Patents

Literature

178results about How to "High movement reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

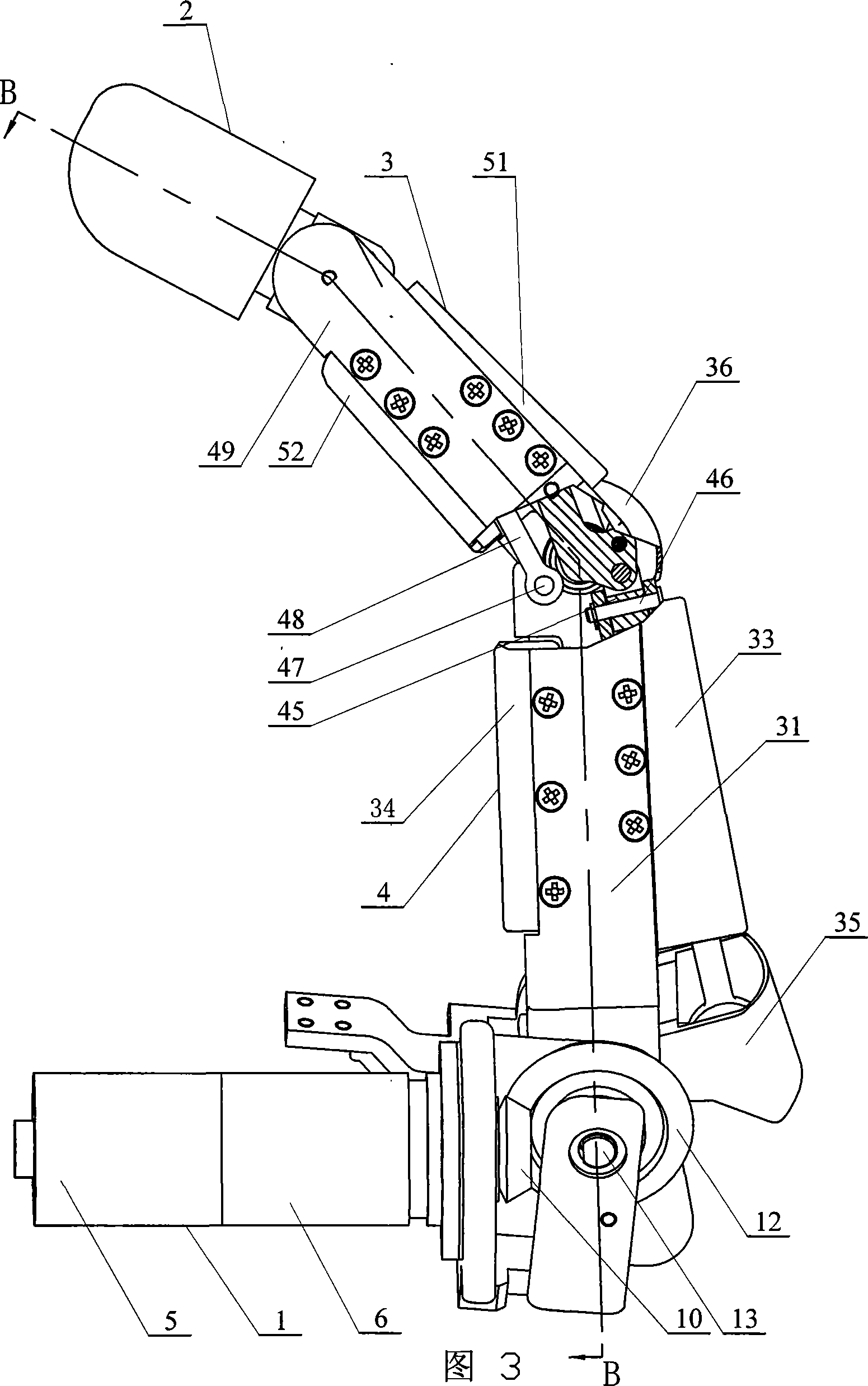

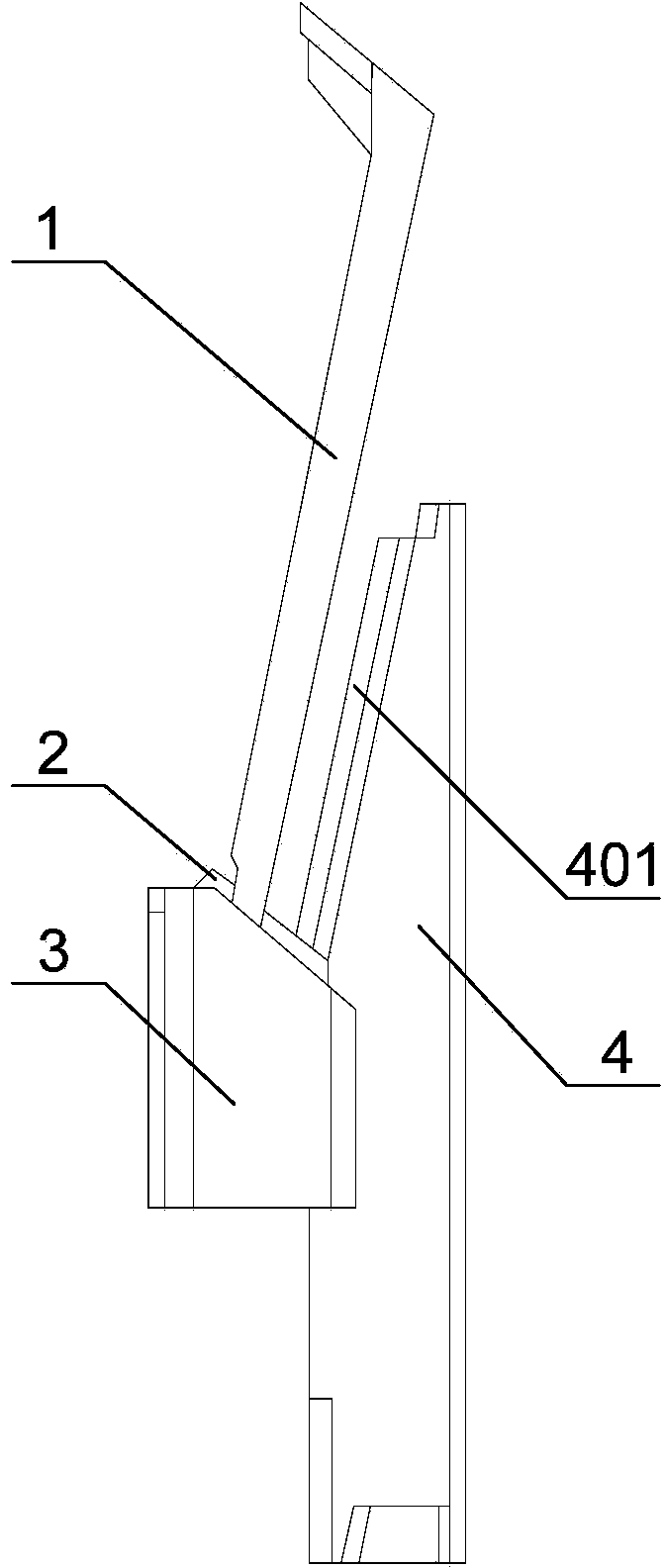

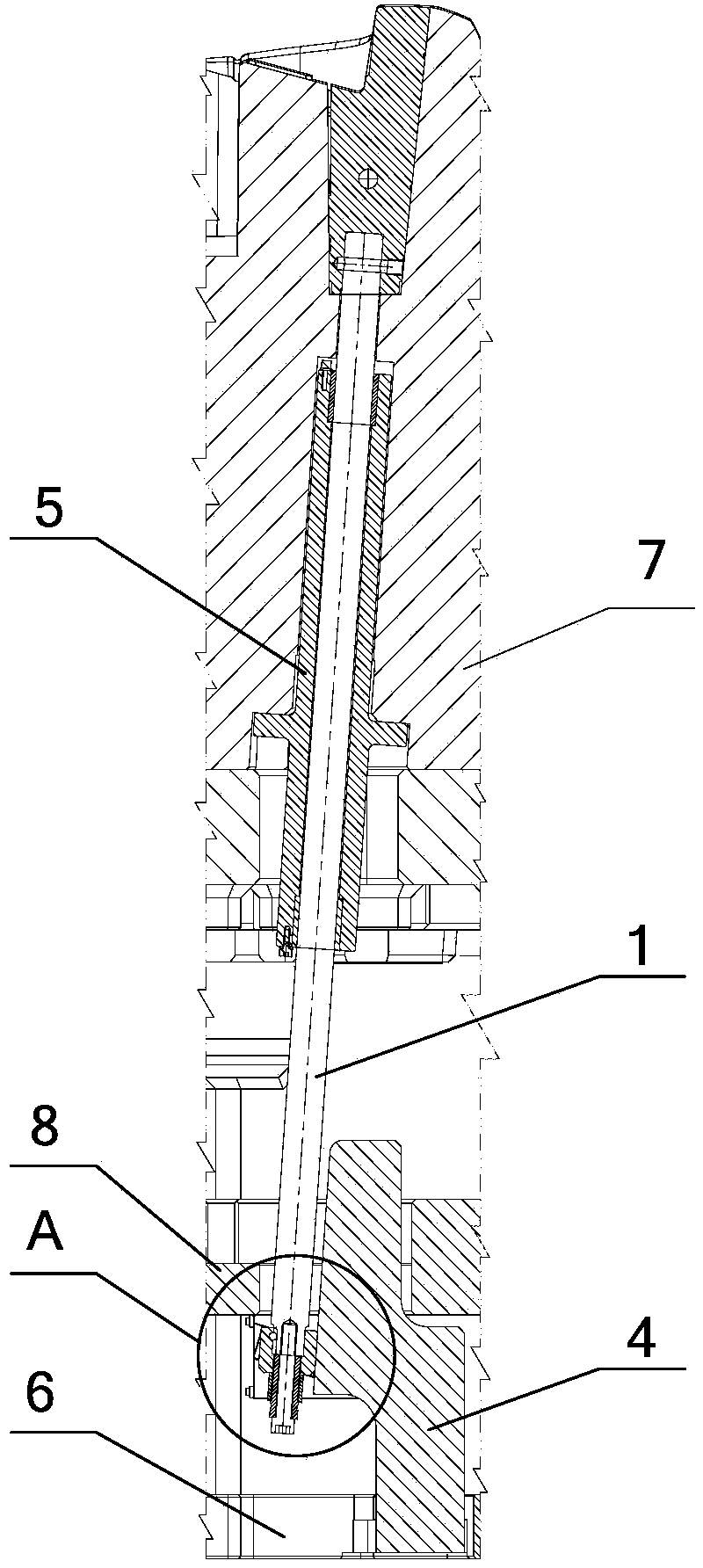

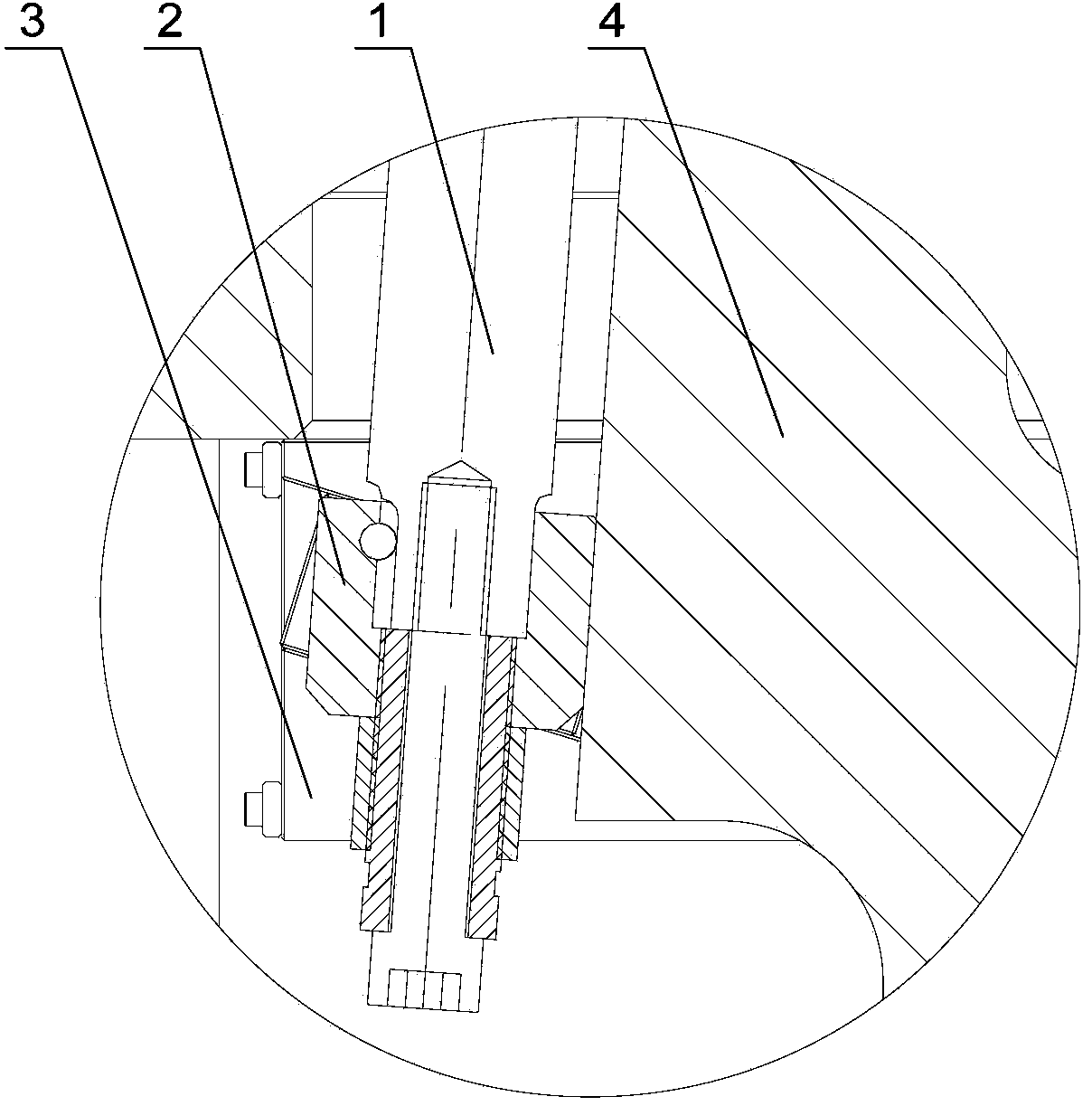

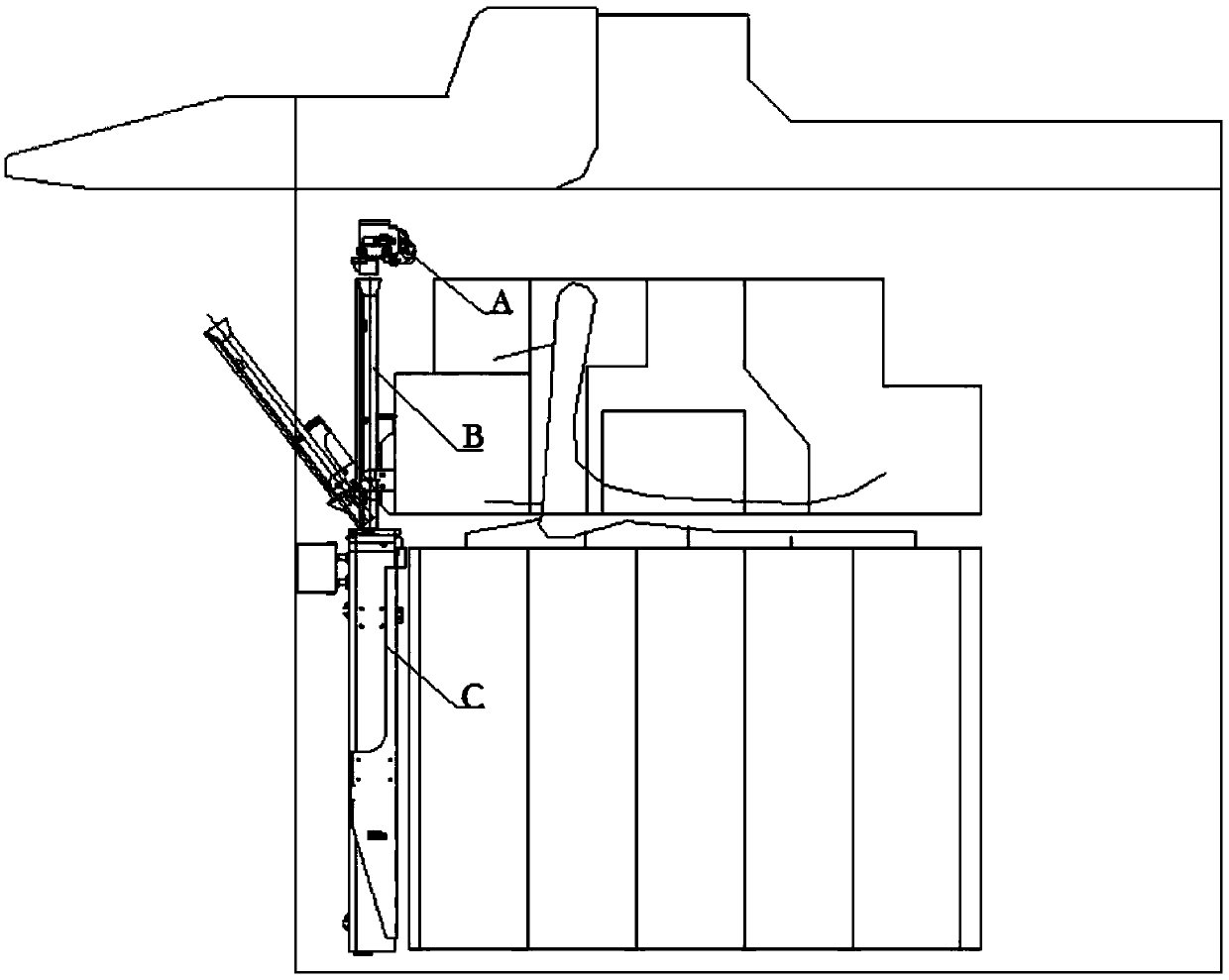

Device for sampling shallow soil of extraterrestrial star

InactiveCN102680275AReduce couplingSimple control algorithmWithdrawing sample devicesEngineeringShovel

The invention relates to a device for sampling shallow soil of an extraterrestrial star. The device comprises two parts, namely a guide rail swing-arm type position mechanism and a terminal executing mechanism, wherein the guide rail swing-arm type position mechanism comprises a guide rail, a moving unit, a swing arm joint, a swing arm and a terminal joint; the terminal executing mechanism comprises a shovel, a ratchet wheel, a sample box and a connecting and separating mechanism; a position mechanism has the advantages of high rigidity, good flexibility and simplicity in the control method and can be used for completing tasks of currently frequently-used four-freedom-degree two-stage space mechanical arms besides sampling the shallow soil of the extraterrestrial star; the terminal executing mechanism mainly relies on a shoveling task method while a ratchet wheel rotary-digging task method as a subsidiary; soil samples can be obtained effectively; the device has functions of temporary storage and primary package for samples; in addition, the samples are transferred into an airtight packaging device on an ascender; and thedevice for sampling soil has a wide application range.

Owner:BEIJING SATELLITE MFG FACTORY

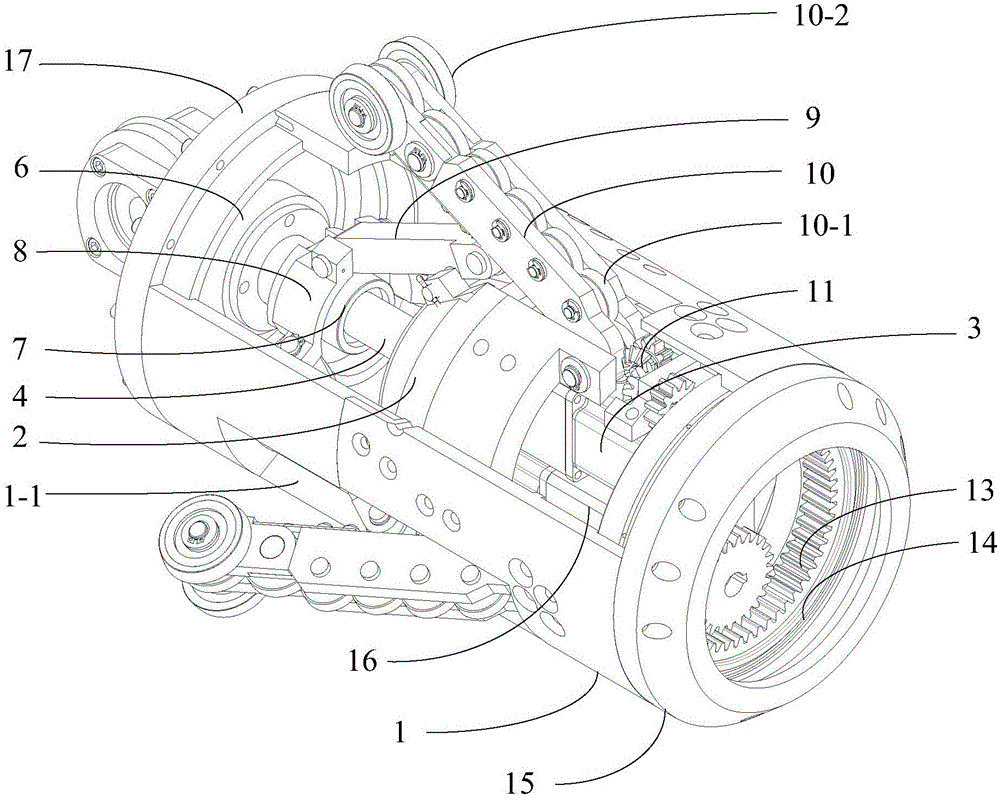

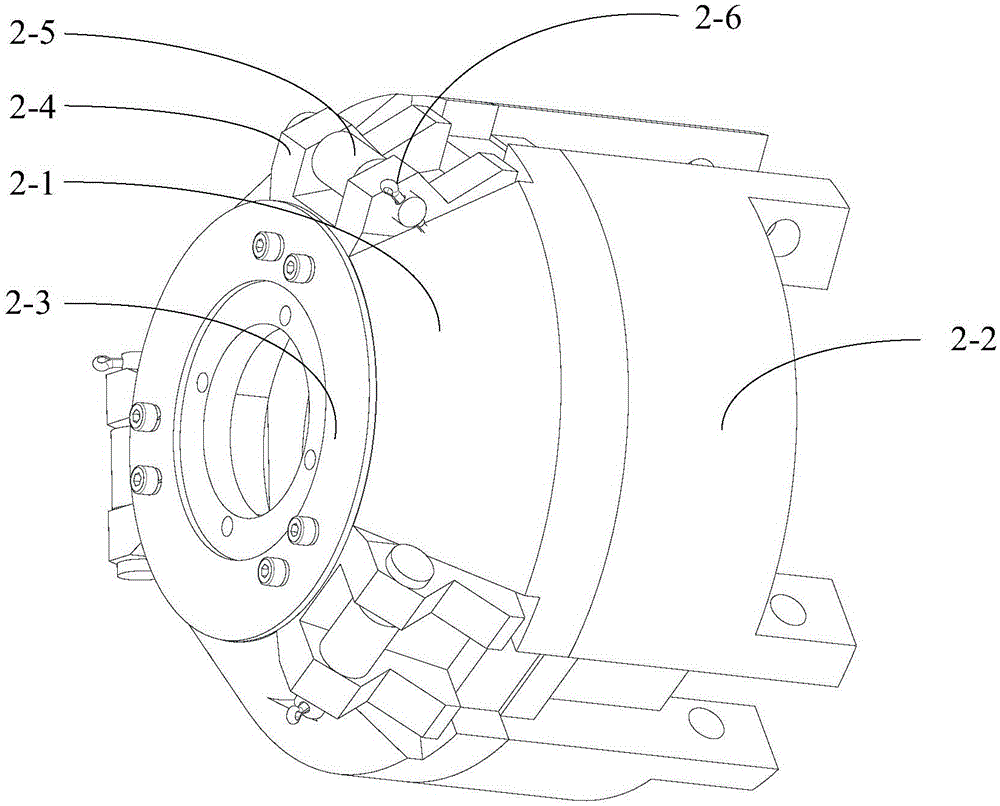

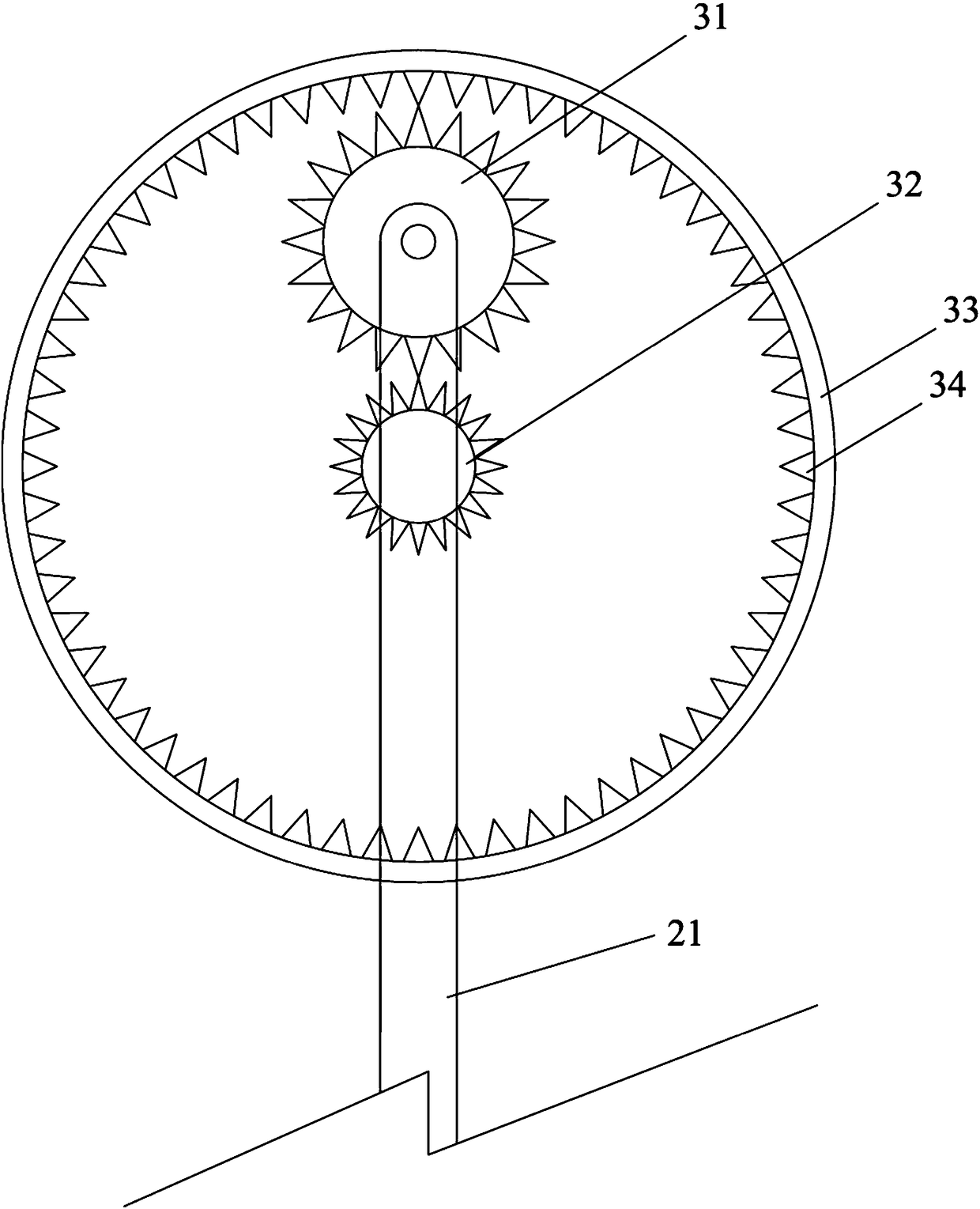

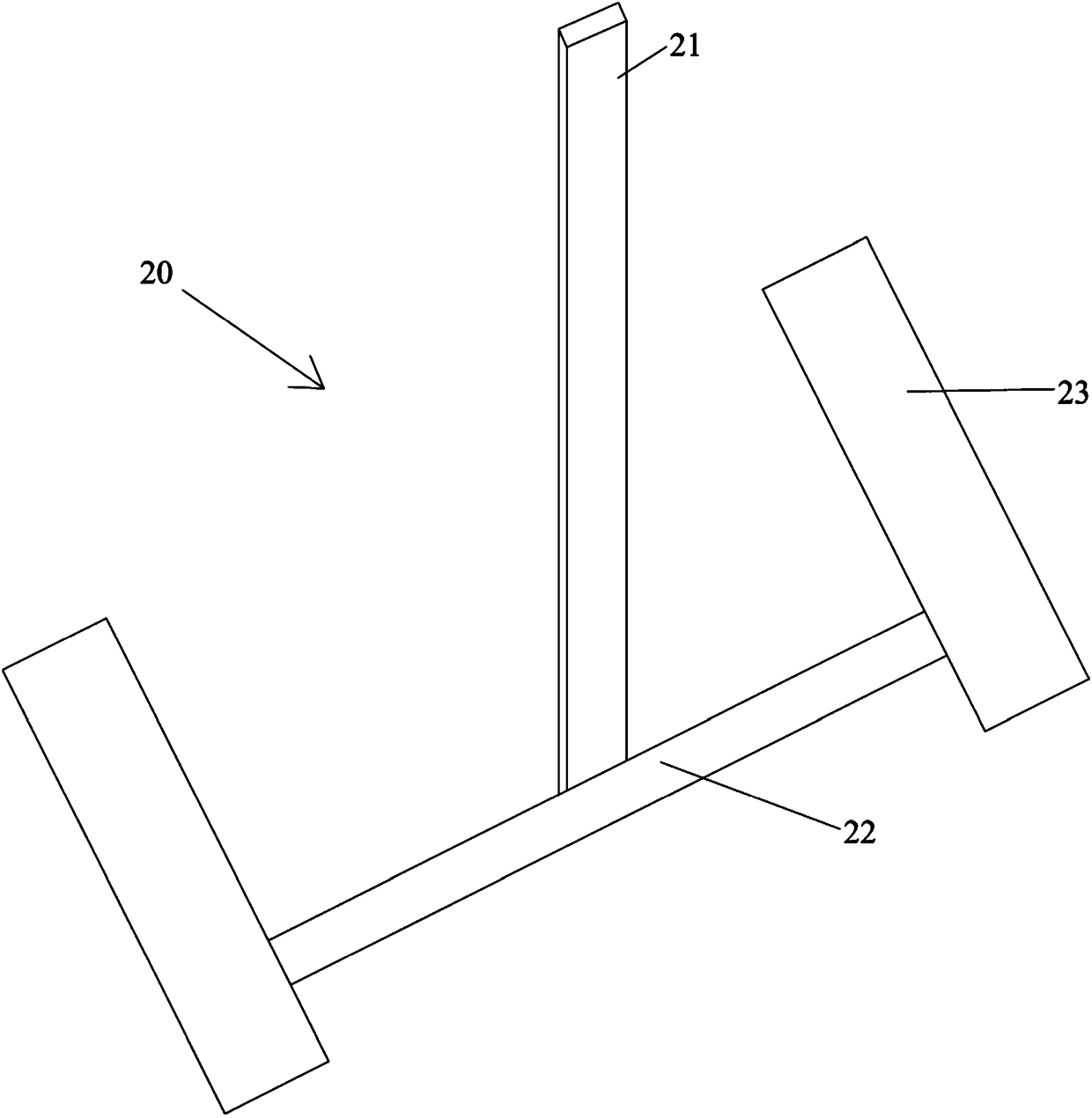

Supporting wheel type pipeline robot driving device

ActiveCN105003791AImprove adaptabilityImprove operational reliabilityPipe elementsInterference fitGear drive

The invention provides a supporting wheel type pipeline robot driving device which is characterized in that a supporting motor gear drives a front bearing embedded gear together with a screw rod to rotate; the rotation of a screw rod is converted to the translation of a nut along the axial direction of the screw rod by a thread pair; a lower supporting arm bracket fixedly connected with the nut synchronously moves along with the nut and controls a position of a lower supporting arm relative to supporting points of a middle shaft rack supporting roll and a main supporting arm, and then expansion / retraction of a supporting arm assembly, and compression on a pipe wall are realized to be adapted to variance in the pipe diameter; in addition, a travelling motor gear drives an inner gear ring and an outer gear ring in interference fit with the inner gear ring in an inner and outer sleeve gear assembly to rotate with a gear ring bearing inner race jointly, then the outer gear ring serves as a driving part to drive three travelling gear assemblies to input straight gears, and finally drives travelling wheels to rotate along the pipe wall. The supporting wheel type pipeline robot driving device is particularly applicable to intra-pipe travelling operation, and has the characteristics of the adaptive capacity to environment of a pipeline is high, a tractive force is high, and the operation is smooth and reliable.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

