Patents

Literature

53results about How to "Guaranteed cleanliness requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

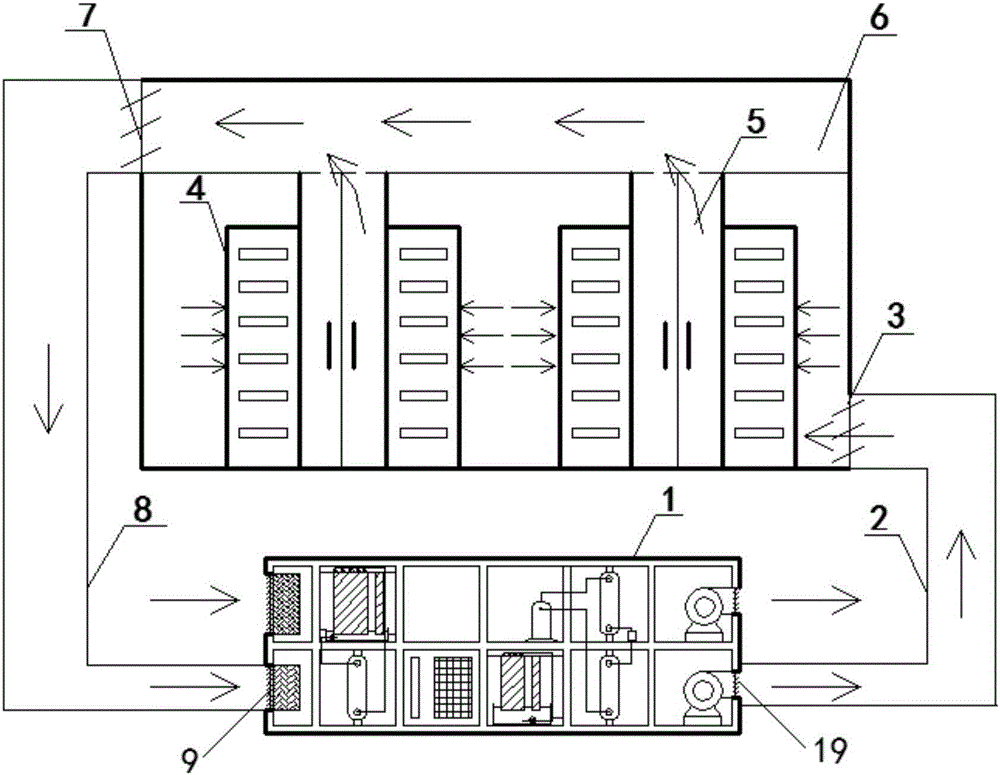

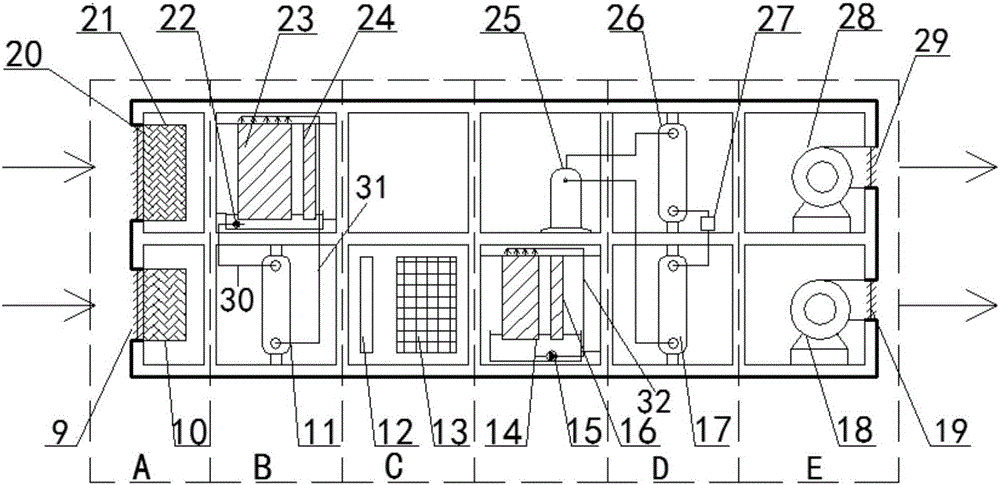

