Patents

Literature

395results about How to "Increase the amount of participation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite powder, magnetic powder core for magnetic powder and preparation method thereof

InactiveCN101118797AExcellent soft magnetic propertiesIncrease the amount of participationInorganic material magnetismInductances/transformers/magnets manufactureAl powderIron powder

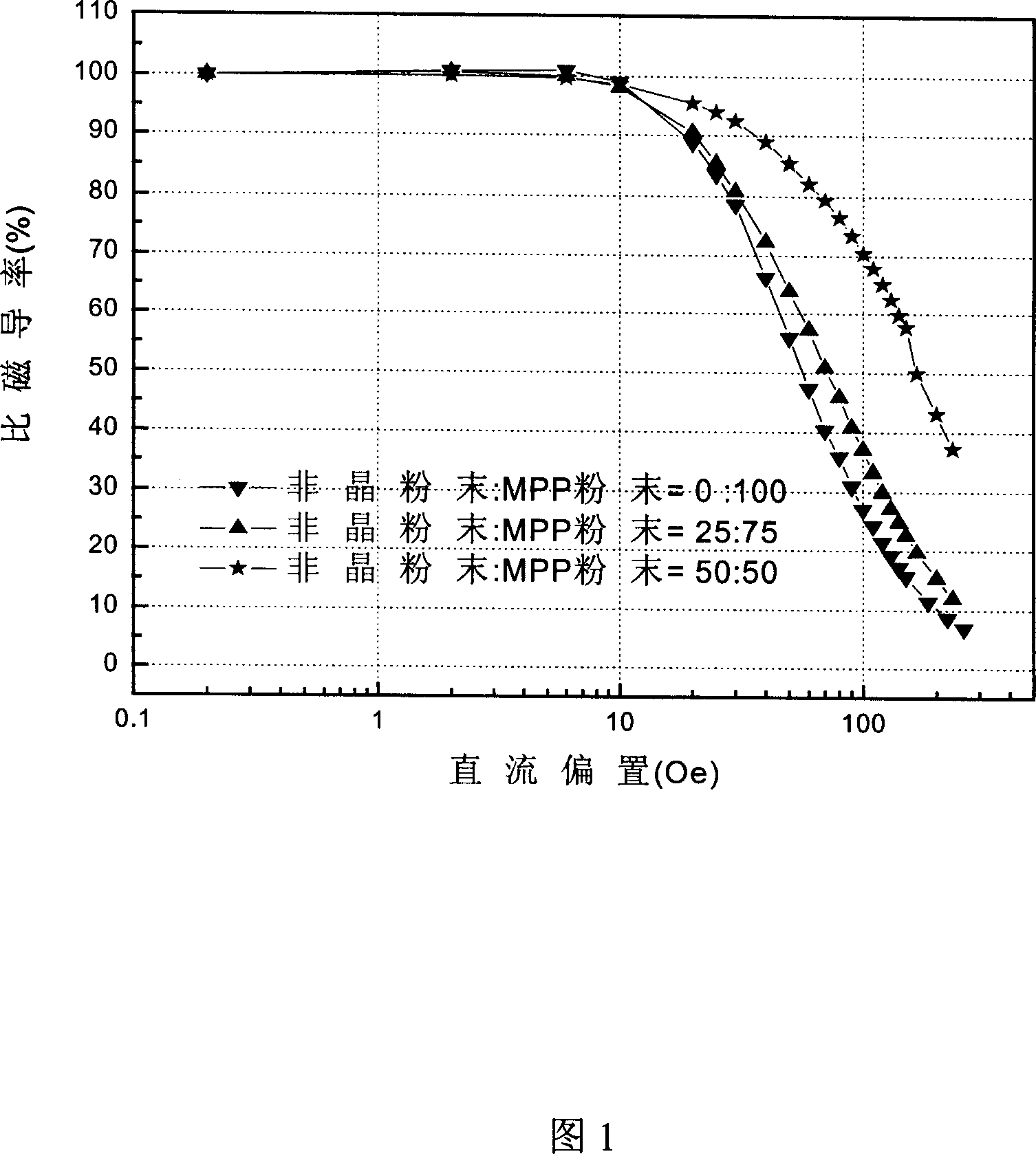

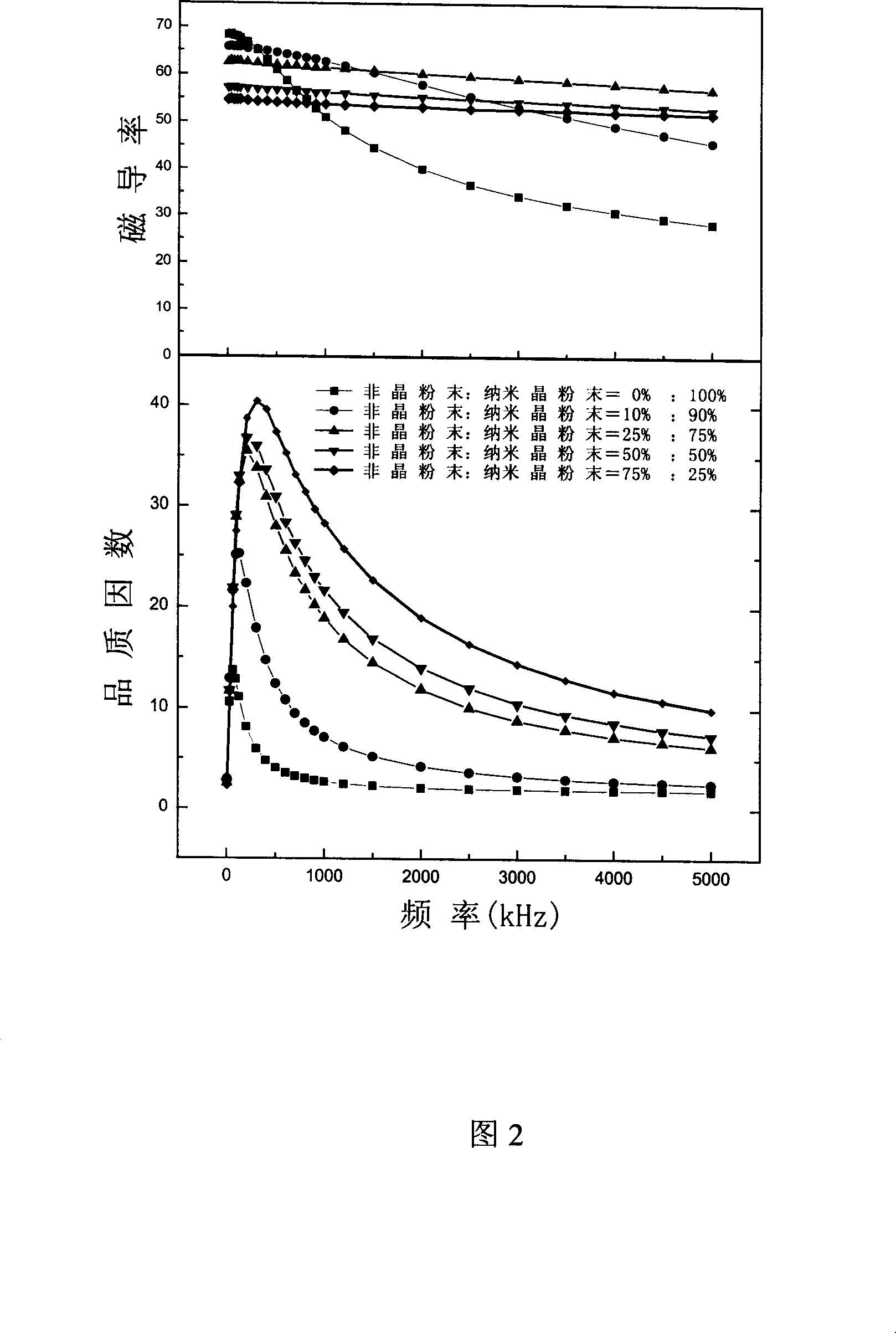

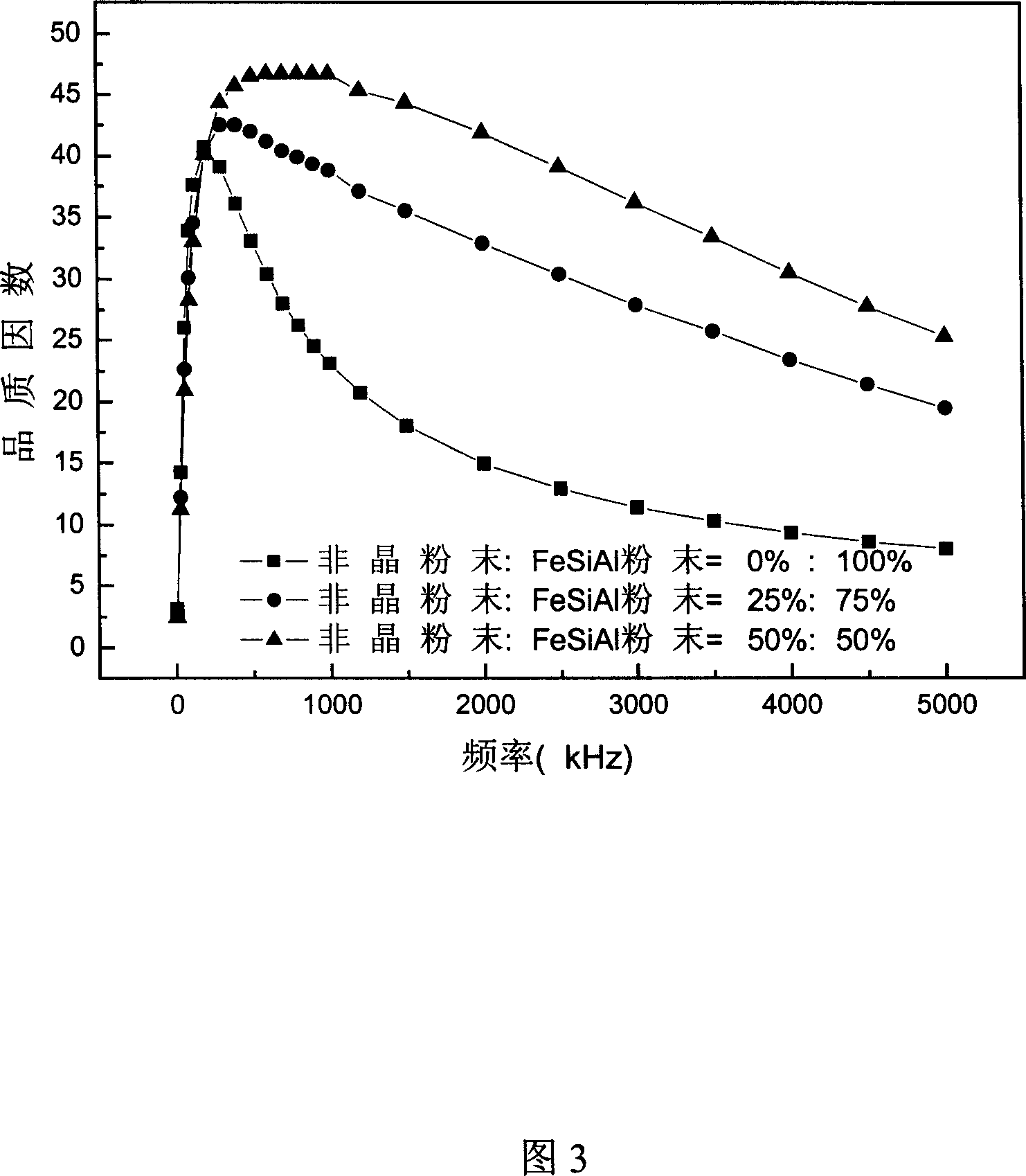

The present invention provides a magnetic powder core, composite powder used for the magnetic powder core, and a production method for the both. The composite powder is blended and formed by powder A and powder B, the content of which comprises 50-96wt percent of the powder A and 4-50wt percent of the powder B; wherein, the powder A is one out of iron powder, Fe-Si powder, Fe-Si-Al powder, Fe-based nanometer crystal powder, Fe-base amorphous powder, Fe-Ni powder and Fe-Ni-Mo powder; the powder B has different demand characteristics compared with the powder A and is selected from at least one out of iron powder, Fe-Si powder, Fe-Si-Al powder, Fe-based nanometer crystal powder, Fe-based amorphous powder, Fe-Ni powder and Fe-Ni-Mo powder. The powder B can be Fe-based soft magnetic amorphous powder as the insulating agent, which can reduce the wastage of magnetic powder core and make up for the declining magnetic conductivity of magnetic powder core caused by the traditional insulating agent. The excellent of soft magnetic properties of the insulating agent is utilized to improve frequency features of the magnetic powder core.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Aluminum-carbon sliding tile and method of producing the same

