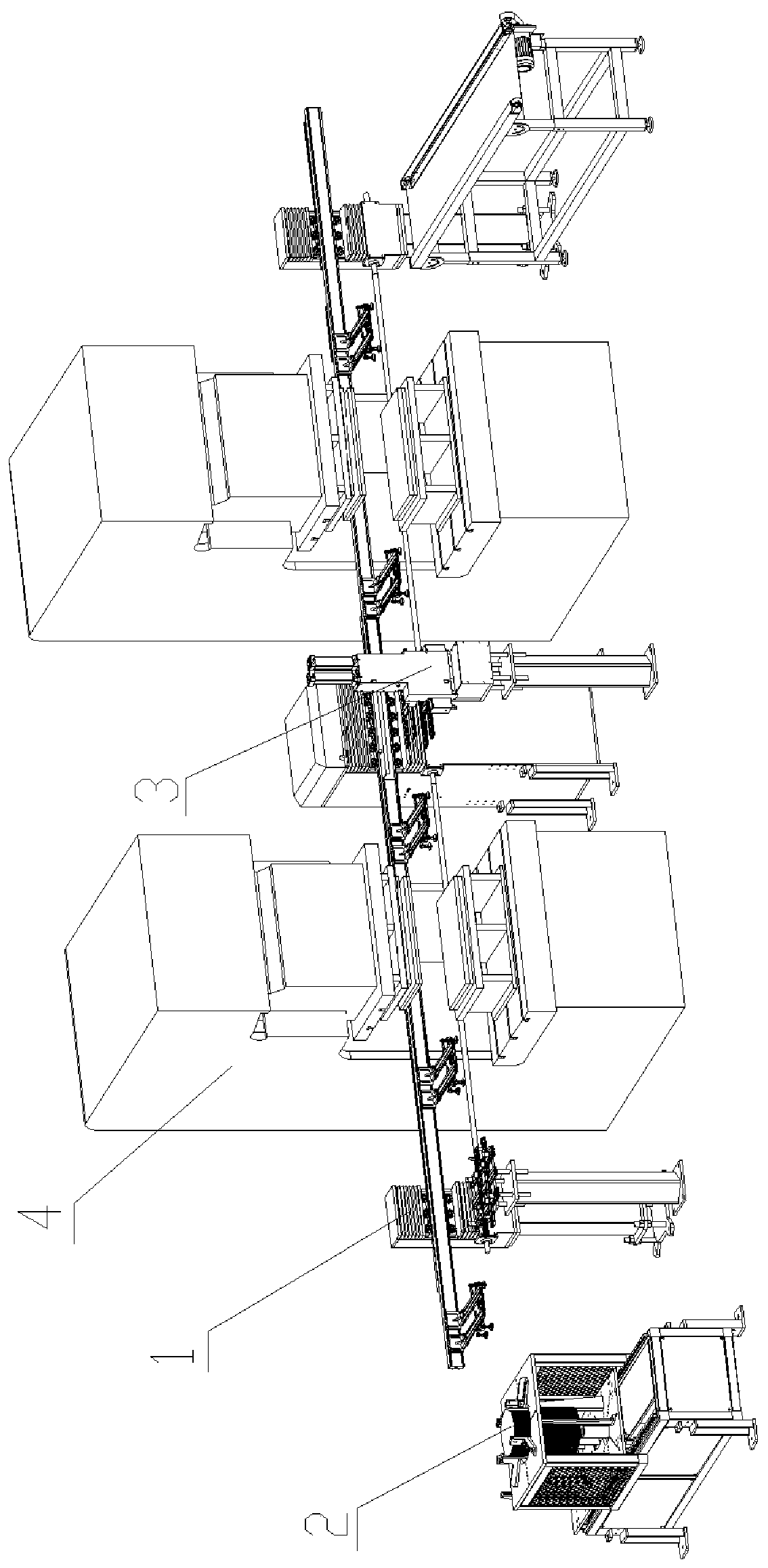

Automatic production line for metal plate punch forming and production process thereof

An automated production line and stamping forming technology, applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve problems affecting product quality and safety accidents, operational errors, time-consuming and labor-intensive problems, and achieve the effect of improving operation efficiency and stamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention relates to a sheet metal stamping and forming automatic production process, the process steps are:

[0057] Step 1. Place the sheet metal parts to be punched in the positioning mechanism, then move the sliding plate 2.3 to drive the punched sheet metal parts to the bottom of the storage platform 2.5, and the piston rod of the jacking cylinder 2.8 passes upwards through the perforation 2.3 of the sliding plate 2.3. After 1, lift up the sheet metal parts to be stamped, so that the sheet metal parts to be stamped pass through the feeding hole 2.5.1 and are restricted by the storage rack 2.6 to prevent falling;

