Patents

Literature

54results about How to "Good inkjet effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ink-jet recording method and ink-jet ink

InactiveUS7195340B2Good inkjet effectExcellent ejection stabilityMeasurement apparatus componentsPrintingThermal energyEngineering

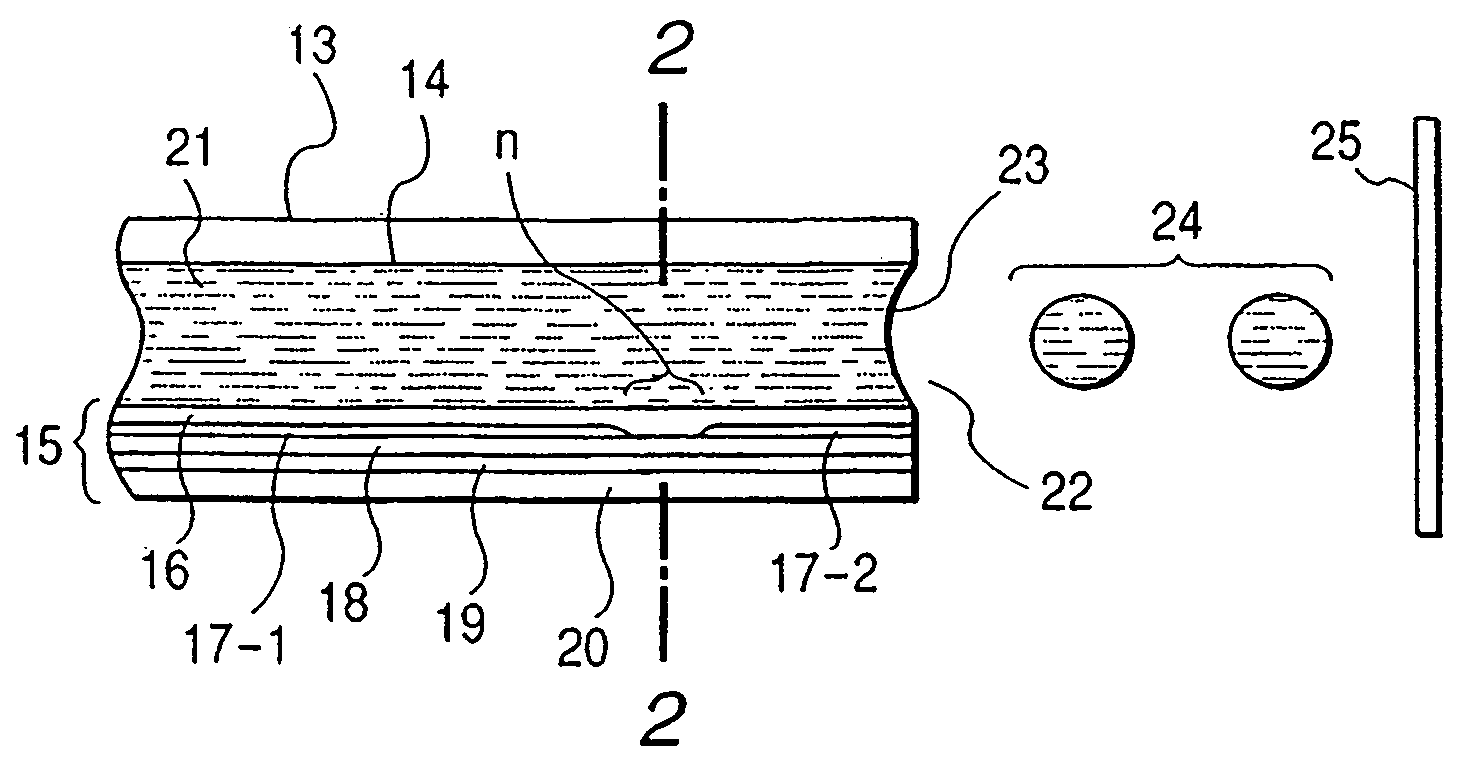

Disclosed herein is an ink-jet recording method comprising a step of applying thermal energy to an ink to generate bubbles thereby ejecting the ink from an ejecting portion to record, wherein the relationship among a cloud point (T) of a liquid obtained by removing coloring material from the ink, a temperature T0 of the ink before formation of the bubbles in a portion in which the bubbles are generated and a temperature T1 of a part of the ink, which includes a portion in contact with the bubbles and surrounds the bubbles, satisfies T0<T<T1.