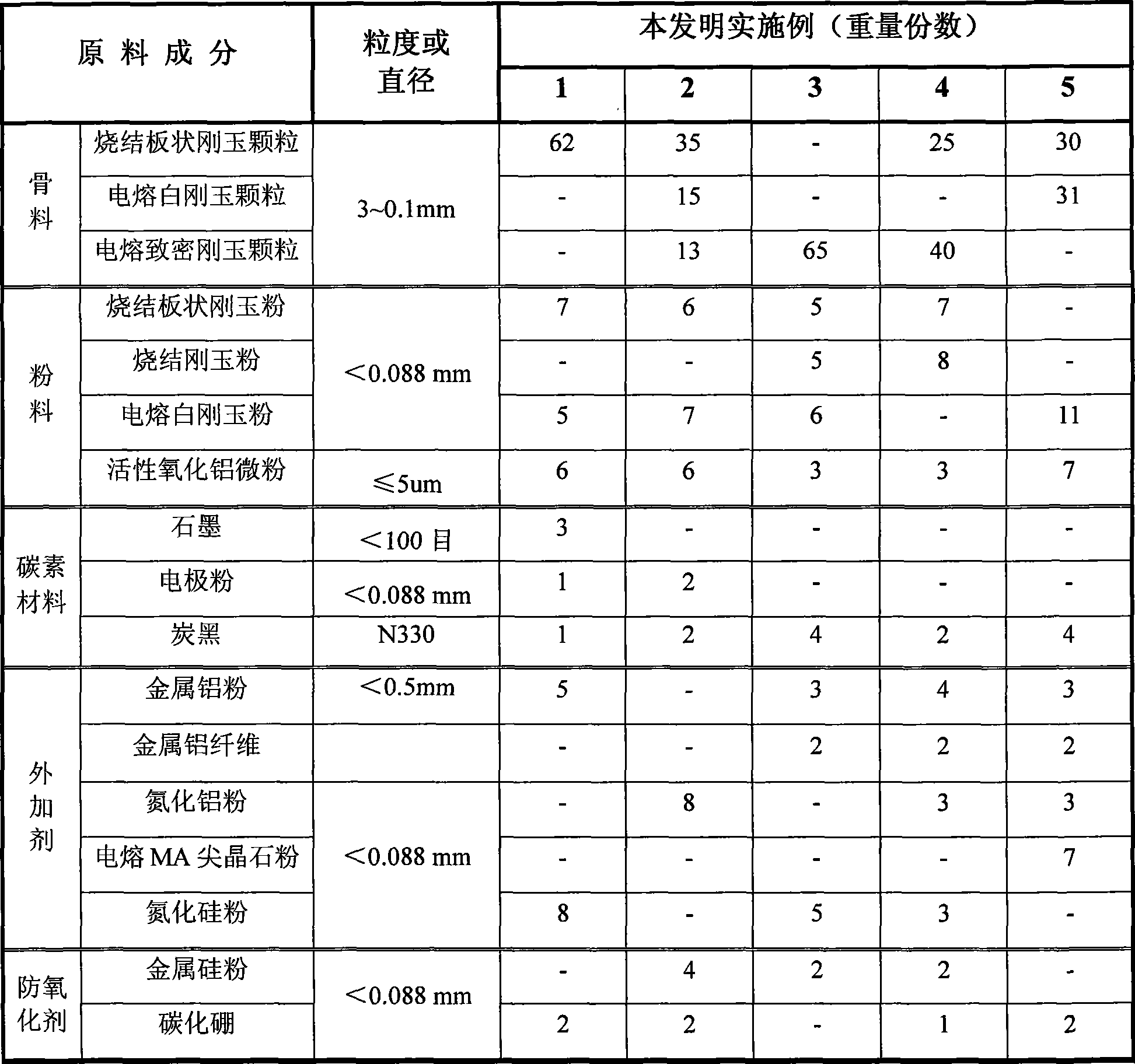

The invention provides an aluminum-carbon sliding brick, which comprises the following compositions: 60 to 75 percent of aggregate, 15 to 30 percent of powder, 1 to 6 percent of carbon element materials, 2 to 7 percent of antioxidant and 3 to 20 percent of additive. The production method for the aluminum-carbon sliding brick comprises the following steps: firstly, the powder in the raw materials is premixed and prepared into mixed powder for standby; secondly, mixing is performed according to the feeding order of granular materials, a binder and the mixed powder; thirdly, the mixture is discharged and subjected to mechanical pressing; and fourthly, a green brick is dried and prepared into the aluminum-carbon sliding plate brick by an unfired technology or a light burning technology. The method adds nitride and spinel materials in the sliding brick to substantially improve the thermal shock stability of the sliding brick, so as to achieve the level of the aluminum-zirconium-carbon sliding brick; and because the addition of Al metals is adequately increased, air holes can be filled, and the method reduces the brittleness of materials, is favorable for green brick formation, and improves the volume density, the normal temperature strength and the high temperature strength, so as to improve the oxidation resistance of the sliding brick. The aluminum-carbon sliding brick produced by the method not only has good product quality and high strength but also has simple procedure and saves the sintering cost.

Owner:鞍山钢铁集团耐火材料有限公司

Preparation method of macroporous aluminum oxide with diplopore distribution

InactiveCN101214454AStrong combinationOvercoming low mechanical strengthCatalyst carriersCarbon blackPetroleum

A preparation method of a large-pore aluminum oxide with double-pore spread structure. First, aluminum oxide, a poreforming agent and solid silica are mixed, and receive ball-milling treatment in a ball milling machine; the mixture after treatment is kneaded into a plastic body by aqueous solution with cationic surfactant, extrusion aid, peptizator, etc. dissolved in, and put into the water vapor atmosphere to be treated; and the prepared mould is dried and baked, to obtain the final aluminum oxide carrier. The poreforming agent is one or the mixture of carbon black, cellulose and starch, and the loading is 3.0 to 15w percent of the weight of the aluminum oxide; the solid silica is silica aerogel, and the loading is 1.0 to 10w percent of the weight of the aluminum oxide; in the ball milling machine, the ball-material ratio is 15:1 to 10:1, and the ball milling time is 0.5 to 3.0h; the treatment temperature of the water vapor is 120 DEG C to 180 DEG C, and the treatment time is 0.5 to 6.0h. The aluminum oxide prepared by the invention has double-peak channel structure and high strength, and is applicable in fields of petrochemical, petroleum processing, environmental protection, etc.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Bottom surface-integrated wear-resistant fluorosilicone-based super-amphiphobic coating, and preparation method and application thereof

The invention discloses a bottom surface-integrated wear-resistant fluorosilicone-based super-amphiphobic coating, and a preparation method and application thereof. The preparation method comprises the following steps: 1) performing synergistic modification treatment on two or more nanoparticles to obtain modified blended particles; 2) adding the blended modified particles into a dispersing solvent, performing ultrasonic dispersion for 1 to 2 hours and then mechanically stirring; 3) adding a certain amount of tert-butyl acetate into fluoro-siloxane resin and performing shearing dispersion to obtain substrate material emulsion; 4) mixing the blended modified particle turbid liquid in the step 2 and the substrate material emulsion in the step 3, adding a coupling agent, heating, stirring anddispersing, and performing dispersion by a high-speed shearing dispersing machine to obtain super-amphiphobic coating; and 5) stirring the super-amphiphobic coating uniformly, spray-coating the surface of an object with the super-amphiphobic coating and drying at room temperature for 10 to 30 minutes to successfully prepare the wear-resistant integrated super-amphiphobic coating. The wear-resistant super-amphiphobic organic-inorganic hybrid coating is obtained by connecting a fluorine-silicon substrate and the blended modified particles through chemical grafting copolymerization reaction.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Non-steamed brick and preparation method thereof

ActiveCN102336550AAchieving zero emissionsGood mechanical propertiesSolid waste managementCeramic shaping apparatusBrickAdhesive

The invention discloses a non-steamed brick and a preparation method thereof. The non-steamed brick comprises the following components in percentage by weight: 60 to 85 percent of iron tailings, 5 to 18 percent of river sand, 8 to 20 percent of cement, and 0.5 to 3 percent of admixture, wherein the admixture is one or more of high-strength adhesive, water reducing agent and waterproof agent. The preparation method comprises the steps of proportioning, mixing, pressure molding and natural curing. Proved by practice, the non-steamed brick has simple component, low cost and excellent comprehensive performance; and the preparation method is mild in conditions and easy in operation.

Owner:武钢资源集团有限公司 +1

Graphene-modified conductive silver paste and preparation method thereof

ActiveCN106816202AGood dispersionPrevent oxidationNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteSolvent

The invention provides a graphene-modified conductive silver paste and a preparation method thereof. The graphene-modified conductive silver paste mainly comprises silver nanowires, graphene materials, a binder and a solvent. The graphene materials comprise one or a combination of at least two materials selected from graphene, a graphene nanosheet, biomass graphene or graphene oxide. According to the technical scheme of the invention, the silver nanowires and the graphene materials are adopted together as an electrically conductive agent, and the silver nanowires are filled into gaps among graphene material sheet layers. Therefore, the graphene material sheet layers are connected in series through the silver nanowires, and the above two parts play a synergistic effect to realize the conductive performance. Meanwhile, the graphene materials are covered on the surfaces of the silver nanowires, so that the oxidation of the silver nanowires is avoided. The system stability and the stable exertion of the conductive performance are better ensured. Moreover, by means of the binder and other components, the adhesive force of the system is improved obviously. The printability of the conductive silver paste is improved.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

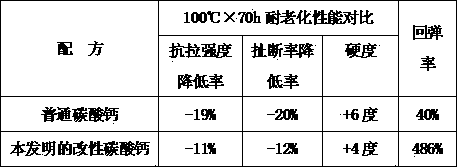

Modified calcium carbonate for wear-resistant rubber shoe soles and preparation method thereof

ActiveCN103408801AUniform particle sizeLarge specific surface areaSolesPigment treatment with macromolecular organic compoundsDispersityRubber material

The invention provides a modified calcium carbonate for wear-resistant rubber shoe soles, which is prepared from the following raw materials in parts by weight: 95-100 parts of ground calcium carbonate, 0.2-0.3 part of stearyl alcohol based polyethenoxy ether, 0.3-0.4 part of polyoxyethylene sorbitan fatty acid ester, 0.1-0.4 part of PE (polyethylene) wax, 0.5-0.8 part of triphenyl phosphite, 0.5-1 part of teflon micropowder, 0.1-0.3 part of ananti-aging agent 4020, 1-2 parts of ABS (acrylonitrile-butadiene-styrene) high rubber powder, 0.2-0.5 part of high-wear-resistance carbon black, 0.1-0.2 part of zirconium fluoride, 1-2 parts of dioctyl terephthalate (DOTP), 0.5-0.6 part of polyvinyl alcohol and 1-2 parts of a titanate coupling agent TMC-TTS. The preparation method comprises the following steps: drying calcium carbonate, proportionally and sequentially adding the other raw materials in batches, thoroughly mixing in a high-speed stirrer, drying and grinding. The modified calcium carbonate provided by the invention has the advantages of favorable dispersity and favorable wear resistance, and can lower the cost and enhance the working properties and wear resistance of shoe rubber when being used in shoe sole rubber materials.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

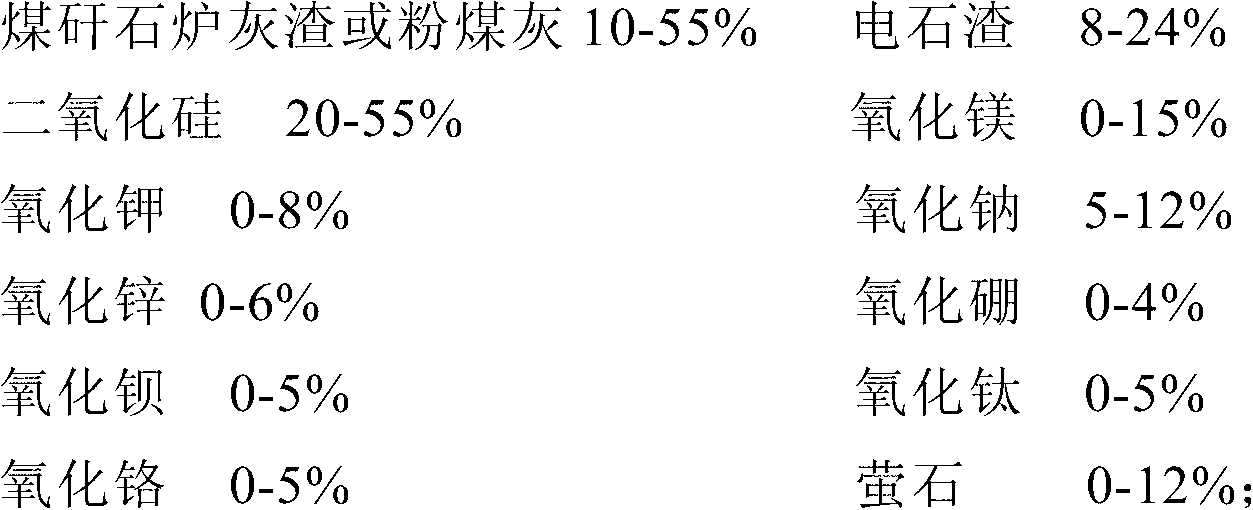

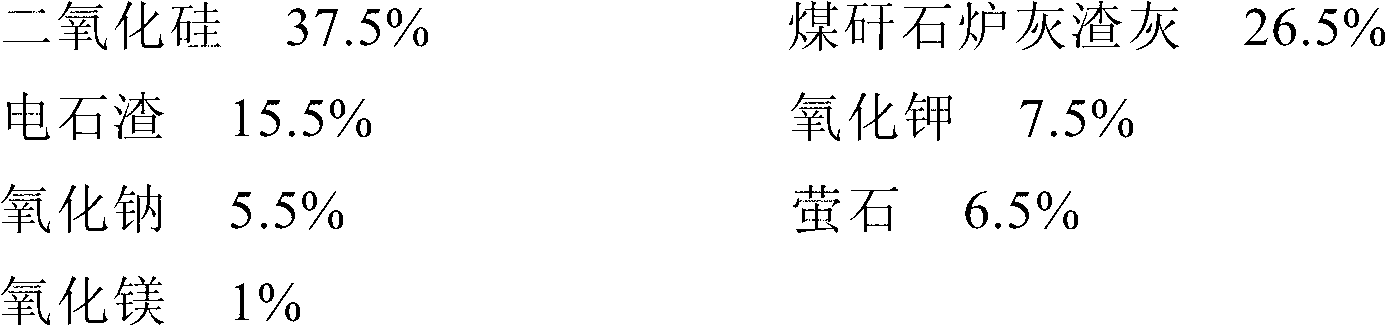

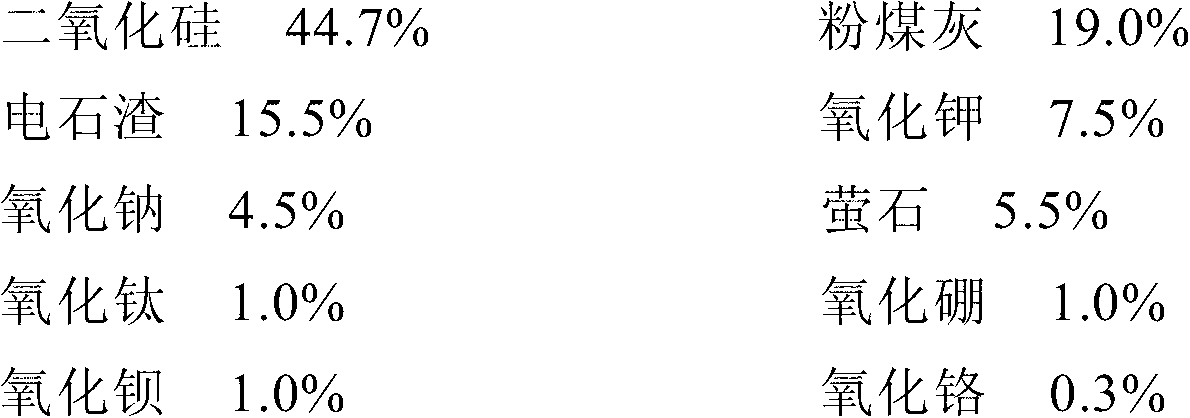

Method for preparing microcrystalline glass from kaolin-type coal gangue or fly ash and carbide slag