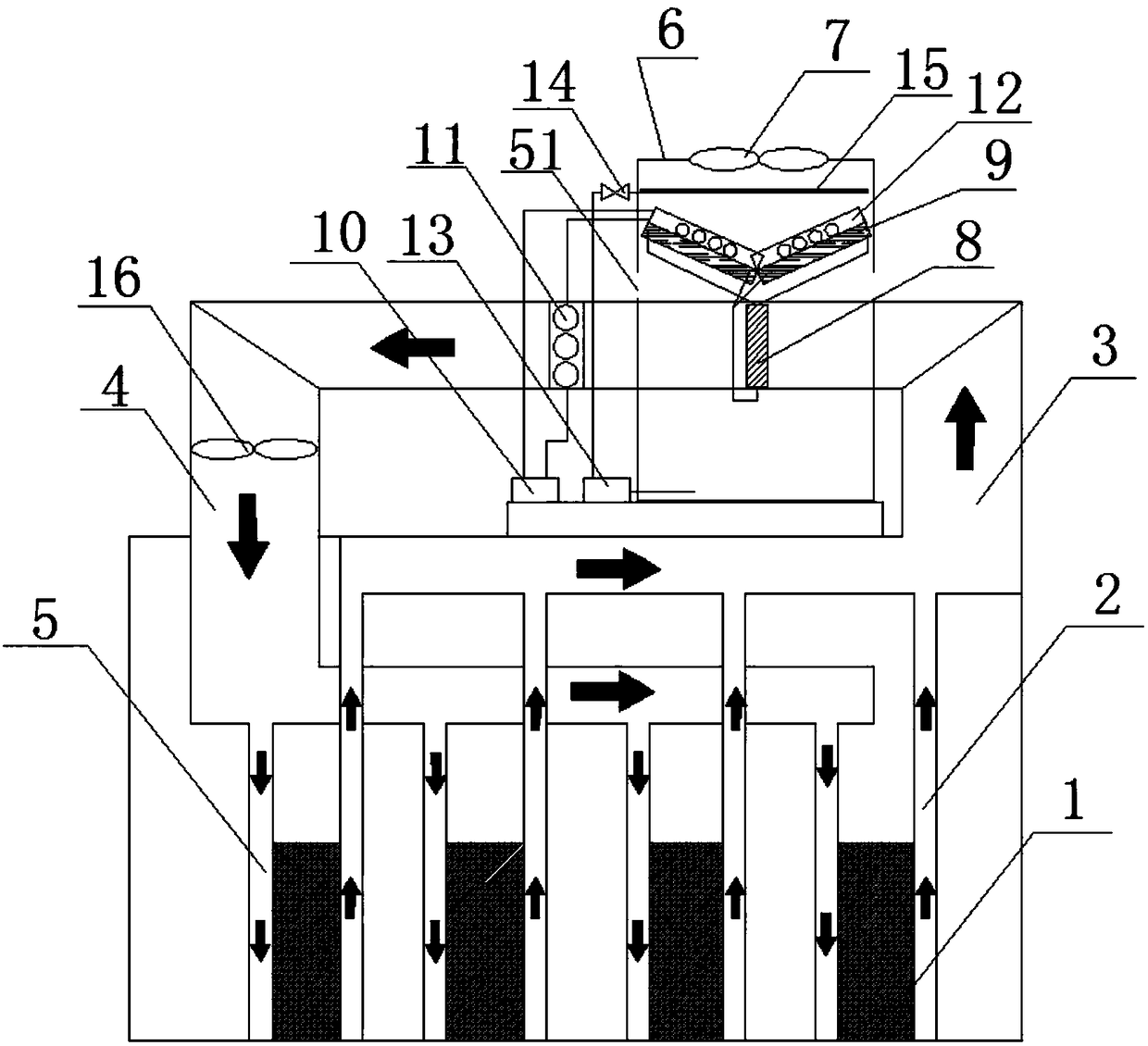

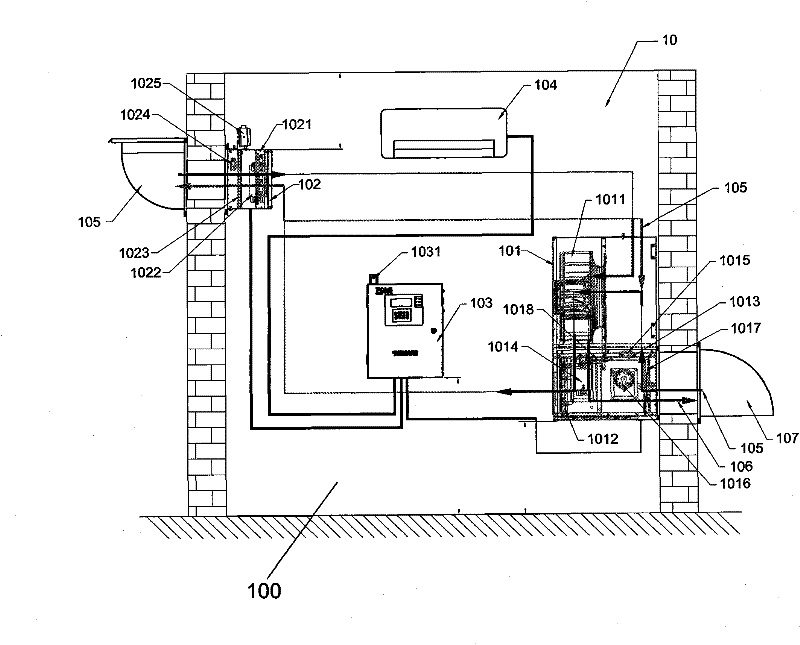

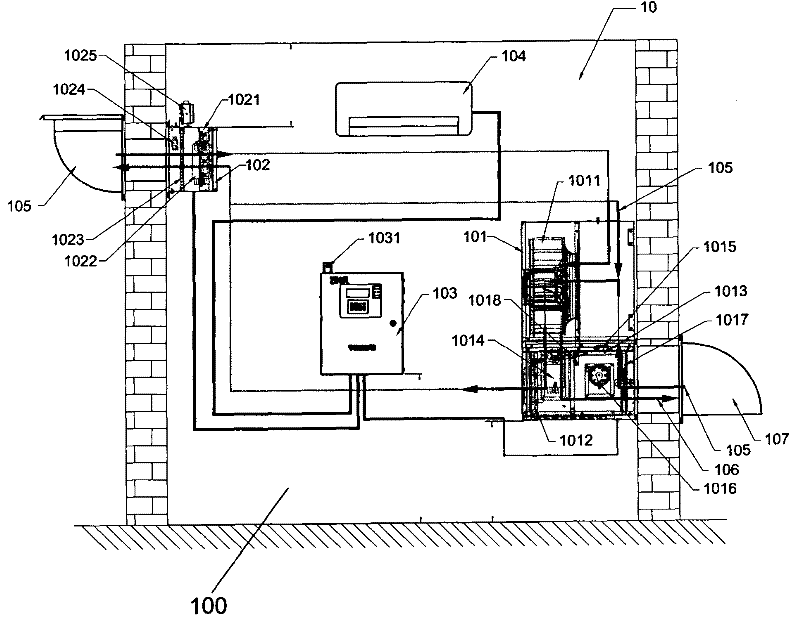

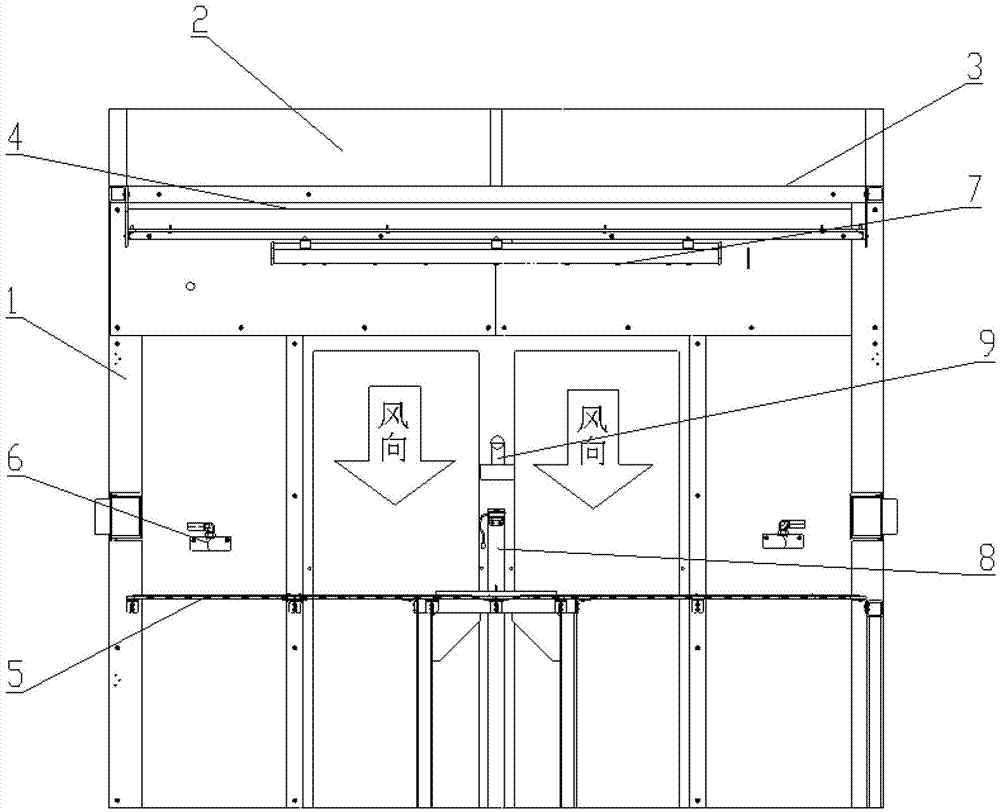

Sealed hot channel-full air returning dried-air energy central air conditioning system for data center

InactiveCN106247501ASimple structureLow costDucting arrangementsLighting and heating apparatusData centerOperation mode