Owner:CANON KK

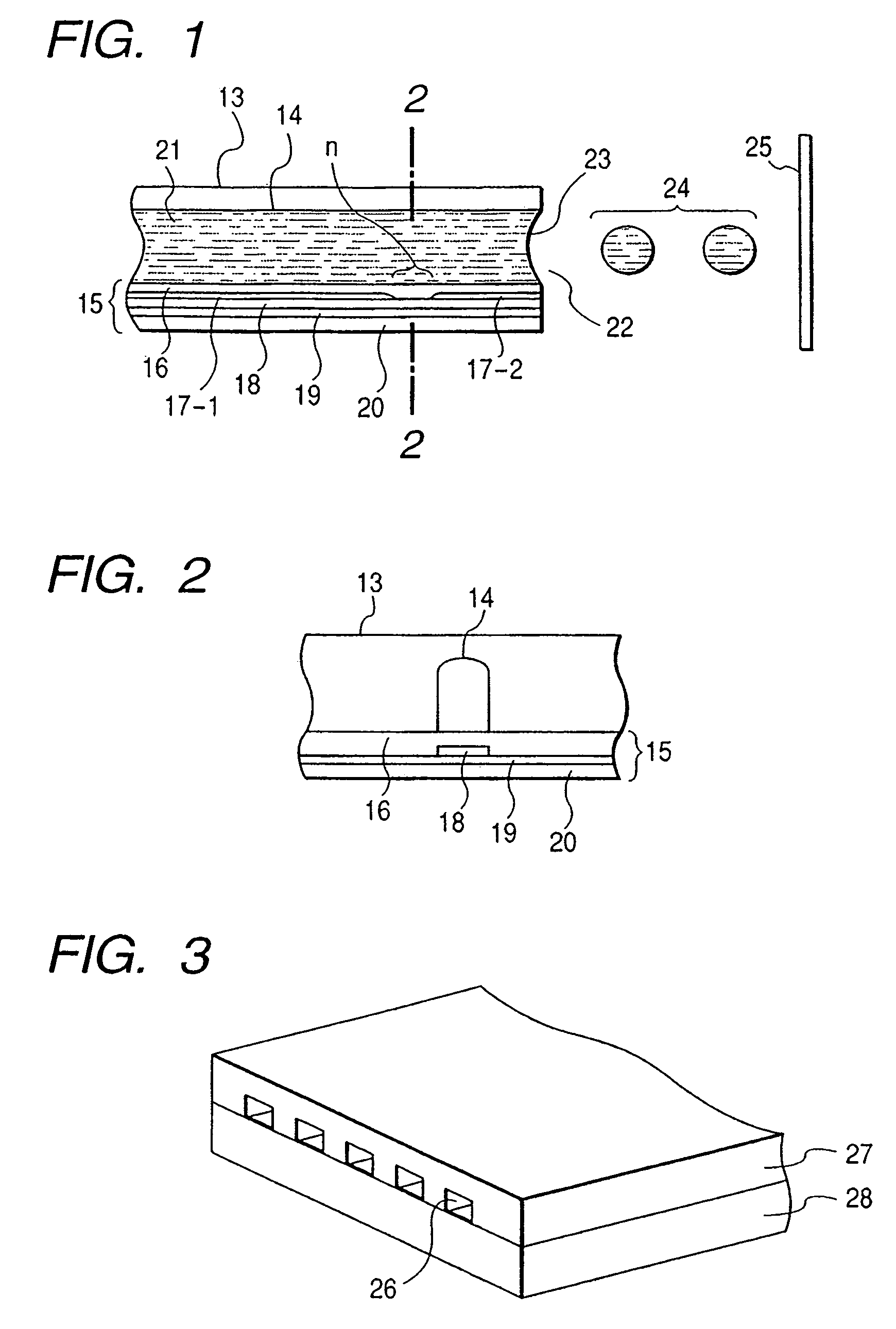

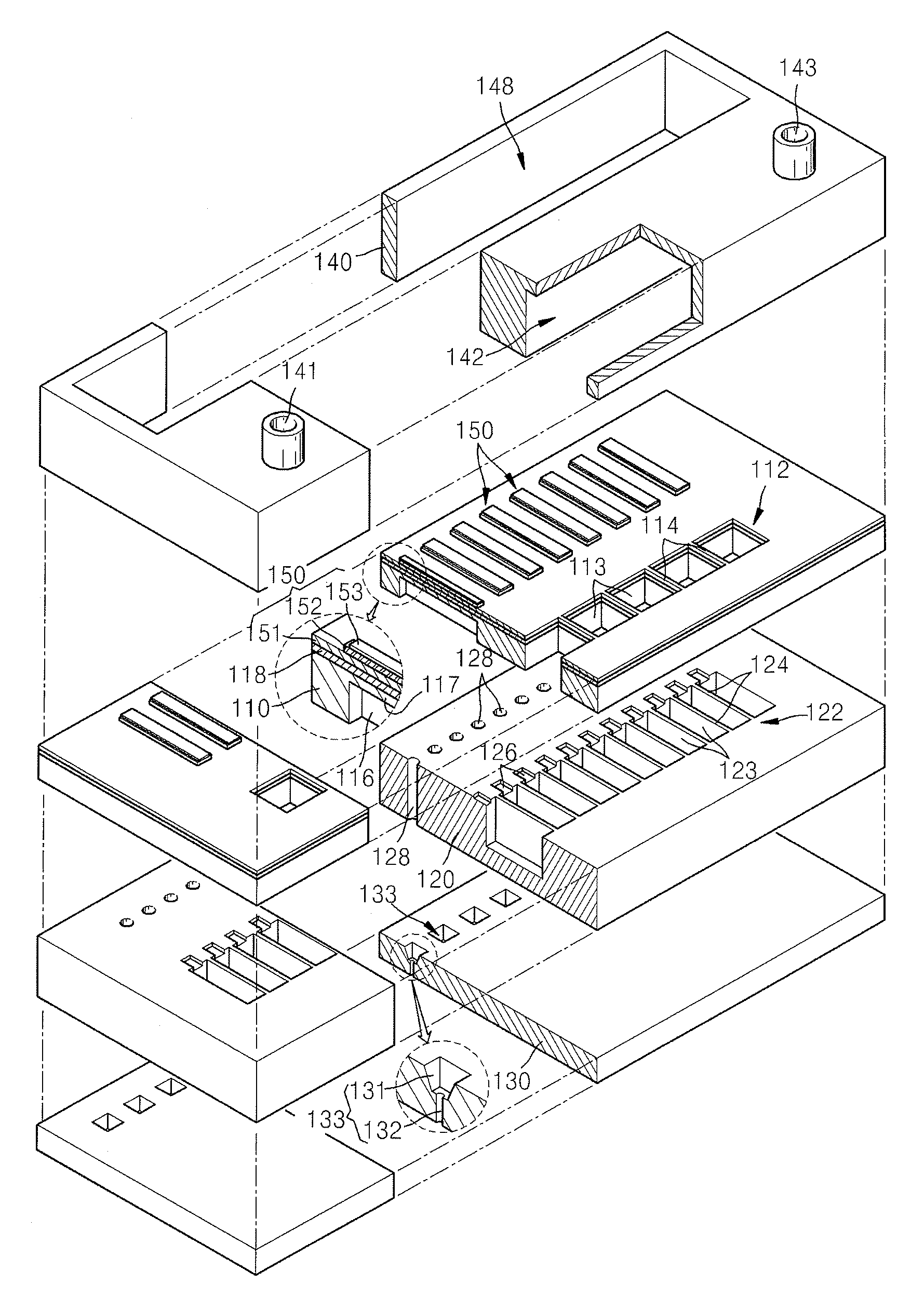

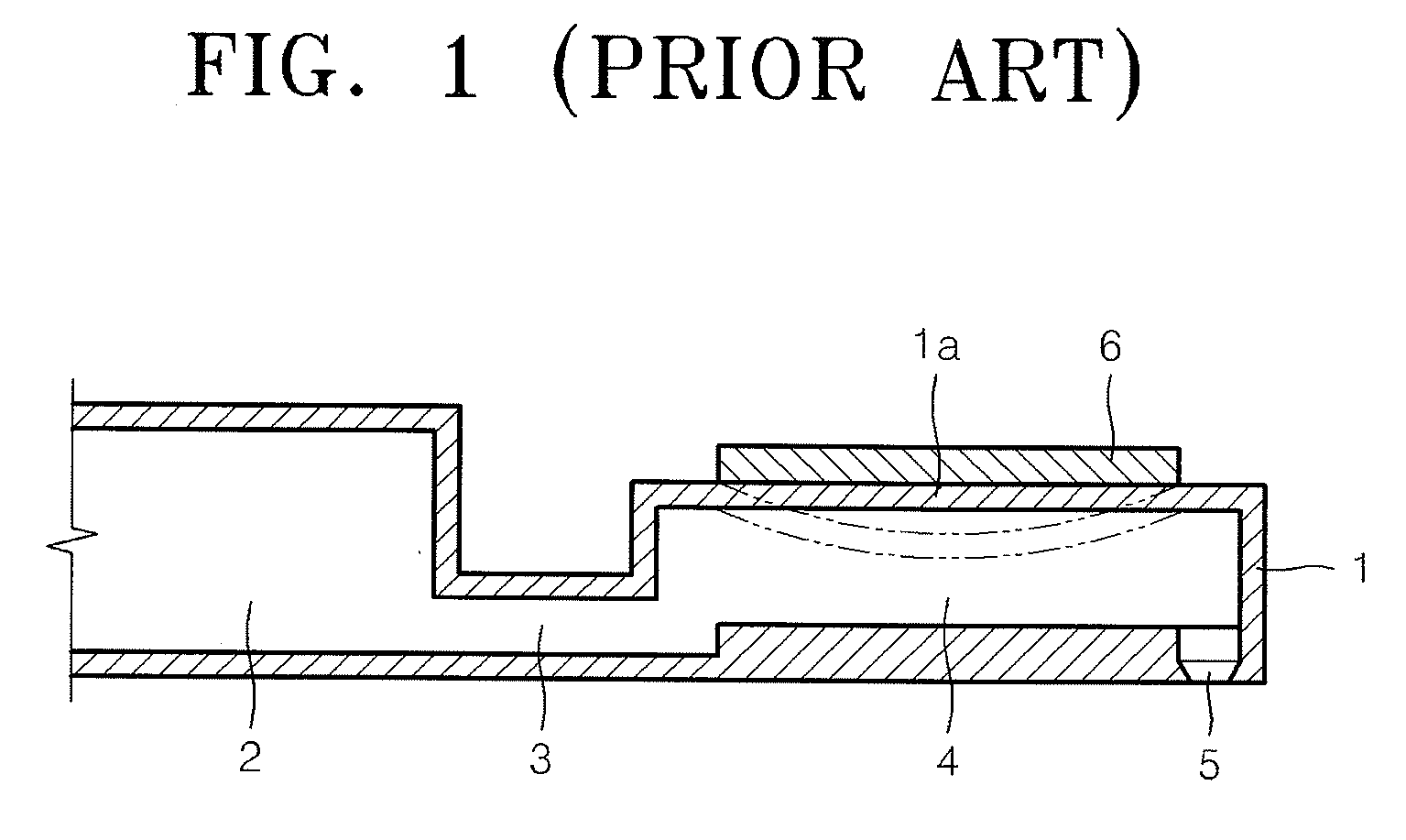

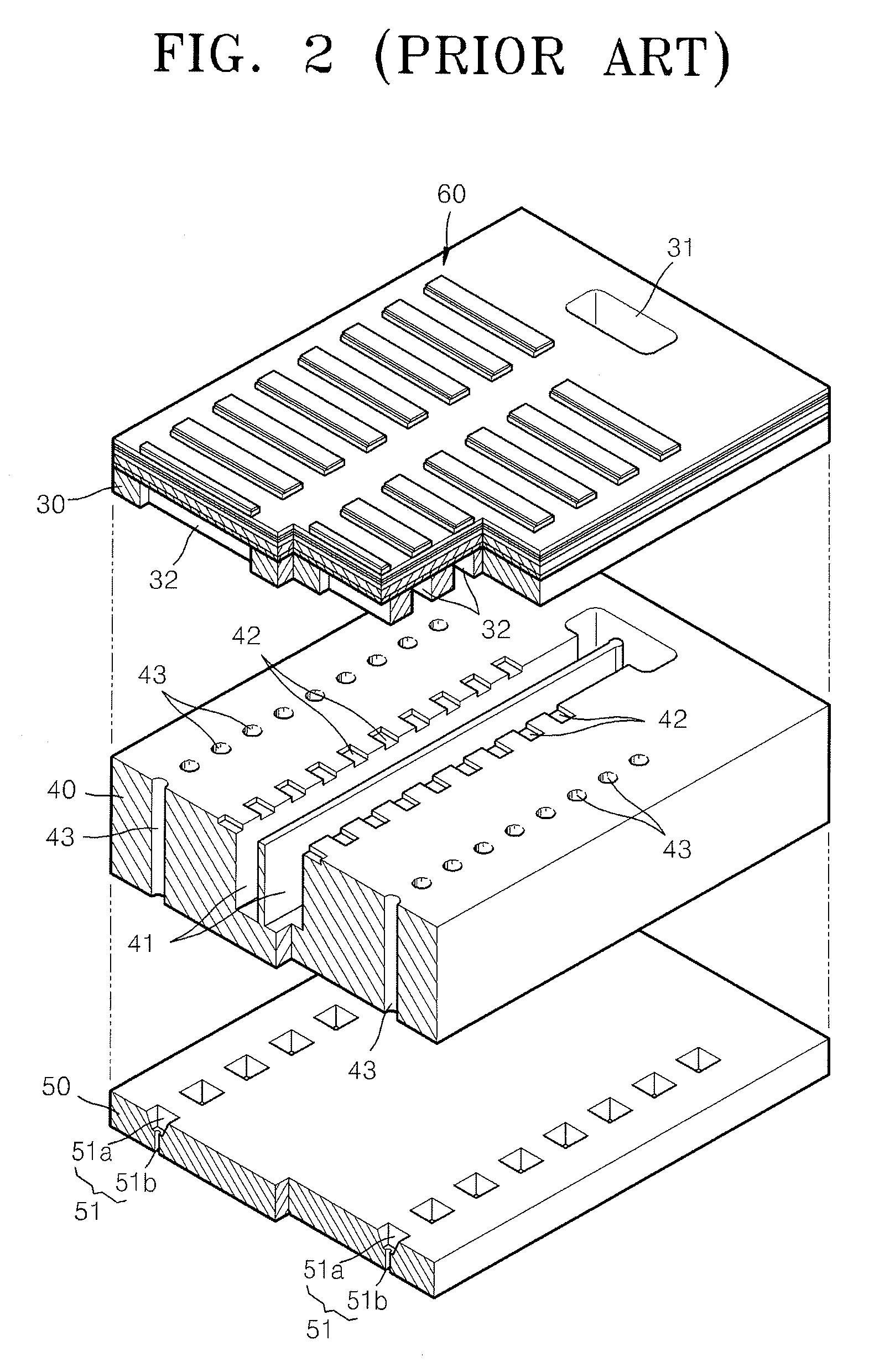

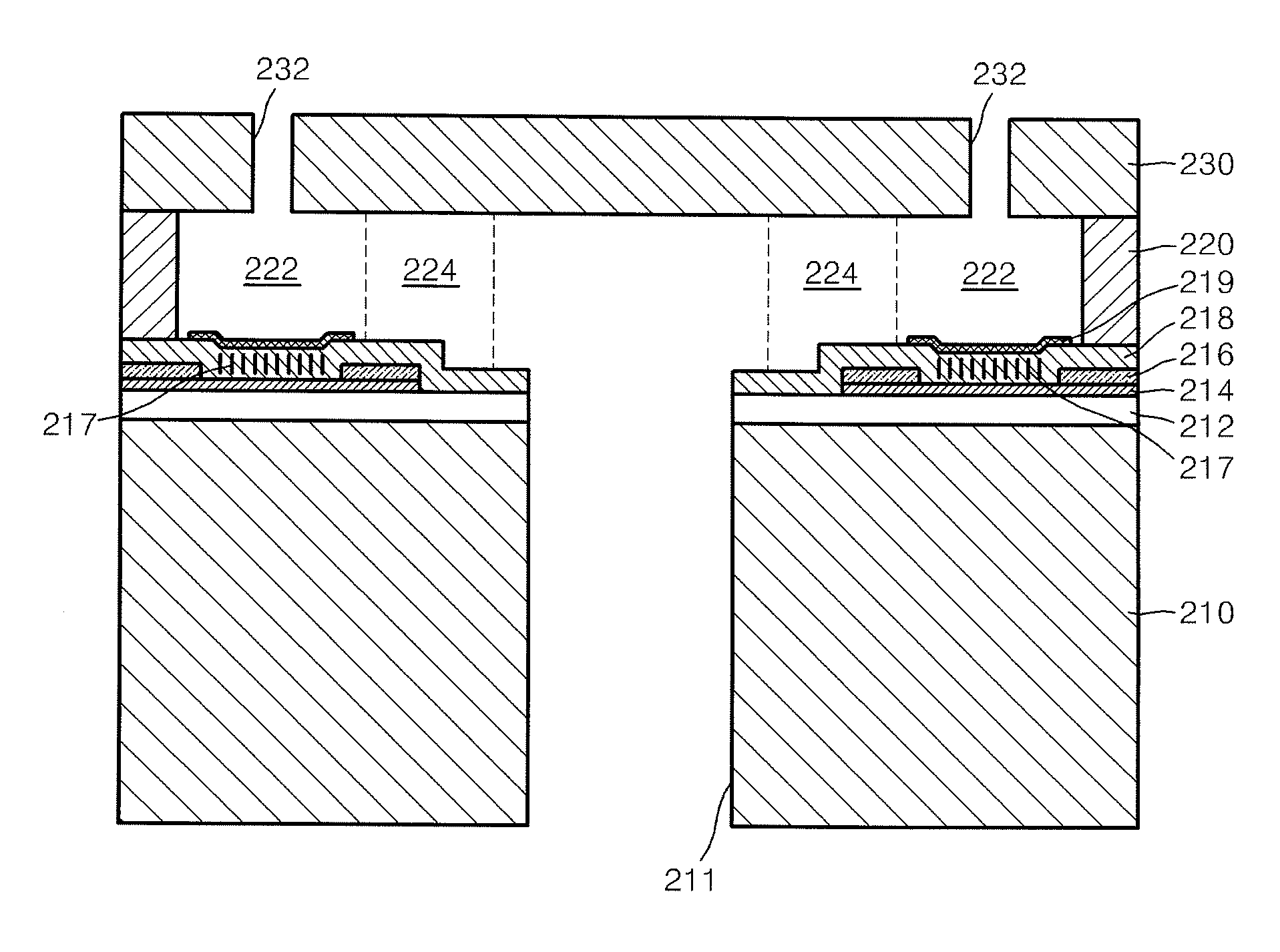

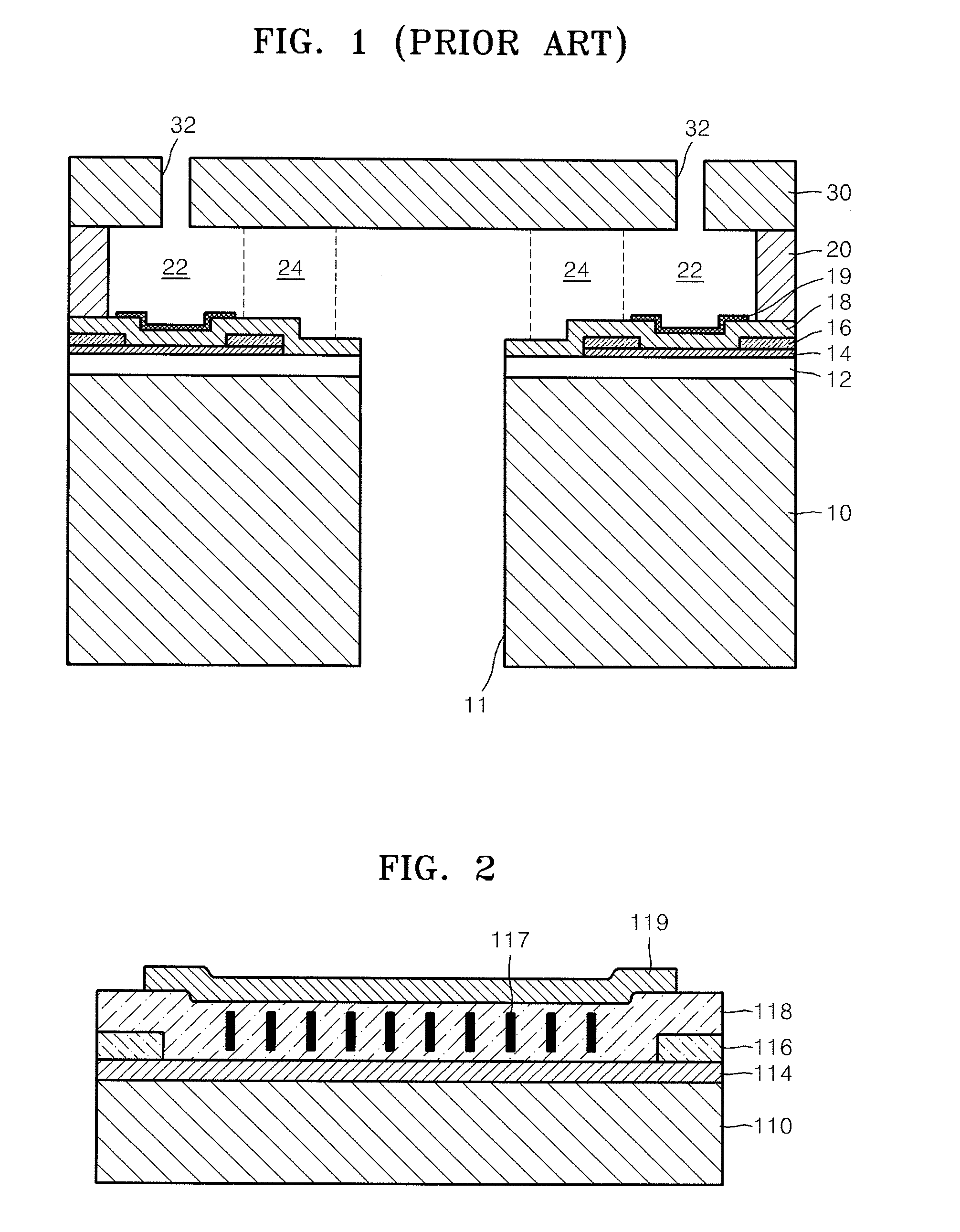

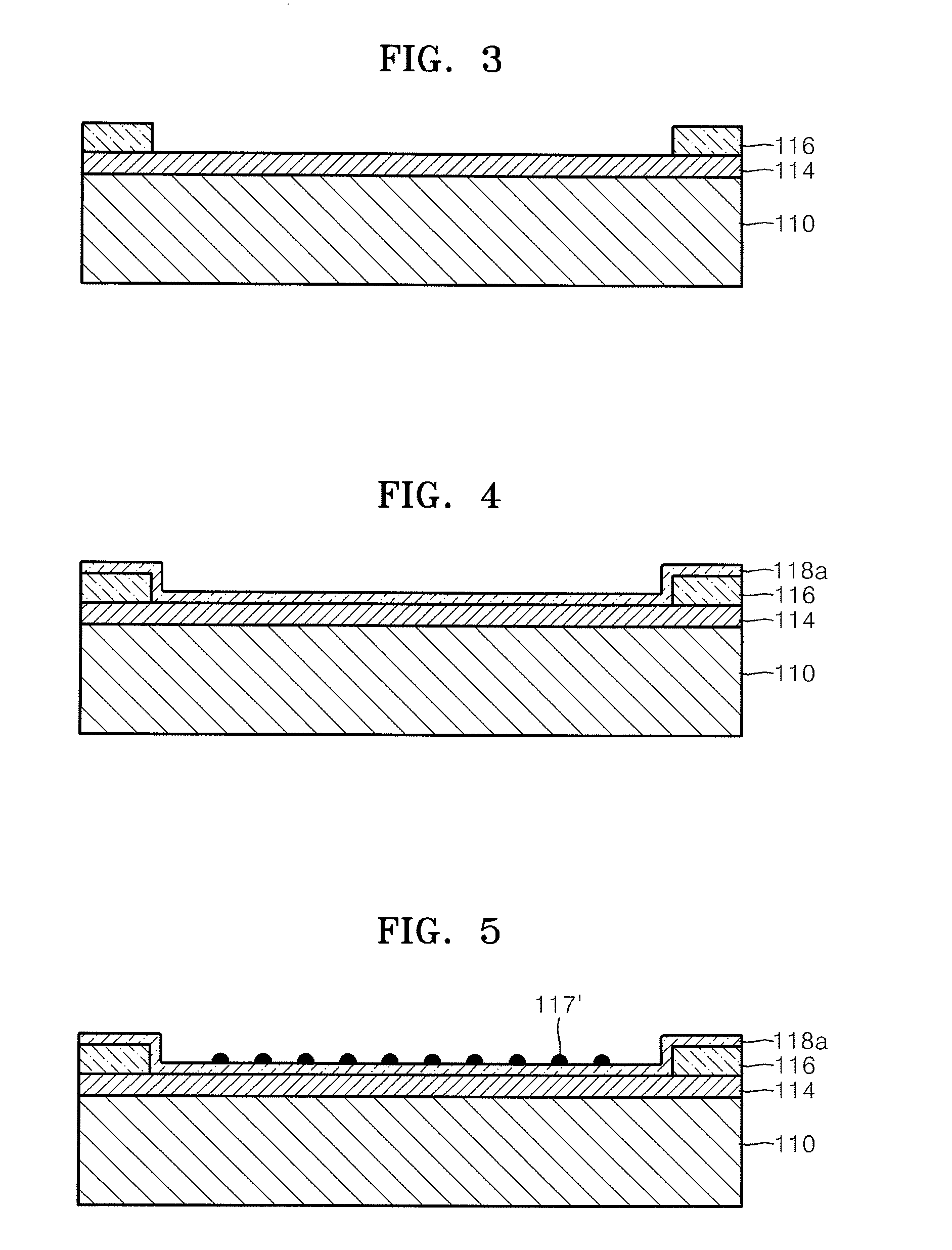

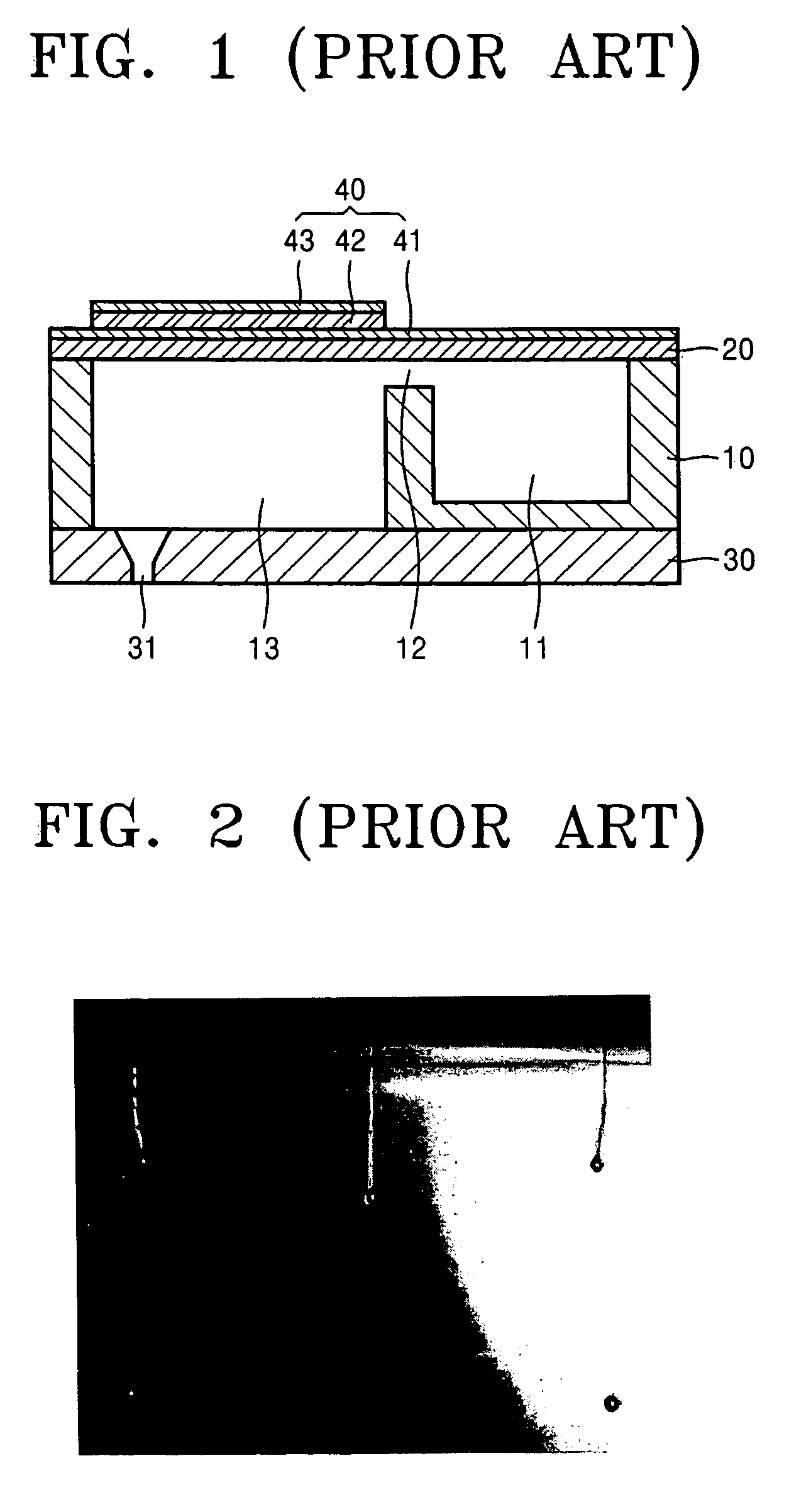

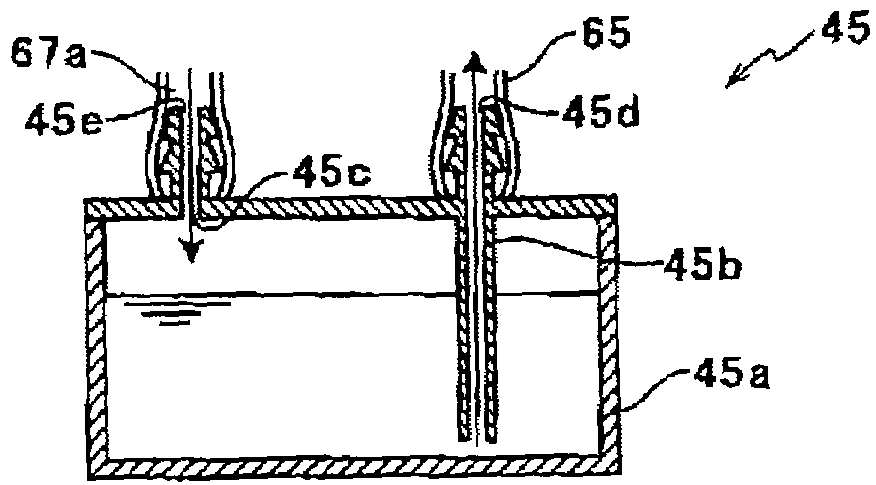

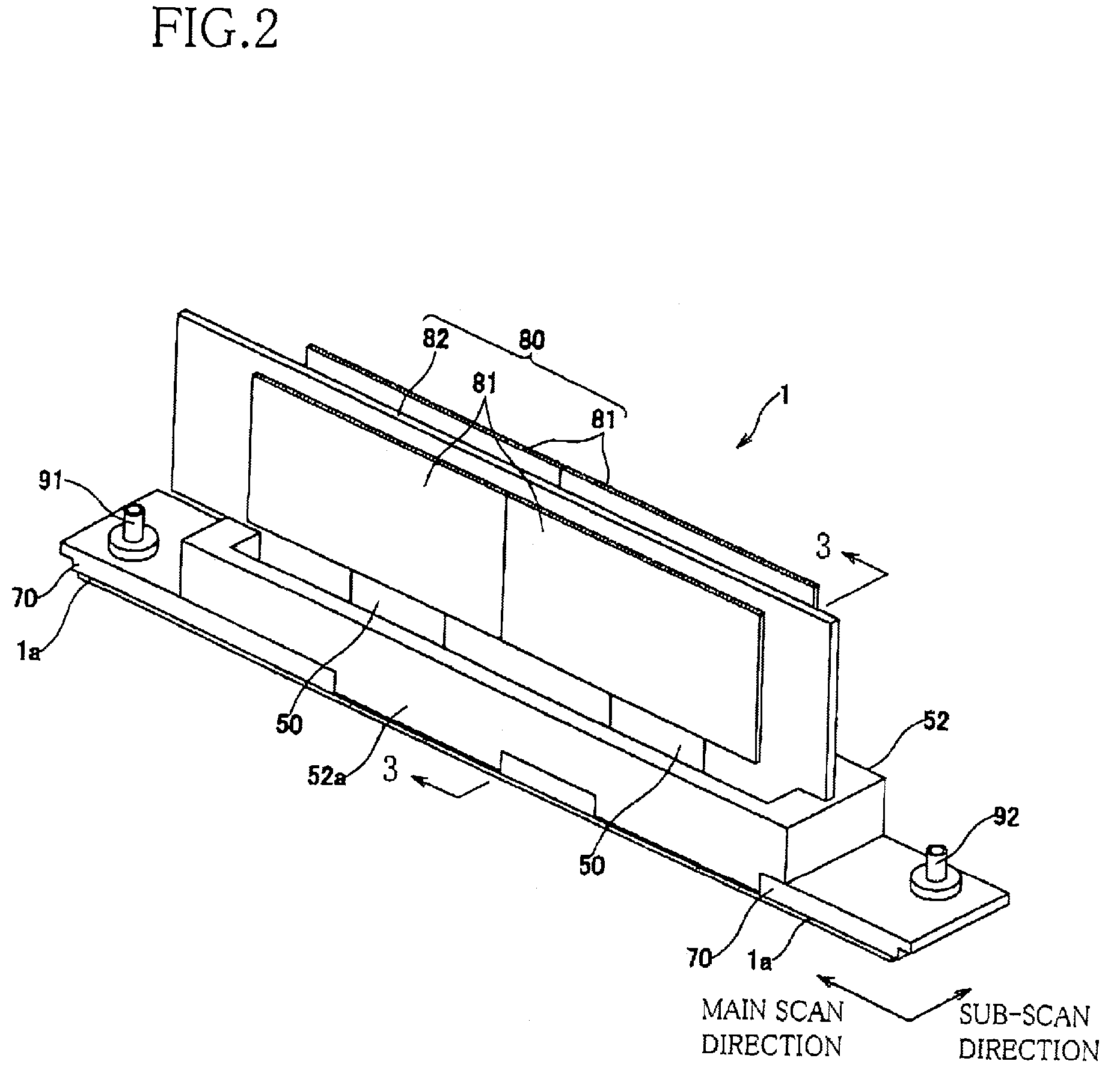

Inkjet printhead having bezel structure to remove ink bubbles

An inkjet printhead having a bezel structure to remove ink bubbles. The inkjet printhead includes a channel plate having an ink channel, actuators formed on the channel plate to provide driving forces to eject the ink, and an ink-supply bezel coupled to the channel plate. The ink-supply bezel includes an ink reservoir that is connected to an ink inlet and stores ink that is to be supplied to the ink channel, an ink supply port through which ink is supplied to the ink reservoir, and an air discharge port through which bubbles that are removed from the ink of the ink reservoir are discharged. The ink supply port and the air discharge port can be formed closed to both ends of the top surface of the ink reservoir, respectively. The ink supply port can have a bottom end lower than that of the air discharge port. The ink reservoir can include a sloped ceiling surface. Therefore, ink bubbles can be effectively removed from the ink before the ink is supplied to the ink channel.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

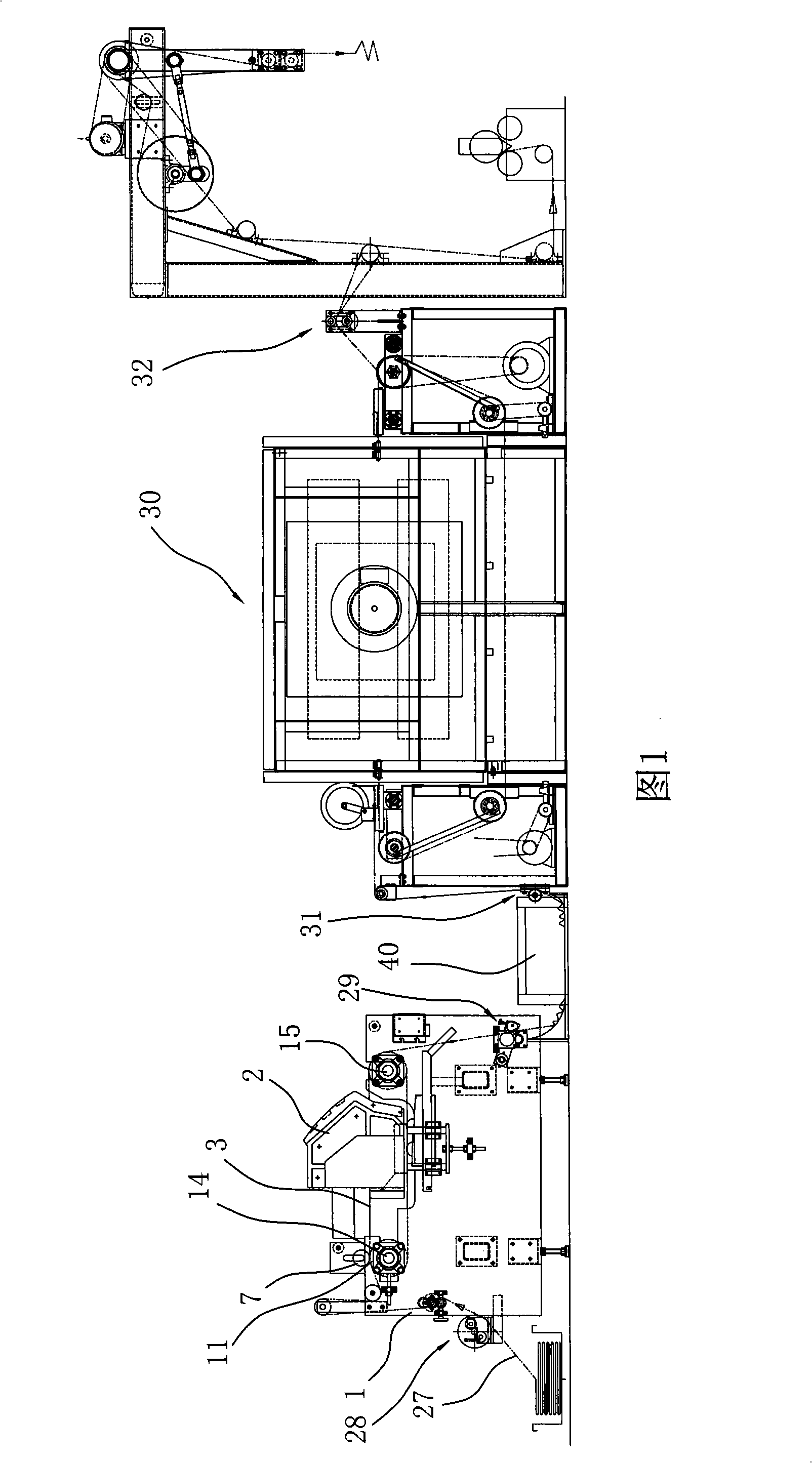

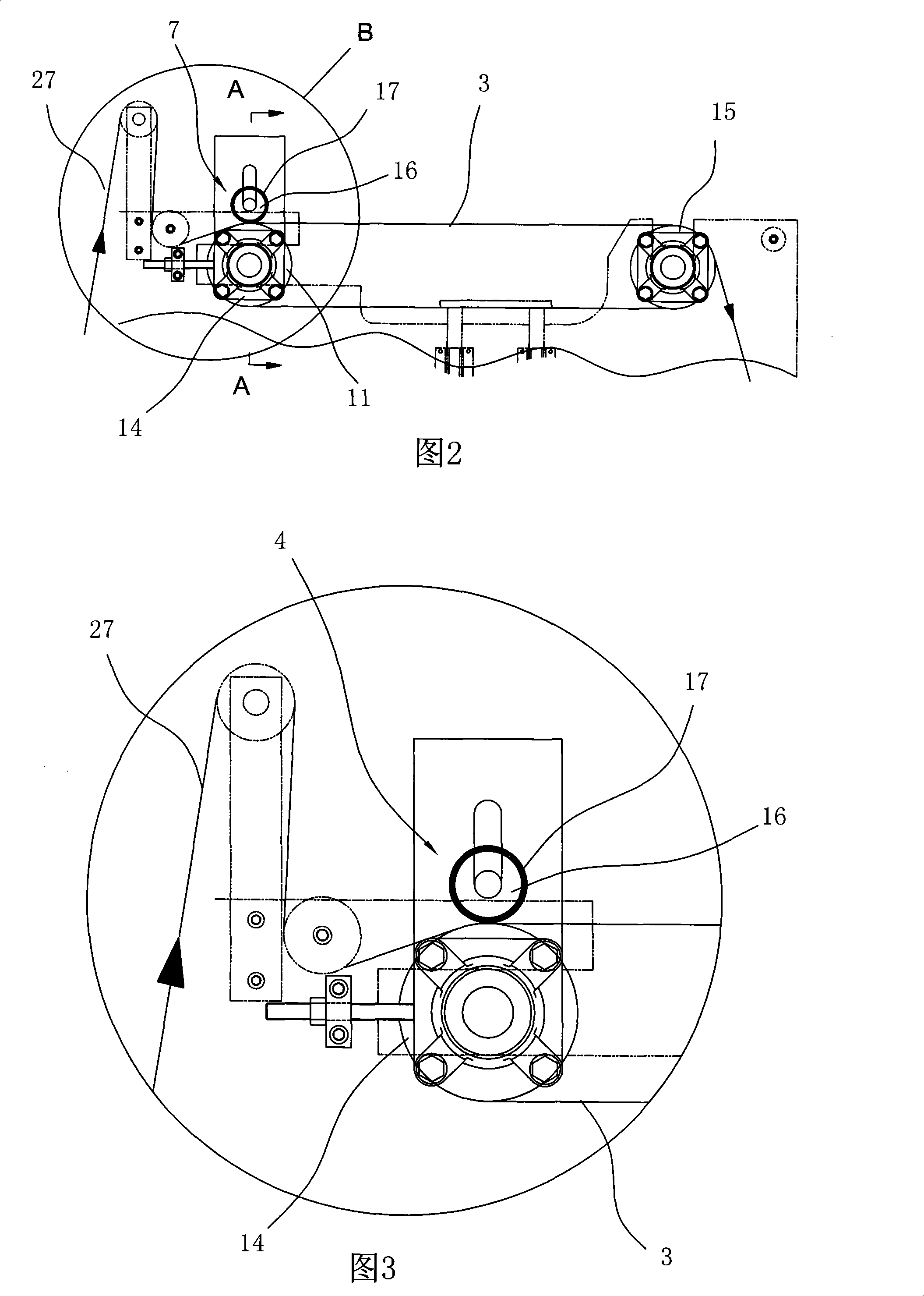

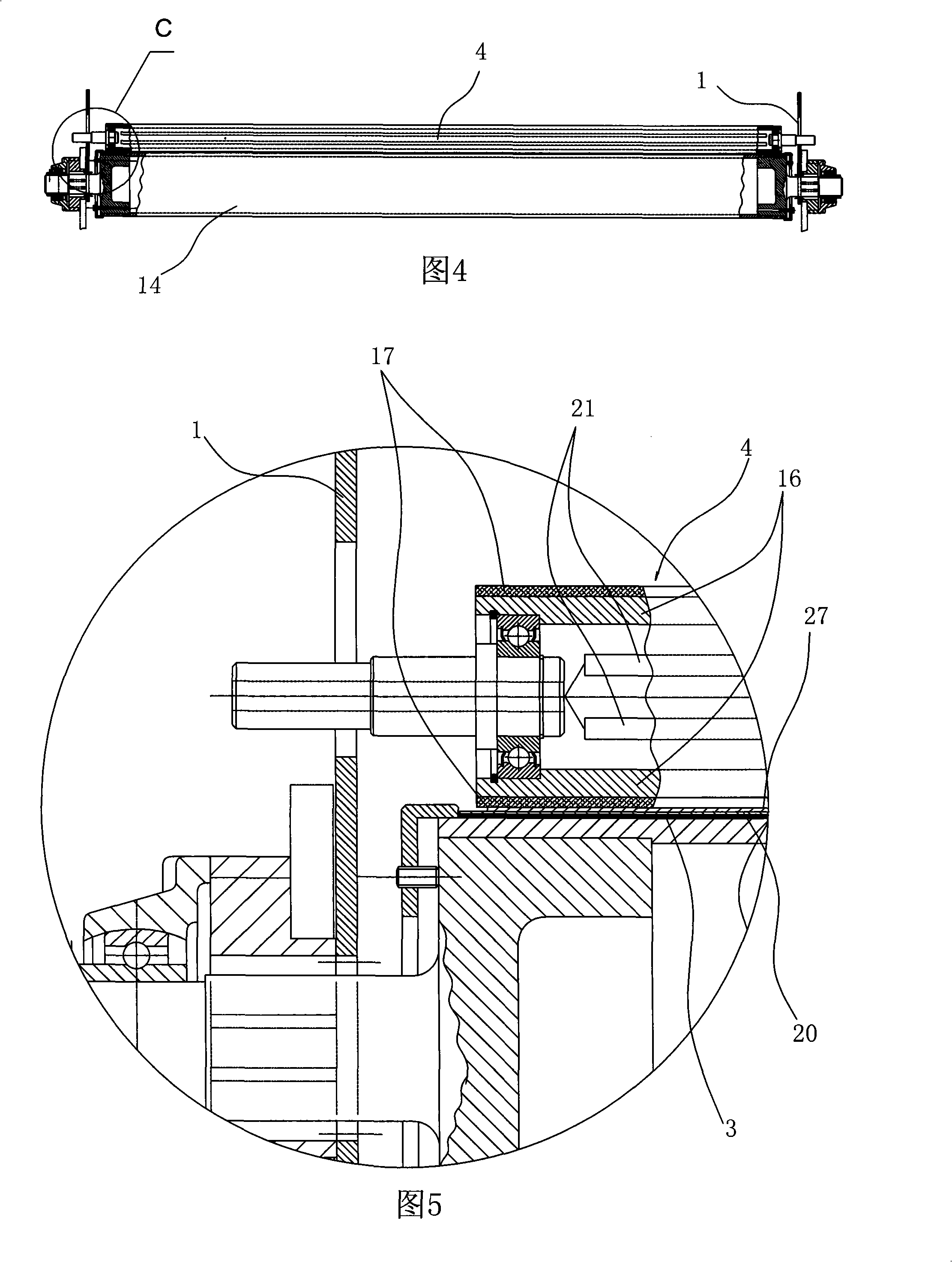

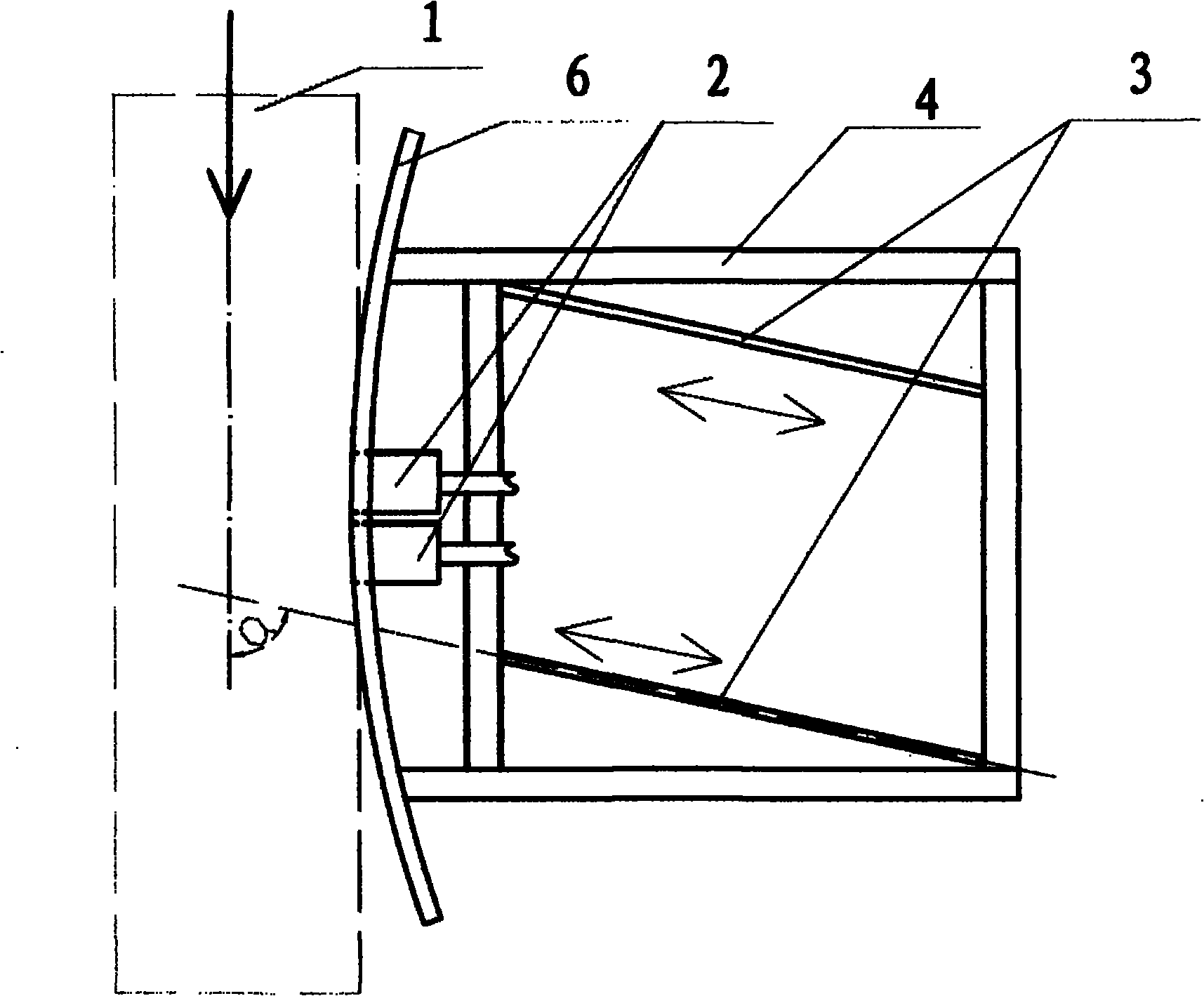

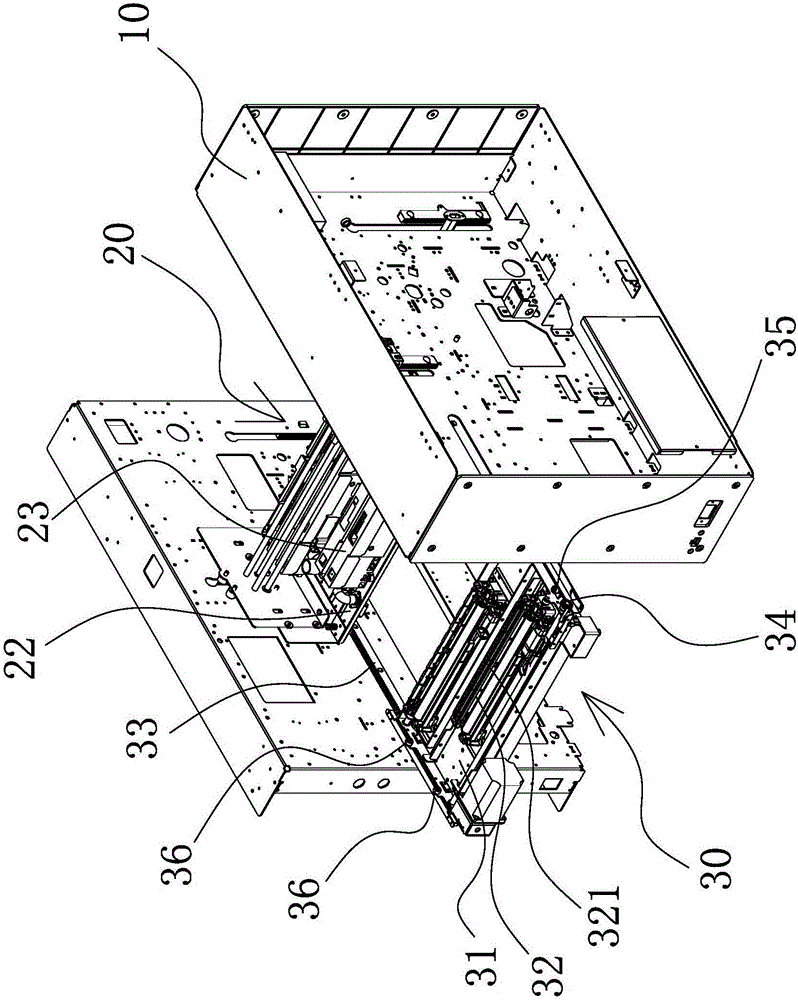

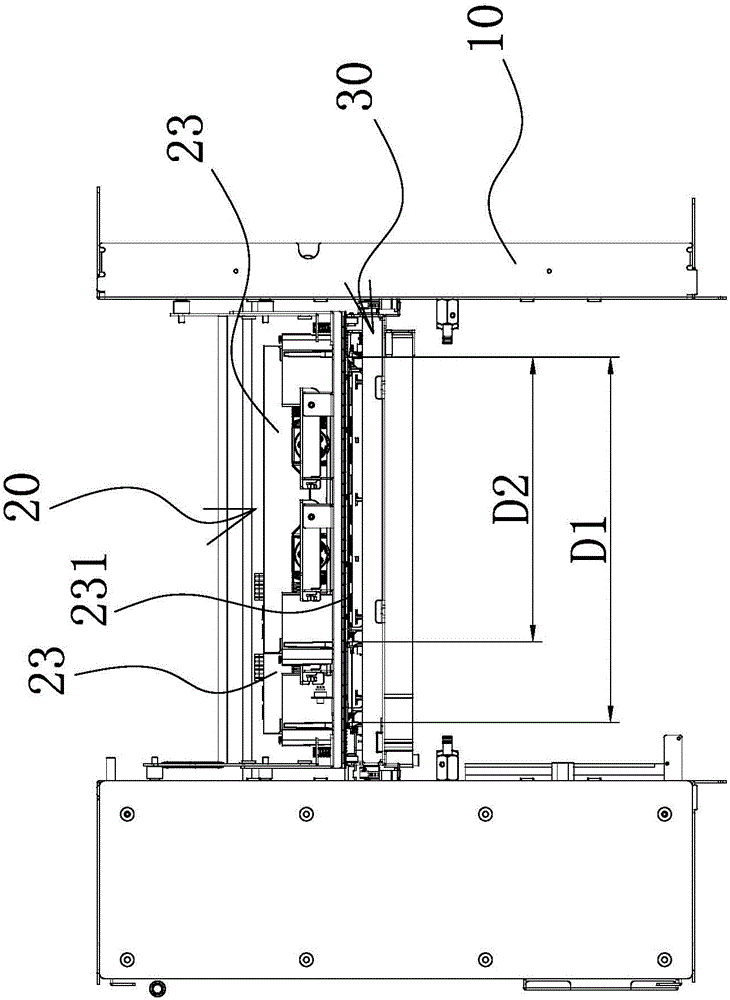

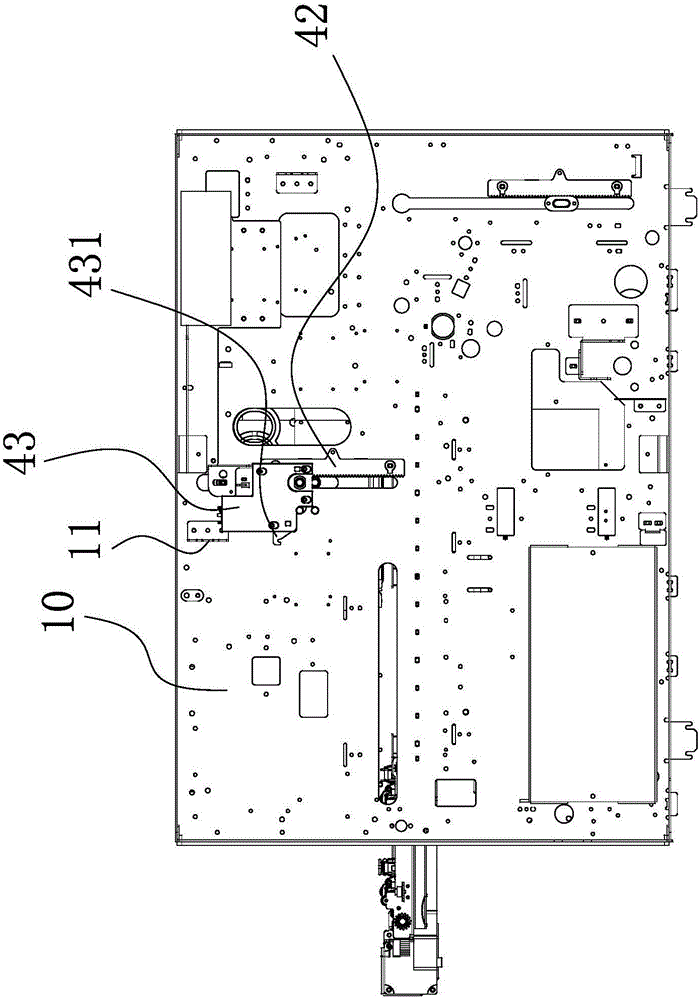

Waterless decorating machine

InactiveCN101402289AAvoid damageMeet the different needs of stickinessTypewritersOther printing apparatusConduction bandEvaporation

The invent relates to an anhydrous printing machine, which has a baking function, and is provided with a flexible patching device matched with a cloth guide conveying element, a conduction band walking straight mechanism, a carrier roller device, and an assistant nozzle arranged on a printing spray head. In order to match a pigment fixation assistant manufactured by an applicant, the pigment fixation assistant can match with a common pigment to spray and print for natural fabrics; the prior printing spray head is improved and additionally provided with a baking device to reduce subsequent evaporation and water washing equipment in the prior printing technique, save the space occupied by the equipment and reduce the cost for production equipment. At the same time, the anhydrous printing machine is also provided with the flexible patching device, the conduction band walking straight mechanism and the carrier roller device, keeps the moving track of conduction band conveying element stable, has good effect for bonding fabrics, keeps consistent speed with the printing spray head all along, and achieves the aim of accurately printing flower patterns. Moreover, the baking device has reasonable structure and smaller volume, and saves occupied area.

