Patents

Literature

546results about How to "Improve stamping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High Strength Thin-Gauge Steel Sheet Excellent in Elongation and Hole Expandability and Method of Production of Same

InactiveUS20080000555A1High strengthHigh elongationFurnace typesMetal rolling arrangementsSectilityHigh intensity

The present invention provides high strength thin-gauge steel sheet with excellent elongation and hole expandability having a tensile strength of 500 MPa or more and a method of production of high strength thin-gauge steel sheet with excellent elongation and hole expandability enabling production of this on an industrial scale, that is, high strength thin-gauge steel sheet comprised of, by mass %, C: 0.03 to 0.25%, Si: 0.4 to 2.0%, Mn: 0.8 to 3.1%, P≦0.02%, S≦0.02%, Al≦2.0%, N≦0.01%, and a balance of Fe and unavoidable impurities and having a microstructure comprised of ferrite with an area fraction of 10 to 85% and residual austenite with a volume fraction of 1 to 10%, an area fraction of 10% to 60% of tempered martensite, and a balance of bainite.

Owner:NIPPON STEEL CORP

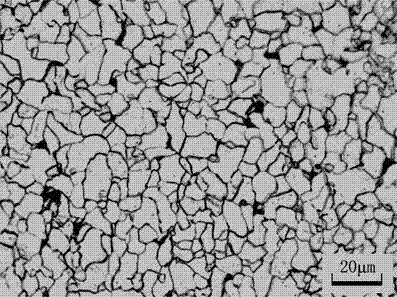

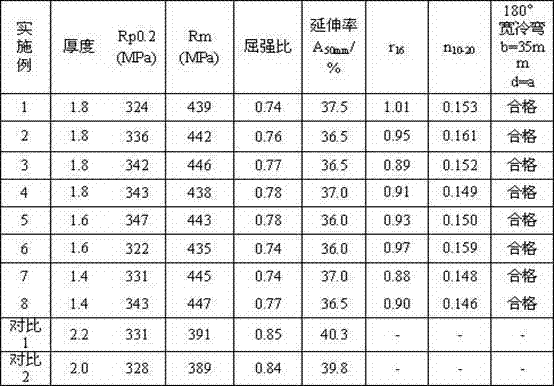

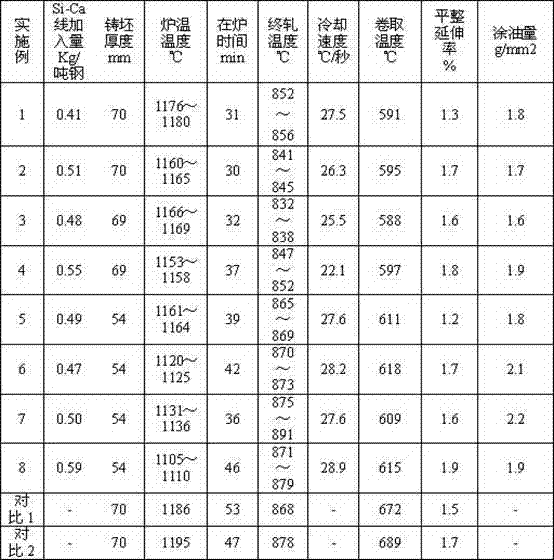

Sheet-billet produced hot-rolled pickled steel with thickness of 1.8mm or lower for automobile and production method thereof

InactiveCN102787273ALow yield ratioImprove surface qualityWork treatment devicesMetal rolling arrangementsCar manufacturingHigh pressure water

The invention relates to a sheet-billet produced hot-rolled pickled steel with thickness of 1.8mm or lower for an automobile, which comprises the following chemical components by weight: 0.04-0.07% of C, 0.10-0.30% of Si, 0.60-1.30% of Mn, 0.025% of P or less, 0.012% of S, 0.02-0.04% of Ti and 0.010-0.030% of Als. The preparation method of the sheet-billet produced hot-rolled pickled steel with thickness of 1.8mm or lower comprises the following steps: desulphurizing molten iron, smelting by a converter, alloying, treating by a ladle furnace, casting and rolling continuously, dephosphorizing high-pressure water by controlling the pressure at 25-35Mpa, controlling rolling, cooling by laminar flow, curling, pickling by acid, levelling by controlling the extension rate at 2% or lower, and finishing by adopting static oil removal. The produced thin hot-rolled pickled steel for the automobile, which has the tensile strength of 400MPa or higher and the thickness of 1.8 mm or lower, has the characteristics of low yield ratio, high surface quality, short production cycle and low cost, achieve the match of high strength and good stamping performance and can replace the cold-rolled high-strength steel to manufacture the automobile.

Owner:武钢集团有限公司

Preparation method for reducing scales generated on surfaces of hot-rolled steel plates

InactiveCN101947557ALower the furnace temperatureReduce the number of spawnsTemperature control deviceWork treatment devicesChemical compositionSheet steel

The invention belongs to the technical field of hot-rolled strips and relates to a method for controlling the surface quality of hot-rolled steel plates, namely a preparation method for reducing scales generated on the surfaces of the hot-rolled steel plates. The chemical components of the steel in the method have wider application range and are especially suitable for the hot-rolled steel platescontaining such microalloying elements as Nb, V, Mn and Si. The hot-rolled steel plates have the following chemical components by weight: not less than 0.05% and not more than 0.20% of C, not more than 0.70% of Si, not less than 0.20% and not more than 2.00% of Mn, not less than 0.02% and not more than 0.10% of Nb, not less than 0.03% and not more than 0.15% of V, not more than 0.12% of Ti, not more than 0.040% of P, not more than 0.030% of S and the balance Fe and inevitable impurities. The control method dispenses with improvement of existing equipment, is simple and controllable in processconditions, realizes the aim of reducing the scales by controlling the slab tapping temperature, the finish rolling, initial rolling and final rolling temperature, the coiling temperature and the cooling method and has the advantages of low energy consumption, low cost and wide applicable scope.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

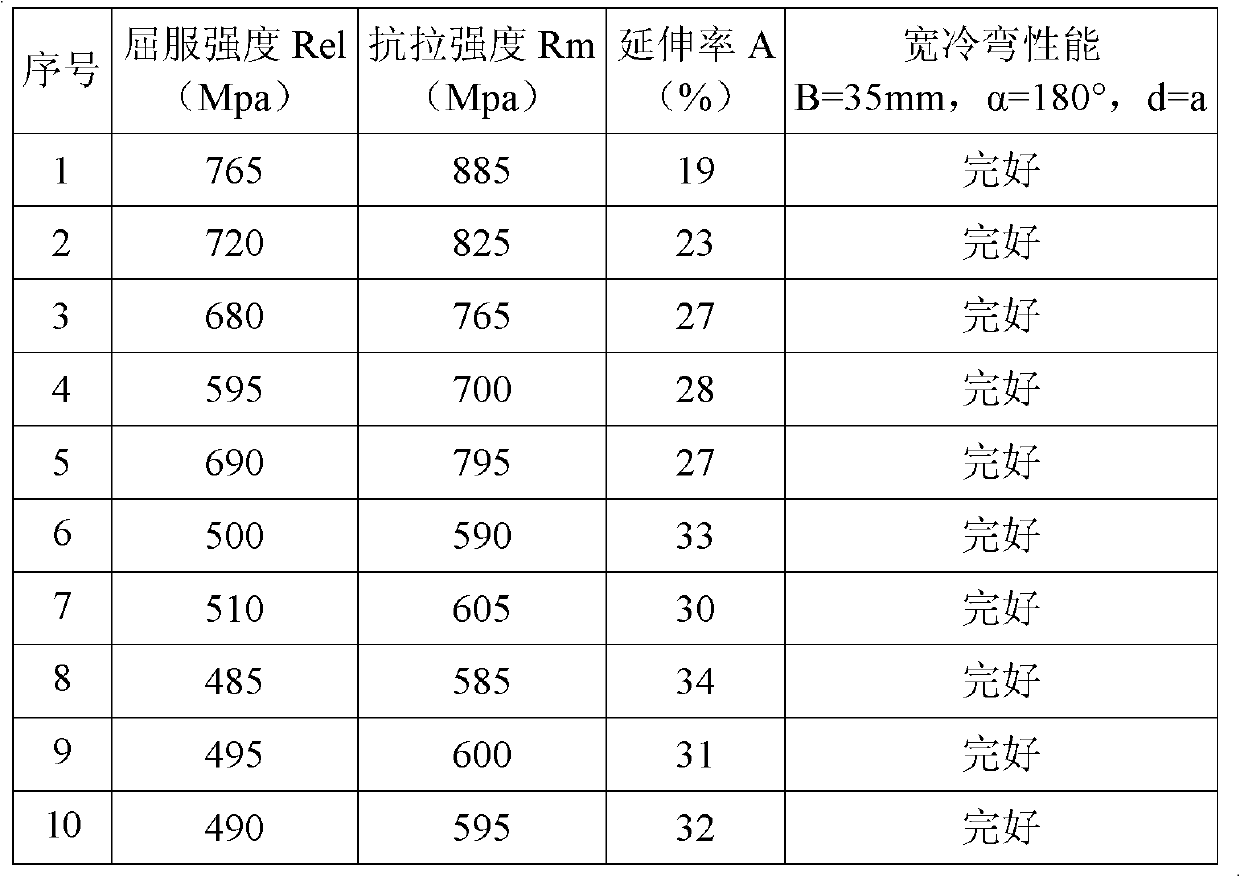

Method for producing hot rolling two-phase steel plate at 700MPa level of tensile strength

InactiveCN101279330AImprove mechanical propertiesLow costTemperature control deviceFurnace typesSheet steelChemical composition

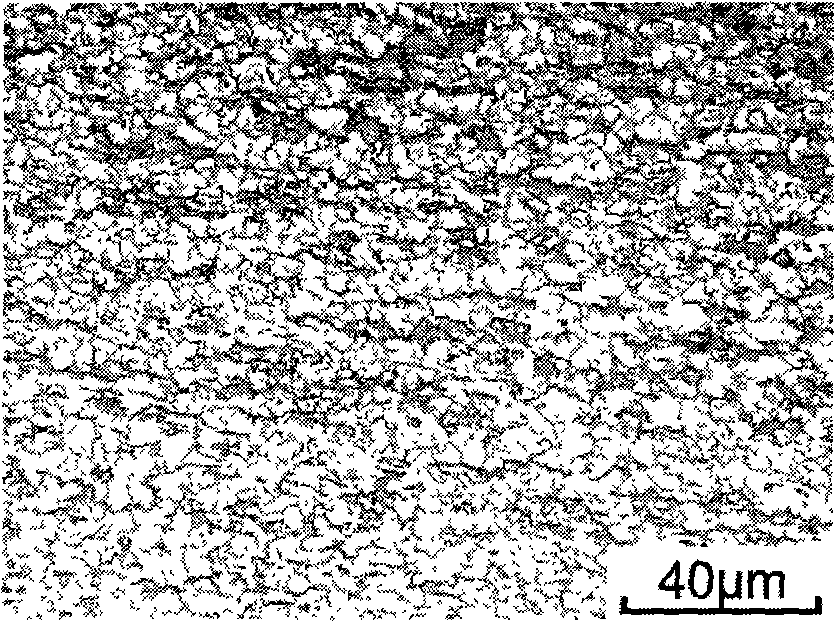

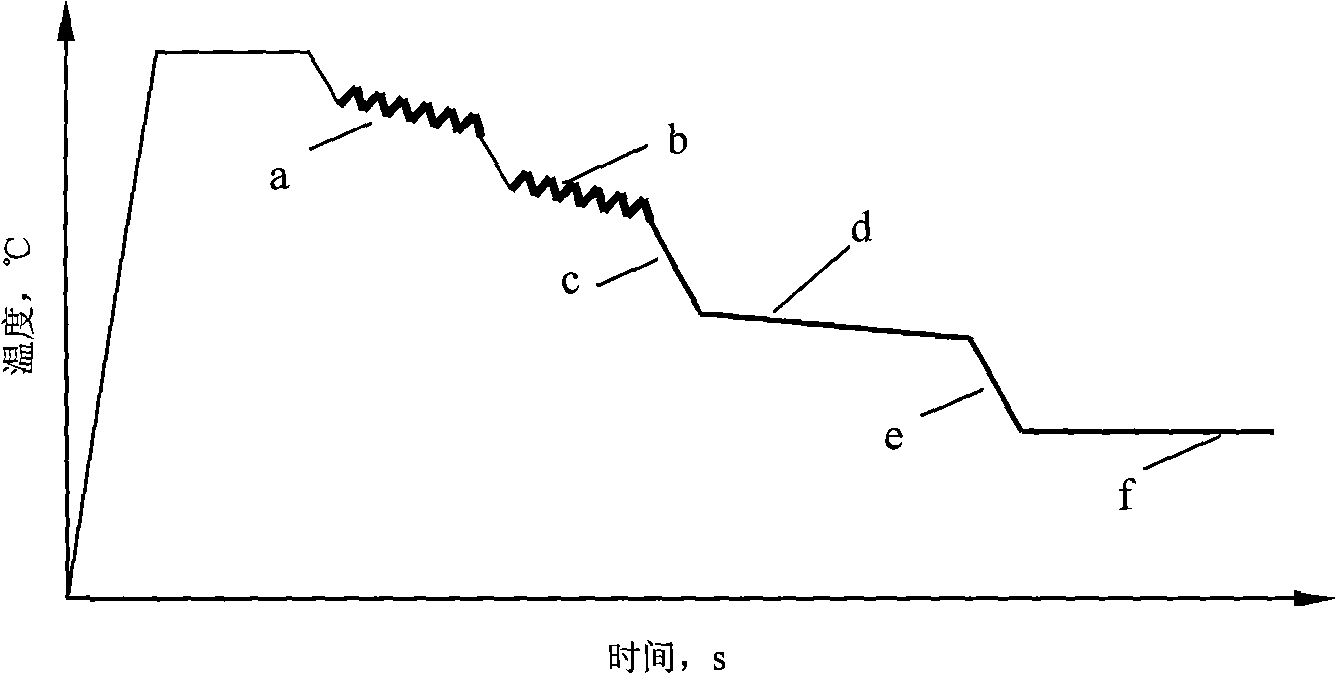

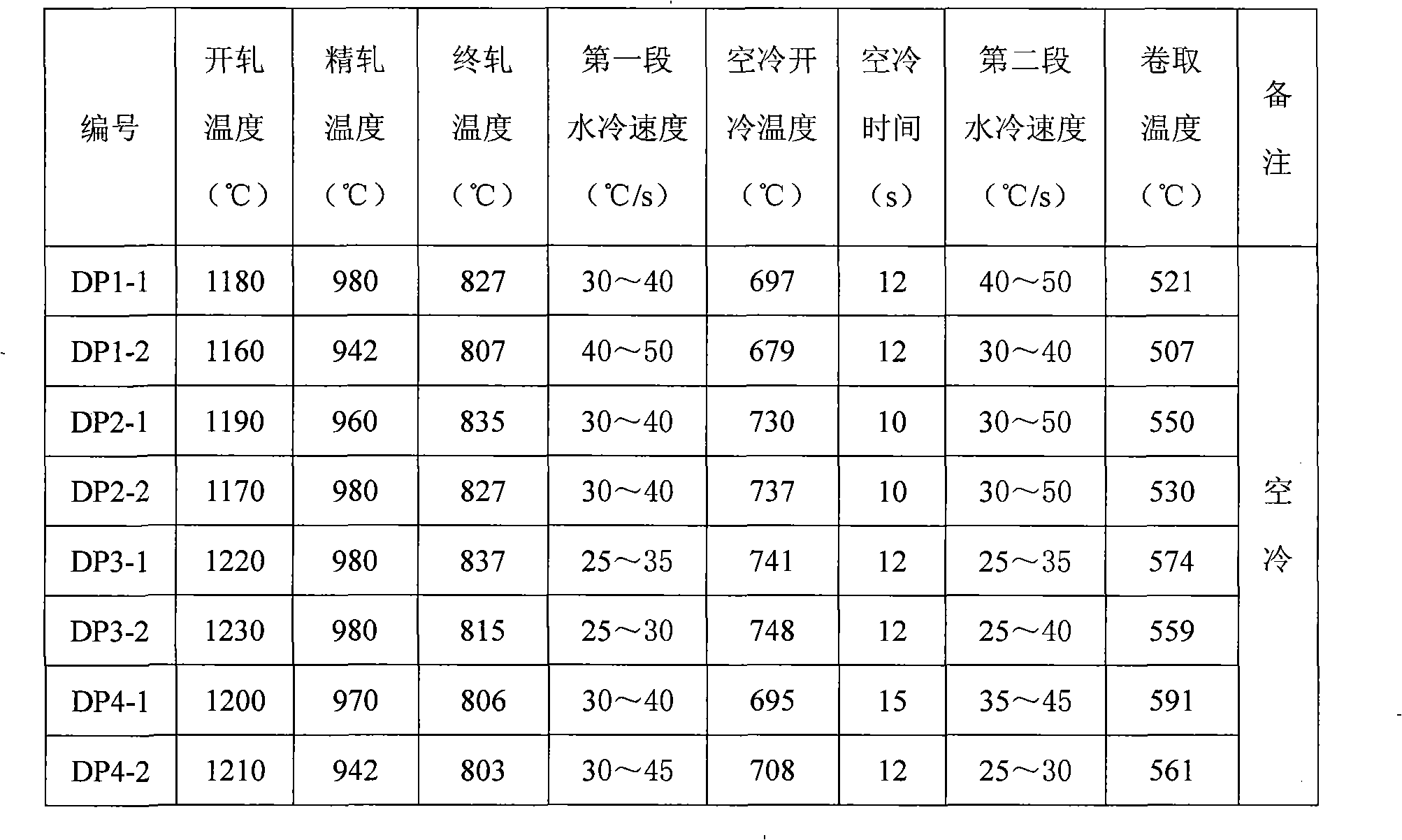

The invention relates to a manufacture method for a thermal rolling double-phase steel plate with 700MPa of anti-tension intensity; the main chemical components of the invention calculated by weight percentage include: 0.03 to 0.08 percent of C, 0.50 to 0.70 percent of Si, 1.00 to 1.60 percent of Mn, 0 to 0.60 percent of Cr, 0 to 0.40 percent of Mo, and 0.02 to 0.05 percent of Nb, and the rest is Fe; the thickness specification of the invention is 3.0 to 4.0mm; the invention is provided with a polygonal ferrite and a martensite double-phase tissue; a few amount of grain bainites appear; wherein, the volume percent of the ferrite is 70 to 90 percent; the volume percent of the martensite is 30 to 10 percent; the average crystal grain dimension of the ferrite is 5Mum. The invention is rolled by a controlled rolling and controlled cooling technology; a beginning rolling temperature is controlled between 1250 to 1150 DEG C; the stopping rolling temperature is controlled between 800 to 850 DEG C; the cooling speed for a first section is controlled between 25 to 50 DEG C / s; after cooling the temperature is 680 to 750 DEG C; a second section controllable cooling is carried out after cooling the temperature between 670 to 700 DEG C by air; the cooling speed for a second section is controlled between 25 to 50 DEG C / s; the stopping cooling temperature, namely the coiling temperature is between 500 and 600 DEG C; then the steel plate is cooled to the room temperature by air.

