Patents

Literature

237results about How to "Flexible opening and closing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

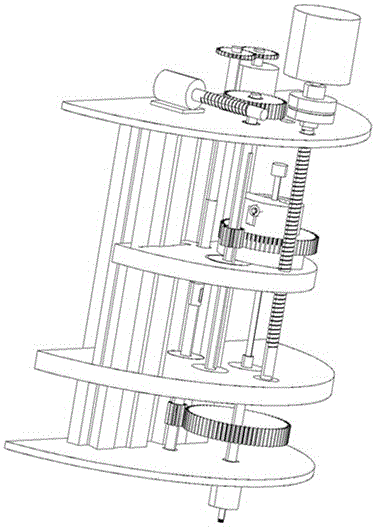

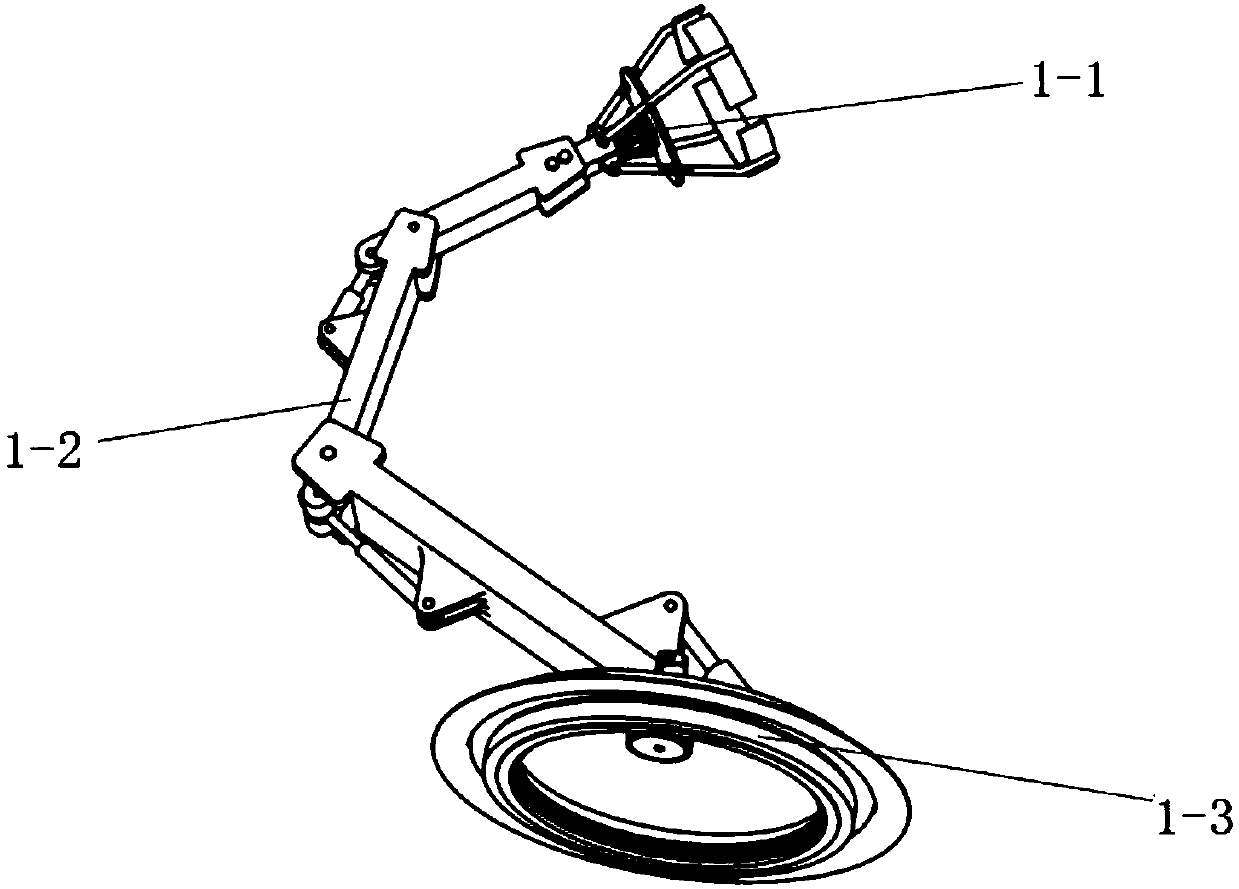

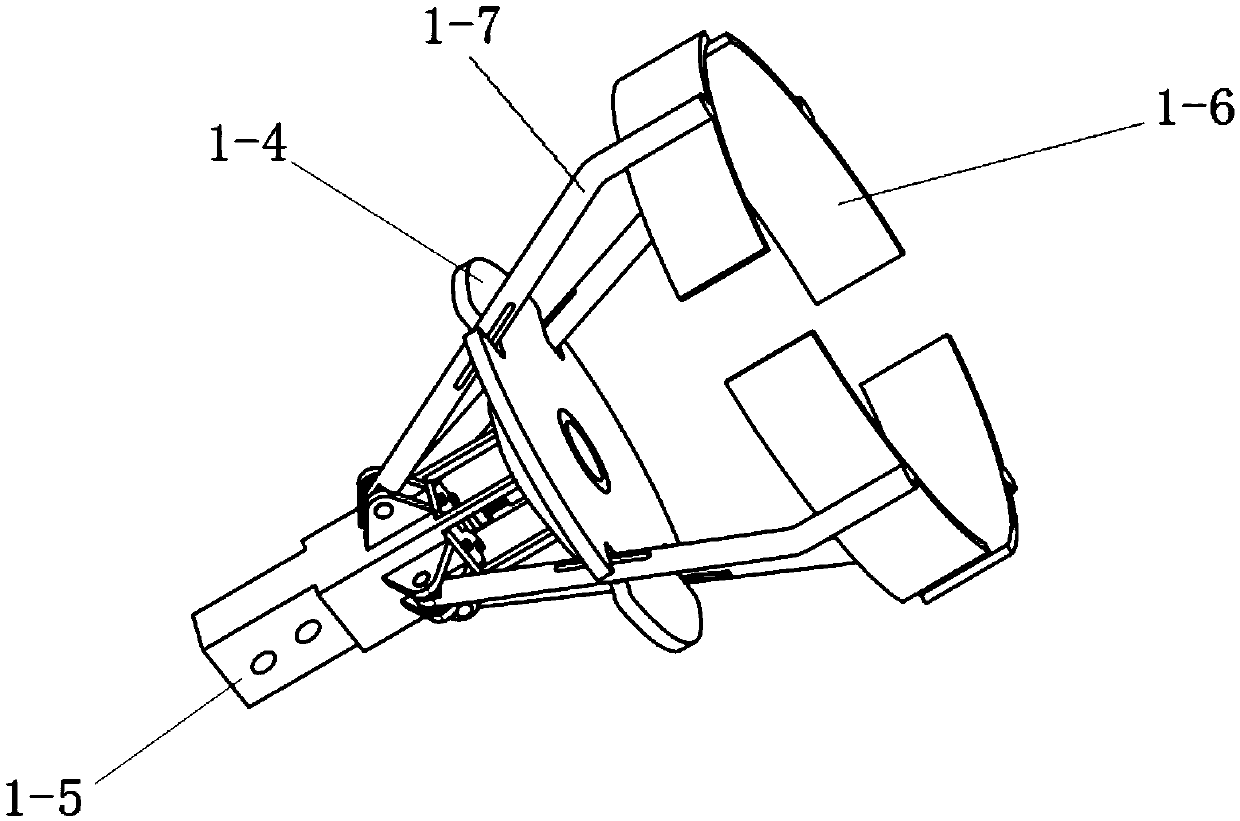

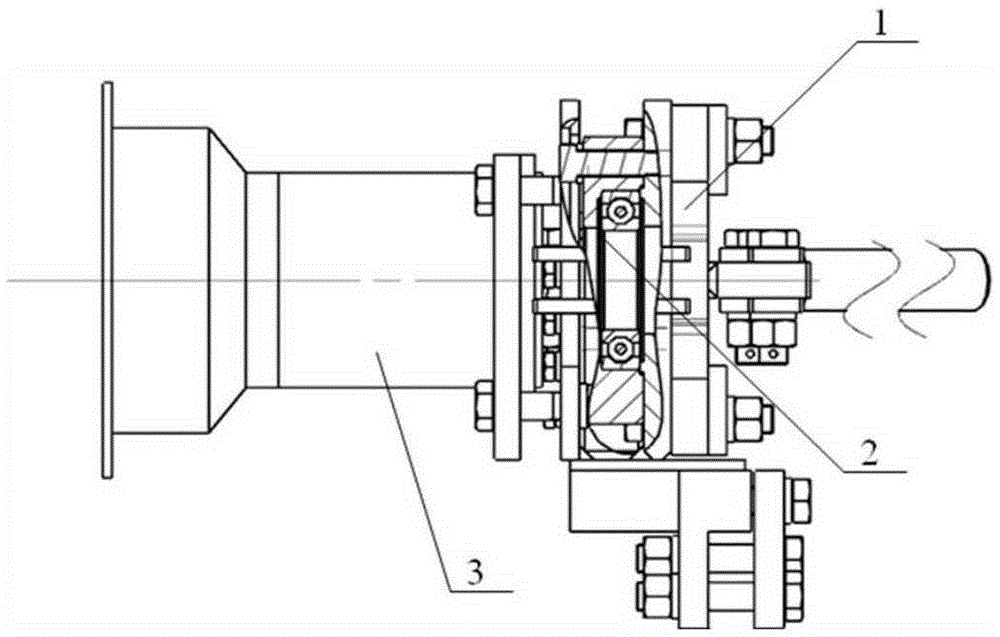

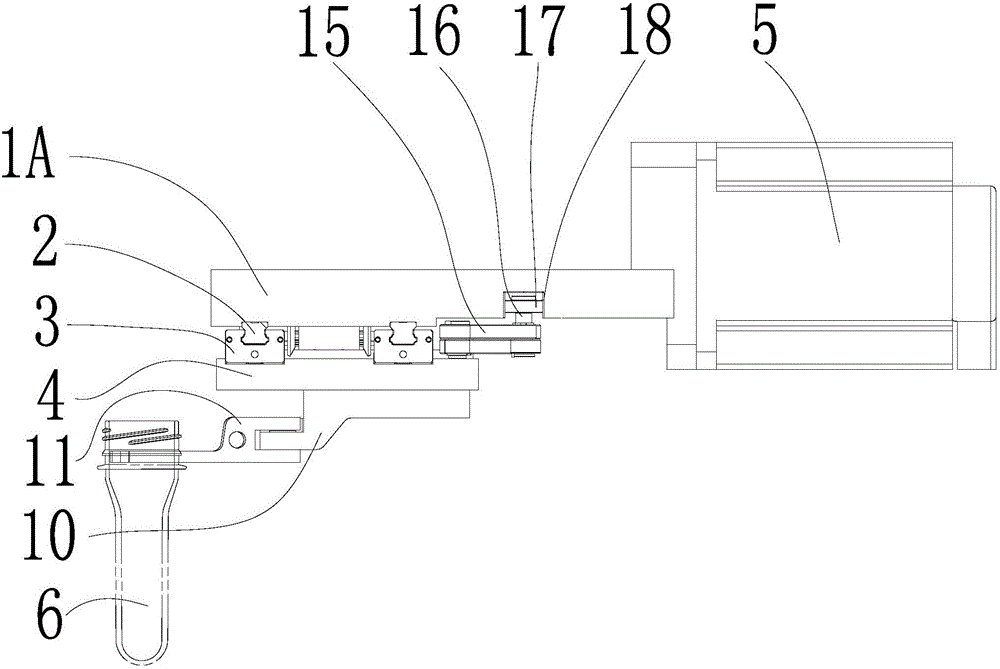

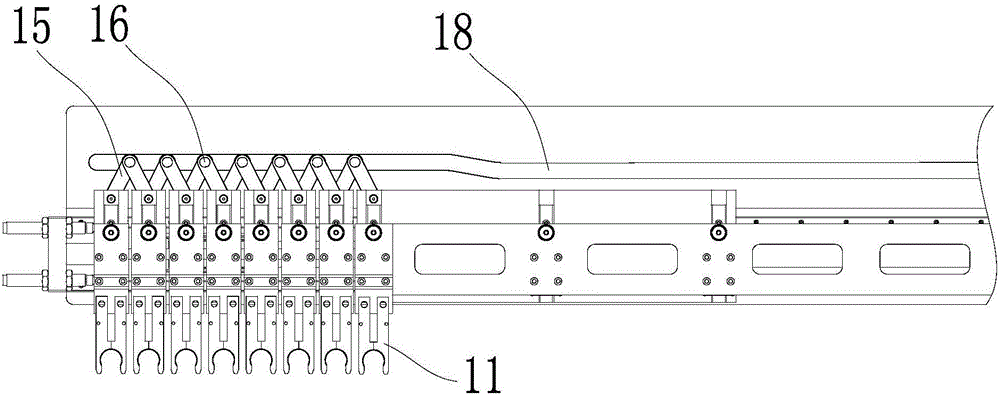

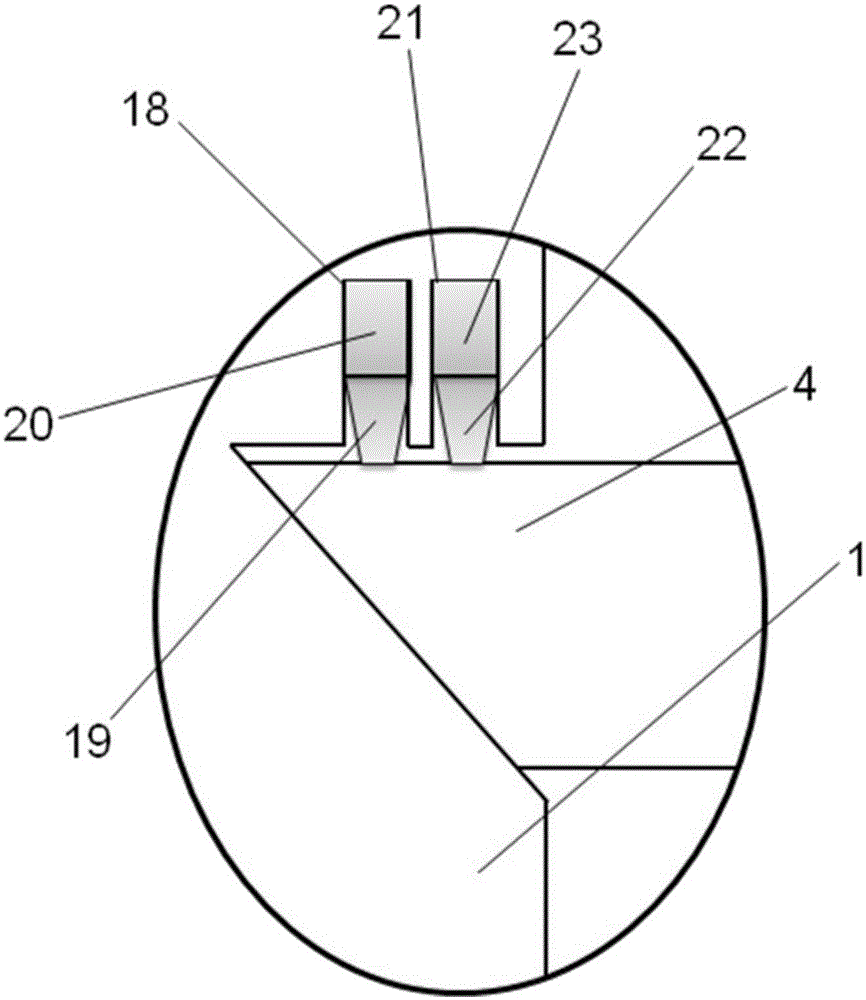

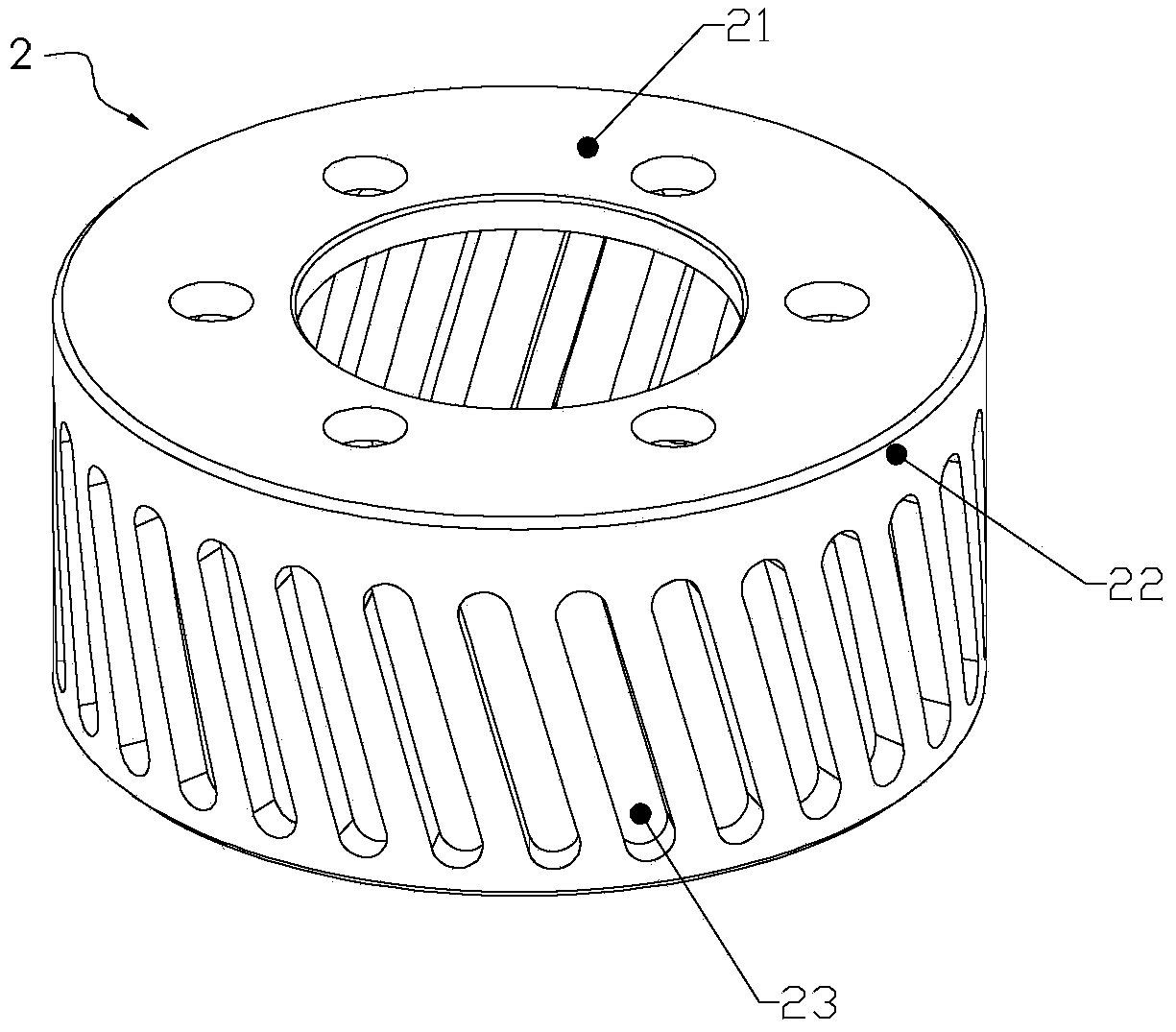

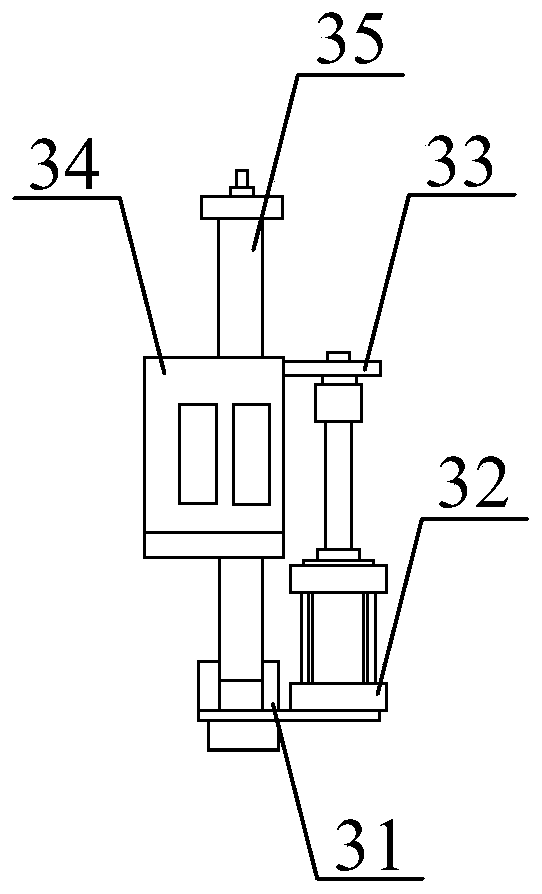

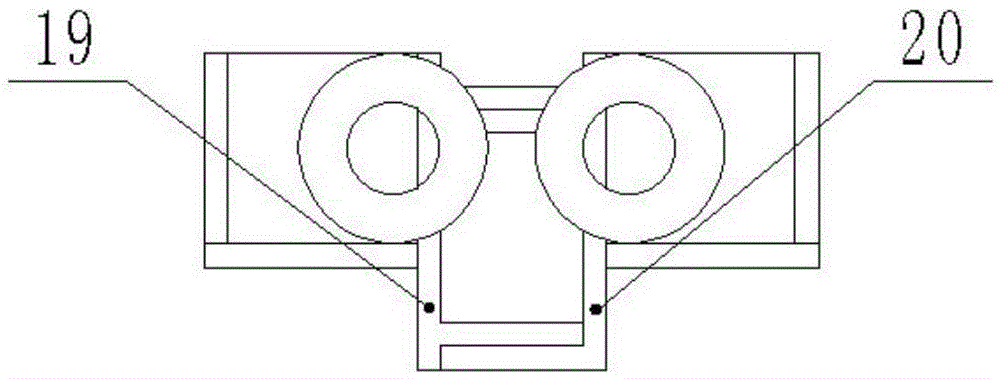

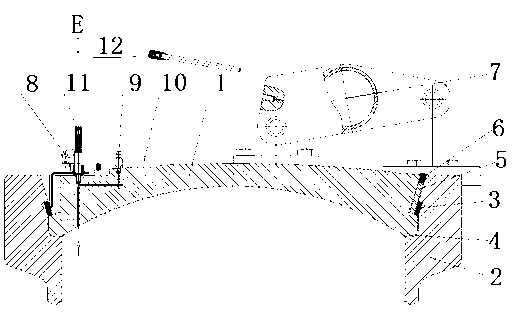

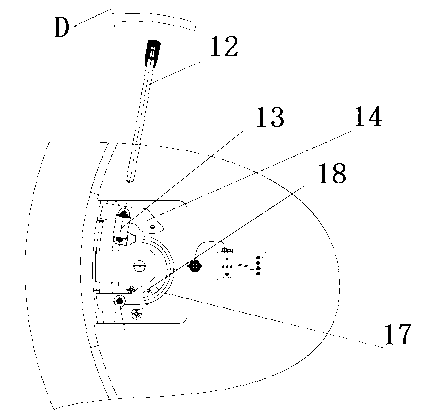

Minimally-invasive surgery assistant robot

InactiveCN105919670ACompact structureIncrease stiffnessProgramme-controlled manipulatorSurgical robotsLess invasive surgeryBall screw

The invention provides a minimally-invasive surgery assistant robot, relates to the field of surgery robots, particularly relates to a minimally-invasive surgery assistant robot and aims to solve the problem that an existing robot hardly opens high-quality and high-accuracy wounds in minimally-invasive surgery. The robot comprises a main shaft lifting mechanism, a main shaft rotating mechanism and a main shaft tail end opening and closing mechanism, wherein the main shaft lifting mechanism is used for driving a ball screw-nut pair via a coupler by using a motor, so that a movable plate exerts the lifting function on a guide rail pair; the main shaft rotating mechanism is used for transmitting torque to a long sleeve by driving two pairs of gears via the motor, then transmitting the torque to a main shaft and enabling the main shaft to rotate; the main shaft tail end opening and closing mechanism is used for transmitting the torque via a worm and gear and a pair of gears by using the motor, lifting a turntable and stretching an inner rod so as to close a tail end surgical instrument.

