Patents

Literature

296results about How to "Improve refining efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

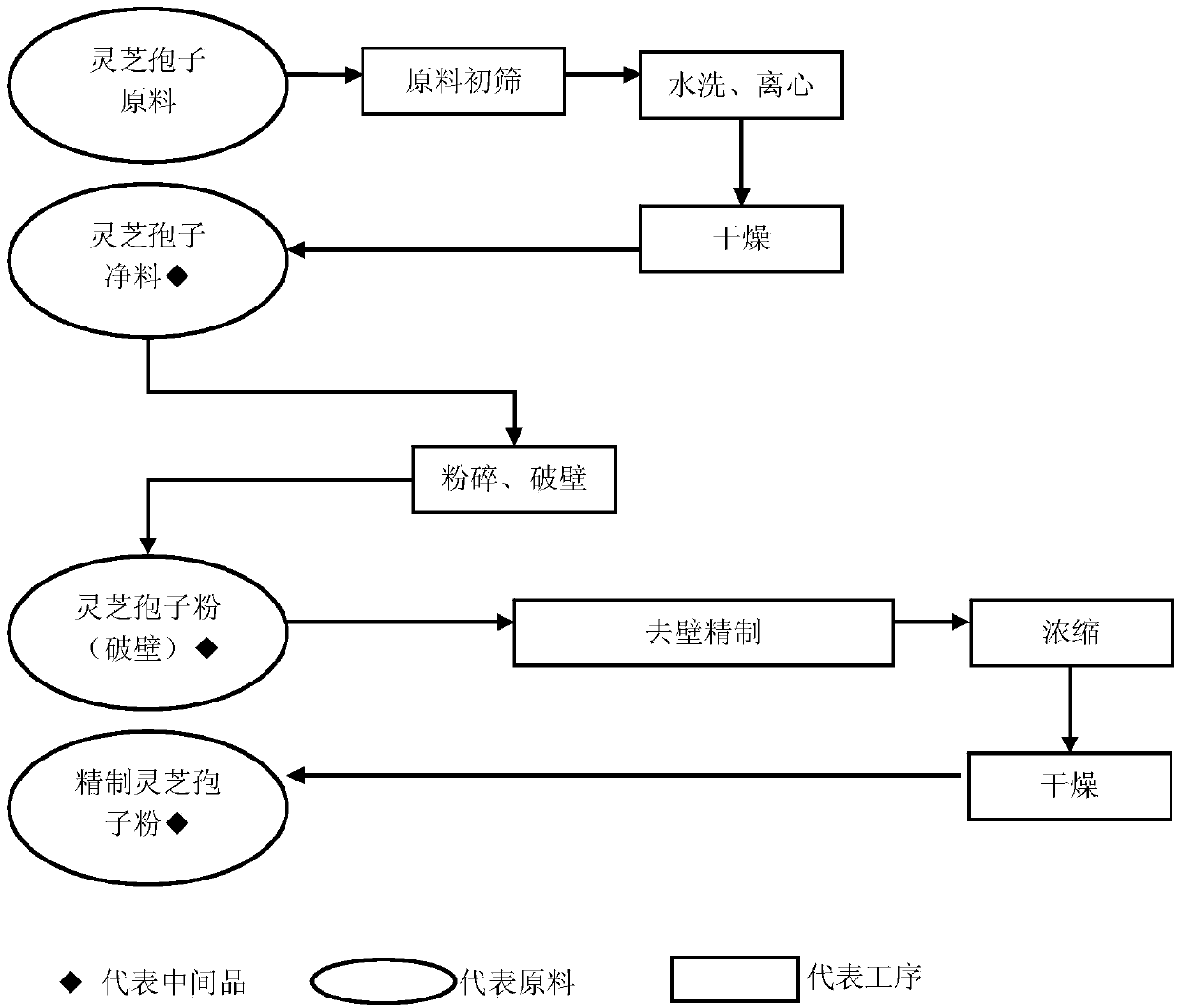

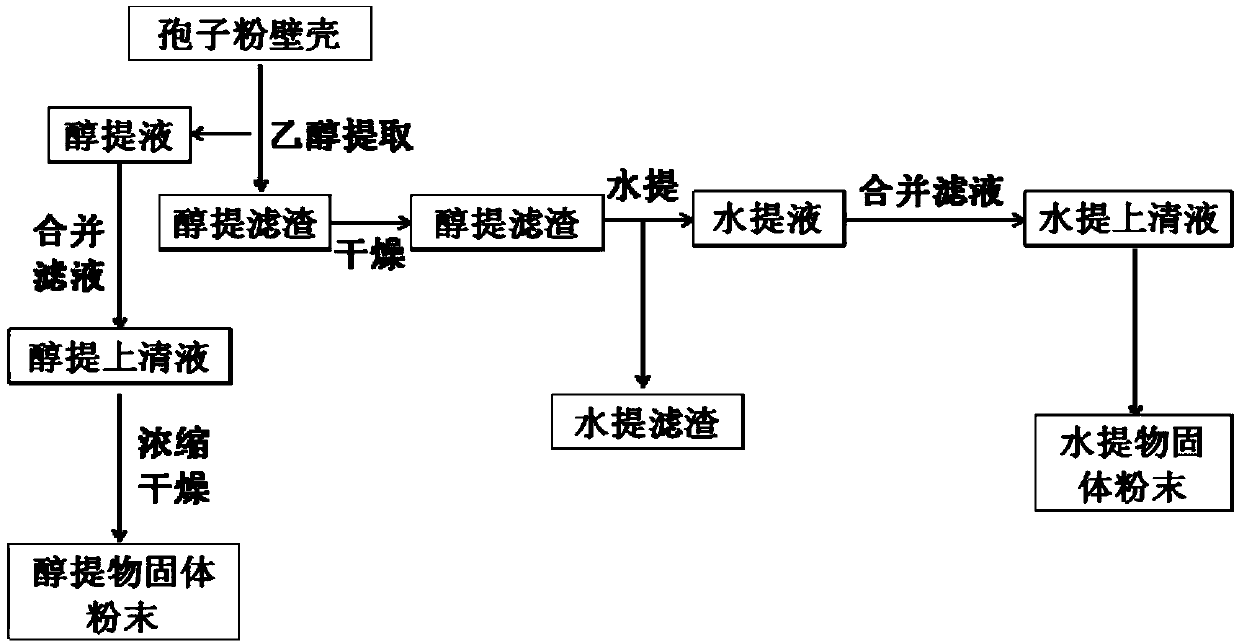

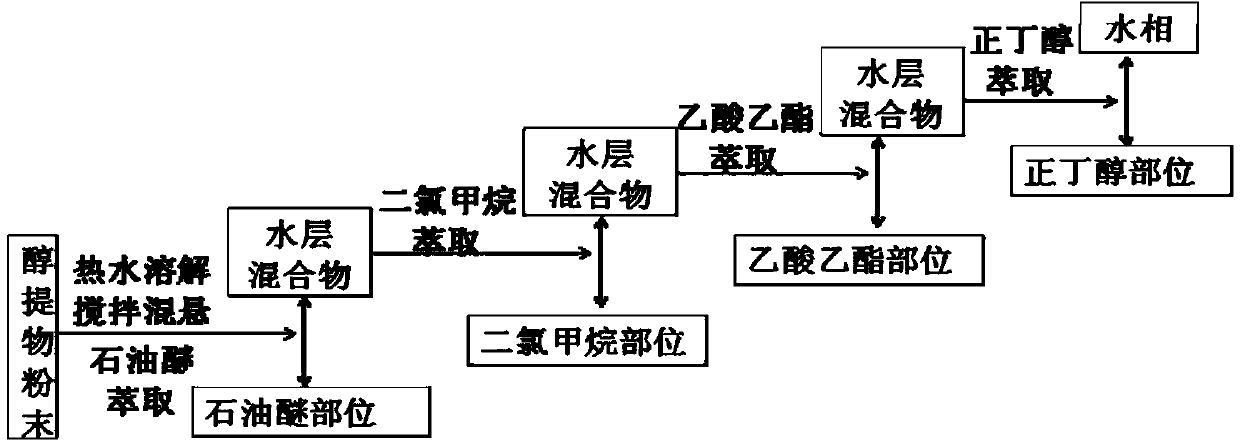

Purification process, comprehensive utilization method and application of ganoderma lucidum spores powder

ActiveCN104013652AProcess ScienceStrong maneuverabilityDigestive systemAntinoxious agentsDichloromethaneAqueous extract

The invention discloses a purification process of ganoderma lucidum spores powder. The process comprises the following steps: removing shells of shell-broken ganoderma lucidum spores powder; after immersing by a 20-95% ethanol solution in volume fraction and water, separating shells to obtain a shell-broken ganoderma lucidum spores powder filtrate and shells of ganoderma lucidum spores powder; concentrating and drying the filtrate to obtain purified ganoderma lucidum spores powder; preparing shell alcohol extract solid powder, dichloromethane extract solid powder, ethyl acetate extract solid powder, shell aqueous extract solid powder, normal butanol extract solid powder, water phase powder or chitosan from shells of ganoderma lucidum spores powder by virtue of a comprehensive recycling process. According to the invention, ineffective component (shells) of the spores powder is separated and effective components (polysaccharide, triterpene and the like) are enriched by breaking shells and purifying, so that the content of the effective components of the purified ganoderma lucidum spores powder is remarkably improved and the effect is remarkably enhanced. The shells are comprehensively utilized, so that the economic benefit is improved.

Owner:JINHUA SHOUXIANGU PHAMACEUTICAL CO LTD

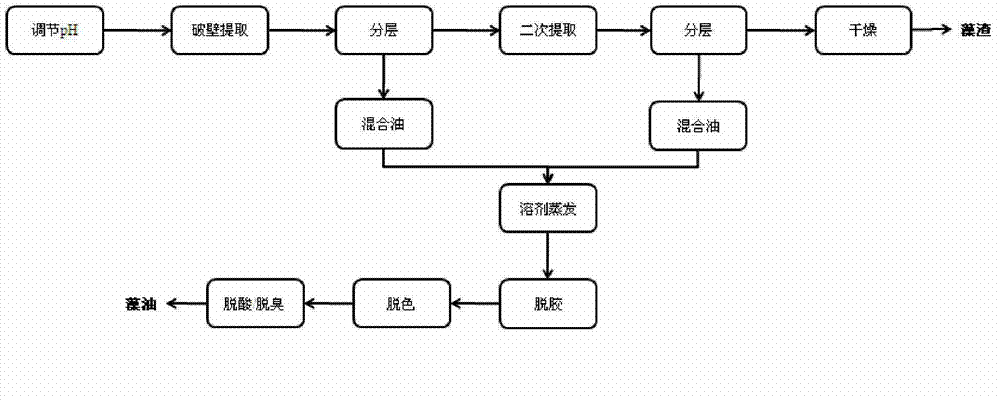

Method for extracting grease from schizochytrium

ActiveCN102965182ASimple processLow costMicroorganism based processesFatty-oils/fats productionFlocculationOil and grease

The invention discloses a method for extracting grease from schizochytrium. The method comprises the following steps: (1) adjusting the pH (Potential of Hydrogen) of the fermentation broth of the schizochytrium until reaching an acid stage, and then adding an organic solvent to stir, so as to realize the wall breaking of schizochytrium cells and extraction of microalgae oil; (2) adding a flocculant to the fermentation broth obtained in step (1) to flocculate, and extracting by the organic solvent to obtain crude algae oil; and (3) treating the crude algae oil by degumming, discoloring, and deacidifying / deodorizing, so as to obtain the microalgae oil rich in DHA (Docosahexaenoic Acid). According to the method disclosed by the invention, autolysis wall-breaking technology is adopted, so that the technological process in wall breaking and extraction of the schizochytrium can be simplified, the operation time in wall breaking can be shortened, the investment on equipment is decreased, and the cost is lowered; and the biological flocculant flocculation technology is carried out, therefore, the demulsification technological process is simplified, the time for layering is shortened, the layering effect is improved, the load due to wastewater discharge and water treatment caused by the demulsification process can be avoided, and the cost of water treatment can be lowered.

Owner:ENN SCI & TECH DEV

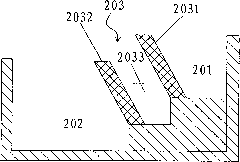

Method for reclaiming and cyclic utilizing residue molten steel slag in steel making

InactiveCN1804047AWell mixedReduce oxidationBlast furnace componentsBlast furnace detailsSulfurSludge

The method to pour residual hot steel sludge for recovery in steel production comprises: a. after casting, pouring the residual steel sludge into empty ladle; b. conveying the sludge to converter and tapping; c. refining; d. casting; repeating. This invention makes full use of the sulfur capacity and strong reducibility to absorb inclusion and improve liquid steel cleanness rapidly, overcomes the consumption for low-melting, and reduces pollution and cost.

Owner:HEBEI IRON AND STEEL

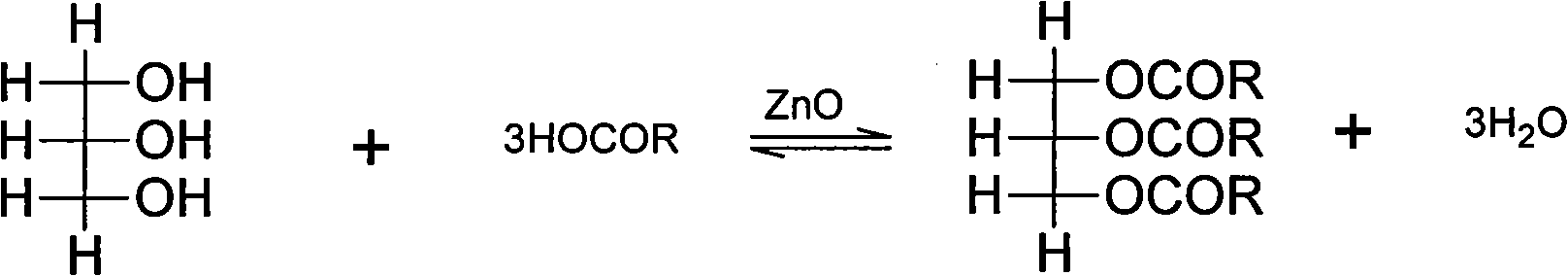

High-acid value rice bran oil esterification depickling process

InactiveCN101319167APromote esterification reactionLow acid valueFatty acid esterificationFatty-oils/fats refiningPre treatmentRice Bran Extract

The invention relates to an esterification deacidification process for high acid number rice bran oil, and the process can well solve the problem of a low refining rate. The esterification deacidification process for high acid number rice bran oil comprises grease pretreatment, namely two steps of degumming and decolorizing. A decolorized substance is obtained after the decolorizing, and then esterification deacidification is carried out. The concrete operating method comprises the following steps of: adding glycerin after the decolorized substance is stirred and heated at a vacuum degree of 0.09 MPa; adding a catalyst of zinc oxide or zinc to carry out a catalytic reaction to generate low acid number rice bran oil with an acid number of 5-7mgKOH / g. The zinc oxide or zinc which is taken as the catalyst of the esterification deacidification of the high acid number bran oil can effectively boost the esterification reaction and rapidly reduce the acid number; simultaneously the process overcomes the problems of the low refining rate lying in a traditional refining method and a great deal of sewage produced by a chemical alkali refining method; the zinc oxide or zinc has a low price, thereby reducing production cost; compared with other chemical esterification catalysts, the zinc oxide or zinc has a very low toxity, thereby being very suitable for the production of edible grease.

Owner:HEFEI UNIV OF TECH

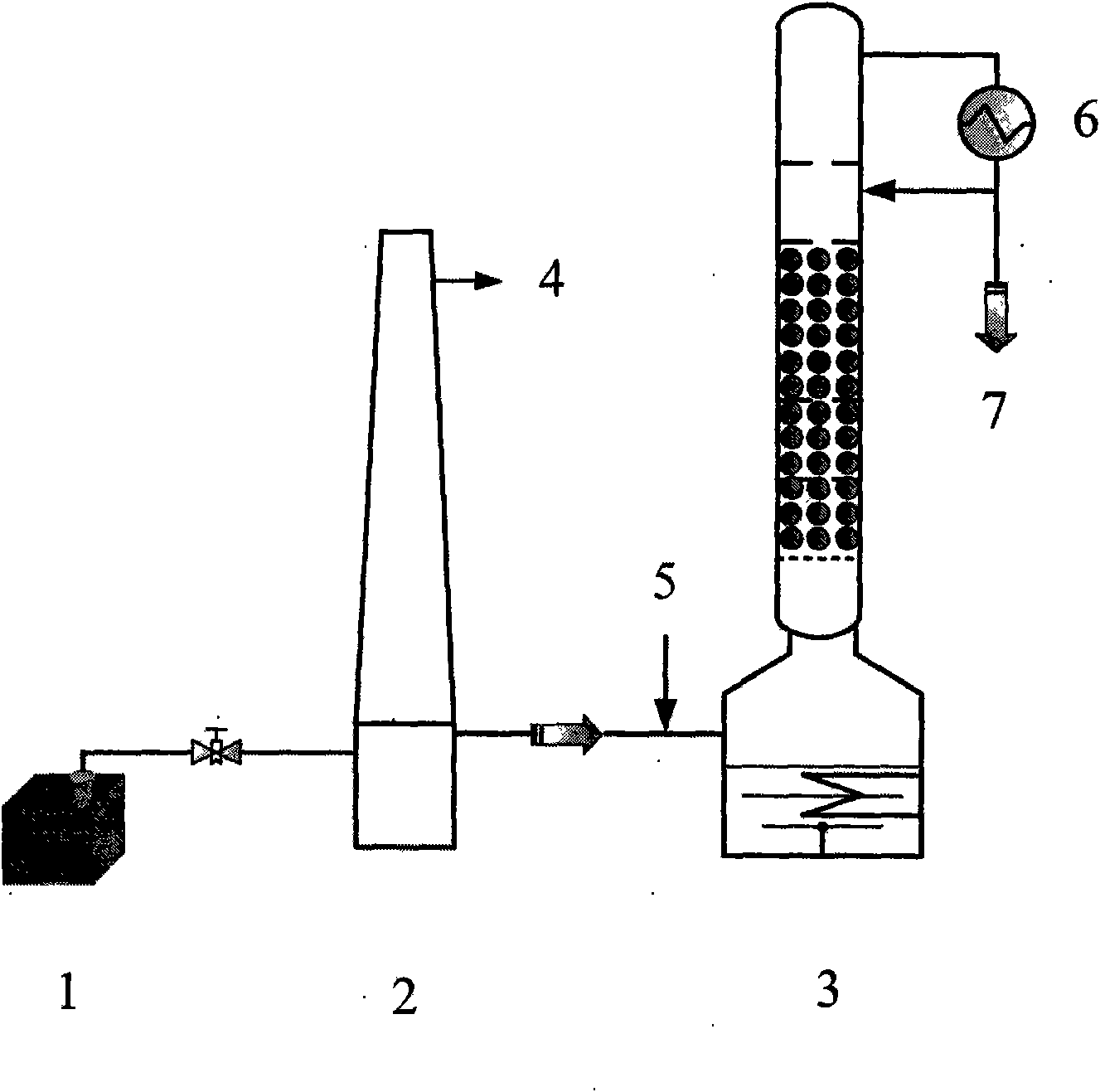

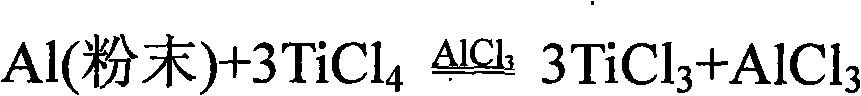

Method of refining titanium tetrachloride by using aluminium powder and vash oil mixture

InactiveCN101549885AEfficient removalImprove refining efficiencyTitanium halidesTitanium chloridePhysical chemistry

Method of refining titanium tetrachloride by using aluminium powder and vash oil mixture. The method is refining of coarse titanium tetrachloride containing high content of vanadium impurities. Mixing aluminium powder, vash oil and a few AlCl[3] in certain percentage and adding into bottom of fractionating tower containing coarse titanium tetrachloride. Heating the bottom of fractionating tower at a temperature of 139 DEG and regulating reflux ratio of the tower, this moment the aluminium powder and mineral oil deoxidizing the VOCl[3] into lower valency indissoluble precipitate VOCl[2] and being removed, and the TiCl[4] and some low boiling point chemical compounds volatilizing into a reflux unit, extracting cuts of 136-137 DEG boiling point, then condensing to get fine titanium tetrachloride. The vanadium-removed fine titanium tetrachloride contains vanadium content of V%<=0.0007%. The vanadium removing process and the fractionating process are all proceeded in the fractionating tower that saves device. The invention reduces a large amount of residue and sewage discharge, and consumes less materials relative to technics of using aluminium powder and mineral oil to remove vanadium alone, the invention provides high refining efficiency, simple operation and continuous, and has economic and environmental benefit of energy-saving and emission-reduction.

