Multi-target-line dynamic combustion performance testing system for solid propellant

A solid propellant, combustion performance technology, applied in the direction of fuel oil testing, material inspection products, etc., can solve the problems of long test cycle, etc., to achieve the effect of easy implementation, shortening the development and production cycle, and reducing costs

Inactive Publication Date: 2011-06-15

XIDIAN UNIV +1

View PDF7 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the commonly used solid propellant burning rate test method can only test the burning rate of samples with a single pressure and temperature. When testing the burning rate pressure index and burning rate temperature sensitivity coefficient, it is necessary to repeat the operation dozens or even dozens of times. The cycle is long, so a simple, efficient, and fast method for testing the combustion performance of solid propellants is needed to shorten the production cycle of solid propellants

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

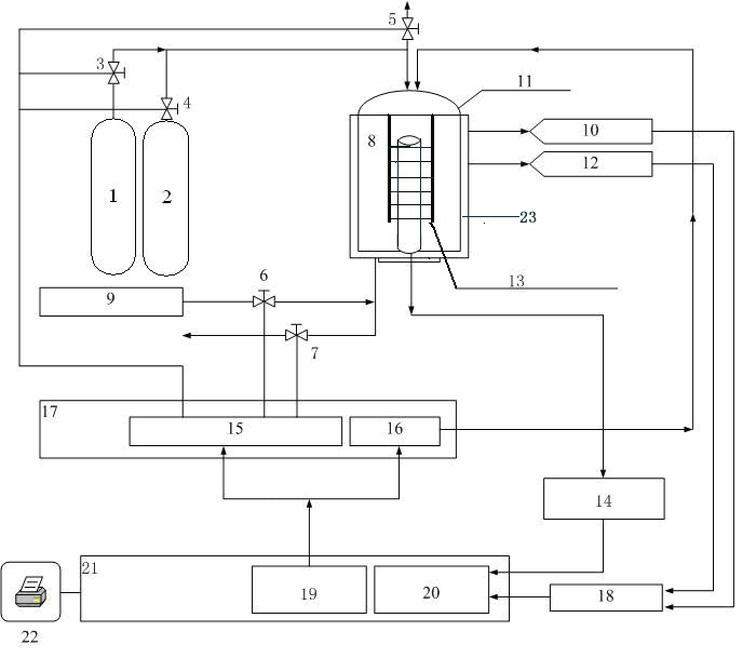

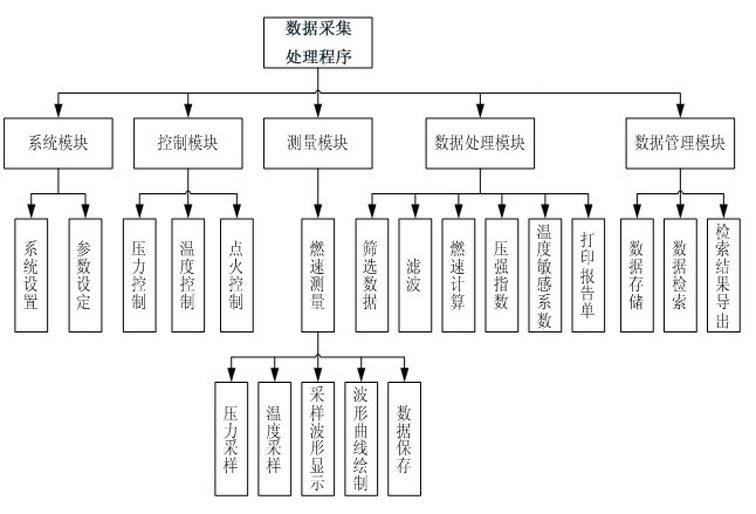

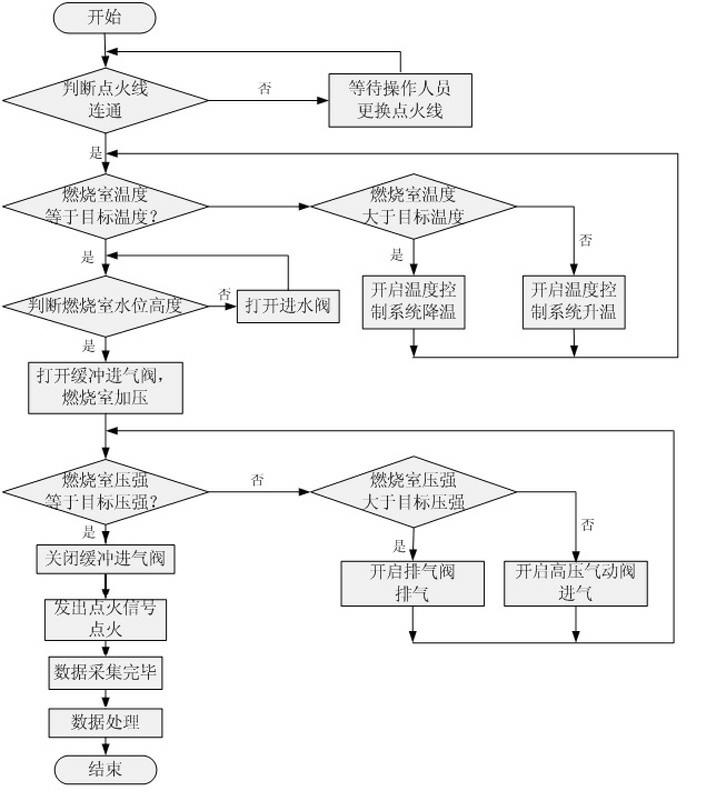

The invention discloses a multi-target-line dynamic combustion performance testing system for a solid propellant, which comprises a combustion chamber and gas distribution unit, a test and control unit and a data collecting and processing unit, wherein the combustion chamber and gas distribution unit comprises a combustion chamber, a constant-temperature tank, a high-pressure nitrogen cylinder, a buffer nitrogen cylinder, a relevant valve pipeline, a nitrogen booster pump and a multi-target-line explosive support used for fixing a sample to be tested, wherein one end of the multi-target-line explosive support is provided with an ignition wire connecting post, a ground wire connecting post and 6 to 10 target line connecting posts in the combustion chamber; and the data collecting and processing unit is used for dispatch and control of all function blocks of the testing and controlling unit, analysis and processing of tested data and data management. The testing system can reflect the change of the combustion speed of the solid propellant with the change of pressure by stages, and belongs to the range of testing of dynamic combustion speed; and the traditional target line method and the underwater acoustic emission method can only test the static combustion speed in a single constant-pressure condition, therefore, the testing system disclosed by the invention can obtain a conclusion closer to the actual combustion condition of the solid propellant in a solid-propellant rocket engine.

Description

Solid propellant multi-target line quasi-dynamic combustion performance test system technical field The invention relates to a testing system for quasi-dynamic combustion performance of solid propellant. Background technique The burning rate of solid propellant refers to the distance that the solid phase disappears along the normal direction of the solid propellant surface per unit time, referred to as the burning rate of solid propellant. It determines the energy release rate of solid propellants, and is also the core parameter for calculating other combustion properties of solid propellants (burning rate pressure index, burning rate temperature sensitivity coefficient, erosion ratio, etc.). Regardless of the changes in the pressure, initial temperature, air velocity and other influencing factors during combustion, they will eventually be reflected in the changes in the burning rate. In addition, it also directly affects the ballistic performance, flight speed and workin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N33/22

Inventor 刘科祥赵凤起樊学忠裴庆郝海霞仪建华蔡德芳

Owner XIDIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com