Novel fixed pressure ring type fast opening blind plate and opening and closing method of novel fixed pressure ring type fast opening blind plate

A fixed pressure ring, a new type of technology, applied in the direction of pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve the problems of complex processing, poor stress, and laborious opening and closing, and achieve high safety and reliability. The effect of good force state and flexible opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

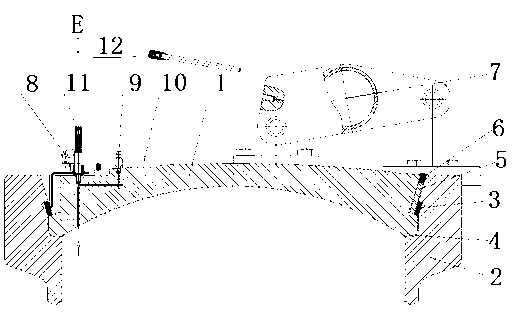

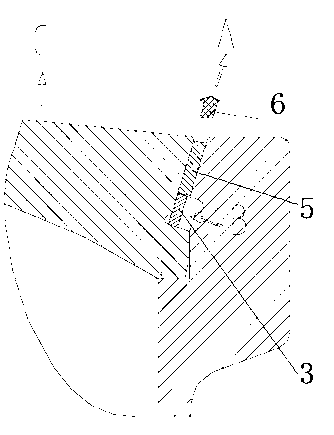

[0016] A new type of fixed pressure ring type quick opening blind plate, such as figure 1 and figure 2 As shown, it includes: head cover 1, cylinder flange 2, fixed pressure ring 3, seal 4, limit ring 5, dustproof ring 6, rotating arm mechanism 7, opening and closing mechanism 8, pressure transmitter 9, Sound and light alarm 10, etc., among which:

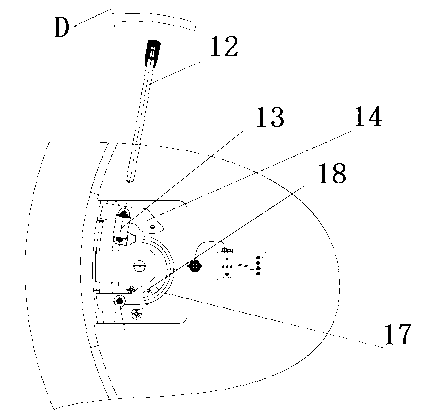

[0017] A limit ring 5 is provided between the head cover 1 and the cylinder flange 2, and a card slot is provided on the cylinder flange 2 for accommodating the fixed pressure ring 3; a rotating arm mechanism 7, Opening and closing mechanism 8 (including handle base 13, first connecting plate 14, second connecting plate 18, U-shaped connecting ring 17, etc., see figure 2 ), a pressure transmitter 9 and an audible and visual alarm 10, one end of the fixed pressure ring 3 is connected to one end of the handle base 13 through the first connecting plate 14, and the other end of the handle base 13 is connected to the second through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com