Owner:UNIV OF SCI & TECH BEIJING

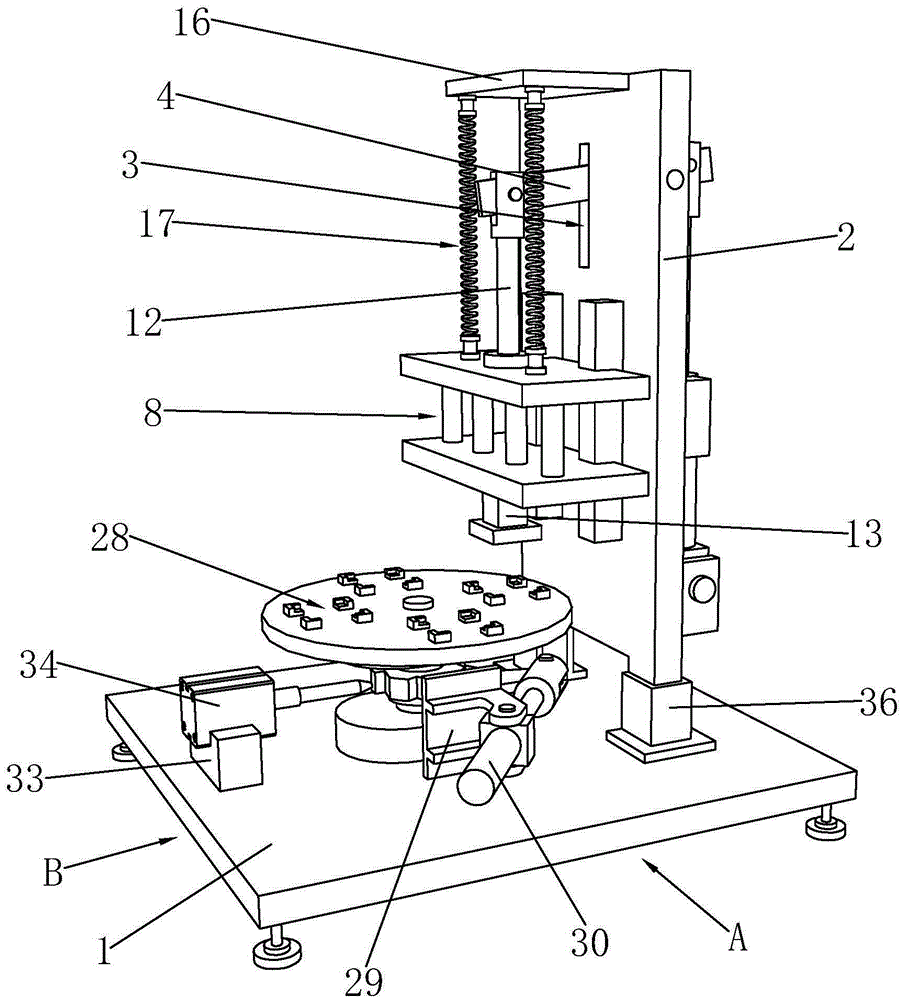

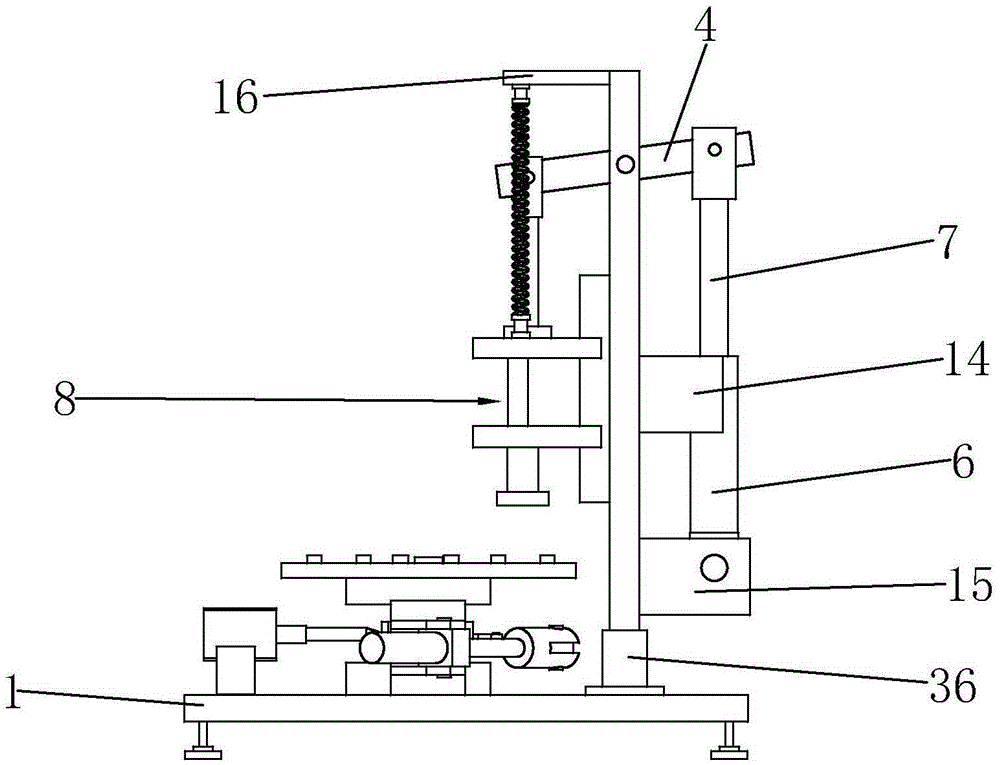

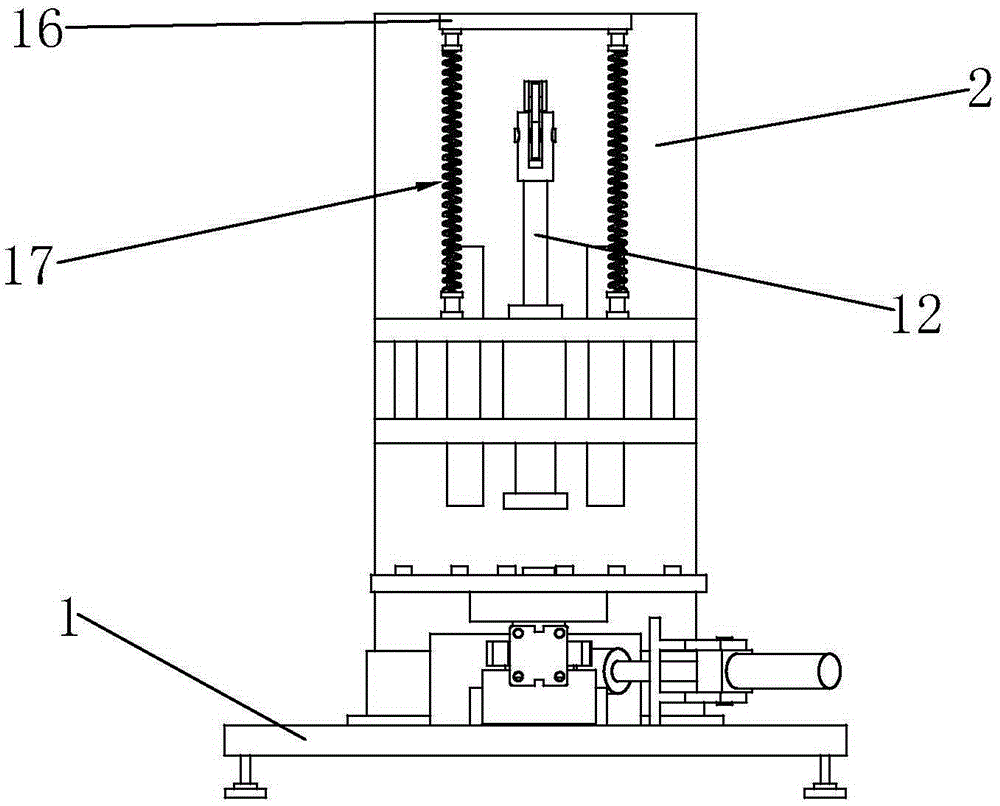

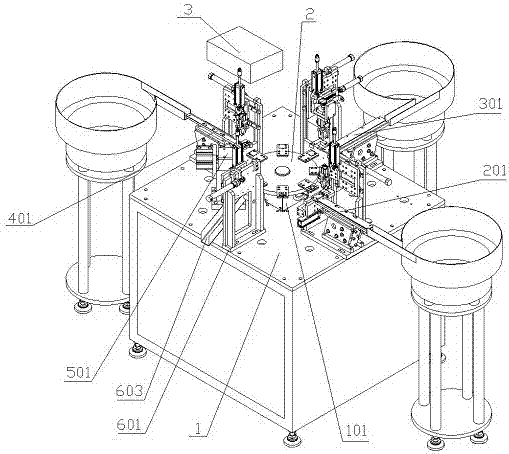

Stamping equipment applied to motor rotor punching sheet production

InactiveCN105429384AImprove stabilityHigh precisionMetal-working feeding devicesManufacturing stator/rotor bodiesEngineeringPunching

The invention discloses stamping equipment applied to motor rotor punching sheet production. The stamping equipment comprises a mounting base and a supporting rack; a groove is formed in the supporting rack; a connecting plate is rotationally connected in the groove; a stamping assembly is arranged on one side of the supporting rack; a stamping push rod is fixedly connected with the stamping assembly; a stamping driving mechanism is arranged on the other side of the supporting rack; the connecting plate is rotationally connected with the stamping push rod and the stamping driving mechanism; a supporting platform is arranged on the supporting rack; an elasticity mechanism is arranged between the supporting platform and the stamping assembly; an interval turning mechanism is arranged on the mounting base; the interval turning mechanism comprises an interval driving mechanism and a rotating mechanism; the rotating mechanism is rotationally connected with the interval driving mechanism; and a stop mechanism is arranged on the supporting rack. The stamping equipment can rapidly perform stamping on a certain batches of rotor punching sheets as well as can perform periodical stamping on the same rotor punching sheet to enable the obtained rotor punching sheet to be higher in stamping property, high in the production efficiency, good in punching effect and high in practicability.

Owner:SHENGZHOU LIDA ELECTRIC APPLIANCES FACTORY

Hot rolled steel plate for punch process and method of manufacturing the same

InactiveCN101293321ALow phase transition pointReduce nucleation rateTemperature control deviceSheet steelPunching

The invention belongs to the technical field of metal materials and preparation thereof, in particular to a hot-roll steel plate used for punching processing and a preparation method thereof. The invention is that boron alloy is added in the refining process of a low carbon-aluminum piping steel; the mol ratio of boron and nitrogen in a steel liquid is 0.81 to 1.10; the content of the nitrogen in the steel during the continuous casting process is not higher than 60ppm; the temperature for a casting blank to enter a soaking furnace is 900 to 949 DEG C; rough rolling is carried out after the soaking furnace is heated to the temperature of 1050 to 1099 DEG C; the temperature of a low-carbon steel plate containing boron or tape reel is lower by 40 to 60 DEG C than the transformation temperature of a traditional low-carbon steel austenite without boron to a ferrite in the refining process; after final rolling, a plate belt is cooled to the temperature of 560 to 650 DEG C at the speed of 5 to 20 DEG C / s; the temperature of a steel belt is 540 to 630 DEG C when coiling. The hot-roll steel plate used for punching processing manufactured by the method can ensure that the yielding strength of a product is lower than 260MPa, the anti-tension intensity is lower than 370MPa and the extension rate is higher than 45 percent.

