Patents

Literature

715 results about "Nitrogen cylinder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

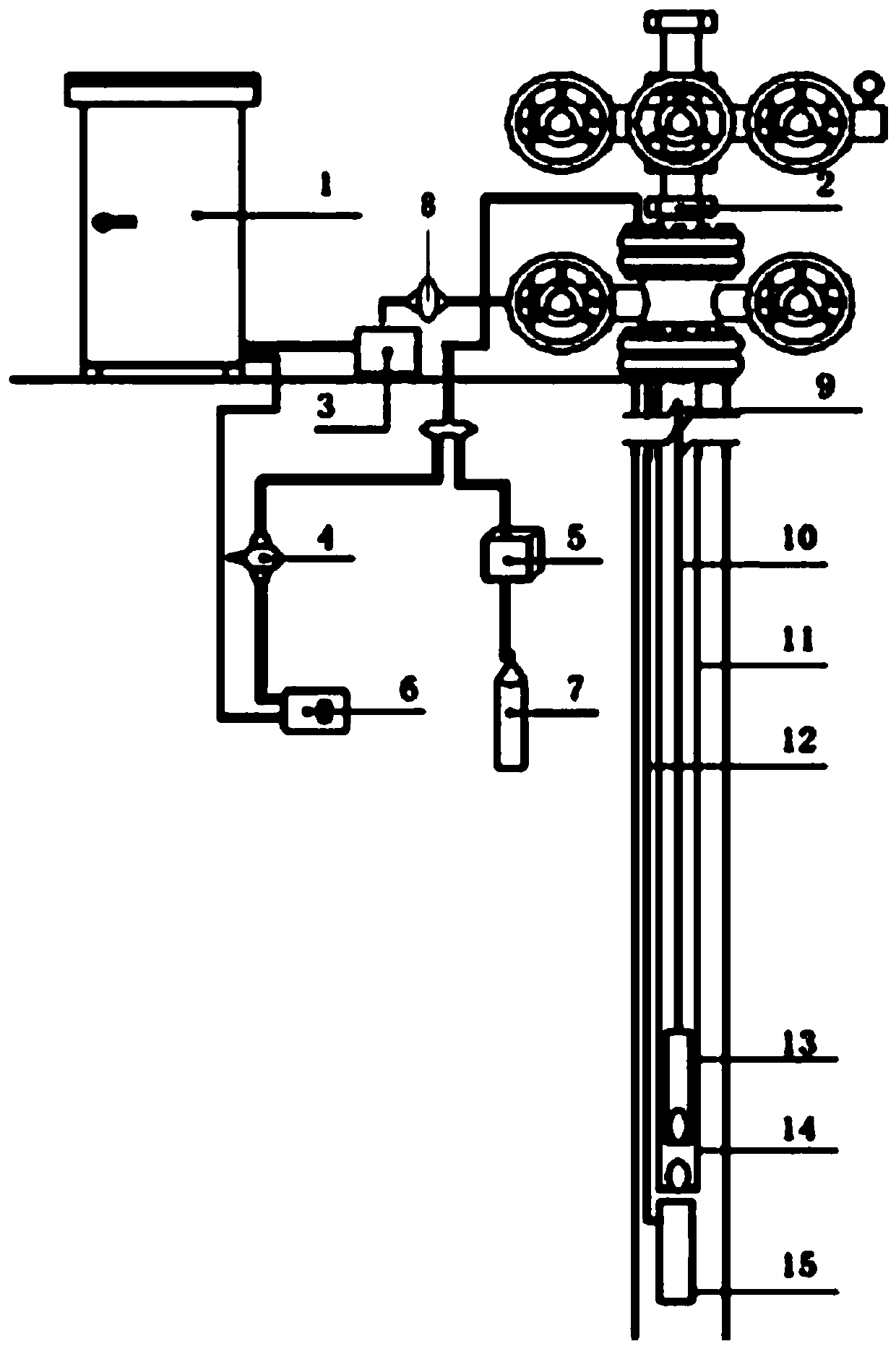

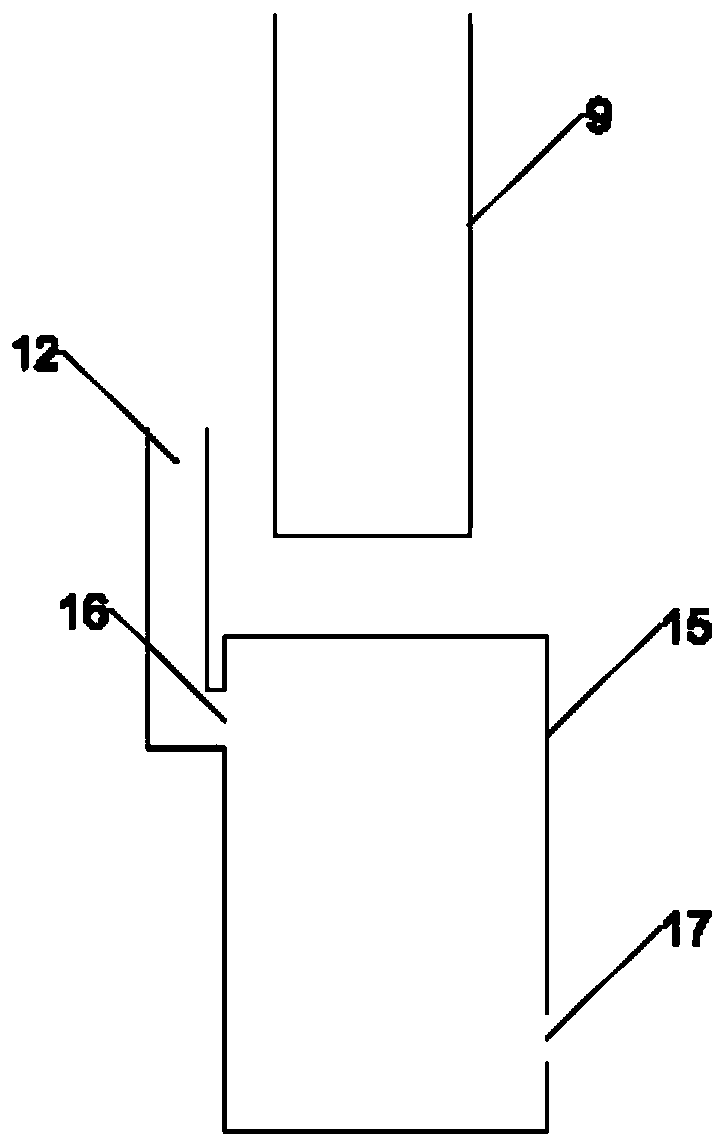

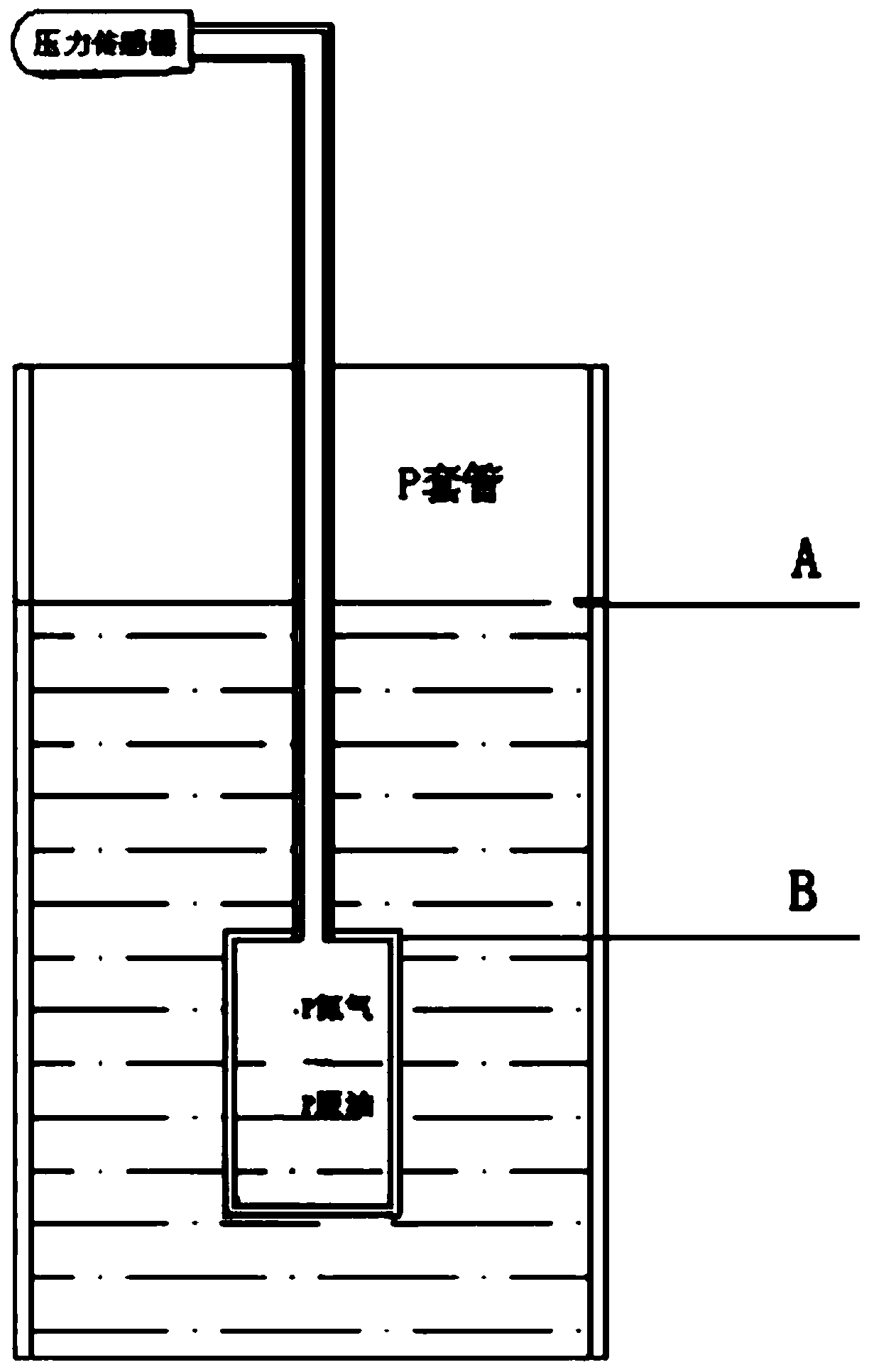

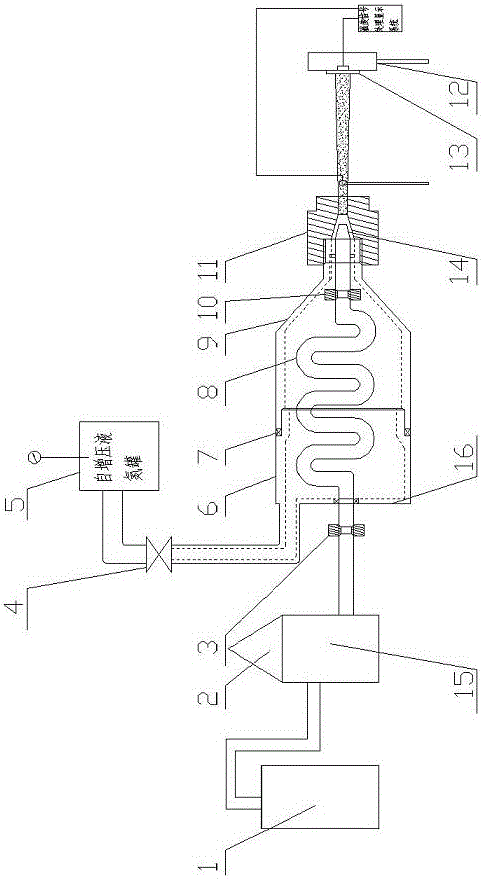

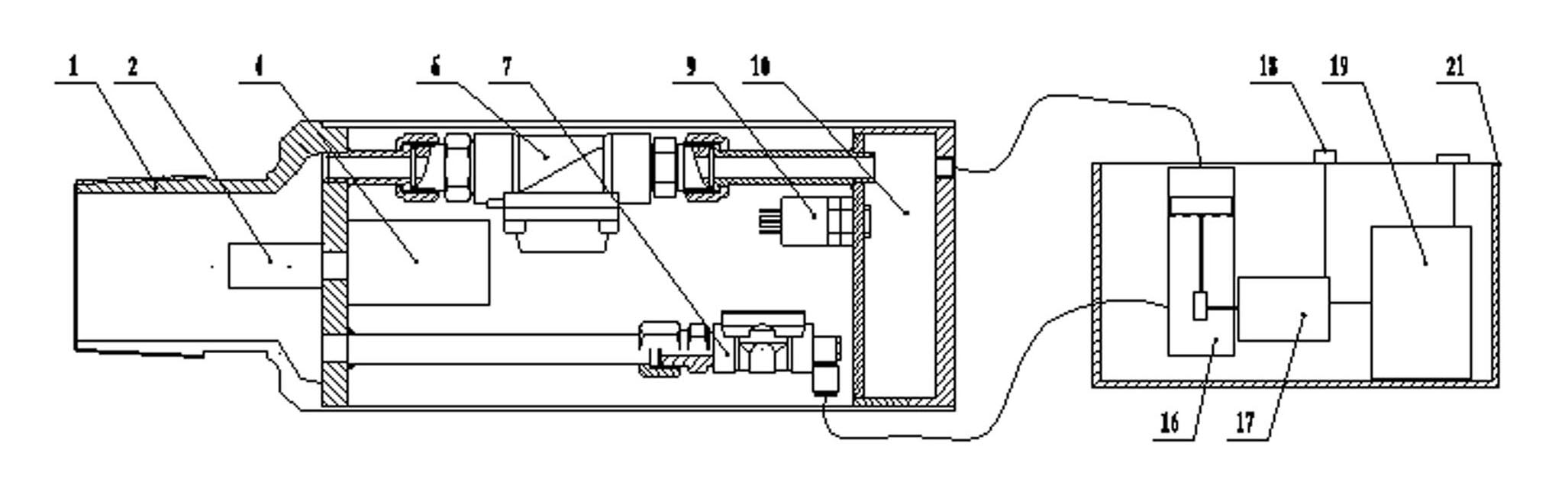

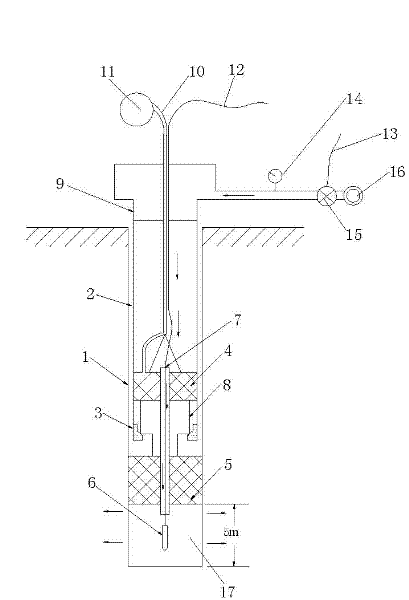

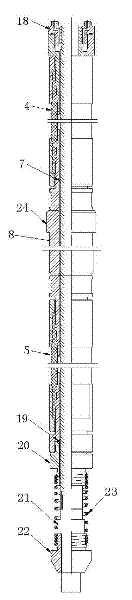

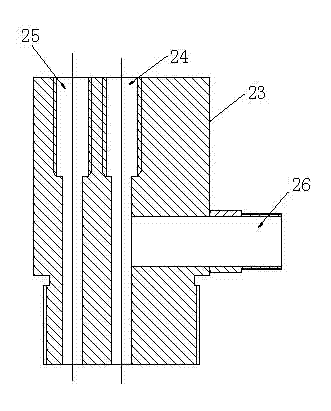

Gas-conducting pressure measuring intermittent producing oil exploitation device

The invention discloses a gas-conducting pressure measuring intermittent producing oil exploitation device. The gas-conducting pressure measuring intermittent producing oil exploitation device makes contact with well liquid during working, the gas-conducting pressure measuring intermittent producing oil exploitation device comprises gas conducting and pressure measuring equipment used for measuring the hydrostatic fluid column pressure, controlling equipment used for receiving data of the gas conducting and pressure measuring equipment so as to control oil pumping equipment to realize intermittent oil production, and the oil pumping equipment making direct contact with the well liquid, wherein the gas conducting and pressure measuring equipment comprises tubular billet pressure measuring equipment and sleeving pressure measuring equipment, the tubular billet pressure measuring device comprises a nitrogen cylinder, a nitrogen booster pump, a capillary steel pipe used for conducting nitrogen, a pressure transmitting cylinder used for bearing the nitrogen and tubular billet pressure sensors connected to an outlet of the nitrogen booster pump and an inlet of the capillary steel pipe which are sequentially connected, and the sleeving pressure measuring device comprises a sleeving pressure sensor connected with the oil pumping equipment. Controller equipment receives data of a data collector to control the working frequency of oil extraction equipment or start and stop of the oil extraction equipment, so that the intermittent production is realized to achieve the effect of reducing the production cost.