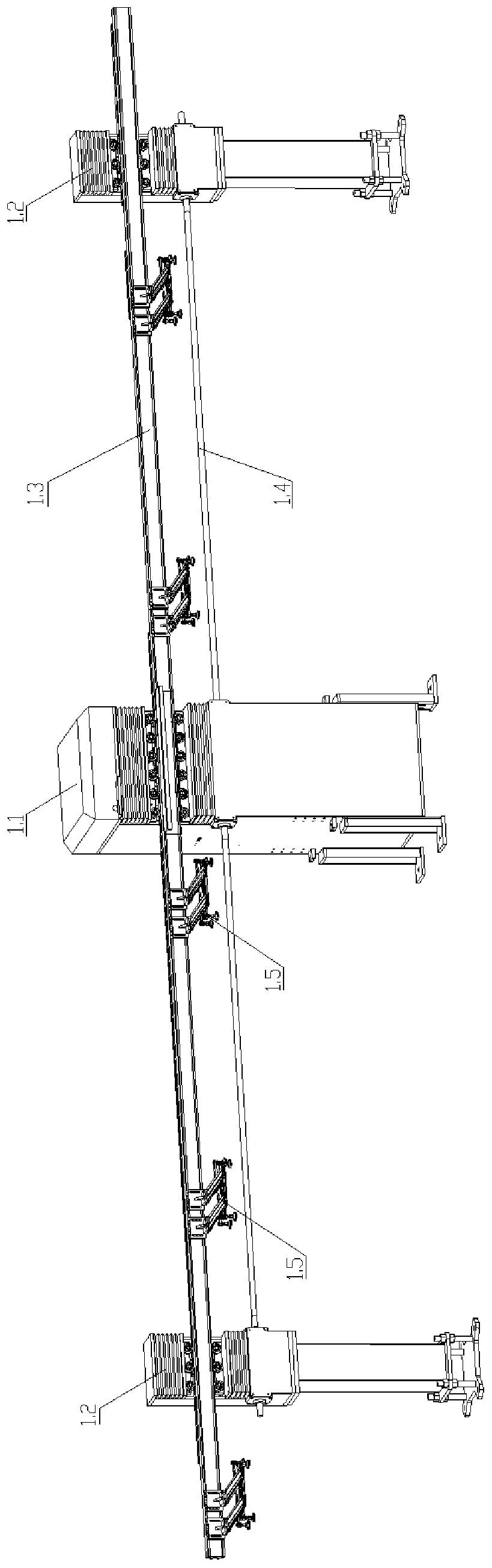

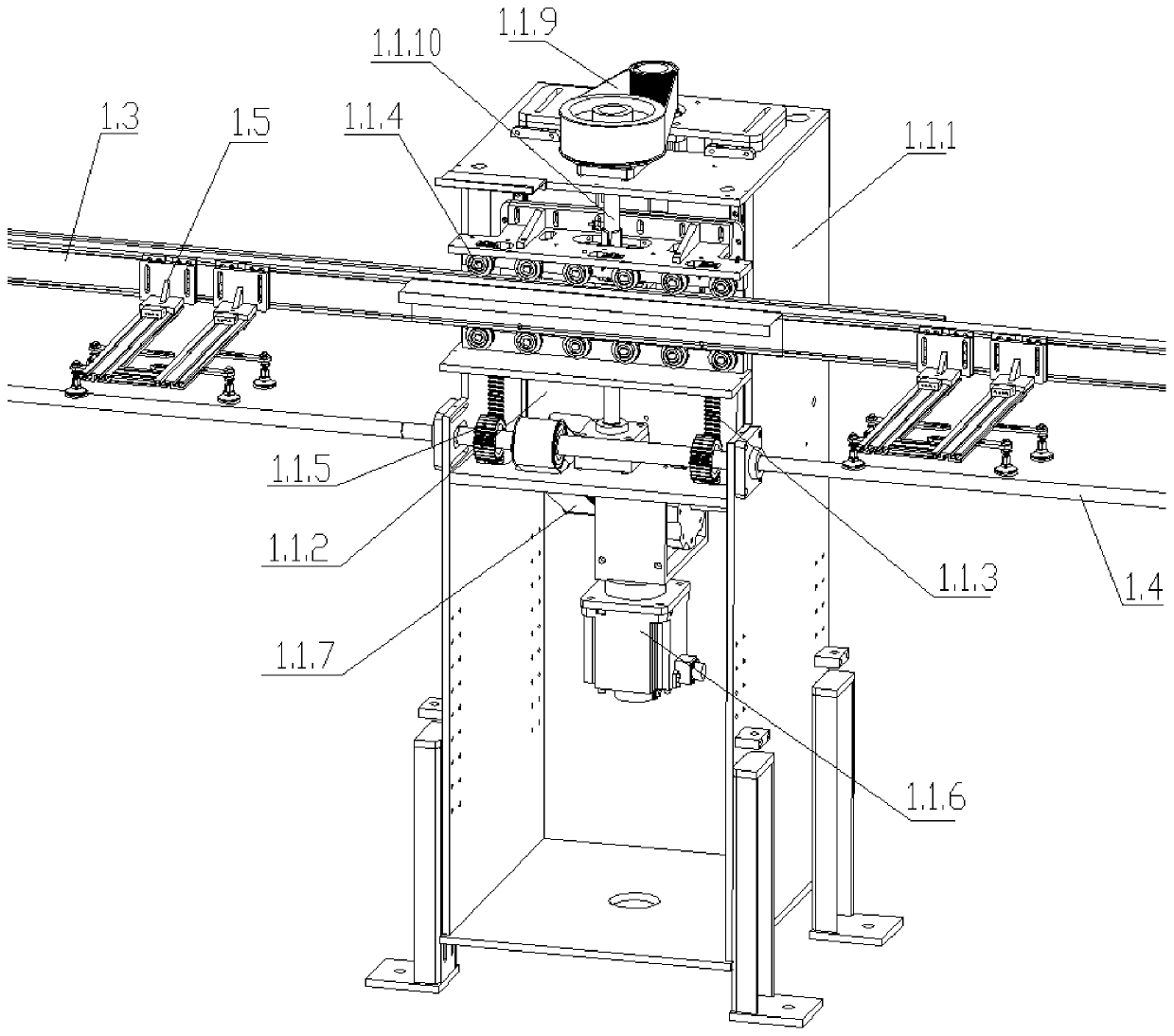

[0058] Step 2: Start the drive motor 1.1.8 of the transfer arm to make the transfer arm 1.3 move left and right, the transfer arm 1.3 drives the grabbing arm 1.5 to the top of the sheet metal part to be stamped, and lift the drive motor 1.1.6 to start the control body lift plate 1.1.2 Descend, and drive the transfer arm 1.3 to lower to make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com