Patents

Literature

225results about How to "Reduce filtration efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electret filter media

InactiveUS6119691AReduce filtration efficiencyImprove filtering effectSynthetic fibresBreathing filtersMicrometerFilter media

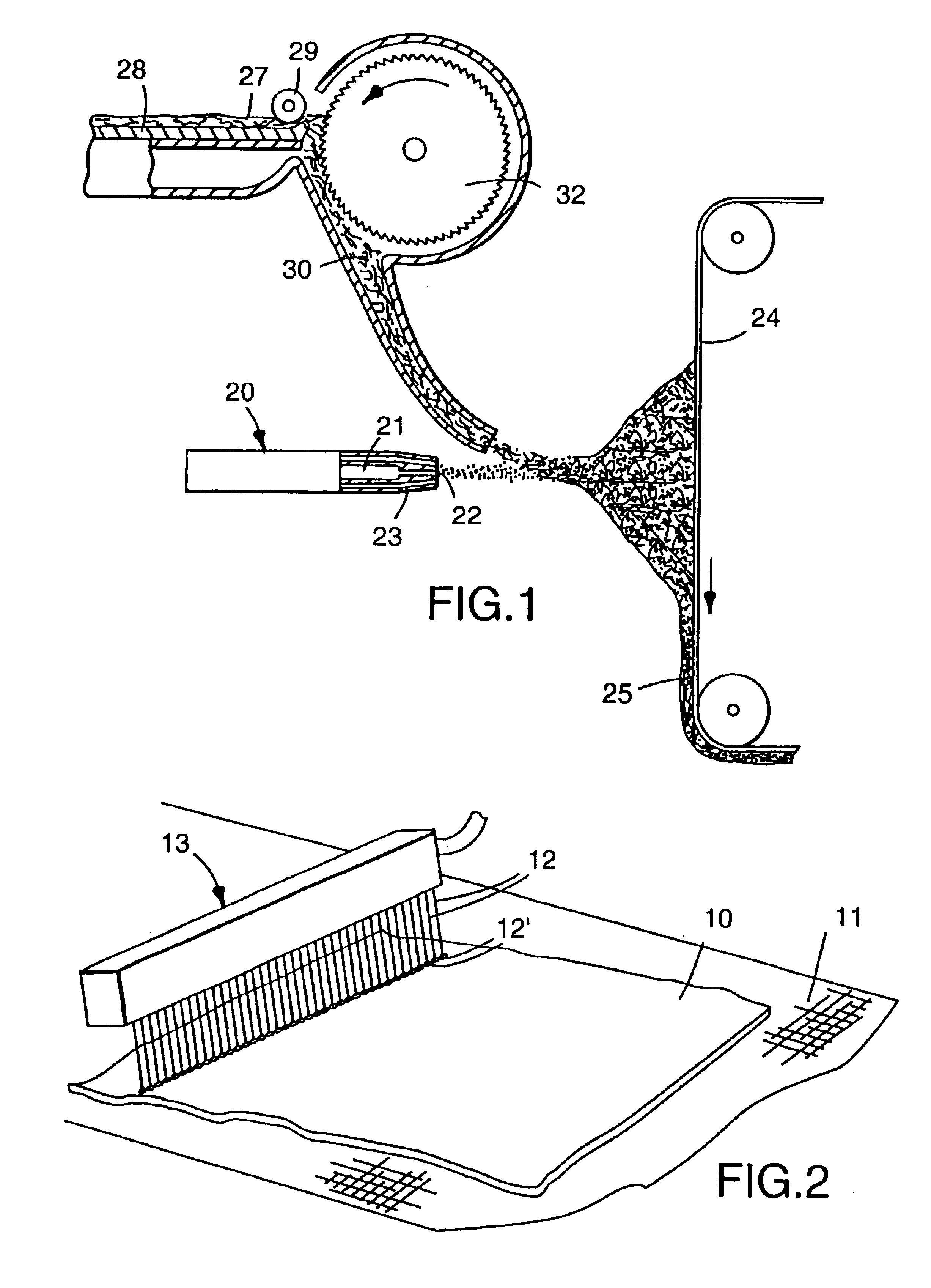

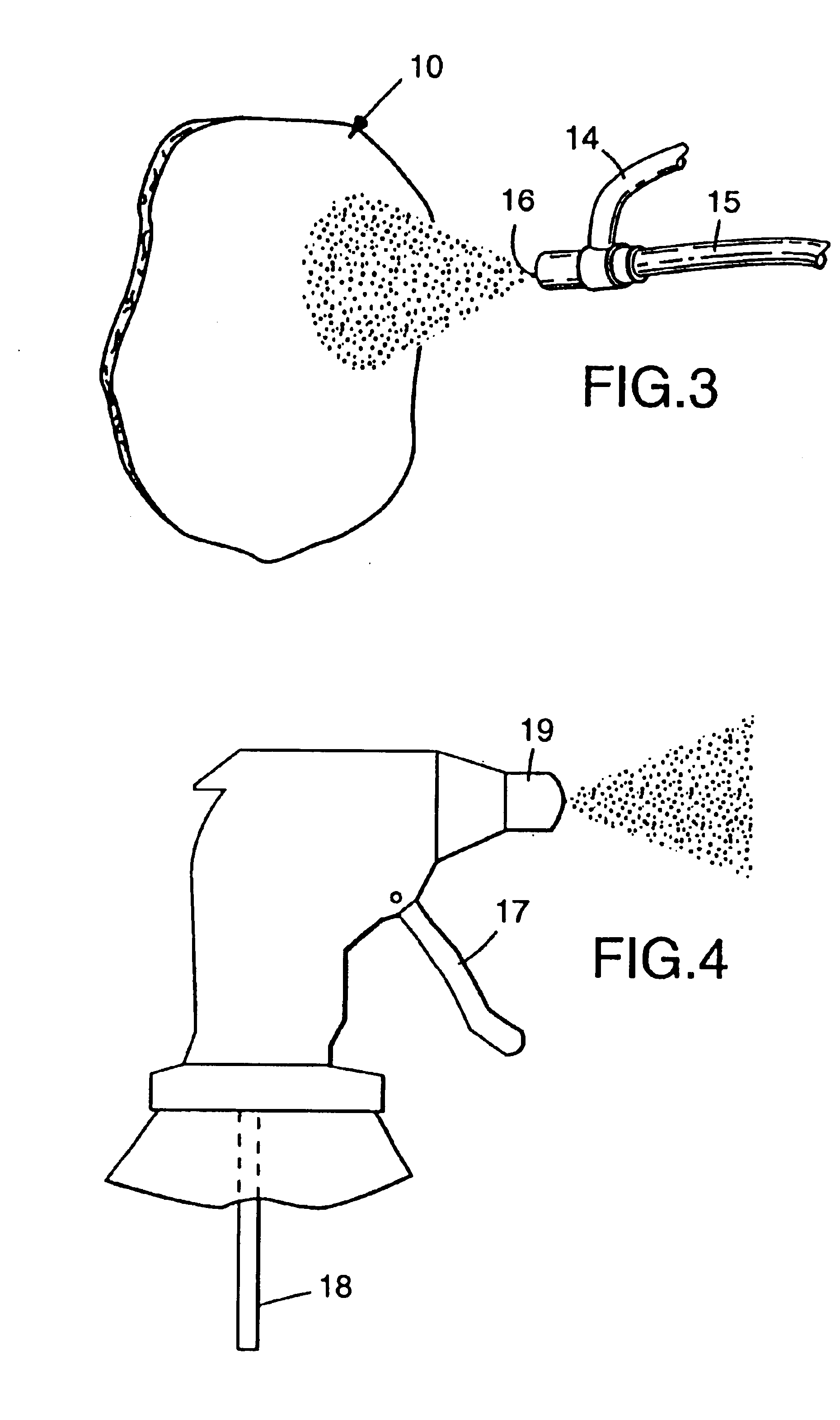

An electret filter media, and mask, that is made of a nonwoven web of thermoplastic microfibers. The thermoplastic microfibers are of substantially the same composition, are nonconductive, and have an effective fiber diameter less than about 15 micrometers. The nonwoven web also has sufficient unpolarized trapped charge to exhibit an initial filtration quality factor of at least 0.31 when measured under the DOP Penetration and Pressure Drop Test.

Owner:3M CO

Electret filter media and filtering masks that contain electret filter media

InactiveUS6783574B1Reduce filtration efficiencyImprove filtering effectSynthetic fibresBreathing filtersFilter mediaRespiratory mask

Electret filter media comprising a nonwoven web of thermoplastic nonconductive microfibers having trapped charge, said charge provided by (1) subjecting the nonwoven web to a corona treatment, followed by (2) impingement of jets of water or a stream of water droplets on the web at a pressure sufficient to provide the web with filtration enhancing electret charge and (3) drying the web. This electret filter media may be used in a respiratory mask to provide extraordinarily good filtration properties.

Owner:3M CO

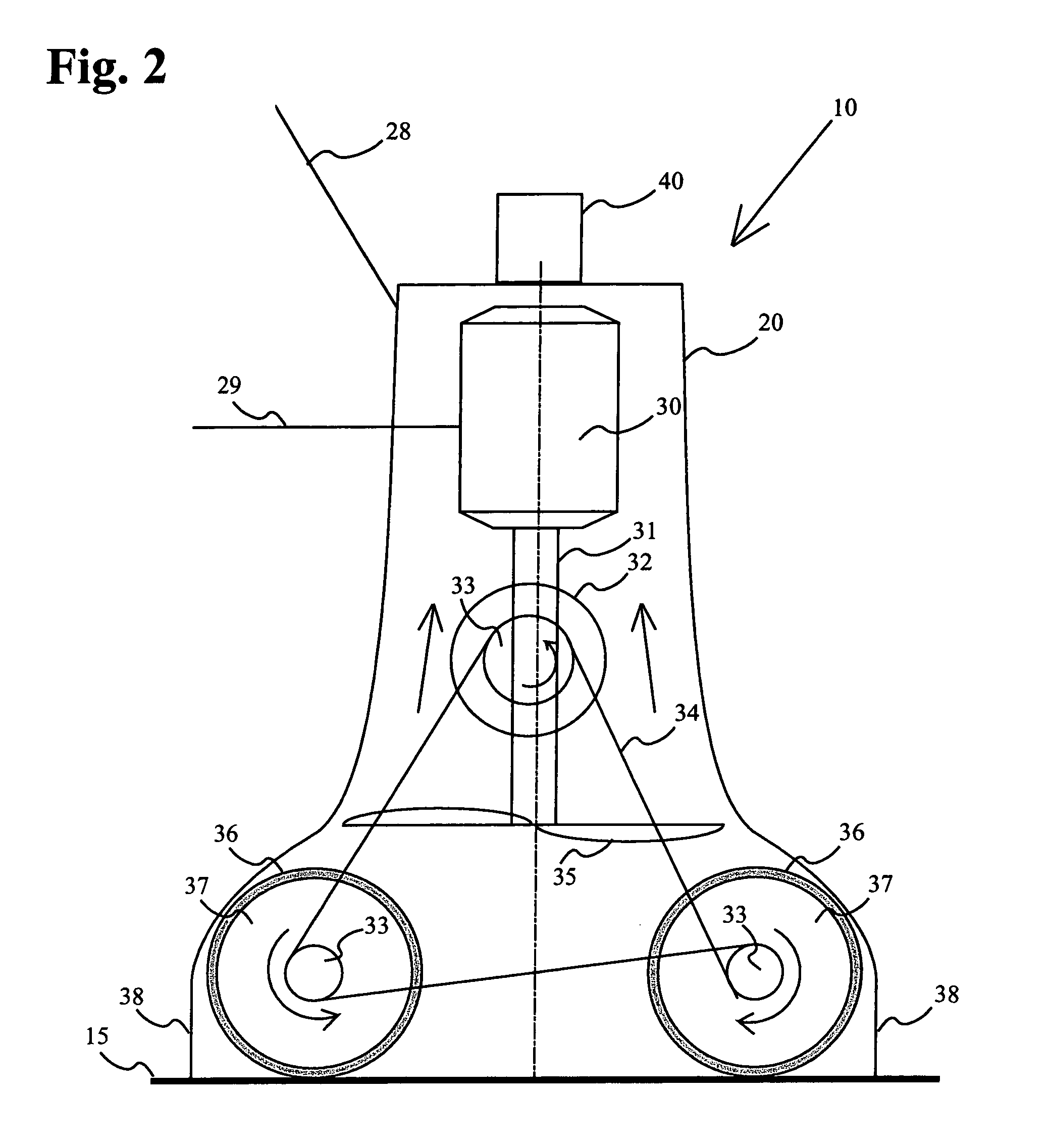

Open-air filtration cleaning device for pools and hot tubs

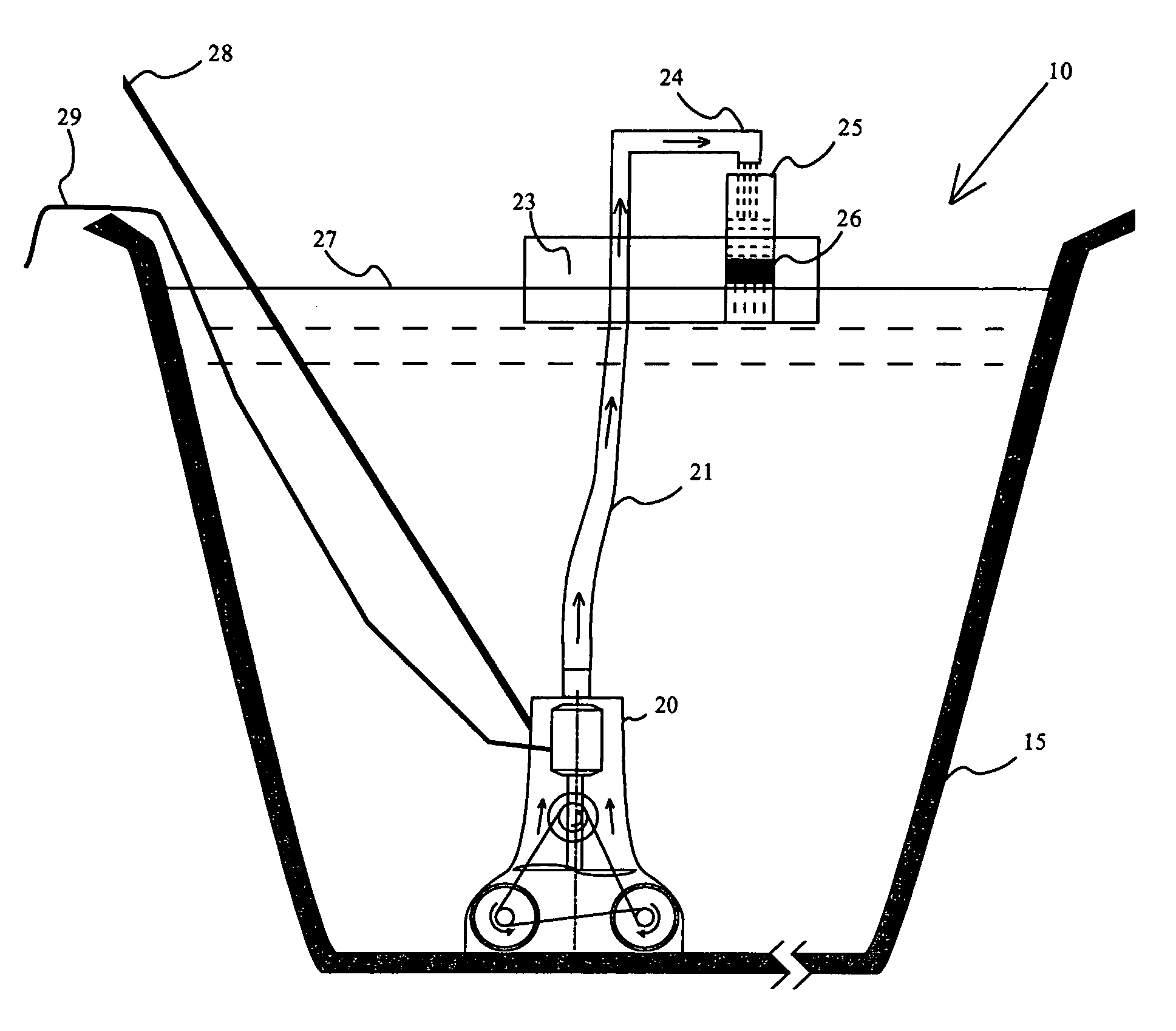

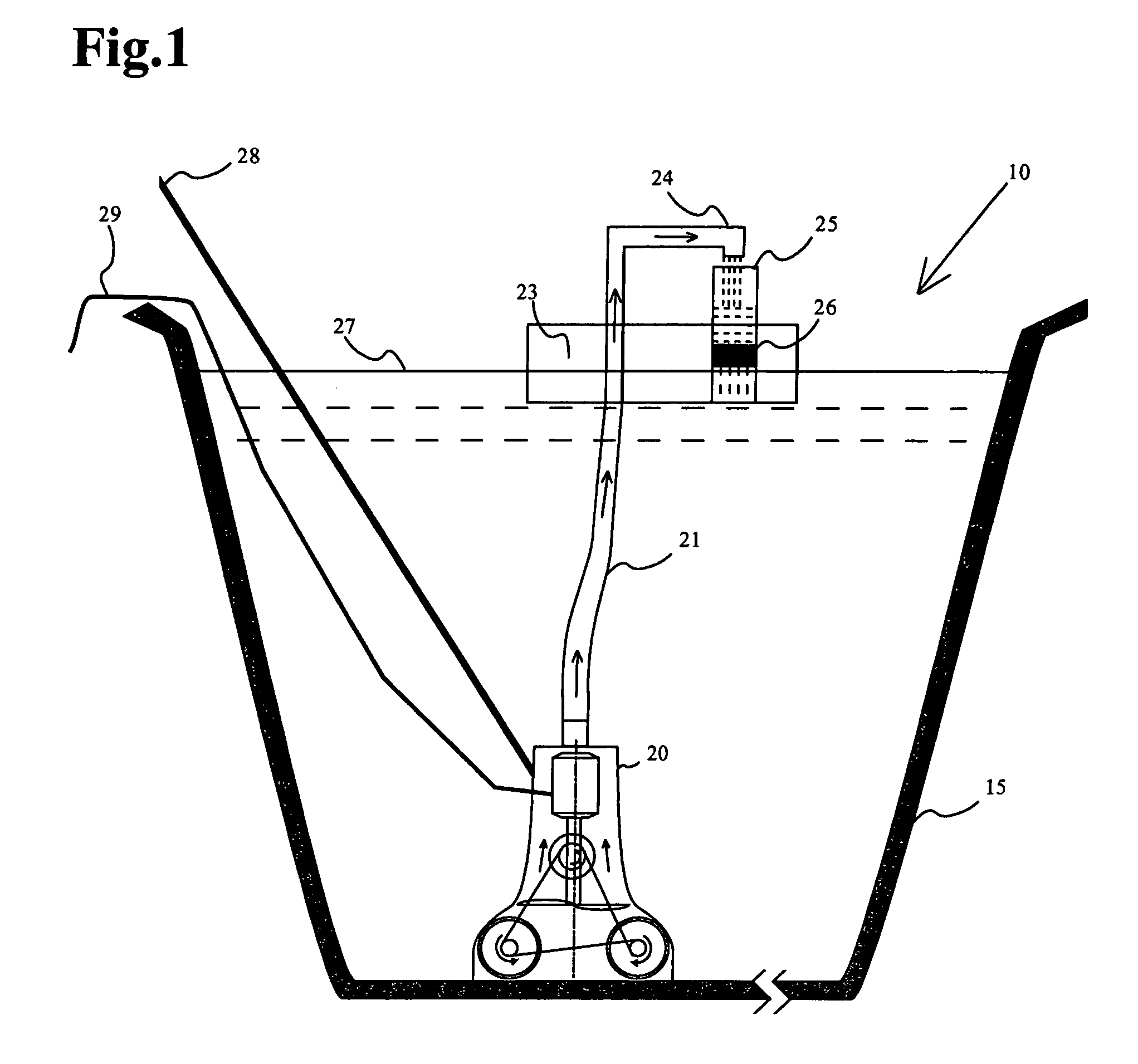

InactiveUS6942790B1Guaranteed uptimeLow costWater cleaningHollow article cleaningImpellerMotor drive

An open-air filtration device cleans swimming pools and hot tubs in an efficient, reliable manner. An open-air filter with a suction chamber unit comprises two scrubbing brushes and an impeller powered by a motor drive. Water containing debris is pumped to a level above the swimming pool or hot tub surface. The debris containing water is discharged through a spout into a filter tube. A filter element associated with the filter tube, and open to atmosphere filters the debris containing water by gravitational forces solely. The spout and filter tube are, optionally, attached to a pole that manually propels the suction unit. They may alternatively be attached to a floating platform that floats on the water surface of the pool or hot tub. If filter efficiency decreases, the water level in the filter tube rises, indicating that the filter element must be replaced. A rise in water level is visually observed or detected automatically and communicated using a visible or audible alarm.

Owner:DOLTON EDWARD

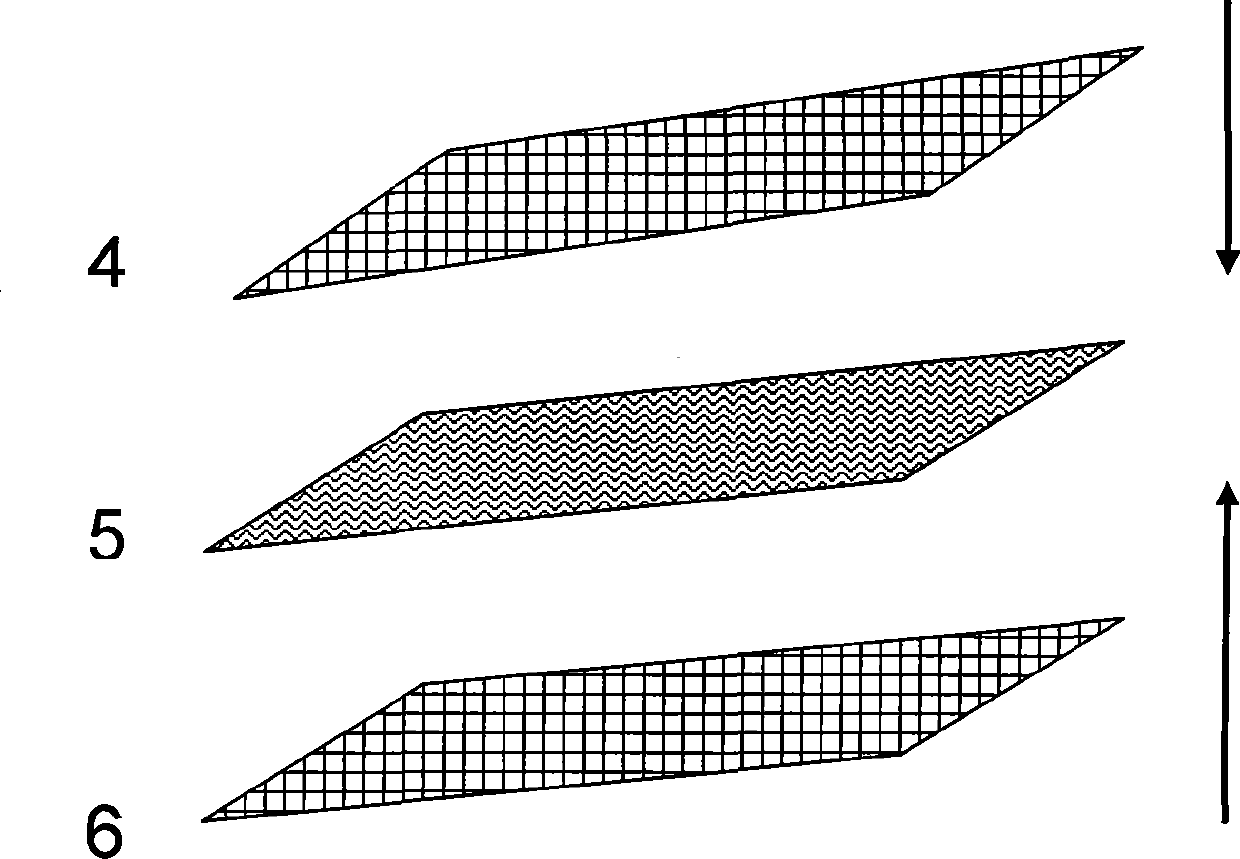

Synthetic filter material, filter-paper-free metal-free synthetic filter element, manufacturing method of filter element, and filter

InactiveCN103590874AStrong impact resistanceHigh temperature resistantPressure lubricationLubricant mounting/connectionFiberMineral particles

The invention provides a synthetic filter material synthesized through inter-amalgamation and lamination of multi-fiber filter materials and wood or mineral particle filter materials, a filter element and manufacturing method thereof, and an oil filter matched with an internal combustion engine. The filter element is free of filter paper and a metal support frame, the filter element frame and the cover plates of the filter element are made of modified nylon materials, the whole sealed filter element is formed through ultrasonic welding, the filter material is filled between 3-8 groups of blades and the frame, and the filter element does not fracture and deform after 20,000 times of impact of pulse anti-fatigue detection under the pressure of 1.6MPa. The filter element is stable and solid in structure, high-temperature and high-pressure engine oil resistance of the filter element is enhanced, the synthetic material of the filter element can filter impurities such as metal abrasive dust and carbon powder generated during combustion of an engine and mixed into the engine oil, and gel gradually generated by the engine oil to the maximum extent, the plant particle filter materials of the filter element contain antioxidant which releases slowly and can perform oxidation-reduction on online engine oil, the replacement mileage of the lubricating engine oil and the oil filter is prolonged to 30,000-100,000 kilometers, and emission of harmful tail gas is reduced.

