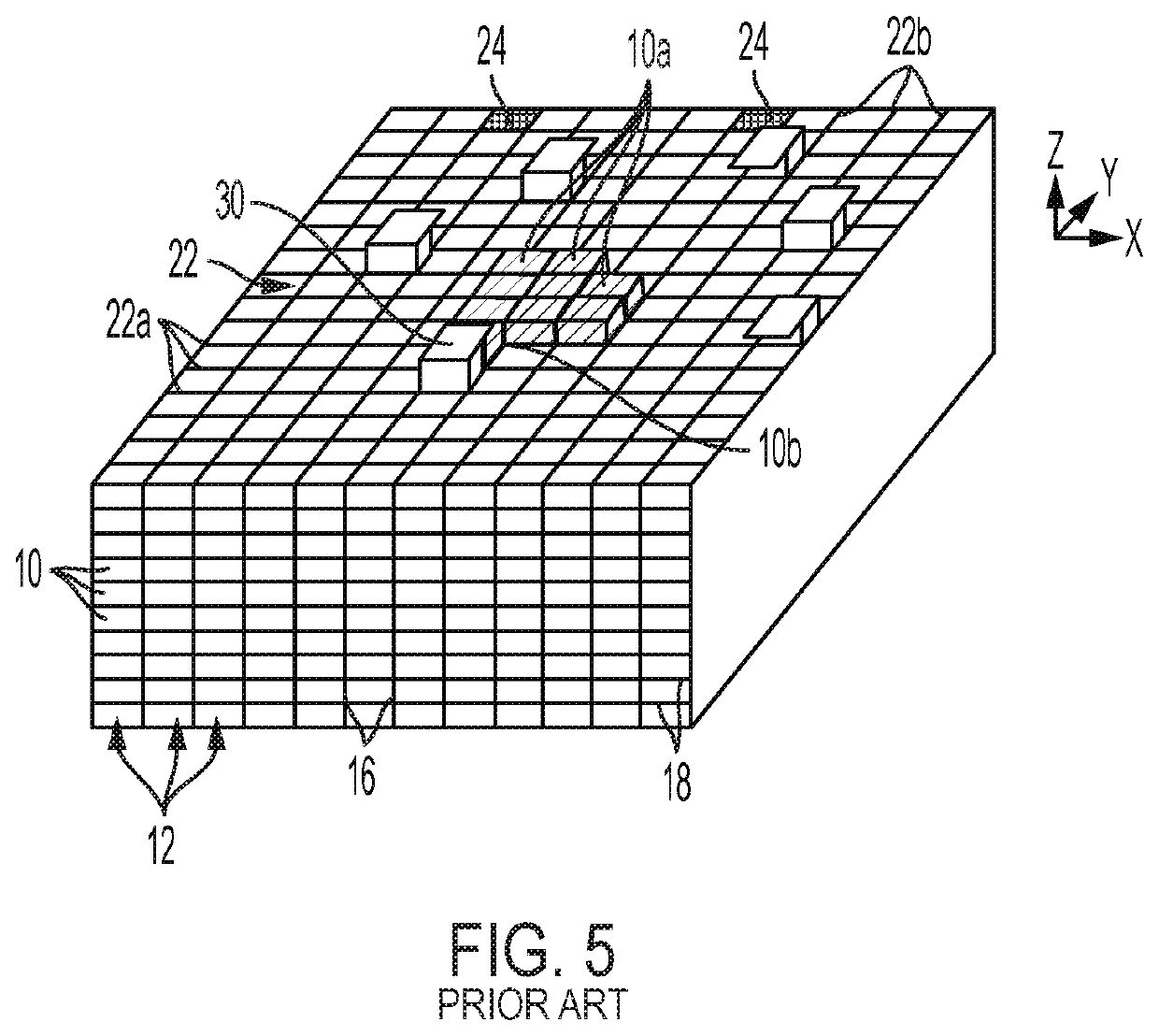

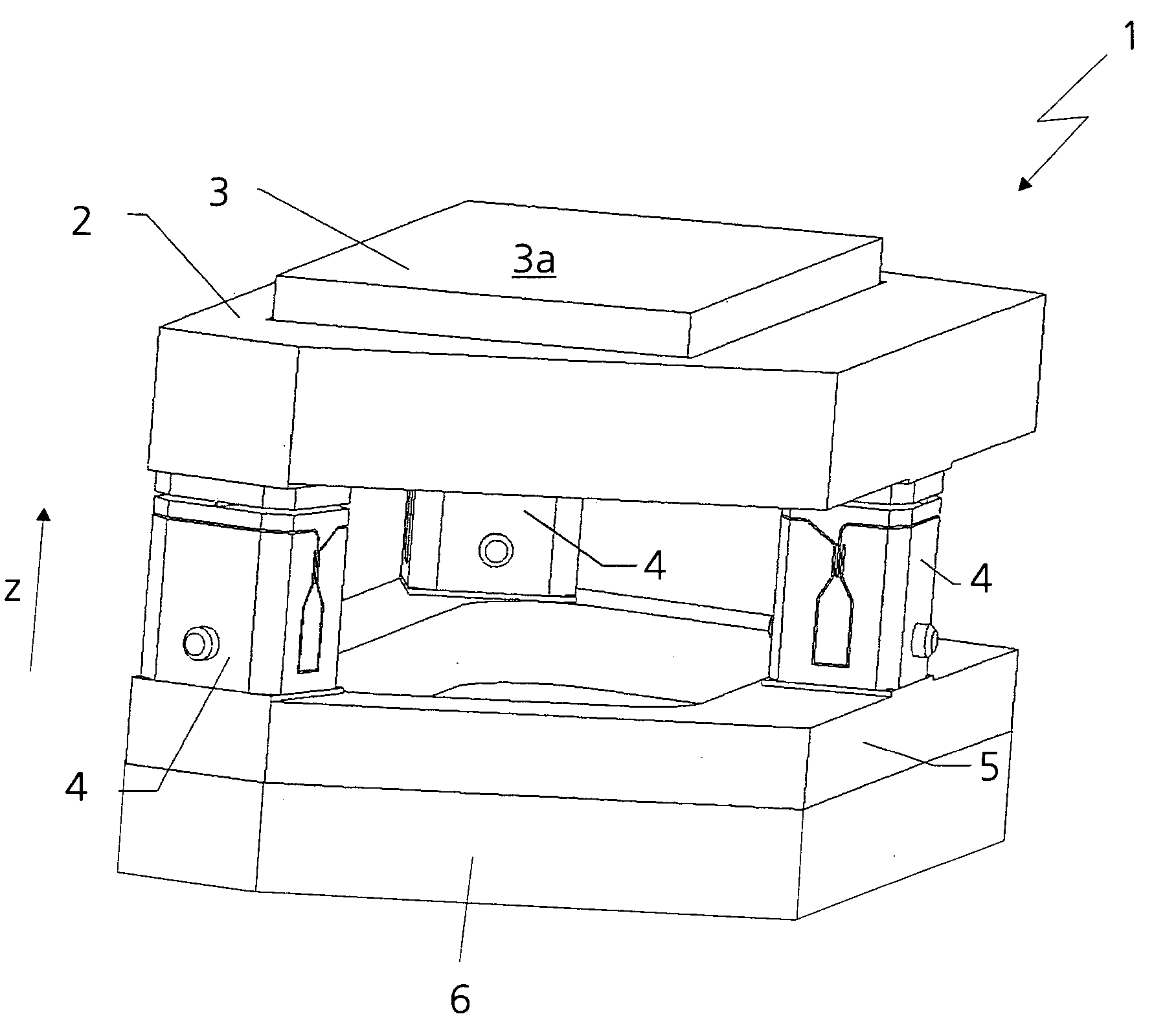

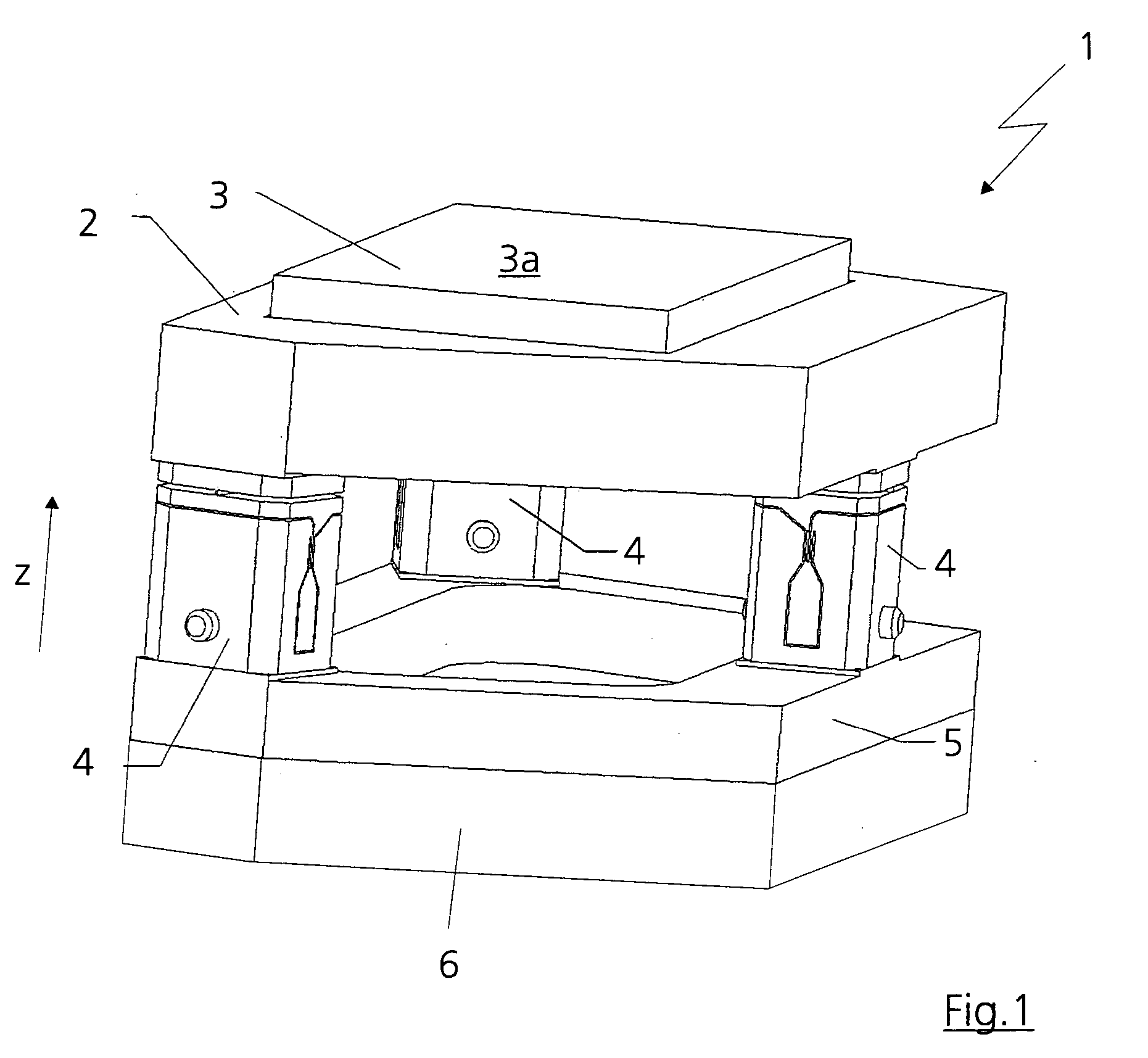

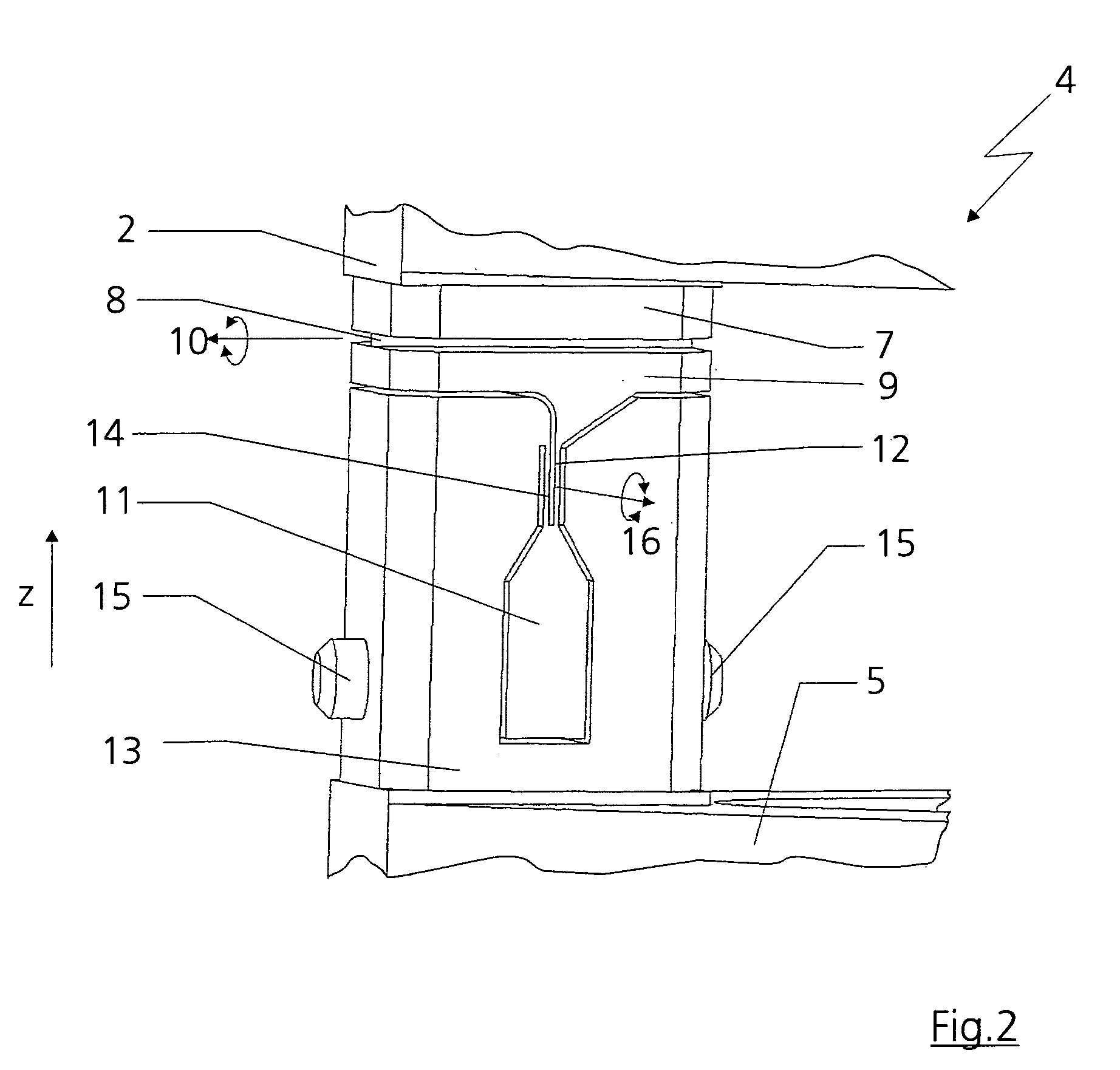

Holding and positioning apparatus for an optical element

InactiveUS20060007563A1Imaging error can be compensatedSuppresses undesired vibrationPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringActuator

In a holding and positioning apparatus for an optical element, the optical element is mounted in a mounting ring and the mounting ring is mounted via at least one manipulator unit. The manipulator unit has a linear actuating element. The manipulator unit has a manipulator head, a movable manipulator part and a manipulator foot, the manipulator head being connected to the movable manipulator part via a solid body joint. The movable manipulator part is connected to the manipulator foot via an actuator and at least one solid body joint, the linear actuating element being coupled to the manipulator foot and the actuator.