Owner:CENT IRON & STEEL RES INST +1

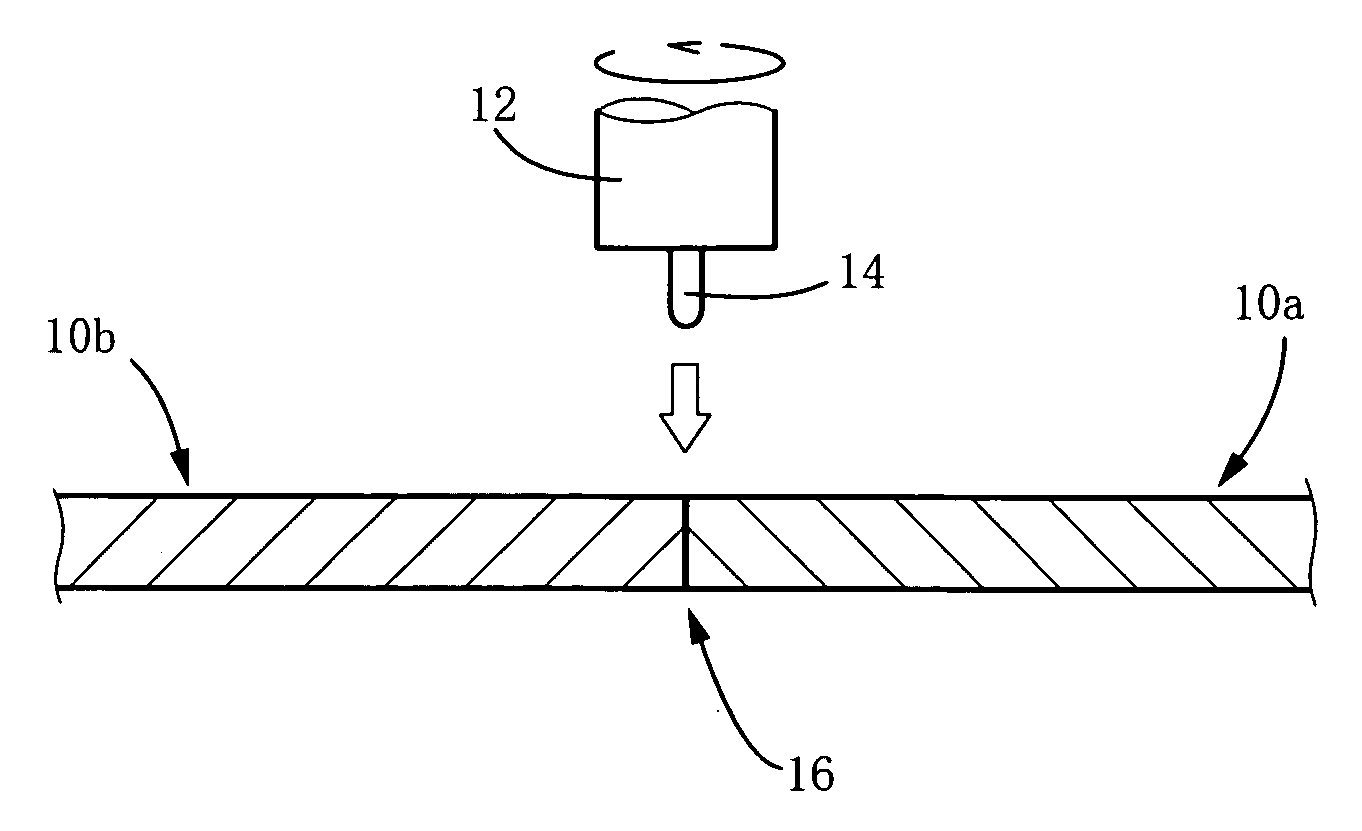

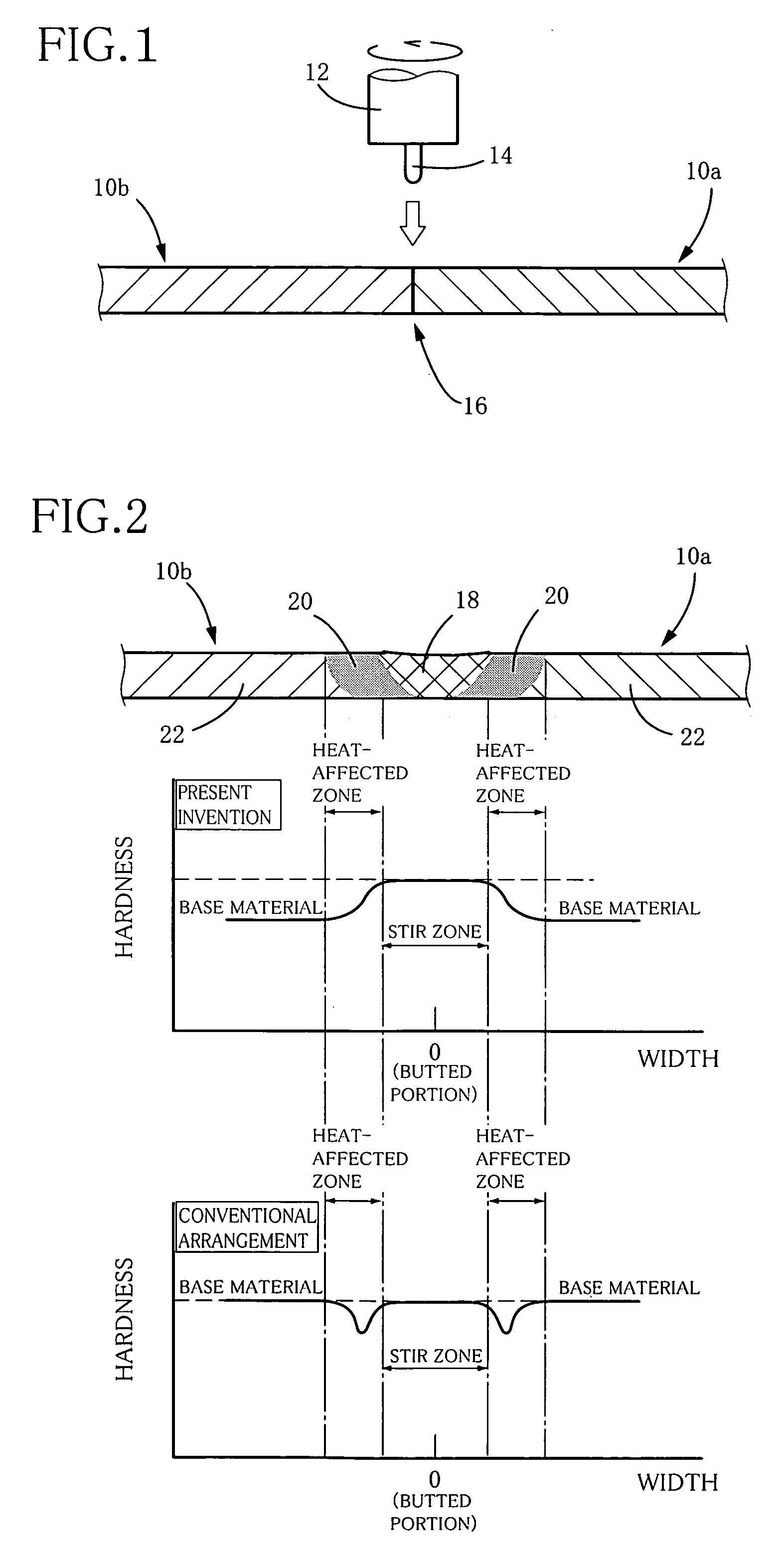

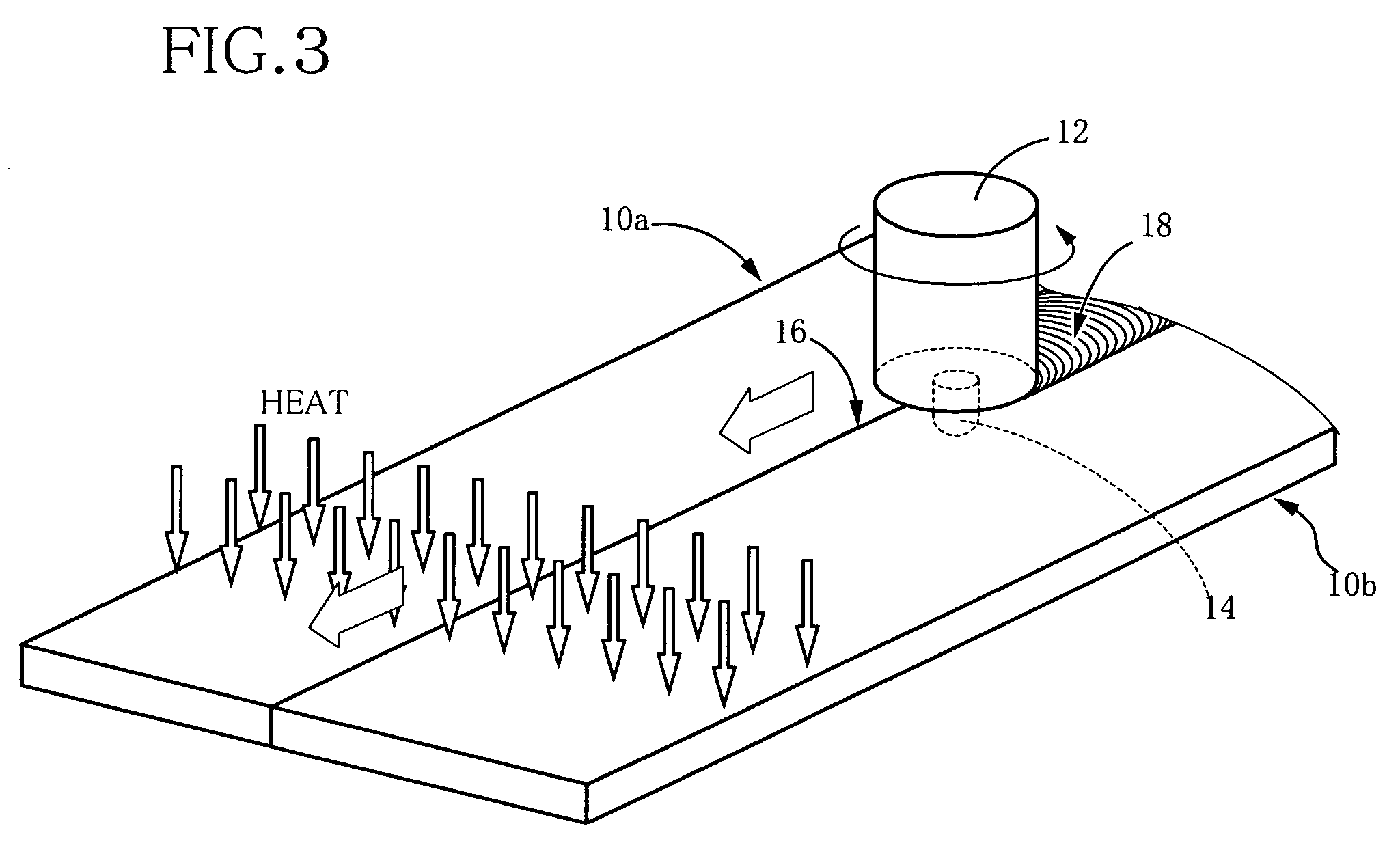

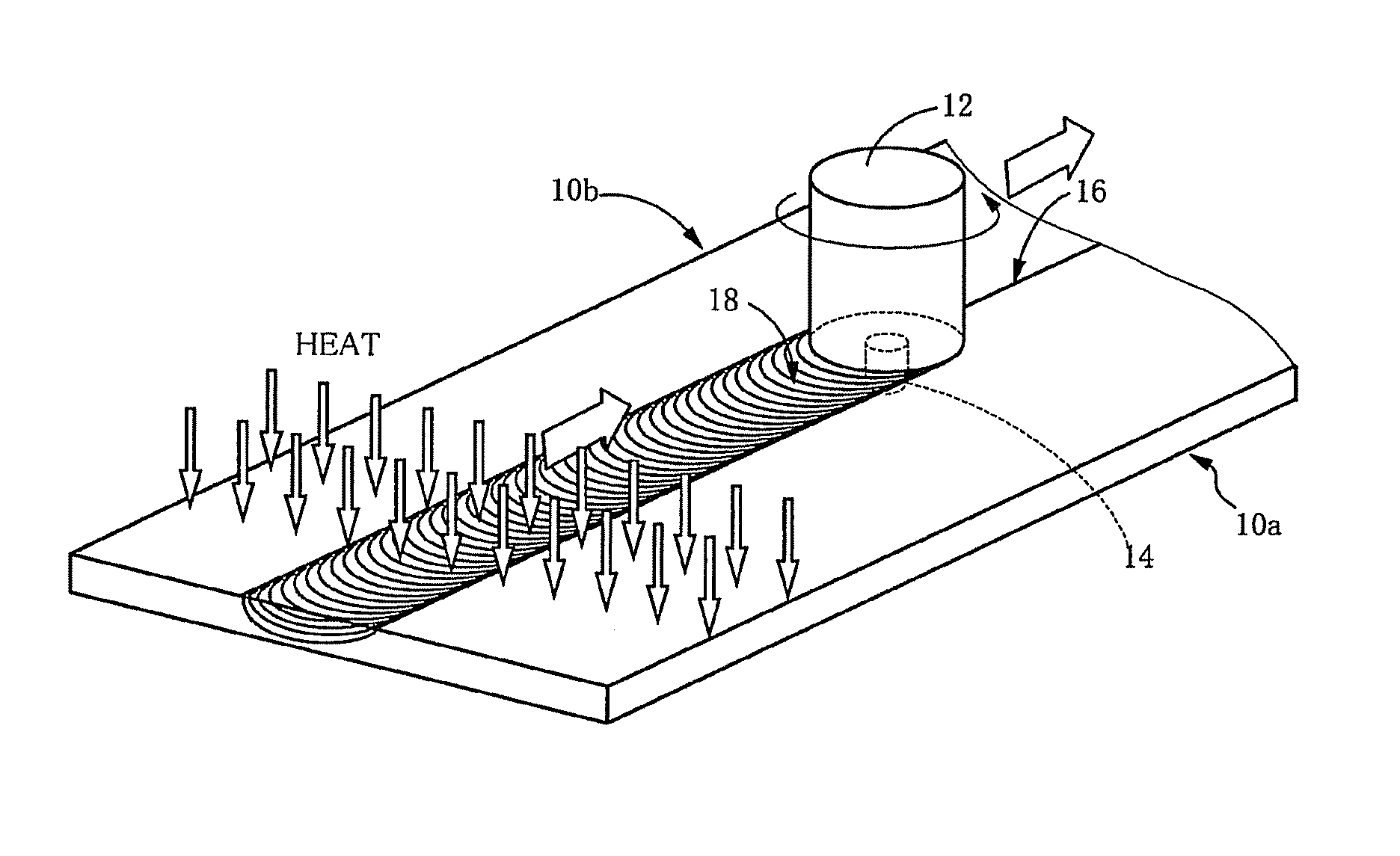

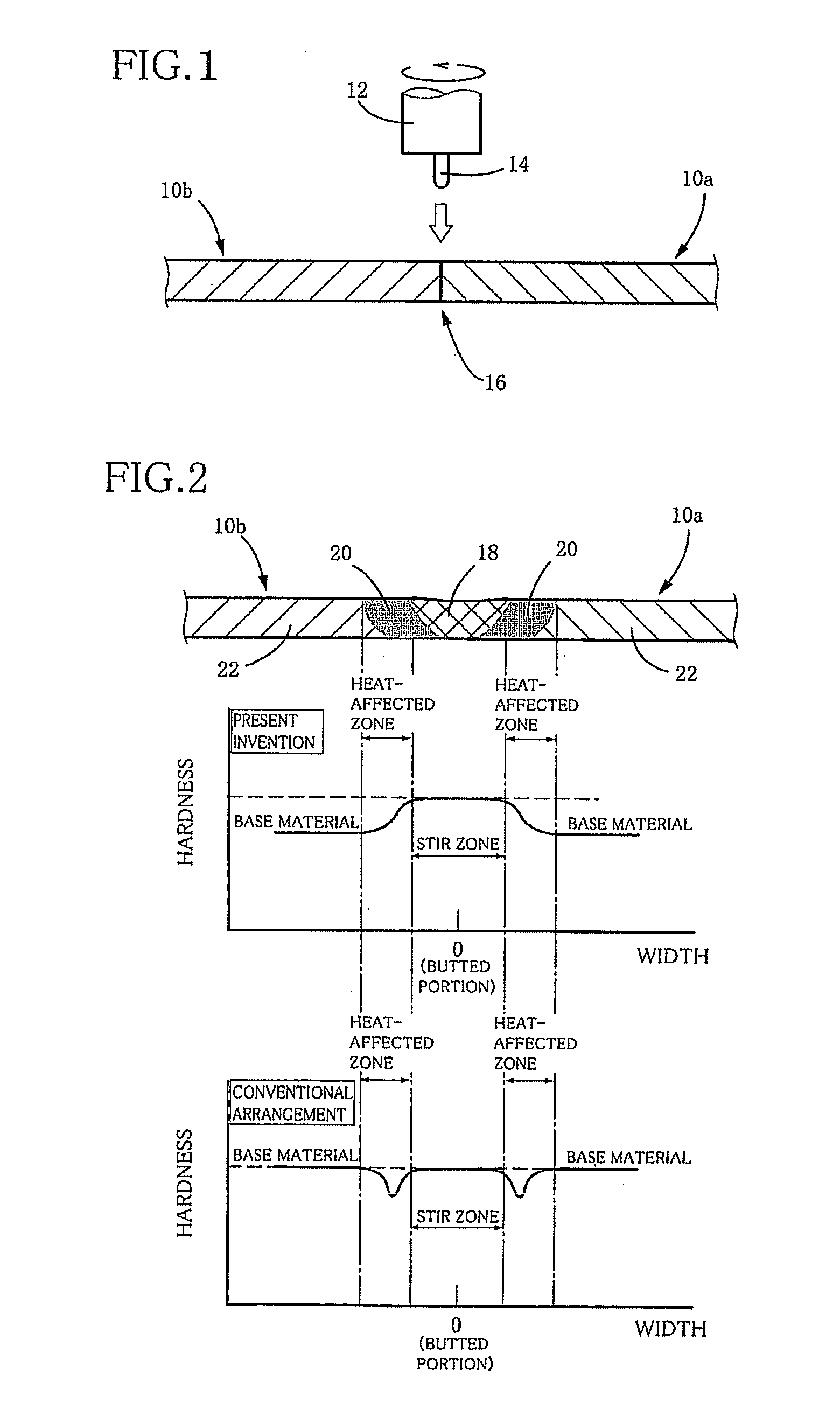

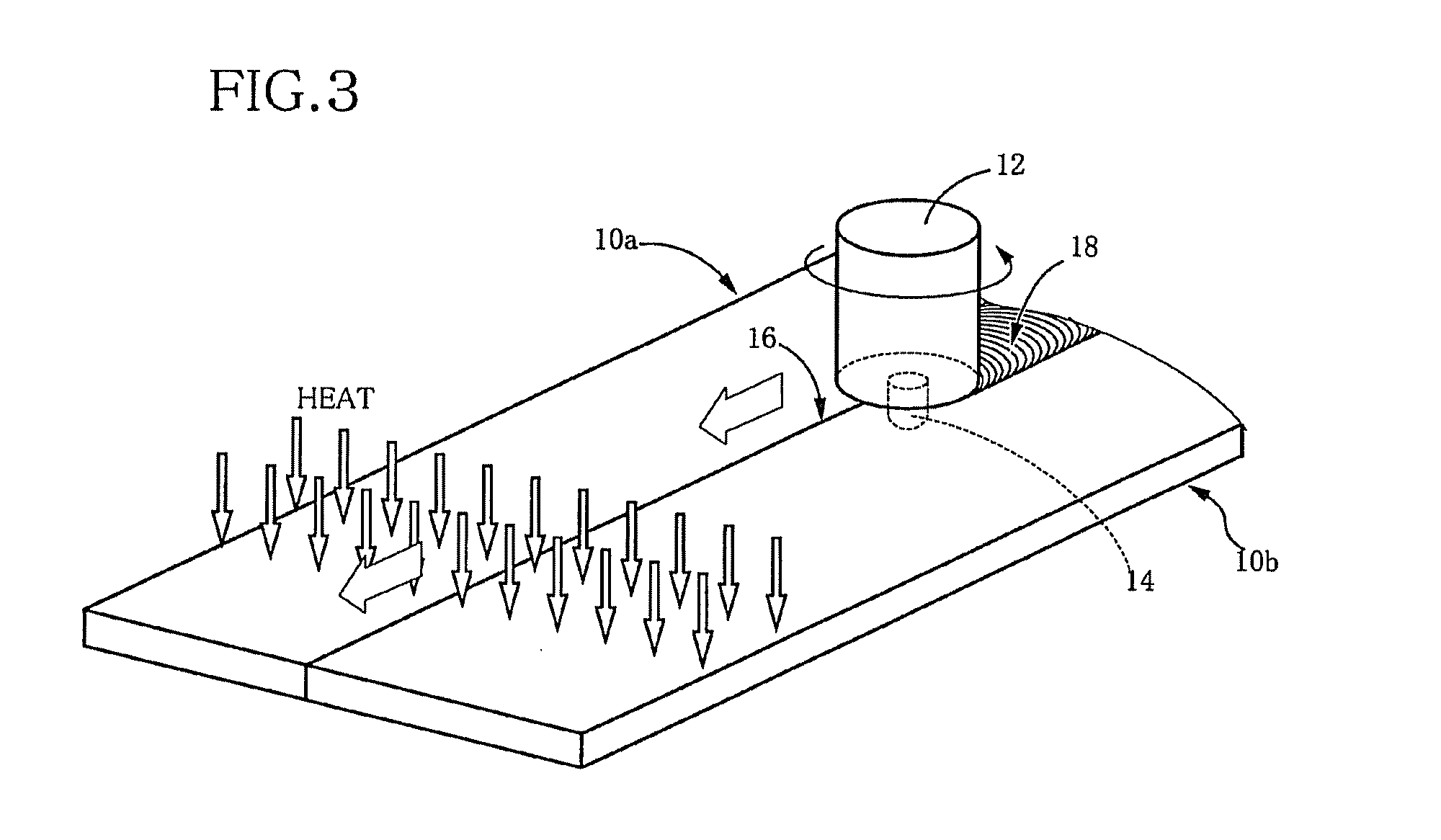

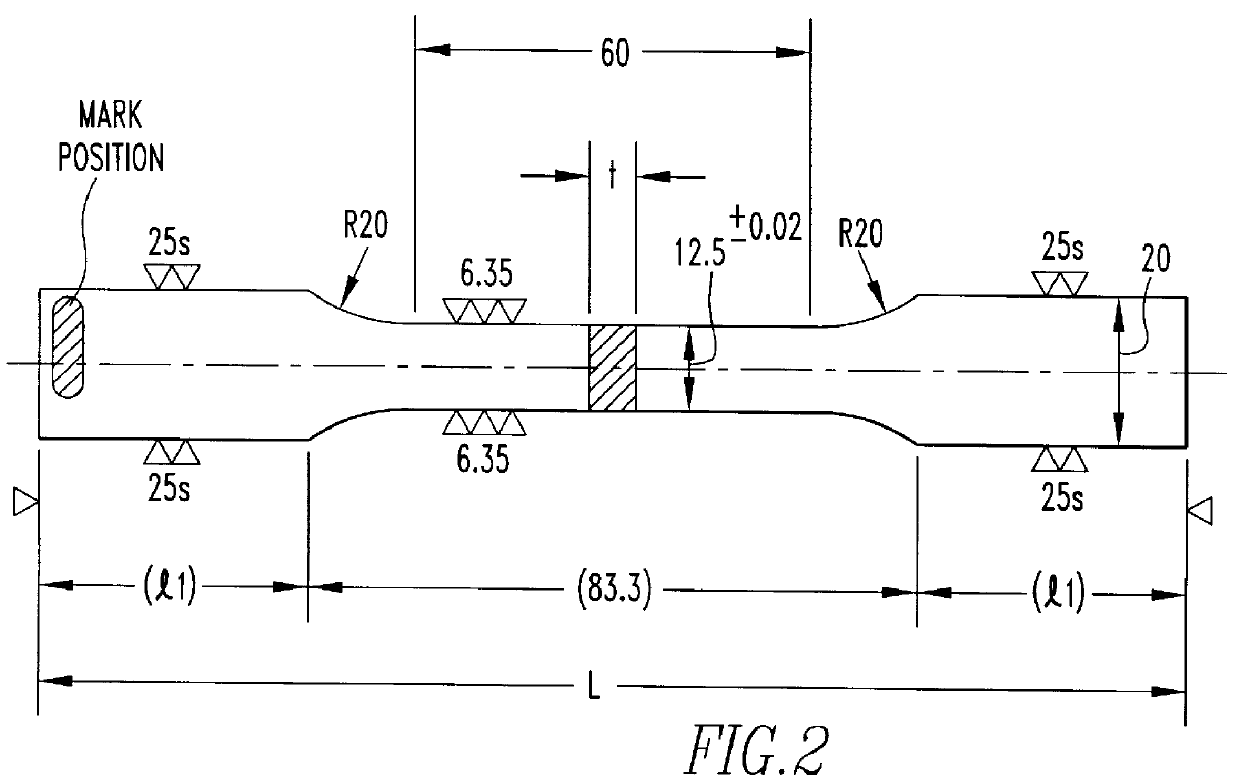

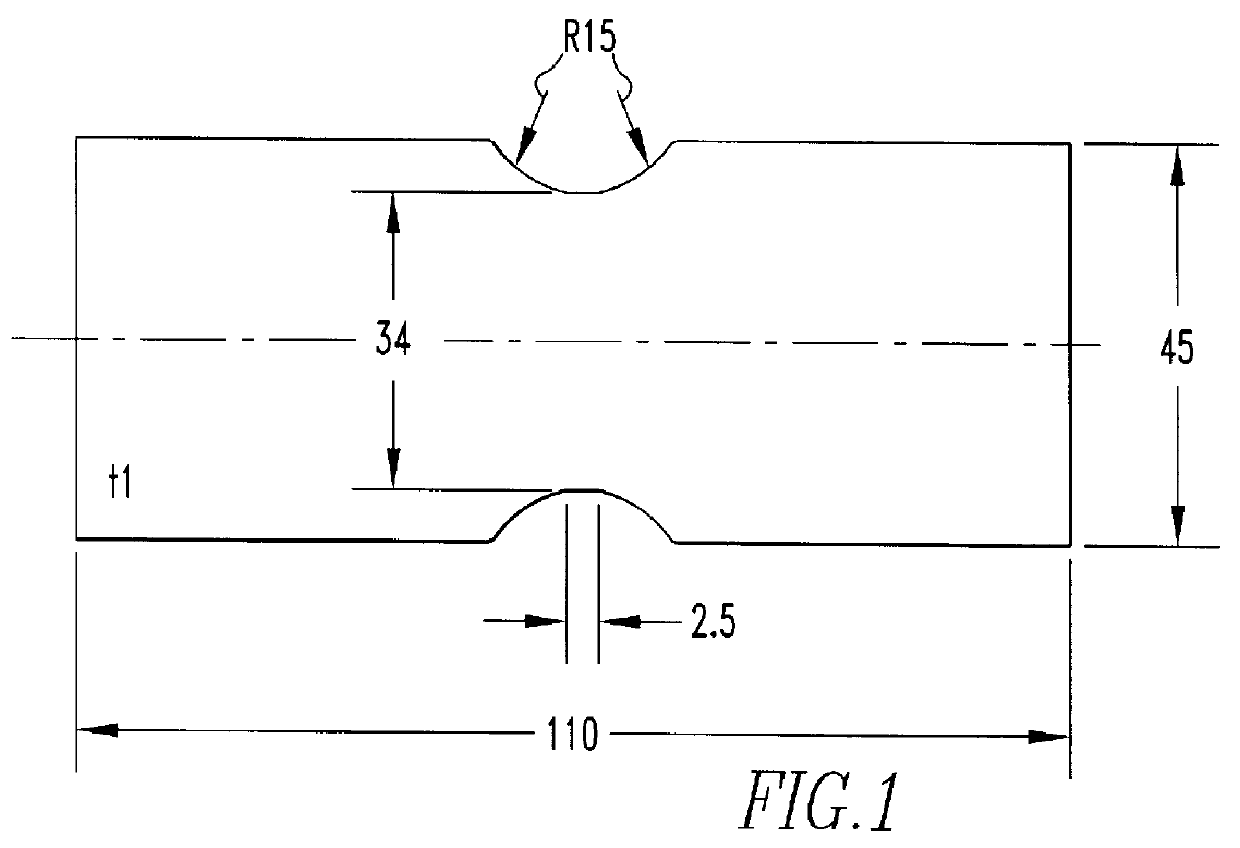

Method of joining heat-treatable aluminum alloy members by friction stir welding and joined product obtained by the method and used for press forming

InactiveUS20070138239A1Avoid stress concentrationReduce hardnessWelding/cutting media/materialsWelding/soldering/cutting articlesFriction stir weldingHeat treating

A method of joining heat-treatable aluminum alloy members by friction stir welding, including the steps of: a T4-treatment-performing step of performing a T4 treatment on heat-treatable aluminum alloy members so as to impart T4 temper to the heat-treatable aluminum alloy members; a joining step of joining the heat-treatable aluminum alloy members with T4 temper by friction stir welding to provide a joined product; and a reversion-treatment-performing step of performing a reversion treatment, the reversion-treatment-performing step being carried out prior to or after the joining step.

Owner:SUMITOMO LIGHT METAL INDS LTD

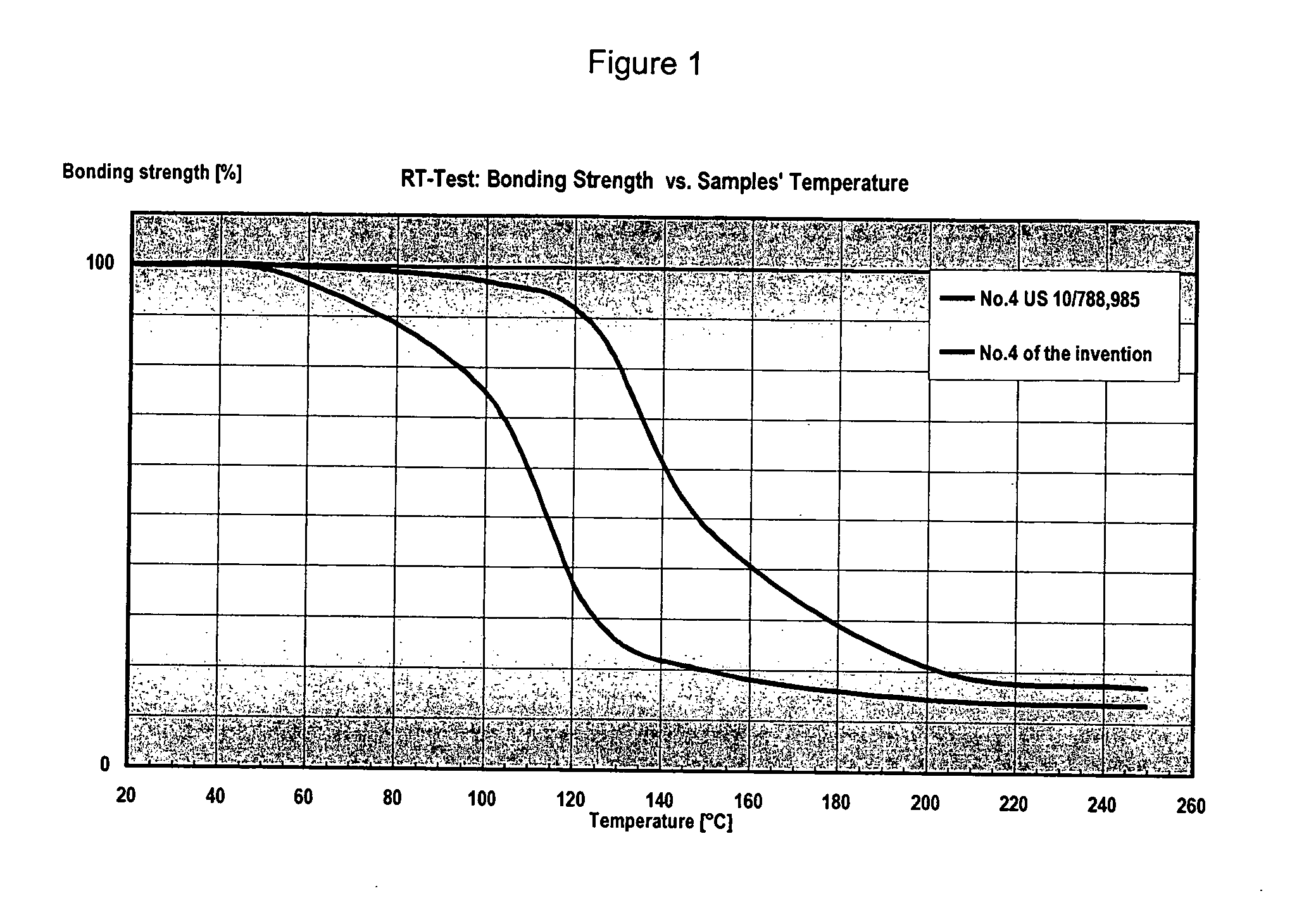

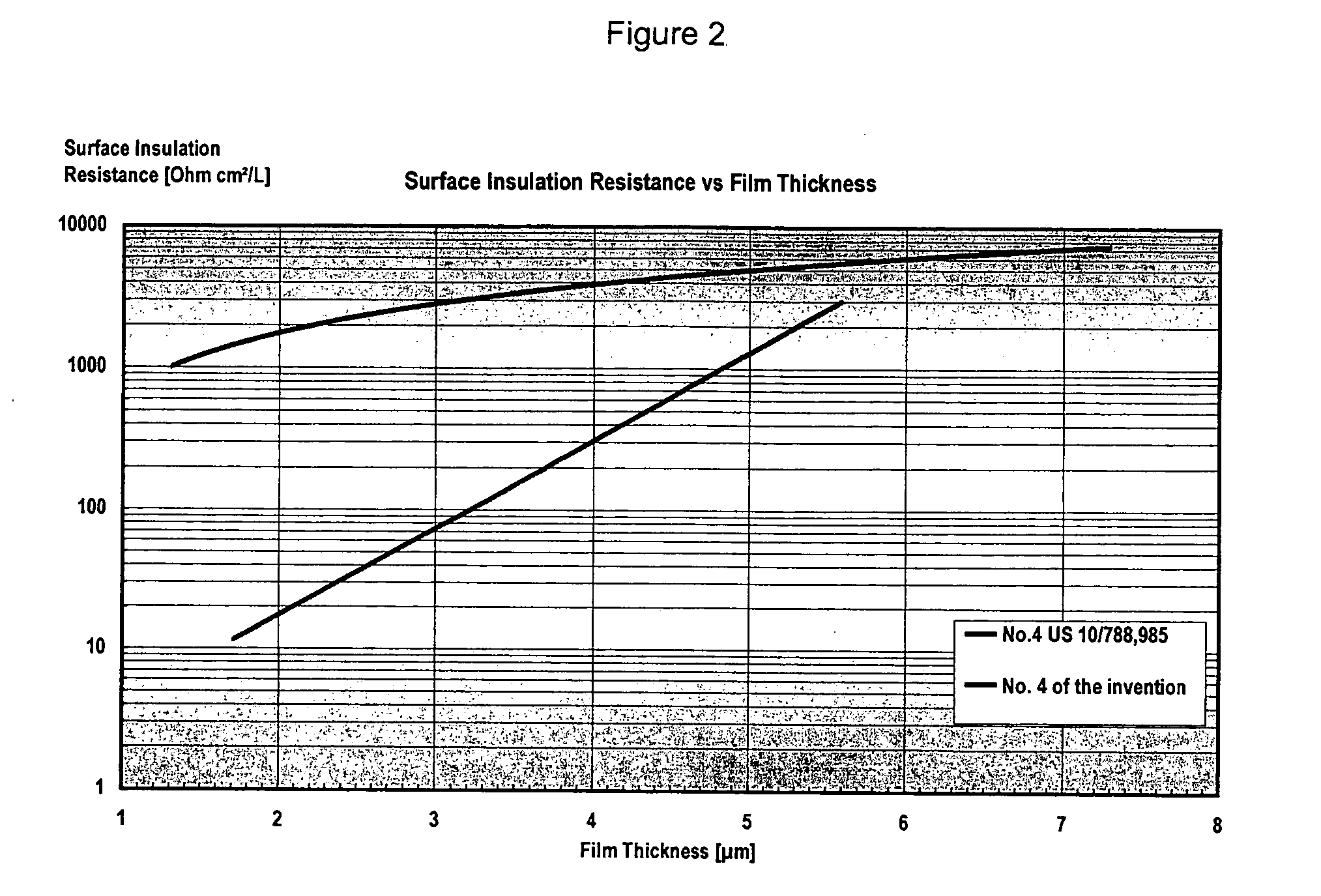

Self-bonding coating composition

InactiveUS20070087201A1Excellent bonding strength and corrosion resistanceIncrease temperatureMaterial nanotechnologySynthetic resin layered productsOrganic solventElectrical steel

A self-bonding coating composition for the production of electrical steel sheets cores comprising A) 100 parts per weight of at least one epoxy resin based on bisphenol-A-type and / or bisphenol-F-type, 100% of solids, B) 0.1 to 200 parts per weight of nano particles having an average radius ranging from 2 to 600 nm, C) 0 to 25 parts per weight of at least one curing agent selected from the group consisting of dicyandiamide, blocked isocyanate and Lewis acid or selected from the group consisting of phenolic resin, carboxylic acid, anhydride and Lewis acid, 100% of solids, D) 0.1 to 10 parts per weight of at least one additive, and E) 50 to 200 parts per weight of water or at least one organic solvent, ensuring increased re-softening temperatures as well as excellent bonding strength, corrosion resistance and electrical insulation of the coating.

