Patents

Literature

1334results about How to "Reasonable structure layout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

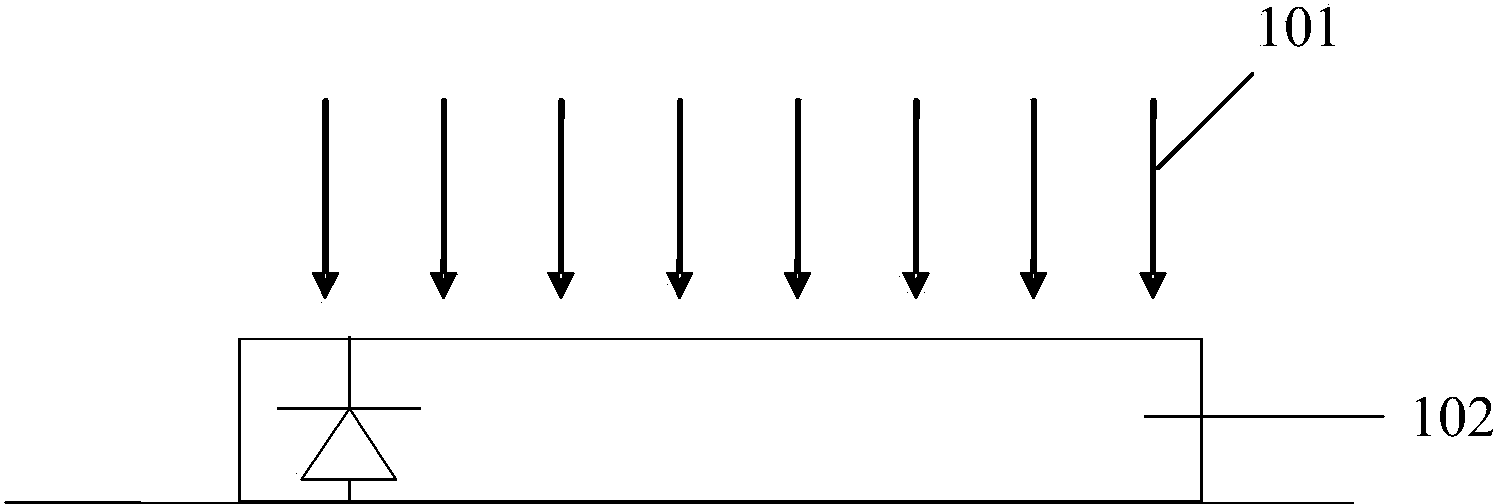

Compound optical sensor and manufacture method and use method thereof

ActiveCN104318199AReasonable structure layoutSmall footprintTransistorSolid-state devicesFingerprintPixel array

The invention discloses a compound optical sensor and a manufacture method and a use method thereof. The compound optical sensor comprises a light source, a transparent substrate, a first pixel array area, a second pixel array area and a third pixel array area, wherein the transparent substrate is provided with a first surface and a second surface, and the first surface and the second surface are opposite; the first pixel array area is positioned on a first surface and is used for receiving the ray, which is reflected by external objects, of the light source; the second pixel array area is positioned on the first surface and is used for receiving the ray, which is reflected by a fingerprint, of the light source; and the third pixel array area is positioned on the first surface and is used for receiving visible light ray emitted from environment. The compound optical sensor exhibits simplified structure and low manufacture process difficulty, application functions are increased, and production cost is lowered.

Owner:SHANGHAI OXI TECH

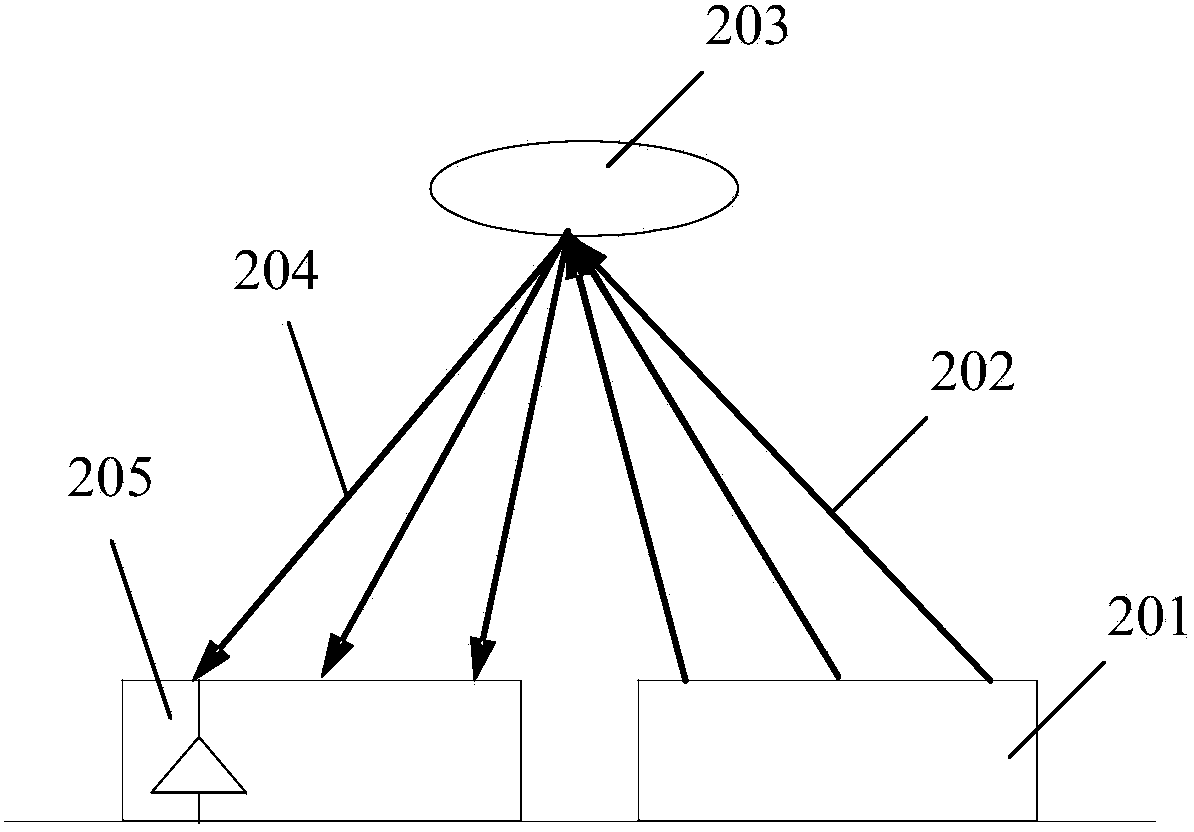

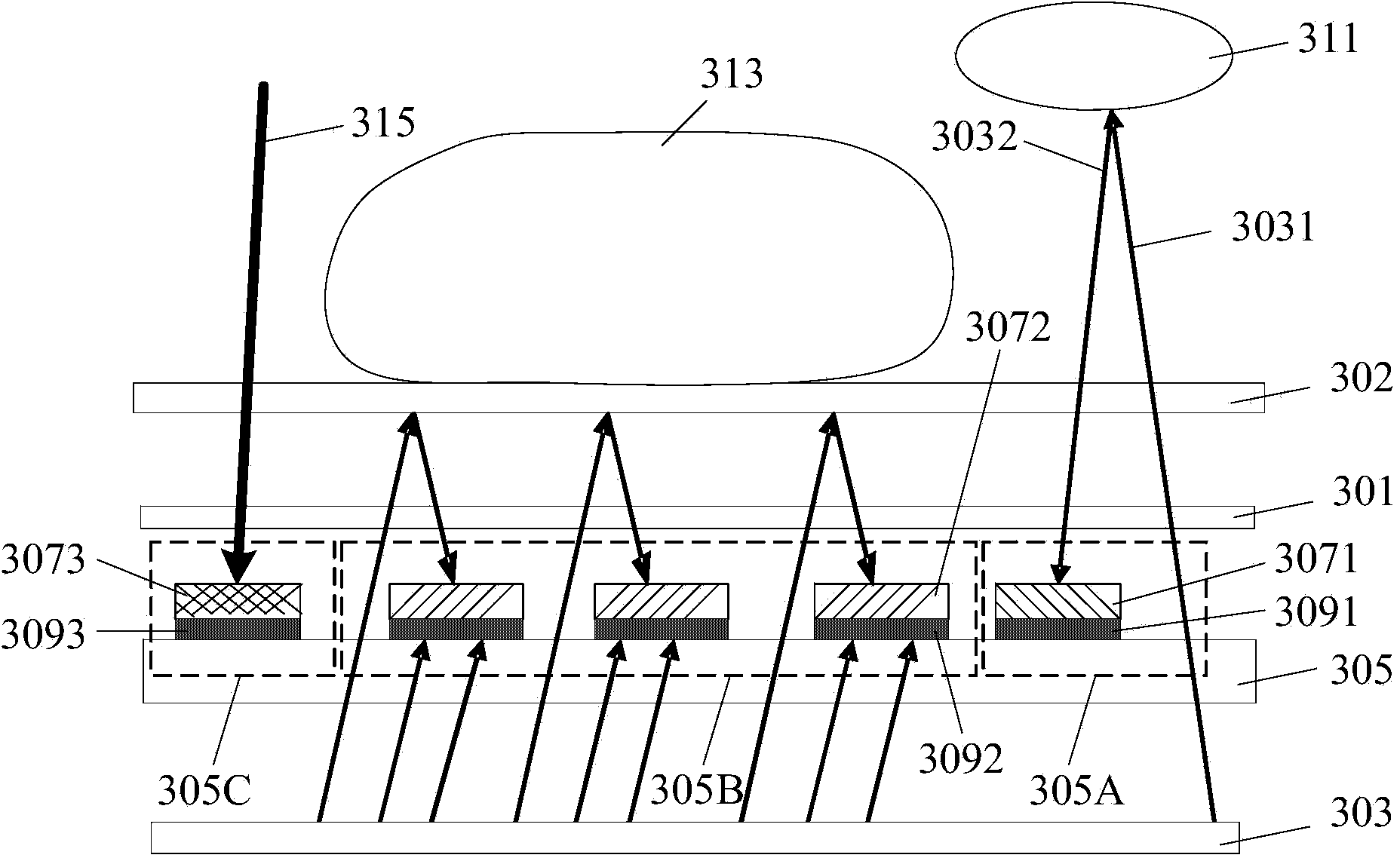

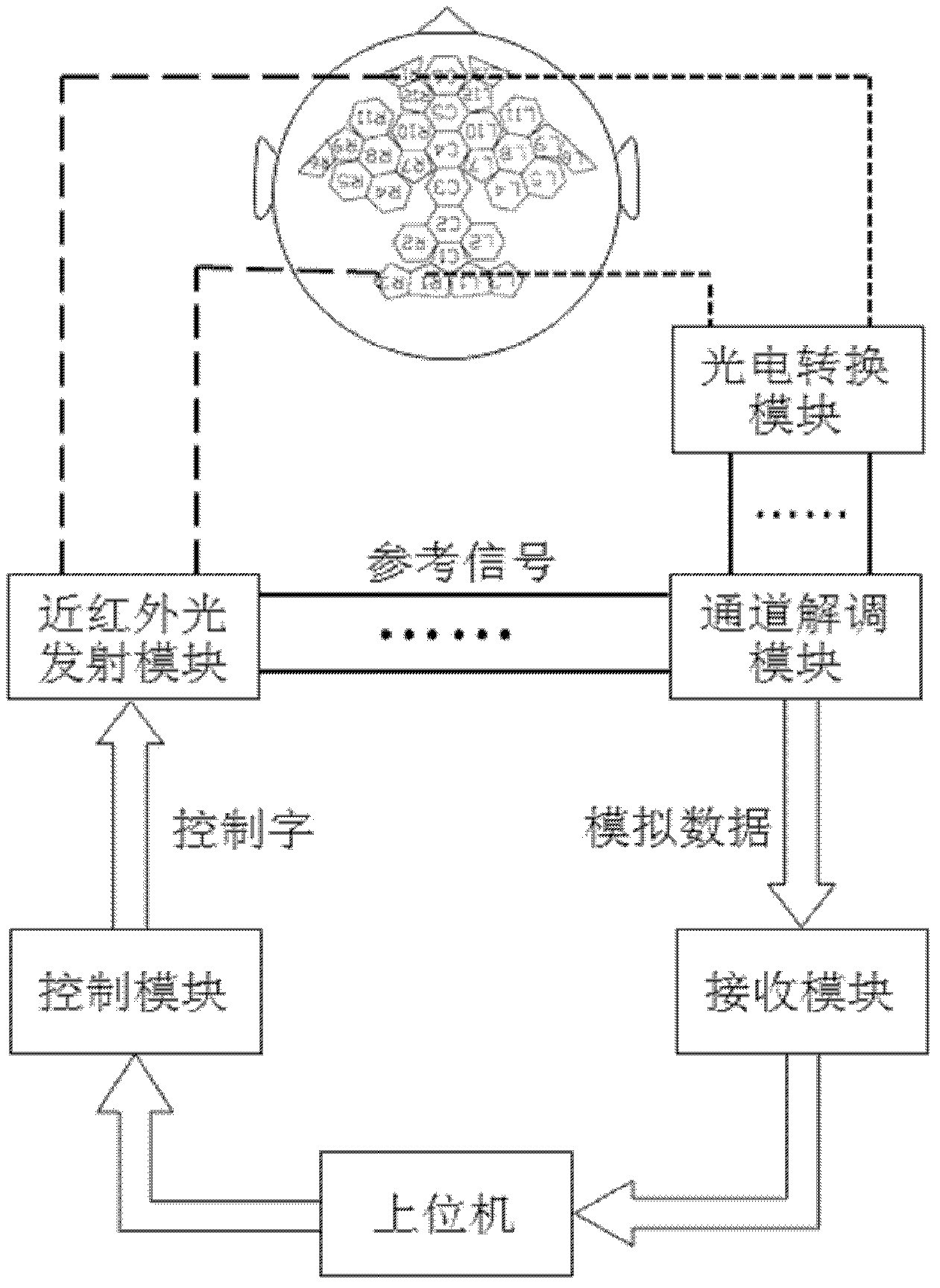

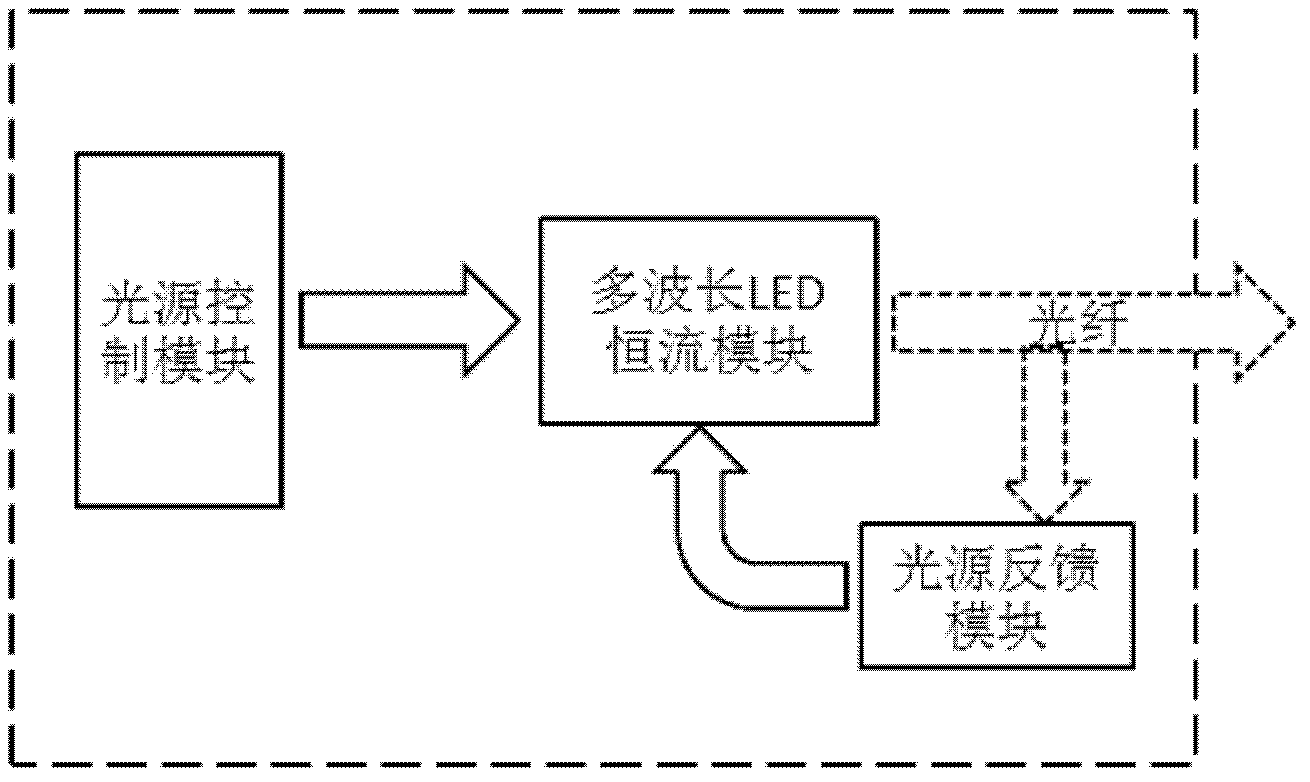

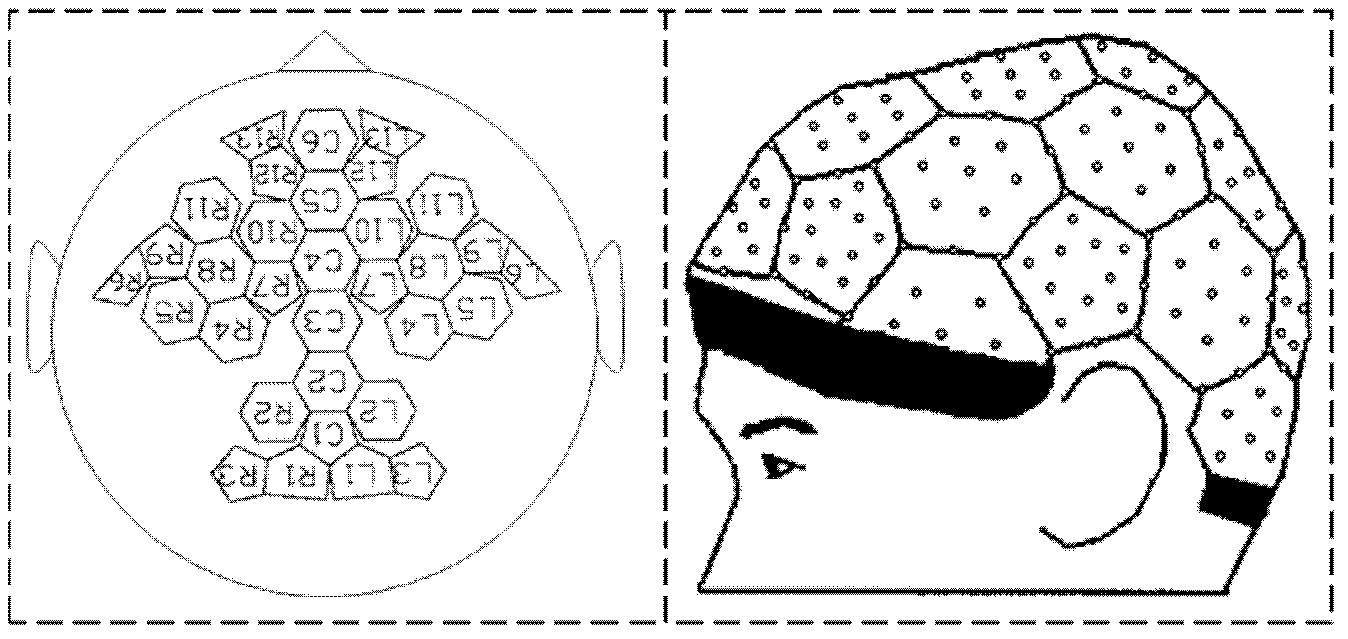

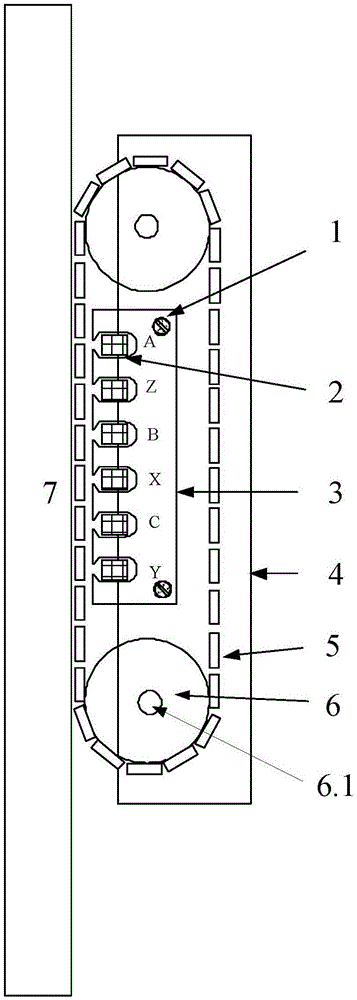

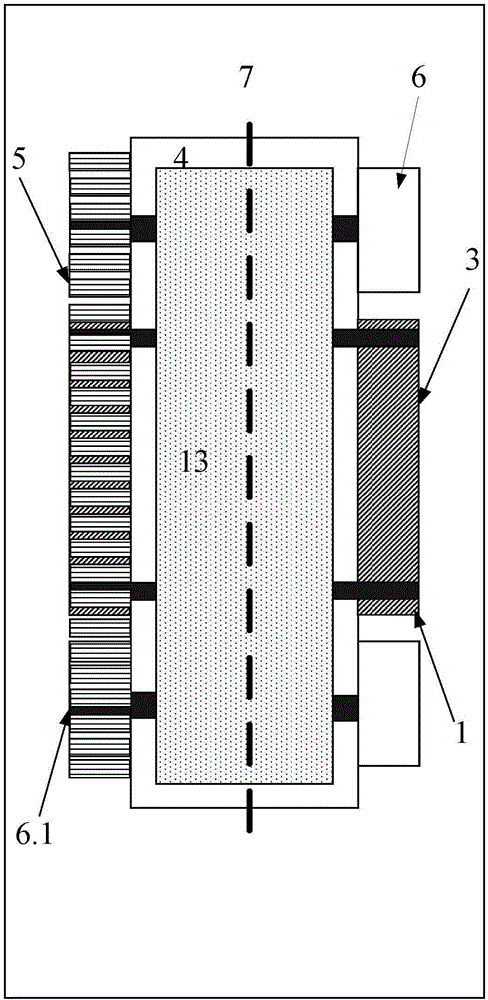

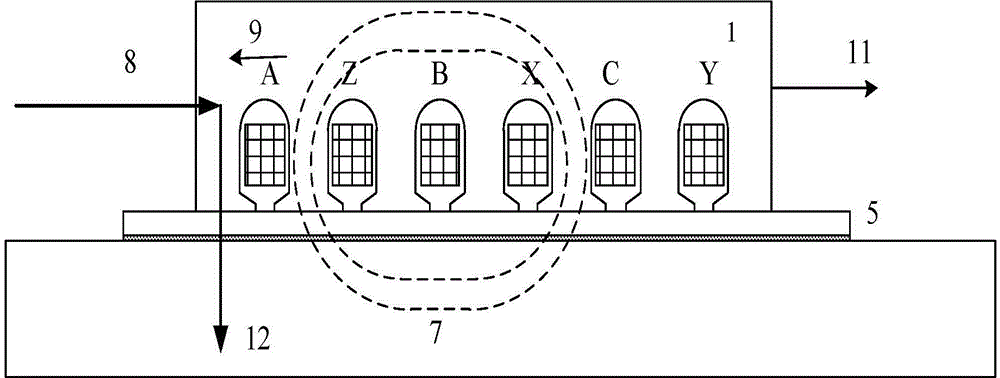

Multi-channel parallel near infrared spectrum imaging system

ActiveCN103156620ALow cost to manufacture and useHigh costDiagnostic recording/measuringSensorsMulti wavelengthInfrared

The invention discloses a multi-channel parallel near infrared spectrum imaging system. A multi-wavelength light emitting diode (LED) is applied to finishing emission of near-infrared light. An avalanche photodiode is used for detecting a weak optical signal, the simulating lock-in amplifier technology is used for achieving amplification of the signal, and a near infrared spectrum cerebral function imaging helmet disclosed in Chinese patent application CN200520002784.8 can be used for improving the partial unreasonable design of a self-adaptation head portion. The multi-channel parallel near infrared spectrum imaging system can achieve continuous rapid accurate detection and collection of cerebral blood oxygen signals, overcomes the defect of an existing functional near infrared system, and brings superiority of the near infrared spectrum imaging technology compared with other cerebral function imaging technologies into full play.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