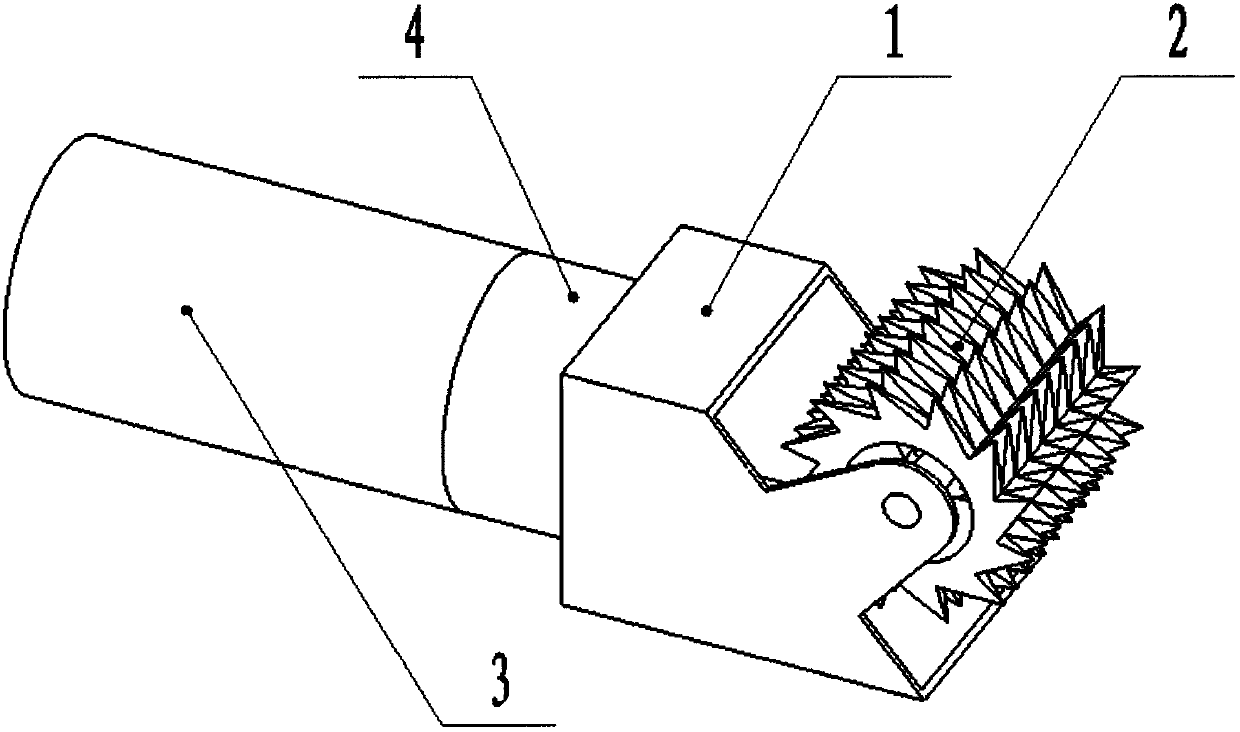

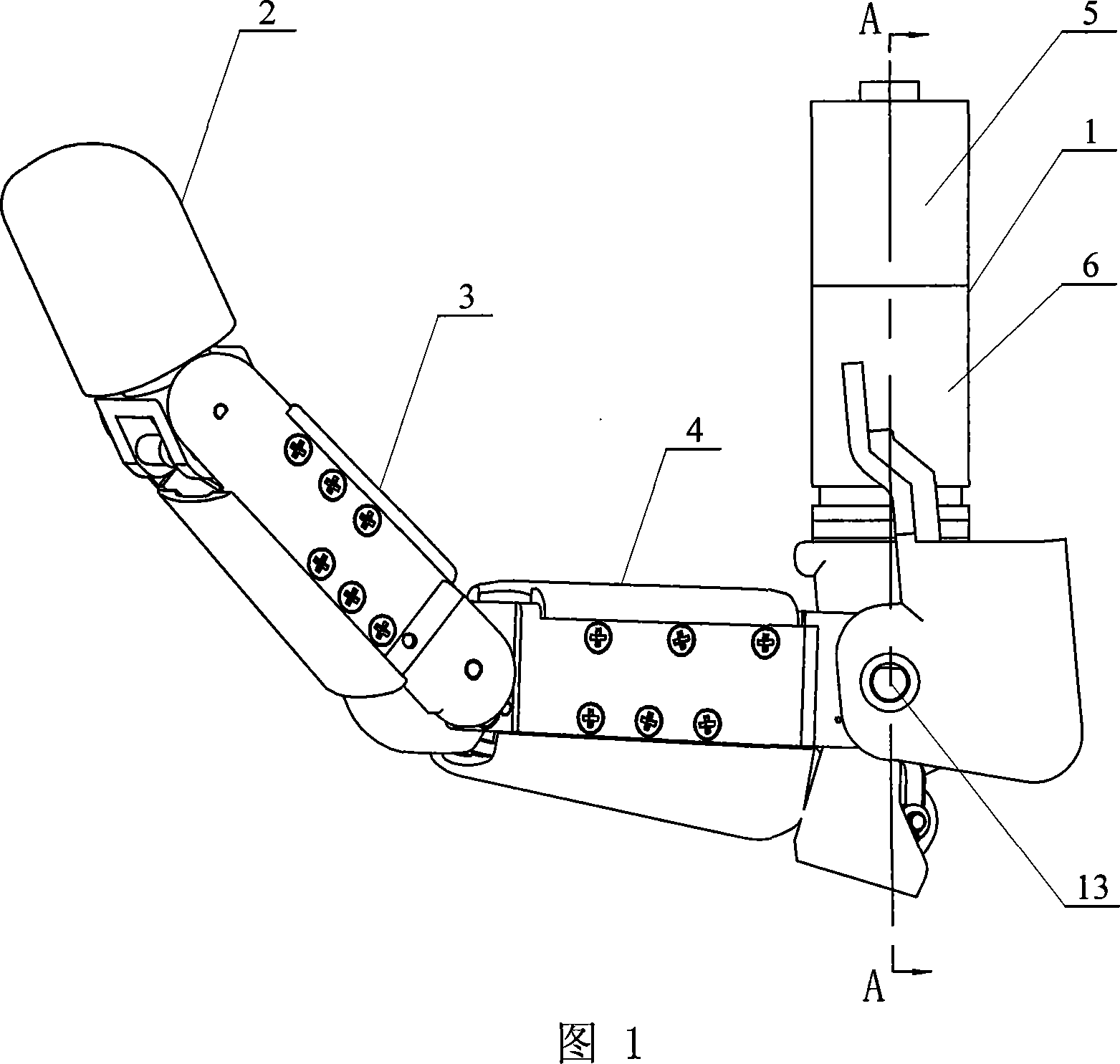

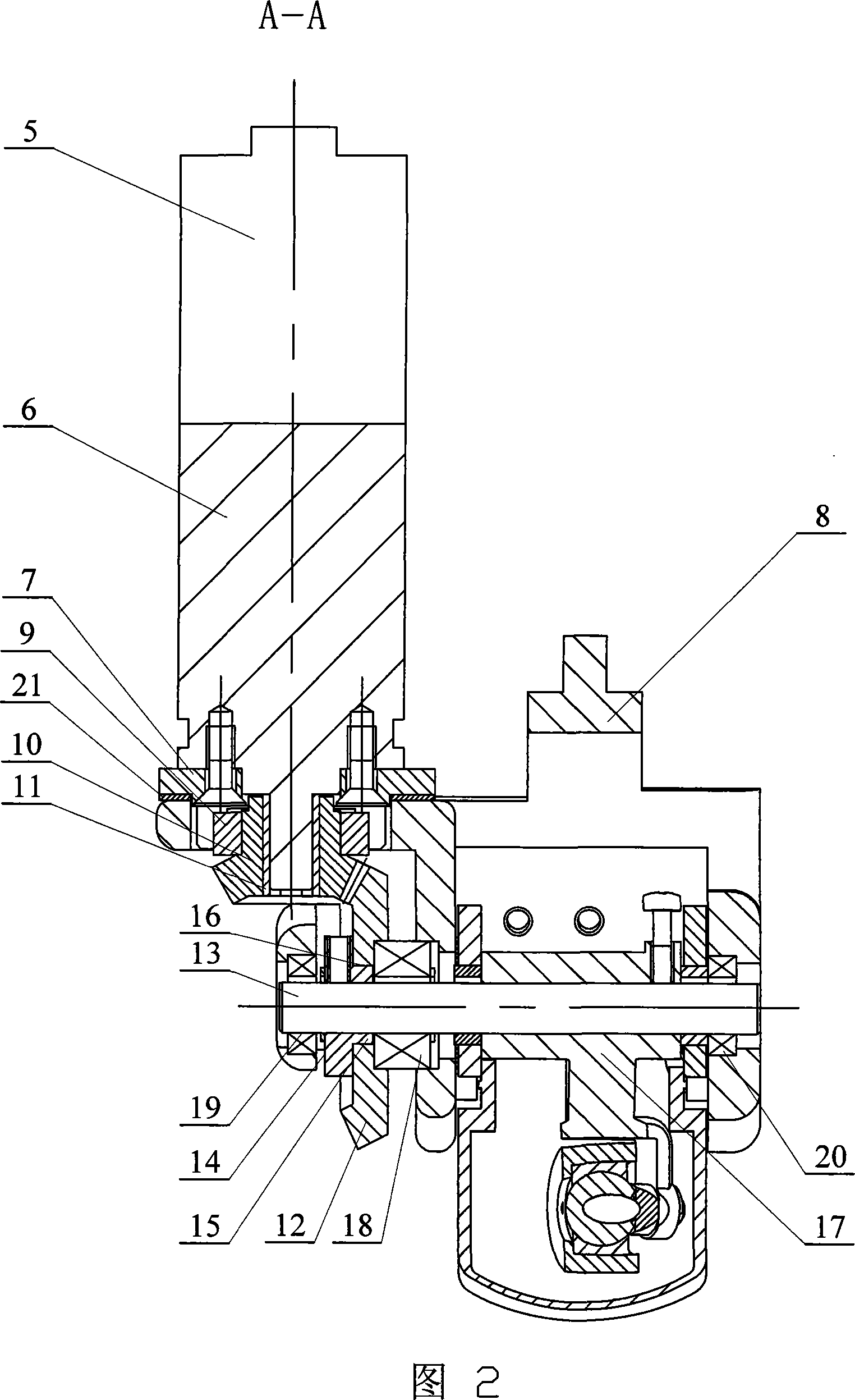

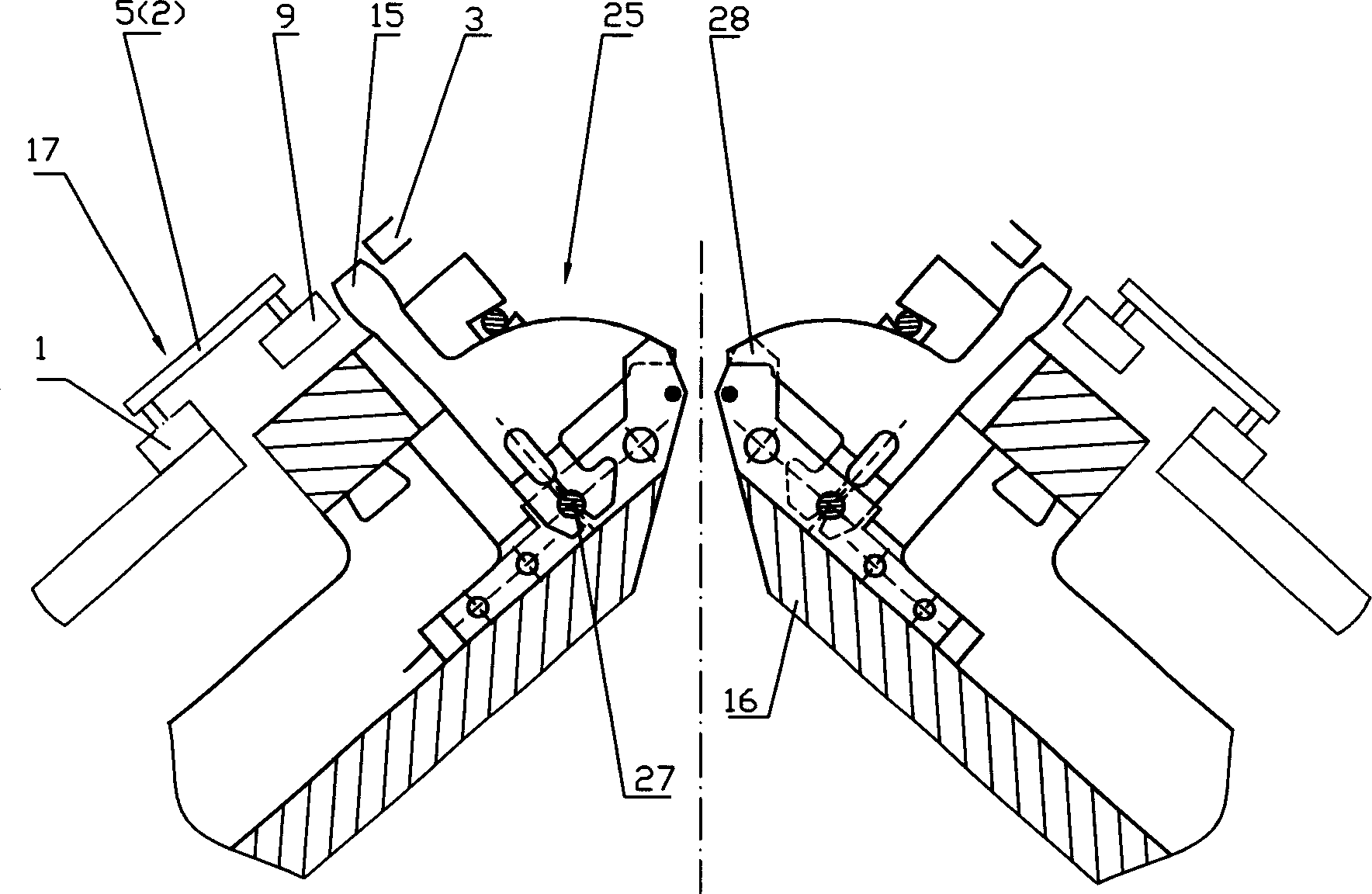

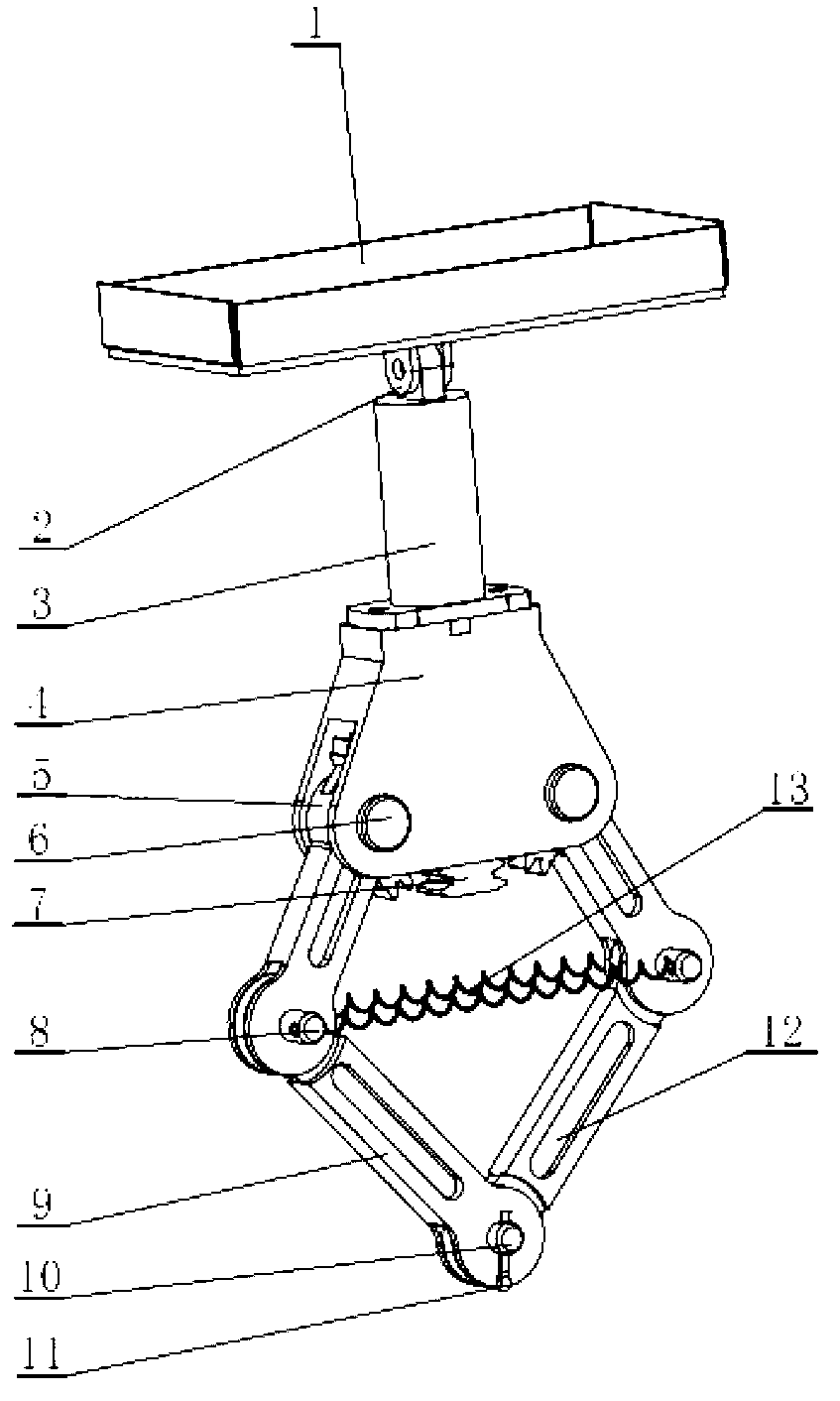

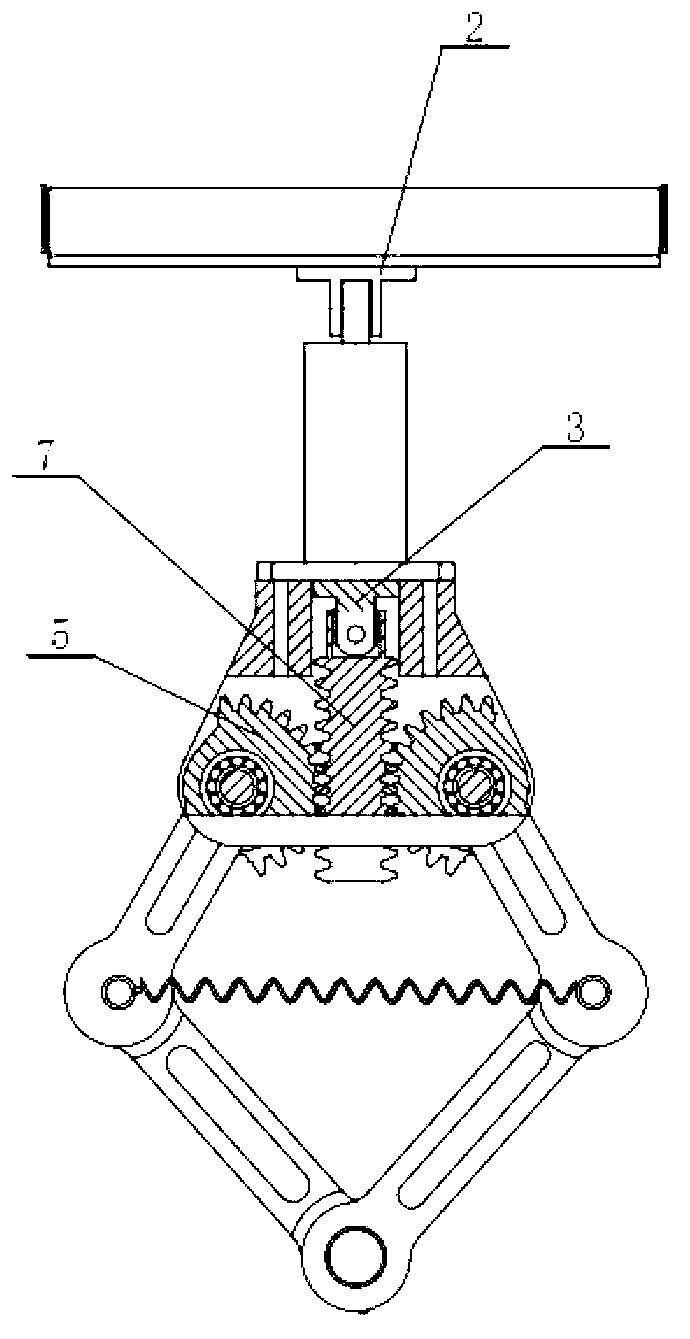

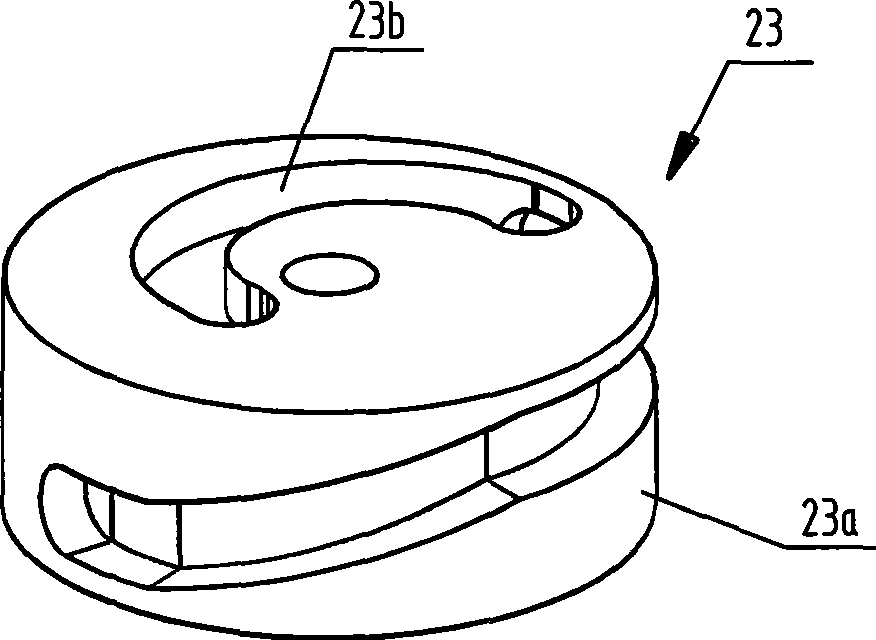

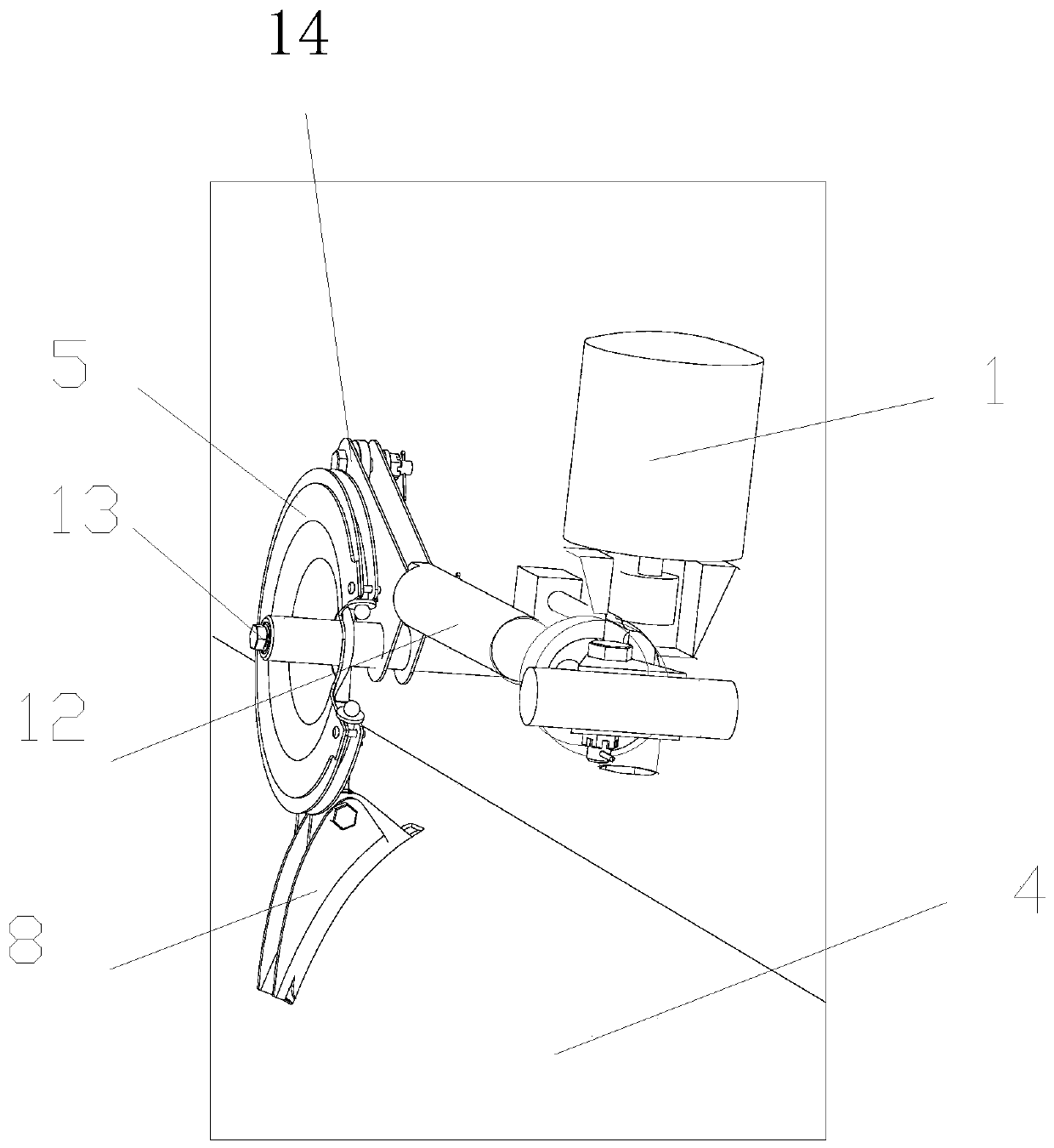

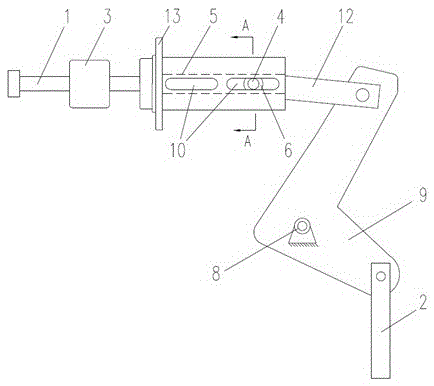

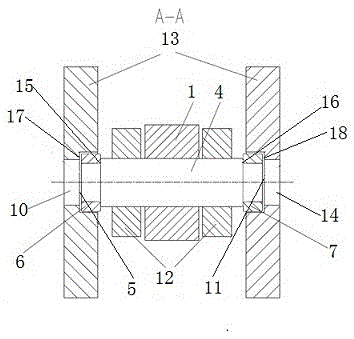

Thumb mechanism for under-driven adaptive prosthetic hand

InactiveCN101057791AImprove motor flexibilityHigh movement reliabilityArtificial handsEngineeringBiological activation

The invention discloses a thumb device for artificial hand. The driving device (1) is in rotary connection with the back part of near knuckle (4), the front part of near knuckle is in rotary connection with back part of middle knuckle (3), and the front end of middle knuckle is in rotary connection with the back part of far knuckle (2). The middle knuckle and near knuckle imitate deficient activation motion of real hand driven by middle knuckle shaft disk, the middle knuckle and far knuckle imitate coupling motion of real hand driven by coupling rod; and the knuckle number of thumb is imitative to that of real hand. The invention is characterized by simple structure, real-like appearance and flexible motion of each knuckle.

Owner:HARBIN INST OF TECH

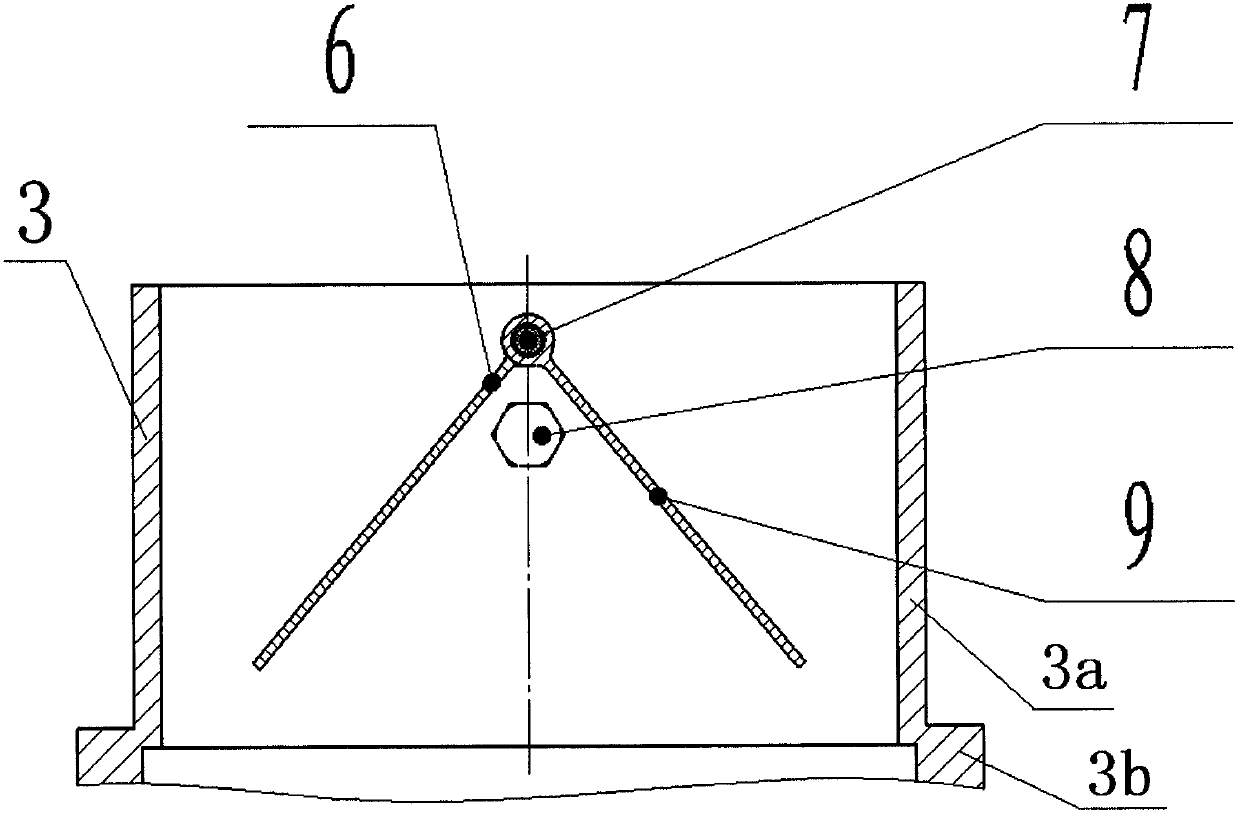

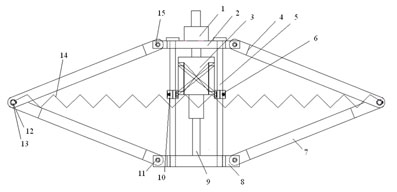

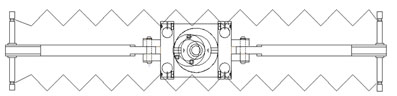

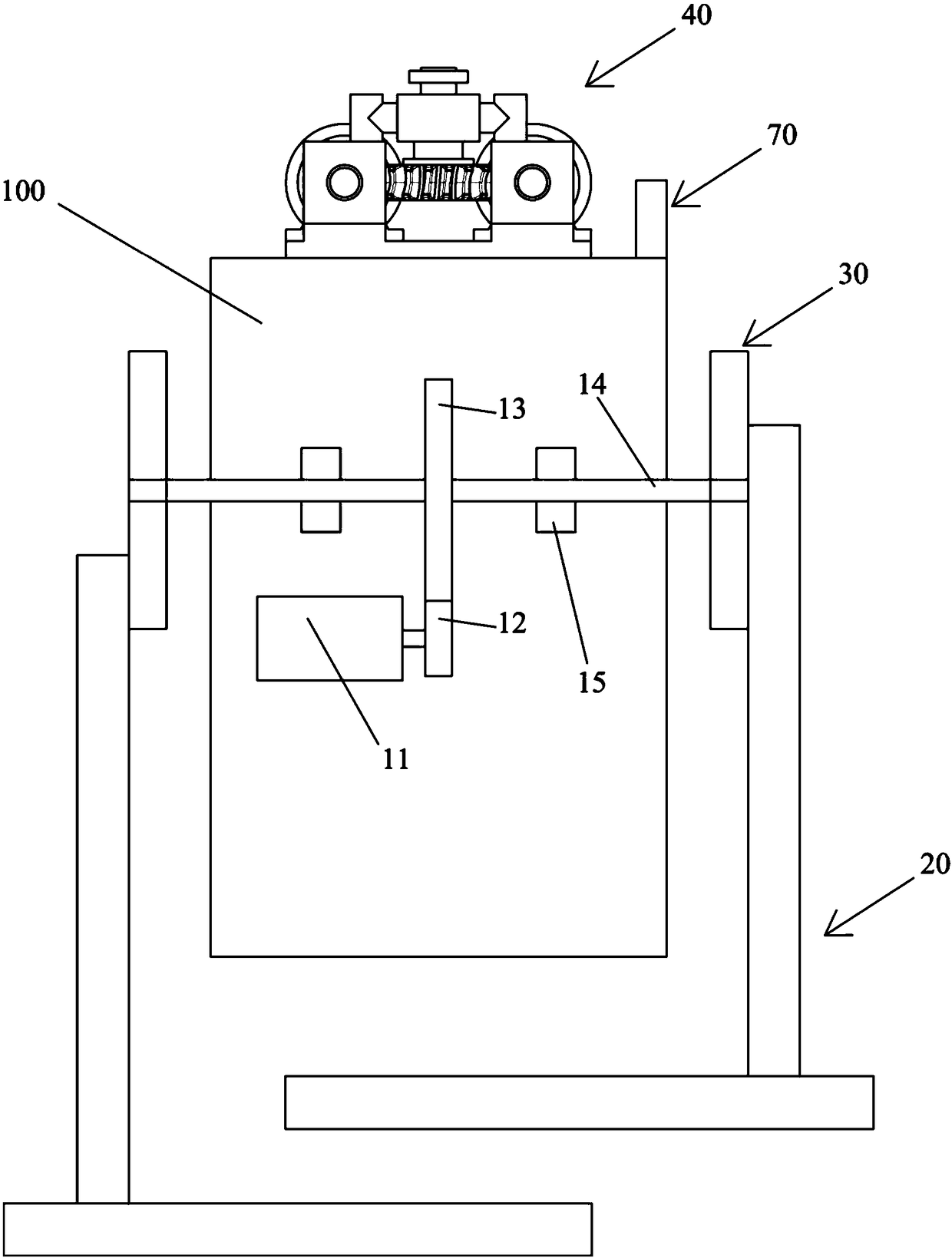

Motor drive-based robot vertical bounce mechanism

InactiveCN102050165AImprove obstacle performanceSimple structural designVehiclesMotor driveEngineering