The invention discloses a method for preparing microcrystalline glass from kaolin-type coal gangue or fly ash and carbide slag. The method comprises the following steps of: (1) pre-treatment of raw materials: the coal gangue needs to be sequentially subjected to carbon removal and iron removal, the fly ash can be directly subjected to iron removal, and the carbide slag needs to be subjected to graphite electrode chip removal; (2) material proportioning: the refractory coarse slag obtained after burning the coal gangue needs to be added in the proportioned materials; (3) melting: melting is performed in a low-temperature range, a part of unmelted mass points is reserved, and air bubbles in melted solution are eliminated; (4) forming: forming is performed by adopting a calendaring method, a pouring method or a sintering method; and (5) heat treatment: a microcrystalline glass blank is obtained via heat treatment, and the finished product is obtained after finish machining. According to the invention, wastes such as the kaolin-type coal gangue or the fly ash and the carbide slag can be abundantly used for producing high-performance microcrystalline glass containing granular patterns, which is similar to natural stone, and even similar to natural jade.

Owner:北京盛康宁科技开发有限公司

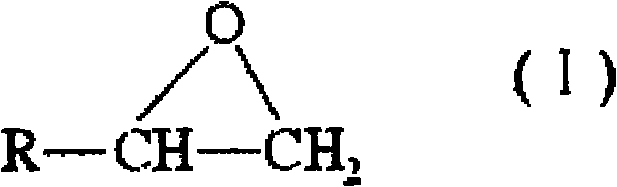

Preparation method of collagen fiber for artificial hair

The invention discloses a preparation method of collagen fiber for artificial hair and is characterized in that collagen fiber (or gelatin) is mixed with polyvinyl alcohol, and a certain amount of monofunctional epoxy compound used as crosslinker is added to obtain spinning stock solution with a certain concentration and viscosity; nascent fiber can be obtained from the stock solution by wet spinning; the fiber is cross-linkingly treated by aldehydes and the aqueous solution of metals ion to obtain wig protein fiber. The fiber number of the wig protein fiber is 30-120dtex, and the breaking strength is 1.5-3.0cN / dtex.

Owner:HENAN REBECCA HAIR PRODS TNC +2

Method for preparing acrylic fibre with wet-process

InactiveCN101270501AGood molding effectIncrease the amount of participationSpinnerette packsFilament manufactureState of artEngineering

A preparation method for wet acrylic fiber is characterized by including the following steps in turn: a, spinning and shaping; b, washing and drafting; c, oiling; d, drying; e, winding; f, shaping. Furthermore, compared with the prior art, the invention makes improvement on the shaping technique and post treatment technique through the specific design of a silk spray plate and selects proper spinning, shaping and post treatment condition technique parameters through a plurality of tests to improve the coagulation bath circulation amount, improve the adding amount and the drafting times of an oil agent and improve the winding door pressure. The acrylic fiber manufactured by the invention improves the shaping effect of the fiber.

Owner:浙江杭州湾腈纶有限公司

Efficient dephosphorization process for converter

ActiveCN102965463AMeet the phosphorus content control requirementsGood dephosphorization effectManufacturing convertersProcess efficiency improvementSteelmakingMolten steel

The invention relates to an efficient dephosphorization process for a converter, and belongs to the technical field of converter steelmaking. In the process, end slag of the converter is not poured out and is used for the next dephosphorization in the converter; in order to improve the smelting effect in the stage of dephosphorization in circulation of the converter, the lance position and the oxygen supply in the stage of dephosphorization and a slagging technological means are controlled to realize the efficient dephosphorization by using the end slag of the converter, so that the lime consumption can be reduced, the dephosphorization effect of the converter is improved, and compared with those of the conventional process, the lime consumption can be saved by 40 to 60 percent, the consumption of caustic calcined dolomite is saved by 40 to 46 percent, and the mass fraction of phosphorous in terminal molten steel of the converter is less than 0.006 percent.

Owner:SHOUGANG CORPORATION

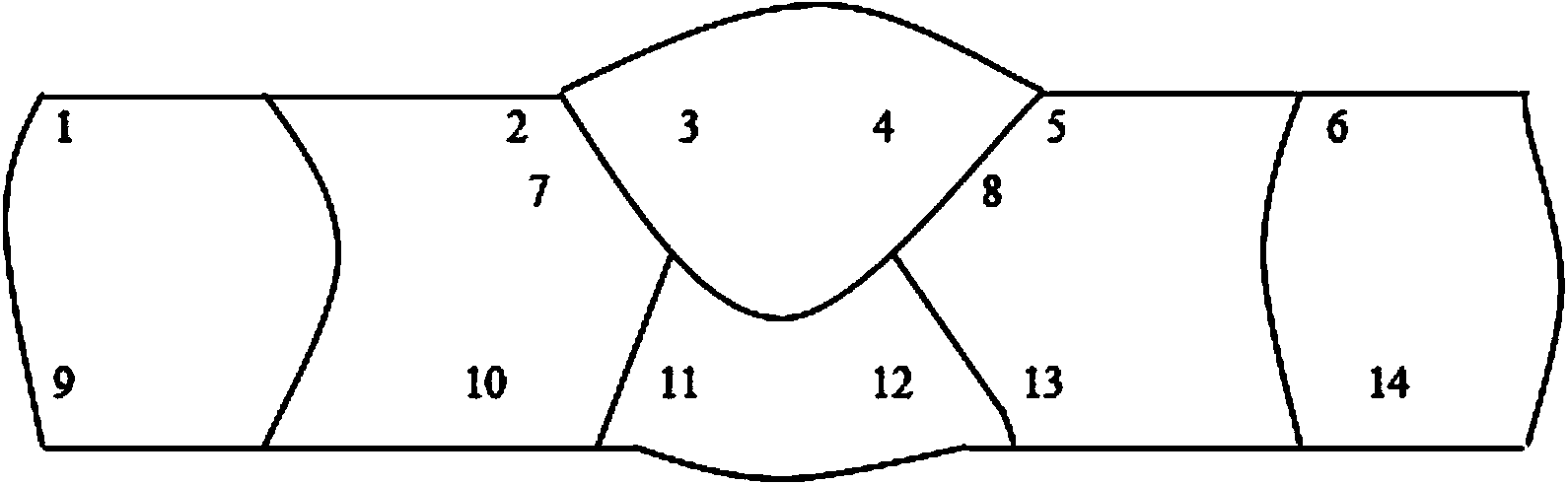

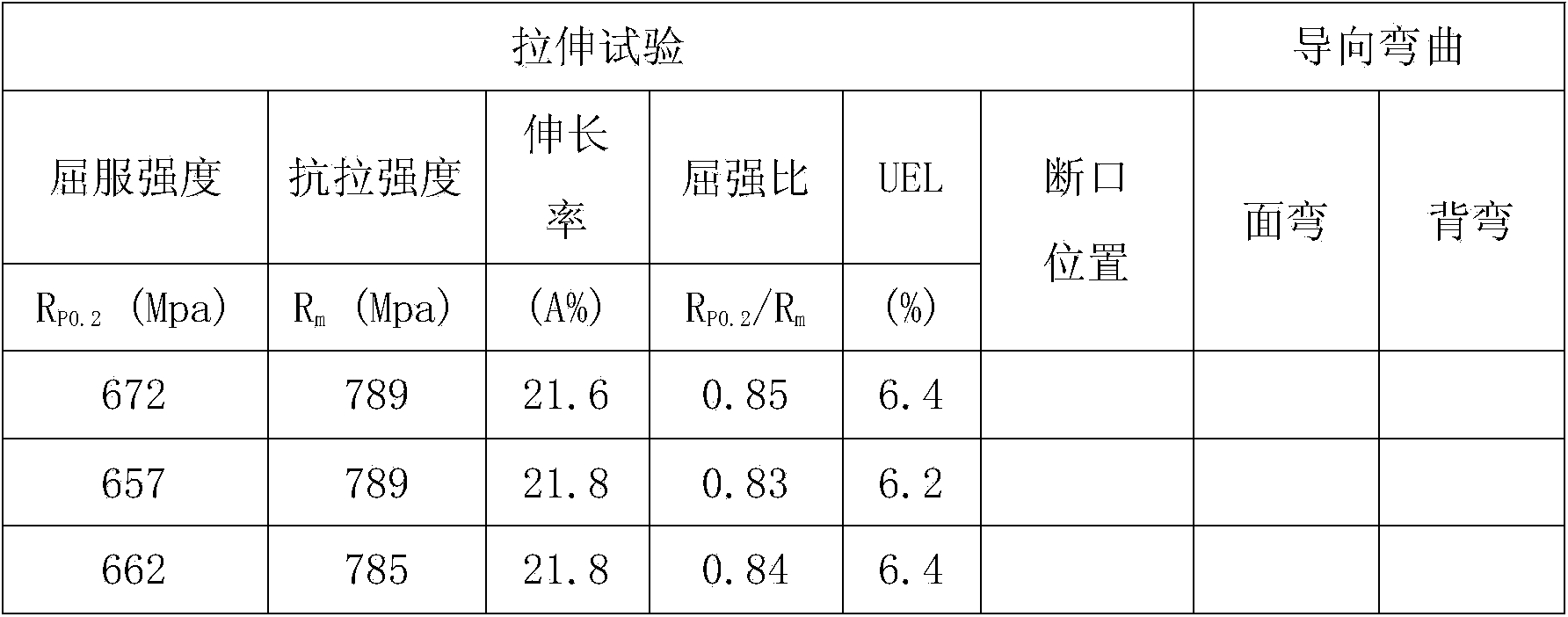

Manufacturing method of X90 grade pipeline steel large-opening-diameter thick-wall longitudinal submerged-arc welded pipe

ActiveCN103521550AHigh strengthGood low temperature toughnessArc welding apparatusEngineeringArc welding

The invention discloses a manufacturing method of an X90 grade pipeline steel large-opening-diameter thick-wall longitudinal submerged-arc welded pipe. A refined welding process is four-wire inner welding five-wire outer welding submerged-arc automatic welding. Through the method, the manufacture of the X90 grade large-opening-diameter thick-wall longitudinal submerged-arc welded pipe with the diameter of phi 1219 mm and the wall thickness of 24.2-30.4 mm can be completed. After the pipe is manufactured, the longitudinal submerged-arc welded pipe not only has good mechanical properties and higher pipe body uniform elongation rate, but also realizes the strong toughness matching of a welded pipe welded joint. The X90 grade pipeline steel large-opening-diameter thick-wall longitudinal submerged-arc welded pipe manufactured by the method not only realizes the strong toughness matching of the welded joint, but also has excellent pipe body performance, relatively high pipe body uniform elongation rate and precise welded pipe geometric size.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Nano diamond nano copper composite lube additive

The invention discloses a diamond nanometer copper compounded lubricating oil additive in nanometer technical domain and mechanical fluid oil technical domain, which is characterized by the following: the nanometer diamond and nanometer copper are prepared to lube oil additive with diverse functional requirement; the high lubricating and high-intensity low restoring type fits for precision equipment, new device, high-grade car and gearbox and can diminish adding quantity of nanometer copper; the high lubricating and high-intensity high restoring type fits for wearing machinery and equipment and car and can enlarge the adding quantity of nanometer copper power. This invention possesses good dispersibility and does not need stirring and so on disposing craft.

Owner:孙文志

High-doping ratio red mud sintered brick and preparation method thereof

InactiveCN103319150AIncrease the amount of participationReduce energy consumptionConstruction waste recoverySolid waste disposalBuilding materialNational standard

The invention discloses a high-doping ratio red mud sintered brick and a preparation method thereof. The high-doping ratio red mud sintered brick comprises, by weight, 30 to 70 parts of red mud, 10 to 40 parts of waste building materials, 14 to 30 parts of waste glass materials, 0.5 to 1 part of waste barium carbonate materials and water, wherein the weight of the water is 23 to 27% of the total weight of the above materials. The preparation method utilizes a plurality of waste materials as raw materials, and prepares the raw materials into fired bricks having performances satisfying qualified product or first-grade product requirements in the national standard by a suitable processing method. The high-doping ratio red mud sintered brick has a high red mud addition amount, low energy consumption and radioactivity below the national standard. The high-doping ratio red mud sintered brick is prepared from the raw materials having wide sources, belongs to the field of waste utilization and avoids secondary pollution. The preparation method has simple processes and a low production cost, can be industrialized easily and has very ideal use effects.

Owner:GUIZHOU UNIV

Zirconium mullite sagger

The invention provides a zirconium mullite sagger which comprises the following raw materials: natural mullite, tabular corundum, zircon sand, alpha-alumina micro powder, silicon dioxide micro powder, kaolin and a binding agent, wherein the natural mullite consists of mullite granules of which the particle size is within 0.5-1 mm and mullite powder granules of which the particle size is smaller than 0.5 mm; the mass ratio of the mullite granules to the mullite powder granules is (3-4):(6-8); the tabular corundum consists of tabular corundum granules of which the particle size is within 0.1-0.5 mm and tabular corundum powder granules of which the particle size is smaller than 0.1 mm; the mass ratio of the tabular corundum granules to the tabular corundum powder granules is (4-5):(3-4); the particle size of the zircon sand is less than 0.1 mm. The zirconium mullite sagger has the advantages of corrosion resistance and freedom of falling residues, the materials are small in heat capacity and thermal expansion, and the circulation use number is large.