Owner:PEKING UNIV

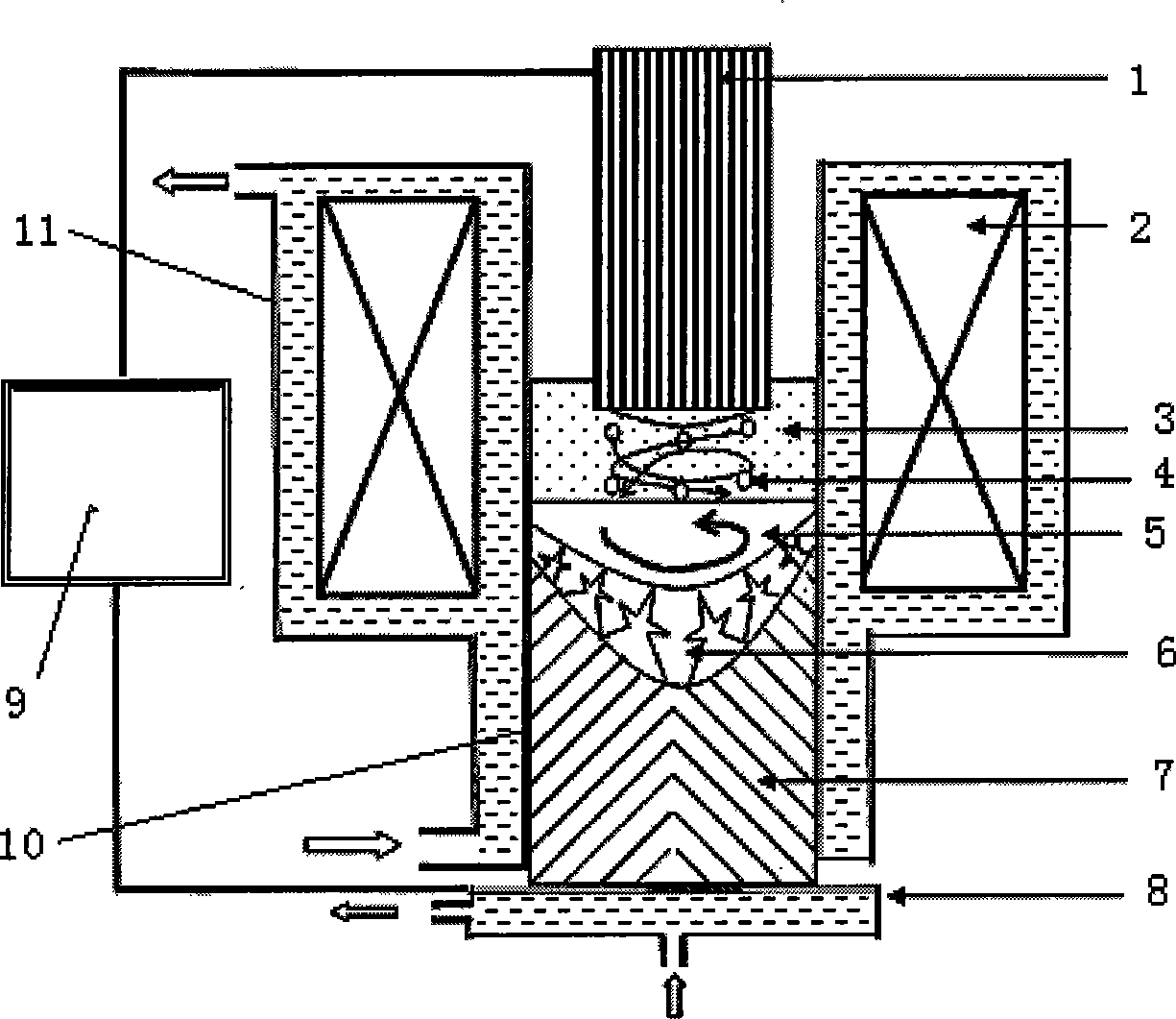

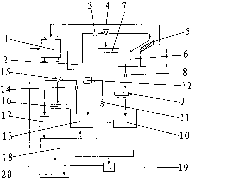

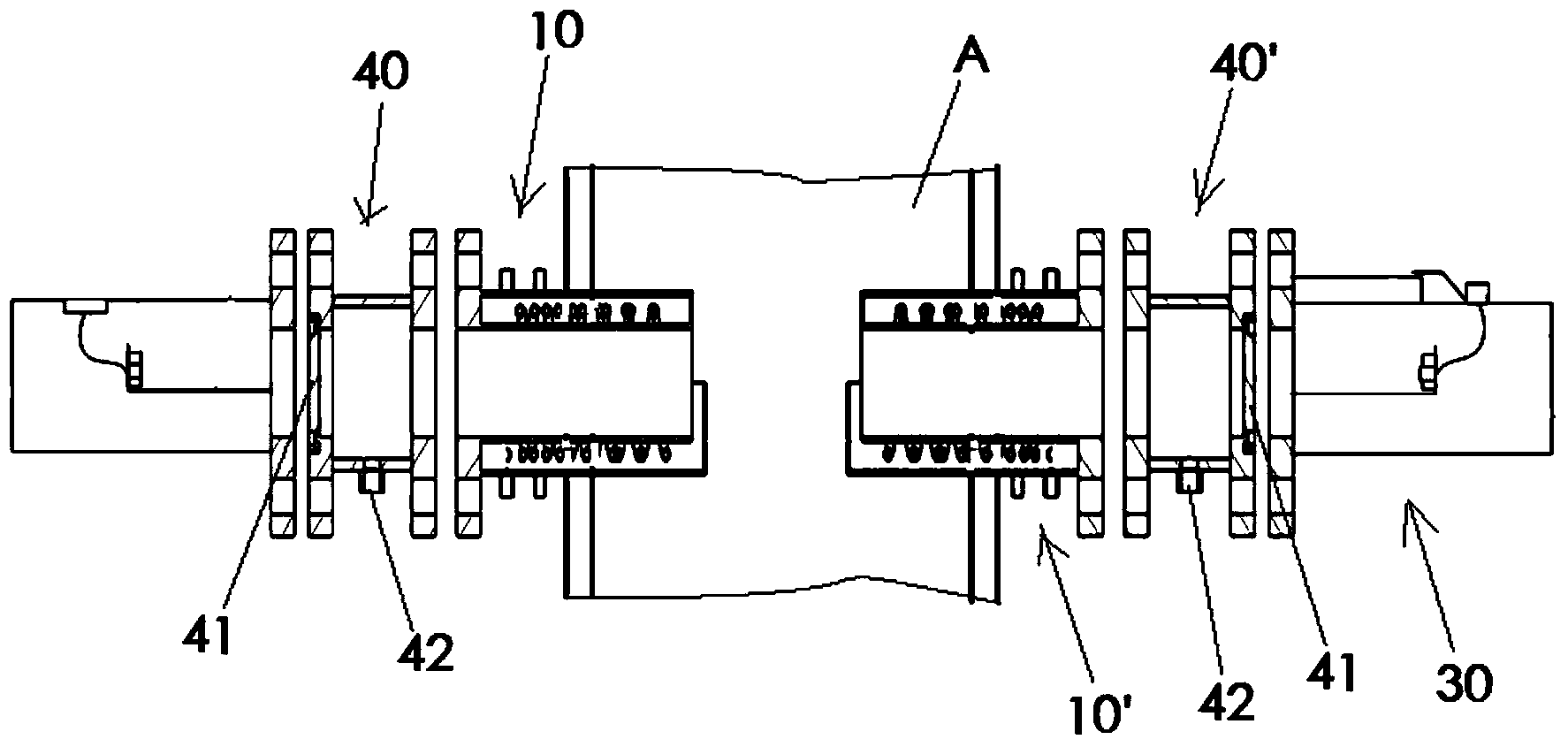

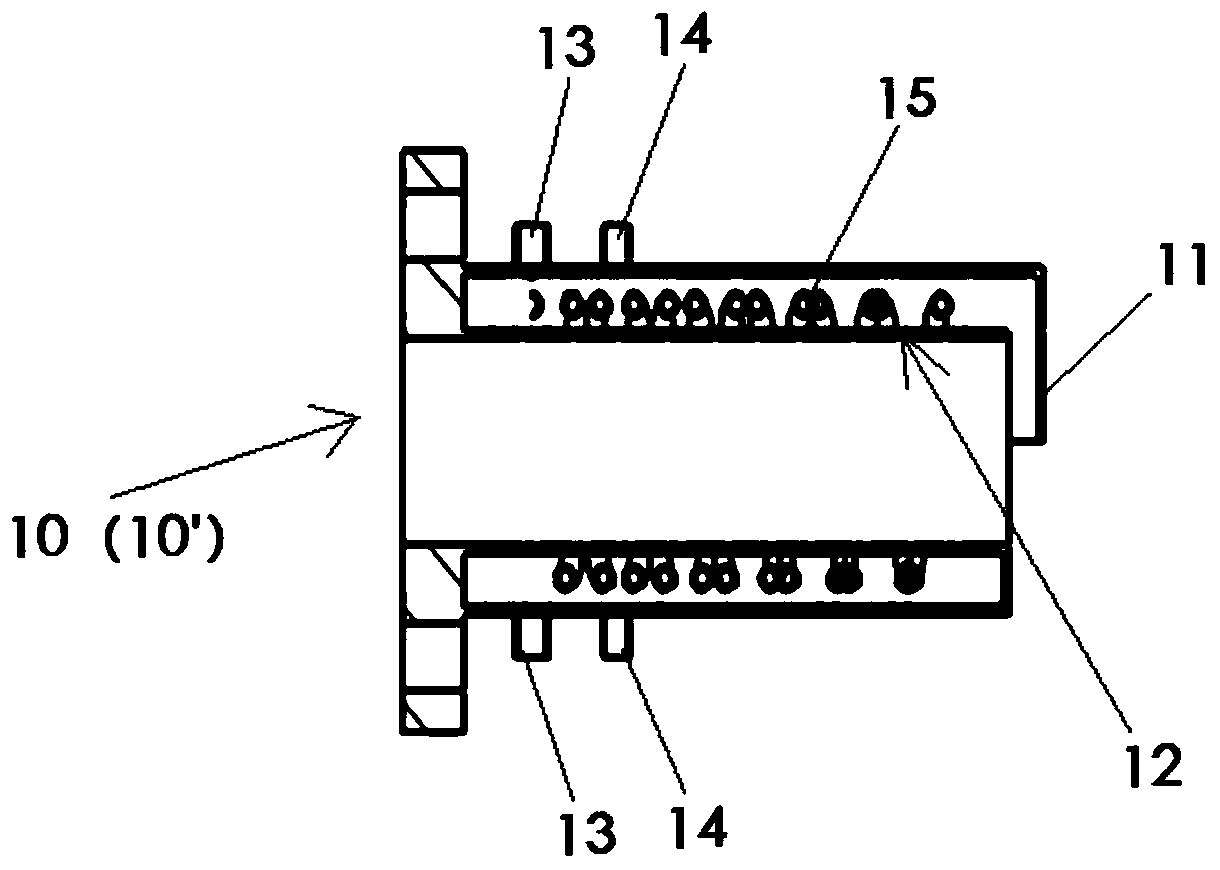

Electroslag smelting casting device with additional electromagnetic stirring and method

The invention relates to an electroslag casting device additionally provided with electromagnetic stirring and a method thereof. The electroslag casting device belongs to the technical field of special steel electroslag metallurgy and comprises a crystallizer, a crystallizer water jacket and an electromagnetic stirrer; an annular magnet is sleeved on the outer wall of the crystallizer and positioned at the middle-upper part of the crystallizer, a loop is wound on an iron core of the annular magnet, an electromagnetic stirrer water jacket is arranged at the periphery of the annular electromagnet, and the electromagnetic stirrer water jacket is communicated with the crystallizer water jacket; a melting consumable electrode forms molten steel drops which then enter a slag layer; the molten steel drops fall down in a spiral line way in the slag layer under the action of the rotary electromagnetic field and then enter a steel ingot liquid tank; the steel ingot liquid tank raises continuously and also enters into an effective magnetic field action region of the electromagnetic stirrer; and meanwhile, electric current in the molten steel is acted with the rotary magnetic field to produce the electromagnetic force which then drives the molten steel to rotate. The invention has simple equipment, and has the obvious functions of improving the surface quality, the subsurface quality and the solidifying tissue of a casting blank and the isometric crystal ratio, and lightening the internal defects, such as the center segregation, the center looseness, and the like.

