Patents

Literature

2188results about How to "Easy to open and close" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

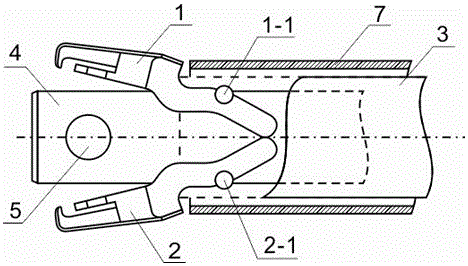

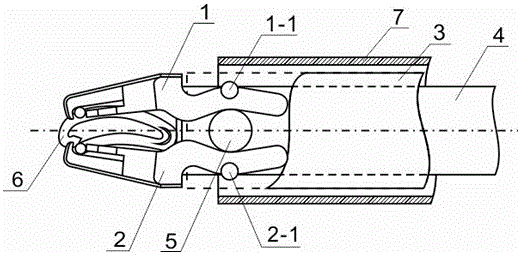

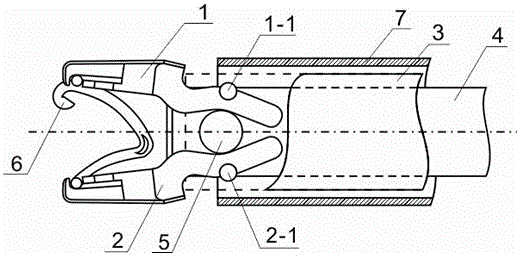

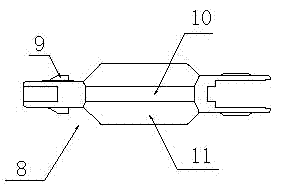

clip applier for surgical ligation

Owner:徐保利

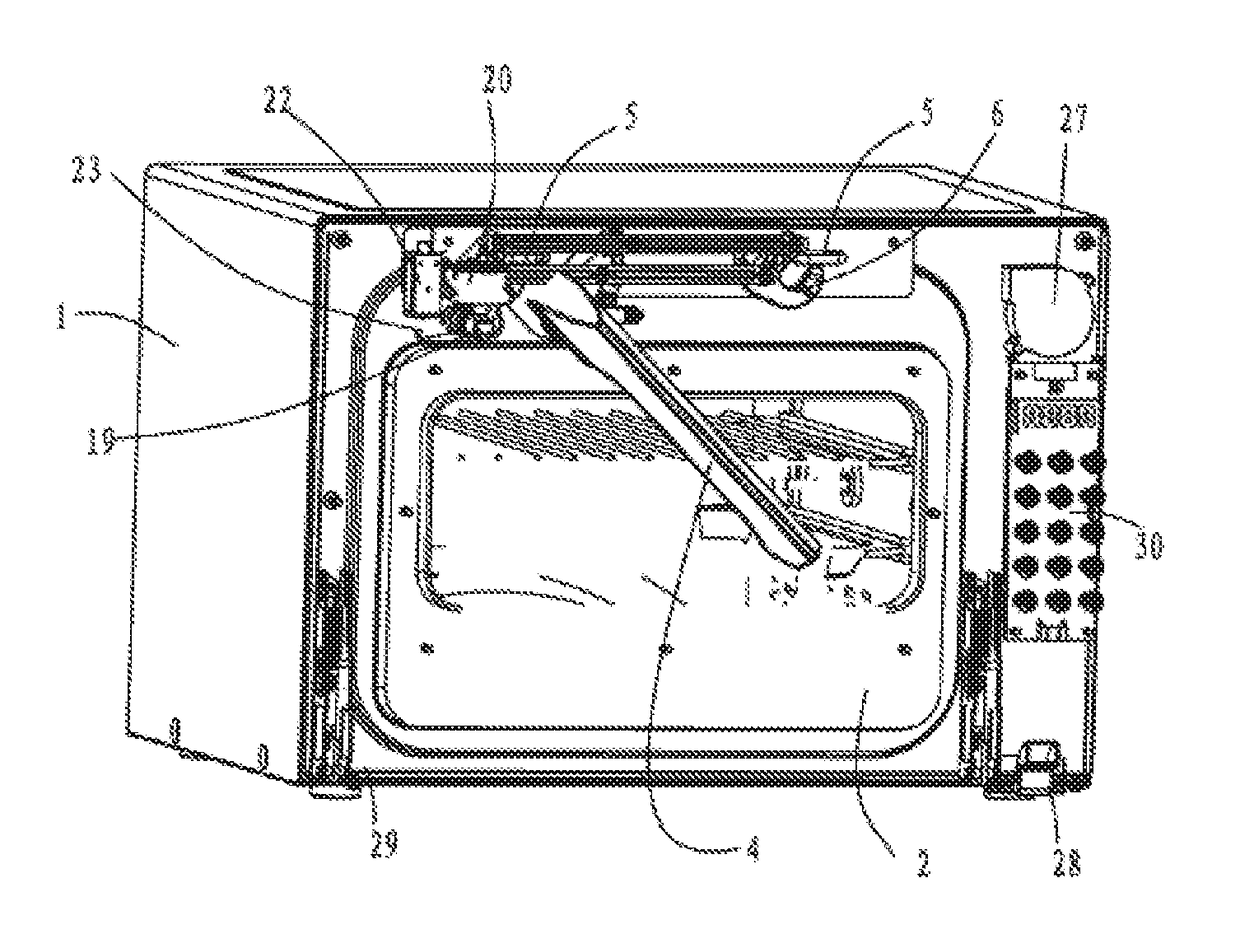

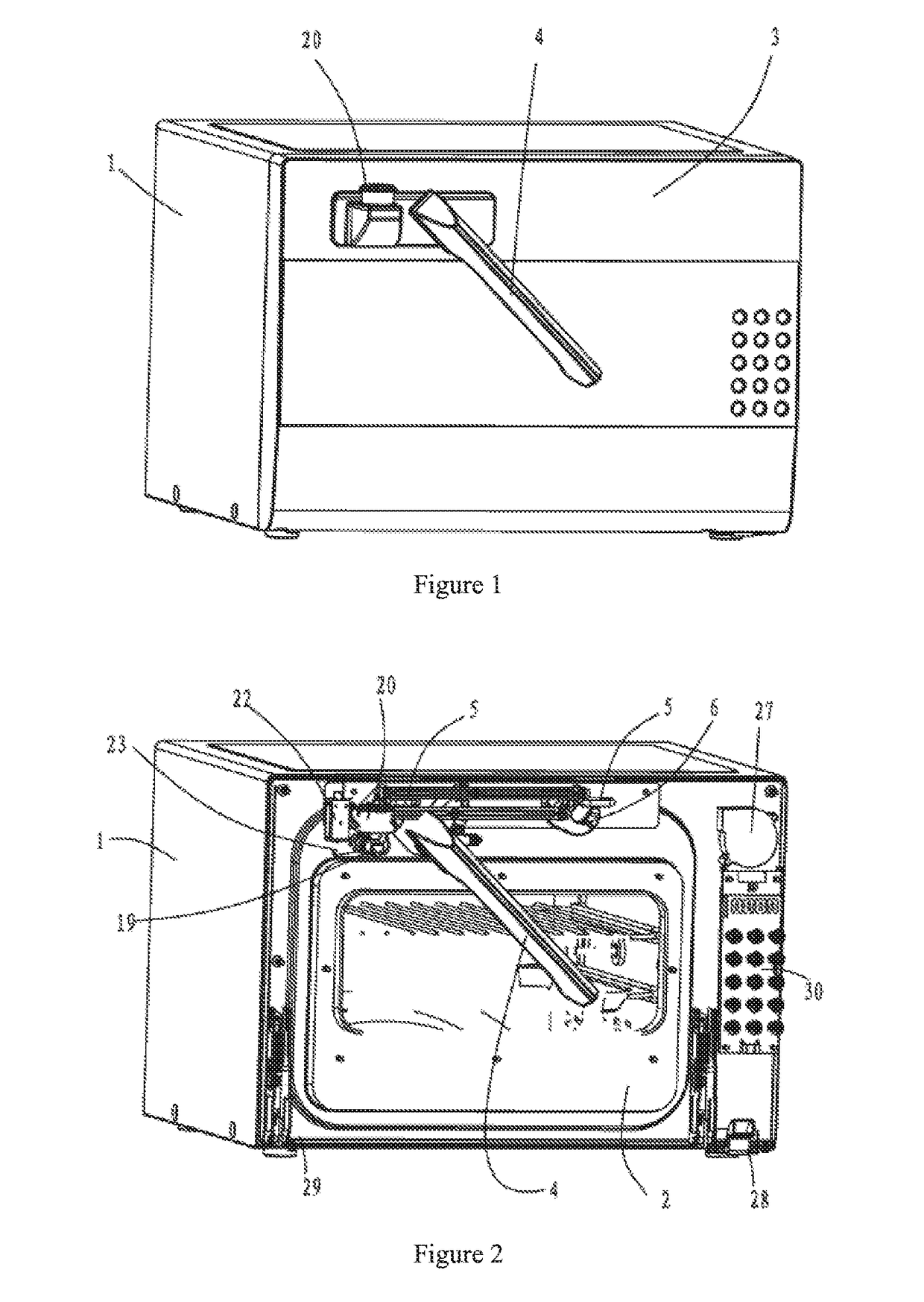

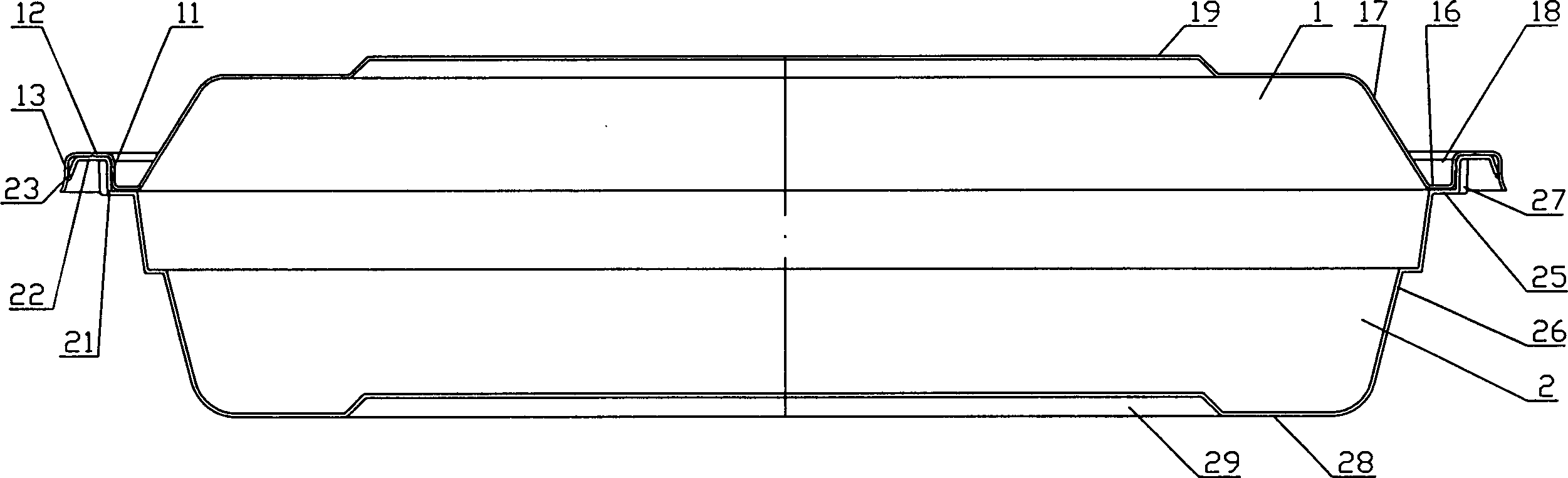

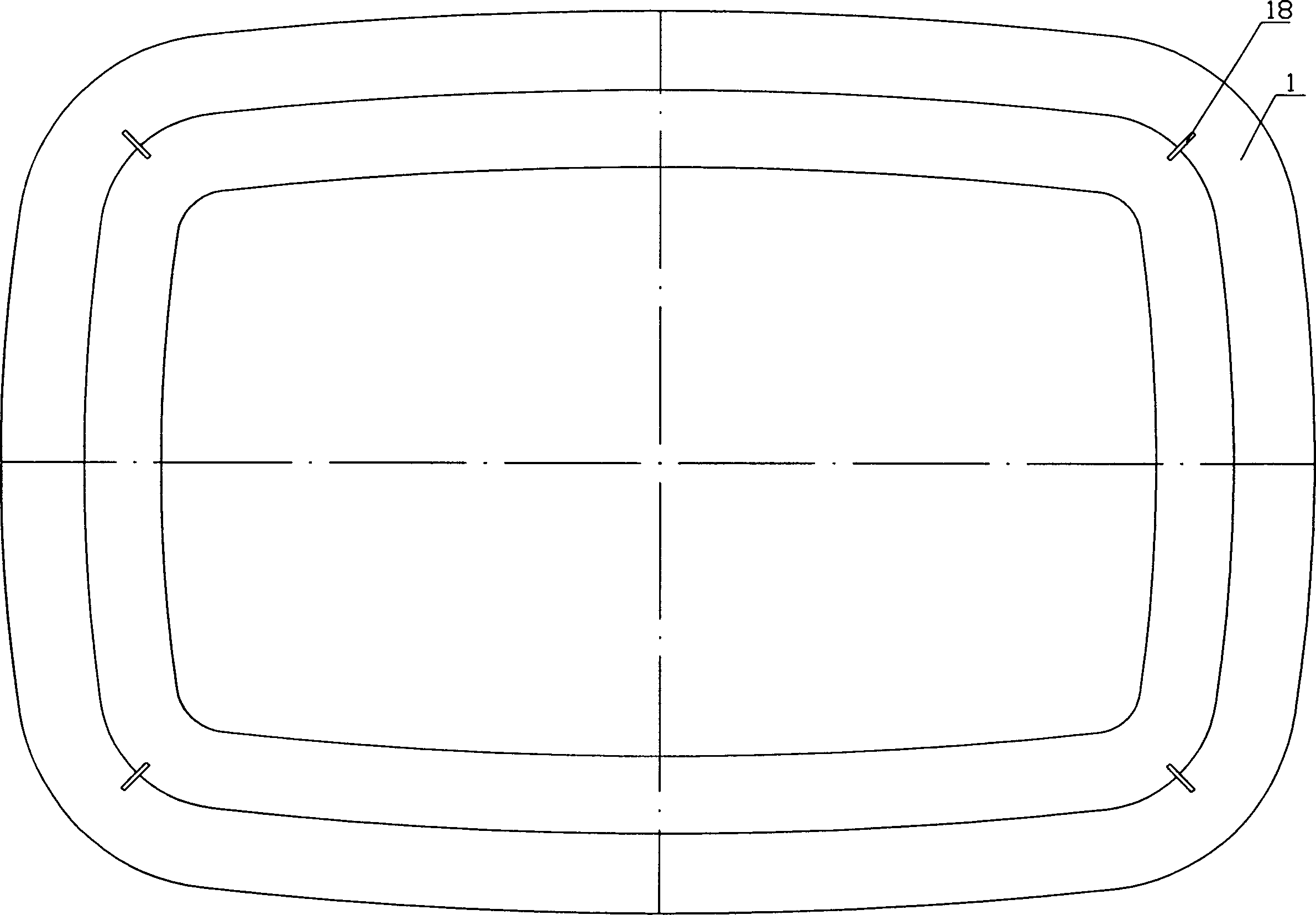

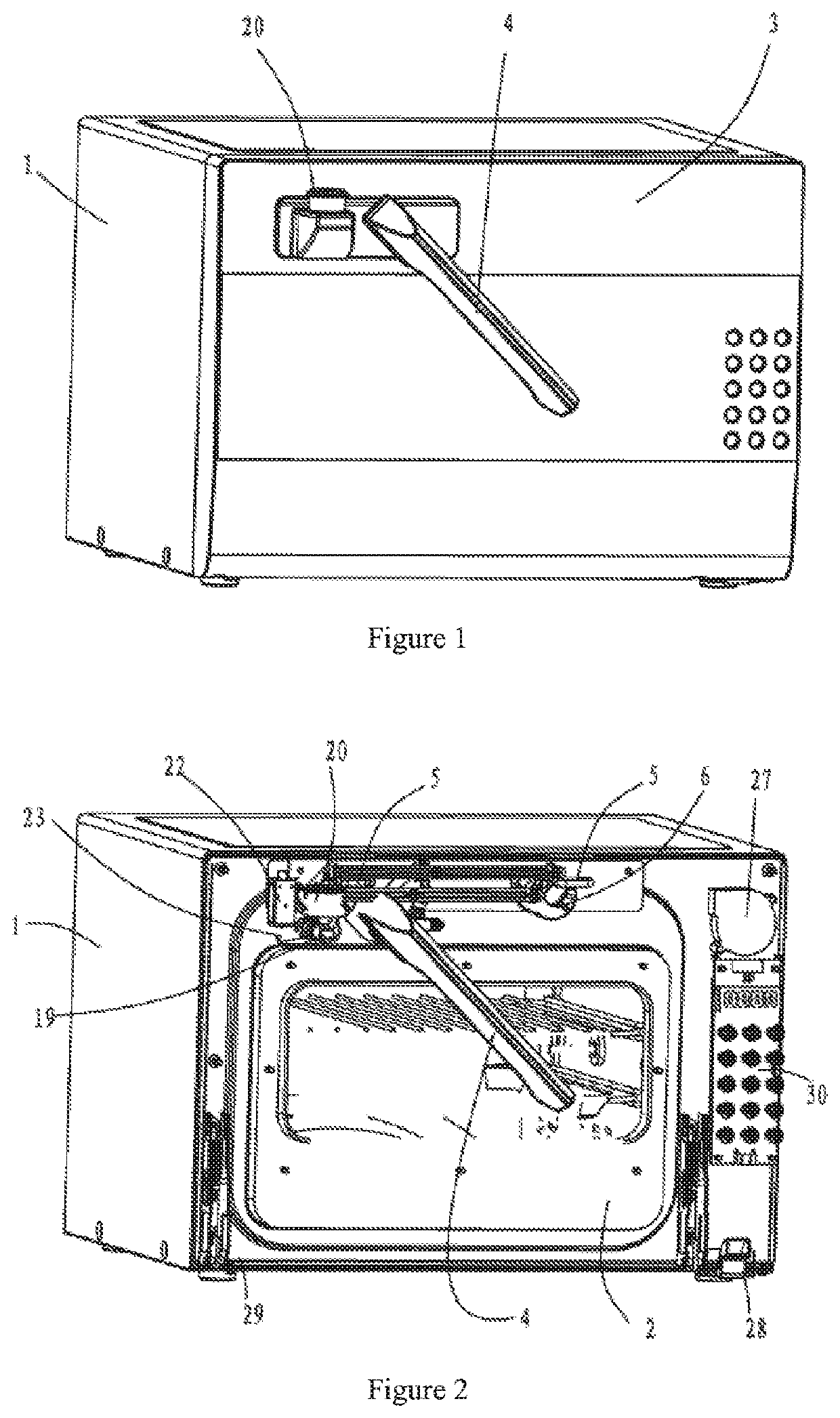

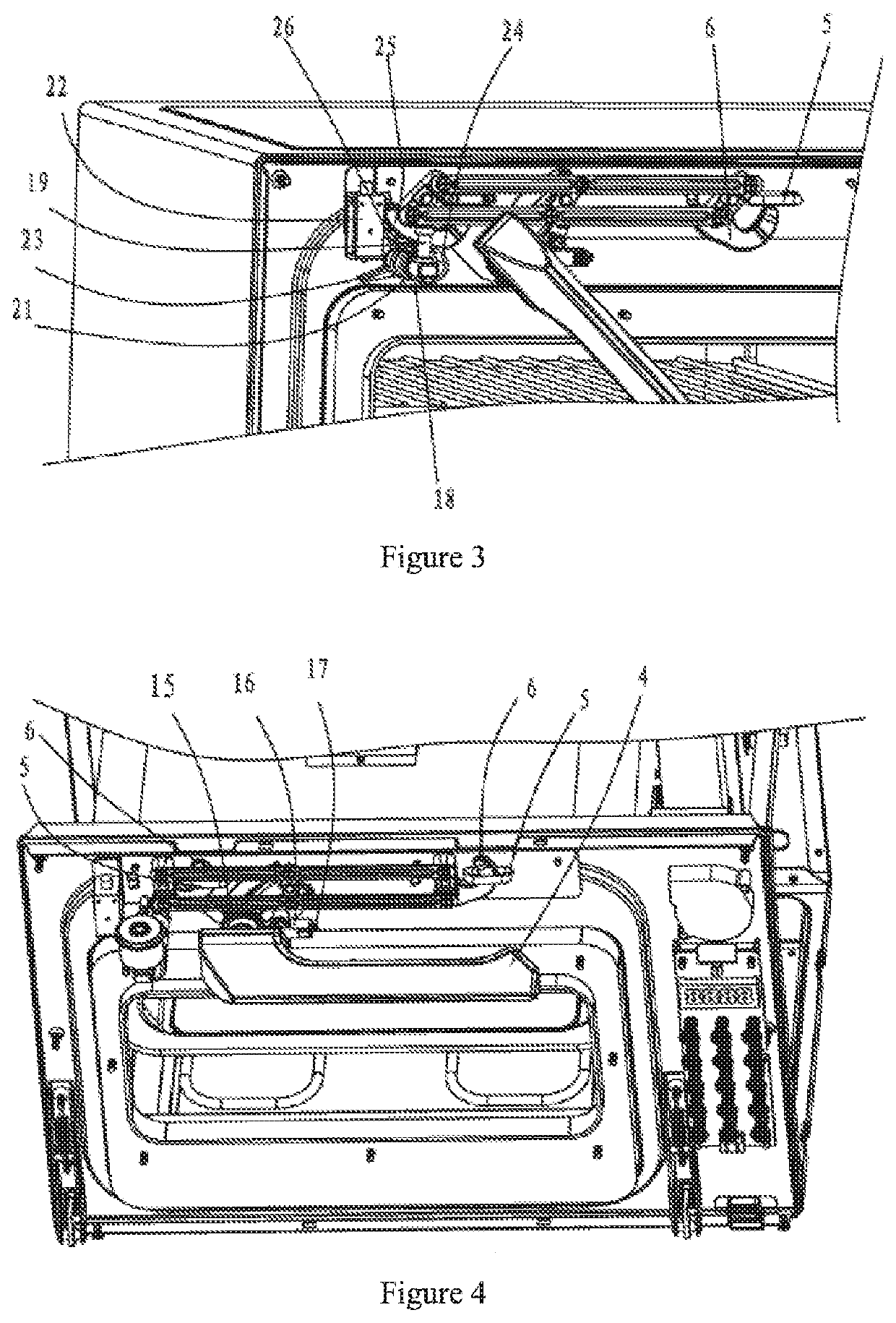

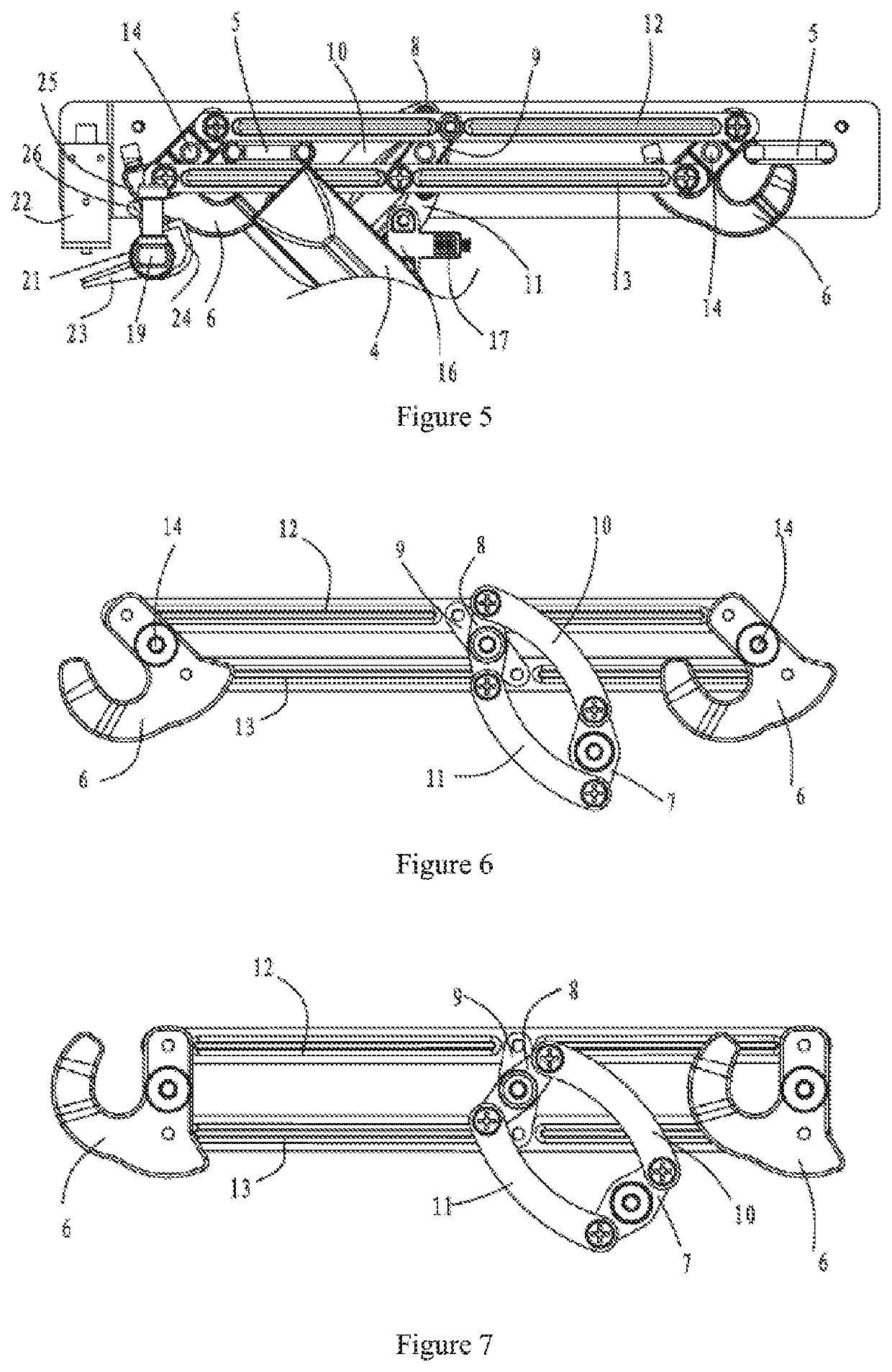

Pressure Oven

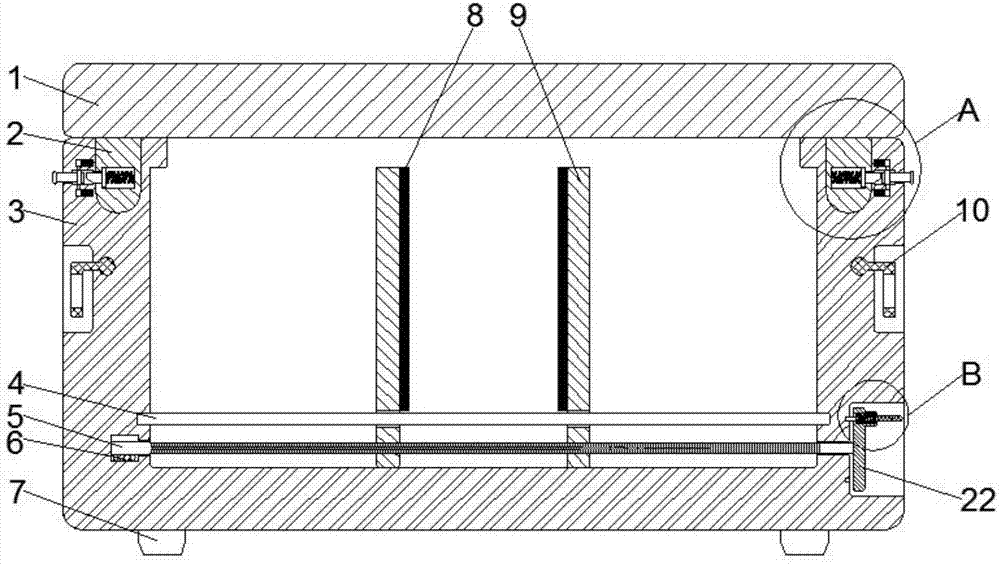

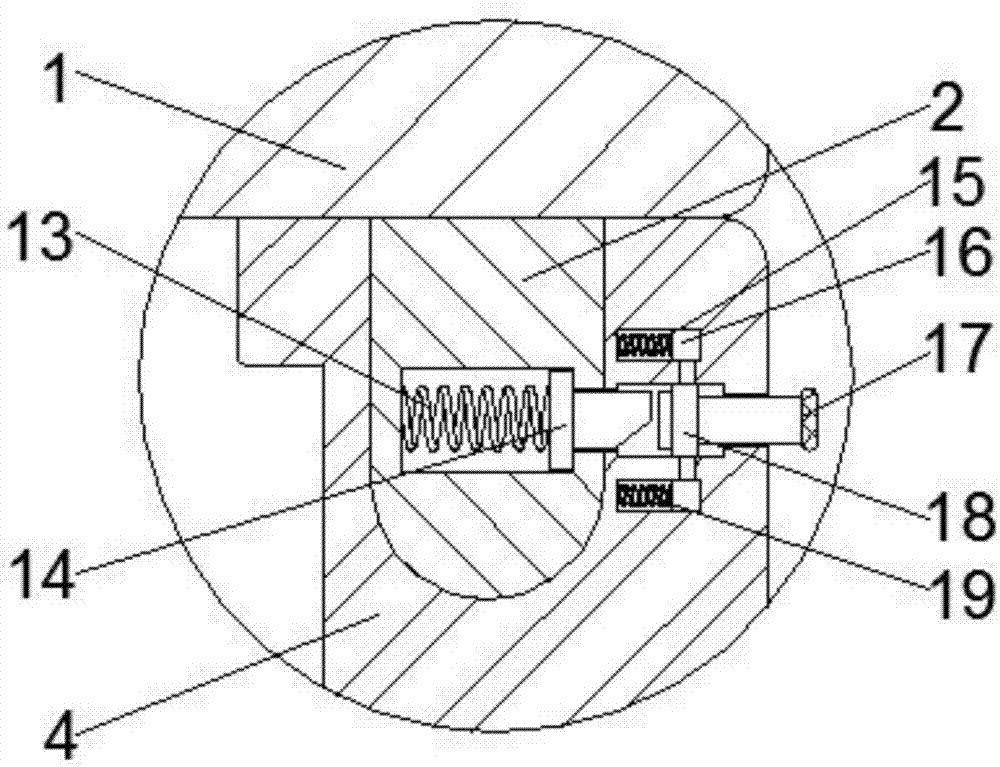

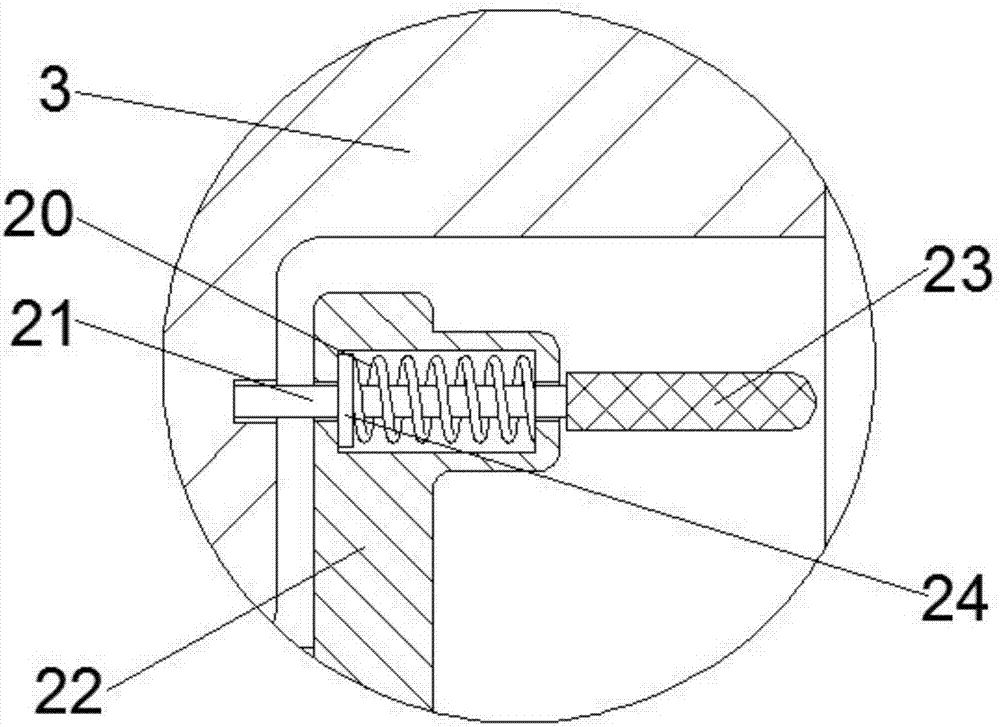

ActiveUS20180199756A1Reasonable structural designConvenient for opening and closingRoasters/grillsPressure-cookersUltimate tensile strengthRelief valve