Owner:沃卡瑞(天津)贸易有限公司

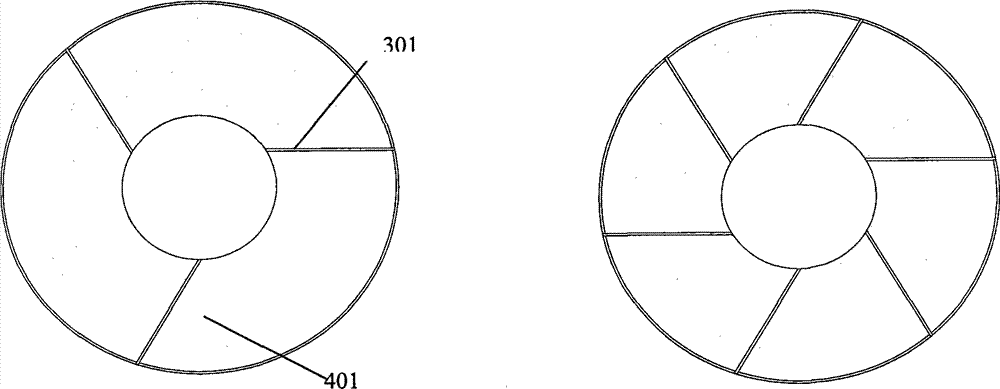

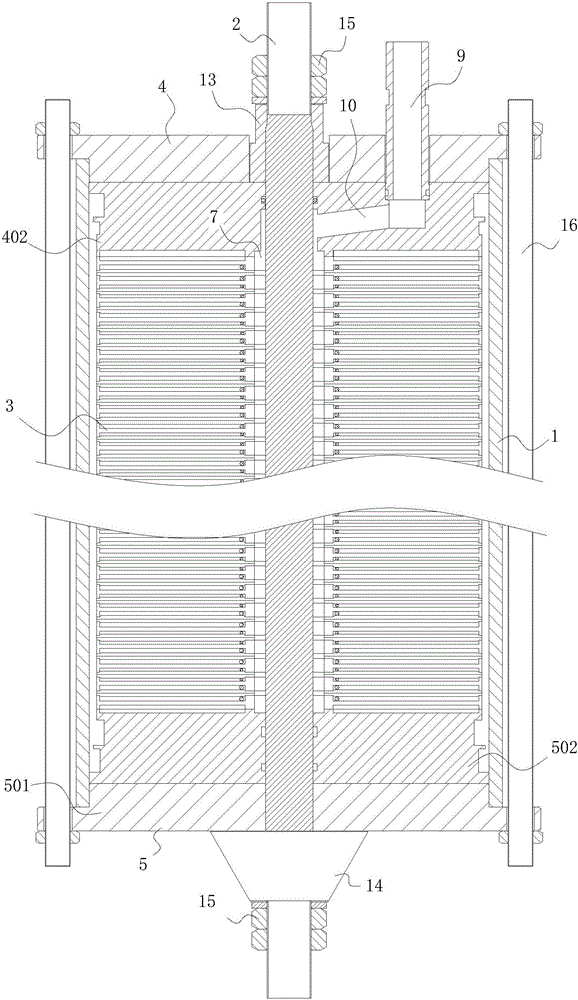

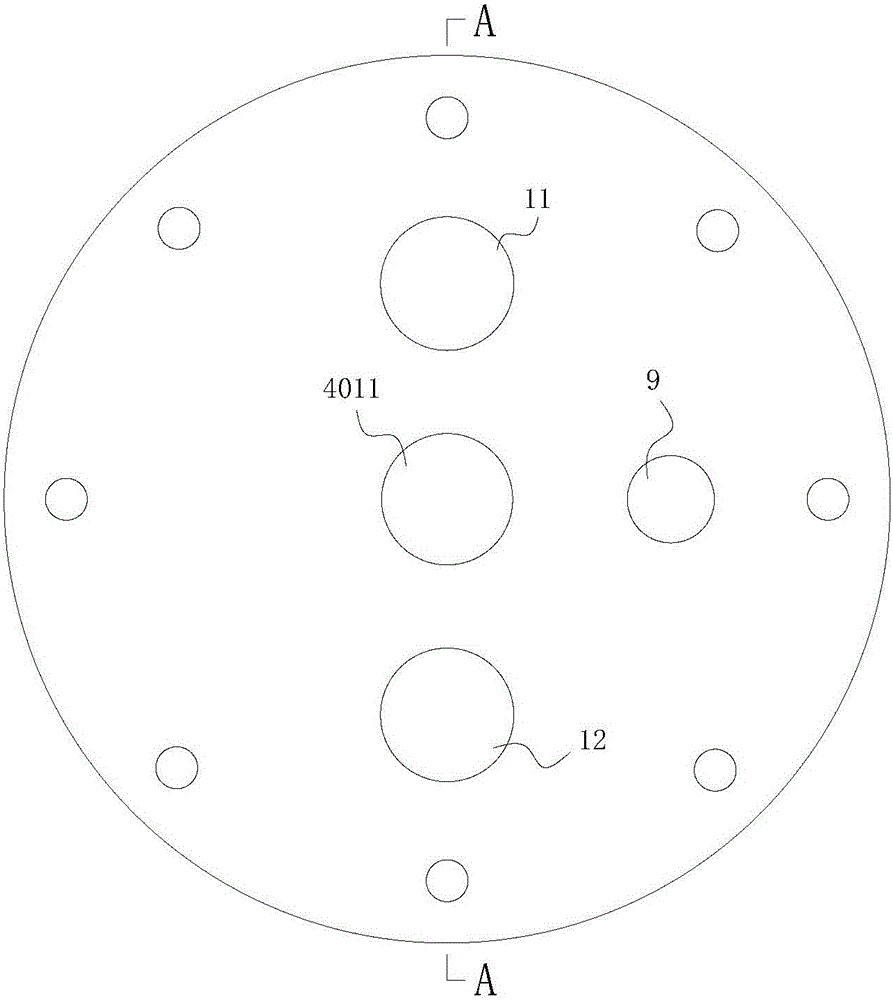

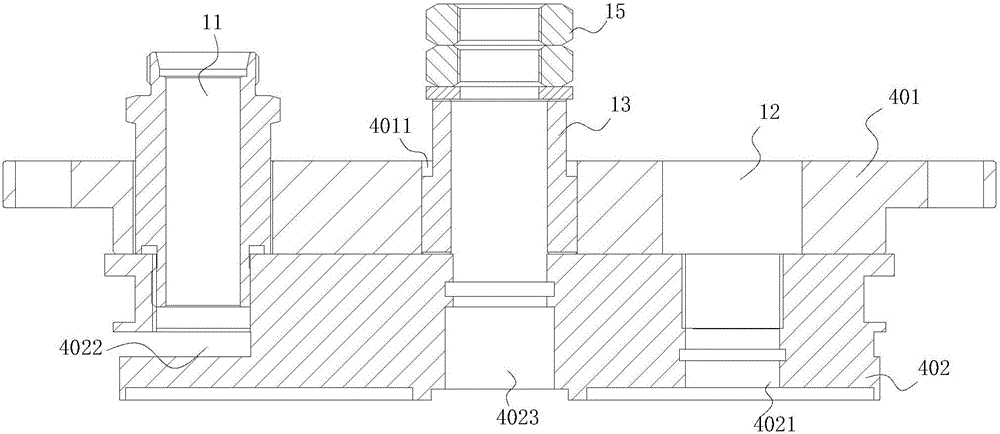

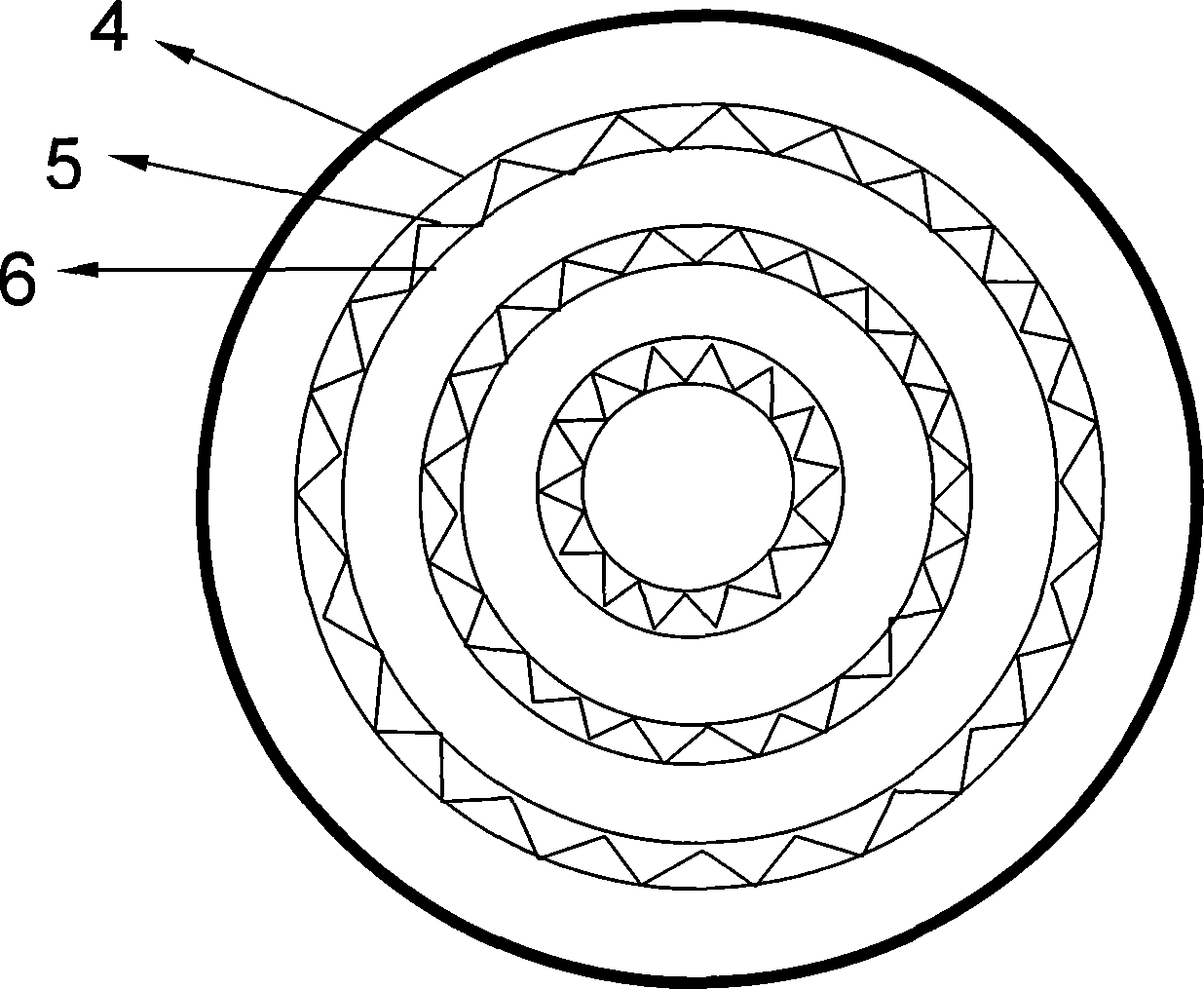

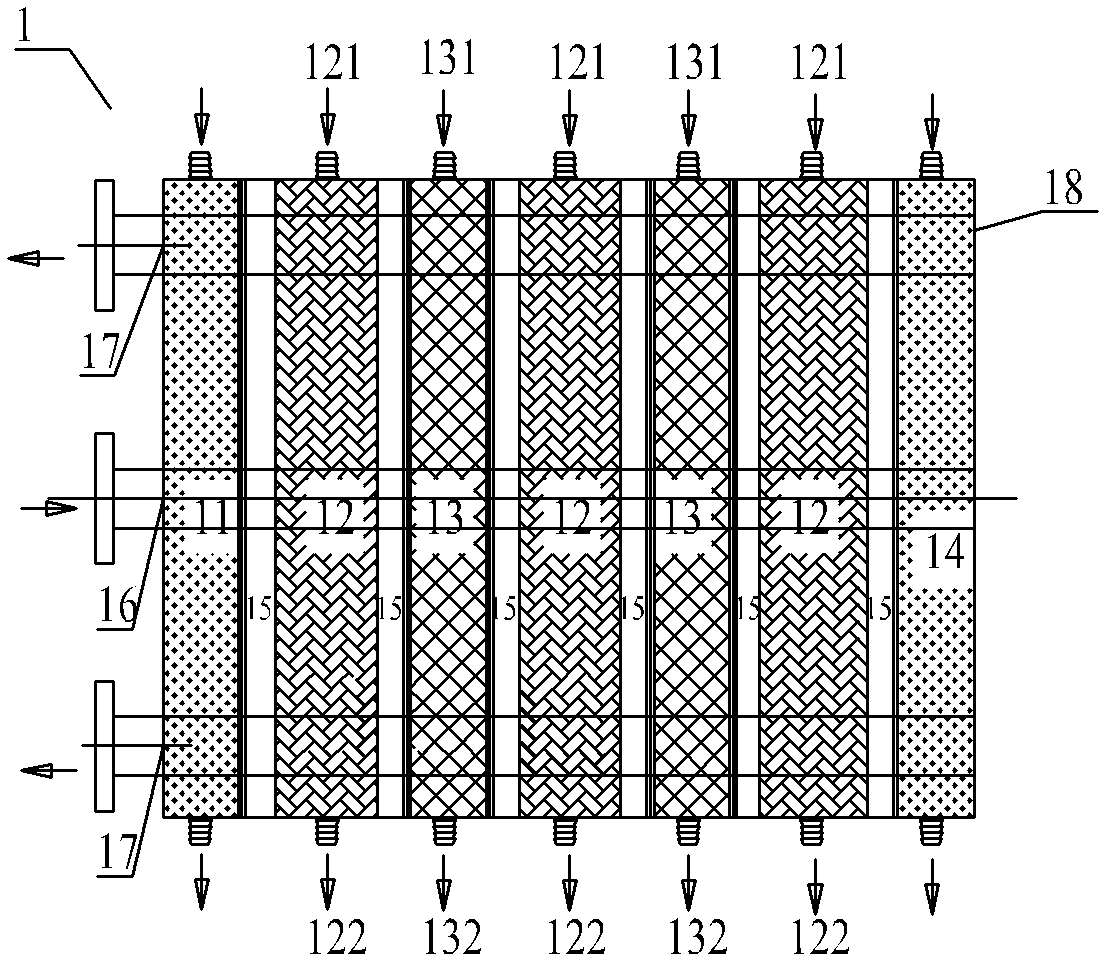

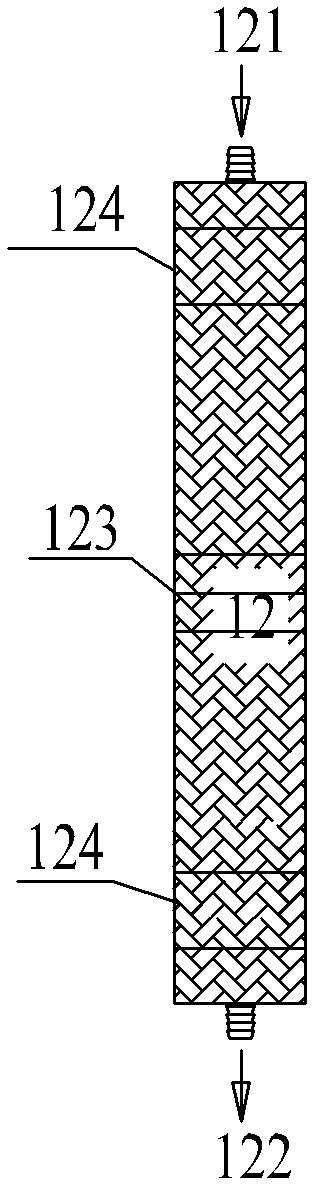

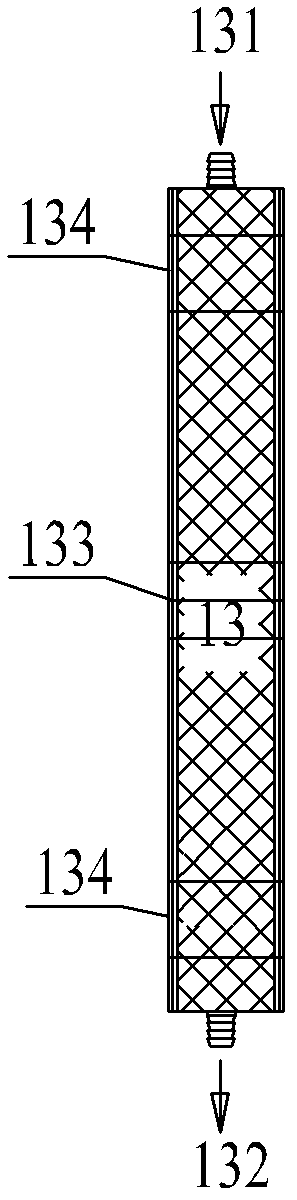

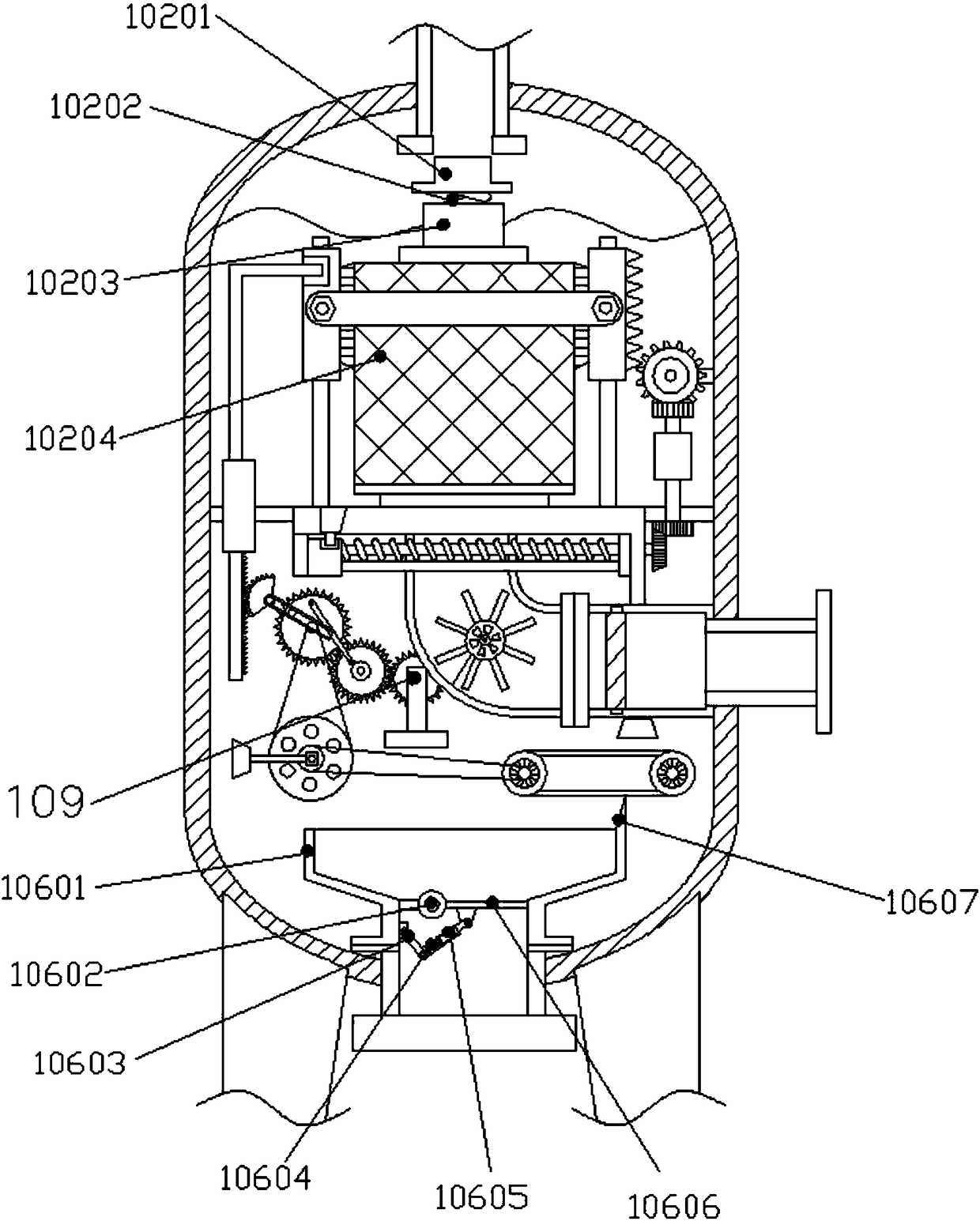

Membrane filtration assembly

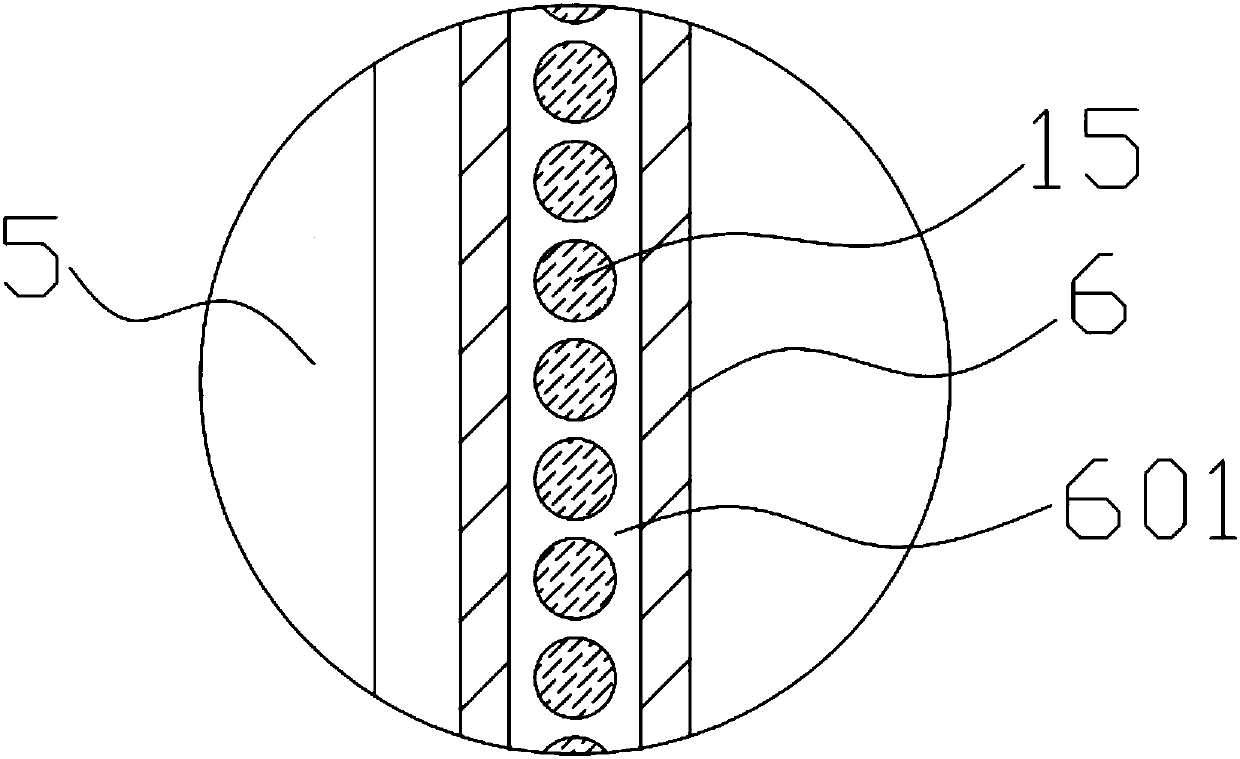

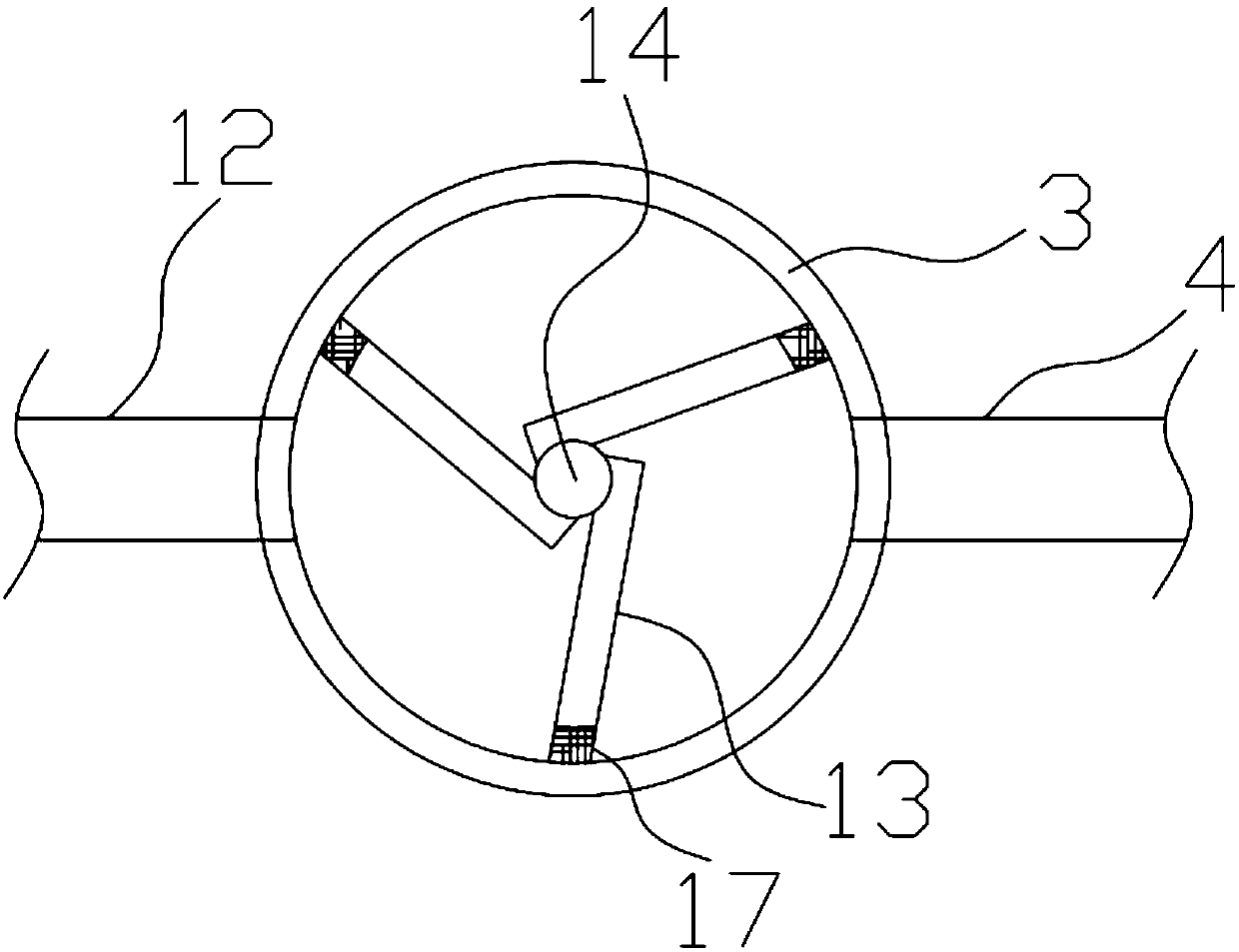

InactiveCN105771666AReduce filtration efficiencyImprove filtration efficiencyMembranesReverse osmosisNanofiltrationMembrane configuration

The invention relates to a membrane filtration assembly, in particular to a nanofiltration or reverse osmosis membrance filtering assembly in the water treatment field. The invention discloses the membrane filtration assembly high in filtering efficiency in order to overcome the defect that an existing membrane filtration assembly is low in filtering efficiency. The assembly comprises a shell, a mandrel, a filtering structure, an upper cover assembly and a lower cover assembly. The upper cover assembly is arranged at the upper end of the mandrel, the lower cover assembly is disposed at the lower end of the mandrel, the mandrel is sleeved with the filtering structure, the filtering structure is axially pressed between the upper cover assembly and the lower cover assembly through a fastening structure, and the shell is arranged outside the filtering structure and connected with the upper cover assembly and the lower cover assembly. The filtering stricture comprises a plurality of flow guide discs and membranes, the flow guide discs and the membranes are sequentially sleeved with the mandrel in the axial direction of the mandrel. Each membrane is installed between every two adjacent flow guide discs. By selecting and combining some key parameters of the membranes through the membrane filtering assembly, filtering efficiency of the membrane filtering assembly can be higher, and the filtering rejection rate is unexpectedly good.