Owner:HARBIN UNIV OF SCI & TECH

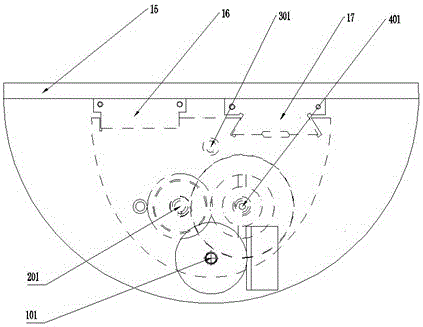

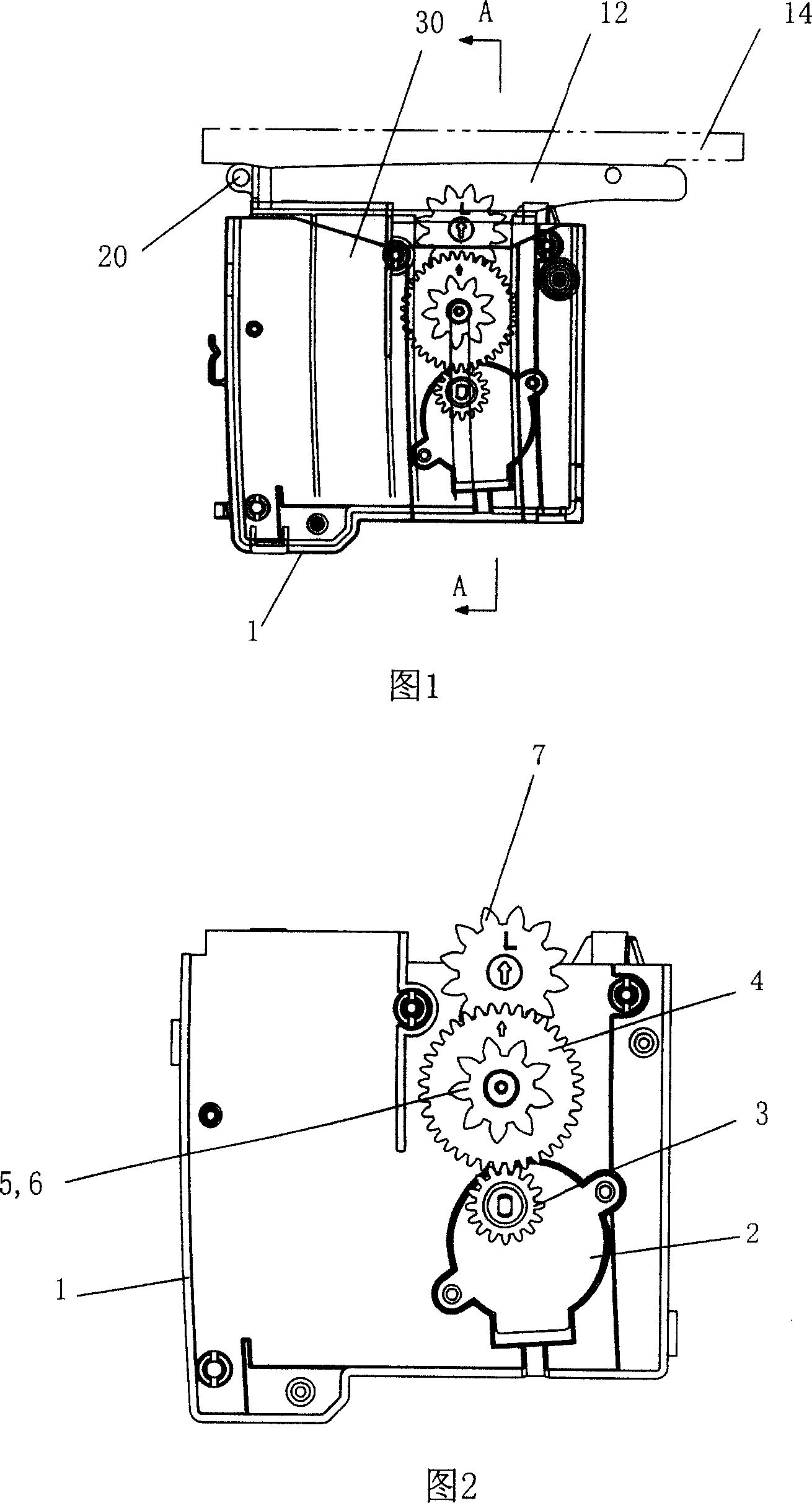

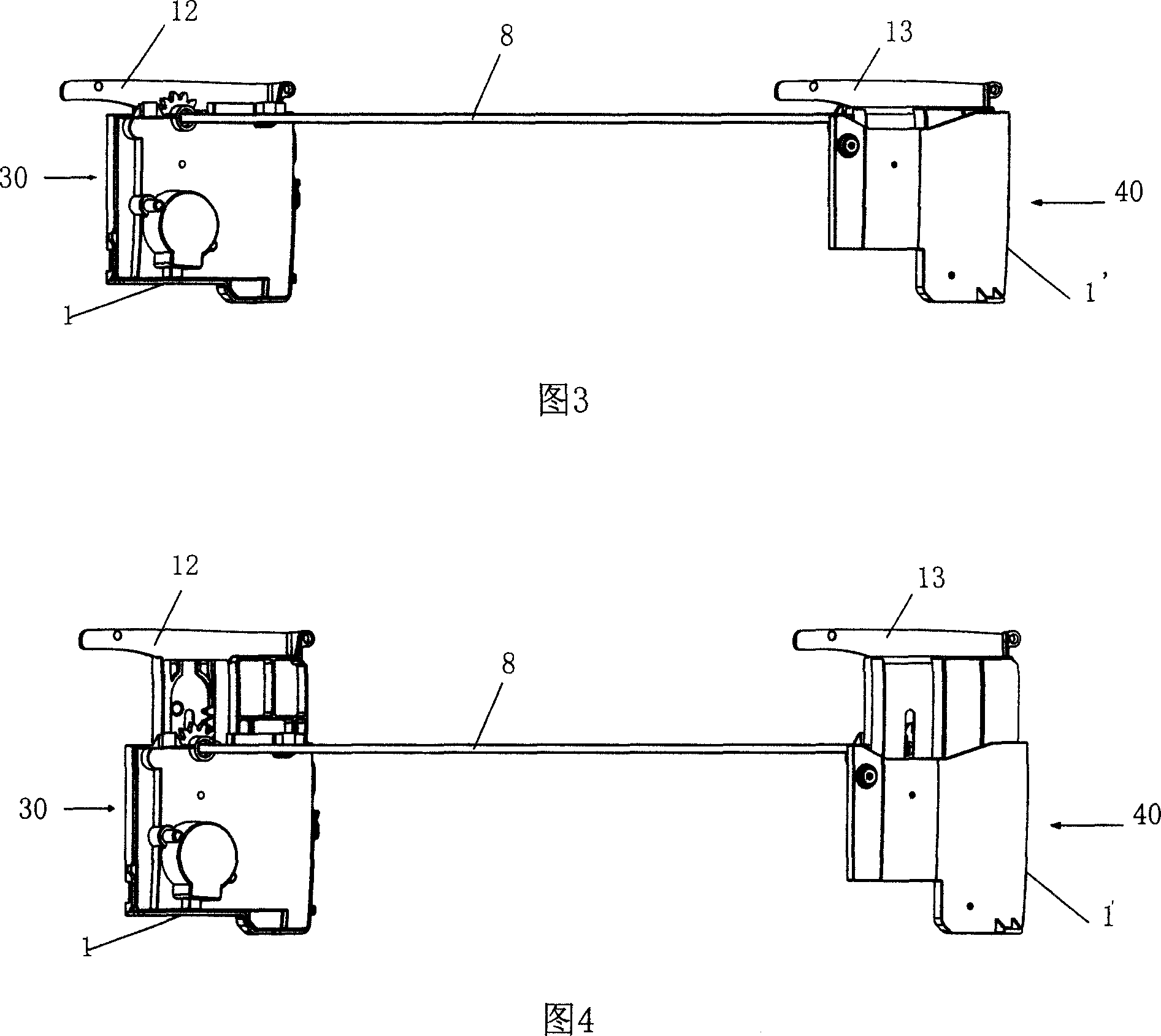

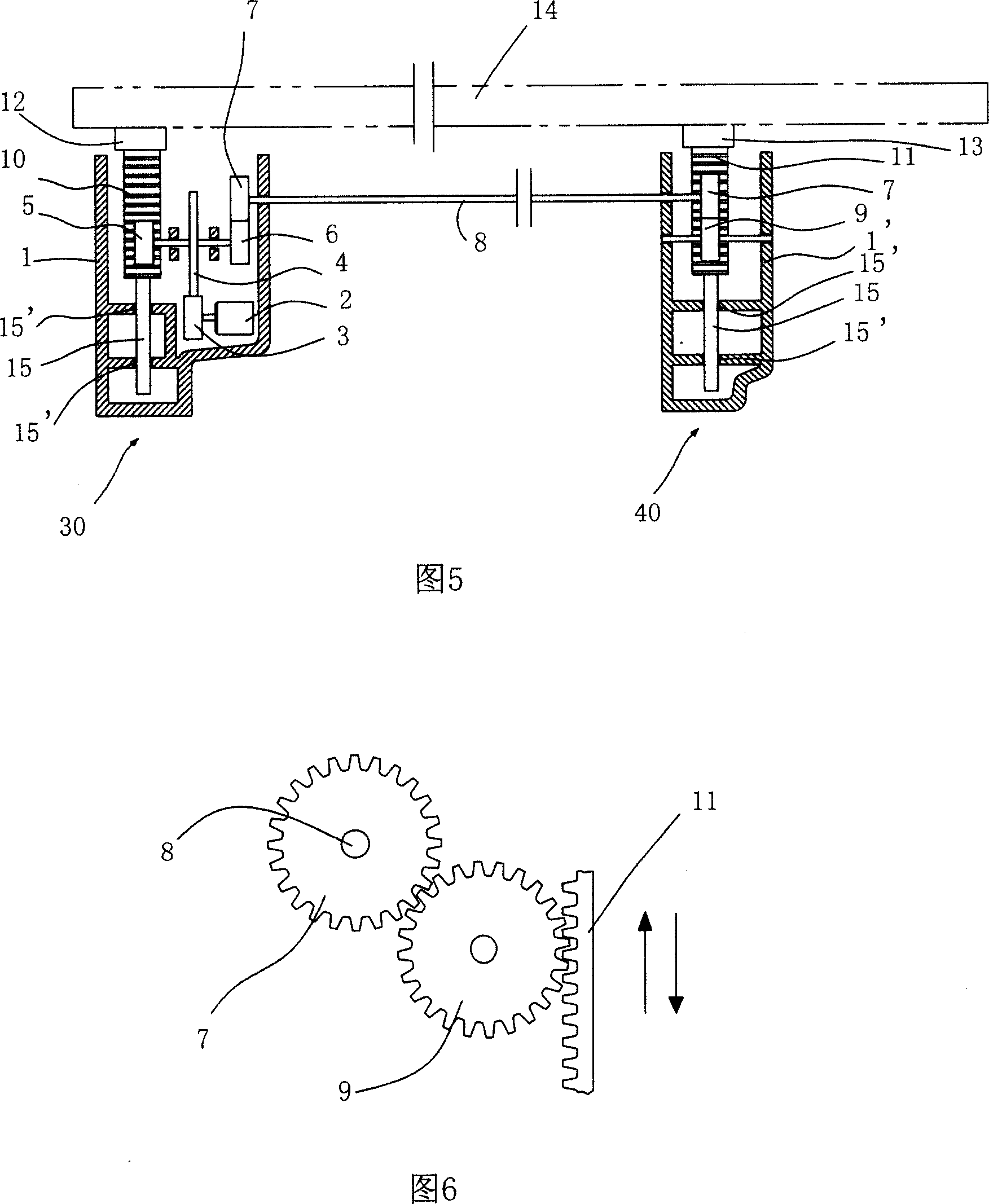

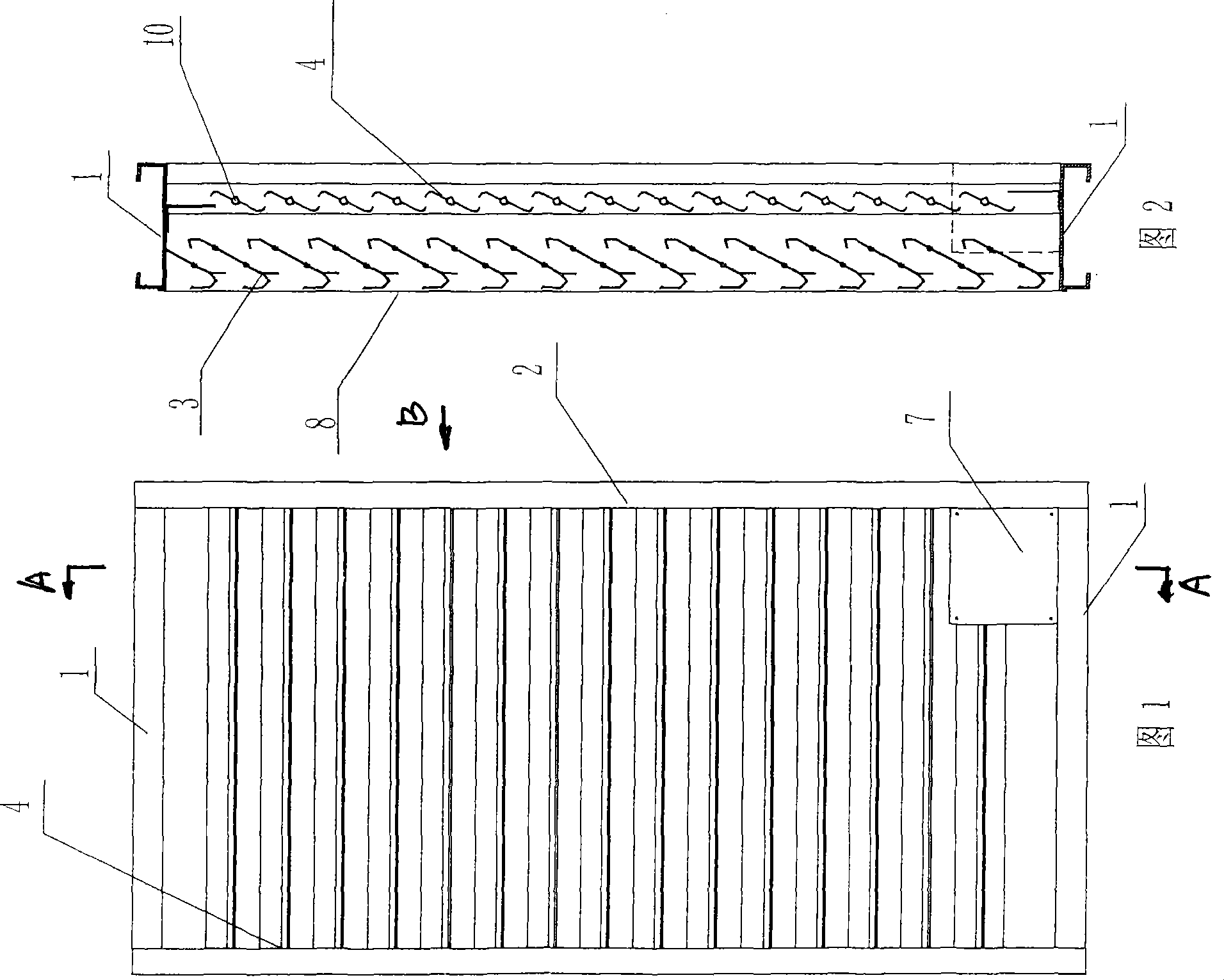

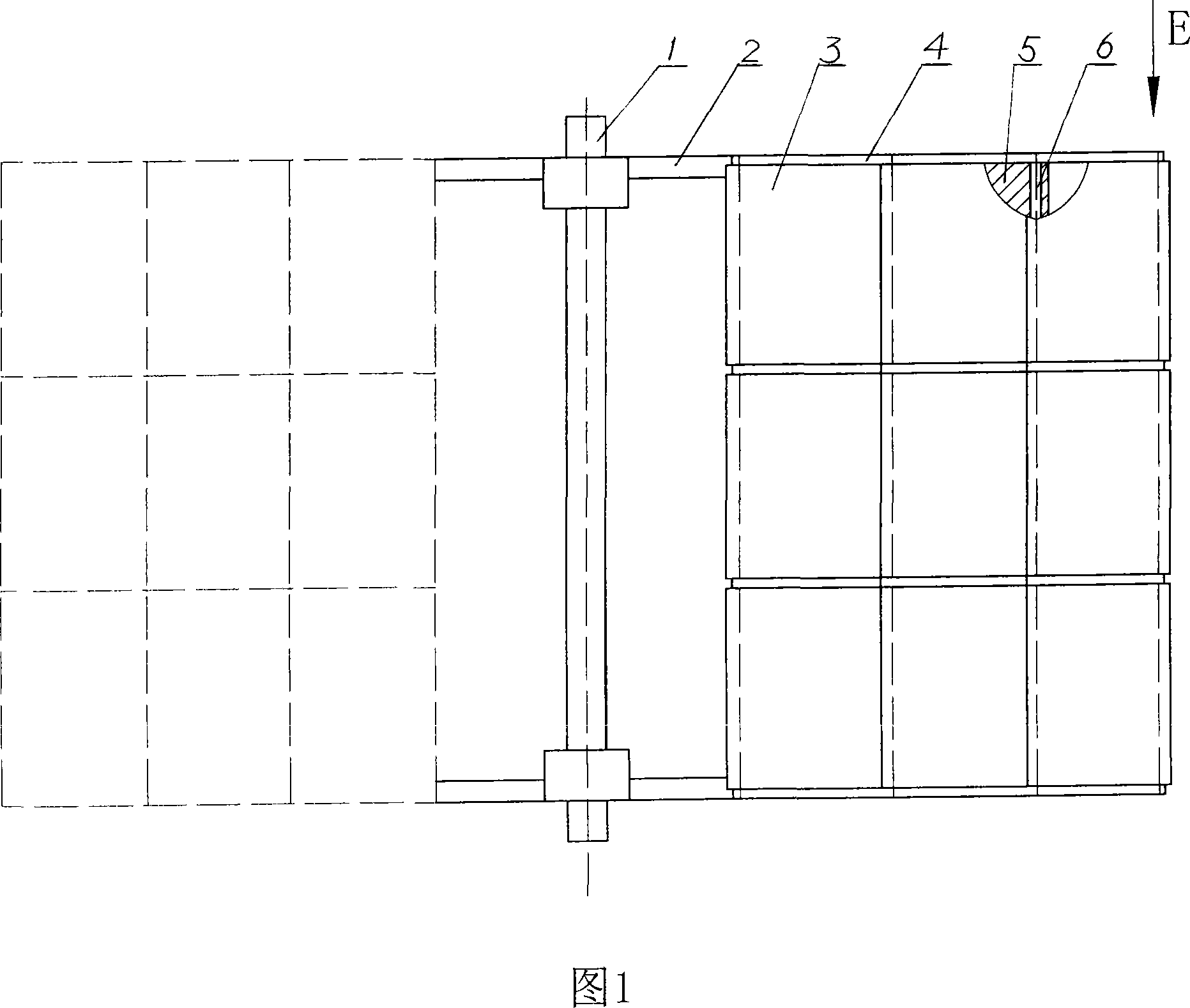

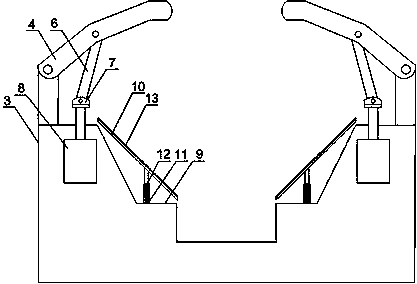

Folding driving mechanism for air conditioner air intake grid

ActiveCN101109558AControl opening and closingFlexible opening and closingAir-flow control membersGear driveEngineering

The invention discloses a drive for opening / closing an air-intake grid of an air conditioner, which comprises a casing of the air conditioner, an air-intake grid that can open / close on the casing, and a drive to open / close the air-intake grid. The drive is a fully integrated gear rack drive that can make the air-intake grid open / close. The output part of the fully integrated gear rack drive, namely the rack, is connected with the air-intake grid. The structure of the drive comprises a main driving mechanism at one end of the casing of the air conditioner and a driven mechanism at another end of the casing of the air conditioner, and the main driving mechanism and the driven mechanism are respectively arranged in a left and a right half closed box. By a step motor and a pinion on the shaft of the motor, a bull gear is driven, a first gear that is coaxial with the bull gear drives a first rack at the left side. A second gear that is coaxial with the bull gear drives first driving gears at the two ends of a long shaft, and a second driving gear drives a second rack at the right side. The synchronous and same-directional movement of the first rack and the second rack realize the synchronous movement of the air-intake grid at left and right side, so that the grid will open when the air conditioner is on, and close when the air conditioner is off.

Owner:HAIER GRP CORP +1

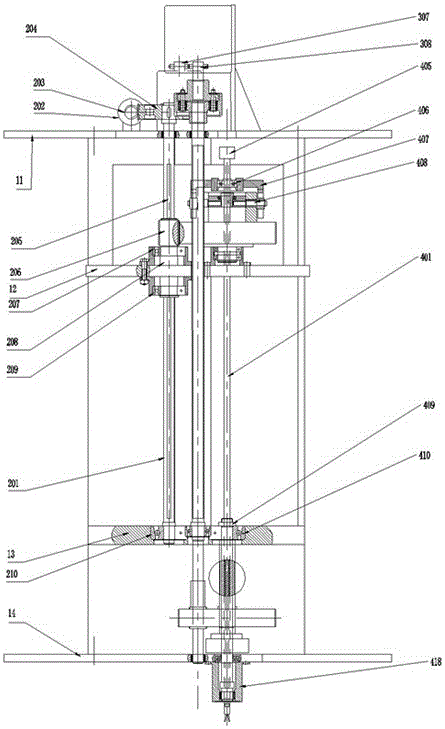

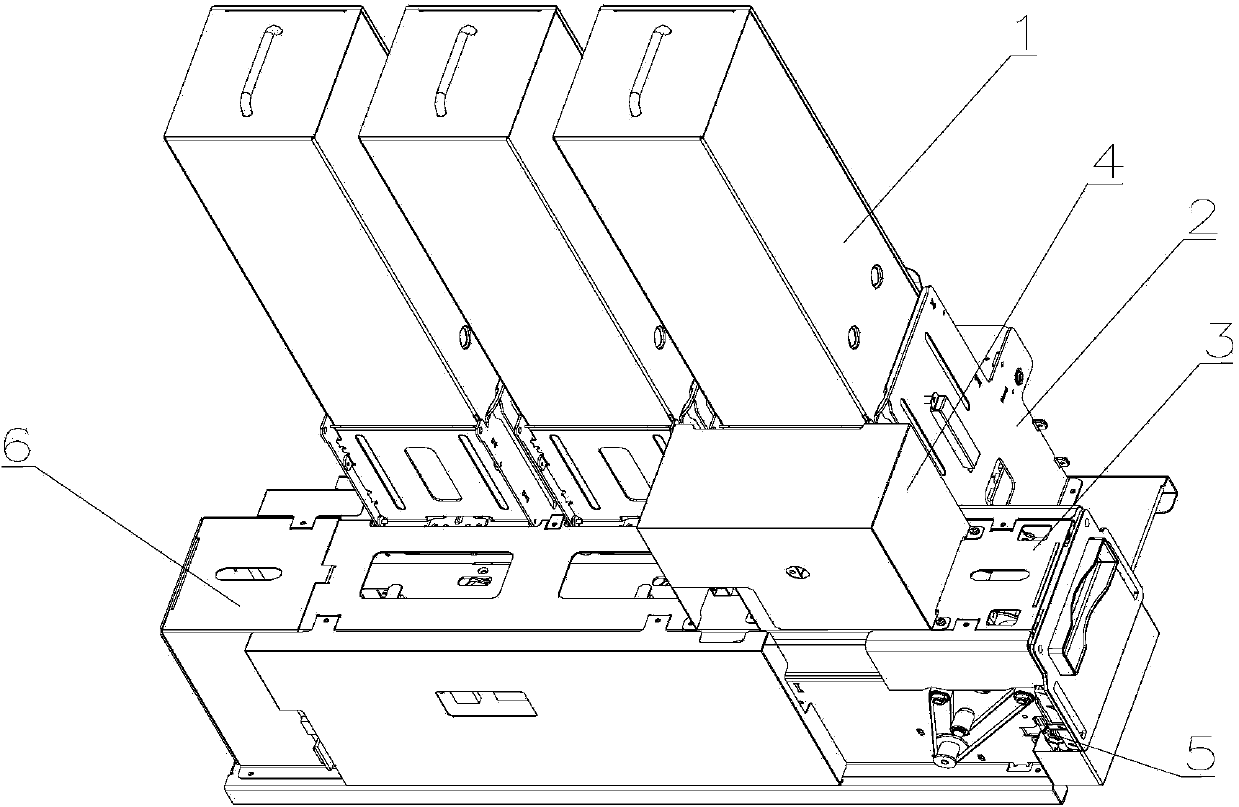

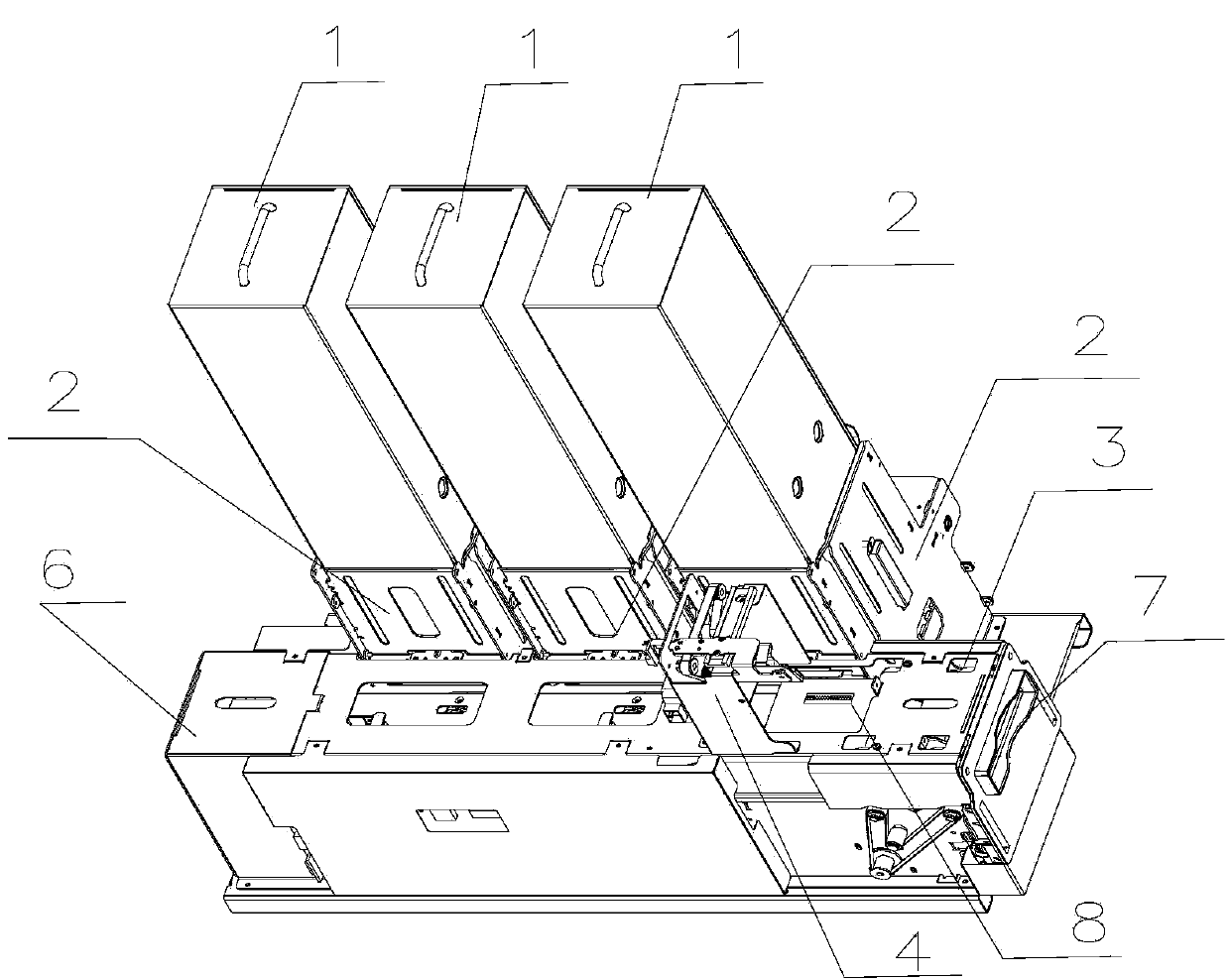

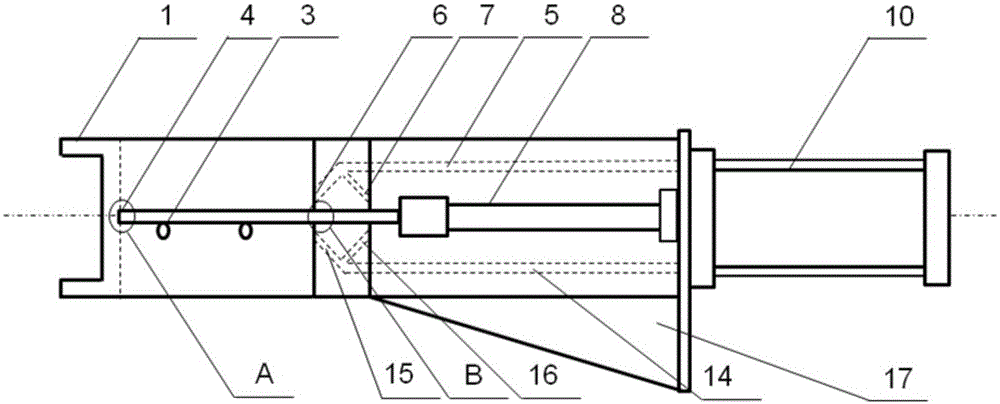

Method for issuing high-capacity internetbank verification modules

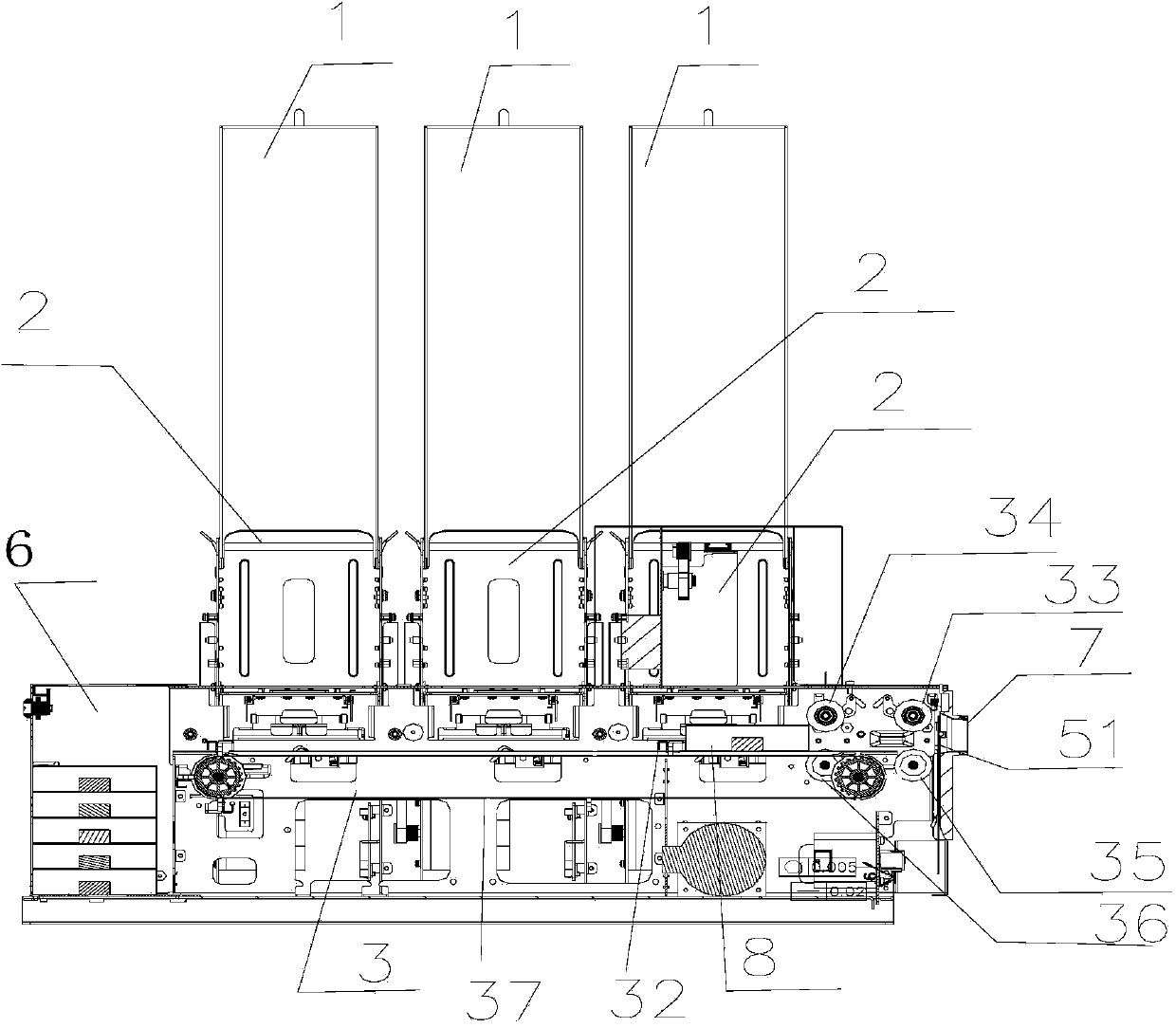

ActiveCN104200241ACompact structureSave spaceComplete banking machinesConveying record carriersLarge capacityAutomation

The invention discloses a method for issuing high-capacity internetbank verification modules. The method includes steps of (1) transmitting any one of KEY boxes stored in storage boxes to a transmission channel in a transmission mechanism by a pushing mechanism, transmitting the KEY box to a gate mechanism from the transmission channel by the transmission mechanism, opening a gate of the gate mechanism to let the KEY box extend out of the gate, and issuing the KEY box to a user; (2) if the user fails to take away the KEY box within a preset time (detecting whether the KEY box is taken away or not by a thru-beam sensor), transmitting the KEY box back to a recovery box through the transmission passage by the transmission mechanism. The method for issuing the high-capacity internetbank verification modules automatically has the advantages of automation and intelligentization and is applicable to issuing high-capacity KEY boxes.

