Patents

Literature

72results about How to "Ensure connection reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

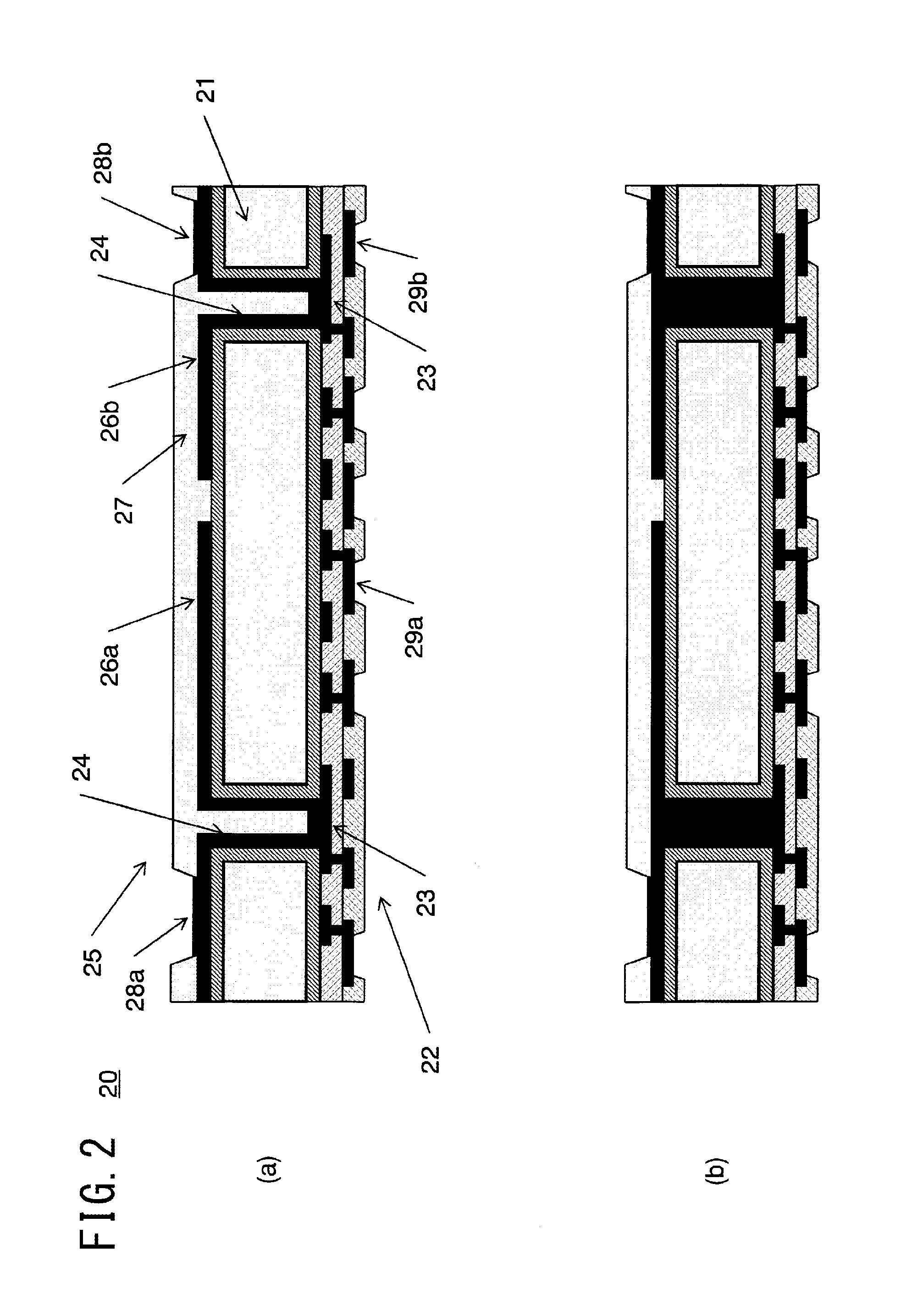

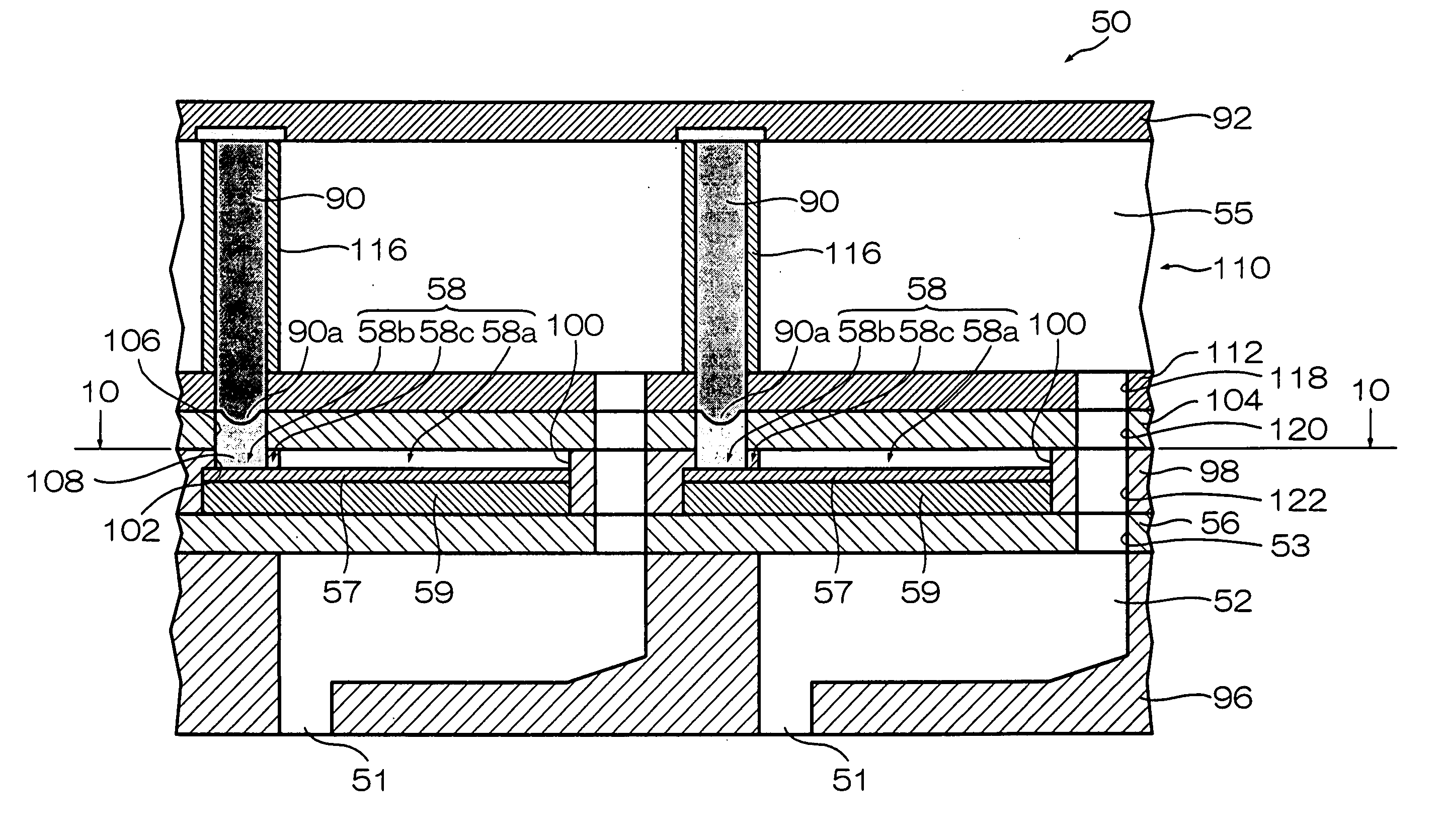

Method of manufacturing printed-circuit board

InactiveUS6889433B1Reduced connection reliabilityHigh densityLine/current collector detailsInsulating substrate metal adhesion improvementConductive pasteEngineering

By filling a predetermined amount of conductive paste into an opening for forming a through hole or a VH formed in a resin insulating layer of a circuit board, and pressurizing the filled conductive paste under the condition of reduced pressure, removing air bubble strapped in the conductive paste.

Owner:IBIDEN CO LTD

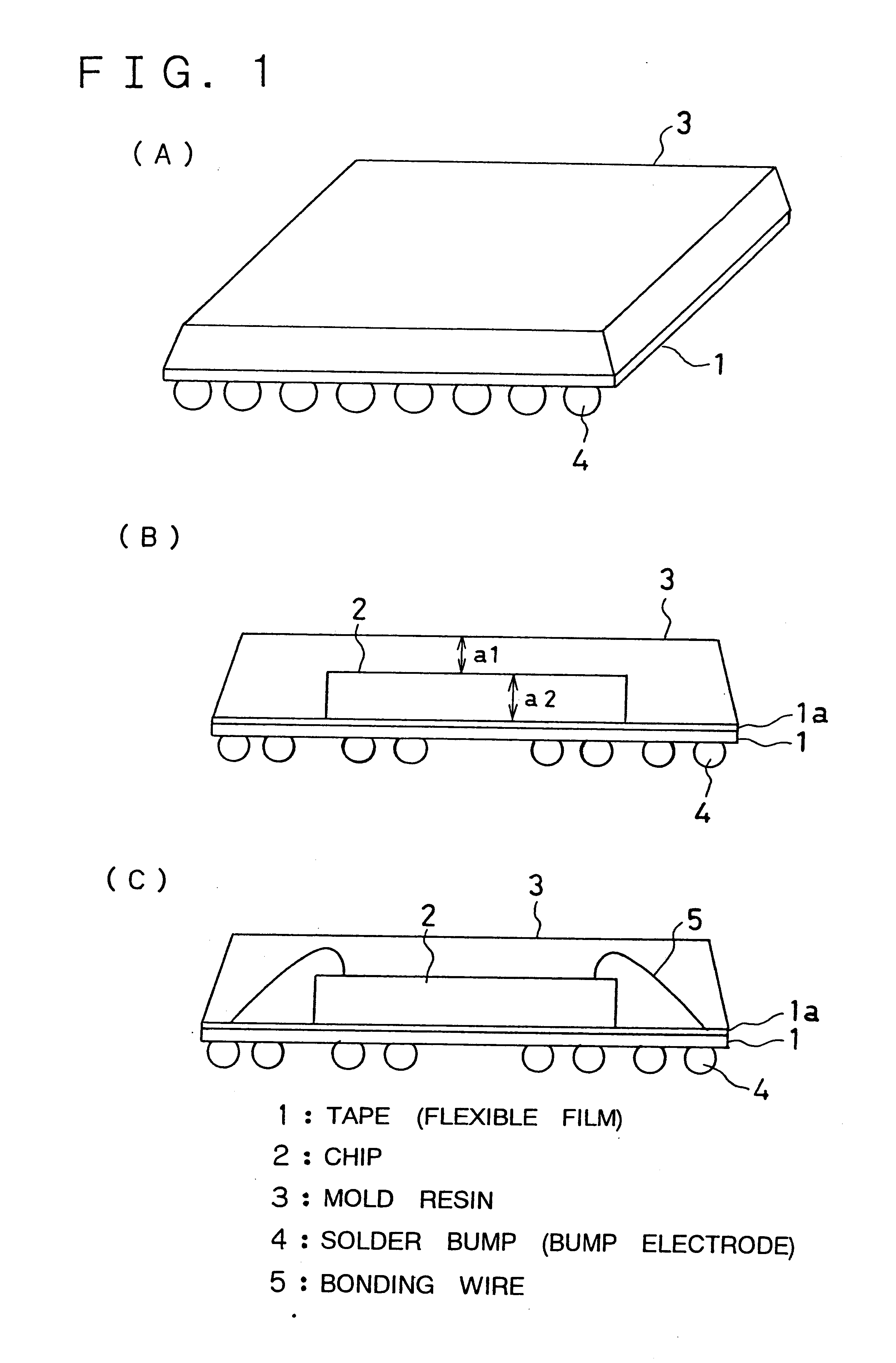

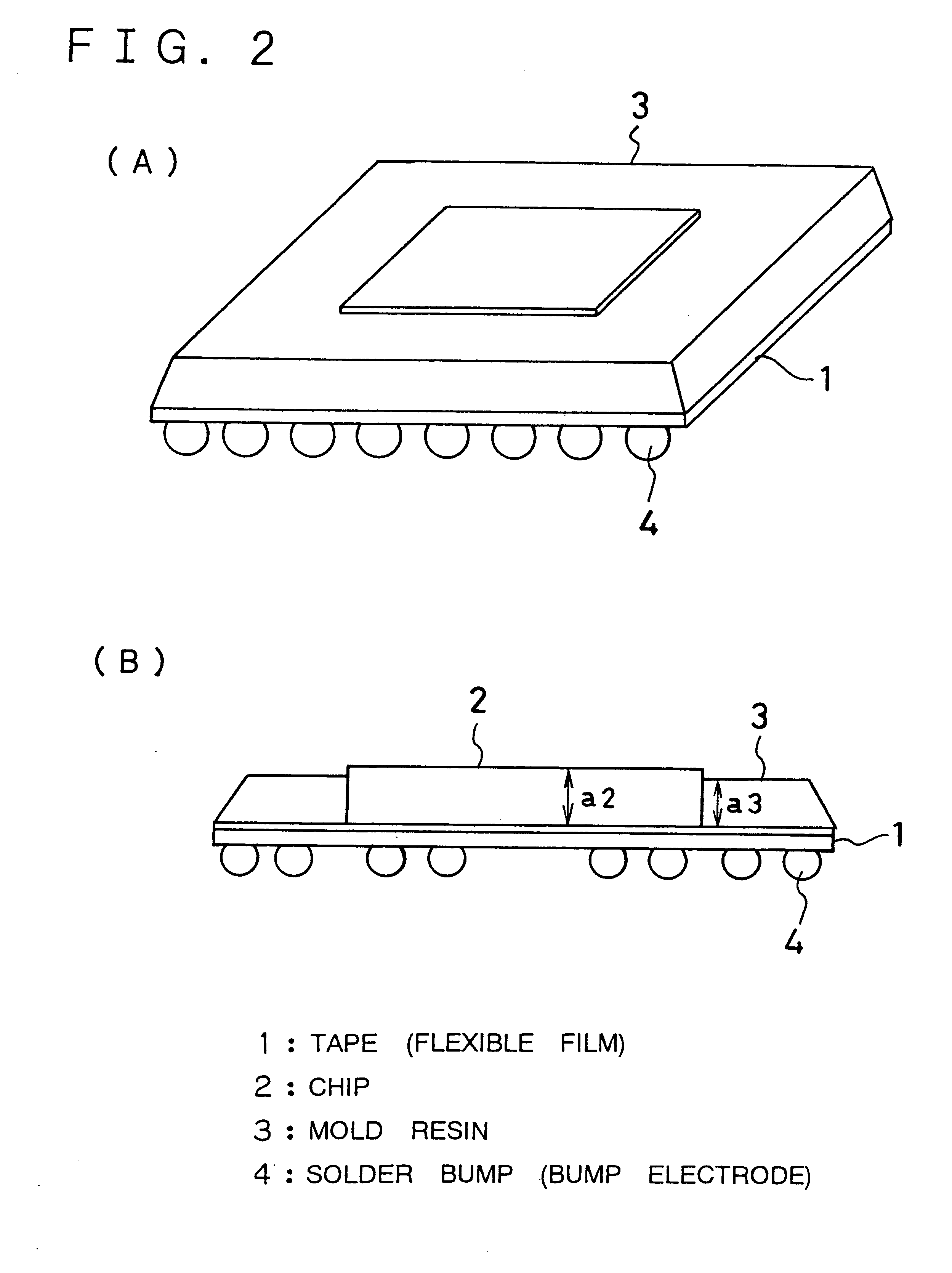

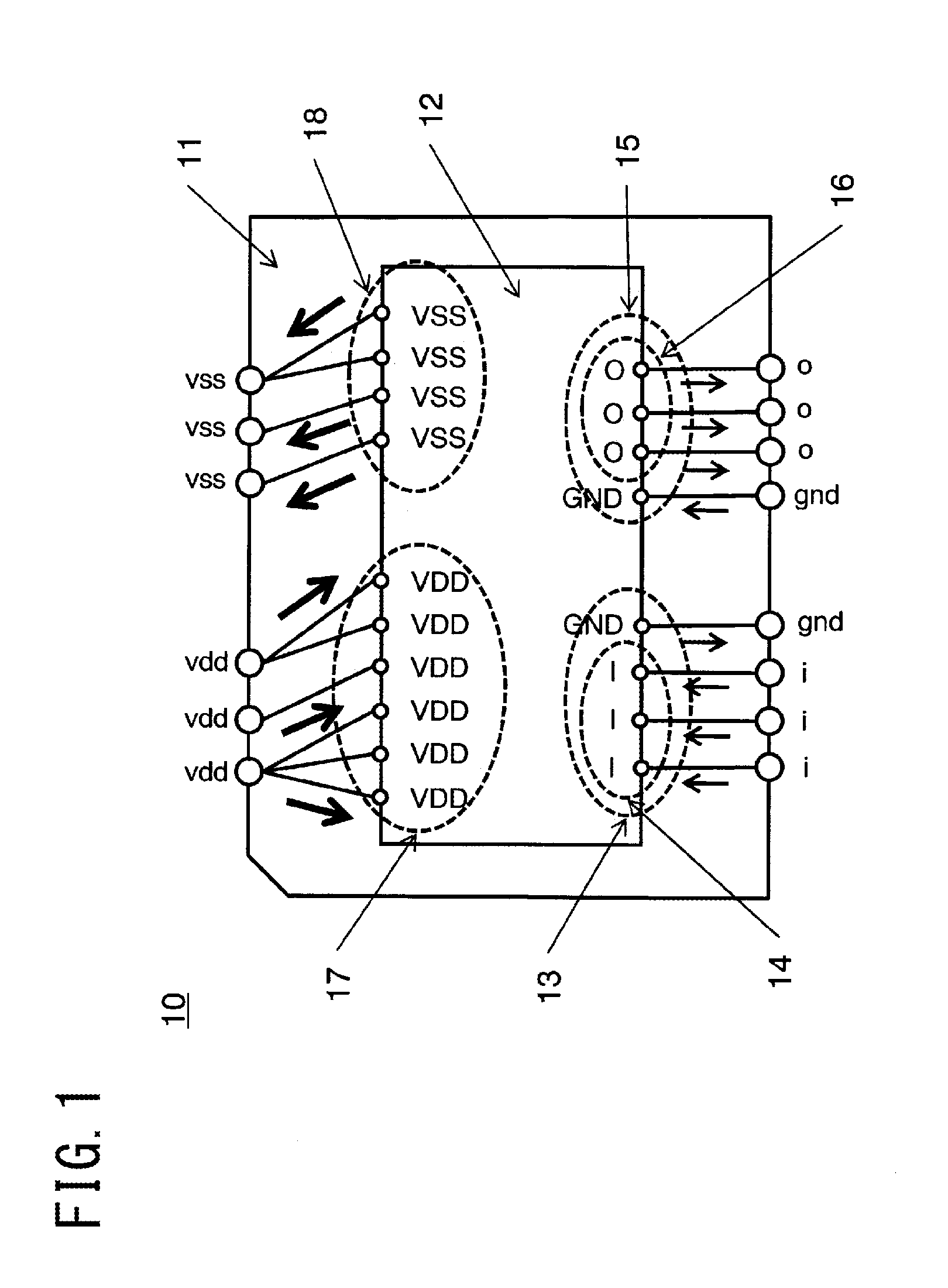

Semiconductor device

InactiveUS6396159B1Reduce spacingIncrease the number ofSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipElectrode

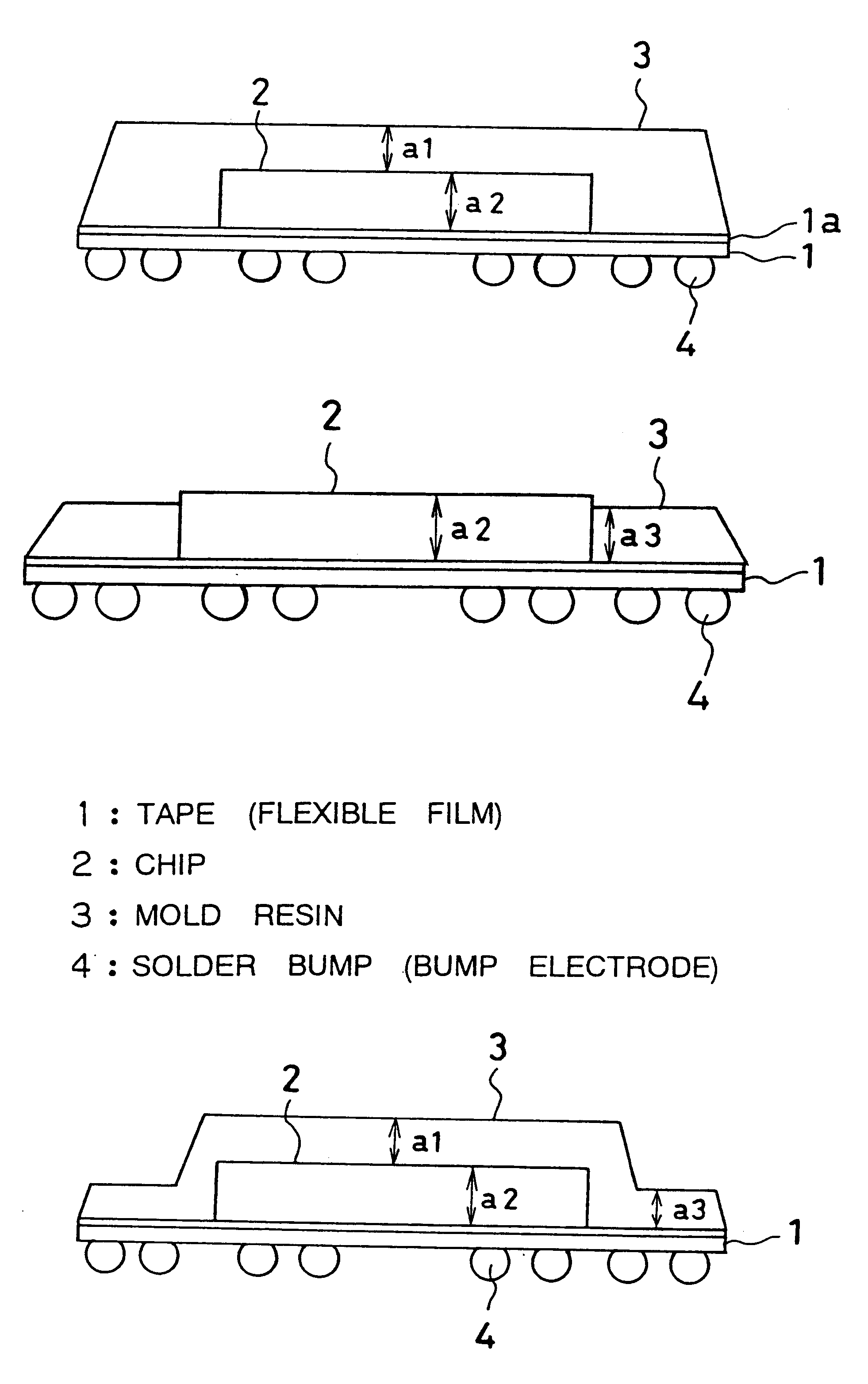

A semiconductor device which eliminates a thermal stress in the semiconductor device or warp in a package of the semiconductor device to increase reliability. To achieve this, the semiconductor device has a structure in which an insulation flexible film and a semiconductor chip are stuck together. The insulation flexible film has on the obverse side a plurality of electrode pads and, on the reverse side, a plurality of electrodes electrically connected to the plurality of electrode pads. The semiconductor chip is sealed on the chip-mounting side of the insulation flexible film with resin, with a thickness of the resin above the semiconductor chip equal to or less than the thickness of the semiconductor chip.

Owner:NEC ELECTRONICS CORP

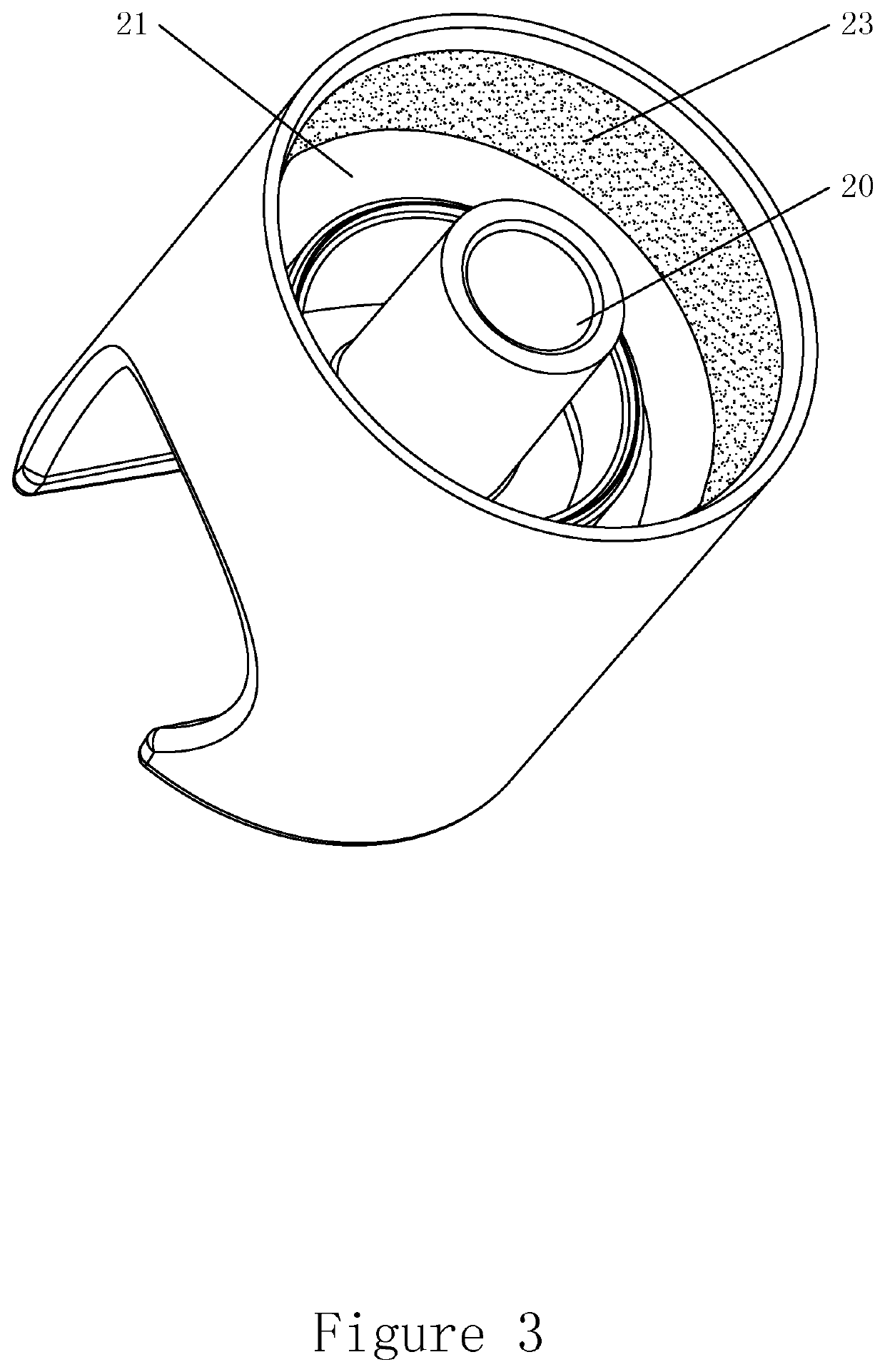

Connectable cable organizer

ActiveUS9879803B2Simple structureEasy to manufacturePipe supportsElectrical apparatusMechanical engineering

