Patents

Literature

51results about How to "Increase draft ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Curing treatment method of carbon fiber precursor polyacrylonitrile fiber

InactiveCN102181963AGood for cyclization reactionRaise the degree of orientationFibre chemical featuresAir atmosphereCarbon fibers

The invention relates to a curing treatment method of a carbon fiber precursor polyacrylonitrile fiber. The method comprises the following steps: pre-cyclizing the polyacrylonitrile fiber precursor in the atmosphere of inert gas; carrying out cyclizing and plastic drawing in the atmosphere of inert gas and water vapor; and carrying out oxidation crosslinking in the atmosphere of air, thus obtaining a pre-oxidized polyacrylonitrile fiber. The method has the following beneficial effects: carrying out heat treatment on the fiber in the inert atmosphere is beneficial to implementation of cyclization reaction in the molecules to form rigid ladderlike molecules with regular structure and strong heat resistance, and at the same time, a defined amount of water vapor is introduced to obtain a higher drawing ratio by enhancing the plasticity of the molecular chains in the fiber, thus improving the orientation degree of the rigid molecules along the fiber axis.

Owner:DONGHUA UNIV

Method for producing high strength fine-denier polyamide fiber 6 fully drawn yarn

ActiveCN101476169AIncrease draft ratioReduce tensionSpinning head liquid feederMelt spinning methodsYarnHigh intensity

The invention provides a method for producing fine chinlon 6 fully drawn yarn with high strength which includes steps as follows: (1) chinlon 6 slice enters into a screw extruder with electrical heating function through a storage hopper that makes slice showing melt shape; (2) the melt material is pressed in a spinning subassembly through a metering pump quantificationally, and is spout by a spout plate for forming filament bundle in a spining box body; (3) the filament bundle is cooled by side wind through the spinning box body and is cooled further through a corridor; (4) the cooled filament bundle is oiled by an oil roll; (5) oil in the filament bundle is more uniform and has high amplexus degree through confounding; (6) the filament bundle passes through a first group filament guide roll and a second group filament guide roll for drafting forming, then passes through a third filament guide roll to reel. A grade product produced by the method has average more than or equal to 6.0cN / dtex rupture strength that is higher 22% than the product produced by normal method, and has better transparent sense and visual effect, the produced clothes has better flexible sense and handle sense for wearing cosily.

Owner:烟台华润锦纶有限公司

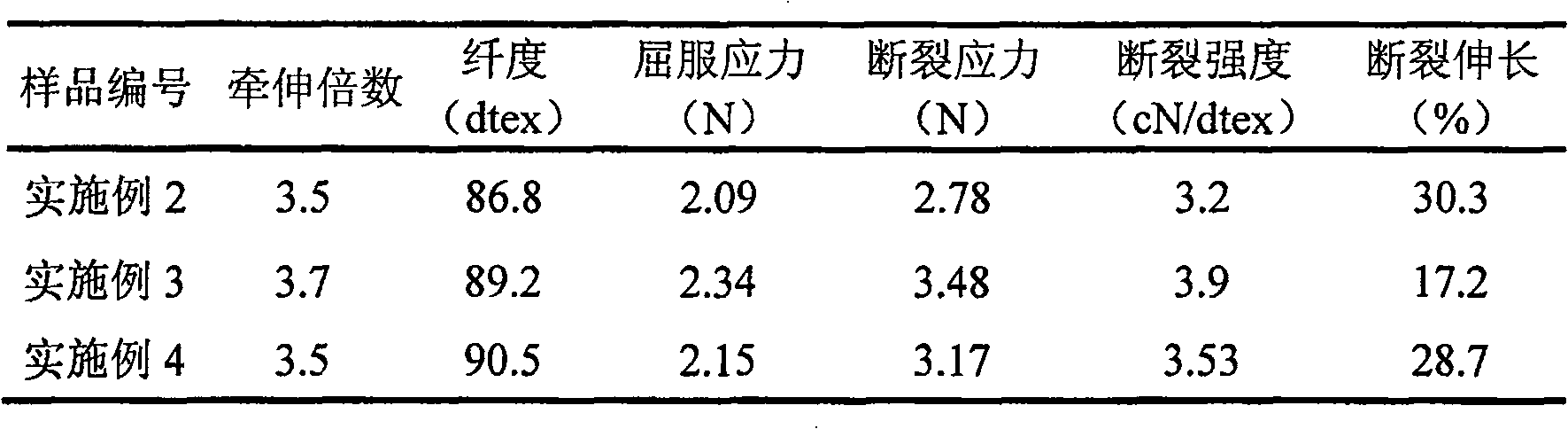

Modified polyphenylene sulfide fiber and method for making same

InactiveCN101187088AHigh glossImprove mechanical propertiesMonocomponent synthetic polymer artificial filamentMelt spinning methodsUltimate tensile strengthSilicon dioxide

The invention provides a modified polyphenylene sulfide fiber and process for preparing, whose components and parts by weight comprise 100 parts of polyphenylene sulfide and 0.2-2 parts of nano-silica whose surface is treated, the particle size of the silica is 20-60 nanometer, and the denier of the fiber is 85-91 dtax. The invention prepares the polyphenylene sulfide fiber through modifying polyphenylene sulfide resins and using special spinning process, the fiber strength and tension toughness are all improved, simultaneously, the glossiness of the fiber is further improved, the spinning is capable of being done by a common spinning device, the cost of spinning is reduced, the fluidity of substrate is changed better during spinning, the temperature of spinning is reduced by 5-10 DGE C, the draft multiple of as-spun fiber is improved, and the mechanical properties of the fiber are capable of being improved.

Owner:DONGHUA UNIV

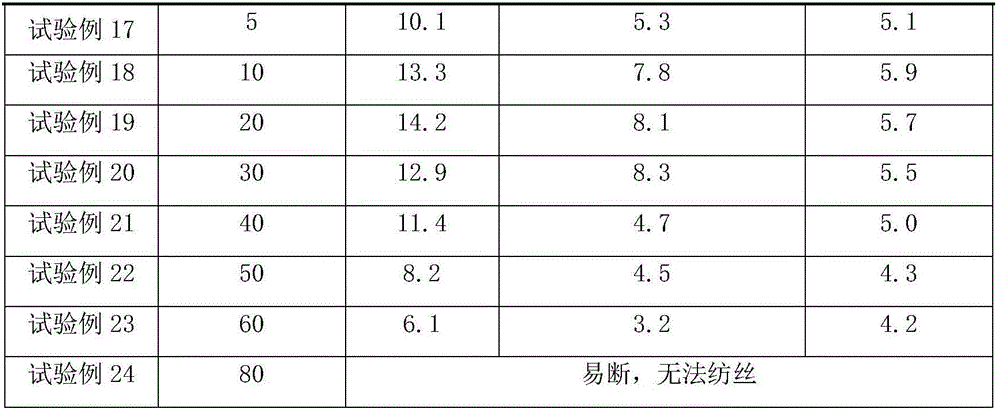

Method for preparing acrylic fibre with wet-process

InactiveCN101270501AGood molding effectIncrease the amount of participationSpinnerette packsFilament manufactureState of artEngineering

A preparation method for wet acrylic fiber is characterized by including the following steps in turn: a, spinning and shaping; b, washing and drafting; c, oiling; d, drying; e, winding; f, shaping. Furthermore, compared with the prior art, the invention makes improvement on the shaping technique and post treatment technique through the specific design of a silk spray plate and selects proper spinning, shaping and post treatment condition technique parameters through a plurality of tests to improve the coagulation bath circulation amount, improve the adding amount and the drafting times of an oil agent and improve the winding door pressure. The acrylic fiber manufactured by the invention improves the shaping effect of the fiber.

Owner:浙江杭州湾腈纶有限公司

High-strength low-contract polyphenylene sulfide filament and preparation method thereof

ActiveCN102560717AIncrease draft ratioExtended heat setting timeArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFinenessMelt extrusion

The invention relates to high-strength low-contract polyphenylene sulfide (PPS) filament and a preparation method thereof. In the high-strength low-contract PPS filament, monofilament line density is 2-4 dtex, breaking strength is 4-6 cN / dtex, elongation at break is 15-20%, and dry heat contractibility rate (processing the filament for 30min at the temperature of 180 DEG C) is less than 5%. The preparation method includes drying and crystallizing PPS slices, melt-extruding, spinning, cooling, applying oil, and winding preliminarily; then adopting level 1 to level 3 drafting to obtain draft filament; and conducting heat setting processing on the draft filament, and obtaining the high-strength low-contract PPS filament, wherein the heat setting processing includes two steps of dynamic heat setting and static heat setting. The high-strength low-contract PPS filament fiber is high in manufacture yielding rate, even in fiber fineness and good in breaking strength, elongation at break, boiling water shrinkage and dry heat contractibility and is far better in comprehensive performance than the existing PPS filament products in the market.

Owner:DONGHUA UNIV

Method for processing small-specification blending modified polypropylene light-emitting rope for fishing

InactiveCN101994267AHigh breaking strengthHigh strengthSpinning head liquid feederFilament manufacturePolypropyleneYarn

The invention relates to a method for processing a small-specification blending modified polypropylene light-emitting rope for fishing, belonging to the method for processing the light-emitting rope for fishing and needing providing a method for processing the small-specification blending modified polypropylene light-emitting rope for fishing. The small-specification blending modified polypropylene light-emitting rope for fishing is processed by adopting the raw materials of PP resin, HDPE resin, light-emitting powder and assistant. The method is characterized in that a mixture of the PP resin, the light-emitting powder, zinc stearate and white oil is extruded and pelleted to obtain a blending material matrix; a mixture of the blending material matrix, the PP resin and the HDPE resin is melted and extruded by an extruding machine, a raw silk obtained through melting and extruding is cooled and pre-drafted, and a pre-drafted silk is subjected to two times of thermal drafting and then cooled with airflow; the single silk bundle is split into a blending modified polypropylene light-emitting silk for fishing, 36 light-emitting silks are twisted to a Z-direction light-emitting rope yarn, 6 Z-direction light-emitting rope yarns are manufactured into an S-direction rope yarn, and 3 S-direction light-emitting rope yarns are twisted into a small-specification blending modified polypropylene light-emitting rope for fishing in a Z direction. The invention is used for the light-emitting rope for fishing.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

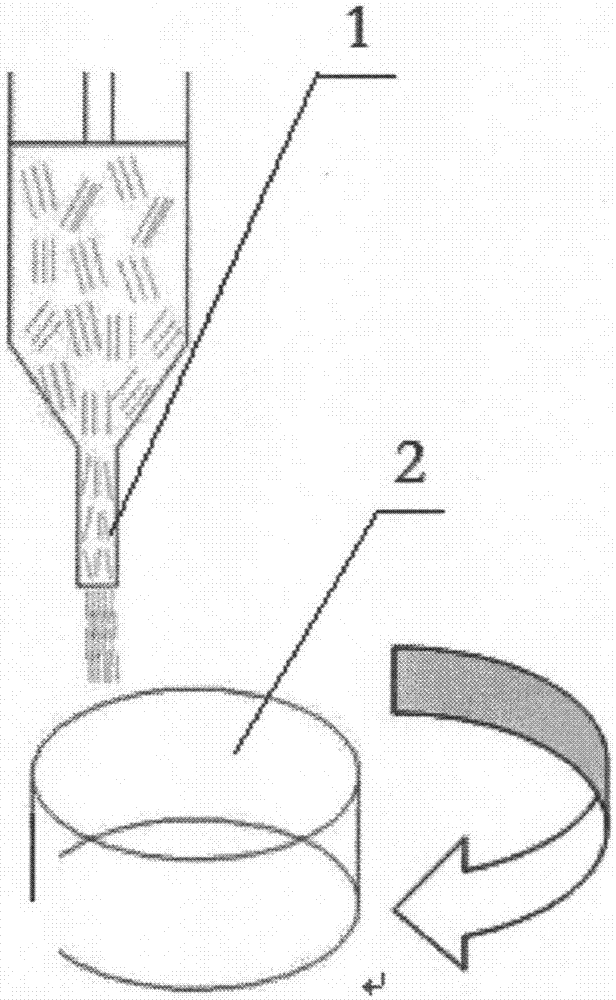

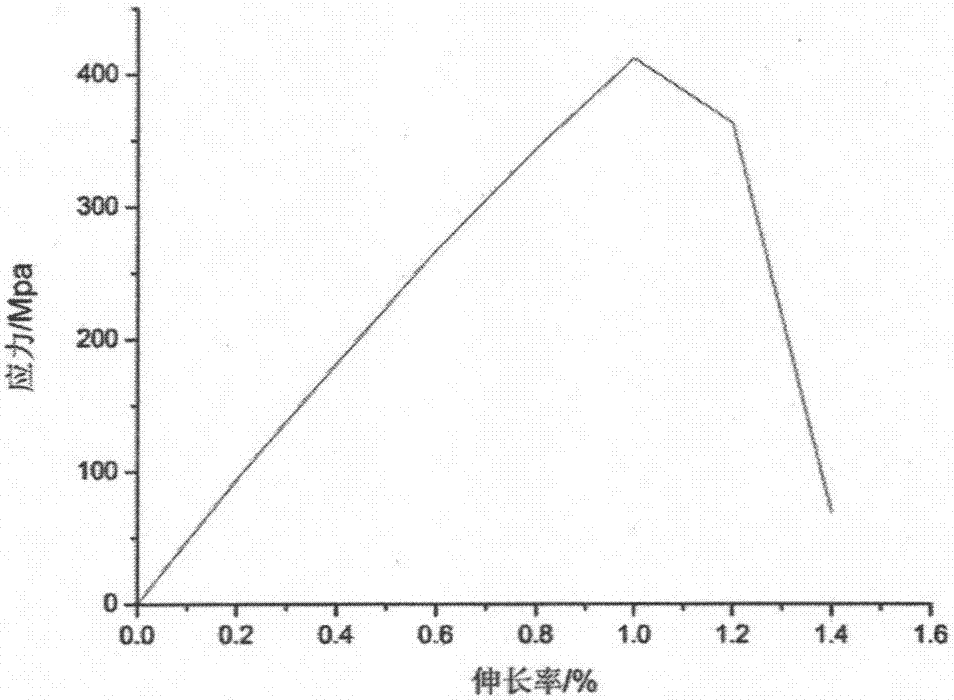

Oxidized graphene dry-jetting and wet-spinning method

InactiveCN106894113AIncrease draft ratioGood orientationFibre chemical featuresWet spinning methodsColloidUltimate tensile strength

The invention provides an oxidized graphene dry-jetting and wet-spinning method. The oxidized graphene dry-jetting and wet-spinning method is characterized in that an improved Hummers method is adopted to prepare oxidized graphene, an oxidized graphenespinning solution is prepared after washing and is extruded out of a capillary spinning tube and enters a coagulating bath through an air layer to solidify, colloid fiber is obtained, and graphene fiber is prepared through reduction after drying. The graphene slice layer screening process can be omitted, industrial production is promoted, the draft multiple of the colloid fiber can be improved through the air layer by adopting the oxidized graphene dry-jetting and wet-spinning method, the orientation of the slice layer in the fiber is improved, and the fiber strength is improved.