Owner:HUNAN GREATWALL INFORMATION FINANCIAL EQUIP

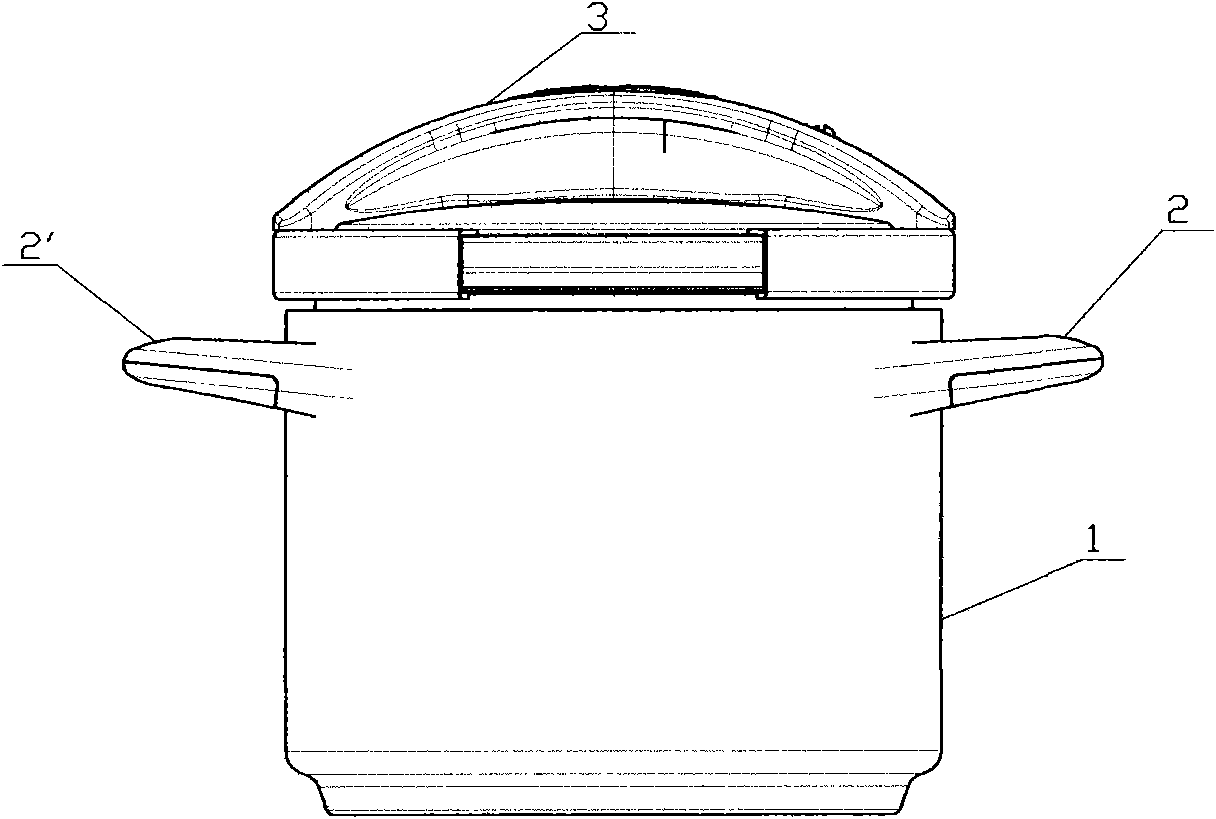

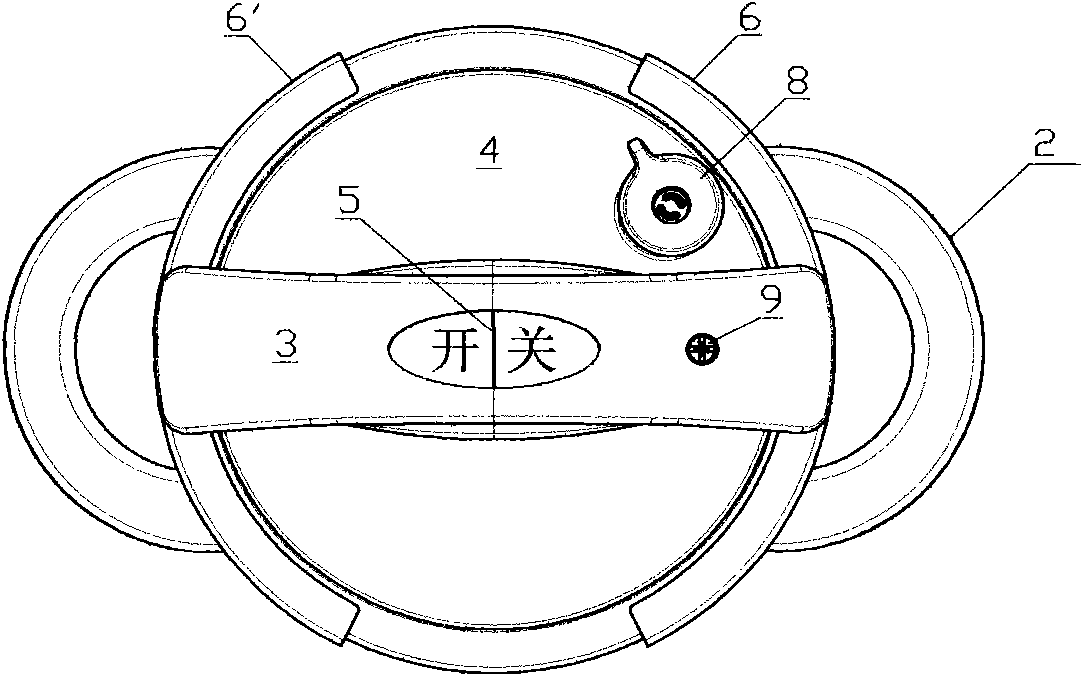

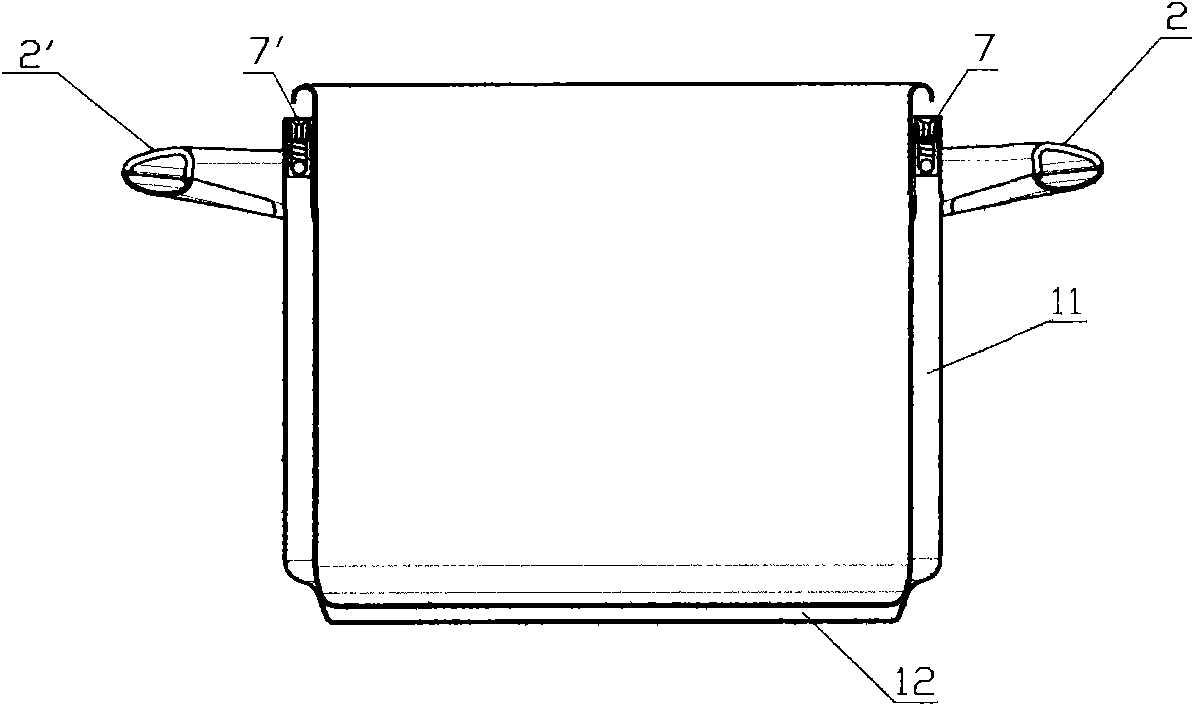

Button opening-closing type sandwich interlayer pressure pan

The invention relates to a button opening-closing type interlayersandwich pressure pan comprising a pan body, pan ears, a pan cover handle and a compound pan bottom. A regulating valve and a safety valve are arranged on a cover panel of the button opening-closing type sandwich pressure pan, a set of dragged opening and closing mechanism drives a pair of moving slide blocks on the cover panel, one ends of the slide blocks are welded with pressure opening-closing rings, a cover and the pan body are banded hooped by a pair of rings, the pressure cover is closed or opened along with the opposite or reverse movement of the opening-closing rings, a button is pressed to generated dragging force so that rocking bars are scratched up and down to drive a vertical side gear, and then the vertical side gear is meshed engaged with a circular gear through racks on the other ends of the slide blocks and is driven to the slide blocks to drag the opening-closing rings. A clip sleeve is arranged on the pan body in which a one-way valve is arranged, and the air pressure in the clip sleeve is 0.3 KPa-0.5 KPa; and the air pressure in the pan is controlled to 0-1 bar by the regulating valve. The sandwich interlayer pressure pan has the advantages of stable and firm structure, good safety, high efficiency, energy saving and convenient use, has the functions of smoldering, pressure maintaining and reboiling without fire and is suitable for various pressure pan cookers.

Owner:XINXING XIANFENG STAINLESS STEEL PROD MFGR CO LTD

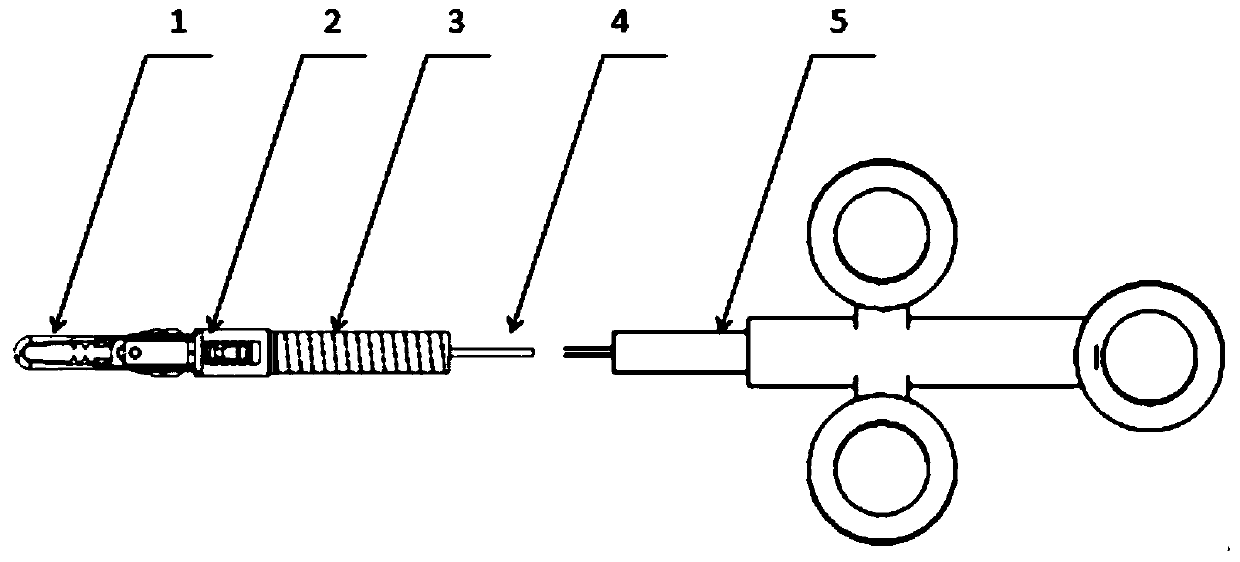

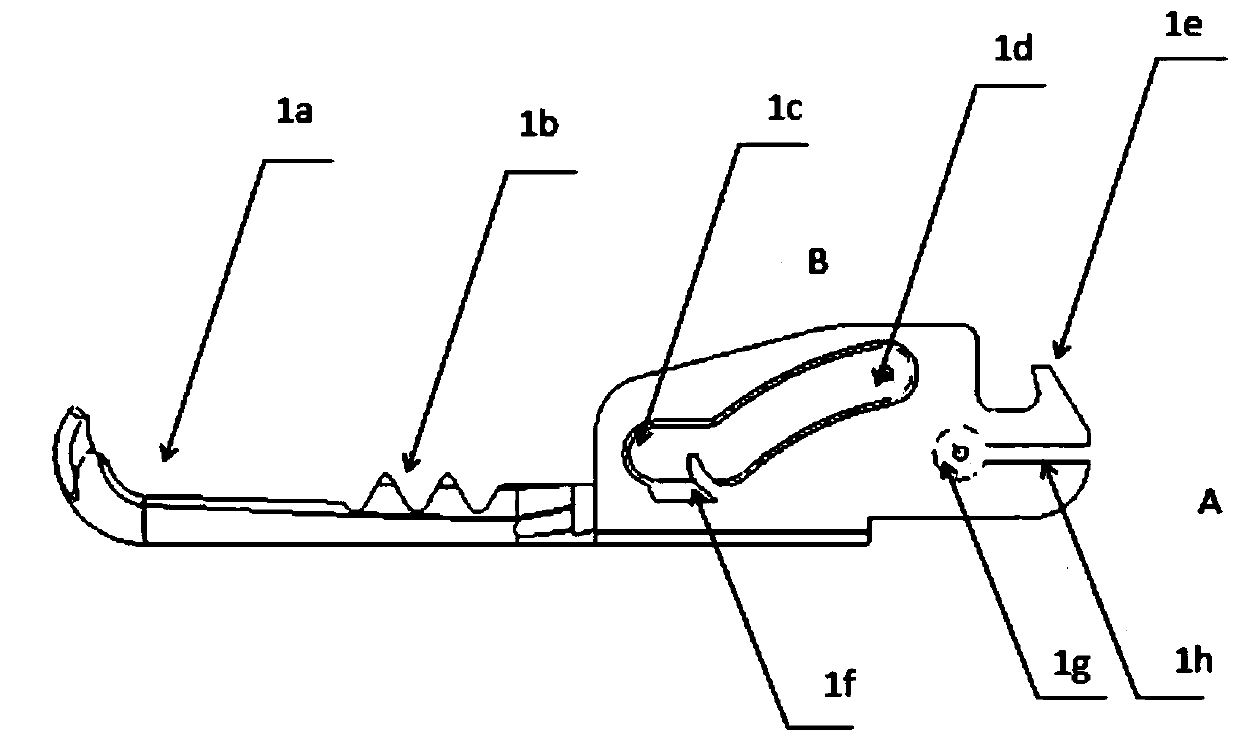

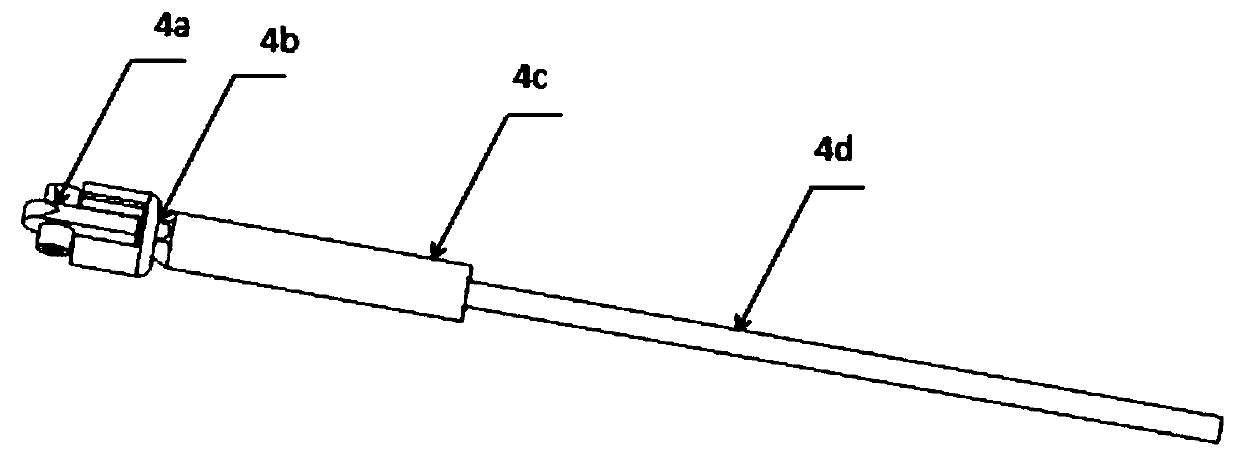

Medical hemostatic clips

PendingCN109805977ASimple structureSimple and fast operationSuture equipmentsWound clampsPull forceEndoscope

The invention provides medical hemostatic clips. The medical hemostatic clips are used for endoscope-guided hemostasis and tissue suture surgery of digestive tracts, wherein the medical hemostatic clips comprise tongs, a locking sleeve, a spring pipe, a control wire and a handle. By applying axial pushing force and pulling force on the handle, the control wire can be driven to achieve opening, closing and locking of the tongs; moreover, the tongs and the locking sleeve can be detached from the spring pipe very easily, and while the tongs and the locking sleeve are detained in a human body, functions of hemostasis and tissue sutures are achieved.

Owner:MICRO TECH (NANJING) CO LTD

Skirt plate of railway vehicle

ActiveCN103661451ASimple structureReduce weightRailway transportAxle-box lubricationEngineeringBolt connection

The invention relates to a skirt plate of a railway vehicle. The top of the shirt plate is hung on and fixed to a vehicle body through a rotating shaft, and the shirt plate rotates with the rotating shaft serving as the center. The shirt plate is simple in structure, light in weight and capable of being flexibly opened and closed, due to slide grooves, parts can be connected with the shirt plate through bolts without welding, and the installation position can be adjusted according to the size error.

Owner:CRRC QINGDAO SIFANG CO LTD

Anti-explosive container

ActiveCN1888810ANot easy to wearFlexible opening and closingAmmunition storageMechanical engineeringDetonator

A blast resistant container relates to outside canister, fixed board and top plate. There is handle and blast-release hole on top plate; outside canister connects with top plate by spline. The top plate owns wave absorber plate and the bottom of outside canister owns some supported vertical plate fixed with fixed board. Outside canister owns inside canister and it is made up by inner top plate and inside closed canister without coping, and the inside of the top bottom compounds with the inside wall of the inner top plate by thread bayonet. Inner top plate owns handle and at least two blast-release holes, and its rim owns hook side for the outer rim of top bottom to inside canister; and the top and down bottom of the inside canister owns up and down wave absorber plate. It is safe for carrying the blast starting equipment and detonator in the same carrying vehicle and reduces the influence for the ambience, people and establishment when the canister blasts. It is easy for starting and stopping, large capability, long life and good blast resistant performance to be able to demolish equipment dedication carrying vehicle.

Owner:ZHEJIANG LUJIESHUN COMPARTMENT MFG

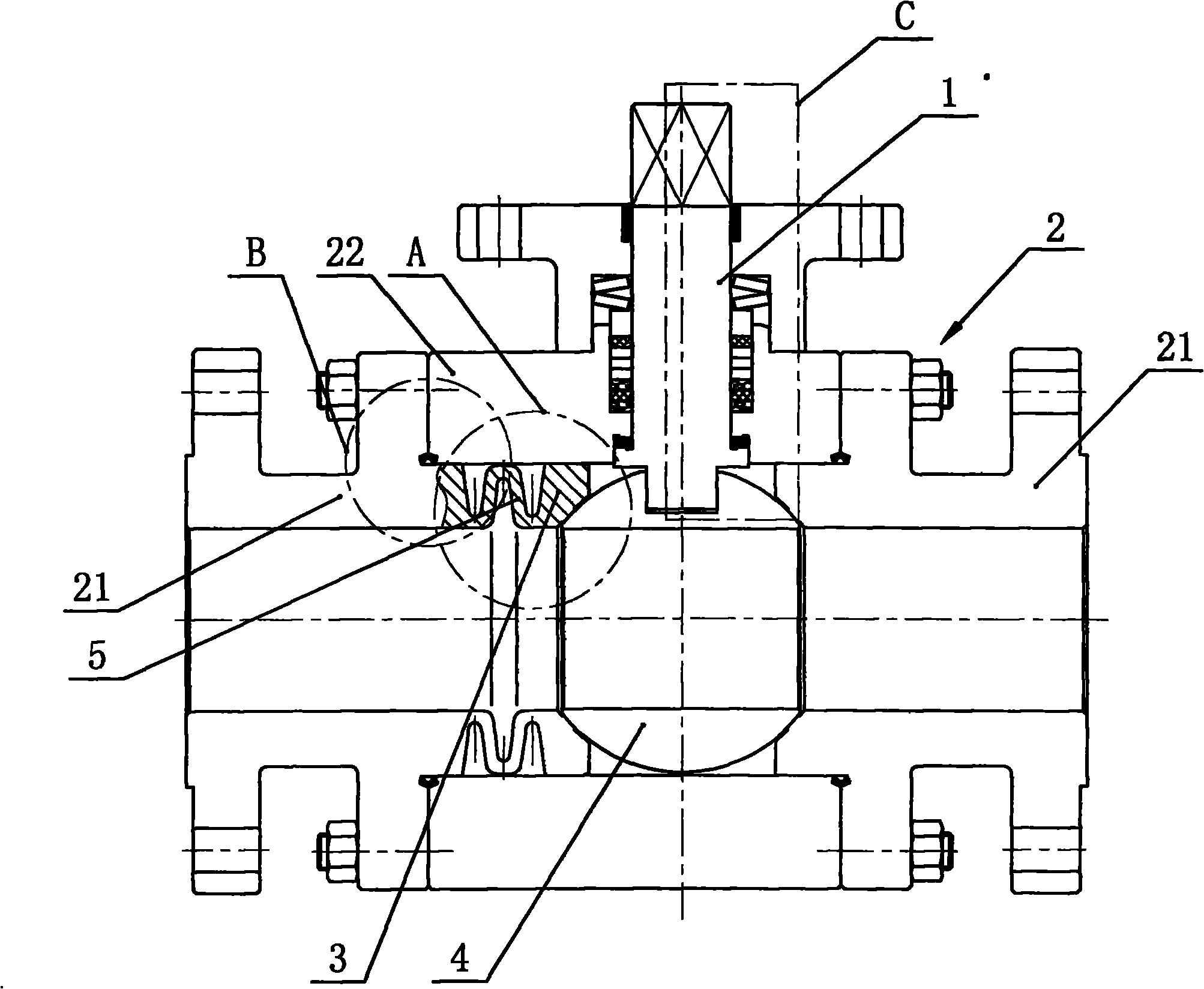

Integrated high-temperature high-pressure metal seal ball valve

InactiveCN101813201AReasonable structureFlexible opening and closingSpindle sealingsPlug valvesHigh pressureMetal

The invention relates to a valve, in particular to an integrated high-temperature high-pressure metal seal ball valve. The invention adopts the following scheme that: the integrated high-temperature high-pressure metal seal ball valve comprises a valve rod, a valve body, a valve seat and a valve core ball. The valve is characterized in that the valve seat and the valve body are integrally arranged, and a transversal ripple structure is formed at the integral joint of the valve seat and the valve body. By adopting the scheme, the invention overcomes the defects of the prior art and provides a novel integrated high-temperature high-pressure metal seal ball valve with reasonable structure, flexible opening and closing, high efficiency and good seal effect.