Owner:绍兴东升数码科技有限公司

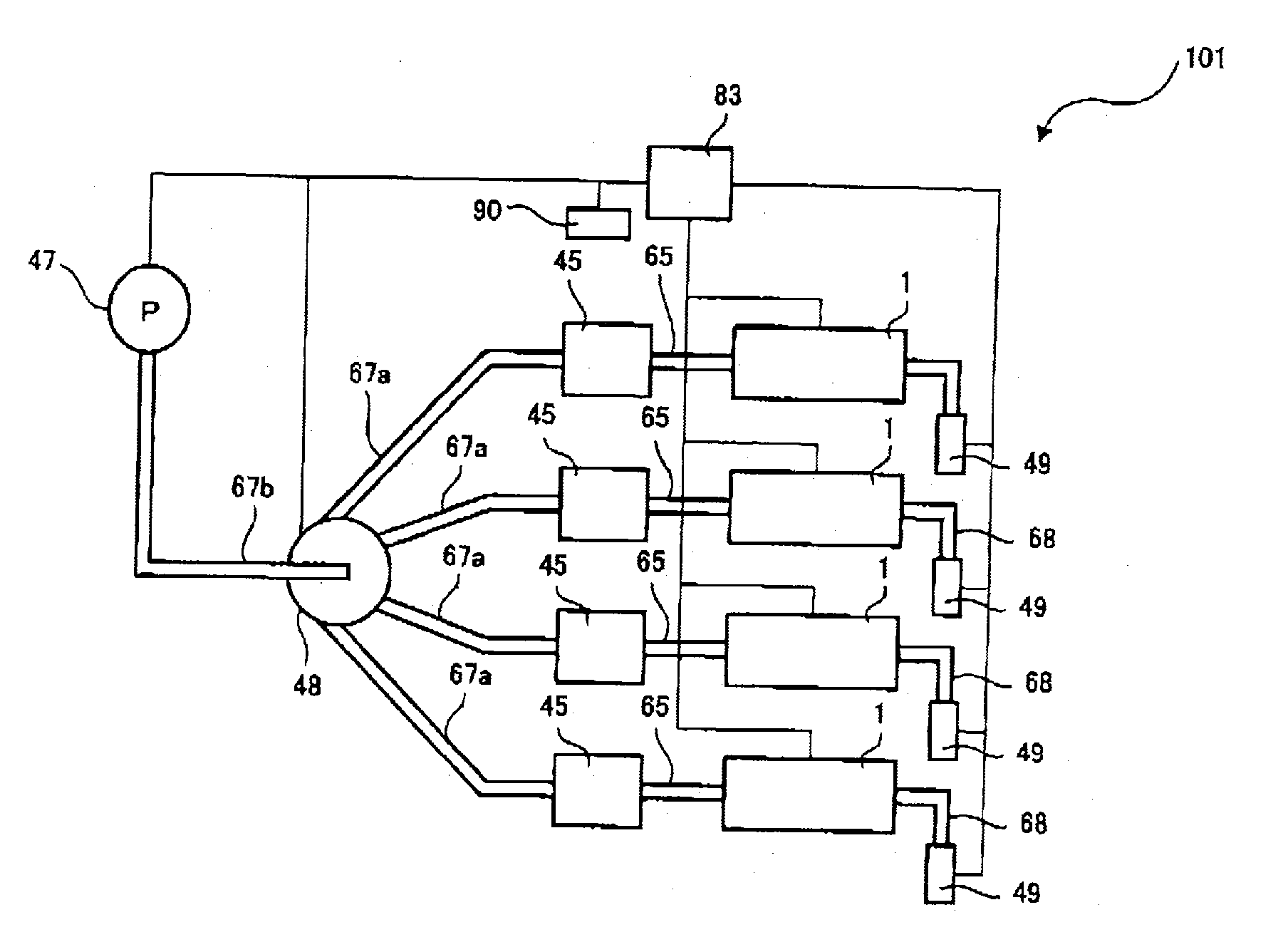

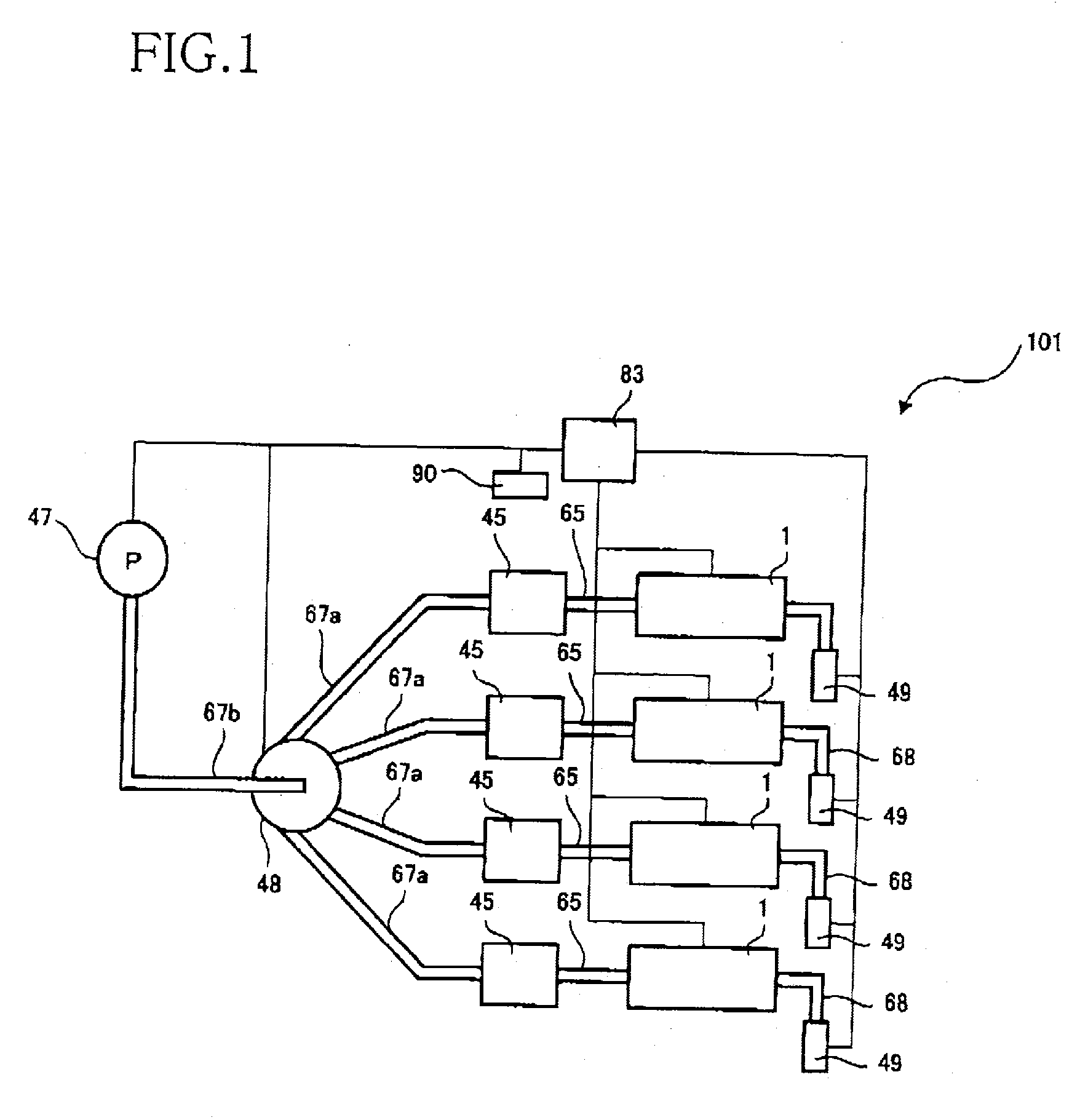

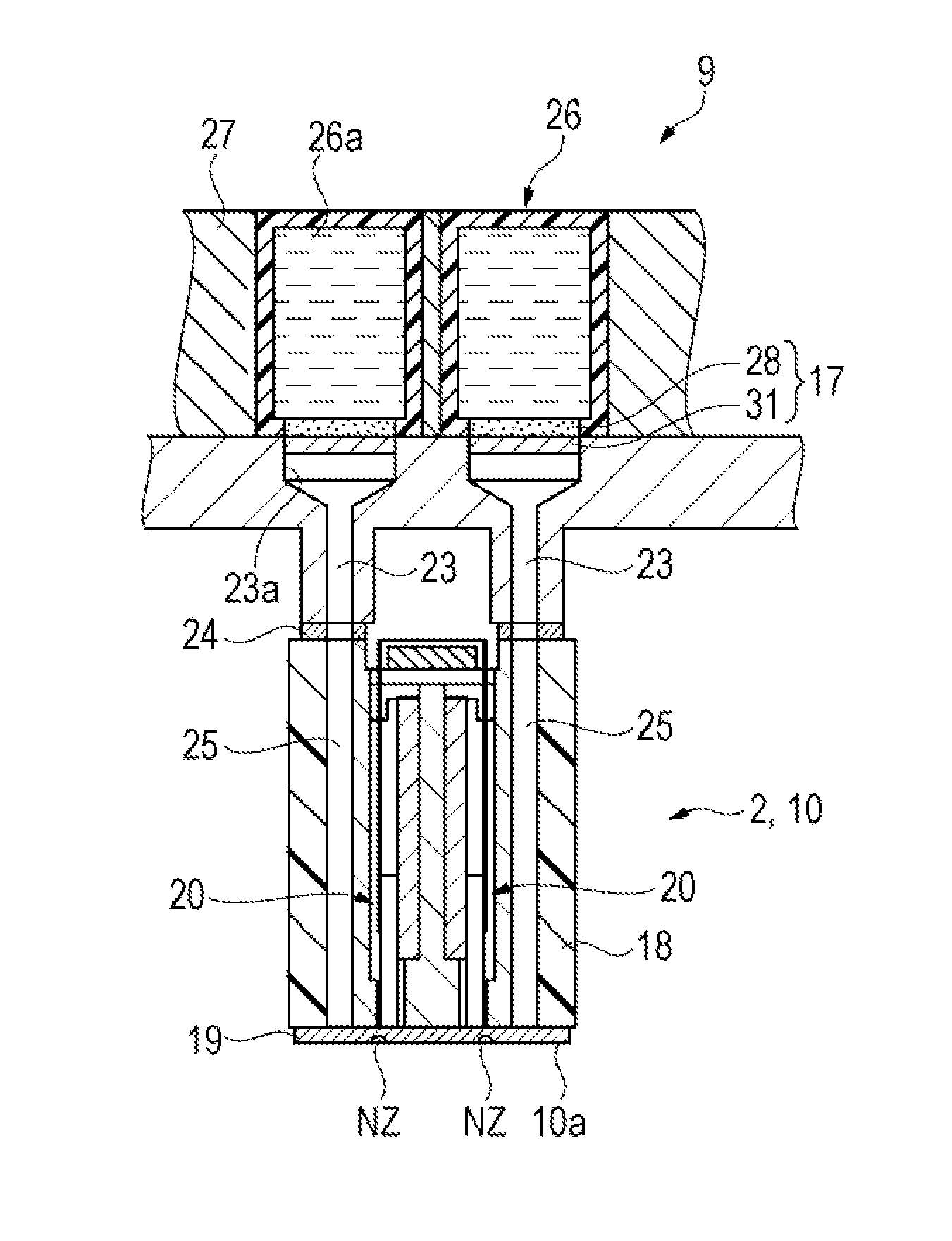

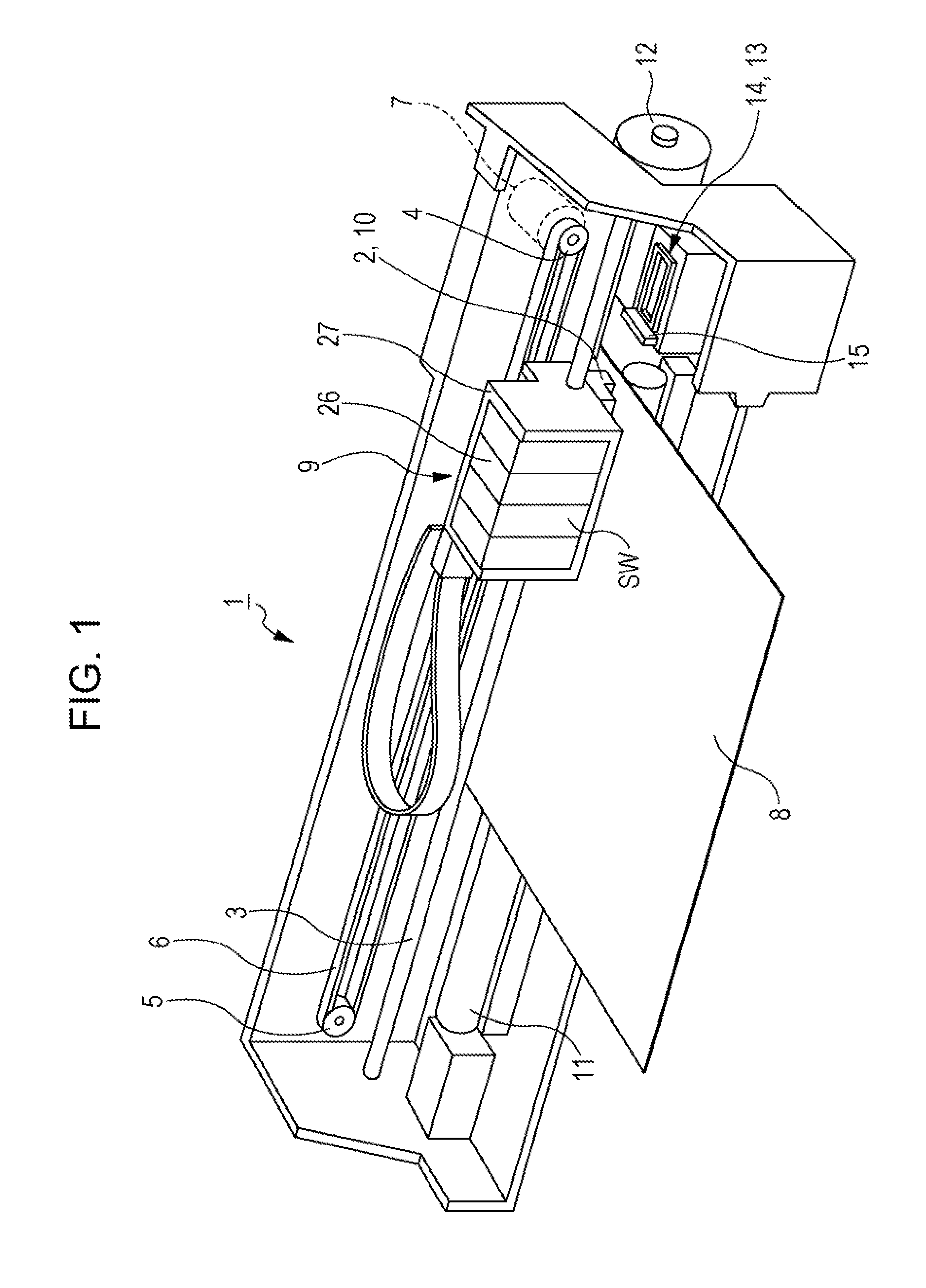

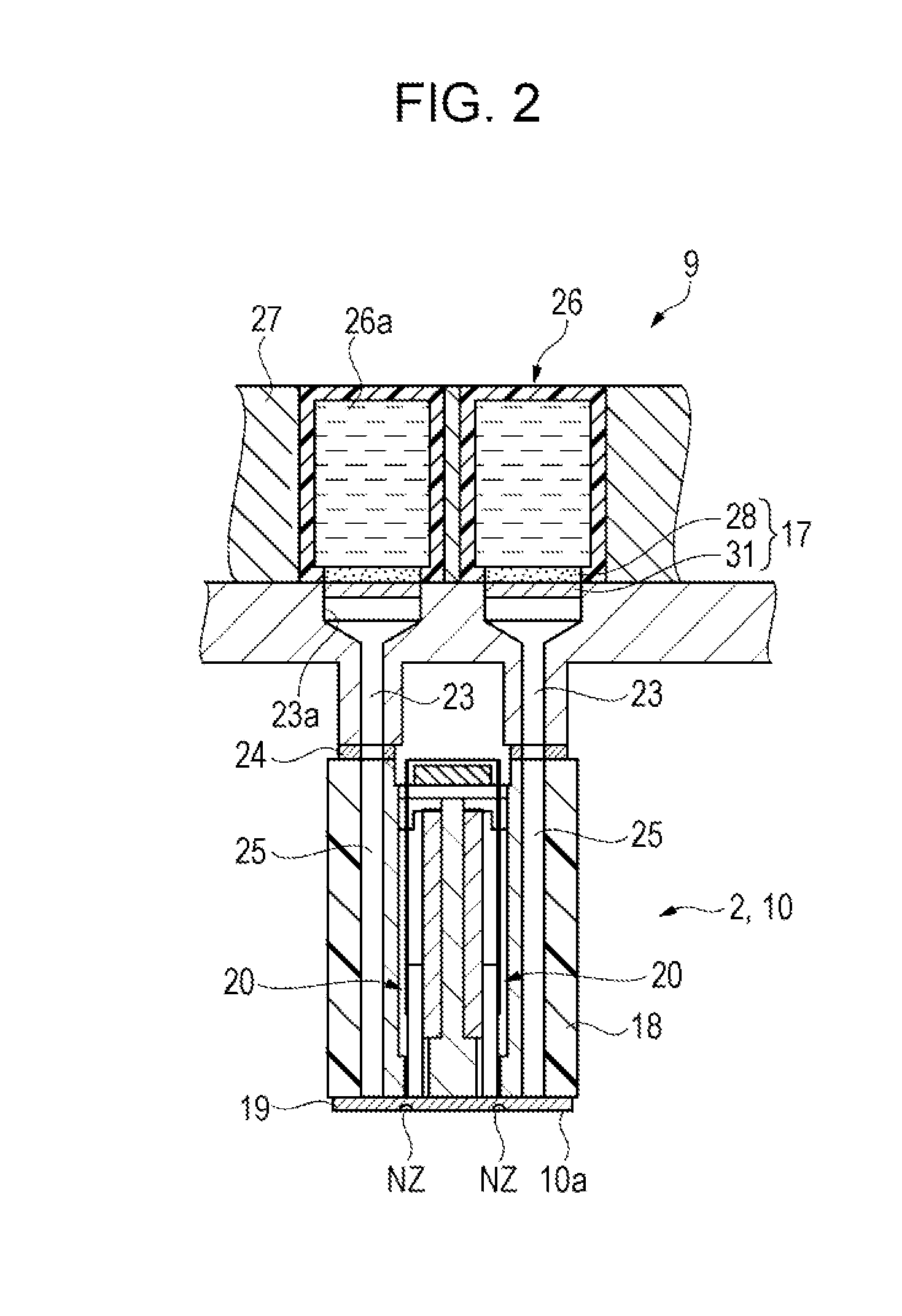

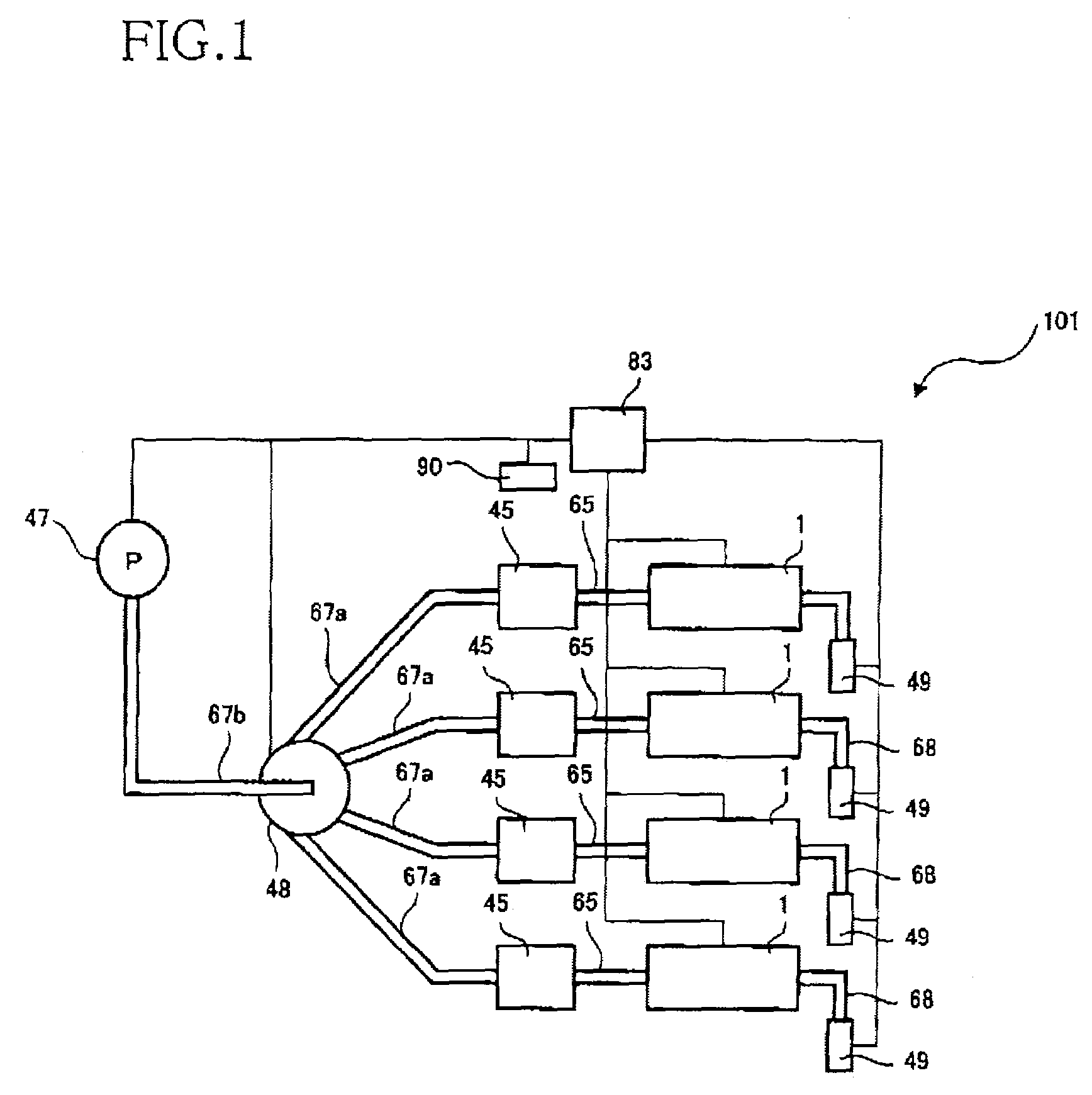

Ink-Jet Printer And Method Of Controlling Ink-Jet Printer

An ink-jet printer, including an ink-jet recording head having an ink inflow passage including an ink inlet, and an air-discharge passage which allows the ink inflow passage to communicate with an atmosphere; an air-discharge valve which selectively opens and closes the air-discharge passage; an ink tank which stores the ink and which has an ink outlet and an air inlet; a connector having an ink supply passage which communicates, at one end thereof, with the ink outlet of the ink tank and communicates, at an other end thereof, with the ink inlet of the recording head; an air supplying device which supplies the air to the ink tank via the air inlet thereof; an obtaining portion which obtains one of an elapsed time, t, from a reference time, and a volume, V, of an air present in the ink supply passage and the ink inflow passage at the elapsed time t, based on an other of the elapsed time t and the air volume V, and a following relationship: V=a·ebt, where a and b are coefficients and e is a base of a natural logarithm; and a control portion which controls, based on the obtained one of the elapsed time t and the air volume V, an operation of the air supplying device and / or the air-discharge valve, so that the volume V of the air at the elapsed time t is discharged through the air-discharge passage opened by the air-discharge valve.