Owner:MAXDAO

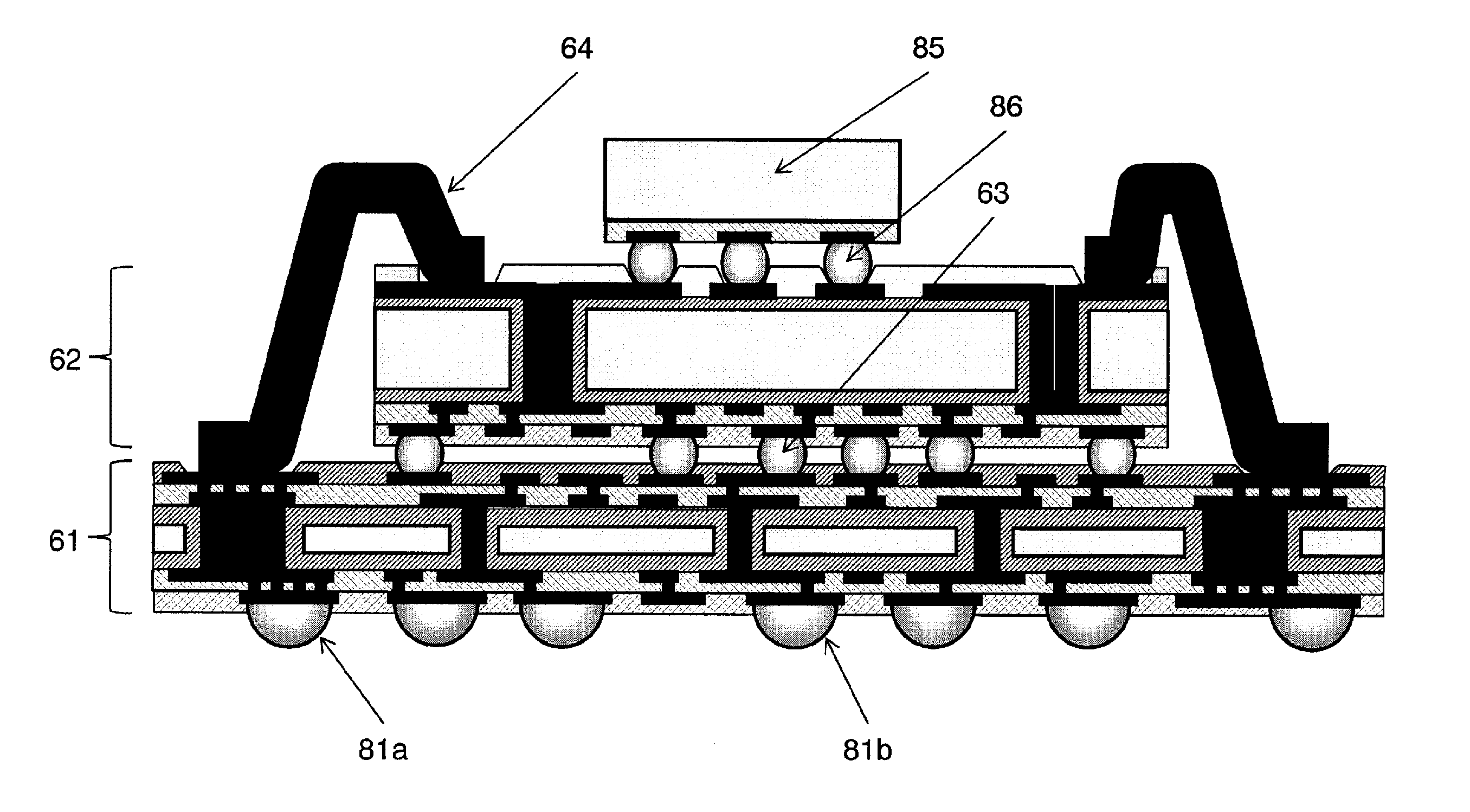

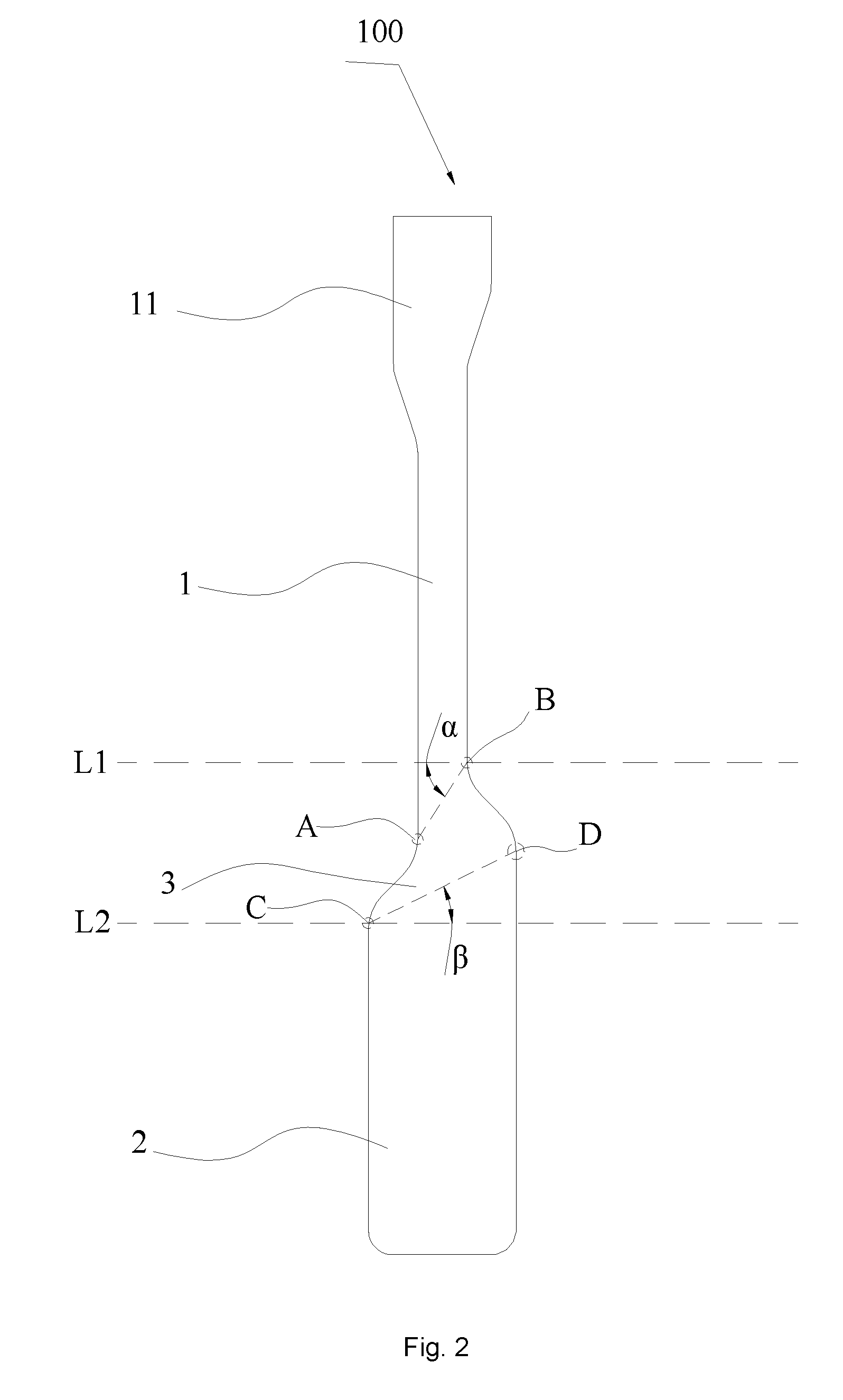

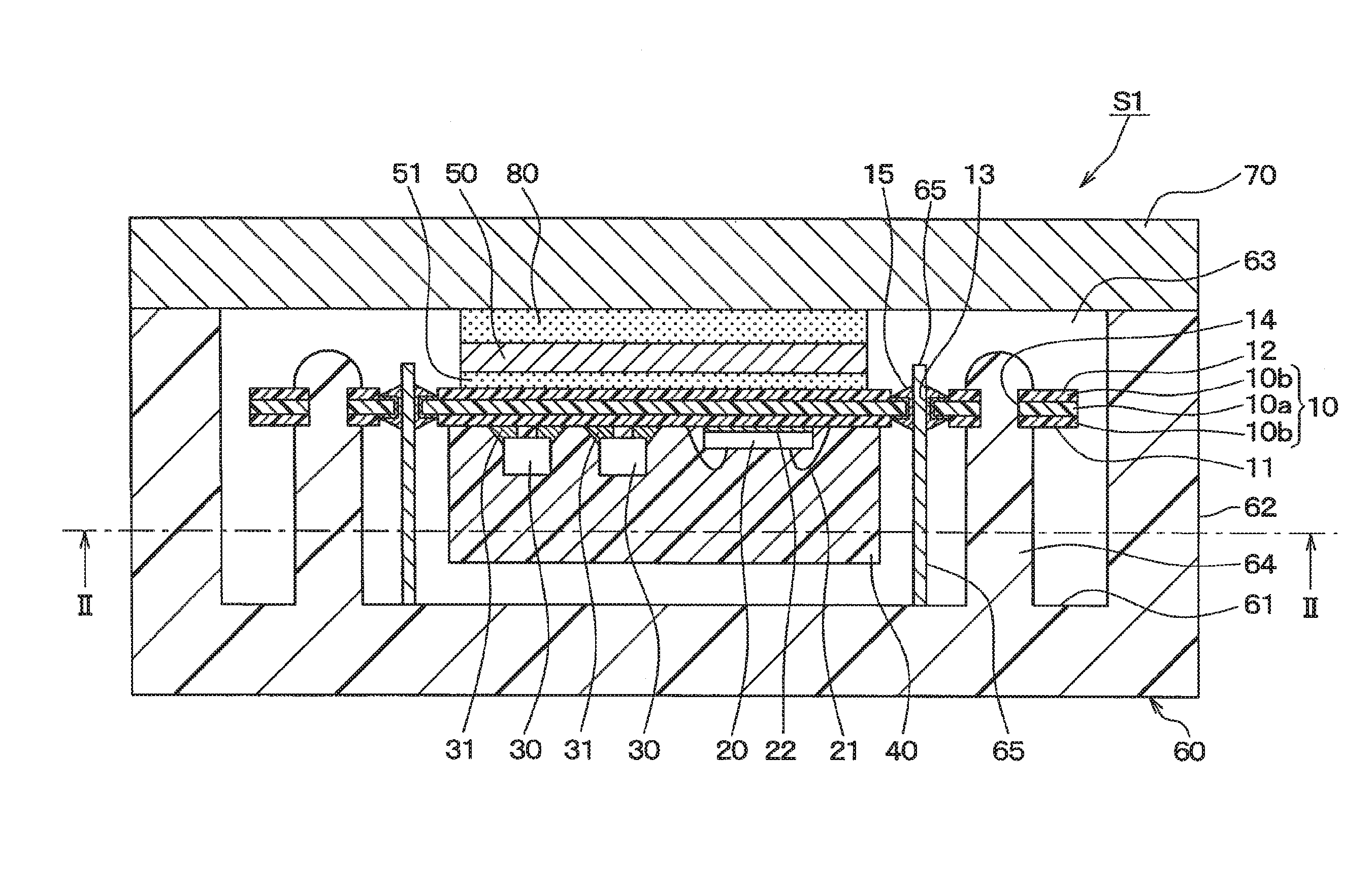

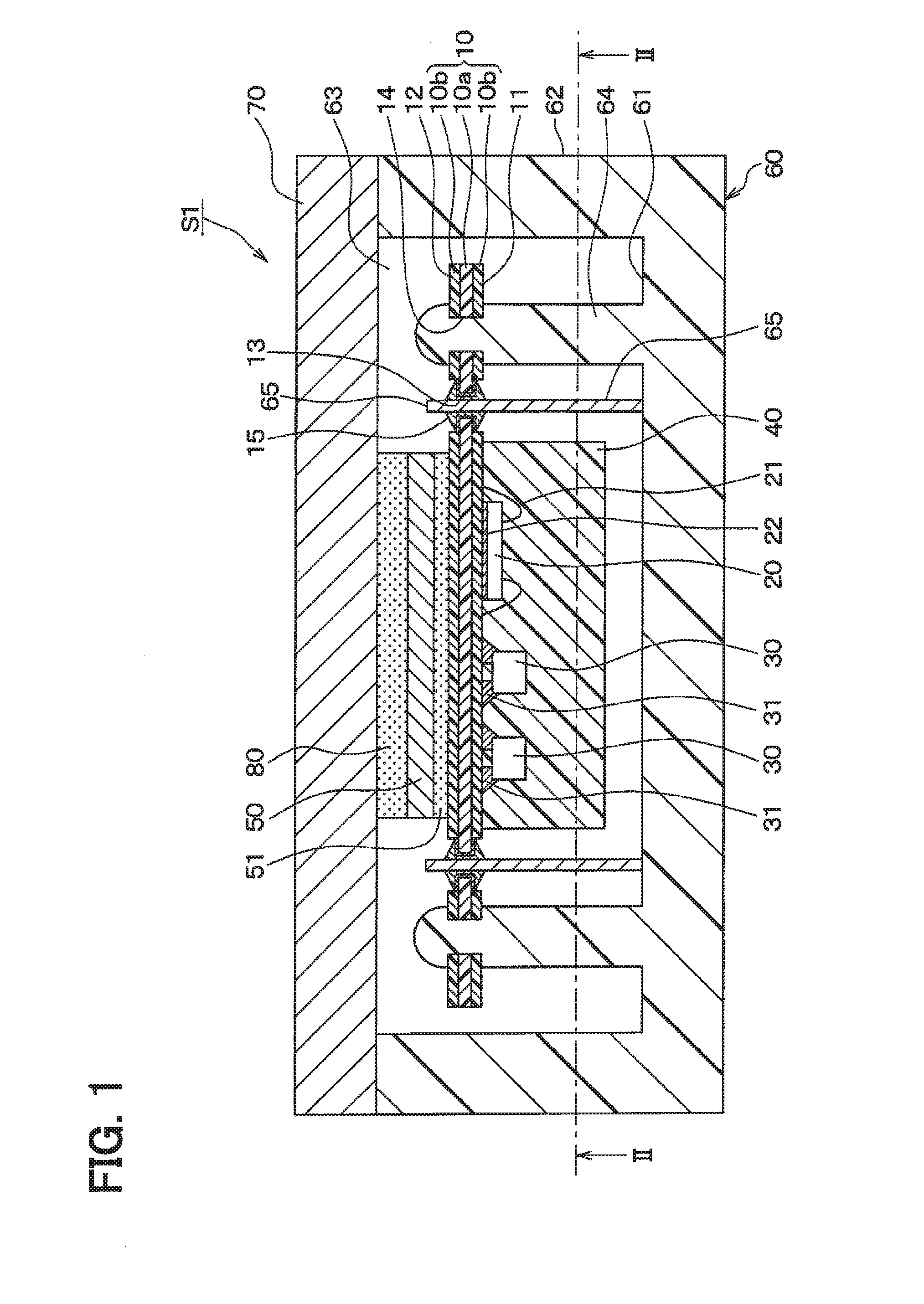

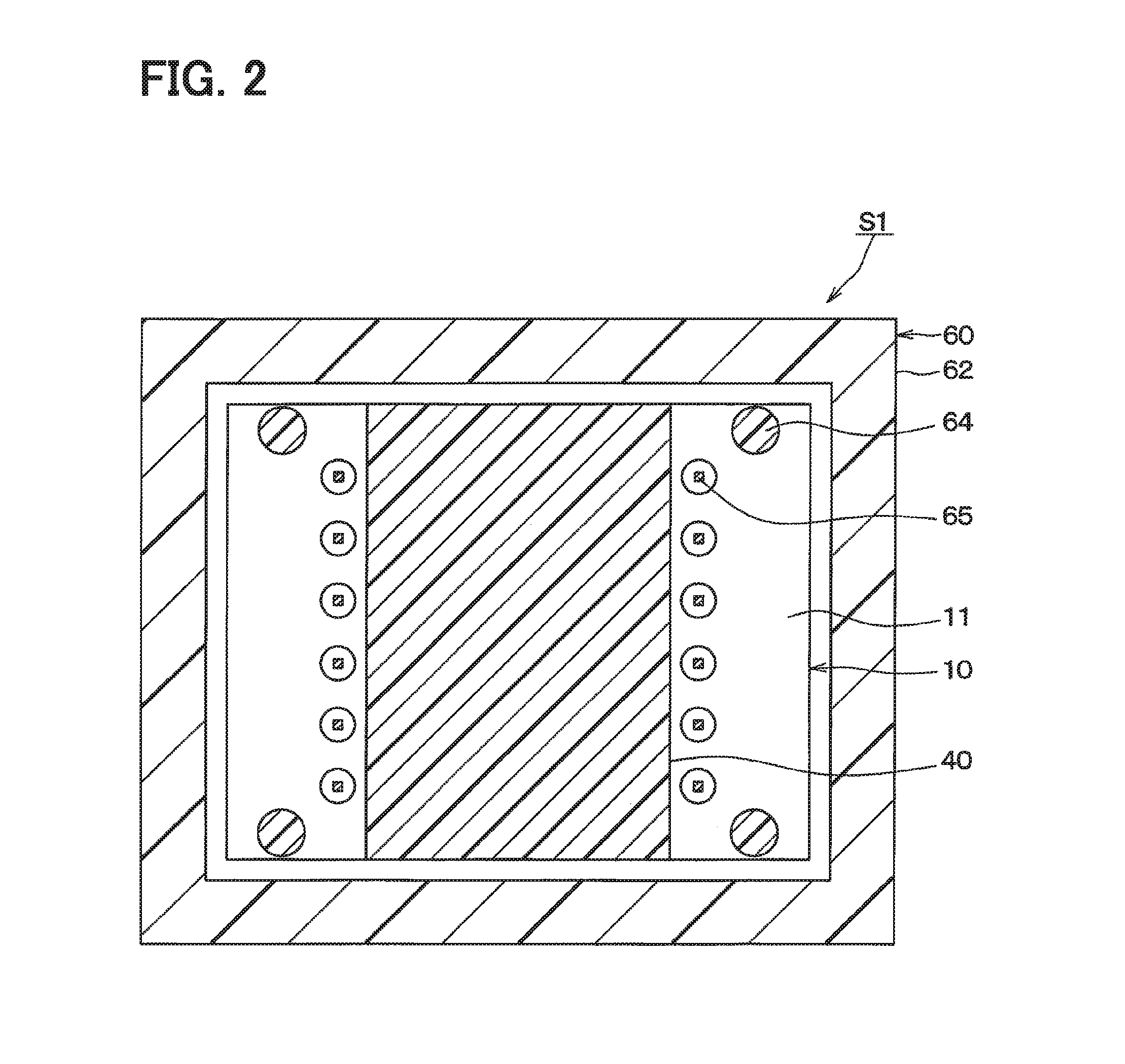

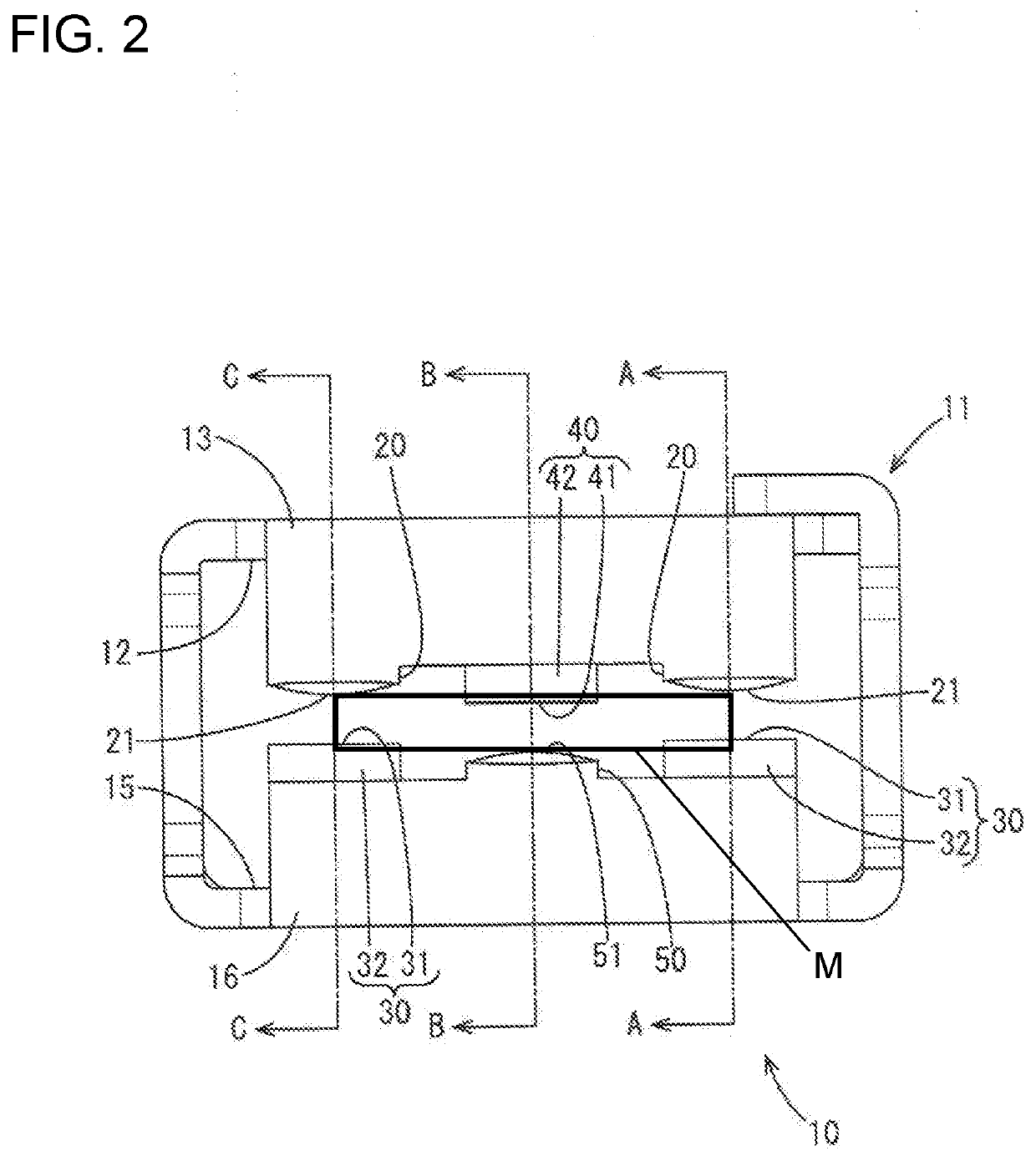

Semiconductor module carrying the same

InactiveUS20150108604A1Ensure connection reliabilityGood effectSemiconductor/solid-state device detailsSolid-state devicesElectricitySemiconductor chip

In the conventional high-speed, large-current semiconductor chip, all the electric connecting terminals were placed on one surface of the chip. For this reason, to supply stable supply currents or reduce noises mixed into the signal system from the power supply, many terminals were assigned to supply current inflow terminals and supply current outflow terminals. As a result, there is a problem that the terminal number of a semiconductor device is increased and the mounting area thereof is increased.The electrical connecting terminals for power supply system and those for signal system are separately placed on both sides of a semiconductor chip. By the configuration to enlarging the permissible current value of a path through which a large current flows, stabilization of feeding supply currents, reduction of noises mixed into signal systems, reduction of mounting areas due to pin count reduction, and increase of heat dissipation effects can be realized even with a decreased pin count. Moreover, by the semiconductor module on which the semiconductor chip is mounted, stable characteristics can be realized even in high-speed operation necessitating large currents.

Owner:ZYCUBE

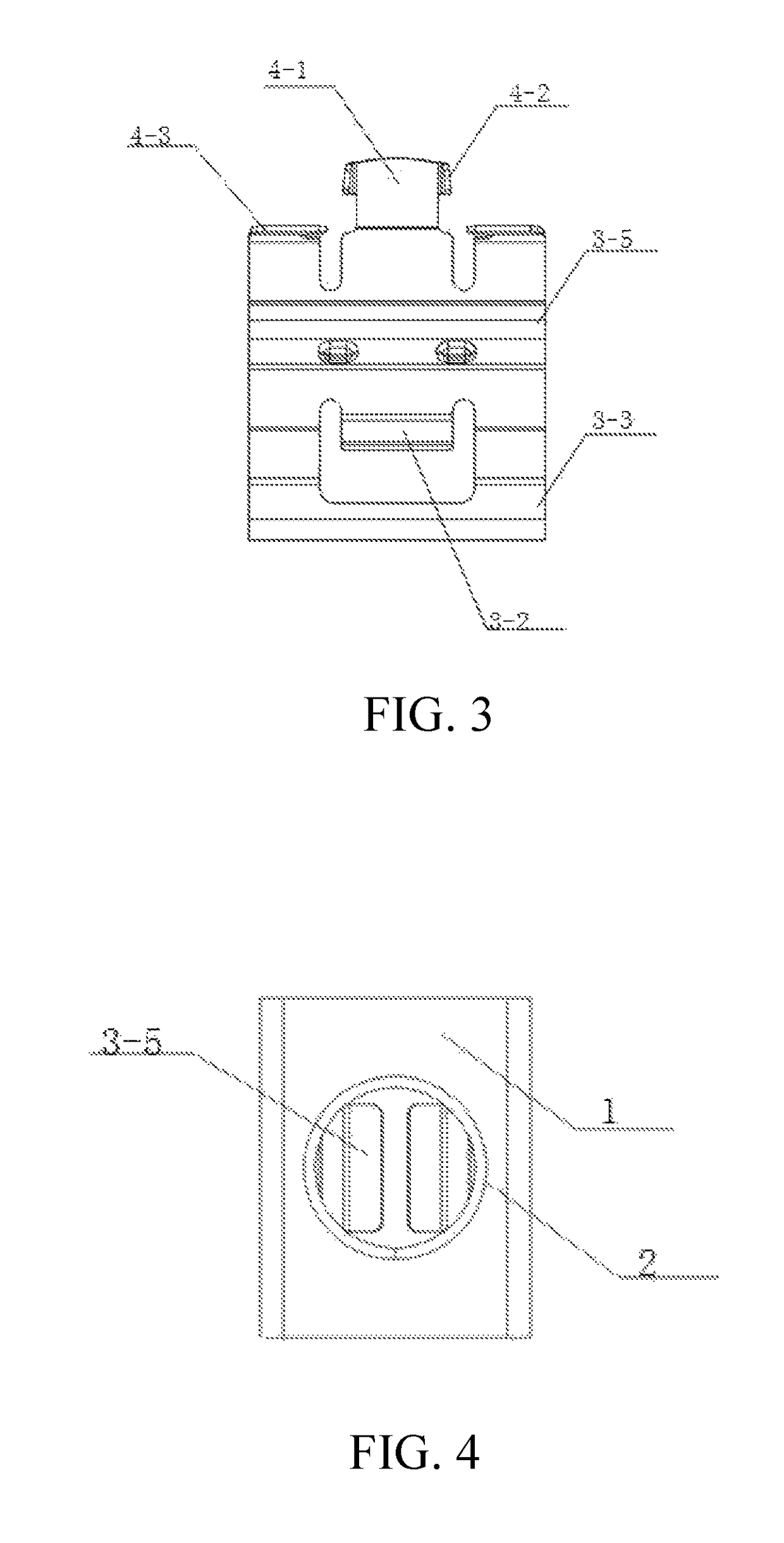

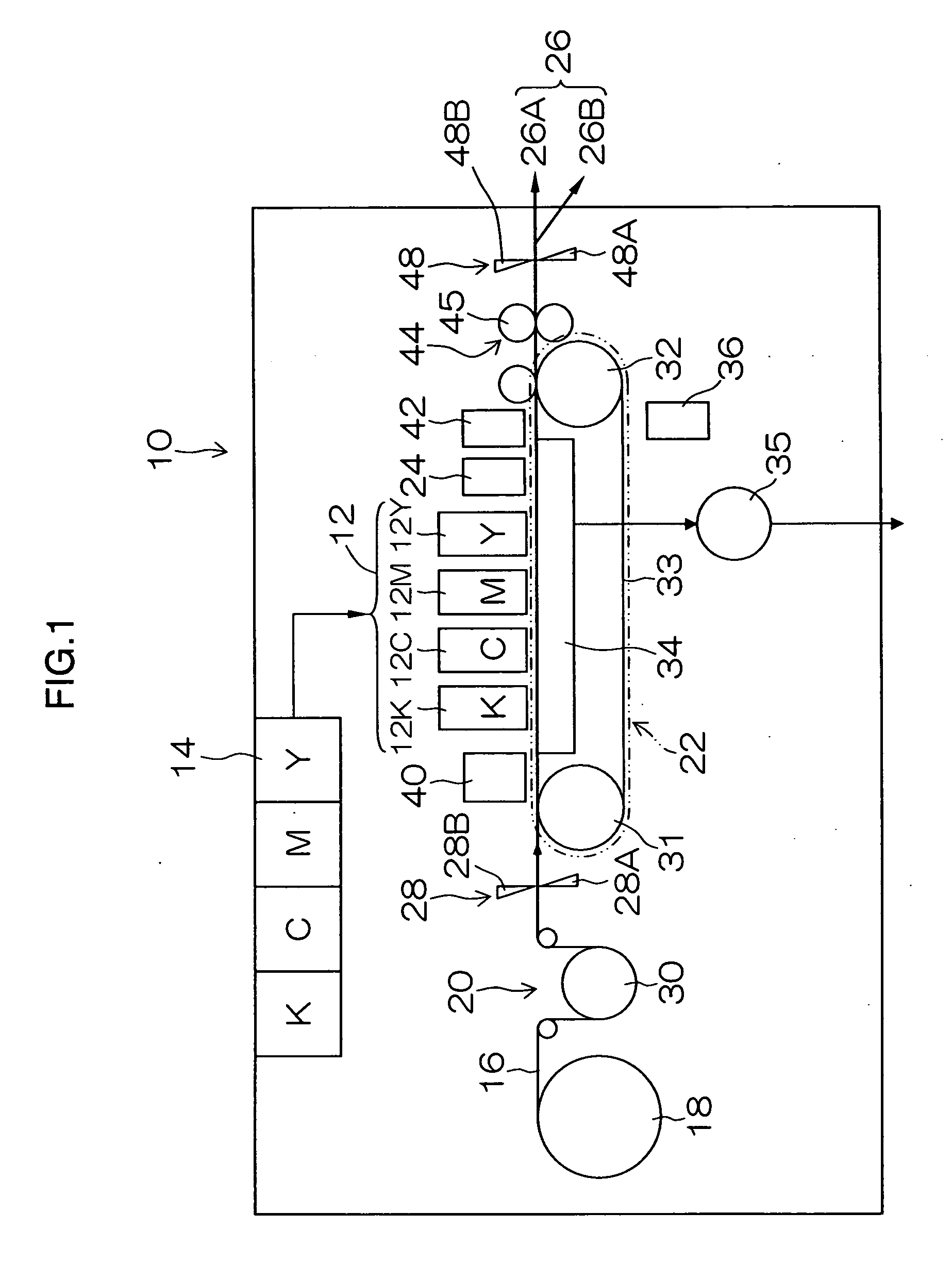

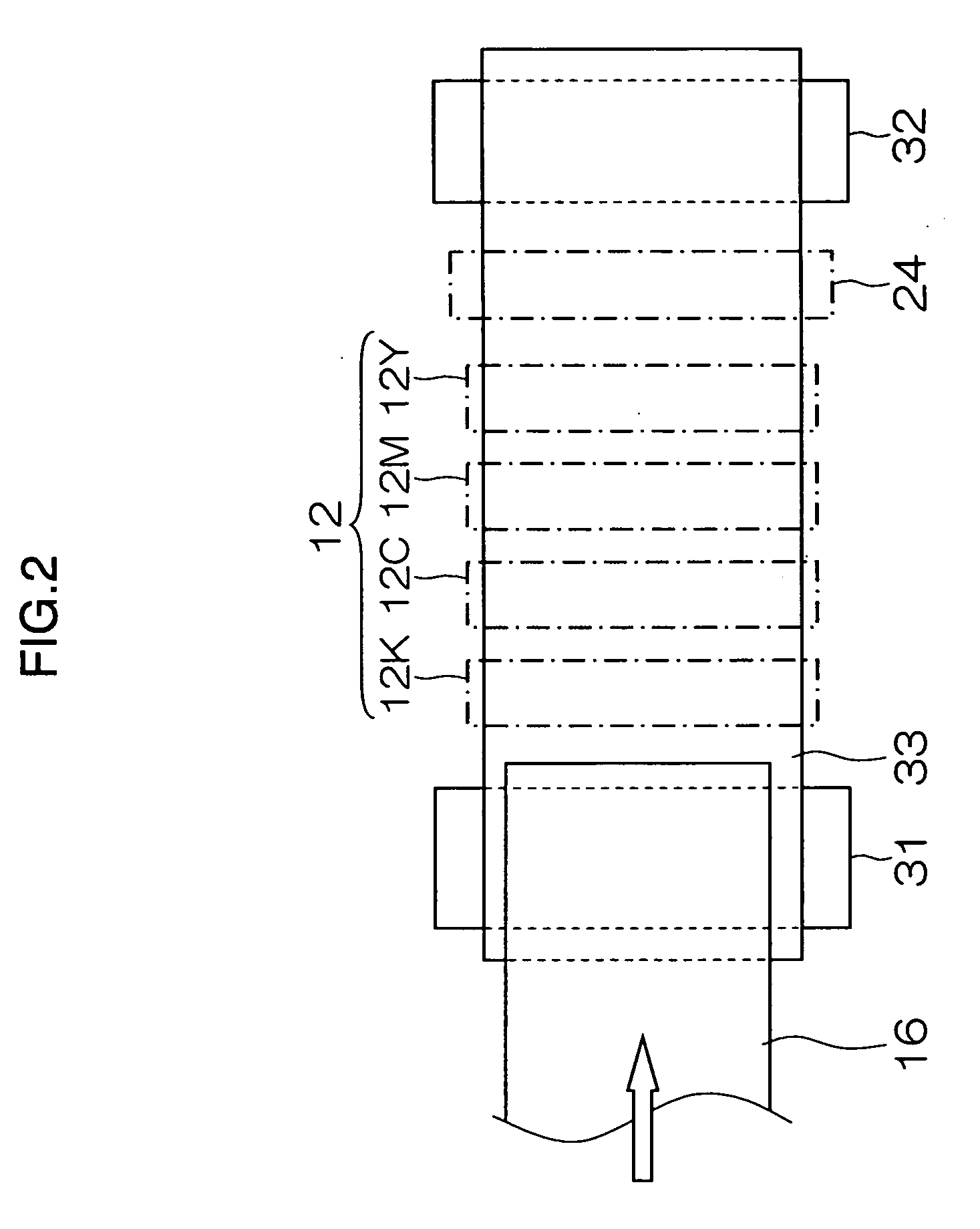

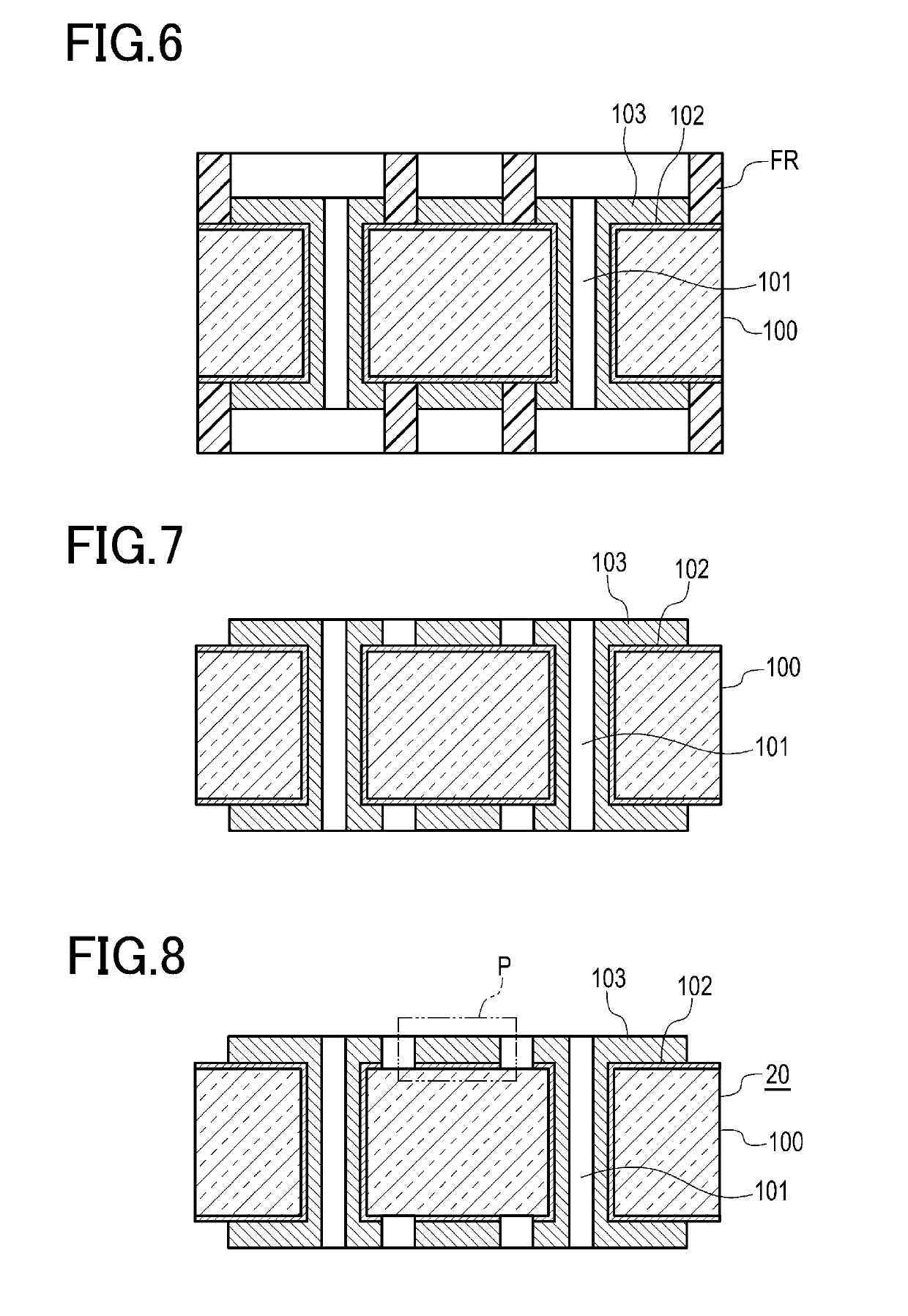

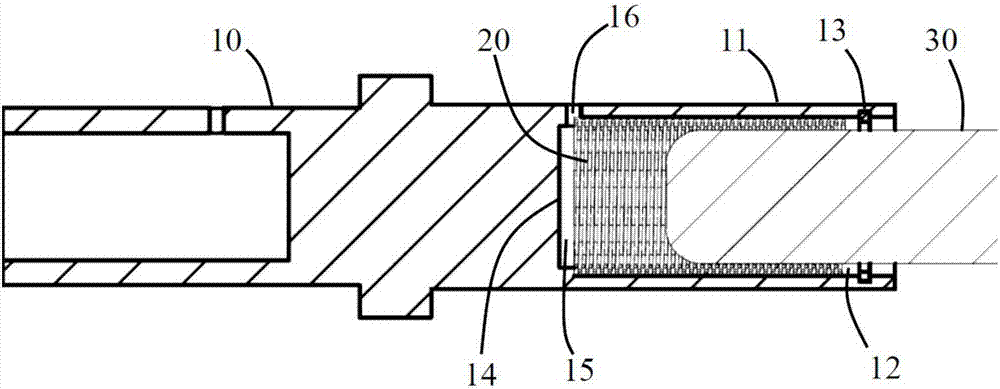

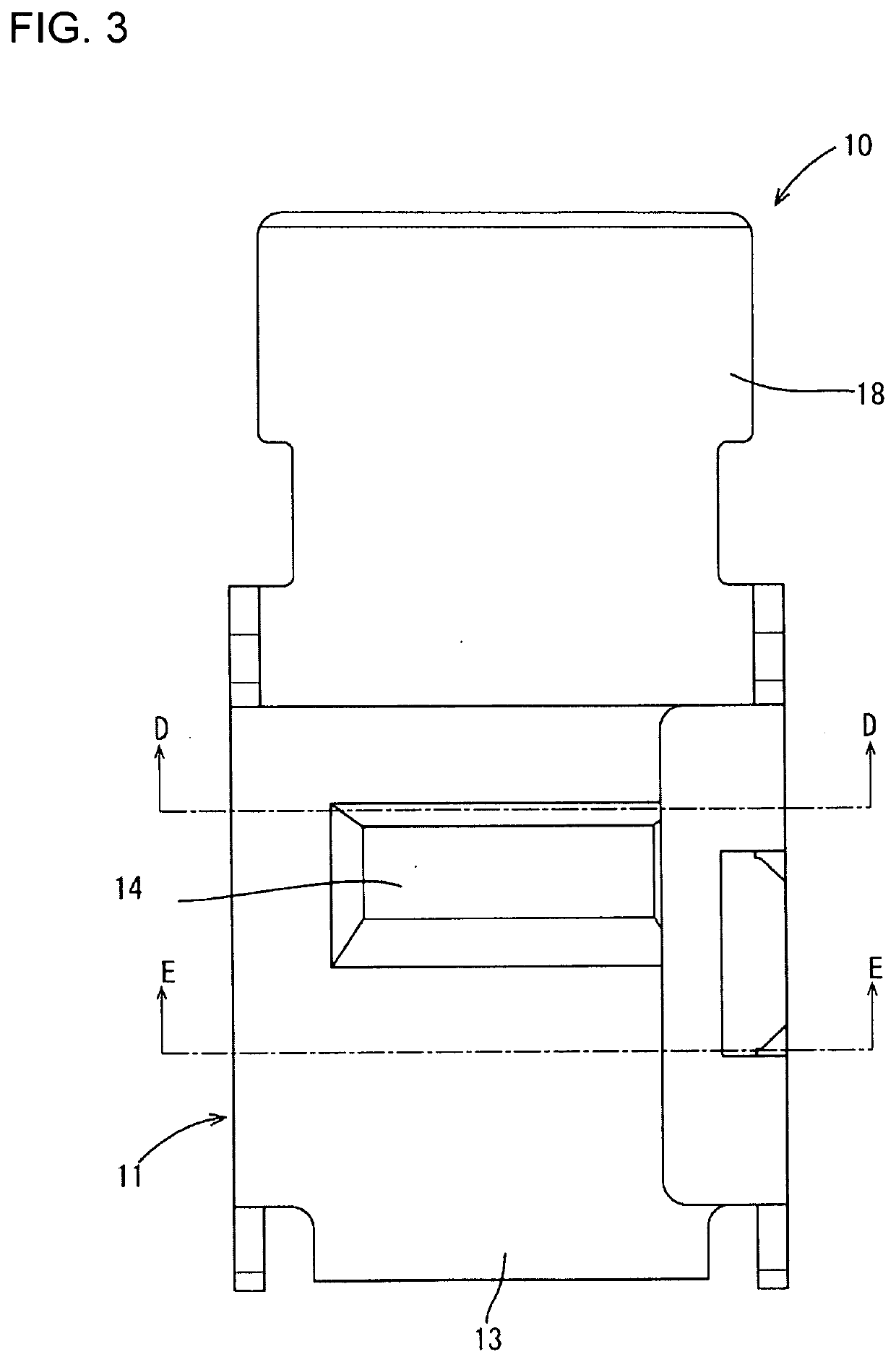

Liquid ejection head and method of manufacturing liquid ejection head

InactiveUS20070058004A1Simple manufacturing processGuaranteed reliabilityPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusResistLiquid state

The method manufactures a liquid ejection head comprising a pressure chamber which accommodates liquid, a diaphragm which forms a portion of the pressure chamber, a piezoelectric element which is disposed on the diaphragm and deforms the pressure chamber through the diaphragm to pressurize the liquid in the pressure chamber so as to eject the liquid from an ejection port in connection with the pressure chamber. The method comprises: a resist layer forming step of applying a resist in a liquid state onto the diaphragm on which the piezoelectric element has been disposed so as to cover the piezoelectric element, and curing the resist to form a resist layer on the diaphragm; a space forming step of separately removing the resist covering a movable portion of the piezoelectric element and the resist covering an electrical connection portion of the piezoelectric element, by exposing and developing the resist formed on the diaphragm, to separately form a movement space and a connection space for the piezoelectric element, in the resist layer; and a conductive material filling step of filling a conductive material into the connection space formed in the resist layer.