Owner:DONGHUA UNIV

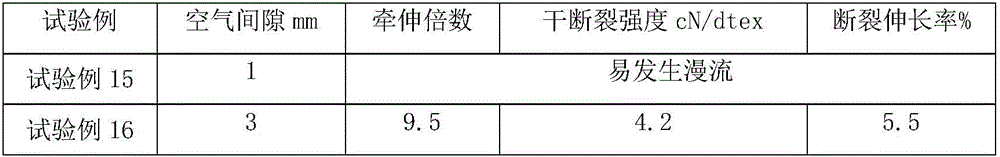

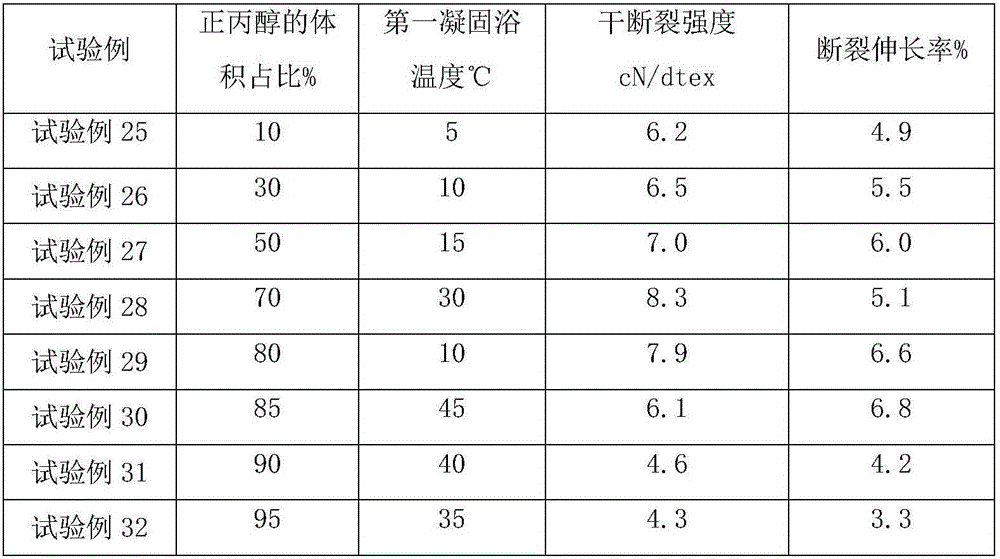

Method for preparing cellulose fibers by dry-wet spinning

ActiveCN106048741AImprove solubilityReduce processing timeArtificial filaments from cellulose solutionsFilament manufacturePolymer sciencePhosphoric acid

The invention discloses a method for preparing cellulose fibers by dry-wet spinning. The method comprises the following steps: dissolving cellulose fibers in phosphoric acid / polyphosphoric acid compound solution and preparing the original liquid glue in the liquid crystal state by using a double-screw extruder; preheating the original liquid glue and then feeding to a metering pump; adjusting glue feeding quantity; spraying out the original liquid glue through a spinneret plate; allowing the original liquid glue to be subjected to air bath, first coagulating bath and second coagulating bath successively, wherein the air gap is 3-50mm and a solution comprising three components is used in each of the first coagulating bath and the second coagulating bath; carrying out water washing, neutralization, hot water washing, oil applying, drying, winding and the like to prepare the finished fire. The method is characterized in that filament spinning and forming time is short; filaments are formed quite uniformed; production efficiency is high, the fiber index is excellent and the like; no by-product is generated; the environment is less polluted; and cost is low.

Owner:吉林国兴复合材料有限公司

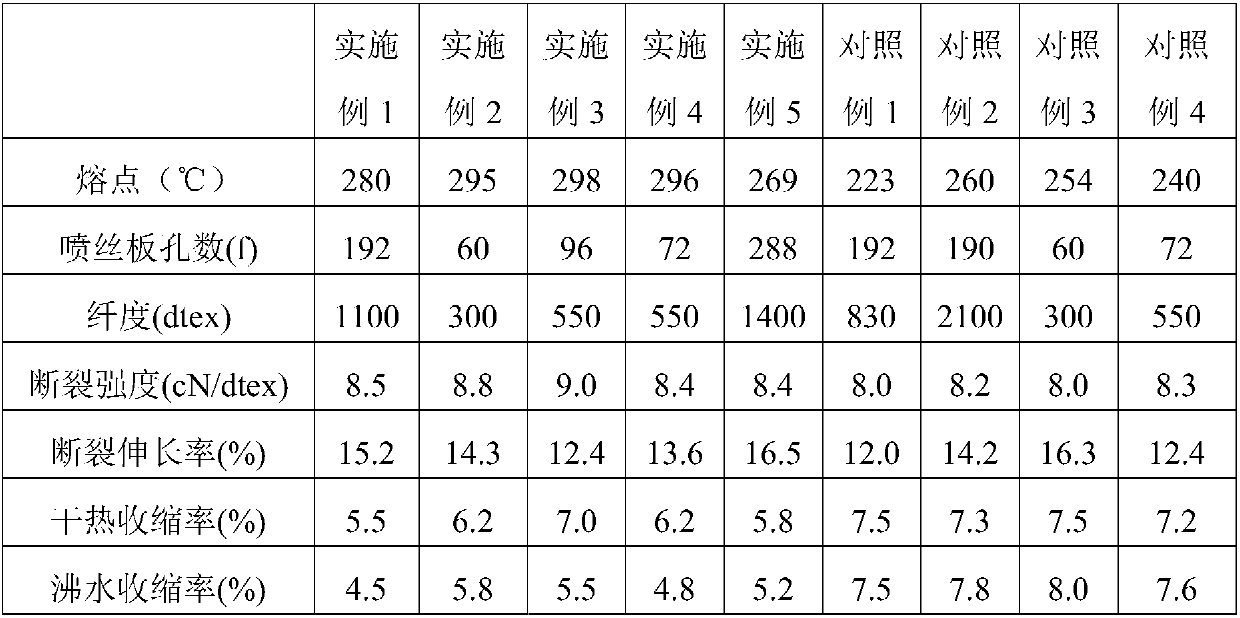

Copolyamide industrial yarn and preparation method thereof

PendingCN109930230AIncrease draft ratioHigh breaking strengthFilament/thread formingArtifical filament manufactureSolid phasesChemistry

The invention provides a copolyamide industrial yarn and a preparation method thereof. The copolyamide industrial yarn is prepared by polymerizing raw materials including a monomer, the monomer includes 1, 5-pentanediamine, a first dibasic acid and a second dibasic acid, wherein the first dibasic acid is terephthalic acid; the preparation method of the copolyamide industrial yarn comprises the following steps: 1) preparing the raw materials into a mixed solution; 2) polymerizing, granulating and solid-phase-tackifying the mixed solution to obtain tackifying copolyamide resin, and heating and melting the tackifying copolyamide resin to obtain tackifying copolyamide melt; 3) spinning the tackified copolyamide melt to obtain virgin yarn; 4) carrying out cooling, oiling, stretching and windingforming on the virgin silk to obtain the copolyamide industrial yarn. The copolyamide industrial yarn has good high temperature resistance and thermal stability.

Owner:CATHAY WUSU BIOMATERIAL CO LTD +2

Preparing method of PET/PTT parallel complex filament with high self-crimpiness

InactiveCN110565184AIncrease draft ratioImprove mechanical propertiesArtificial filament washing/dryingArtificial filament heat treatmentUltimate tensile strengthHeat setting

The invention discloses a preparing method of a PET / PTT parallel complex filament with high self-crimpiness. PET and PTT are sliced, dried and crystallized, afterwards, the PET and PTT are fused separately and subjected to extrusion molding through a parallel-type spinneret plate, oil is applied after cooling, then level 1-3 drafting and heat setting treatment are adopted, during drafting, the total drafting rate is controlled to be 3-3.5, the level-1 drafting rate is 2.8-3.0, and the temperature is controlled to be 75-80 DEG C. According to the preparing method of the PET / PTT parallel complexfilament with high self-crimpiness, methods like multi-level drafting for increasing the drafting rate are adopted, and the effects of improving the fiber strength, moderately lowering the elongationat break, and greatly improving the self-crimpiness are achieved.

Owner:TONGKUN GRP +1

Efficient processing method for fine yakwool yarn for worsted products

The invention relates to an efficient processing method for fine yakwool yarn for worsted products. The method includes pretreating yakwool fibrous materials; adding wool oil; subjecting yakwool fibers to carding process, first pre-drawing process, first sliver lapping process, first combing process, second pre-drawing process, second sliver lapping process and second combing process; performing gilling process and spinning process to obtain the yakwool yarn with fineness of 80-120Nm. The processing method combining cotton-type carding and wool spinning gilling is adopted according to features of the yakwool fibers, the fine yakwool yarn with fineness of 80-120Nm can be finally obtained, utilization rate of yakwool is increased greatly, and added value of yakwool worsted products is enhanced; meanwhile, the technical means combining superhigh draft and all-compact spinning is applied to the spinning process, so that draft multiple can be increased effectively, the roving process is omitted, processing cost is reduced, production efficiency is improved, and efficient processing is realized.