Owner:BROTHER KOGYO KK

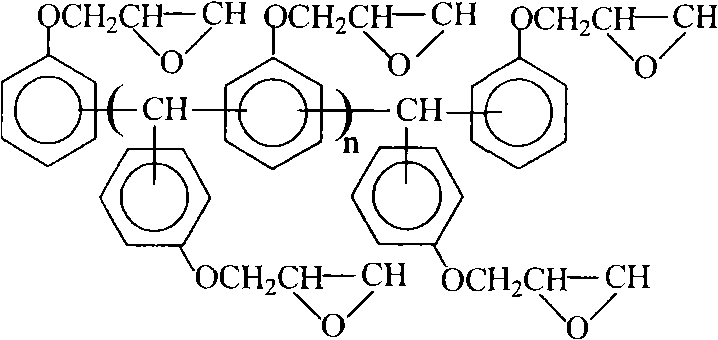

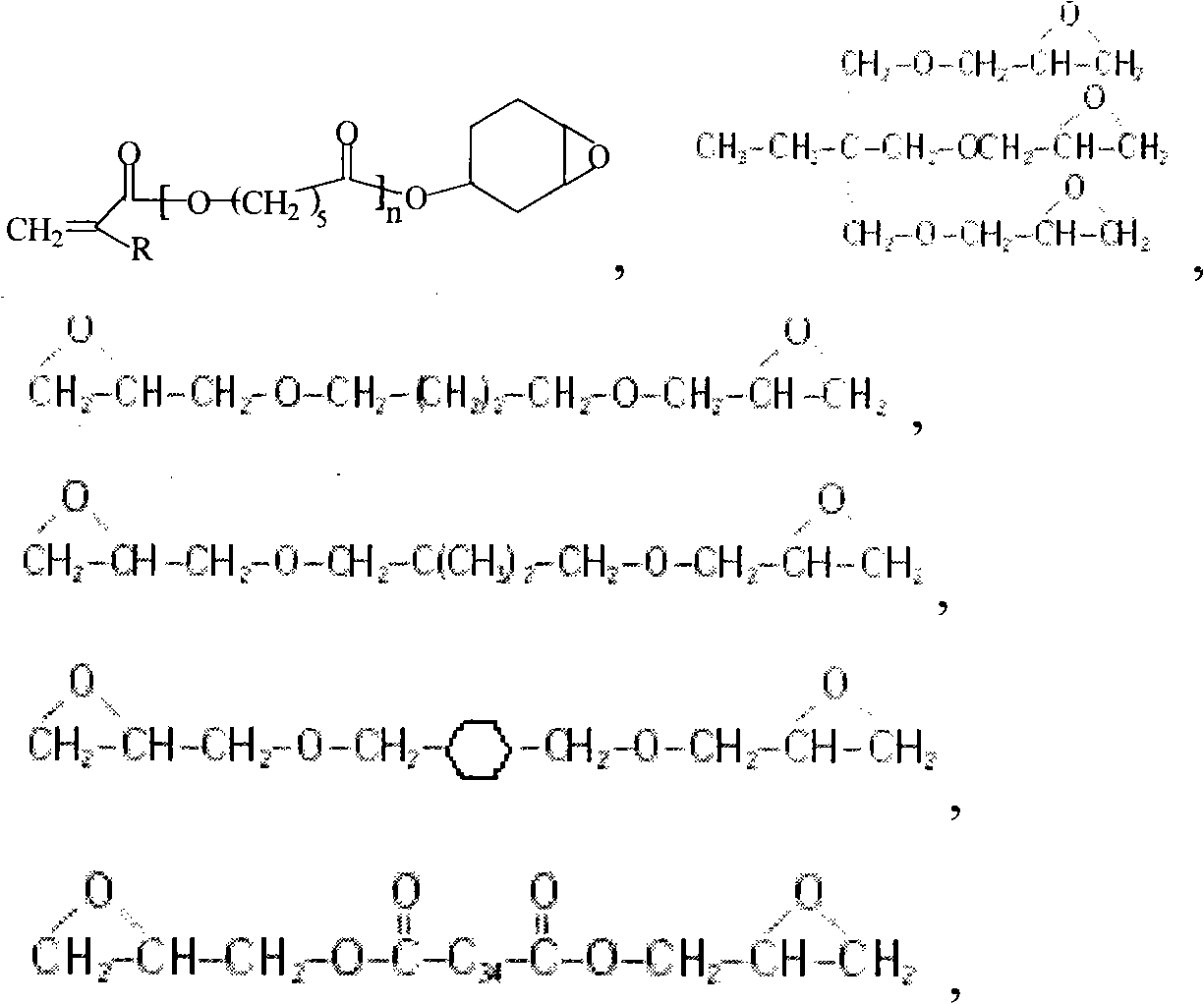

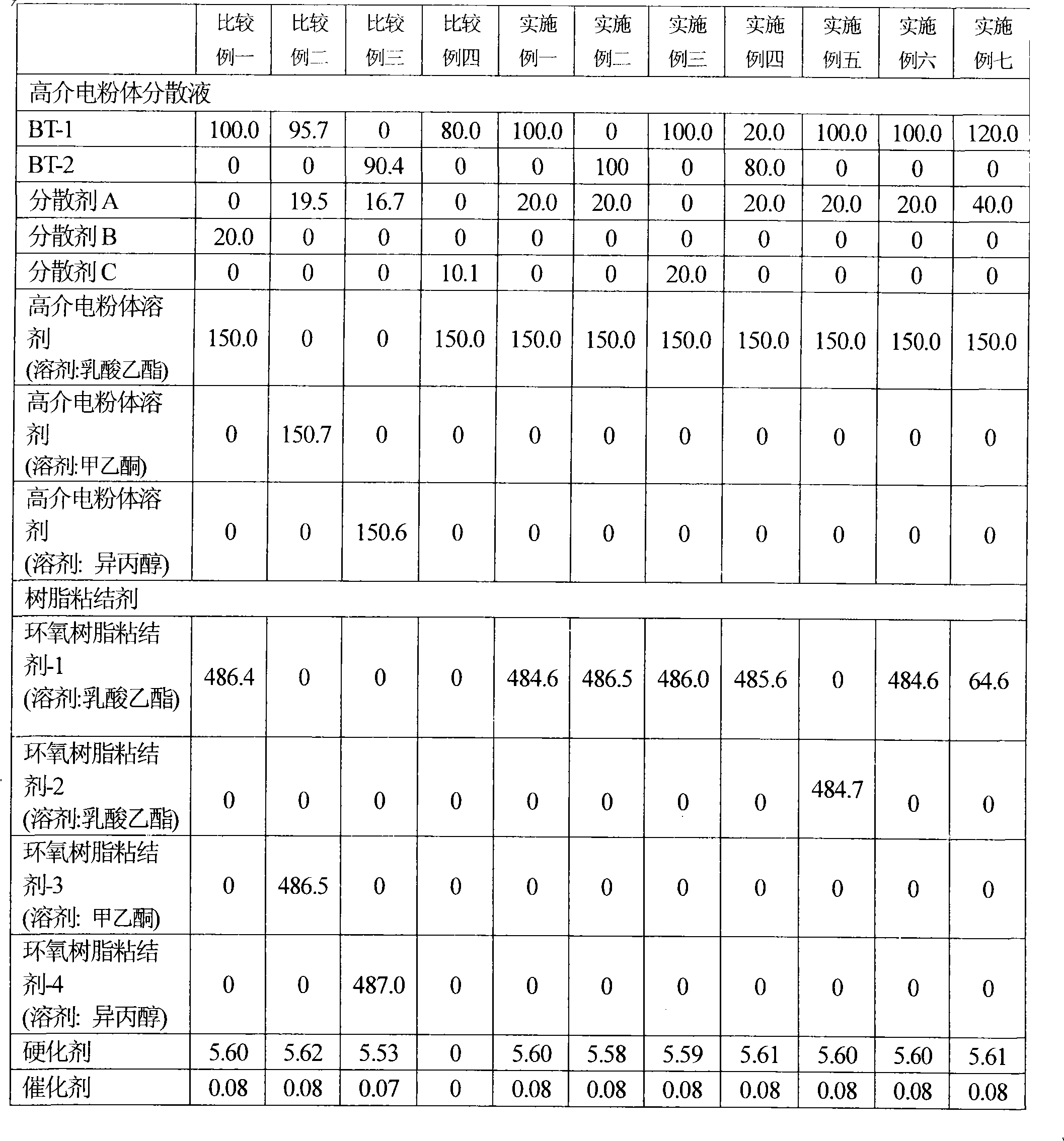

Curable cross-linked type ink composition and dielectric film

InactiveCN101525511AGood inkjet effectImprove heat resistanceFixed capacitor dielectricPrinted electric component incorporationCross-linkEpoxy

The invention relates to a curable cross-linked type ink composition and a dielectric film. The curable cross-linked type ink composition comprises approximate 1 to 10 weight portions of cross-linked curable epoxide resin system, approximate 1 to 30 weight portions of ferroelectric ceramic powder body, approximate 0.1 to 10 weight portions of macromolecular dispersant, and approximate 50 to 96 weight portions of solvent. The ink composition is suitable to manufacture super-dielectric films applied to embedded type capacitors in an ink jet mode.

Owner:IND TECH RES INST

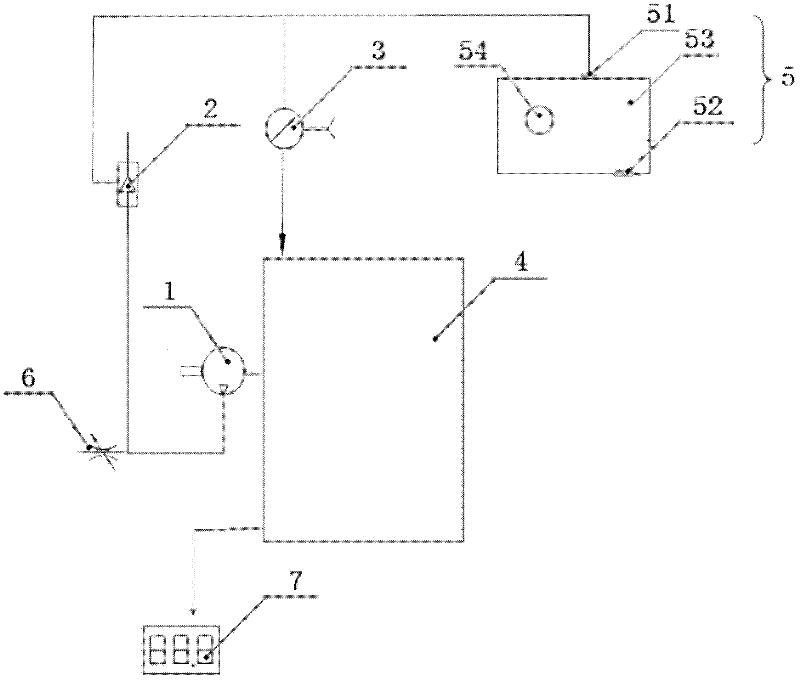

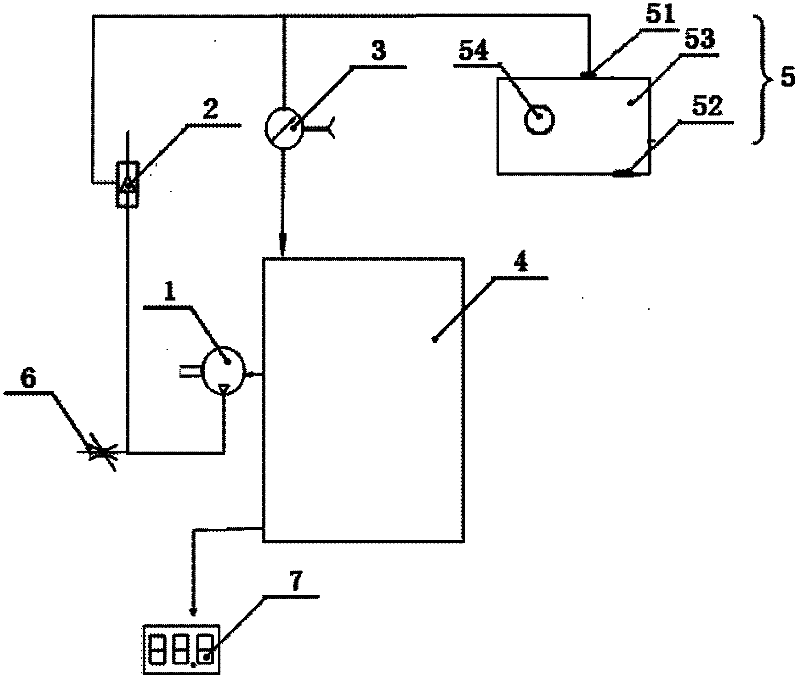

Rigid printed circuit board spray printing negative-pressure ink supply pressure control system and method

InactiveCN102501606AEnsure negative pressure stabilityGood inkjet effectPrintingMicrocontrollerAutomatic control

The invention provides a negative-pressure ink supply pressure control system and method of rigid printed circuit board spray printing equipment. The system comprises a vacuum pump, a vacuum generator, a gas pressure transducer, a singlechip and a spray head device, wherein the vacuum pump is connected with the vacuum generator, the vacuum generator is connected with the spray head device, and the spray head device is simultaneously connected with the gas pressure transducer; and the gas pressure transducer is connected with the data input end of the singlechip, and the signal output end of the singlechip is connected with the vacuum pump. The method is used for monitoring the negative pressure condition in the spray head device through the gas pressure transducer and the singlechip in real time, the operating current of the vacuum pump is adjusted so as to realize automatically controlling the stable negative pressure of the spray head device. According to the technical scheme provided by the invention, automatic control on the stable negative pressure in a negative-pressure ink supply system is realized.

Owner:江苏汉印机电科技股份有限公司

Ink jet head, control method therefor, and ink jet recording apparatus

InactiveUS7311384B2Improve high-speed stabilityAchieve stabilityOther printing apparatusEngineeringVoltage

Owner:FUJIFILM CORP +1

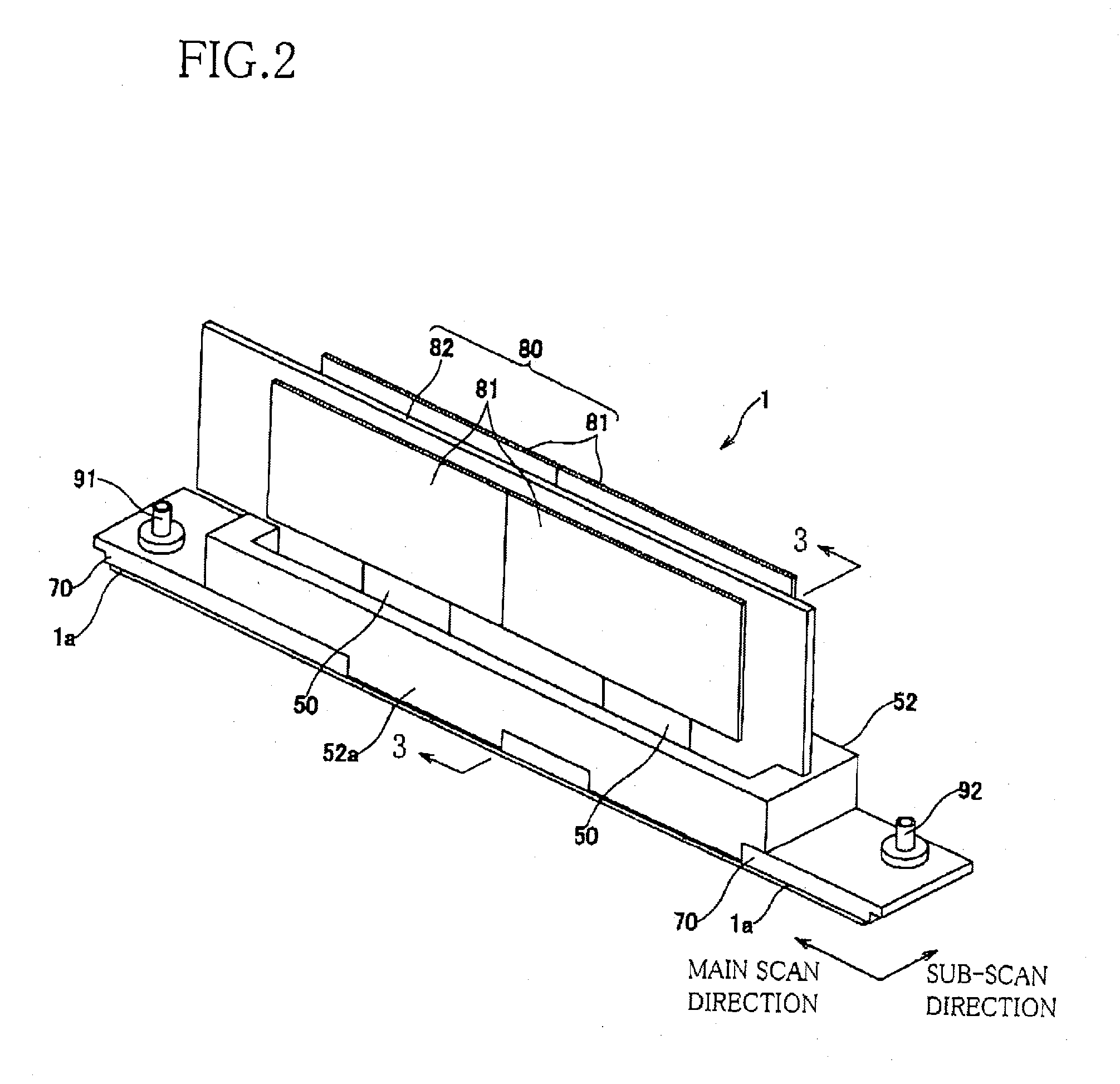

Liquid ejecting apparatus

ActiveUS20140049581A1Prevent leakageGood inkjet effectPower drive mechanismsEngineeringExternal Liquid

A liquid ejecting apparatus includes a carriage having a removable liquid receptacle that holds a liquid or a removable connector connected via a flexible liquid channel to an external liquid receptacle that holds a liquid, an ejecting head, mounted in the carriage, that has a nozzle that ejects the liquid, and a maintenance unit that runs maintenance on the ejecting head; the ejecting head has a filter disposed so as to be capable of contact with a liquid absorption member provided in the liquid receptacle and in the connector.

Owner:SEIKO EPSON CORP

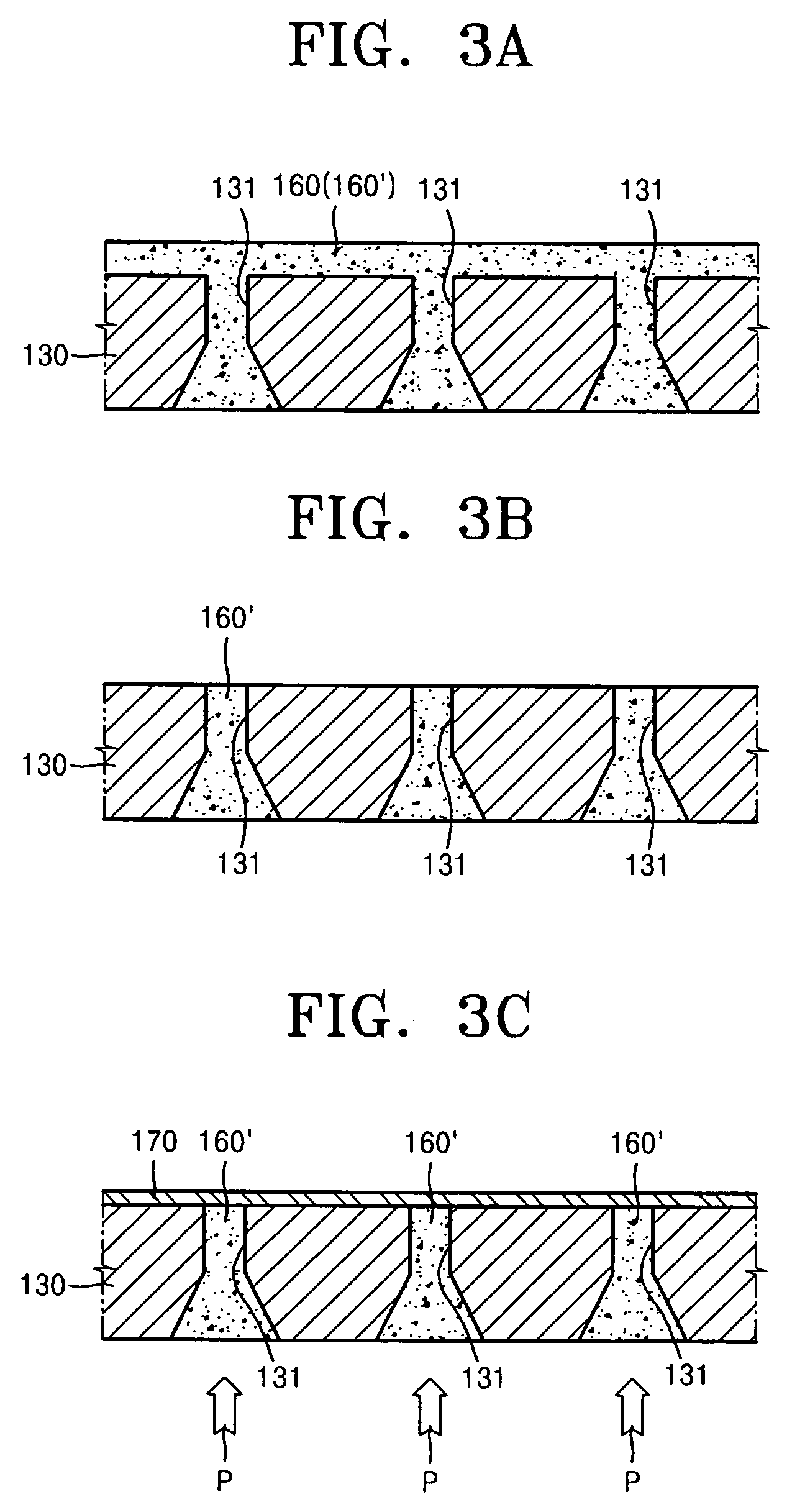

Heating structure with a passivation layer and inkjet printhead including the heating structure

InactiveUS7780270B2Good inkjet effectInking apparatusLiquid surface applicatorsCarbon nanotubeMaterials science

A heating structure of an inkjet printhead and an inkjet printhead including the heating structure. The heating structure includes a substrate, a heater formed on the substrate, an electrode formed on the heater, a passivation layer formed to cover the heaters and the electrodes, and carbon nanotubes (CNTs) formed in the passivation layer.

Owner:HEWLETT PACKARD DEV CO LP

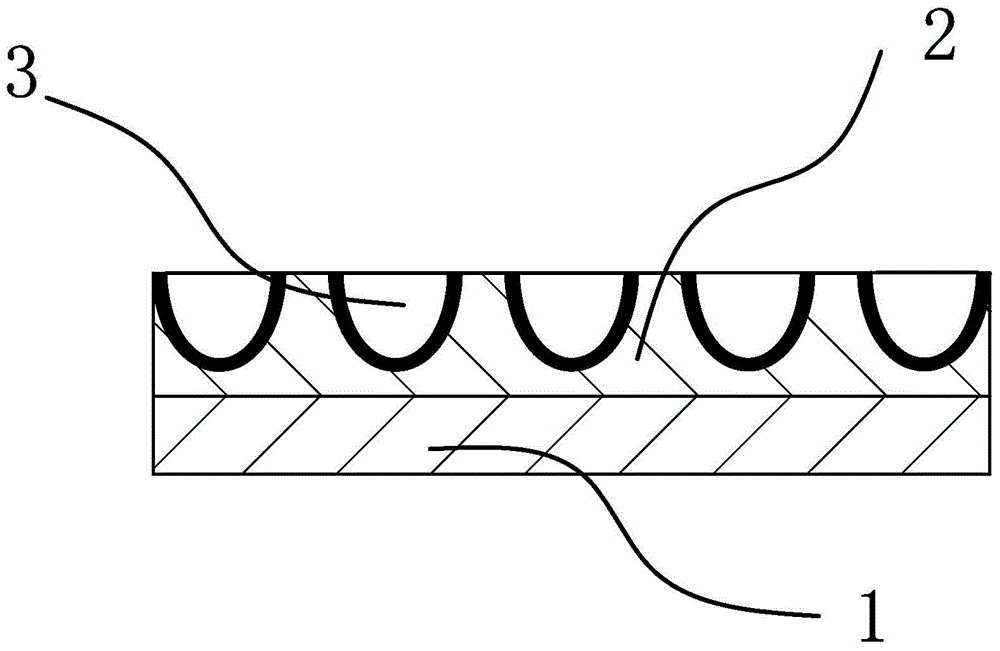

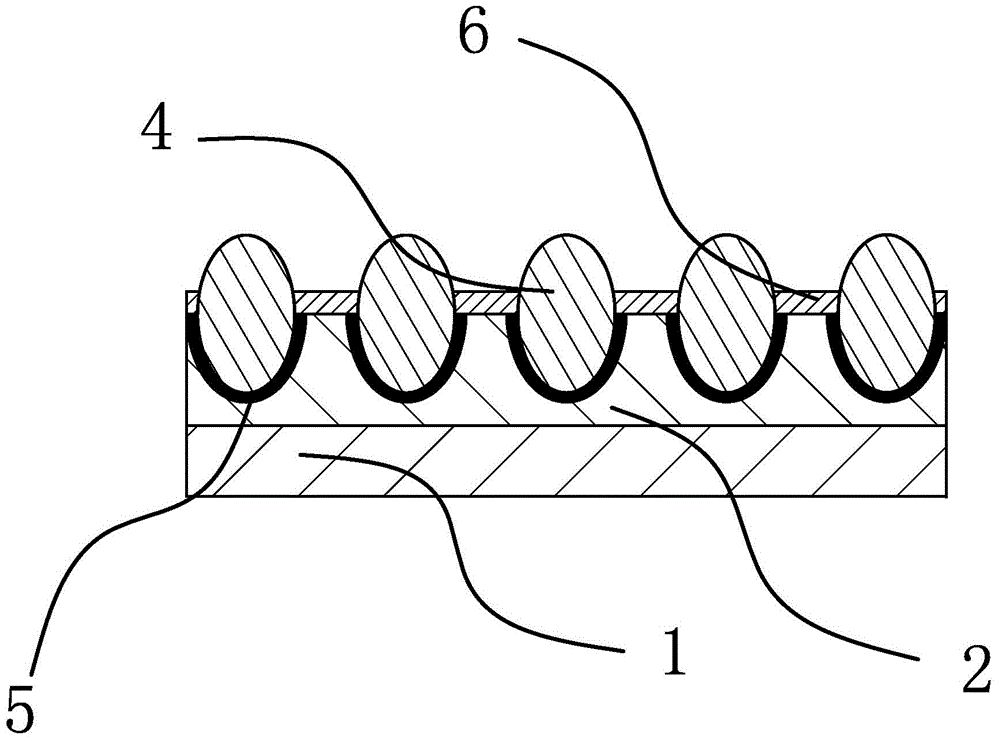

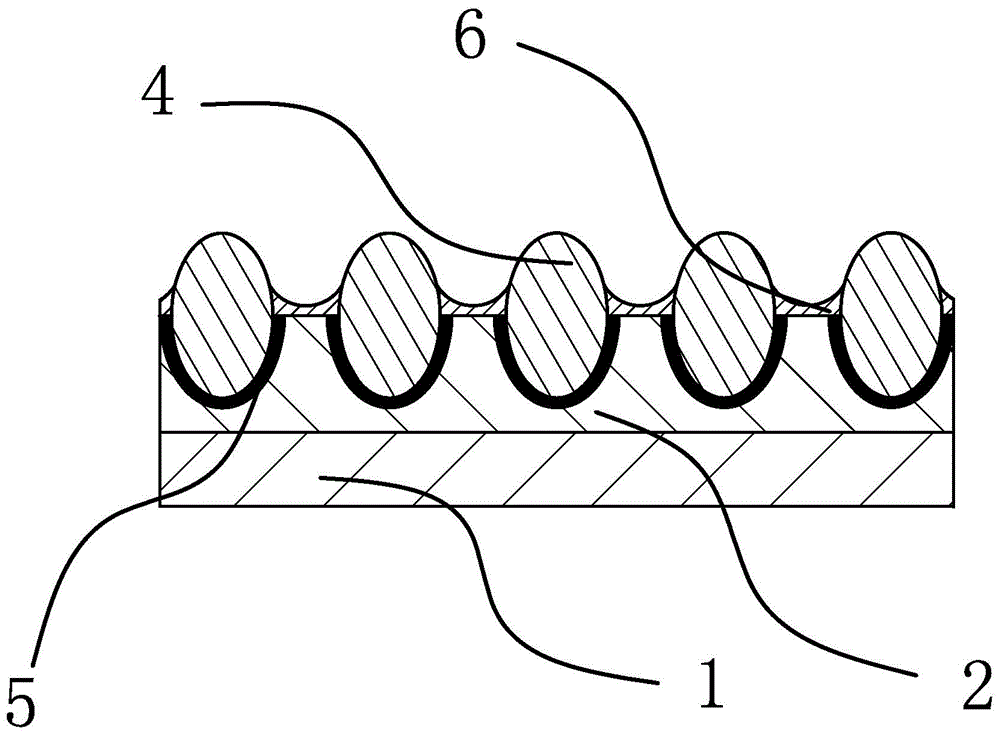

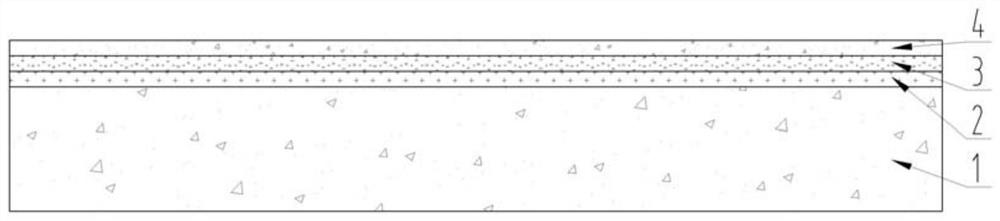

Thermosensitive type light reflection film capable of being jet printed

ActiveCN104932047AGood inkjet effectHigh coefficient of retroreflectionSynthetic resin layered productsGlass/slag layered productsLight reflectionReflective layer

The invention relates to a thermosensitive type light reflection film capable of being jet printed, and belongs to the technical field of reflecting materials. The existing problem that high retro-reflecting coefficient and jet printing can not be achieved simultaneously is solved, the light refection film comprises a thermosensitive adhesive layer and a resin layer which are overlapped in sequence from top to bottom and fixed, multiple grooves are formed in the upper portion of the resin layer, each groove is internally embedded with a glass bead, a reflecting layer is laid between a groove wall of each groove and the corresponding glass bead, coatings capable of being jet printed are arranged on the upper surface of the resin layer, and the upper portion of each glass bead is higher than the corresponding coating capable of being jet printed. The thermosensitive type light reflection film capable of being jet printed has a better jet printing effect, and the double-effect of higher retro-reflecting coefficient is achieved. The coatings capable of being jet printed between each two glass beads are designed to be shaped like a sunken arc surface, so that the effect that the retro-reflecting coefficient is greater than 400 cd.lx<-1>.m<-2> is achieved.

Owner:ZHEJIANG YGM TECH CO LTD

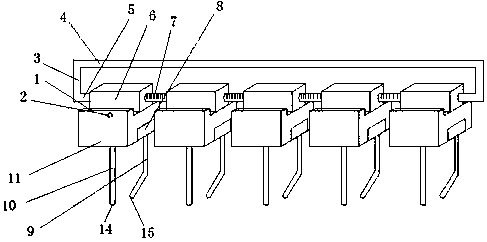

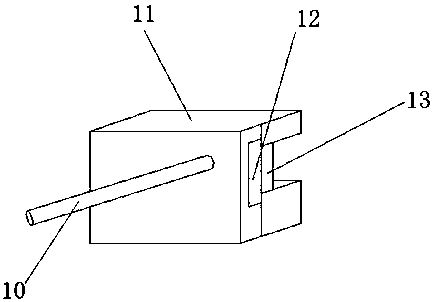

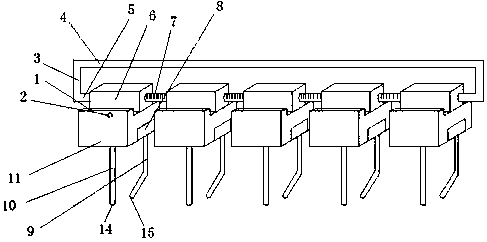

Ink jetting device printing head for printed circuit board

InactiveCN109955590AEasy to printEasy to operateTypewritersOther printing apparatusPrinted circuit boardBlow out

The invention discloses an ink jetting device printing head for a printed circuit board. The ink jetting device printing head comprises printing head devices and a lateral connecting rod. A clamping groove is formed in one side of a fixed connecting column. Air blowing devices are arranged on one sides of the printing head devices. The lower ends of the air blowing devices are provided with air outlet pipelines and air outlets. One end of the lateral connecting rod is provided with a fixed cross rod. A movable connecting rod is arranged on the other side of the lateral connecting rod. Distancescales are arranged on the outer surface of the lateral connecting rod. The ink jetting device printing head for the printed circuit board is provided with the air blowing device, the movable connecting rod and the clamping groove, so that ink oil which is just sprayed onto the circuit board can be blow-dried by hot air blown out, and the condition that the ink oil cannot be fixed to the circuitboard in a short time is avoided. The distances between the printing head devices are controlled within a reasonable range by sliding the printing head devices left and right and observing the distance scales. The ink jetting device printing head for the printed circuit board is applicable to different working conditions and has a better application prospect.