Owner:CHENGDU MEIFUTE MEMBRANE TECHNOLOGY CO LTD

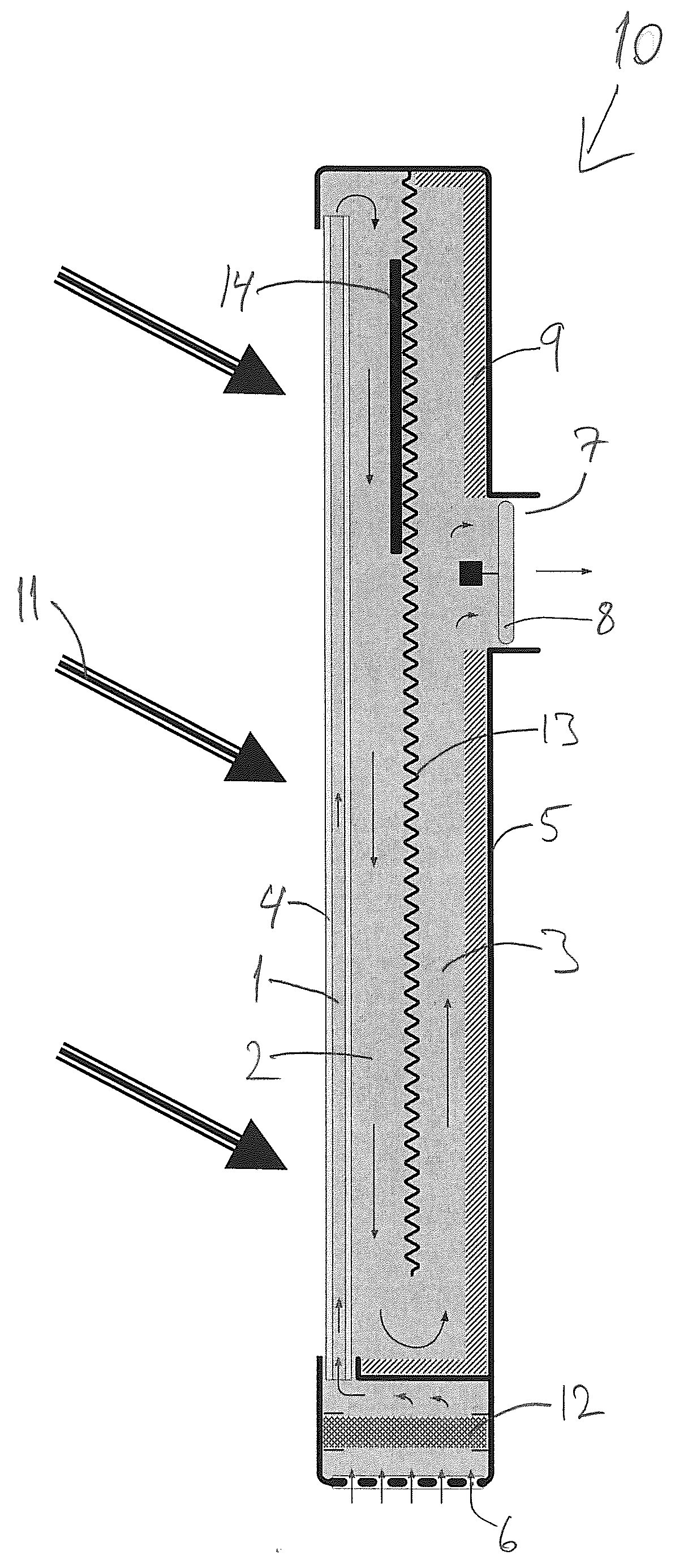

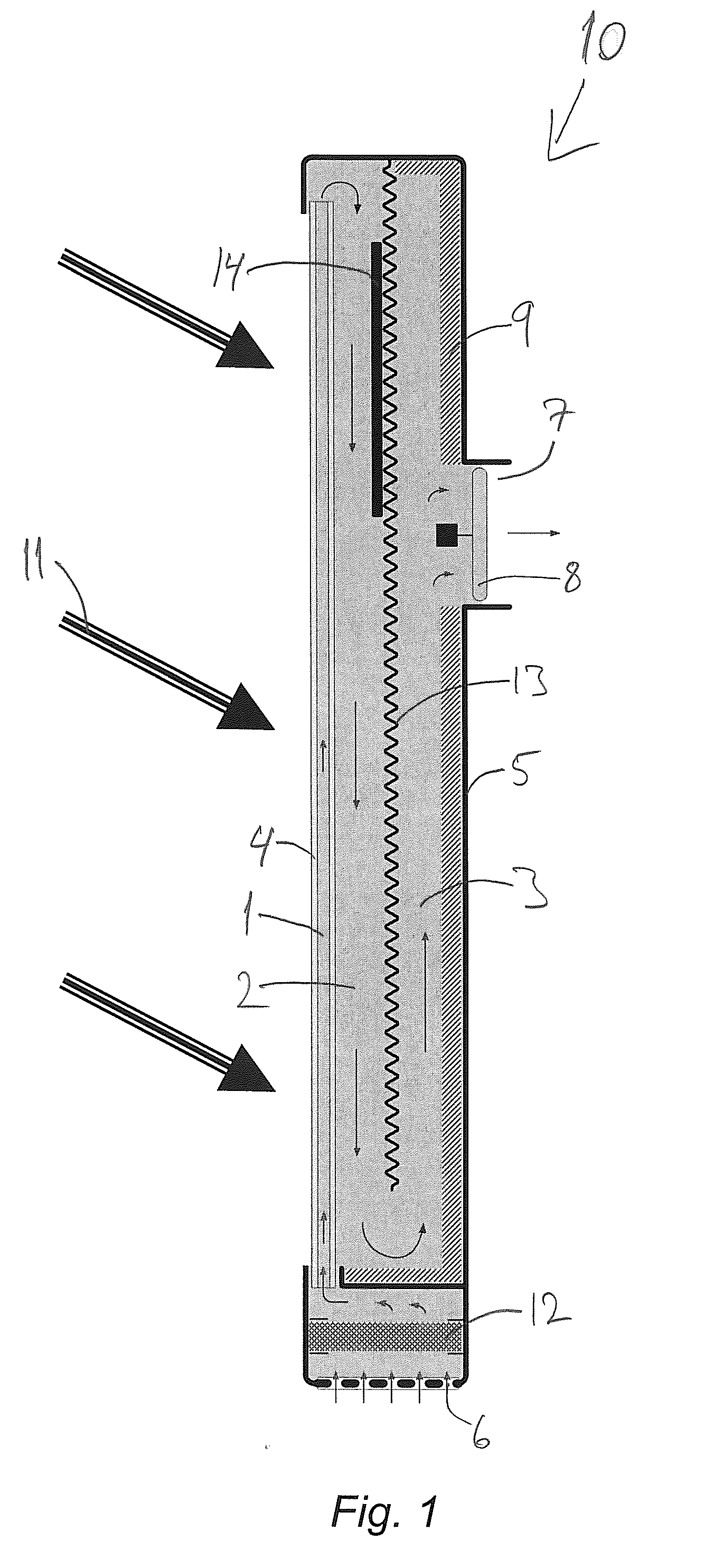

Solar air heater for heating air flow

InactiveUS20100186734A1Minimize amount of heatQuantity minimizationSolar heating energySpace heating and ventilationSolar air heaterSemi transparent

The invention relates to a solar air heater comprising—at least one transparent or translucent front panel comprising at least one first flow passage, said first flow passage substantially elongated and extending along the surface of the front panel,—a back panel preferably substantially parallel with the front panel,—at least one heat absorbing element, preferably located between the front panel and the back panel,—at least one air inlet,—at least one air outlet,—at least a second flow passage between the front panel and the heat absorption element, and—at least a third flow passage between the heat absorption element and the back panel, whereby air flowing through the solar air heater from an air inlet to an air outlet will pass at least a first, a second and a third flow passage. In a further embodiment of the invention the solar air heater comprises means for driving and / or inverting the airflow through said solar air heater, whereby heating and / or ventilation of a room and / or a building connected to said solar air heater can be provided.

Owner:ARNDT

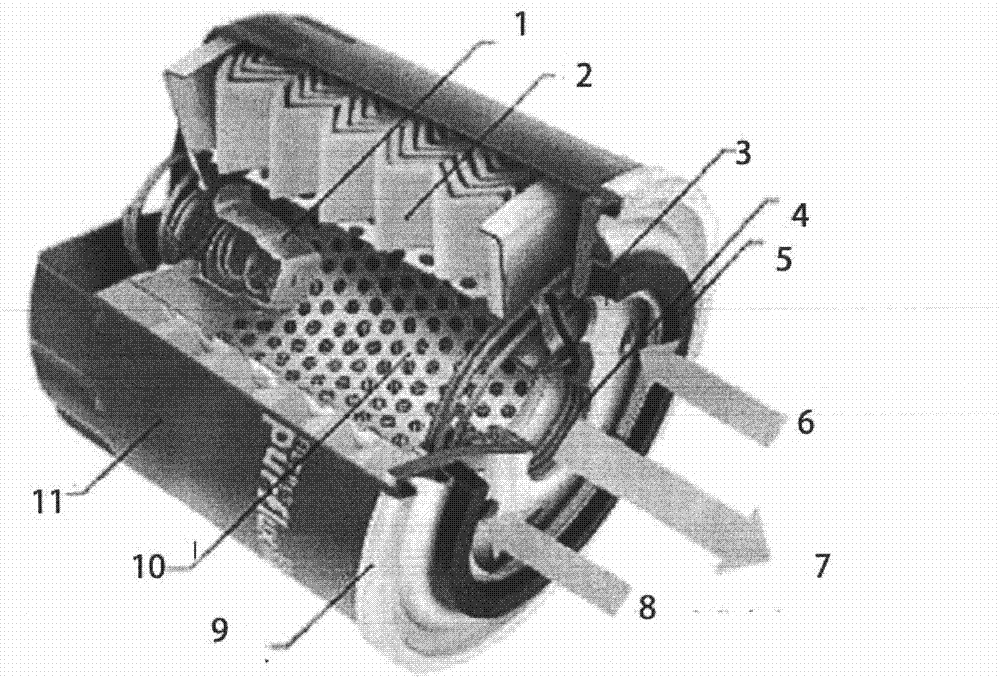

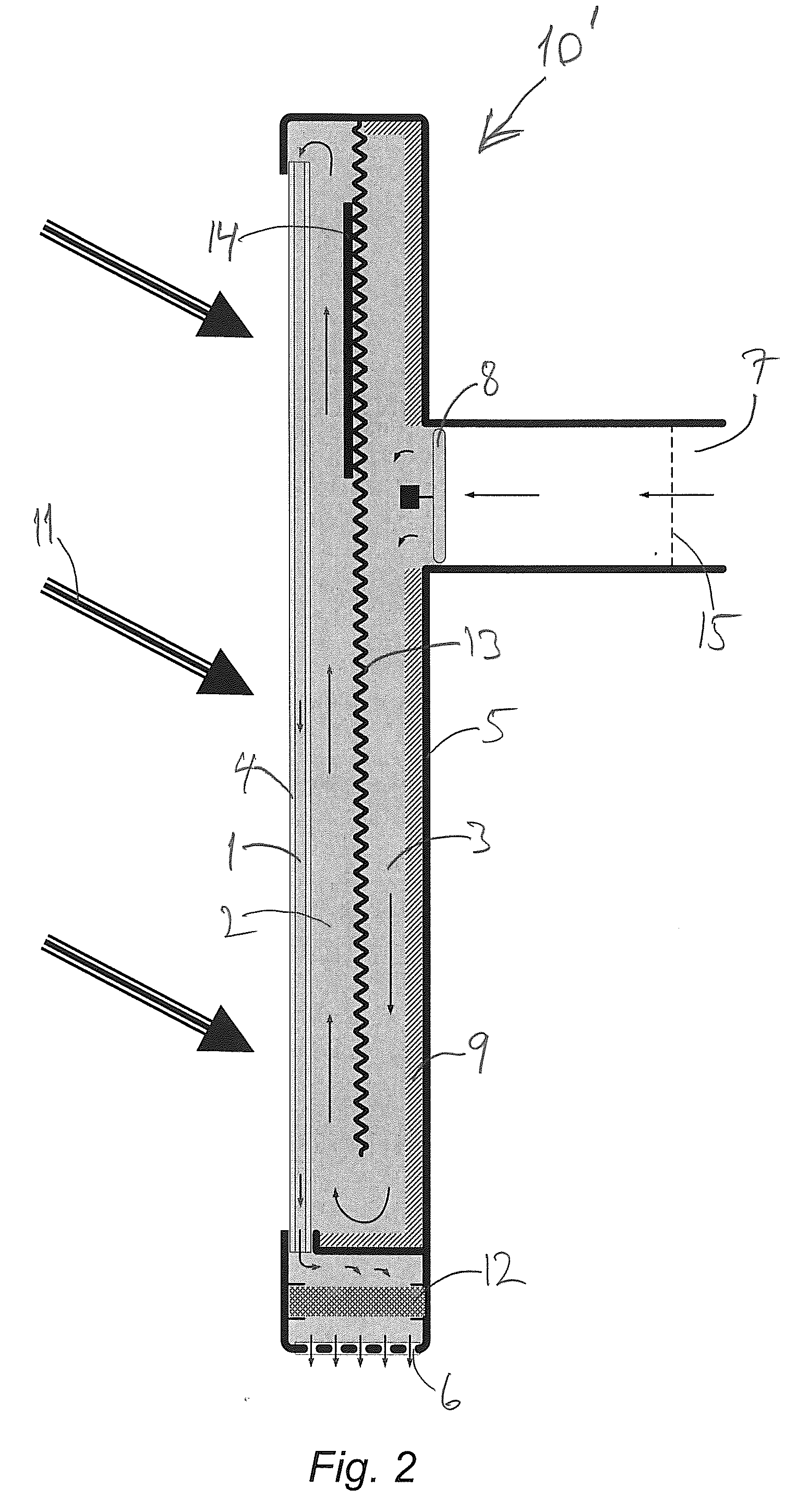

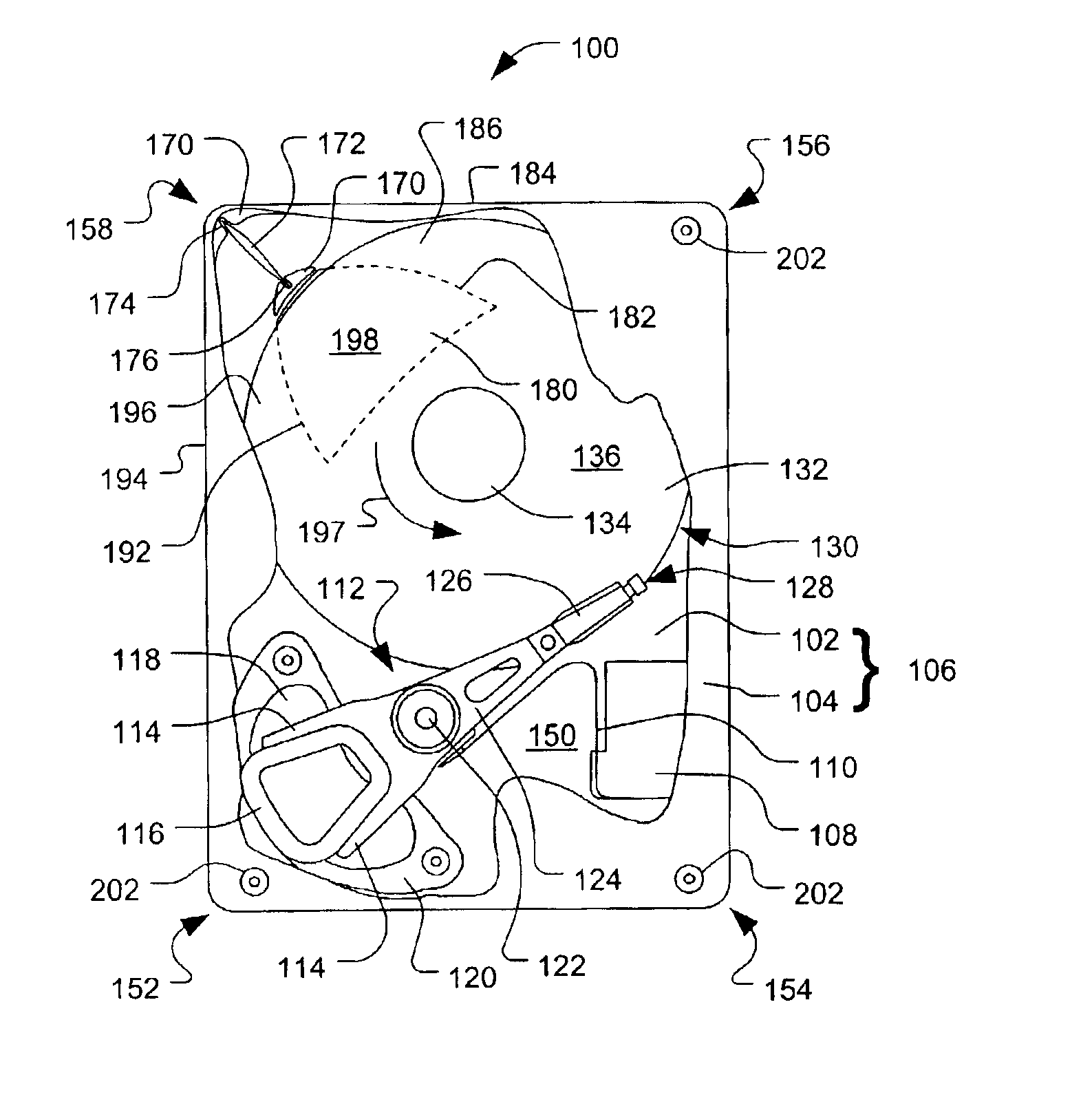

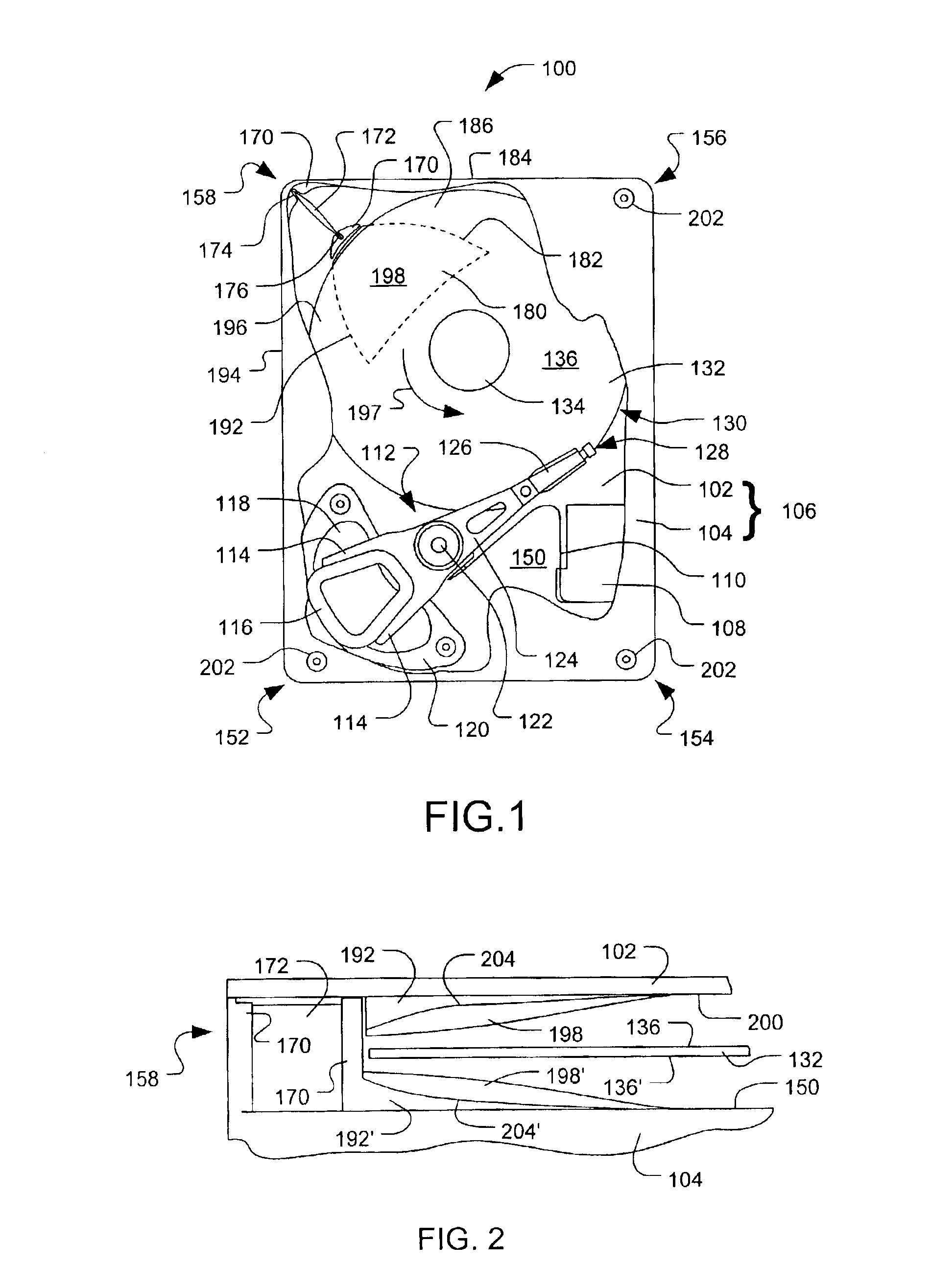

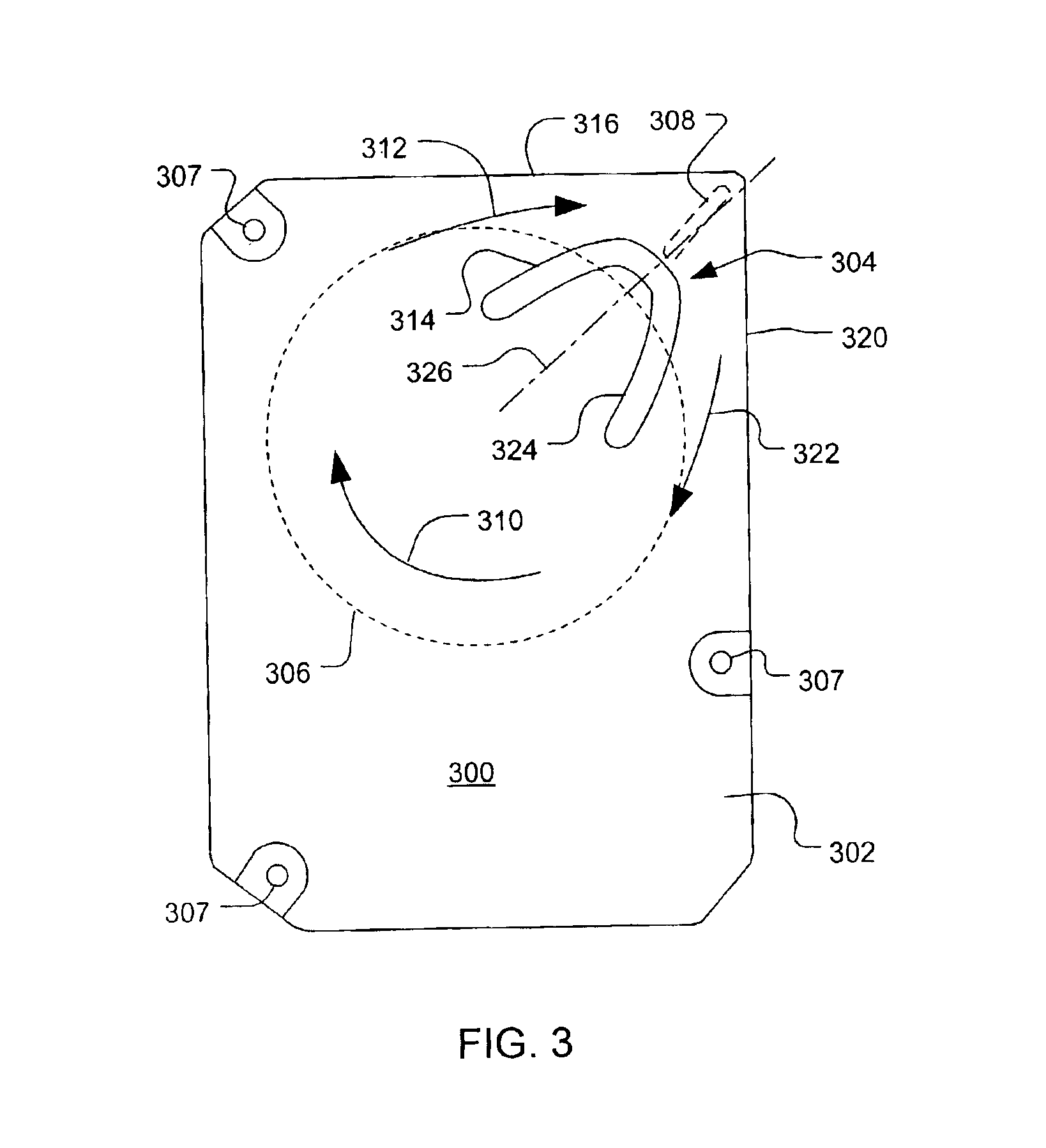

Disc drive housing with air guide

InactiveUS6894867B2Improves filter efficiencyEffectively channelUndesired vibrations/sounds insulation/absorptionReducing carrier contaminationEngineeringMechanical engineering

The present invention relates to an air guide for use in a disc drive such that air flow can be redirected to improve the efficiency of a filter located within the disc drive. Embodiments of the present invention provide for an air guide having air guide surfaces that, in conjunction with sides of the disc drive housing, are configured to channel air flow off a spinning disc, through a filter, and back into the mainstream air flow. The air guide may be formed as an integral unit with either the inner major surface of the cover or of the baseplate, or both, such that the air guide may extend over part of the disc surface and provide an effective channel for air flow without the need for additional assembly processes during manufacture.