Owner:NORTHEASTERN UNIV

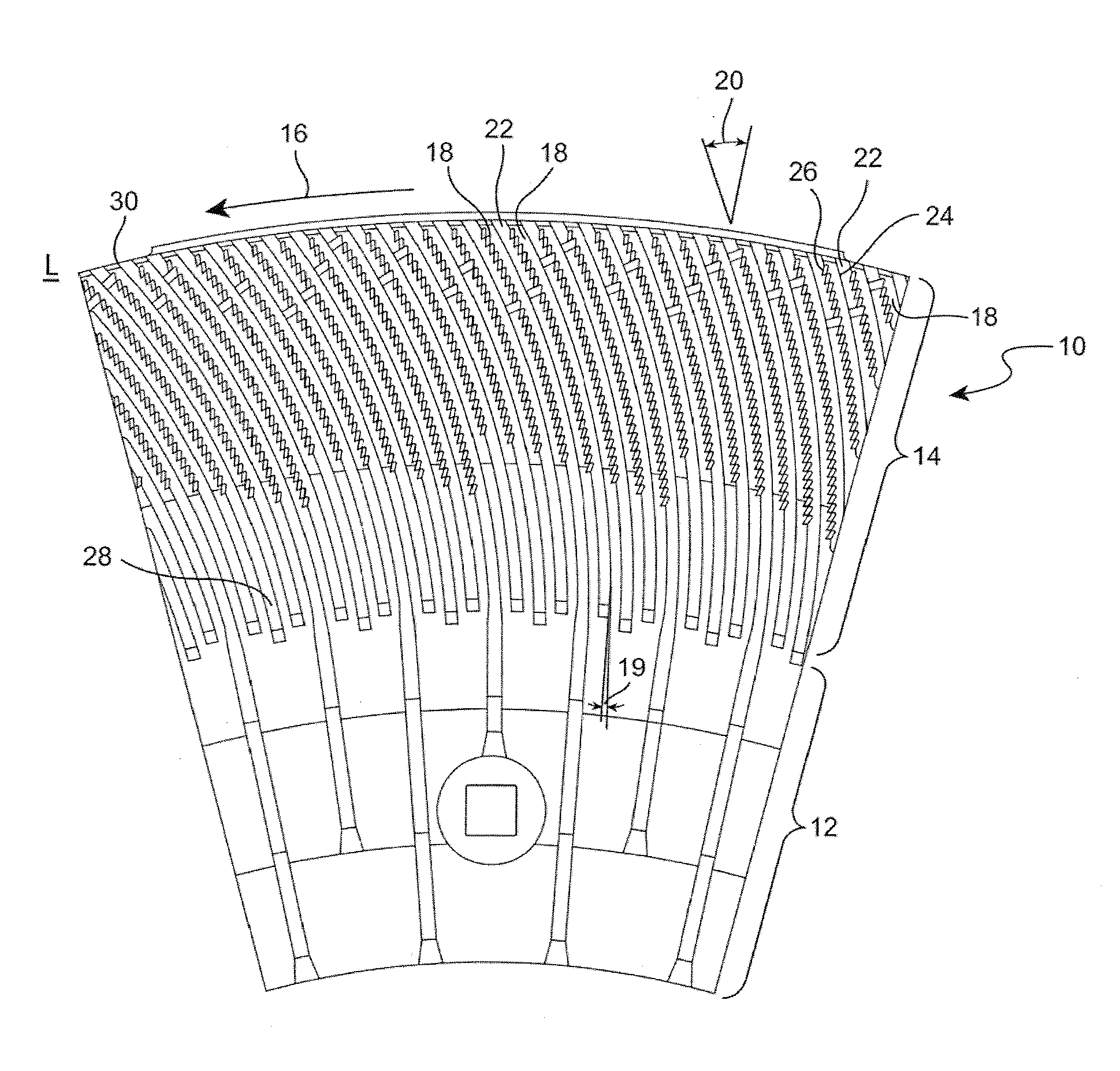

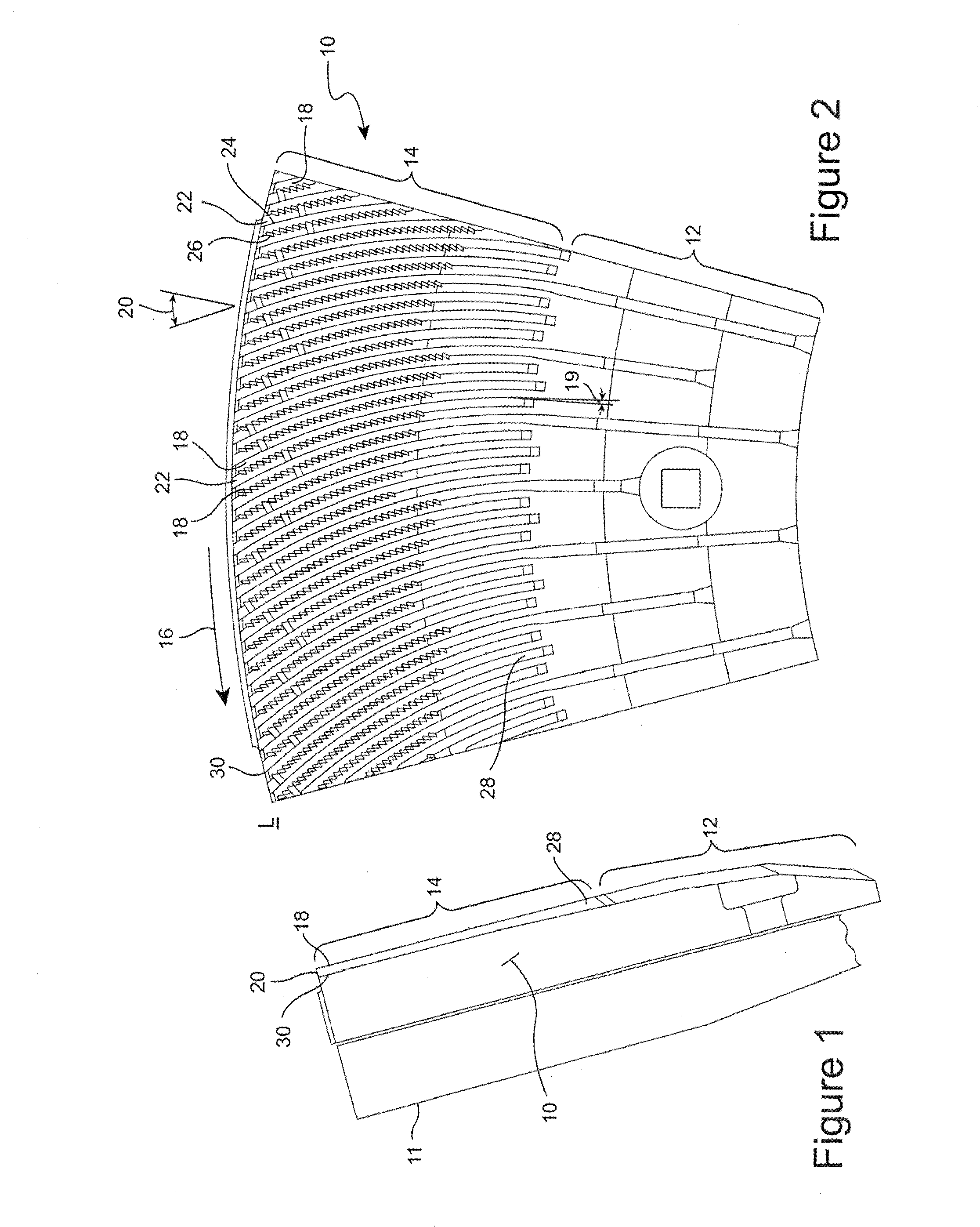

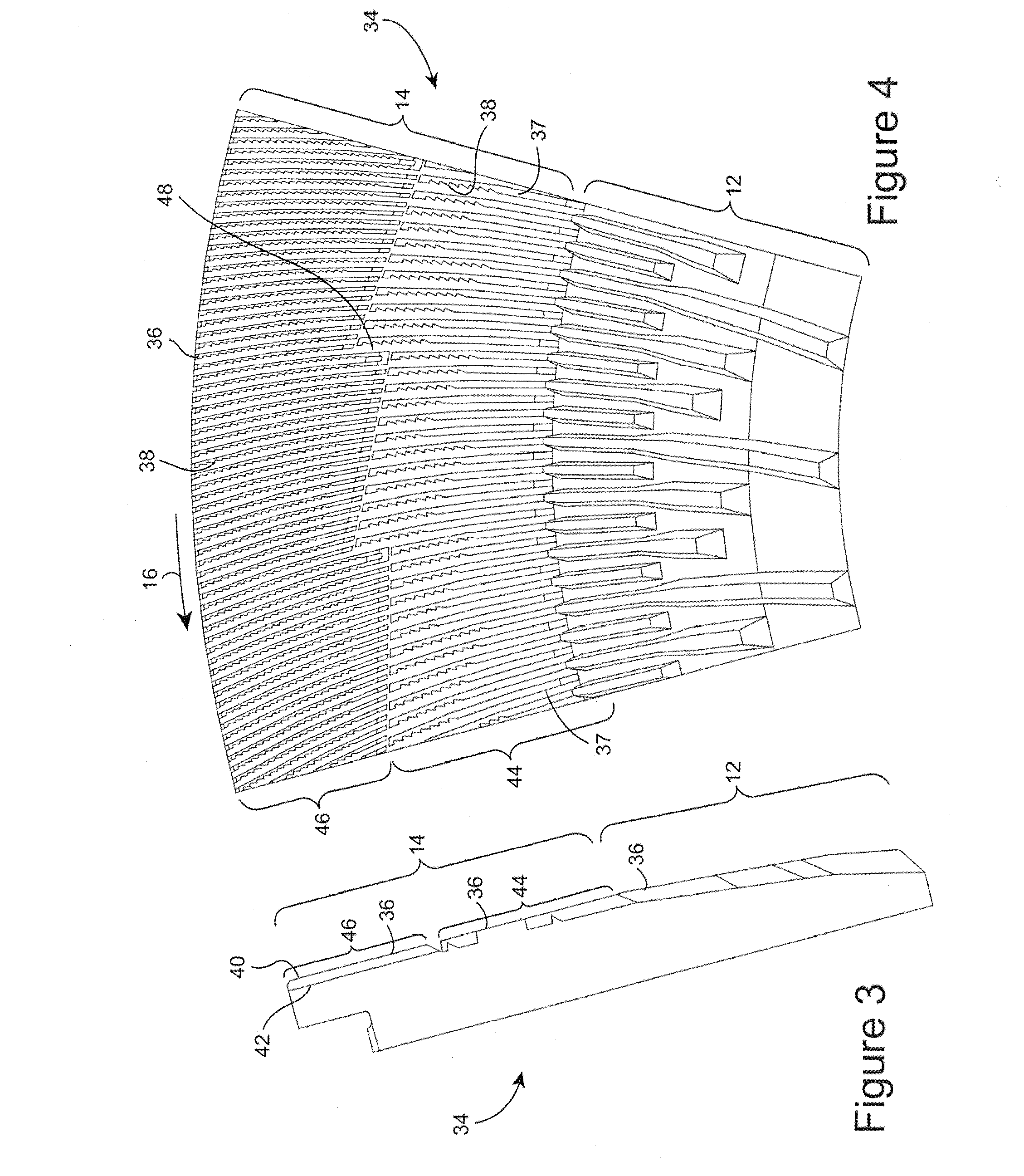

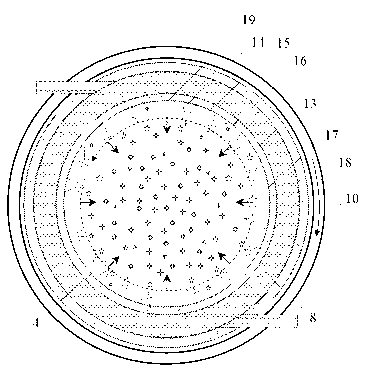

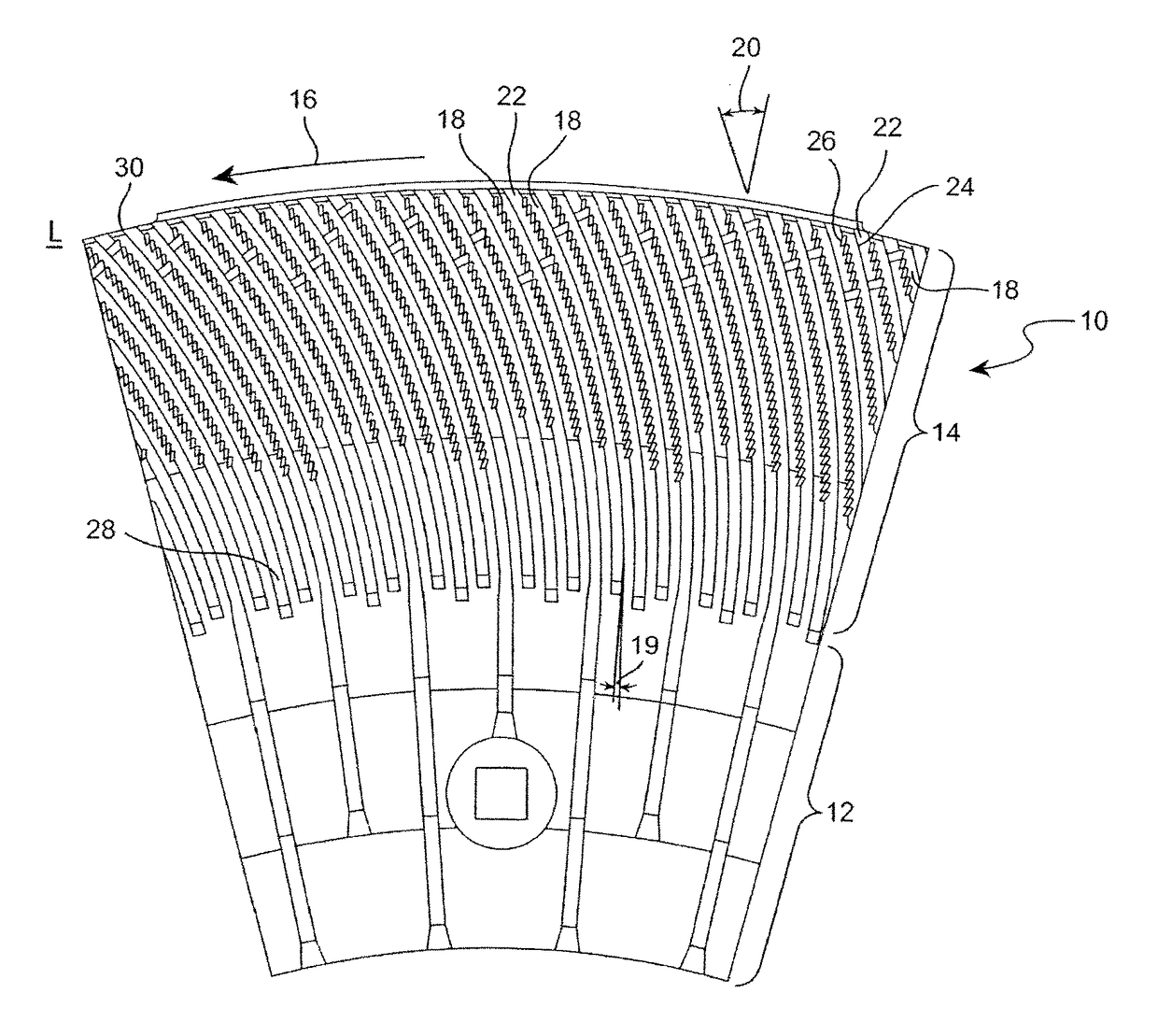

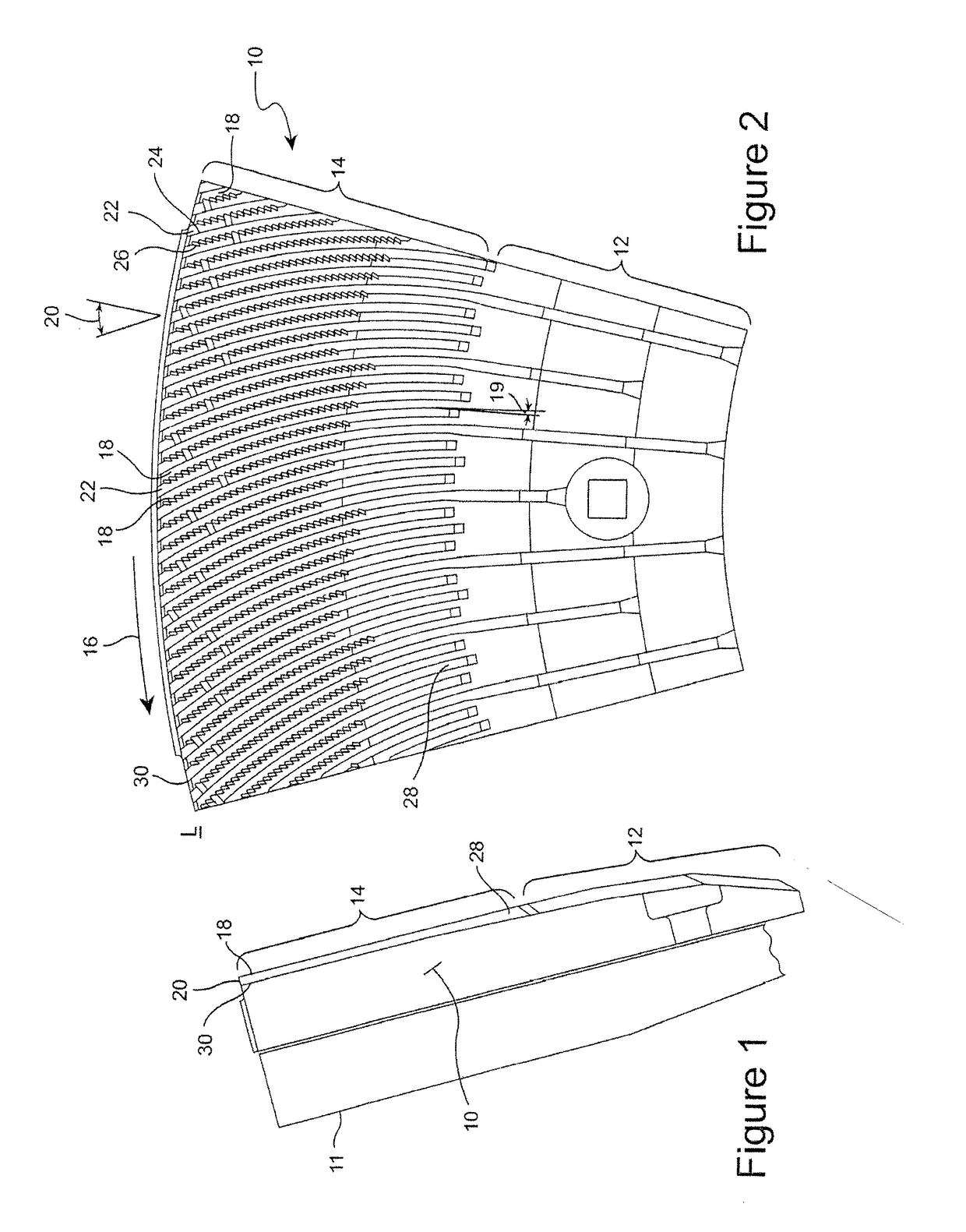

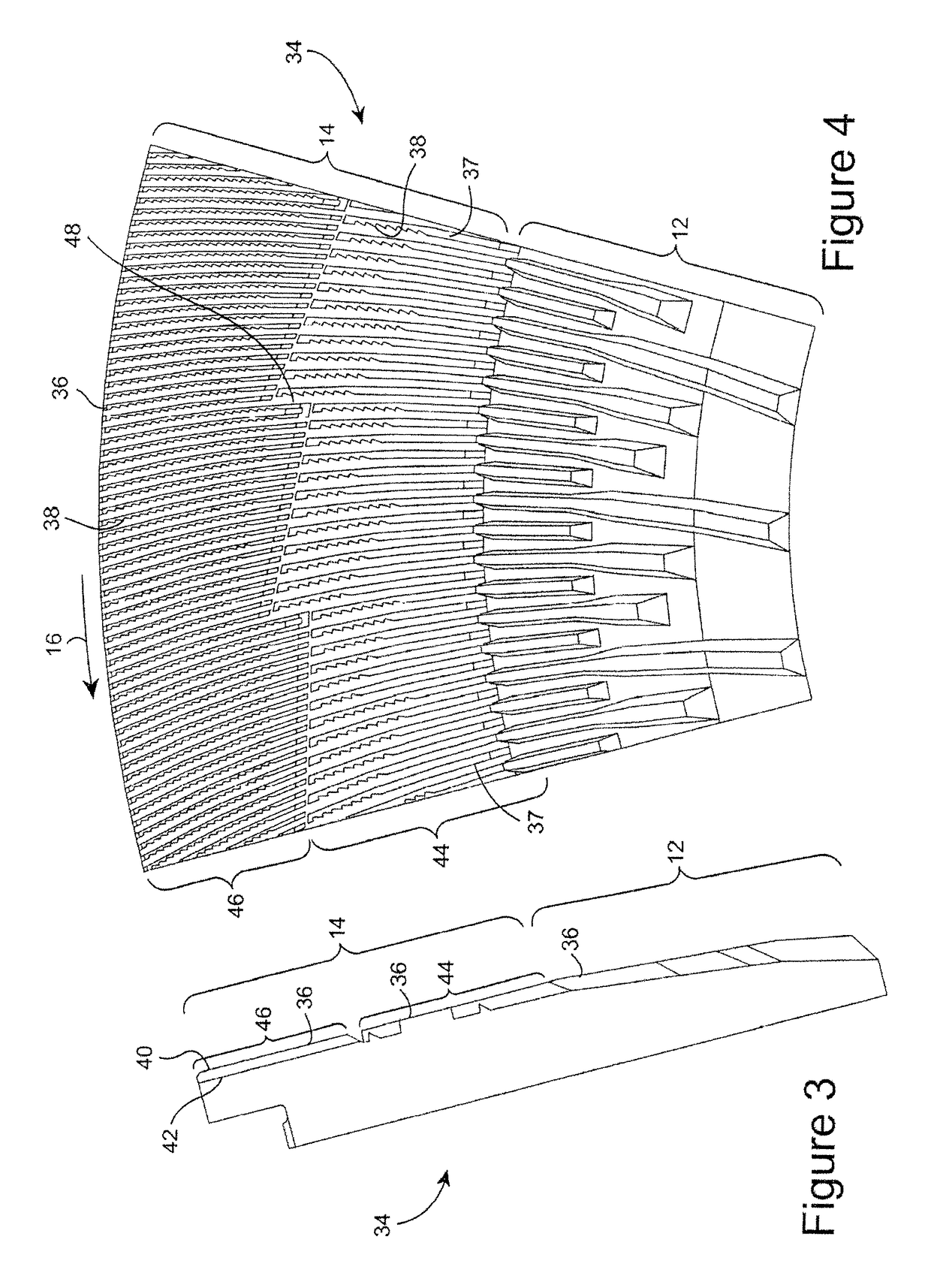

Rotor refiner plate element for counter-rotating refiner having curved bars and serrated leading edges

ActiveUS20130015281A1Improve refining efficiencyReduce decreaseCocoaPulp beating/refining methodsLeading edgeEngineering

A refining plate segment for a mechanical refiner of lignocellulosic material including: a refining surface on a substrate, wherein the refining surface faces a refining surface of an opposing refiner plate, the refining surface including bars and grooves between the bars, wherein an angle of each bar with respect to a radial line corresponding to the bar increases at least 15 degrees along a radially outward direction, and the angle is a holdback angle in a range of 10 to 45 degrees at the periphery of the refining surface, and wherein the bars each include a leading sidewall having an irregular surface, wherein the irregular surface includes protrusions extending outwardly from the sidewall towards a sidewall on an adjacent bar and the irregular surface extends from at or near the outer periphery of the refining surface extends radially inwardly along the bars without reaching an inlet of the refining surface.