Owner:WUJIANG XINGYE TEXTILE CO LTD

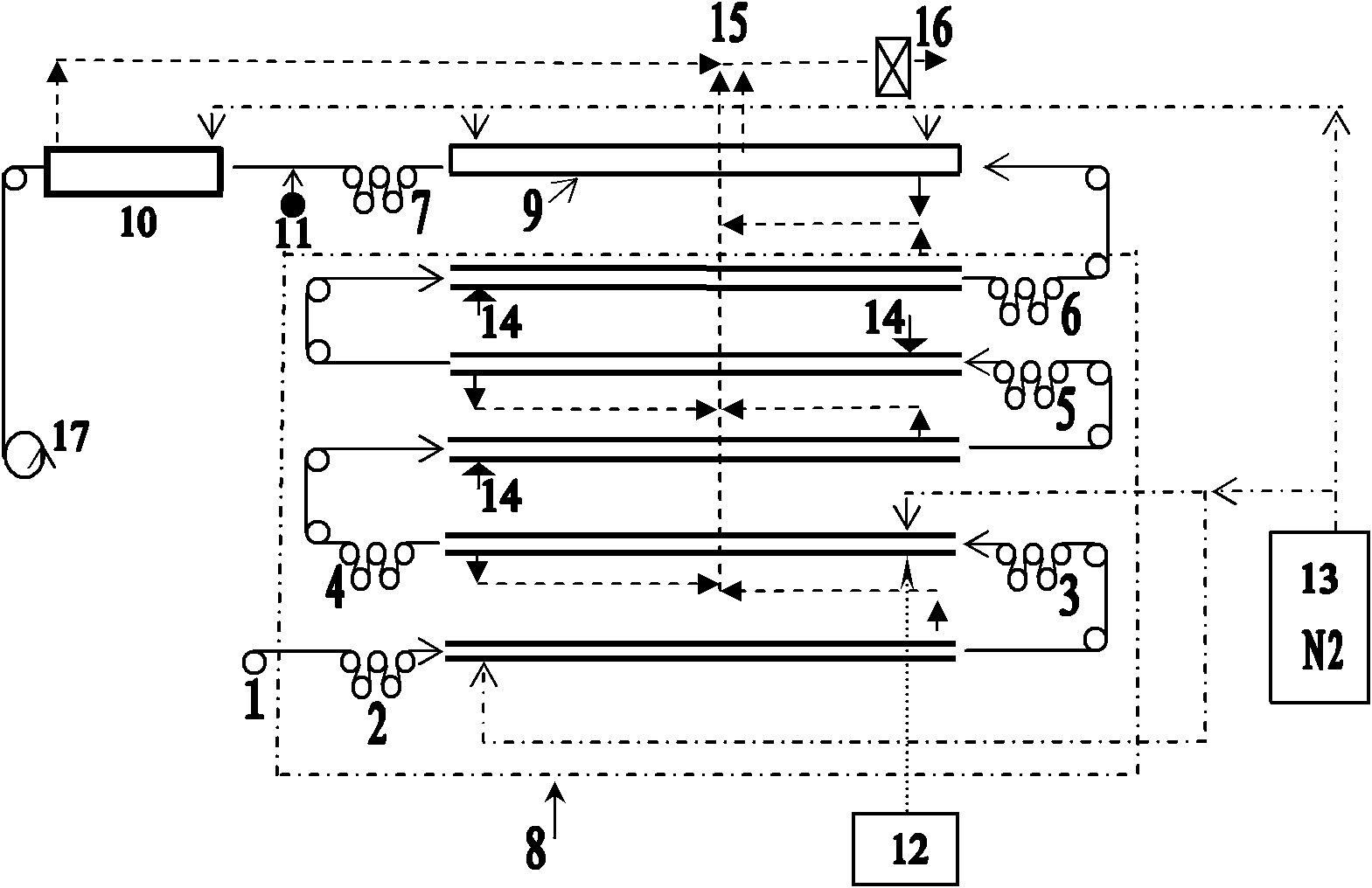

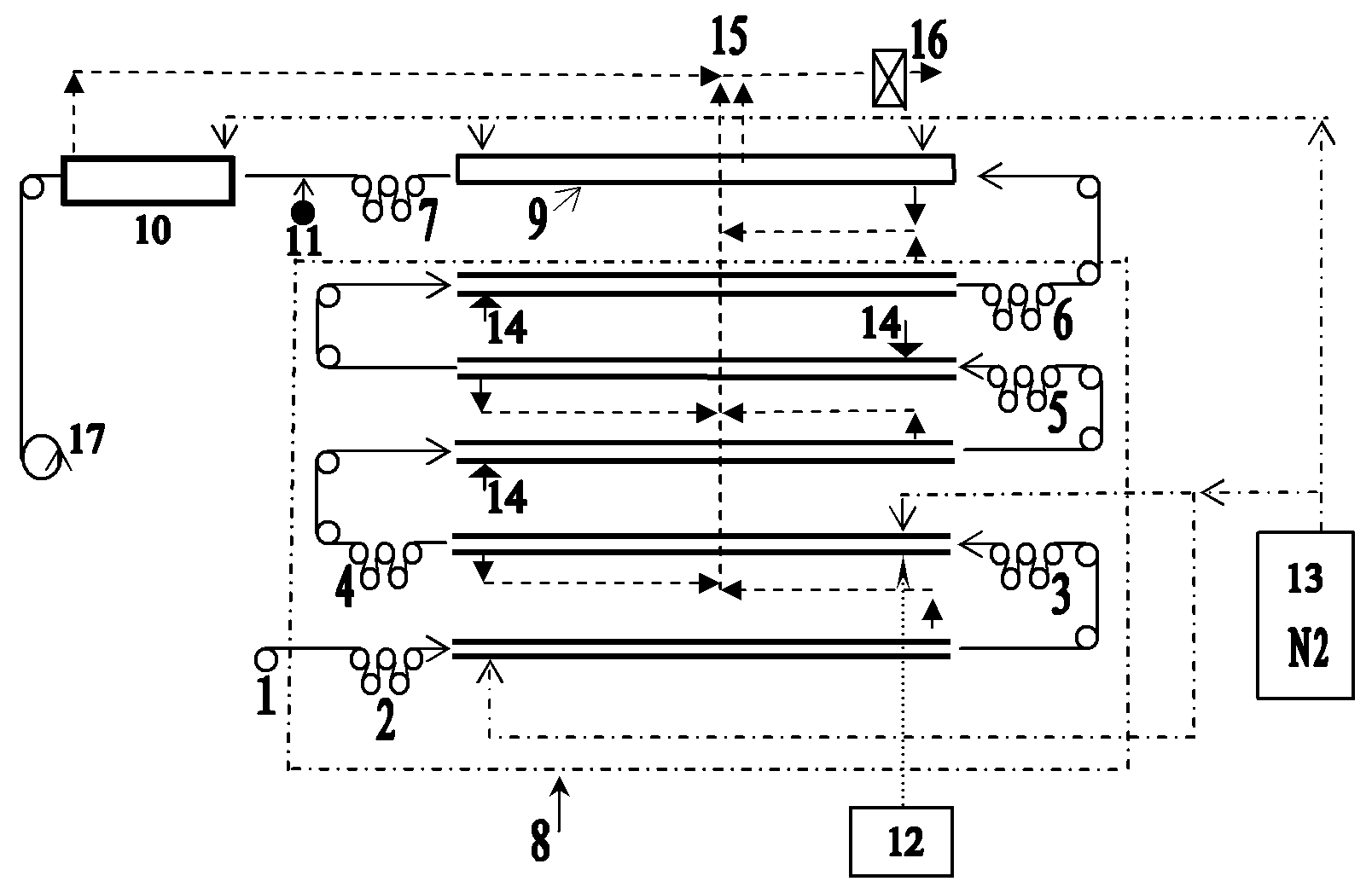

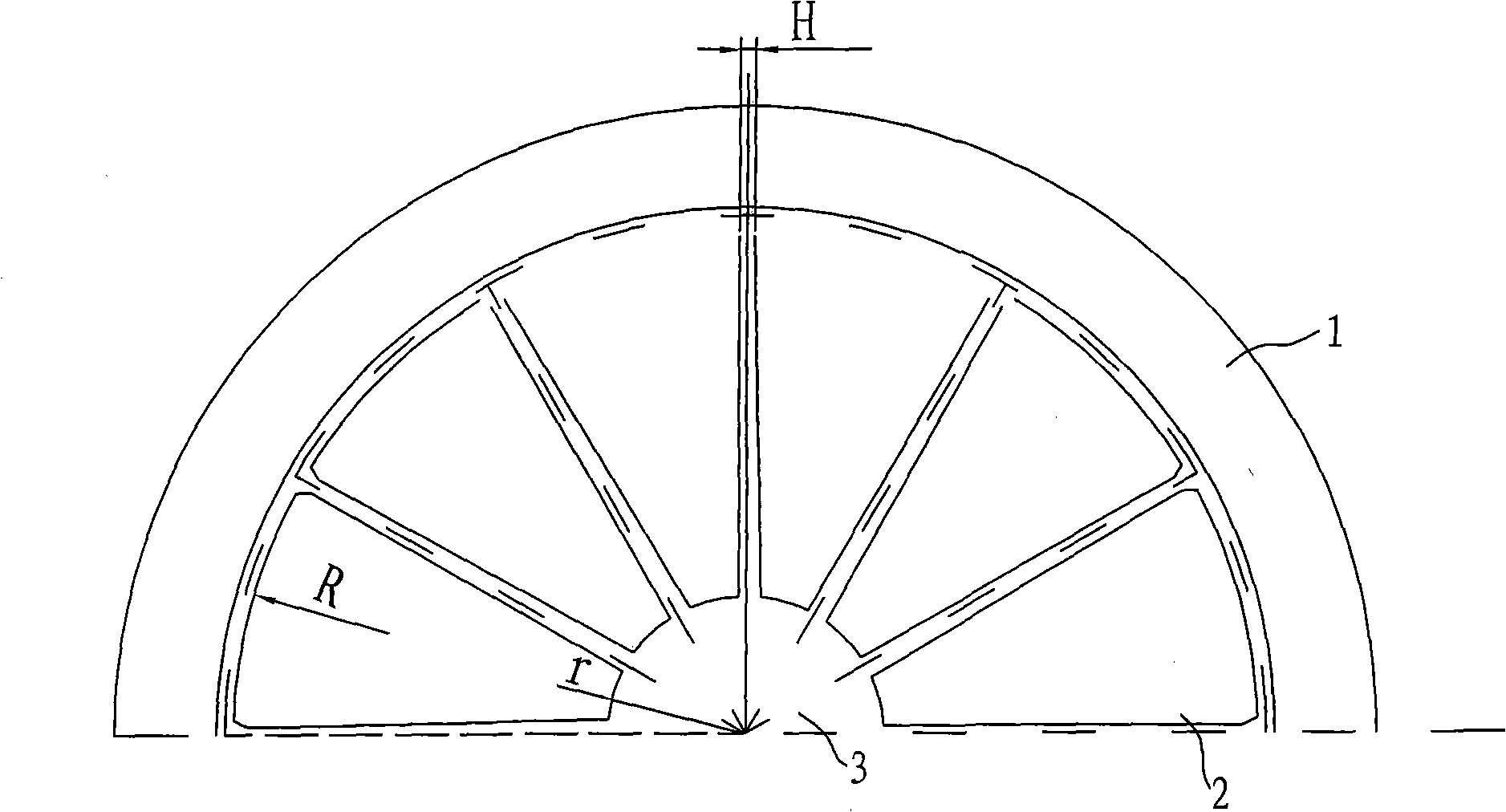

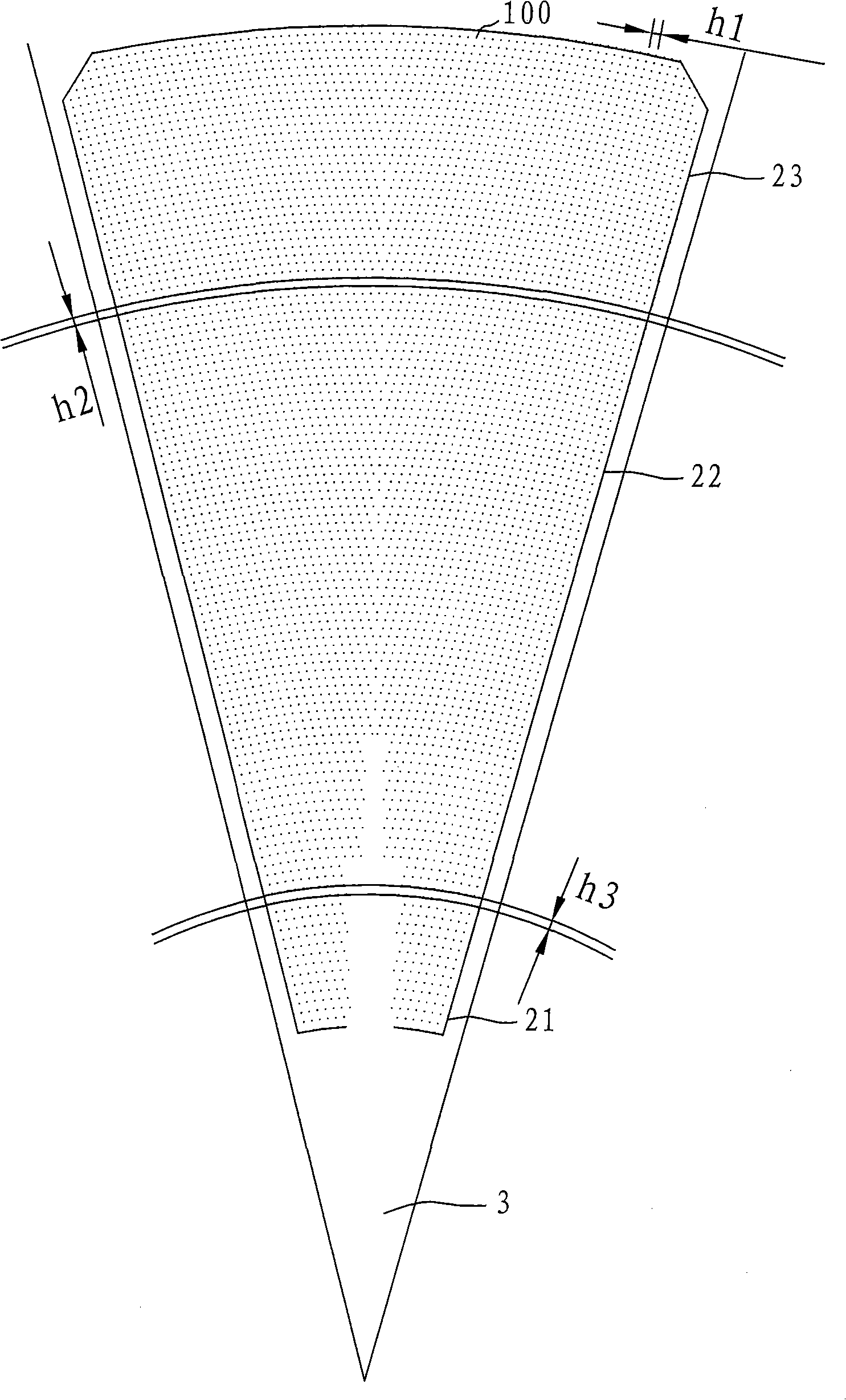

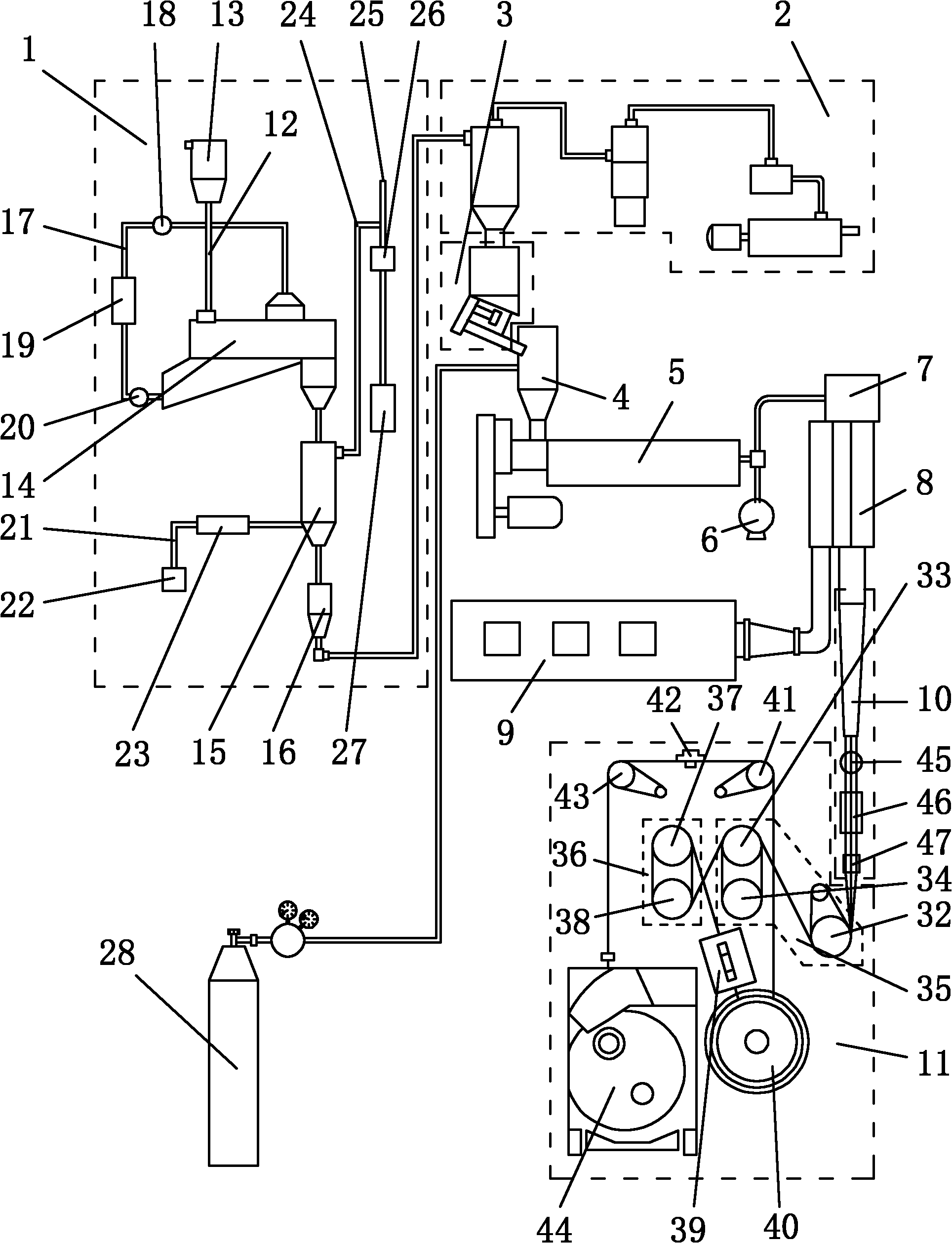

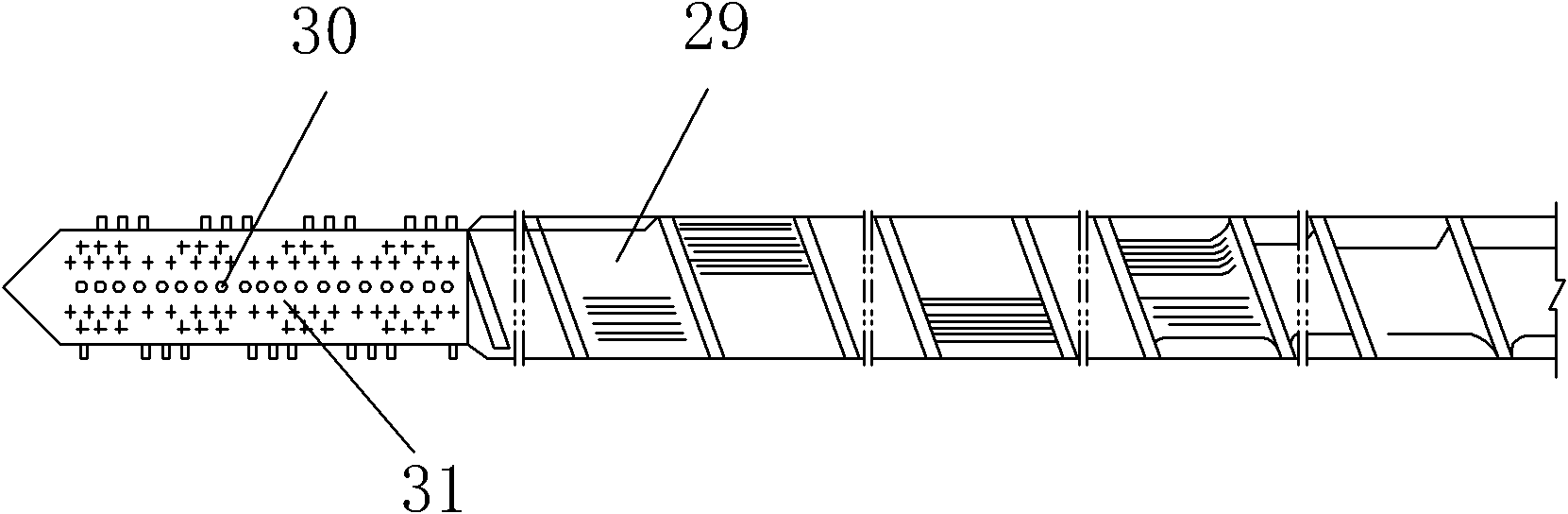

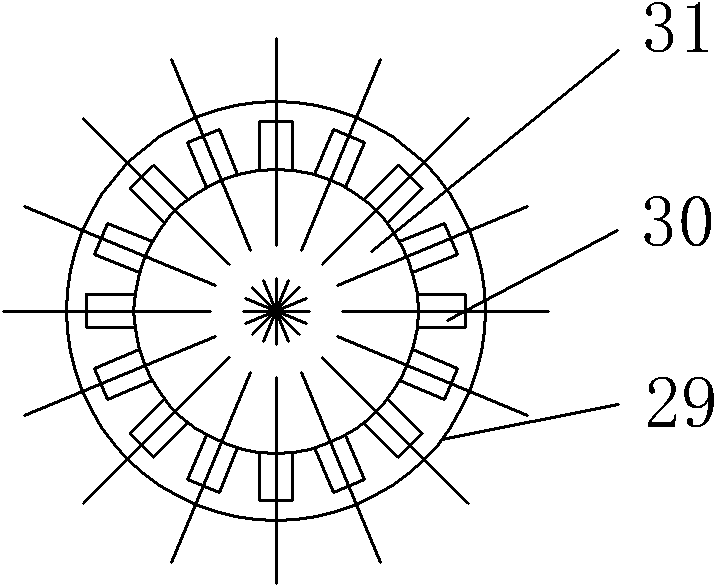

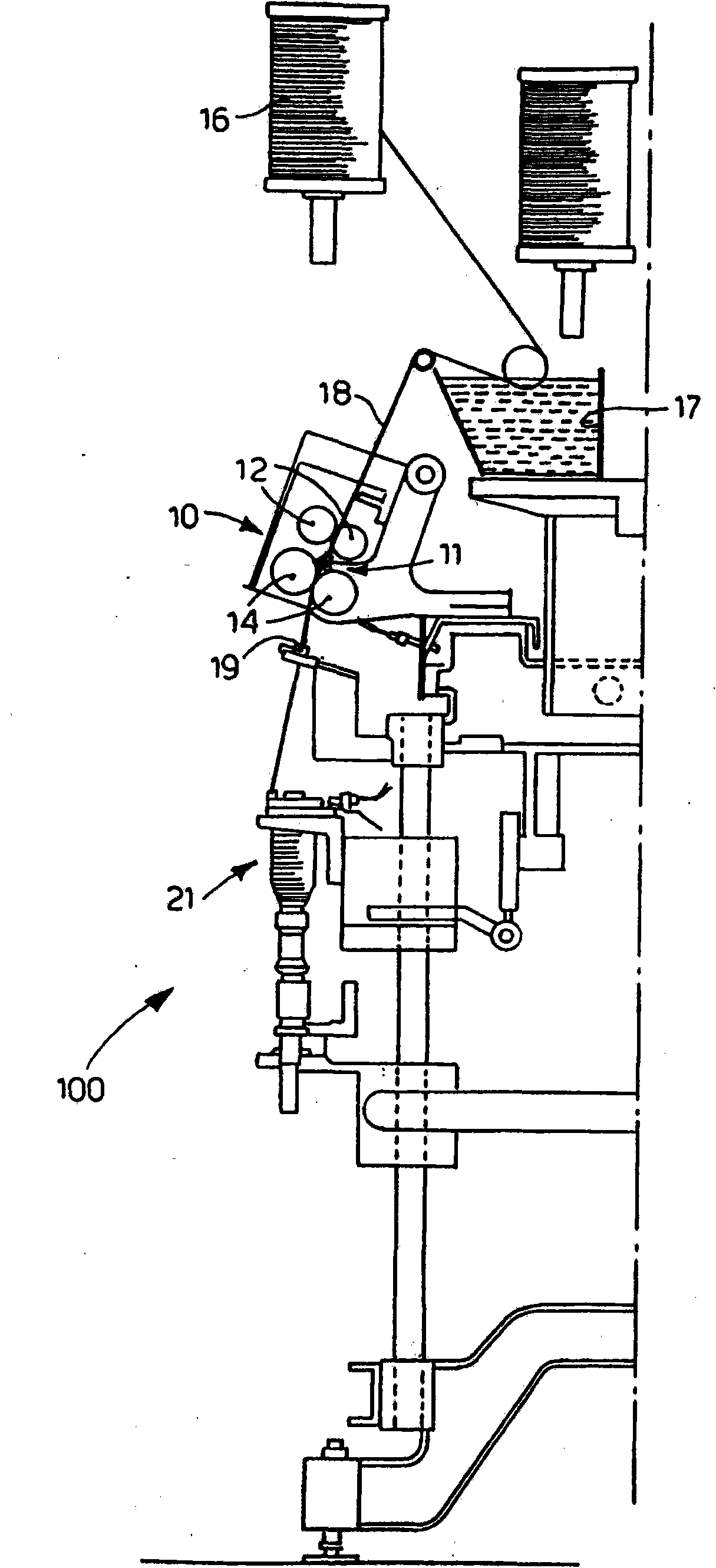

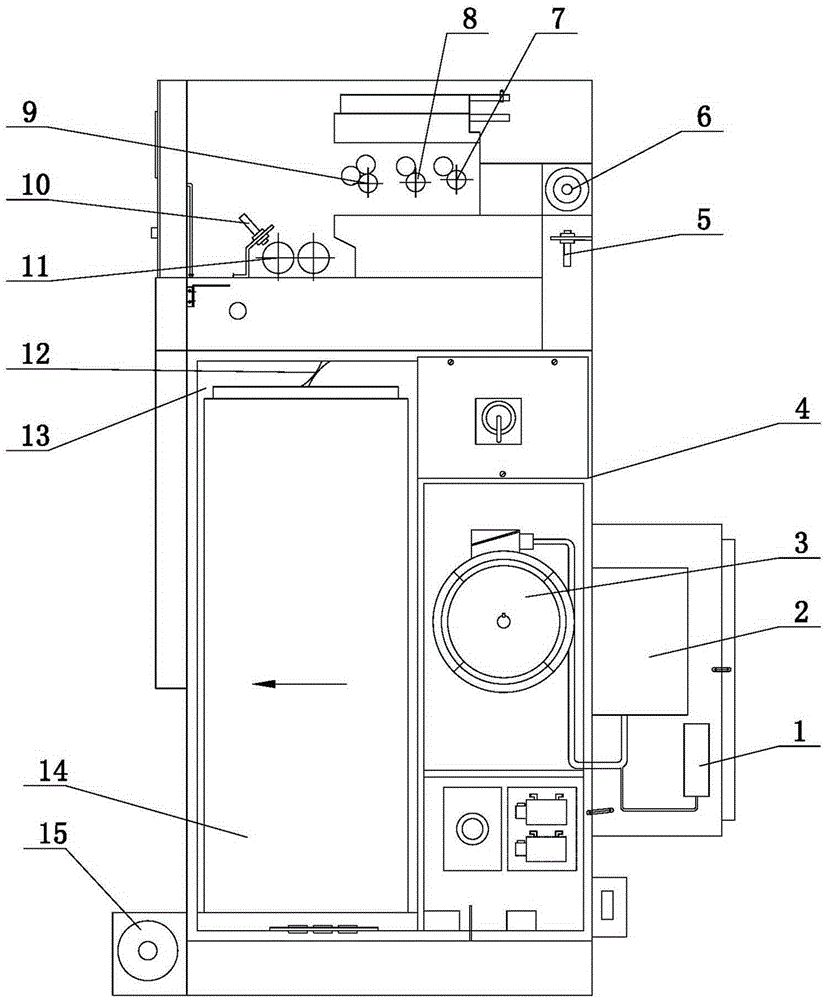

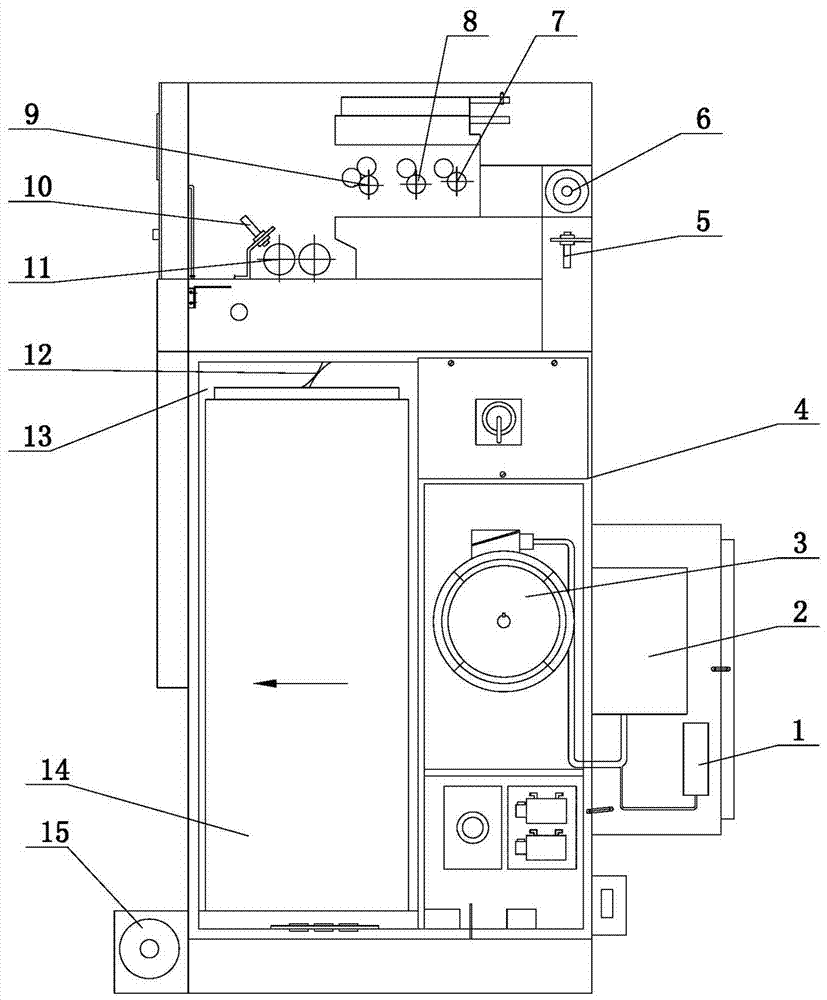

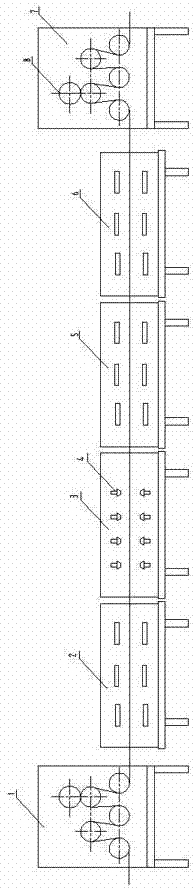

Continuous terylene BCF (Bulk Continuous Filament) spinning machine

InactiveCN102140703AIncrease frictionIntensified shearingArtificial thread manufacturing machinesFilament-forming treatmentTensile strainEngineering

The invention discloses a continuous terylene BCF (Bulk Continuous Filament) spinning machine which belongs to the technical field of chemical fiber spinning equipment. The continuous terylene BCF spinning machine comprises a material dryer, a material absorbing device, a metering device, a material mixing hopper, a screw extruder, a diphenyl furnace, a spinneret plate with trilobal or Y-shaped spinneret micropores, a lateral air blowing device, a spinning channel and a tensile strain winder, wherein the tensile strain winder comprises primary tension devices, and each primary tension device comprises a feeding heat roller and two traction heat rollers; and the continuous terylene BCF spinning machine is characterized in that the material dryer comprises a feeding hopper, a crystallization bed, a drying tank and a storage hopper which are connected through material delivering pipes; the material mixing hopper is communicated with a nitrogen device or a steel nitrogen cylinder; the front section of a screw of the screw extruder is a mixing head provided with a plurality of round nails; and the tensile strain winder comprises a secondary tension device behind or between the primary tension device. The continuous terylene BCF spinning machine can spin a high-quality terylene BCF used for carpet suede materials, which has soft hand feel, high strength, good elasticity, good bulkiness and good spinnability, can be printed and dyed, and is dyed in the mass.