The invention relates to a motor drive-based robot vertical bounce mechanism and belongs to the technical field of bounce robots. The mechanism is characterized by comprising a base (8), an upper cover plate (2), a central motor (1), a central guide pillar (9), a central cylindrical cam (3), two ridge rods and two folding mechanisms, wherein the central cylindrical cam (3) is fixedly connected to an output shaft at the lower end of the central motor (1) and is matched with the central guide pillar (9) through a central blind hole; the two ridge rods are symmetrically fixed on corresponding side guide pillars (5) and are matched with a groove of the central cylindrical cam (3); and the folding mechanisms are hinged between the upper cover plate (2) and the base (8). A spiral groove on the outer surface of the central cylindrical cam is moved downwards under the exogenic action when the central cylindrical cam is rotated, a six-bar mechanism is driven to deform, the gravity of the mechanism is moved downwards, and an extension spring generates internal stress, so that the motor drive-based robot vertical bounce mechanism makes a robot bounced, and has a compact structure design and high movement reliability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

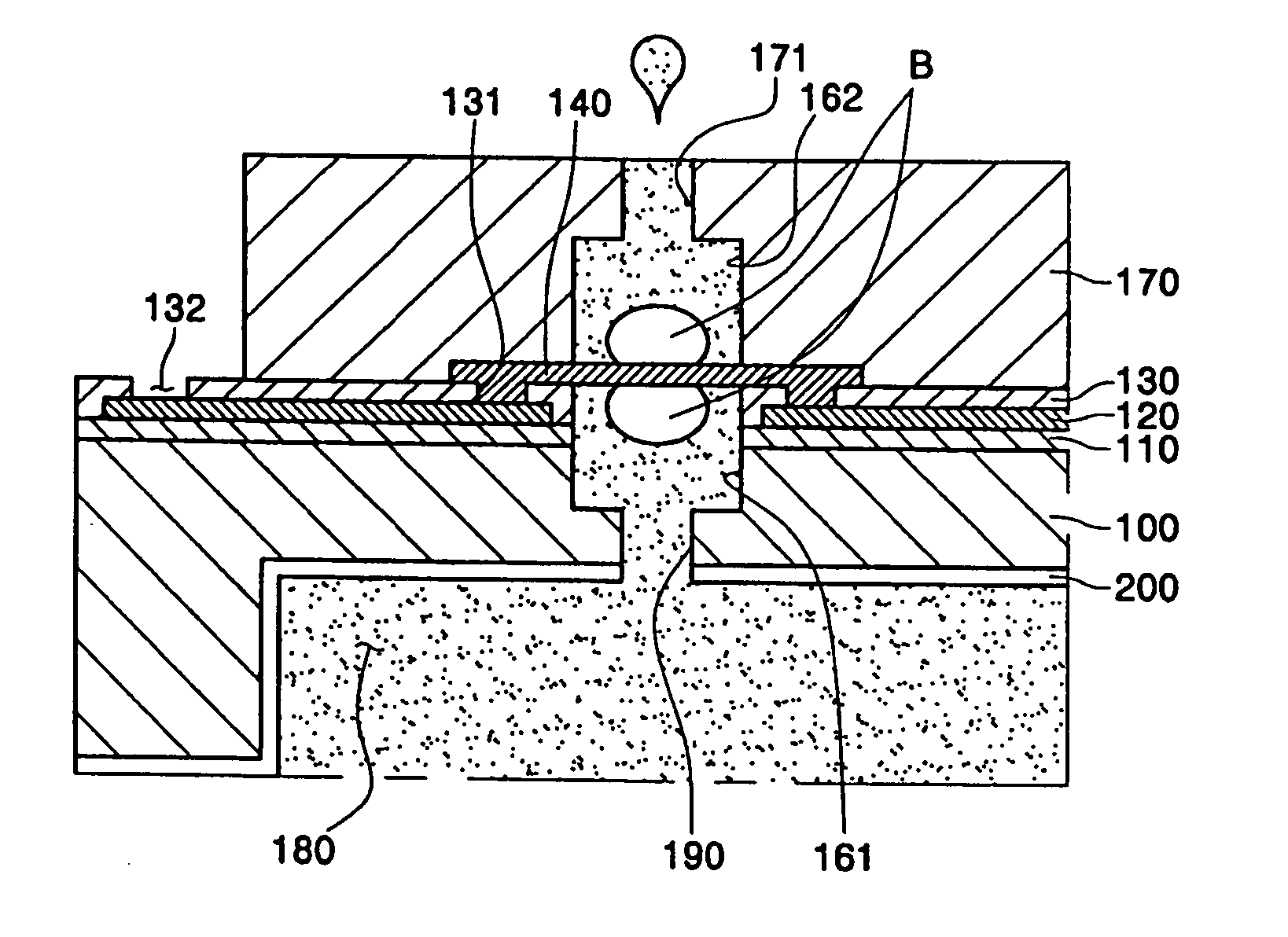

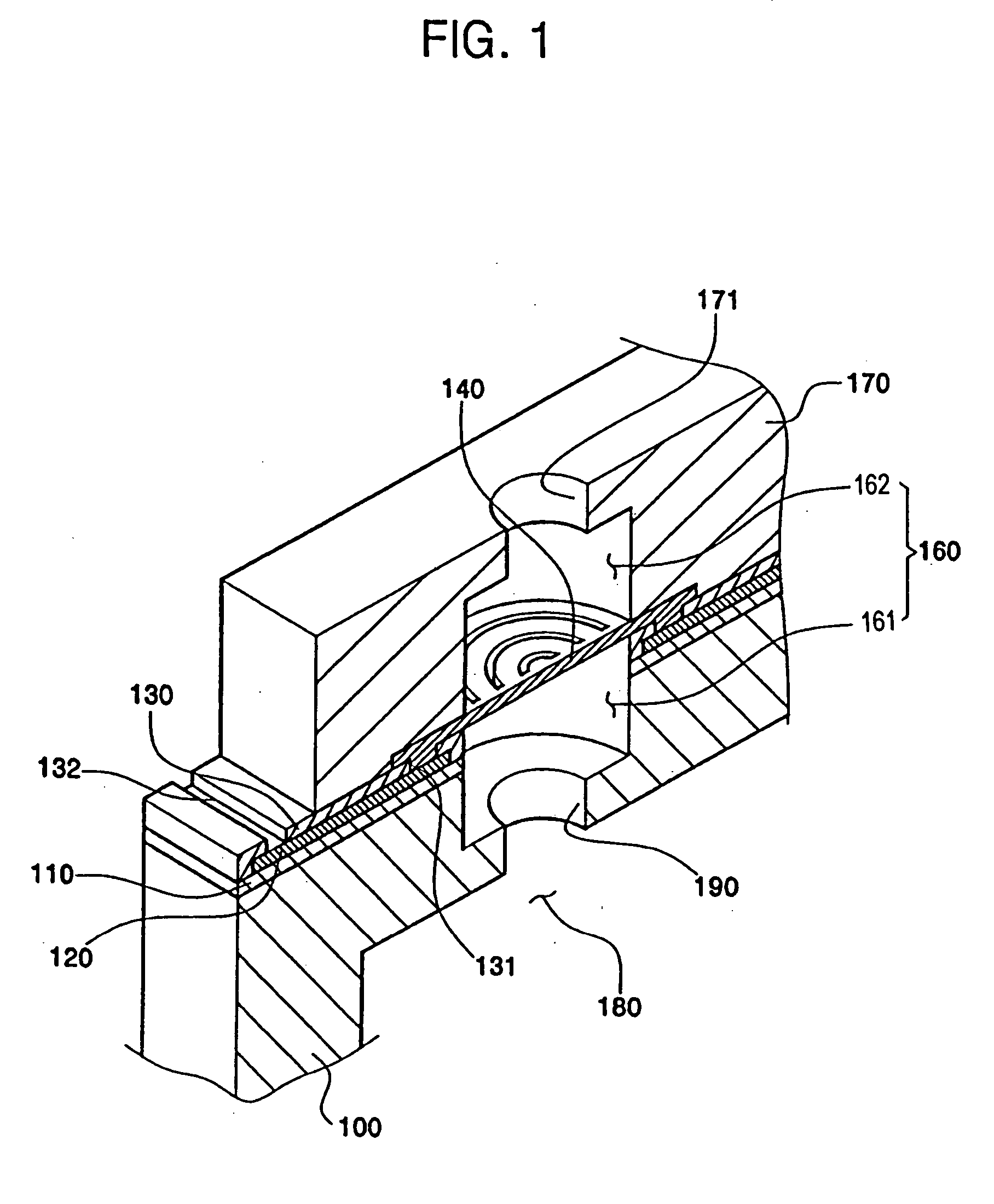

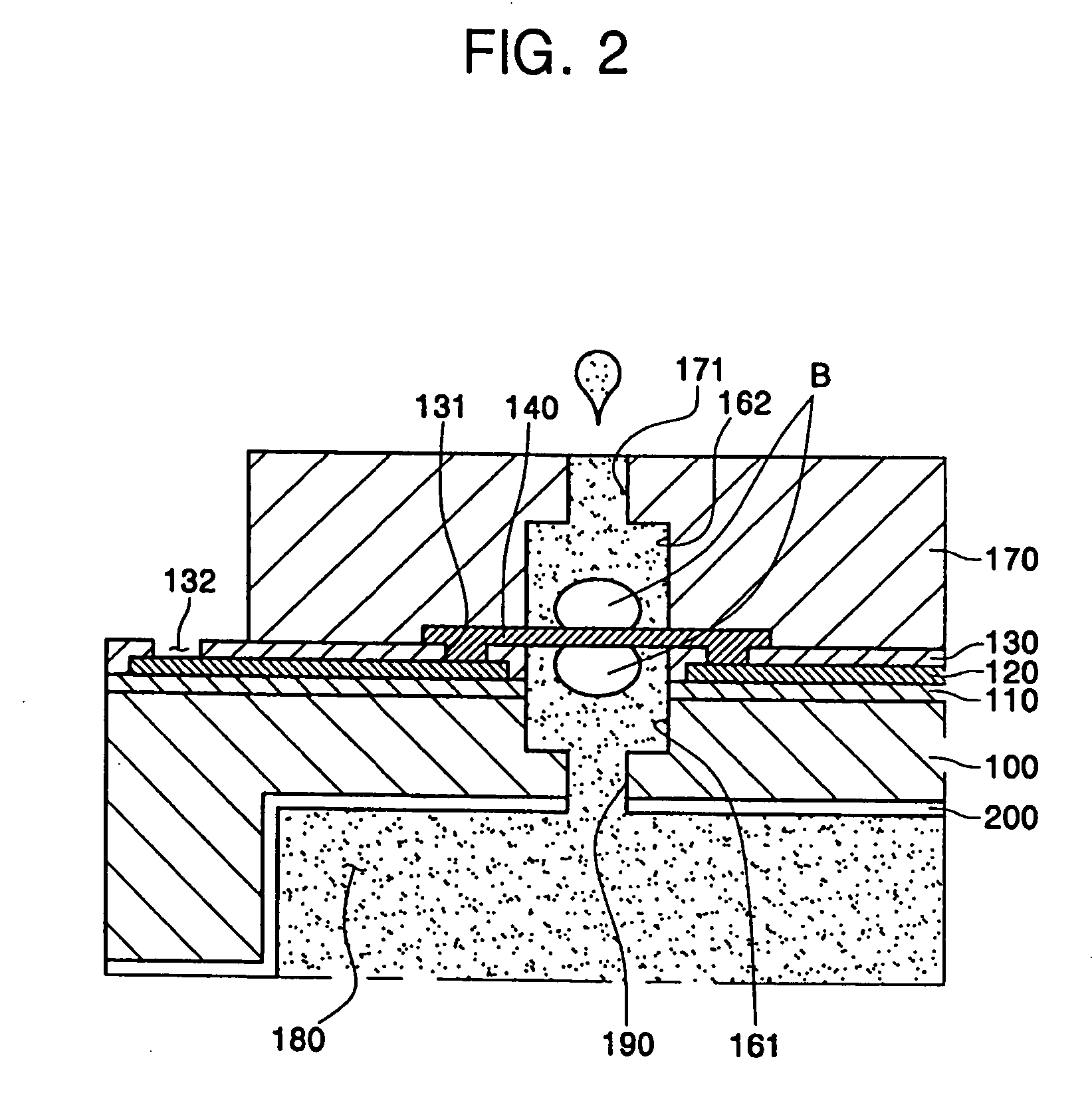

Inkjet printer head and method of manufacturing the same

InactiveUS20060061629A1Good inkjet effectImprove ejection effectPrintingManufacturing technologyEngineering

An inkjet printer head includes a substrate having a manifold and an ink channel to supply ink, a nozzle plate formed on the substrate, a chamber formed between the substrate and the nozzle plate and extending toward the substrate and the nozzle plate, an electrode formed at an interface between the substrate and the nozzle plate and around the chamber, and a heater having both ends extending in contact with the electrode to be suspended on the chamber in direct contact with the ink and to generate bubbles from both surfaces thereof. The inkjet printer head is capable of improving manufacturing process efficiency by omitting a process of separately forming a heater passivation layer, operating the heater at low electric power by omitting the heater passivation layer, improving integrity of a nozzle by lowering a working voltage, and improving reliability in manufacturing processes by locating the suspended heater to be in parallel with the substrate and the electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

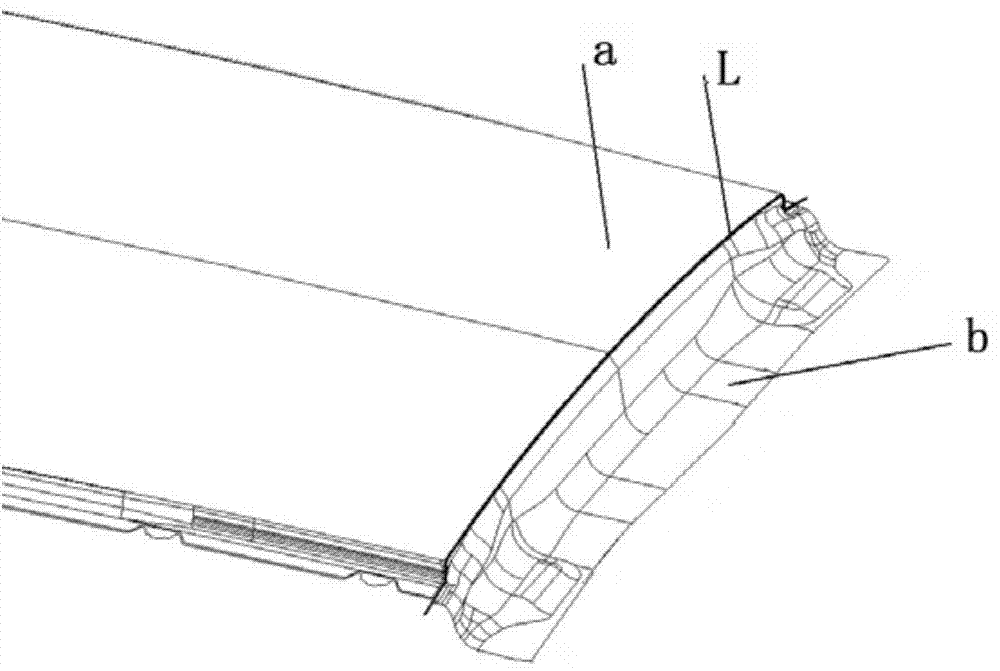

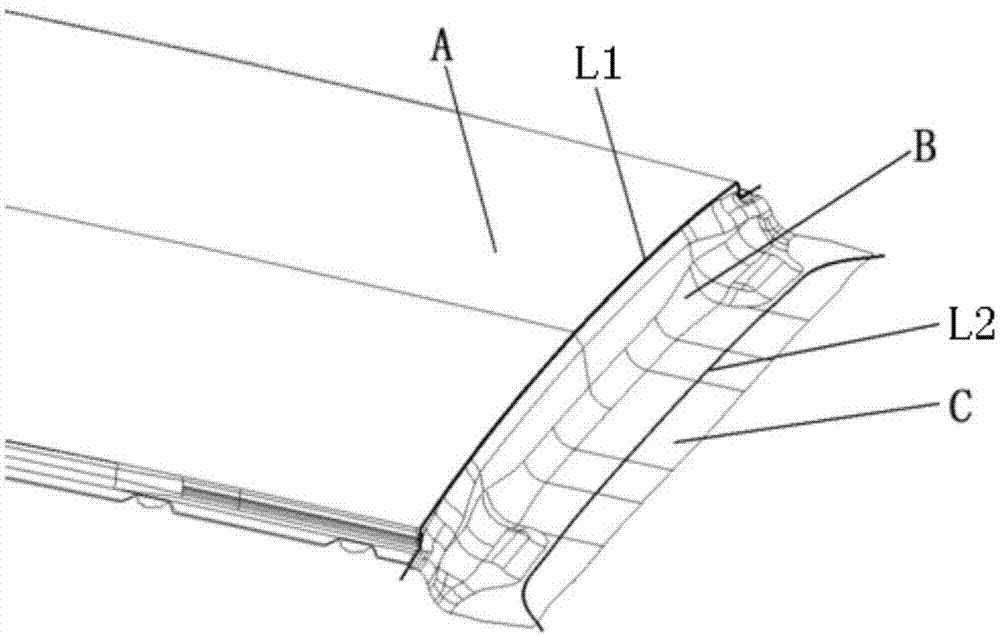

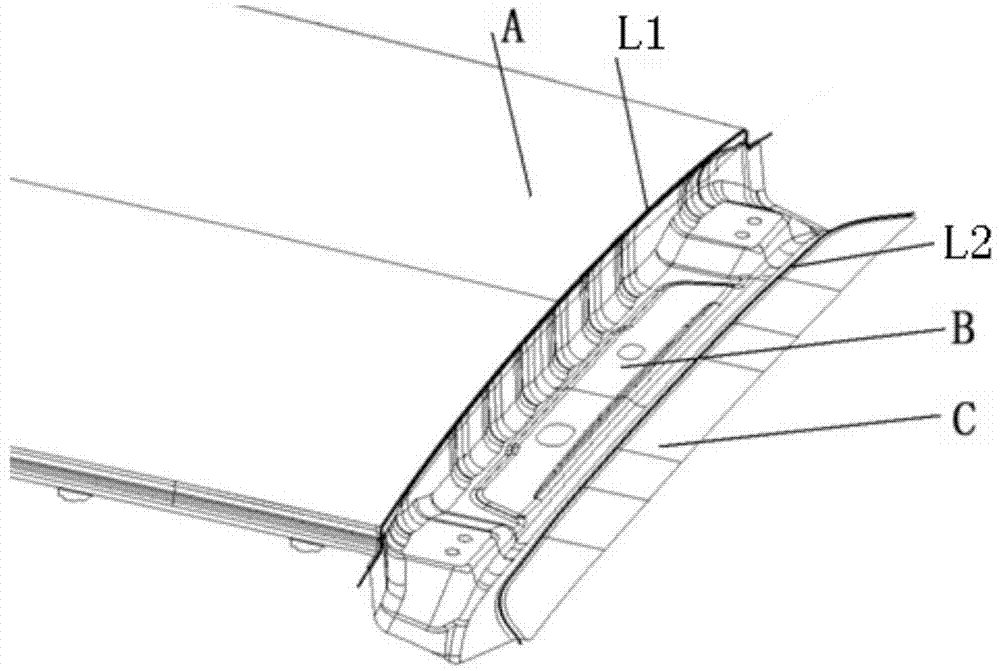

Stamping molding process for outer plate tail part of head cover of automotive covering part and stamping mold

InactiveCN104707903AHigh movement precisionHigh movement reliabilityShaping toolsVehicle componentsEngineeringTail region

The invention discloses a stamping molding process for an outer plate tail part of a head cover of an automotive covering part and a stamping mold. The process comprises the following steps: (11) in a previous procedure of tail part molding, reserving a product waste part of a tail region without trimming; (12) in a tail molding procedure, pressing a top region and a tail region of a blank; (13) carrying out side arranging and molding on a molding part; and (14) in a next procedure after tail molding, carrying out trimming operation by employing the edge of the final product of the tail part as a trimming line, and removing the waste part except the tail product of the head cover. Therefore, according to the stamping molding process for the outer plate tail part of the head cover of the automotive covering part, by virtue of a treatment scheme of simultaneously swaging at two ends, and secondary molding and work hardening in the middle, the molded plate part cannot easily rebound and deform; the accuracy easily reaches the standard; the debugging workload is reduced; meanwhile, the molded plate part becomes thin through secondary molding and extension; and the strength of the molded plate part is increased.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

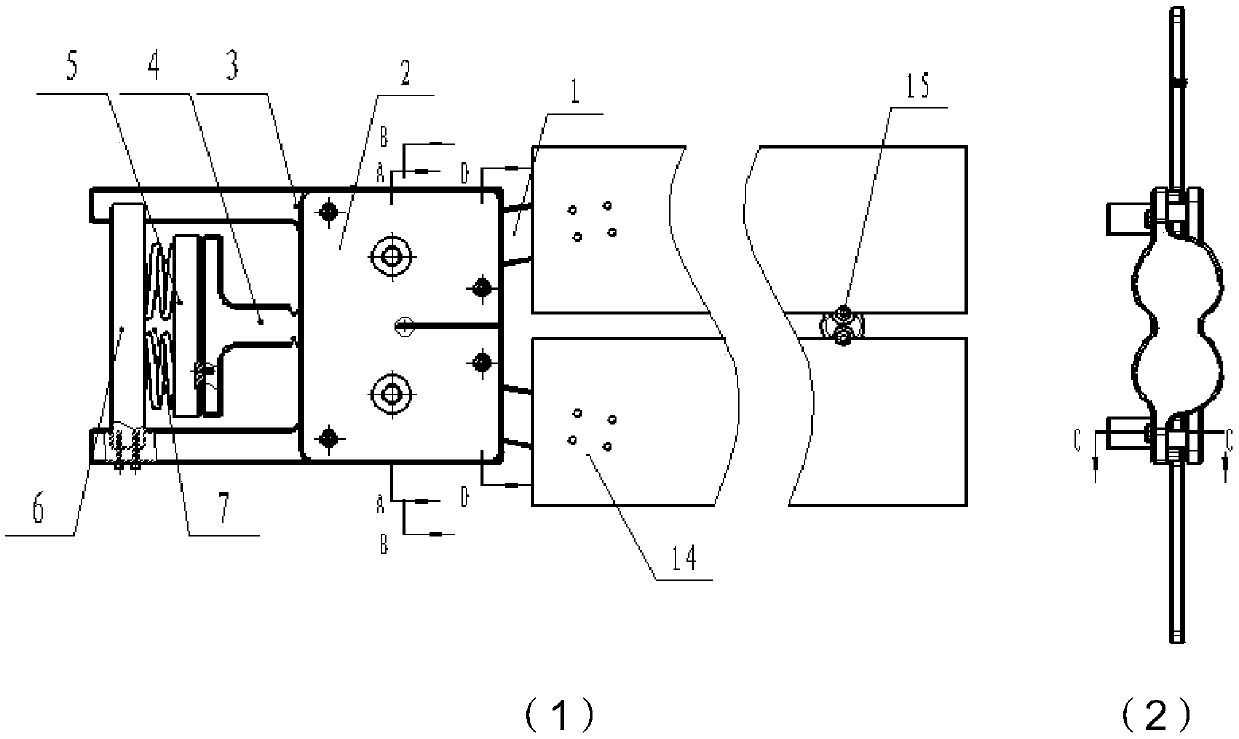

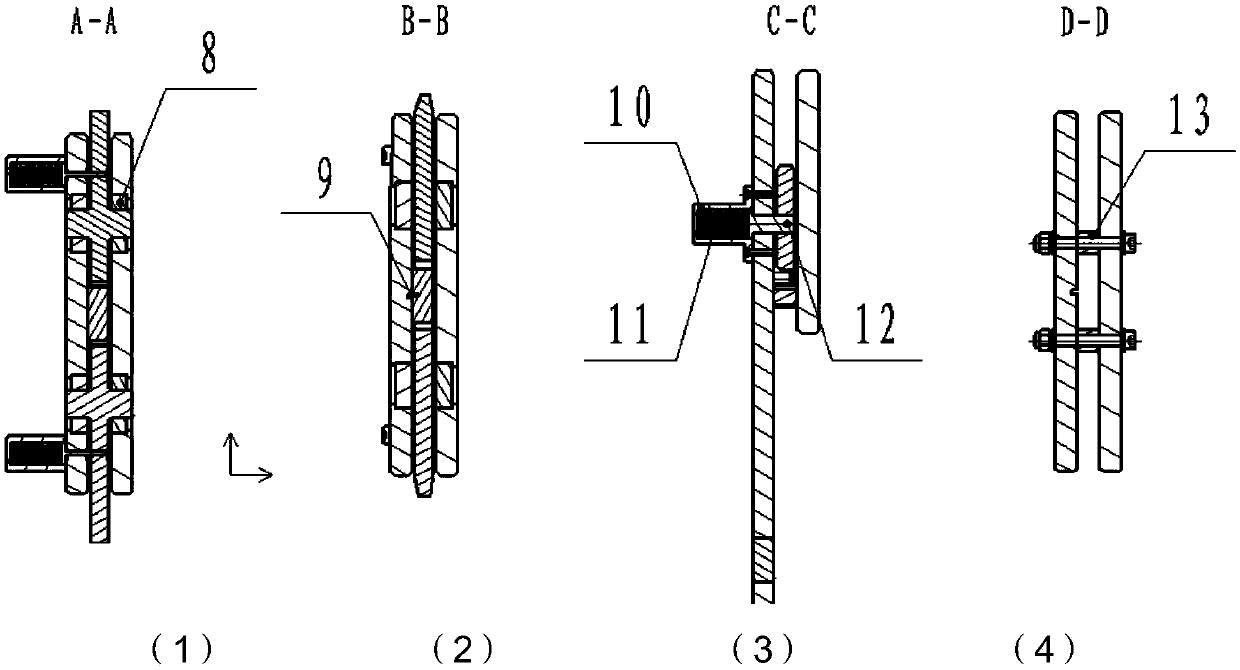

Sinker control device for straight-bar machines

The invention relates to a depositing piece control device in a flat knitting machine. Its technical project: it is installed on the machine head by connecting components, has a machine base, there is a return triangle on the top side of the machine base, there are the first and second parallel four-link mechanisms on the left and right sides of the machine base, respectively, the translational rods of the four-link mechanisms are both set with needle pulling triangles, where one link connects with the corresponding positions of the corresponding rods in the first and second four-link mechanisms so as to form the third parallel four-link mechanism; there is a magnetic block inserted in the needle pulling triangle. It has the remarkable effects of reliable movement, small working noise and stable running and simple fabrication and low cost.