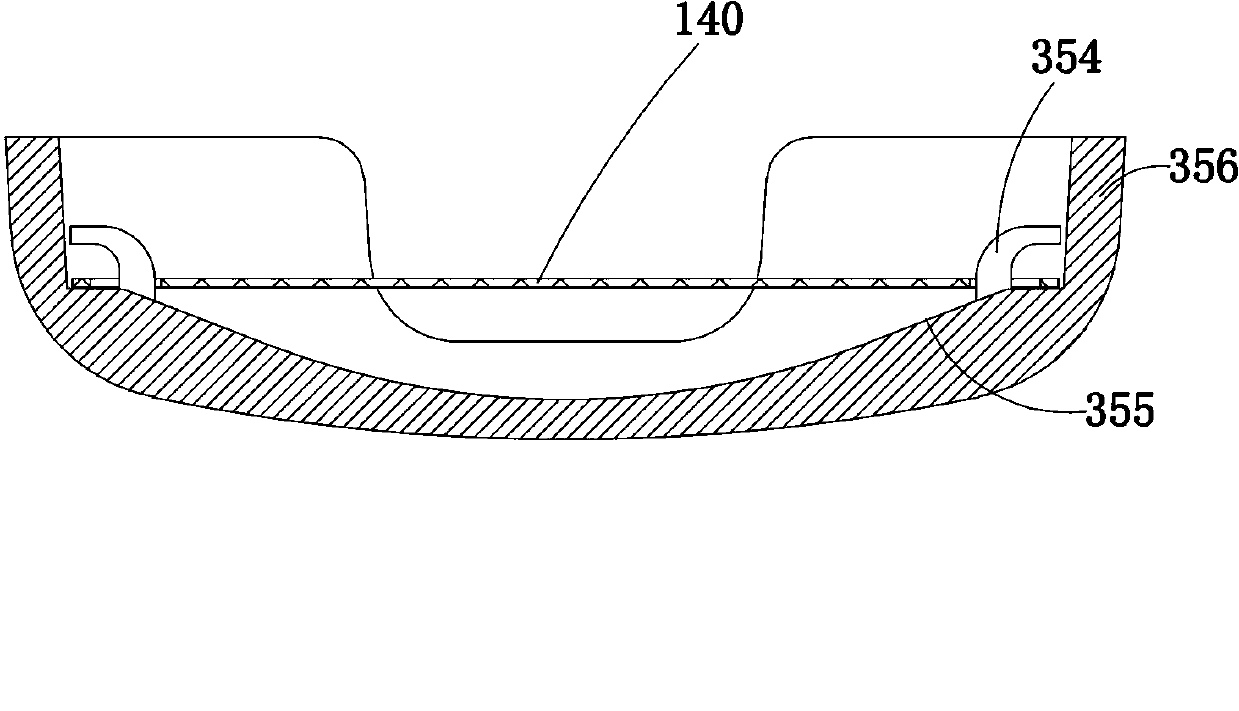

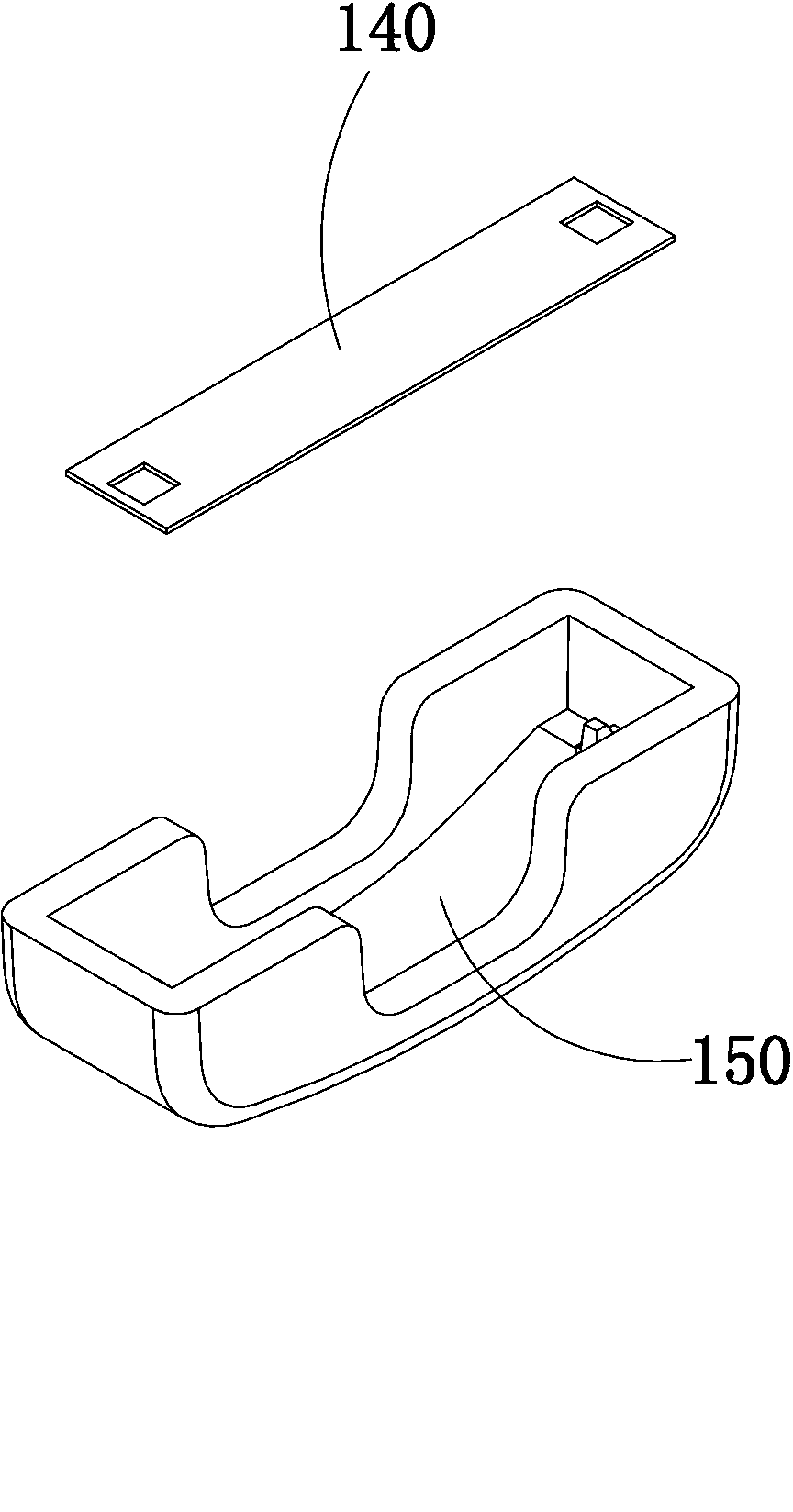

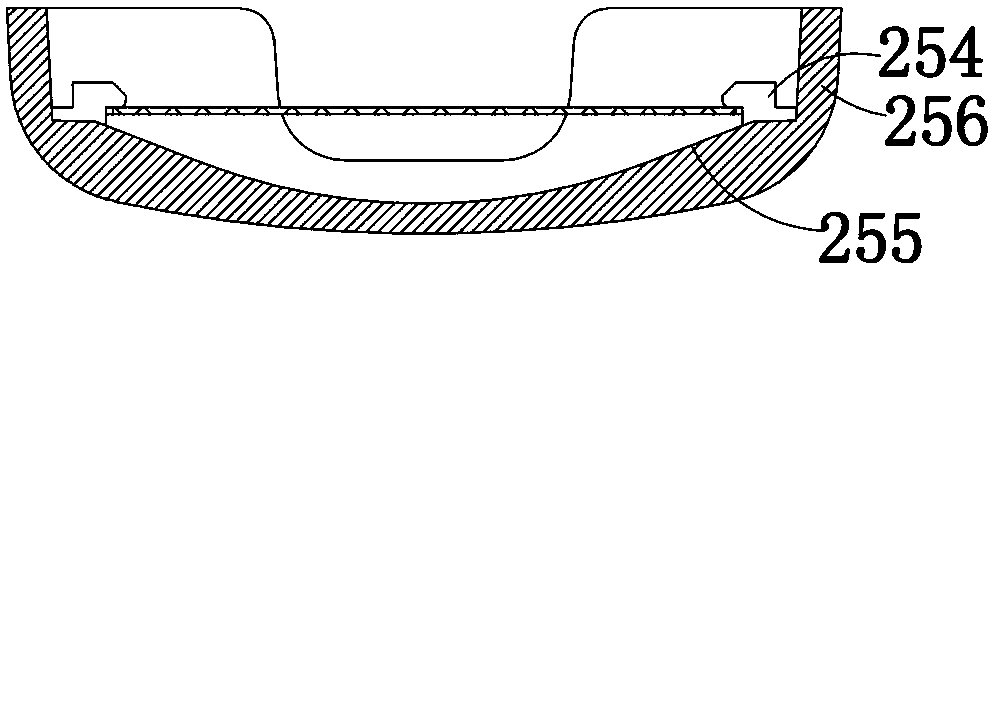

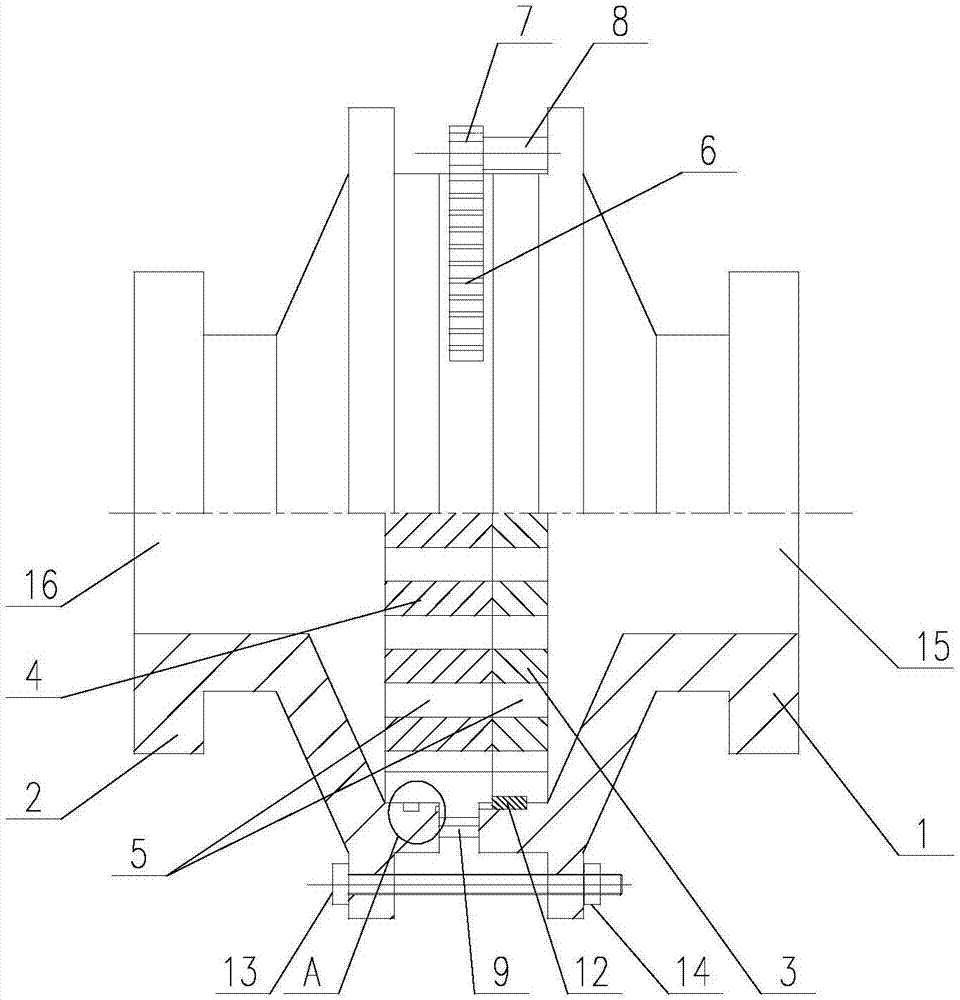

The present invention relates to a pressure oven with a pressurized inner container. The pressure oven includes an oven body, the inner container, an oven door and a handle, where the bottom side of the oven door is rotatably connected with the oven body, the handle is provided on top of the oven door, two locking catches are horizontally provided on the front face of the oven body, the corresponding inner surface of the oven door is provided with two locking hooks, and the handle drives the two locking hooks to rotate via a linkage drive device so as to achieve locking or unlocking between the locking hooks and the locking catches. The pressure oven has a rational structural design, the oven door is convenient for opening and closing, and a pressure relief valve is designed to be on the oven door so as to help combine the oven as an integral part of the entire kitchen. In addition, heating electronic elements are located at the back faces of the oven door and the oven body, such that two side faces of the oven body do not have a heating element. The heating element in the oven door is cooled by a cooling fan, the heat from the heating element at the back face of the oven body is dissipated via heat dissipation holes, such that no heat dissipation hole is needed on the two side faces of the oven body. The oven has an attractive appearance, the inner container is an integral body with a high tensile strength, has no gap, and is easy to clean. The pressure oven can be secured by a hanging hook and can be easily dismounted.