Owner:浙江宏明阀门有限公司

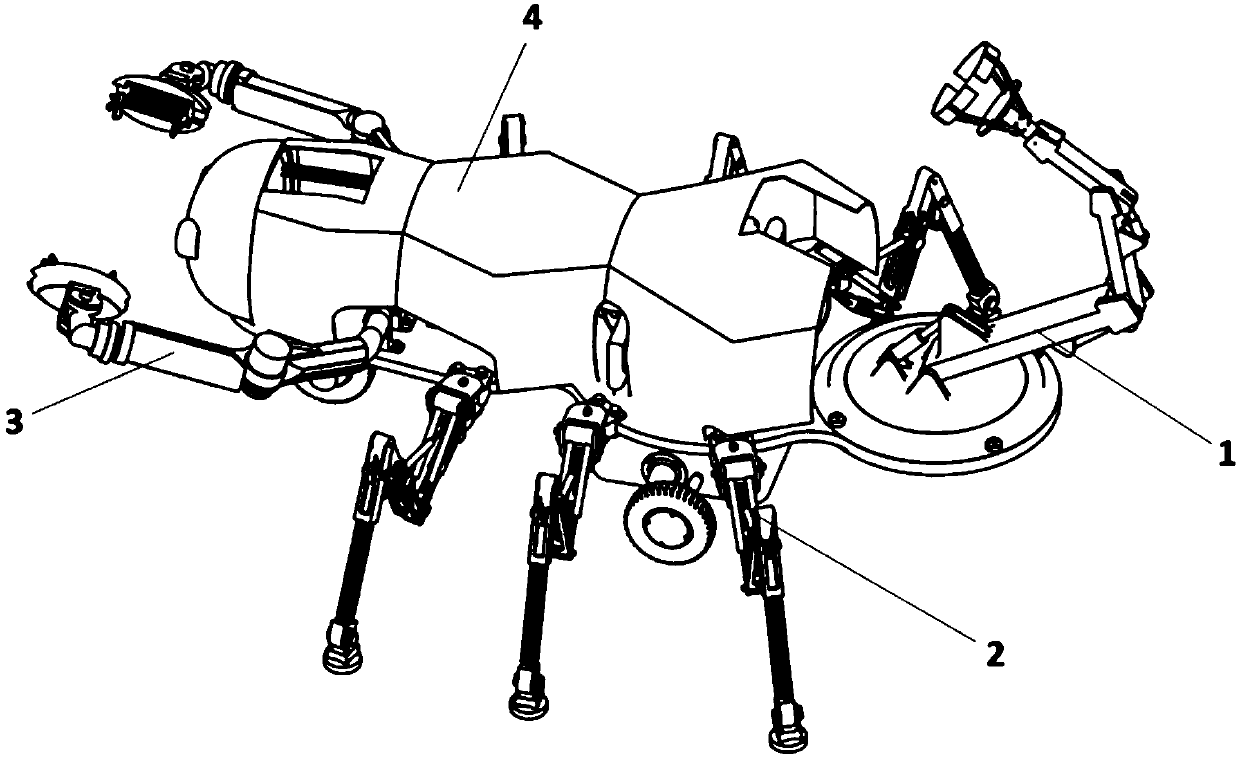

Ball park service robot

PendingCN108673527AWide working areaAdjustable openingBall sportsManipulatorControl engineeringObstacle avoidance

The invention relates to a ball park service robot, and belongs to the field of intelligent robots. The ball park service robot comprises a ball delivering device, a haulage motor walking device, a ball grabbing mechanism and a robot body, the ball delivering device is arranged at the back end of the robot body, the haulage motor walking device is arranged at the middle portion of the robot body,and the ball grabbing mechanism is arranged at the front portion of the robot body; and through electromechanical liquid cooperative control, automatic walking, obstacle avoidance, collecting and shooting functions of the ball park service robot are completed. The robot is simple in overall structure, concise in mechanism, reliable in running, low in manufacturing cost and low in running and maintaining cost, collecting and shooting of large balls like basketballs can be achieved, and the ball park service robot can be widely applied to ball park exercise training for various balls.

Owner:KUNMING UNIV OF SCI & TECH

Ball valve

InactiveCN1337535ASmall opening and closing torqueFlexible opening and closingPlug valvesScrew threadFriction Problem

The present invention relates to a ball valve, its valve rod and left-hand screw thread end of its uspporting shaft are respectively equipped with an upper nut and a lower nut which respectively possess a pair of symmetrical lugs, and two lugs positioned on same side of said upper nut and lower nut are respectively hinge-connected with one end of one link joint, and another end of the link joint is hinge-connected with half-valve core with spherical external surface of said side, and the upper end surface of upper nut possesses a ring groove in which can open-ended spring is fixedly mounted, a positioing pin is inserted into valve cavity, and on the positioning pin a press plate is fixedly mounted. The opening and closing processes of said valve are implemented by means of separation and contact of two semi-spherical valve cores and valve seat seal component, they do not produce friction, so that said ball valve has no leakage and its service life is long as compared with existent ball valve.

Owner:甘靖

Multi-purpose self-return positioning door shaft

InactiveCN103147644ASimple structureFlexible positioningBuilding braking devicesHingesMechanical engineeringPortal axle

Owner:初恒毅

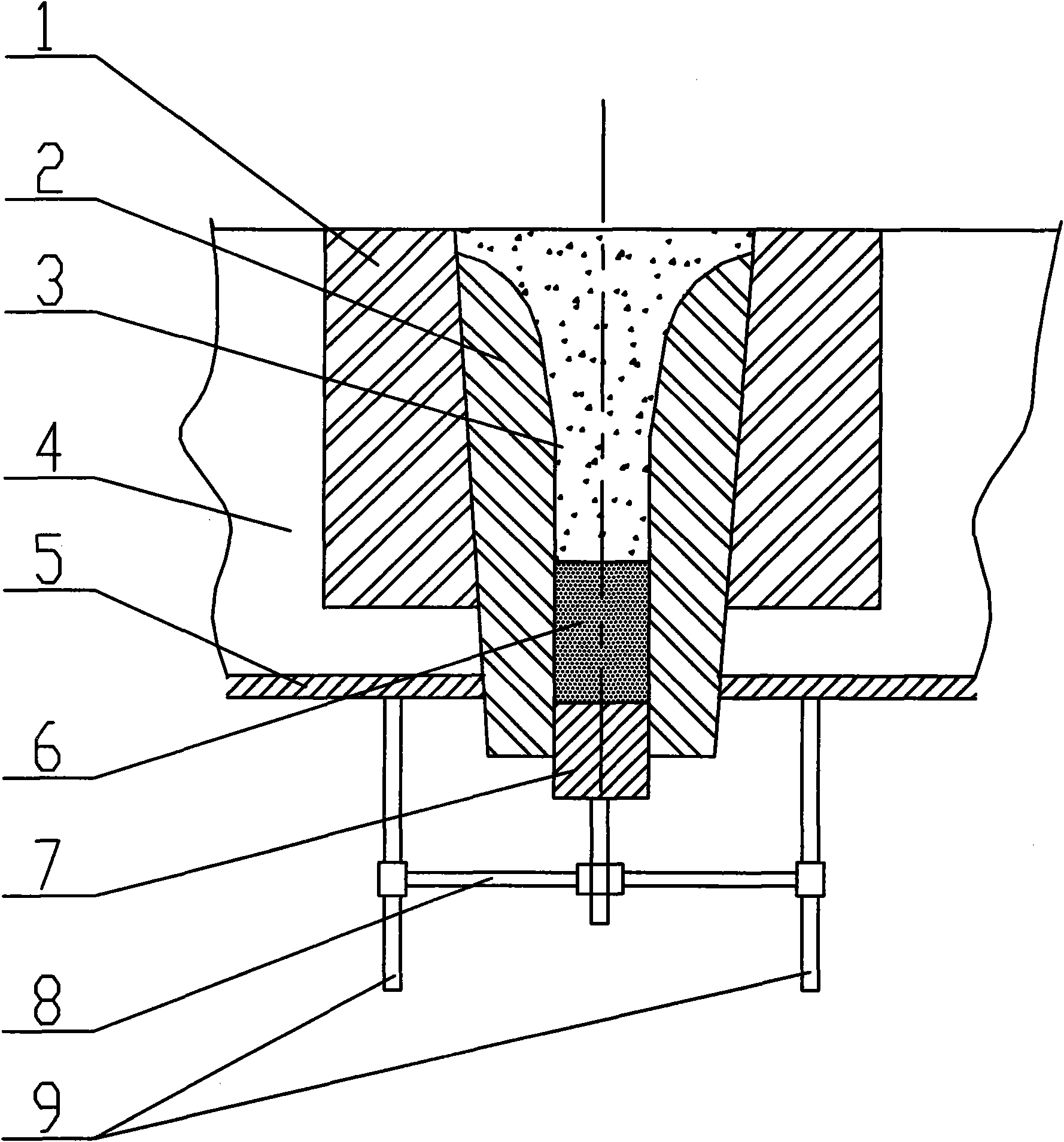

Nozzle structure at bottom of refining furnace and nozzle filling method

InactiveCN101579733AClose tightlyReduce the phenomenon of loose flow pouringMelt-holding vesselsBrickRefractory

The invention relates to a nozzle structure at the bottom of a refining furnace and a nozzle filling method. The nozzle structure at the bottom of the refining furnace comprises a seating brick, a nozzle brick, refractory lining, a refining furnace base, a plug, a rotatable bracket and a supporting frame, and is characterized in that: the nozzle brick is manufactured by adopting aluminum-carbon refractory material taking resin as bonding agent, and the chamfer angle of the upper mouth of an inner cavity of the nozzle brick is R58mm. The nozzle filling method comprises the following steps: in the situation that the lower mouth of the inner cavity of the nozzle brick is plugged and locked by the plug, cast-iron scrap is filled in the inner cavity of the nozzle brick to the height of 80-120mm and tamped, and then flow guiding sand is filled at the upper layer of the cast-iron scrap to the upper edge of the inner cavity of the nozzle brick and tamped so as to complete the plugging and filling of the nozzle, wherein the flow guiding sand adopts zirconium flow guiding sand. The invention has the advantages that: the aluminum-carbon refractory nozzle brick taking resin as bonding agent can meet the requirement of multi-box casting of the refining furnace, simultaneously the radian at the upper end of the inner cavity of the nozzle brick is changed from R90 to R58, the nozzle is tightly closed in the casting process, and the use of the zirconium flow guiding sand and the improvement of the filling method realize that multi-box casting molten steel of the refining furnace can automatically flow out along with the falling of the flow guiding sand, thus achieving the purpose of automatic casting.

Owner:INNER MONGOLIA FIRST MACHINERY GRP

Cake oven with split structure

InactiveCN101461670AImprove lightweight performanceIncrease flexibilityRoasters/grillsEngineeringFront edge

The invention discloses a cake oven in a joining structure, including a tray seat, a tray cover hinged to the rear side edge of the tray seat, a first heating pipe provided on the bottom surface of the tray seat, a second heating pipe provided on the top surface of the tray seat, and a temperature controller provided on the top surface of the tray seat, wherein, the temperature controller is connected to the first heating pipe and the second heating pipe through wires; a first handle is provided at the bottom of the front edge of the tray seat, correspondingly a second handle is provided at the top of the front edge of the tray seat, and the second handle is matched with the first handle; the top surface of the second handle is provided with a rotary button, and the rotary button is connected to the temperature controller through wires; the tray seat and tray cover are hinged and respectively provided on the top and bottom of one side, which has compact structure and convenient disassembly and assembly; the matched first and second handles are mounted at the other side of the tray seat and the tray cover, which has easy operation and convenient use; and locks are provided between the first handle and second handle, which has firm connection solid and flexible start and stop.

Owner:施军达

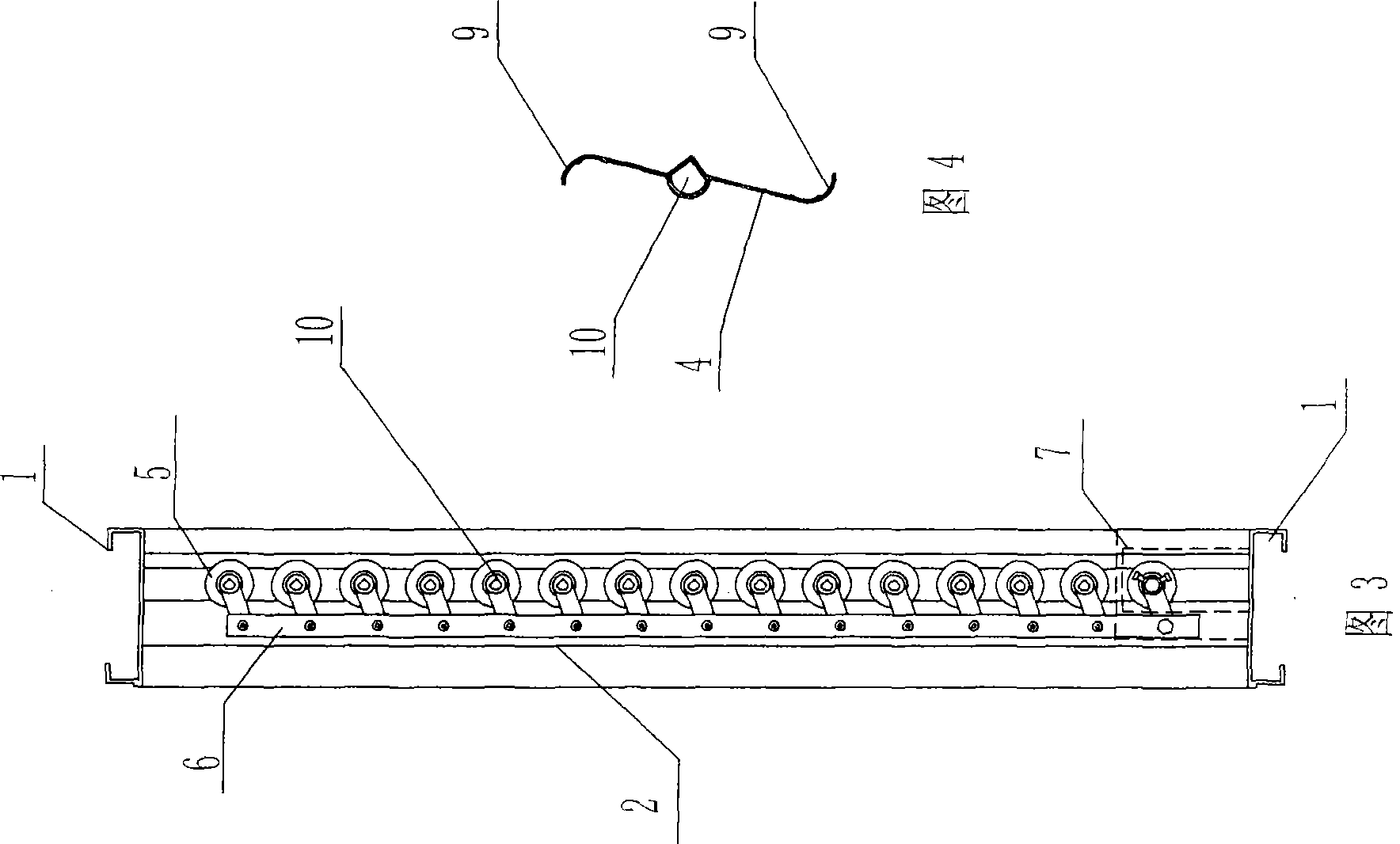

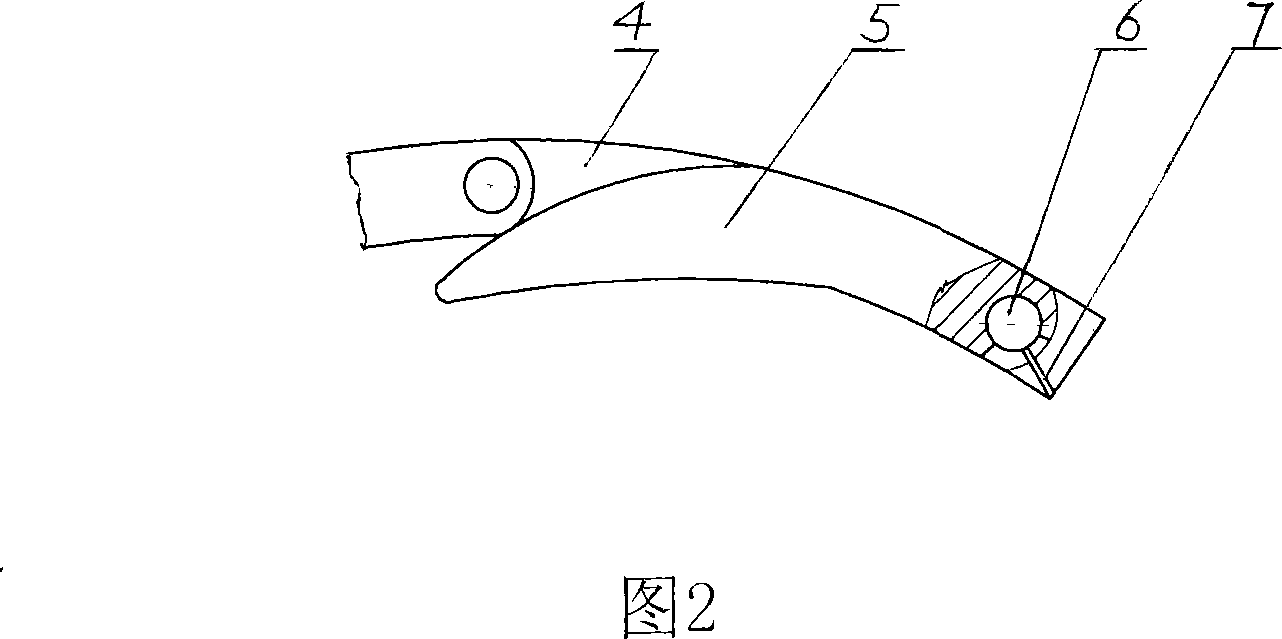

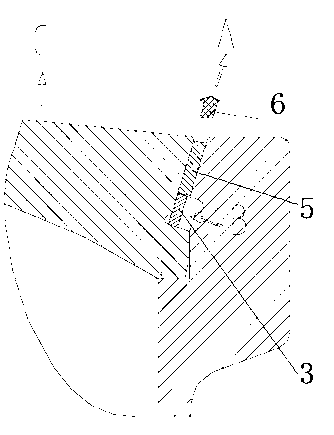

Electric stormproof louvre

InactiveCN101519944AFlexible opening and closingOvercome the fatal shortcoming of aging deformationSpecial door/window arrangementsManufacturing technologySteel ball

An electric stormproof louvre belongs to the manufacture technical field of ventilation facilities and mainly comprises an outer frame consisting of an upper and lower frame (1) and a side frame (2), a fixing stormproof blade (3) arranged at the inner part of the outer frame, an adjustable stormproof valve (4) provided with a rotating shaft (10), an electric executing mechanism (7) arranged at the bottom of the outer frame, a connecting bar drive device (6) arranged at the side of the side frame (2) and respectively connected with the electric executing mechanism (7) and one end of the rotating shaft (10), a full-closed type stainless steel ball bearing (5) arranged between the rotating shaft (10) and the side frame (2), a stainless steel protecting net (8) arranged outside the fixing stormproof blade (3), and the like. Two ends of the adjustable stormproof valve (4) are respectively provided with a 90-degree round hook structure. The invention has reasonable integral structure design and can effectively improve the rainproof property.

Owner:浙江浙风科技有限公司

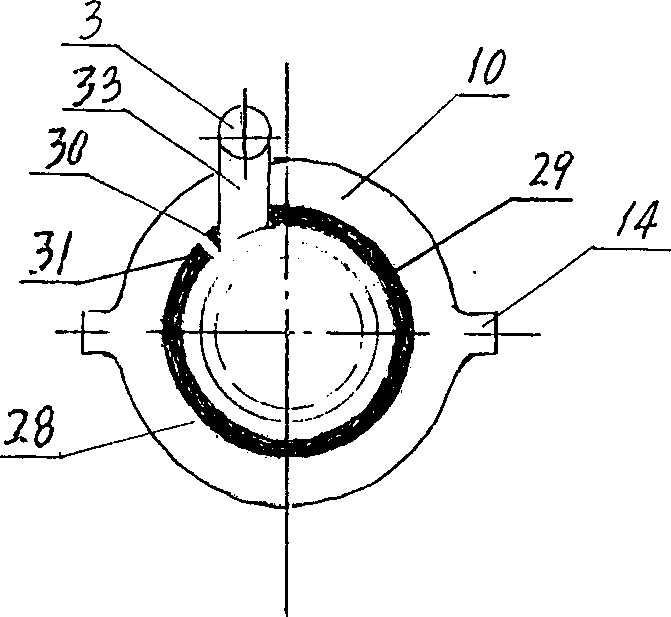

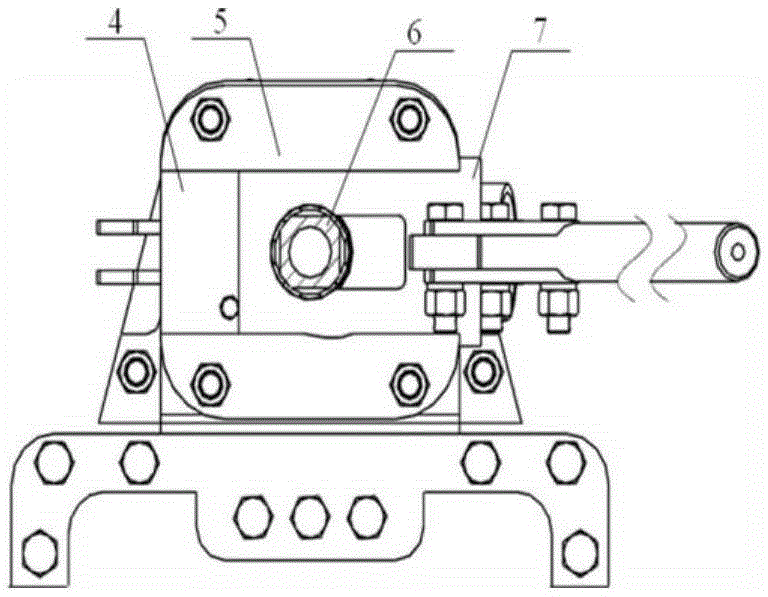

Multifunctional manual clamp holder for drilling rig

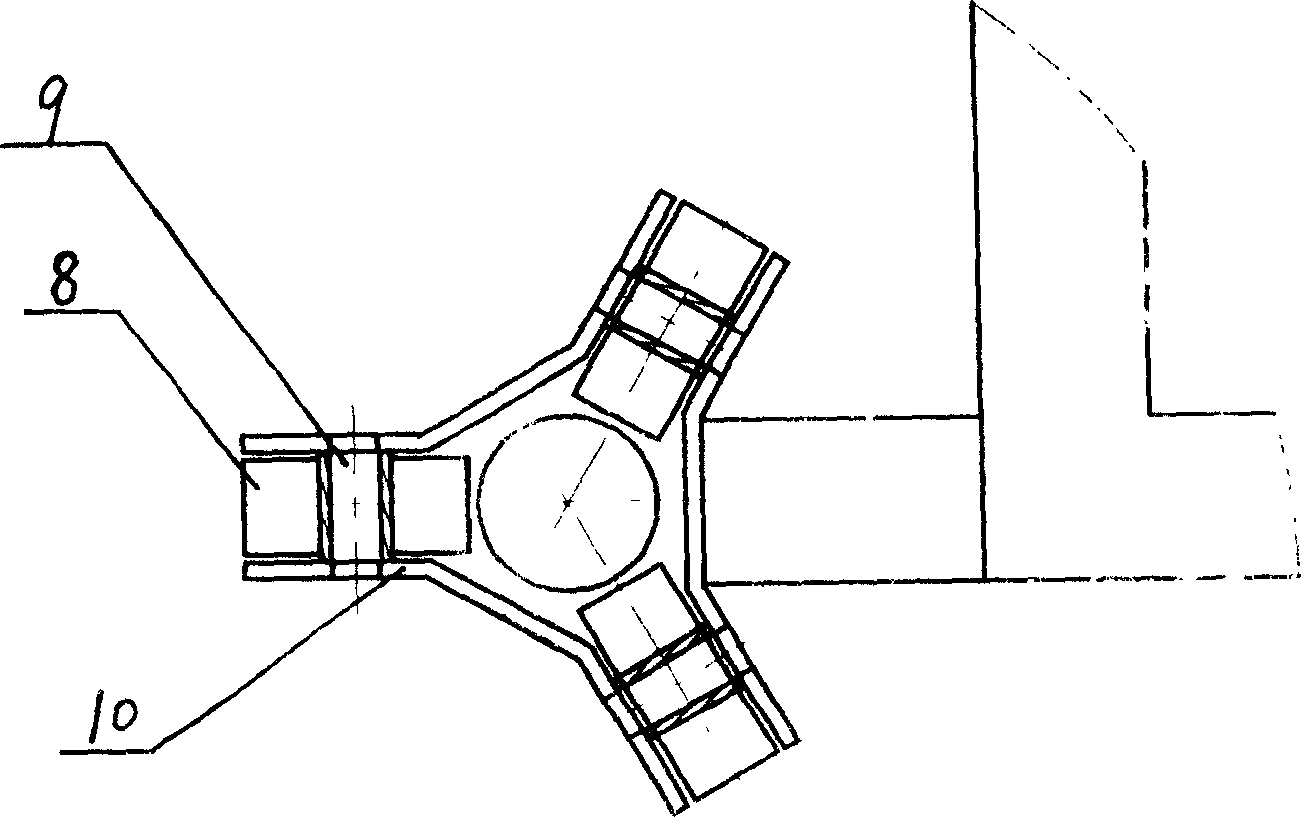

ActiveCN105239937ASimple structureEasy to assemble and disassembleDrilling rodsDrilling casingsEngineeringDrill pipe

A multifunctional manual clamp holder for a drilling rig comprises a manual clamping device, a drill stem centralizing mechanism and a dust collection device. The manual clamping device is detachably fixed onto a feeding body of the drilling rig, a quadrangular prism portion for clamping is formed at a proper position of a drill stem body, the drill stem centralizing mechanism is arranged in the manual clamping device, and the dust collection device is arranged at the front end of the manual clamping device. The manual clamping device comprises a body mounting frame, a guide plate, outer retaining plates and a fastening plate; the drill stem centralizing mechanism comprises a guide bearing and an outer end cover; the dust collection device comprises a main frame, a dust seal ring and a rubber cover. The multifunctional manual clamp holder for the drilling rig is simple in integral structure, convenient to mount and demount, flexible in opening and closing and capable of reducing radial movement of the drill stem; due to integration of the manual clamping device, the drill stem centralizing mechanism and the dust collection device, coal dust and stone chips generated in a drilling process are effectively prevented from entering gaps of the clamp holder, and construction environment is improved while flexibility in opening and closing of the clamp holder is guaranteed.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