Owner:EI DU PONT DE NEMOURS & CO

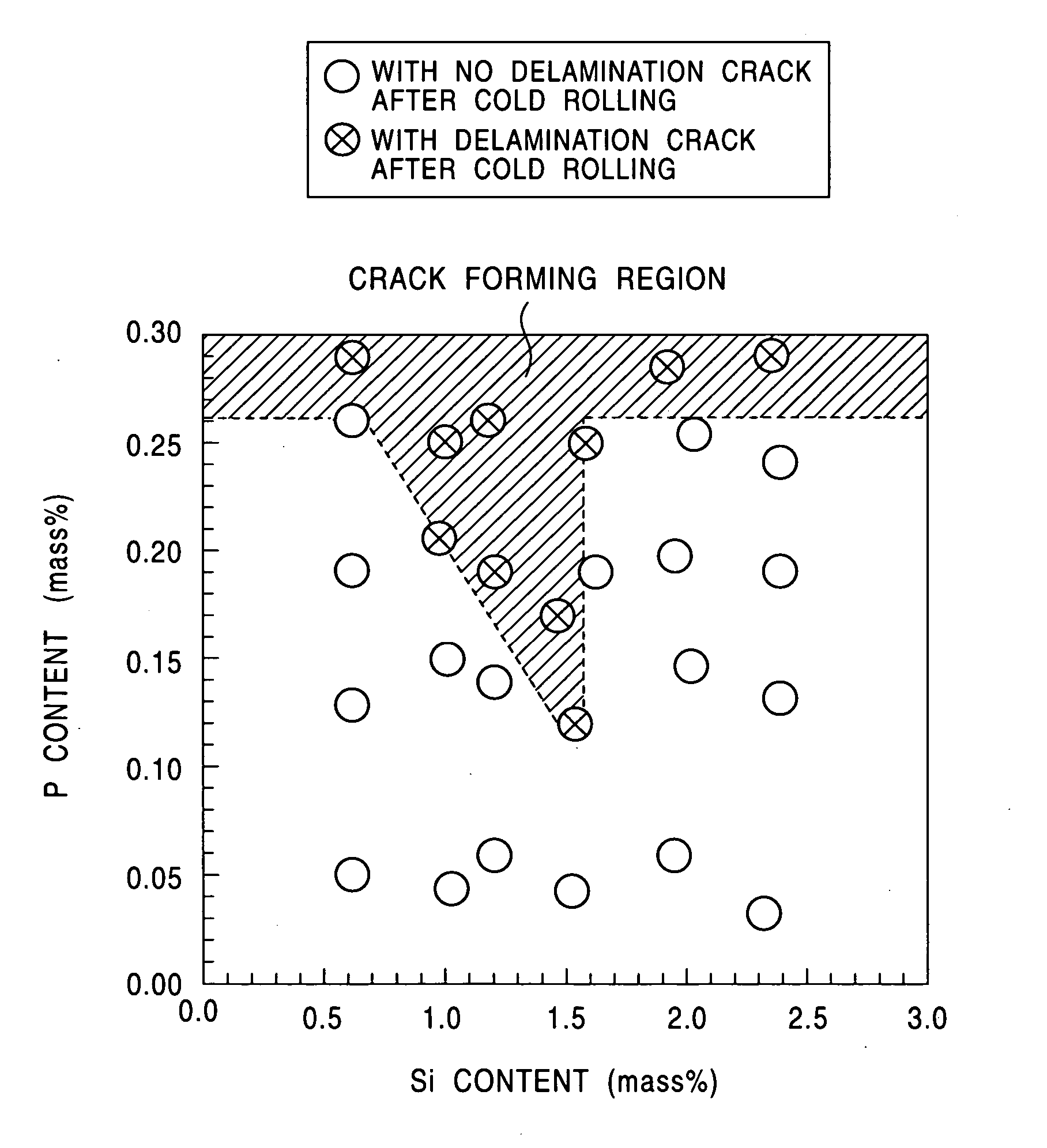

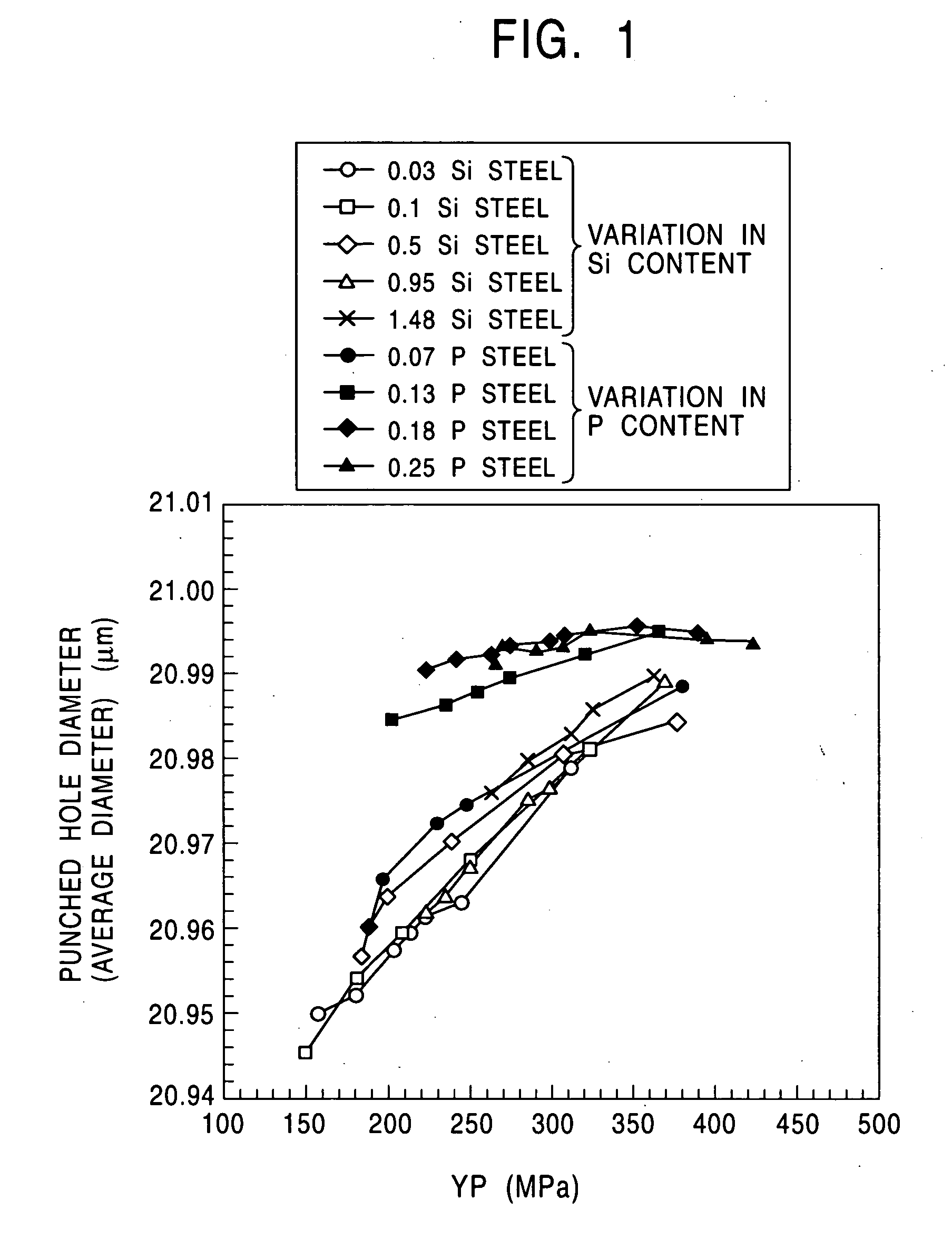

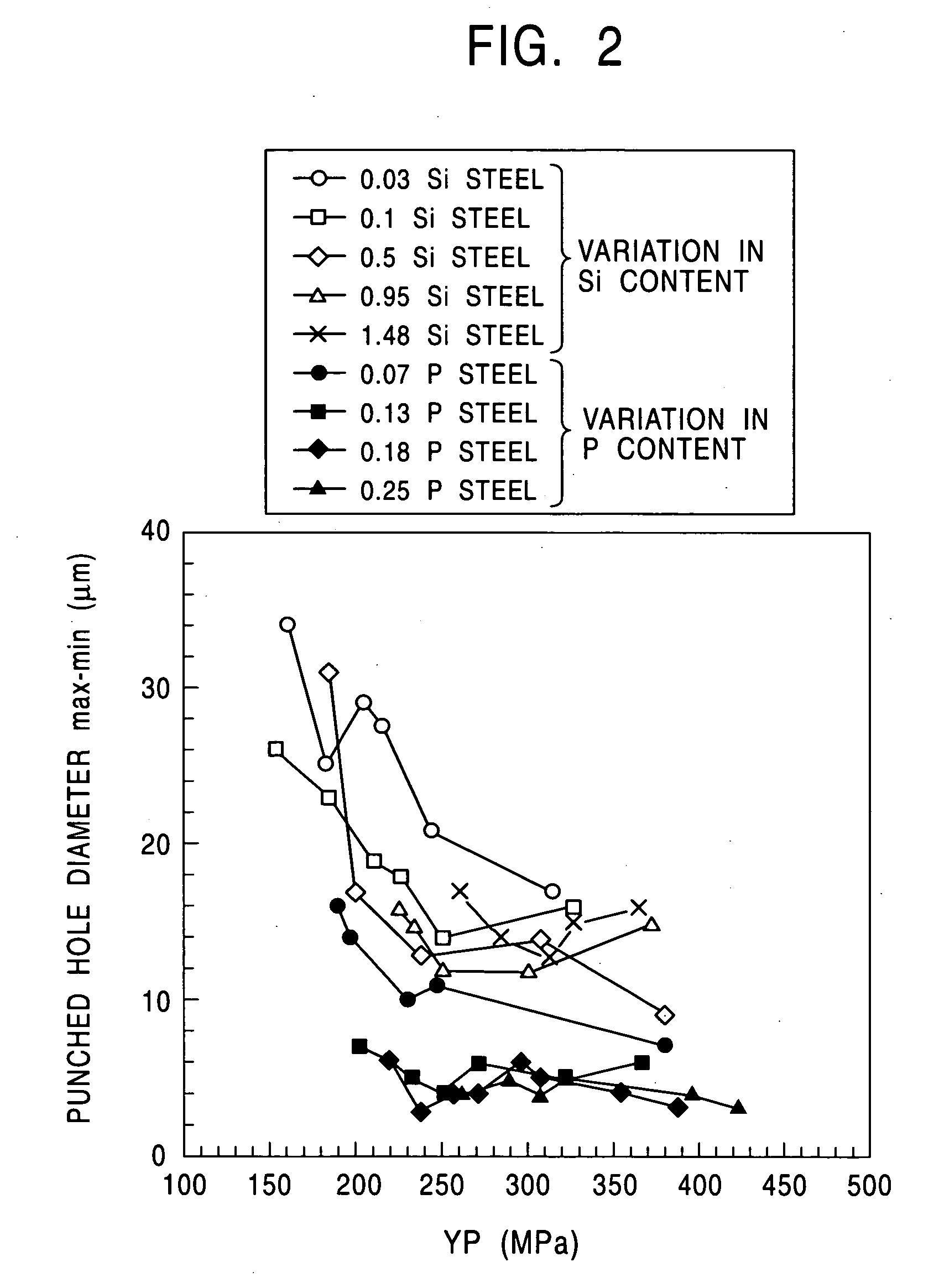

Nonoriented electromagnetic steel sheet

InactiveUS20040149355A1Reduce regionHigh magnetic flux densityInorganic material magnetismFurnace typesSheet steelElectrical steel

The present invention provides a non-oriented electrical steel sheet containing: 0-0.010% of C; at least one of Si and Al in a total amount of 0.03% to 0.5%, or more than 0.5% to 2.5%; 0.5% or less of Mn; 0.10% or more to 0.26% or less of P; 0.015% or less of S; and 0.010% or less of N, on a mass percentage basis, wherein the non-oriented electrical steel sheet has excellent dimensional accuracy during a punching step. When the Si content is low, the non-oriented electrical steel sheet has the excellent balance between high magnetic flux density and low core loss. When the Si content is medium or high, the non-oriented electrical steel sheet has the excellent balance between high magnetic flux density and high strength.