Owner:FUJIFILM CORP

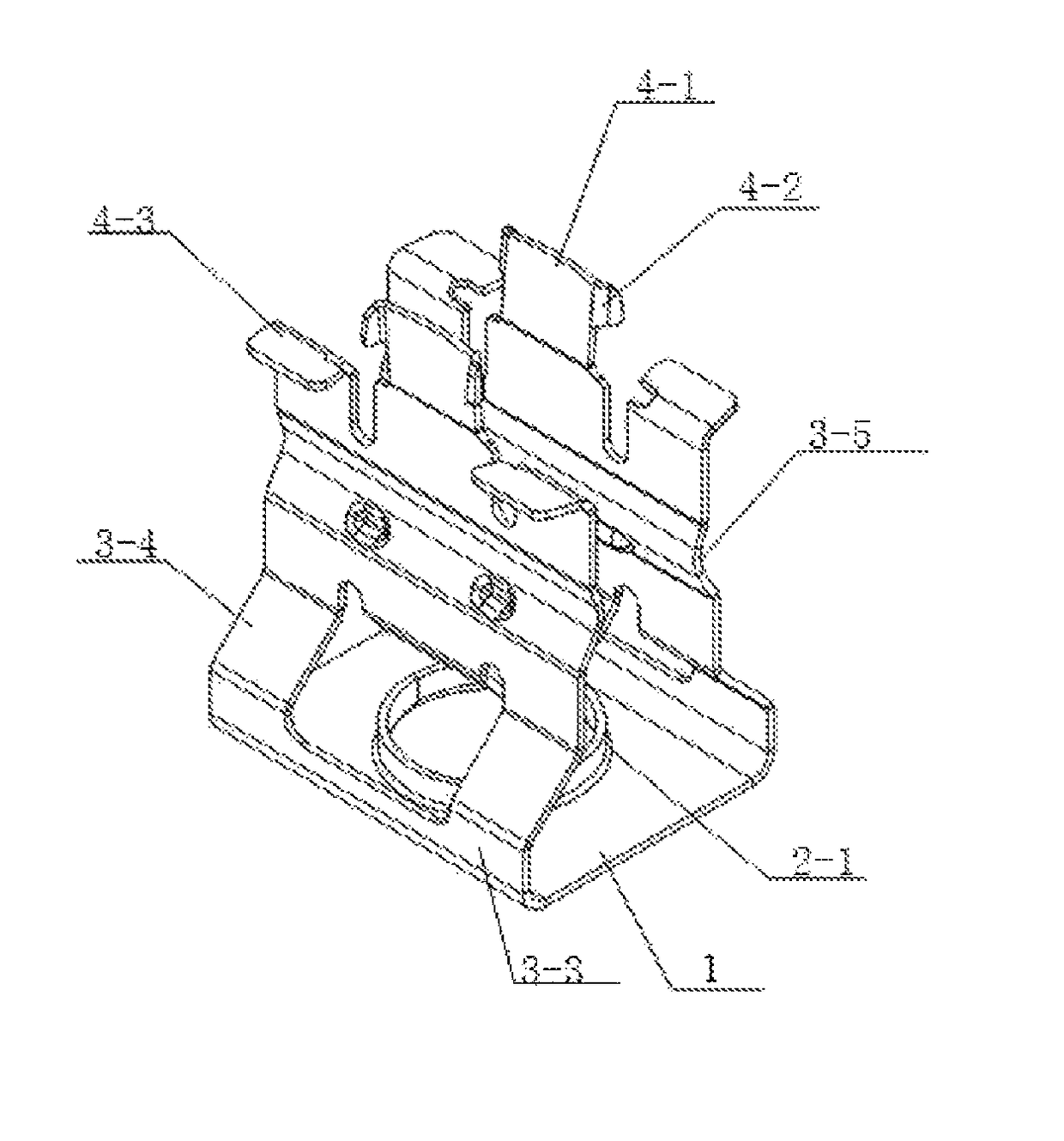

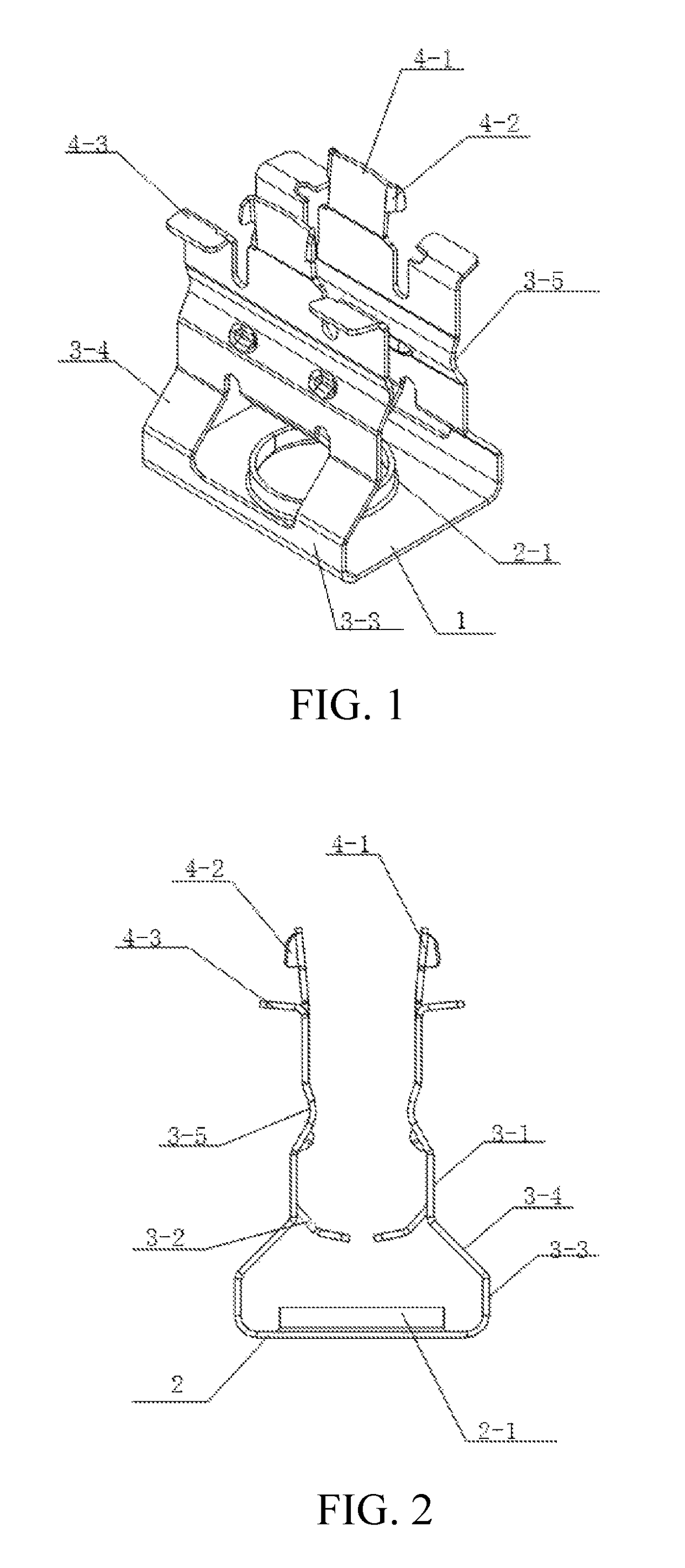

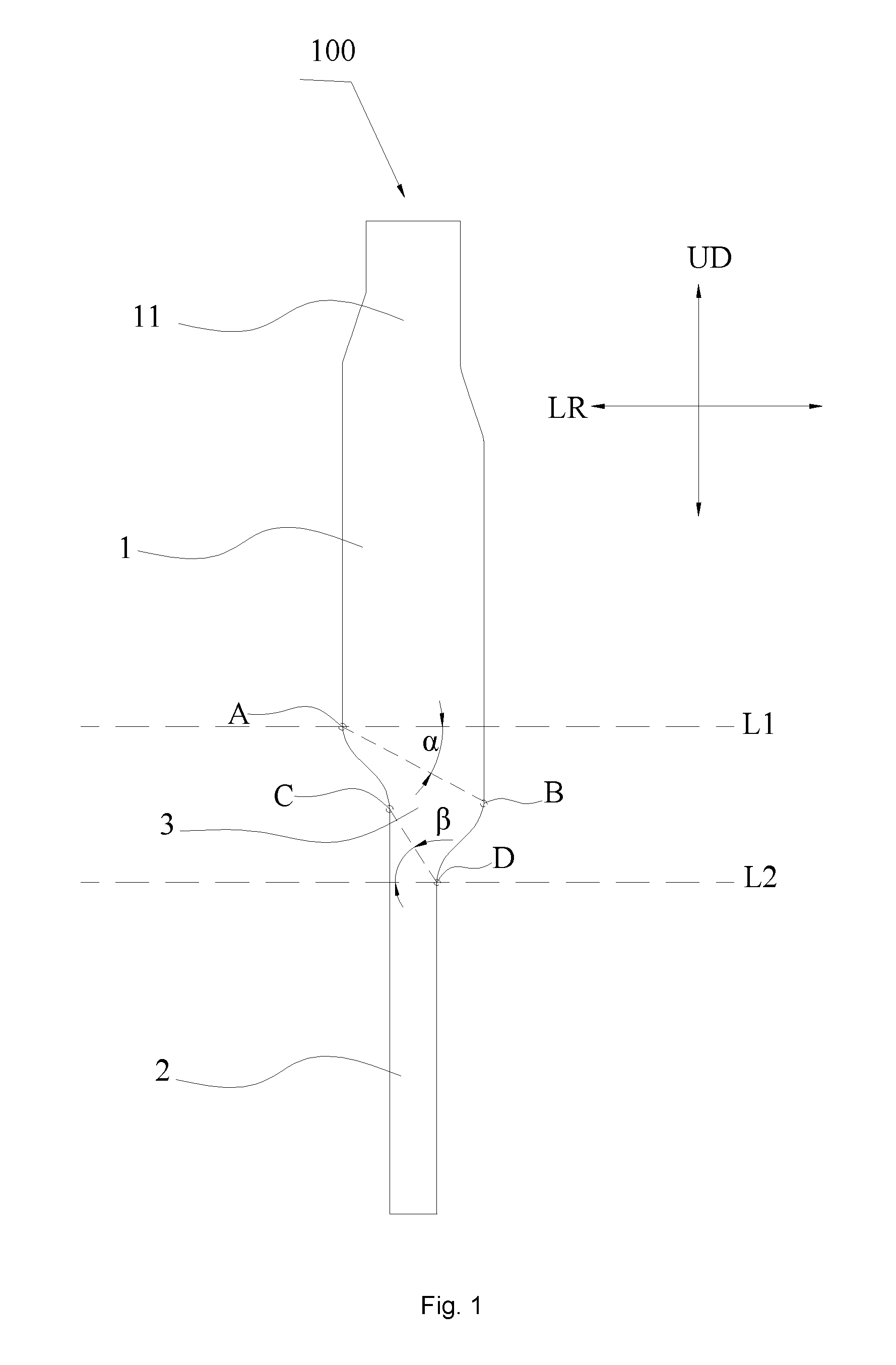

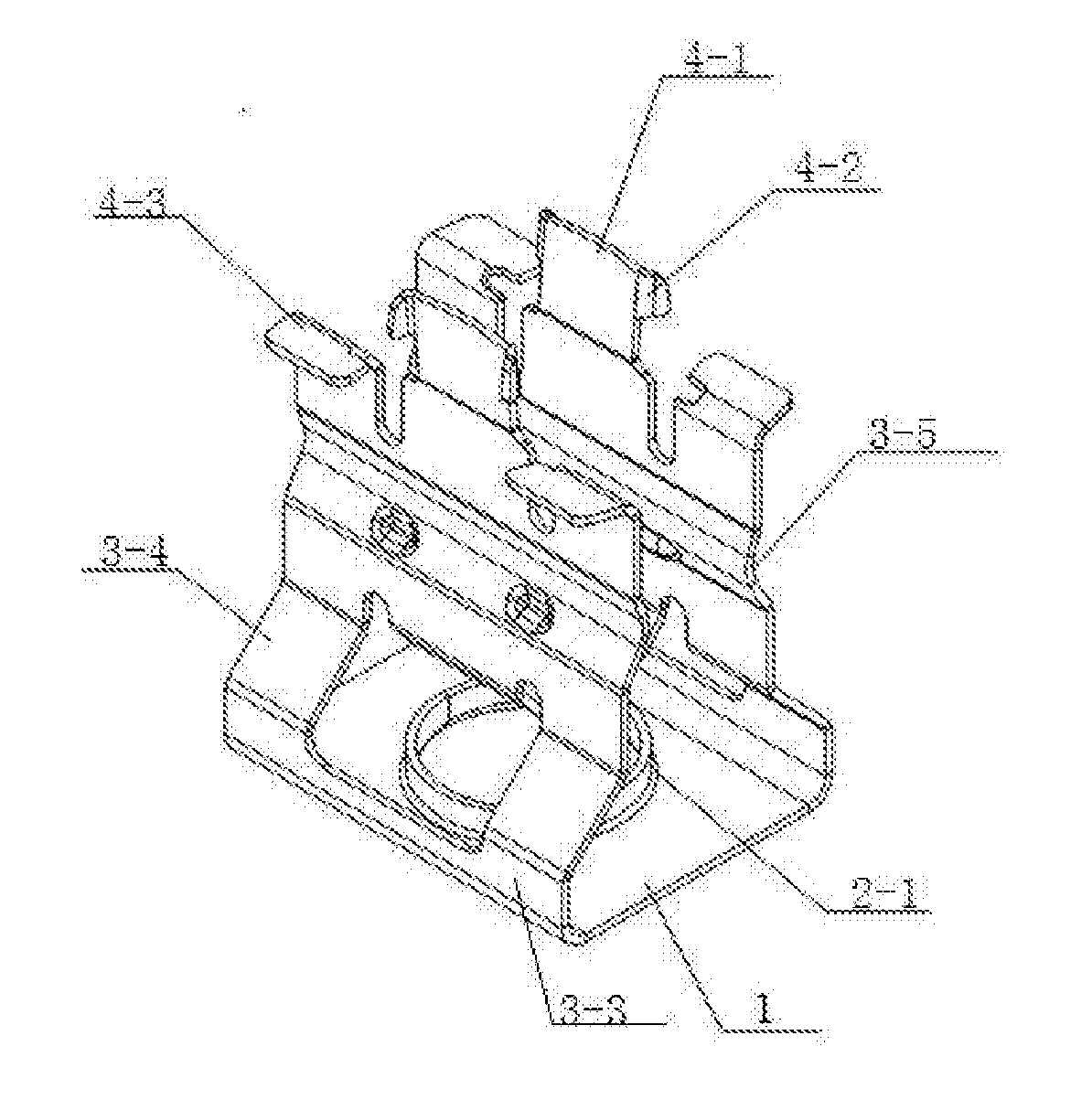

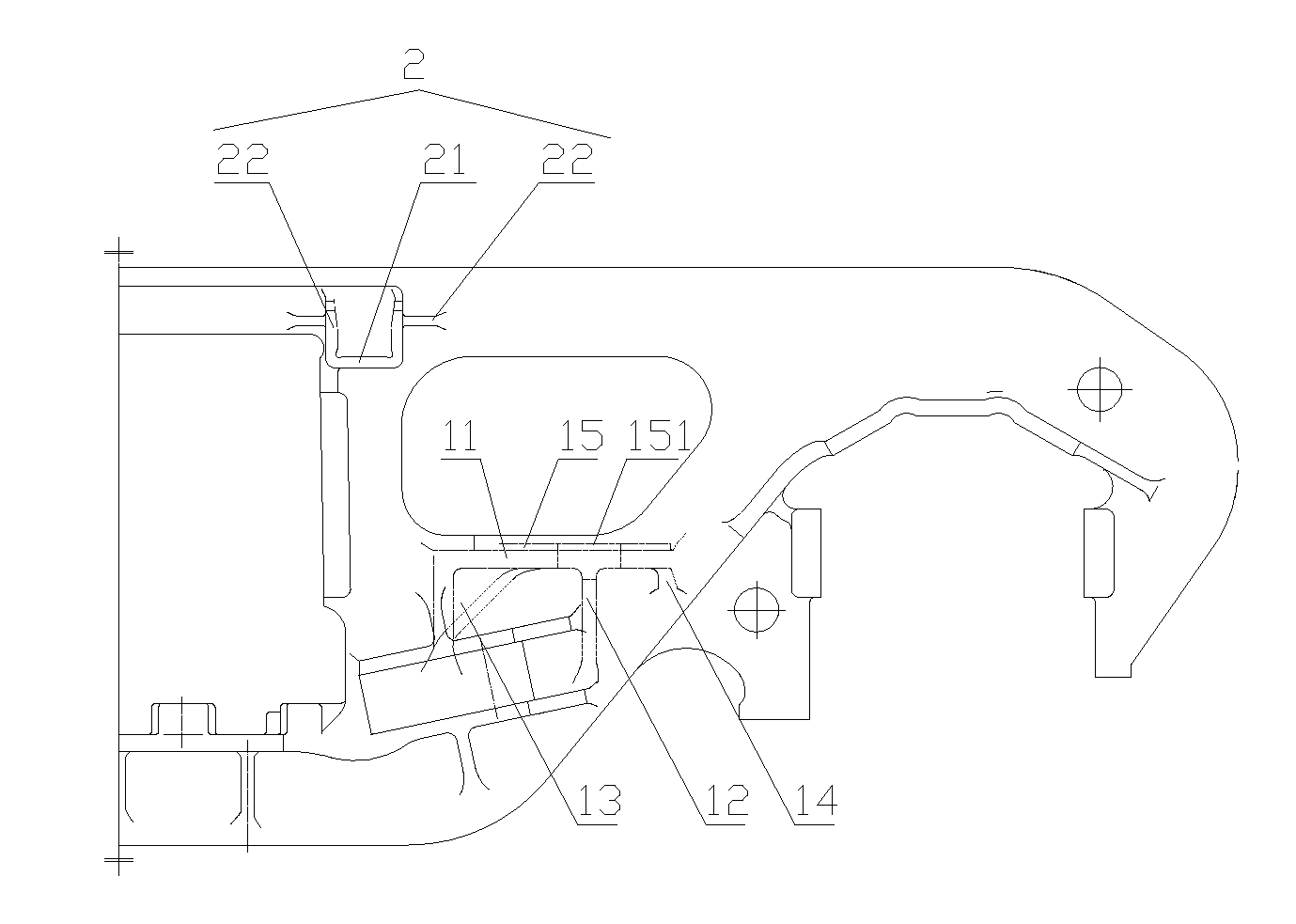

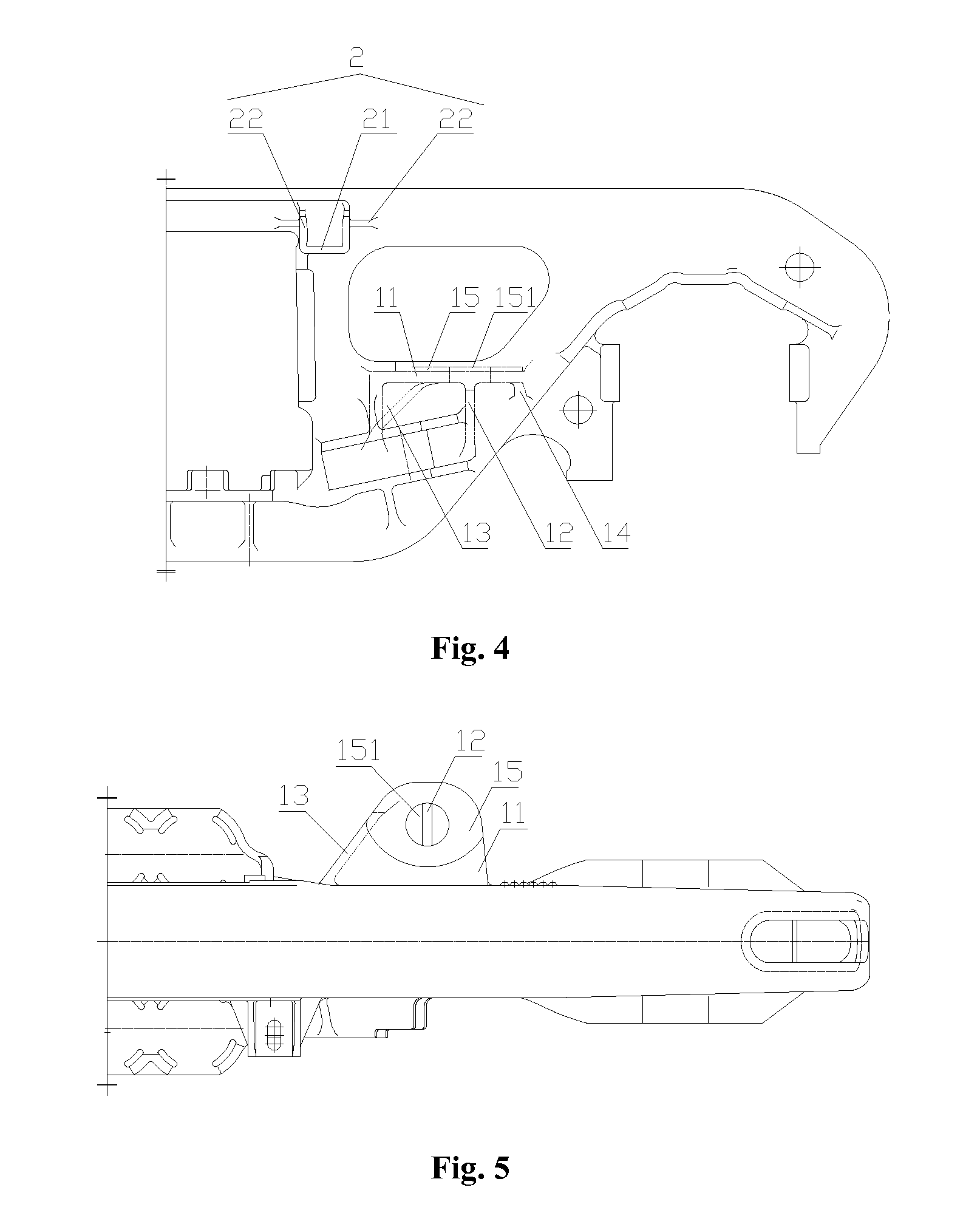

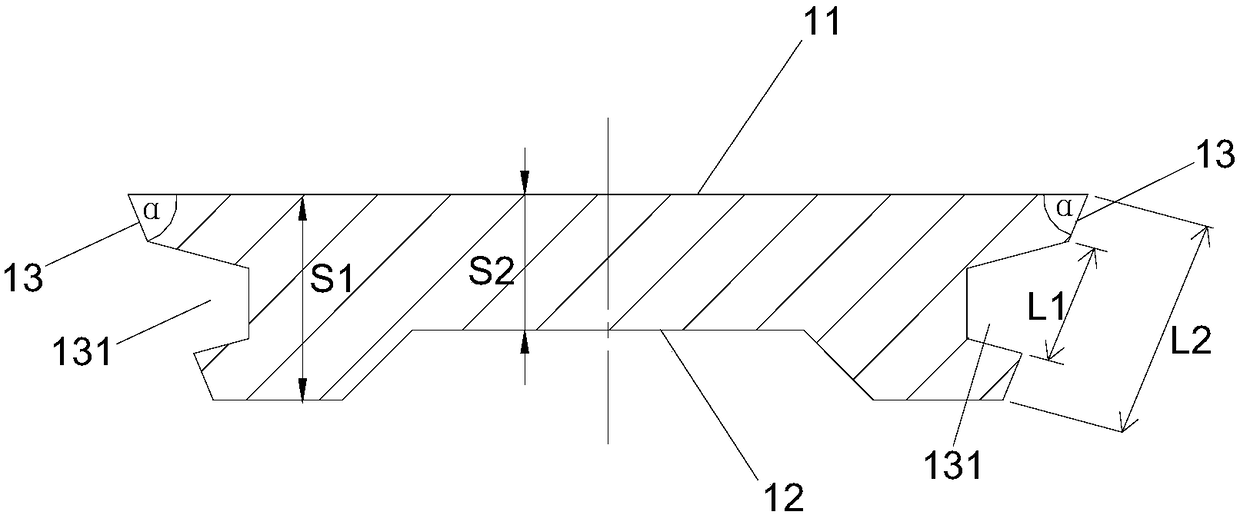

Contact piece of gold finger, gold finger and connector comprising the gold finger

ActiveUS9055684B2Improve abilitiesEnsure connection reliabilityElectrically conductive connectionsPrinted circuit aspectsBiomedical engineeringBody segment

A contact piece of a gold finger comprises: a first main body segment; a second main body segment; and a transition segment connected to the first main body segment and the second main body segment, respectively, in a vertical direction, in which an upper edge and a lower edge of the transition segment are inclined with respect to a lateral direction respectively. A gold finger and a connector comprising the same are also provided.

Owner:BYD CO LTD

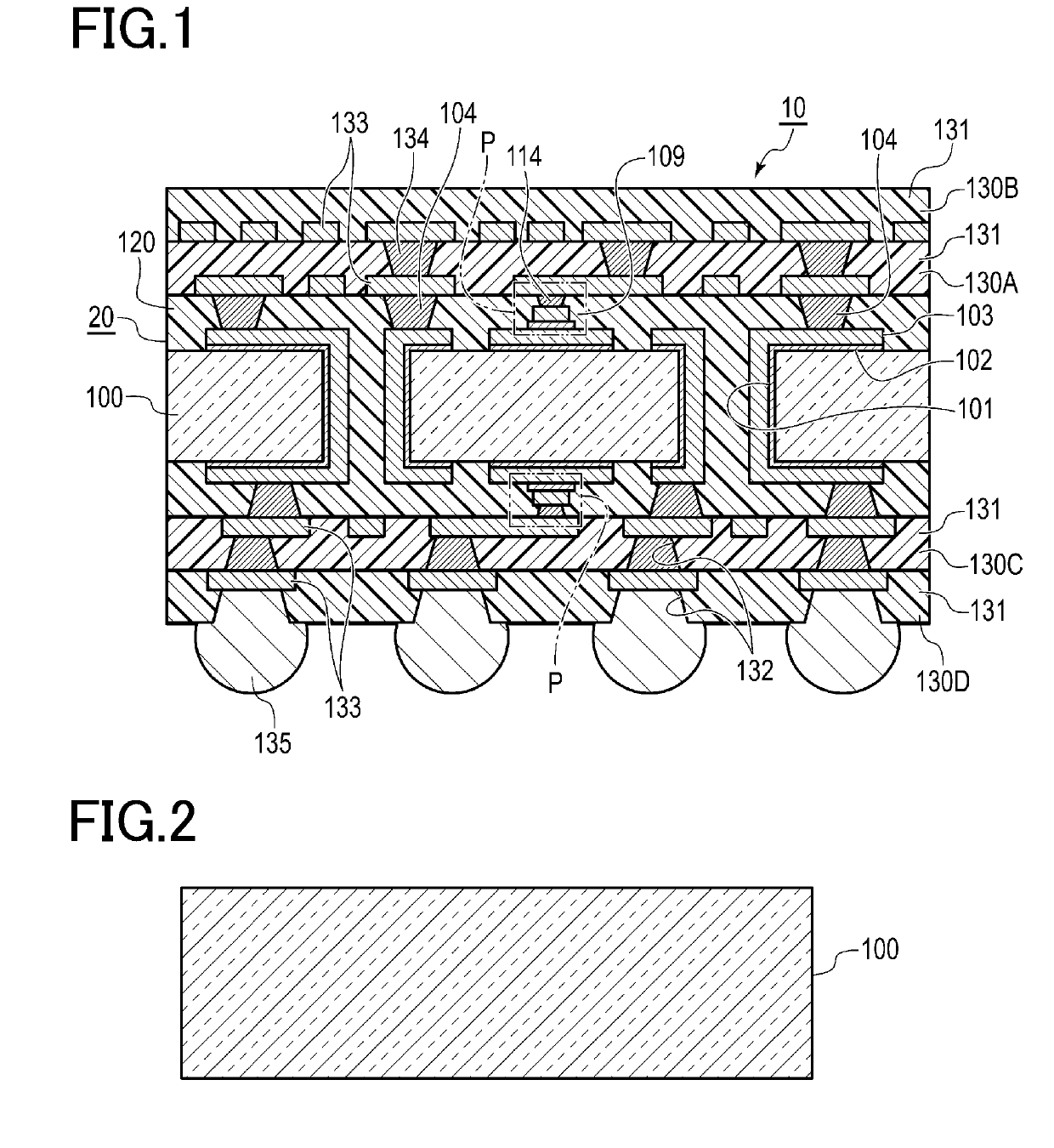

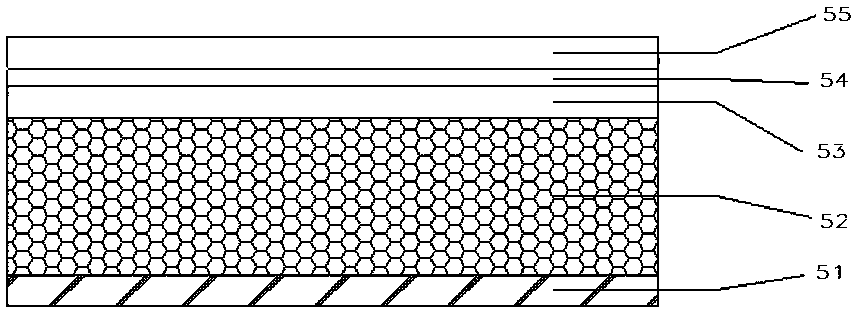

Electronic component and method of producing electronic component

ActiveUS20190269013A1Improve reliabilityReduction factorSemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsCopper

An electronic component includes a glass base in which through holes are formed passing through both surfaces thereof; an insulating resin layer laminated on each of both surfaces of the glass base and including a copper plated layer formed therein; and a capacitor including a lower electrode formed on the copper plated layer, a dielectric layer laminated on the lower electrode, and an upper electrode laminated on the dielectric layer. In the electronic component, the upper electrode has a region that is parallel to the copper plated layer and is formed so as to be smaller than a region of the dielectric layer parallel to the surface of the copper plated layer or a region of the lower electrode parallel to the surface of the copper plated layer.

Owner:TOPPAN PRINTING CO LTD

Electronic apparatus

InactiveUS20160150655A1Stress causedReduce harmClosed casingsPrinted circuit aspectsEngineeringElectronic component

An electronic apparatus includes a board, an electronic component, a mold resin a rod-like connection terminal and a case. The board includes: a first surface; a second surface, which is opposite to the first surface; a wire pattern; and a through-hole having a metal member connected to the wire pattern. The electronic component mounted on the first surface of the board. The mold resin seals the electronic component on the first surface of the board. The rod-like connection terminal inserted into the through-hole from a distal end of the through-hole and electrically connected to the metal member. The case having a surface on which the connection terminal stands and accommodating the board on which the electronic component is mounted. The board is arranged such that the first surface on which the electronic component and the mold resin are arranged faces the surface of the case on which the connection terminal stands.