Owner:冯加林

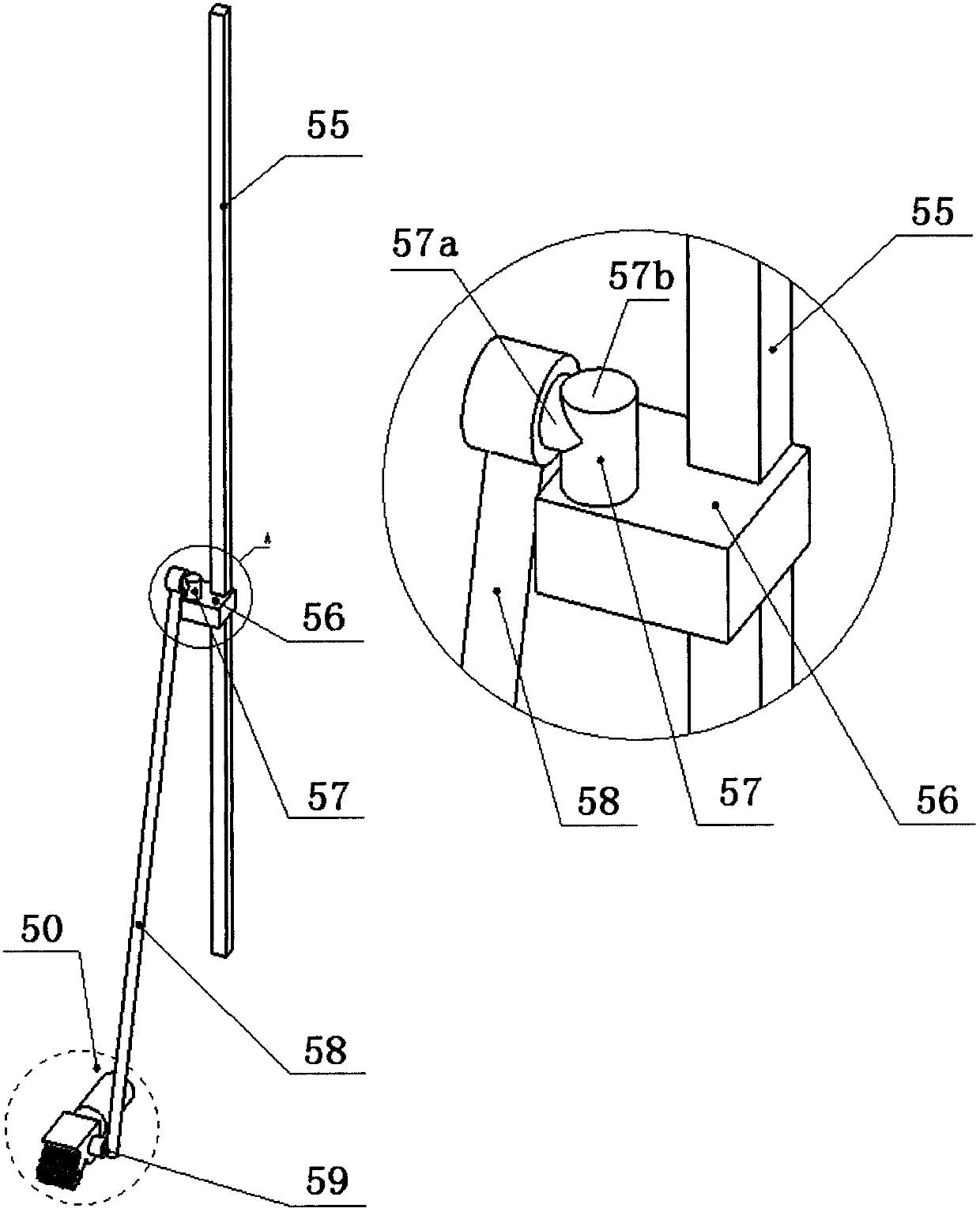

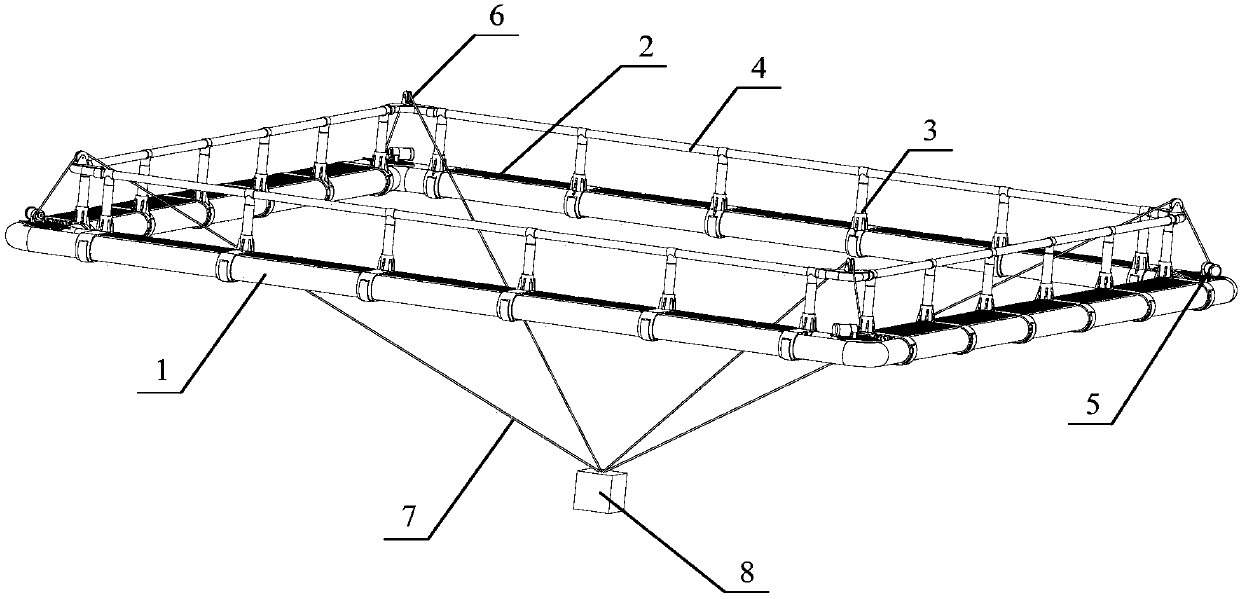

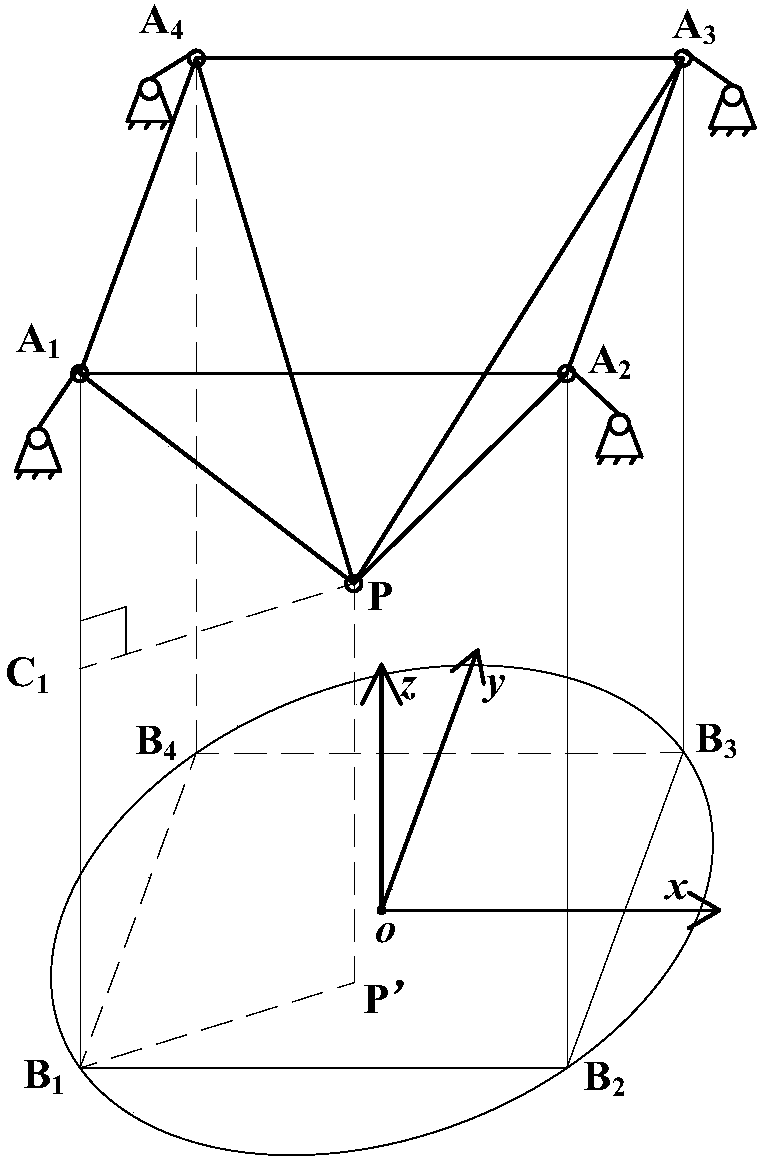

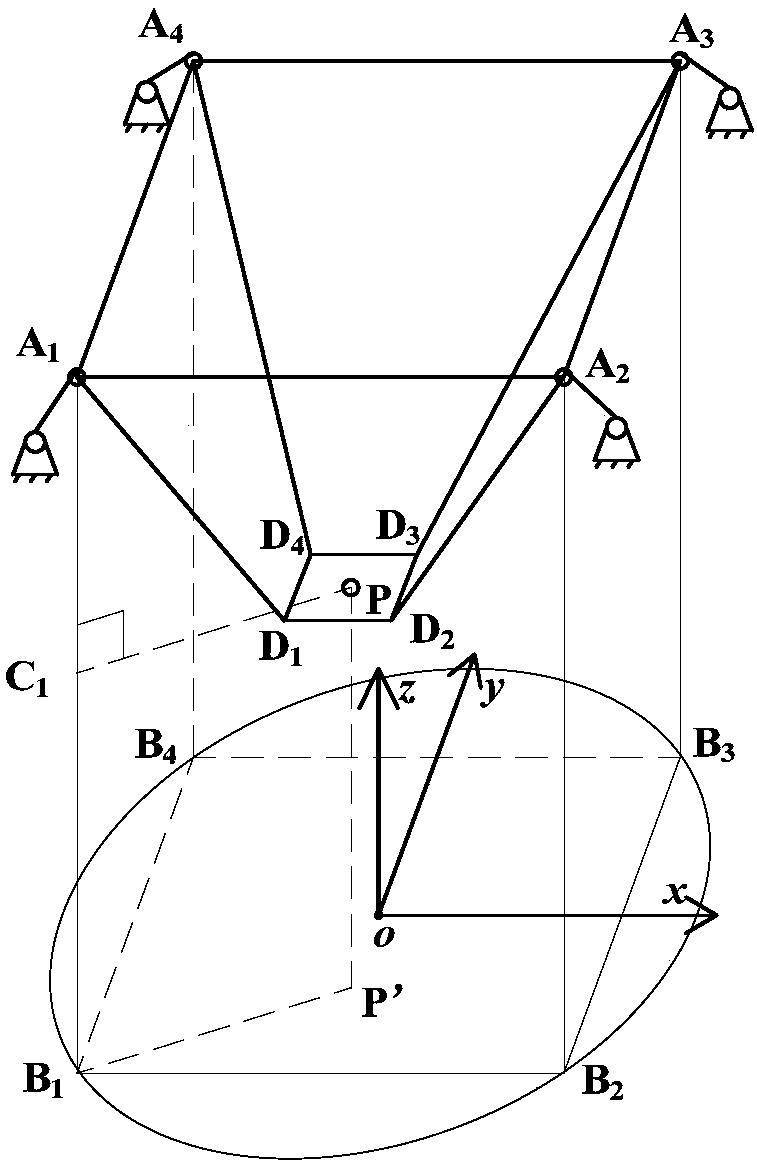

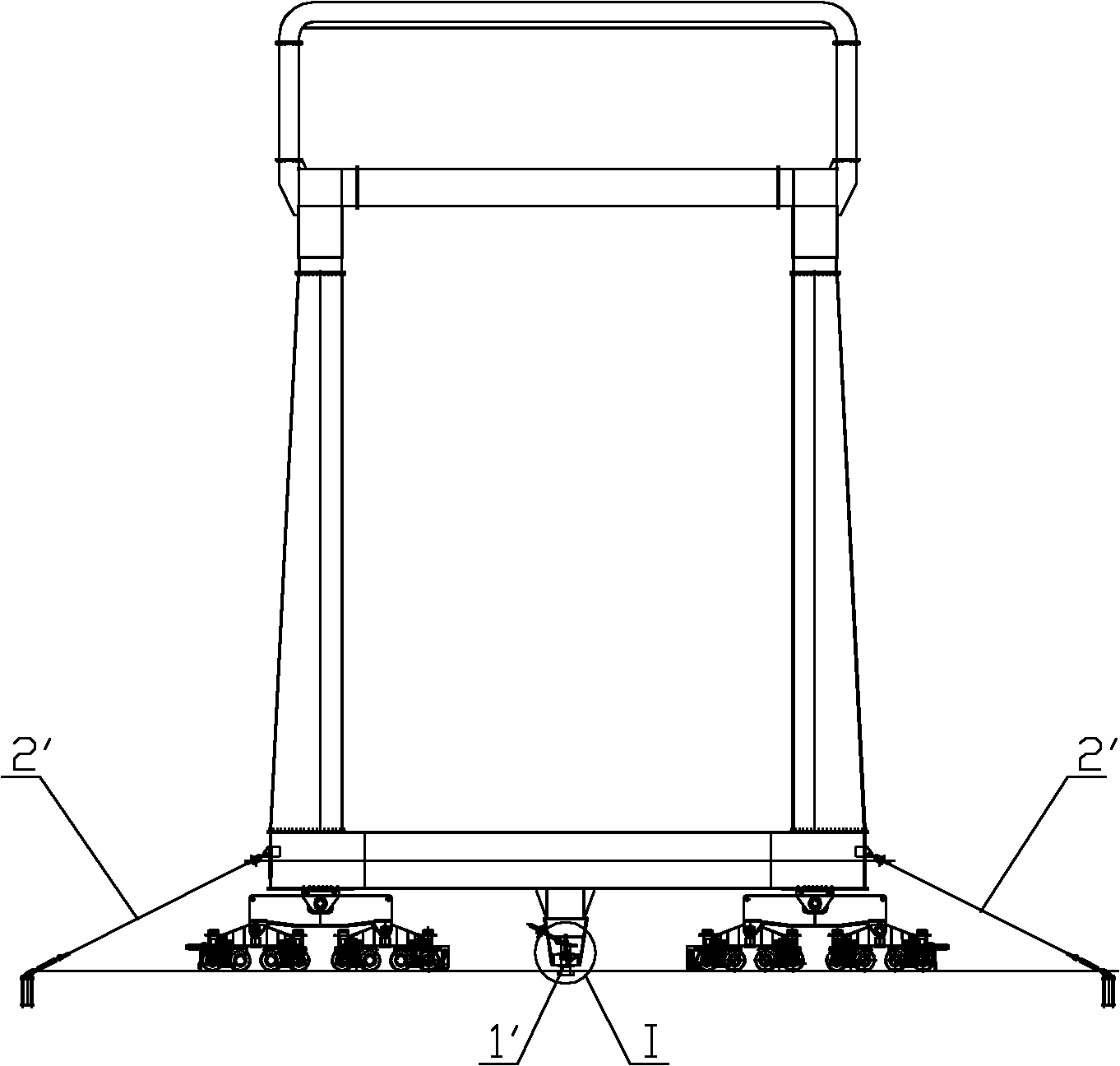

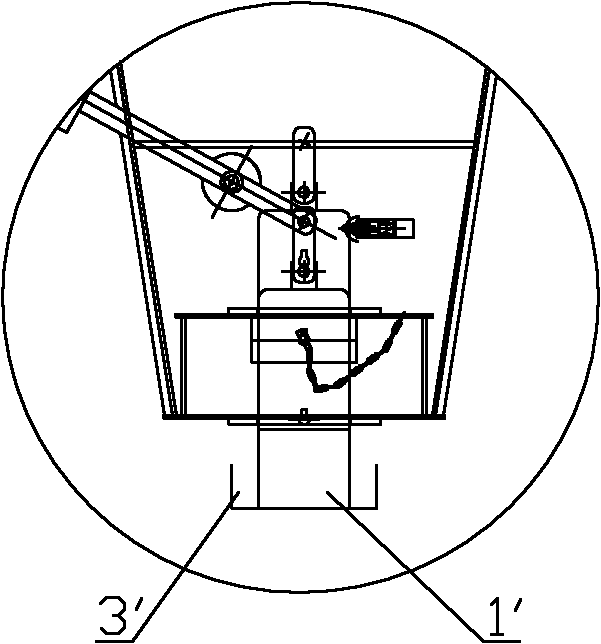

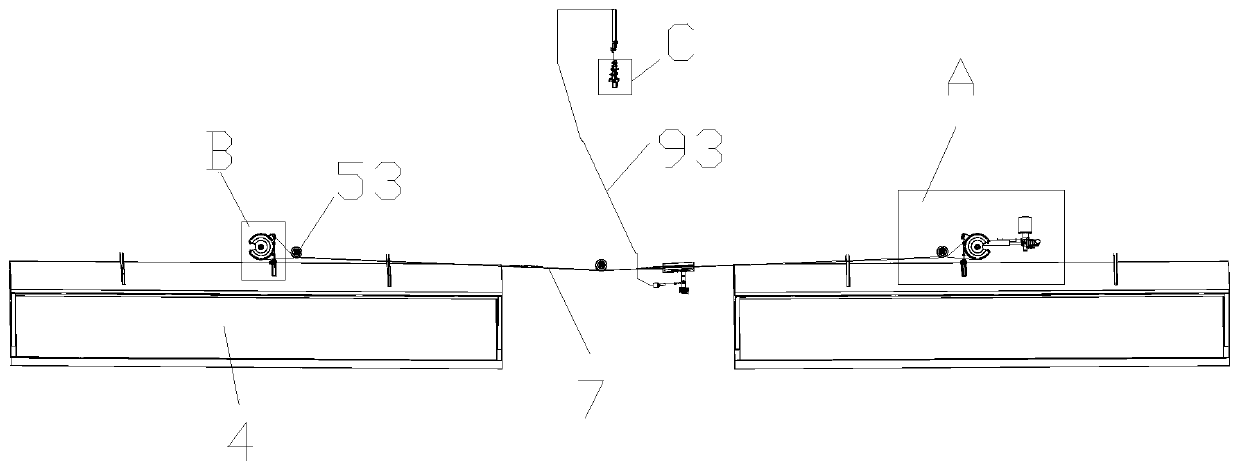

Cable parallel driving based offshore cage cleaning robot and cleaning method

PendingCN107309866AAvoid influenceReduce motion lagProgramme-controlled manipulatorHollow article cleaningUnderwaterMotion controller

The invention relates to a cable parallel driving based offshore cage cleaning robot and a cleaning method. The robot comprises a tail end cleaning mechanism, a motion controller and at least two flexible rope parallel branch chains uniformly distributed on a cage body, wherein the tail end cleaning mechanism is located in the cage, and the flexible rope parallel branch chains are connected between the cage body and the tail end cleaning mechanism; each flexible rope parallel branch chain comprises a winding motor fixed on the cage body as well as a driving cable, and the driving cable is connected to the tail end cleaning mechanism by the winding motor; the motion controller controls coordinating motion of the at least two flexible rope parallel branch chains, so that the tail end cleaning mechanism performs underwater three-dimensional motion in the cage. Underwater three-dimensional motion of the tail end cleaning mechanism is realized by means of a parallel driving manner, multiple driving cables of the tail end cleaning mechanism are mutually restrained, so that underwater stability is improved, positioning precision is improved easily, and the requirement of the offshore cage for automatic cleaning can be met.

Owner:SOUTH CHINA AGRI UNIV

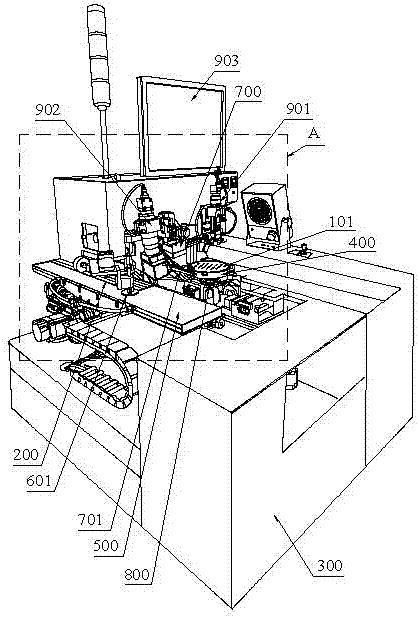

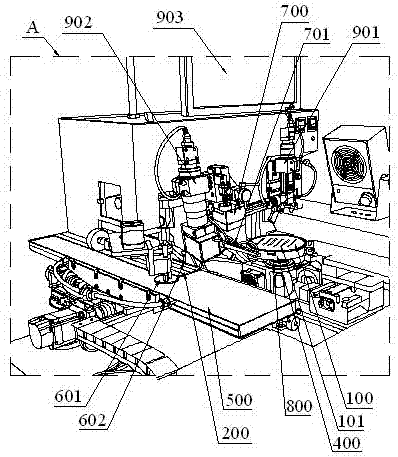

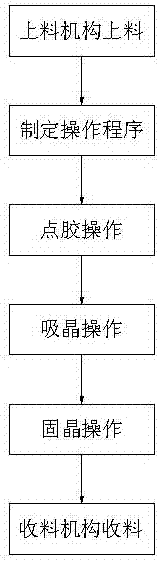

Chip mounter for CSP LEDs, and processing process for chip mounter

InactiveCN107305916AImprove production yieldImprove production and processing efficiencySemiconductor devicesAdhesiveEngineering

The invention discloses a chip mounter for CSP LEDs, and a processing process for the chip mounter. LED chips arranged and attached on a blue film in an array mode can be directly welded and fixed on a substrate; the chip mounter comprises a machine frame, a crystal adsorption table arranged on the machine frame and capable of being equipped with the blue film, a movable crystal fixing worktable arranged on the machine frame and used for bearing the substrate, and an adhesive dispensing mechanism capable of performing adhesive dispensing operation on a corresponding bonding pad of the substrate; the chip mounter further comprises a crystal adsorbing and fixing mechanism with a swing arm capable of performing vacuum adsorption on the LED chips on the blue film on the crystal adsorption table and directly welding and fixing the LED chips to the bonding pad subjected to adhesive dispensing, and an ejector mechanism capable of ejecting the LED chips to facilitate the crystal adsorbing and fixing mechanism to perform adsorption operation on the LED chips; the chip mounter further comprises an image identification control apparatus; the image identification control apparatus consists of an optical crystal adsorption apparatus and an optical crystal fixing apparatus; the chip mounter further comprises an intelligent control apparatus capable of controlling each part of the chip mounter to work; and the chip mounter further comprises a feeding mechanism and a discharging mechanism.

Owner:ZHONGSHAN HONGCHANG ELECTRIC & LIGHTING TECH

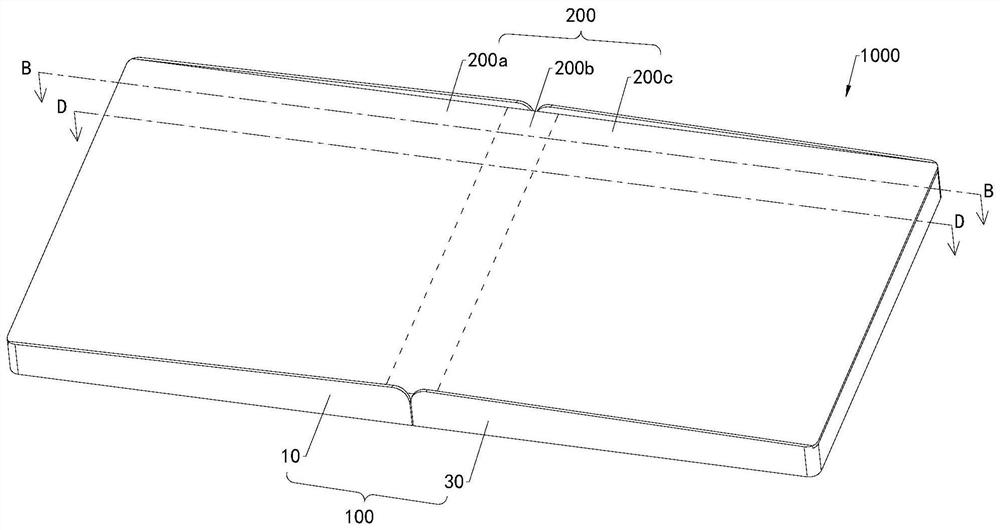

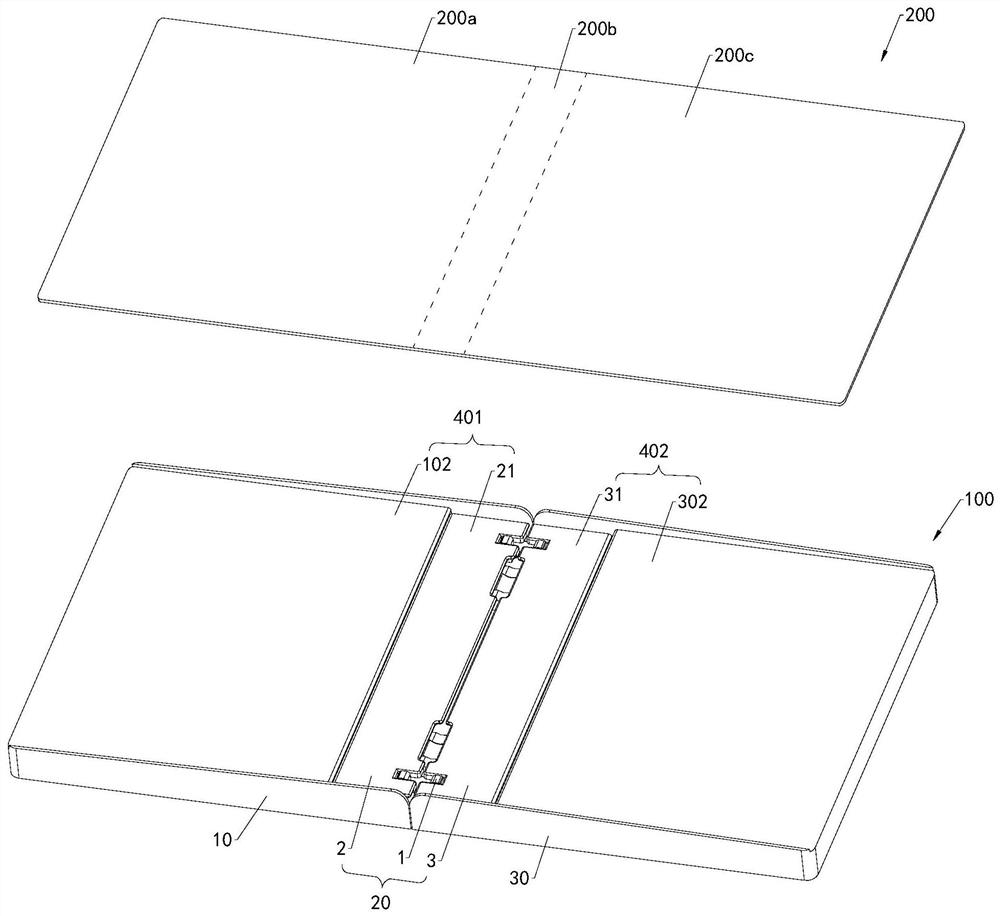

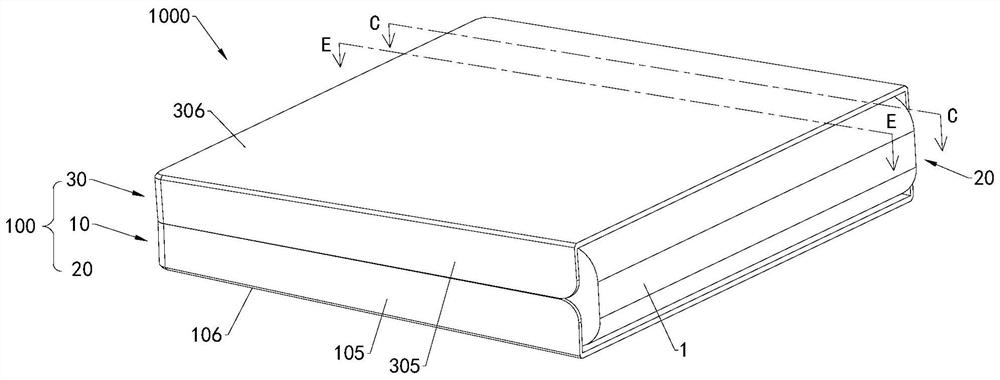

Folding device and electronic equipment

PendingCN113805646ALow costReduced parts countToothed gearingsDetails for portable computersEngineeringFlexible display

The invention discloses a folding device and electronic equipment. The folding device is used for supporting the flexible display screen and comprises a first shell, a rotating mechanism and a second shell. The rotating mechanism comprises a middle shell, a first supporting piece and a second supporting piece, one end of the first supporting piece is rotationally connected with the middle shell, the other end of the first supporting piece is fixedly connected with the first shell, the supporting face of the first supporting piece and the supporting face of the first shell are spliced to form a first supporting face, one end of the second supporting piece is rotationally connected with the middle shell, and the other end of the second supporting piece is fixedly connected with the second shell. The supporting face of the second supporting piece and the supporting face of the second shell are spliced to form a second supporting face. When the first shell and the second shell are oppositely folded to a closed state, the first supporting piece and the second supporting piece are far away from each other, and the first supporting face and the second supporting face gradually get close to each other in the direction far away from the middle shell. The number of parts of the main movement mechanism of the rotating mechanism of the folding device is small, and the control precision is high.

Owner:HUAWEI TECH CO LTD

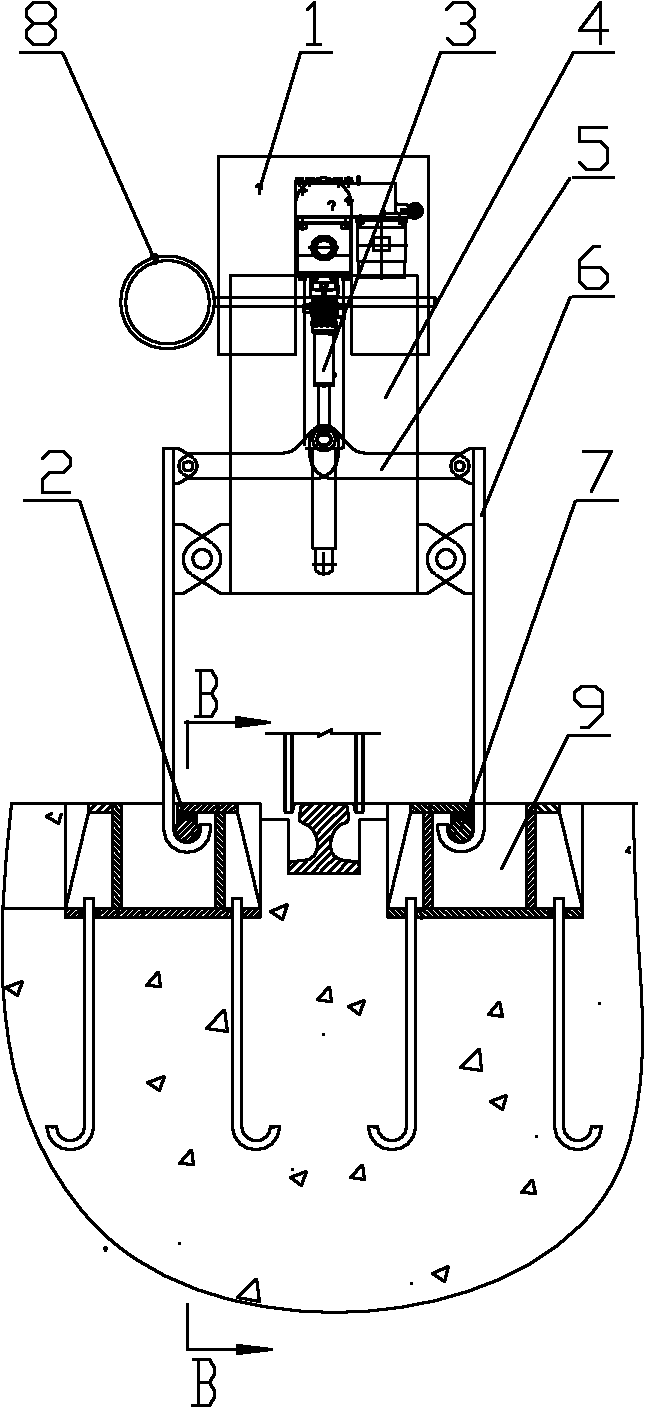

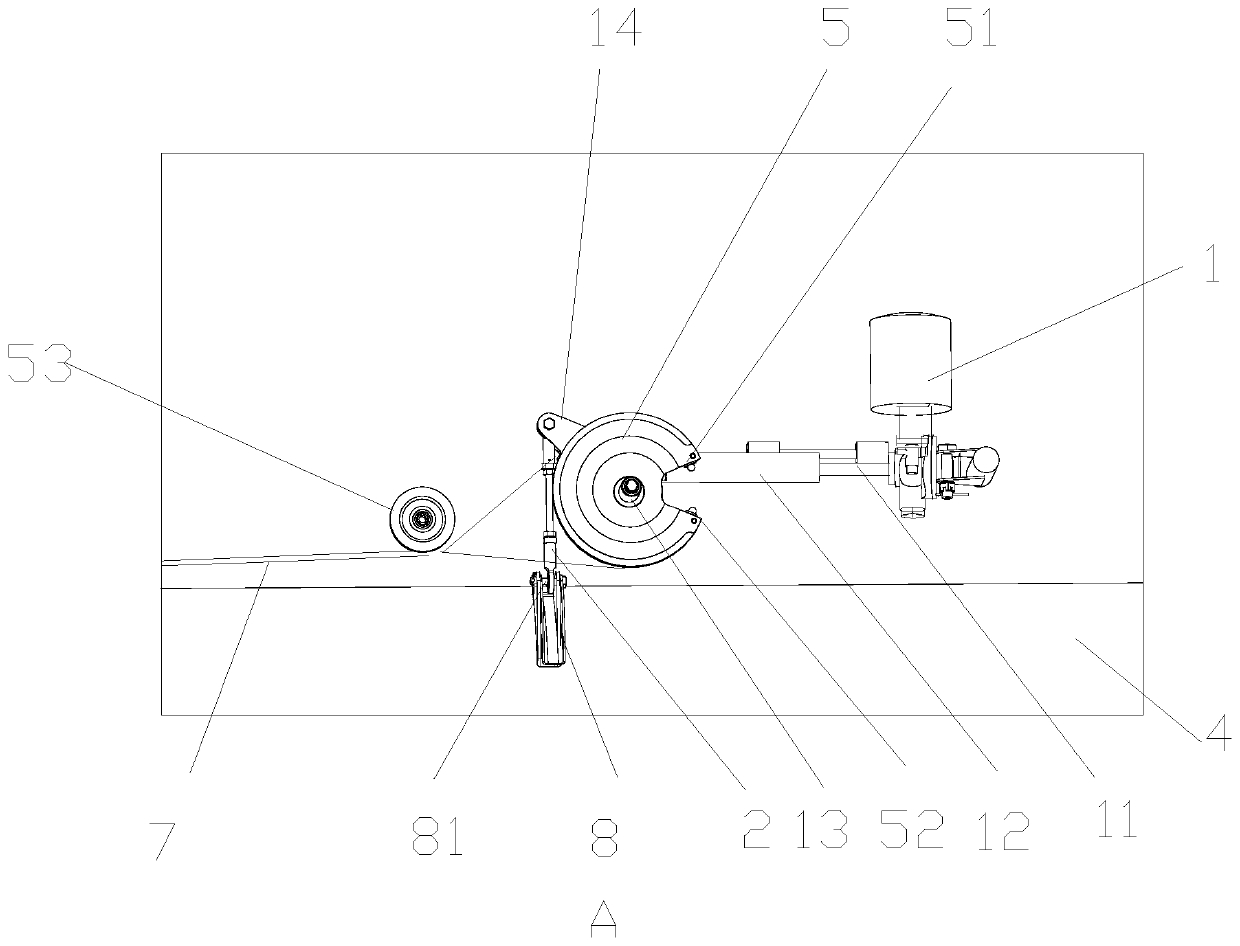

Port hoisting machinery and anchoring wind-preventing mechanism thereof

InactiveCN102311049APrevent rolloverImprove locking efficiencySafety gearEngineeringUltimate tensile strength

The invention discloses an anchoring wind-preventing mechanism of a port hoisting machinery. The anchoring wind-preventing mechanism comprises an anchoring base (1) rigidly connected with the trolley body of the port hoisting machinery, and further comprises an anchoring hook claw (6) disposed on the anchoring base (1) and a driving device capable of driving the anchoring hook claw (6) to hook or loose a positioning pillar (7) in an anchoring pit (9); the anchoring wind-preventing mechanism further comprises a locking member for locking or unlocking the working position of the anchoring hook claw (6). The anchoring wind-preventing mechanism integrates the anchoring function and the wind-preventing function into one, and realizes the anchoring and the wind-preventing functions of the engineering machinery simultaneously, thus the structure is simplified and the working reliability is relatively high; moreover, the mechanism can reduce the labour intensity of the operation staff, realize the quick-locking and improve the efficiency of locking the engineering machinery; and besides, the invention further discloses a port hoisting machinery including said anchoring wind-preventing mechanism.

