Patents

Literature

80results about How to "Balance axial force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

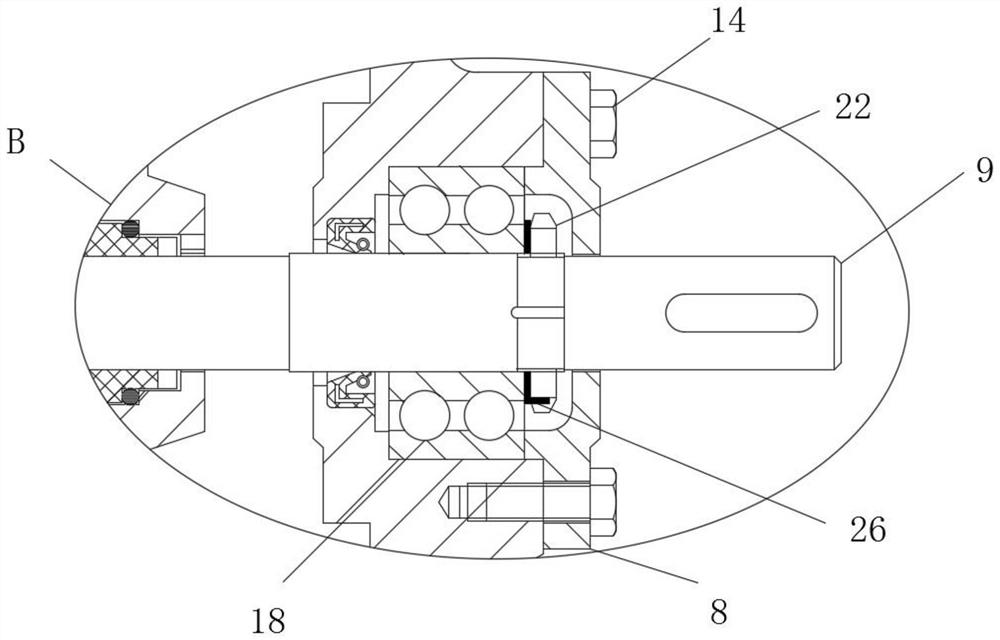

Easily controlling hydraulic corner self-servo valve

ActiveCN102562701ASmall resistance and hydraulic clamping forceGood dynamic characteristicsServomotor componentsPhysicsHollow cylinder

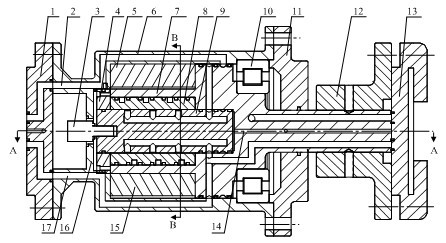

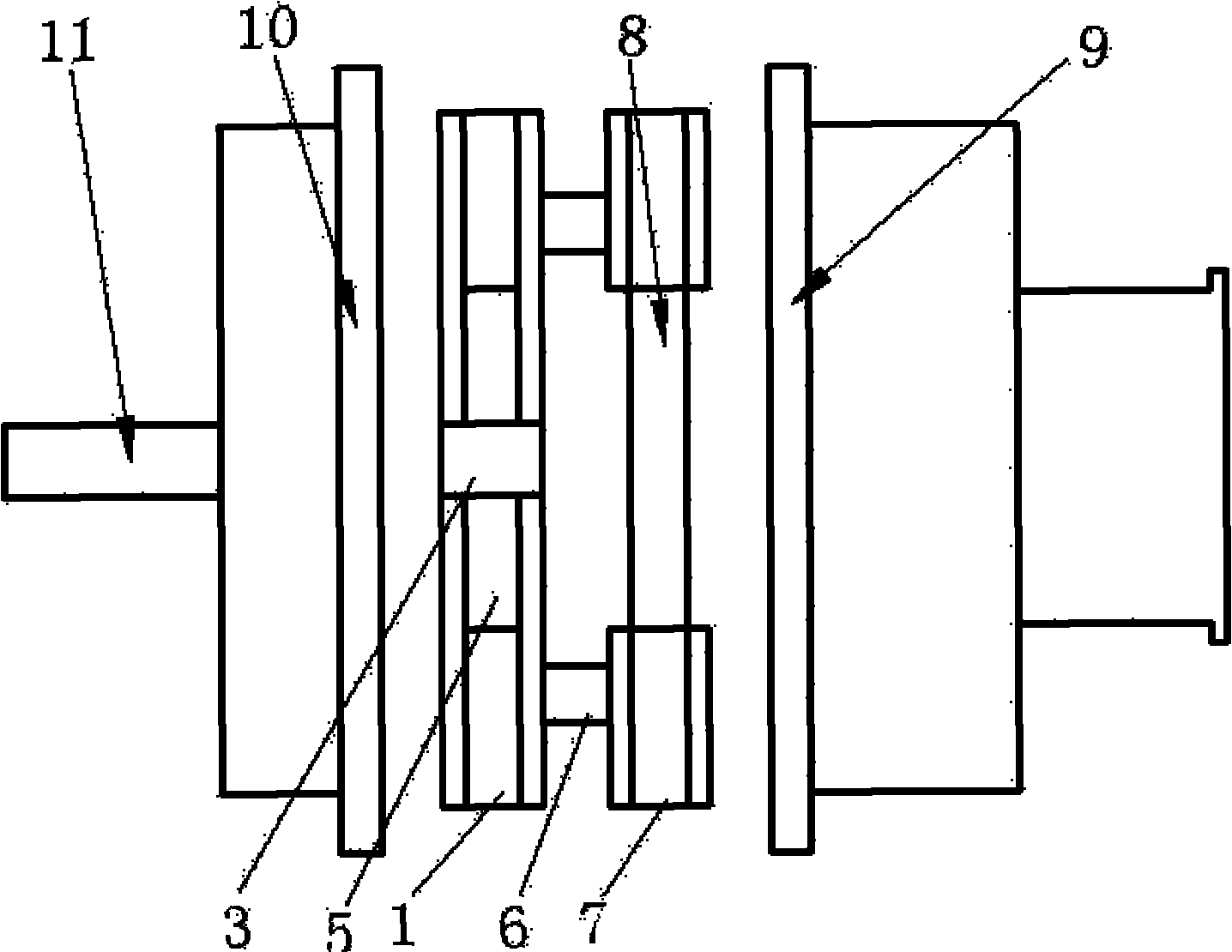

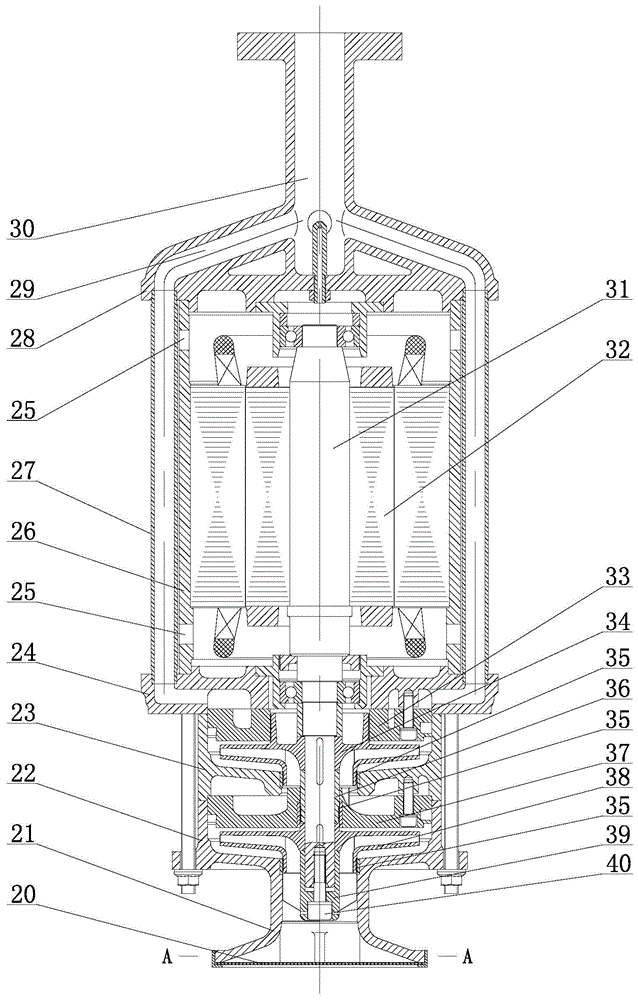

The invention relates to an easily controlling hydraulic corner self-servo valve which is characterized in that a blade (15) is arranged on the outer wall of a hollow column body (35) of a valve body (7); the initial assembly position of the blade (15) is in axis symmetric arrangement with that of a fixed baffle block (5); a valve sleeve (8) is arranged in a the hollow column body (35), and a valve core (8) is arranged in a small hollow circle (34) of the valve body (7); a high pressure oil inlet P and a low pressure oil outlet T of a left end cover (1) are respectively communicated with high and low pressure outer oil annular slots (31 and 28) of the valve body (7) correspondingly through high and low pressure oil channels (2 and 17) of a cylinder body (6); high and low pressure inner oil annular slots (32 and 30) of the valve body (7) are correspondingly communicated with core body high and low pressure oil annular slots (39 and 40) of the valve core (9); and core body high and low pressure oil channels (38 and 41) enter a first working chamber and a and second working chamber correspondingly through upper and lower semi-circle oil annular slots (36 and 37) of the valve sleeve (8). According to the invention, the easily controlling hydraulic corner self-servo valve has the characteristics that the preparation is convenient, the radial force and the axial force subjected by the valve core are both balanced, the resistance of the valve core is low, the dynamic characteristics are good, and the servo blind area is small.

Owner:武汉科技大学资产经营有限公司

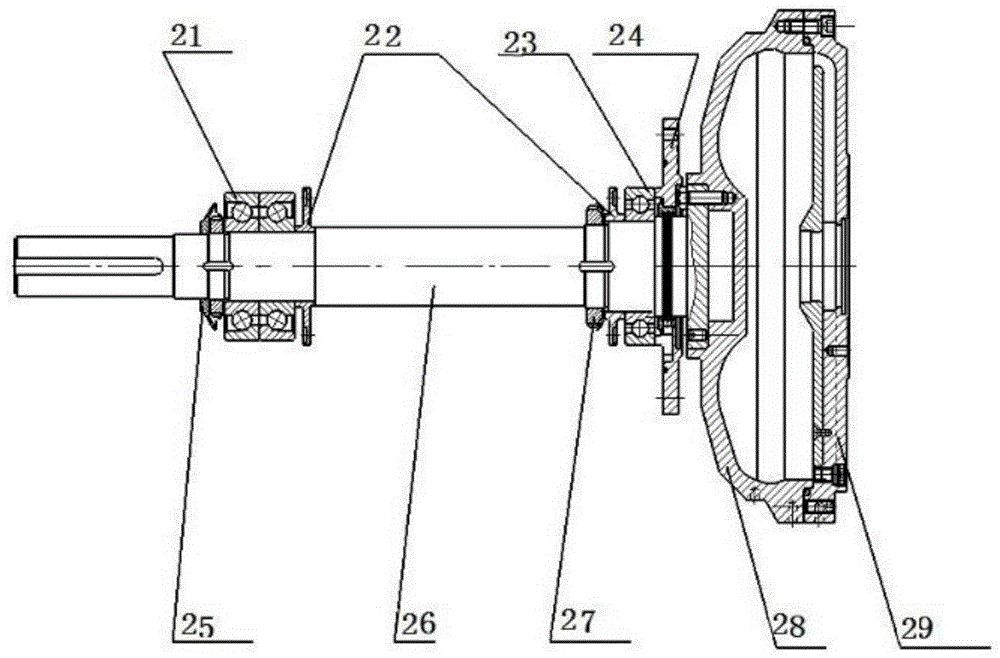

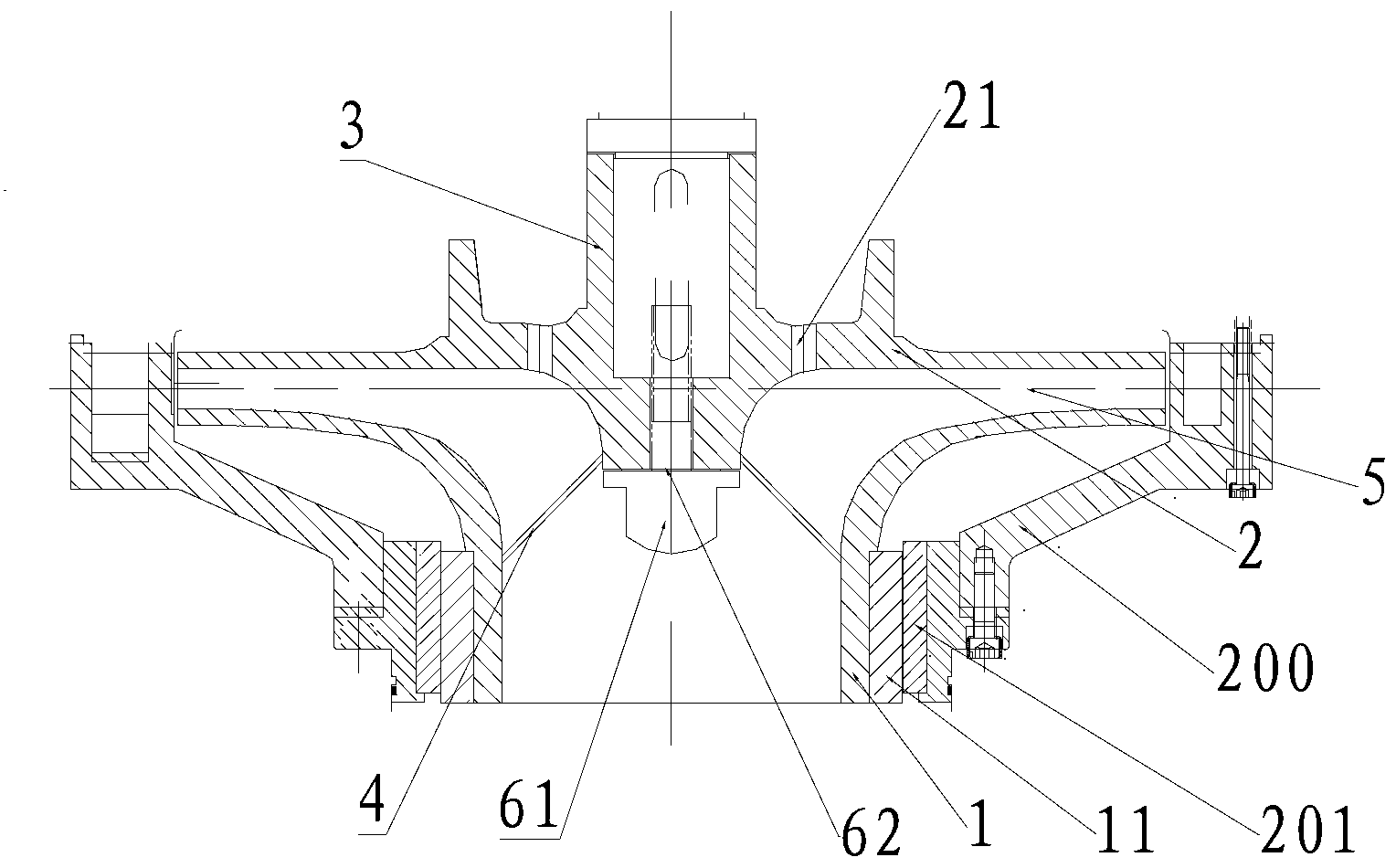

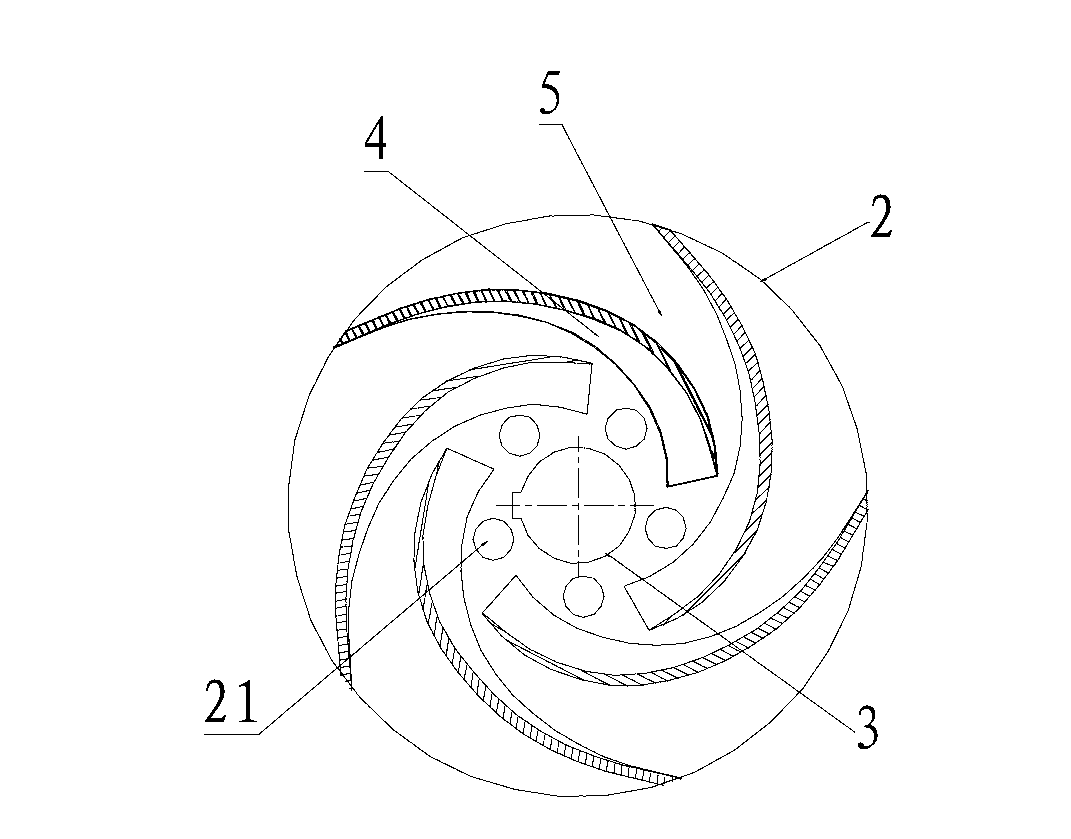

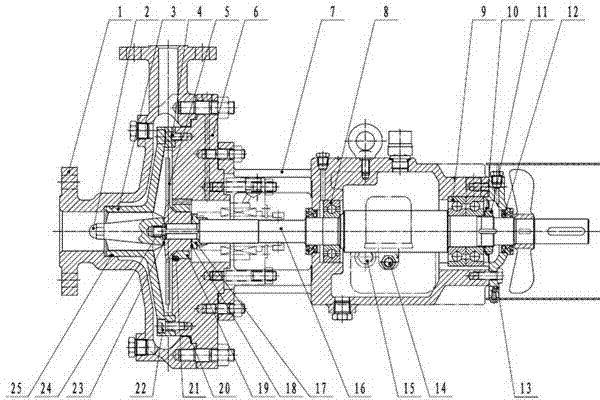

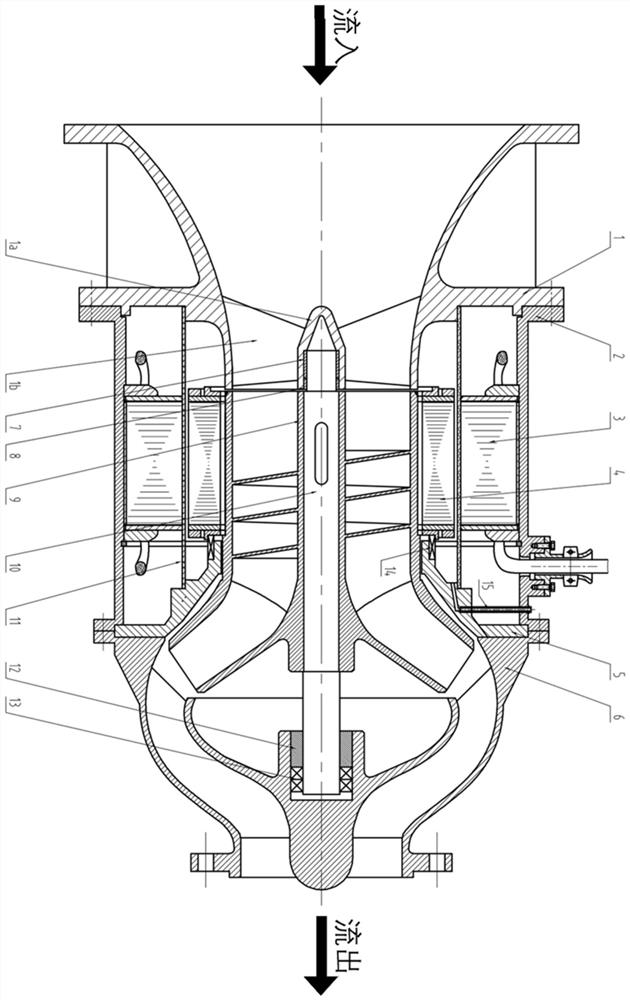

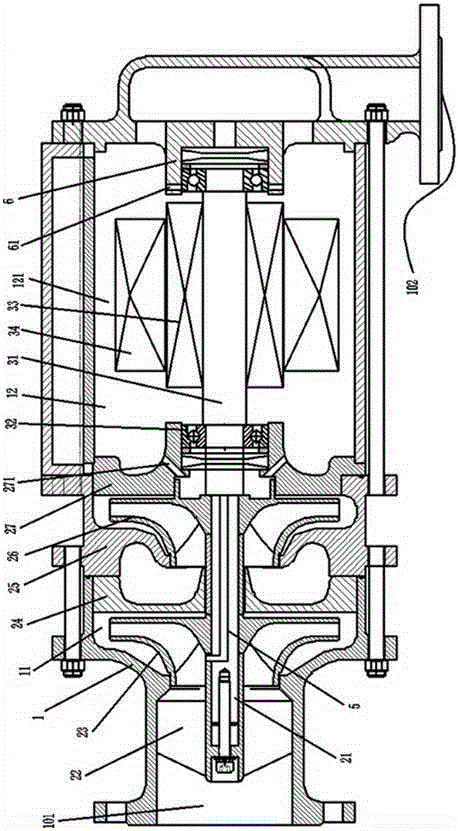

Small seawater desalination pump device

ActiveCN104533802ACompact structureEasy to install and maintainGeneral water supply conservationSeawater treatmentElectromagnetic clutchEngineering

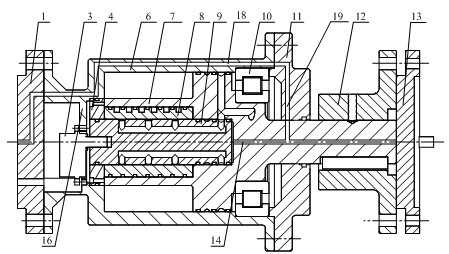

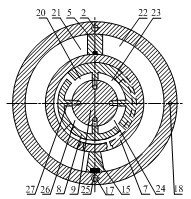

The invention discloses a small seawater desalination pump device which comprises a variable-frequency motor, an electromagnetic clutch, a high pressure generation device and an energy recycling device. The energy recycling device is a turbine device, a turbine rotor is arranged in the turbine device, a rotary shell type high pressure pump is arranged in the high pressure generation device, and a main shaft of the variable-frequency motor, the electromagnetic clutch, the turbine rotor and a rotor of the rotary shell type high pressure pump are coaxially connected. The small seawater desalination pump device is compact in structure, and a turbine is additionally and coaxially arranged on a rotary shell pump, so that the high pressure generation device and the energy recycling device are integrated, functions are integrated, installation maintenance are easy, and besides, the small seawater desalination pump device further has the advantages that parts are not influenced mutually and axial force can be effectively balanced.