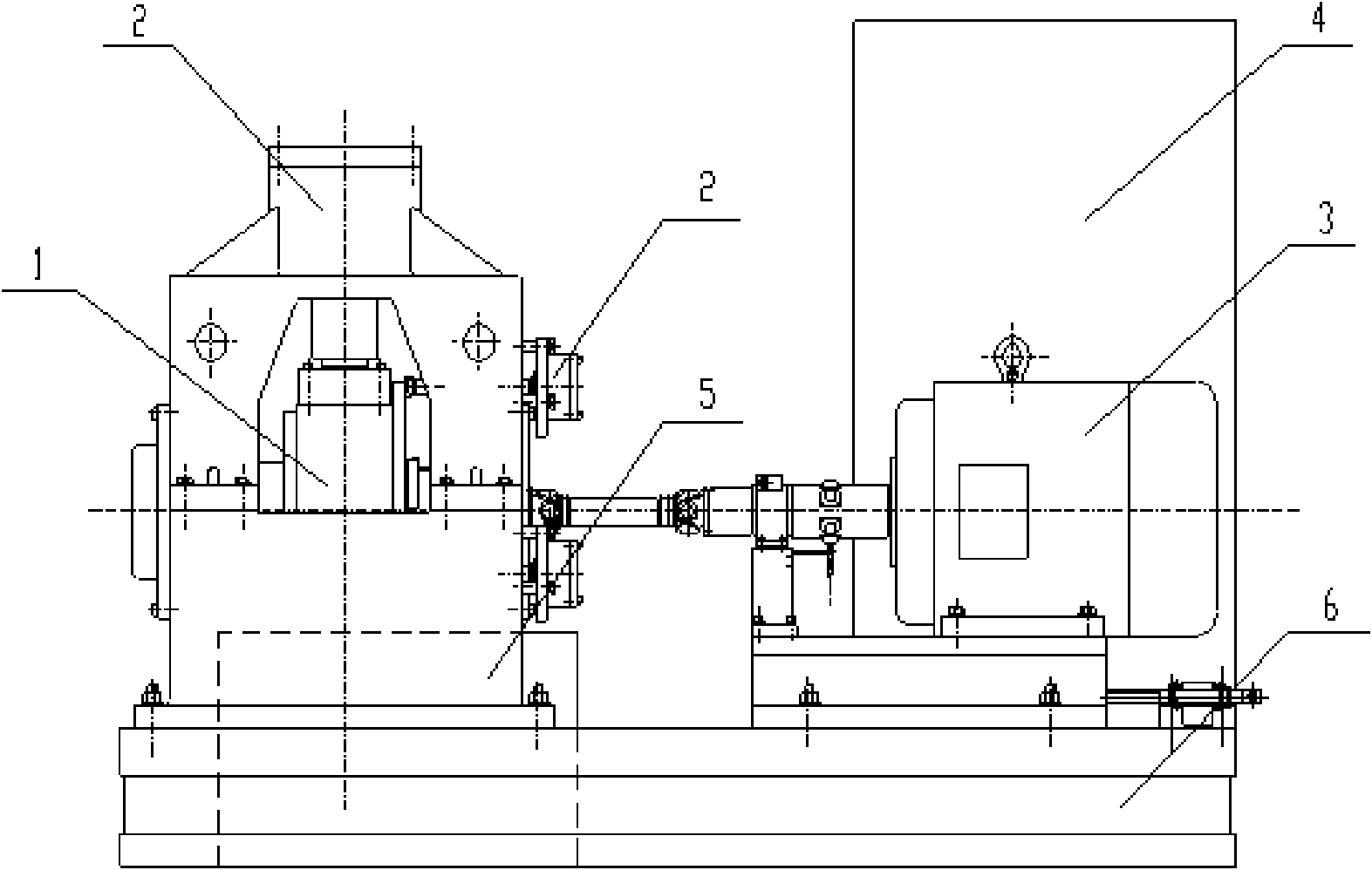

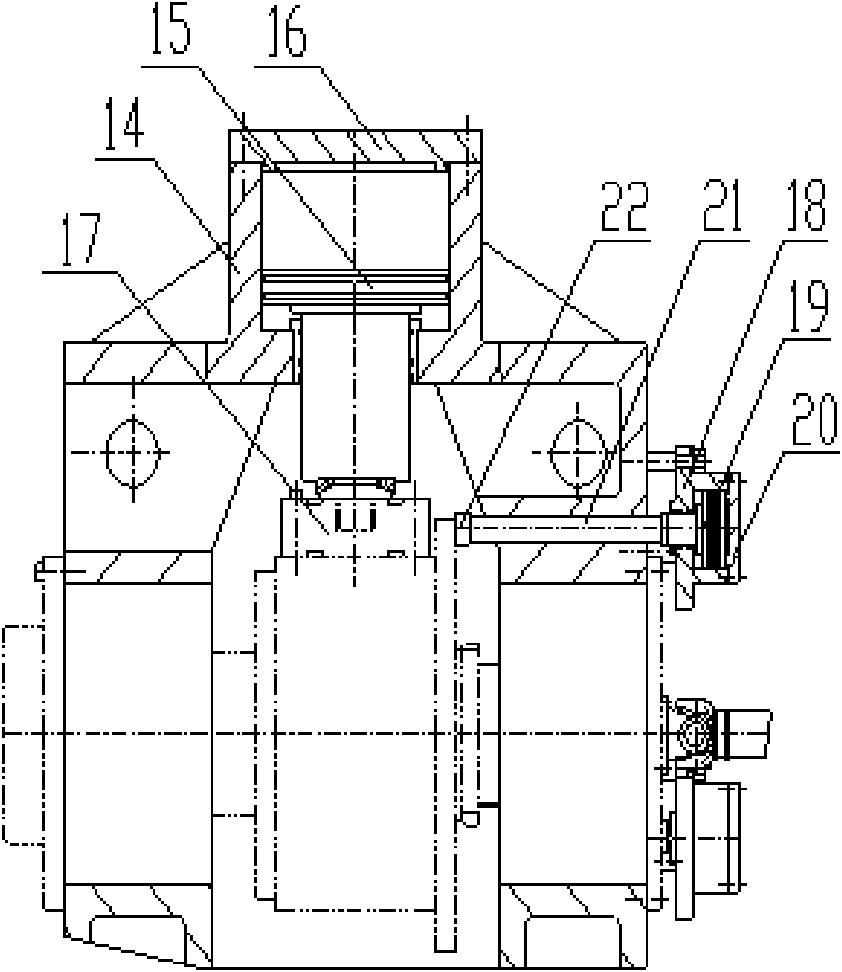

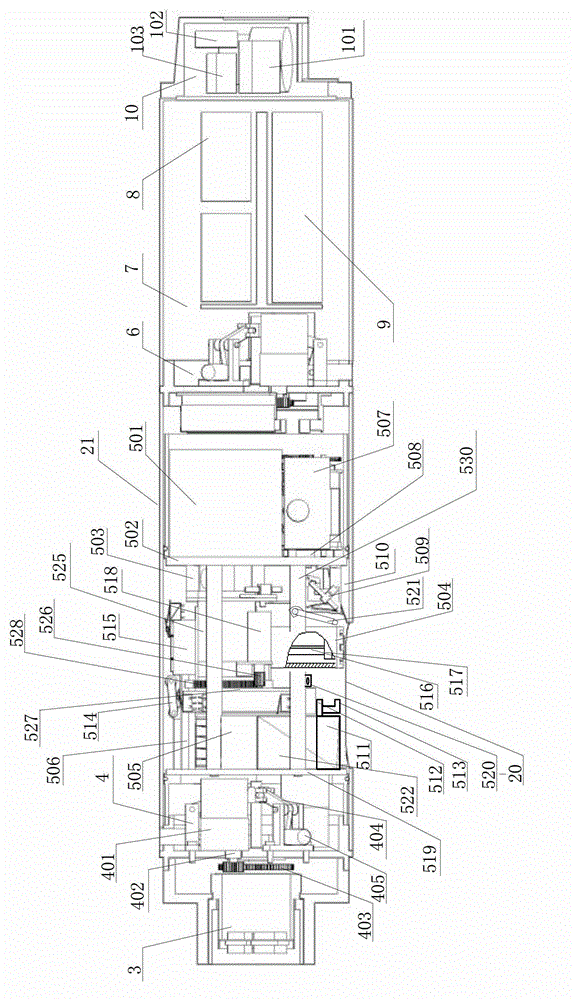

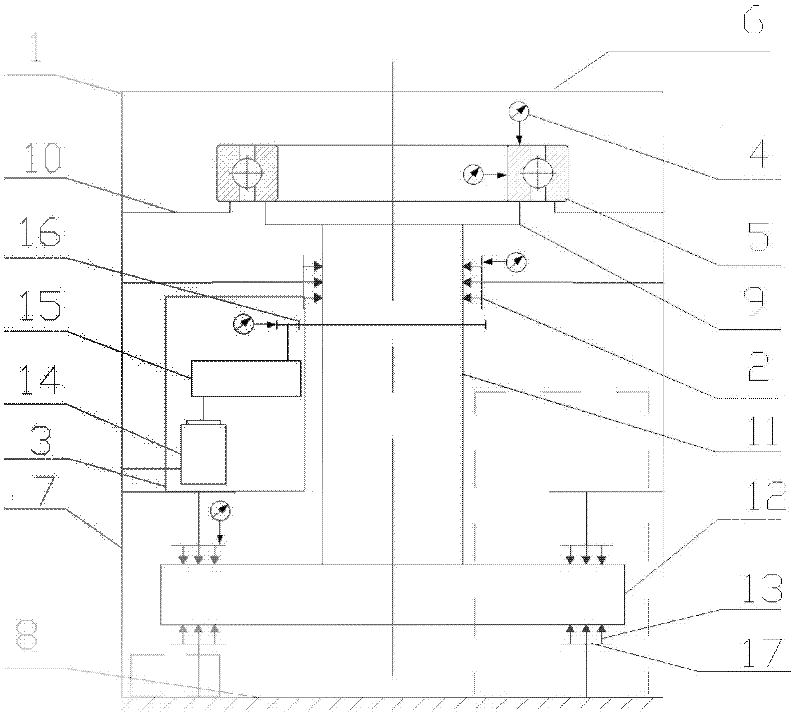

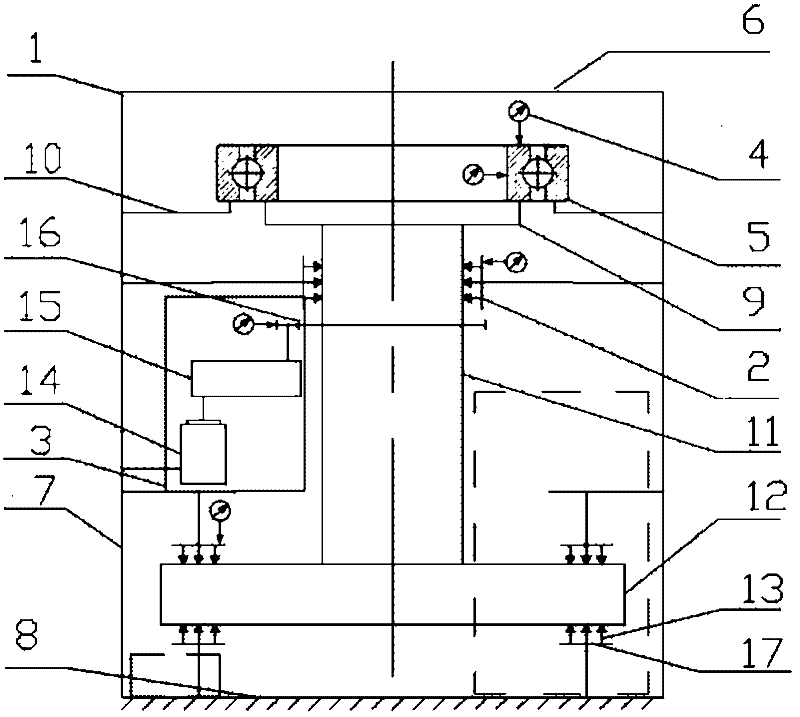

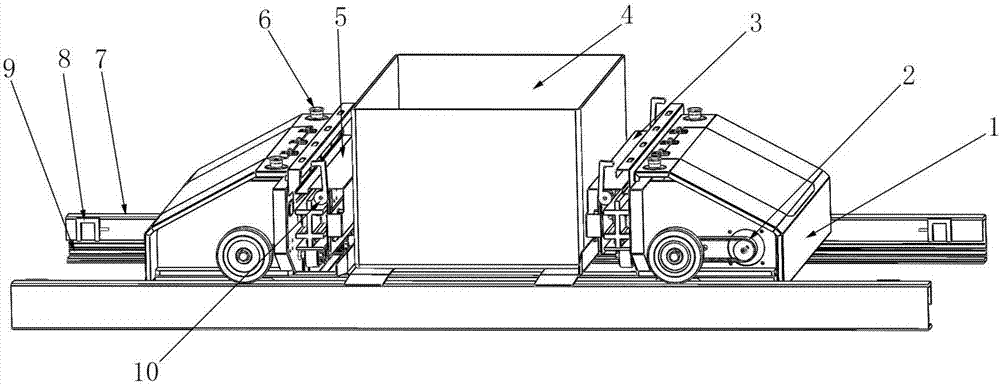

Large bearing testing machine

InactiveCN101660970ALoad accuratelyImprove structural rigidityMachine bearings testingWork measurementProper timeTest procedures

The invention belongs to the technical field of bearing tests, in particular to a large bearing testing machine. The large bearing test machine is characterized by consisting of a test unit, a loadingunit, a drive unit, a control unit, a hydraulic power unit and a workbench. The loading unit, the drive unit and the control unit are arranged on the workbench, the test unit is arranged on the loading unit, the hydraulic power unit is arranged behind the workbench and connected with the loading unit, the control unit is matched with the test unit, the loading unit, the drive unit, and the hydraulic power unit respectively. The test unit is used for receiving a large bearing for test, the loading unit applies radial load, axial load and capsizing moment to the test bearing, the drive unit drives the test bearing to rotate at a specified rotation speed and torque, and the control unit controls electrical operation and protection, monitors test operation, analyzes test procedures and results, and give feedbacks at proper time.

Owner:汇洲智能技术集团股份有限公司

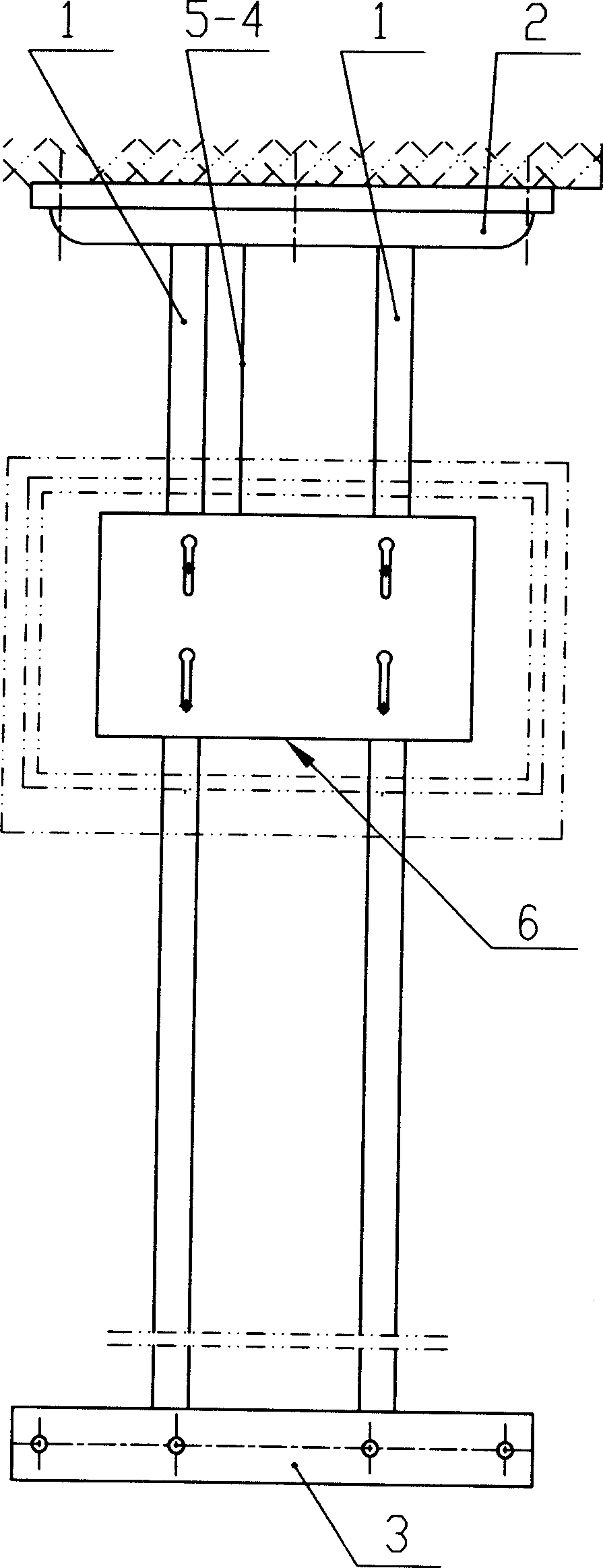

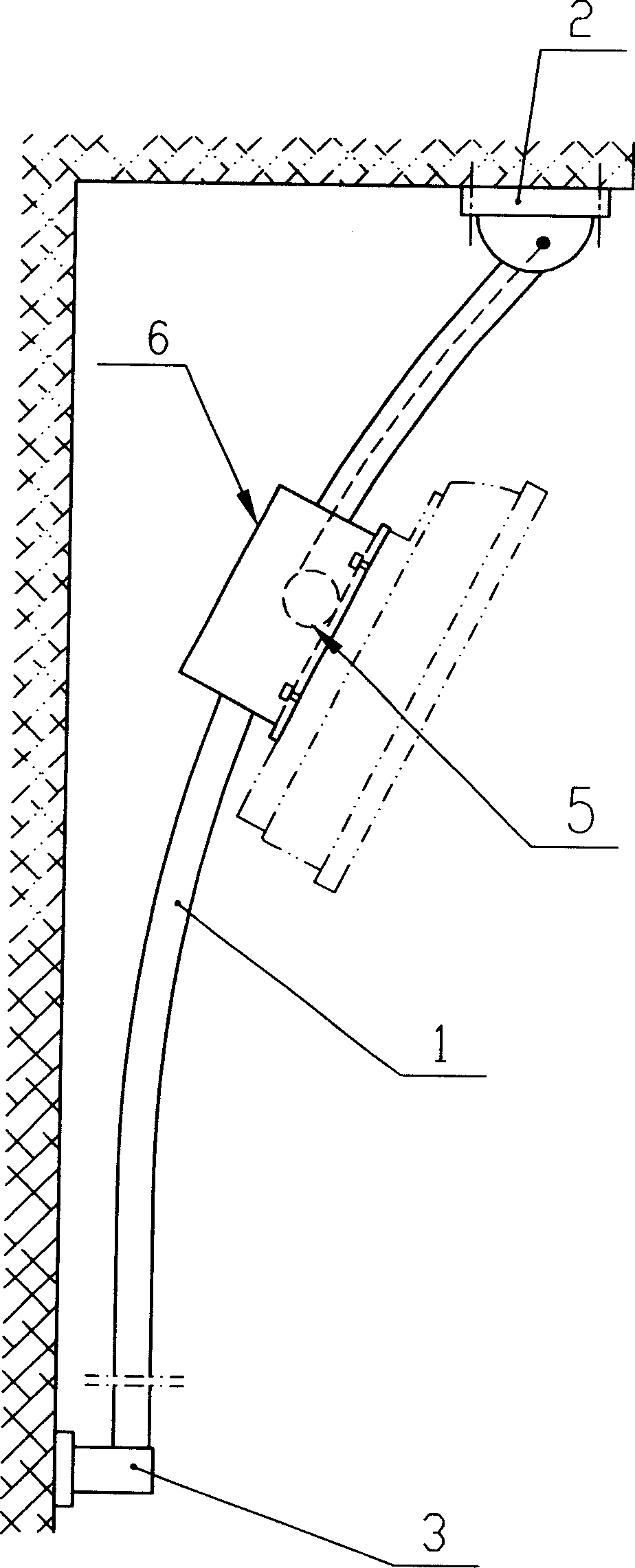

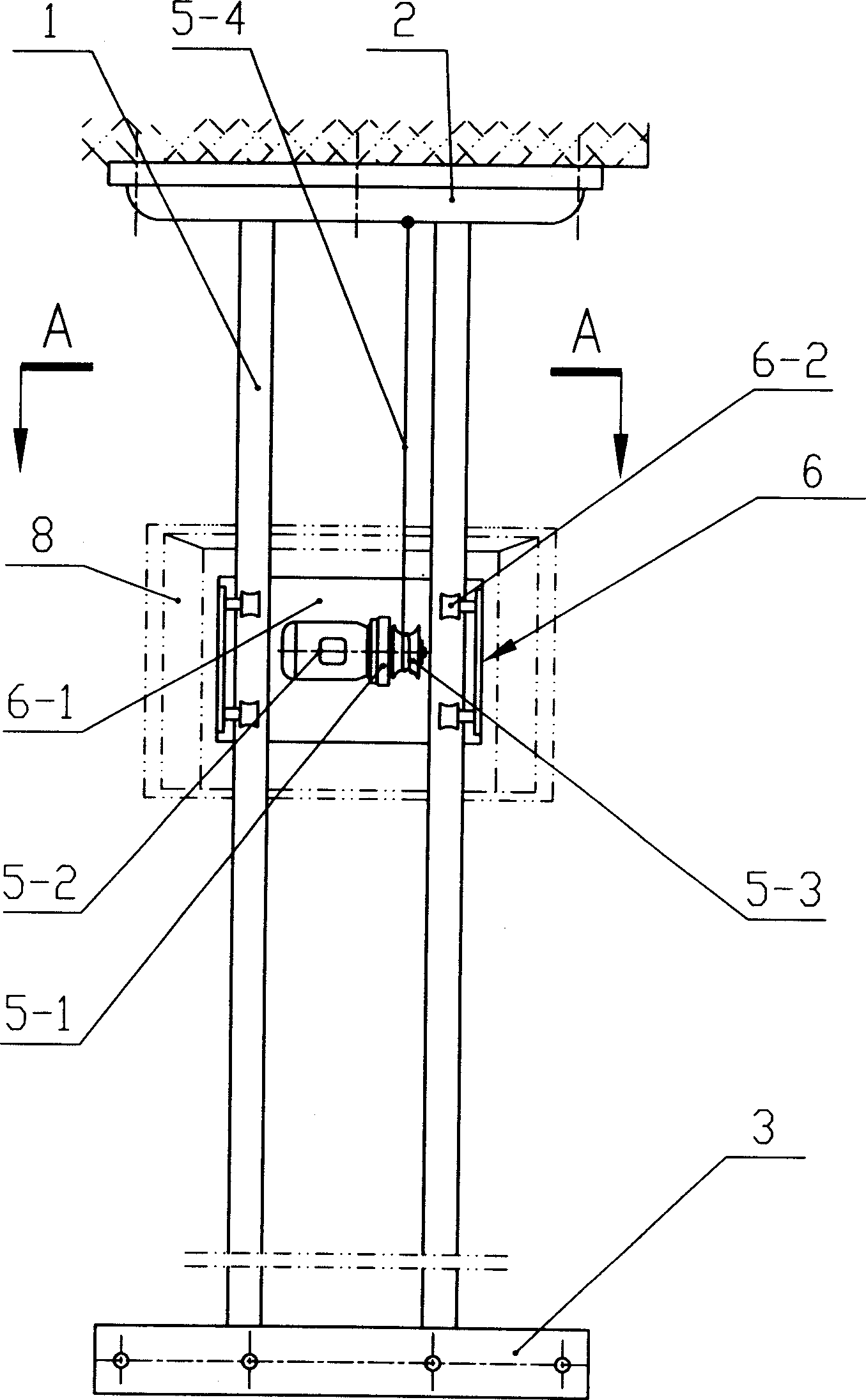

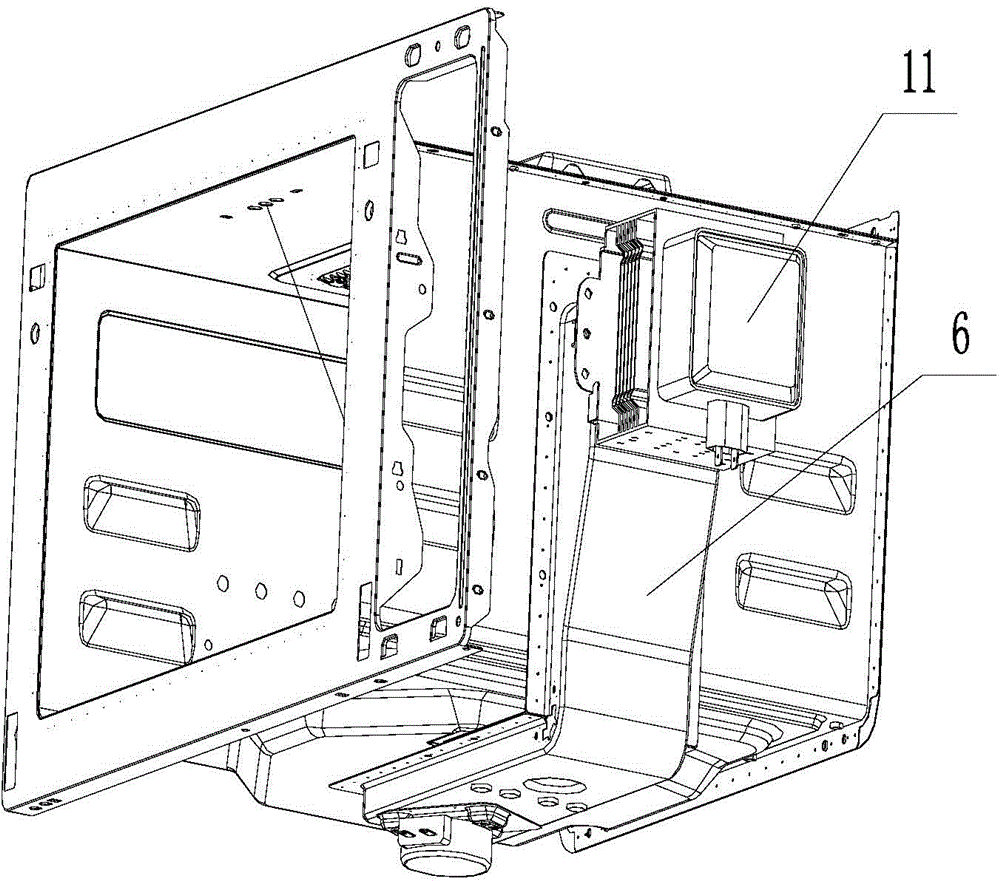

Television receiver lifter

InactiveCN1815634AReduce stressAvoid deformationTelevision system detailsMachine supportsTelevision receiversGear wheel

The invention discloses a TV set riser capable of adjustable high and low positions, and visual angle inside room. The riser includes guide rail, guiding piece, and elevating gear. Upper connecting piece and lower connecting piece are installed on two ends of the guide rail. There is sliding fit between the guiding piece and the guide rail. The lifting gear includes reducer of motor and electric controller. Being installed on the guiding piece, the reducer includes output shaft and rolling wheel connected to each other fixedly or in transfer motion. One end of rope or strap is connected to the rolling wheel, and the other end is connected to the upper connecting piece, or upper end of the guide rail. Or output shaft of the reducer is connected to chain wheel, chain or gear wheel, rack in transfer motion. Features are: reasonable stress, compact structure arrangement, and easy of maintenance.