Owner:JEREH ENERGY SERVICES

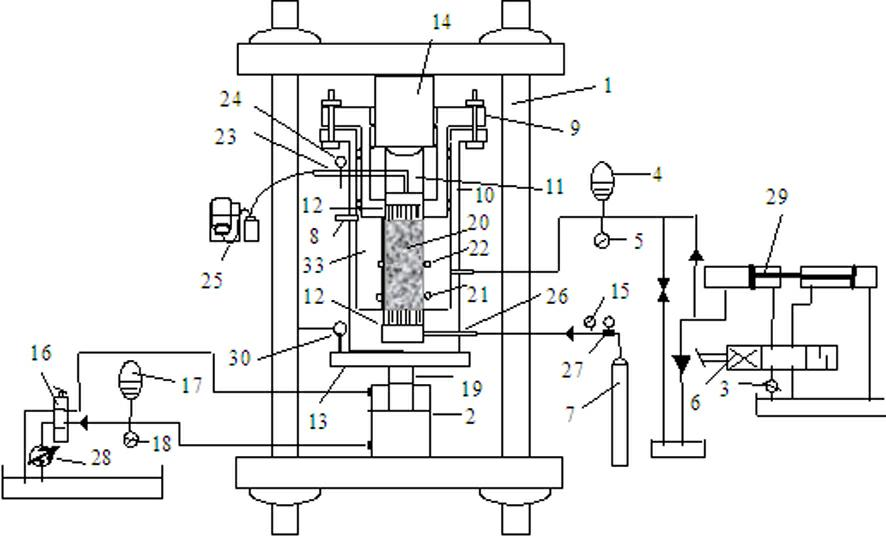

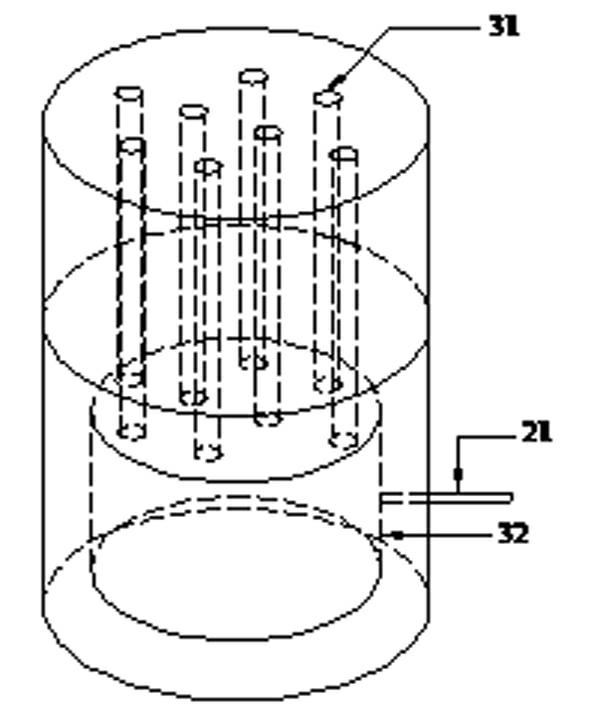

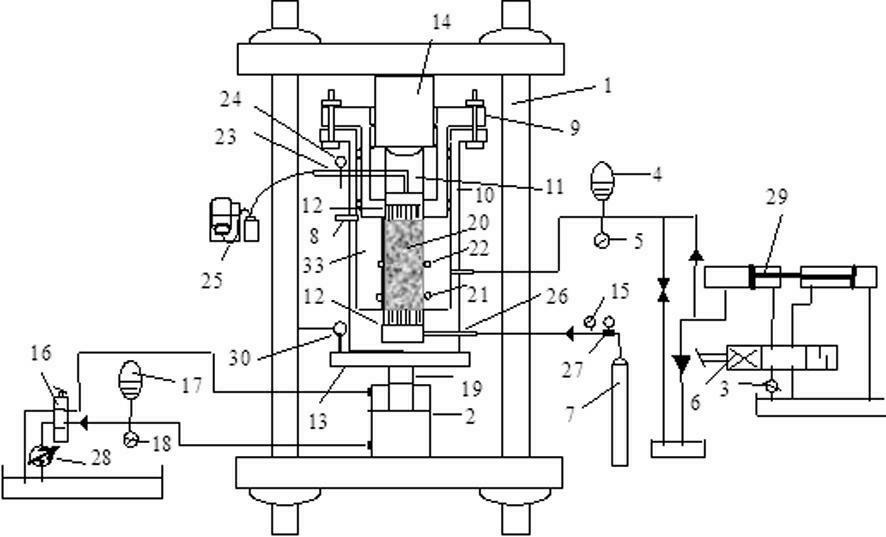

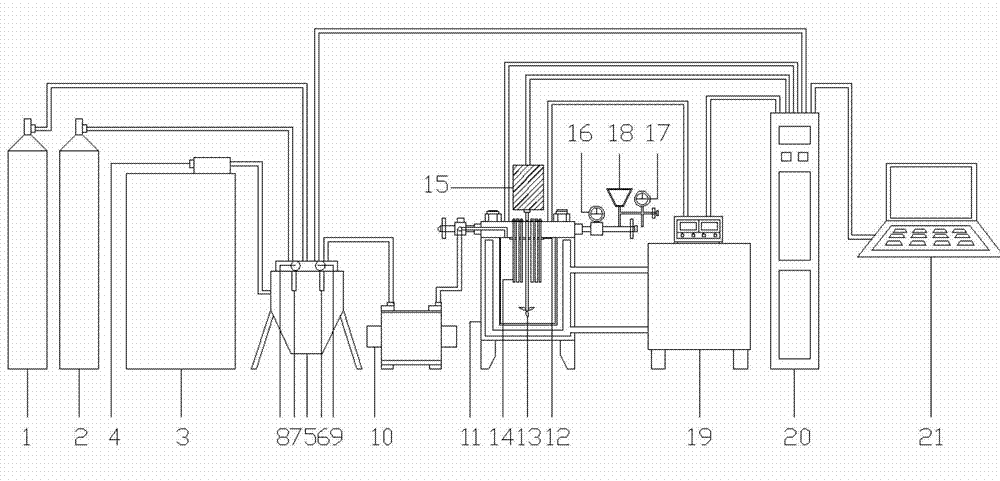

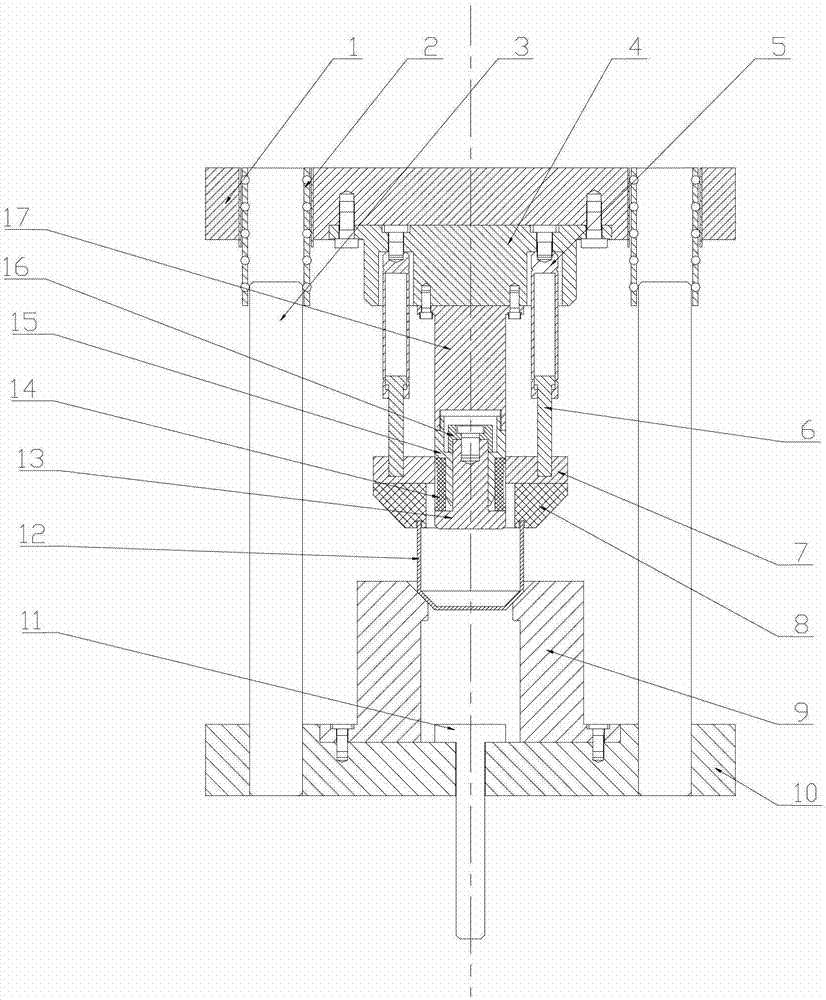

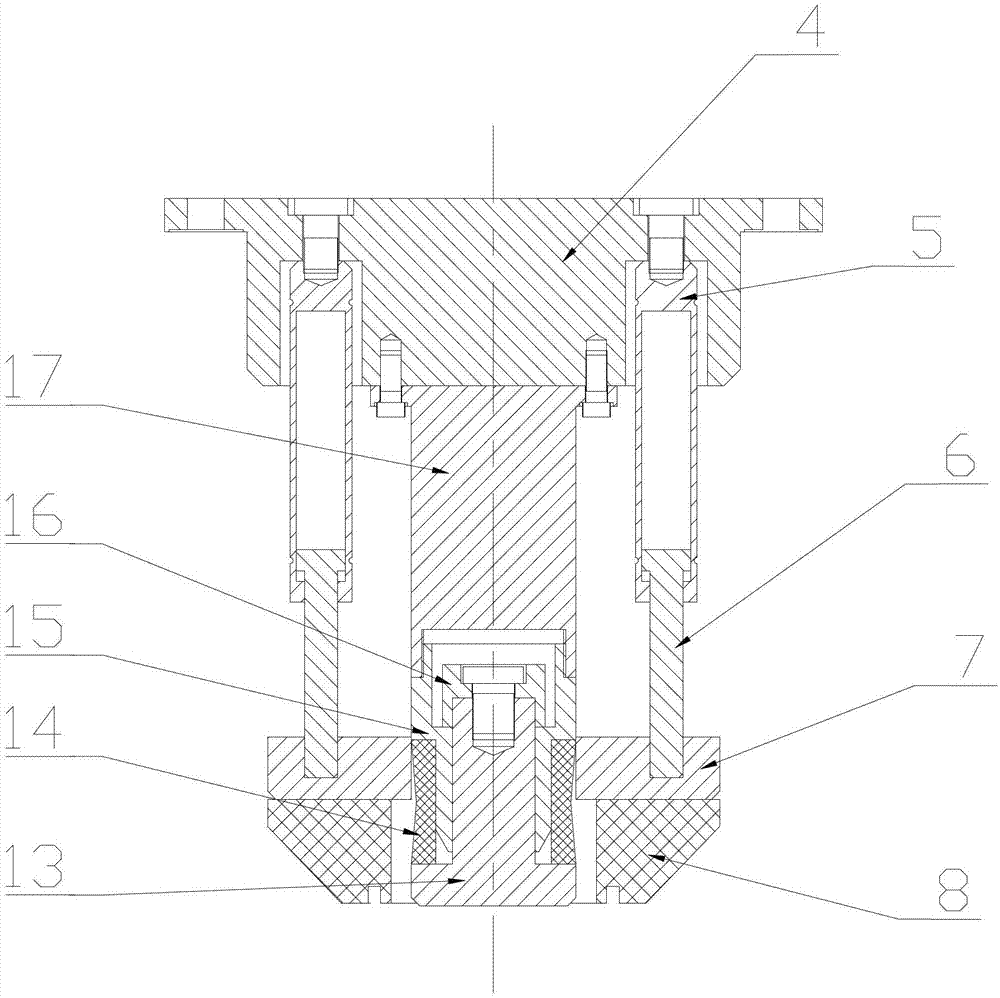

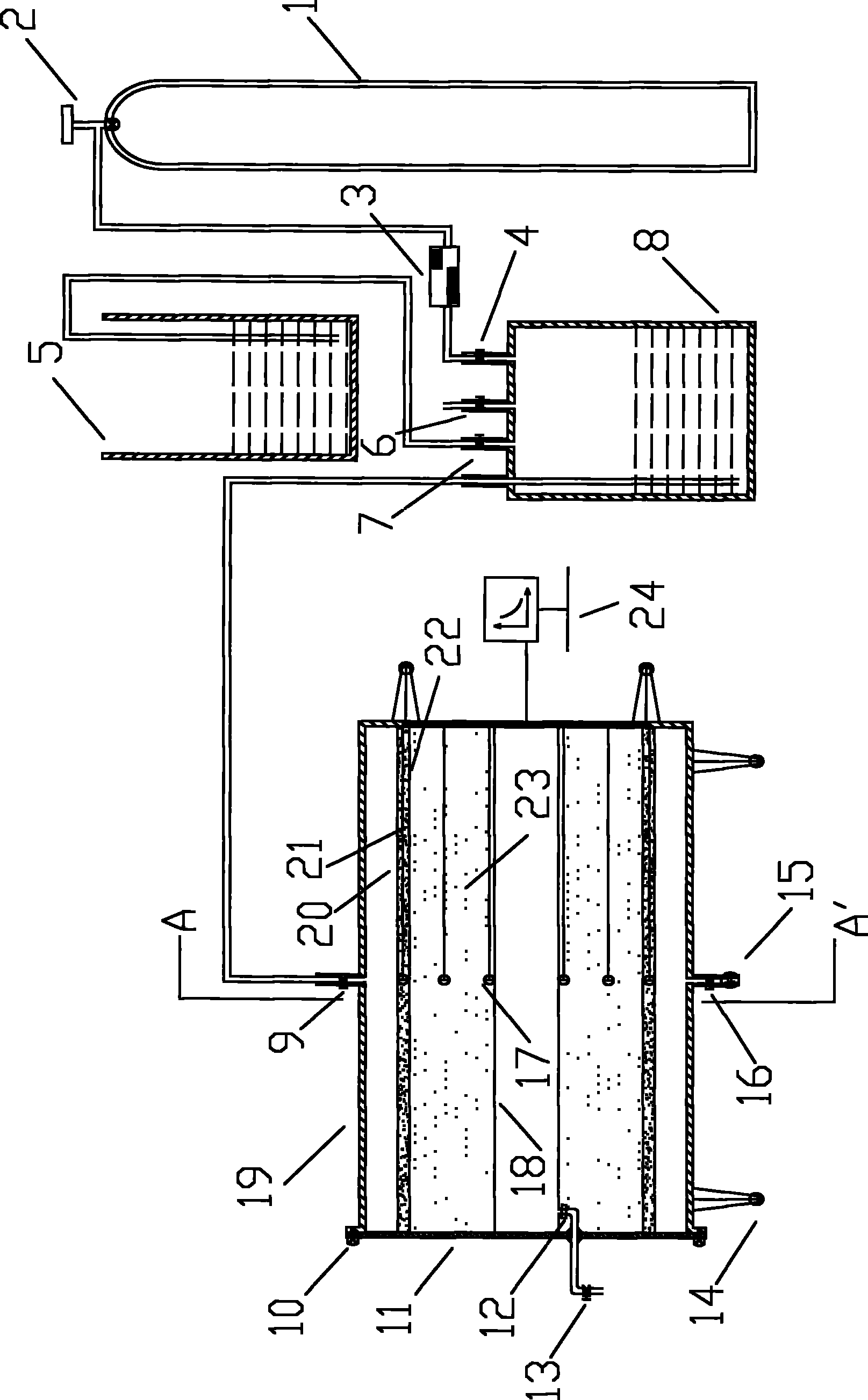

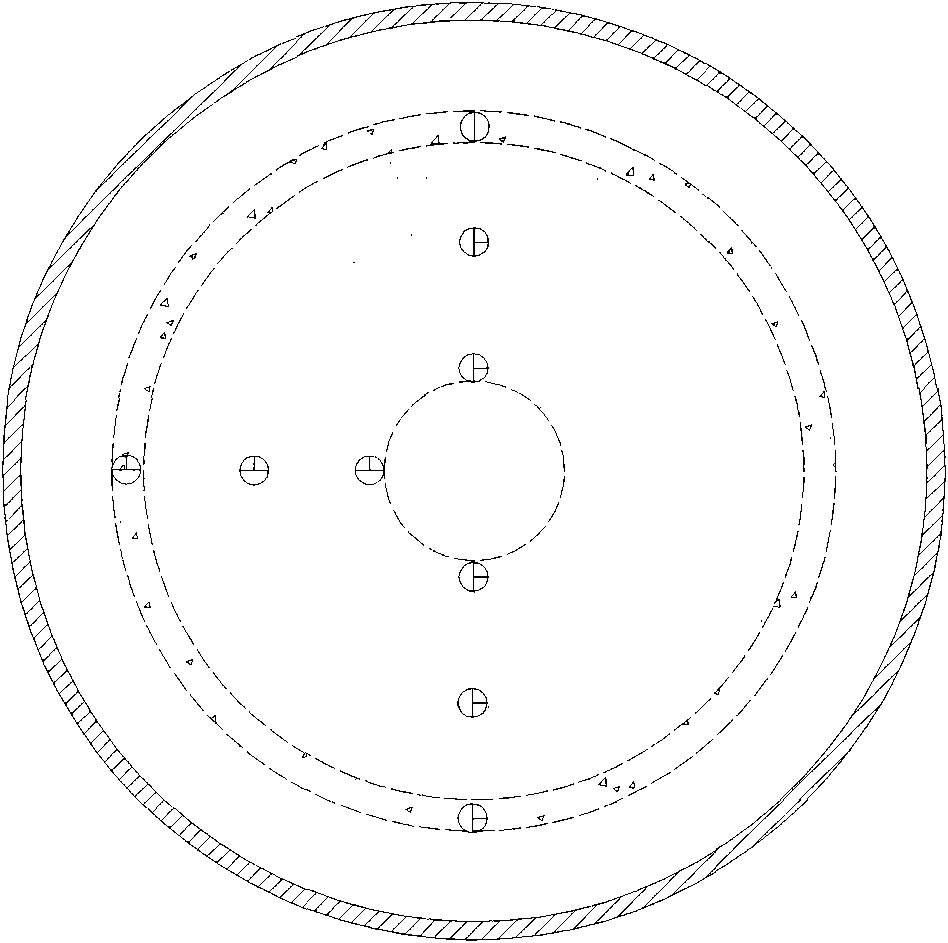

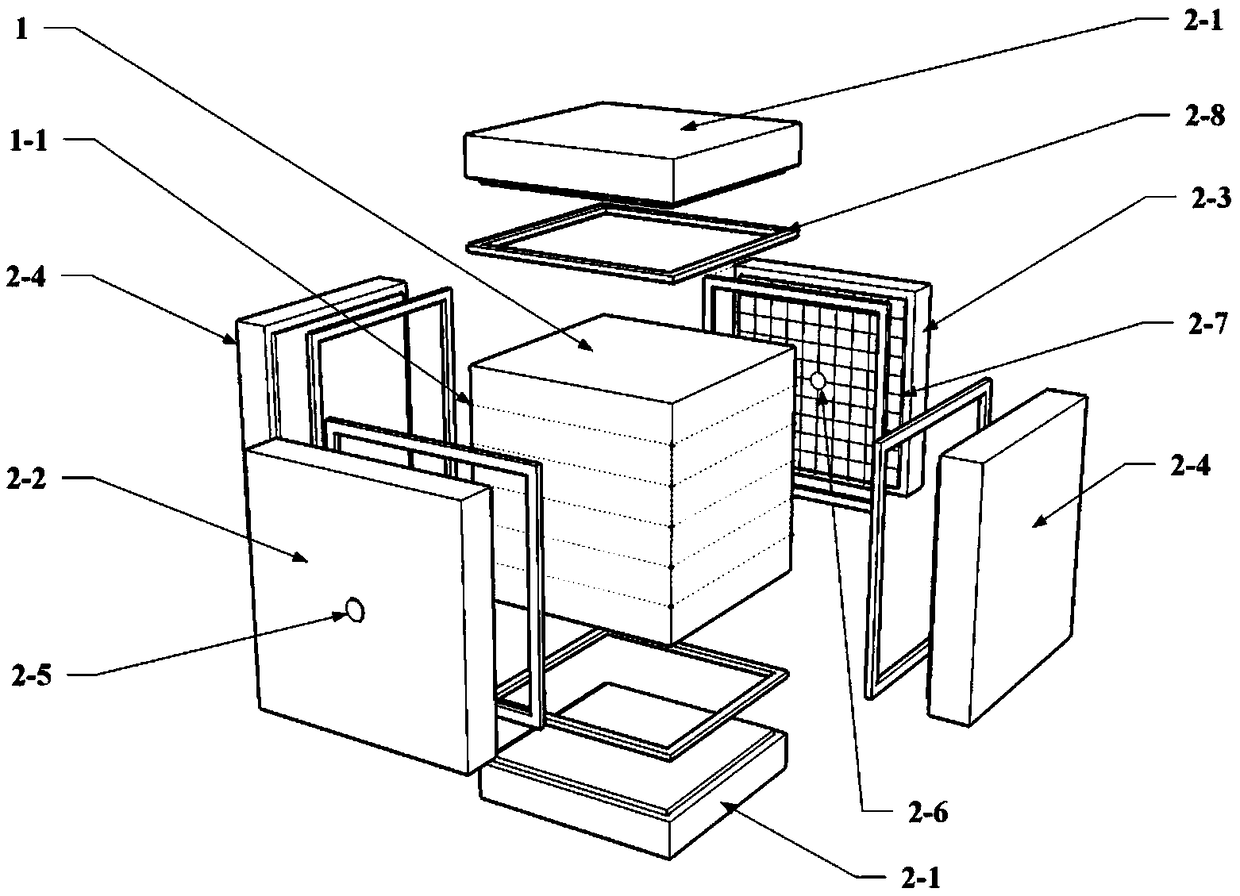

Device for testing gas seepage and creepage coupling action of rocks

InactiveCN102494981AApply evenlyGood voltage stabilization effectInvestigating material ductilityPermeability/surface area analysisCouplingStress level

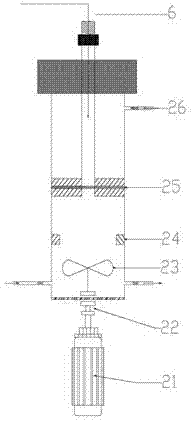

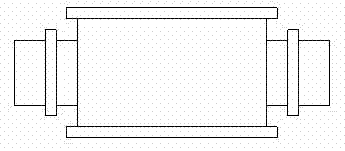

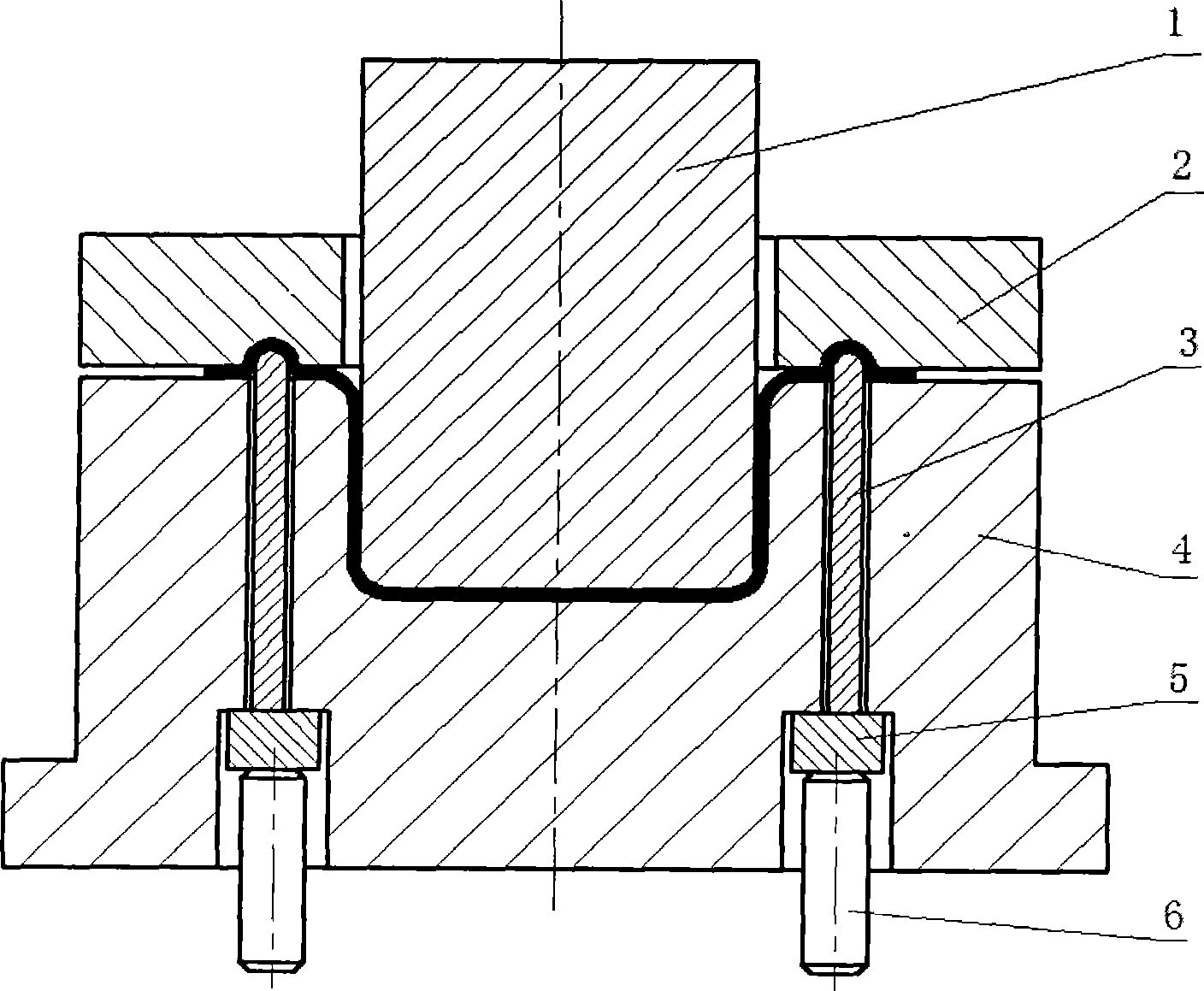

The invention provides a device for testing gas seepage and creepage coupling action of rocks. The device comprises an upper seat, a lower seat, a motor oil pump, a high-pressure nitrogen cylinder and an oil pump, wherein the upper seat is connected with the lower seat; a gas cavity with honeycomb-shaped gas holes is connected to each of the upper seat and the lower seat; the gas cavity which is provided with the honeycomb-shaped gas holes and connected with the upper seat is connected with an outlet pipe; the gas cavity which is provided with the honeycomb-shaped gas holes and connected with the lower seat is connected with a gas inlet pipe; the lower seat and the gas cavity which is provided with the honeycomb-shaped gas holes and connected with the lower seat are connected with a carrying plate; the carrying plate is connected with a loading oil cylinder through a pressurization piston rod; the motor oil pump is connected with the loading oil cylinder; the high-pressure nitrogen cylinder is connected with the gas inlet pipe; and the oil pump is connected with the oil cylinder and a triaxial cavity. The device can be used for performing a gas seepage and creepage coupling test on the rocks under different stress levels and different gas seepage pressures, so that the creepage test for a rock sample can be finished successfully under constant stress; and data is real and reliable.

Owner:HUNAN UNIV OF SCI & TECH

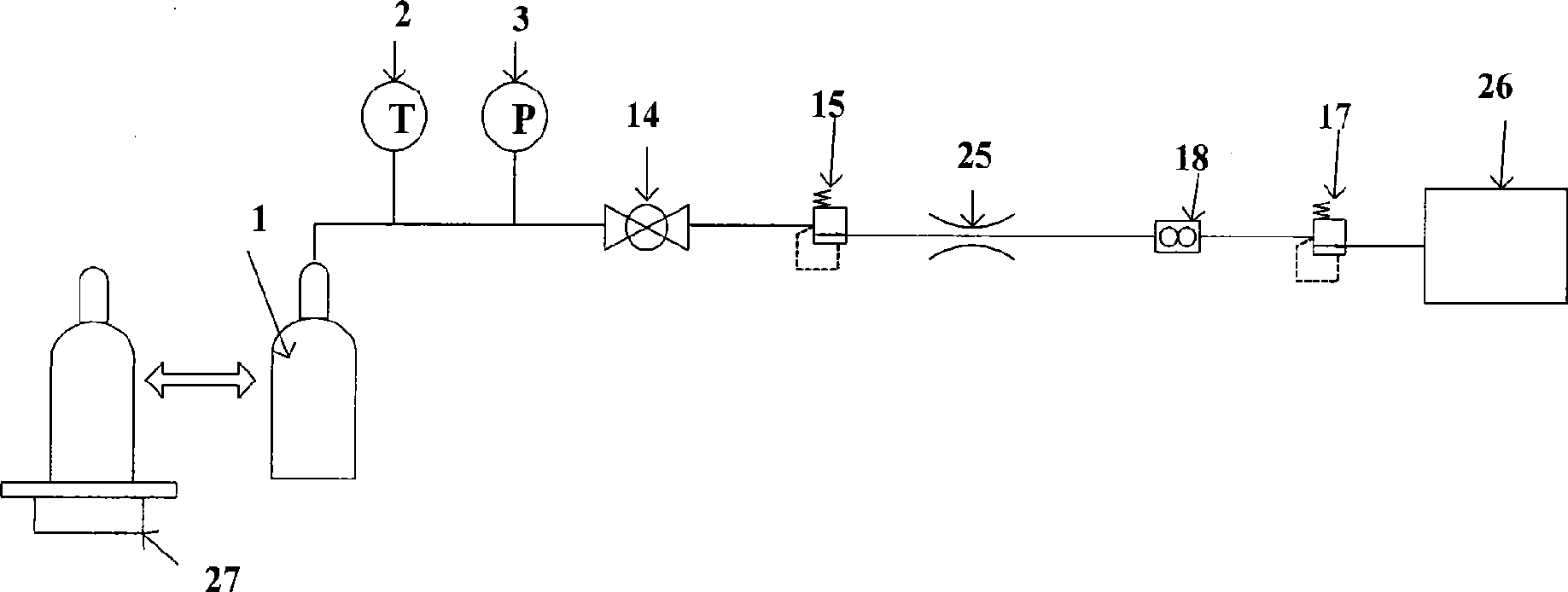

Detection system and method for mesomeric state hydrogen gas consumption

InactiveCN101470020AEasy to pour directlyEasy to pour directly intoFuel cell auxillariesWeighing apparatus for materials with special property/formFlame arresterGas cylinder

The invention relates to a steady hydrogen gas consumption detection system and a detection method thereof, belonging to the gas detection technical field. In the system, the main pipeline connected with the bottle valve of a high pressure bottle is mounted with a bottle mouth electromagnetic valve, a ferrule type joint, a detachable pipeline swirling valve, a primary road electromagnetic valve, a primary road manual valve, a first stage decompression valve, a safety valve, a second decompression valve, a flux controller and a flame arrester in turn. The method measures the weights before and after discharging the gas of the gas bottle, the temperatures and the pressures at the tail block of the gas bottle and the bottle valve, to obtain three hydrogen gas consumption value groups. The invention arranges a hydrogen bottle, a hydrogen gas bottle purging pipeline and a temperature pressure sensor in the bottle to improve measurement accuracy, comprises a filling pipeline to simply and directly fill gas into the high pressure gas bottle, and utilizes weighting method and counter weight calibration as reference, thus being convenient for the research on steady hydrogen gas consumption detection.