Owner:ZHEJIANG KINGKIND SECURITY TECH CO LTD

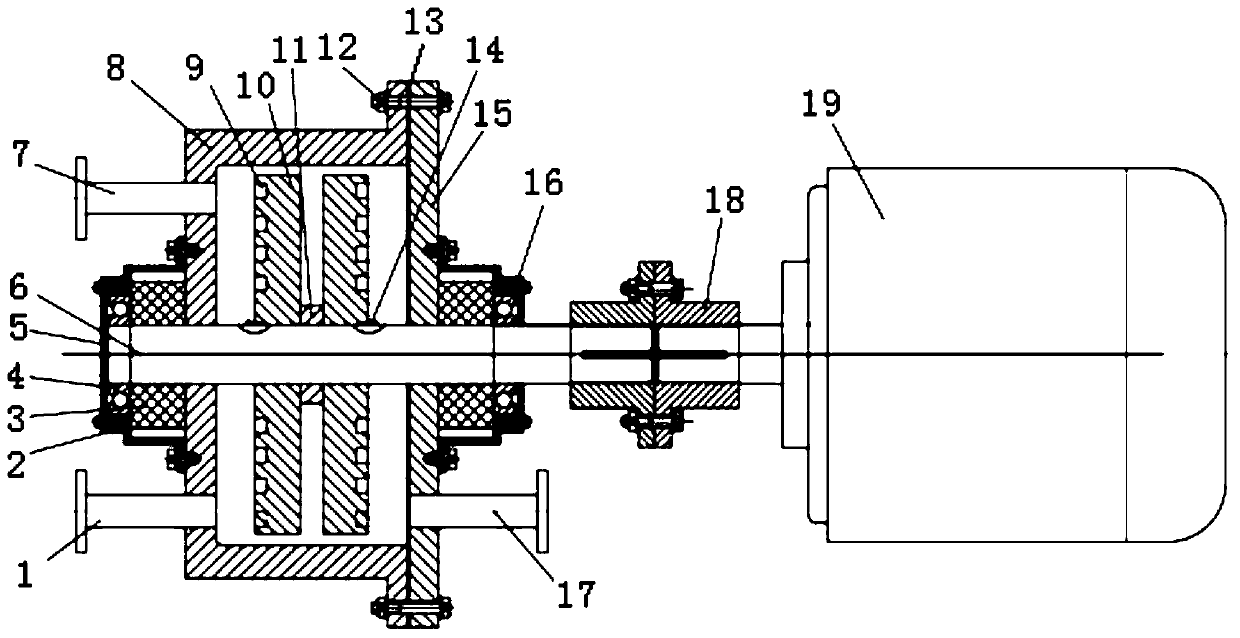

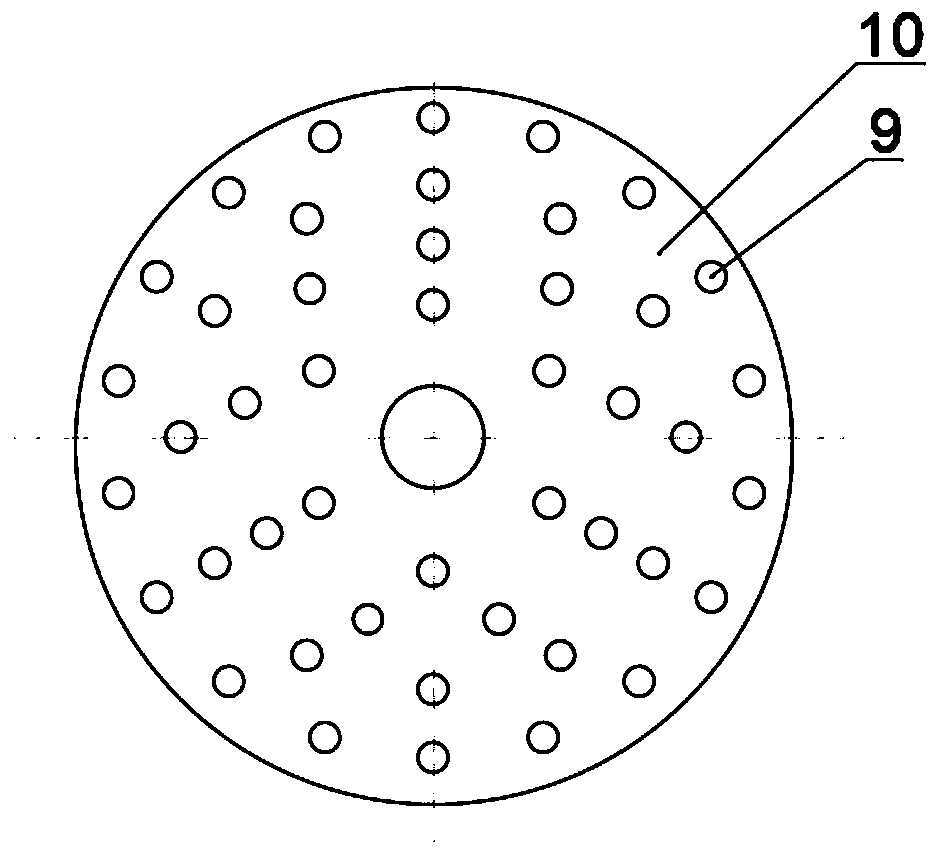

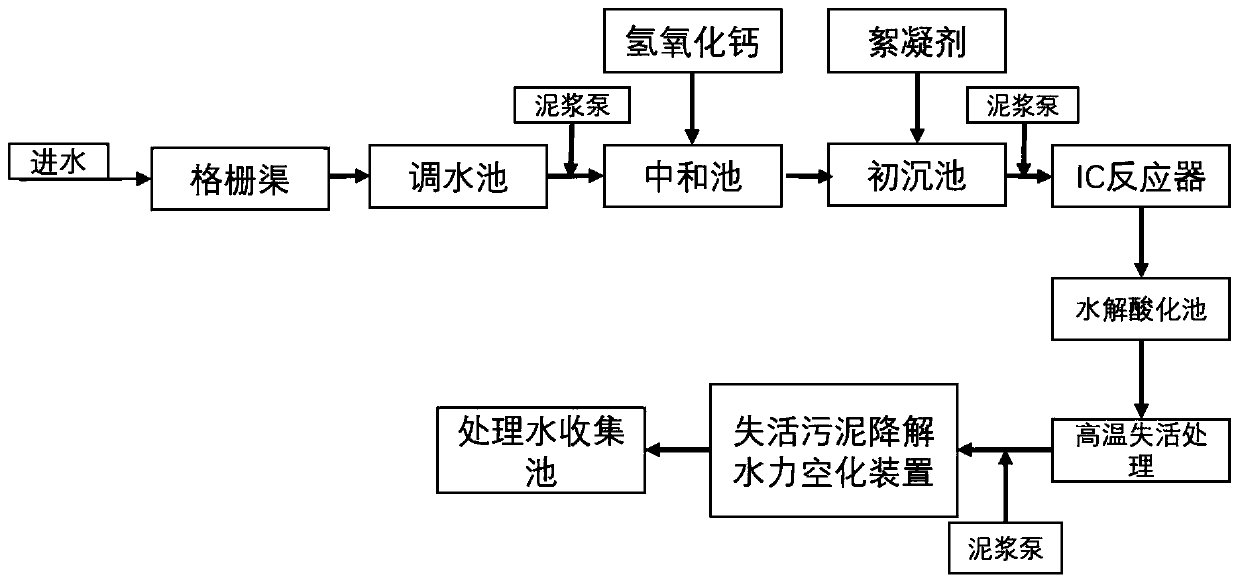

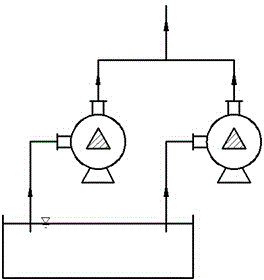

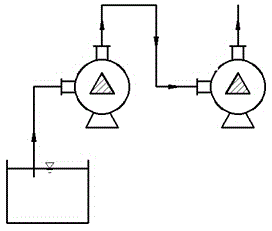

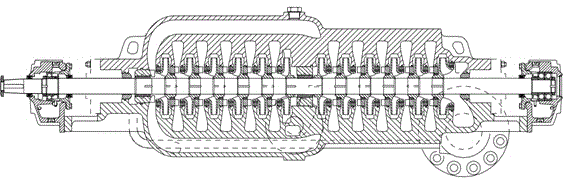

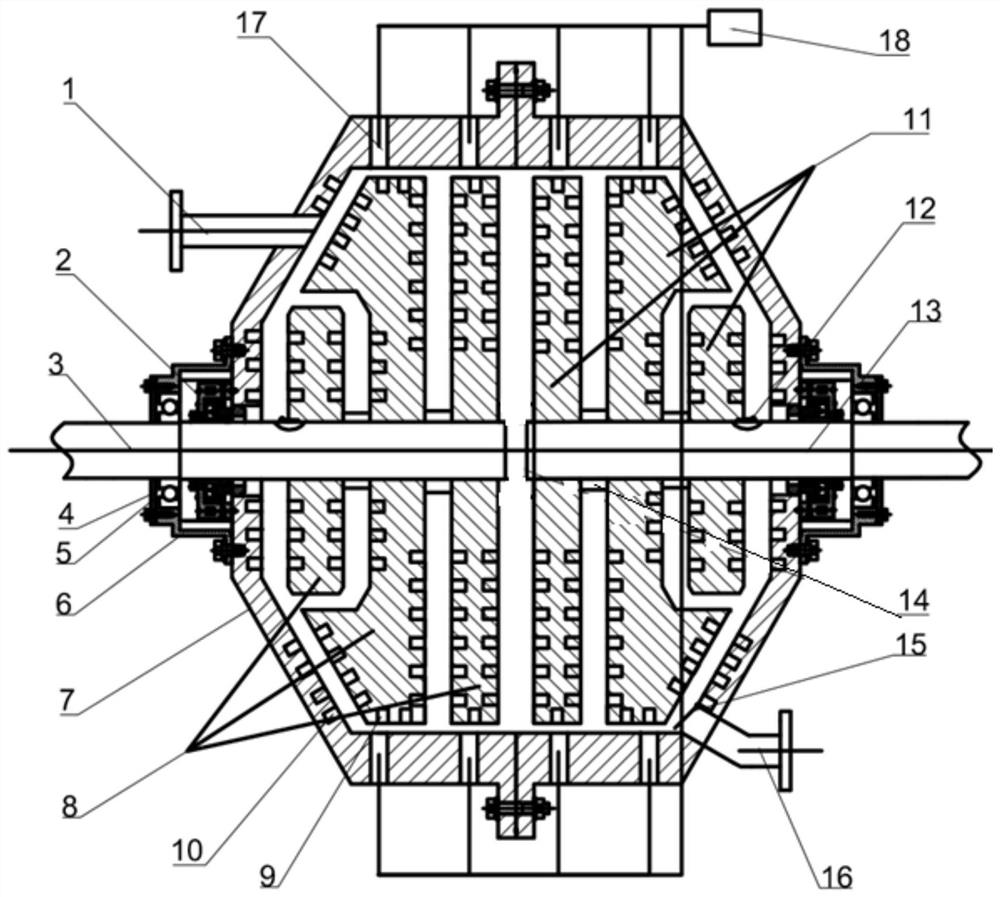

Deactivated sludge degradation hydraulic cavitation device

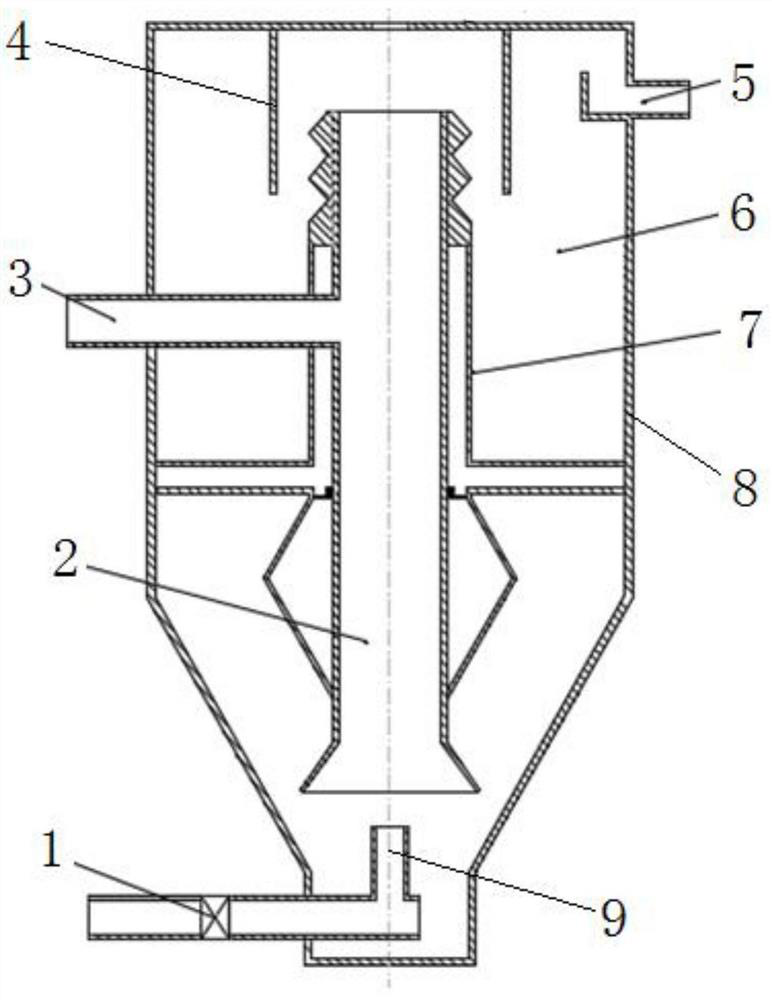

ActiveCN110217957ALarge amount of processingEfficientSludge treatment by thermal conditioningSludge treatment by oxidationChemical LinkageCavitation

The invention discloses a deactivated sludge degradation hydraulic cavitation device which comprises a stator and a rotating shaft, wherein a cavitation cavity is formed inside the stator; a water inlet tube and a water outlet tube are arranged on the stator; the rotating shaft is mounted in the stator; one end of the rotating shaft extends outside the stator; the extending end is connected with atransmission device; two wheel discs which are partitioned through a shaft sleeve are arranged on the rotating shaft; the wheel discs are positioned in the cavitation cavity of the stator; cavitationpores are distributed in sides opposite to the inner wall of the cavitation cavity, of the two wheel discs; and the cavitation pores are blind holes. Through a high temperature and high pressure resulted in hydraulic cavitation, chemical bonds among atoms of water molecules and dissolved oxygen molecules in sludge can be broken, then hydroxyl radicals of intense oxidation can be formed, and the purpose of degrading macromolecule organic matters can be achieved. When being adopted to degrade deactivated sludge, the deactivated sludge degradation hydraulic cavitation device is large in treatment capacity, feasible in continuous operation, high in efficiency, free of emission, free of pollution and good environment protection, and has the characteristics of being good in adaptability, easy to control, simple in structure and high in efficiency.

Owner:SHANDONG UNIV +1

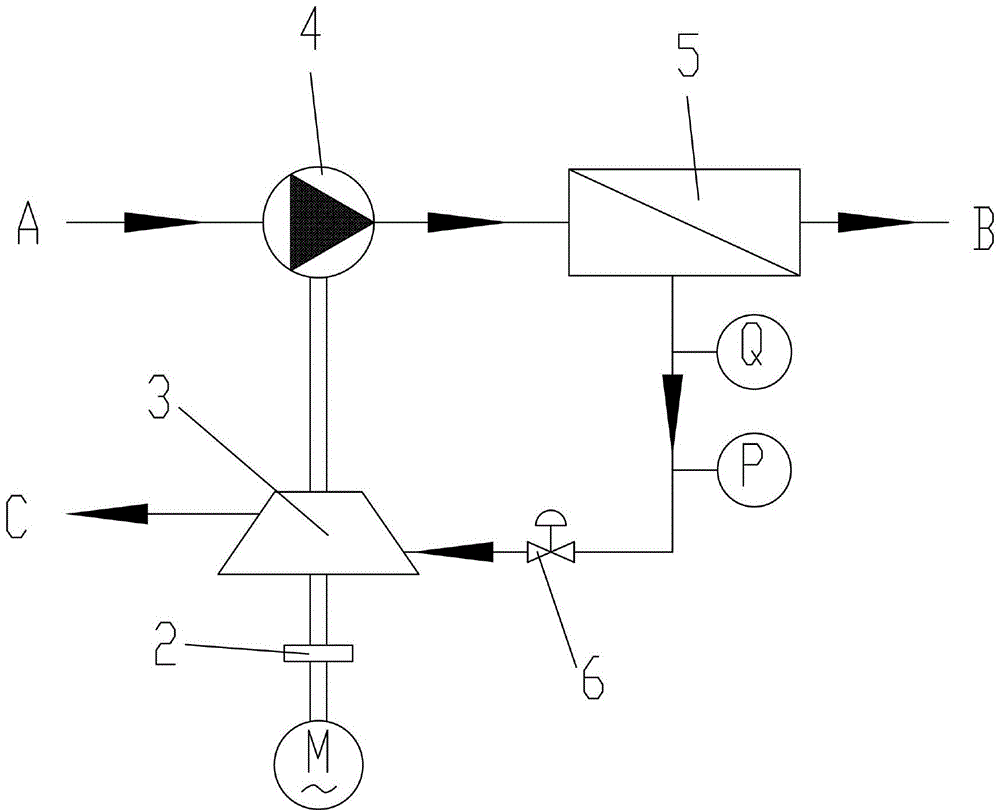

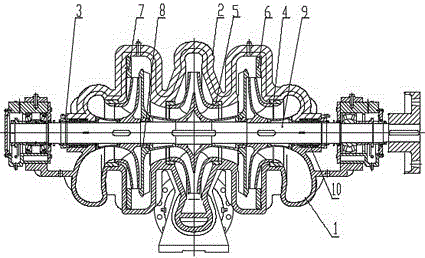

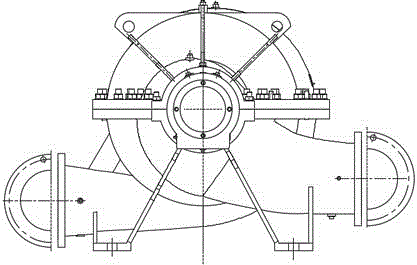

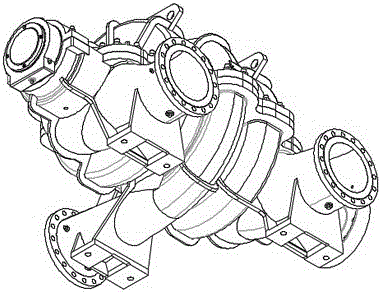

Four-stage series-and-parallel connection pump

InactiveCN104533797ARealize concatenationRealize functionPump controlRadial flow pumpsImpellerElectrical and Electronics engineering

The invention relates to a four-stage series-and-parallel connection pump. Four stages of impellers are connected in series two by two to form two series connection impeller sets. The two series connection impeller sets are symmetrically arranged on a water pump water inlet, a connection channel is formed between the two series connection impeller sets and is communicated with the water pump water inlet, a series-and-parallel connection reversing valve is arranged on the connection channel, and a one-way valve is installed between the connection channel and the water pump water inlet and used for achieving series connection and parallel connection of the four stages of impellers. According to the single pump with the four stages of impellers, through cooperation action of the series-and-parallel connection reversing valve and the one-way valve, series connection and parallel connection functions can be achieved at the same time. One pump is driven by only one motor, various purposes such as fire distinguishing, cooling and drainage can be achieved simultaneously, the structure is impact, axial force is naturally balanced, and the four-stage series-and-parallel connection pump has very good application prospects.

Owner:SHANGHAI MARINE EQUIP RES INST

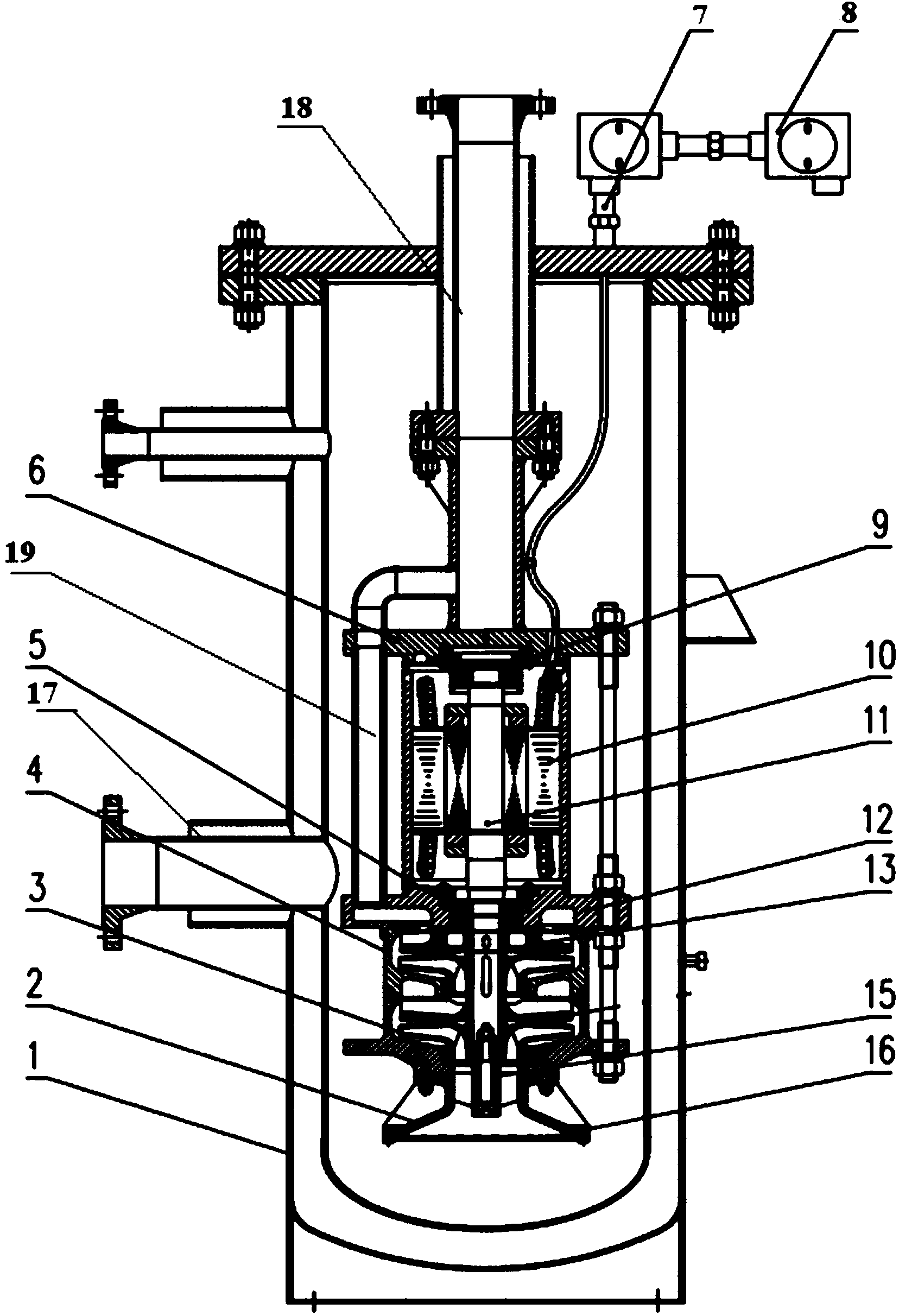

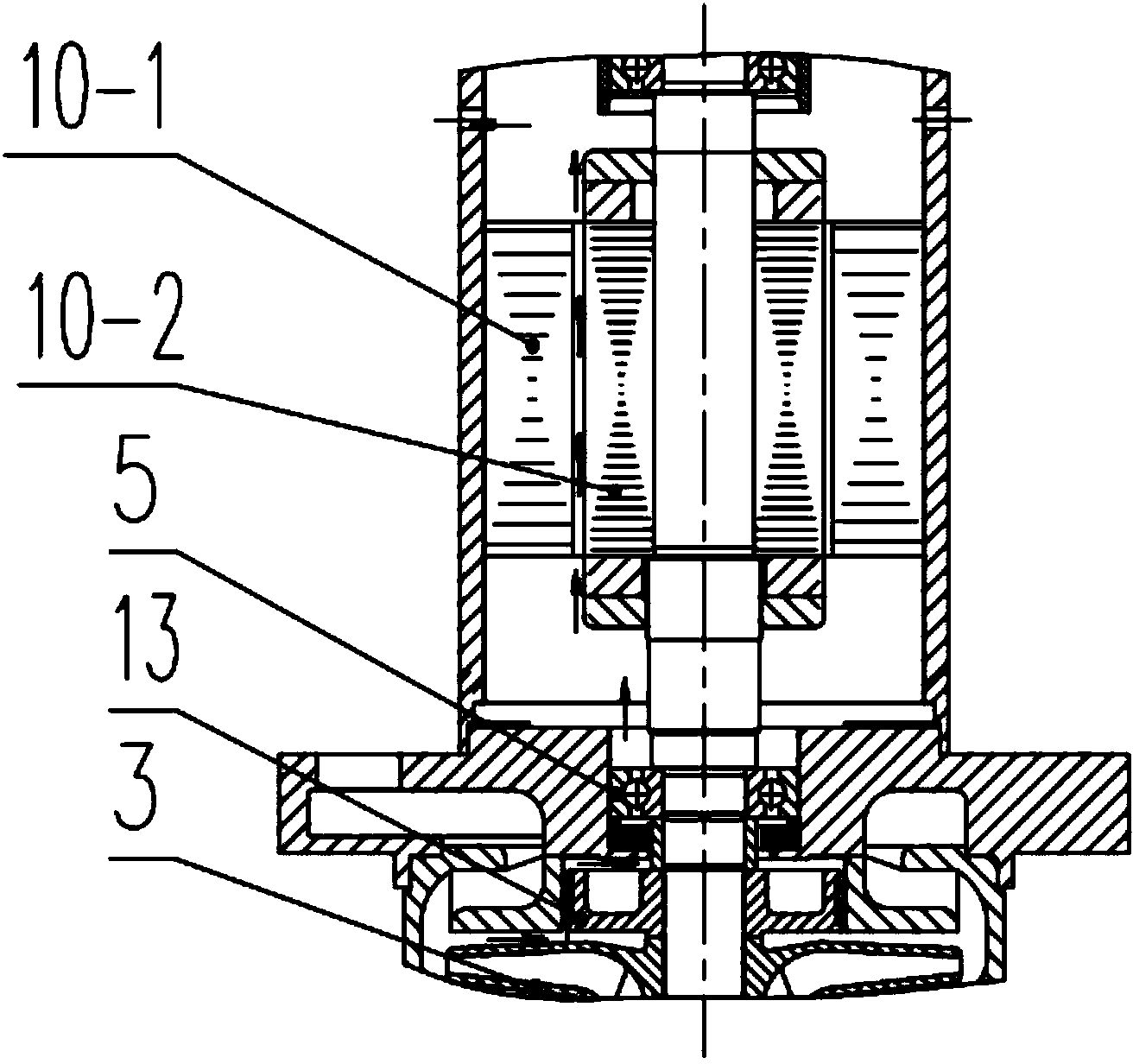

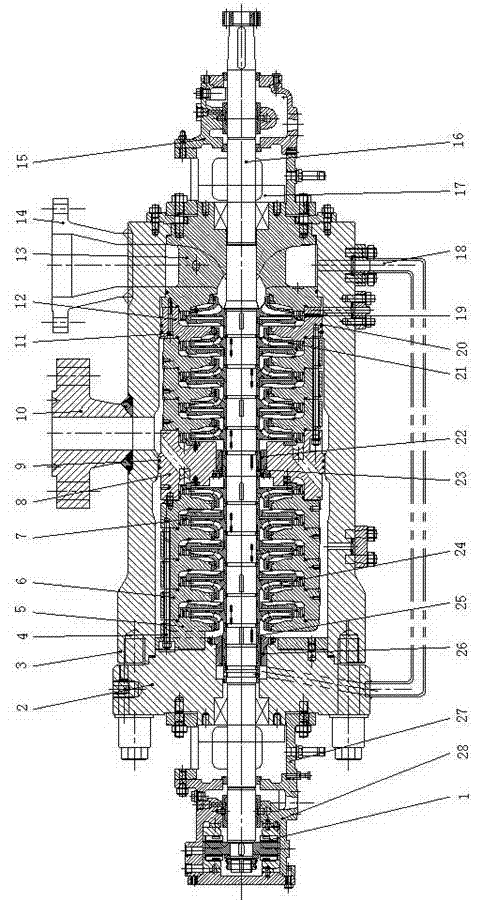

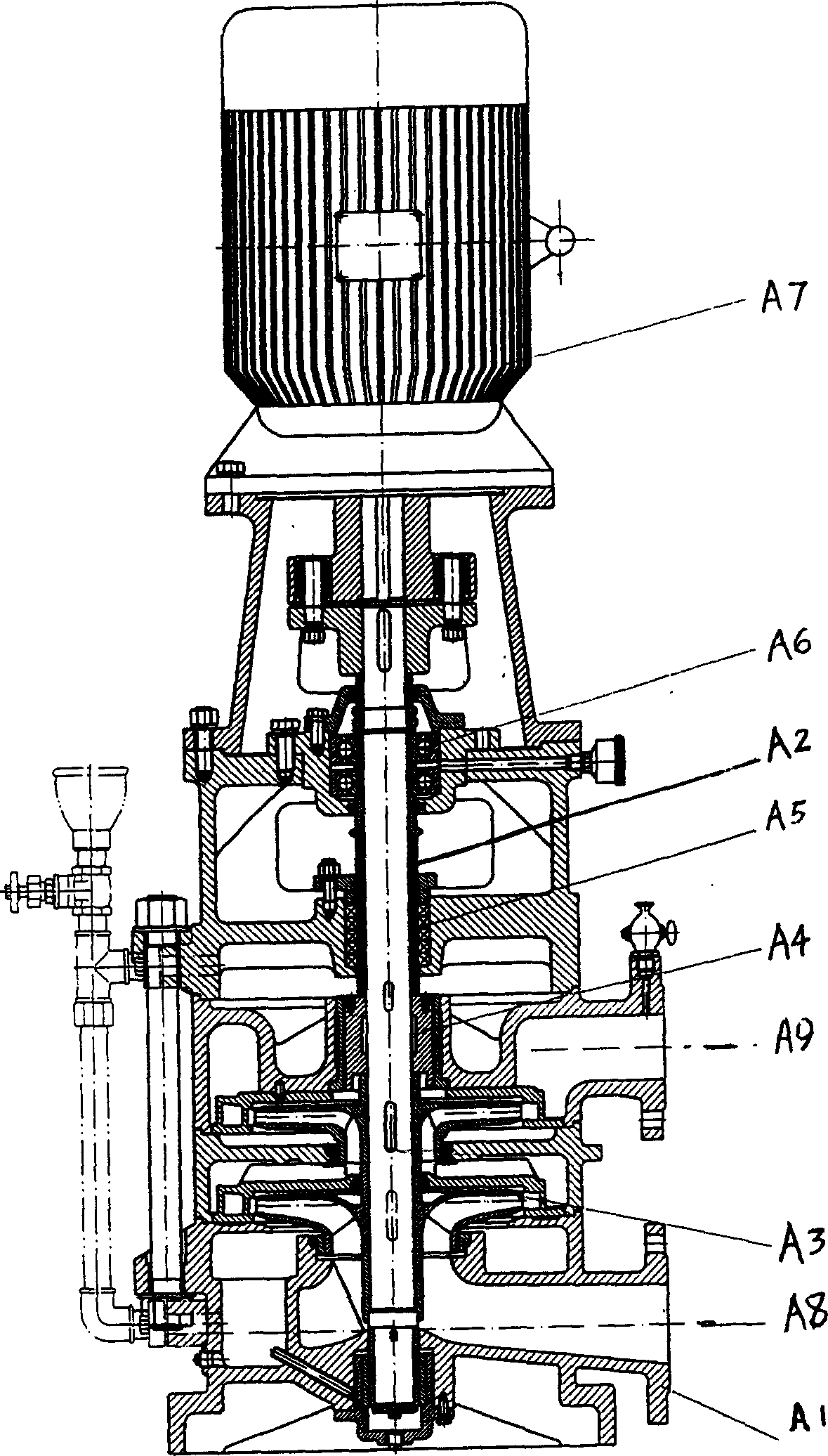

Vertical pump pool multi-stage immersed pump

InactiveCN103821732ABalance axial forceSafe and reliable structureSpecific fluid pumpsPump componentsWorking environmentEngineering

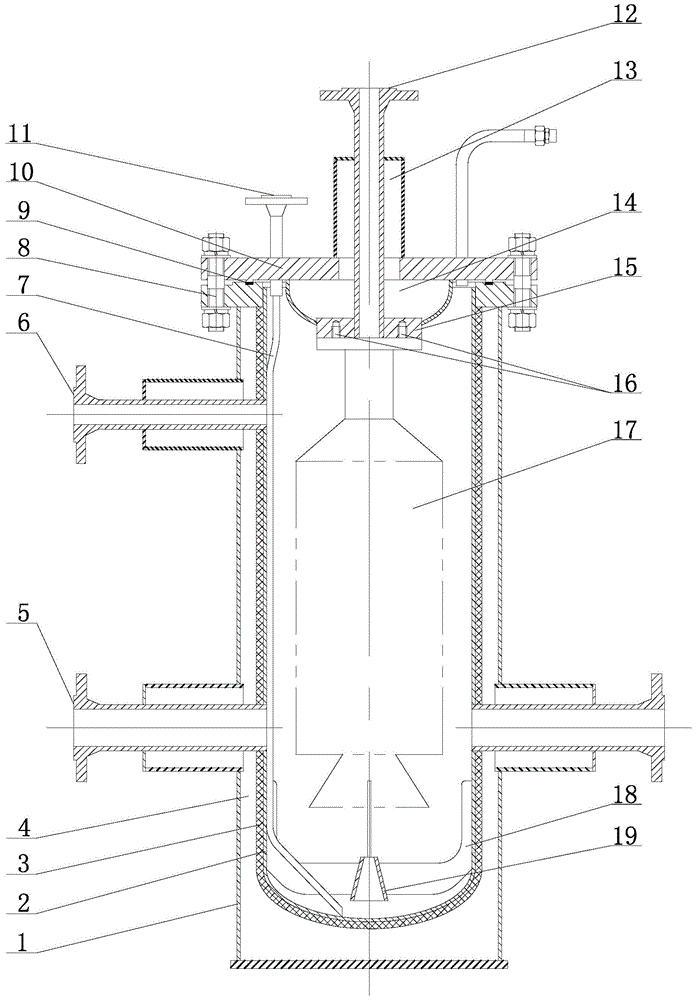

The invention discloses a vertical pump pool multi-stage immersed pump which comprises a pump pool and a pump set arranged in the pump pool. A vacuum heat preservation interlayer is arranged on the side wall of the pump pool. The side wall of the pump pool is connected with a medium inlet pipe, and the top of the pump pool is connected with a medium outlet pipe. The pump set is formed by axially connecting an immersed motor and a pump body, and the immersed motor and the pump body are coaxially connected. A reflowing hole is formed in a shell body of the immersed motor. The pump body comprises a suction segment and a middle segment. An outlet of the pump set is communicated with the medium outlet pipe through a liquid outlet pipe. The vertical pump pool multi-stage immersed pump has the advantages of being safe in structure, stable in performance and efficient, saving energy, being good in sealing performance and the like, and can meet the work requirement of safety production in a low-temperature work environment.