Owner:CARL ZEISS SMT GMBH

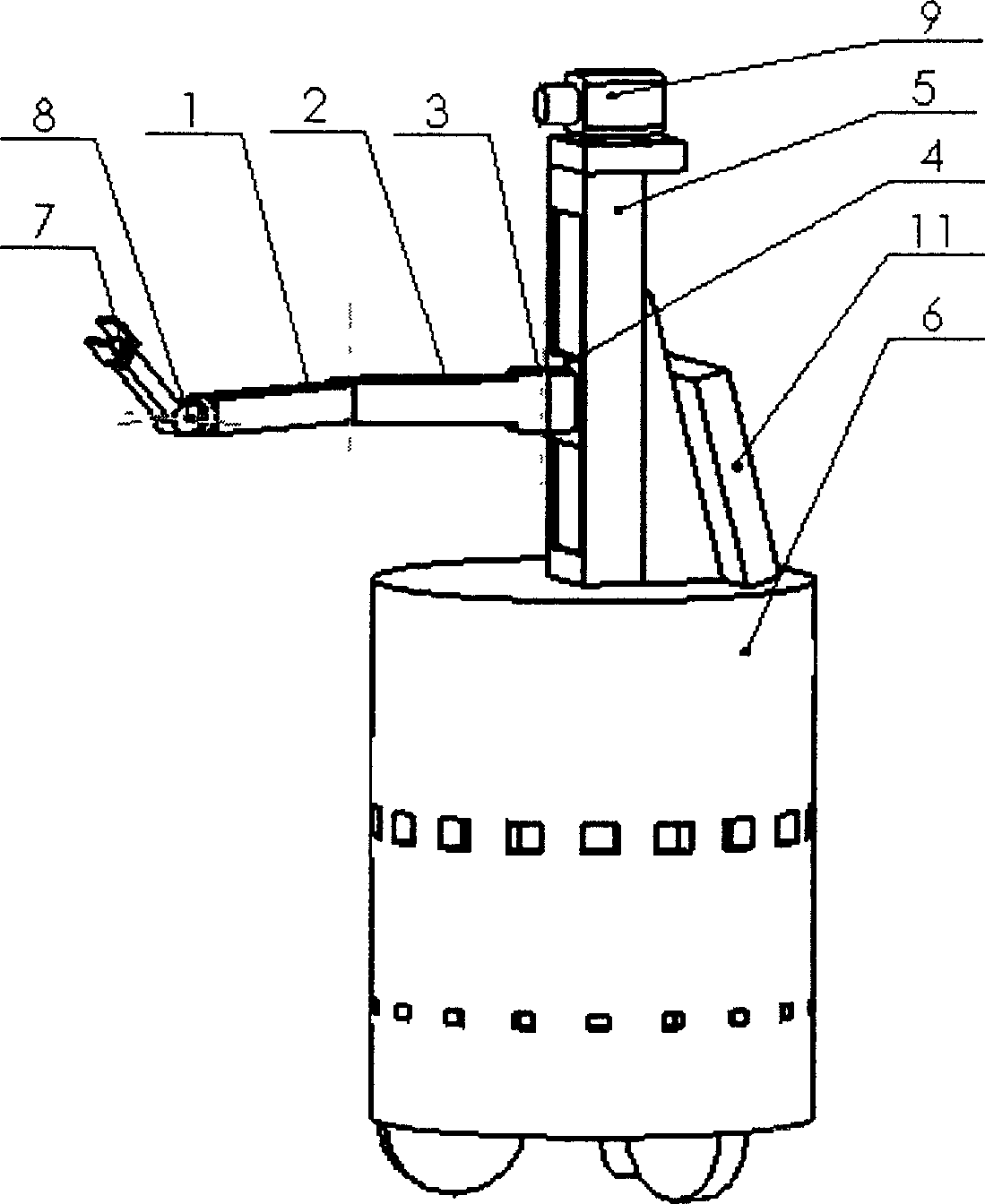

Service-oriented movable manipulator system

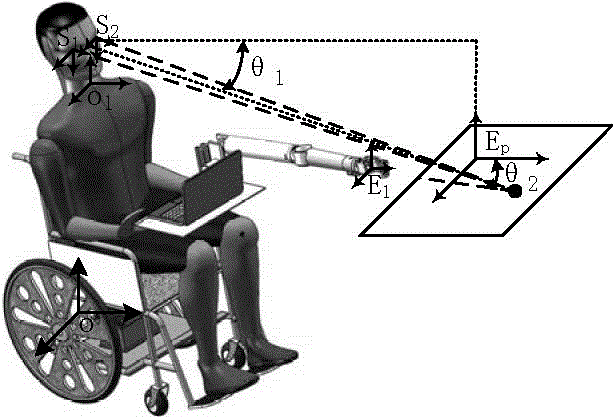

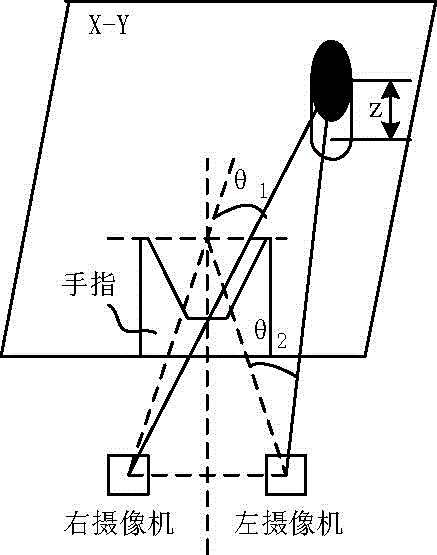

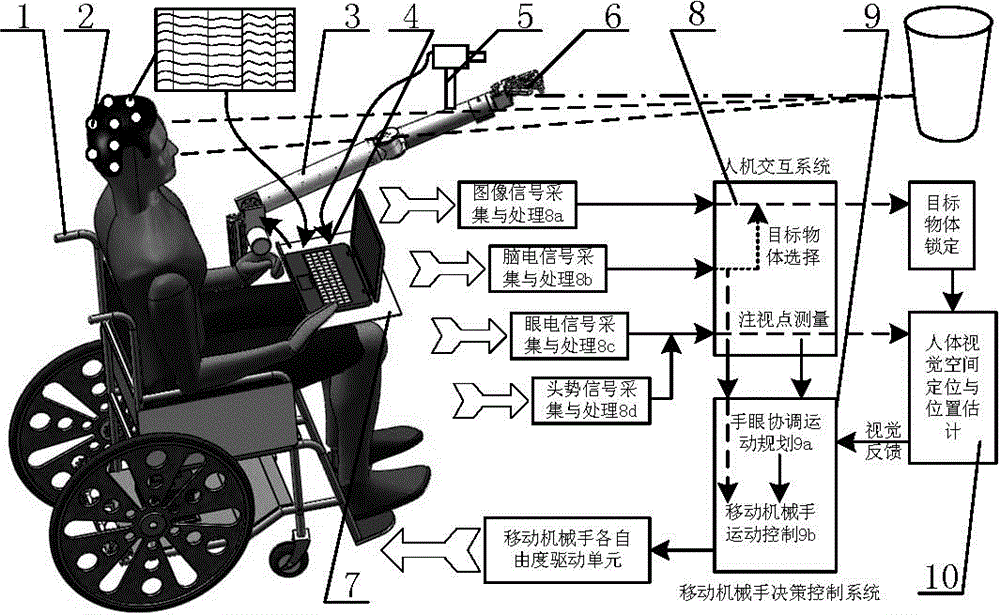

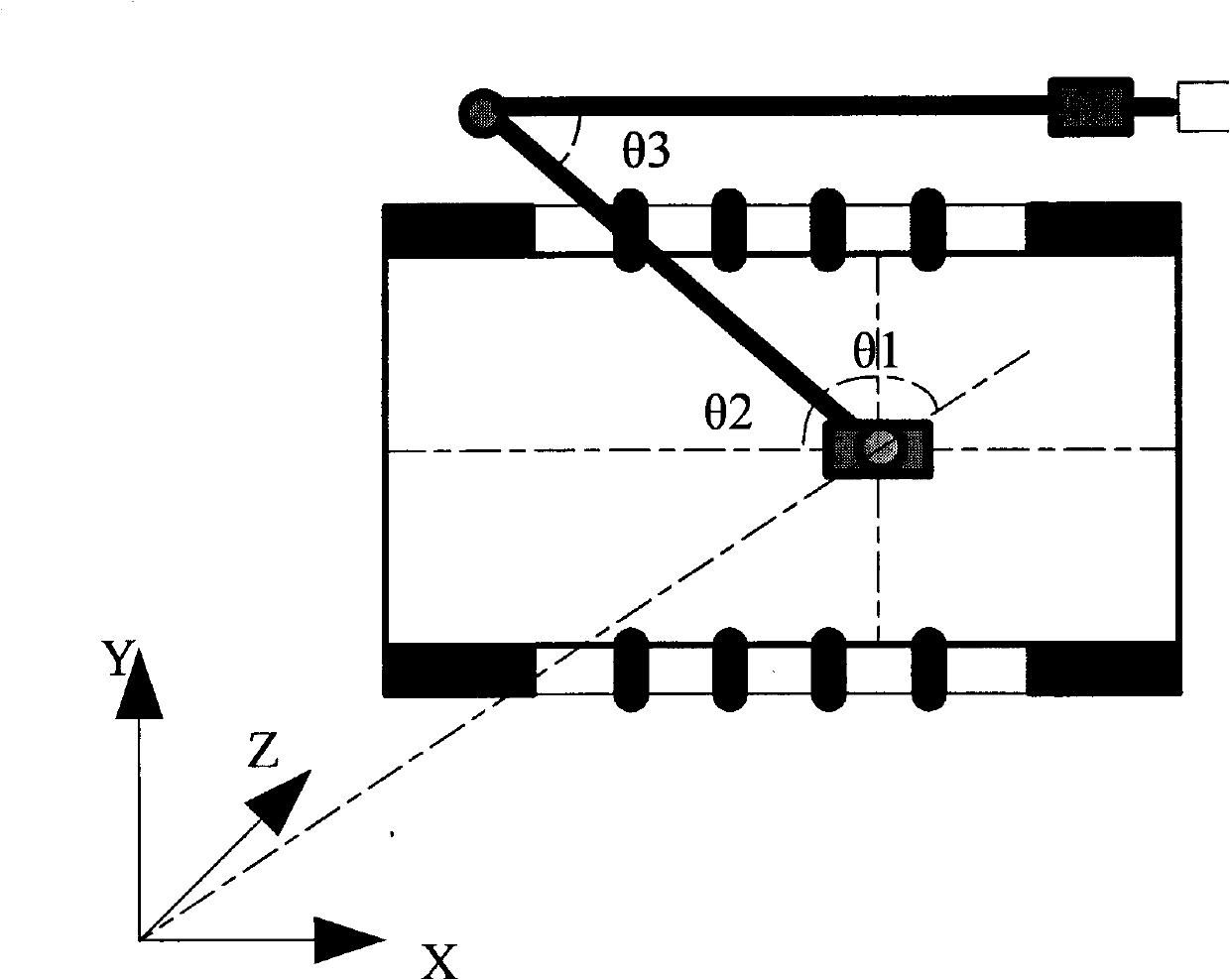

The invention discloses a service-oriented movable manipulator system. The hand-eye coordinated movement of human vision and a movable manipulator is achieved for the target discovery and orientation of human contact movement and the process that arms approach a target and the target is aimed. The service-oriented movable manipulator system mainly comprises a head information collecting system 3, a man-machine interactive system 8, a movable manipulator decision control system 9, a human visual special orientation and position estimation system 10 and the like, wherein the man-machine interactive system 8 is composed of a picture signal collecting and processing module 8a, an electroencephalogram collecting and processing module 8b, an electro-oculogram collecting and processing module 8c and a head gesture signal collecting and processing module 8d. According to the human visual special orientation and position estimation system 10, the target discovery is formed with the characteristics of eye fixation points, the special orientation and position of a target object are estimated on the basis of electro-oculogram and head motion information, and accordingly motion planning and motion control of the movable manipulator are achieved, and the hand-eye coordinated movement of a human body and the movable manipulator is achieved.

Owner:山东华工科技发展集团有限公司

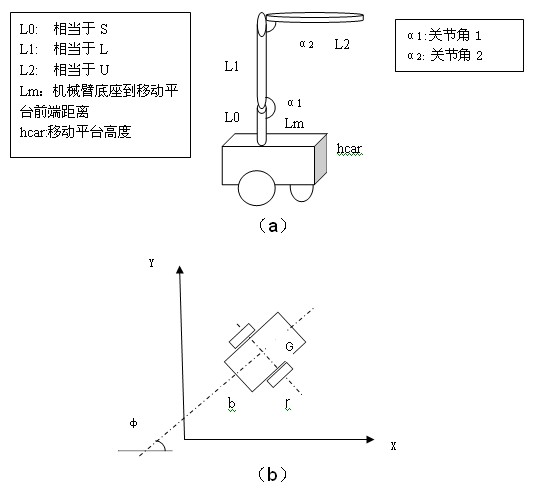

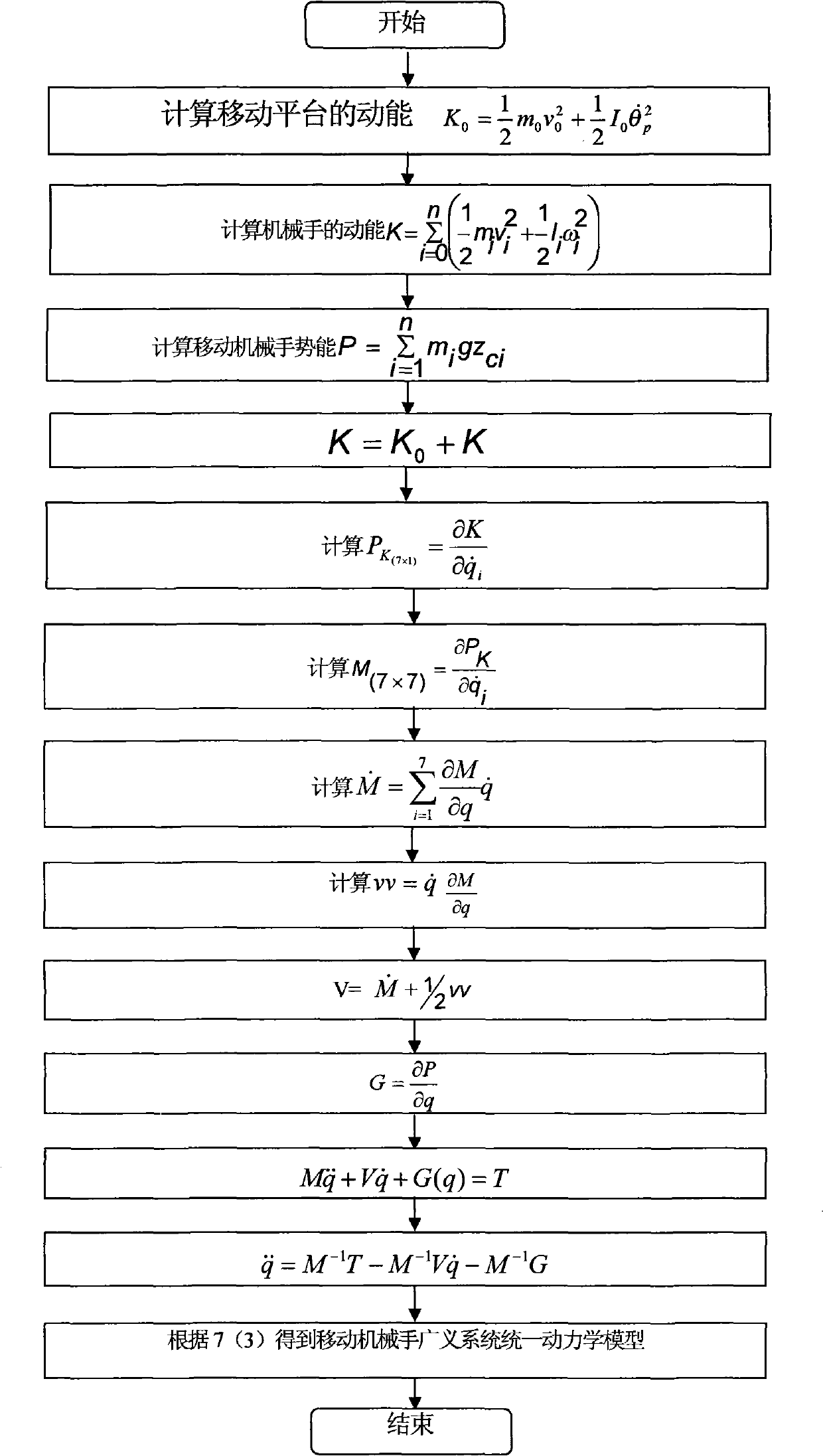

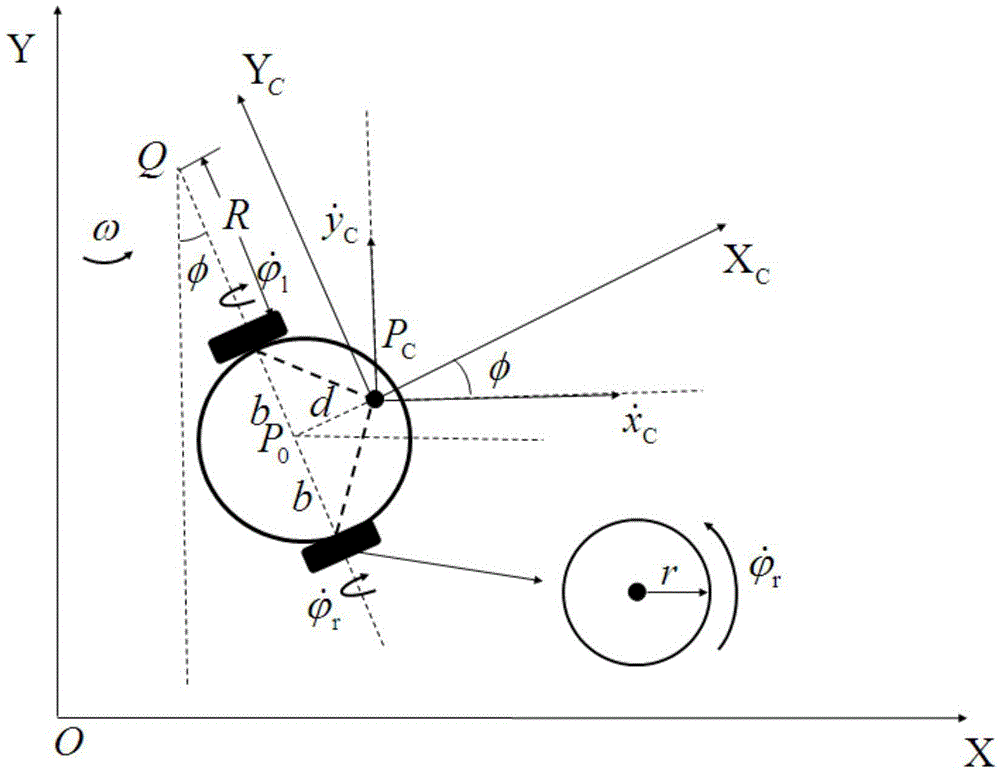

Unified dynamic modeling method of generalized system of crawler-type mobile manipulator