Owner:SEAGATE TECH LLC

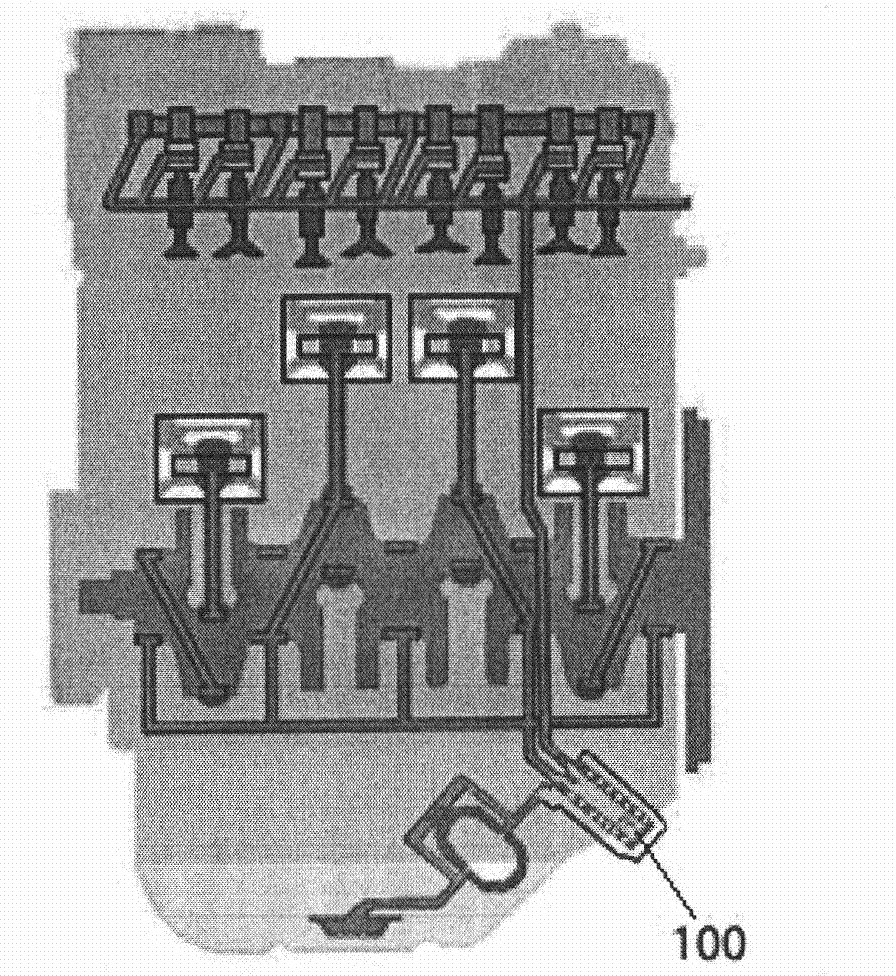

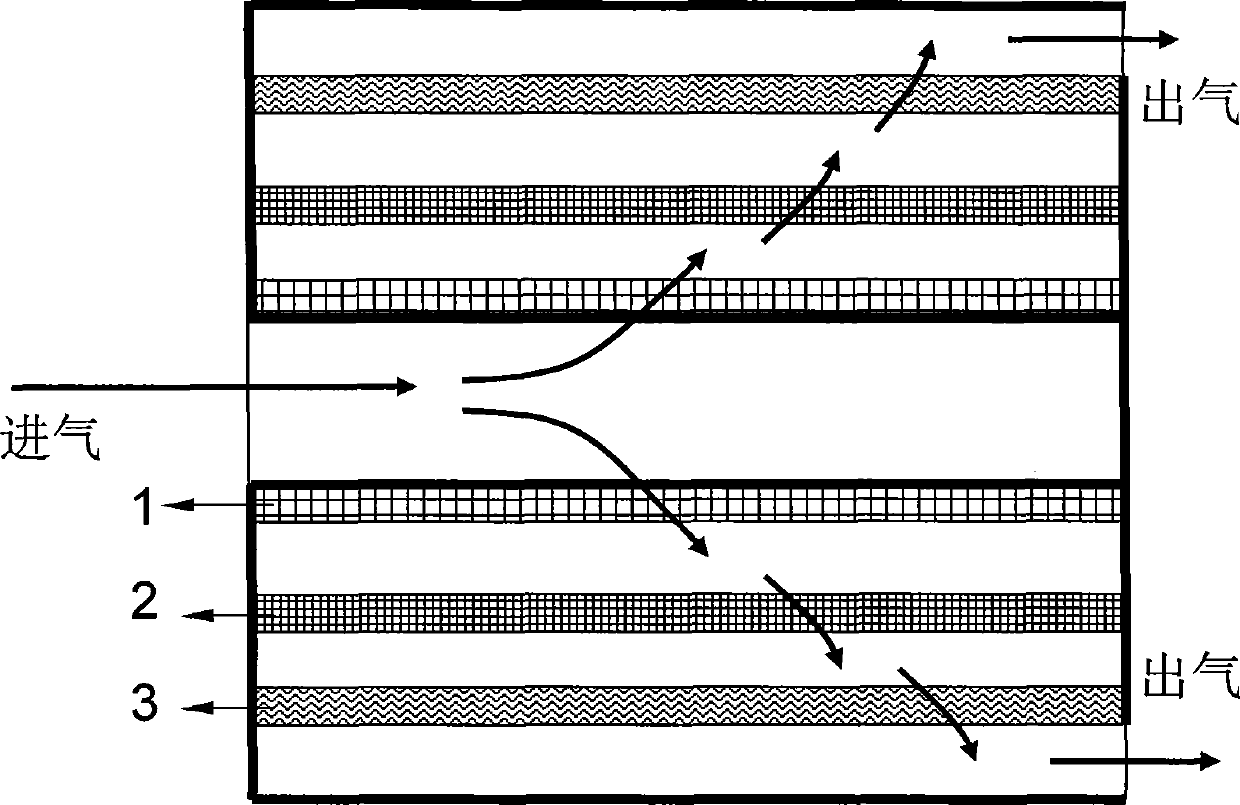

Post-treatment purifier for internal combustion engine particle emission

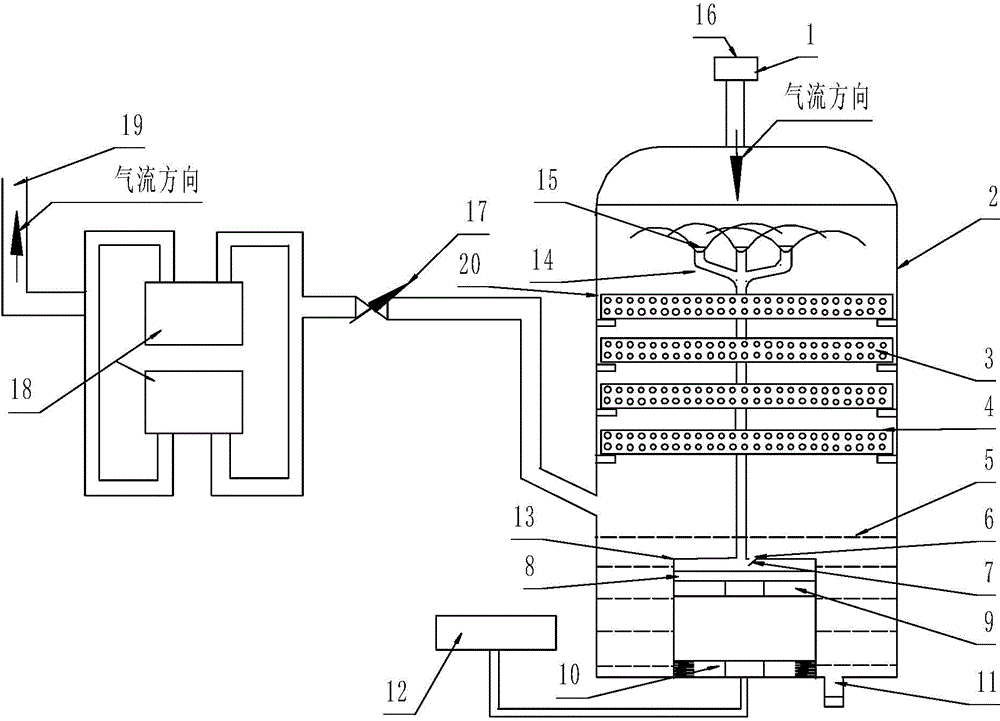

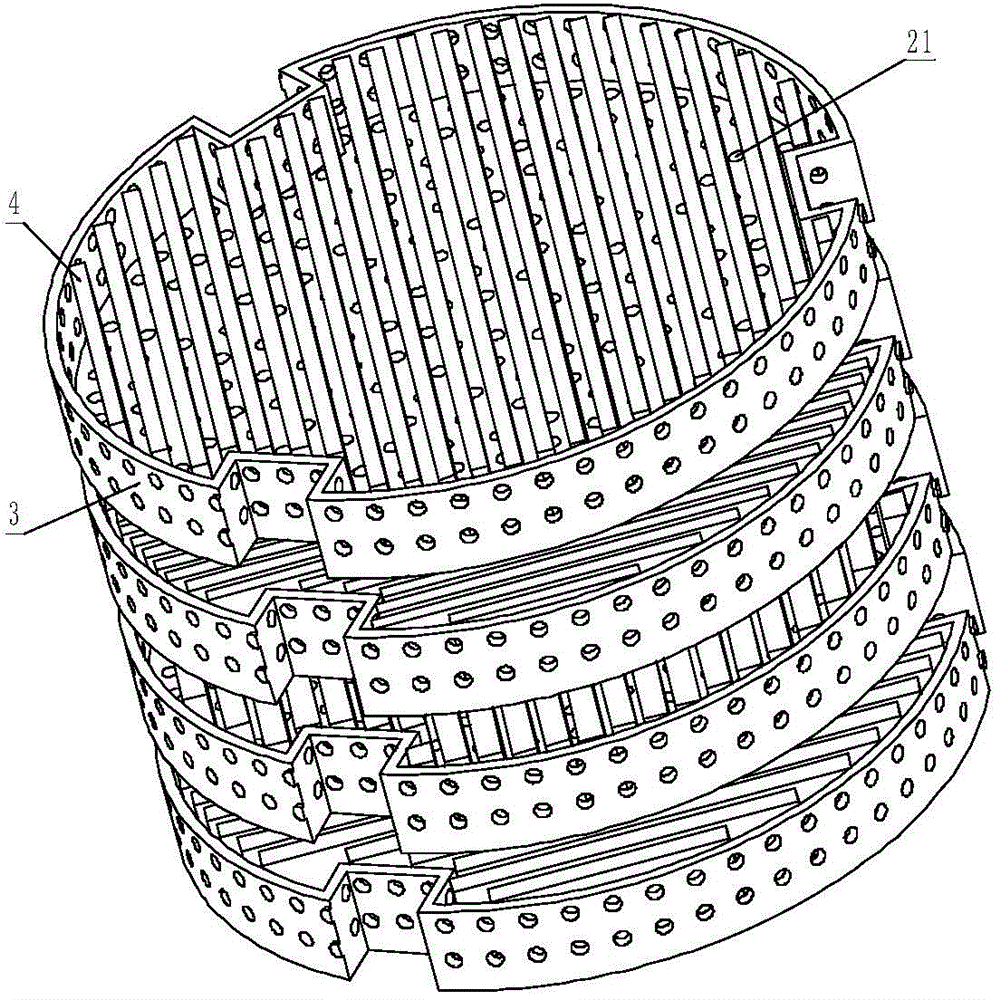

InactiveCN103861396AReduce filtration efficiencyImprove filtration efficiencyDispersed particle filtrationExhaust apparatusParticulatesFiltration

The invention provides a post-treatment purifier for internal combustion engine particle emission, and belongs to the technical field of environmental protection. The purifier is characterized by employing coercive means of circulation to change the exhaust path, so that all the exhaust passes through the filter; at the same time, the purifier employs filter combination with different trapping efficiencies (material, shape, density), so that smoke or / and particles with different particle sizes are respectively trapped to improve the trapping efficiency; and the purifier solves the problem of the surge of exhaust backpressure caused by rapid accumulation of smoke or / and particle in a trap device for internal combustion engine particle discharge of the prior art. Regeneration of particles can be carried out in any continuous or / and intermittent regeneration mode, such as filter catalyst coating, or be combined with other regeneration mode. The purifier reaches an overall filtration efficiency range as wide as 30-90%, and can be used as post-treatment purifier for a variety of internal combustion engine particle emission. After loading on a diesel engine, the particle emission can reach higher than grade four in national standard.

Owner:北京英泰世纪环境科技有限公司

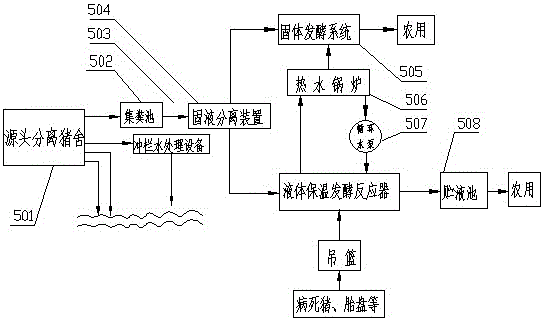

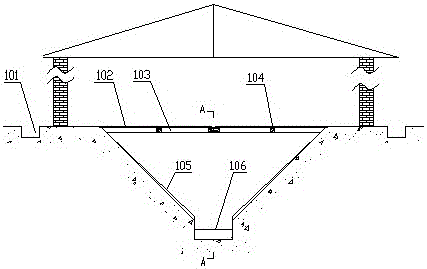

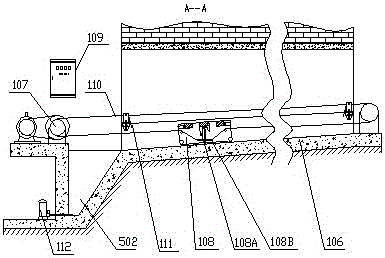

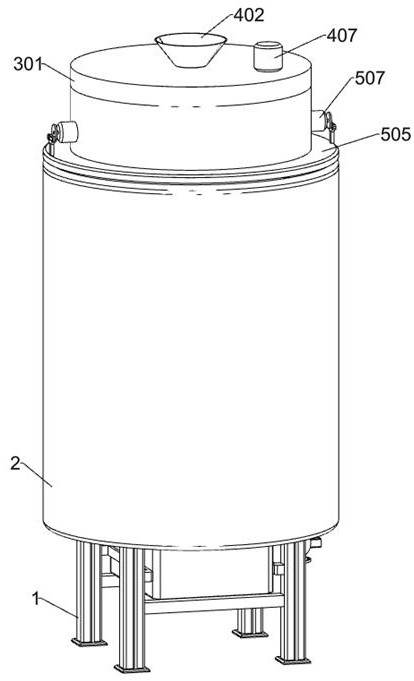

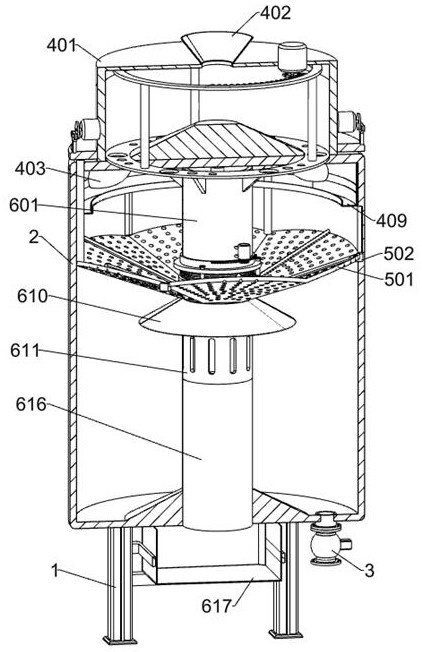

System and method for controlling excrement and urine of poultries and placentae of disease-caused dead poultries in large-scale farm

ActiveCN106116736AIn line with the cycleReduce the burden onBio-organic fraction processingAnimal corpse fertilisersSludgeThermal insulation

The invention relates to a system and method for controlling excrement and urine of poultries and placentae of disease-caused dead poultries in a large-scale farm. The system comprises a source separated poultry house, a solid-liquid separation system, a liquid high-temperature aerobic fermentation system, a solid fermentation system, a stink-flue gas treatment system, a circulating water system and a detection control system, wherein the source separated poultry house is a poultry house in which rainwater and sewage are separated, drinking water and sewage are separated, and fence flushing water and the excrement and urine of the poultries are separated; the solid-liquid separation system comprises a excrement collecting pool, a sludge pump and a solid-liquid separation device; the liquid high-temperature aerobic fermentation system comprises a liquid thermal-insulation fermentation reactor; the stink-flue gas treatment system comprises a stink heat exchange condenser, a flue gas heat exchange condenser, a biological deodorization filter tower, an aeration fan, an air blower and an induced draft fan; and the detection control system comprises a material temperature sensor, a material level sensor, a pressure sensor, a water temperature sensor and a controller. According to the system, the harmless treatment, the reduction and the recycling are realized, the environment is protected, and the energy is saved.

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD +1

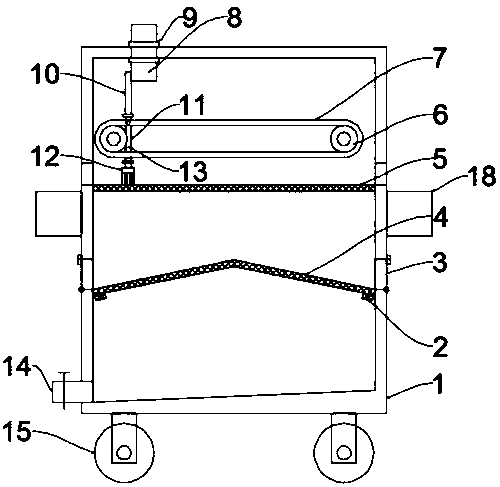

Low-temperature vacuum dehydration and drying equipment as well as process thereof

ActiveCN103285637AImprove compactnessReduce moistureFiltration separationFilter systemProcess engineering

The invention discloses a set of low-temperature vacuum dehydration and drying equipment as well as a process thereof, wherein the equipment comprises a filtering system, a filter pressing system, a heating and circulating system, a vacuumizing system as well as an air compressor system, wherein the filtering system comprises at least one diaphragm filtering plate and at least one heating filtering plate; material chambers are arranged between the heating filtering plates and the diaphragm filtering plates; the diaphragm filtering plates are provided with first material inlets and first outlets; the heating filtering plates are provided with second material inlets and second outlets; the first material inlets and the second material inlets are respectively connected with the material chambers; the first outlets and the second outlets are connected; the diaphragm filtering plates are also provided with first liquid inlets and first liquid outlets; the heating filtering plates are also provided with second liquid inlets and second liquid outlets; one end of the filter pressing system is connected with the first liquid inlets of the diaphragm filtering plates, and the other end of the filter pressing system is connected with the first liquid outlets; one end of the heating and circulating system is connected with the second liquid inlets of the heating filtering plates, and the other end of the heating and circulating system is connected with the second liquid outlets. By the set of low-temperature vacuum dehydration and drying equipment, the working procedures of dehydration, washing, filter pressing, drying and the like of materials can be completed.

Owner:SHANGHAI CEO ENVIRONMENTAL PROTECTION TECH CO LTD +1

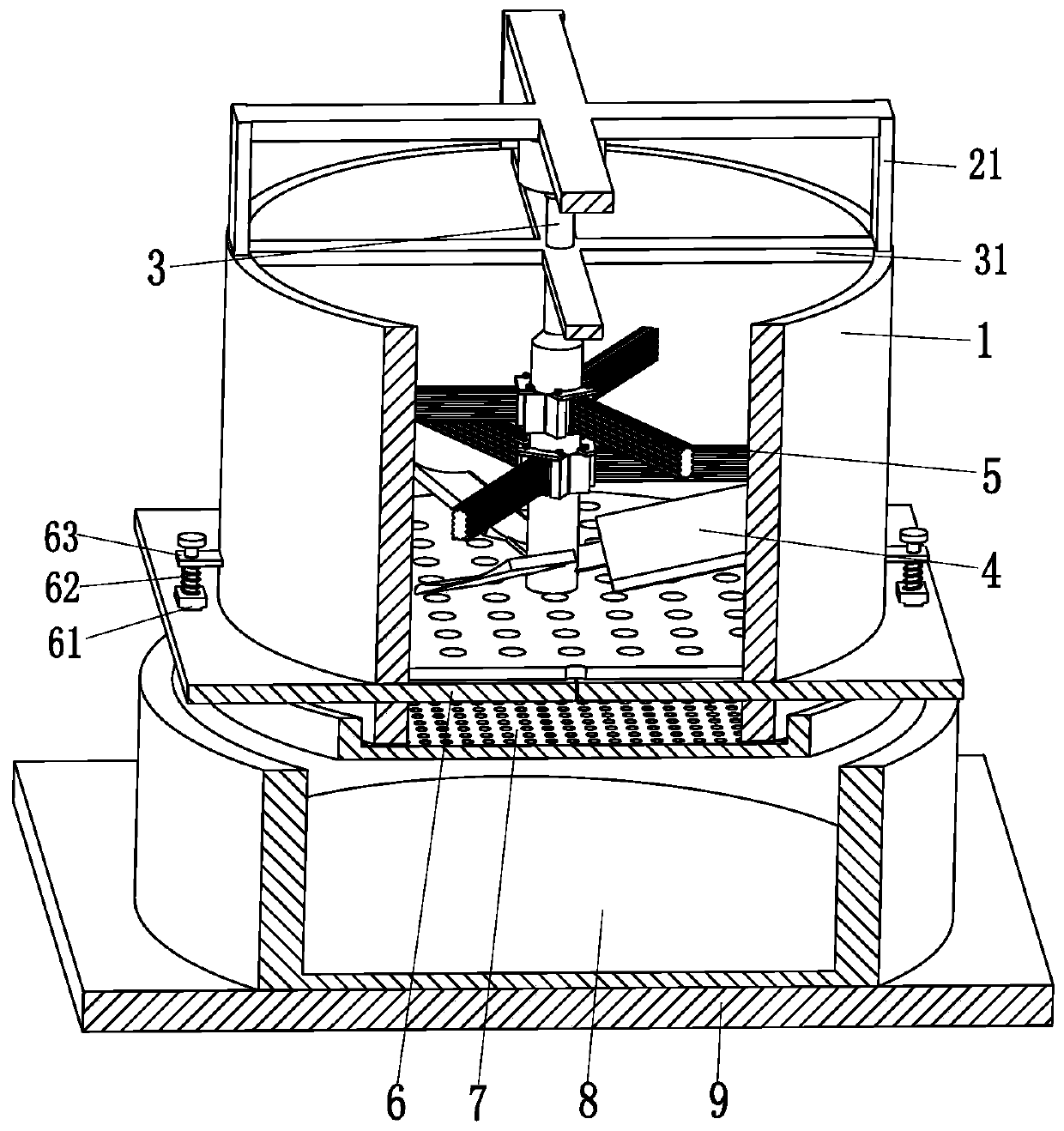

Filter with particulate matter separation function for oil field demulsifier production

ActiveCN114042347AAvoid excessive accumulationAvoid blockingMoving filtering element filtersDemulsifierParticulates

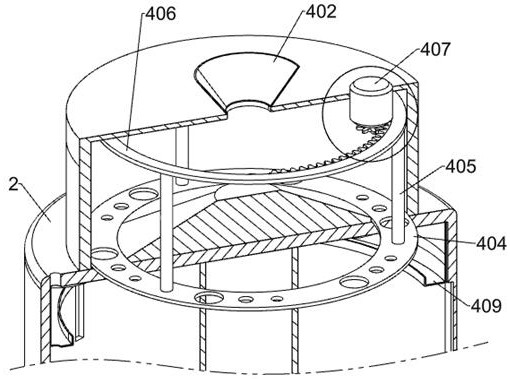

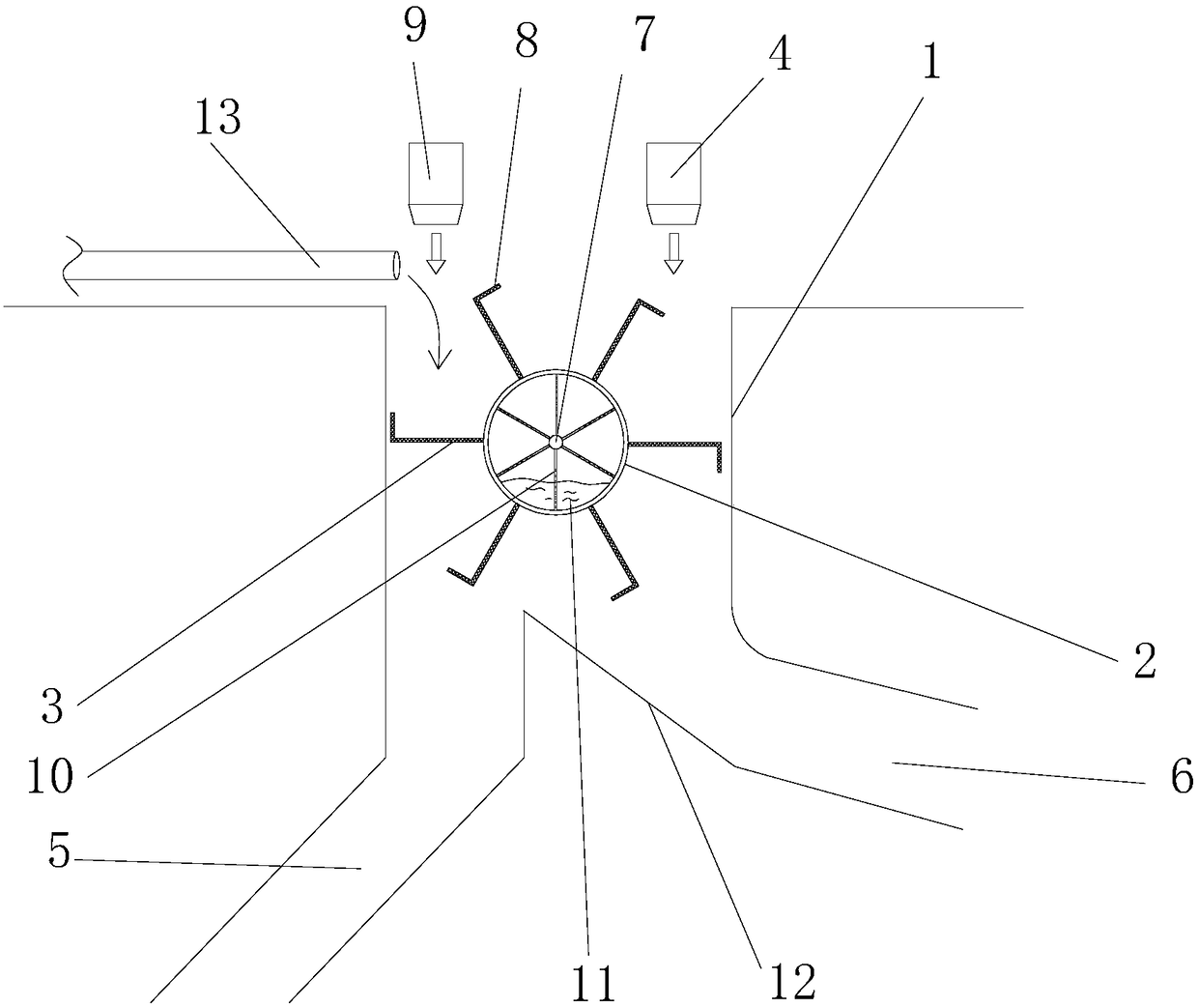

The invention relates to the technical field of demulsifier production, in particular to a filter with a particulate matter separation function for oil field demulsifier production. The technical problems that separated particle impurities are inconvenient to discharge out of a filtering device, normal use of the filtering device is reduced, and the filtering efficiency of a demulsifier is reduced are solved. According to the technical scheme, the filter with the particulate matter separation function for oil field demulsifier production comprises a supporting shell, a feeding mechanism, a vibration filtering mechanism and the like, the inner side face of the bottom of the supporting shell is provided with a protrusion, the feeding mechanism is arranged above the supporting shell, and the vibration filtering mechanism is arranged on the upper portion of the inner side face of the supporting shell. By designing the feeding mechanism, non-uniform discharging of an oil field demulsifier caused by different pressures of the oil field demulsifier to the bottom of the material containing shell is avoided, by designing the vibration filtering mechanism, the filtering efficiency of the sieve plate is improved, and meanwhile, the situation that too many impurity particles are accumulated, and filtering holes in the sieve plate are blocked is avoided.