Owner:福州市鼓楼区赢泰润丰投资管理有限公司

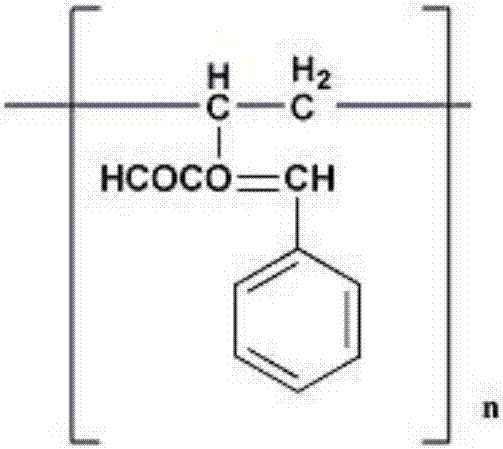

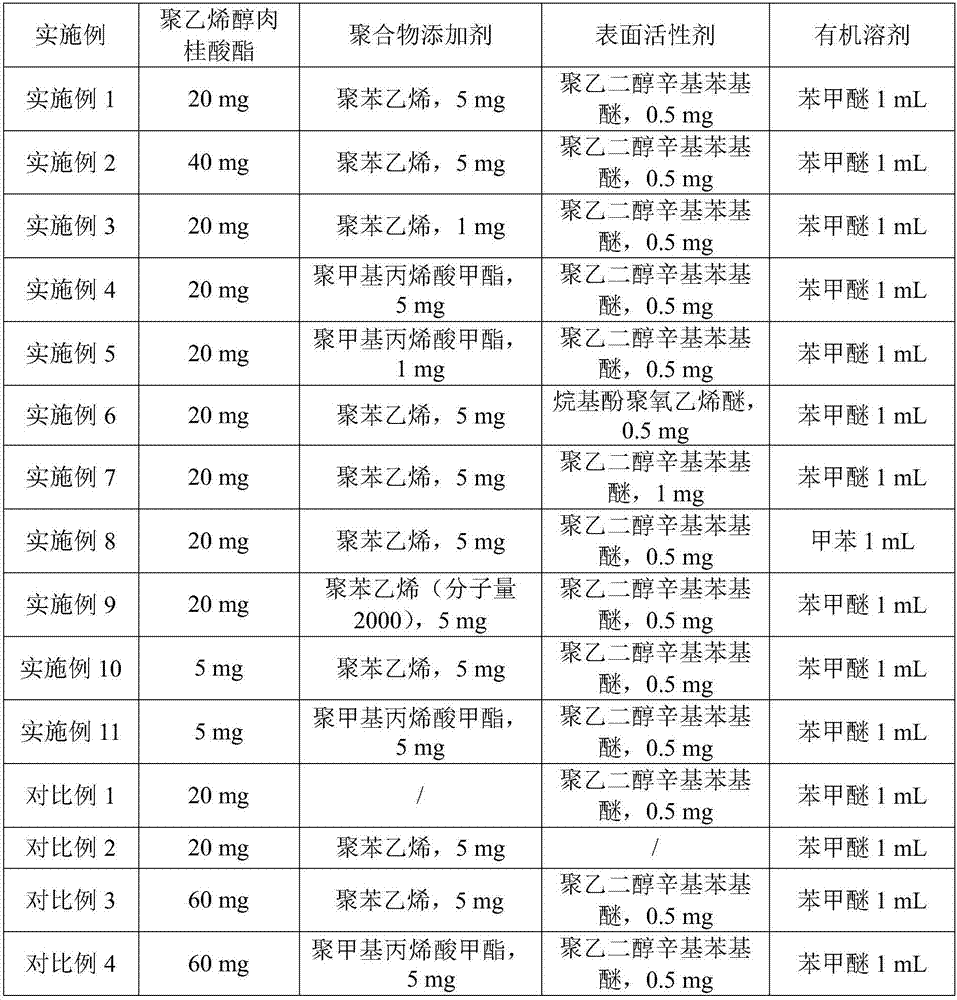

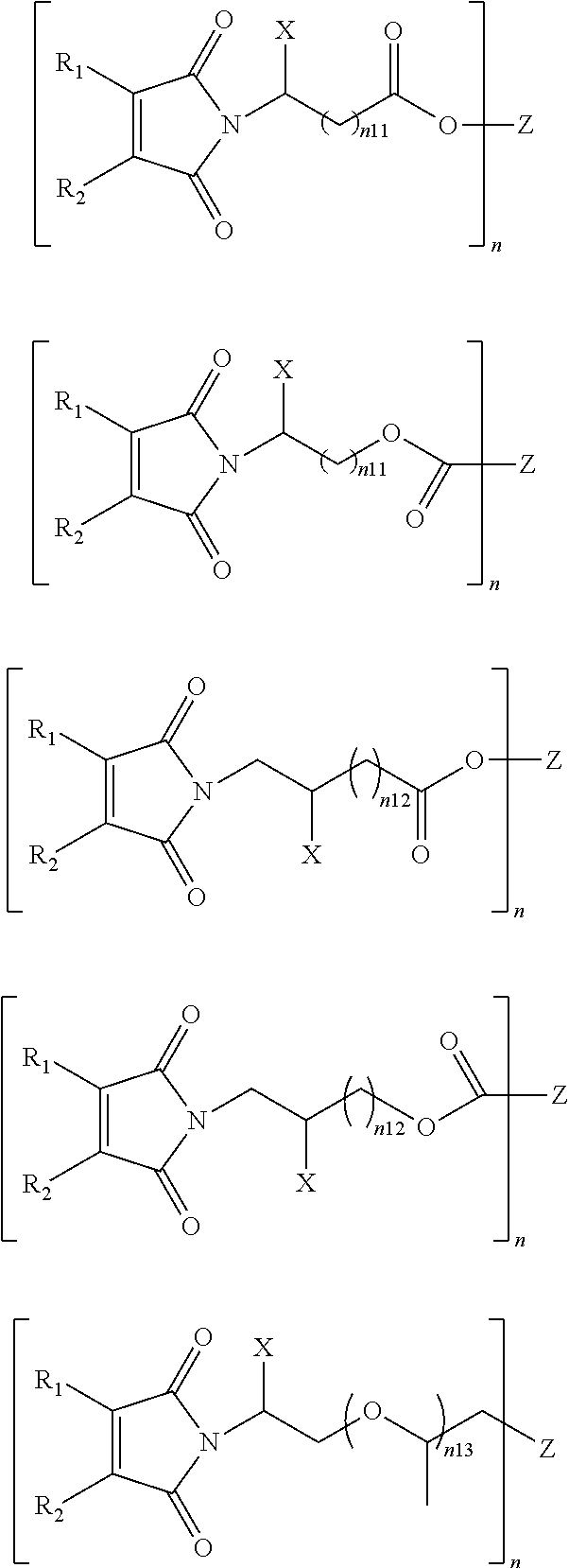

Ink for preparing dielectric layer of transistor, ink film and preparation method and applications thereof

InactiveCN106947320AGood inkjet effectGood film formingSolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionOrganic film

The invention relates to ink for preparing a dielectric layer of a transistor, an ink film and a preparation method and applications thereof. The ink contains poly(vinyl alcohol cinnamate), a polymer additive, a surfactant and an organic solvent; the weight-average molecular weight of the poly(vinyl alcohol cinnamate) is 10,000-50,000; the weight-average molecular weight of the polymer additive is 1,000-50,000, the polymer additive is selected from at least one of polystyrene and polymethyl methacrylate; relative to the 1mL of organic solvent, the content of the poly(vinyl alcohol cinnamate) is 1-50mg, the content of the polymer additive is 0.1-25mg, and the content of the surfactant is 0.05-1mg. The ink disclosed by the invention has excellent ink jetting performance and film forming performance, as well as crosslinking characteristic under ultraviolet light, the dielectric layer of a transistor prepared from ink can prevent ink from permeating, and also can barrier the electronic transmission, the insulating performance of the dielectric layer can be improved, and the dielectric layer of the organic film transistor can be prepared from ink by adopting an ink-jet printing method.

Owner:SHANGHAI MI FANG ELECTRONICS LTD

Ink composition and ink-jet recording method

InactiveUS20050165130A9Good inkjet effectMeasurement apparatus componentsInksOrganic solventSURFACTANT BLEND

The present invention provides an aqueous ink composition including a hydrophilic organic solvent, a surfactant, and a colored fine particle dispersion which contains an oil-soluble dye, and exhibiting a dynamic surface tension of 25 to 35 mN / m, as well as an ink-jet recording method including a step of carrying out recording using the aqueous ink composition.

Owner:FUJIFILM HLDG CORP

Ink jet recording apparatus and ink jet recording method

ActiveUS7080899B2Good inkjet effectMeasurement apparatus componentsDuplicating/marking methodsSurface roughnessRecording media

An ink jet recording apparatus for jetting ink onto a recording medium having: an ink cartridge; an ink jet recording head; and an ink supply tube which connects the ink cartridge and the ink jet recording head, wherein a driving frequency of the ink jet recording head is 15 kHz or above, and an average surface roughness of an inner surface of the ink supply tube is 200 to 2,000 nm.

Owner:KONICA MINOLTA INC

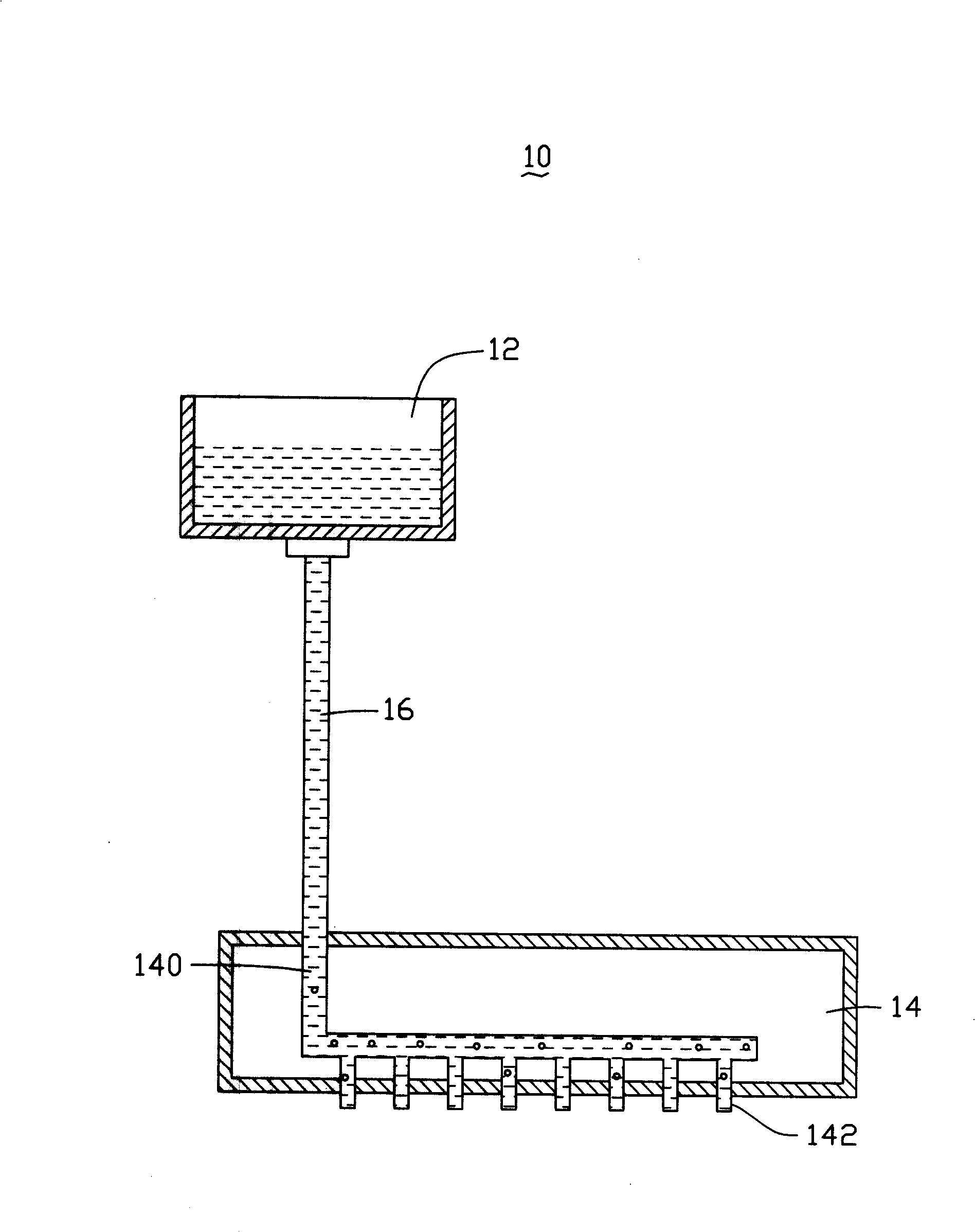

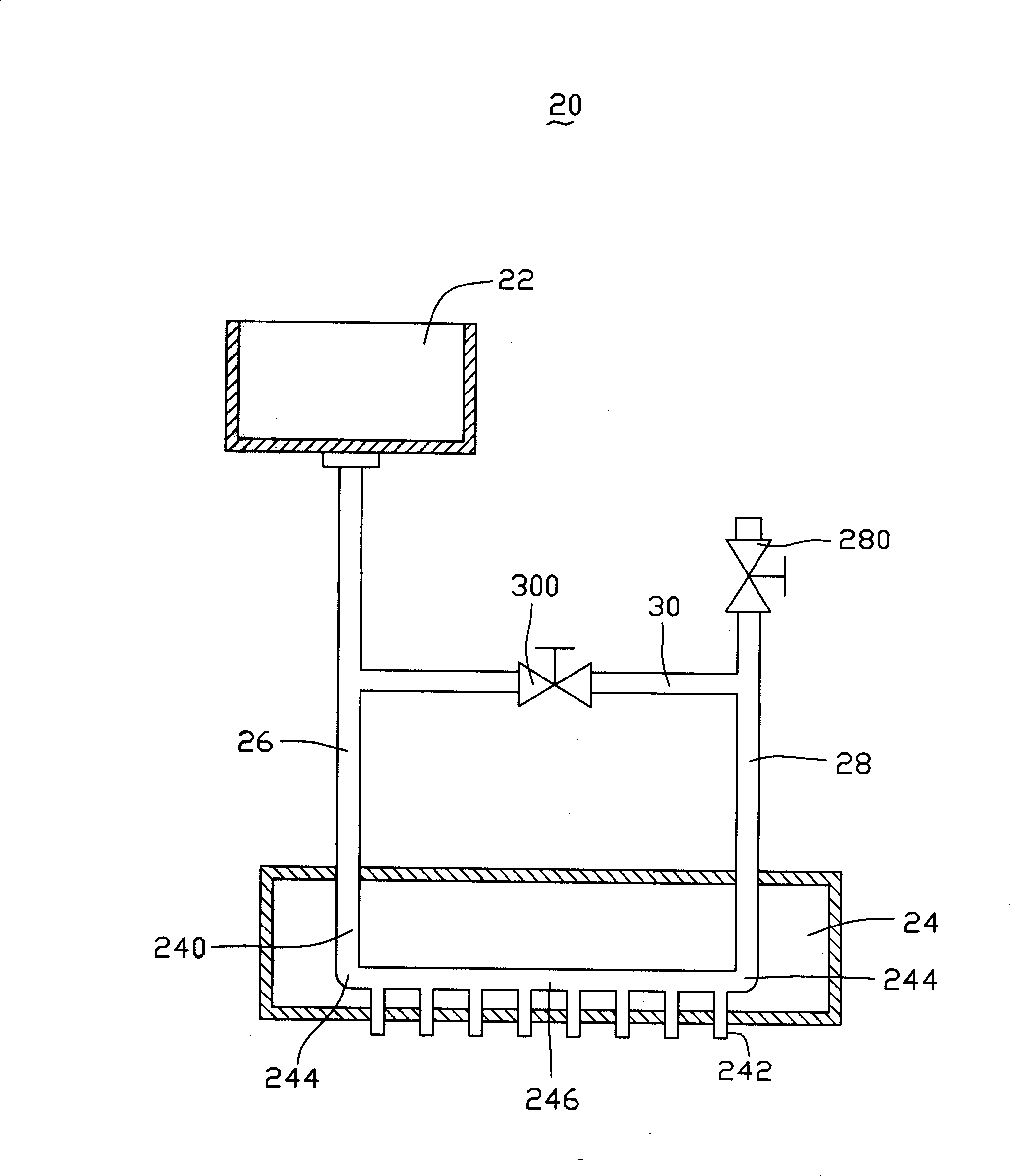

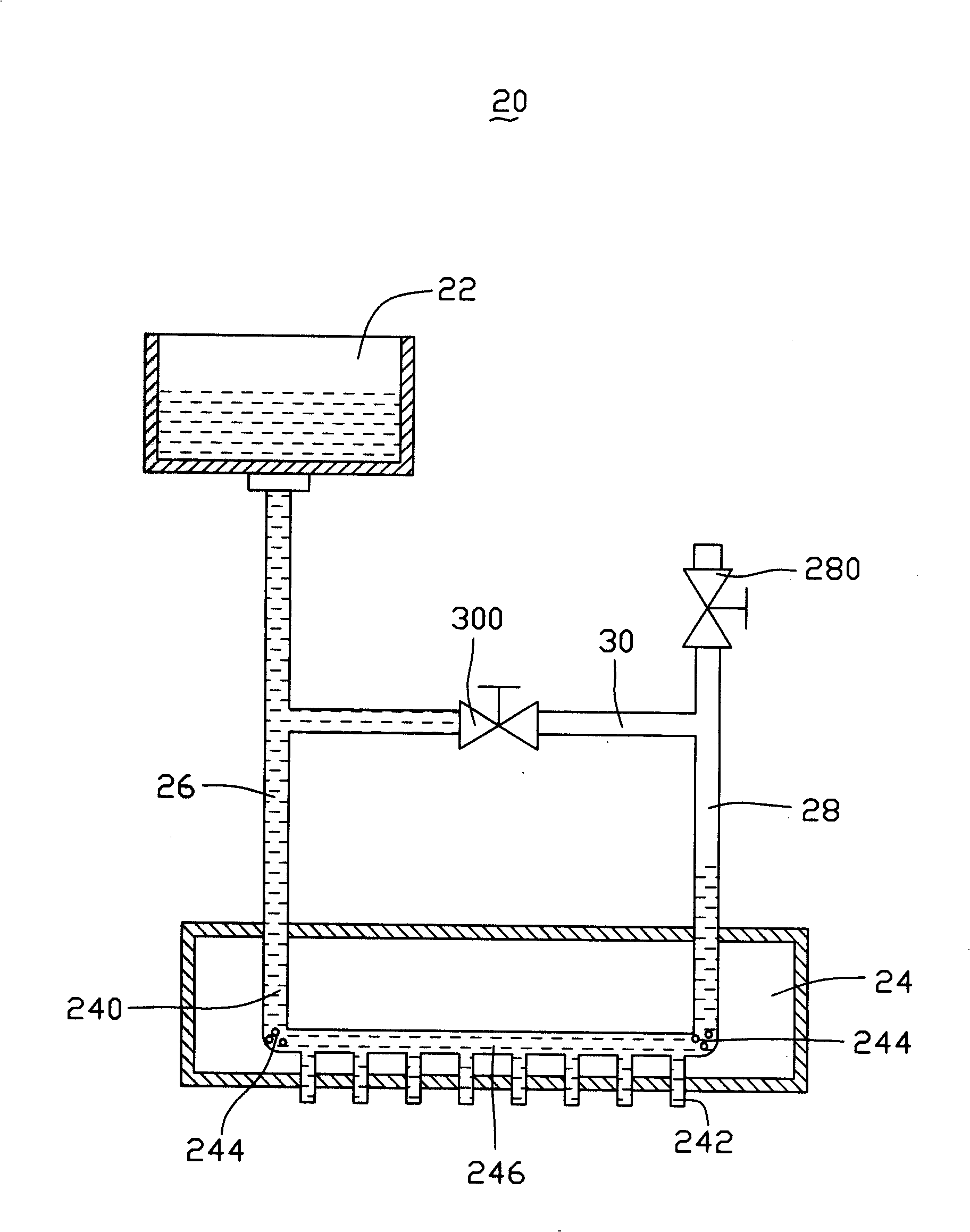

Ink-jet apparatus and method for eliminating air bubble of ink jet head

The invention relates to an ink jet device and a method for eliminating bubbles in an ink jet head. The ink jet device comprises an ink supply tank and at least one ink jet head, and at least one input pipe is connected between the ink supply tank and at least one ink jet head. The ink jet device also comprises at least one vent-pipe and at least one balance pipe. At least one vent-pipe is communicated with the air through a vent valve. At least one balance pipe is used for connecting with at least one input pipe and at least one vent pipe. At least one balance pipe is provided with a non return valve used for preventing the ink from flowing towards at least one input pipe form at least one vent pipe.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

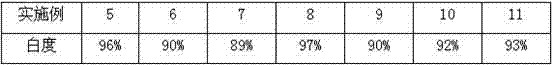

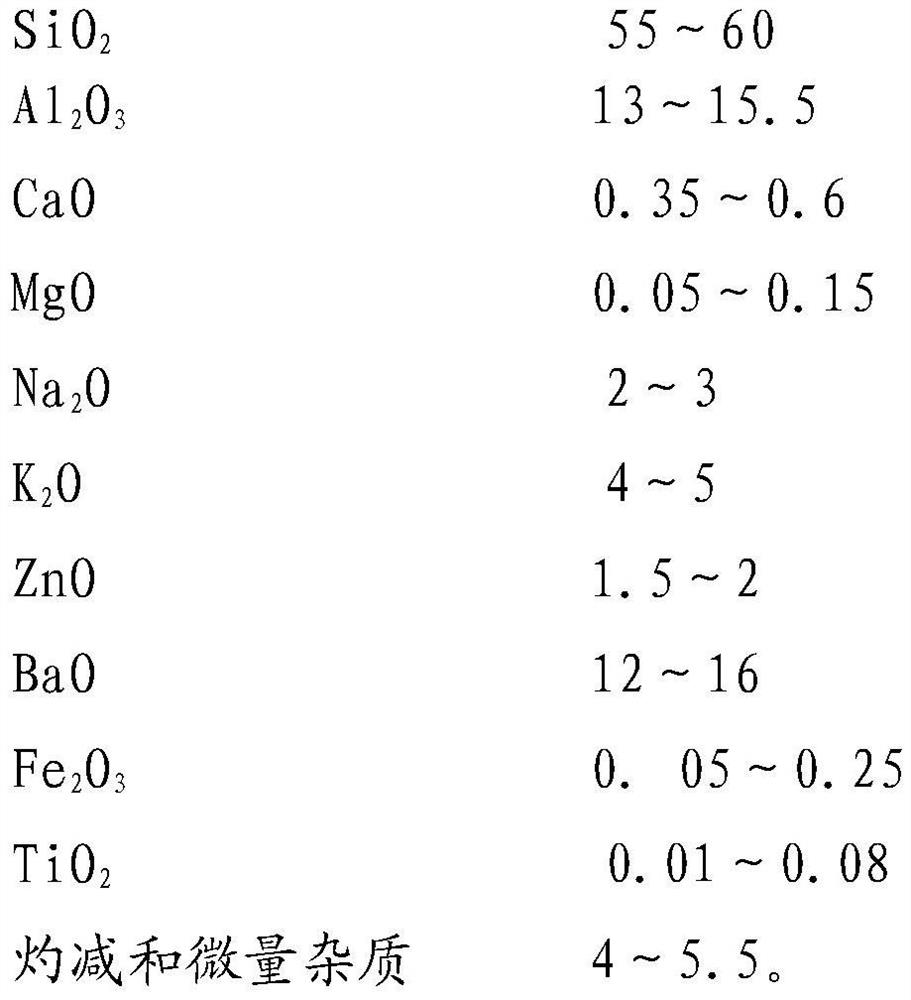

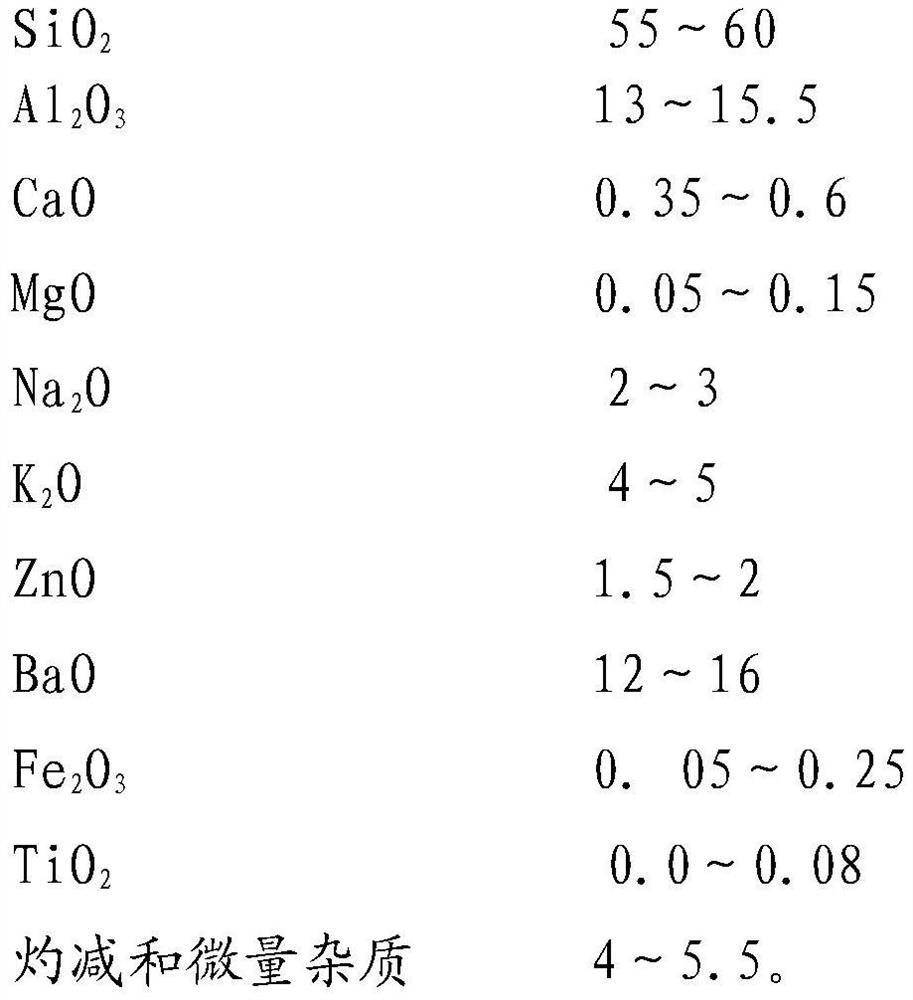

A kind of ultra-white water-based ceramic inkjet ink and preparation method thereof

The invention relates to extra-white aqueous ceramic ink-jet ink. Ceramic pigment is sol prepared from a zirconium oxide precursor and a silicon oxide precursor through a sol-gel method. The white ceramic pigment is prepared by the sol-gel method, has small particle size and good sphericity, solves the technical problem of long time and high energy consumption when the traditional ceramic ink-jet ink is ground, can keep active groups through the sol-gel reaction, can be sintered at a low temperature, and overcomes the technological difficulty that zirconium oxide pigment in the prior art is required to be sintered and adhered tightly at 1500 DEG C. The preparation method of the extra-white aqueous ceramic ink-jet ink comprises the steps of sol preparation and grinding, the preparation method is simple, the prepared extra-white aqueous ceramic ink-jet ink has the advantages of high whiteness, good ink-jetting effect, suitability for high-precision ink-jet printing cartridge and the like.