Owner:TSINGHUA UNIV

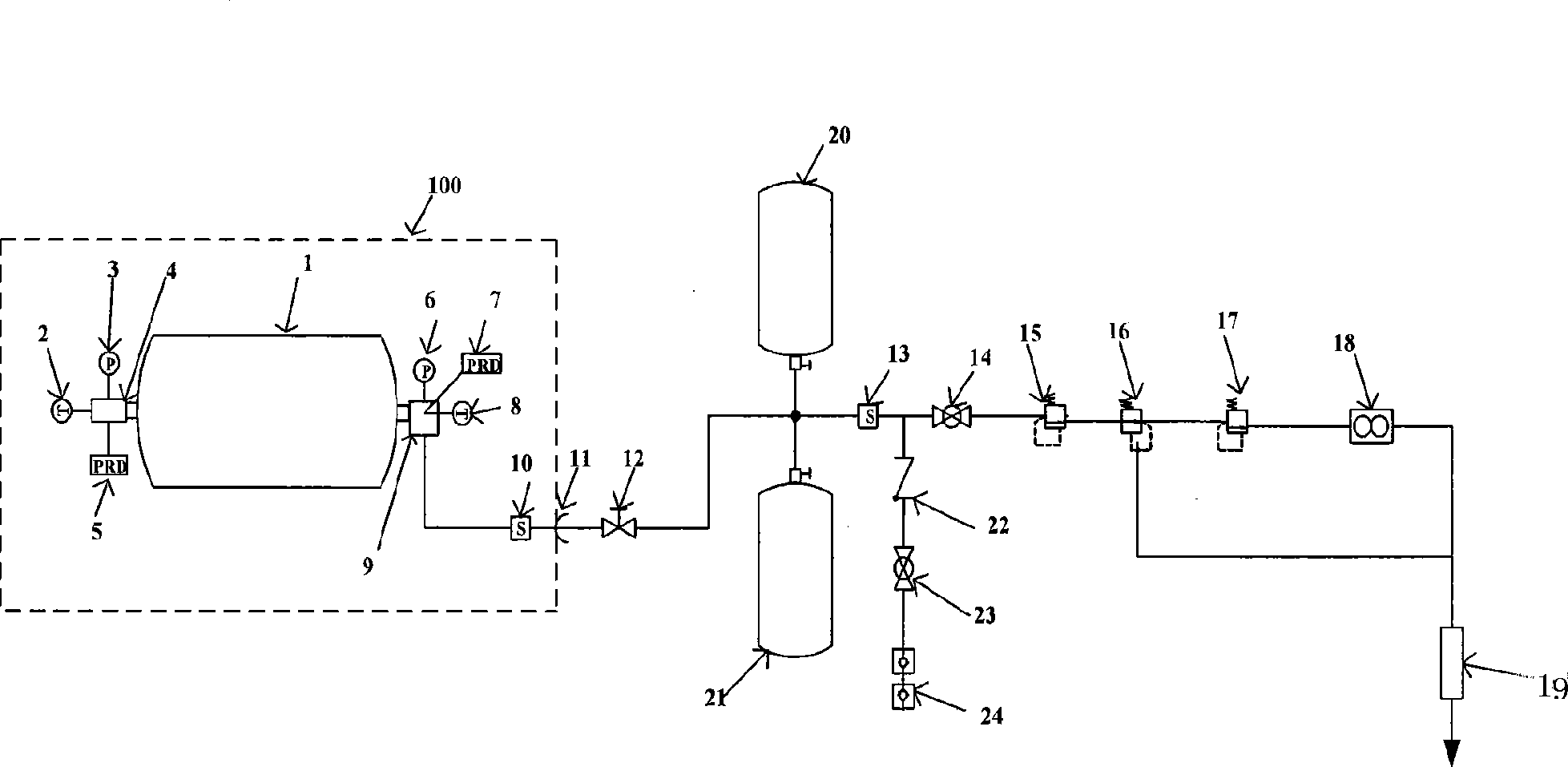

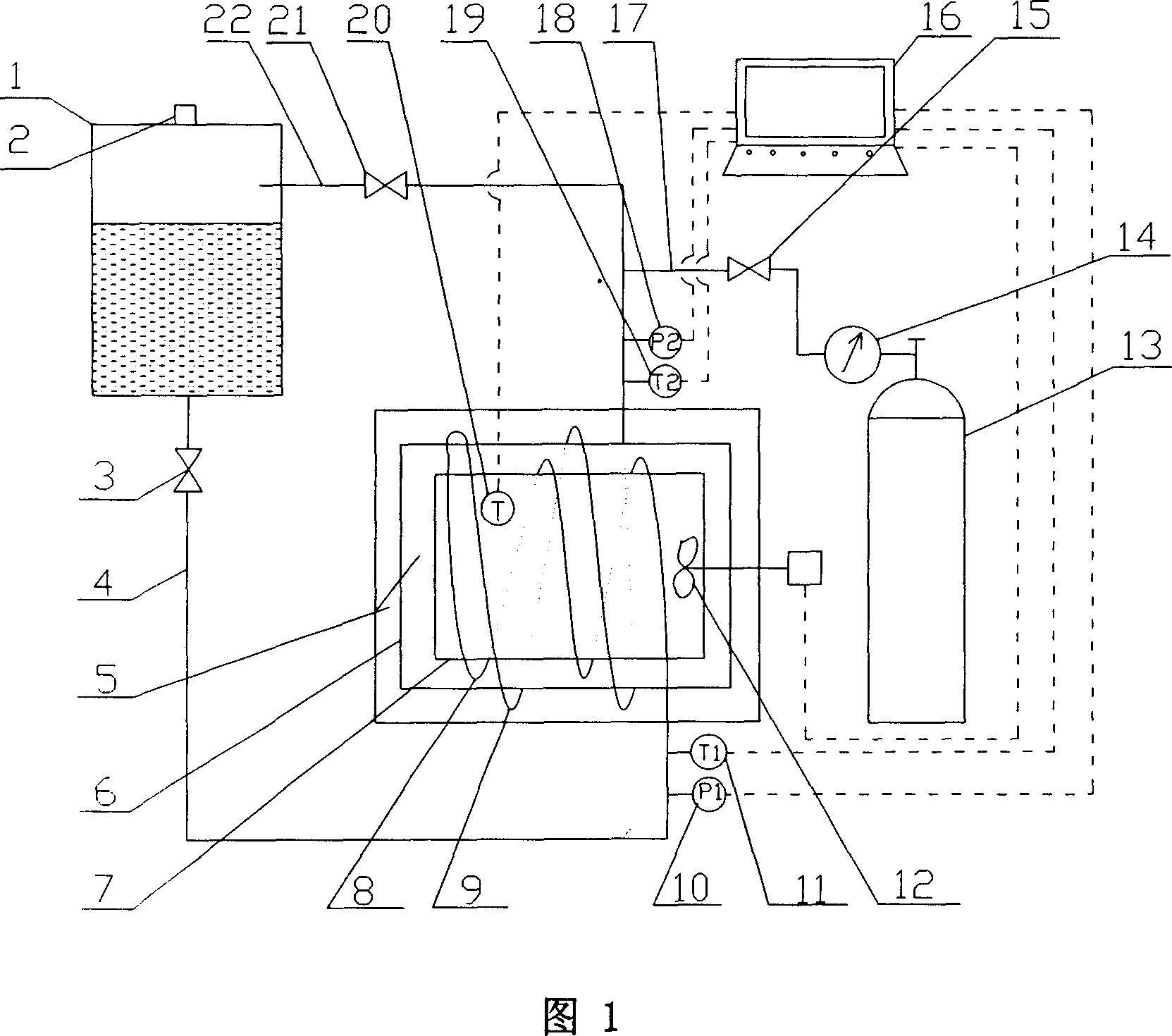

Leaching experimental facility for in-situ leaching uranium mining

ActiveCN103711462ARealize concentration measurementRapid dissolution equilibriumSurveyFluid removalMagnetic tension forceAutomatic control

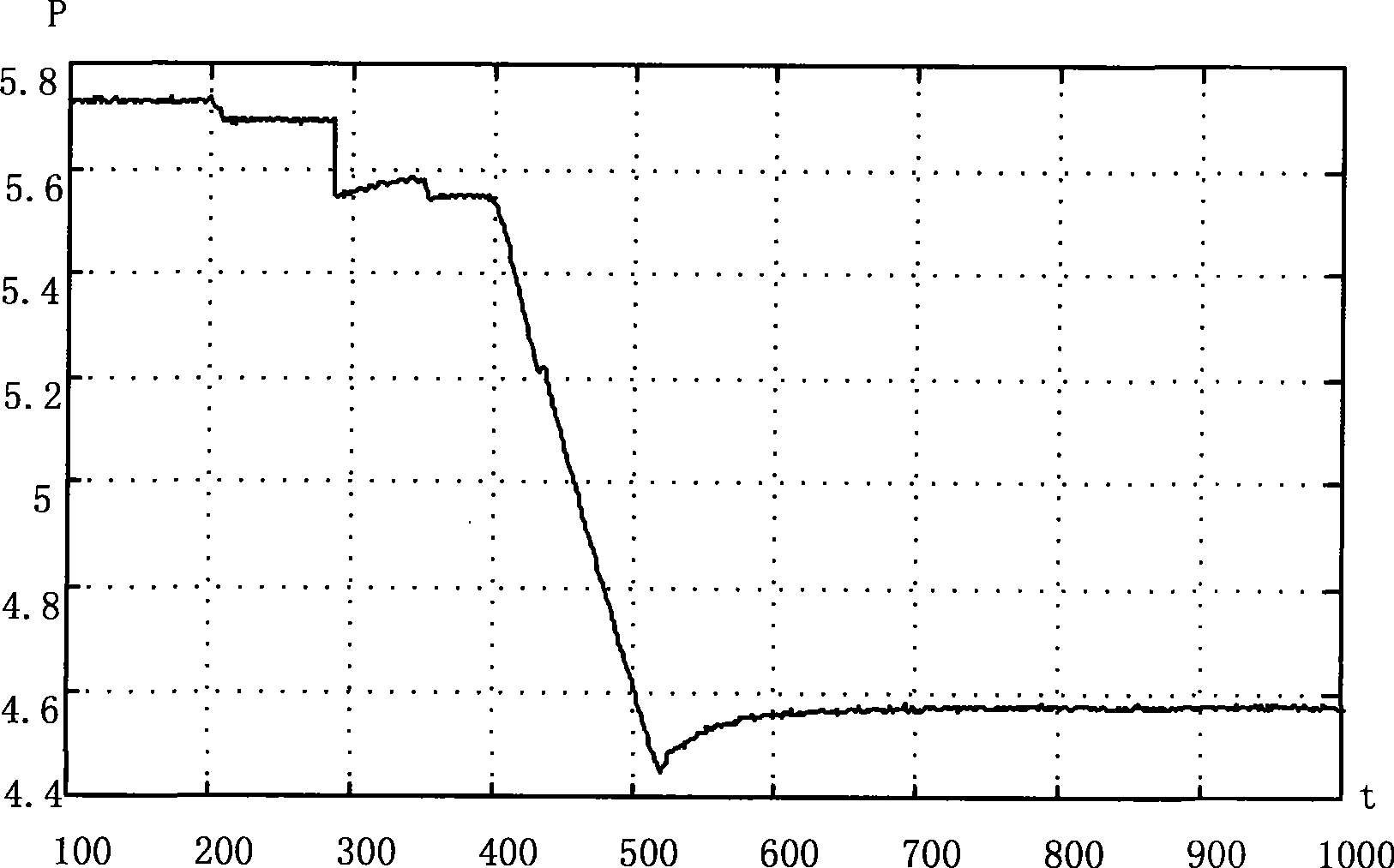

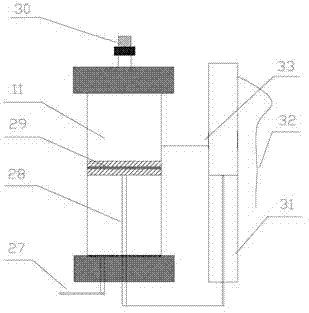

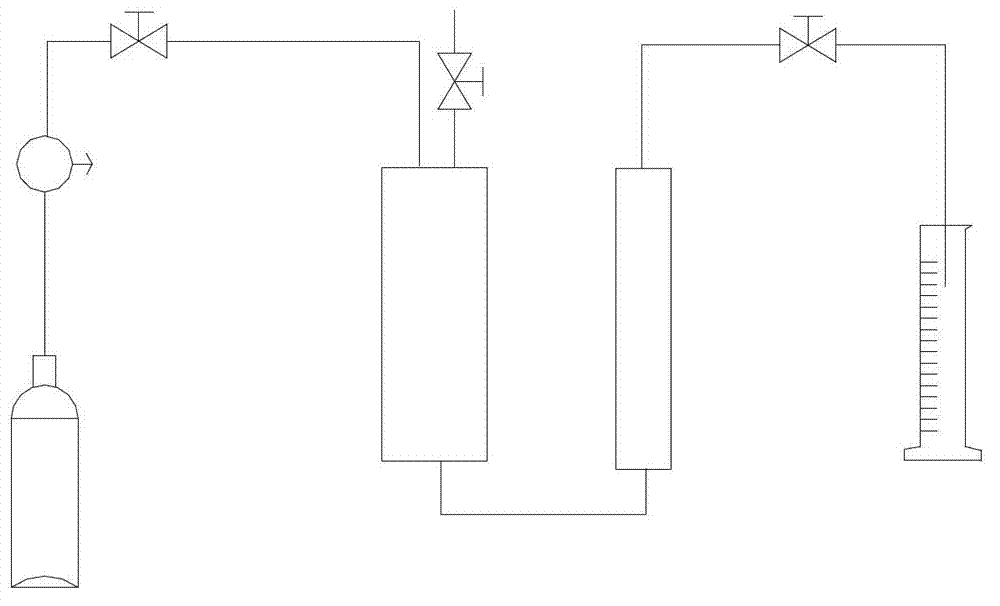

The invention belongs to the technical field of experimental devices for scientific researches on in-situ leaching uranium mining, and particularly relates to a leaching experimental facility for in-situ leaching uranium mining. A gas source comprises an oxygen source and a carbon dioxide source; gas and liquid are mixed and dissolved by using a magnetic stirring device in a stirring container; dissolving pressure is controlled by a nitrogen cylinder via a stirring container pressure return valve; the pressure provided by a plunger pump is adjusted through an intermediate container pressure return valve in an experiment until the pressure in a liquid injection intermediate container is the same with the pressure in the stirring container; leaching liquid is pressed in the liquid injection intermediate container by a pressure adjusting portion; a rock core is arranged in a full-diameter rock core holding unit; a ring pressure pump and a pressure sensor are arranged at two ends of the holding unit; an outlet end is provided with a leaching pressure return valve; formation pressure is simulated; oxygen in leaching agent is controlled so that the oxygen cannot be separated out; the mass of the liquid is measured by a balance measuring system; and the experiment is automatically controlled by a computer.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

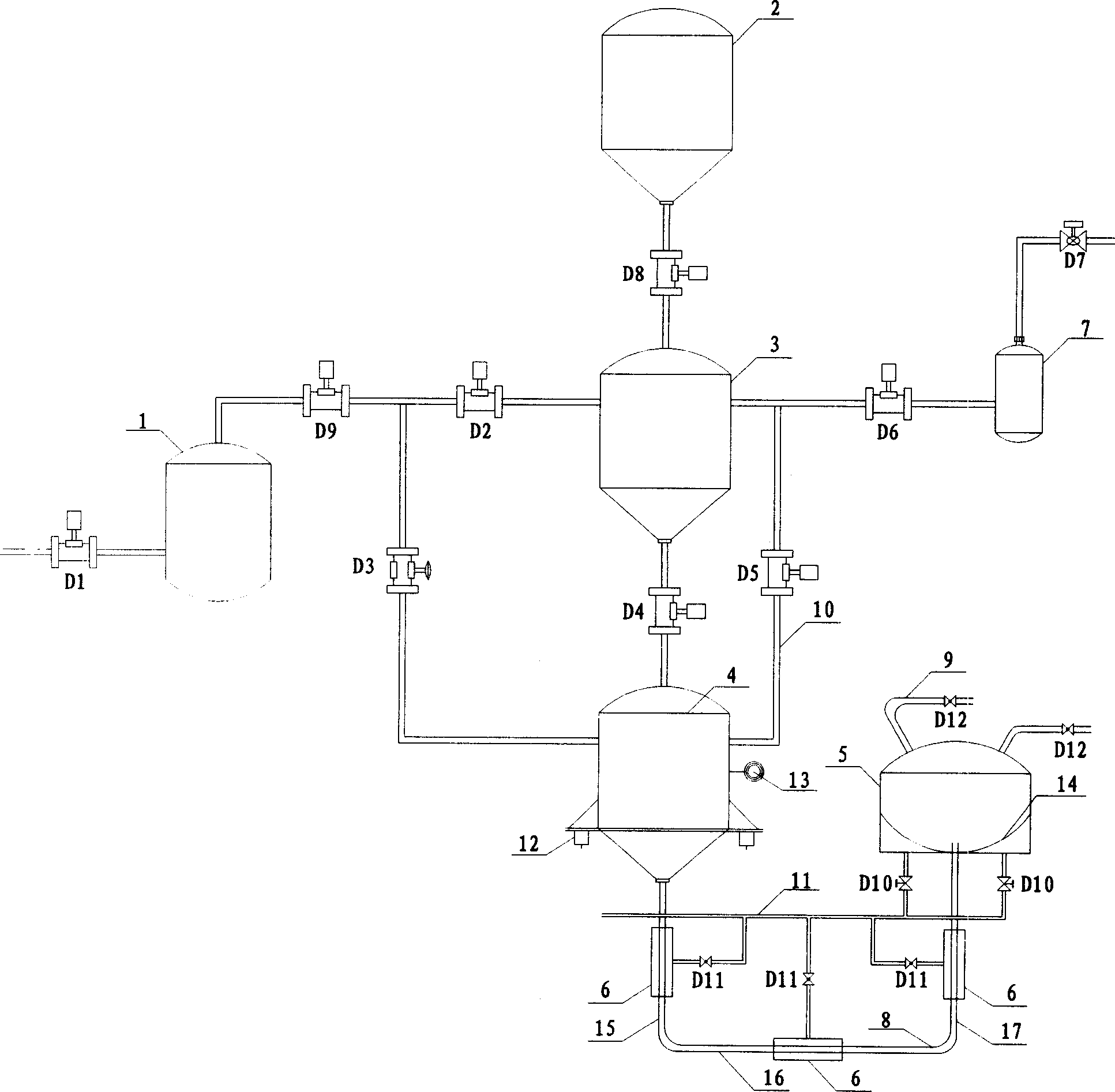

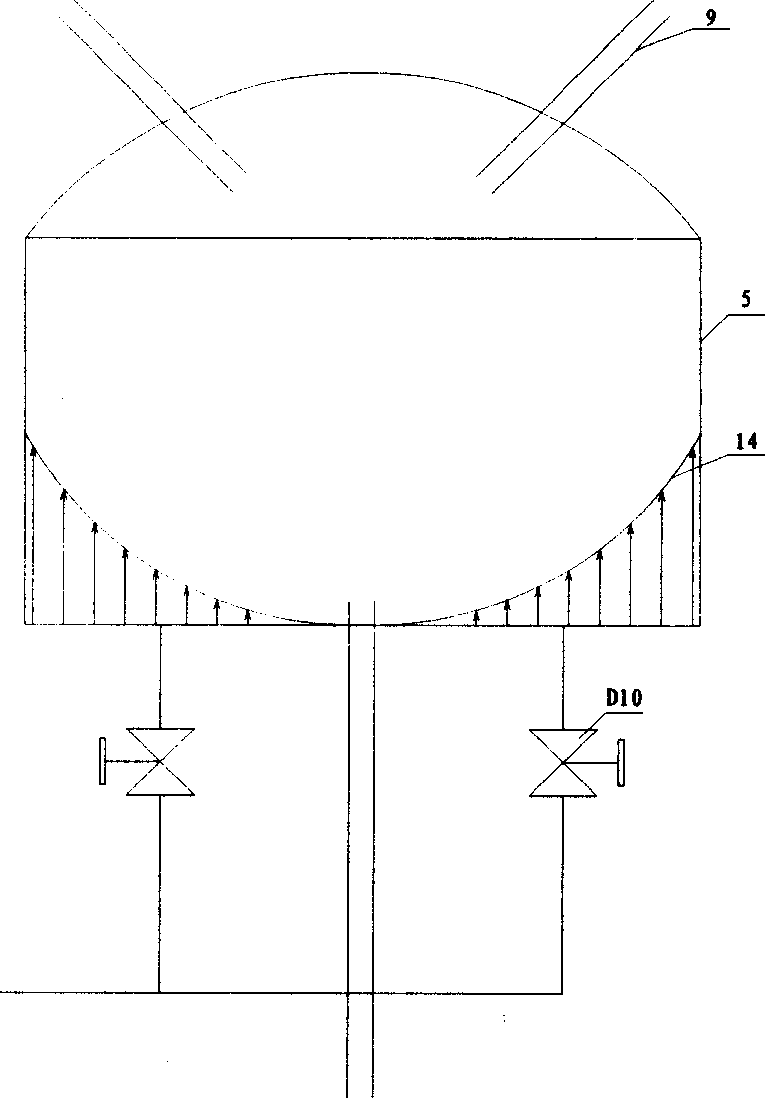

Dry coal pressure closed phase conveyer with several discharge branches

InactiveCN1715160AAvoid the disadvantage of not being able to transport powder continuously and stablyReduce interactionBulk conveyorsCombined combustion mitigationEngineeringNitrogen gas

The pressurized and closed dry coal powder conveyer with several discharge branches includes normal pressure coal portions bin; connected variable pressure bin with gas inlet connected to the nitrogen cylinder, coal powder outlet connected to pressurizing bin and gas outlet connected with filter and the pressurizing bin; pressurizing bin with gas inlet connected to the nitrogen cylinder and coal powder outlet connected to the powder distributor; and powder distributor with lower end connected to nitrogen pipeline and outlet with set shunt branch pipeline. The present invention has powder buffer connected to the pressurizing bin and no mechanical rotating part, and is suitable for closed conveying of high pressure powder. Installing the powder distributor realizes the homogeneous multiple branch conveying with one locking bin system in high overall stability and homogeneous distribution.