Owner:浙江义乌金汇化纤有限公司

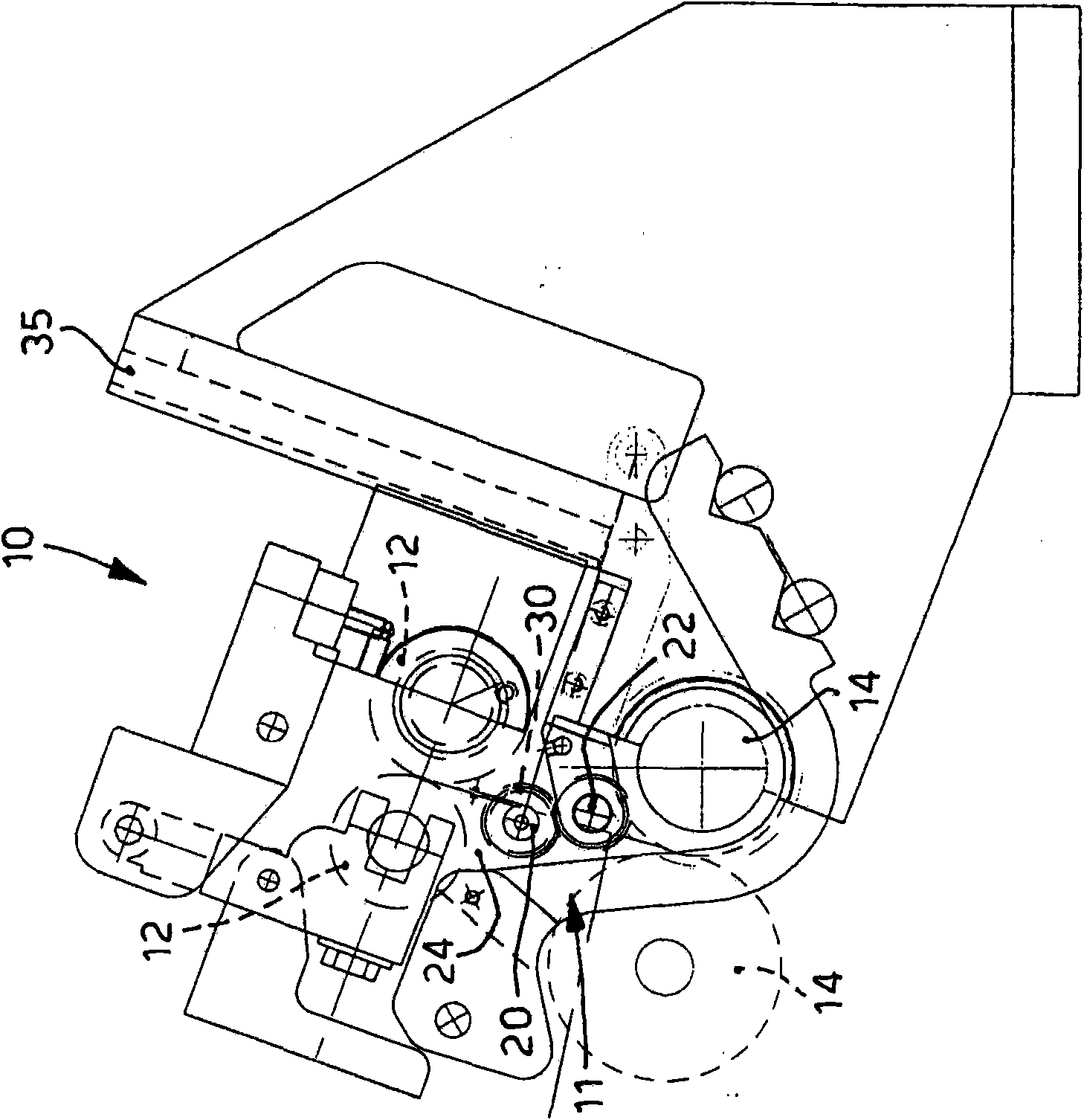

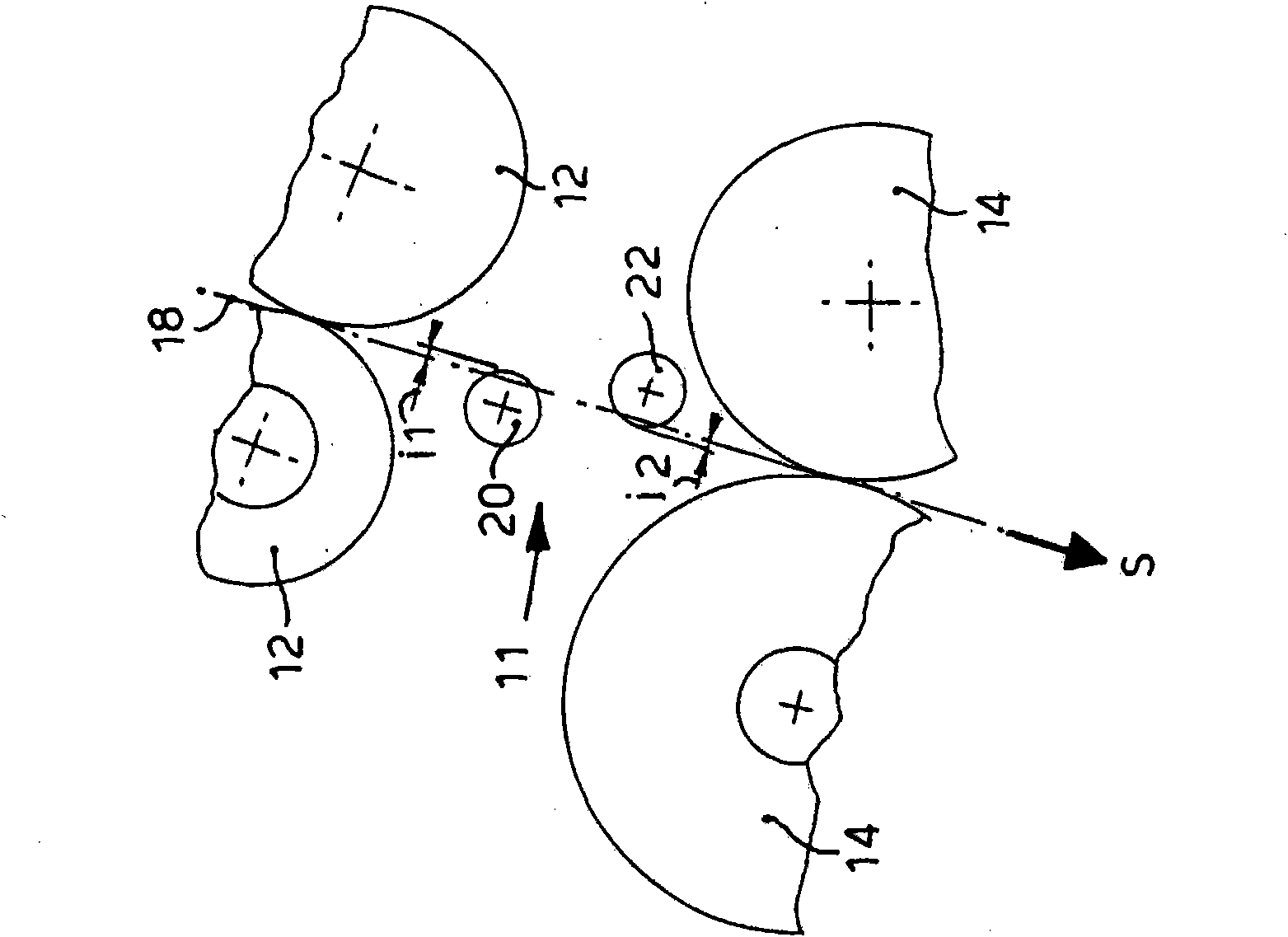

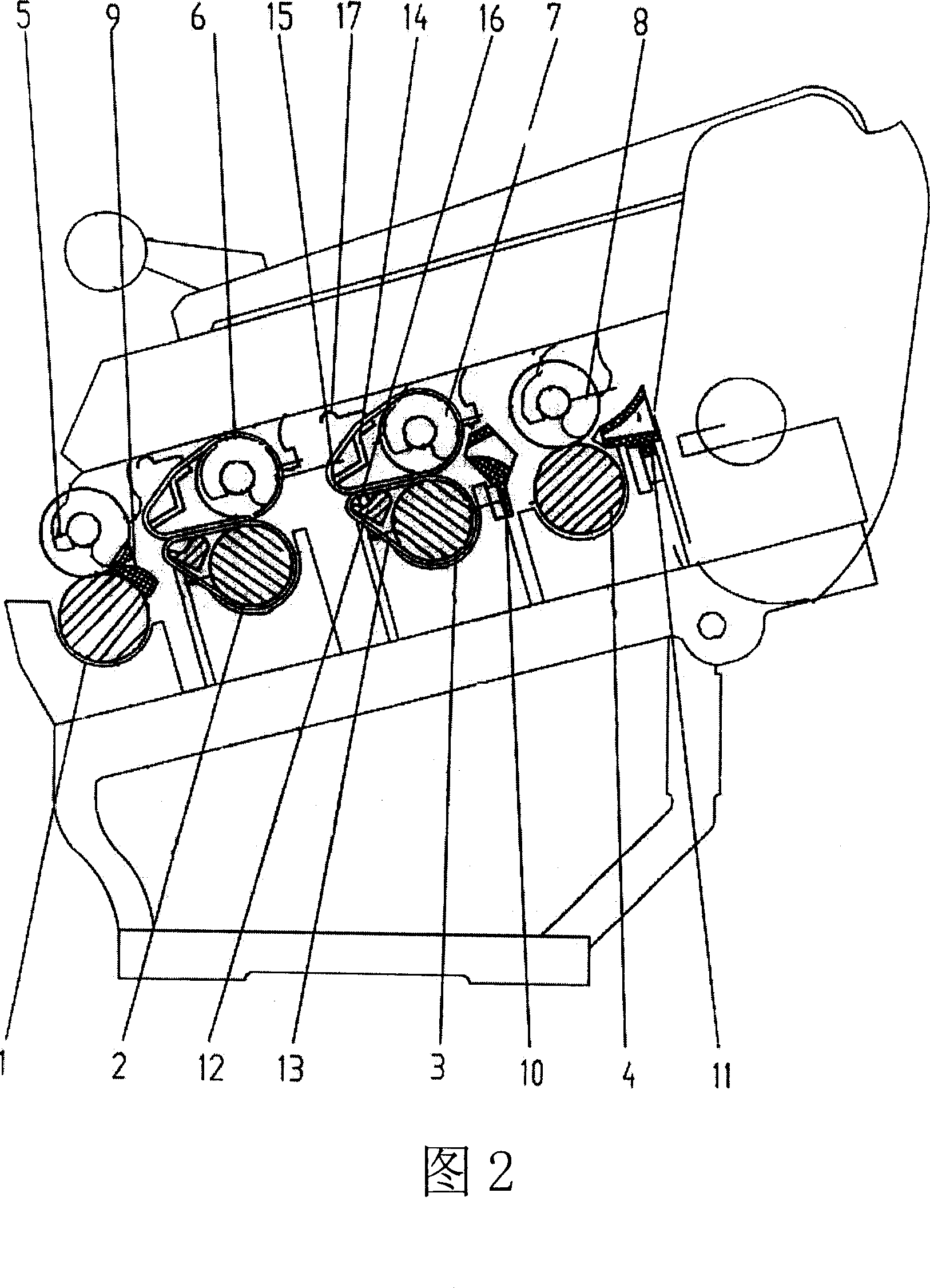

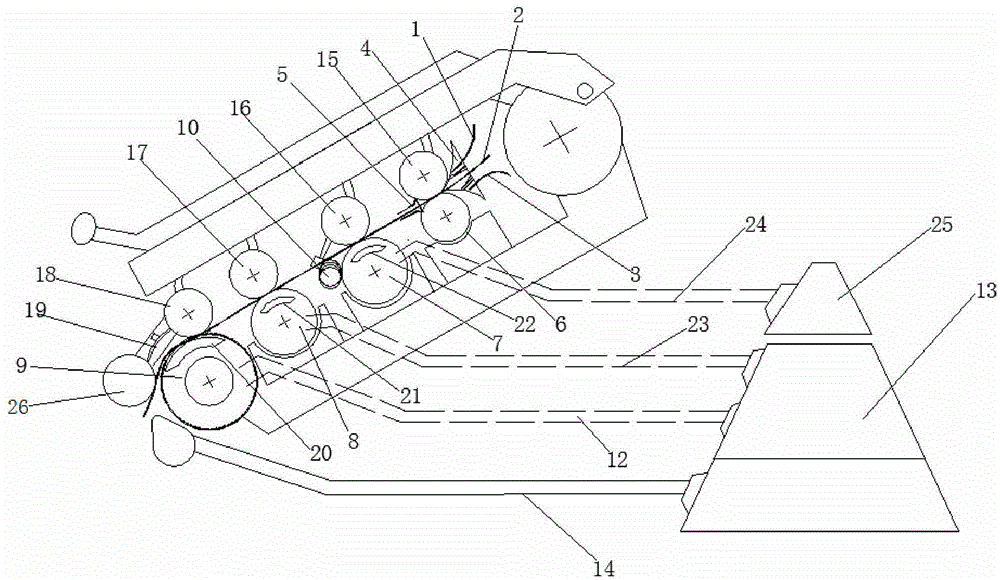

Drafting unit

A drafting unit (10) for drafting discontinuous textile fibers comprises a first pair of feed rolls (12) that feed a sliver or strip (18) toward a second pair of drafting rolls (14) that draft the sliver or strip (18). The drafting unit also comprises a control device (11) to control the drafting disposed between the first pair of feed rolls (12) and the second pair of drafting rolls (14), which comprises a third pair of control rolls (20, 22), of which a first roll (20) on one side of the sliver or strip (18) and a second roll (22) on another side of the sliver or strip (18). The control rolls (20, 22) act on the sliver or strip (18) arriving from the first pair of feed rolls (12) in order to take it at a determinate speed of feed toward the second pair of drafting rolls (14).