Owner:CHANGZHOU NEW DISTRICT SAIEN ELECTROMECHANICAL EQUIP

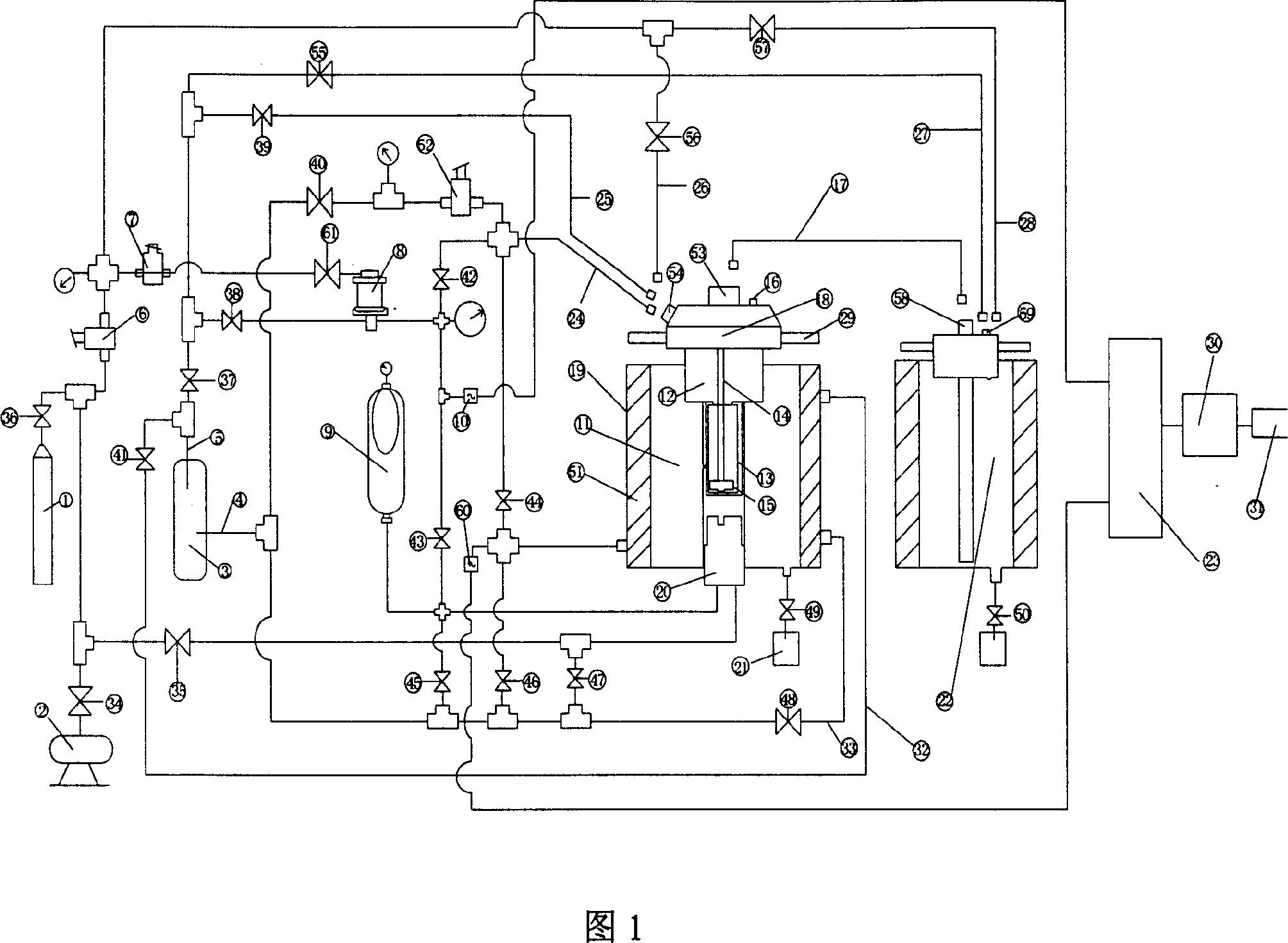

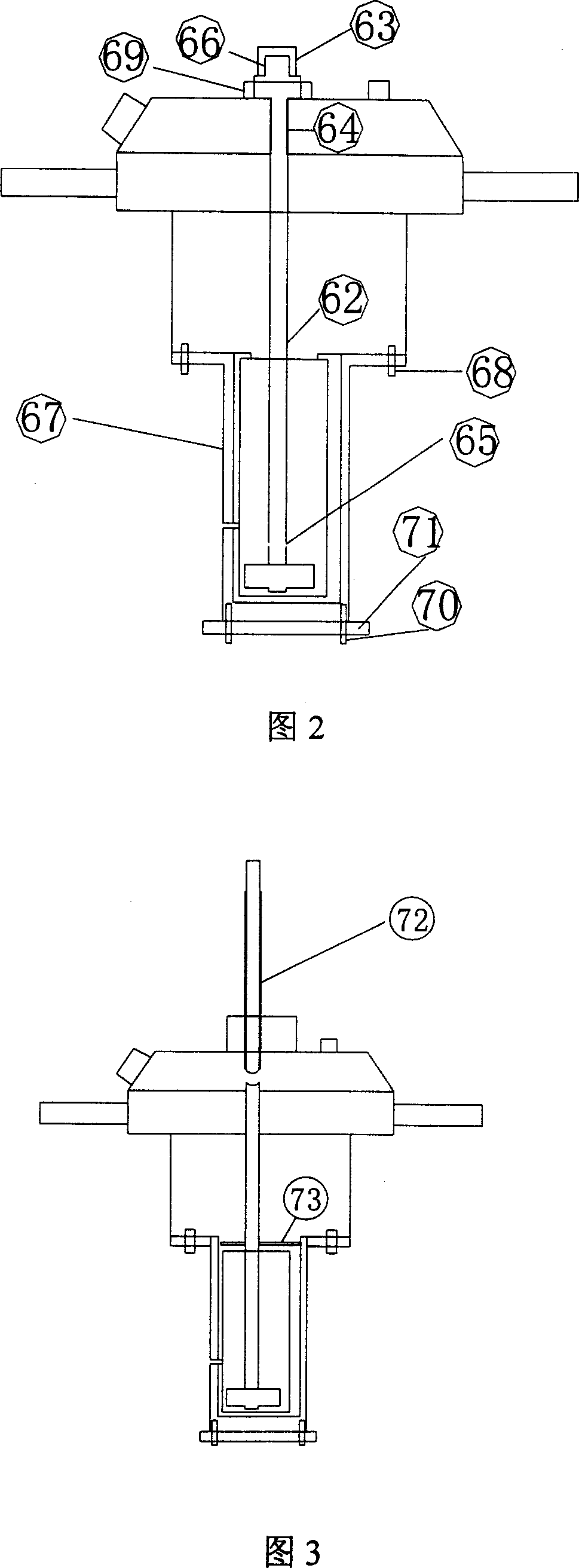

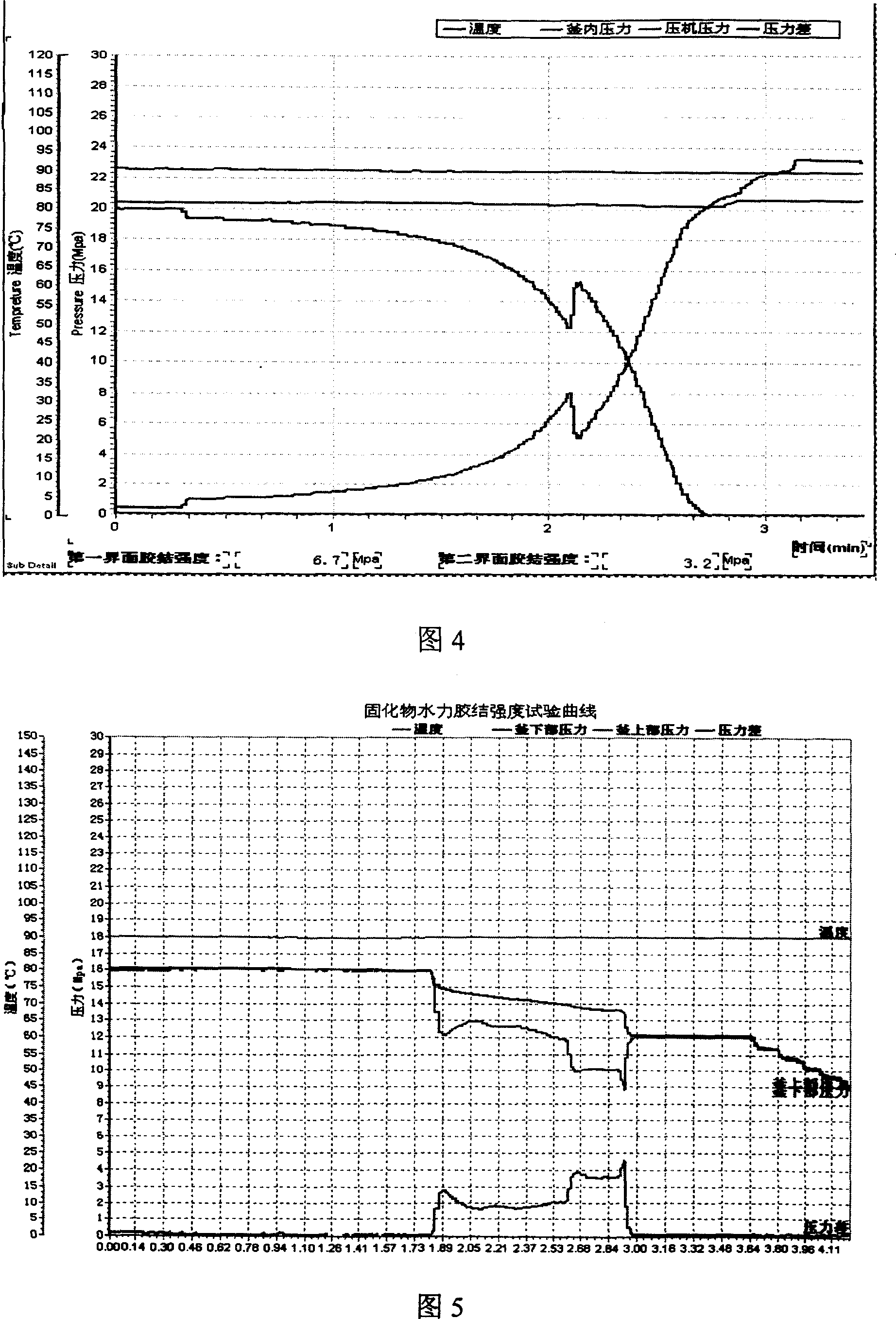

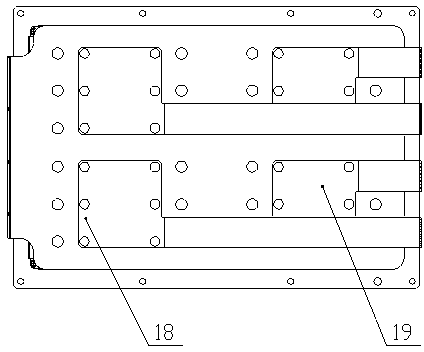

High-temperature high-pressure clay cake interface agglutination simulating-estimating device

ActiveCN101109281AOptimize formulation designImprove construction qualitySealing/packingPressure systemWell drilling

The invention provides a lab device for evaluating the hi-pressure and hi-temperature cementing quality of mud cakes, which essentially comprises a hi-temp and hi-pressure vessel 19, a simulated wellhole 13, an intermediate container 22, a heating and a cooling system, a pressure source and a pressure system, a data acquisition controller 23, a computer 30 and an output equipment 31. The function of the invention is to simulate the in-well pressure and temperature condition, realize such continuous experimental operations as well-hole type filtering of drilling fluid, rinsing and replacing of drilling fluid, injecting of well-solidifying fluid and curing of well-solidifying fluid, etc., simulate and evaluate the impact of in-well drilling fluid and the existing of mud cake on the cementing quality of the interface of the well-solidifying fluid, evaluate the flushing effects of different flushing fluids on circular space, measure the shearing and cementing strength of the interface between the flushing fluid and the circular space, measure the hydraulic cementing strength of the interface between the flushing fluid and the circular space, and provide experimental data for the optimal selection and engineering design for the drilling fluid and well-solidifying fluid in well drilling in oil field.

Owner:CHINA PETROLEUM & CHEM CORP +1

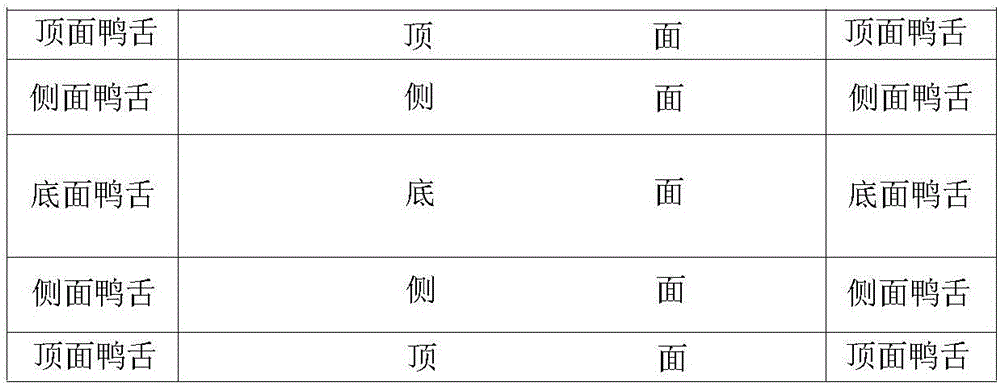

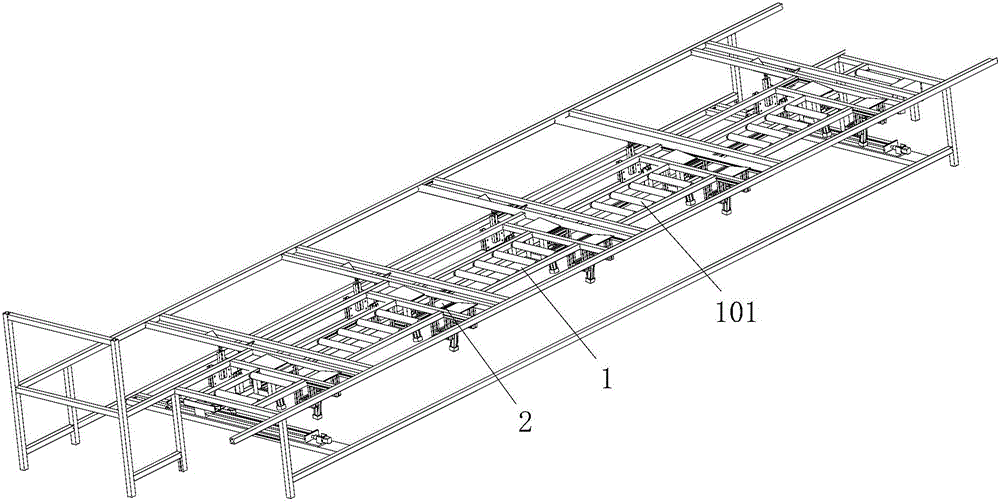

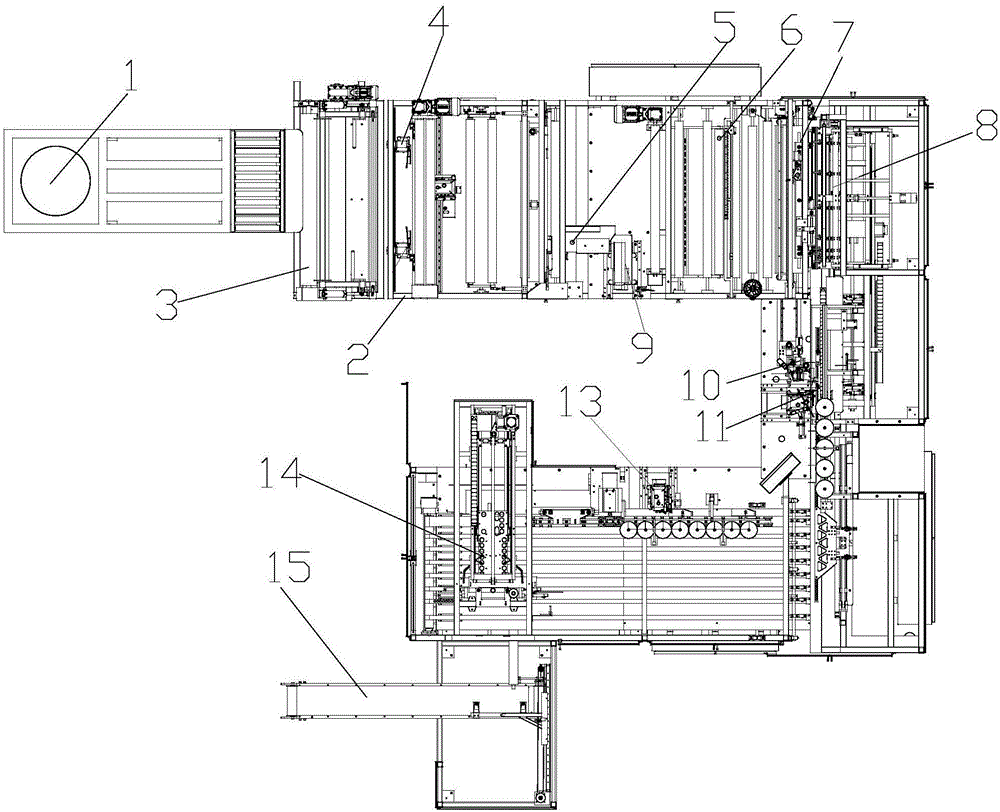

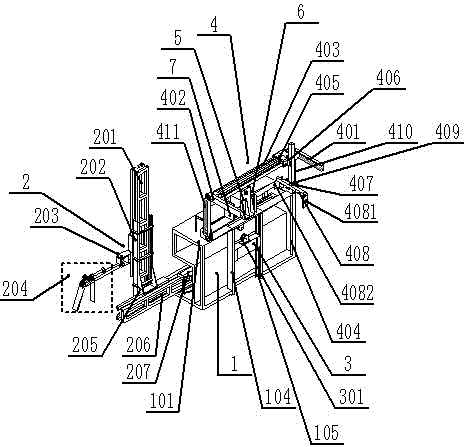

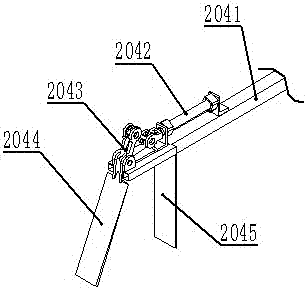

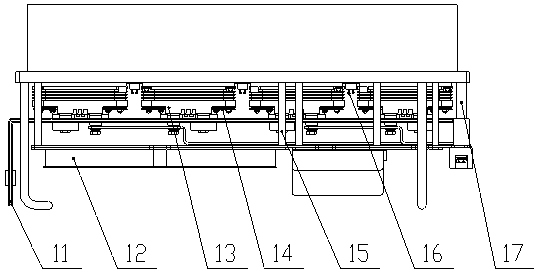

Automatic package machine for corrugated cartons with different lengths

InactiveCN105730772AHigh conveying precisionModerate delivery speedWrapper twisting/gatheringCartonEngineering

The invention discloses an automatic package machine for corrugated cartons with different lengths. The automatic package machine comprises a rack. An initial material position containing area, a wrapping forming area and a carton sealing area are sequentially arranged on the rack in the carton conveying direction. A material conveying device is arranged below the initial material position containing area. A carton containing area is arranged in the wrapping forming area. A top face folding mechanism, a front end folding system and a tail end folding system are arranged in the carton containing area. A side face folding mechanism is arranged below the carton containing area. Each of the front end folding mechanism and the tail end folding mechanism comprises a side face duck tongue folding mechanism, a top face duck tongue folding mechanism and a bottom face duck tongue folding mechanism. A plurality of powerless transmission rollers are arranged in the carton sealing area in the length direction of the carton sealing area. A two-end carton sealing mechanism, a length direction carton sealing system and a width direction carton sealing system are arranged in the carton sealing area in the carton conveying direction. By means of the automatic package machine, packaging of carton type products of different specifications and different sizes can be achieved, and the application range is wide.

Owner:SHANDONG UNIV OF SCI & TECH

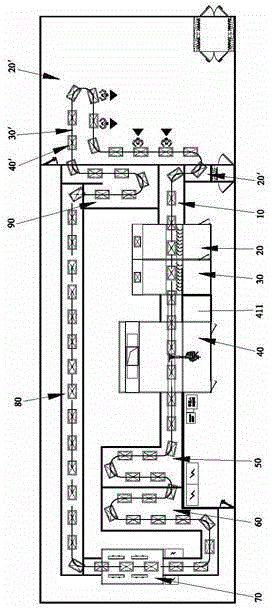

Fully-automatic dust-free painting line of plastic component

ActiveCN104588247AHigh degree of automationReduce manpower consumptionLiquid surface applicatorsCoatingsEngineeringFully automatic

The invention discloses a fully-automatic dust-free painting line of a plastic component. The painting line comprises a preheating furnace, a first dust-removing cabinet, a second dust-removing cabinet, a spraying room, a leveling device, an IR (infrared) furnace, a UV (ultraviolet) light curing machine, a PU (polyurethane) curing oven, a cooling device and a component loading and unloading area, wherein the preheating furnace, the first dust-removing cabinet, the second dust-removing cabinet, the spraying room, the leveling device, the IR furnace and the UV light curing machine are sequentially and transversely connected and are positioned on the front side of the PU curing oven. Operation procedures, such as continuous dust removal, paint spraying, baking, drying and cooling, are sequentially finished by matching and using each device, the automation degree is high, labor consumption is reduced, the production efficiency is effectively improved, and meanwhile, the painting quality is improved; intelligent control is realized, and the aims of energy conservation, emission reduction, waste removal, production cost reduction and the like are fulfilled by arranging each electric sensor; the painting line is reasonable in structural layout, can be used for painting a UV paint and a PU paint to a workpiece, and is strong in function and wide in application range.

