Method of refining titanium tetrachloride by using aluminium powder and vash oil mixture

A technology of titanium tetrachloride and crude titanium tetrachloride, applied in the direction of titanium halide, etc., can solve the problem of few reports on vanadium removal process, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

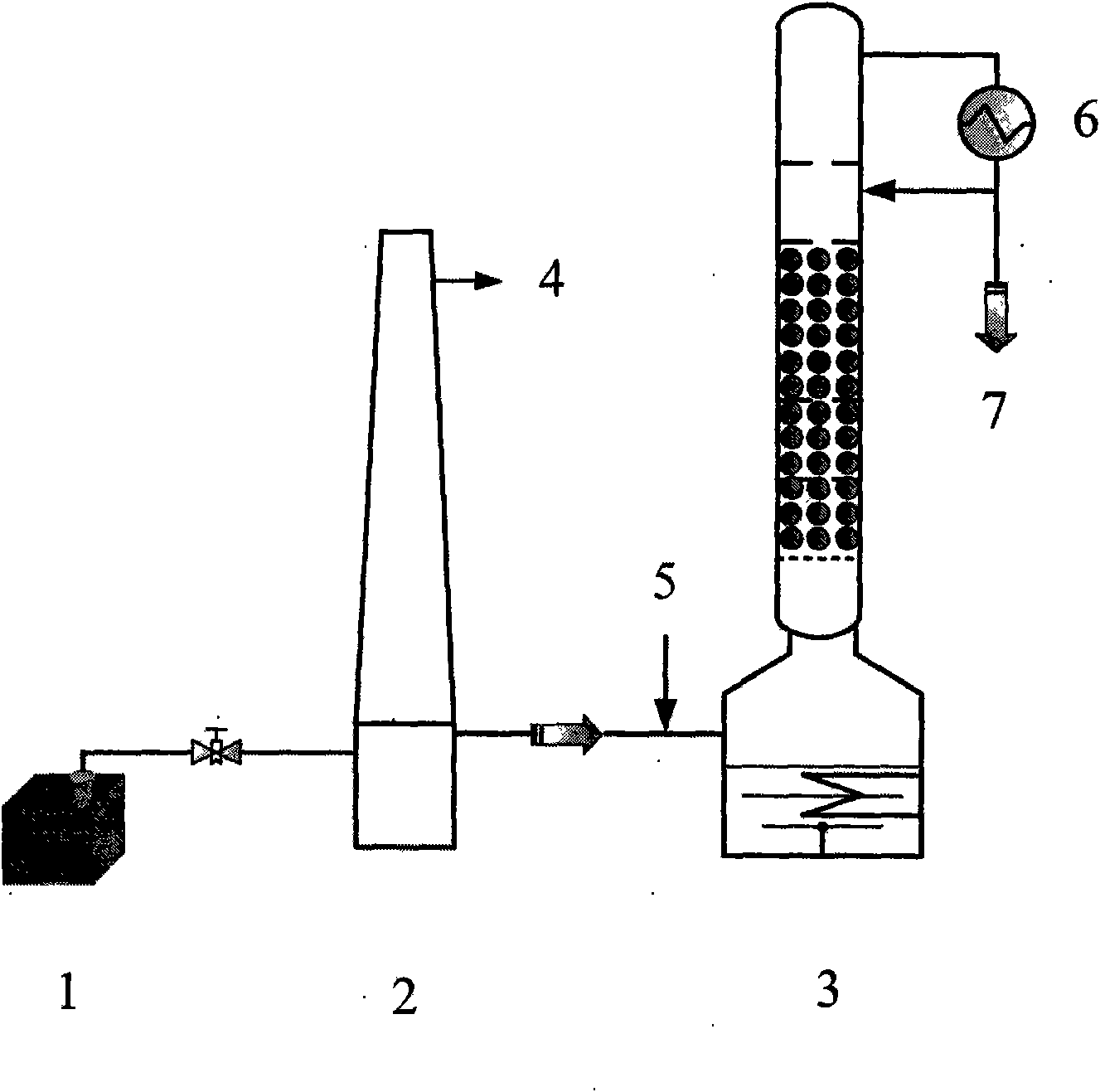

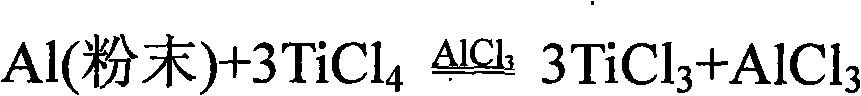

[0023] 1. In a rectification column kettle device (see attached figure 1 ), add crude titanium tetrachloride (vanadium content is 0.29wt%) 150g, aluminum powder 0.20g, white oil 0.60g and AlCl 3 0.15 g (average particle size: 200±20 mesh) was mixed, and the mixture was heated to boiling temperature of 138° C. and kept under reflux for 20 minutes. Then raise the temperature to 139-141°C, and collect the distillate whose temperature ranges from 136°C to 137°C at the top of the tower, which is refined titanium tetrachloride. After analysis, the V content of this product was 3 ppm.

[0024] 2. In a rectification column kettle device (see attachedfigure 1 ), add crude titanium tetrachloride (0.29wt% vanadium content) 150g, white oil 1.2g, stir and heat the mixture to boiling temperature 138°C and keep reflux for 100min, observe that there is obvious brown-black precipitate sticking in the tower kettle inner wall of the container. Then raise the temperature to 139-141°C, and coll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com