Owner:东营市宝泽能源科技有限公司 +1

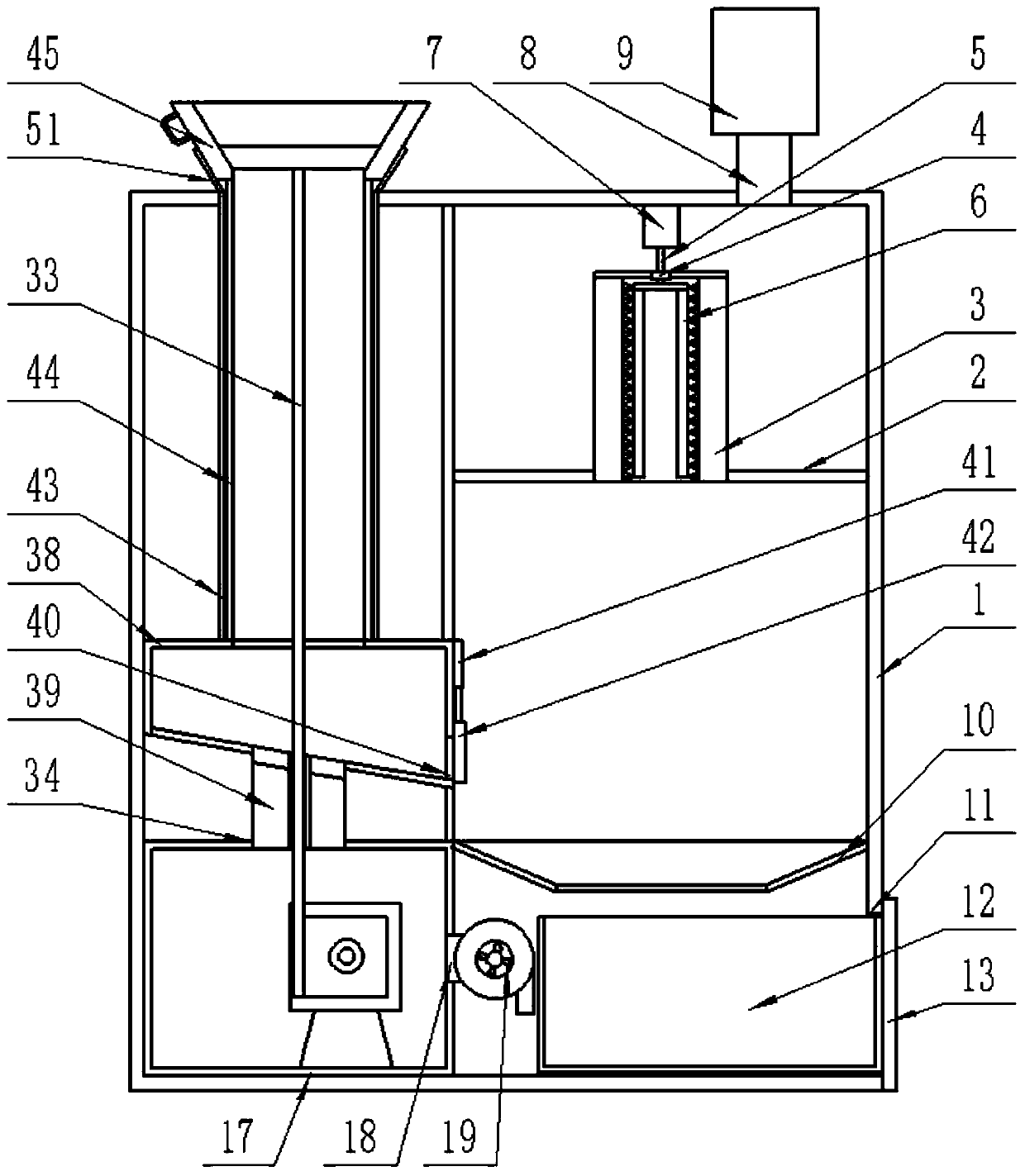

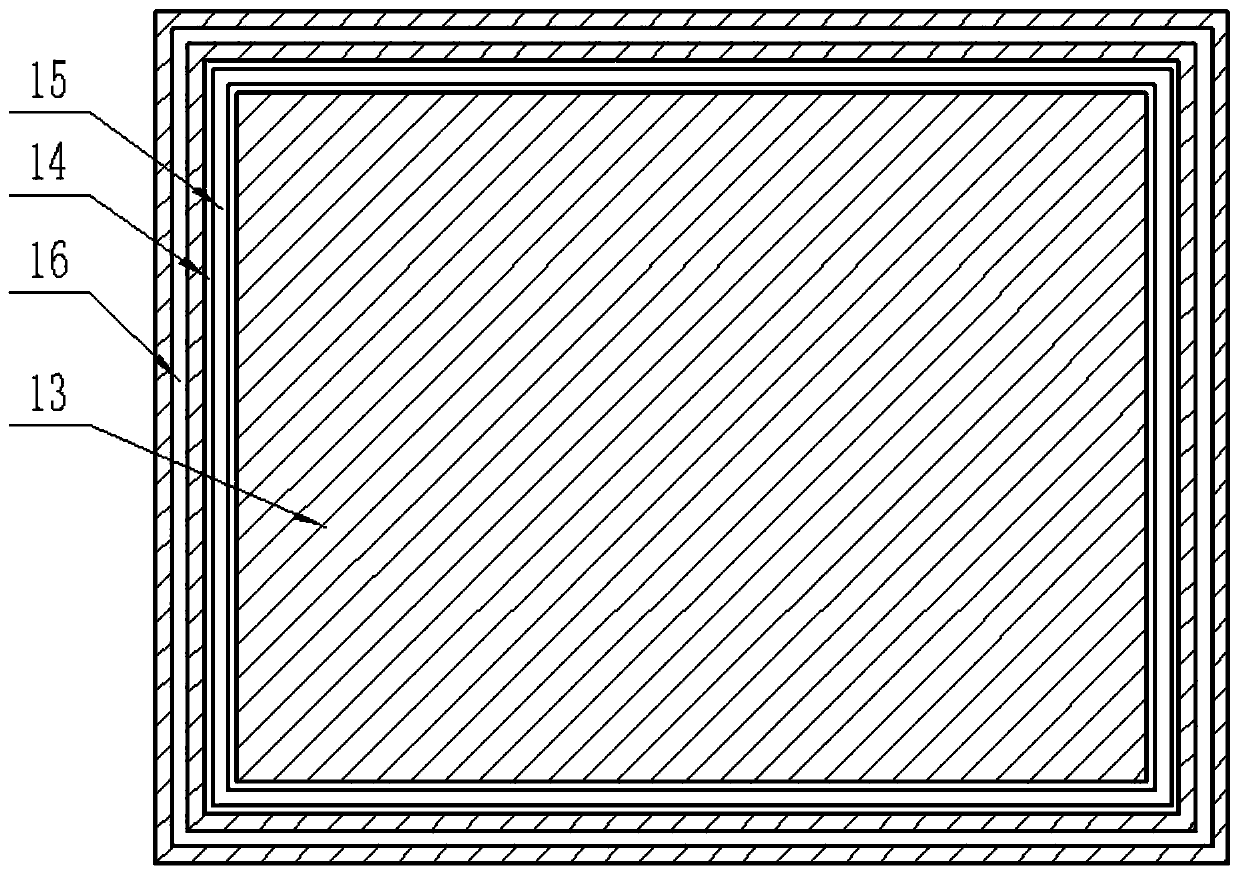

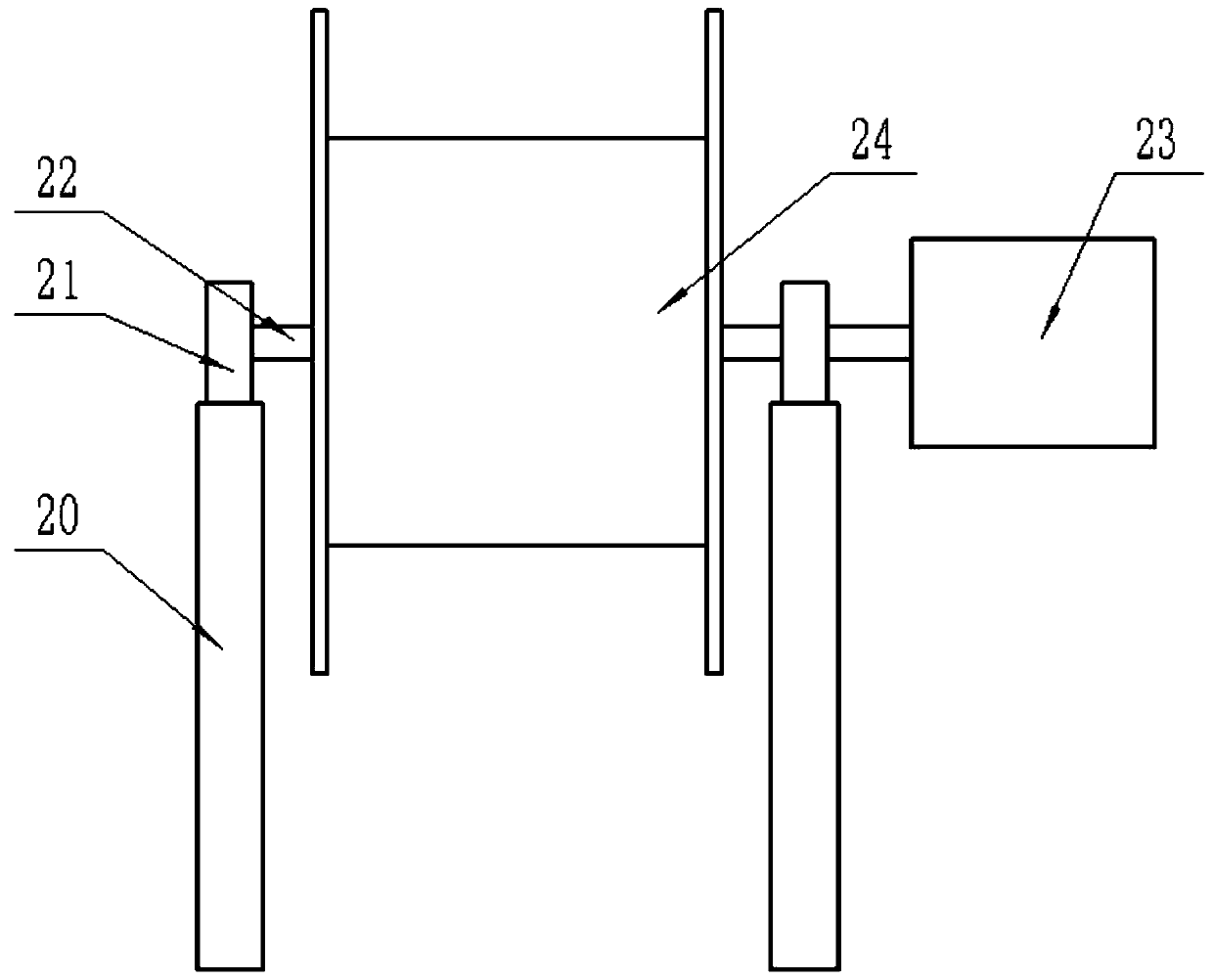

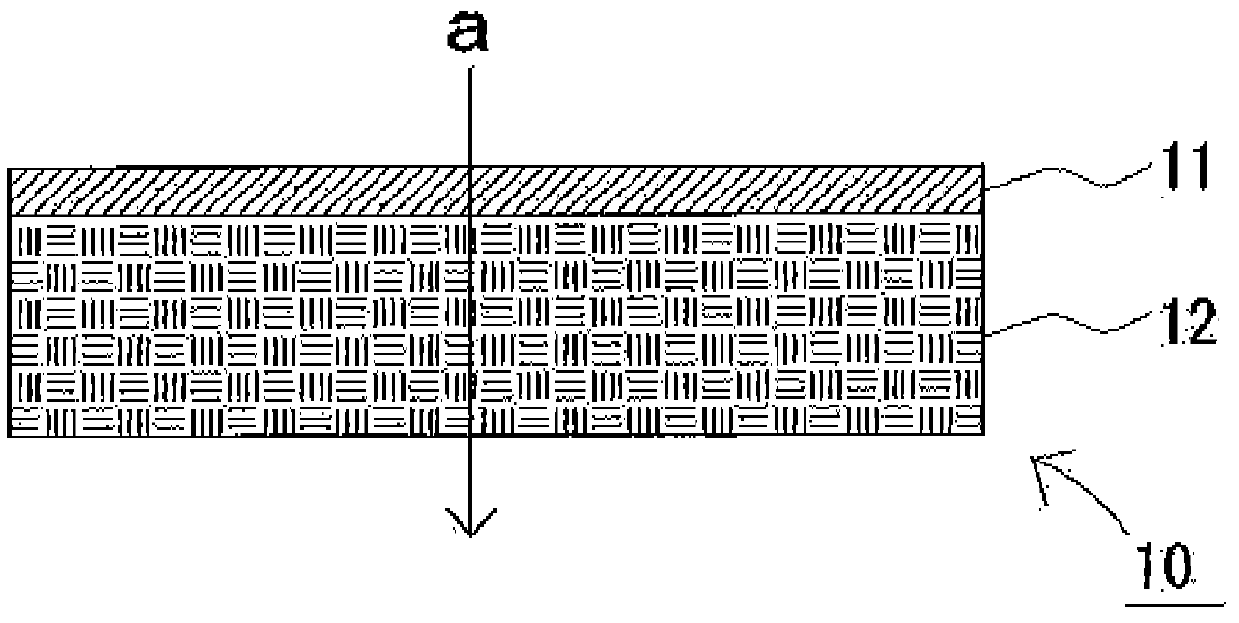

Circulating filtration system for sewage treatment

InactiveCN108096910AImprove filtration efficiencyReduce filtration efficiencyMoving filtering element filtersFiltrationSewage

The invention discloses a circulating filtration system for sewage treatment. The circulating filtration system comprises a shell, a rotary drum rotatably arranged on the shell around its own axis, aplurality of filter screen plates circumferentially arranged at intervals on the outer circle of the rotary drum, and a cleaning device for cleaning the filter screen plates, wherein the axis of the rotary drum is horizontally arranged and the filter screen plates are arranged in the radial direction of the rotary drum; water to be treated flows from top to bottom and passes through the filter screen plate rotated to the left side of the rotary drum to realize filtration; and filtered impurities are attached to the filter screen plates and rotated to the right side of the rotary drum to be cleaned by the cleaning device arranged on the right side, and a drainage channel for collecting and discharging clear water and an impurity discharging channel for collecting and discharging cleaned impurities are arranged below the rotary drum from left to right. The circulating filtration system can improve the sewage pretreatment efficiency, has a simple structure, a high automation degree, and alow equipment cost and is beneficial to popularization.

Owner:重庆精创联合环保工程有限公司 +1

Long-acting electret PP non-woven fabric and preparation method thereof

ActiveCN111321516AReduce surface tensionLow densityUltrasonic/sonic fibre treatmentConjugated synthetic polymer artificial filamentsFiberPolymer science

The invention provides long-acting electret PP non-woven fabric. The long-acting electret PP non-woven fabric is mainly prepared from the following components in parts by weight: 30 to 35 parts of electret master batch, 36 to 44 parts of melt-blown polypropylene, 8 to 17 parts of surface-treated silicon dioxide, 3 to 5 parts of polyvinylidene fluoride, 5 to 7 parts of polytetrafluoroethylene and 3to 5 parts of PFA. According to the long-acting electret PP non-woven fabric and the preparation method thereof provided by the invention, after the non-woven fabric is treated by an electret process, the filtering performance and charge storage performance of fibers are greatly improved, the high temperature resistance and high humidity resistance of the non-woven fabric are effectively improved, meanwhile, the hydrophobic and oleophobic properties of the fibers are also improved, and the service life is prolonged. In addition, the long-acting electret non-woven fabric also has the functionsof antibiosis, disinfection, deodorization and the like.