Owner:阿太克斯有限公司 +1

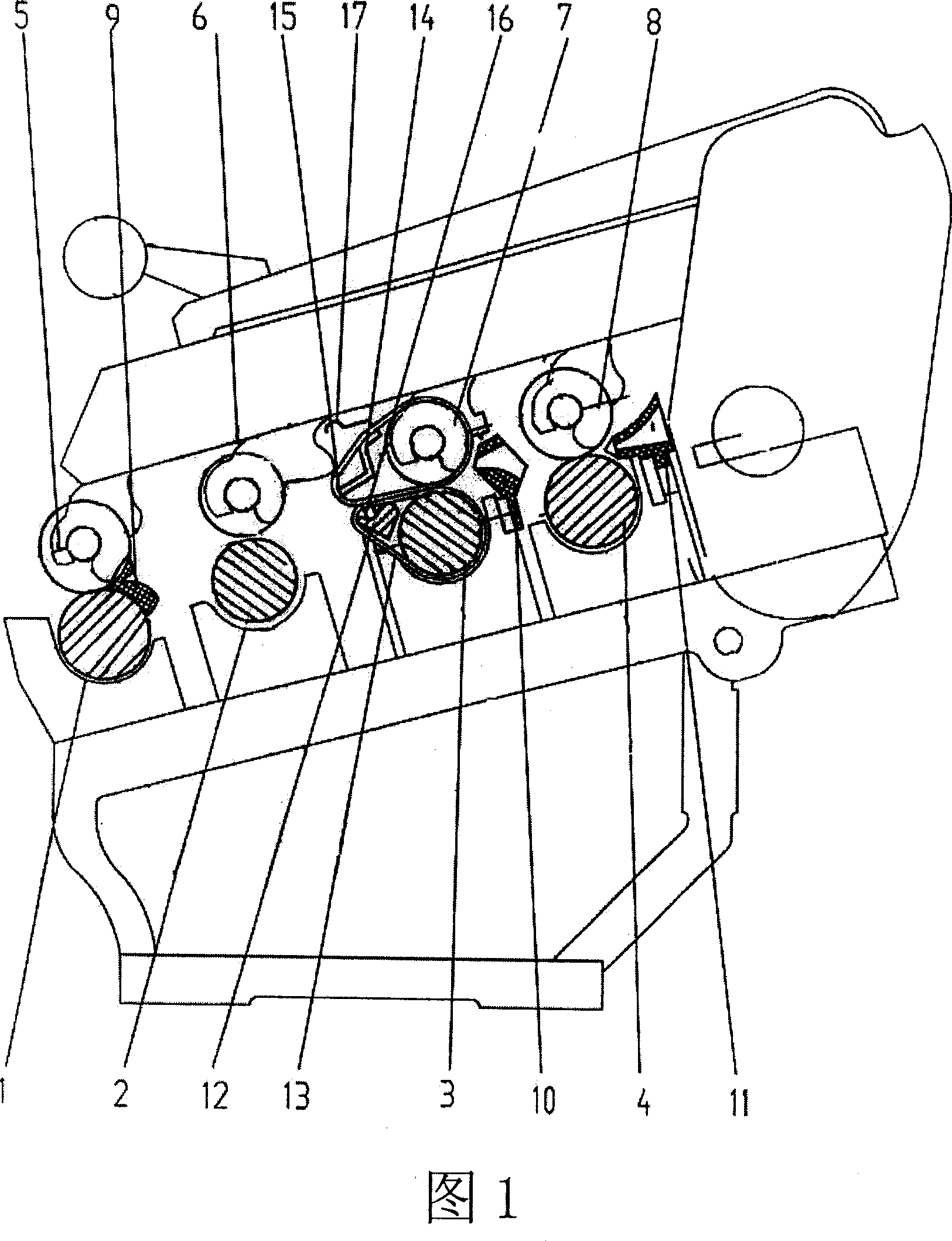

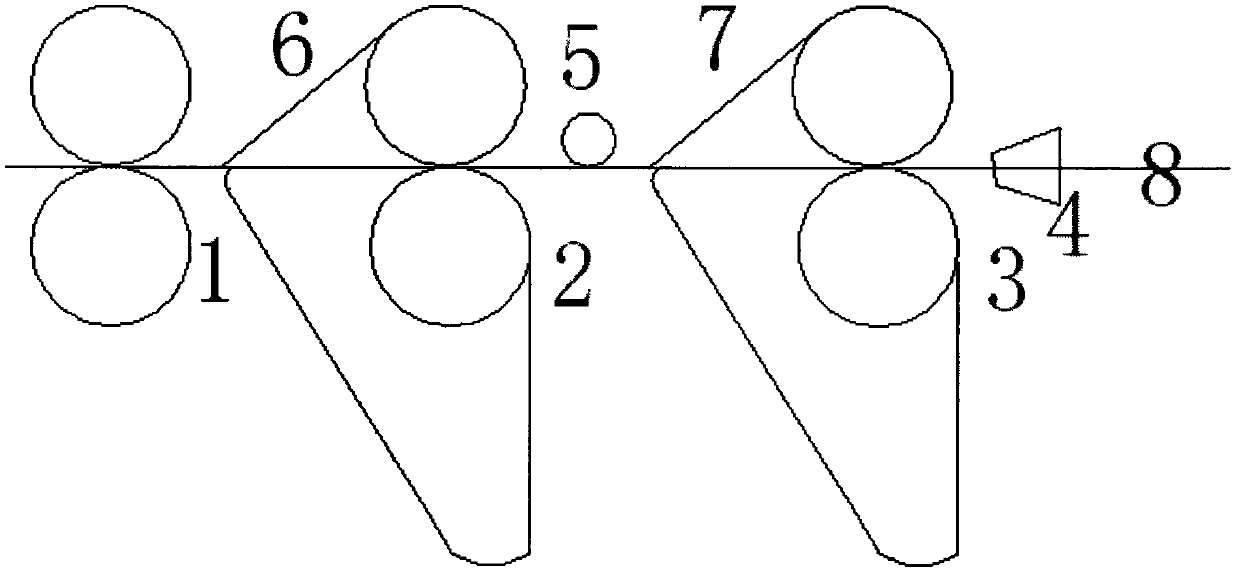

Drafting device and control method of flyer frame

InactiveCN101092766AIncrease draft ratioImprove spinning qualityDrafting machinesKnurlingStructural engineering

This invention relates to a drafting system and a control method for roving machines, in which the drafting system includes a four roller drafting pattern, a four roller double-zone double apron drafting pattern, the four lines of lower rollers contain the following from the front to back: the first includes a metal groove roller, the second includes a metal knurling roller, the third is metal knurling roller and the fourth includes a metal groove roller, the four lines of upper rollers are: the first one is a roller cladding spring materials, the second is a metal apron roller or an apron upper roller cladding spring materials, the third one is a metal apron upper roller or an apron upper roller cladding spring materials and the fourth one is a belt roller cladding spring materials. The control method includes: double -apron low times of drafting is done for the front region, 2.5-10 times of double-apron middle times of drafting for the middle region and 1.1-2 times of low drafting for the back region.

Owner:TIANJIN HONGDA TEXTILE MACHINERY

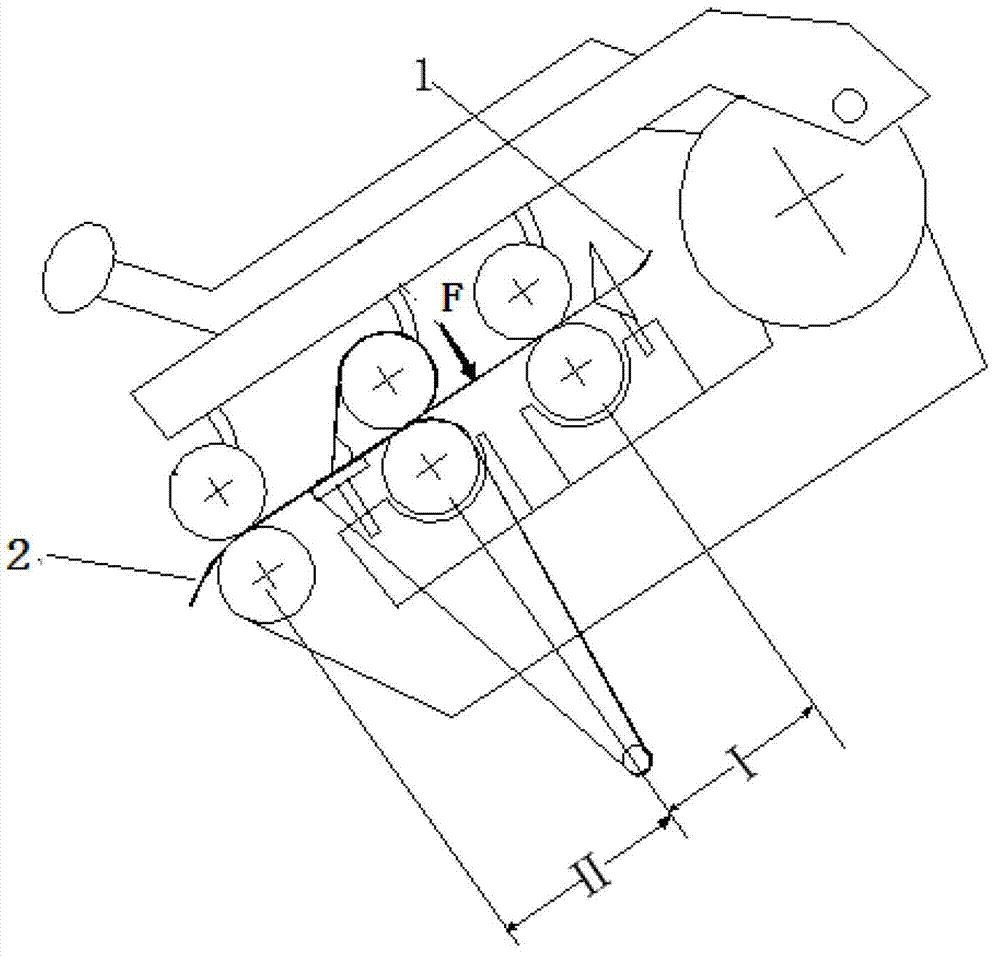

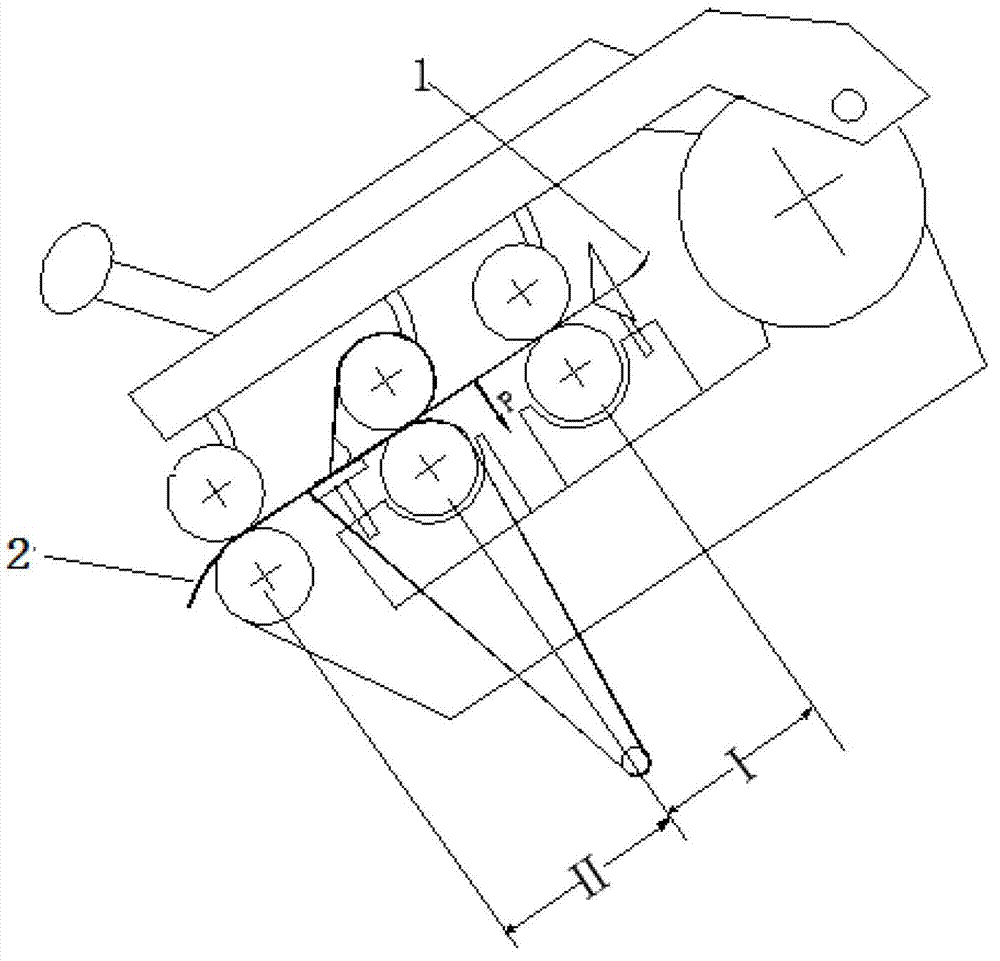

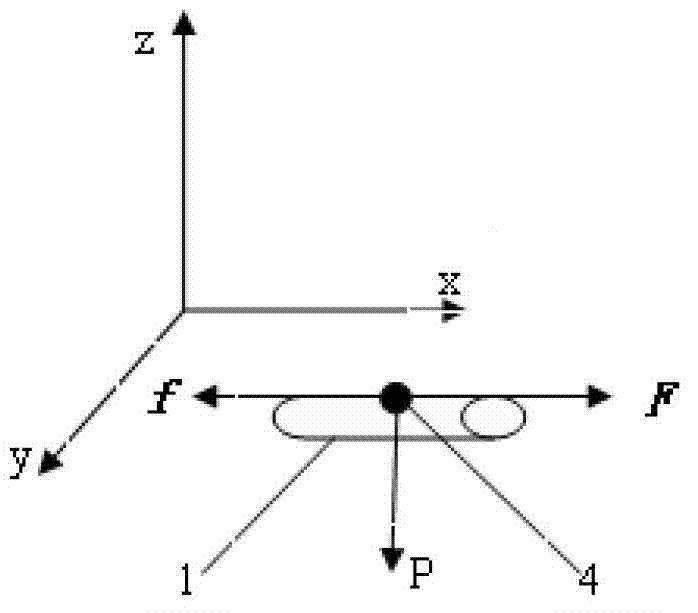

Method for controlling twist redistribution

The invention discloses a method for controlling twist redistribution. According to the invention, a back zone force application method is adiopted to apply external force on a strip located in a drawing back zone, a force application point is located on the strip surface of the drawing back zone, component force is produced by the applied external force in a vertical direction of the strip surface of the drawing back zone, a stable frictional force zone is provided for the position of the force application point, the strip is not easy to turn over, simultaneously, compactness of the strip can be effectively improved, twist redistribution can be effectively avoided, and resultant yarn levelness is improved.