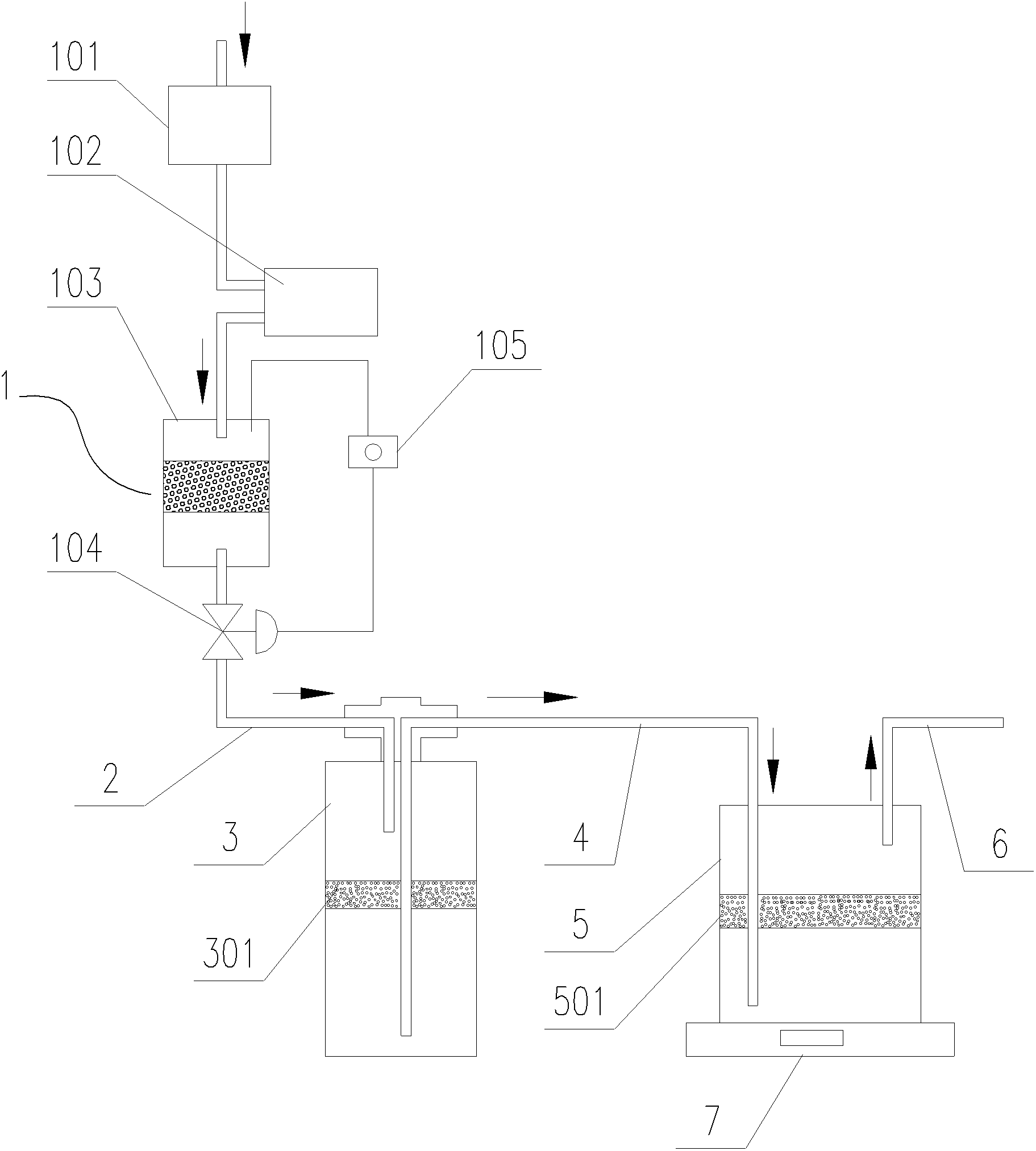

The invention discloses a sealed hot channel-full air returning dried-air energy central air conditioning system for a data center. The sealed hot channel-full air returning dried-air energy central air conditioning system comprises a dried-air energy central air conditioning unit; the dried-air energy central air conditioning unit is connected with the data center through an air returning pipe and can recycle return air in the data center and process the return air so that the return air can become air meeting the air supply condition; and the dried-air energy central air conditioning unit is further connected with the data center through an air supply pipe, and the air meeting the air supply condition can be fed into the data center through the air supply pipe and a machine room air supply outlet. According to the sealed hot channel-full air returning dried-air energy central air conditioning system for the data center, the full year cool supply requirement of the data center can be effectively ensured, the phenomenon that disordered air distribution occurs in the data center can be avoided, and meanwhile reasonable adjustment of three operation modes can be achieved according to different weather conditions.