Owner:ANDRITZ INC

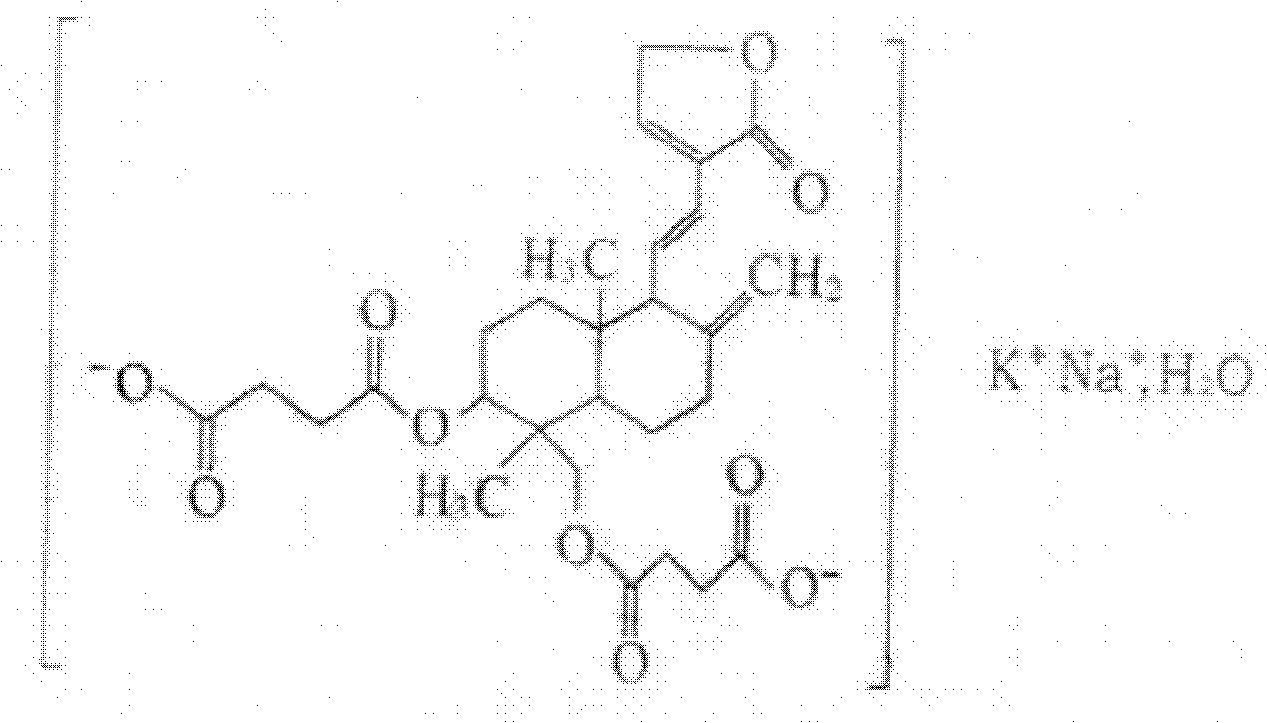

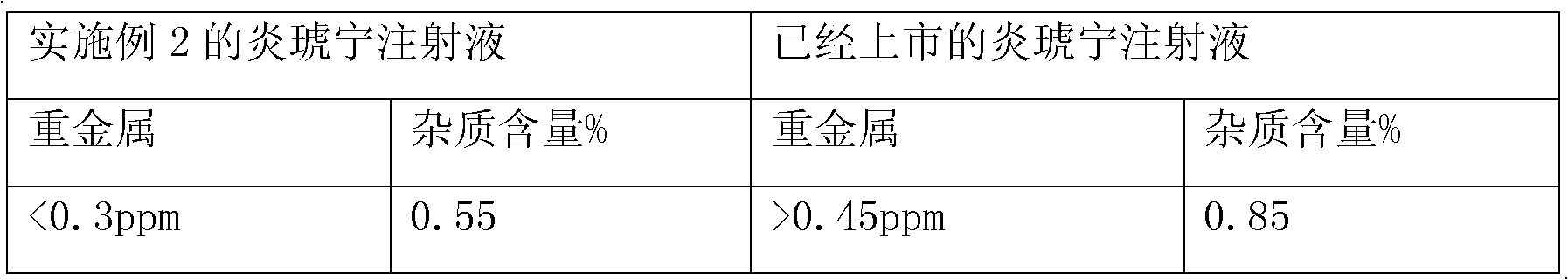

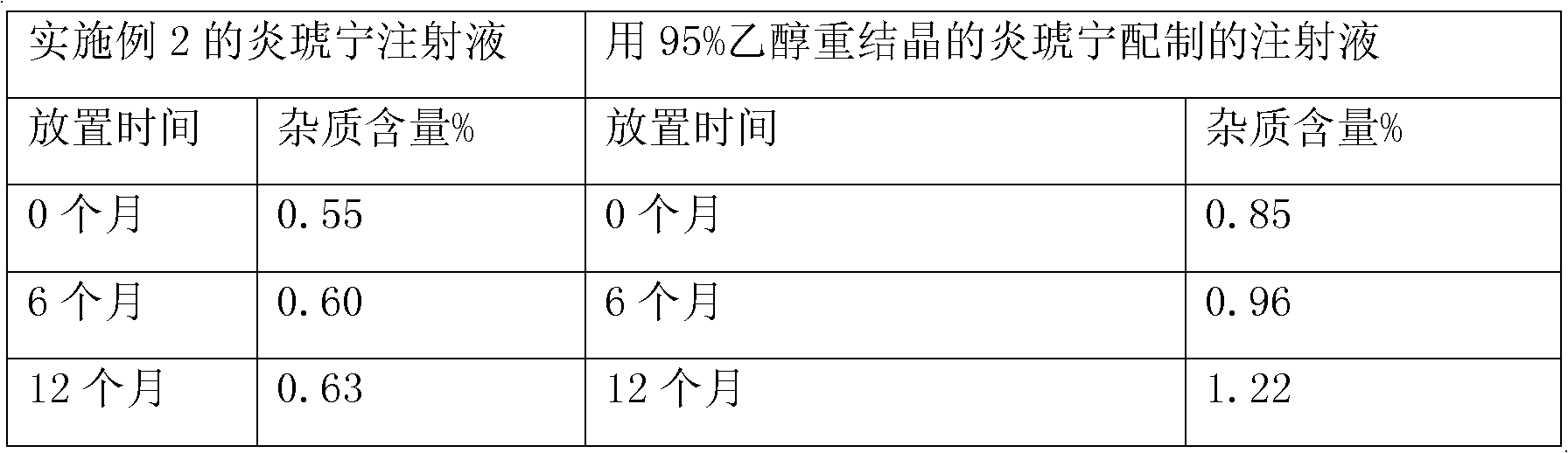

Stable potassium sodium dehydroandroan drographolide succinate compound and pharmaceutical composition thereof

InactiveCN102367243ASlow degradationGood stabilityOrganic active ingredientsOrganic chemistrySolventActivated carbon

The invention relates to a stable potassium sodium dehydroandroan drographolide succinate compound and a pharmaceutical composition thereof. The compound is prepared by the following steps: adding potassium dehydroandrograpolide succinate in an ethanol solution, and stirring to obtain a white suspending liquid; at room temperature under normal pressure adding sodium bicarbonate solution dropwisely with introducing nitrogen and stirring for reacting until clear to obtain a yellow solution; cooling the yellow solution, then precipitating crystals; carrying out recrystallization 1-3 times on thecrystals with a mixed solution, and simultaneously decoloring with active carbon to obtain white crystals, wherein, the mixed solution comprises ethyl acetate and ethanol, and the ratio of ethyl acetate to ethanol is 2 to 1.

Owner:河北三禾实创生物科技有限公司

Method and improved device for argonoxygen refining of low-carbon ferrochrome

The invention provides a method and an improved device for argonoxygen refining of low-carbon ferrochrome. In the method, high-carbon ferrochrome melt is subjected to argonoxygen refining under conditions of large oxygen volume blowing and a higher temperature, the high high-carbon ferrochrome melt is subjected to a violent and uniform oxidization reaction performed under large oxygen volume throughout an oxidization period by utilizing and controlling a splashing process in the oxidization period of the refining, and thus, the carbon reducing process of the melt is accelerated and the loss of chrome is reduced. To prevent serious splashing out of a furnace, a refining converter is improved. When the method and the device are used, low-carbon ferrochrome in which the carbon content (weight percentage) is lower than 0.15 percent can be obtained, and the loss (weight percentage) of the chrome is less than 5 percent. The control method adopted by the invention is favorable for production operation and realization of one-line automatic control.