Owner:ZHONGSHAN JINGUANG HOUSEHOLD APPLIANCE MFG CO LTD

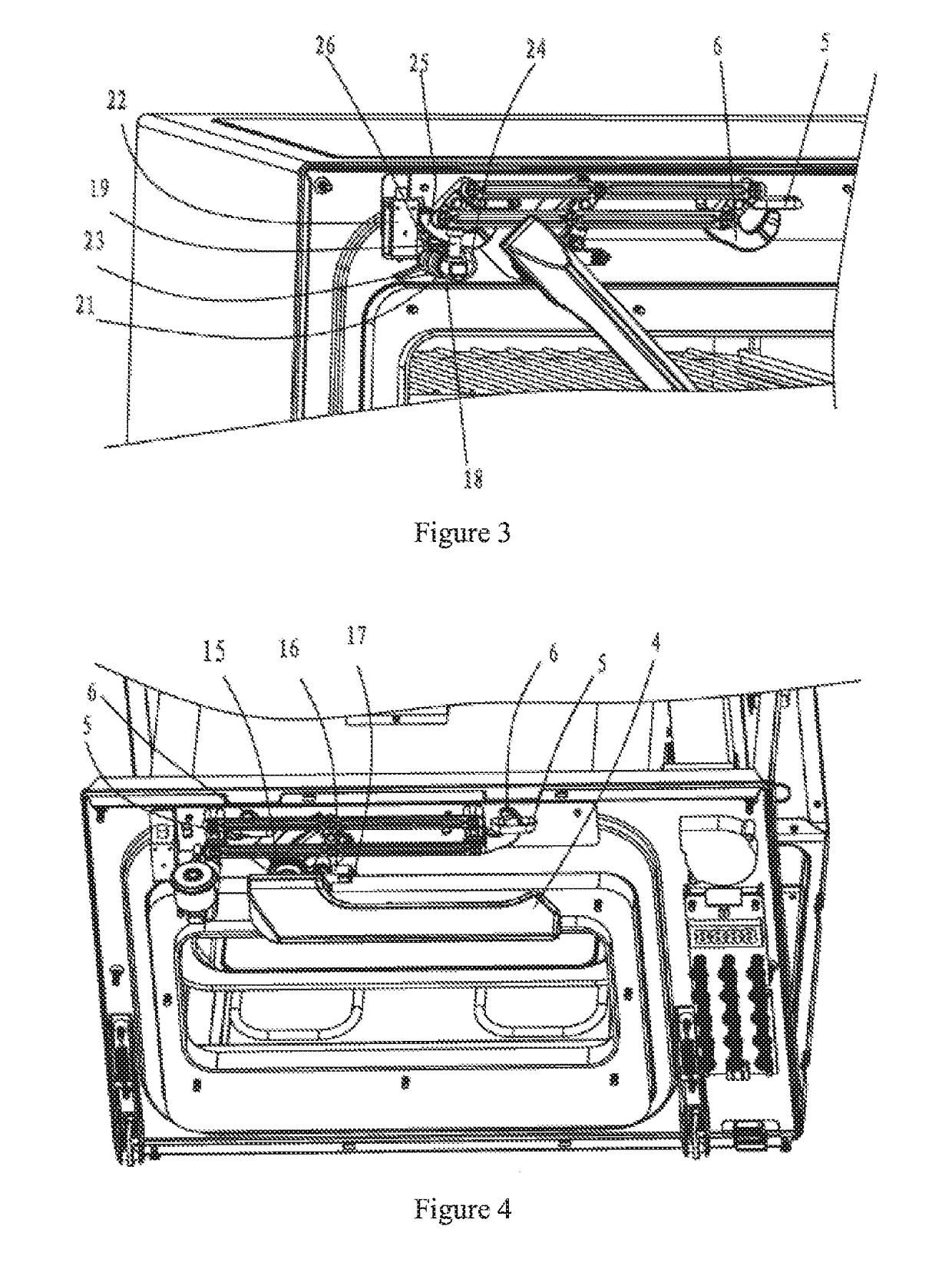

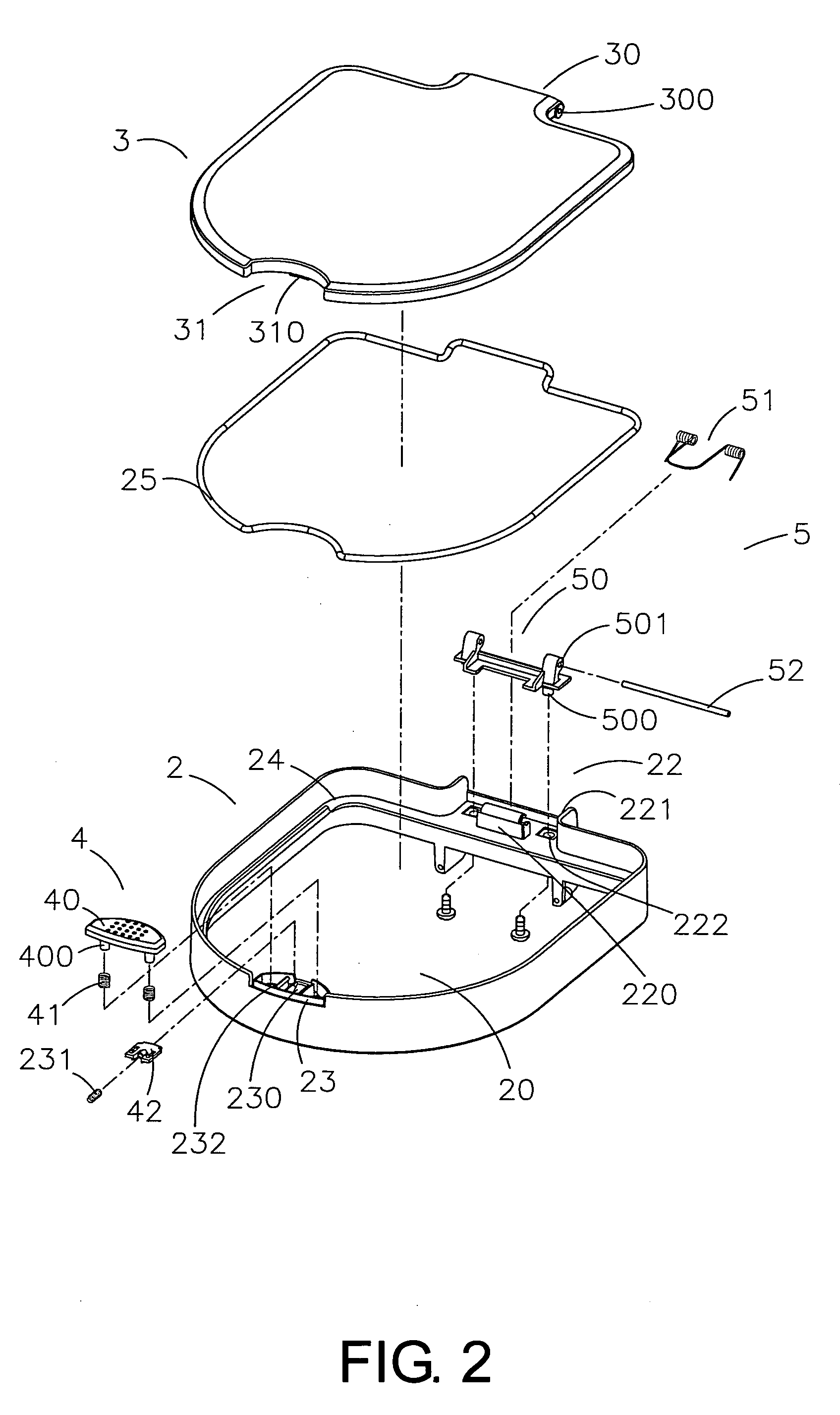

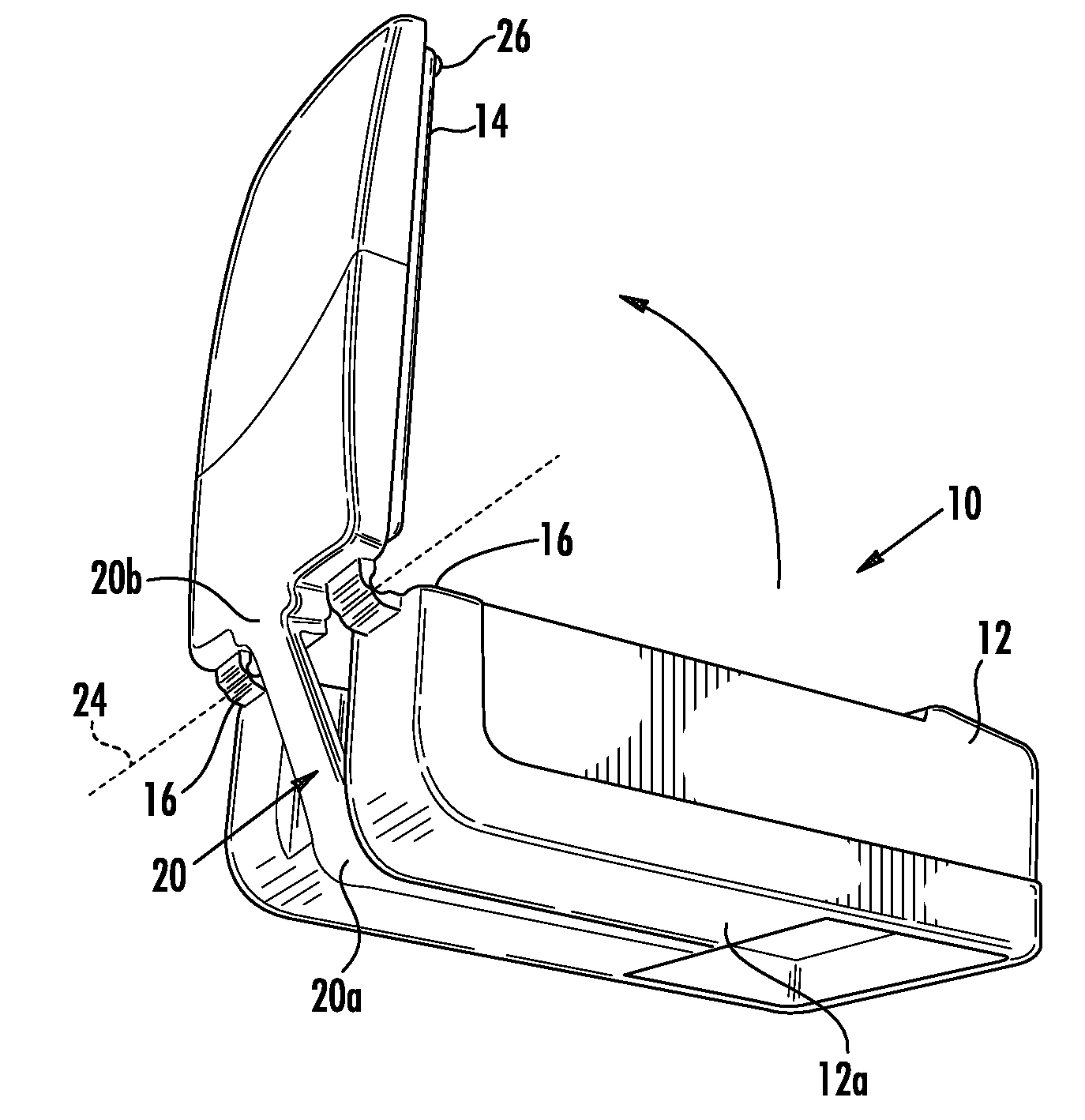

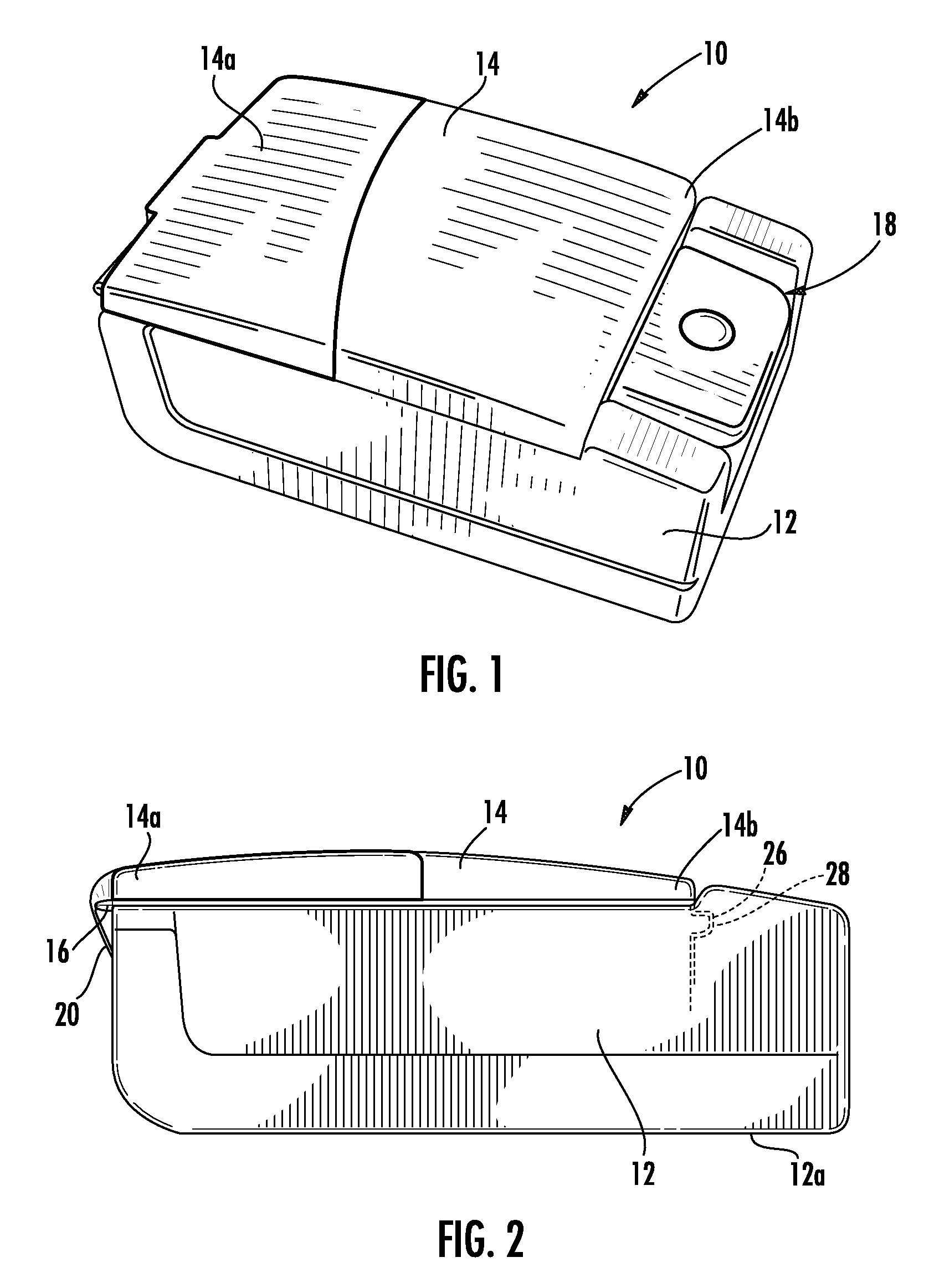

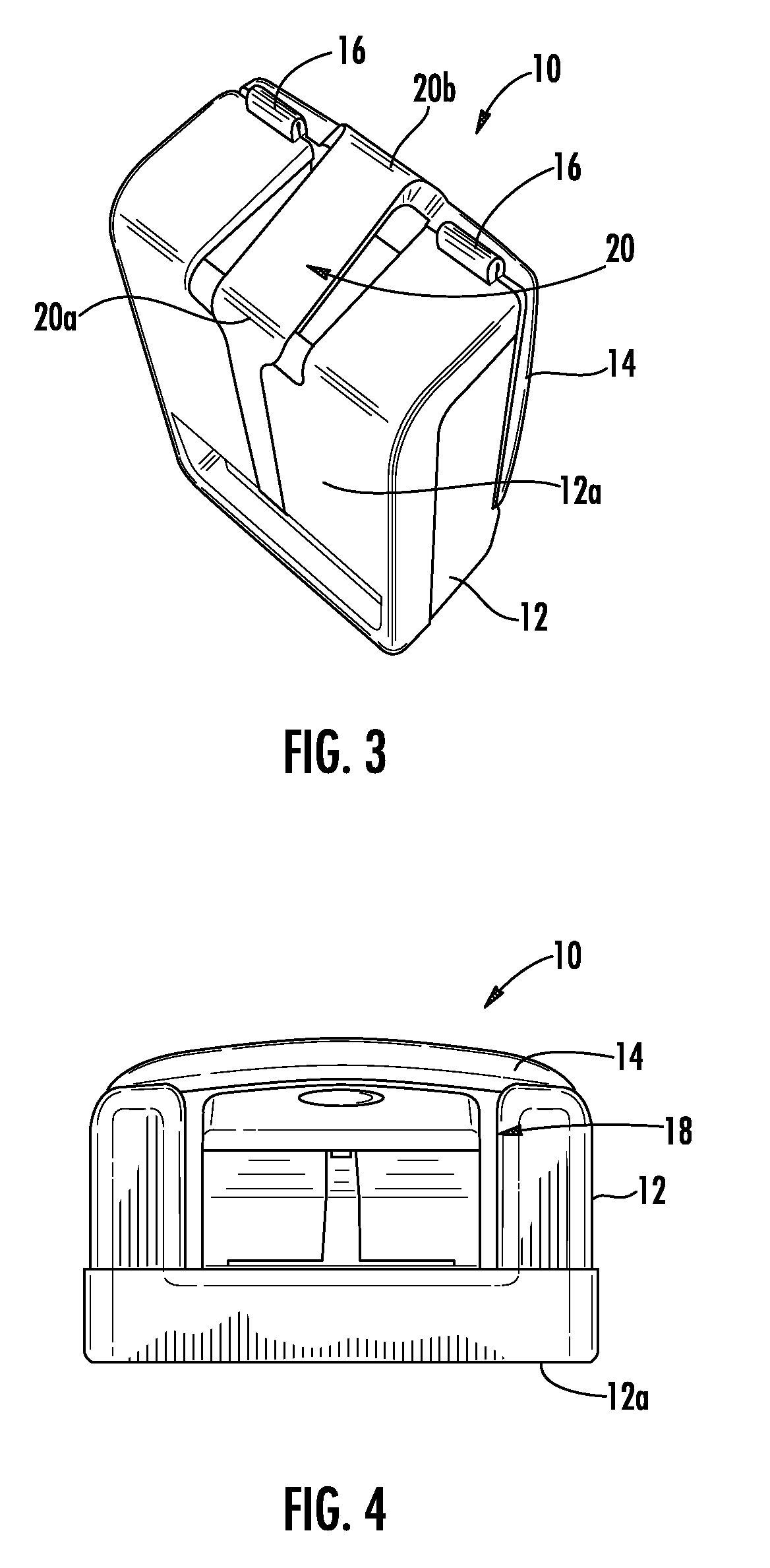

Garbage bin lid

InactiveUS20100006572A1Convenient to open and closeConvenient to attach and useRefuse receptaclesLidsEngineeringMechanical engineering

Owner:CHIOU CHIN FU

Method for manufacturing ultrafine powder from polytetrafluoroethylene through irradiation cracking

InactiveCN102672968AHigh powerHigh radiation processing efficiencyGrain treatmentsAirflowPolytetrafluoroethylene

The invention discloses a method for manufacturing ultrafine powder from polytetrafluoroethylene through irradiation cracking. The method is characterized in that polytetrafluoroethylene raw materials are dried; the dried polytetrafluoroethylene raw materials are subjected to low-temperature cold treatment by liquid nitrogen; the polytetrafluoroethylene raw materials subjected to the low-temperature treatment are crushed into powder materials with the particle diameter being 100-1000mum by a crushing machine; the powder materials are subjected to sealed package under the gas protection effect; the packed powder materials are placed into an electronic accelerator irradiation system for irradiation cracking; and the irradiated powder materials pass through an air flow crushing machine to be subjected to air flow crushing and grading, and the ultrafine polytetrafluoroethylene powder with the particle diameter reaching 0.2-3mum is obtained. The method has the characteristics that the preparation process is simple, the control is easy, the energy consumption is low, the process continuous degree is high, the product performance is stable, the prepared ultrafine polytetrafluoroethylene powder has the characteristics that the dispersibility is good, and the agglomeration cannot easily occur. The prepared ultrafine polytetrafluoroethylene powder can be widely applied to the fields of paint, ink, dray powder lubricating agents and space flight and aviation appliances, and the material performance is obviously improved.

Owner:四川久远科技股份有限公司

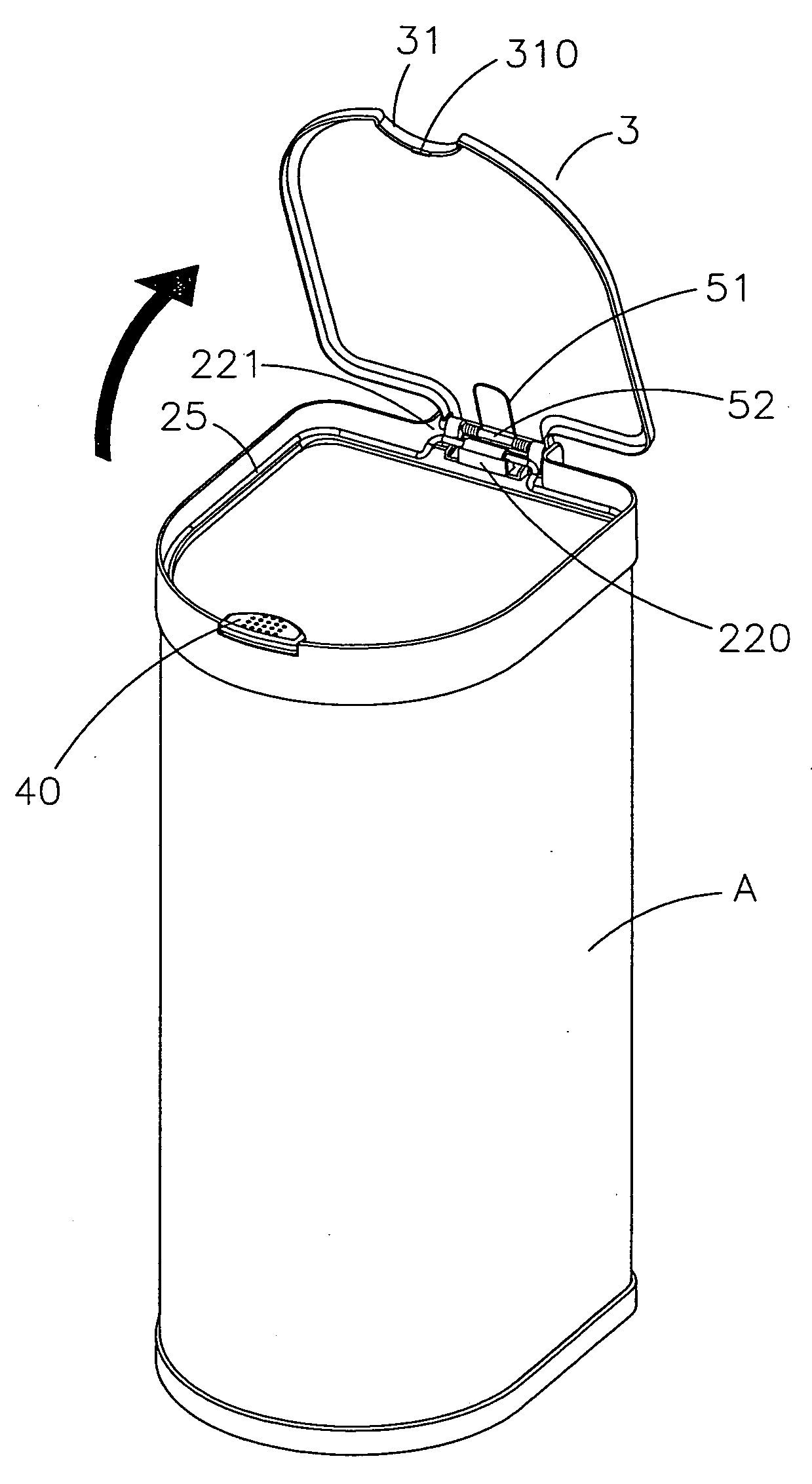

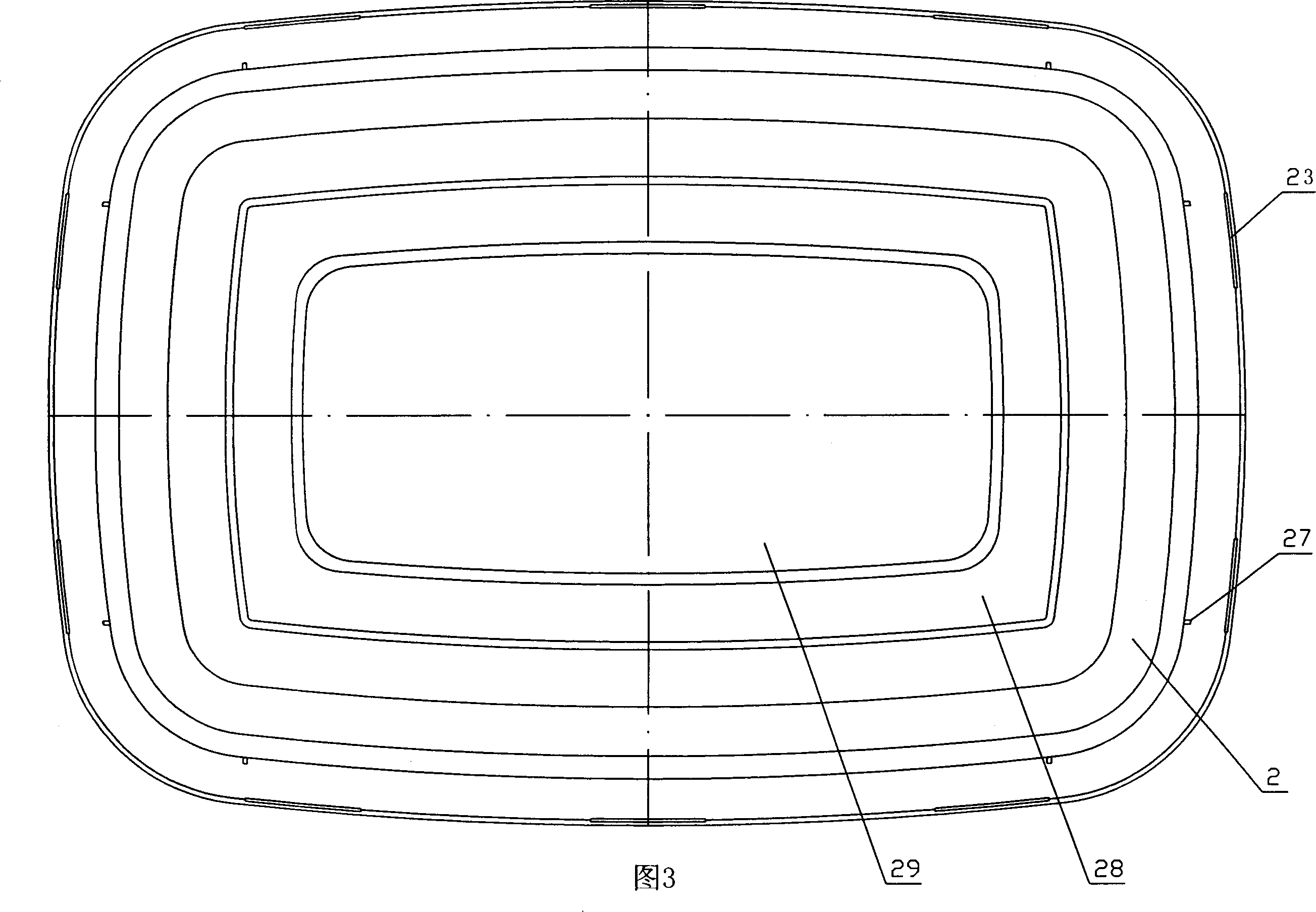

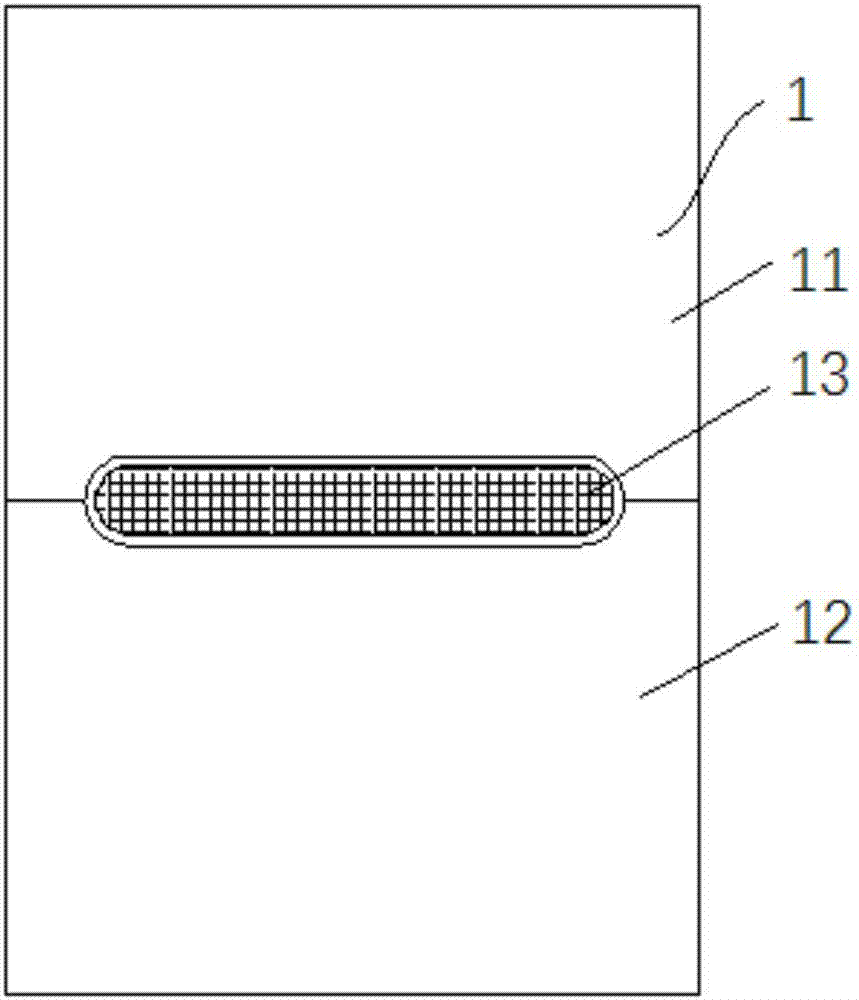

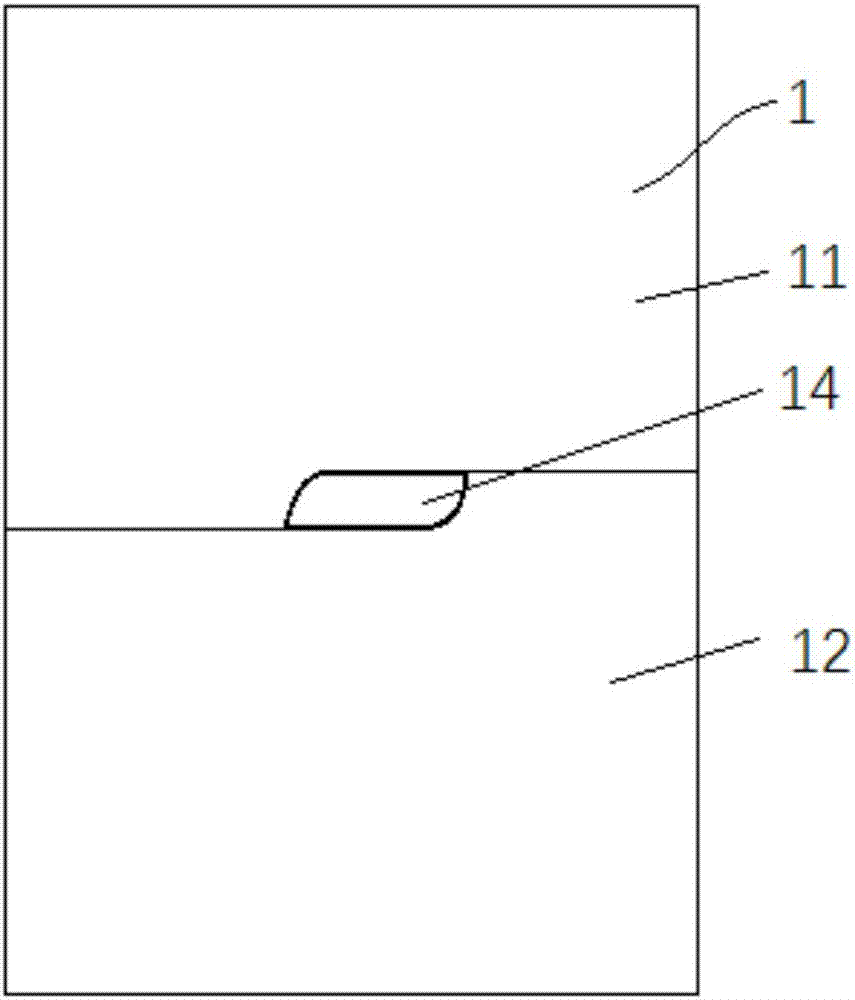

Full closed superthin food container

ActiveCN1820679AReasonable structureEasy to open and closeOther accessoriesLidsEngineeringCompressive strength

Owner:MEIYANG PLASTIC METALS PRODS QUANZHOU

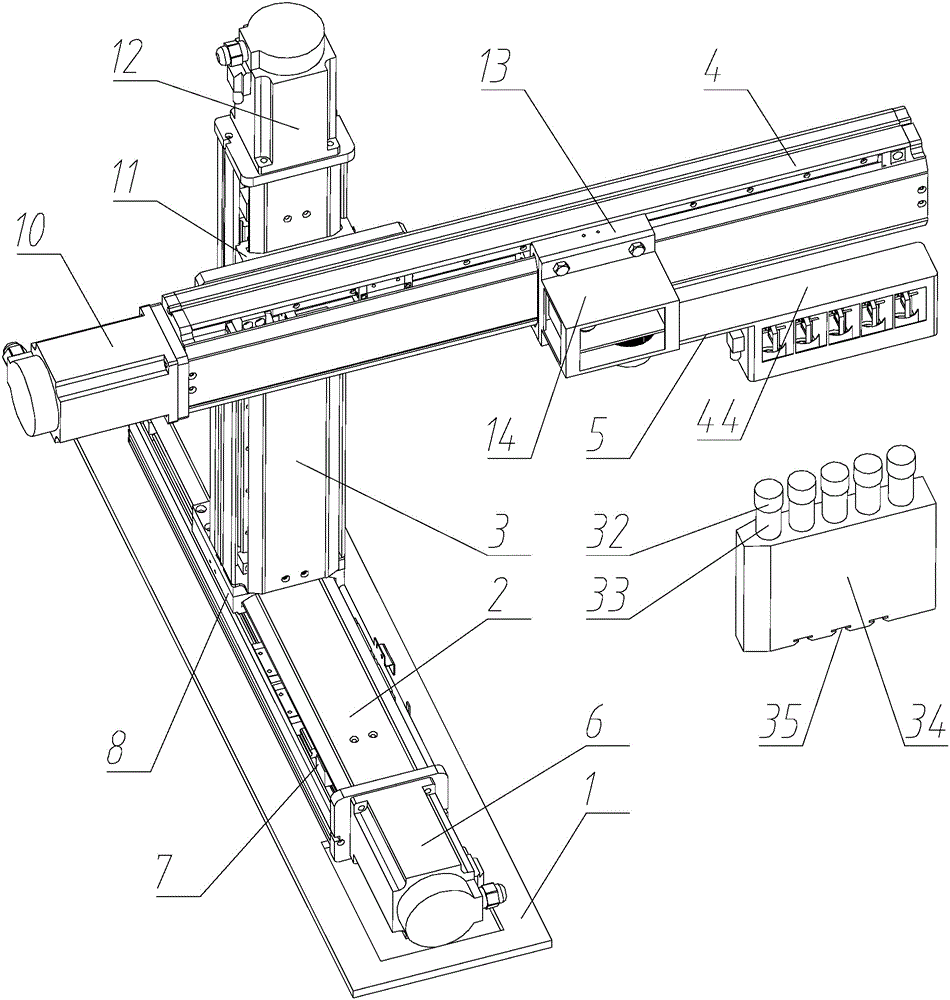

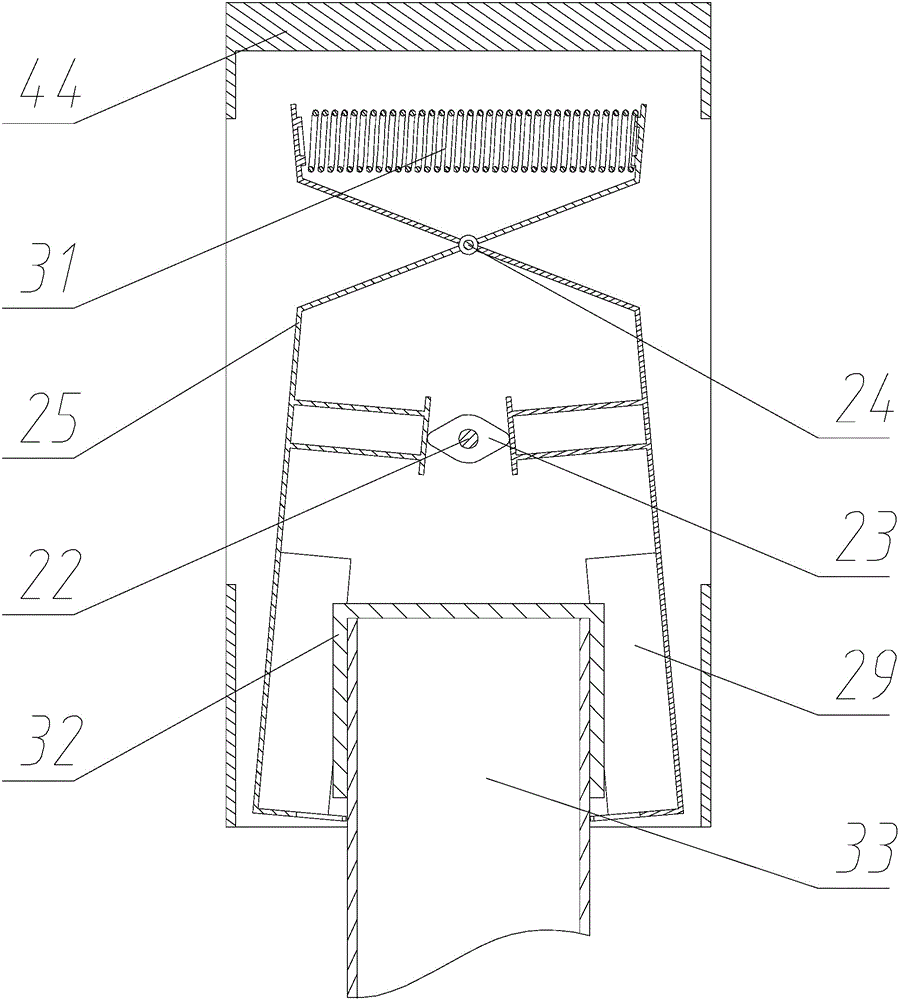

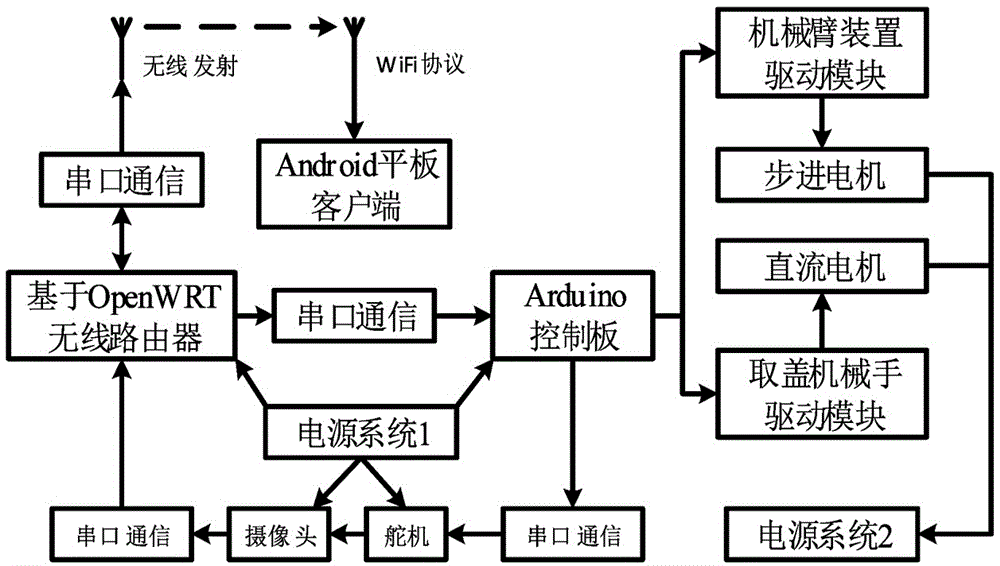

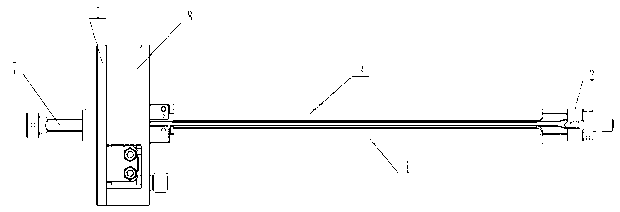

Automatic fast test tube cover taking robot and cover taking method

ActiveCN106272368AReduce the numberTime-consuming and laborious to solveProgramme-controlled manipulatorGripping headsBlood collectionEngineering

The invention relates to an automatic fast test tube cover taking robot and a cover taking method. The robot comprises a base, wherein an X-axis mechanical arm for controlling movements in front and back directions is arranged on the base, a Z-axis mechanical arm for controlling up and down movements is vertically arranged on the X-axis mechanical arm, a Y-axis mechanical arm for controlling left and right movements is vertically arranged on the Z-axis mechanical arm, and a cover taking mechanical hand is arranged on the Y-axis mechanical arm; and a mechanical arm rotation driving mechanism is arranged at one end of the cover taking mechanical hand, and a cover taking mechanism is arranged at the other end. The automatic fast test tube cover taking robot can automatically complete a cover taking task of a blood collection test tube, can adapt to blood collection test tubes and test tube racks in different specifications, and can recover test tube covers.