Owner:DENSO CORP

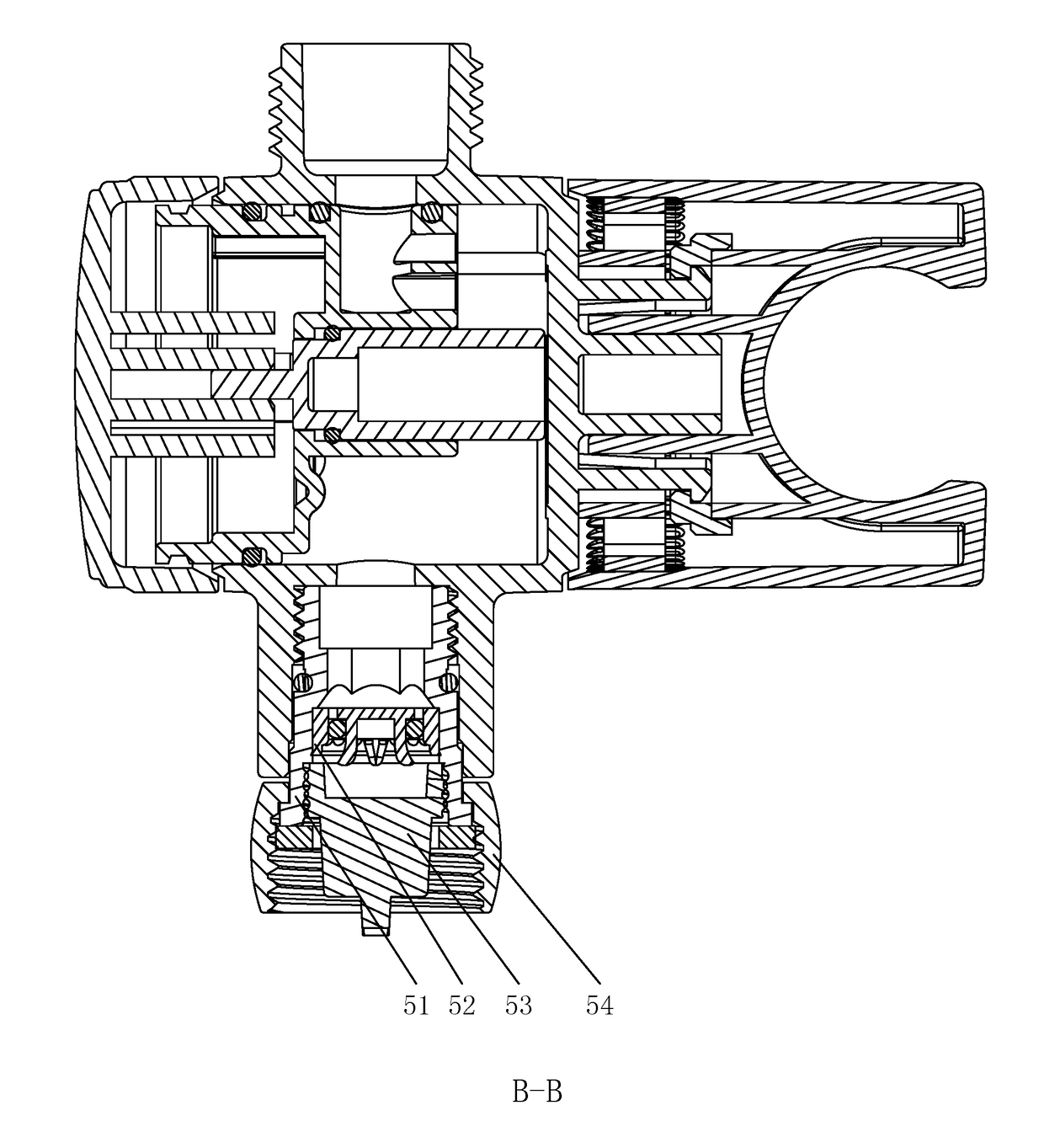

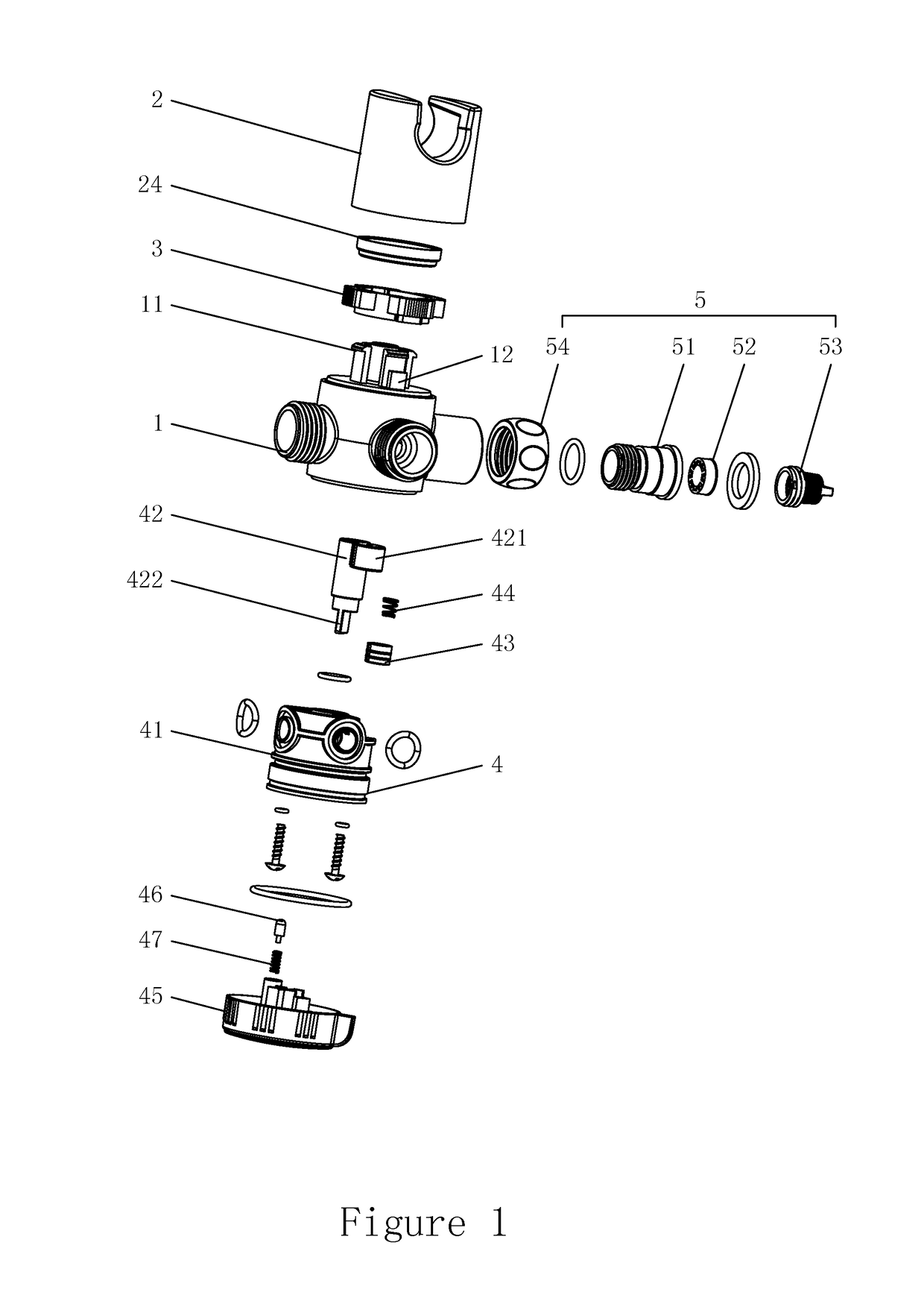

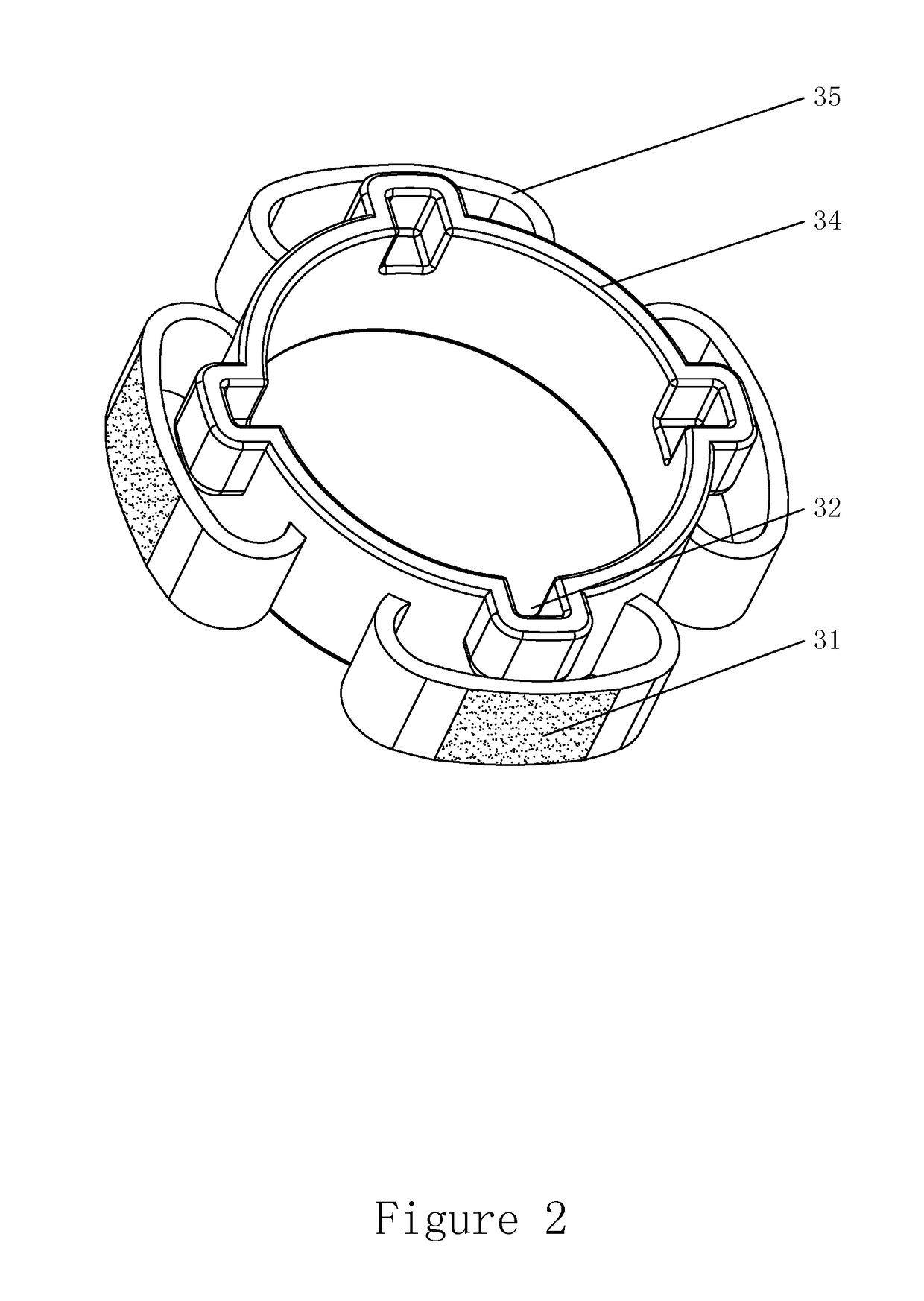

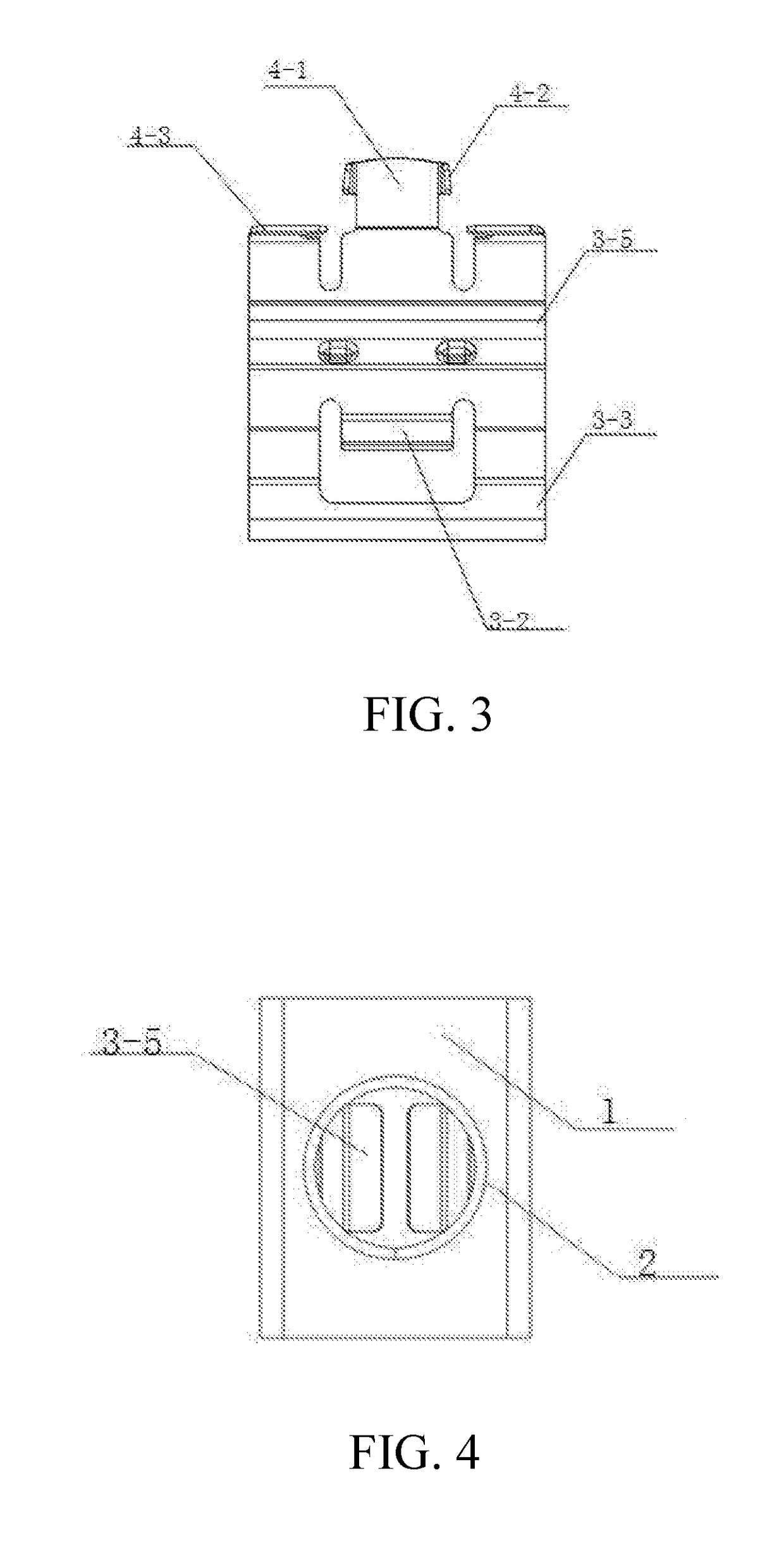

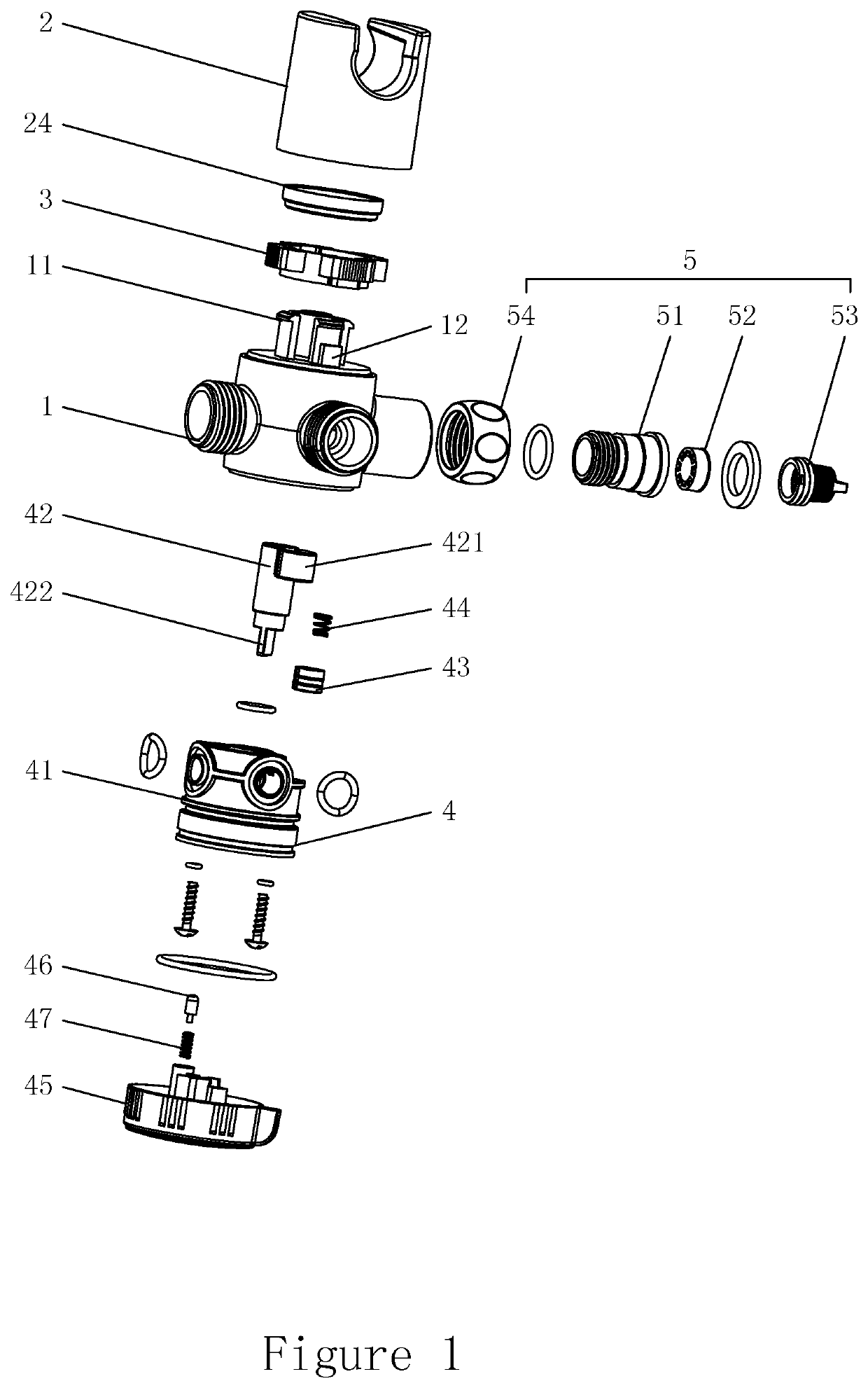

Water separator with shower seat

ActiveUS20180282983A1Simple structureSave waterWatering devicesDomestic plumbingMechanical engineeringShower

A water separator with a shower seat includes a valve body, a frictional unit, a shower seat, and a water outflow switching mechanism. The valve body is provided with a plurality of snap-fit joints disposed circumferentially. The frictional unit is mounted on the valve body and an outer wall thereof is provided with a first frictional surface. The shower seat is provided with a connecting chamber having an open end, and a snap-fit surface and a second frictional surface are circumferentially disposed in the connecting chamber, respectively. The water outflow switching mechanism is mounted in the valve body. Hook heads of the snap-fit joints are snapped to the snap-fit surface to prevent the shower seat from getting separated from the valve body. When the shower seat rotates with respect to the valve body, the first frictional surface and the second frictional surface rotate accordingly and interact with each other.

Owner:FUJIAN XIHE SANITARY WARE TECH

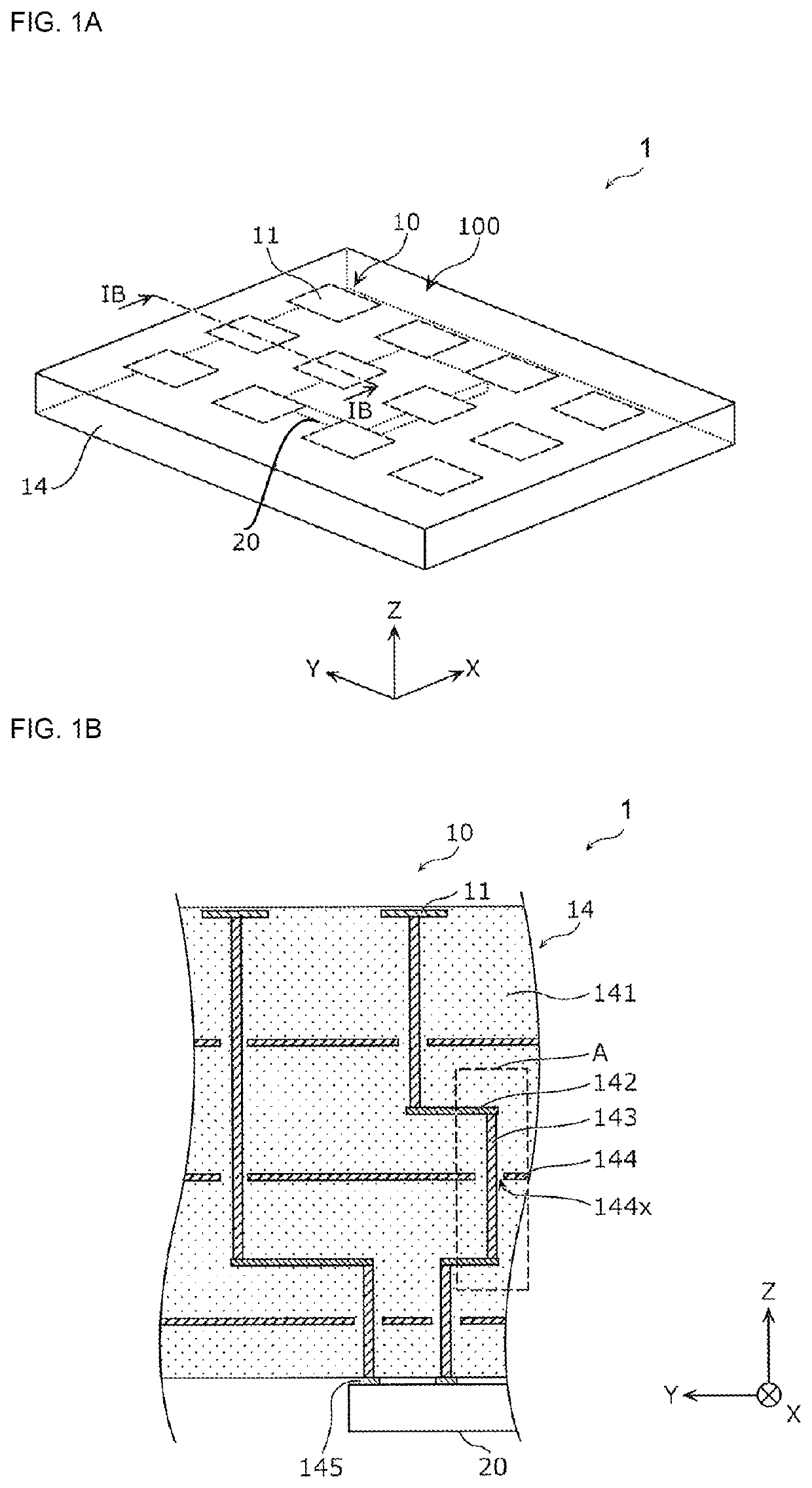

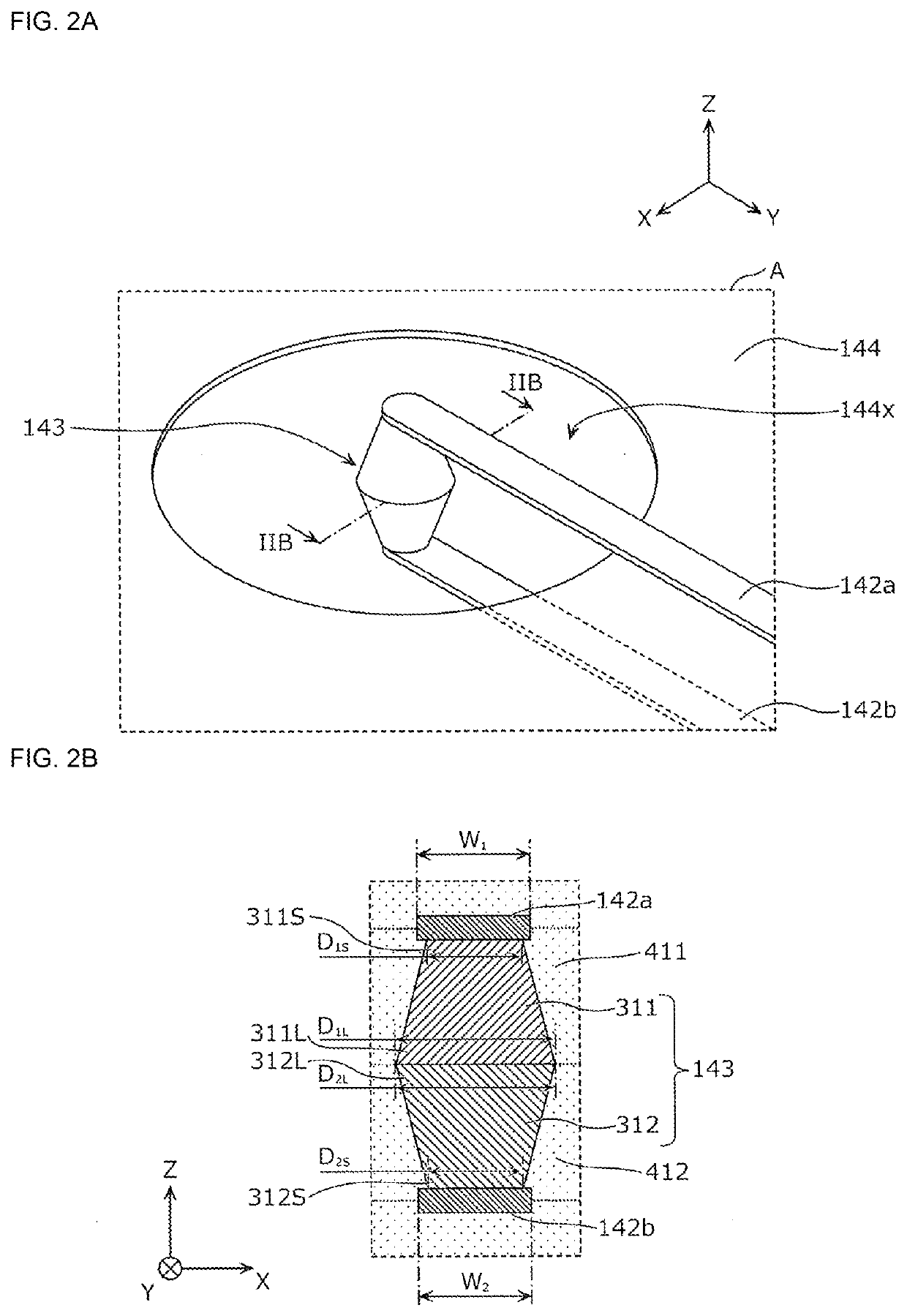

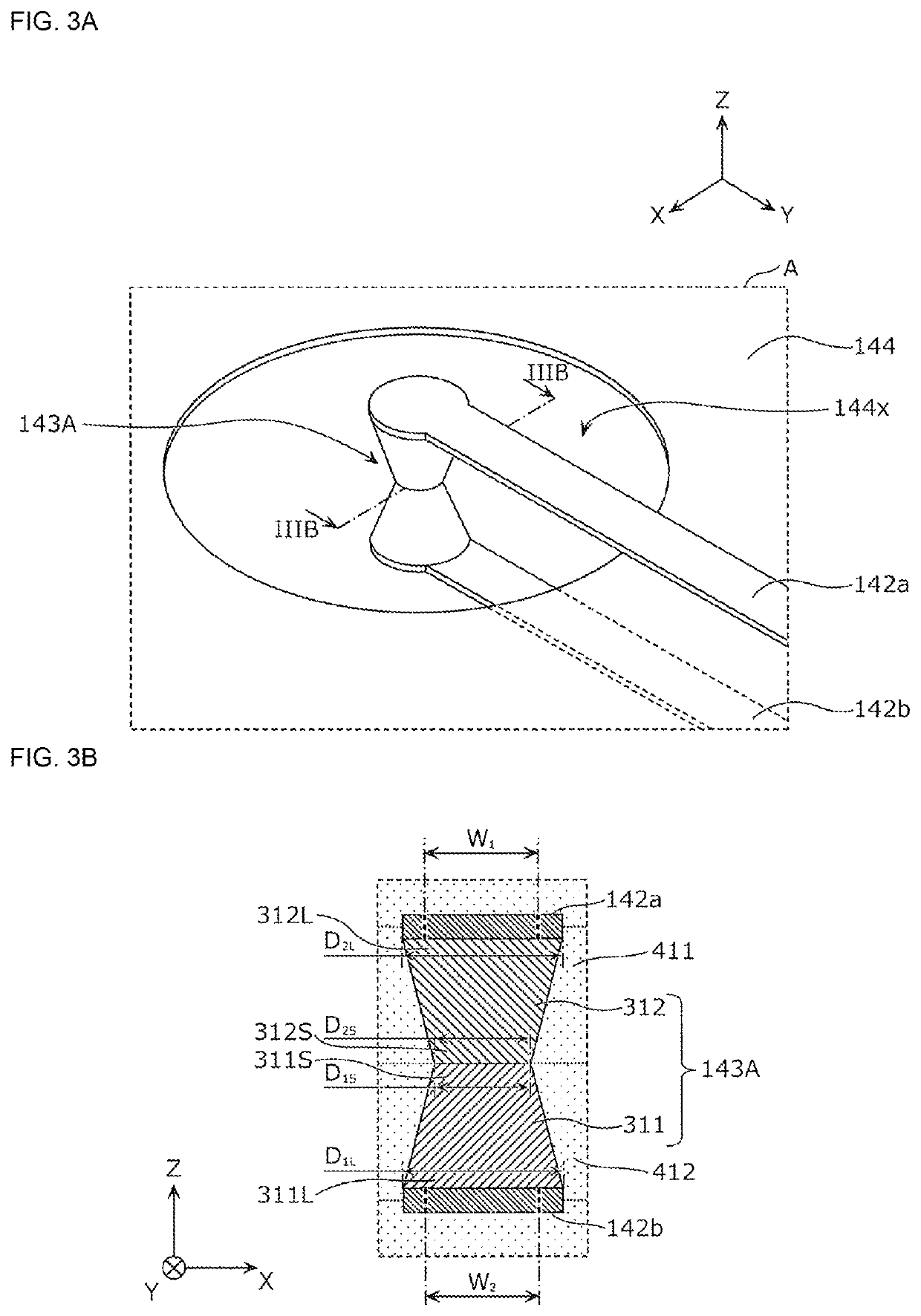

Multilayer substrate and antenna module

ActiveUS20200337157A1Inhibition lossShorten the lengthPrinted circuit detailsPrinted circuit aspectsElectrical conductorEngineering physics

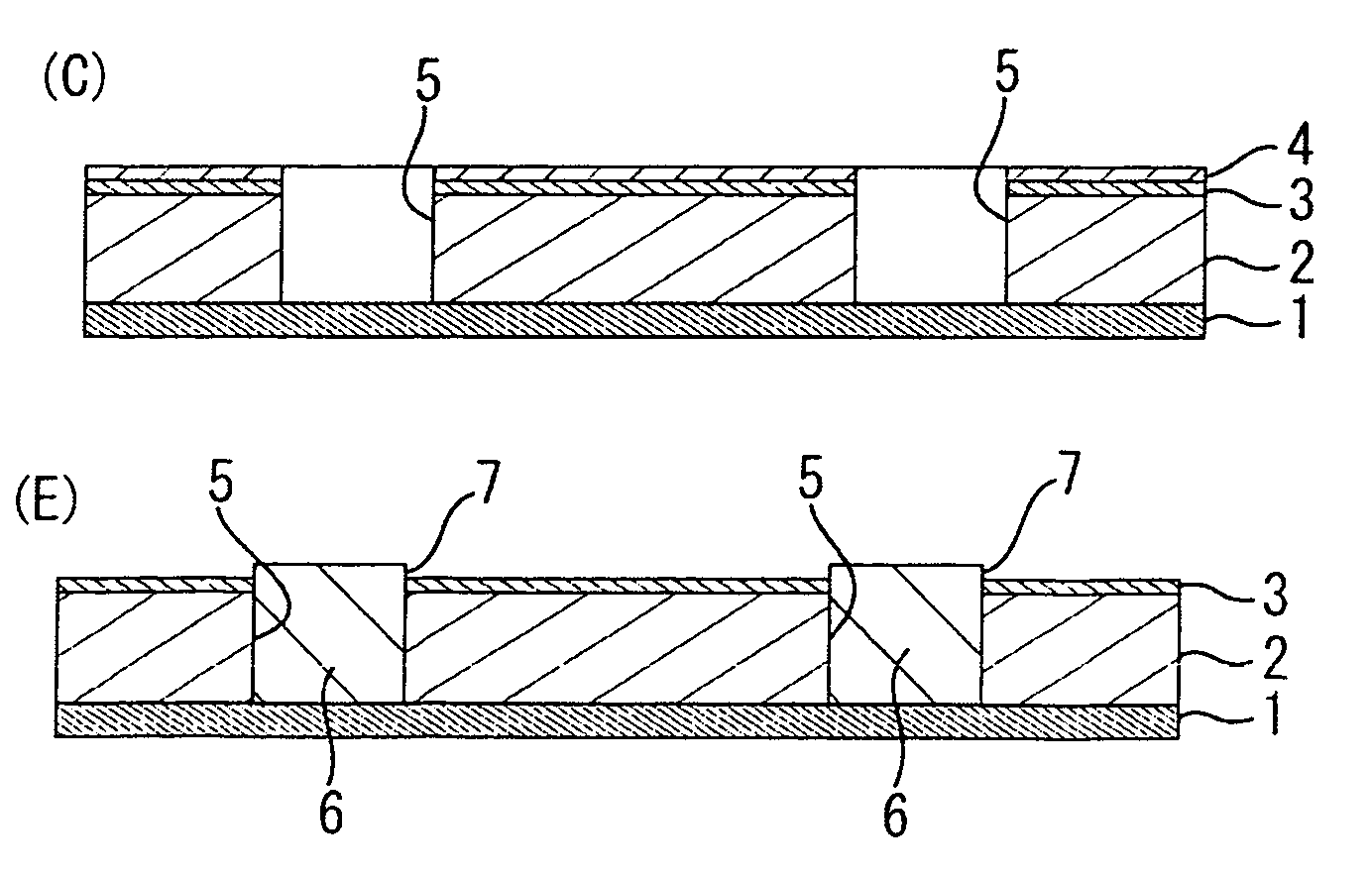

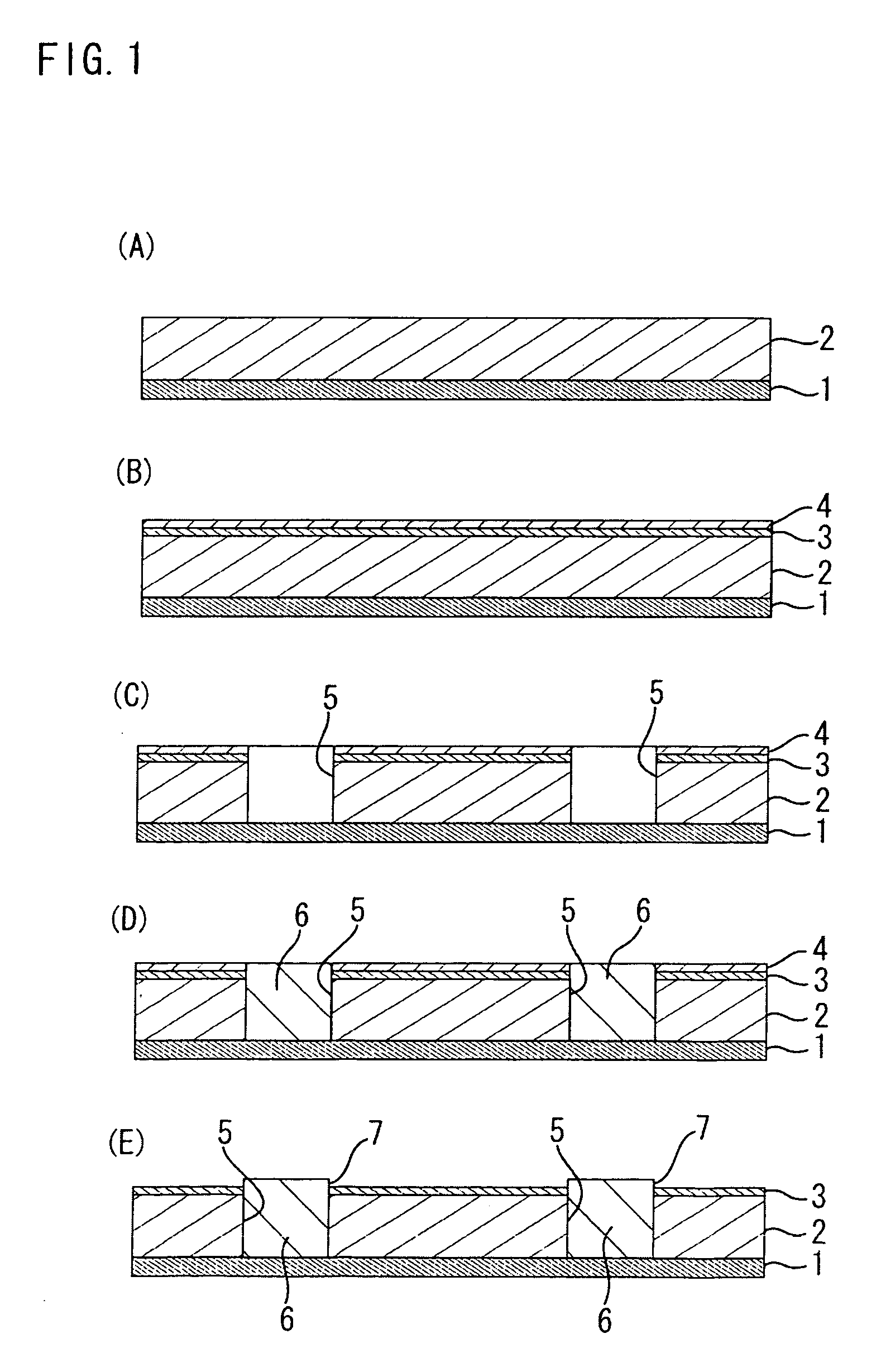

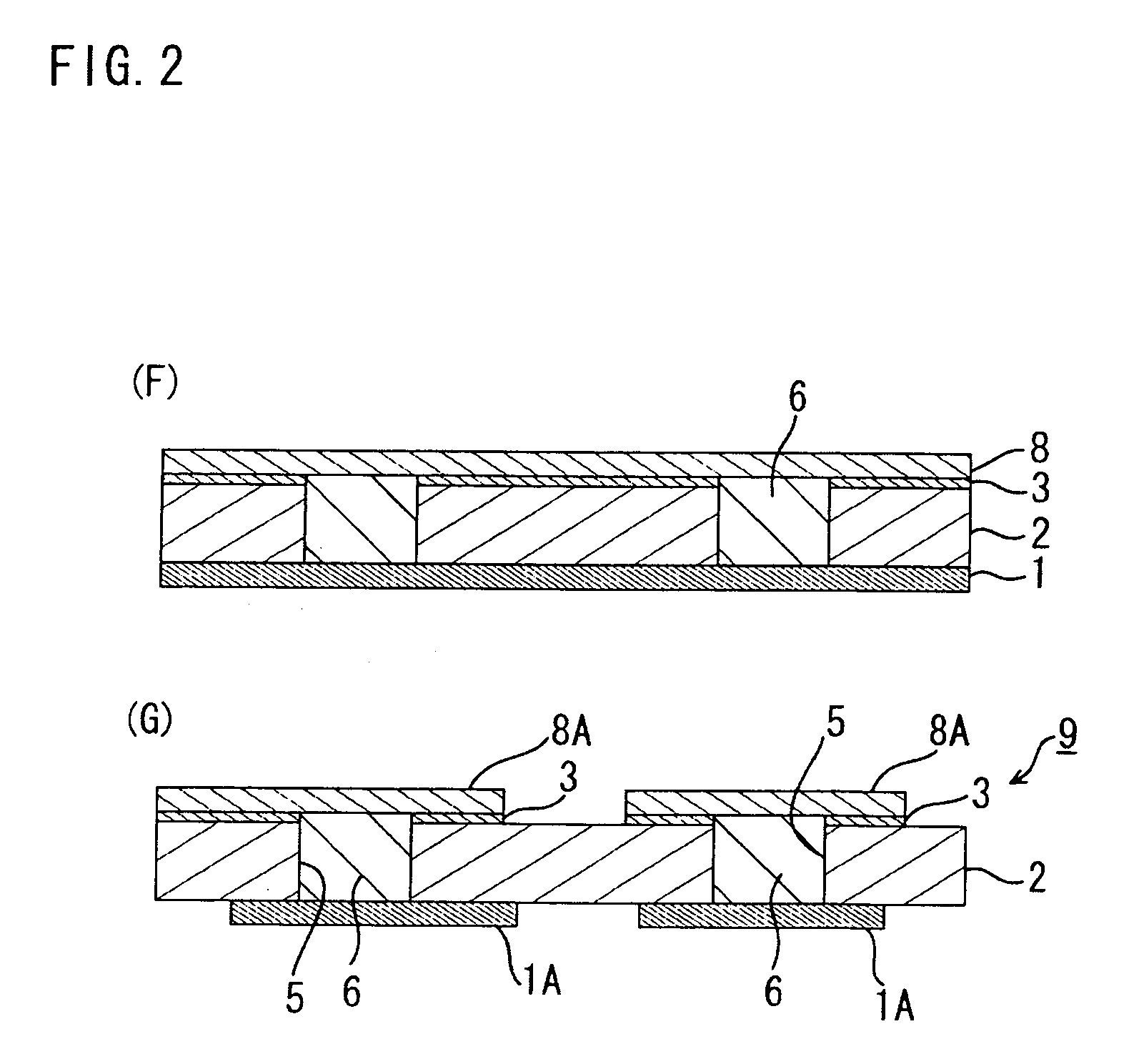

A multilayer substrate includes a plurality of insulator layers laminated, a column conductor extending through two or more insulator layers among the plurality of insulator layers. The column conductor includes a first via conductor extending through a first insulator layer and a second via conductor extending through a second insulator layer adjacent to the first insulator layer. Each of the first via conductor and the second via conductor has a tapered shape in which a cross section decreases from one end portion to the other end portion in the lamination direction of the plurality of insulator layers. The first via conductor and the second via conductor are directly bonded to each other at large diameter portions that are end portions with a large cross section or small diameter portions that are end portions with a small cross section.