Owner:JIANGNAN UNIV

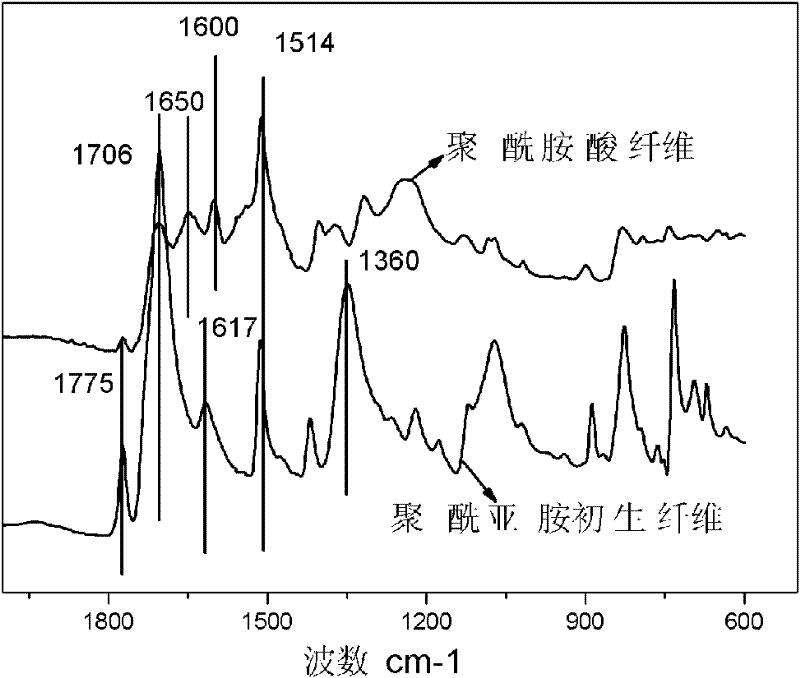

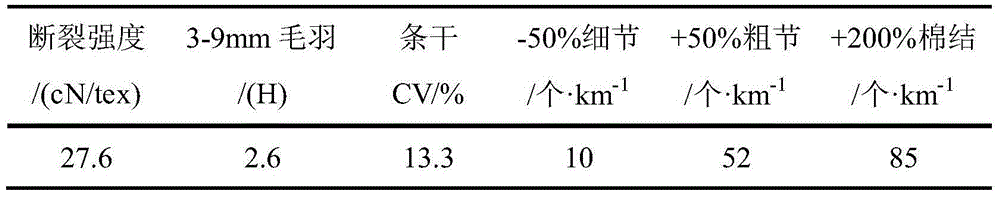

Polyacrylonitrile fibers and wet spinning method thereof

ActiveCN110055601APlay a plasticizing roleIncrease draft ratioArtificial filament washing/dryingArtificial filament heat treatmentEngineeringHeat setting

The invention relates to polyacrylonitrile fibers and a wet spinning method thereof. According to the main technical scheme, the wet spinning method of the polyacrylonitrile fibers comprises the following steps: spinning: extruding a spinning solution through a spinning hole of a spinning assembly to obtain a spinning fine flow; solidifying and forming: enabling the spinning fine flow to enter a coagulation bath for coagulation forming to obtain nascent fibers; hot drafting treatment: carrying out multi-stage thermal drafting treatment on the nascent fibers; washing: washing the fibers subjected to hot drafting treatment; and drying and heat setting treatment: sequentially drying and heat-setting the washed fibers to obtain the polyacrylonitrile fibers. The polyacrylonitrile fibers are prepared by the wet spinning method of the polyacrylonitrile fibers. The polyacrylonitrile fibers are mainly used for ensuring the spinnability of the spinning solution in the spinning process, and the mechanical property of polyacrylonitrile fibers is improved.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Processing process of high-strength high-stretchability chinlon industrial yarn

InactiveCN106987913AMeet material needsMeet needsArtificial filament heat treatmentDry spinning methodsYarnThree level

The invention discloses a processing process of high-strength high-stretchability chinlon industrial yarn. The processing process includes the following steps of 1, preparation of a spinning solution; 2, spinning forming; 3, cooling; 4, drafting setting, wherein drafting setting is carried out on primary cellosilk beams, three-level hot drafting is adopted for drafting, the first-level hot drafting multiple ranges from 2 to 2.1, the second-level hot drafting multiple ranges from 1.8 to 1.9, the third-level hot drafting multiple ranges from 1.5 to 1.7, and tension hot setting is adopted for setting; 5, winding. In this way, the process is simple and easy to control, and the prepared chinlon industrial yarn is high in breaking strength and low in dry heat shrinkage rate, further has the advantages of being excellent in abrasion resistance, fatigue resistance, impact resistance and the like, and can meet the requirements of safety air bag materials.

Owner:CHANGSHU POLYESTER

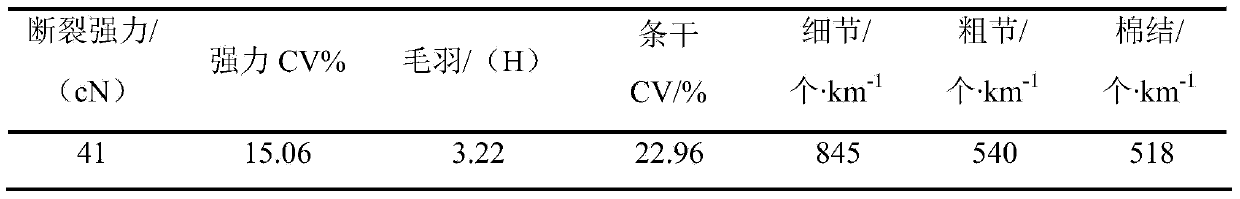

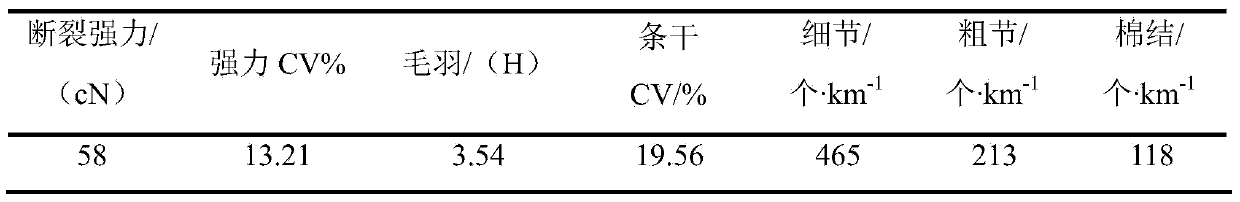

Making process of superfine denier modal fiber compact siro spinning knitting yarn

The invention discloses a fine denier fiber compact siro spinning knitting yarn and a making process thereof. The making process of the yarn comprises the steps that 0.8 dtex*34 mm superfine denier fibers are separately subjected to a blowing procedure, carding of a cotton carding procedure, finishing of a drawing procedure and a roving procedure to be prepared into roving slivers with suitable weight and moderate twist degree, two kinds of rovings are fed into a spun yarn rear area double-horn opening during spinning in sequence, a compact siro spinning knitting yarn is made through high-multiple drafting, a suitable twist degree design and the use of other process special pieces, partial defect yarns and single yarns are cleaned away through a spooling procedure, the superfine denier modal fiber 120-count compact siro spinning knitting yarn is made, and the relative humidity of the environment of all procedures is 56-60%. The yarn and the process have the advantages that the made yarn has a compact structure, little hairness, good yarn slivers and moderate strength, the produced yarn can be made into various high-end textile underwear fabrics, and a super-comfortable textile product is added for the field of textiles.

Owner:JIHUA 3542 TEXTILE CO LTD

Method for producing high strength fine-denier polyamide fiber 6 fully drawn yarn

ActiveCN101476169BIncrease draft ratioReduce tensionSpinning head liquid feederMelt spinning methodsYarnEngineering

The invention provides a method for producing fine chinlon 6 fully drawn yarn with high strength which includes steps as follows: (1) chinlon 6 slice enters into a screw extruder with electrical heating function through a storage hopper that makes slice showing melt shape; (2) the melt material is pressed in a spinning subassembly through a metering pump quantificationally, and is spout by a spout plate for forming filament bundle in a spining box body; (3) the filament bundle is cooled by side wind through the spinning box body and is cooled further through a corridor; (4) the cooled filament bundle is oiled by an oil roll; (5) oil in the filament bundle is more uniform and has high amplexus degree through confounding; (6) the filament bundle passes through a first group filament guide roll and a second group filament guide roll for drafting forming, then passes through a third filament guide roll to reel. A grade product produced by the method has average more than or equal to 6.0cN / dtex rupture strength that is higher 22% than the product produced by normal method, and has better transparent sense and visual effect, the produced clothes has better flexible sense and handle sense for wearing cosily.

Owner:烟台华润锦纶有限公司

Automatic bar breaking device of drawing frame and bar breaking device using device

The invention provides an automatic bar breaking device of a drawing frame and a bar breaking device using the device and belongs to the technical field of spinning machinery, and particularly relates to the automatic bar breaking device of the drawing frame and the bar breaking device using the device. The automatic bar breaking device of the drawing frame, provided by the invention, has a simple structure, can be used for accurately breaking bars, does not have a condition of automatically operating when the bars are not broken and has high reliability. The automatic bar breaking device comprises a machine case, wherein a first roller connected with a main motor is arranged on the upper side in the machine case; a bar silo is arranged on the lower side in the machine case; a creel changing motor is arranged at the bottom of the machine case; and a guide roller is arranged at the part, corresponding to the bar silo, on the upper side in the machine case. The automatic bar breaking device of the drawing frame is characterized in that a roller set connected with a servo motor is arranged at the part corresponding to the first roller; a cotton bar feeding speed sensor is arranged at the part, corresponding to a feeding hole of the machine case, in the machine case; and a cotton bar output speed sensor is arranged at the part, corresponding to the guide roller, in the machine case.

Owner:沈阳宏大华明纺织机械有限公司

Super-high-draft device

The invention relates to a super-high-draft device which comprises a front roller, a middle roller, a rear roller, a pressure bar, a bell mouth and leather collars, and is characterized in that a pressure bar is additionally mounted in a rear zone of the conventional draft device and the leather collar is additionally mounted on the rear roller, so that the friction field of the rear zone is increased, and control of floating fibers in the rear draft zone is strengthened. Harmful feathers are reduced, and the draft multiple is improved.