Owner:青岛科凯达橡塑有限公司 +1

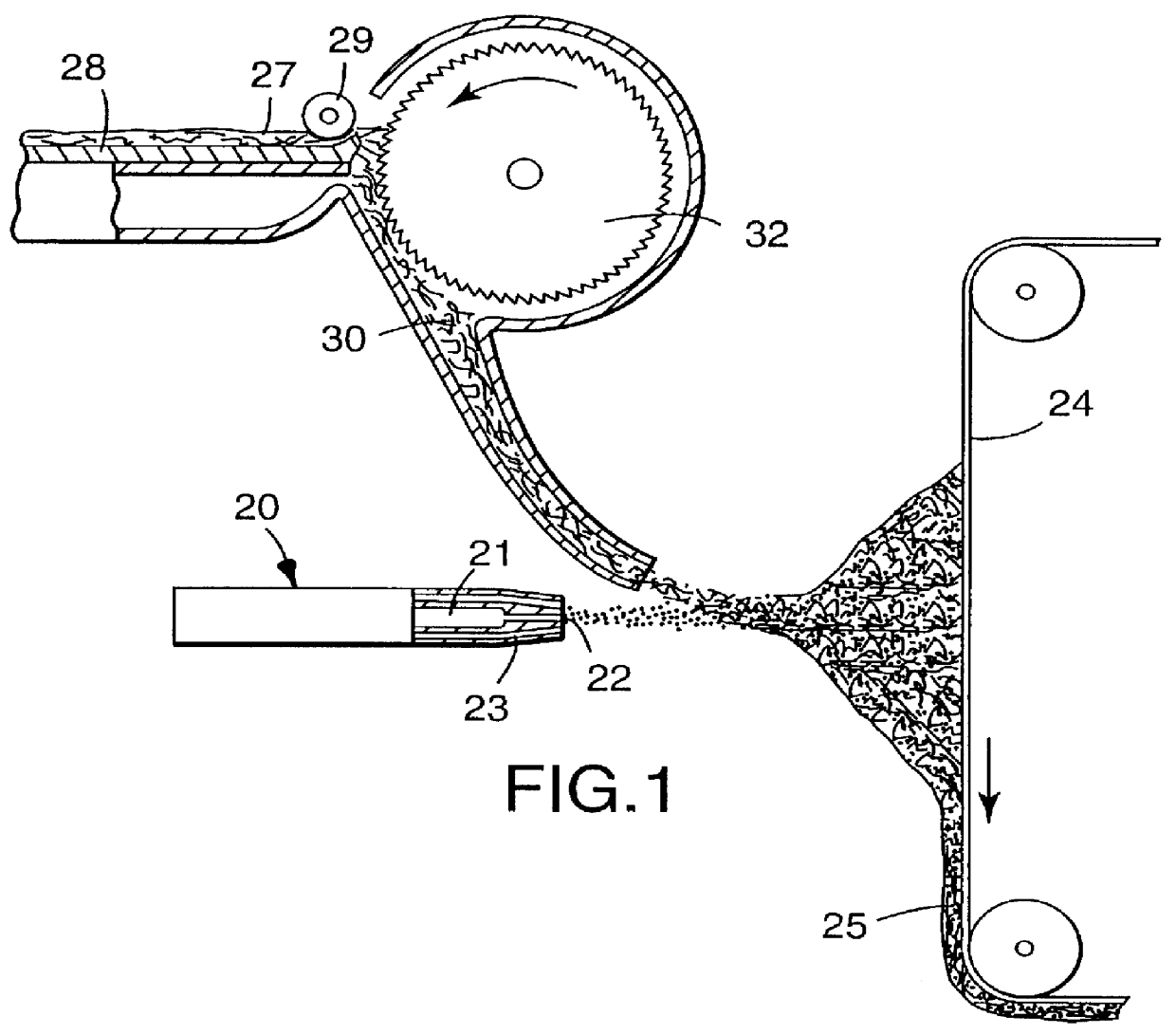

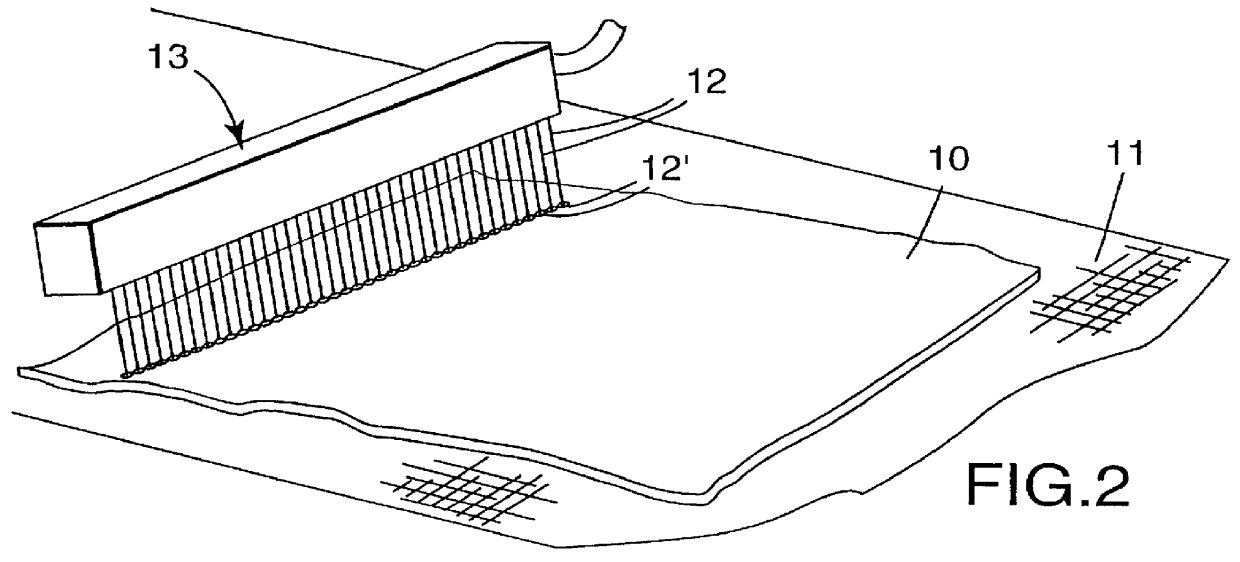

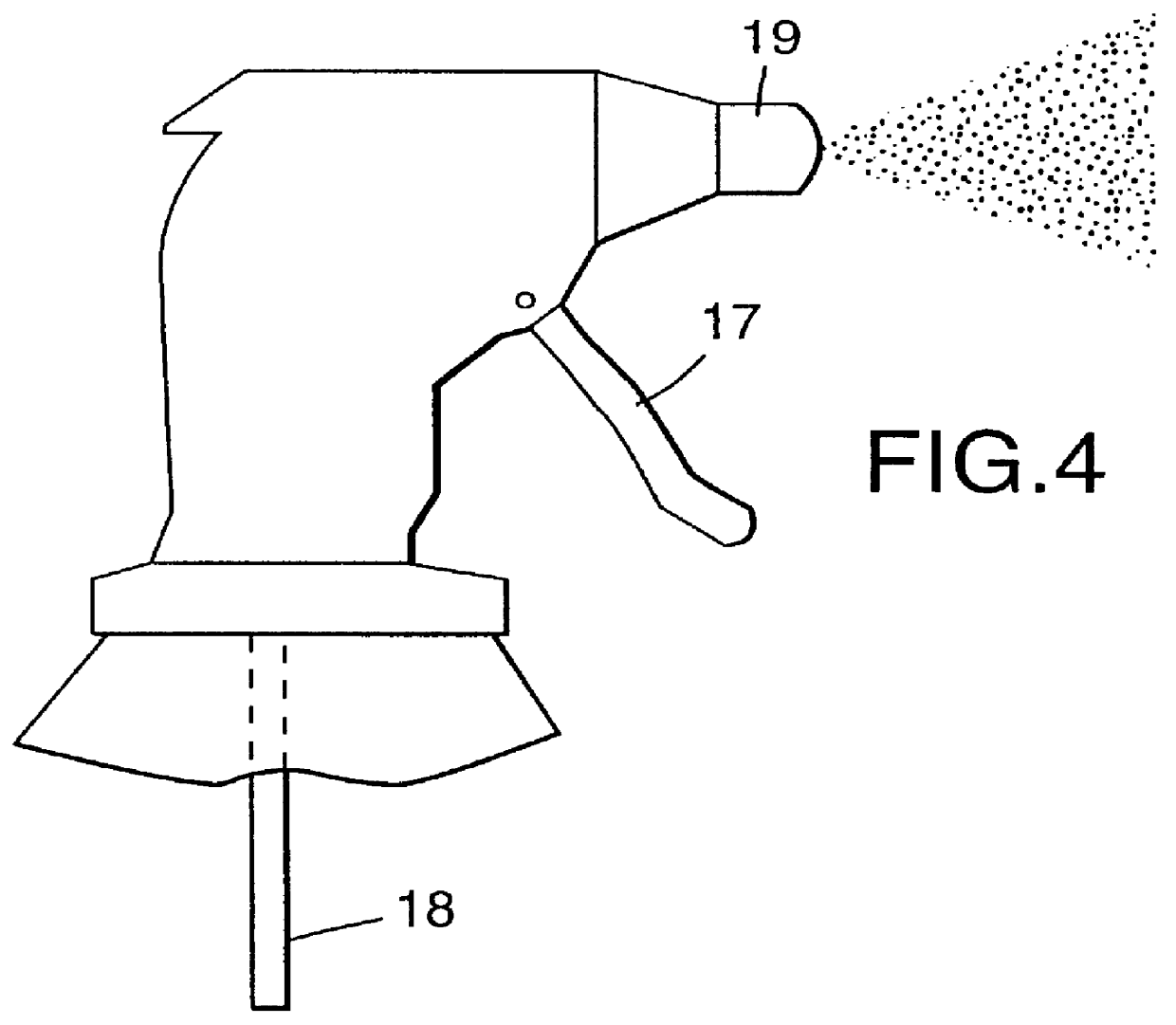

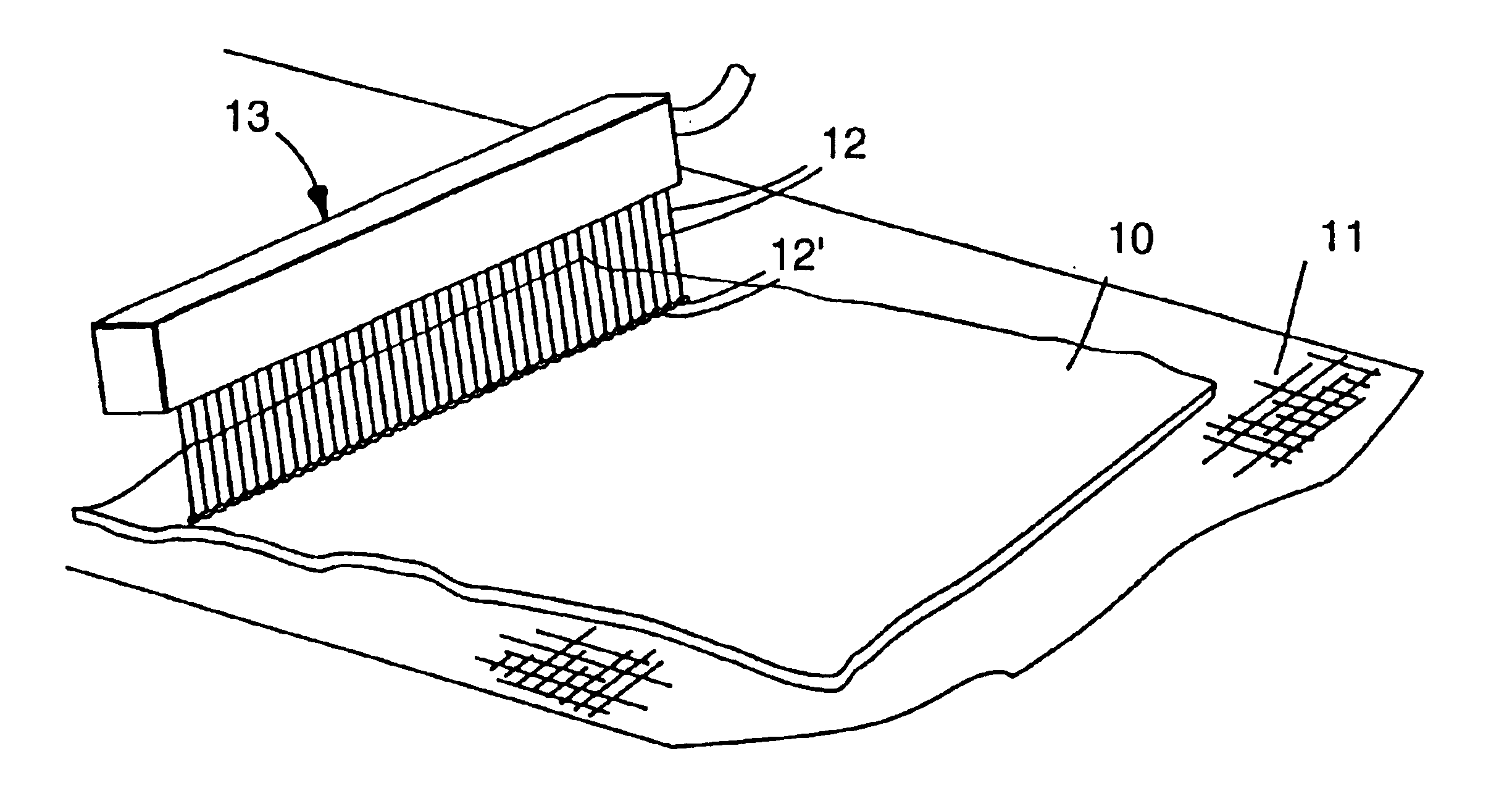

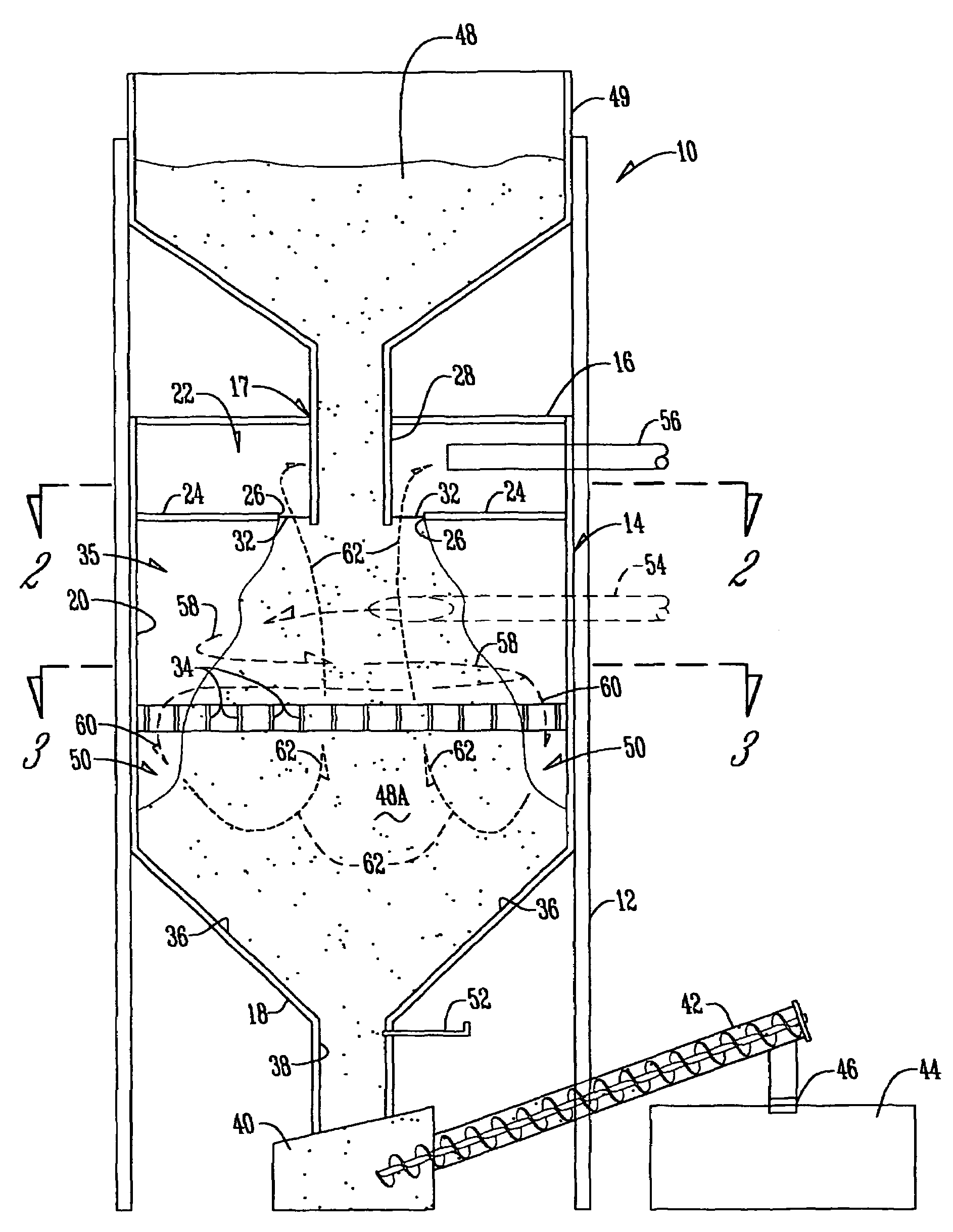

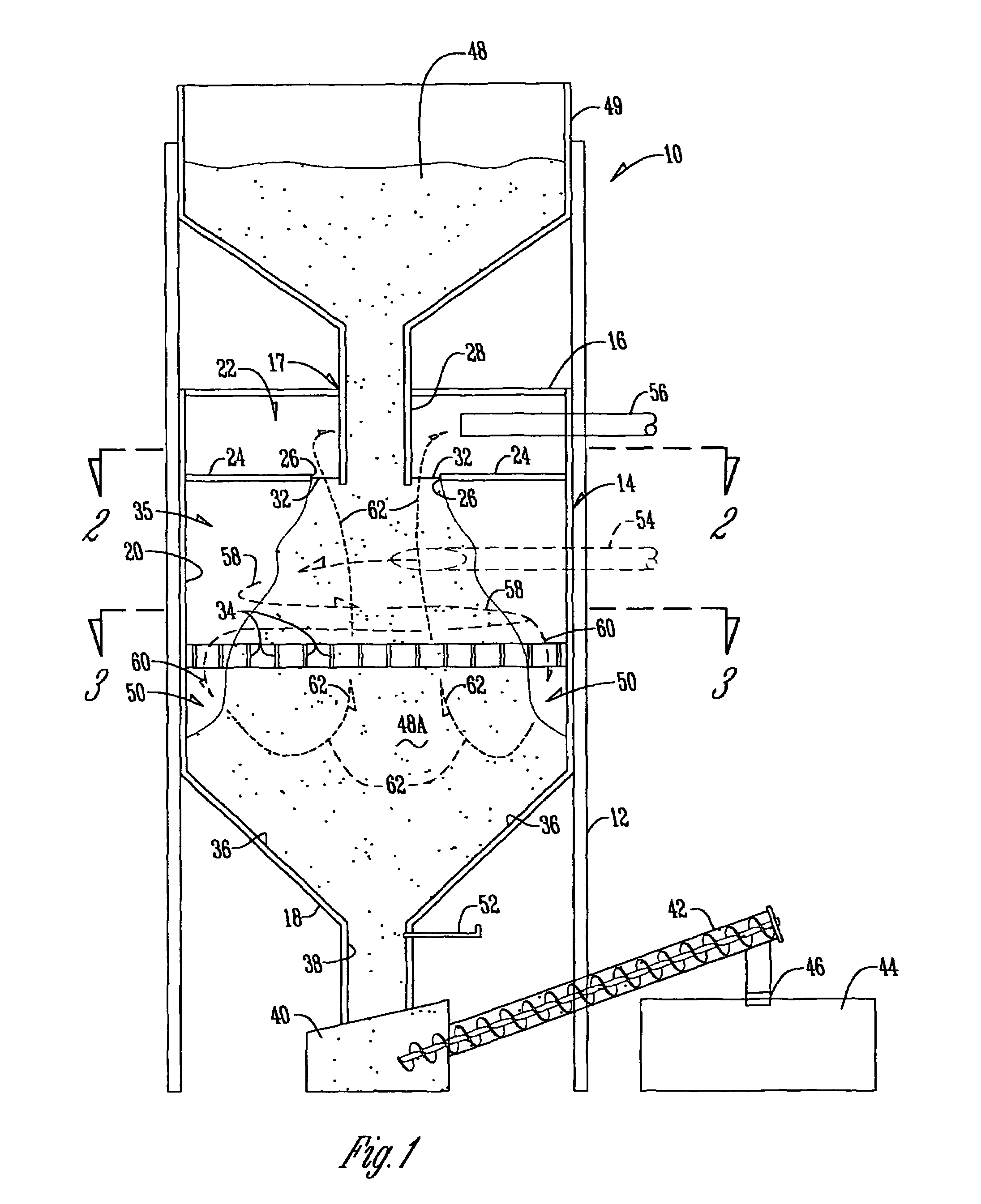

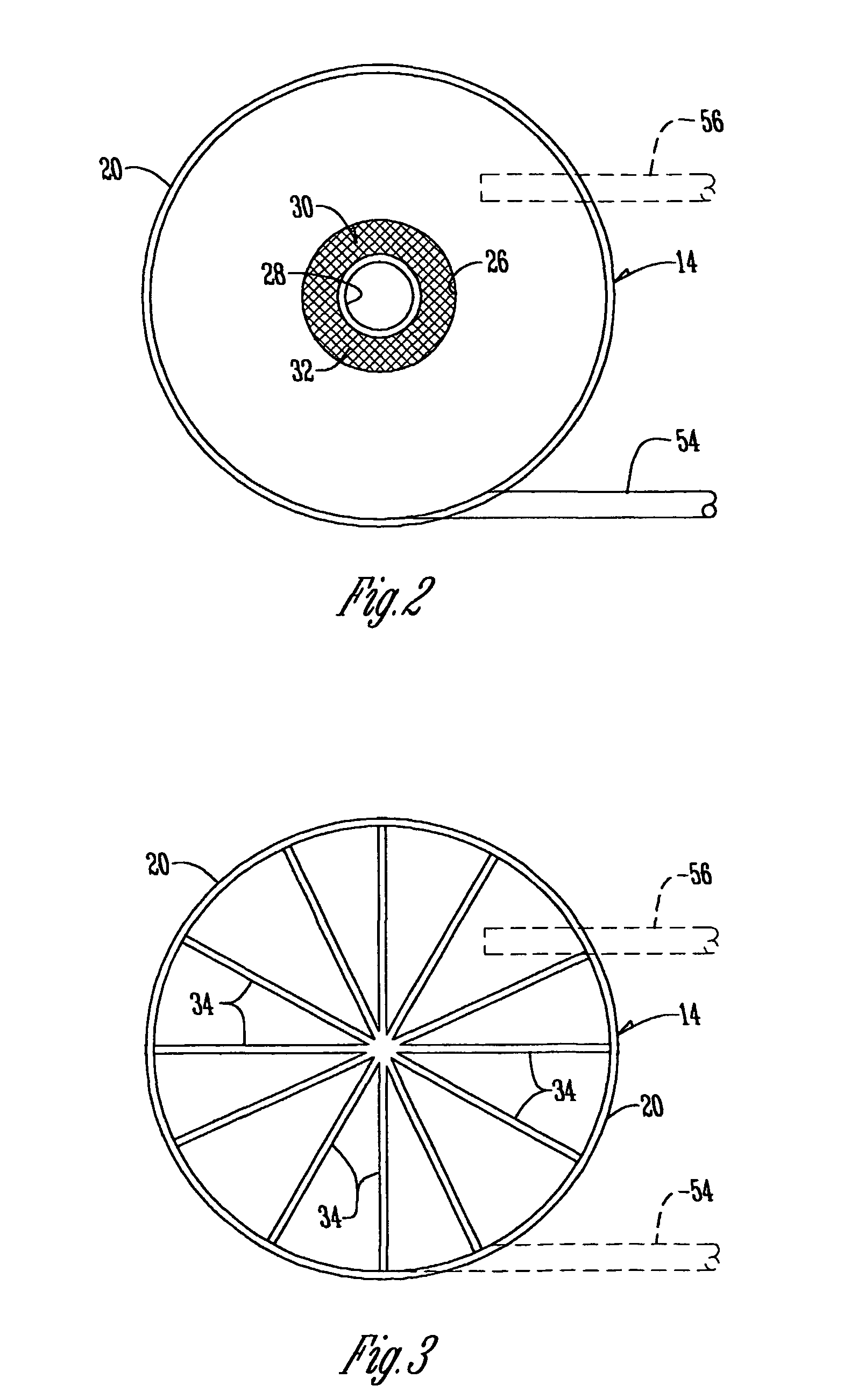

Method and apparatus for filtering gas with a moving granular filter bed

InactiveUS7309384B2Facilitate material flowIncrease flow rateCombination devicesDispersed particle filtrationParticulatesEngineering

Owner:IOWA STATE UNIV RES FOUND

Paecilomyces lilacinus and scale preparation method thereof

ActiveCN104928186AEffective controlIncrease productionFungiMicroorganism based processesPaecilomyces lilacinusNematode

Owner:湖北龙翔生物制品发展有限公司

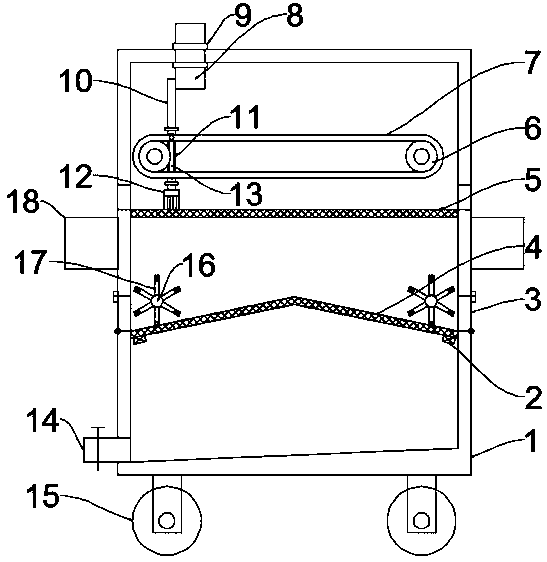

Cutting fluid recovering device for machining

InactiveCN107584327AGuaranteed Filtration SpeedAvoid accumulationMaintainance and safety accessoriesGratingEngineering

The invention discloses a cutting fluid recovering device for machining. The cutting fluid recovering device comprises a bracket, wherein a second collecting box, a separating cabin and an absorbing cabin are successively fixed on the bracket; the second collecting box is connected with the bottom of one side of the separating cabin through a guide slot; the middle part on the other side of the separating cabin is connected with the top end of the absorbing cabin through a guide pipe; a filtering box and a third collecting box are successively connected with the bottom of the absorbing cabin through a liquid draining pipe; a filtering plate is fixed on the upper part in the separating cabin; a rotating shaft of a motor extends into the separating cabin and is fixed with a grating plate; anabsorbing column is arranged in the absorbing cabin; a wire is arranged in an interlayer; the bottom of the absorbing cabin is in threaded connection with the top of a first collecting box. Accordingto the invention, the filtering plate, the grating plate, the absorbing column and the filtering box are adopted for treating the cutting fluid in turn, so that the impurities in the cutting fluid can be effectively removed, the device has a self-cleaning function, the recycling efficiency of the cutting fluid is guaranteed and the maintenance frequency is reduced.

Owner:WUXI ZHIGURUITUO TECH SERVICE CO LTD

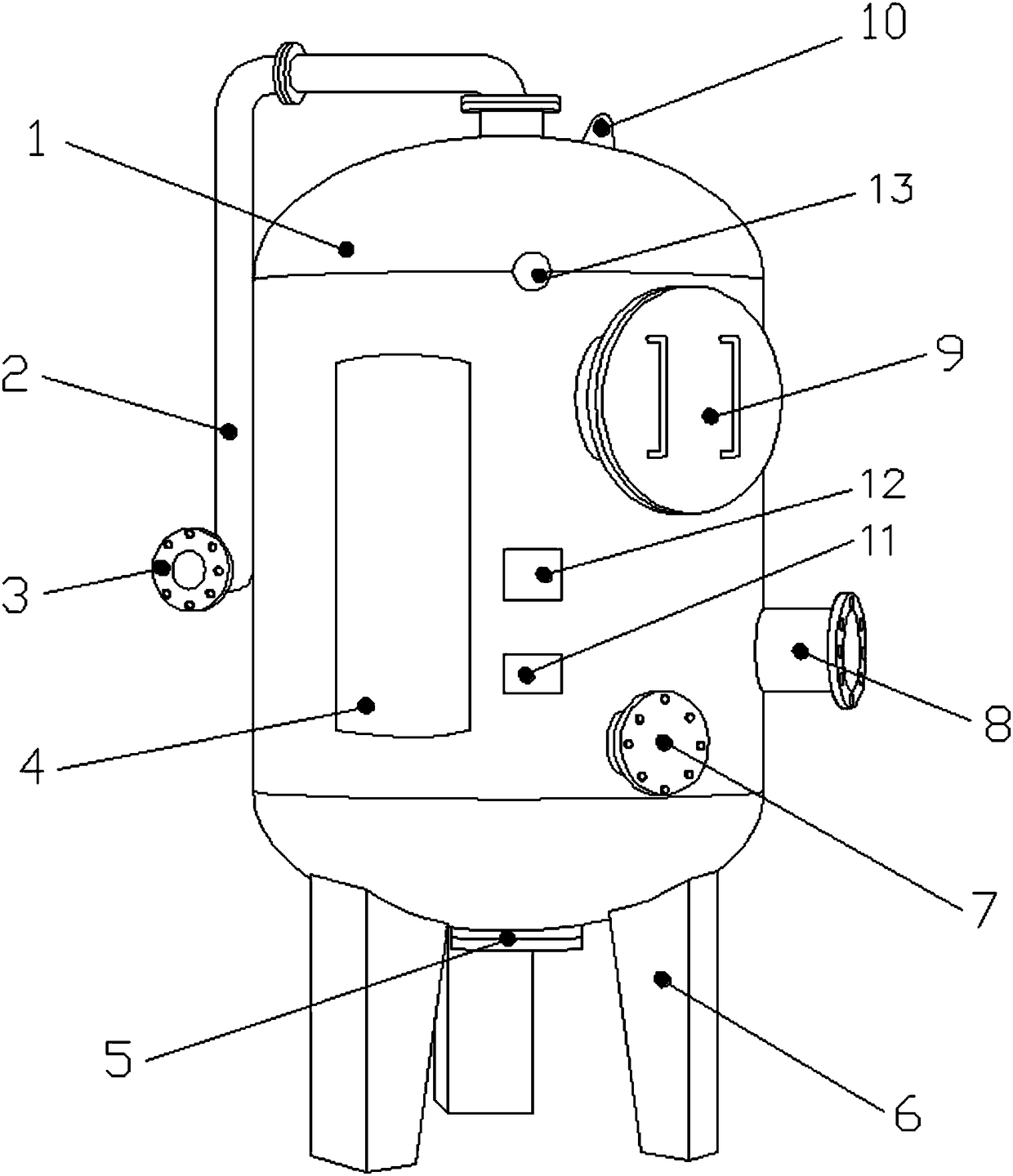

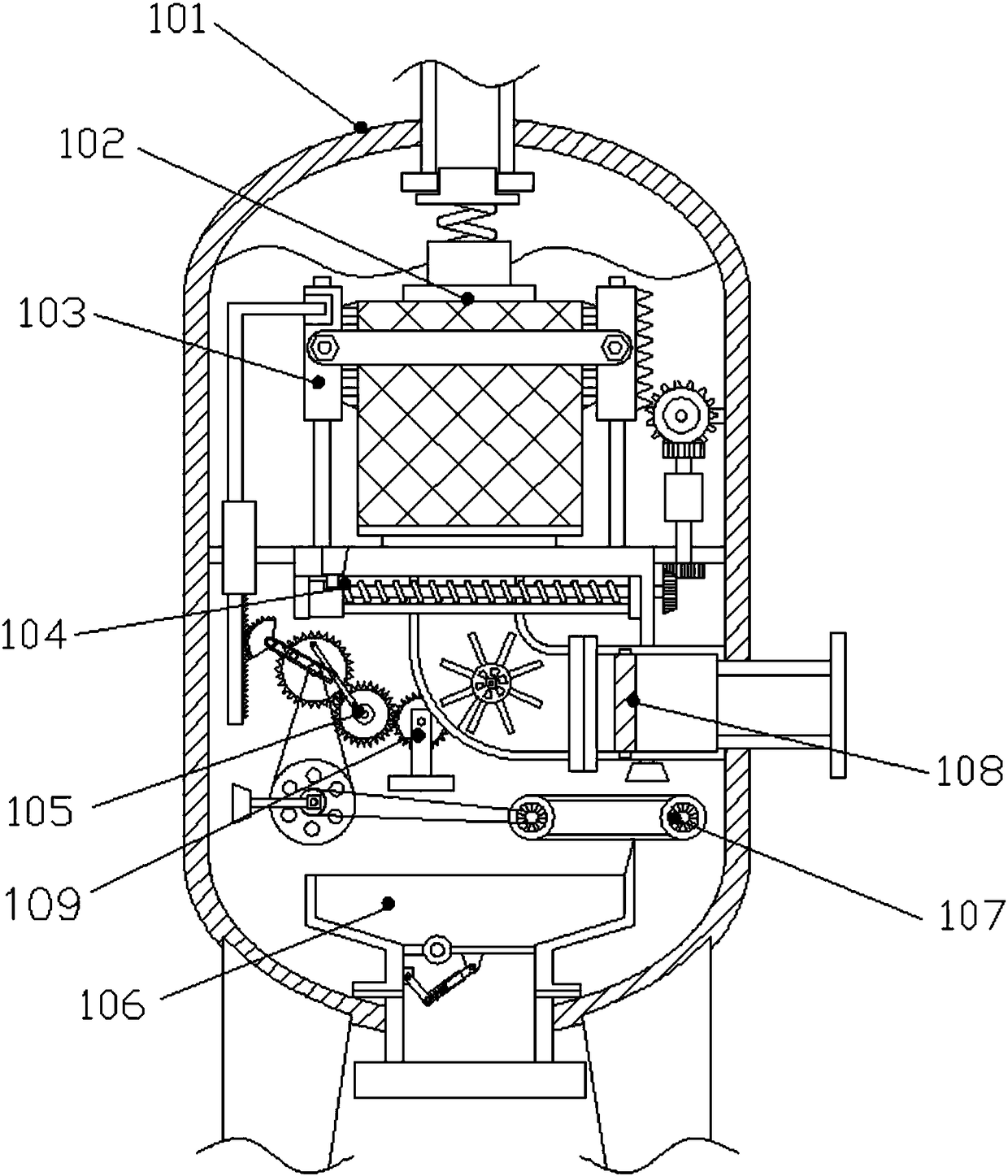

Automatic filter core cleaning device for petroleum exploitation

ActiveCN108421295AReduce filtration efficiencyReduce workloadStationary filtering element filtersTimerPetroleum

The invention discloses an automatic filter core cleaning device for petroleum exploitation. The automatic filter core cleaning device comprises a filter tank body, a petroleum induction pipe, a connection flange plate, a product nameplate, a filter residue discharge opening, an anti-skid support leg, an observation opening, a petroleum discharge pipe, a facility maintenance door, a fixed liftingring, a cleaning switch, a timer, and an alarm. By a filter residue cleaning mechanism, filter residues on the surface of the filter core of a filter device for petroleum exploitation can be removed automatically; the degradation of the filtering efficiency and quality of the petroleum filtering device is avoided, the work load for the operators is reduced, the practicality is enhanced, furthermore, through the timer and the alarm, the filter core can be replaced in time, and solved is the problem that the petroleum quality is influenced because the filter core is not changed in time during the production process.

Owner:NANTONG UPSTAR FILTERING EQUIP

Composite caustic silica gel manufacturing method and gels made thereby

InactiveUS20090001014A1Avoid introducingEase in salt removalSilicaOther chemical processesFiltrationSilica gel

New silica gel materials and novel methods of producing such are provided. The method itself entails a manner of mixing the reactants together in a one-pot process such that the time required for aging is reduced without compromising the ability to target pore size production. In such a way, the pH of the reaction drives pore size development, thereby permitting a more efficient process to be followed in terms of expensive drying / heating steps being reduced timewise, if not altogether. Furthermore, in one embodiment, the resultant gel materials exhibit a certain pore size minimum while simultaneously exhibiting a degree of softness heretofore unavailable. As such, not only is this novel method more efficient in silica gel manufacture, but the resultant materials are completely novel as well. The gel materials made therefrom may be utilized in a variety of different end uses, such as cooking oil filtration, soft skin cleansers, dental abrasives, and the like. Methods of production and use, as well as the novel gel materials themselves, particularly caustic and composite gels, are thus encompassed within this invention.

Owner:J M HUBER CORP

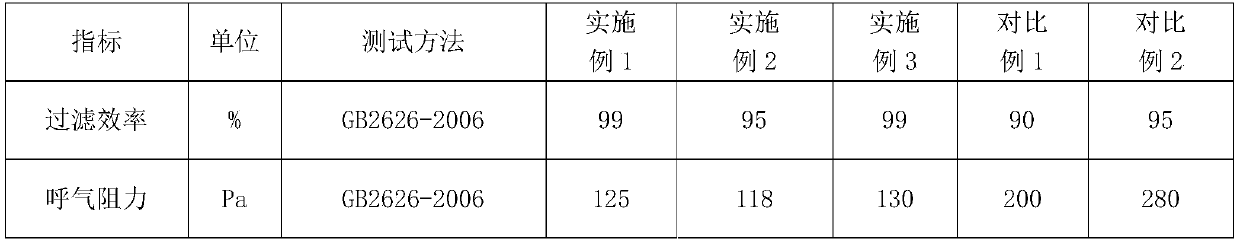

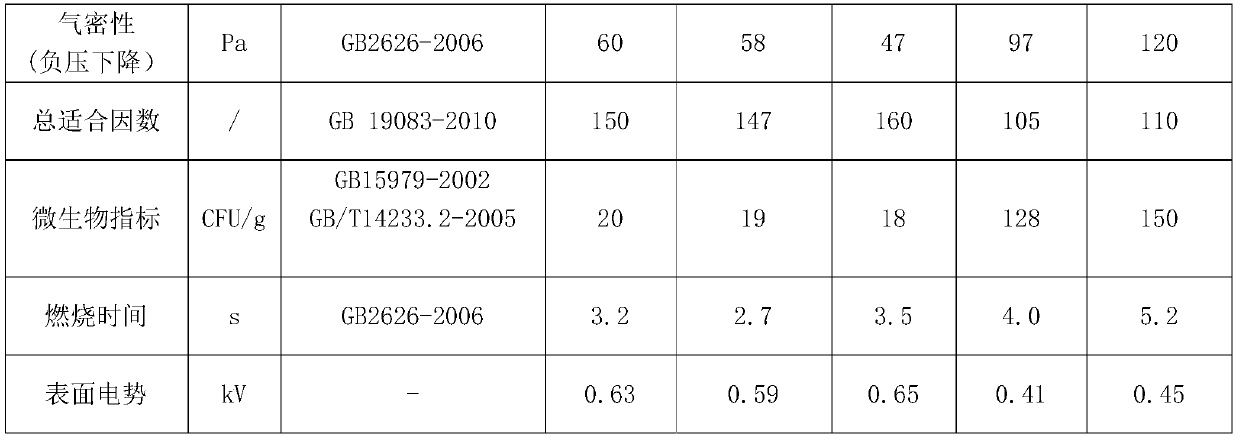

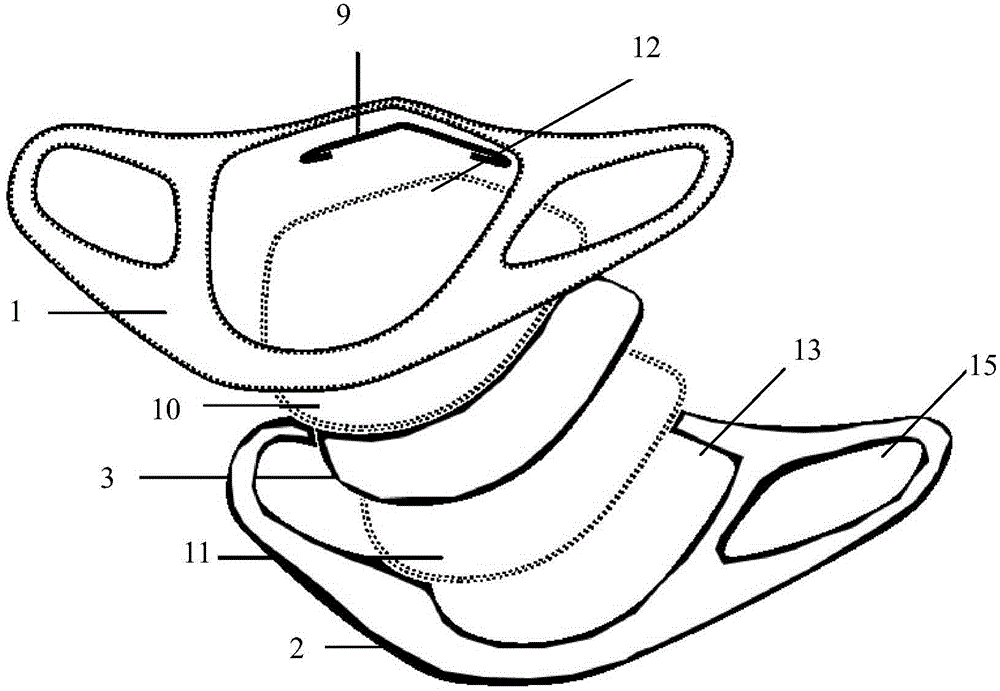

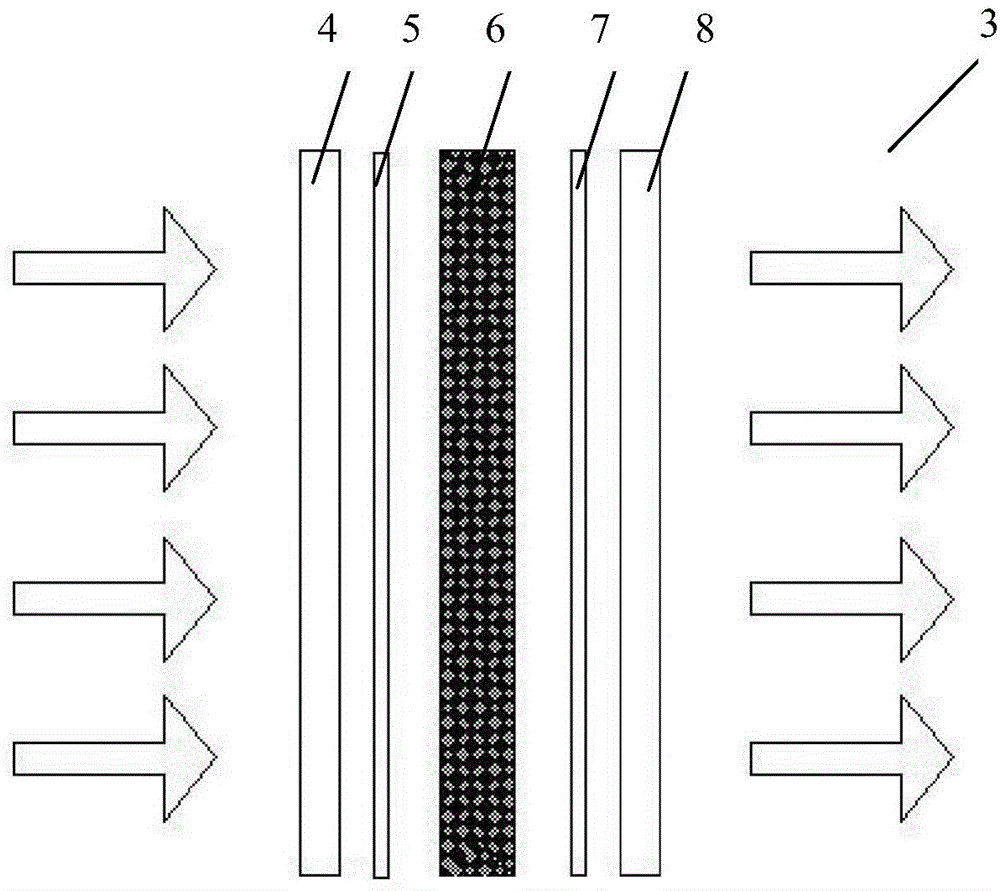

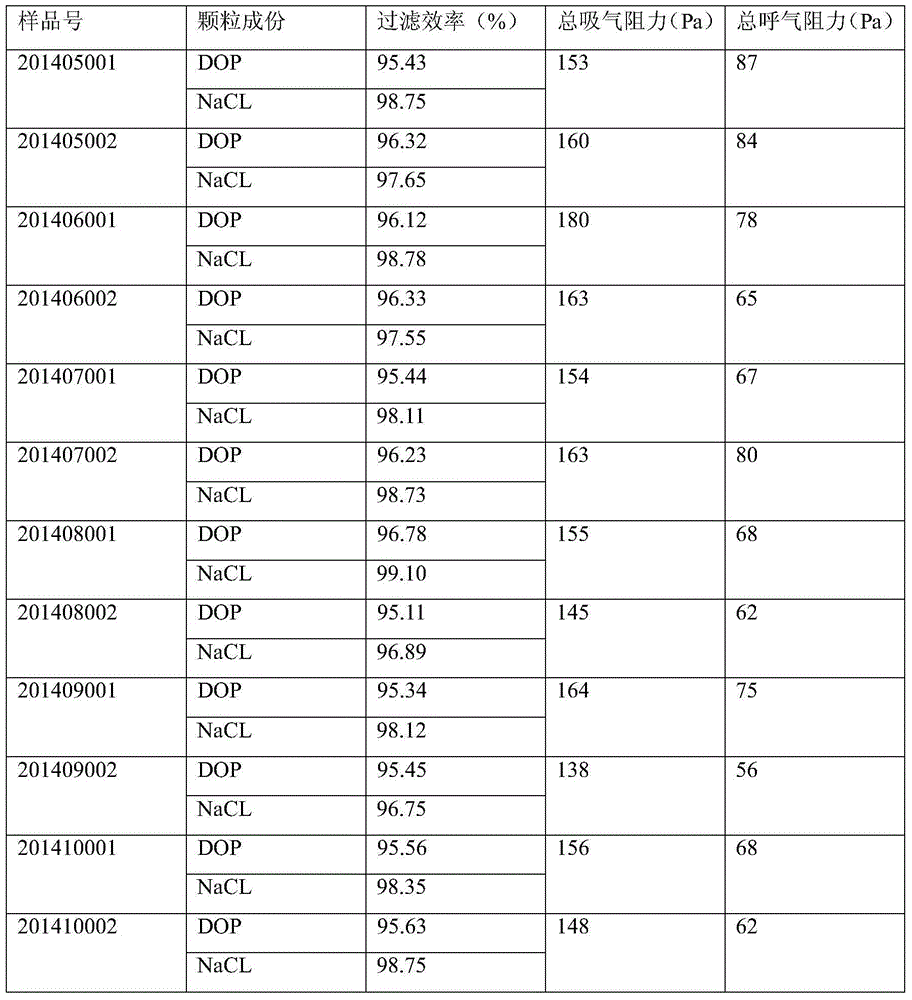

Antibiosis and haze prevention mask

The invention discloses an antibiosis and haze prevention mask which comprises a surface layer and a lining, and an antibiosis and haze prevention functional layer is arranged between the surface layer and the lining. The functional layer is composed of a first fiber layer, a silver-loaded short fiber non-woven fabric layer, a silver-loaded filament filter layer, an efficient filter layer and a second fiber layer from outside to inside; the first fiber layer and the second fiber layer are each composed of linen cloth or cotton and linen cloth or all cotton cloth or blended cloth; the silver-loaded short fiber non-woven fabric layer is composed of polypropylene fiber or terylene non-woven fabric, and a layer of nano-silver is arranged on the surface of the non-woven fabric; the silver-loaded filament filter layer is composed of multiple filaments, the filaments are hollow polyester filaments, the line diameter of the filaments is 20-30 micrometers, and nano-silver is impregnated in a hollow inner cavity of each filament; the efficient filter layer is composed of polypropylene ultra-thin fiber, and the surface of the polypropylene ultra-thin fiber is coated with teflon. The antibiosis and haze prevention mask has the advantages of being resistant to bacteria, and capable of preventing haze and being used repeatedly.