Owner:东莞市慧江平成机械有限公司

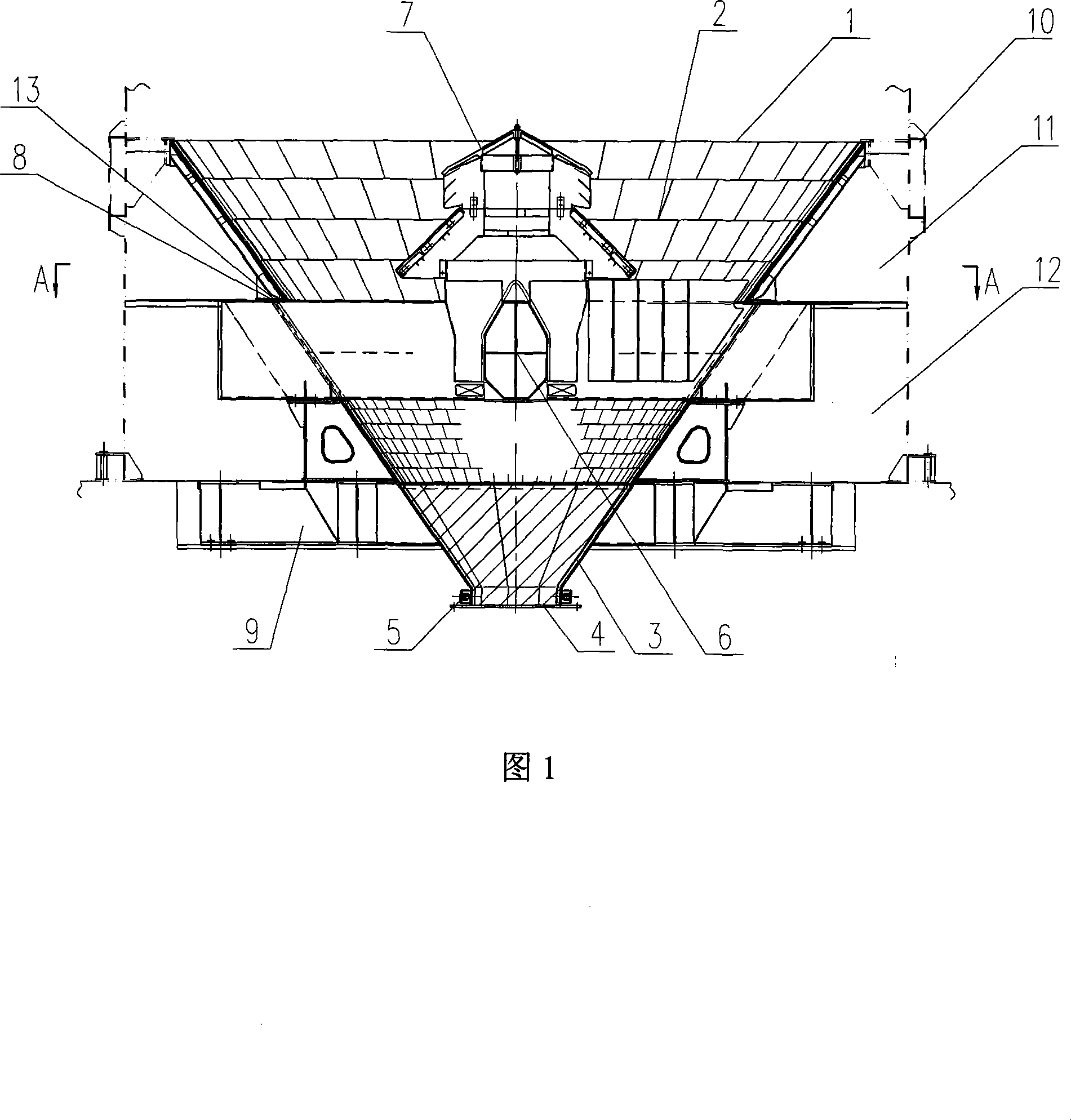

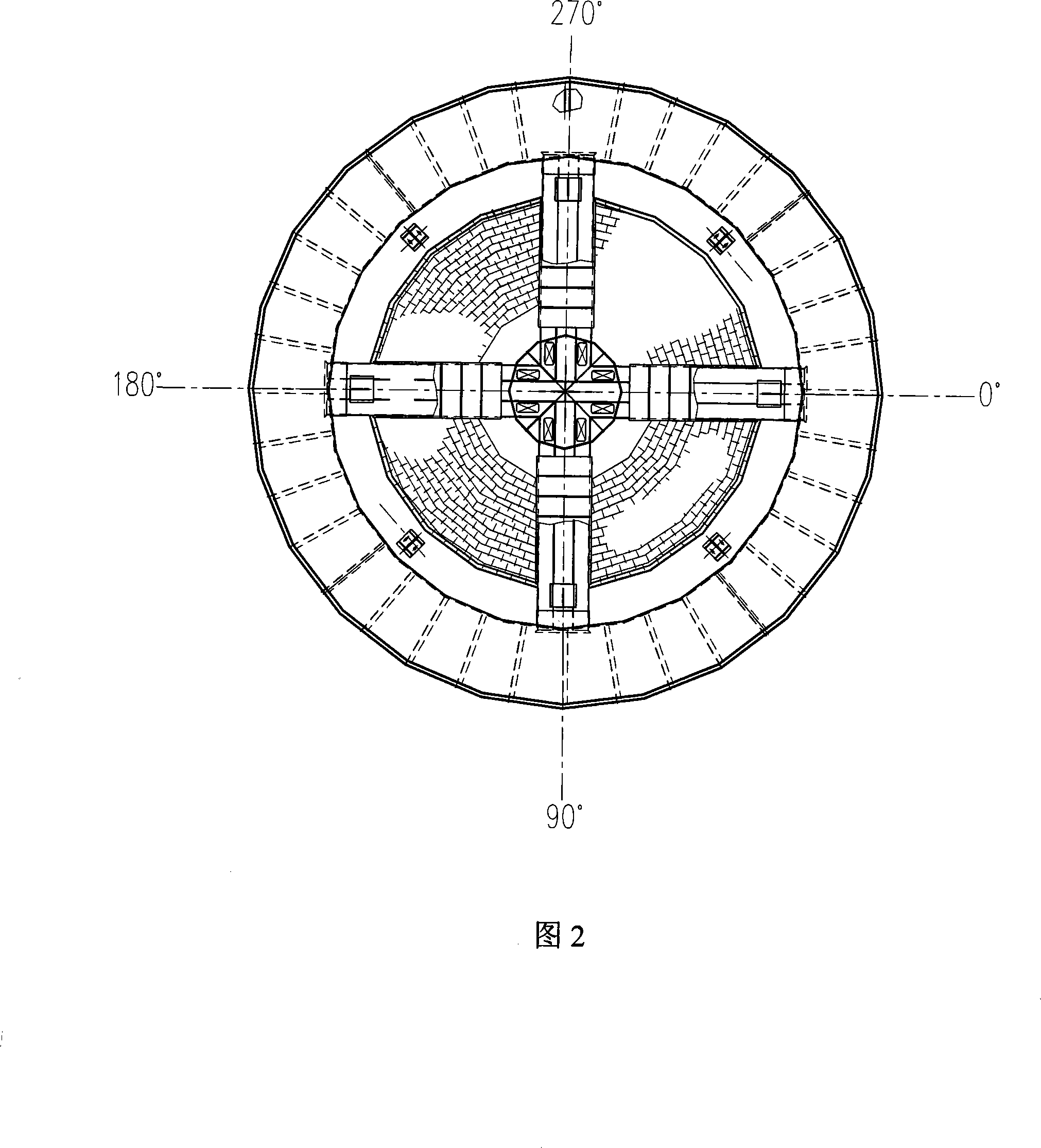

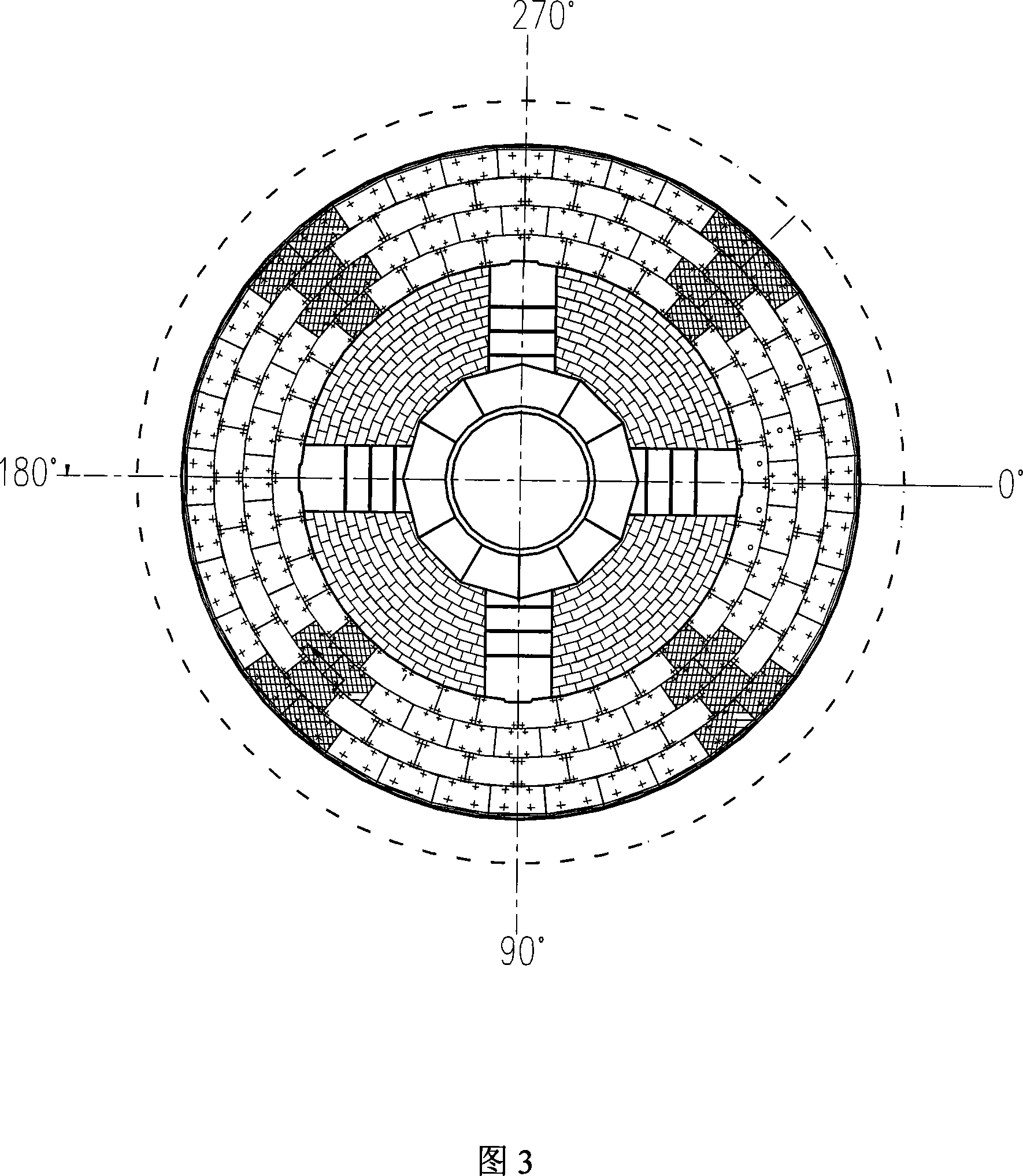

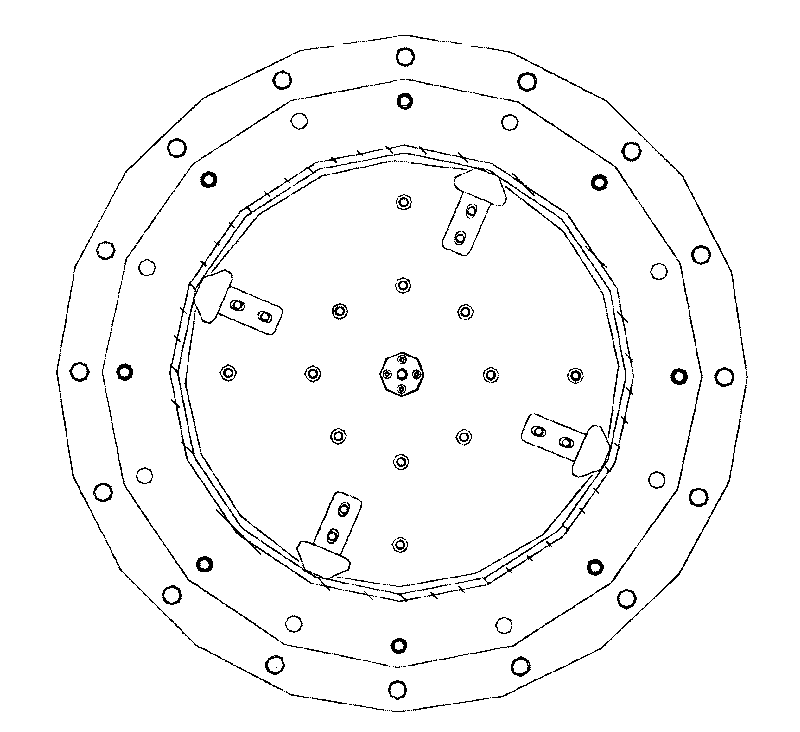

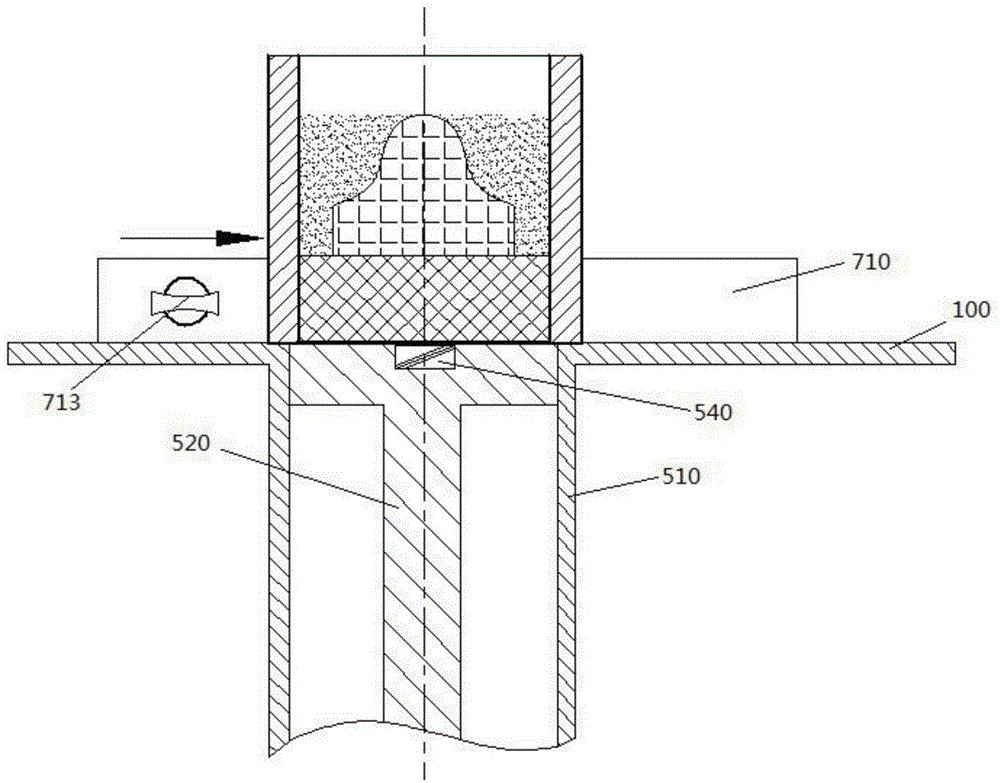

Special-purpose gas supplying device for coke dry quenching unit

The invention relates to an air supply facility specially used for a dry out furnace. The facility is composed of an upper cone funnel, a lower cone funnel, a dry out furnace casing body, a ring-shaped air channel, a cross air channel, and a central windshield, wherein the upper cone funnel and the lower cone funnel are sleeved and inserted with each other, the ring-shaped air channel is composed of an annular gap which is formed by a sleeve and inserting ledge, and the cross air channel is positioned on the upper portion of the lower cone funnel and is horizontally arranged, the centre of the cross air channel coincides with the centre of the dry out furnace and extends upwards and is communicated with the central windshield which is arranged on the cone funnel, the facility employs a combining air supply form of that peripheral air rings supply air from outside in and the central windshield supplies air from inside out on the upper portion of the furnace body. The facility can effectively resolve the problem that the cooling cycle air entering the dry out furnace is uniformly distributed in the periphery direction of the dry out furnace, which is favorable for achieving uniform cooling of the coke in the furnace, thereby improving the cooling property of the dry out furnace, increasing the cooling efficiency of the dry out furnace, and reducing the dry out time of the coke in the dry out furnace.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

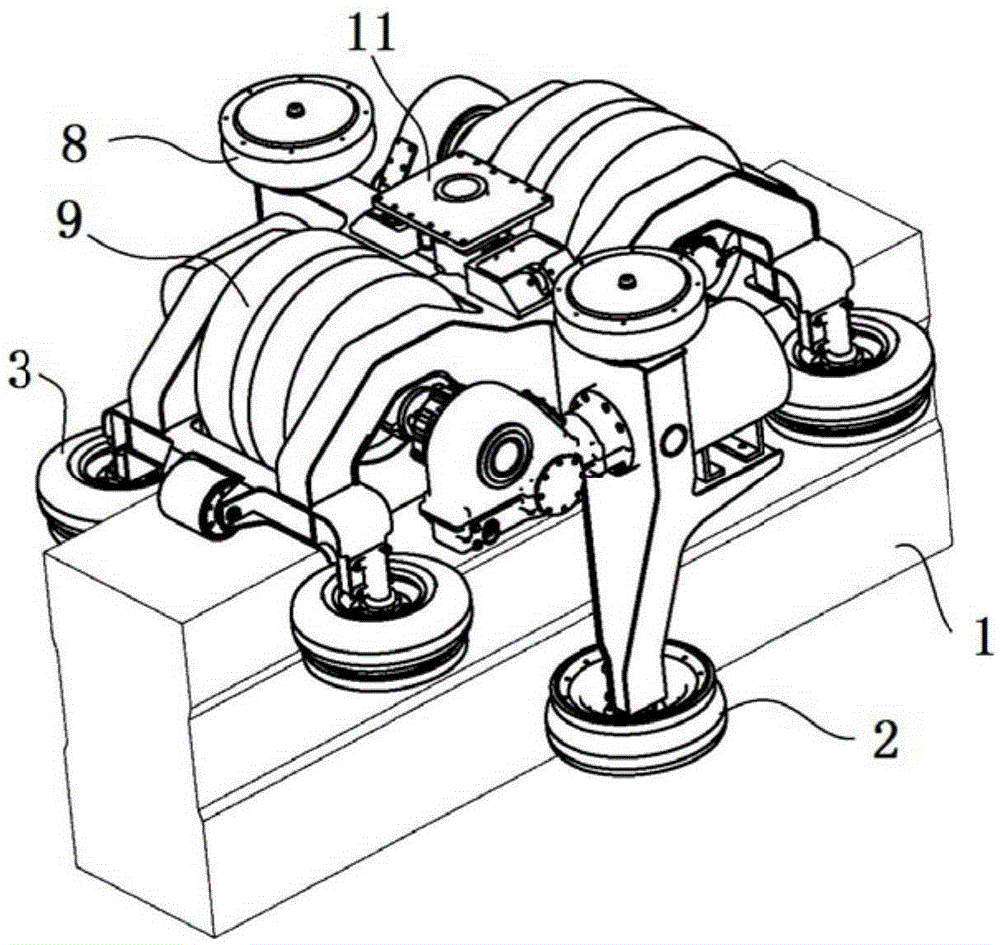

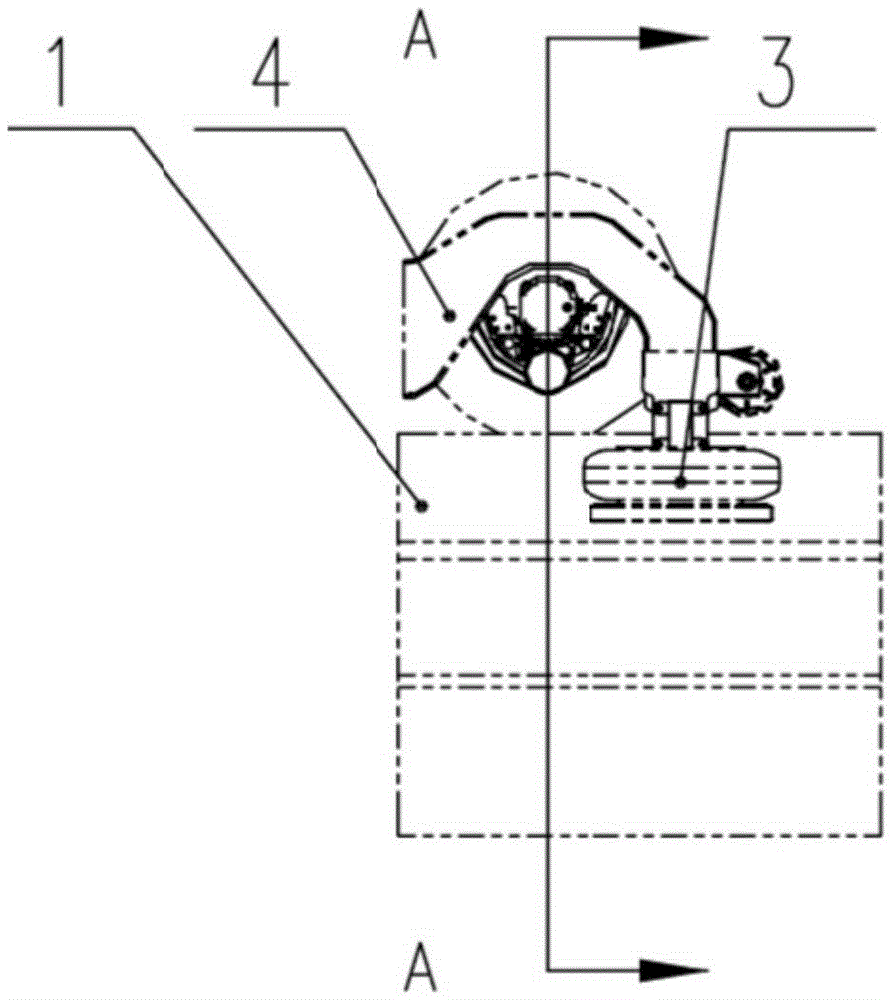

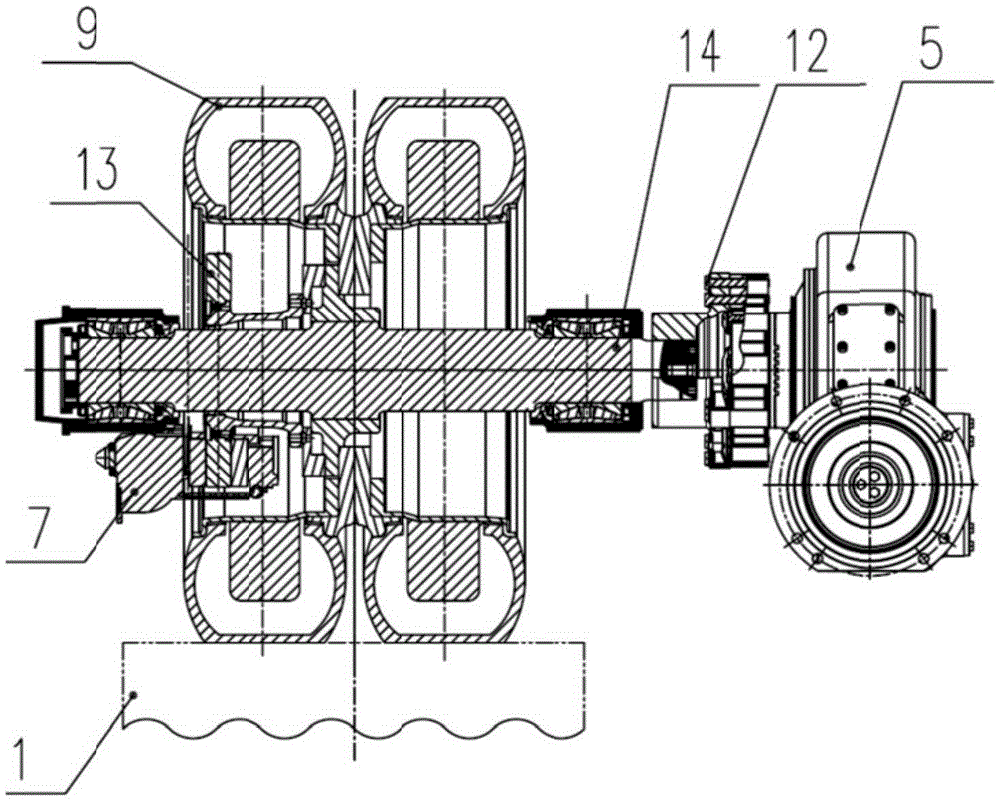

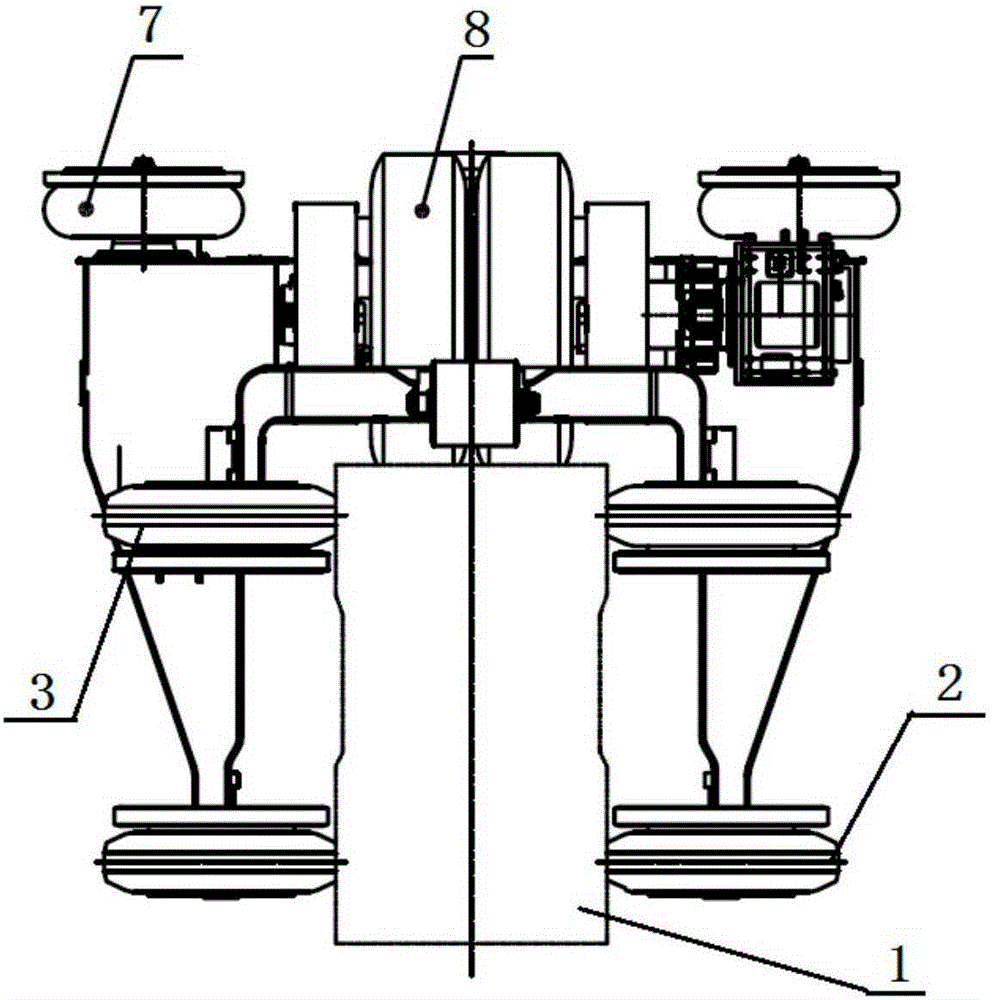

Straddling type mono-rail bogie without primary spring

The invention discloses a straddling type mono-rail bogie without a primary spring. The straddling type mono-rail bogie comprises a frame and further comprises a traction device, a basic braking device, a vibration reducing device, a gear case, stabilizing wheels, guiding wheels and walking wheels, and the traction device, the basic braking device, the vibration reducing device, the gear case, the stabilizing wheels, the guiding wheels and the walking wheels are arranged on the frame. A traction motor longitudinally arranged and the gear case are directly hung on the outer side of the frame in a rigidity manner. An output shaft of the gear case is connected with an axle through a split coupling. The frame is provided with a split type shaft box composed of an upper shaft box body and a lower shaft box body. The upper shaft box body and the lower shaft box body are detachably and fixedly connected. The upper shaft box body is fixed to the frame and used for installing the basic braking device. Wheel replacing is achieved without vehicle erecting, and daily maintaining work of a vehicle is greatly improved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

