Air pressurization system with centrifugal oil pump for fuel cell

A technology of centrifugal oil pump and fuel cell, which is applied in the direction of electrical components, pumps, pump devices, etc., can solve the problems of easy failure and poor axial force balance, so as to improve the service life, reduce time and cost, and facilitate maintenance and replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

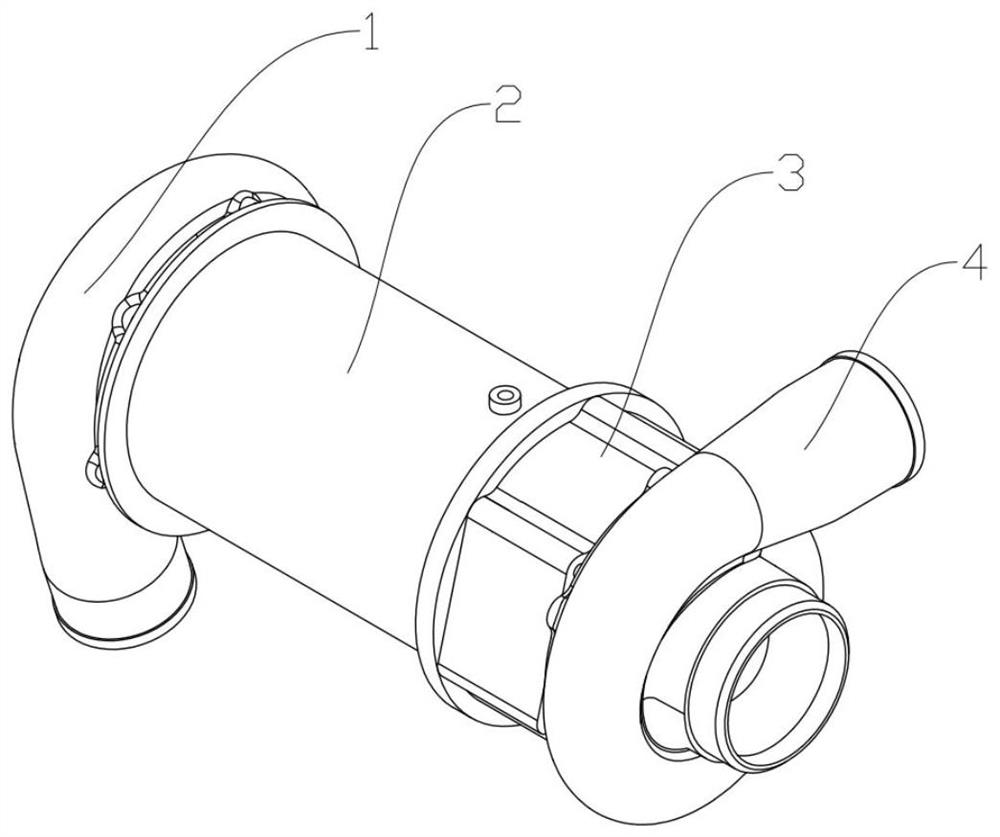

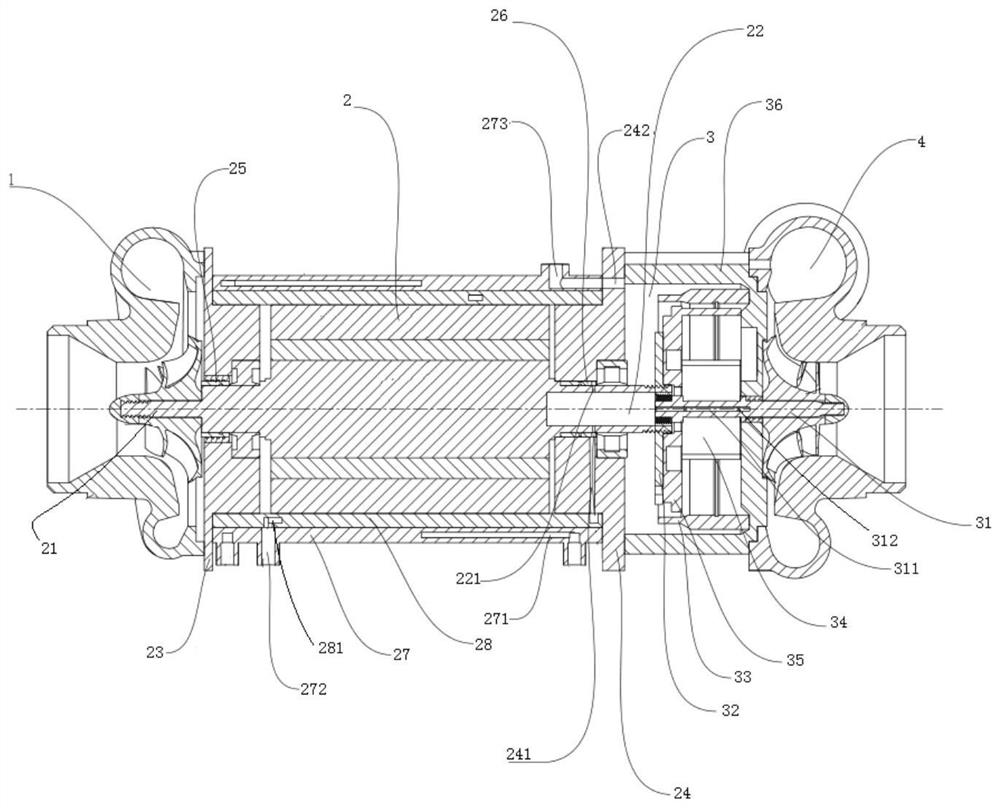

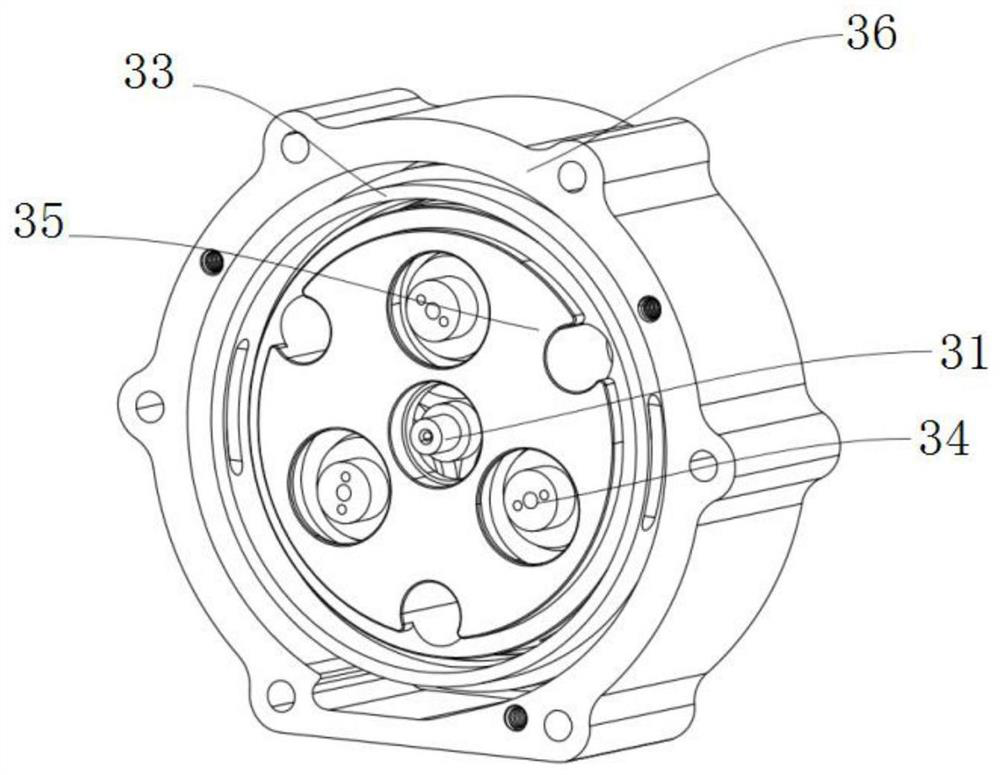

[0031] Embodiment 1: as figure 1 , 2 A fuel cell air pressurization system with a centrifugal oil pump is shown, including a centrifugal oil pump 1, a double output shaft motor 2, a speed increaser 3, and a centrifugal air compressor 4. When the system is working, it can operate according to the fuel cell stack The required power is adjusted by the frequency converter to adjust the speed of the water-cooled double-output shaft motor 2 .

[0032] The double output shaft motor 2 is a shaft structure with two ends extending out, including a first gland 23, a second gland 24, and a first motor shaft 21 and a second motor shaft 22 symmetrically arranged on both sides of the body of the dual output shaft motor 2. The second motor shaft 22 is a hollow structure and at least one first oil hole 221 is opened in the radial direction on the side wall of the second motor shaft 22, and one end of the first motor shaft 21 passes through the first gland 23 and is connected to the centrifuga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com