Owner:XI'AN POLYTECHNIC UNIVERSITY

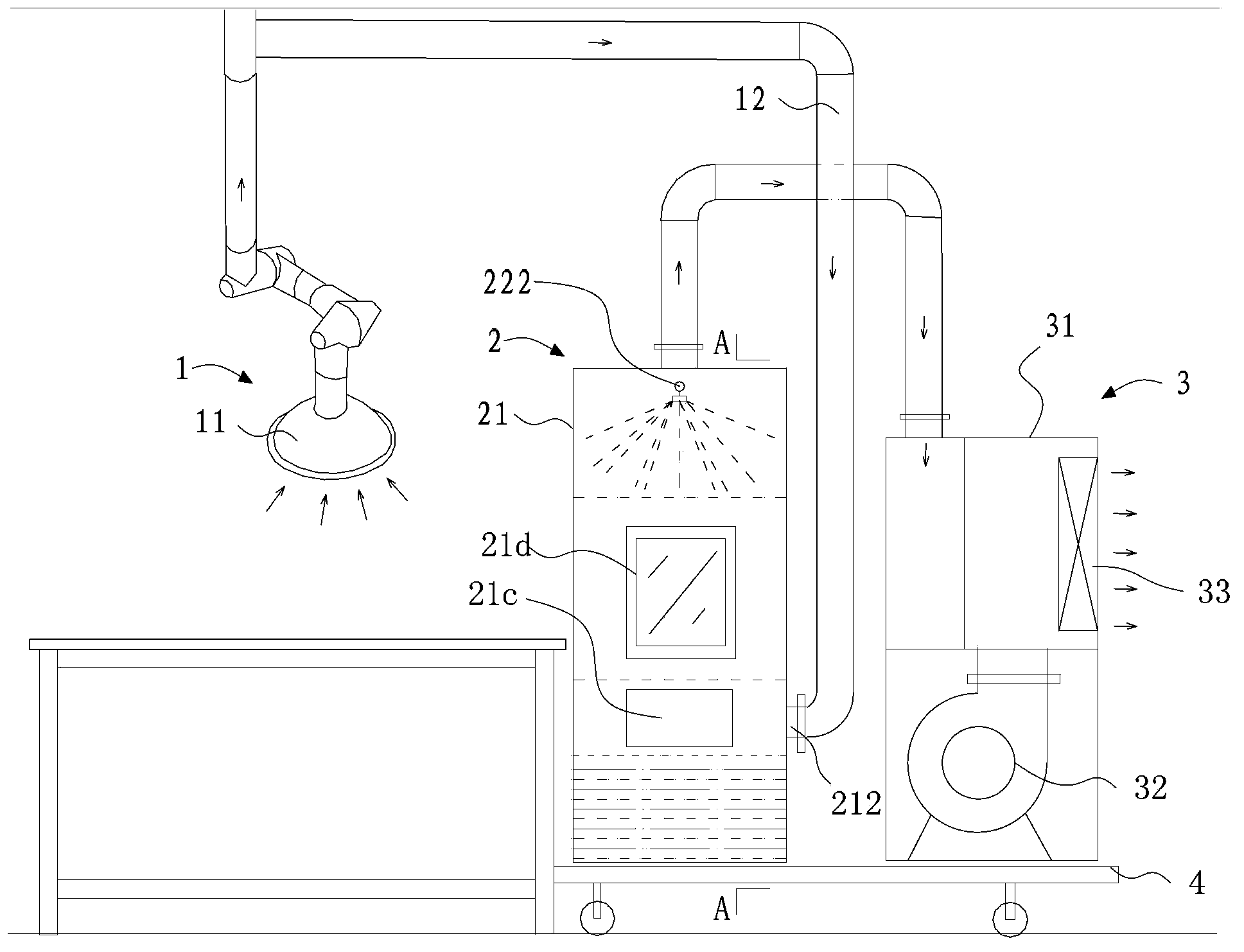

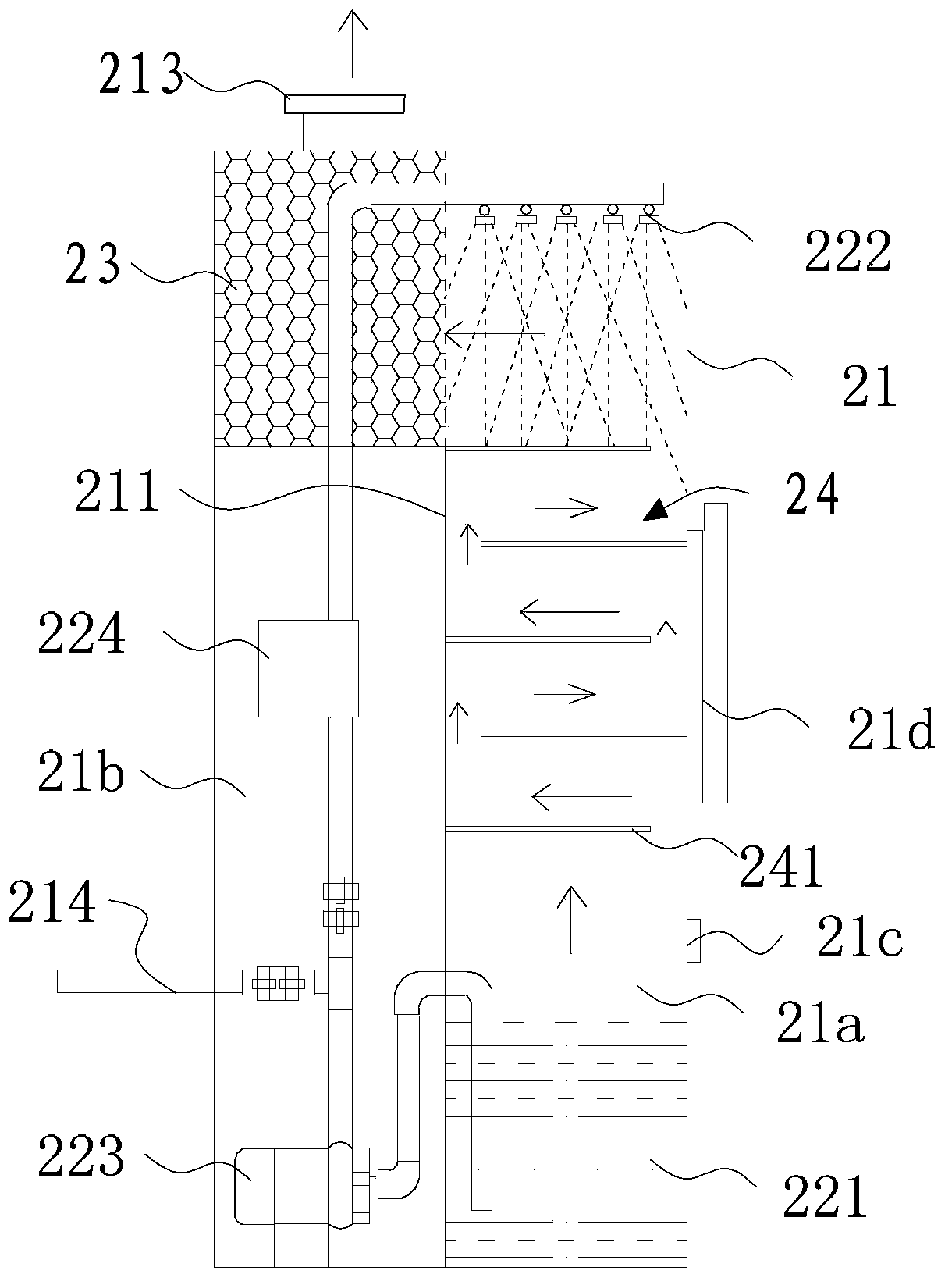

