An improved inkjet mechanism

An improved nozzle technology, which is applied in printing and other directions, can solve the problems of unreasonable layout of inkjet nozzles, affecting the working efficiency of the whole machine, and the inability to adjust local positions, etc., to achieve ideal inkjet effects, convenient control, and overall structural layout reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

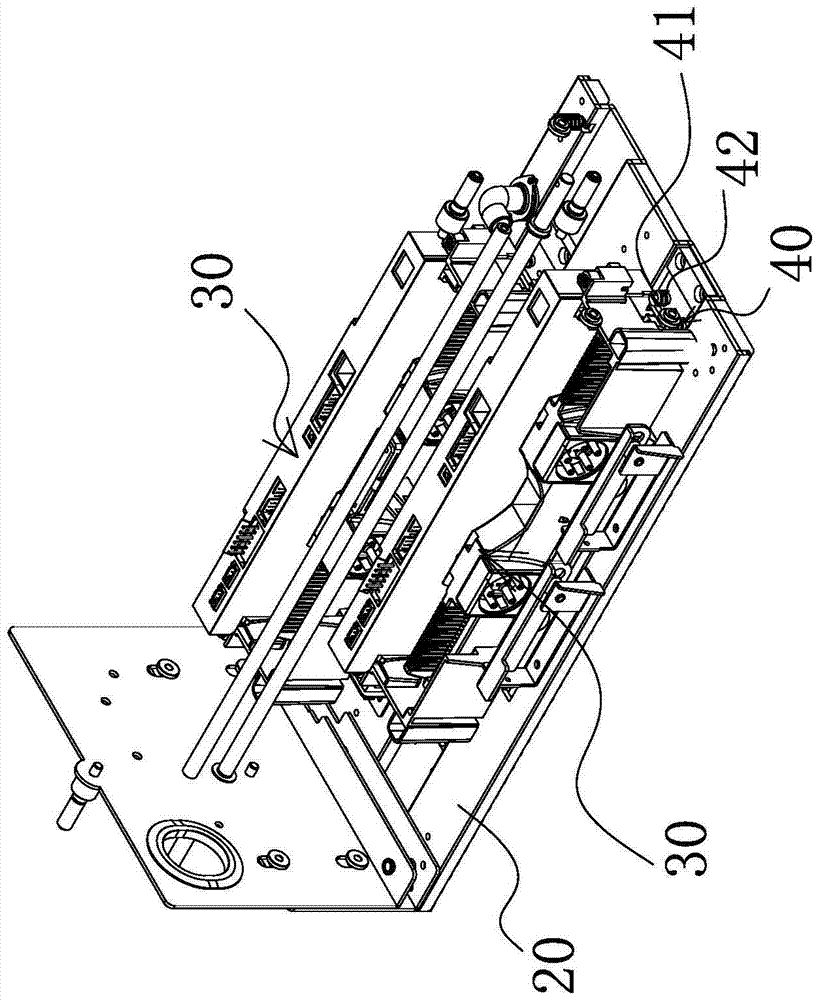

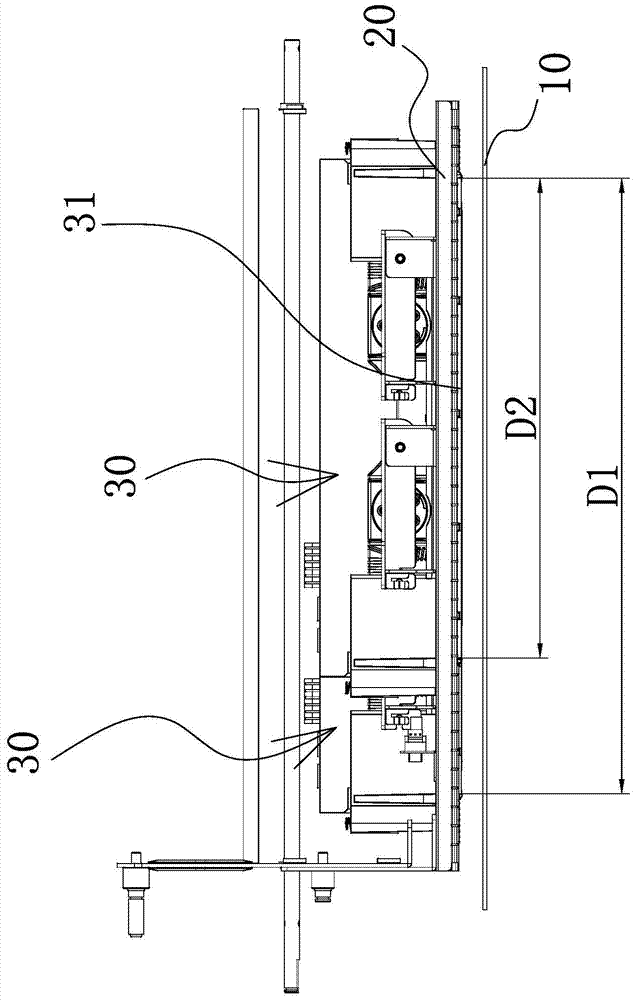

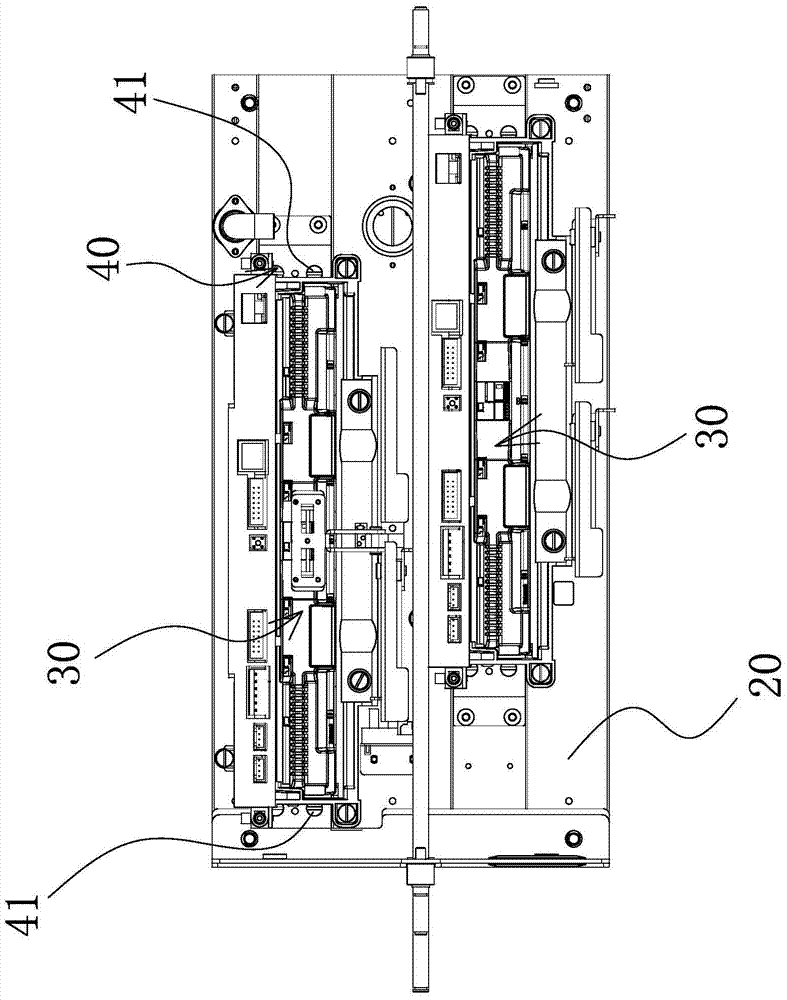

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0031] The invention protects an improved inkjet mechanism for printing ink on printing media such as paper. The inkjet mechanism is preferably applied to printers, and can also be applied to other printing equipment such as printing machines.

[0032] Furthermore, the improved inkjet mechanism can not only print monochrome characters or patterns, but also change the ink color and pipeline layout according to actual needs, thereby realizing color printing, with flexible use and wide versatility.

[0033] Most of the printing equipment currently on the market has a simple structural design, and the layout of the inkjet nozzle 30 is unreasonable. The nozzle 30 is fixedly installed on the frame, and the position can only be mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com