Owner:CHANGCHUN UNIV OF TECH

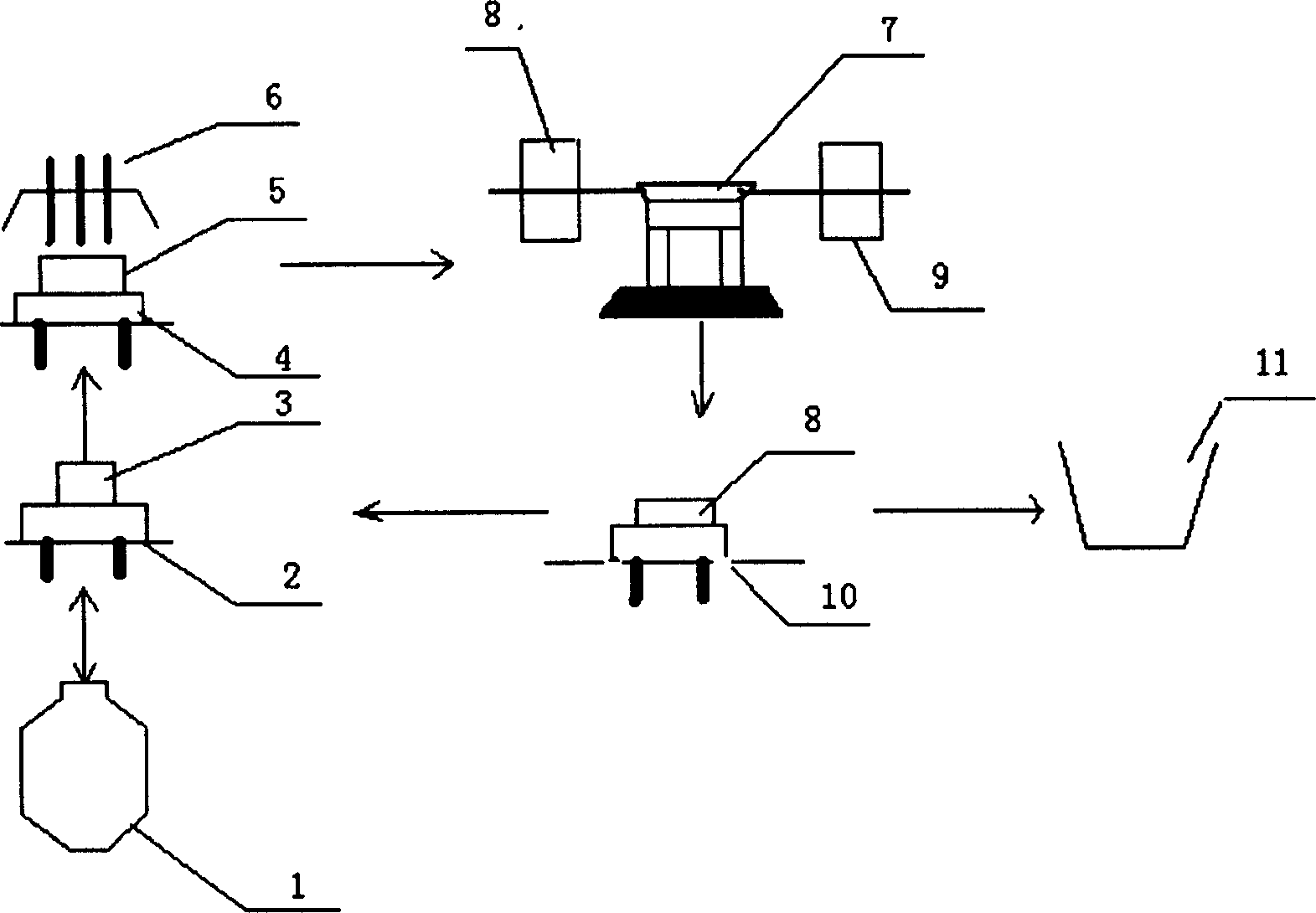

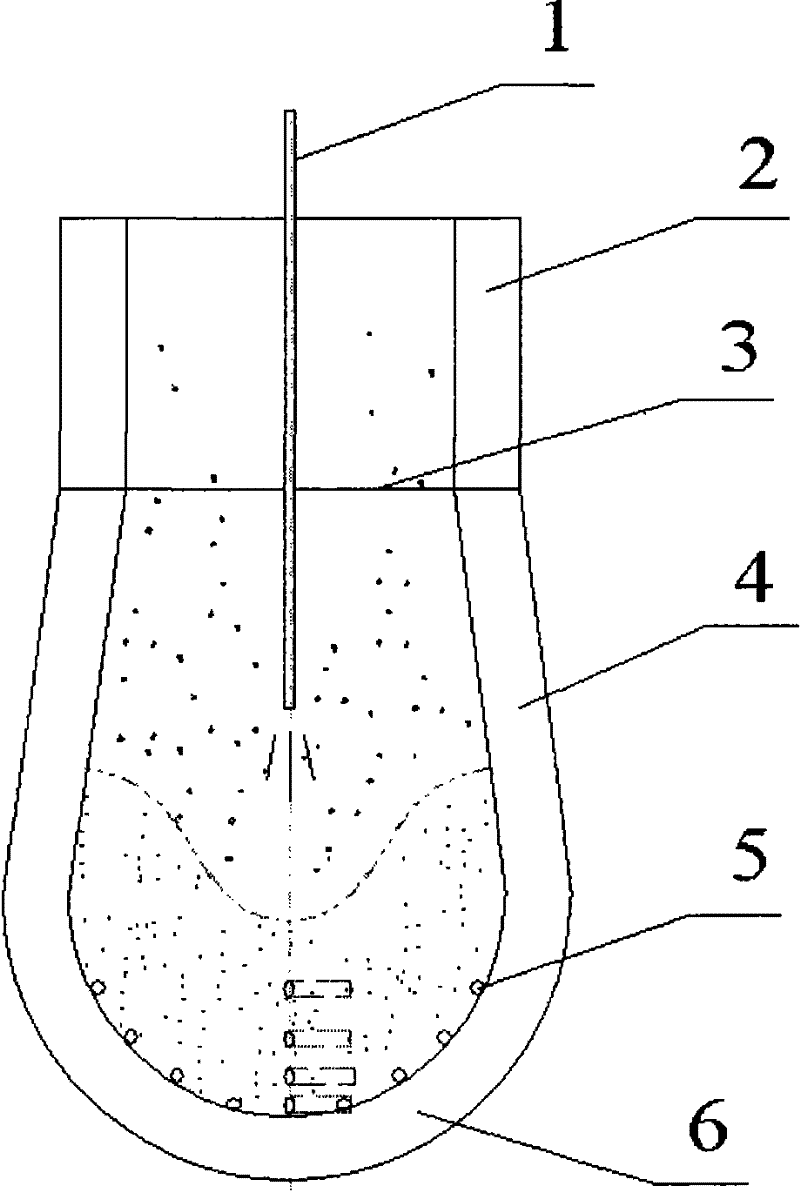

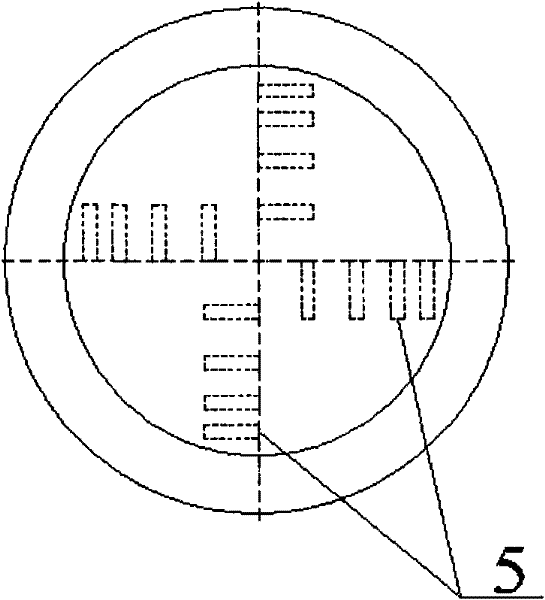

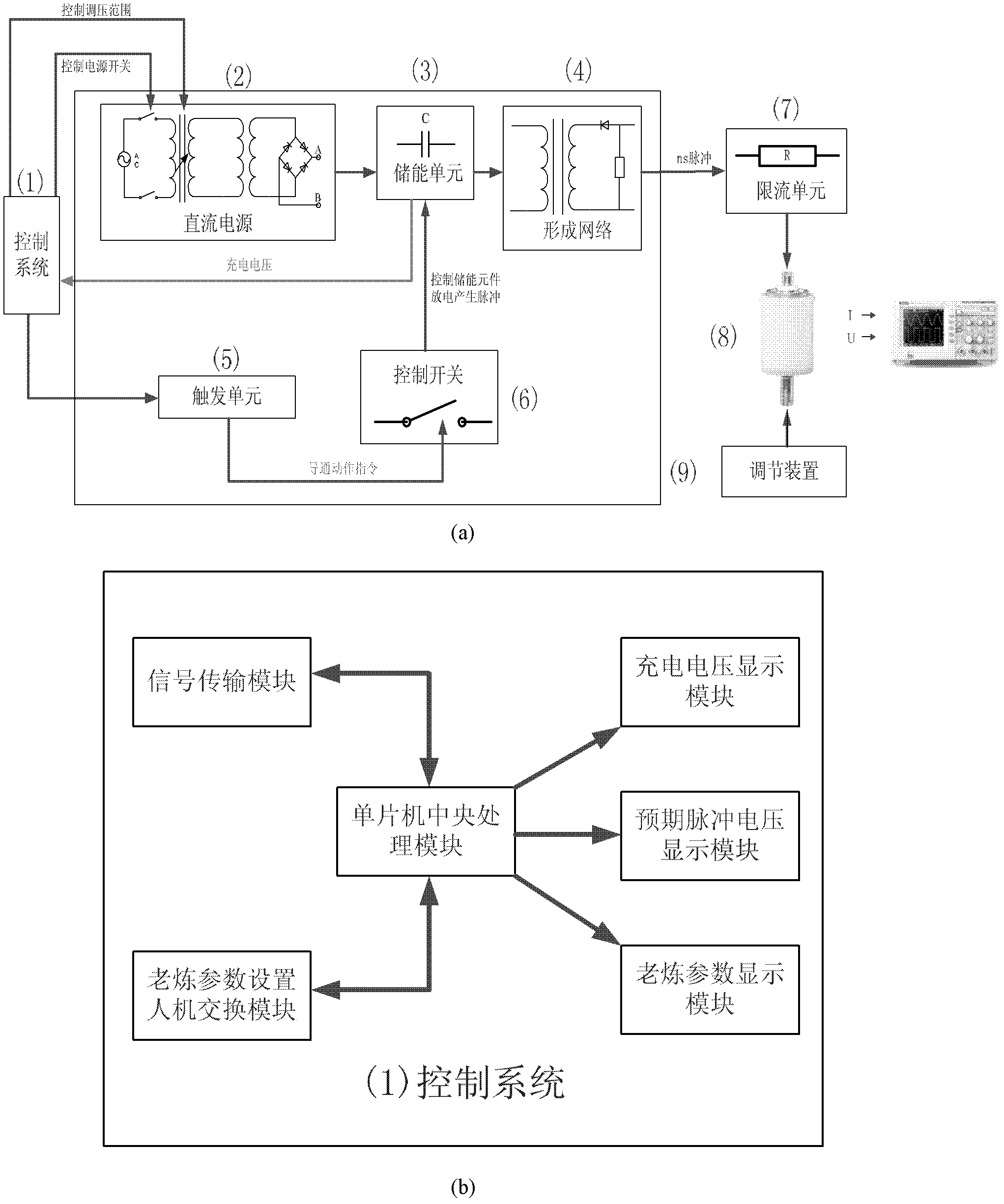

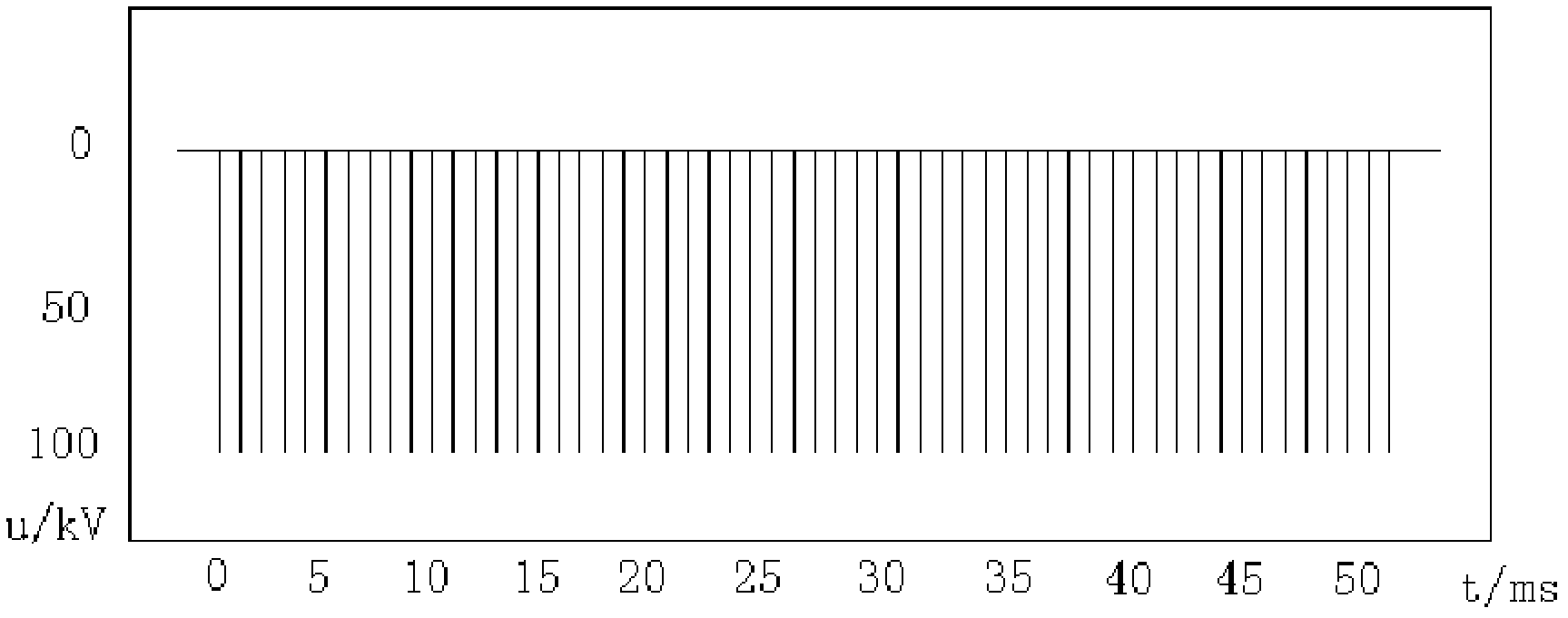

Nanosecond continuous pulse ageing device and method of vacuum interrupter

InactiveCN102426954AGood aging effectImprove insulation withstand voltage performanceElectric switchesCurrent limitingNanosecond

The invention relates to a nanosecond continuous pulse ageing device and method of a vacuum interrupter. The nanosecond continuous pulse ageing device comprises a control system, a direct-current power supply, an energy storage unit, a forming network, a triggering unit and a control switch part, wherein the control system is connected to the direct-current power supply and the triggering unit; the output end of the direct-current power supply is connected with the energy storage unit and the triggering unit is connected with the control switch; the energy storage unit is connected with the forming network and the forming network is used for outputting a pulse voltage to the vacuum interrupter through a current limiting unit; the control unit is connected with the energy storage unit and the lower part of the vacuum interrupter is provided with an adjusting device. According to the method provided by the invention, by adjusting the energy of one time of the discharging process and controlling discharging times in the unit time, the ageing degree and the ageing tendency are controlled and the ageing uniformity of the vacuum interrupter is improved. In the invention, a nanosecond-grade continuous pulse source is taken as an ageing power supply of the vacuum interrupter. The best ageing effect of the vacuum interrupter can be achieved by controlling the discharging energy of single pulse, the repetition frequency and the action time of the continuous pulse.

Owner:XI AN JIAOTONG UNIV

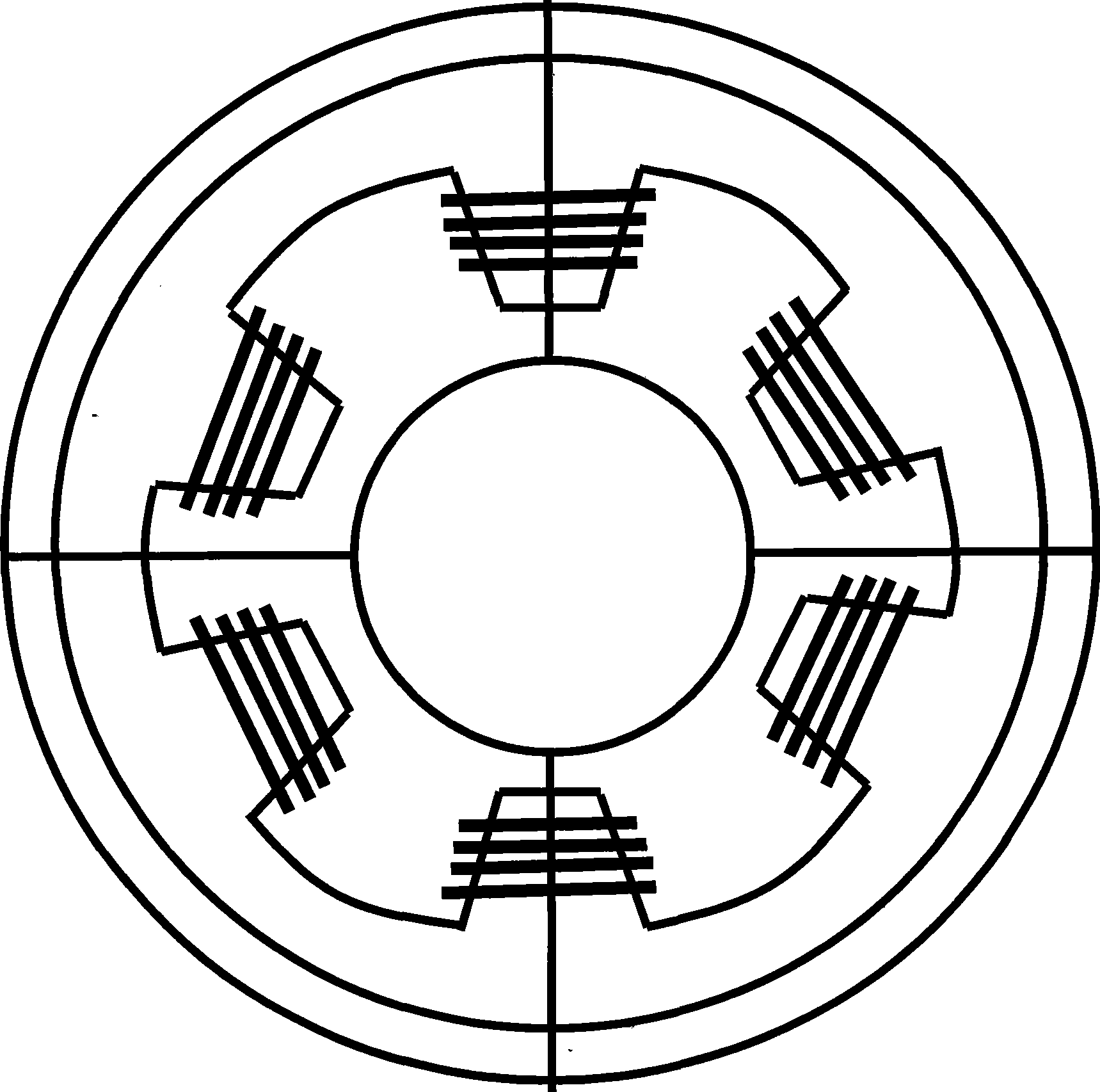

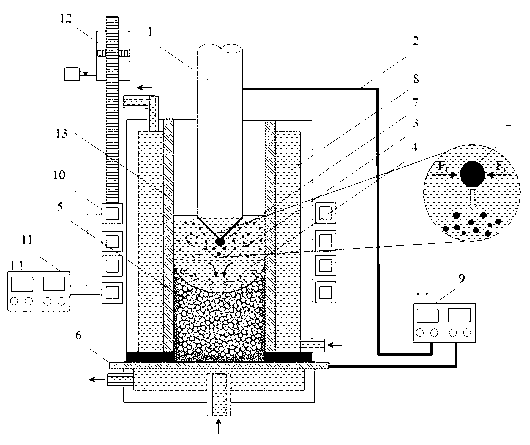

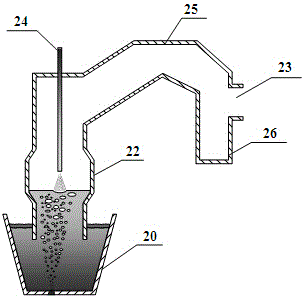

Magnesium alloy furnace material fluxless remelting refining method and device

The invention relates to a method of refusion refining for magnesium alloy furnace charge without the fluxing agent and its apparatus. Magnesia fused mass is refined using complex multi-refining method after preheating and drying magnesium alloy furnace charge, including the steps of: fusing furnace charge, stirring refining or (and blowing refining), forced sedimentating, filter refining, static refining, discharging and casting, accordingly the high-quality purification of fusing body is performed by efficiently eliminating all kinds of impurity and gas in the magnesium alloy furnace charge. The apparatus mostly includes crucibles, pretreatment chambers in order fixed in the crucibles, one or more filter chamber and casting chambers, each adjacent two chambers communicated by fused mass flowing channels, stirring units or (and blowing units) in the pretreatment chambers, first-order filter unit airproofed and fixed in each filter chamber. The apparatus can perform continuous complex multi-refining and casting / producing of magnesia fused mass, with greatly-improved refining quality and purified effect of magnesium alloy fused mass, while the problem that the filter apparatus is easy to be blocked in the process of filtering is solved.

Owner:重庆硕龙科技有限公司

C4 hydrocarbon deep desulfurization method and thiol and disulfide removal agent used therein

ActiveCN101591213AImprove pore structureImprove adsorption capacityOther chemical processesAdsorption purification/separationMolecular sieveBisulfide

The invention relates to a thiol and disulfide removal agent which is an X molecular sieve exchanged from positive ions Cs<+>, Mg<2+>, La<3+>, Ce<3+>, Cu<2+>, Zn<2+>, Mn<2+> or a Y molecular sieve exchanged from positive ions Cs<+>, Mg<2+>, La<3+>, Ce<3+>, Zn<2+>, Mn<2+>.The invention further discloses a C4 hydrocarbon deep desulfurization method which adopts the thiol and disulfide removal agent, in the invention, removal is carried out continuously and systematically on H2S, COS, thiol and disulfide in the C4 hydrocarbon; the method is easy to operate; C4 hydrocarbon can be refined to ensure that total sulfer therein is less than 0.5ppm and the carbonyl sulfide is less than 0.05ppm.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