Owner:CHINA THREE GORGES UNIV

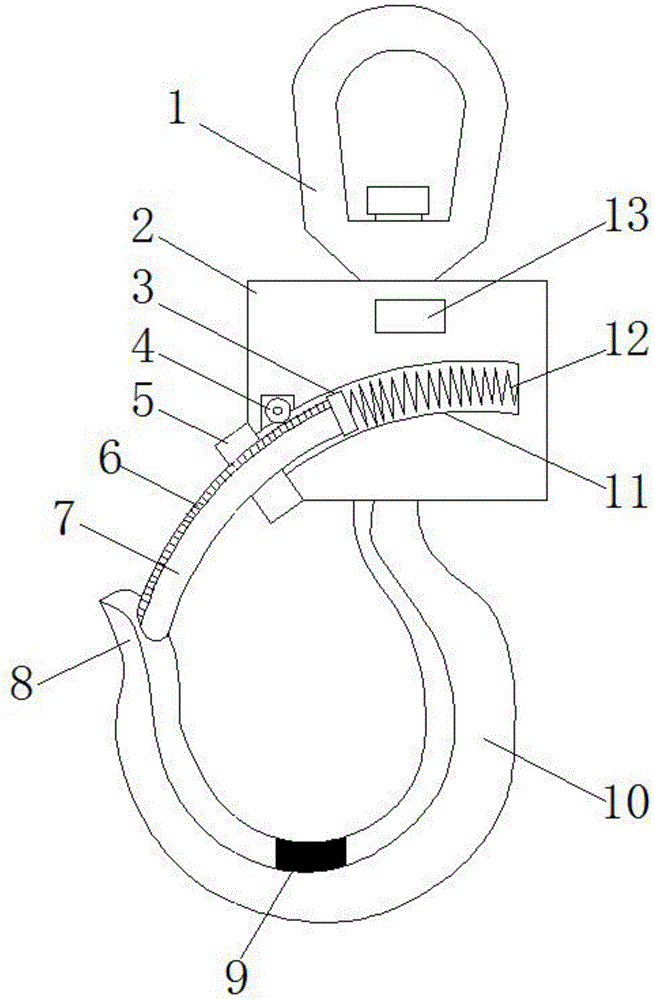

Crane automatic locking hook

InactiveCN105417358AImprove securityImprove stabilityLoad-engaging elementsMicro motorPressure sensor

The invention discloses a crane automatic locking hook. The hook comprises a suspension ring, an automatic locking device, a micro motor, an arc lock pin, and a hook body; the top of the automatic locking device is connected to the suspension ring; the bottom of the automatic locking device is connected to the hook body; the tail part of the hook body is provided with a hook tip; a pressure sensor is arranged in the bottom of the side face of the hook body, and is connected to a micro controller in a wireless mode; the micro controller is arranged in the automatic locking device and is provided with an arc sliding chute; the end part of the arc sliding chute is communicated with a locking chute hole, the arc lock pin is arranged in the arc sliding chute, the end part of the arc lock pin is provided with a limit stop, the tail end of the limit stop is connected to a reset spring, the upper end face of the arc lock pin is provided with a rack, and the micro motor is arranged on the arc sliding chute that is closed to the locking chute hole end. The crane automatic locking hook has the advantages that the arc lock pin can be automatically locked, the automation degree is high, the locking is firm, the effect of unhooking is good, and the safety and stability of hook application are enhanced.

Owner:ANHUI CHAOSHENG HOISTING MACHINERY CO LTD

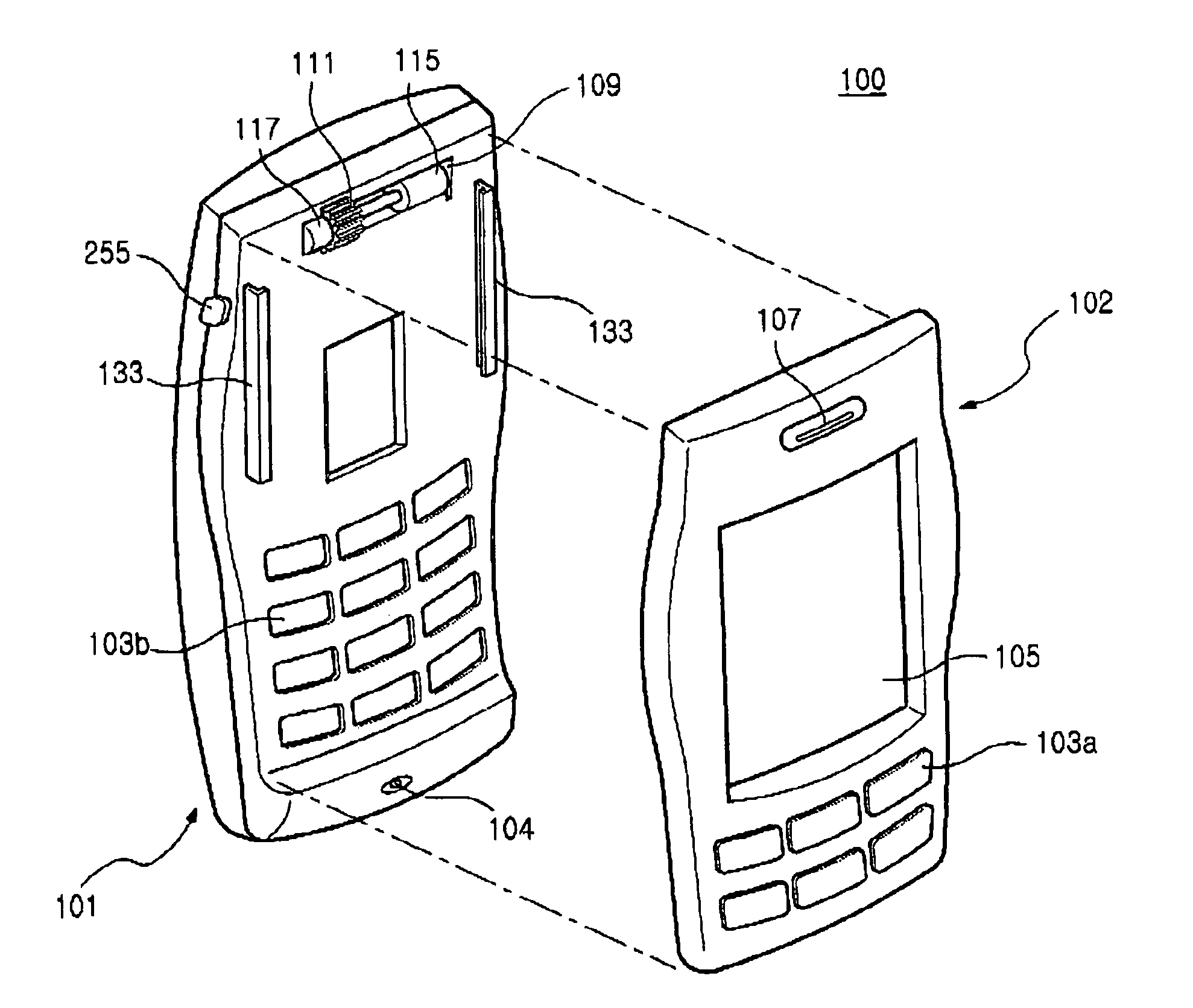

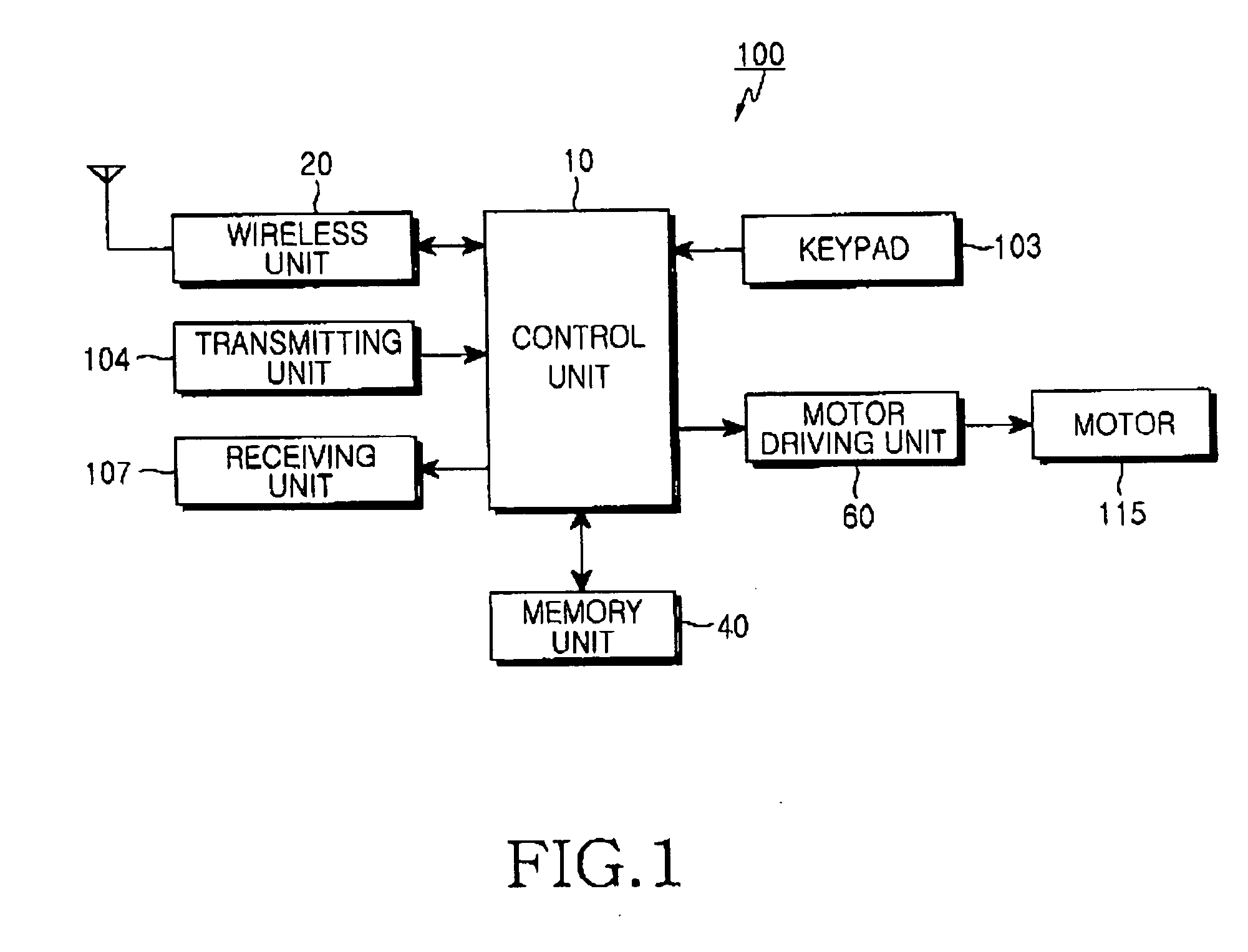

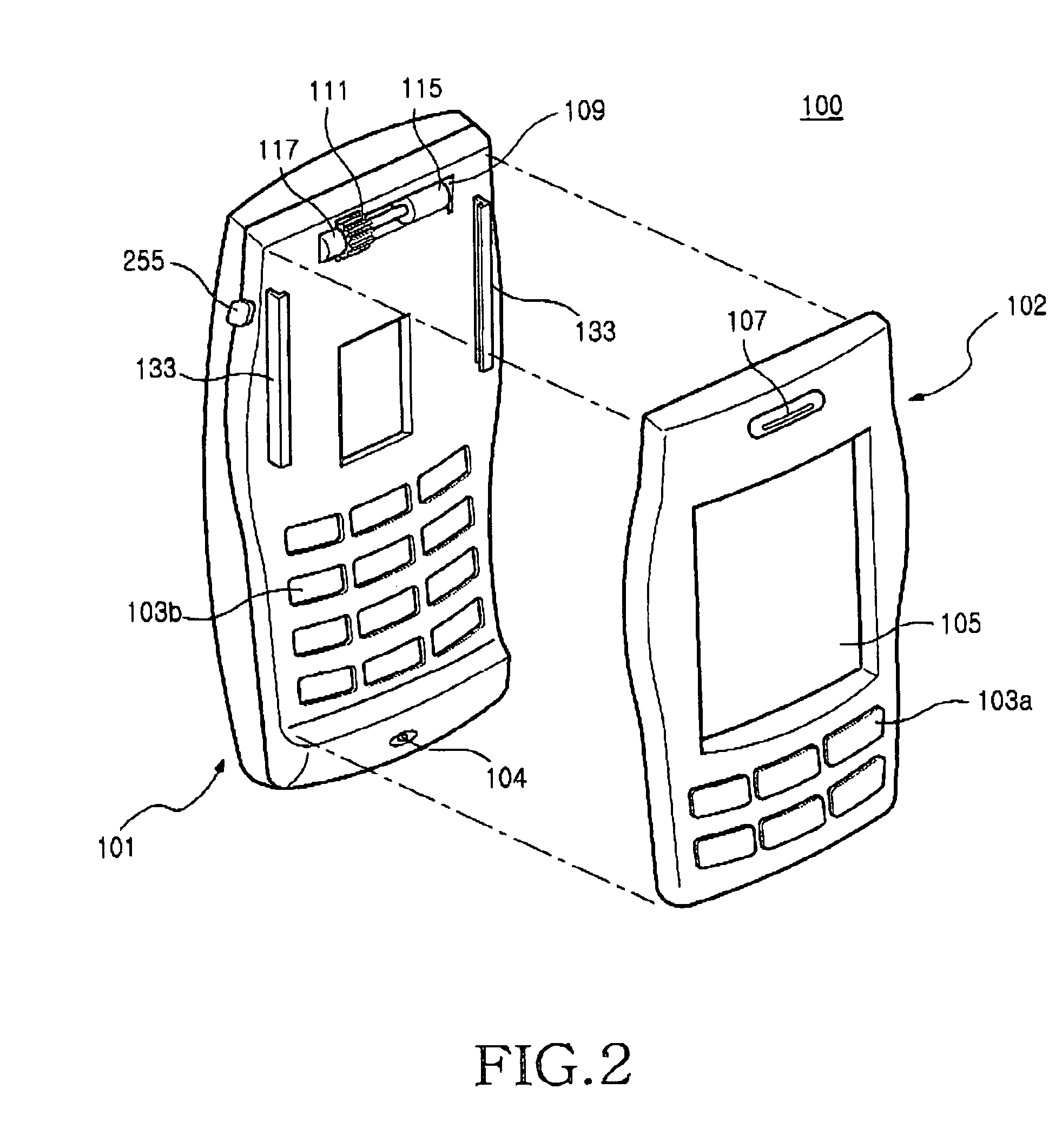

Sliding-type portable wireless terminal and method for controlling sliding movement in the same

InactiveUS20050064921A1Easy to open and closeEasy to closeTransmissionTelephone set constructionsMovement controlWireless

Disclosed is a sliding-type portable wireless terminal capable of easily opening and closing a sub-body in a lengthwise manner and a method for controlling a sliding movement thereof. The sliding type portable wireless terminal includes a main body and a sub-body movable from an open position to a closed position with respect to the main body by slidably moving in a lengthwise direction with respect to the main body. The sliding type portable wireless terminal has a first gear installed on an upper portion of the main body, a second gear provided at a rear portion of the sub-body in such a manner that the second gear is engaged with the first gear, with a motor connected to the first gear so as to provide rotational force to rotate the first gear, and a control unit for controlling an operation of the motor in response to a predetermined key input signal by a user for controlling a sliding movement of the sub-body.

Owner:SAMSUNG ELECTRONICS CO LTD

Express box capable of being recycled

InactiveCN107985790AAvoid damageEasy to open and closePackage recyclingContainers to prevent mechanical damageEngineeringGarbage output

The invention discloses an express box capable of being recycled. The express box capable of being recycled comprises a box cover and a box body. The box cover is connected with the box body through aclamping and connecting structure, and two symmetrically-arranged first handles are rotationally connected to the upper end of the box cover. A screw is rotationally connected to the bottom in the box body. One end of the screw penetrates the inner wall of the box body and is provided with a flywheel in a welding manner. A bottom plate is arranged above the screw. The two ends of the bottom plateare fixedly connected with the inner walls of the two sides of the box body correspondingly. The screw is sleeved with two symmetrically-arranged clamping plates in a threaded manner. The ends, awayfrom the screw, of the clamping plates penetrate the bottom plate and extend upwards. The bottom plate is provided with sliding openings corresponding to the clamping plates. The express box is novelin structure, through the clamping and connecting structure and uniform cushion blocks, express box opening and closing are rapid and convenient, and the problems that the expressage industry efficiency is low, and the work time is long are solved; the express box is uniform in specification and can be recycled many times to be used, garbage output is reduced, resource consumption is reduced, costis reduced, the express box is more environment-friendly, and popularization is facilitated.

Owner:合肥美青工业设计有限公司

Reclosable container with easily openable closure

InactiveUS20070062964A1Easy to open and closeEasy to openTable equipmentsRefuse receptaclesLocking mechanismEngineering

In accordance with the present invention, an easily openable container includes an elastic member that is connected to the container when the closure is in an open condition. Thus, the elastic member is at rest when the cover closure is open and spring-biases the closure to an open condition. When the closure is closed against the spring-biasing of the elastic material, the elastic member is stretched and held stretched when the closure in the front of the closure is engaged, such as by a snap closure or any other releasable connection. When the locking mechanism is released, the closure pops open by contraction of the elastic member.

Owner:ITEM SOURCE

Hinge assembly and instrument with hinge assembly

ActiveCN108661470AEasy to open and closeSimple structurePin hingesWing suspension devicesMechanical engineeringHinge angle

The invention relates to a hinge assembly and an instrument with the hinge assembly. The hinge assembly comprises a hinge seat fixed on a body, a first hinge shaft and a second hinge shaft are fixed on the hinge seat, the first hinge shaft and the second hinge shaft are rotationally connected with a first hinge arm and a second hinge arm respectively, and a driving groove is formed in the second hinge arm; the hinge assembly further comprises a third hinge shaft, the third hinge shaft is fixedly connected with a door body, the third hinge shaft is in sliding connection with the driving grooveto form a sliding pair, the third hinge shaft is rotationally connected with a first hinge arm to form a rotating pair, and the third hinge shaft slides in the driving groove and rotates around the first hinge shaft and the second hinge shaft to the driving force of the door body to enable the door body to generate displacement in the horizontal plane. The hinge assembly is simple in structure; and the door body does not interfere with an obstacle on one side in the opening process, so that the door body is opened and closed more conveniently, the function that appliances such as household appliances and furniture can be freely embedded can be achieved, and convenience is brought to a user to install and use.

Owner:QINGDAO HAIER MOLDS

Titanium alloy fine casting melting method

InactiveCN101143381AWide operating temperature rangeSmall operating temperature rangeFoundry mouldsFoundry coresWaxInvestment casting

The invention relates to a method of processing titanium alloy. The method of casting and melting the titanium alloy is: after wax pattern is made, a shell is made; and then processes of de-waxing, roasting, pouring and post-processing are practiced. Wherein, the process of roasting adopts fireproof silica solution coating to make the shell. Refractory fillers are yttrium oxide of 95 per cent and zirconia mixture powder of 5 per cent. The shell is made up of 6 layers and a half to 8 layers and a half. The process of melting begins when vacuum of the melting and the pouring reach 6.65 to 0.665 Pa. When the temperature of titanium reaches the required temperature, a centrifugal rotary table is started and rotational speed is adjusted to reach all values. The whole pouring process is completed within 3 to 5 minutes. After a casting is cooled in a furnace until the temperature of the casting is below 400 DEG C, a precise casting of titanium alloy is manufactured. The titanium alloy manufactured by the invention has a wider operation temperature range, the low temperature of which is 253 DEG C below zero and the high temperature of which is 550 DEG C. The titanium ally manufactured by the invention has low density, light weight, high strength, good resistance to decay and stable property, which can be used in different medium such as nitric acid and manganic acid.

Owner:DALIAN JINMEI VALVE

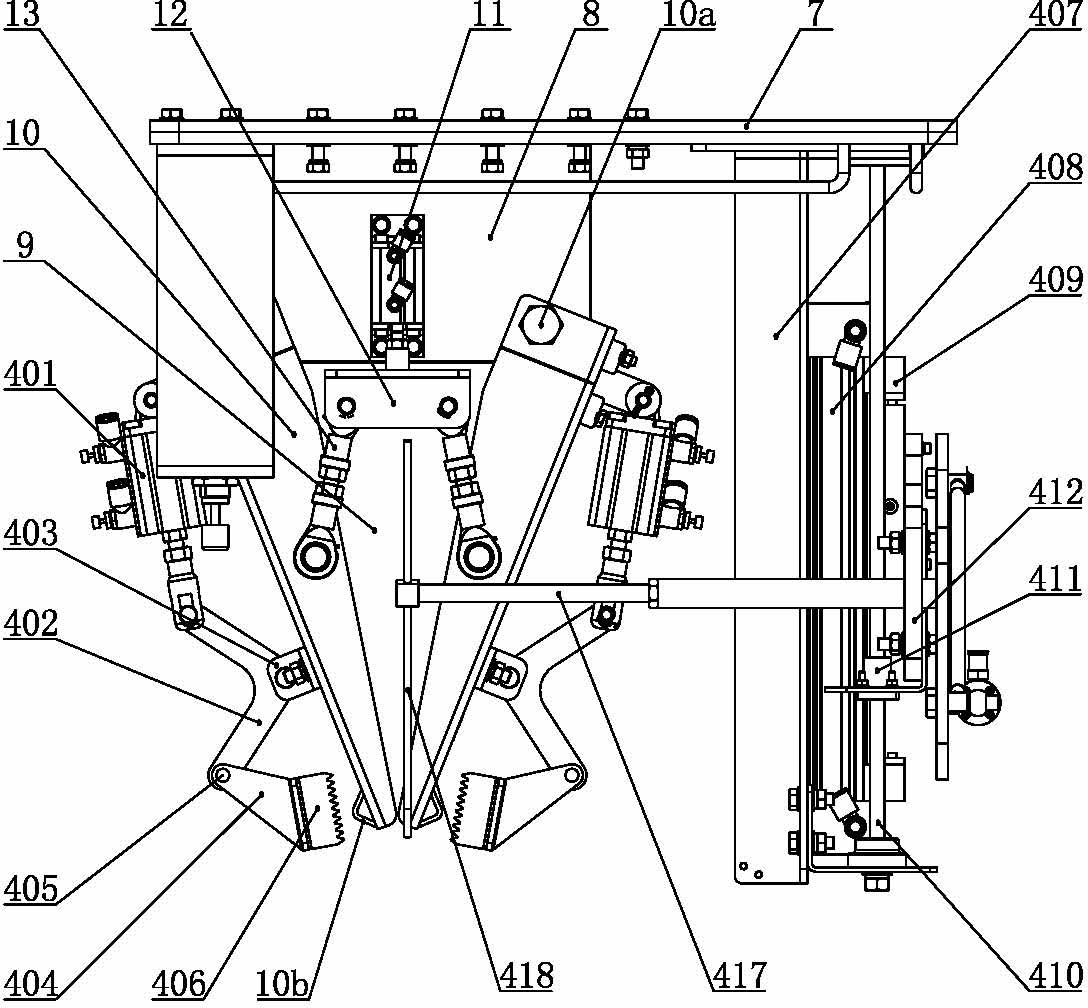

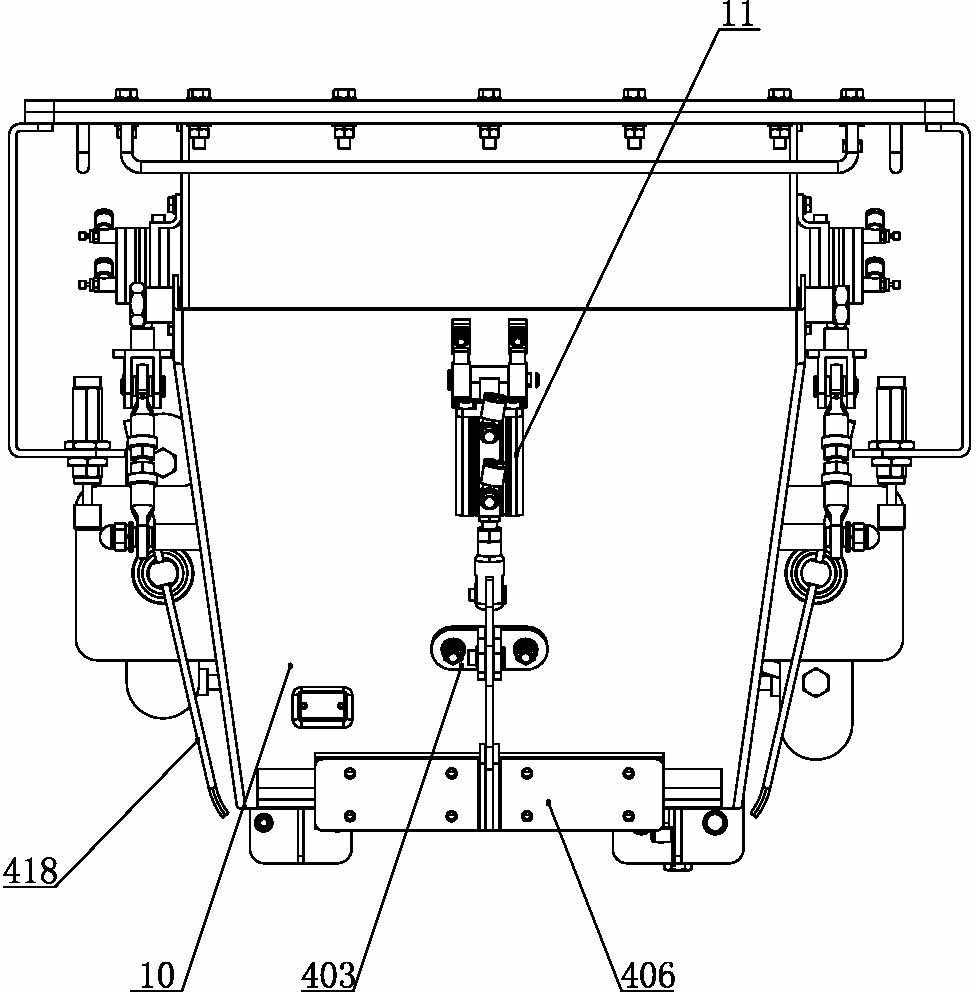

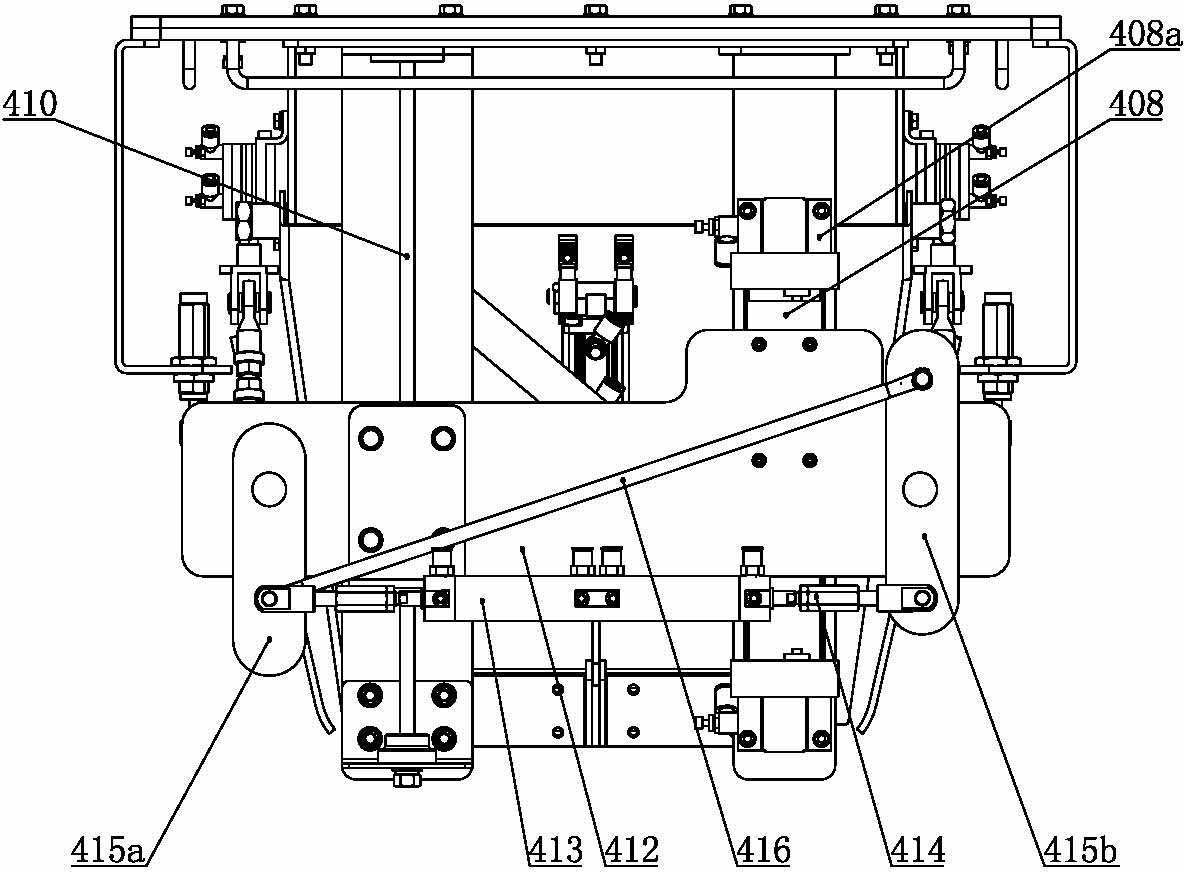

Bag filling, clamping and expanding mechanism with automatic bag loading function

