Post-treatment purifier for internal combustion engine particle emission

A technology for purifying device and particulate matter, applied in exhaust device, muffler device, dispersing particle filtration and other directions, can solve the problems of DPF burning, melting, and restricting the popularization and use of DPF, and achieve the effect of low cost and improving filtration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This example is a sample made by using the device for the post-treatment and purification of the internal combustion engine particulate matter in combination with the front-end DOC, see the brief Figure 5 .

[0046] The engine bench test is used to test the conversion efficiency of particulate matter. The working condition adopts 13 state points from idling speed to rated speed. After stabilization, the concentration of PM in the exhaust gas is measured, and after the collection is completed, it is converted into the total emission of PM. The engine is a domestically produced 1.8L diesel engine.

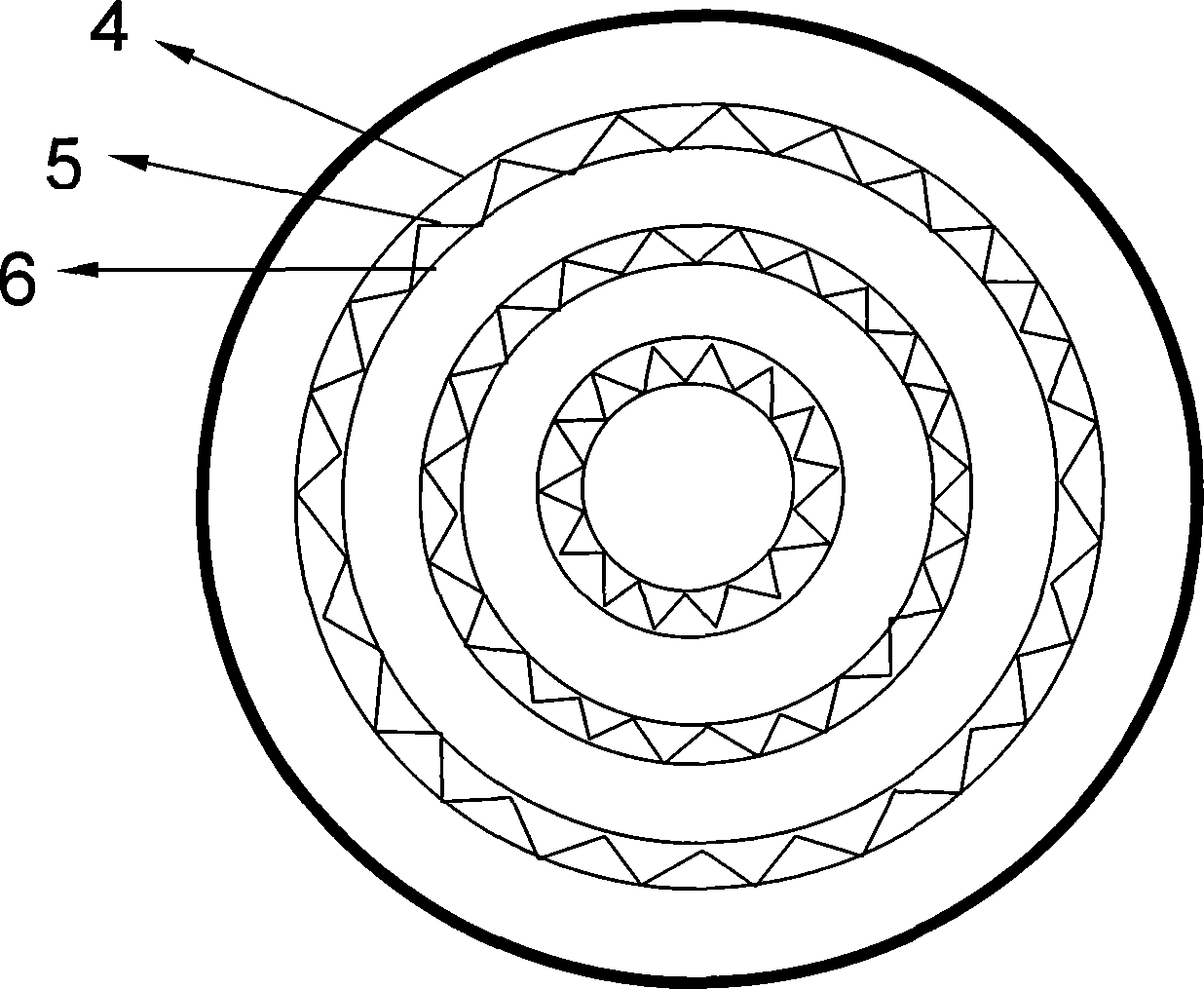

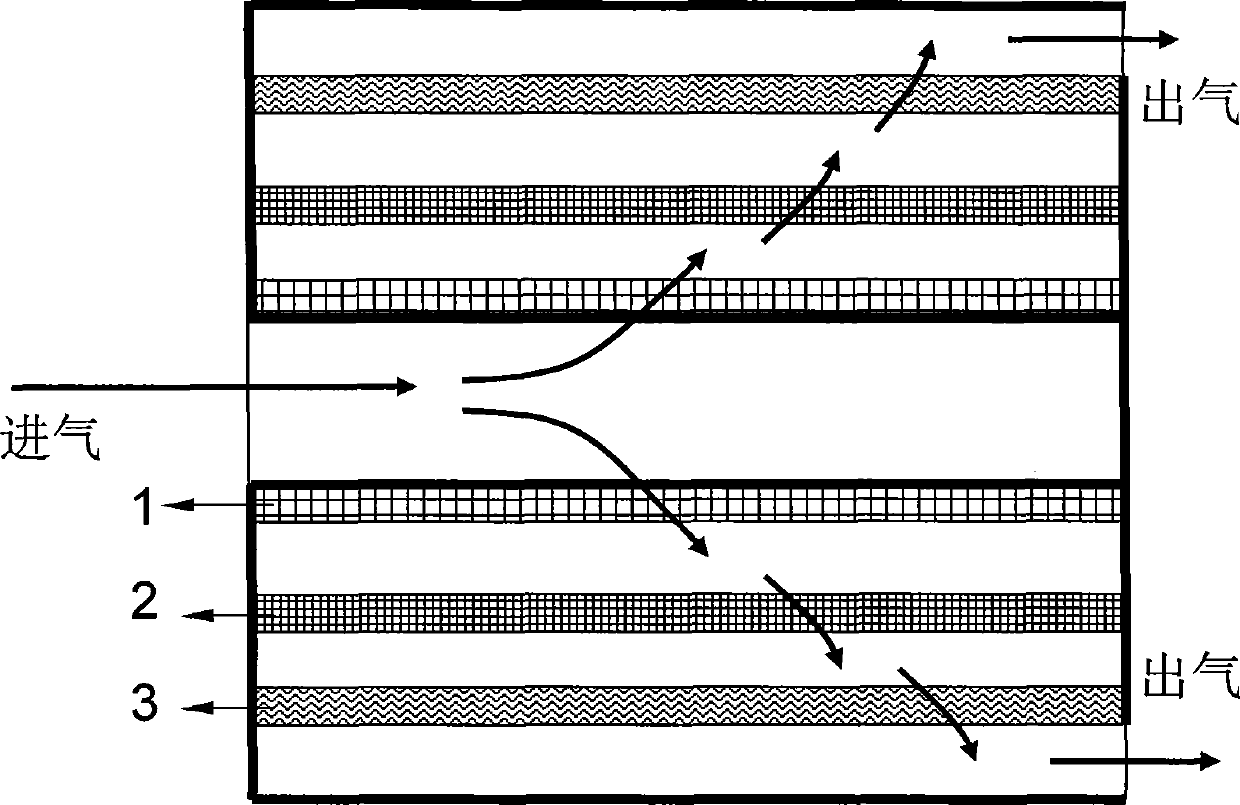

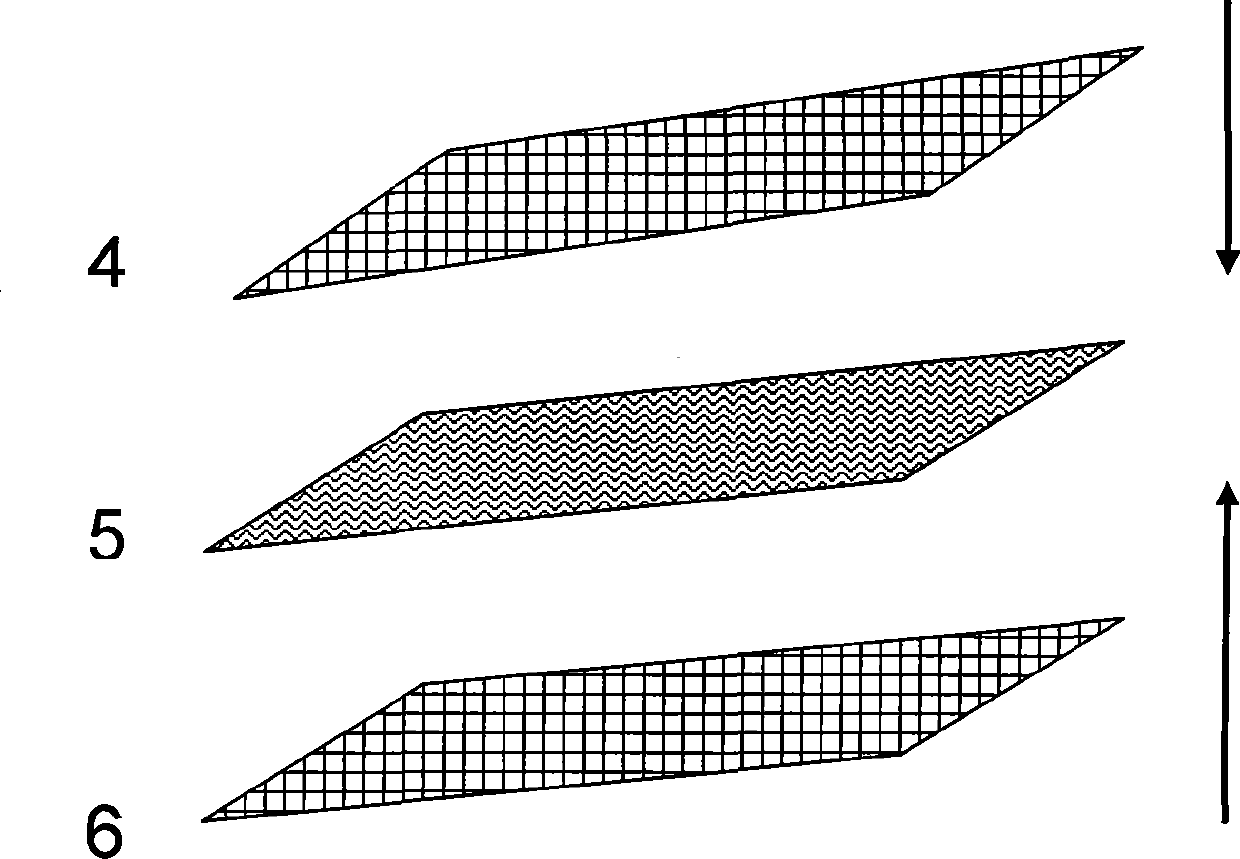

[0047] In order to improve the light-off temperature, the DOC in the front section adopts a 400-mesh 2.0L metal carrier, and the particulate matter purification part in the rear section adopts a 3-layer filter structure. Some use metal mesh panels.

[0048] Pressure sensors are placed before and after the whole device, and all pressure sensors are connected to the pressure ...

Embodiment 2

[0054] This example is a sample made by using the device for the post-treatment and purification of the internal combustion engine particulate matter in combination with the front-end DOC, see the brief Image 6 .

[0055] The front section is the same as in Example 1, and the first layer of the particle purification part in the back section adopts a ring-shaped iron-chromium-aluminum wire mesh structure, and the surface is coated with a precious metal catalyst to improve the oxidation ability of large particles and implement passive regeneration. The other two-stage filter body adopts the same structure as that of Example 1 and the iron-chromium-aluminum fiber felt structure.

[0056] The engine is the engine in Example 1. After installing the purification device, the particle emission is 0.021g / kwh, and the conversion efficiency reaches 79%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com