Owner:XIAN THERMAL POWER RES INST CO LTD

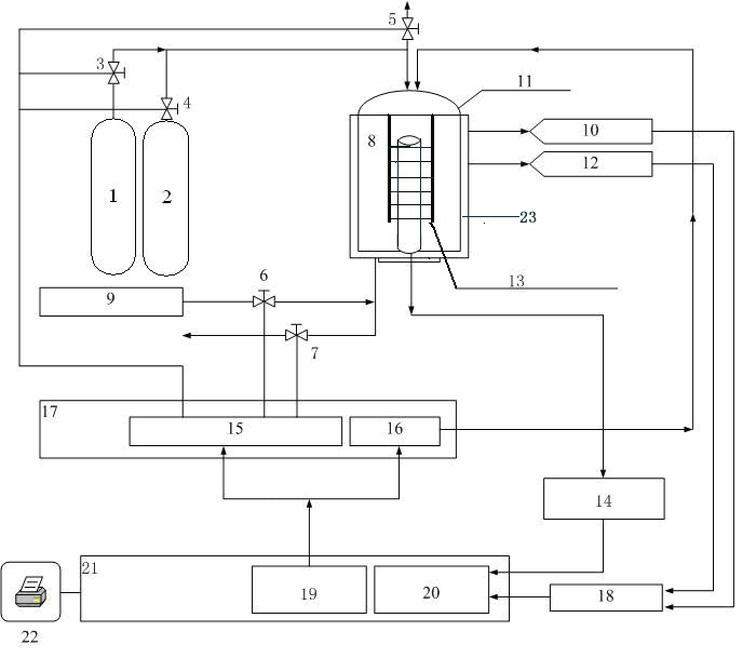

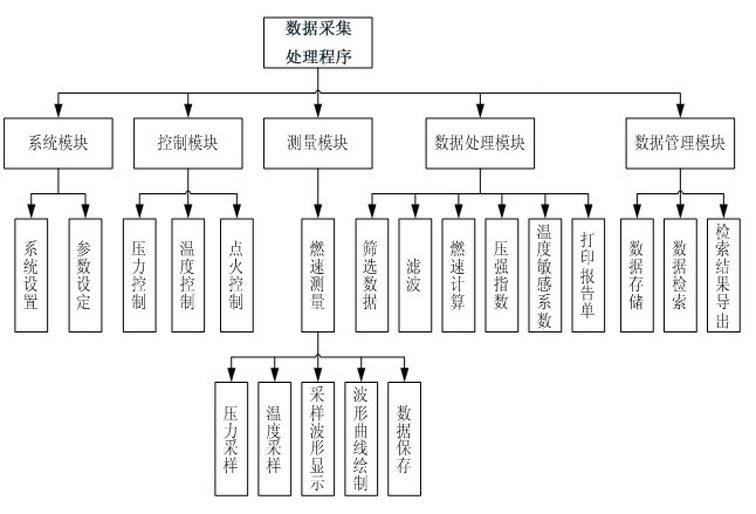

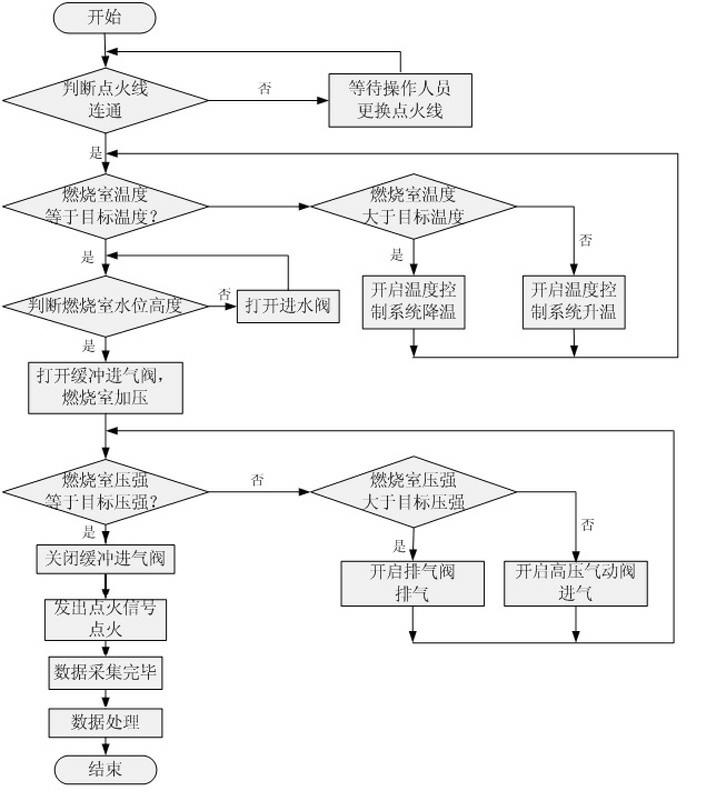

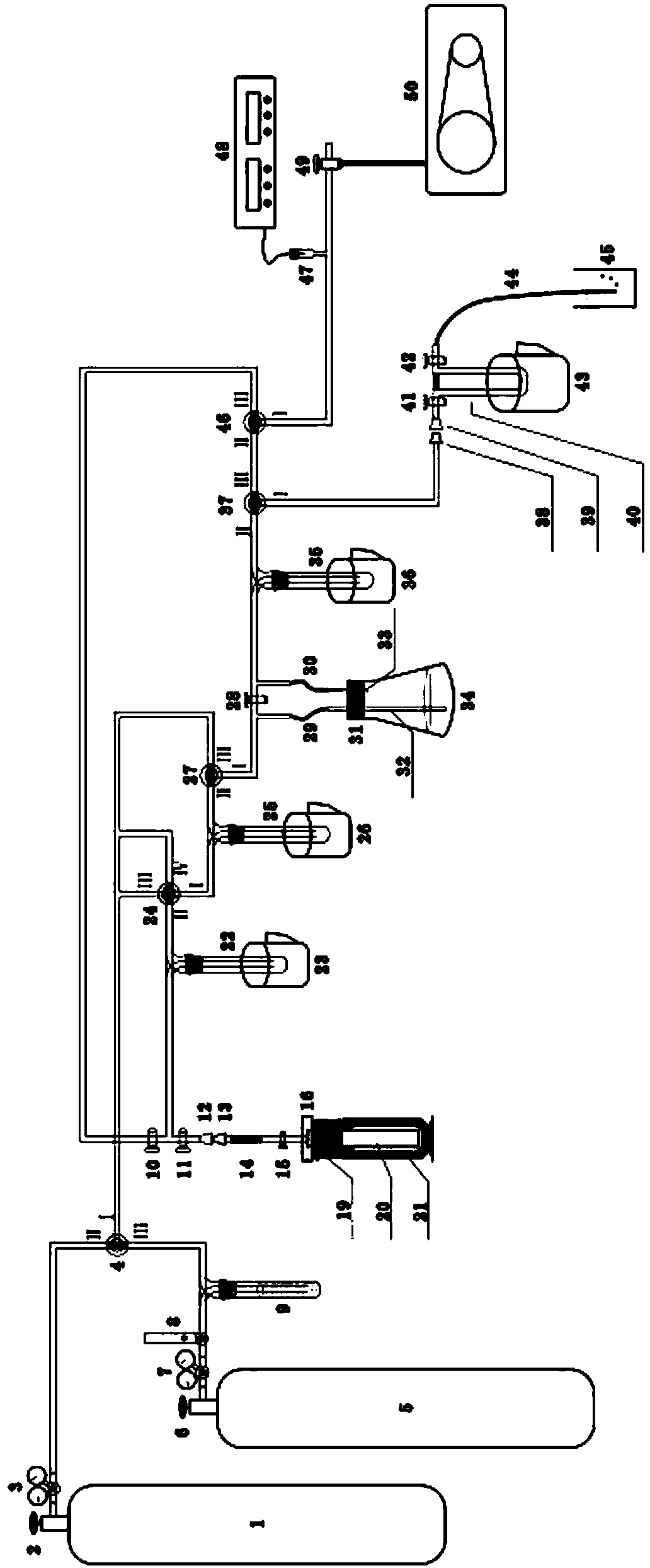

Multi-target-line dynamic combustion performance testing system for solid propellant

InactiveCN102095839AShorten the development and production cycleLow costFuel testingCombustion chamberEngineering

The invention discloses a multi-target-line dynamic combustion performance testing system for a solid propellant, which comprises a combustion chamber and gas distribution unit, a test and control unit and a data collecting and processing unit, wherein the combustion chamber and gas distribution unit comprises a combustion chamber, a constant-temperature tank, a high-pressure nitrogen cylinder, a buffer nitrogen cylinder, a relevant valve pipeline, a nitrogen booster pump and a multi-target-line explosive support used for fixing a sample to be tested, wherein one end of the multi-target-line explosive support is provided with an ignition wire connecting post, a ground wire connecting post and 6 to 10 target line connecting posts in the combustion chamber; and the data collecting and processing unit is used for dispatch and control of all function blocks of the testing and controlling unit, analysis and processing of tested data and data management. The testing system can reflect the change of the combustion speed of the solid propellant with the change of pressure by stages, and belongs to the range of testing of dynamic combustion speed; and the traditional target line method and the underwater acoustic emission method can only test the static combustion speed in a single constant-pressure condition, therefore, the testing system disclosed by the invention can obtain a conclusion closer to the actual combustion condition of the solid propellant in a solid-propellant rocket engine.

Owner:XIDIAN UNIV +1

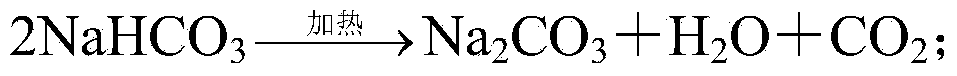

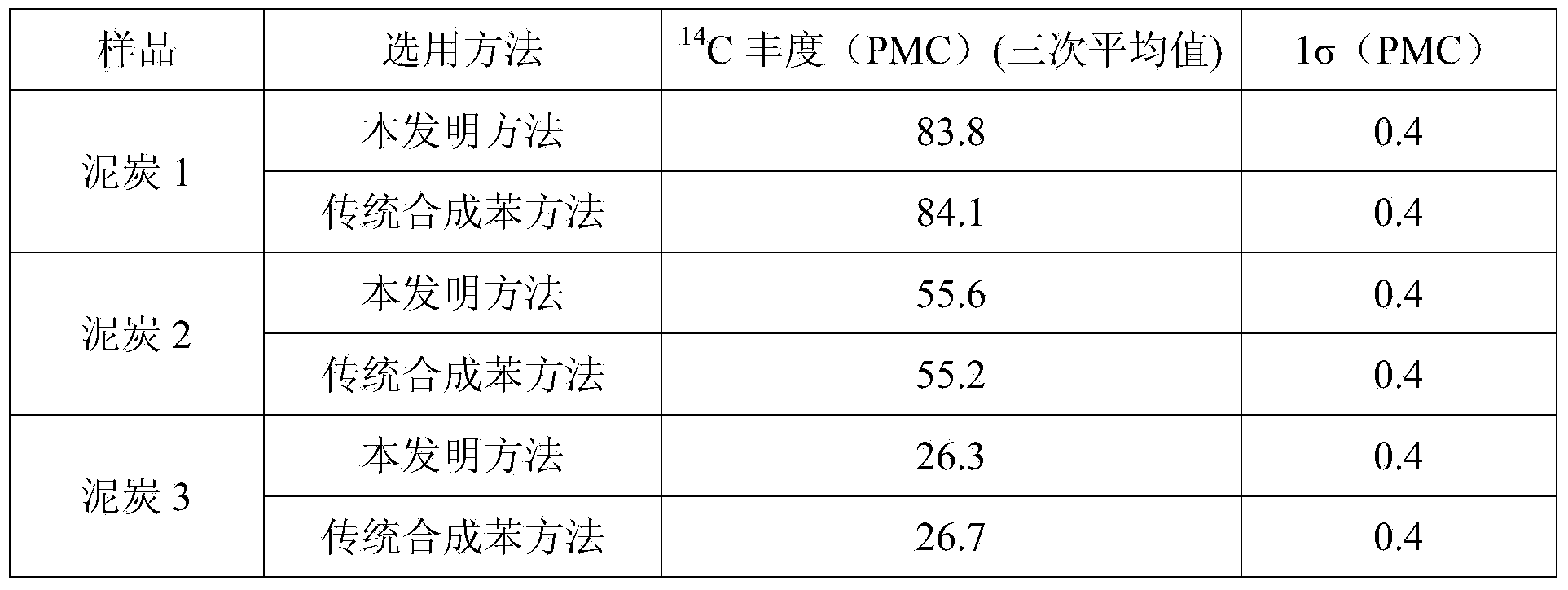

Pretreatment method and device for measuring 14C abundance of organic compound type sample

InactiveCN103822811AGuaranteed test accuracyReduce processing costsPreparing sample for investigationChemical treatmentCombustion chamber

The invention relates to a pretreatment method for measuring 14C abundance of an organic compound type sample. The method includes transferring carbon atoms in the organic compound into CO2 molecules through combustion, reacting CO2 with a NaOH solution to obtain a saturate NaHCO3 solution, heating the saturate NaHCO3 solution to obtain a saturate Na2CO3 solution, and adopting the saturate Na2CO3 solution for 14C abundance tests. The invention also provides a device used for the method. The device mainly comprises an oxygen cylinder, a nitrogen cylinder, a cold trap A, a three-way stopcock A, a combustion chamber, a cold trap B, a stone, a cold trap C, a three-way stopcock B, a conical flask, a cold trap D, a three-way stopcock C, a U-shaped gas sample collector, a three-way stopcock D, a vacuum gauge, a vacuometer, a piston D and a vacuum pump. On the basis of guaranteeing the measuring accuracy, the method largely simplifies the chemical treatment process, increases the time efficiency and reduced the cost.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

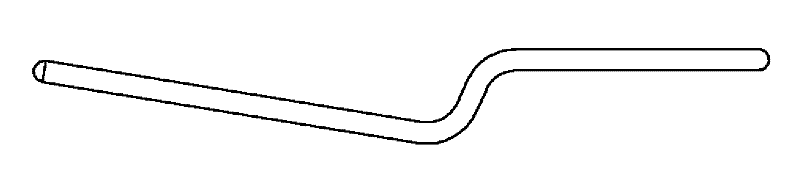

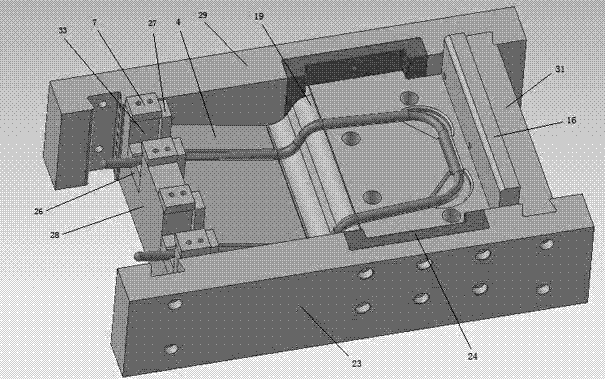

Bend molding die for automotive seat headrest pipe fittings

ActiveCN102397943ANo warpage under pressureEasy to processShaping toolsPipe fittingNitrogen cylinder

The invention provides a bend molding die for automotive seat headrest pipe fittings, which can one-step bend mold the pipe fittings with low process difficulty, high efficiency and low cost. It is comprised of an upper die structure and a lower die structure. The upper die structure includes an upper die plate, the upper part of the upper die plate being connected to the upper die junction platethrough an upper backup plate, the lower part of the upper die being connected to the upper die dead plate through an upper backup plate. The lower die structure includes a lower die plate, the lowerpart of the lower die plate being mounted with a lower backup plate, the lower part of the upper die dead plate being provided with a molding male die structure, the upper part of the lower die platebeing provided with a molding female die structure. The invention is characterized in that the molding male die structure comprises a molding male die and a pressure plate, the molding male die is fixed on the lower part of the upper die dead plate, the pressure plate is connected to the lower part of the upper die dead plate through an upper die unloading screw, a nitrogen cylinder is mounted onthe upper die junction plate, the mandrel of the nitrogen cylinder holds tightly against the upper part of the pressure plate after it drills through the upper die plate, the upper backup plate and the upper die dead plate; the molding female die structure comprises female die frame body, a molding female die and a locating structure, the molding female die being mounted within the female die frame body and facing the molding female die structure, the locating structure being positioned within the female die frame body and transversely two ends of the molding female die; the molding female die comprises a fixed female die and a movable female die, the molding male die and the movable female die are provided with bend molding grooves which cooperate; the fixed female die is fixed on the lower backup plate, the movable female die being mounted on the lower backup plate through the lower die unloading screw, and being held tightly by the lower mandrel.

Owner:中山邦塑精密塑胶有限公司

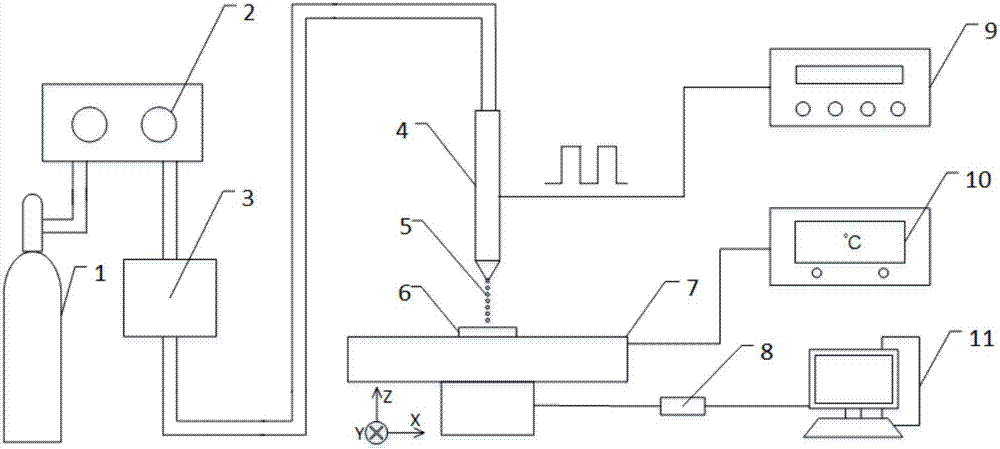

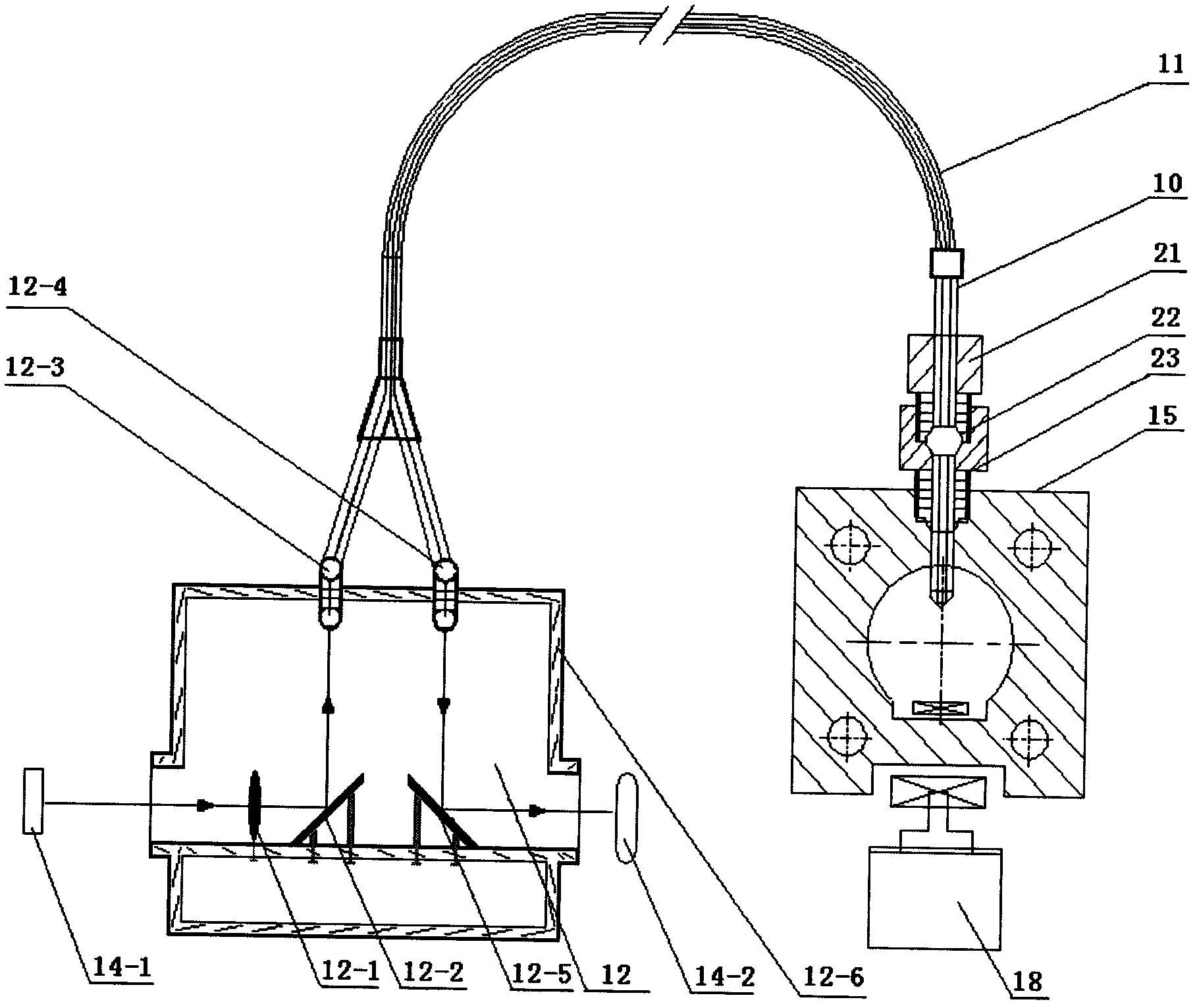

Micro-droplet jetting printing device and method for preparing graphene metamaterial microstructure through device

ActiveCN106891414AFast formingAdditive manufacturing apparatusCeramic shaping apparatusElectricityCvd graphene

The invention discloses a micro-droplet jetting printing device and a method for preparing a graphene metamaterial microstructure through the device. The micro-droplet jetting printing device and the method are used for solving the technical problem that an existing method for preparing the graphene metamaterial microstructure is complex. According to the technical scheme, the device comprises a nitrogen cylinder, pressure controllers, a liquid accumulator, a piezoelectric micro sprinkler, a microstructure substrate, a three-dimensional associated movement base plate, a three-dimensional associated movement base plate controller, a piezoelectric ceramic driver, a temperature controller and a computer. The method comprises the steps that graphene dispersion liquid is dispersed into picoliter-order uniform graphene micro-droplets through the piezoelectric micro sprinkler, and the liquid droplet diameter and the jetting frequency are adjusted through the piezoelectric ceramic driver; and then the three-dimensional associated movement base plate is controlled through the computer, the accumulation track of the graphene micro-droplets on the substrate is controlled, the graphene microstructure is obtained through point-by-point, line-by-line and layer-by-layer accumulation, meanwhile, the temperature controller is utilized for controlling the evaporation rate and solute migration in the graphene micro-droplet deposition process, and complex graphene metamaterial microstructure patterns are obtained. The method is simple and practicable.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