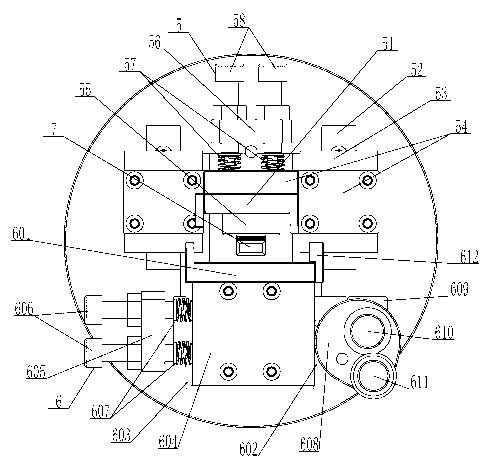

The invention relates to a bag filling, clamping and expanding mechanism with an automatic bag loading function. The left side and the right side of V-shaped discharging fixing plates of the mechanism are respectively provided with an openable discharging duckbilled plate, the upper ends of the two V-shaped discharging fixing plates are respectively provided with discharging air cylinders, in addition, the lower ends of piston rods are respectively hinged with the middle of a discharging connection pair, the discharging connection pair is in horizontal arrangement, in addition, two ends of the discharging connection pair are symmetrically hinged with discharging connecting rods, the lower ends of the discharging connecting rods are respectively and symmetrically hinged with the middle of the side surface of each discharging duckbilled plate, the outer side of the lower end opening of each discharging duckbilled plate is respectively provided with a bag clamping seat, the outer wall ofthe upper end of each discharging duckbilled plate is respectively and fixedly provided with a bag clamping air cylinder, in addition, the lower end of a piston rod of each bag clamping air cylinder is respectively hinged with the upper end of an L-shaped bag clamping connecting rod, the middle of each L-shaped bag clamping connecting rod is respectively hinged onto the outer wall of each discharging duckbilled plate, the lower part of each L-shaped bag clamping connecting rod is respectively and fixedly connected with the upper end of a bag clamping rubber block installing plate, and the lower end of each bag clamping rubber block installing plate is respectively and fixedly provided with a bag clamping rubber block with sawtooth surfaces. The mechanism has the advantages that bag openings can be conveniently, fast and fixedly arranged on discharging openings, and the opening and the closing of the discharging openings are convenient.

Owner:JIANGSU MUYANG GRP CO LTD

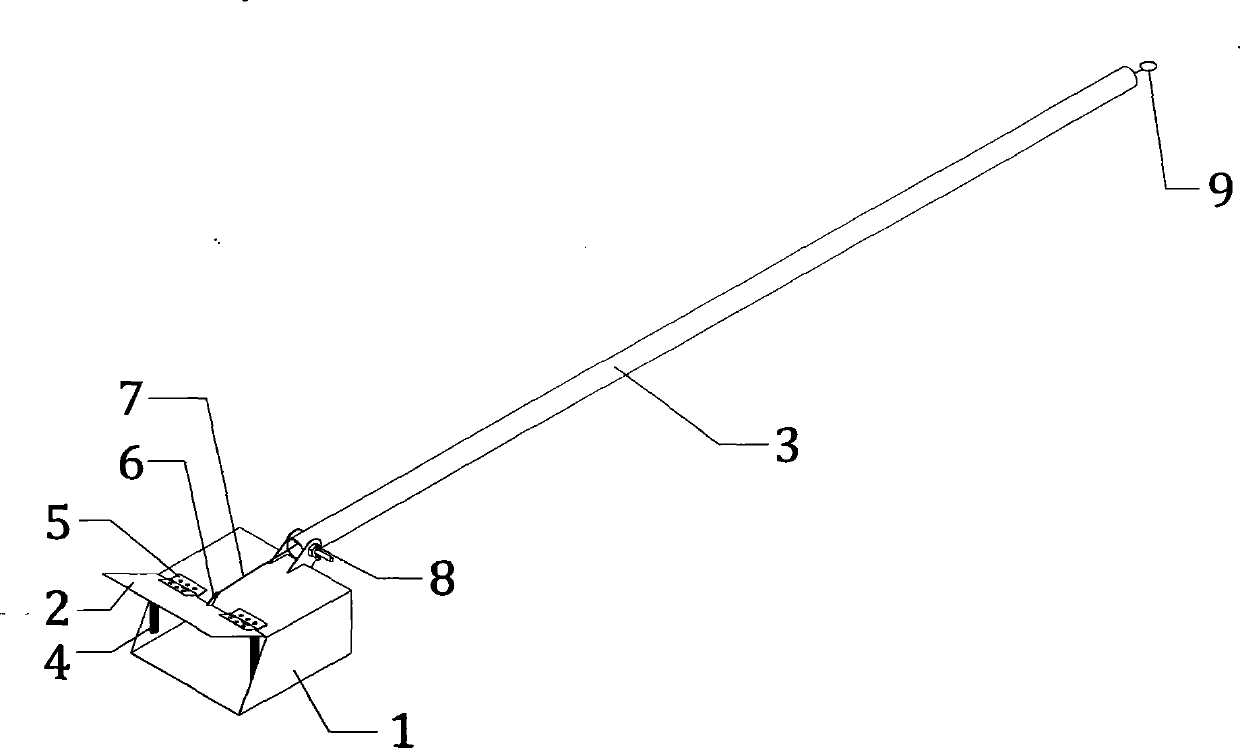

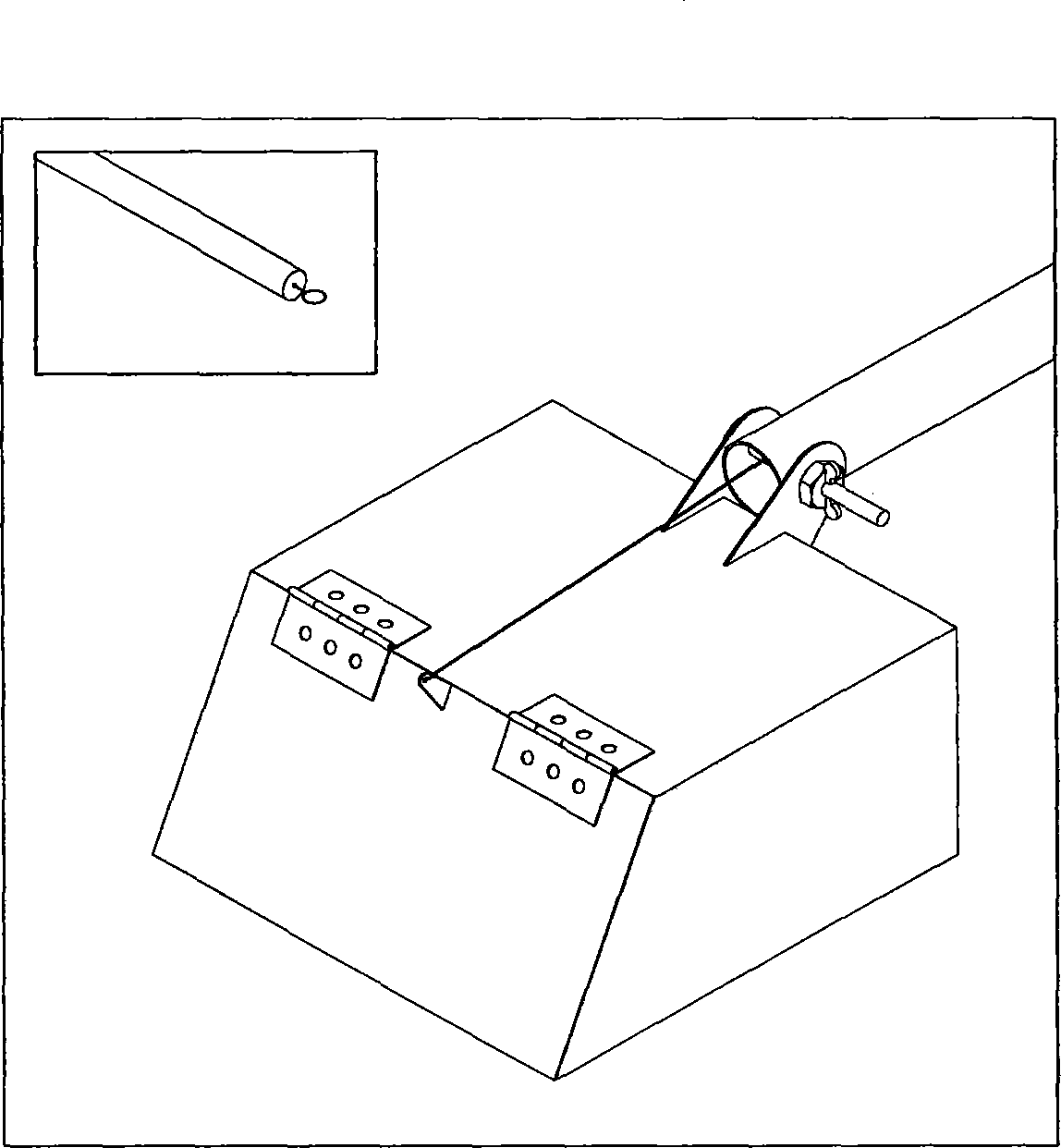

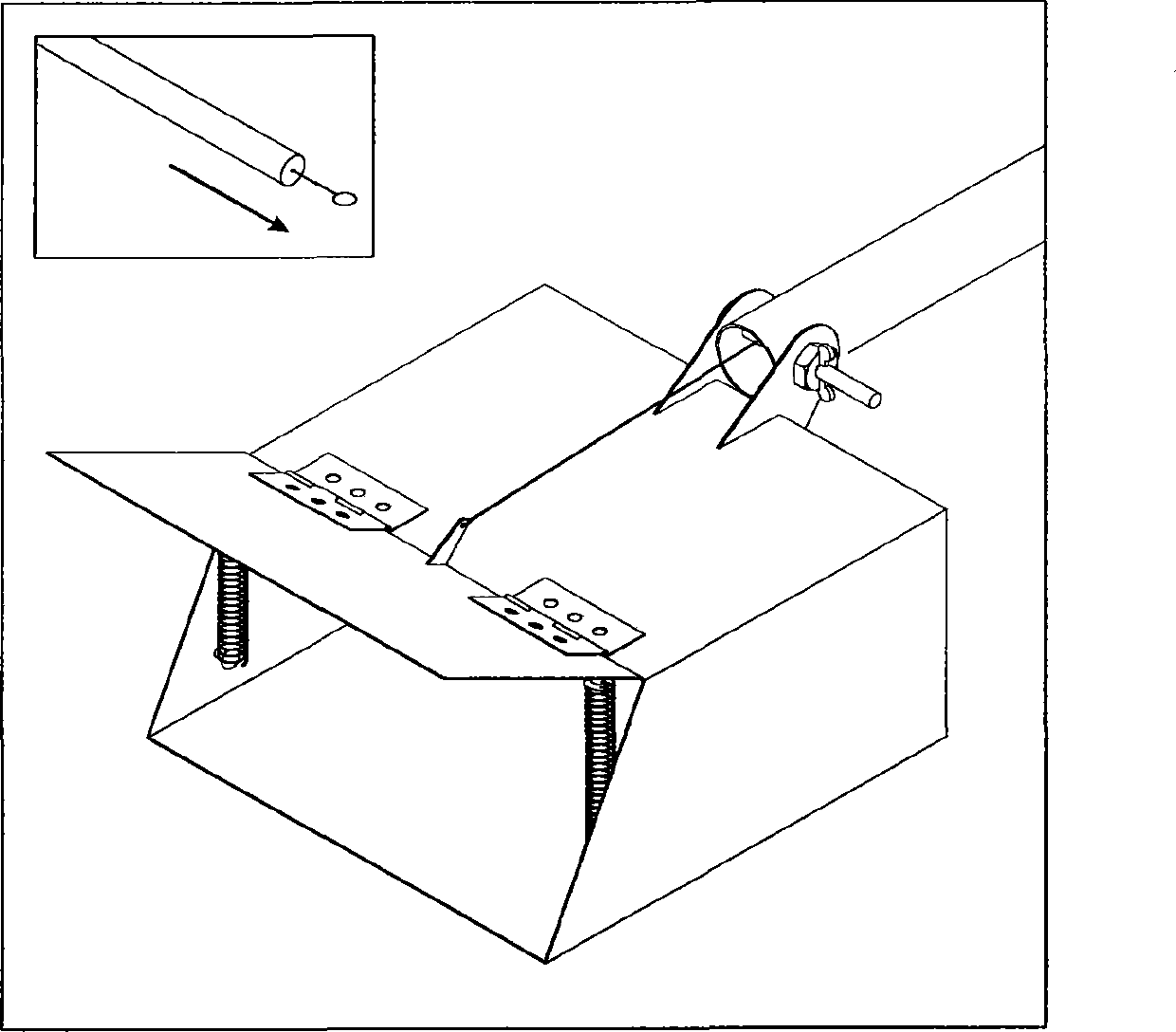

An angle-adjustable multi-function sampling shovel

InactiveCN102706697AConvenience auto shut offEasy to open and closeWithdrawing sample devicesFresh water organismEngineering

The present invention relates to an aquatic organism sampling device, and specifically is a sampling shovel for easy acquisition of freshwater mussels attached in water pipes and benthic organisms in shallow water sediments. The sampling shovel is composed by a sampling container, an open and close device for a sampling container cover, and an angle adjustment device. By a self-closing device and a pulling open device, the open and the close of the sampling container can be controlled, and the angle between a holding rod and the sampling container can be adjusted. The sampling shovel of the invention has the advantages of simple structure, convenient operation, high controllability, reliable and flexible operation, and low cost. The sampling shovel can be applied for the operation processes of acquiring the freshwater mussels attached in the water pipes and such unavailable samples at high places, and sampling the benthic organisms in the shallow water sediments.

Owner:杜梦 +2

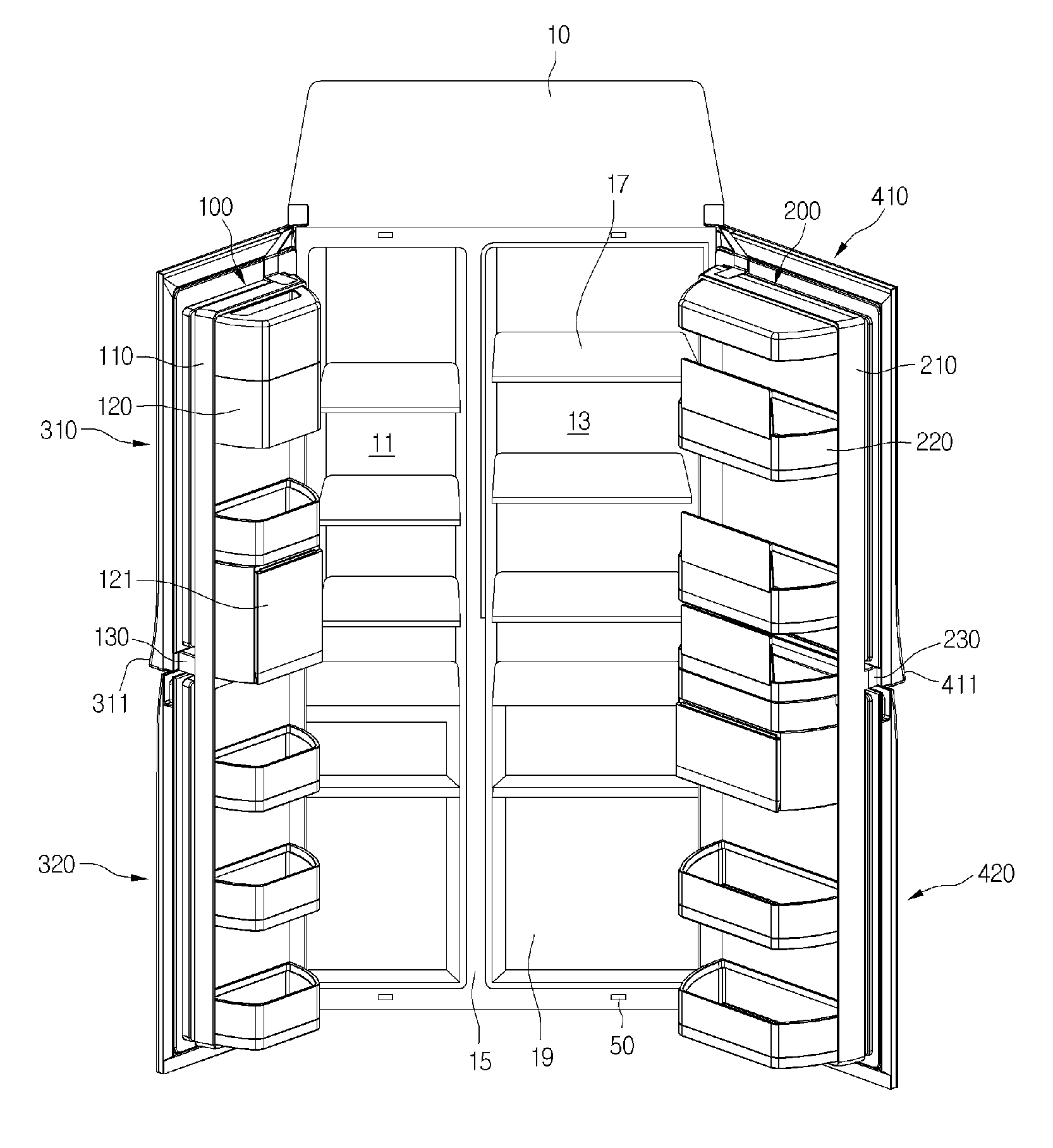

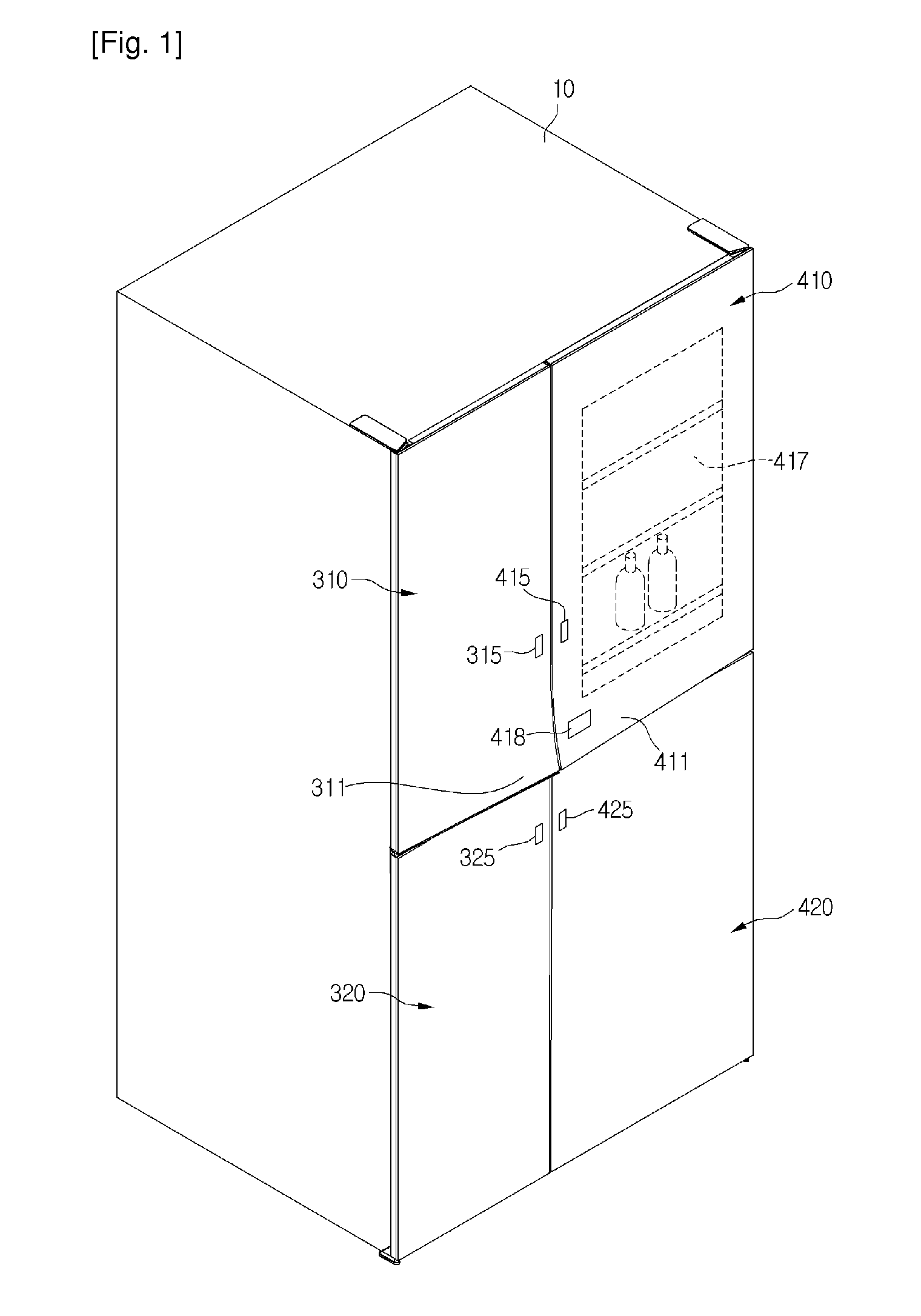

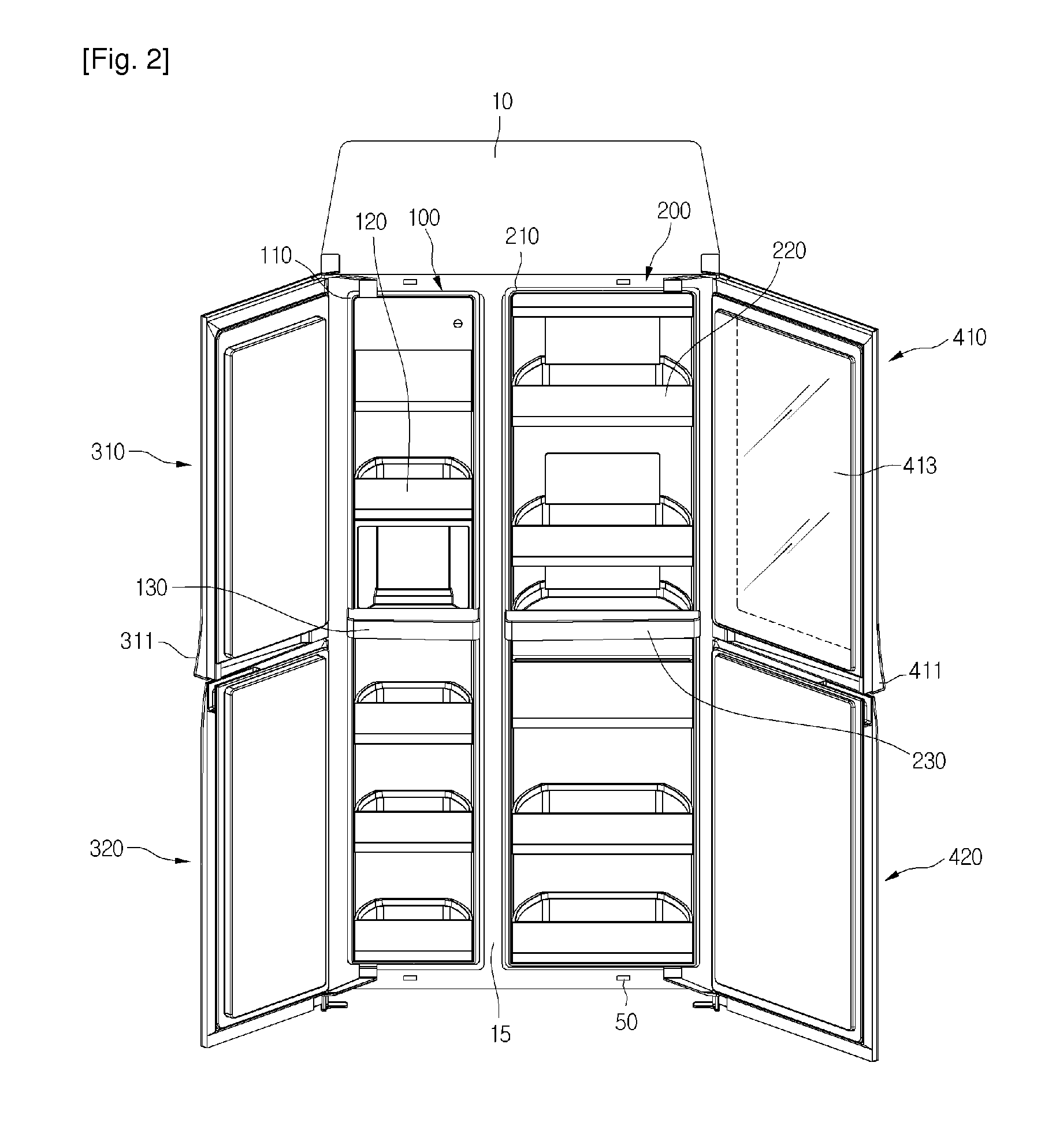

Refrigerator

ActiveUS20120286639A1Easy to open and closeMinimize leakageLighting and heating apparatusFurniture partsHinge angleEngineering

A refrigerator is provided. The refrigerator includes a cabinet having a first storage chamber, a plurality of doors which open and close an access opening formed at a front surface of the first storage chamber, a hinge assembly which rotatably couples each door to the cabinet, and a basket assembly rotatably coupled to the cabinet with respect to the hinge assembly, the basket assembly being configured to define a second storage chamber which is received in the first storage chamber. The basket assembly includes a basket frame defining the second storage chamber and a basket mounted on the basket frame to receive food stuff when at least one of the doors is opened. The basket assembly is configured such that an access into the basket is enabled through a front face and rear face of the basket assembly.

