Continuous terylene BCF (Bulk Continuous Filament) spinning machine

A spinning machine, polyester technology, applied in the direction of stretch spinning, filament forming treatment, textile and papermaking, etc., can solve the problem of difficult to maintain melt viscosity, temperature uniformity and stability, affect quality, and spinnability. In order to achieve the effect of intensifying the friction and shearing of the melt, improving the uniformity and stability, and improving the breaking strength of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

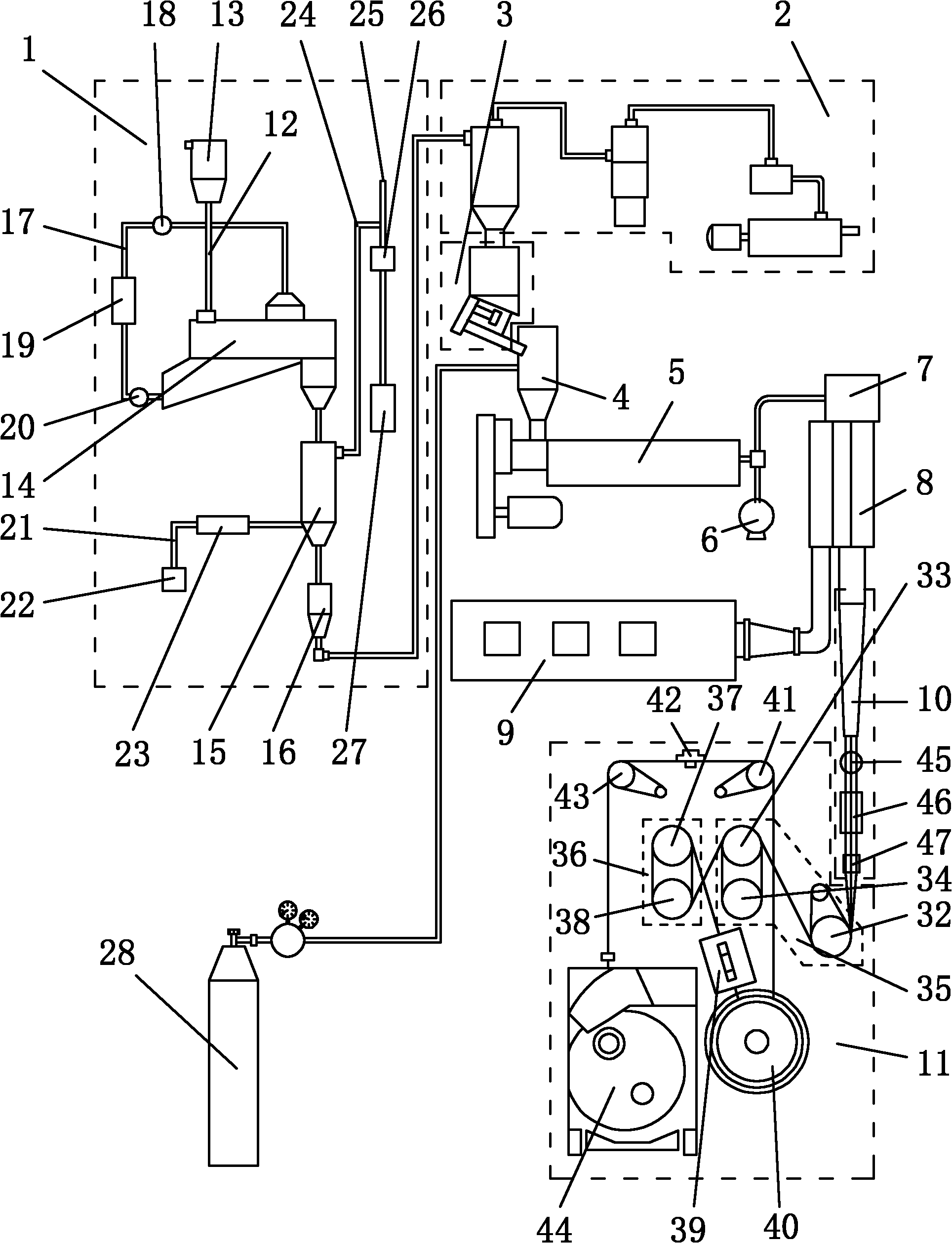

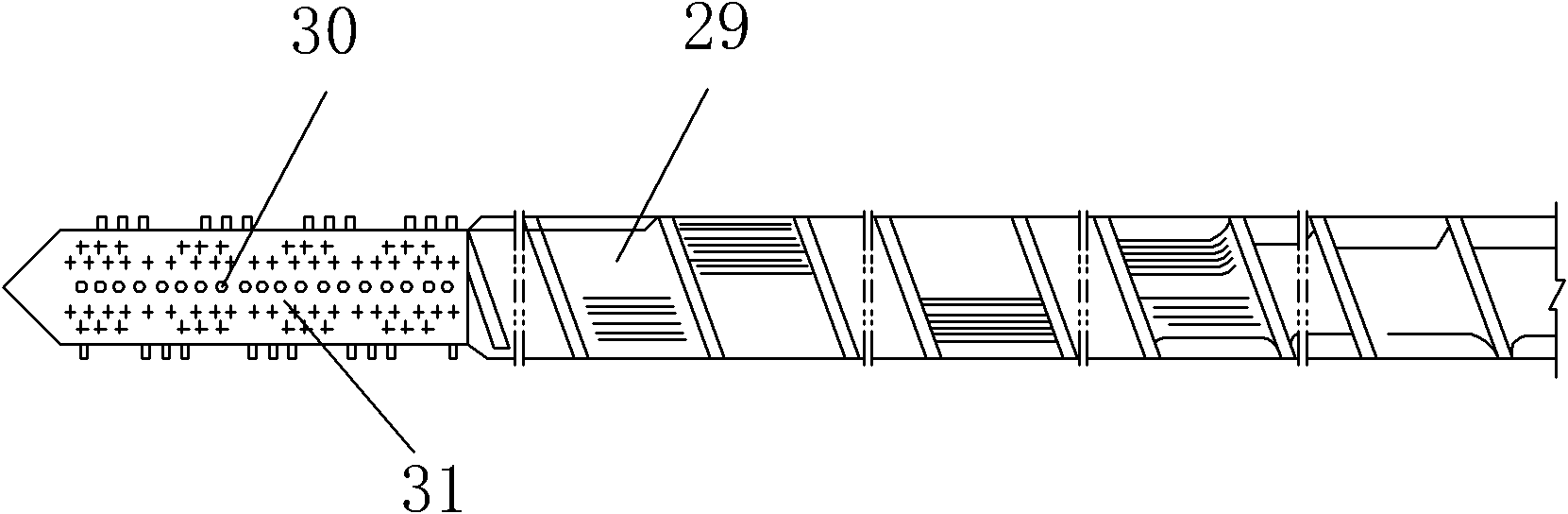

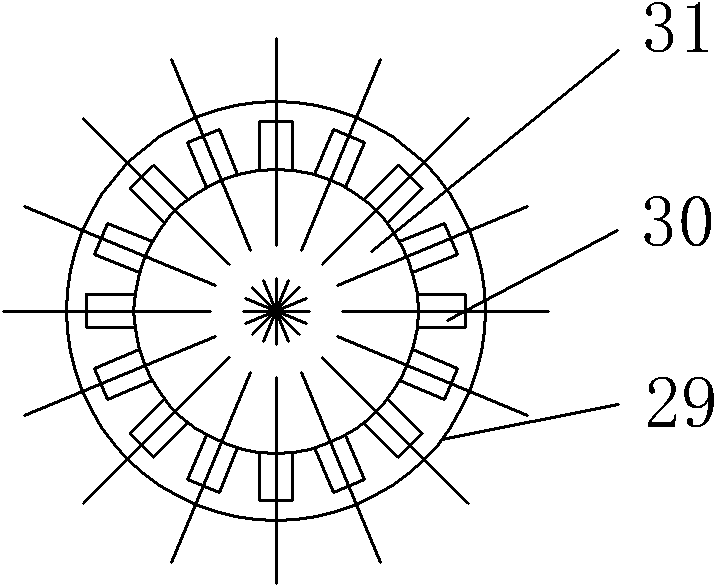

[0011] Depend on Figure 1-3 Represented is an embodiment of the present invention, and it comprises raw material drying device 1, suction device 2, metering device 3, mixing hopper 4, screw extruder 5, biphenyl furnace 6, and the micropore of spinneret becomes trefoil Spinneret 7, side blowing device 8, air cooler 9, spinning shaft 10, stretching deformation winding device 11; Raw material drying device 1 is connected by feed hopper 13, crystallization bed 14, Composed of drying tank 15 and storage hopper 16, crystallization bed 14 is connected with hot air pipe 17 for conveying and discharging hot air, and fan 18, air heater 19, pulse fan 20 are installed in turn on hot air pipe 17; drying tank 15 The lower end is connected with an air inlet pipe 21, and the air dehumidifier 22 and the air heater 23 are housed on the air inlet pipe 21, and the upper end of the drying tank 15 is connected with an exhaust pipe 24, and the upper end of the exhaust pipe 24 is connected with an e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com