InactiveCN101526801AAvoid control errorOvercoming control difficultiesSimulator controlManipulatorDynamic methodSimulation

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

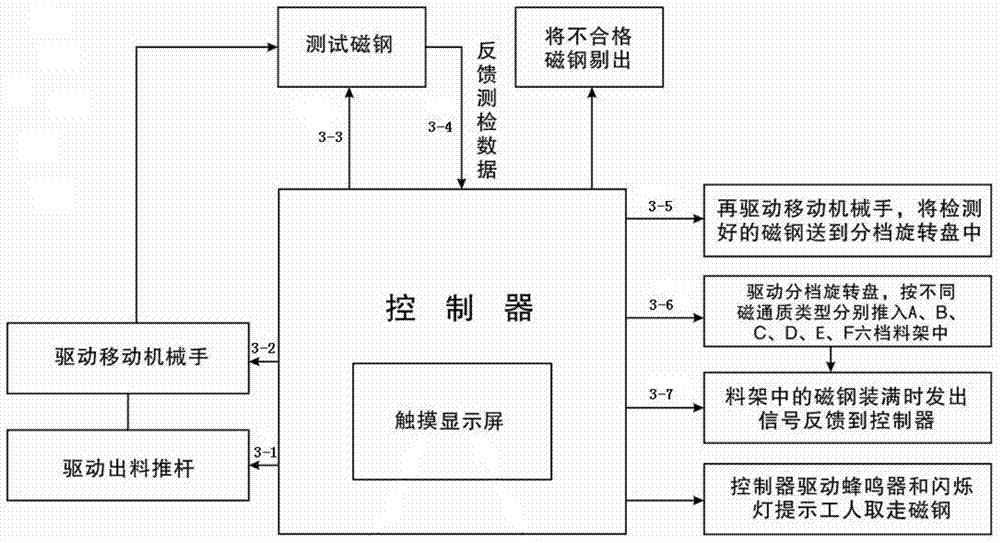

Equipment and method for automatically detecting magnetic flux of special magnetic steel for electronic power motor of steering wheel of automobile

InactiveCN104515959AImprove accuracySorting error reductionMagnetic property measurementsSortingProduction rateSteering wheel

The invention relates to equipment and a method for automatically detecting the magnetic flux of special magnetic steel for an electronic power motor of a steering wheel of an automobile. The equipment consists of a detection waiting platform, a detection platform, a rotary table and a charging hopper frame which are sequentially arranged, wherein a discharging cylinder pushing rod is arranged at one end of the detection waiting platform, and a detection waiting movement station is arranged at the other end of the detection waiting platform; a magnetic steel discharging hopper frame is further arranged on the detection waiting platform and is positioned between the discharging cylinder pushing rod and the detection waiting movement station; a movement manipulator is arranged on the detection platform; a vacuum suction cup is arranged below the material taking end of the movement manipulator; a charging pushing rod and six graded material baskets are arranged on the rotary table; the material baskets and the charging hopper frame are correspondingly placed. The equipment has the benefits that the equipment replaces a mode of manually detecting and sorting the magnetic steel, so that the labor production rate is effectively improved, the production cost is reduced, errors in the manual detection and sorting processes are reduced, and the quality of products is greatly improved.

Owner:ZHEJIANG RONGCHUANG MAGNETIC IND

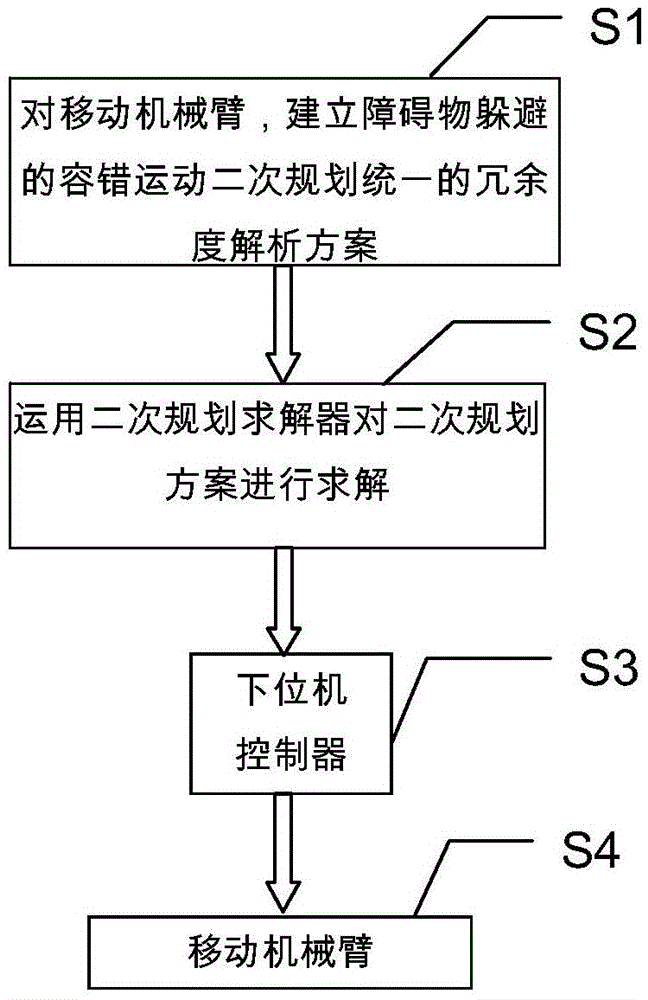

Fault tolerant motion planning method for obstacle avoidance of mobile manipulator

InactiveCN105563490AAvoid the tedious process of constantly testing/tuning parametersProgramme-controlled manipulatorDrive wheelPlanning approach

The invention provides a fault tolerant motion planning method for obstacle avoidance of a mobile manipulator. The method includes the following steps that (1) a joint or a driving wheel which is locked due to faults is determined, a uniform redundancy analysis scheme for secondary planning is built for the mobile manipulator, and the minimum performance index designed in the analysis scheme is a quadratic function of a joint velocity vector of a mobile platform and the mobile manipulator; (2) the uniform coordinated redundancy analysis scheme for secondary planning is solved by using a secondary planning solver; and (3) a solving result is transmitted to a lower computer controller, and the mobile platform and the mobile manipulator are driven to complete a given tail end task cooperatively at the same time. Due to uniform description and planning of the mobile platform and the mobile manipulator, as long as the serial number and the locking angle of the joint or the driving wheel which is locked due to faults are known, automatic fault tolerant processing can be conducted; the mobile platform of the mobile manipulator and the mobile manipulator are controlled to move cooperatively at the same time, obstacles can be avoided, and the given tail end task is completed.