Owner:JFE STEEL CORP

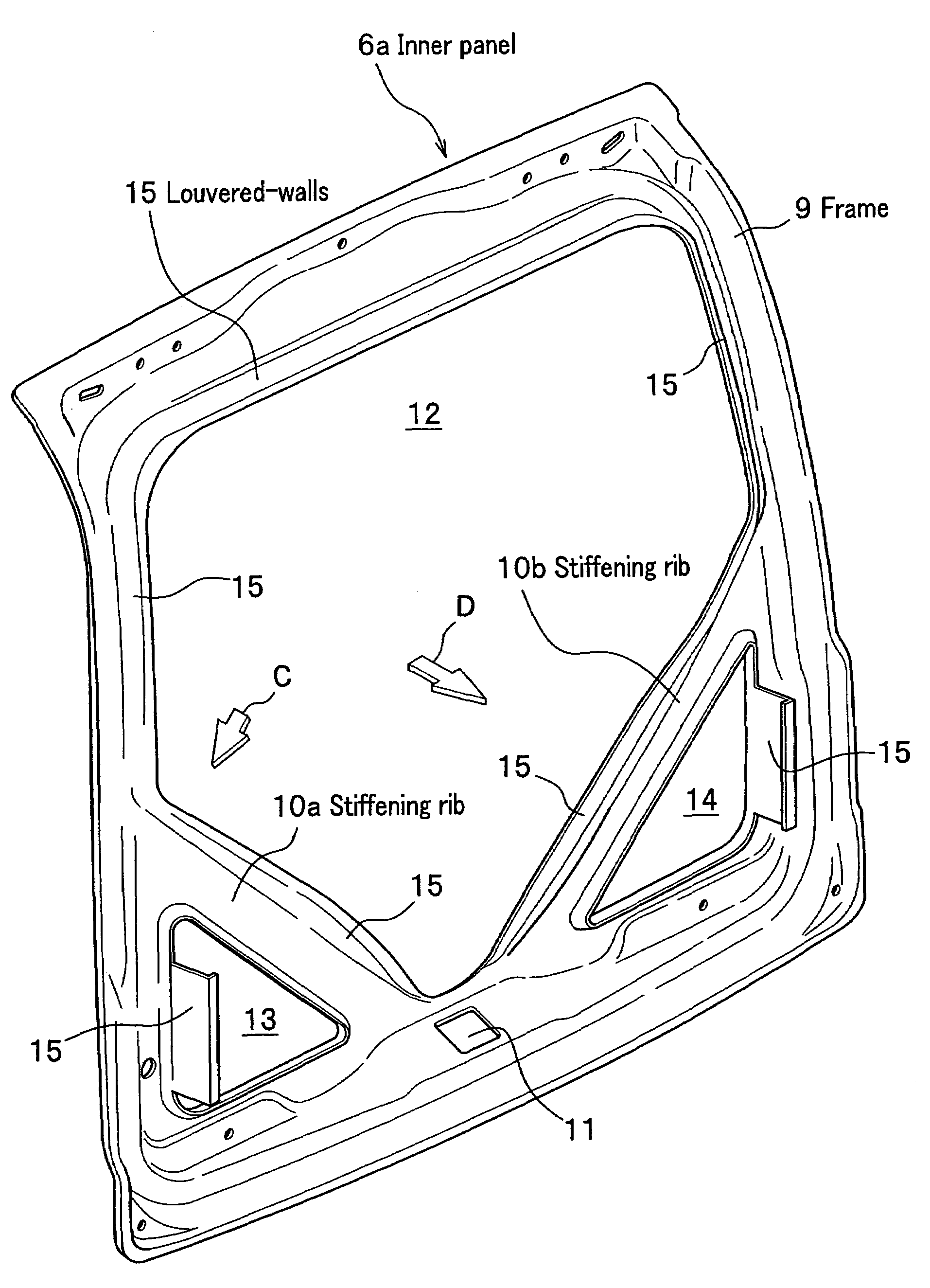

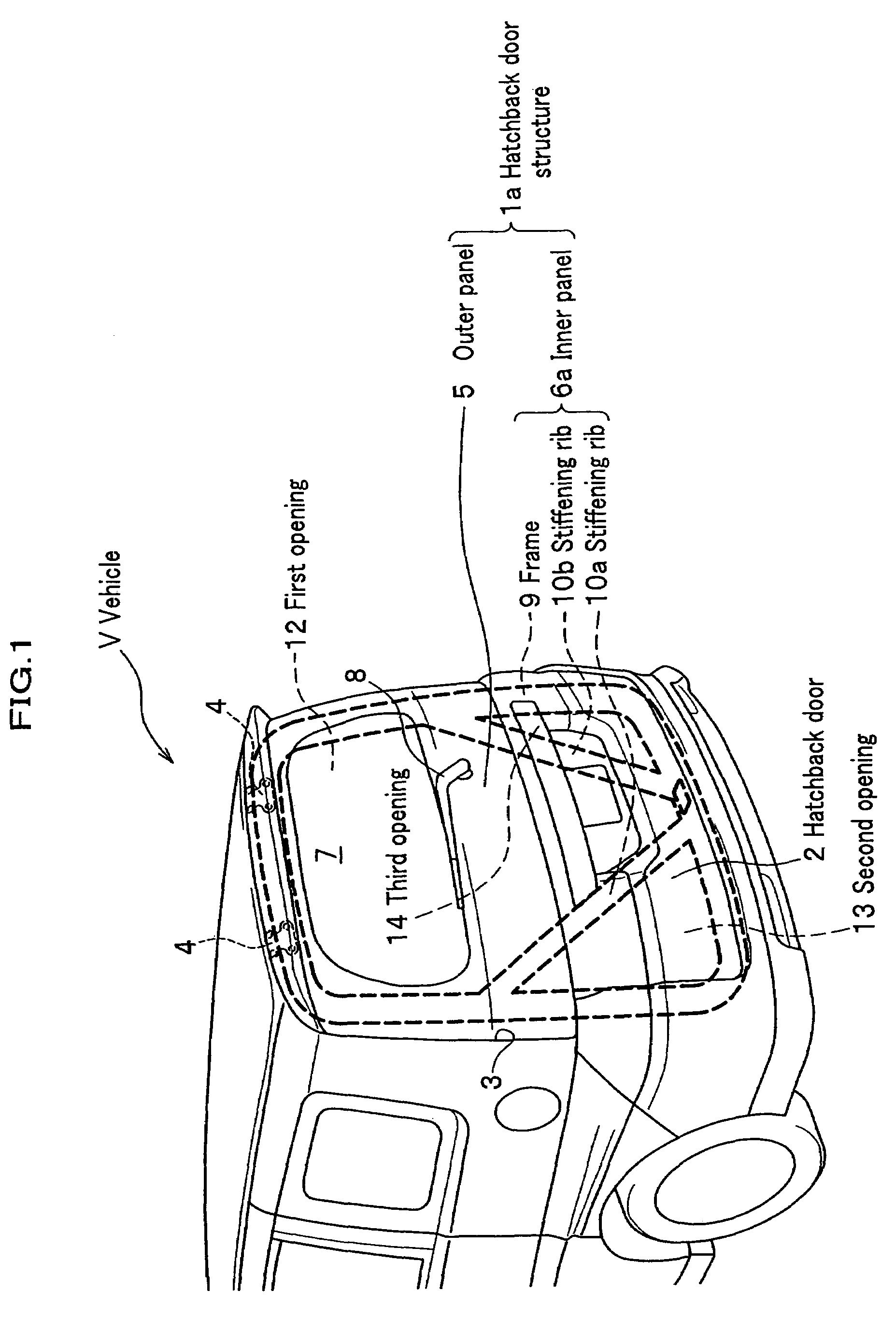

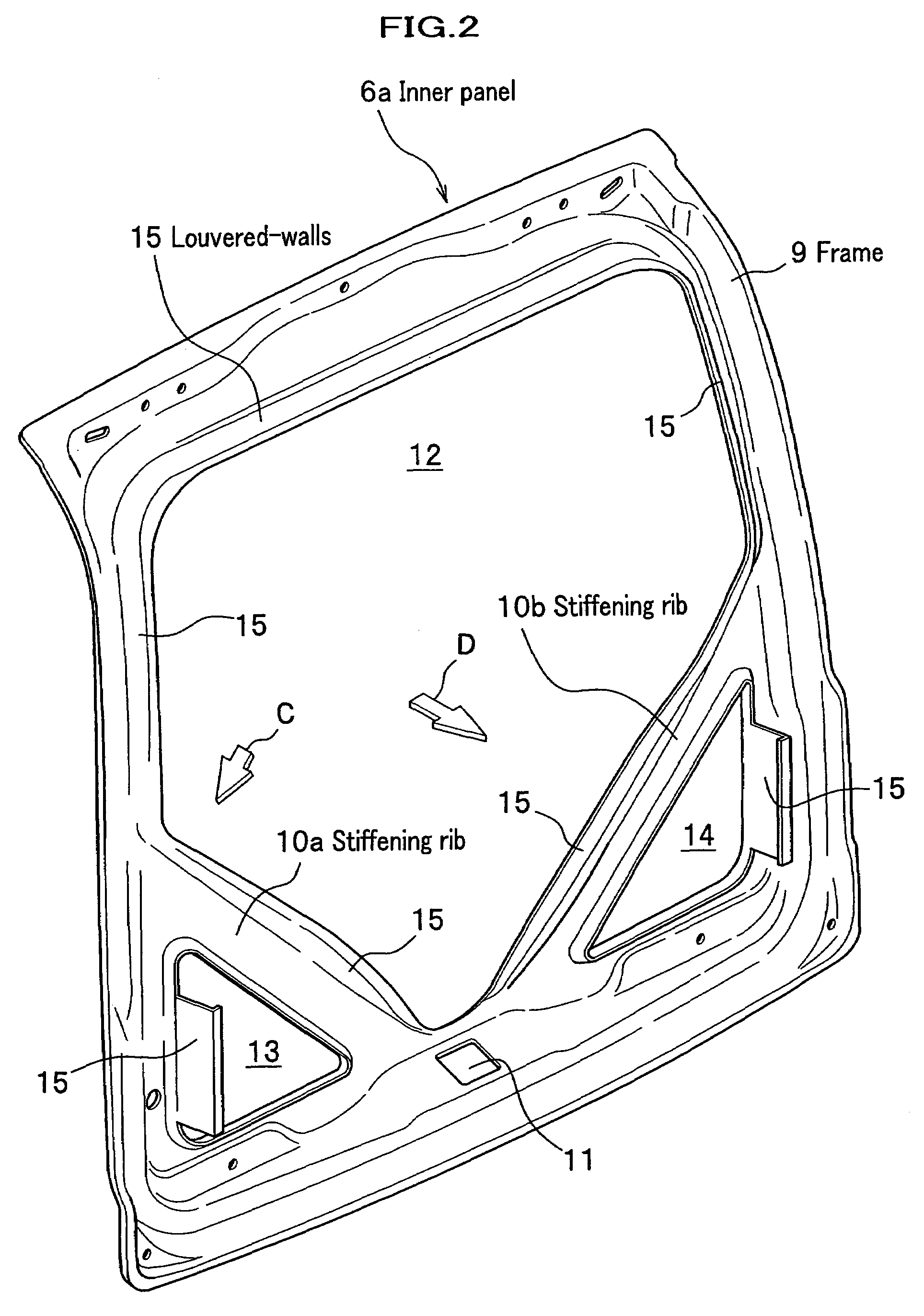

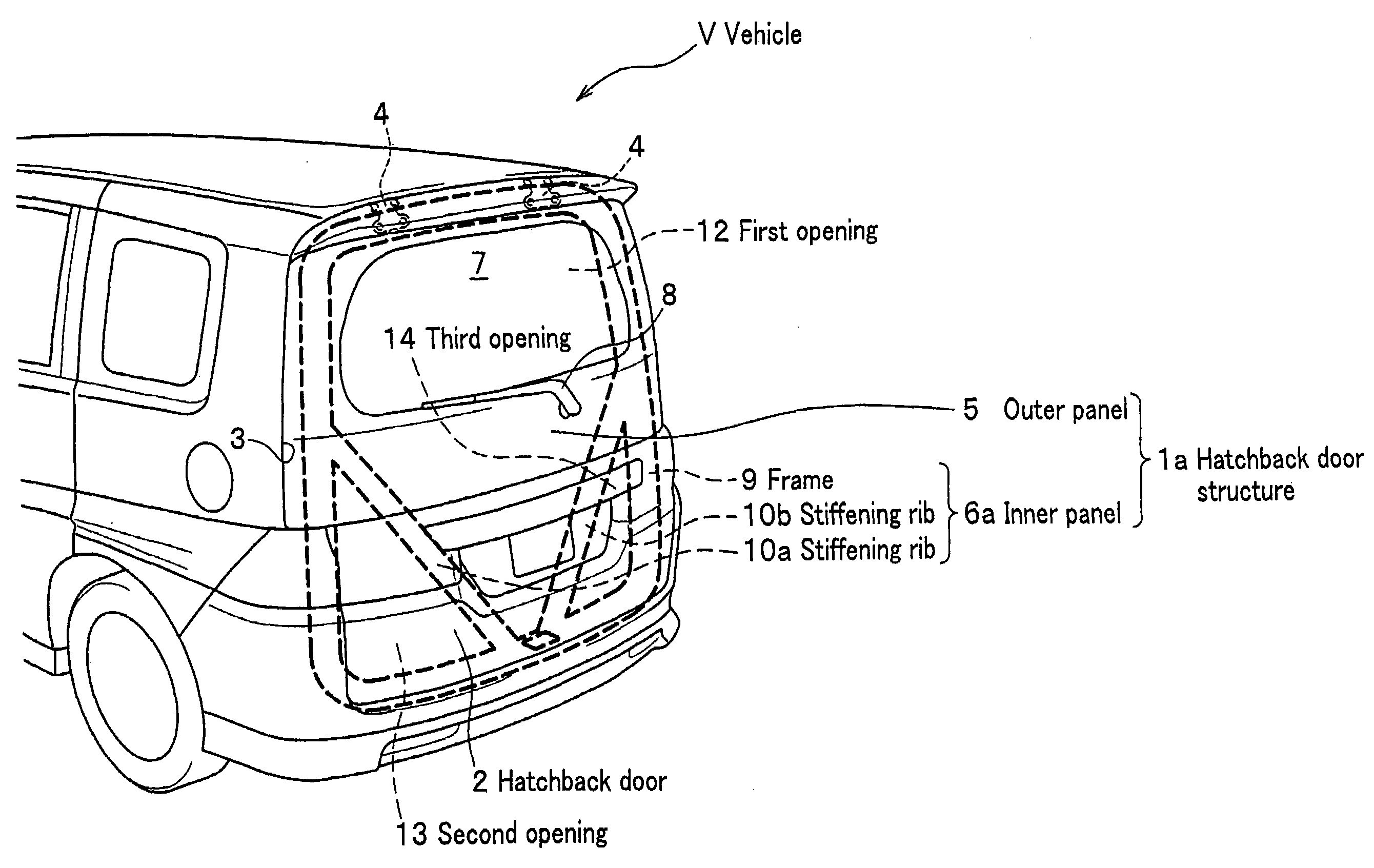

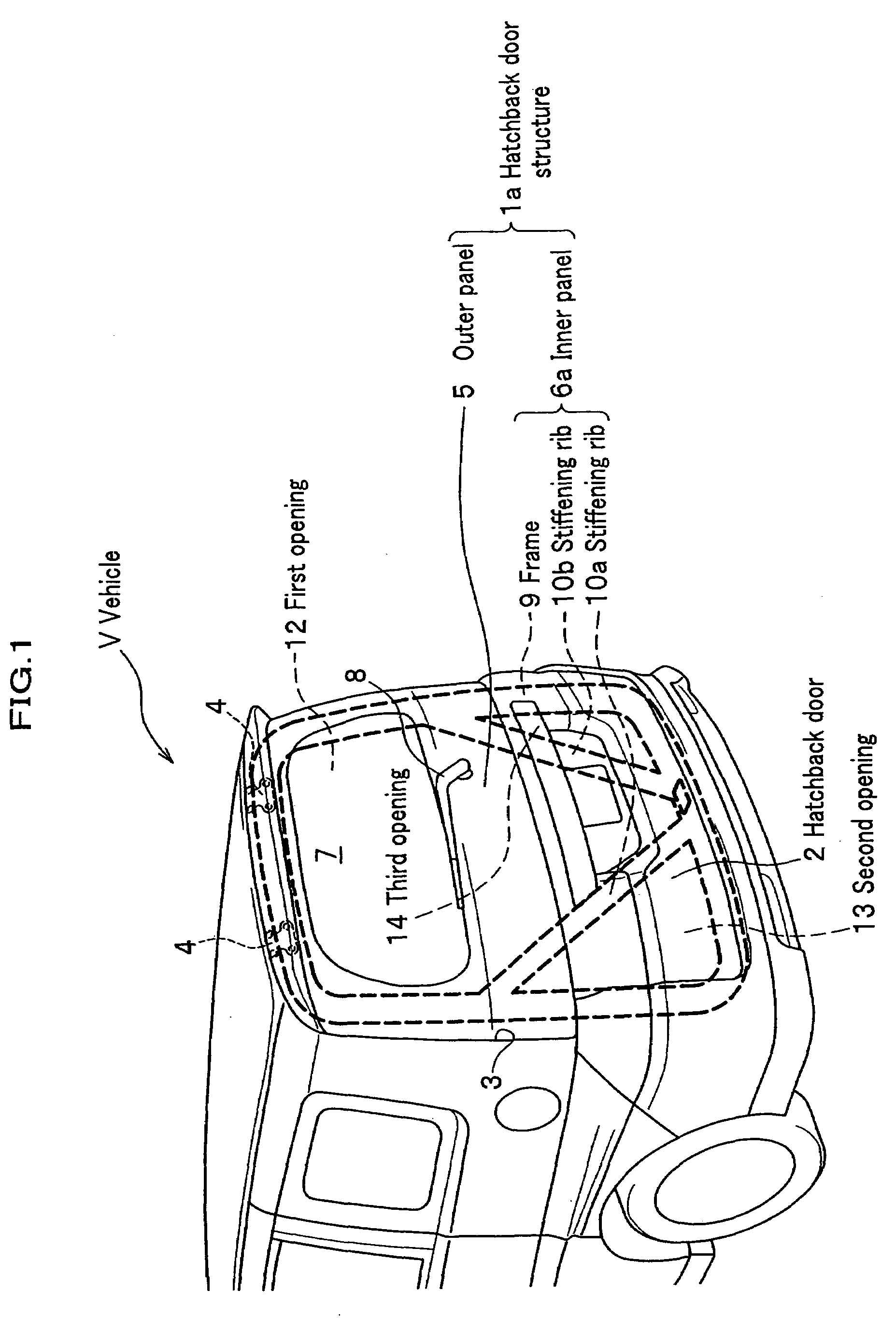

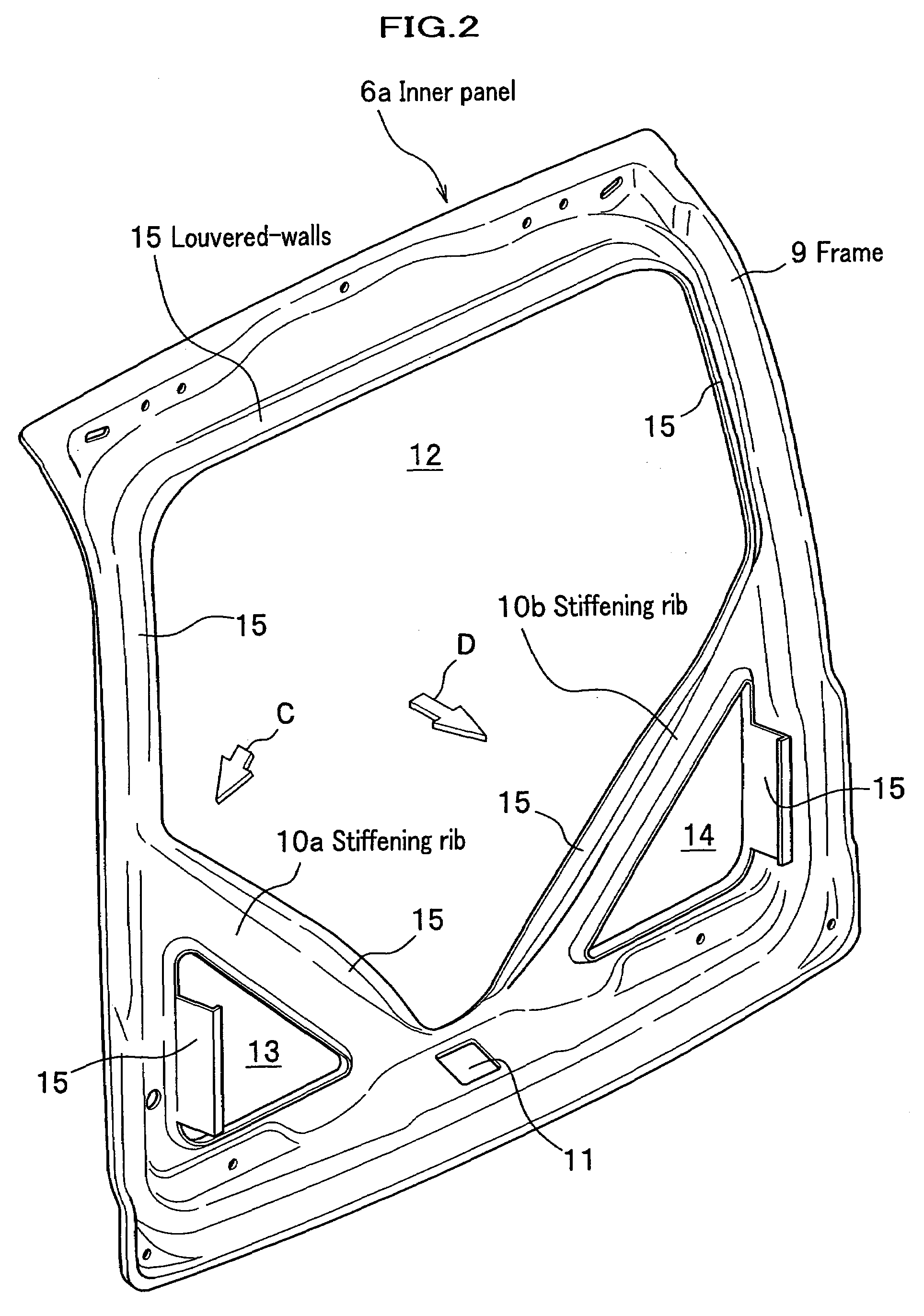

Hatchback door structure for vehicles

ActiveUS7537267B2Reduce weightImprove rigidityMonocoque constructionsVehicle bodiesEngineeringCar door

Owner:HONDA MOTOR CO LTD

Manufacture method of cold-rolled electrolytic tin substrate

ActiveCN102794301AStable productionReduce manufacturing costWork treatment devicesFurnace typesHydrogenPush pull

The invention discloses a manufacture method of a cold-rolled electrolytic tin substrate. The manufacture method comprises the steps of: (1) processing the produced molten iron by converter smelting, vacuum treatment, continuous casting and hot rolling after desulfuration to obtain a cold-rolled material; (2) pickling by a shallow-trench turbulent push-pull hydrochloric acid pickling set; (3) carrying out cold rolling for the first time by using a six-roller HC reversing mill, and rolling to a semi-product with a thickness of 0.5 to 0.6 mm after passing through 4 to 7 rolling passes; (4) cleaning by an electrolytic degreasing set; (5) carrying out annealing for the first time in a full-hydrogen shine-cover annealing furnace; (6) carrying out cold rolling for the second time by using the six-roller HC reversing mill; (7) carrying out annealing for the second time in the full-hydrogen shine-cover annealing furnace; (8) leveling by using a four-roller leveling machine, wherein the rolling force is controlled between 3000 to 4500kN; and (9) trimming by a re-reeling set, oiling, packaging and storing in a warehouse. The manufacture method disclosed by the invention has the advantages of stable production and low production cost, and can meet the requirement for high-quality electrolytic thin substrate in the food package industry.

Owner:山东泰山轧钢有限公司

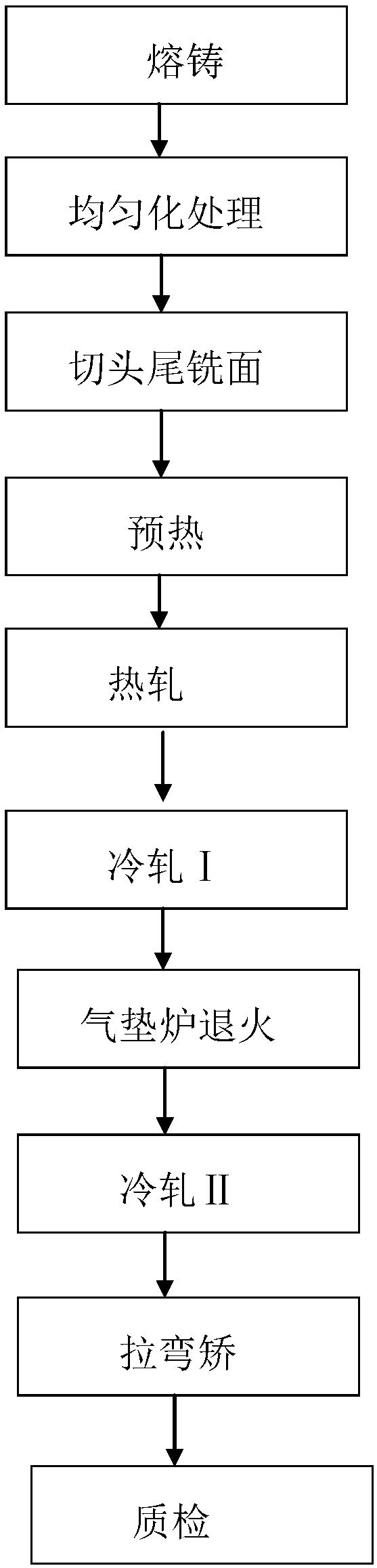

5182 aluminum alloy and technology method for preparing tank cover material strip through aluminum alloy

ActiveCN106834825AHigh strengthImprove performance uniformityTemperature control deviceRolling mill drivesUltimate tensile strengthImpurity

The invention discloses a 5182 aluminum alloy. The aluminum alloy is composed of Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti, and remaining Al and some inevitable impurities. A preparing technology of a tank cover material strip through the 5182 aluminum alloy comprises the steps of firstly, taking of the 5182 aluminum alloy; secondly, hot rolling, cooling and obtaining a blank for cold rolling; thirdly, primary cold rolling, and obtaining a cold-rolled intermediate product, wherein the total deformation amount ranges from 66% to 78%; fourthly, air cushion furnace annealing; fifthly, secondary cold rolling, wherein the total deformation amount ranges from 71% to 76%; sixthly, stretch bending and correcting. According to the 5182 aluminum alloy and the preparing technology of the tank cover material strip through the 5182 aluminum alloy, through high alloying, the alloy strength is improved, meanwhile, the content of Fe and Si is reasonably controlled, and bank mark generation is restrained; continuous air cushion furnace annealing is adopted, through high-temperature short-time annealing, the grains are adjusted and controlled, uniformity of the strip performance is improved, and meanwhile the strip surface quality is ensured.

Owner:广西南南铝加工有限公司

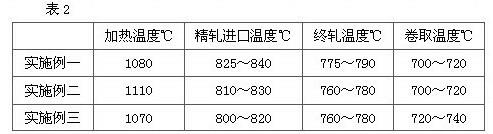

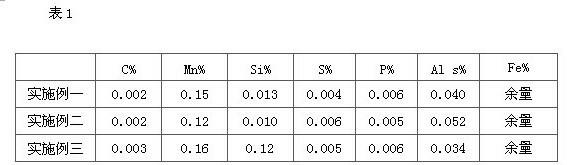

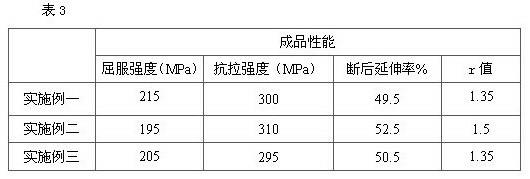

Processing method for producing low-cost high-formability IF (interstitial-free) steel

InactiveCN102581008AHigh drawabilityIncrease productivityTemperature control deviceMetal rolling arrangementsSlow coolingWater cooling

The invention relates to a processing method for producing low-cost high-formability IF (interstitial-free) steel, which is based on thin-slab continuous casting and rolling and adopts a ferrite rolling process to produce the IF steel, belonging to the technical field of IF steel production. The processing method comprises the following working procedures of steelmaking, continuous casting, heating, rolling, cooling and coiling. A thin-slab continuous casting machine is adopted, the thickness of a continuous casting slab is at most 100mm, and the charging temperature is at least 880 DEG C. During hot rolling, a roughing mil and a finishing mill keep a continuous rolling relationship and keep micro-tension control, and water cooling equipment is used between the roughing mil and the finishing mill and is used for uniformly reducing the temperature of an intermediate slab with a thickness of 12-25mm from the temperature at least 950 DEG C of the outlet of the roughing mil into the range of 750-850 DEG C. Finish rolling is carried out in a ferrite area, and a lubrication rolling technology is adopted. The coiling temperature is higher and is 680-760 DEG C, slow cooling is carried out after coiling, and thereby an annealing process is finished. The invention provides a method for obtaining high-formability hot rolled sheets without cold rolling and cover annealing. The method has the advantages of being simple in process, low in cost, high in production efficiency, short in flow and the like, and the formability of products is higher.

