Method for preparing acrylic fibre with wet-process

An acrylic fiber, wet-laid technology, applied in wet-spinning, spinneret assembly, filament generation, etc., can solve the problems of difficult to achieve product quality, low output, etc. Door pressure, easy diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

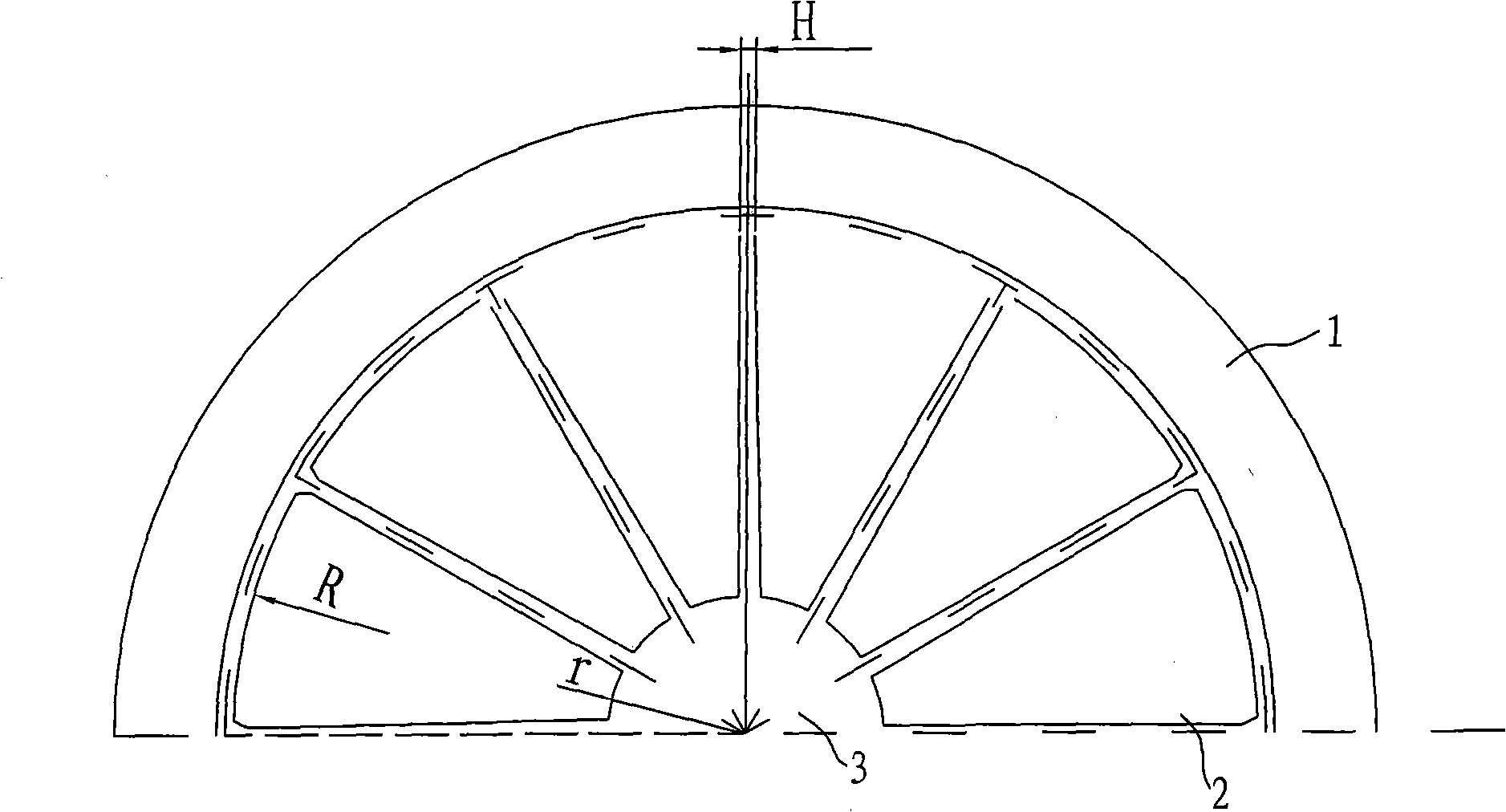

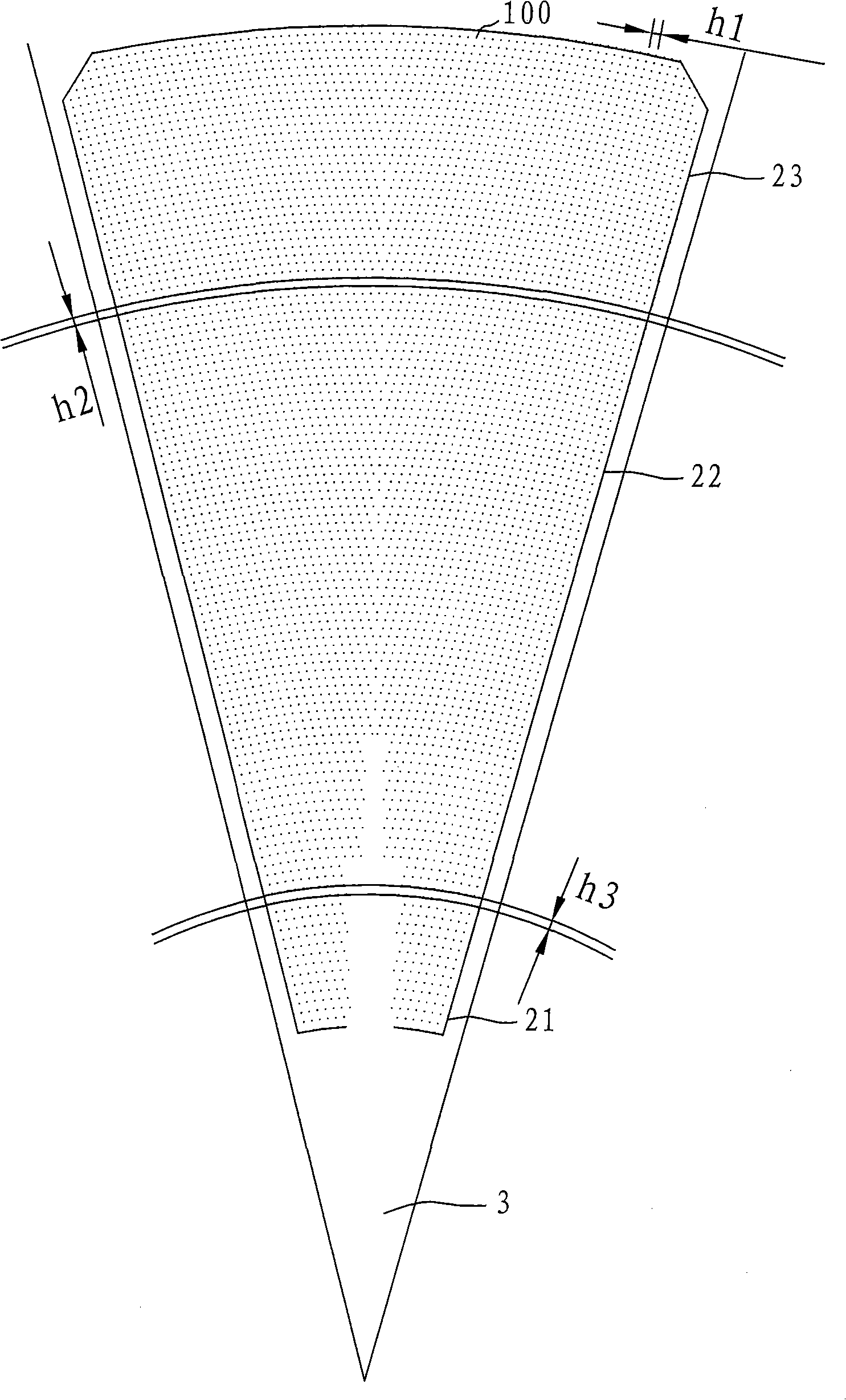

Image

Examples

Embodiment

[0023] Embodiment: the preparation method of the wet-process acrylic fiber in the present embodiment: comprise the steps successively:

[0024] a. Spinning forming: take polyacrylonitrile dry powder (PAN) as raw material, and use dimethylacetamide (DMAC) as solvent to prepare a polymer stock solution with a mass percentage concentration of 23 to 26%, preferably 24.5%. After being heated by a heater, it is extruded from the hole on the spinneret to form a monofilament. The temperature of the heater is controlled at 120-130°C, preferably 125°C, and the pre-spinning pressure is controlled at 450-550Kpa, preferably 500kpa. The bath temperature is 45-49°C, preferably 47°C, the mass percentage concentration of dimethylacetamide in the coagulation bath is 51-54%, preferably 52.3%, and the circulation rate of the coagulation bath is 30000-40000kg / h, preferably 34105kg / h Preferably, as-spun fibers are produced;

[0025] b. Washing and drawing: the as-spun fiber is passed through 8 was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com