Owner:SANY GRP

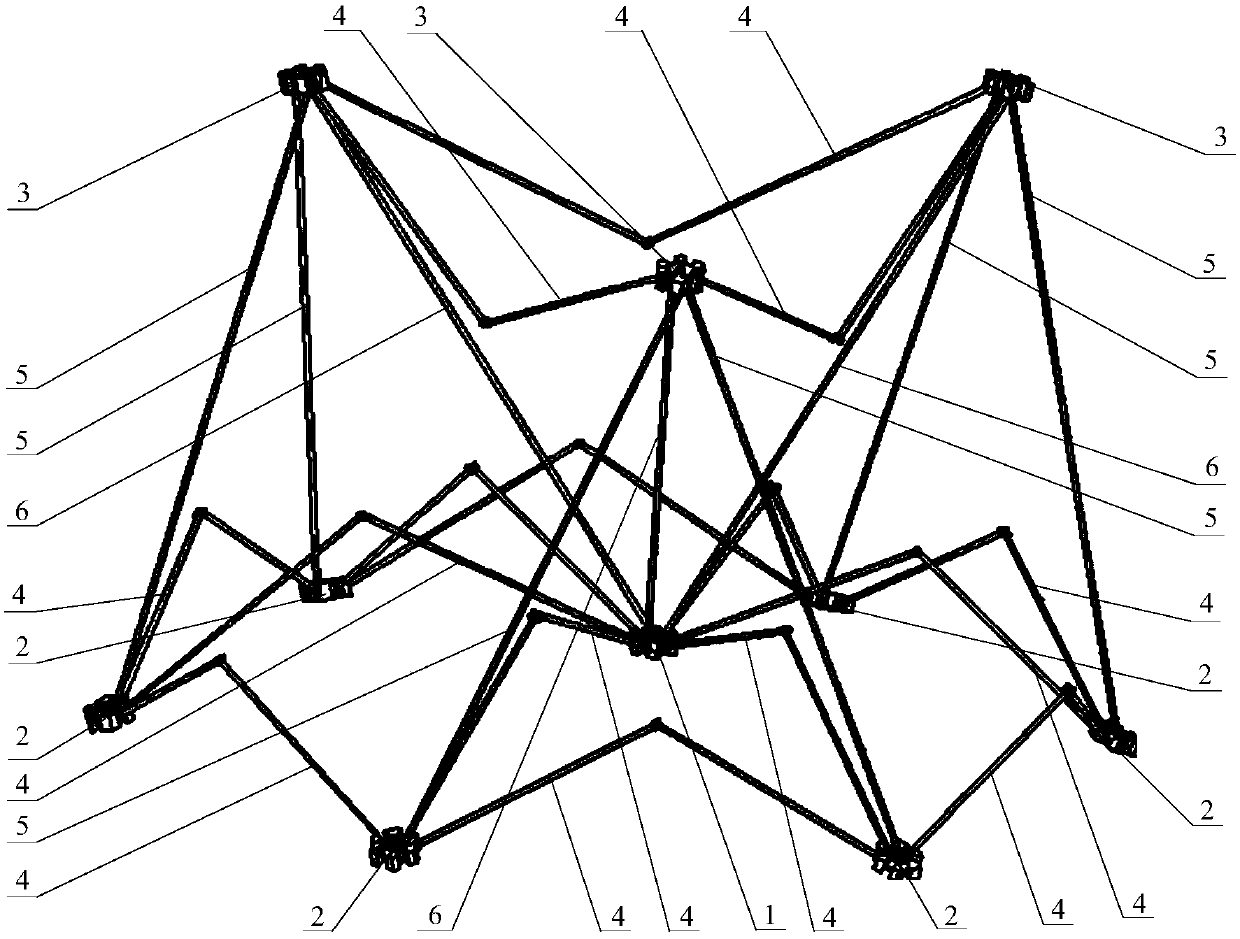

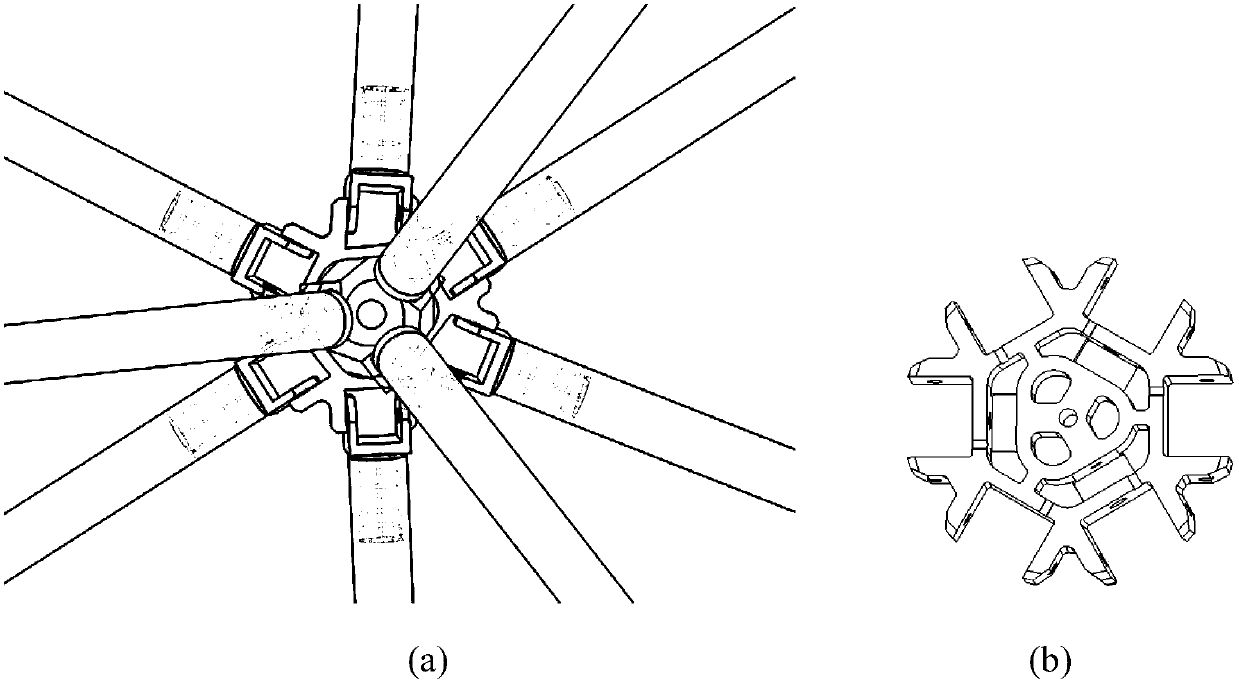

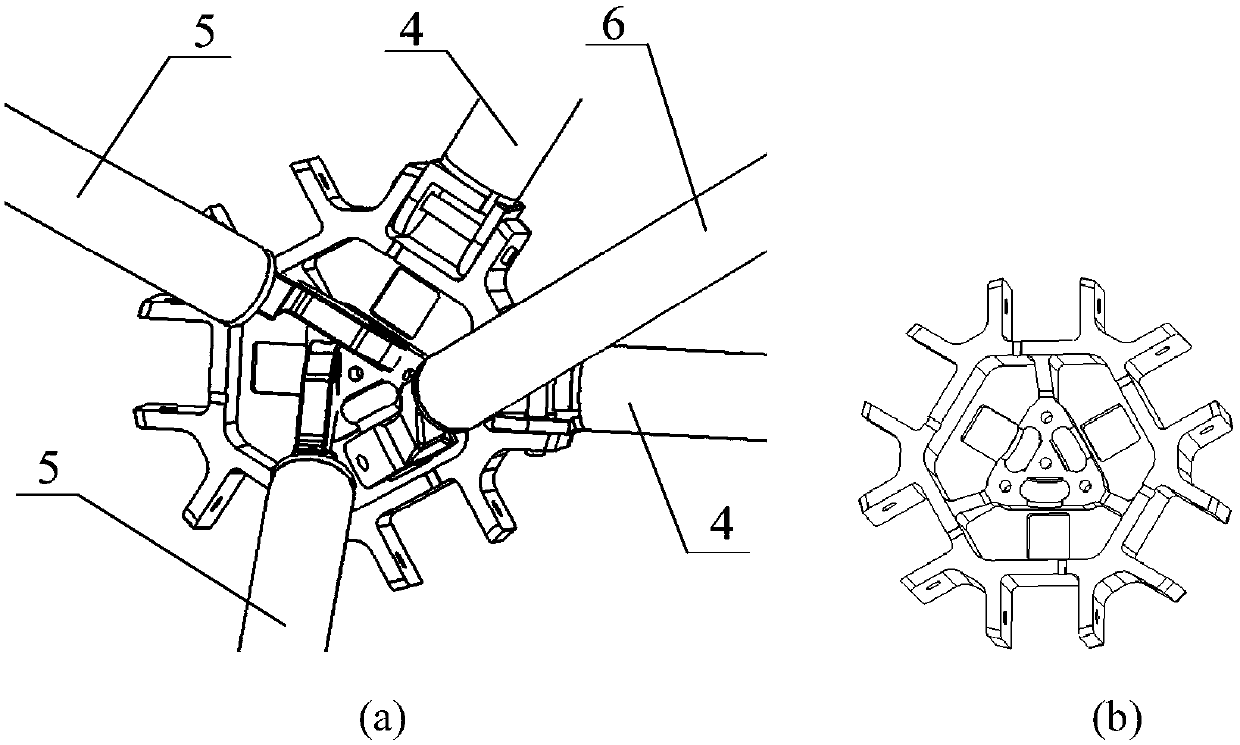

Expandable combined unit and large-space expandable mechanism with same

ActiveCN107685880ASimple structureSingle formCosmonautic vehiclesCosmonautic partsBiomedical engineeringEngineering

Owner:XIAN INSTITUE OF SPACE RADIO TECH

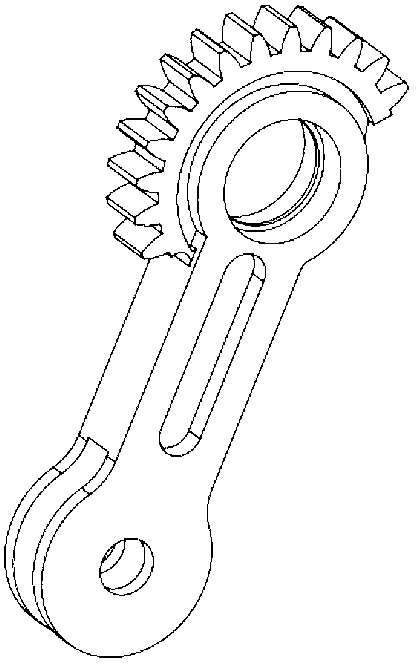

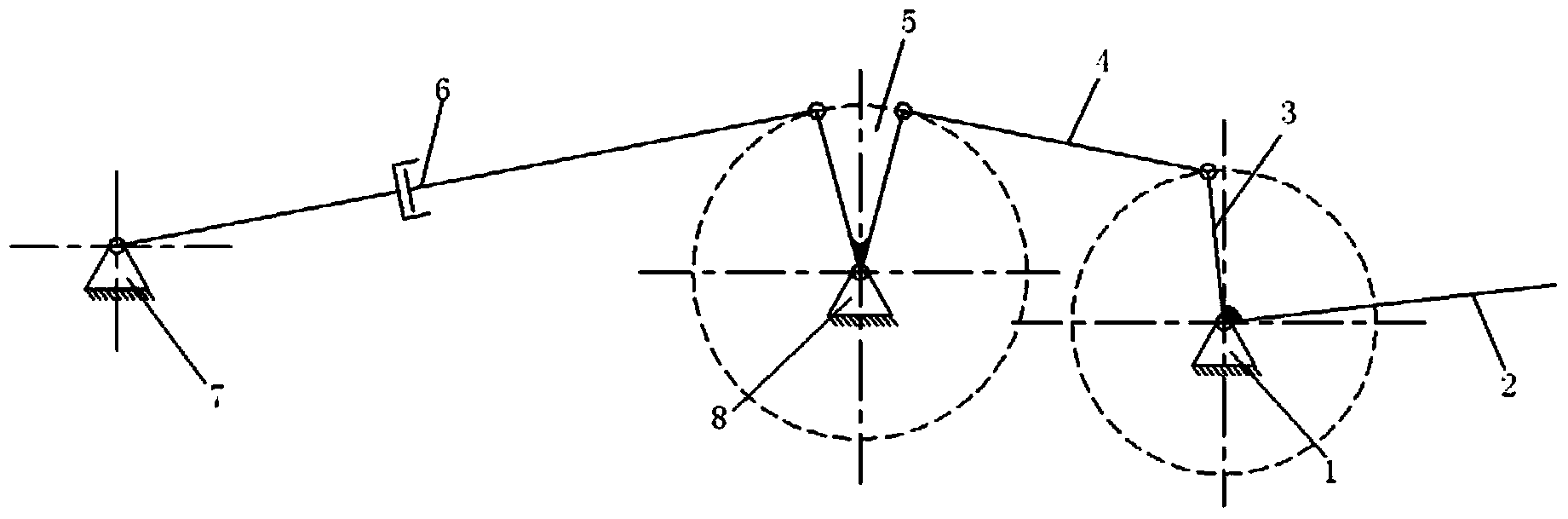

Robot bouncing mechanism based on hydraulic drive

The invention discloses a robot bouncing mechanism based on hydraulic drive. A hydraulic cylinder pushes a bilateral rack to drive the center of gravity of a five-rod mechanism which is composed of a belt tooth connecting rod, a second connecting rod and a third connecting rod to move downwards, an spring is stretched to store elastic potential energy at the same time, oil return of the hydraulic cylinder is controlled, the spring is released instantly to drive the whole mechanism to bounce, and the movement reliability is high. By means of the bouncing mechanism, the linear force of the spring is converted into non-linear bounce motive power, and more energy is stored under the condition of the same displacement. The bouncing mechanism takes advantage of hydraulic drive, the hydraulic cylinder is mounted on a drive joint directly, the use of a reducer is avoided, and the structure of a robot is simplified. The obstacle climbing ability and the activity range of the robot are improved notably if the bouncing mechanism is combined with a moving mode. According the bouncing mechanism, movement and power are transmitted in the mode that the rack is meshed with a gear, and thus the robot bouncing mechanism based on hydraulic drive has the advantages of being reliable in operation, long in service life, compact in structure, high in transmission precision and large in transmission power.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

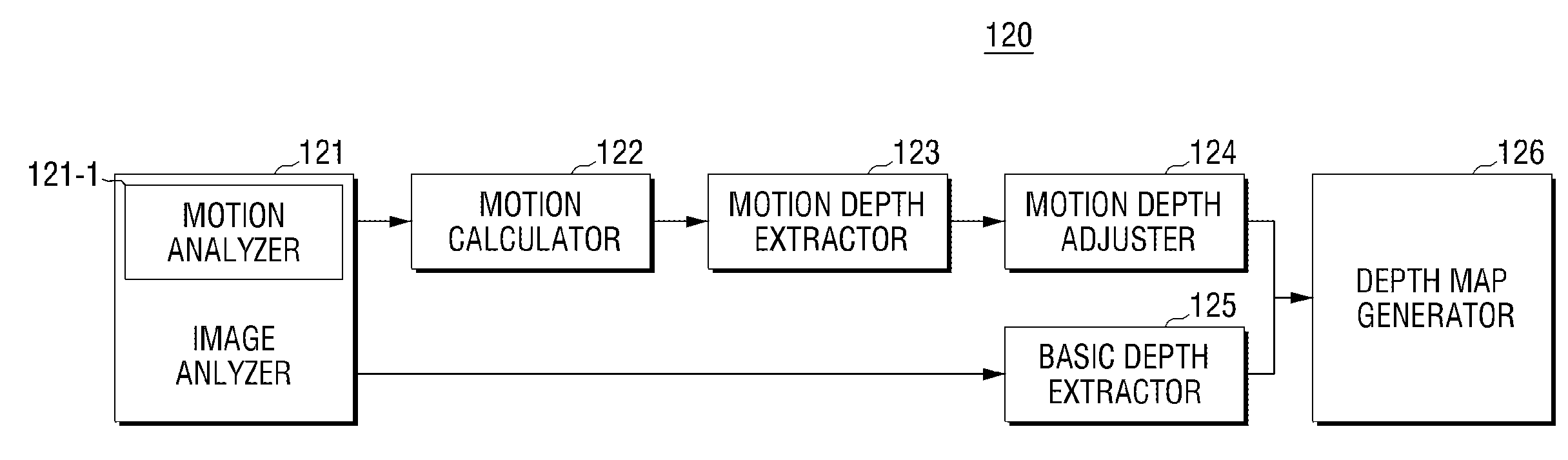

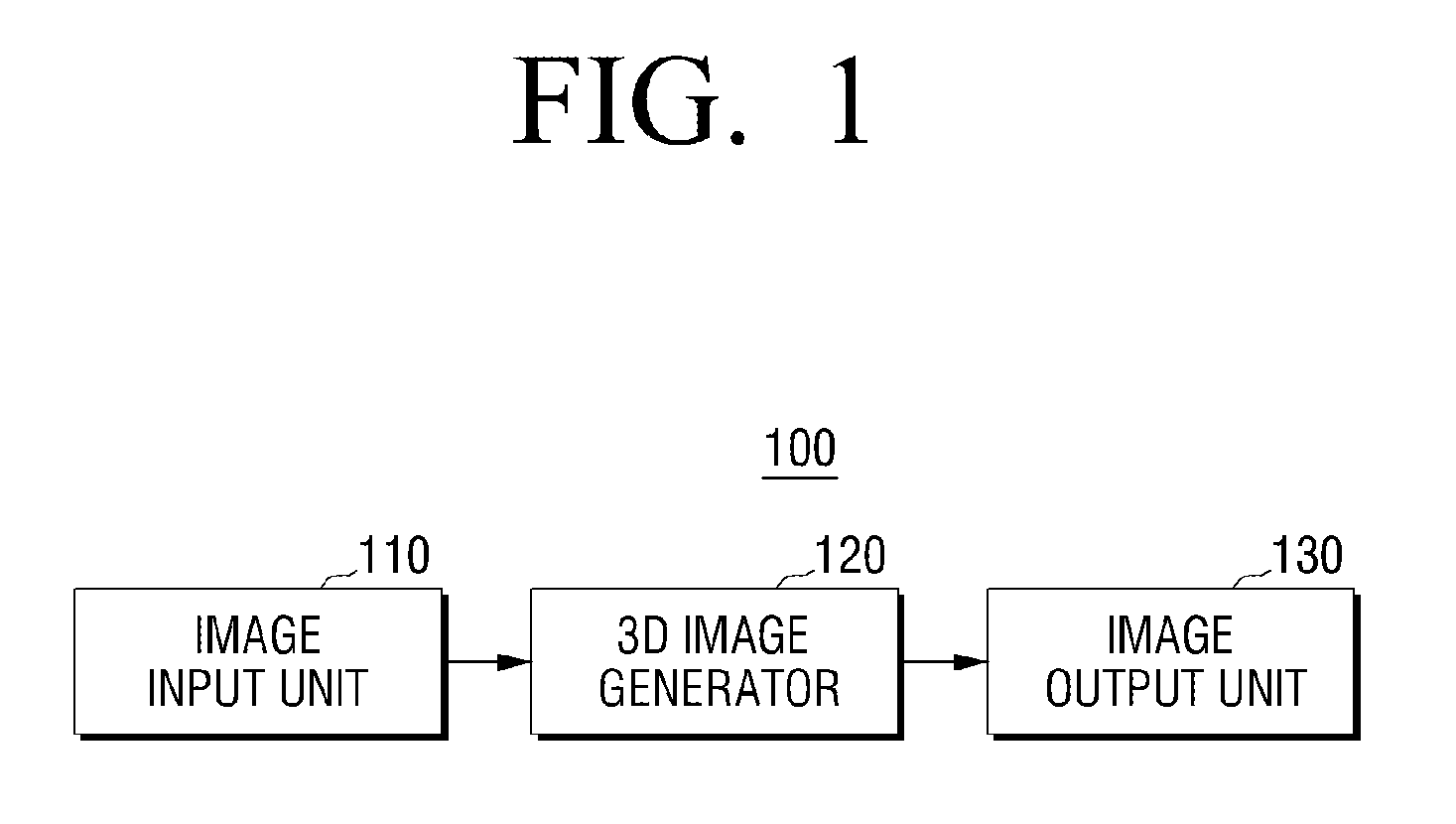

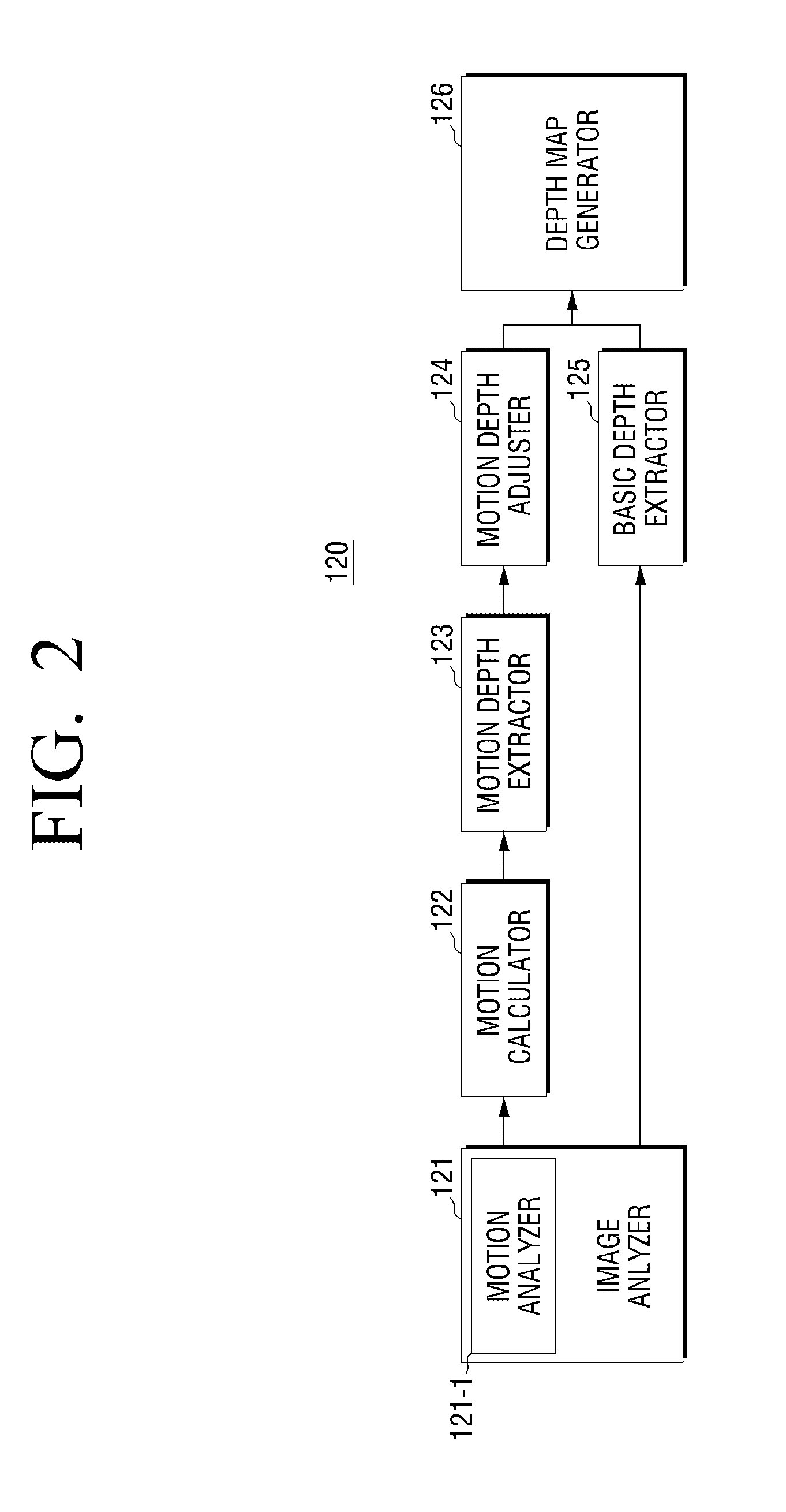

3D display apparatus and method for extracting depth of 3D image thereof

InactiveUS20120121163A1Low reliabilityImprove reliabilityTelevision system detailsCharacter and pattern recognitionComputer graphics (images)3d image

A three-dimensional (3D) display apparatus and a method for extracting a depth of a 3D image of the 3D display apparatus are provided. The 3D display apparatus includes: an image input unit which receives an image; a 3D image generator which generates a 3D image of which a depth is adjusted according to a relative motion between global and local motions of the image; and an image output unit which outputs the 3D image.

Owner:SAMSUNG ELECTRONICS CO LTD

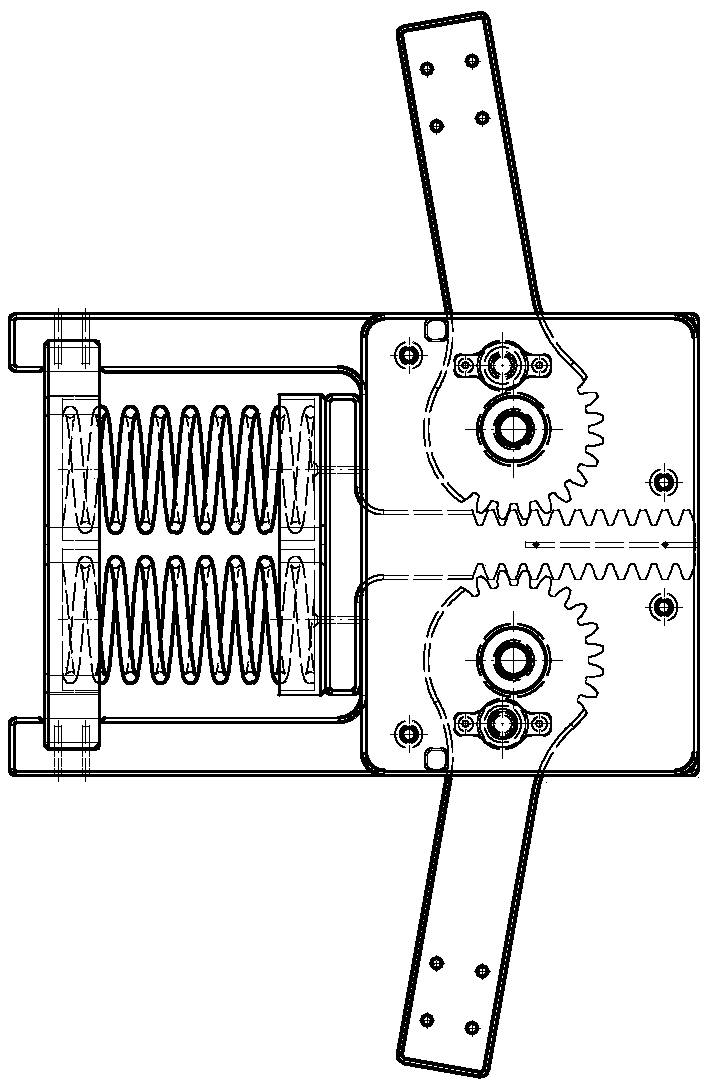

Patrol missile folding wing mechanism

ActiveCN109631686AGood transmission synchronizationReduce contact gapProjectilesSurface mountingLocking mechanism

The invention discloses a patrol missile folding wing mechanism. The patrol missile folding wing mechanism comprises gears, racks, a bottom fixing plate, an upper clamping plate, a spring unit, an unfold locking mechanism and a fold locking mechanism. The bottom fixing plate is fixed to the top of a missile body. Strip guide grooves are formed in the upper surface of the bottom fixing plate. The strip guide grooves are parallel to the axial line of the missile body. Upper and lower rotating shafts of each gear are separately inserted in inner rings of two bearings. The outer rings of the two bearings are separately inserted in holes of the upper clamping plate and the bottom fixing plate. The racks are straight plate components with engaging teeth on two sides. The engaging teeth on two sides are engaged with the two gears. The rear ends of the racks are connected with the spring unit. The spring unit is fixed onto the bottom fixing plate. Positioning pins are mounted on the lower surfaces of the racks. The positioning pins slide along the guide grooves. The upper clamping plate is fixed to the bottom fixing plate by a connecting component. Moving reliability is high, the unfoldingprocess is stable, and unfolding and locking of the folding mechanism can be achieved.