Owner:JISHOU UNIVERSITY

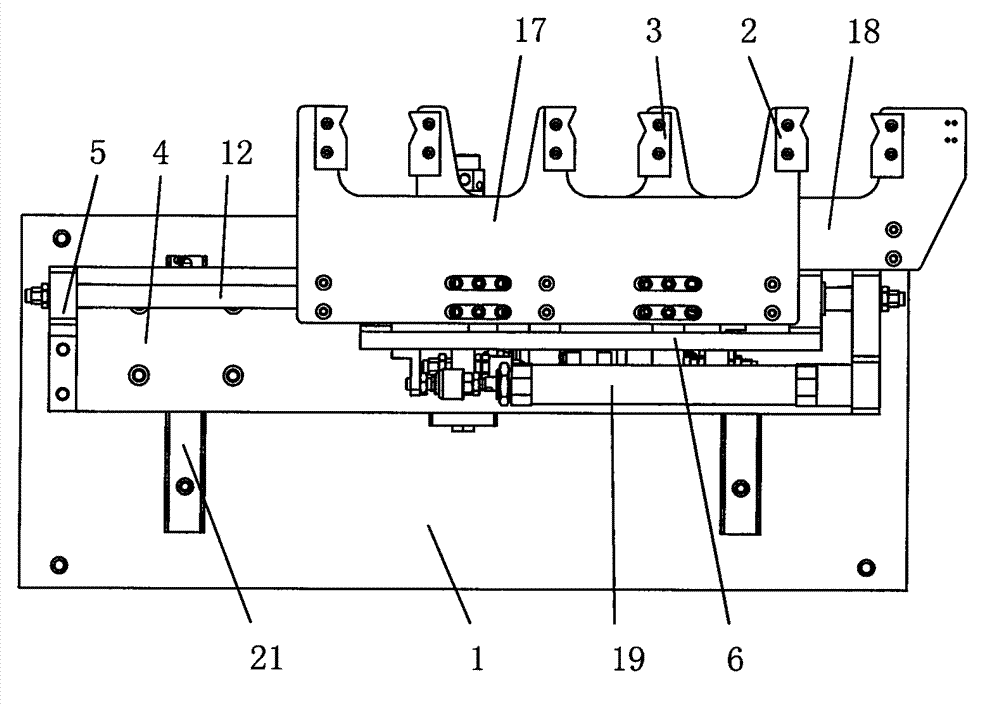

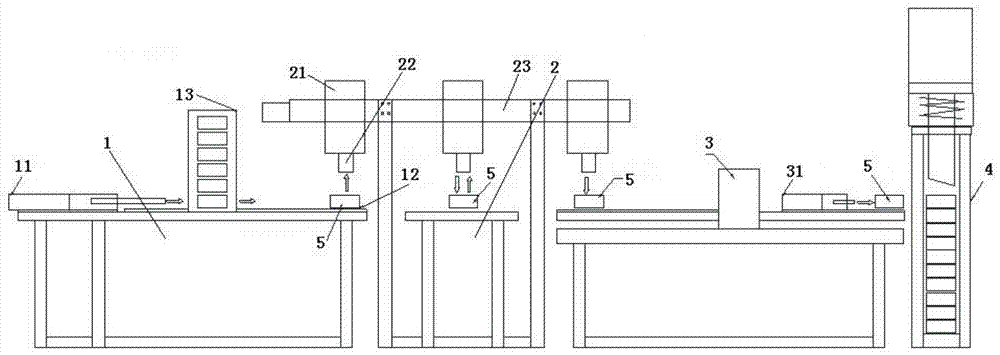

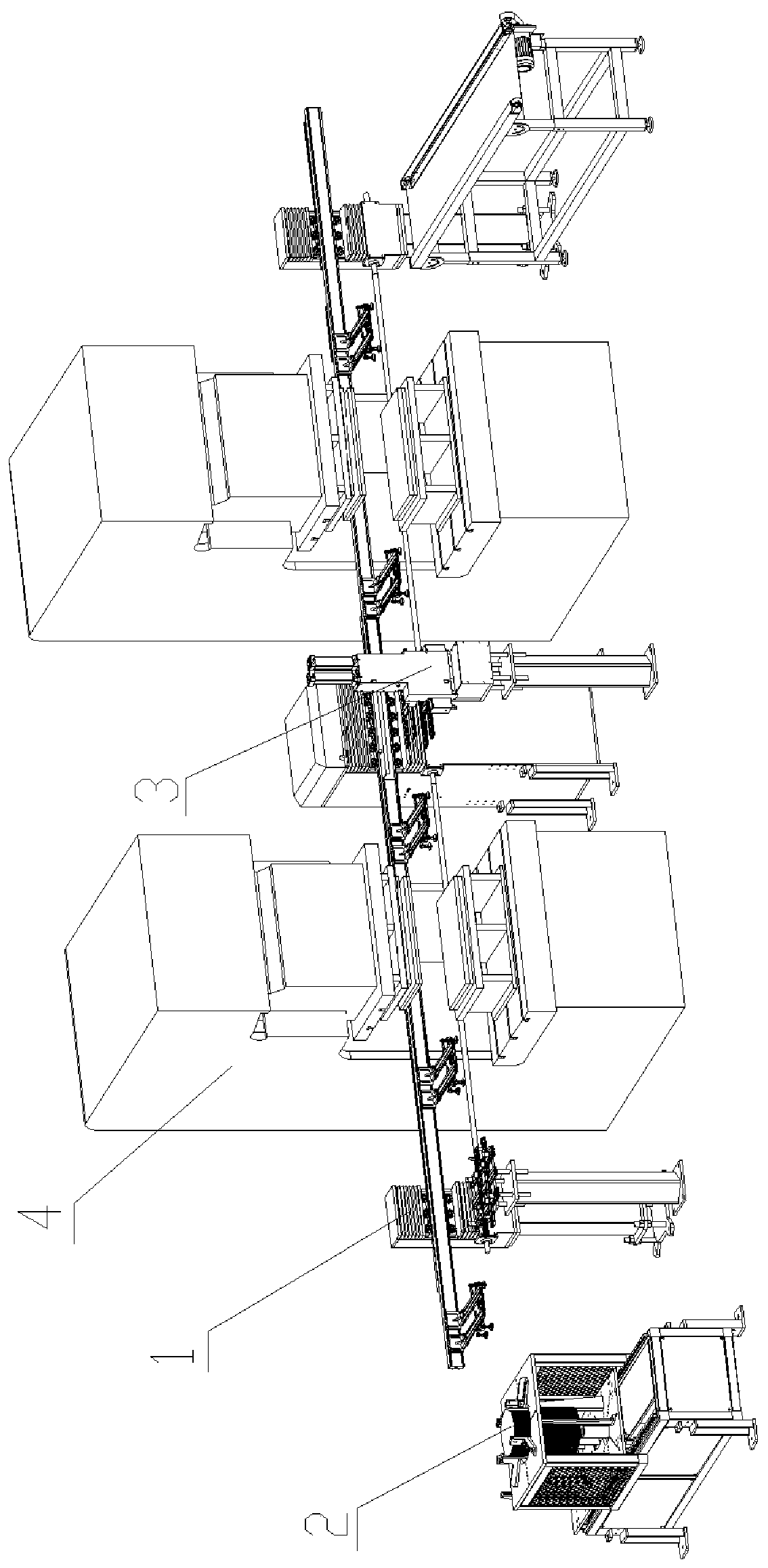

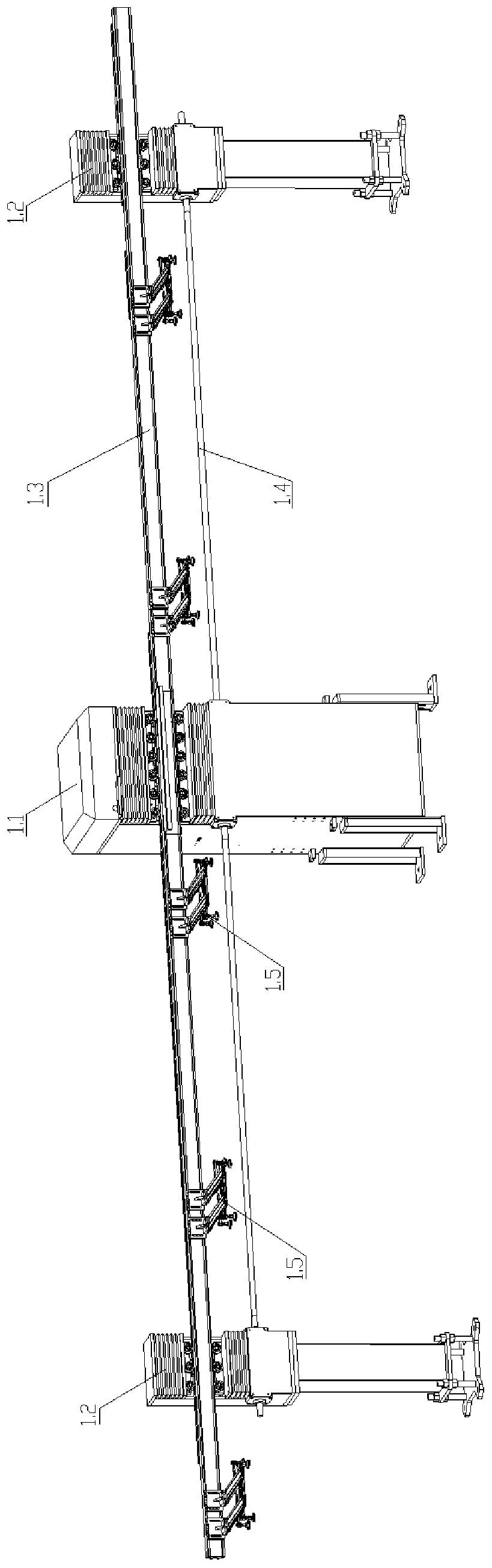

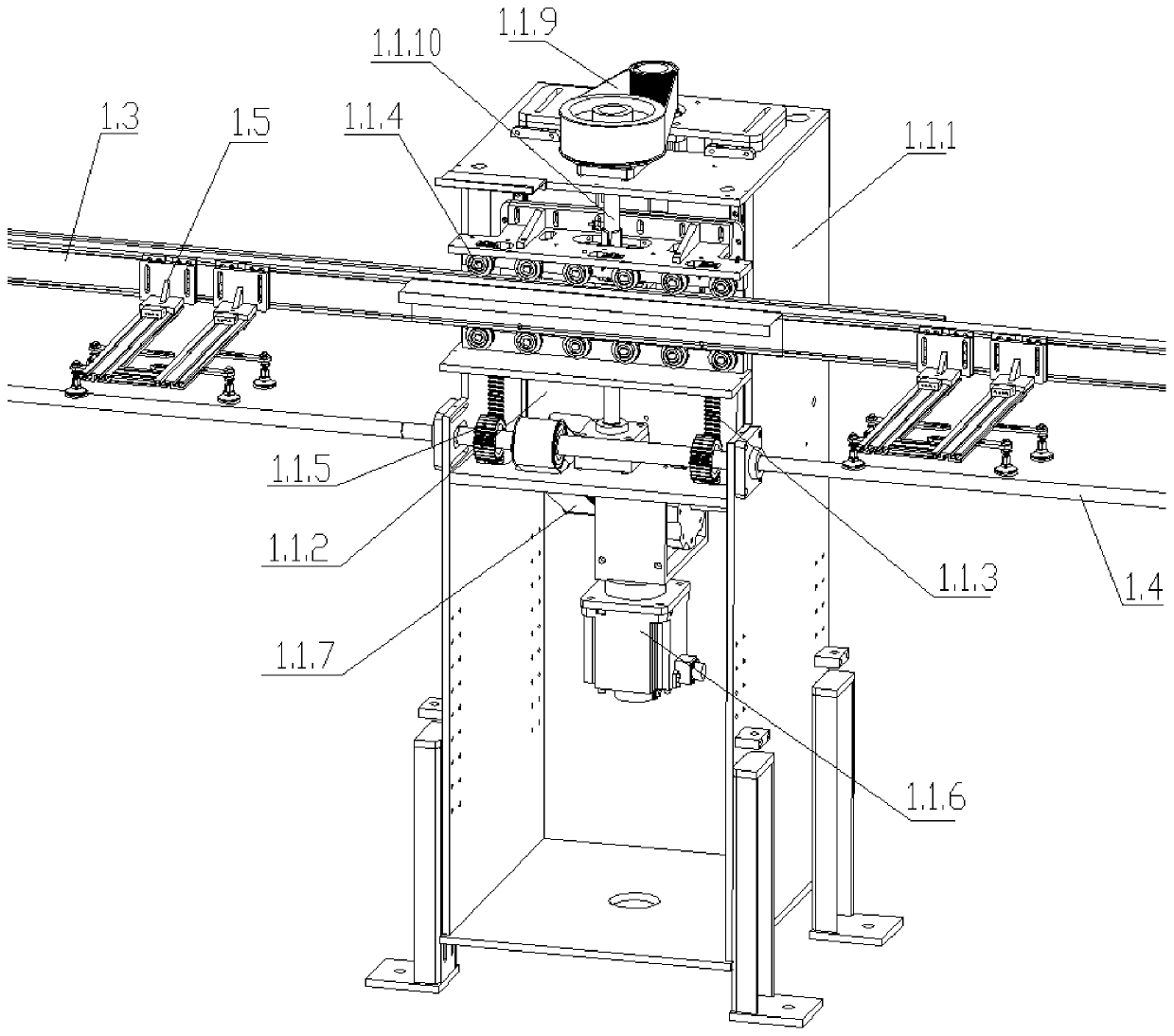

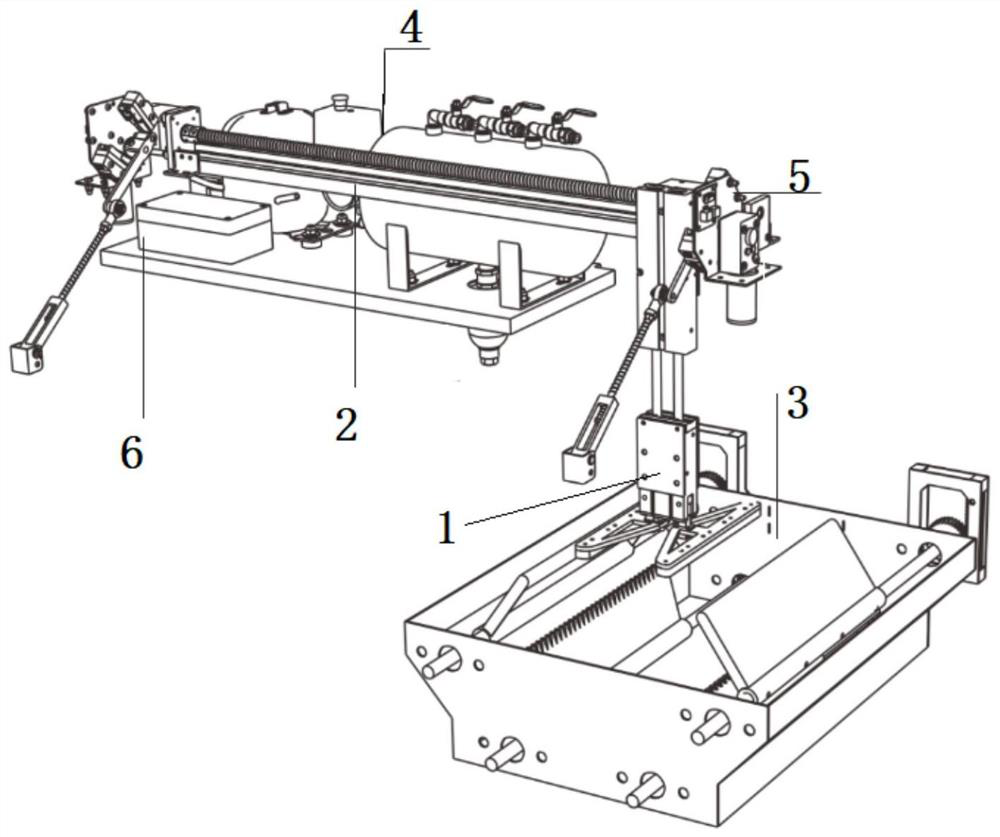

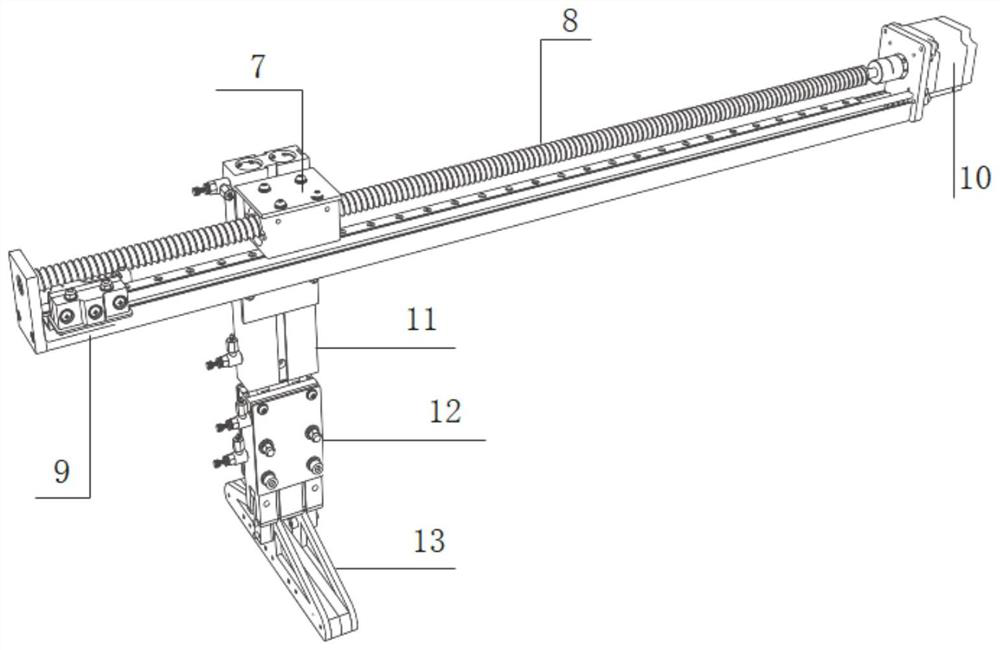

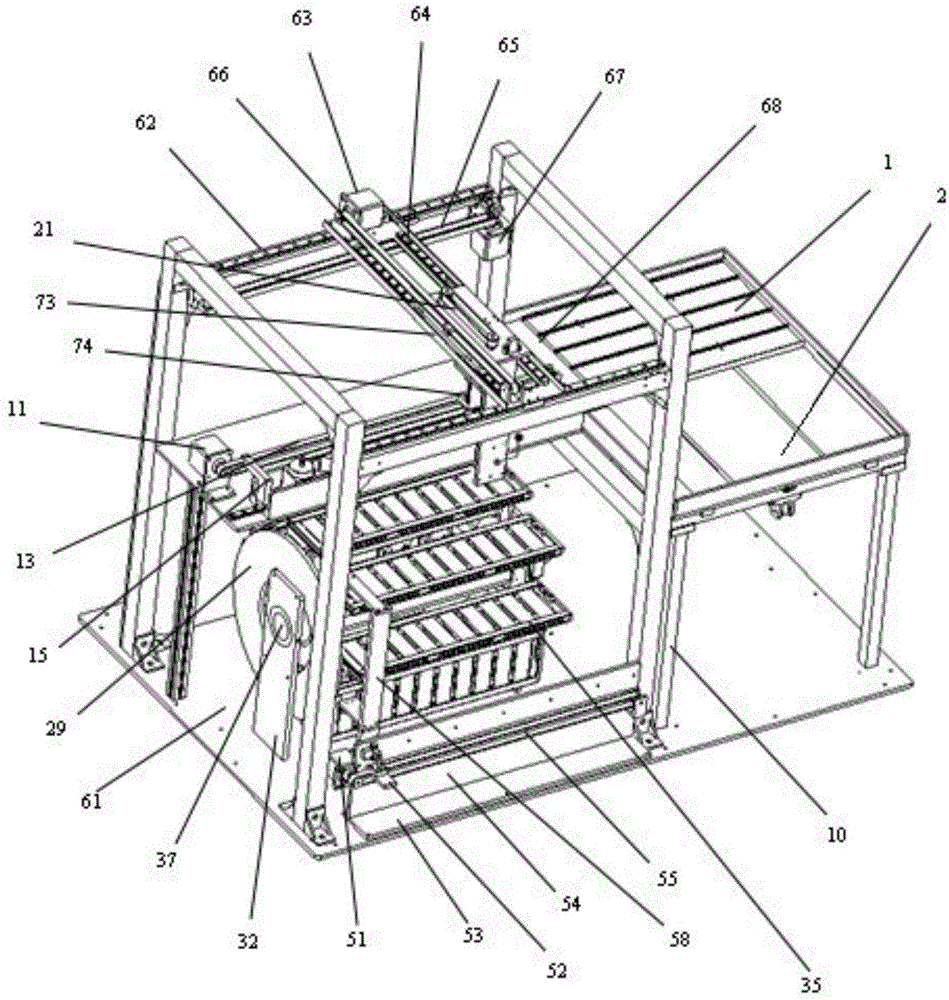

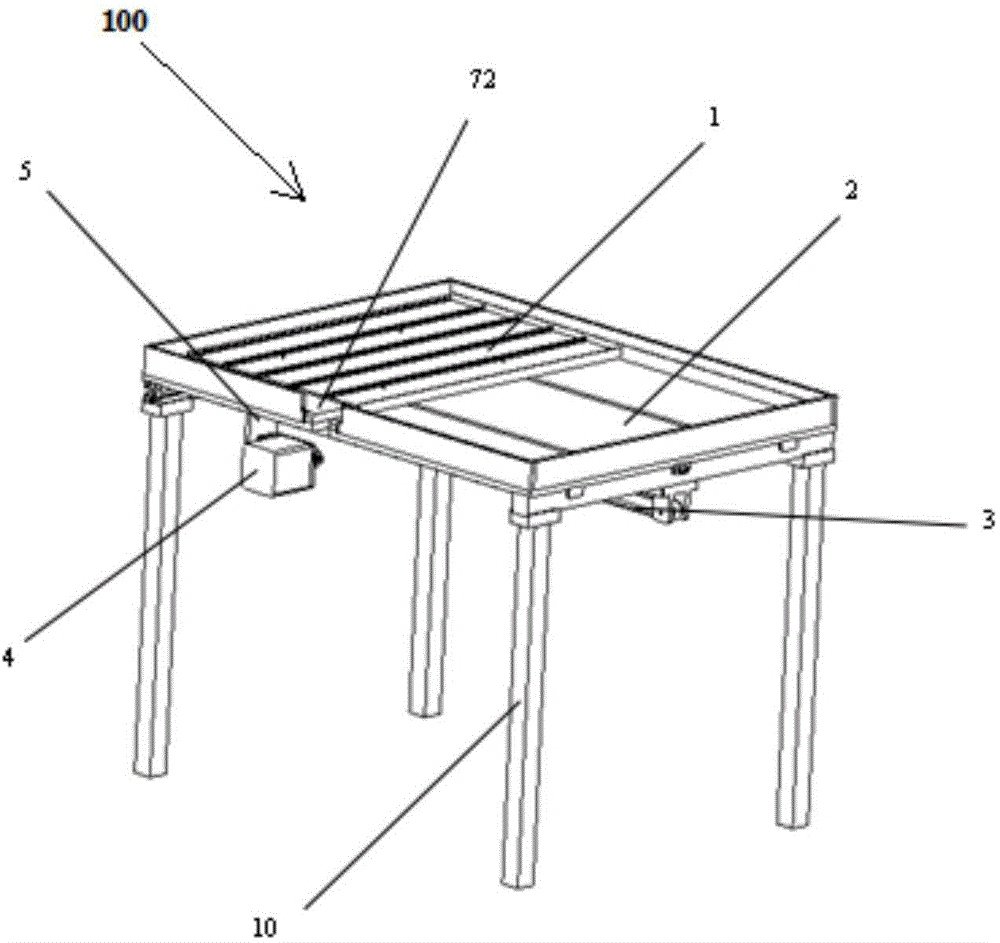

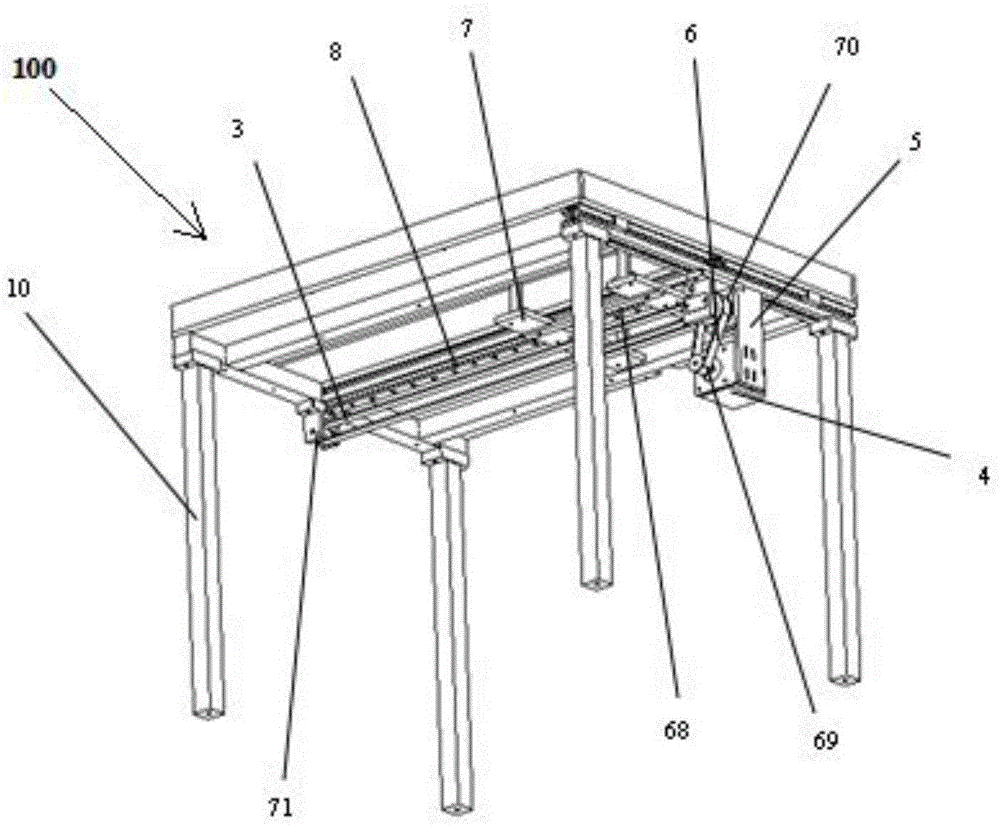

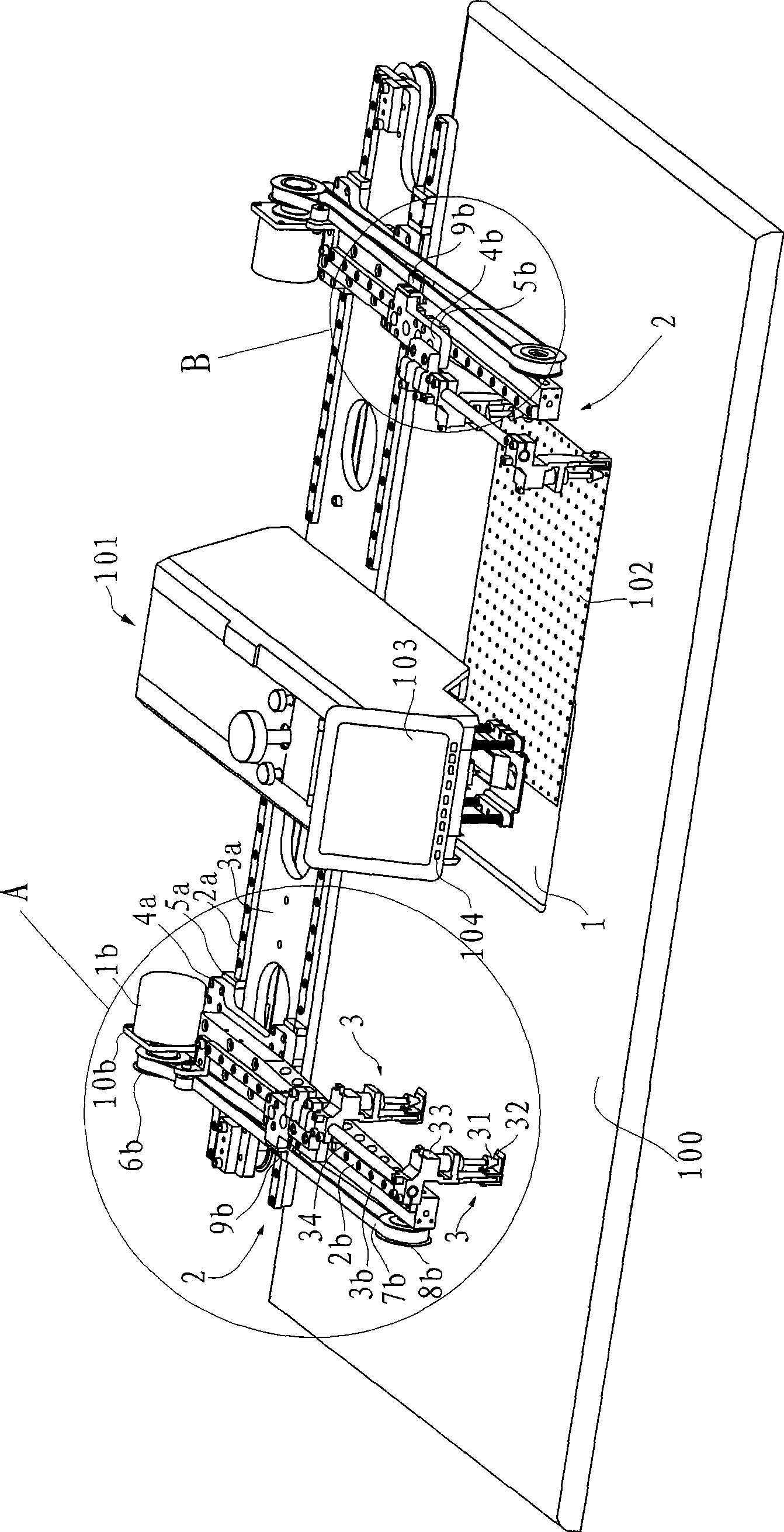

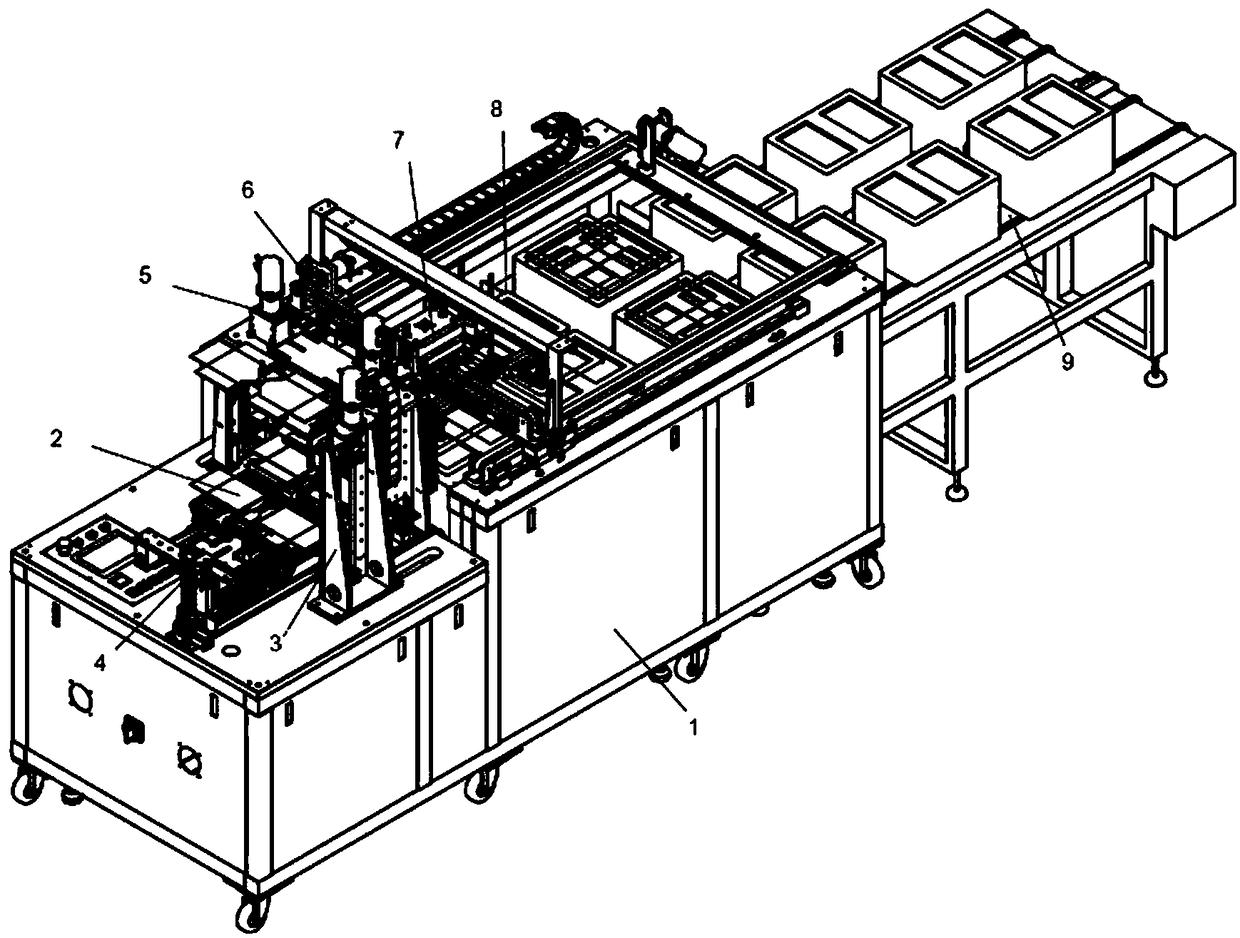

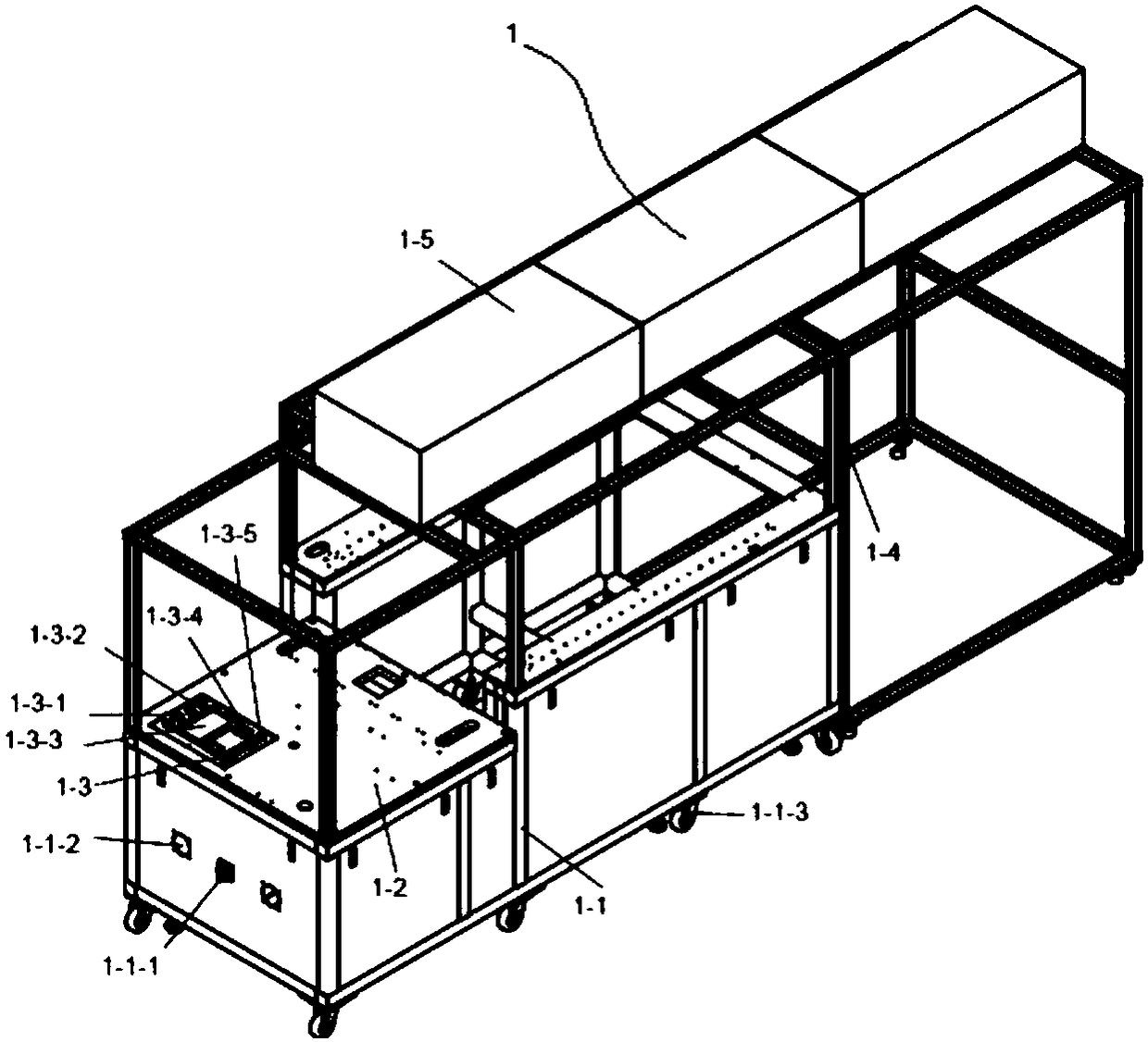

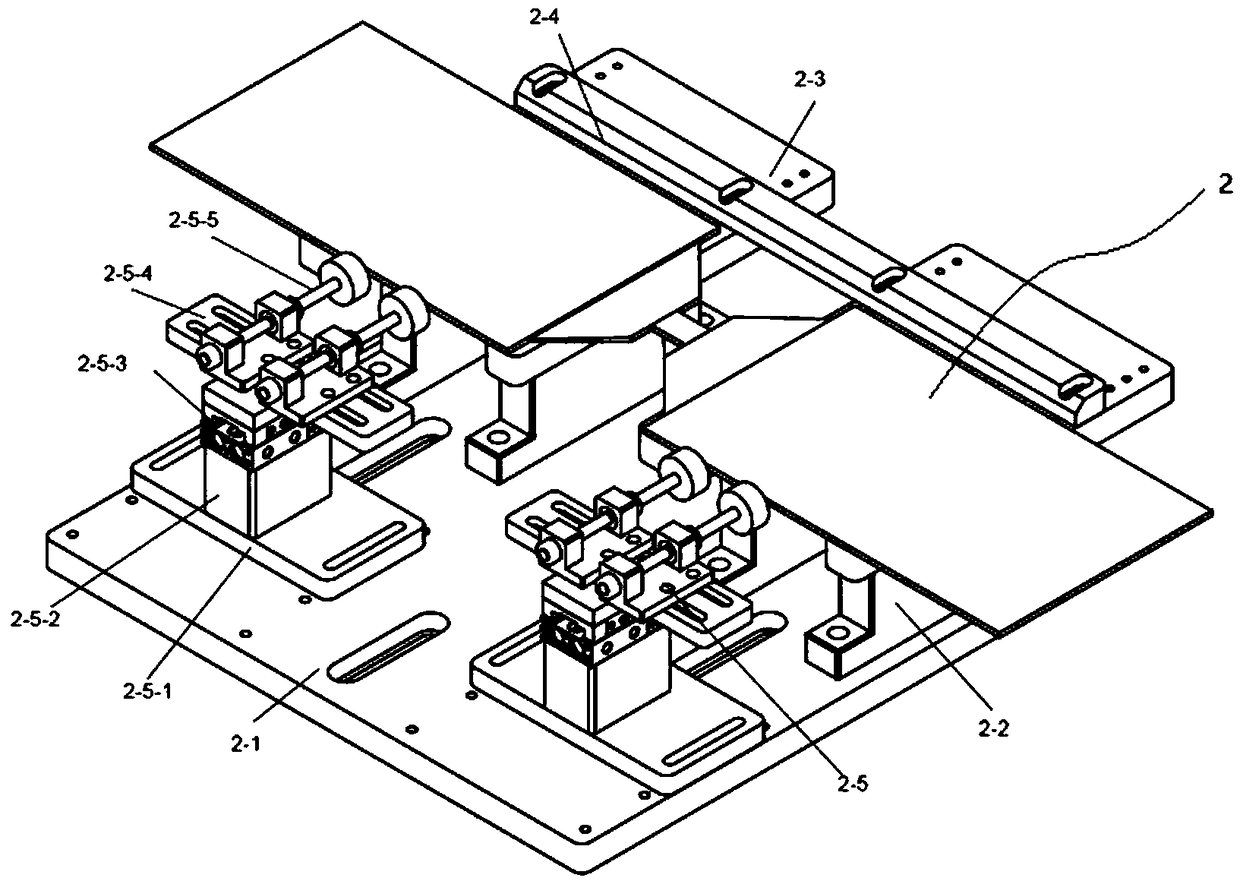

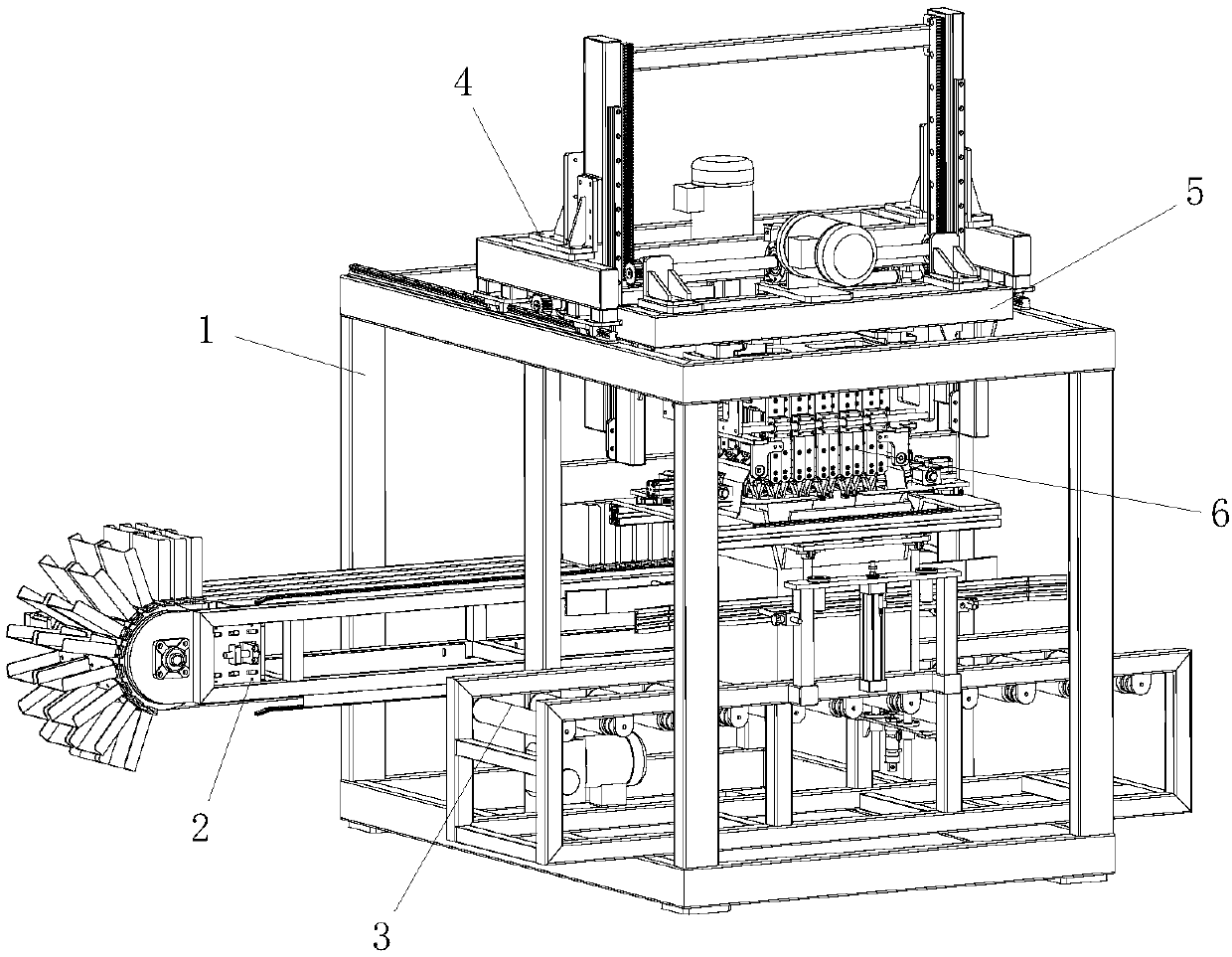

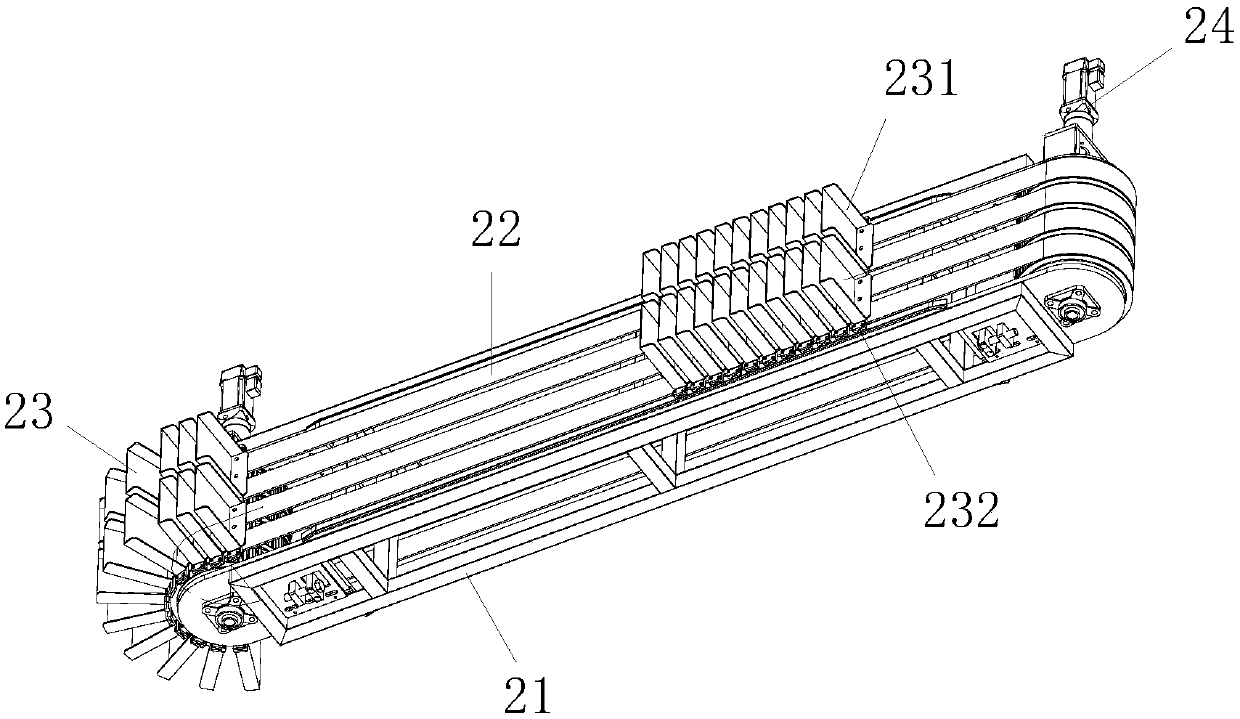

Automatic production line for metal plate punch forming and production process thereof

InactiveCN110369587AImprove work efficiencyImprove stamping effectMetal-working feeding devicesStripping-off devicesProduction linePunching

The invention discloses an automatic production line for metal plate punch forming and a production process thereof. The automatic production line comprises a feeding assembly (2), a connection rod type mobile manipulator assembly (1), a horizontal overturn assembly (3), a punching machine (4) and a discharging conveyer (5), wherein the feeding assembly (2) is used for storing and enhancing a to-be-punched metal plate; the connection rod type mobile manipulator assembly (1) is used for grabbing the to-be-punched metal plate in the feeding assembly (2) and transferring the to-be-punched metal plate to the punching machine (4); the horizontal overturn assembly (3) is used for carrying out 180-degree horizontal overturn on the to-be-punched metal plate so as to realize double-side punching; the punching machine (4) is used for punching the to-be-punched metal plate of the connection rod type mobile manipulator assembly; and the connection rod type mobile manipulator assembly (1) is further used for the metal plate punched by the punching machine (4) to the discharging conveyer (5). The automatic production line for metal plate punch forming and the production process thereof have theadvantages of being high in processing efficiency, good in processing effect and good in processing consistency.