Owner:LG ELECTRONICS INC

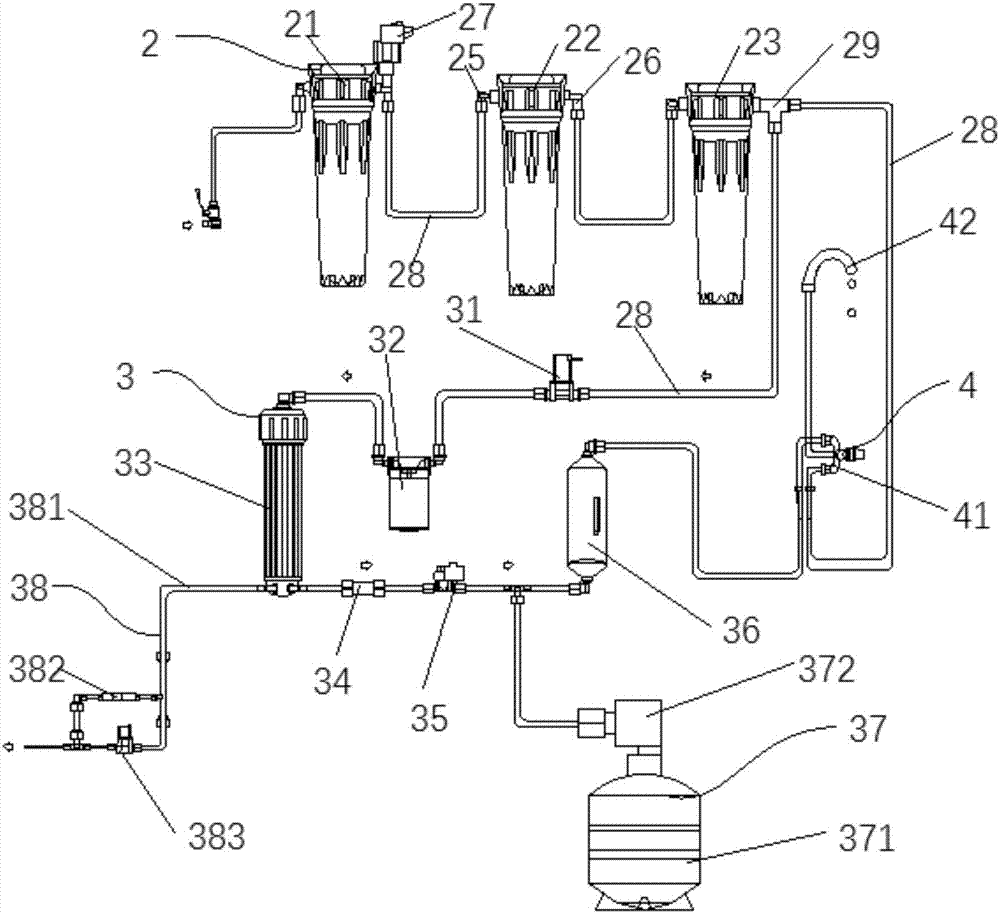

TDS value-adjustable direct drinking water purifier

InactiveCN107324525AEnhance physical fitnessSimple structureWater treatment parameter controlTreatment involving filtrationThree stageUltrafiltration

The invention provides a TDS value-adjustable direct drinking water purifier. The water purifier comprises a hollow shell, an ultrafiltration system, a reverse osmosis system and a mixing system, and the ultrafiltration system and the reverse osmosis system are arranged in the shell and the mixing system is arranged outside the shell. The ultrafiltration system is used for purifying raw water to obtain mineral water. The reverse osmosis system is used for further purifying mineral water produced by the ultrafiltration system to obtain purified water. The mixing system is used for mixing and adjusting mineral water produced by the ultrafiltration system and purified water produced by the reverse osmosis system so that direct drinking water is produced. The ultrafiltration system comprises three stages of filter cores orderly connected in series through pipes. The reverse osmosis system comprises a reverse osmosis film and is connected to the ultrafiltration system through a pipe. The mixing system is connected to the ultrafiltration system and the reverse osmosis system through pipes. The water purifier can conveniently and effectively regulate the mineral content in the direct drinking water and make the direct drinking water satisfy the demand for drinking of different populations in different regions and is safe and healthy.

Owner:江苏全给净化科技有限公司

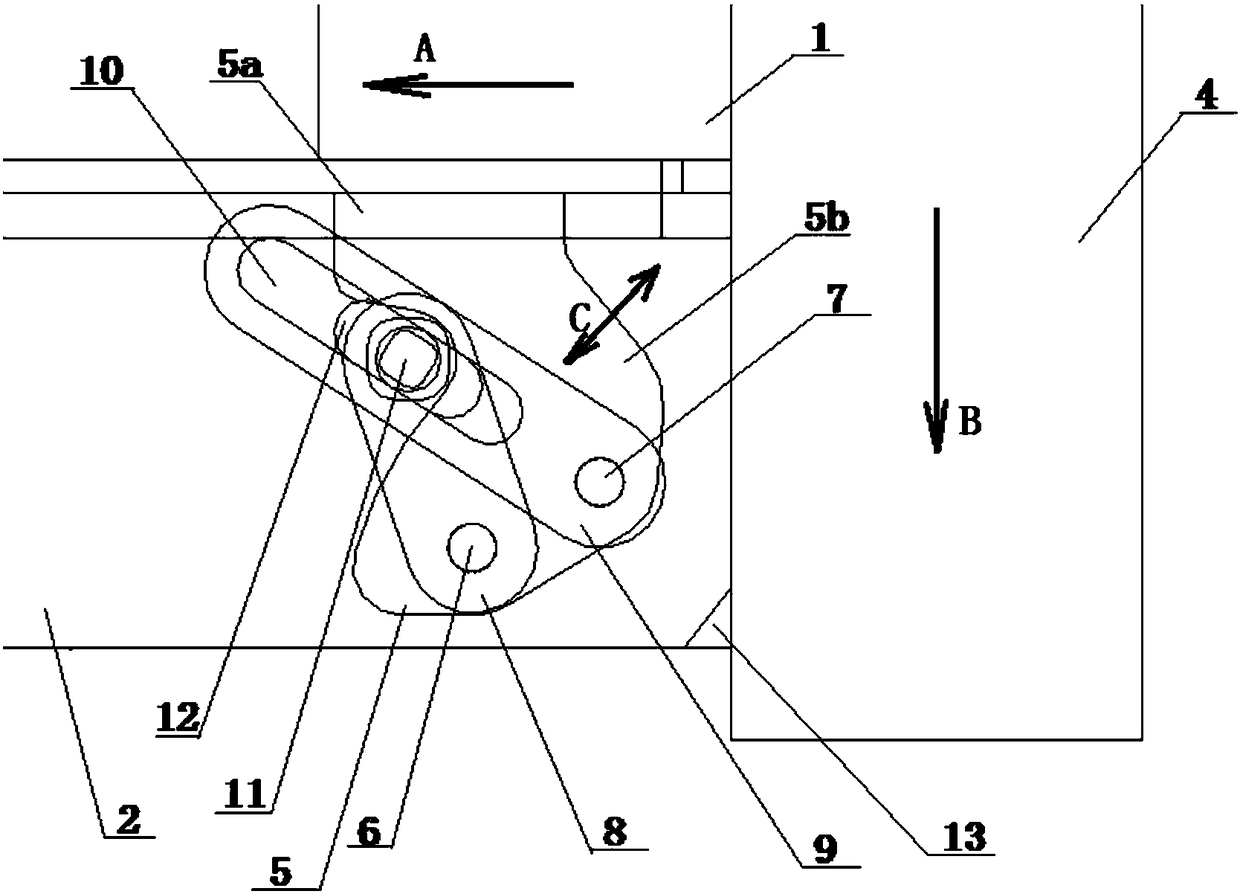

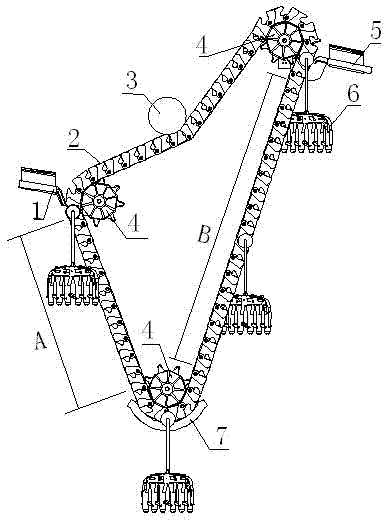

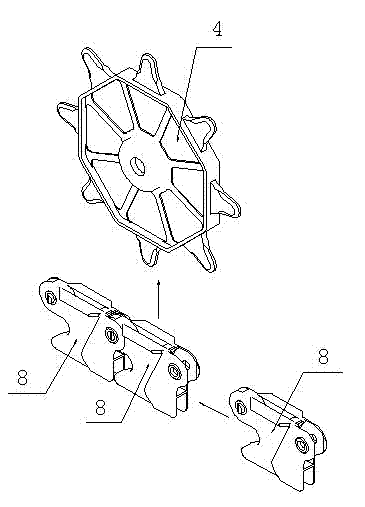

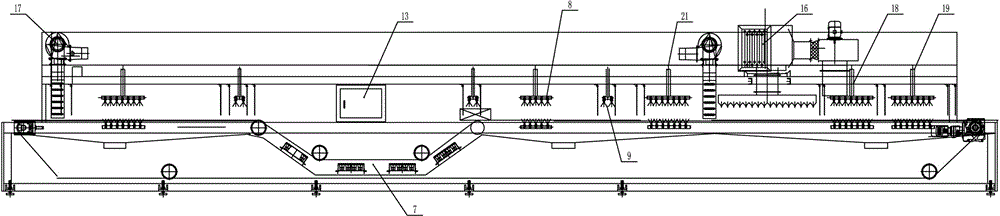

Clothes hanger station arriving and leaving conveying system

The invention discloses a clothes hanger station arriving and leaving conveying system, and solves the problems that a conveying chain in the conventional flexible clothes hanger station arriving and leaving conveying system has a complex structure and is inconvenient to produce and assemble and low in using stability. The technical scheme is that: the clothes hanger station arriving and leaving conveying system comprises a station arriving guide rail, a station leaving guide rail, a conveying chain and a plurality of driving wheels, wherein the conveying chain is lapped with the driving wheels and comprises a plurality of chain plates. The system is characterized in that: the head of each chain plate is hinged with the tail of an adjacent chain plate; a hinge point of each chain plate inclines to the inner side of the conveying chain; the head of each chain plate is provided with a hook interface on the outer side of the hinge point on each chain plate; the conveying chain is provided with a descending part for driving a clothes hanger to descend and an ascending part for driving the clothes hanger to ascend; hook interfaces on the descending part and the ascending part on the conveying chain are in a closed state; hook interfaces on the conveying chain, which are positioned at the driving wheels, are in an open state; and the station arriving guide rail and the station leaving guide rail are close to one driving wheel respectively.

Owner:INA INTELLIGENT TECH (ZHEJIANG) CO LTD

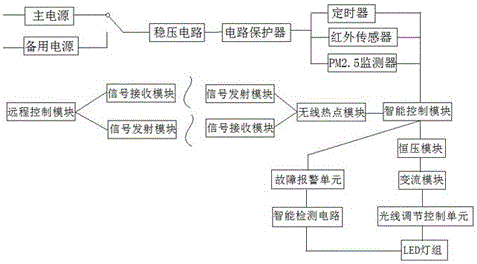

Intelligent LED street lamp and control method thereof

InactiveCN106028506AGet it in timeReduce wiringElectrical apparatusElectroluminescent light sourcesRemote controlEffect light

The invention relates to the field of lighting systems, in particular to an intelligent LED street lamp and a control method thereof. The intelligent LED street lamp mainly comprises the following components: a power supply module, a voltage stabilizing circuit, a circuit protector, an infrared sensor, an intelligent control module, a wireless hotspot module, a remote control module, a fault alarm unit and the like. A novel LED street lamp brightness stepless regulation concept is adopted; the LED street lamp can carry out intelligent brightness adjustment according to the road traffic flow condition, the weather condition and the season change, so that intelligentization is achieved by the LED street lamp. The power supply module is optimally utilized through intelligent management; and electric energy is saved, so that the lighting quality of the street lamp is ensured; and meanwhile, the service lifetime of the LED street lamp is prolonged.

Owner:JILIN LANRUI ELECTRONICS TECH

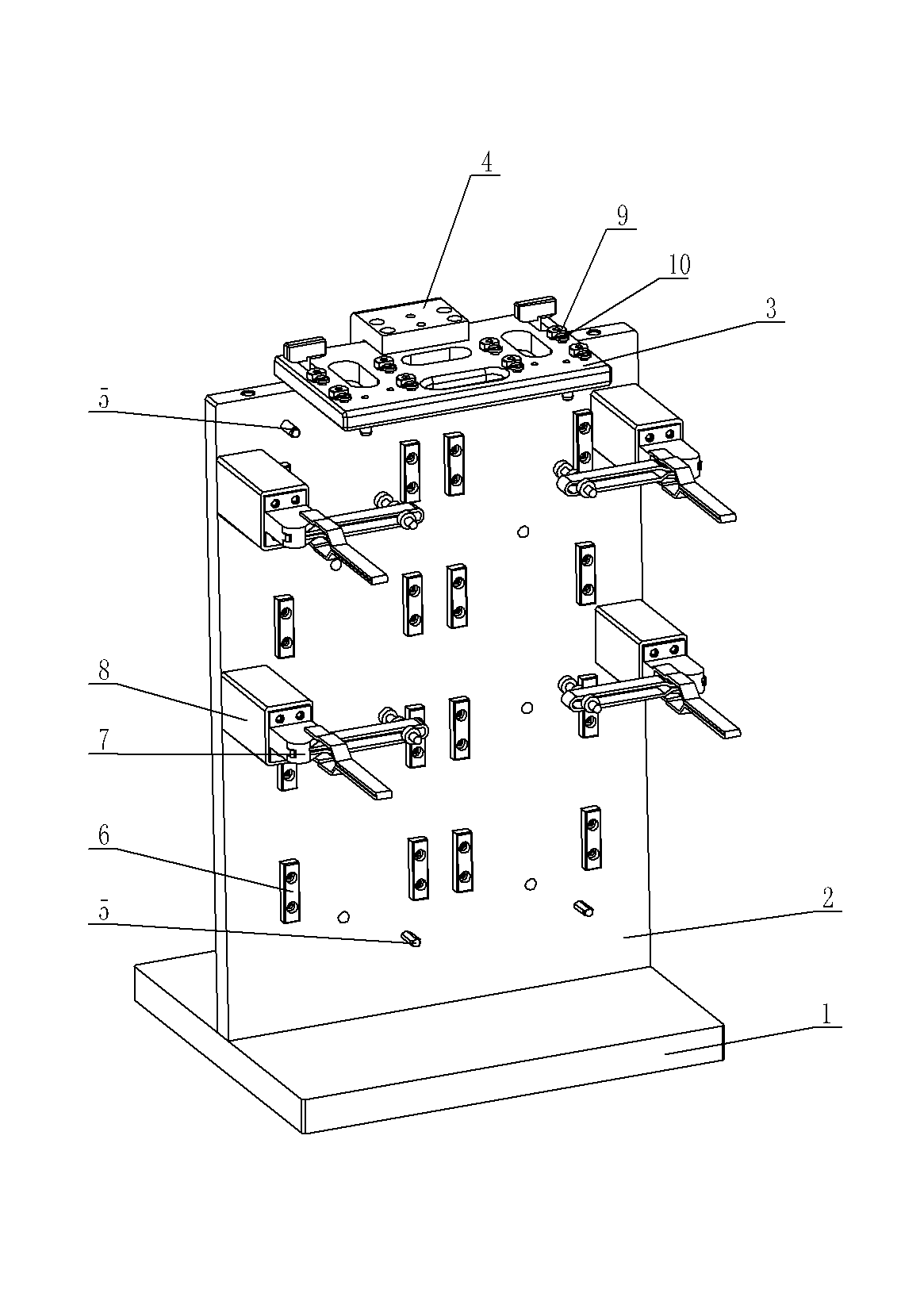

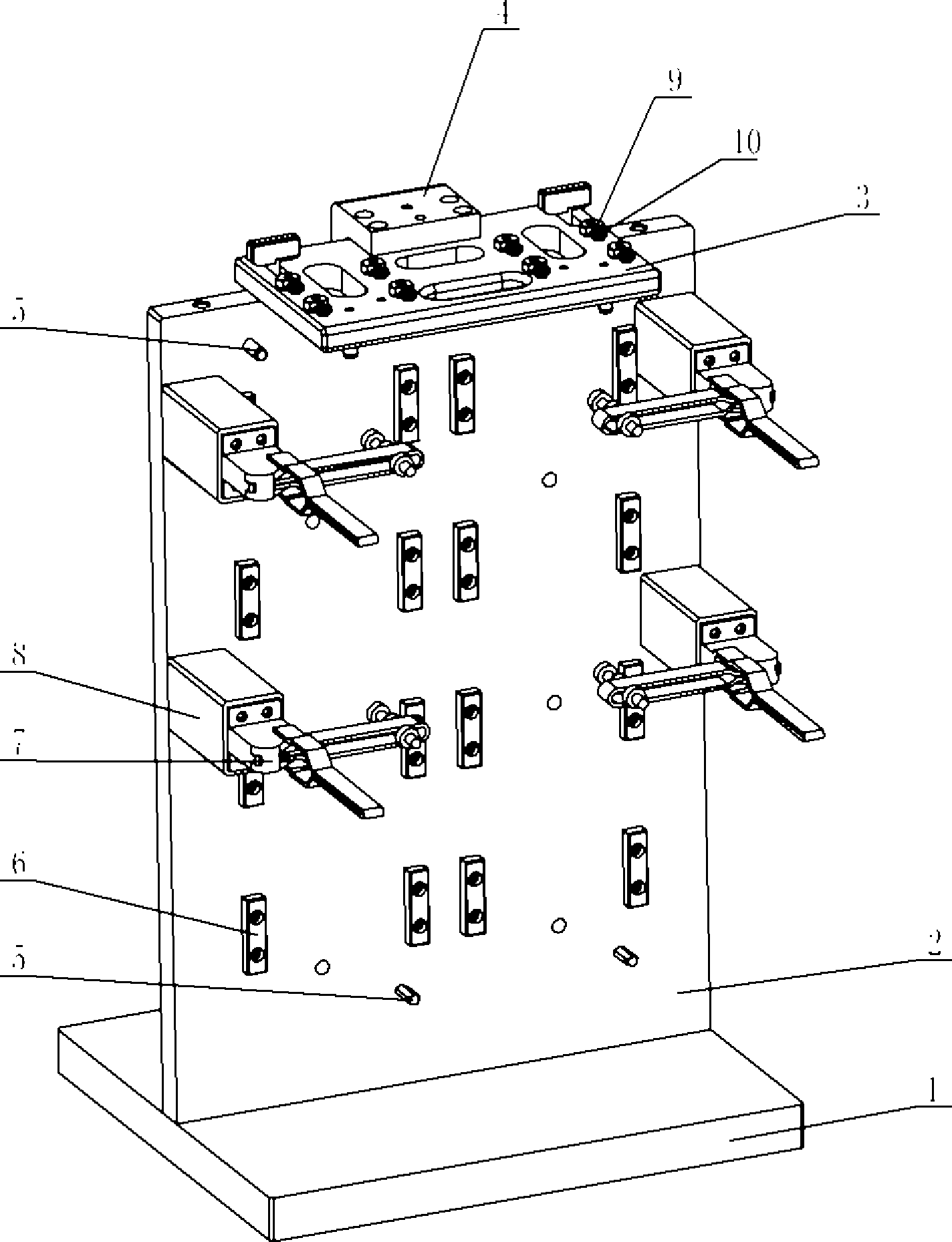

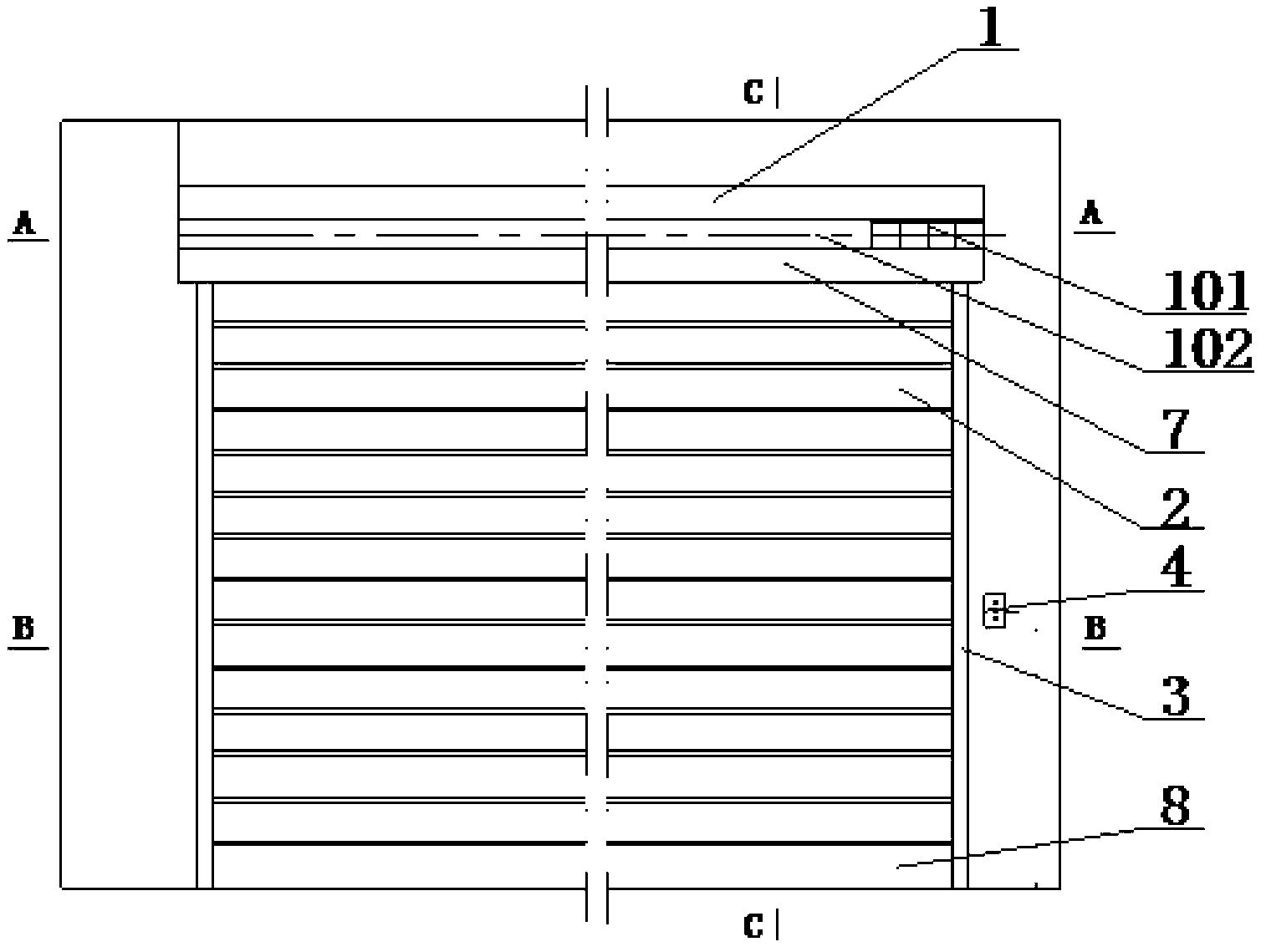

Drilling fixture for cylinder cover

InactiveCN102554659APrecise positioningClamp firmlyPositioning apparatusDrill jigsMechanical engineeringDrill bushing

The invention provides a drilling fixture for a cylinder cover, which can effectively improve positioning precision and clamping precision of a workpiece, accordingly guarantees machining precision of the workpiece, can greatly reduce labor intensity of workers, enhances production efficiency and lowers production cost. The drilling fixture comprises a bottom plate, and a fixing plate is vertically mounted on the bottom plate. The drilling fixture is characterized by further comprising a workpiece positioning and clamping device and a plate jig, the workpiece positioning and clamping device is fixed onto a workpiece clamping surface of the fixing plate, the plate jig is connected with the upper end of the fixing plate by a hinge device, and a drill bushing is correspondingly mounted on the plate jig according to a to-be-drilled position of the workpiece.

Owner:WUXI DAWN DIE & STAMPING

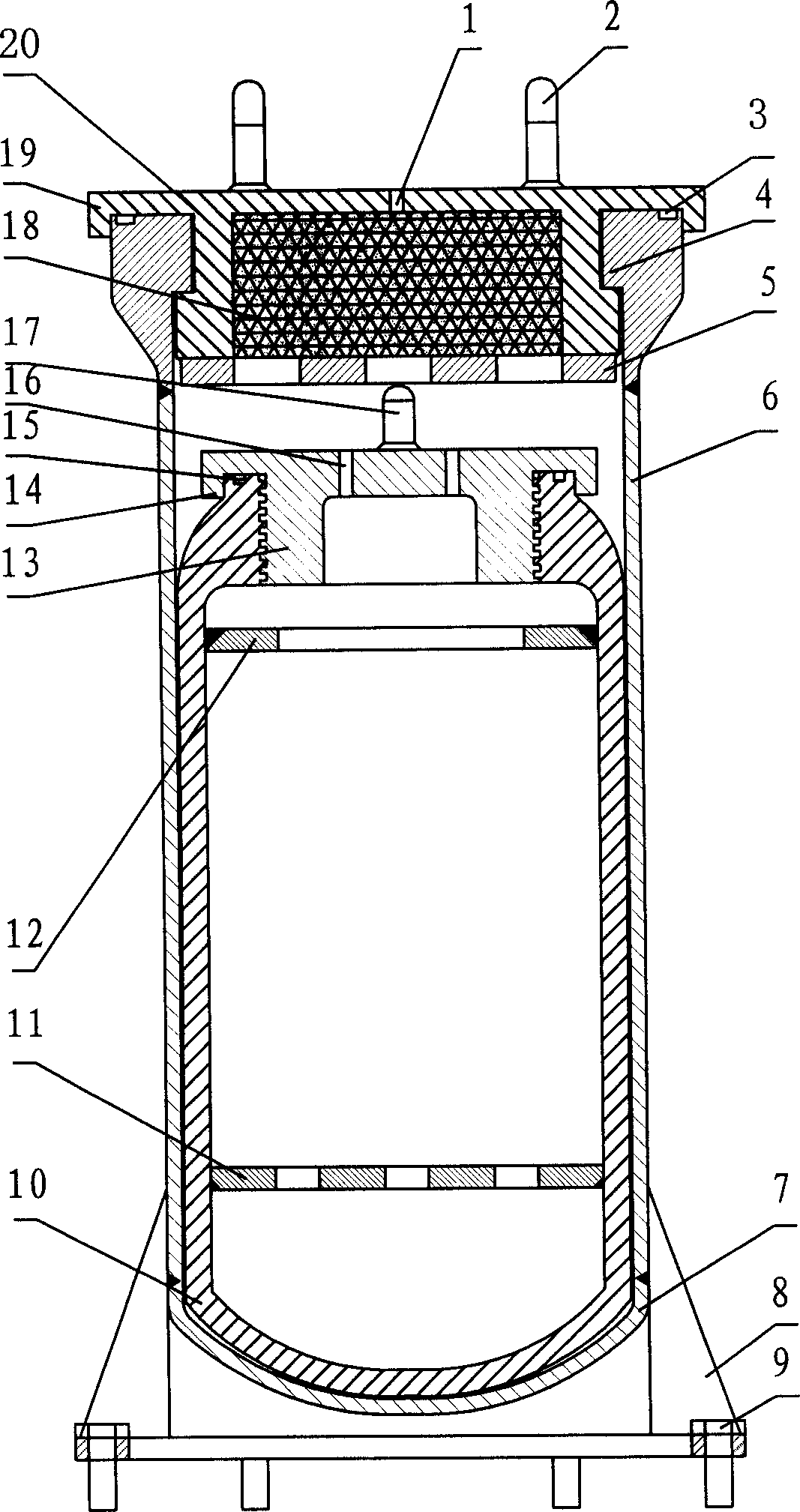

Anti-explosive container

ActiveCN1888810ANot easy to wearFlexible opening and closingAmmunition storageMechanical engineeringDetonator

A blast resistant container relates to outside canister, fixed board and top plate. There is handle and blast-release hole on top plate; outside canister connects with top plate by spline. The top plate owns wave absorber plate and the bottom of outside canister owns some supported vertical plate fixed with fixed board. Outside canister owns inside canister and it is made up by inner top plate and inside closed canister without coping, and the inside of the top bottom compounds with the inside wall of the inner top plate by thread bayonet. Inner top plate owns handle and at least two blast-release holes, and its rim owns hook side for the outer rim of top bottom to inside canister; and the top and down bottom of the inside canister owns up and down wave absorber plate. It is safe for carrying the blast starting equipment and detonator in the same carrying vehicle and reduces the influence for the ambience, people and establishment when the canister blasts. It is easy for starting and stopping, large capability, long life and good blast resistant performance to be able to demolish equipment dedication carrying vehicle.