Owner:HEBEI IRON AND STEEL

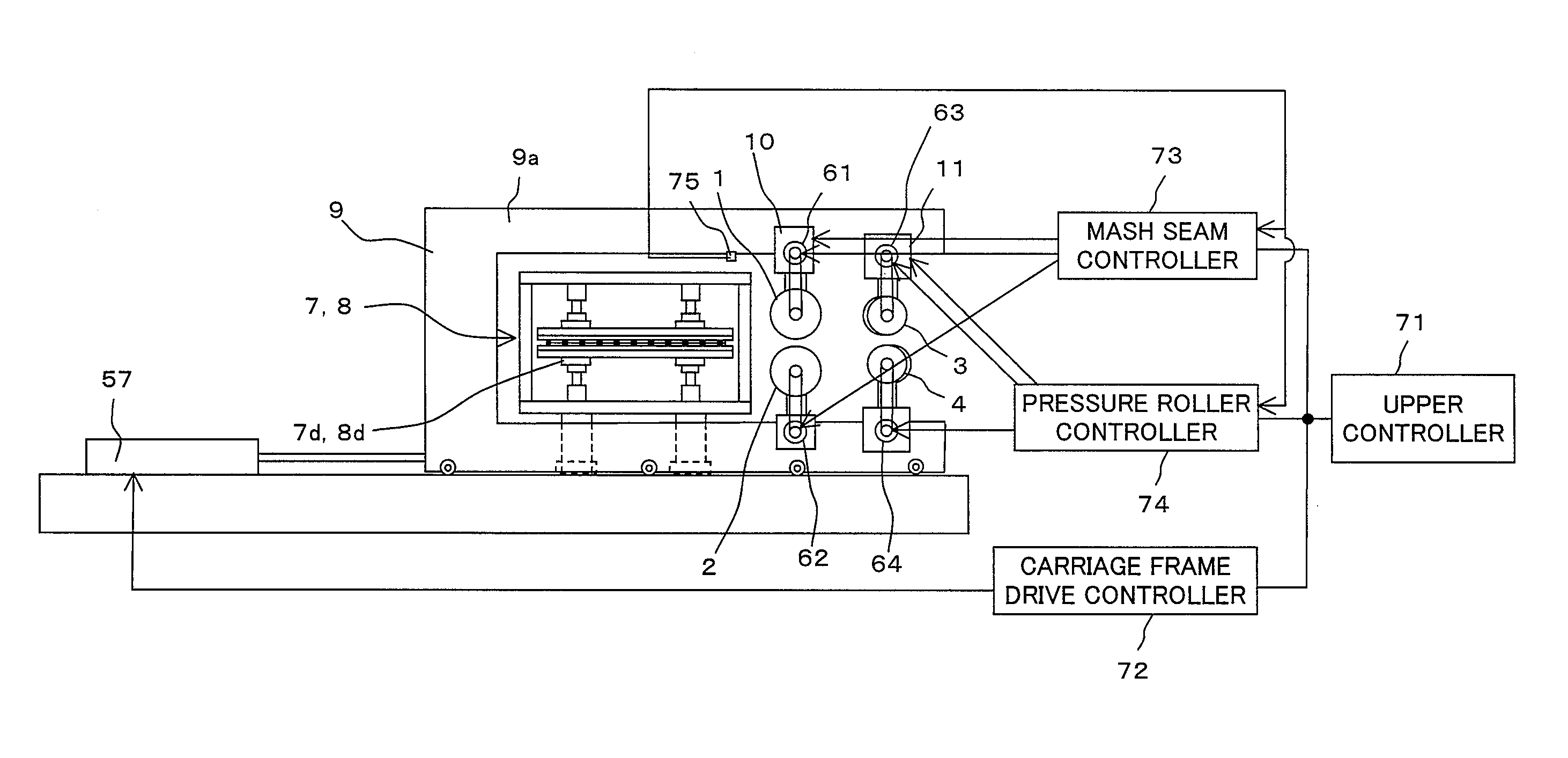

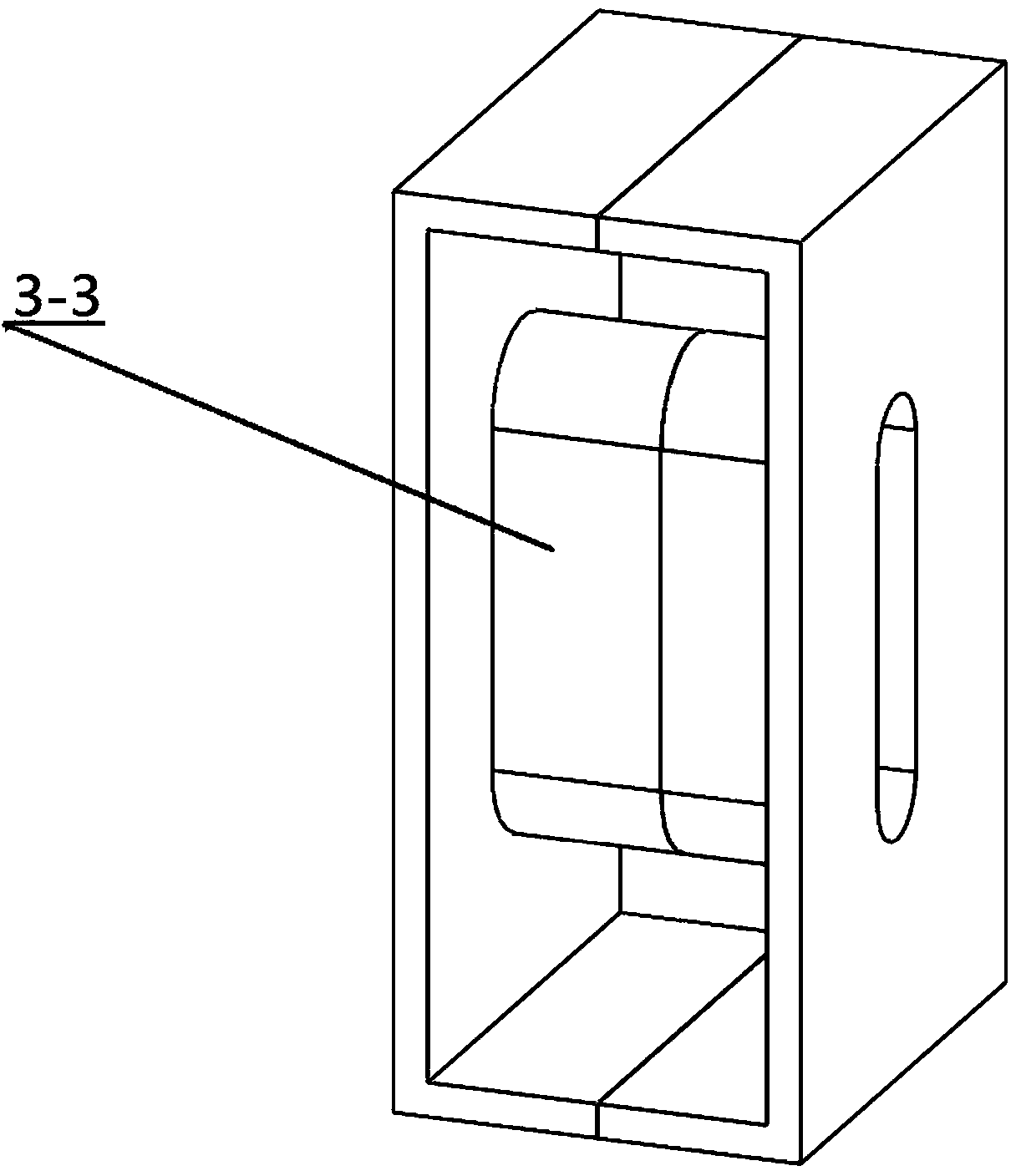

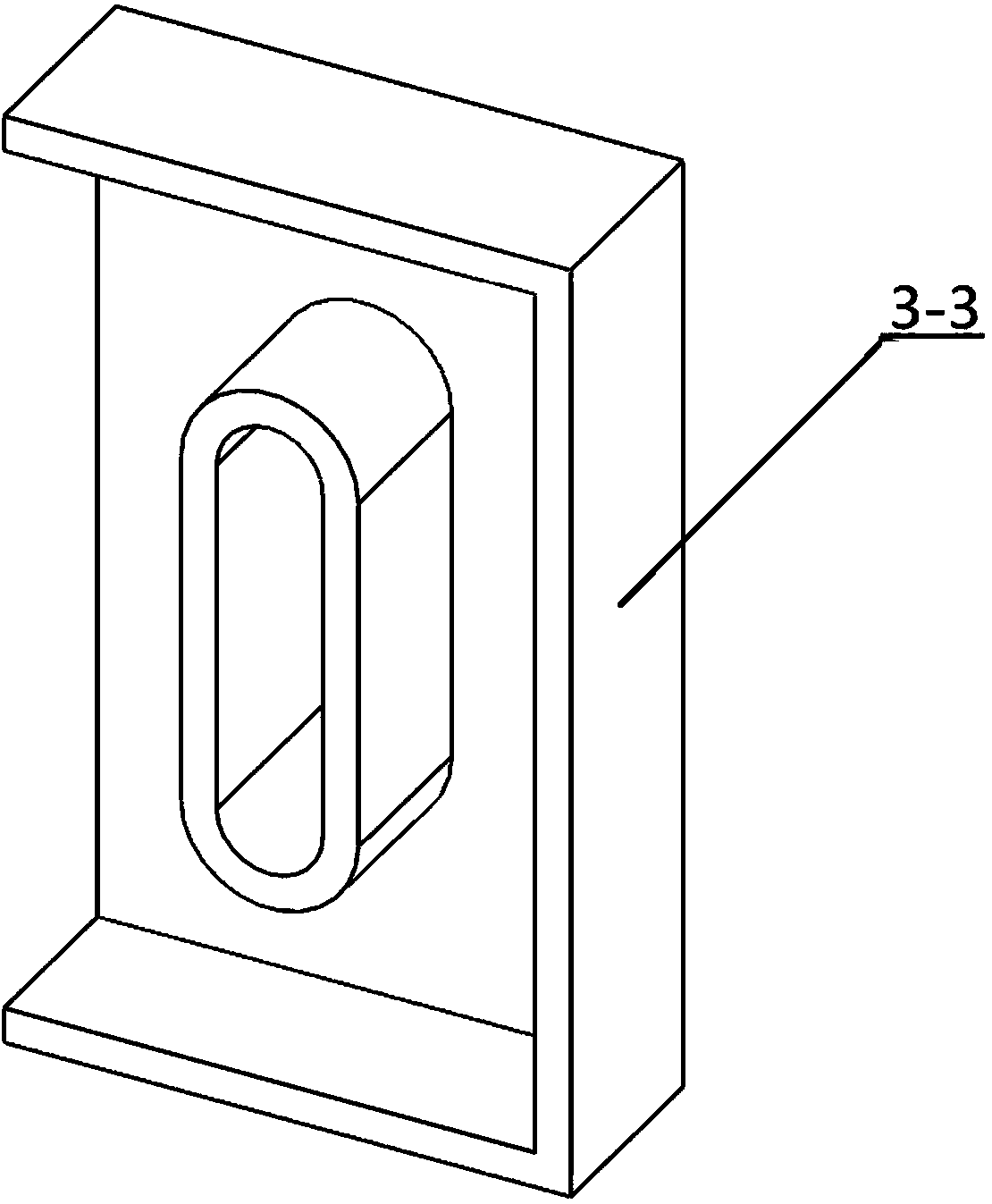

Metal plate joining method and apparatus

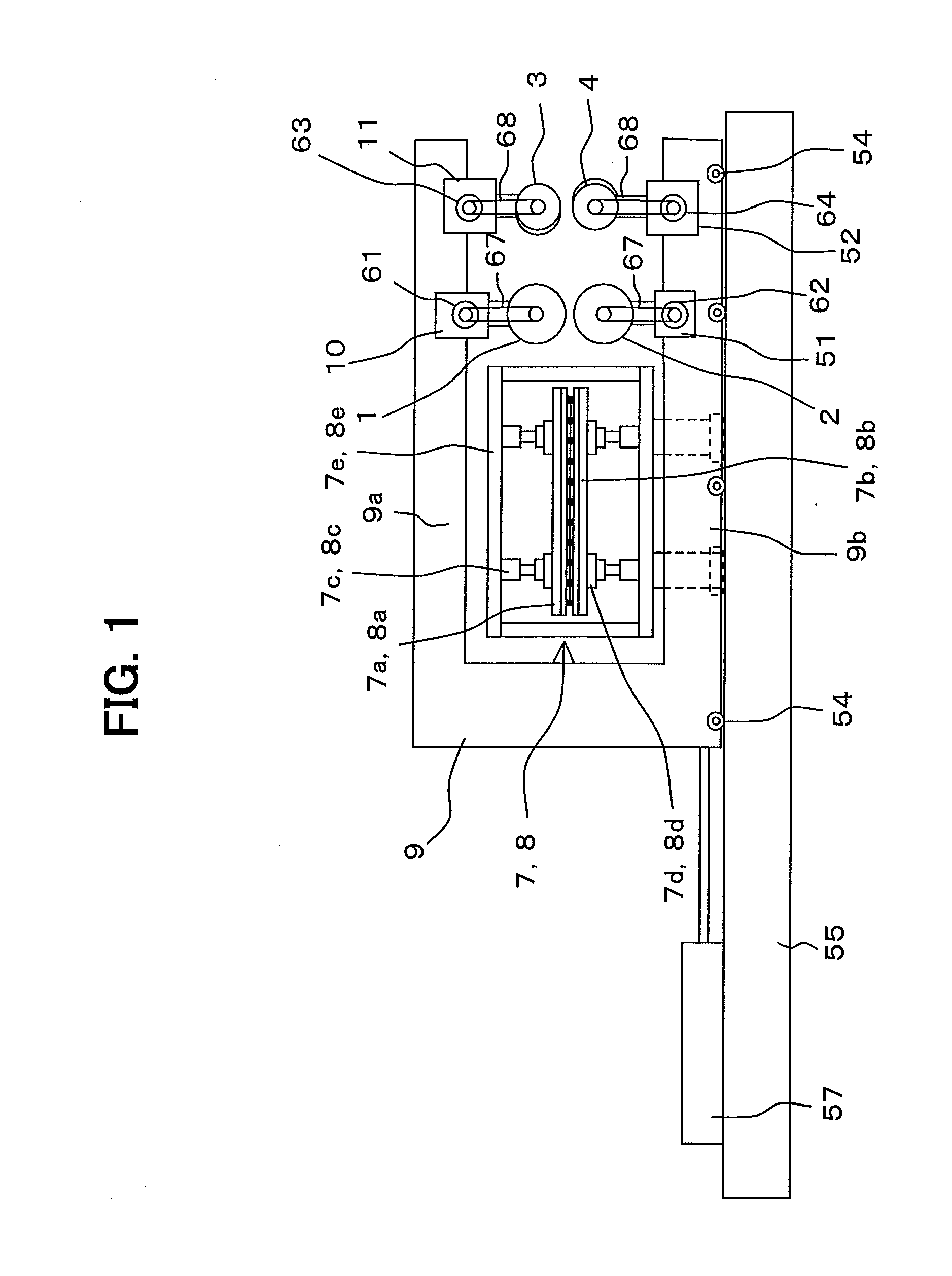

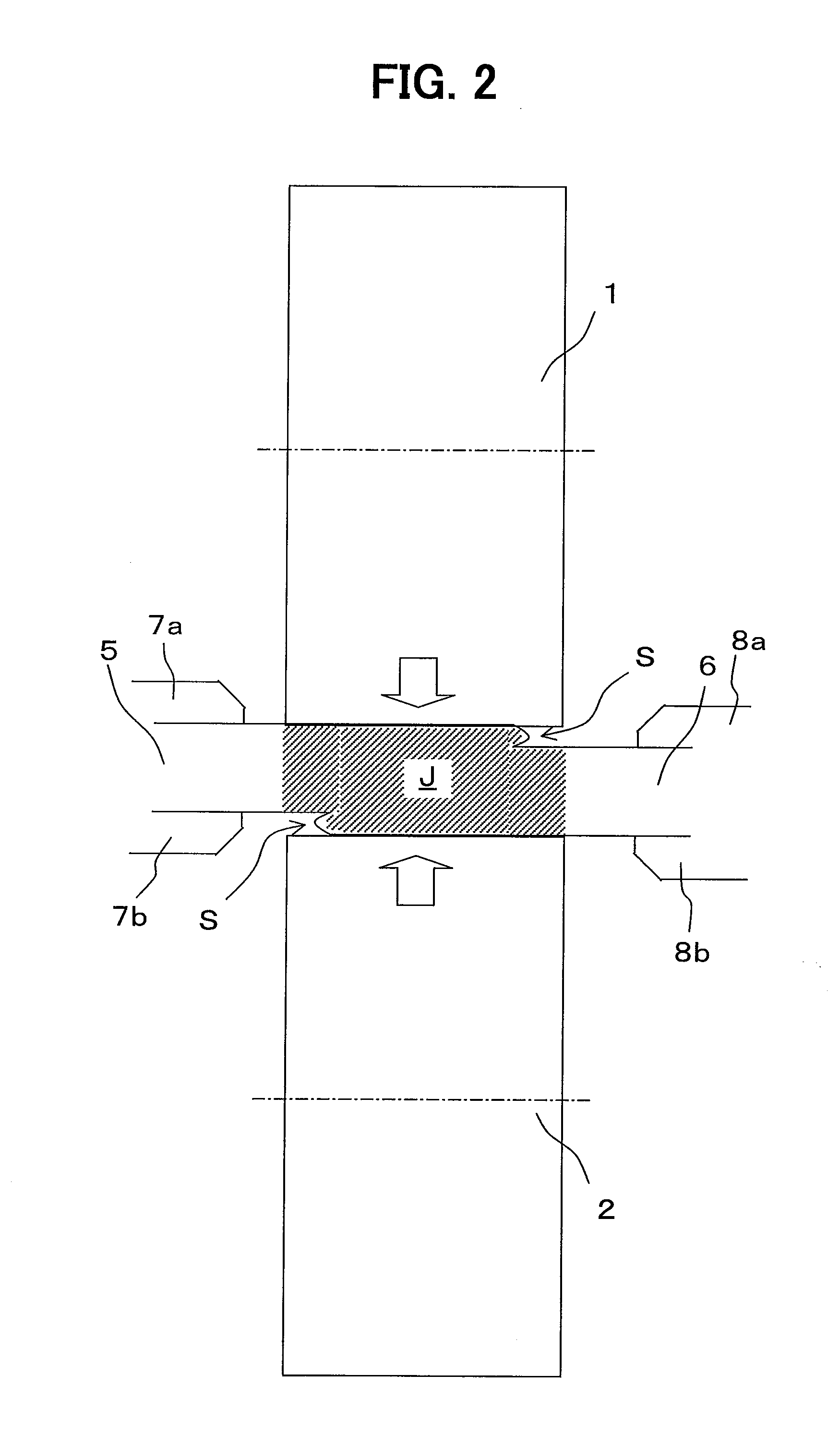

ActiveUS20110163074A1High degreeIncrease the amount of cuttingWelding/cutting auxillary devicesRectilinear seam weldingEngineeringMetal

A pair of upper and lower pressure rollers 3, 4 is disposed so that their axes 15, 16 are tilted in a horizontal plane in respective directions opposite to each other with respect to a straight line perpendicular to a welding line of a joint portion J. The pressure rollers 3, 4 are positively driven by corresponding electric motors 63, 64 to thereby roll the joint portion. Thus, steps defined at the joint portion can be smoothed and a step gradient can be reduced to ensure a high degree of joint strength.

Owner:PRIMETALS TECHNOLOGIES JAPAN LTD

Hatchback door structure for vehicles

ActiveUS20070170751A1Reduce weightImprove rigidityMonocoque constructionsVehicle bodiesEngineeringCar door

Owner:HONDA MOTOR CO LTD

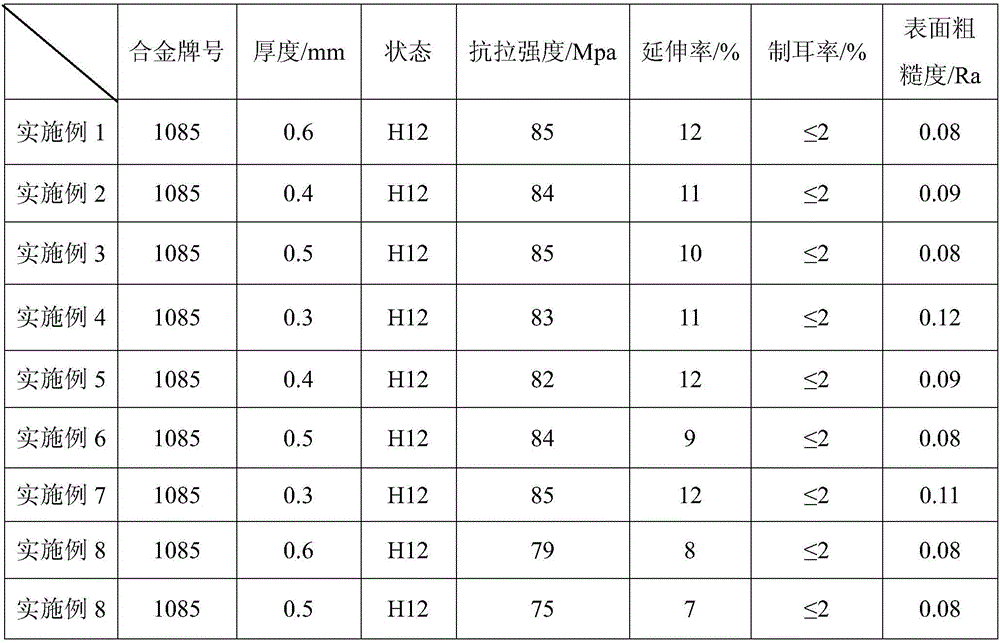

Production method of aluminum strip for cosmetic bottle cap

The invention discloses a production method of an aluminum strip for a cosmetic bottle cap. The production method comprises the steps of: (1) preparation of an ingot and adoption of a new alloy, wherein the ingot comprises the following elements in percentage by weight: not more than 0.08% of Si, not more than 0.1% of Fe, not more than 0.03% of Cu, not more than 0.02% of Mn, not more than 0.02% of Mg, not more than 0.02% and not less than 0.01% of Ti, and the balance of Al; (2) surface milling; (3) uniform heating; (4) hot rolling; (5) cold rough rolling; (6) cleaning; (7) intermediate annealing; (8) cold finish rolling; (9) stretching, bending, straightening and cleaning of trimmings; and (10) checking. The aluminum strip has such excellent characteristics as smooth and bright surface, stable mechanical performance, precise dimensional tolerance, easy punch forming, low earing ratio after punching of the bottle cap and good anodizing effect, and is suitable for producing top-grade cosmetic bottle cap.