Owner:FOSHAN CAIGUI NEW MATERIAL CO LTD

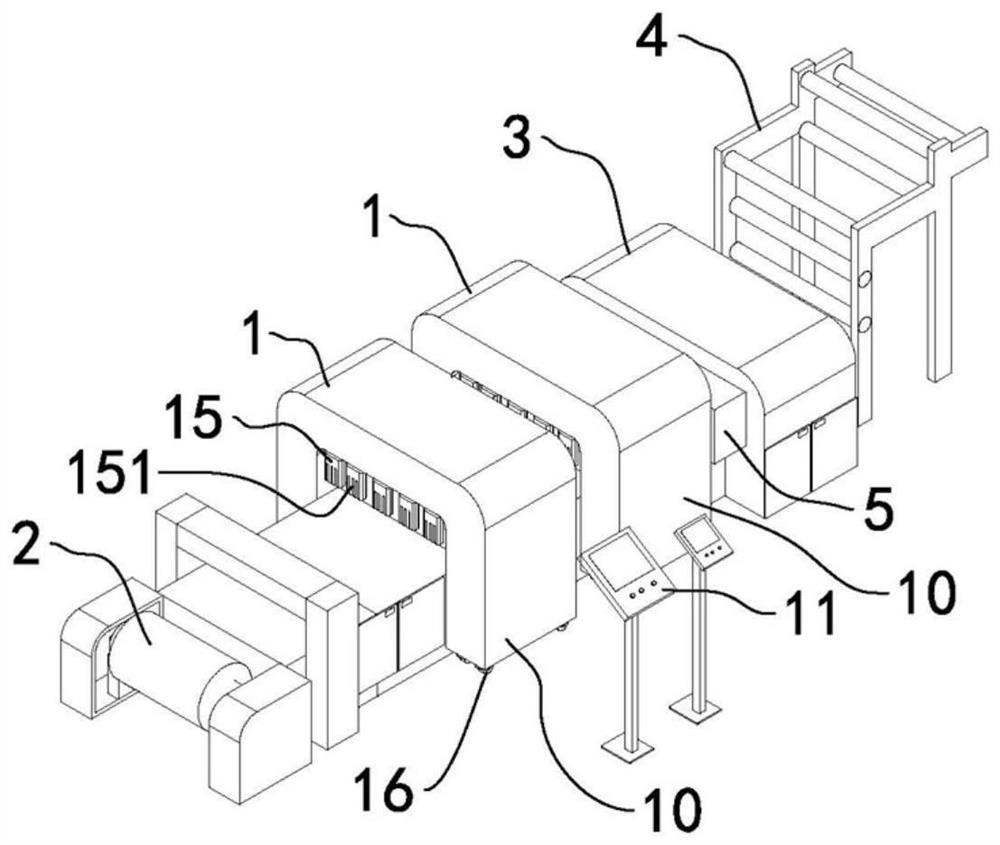

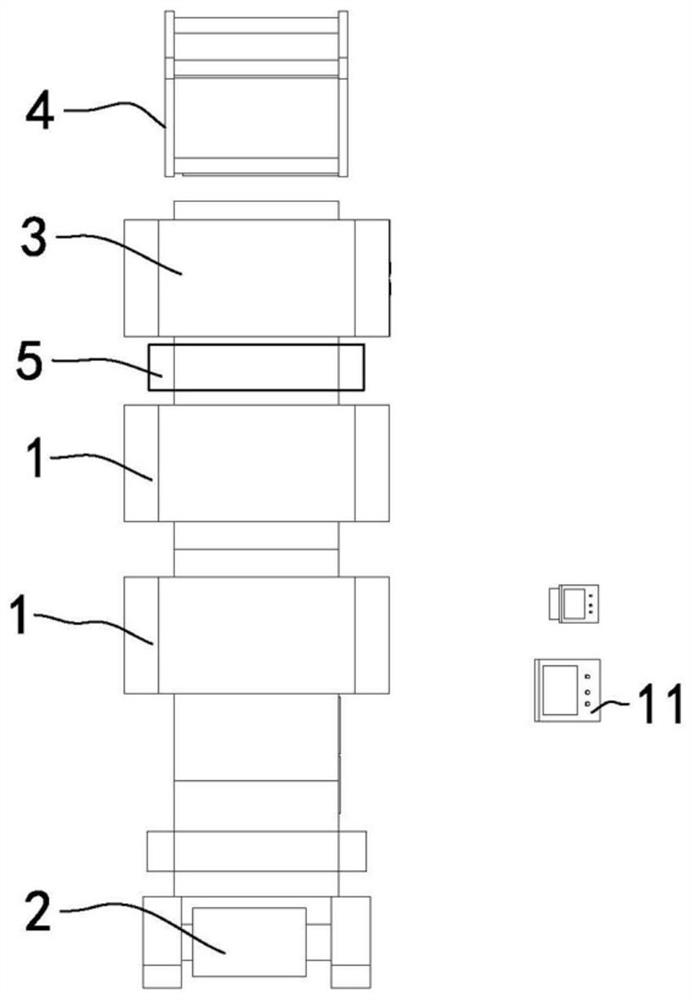

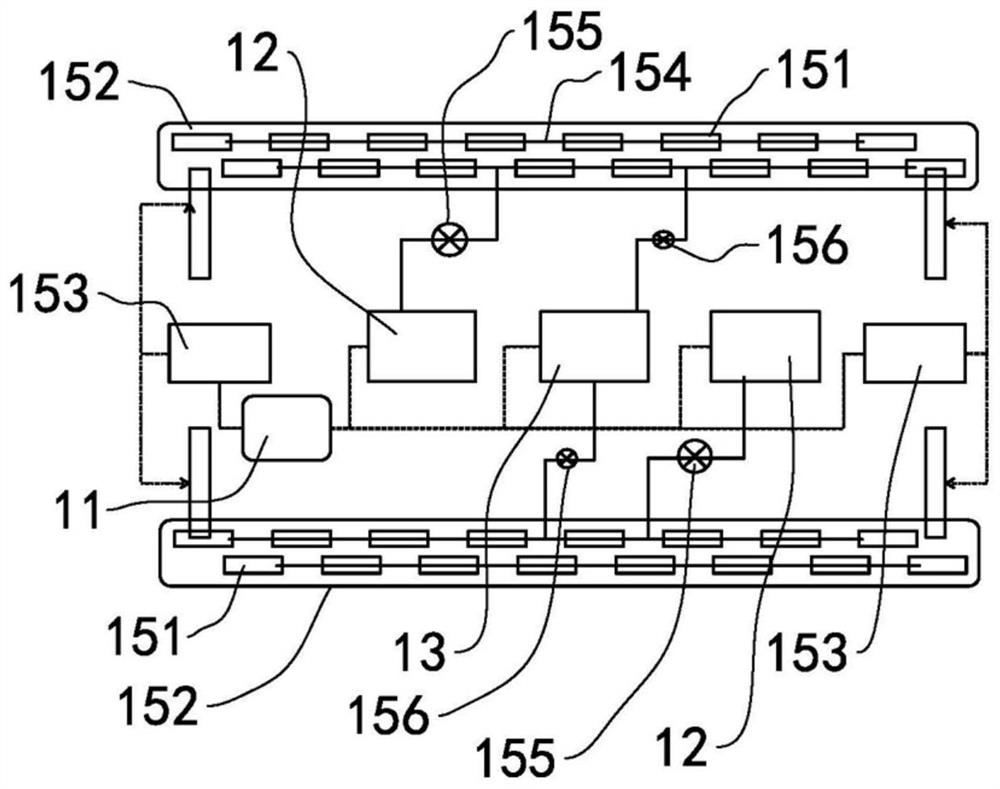

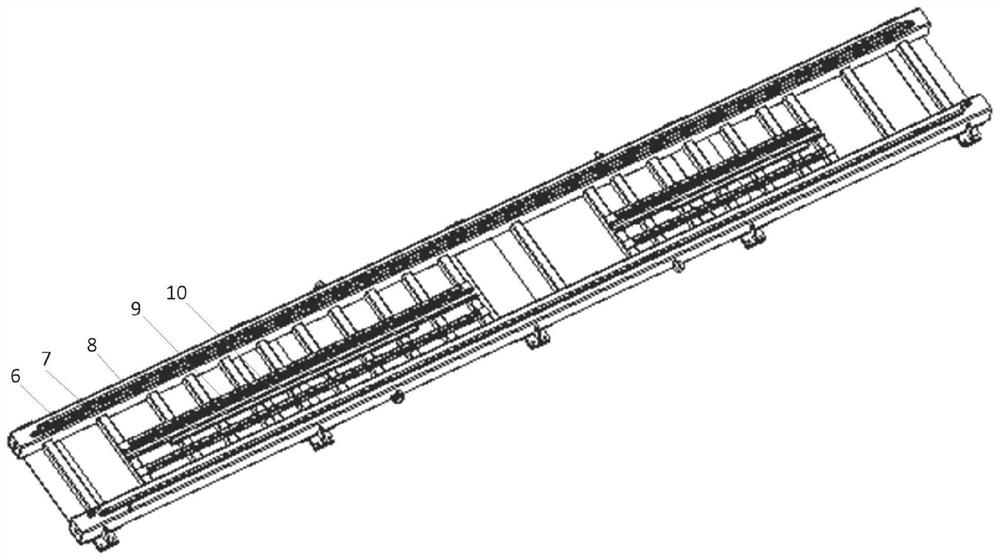

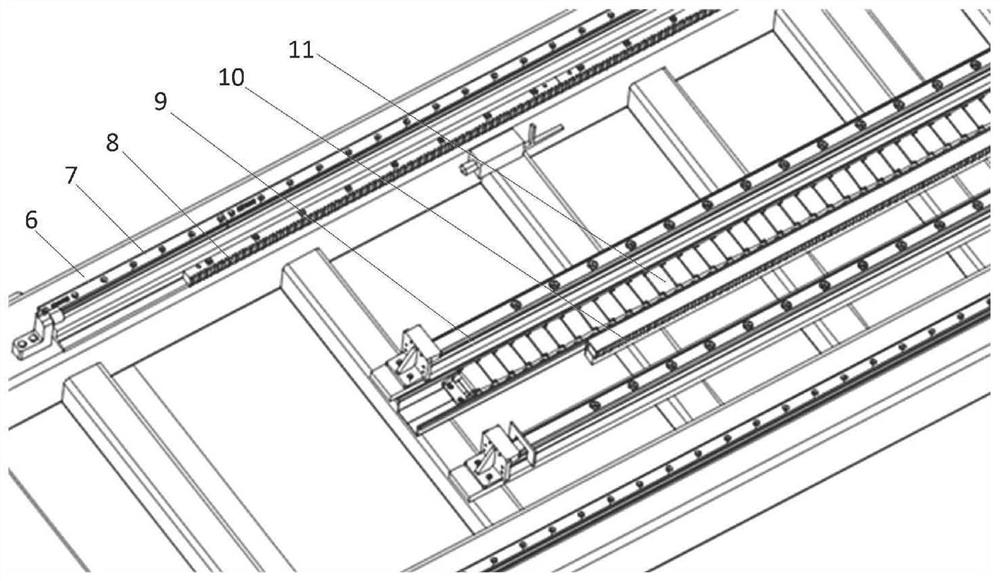

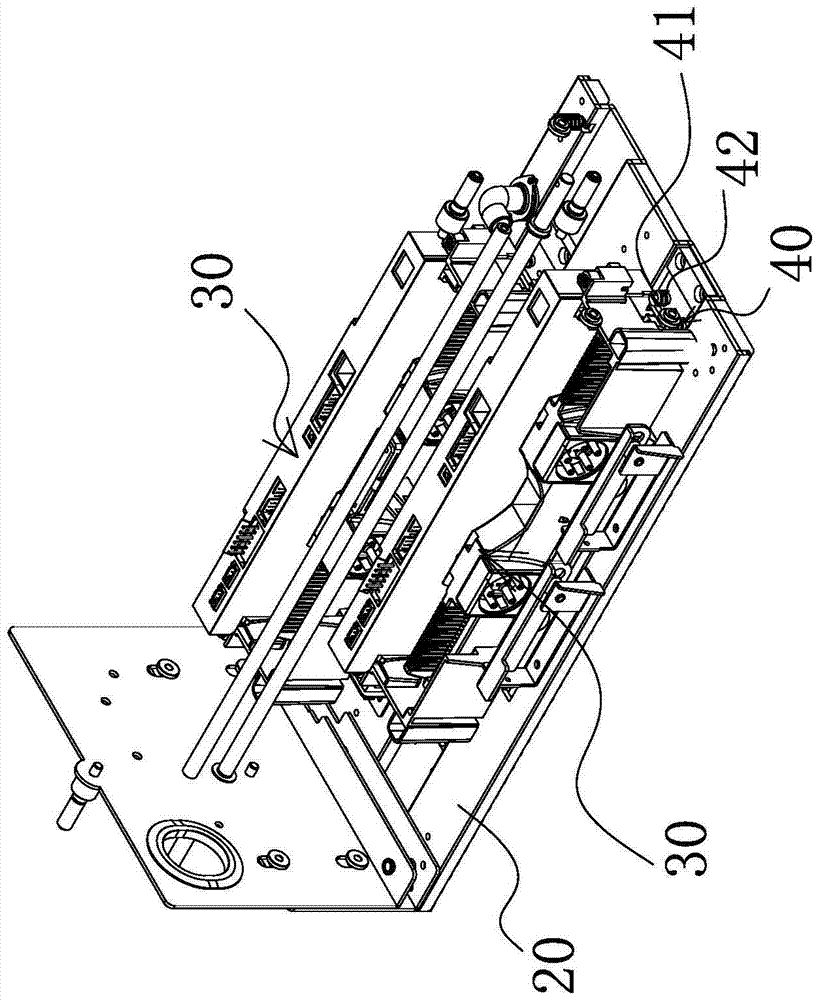

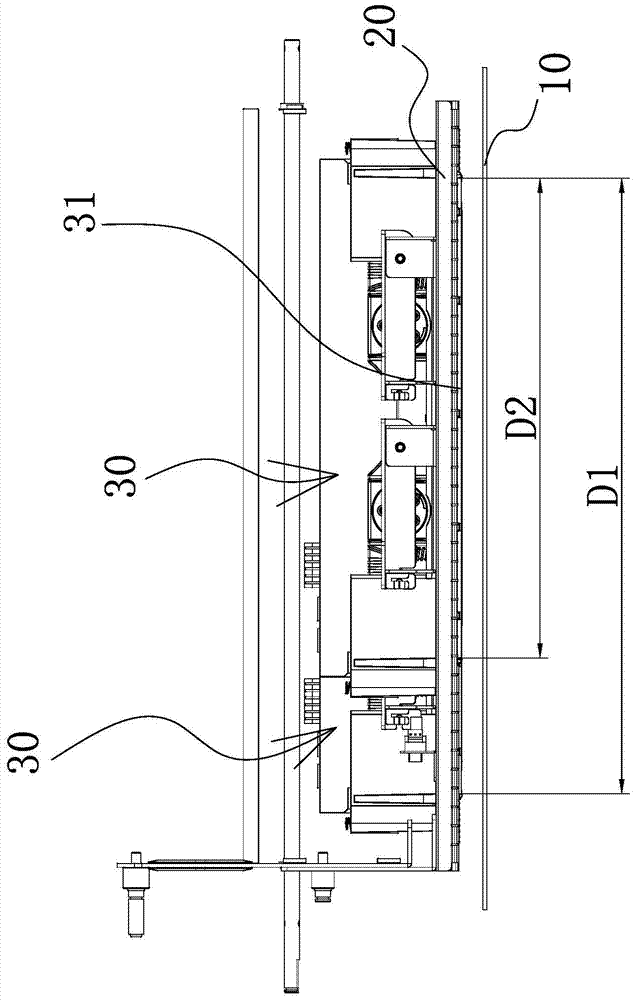

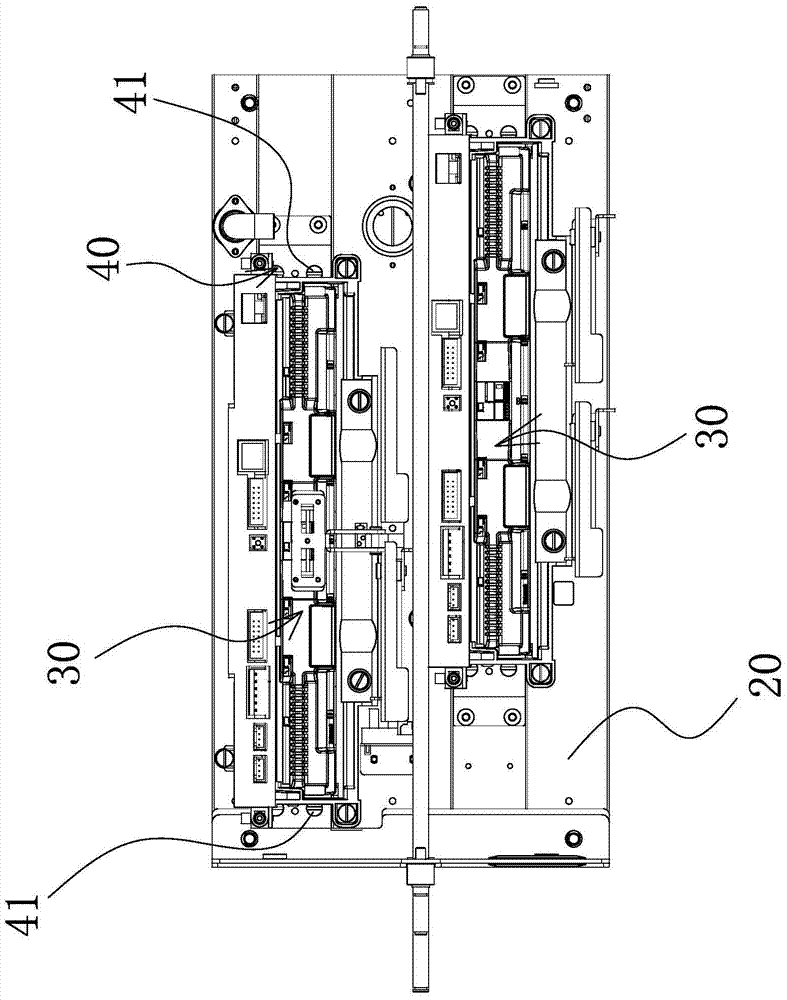

Digital ink jet dyeing machine

PendingCN113103762ADoes not produce dot-like graininessLarge particle size rangeTypewritersDyeing processColor printingEngineering

The invention discloses a digital ink jet dyeing machine. The digital ink jet dyeing machine comprises an unwinding and cloth feeding device, an ink jet device, a drying device and a winding device which are sequentially arranged in the fabric feeding direction, wherein the ink jet device comprises a machine body, a controller, an ink box, a cleaning liquid box, a waste liquid barrel and an ink jet module; the machine body is provided with at least two groups of ink jet modules, at least one ink box, at least one cleaning liquid box and at least one waste liquid barrel; each ink jet module comprises spray heads, a positioning frame and a supporting and moving mechanism; a plurality of spray heads arranged in parallel form spray head groups; and each ink jet module comprises at least one spray head group. According to the scheme, the fixed single-channel spray heads are adopted, and ink of a single color being subjected to color matching is evenly dotted on a textile so as to complete digital pure color printing, so that the most headache point-shaped granular feeling of a conventional digital printing machine is avoided, the color development effect is greatly improved compared with the color development effect of pure color printing of the printing machine, and the digital ink jet dyeing machine has the advantages of quick cleaning.

Owner:浙江环峪科技有限公司

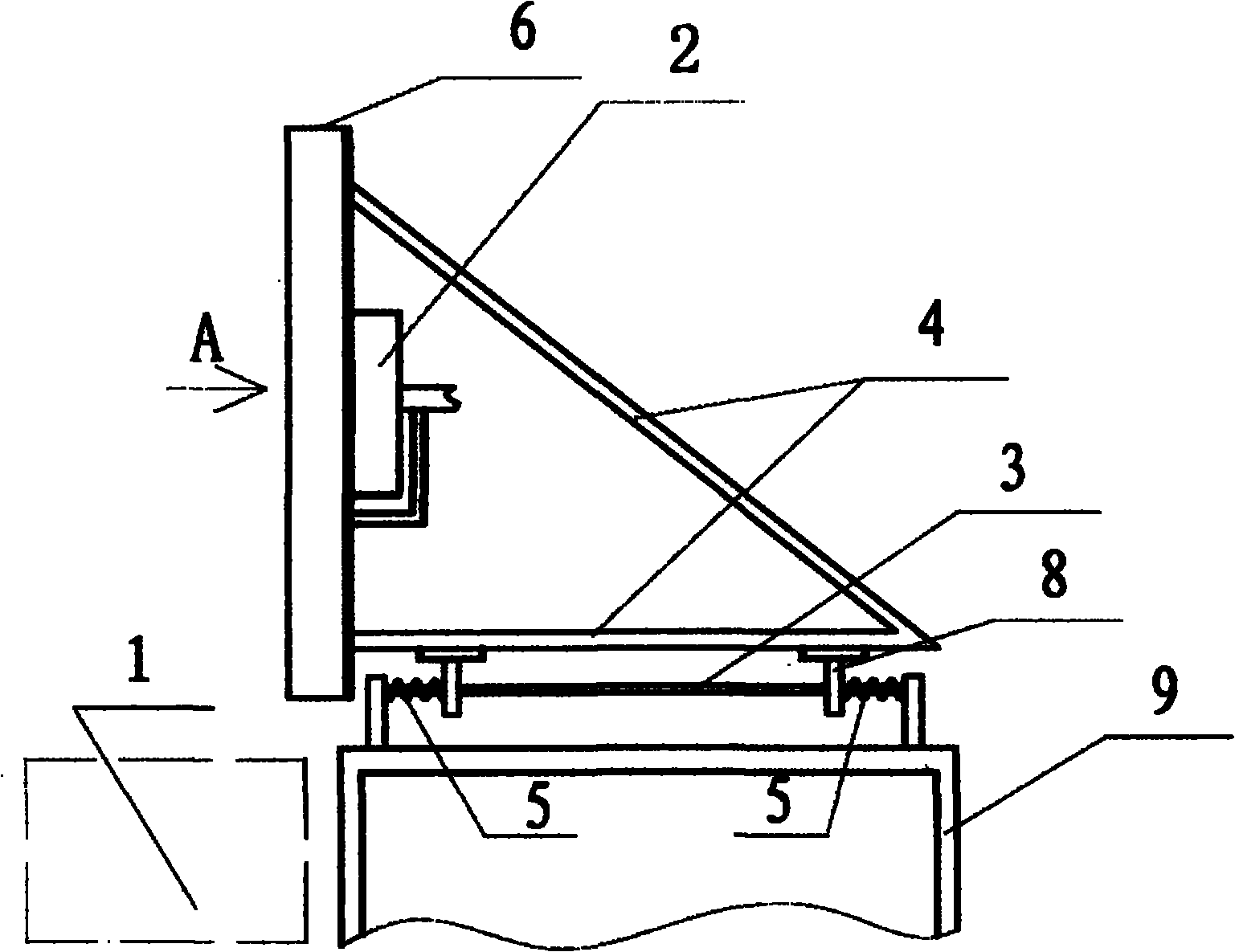

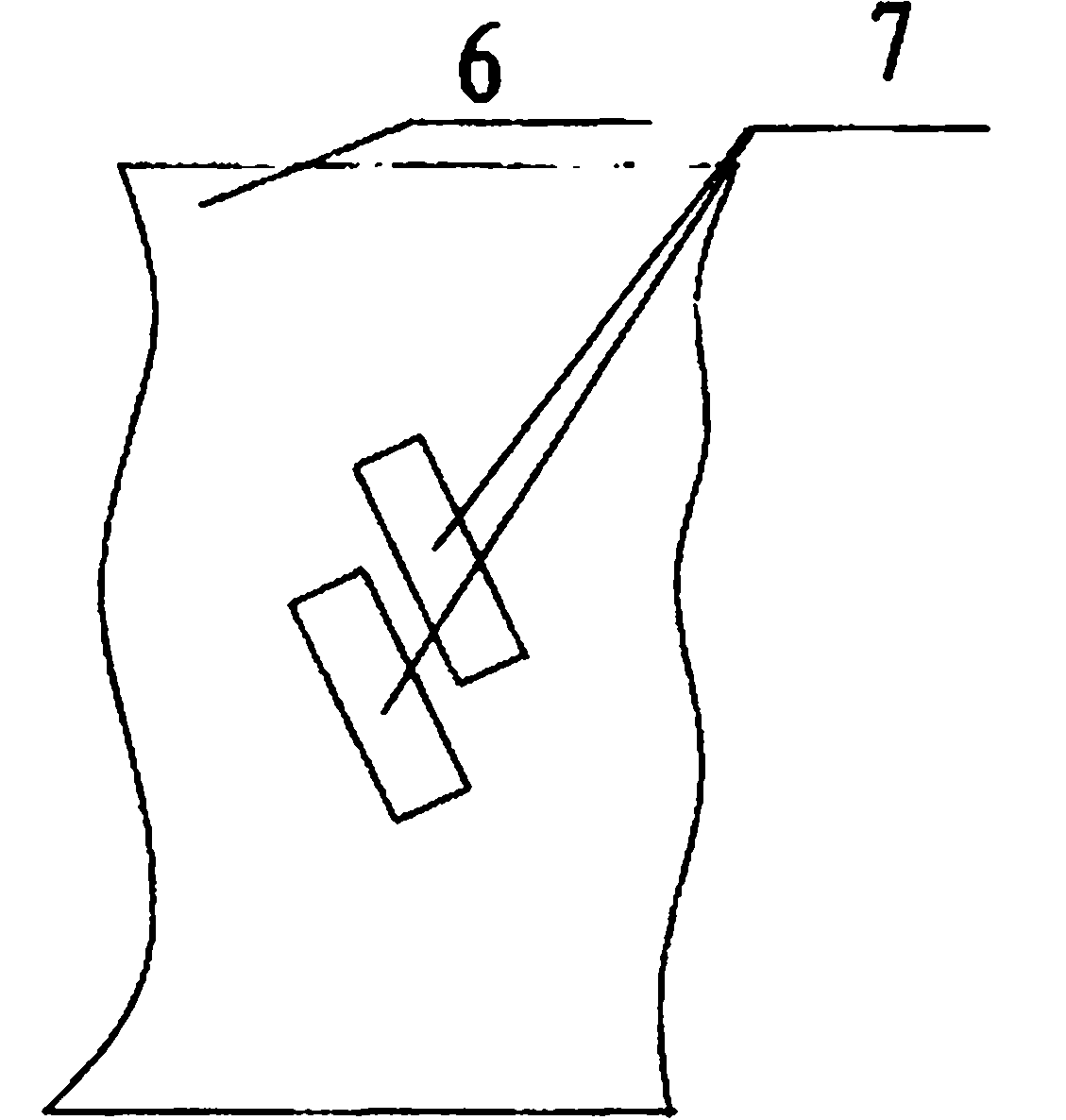

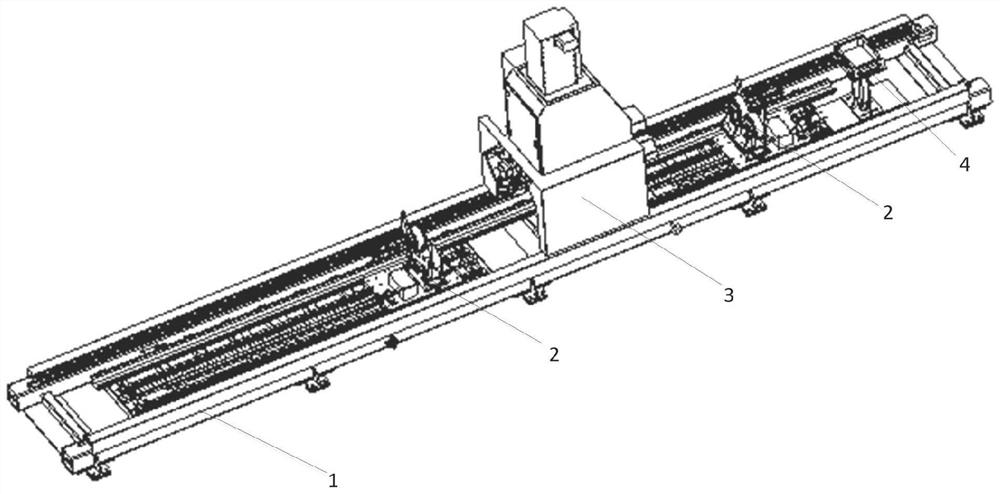

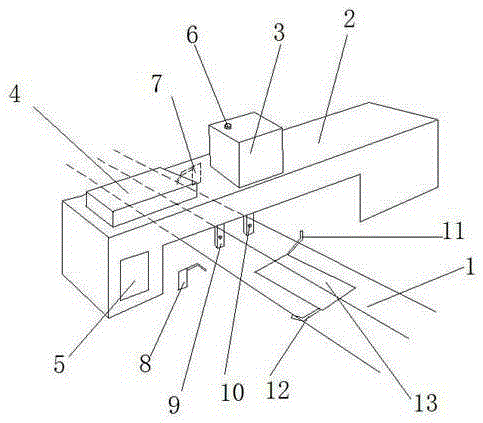

Industrial code-spraying equipment

ActiveCN101844459AAvoid vibrationOvercoming technical challenges for widespread deploymentTypewritersPower drive mechanismsProduction lineHigh definition

The invention discloses industrial code-spraying equipment which comprises a conveying belt (1) and a high-definition spray printing machine (2). A fixed bracket (9) is mounted at one side of the conveying belt (1), an arc plate bracket (4) is assembled on a guide rail (3), provided with a bracket offsetting spring (5) at a part in contact with the guide rail (3) and connected with an arc plate (6), and the high-definition spray printing machine (2) is mounted on the arc plate (6) which is provided with a high-definition spray printing machine ink jet hole (7) in the middle. In the invention, under the condition that an ink jet product production line is not changed, the impact and the vibration of a spraying head are effectively eliminated, the distance change between the spraying head and the product, which is caused by the size deviation of the sprayed product, can be automatically eliminated, the spraying head is constantly attached to the product so that clear ink jet effect is kept, and the high-definition code-spraying machine can be well used in an impact and vibration environment.

Owner:GUIZHOU CHITIANHUA PAPERS

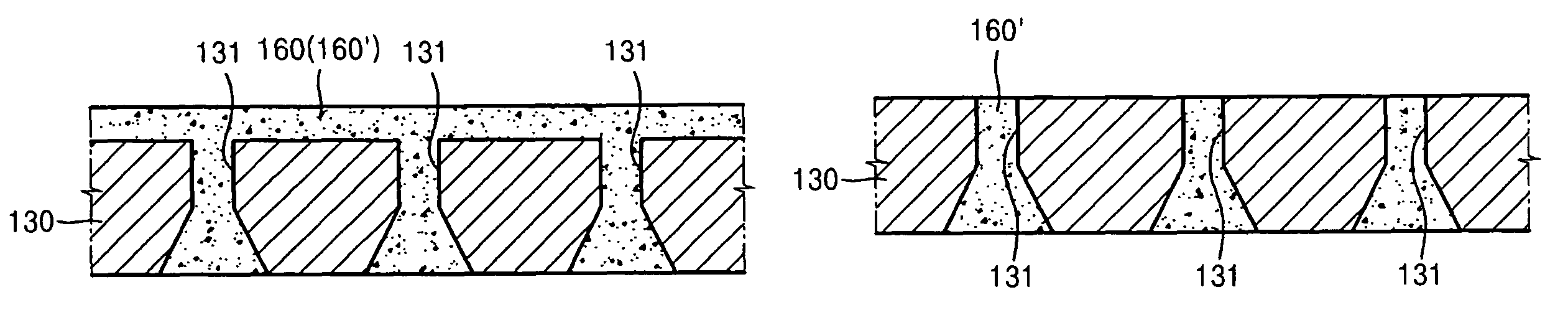

Method of forming hydrophobic coating layer on surface of nozzle plate of inkjet head

An inkjet head having a hydrophobic coating layer and a method of forming the hydrophobic coating layer on a surface of a nozzle plate of the inkjet head. The method includes filling a wax into a plurality of nozzles formed in the nozzle plate while coating the surface of the nozzle plate with wax, removing the wax from the surface of the nozzle plate, forming a hydrophobic coating layer on the surface of the nozzle plate, melting the wax filled in the nozzles, and removing portions of the hydrophobic coating layer covering the nozzles by discharging the melted wax through the nozzles using heat and / or pressure. Therefore, the hydrophobic coating layer is uniformly formed only on an outer surface of the nozzle plate, without forming the hydrophobic coating layer in an inner surface of the nozzles, thereby improving an ink ejecting performance of the nozzles.