Owner:CHINA NAT OFFSHORE OIL CORP +2

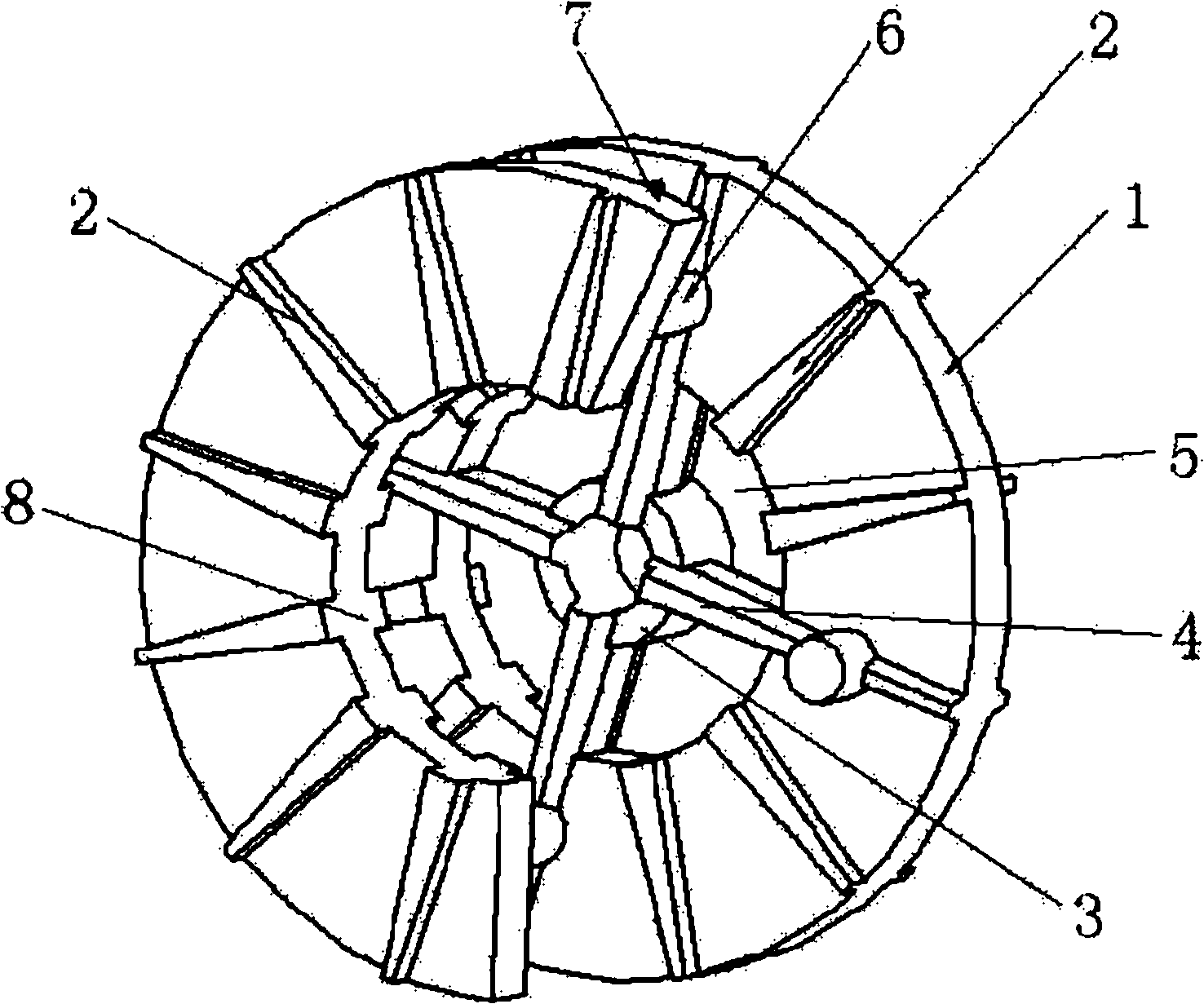

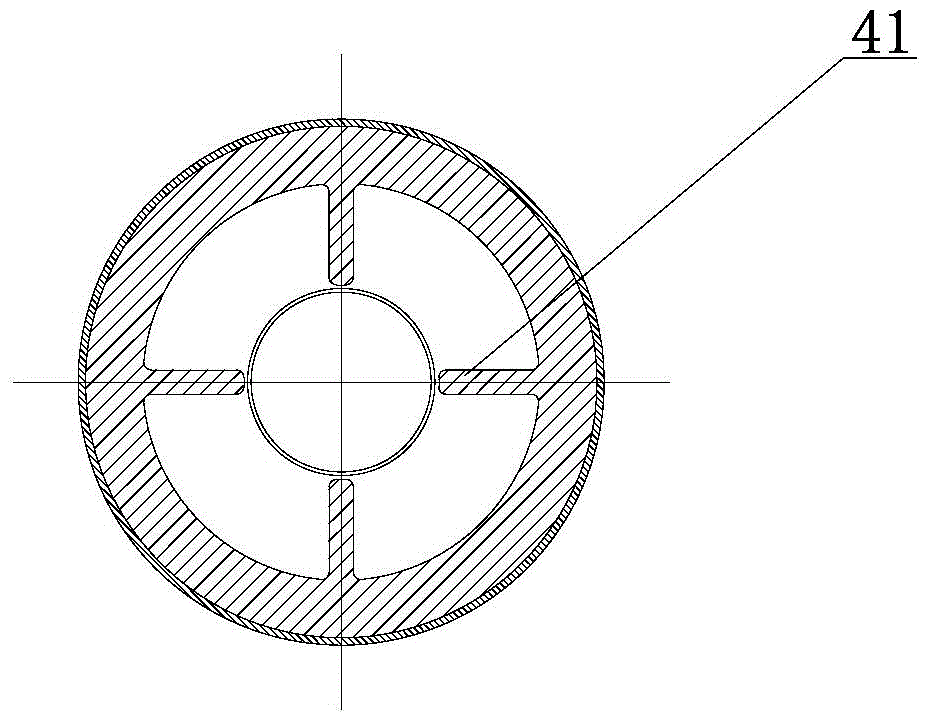

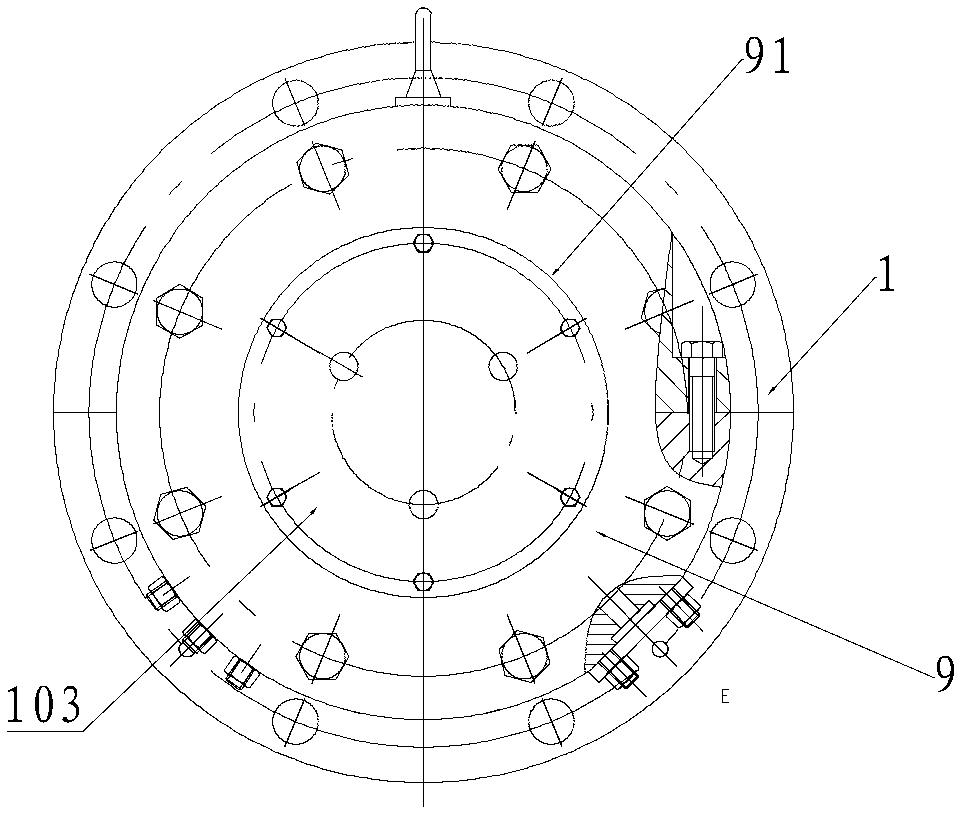

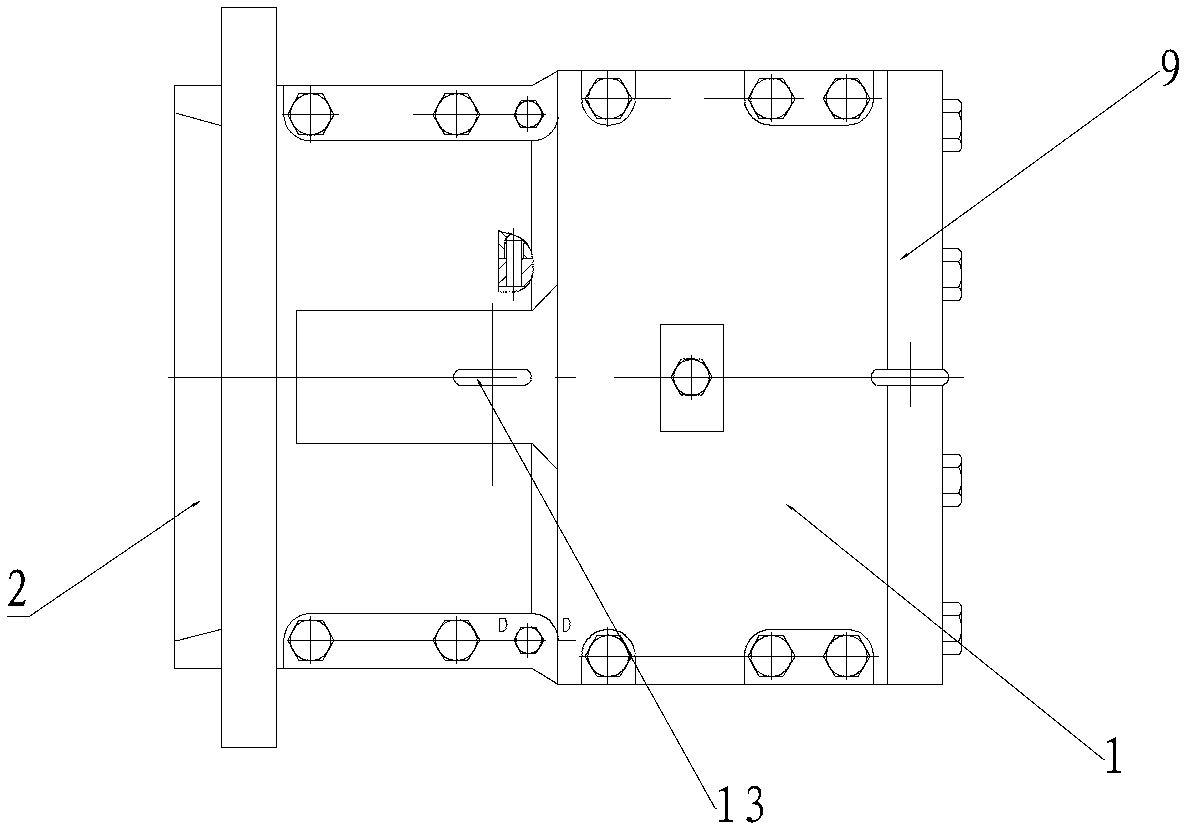

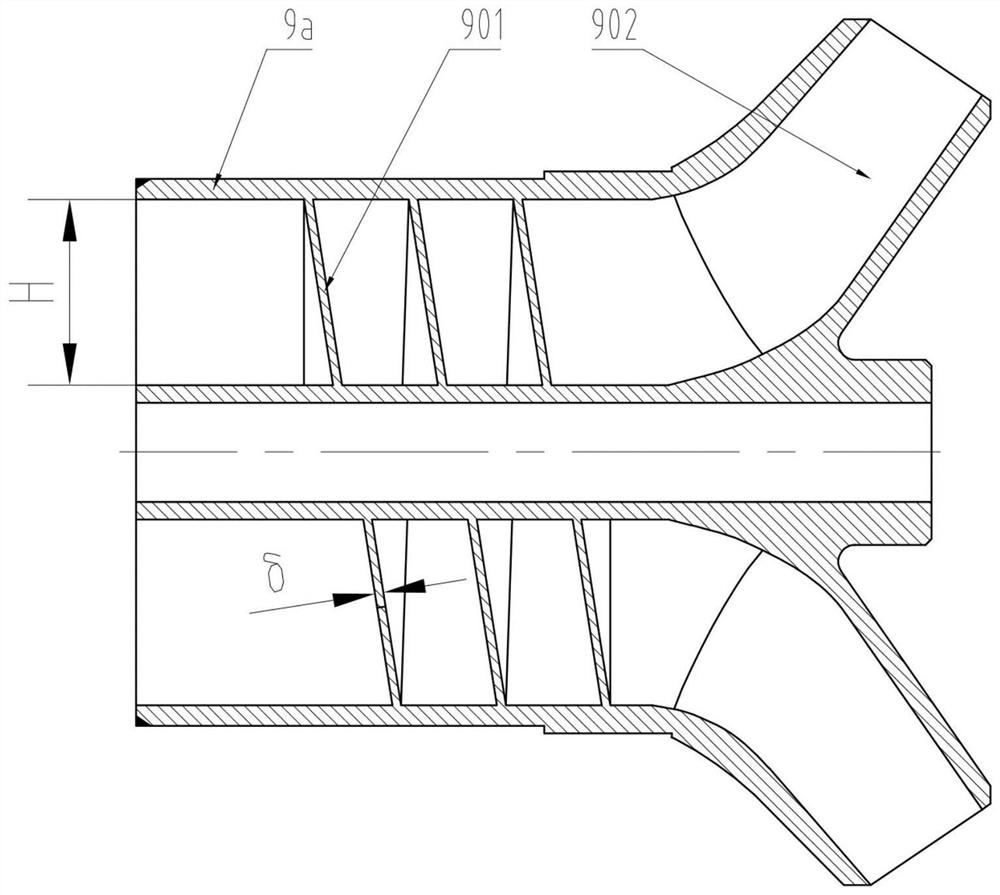

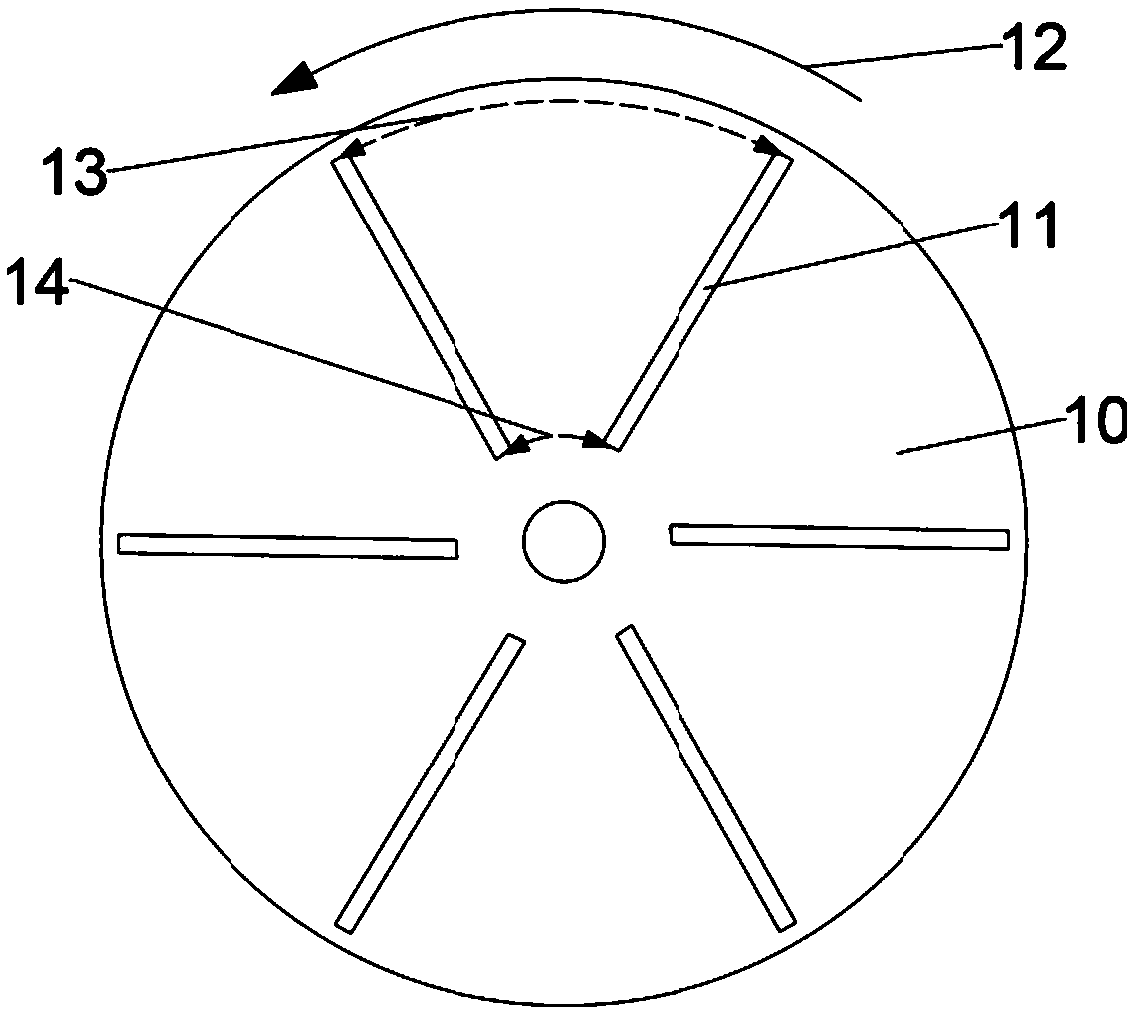

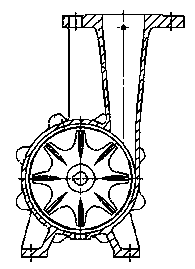

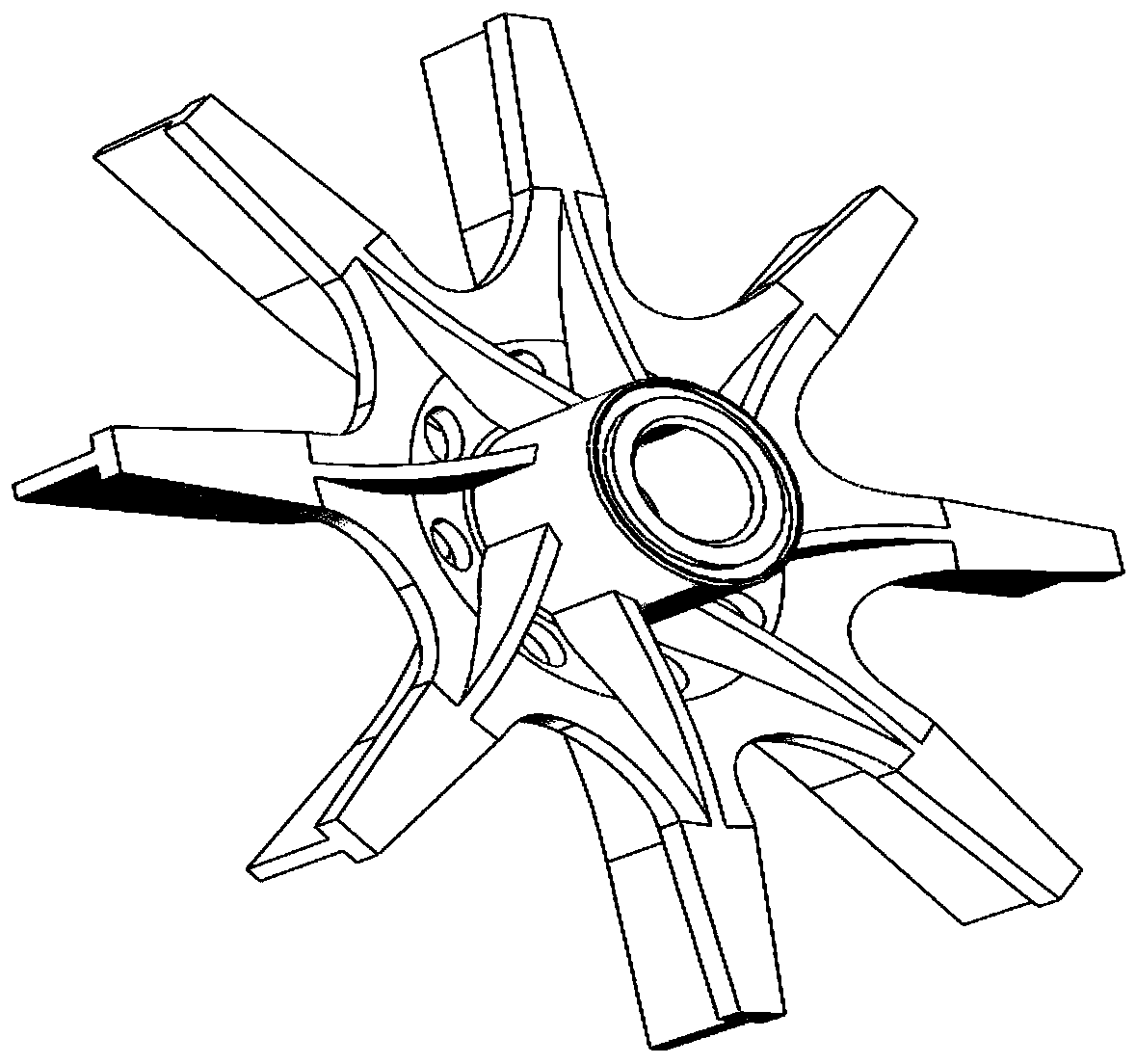

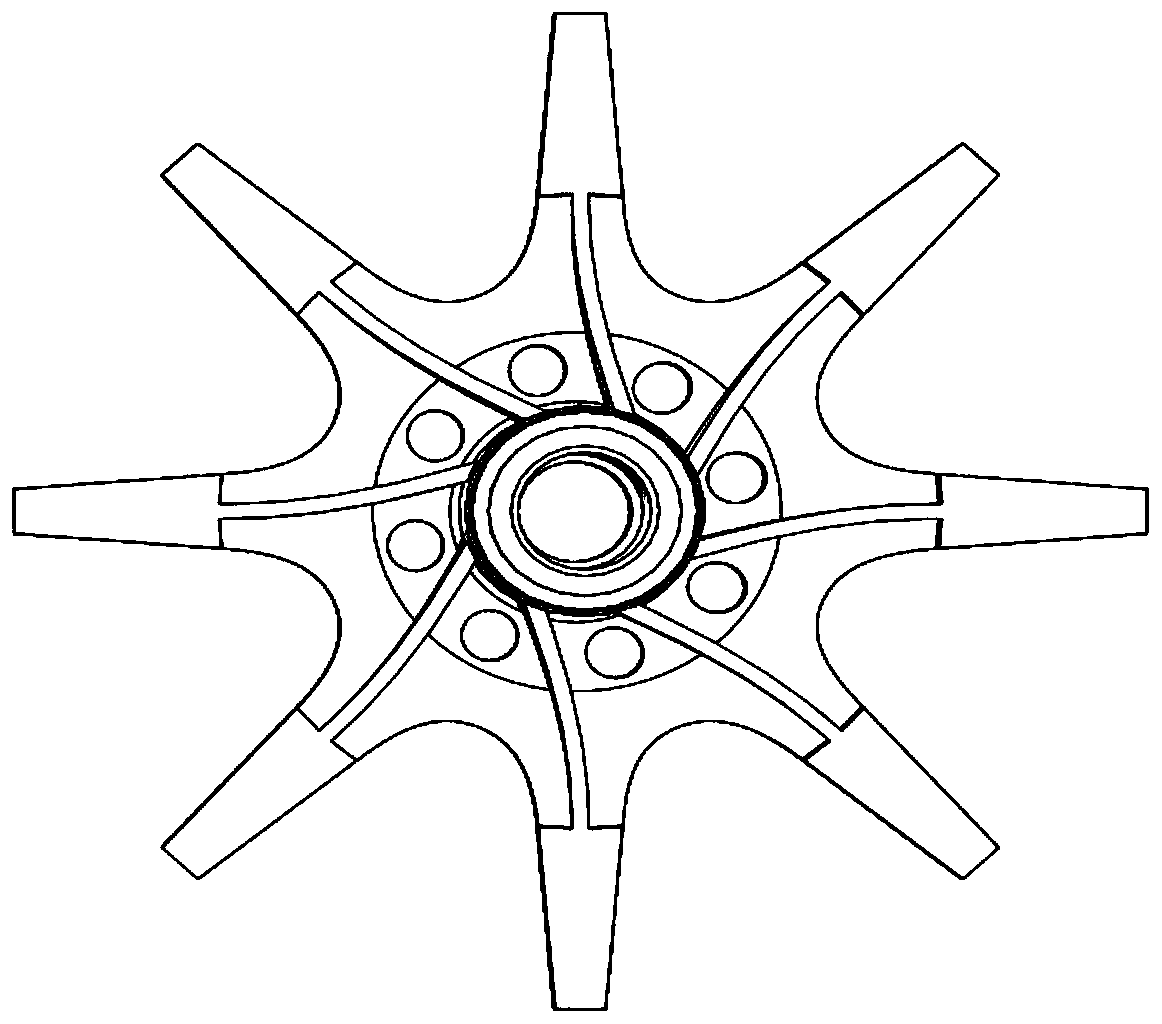

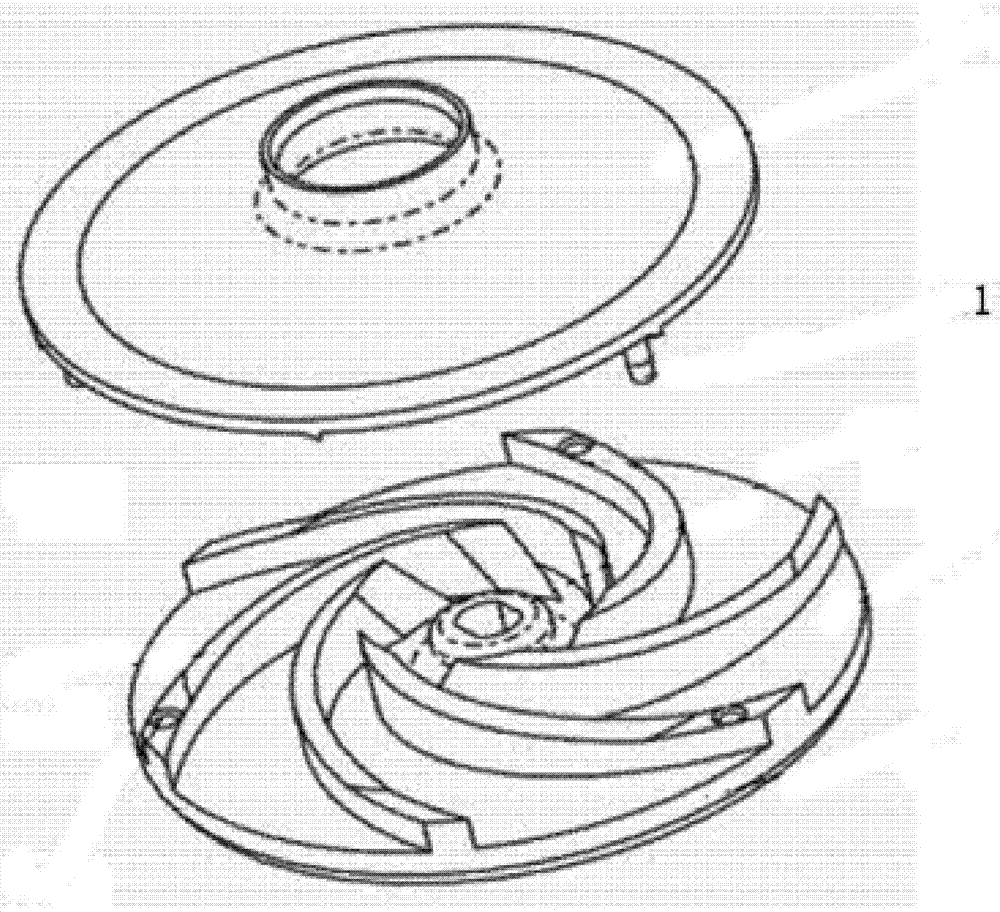

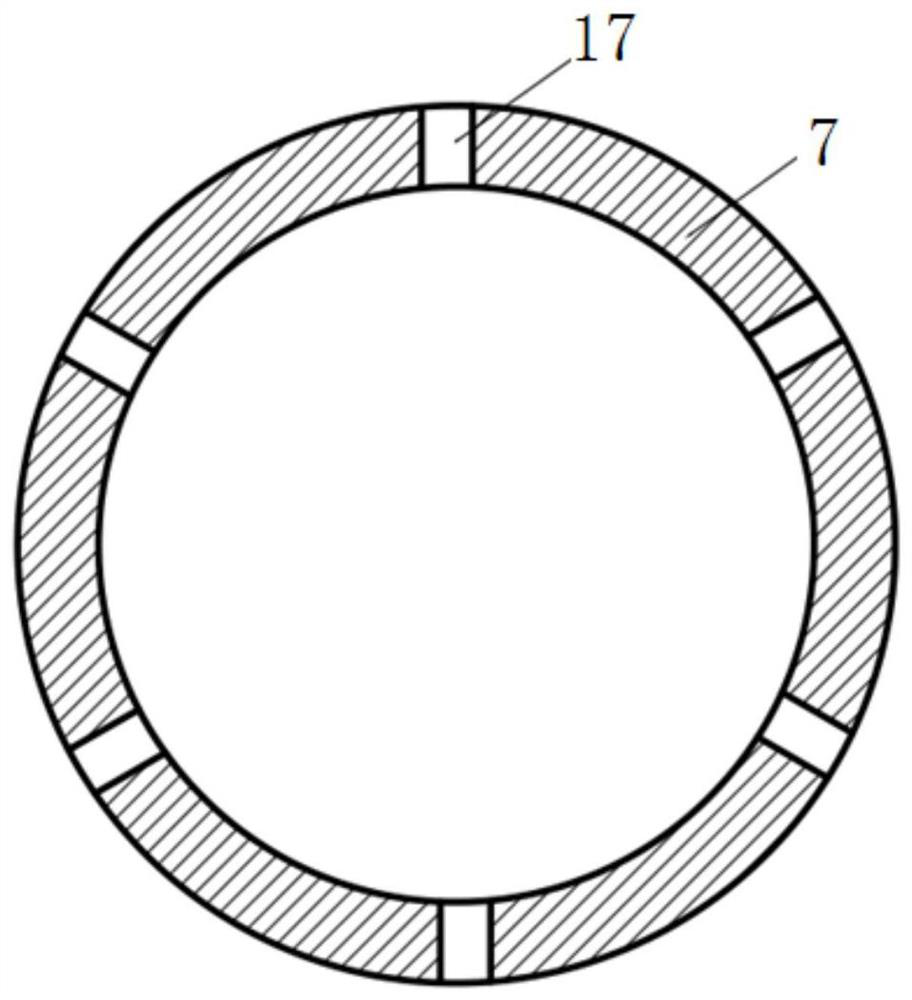

Double-disc straight blade impeller for subsea mud lift pump

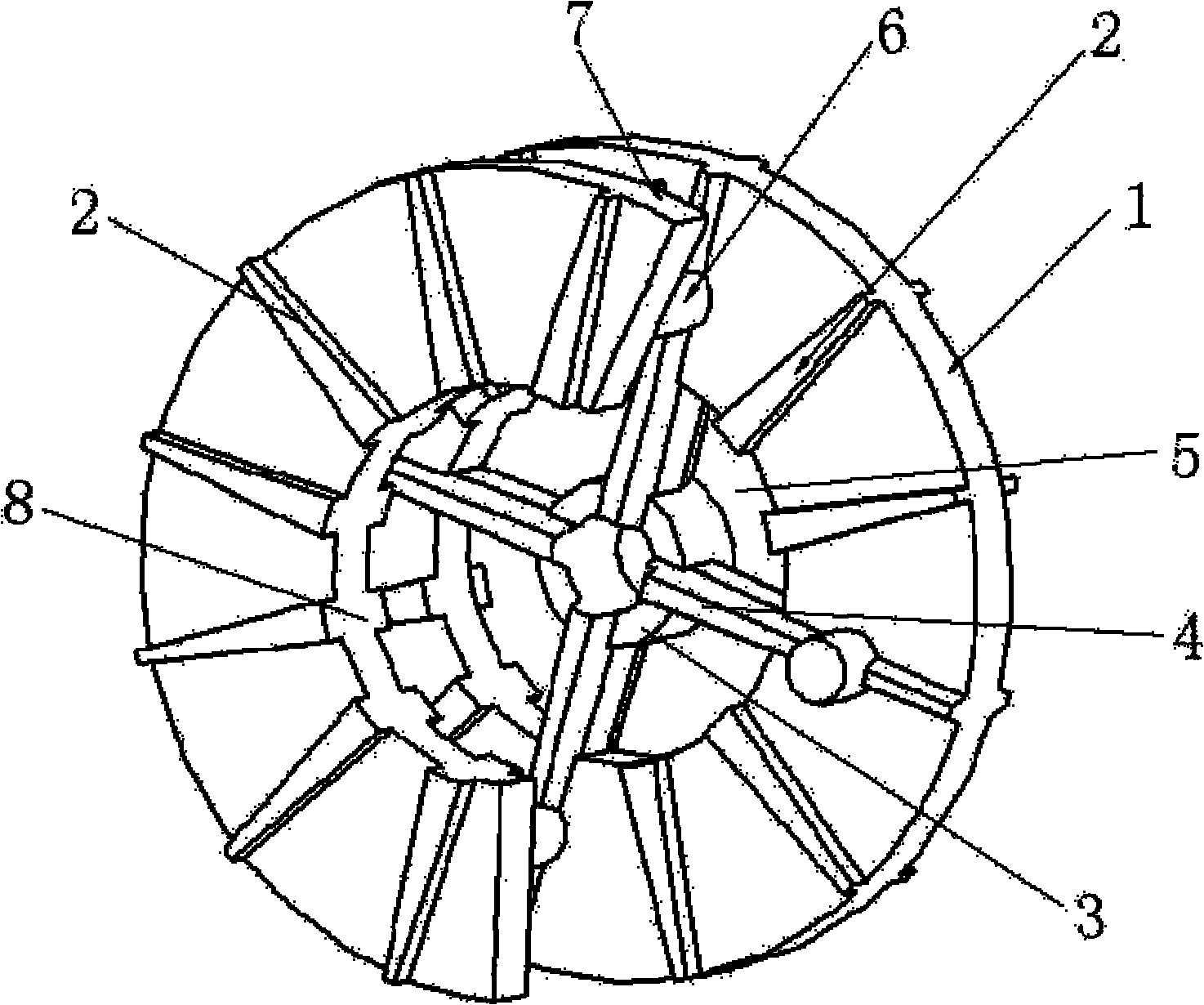

The invention relates to a double-disc straight blade impeller for a subsea mud lift pump. The impeller is characterized by comprising a ring-shaped driving wheel, wherein two lateral surfaces of the driving wheel are radially and symmetrically provided with a plurality of same radial straight blades, the ring center of the driving wheel is provided with a hub, four long blades are uniformly arranged on the hub at intervals, and each long blade is integrated with the corresponding radial straight blade on the two lateral surfaces of the driving wheel; the four long blades on one side of the driving wheel are provided with a connecting arm respectively, and the driving wheel is connected with a ring-shaped driven gear through the four connecting arms; and the two lateral surfaces of the driven gear are radially and symmetrically provided with a plurality of same radial straight blades. The impeller has strong multi-phase conveying capability, blockage resistance, abrasion resistance, flat flow lift curve, wide working range, small axial force and no sealing pressure, so the impeller can be widely applied to the subsea mud lift pump in a partition-free water pipe well drilling process.

Owner:CHINA NAT OFFSHORE OIL CORP +1

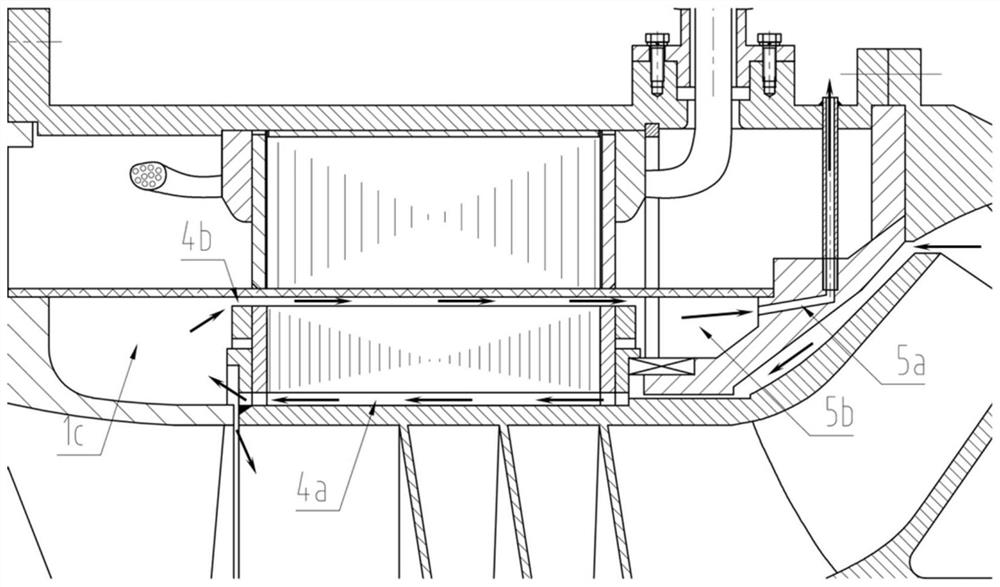

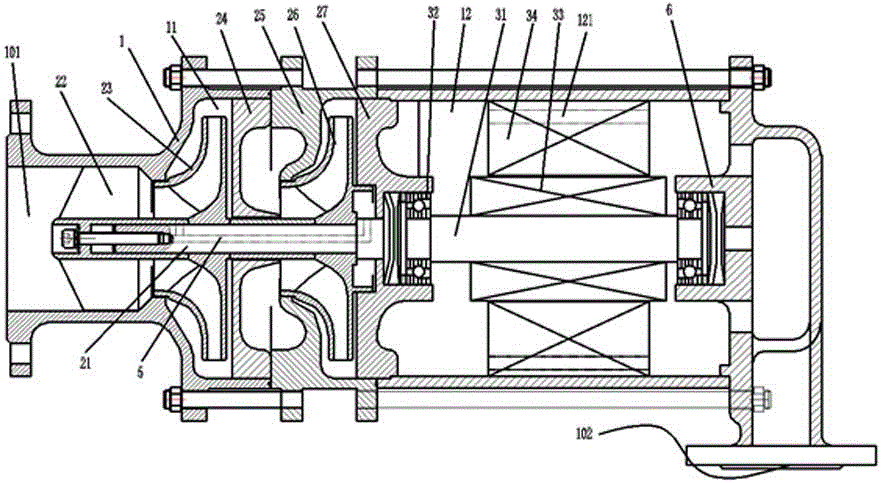

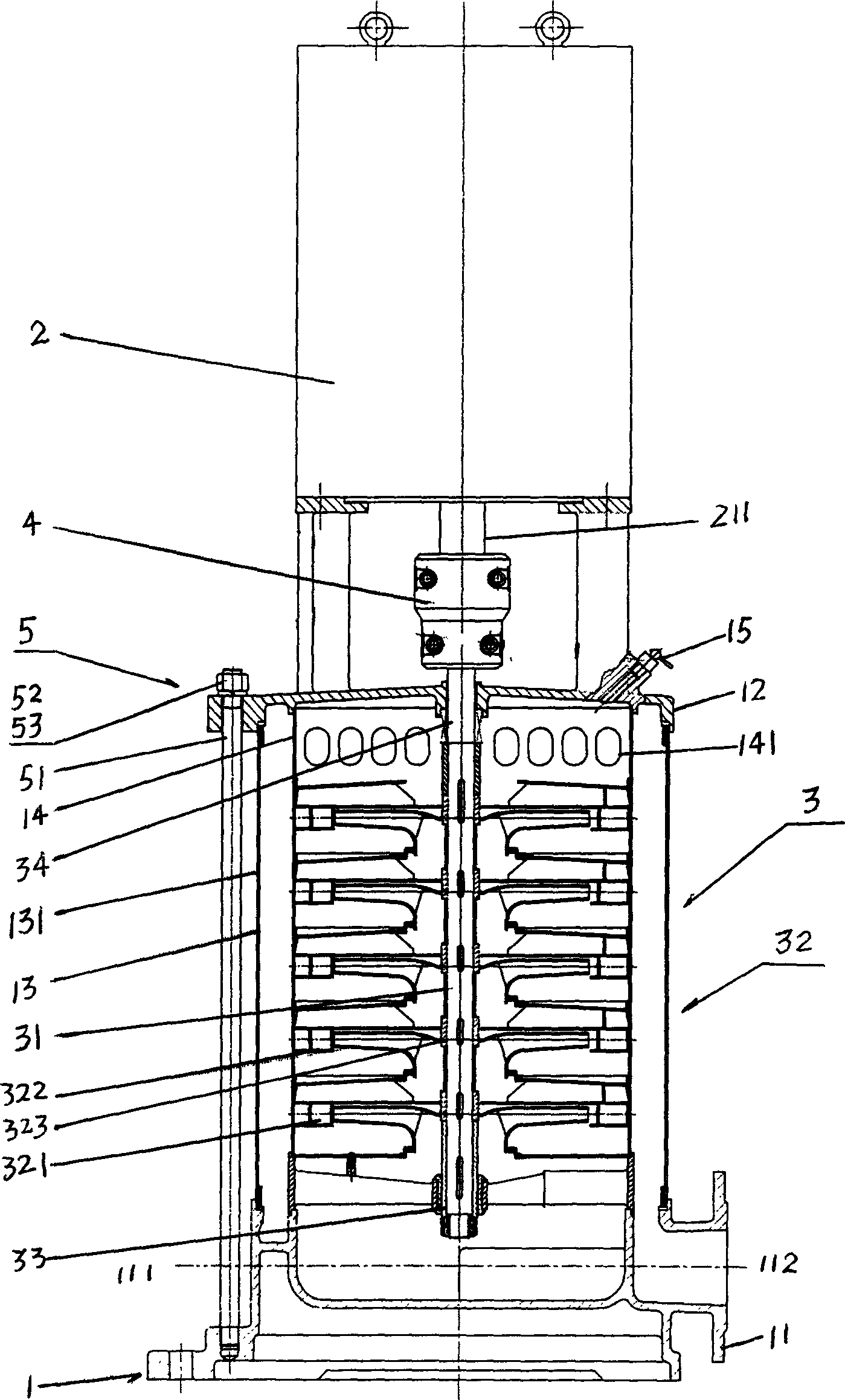

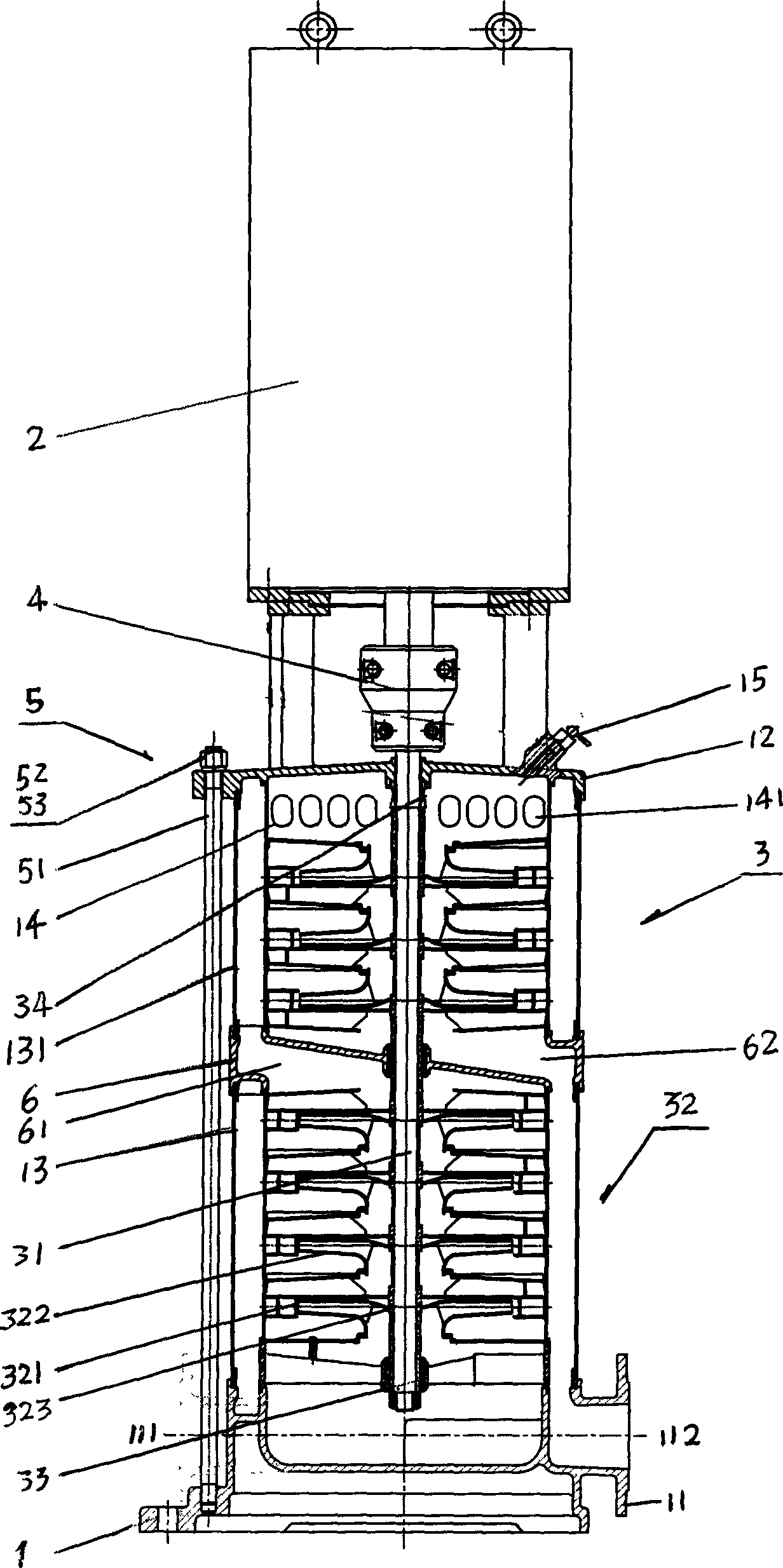

Multi-stage submersible pump system

ActiveCN104895800AImprove suction performanceEasy dischargePump componentsPump installationsThermal insulationEngineering

The invention belongs to the field of centrifugal pumps and particularly relates to a multi-stage submersible pump system. The system comprises a pump pond and a pump body. A pump casing comprises a suction section, a middle section, a lower end cover, a motor casing and an upper end cover. The upper end cover is integrally cast formed, the upper and lower end covers are communicated through at least four liquid outlet tubes, sections of flow channels in the upper end cover and the liquid