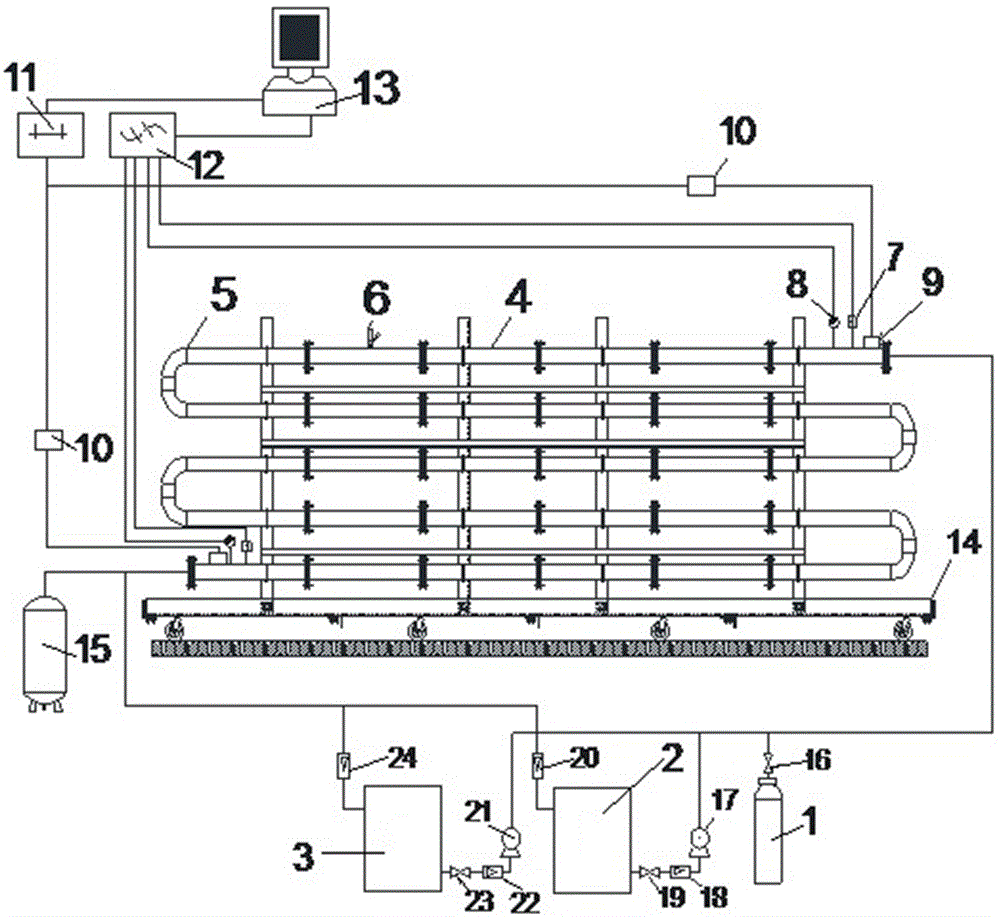

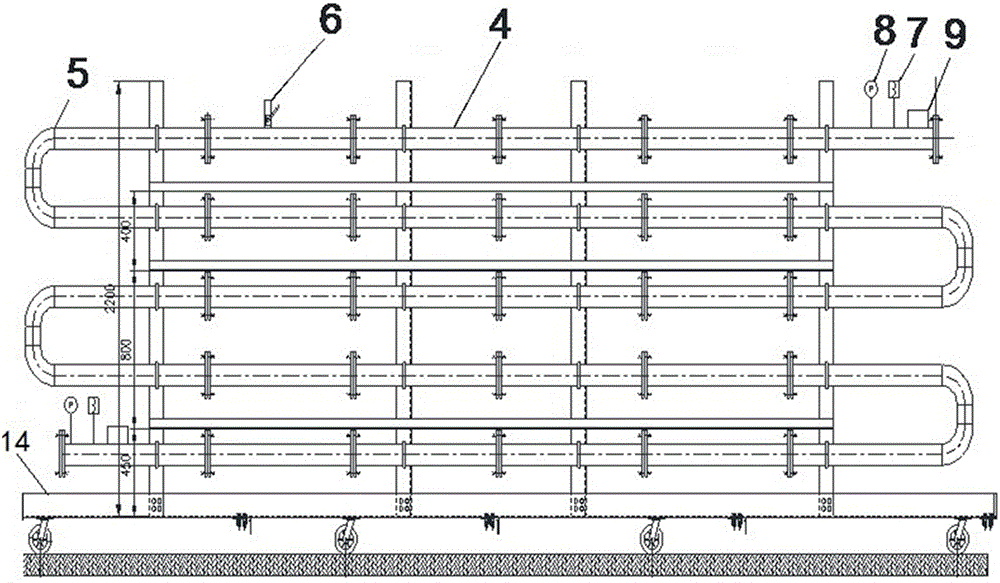

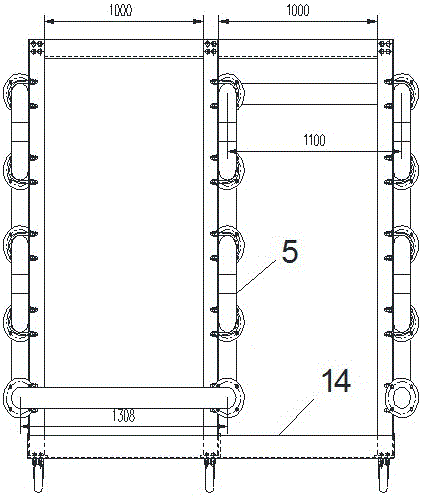

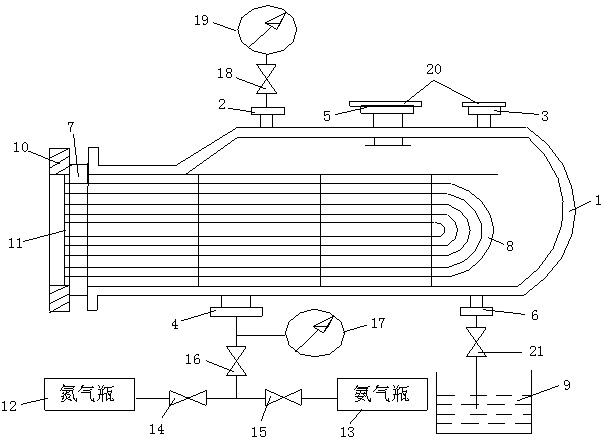

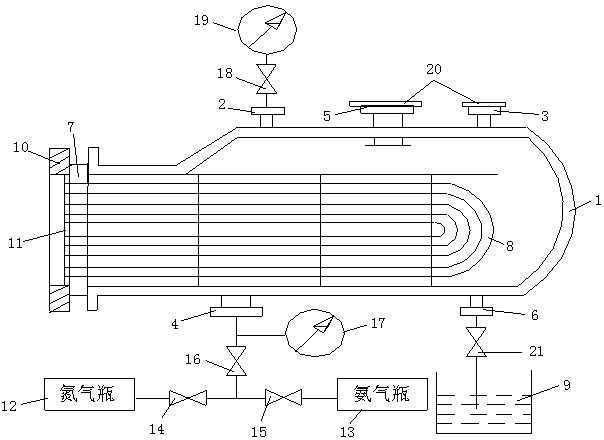

Pipeline leakage detecting and positioning experimental system and detection method thereof

The invention relates to a experimental system for scientific research, in particular to a pipeline leakage detecting and positioning experimental system and a detection method thereof, and the system is used for realizing detection and positioning experiments on leakage of long-distance gas conveying pipelines and long-distance liquid conveying pipelines by virtue of different leakage detection methods. The pipeline leakage detecting and positioning experimental system comprises a conveying pipeline, a medium conveying device, a negative-pressure wave detection device and an acoustic emission detection device; the medium conveying device comprises a conveying pipeline, a medium container, a surge tank, a water pump, an oil pump, a water tank outlet flowmeter, a water tank inlet flowmeter, an oil tank outlet flowmeter, an oil tank inlet flowmeter, a nitrogen cylinder outlet valve, a water tank outlet valve and an oil tank outlet valve; a bent part of the conveying pipeline is of a U-shaped pipeline, and the rest part of the conveying pipeline is a straight pipeline section; the negative-pressure detection device comprises a pressure sensor, an electromagnetic flowmeter, a data acquisition card and a computer; the acoustic emission detection device comprises an acoustic emission sensor, a signal preamplifier, an acoustic emission detection instrument and a computer; the acoustic emission detection instrument is used for processing signals, and transmitting the signals to the computer of the acoustic emission detection instrument so as to analyze the signals.

Owner:NANJING TECH UNIV

Abyssal environment simulation device suitable for testing material corrosion behavior

InactiveCN103196819AEasy to useDissolved oxygen content stable controlWeather/light/corrosion resistanceHydraulic pumpNitrogen gas

The invention provides an abyssal environment simulation device suitable for testing material corrosion behavior. The abyssal environment simulation device comprises a high pressure autoclave, a hydrostatic pressure control system of simulated abyssal environment and a simulated environment monitoring control system. The hydrostatic pressure control system of simulated abyssal environment comprises a nitrogen cylinder, an oxygen cylinder, a water tank, a liquid supply tank and a hydraulic pump, artificial sea water is stored in the water tank, a water pump injects the artificial sea water into the liquid supply tank, the nitrogen cylinder and the oxygen cylinder are connected with the liquid supply tank, and the hydraulic pump is connected between the liquid supply tank and the high pressure autoclave so as to inject the artificial sea water meeting the dissolved oxygen content into the high pressure autoclave; the simulated environment monitoring control system comprises a compound sensor, a working electrode, a reference electrode, a temperature control device, a singlechip signal processor and a computer. The abyssal environment simulation device can simulate the characteristic environment parameters, such as the hydrostatic pressure, the environment temperature, the dissolved oxygen content, the pH value, the flow rate and the salinity, of the corrosive medium for the material in the abyssal environment, and is used for testing the related corrosion electrochemistry behaviors of the material in the simulated abyssal environment.

Owner:三亚哈尔滨工程大学南海创新发展基地

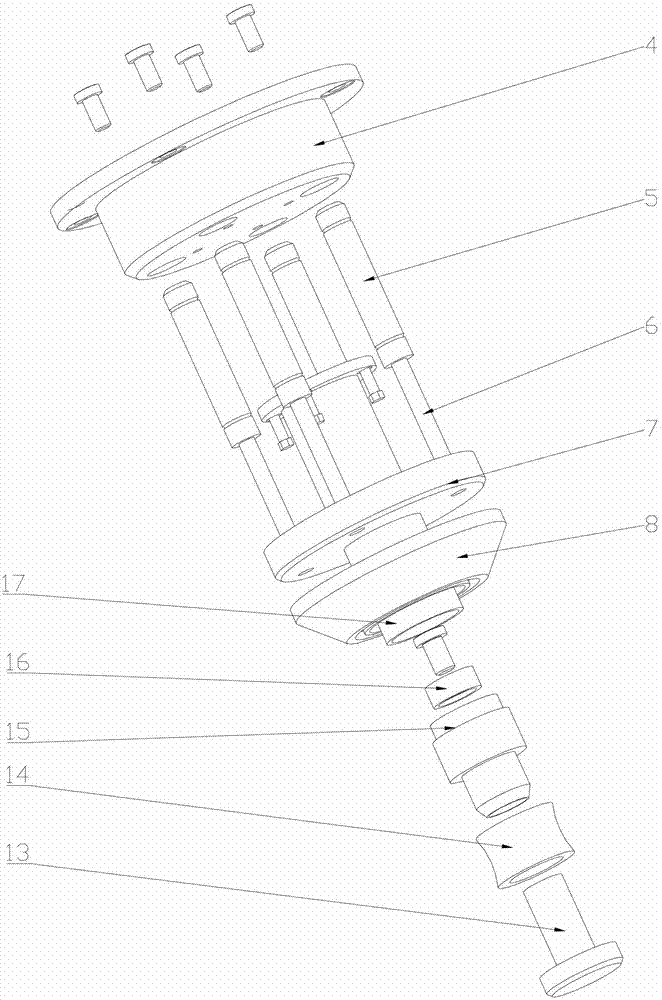

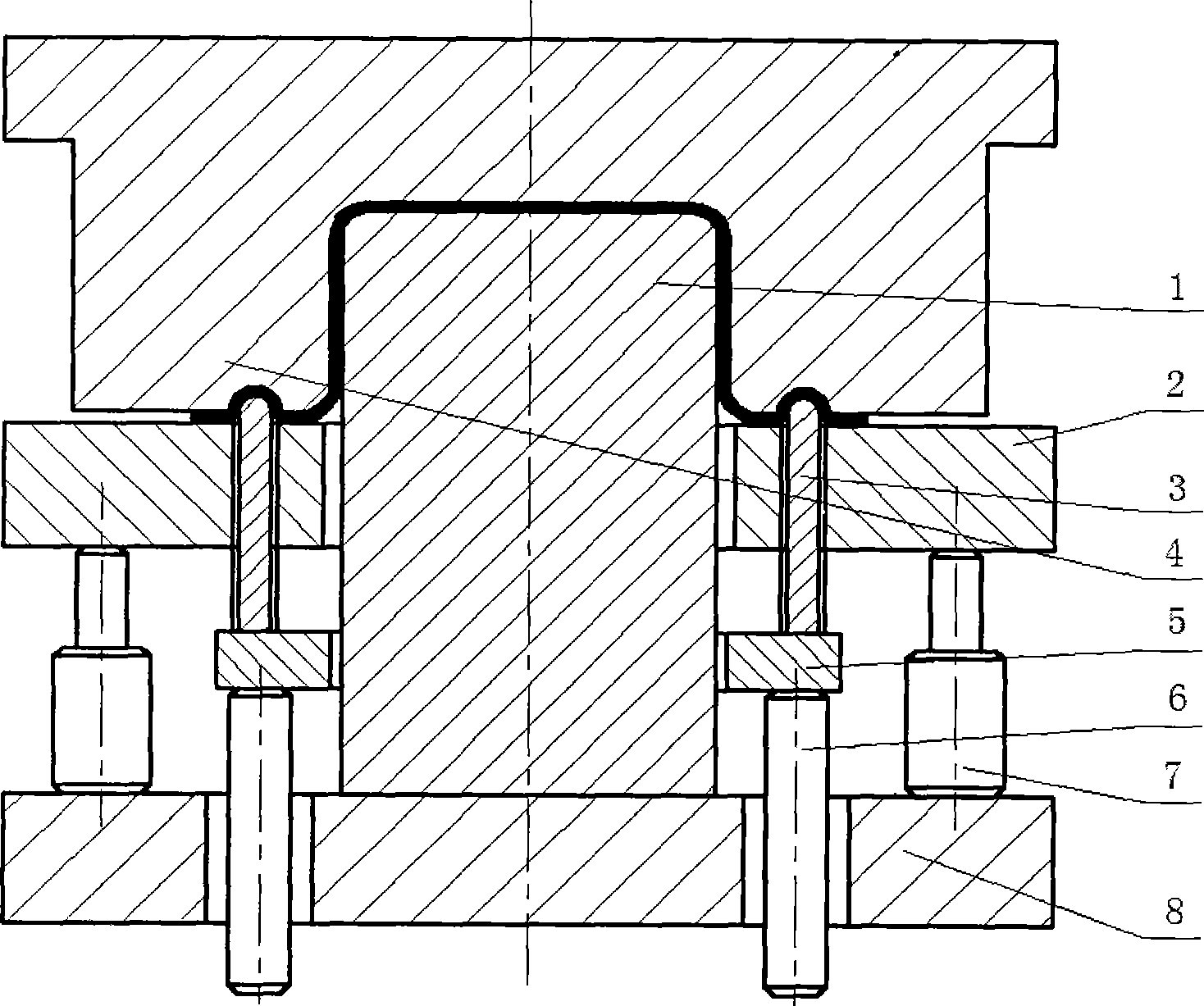

Several-time drawing formation device for deep-cylinder-shaped piece

InactiveCN103084483AControl flowGuaranteed deep drawing processShaping toolsPolyurethane elastomerBall bearing

Disclosed is a several-time drawing formation device for a deep-cylinder-shaped piece. The several-time drawing formation device for the deep-cylinder-shaped piece comprises an upper die base and a lower die base. The upper die base and the lower die base are connected with guide pillars through ball bearing guide bushings, a protrusion locating piece is fixedly installed on the upper die base, nitrogen cylinders are arranged on the lower end of the protrusion locating piece, piston rods of the nitrogen cylinders and blank holders tightly press blank materials through a groove at the lower end of a rubber block, a protrusion main body is installed on the protrusion locating piece and is composed of a protrusion die, a polyurethane elastomer, a locating ring, a pressing plate and a protrusion die connecting piece, a cone-shaped concave mould is fixed on the lower die base, and an ejector rod ejects out a workpiece after several-time drawing are finished. Due to the fact that a nitrogen cylinder flange pressing device and the polyurethane elastomer are both used on the several-time drawing formation device for the deep-cylinder-shaped piece, efficiency and quality of drawing formation can be ensured.

Owner:XI AN JIAOTONG UNIV +1

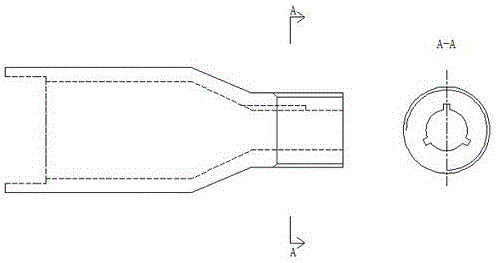

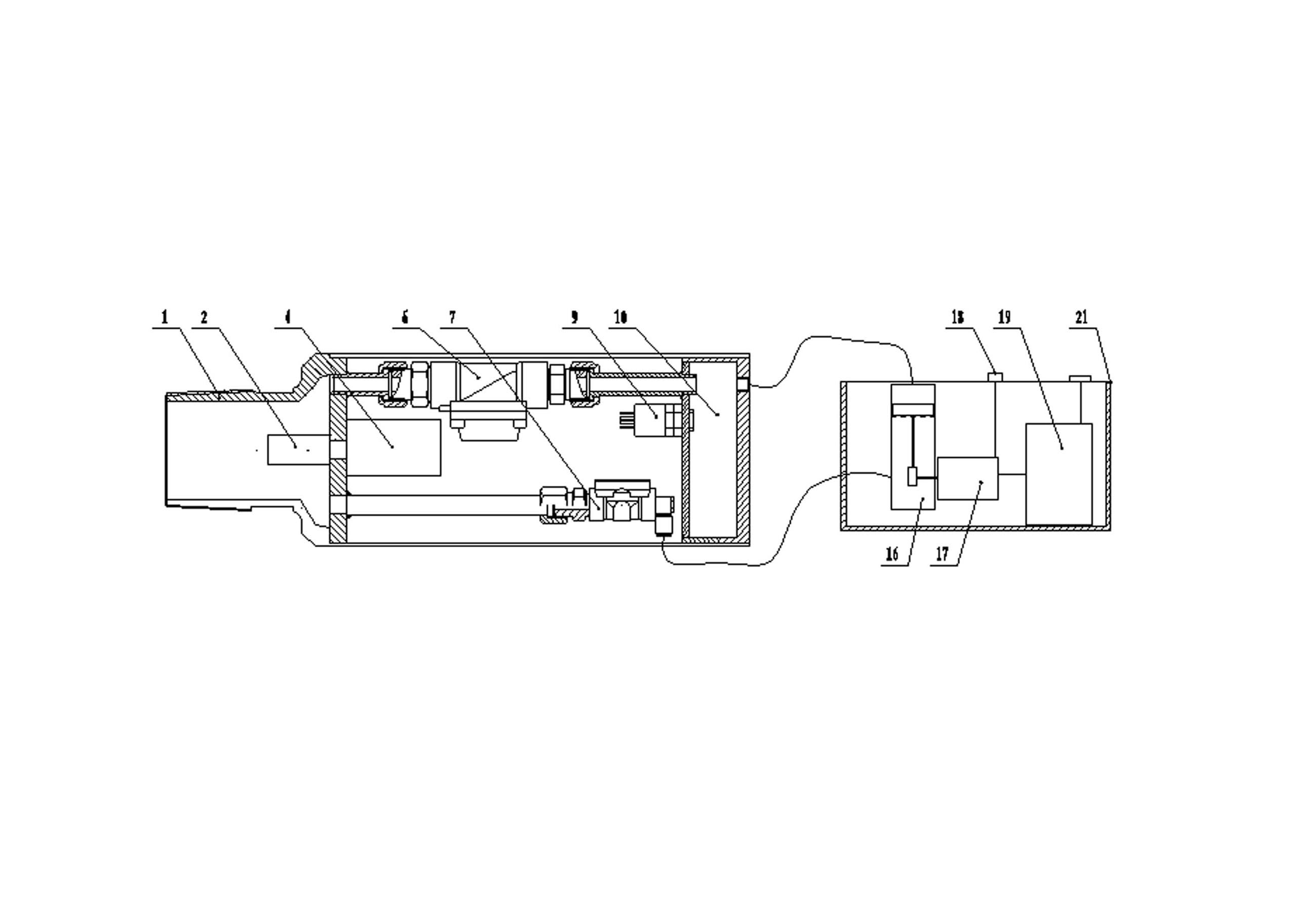

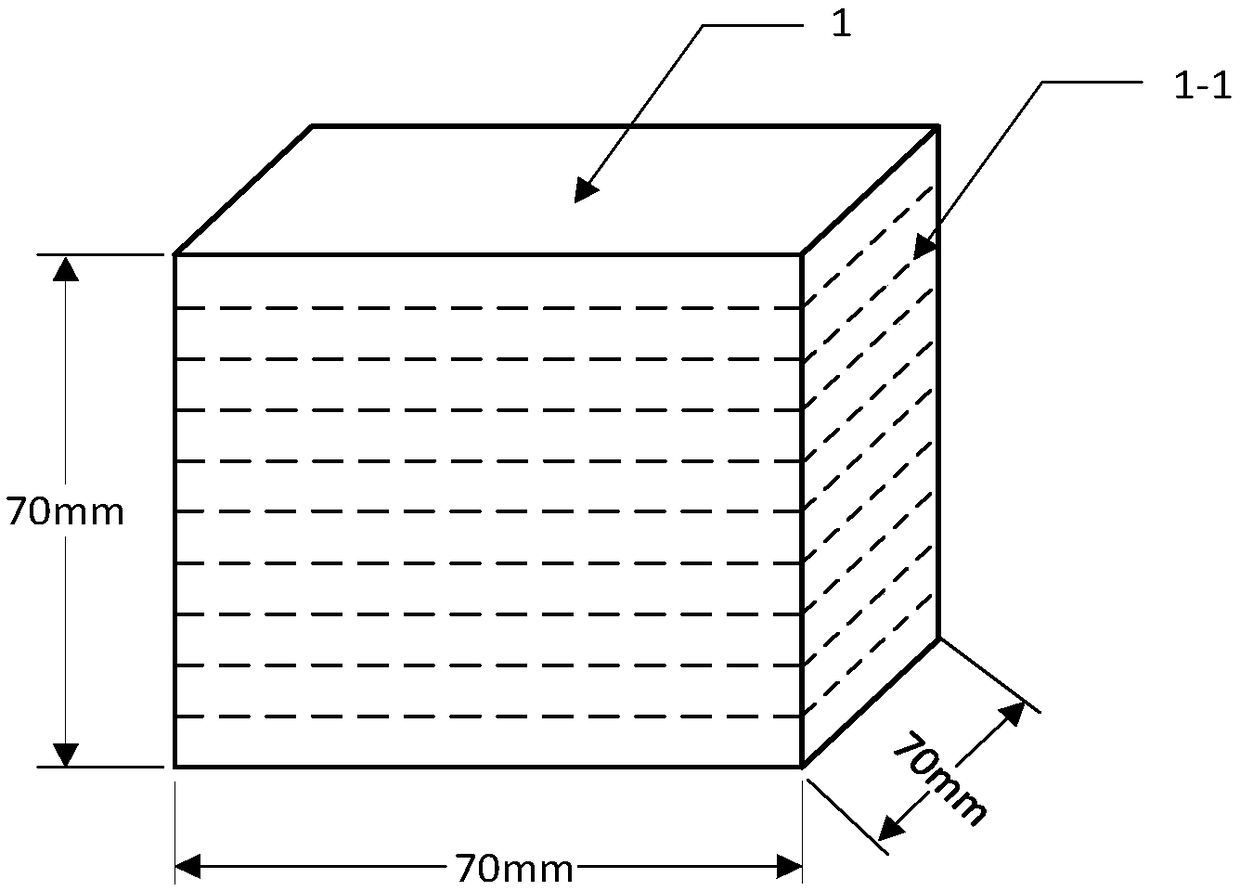

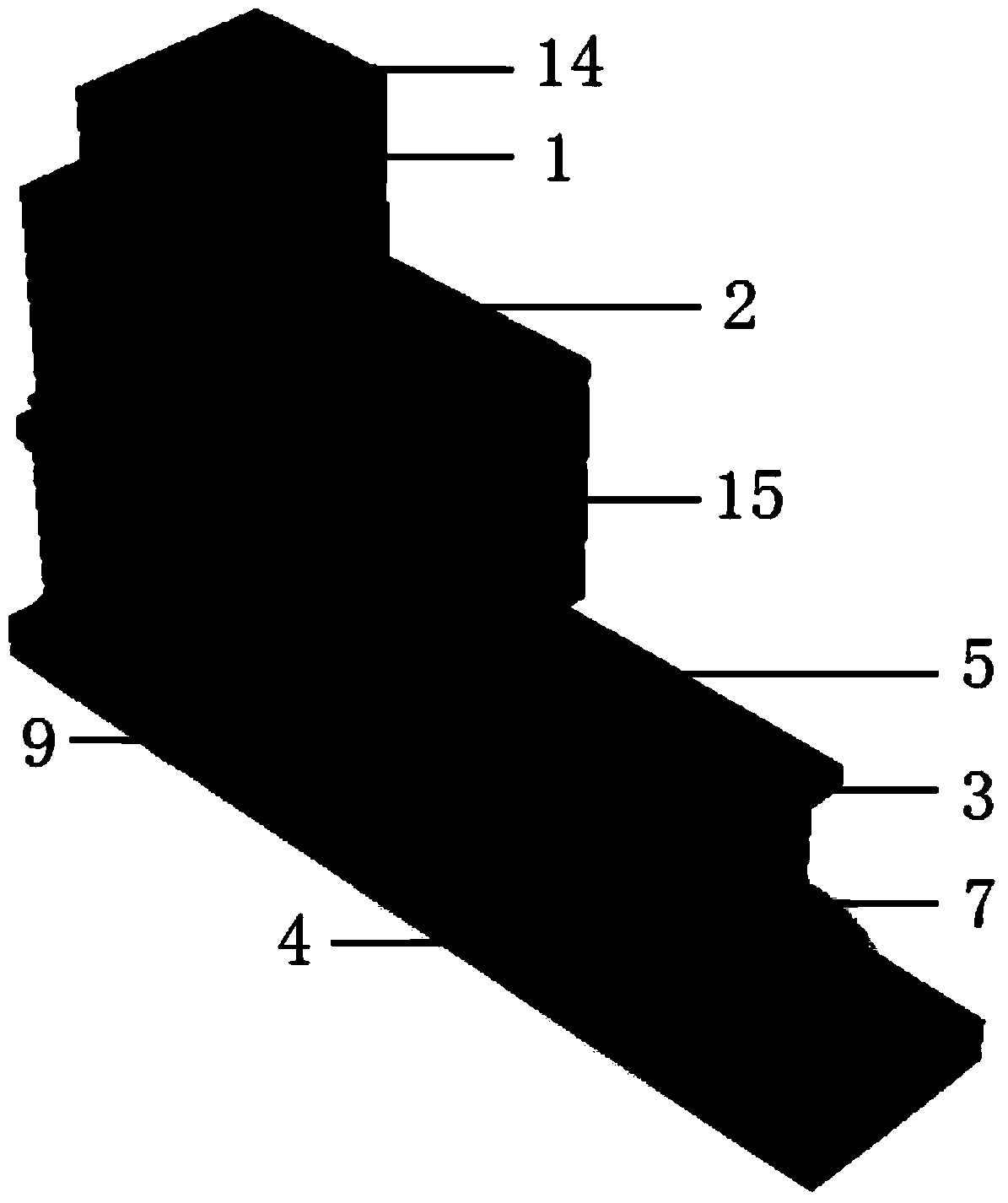

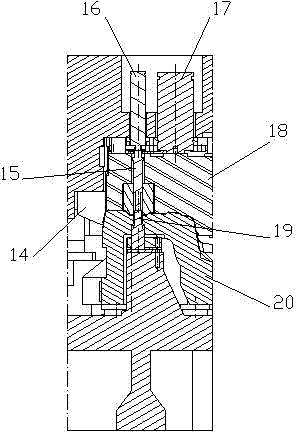

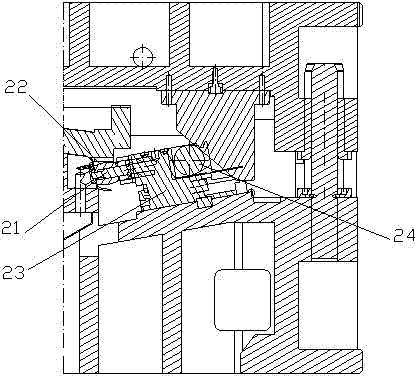

Low-temperature abrasive jet machining device

ActiveCN106670983AHigh removal rateRealize processingAbrasive feedersAbrasive machine appurtenancesLiquid nitrogen containerHydrophobic polymer

