Filtering device for recycling water-based cleaning solution used for optical glass lenses

A technology of optical glass and filter device, which is applied in the direction of filtration separation, filter circuit, fixed filter element filter, etc. It can solve the problems that the mesh of the filter screen is easily blocked and affects the filtration efficiency, so as to improve the filtration efficiency and avoid blockage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

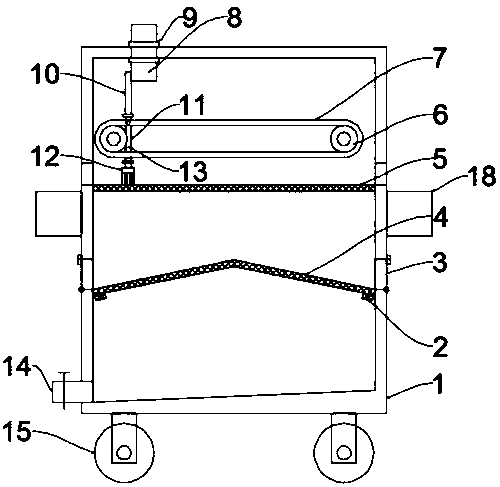

[0022] see figure 1 , in an embodiment of the present invention, a water-based cleaning liquid recovery and utilization filter device for optical glass lenses, including a box body 1, a first filter screen 5 and a second filter screen 4, and the four corners of the bottom of the box body 1 are installed There are supporting legs, and rollers 15 are installed at the bottom of the supporting legs. The rollers 15 are self-locking rollers to facilitate the movement of the device. One side of the bottom of the box body 1 is connected with a liquid outlet pipe 14, and the bottom of the inner cavity of the box body 1 is directed towards the liquid outlet. One side of the pipe 14 is inclined to facilitate liquid drainage. The first filter screen 5 and the second filter screen 4 are installed at intervals from top to bottom in the box body 1, and the liquid inlet pipe 8 is connected to the top of the box body 1. A drive mechanism for driving the liquid inlet pipe 8 to move left and rig...

Embodiment 2

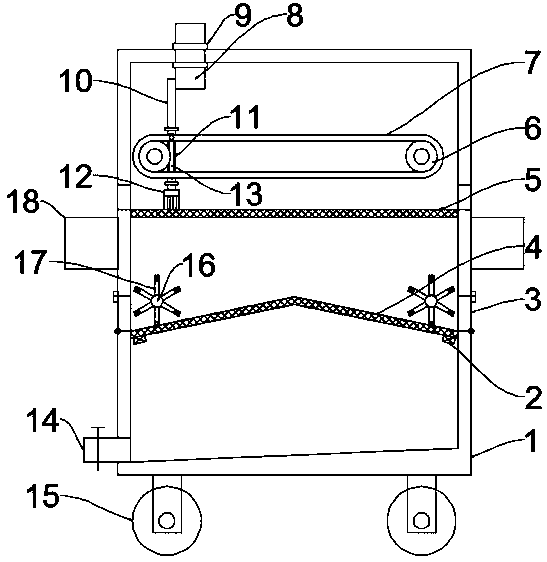

[0024] see figure 2 The difference between this embodiment of the present invention and Embodiment 1 is that a cleaning mechanism is installed above both sides of the second filter screen 4 in the box body 1, and the cleaning mechanism includes an installation shaft 16 and a brush plate 17. One end of the mounting shaft 16 is fixedly connected with the output shaft of the motor through a coupling, and a plurality of brush plates 17 are fixed circumferentially and equidistantly on the mounting shaft 16, and the brushes at the ends of the brush plates 17 are in contact with the top of the second filter screen 4, When it is necessary to discharge sundries, start the motor, and the motor drives the brush plate 17 to rotate to the side close to the miscellaneous discharge door 3 through the installation shaft 16, thereby continuously pushing the sundries on the second filter screen 4 to the miscellaneous discharge door 3 to speed up Trash removal speed.

[0025] The working princ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com