Owner:SAMSUNG DISPLAY CO LTD

A kind of full-body porcelain tile combined with inkjet effect and preparation method thereof

Owner:GUANGDONG SUMMIT CERAMIC CO LTD +1

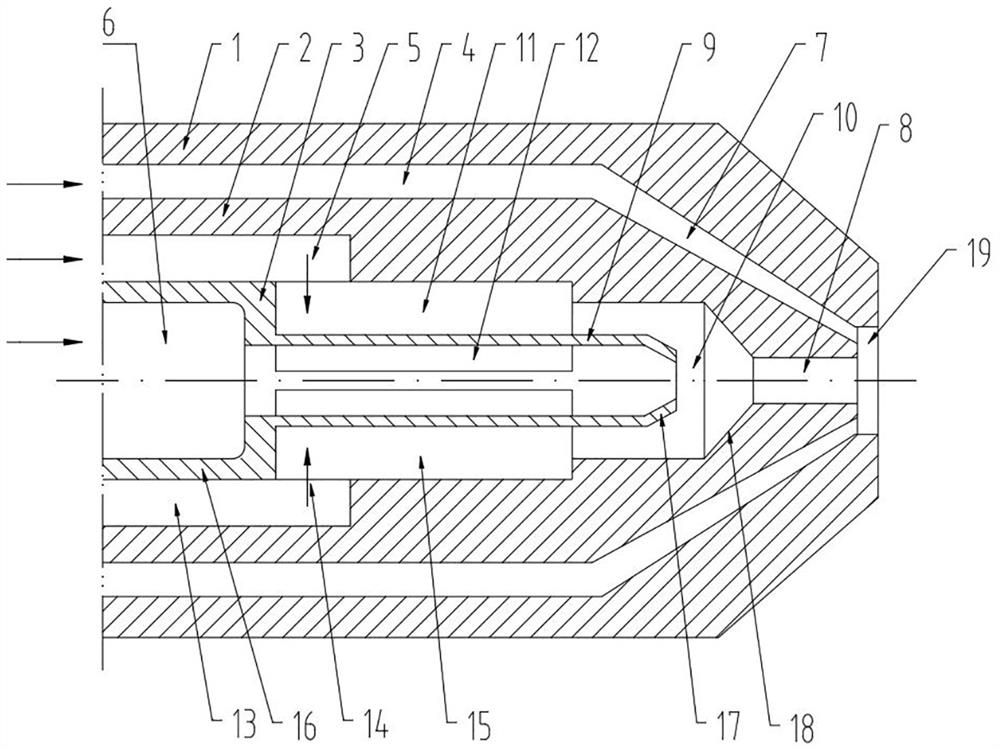

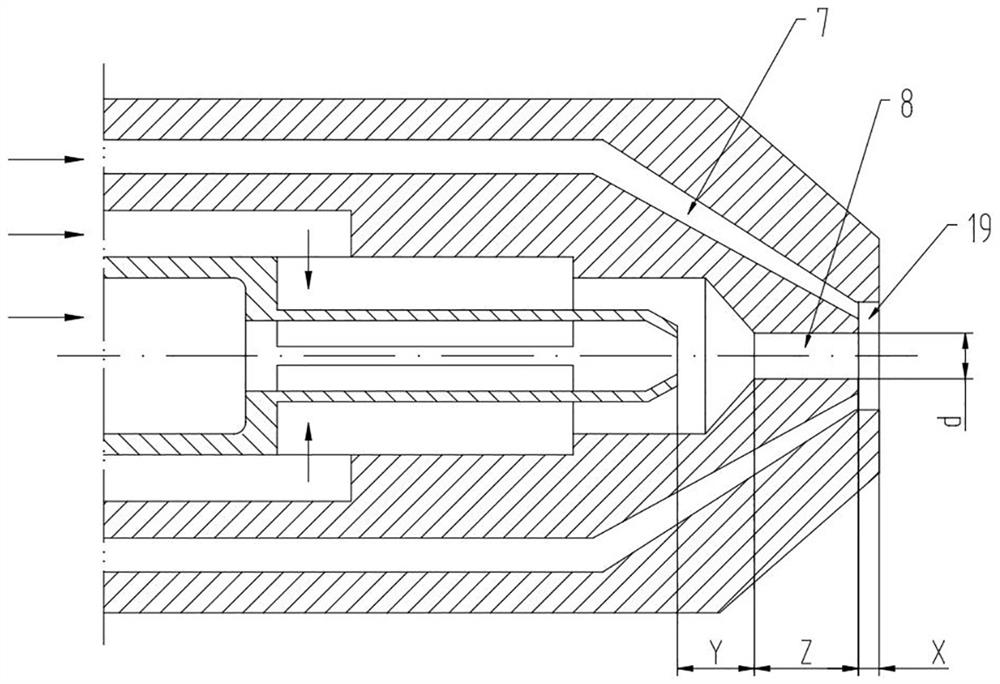

Colorful jet drawing device for ceramic colored drawing process

ActiveCN112295768AImprove the mixing effectGood inkjet effectLiquid spraying apparatusEngineeringMixing effect

The invention discloses a colorful jet drawing device for a ceramic colored drawing process. The colorful jet drawing device comprises a spraying device, the spraying device is provided with a nozzle,the nozzle comprises an outer cylinder part (1), a middle cylinder part (2), an inner cylinder part (3), a first gas channel (4), a second gas channel (5), a liquid channel (6), a first outlet channel (7) and an outlet hole (8), and the second gas channel is a temperature regulating gas channel or a heating gas channel; and the inner cylinder part is provided with a first inner cylinder section (9) located at the downstream part, and a mixing cavity (10) is formed between the downstream part of the first inner cylinder section and the downstream part of the middle cylinder part. The colorfuljet drawing device is characterized in that a plurality of first cyclone heat conduction sheets (11) distributed in the circumferential direction are arranged in the second gas channel, and a plurality of second cyclone heat conduction sheets (12) distributed in the circumferential direction are arranged on the inner wall of the first inner cylinder section. The colorful jet drawing device has theadvantages that the mixing effect is improved, and working liquid is preheated before being mixed, so that the working liquid is in the preset liquid activity / flowability, and the spray drawing effect of the working liquid is improved.

Owner:JINGDEZHEN UNIV

Inkjet ink and inkjet image formation method using same

ActiveUS20130095236A1High photo curing sensitivityGood weather resistanceInksElectrostatic spraying apparatusVinyl etherWeather resistance

Provided is an ultraviolet curable inkjet ink and an inkjet image formation method that uses said inkjet ink. The inkjet ink can be ejected from an inkjet head without being diluted by a solvent, has high photo curing sensitivity and produces high quality images with excellent weather resistance (smear resistance). The inkjet ink is characterized by a polymerizable compound which contains a maleimide compound having a chiral group and a compound selected from a vinyl ether compound and a N-vinyl compound.

Owner:KONICA MINOLTA INC +1

Ink jet system of printing equipment

ActiveCN105128530ASmooth movementEasy to controlPrintingElectrical and Electronics engineeringNozzle

The invention provides an ink jet system of printing equipment, and belongs to the technical field of printing machinery. The ink jet system of the printing equipment comprises a frame, an ink jet mechanism and a nozzle cleaning mechanism, wherein the ink jet mechanism comprises a conveying channel horizontally arranged and used for conveying a printing medium, a working flat plate movably mounted above the conveying channel, and at least one nozzle detachably inserted on the working flat plate; the working flat plate can be displaced in the vertical direction to be near or far from the conveying channel; an ink outlet for jetting ink to the printing medium is formed in the lower end surface of the nozzle; the ink jet direction of the ink outlet is perpendicular to the conveying direction of the conveying channel; and the nozzle cleaning mechanism is arranged below the working flat plate, and is used for cleaning ink in the nozzle. The ink jet system of the printing equipment has the advantages of reasonable design and reliable work.

Owner:宁波荣大创想智造科技有限公司

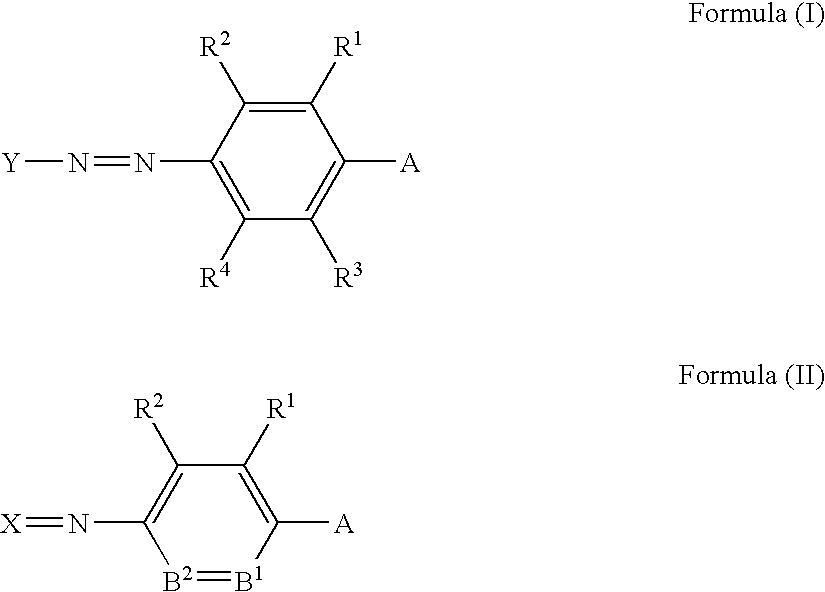

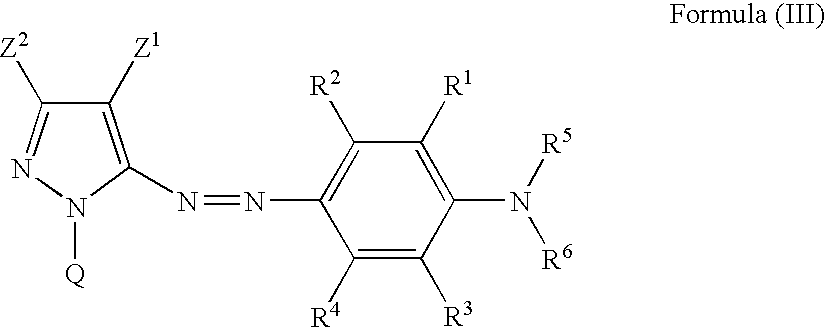

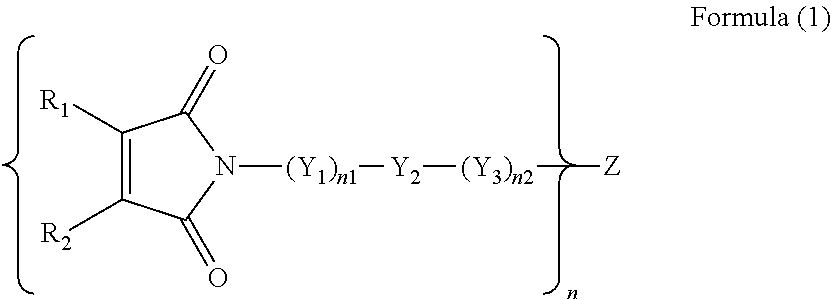

Aqueous pigment dispersion and aqueous ink for ink jet recording

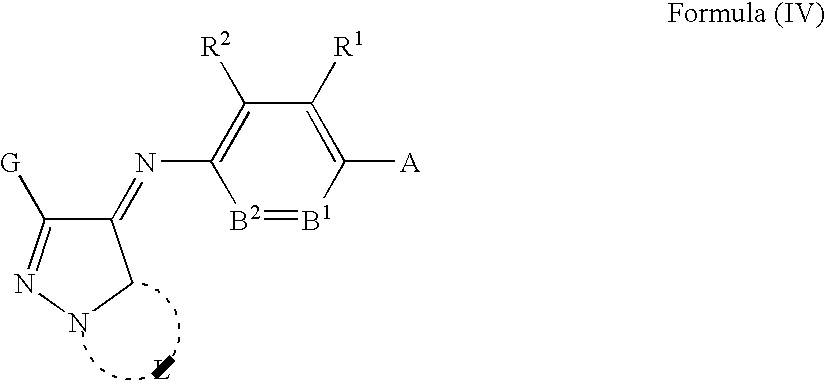

InactiveUS20120165438A1Good storage stabilityExcellent toneDisazo dyesDuplicating/marking methodsX-rayAqueous medium

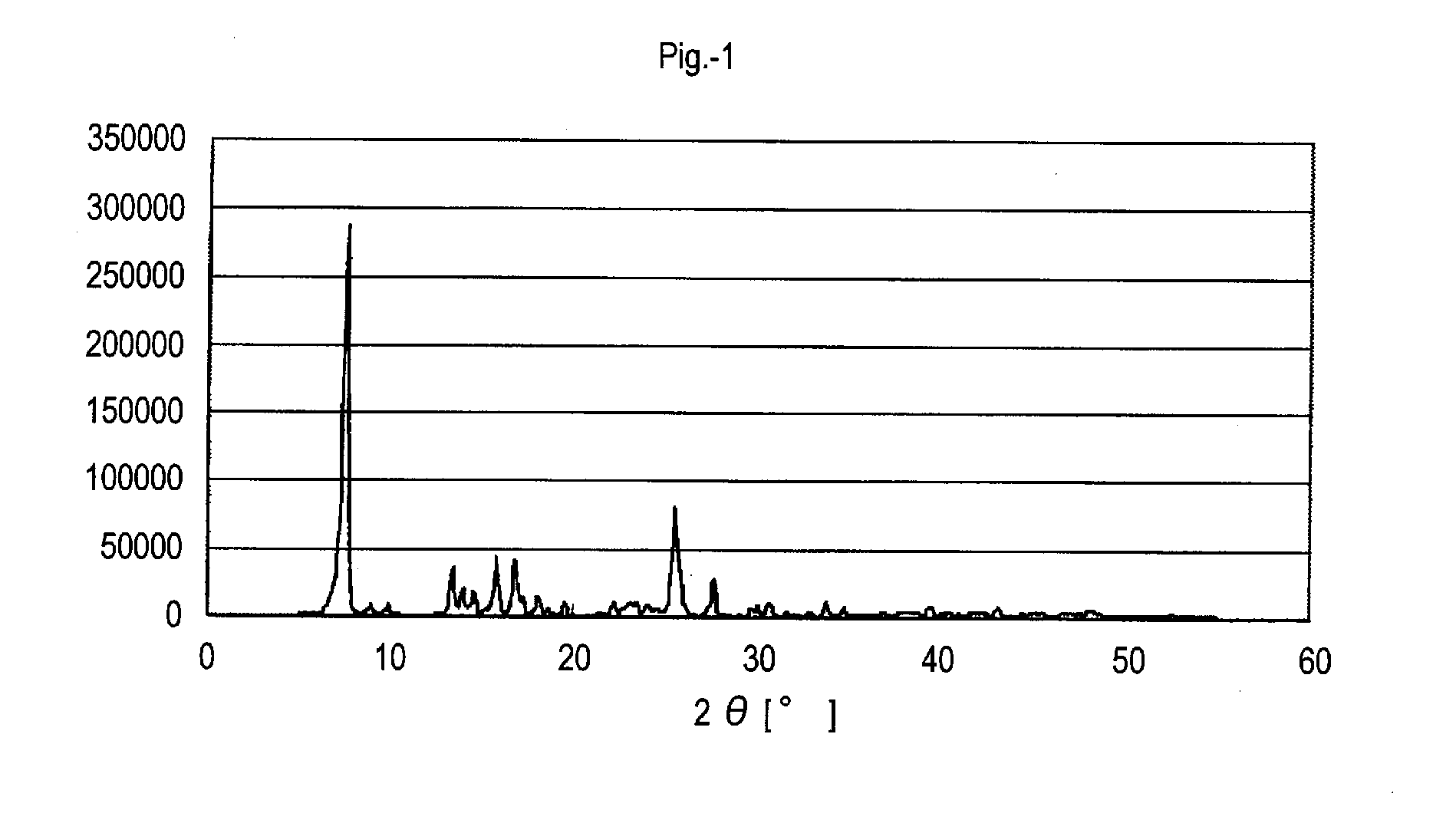

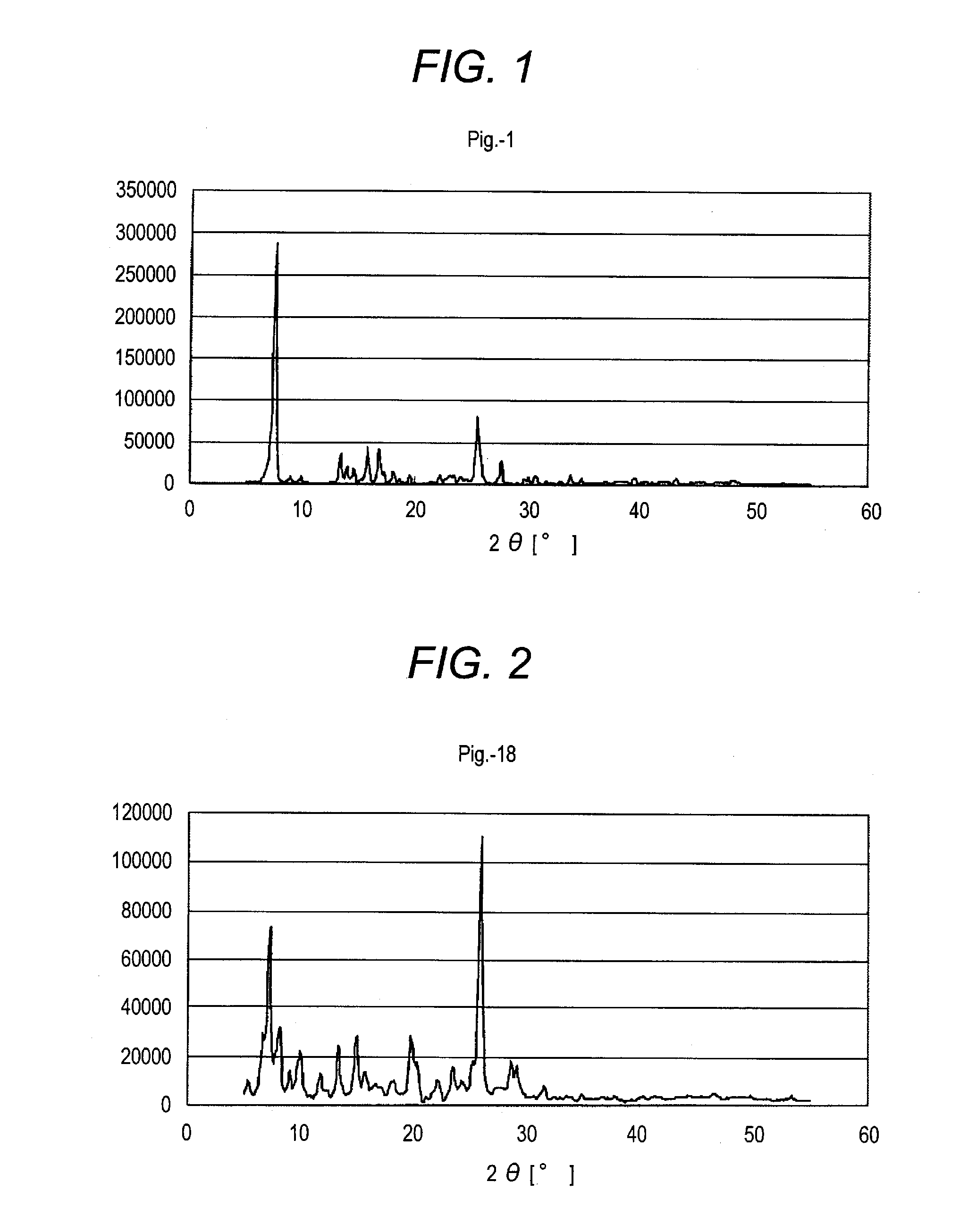

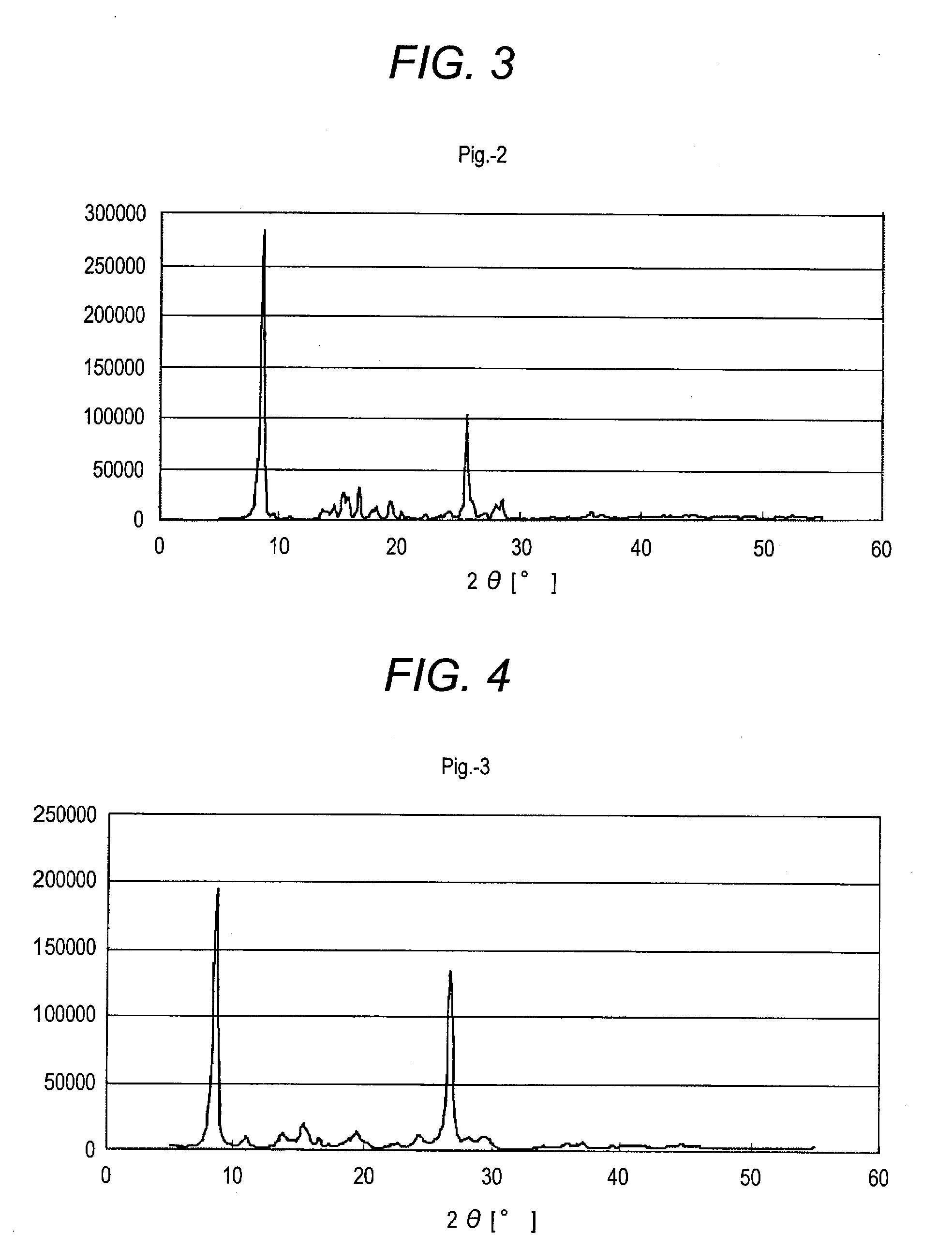

[Problem] To provide an aqueous ink for inkjet recording, which realizes excellent ink ejection properties, tinctorial strength, and image fastness.[Means for Resolution] An ink containing a pigment dispersion containing A and B, and an aqueous medium:A: an azo pigment represented by the following formula (1) and having at least one characteristic peak at Bragg angles (2θ) of 5 to 15° and 20 to 30° in X-ray diffraction with characteristic Cu Kα line; andB: a vinyl polymer containing a hydrophobic structural unit (a) and a hydrophilic structural unit (c).

Owner:FUJIFILM CORP

Code spraying system and method for large cylindrical workpiece

ActiveCN113858822APowerful coding functionControl inkjet speedTypewritersOther printing apparatusFace detectionEngineering

The invention discloses a code spraying system and method for a large cylindrical workpiece. The system comprises a base, two supporting and weighing mechanisms which are used for supporting the two ends of the cylindrical workpiece and weighing the weight of the cylindrical workpiece, can move relative to the axial direction of the cylindrical workpiece to adjust the distance, and can drive the circumferential rotation of the cylindrical workpiece, and a code spraying mechanism erected between the two supporting and weighing mechanisms. The code spraying mechanism can axially move relative to the cylindrical workpiece, is provided with a code spraying head and can ascend, descend and rotate. A code spraying device is provided with an axial detection encoder, an end face detection mechanism and a circumference mark detection mechanism. The system is provided with a control device which is used for controlling the circumferential rotation speed of the supporting and weighing mechanisms, the axial movement speed of the code spraying device, ascending and descending of the code spraying head and switching of the code spraying direction, and the axial ink spraying speed and the circumferential ink spraying speed are respectively controlled according to the axial movement speed of the code spraying mechanism and the circumferential rotation speed of the supporting and weighing mechanisms. The code spraying system has the advantages of good flexibility, strong expansibility and the like.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP +1