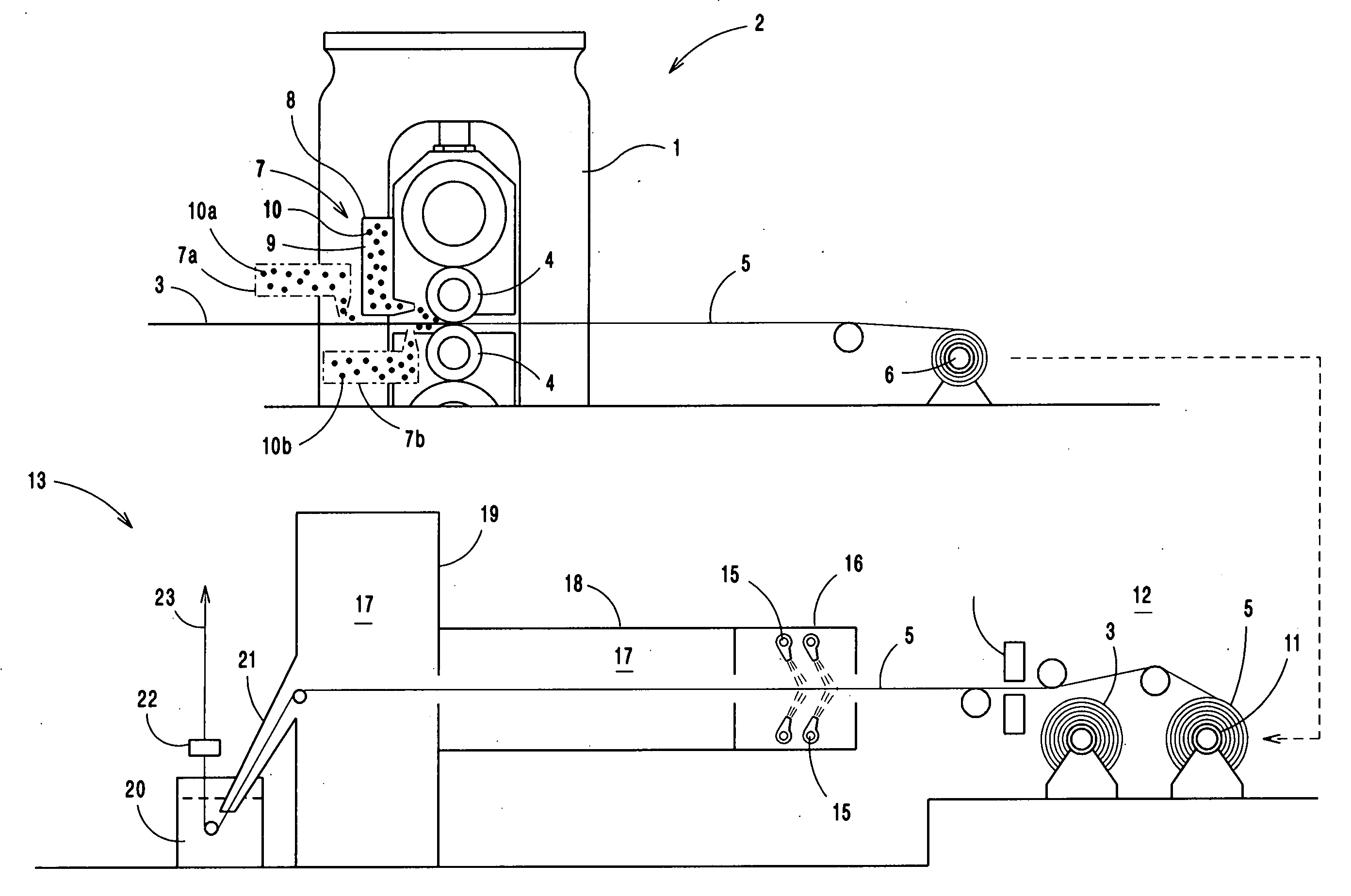

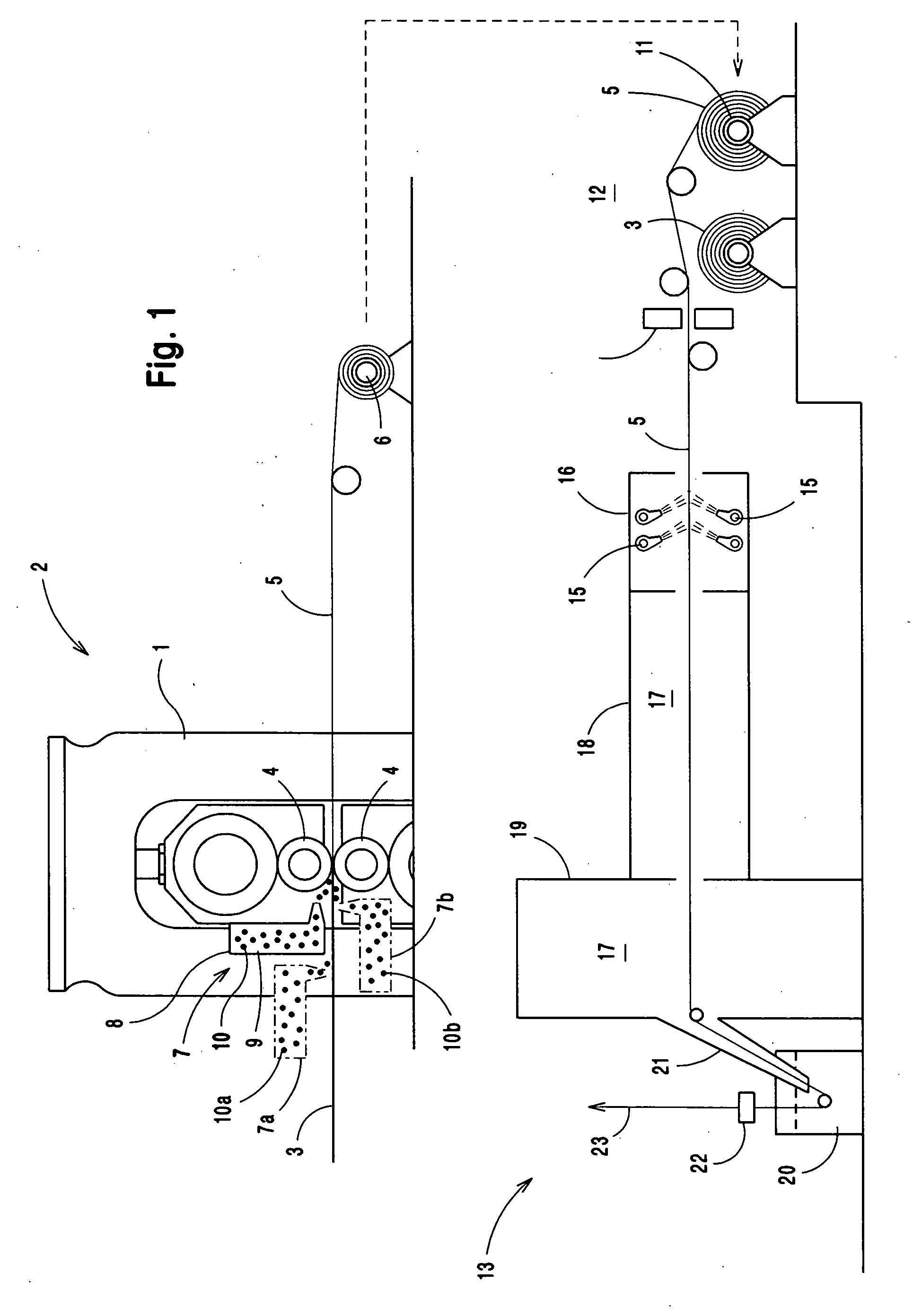

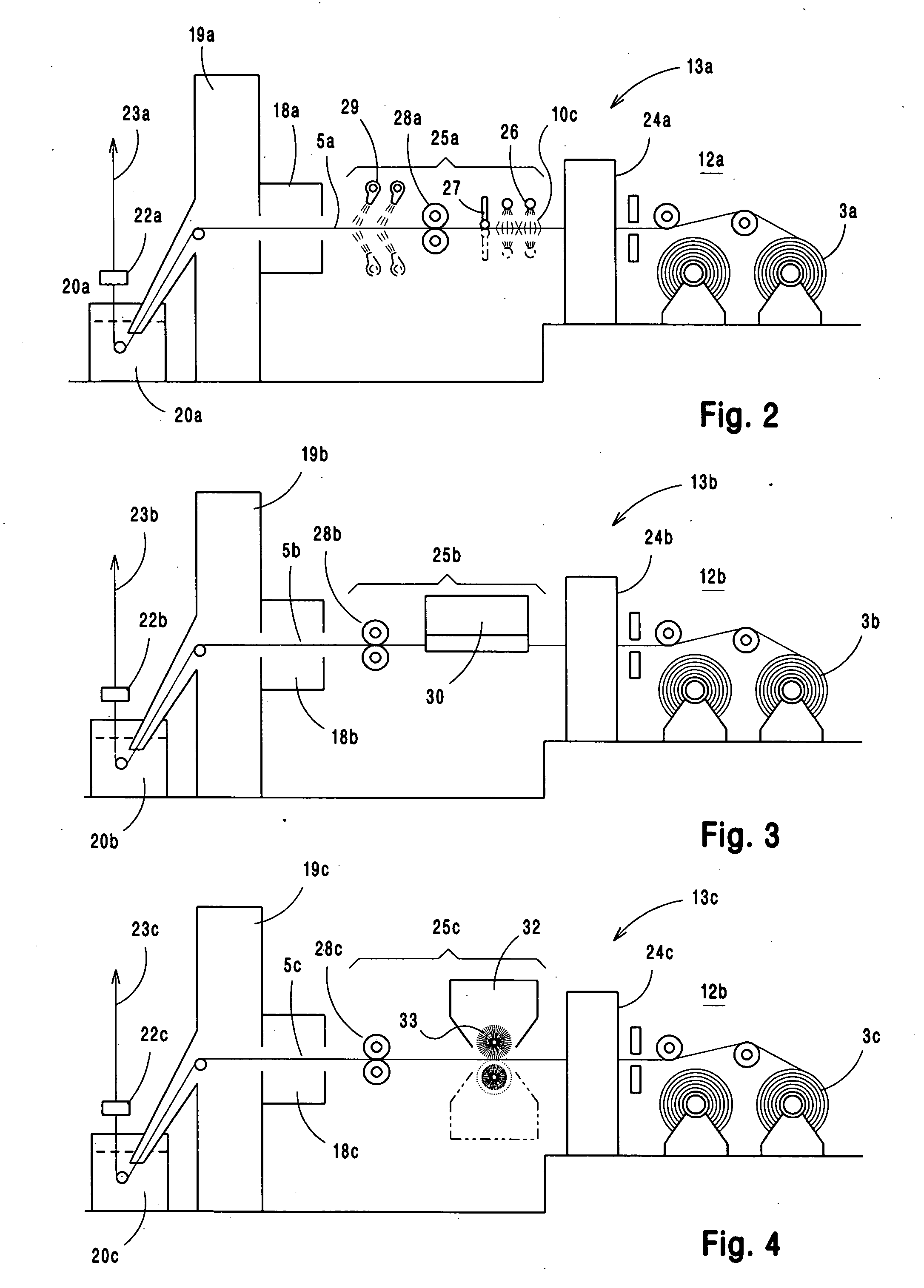

Waste paper regeneration environmental protection device and method

InactiveCN101798768AReasonable configurationHigh degree of automationFinely-divided cellulose conservationSludgeWater circulation

The invention relates to papermaking method and device, in particular relates to waste paper regeneration environmental protection device and method. The waste paper regeneration device is provided with a hydraulic pulper, a first stock tank, a first desander, an inclined sieve, a second stock tank, a pulping machine, a third stock tank, a header box, a fourth stock tank, a second desander, a pressure sieve, a paper machine, a boiler, a reaction tank and a wastewater filter tank. By adopting the waste paper regeneration method and device, a closed production and water circulation mode is formed. Compared with the prior art, the invention has reasonably configured device system composition, higher degree of automation, convenient operation and higher pulping efficiency, can recycle afterheat and wastewater after being processed into purified water, realizes the energy-saving and environmental-protection effect, obviously improves the product quality through detection and can regularly clean sludge and coal ash in the wastewater filter tank to be used as field fertilizers, thereby changing waste into valuable without pollutant emission.

Owner:侯俊民

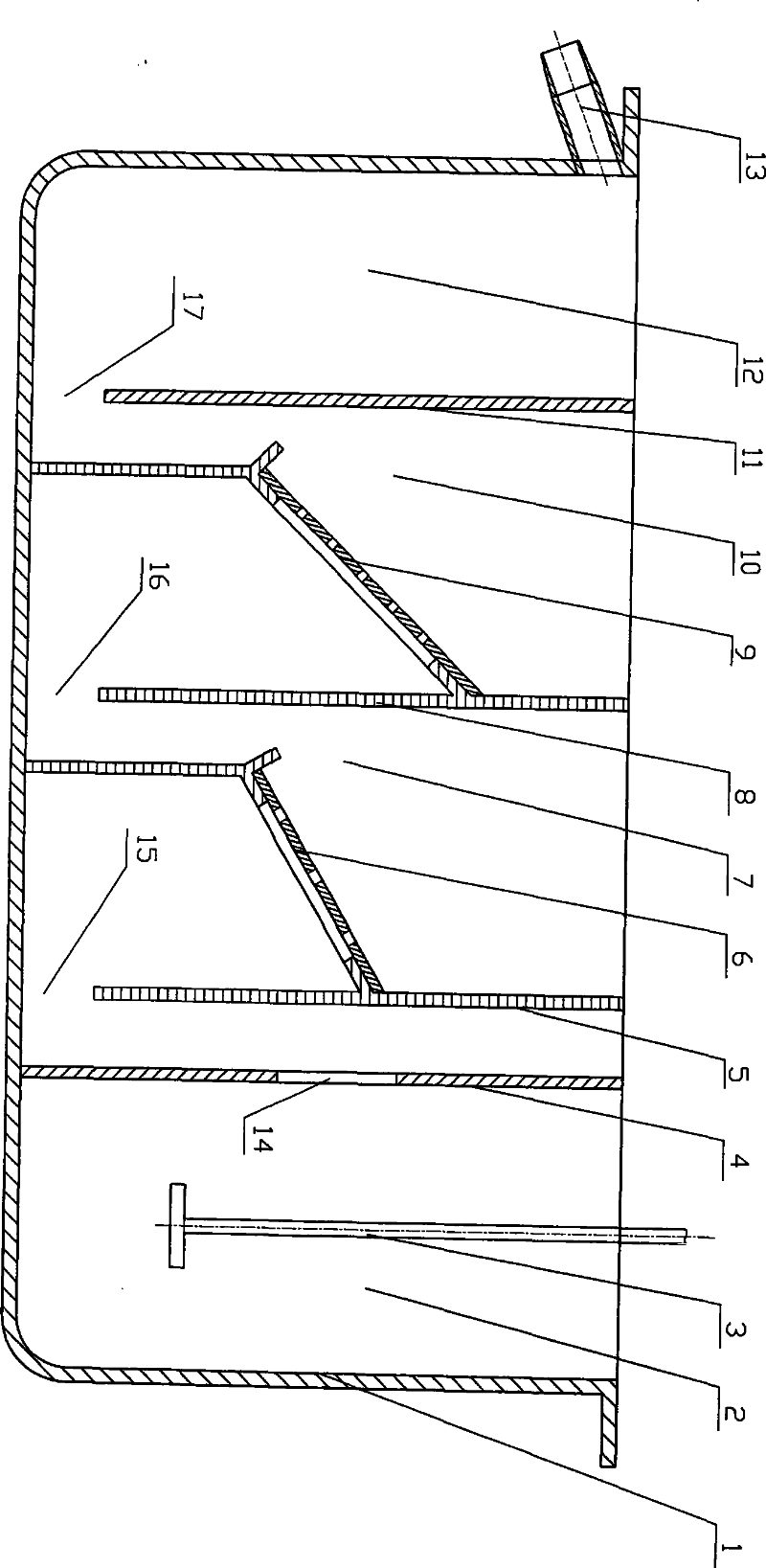

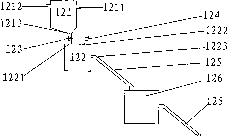

Method for controlling electroslag melting casting by added transient magnetic field and electroslag smelting casting device

The invention discloses a method for controlling electroslag melting casting by an added transient magnetic field. The method includes adding a transient magnetic field to a melting end of an electroslag remelting mother electrode, a liquid slag tank and a metal melting tank so that the transient magnetic field acts on large metal molten drops which are generated by initial melting at the tail end of the electrode and are converging to become big; under joint action of alternating lorentz force and pressure waves generated by the transient magnetic field, dispersing the metal molten drops in a burst manner into small metal molten drop groups, and randomly dispersing the small metal molten drop groups into the liquid slag tank to sufficiently contact with liquid slag after passing the liquid slag tank; after washing, enabling included foreign substances and impurities in the small metal molten drops to enter the liquid slag quickly, slowly settling and converging the foreign substances and impurities into the metal melting tank below the liquid slag tank, and finally crystallizing and solidifying to form solidified cast ingots. The invention further provides an electroslag melting casting device. By adding the transient magnetic field during electroslag melting casting and fining the molten drops by the aid of unique electromagnetic effect of the transient magnetic field, the purposes of improving refining efficiency, fining crystalline grains and reducing segregation of cast ingots are achieved, and industrial application value is realized.

Owner:SHANGHAI UNIV

Processing technique for wall-breaking ganoderma lucidum spore powder

InactiveCN108888638AEfficient removalReduce the difficulty of dissolutionPlant ingredientsSporeAdditive ingredient

The invention provides a processing technique for wall-breaking ganoderma lucidum spore powder and relates to the technical field of bio-pharmaceuticals. The extraction method comprises the steps of pretreatment, ultrasonic treatment, enzyme treatment, freezing, wall breaking and sterilization. According to the method, under a synergistic effect of ultrasonic wave, freezing, enzyme treatment and wall breaking, the impurities in the ganoderma lucidum spore powder are effectively removed through deionized water washing, coarse crushing, ultrasonic treatment and enzyme treatment; dissolving difficulty is effectively reduced due to the addition of a wall-dissolving enzyme; the super-freezing and airflow wall-breaking double technique is adopted for breaking the wall of the ganoderma lucidum spore powder; the technological operation is simple; the preparation cost is low; the problems that the wall breaking of the present ganoderma lucidum spore powder is incomplete, the nutritional ingredients of the ganoderma lucidum spore powder are incompletely maintained and the nutritional ingredients are damaged can be effectively solved.