Owner:CAIHONG DRONE TECH CO LTD

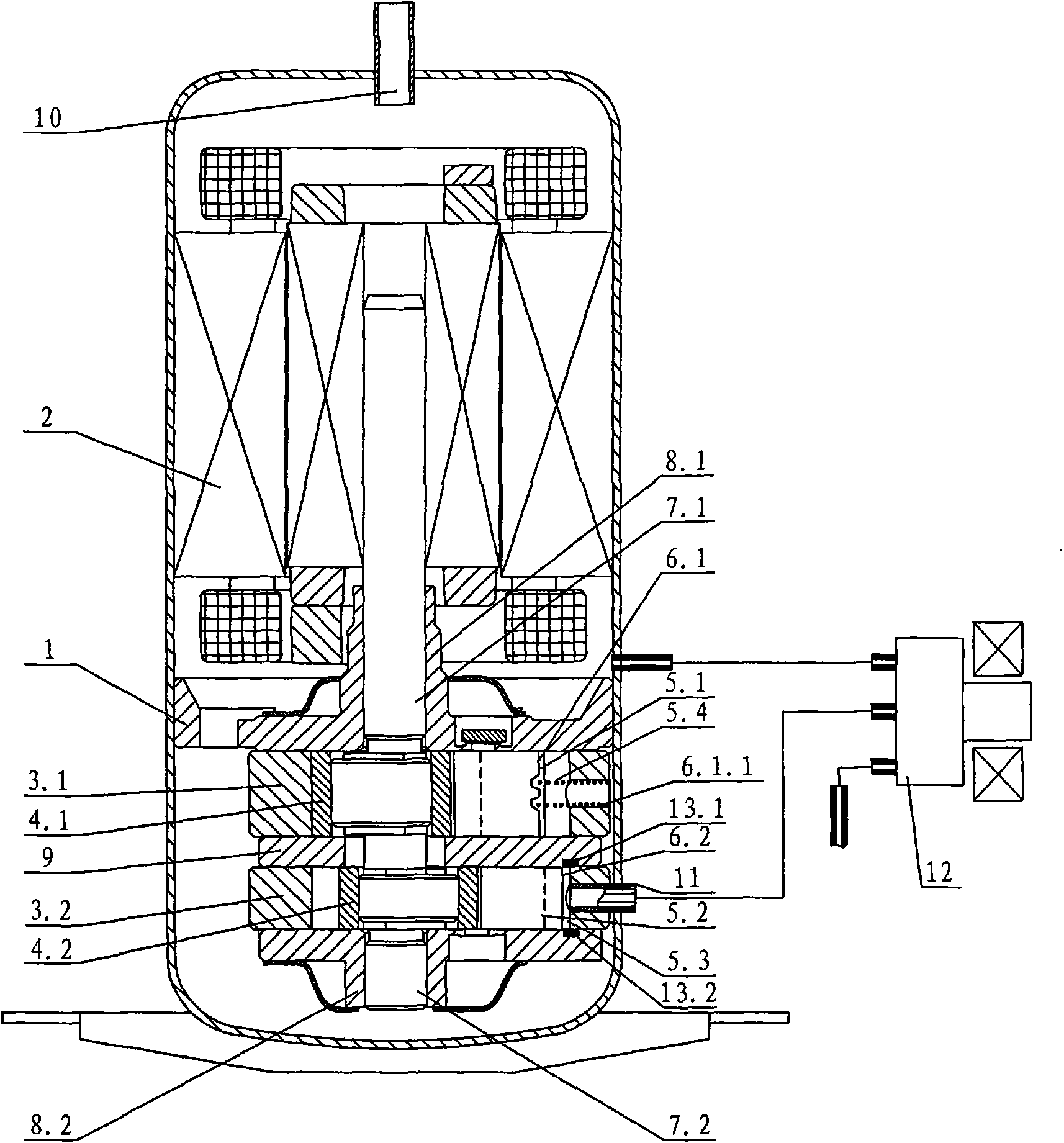

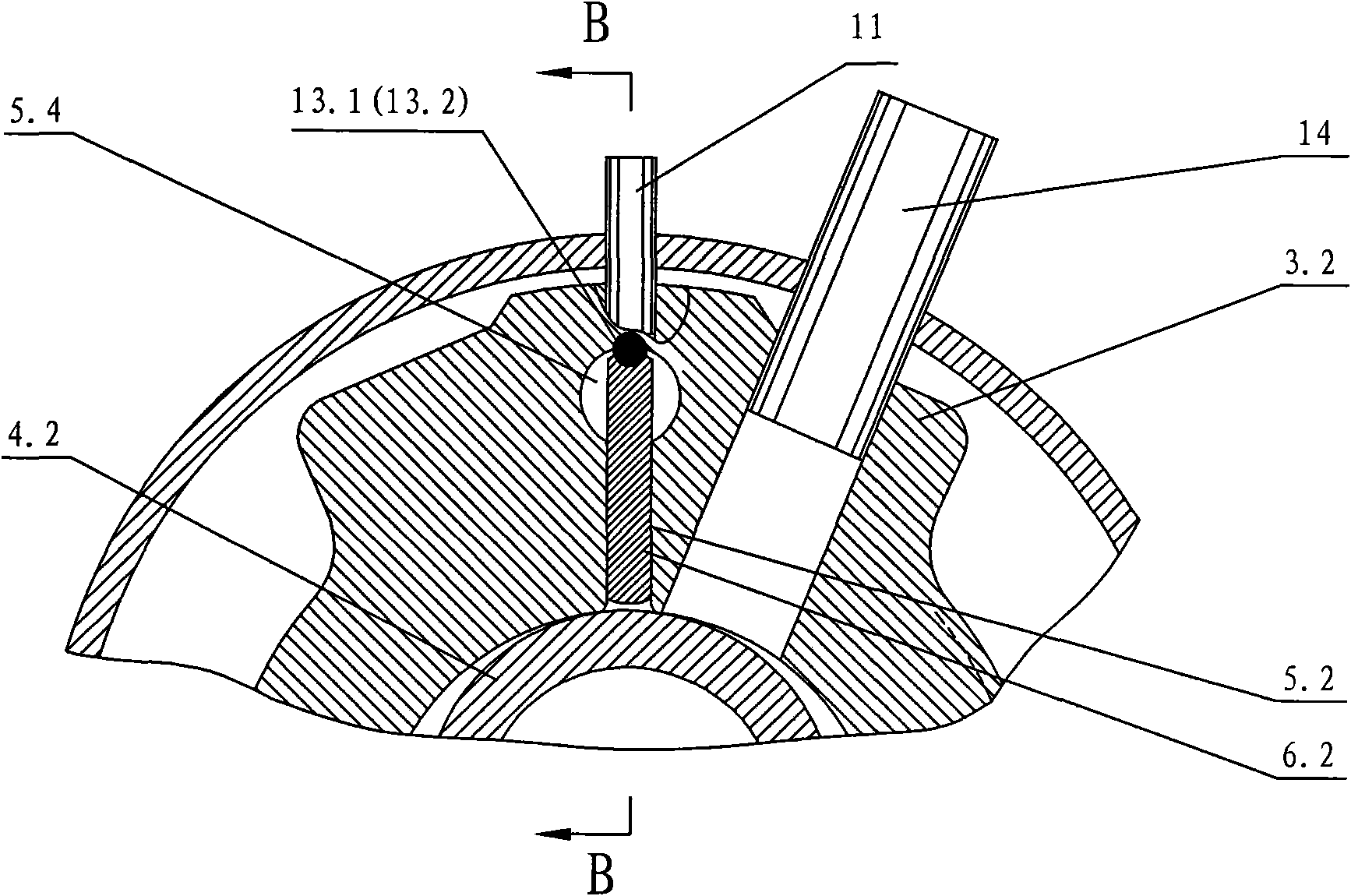

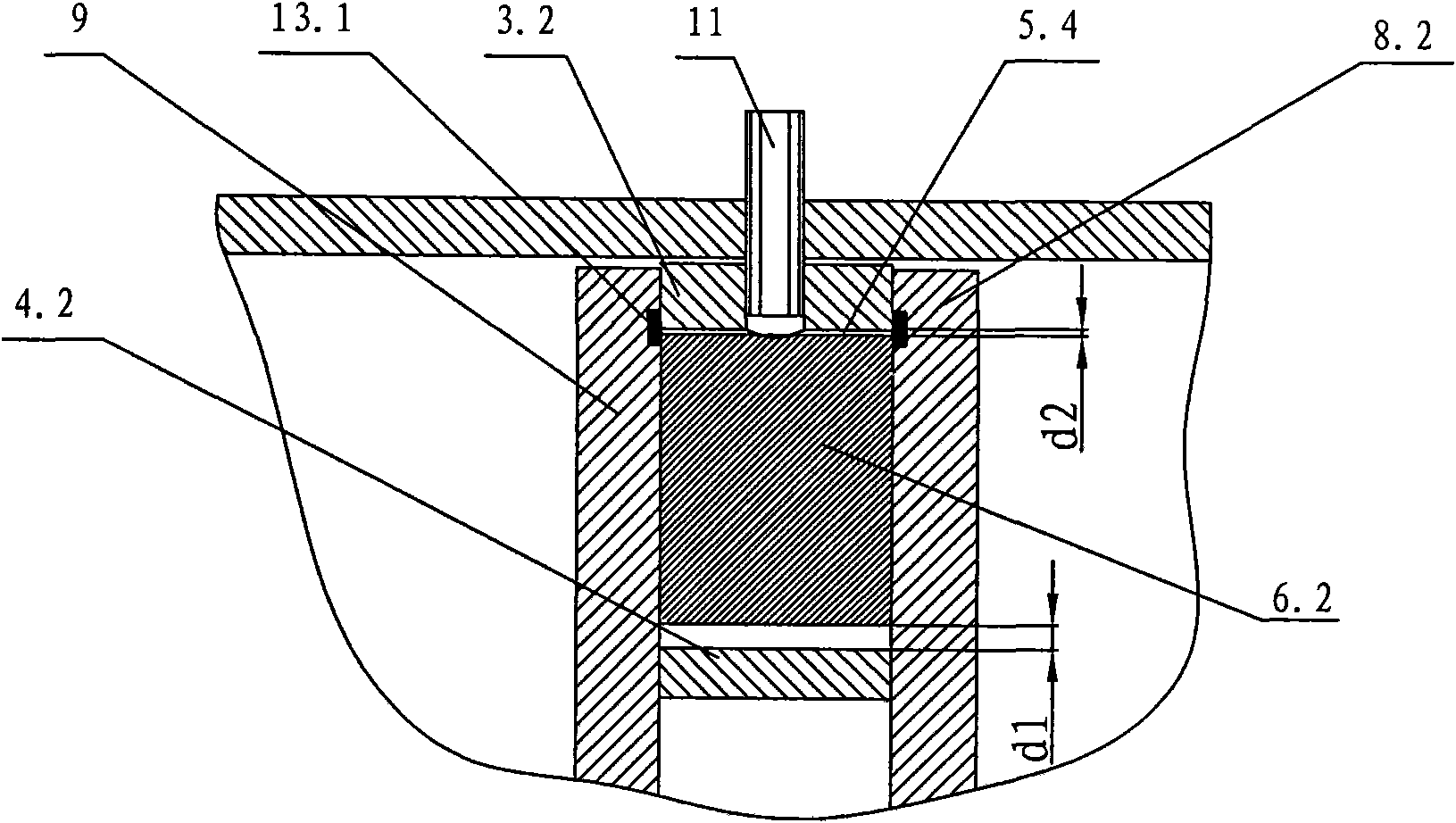

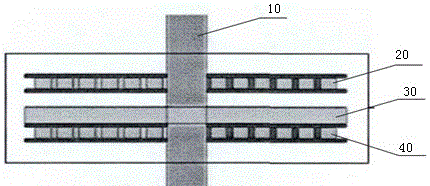

Slip sheet control device of rotary compressor

ActiveCN101624986AImprove controlHigh movement reliabilityRotary/oscillating piston combinations for elastic fluidsMachines/enginesPressure transmissionSlip sheet

The invention discloses a slip sheet control device of a rotary compressor, comprising a compression assembly and a motor assembly which are arranged in a sealing housing, wherein the compression assembly comprises a first cylinder, a second cylinder, an eccentric crank shaft, an upper bearing, a lower bearing and a middle clapboard arranged between the first cylinder and the second cylinder; the upper bearing and the lower bearing support the eccentric crank shaft; a first piston, a second piston, a first slip sheet slot and a second slip sheet slot are respectively arranged in each cylinder; a fist slip sheet and a compression spring are arranged in the first slip slot, a second slip sheet is arranged in the second slip sheet slot, and the second slip sheet slot is communicated with a slip sheet cavity which is communicated with a pressure transmission tube; a magnet absorbing and braking the second slip sheet is arranged on the bearing or the middle clapboard in the slip sheet cavity at the back of the second slip sheet; the back of the second slip sheet is provided with a small head which moves in the same direction with the second slip sheet and improves the movement reliability thereof, and one side of the small head, which faces to the magnet, is provided with a clearance space. The invention has the characteristics of reliable performance, high safety degree and long service life.

Owner:GUANGDONG MEIZHI COMPRESSOR

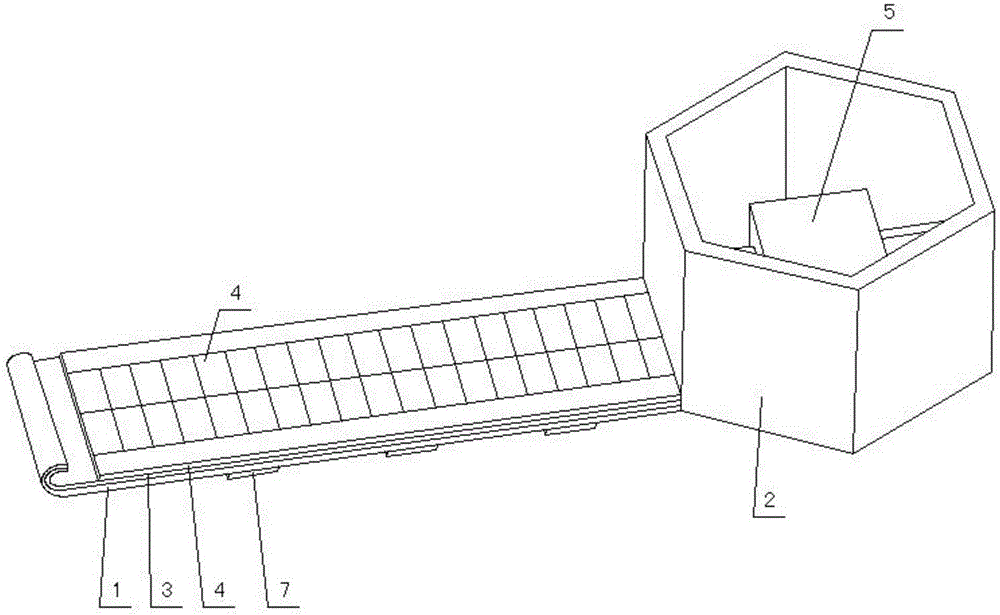

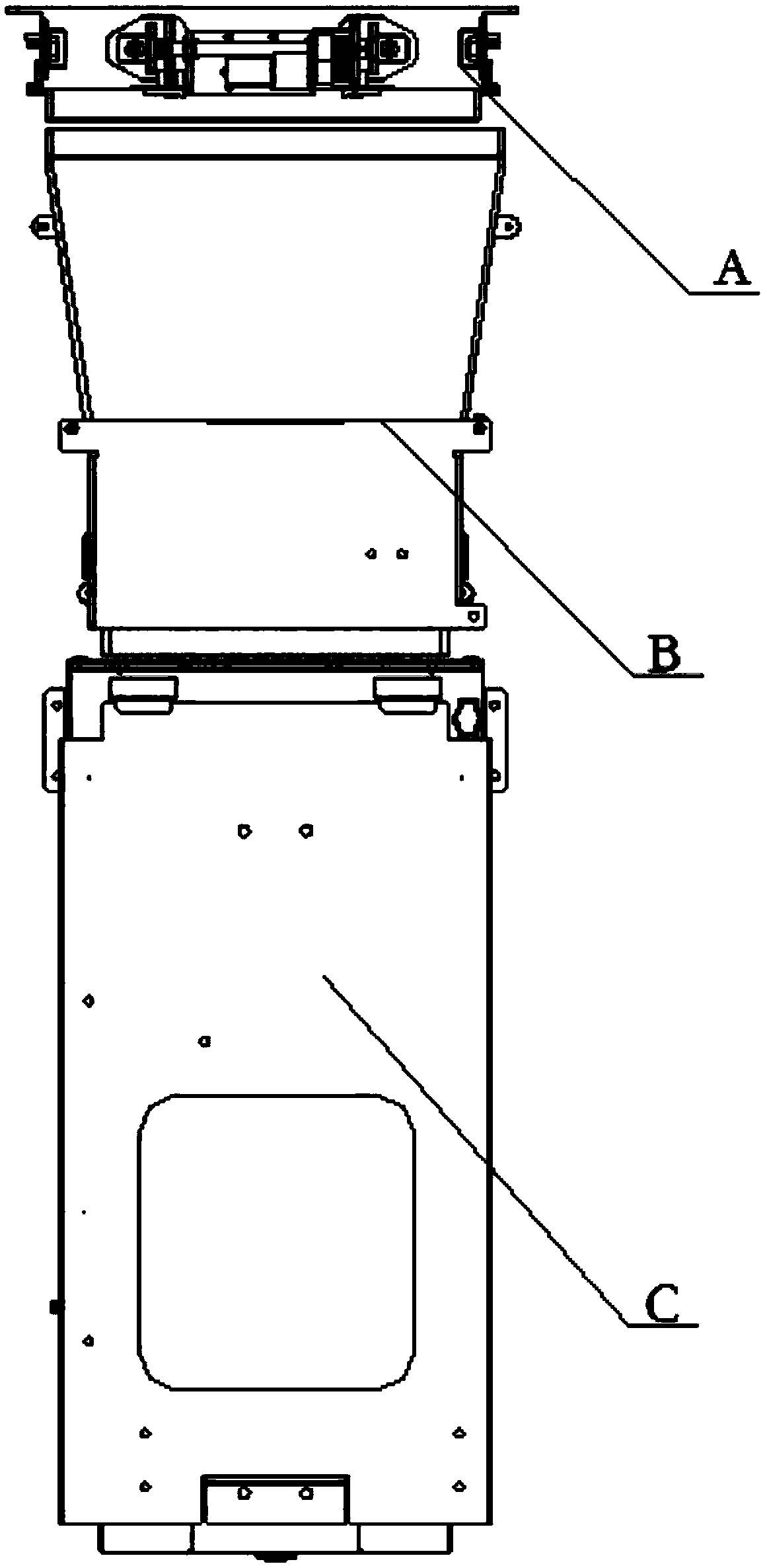

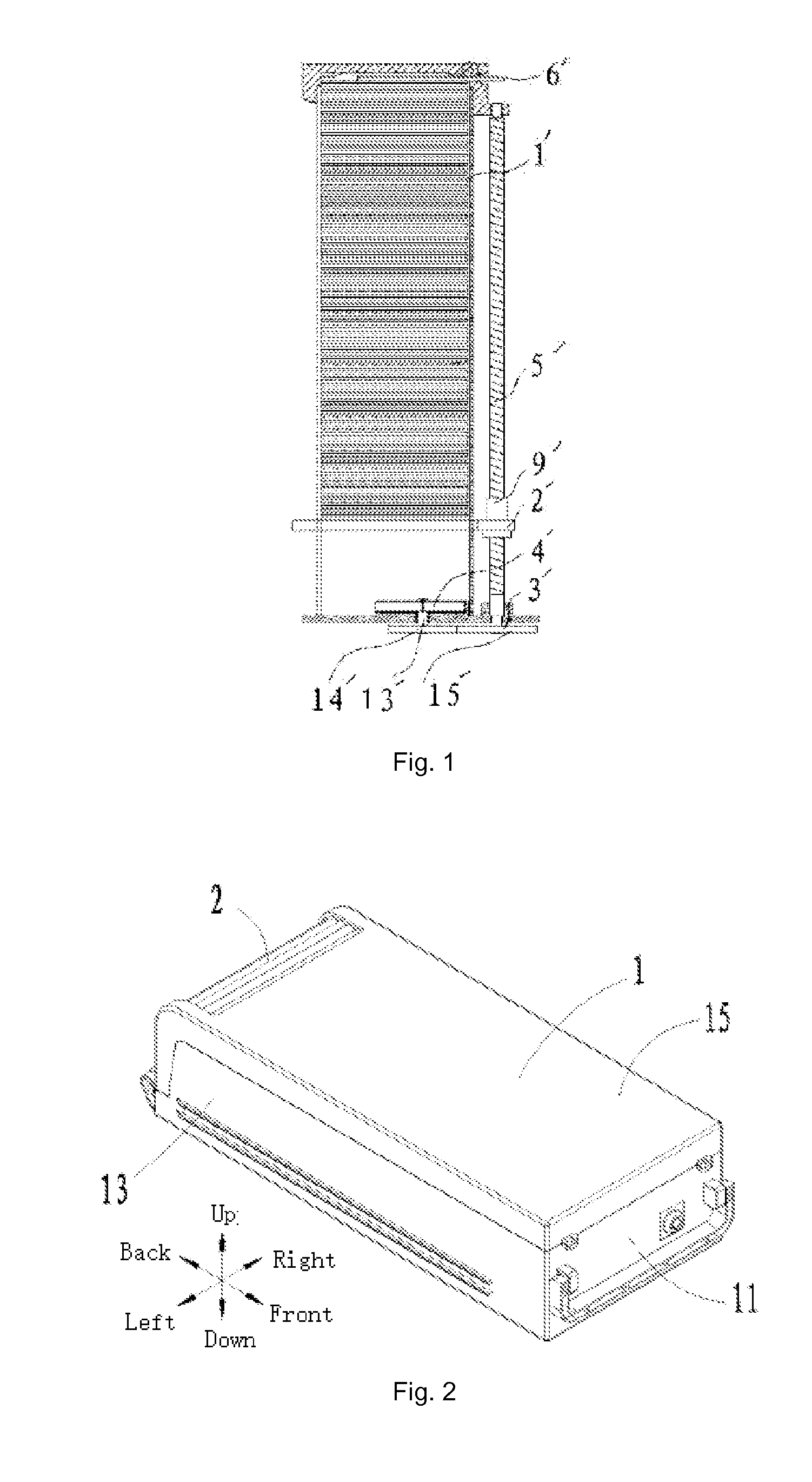

Flexible solar cell array based on shape memory polymer composite material and expansion method of flexible solar cell array

InactiveCN105207577AOvercoming complexityOvercome stabilityPV power plantsPhotovoltaic energy generationEngineeringSolar cell

The invention provides a flexible solar cell array based on a shape memory polymer composite material and an expansion method of the flexible solar cell array, belongs to the field of space solar cells, and aims to solve the problems that an expansion control process is not stable enough, the reliability is poor, and a flexible solar cell array film expansion driving technology is not mature enough in the prior art. The flexible solar cell array based on the shape memory polymer composite material comprises a group of flexible solar cell units; one end of each flexible solar cell unit support frame (1) is fixed to a power supply body (2), and a heating layer (3) and a flexible solar cell array veneer (4) are sequentially adhered to one side of the support frame (1); a power source (5) is used for providing energy to the heating layers (3). According to the expansion method of the flexible solar cell array based on the shape memory polymer composite material, the heating layers (3) are used for rising the temperature to soften a vertical structure to enable the flexible solar cell array to be in an expanded state. The flexible solar cell array and the expansion method thereof have the advantages of being stable in movement and high in reliability.

Owner:HARBIN INST OF TECH

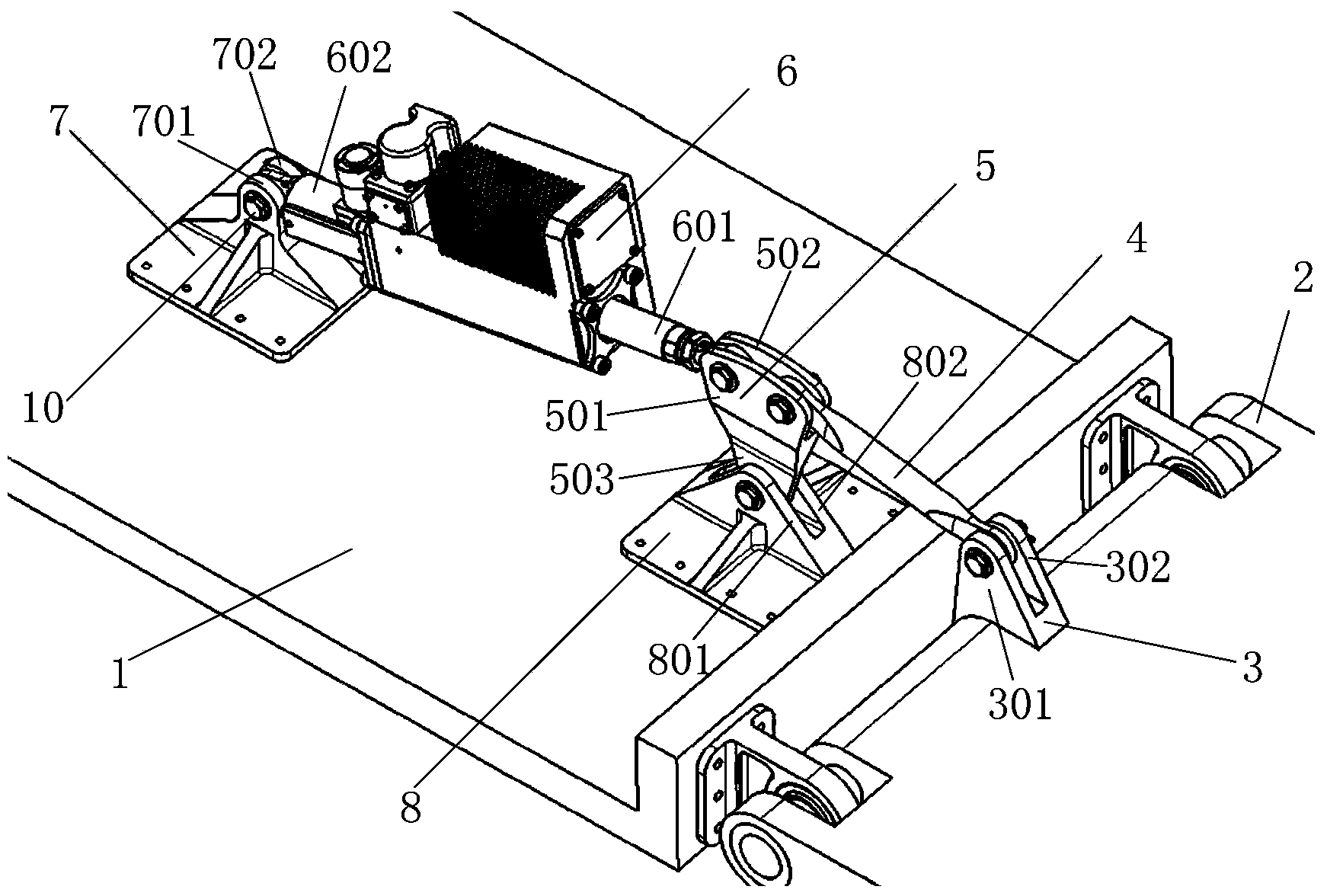

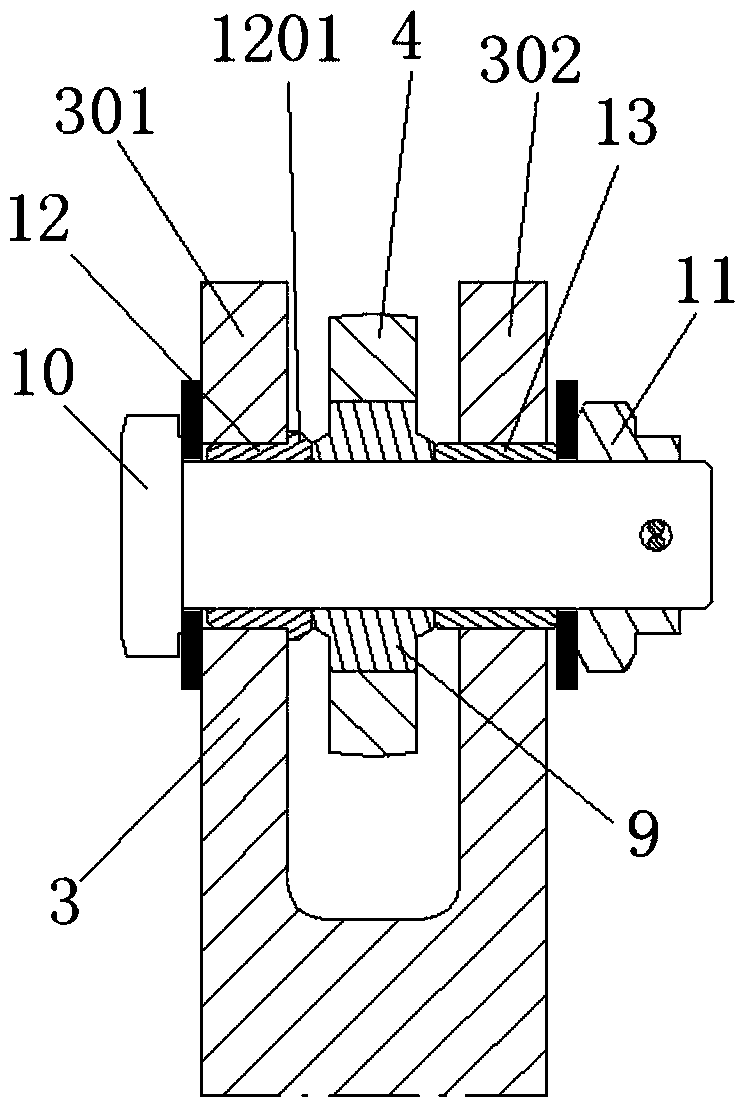

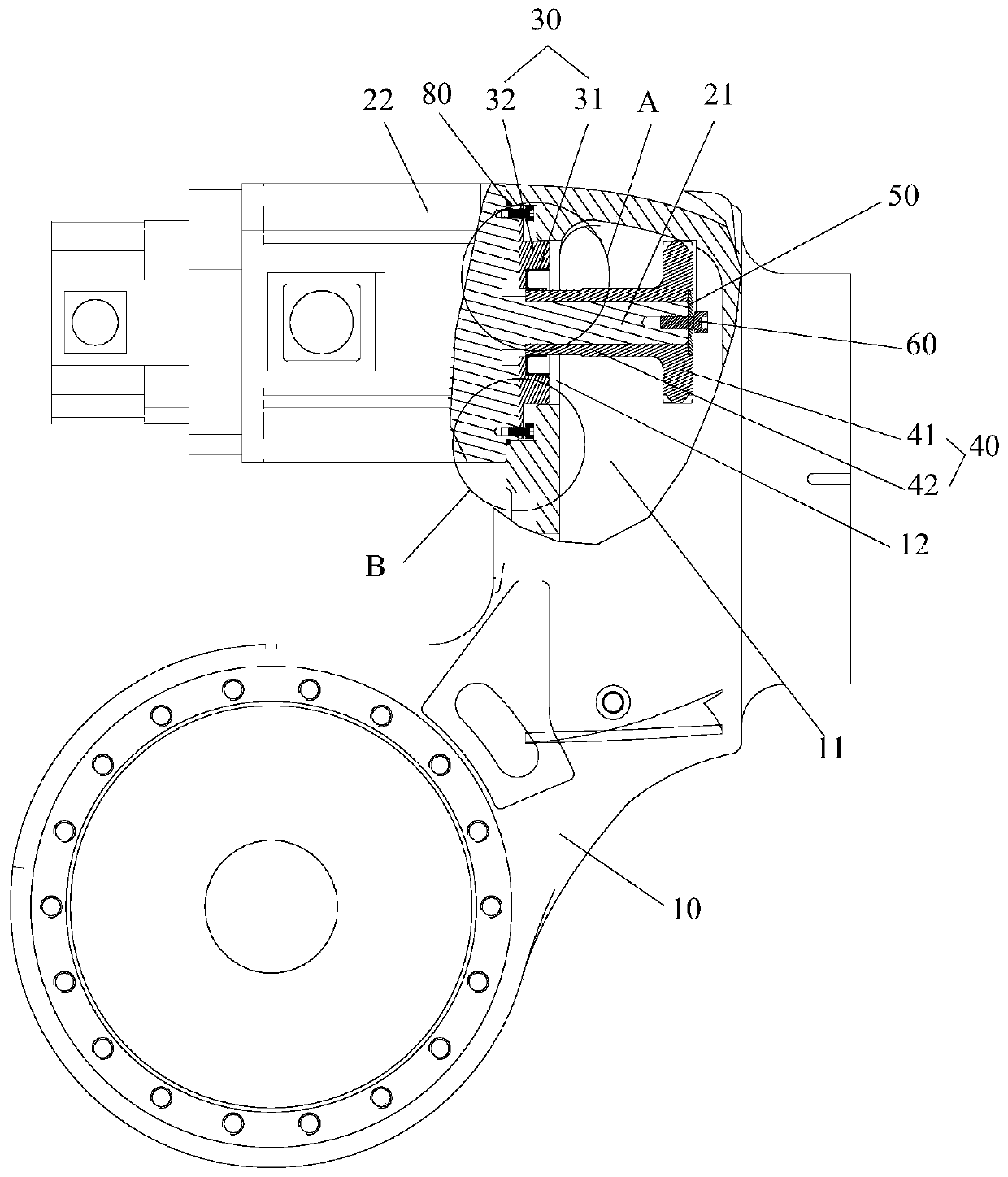

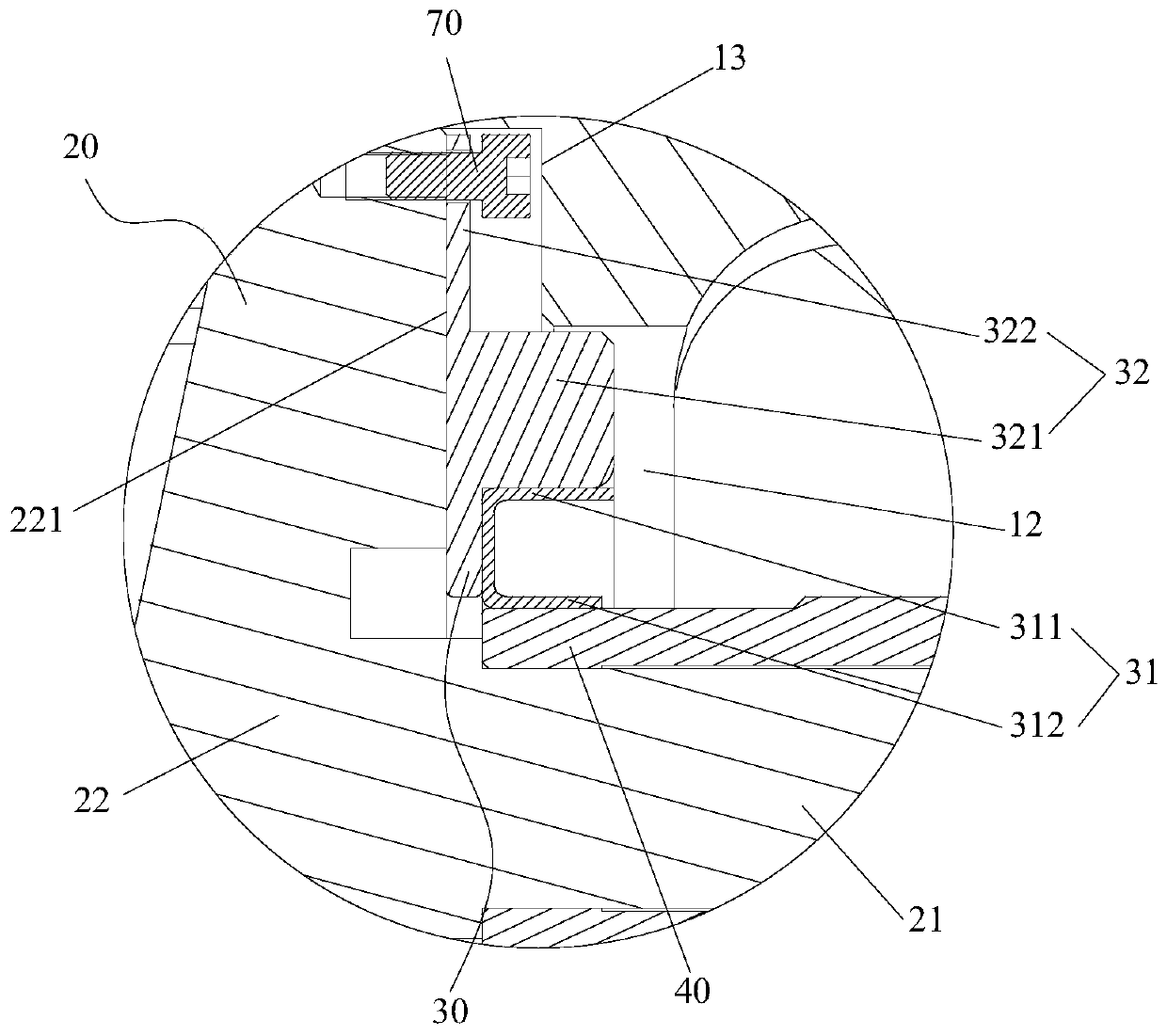

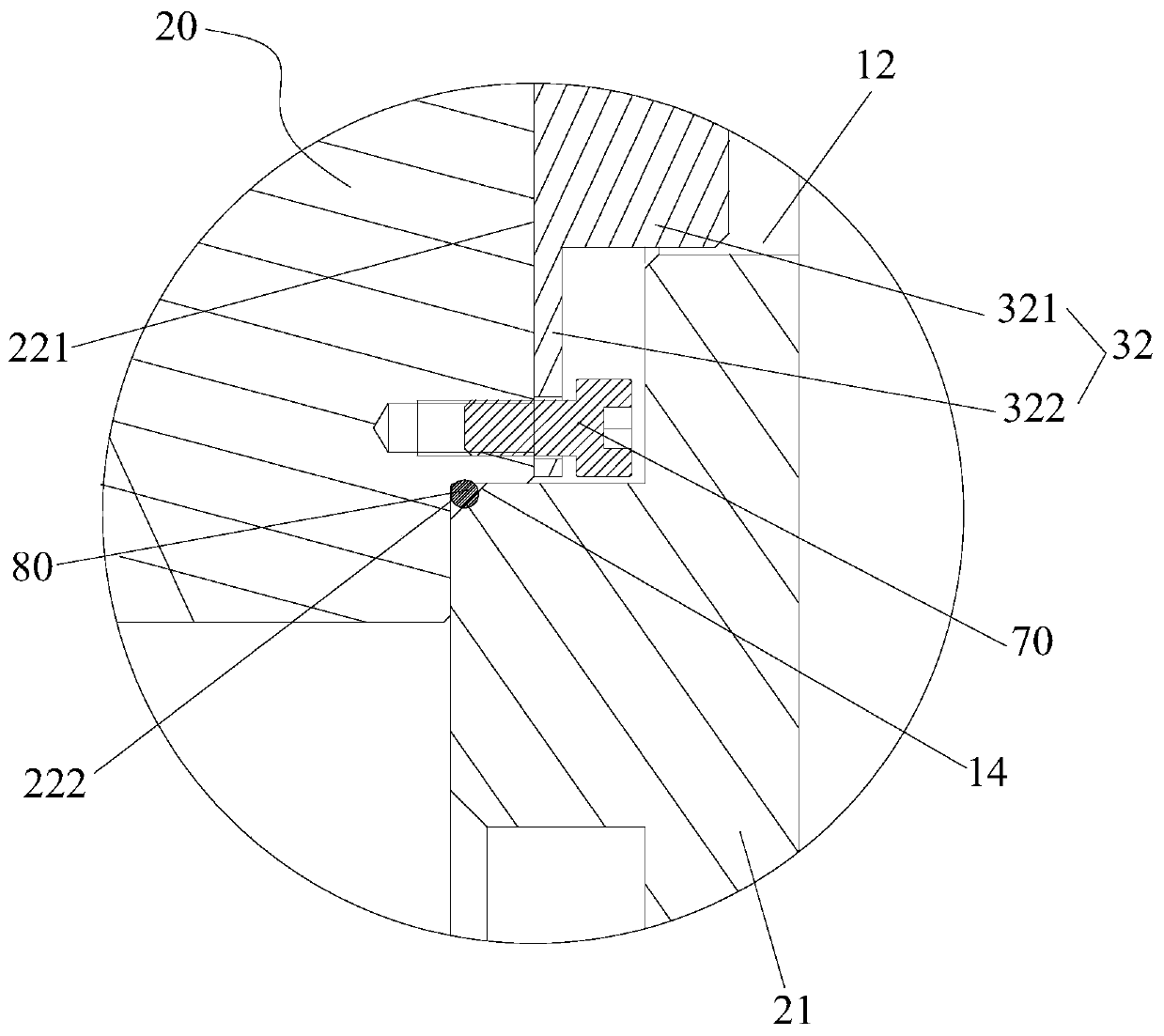

Double-rocker transmission mechanism applicable to movable control surface of aerial vehicle