Owner:江阴市万和自动设备有限公司

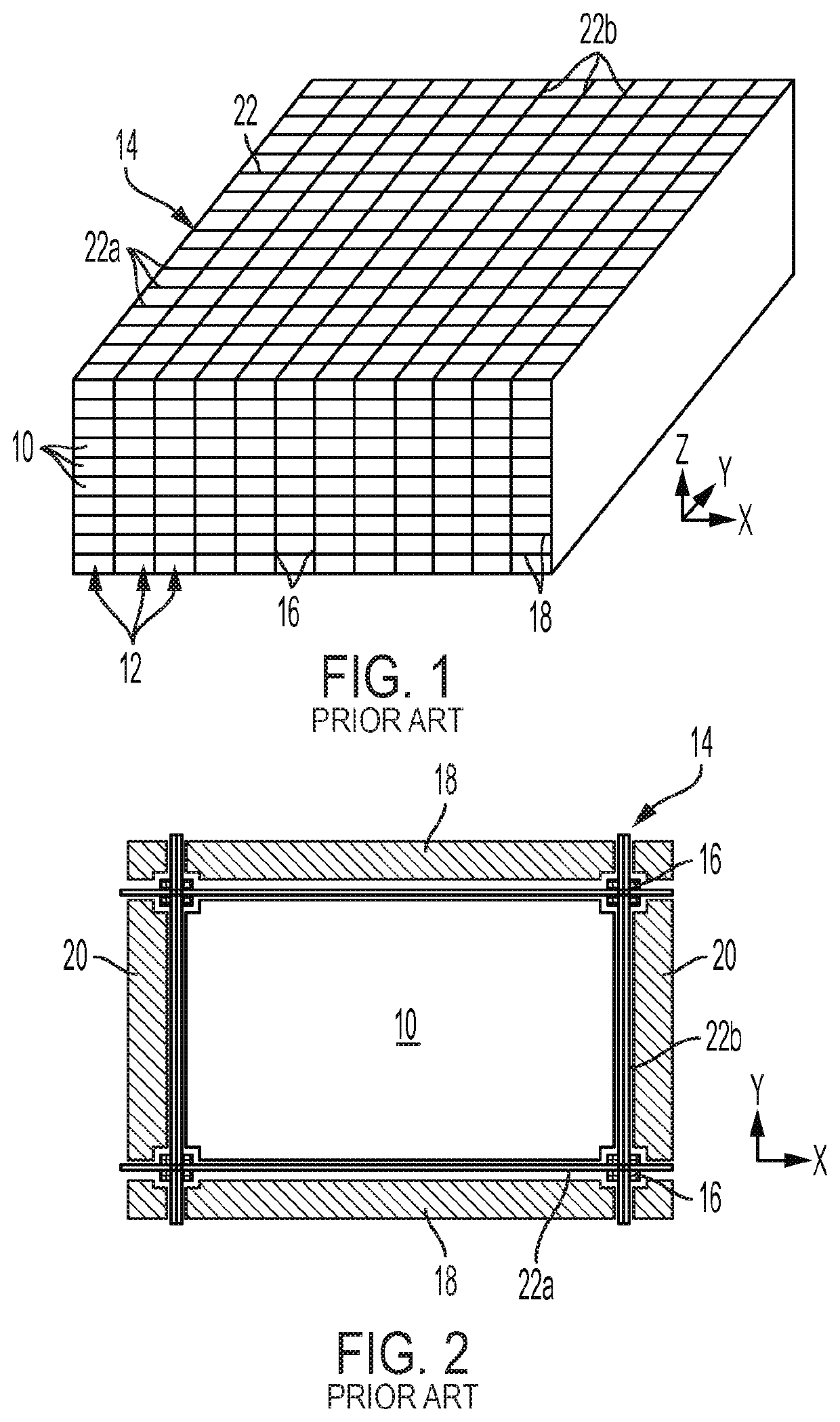

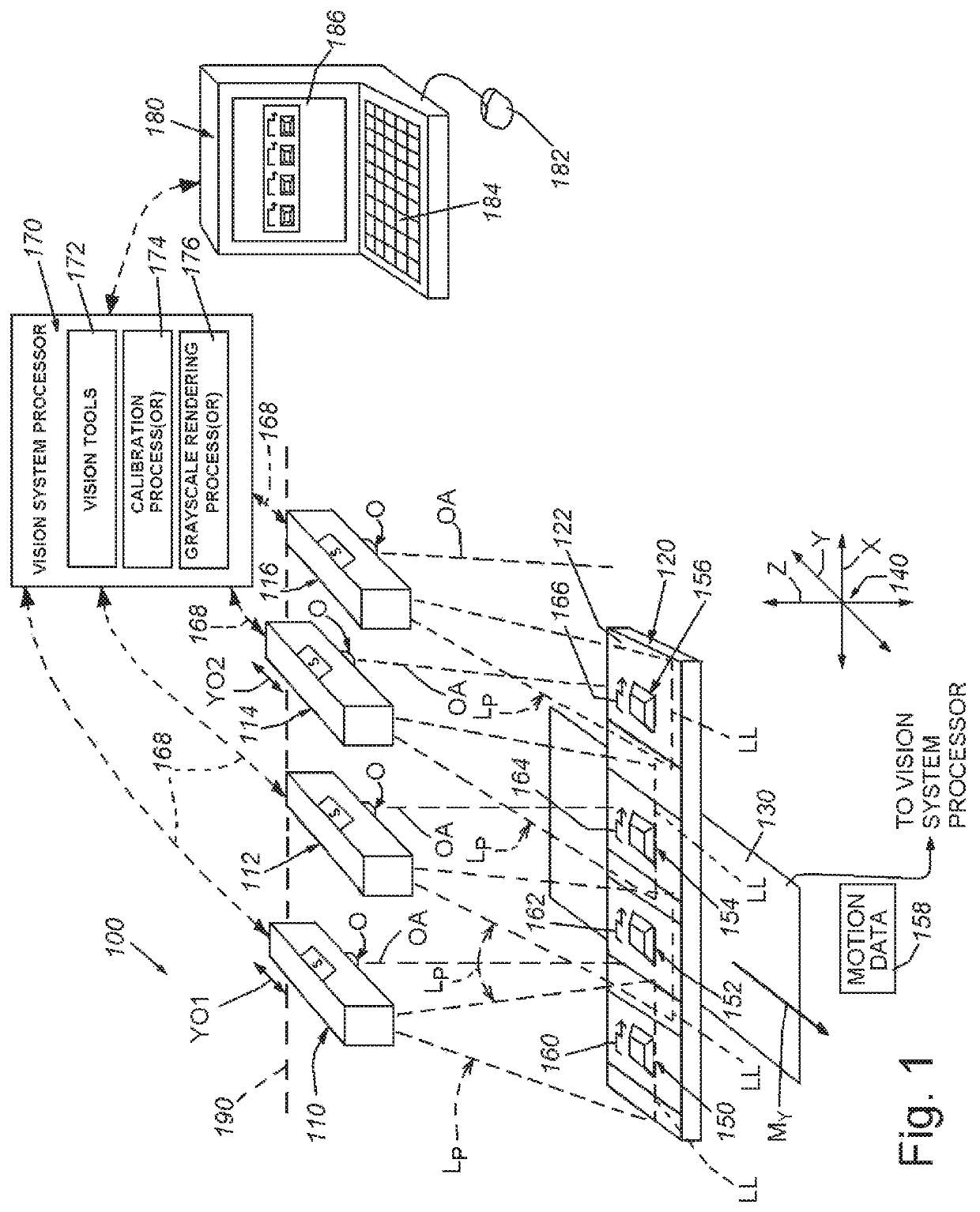

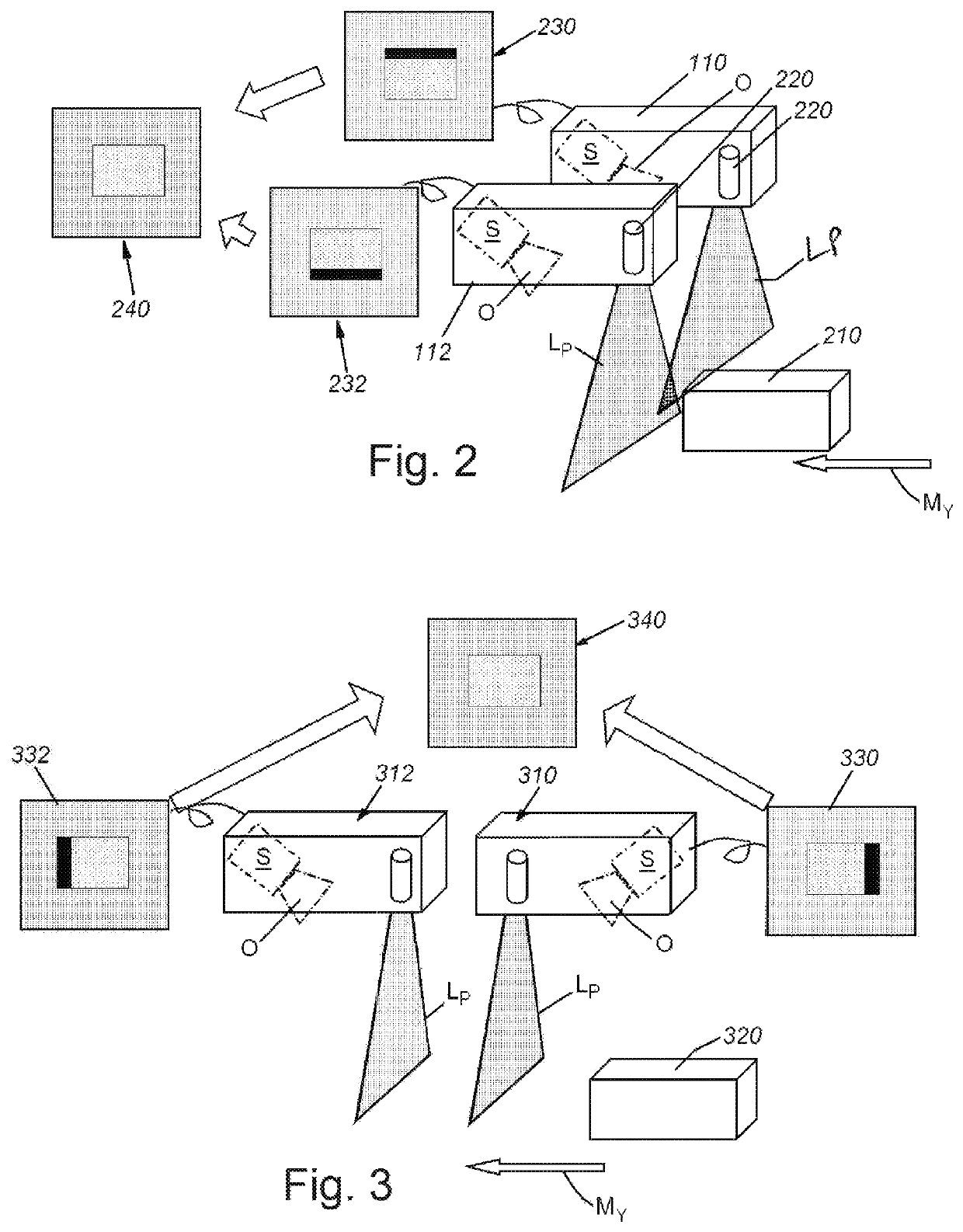

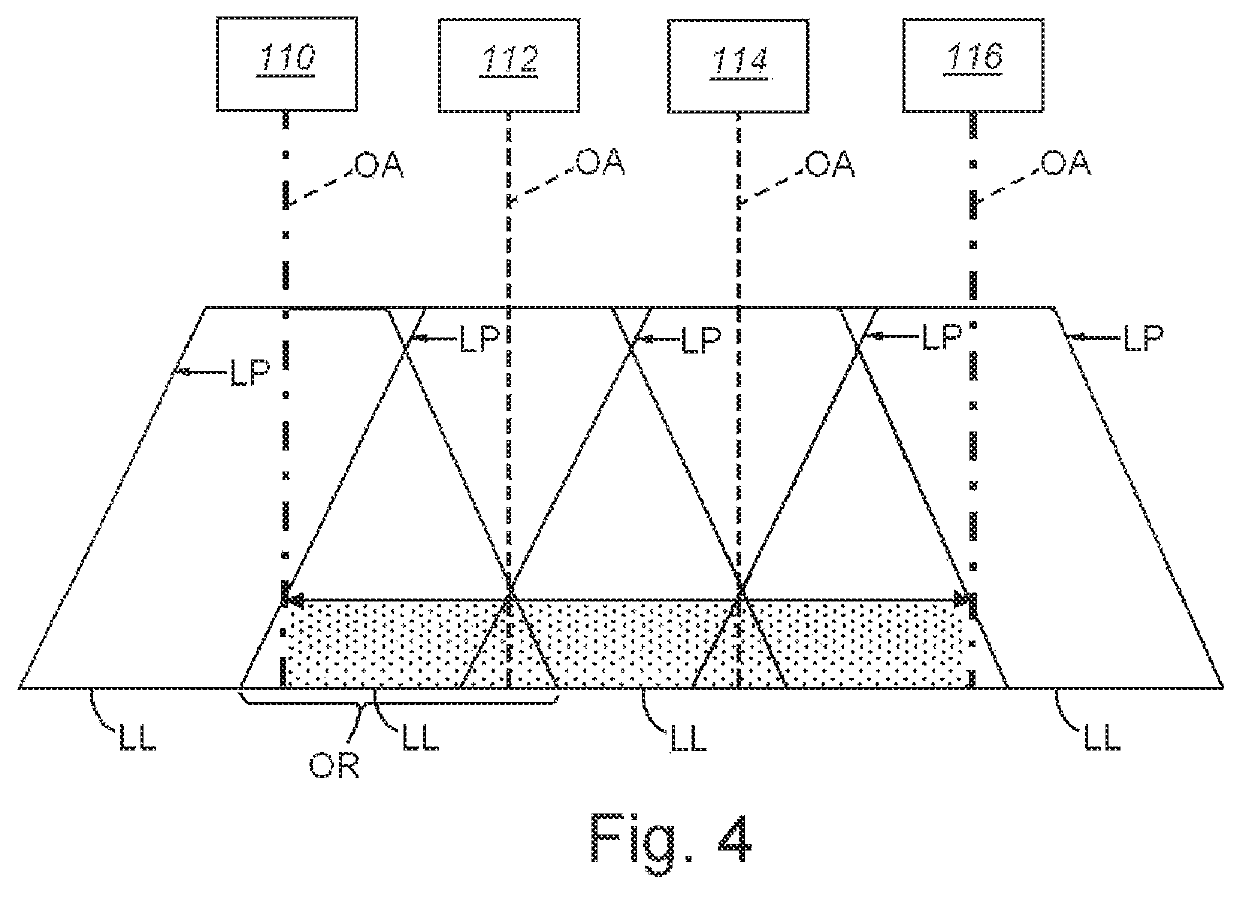

System and method for calibrating one or more 3D sensors mounted on a moving manipulator

ActiveUS10812778B1Accurate factory-based calibrationEasy to set upImage enhancementImage analysis3d sensorEngineering

This invention provides a system and method for concurrently (i.e. non-serially) calibrating a plurality of 3D sensors to provide therefrom a single FOV in a vision system that allows for straightforward setup using a series of relatively straightforward steps that are supported by an intuitive graphical user interface (GUI). The system and method requires minimal data input about the scene or calibration object used to calibrate the sensors. 3D features of a stable object, typically employing one or more subobjects, are first measured by one of the image sensors, and then the feature measurements are used in a calibration in which each of the 3D sensors images a discrete one of the subobjects, resolves features thereon and computes a common coordinate space between the plurality of 3D sensors. Sensor(s) can be mounted on the arm of an encoderless robot or other conveyance and motion speed can be measured in setup.

Owner:COGNEX CORP

Bag breaking mechanism and automatic object and bag separation system

ActiveCN112124720ANo need to change delivery habitsEasy to grabGripping headsConveyor partsRobot handClassical mechanics

The invention provides a bag breaking mechanism and an automatic object and bag separation system. A garbage bag is grabbed to the position above the bag breaking mechanism through a movable mechanical arm, then the plastic garbage bag is scratched through the bag breaking mechanism, and reliable separation of garbage and the garbage bag is achieved. The automatic object and bag separation systemis characterized by comprising a mechanical arm unit, a horizontal moving unit, the bag breaking mechanism, a power unit and a control unit, the mechanical arm unit is used for grabbing the bag put into the bag breaking mechanism, the horizontal moving unit is used for driving the mechanical arm unit to horizontally move above the bag breaking mechanism, the bag breaking mechanism is used for tearing the bag after the mechanical arm unit grabs the bag, so that the object in the bag falls off, and the bag is separated from the object in the bag, the power unit provides power for the mechanicalarm unit, the horizontal moving unit and the bag breaking mechanism, and the control unit controls the mechanical arm unit, the horizontal moving unit, the bag breaking mechanism and the power unit tooperate.

Owner:万谦科技(北京)有限公司

Full-automatic smearing and staining machine

ActiveCN104990782AImprove biosafety levelImprove security levelPreparing sample for investigationStainingElectric machinery

The invention provides a full-automatic smearing and staining machine and belongs to the technical field of medical health clinical examination. The full-automatic smearing and staining machine is a set of examination equipment for automatic smearing and staining of samples, mainly solves the problem that at present, sample smearing and staining can be finished only by manual operation, and is used for smearing, staining and processing before microscopic examination of microbes and other pathogens. The full-automatic smearing and staining machine is mainly characterized in that an electric sampling device mainly comprises a sampling disc, a multi-slot straight plate, a U-shaped fixing bracket, a sampling motor and the like, an automatic sample conveying device mainly comprises a sample conveying rod, a sample conveying motor, a sample conveying slide rail and the like, a three-dimensional movable manipulator device mainly comprises a three-dimensional manipulator, an uncovering motor, a sample selecting and smearing rod, a CCD high-definition camera and the like, a smearing and staining device mainly comprises a left support, a right support, a central shaft, a left slide holder support frame, a right slide holder support frame, slide holders, a slide rotating track eccentric rod, a slide rotating track eccentric plate, a heating tube, a first reagent spout, a second reagent spout, a stepping motor and the like, and a reagent adding device mainly comprises a reagent adding motor and the like.

