Cavitation device for strengthening refining production of cellulose pulp

A cellulose pulp and cavitation technology, which is applied in the post-treatment of cellulose pulp, fiber raw material treatment, papermaking, etc., can solve the problems of limitations and high energy consumption, and achieve improved efficiency, increased contact area, increased sharpness and friction force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

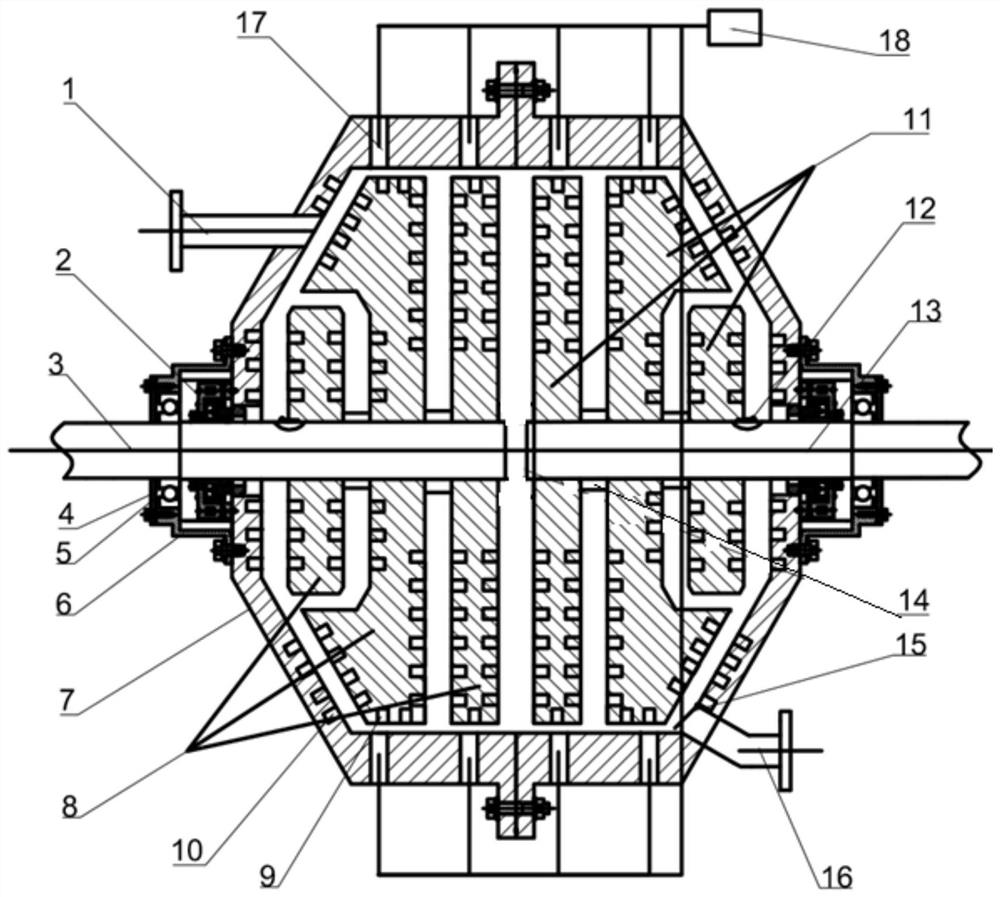

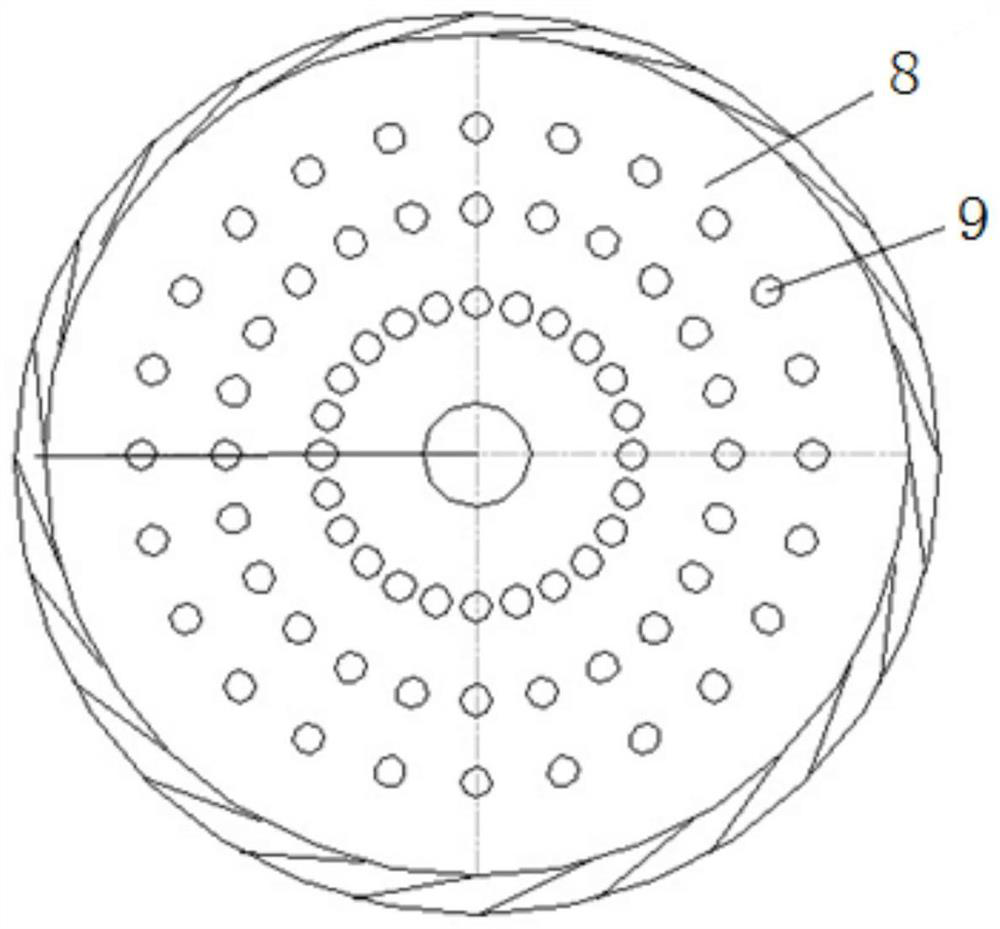

[0034] The cavitation device for refining production of reinforced cellulose pulp of the present invention, such as figure 1 As shown, it includes a stator 7, a rotating shaft, a rotor and an ultrasonic transducer 17. The rotating shaft includes a first rotating shaft 3 and a second rotating shaft 13 . The rotors comprise a first set of rotors 8 and a second set of rotors 11 .