Owner:DALISHEN ALUMINUM

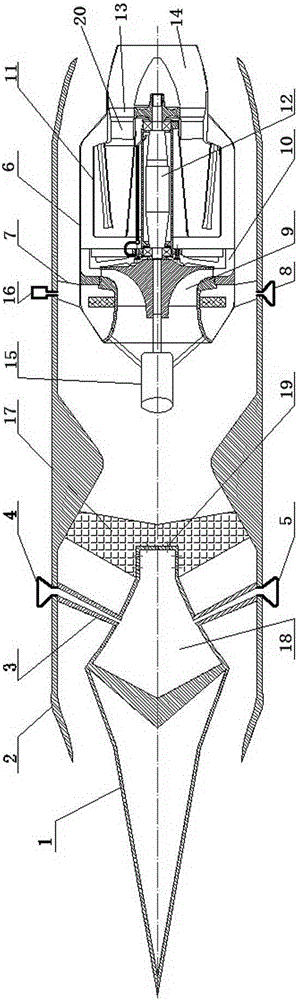

Stamping-turbine air injection composite aero-engine

ActiveCN105221295ASingle stage pressure ratio highReduce consumptionRam jet enginesComposite engine plantsRamjetAviation

The invention discloses a stamping-turbine air injection composite aero-engine and aims to solve the problems that the existing gas turbine engine is complicated in structure and limited in running speed range, and a ramjet engine cannot voluntarily start, cannot run at a low speed, is difficult in cooling, and has higher requirements for the high temperature resistance of a complete machine. The stamping-turbine air injection composite aero-engine comprises a stamping air inflow cone, an outer duct engine case, an inlet guide blade, a liquid oxygen regulating valve, a liquid nitrogen regulating valve, an inner duct engine case, a rectifying blade, a fuel oil regulating valve, a centrifugal compressor, a diffuser, a combustor, a concentric shaft, a worm wheel, an inner duct rectifying nozzle, a starting dynamo and the like. The stamping-turbine air injection composite aero-engine effectively utilizes the stamping effect and advantages of a turbojet engine, participates in precooling treatment, effectively solves the problems that the ramjet engine takes air in the starting and high-speed states, and the engine power is limited, is simple in structure, low in cost, high in efficiency, wide in running speed range and low in running speed of the complete machine, and has a better application prospect.

Owner:SOUTHWEAT UNIV OF SCI & TECH

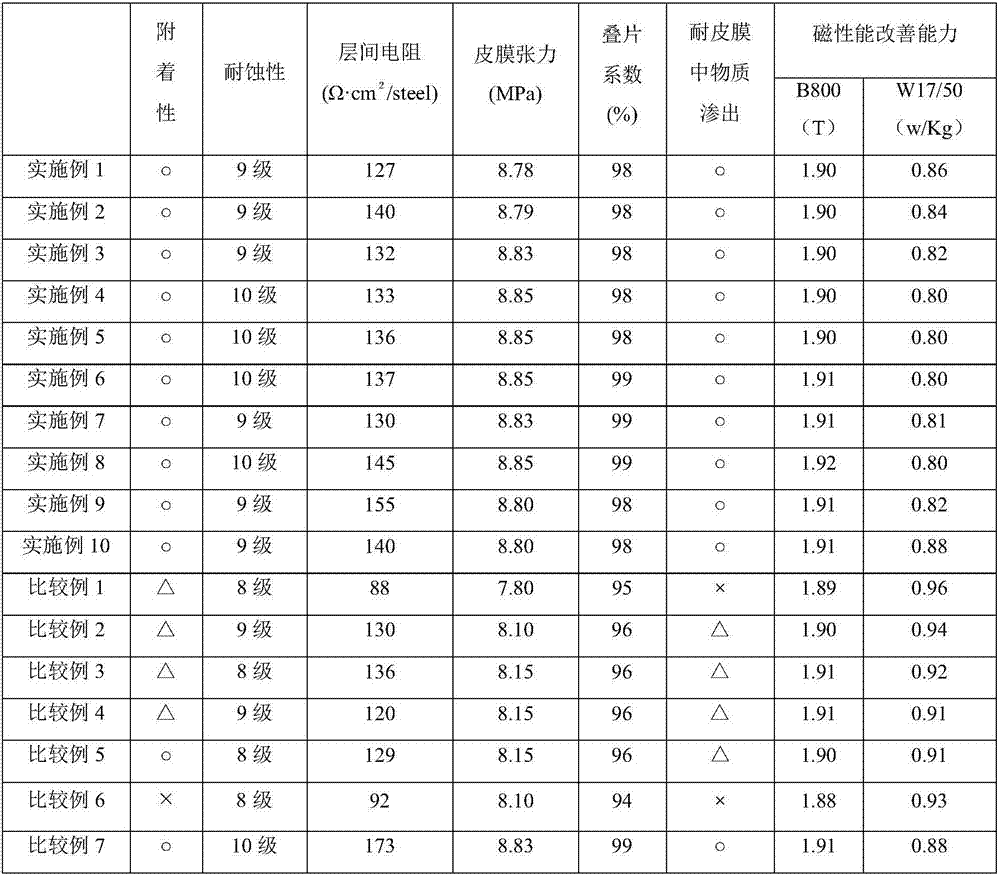

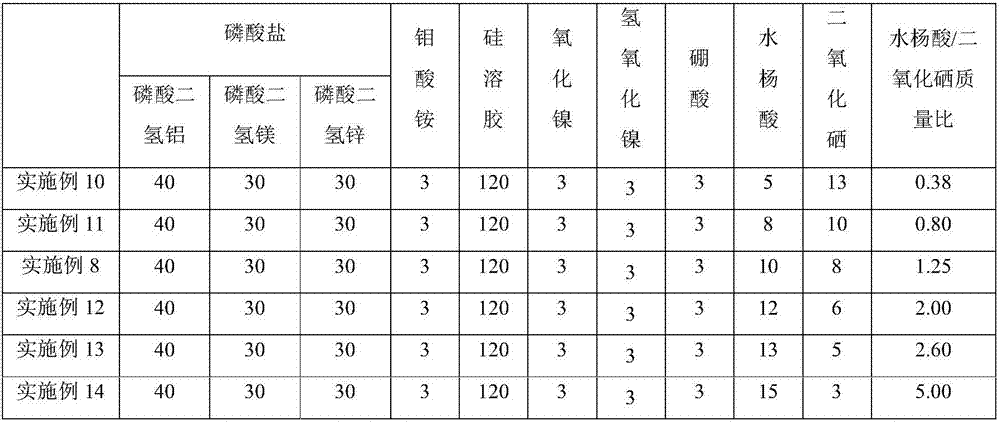

Chrome-free insulating coating composition and preparation method and oriented silicon steel plate

ActiveCN107190252AEasy to recycleImprove the level ofInorganic material magnetismQuartz/glass/vitreous enamelsOrganic acidMolybdate

The invention provides a chrome-free insulating coating composition and a preparation method and an oriented silicon steel plate. The coating composition comprises the following components of, by weight, 100 parts of phosphate solutions, 1-5 parts of molybdate, 50-150 parts of silica sols, 3-13 parts of selenium dioxide, 1-10 parts of metallic oxide and / or metal hydroxide, 5-15 parts of organic acid, 1-6 parts of boric acid and 100-300 parts of water. The preparation method of the composition comprises the steps that the phosphate solutions, the boric acid and the water are added; the selenium dioxide and the organic acid are sequentially added; and the metallic oxide and / or metal hydroxide and the molybdate are added, then the silica sols are added, and the composition is obtained. The oriented silicon steel plate comprises a pedestal and a chrome-free insulating coating formed on the surface of the pedestal, and the chrome-free insulating coating is obtained by coating the chrome-free insulating coating composition on the surface of the pedestal. The chrome-free insulating coating has extremely high interlayer resistance, surface hardness and surface tension and shows the excellent magnetic property improved effect.

Owner:WUHAN YUANRONG TECH CO LTD

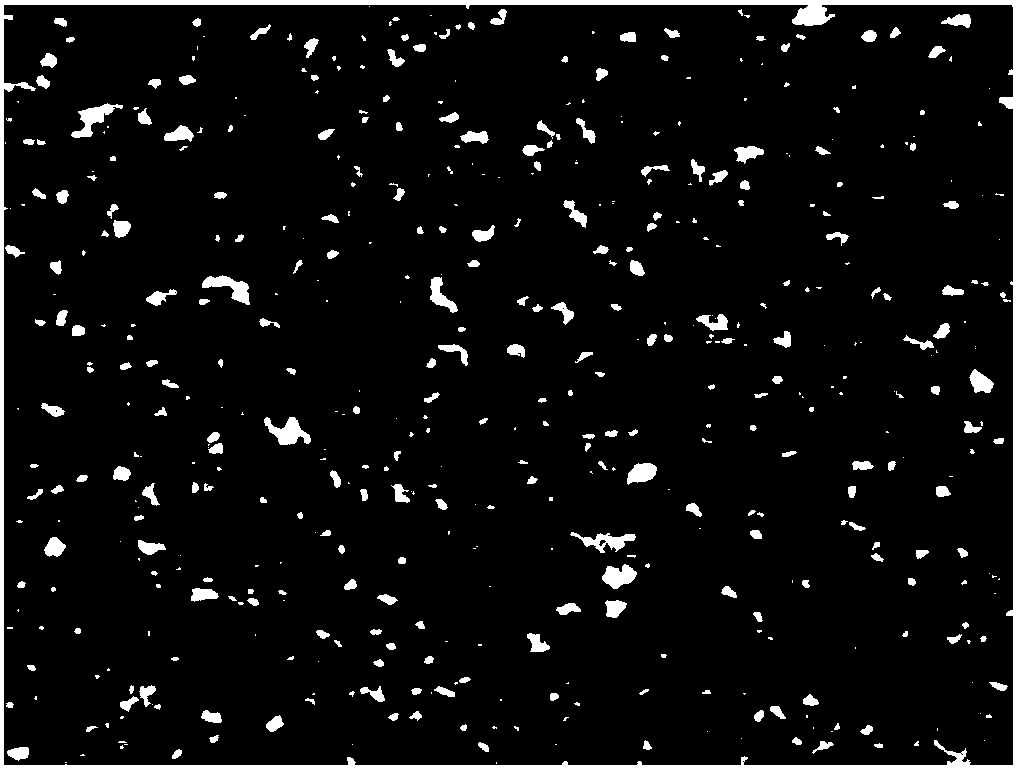

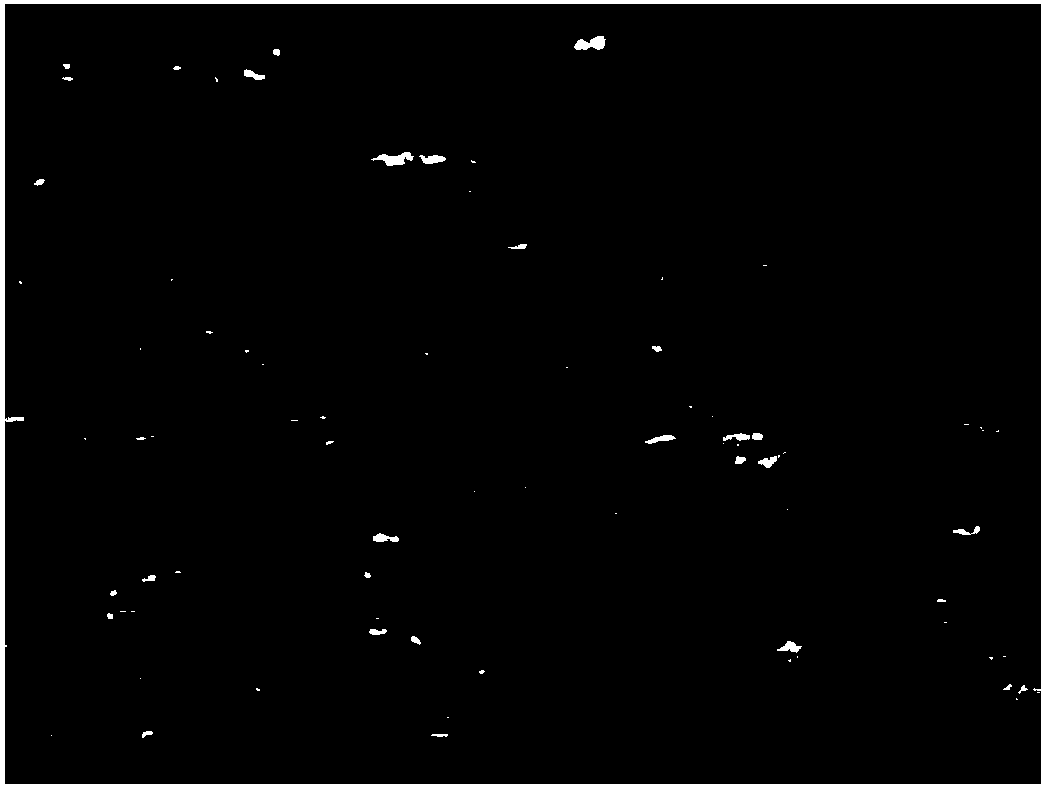

Production method of aluminum plates and aluminum strips for cosmetic mirror surface aluminum caps

ActiveCN106319292ASolve the shortcomings of uneven online refinementEvenly meltedSmelting processDistribution system

The invention relates to a production method of aluminum plates and aluminum strips for cosmetic mirror surface aluminum caps. The manufacturing process comprises the steps of smelting, casting, homogenizing treatment, hot rolling, cold rolling, intermediate annealing and cold rolling of finished products. In the smelting process, a bottom-mounted electromagnetic stirring system is adopted; in the casting process, an automatic speed regulation system is adopted; in the hot rolling system, a hot rough rolling pass automatic distribution system is adopted; and in the intermediate annealing system, a large natural gas furnace is adopted for annealing. Through cooperation of all the procedures, product ingredients can be made uniform, and finished products are uniform in surface roughness, fine, smooth, good in smooth finish, free of surface defects such as stripes, black lines and color difference; the mirror surface effect is good after materials are subjected to anodic oxidation and electroplating, and the application requirements for deep drawing and tensile properties of the aluminum plates and the aluminum strips for the cosmetic mirror surface aluminum caps are met.

Owner:HENAN MINGTAI AL INDUSTRIAL CO LTD

Method of joining heat-treatable aluminum alloy members by friction stir welding

InactiveUS20090250144A1Avoid stress concentrationReduce hardnessWelding/soldering/cutting articlesMetal working apparatusHeat treatedFriction stir welding

A method of joining heat-treatable aluminum alloy members by friction stir welding, including the steps of: a T4-treatment-performing step of performing a T4 treatment on heat-treatable aluminum alloy members so as to impart T4 temper to the heat-treatable aluminum alloy members; a joining step of joining the heat-treatable aluminum alloy members with T4 temper by friction stir welding to provide a joined product; and a reversion-treatment-performing step of performing a reversion treatment, the reversion-treatment-performing step being carried out prior to or after the joining step.

Owner:SUMITOMO LIGHT METAL INDS LTD

Al-Mg based alloy sheets with good press formability

By careful control of composition and processing, Al-Mg based alloy sheets with preferred grain sizes and crystallographic textures that result in good press formability are disclosed. The Al-Mg alloy preferably contains 2-6 wt % Mg, and at least 0.03 wt % of at least one element selected from Fe, Mn, Cr, Zr, and Cu. The crystallographic texture is comprised of grains with a volume fraction in a range of about 5% to 20% in the CUBE orientation {100} <001>, a volume fraction in a range of about 1% to 5% in the GOSS orientation {110} <001>, a volume fraction in a range of about 1% to 10% in each of the BRASS orientation {110} <1+E,ovs 1+EE 2>, S orientation {123} <63+E,ovs 4+EE >, and COPPER orientation {112} <11+E,ovs 1+EE >, wherein the grain size is in a range of about 20 to 70 mu m.

Owner:KOBE STEEL LTD +1

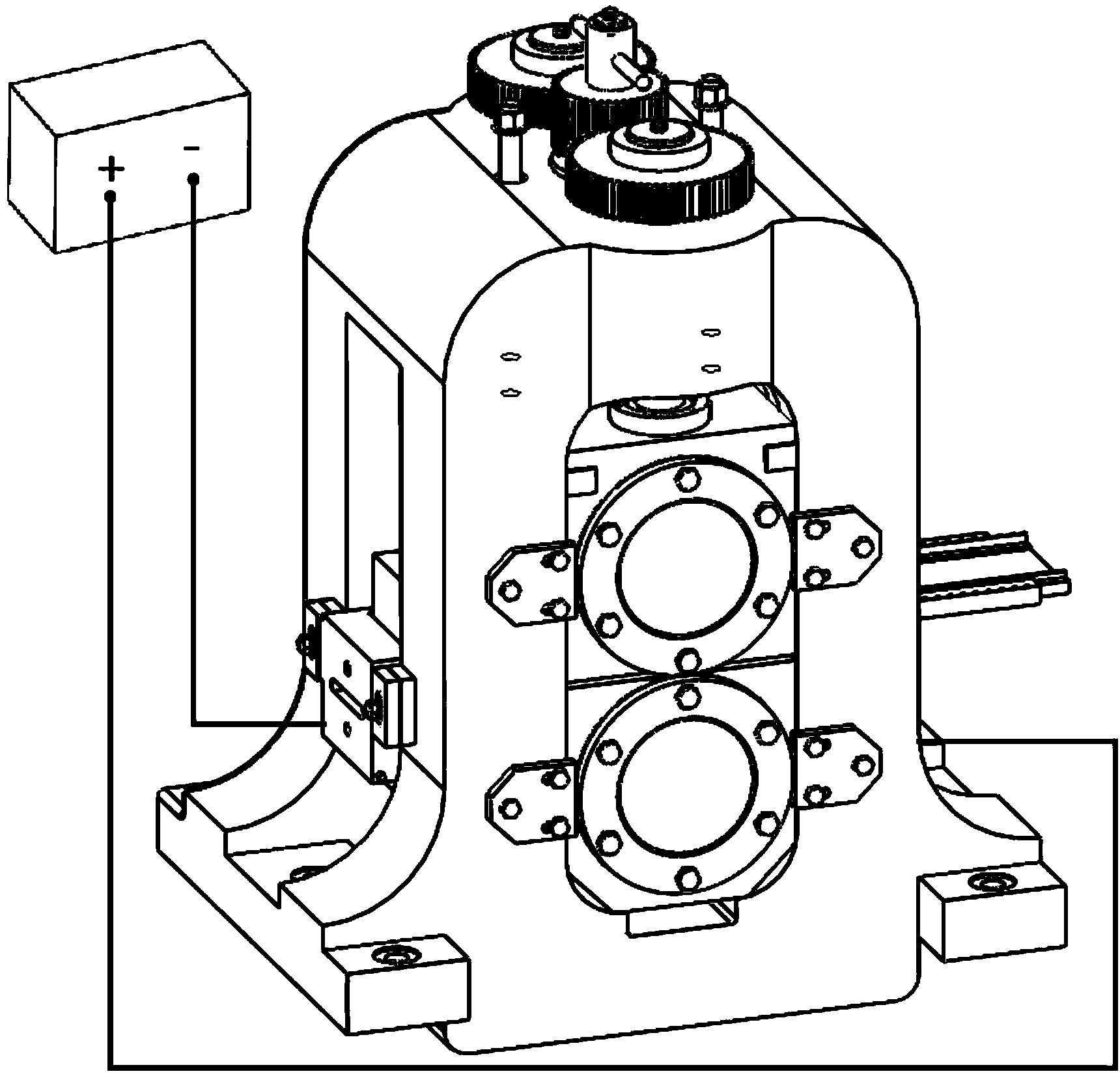

Electroplastic equal-diameter rolling mill

ActiveCN103846278AImprove working conditionsIncreased Equal Angle Rolling EfficiencyMetal rolling stand detailsMetal rolling arrangementsMetallic materialsSuperalloy

The invention discloses an electroplastic equal-diameter rolling mill. The electroplastic equal-diameter rolling mill is mainly characterized in that on the basis of a two-high rolling mill, an equal-diameter angular rolling mechanism consisting of a guiding plate and an equal-diameter angle mold and an electroplastic processing mechanism consisting of an electrical pulse interface and a power supply are added. The electroplastic equal-diameter rolling mill disclosed by the invention has the beneficial effects that the necessary preheating and hot-rolling equipment in the conventional equal-diameter angular rolling process is omitted, annealing treatment does not need to be carried out on plates after rolling, the rolling process can be carried out under the normal temperature, so that the procedure and the processing cost are greatly reduced; and continuous rolling also can be carried out, the processing process is simple and high-efficiency, not only can the effect of greatly improving the comprehensive mechanical performance of the plates after conventional equal-diameter angular rolling be obtained, but also the fussy procedure and the heavy equipment in the conventional equal-diameter angular rolling process are greatly simplified. The electroplastic equal-diameter rolling mill is suitable for carrying out rolling and performance improvement on metal materials such as magnesium alloy with low plasticity and difficult rolling and metal materials such as high-temperature alloy and high-strength steel with high strength and difficult deformation.