outlet tubes are circular, and the flow channel and liquid outlet tube connection positions are in smooth transition. A horn tube is arranged on the lower portion of the suction section, and two to six of first guide sheets are distributed along the inner circumference of the horn tube uniformly. A suction filter screen is arranged at the suction end of the horn tube, exhaust holes are formed in the upper and lower portions of the motor casing respectively, and a triangular labyrinth groove is formed in the first-stage impeller, final-stage impeller and shaft sleeve clearance fit positions respectively. According to the system, the pump body suction efficiency is high, the pump pond thermal-insulation effect is good, the flexibility and the economy of the whole system are improved due to the final-stage guide blade unique structure, and by the aid of the axial force balance and bearing lubrication structure, the axial force can be balanced, and the pressure and the flow of bearing lubrication liquids are guaranteed.

Owner:ZIBO BOSHAN LVYUAN GAS EQUIP CO LTD

Double-inlet horizontal split centrifugal pump

InactiveCN106122032ALess prone to cavitationStructural symmetryPump componentsRadial flow pumpsEngineeringAxial force

The invention discloses a double-inlet horizontal split centrifugal pump. The double-inlet horizontal split centrifugal pump comprises a pump body and a pump cover; and the pump body and the pump cover are sealed through a filler gland. The double-inlet horizontal split centrifugal pump is characterized in that water sucking ports are respectively formed in two ends of the same side of the pump body; a water outlet is formed in the other side of the pump body, and is positioned in the axial center; primary double-suction impellers and a secondary impeller are arranged in the pump; the water sucking ports are connected with the primary double-suction impellers; the primary double-suction impellers are connected with the secondary impeller; the primary impellers and the secondary impeller are fixed through a sealing ring; and the two primary double-suction impellers are arranged back to back. The centrifugal pump is equivalent to two double-suction pumps connected in parallel for synchronously working; under the same outer diameters of the double-suction pump impellers, the flow lift can be increased by one time; the inlet and the outlet are in the same direction, and are perpendicular to the pump shaft, so that the arrangement and the installation of the pump and the water inlet and outlet pipes are facilitated; and the impellers are symmetrically structured without axial force, and are stably operated.