Owner:浙江立鑫高温耐火材料有限公司

Aqueous urethane dispersants

InactiveCN1615322AIncrease the amount of participationLow viscosityPigmenting treatmentTransportation and packagingSide chainPolypropylene glycol

A polyurethane polymer containing 35 to 90 wt% of a poly(C2-4 alkylene oxide) based on the total weight of the polymer, wherein not less than 60% of the poly(C2-4 alkylene oxide) is poly(C2-4 alkylene oxide). Ethylene oxide, and wherein at least 5% of the poly(C2-4 alkylene oxide), based on the total weight of the polymer, is bound to the side chain, and when the polyurethane contains 35 to 45% by weight of poly(C2-4 alkylene oxide) Oxygen), for example, by using bis(hydroxymethyl)propionic acid, cyclohexanedimethanol, polypropylene glycol (1000), N-methylpyrrolidone, and a compound available from 2,4-toluene diisocyanate, methoxypolyethylene When a polymer is produced by reacting α,α-dihydroxypolyethylene glycol obtained by diol (750) and diethanolamine, it contains 10 to 180 milliequivalents (meq) of acid groups per 100g of polymer.

Owner:THE LUBRIZOL CORP

Method based on high-silicon high-phosphorus molten iron converter low slag material consumption to melt low-phosphorus steel

ActiveCN108624735ASimple and fast operationEasy to masterManufacturing convertersProcess efficiency improvementSlagMaterial consumption

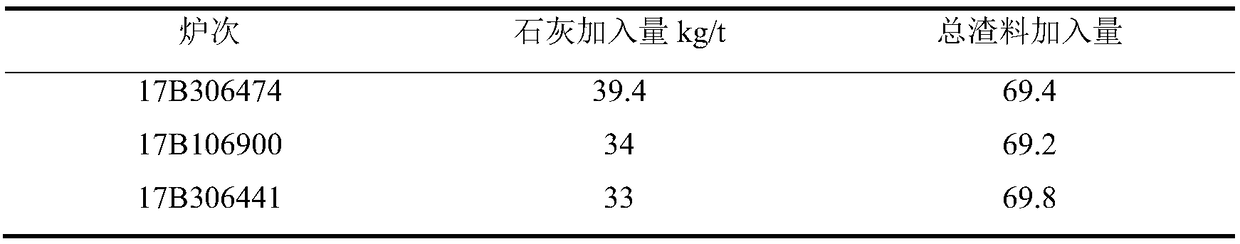

The invention relates to a smelting technology method of a steel technological process and specifically relates to a method based on high-silicon high-phosphorus molten iron converter low slag material consumption to melt low-phosphorus steel. The method comprises the following steps: utilizing single-slag operation under the conditions that Si of molten iron putting into a furnace is larger thanor equal to 0.55% and smaller than or equal to 0.8% and P of molten iron putting into the furnace is larger than or equal to 0.17% and smaller than or equal to 0.22%; making a molten iron temperaturelarger than 1250 DEG C and a scrap steel ratio larger than 25%; utilizing a less-slag material, adding the less-slag material into a melting model and controlling the adding amount of an auxiliary material. When Si of general molten iron putting into the furnace is larger than or equal to 0.6% or P of the general molten iron putting into the furnace is larger than or equal to 0.12%, a duplexing method or a double-slag method is utilized by a converter. Under the situations of molten-iron-free three-removal pretreatment and converter duplexing method dephosphorization, operation of the method disclosed by the invention utilizes a single-slag method; under the premises that converter lime consumption is smaller than 40kg / t and a new slag material consuming total amount is smaller than 70kg / t, the condition that P is smaller than 0.012% when a smelting point C is larger than or equal to 0.065% is ensured at the same time. The method disclosed by the invention can effectively reduce novelslag material consumption of high-silicon high-phosphorus molten iron converter smelting, is favorable for reducing industrial waste generation and reduces production cost of per ton of steel.

Owner:UNIV OF SCI & TECH BEIJING +1

Transparent enhanced filling mastre batch

The invention discloses a transparent reinforced filling mother stock which comprises the following materials in weight percentage: 10 to 25 percent of polythene, 65 to 85 percent of transparent glass powder, 3 to 7 percent of polyethylene wax and 1-3 percent of aluminic acid ester. The polythene is the low-density or linear low-density polythene, and the transparent glass powder is a nonmetal silicate. The transparent reinforced filling mother stock which has a higher addition level can reduce the contractibility of plastics and the deformation caused by contraction; the transparent reinforced filling mother stock can not only reinforce the rigidity of products but also increase the weight of the products. The filling mother stock has good dispersibility and good solubility with polypropylene and polyethylene. Even a great amount of filler stock is added, the products with good outside fineness can still be obtained. The filling mother stock can not only make the products keep good mechanical properties, but also prolong the service life of the products.

Owner:赵建伟

Modified calcium carbonate for anti-ultraviolet electric cable material, and preparation method thereof

InactiveCN103554704AUniform particle sizeLarge specific surface areaPlastic/resin/waxes insulatorsDispersityUltraviolet

The present invention provides modified heavy calcium carbonate for a fire retardation electric cable material. The modified heavy calcium carbonate is prepared from the following raw material components, by weight: 95-100 parts of calcium carbonate, 1-2 parts of octylphenol polyoxyethylene ether, 0.2-0.3 part of peregal O, 1-1.5 parts of dioctyl maleate, 0.2-0.4 part of zinc stearate, 0.1-0.2 part of magnesium oxide, 0.1-0.3 part of polyethylene wax, 0.1-0.4 part of an ultraviolet absorber UV-P, 1-2 parts of chitosan, 1-1.5 parts of polyphosphoric acid, and 2-3 parts of methyltriethoxysilane. The preparation method comprises: drying calcium carbonate, adding other raw materials according to the ratio, completely mixing in a high speed stirrer, and carrying out drying and grinding to obtain the finished product. The obtained modified calcium carbonate has characteristics of good dispersity and good ultraviolet resistance, and can be used for fire retardation electric cable materials so as to reduce cost and improve various processing performances of the electric cable material.

Owner:安徽金阳电器科技发展有限责任公司

High efficiency corrosion inhibiting scale retardant

InactiveCN1715451AHigh corrosion inhibition performanceImprove dispersionScale removal and water softeningHigh concentrationPhosphate

The high efficiency corrosion and scale inhibitor consists of polyhydrolic alcohol phosphate ester 30-40 wt%, zinc sulfate 15-30 wt%, acrylic acid, acrylate and sulfonate copolymer 5-10 wt%, except water. The high efficiency corrosion and scale inhibitor is used as scale inhibitor and corrosion inhibitor in circular cooling water of oil refinery, chemical plant, chemical fertilizer plant, air conditioning system, heat exchanger of copper, etc. and is especially suitable for use in water flooding recovery. The outstanding advantages of the present invention include operating capacity in relatively high concentration of total soluble solid content up to 30 g / L in cooling water, and high corrosion and scale inhibiting effect even if in oil containing sludge water condition.

Owner:SHANGHAI WANSEN WATER TREATMENT CO LTD

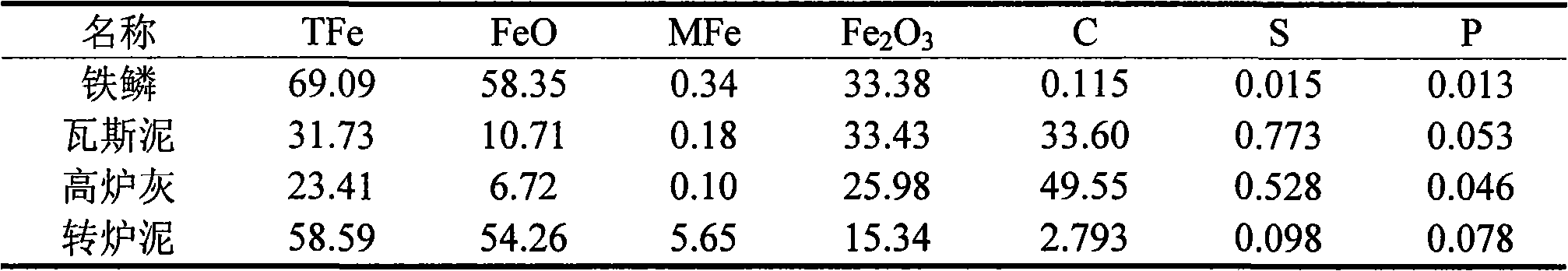

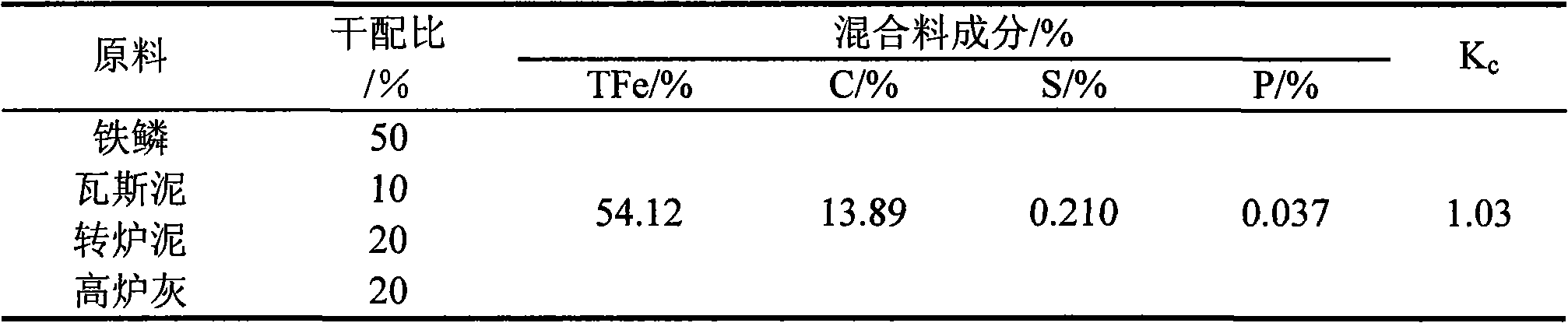

Rotary furnace cooling agent made of metallurgical waste material product and using method thereof

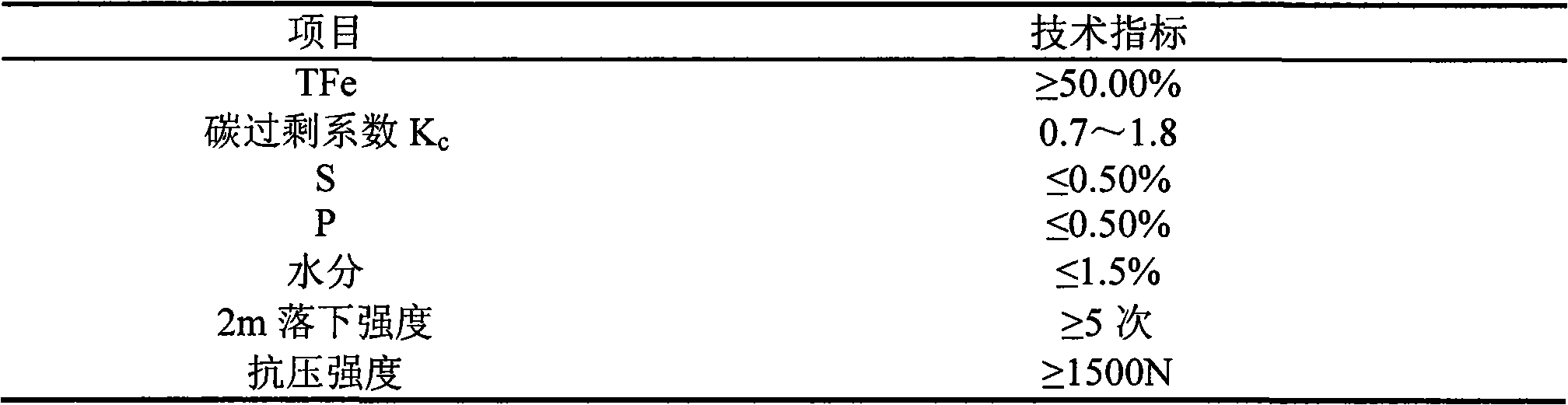

ActiveCN101560583AImprove slag removal effectEmission reductionManufacturing convertersProcess efficiency improvementChemical compositionEconomic benefits

The invention provides a rotary furnace cooling agent and a manufacturing method thereof. The cooling agent is a carbonic and ferreous conglomeration which mainly takes iron scale, carbonic waste material and ferreous waste material as raw materials, and prepared by additionally adding caking agent into the raw materials. The weight percentage of the main chemical compositions of the cooling agent meets the following condition: the carbon content is 5-25%, the content of TFe is more than or equal to 50%, the content of S is less than or equal to 0.50% and the content of P is less than or equal to 0.50%. The manufacturing method comprises: the wet materials in the carbonic waste material and the ferreous waste material are firstly dried and crushed by a crusher, and then enters a blending machine to be mixed together with the dry materials such as the iron scale and the like; the mixture is added with the caking agent to be evenly mixed, and the mixed material is sent into a mixing mill and then into a twin-roller ball press machine to be pressed into conglomeration; the pressed conglomeration is screened by a sieving machine, and the qualified screened conglomeration can be sent into a dry furnace to be dried, so that the finished product conglomeration can be obtained. The rotary furnace cooling agent completely uses the waste materials generated in the steel production, and can be used for replacing the common waste steel to be applied in smelting of a rotary furnace, so that no special reduction plant is needed for use, the process flow is short, the cost is low, the using method is flexible, the adding quantity is large, the recovery rate is high, the field operation is seldom affected, the economic benefit and the environmental protection benefit are remarkable, and the promotion and application values are excellent.