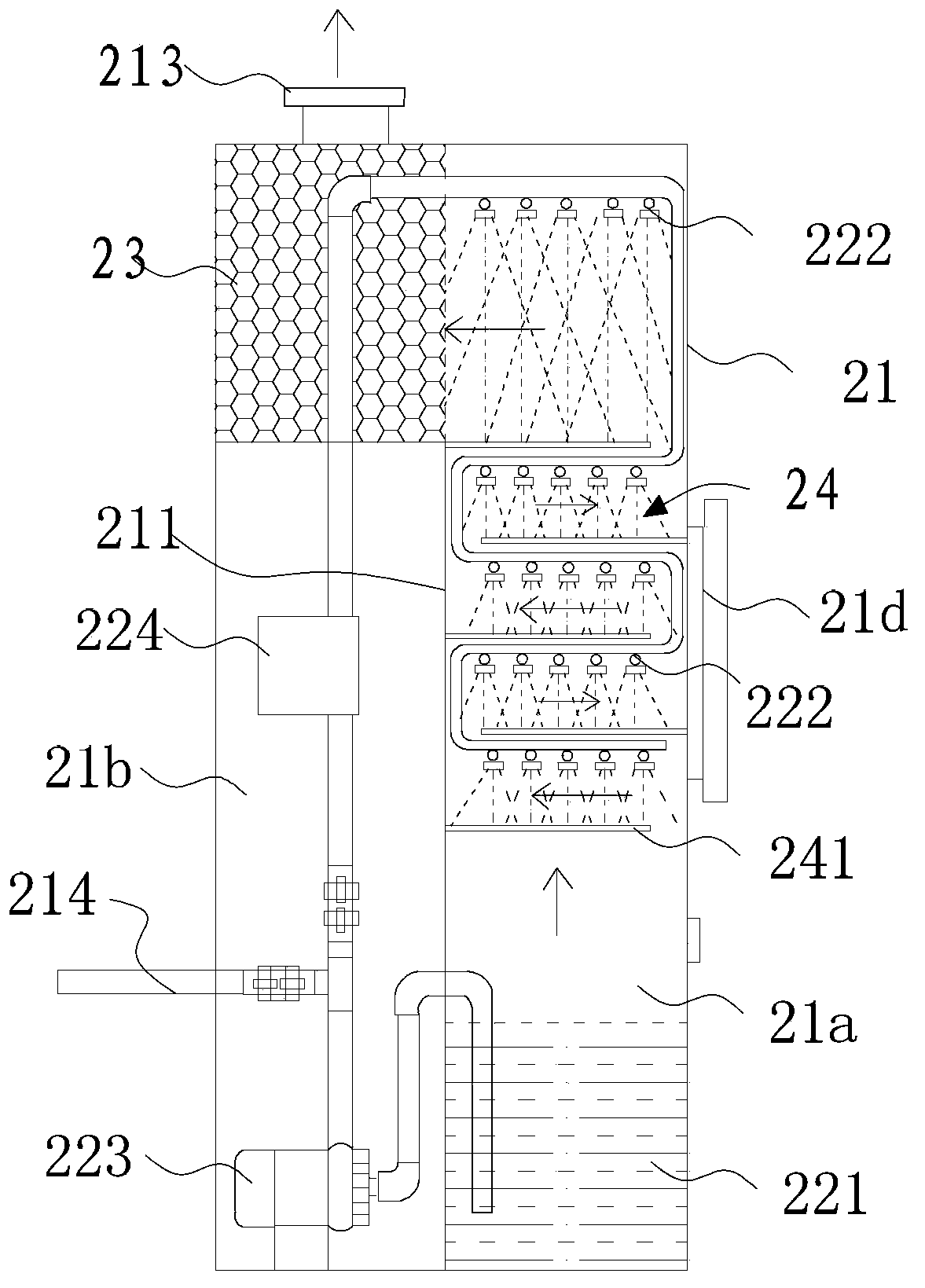

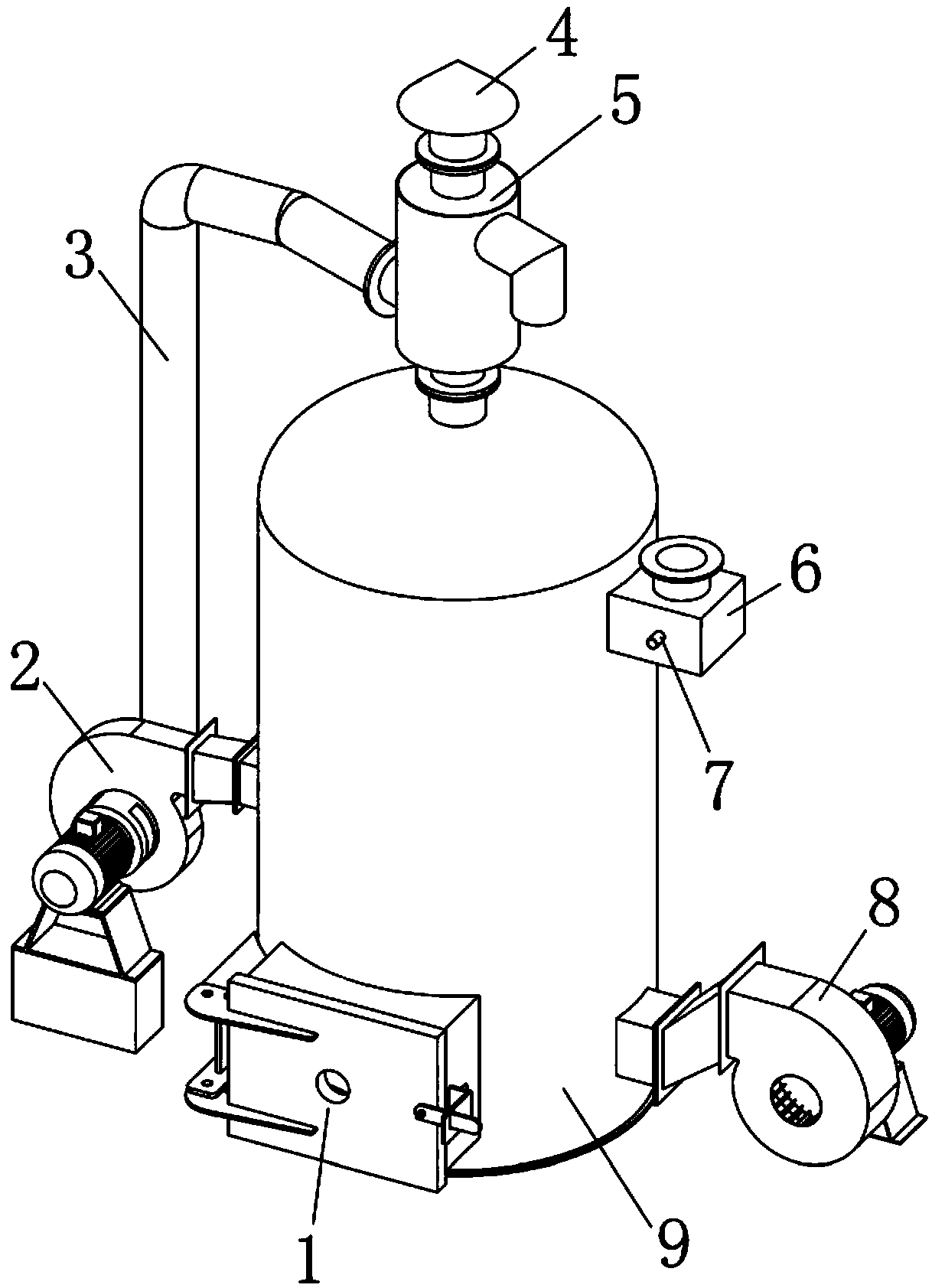

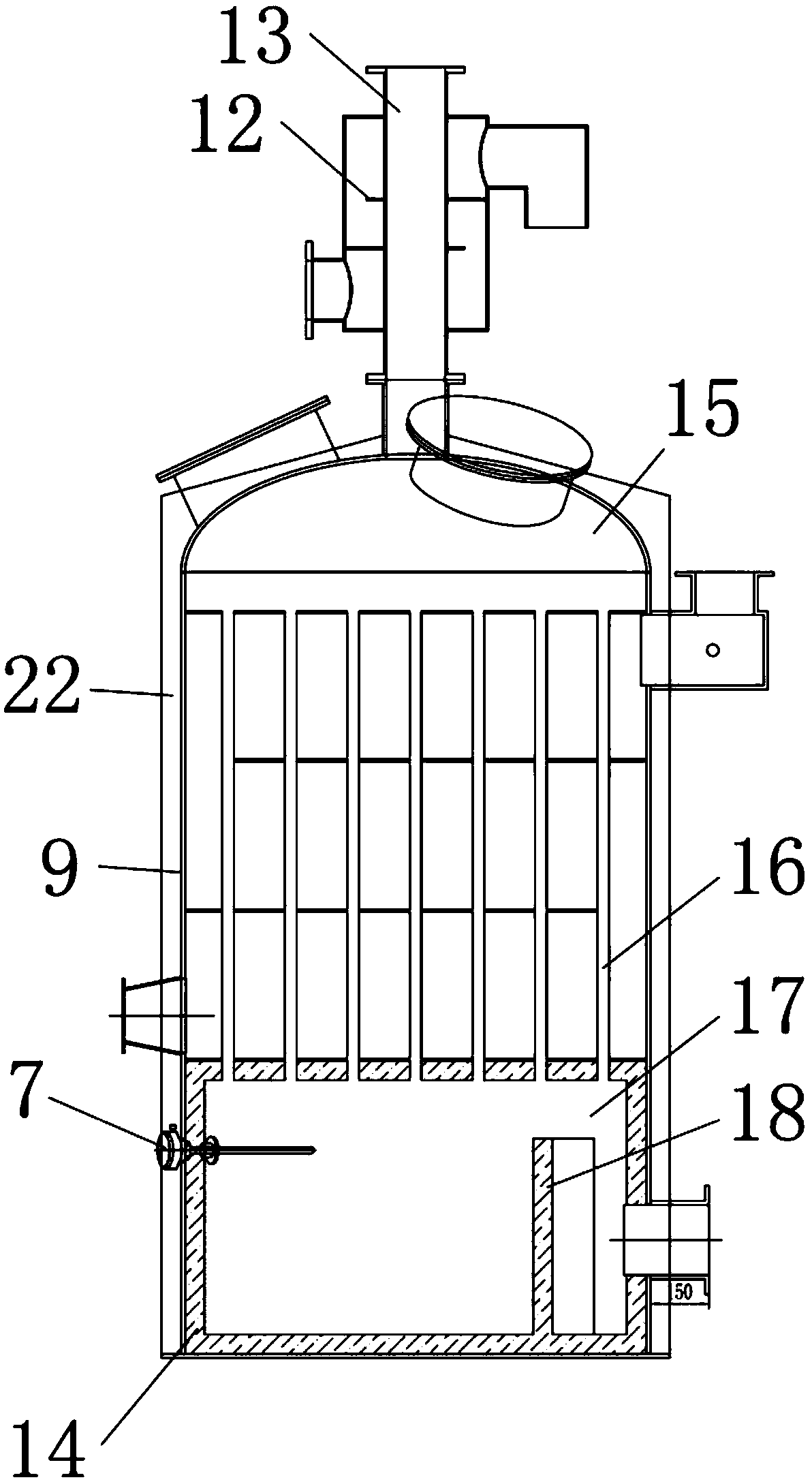

Waste gas and dust treating device

InactiveCN103505969ASimple structureMeet cleanliness requirementsUsing liquid separation agentAfter treatmentEmission standard