ActiveCN104290901AHigh movement reliabilityImprove connection stiffnessWithout power ampliicationServo actuatorFlight vehicle

The invention relates to a double-rocker transmission mechanism applicable to a movable control surface of an aerial vehicle. A first hinged joint pair is formed between a rocker and a connecting bar, a second hinged joint pair is formed between the connecting bar and an auxiliary rocker, a third hinged joint pair is formed between the auxiliary rocker and a linear servo actuator, a fourth hinged joint pair is formed between the linear servo actuator and a first base, and a fifth hinged joint pair is formed between the auxiliary rocker and a second base; in each hinged joint pair, the axial movement of a hinge bearing is prevented by the way that a bush 12 and a sleeve 13 arranged on corresponding connecting lugs are in abutted connection with two sides of an inner ring of a hinge bearing 9 on a connector between two connecting lugs. The double-rocker transmission mechanism applicable to a movable control surface of an aerial vehicle provided by the invention can avoid exposure of a driving part of the mechanism to external high-temperature environments, so that the movement reliability of the mechanism is improved.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

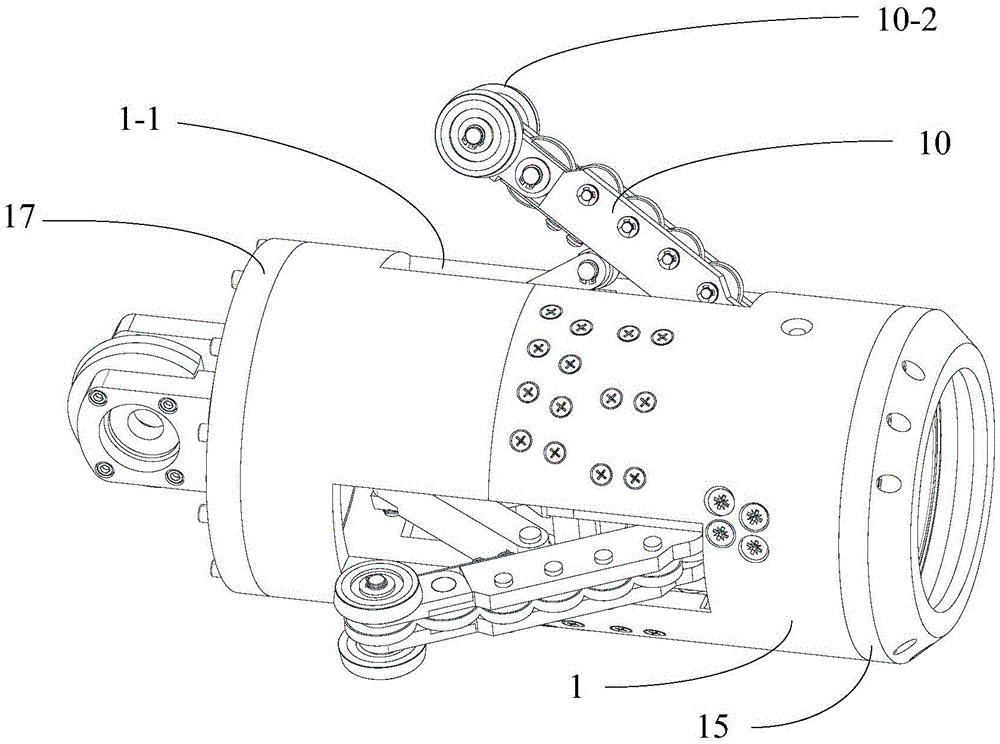

Robot joint and robot with robot joint

ActiveCN111409099AHigh movement reliabilityEasy to useProgramme-controlled manipulatorEngine sealsSimulationElectric machinery

The invention provides a robot joint and a robot with the robot joint. The robot joint comprises a first joint body, a second joint body, a drive device and a seal assembly. The first joint body is provided with a storage cavity and an installing hole communicating with the storage cavity, and the storage cavity is used for storing lubricating media. The second joint body is movably connected withthe first joint body. The drive end of the drive device penetrates through the installing hole and is in drive connection with the second joint body so that the drive end can be used for driving thesecond joint body to move. The seal assembly is located between the hole wall of the installing hole and the outer surface of the drive end so as to seal the connected position of the installing holeand the drive end. The robot joint and the robot effectively solve the problem that in the prior art, lubricating oil located in a robot joint is likely to enter a motor, and consequently normal usageof the motor is influenced.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Link gear of knitting cam

ActiveCN101476203ASimple structureReduce manufacturing costWeft knittingElectric machineryEngineering

The invention relates to a knitting triangle link gear which includes an installation seat transmission fork and a knitting triangle, the transmission fork is hinged on the installing seat, two ends connect with a knitting triangle A and a knitting triangle B respectively, also includes a cam and a motor, a circle side and an end surface of the cam are equipped with a curved surface cam groove and a plane cam groove, the cam connects with an output shaft of the motor and locates on one side of the knitting triangle B, the knitting triangle B is inserted in the curved surface cam groove of the cam through a pin set on the knitting triangle B for driving joint, the knitting triangle C is inserted in the plane cam groove of the cam through a pin set on the knitting triangle C for driving joint, when the cam runs, the cam pushes corresponding knitting triangle moving through the curved surface cam groove and the plane cam groove respectively. The knitting triangle link gear has advantages that the knitting triangle link gear has fewer accessory, simple structure, low cost, succinct drive line and high reliability for moving which process link drive according with moving relationship among three knitting triangles.

Owner:冯加林 +1

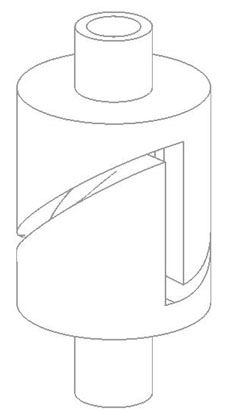

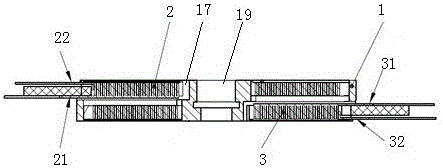

Dynamic repulsion disk and repulsion mechanism using same

ActiveCN105161325AHigh movement reliabilityRapid disconnectionSwitch power arrangementsDual coilSwitchgear

The invention relates to the technical field of power distribution network high voltage switchgear equipment, in particular to a dynamic repulsion disk and a repulsion mechanism using the same. When a dynamic repulsion disk is in use, the dynamic repulsion disk is fixedly connected with a transmission rod; and the dynamic repulsion disk comprises a disk-shaped skeleton, and a first dynamic repulsion coil and a second dynamic repulsion coil fixed on two sides of the skeleton axially. The dynamic repulsion disk adopts a single-disk and double-side dual-coil structure; when the dynamic repulsion disk is in use, the energized dynamic repulsion coil and the corresponding static repulsion coil generate electromagnetic repulsion to drive the transmission rod to move at a high speed; and by using the dynamic repulsion disk, the movement reliability of an operating mechanism can be improved, rapid close and cut-off of circuits can be realized, the impact on systems from an electromagnetic transient effect is reduced, and the power supply quality is improved.

Owner:PINGGAO GRP +1

Injection mold and angle ejecting mechanism thereof

The invention discloses an angle ejecting mechanism. The angle ejecting mechanism comprises an angle ejecting rod, an angle ejecting base, an angle ejecting base slide block and a support guide block, wherein the angle ejecting rod and the angle ejecting base slide block are fixed; the angle ejecting base slide block and the angle ejecting base are connected with each other in a sliding mode; the support guide block is fixedly connected with a base plate of an injection mold, and is provided with a first guide structure which is parallel to the ejection direction of the angle ejecting rod; the angle ejection base slide block is provided with a second guide structure in sliding fit with the first guide structure. The angle ejecting mechanism is additionally provided with the support guide block, so that the lateral force formed by the angle ejecting mechanism in the ejecting process is transferred to the support guide block by the angle ejecting base slide block via the sliding fit between the first guide structure and the second guide structure; the lateral force borne by the angle ejecting rod is offset by the counterforce generated by the support guide block, so that the angle ejecting rod is unlikely to deform; the motion smoothness of the angle ejecting mechanism is ensured; the motion reliability of the angle ejecting mechanism is improved. The invention also discloses the injection mold applying the angle ejecting mechanism.

Owner:SHENZHEN SILVER BASIS TECH

Anti-theft envelope cash loading device

ActiveCN105513197AEven by forceImprove stabilityCoin/currency accepting devicesElectrical and Electronics engineeringAnti theft

The invention discloses an anti-theft envelope cash loading device. The anti-theft envelope cash loading device includes a gate mechanism, a channel and a cash box; the lower inlet of the gate mechanism is connected with the upper part of a channel; the lower end of the channel is connected with the upper part of the cash box; according to the gate mechanism, a crank is driven to move through a driven gear, and under the action of the crank, a gate can be controlled to slide back and forth in a gate frame; and according to the cash box, in the push movement of a low movement, an unlocking slider is controlled to move through an unlocking push rod, a rack is controlled to move through an opening and closing push rod, and therefore, a cash box door can be controlled to rotate and move, and the cash box door can be opened. The gate mechanism of the anti-theft envelope cash loading device of the invention has the advantages of simple and compact structure, small opening and closing range and small occupied space; the envelope space of the gate can be reduced, and the gate can be uniformly stressed, the stability and reliability of the gate are high; and an unlocking mechanism is simple, convenient and practical, and can store banknotes and coins of any denominations.

Owner:HEBEI HUIJIN ELECTROMECHANICAL

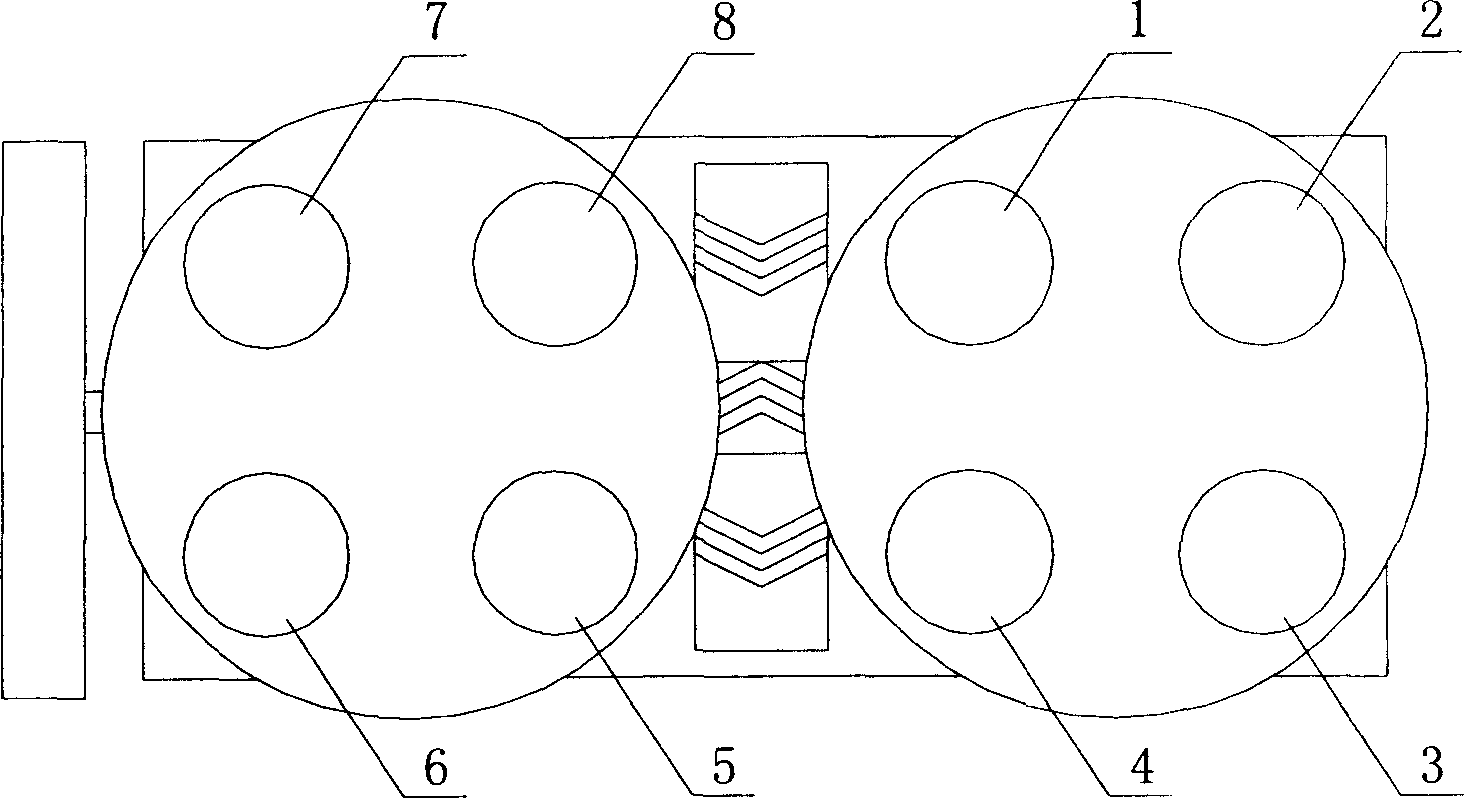

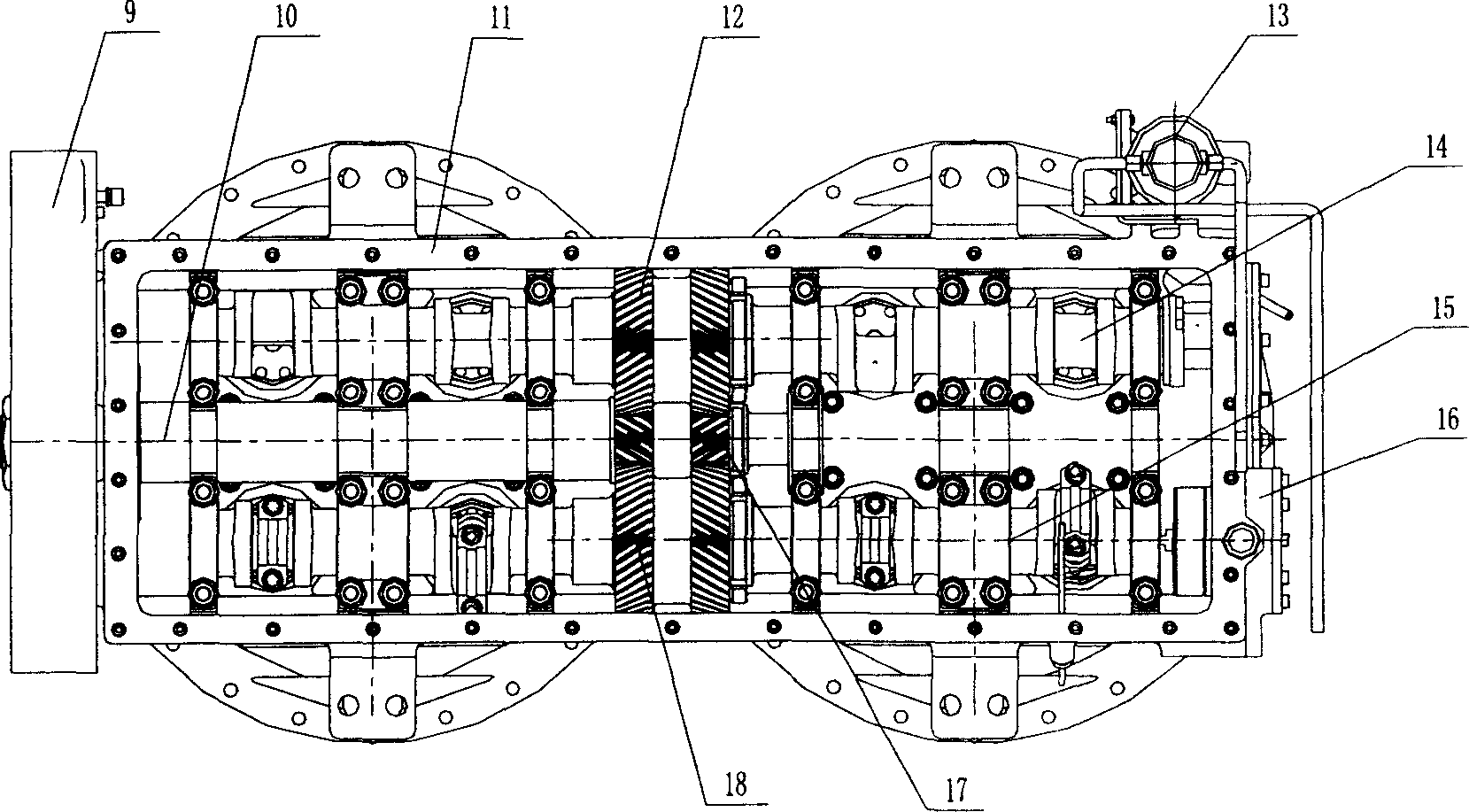

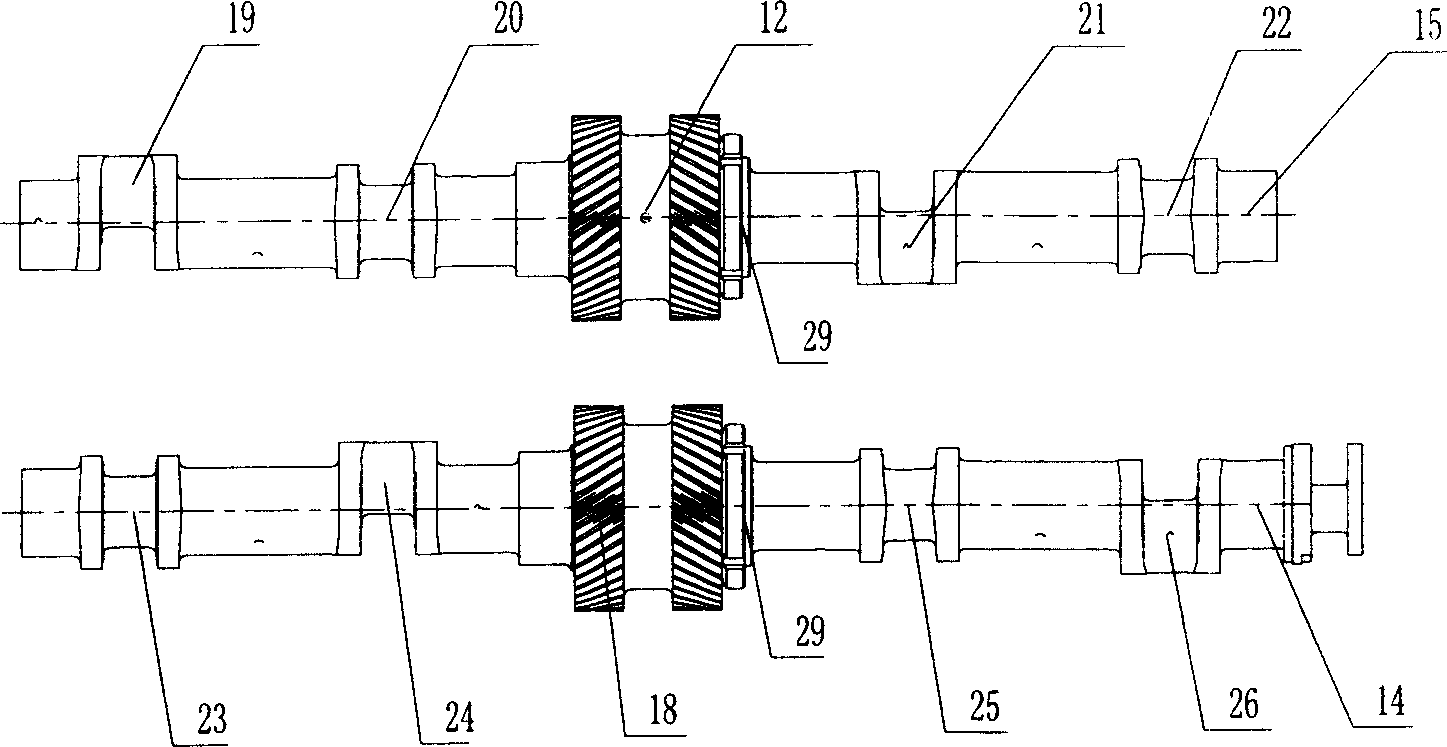

Drive system of 8-cylinder hot-air engine

A driving system of hot air engine (HAE) with eight cylinders is prepared as laying right and left crankshafts (RALC) in parallel way and connecting them to output shaft by gear driving mechanism to form U form driving structure, setting four crank throws on each of RALC and using adjacent four crank throws at right and left ends of RALC to a driving unit for one HAE with four cylinders, applying 90 degree and 180 degree as well as 270 degree as phase difference of four crank throws and applying 90 degree of erection phase difference for RALC, setting gear driving mechanism between RALC and using herringbone gear as said gear.

Owner:SHANGHAI MICROPOWERS

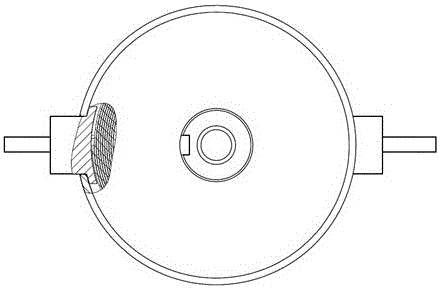

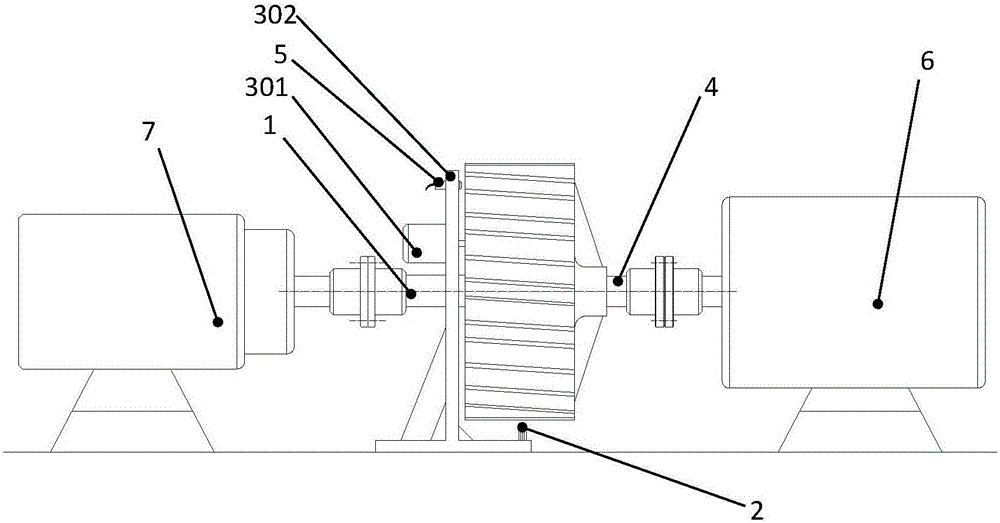

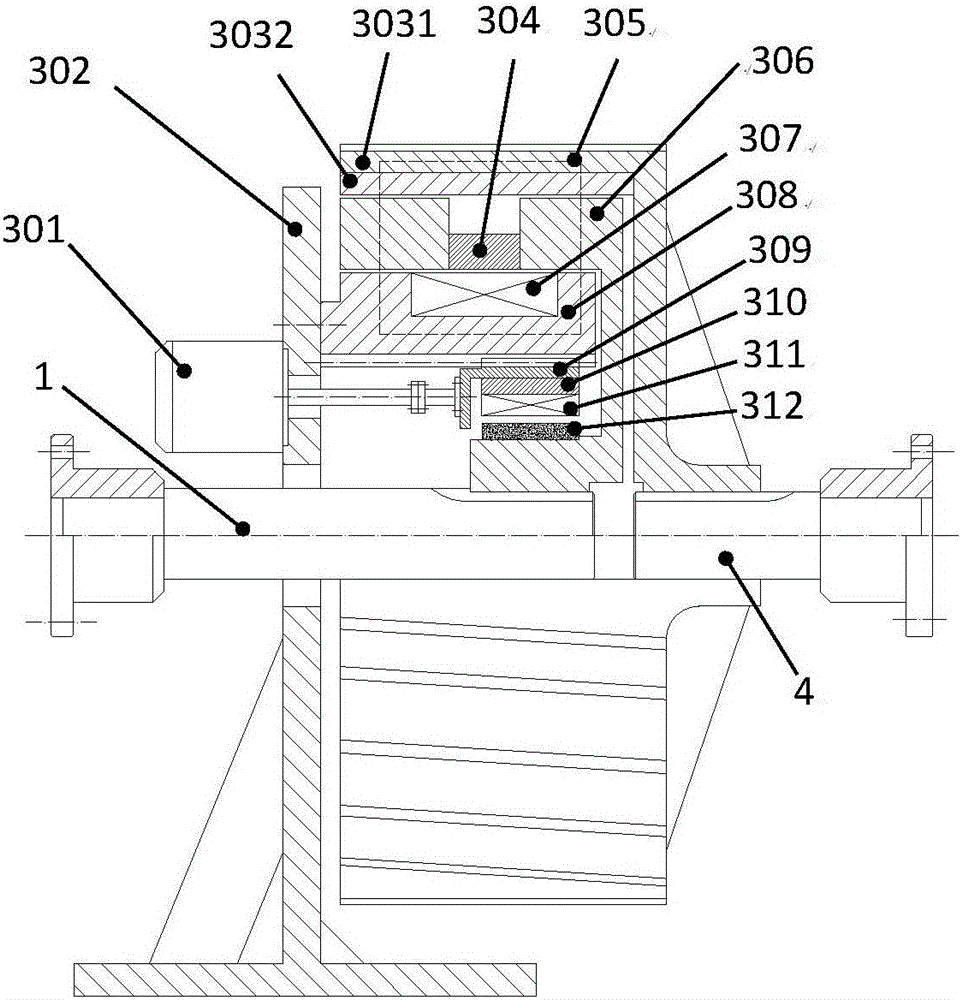

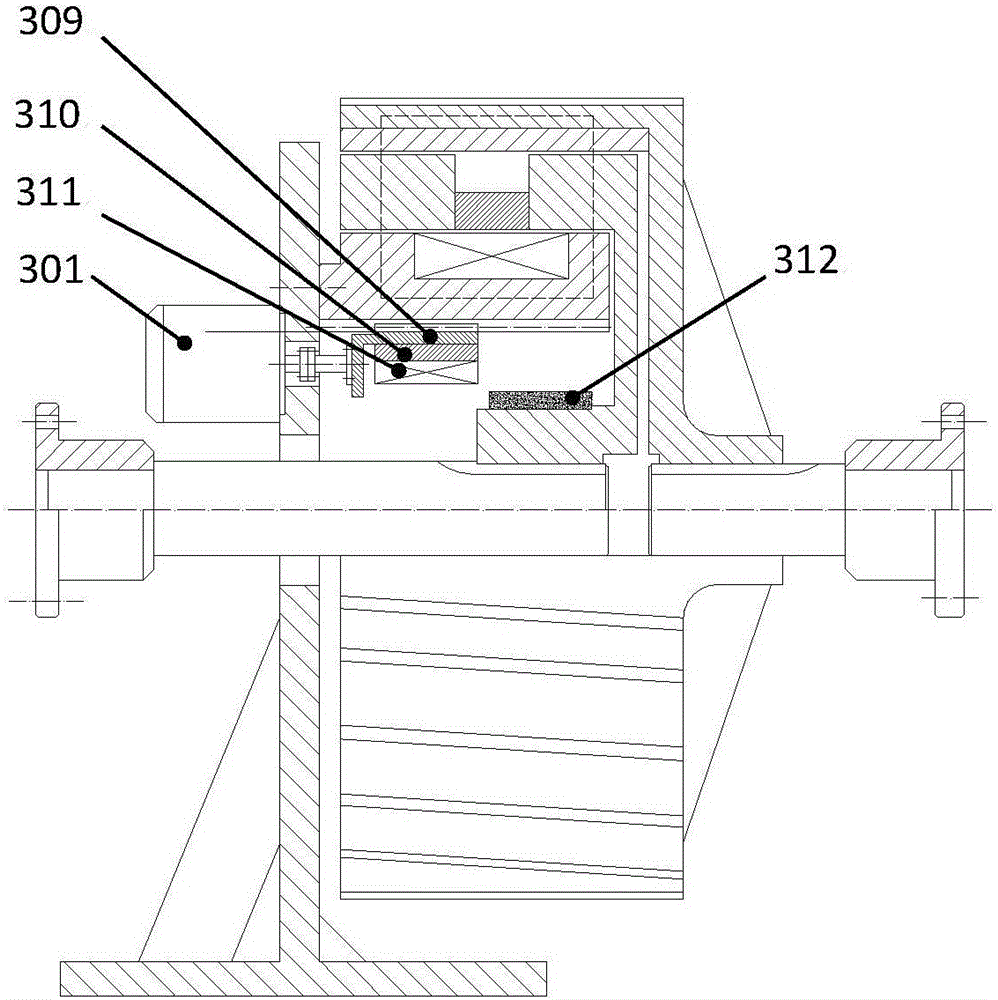

Coil static electromagnetic eddy current speed regulator

ActiveCN105790543AImprove cooling effectSolve the problem of unreliable movementDynamo-electric gearsAsynchronous induction clutches/brakesMotor speedElectric machine

The invention discloses a coil static electromagnetic eddy current speed regulator, and belongs to the field of industrial motor speed regulation and energy saving. The speed regulator mainly is composed of an eddy current transmission part, a generator part and a control part. The outer layer of an outer rotor is the outer rotor A; the outer rotor A is made of a ferromagnetic material; the inner layer of the outer rotor is the outer rotor B; the outer rotor B is made of a copper material; when the magnitude of a transmission torque needs to be regulated, the executer of the control part drives a spline shaft, a generator silicon steel sheet and a generator armature to slide axially; a generator power is regulated through changing the intersection area of a permanent magnet and the armature; further the current magnitude in an excitation coil is changed; a magnetic flux is changed; and finally the transmission torque is changed. The speed regulator is high in reliability and easy in regulation; the generator is built in the speed regulator, and therefore, the energy saving demand can be satisfied; according to the device, the permanent magnet is replaced by an electromagnet, and therefore, the demagnetization phenomenon is avoided; and the speed regulation is realized under the condition of a fixed air gap.