Owner:ANGANG STEEL CO LTD

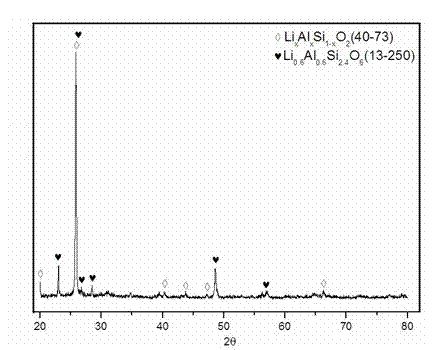

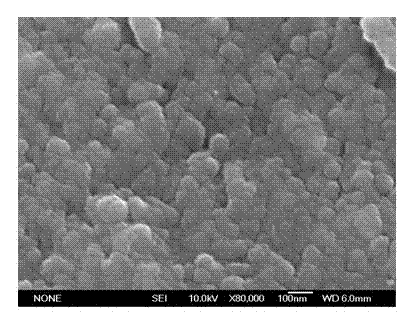

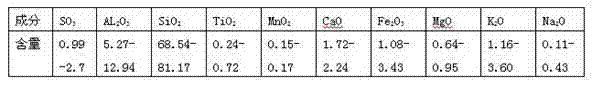

Method for manufacturing low-swelling microcrystalline glass through microwave heat treatment of gold tailings

ActiveCN103086602AIncrease the amount of participationReduce stockpilesThermal dilatationHeat stability

The invention relates to a method for manufacturing low-swelling microcrystalline glass through microwave heat treatment of gold tailings. The low-swelling microcrystalline glass comprises the following raw materials in percentage by weight: 40-50% of gold tailings, 20-25% of quartz, 13-18% of aluminum oxide, 5-13% of lithium carbonate, 2-4% of magnesium oxide, 2-4% of titanium oxide, 0.5-1% of zirconium oxide and 1-3% of borax. The method comprises the following steps: evenly mixing the raw materials, placing into an aluminum oxide crucible, and melting by microwave heating, thus obtaining glass metal; and transferring the molded glass metal into an industrial microwave oven, annealing, and performing crystallization treatment to obtain the product. According to the invention, the mining waste gold tailings are used as the main raw material, and the waste is changed into a valuable substance, thereby realizing the comprehensive utilization of the waste; a one-step heat treatment process is adopted, and the production cycle is shortened; the industrial microwave oven is used for heating in the melting, annealing and crystallization processes, thereby ensuring high heating speed and no pollution; for the obtained sample, grains are refined, the structure is uniform, and energy is saved; and the obtained microcrystalline glass is low in heat expansion coefficient and high in heat stability.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

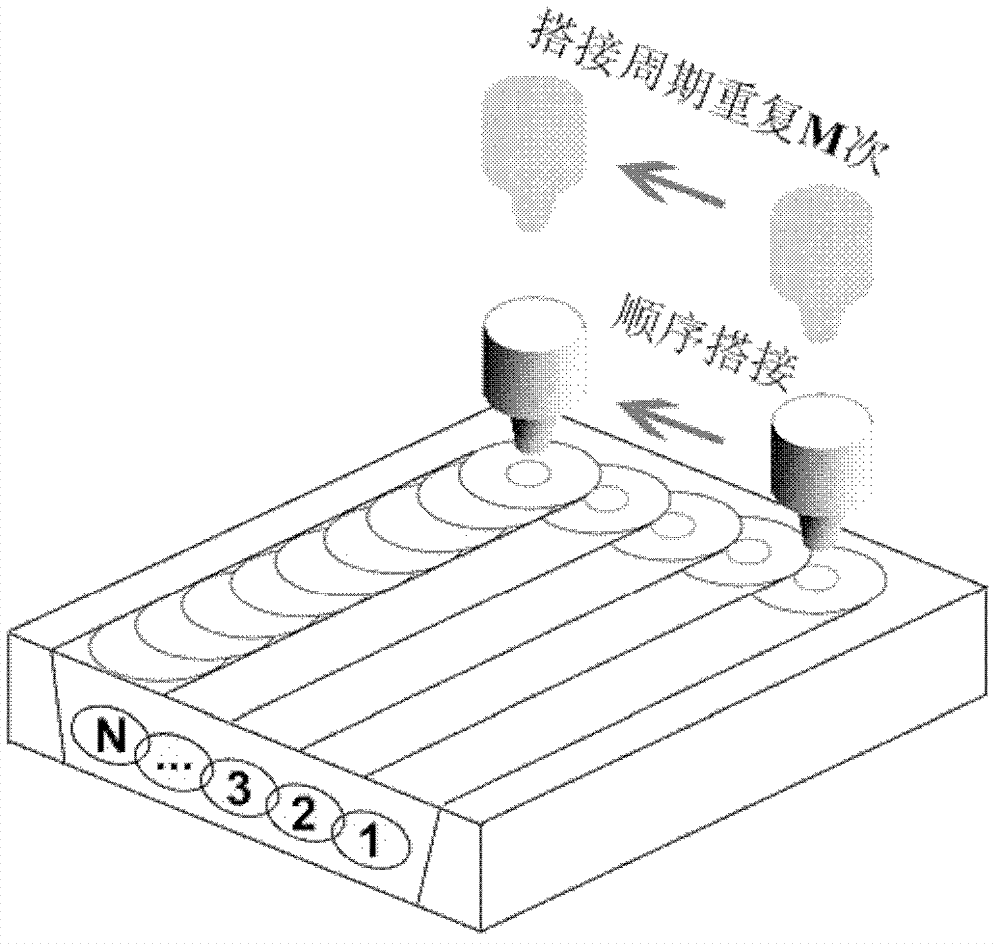

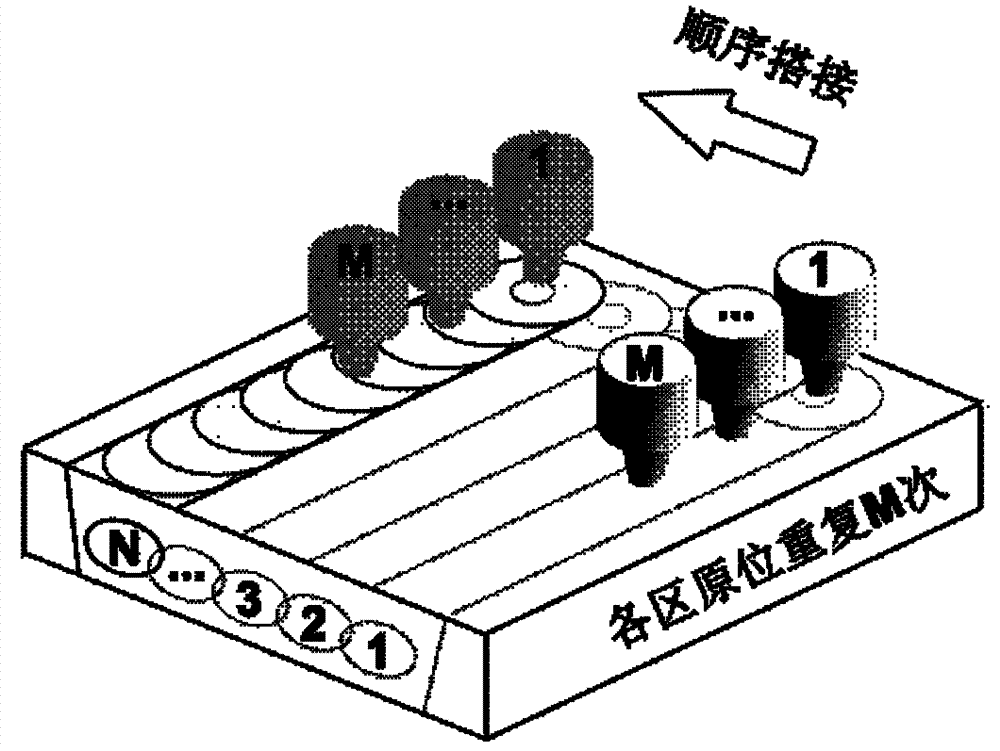

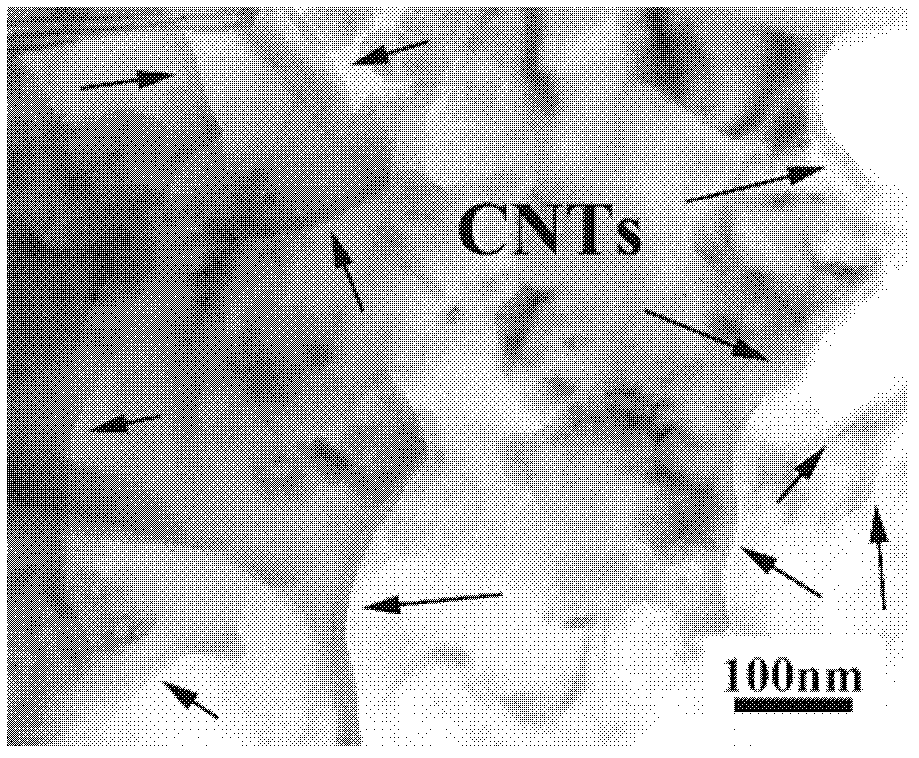

Preparation method of high-volume-fraction carbon-nanotube-enhanced metal-based composite material

The invention discloses a preparation method of a high-volume-fraction carbon-nanotube-enhanced metal-based composite material. The invention belongs to the technical field of composite material preparation. According to the invention, metal powder and carbon nanotube are adopted as raw materials; a carbon-nanotube-enhanced metal-based composite material billet is prepared with a powder metallurgy method; and the obtained powder metallurgy billet is subjected to friction stir processing, such that the carbon-nanotube-enhanced metal-based composite material is obtained. The method provided by the invention has the advantages that: (1) the morphology and size of the carbon nanotube are not restricted; the carbon nanotube does not need other preprocessing processes (such as acid treatment, pre-dispersion, and the like); the dose of carbon nanotube is high, and the content can be accurately controlled; (2) in the prepared composite material, carbon nanotube dispersion is uniform, aspect ratio is high, and damage is low; (3) the gains of the prepared composite material is substantially refined (smaller than 5mum); and (4) the prepared composite material has excellent mechanical properties.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Modified heavy calcium carbonate for fire retardation electric cable material, and preparation method thereof

InactiveCN103554551ALarge specific surface areaImprove applicabilityPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsAluminateDispersity

The present invention provides modified heavy calcium carbonate for a fire retardation electric cable material. The modified heavy calcium carbonate is prepared from the following raw material components, by weight: 90-100 parts of heavy calcium carbonate, 0.2-0.5 part of butyl naphthalene sulfonate, 0.5-0.8 part of sodium alcohol ether sulphate, 1-2 parts of epoxidized triglyceride, 0.1-0.2 part of stearic acid, 0.1-0.2 part of barium stearate, 0.2-0.3 part of dimethicone. 1-2 parts of carboxymethyl cellulose, 0.6-0.8 part of alumina, 1-3 parts of triphenyl phosphate, and 1-2 parts of distearoyl isopropoxy aluminate. The preparation method comprises: drying calcium carbonate, adding other raw materials according to the ratio, completely mixing in a high speed stirrer, and carrying out drying and grinding to obtain the finished product. The obtained modified calcium carbonate has characteristics of good dispersity and good fire retardation, and can be used for fire retardation electric cable materials so as to reduce cost and improve various physical properties of the electric cable material.

