Cutting machine

A cutting machine and frame technology, applied in the field of fabric cutting equipment, can solve the problems of unsatisfactory cutting quality of multi-layer fabrics, lower mechanical cutting accuracy, and uneven feeding of fabrics, etc., so as to improve cutting quality and facilitate equipment maintenance , the effect of reasonable structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

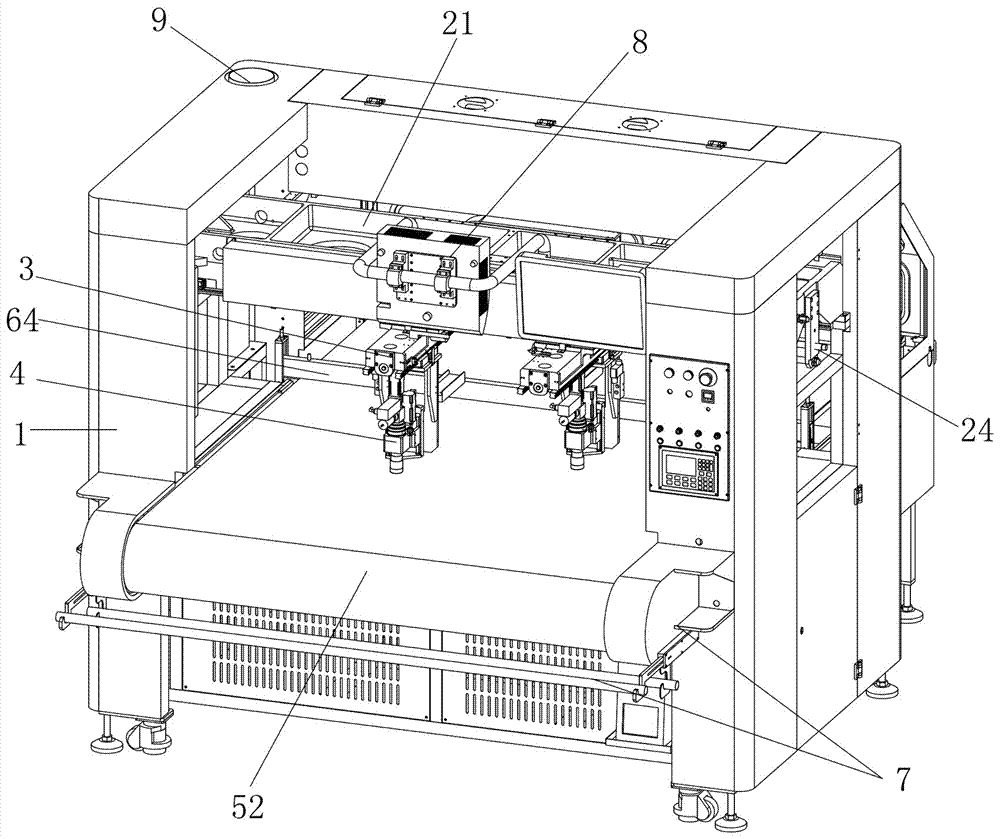

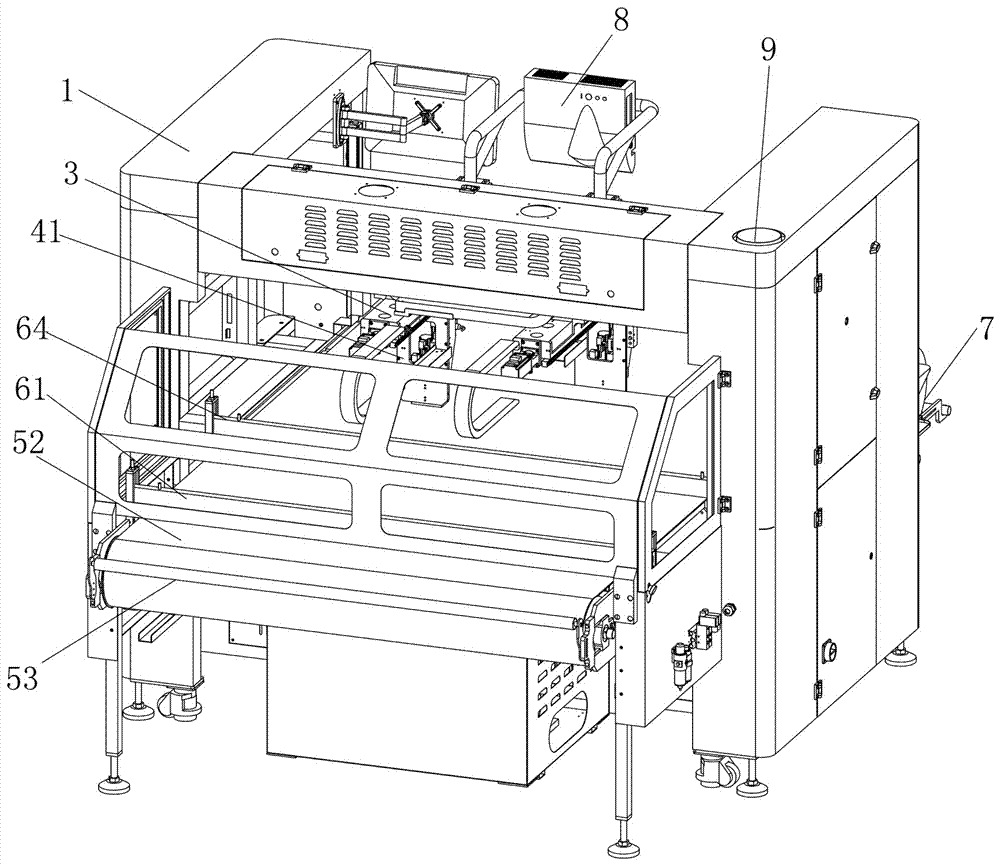

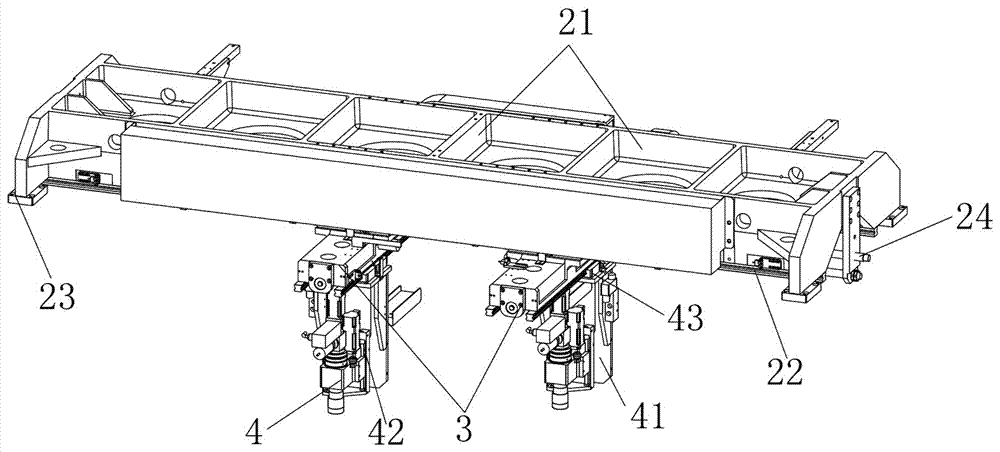

[0028] Refer to attached figure 1 to attach Figure 8 The specific embodiment of the present invention is introduced.

[0029] Such as Figure 1-8 Shown, a kind of cutting machine comprises frame 1 and the feeding device that is arranged on the frame 1; On the frame 1 along the feeding direction of the feeding device, a feeding port, a cutting station and a product collecting station are arranged successively, and the product A waste material recovery device 7 is arranged outside the collecting station, and the frame 1 is provided with a gantry 21 above the cutting station. There is a moving device that drives the knife seat 4 to move in the three-dimensional space, and a traction pressing device and a fixed pressing device are sequentially arranged between the feeding port and the cutting station along the feeding direction. The frame 1 is provided with a projection preview device above the cutting station, and the projection preview device is a projector 8 .

[0030] Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com