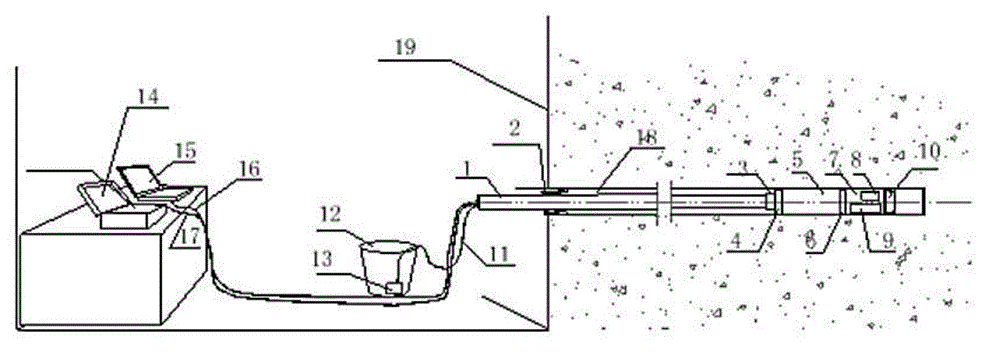

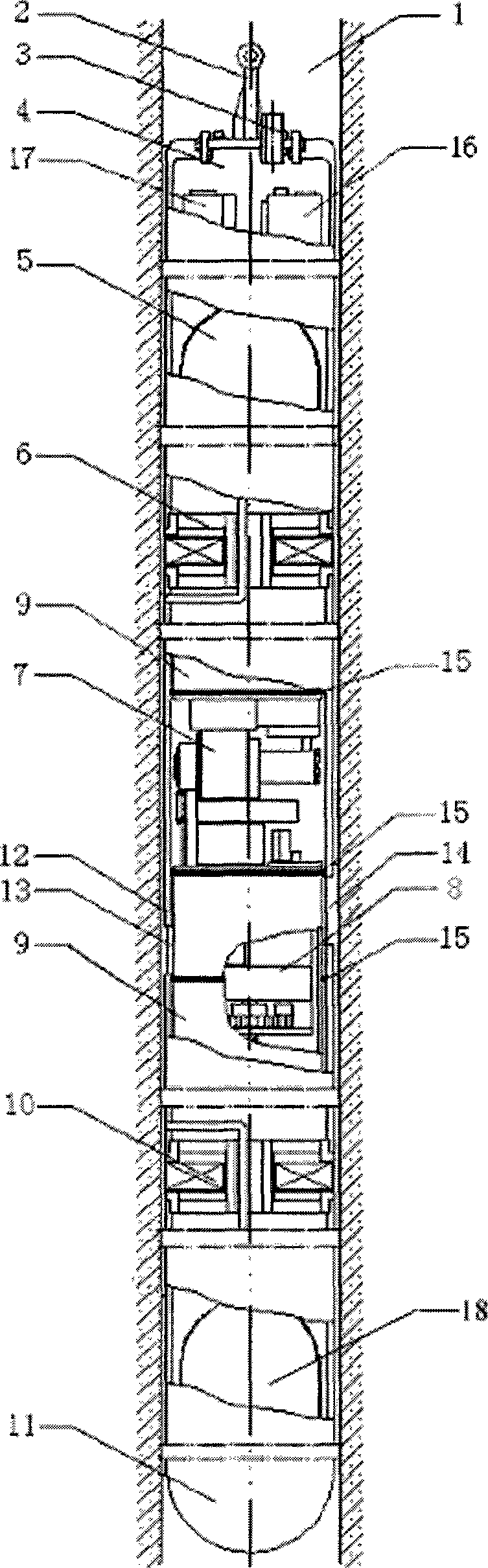

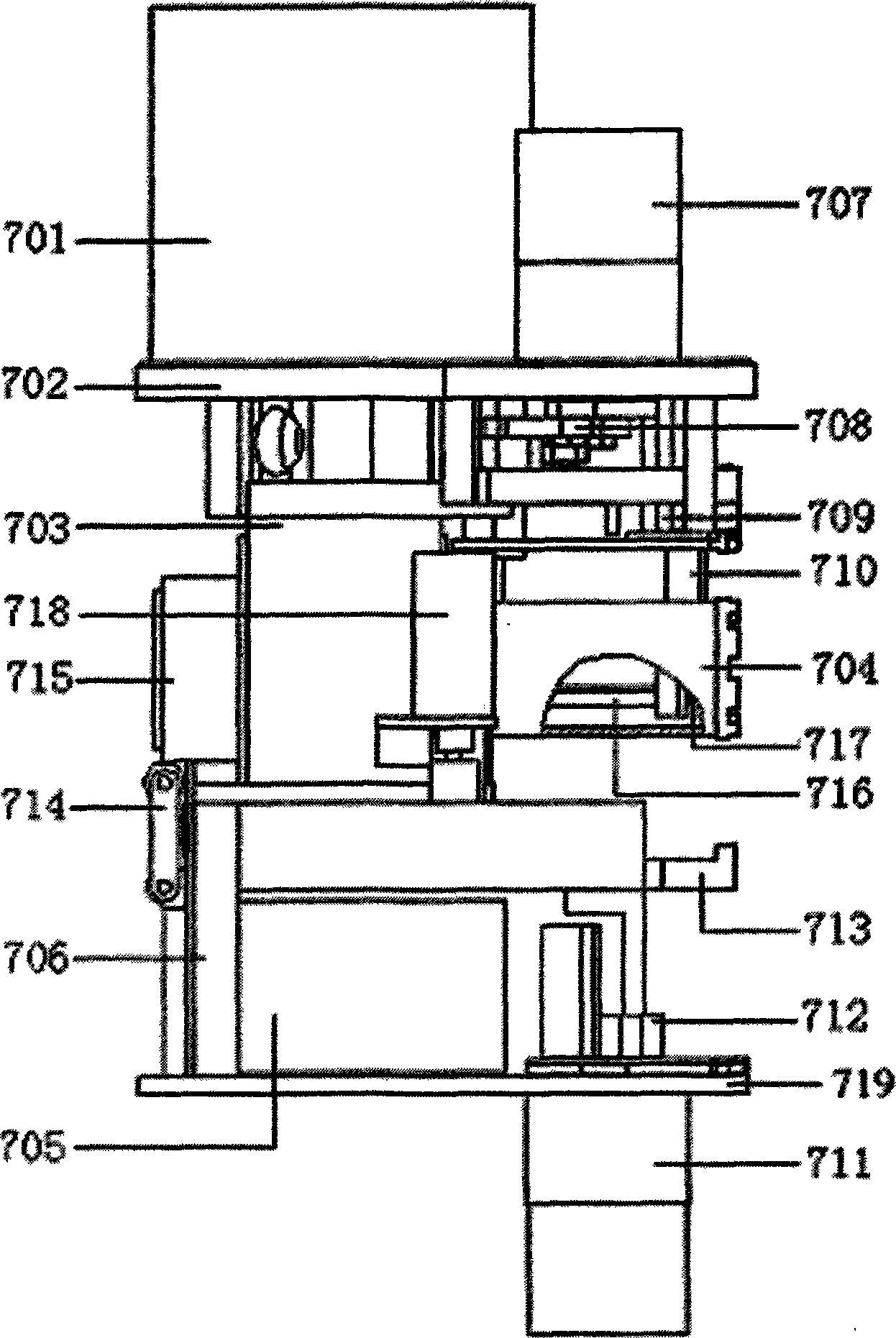

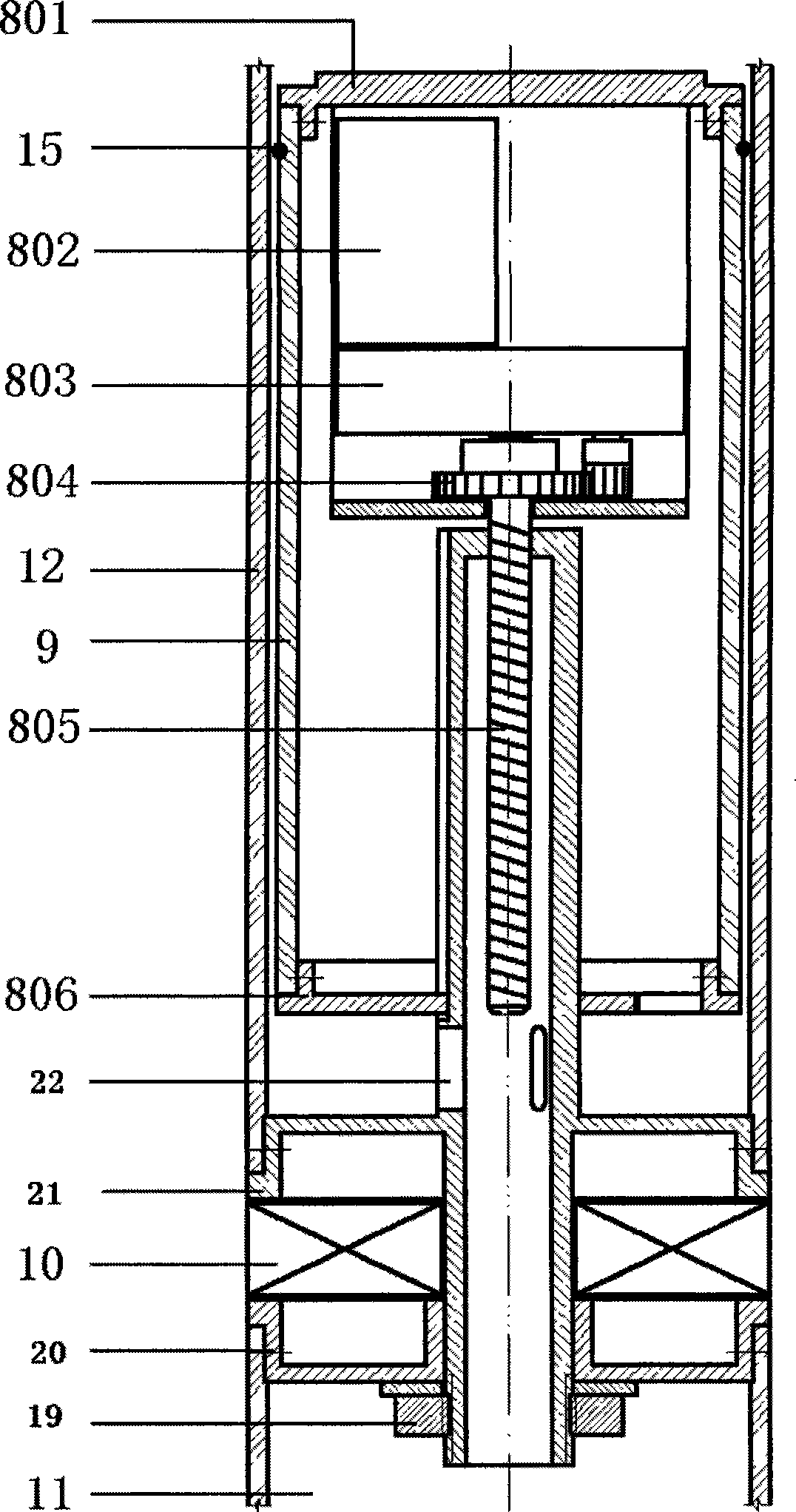

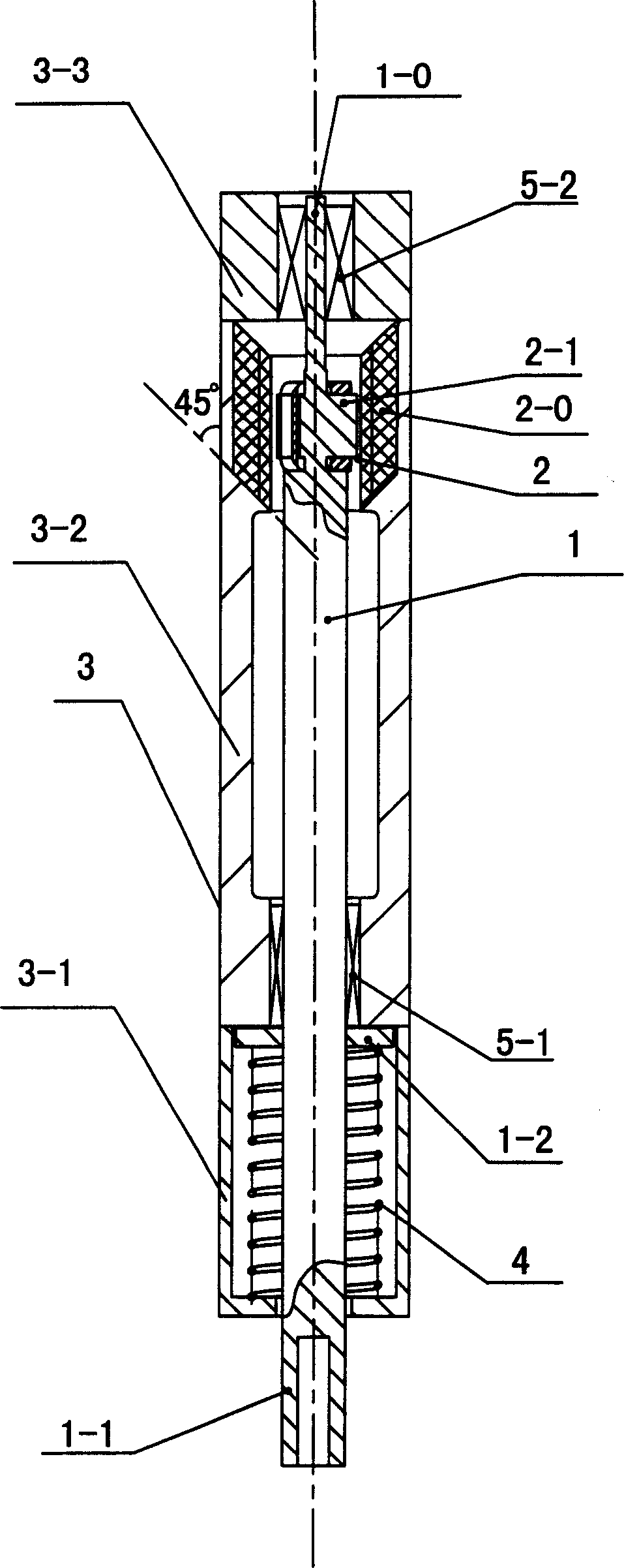

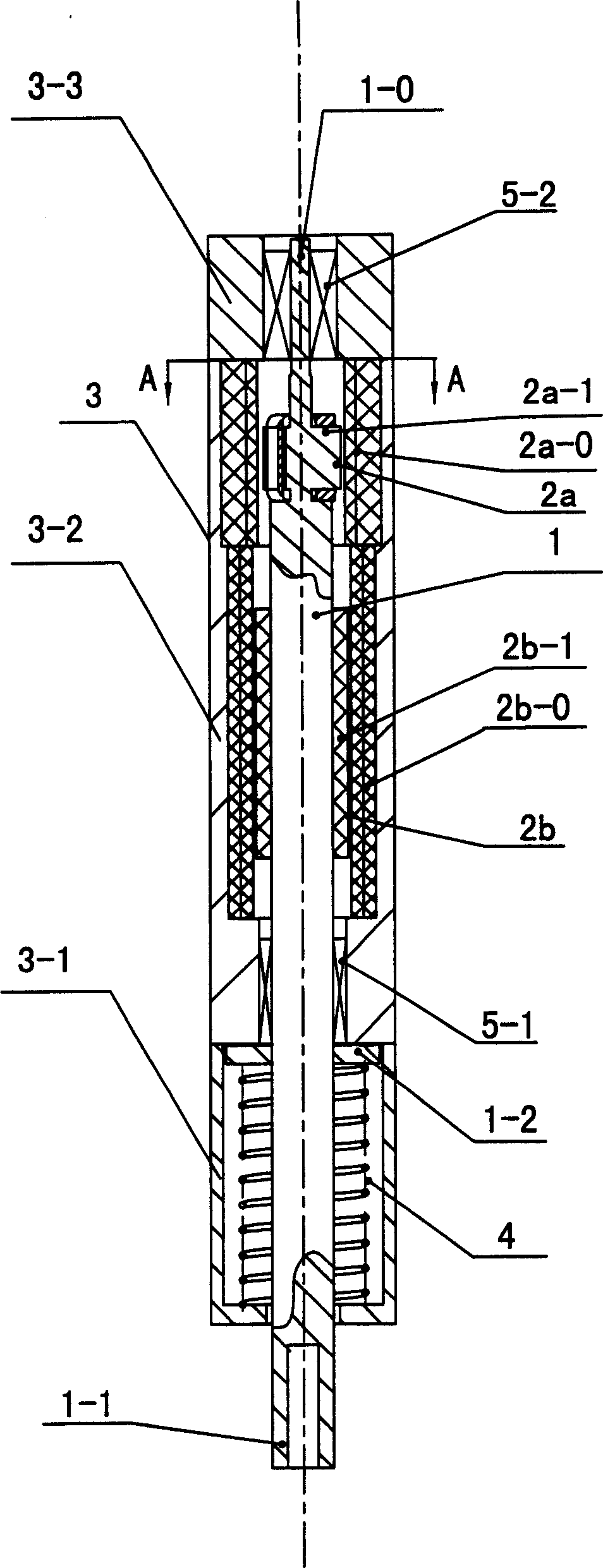

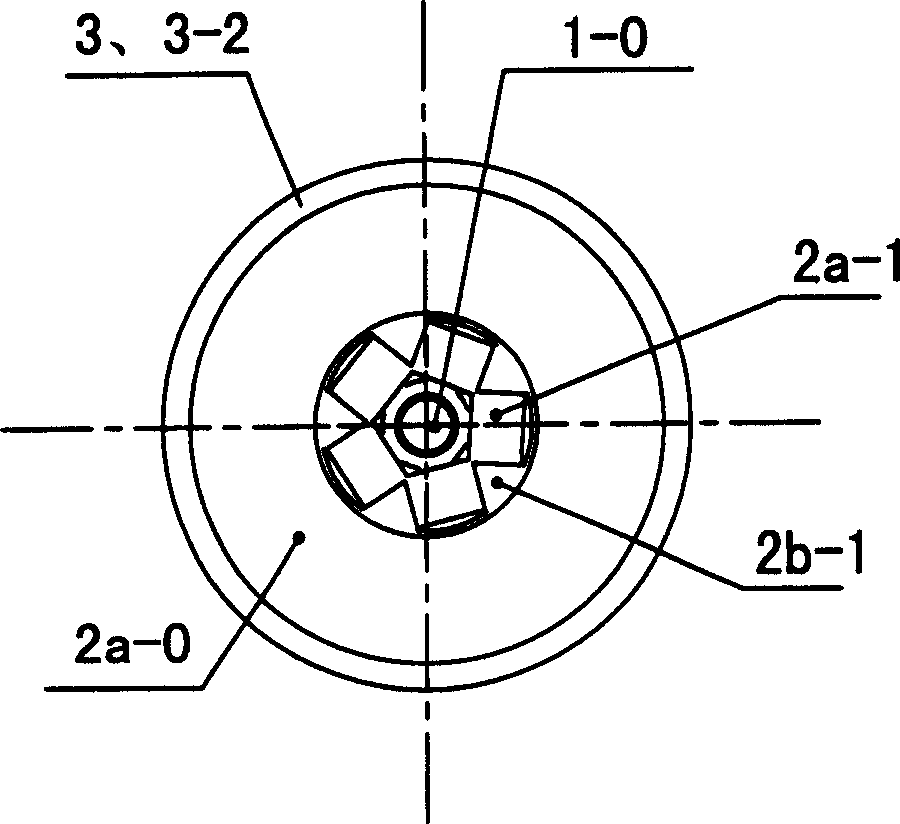

Horizontal hole ground stress measurement device based on BWSRM (Borehole Wall Stress Relief Method) principle

InactiveCN102979520ASmall sizeReduce broken coreConstructionsBorehole/well accessoriesStress measurementMeasuring instrument

The invention relates to a horizontal hole ground stress measurement device based on a BWSRM (Borehole Wall Stress Relief Method) principle, which is used for the technical field of measurement of stress of rocks in an underground cavity or a mine opening. The horizontal hole ground stress measurement device comprises a sealed cable joint, a stress measurement main working part, a multiway stress measuring instrument, a measurement control unit and a detection part, wherein the sealed cable joint is connected with the front end of the stress measurement main working part to be used as an output port for a power cable and a communication cable of the integral device; the stress measurement main working part is sequentially connected with the multiway stress measuring instrument, the measurement control unit and the detection part; the multiway stress measuring instrument is used for recording variation of stress on a working surface in the process that a thin-walled diamond core drill implements ring-shaped cutting on surrounding rocks of the hole wall of a borehole; and the detection part is used for observing and recording the quality condition of the hole wall of the borehole in the process of propelling integral equipment into the horizontal borehole to a working hole depth and providing reference basis for a local hole section which is selected to be subjected to stress relief. According to the invention, the integral measuring process is controlled sufficiently by an electromechanical integration technology through adopting a main control module; and test reliability and measurement accuracy can be greatly improved. The horizontal hole ground stress measurement device is convenient to carry and apply in the field and easy to operate in the field and can carry out three-dimensional ground stress actual measurement easily.

Owner:SHANGHAI JIAO TONG UNIV

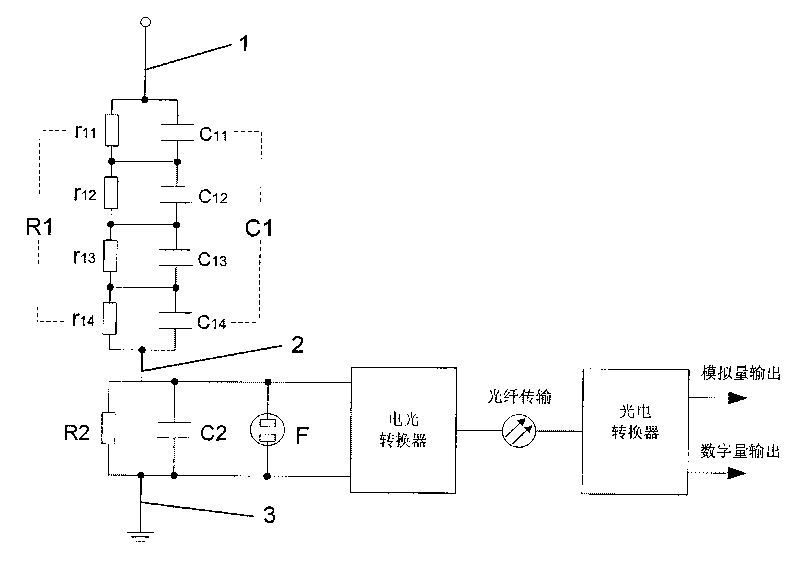

Gas insulation-based DC high voltage measuring device

ActiveCN101713793AReduce distractionsReduce volumeNon-electrical signal transmission systemsCurrent/voltage measurementCapacitanceLow voltage

The invention relates to the DC high voltage transmission test technology of a power system, and discloses a gas insulation-based DC high voltage measuring device, which comprises a high voltage unit, a low voltage unit, a base, and an insulated sleeve fixed on the base; the high voltage unit is connected in series with the low voltage unit, and a high voltage terminal, a medium voltage terminal and a low voltage terminal are respectively led out; the high voltage unit is arranged in the insulated sleeve which is sealed by upper and lower end covers and is filled with SF6 gas; the high voltage terminal is led out from the upper end cover, and the medium voltage terminal is led out from the lower end cover and is connected with the low voltage unit; the high voltage unit and the low voltage unit respectively consist of voltage divider modules which are connected in series, and the series of the voltage divider modules forming the high voltage unit is greater than that of the voltage divider modules forming the low voltage unit; and the voltage divider modules consist of voltage sharing capacitors and divider resistors which are connected in parallel.

Owner:XIAN HIGH VOLTAGE APP RES INST CO LTD

Gangway bridge device

InactiveCN104627325ARealize transportationReasonable structure layoutCargo handling apparatusPassenger handling apparatusMarine equipment

The invention discloses a gangway bridge device and relates to the technical field of marine equipment. The gangway bridge device comprises a base and a rotary platform which is installed above the base, wherein the rotary platform is connected with the base through a rotary mechanism, and a cab is arranged on the rotary platform. The gangway bridge device is characterized in that the rotary platform is connected with a gangway bridge, safety guardrails are arranged on the two sides of the gangway bridge, and a butt joint device is arranged at the suspended end of the gangway bridge. Compared with the prior art, the gangway bridge device has the advantages that the structural arrangement is reasonable, operation is stable, and staff can be transported between a ship and a marine platform in complicated and severe environments.

Owner:SOUTH CHINA MARINE MACHINERY

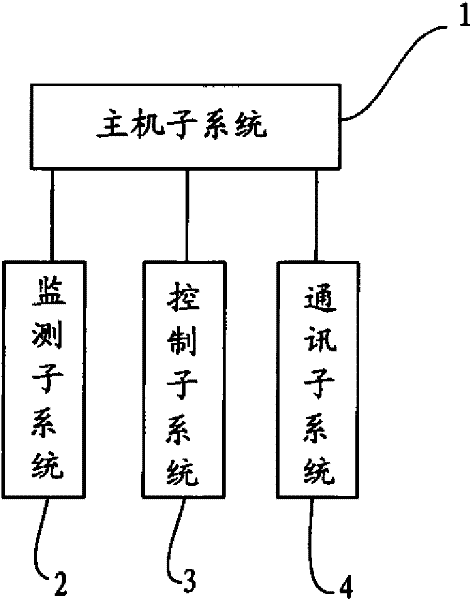

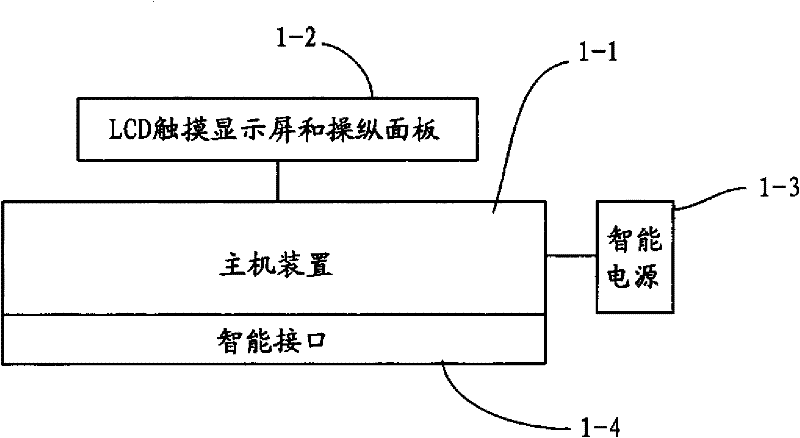

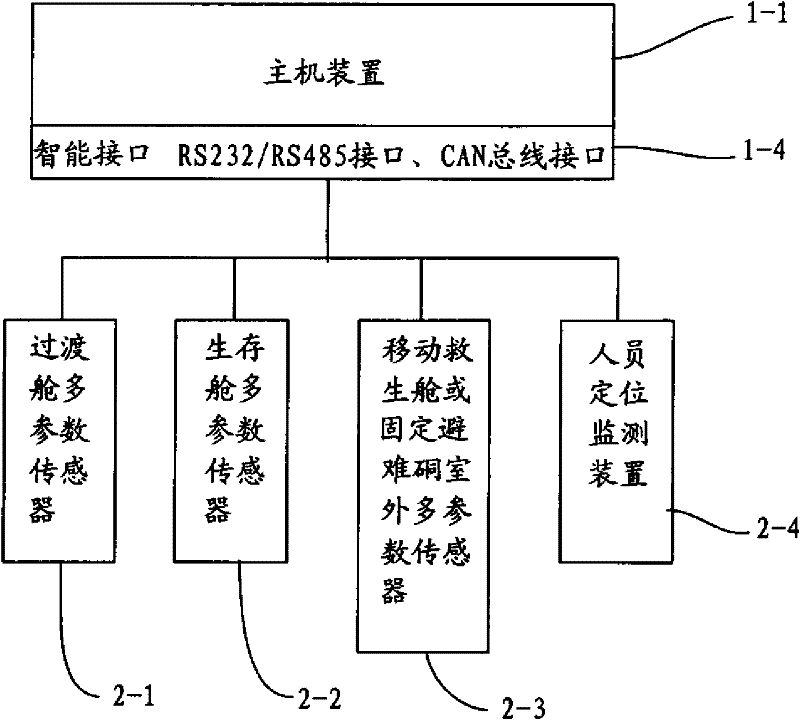

Monitoring and control system for mobile rescue cabin or fixed refuge chamber

ActiveCN102296983AWidely used valueGuaranteed production effectMining devicesSafety equipmentsVoice communicationEmergency rescue

The invention relates to a downhole safety monitoring system for mines and in particular relates to a monitoring control system for a mobile rescue capsule or a fixed refuge chamber. The monitoring control system comprises a host sub-system, as well as a monitoring sub-system, a control sub-system and a communication sub-system which are connected with the host sub-system, wherein a host device of the host sub-system is connected with various detection sensors through intelligent interfaces to form the monitoring sub-system; the host device is connected with various environmental control devices through intelligent interfaces to form the control sub-system; and the host device is connected with a video device, a voice communication device and a networking system through intelligent interfaces to form the communication sub-system. According to the monitoring control system, various parameter sensor data and personnel number information can be collected in real time, the survival environment parameters are monitored and automatically regulated, and the monitoring data and the voice and video information are transmitted to a ground monitoring center and a control command is received by virtue of a downhole transmission network, so that the downhole safety monitoring system for mines is an essential core system of guaranteeing downhole safe production and emergency rescue of coal mines and non-coal mines.