Owner:MURATA MFG CO LTD

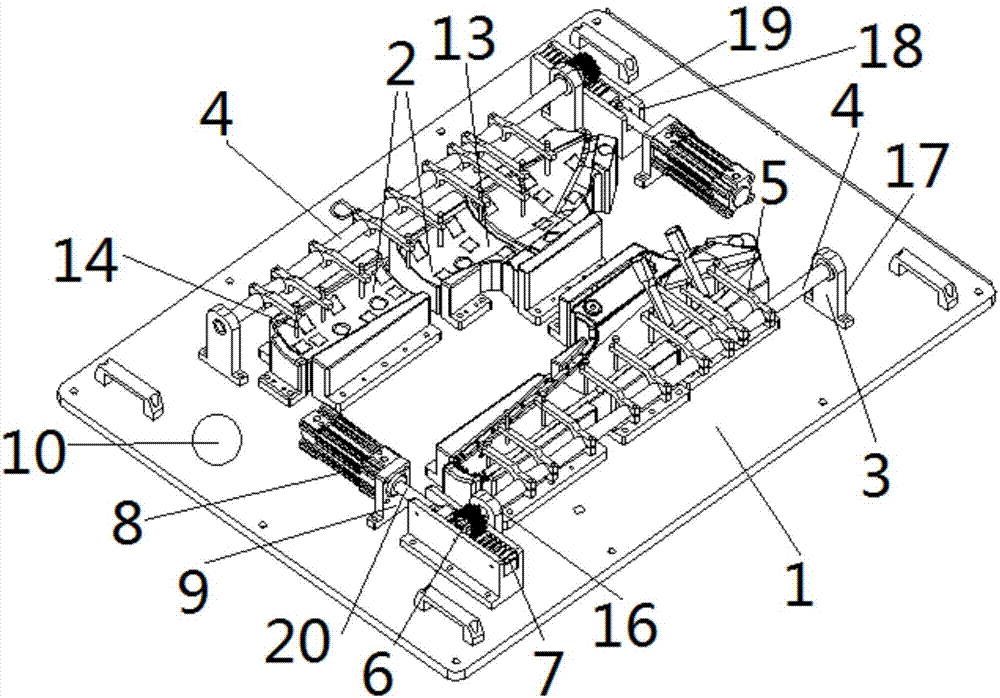

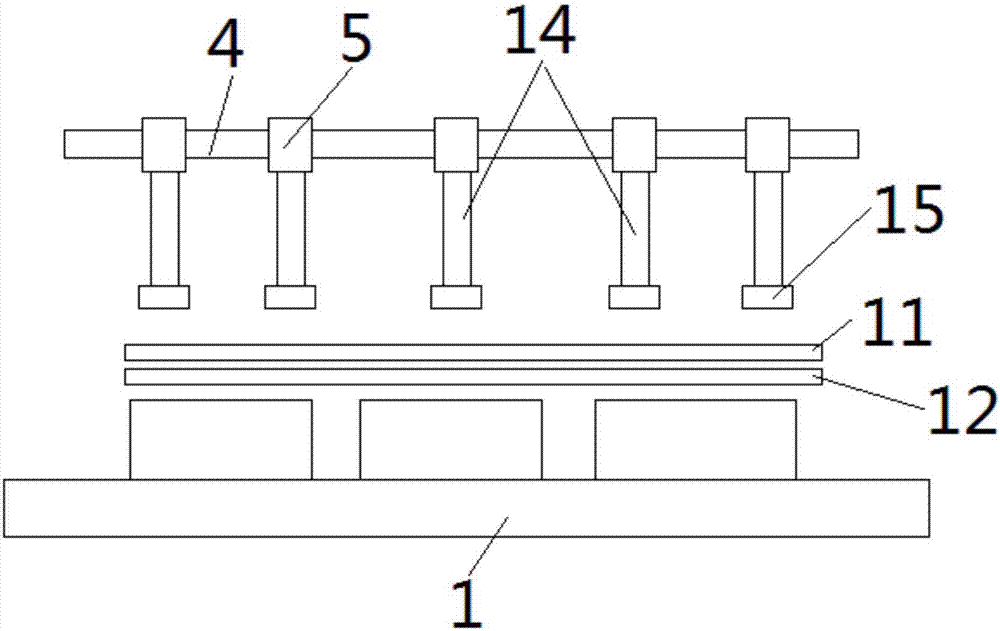

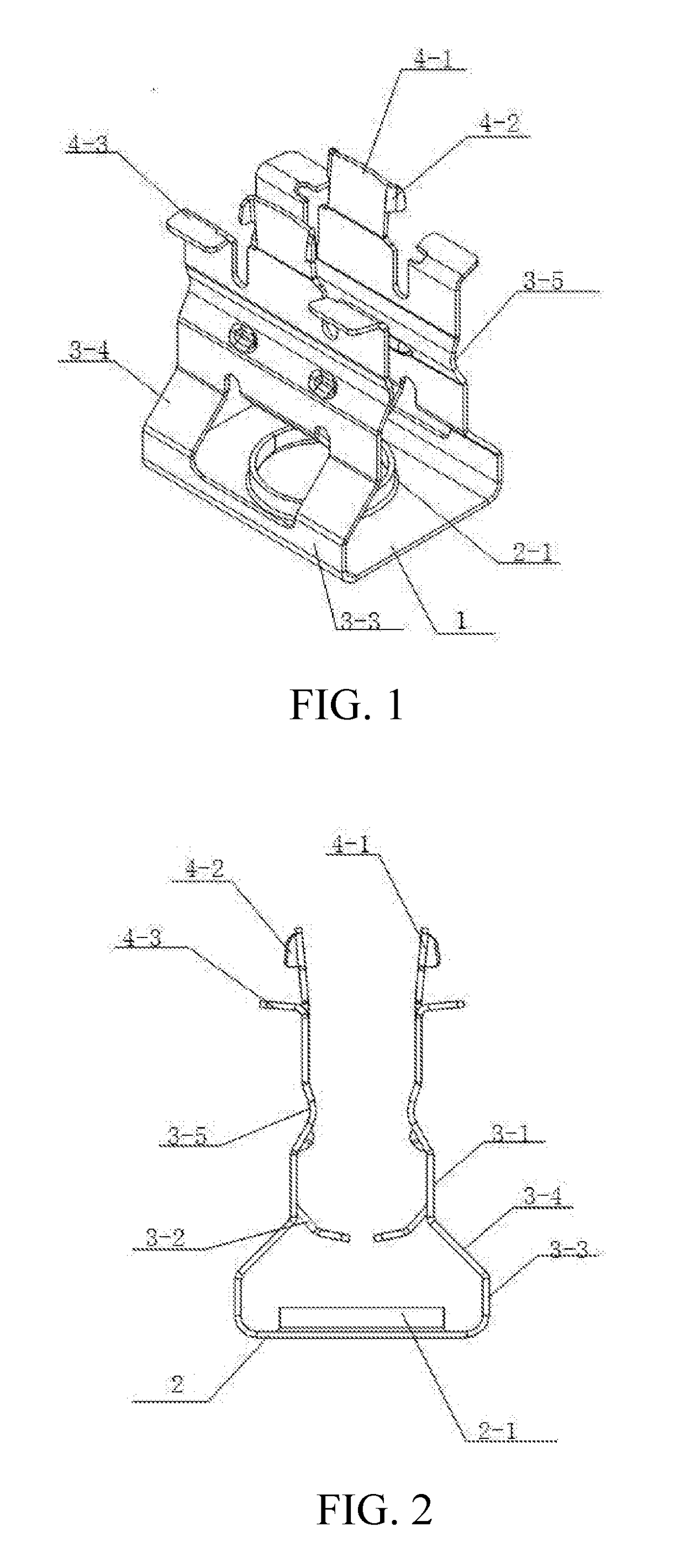

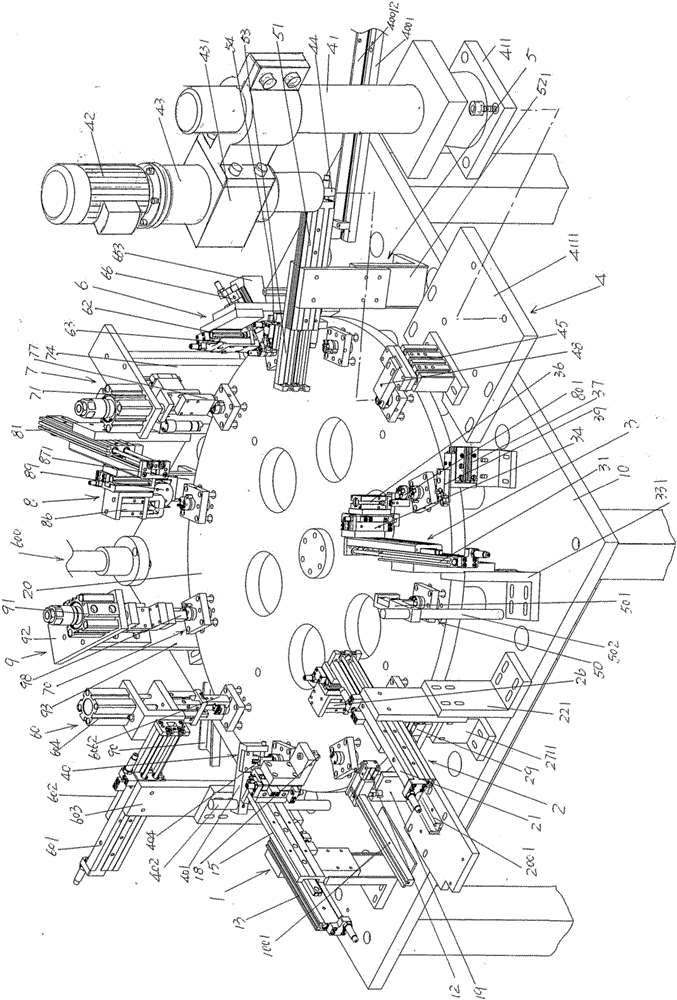

Auxiliary tool for processing of decorative plate for edge beam of car door

PendingCN107364217AReliable implementation of sticky connectionsEnsure connection reliabilityLamination ancillary operationsLaminationGear wheelRack and pinion

The invention provides an auxiliary tool for processing of a decorative plate for the edge beam of a car door, belonging to the technical field of production equipment for decorative plates used for the edge beams of car doors. A tool base (1) of the auxiliary tool is provided with a plurality of locating blocks (2) and an installation block (3); a rotating shaft (4) on the installation block (3) is provided with a pressing block (5); one end of the rotating shaft (4) is provided with a gear (6); the gear (6) is engaged with a rack (7); the rack (7) is connected with a telescoping rod (9); and the telescoping rod (9) is connected with a control part (10). The auxiliary tool provided by the invention is simple in structure, can conveniently complete press fitting and bonding of an edge beam decorative plate member I and an edge beam decorative plate member II, ensures connection reliability and smoothness after press fitting and bonding of the edge beam decorative plate member I and the edge beam decorative plate member II, and improves the processing quality and processing efficiency of the decorative plate for the edge beam of the car door.

Owner:WUHU GUOFENG PLASTIC TECH

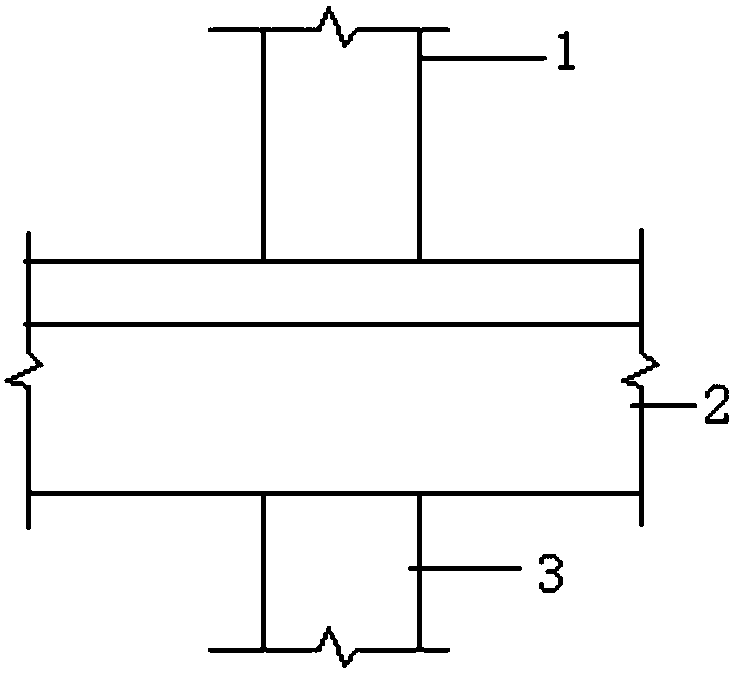

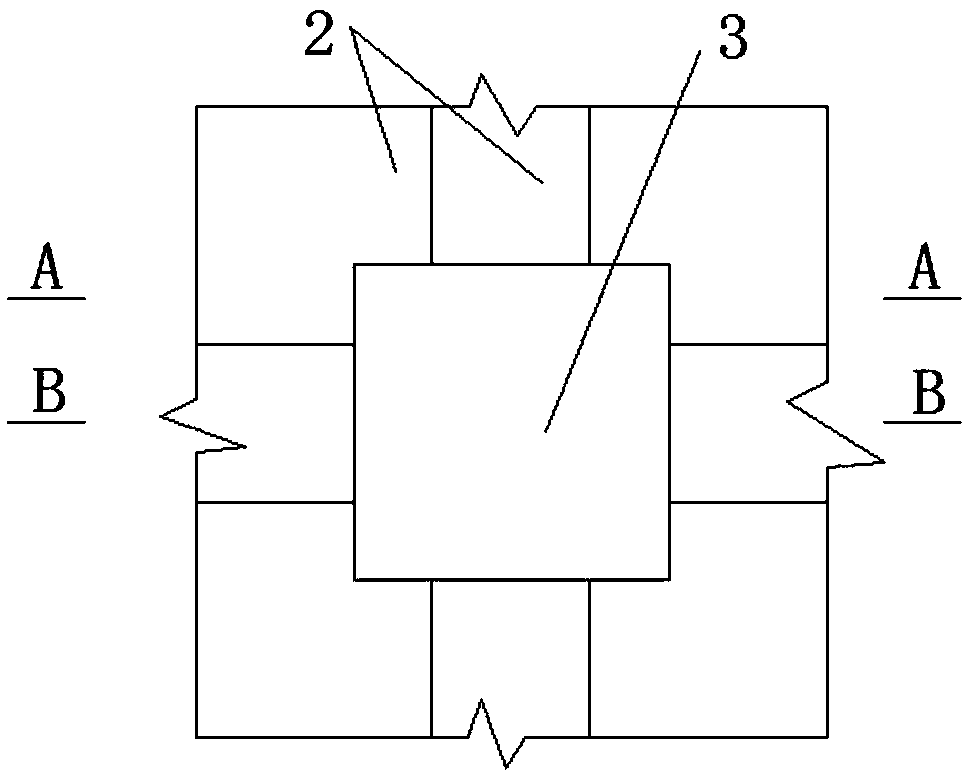

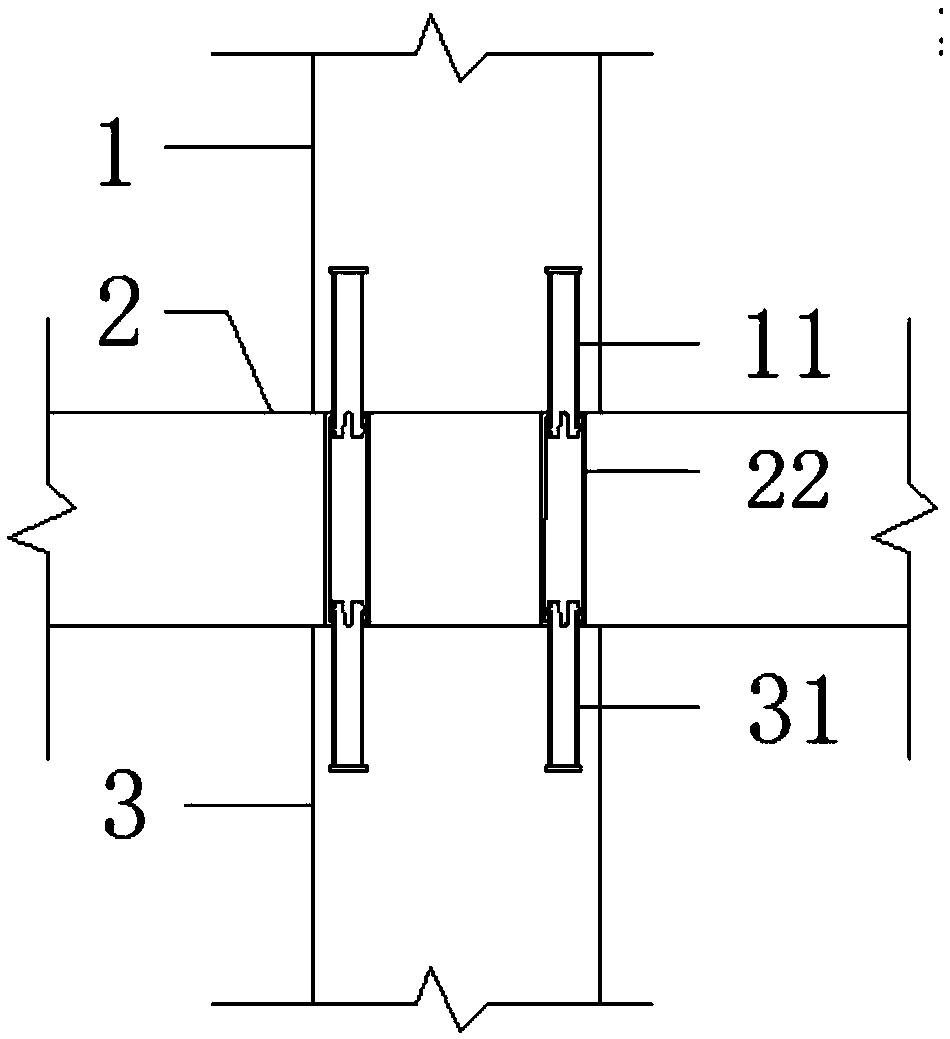

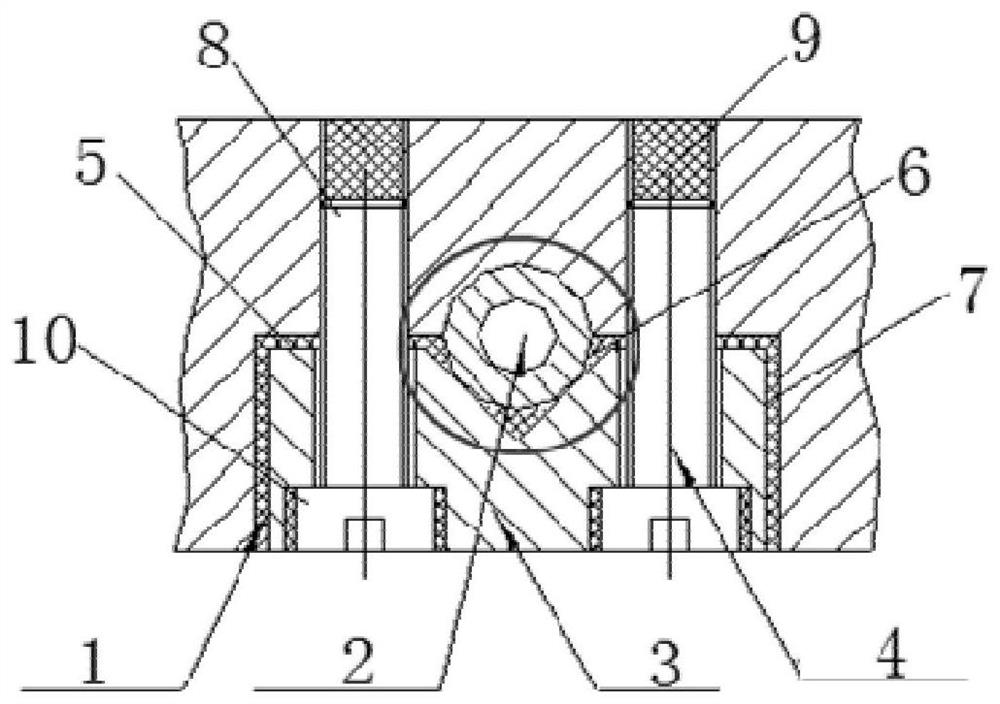

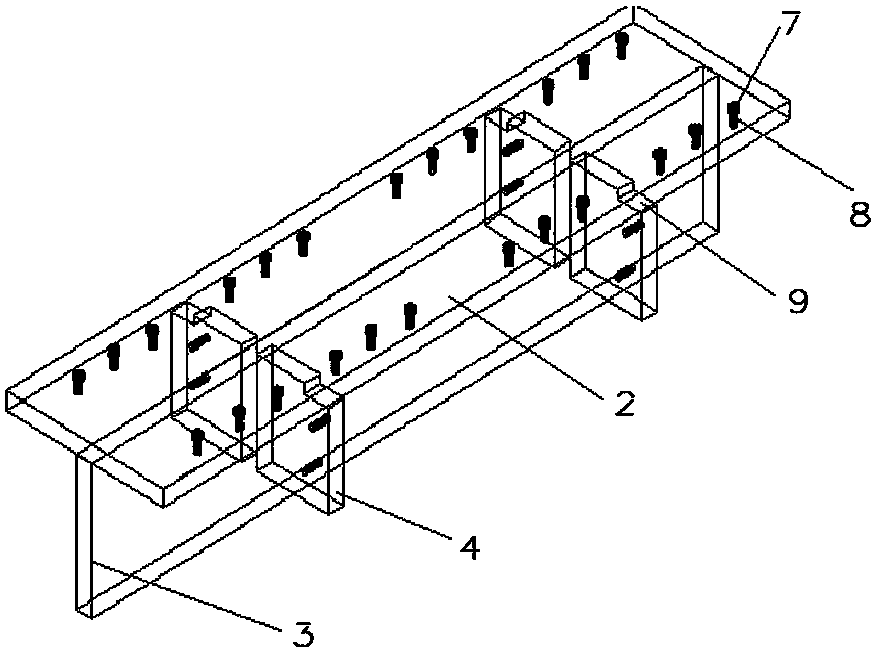

Damping energy dissipation assembling node of precast column and integrated precast beam panel, and construction method thereof

ActiveCN108867885AAvoid double pouringImprove integrityProtective buildings/sheltersShock proofingNeck partsPre embedding

The invention relates to a damping energy dissipation assembling node of a precast column and an integrated precast beam panel, and a construction method thereof. The assembling node comprises the integrated precast beam panel and the precast column, wherein the precast column comprises a lower precast column and an upper precast column; flaring steel pipes I are pre-embedded to the upper surfaceof the lower precast column; the integrated precast beam panel is arranged on the lower precast column and is pre-embedded with a damping steel pipe and multiple necking steel pipes; the upper precastcolumn is arranged on the integrated precast beam panel; a connecting steel pipe and multiple flaring steel pipe II are pre-embedded to the lower surface of the upper precast column; the free end ofthe connecting steel pipe extends into the damping steel pipe; the flaring steel pipes I and the flaring steel pipes II are coaxial in a one-to-one correspondence way and extend into two ends of the corresponding necking steel pipes; flaring parts are arranged at the free ends of the flaring steel pipes I and the flaring steel pipes II; necking parts are arranged at two ends of the necking steel pipes; the corresponding flaring parts of the flaring steel pipes I and the flaring steel pipes II are clamped into the necking parts so as to realize clamping; a connecting structural steel is also preserved on the upper surface of the lower precast column; the free end of the connecting structural steel penetrates through the damping steel pipe and extends into the connecting steel pipe.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES

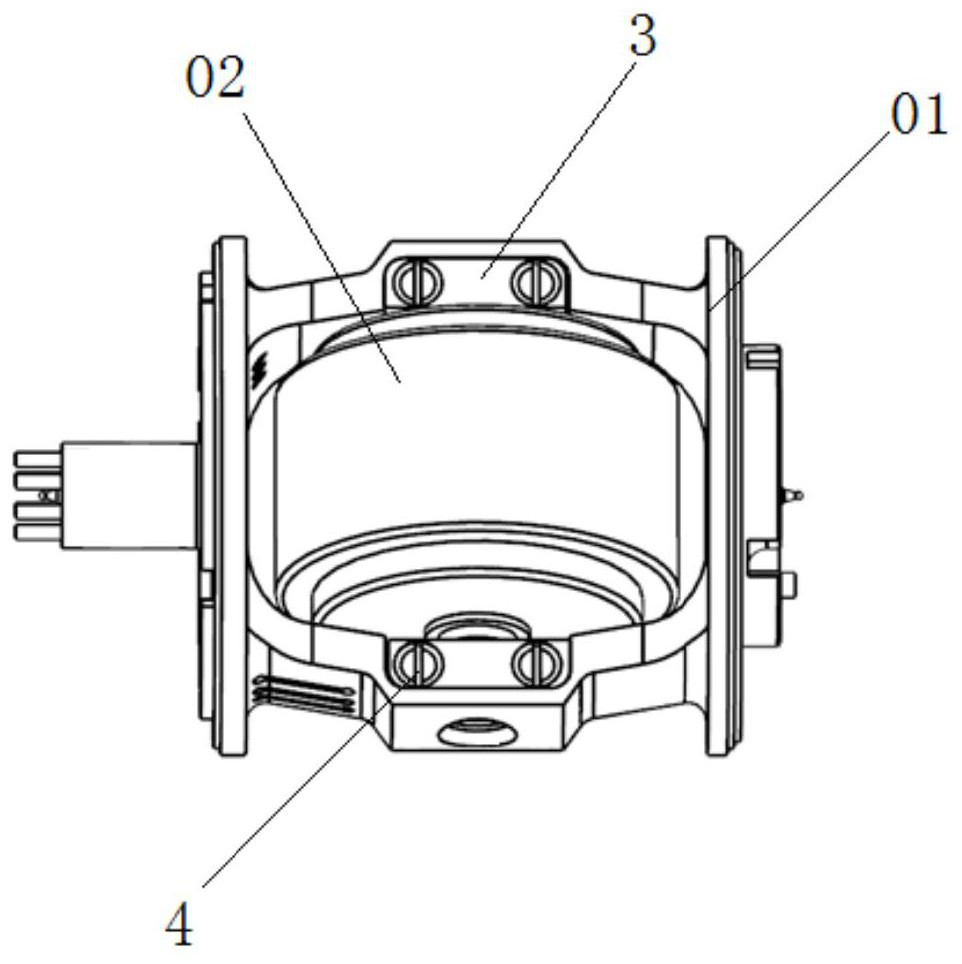

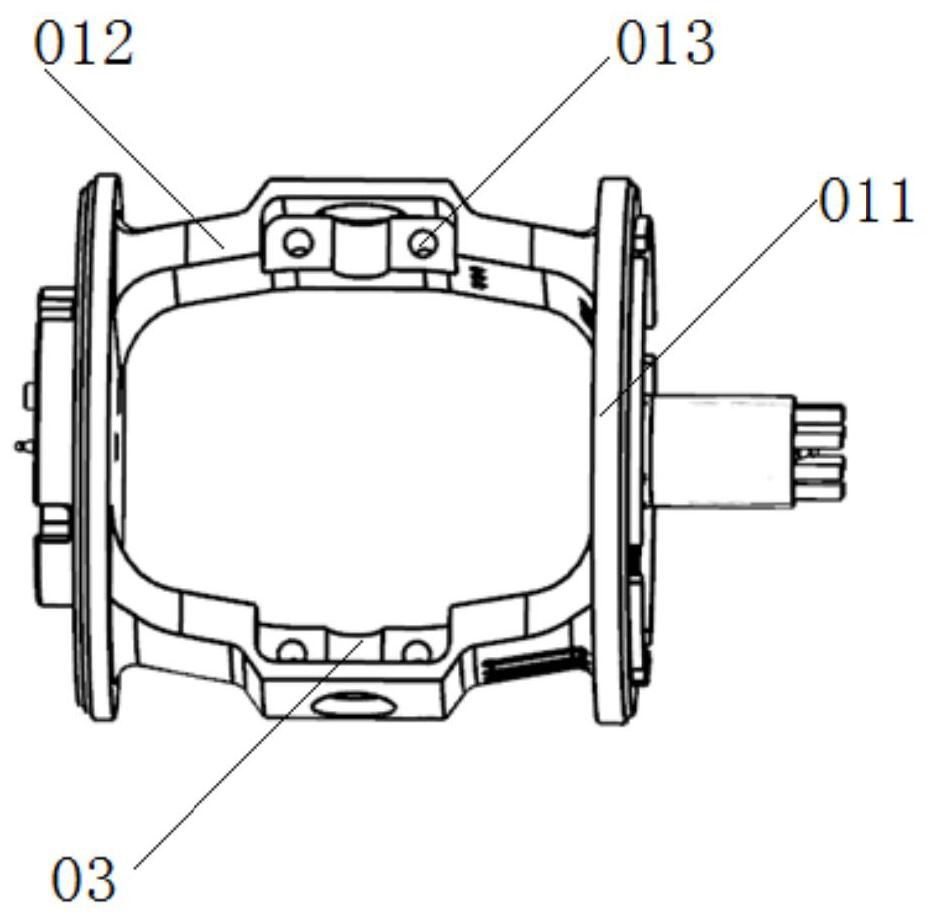

Method for installing dynamic pressure motor and frame assembly

ActiveCN114178152AEnsuring Centroid StabilityImprove stabilityLiquid surface applicatorsWork holdersGyroscopeElectric machinery

The invention belongs to the technical field of two-floating gyroscope installation and adjustment, and particularly relates to an installation method of a dynamic pressure motor and a frame assembly. The problems that due to the fact that the combination portion of a motor shaft of an H-type double-stator dynamic pressure motor and a frame assembly is different in deformation after thermal expansion and cold contraction, and due to the improper gluing portion, installation sequence and glue using amount, the mass center of a floater assembly is unstable, and finally the stability of a gyroscope becomes poor are solved. According to the invention, a proper gluing part is selected, a specific gluing method is adopted, a proper assembly sequence is matched, and meanwhile, the glue consumption of the corresponding gluing part is controlled, so that the mass center stability of the floater assembly after assembly can be ensured, and the stability of the gyroscope is further improved. The method is an important process measure for supporting the mass production of gyroscopes, solving the long-term stability of the drift coefficient of the gyroscopes and the performance change of the H-type double-stator dynamic pressure motor, and is suitable for medium-high-precision liquid floated gyroscopes, especially liquid floated gyroscope systems adopting dynamic pressure bearings.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

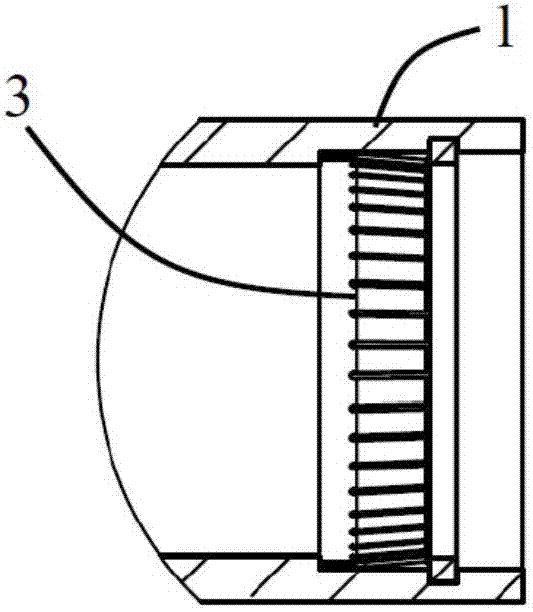

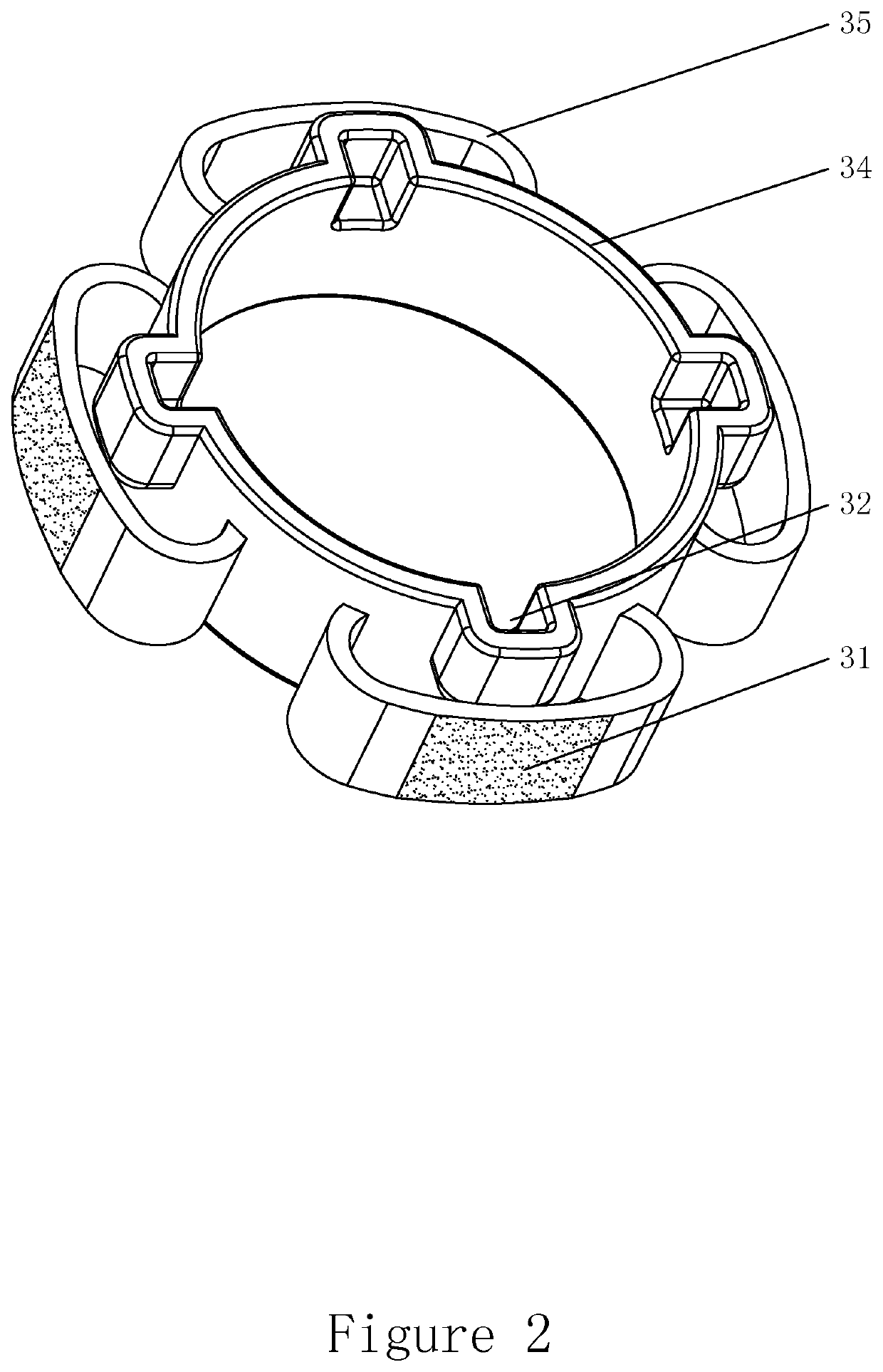

Electrical connection device

PendingCN107317124AIncrease the number ofEnsure connection stabilityEngagement/disengagement of coupling partsClamped/spring connectionsElectricityElectrical connection

The invention provides an electrical connection device. The electrical connection device is provided with a jack main body and a spring piece, wherein the spring piece is arranged in the jack main body, the jack main body is provided with an annular wall and an accommodating cavity, the accommodating cavity is encircled by the annular wall, the spring piece is arranged in the accommodating cavity and is provided with a first coil and a second coil, and the first coil and the second coil are in contact with the annular wall. Compared with the prior art, the electrical connection device has the advantages that the spring piece is arranged in the jack main body, so that the spring piece is sleeved on the jack main body and is in contact with a pin main body in a clamping way, the number of contacts is increased by the spring piece, the connection stability and reliability among the jack main body, the pin main body and the spring piece is guaranteed, and complete and effective contact still can be maintained when the electrical connection device is in an extreme shaking environment.