Owner:安徽华驰动能科技有限公司

High-strength steel for automotive wheels and manufacture method thereof

InactiveCN101831585AHigh strengthHigh fatigueManufacturing convertersMetal rolling arrangementsSheet steelHigh intensity

The invention relates to high-strength steel for automotive wheels and a manufacture method thereof, belonging to the technical field of high-strength stamping steel. The steel for automotive wheels comprises the following components in percentage by weight: 0.07-0.12 percent of C, 0.01-0.1 percent of Si, 1.0-1.2 percent of Mn, 0.008-0.015 percent of P, not more than 0.008 of S, 0.020-0.040 percent of Al and the balance of Fe and other impurity elements. The manufacture method has the processes of: molten iron preprocessing for desulfurization, processing by a top-and-bottom combined blown converter, refining treatment by an LF furnace, continuous casting of plate blanks, thermal rolling and finished product obtaining. Compared with traditional steel for wheels, the invention has the advantages that the tensile strength can reach 380-480 MPa, and the elongation rate is 26.0-43.0 percent under the condition that noble metals, such as Nb, and the like are not added. The steel plate with high strength, high fatigue resistance and high stamping performance can be obtained with low alloying cost to effectively lighten the self weight of an automobile and reduce the oil consumption; and therefore, the high-strength steel is an ideal steel plate for producing automobile wheel rims and spokes.

Owner:SHOUGANG CORPORATION +1

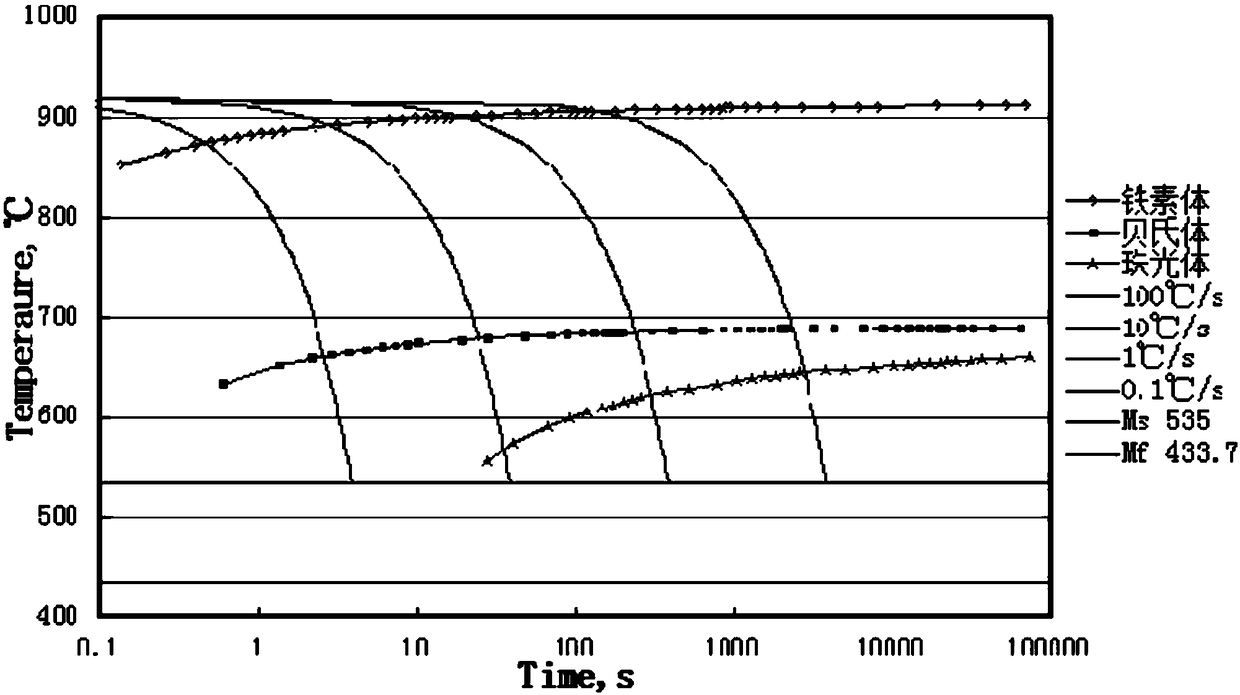

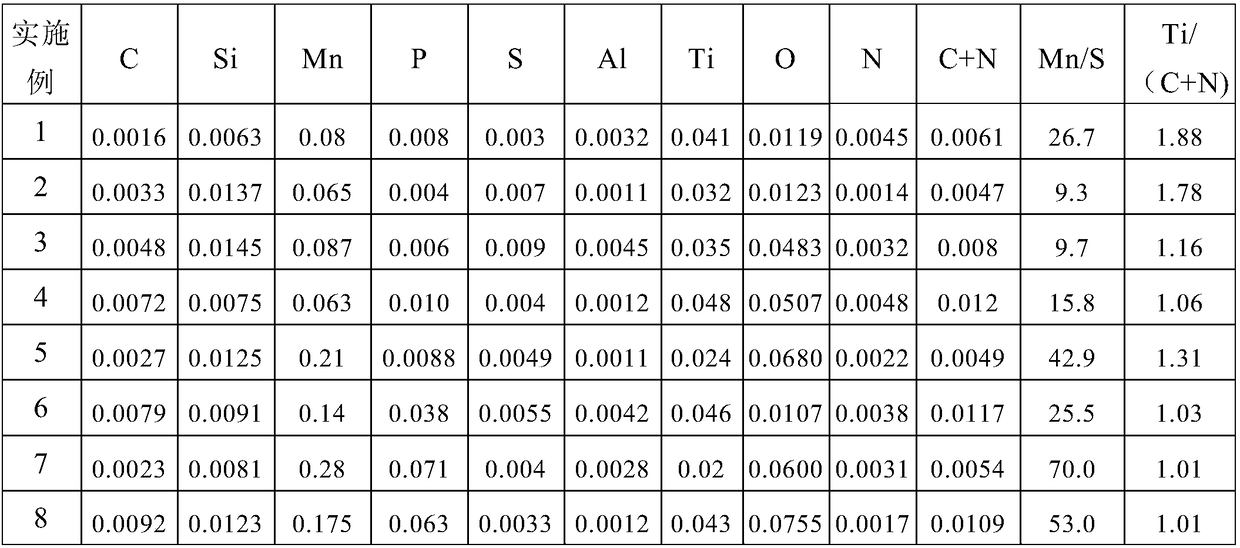

Steel adapting to high deformation and punching and used for high-surface-quality aluminum-coated substrates and production method thereof

ActiveCN108796363AImprove mechanical propertiesEnhanced interface bindingChemical compositionPunching

The invention discloses steel adapting to high deformation and punching and used for high-surface-quality aluminum-coated substrates and a production method thereof. The steel comprises the followingchemical components of, by weight, percentage, no more than 0.01% of C, 0.006-0.015% of Si, 0.05-0.3% of Mn, no more than 0.015% of P, no more than 0.01% of S, no more than 0.005% of Al, no more than0.005% of N, 0-0.05% of Ti, 0.01-0.08% of O, and the balance of Fe and inevitable impurities; and meanwhile, C+N is not more than 0.012, Mn / S is not less than 8, and Ti / (3.42N+4C) is not less than 1.The tensile strength of the steel for the aluminum-coated substrates is 280-380 MPa; and the ductility is above 40%; the steel components adopt low C-Si-Mn design similar to pure iron; a proper amountof Ti is added; the steel is produced by adopting a rolling control mode; the production process is simple; and the cost is lower. Besides of excellent plasticity and steel aluminum coating performance, the steel can meet single-pass high deformation (80-90%) requirement; and the steel is mainly used for producing aluminum-coated plate strips.

Owner:BAOSHAN IRON & STEEL CO LTD

Pickle sheet for 400MPa-level automobile structure and production method of pickle sheet

The invention discloses a hot-rolling pickle sheet for a 400MPa-level automobile structure and a production method of the pickle sheet. Main elements of the hot-rolling pickle sheet comprise 0.06 percent to 0.08 percent of C, Si smaller than or equal to 0.05 percent, 1.0 percent to 1.15 percent of Mn, 0.02 percent to 0.05 percent of Al, P smaller than or equal to 0.015 percent, S smaller than or equal to 0.008 percent, and the balanced Fe and trace elements. When the hot-rolling pickle sheet with the thickness of 2 mm to 6 mm is rolled, the heating temperature ranges from 1160 DEG C to 1220 DEG C, the final rolling temperature ranges from 820 DEG C to 860 DEG C, a front-segment-area rapid cooling mode is adopted in a cooling mode, and the reeling temperature ranges from 560 DEG C to 600 DEG C. Low-carbon low-silicon component design is adopted, and through control over the technology in the rolling process and the acid pickling process, the hot-rolling pickle sheet for the automobile structure can be produced and is good in surface quality and stamping performance.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

400 MPa-tensile-strength high-strength carbon-manganese constructional steel and manufacturing method thereof

The invention discloses 400 MPa-tensile-strength high-strength carbon-manganese constructional steel and a manufacturing method of the 400 Mpa-tensile-strength high-strength carbon-manganese constructional steel. The 400 Mpa-tensile-strength high-strength carbon-manganese constructional steel comprises the following chemical ingredients in percentage by weight: 0.10-0.20% of carbon, no more than 0.30% of silicon, no more than 0.40% of manganese, 0.010-0.030% of aluminum, no more than 0.02% of phosphorus, no more than 0.015% of sulphur, and the balance of Fe and inevitable impurities. A cold-rolled high-strength carbon-manganese constructional steel plate is obtained through controlling the technological processes like converter smelting, continuous casting and hot rolling, wherein the yield strength is 250 MPa-280 MPa, the tensile strength is equal to or more than 400 MPa, and the elongation is equal to or more than 32%. By increasing the content of the carbon, the expensive metal is replaced and the production cost is lowered; due to the processes, the carbon and the Fe form dispersed thin carbide which is uniformly distributed in ferrite, so that the obtained cold-rolled carbon-manganese constructional steel plate has the characteristic of high strength.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

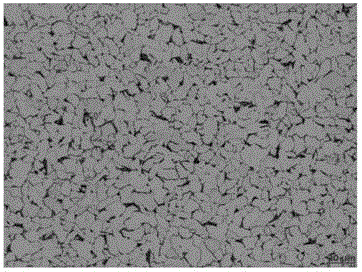

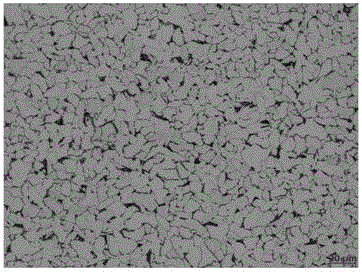

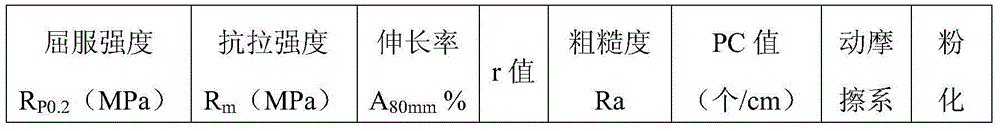

Self-lubrication alloying galvanized steel plate for automobiles and preparation method of self-lubrication alloying hot galvanized steel plate

The invention discloses a self-lubrication alloying hot galvanized steel plate for automobiles and a preparation method of the self-lubrication alloying galvanized steel plate. The self-lubrication alloying galvanized steel plate is prepared from the following chemical components in percentage by mass: 0.0007-0.002% of C, less than or equal to 0.01% of Si, 0.08-0.15% of Mn, less than or equal to 0.015% of P, less than or equal to 0.009% of S, 0.02-0.04% of Als, 0.06-0.09% of Ti, less than or equal to 0.004% of N, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: pre-treating molten iron, smelting in a converter, refining, performing continuous casting, performing hot continuous rolling, pickling, performing cold continuous rolling, annealing, performing hot galvanizing, alloying, rolling a self-lubrication coating by using a roller, drying, and finishing. By controlling the roller system polishing precision and the surface roughness of a roll coating machine, the roller coating process parameters, the temperature of a drying furnace, the machine set speed and the finishing process parameter, the self-lubrication property is achieved. The preparation method is low in production cost and simple in production process, when a self-lubrication alloyed plate prepared by using the preparation method is compared with an ordinary alloyed plate, the lubrication is remarkably improved, the stamping property is also remarkably improved, and the manufacturing of complex components can be completely met.

Owner:WUHAN IRON & STEEL (GROUP) CORP

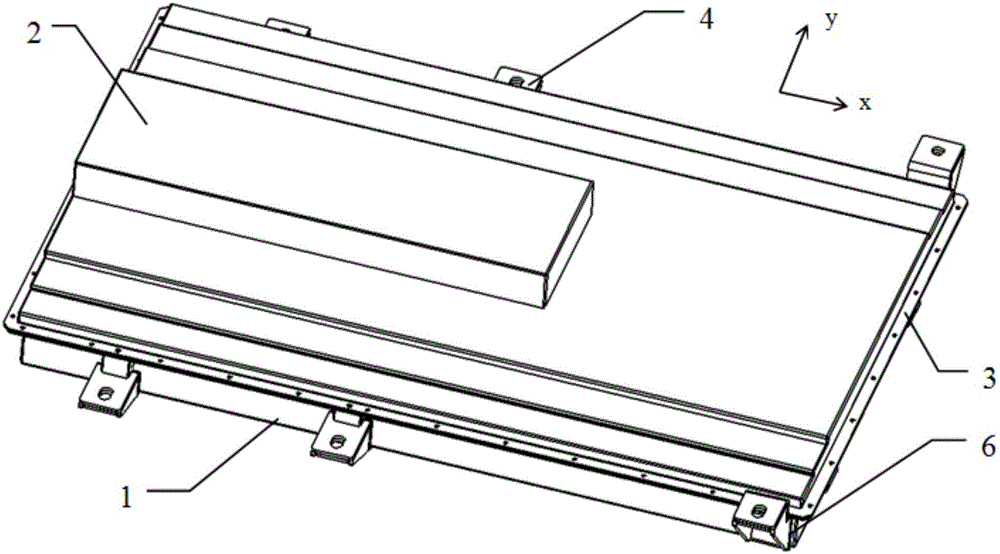

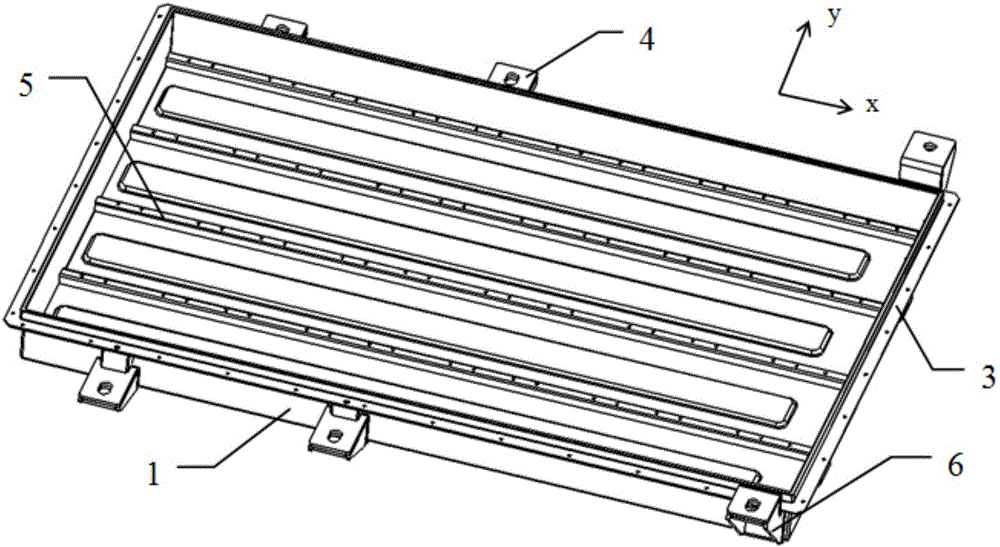

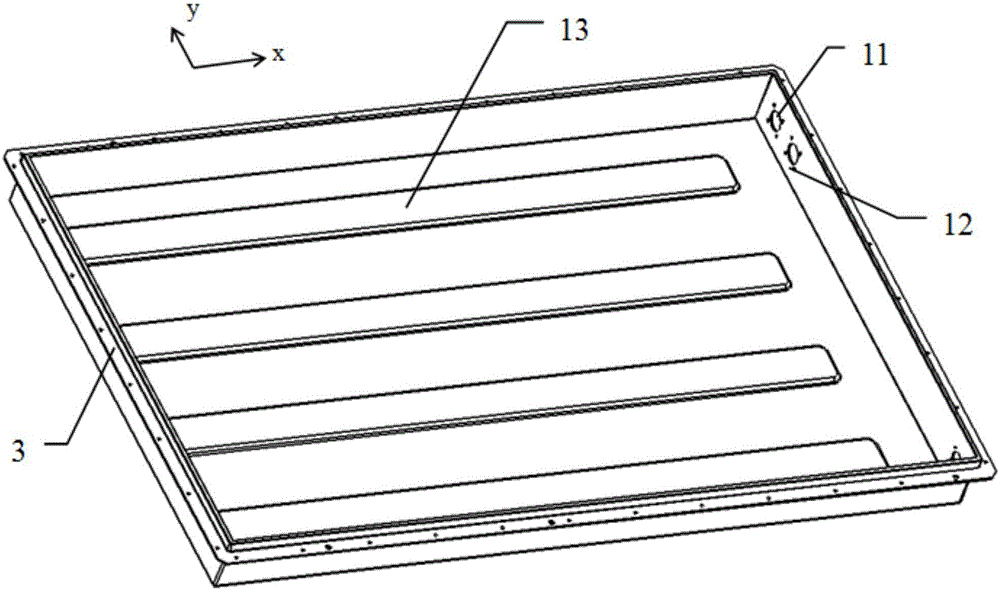

Aluminum battery box body for electric vehicle and manufacturing method of aluminum battery box body

PendingCN106654087AImprove cooling effectIncrease load capacity and reliabilitySmall-sized cells cases/jacketsLarge-sized cells cases/jacketsElectric vehiclePoor quality

The invention discloses an aluminum battery box body for an electric vehicle and a manufacturing method of the aluminum battery box body. A split assembly and combination design is adopted by a battery box body structure, and the battery box body structure comprises a battery box shell, a battery box cover, a suspension scrolling box, brackets, inner brackets and reinforcing rib plates. Through the arrangement of convex ring blocks of the battery box shell, a heat emission hole in a side plate and the inner brackets, the internal heat dissipation effect of the battery box body is improved; through a bracket design of the rib plate structure, the load capacity and the reliability of the battery box body are improved; and a lightweight high-strength improved aluminum alloy is adopted as the material, so that the strength of the plate and the stamping property are improved while the weight of a product is reduced through optimizing aluminum alloy components. A stamping and integral forming structure is adopted by the battery box shell, the battery box cover, the suspension scrolling box and the brackets, so that the problems of multiple casting defects, poor quality, high welding cost, a difficulty in deformation control and the like of the aluminum battery box body in the prior art are solved. The aluminum battery box body has the characteristics of light weight of the product, high overall strength, a good heat dissipation effect, few welding procedures, long service life and the like.

Owner:ZHEJIANG TAOTAO IND & TRADE

High tensile cold-rolled steel sheet excellent in ductility and in strain aging hardening properties, and method for producing the same

InactiveUS6692584B2Improve ductilityImprove stamping effectFurnace typesHeat treatment furnacesSheet steelHigh intensity

The present invention provides a high tensile cold-rolled steel sheet having superior ductility, strain age-hardening characteristics, and crash resistance properties, and also provides a manufacturing method therefor. As a particular means, a thin cold-rolled steel sheet containing 0.05% to 0.30% of C, 0.4% to 2.0% of Si, 0.7% to 3.0% of Mn, 0.08% or less of P, 0.02% or less of Al, and 0.0050% to 0.0250% of N on a mass % basis is manufactured in which N / Al is 0.3 or more. This thin cold-rolled steel sheet is heated to a temperature between (an Ac1 transformation point) and (an Ac3 transformation point+50° C.), is cooled at a cooling rate of 5 to 150° C. / second in the range of at least 600 to 500° C., and is held in the temperature range of 350 to 500° C. This steel sheet has superior ductility, strain age-hardening characteristics having a DeltaTS of 50 MPa or more, and crash resistance properties.

Owner:JFE STEEL CORP

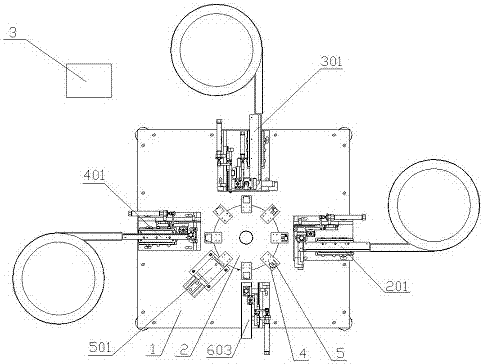

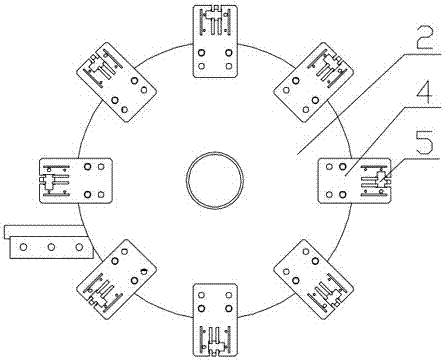

Automatic assembling machine for electronic components

ActiveCN106881589APrecise positioningIncrease productivityAssembly machinesMechanical equipmentMachine

The invention discloses an automatic assembling machine for electronic components, and belongs to the technical field of mechanical equipment manufacturing. The automatic assembling machine comprises a machine frame (1), a rotary table (2) arranged on the machine frame, and a PLC (3). The machine frame (1) is provided with a driving part used for driving the rotary table (2) to rotate. A plurality of templates (4) are evenly arranged on the rotary table (2) in the circumferential direction. One ends of the templates (4) are fixedly connected with the rotary table (2), and the other ends of the templates (4) are provided with grooves (5) which are matched with the electronic components and used for placing the electronic components. An electronic component conveying device, a platen conveying device, a rivet conveying device, a rivet punching device and an electronic component recovery device are sequentially arranged on the periphery of the rotary table (2). According to the automatic assembling machine for the electronic components, the electronic components can be assembled in an automatic cycle mode, production quality is good and production efficiency is high.

Owner:LINHAI ZHONGCHUANG AUTOMATIC EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com