Owner:中安金力(北京)安全生产技术研究院

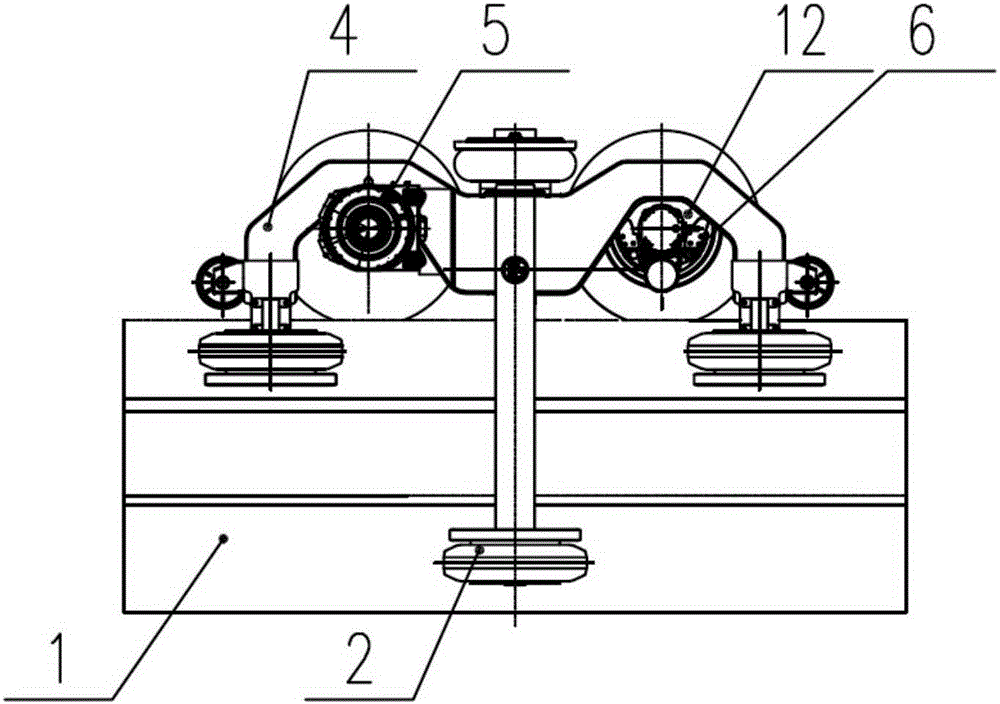

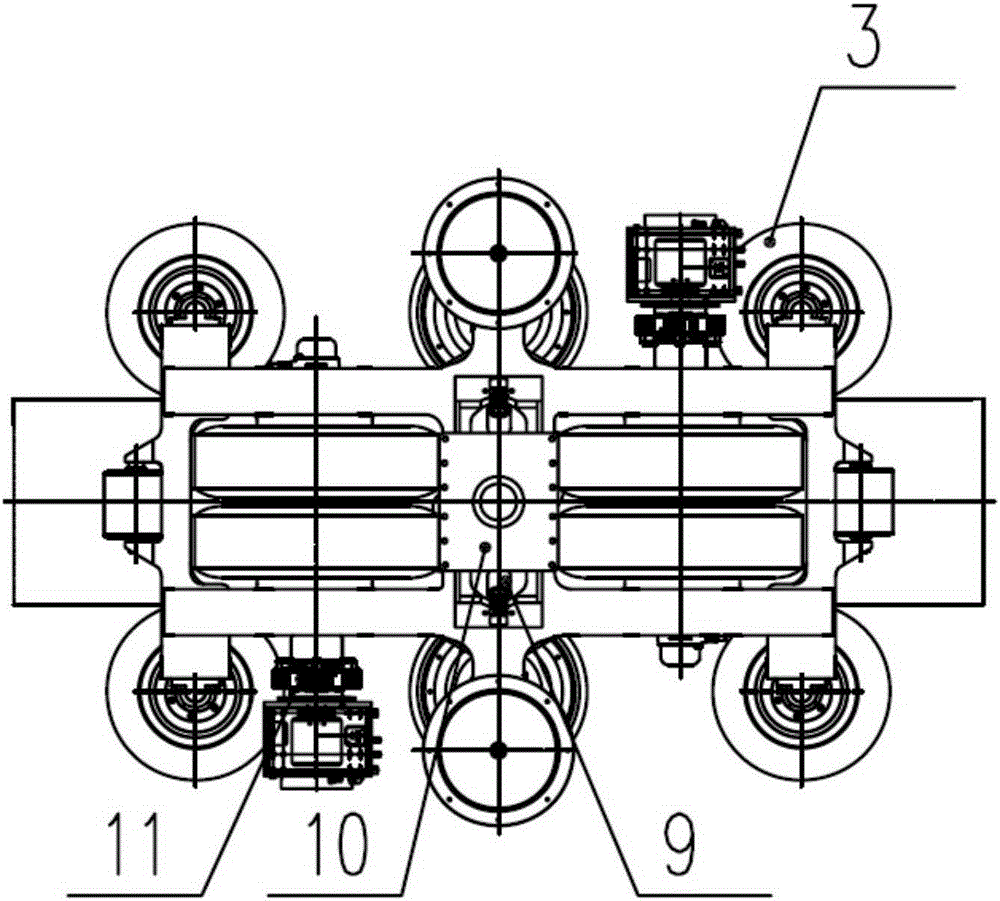

Directly-driven straddling-type gearless single-rail bogie

ActiveCN105292134AImprove dynamic performanceSimple structureMonorailsElectric motor propulsion transmissionBogieVehicle dynamics

The invention discloses a directly-driven straddling-type gearless single-rail bogie. The single-rail bogie comprises a frame, a traction device, a basic braking device, a shock reduction device, stabilizing wheels, guiding wheels and walking wheels, wherein the traction device, the basic braking device, the shock reduction device, the stabilizing wheels, the guiding wheels and the walking wheels are installed on the frame. An axle of the walking wheel pair is directly linked with a permanent magnet motor suspended on the frame through a split coupling, a split axle box composed of an upper axle box body and a lower axle box body is installed on the frame, the upper axle box body and the lower axle box body are detachably and fixedly connected, and the upper axle box body is fixed to a side beam of the frame and used for installing the basic braking device. The direct traction transmission technology of the permanent magnet motor is utilized, in this way, the structure is greatly simplified, the weight is reduced, transmission efficiency is improved, and environmental-protection capacity and vehicle dynamics properties are improved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

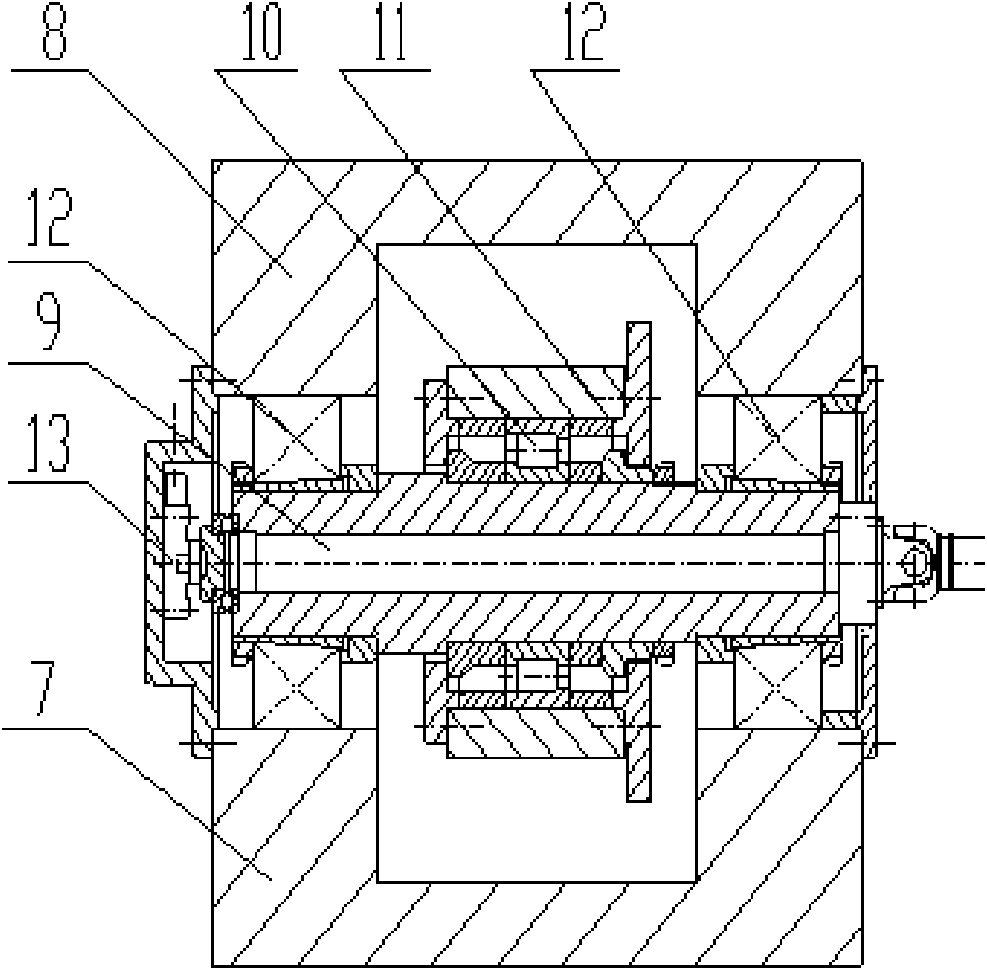

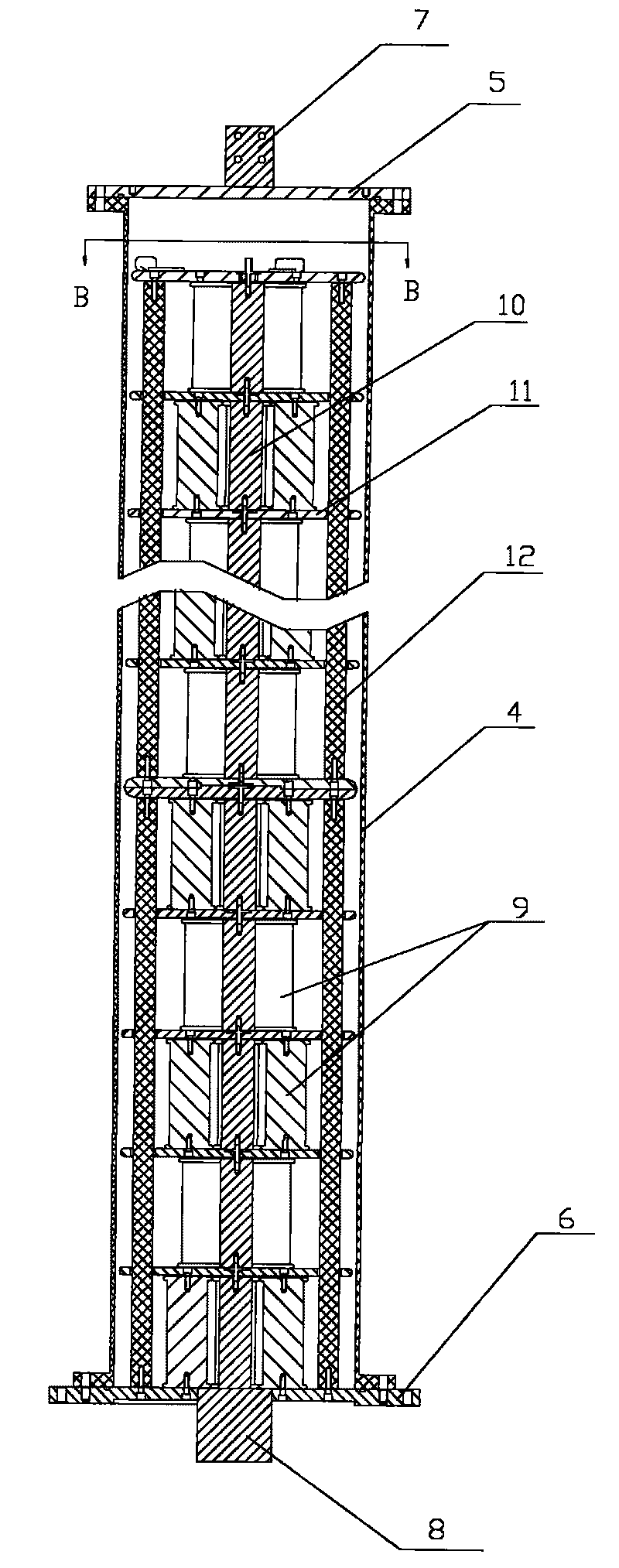

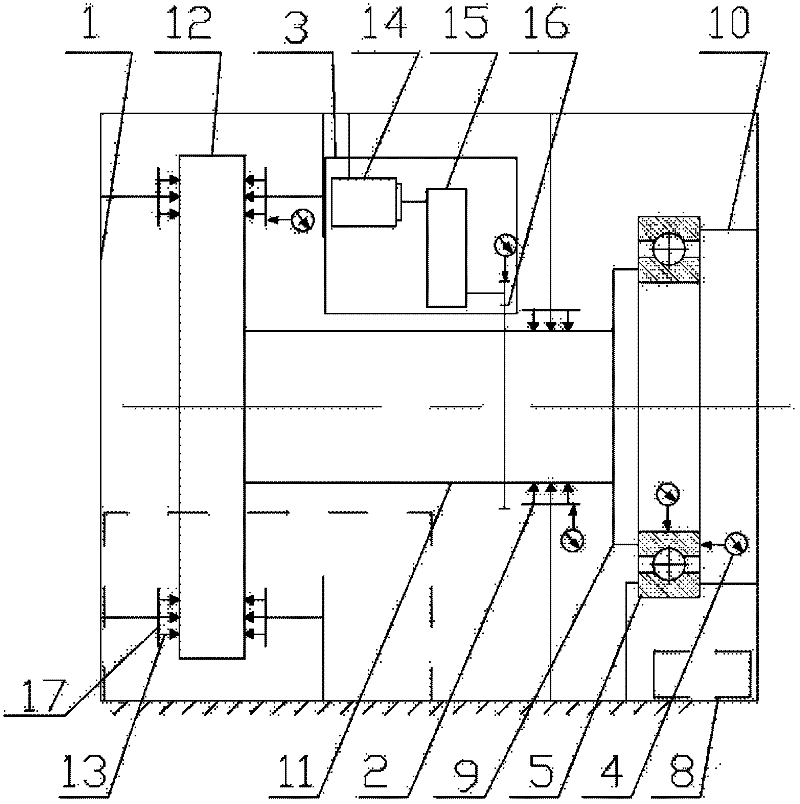

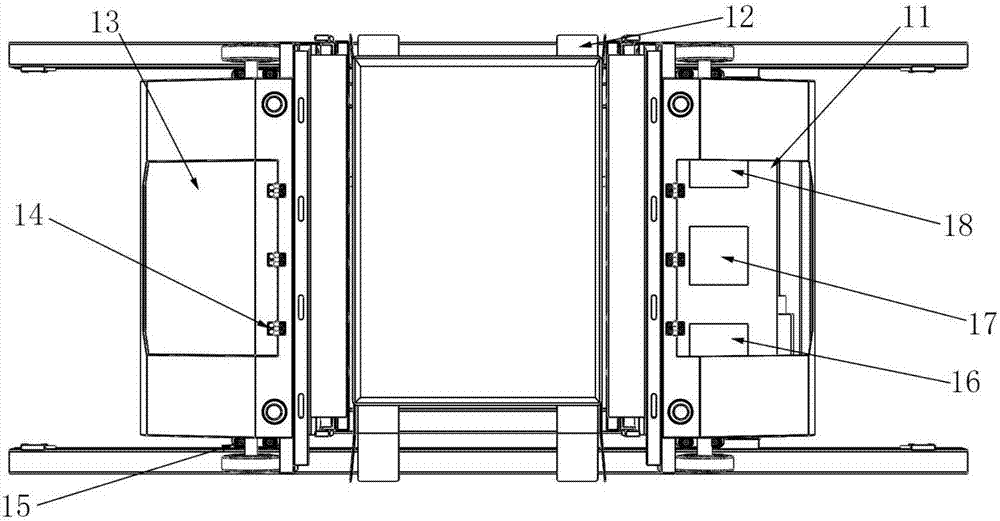

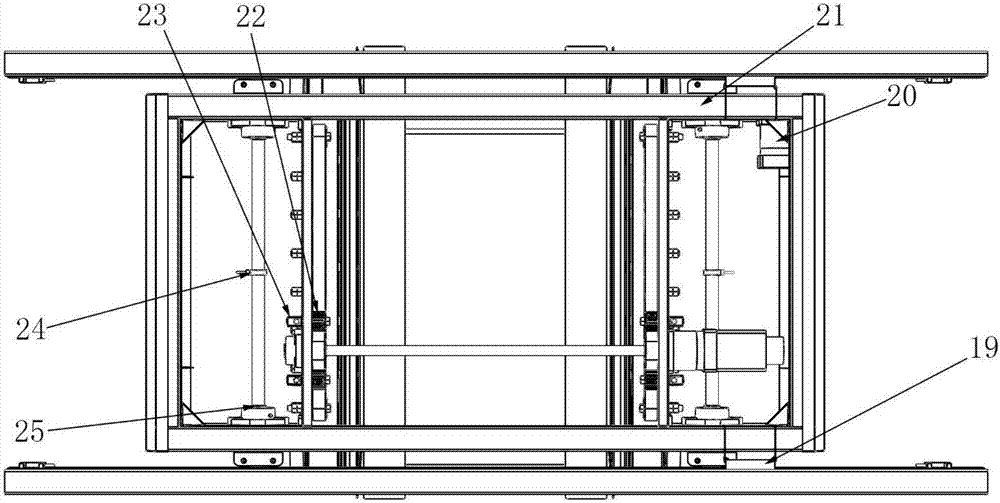

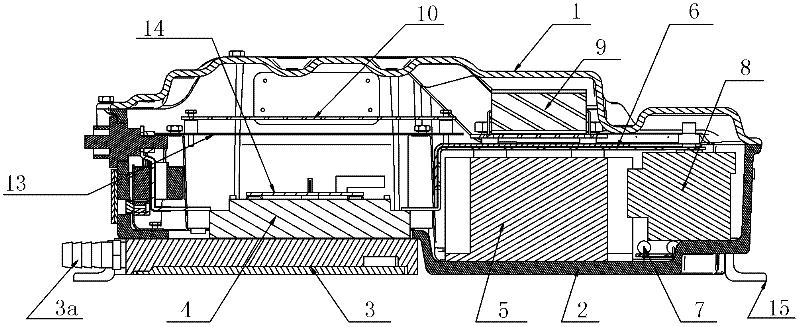

A Large Bearing Test Bench with Static Pressure Loading and Closed Structure

ActiveCN102288410AIncrease stiffnessReduce volumeMachine bearings testingReduction driveControl system

The invention belongs to the technical field of bearing test and relates to a bearing test table, which consists of four parts, namely a closed mechanical structure, a hydrostatic loading system, a driving system and a measurement and control system, wherein the closed mechanical structure consists of a test bearing, a test table end cover, a connecting part, a vertical column, a base and the like, and a loading disk, the test bearing, the end cover, the vertical column and the base form an internal closed structure; the hydrostatic loading system realizes radial loading, axial loading and overturning moment loading by an axial loading seat and an oil cylinder and a radial loading seat and the oil cylinder and performs application according to a test bearing load spectrum; a motor, which is fixed on the base, of the driving system drives the loading disk and the test bearing to rotate by a speed reducer and a driving gear; and the measurement and control system comprises a sensor, a computer, a control cabinet, the sensor, an actuator and the like. By using a floating hydrostatic loading technology, the influence of a test table bearing on the performance data of the test bearing is reduced. The test table is high in rigidity, small in volume and low in cost.

Owner:DALIAN UNIV OF TECH

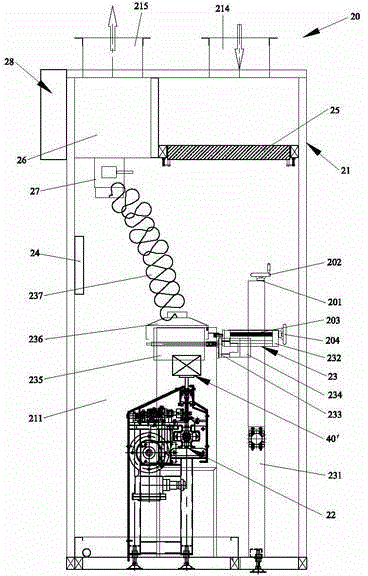

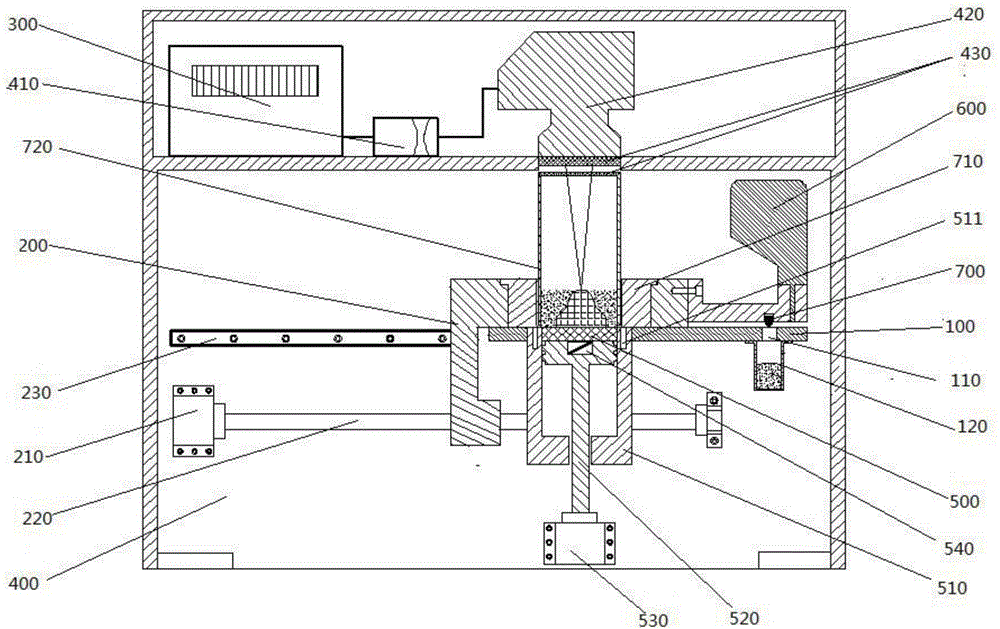

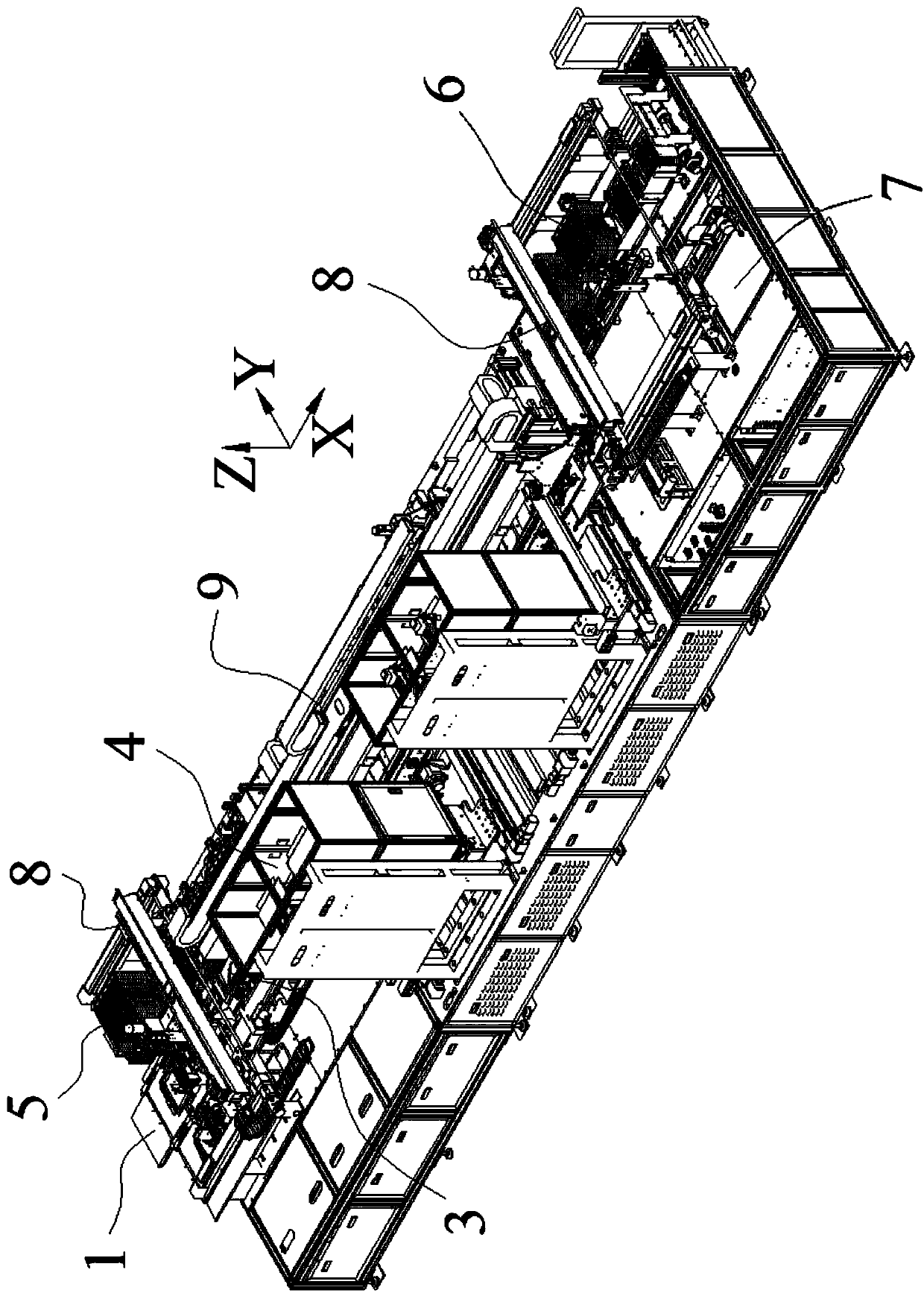

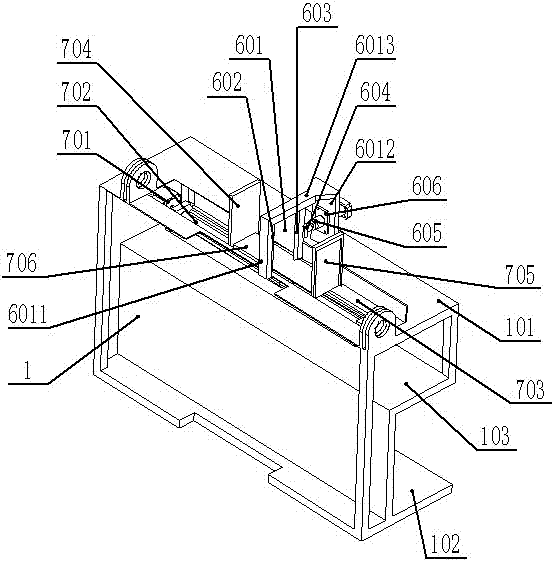

Single-cylinder type desktop type laser area selecting fusion forming device and control method

InactiveCN104923788AReasonable structure layoutEasy to operateAdditive manufacturing apparatusMetal powderMaterials science

The invention discloses a single-cylinder type desktop type laser area selecting fusion forming device and a control method. A printed component and a base plate are directly ejected in a powder taking mechanism through a forming cylinder, the powder taking mechanism can be integrally taken out, metal powder cannot be left in the corner of the forming cylinder, the component is taken out by dismounting the powder taking mechanism, and therefore the residual metal powder can be collected, material waste in the forming process is reduced, and the production cost is greatly saved. The size and the overall weight of the single-cylinder type desktop type laser area selecting fusion forming device are greatly reduced compared with those of a current device, the height is only 1 / 3 of the height of a conventional device, the width is only 1 / 2 of the width of the conventional device, the overall weight of the device is about 1 / 8-1 / 6 of the weight of the conventional device, the whole forming device can be placed on a desktop to be used, the manufacturing cost of the device is greatly reduced compared with that of the conventional device, and the small fine metal component manufacturing and small and medium-sized enterprise bearing capability can be achieved; the whole forming device is reasonable in structural layout, operation is easy and convenient, and the development of the metal 3D printing technology can be promoted conveniently.