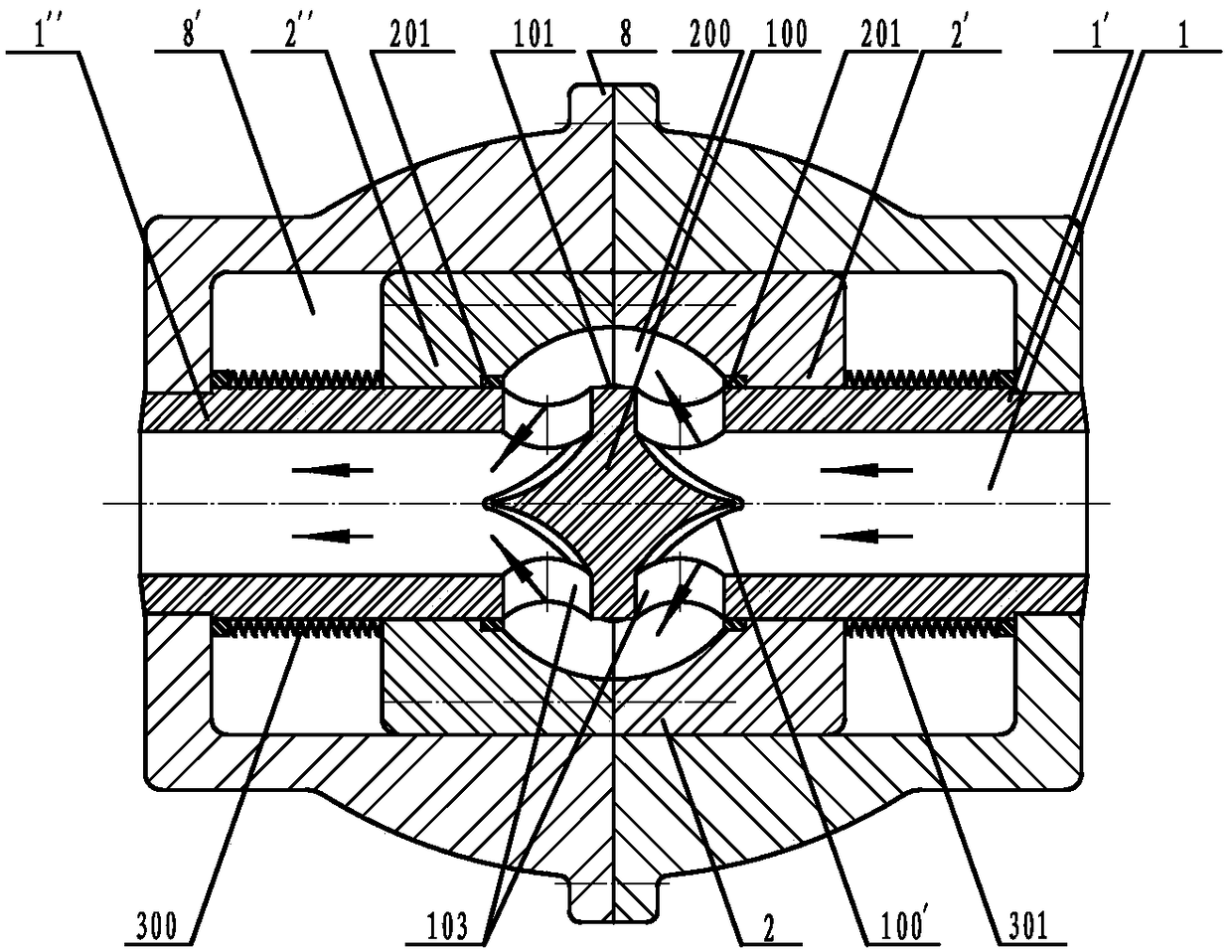

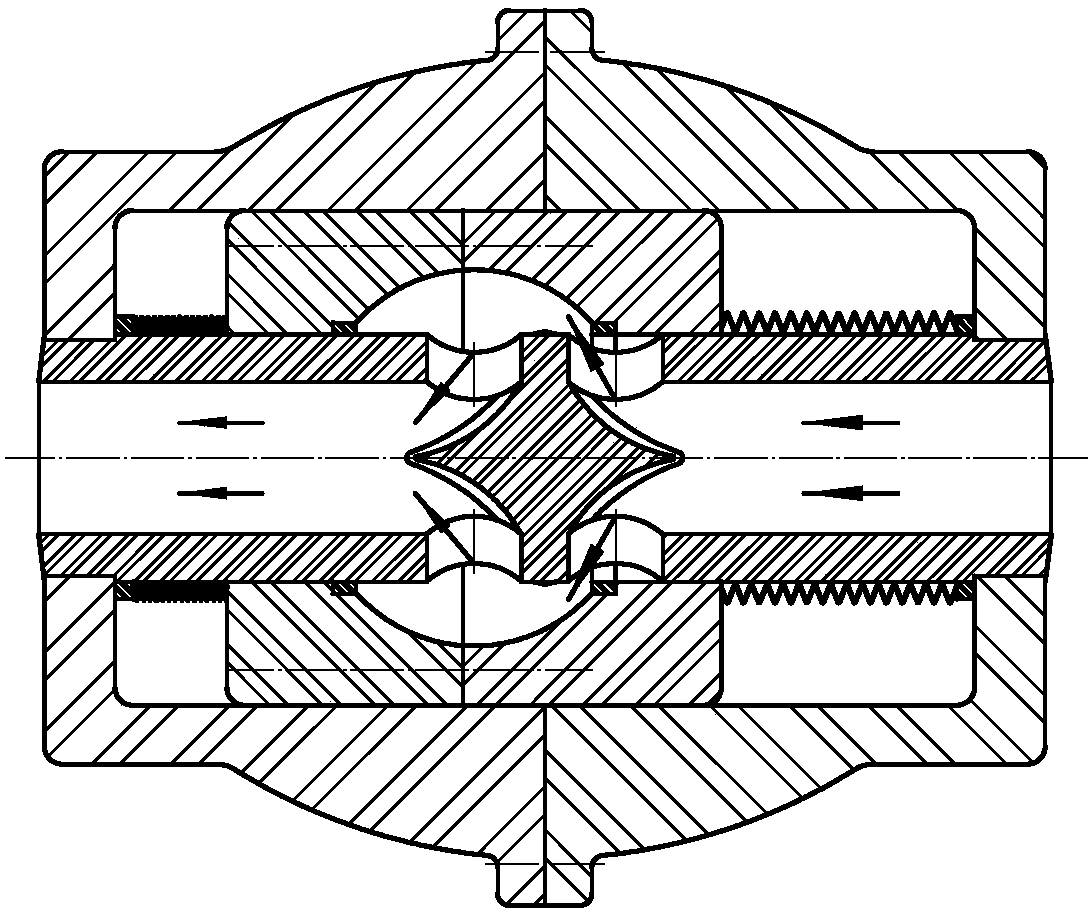

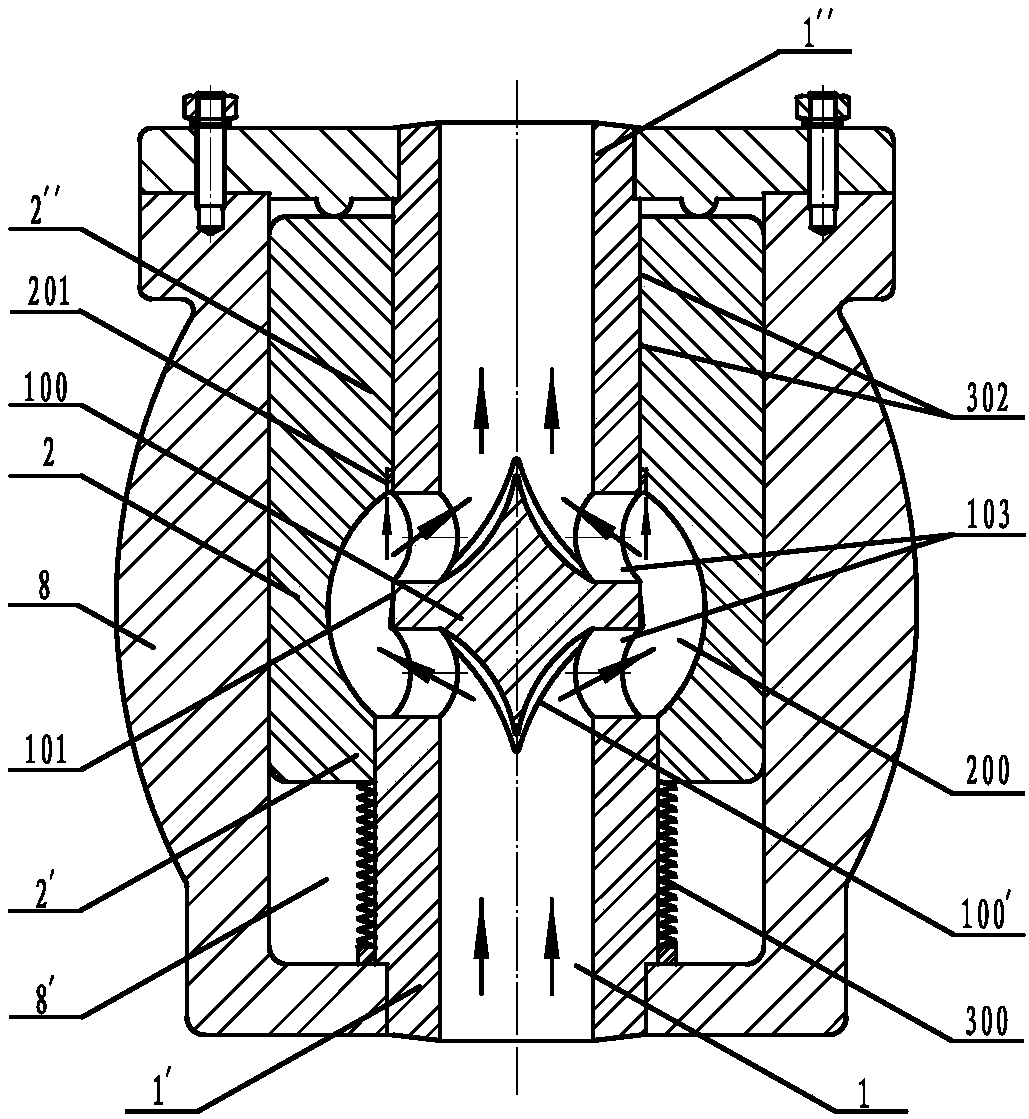

Double valve body core pipe valve

ActiveCN108426044ASimple structureEasy to manufactureOperating means/releasing devices for valvesCheck valvesReciprocating motionEngineering

A double valve body core pipe valve is the main part of a double valve body core pipe valve plate in a core pipe valve mother series invented by the inventor originally. A valve core pipe wrapped in an outer valve body inner cavity is a fixed part which coaxially penetrates through a sleeve pipe I of a valve body, a valve body inner cavity and a sleeve pipe II of the valve body. An axial interlayer is arranged in the middle of the valve core pipe. The two adjacent axial edges of the interlayer are provided with at least one radial communicating hole of the input section and the output section.An annular valve core surrounding the interlayer and an annular valve seat of the larynx part of at least one of the sleeve pipe I and the sleeve pipe II form a sealing pair. The difference of the outer diameters of the input section and the output section is larger than or equal to 0. The input section and the sleeve pipe I as well as the output section and the sleeve pipe II are in shaft hole type fit, and at least one combined part is sealed. Under the action of bidirectional potential energy, the valve body does axial reciprocating motion in an outer valve body inner cavity, and opening,closing and function conversion are achieved. Opening and closing resistance is small, leakage is avoided, extending characteristics are wide, safety, reliability and flexibility are achieved, maintenance is reduced, efficiency is improved, and the double valve body core pipe valve adapts to various work conditions.

Owner:卢星霖

Shuttle type vibration damping break valve

InactiveCN101220867AFlexible opening and closingIncreased opening and closing sensitivity and reliabilityValve members for absorbing fluid energyLift valveRetaining ringHigh energy

The invention provides a shuttle-typed damping check valve, which solves the problem that the existing check valve has insensitive start and closeness, much noise and high energy consumption. The vertical communication section (34) of the inlet passage (28) and the outlet passage (29) of a valve body (1) are provided with valve seats (30); a guide sleeve (31) which is arranged above the valve seat is connected with the valve body (1) or a valve seat (4); the column surface of the guide sleeve is provided with a through hole (33) and the guide sleeve is movably matched with a valve flap; the valve flap (2) is hermetically matched with a valve seat (30); a valve rod (17) is connected with the valve cover (4) through a thread; the lower end surface of the valve rod (17) is an arc surface which is contacted with the bottom plane point of the internal chamber of the valve flap (2); the valve rod (17) is connected with a retaining ring (3); the lower surface of the retaining rind (3) is contacted with the step surface of the internal chamber of the valve flap (2); the upper surface of the retaining ring (3) is contacted with the lower end surface of a liner (23); the internal wall of the liner (23) is connected with the thread of the external wall of the valve rod (17); a flexible pad or a damping element (24) is arranged between the upper surfaces of the flange of the liner (23) and the valve flap (2).

Owner:WINJET HIGH TECH INVESTMENT BEIJING

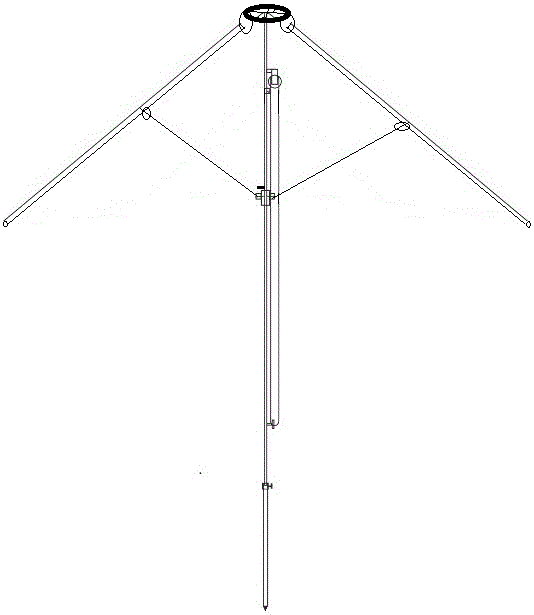

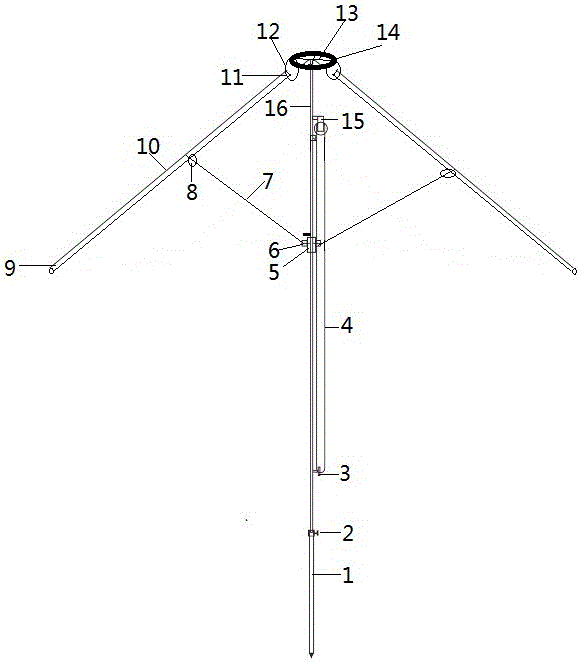

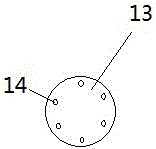

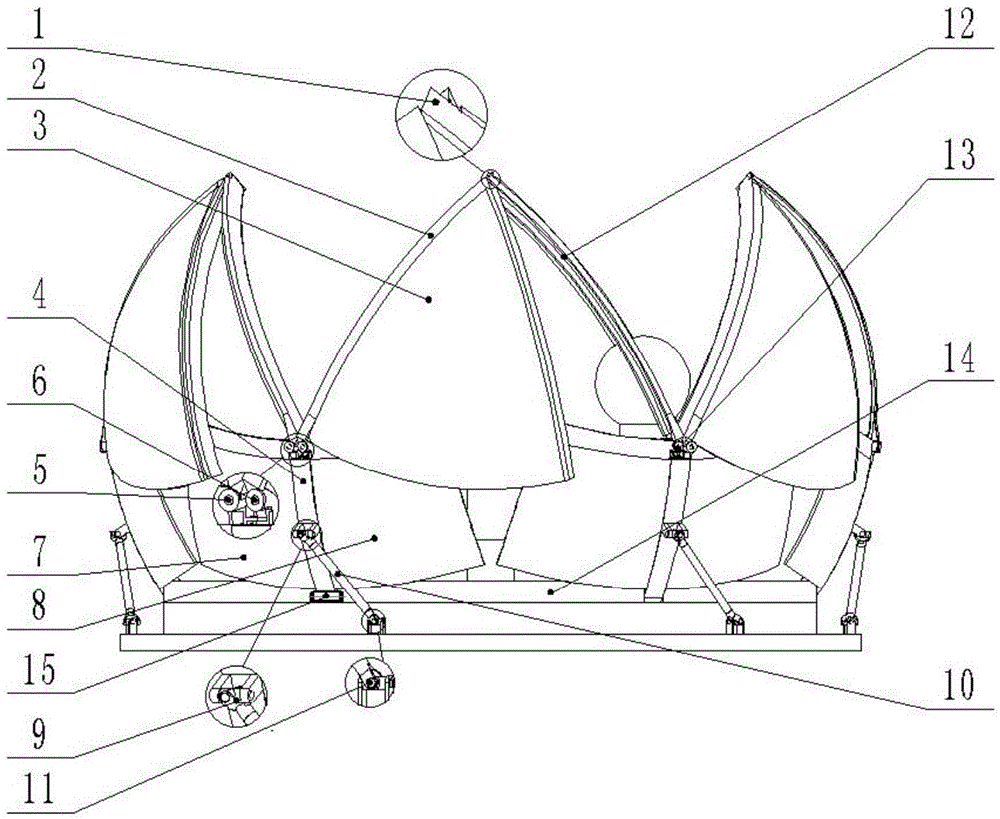

Crop anti-hail umbrella

InactiveCN106171694AFlexible opening and closingHeight adjustablePlant protective coveringsPush and pullEngineering

The invention discloses an anti-hail umbrella for crops. A support rod sleeve (1) is inserted into the soil to fix it, a nylon rope (4) is fastened to a sliding sleeve (5), and the nylon rope (4) is pulled downward, and the sliding sleeve (5) Moving upwards, the push-pull rod (7) is stretched, and when the sliding sleeve moves upwards to the position of the fixed pulley (15), the anti-hail umbrella is fully opened, and is fixed on the circlip (3) with nylon knots; autumn and winter The umbrella is closed in season to prevent the heavy snow from crushing the hailproof net above, and prolong the service life of the hailproof net on the umbrella surface; the height of the hailproof umbrella can be adjusted, the movement is convenient, the cost is low, the process is simple, and it is safe and practical.

Owner:史占彪

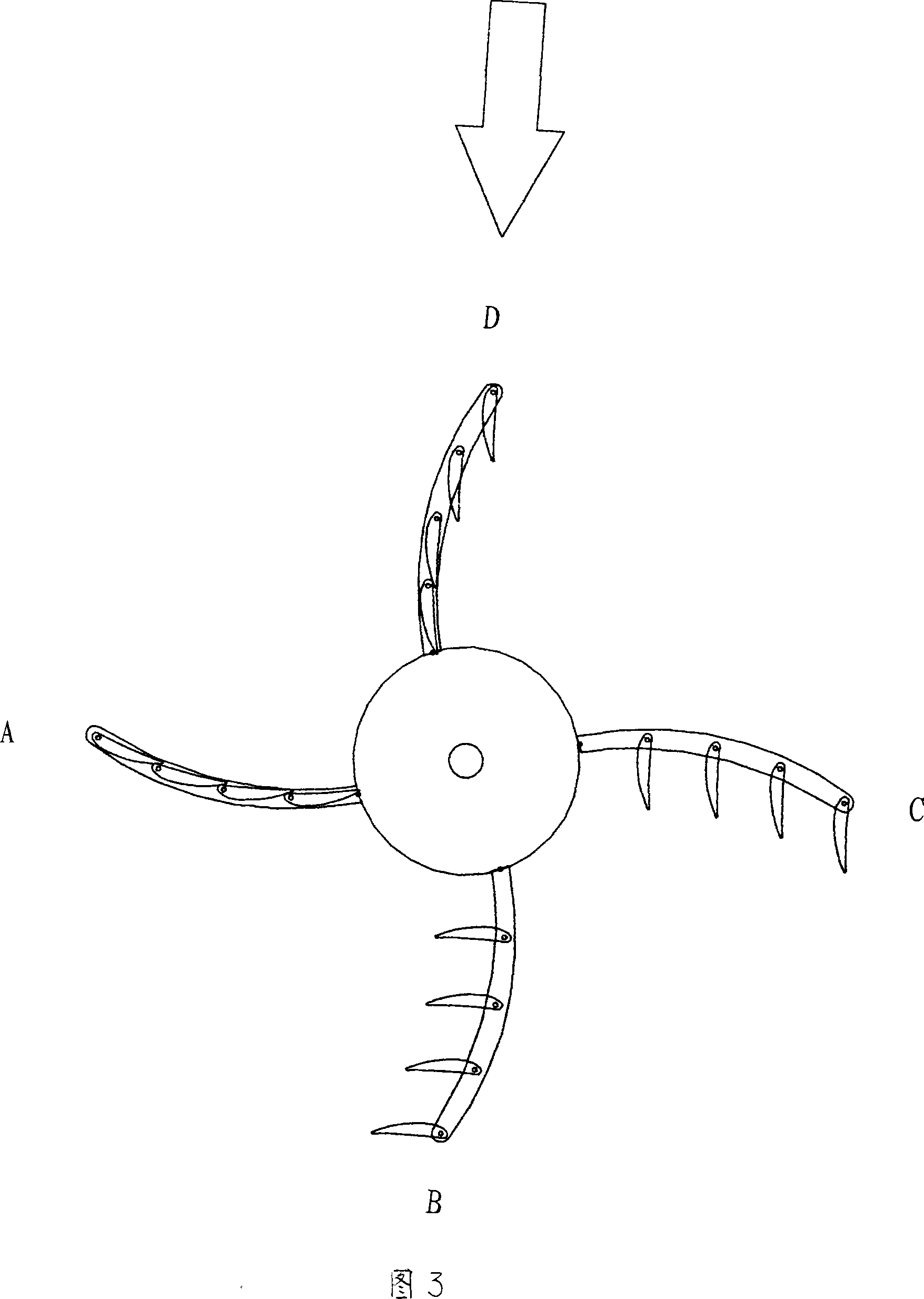

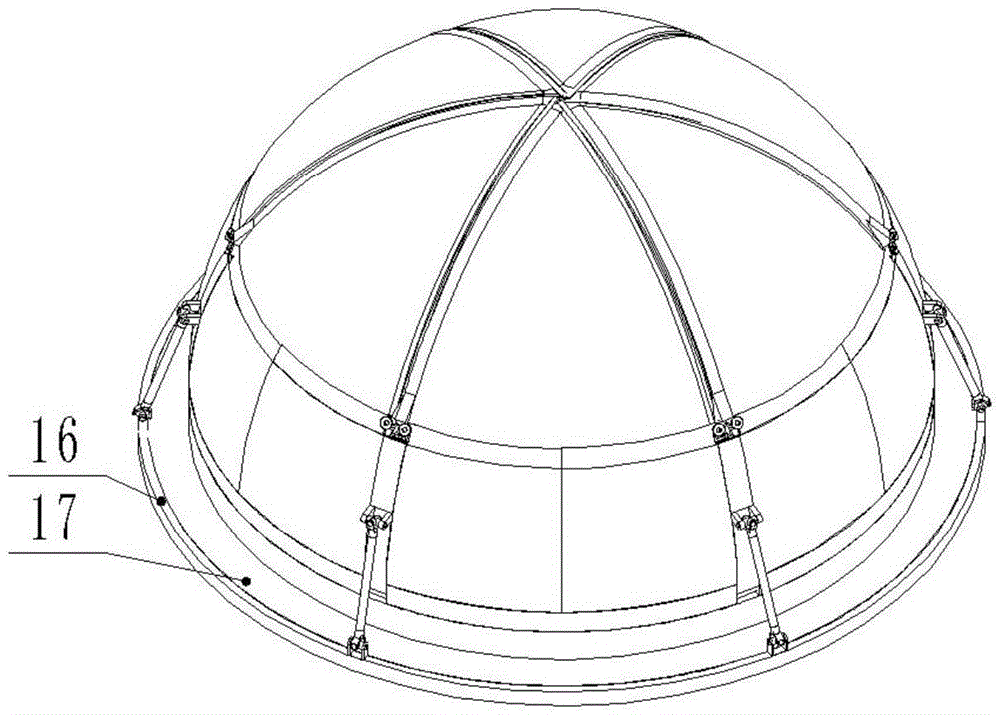

Vertical shaft wind power machine wind wheel

InactiveCN101067409AFlexible opening and closingGood rideRenewable energy generationMachines/enginesLeading edgeHigh energy

A vertical shaft wind wheel relates to the device to use the wind energy. It is made up of the central axis, the connecting pole and more than 3 vanes. The vane is the arc curved vane which is set with the arc cross support and the vertical axis in the arc curved; the rectangle grid forms between the cross support and the vertical axis. The grid part is set with the active wind vane and the limiting part to control the wind vane rotating angle. The wind vane section is the airfoil shape which the front part matches with the vertical axis. The invention is installed on the vertical axis wind fan which the central axis and the arc vane are vertical to the ground. Under the level wind force, the wind vane on vane is forced by the thrust F1, the oblique force F2 and the lift force F3 to generate the moment M1, M2 and M3 to make the wind wheel rotate in a same direction; it would rotate continuously until the wind force stops. The invention can transform the wind energy into the electric energy or mechanism energy by many modes; also it has low request for the starting wind speed and high wind energy using efficiency.

Owner:戴玉毅

Bottle blank distance separating mechanism for plastic bottles

ActiveCN106313483AReduced opening and closingRealize the separation effectDomestic articlesEngineeringPlastic bottle

The invention discloses a bottle blank distance separating mechanism for plastic bottles and aims to overcome defects that existing bottle blank distance separating mechanisms can realize bottle blank distance separation only and cannot move blanks to mold closing stations. According to the technical scheme, the mechanism comprises a rack and guide rails; a distance separating assembly comprising a clamping jaw fixing seat, a clamping jaw and a distance separating chain plate is arranged on the guide rails; a distance separating groove which is parallel with the guide rails and comprises a bent transition section is formed in the rack; a left distance separating groove section and a right distance separating groove section which extend from two ends of the bent transition section of the distance separating groove are straight grooves and have equal distances with the guide rails, and the distance between the left distance separating groove section and the guide rails is larger than that between the right distance separating groove section and the guide rails; and a moving piece capable of moving in the distance separating groove is arranged in the distance separating groove and is connected with the distance separating assembly. The mechanism has the advantages as follows: the moving travel of the bottle blanks is effectively increased, a blank moving mechanism is omitted, the bottle blank distance separating mechanism can move the blanks to a mold closing station, can separate distances reliably and has the long travel, and fault points are effectively reduced.