Owner:GUANGXI XIUMEI ZHUANGXIANG ENERGY ENVIRONMENTAL PROTECTION CO LTD

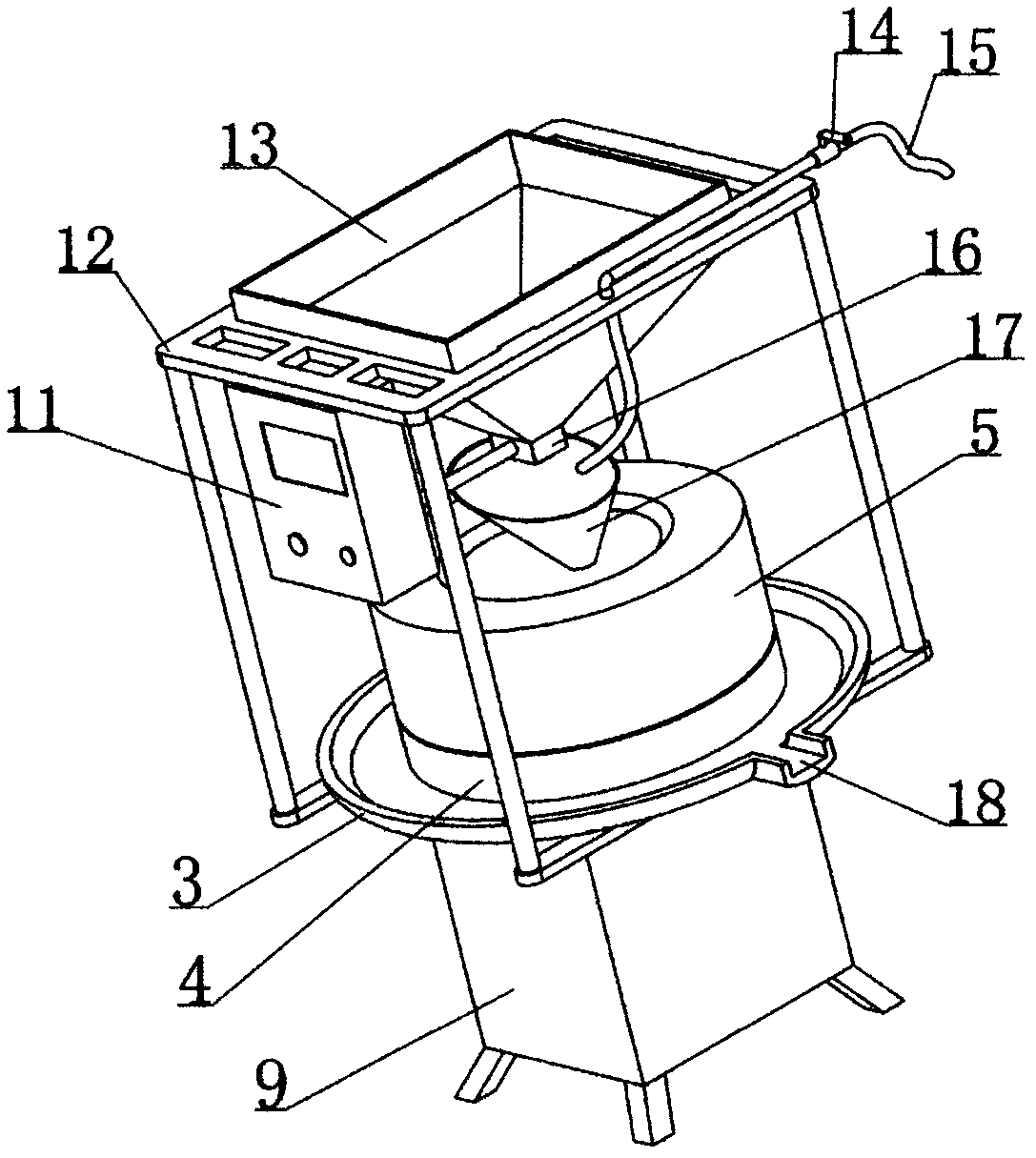

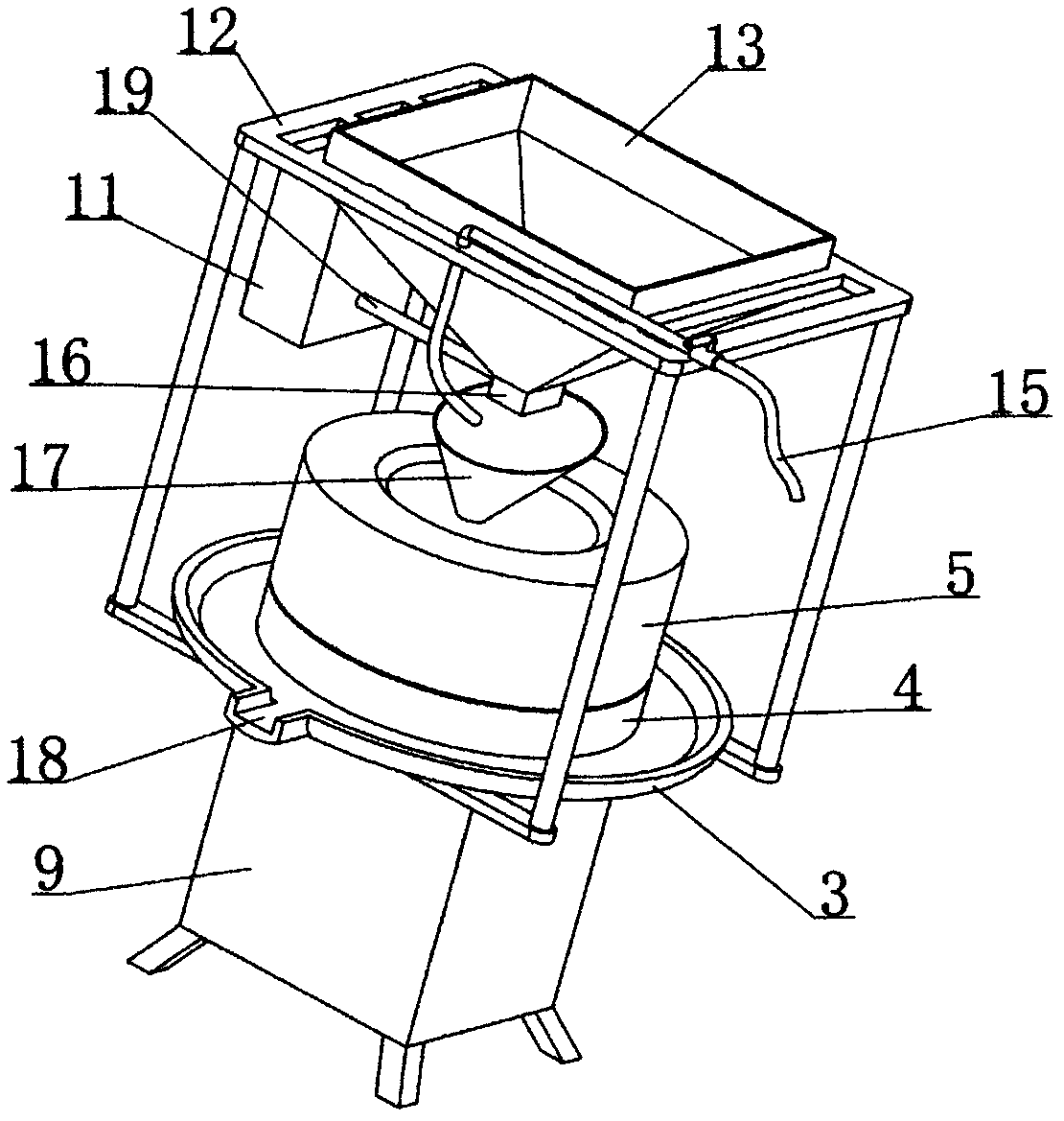

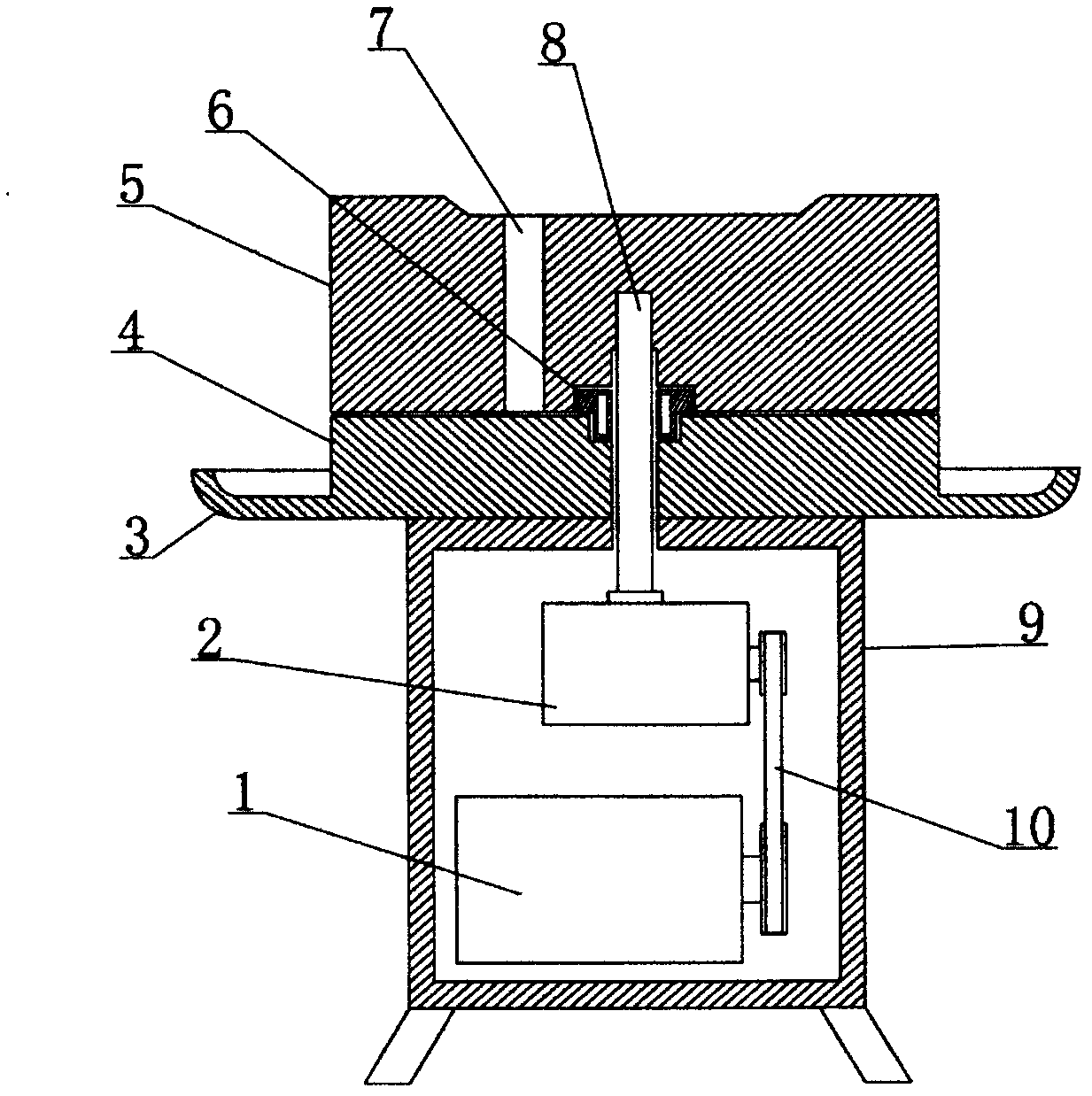

Automatic feeding type no-clean burrstone mill for soybeans, peanuts and rice

The invention discloses an automatic feeding type no-clean burrstone mill for soybeans, peanuts and rice. The automatic feeding type no-clean burrstone mill comprises a base, a lower abrasive disk, a milk collection tray and an upper abrasive disk, wherein a hopper is arranged above the upper abrasive disk; the discharge port at the lower end of the hopper is provided with a material shifting shaft; the material shifting shaft is driven by a feed motor; and an water inlet pipe is arranged above a feeding hopper. The automatic feeding is controlled by the motor, water is automatically fed, and the upper abrasive disk is driven by the motor, so that the milk grinding efficiency is greatly improved, and the manual workload is reduced.

Owner:宁现林

Rotor refiner plate element for counter-rotating refiner having curved bars and serrated leading edges

ActiveUS9708765B2Increased operating lifeImprove refining efficiencyCocoaPulp beating/refining methodsLeading edgeEngineering

A refining plate segment for a mechanical refiner of lignocellulosic material including: a refining surface on a substrate, wherein the refining surface faces a refining surface of an opposing refiner plate, the refining surface including bars and grooves between the bars, wherein an angle of each bar with respect to a radial line corresponding to the bar increases at least 15 degrees along a radially outward direction, and the angle is a holdback angle in a range of 10 to 45 degrees at the periphery of the refining surface, and wherein the bars each include a leading sidewall having an irregular surface, wherein the irregular surface includes protrusions extending outwardly from the sidewall towards a sidewall on an adjacent bar and the irregular surface extends from at or near the outer periphery of the refining surface extends radially inwardly along the bars without reaching an inlet of the refining surface.

Owner:ANDRITZ INC

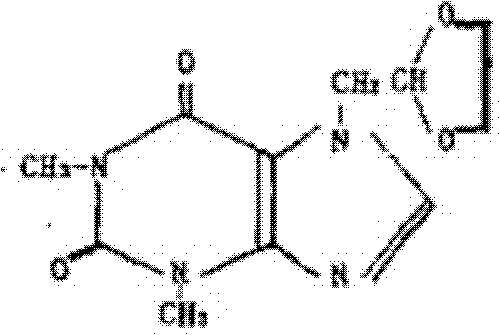

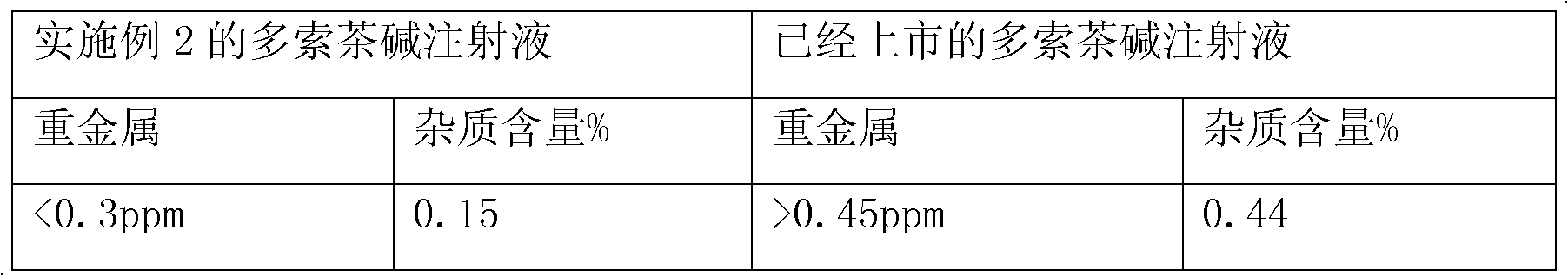

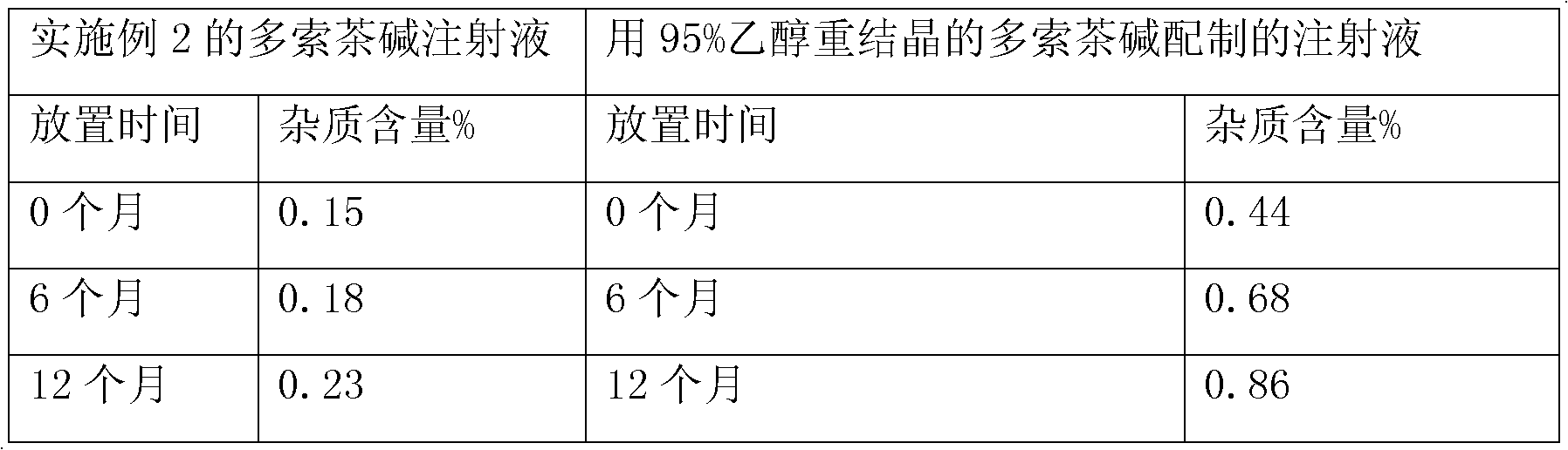

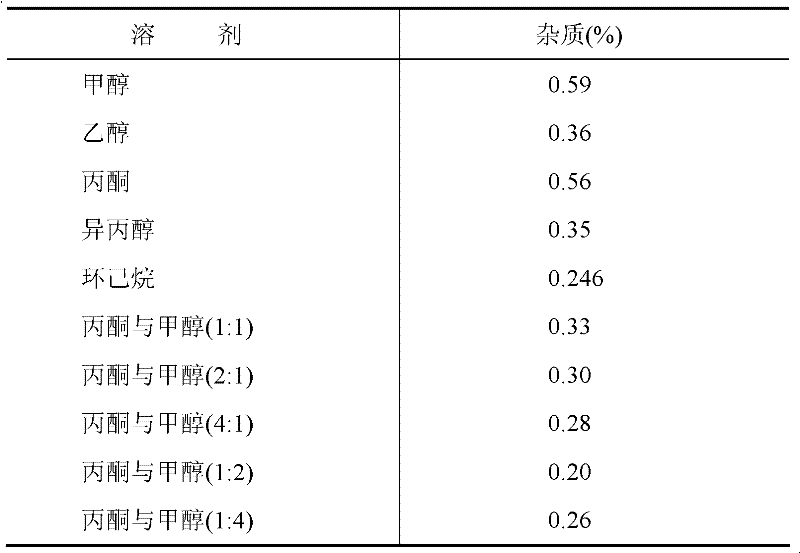

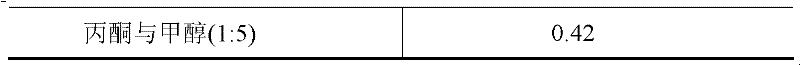

More stable doxofylline compound and pharmaceutical composite thereof

InactiveCN102367254ASlow degradationHigh purityPowder deliveryOrganic chemistryDoxofyllineActivated carbon

The invention relates to a more stable doxofylline compound and a pharmaceutical composite thereof. The preparation method of the doxofylline compound comprises the following steps: recrystallizing crude doxofylline with a mixed solvent of ethyl acetate and methanol for 1-3 times and decoloring with activated carbon to obtain off-white crystals, wherein the ratio of ethyl acetate to methanol is 1:2.

Owner:河北三禾实创生物科技有限公司

Copper-removal composition used for secondary lead refining and application thereof

The invention discloses a copper-removal composition used for secondary lead refining. The copper-removal composition is composed of 30-45 wt% of Fe, 40-55 wt% of S, 3-15 wt% of SiO2 and 0.0002-0.02 wt% of lead powder. The copper-removal composition is added into liquid lead for a copper removal reaction, copper dross is fished out after the reaction to obtain liquid lead with copper removed, and refined lead is obtained after the liquid lead with copper removed is subjected to fluxing cleaning through caustic soda flakes and ingot casting. The invention further provides an application of the copper-removal composition in secondary lead refining. According to the copper-removal composition, the removal rate to copper in the liquid lead is high; smoke and odor do not exist in the copper removal reaction, and the working environment is good.

Owner:ZHEJIANG TIANNENG POWER SOURCE MATERIAL

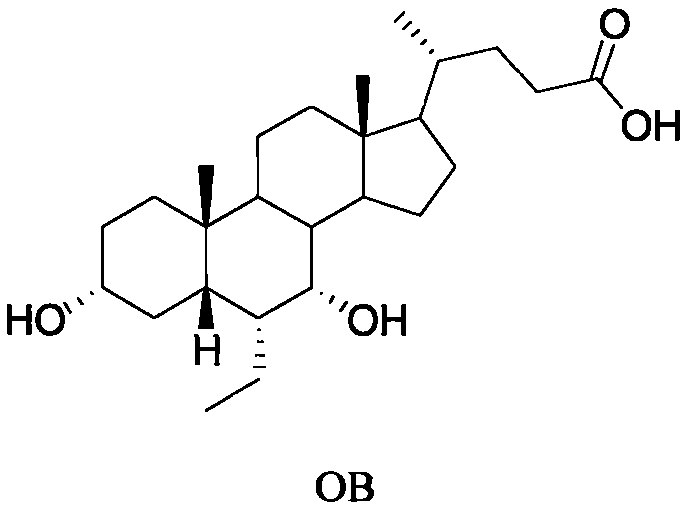

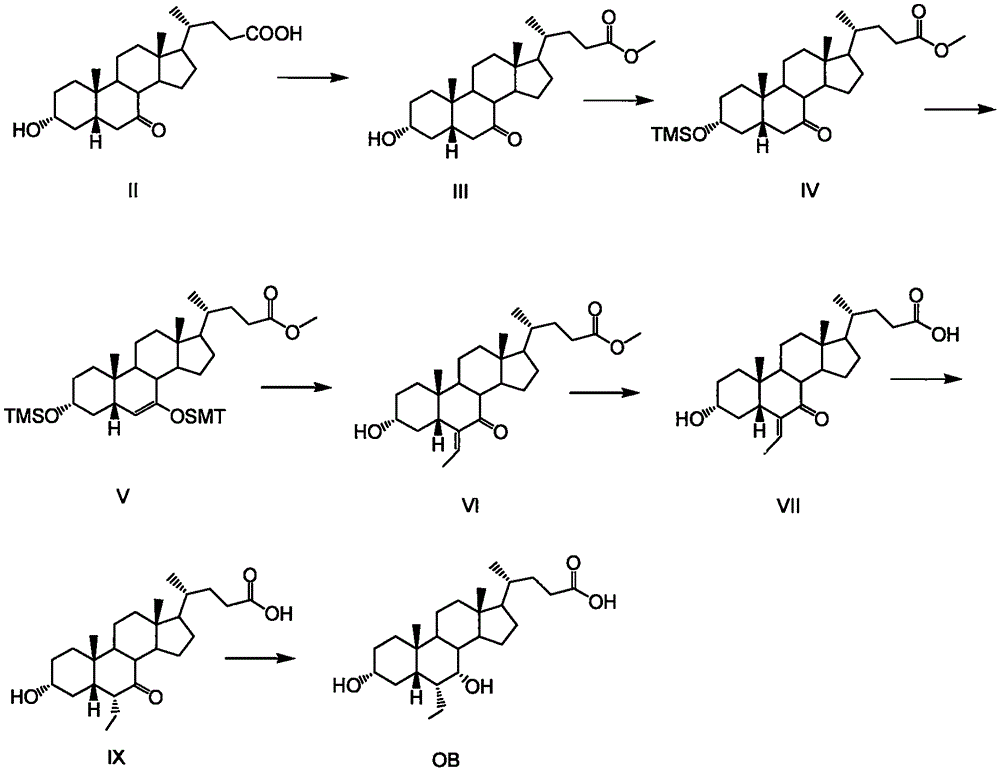

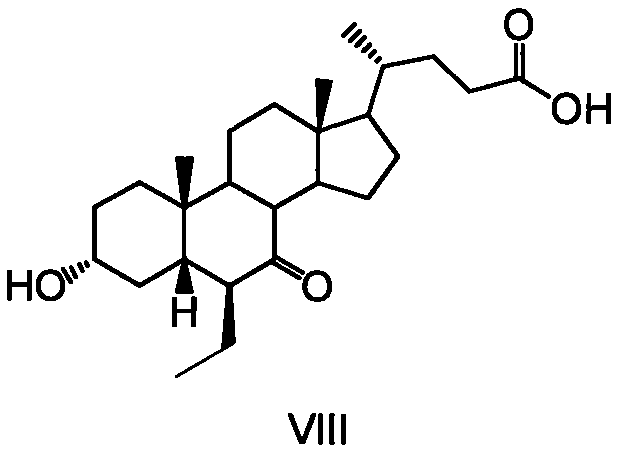

A method for preparing obeticholic acid and related compound

ActiveCN106589039AImprove refining efficiencyReduce the introductionSteroidsBulk chemical productionProtecting groupCholane

This invention provides a new method for preparing obeticholic acid which belongs to the technical field of medicine. Its raw material is E / 2 -3alpha-hydroxy-b-ethylidene-keto-5beta-cholane-24-acid methyl ester(OB-4)which can be gained easily. First, OB-3 can be produced through hydroxy-protection with tetra hydropyrane protecting group. Then, OB-2 can be produced through hydrogenation-reduction in alkaline aqueous solution. Then, OB-1 can be produced through reducing again. At last, the target product--obeticholic acid can be got through catalyzing and removing tetrahydropyrane. The method is simple in production process, the content of isomer impurity is low, and the method is a new synthetic method of obeticholic acid suitable for industrial production.