Owner:广东信达雅三维科技有限公司 +2

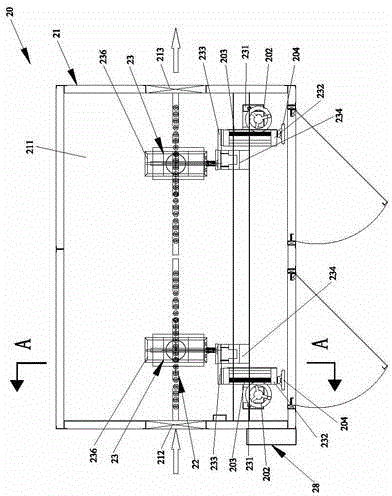

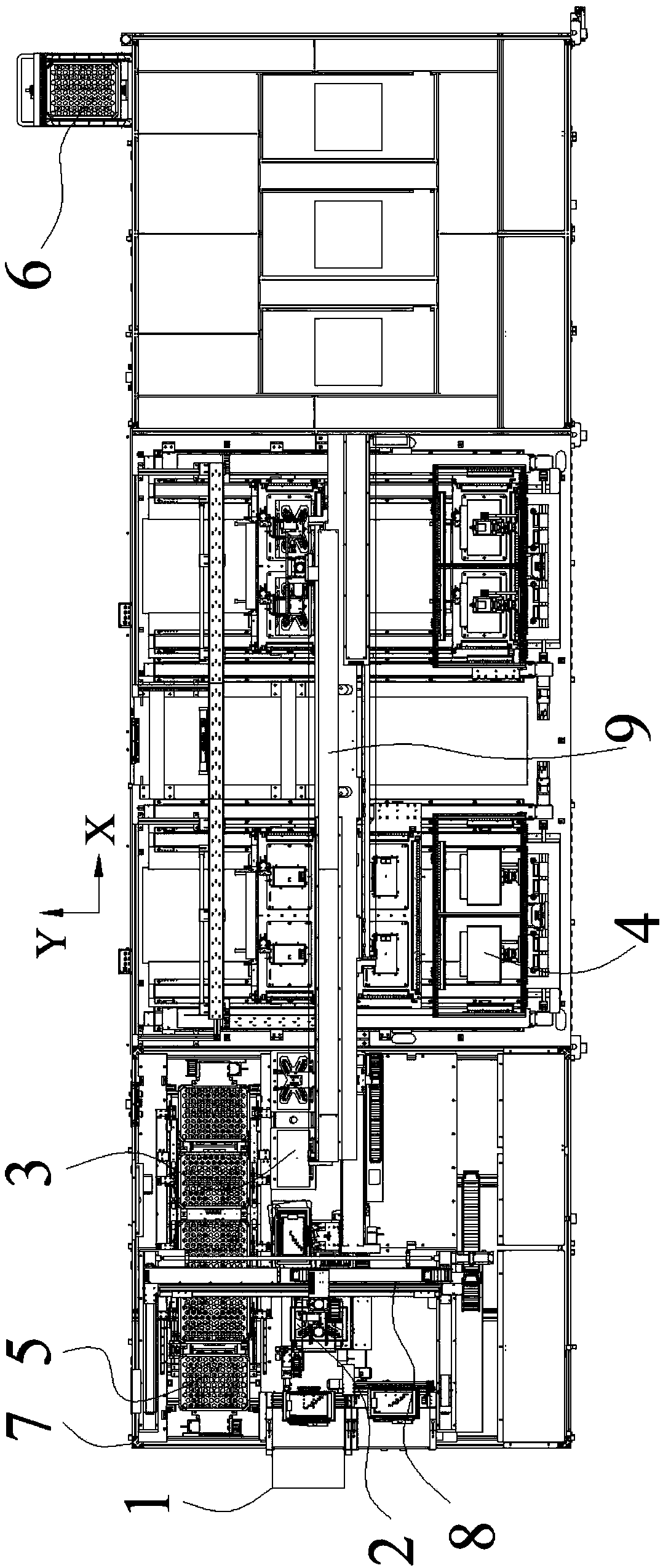

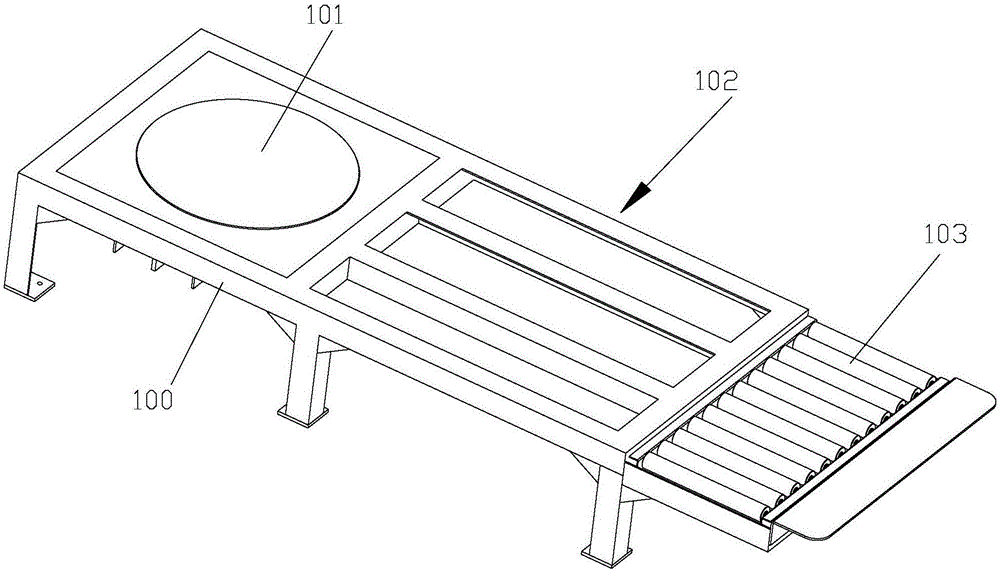

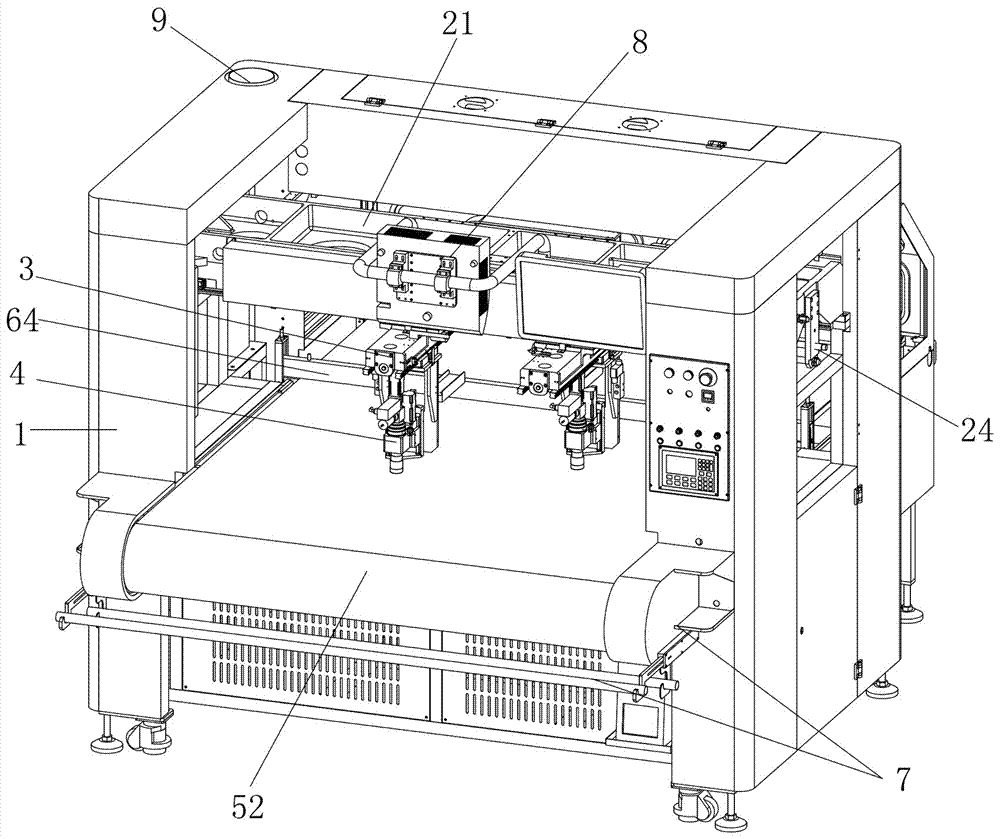

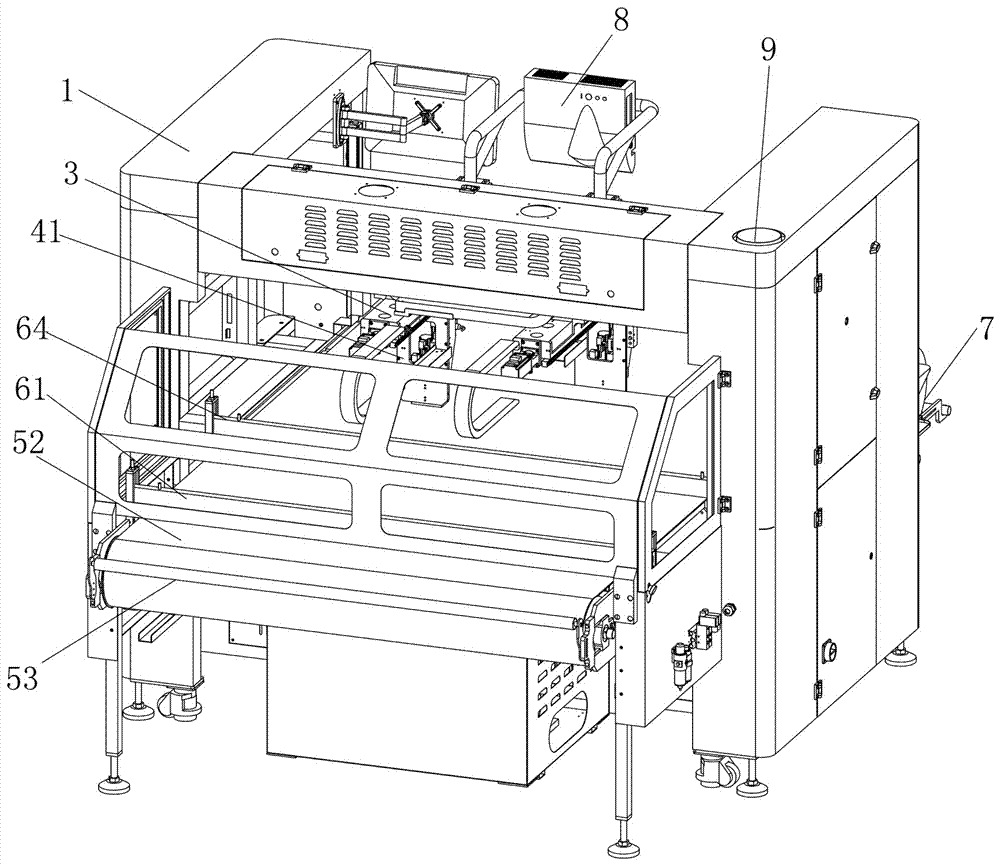

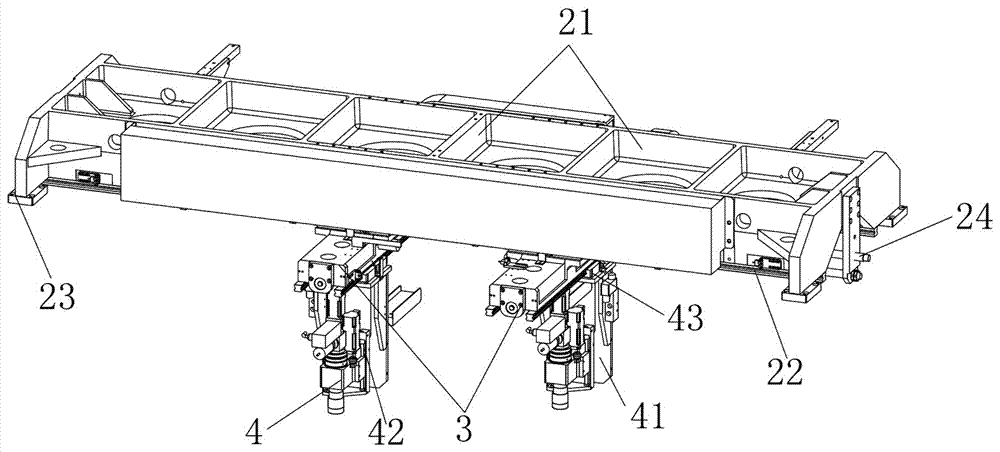

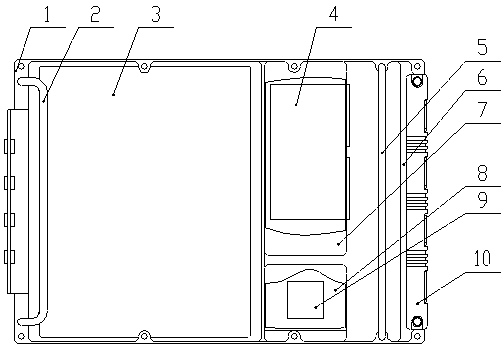

Panel inspection device

PendingCN107826745AImprove the efficiency of optical inspectionReduce human inputConveyor partsEngineeringTest platform

The invention relates to the technical field of panel optical inspection devices, in particular to a panel inspection device. The panel inspection device comprises a base, and is characterized in thata sheet allocating device, an automatic optical inspection device, a discharging device and a storing device are sequentially arranged in the conveying direction of a panel on the base. The sheet allocating device is used for bearing a to-be-inspected panel to be transferred to an inspection platform on the automatic inspection device. The automatic optical inspection device is used for performing optical inspection on the to-be-inspected panel on the inspection platform. The discharging device is used for transferring the panel which is identified as a finished product by the automatic optical inspection device. The storing device is used for storing the panel which is identified as an NG product by the automatic optical inspection device. The panel inspection device is reasonable in structural layout, is high in panel inspection efficiency, improves the panel inspection efficiency greatly, and has a great popularization value.

Owner:KUSN JINGXUN ELECTRONICS TECH

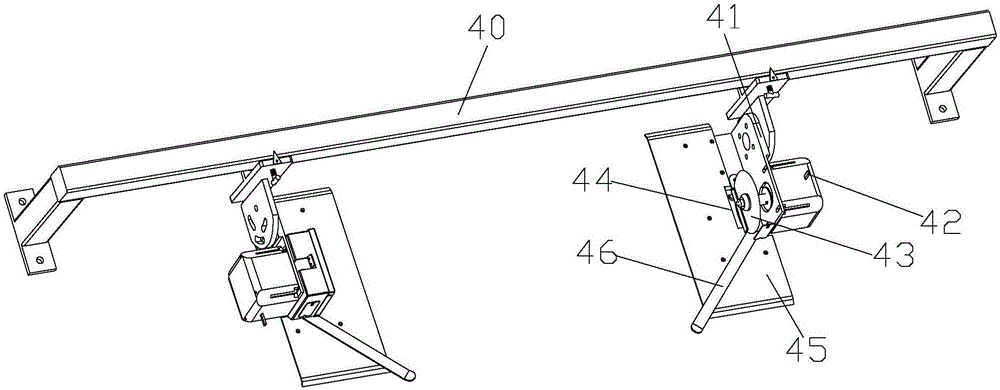

Full-automatic pillowcase machine

ActiveCN107435189AReasonable structure layoutMeet production and processing needsMechanical cleaningPressure cleaningEngineeringAssembly line

The invention relates to a full-automatic pillowcase machine. The machine comprises a feeding buffer area, a machine frame, a feeding component, a trimming device, an edge folding device, a sewing machine, a cloth slow storing mechanism, a correction device, a fixed-length cloth cutting-off mechanism, a label feeding device, a first binding-off device, a second binding-off device, a bag turning device and a collecting device, wherein the feeding component, the trimming device, the edge folding device, the sewing machine, the cloth slow storing mechanism, the correction device, the fixed-length cloth cutting-off mechanism, the label feeding device, the first binding-off device, the second binding-off device, the bag turning device and the receiving device are arranged on the machine frame; the feeding buffer area is located on one side of the machine frame; the feeding component, the trimming device, the edge folding device, the cloth slow storing mechanism, the correction device and the fixed-length cloth cutting-off mechanism are sequentially distributed on the machine frame; the label feeding device and the first binding-off device which are longitudinal distributed are arranged at the lower end of the fixed-length cloth cutting-off mechanism; the second binding-off device and the bag turning device are transversely distributed are arranged on one side of the lower end of the first binding-off device; the collecting device is arranged at the lower end of the bag turning device. The full-automatic pillowcase machine is reasonable in overall structural layout, assembly line processing of pillowcases can be automatically completed, the production efficiency is high, and the machine meets actual production and processing requirements.

Owner:SUZHOU TRANSPARENT TECH CO LTD

Wall building robot and working method thereof

PendingCN107443353APrecise positioningReduce mistakesProgramme-controlled manipulatorGripping headsDrive motorTransfer mechanism

A wall building robot comprises a workbench body. The workbench body is provided with a brick car transferring mechanism, a double-four-axis linkage control system, an automatic claying machine, a hydraulic brick cutting machine, a brick clamping pallet, and a lifting and translation mechanism. The brick car transferring mechanism moves up and down on a workbench through a first workbench body guide rail and a second workbench body guide rail. The double-four-axis linkage control system conducts spatial positioning and moving on a brick taking manipulator. The automatic claying machine and the hydraulic brick cutting machine are parallel to each other and are both arranged across the brick clamping pallet. The automatic claying machine is connected with the workbench body through a hopper supporting plate and provided with a hopper, an impeller, and a driving motor. The hydraulic brick cutting machine is provided with a cutting blade bracket. The lifting and translation mechanism is arranged on a hollow position between a workbench body base in the workbench body and a workbench top supporting frame. The wall building robot can replace manpower to carry out brick taking, claying, brick cutting, wall building and other action, and is high in automation degree and efficiency and convenient to use.

Owner:洛阳海特智能科技有限公司

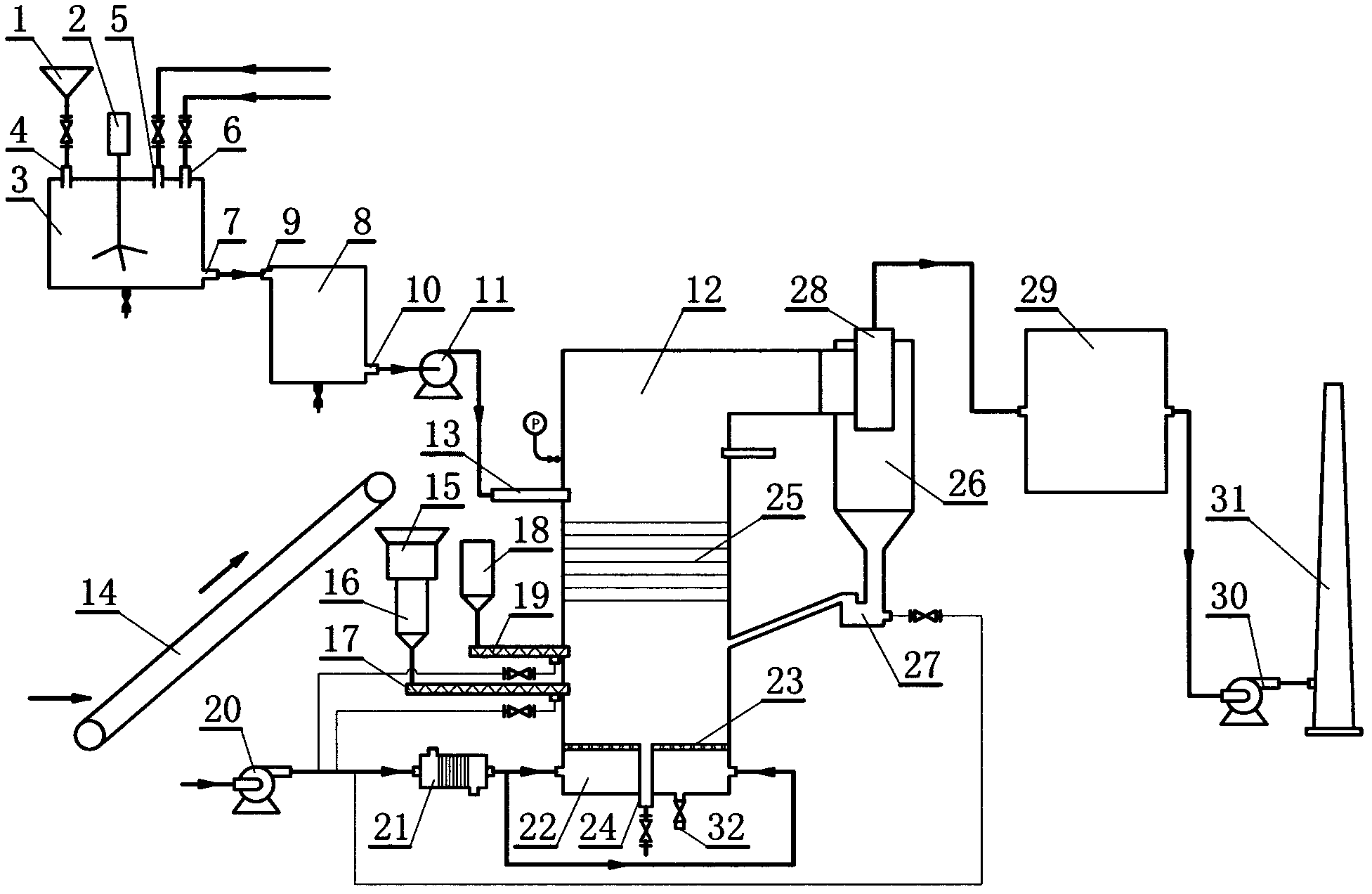

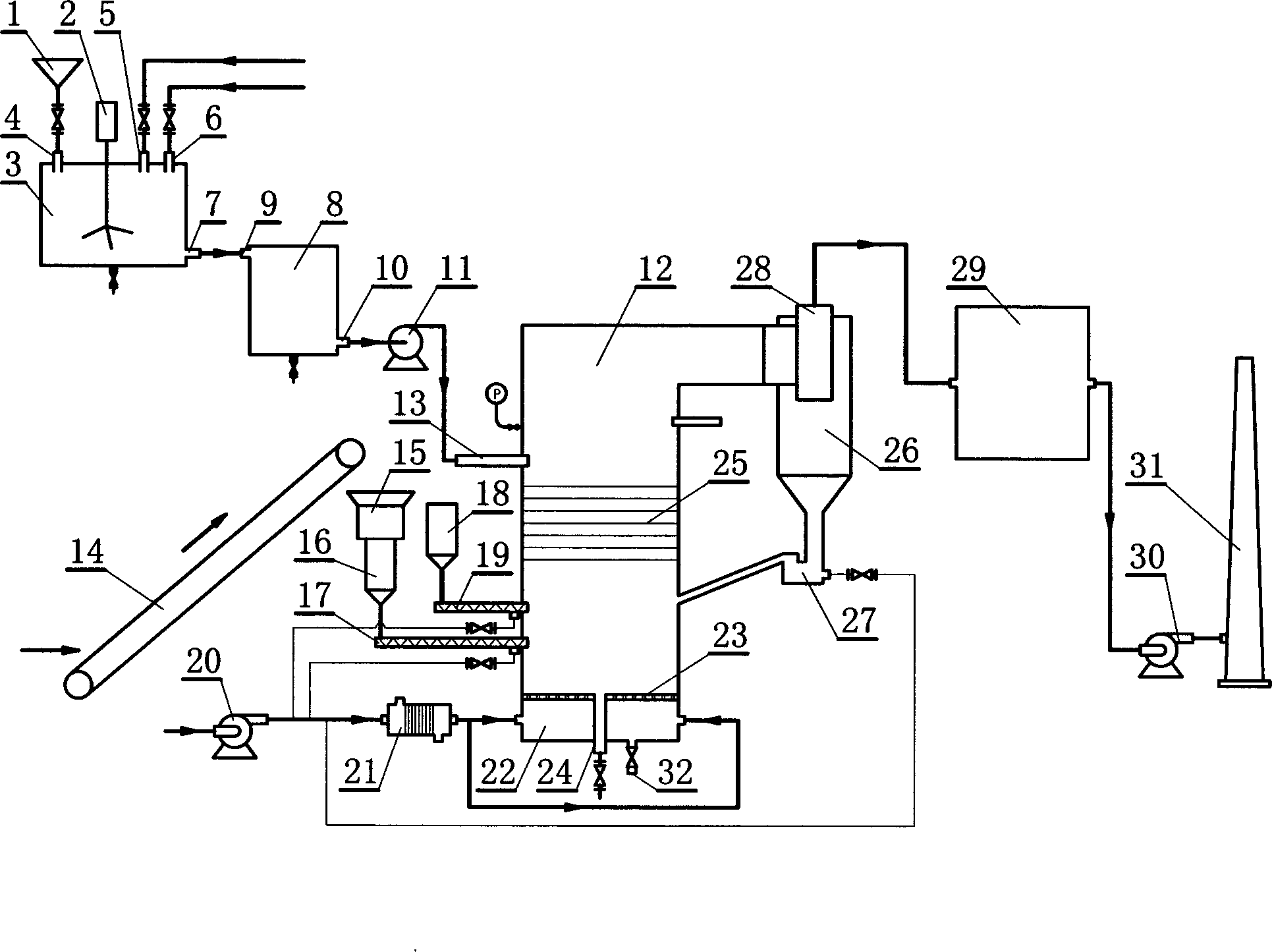

Movable type contaminated soil remediation system adopting recirculating fluidized bed

The invention relates to a movable type contaminated soil remediation system adopting a recirculating fluidized bed, belonging to mechanical equipment. The remediation system takes the recirculating fluidized bed as a reactor; three drug feeding ways of gas state, liquid stage and solid stage, and two heat tracing devices are arranged, so that the contaminated soil can be rapidly remedied by adopting remediation drugs of different states and kinds at different temperatures and pressures according to the characteristics of the contaminated soil, and the movable type contaminated soil remediation system is not only suitable for various soils contaminated by volatile organic compound, semi-volatile organic compound, polycyclic aromatic hydrocarbon, polychlorinated biphenyl, petroleum hydrocarbon, pesticide, heavy metals and the like, but also not limited by types of solid, liquid or gas drugs. The movable type contaminated soil remediation system adopting the recirculating fluidized bed is reasonable in structural layout, convenient in moving, wide in scope of application, high in reaction speed, good in flexibility, and safe and stable in operation, is economically feasible, can be suitable for large-scale centralized processing of the contaminated soil as well as in-situ remediation, thereby having excellent environmental protection benefit and social benefit.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Cutting machine

InactiveCN106930092ANo misalignmentEnsure consistencySevering textilesThree-dimensional spaceEngineering

The invention discloses a cutting machine. The cutting machine comprises a frame and a feeding device which is arranged on the frame, wherein a feed inlet, a cutting station and a product collecting station are successively arranged on the frame along the feeding direction of the feeding device; a portal frame is arranged above the cutting station of the frame, the portal frame hoists at least one tool apron for mounting a tool, a mobile device which drives the tool apron to move in a three-dimensional space is arranged between the portal frame and the tool apron, and a traction material pressing device and a fixed pressing device are successively arranged along the feeding direction between the feed inlet and the cutting station. Cloth and a conveyor belt are clamped together and moved through the traction pressing device, so that the cloth in the transfer process is not staggered, and meanwhile, the cloth is tightly pressed to the conveyor belt through the fixed pressing device, so that the cloth cutting consistency and precision are guaranteed, and the problem that the cloth which is cut is easy to be staggered is solved.

Owner:GBOS LASER INC

Geological borehole wall rock strain measurement device

InactiveCN101240707AHigh precisionSmall sizeElectric/magnetic detection for well-loggingElectrical/magnetic solid deformation measurementStress measurementMeasurement device

The present invention relates to a geologic drill hole wall wall rock strain measurement device in rock stress gaging practice field. In the invention, lifting mechanism connects with upper end of outer cylinder sleeve, hermetically-sealed cable joint connects with electronic equipments cabin which is at the bottom of lifting mechanism, multipath strain measurement instrument and computer control unit are placed in electronic equipments cabin, the bottom of electronic equipments cabin has a cooling pump cabin, bottom of cooling pump cabin has a upper packer which is fixed in the outer cylinder sleeve by upper bracket of packer, the bottom packer connects with the bottom part of outer cylinder sleeve by the bottom bracket of packer, strain measurement main working part which is placed between upper packer and lower packer integrates with inner cylinder sleeve and push mechanism, front work window and back work window are placed at the corresponding place in outer cylinder sleeve, lower equipment cabin situated at tail of outer cylinder sleeve. The product of the present invention decreases probability of breaking core, improves success rate of stress measurement, and can be used in hundreds-meter deep hole.

Owner:SHANGHAI JIAO TONG UNIV

Integrated adhesive head of sheet adhesive machine

InactiveCN1533239AReasonable structure layoutAssembly is smallPrinted circuit assemblingElectrical componentsAdhesiveDrive motor

An integrated head of a plate overlayer includes a drive motor, a mainshaft and a suction mouth characterizing that the rotor of the motor is fixed on the mainshaft directly, the said stator of the motor is fixed on the frame of the head directly, the internal mainbody of the head frame is a vertical regular multiprism or cylinder tube wall, the said manshaft is placed at the axle wire of the internal tube wall of the head, the stator is fixedly mounted on the internal tube wall symmetric radially and longitudinal axially and the rotor is fixedly mounted on the surface of the mainshaft correspondingly.

Owner:广州市羊城科技实业有限公司

Clamping type intelligent e-commerce warehousing shuttle vehicle and control method thereof

The invention discloses a clamping type intelligent e-commerce warehousing shuttle vehicle and a control method thereof. The clamping type intelligent e-commerce warehousing shuttle vehicle comprises a pair of shuttle vehicle frames, a shuttle vehicle chassis, a traveling mechanism, a two-time stretching fork mechanism, a current collecting device, a bearing plate and a bearing platform. The intelligent shuttle vehicle can be accurately positioned on all layers of an automatic stereoscopic warehouse and can flexibly store and take goods baskets in different storage positions so that the using efficiency of the shuttle vehicle can be maximized, and the operating stability and reliability of the shuttle vehicle are ensured.