Owner:易讯科技(苏州)有限公司

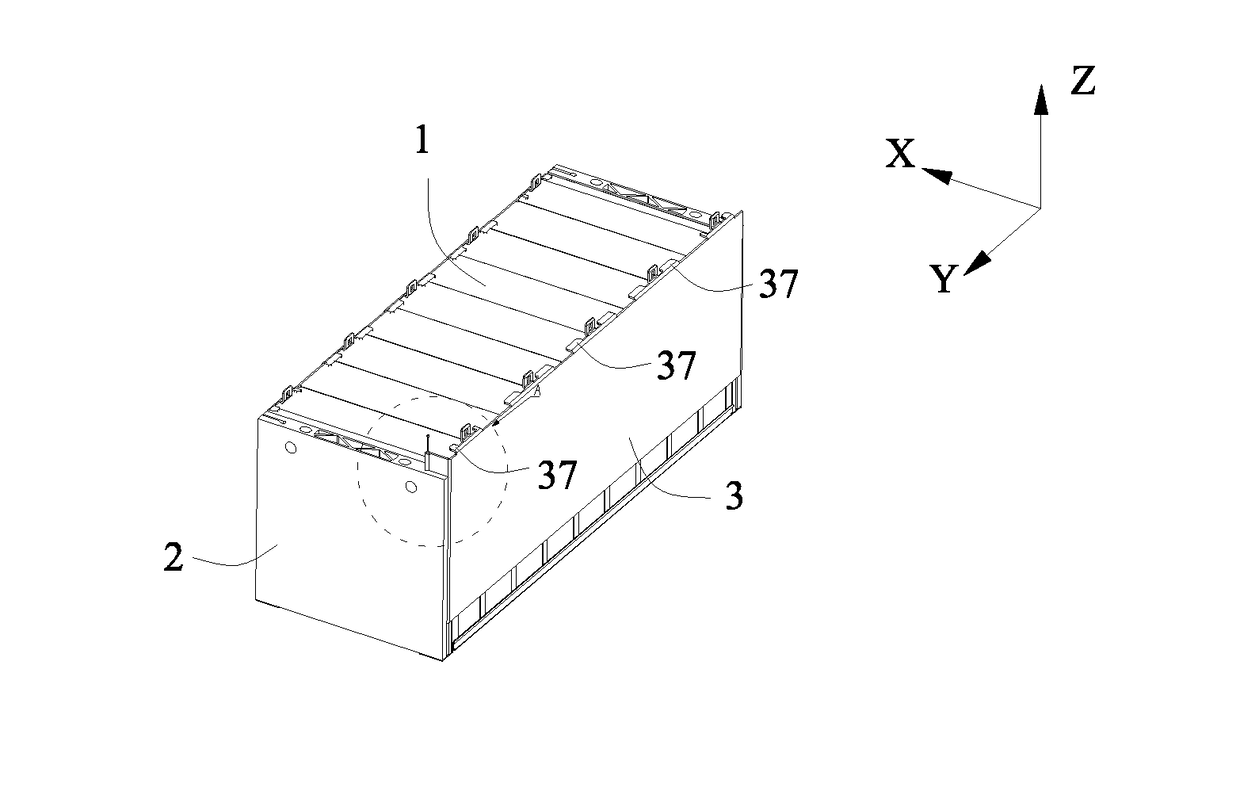

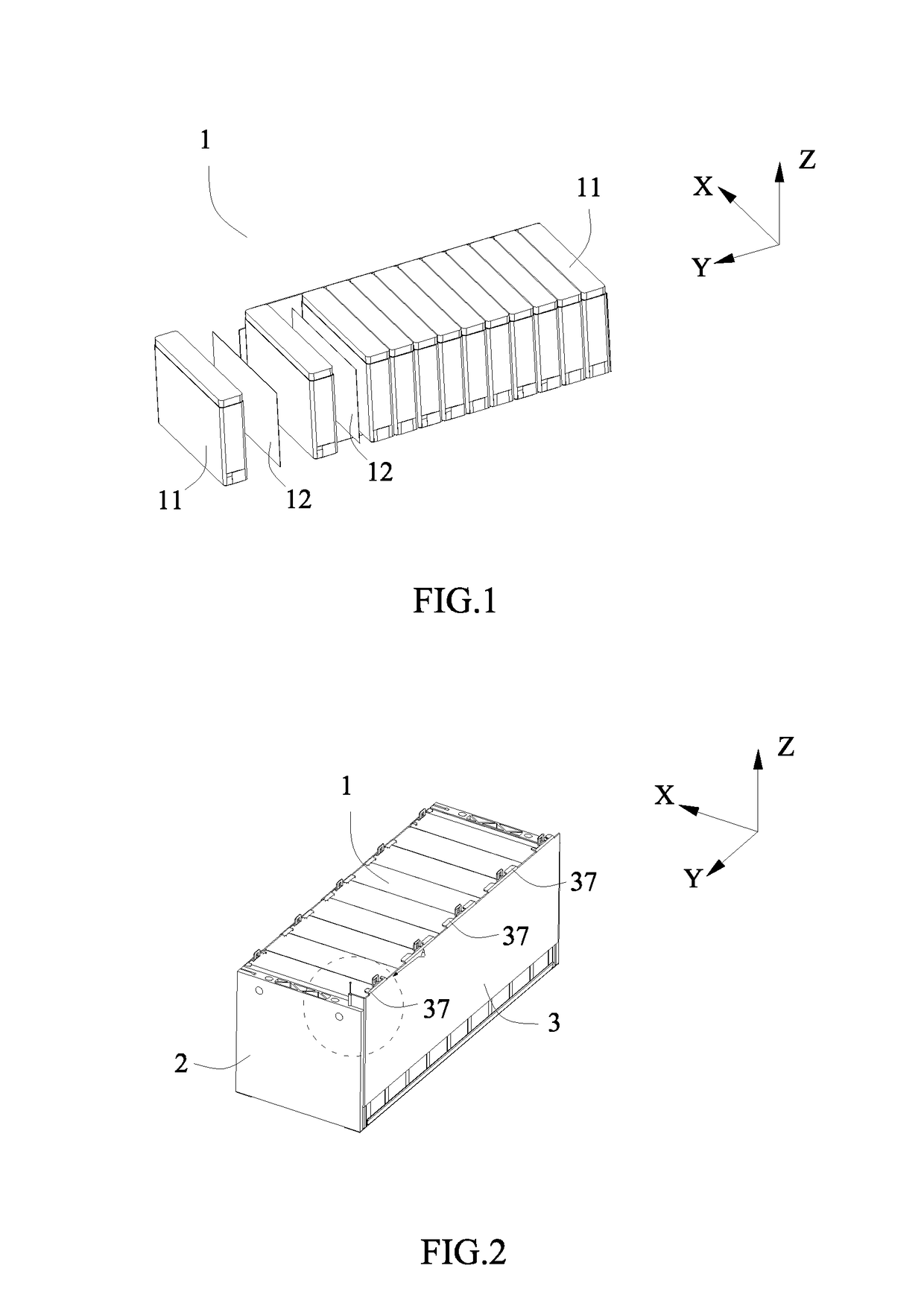

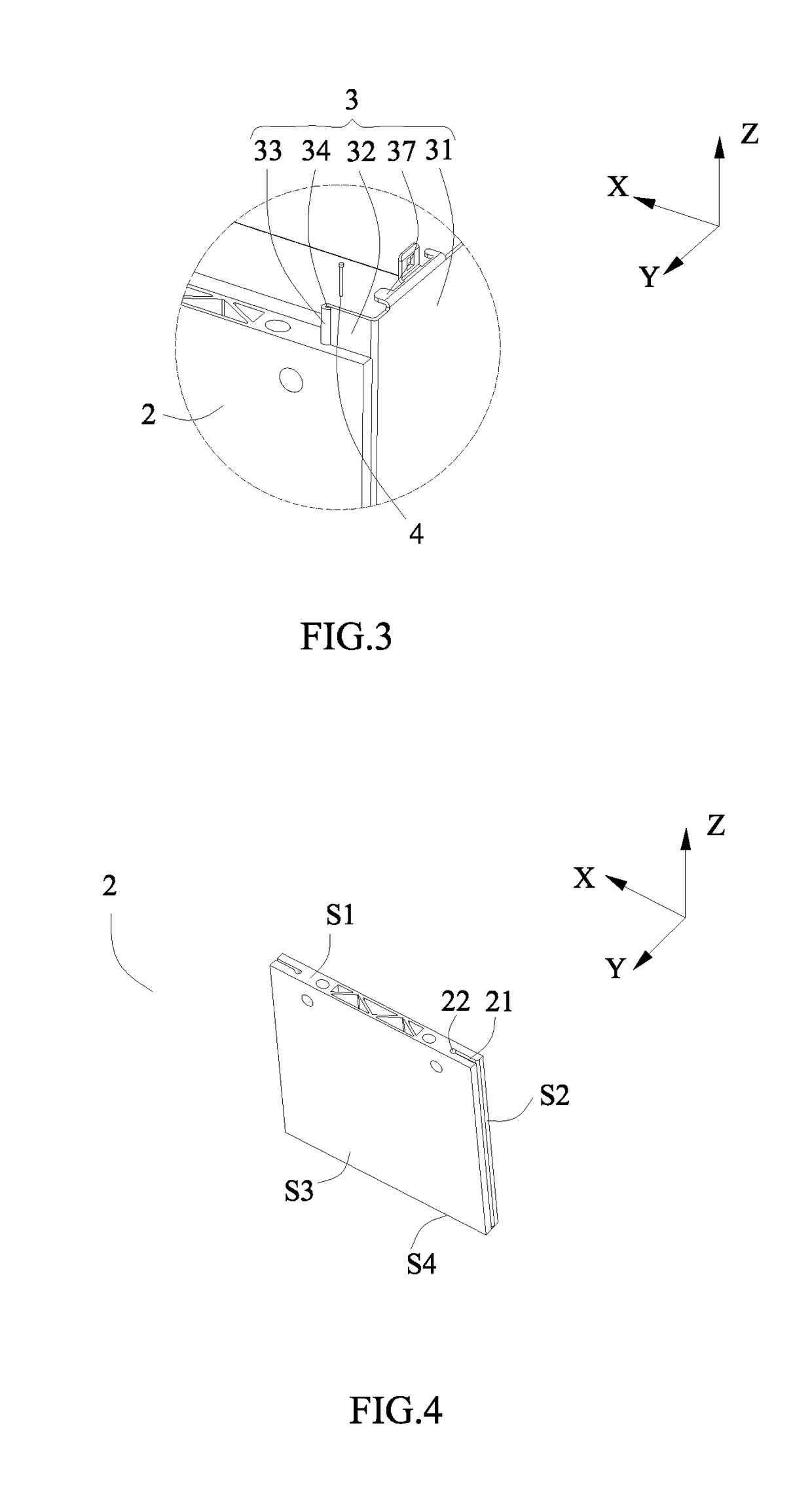

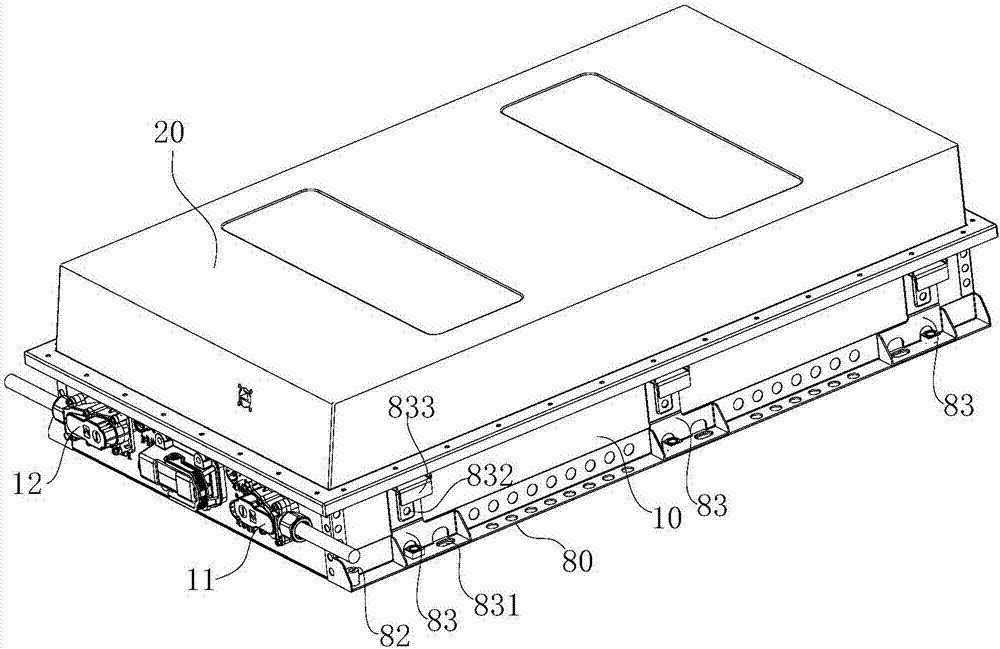

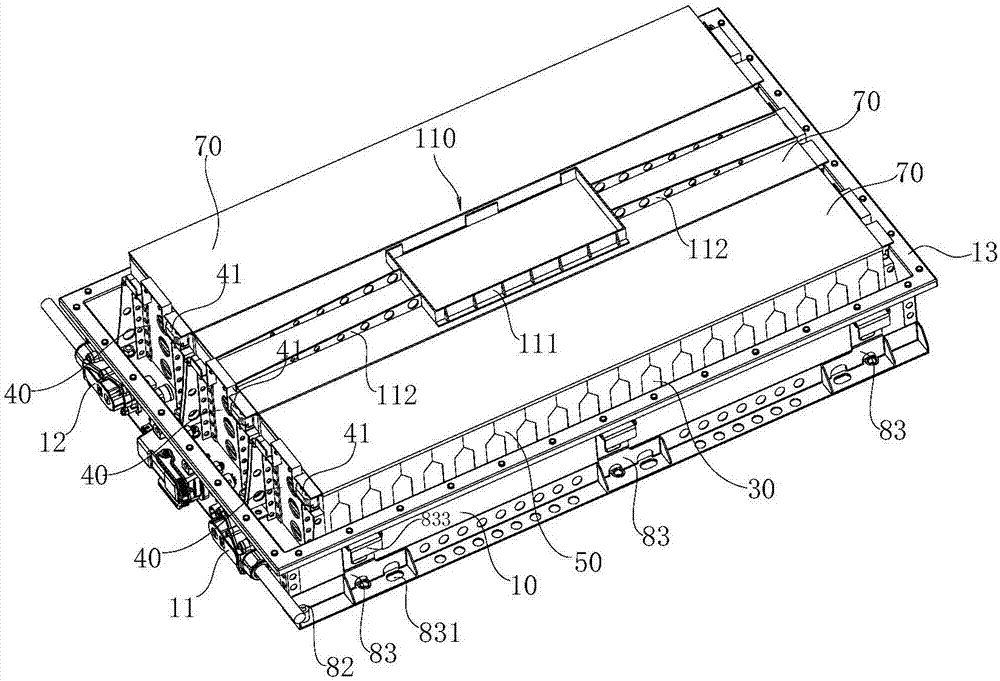

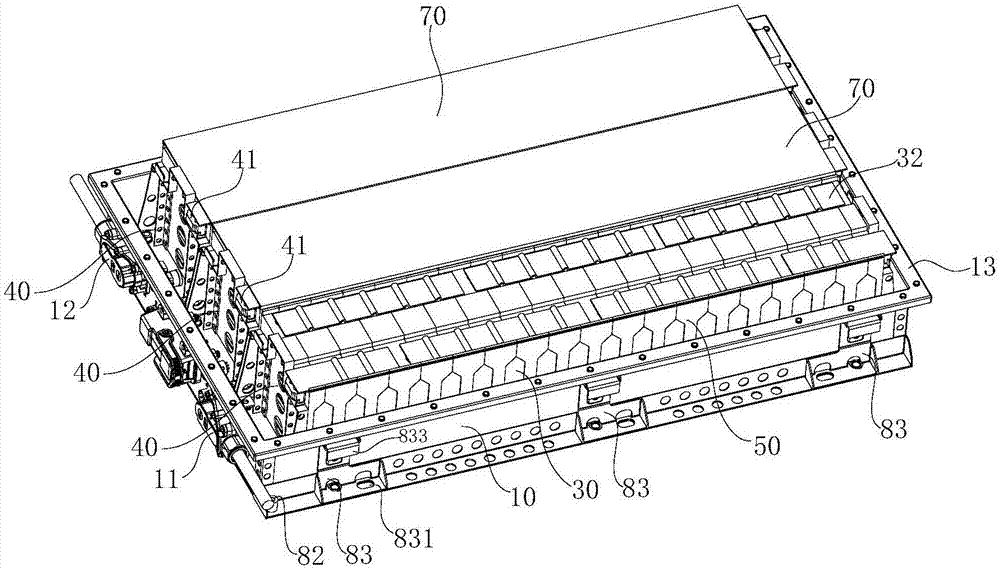

Battery module

ActiveUS20180331337A1Simplify the assembly processImprove assembly accuracySecondary cellsCell component detailsMechanical engineeringBattery pack

Owner:CONTEMPORARY AMPEREX TECH CO

Battery cell lead structure for battery module

InactiveCN107994195AEnsure connection reliabilityEnsure reliabilityCurrent conducting connectionsCells structural combinationElectricityWave shape

The invention relates to a battery cell lead structure for a battery module. The battery cell lead structure comprises a bottom support for mounting the battery module, wherein the bottom support is of an open tank structure, and a module cathode connecting end and a module anode connecting end are respectively arranged on the side wall of the bottom support; the battery module comprises a plurality of battery packs which are arranged in parallel, and each battery pack comprises a plurality of battery cells which are sequentially arranged along the length direction of the bottom support, the battery cells on the outermost sides of battery packs are provided with support frames, locking screw rods are arranged between the support frames on two sides of the battery packs and are parallel tothe length directions of the battery packs, and two ends of the locking screw rods are fixed with the support frames on two sides of the battery packs; electric connecting pieces are arranged on wiring heads of the battery cells, extends towards two sides of the battery packs, are electrically connected with electric connecting heads on the support frames and are wave-shaped; and cover plates arearranged at the upper ends of the battery packs, and the lower plate surfaces of the cover plates prop against the electric connecting pieces. The wave-shaped electric connecting pieces prop against the cover plates, so that the conductance firmness between the electric connecting pieces and the battery cells can be guaranteed.

Owner:ANHUI OFFNENBACH NEW ENERGY TECH CO LTD

Connectable Cable Organizer

ActiveUS20170204995A1Simple structureEasy to manufacturePipe supportsElectrical apparatusEngineeringMechanical engineering

Owner:MAXDAO

Water separator with shower seat

ActiveUS10781578B2Rotating torque of the shower seat will not decreaseEnsure connection reliabilityWatering devicesDomestic plumbingEngineeringMechanical engineering

A water separator with a shower seat includes a valve body, a frictional unit, a shower seat, and a water outflow switching mechanism. The valve body is provided with a plurality of snap-fit joints disposed circumferentially. The frictional unit is mounted on the valve body and an outer wall thereof is provided with a first frictional surface. The shower seat is provided with a connecting chamber having an open end, and a snap-fit surface and a second frictional surface are circumferentially disposed in the connecting chamber, respectively. The water outflow switching mechanism is mounted in the valve body. Hook heads of the snap-fit joints are snapped to the snap-fit surface to prevent the shower seat from getting separated from the valve body. When the shower seat rotates with respect to the valve body, the first frictional surface and the second frictional surface rotate accordingly and interact with each other.