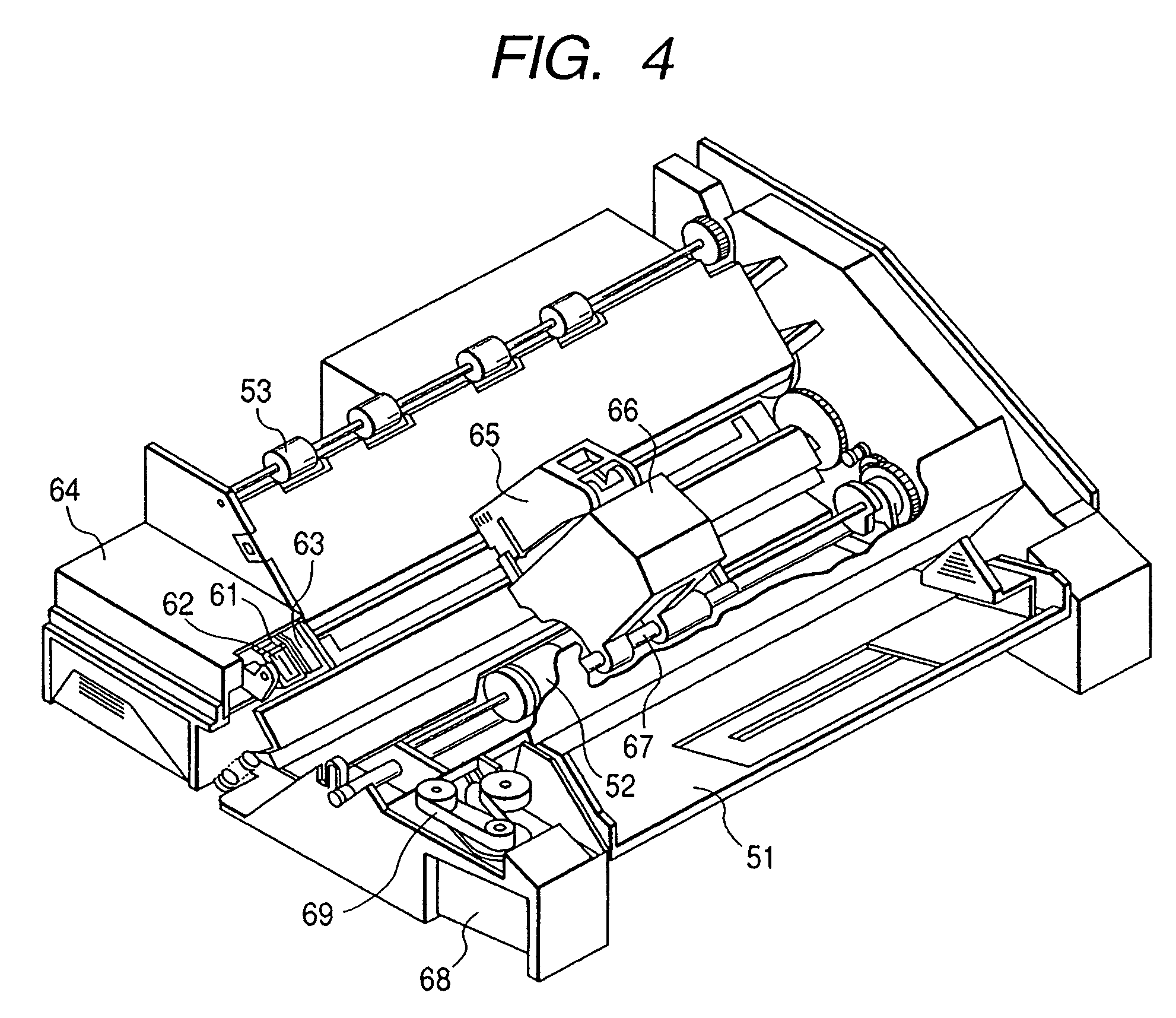

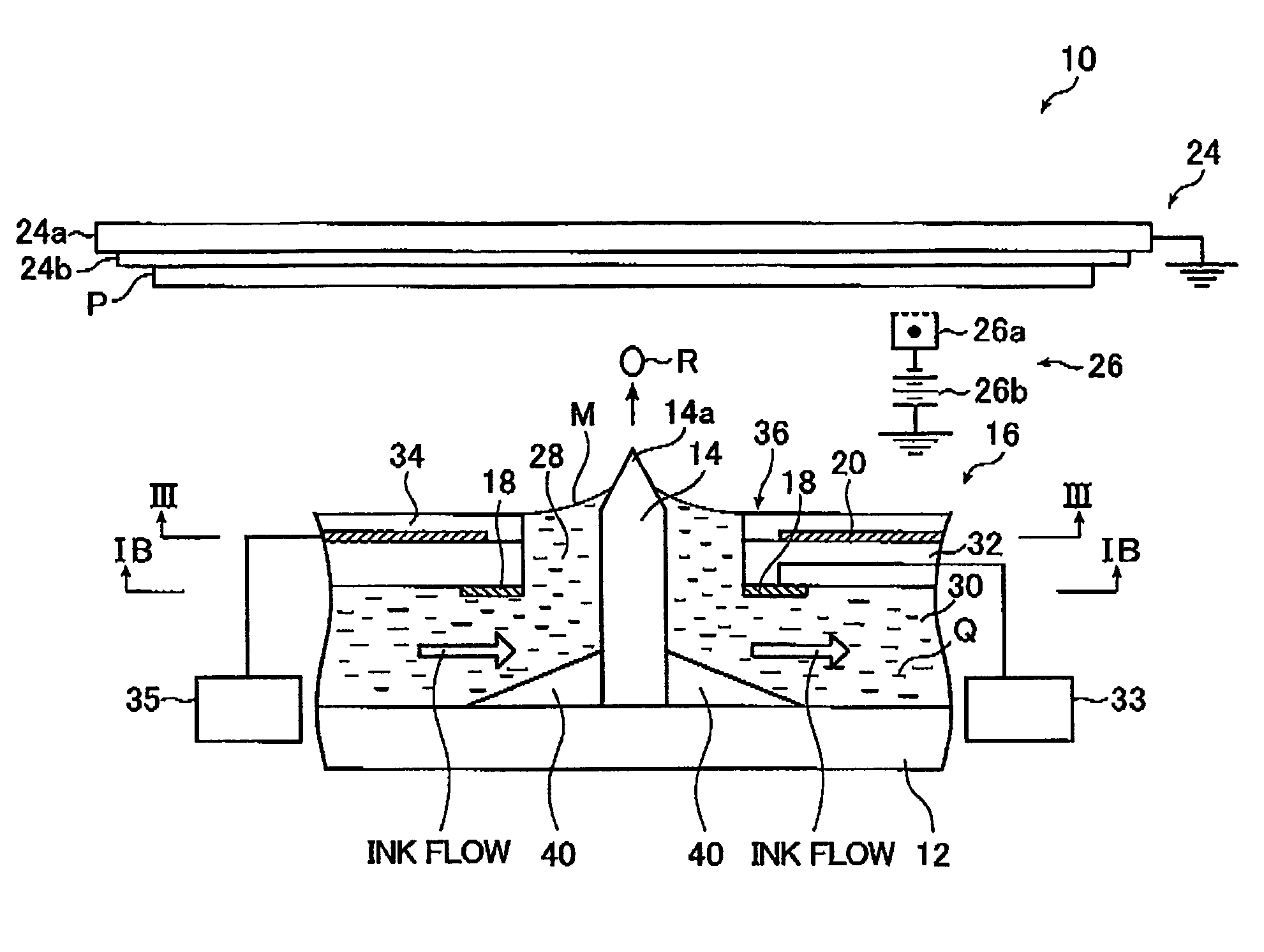

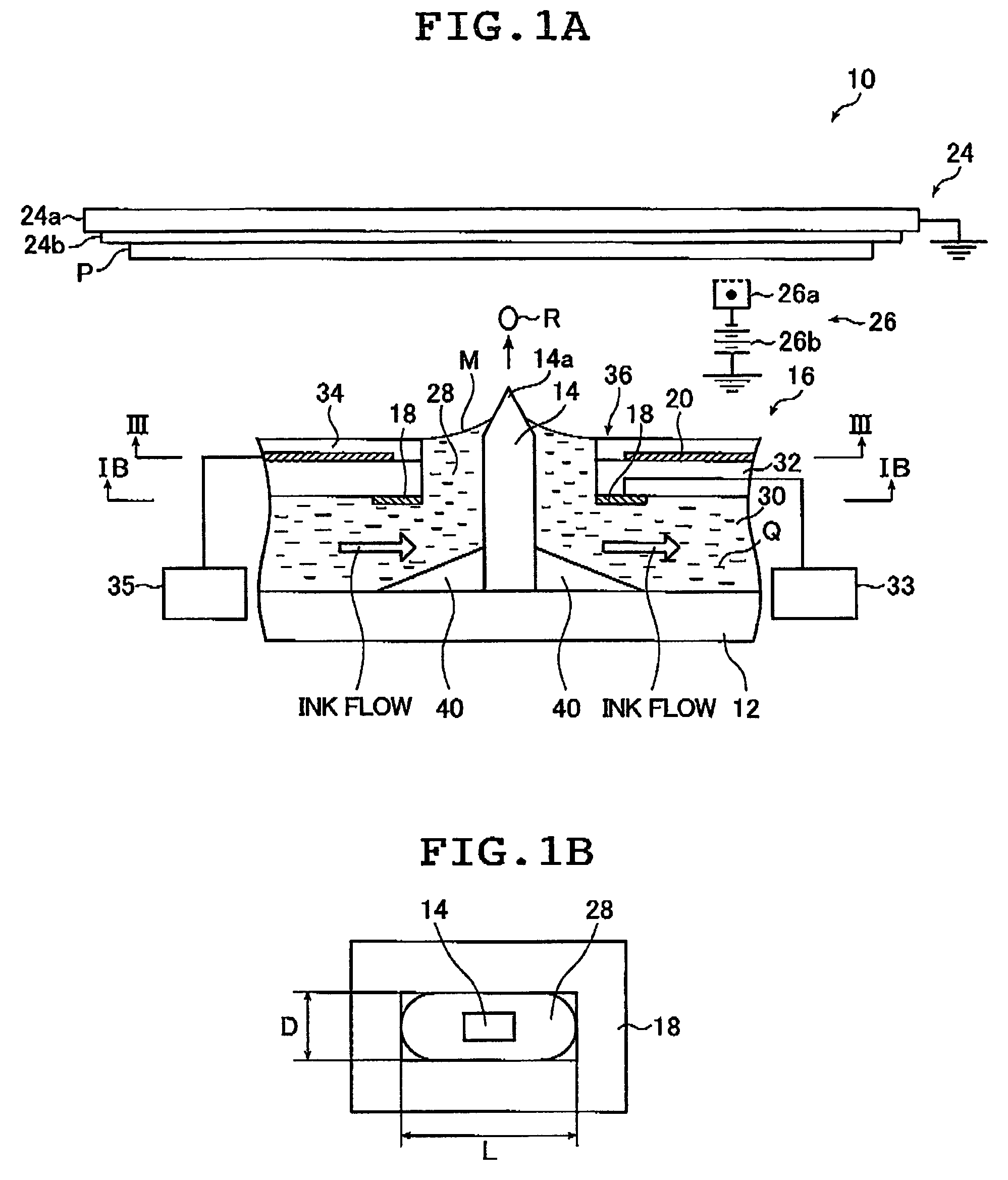

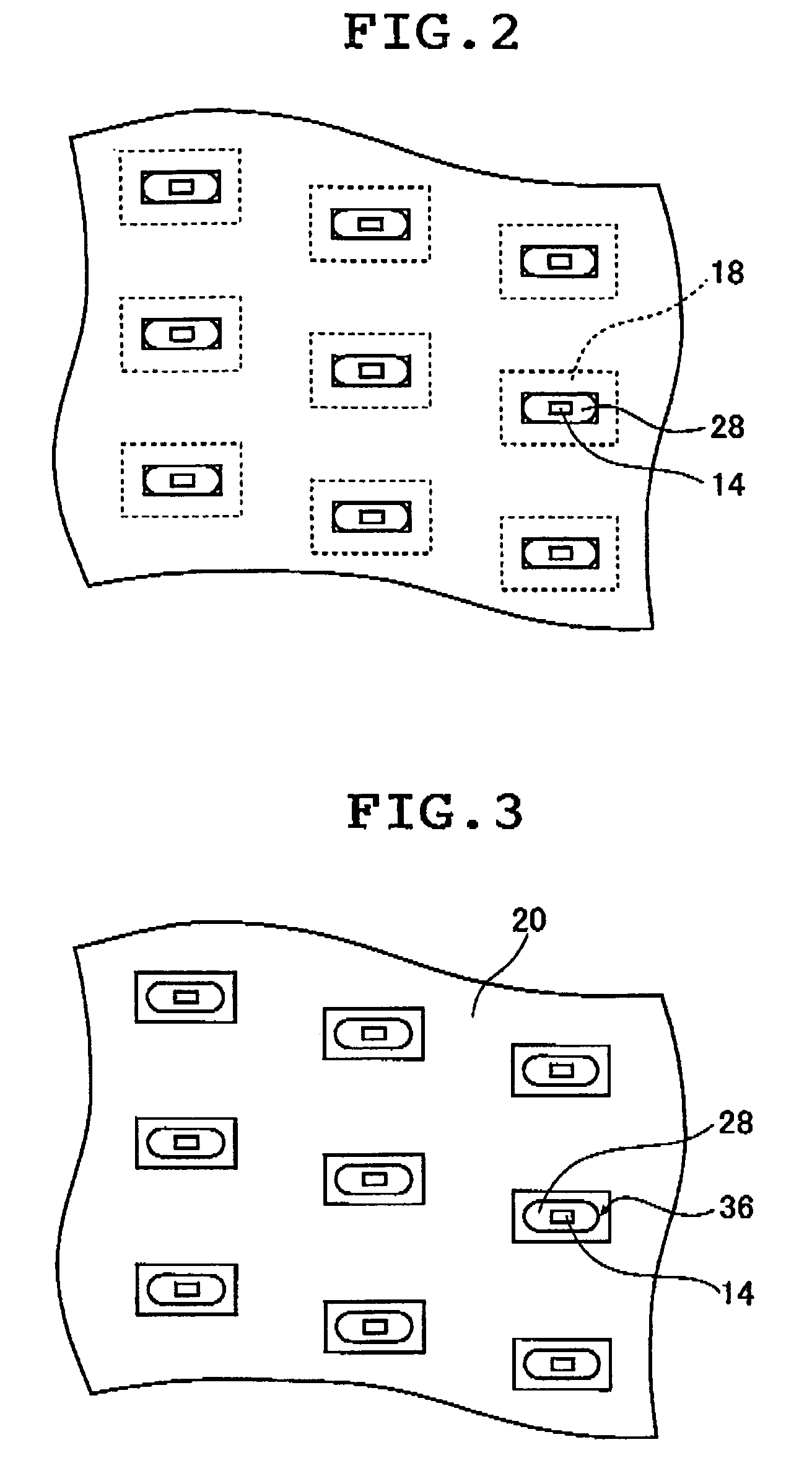

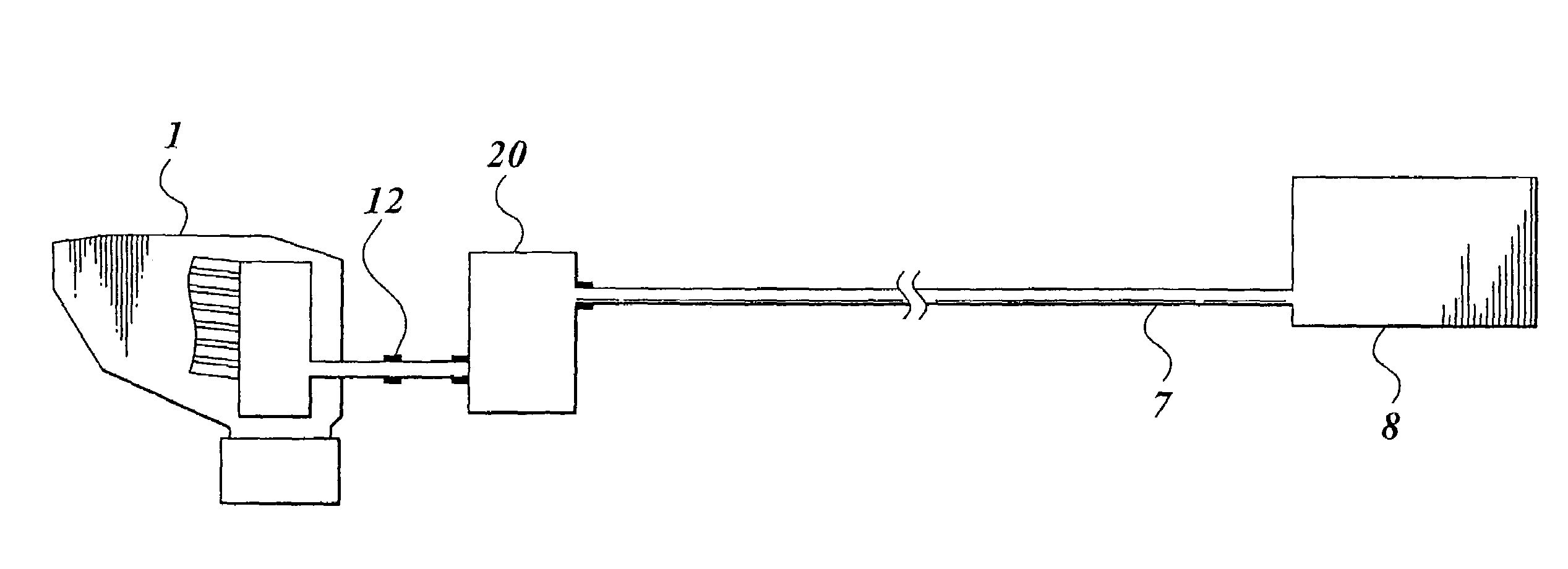

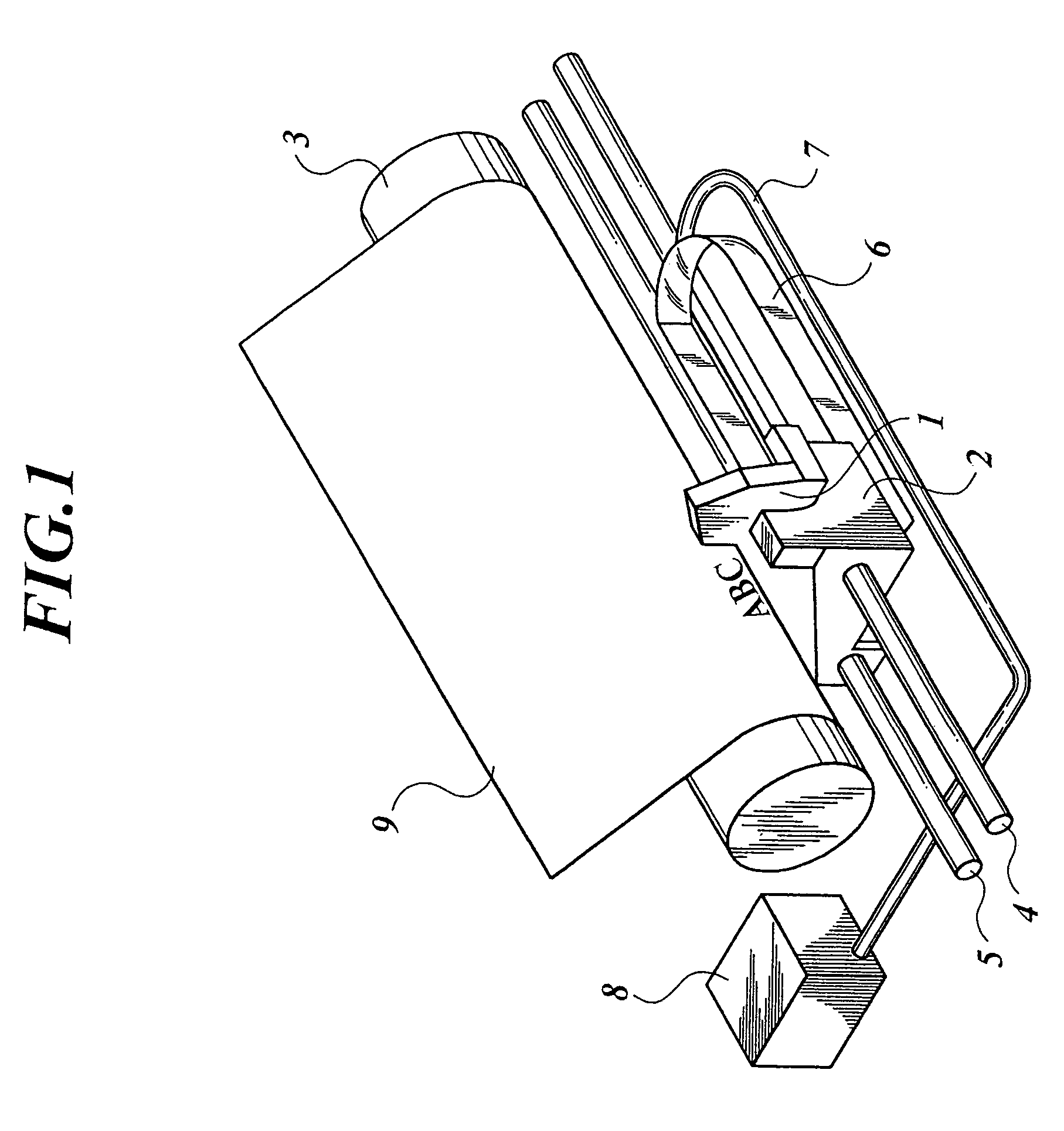

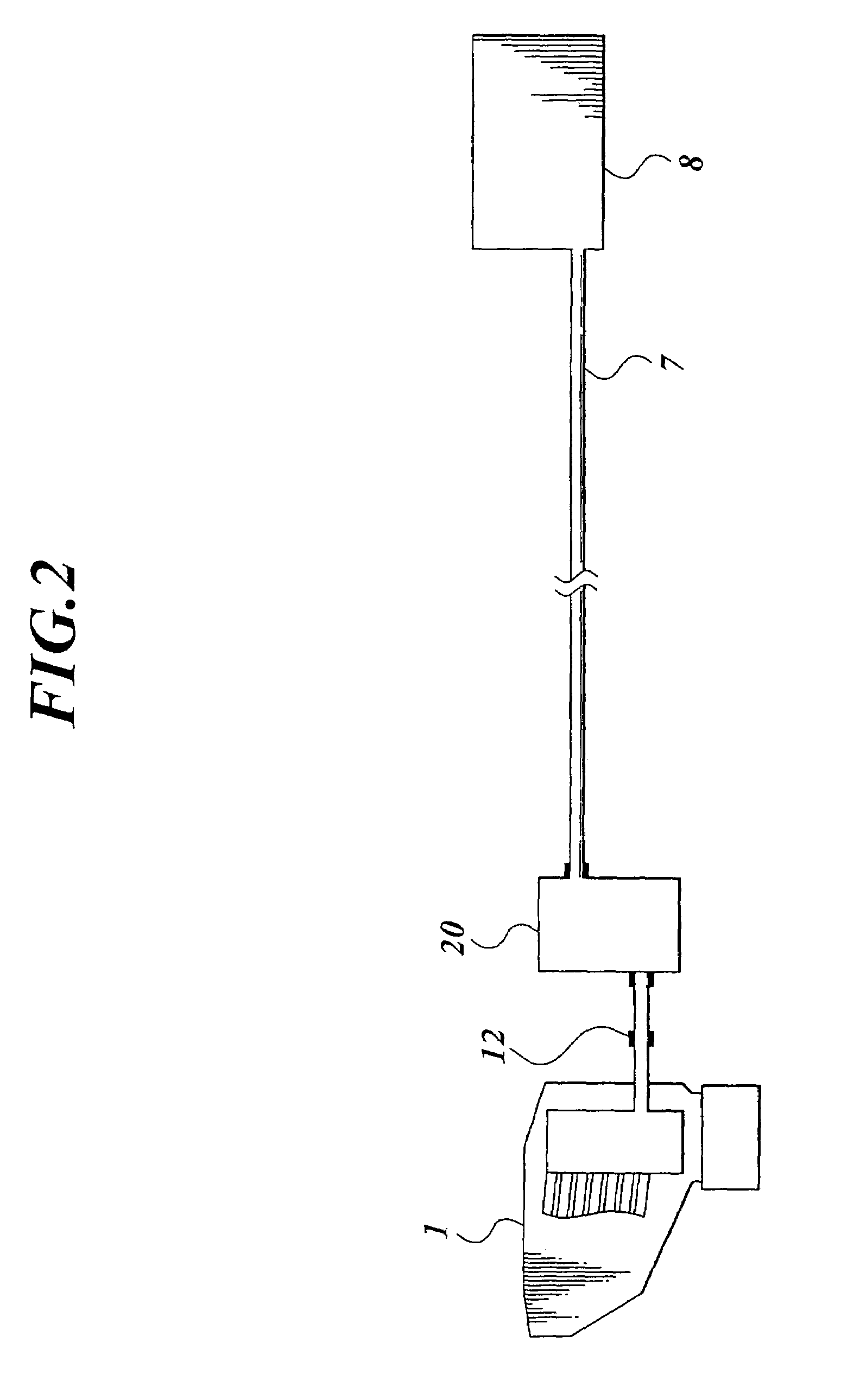

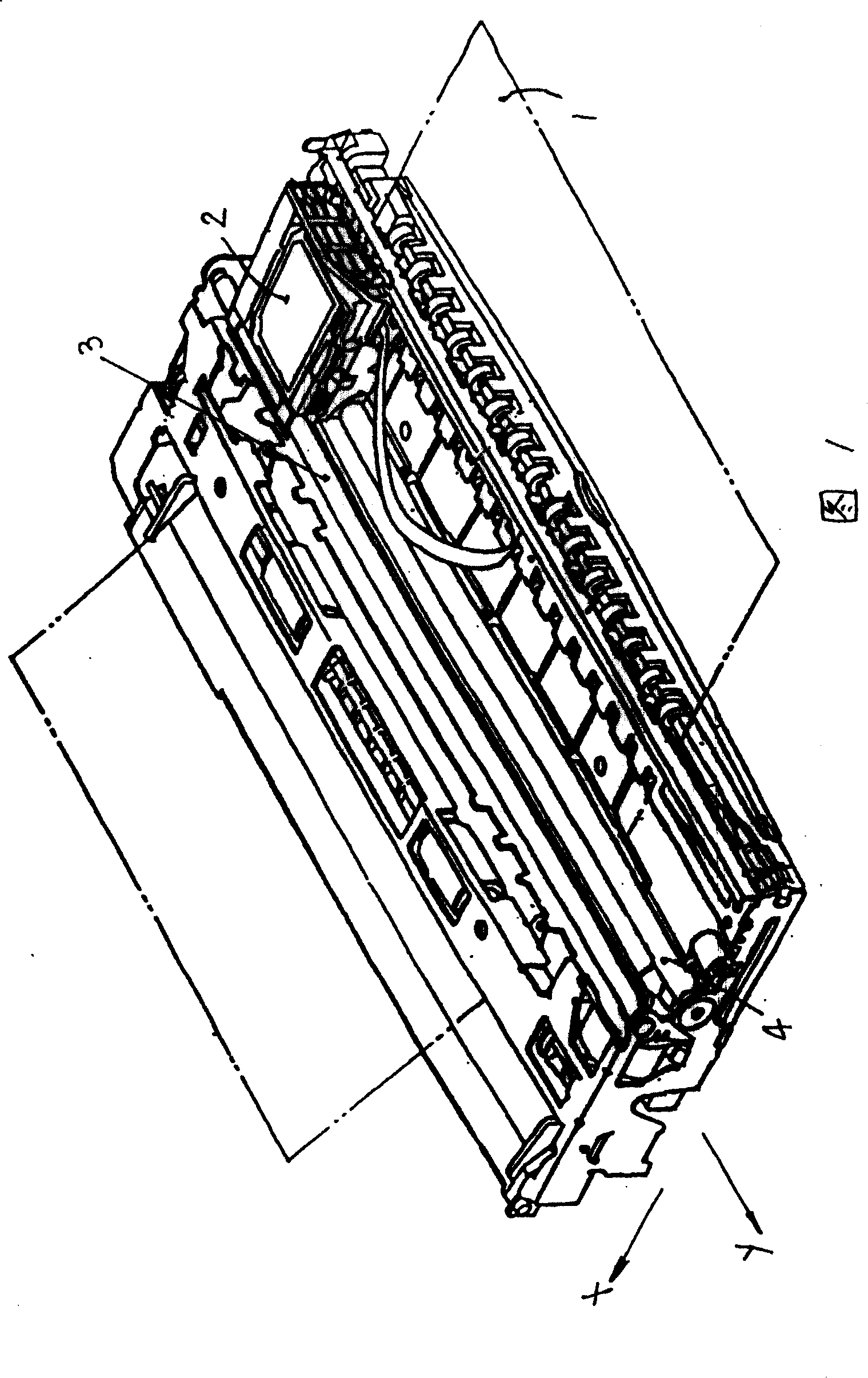

Ink-jet printer and method of controlling ink-jet printer

ActiveUS7328983B2Good inkjet effectUseless consumption of ink is preventedPrintingAir volumeComputer printing

An ink-jet printer, including an ink-jet recording head having an ink inflow passage including an ink inlet, and an air-discharge passage which allows the ink inflow passage to communicate with an atmosphere; an air-discharge valve which selectively opens and closes the air-discharge passage; an ink tank which stores the ink and which has an ink outlet and an air inlet; a connector having an ink supply passage which communicates, at one end thereof, with the ink outlet of the ink tank and communicates, at an other end thereof, with the ink inlet of the recording head; an air supplying device which supplies the air to the ink tank via the air inlet thereof; an obtaining portion which obtains one of an elapsed time, t, from a reference time, and a volume, V, of an air present in the ink supply passage and the ink inflow passage at the elapsed time t, based on an other of the elapsed time t and the air volume V, and a following relationship: V=a·ebt, where a and b are coefficients and e is a base of a natural logarithm; and a control portion which controls, based on the obtained one of the elapsed time t and the air volume V, an operation of the air supplying device and / or the air-discharge valve, so that the volume V of the air at the elapsed time t is discharged through the air-discharge passage opened by the air-discharge valve.

Owner:BROTHER KOGYO KK

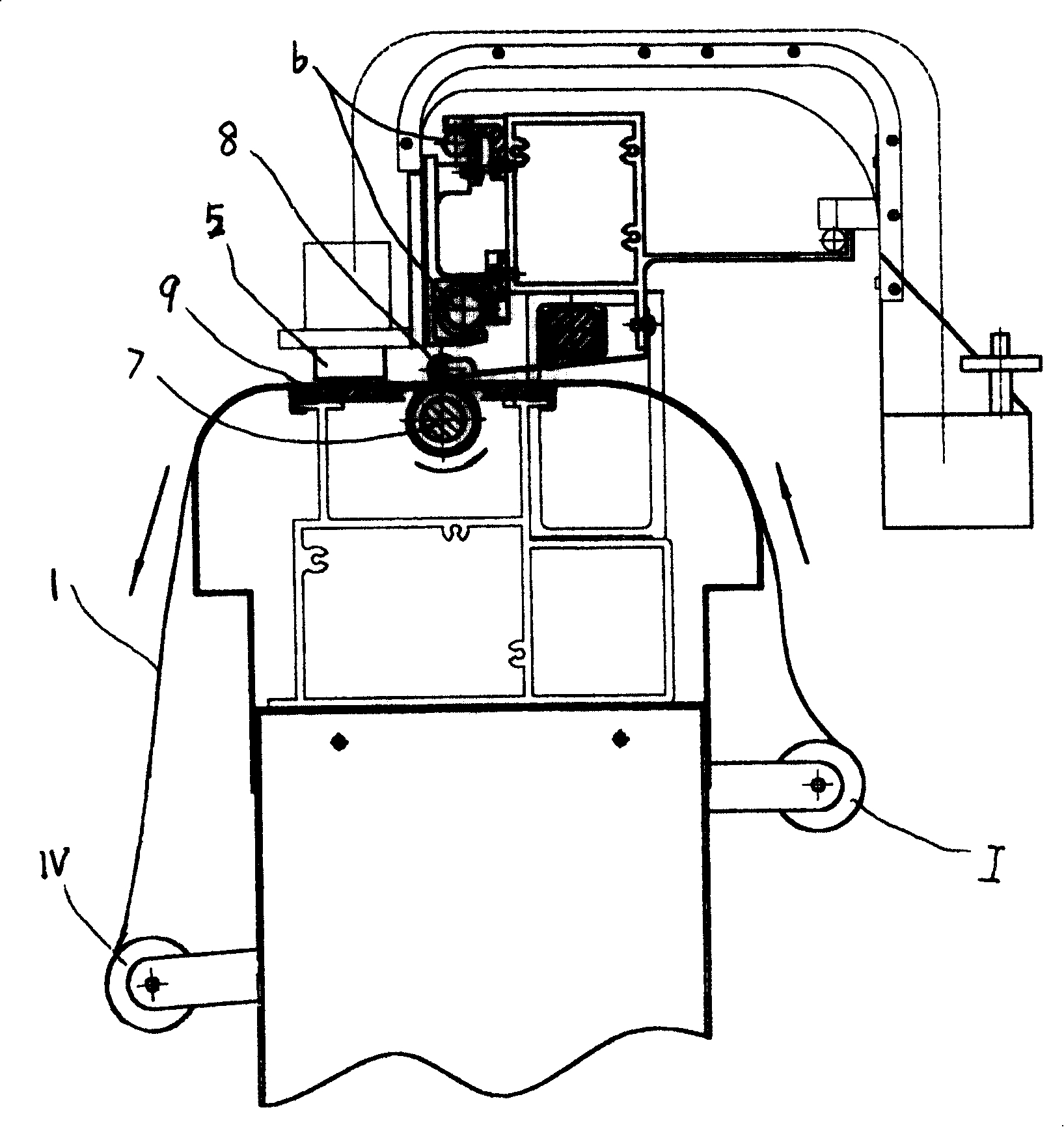

Ink-jet head fixed digital jet printer with guide tape to feed medium

InactiveCN100395111CConvey levelingImprove printing qualityLabelling deformable materialsOther printing apparatusPrinting inkEngineering

The invention relates to a color inkjet printer with a fixed blowing head printing fast on the continuously transferred medium. The printer includes unrolling device, medium transferring device, printing device and rolling device. Its features lies on that the blowing head is fixed on the blowing head stand of which the blowing holes' centers' link is almost perpendicular to the medium transferring direction, guiding belts set in the medium transferring device with a width larger than or equal to the width of the medium, guiding belt glue at least set on the contacting section with the printing medium. So the printer has a wide adapting range and suitable to mediums of different thickness; the service is highly reliable with a fine blowing effect; blowing heads can be handily added or lessened so can the colors of printing inks so to improve the printing quality remarkably. Blow the inks of different at different time by different groups which facilitates the ink drying and solidificating.

Owner:HANGZHOU HONGHUA DIGITAL TECH

Automatic inkjet printer

The invention discloses an automatic inkjet printer, which comprises a track and an inkjet printer cabinet, wherein the track is located below the inkjet printer cabinet; the top part of the inkjet printer cabinet is provided with an ink storage box; the inkjet printer cabinet is internally provided with inkjet nozzles arranged side by side; the inkjet nozzles are connected onto the ink storage box through an inkjet pipe; a solenoid valve for controlling an inkjet switch is arranged above the ink storage box; the left top part of the ink storage cabinet is provided with an ink suction box; the left side of the track is provided with a first limiting switch; the right side of the track is provided with a second limiting switch; an operating plate is arranged on the track; the left lower corner of the operating plate is provided with a first triggering rod; the right upper corner of the operating plate is provided with a second triggering rod; and a power supply is arranged on the inkjet printer cabinet. The automatic inkjet printer provided by the invention has the advantages of simple structure, good inkjet effects and high automatic degree.

Owner:衡阳唯美印务有限公司

An improved inkjet mechanism

The invention provides an improved inkjet mechanism, which belongs to the technical field of printing machinery. The improved inkjet mechanism includes: a conveying channel, which is arranged horizontally and used to convey printing media; a working plate, which is movably installed above the conveying channel, and the working plate can be displaced in the vertical direction to approach or move away from the conveying channel The spray head is detachably mounted on the working flat plate and is arranged as at least one, the lower end surface of the spray head is provided with an ink outlet for spraying ink on the printing medium, and the direction of ink ejection from the ink outlet is consistent with the direction of the delivery channel The conveying direction is vertical; the adjustment assembly is arranged on the working plate and corresponds to the nozzles one by one. The vertical distance of the printing medium below is a preset distance. The improved inkjet mechanism has the advantages of convenient adjustment and ideal inkjet effect.

Owner:宁波荣大创想智造科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com