Owner:HEFEI UNIV OF TECH

High-voltage IGBT converter module

ActiveCN102801285ASimple designLow costCooling/ventilation/heating modificationsPower conversion systemsDriver circuitHigh voltage igbt

The invention discloses a high-voltage isolated gate bipolar transistor (IGBT) converter module, which adopts a drawer or vertical structure in which each component is mounted therein in a laminated way. A radiator is arranged at the bottom of the converter module; high-voltage IGBT components are arranged above the radiator and are uniformly arranged on the upper surface of the radiator; a high-voltage low-sensitivity busbar is arranged above the high-voltage IGBT components and is conductively connected with the IGBT components; an alternating current busbar is arranged above the horizontal side of the high-voltage low-sensitivity busbar and is conductively connected with the high-voltage IGBT components; a control box is arranged above the alternating current busbar and is fixed on the radiator; a gate driving power is arranged in a power box beside the control box; and a high-voltage gate driving circuit is arranged in a driving mounting box on the upper layer of the converter module. The converter module is simple in structure, attractive in appearance, safe and reliable, excellent in each performance and good in maintainability and interchangeability, and can meet the high-voltage large power occasions of intercity power train units, maglev trains, locomotives and the like.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

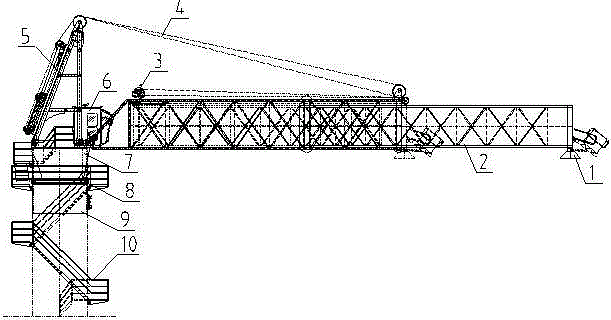

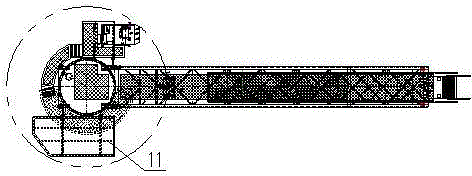

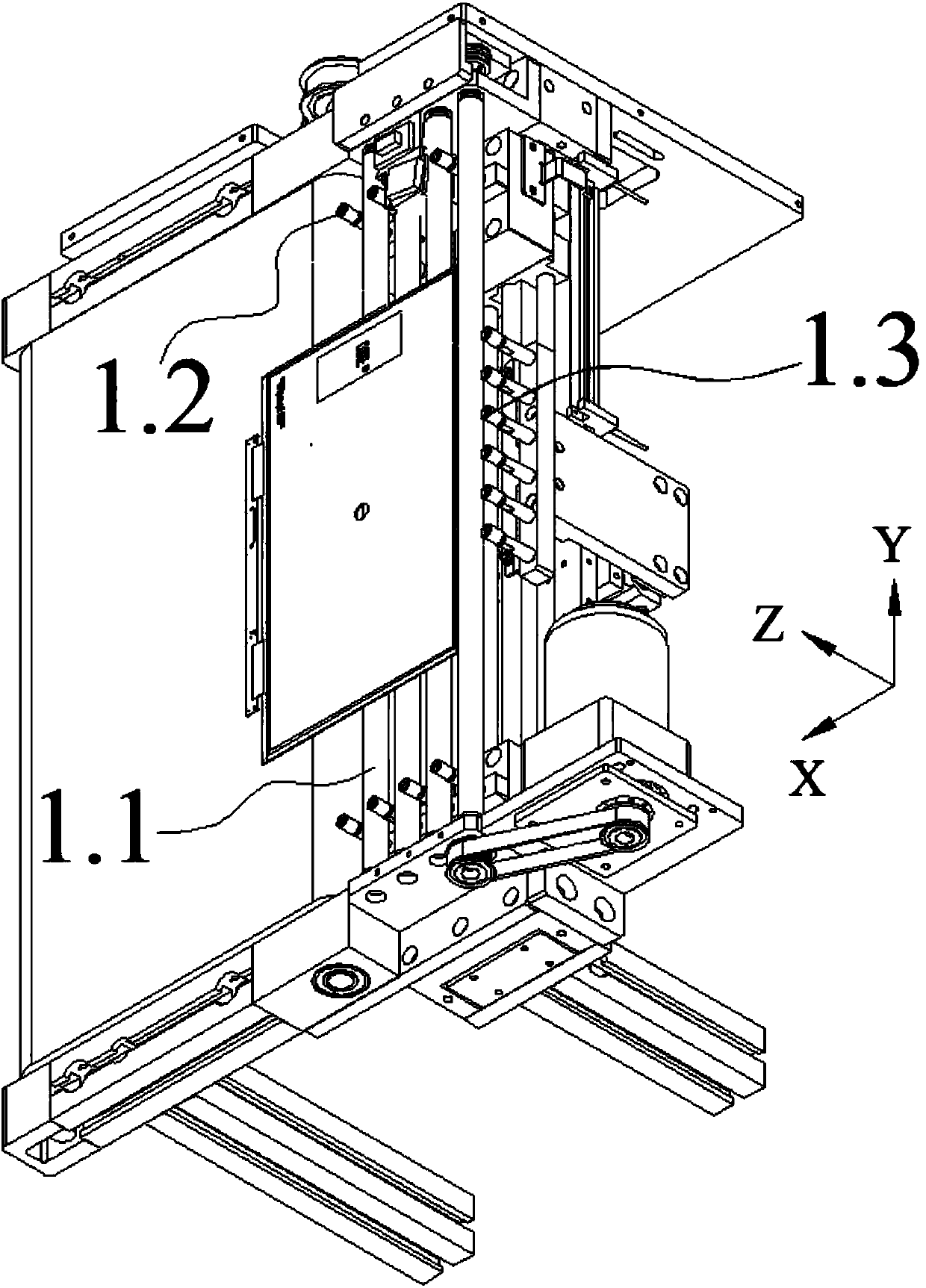

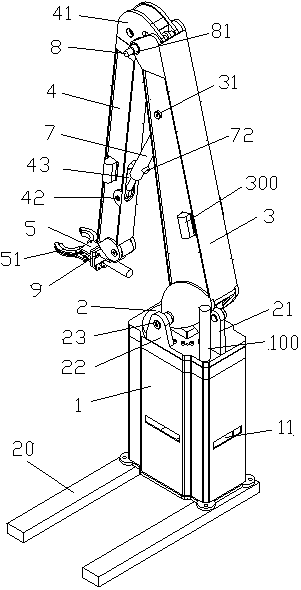

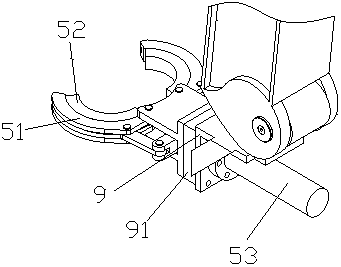

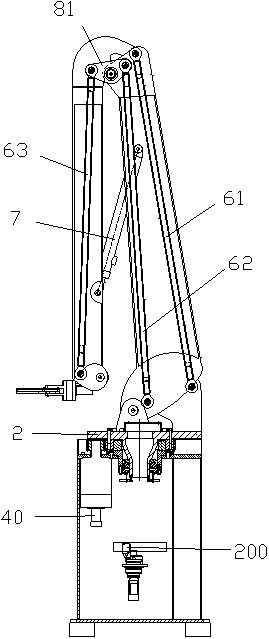

Robot for drilling operation

ActiveCN103696711ALarge amount of deformationPrecise positioningDrilling rodsDrilling casingsImaging processingMaster controller

The invention provides a robot for drilling operation. The robot comprises a base, a rotary table and a mechanical arm, wherein rotary table is arranged on the base, the mechanical arm is hinged with the rotary table and comprises a front arm and a rear arm, and the front arm and the rear arm are of box grinder type structures. The robot for drilling operation, provided by the invention, adopts bionic structure design to realize reasonable structural layout; the front arm and the rear arm simulate an upper arm and a forearm of a human body to be designed to the box grinder type structures, the strength of the front arm and the rear arm is enhanced, and high deformation during robot operation is avoided; meanwhile, a horizontal connecting rod and a bearing connecting rod are arranged in the front arm and the rear arm, the strength is enhanced, and the appearance attractiveness of the robot is also improved; a master controller controls positioning accuracy of the robot via a proportional valve and an absolute encoder so that the robot can be accurately positioned; an image processing and positioning device is additionally arranged and used for accurately distinguishing the position of a drill rod; and a collision prevention sensor is arranged for the sake of safety during operation.

Owner:QINGDAO JIERUI IND CONTROL TECH CO LTD

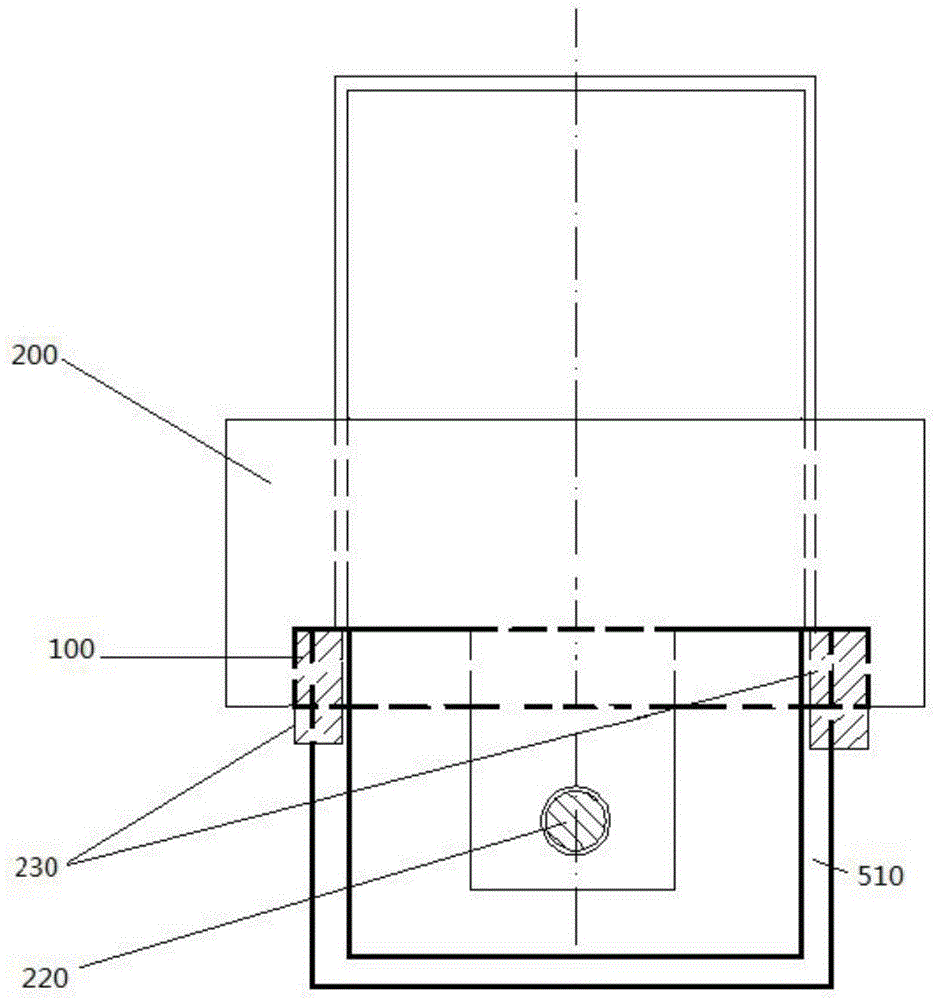

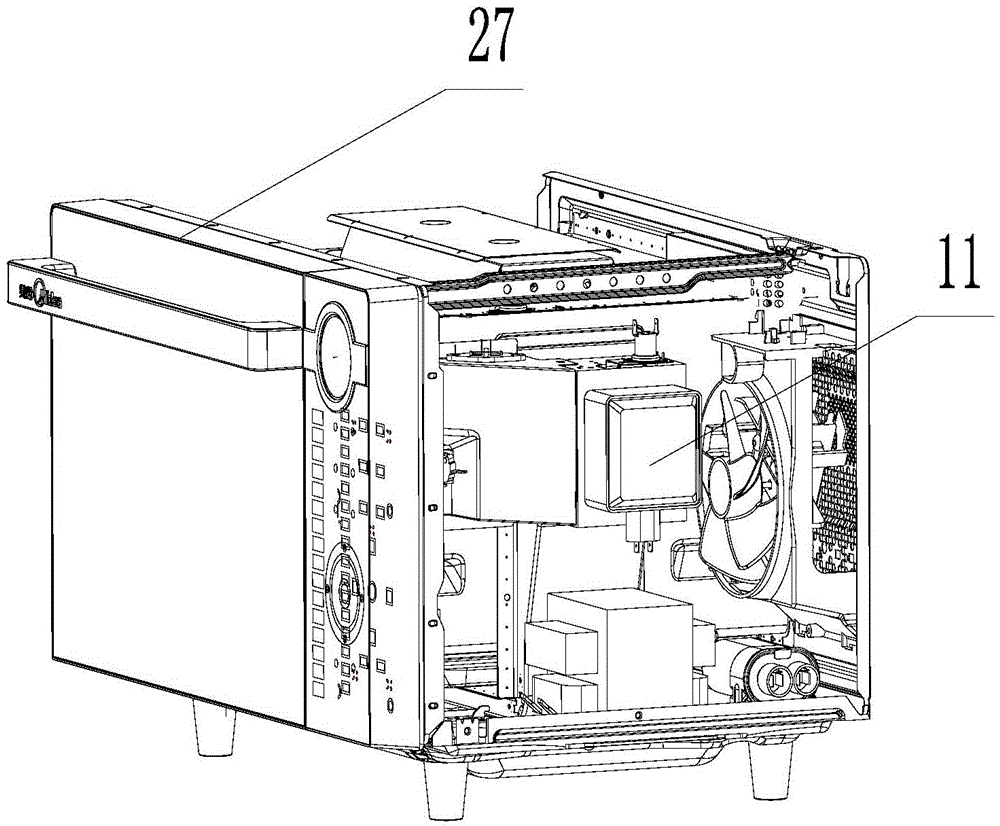

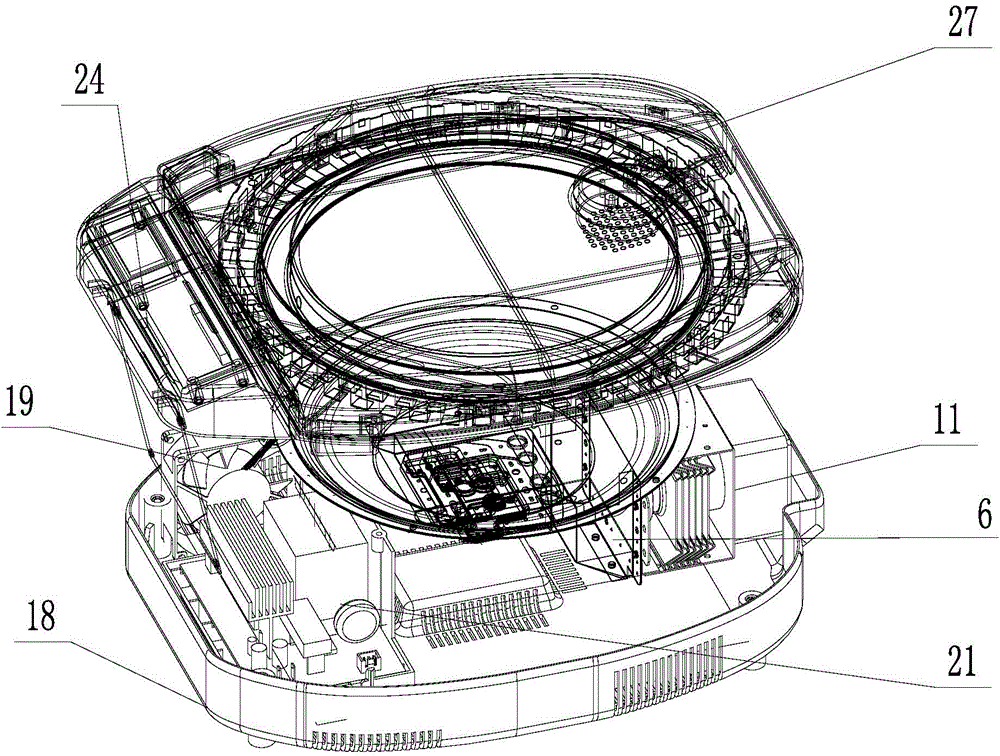

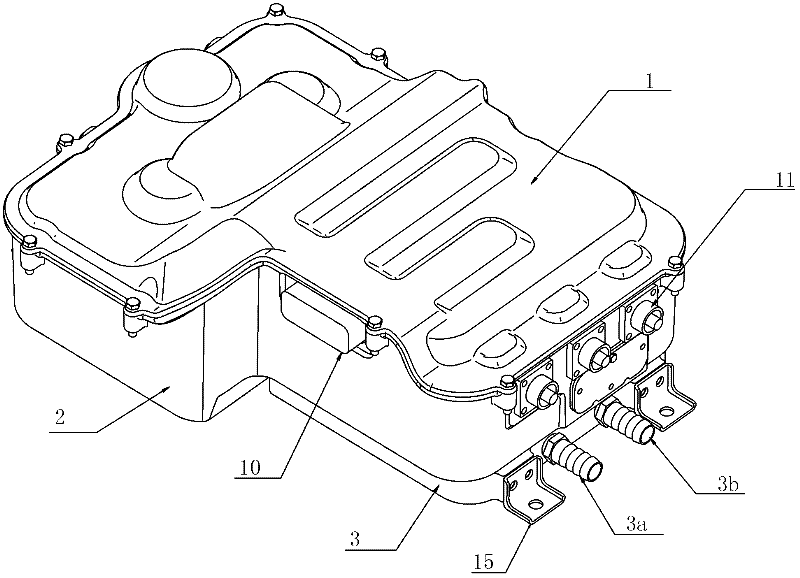

Cavity structure of microwave rice cooker

ActiveCN104864427AReduce radial sizeCompact structureDomestic stoves or rangesLighting and heating apparatusMicrowaveCooker

The invention discloses a cavity structure of a microwave rice cooker. The cavity structure comprises a cavity body (2), a microwave transmitting mechanism and a stirring component, wherein the cavity body is internally provided with a cooking cavity, a top opening of the cooking cavity is formed in the top cover (1), and the microwave conveying mechanism comprises a waveguide component (6) with a transverse part and a decurrent part; a magnetron (11) is arranged on the decurrent part, the microwave is` input into the microwave transmitting cavity (63) by virtue of a microwave inlet (12), and the transverse part is connected with the bottom of a bottom cover; the microwave is fed into the cooking cavity by virtue of a microwave feeding port (9), the stirring component comprises a microwave stirring plate (4) and a stirring motor (7), the microwave stirring plate is disc-shaped and is arranged on the inner side of the bottom cover (5); the stirring motor is arranged on the bottom of the transverse part, and the microwave stirring plate is driven to rotate by virtue of the microwave stirring plate so as to stir the microwave fed into the cooking cavity. The cavity structure is small in body type and cavity body, compact in structure, and capable of favorably realizing the microwave heating for the cooking cavity.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

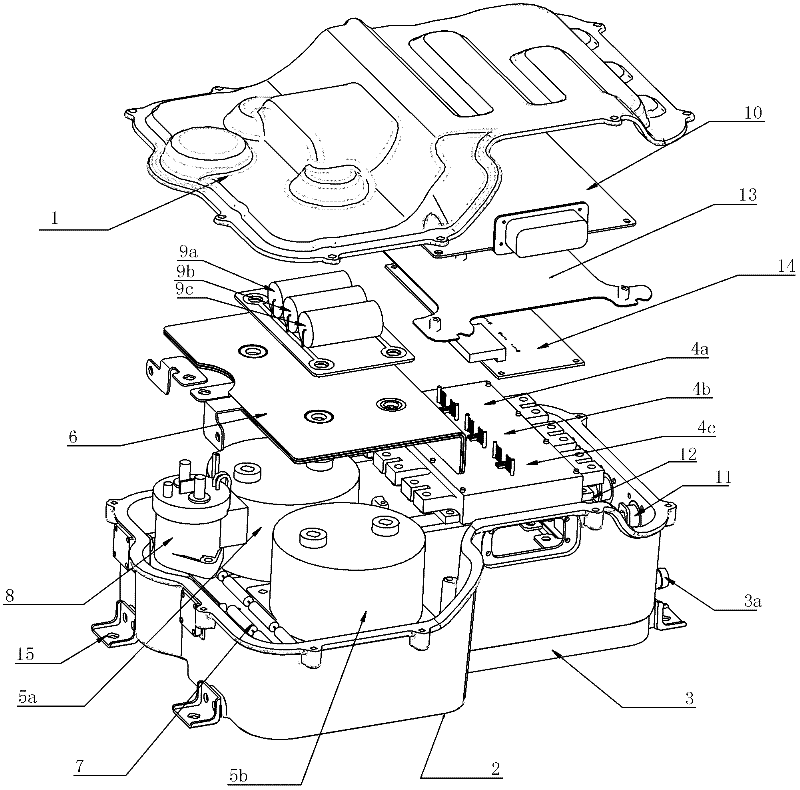

Water-cooled motor controller for high power density electric vehicle

InactiveCN102413671AImprove power densityEasy and flexible operationCircuit arrangements on support structuresCooling/ventilation/heating modificationsCapacitanceBusbar

The invention provides a water-cooled motor controller for a high power density electric vehicle. In the controller, an opening is formed at the bottom of one side of a shell, and a water cooling radiator is arranged at the opening; a power module, a direct current bus support capacitor, a pre-electrified resistor, a main relay and a current sensor are arranged in the shell respectively; the power module is arranged on the upper surface of the water cooling radiator; the direct current bus support capacitor, the pre-electrified resistor, the main relay and the current sensor are fixed in the shell respectively through bolts; the power module, the direct current bus support capacitor and the main relay are connected through a conflux busbar to form a high-voltage loop; a power factor correction capacitor is fixed on the conflux busbar; a drive circuit board which is used for a power module is arranged above the power module; a separator and a control circuit board are arranged above the drive circuit board sequentially; and a plurality of power cable connectors used for assembling power cables pass through the lateral wall of the shell. The water-cooled motor controller has the advantages of flexible and convenient operation process, strong radiation capability, high power density, good electromagnetic compatibility and safe and reliable use effect.

Owner:TIANJIN QINGYUAN ELECTRIC VEHICLE

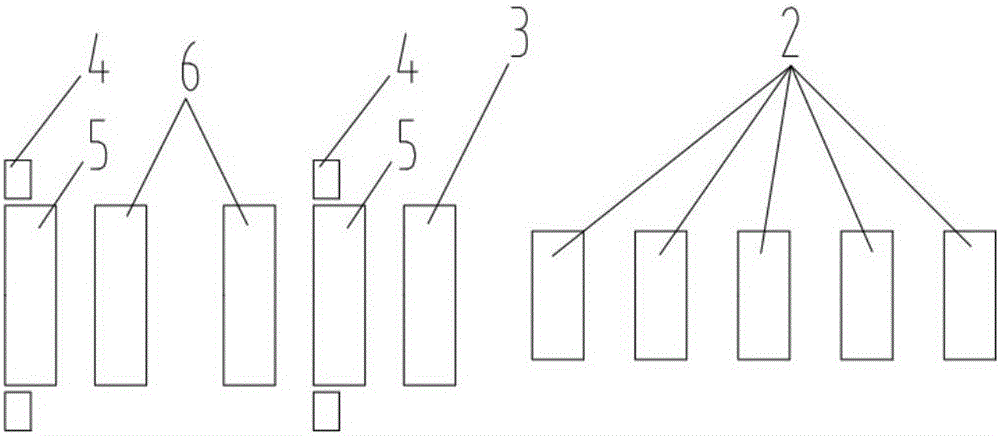

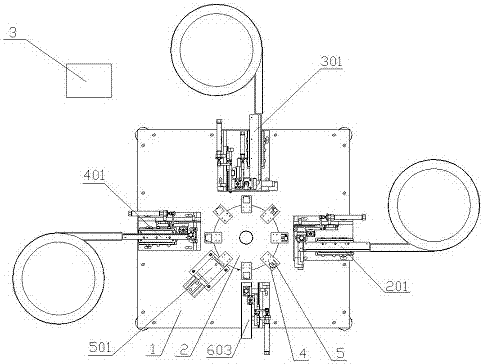

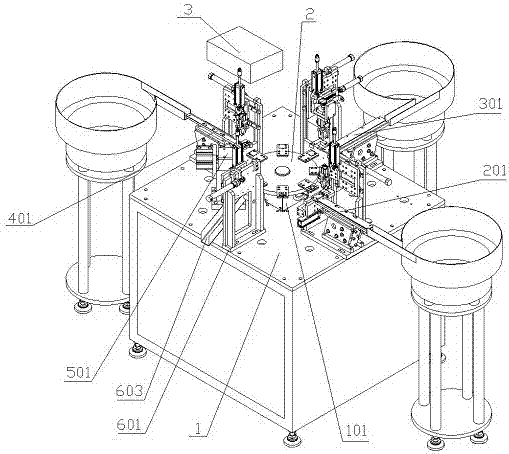

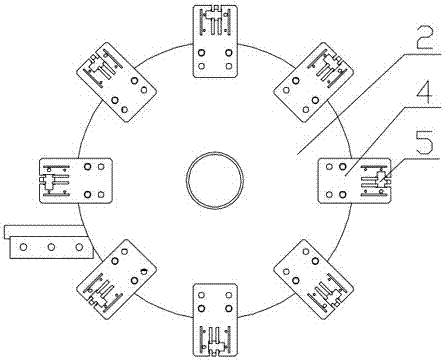

Automatic assembling machine for electronic components

ActiveCN106881589APrecise positioningIncrease productivityAssembly machinesMechanical equipmentMachine

The invention discloses an automatic assembling machine for electronic components, and belongs to the technical field of mechanical equipment manufacturing. The automatic assembling machine comprises a machine frame (1), a rotary table (2) arranged on the machine frame, and a PLC (3). The machine frame (1) is provided with a driving part used for driving the rotary table (2) to rotate. A plurality of templates (4) are evenly arranged on the rotary table (2) in the circumferential direction. One ends of the templates (4) are fixedly connected with the rotary table (2), and the other ends of the templates (4) are provided with grooves (5) which are matched with the electronic components and used for placing the electronic components. An electronic component conveying device, a platen conveying device, a rivet conveying device, a rivet punching device and an electronic component recovery device are sequentially arranged on the periphery of the rotary table (2). According to the automatic assembling machine for the electronic components, the electronic components can be assembled in an automatic cycle mode, production quality is good and production efficiency is high.

Owner:LINHAI ZHONGCHUANG AUTOMATIC EQUIP

Steel plate wall climbing robot

InactiveCN103332232ASimple structureSimple mechanical structureVehiclesElectricityMetallic materials

The invention discloses a steel plate wall climbing robot which comprises a chassis and a running device mounted on the chassis, wherein the running device comprises a track mounted on the chassis by chain wheels; windings and an iron core are arranged in a scope defined by the track; the windings parallel to the track are wound in the iron core; the iron core is mounted on the chassis; and the track is made of a whole metal material which can conduct electricity but cannot conduct magnetism. The robot is simple in structure, easy to assemble and high in adsorption force, and operates flexibly.

Owner:NAVAL UNIV OF ENG PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com