Ink for preparing dielectric layer of transistor, ink film and preparation method and applications thereof

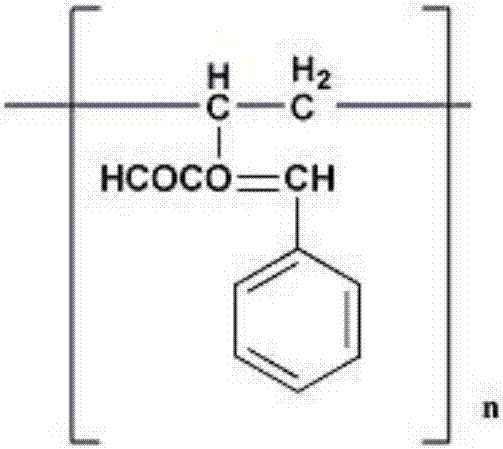

A technology of transistors and dielectric layers, applied in the field of organic electronic device materials, can solve the problems of long annealing time, low ink film preparation efficiency, solution waste, etc., to improve production efficiency and production scale, excellent inkjet performance and film formation Performance, effect of preventing ink penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The second aspect of the present disclosure provides the preparation method of the ink provided by the first aspect of the present disclosure, the method comprising: mixing polyvinyl alcohol cinnamate, polymer additives, surfactants and organic solvents to obtain the ink.

[0038] According to the second aspect of the present disclosure, the method may further include: mixing the polyvinyl alcohol cinnamate, the polymer additive, the surfactant and the organic solvent, followed by stirring, ultrasonication and filtering in sequence. Stirring, ultrasonication and filtration are well known to those skilled in the art. Stirring and ultrasonication are used to disperse the components in the ink and reduce precipitation. The stirring time can be 0.1-2h, the ultrasonic frequency can be 20-40kHz, and the time can be 1- 10min; Filtration treatment is used to filter the precipitated part in the ink, prevent the nozzle of the printer from being blocked and improve the printing eff...

Embodiment 1

[0048] This example is used to illustrate the ink of the present disclosure and its preparation method.

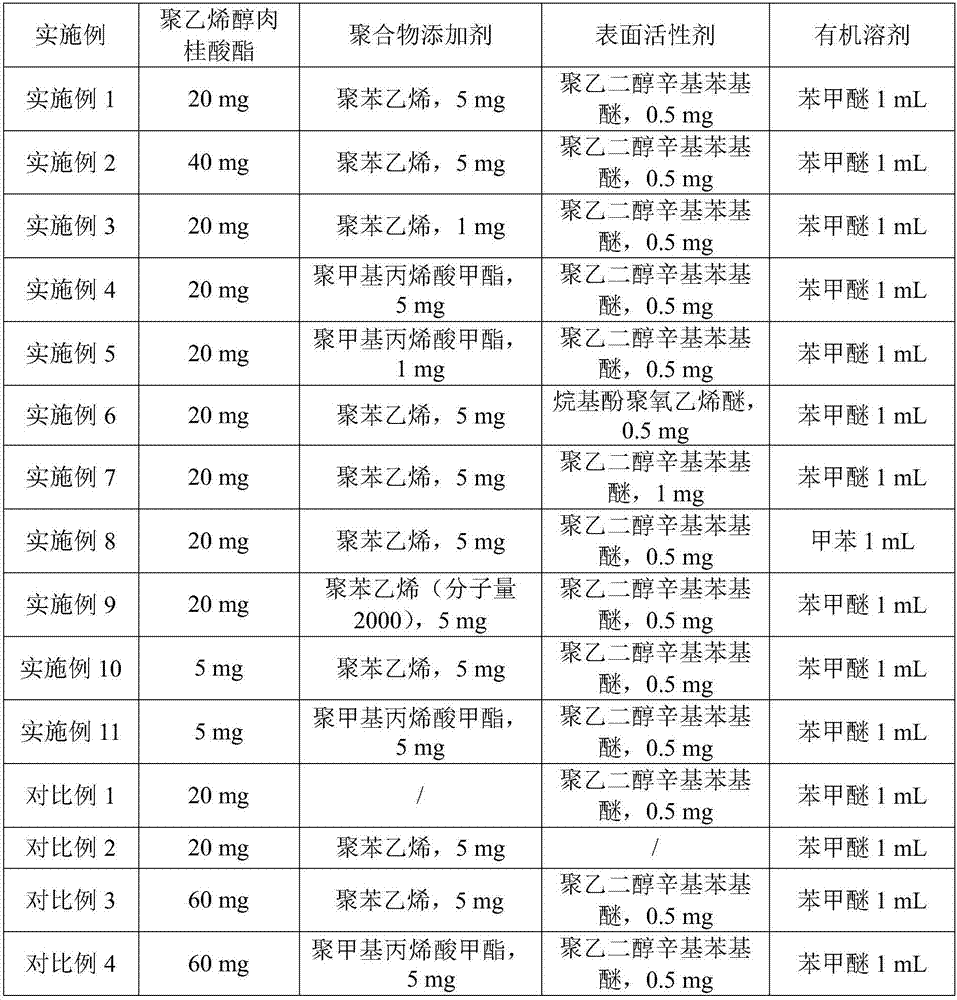

[0049] Take 20mg of PVCN and add it into a glass bottle, then add 1mL of anisole solution, 5mg of polystyrene (Sigma Aldrich company, grade 41147, molecular weight 20,000) and 0.5mg of polyethylene glycol octylphenyl ether into the glass bottle. The active agent was magnetically stirred for 1 hour, then ultrasonicated for 5 minutes, and then filtered with a 0.22 μm organic filter head to obtain the ink of this example.

Embodiment 2-11

[0051] The composition and content of the ink are shown in Table 1, and the inks of Examples 2-11 were prepared by the steps of Example 1 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com