Owner:SUZHOU LANXITE BIOTECH

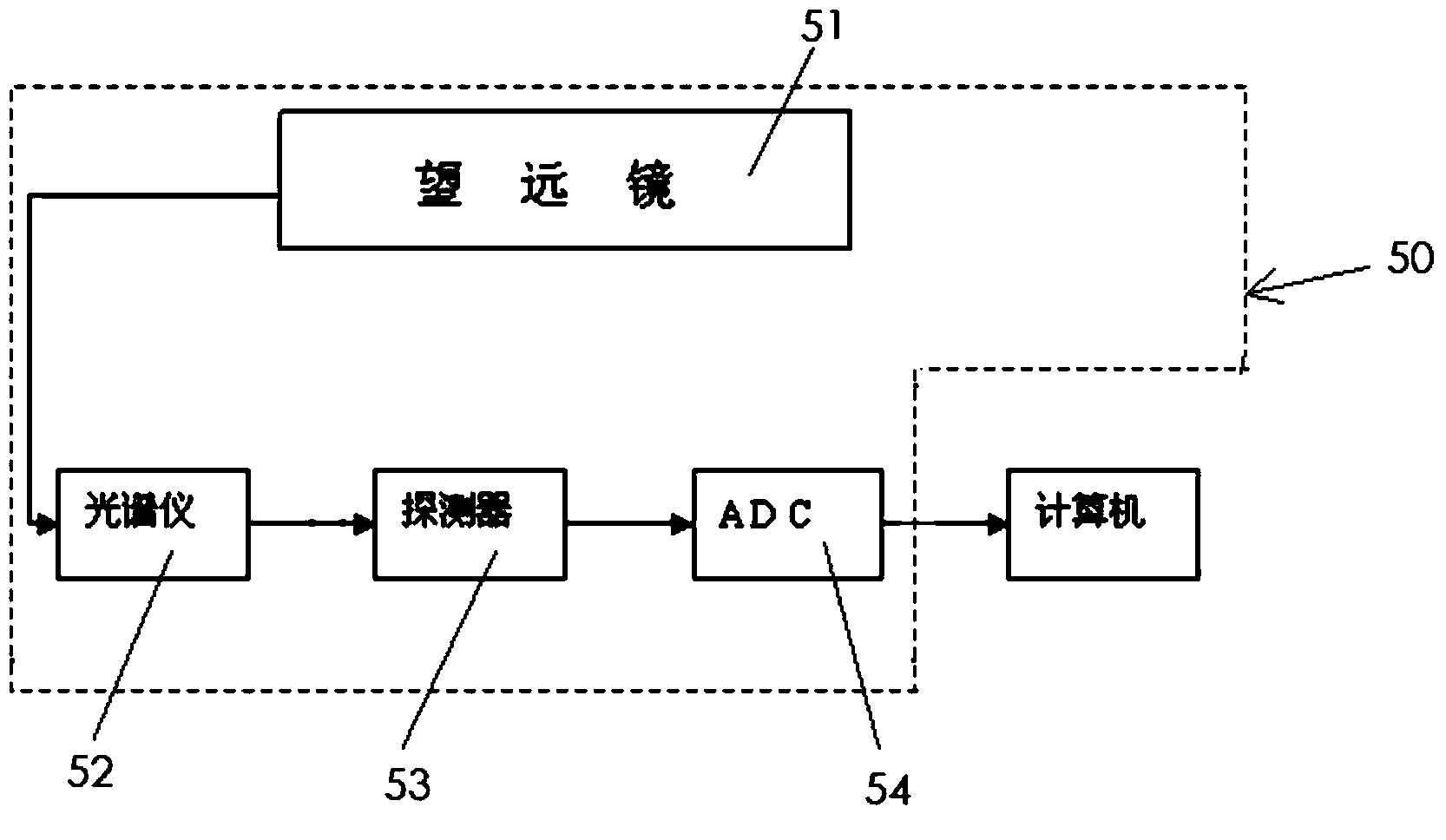

Copper converter converting control system

The invention discloses a copper converter converting control system which comprises a slag forming end point detection unit and a copper forming end point detection unit, wherein the slag forming end point detection unit is used for online collecting characteristic spectrum emission intensity signals of PbO and PbS of the melt in a copper converter in the slag forming period; the copper forming end point detection unit is used for online collecting gas concentration signals of SO2 in flue gas in a copper converter gas duct A in the copper smelting period; a data processing unit is used for analyzing and processing the signals collected by the slag forming end point detection unit and the copper forming end point detection unit to judge whether the converting reaches the slag forming end point and the copper forming end point, and performs regulation and control to determine whether the blowing out is performed. The control system can accurately judge the slag forming end point and the copper forming end point, so that the phenomena including over-blowing, under blowing and the like can be avoided, the safety production of copper converter converting is ensured, and the efficiency of copper smelting is improved.

Owner:HEFEI GOLD STAR MECHATRONICS TECH DEV CO LTD

Novel maltodextrin production process

InactiveCN109680023AGuaranteed SolubilityEffective control of DE value rangeFermentationIon exchangeEvaporation

The invention provides a novel maltodextrin production process, which uses starch as raw materials. Through a liquidation work procedure, a saccharification work procedure, a deslagging and decoloringwork procedure, an ion exchange work procedure, an evaporation concentration work procedure and a spray drying work procedure, maltodextrin with a low DE value is obtained. The DE value of the maltodextrin product is 6 to 8, wherein in the liquidation work procedure, a processing process using three times of spraying, twice enzyme adding and three sections of maintenance is used for processing the starch. The maltodextrin production process has the advantages of practicability and high applicability. The maltodextrin with the low DE value (the DE value is 6 to 8) produced by the maltodextrinproduction process has the advantages that the product quality is stable; the appearance is uniform; no maltodextrin retrogradation occurs.

Owner:山东兆光色谱分离技术有限公司 +1

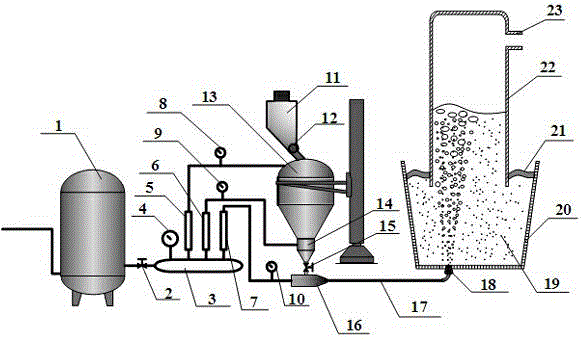

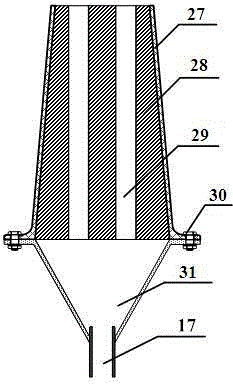

Device and method for single snorkel vacuum degassing refining of molten steel by employing bottom injection

The invention belongs to the technical field of steel refining, and particularly relates to a device and a method for single snorkel vacuum degassing refining of molten steel by employing bottom injection. The device disclosed by the invention comprise an air supply system, a powder spray system, a single snorkel vacuum degassing refining furnace, wherein an airflow distributor on the air supply system is branched into three gas circuits which are connected with the powder spray system; a powder airflow delivery pipe in the powder spray system is connected with a bottom powder injection element; the bottom powder injection element is built at the bottom of a ladle furnace of the single snorkel vacuum degassing refining furnace; and an opening is formed in the lower end of a vacuum chamber of the single snorkel refining furnace and is inserted into a steel ladle molten pool. The method for single snorkel vacuum degassing refining of molten steel by employing bottom injection comprises the following steps: firstly, blowing a gas and stirring molten steel; blowing powder into the steel ladle through the bottom powder injection element under the transportation of a carrier gas flow; and after the blowing time is ended, entering the next work circle. The device and the method are easy to achieve, short in production cycle, and high in production capacity; equipment investment and operation costs on an overhead bunker and a wire feeding mechanism are reduced; the technological operation is simple; and energy conservation and emission reduction are facilitated.

Owner:NORTHEASTERN UNIV

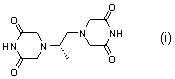

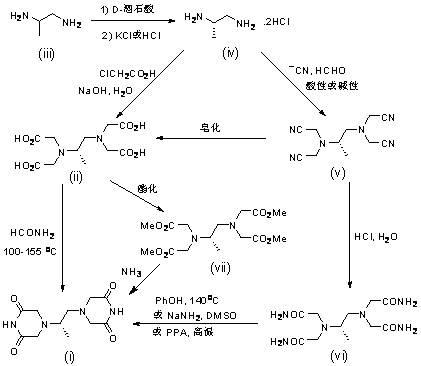

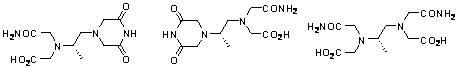

Preparation method of high-purity dexrazoxane

ActiveCN102675227AIncrease the degree of steamingGood dispersionOrganic chemistryPressure reductionSodium salt

The invention relates to a preparation method of high-purity dexrazoxane, which comprises the following steps of: (1) cyclization reaction: carrying out cyclization reaction between (S)-1, 2-propane diamine-N, N, N', N'-tetracetic acid or disodium salt of (S)-1, 2-propane diamine-N, N, N', N'-tetracetic acid and formamide, wherein a high boiling point solvent is used; (2) preparation of salt-containing crude product: evaporating the mixture, which is obtained after reaction, for removing the formamide by pressure reduction and concentration, adding organic solvent into the mixture, and filtering to obtain solid; (3) preparation of crude product: adding dioxane into the salt-containing crude product, heating for backflow, filtering, concentrating the filtrate, adding organic solvent into the filtrate to obtain the crude product of dexrazoxane; and (4) refining: adding the crude product of dexrazoxane into N, N'-dimethyl formamide, heating for dissolving, dropwise adding the solvent, carrying out crystallization, filtering to obtain solid, washing the obtained solid with the solvent, drying to finally obtain the high-purity dexrazoxane. The method for synthesizing dexrazoxane is stable in yield and easy in condition control; the product purity is higher than 99.5% and residual organic solvent is little, and the synthesis cost can be reduced.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Phosphoric acid impurity removal process in preparing activated carbon by phosphoric acid method

The invention discloses a phosphoric acid impurity removal process in preparing activated carbon by a phosphoric acid method. The phosphoric acid impurity removal process comprises the following steps of: (1) adding superfluous concentrated sulfuric acid solutions to a phosphoric acid solution in a first reactor, and stirring to form a calcium sulfate precipitate; (2) filtering to separate out calcium sulfate impurities, and sending filter liquor to a second reactor; (3) adding barium phosphonate or barium hydroxide into the second reactor to ensure that excess sulfuric acid is formed into a barium sulfate precipitate, and filtering to obtain a preliminarily refined phosphoric acid solution; and (4) flowing the preliminarily refined phosphoric acid solution through H type cation exchange resin to remove cation impurities to obtain a finally refined phosphoric acid solution. The phosphoric acid impurity removal process has the advantages that because calcium ions are firstly removed in the impurity-containing phosphoric acid, more impurity-containing phosphoric acid can be refined in an exchange process at a time, so that the use efficiency of an ion exchange is improved, and a phosphoric acid solution with a higher concentration can be simultaneously obtained.

Owner:FUJIAN YUANXIANG CHEM

Process for applying a metallic coating, an intermediate coated product, and a finish coated product

InactiveUS20070003778A1Small sizeImprove refining efficiencyHot-dipping/immersion processesPretreated surfacesDip-coatingMetallic coating

The present invention is directed to a method of refining spangle facet size in a hot-dip coated product by applying grain-refining particles to the surface of a steel substrate before immersion into the hot-dip coating bath, to an intermediate coated steel sheet, and to a finish coated steel sheet having a different coating spangle facet size on opposite surfaces.

Owner:SEVERSTAL SPARROWS POINT

Method for synthesizing o-cresol formaldehyde epoxy resin by using cosolvent and recovering cosolvent

The invention discloses a method for synthesizing o-cresol formaldehyde epoxy resin by using a cosolvent and recovering the cosolvent. The method comprises the following steps: mixing chloropropylene oxide with the cosolvent, adding the mixture into o-cresol formaldehyde resin, and carrying out a base catalysis pre-reaction; carrying out a base catalysis ring closure reaction, and carrying out reduced pressure distillation to separate out reaction wastewater; distilling the cosolvent and excess chloropropylene oxide after the ring closure reaction to obtain crude resin; and adding chloropropylene oxide and the wastewater obtained after the ring closure reaction into the crude resin, carrying out salt-out extraction, discharging the above obtained salt-out extracted water phase, distilling the above obtained organic phase to recover chloropropylene oxide and the cosolvent, and refining the remaining crude resin to obtain the o-cresol formaldehyde epoxy resin. The method has the advantages of effective enhancement of the ring closure reaction effect, reduction of the amount of polymer wastes, effective recovery and cycle use of the cosolvent, and great reduction of the production cost.

Owner:CHINA PETROLEUM & CHEM CORP

Purifying method of antioxidant 168

ActiveCN102718797AGood crystal shapeImprove stabilityGroup 5/15 element organic compoundsEthyl acetateAnoxomer

The invention relates to a purifying method of an antioxidant 168. The method comprises the following steps that coarse products of the antioxidant 168 are recrystallized for once to three times by mixed solvents consisting of ethyl acetate and carbinol according to a mixture ratio being 5:1, and antioxidant 168 crystals with the purity higher than 99.5 percent are obtained.

Owner:营口风光新材料股份有限公司

Production method of high-strength easily-dispersed toilet wiping paper

PendingCN112553962AGood flexibilityHigh folding resistanceNon-fibrous pulp additionNatural cellulose pulp/paperPulp (paper)Paper sheet

The invention relates to a production method of high-strength easily-dispersed toilet wiping paper, wherein the production method comprises the following steps: (1) respectively putting softwood pulpand hardwood pulp into a long-fiber pulper and a short-fiber pulper, adding CMC on a pulp board, respectively pulping after adding water, and respectively pumping into a long-fiber pre-beating pulp pool and a short-fiber pre-beating pulp pool; (2) adding water into the softwood pulp from the long-fiber pre-beating pulp pool, grinding the softwood pulp by a grinding machine, cutting off fibers, separating and brooming, and then feeding the softwood pulp into a long-fiber post-beating pulp pool; (3) adding water into the hardwood pulp from the short-fiber pre-beating pulp pool, defibering the hardwood pulp by a defibering machine, and enabling the defibered hardwood pulp to enter a short fiber post-beating pulp pool; (4) pumping the softwood pulp and the hardwood pulp into a mixed pulp pool,adding water into the mixed pulp pool, then enabling the mixed pulp to enter a pulping machine, further separating and brooming fibers, and enabling the separated and broomed fibers to enter a pulping pool; and (5) feeding the pulp discharged from the pulping pool into a paper machine for forming, squeezing and drying. Compared with the prior art, the method is simple in process and convenient tooperate, and the produced paper has the advantages of being good in strength, easy to disperse and the like.

Owner:上海东冠纸业有限公司

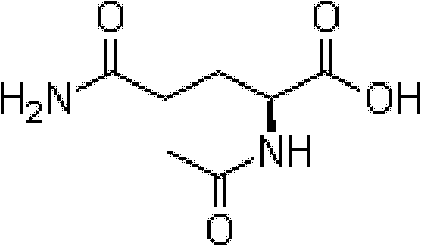

More stable aceglutamide compound and medicinal composition thereof

InactiveCN102358721ASlow degradationLong storage periodOrganic active ingredientsNervous disorderSolventActive carbon

The invention relates to more stable aceglutamide compound and a medicinal composition. The more stable aceglutamide compound is prepared by the following steps of: recrystallizing crude aceglutamide by 1-3 times with a mixed solvent prepared by mixing methanol with acetone in the ratio 2:1; and decolorizing with active carbon to obtain a white crystal, wherein the ratio of the crude aceglutamideto the mixed solvent is 1:10; and the using amount of the active carbon is 5 percent of the solution volume.

Owner:河北三禾实创生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com