Owner:MAGNA MAGNETOMOTIVE CO LTD

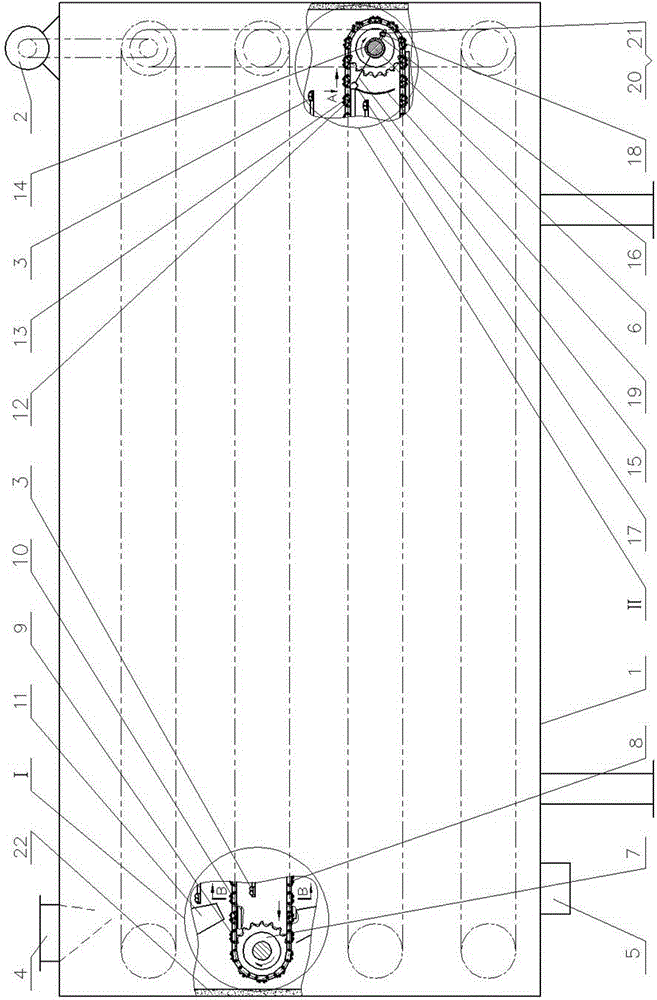

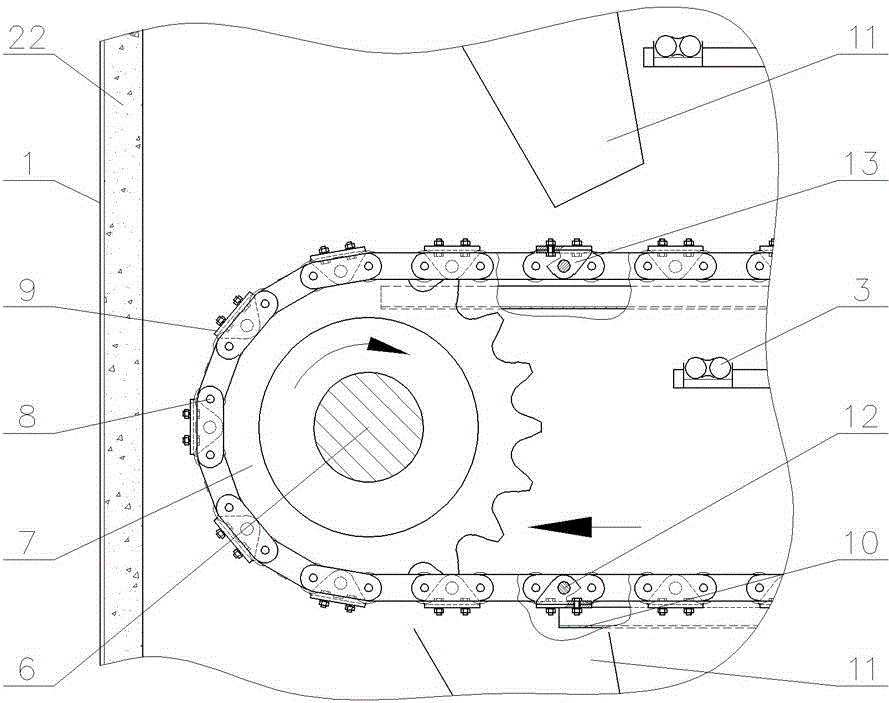

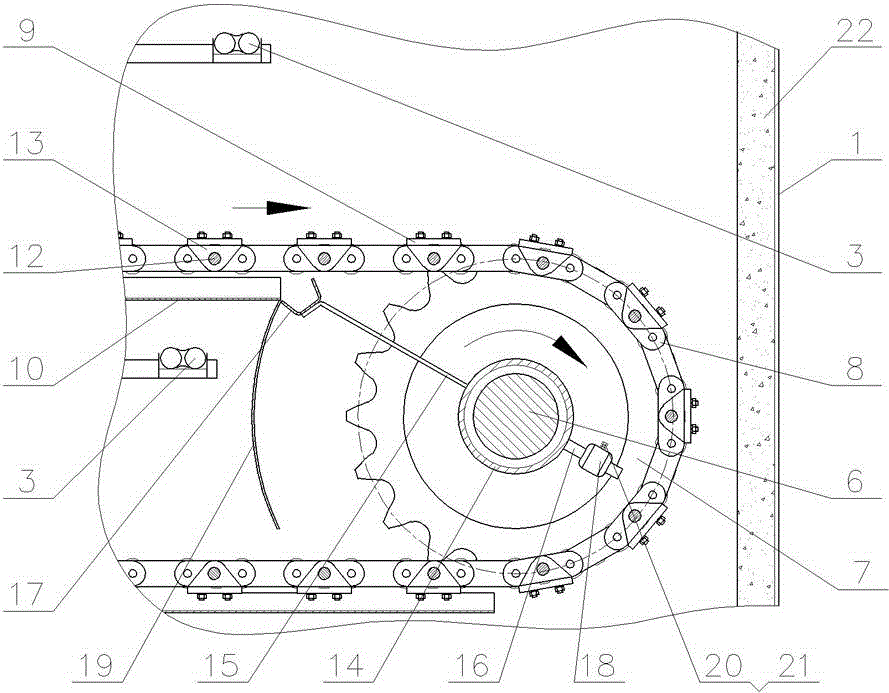

Turnover-falling infrared corncob drying machine

InactiveCN104686649AImprove heat transfer efficiencyStrong penetrating powerSeed preservation by dryingEngineeringMechanical engineering

The invention provides a turnover-falling infrared corncob drying machine. The turnover-falling infrared corncob drying machine is characterized in that a plurality of conveying devices driven by a transmission to run are arranged in a box, a plurality of setting rods are fixed on bent plates, correspondingly extending inwards, of two chains of the same conveying device by use of two joints at the end portions, carrying grooves are formed under the horizontal sections of the upper and lower sections of each conveying device corresponding to the chains, respectively, a falling device is arranged under the tail end of the carrying groove of the upper section, a supporting rod and an adjusting rod are fixed on the two sides of the outer circle of a supporting sleeve sleeving a shaft, respectively, a bearing groove located at the tail end of the carrying groove in a non-working state is fixed at the outer end of the supporting rod, the lower end of a baffle plate of which the circular arc center is located in the axis of the supporting sleeve is located under the tail end of the carrying groove, an adjusting block is locked to the adjusting rod by use of a screw and a nut, a guide groove is formed under the tail end of the carrying groove of the lower section, a radiation device is arranged above the carrying groove, and a feeding hole is formed in the top of the box, while a discharge hole is formed in the bottom of the box. The turnover-falling infrared corncob drying machine is high in drying efficiency, good in drying uniformity, simple in structure, and reliable in working.

Owner:SHANDONG UNIV OF TECH

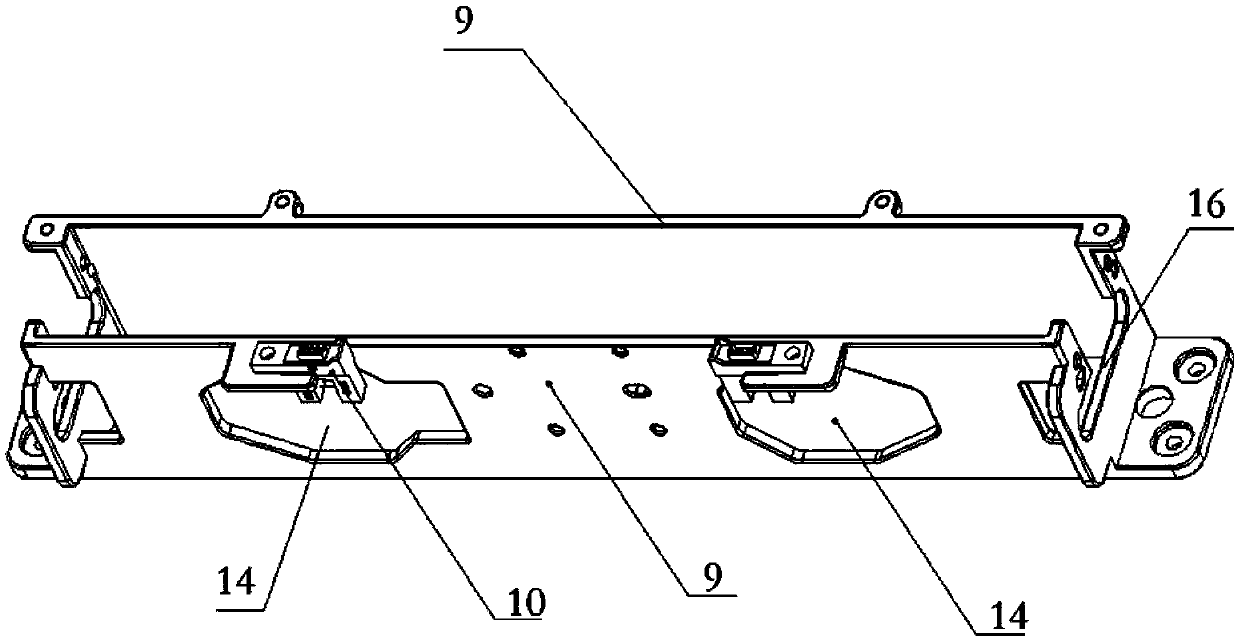

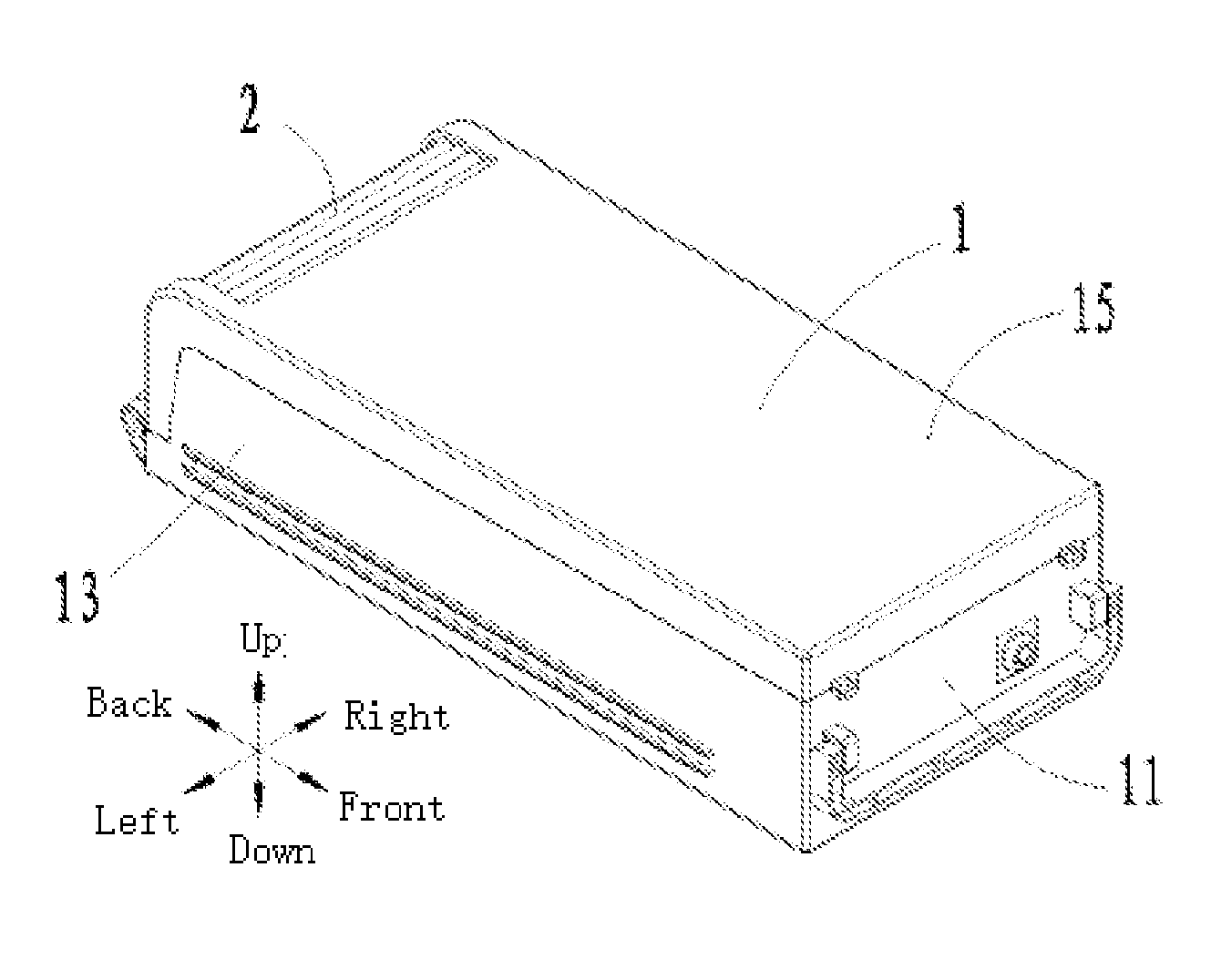

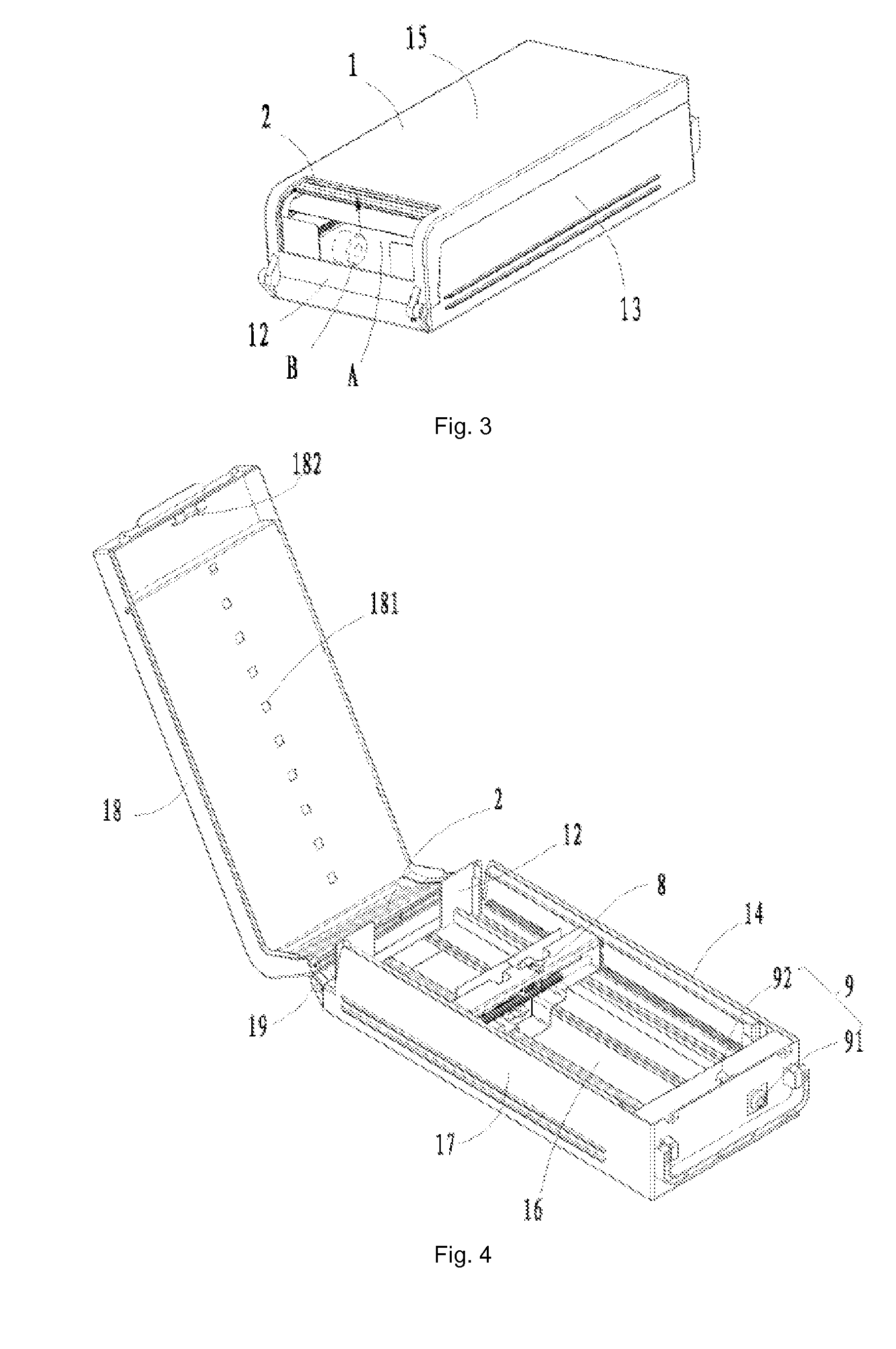

Cassette for storing sheet media

InactiveUS20160176665A1High movement reliabilitySmooth motionCard-filingCoin/currency accepting devicesMagnetic tapeDrive shaft

A cassette for storing sheet media includes a box body with an opening, wherein the cassette further includes a pressing plate located in the box body, and a self-driven mechanism for driving the pressing plate to move towards the opening; the self-driven mechanism includes a support frame connected with the pressing plate, a driving shaft arranged on the support frame and driven by an elastic energy storage element, travelling gears synchronously moving on the two sides of the support frame, and guide racks matched with the travelling gears and extending along a stacking direction of the sheet media; and the travelling gears are driven by the driving shaft.

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD

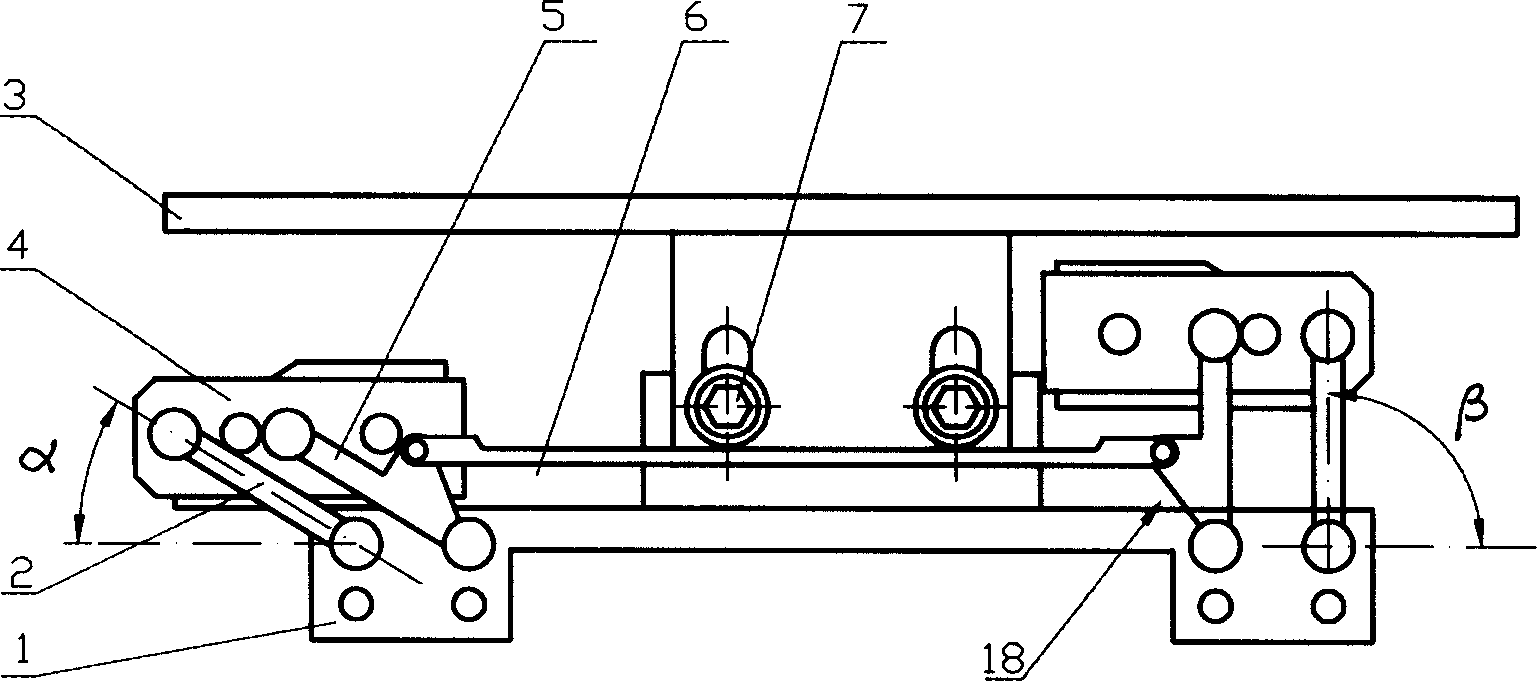

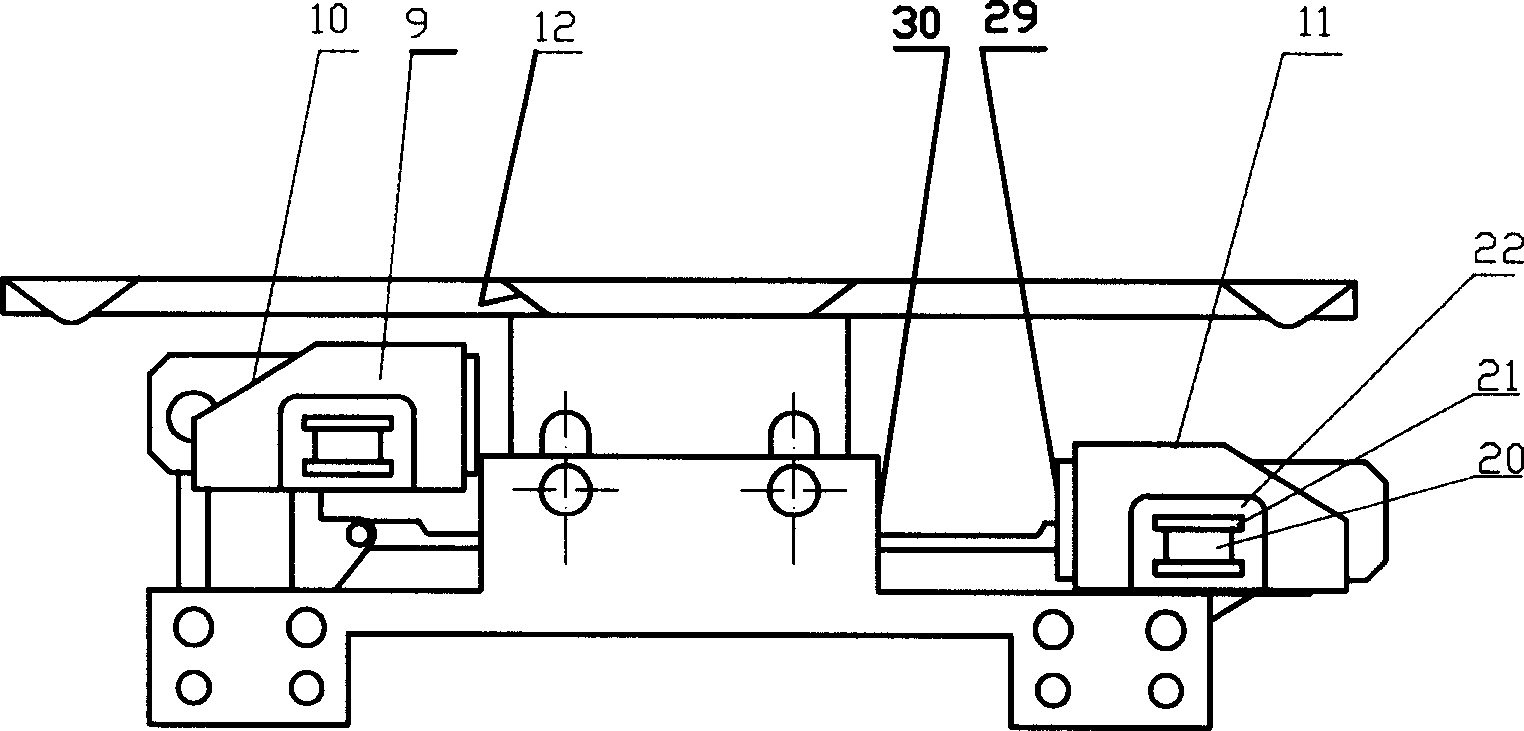

Light aircraft flap manipulation device

PendingCN109911180AReduce power loadEasy maintenanceWith power amplificationActuated personallyFailure rateEngineering

The invention discloses a light aircraft flap manipulation device, wherein a flap driving mechanism comprises a motor, the output shaft of the motor is fixedly connected with a worm, the outer side ofthe worm is screwed and coupled with a worm shaft barrel, and the end of the worm shaft barrel is hinged with a triangle, and one end of the triangle is fixedly connected with a first rotating shaft;a flap linkage mechanism comprises a first pull rod and a second pull rod, the first pull rod and the second pull rod are respectively hinged in two flap rotating positions, the upper end of the first pull rod is hinged with one end of the triangle, the first rotating shaft is fixedly installed with a first fan-shaped rocker, the upper end of the second pull rod is hinged with a connection block,the lower end of the connection block is fixedly installed on a second rotating shaft, the second rotating shaft is fixedly installed with a second fan-shaped rocker, and the first fan-shaped rockerand the second fan-shaped rocker are connected with two guide cables. The device may better reduce the aircraft power load, achieve the synchronous rotation of flaps, reduce the failure rate, and be convenient for maintenance.

Owner:重庆恩斯特龙通用航空技术研究院有限公司

Improved robot structure

InactiveCN108237007ASimple structureReasonable designProgramme-controlled manipulatorWaste processingDrive shaftAgricultural engineering

The invention discloses an improve robot structure which comprises a rack. A walking device is arranged on the rack and comprises a walking motor, an output gear, a transmission gear and two foot tools. The walking motor is arranged in the rack, the output gear is connected with the walking motor, and the transmission gear is meshed with the output gear. A transmission shaft is arranged at the center of the transmission gear and is arranged on a shaft bracket, and the shaft bracket is arranged on the rack. A planetary gear device is respectively arranged at the two ends of the transmission shaft and comprises a planet wheel, a sun wheel and a disc, the sun wheel is fixedly arranged on the transmission shaft, and the disc is rotationally arranged on the transmission shaft. A gear ring is arranged on the disc, and the planet wheel is respectively meshed with the sun wheel and the gear ring. The walking device is used for controlling the foot tools to alternately move through the planetary gear device, so that a robot can keep moving steadily forward. The improve robot structure has the advantages of simple structure, reasonable design and high movement reliability.

Owner:许玉春

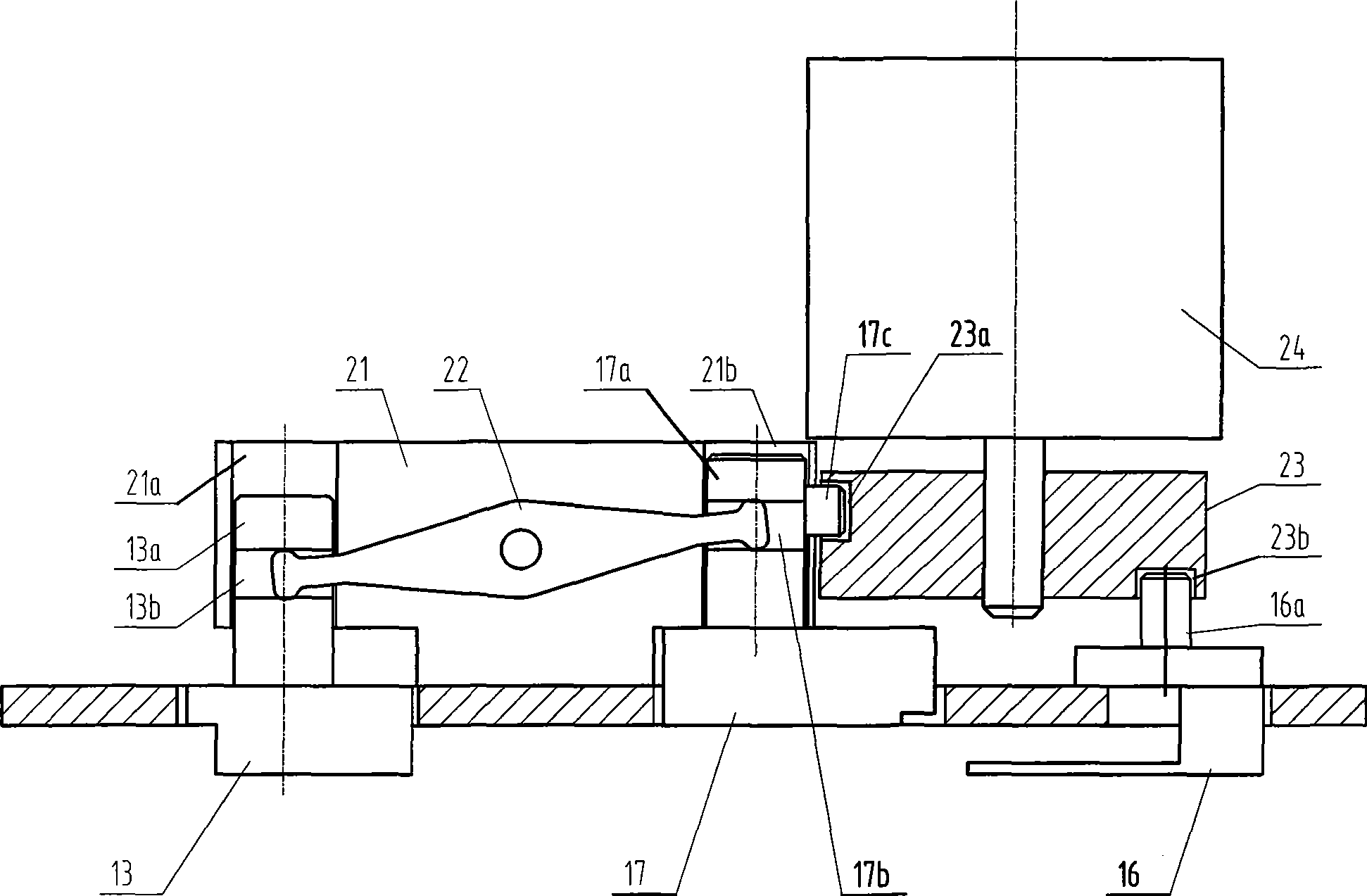

Circuit breaker and transmission device thereof

ActiveCN105655210AReduce frictionReduce wearProtective switch operating/release mechanismsEngineeringFriction force

The invention relates to a circuit breaker and a transmission device thereof. The circuit breaker comprises the transmission device. The transmission device comprises a transverse pull rod connected with a movable contact, and a connecting lever connected with the transverse pull rod in a transmission mode through a connection plate so as to drive the rotation axis of the left-right movement of the transverse pull rod to extend in the front-back direction. One end of the connection plate is connected with the crank arm in a hinged mode, and the other end of the connection plate is connected with the transverse pull rod in a hinged mode through a hinge pin shaft with the axis extending in the front-back direction. The transmission device further comprises a hinge pin shaft guide piece. A hinge pin shaft guide structure matched with the hinge pin shaft in a guide and movement mode in the left-right direction is arranged on the hinge pin shaft guide piece. Due to the constraint of the hinge pin shaft guide structure, the hinge pin shaft only transmits acting force in the left-right direction to the transverse pull rod. The transverse pull rod basically does not bear vertical component force transmitted by the crank arm. Therefore, the friction force between a transverse pull rod guide structure and the transverse pull rod can be small, abrasion to the transverse pull rod guide structure and the transverse pull rod is small, and the improvement of the transmission efficiency and the movement reliability is facilitated.

Owner:PINGGAO GRP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com