A low-temperature abrasive jet machining device is characterized by comprising an abrasive jet generation system, a cooling system and a machining system. The abrasive jet generation system mainly comprises a nitrogen cylinder (1), a grinding bin (2), a gas-powder mixing device (15), an abrasive jet pipe (8) and an abrasive jet nozzle (14). The cooling system mainly comprises a self-pressurizing liquid nitrogen container (5), a liquid nitrogen safe valve (4) and a cooling pipe (16); and one end of the cooling pipe (16) is connected with the self-pressurizing liquid nitrogen container (5) through the liquid nitrogen safe valve (4), and the other end of the cooling pipe (16) is connected with a composite nozzle (11). The abrasive jet pipe (8) and the abrasive jet nozzle (14) connected with the abrasive jet pipe (8) are both installed in the cooling pipe (16) so as to achieve cooling in the flowing process of abrasives, and while the abrasives are ejected out of the abrasive jet nozzle (14), the abrasives are mixed with low-temperature nitrogen entering the composite nozzle (11) through the cooling pipe (16) and then are ejected to a workpiece (13) through an ejection port of the composite nozzle (11). According to the low-temperature abrasive jet machining device, the structure is simple, machining efficiency is high, and the problem of low-temperature quick machining of a hydrophobic polymer is solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

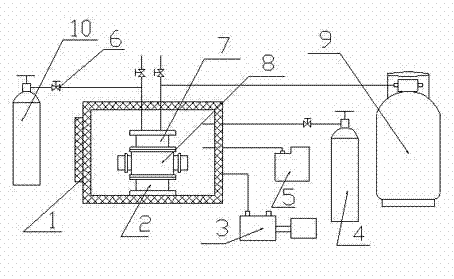

Accumulator ultralow-temperature leak test device and method

ActiveCN104713684AUltra-low temperature leak detection is convenientDetection of fluid at leakage pointEngineeringHelium mass spectrometer

The invention provides an accumulator ultralow-temperature leak test device and method. The device is mainly composed of a vacuum leak test box for containing an accumulator, a liquid nitrogen low-temperature dewar flask connected with the vacuum leak test box through a pipe with a stop valve, a helium cylinder, a nitrogen cylinder, a vacuum pump, a compressed air source, a pressure gauge located in the vacuum leak test box, a temperature sensor, a sealing tool for vertically sealing the accumulator, a glove operation connector located on a box body and the like. The sealing tool is provided with three holes, namely a liquid nitrogen injection opening, a liquid nitrogen discharge opening and a helium injection opening, and the three holes are connected into the external liquid nitrogen low-temperature dewar flask, a safety discharge region and the helium cylinder through inside-outside connection pipes of the vacuum leak test box respectively. Furthermore, the vacuum leak test box is further provided with a helium mass spectrometer access opening, one end of the helium mass spectrometer access opening is connected with an external helium mass spectrometer, and the other end of the helium mass spectrometer access opening is located in a suction cavity in the helium mass spectrometer. By means of the accumulator ultralow-temperature leak test device, ultralow-temperature leak test can be conducted on the accumulator conveniently.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Automatic infrasonic wave non-pressure oil well liquid level monitoring instrument

InactiveCN102022108AAutomatic continuous and stable workSurveyConstructionsInfrasonic wavesAcoustic wave

The invention relates to an automatic infrasonic wave non-pressure oil well liquid level monitoring instrument. A gas storage chamber, a gas chamber pressure sensor, a gas emission device, an infrasonic wave receiving and processing device and a gas-collecting device are arranged in a shell of the monitoring instrument; the gas chamber pressure sensor is connected with the gas storage chamber; the monitoring instrument is also provided with a gas generation device; a gas inlet of the gas generation device is connected with the gas-collecting device through a pipeline; and a gas outlet of the gas generation device is connected with the gas storage chamber through a pipeline. The automatic infrasonic wave non-pressure oil well liquid level monitoring instrument extracts gas from an oil well sleeve, and pressurizes and injects the gas into the gas storage chamber to generate an infrasonic wave pulse required by the measured liquid level; and gunpowder sound bombs or nitrogen cylinders are replaced, so that the automatic infrasonic wave non-pressure oil well liquid level monitoring instrument can work on the non-pressure oil well for a long time automatically, continuously and stably.

Owner:SHENYANG SENSOR TECH

Tester for testing discount rule of water pressure of grouting circle of anti-water pressure emission-limit tunnel

InactiveCN101893617ARealize simulationEasy to controlUnderground chambersFluid pressure measurementPore water pressureEngineering

The invention relates to a tester for testing a discount rule of a water pressure of a grouting circle of an anti-water pressure emission-limit tunnel, comprising a pressure chamber, a simulation tunnel, pressurized equipment and measurement equipment, wherein the pressurized equipment comprises a nitrogen cylinder, a control valve, a pressure regulating valve, a switch, a water tank and an air-water exchange tank; the pressure chamber is a cylindrical container, comprising a switch, a flange plate, a support and a pressure chamber sleeve; the pressurized equipment utilizes the nitrogen cylinder combining with the air-water exchange tank for pressurization to provide a stable osmotic pressure for the pressure chamber; the simulation tunnel, a simulation grouting material and stimulation wall rock are placed in the pressure chamber; the diameter of the grouting material can be converted according to test requirements and geometric similarity; and the simulation tunnel can be precasted into be of different shapes and sizes according to the test requirements and geometric similarity. The measurement equipment can realize accurate measurement on pressure and flow rate. The tester can be used for researching the discount rule of hydraulic pressure of the grouting circle of the anti-water pressure emission-limit tunnel.

Owner:TONGJI UNIV

Automatic testing method of wire line coring drilling hoisting-free pressurized water test

ActiveCN102221712AQuality improvementImprove efficiencySurveyGeological measurementsCoringStreamflow

The invention relates to an automatic testing method of a wire line coring drilling hoisting-free pressurized water test. The method effectively solves the problems of accurately measuring the pressure in a pressurized water test section and fully exerting the advantages of automatic testing of the wire line coring drilling hoisting-free and pressurized water test. The method comprises the following steps of: drilling a rock by using a drilling tool, taking out the rock core when the drilled hole reaches the test length, uplifting a hollow drill rod, hoisting a pressurized water test embolismby using an inflatable rubber tube, filling the pressurized water test embolism into the hollow drill rod, making the pressurized water test embolism extend out of a drill bit at the lower part of the hollow drill rod, communicating the inflatable rubber tube and a nitrogen cylinder, charging air to the embolism, closing the hollow drill rod and the drilled hole, connecting a pressure sensor of the test section and a flow sensor outside the drilled hole to a pressurized water test comprehensive tester through cables, sealing with an orifice sealer, pressurizing water to the drilled hole section by using a water pump through the orifice sealer and the hollow drill rod, and acquiring data. According to the automatic testing method disclosed by the invention, wire line coring, pressurized water test and automatic testing are fused together, therefore the exploration quality and the exploration efficiency of deep holes in water conservancy and water electricity are greatly improved, and the labor intensity is effectively reduced.

Owner:YELLOW RIVER ENG CONSULTING

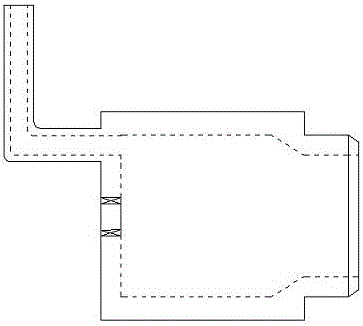

Mould with alterable brake bead resistance

This invention discloses a mould with alterable brake bead resistance, comprising a punch, a matrix, a pressure plate, a brake bead, a brake bead bolster, an ejector rob and a nitrogen cylinder. The brake bead is separated from the matrix or the pressure plate, and the brake bead passes through the matrix or the pressure plate upwards, the lower end of the brake bead contact with the upper end of the ejector rob through the brake bead bolster. The ejector rob of the air cushion of the machine tool pushes the brake bead bolster and the brake bead bolster moves, the height of the brake bead is controlled by the air cushion through the ejector rob. In the entire drawing process, the brake bead resistance changes with the change of the stamping route. The brake bead resistance of this mould can be controlled easily and it is very useful to improve the quality of the product.

Owner:重庆工学院

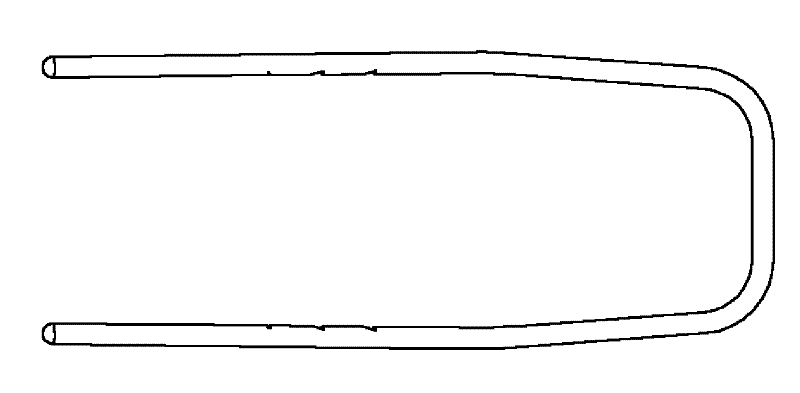

Leak detection device for U-shaped waste heat boiler pipe column

InactiveCN102384827AEasy to detectLeak detection is accurate and convenientDetection of fluid at leakage pointGas cylinderProcess engineering

The invention relates to a leak detection device for a U-shaped waste heat boiler pipe column, and aiming to realize the purpose, the invention adopts the technical scheme that a compression ring is arranged on one side of a pipe plate far from an opening of a casing and connected with the casing; test paper is attached on the end surface of the pipe plate near to the compression ring and two end ports of each U-shaped pipe; a nitrogen bottle and an ammonia bottle are connected to a water inflow interface respectively and communicated with a main valve through a first valve and a second valve respectively; a first ammonia pressure gauge is arranged between the main valve and the water inflow interface; a first interface is connected with a second ammonia pressure gauge through a third valve; closure plates used for sealing a steam outlet and a second interface are arranged at the steam outlet and the second interface respectively; and an emptying valve is arranged at a discharge outlet and connected with a water tank. Through adopting the technical scheme, the leak detection device forms an independent closed system through introducing ammonia and nitrogen in the casing and closing all the valves connected with the container, and the position of a leakage point can be found out as the ammonia can be effused out through a leakage point and color change occurs at the display paper.

Owner:ANHUI HUAIHUA

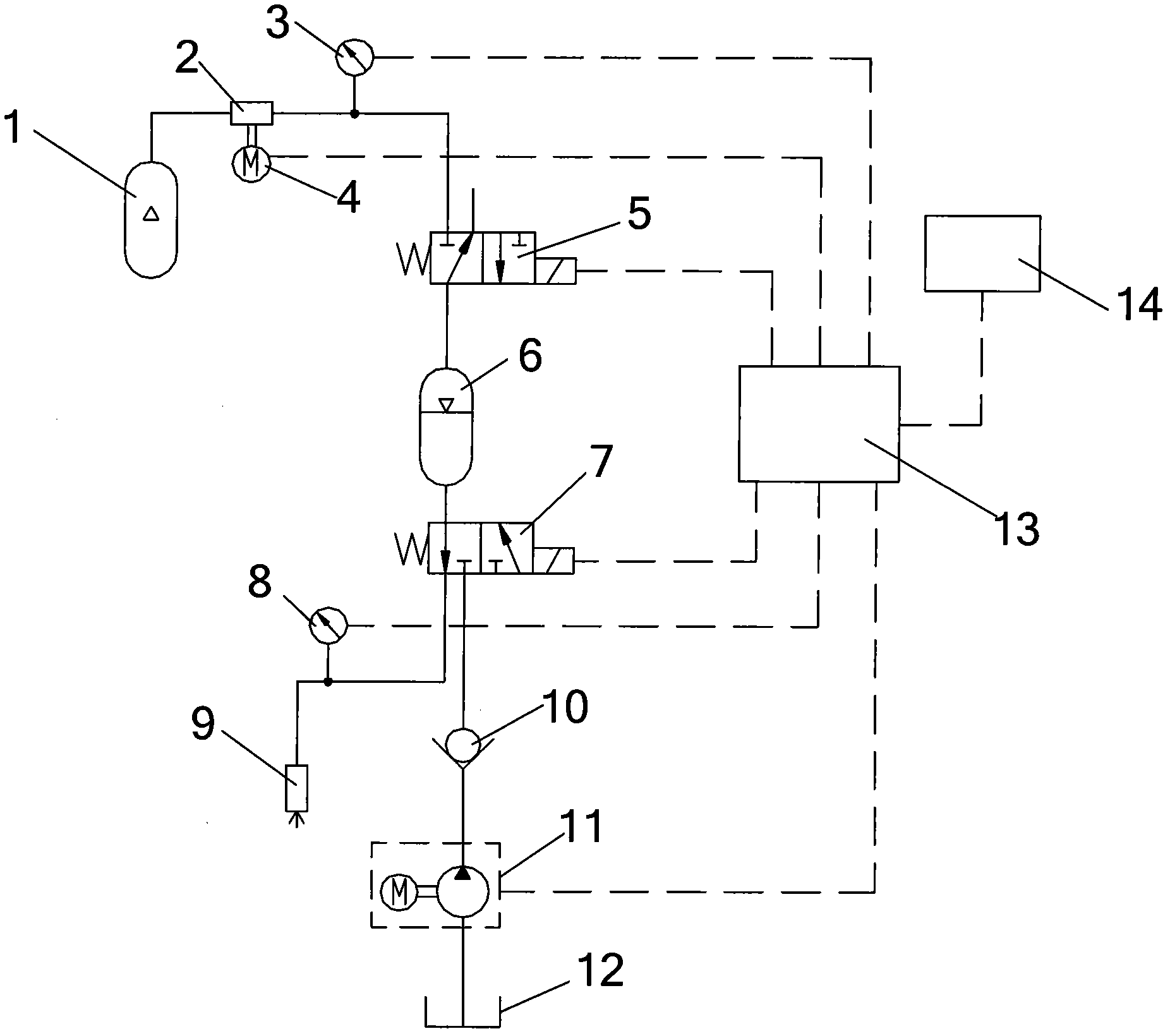

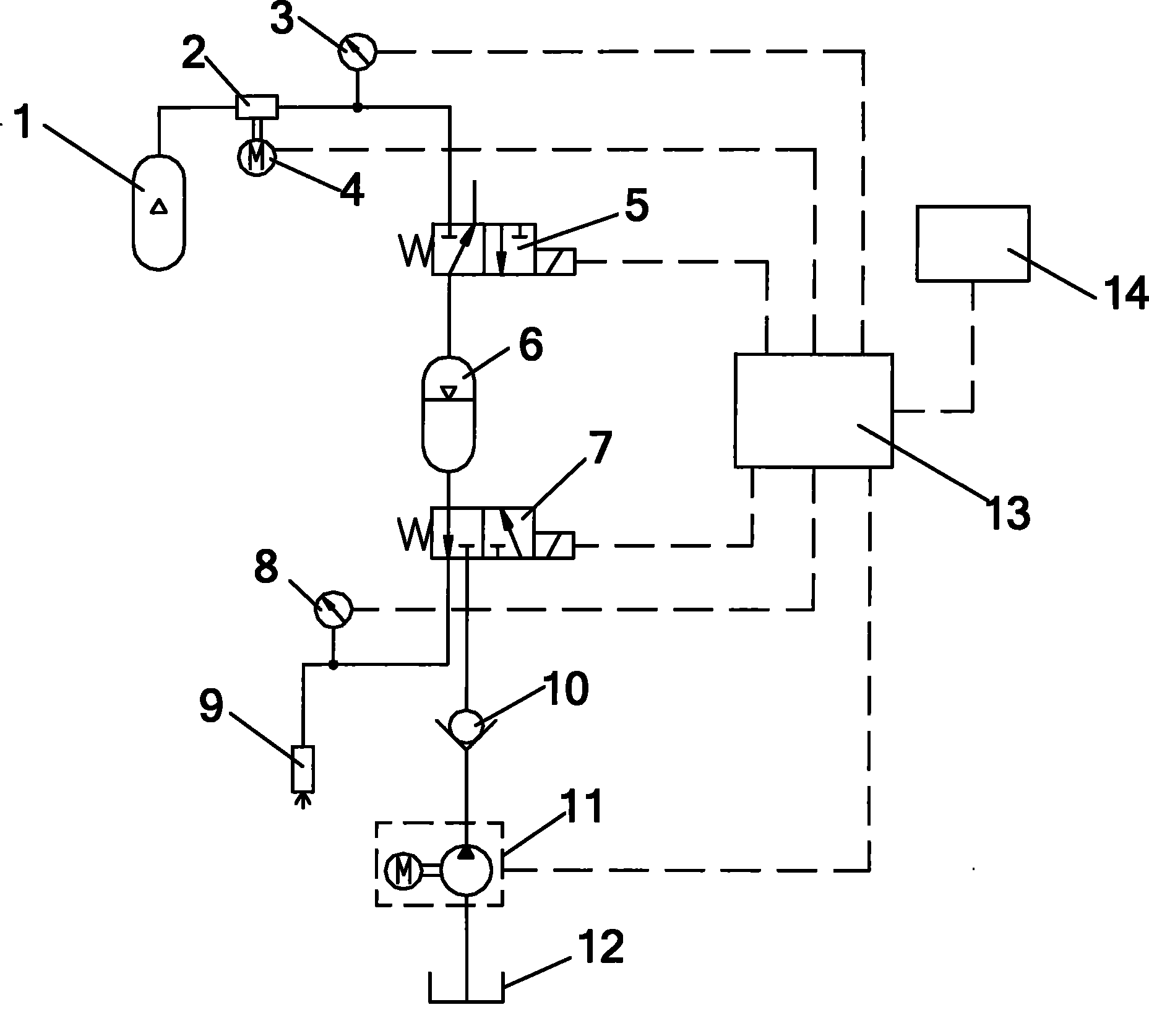

Stabilized-pressure oil supply system of high-pressure direct-injection injector and control method thereof

InactiveCN101963120AOil pressure fluctuation is smallMeet the requirements of the experimentElectrical controlEngine testingFuel tankHigh pressure

The invention provides a stabilized-pressure oil supply system of a high-pressure direct-injection injector and a control method thereof. The stabilized-pressure oil supply system mainly comprises a high-pressure nitrogen cylinder, a pressure reducer, a step motor, a pressure sensor A, a two-position three-way electromagnetic valve A, an accumulator, a two-position three-way electromagnetic valve B, a pressure sensor B, an injector, a check valve, a fuel pump, an oil tank, a controller and a display screen. The stabilized-pressure oil supply system can automatically regulate the injection pressure of the injector of the stabilized-pressure oil supply system to a set injection pressure through the controller of the stabilized-pressure oil supply system according to the pressure parameter set on the display screen and can reduce the oil pressure fluctuation in the injection of the injector. The stabilized-pressure oil supply system has an accumulator oil supply path, so the fuel supply to the accumulator can be realized without detaching the pipe.