Owner:湖南长一泵业有限公司

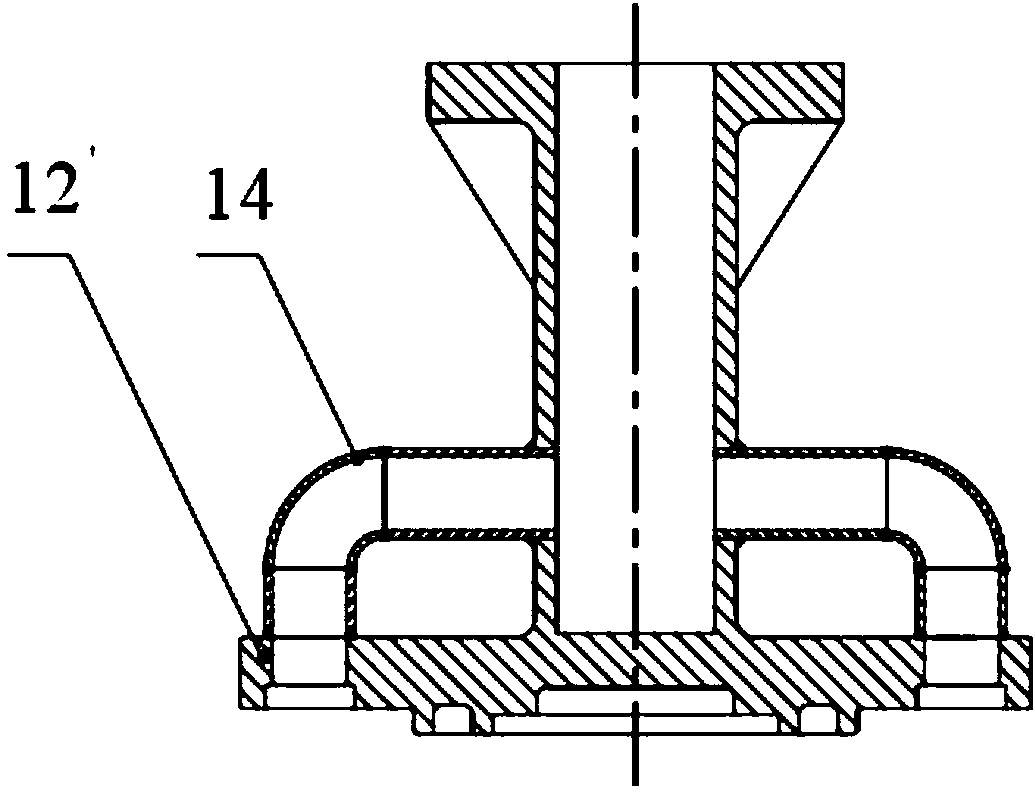

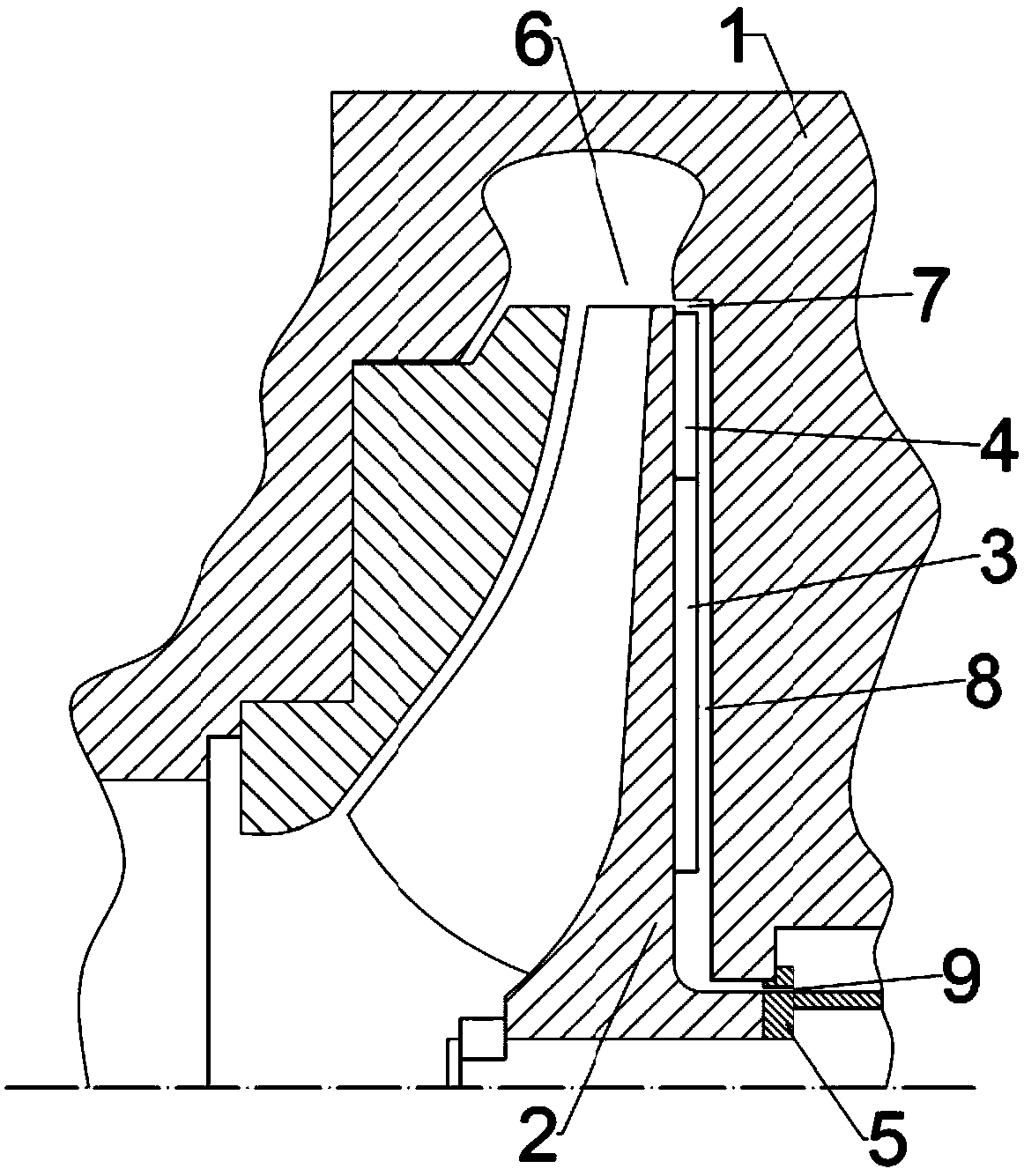

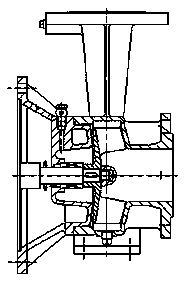

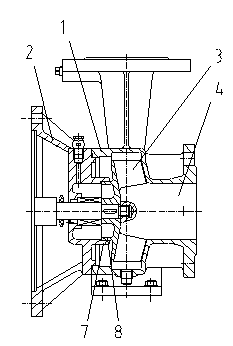

Sewage pump with automatic axial thrust balancing function

The invention relates to a sewage pump with an automatic axial thrust balancing function. The sewage pump comprises a pump body and an impeller which is provided with a hub. A water groove is formed in the hub. A connecting hole and a water outlet are formed in the pump body. The water groove is connected with the connecting hole and the water outlet in sequence. High-pressure water in the impeller is discharged from the pump body through the water groove in the hub, the connecting hole and the water outlet in sequence, and axial thrust is balanced. Compared with the prior art, the sewage pump has the advantages that axial thrust is automatically balanced, the structure is simple, and service life is long.

Owner:SHANGHAI RAYBON MACHINERY GRP

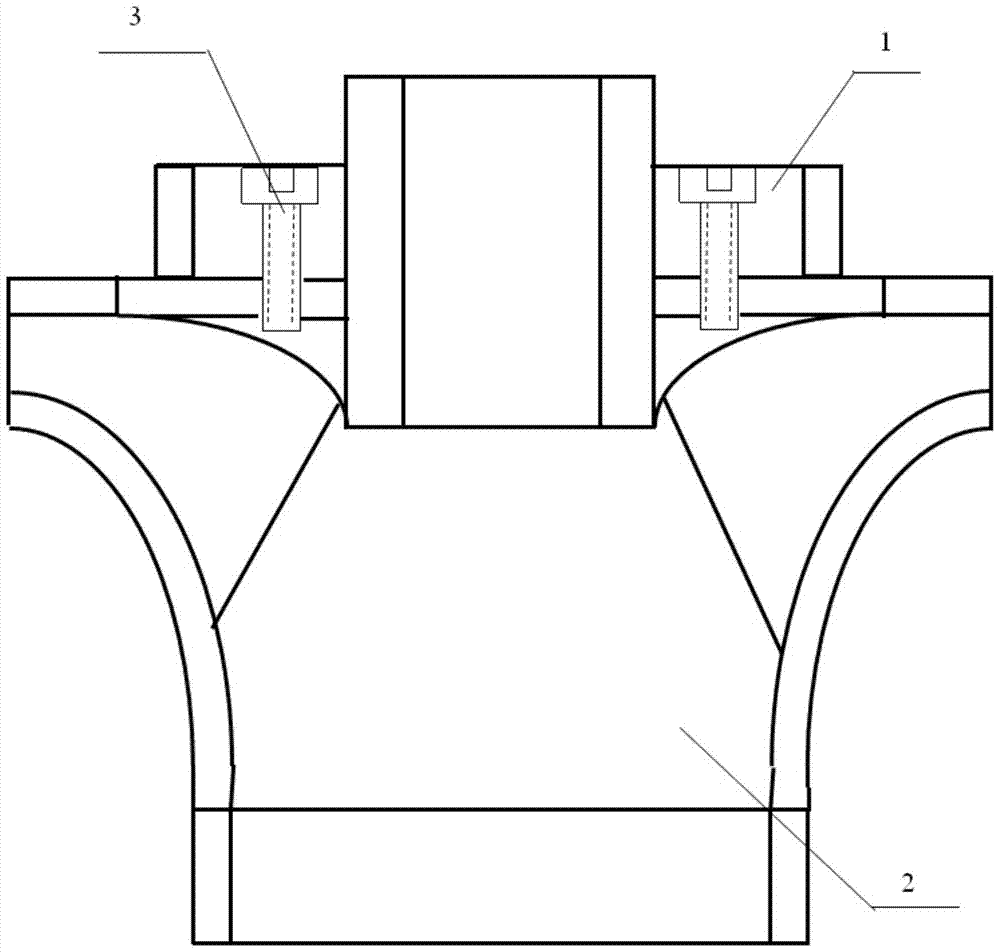

Bearing for main feed water pump

ActiveCN103195737AGuaranteed safe operationBalance axial forcePump componentsPumpsAxial displacementAxial force

The invention discloses a bearing for a main feed water pump. The bearing comprises an oil retaining disc, a thrust disc, an axial displacement measuring disc and a bearing block; the oil retaining disc is sleeved on a pump shaft, and the bearing block is sleeved on the radial outer side of the oil retaining disc, the radial outer side of the thrust disc and the radial outer side of the axial displacement measuring disc; a front thrust pad seat and a rear thrust pad seat are fixed onto the inner circumference of the bearing block and are symmetrically arranged on the front side and the rear side of the thrust disc; a plurality of front thrust pads which are uniformly distributed around the pump shaft are arranged between the front thrust pad seat and the front end surface of the thrust disc; and a plurality of rear thrust pads which are uniformly distributed around the pump shaft are arranged between the rear thrust pad seat and the rear end surface of the thrust disc. The bearing has the technical advantages that axial force on the pump shaft is balanced under a synergetic effect of the front thrust pads, the thrust disc and the rear thrust pads when the main feed water pump runs, the pump shaft is prevented from being damaged during running, and the safety running of the main feed water pump is guaranteed.

Owner:SHANGHAI APOLLO MACHINERY

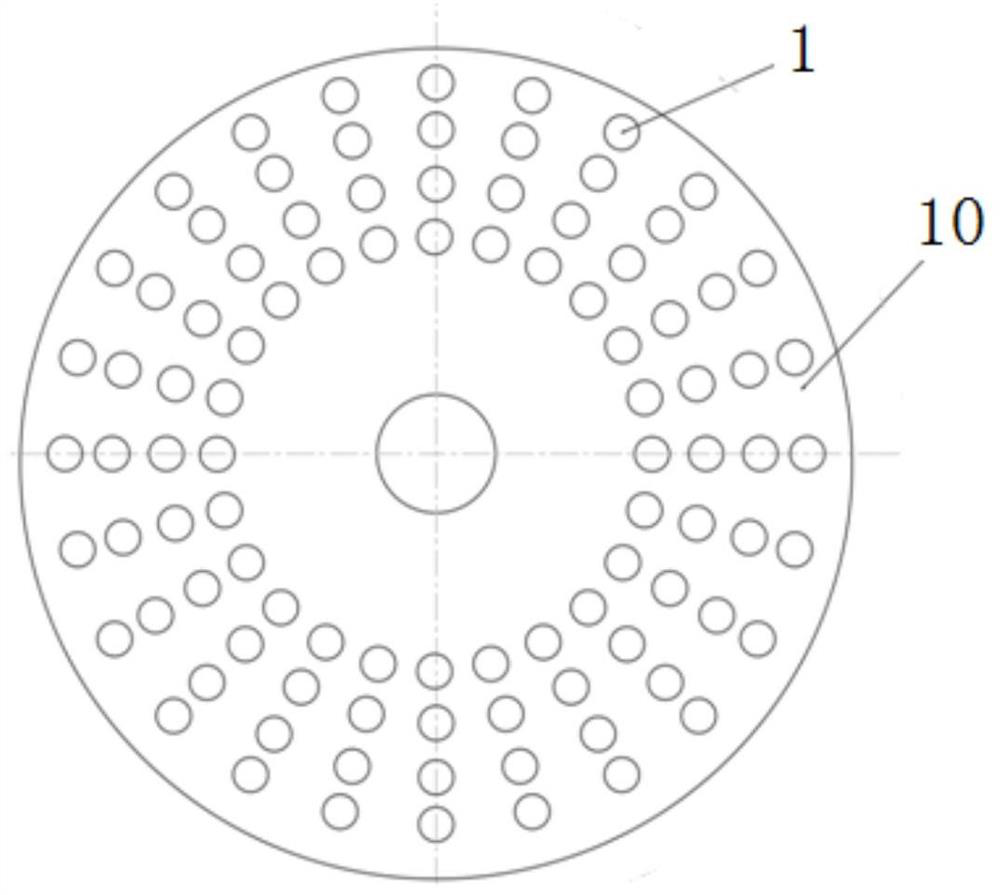

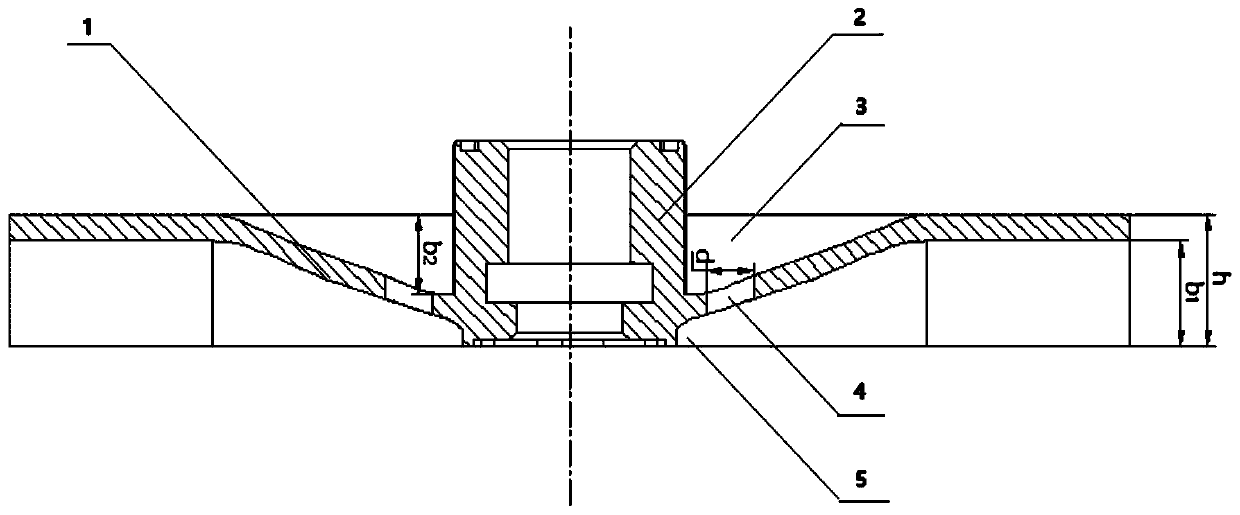

Impeller for residual heat removal pump

The invention discloses an impeller for a residual heat removal pump in the field of nuclear power equipment. The impeller for the residual heat removal pump comprises a front cover plate, a rear cover plate, and a hub which penetrates through the circle center of the rear cover plate, N pieces of vanes are evenly distributed on the periphery of hub between the bottom face of the rear cover plate and the top face of the front cover plate, an impeller passage is formed between any two adjacent vanes, M pieces of balancing holes are evenly distributed on the periphery of the hub between the vanes and the hub radial direction in the rear cover plate, and an impeller opening ring is sleeved on the front cover plate. The impeller for the residual heat removal pump has the advantages that anti-cavitation performance of the impeller is effectively improved, and service life is effectively prolonged. After the impeller is sleeved on a pump shaft of the residual heat removal pump, axial force which is exerted on the pump shaft is effectively balanced, and nonoccurrence of damage or function loss or lift reduction in a continuous operation process of the residual heat removal pump is guaranteed.

Owner:SHANGHAI APOLLO MACHINERY

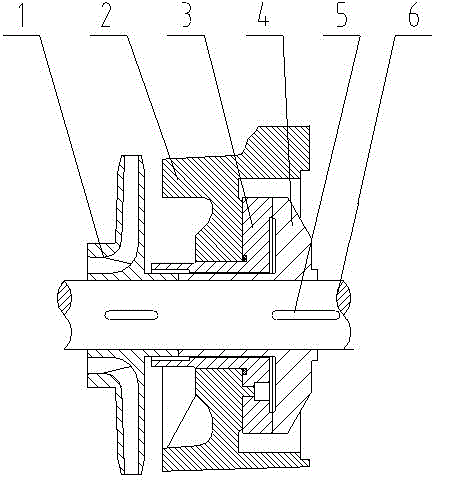

Leakage-free hydraulic buffering vacuum breaker valve

PendingCN110056690AGuaranteed sealing performanceExtended service lifeEqualizing valvesHydro energy generationHydraulic cylinderWater turbine

The invention provides a leakage-free hydraulic buffering vacuum breaker valve. According to the vacuum breaker valve, a hydraulic cylinder and the valve plate are arranged, wherein the hydraulic cylinder is installed on the valve plate and acts together with the valve plate, a sliding seal between the bottom of the hydraulic cylinder and a valve rod is located inside a hydraulic buffering cavity,so that complete sealing in the hydraulic cylinder is guaranteed, hydraulic buffer oil is in a completely sealed state, sealing abrasion leakage is avoided, and the service life of the vacuum breakervalve is prolonged; moreover, a throttling valve is arranged, the buffering effect of the valve plate in the closing position is improved, noise generated through collision of the valve plate and a valve seat is reduced, a supporting sleeve plays a role in supporting the hydraulic cylinder, and further balances radial force of opening and closing of the valve plate so as to prolong the fatigue life of the vacuum breaker valve, meanwhile, a spring is arranged, so that axial force is balanced; and in addition, the vacuum breaker valve is simple in structure, reasonable in design, safe and reliable, and potential safety hazards during operation of a water turbine are effectively reduced.

Owner:秦皇岛森润滋科技有限公司

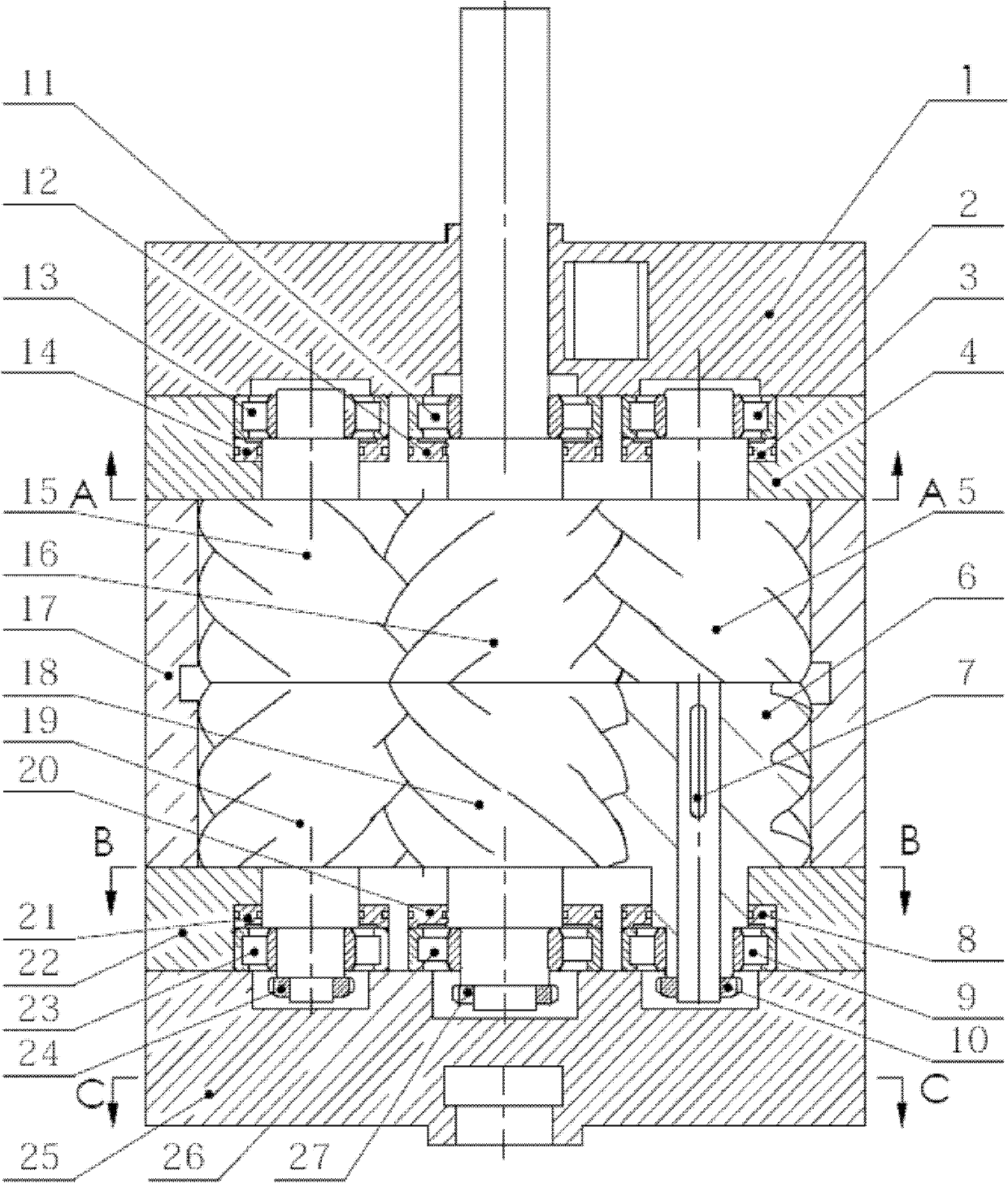

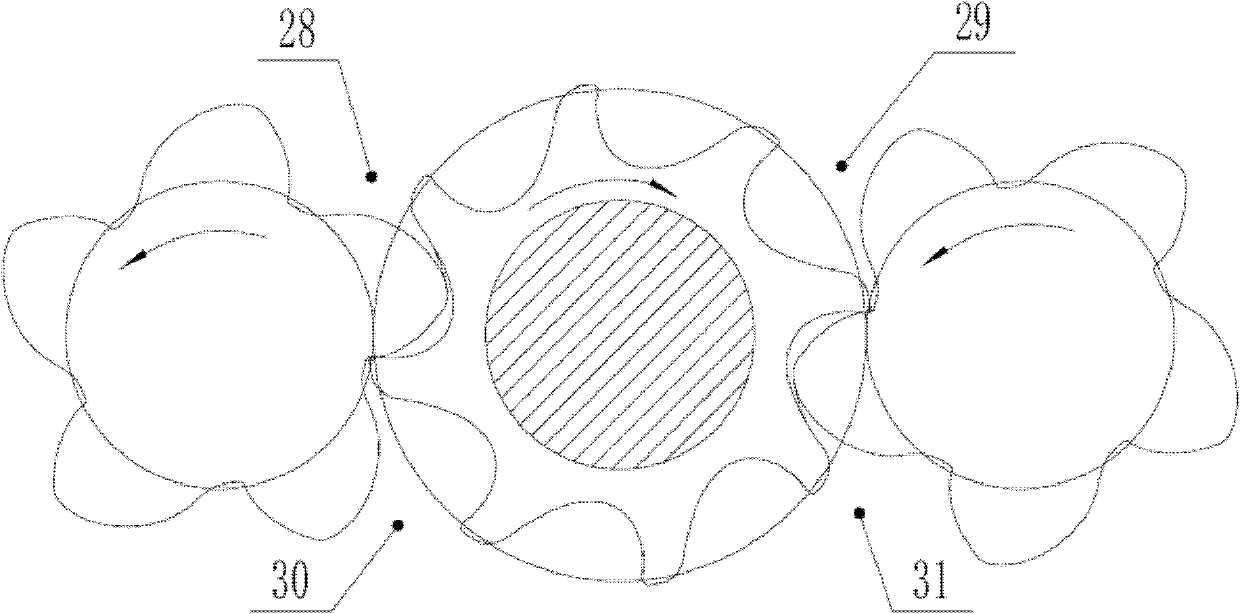

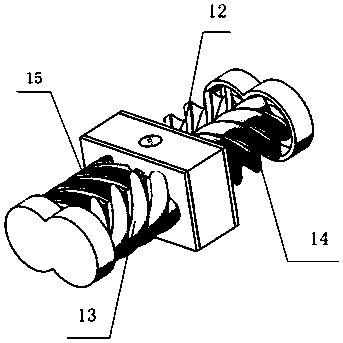

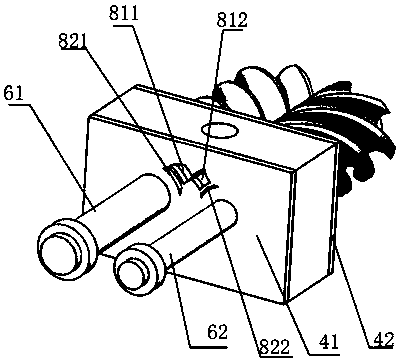

Symmetrical series tri-rotor screw compressor

InactiveCN101793251ABalance axial forceReduce wearRotary piston pumpsRotary piston liquid enginesRolling-element bearingFriction loss

The invention relates to a symmetrical series tri-rotor screw compressor. The screw compressor comprises a compressor engine body used for limiting three parallel rotors, an active rotor, a driven rotor, exhaust bearing seats separately arranged on the front and back ends of the engine body, an oil thrower, a rolling bearing and an exhaust end cap, wherein the three rotors are arranged symmetrically in series. The invention is characterized in that the screw compressor has a plurality of meshing areas, larger air displacement and excellent force characteristics, the radial force and torsion of a middle female rotor cancel each other and the axial forces of the three rotors are completely balanced in the work process. Therefore, the power performance of the compressor can be greatly improved, the mechanical friction loss can be reduced, the viscous friction loss in the fuel injection compressor can be lowered, and the operation efficiency and reliability of machines can be increased.

Owner:XI AN JIAOTONG UNIV

High-pressure tangent pump

The invention discloses a high-pressure tangent pump, which comprises a pump body, guide vanes, an impeller, an angular contact ball bearing, a shaft and a throat bush. The pump body is connected with a pump cover. The pump cover is connected with a bearing bracket. The guide vanes are fixedly installed on the pump cover. The impeller is arranged between the guide vanes and the pump cover and is fixedly installed on the shaft. An adjusting sleeve is installed on one side of the impeller. The throat bush is fixedly installed on the pump cover through screws I. A deep groove ball bearing is installed on the shaft. The angular contact ball bearing is installed on the shaft through a round nut and a bearing cover. Bearing protectors are installed on one side of the bearing cover and the bearing bracket. The hydraulic model of the pump body and the impeller are designed by adopting a partial flow pump theory; the designed impeller blades effectively balance axial force and the service life of the bearing is prolonged; and the high-pressure tangent pump is suitable for working conditions of small flow and high lift, the operation stability is high, the efficiency is high and the energy is saved.