Owner:JIANGNAN UNIV

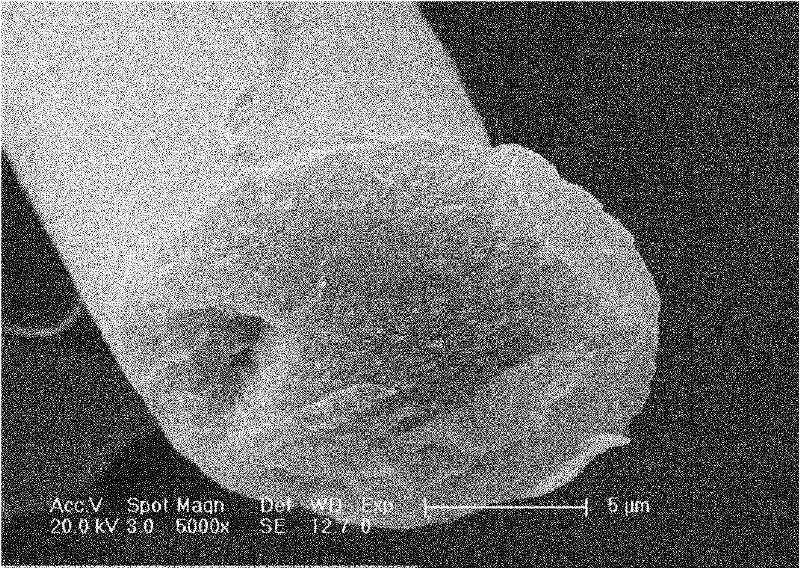

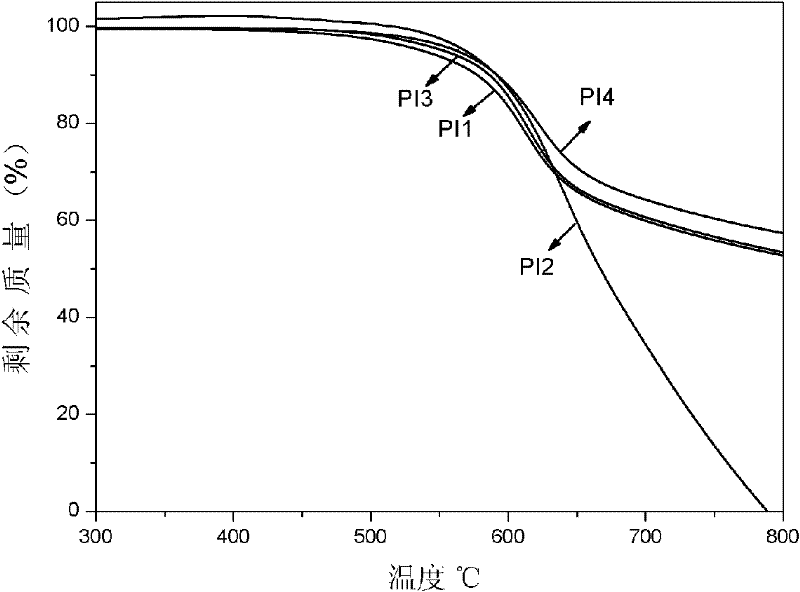

Polyimide fiber and preparation method thereof

ActiveCN101984157BImprove rigidityGood flexibilityMonocomponent synthetic polymer artificial filamentUltimate tensile strengthDraw ratio

The embodiment of the invention discloses a method for preparing polyimide fibers, and in the method, a fully rigid polyimide fiber with an aromatic heterocyclic structure is prepared by using biphenyltetracarboxylic dianhydride, p-phenylenediamine and 2-(4-Aminophenyl)-5-aminobenzimidazole as raw materials. In the invention, by using the asymmetry of the structure of the 2-(4-Aminophenyl)-5-aminobenzimidazole, the flexibility of the prepared polyimide fiber is improved, so that the polyimide fiber has a better liquidity in the subsequent processing procedures, which increases the draw ratio of the polyimide fiber, improves the degree of orientation of the polyimide fiber and is benefical to overcoming the defects produced in the process of preparing the polyimide fiber, therefore, the prepared polyimide fiber has a high tensile strength. Experimental results show that the tensile strength of the polyimide fiber prepared by using the method of the invention reaches 2.5 GPa.

Owner:吉林省亚安新材料有限公司

PTT/PET composite elastic short fiber for spinning and preparation method thereof

InactiveCN112144128ALow component contentIncrease draft ratioArtificial filament heat treatmentConjugated synthetic polymer artificial filamentsFiberPolymer science

The invention discloses a PTT / PET composite elastic short fiber for spinning and a preparation method thereof. The PTT / PET composite elastic short fiber for spinning is formed by composite spinning ofthe following raw materials including, by mass, 30%-95% of PET slices and 5%-70% of PTT slices, wherein the raw material intrinsic viscosity of the PET slices is 0.42-0.83 d L / g, and the raw materialintrinsic viscosity of the PTT slices is 0.67-1.10 d L / g. According to the PTT / PET composite elastic short fiber, by reducing the PTT component content and reasonably selecting the viscosity ratio ofthe two components, the draft multiple of the PET / PTT composite fiber is increased, generation of the moment difference of the two components of the fiber is guaranteed, the improvement of the mechanical property and the curling property of the fiber is promoted, and the problems of doffing and the like of the PET / PTT composite fiber during spinning are solved.

Owner:SHANGHAI HAIKAI BIO MATERIAL CO LTD

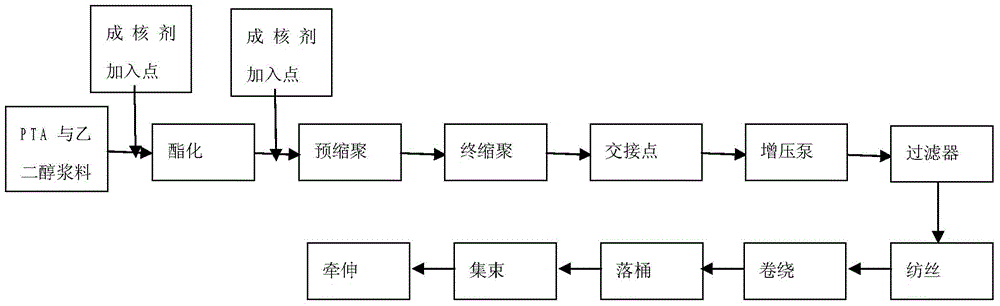

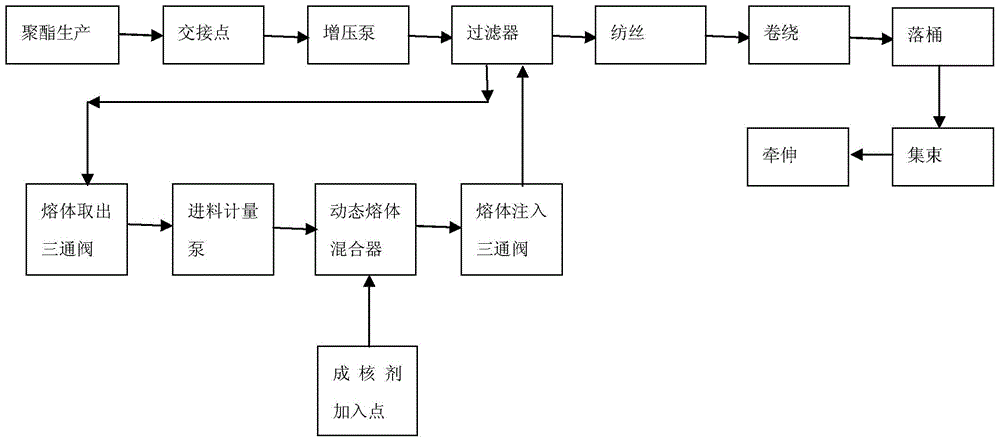

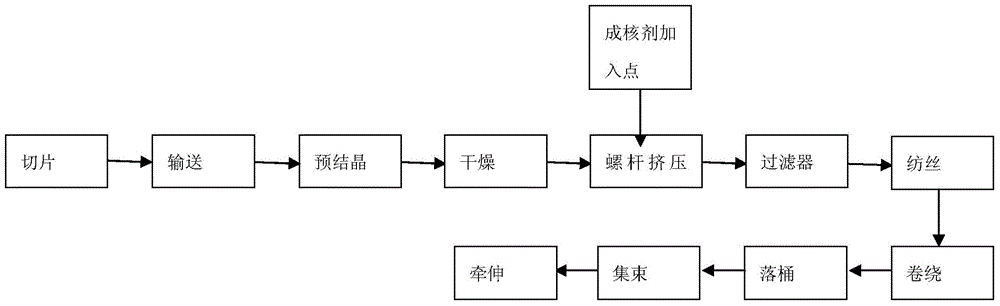

A kind of production method of high-strength fine denier bright polyester staple fiber

ActiveCN104514037BOrientation is easy to maintainOrientation maintainedFilament/thread formingMonocomponent polyesters artificial filamentBreaking strengthSlow cooling

The invention discloses a production method of high-strength fine-denier lustrous polyester fiber staple fibers. The method is that the esterification reaction is performed for terephthalic acid and ethylene glycol polyester to obtain a terephthalate melt; after being processed by pre-polycondensation, final polycondensation and spinning intersection, the terephthalate melt is fed into a melt pipeline of a spinning device under a certain pressure; the melt passes through a booster pump and a filter to enter a spinning box body and then is extruded from a fine hole in a spinning plate, and the extruded melt is cooled through circular blowing air of a circular blowing barrel and then is gradually slimed and solidified and formed under the coiling and stretching tension force effect; strands from a spinning machine passes through a coiling machine and then is fed into a storing barrel for back draft. The method is specifically characterized in that 1200 to 3000ppm nucleating agents, namely, nano barium sulfate are added to the melt; the viscosity of the spinning melt is 0.7 to 1.0dl / g; a 10 to 30mm slow cooling circular blowing device is additionally arranged between the spinning plate and a circular blowing barrel; the back draft rate is 3.5 to 3.8 times. The polyester fiber staple fibers special for sewing threads has the fineness of 0.7 to 0.9dtex, and the breaking strength is more than 6.40cn / dtex.

Owner:SINOPEC YIZHENG CHEM FIBER +1

A kind of gel spinning method of making chitosan fiber

ActiveCN110359101BIncrease draft ratioIncrease spinning speedArtificial filament washing/dryingWet spinning methodsFiberPolymer science

The invention relates to a gel spinning method for making chitosan fiber. The gel spinning method includes: enabling spinning liquid to sequentially enter an air layer, coagulating bath and plasticizing bath after being extruded through a spinneret orifice to obtain the chitosan fiber, wherein the spinning liquid is a semi-dilute solution of chitosan greater than or equal to 1x10<6>g / mol in weightaverage molecular weight, and sodium organophosphate is contained in the spinning liquid; before extruding, the spinning liquid is heated to increase temperature when the spinning liquid reaches thespinneret orifice from 3-6 DEG C to 30-40 DEG C; the air layer is provided with an air blowing device, air blowing temperature is 30-40 DEG C, temperature of the coagulating bath is 30-40 DEG C, and temperature of the plasticizing bath is 50-60 DEG C. Compared with wet-process spinning or dry-spraying wet-process spinning, the gel spinning method has obvious advantages, and the problem that chitosan fiber prepared by wet-process or dry-spraying wet-process spinning is poor in mechanical performance can be solved effectively, so that the gel spinning method has great popularization value.

Owner:JIAXING UNIV +1

Four-roller three-thick-yarn feeding full compact spinning device, spinning method thereof and color yarn

The invention discloses a four-roller three-thick-yarn feeding full compact spinning device which comprises four groups of drafting roller pairs. A distance-adjustable three-flared-opening feeding unit is additionally arranged at a position of the yarn guide rod of a back roller; a mechanical magnetic collector is additionally arranged on the back roller; a middle-rear roller is a narrow groove type positive pressure hollow roller; the jaw portion of the middle-rear roller is additionally provided with a separating roller unit; a front-middle roller is a narrow groove type negative pressure hollow roller; a front roller is a large-diameter narrow groove type negative pressure hollow roller. A yarn spinning method utilizing the four-roller three-thick-yarn feeding full compact spinning device comprises feeding three thick yarn of A thick yarn, B thick yarn and C thick yarn through the distance-adjustable three-flared-opening feeding unit in a spinning process from the rear roller, and obtaining needed yarn through four-roller-and-three-section draft. According to the four-roller three-thick-yarn feeding full compact spinning device, the total draft multiple can be improved to more than 300 times to the maximum, accordingly the simultaneous feeding of three kinds of thick yarn of an ordinary fixed quantity for spinning can be achieved, and the spinning efficiency can be effectively improved. Besides, high-quality color yarn can be provided.

Owner:江苏悦达棉纺有限公司

Modified polyphenylene sulfide fiber and method for making same

InactiveCN100567601CHigh glossImprove mechanical propertiesMonocomponent synthetic polymer artificial filamentMelt spinning methodsPolymer scienceSilicon oxide

The invention provides a modified polyphenylene sulfide fiber and a preparation method thereof. The components and parts by weight include: 100 parts of polyphenylene sulfide (PPS); 0.2 to 2 parts of nano silicon dioxide after surface treatment, two The particle size of silicon oxide is 20-60 nanometers; the fineness of the fiber is 85-91dtax. The present invention modifies the polyphenylene sulfide resin and adopts a specific spinning process to prepare polyphenylene sulfide fiber, the fiber strength and tensile toughness are improved, and the glossiness of the fiber is also improved at the same time. The spinning equipment is used for spinning, which reduces the spinning cost, and the fluidity of the matrix becomes better during the spinning process, the spinning temperature is reduced by 5-10°C, the draft ratio of the primary fiber is improved, and the mechanical properties of the fiber Improved.

Owner:DONGHUA UNIV

A processing method for fishing small-scale blended modified polypropylene luminous rope

InactiveCN101994267BHigh strengthHigh breaking strengthSpinning head liquid feederFilament manufactureYarnFiber

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Automatic sliver breaking device for draw frame and sliver breaking method using the device

An automatic sliver-breaking device for a draw frame and a sliver-breaking method using the device belong to the technical field of textile machinery, and more specifically relate to an automatic sliver-breaking device for a draw frame and a sliver-breaking method using the device. The invention provides an automatic sliver-breaking device for a drawing frame with simple structure, accurate sliver breaking, no automatic start-up of unbroken sliver, and high reliability. The invention comprises a machine case, a first roller connected to the main motor is arranged on the top of the case, a bar silo is arranged on the bottom of the case, a can changing motor is arranged on the bottom of the case, and a guide roller is arranged on the top of the case corresponding to the bar silo. It is characterized in that: a roller group connected with a servo motor is arranged corresponding to the first roller; a feeding sliver speed sensor is arranged in the casing corresponding to the feed port of the casing; an output cotton sliver is arranged in the casing corresponding to the guide roller. bar speed sensor.

Owner:沈阳宏大华明纺织机械有限公司

Industrialized polyimide fiber drafting method

ActiveCN102943331BSmall impact heat loadImproved physical-mechanical propertiesTextiles and paperYarnPart type

Disclosed is an industrialized polyimide fiber drafting method. The method includes that a certain deniers of polyimide yarn sheets with uniform tension are placed in a four-part type hotbox environment and clamped by a rubber roller, under a certain feeding speed, the yarn sheets achieve a certain multiple drafting through a speed difference between a front drafting machine and a rear drafting machine, and the four-part type hotbox is a combination of a prehearing section hotbox, a superheated steam humidifying section hotbox, a high temperature drafting hotbox and a setting hotbox. During the process of the fiber treatment, the temperature changing gradient is reasonable, the impact thermal load which is stressed on the fibers is small, and the probability that the yarn sheets generate broken filaments is remarkably reduced. The fibers are subjected to superheated steam humidifying treatment before the high temperature drafting, the static electricity in the yarn sheets is eliminated, the drafting force of the same number of fibers is reduced by 25%, the draft multiple is increased by 30%, and the strength of the fibers is increased 40%. After the polyimide fibers are subjected to the drafting and high temperature setting, the internal stress of the polyimide fibers is eliminated, the stability of the fiber structure is improved, and the shrinking rate of the polyimide fibers is maintained about 2%.

Owner:JIANGSU AOSHEN HI TECH MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com