Owner:ZHEJIANG LUJIESHUN COMPARTMENT MFG

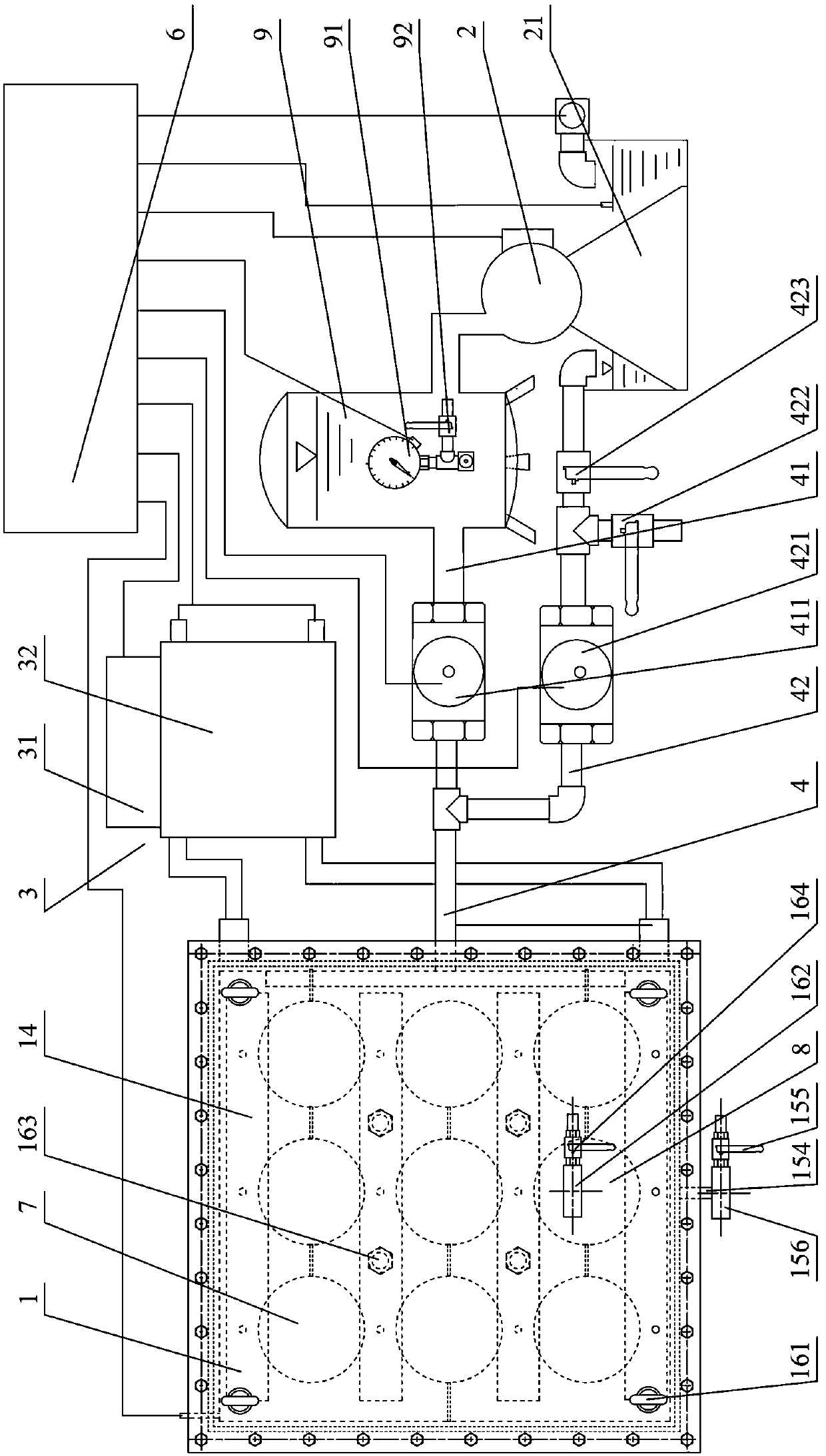

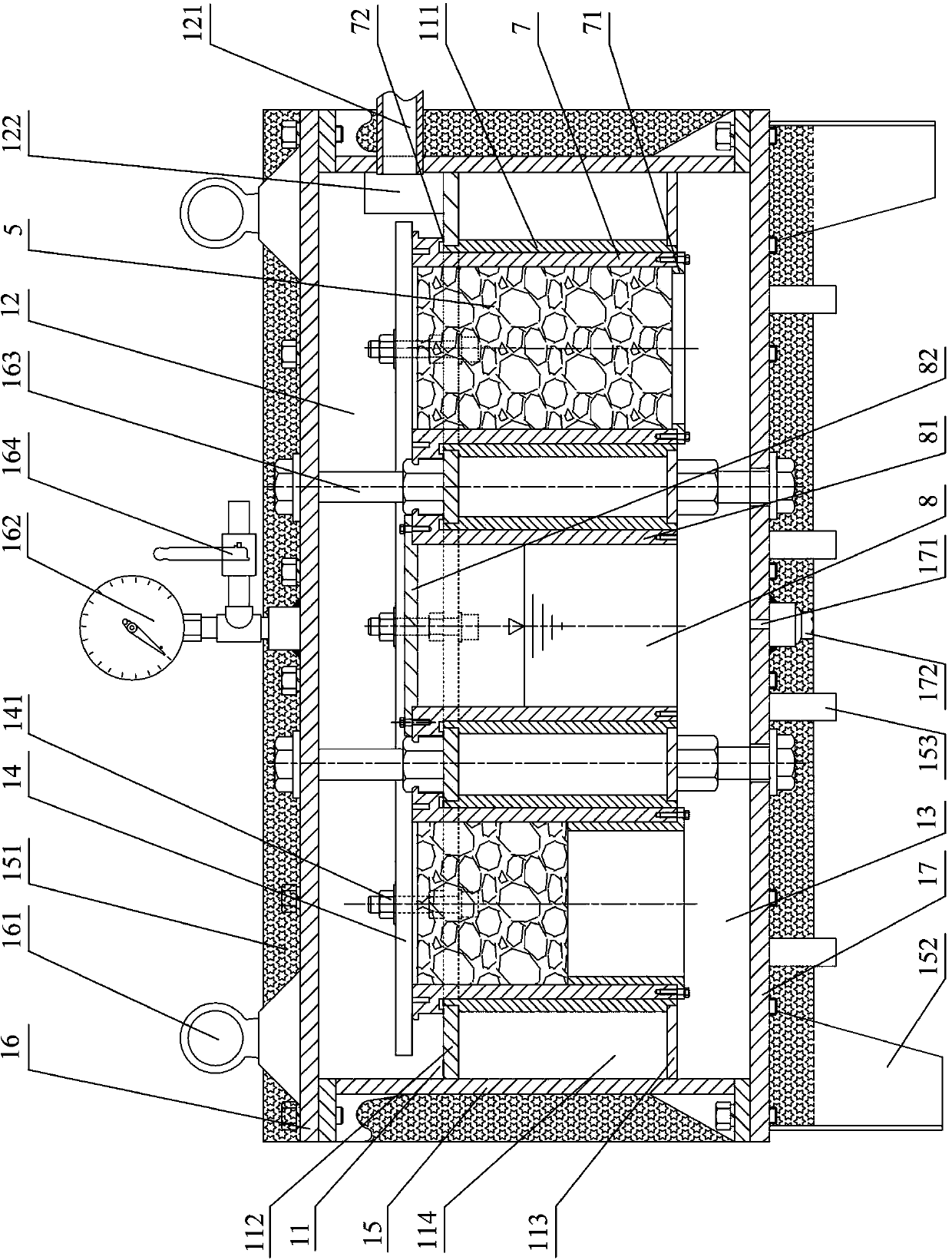

Pressure oven

ActiveUS10694891B2Simple and easy-to-operate door locking mechanismReasonable structural designRoasters/grillsPressure-cookersEngineeringLaboratory oven

The present invention relates to a pressure oven with a pressurized inner container. The pressure oven includes an oven body, the inner container, an oven door and a handle, where the bottom side of the oven door is rotatably connected with the oven body, the handle is provided on top of the oven door, two locking catches are horizontally provided on the front face of the oven body, the corresponding inner surface of the oven door is provided with two locking hooks, and the handle drives the two locking hooks to rotate via a linkage drive device so as to achieve locking or unlocking between the locking hooks and the locking catches. The pressure oven has a rational structural design, the oven door is convenient for opening and closing, and a pressure relief valve is designed to be on the oven door so as to help combine the oven as an integral part of the entire kitchen. In addition, heating electronic elements are located at the back faces of the oven door and the oven body, such that two side faces of the oven body do not have a heating element. The heating element in the oven door is cooled by a cooling fan, the heat from the heating element at the back face of the oven body is dissipated via heat dissipation holes, such that no heat dissipation hole is needed on the two side faces of the oven body. The oven has an attractive appearance, the inner container is an integral body with a high tensile strength, has no gap, and is easy to clean. The pressure oven can be secured by a hanging hook and can be easily dismounted.

Owner:ZHONGSHAN JINGUANG HOUSEHOLD APPLIANCE MFG CO LTD

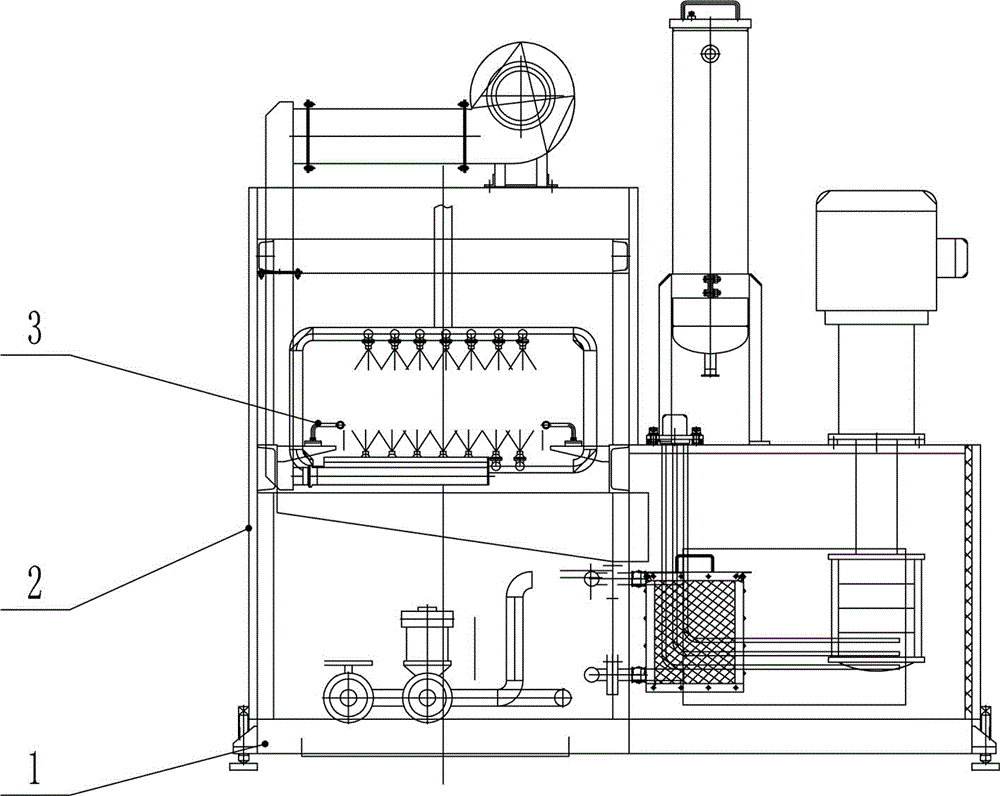

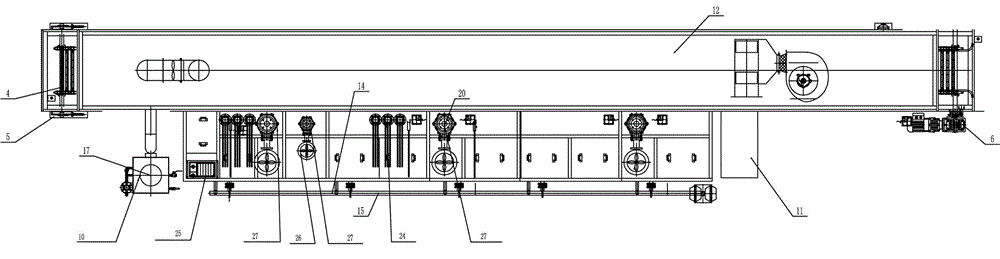

Full-automatic cleaning oil-coating device

InactiveCN104646334AEasy to open and closeGuaranteed cleanliness requirementsLiquid surface applicatorsCoatingsMegasonic cleaningEngineering

A full-automatic cleaning oil-coating device comprises a machine base, wherein a machine frame and an electrical appliance control device are arranged on the machine base, a guide rail and a stainless steel conveying net chain are arranged at the upper portion of the machine frame, the stainless steel conveying net is provided with a net belt chain tensioning device and a chain stepless speed-regulating conveying system, a sealing cover is arranged at the upper portion of the stainless steel conveying net chain, a spraying-cleaning device, a first cutting water air knife, an ultrasonic cleaning system, a second cutting water air knife, a spraying-rinsing device, a third cutting water air knife, a compressed air water blowing device, an air blow-drying system, an oil coating device and a deoiling device, and a cleaning liquid filtering system is arranged on the side face of the machine frame. The full-automatic cleaning oil-coating device is provided with a movable overhaul window, an overhaul door is convenient, flexible and safe to open and close and has an interlocking function, and the full-automatic cleaning oil-coating device cannot be started if the door is not closed well. The full-automatic cleaning oil-coating device is provided with a good steam pumping and discharging system and prevents mist from escaping outside. In addition, the circular filtering system provides cleaning liquid having constant cleaning effect for liquid grooves, the cleanliness requirements of parts can be ensured, and re-utilization rate of the liquid can be improved.

Owner:YICHANG WASHING MACHINE

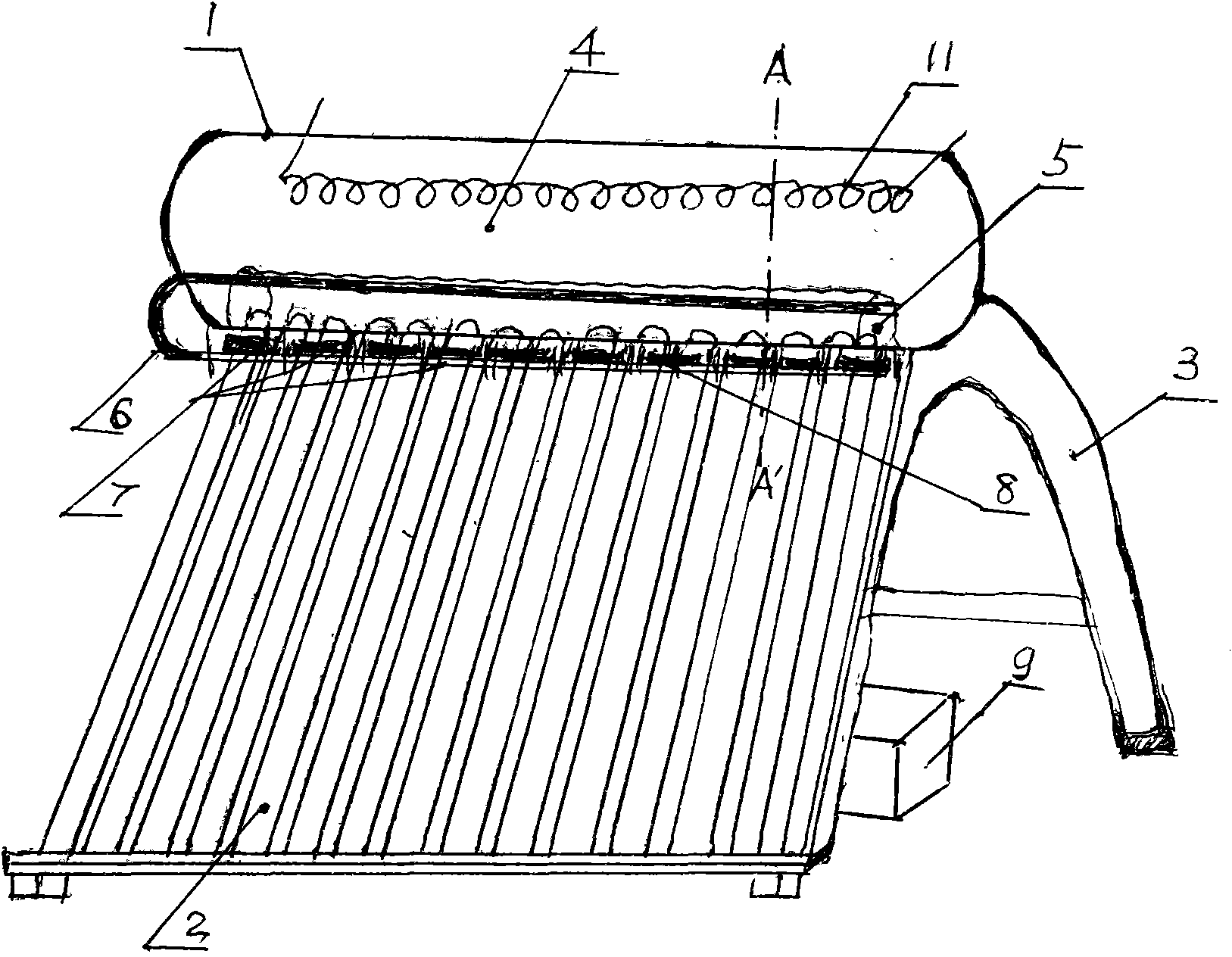

Automatic high-efficiency power generation solar water heater

InactiveCN101539338AEfficient chargingImprove efficiencySolar heating energySolar heat devicesThermal energyWater tanks

The invention provides an automatic high-efficiency power generation solar water heater, and belongs to the field of solar energy utilization. For improving the utilization rate of solar energy and heat energy, a widely used monofunctional solar water heater is improved to first ensure a certain amount of hot water for bathing, then automatically use heat energy for high-efficiency power generation without manual operation, and finally store power in a storage battery for heating the water in a water tank when the temperature of the water is low or at night as well as lighting domestically and supplying power to televisions, computers, and the like. Usually, the solar water heater can generate more than one kilowatt-hour of the power in summer, and is an unexpected gift for the floating herdsmen. An evacuated solar collector tube with or without water can be used; for improving the efficiency of thermo-electric generation, large temperature difference is required; the water tank is divided into a large part and a small part; a temperature memorizing alloy push rod pushes an isolating baffle to open or close a water pass between the two parts to allow the temperature of the small amount of water in the small part to rise quickly; and heat is led out by a Qu inorganic superconduct heating pipe. Given popularization across China, the solar water heater has the power generation potential far more than that of the Three Gorges Dam.

Owner:彭映斌

Pavement material dynamic water pressure washing tester

ActiveCN103439210AEffectively test water damage resistanceReduce noiseInvestigating abrasion/wear resistanceRoad surfaceEngineering

The invention discloses a pavement material dynamic water pressure washing tester which comprises a closed test box and a water supply system, wherein a mounting seat is fixedly arranged in the closed test box and is used for dividing an inner cavity of the closed test box into an upper forward washing cavity and a lower reverse washing cavity; a plurality of positioning barrels are arranged on the mounting seat; at least one positioning barrel is provided with a reverse washing barrel of which the upper end is closed and the lower end is communicated with the reverse washing cavity; the residual positioning barrels are provided with test piece carriers for fixing a pavement material test piece; a dynamic water inlet / outlet connected with the water supply system is formed in the forward washing cavity. The pavement material dynamic water pressure washing tester can truly simulate an actual washing condition of a pavement material; a test result is reliable; the pavement material dynamic water pressure washing tester is suitable for various types of mixtures.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

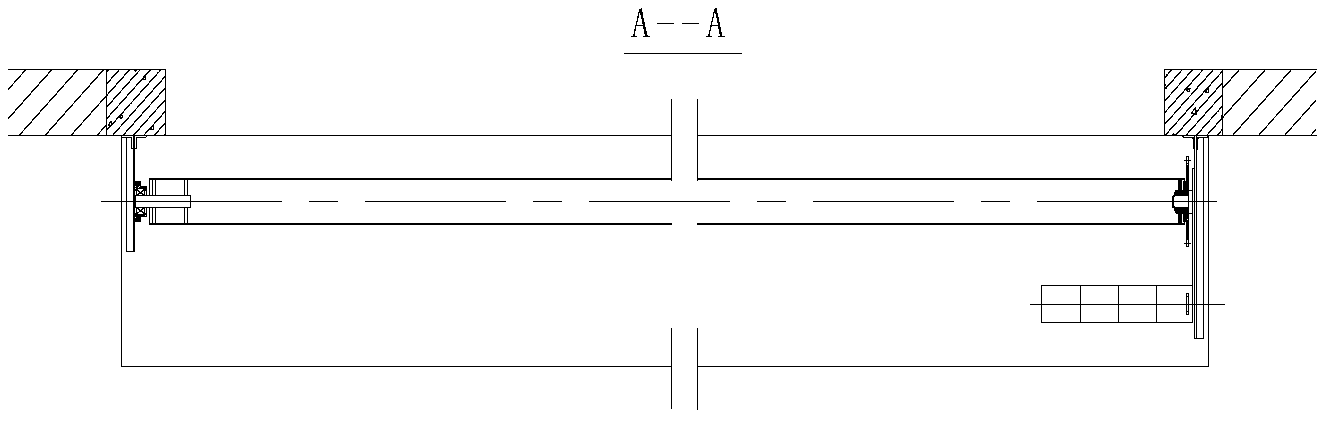

Battery winding needle structure

ActiveCN103326071AEasy to open and closeImprove winding efficiencyFinal product manufactureSecondary cellsEngineeringPole piece

The invention discloses a battery winding needle structure which comprises a first needle body and a second needle body and also comprises a vertical adjusting component and a transverse adjusting component, wherein the vertical adjusting component controls the opening and closing of the first needle body and the second needle body in the vertical direction; the transverse adjusting component controls the displacement movement of the first needle body and the second needle body in the transverse direction. According to the winding needle structure, positive and negative pole pieces and a diaphragm can simultaneously enter a winding needle, thus improving the cell winding efficiency and quality.

Owner:SHENZHEN YINGHE TECH

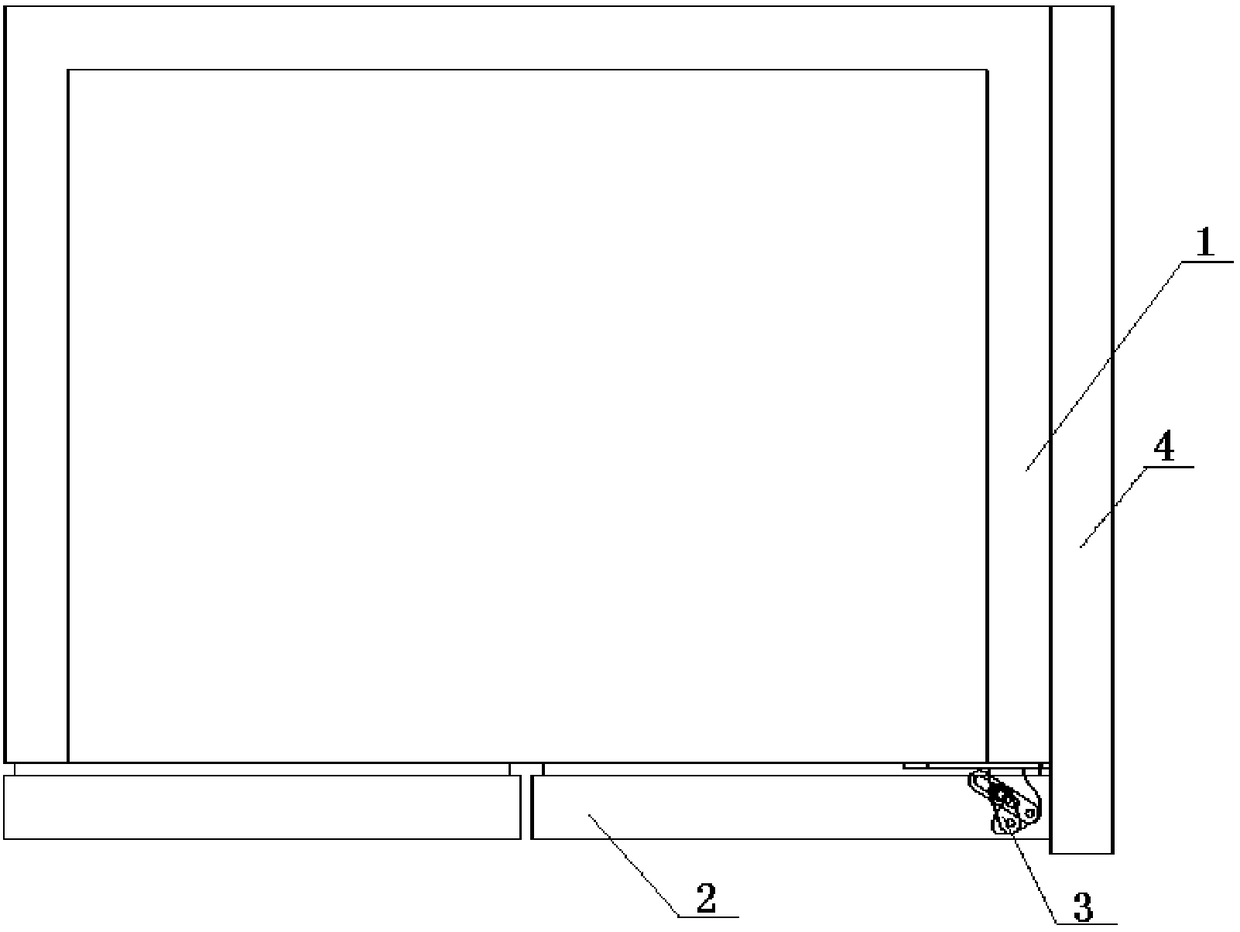

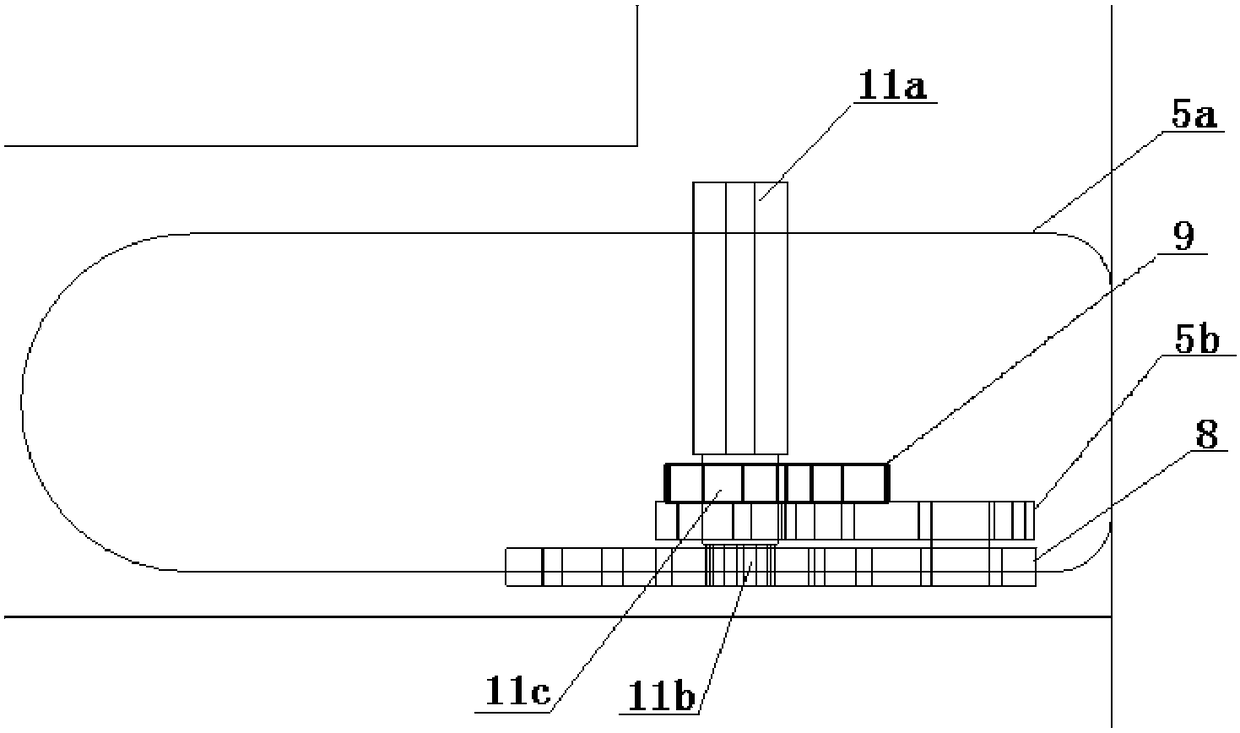

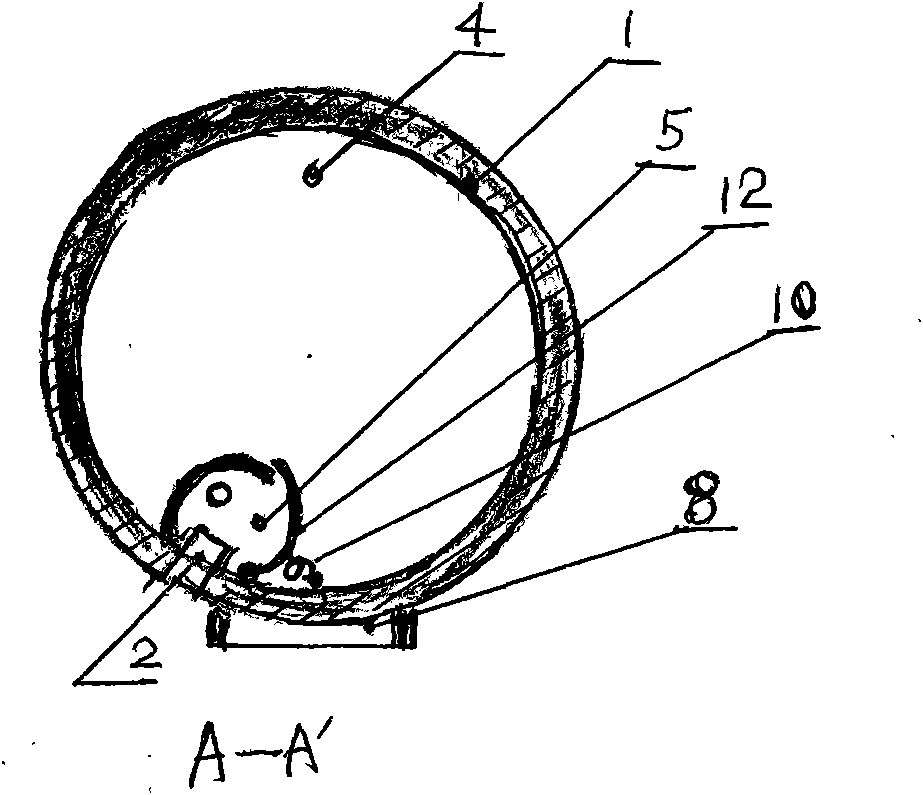

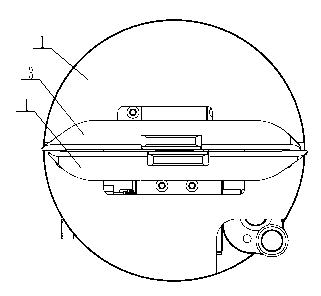

Shock-resisting steel explosion-venting rolling shutter door

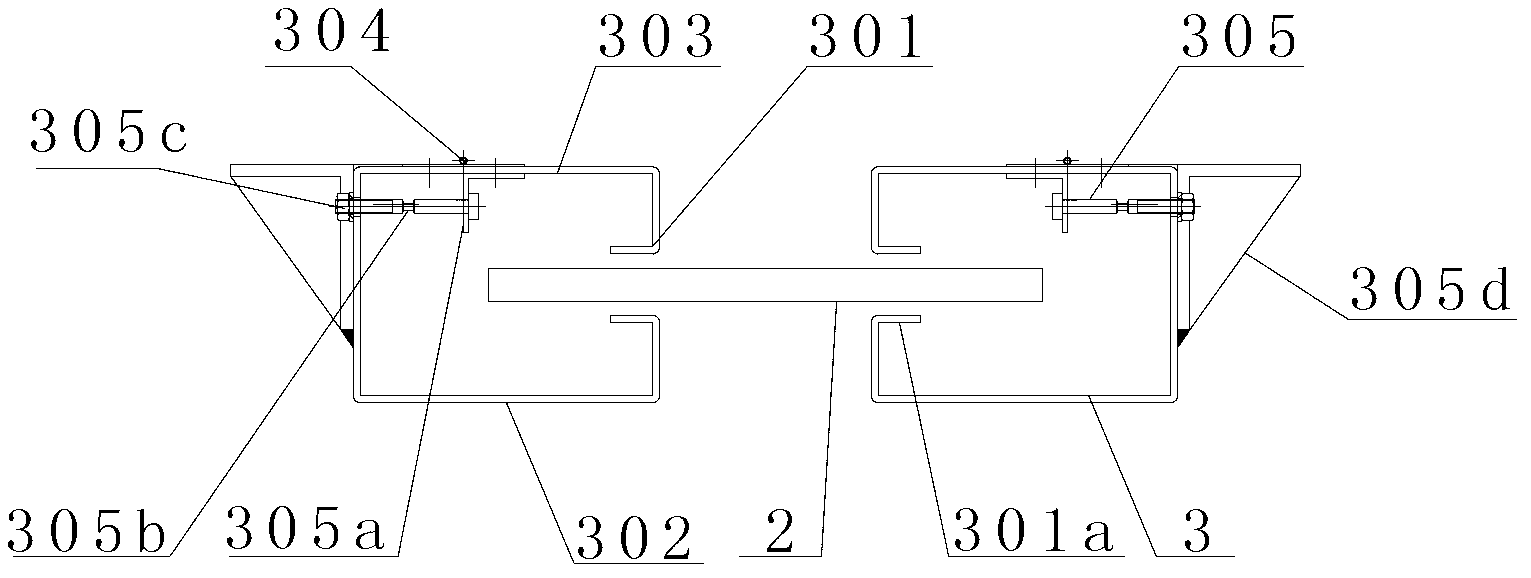

InactiveCN103225473AEasy to open and closeGood ventDoor/window protective devicesWar-like protectionShock waveRolling shutter