Owner:DANAI PUMPS

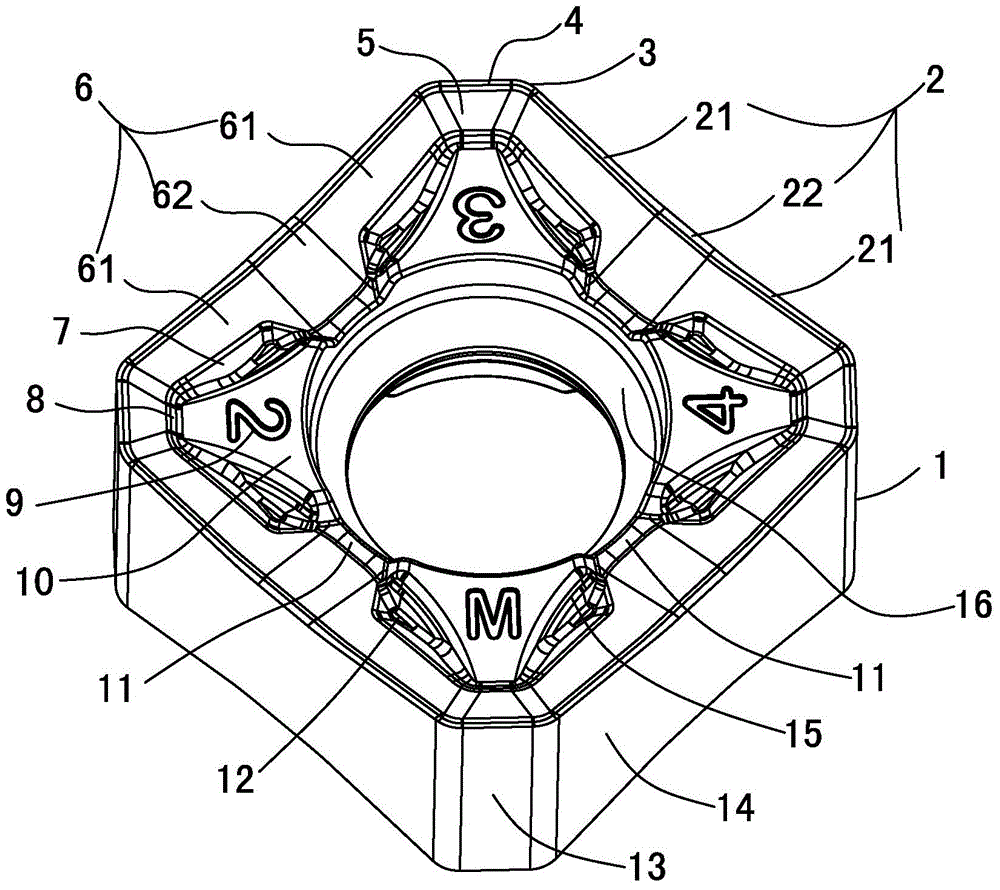

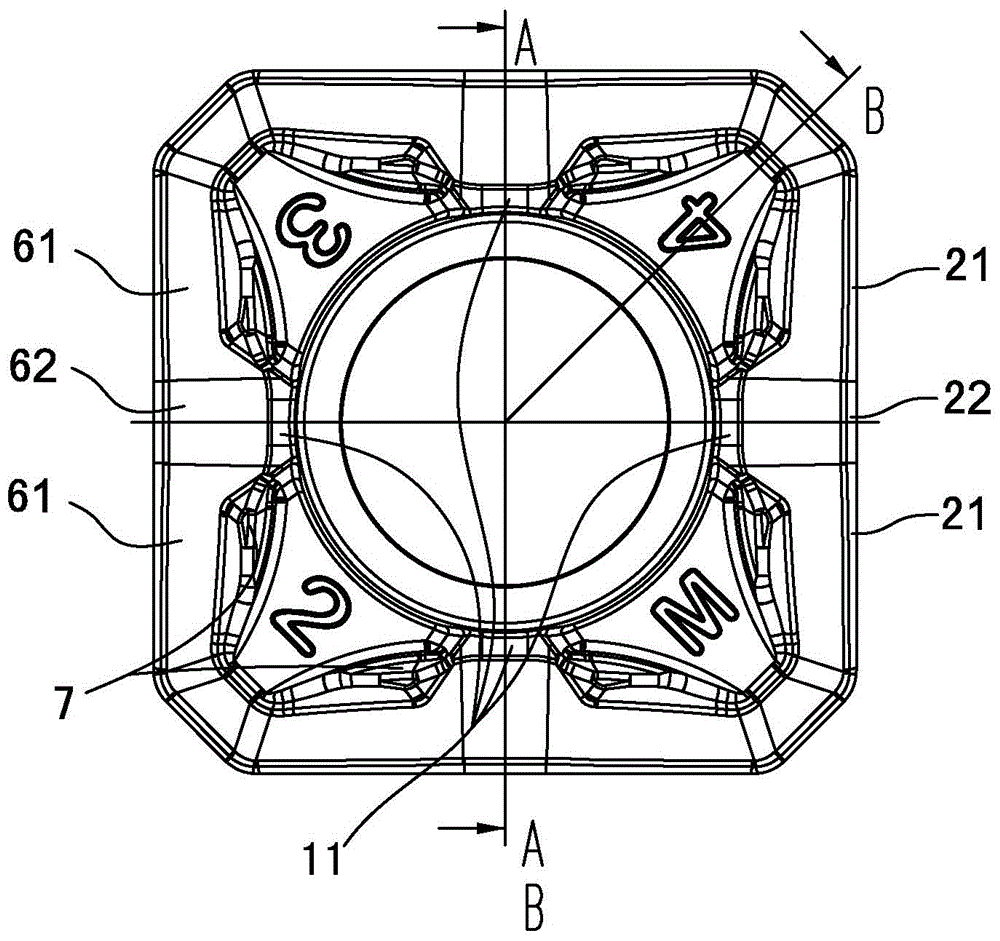

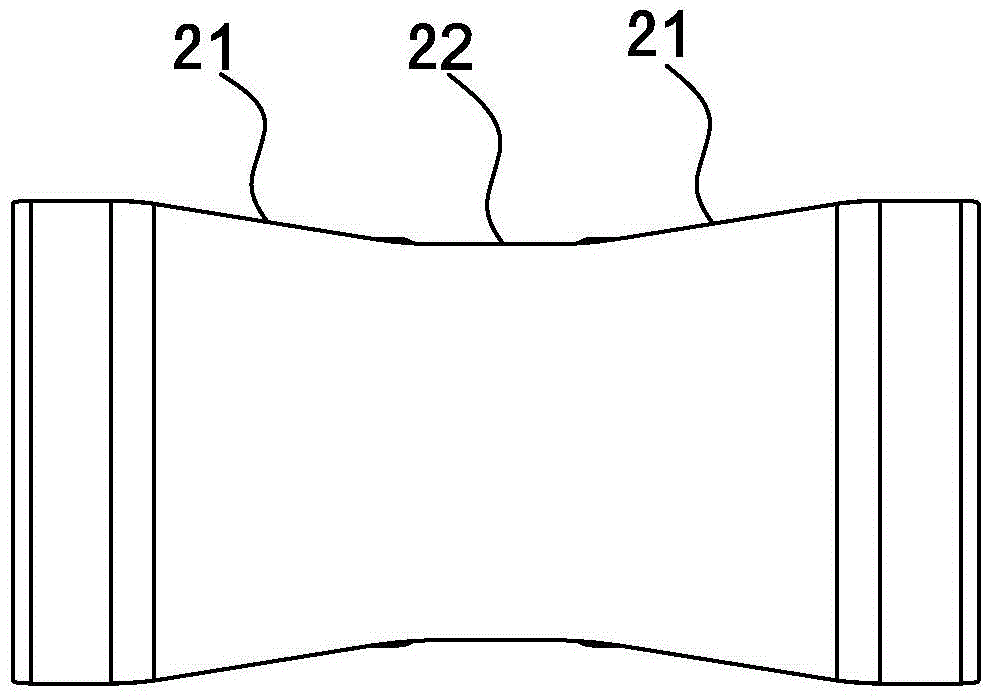

Negative-type milling blade

ActiveCN104439461AAvoid rough cuttingImprove economyTransportation and packagingMilling cuttersBearing surfaceSwarf

The invention discloses a negative-type milling blade comprising a blade body, wherein the blade body has an upper surface, a lower surface and a quadrangular peripheral surface and is also provided with a through hole and bosses around the through hole, and a main cutting edge and a smoothing edge are alternately arranged on the peripheral surface in sequence; the main cutting edge has a concave structure and gradually tilts close to opposite surfaces of the upper and lower surfaces from two ends respectively, and a non-tilting smooth middle part of the main cutting edge is formed at a position which is 1 / 6-1 / 3 of the length of the edge on the main cutting edge; and the front tool face of the non-tilting smooth middle part of the main cutting edge of the negative-type blade body is connected to the through hole perpendicular to the upper and lower surfaces by extending at a positive angle gently, and an open scrap accommodating groove leading to the through hole is formed at the bosses. According to the negative-type milling blade disclosed by the invention, by designing of the concave structure of the main cutting edge of the cutting blade and combining the design of a special opening structure groove at a bearing surface chip breaker groove of the blade, cutting force distribution and cutting flowing can be optimized, processing of self breaking scraps can be performed, and the processability and stability of a cutter are improved.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY

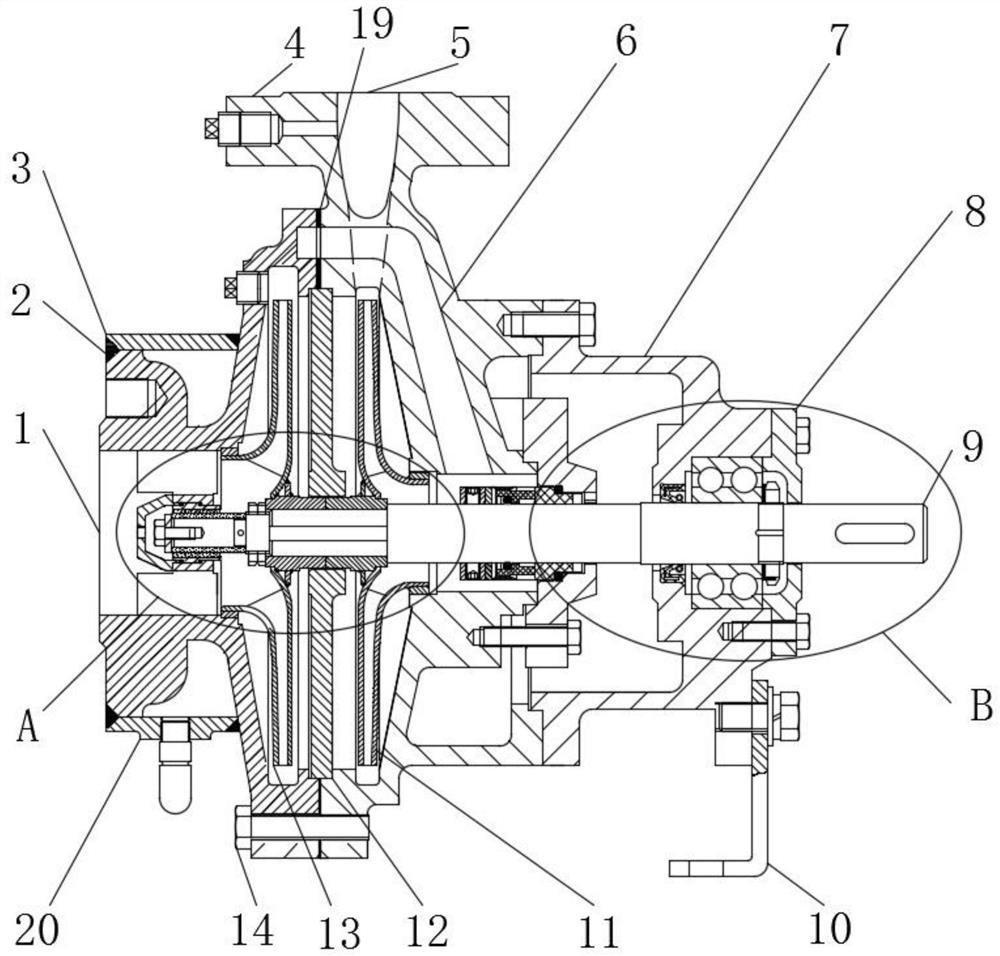

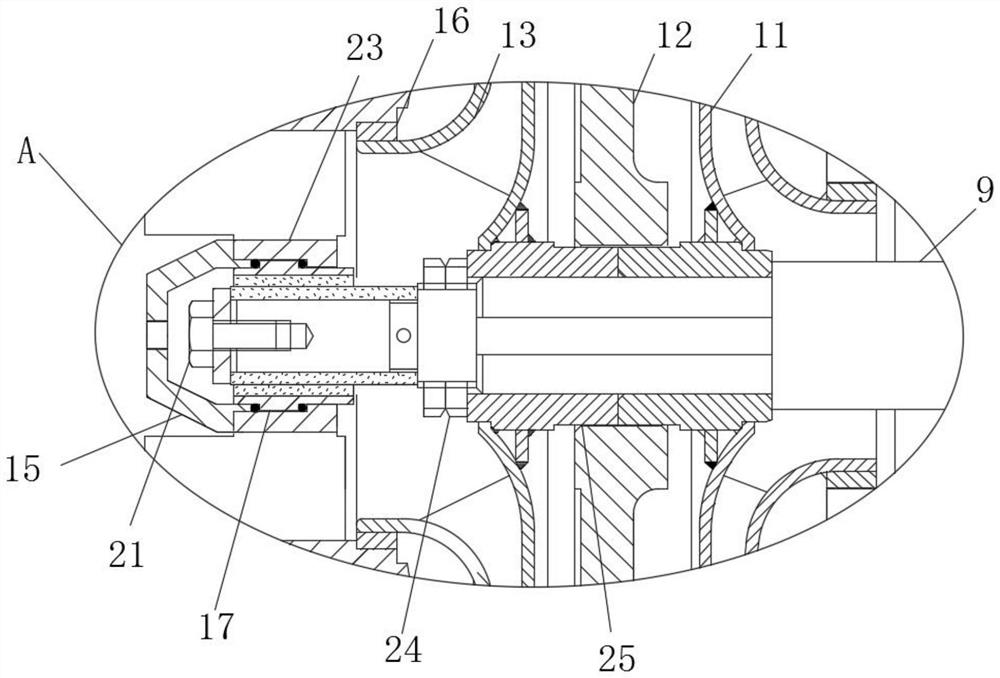

Impeller built-in type high-speed centrifugal pump

ActiveCN112460031ABalance axial forceOptimize layoutSpecific fluid pumpsPump componentsElectric machineEngineering

The invention provides an impeller built-in type high-speed centrifugal pump which comprises a shell and a rotating wheel. The rotating wheel is rotatably mounted in the shell. The impeller built-in type high-speed centrifugal pump is characterized in that the impeller built-in type high-speed centrifugal pump further comprises a motor stator and a motor rotor, the motor stator is mounted on the shell, the motor rotor is fixedly connected with the rotating wheel, the rotating wheel comprises an inducer and a centrifugal impeller, an outer ring is arranged on the edge of the outer side of the inducer, and the outer ring of the inducer is fixedly connected with the inner circle of the motor rotor; the motor stator is electrified, so that the motor rotor rotates; the centrifugal impeller andthe inducer rotate synchronously; and the rotating speed of the rotating wheel is not lower than 2800 r / min. The problem that the water outlet direction of a traditional centrifugal pump is perpendicular to the rotation axis of the pump is solved, meanwhile, the structural size of the traditional centrifugal pump is reduced, the axial force of the rotor is reduced, and the requirements of high-speed navigation devices such as torpedoes for high lift, large flow, stable operation and compact structures of water jet propulsion pumps can be met.

Owner:JIANGSU UNIV

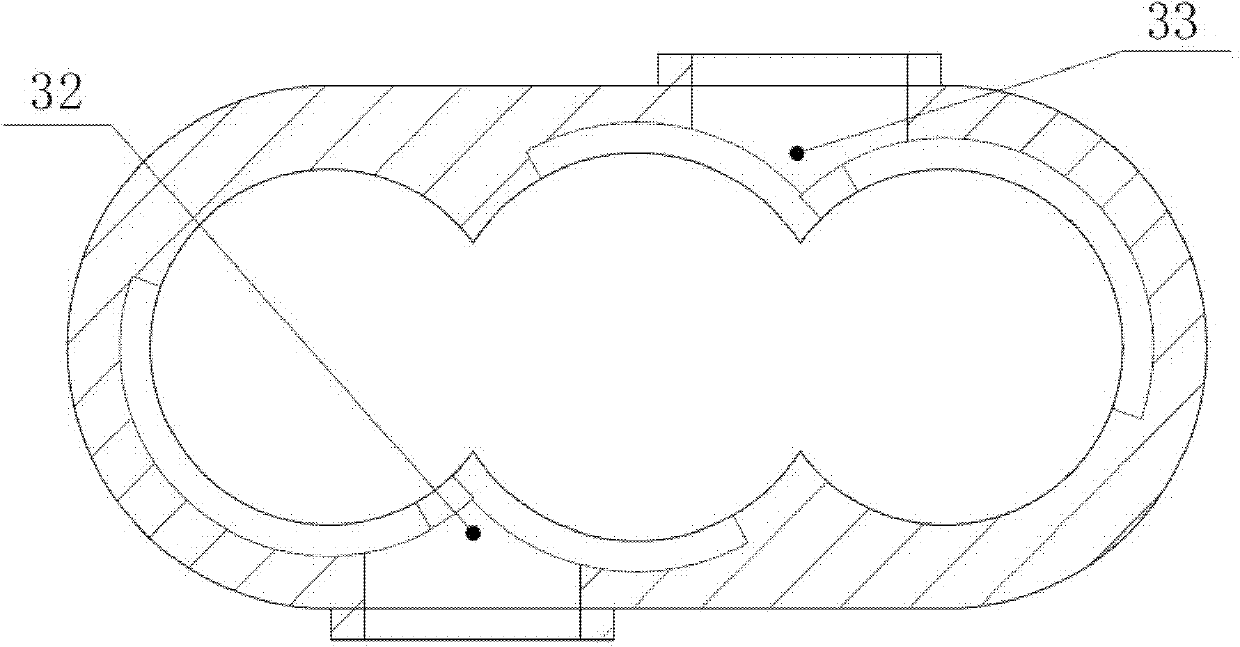

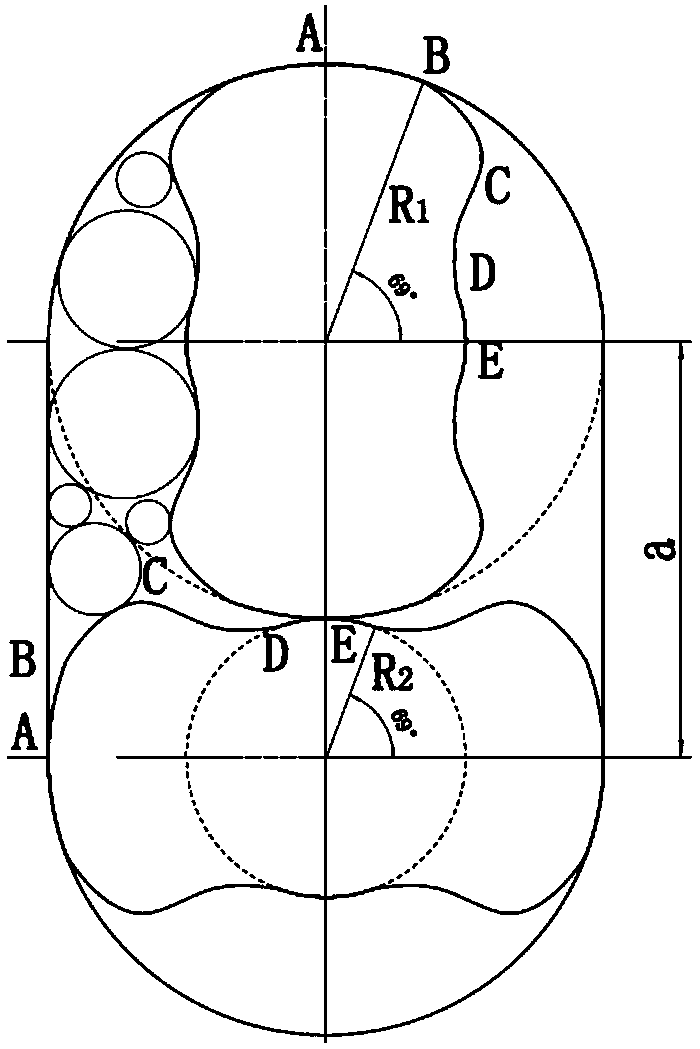

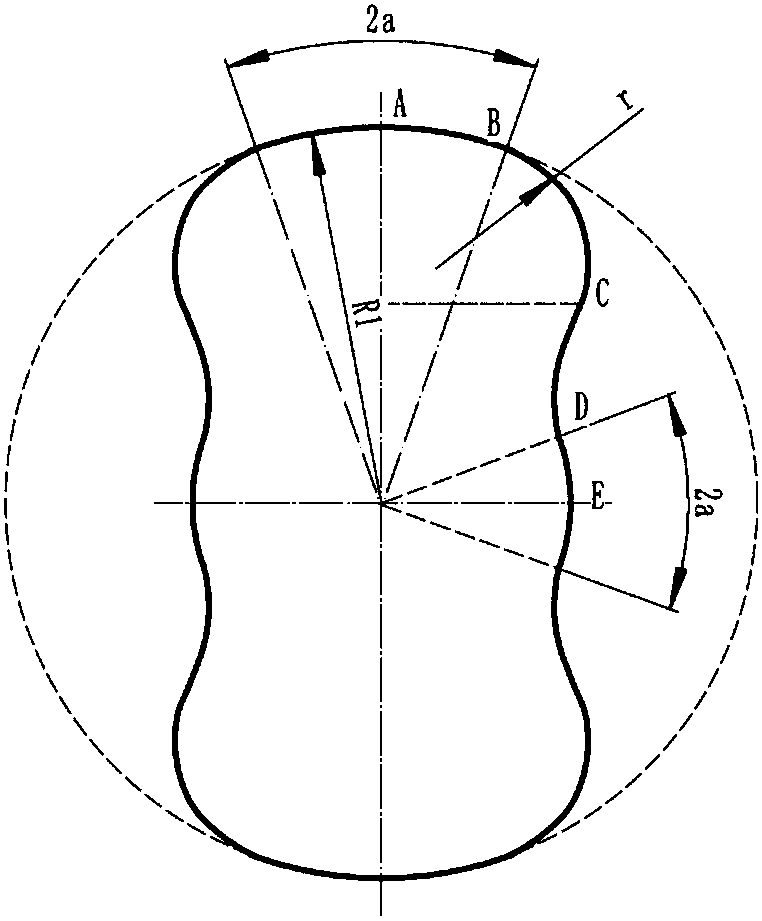

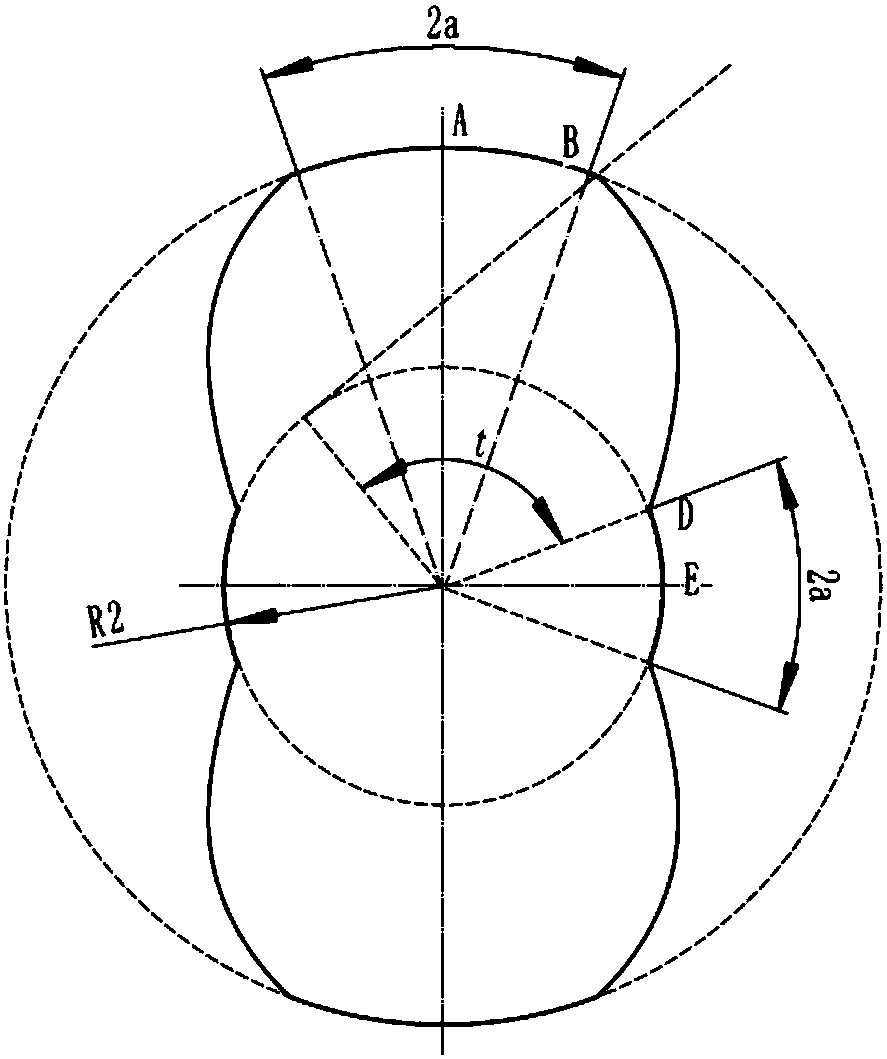

Wide head rotor of high vacuum displacement pump

ActiveCN107061271AWide working pressure rangeIncrease the shaft diameterPump componentsRotary piston pumpsMetal frameworkEngineering

The invention discloses a wide head rotor of a high vacuum displacement pump. In an existing cam pump technology, seal between a pump body and a rotor is linear pump, and therefore, vacuum capacity is easily caused to drop after the rotor and the pump body are worn. The end surface of the wide head rotor of the high vacuum displacement pump is of an axisymmetric structure, and a 1 / 4 molded line of the end surface consists of three parts: a top end wide head circular arc AB, a transition curve BD and an intermediate circular arc DE, and the rotor is formed by wrapping a metal framework and rubber; and the top end wide head circular arc AB and the intermediate circular arc DE of the wide head rotor are two conjugate curves. The wide head rotor effectively increases a working pressure range of the high vacuum displacement pump, ensures lasting stability of conveying pressure, reduces pulsation and improves working efficiency.