Owner:FUJIAN XIHE SANITARY WARE TECHNOLOGY CO LTD

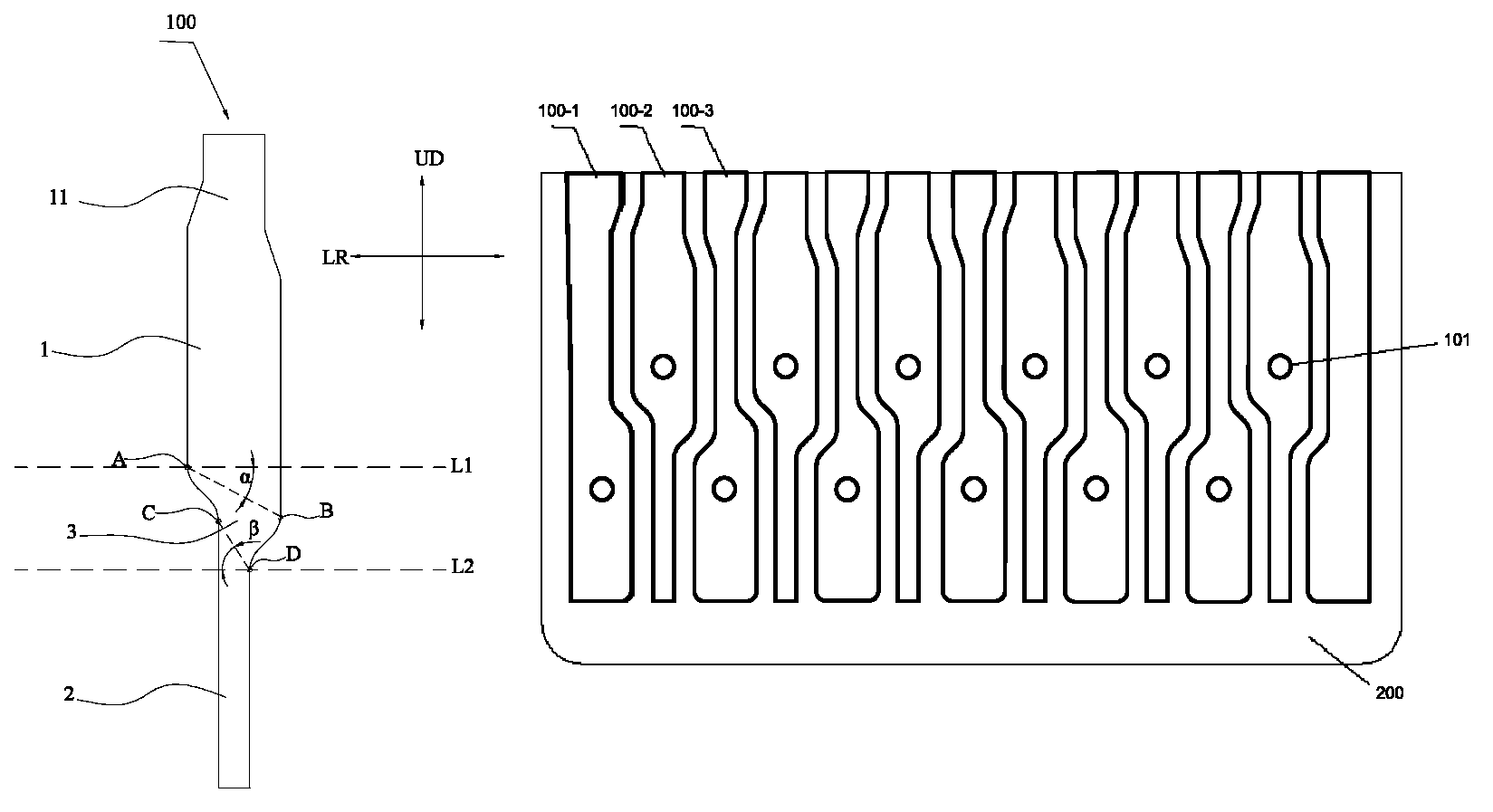

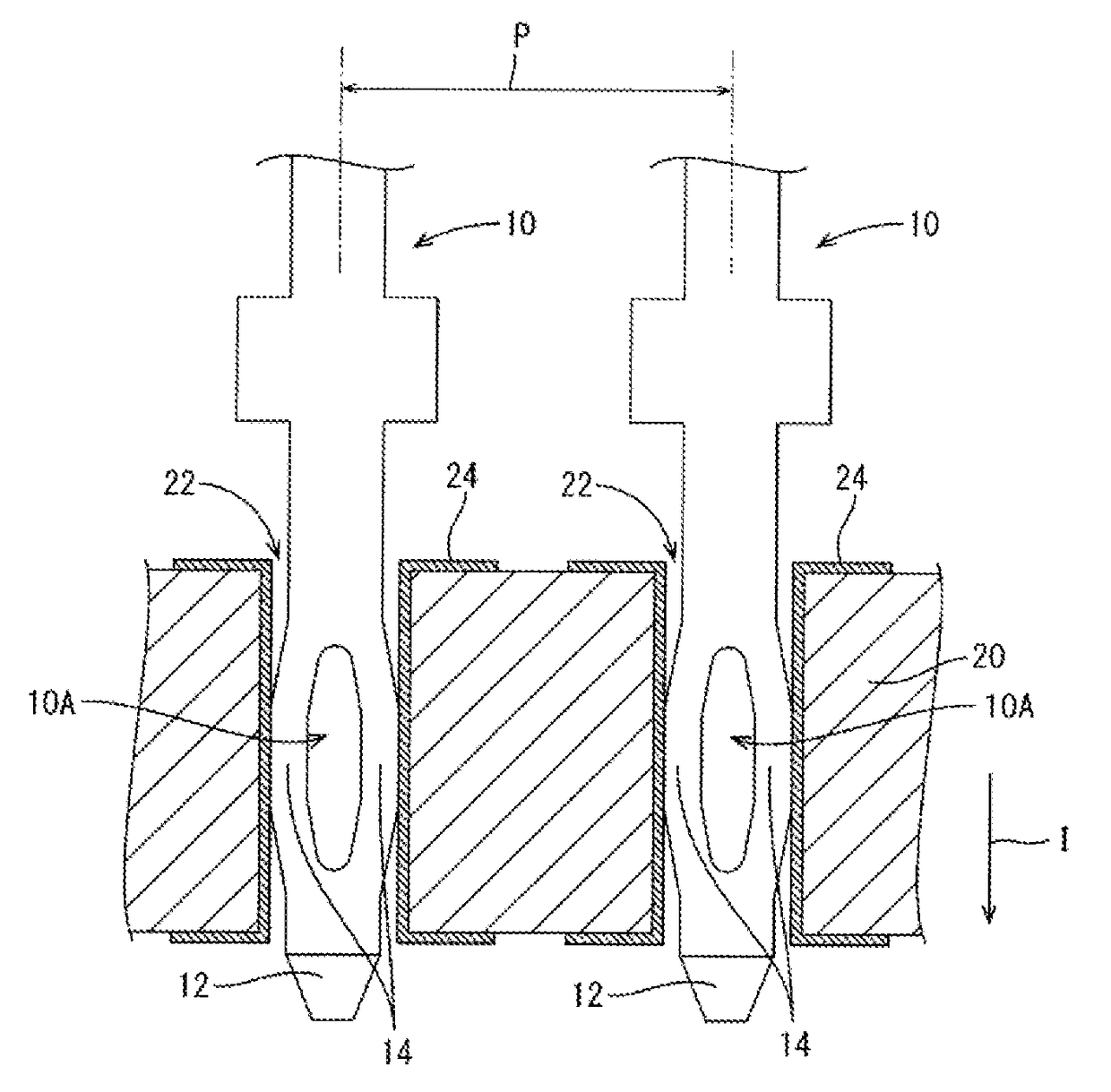

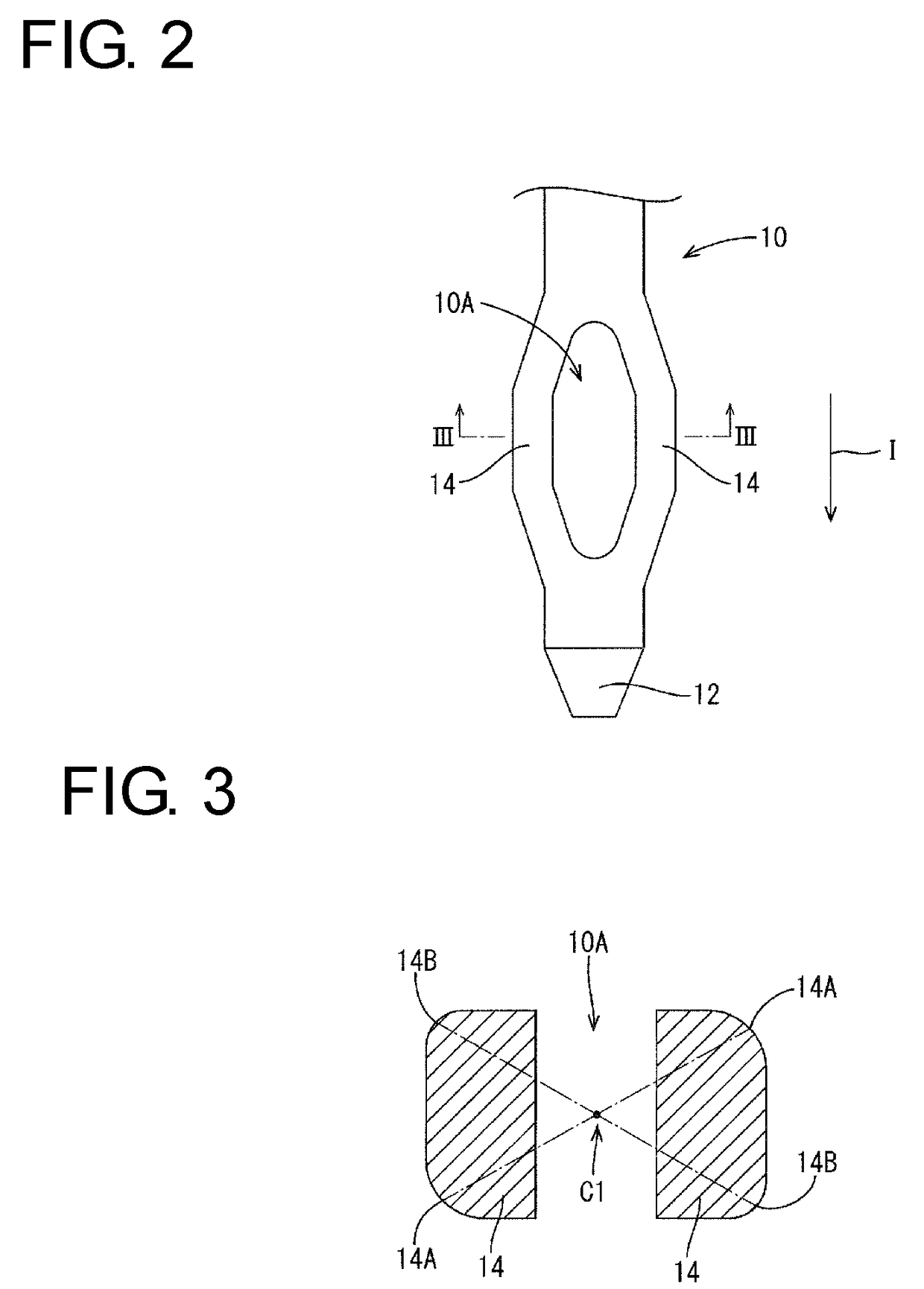

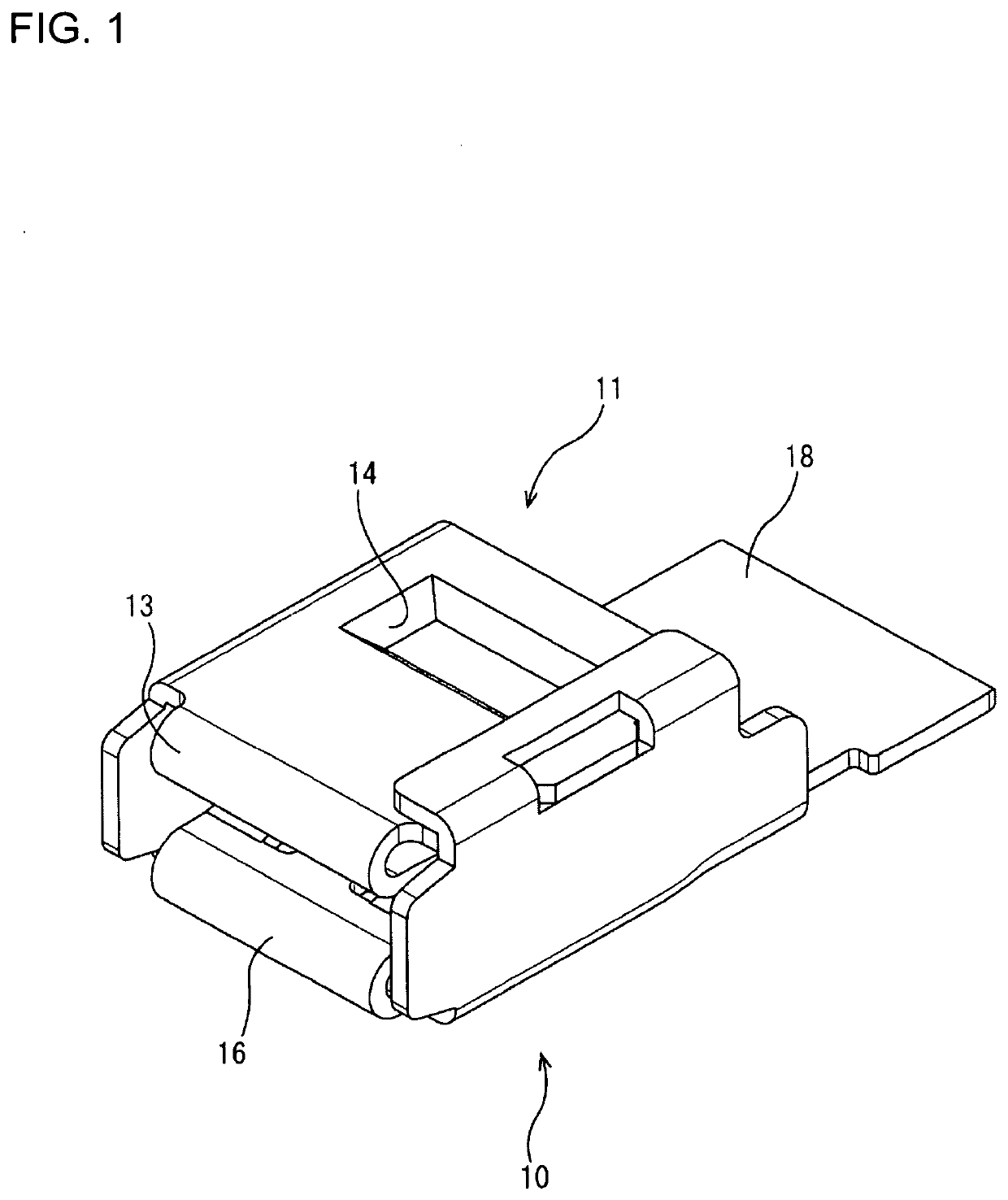

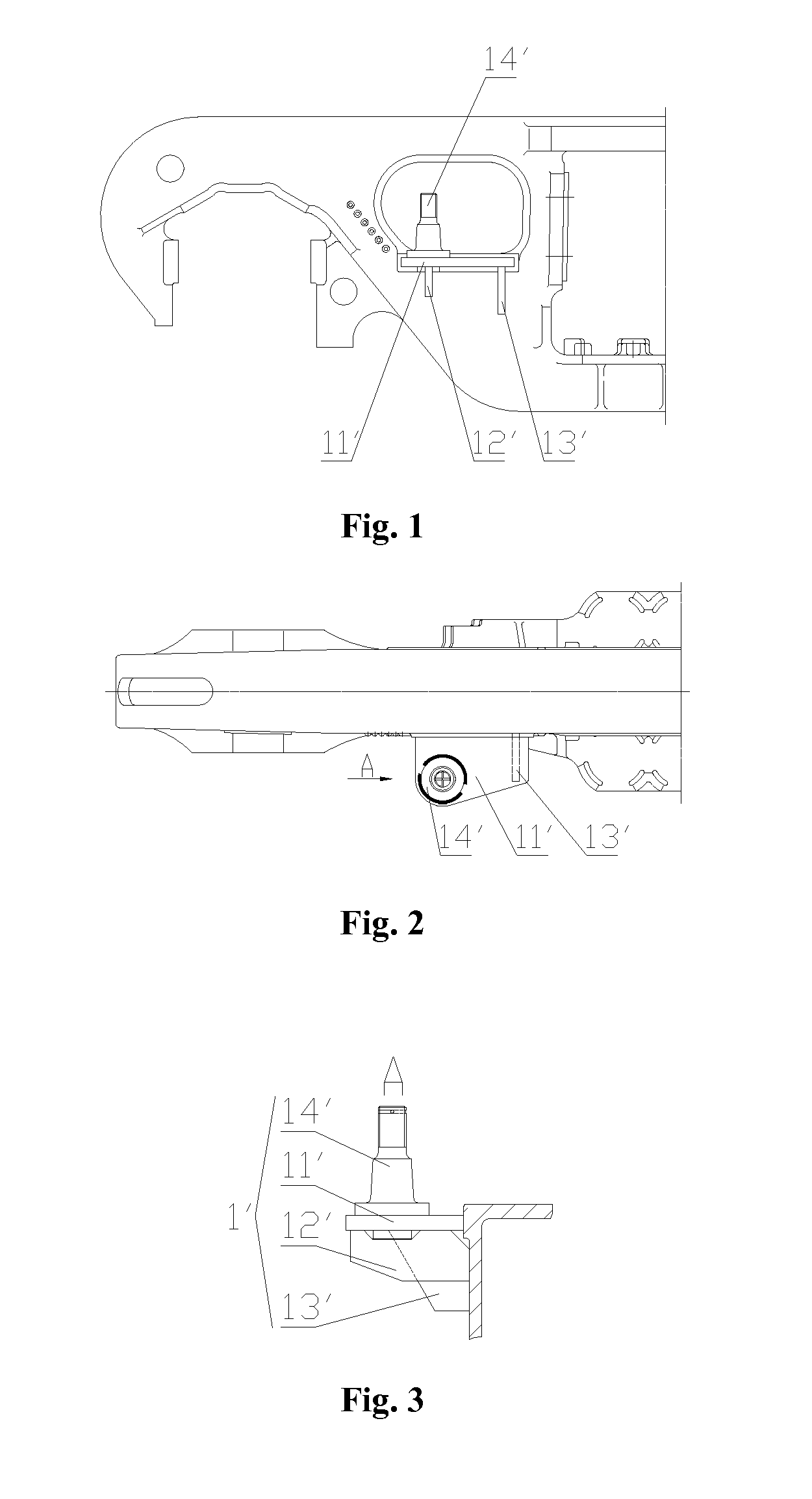

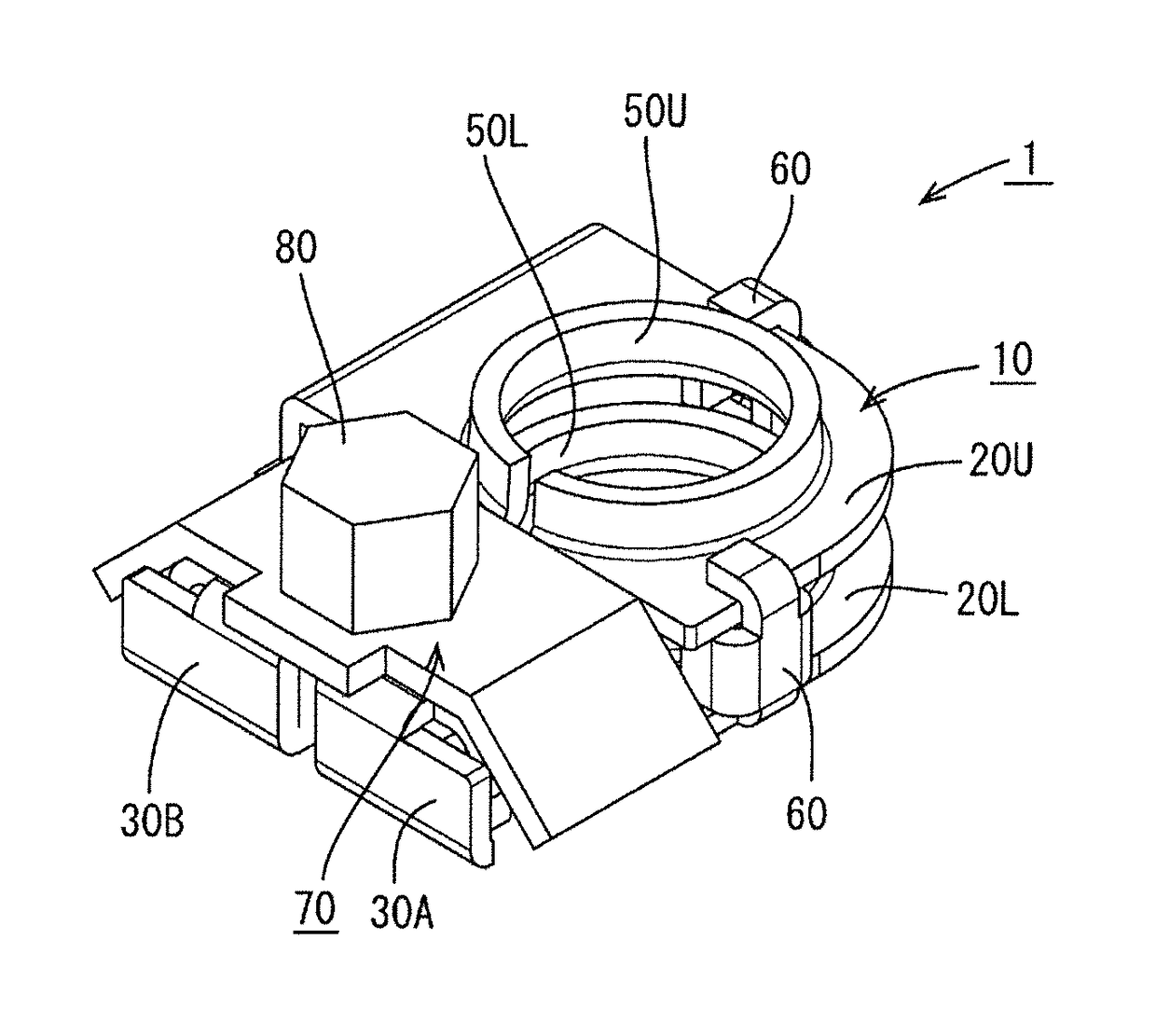

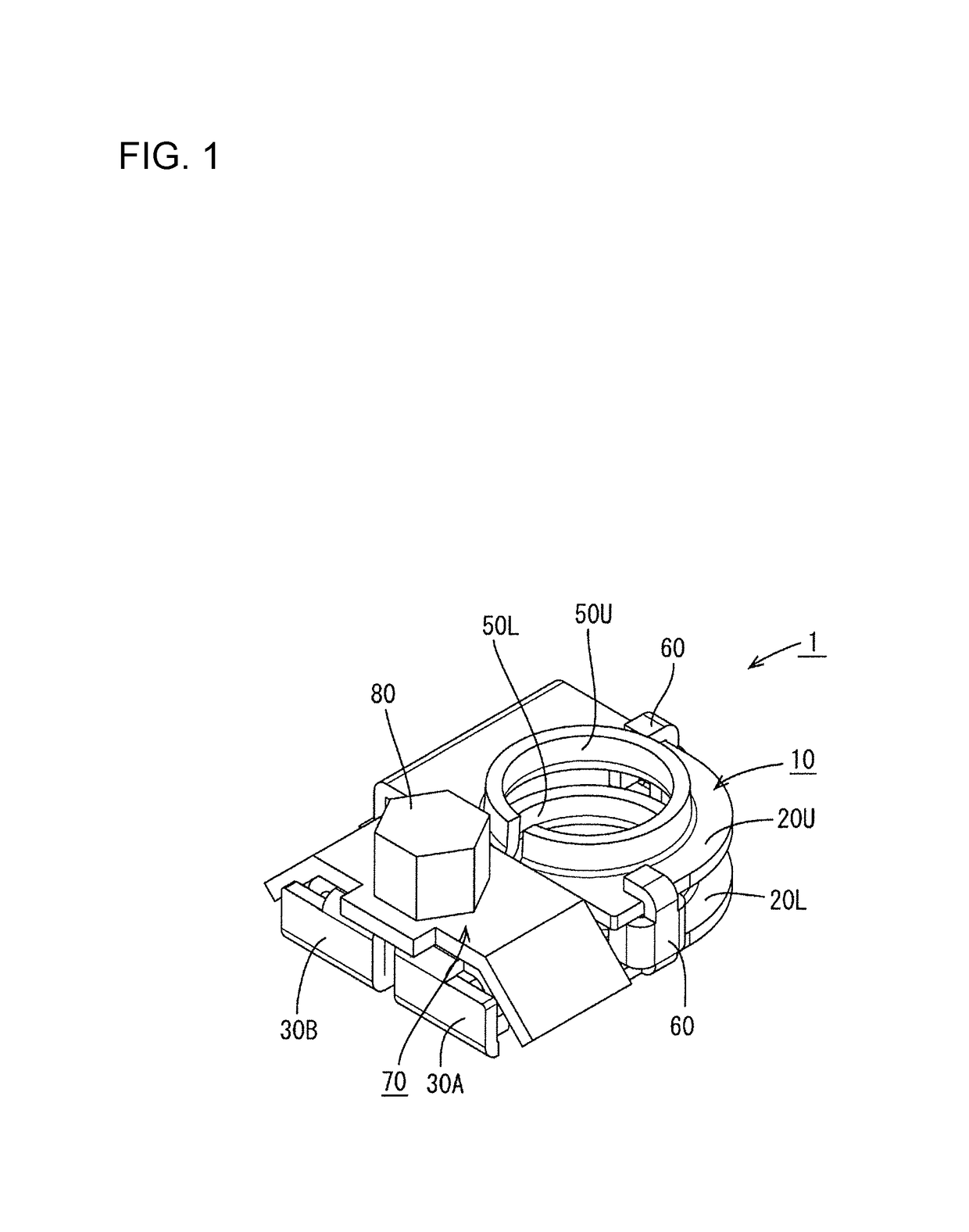

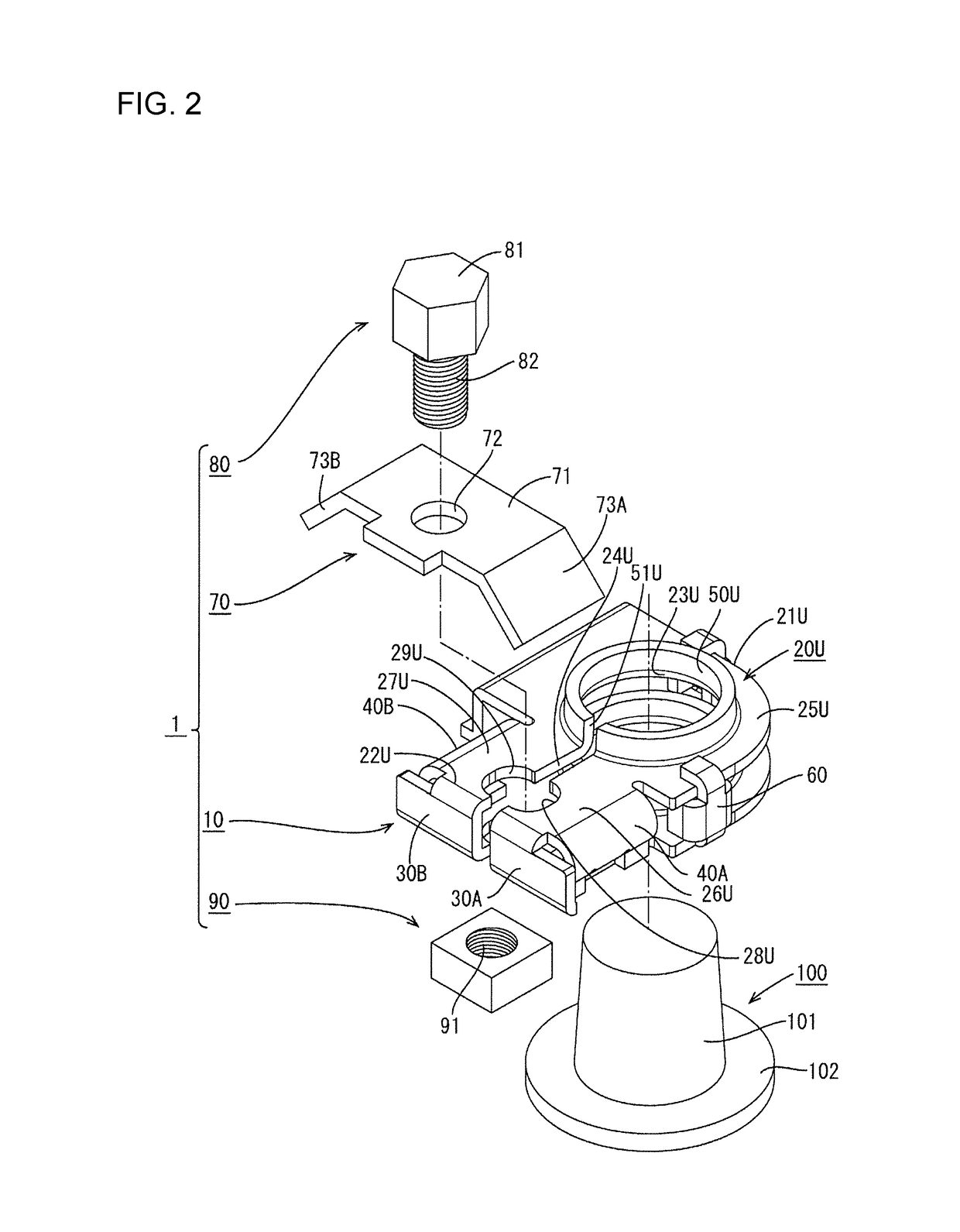

Press-fit terminal and board connector

ActiveUS20180083377A1Improve performanceEnsure connection reliabilityCoupling device connectionsContact pressure

A press-fit terminal held in a through hole provided in a board by being inserted into the through hole along an inserting direction includes a first contacting portion and a second contacting portion configured to resiliently contact an inner peripheral surface of the through hole. A value obtained by dividing a radius of curvature of the second contacting portion by a radius of curvature of the first contacting portion is 0.75 or smaller in a cross-sectional view perpendicular to the inserting direction. By providing the first and second contacting portions adjacent between adjacent press-fit terminals, a contact part where a contact pressure applied to the inner peripheral surface is small and a contact part where a contact pressure applied to the inner peripheral surface is large are adjacent between adjacent through holes. Thus, it can be suppressed that damaged parts of the board approach between the adjacent through holes.

Owner:AUTONETWORKS TECH LTD +2

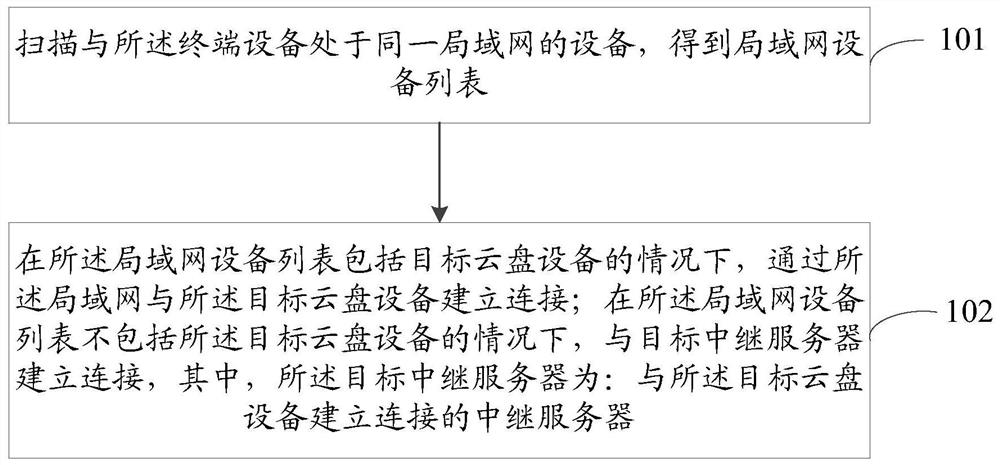

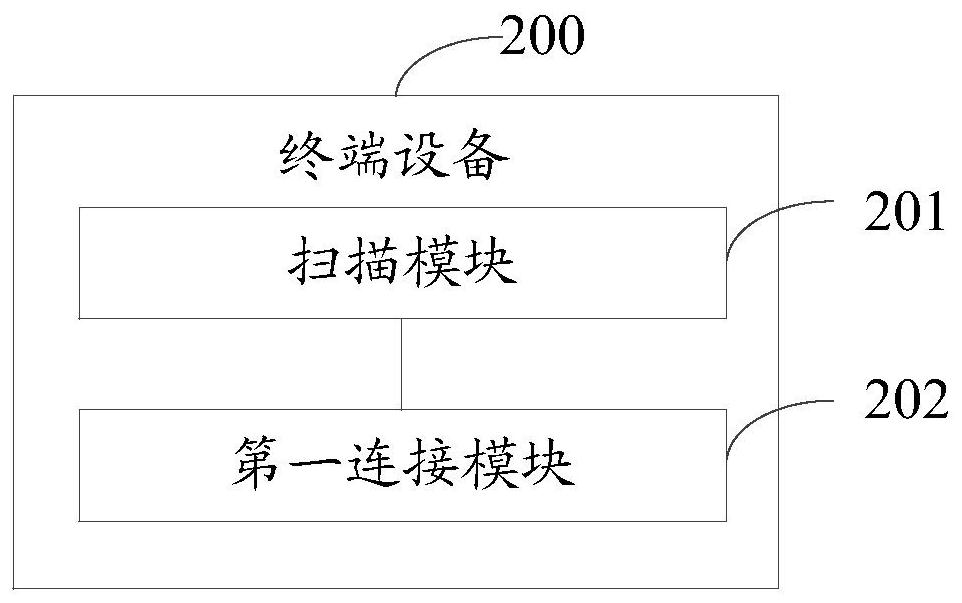

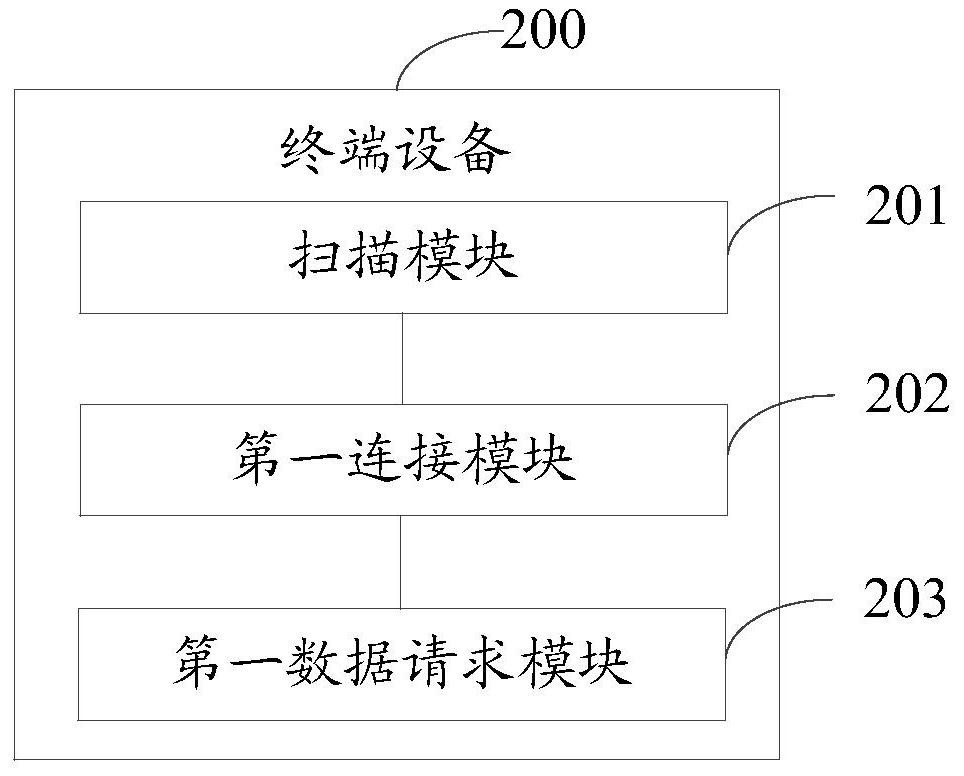

Connection method and terminal equipment

ActiveCN112752353AIncrease data transfer rateEnsure connection reliabilityConnection managementTransmissionData transmissionTrunking

The invention provides a connection method and terminal equipment, and the connection method is applied to the terminal equipment, and comprises the steps: scanning equipment located in the same local area network as the terminal equipment, and obtaining a local area network equipment list; under the condition that the local area network equipment list comprises target cloud disk equipment, establishing connection with the target cloud disk equipment through the local area network; and under the condition that the local area network equipment list does not comprise the target cloud disk equipment, establishing connection with a target relay server, wherein the target relay server is the relay server which establishes connection with the target cloud disk equipment. As the terminal equipment is connected with the target relay server only when the terminal equipment and the target cloud disk equipment are not located in the same local area network, and the terminal equipment and the target cloud disk equipment are connected through the local area network when the terminal equipment and the target cloud disk equipment are located in the same local area network, the data transmission rate of the local area network is higher; and therefore, the data transmission rate between the terminal equipment and the cloud disk equipment can be improved.

Owner:CHINA MOBILE M2M +1

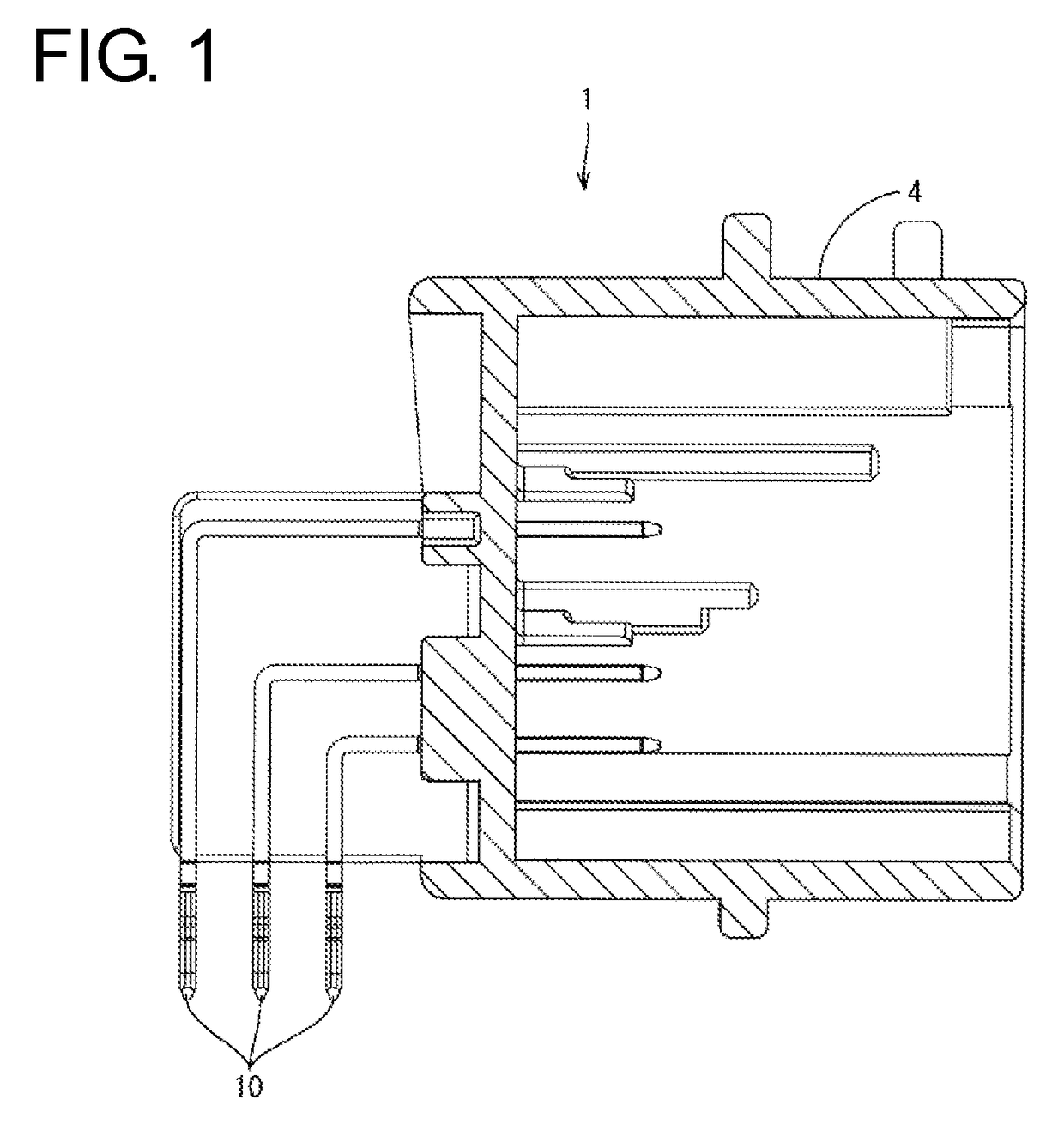

Female terminal

ActiveUS20200161787A1Reduce contact pressureInhibit wearCoupling contact membersContact pressureEngineering

A female terminal (10) includes a female body (11) having a ceiling wall (12) and a bottom wall (15) facing each other. First contact pressure applying portions (20) apply a contact pressure by contacting a male terminal from the side of the ceiling wall (12), and second contact pressure applying portions (30) apply a contact pressure by contacting the male terminal from the side of the bottom wall (15). First contact portions (21) of the first contact pressure applying portions (20) and second contact portions of the second contact pressure applying portions (30) are shifted from each other in the front-rear direction. The contact pressure applied by the first contact pressure applying portions (20) is lower than the contact pressure applied by the second contact pressure applying portions (30).

Owner:AUTONETWORKS TECH LTD +2

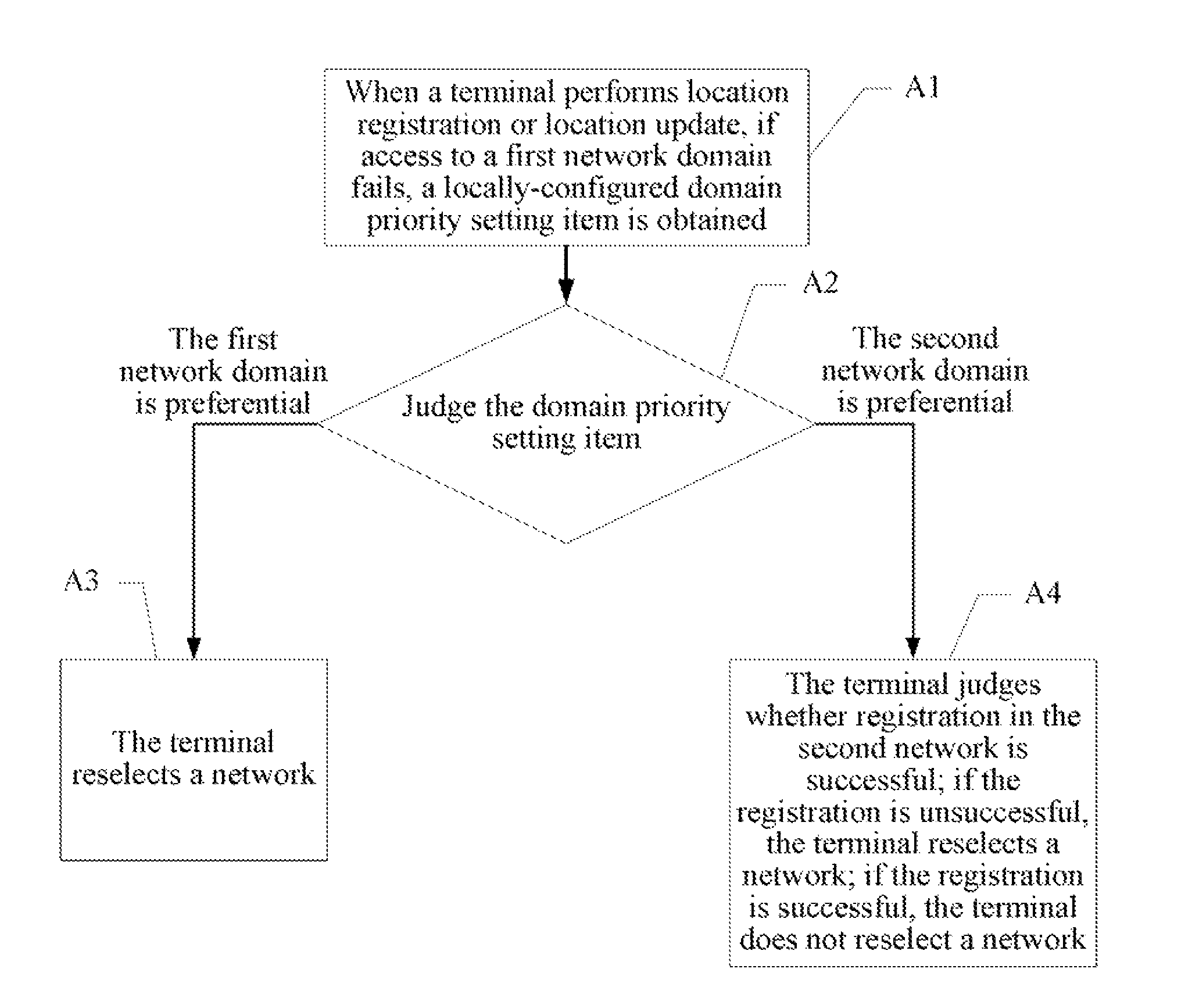

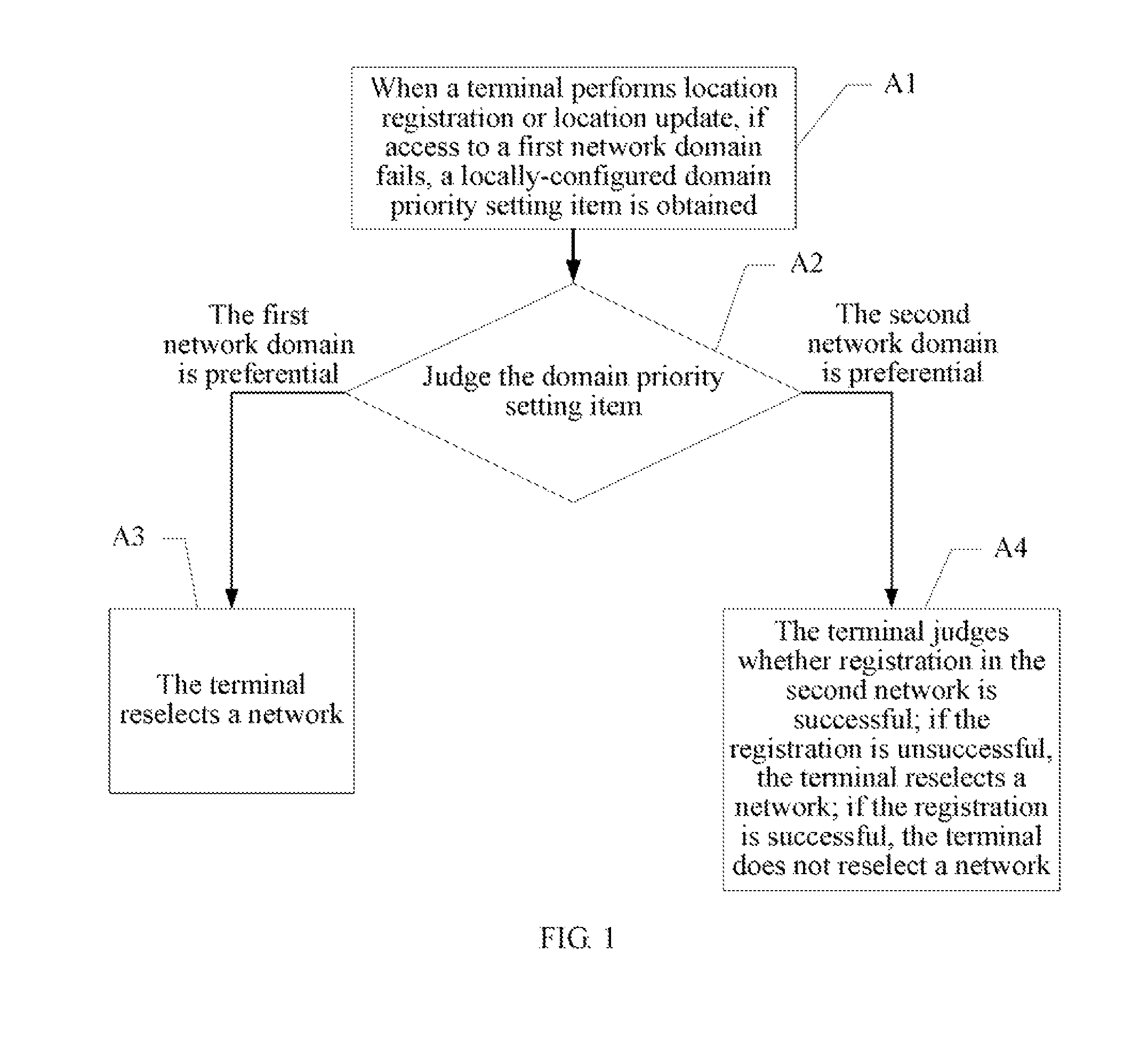

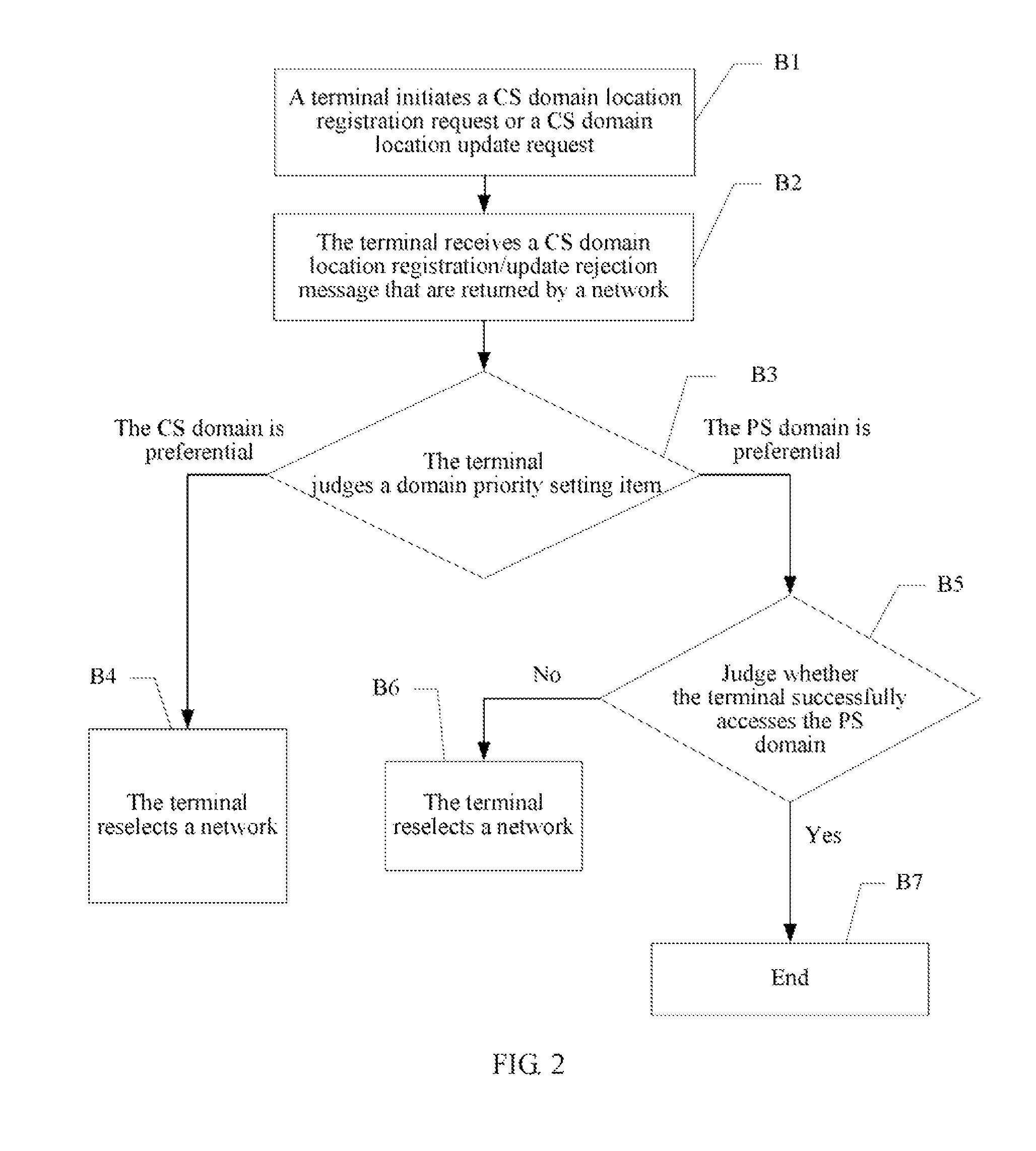

Network selection method and terminal device

ActiveUS8606273B2Ensure connection reliabilityNetwork traffic/resource managementAssess restrictionPriority settingTerminal equipment

A network selection method and a terminal device are provided. When a terminal performs location registration or location update, if access to a first network domain fails, a locally-configured domain priority setting item is obtained; if the domain priority setting item indicates that the first network domain is preferential, the terminal reselects a network; if the domain priority setting item indicates that a second network domain is preferential, the terminal judges whether registration in a second network is successful; if the registration is unsuccessful, the terminal reselects a network; if the registration is successful, the terminal does not reselect a network.

Owner:HUAWEI DEVICE CO LTD

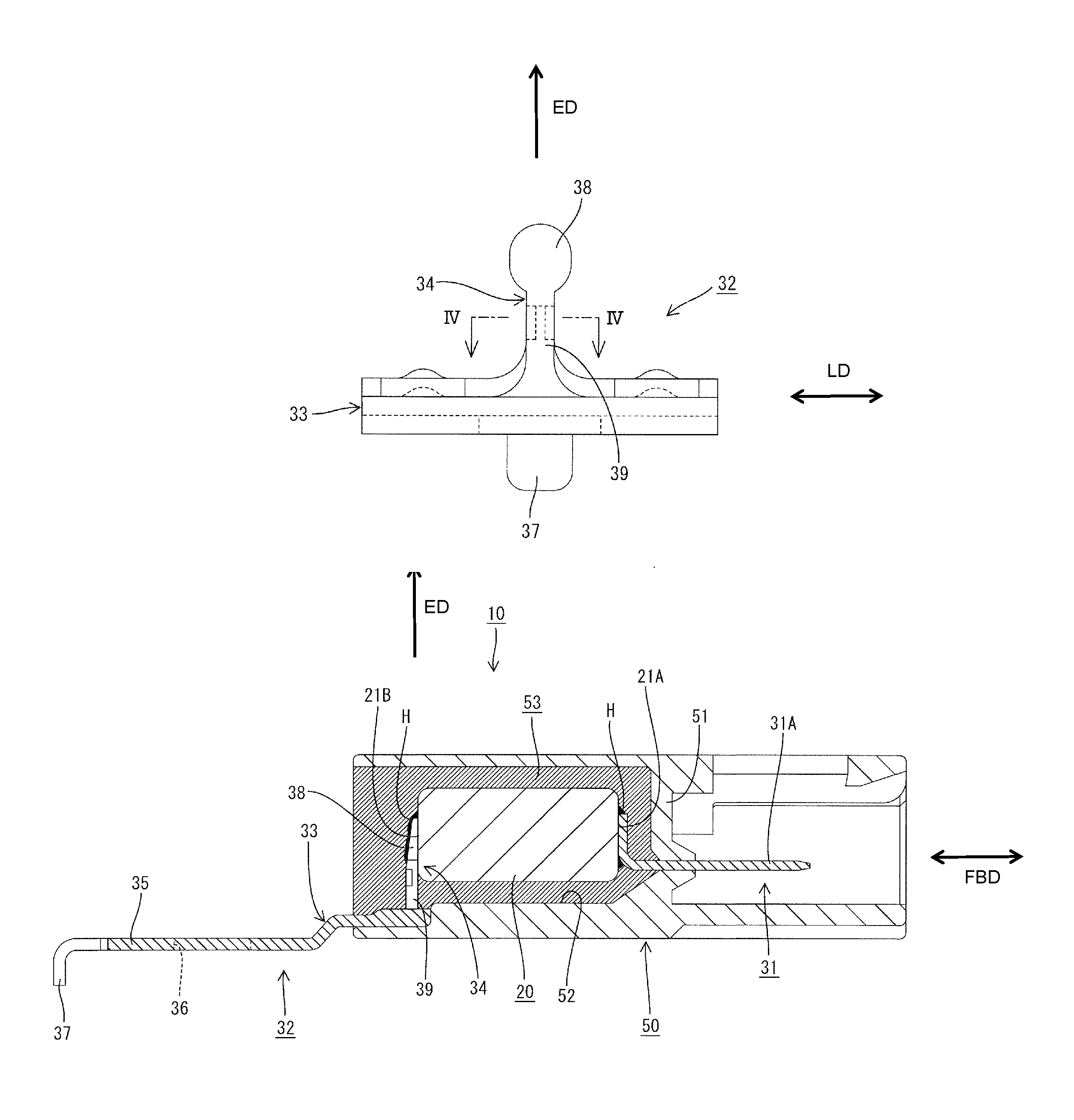

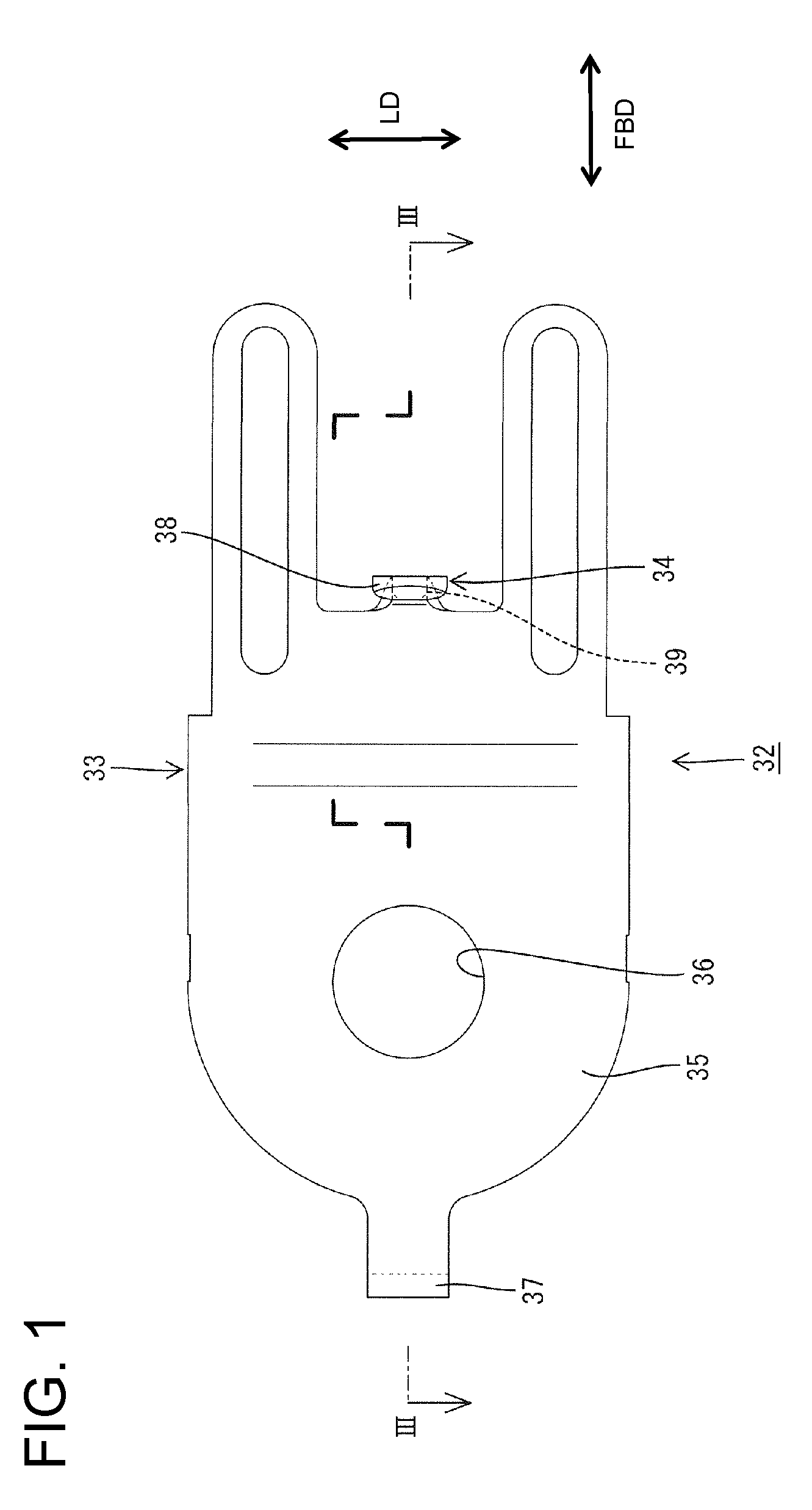

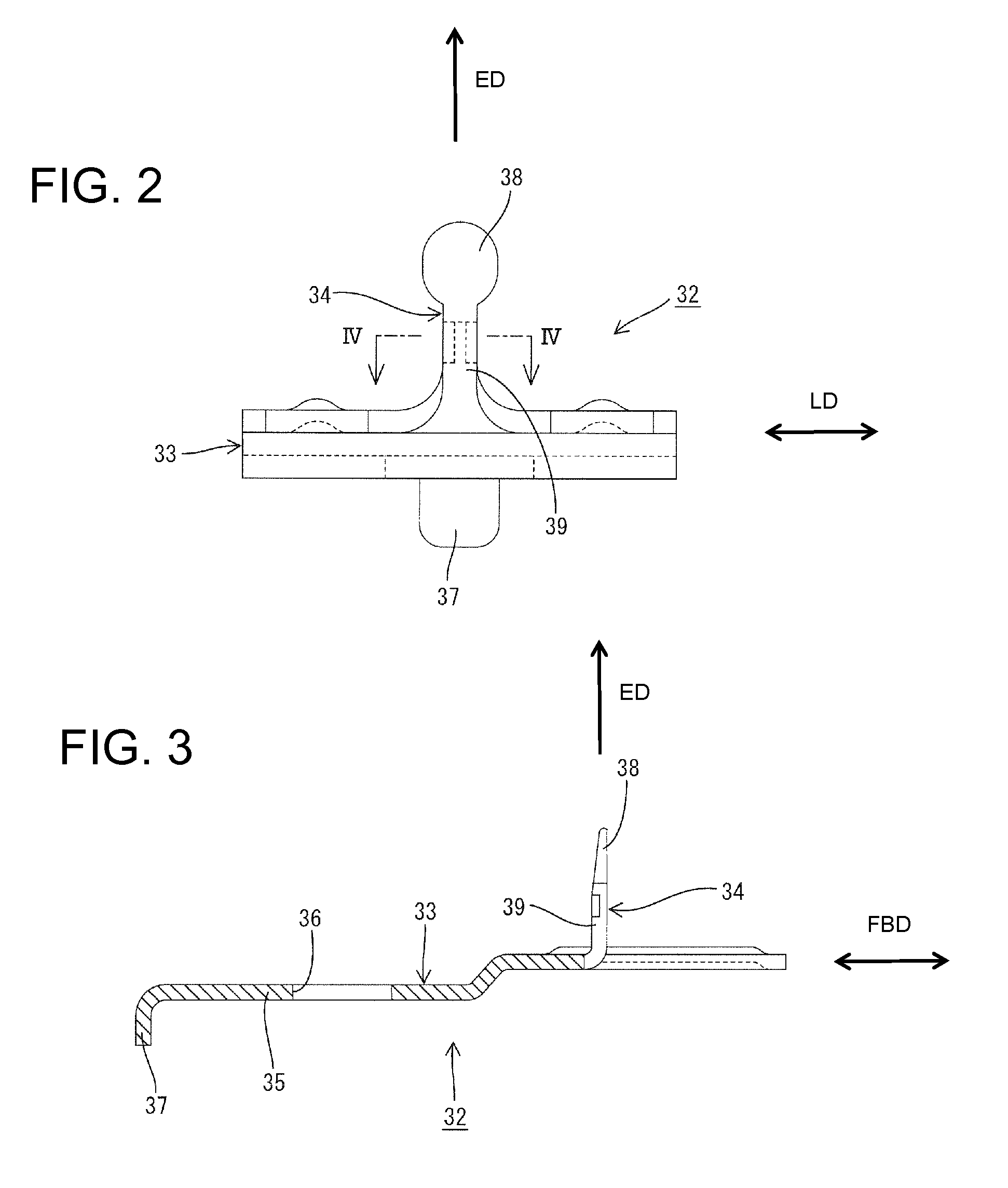

Electrical connector having an electronic device

ActiveUS8602821B2Increase soldering temperatureShort timeRelieving strain on wire connectionContact member assembly/disassemblyEngineeringElectrical connector