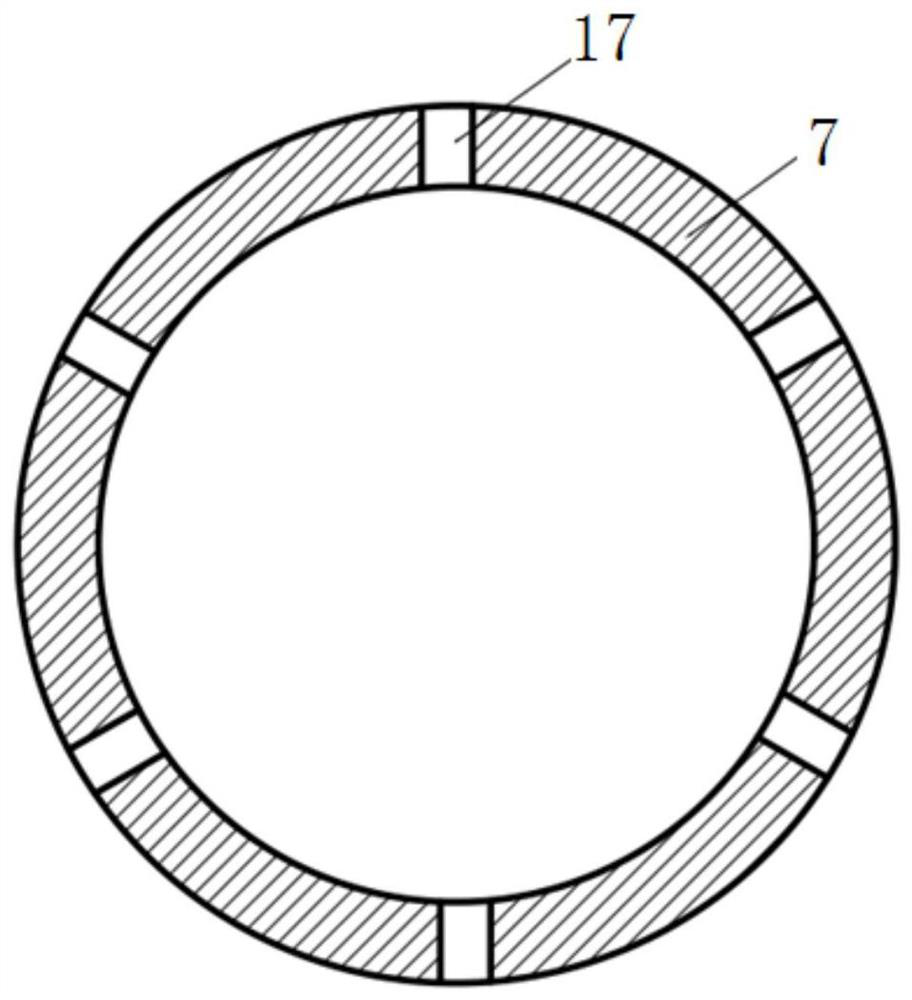

[0035] The stator 7 is a closed cylinder, which is enclosed by two half-shells, and the outer sides of the two half-shells are tapered. Ultrasonic transducers 17 are distributed on the inner wall of the stator 7 . Each ultrasonic transducer 17 is connected with an external ultrasonic generator 18 to induce ultrasonic cavitation. see figure 2 , the ultrasonic transducers 17 are embedded in the inner wall of the stator 7 along the axial and circumferential directions in the form of 2 to 8 ultrasonic transducers at equal intervals. The number of ultrasonic generators 18 is 1-4, the frequency is 40-8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com