Owner:安徽金阳电器科技发展有限责任公司

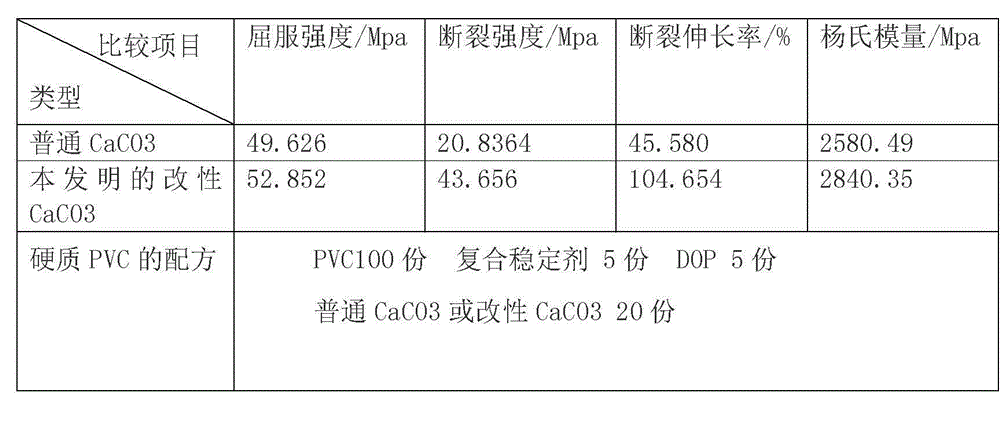

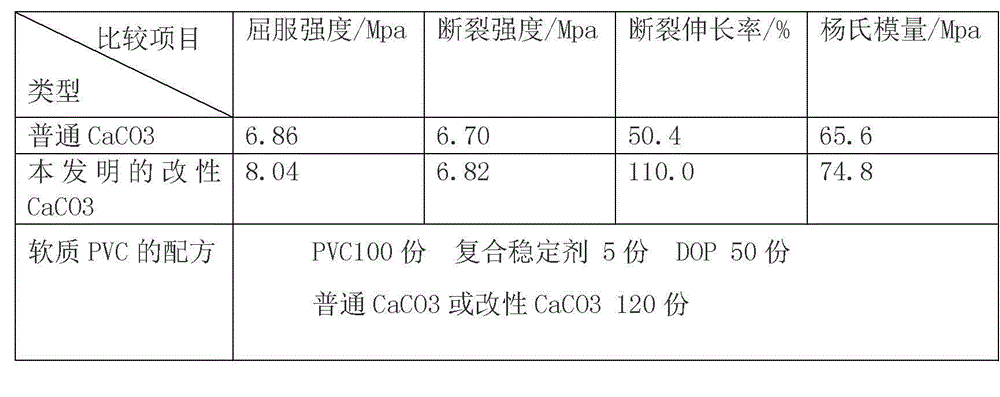

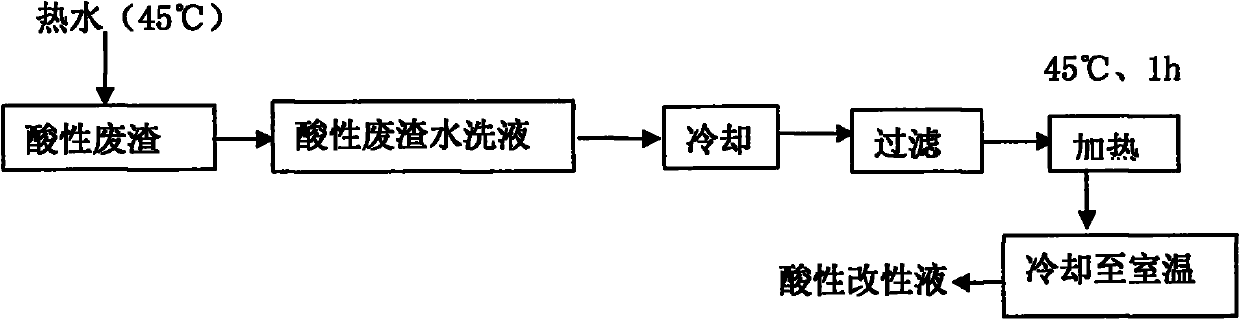

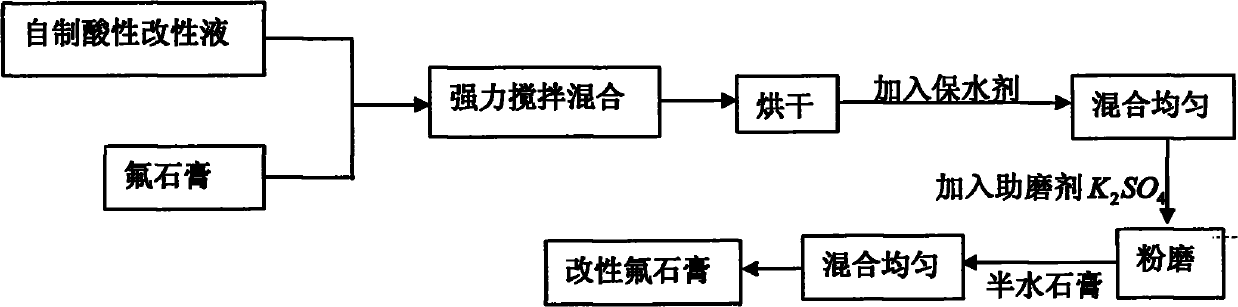

Waste fluorine gypsum activating technique

InactiveCN102020429AReasonable compositionLow costSolid waste managementChemical industryProcess engineering

The invention relates to a recycling and modifying method of chemical industry by product fluorine gypsum, belonging to the field of solid waste recycling. The method comprises the following steps of: (1) preparing a modifying solution, namely washing acidic waste residue with hot water, recycling washing fluid, cooling, filtering, heating and cooling under natural conditions to obtain a self-made acidic modifying solution; (2) processing raw materials, namely adding the acidic modifying solution for neutralization and maintaining the fluorine gypsum to be mildly acidic; (3) selecting a modifying agent, namely selecting a water-retaining agent, grinding additive and a crystal seed as required; and (4) mixing and stirring the fluorine gypsum with the modifying agent under certain conditions. The invention has the advantages that the modifying solution is self-made, thus treating waste by waste and reducing modification cost; the quality of the product obtained by adopting the method is higher than that of products obtained by adopting other methods, and adding amount of the fluorine gypsum when being taken as cement retarder is improved to 6% from 3%, thus reducing cost of cement; and the modified fluorine gypsum and coal ash can be comprehensively applied to cement concrete and road repairing industries.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