Owner:张士生

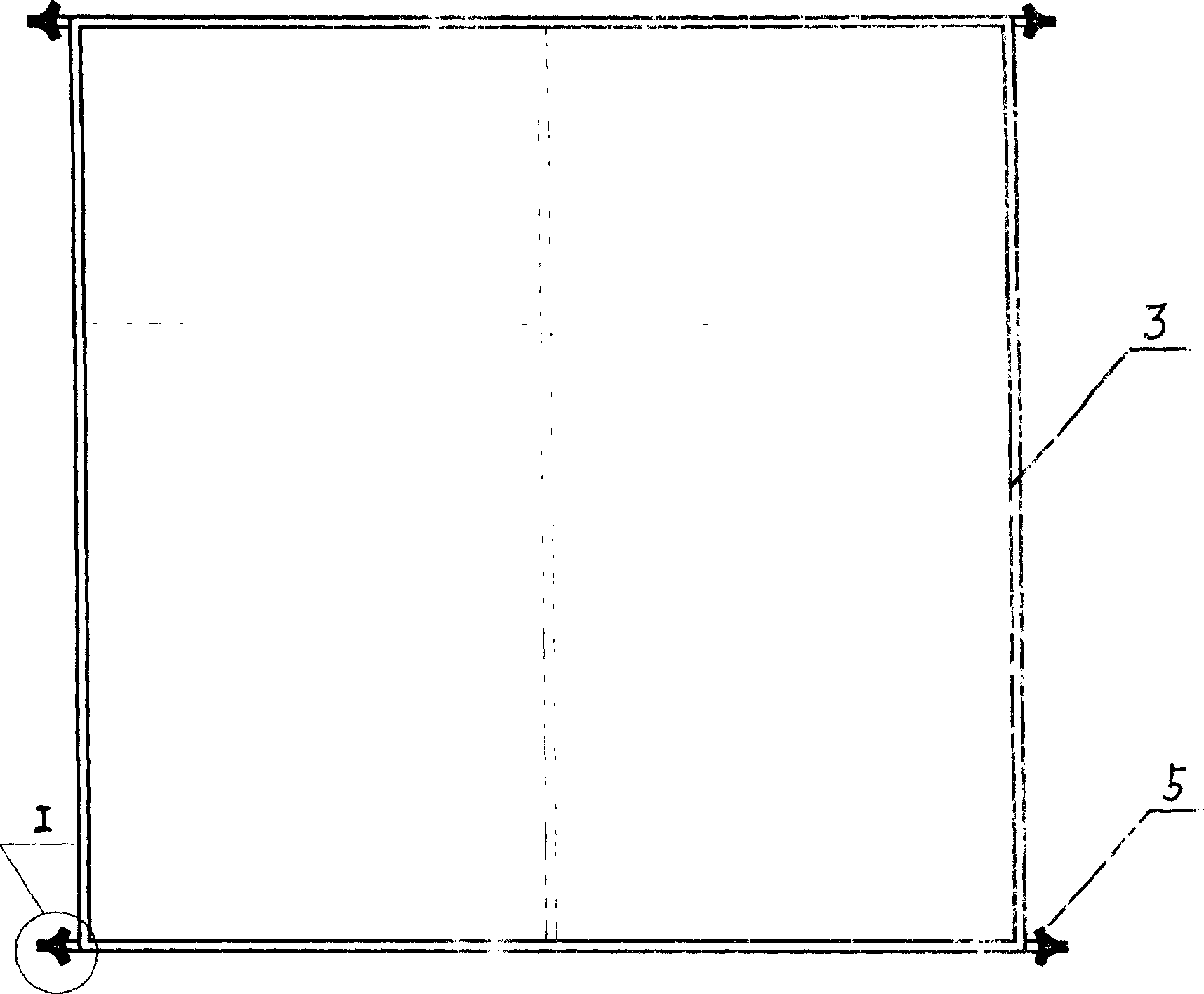

Anti-jamming pneumatic slide plate gate of pulverized coal pipeline and work method based on anti-jamming pneumatic slide plate gate

ActiveCN105135034ASolve the jamAvoid influenceOperating means/releasing devices for valvesSlide valveAnti jammingCoal pipeline

The invention discloses an anti-jamming pneumatic slide plate gate of a pulverized coal pipeline and a work method based on the anti-jamming pneumatic slide plate gate. The anti-jamming pneumatic slide plate gate comprises a rectangular frame which is connected with the pulverized coal pipeline through fixing bolts, wherein a slide plate which can block airstreams in the pulverized coal pipeline is arranged in the center of the rectangular frame; the rectangular frame comprises a front side frame, a rear side frame, a left side frame and a right side frame; the left and right side frames are separately provided with a sliding rail, so that the slide plate can slide along the sliding rails of the rectangular frame; the slide plate is connected with a slide plate draft device; asymmetrical chevron air passages are arranged above the rear side frame; symmetrical chevron air passages are arranged below the rear side frame; the air passages are all connected with compressed air pipelines; the compressed air pipelines are connected with a compressed air source; electromagnetic valves are arranged on the compressed air pipelines; the electromagnetic valves are connected with compressed air control systems; and in processes of inserting the slide plate into the rectangular frame and pulling the slide plate out of the rectangular frame, dust accumulated on the upper part, the lower part, the front part and the rear part of the slide plate is cleaned through airstreams in the compressed air pipelines, so that the problem of jamming of the slide plate caused by large friction force of the dust is solved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

Improved piston-type control valve

InactiveCN104061337AFlexible opening and closingReduce wearOperating means/releasing devices for valvesValve members for absorbing fluid energyInlet channelCavitation

The invention discloses an improved piston-type control valve. The improved piston-type control valve comprises a valve body, and a piston cylinder, a piston and a spring which are arranged on the valve body, wherein a liquid inlet channel and a liquid outlet channel are formed in the valve body; a communicating hole is formed between the liquid inlet channel and the liquid outlet channel; the upper end of the piston is matched with the piston cylinder in a dynamic sealing way; the piston is matched with the piston cylinder to form a movable cavity; the piston can move between a closed position for plugging the opening at the upper end of the communicating hole and an open position far away from the communicating hole; an anti-cavitation cover is arranged at the lower end of the piston. According to the improved piston-type control valve, the anti-cavitation cover is arranged on the piston, so that the phenomenon of cavitation in the communicating hole can be reduced, or even be prevented; moreover, according to the improved piston-type control valve, the piston can also be opened and closed more flexibly, so that the abrasion of the valve seat and the piston cylinder can be reduced, and the service life of the valve seat and the piston cylinder can be prolonged; in addition, a valve cover can also be replaced by reasonably arranging the position of the piston cylinder, so that the cost of machining and manufacturing is reduced.

Owner:GUANGDONG YONGQUAN VALVE TECH

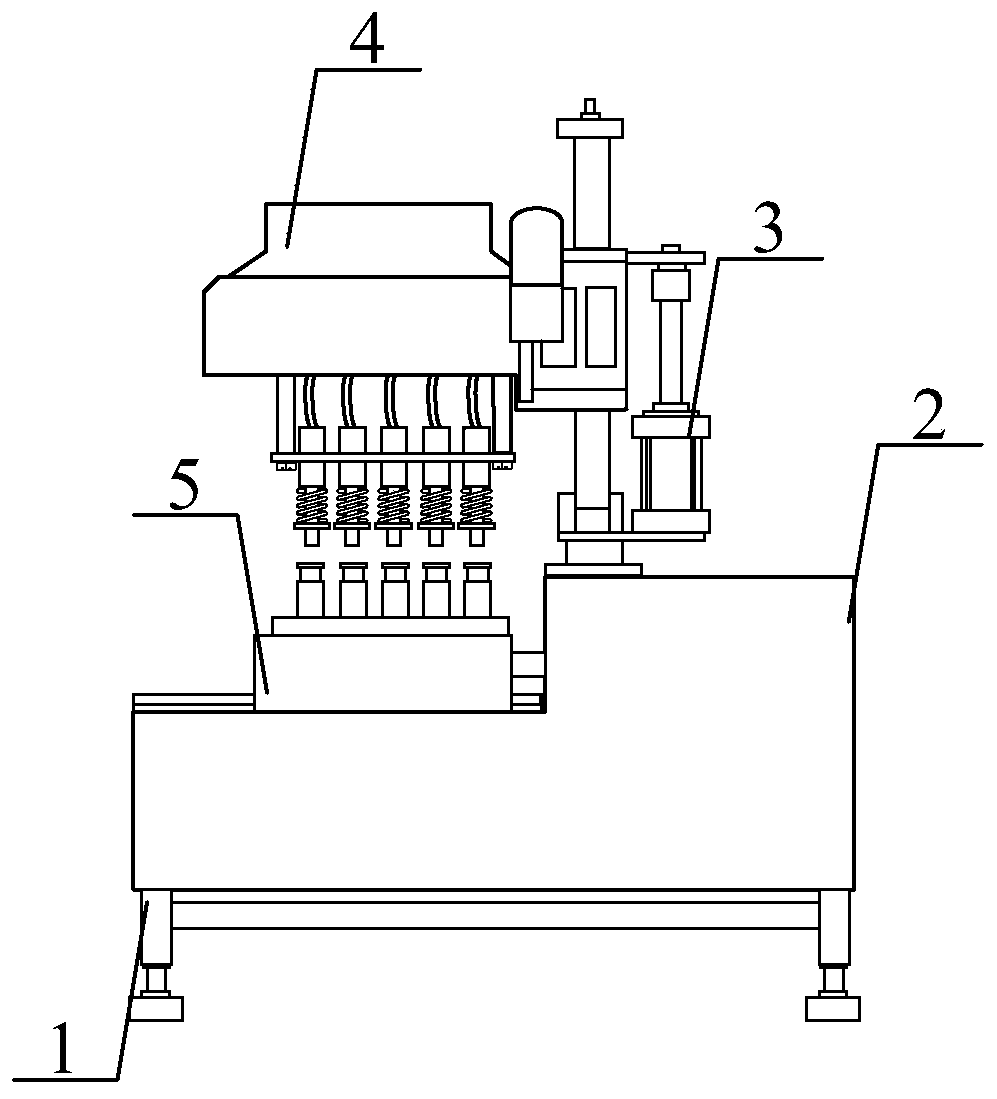

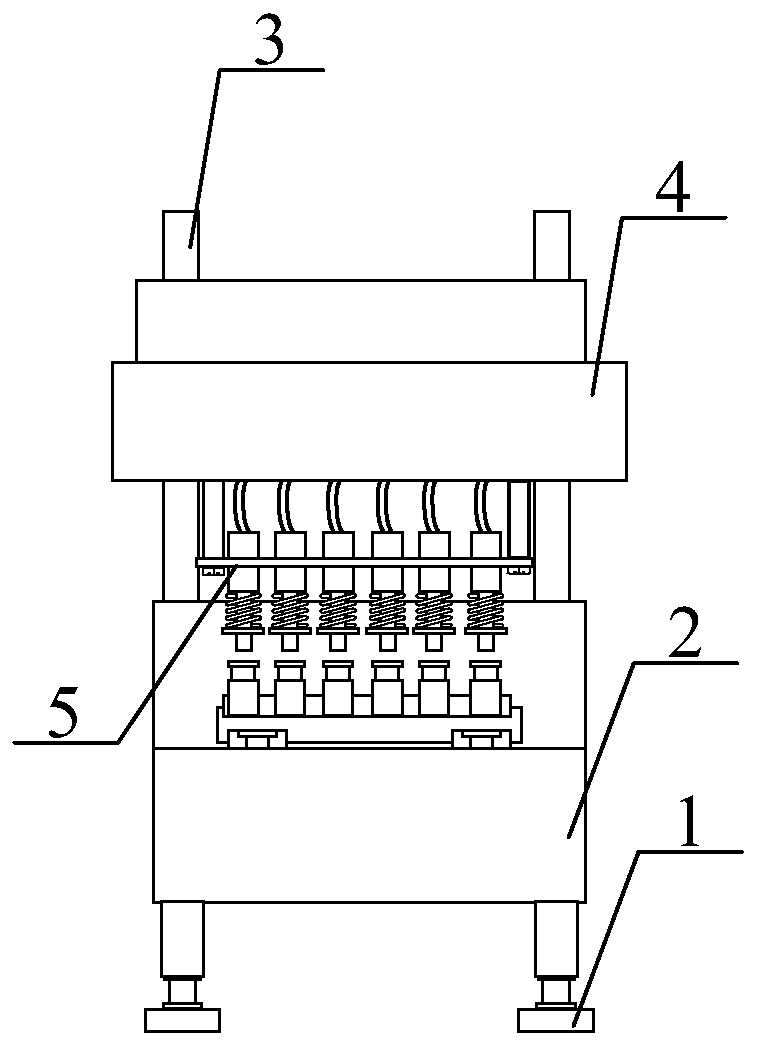

Antiviral oral liquid filling machine

InactiveCN111071510AMeet the usageRealize fillingLiquid materialLiquid bottlingEngineeringMechanical engineering

The invention discloses an antiviral oral liquid filling machine, which comprises regulating supporting legs, a case body, a lifting mechanism, a filling mechanism and a feeding mechanism. By arranging filling nozzles, the antiviral oral liquid filling machine is simple in structure and flexible in starting and stopping, the filling amount of oral liquid can be guaranteed, and the situation of excessive filling or insufficient filling is avoided; by arranging the feeding mechanism, a push rod of an air cylinder retracts to drive a sliding seat to move rightwards on sliding rails, so that oralliquid bottles are placed under the filling nozzles, the tedious step of manual alignment is omitted, the manual labor intensity is reduced, and the filling efficiency is greatly improved; and by arranging the filling mechanism, the oral liquid bottles can be filled once, so that the filling efficiency of the oral liquid is effectively improved.

Owner:徐国华

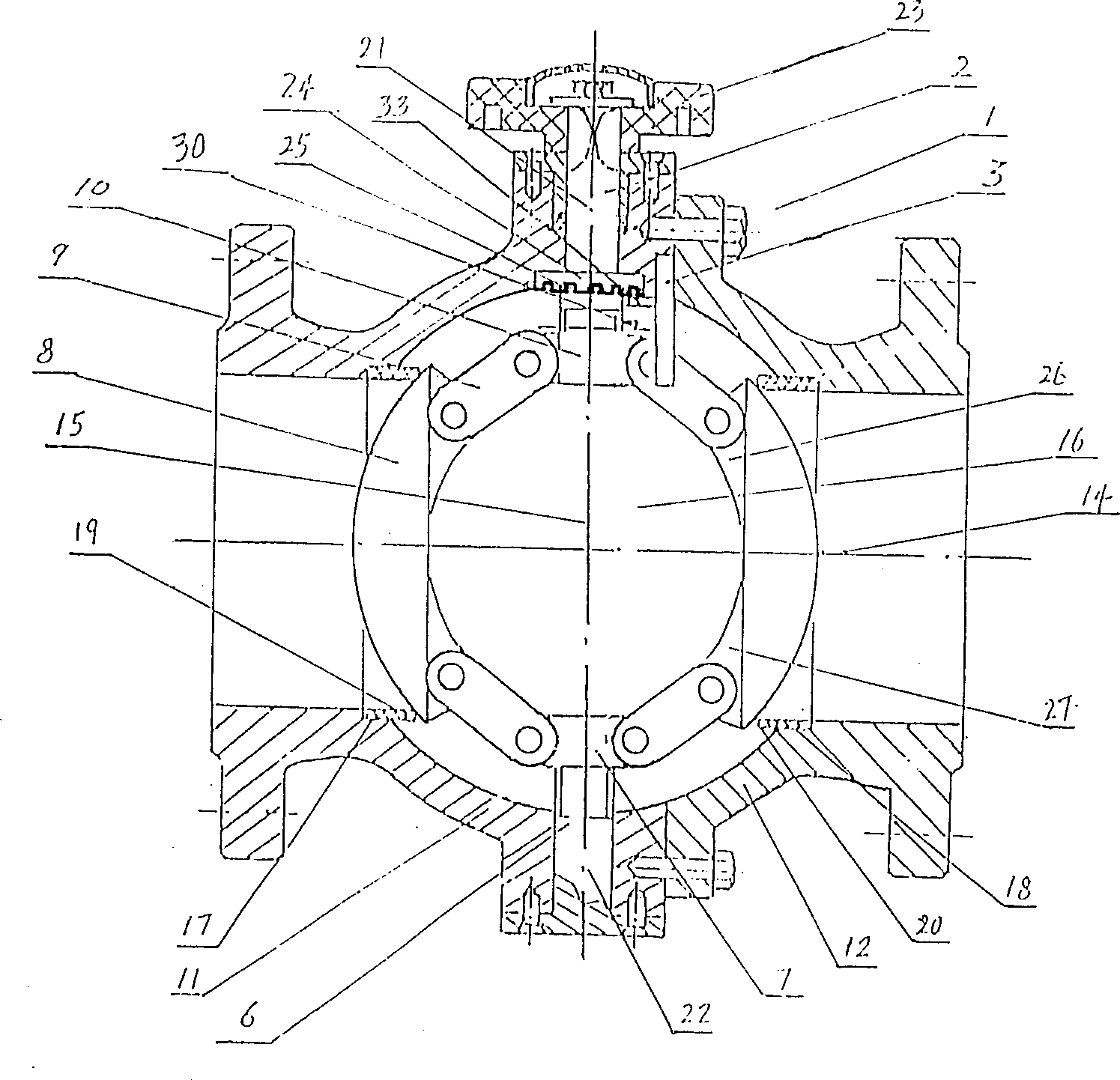

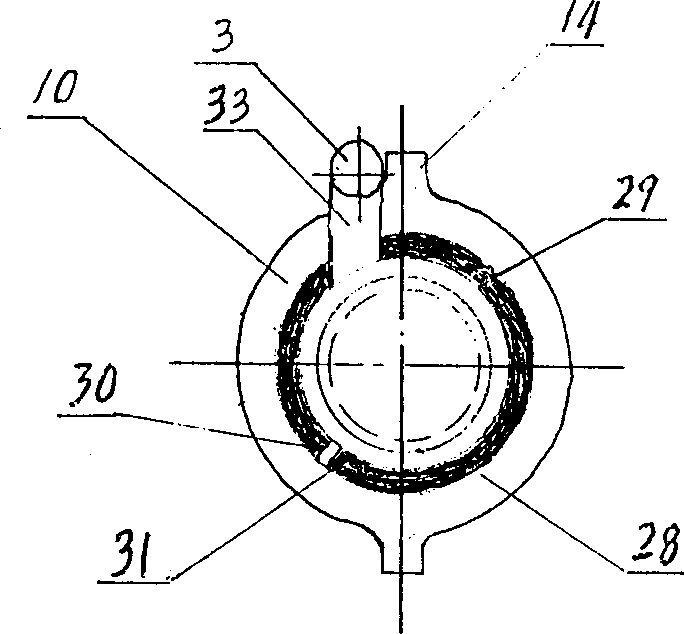

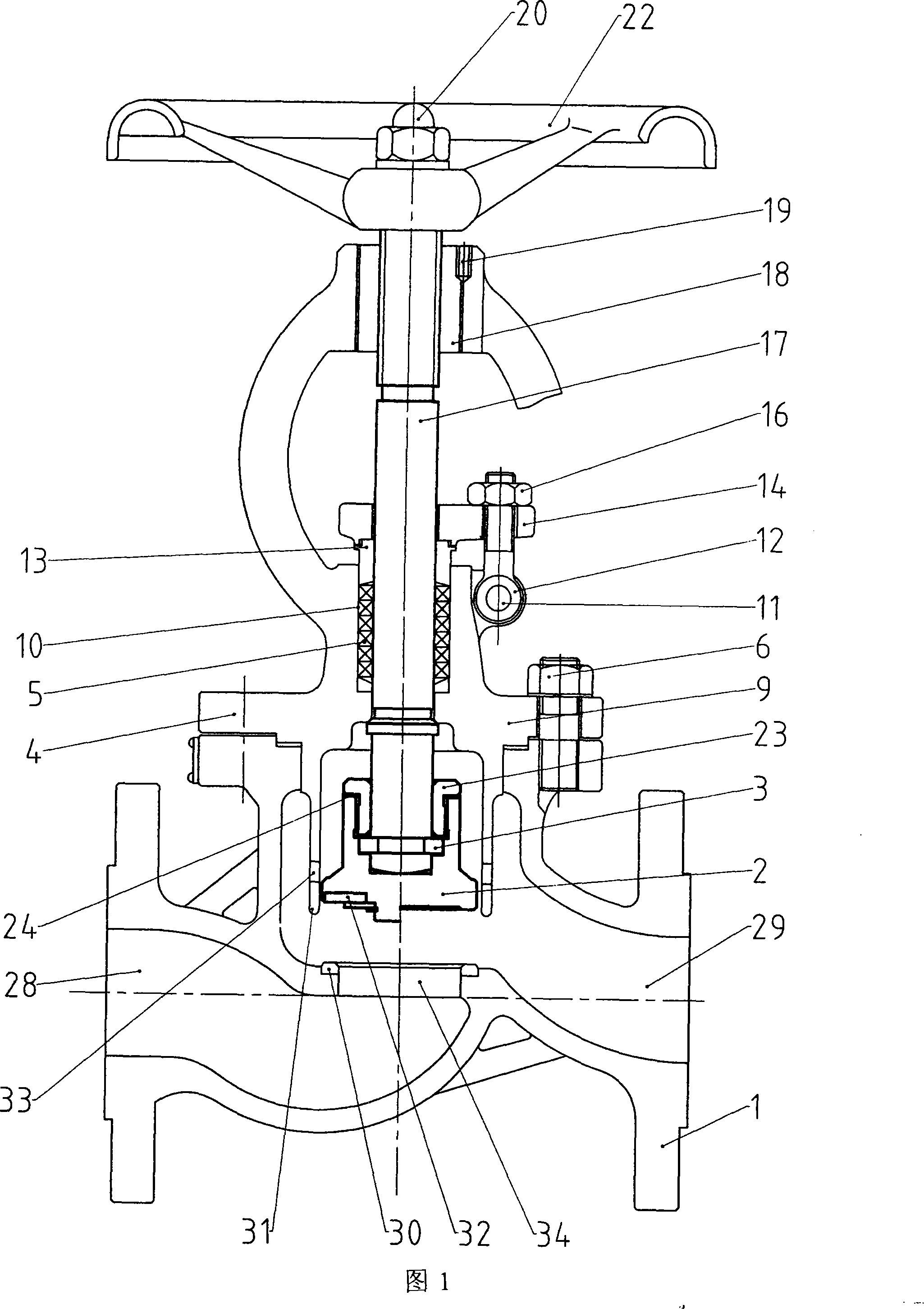

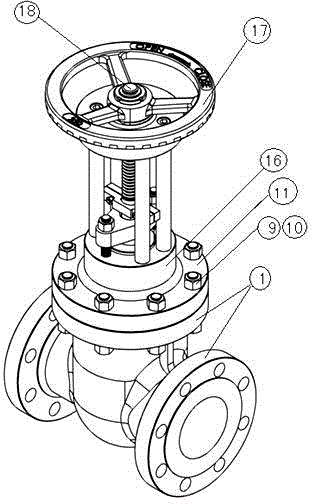

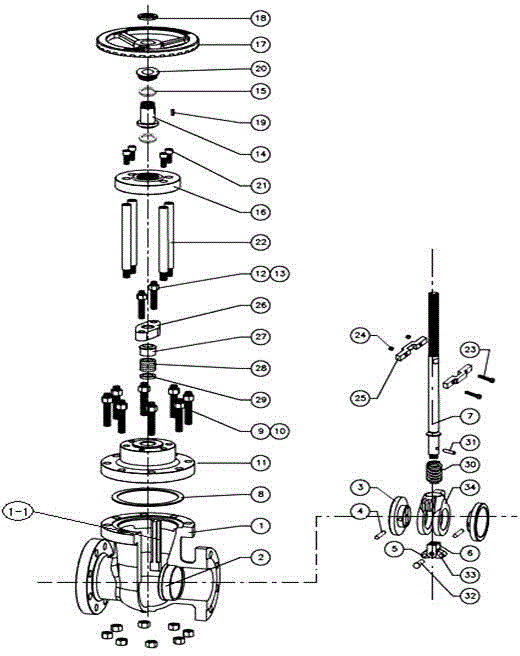

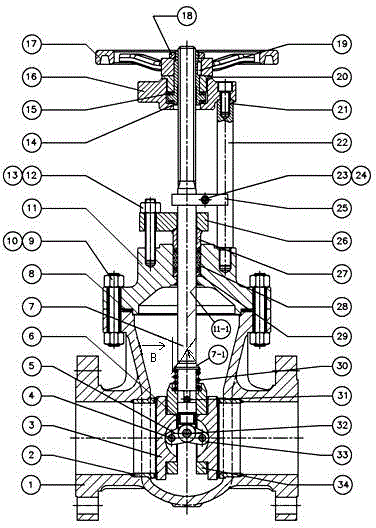

Parallel type double-gate gate valve

The invention belongs to a parallel type double-gate gate valve. The parallel type double-gate gate valve comprises a hand wheel (17) which is fixed at the upper end of a valve rod nut (14) through a circular nut (18). The parallel type double-gate gate valve is characterized in that a valve rod (7) is connected with a hinge frame (6); the hinge frame (6) is connected with a first hinge arm (5) through a second hinge arm (33); the first hinge arm (5) is connected with each gate (3) through a first hinge pin (4); the first hinge arm (5) and the hinge frame (6) are arranged in a gate frame (34) to form a closed part; a spring is arranged between the gate frame (34) and the valve rod (7). According to the parallel type double-gate gate valve, the sealing performance is good, the double-sided forced sealing is achieved, the leakage is not produced, the sealing surface is free of friction loss and abrasion, materials are saved, the cost is low, the detachment and installation and the maintenance are convenient and rapid, the operation torque is small, and the opening and the closing are flexible.

Owner:YINGKOU ESWEITE VALVE CO LTD

Oil pipeline clamping fixture

InactiveCN103662383AFlexible opening and closingStability impactExternal framesHydraulic cylinderEngineering

The invention discloses an oil pipeline clamping fixture comprising a base plate and an adjusting plate. The end of the base plate is hinged to the end of the adjusting plate, each of the base plate and the adjusting plate is provided with a clamping piece, and the clamping pieces are connected with the base plate and the adjusting plate through bolts. The oil pipeline clamping fixture further comprises pressure claws and connecting rods, each pressure claw is hinged to the upper end portion of each clamping piece, each clamping piece is further provided with a hydraulic cylinder, one end of each connecting rod is hinged to the middle of each pressure claw while the other end is hinged to a connecting piece, and a telescopic end of each hydraulic cylinder is connected with the bottom of each connecting piece. For strengthening stability of placement of the bending oil pipe, a bending portion of the bending oil pipe is placed in the clamping piece of the adjusting plate, a straight line portion is placed in the clamping piece of the base plate, the base plate and the adjusting plate form loose-leaf connection, and an included angle between the base plate and the adjusting plate is enable to change along with the winding path of the bending oil pipe, so that the connecting rods enable the pressure claws to be more flexible in opening and closing, and stability affected by vibration of the hydraulic cylinders during opening and closing of the pressure claws is also avoided.