Owner:HANGZHOU DIANZI UNIV

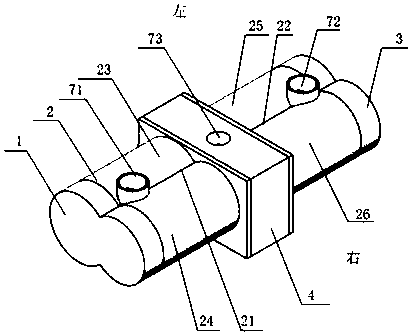

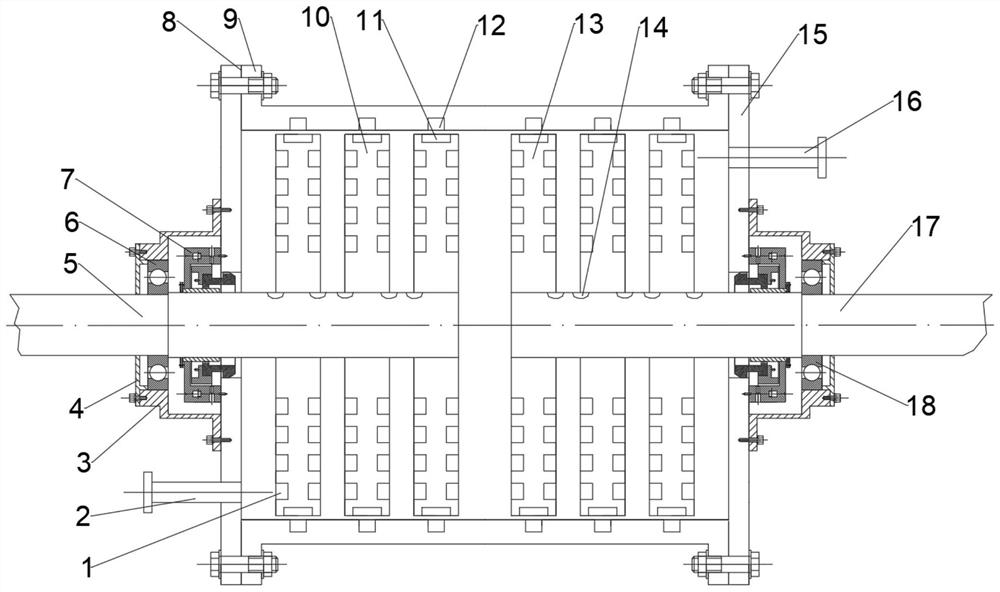

Axial force self-balance type four-screw mechanical device with gas thrust bearings

ActiveCN110206729ASimple structureRealize two-way thrustEngine of intermeshing engagement typeRotary piston pumpsFriction lossThrust bearing

The invention discloses an axial force self-balance type four-screw mechanical device with gas thrust bearings. The mechanical device adopts four screws which are symmetrically arranged and have opposite thread turning directions, the screws in the same housing are engaged with each other by pairs, and the thread turning directions of the screws on the same shaft but different housings are opposite, so that in the normal running process of the mechanical device, axial force on two rotors is basically countered, and the self-balance of the axial force is realized; and two symmetrical thrust bearings are arranged on each shaft, so that remaining axial force on each shaft can be bore by the two symmetrical thrust bearings, small absolute value axial force which cannot be fully self-balanced can be bore, the bi-directional thrust of an exhaust-end bearing of the four-screw mechanical device is realized, and friction losses can be effectively reduced. The gas thrust bearings and the four-screw mechanical device are combined together, the axial force is effectively balanced, the working efficiency is increased, and at the same time, the working stability of a compressor or an expander isimproved.

Owner:XI AN JIAOTONG UNIV

Radial flow type rotating mechanical impeller

InactiveCN109083864AThickenIncrease peripheral speedPump componentsBlade accessoriesImpellerEngineering

The invention discloses a radial flow type rotating mechanical impeller. The radial flow type rotating mechanical impeller comprises an impeller body, and a plurality of main blades and a plurality ofedge blades are arranged on the back surface of the impeller body. The main blades are uniformly distributed on the back surface of the impeller body in the peripheral direction of the impeller body,and the main blades are arranged in a protruding mode. The edge blades are uniformly arranged between the inlet sections of the adjacent main blades in the peripheral direction, and the edge blades are arranged in a protruding mode. According to the radial flow type rotating mechanical impeller, the blade consistency in an area with a larger radius on the back portion of the impeller body is significantly increased, meanwhile, the increase of the blade consistency of an area with a smaller radius is avoided, so that the circumferential velocity increases rapidly after leakage fluid enters a back clearance of the impeller body, the circumferential velocity of the leakage fluid further increases with the decrease of the radius under the drive of the blades on the back portion of the impeller body, the pressure is reduced at the same time, the reduction of fluid pressure in the area with the larger radius facilitates the reduction of the axial force on the back portion of the impeller body, and the axial force of the impeller body is balanced.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Unpressurized LNG (Liquefied Natural Gas) immersed pump

ActiveCN105090058ACompact structureReduce weightPump componentsPump installationsDrive shaftDrive motor

The invention relates to an unpressurized LNG (Liquefied Natural Gas) immersed pump. The unpressurized LNG immersed pump comprises a shell, wherein a first cavity and a second cavity are formed in the shell; a pump main body is arranged in the first cavity; a drive motor is arranged in the second cavity; a liquid inlet and a liquid outlet are formed in the shell; the second cavity is located above the first cavity; the drive shaft of the drive motor is arranged to be coaxial with the pump axle shaft; the outer side of the rotor and stator of the drive motor is provided with an isolating membrane which separates the rotor and stator from the second cavity; and a liquid outlet passage which communicates the first cavity and the liquid outlet is formed between the isolating membrane and the shell. A rotating shaft sealing device of a traditional centrifugal pump is omitted; zero leakage can be realized; the sealing reliability is high; besides, the structure is compact; the weight is light; the size is small, so that the unpressurized LNG immersed pump is suitable for being mounted on vehicles; a bearing is immersed in a medium, so that the bearing is greased by fully utilizing the medium; and outlet liquid is utilized for cooling the motor and the bearing, and taking heat away, so that the service life of the pump and the motor is greatly prolonged.

Owner:HUZHOU SANJING CRYOGENIC EQUIP

Antibiotic wastewater deep degradation device based on hydrodynamic cavitation

InactiveCN111807497AAchieve degradationBalance axial forceWater treatment compoundsWater contaminantsEnvironmental engineeringOrganic matter

The invention provides an antibiotic wastewater deep degradation device based on hydrodynamic cavitation. The device comprises a stator and rotors, the stator is a hollow sealed cylinder, and rotatingshafts are installed at the two ends of the interior of the stator; a plurality of rotors are mounted on each rotating shaft and are of wheel disc structures; the two rotating shafts rotate oppositely in opposite directions; blind holes are distributed in the end surface of the rotors and the inner wall of the stator; cavitation grooves are formed in the circumferential direction of the rotors; amicro gap formed by the blind holes, the cavitation grooves, the rotor wall surface and the stator wall surface forms a current limiting structure so that a current limiting effect is achieved, and the cavitation phenomenon is enhanced; one end of the stator is provided with a feeding pipe, and the other end is provided with a discharging pipe. The two rotors rotate at a relatively high speed sothat cavitation holes in the rotors move relative to the antibiotic wastewater, and the cavitation phenomenon is caused. The method adopts hydrodynamic cavitation to degrade organic matters in the antibiotic wastewater, has the advantages of high efficiency, good magnification, large treatment capacity, continuous operation, low cost and no secondary pollution, and has wide application prospects in the field of wastewater degradation.

Owner:SHANDONG UNIV

High-efficiency constant-pressure tangent fire pump

InactiveCN103511346ARelieve stressMeet the development requirements of high efficiency and energy savingPump componentsPumpsImpellerSemi open

The invention relates to a high-efficiency constant-pressure tangent fire pump. The high-efficiency constant-pressure tangent fire pump comprises a pump body, a pump cover, an impeller, a water suction chamber, a pumping chamber and a diffusion pipe. The high-efficiency constant-pressure tangent fire pump is characterized in that the pumping chamber of the pump body is of a spiral pumping structure, and the spiral pumping chamber is provided with a separation tongue; the impeller is a rear-cover-plate semi-open type impeller with an impeller seal ring; the pump cover is provided with a seal ring. The high-efficiency constant-pressure tangent fire pump has the advantages that efficiency is obviously higher than that of a common constant-pressure fire pump, and the development requirement for high efficiency and energy saving is met; axial force is balanced effectively; mechanical seal bearing pressure is reduced; when the high-efficiency constant-pressure tangent fire pump is made into a vertical structure, a pump inlet and a pump outlet can be deigned to be on the same straight line, and therefore a pump set can be installed on a pipeline like valves.

Owner:SHANGHAI LIANCHENG(GRP) CO LTD

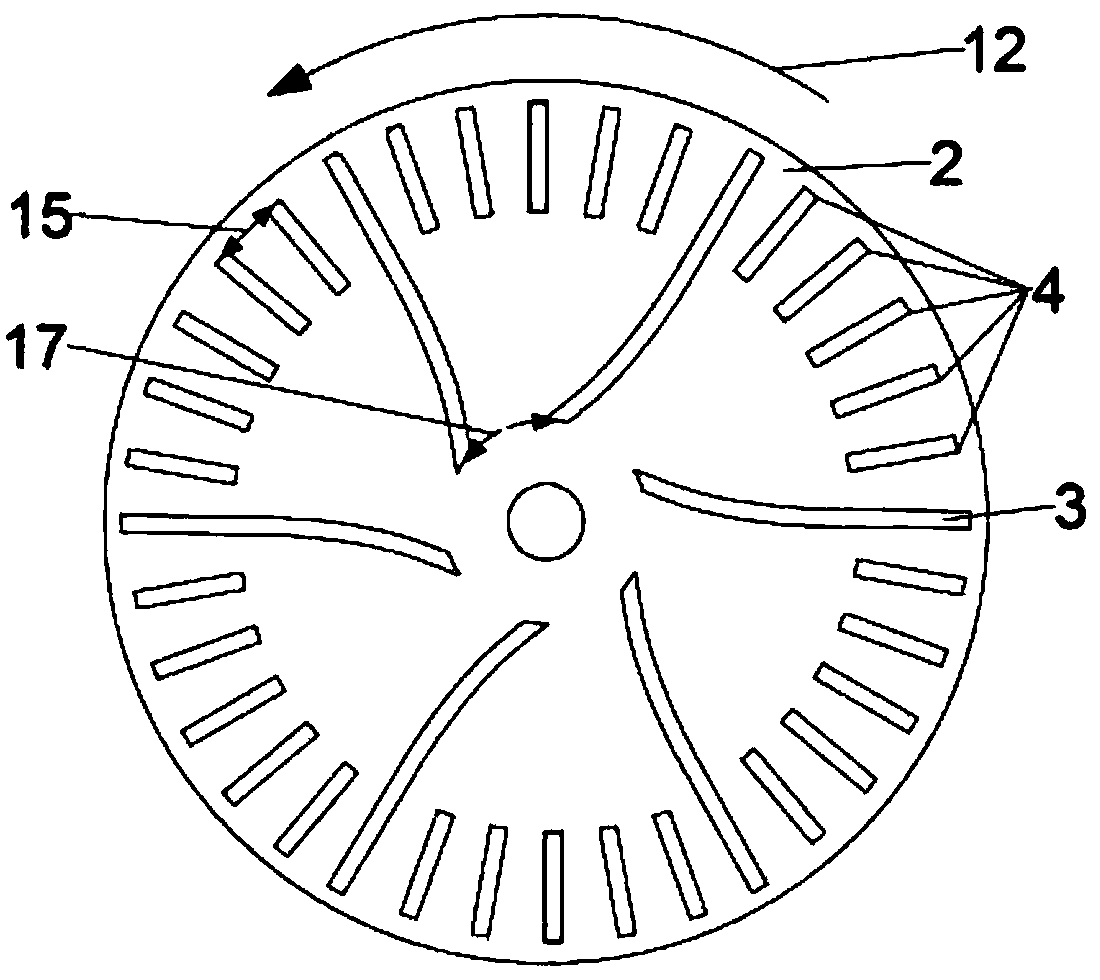

Open impeller structure for high-speed pump

The invention relates to the engineering machinery, and aims to provide an improvement of an open impeller structure. An impeller should have the characteristics of weakening or eliminating a hump curve, balancing the axial force, reducing an extrusion phenomenon, reducing an inlet flow rate and reducing the hydraulic loss of a pump. According to the technical scheme, the open impeller structure for the high-speed pump comprises a hub, a plurality of blade bearing plates which are connected with the hub into a whole and are arranged in a radial mode with the axis of the hub as the center and aplurality of blades which are arranged on the blade bearing plates in a one-to-one correspondence manner, and is characterized in that each blade bearing plate is composed of an inclined section which is close to the hub and is inclined to the axis of the hub and a straight line section perpendicular to the axis of the hub; one part of each blade penetrates through and is embedded in a preset through groove at the inclined section of the blade bearing plate, part of each blade is exposed out of the back face of the impeller to form an auxiliary blade, and the other part of each blade serves as a front blade to be fixed to the front face of the straight-line section of the blade bearing plate and is perpendicular to the plane of the straight-line section.

Owner:ZHEJIANG SCI-TECH UNIV +1

Novel horizontal cantilever energy-saving two-stage pump

PendingCN111664095AStable supportPrevent water leakagePump componentsRadial flow pumpsImpellerBall bearing

The invention discloses a novel horizontal cantilever energy-saving two-stage pump. The novel horizontal cantilever energy-saving two-stage pump comprises a water inlet, a heat preservation jacket, awater inlet flange, a pump body, a rotor, a support leg and a first impeller. The two-stage pump adopts a horizontal cantilever structure; the water inlet flange is arranged at one end of the two-stage pump; the heat preservation jacket is arranged on the flange face of the water inlet flange; the water inlet is formed in the water inlet flange; the water inlet flange is connected with the pump body; the water inlet flange and the pump body are connected through a bolt; a sealing ring is arranged at the joint of the water inlet flange and the pump body; a water outlet is arranged at the upperend of the pump body; a water flow channel and an annular water pressing chamber are arranged in the pump body; a bearing support is arranged on the right side of the pump body; the pump body is connected with the bearing support through a bolt; a bearing gland is connected to the right side of the bearing support; a double-row centripetal ball bearing is arranged in the bearing gland; the rotor is arranged in the pump body; and the support leg is connected below the bearing gland. The two-stage pump runs stably and has good structural stability.

Owner:ANHUI LINE ELECTRIC PUMP

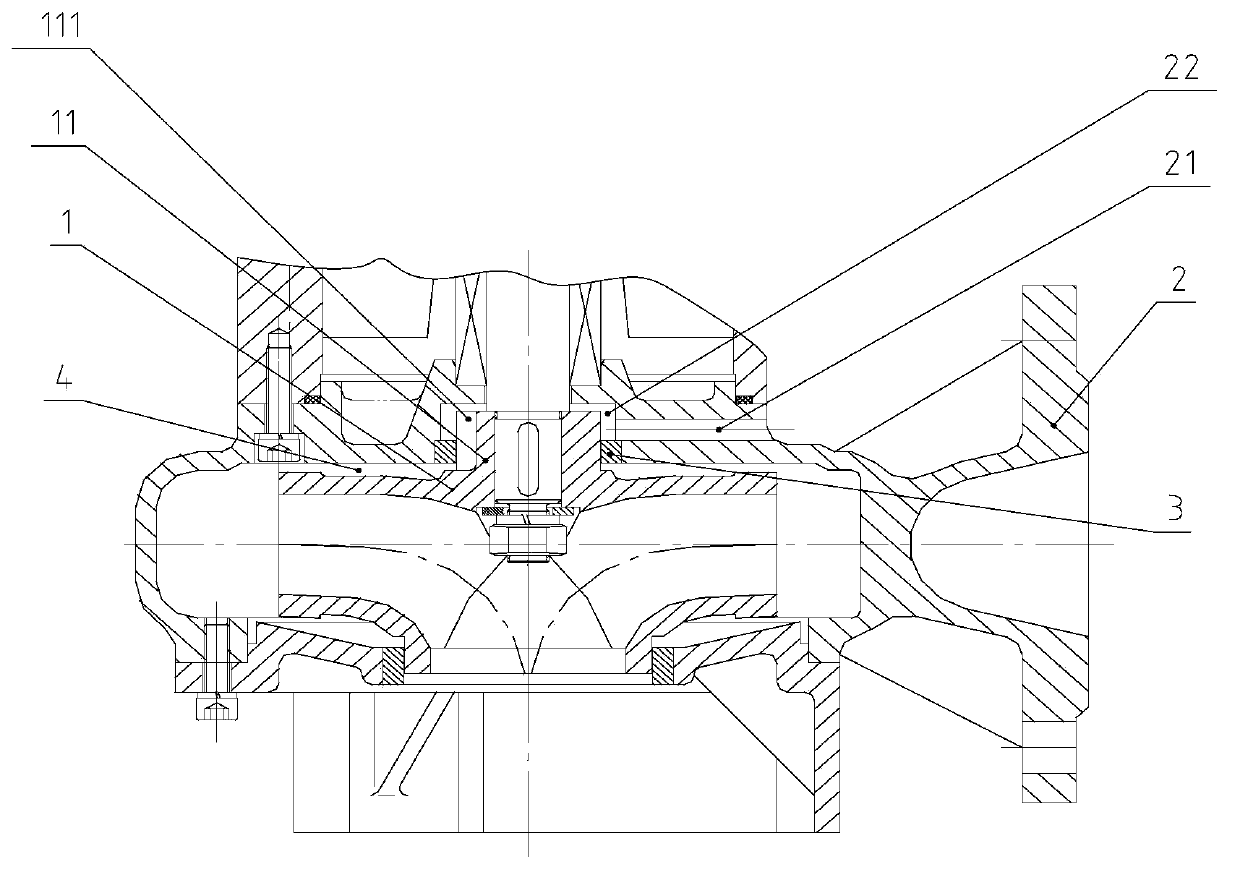

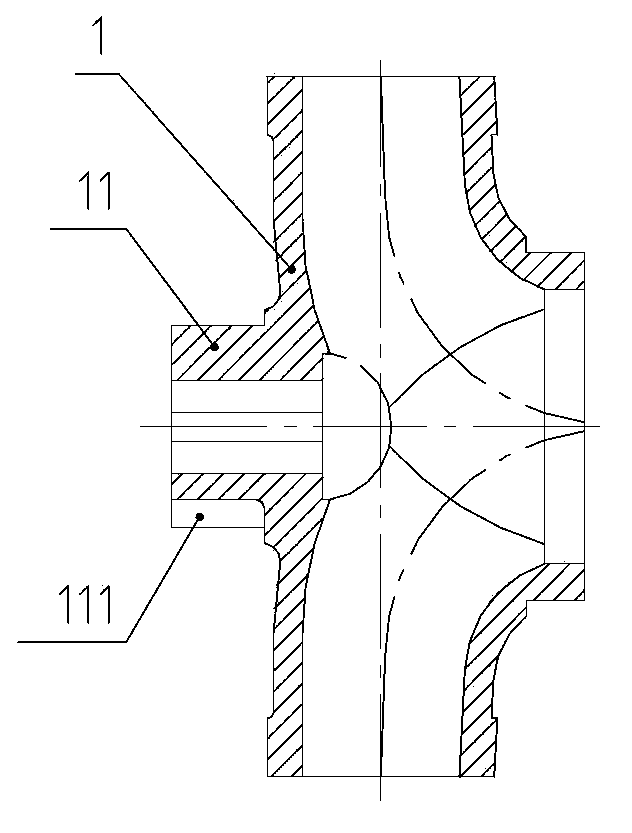

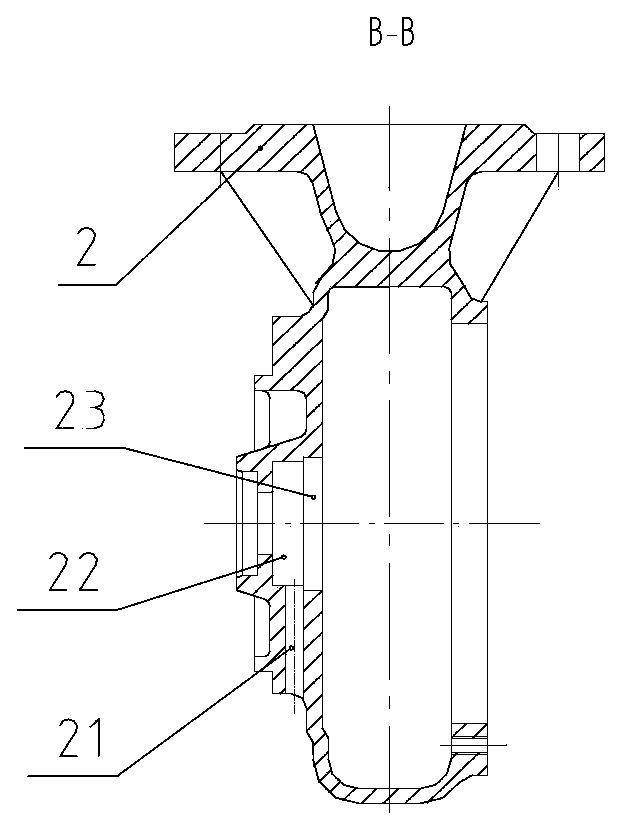

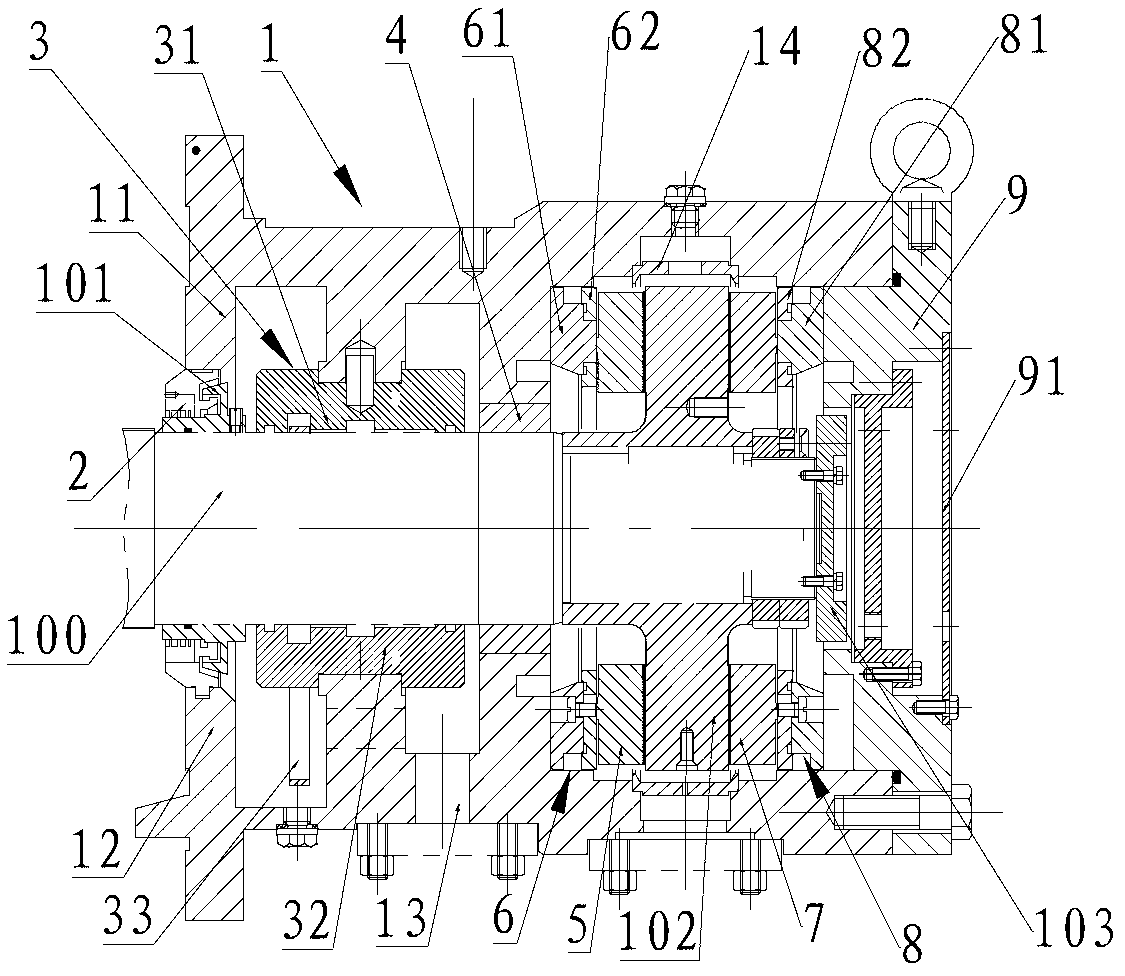

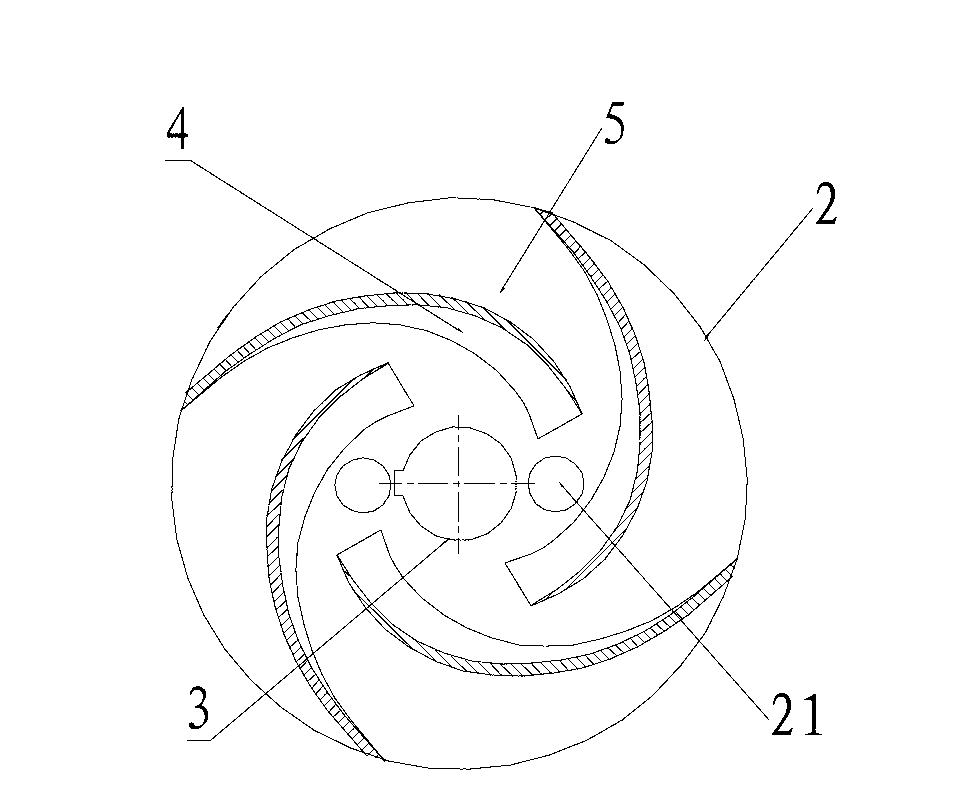

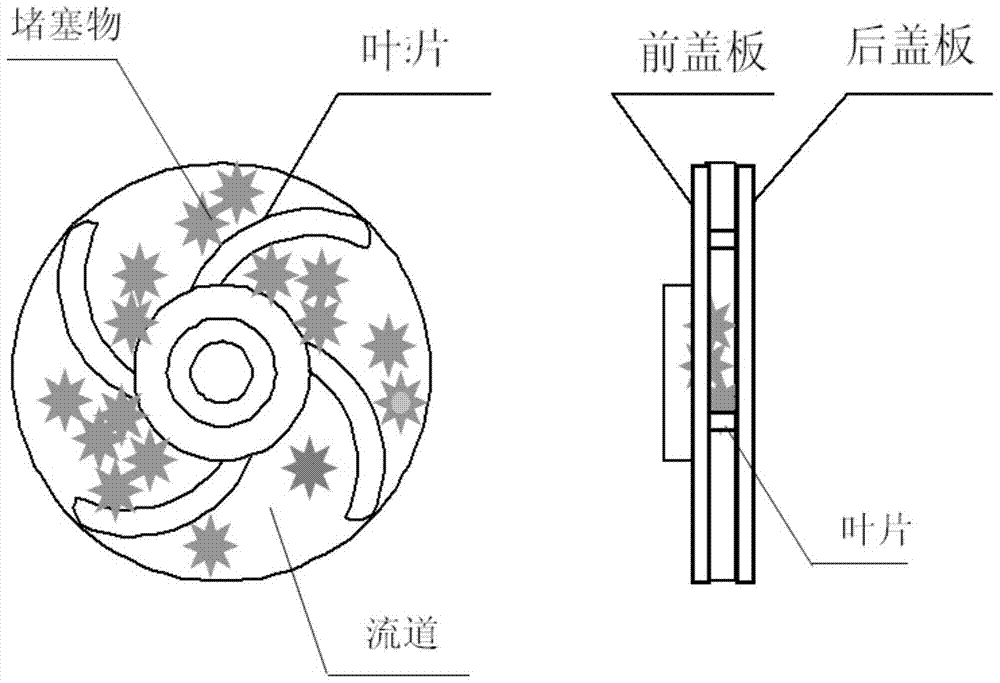

Detachable double-channel closed impeller

The invention discloses a detachable double-channel closed impeller. The detachable double-channel closed impeller is used for a double-channel closed centrifugal pump. The detachable double-channel closed impeller comprises a circular cover plate assembly 1 and an impeller body assembly 2 which are used for forming a double-channel cavity body of the impeller, wherein the impeller body assembly 2 comprises a cover plate part and a liquid inlet sleeve in front of the cover plate part; the circular cover plate assembly 1 is detachably embedded into the cover plate part of the impeller body assembly 2 to form a seamless double-channel cavity body of the closed impeller; a spiral channel in an axial direction and a spiral channel in a centrifugal direction are formed in the double-channel cavity body of the closed impeller; and the spiral channel in the axial direction is connected with the spiral channel in the centrifugal direction to form a spiral vertical channel. According to the detachable double-channel closed impeller disclosed by the invention, the purpose of rapid dredge for the double-channel closed impeller after being blocked can be achieved on the premise of guaranteeing the efficient running of the impeller, so that the blockage treatment time of the impeller is shortened to several minutes from several hours and even more than ten hours.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

Horizontal barrel pump

InactiveCN102852802AImprove reliabilityExtended service lifePump componentsRadial flow pumpsImpellerAxial force

The invention discloses a horizontal barrel pump which comprises a barrel body cover, a barrel body, a pump core, an outlet flange, an inlet flange, a bearing component I, a shaft, a balance tube and a bearing component II, wherein the pump core is sleeved on the shaft, and the barrel body is arranged outside the pump core; one end of the barrel body is provided with the barrel body cover, and the outlet flange and the inlet flange are arranged on the barrel body; one side of the shaft is provided with the bearing component I, while the other side of the shaft is provided with the bearing component II; and one end of the balance tube is connected with the barrel body cover, while the other end of the balance tube is connected with the barrel body. The horizontal barrel pump disclosed by the invention is applicable to a design structure of a high-temperature pump with high rotating speed and high reliability; and each impeller acts on a medium, so that the pressure of the medium rises level by level, and the highest pressure is achieved on the last level, therefore, the reliability and the service life of the shaft are improved and prolonged, most axial force can be balanced out, and the horizontal barrel pump is good in tightness.