Owner:SUMITOMO WIRING SYST LTD

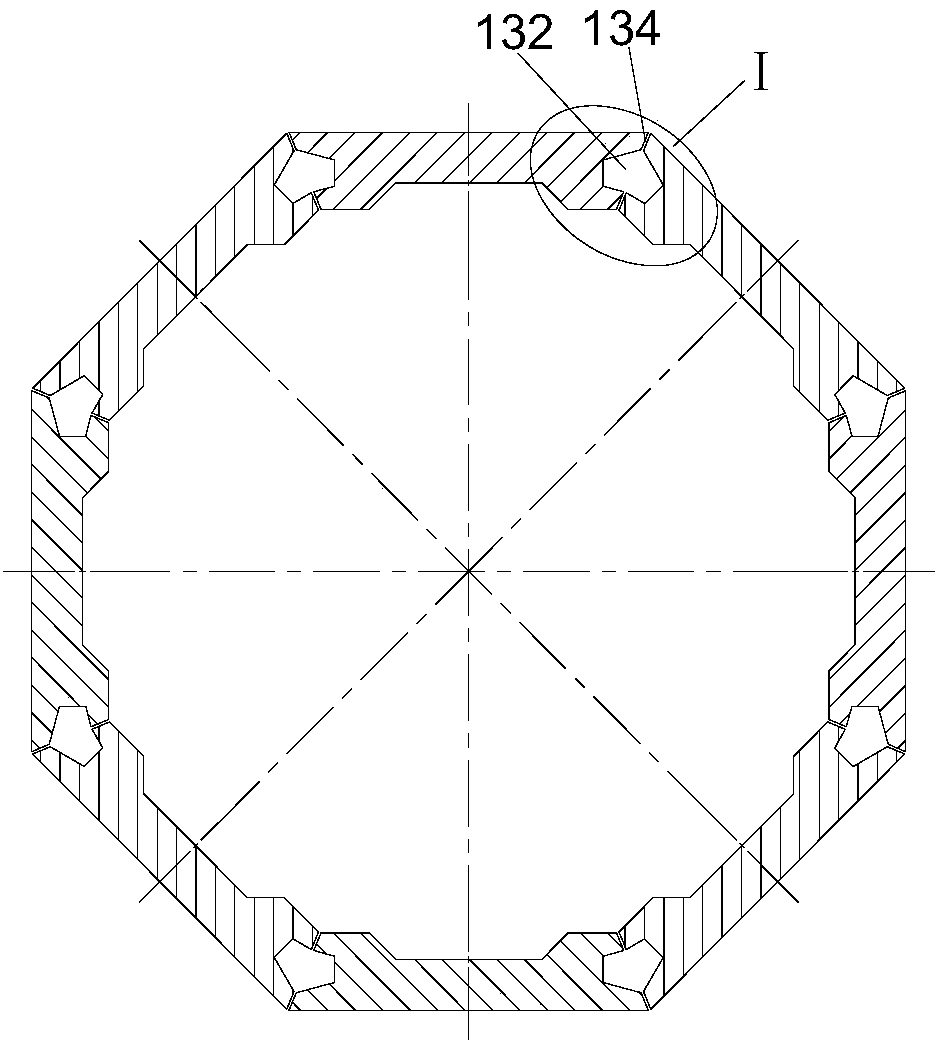

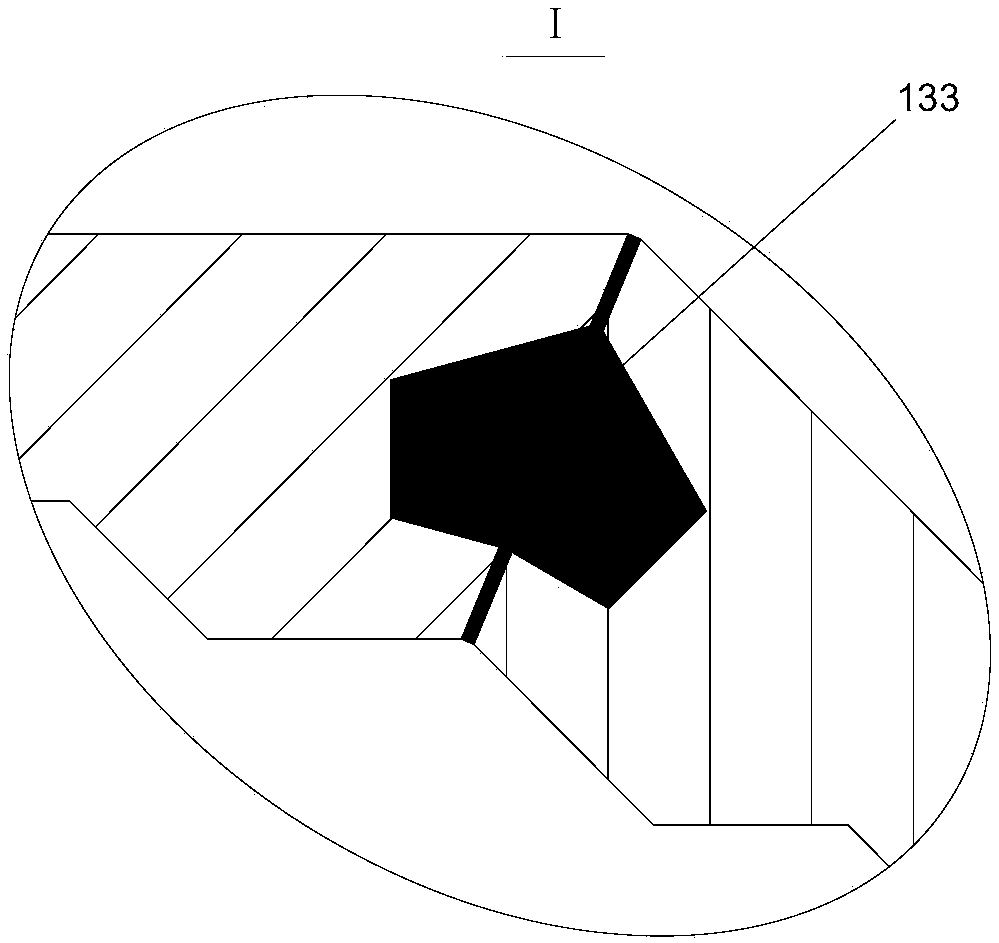

Bogie and side frame thereof

A side frame for a bogie. Two longitudinal sides of the side frame are respectively provided with a supporting seat for connecting an end portion of a connecting rod, and the supporting seat is integrally formed with the side frame by casting. The supporting seat includes a supporting plate, a middle rib and a first side rib. The supporting plate is provided with a through hole. The connecting rod and the supporting seat are thread-connected via a conical pole which is fixedly provided in the through hole. The side frame reduces the welding processes, ensures the installation precision of the supporting seat, and enhances the strength of the supporting seat.

Owner:CRRC QIQIHAR ROLLING CO LTD

Wind generating set, tower drum and component thereof

InactiveCN108412703AQuality is easy to controlQuality assuranceWind motor supports/mountsMachines/enginesAgricultural engineeringTower

The invention relates to the technical field of wind power generation, and particularly discloses a tower drum and a component thereof. The tower drum component comprises an outer vertical surface, aninner vertical surface and two side vertical surfaces, at least one side vertical surface is provided with a longitudinal seam groove in the height direction, the opening of the longitudinal seam groove is formed in the corresponding side vertical surface, and the length of the opening is not larger than the length of the corresponding side vertical surface. Each drum section of the tower drum isformed by splicing the tower drum components with the same structure, the design of a mold is greatly simplified, and the cost is reduced; and connection and fixation between the tower drum components are realized through the longitudinal seam groove structures, and the connection is safe and reliable. The invention further discloses a wind generating set.

Owner:SANY ELECTRIC CO LTD

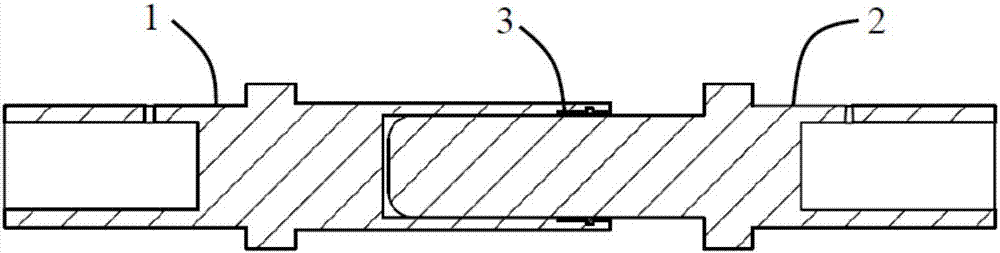

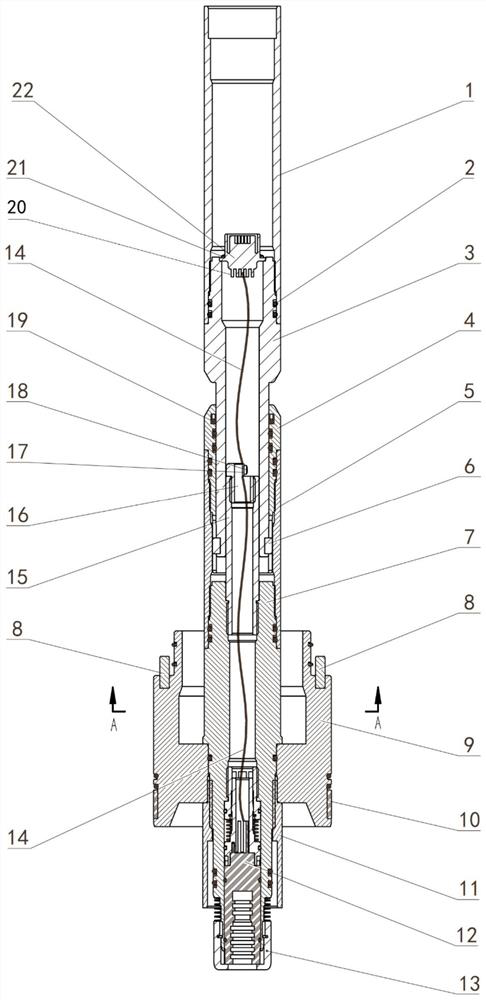

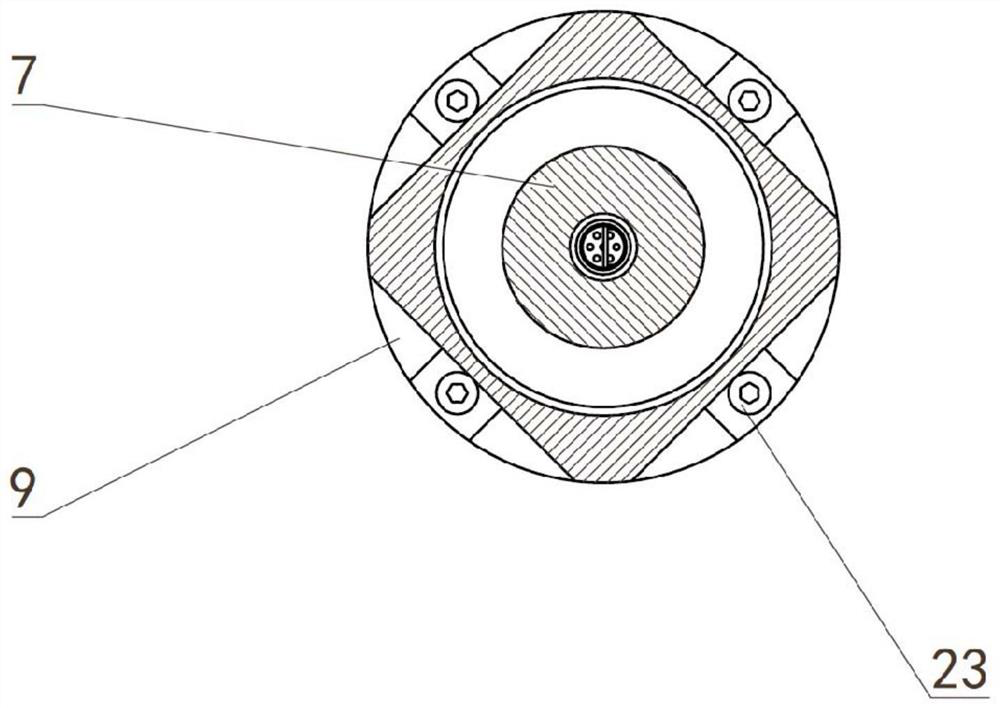

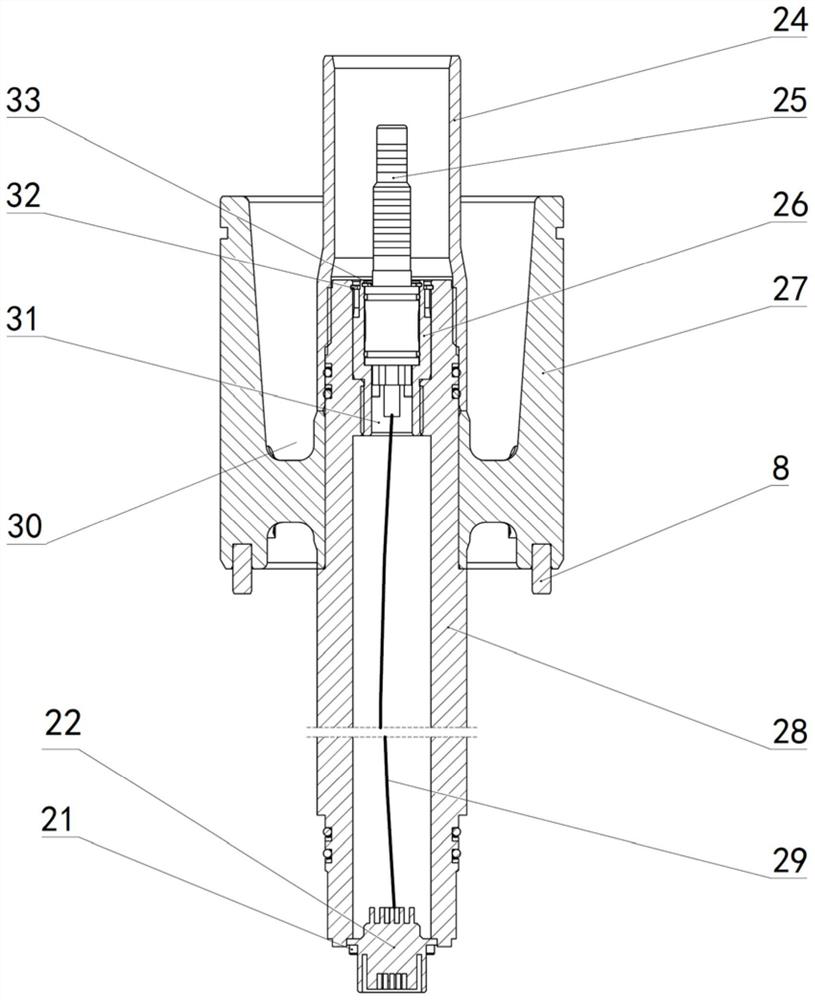

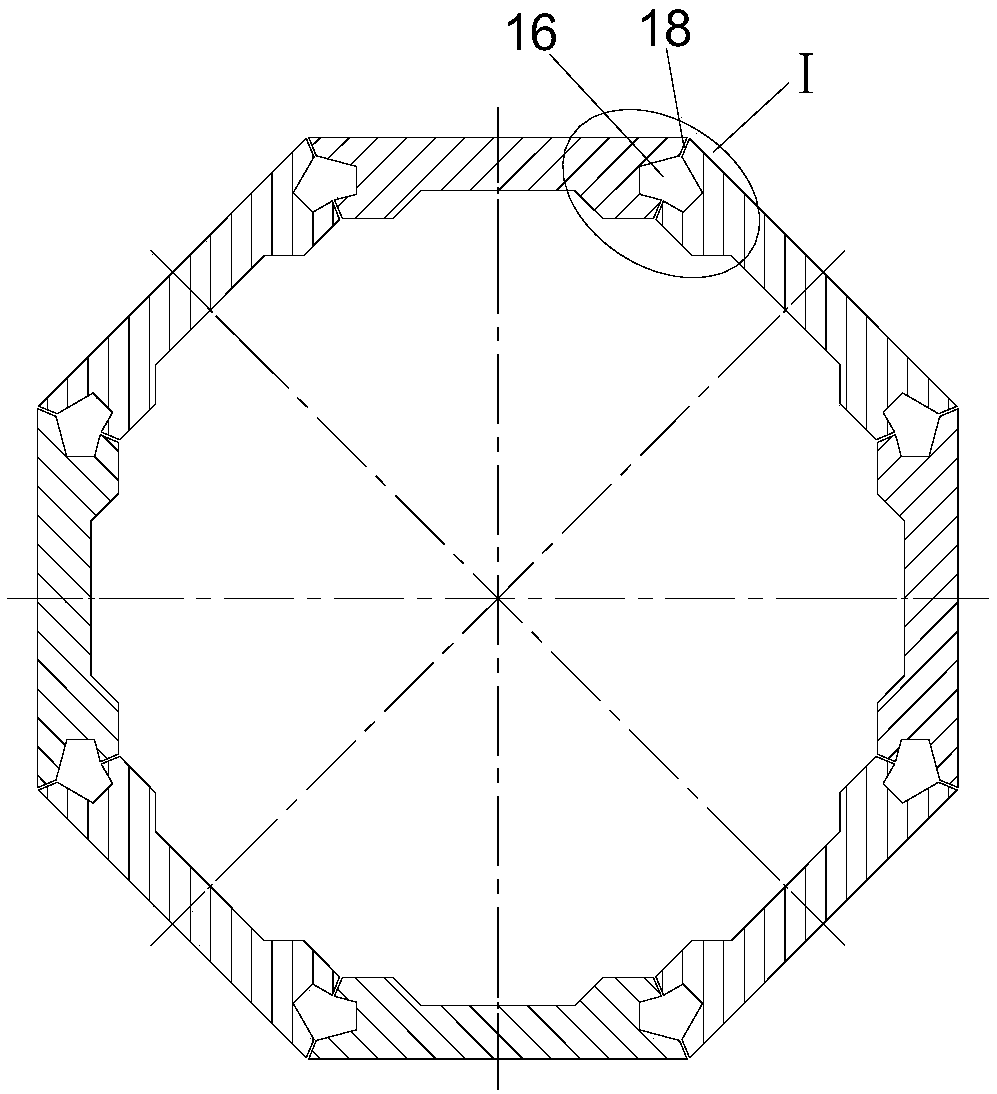

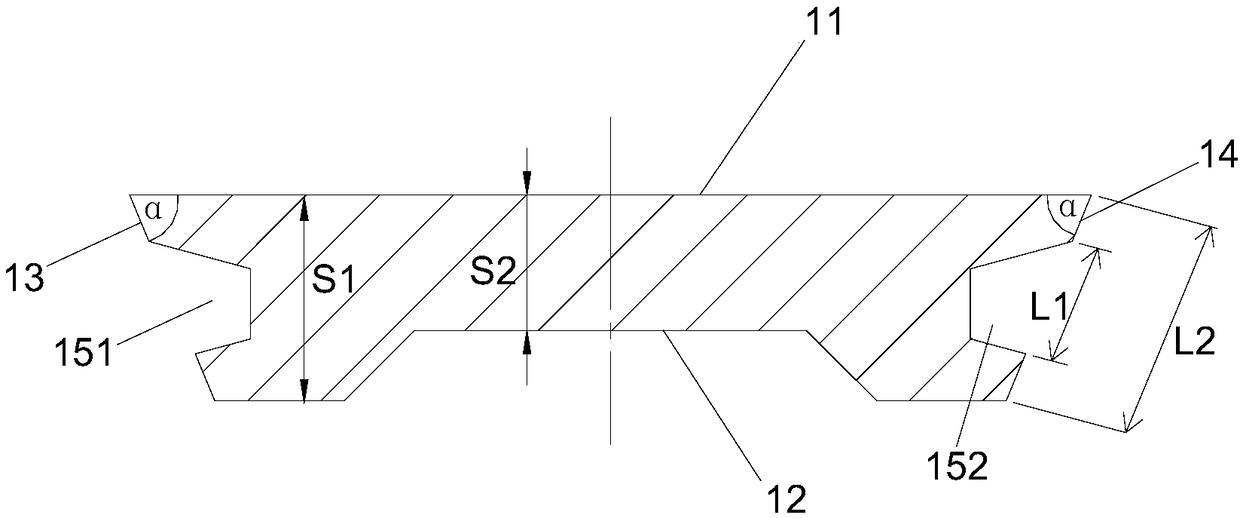

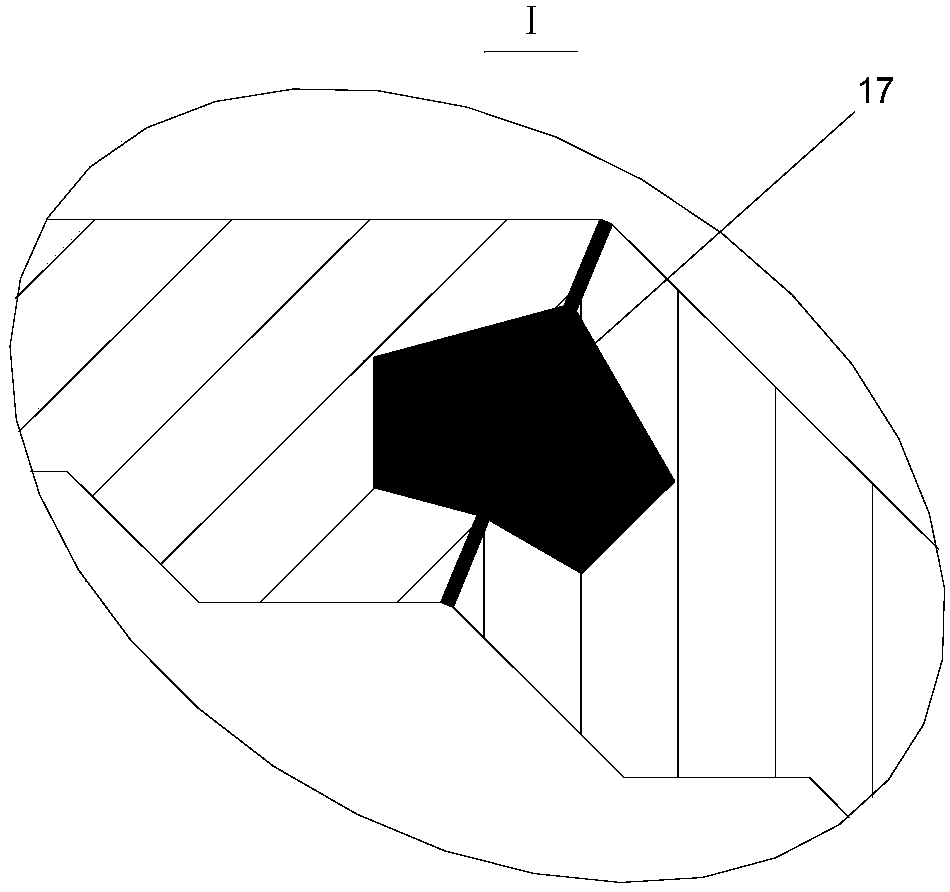

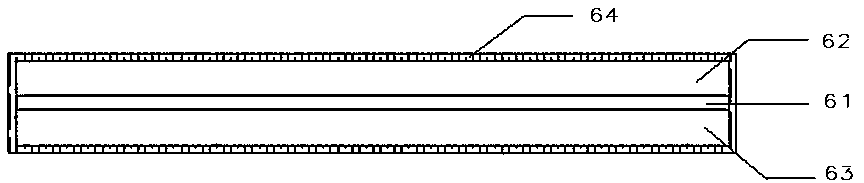

Integrated short connector of instrument while drilling

ActiveCN111878001AMating operation is simpleMeet the mating requirementsSurveyDrilling rodsEngineeringDrill

The invention relates to an integrated short connector of an instrument while drilling. The integrated short connector comprises a telescopic connector assembly, a fixed connector assembly and a drillcollar adapter substitute, wherein the drill collar adapter substitute comprises an upper drill collar adapter substitute and a lower drill collar adapter substitute; the telescopic connector assembly is mounted in the upper drill collar adapter substitute, and the fixed connector assembly is mounted in the lower drill collar adapter substitute; and the telescopic connector assembly is in butt joint with the fixed connector assembly. The connector is integrated with drill collar nipples of all instruments of a rotary geosteering system, and power supply communication in the instruments is achieved while threaded connection of the drill collars of all the instruments is achieved. In the manner of achieving internal communication in the instruments through direct connection of the drill collars, on one hand, the link of manual connection of a field operation is omitted, so that the construction safety risk is reduced, and the operation efficiency is improved; and besides, the threaded connection torque of the drill collars is utilized to ensure the reliability of internal connection power supply communication of the instruments, so that the use and assembly difficulty of the connector is reduced, the overall structure of the connector is simplified, and the length of the connector is shortened.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Wind power generating set and tower tube thereof

InactiveCN108412704AEnsure connection reliabilityQuality is easy to controlFinal product manufactureWind motor supports/mountsEngineeringTower

The invention relates to the technical field of wind power generation and particularly discloses a tower tube. The tower tube comprises at least one tube section in the height direction; each tube section is composed of at least three tower tube members which are spliced end to end in sequence in the circumferential direction; the adjacent tower tube members are mutually spliced and matched in theheight direction to form volume cavities; and the adjacent tower tube members are connected and fixed through grouting materials which fill in the volume cavities. Each tube section of the tower tubeis composed of and spliced by the tower tube members of the same structure, the mold design is greatly simplified, and the cost is reduced. The tower tube members are connected and fixed through thelongitudinal joint groove structure, and connection is safe and reliable. The invention further discloses a wind power generating set.

Owner:SANY ELECTRIC CO LTD

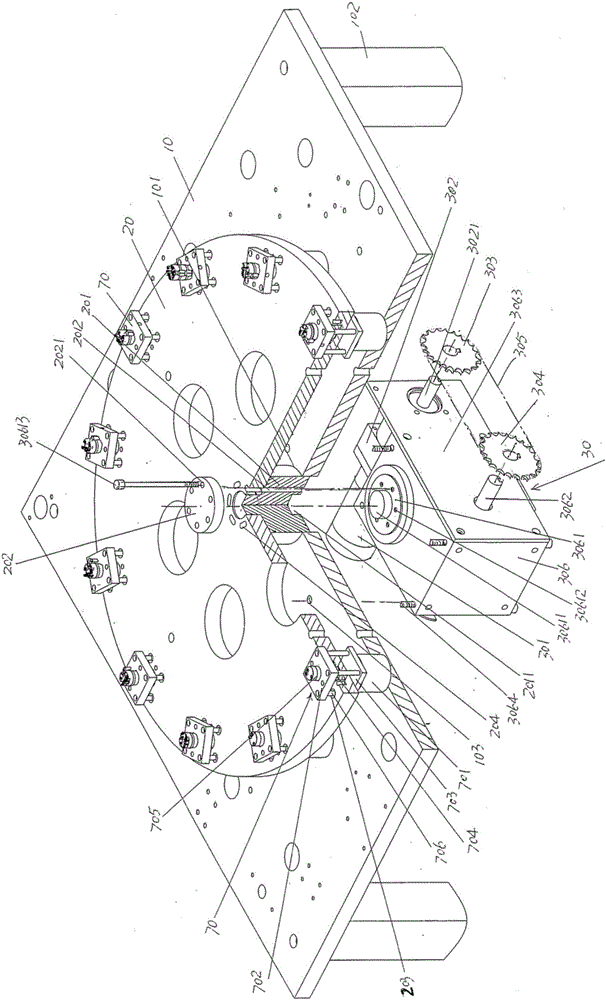

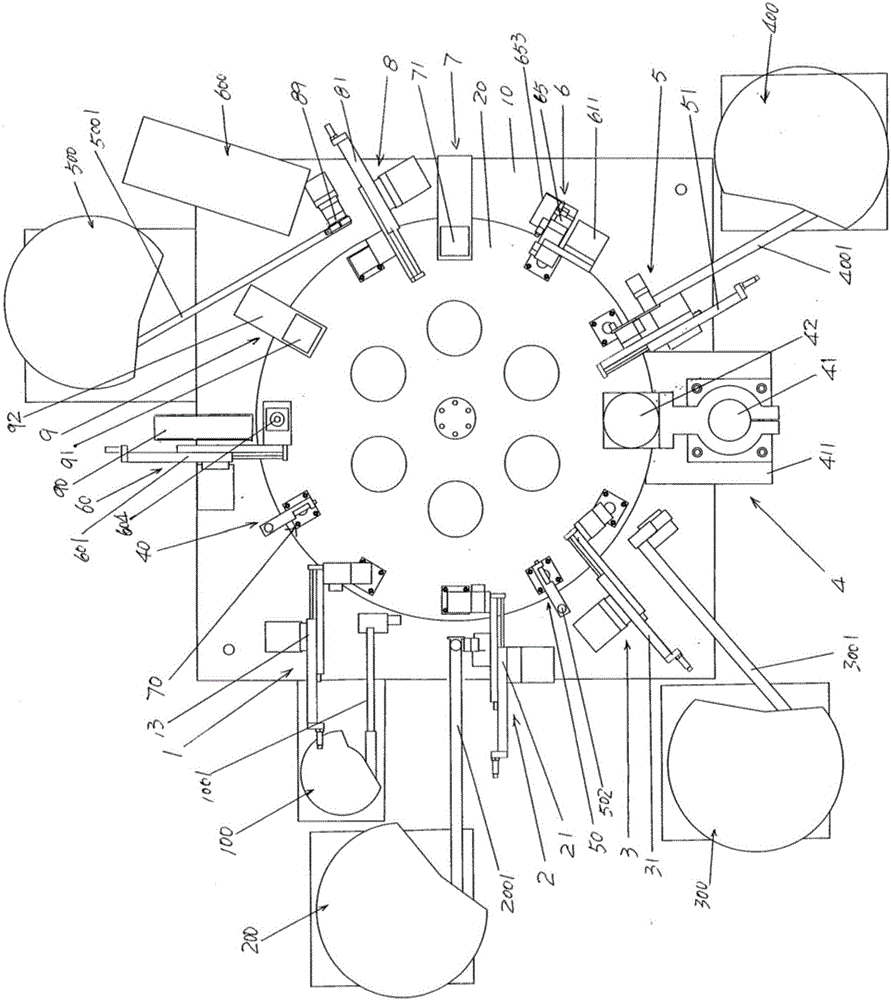

Rotary disk driving mechanism of protector automatic assembly device

The invention discloses a rotary disk driving mechanism of a protector automatic assembly device. The protector automatic assembly device comprises a workbench, a rotary disk and the rotary disk driving mechanism. The rotary disk driving mechanism is characterized in that the rotary disk driving mechanism comprises a rotary disk driving mechanism assembly; the rotary disk driving mechanism assembly comprises a cam divider driving motor, a reduction gearbox, a reduction gearbox output shaft transmission wheel, a cam divider power input shaft transmission wheel, a transmission wheel and a cam divider; the cam divider and the downward side of the workbench are fixed; a cam divider output shaft is connected with the downward side of the rotary disk; the cam divider driving motor is matched with the reduction gearbox; the reduction gearbox output shaft transmission wheel is fixed to a cam divider driving reduction gearbox output shaft; one end of the transmission belt is arranged on the reduction gearbox output shaft transmission wheel in a sleeving manner, and the other end of the transmission belt is arranged on the cam divider power input shaft transmission wheel in a sleeving manner; and the cam divider power input shaft transmission wheel is fixed to a cam divider power input shaft. The size is small; connecting reliability and motion stability are guaranteed; and the requirement for rhythmic motion is met.

Owner:CHANGSHU TIANYN ELECTROMECHANICAL

protective device and a protective method for anti-explosion and anti-shock of a T-beam connecting member

PendingCN109024218AGuaranteed stabilityMake up for the shortcomings of lack of toughnessBridge structural detailsBridge erection/assemblyBridge engineeringShock wave

The invention discloses a protective device and a protective method for anti-explosion and anti-shock of a T-beam connecting member, belonging to the field of bridge engineering. The device comprisesa flange plate, a web plate and a cross diaphragm of a T-shaped beam, wherein a first anti-explosion member is arranged at the lower part of the flange plate, and a second anti-explosion member is arranged on the cross diaphragm; By using the method of superposition of flexible layer and rigid layer, the cushioning of shock wave and the effect of resisting explosive shrapnel and shock are obtainedthrough the combination of different properties of various materials. The device and the method can effectively resist explosion and impact damage, and can be widely applied to the field of T-shapedbridge flange plate and cross diaphragm connection.

Owner:ZHONGBEI UNIV

Battery terminal with unintended deformation prevention features

InactiveUS9705122B2Suppression of deformationUnintended effectSmall-sized cells cases/jacketsCoupling device detailsEngineeringMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com