Stamping-turbine air injection composite aero-engine

An aero-engine and turbojet technology, which is applied in aero-engine and aviation fields, can solve the problems of high requirements on high-temperature resistance of the whole machine, the ramjet engine cannot start by itself, and the operating speed range is limited. The effect of reduced requirements and a wide range of operating speeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

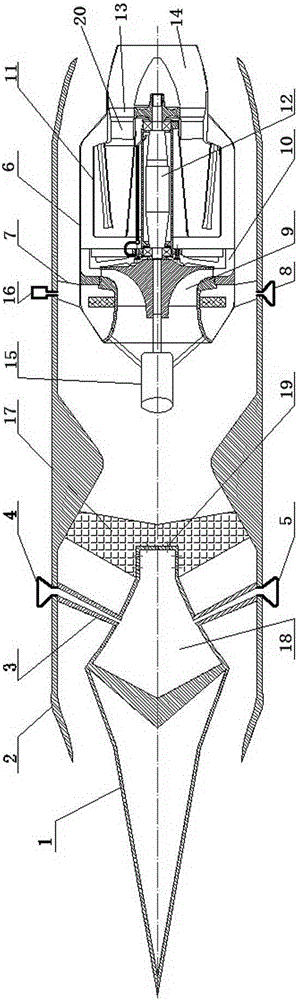

[0040] The ram-turbojet composite aero-engine of this embodiment comprises a ram intake cone, an outer duct casing, an inlet guide vane, a liquid oxygen regulating valve for being connected with a liquid oxygen device, a liquid oxygen regulating valve for being connected with a liquid nitrogen device, Nitrogen regulating valve, internal duct casing set inside the external duct casing, rectifying blades, fuel regulating valve used to connect with the fuel device, centrifugal compressor, diffuser, combustion chamber, concentric shaft, turbine, internal duct rectification The spout, the starting motor connected with the inner duct casing, the power supply device connected with the starting motor, the control system, and the protrusion arranged on the inner side of the outer duct casing.

[0041] At the front end of the outer duct casing, the rear part of the stamped intake cone is provided with a cavity and an air outlet connected to the cavity. The inlet guide vane is a hollow st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com