The invention relates to a shock-resisting steel explosion-venting rolling shutter door comprising a drive system (1), wherein the drive system (1) is arranged on a support plate (5); the support plate (5) is fixedly arranged on the wall of a building; one end of a curtain surface (2) is arranged on the drive system (1); and two sides of the curtain surface (2) extend into notches (301) of open-type guide rails (3) and are capable of moving in the notches (301) of the open-type guide rails (3). The rolling shutter door is characterized in that the open-type guide rails (3) comprise installation parts (302) and explosion venting parts (303) which are connected through hinges (304); and explosion venting devices (305) are arranged between the installation parts (302) and the explosion venting parts (303). The shock-resisting steel explosion-venting rolling shutter door provided by the invention has the advantages that the requirements that the open and the close of the door are easy in normal use and large-size objects can pass are satisfied; and when an explosion accident happens, the curtain surface can be opened by shock wave to realize good explosion venting and pressure releasing functions.

Owner:SHANGHAI SENLIN SPECIAL TYPE STEEL DOOR

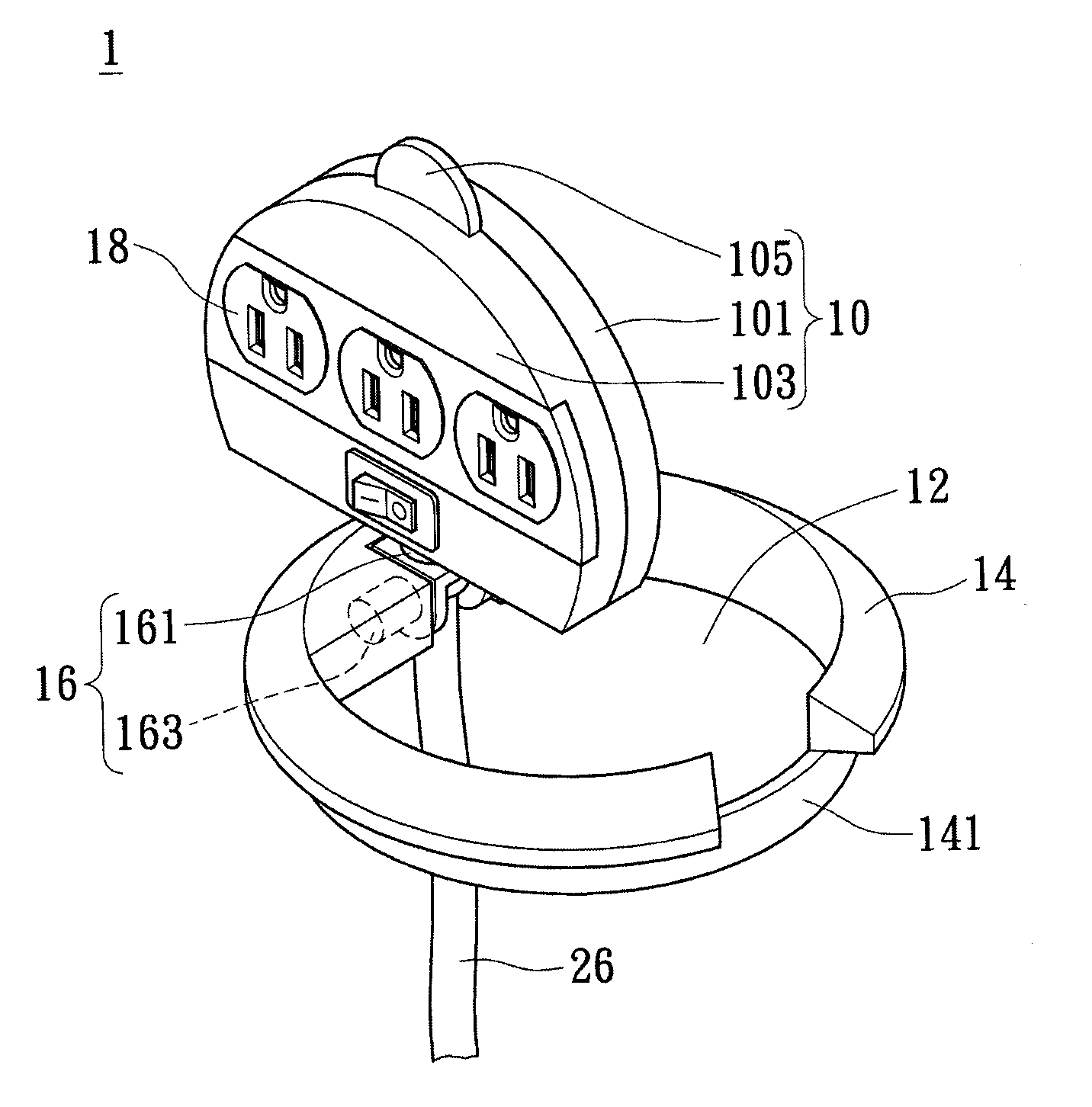

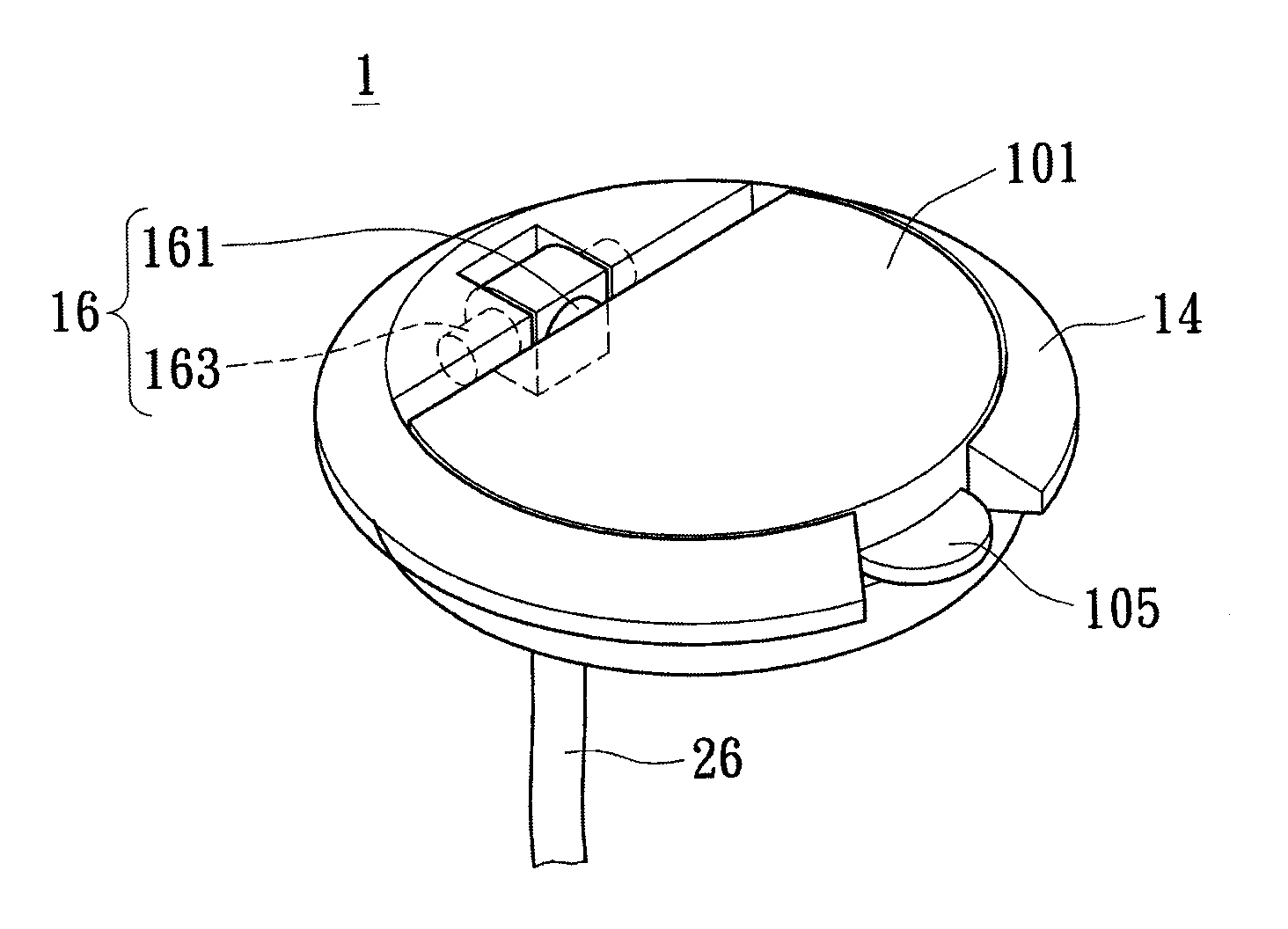

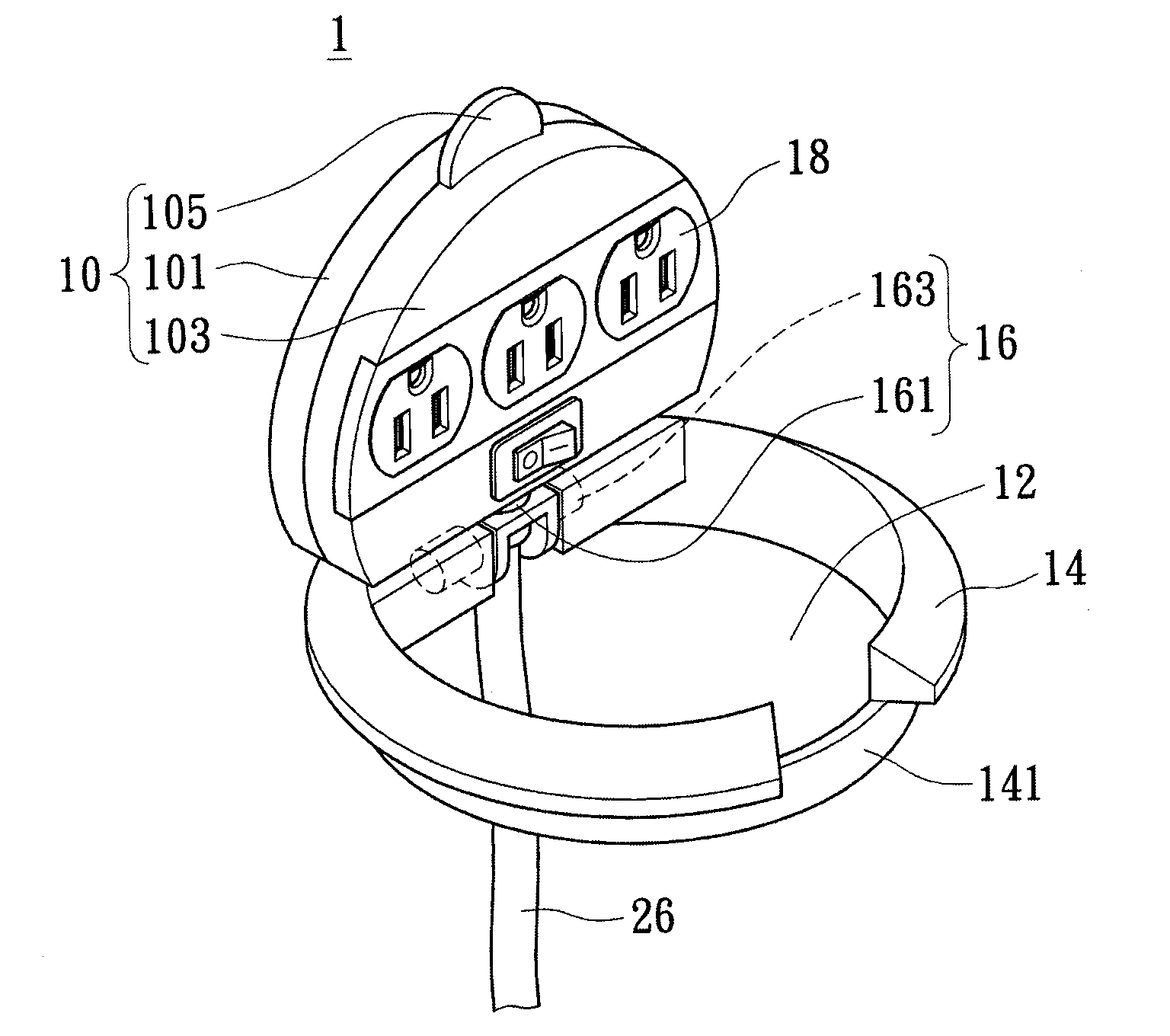

Concealed socket capable of rolling towards multi-directions

InactiveCN102148469AGood reversalEasy to open and closeCoupling device detailsFlexible/turnable line connectorsEngineeringMechanical engineering

Owner:POWERTECH INDAL

Automatic zipper head

Owner:FUJIAN ZIPPER SCI & TECH CO LTD

Axial flow type rotary regulating valve

InactiveCN107477202AReduce volumePrecise positioning operationOperating means/releasing devices for valvesSlide valveEngineeringHigh pressure

The invention provides an axial flow type rotary regulating valve. The valve includes a valve body, the valve body is internally provided with a valve chamber, one side of the valve body is provided with a feeding hole, the other side of the valve body is provided with a discharge hole, the feeding hole and the discharge hole are both communicated with the valve chamber, a flowing channel is formed between the feeding hole and the discharge hole of the valve body, the valve chamber is internally provided with a regulation mechanism, and the regulation mechanism includes a fixed plate and a rotary plate, wherein the fixed plate is in sealed connection with the inner wall of the valve chamber and the rotary plate rotates relative to the fixed plate; the fixed plate is provided with a plurality of first through holes, the rotary plate is attached to one end of the fixed plate and provided with second through holes corresponding to the first through holes, and the rotary plate rotates relative to the fixed plate so as to adjust the matching area between the second through holes and the first through holes. According to the axial flow type rotary regulating valve, a stepper motor is adopted for accurately controlling the rotation angle of the rotary plate so as to control the sectional area of medium circulation, the control is accurate, compared with the straight route, the rotary regulating valve is easier to open and close under high pressure, and the valve is small in size and convenient to install.

Owner:WUZHONG INSTR

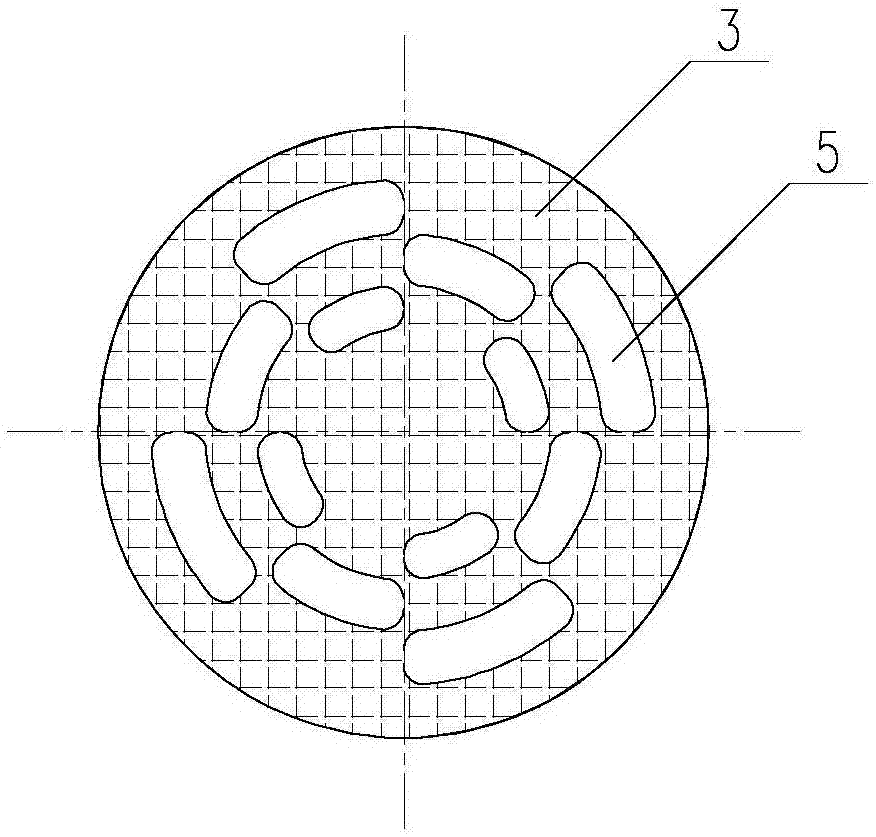

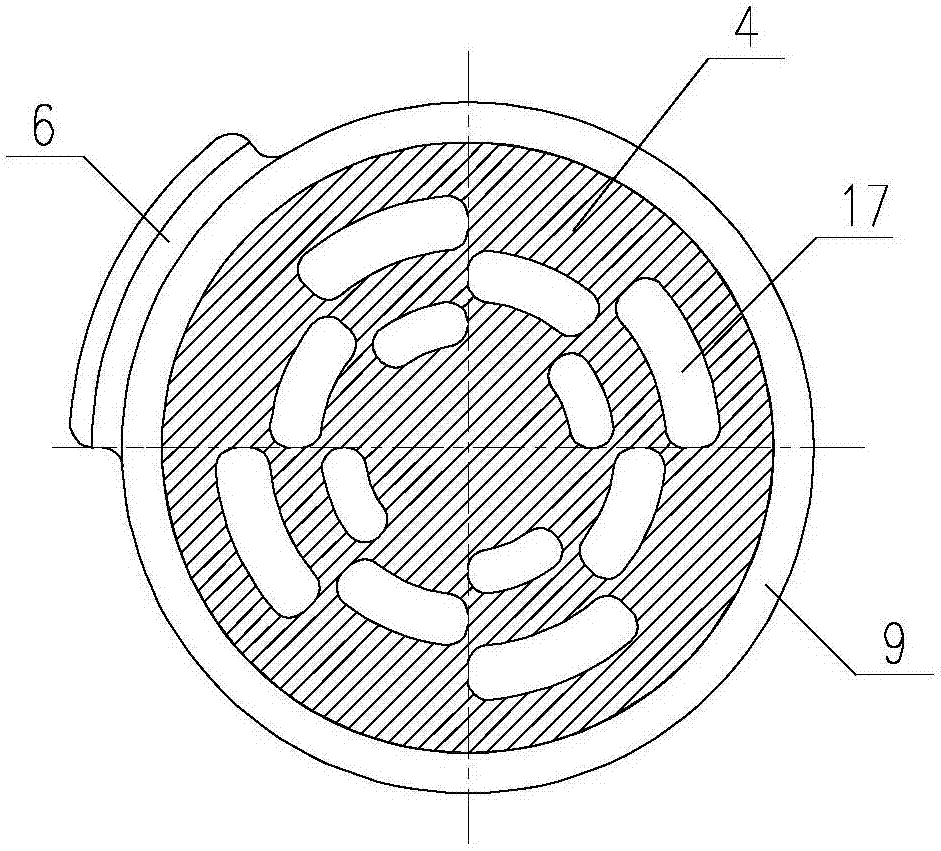

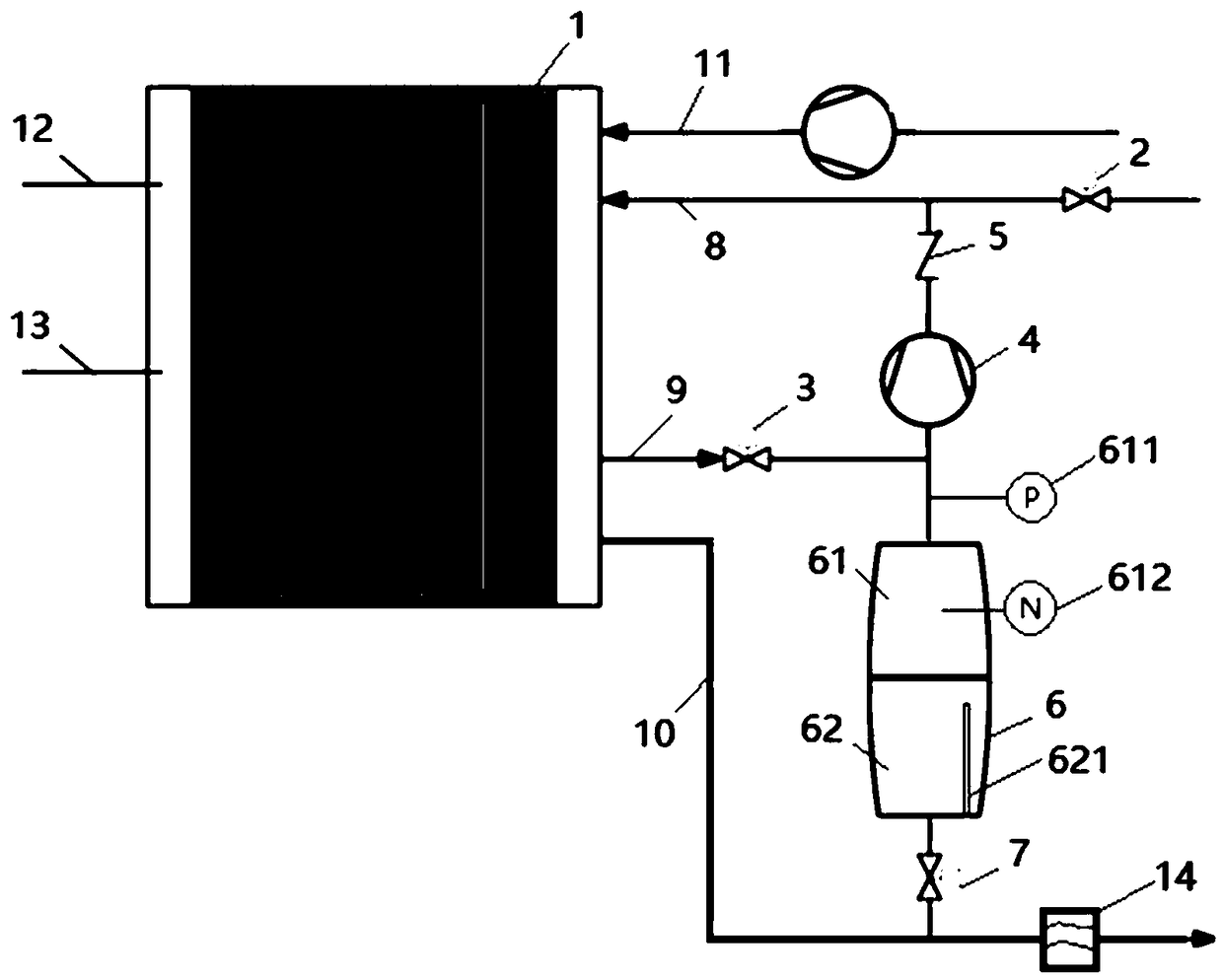

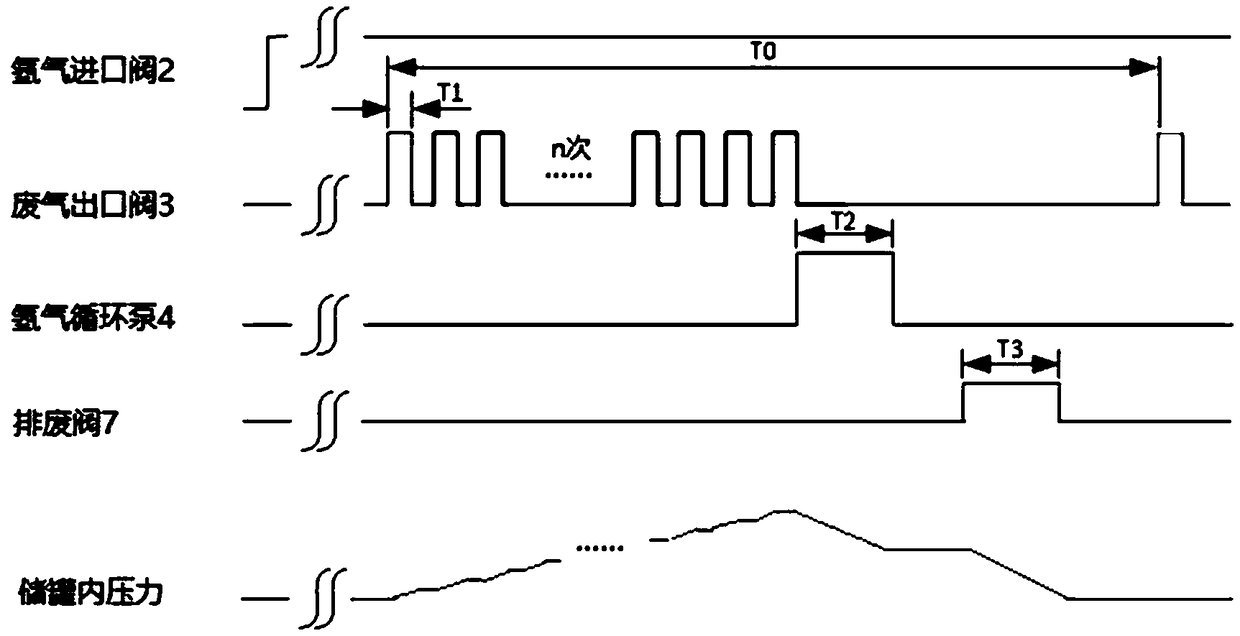

Fuel cell hydrogen recovery device

ActiveCN109411783ASmooth dischargeImplement storageReactant parameters controlWater management in fuel cellsVapor–liquid separatorHydrogen

Owner:氢鑫沃德(上海)新能源发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com