Owner:SHANGHAI HAISHE TECH DEV CO LTD

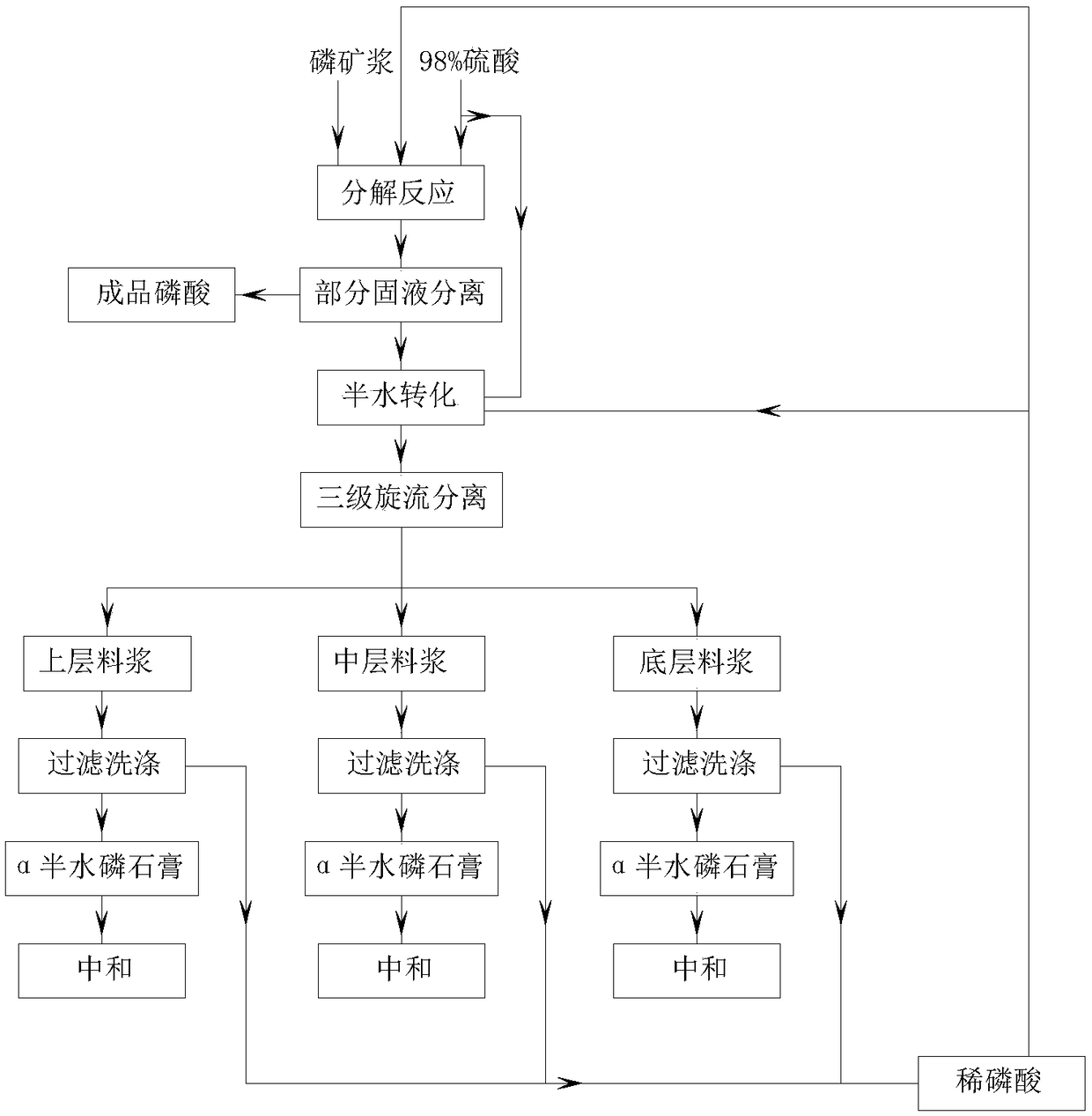

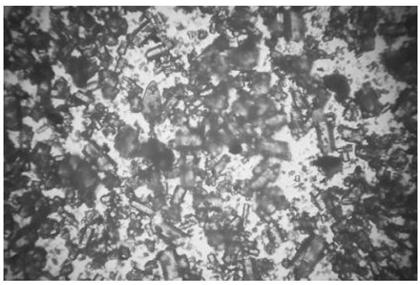

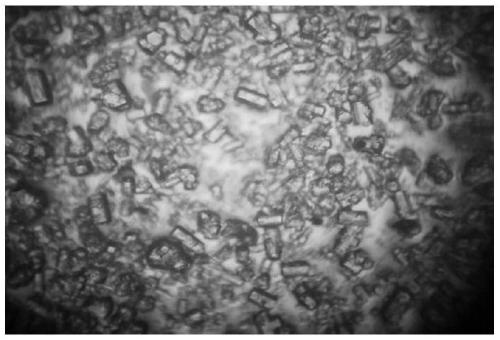

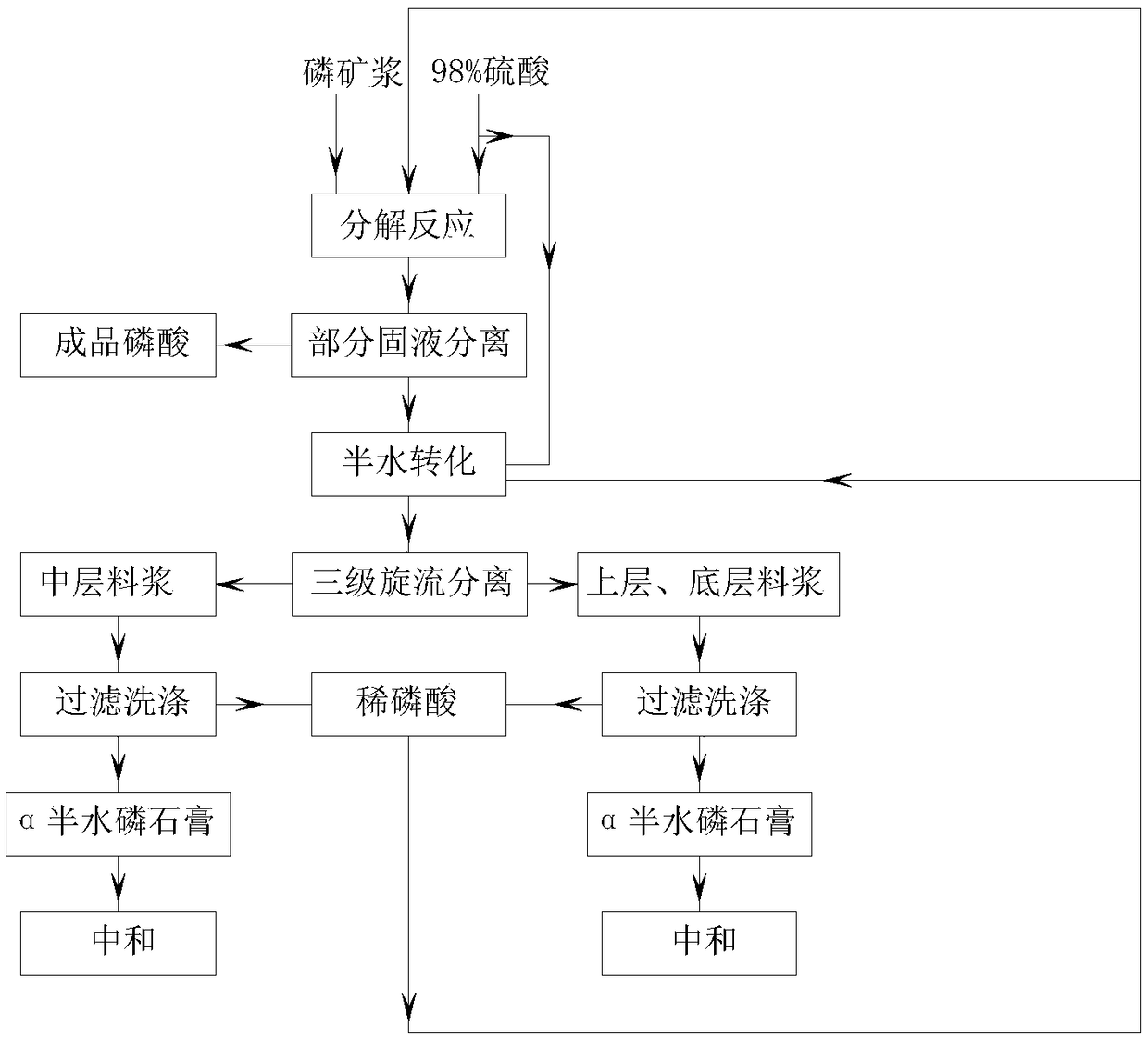

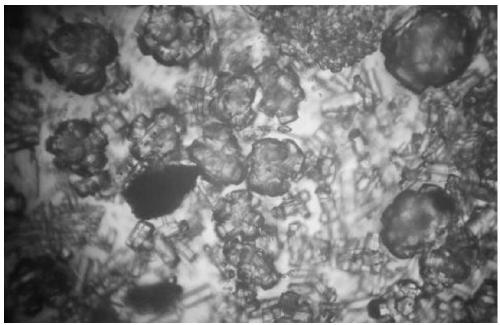

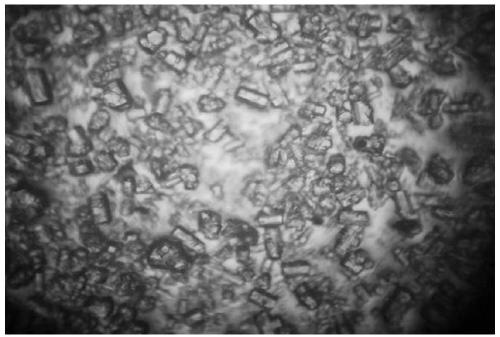

Method of producing wet-process phosphoric acid and alpha-hemihydrate phosphogypsum from middle grade phosphorus ore

ActiveCN109020282ADoes not affect contentIncrease the amount of participationCalcium/strontium/barium sulfatesHigh concentrationFiltration

The invention relates to a method of producing wet-process phosphoric acid and alpha-hemihydrate phosphogypsum from middle grade phosphorus ore and is an energy-saving and low-consumption wet-processphosphoric acid producing method. The method includes: decomposition reaction, solid-liquid separation, hemihydrates conversion reaction, and filtration and washing, wherein the technical parameters in the steps are controlled to finally produce a high-concentration final product of phosphoric acid and high-quality alpha-hemihydrate phosphogypsum; the final product of phosphoric acid is 35-42 wt%in concentration; the alpha-hemihydrate phosphogypsum is 13-15% in omega(H2O), is not more than 0.25% in omega(insoluble P2O5) and is not more than 0.1% in omega(soluble P2O5). Through the classification technology, zero emission of the byproduct, phosphogypsum, is achieved.

Owner:ANHUI LIUGUO CHEM CO LTD

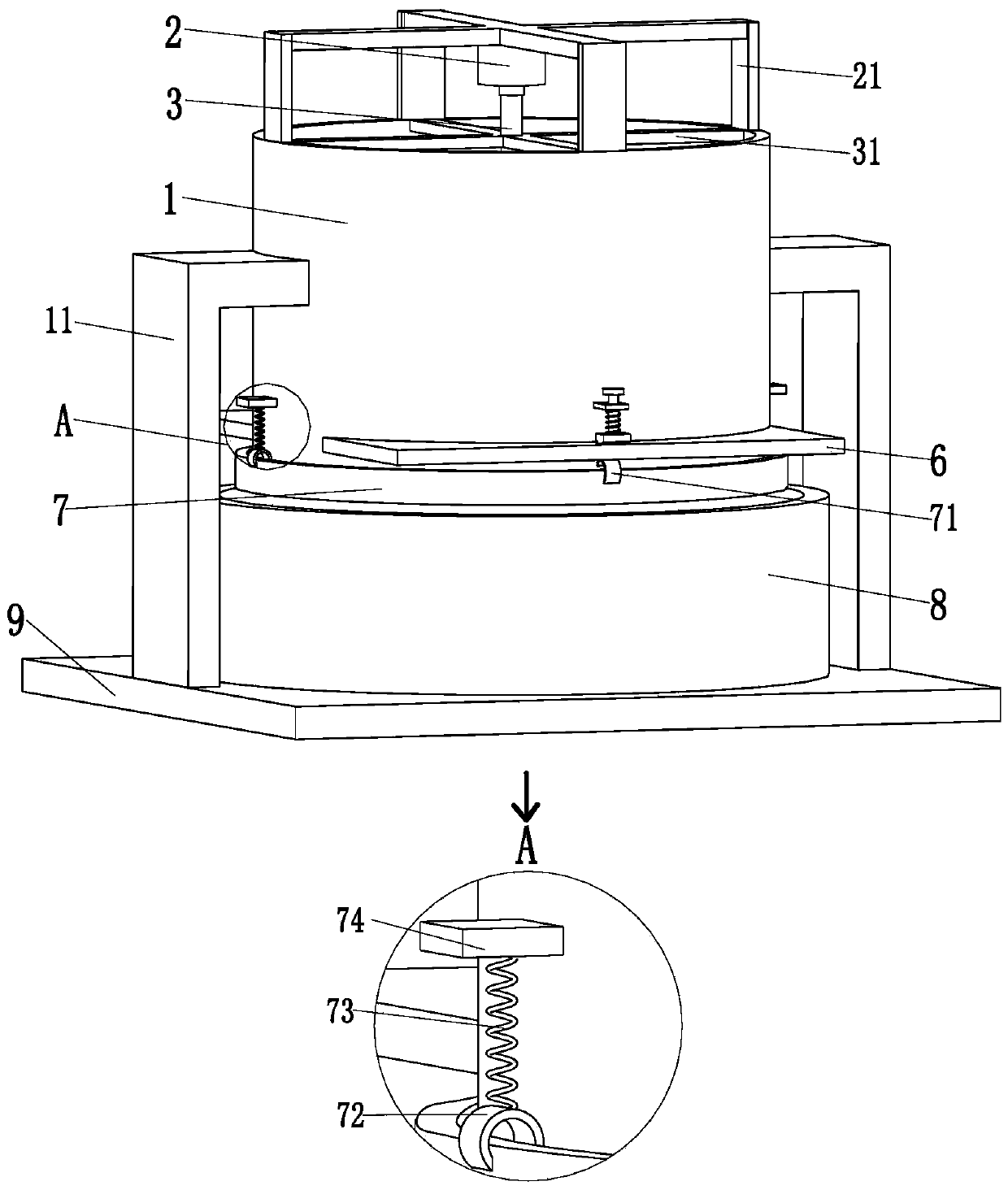

Filtering device for recycling water-based cleaning solution used for optical glass lenses

PendingCN109847448AAvoid cloggingReduce filtration efficiencyFiltration circuitsStationary filtering element filtersCause blockageWater based

The invention discloses a filtering device for recycling water-based cleaning solution used for optical glass lenses, relates to the technical field of filtering devices, and mainly aims to solve theproblem that the filtering efficiency is influenced due to the fact that meshes of a filter screen of an existing water-based cleaning fluid filtering device are liable to be blocked. The filtering device comprises a box body, a first filter screen and a second filter screen. A driving mechanism for driving the liquid inlet pipe to move left and right is arranged above the first filter screen. Thedriving mechanism comprises two groups of belt transmission mechanisms, a movable plate and a connecting rod. The filtering device is provided with a driving mechanism, wherein brush strips are installed at the bottom of a movable plate, two sets of belt transmission mechanisms drive the movable plate to move left and right, and the movable plate drives a liquid inlet pipe to move left and rightthrough a connecting rod, so that cleaning liquid is dispersed, and the cleaning liquid is prevented from falling to one position of a first filter screen to cause blockage of first filter screen holes; meanwhile, the brush strips move left and right to brush impurities on the first filter screen towards the two ends of the first filter screen, so that meshes of the first filter screen are prevented from being blocked, and the filtering efficiency is further improved.

Owner:丹阳广丰光学器材有限公司

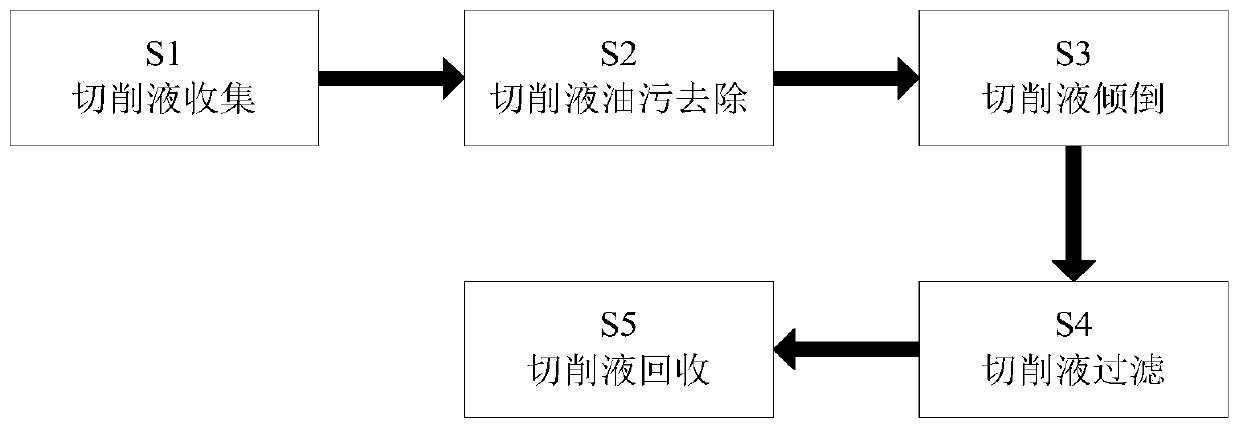

Water-soluble cutting fluid recovery treatment method

InactiveCN110683705AAvoid cloggingPrevent clogging and scratchingFatty/oily/floating substances removal devicesTreatment involving filtrationProcess engineeringFilter paper

The invention relates to a water-soluble cutting fluid recovery treatment method which comprises the following steps: S1, collecting a cutting fluid; S2, removing oil stain of the cutting fluid, namely pouring off and removing sundries such as oil stain floating on the liquid level of the cutting fluid in the step S1; S3, pouring the cutting fluid; S4, filtering the cutting fluid; and S5, recovering the cutting fluid. Corresponding treatment operation of operation procedures of steps S1-S5 of the water-soluble cutting fluid recovery treatment method is completed through cooperation of a stirring bucket, a stirring motor, a stirring rod, blades, an adsorption mechanism, a sealing plate, a filtering net and a recovery bucket. By adopting the method, problems that in conventional operation that a cutting fluid is filtered, the cutting fluid is filtered in a multistage filtration mode generally, the cutting fluid is fed through filter paper of different models to achieve the purpose of removing sundries, but the filter paper can be blocked or scratched by the sundries in the cutting fluid, the cutting fluid is poor in filtration effect, and the filter paper needs to be artificially shaken frequently, can be solved.

Owner:郭寒生

Factory building welding exhaust gas purification apparatus

InactiveCN109692533AReduce filtration efficiencySimple structureDispersed particle filtrationTransportation and packagingWelding fumeExhaust gas

The invention discloses a factory building welding exhaust gas purification apparatus. The apparatus comprises a welding fume purifier, a welding fume purifying device is arranged in the welding fumepurifier, a cleaning device is arranged in the welding fume purifying device, a vacuum gas suction and recovery device is arranged below the welding fume purifying device, a universal telescopic gas suction tube device is arranged above the vacuum gas suction and recovery device, a cleaning device is arranged below the side surface of the welding fume purifier, a rotatable connecting short rod isarranged in the universal telescopic gas suction tube, the connecting short rod swings to drive the universal telescopic gas suction tube to move to purify fume, and the gas suction using a gas suction pump makes the universal telescopic gas suction tube return into the welding fume purifier to make the apparatus conveniently used by a user. The apparatus has the advantages of simple structure andstrong practicability.

Owner:柳州若思纳米材料科技有限公司 +1

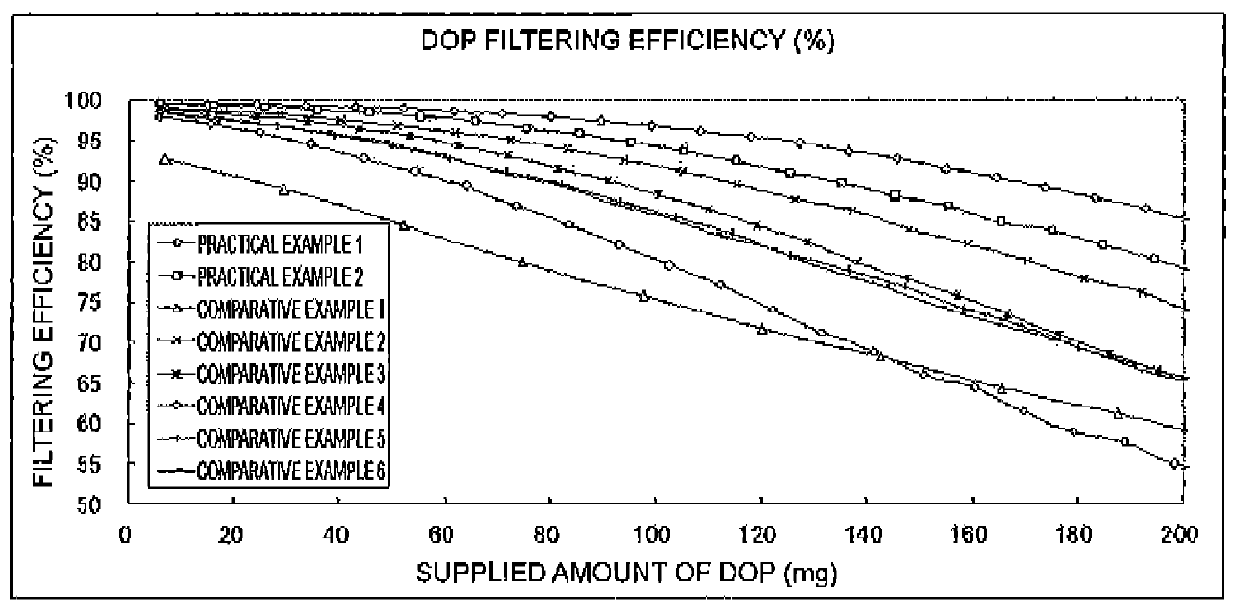

Electrically charged filter and mask

ActiveUS20130047856A1High initial filtering efficiencyImprove efficiencyBreathing filtersLayered productsElectrical polarityNonwoven fabric

Provided is an electrically charged filter which has a high initial filtering efficiency and is not liable to decline in filtering efficiency, by including a liquid-charged nonwoven fabric layer that is charged by application of force via a polar liquid, and a tribo-electrically charged nonwoven fabric layer that is charged by friction between fiber components of a plurality of types.