Owner:CHENGDU KESHENG PETROLEUM TECH

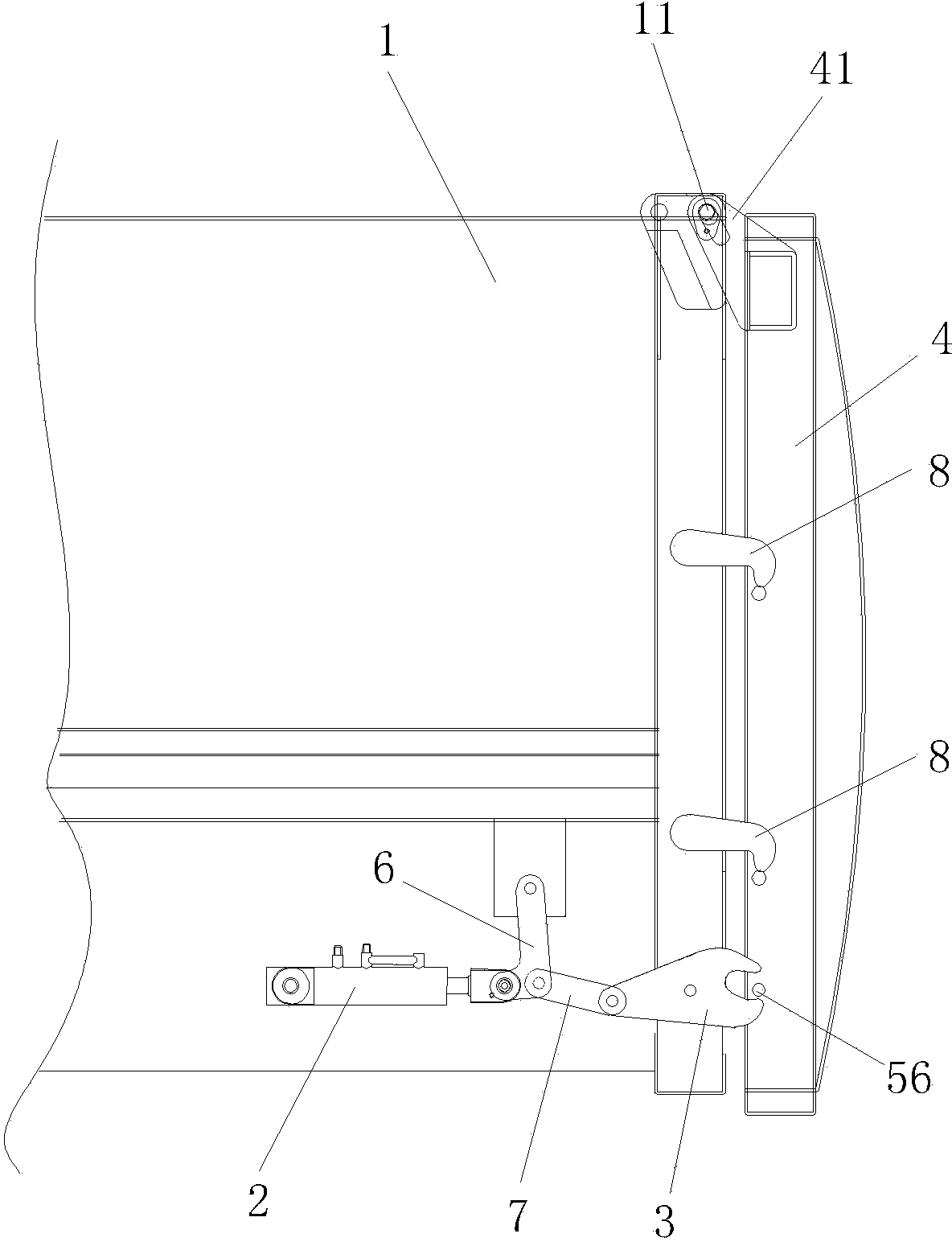

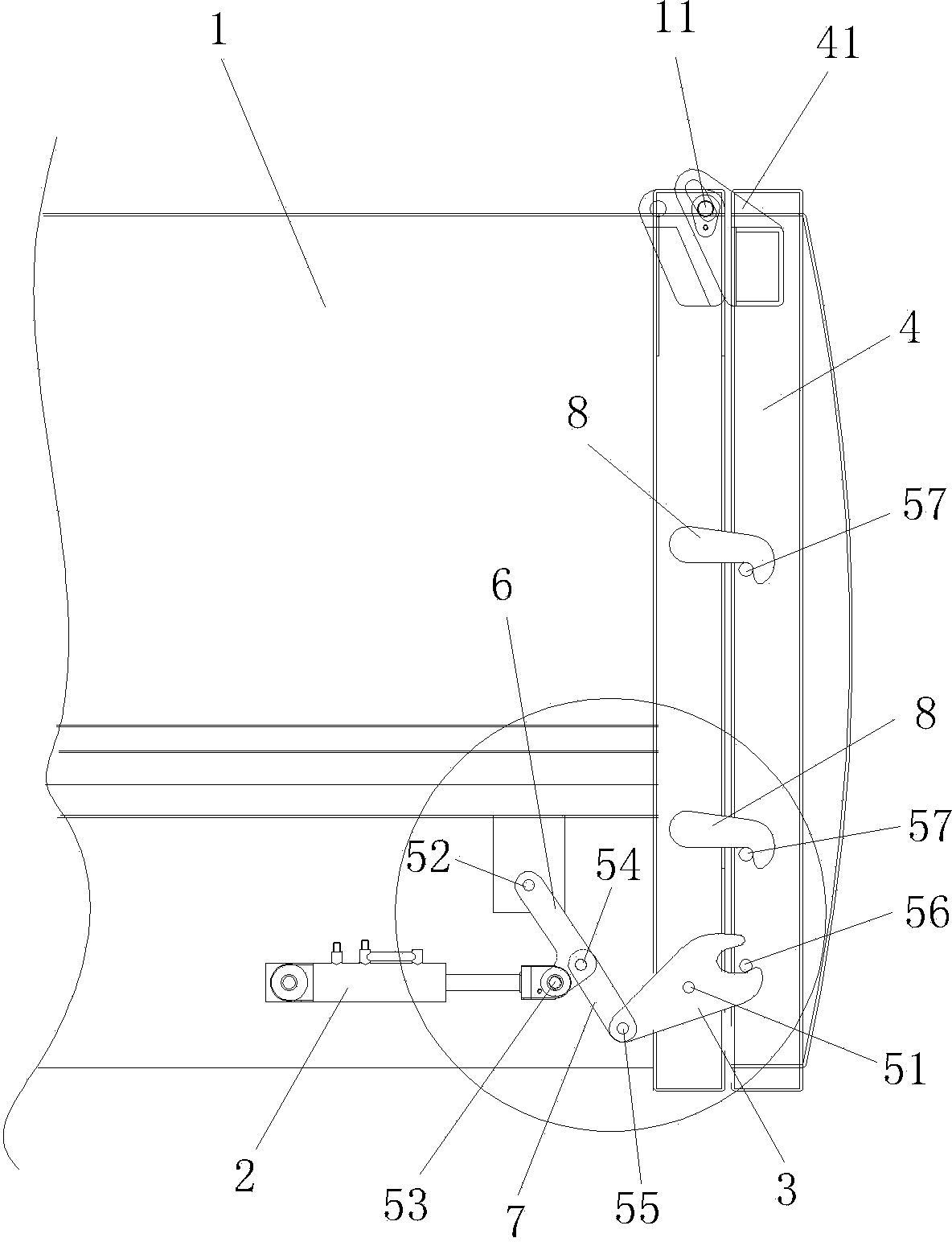

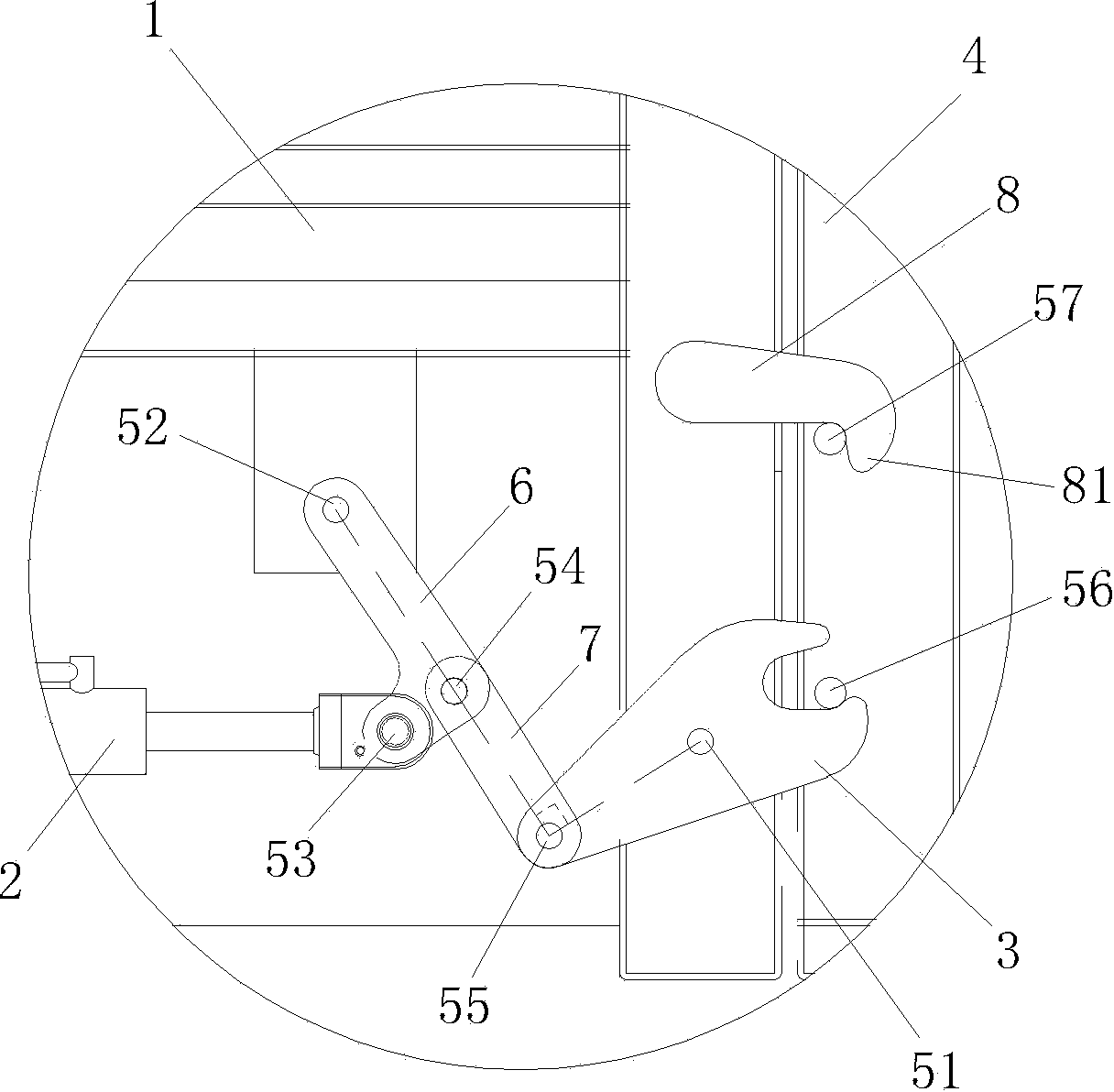

Detachable compression dustbin

ActiveCN103587864AFlexible opening and closingImprove reliabilityRefuse vehiclesEngineeringLocking mechanism

The invention discloses a detachable compression dustbin. The detachable compression dustbin comprises a rear door locking mechanism. The rear door locking mechanism comprises locking oil cylinders, locking arms, L-shaped connecting rods and ejector rods, wherein the middle portions of the locking arms are hinged to the lower rear portions of the side faces of the dustbin body through first hinge pins; the upper ends of the L-shaped connecting rods are hinged to the two sides of the dustbin body through second hinge pins, and the lower ends of the L-shaped connecting rods are hinged to the locking oil cylinders through third hinge pins; one ends of the ejector rods are hinged to the middle portions of the L-shaped connecting rods through fourth hinge pins, and the other ends of the ejector rods are hinged to the front ends of the locking arms through fifth hinge pins; grooves are formed in the rear ends of the locking arms and matched with sixth hinge pins fixed to the side faces of a rear door; locking hooks are fixed to the rear ends of the side faces of the dustbin body, and seventh hinge pins are fixed to the middle portions of the two sides of the rear door and matched with the locking hooks. When the rear door is locked, the centers of the second hinge pins, the centers of the fourth hinge pins and the centers of the fifth hinge pins are located in the same straight lines which are perpendicular to the straight lines formed by connecting the centers of the fifth hinge pins and the centers of the first hinge pins. According to the detachable compression dustbin, the rear door is flexible to open and close and reliable in locking.

Owner:漳州科晖专用汽车制造有限公司

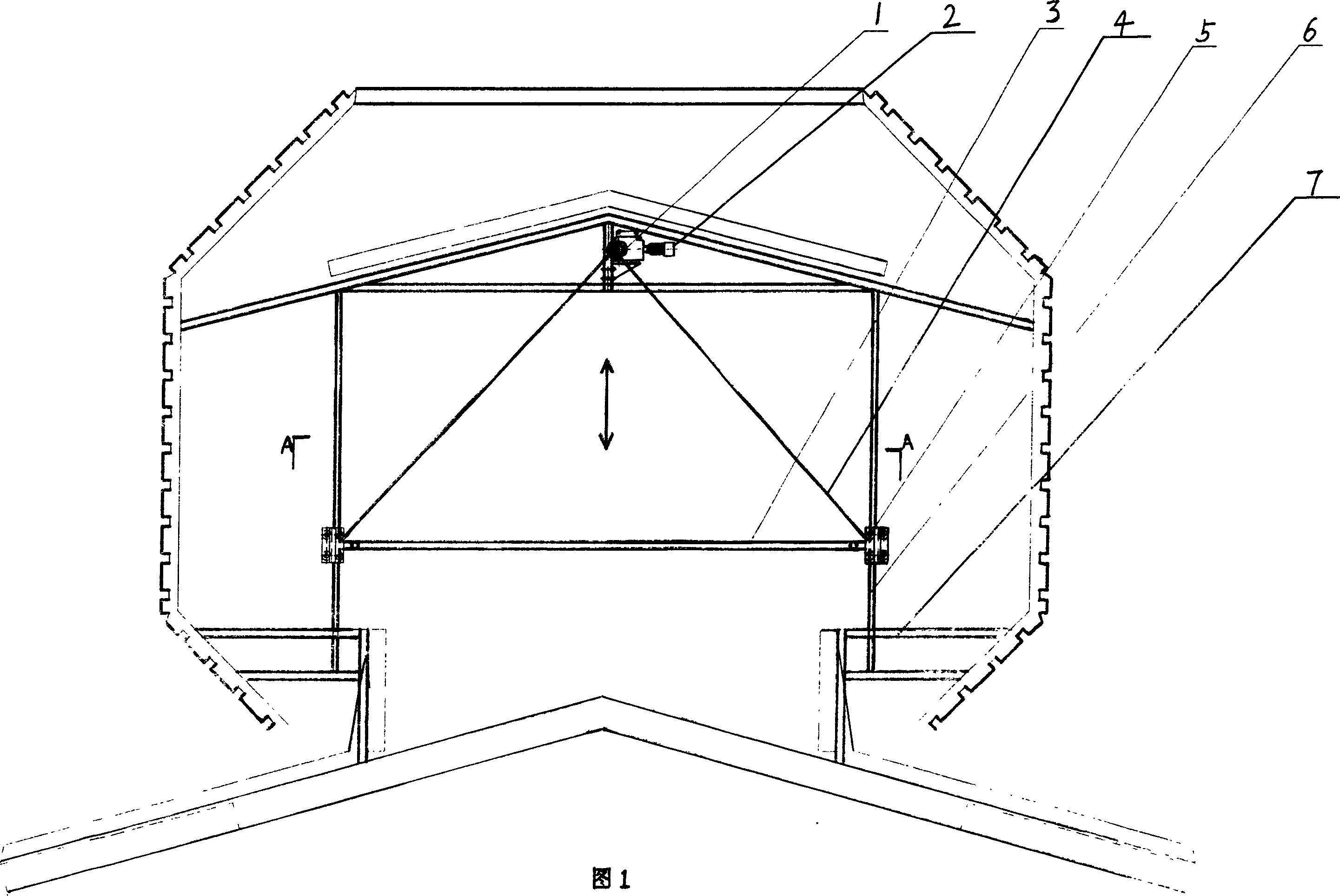

Ventilation skylight

InactiveCN1858505AImprove work efficiencyFlexible opening and closingLighting and heating apparatusVentilation systemsEngineeringReducer

The ventilation skylight includes ventilator frame, valve plate in the throat part and electric opening-closing mechanism. The electric opening-closing mechanism consists of motor, speed reducer, limiter and pull rope. The limiter is connected to the end of the valve plate and movably on a guide body mounted on the ventilator frame, so that the valve plate may be shifted vertically along the guide body. The present invention can regulate the vertical position of the valve plate, and flexible opening and closing of the ventilation skylight.

Owner:孙建和

Armored car protection shell

The invention discloses an armored car protection shell. Side rods of the protection shell are connected with a base through fourth cylindrical pins. Second titanium alloy plates and third titanium alloy plates are welded to the side rods. Fifth cylindrical pins are welded into the rectangular space on the tops of the side rods. A rotary table fixing disc is welded to an armored car body. A rotary table is installed on the rotary table fixing disc and can rotate around the rotary table fixing disc. One ends of first hook joints are connected with side rods of the rotary table, and the other ends of the first hook joints are connected with hook rods. One ends of second hook joints are connected with the rotary table, and the other ends of the second hook joints are connected with the hook rods. According to the armored car protection shell, the battle mode of an armored car can be changed by opening or closing the protection shell so that the battling requirement on the battleground can be flexibly met.

Owner:GUANGXI UNIV

Novel fixed pressure ring type fast opening blind plate and opening and closing method of novel fixed pressure ring type fast opening blind plate

ActiveCN103216615AImprove the state of stressReduce weightPressure vesselsSpherical formPressure stress

The invention discloses a novel fixed pressure ring type fast opening blind plate and an opening and closing method of the novel fixed pressure ring type fast opening blind plate. The inner and outer surfaces of a door cover of the blind plate are both spherical curve surfaces, the weight is light, a fixing ring and pressure ring structure is adopted between the door cover and a tube body flange and is used for mainly bearing the pressure stress, safety and reliability are realized, and the stress is good. After the door cover is closed, a seam between the door cover and the tube body flange is provided with a position limiting ring capable of vertically sliding, the fixed pressure ring is limited in a specified position and cannot move, and safety and reliability are realized. The outer edge of the door cover is aligned with the upper surface of the tube body flange, in addition, a dustproof ring is adopted for sealing, and wind and sand invasion is prevention. Meanwhile, the blind plate is provided with a safe interlocking and pressure sound and light warning linkage device.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