Owner:王海波

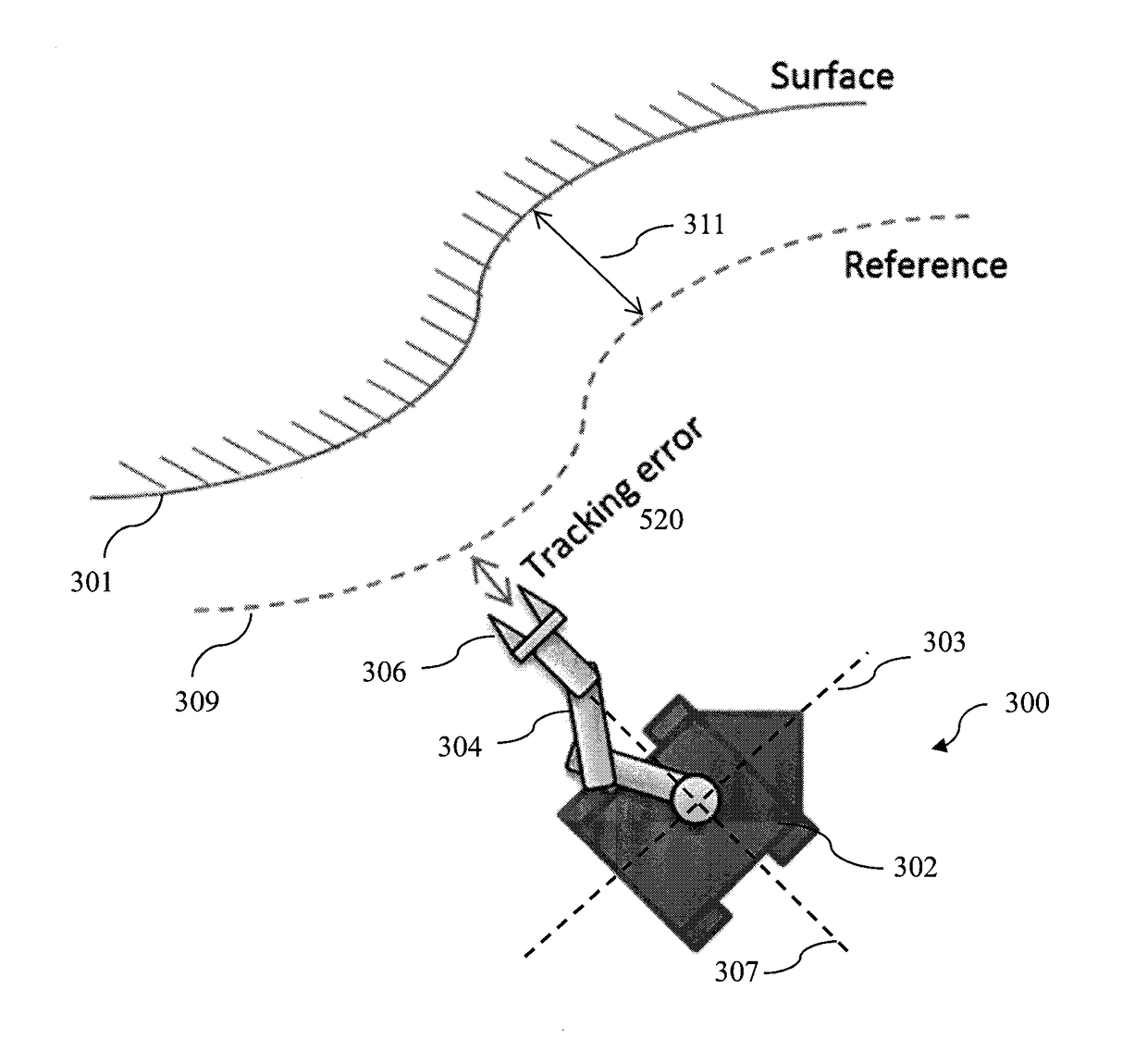

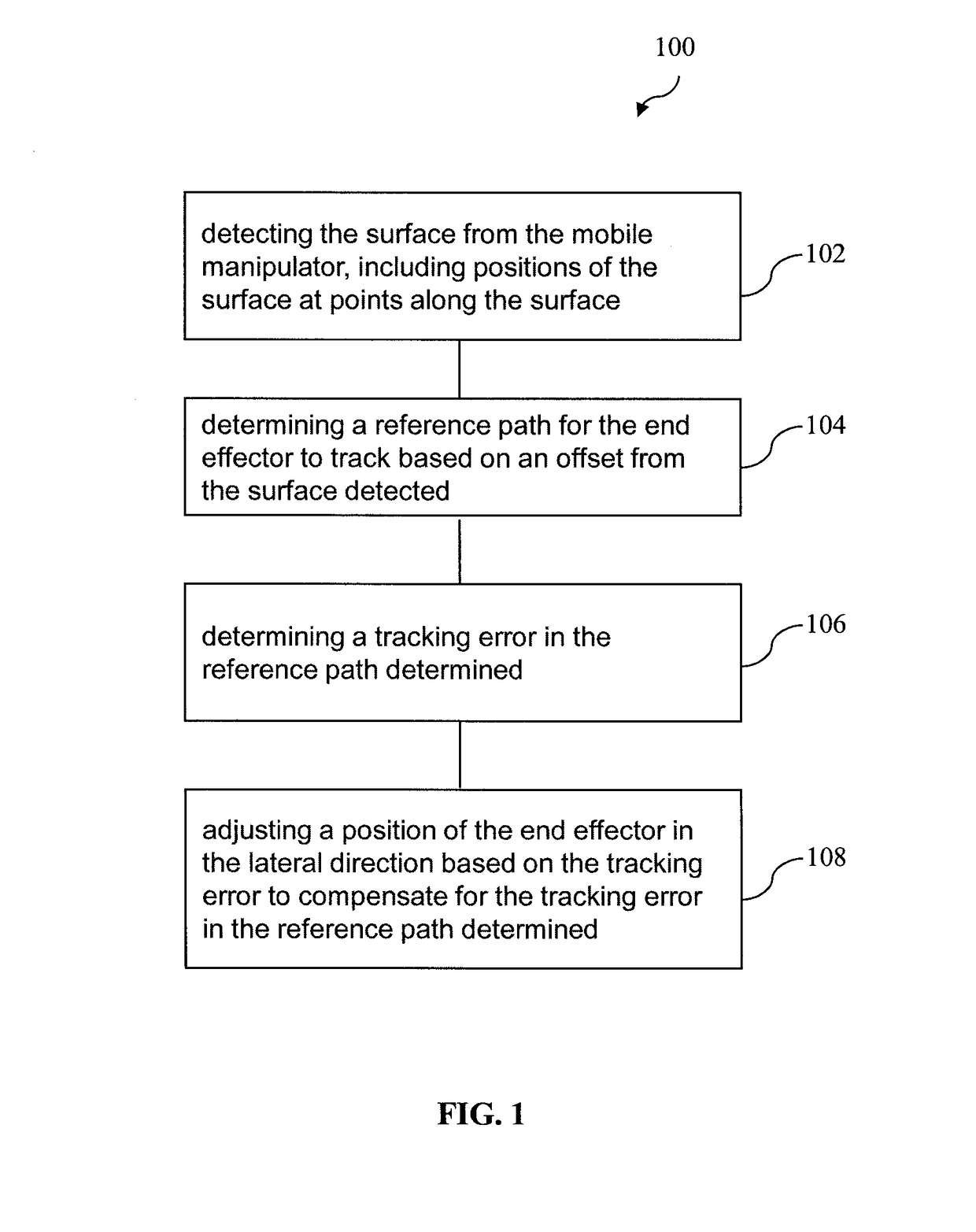

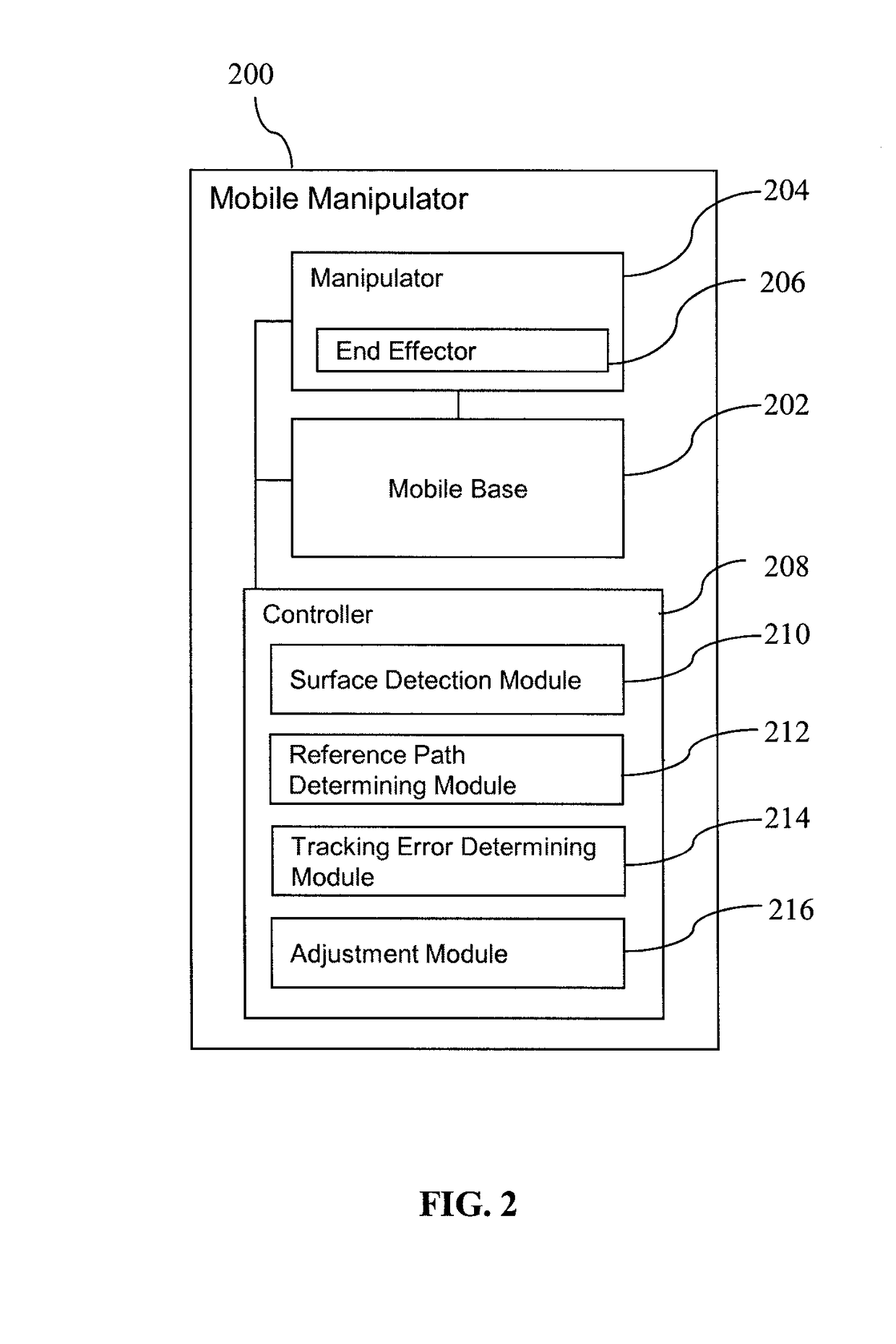

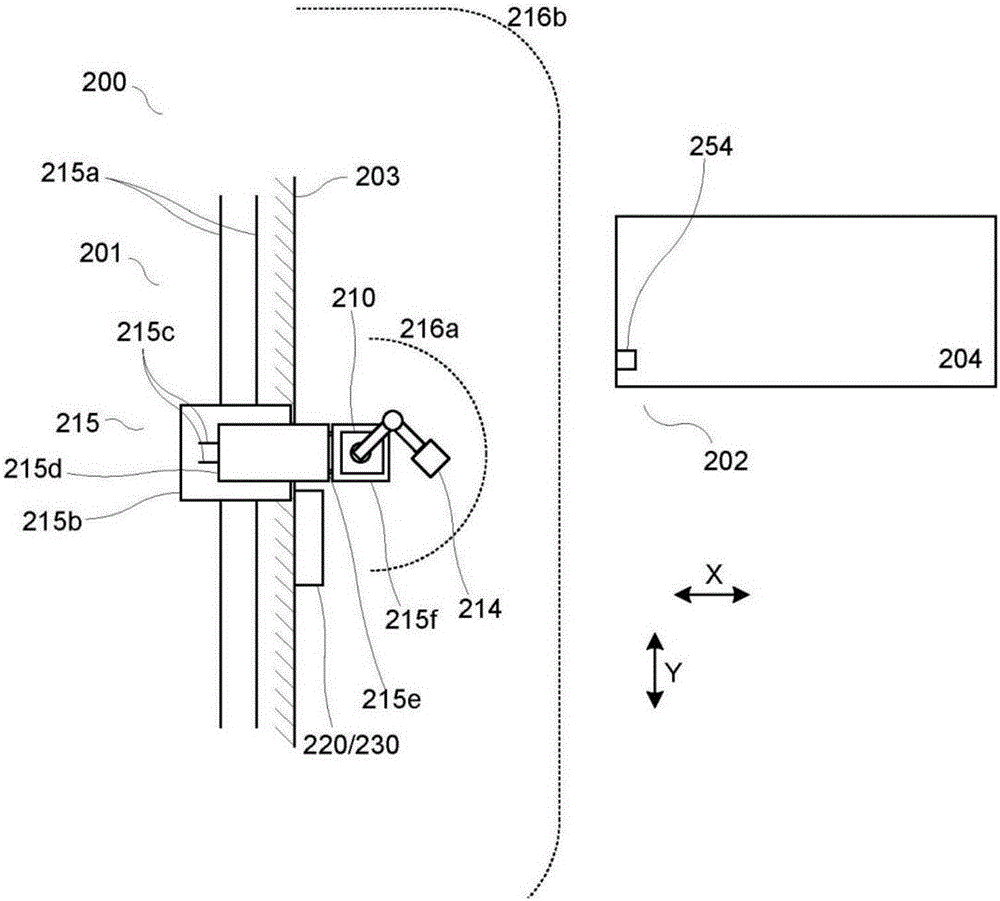

Mobile manipulator and method of controlling the mobile manipulator for tracking a surface

There is provided a method of controlling a mobile manipulator for tracking a surface. The mobile manipulator includes a mobile base movable in an axial direction of the mobile manipulator and a manipulator supported on the mobile base having an end effector adjustable in a lateral direction of the mobile manipulator. The method includes detecting the surface from the mobile manipulator, including positions of the surface at points along the surface, determining a reference path for the end effector to track based on an offset from the surface detected, determining a tracking error in the reference path determined, and adjusting a position of the end effector in the lateral direction based on the tracking error to compensate for the tracking error in the reference path determined. There is also provided a corresponding mobile manipulator.

Owner:AGENCY FOR SCI TECH & RES

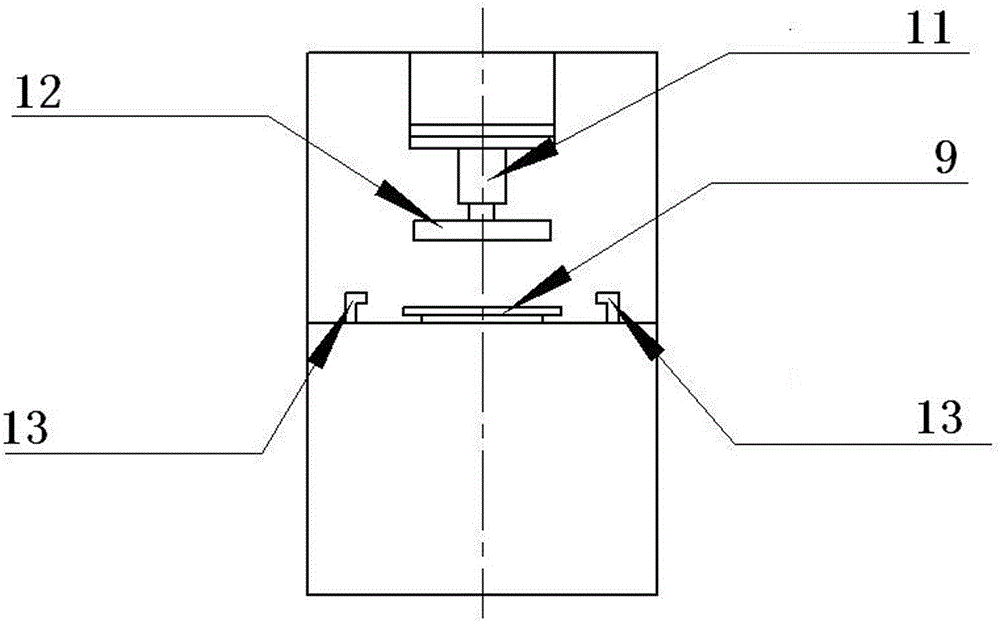

Punching machine and punching method thereof for printed circuit board

InactiveCN101480800AIncrease profitLow costMetal working apparatusManipulatorPunchingMobile manipulator

The invention relates to a punching machine for a printed circuit board, which comprises a punching mechanism, clamping devices and a camera device. The punching machine for a printed circuit board is characterized by further comprising two mobile manipulators which are respectively arranged at two sides of the punching mechanism; each mobile manipulator is provided with a longitudinal mobile mechanism, a transverse mobile mechanism and the clamping device for clamping a printed circuit board; and a control device is used for analyzing and processing the obtained data based on the images transmitted by the camera device, driving the punching mechanism and the camera device according to a program and driving the mobile manipulators to complete the handover of the printed circuit board at a reasonable position. The invention further discloses a punching method of the punching machine for a printed circuit board. Compared with the prior art, the invention has the advantages that the punching speed is improved; the moving inertia of the whole operation of completing the handover between the two mobile manipulators according to the reasonable position calculated by the control device is small, and the large-range high-precision movement needed by a single manipulator is not required; and the stability and reliability of the device and the precision of punching are improved.

Owner:宁波三盾电子科技有限公司

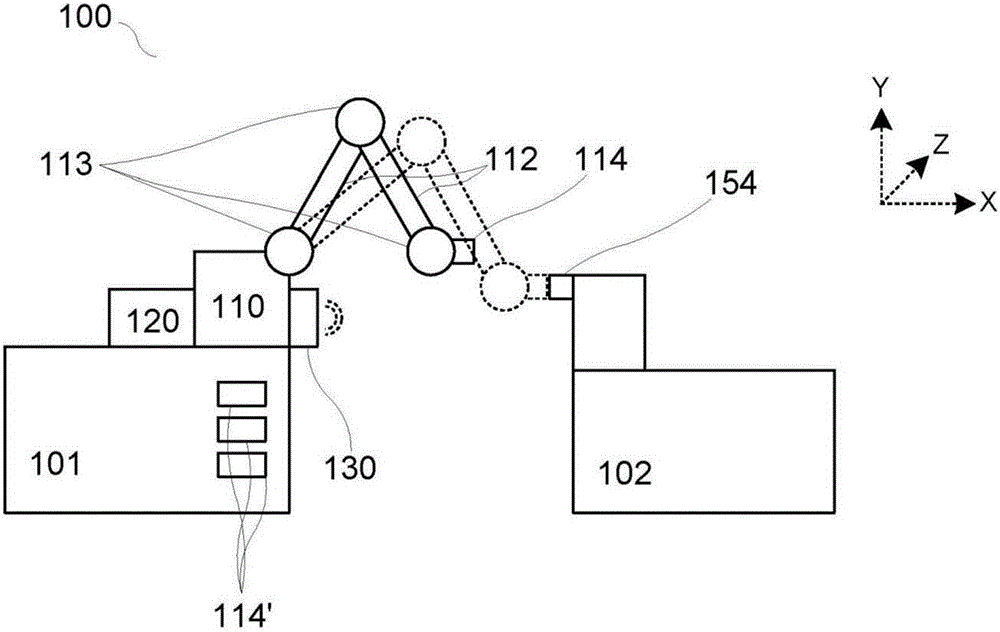

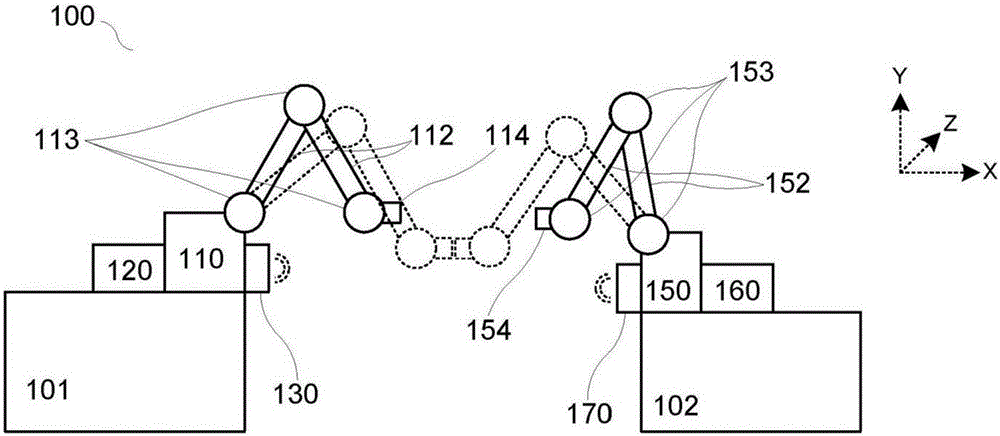

Device and method for establishing a temporary connection between two movable objects

Device (100) for achieving a temporary connection between two objects (101,102) which are movable relative to each other, comprising respective connecting means (114,154), being brought together in order to jointly establish said connection, a movable robot (110), arranged to continuously displace the first connecting means relative to the first object, a control means (120), arranged to control the movements of the robot relative to the first object, as well as a sensor means (130), arranged to continuously read a relative position between the first connecting means and the second connecting means while the said objects move relative to each other. The invention is characterised in that the control means is arranged to, while the objects move relative to each other, continuously control the robot so that the first connecting means is displaced, relative to the first object and up to the second connecting means, and there connects to the second connecting means. The invention also relates to a method.

Owner:ABB (SCHWEIZ) AG

Full-automatic cutting and packaging integrated machine

PendingCN108394599AAvoid lossMeet the needs of mass productionMetal working apparatusConveyor partsLight guideAssembly line

The invention relates to the technical field of LED backlight light guide plate cutting and packaging, in particular to a full-automatic cutting and packaging integrated machine. A movable mechanicalarm is arranged on one side of the upper surface of a rack-protective cover, a front way taking mechanical arm is further installed at the position, on one side of the movable mechanical arm, of the rack-protective cover, a material supporting component is further installed at the position, on one side of the front way taking mechanical arm, of the rack-protective cover, a first cutting componentand a second cutting component are further arranged on one side of the middle portion of the upper surface of the rack-protective cover and are located on the same horizontal line, a discharging carrying platform is further installed on the position, on one side of the first cutting component, of the rack-protective cover, a jacking platform is installed at the position, on one side of the discharging carrying platform, of the rack-protective cover, and an assembly line is further arranged on the side, far away from the movable mechanical arm, of the rack-protective cover. By means of the full-automatic cutting and packaging integrated machine, the requirement of in-batch production can be met, and the production efficiency and the product stability are improved.

Owner:东莞市晋铭自动化设备有限公司

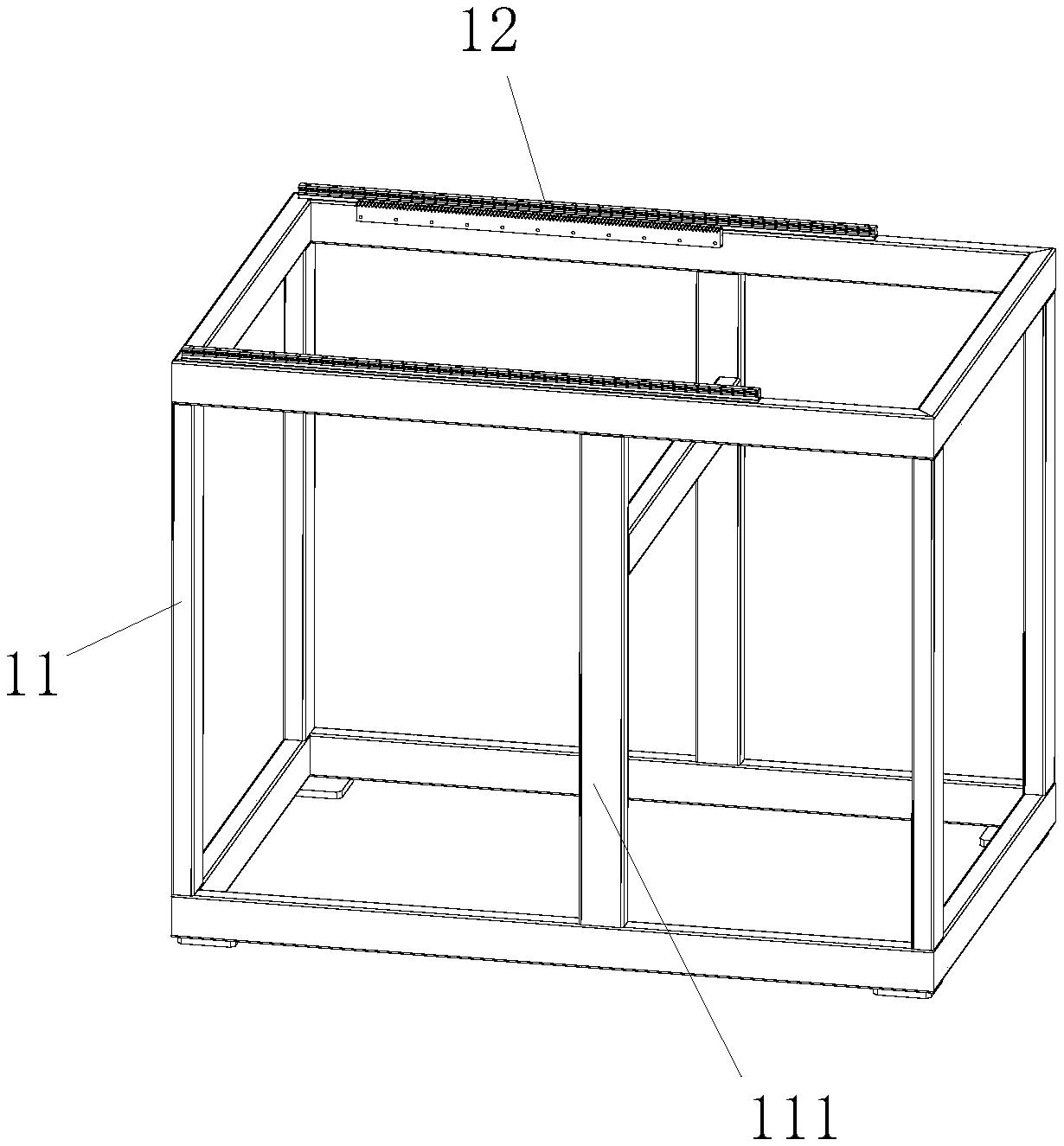

Full-automatic box filler

The invention discloses a full-automatic box filler which comprises a large rack, a time-sharing conveying line, a carton box conveying line, a moving trolley, a lifting mechanism and a mechanical arm. The large rack is fastened to an infrastructure and comprises a rectangular frame. Guide rails are arranged on the two sides of the top of the rectangular frame. The time-sharing conveying line is mounted on the rear side of the interior of the large rack and used for conveying box filling products. The carton box conveying line is mounted on the front side of the interior of the large rack, andused for conveying carton boxes and opening box openings of the carton boxes. According to the full-automatic box filler, the box filling products are conveyed through the time-sharing conveying line, the carbon boxes are conveyed and the box openings of the carton boxes are opened through the carton box conveying line, the position of the lifting mechanism is changed through the moving trolley,the position of the mechanical arm is changed through the lifting mechanism, then the box filling operation is completed through the mechanical arm, the structural design is reasonable, and box filling is achieved fast and automatically.

Owner:储海霞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com