Owner:BEIHANG UNIV

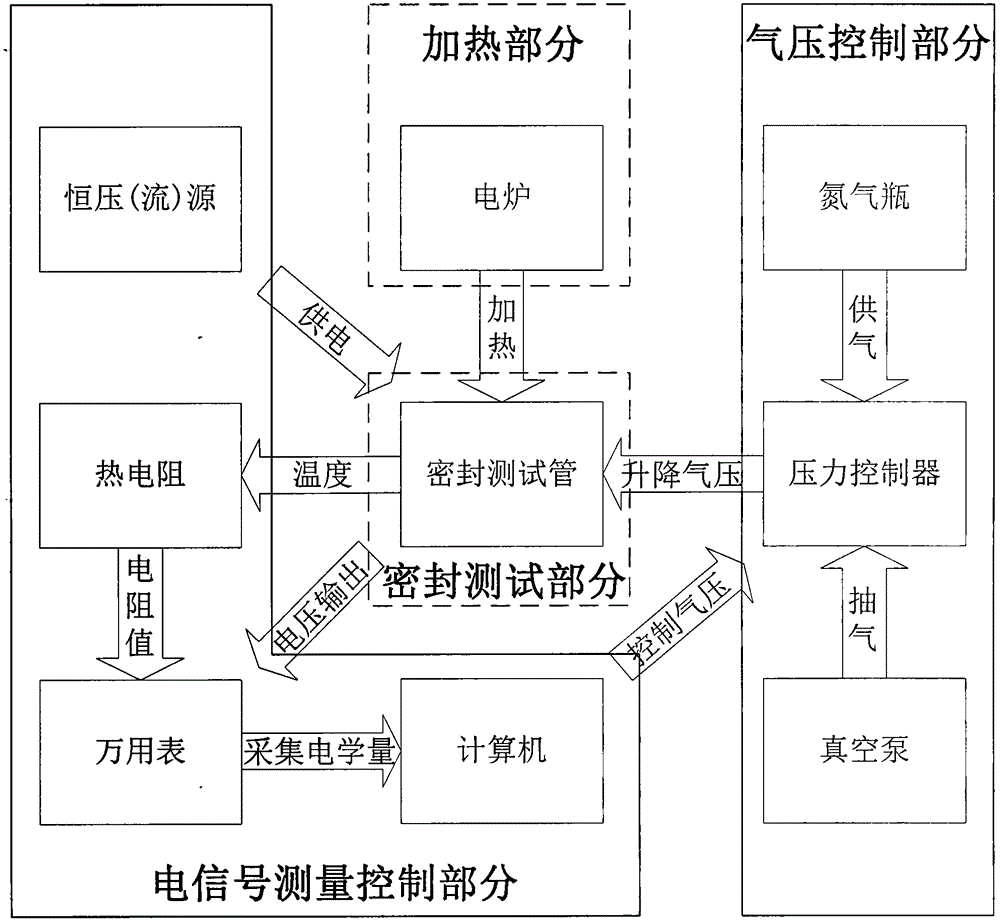

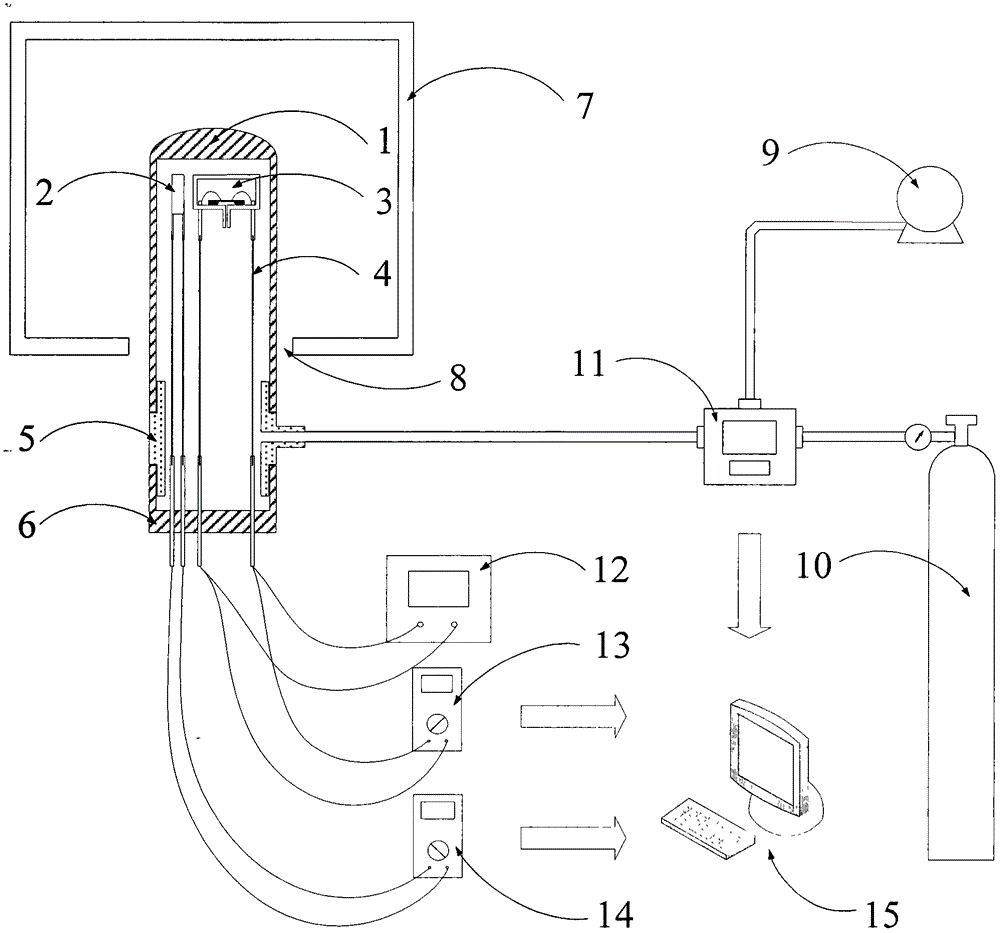

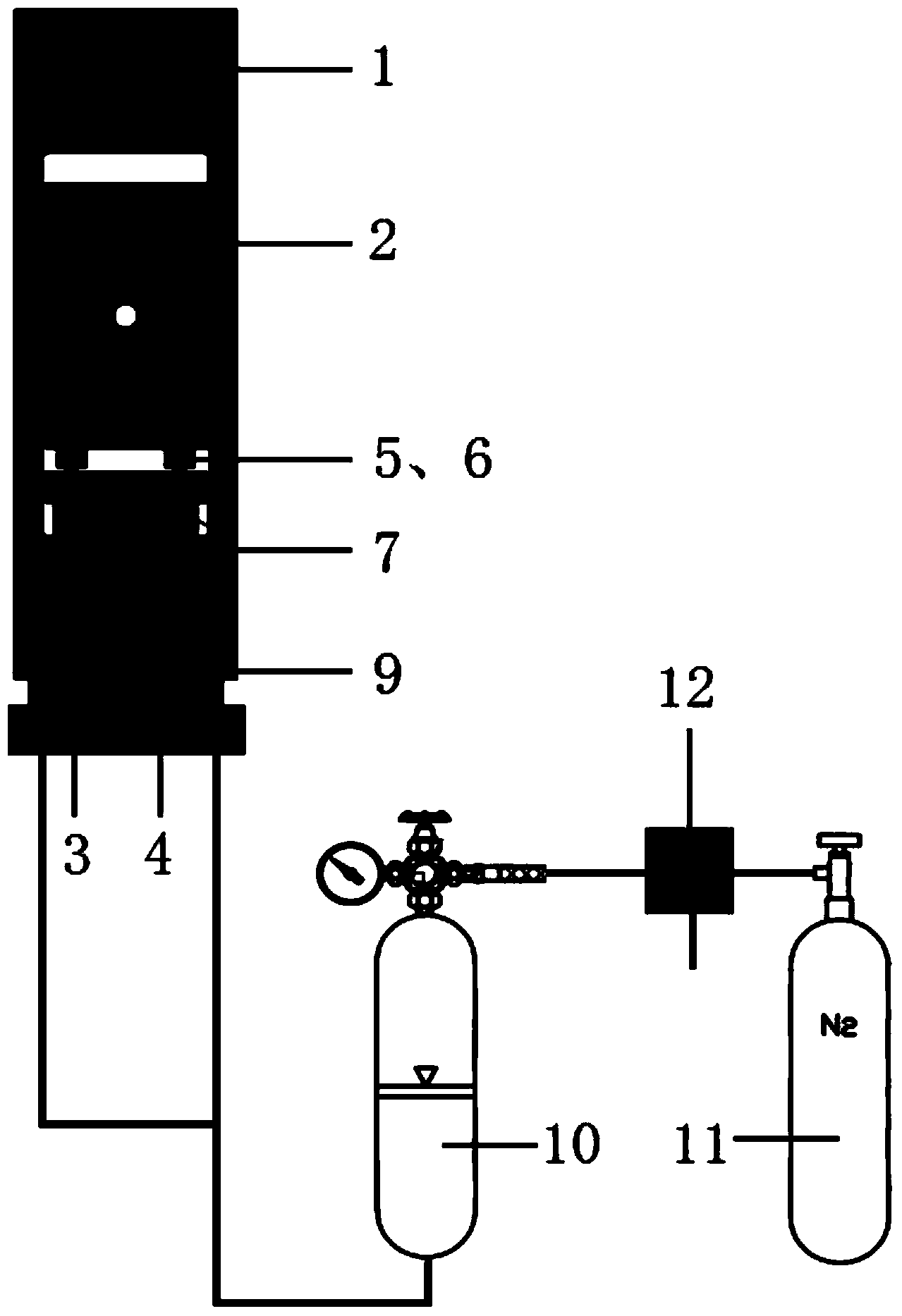

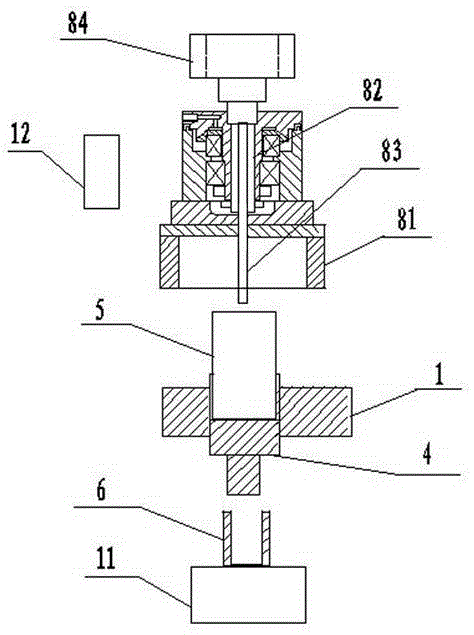

Testing device for high-temperature pressure sensor

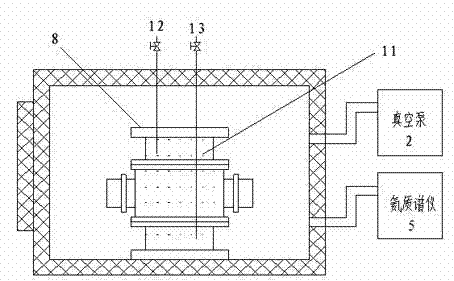

ActiveCN104568310AImprove sealingSolve the sealing problemFluid pressure measurementAviationEngineering

The invention discloses a testing device for an ultrahigh-temperature pressure sensor. The testing device for the high-temperature pressure sensor comprises a sealed testing part, a heating part, an air pressure control part and an electric signal measurement control part, wherein the sealed testing part is composed of a stainless steel tube 1, a thermal resistor 2, a tee fitting 5 and an aviation plug 6, one end of the stainless steel tube 1 is sealed while the other end of the stainless steel tube 1 is open, the sealed testing part is used for providing a needed sealed environment for the high-temperature pressure sensor, the heating part is composed of an electric furnace 7 and is used for providing a needed high-temperature environment for the high-temperature pressure sensor, the air pressure control part is composed of a vacuum pump 9, a nitrogen cylinder 10 and an air pressure controller 11 and is used for providing needed different and stable air pressures in the testing process of the pressure sensor, and the electric signal measurement control part is composed of a constant voltage / current source 12, a multimeter 13, a multimeter 14 and a computer 15 and is used for collecting testing data and achieving signal control. The testing device for the high-temperature pressure sensor can provide the sealed and reliable high-temperature testing environment with the high temperature not smaller than 600 DEG C for the high-temperature pressure sensor.

Owner:PEKING UNIV

Temperature controllable deep cooling treatment system bases on natural circulation

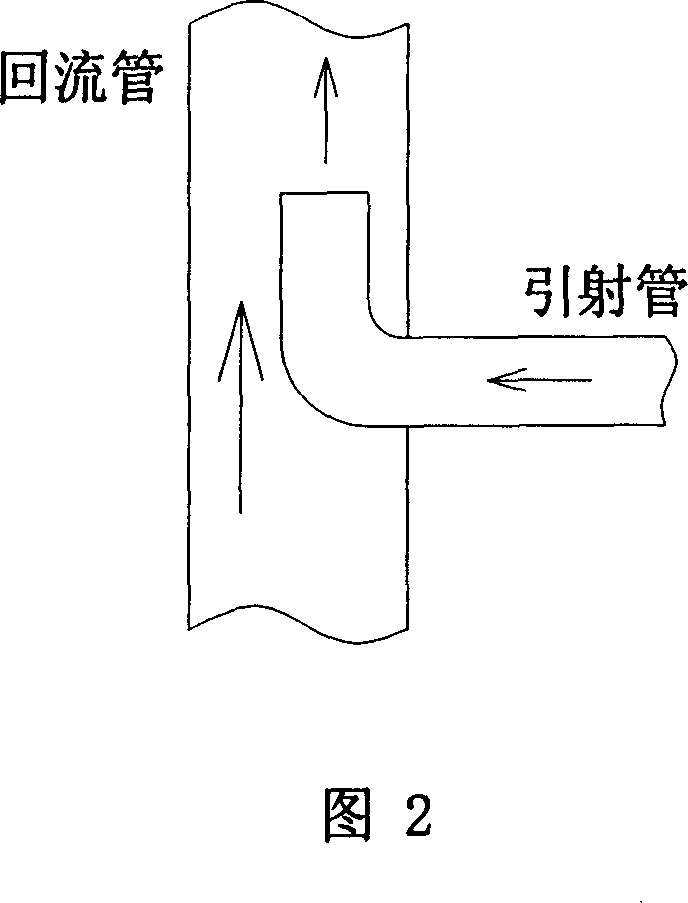

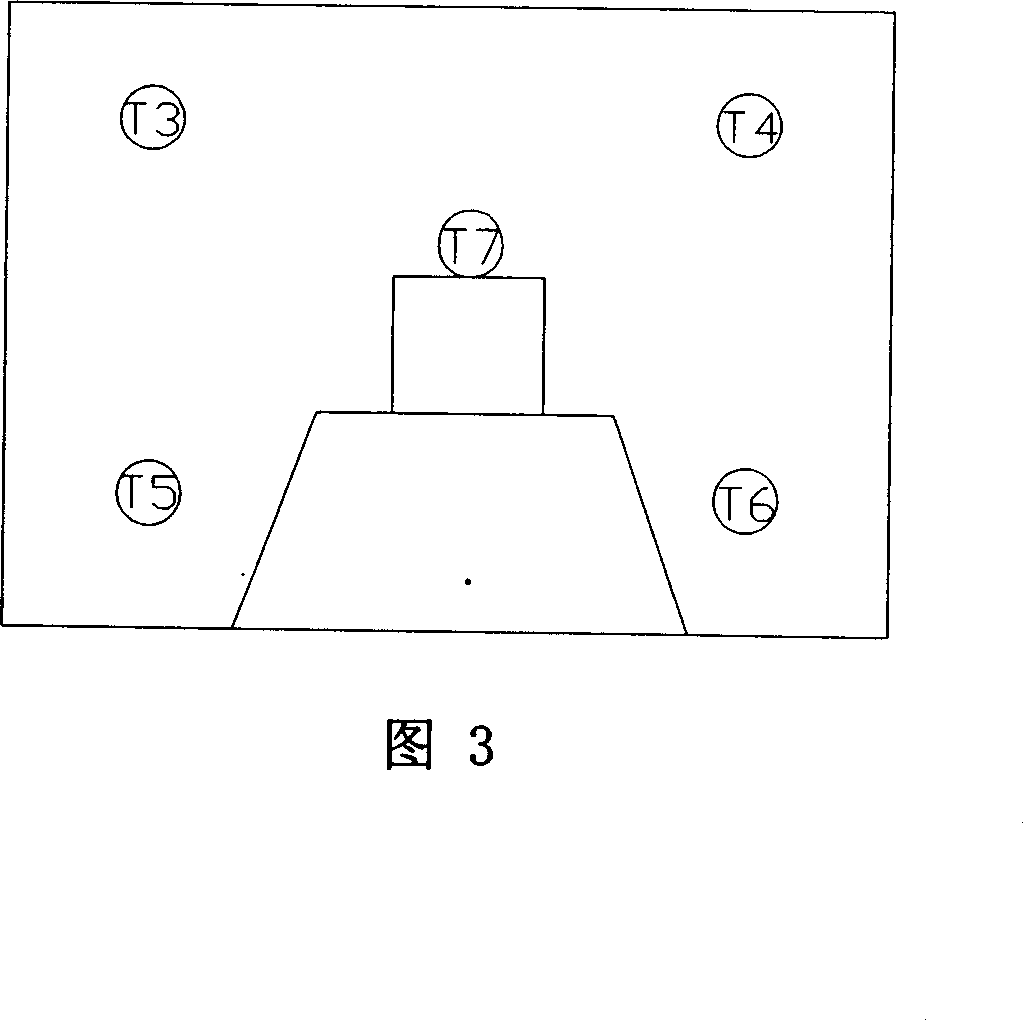

InactiveCN1948516ASave cycle powerSave liquid nitrogen consumptionLiquid nitrogen coolingData acquisition

The invention discloses a system of treatment by deep cooling with temperature controlling based on natural circulation. The system is composed of liquid nitrogen tank, filling port, perfusion valve, perfusion tube, heat insulating layer, cold shield, treatment room for deep cooling, internal coil, external coil, pressure transducer of internal-coil entry, temperature transducer of internal-coil entry, fan, nitrogen cylinder, reducing valve, injection control valve, injection tube, pressure transducer of external-coil entry, temperature transducer of external-coil entry, temperature transducer in treatment room for deep cooling, reflux control valve, reflux tube, data acquisition of computer and control system. The system depends on pressure-difference resulting from different consistency of liquid nitrogen and gas nitrogen to impel coolant of liquid nitrogen for circular flowing. Adjusting of coefficient of heat transfer on the surface of work is realized conveniently by controlling flux of circulate liquid nitrogen and rotate speed of fan. The system has much strongpoint including saving circulate power and consumption of liquid nitrogen, easy to control cooling speed of treatment by deep cooling and treatment temperature etc.

Owner:ZHEJIANG UNIV

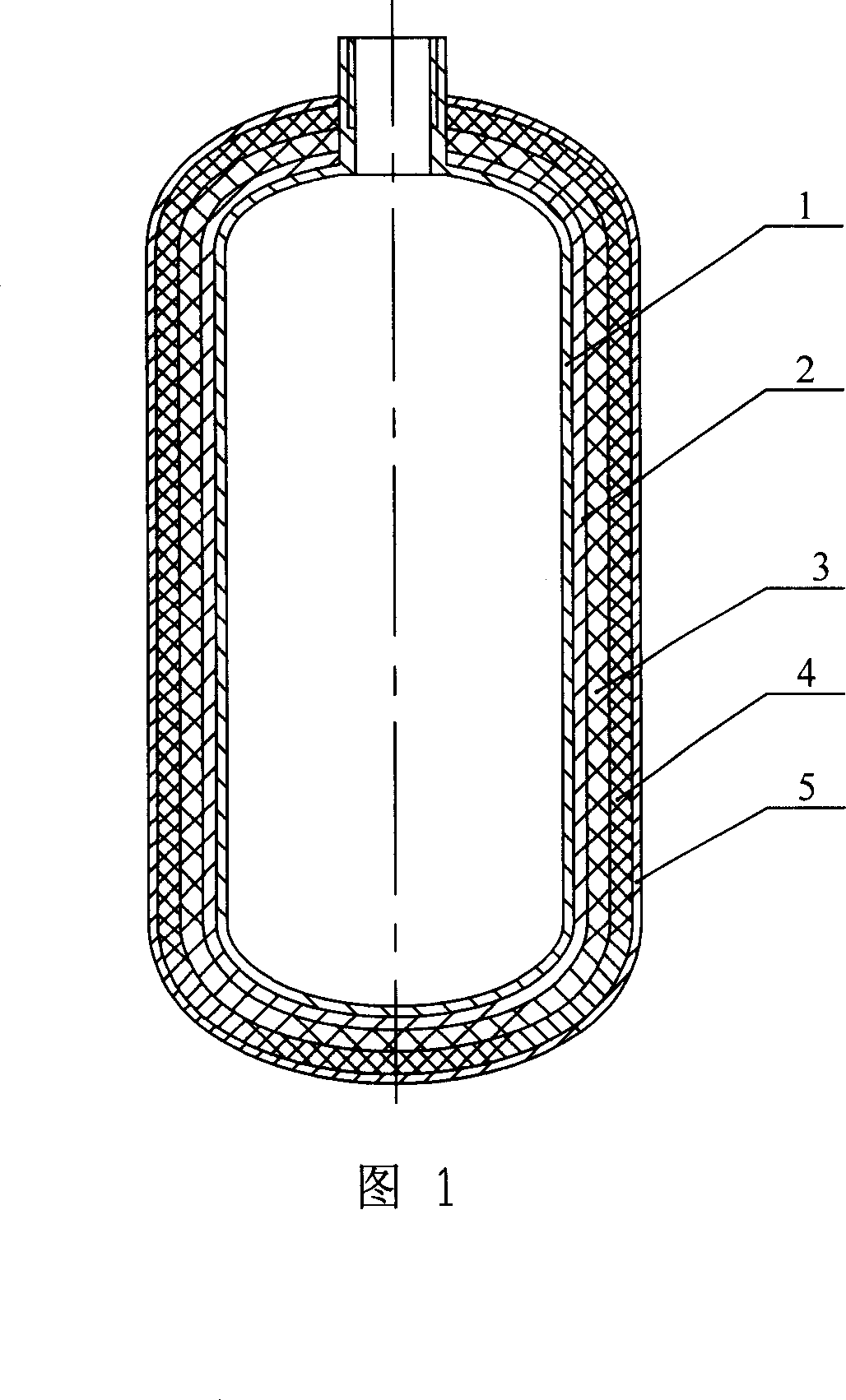

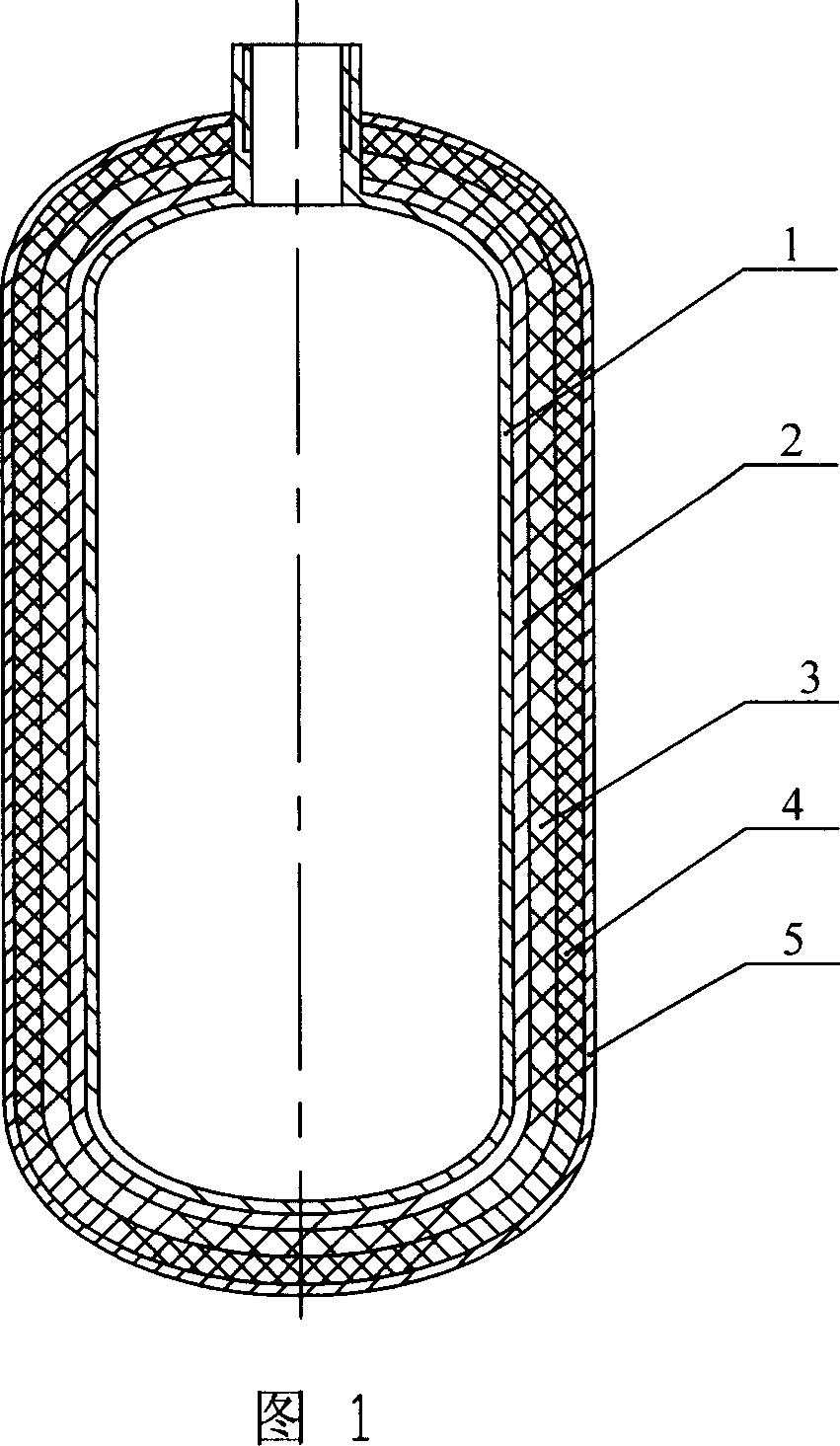

High pressure nitrogen storage bottle made of PBO fiber and carbon fiber composite material and its preparation method

InactiveCN1948816ATo achieve the purpose of structural optimizationSatisfy air tightnessPressure vesselsGlass fiberNeoprene

The invention relates to a nitrogen cylinder and its preparation method, in which, on the outside surface of the neoprene lining is bonded an adhesive layer and the outside surface of the adhesive layer is bonded to the inside surface of the inner structure layer of carbon fibre composite; the inside surface of the outer structure layer of PBO fibre composite is wound on the outside surface of carbon fibre composite inner structure layer and on the outside surface of the outer structure layer of PBO fibre composite is wound an outer protective covering of glass fibre composite. The method consists in: coating an adhesive layer on the outside surface of the lining; overlying a spiral and toroidal wound inner structure layer, an outer structure layer and an outer protective covering; curing and then getting the preset inventive nitrogen cylinder.