Owner:JAPAN VILENE CO LTD

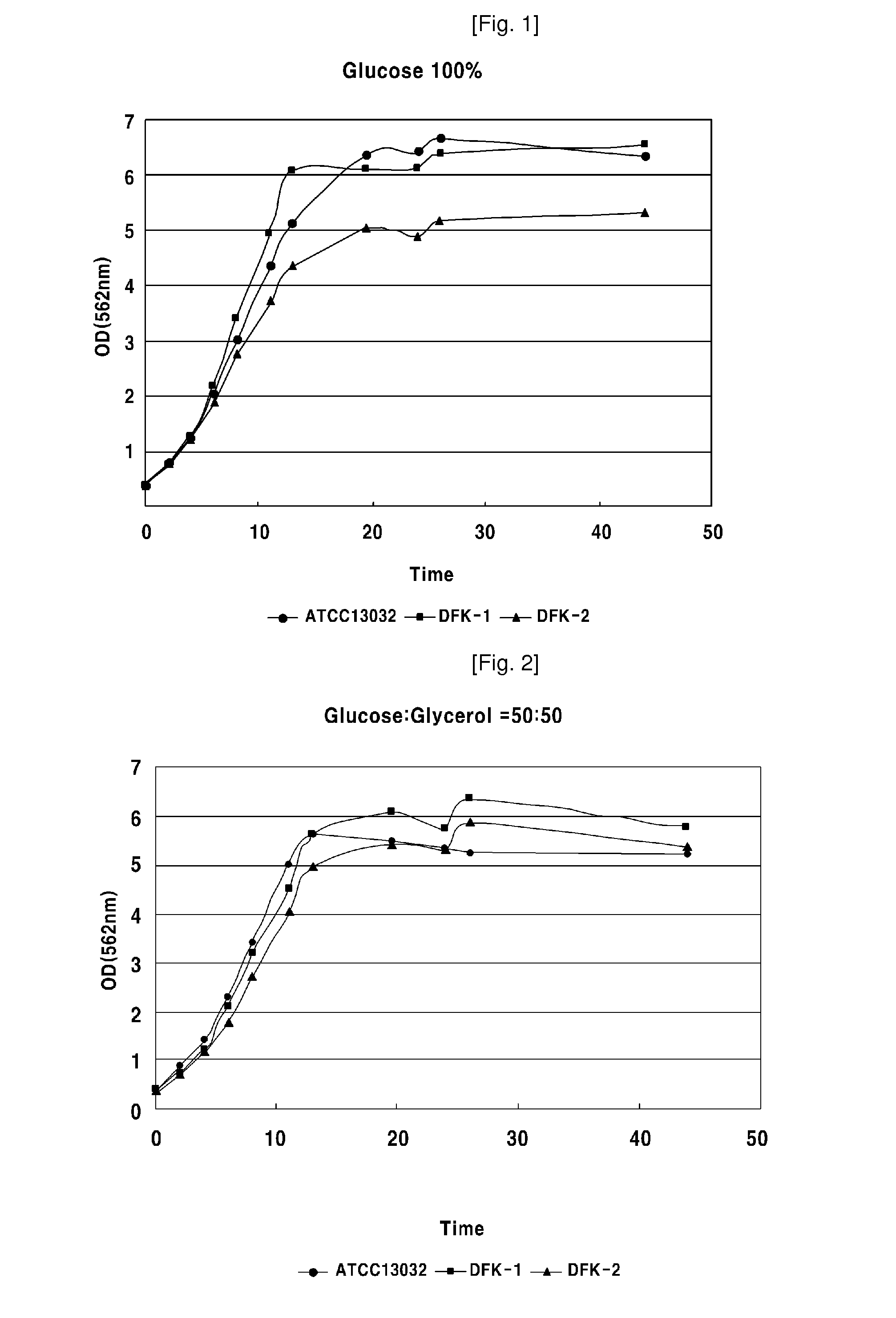

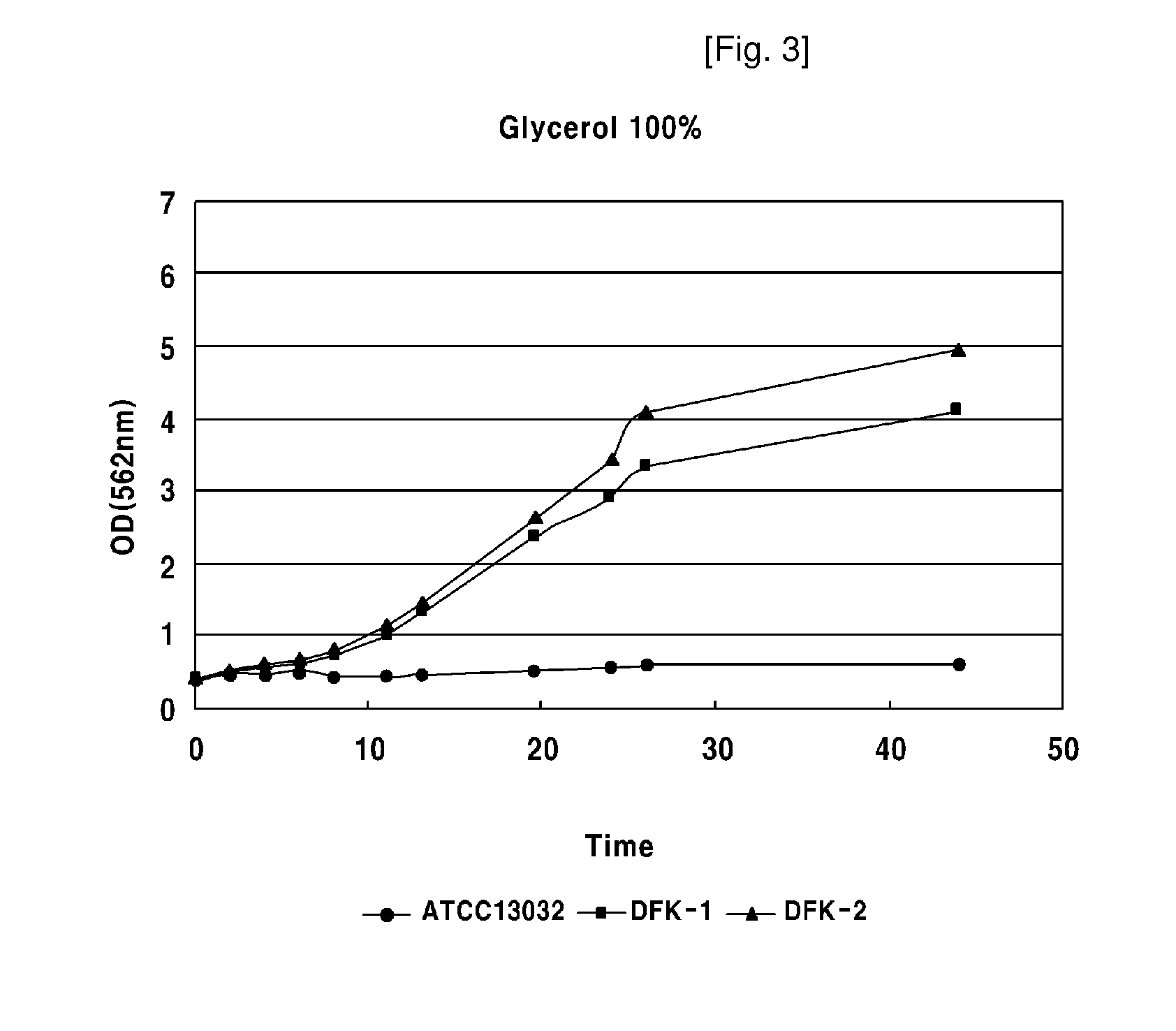

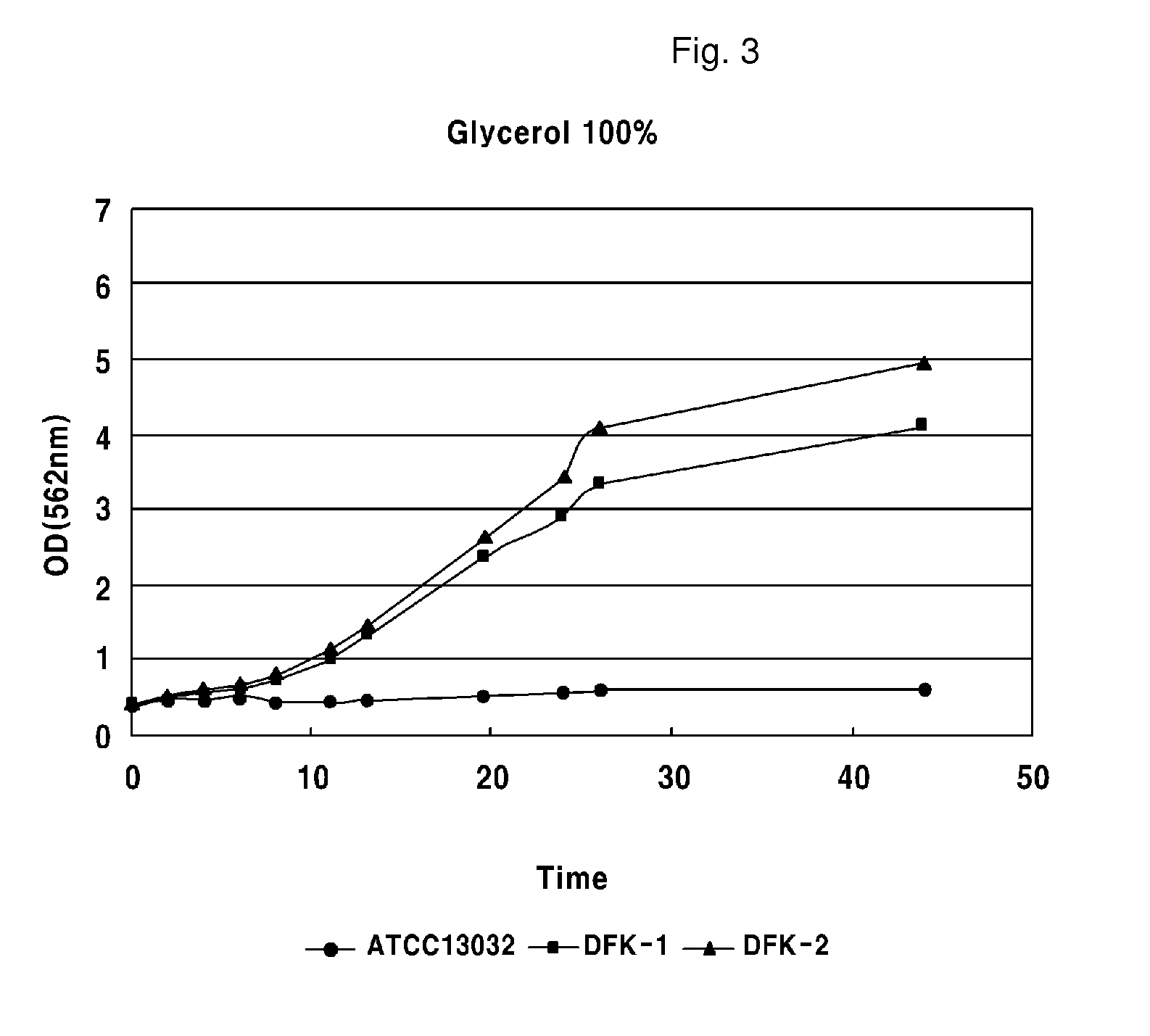

Process for Producing Fermentation Product from Carbon Sources Containing Glycerol using Corynebacteria

ActiveUS20100129884A1Easy to useReduce filtration efficiencyBacteriaTransferasesGlycerolFermentation

The present invention relates to a method for producing fermentation product from various carbon sources containing glycerol using Corynebacteria. More particularly, the present invention relates to a method for producing fermentation product from carbon sources containing glycerol or a part of glycerol with high yield and high productivity, by fermenting Corynebacteria introduced with the foreign gene glpDFK facilitating the use of glycerol and accumulating industrially useful amino acids in the culture medium.

Owner:CJ CHEILJEDANG CORP

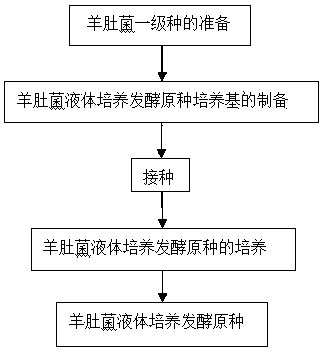

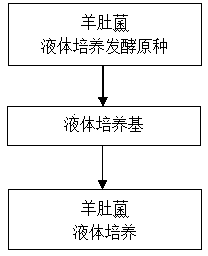

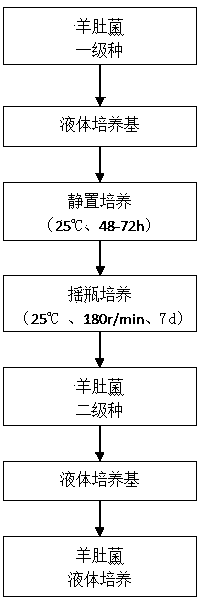

Fermentation stock seed for liquid culture of morchella esculenta, preparation method of fermentation stock seed and method for realizing liquid culture by using stock seed

InactiveCN103804090AThe fermentation process is simpleShorten the fermentation cycleFertilizer mixturesMorchellaCorn meal

The invention discloses a fermentation stock seed for the liquid culture of morchella esculenta, a preparation method of the fermentation stock seed and a method for realizing liquid culture by using the stock seed. The preparation method comprises the following steps: preparing a solid culture medium of morchella esculenta by taking sawdust, wheat bran, corn meal and soybean meal as raw materials; carrying out inoculated culture to form the fermentation stock seed for the liquid culture of the morchella esculenta. The solid fermentation stock seed is not needed to be expanded step by step and can be directly used for the liquid culture of the morchella esculenta; the preparation method is simple in operation and rapid in mycelial growth; compared with the traditional process, the preparation method has the advantages of shortening the fermentation period and remarkably increasing the content of exopolysaccharide in the morchella esculenta.

Owner:GANSU ACAD OF SCI INST OF BIOLOGY

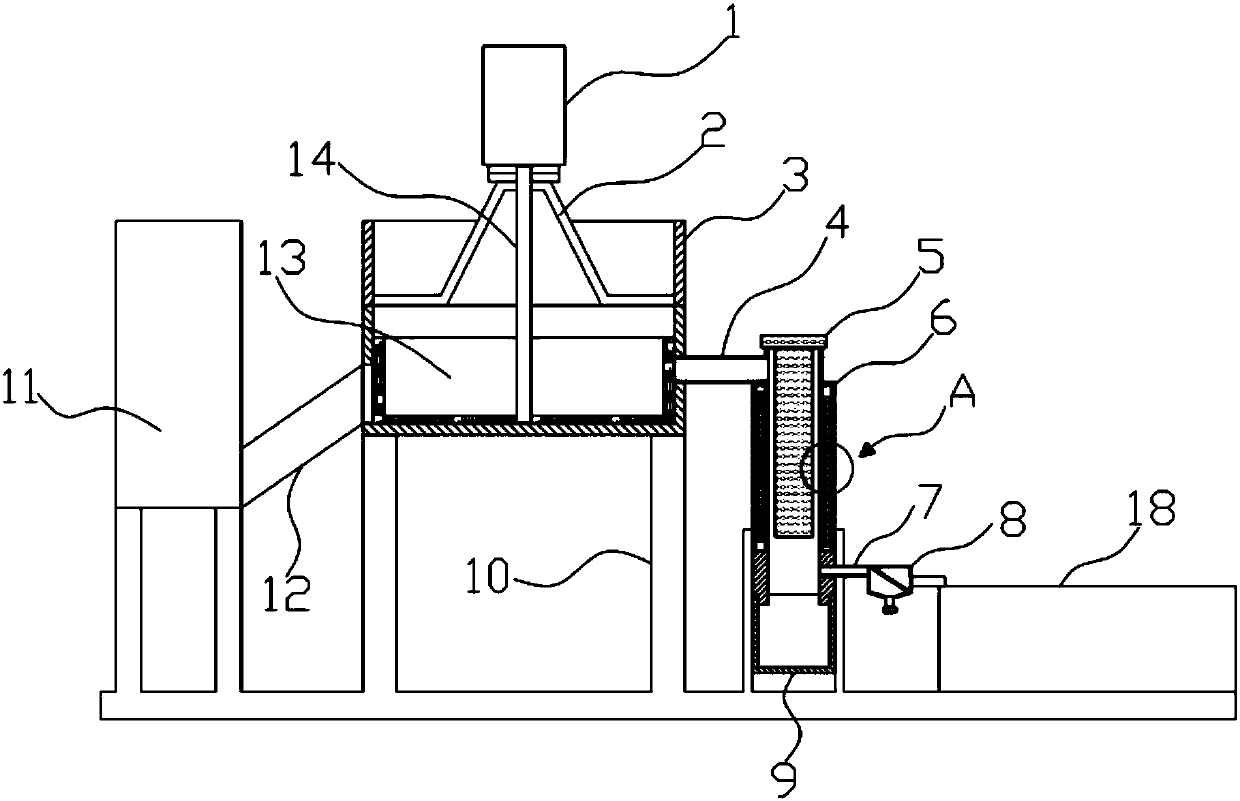

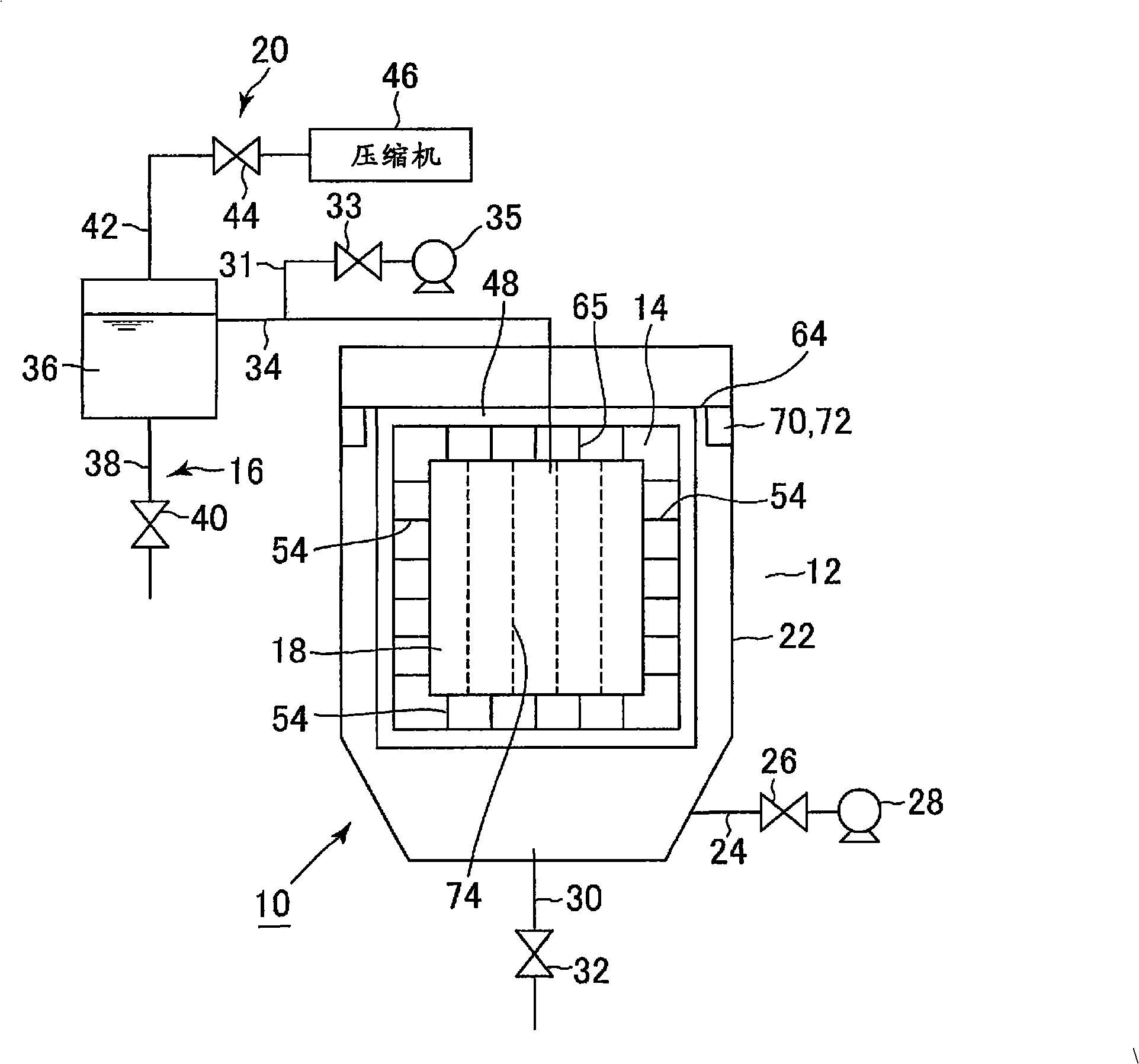

Suction type filtering-condensing apparatus

ActiveCN102099303AGuaranteed passabilityWith self-cleaning functionSludge treatment by de-watering/drying/thickeningStationary filtering element filtersFiltrationEngineering

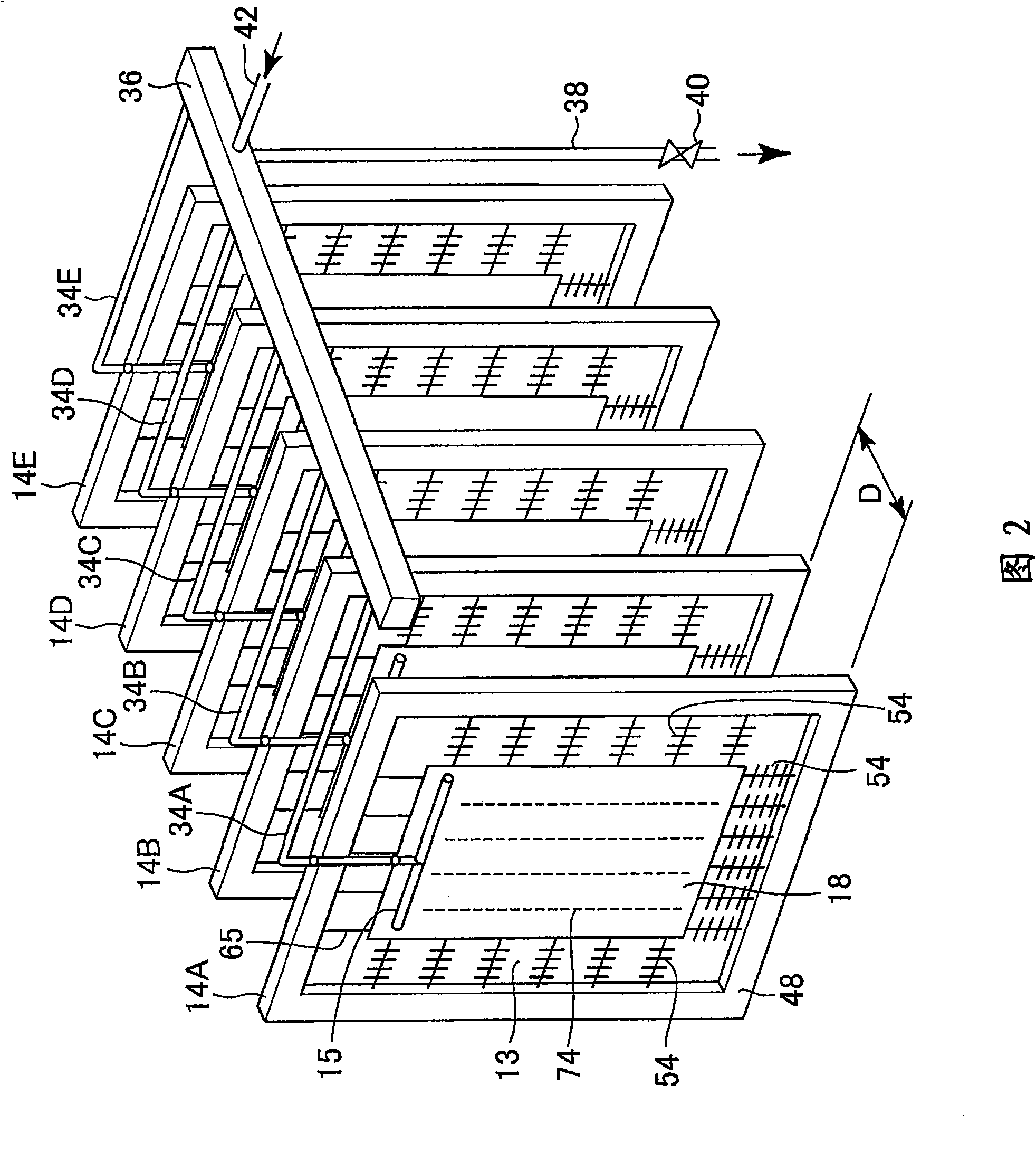

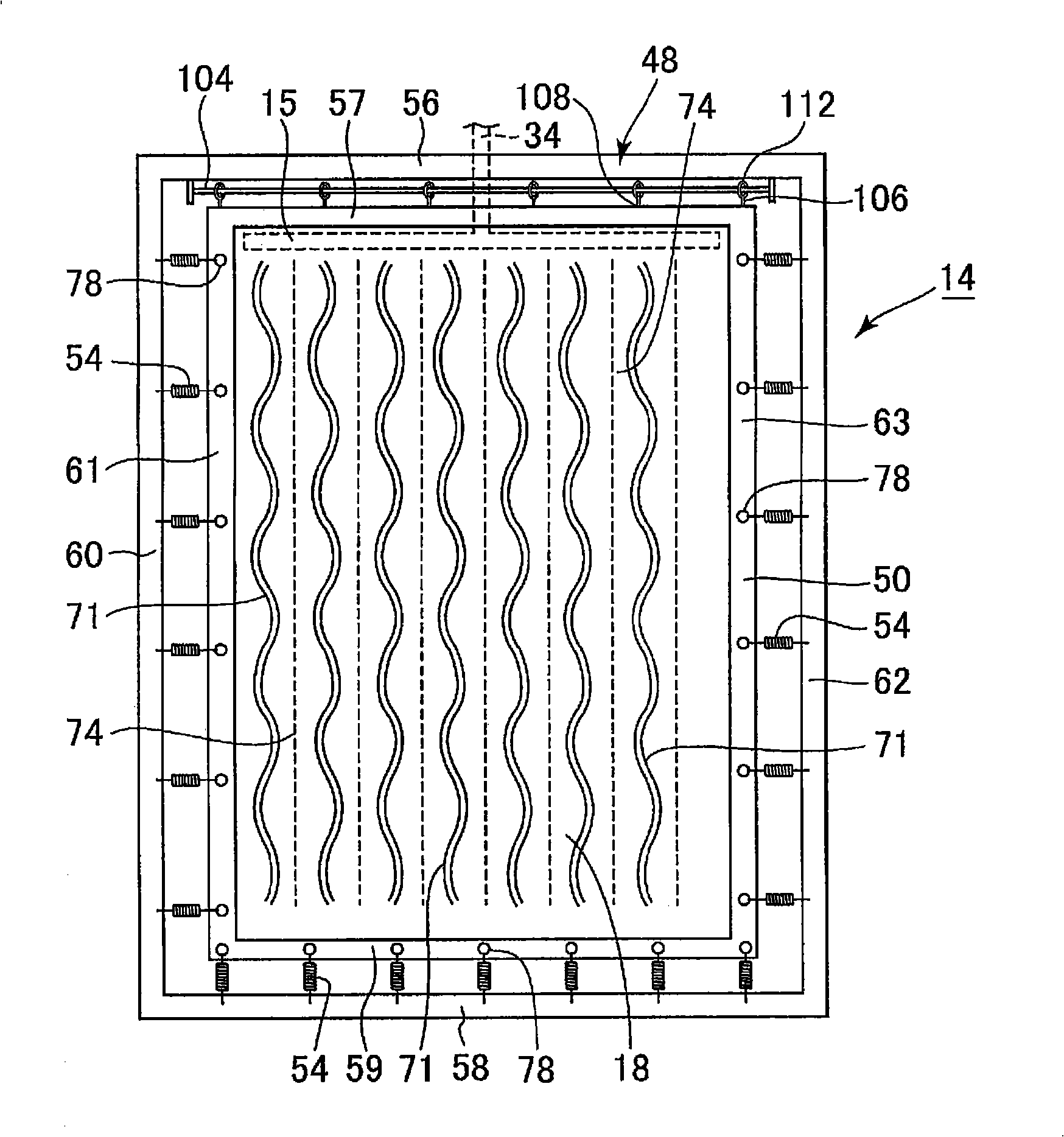

Provided is a suction type filtering-condensing apparatus which does not reduce filtering efficiency and can guarantee filtering performance. The apparatus comprises a filtering-condensing bath (12) for housing treated fluid including filtering-condensing objects, and a plurality of filter plates (14) arranged in the filtering-condensing bath (12) and extending vertically along the filtering-condensing bath (12). Each of the filter plates (14) includes a support plate (50) vertically rugged in its surface and formed into a net shape, and a bag-shaped filter cloth (18) for housing the support plate (50), so that a filter chamber (76) is formed by the inner face of the filter cloth (18) and the support plate (50), and so that a vertically extending main passage for the filtrate is formed between the inner face of the filter cloth (18) and the recess of the support plate (50). Further comprised are a suction means (16) for sucking the filter cloth (18) through the filtering-condensing bath (12), a filter cloth bulging means (20) for bulging the filter cloth (18) through the filtering-condensing bath (12), and a filtrate discharging pipe (38) communicating at its one end with the filter chamber (76). The suction type filtering-condensing apparatus is characterized in that the transverse length of the filter cloth (18) is set larger than the transverse length of the support plate (50), and in that a temporary auxiliary passage (99) for the filtrate is formed, at the time of filtration and condensation of the filtering-condensing objects in the filtering-condensing bath(12)undera predetermined negative pressure according to the suction means (16), to communicate with the filter chamber (76) and to extend vertically of the filter chamber (76).

Owner:METAWATER CO LTD

Tail gas treatment method and device for CVD/CVI technique

ActiveCN104826430AExtend the mixing timeReduce the temperatureUsing liquid separation agentExhaust gasMetal device

The invention provides a tail gas treatment method and device for a CVD / CVI technique. Three stages of adsorption which are cooperated and supported with each other are designed, wherein during the primary adsorption, by using the reverse contact between adsorption oil and the tail gas, the mixing time of the tail gas and oil mist is prolonged, the temperature of the tail gas is lowered, the liquefied solid-liquid organics are instantaneously bonded with the adsorption oil and together fall down onto a carbon felt in a crucible, thus the tail gas adsorption capability is improved; meanwhile, after the oil mist with the organics falls down onto the carbon felt strip in the stainless crucible, the bonding capability of th carbon felt is enhanced; when passing through the gapes and vent holes among the carbon felts, the tail gas is again filtered through the carbon felt of multiple layers of densities and gradients; and when the tail gas is exhausted out of a metal tank body, the adsorption oil at the bottom of the tank can be used for filtering again. Through the multiple stage filter method, the solid-liquid organics content in the tail gas is greatly reduced, thus the work safety factor and cost of a subsequent metal device are increased.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

Process for producing fermentation product from carbon sources containing glycerol using Corynebacteria

Owner:CJ CHEILJEDANG CORP

Method for producing wet-process phosphoric acid and alpha hemihydrate phosphogypsum by using medium-grade phosphorite

ActiveCN109292744ADoes not affect contentIncrease the amount of participationCalcium/strontium/barium sulfatesPhosphorus compoundsHigh concentrationFiltration

The invention relates to a method for producing wet-process phosphoric acid and alpha hemihydrate phosphogypsum by using medium-grade phosphorite. The method is an energy-saving low-consumption wet-process phosphoric acid production method. The method comprises the steps of decomposition reaction, solid-liquid separation, hemihydrate conversion reaction, and filtration and washing, and the high-concentration finished product phosphoric acid and the high-quality alpha hemihydrate phosphogypsum are obtained by controlling process parameters of the steps. The concentration of the obtained finished product phosphoric acid reaches 35-42 wt.%, omega(H2O) of the alpha hemihydrate phosphogypsum is in a range of 13-15% and omega(insoluble P2O5) is less than or equal to 0.1%. Through a grading technology, zero emission of the byproduct phosphogypsum is realized.

Owner:ANHUI LIUGUO CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com