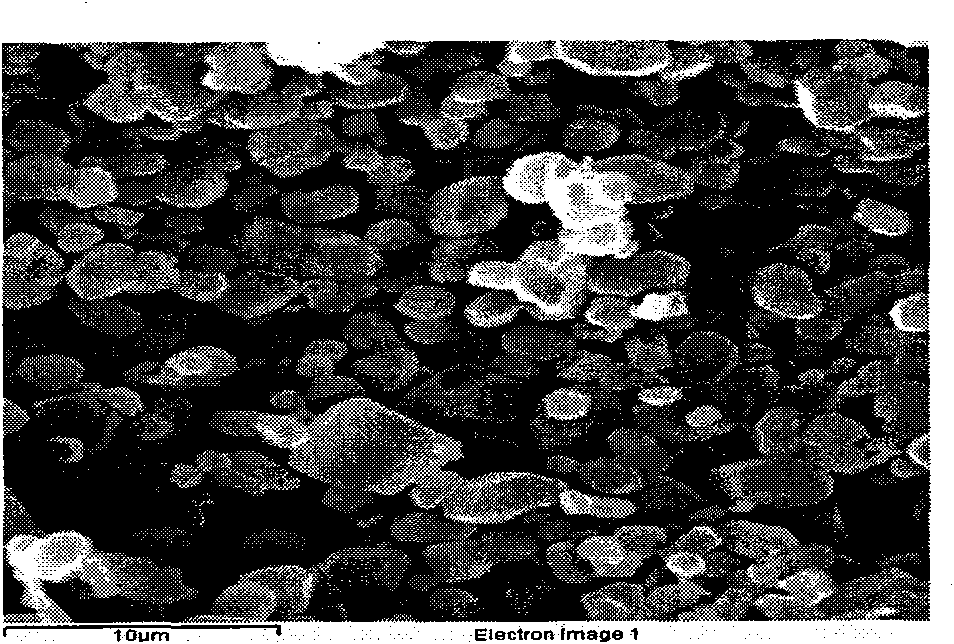

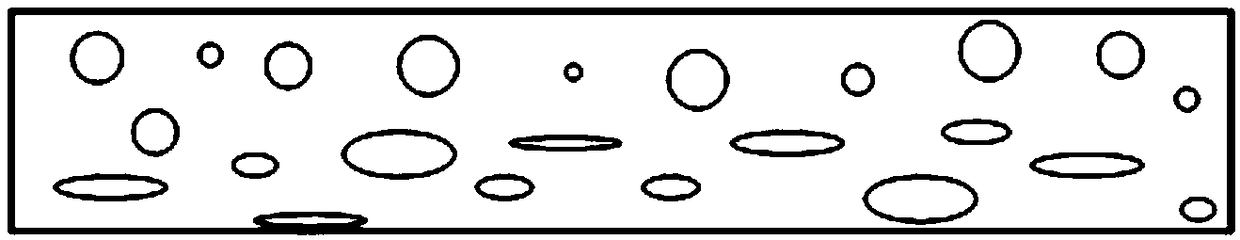

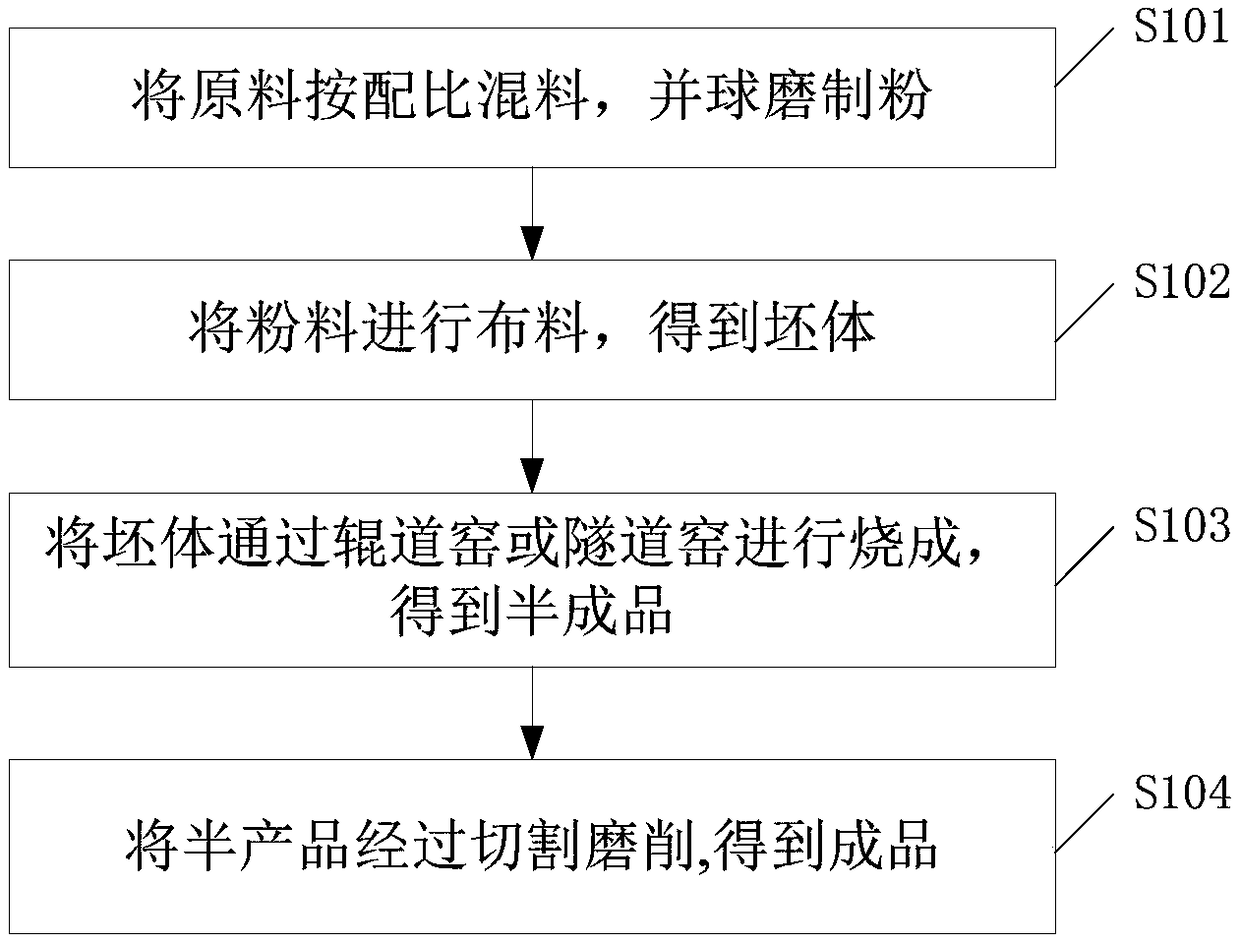

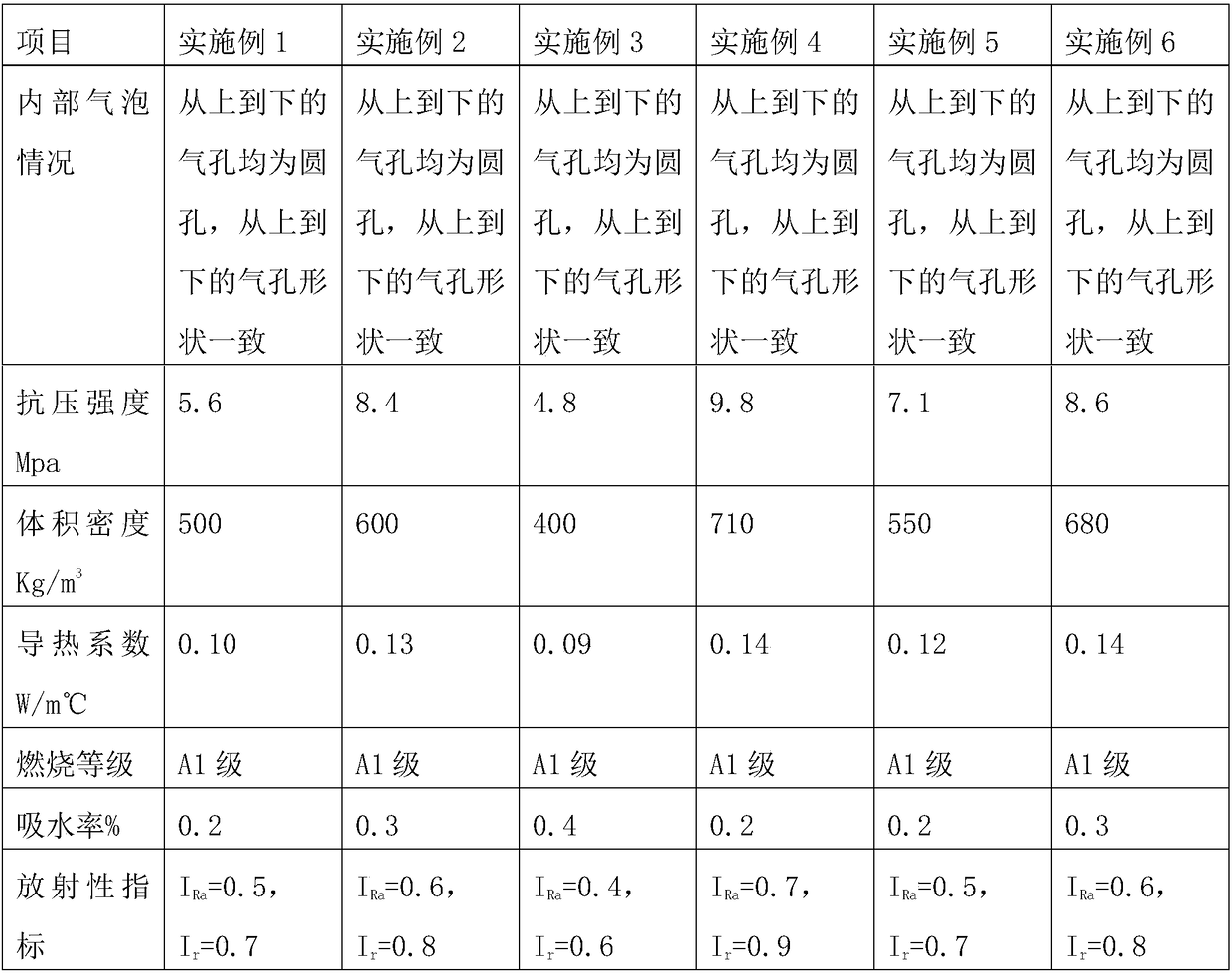

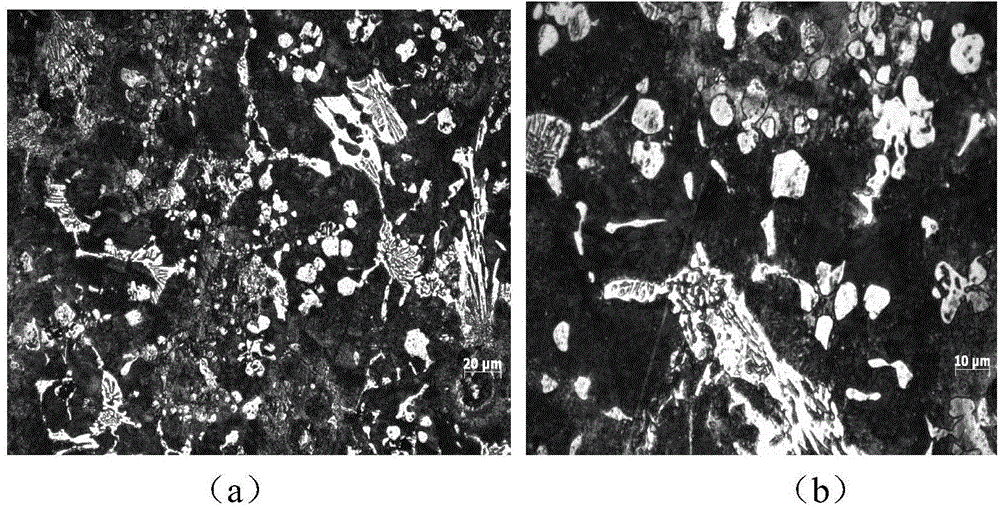

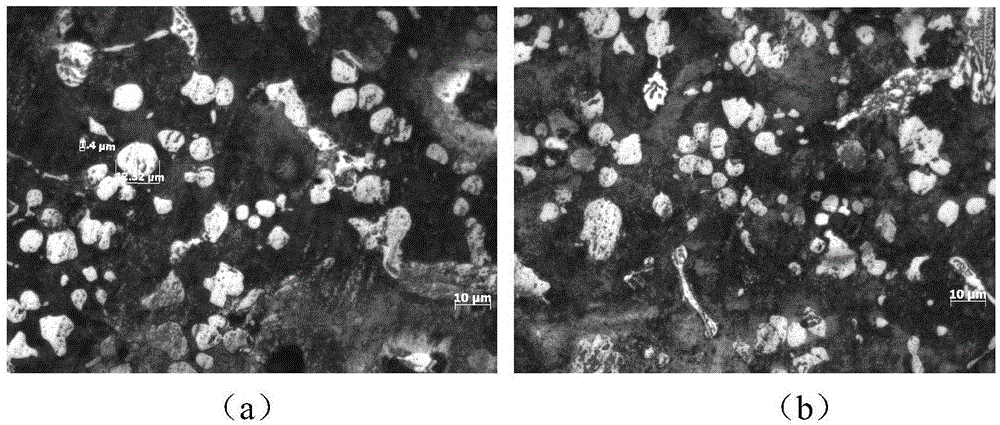

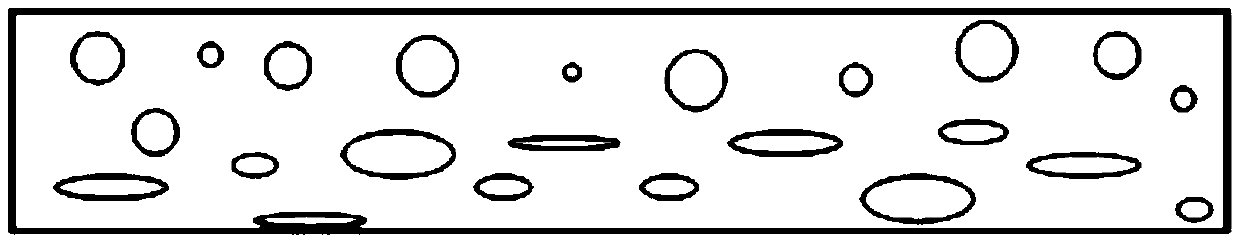

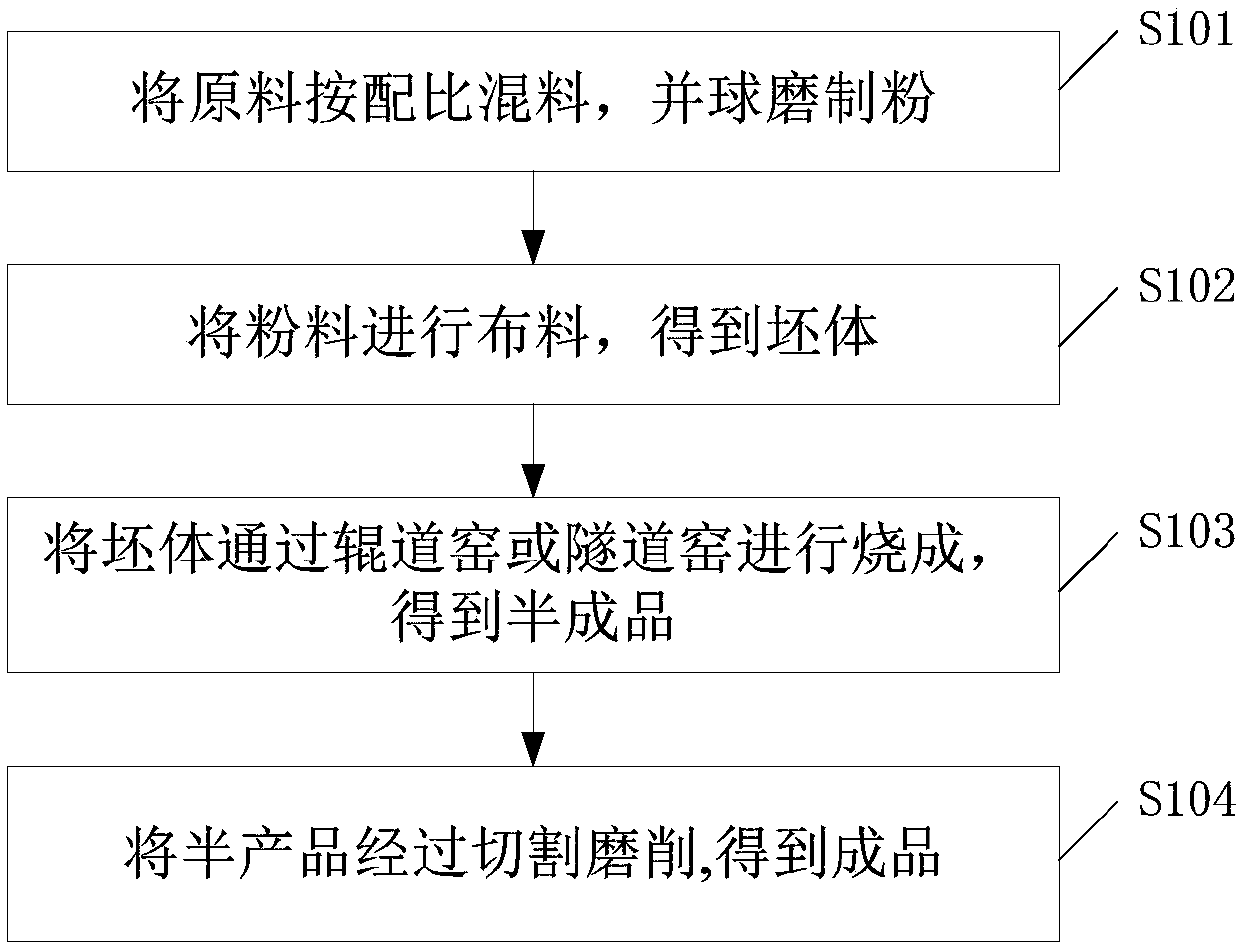

Foam ceramic light-weight plate and preparation method thereof

InactiveCN108863302AOrdinary firing fastFire fastCeramic materials productionCeramicwareSlagCeramic tiles

The invention discloses a foam ceramic light-weight plate, which is mainly prepared from the following raw materials in percentage by weight: 70 to 96 percent of ceramic tile polished waste slag, 0 to10 percent of clay, 0 to 20 percent of feldspar, 0.01 to 0.6 percent of foaming agents and 0.1 to 4 percent of stabilizing agents, wherein the stabilizing agents are manganese dioxide. Correspondingly, the invention also provides a preparation method of the foam ceramic light-weight plate. By using the foam ceramic light-weight plate and the preparation method, air holes are identical from top tobottom at the same cross section of the foam ceramic light-weight plate; the bubble uniformity is high; a tunnel kiln can be used for firing; a roller kiln can also be used for firing.