Owner:HARBIN INST OF TECH

Removing method for air in crosslinked polyethylene insulation power cable

InactiveCN101393789AAvoid quality hazardsInsulation effectInsulating conductors/cablesPower cableWork in process

The invention discloses a method of excluding gas from a cross-linked polyethylene insulated power cable. The method comprises the following steps: one end of a cable, which is a semi-finished article with a bulge after passing through an extruding machine, is communicated with an outlet formed on a gas pipe of a nitrogen cylinder, the pressure of the nitrogen cylinder is 1 to 2.5 MPa, and the other end of the cable is kept opened; the valve of the nitrogen cylinder is opened to allow the gas to continuously flow out from an opening end of the cable with the bulge beginning to disappear slowly, and the valve can be closed until the bulge has no gas to flow out. The method has the advantages of short time and good effect on excluding gas when the method is adopted to exclude the gas from the cross-linked polyethylene insulated power cable, and can totally exclude the gas existed between a cable sheath and insulated shielding, thereby avoiding potential quality troubles of the cable; the method greatly reduces the drying cost of a drying house through adopting high-pressure nitrogen to exclude the gas, thereby saving cost; and the method has the advantages of simple technology and convenient operation.

Owner:圣安电缆有限公司

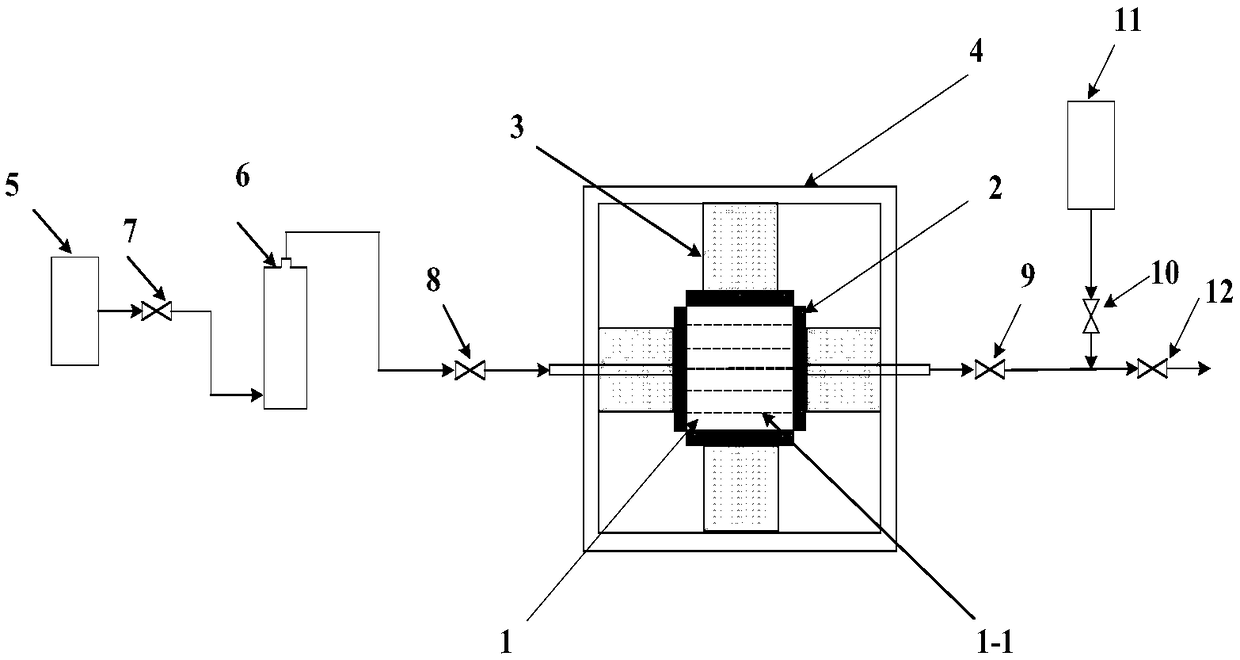

Shale gas well simulated reservoir fracture fracturing liquid flowback rate experimental measurement device and method

ActiveCN109490507AExperimental results are reliableImprove guidanceEarth material testingMaterial weighingMeasurement deviceFracturing fluid

The invention discloses a shale gas well simulated reservoir fracture fracturing liquid flowback rate experimental measurement device and method. The shale gas well simulated reservoir fracture fracturing liquid flowback rate experimental measurement device comprises a clamp, a press machine, a thermostat, a constant-speed and constant-pressure pump, an intermediate container, a constant-speed andconstant-pressure pump outlet valve, a fluid inlet valve, a fluid outlet valve, a nitrogen cylinder outlet valve, a nitrogen cylinder and an outlet valve. The method mainly comprises the steps of 1)rock sample preparation, 2) shale physical property parameter testing, 3) testing parameter calculation, 4) fracturing liquid preparation and density testing, 5) testing parameter testing, and 6) shale flowback rate calculation. The shale gas well simulated reservoir fracture fracturing liquid flowback rate experimental measurement device takes into comprehensive consideration the influence of stratum temperature, stratum stress and fluid pressure on shale flowback rate and quantifies influence factors to reflect the shale flowback rate under real stratum conditions and accordingly to providea theoretical basis for shale flowback scheme optimization.

Owner:SOUTHWEST PETROLEUM UNIV

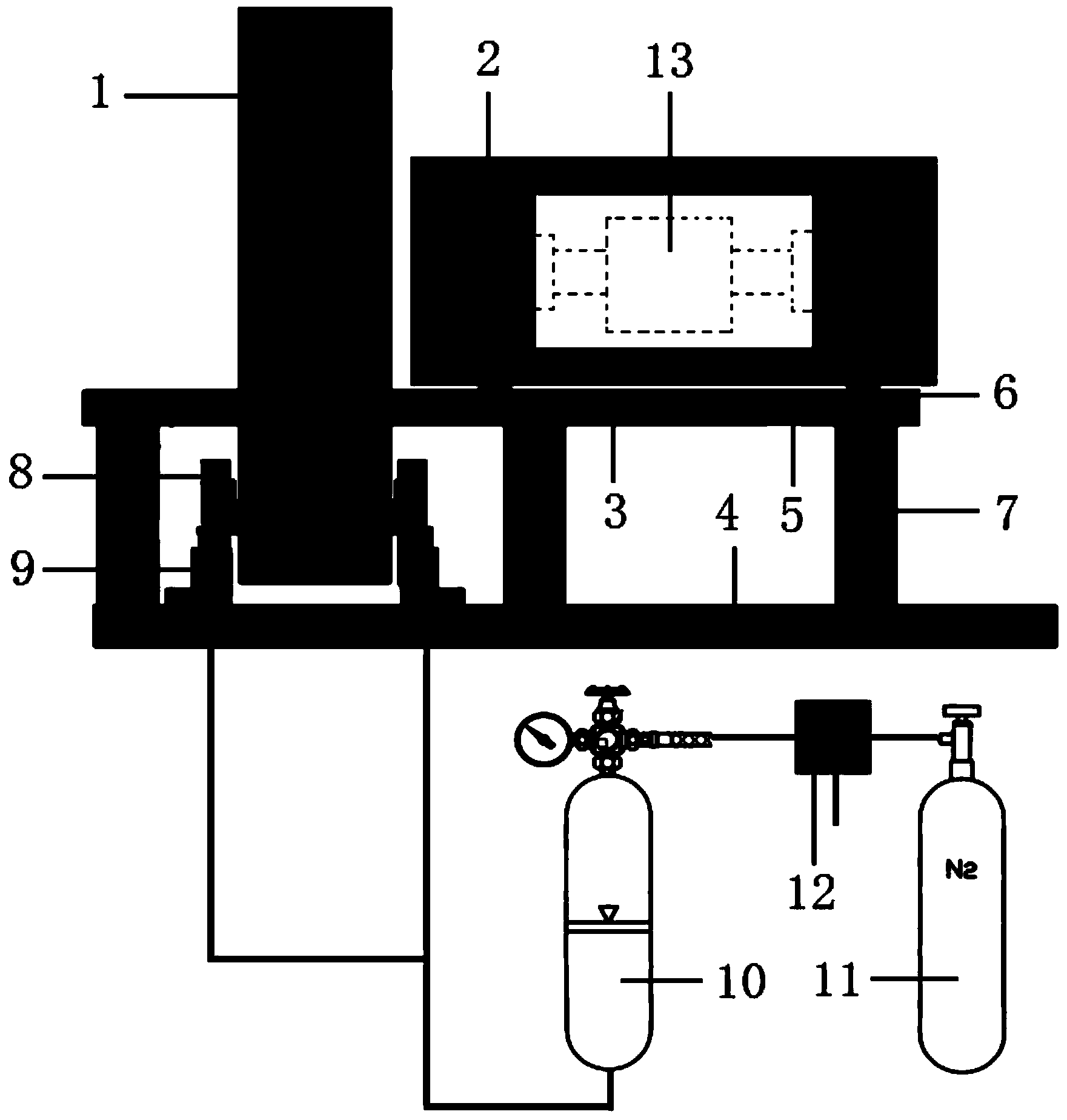

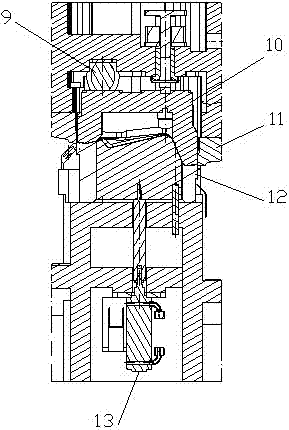

Rigid servo-actuated loading frame structure

ActiveCN103822831AReduce manufacturing costSatisfy the need for destructionMaterial strength using tensile/compressive forcesTriaxial shear testEngineering

A rigid servo-actuated loading frame structure belongs to the technical field of a hard rock true triaxial test machine, and can be used as a basic loading frame structure of the hard rock true triaxial test machine. The rigid servo-actuated loading frame structure comprises a frame unit and a pneumatic hydraulic balancing unit, a horizontal frame in the frame unit is arranged above an upper supporting platform, and the horizontal frame and the upper supporting platform are in sliding fit; the upper supporting platform is fixed above a lower supporting platform, the lower supporting platform is fixed on the ground; a vertical frame is arranged above the lower supporting platform, the vertical frame and the upper supporting platform are connected by a support oil cylinder of a pneumatic hydraulic balance unit; the support oil cylinder is communicated with an energy accumulator, the energy accumulator is communicated with a nitrogen cylinder through an electronic pressure regulating valve, and an electronic pressure regulating valve signal control end is connected to a main control computer; by use of the hard rock true triaxial test machine, a servo-actuated mode of the vertical frame and the horizontal frame can realize that a geometrical center of a rock specimen is invariant, and the vertical frame and the horizontal frame are produced by a whole casting process, and can fully meet the needs of hard rock after-pick failures.

Owner:NORTHEASTERN UNIV LIAONING +1

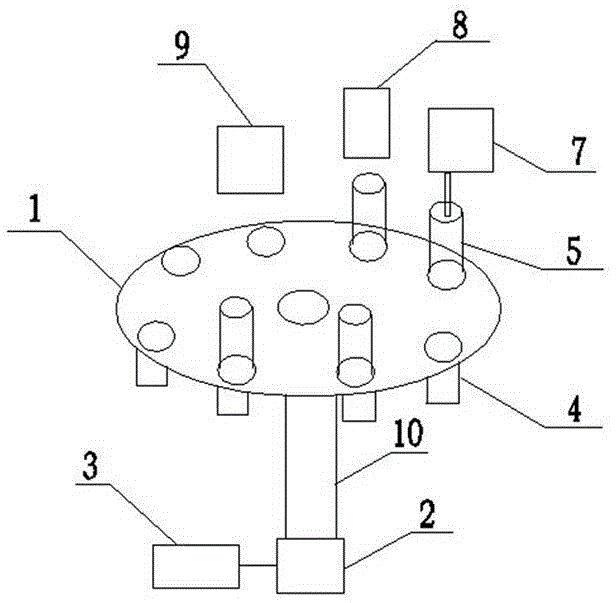

Hose filling and tail sealing machine

ActiveCN104528054AExtended shelf lifeExtended service lifePackaging by pressurising/gasifyingWrapper twisting/gatheringRotational axisNitrogen gas

The invention discloses a hose filling and tail sealing machine. The hose filling and tail sealing machine comprises a rotary plate and a plurality of hose cup bases, wherein the hose cup bases can rotate; a filling mechanism, a benchmarking nitrogen filling mechanism and a tail sealing mechanism are arranged along the rotating direction of the rotary plate in turn; the benchmarking nitrogen filling mechanism comprises a rotating shaft, a sleeve and a photoelectric color mark sensor, wherein the rotating shaft can ascend and descend, the sleeve and the rotating shaft are arranged coaxially, the sleeve can rotate, and the photoelectric color mark sensor is fixedly arranged on one side of the sleeve; the hose cup base can rotate along with the rotation of the rotating shaft; the inner diameter of the sleeve is not smaller than the outer diameter of a hose; the circumferential direction of the sleeve is provided with a plurality of vent holes; a nitrogen filling nozzle which can ascend and descend is fixedly arranged in the center of the sleeve; the bottom of the nitrogen filling nozzle extends from the sleeve; the top of the nitrogen filling nozzle is connected with a nitrogen cylinder. According to the hose filling and tail sealing machine, the automatic benchmarking can be performed on the hose after the filling is achieved due to the benchmarking nitrogen filling mechanism and meanwhile the air inside the hose can be discharged and accordingly the quality life of the paste liquid in the hose is extended.

Owner:NANTONG BAOTIAN PACKING MACHINERY

Trimming, flanging and side punching compound die

The invention discloses a trimming, flanging and side punching compound die which comprises an upper die and a lower die, wherein the upper die is provided with a trimming upper die, a flanging upper die and a side punching upper die; the lower die is provided with a nitrogen spring, a trimming lower die, a flanging lower die and a side punching lower die; the trimming upper die is provided with casting polyurethane, a pressing plate and an upper die trimming block; the trimming lower die is provided with a lower die trimming block and a cylinder ejection mechanism; the flanging upper die is provided with a concave die, a flanging block, a stripping mechanism, a stripping nitrogen cylinder, a pressing plate nitrogen cylinder, an upper die pressing plate and a hole flanging punch; the flanging lower die is provided with a convex die, a setting gage and a lower die pressing plate; and the side punching upper die is provided with a side punching punch, a polyester cyanamide pressing mechanism, a slide wedge and a roller wheel. By using the mode of the compound die, several processing procedures of trimming, flanging and side punching of workpieces made of metal plates can be completed through one set of die, once feeding is performed, the processing accuracy of the workpieces is high, the production efficiency is high, and the die cost is saved.

Owner:JIANGSU RONGTENG PRECISION COMPONENTS

High pressure nitrogen storage bottle made of kevlar fiber and carbon fiber mixed composite material and its preparation method

InactiveCN1948817AOptimized structural formFree from mechanicalPressure vesselsNitrogen gasHigh pressure

The invention relates to a nitrogen cylinder and its preparation method, in which, on the outside surface of the lining is bonded an adhesive layer and the outside surface of the adhesive layer is bonded to the inside surface of the inner structure layer of carbon fibre composite; the inside surface of the outer structure layer of Kevlar fibre composite is wound on the outside surface of the inner structure of the outer structure layer is wound an outer protective covering. The method consists in: coating an elastic adhesive layer on the outside surface of the lining; overlying a spiral and toroidal wound inner structure layer, an outer structure layer and an outer protective covering; curing and then getting the present inventive nitrogen cylinder.

Owner:HARBIN INST OF TECH

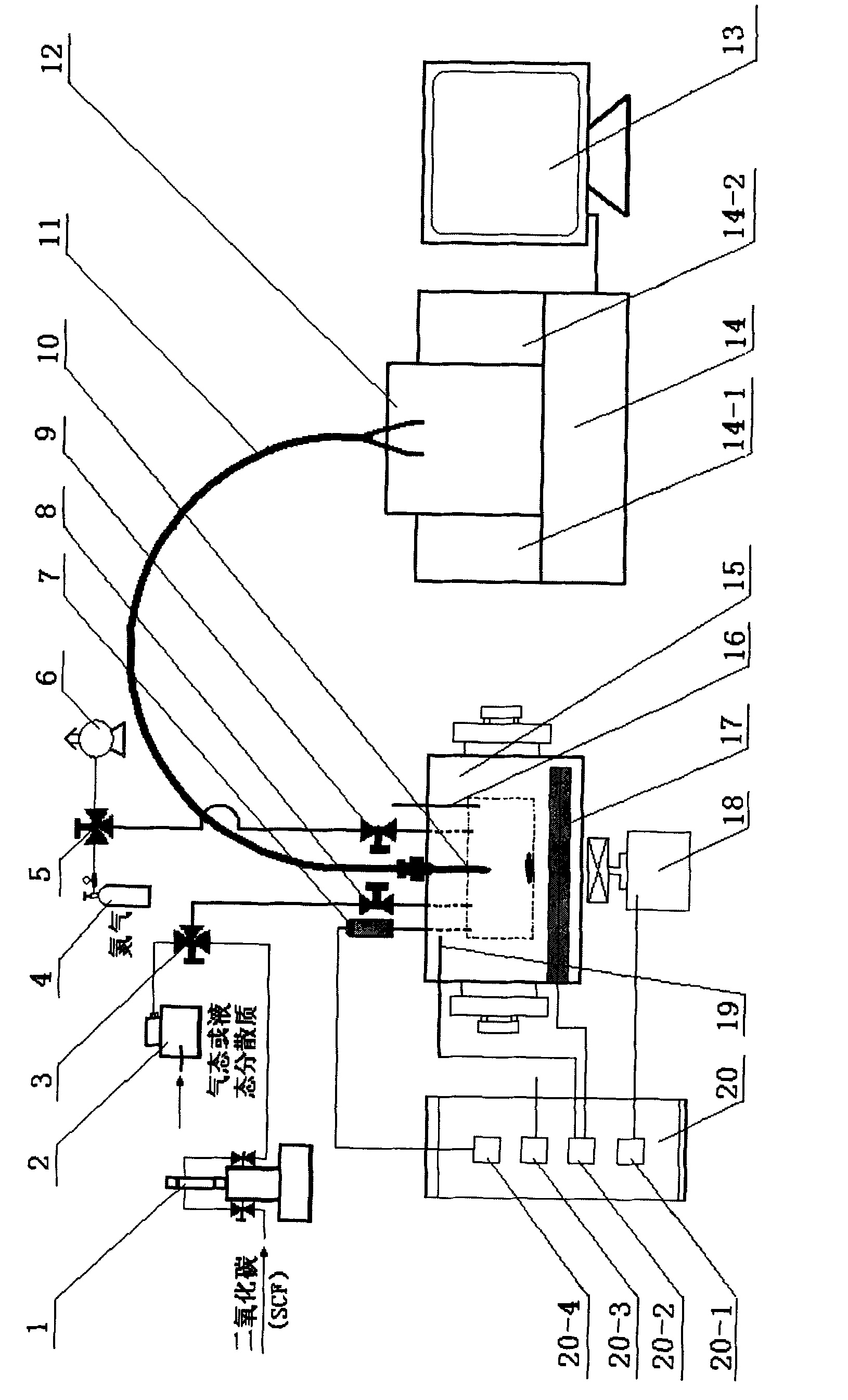

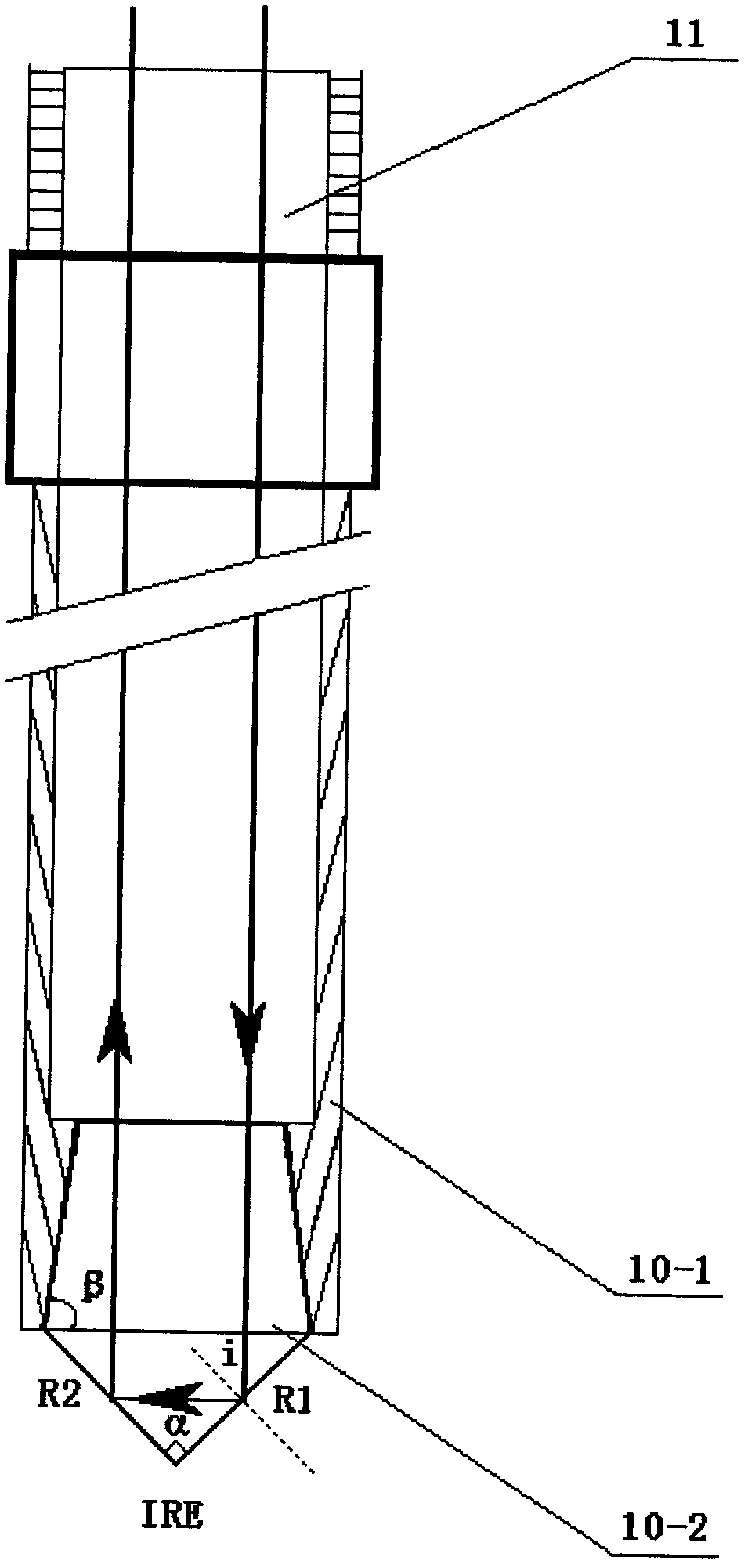

High-pressure in-situ infrared spectroscopy apparatus for monitoring supercritical system on line

InactiveCN102435573AReduce the bearing cross-sectional areaReduce volumeColor/spectral properties measurementsExhaust valveInlet valve

A high-pressure in-situ infrared spectroscopy apparatus for monitoring a supercritical system on line comprises a high-pressure reaction kettle, a controller, an infrared spectrometer and a computer, a sample intake valve and a three-way gas-liquid valve of the high-pressure reaction kettle communicate with a high-pressure injection pump, the high-pressure reaction kettle communicates with a metering pump through the sample intake valve and the three-way gas-liquid valve, communicates with a nitrogen cylinder and a vacuum pump through an exhaust valve and a three-way nitrogen valve and communicates with a pressure sensor through a pipeline, a temperature-measuring thermocouple which is connected with the temperature indicator of the controller through a wire is arranged on the high-pressure reaction kettle, a heater and a temperature-controlling thermocouple which are connected with the temperature controller of the controller through wires are arranged on the high-pressure reaction kettle, the pressure sensor is connected with the pressure indicator of the controller through a wire, and the infrared spectrometer is connected with the computer through a wire. The high-pressure in-situ infrared spectroscopy apparatus also comprises an electromagnetic agitator, an emission bin and an optical fiber, the electromagnetic agitator is arranged under the high-pressure reaction kettle and connected with the speed regulator of the controller, the emission bin is arranged on the infrared spectrometer, and the optical fiber is connected with the emission bin and an infrared sensor inserted into the high-pressure reaction kettle.

Owner:SHAANXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com