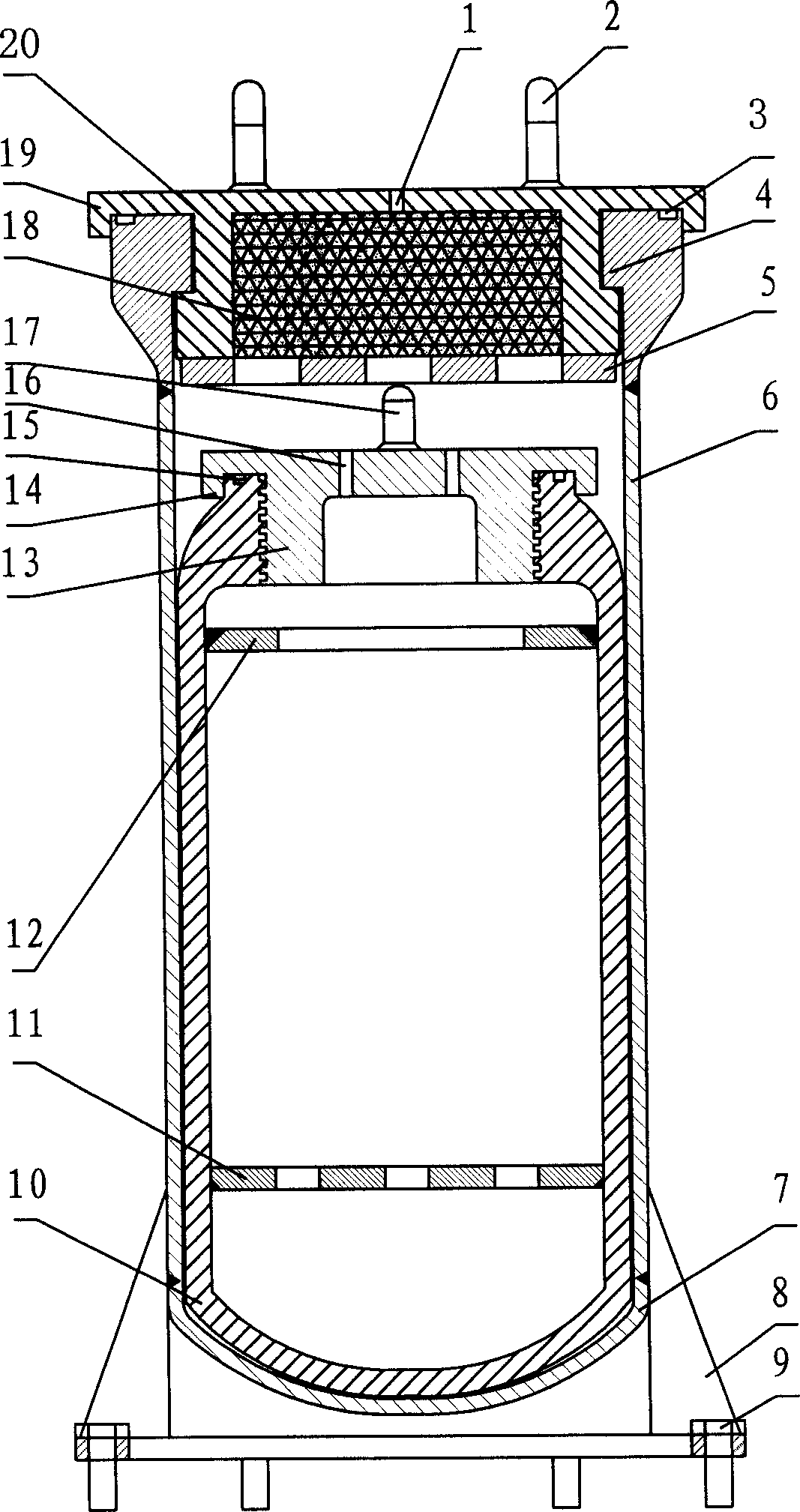

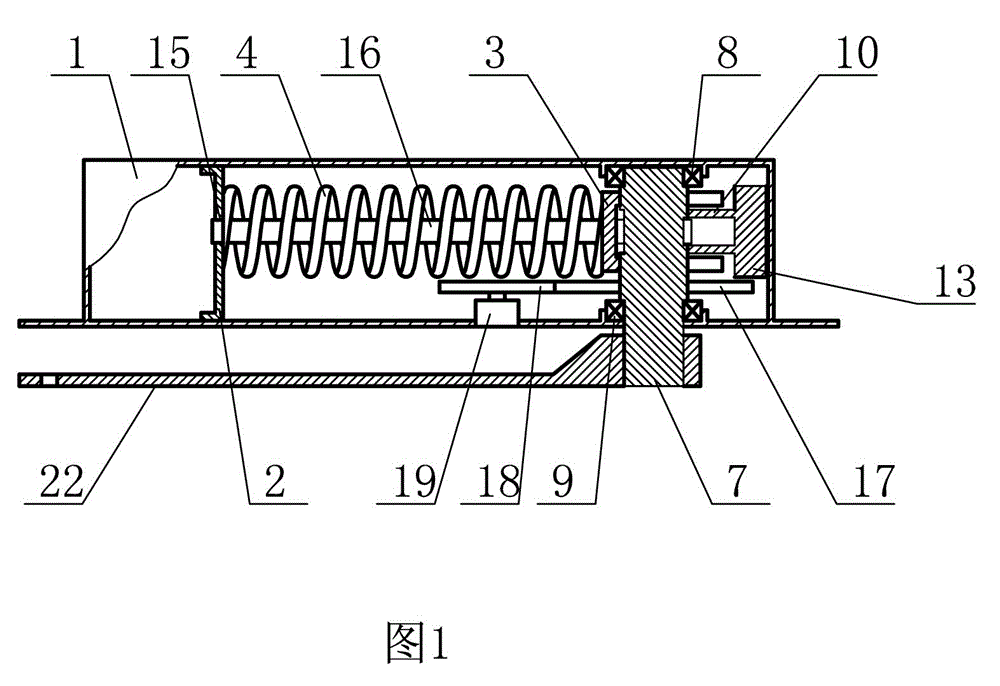

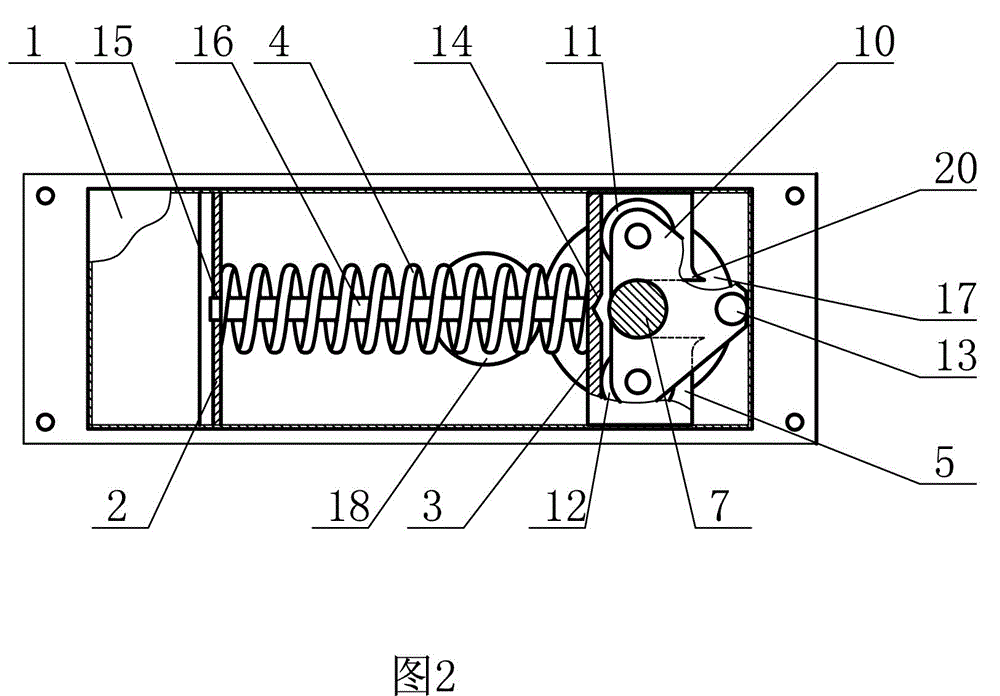

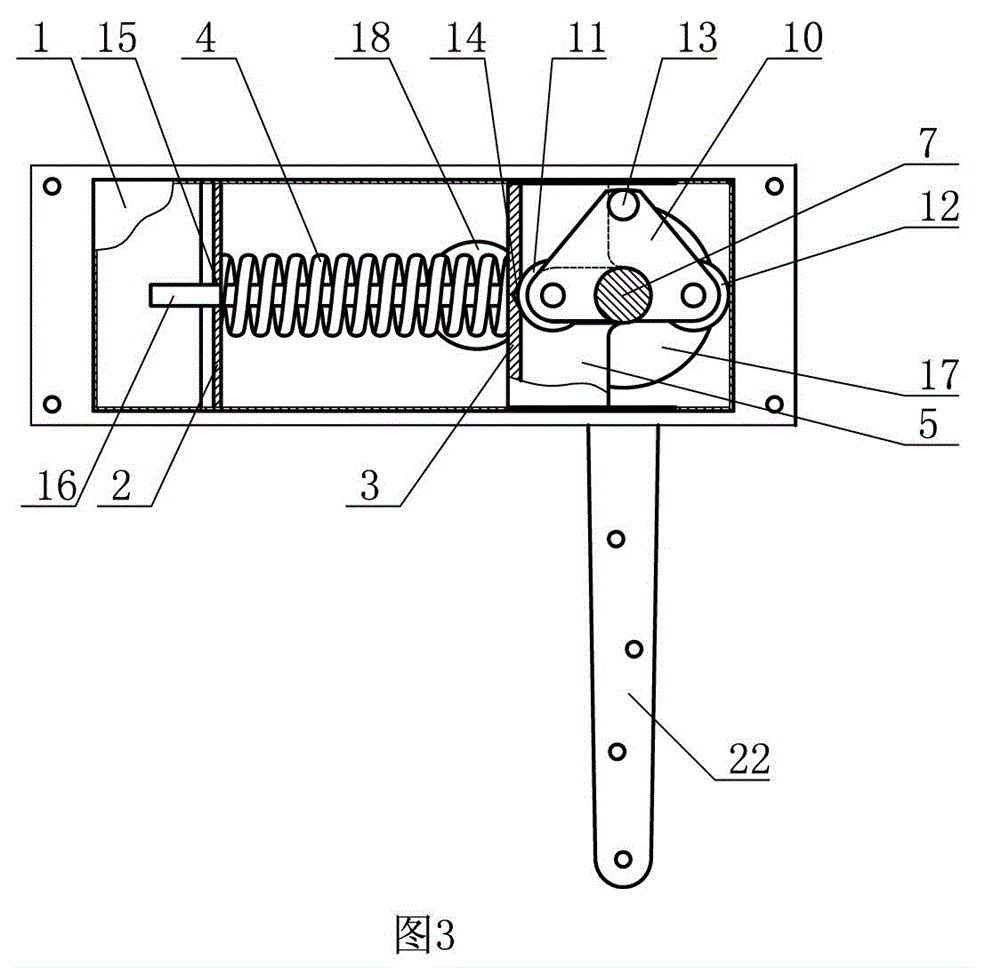

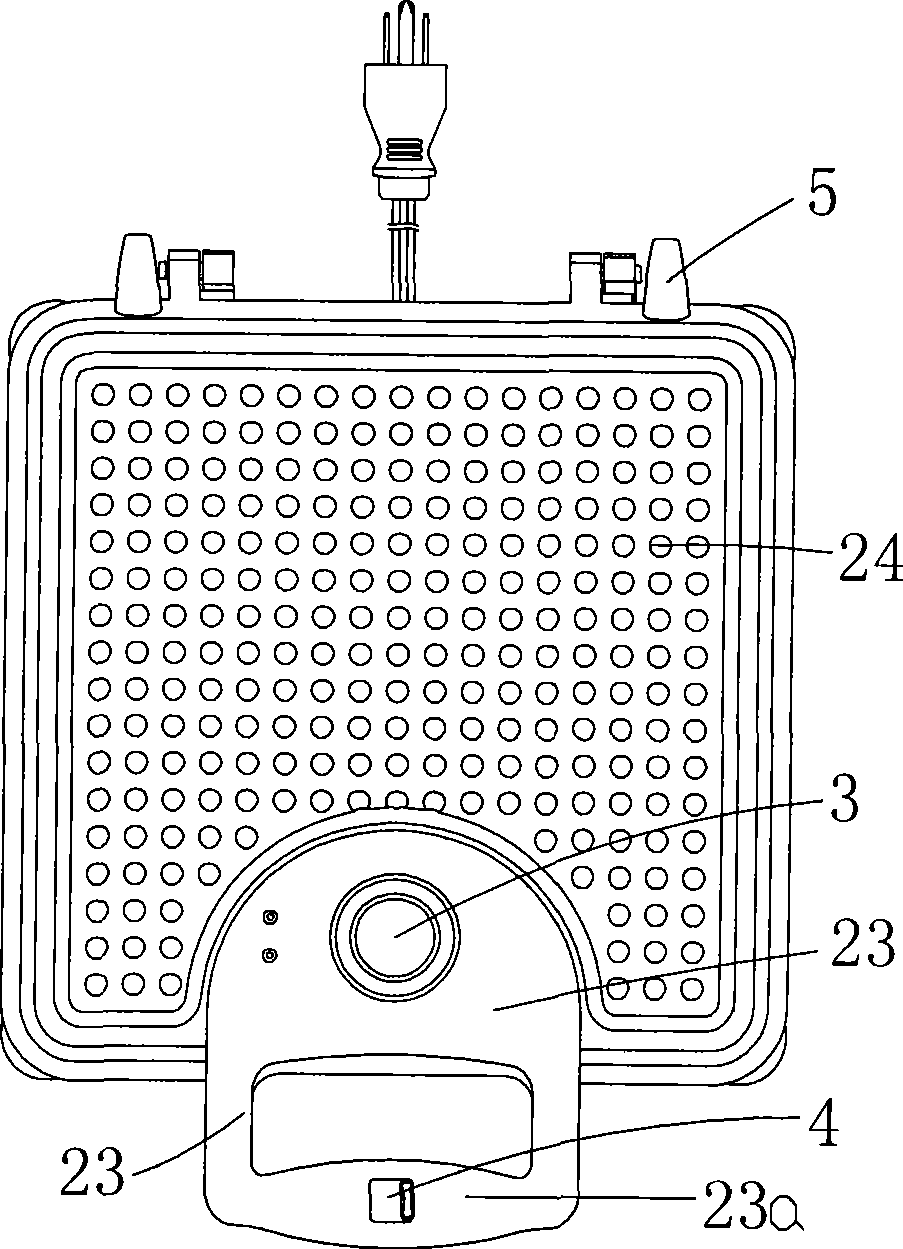

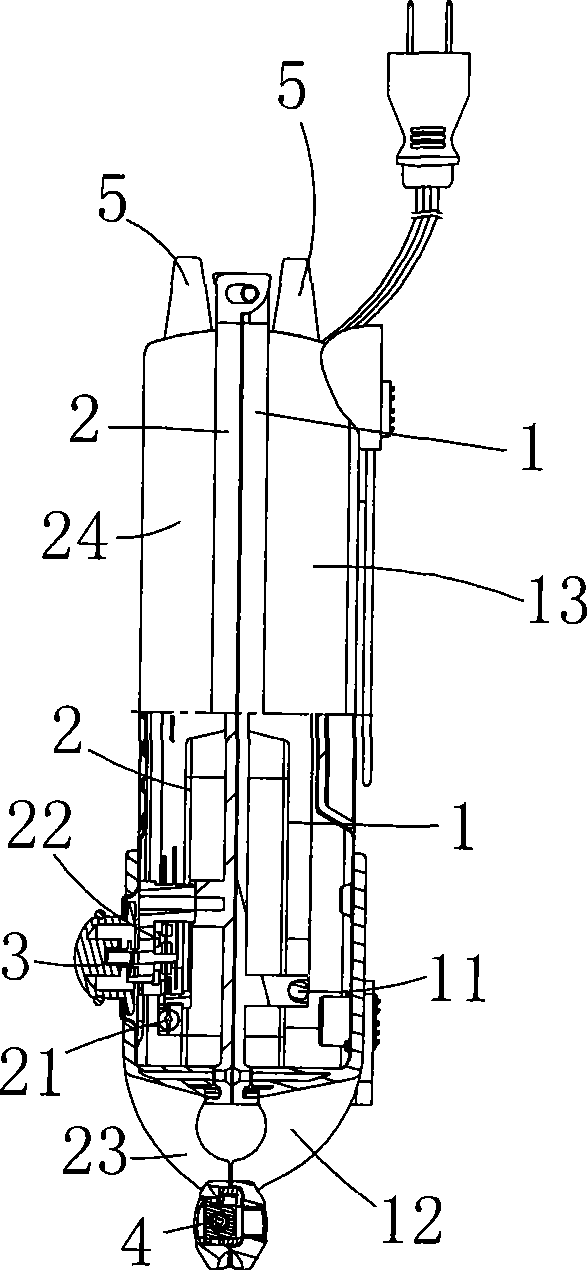

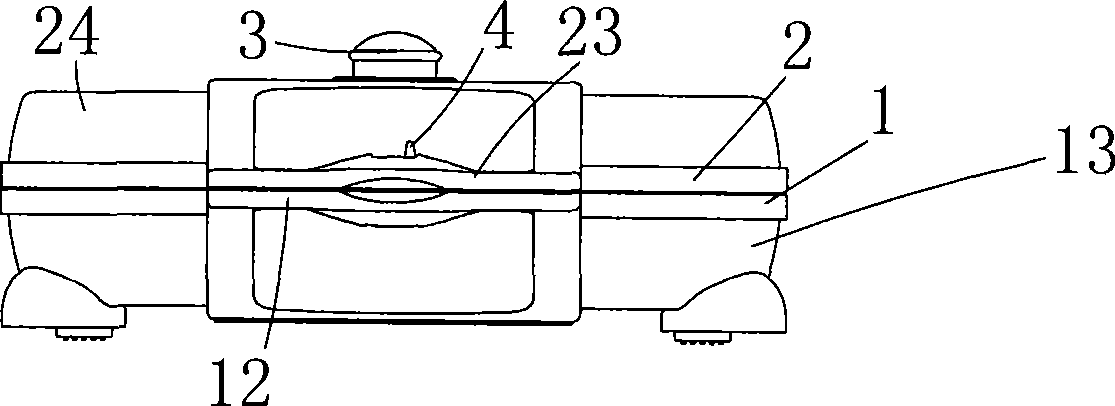

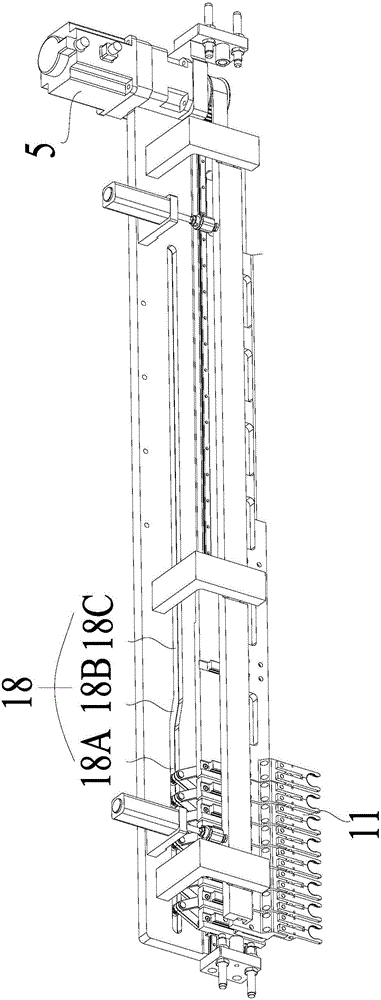

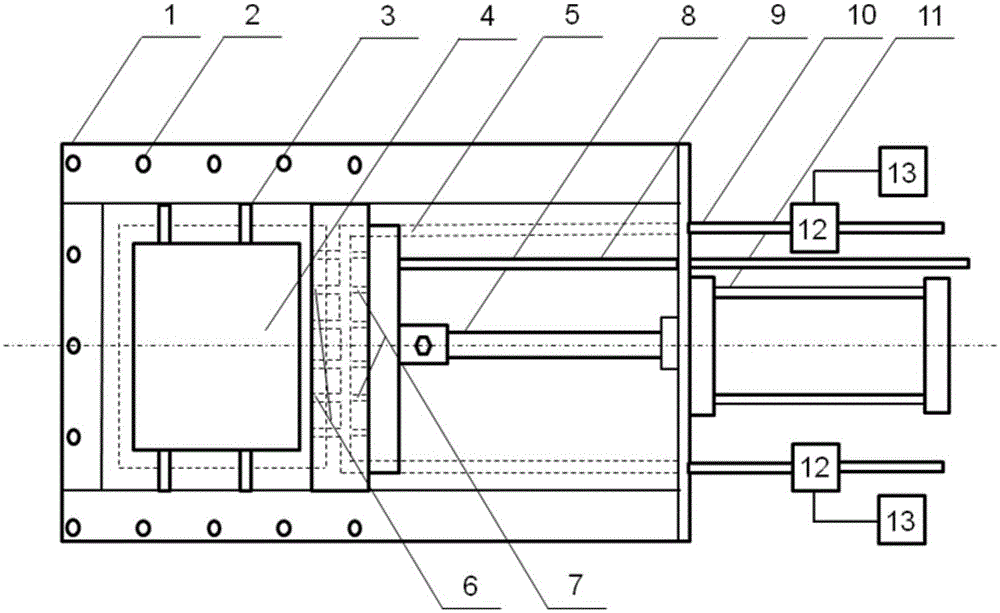

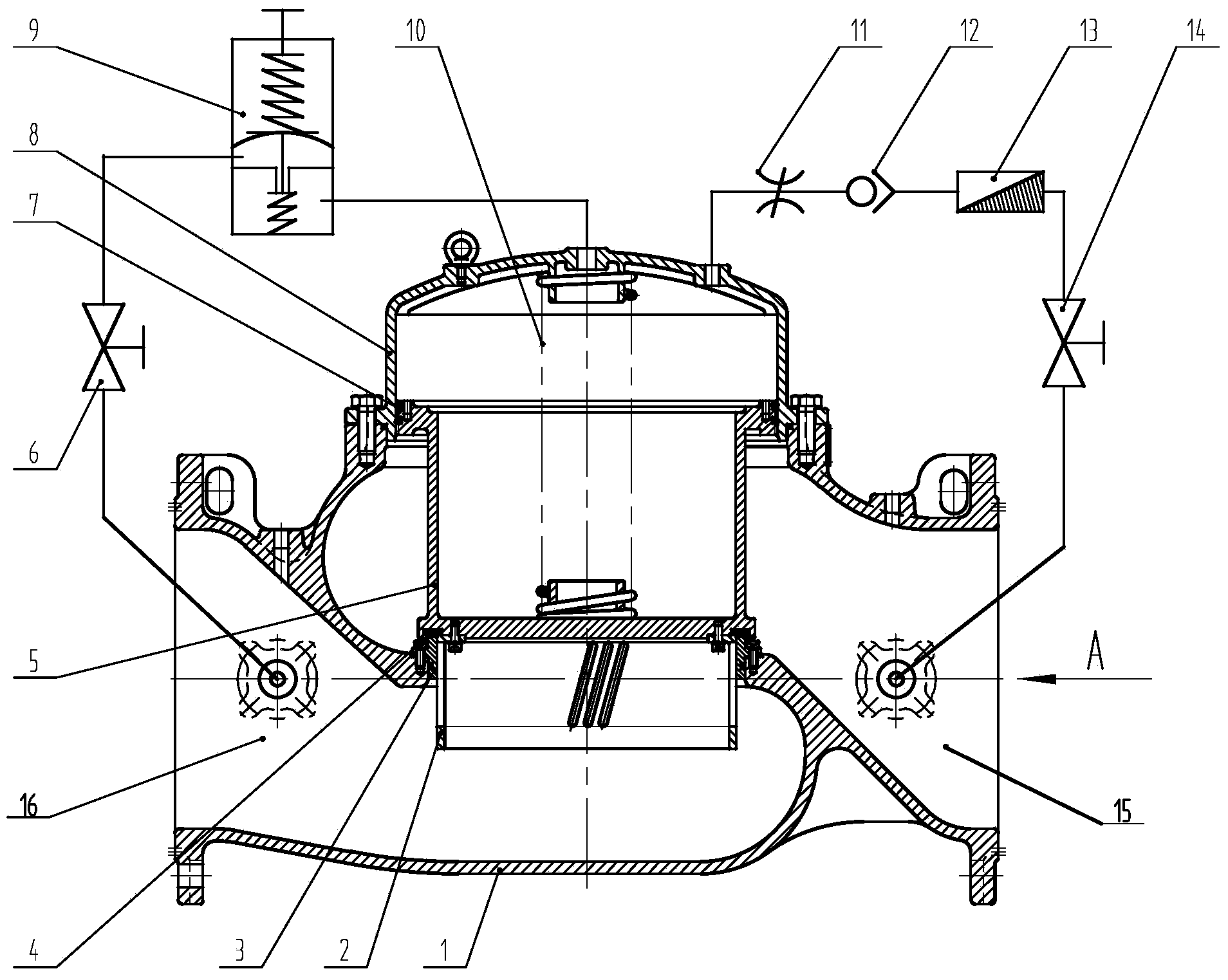

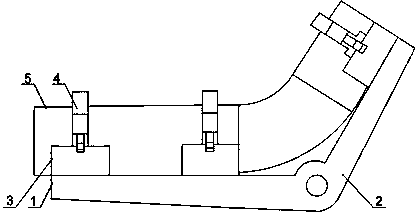

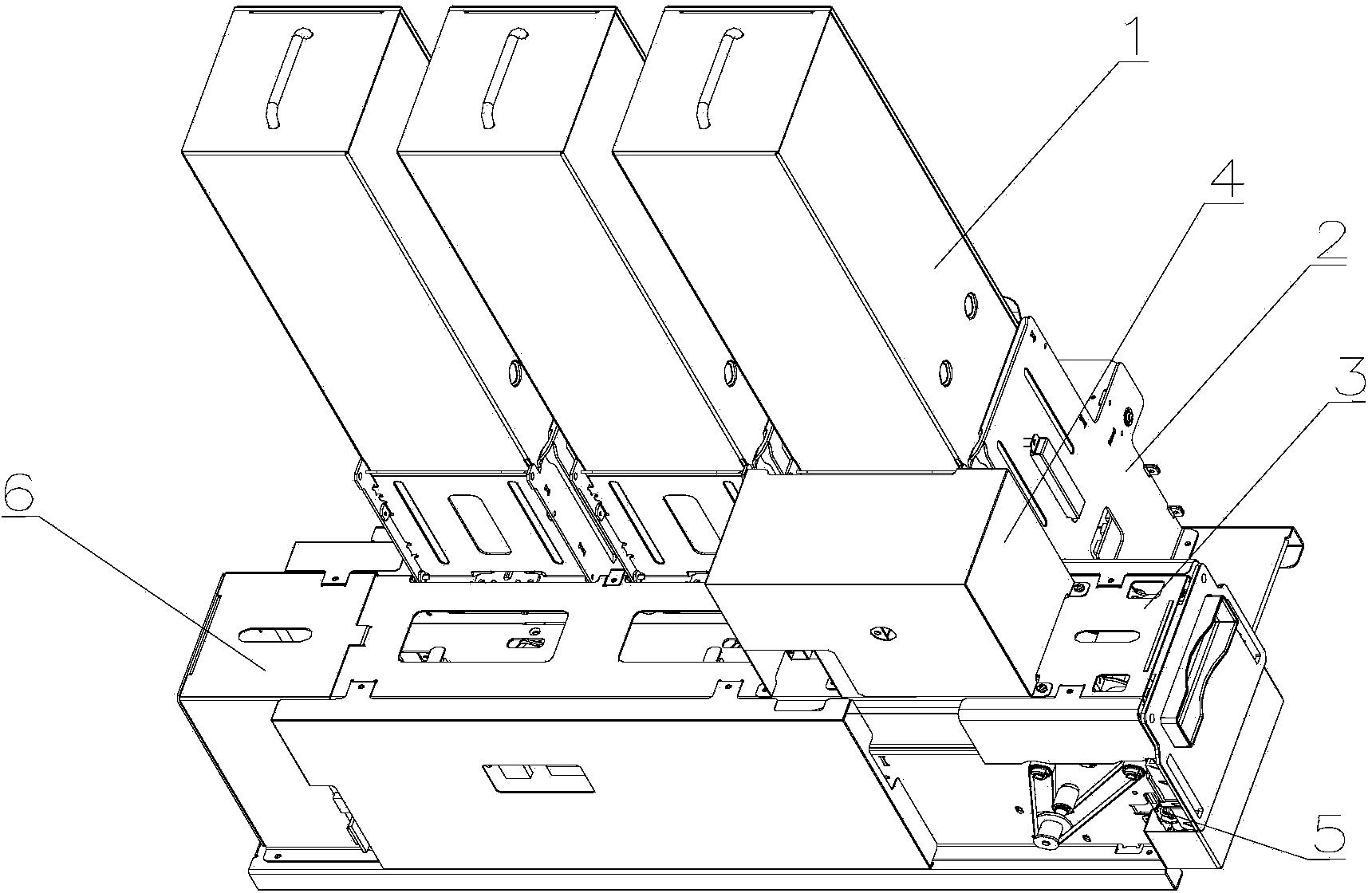

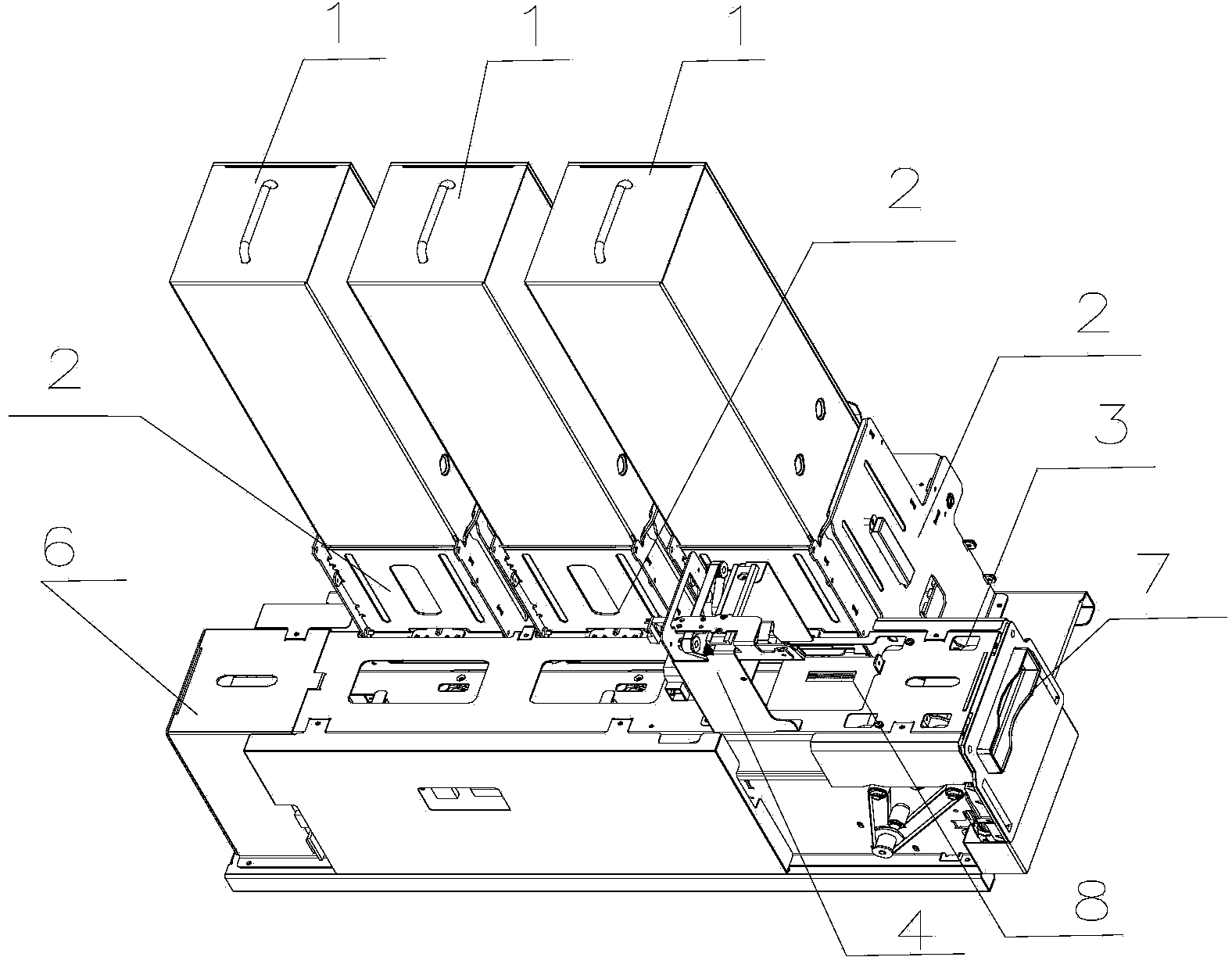

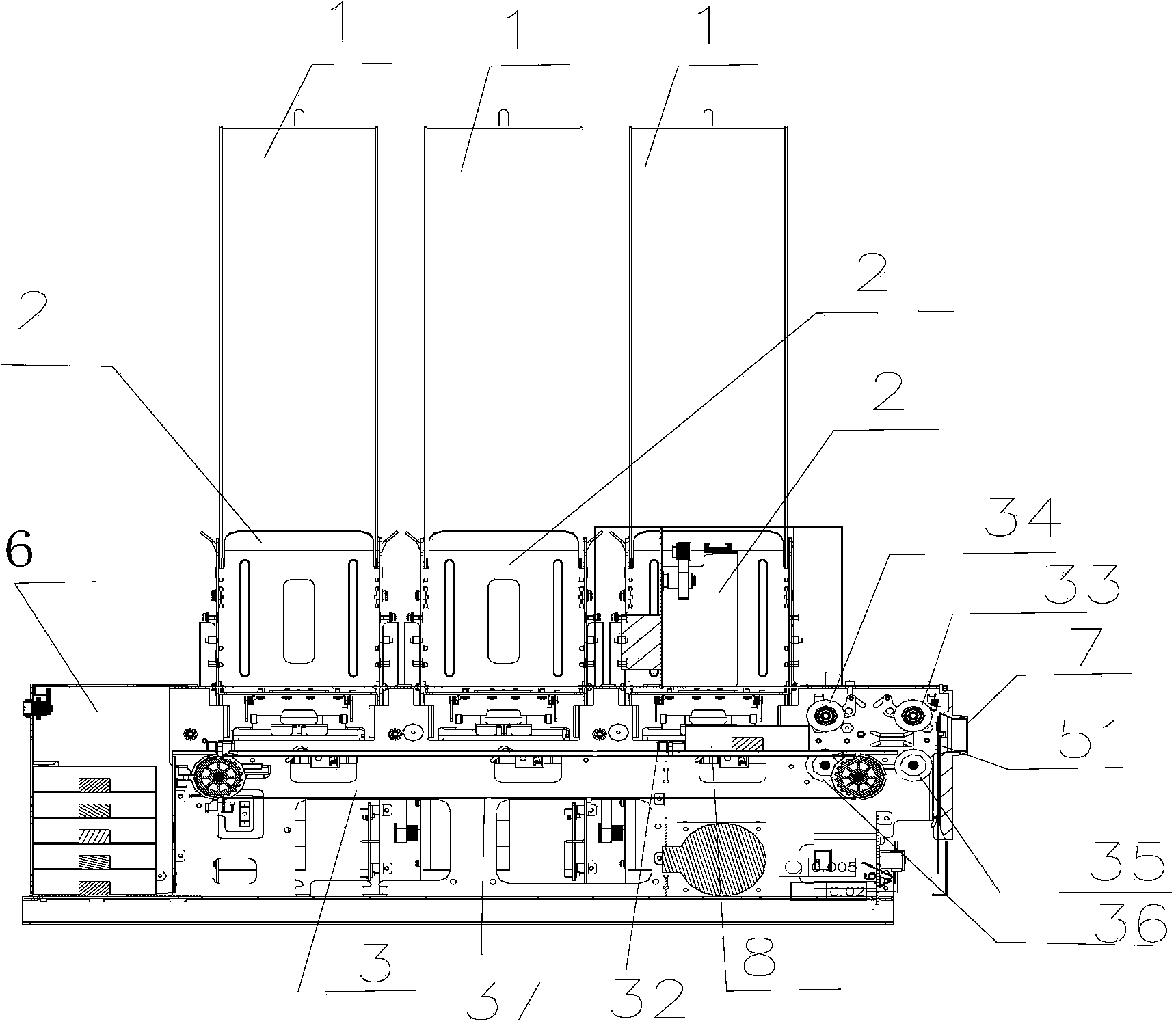

Large-capacity E-bank verification module issuing system for financial self-service system

ActiveCN104239911ACompact structureWon't interfereComplete banking machinesConveying record carriersComputer moduleTransmission channel

The invention discloses a large-capacity E-bank verification module issuing system for a financial self-service system. The large-capacity E-bank verification module issuing system for the financial self-service system comprises storage boxes (1), pushing mechanisms (2), a transmission mechanism (3), a scanning mechanism (4), a gate mechanism (5) and a recovery box (6). The number of the storage boxes and the number of the pushing mechanisms are both N. A plurality of stacked E-bank verification modules are stored in each storage box, and the pushing mechanisms are used for sending KEY boxes in the storage boxes to a transmission channel in the transmission mechanism. The gate mechanism and the recovery box are arranged at the two ends of the transmission mechanism respectively. The KEY boxes are transmitted to the recovery box to be recovered or transmitted to the gate mechanism to be issued to users by the transmission mechanism. The scanning mechanism is used for scanning the identity identification codes on the KEY boxes which pass through the transmission channel. The large-capacity E-bank verification module issuing system for the financial self-service system can automatically issue the E-bank verification modules, has the advantages of automation and intellectualization, and can support issuing of large-capacity KEY boxes.

Owner:HUNAN GREATWALL INFORMATION FINANCIAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com