Owner:KEDA INDUSTRIAL GROUP CO LTD

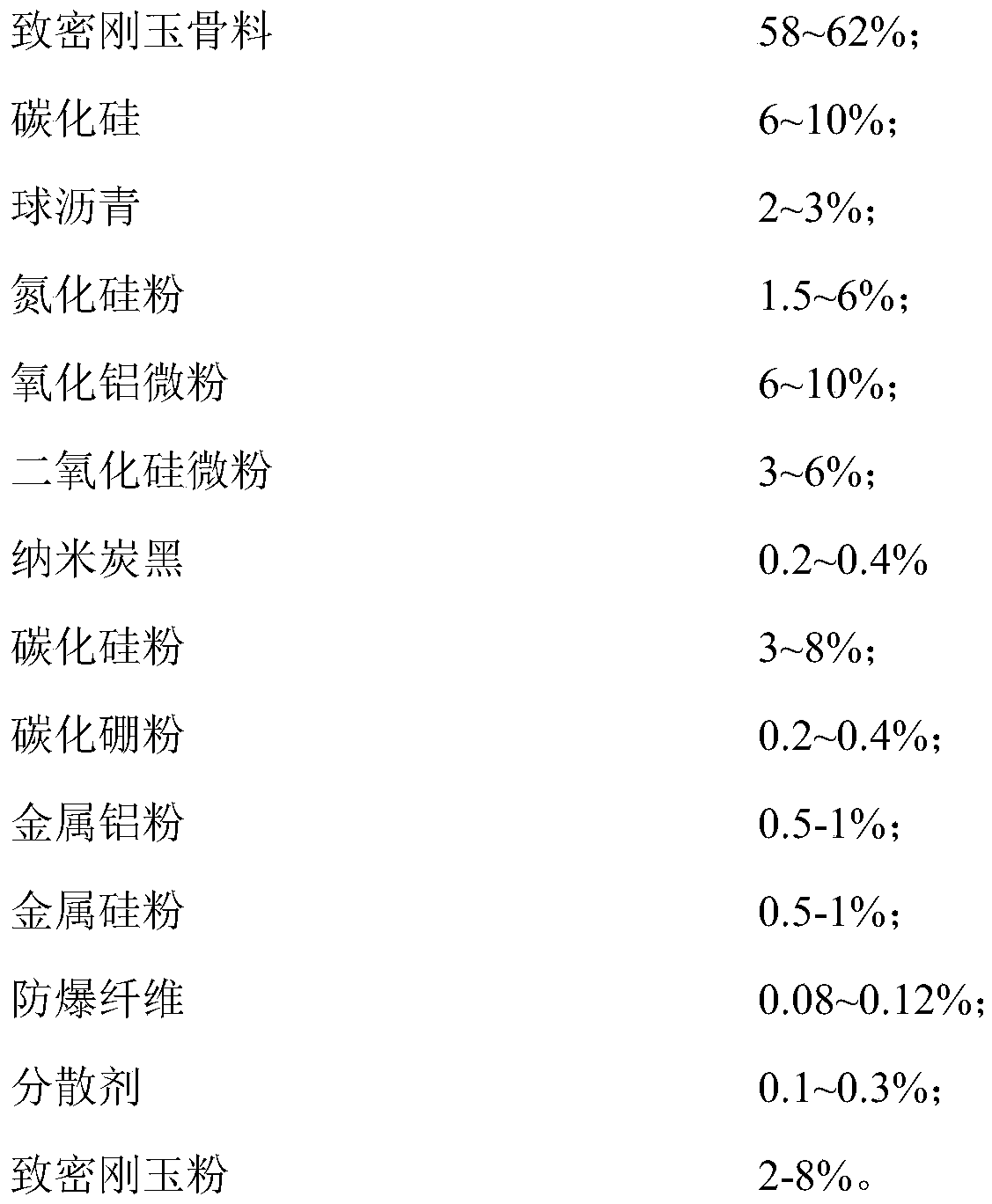

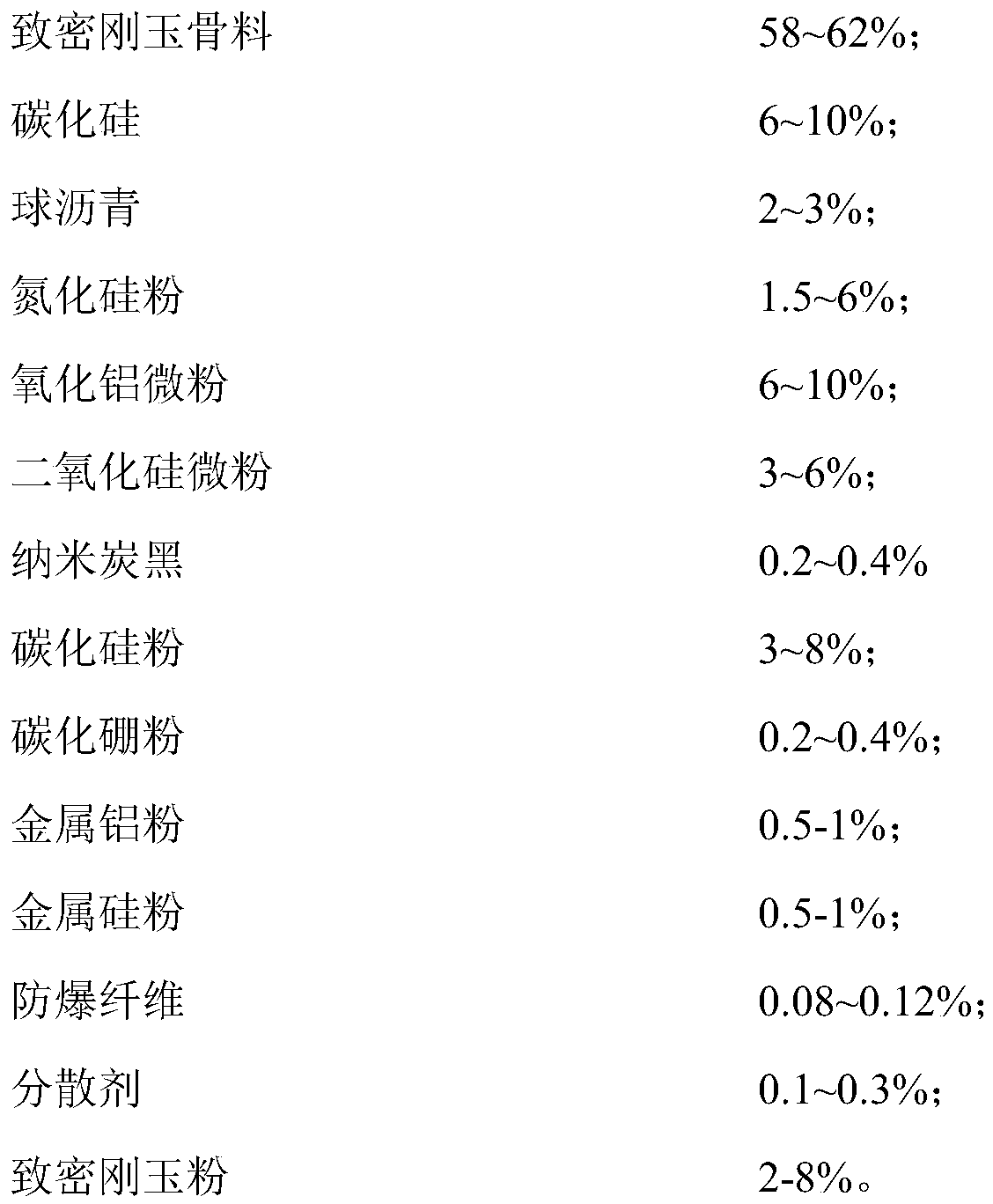

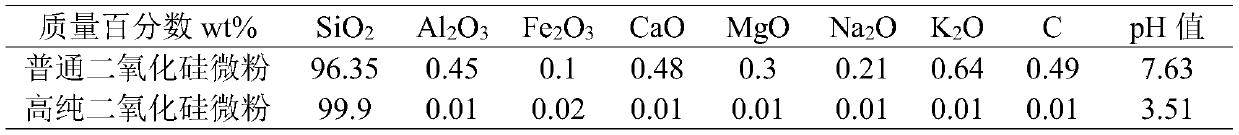

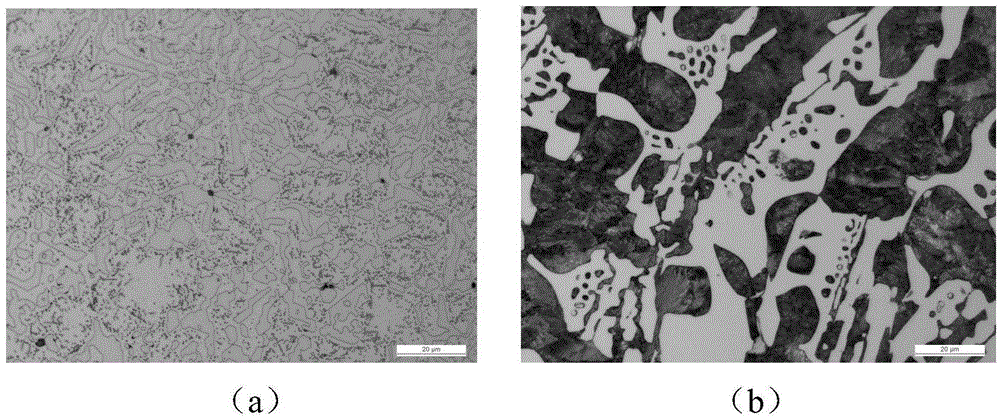

Cement-free iron runner castable for skimmer preformed unit

The invention discloses a cement-free iron runner castable. The cement-free iron runner castable is composed of 58-62% of a compact corundum aggregate, 6-10% of silicon carbide, 2-3% of spherical asphalt, 1.5-6% of silicon nitride powder, 6-10% of alumina micro powder, 3-6% of silicon dioxide micro powder, 0.2-0.4% of nano carbon black, 3-8% of silicon carbide powder, 0.2-0.4% of boron carbide powder, 0.5-1% of metal aluminum powder, 0.5-1% of metal silicon powder, 0.08-0.12% of explosion-proof fibers, 0.1-0.3% of a dispersing agent and 2-8% of compact corundum powder. According to the invention, an iron runner castable system is formed by combining high-purity silicon dioxide micro-powder and aluminum oxide micro-powder, so that the purity, refractoriness and compactness of the castable reach a new height. Through high-purity, high density and the like of the system disclosed by the invention, the heat-state rupture strength, which is the index with most high-temperature representativeness, after heat is preserved by 1 hour at 1400 DEG C reaches 10 MPa or above.

Owner:中冶武汉冶金建筑研究院有限公司

High-vanadium wear-resistant alloy material and production technique thereof

InactiveCN104946964AIncrease the amount of participationIncrease in the number of particlesWear resistantMaterials science

The invention relates to the field of wear-resistant materials, particularly a high-vanadium wear-resistant alloy material and a production technique thereof. The high-vanadium wear-resistant alloy material is composed of the following components in percentage by mass: 2.7-3.5% of C, 7.5-8.5% of V, 0.5-1.5% of Si, 0.8-1.5% of Mn, 2.0-3.5% of Cr, 1.0-2.5% of Mo, 1.0-2.0% of Ti, at most 0.04% of S, at most 0.04% of P and the balance of iron. The V is used instead of the Cr element in the high-chromium cast iron to generate the high-hardness VC carbide particles in the iron base. 1.0-2.0% of Ti element is added into the iron to generate a (V,Ti)C eutectic carbide in the iron. Since the workpiece generally has a certain thickness, certain amounts of chromium (Cr) element and molybdenum (Mo) element are added as hardenability-enhancing elements. The Ti element can be easily combined with the sulfur element to generate the hazardous compound Ti2S, and therefore, the sulfur and phosphorus elements are respectively strictly controlled to at most 0.04% according to the requirements.

Owner:曾松盛

Titanium extraction tailing building decoration plate and production method thereof

ActiveCN108298940AWater resistantFireproofCovering/liningsSolid waste managementEcological environmentSlag

The invention provides a titanium extraction tailing building decoration plate, which is prepared from the following ingredients in percentage by weight: 35 to 45 percent of titanium extraction tailings, 15 to 25 percent of light calcined magnesia powder, 8 to 15 percent of magnesium sulfate heptahydrate, 1 to 5 percent of active filling materials, 3 to 7 percent of crop wastes, 0.5 to 2 percent of modified additives and 15 to 20 percent of water, wherein additional materials are glass fiber mesh cloth and non-woven fabric. Compared with the prior art, the titanium extraction tailing buildingdecoration plate has the beneficial effects that the industrial waste slag titanium extraction tailings obtained by the PanZhiHua Steel blast furnace slag titanium extraction process and the light calcined magnesia powder prepared from low-grade magnesite, and the magnesium sulfate heptahydrate which is byproduct of boracic acid prepared from ascharite are used as major raw materials; green and environment-friendly effects are achieved; the cost is low; the production process is simple. The addition quantity of the PanZhiHua Steel titanium extraction tailings is great; the ecological environment problem caused by the PanZhiHua Steel titanium extraction tailing stacking storage can be effectively solved; meanwhile, the titanium extraction tailing building decoration plate has the advantagesof high intensity, water resistance, fire resistance, anti-corrosion performance, no deformation, no tilting and the like.

Owner:UNIV OF SCI & TECH LIAONING +1

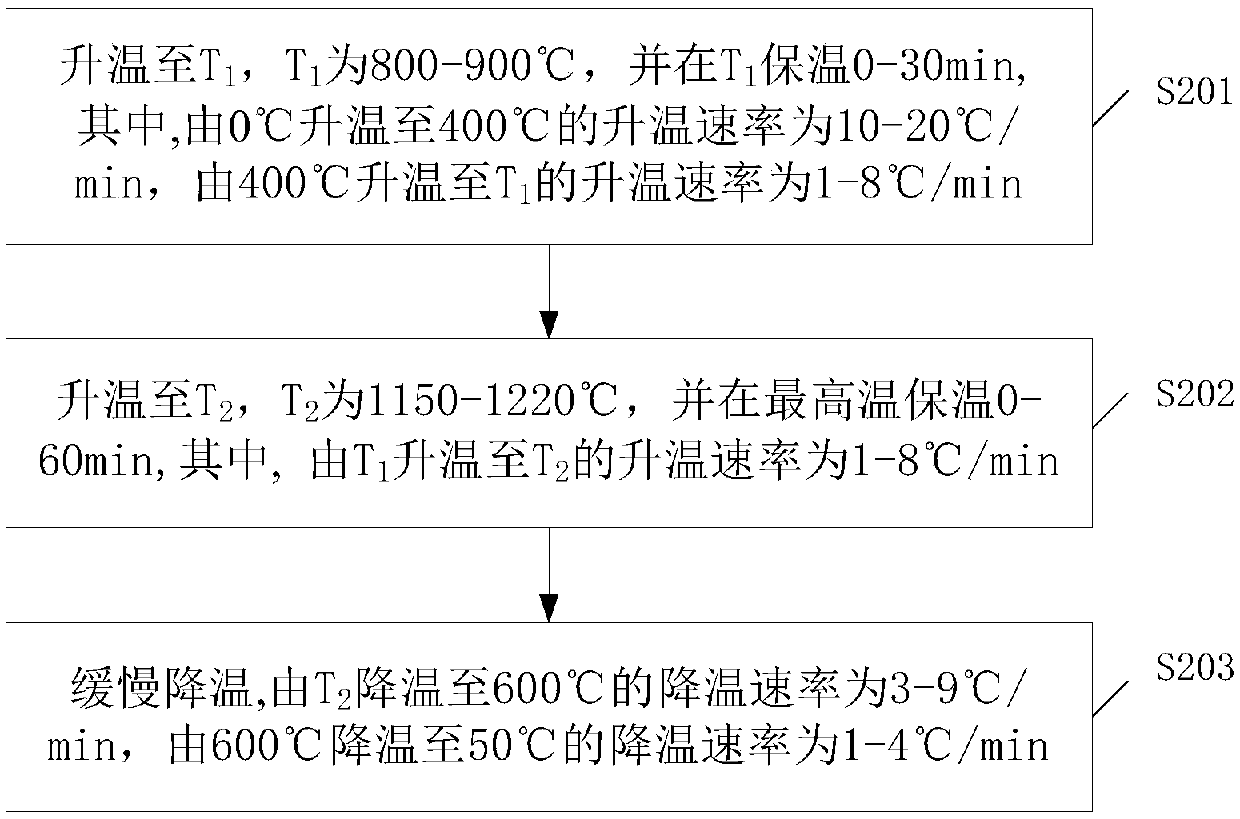

Roller way kiln firing method for lightweight foamed ceramic plates

InactiveCN108675768AReduced oxidation reaction phase timeReduce energy consumptionCeramic materials productionCeramicwareKilnWeight light

The invention discloses a roller way kiln firing method for lightweight foamed ceramic plates; the method comprises the steps: (1) heating up to T1 of 800-900 DEG C, and holding for 0-30 min at T1, wherein the heating rate of heating from 0 DEG C to 400 DEG C is 10-20 DEG C / min, and the heating rate of heating from 400 DEG C to T1 is 1-8 DEG C / min; (2) heating up to T2 of 1150-1220 DEG C, and holding for 0-60 min at the highest temperature, wherein the heating rate of heating from T1 to T2 is 1-8 DEG C / min; and (3) slowly cooling, wherein the cooling rate of cooling from T2 to 600 DEG C is 3-9DEG C / min, and the cooling rate of cooling from 600 DEG C to 50 DEG C is 1-4 DEG C / min. By adopting of the method, low temperature fast firing is realized, and the lightweight foamed ceramic plates obtained by firing have no difference in air holes from top to bottom in same cross-sections, and have high bubble uniformity.

Owner:KEDA INDUSTRIAL GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com