Owner:DANAI PUMPS

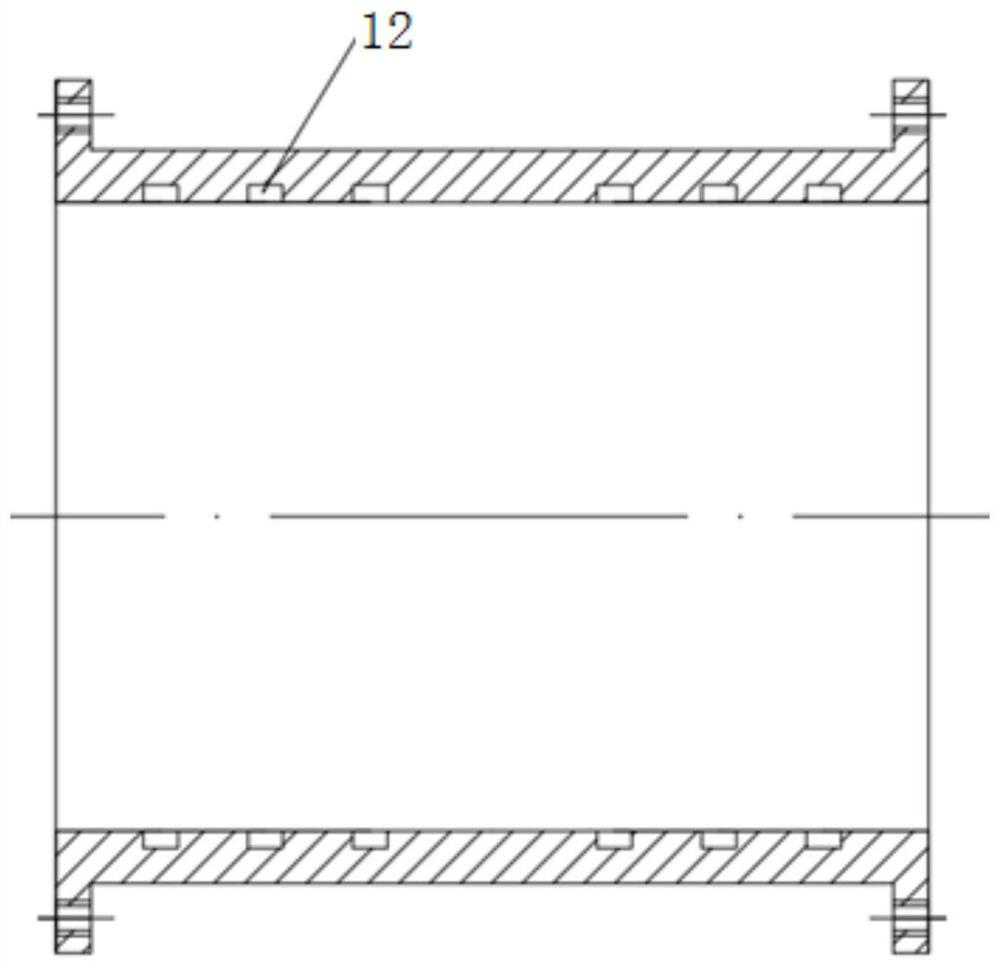

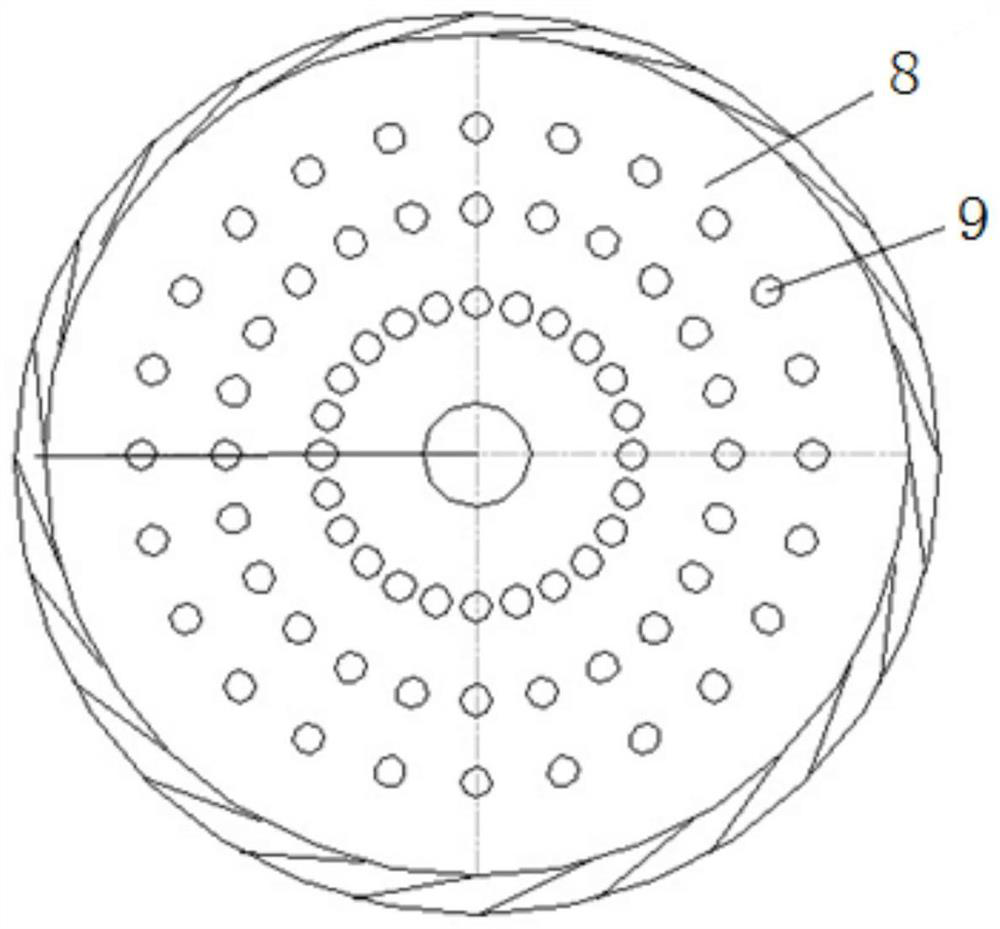

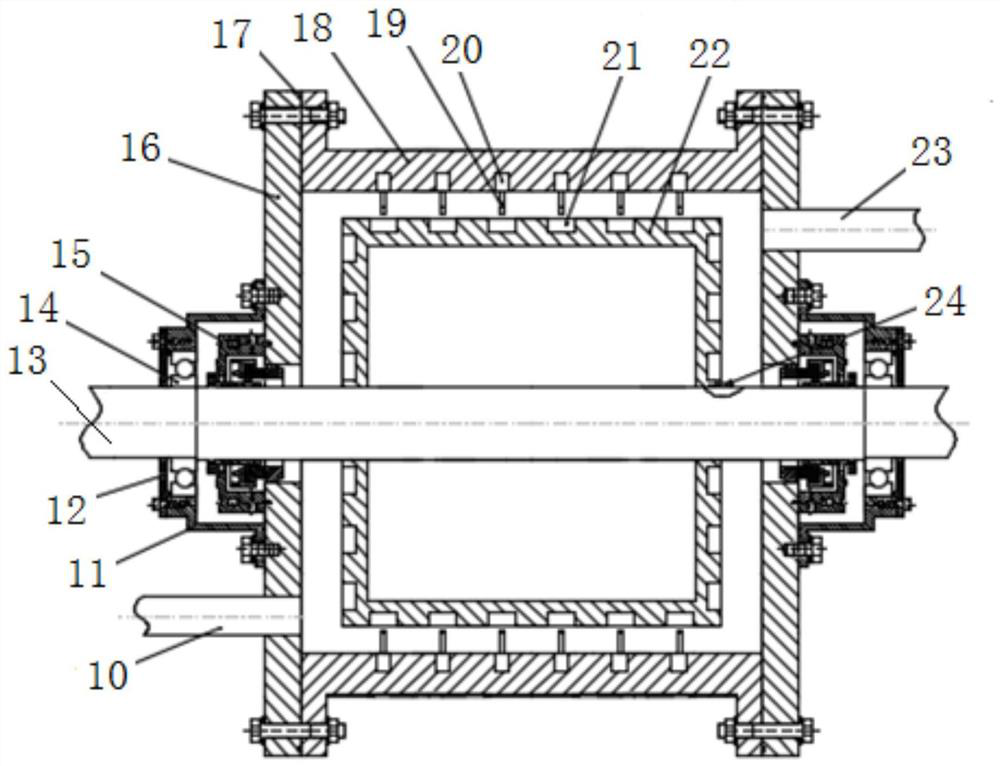

Cavitation device for strengthening refining production of cellulose pulp

ActiveCN112726256AHigh energyImprove the effectCellulosic pulp after-treatmentProcess engineeringStator

The invention discloses a cavitation device for strengthening refining production of cellulose pulp. The cavitation device comprises a stator, a rotating shaft, rotors and ultrasonic transducers, wherein the rotating shaft comprises a first rotating shaft body and a second rotating shaft body, the rotors are composed of a first set of rotors and a second set of rotors, the stator is a closed cylinder, a feeding port and a discharging port are formed in the two opposite sides of the stator respectively, the ultrasonic transducers are distributed on the inner wall of the stator, the first rotating shaft body and the second rotating shaft body are installed on the two opposite side faces of the stator respectively, the first set of rotors and the second set of rotors are arranged in the stator and installed on the first rotating shaft body and the second rotating shaft body respectively, each of the first set of rotors and the second set of rotors at least comprises two separated wheel discs; rotor cavitation holes are distributed in the outer peripheral surface of each wheel disc; and stator cavitation holes are distributed in the inner wall of the stator. According to the invention, the cavitation technology is applied to paper pulp refining, the advantages of being simple, high in efficiency, good in utilization rate and the like are achieved, physical stirring effect is achieved, and the refining process of paper pulp is accelerated through a cavitation reaction.

Owner:SHANDONG UNIV

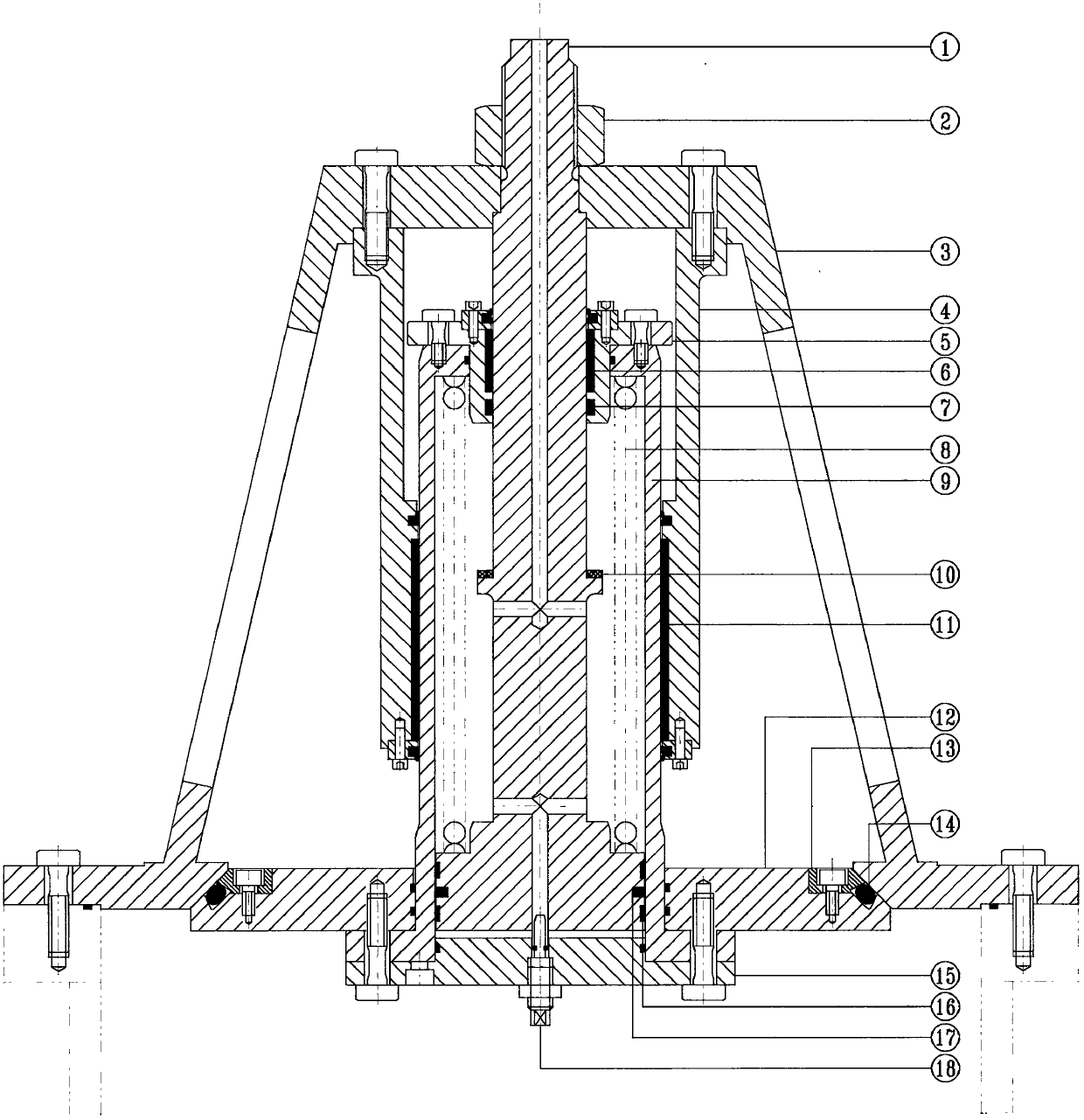

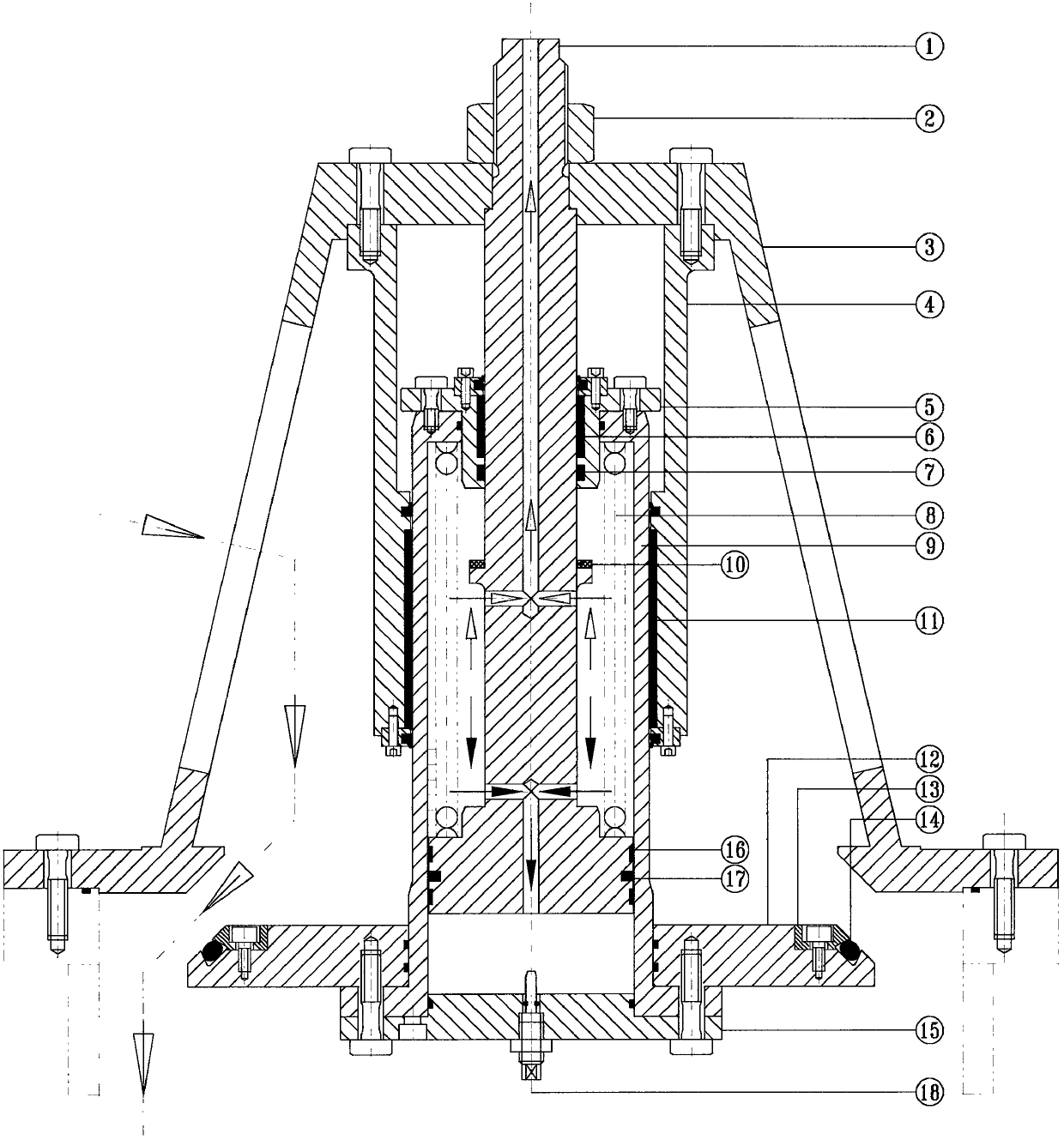

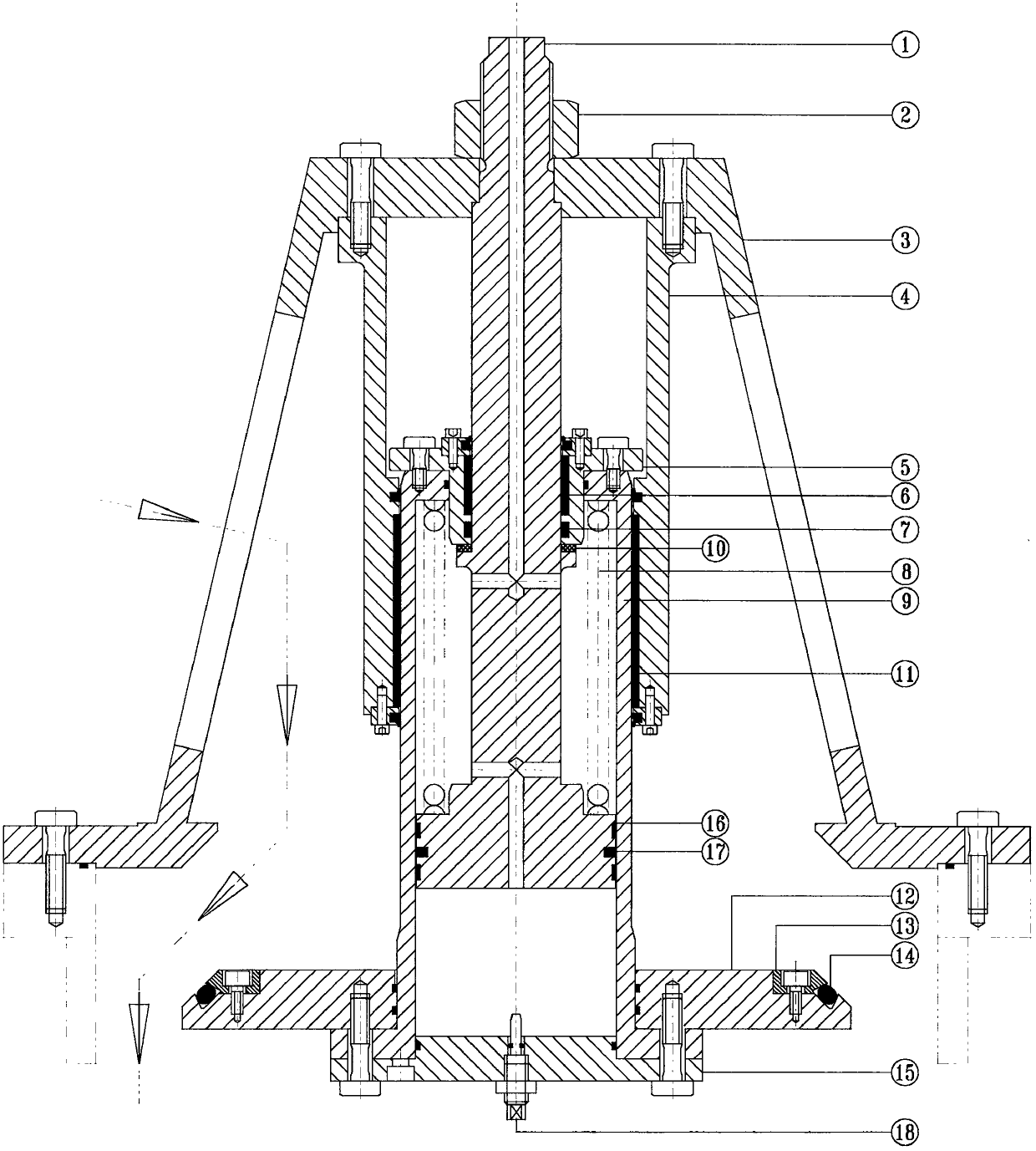

Axial force balancing device of multistage pump

The invention relates to the technical field of multistage pumps, in particular to an axial force balancing device of the multistage pump. The axial force balancing device of the multistage pump is provided with a pump body, a pump shaft, and impellers and is characterized in that a balance disc seat and a balance disc are sleeved on the pump shaft, the inner wall of the balance disc is fixedly connected with the pump shaft, the outer wall of the balance disc is connected with the balance disc seat in a movable mode, and one end of the balance disc is connected with impellers. Besides, the balance disc seat is fixedly connected with the back section of the pump body so as to enable a fluid gap to be formed between the balance disc and the balance disc seat. When fluid passes the fluid gap between the balance disc seat and the balance disc, due to the relative motion between the balance disc and the balance disc seat, a water ring is formed in the fluid gap so as to reach the effect of dynamic seal and cause fluid pressure drop, the pressure which is formed on an lower cavity of the balance disc is larger than pressure of an upper cavity, most axial force generated by impellers is balanced, and therefore the axial force balancing device of the multistage pump has the advantages that service life of the pump is prolonged, structure is reasonable, running is stable, the axial force is balanced, service life of a bearing is long, work time of the pump is prolonged and the like.

Owner:SHANDONG SHUANGLUN

Low-noise tourmaline ecological water purifying pump

InactiveCN1840918AImprove cell activityEnhance metabolic functionWater/sewage treatmentPump installationsClutchImpeller

The invention discloses a low-noise TimeLine economical water-purifying pump, which comprises the following parts: pump chassis, motor rack and cylinder between chassis and rack, wherein the motor and water-cooling device constitutes water-cooling motor, which is sealed by machine on the pump shaft, several adjacent blade components on the pump shaft and rotary component under the pump shaft; a layer of TimeLine is coated on the inner face of cylinder; the water-cooling motor connects the motor rack; two ends of clutch connect the motor shaft and pump shaft separately; the rod-crossing component integrates the motor with pump chassis.

Owner:上海山川泵业制造有限公司

Antibiotic wastewater degradation method and device based on combined action of electrolysis and cavitation

InactiveCN111807583APromote degradationImprove efficiencyWater treatment compoundsWater contaminantsUltrasonic cavitationElectrolysis

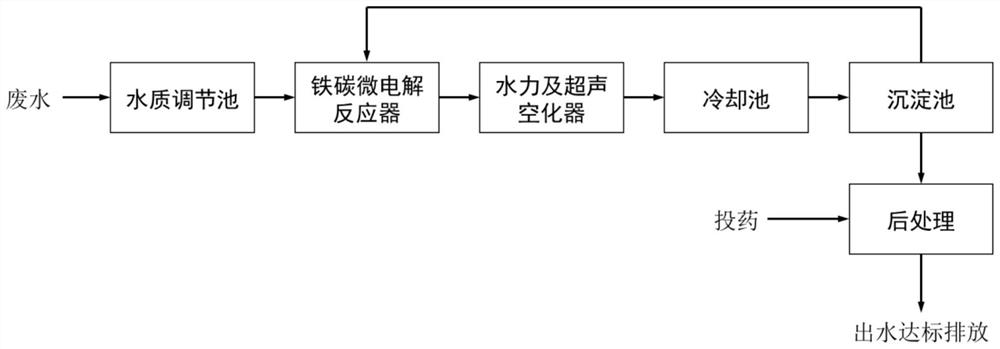

The invention discloses an antibiotic wastewater degradation method and device based on the combined action of electrolysis and cavitation. The method comprises the following steps: (1) wastewater homogenization treatment; (2) carrying out iron-carbon micro-electrolysis reaction, and carrying out catalytic pretreatment on the antibiotic wastewater; (3) carrying out hydraulic and ultrasonic cavitation degradation to degrade antibiotics; (4) cooling and precipitating; (5) post-treatment; the device comprises an iron-carbon micro-electrolysis reactor and a hydraulic and ultrasonic cavitator, wherein a water outlet of the iron-carbon micro-electrolysis reactor is connected with a wastewater inlet of the hydraulic and ultrasonic cavitator. According to the method, the antibiotic wastewater is degraded by utilizing a method of combining iron-carbon micro-electrolysis pretreatment and hydraulic power and ultrasonic cavitation; compared with a single method, a better degradation effect and higher degradation efficiency can be obtained, secondary pollution caused by adding chemicals is avoided, the whole degradation process of the antibiotic wastewater is simplified, the structure is simple, maintenance is convenient, the energy utilization rate is greatly increased, and industrialization is easy to achieve.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com