The invention provides a waste gas and dust treating device. The waste gas and dust treating device comprises a gas collecting device, a purification treatment device and a discharging device, wherein the gas collecting device is used for collecting waste gas and dust; the purification treatment device for purifying waste gas and dust collected by the gas collecting device is communicated with the gas collecting device and comprises a spraying device for spraying a washing liquid for washing the waste gas and the dust collected by a dust collecting device and a defogging device for dewatering and defogging gas which is obtained after the washing liquid sprayed by the spraying device is treated; the discharging device is used for discharging the gas treated by the purification treatment device and is communicated with the purification treatment device. The waste gas and dust treating device is simple in structure, and capable of effectively treating waste gas and dust and enabling the waste gas and the dust to achieve emission standards, thereby reducing pollution to workshop environment as well as harms to human bodies; the gas discharged after treatment of the waste gas and dust treating device can meet the cleaness requirement of the workshop environment and can be directly discharged into the workshop environment, so that both the cleaness requirement and the sealing requirement of the workshop environment are met.

Owner:BEIJING SKYWING TECH CO LTD

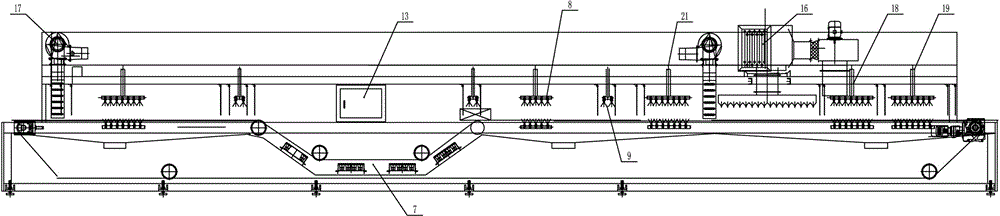

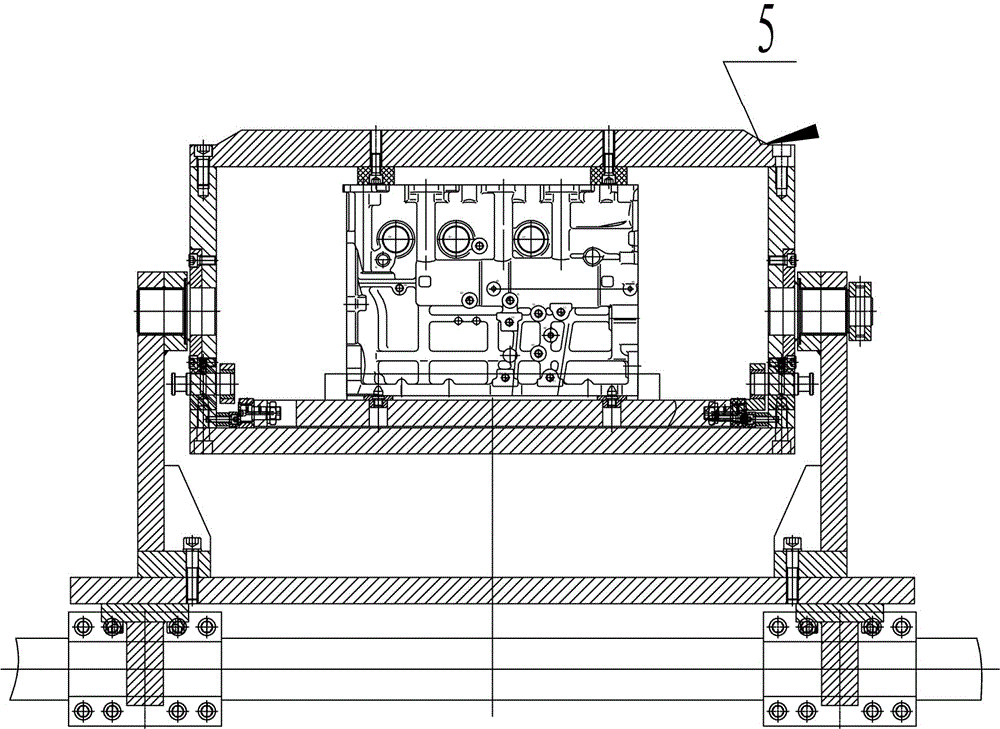

Full-automatic cleaning oil-coating device

InactiveCN104646334AEasy to open and closeGuaranteed cleanliness requirementsLiquid surface applicatorsCoatingsMegasonic cleaningEngineering

A full-automatic cleaning oil-coating device comprises a machine base, wherein a machine frame and an electrical appliance control device are arranged on the machine base, a guide rail and a stainless steel conveying net chain are arranged at the upper portion of the machine frame, the stainless steel conveying net is provided with a net belt chain tensioning device and a chain stepless speed-regulating conveying system, a sealing cover is arranged at the upper portion of the stainless steel conveying net chain, a spraying-cleaning device, a first cutting water air knife, an ultrasonic cleaning system, a second cutting water air knife, a spraying-rinsing device, a third cutting water air knife, a compressed air water blowing device, an air blow-drying system, an oil coating device and a deoiling device, and a cleaning liquid filtering system is arranged on the side face of the machine frame. The full-automatic cleaning oil-coating device is provided with a movable overhaul window, an overhaul door is convenient, flexible and safe to open and close and has an interlocking function, and the full-automatic cleaning oil-coating device cannot be started if the door is not closed well. The full-automatic cleaning oil-coating device is provided with a good steam pumping and discharging system and prevents mist from escaping outside. In addition, the circular filtering system provides cleaning liquid having constant cleaning effect for liquid grooves, the cleanliness requirements of parts can be ensured, and re-utilization rate of the liquid can be improved.

Owner:YICHANG WASHING MACHINE

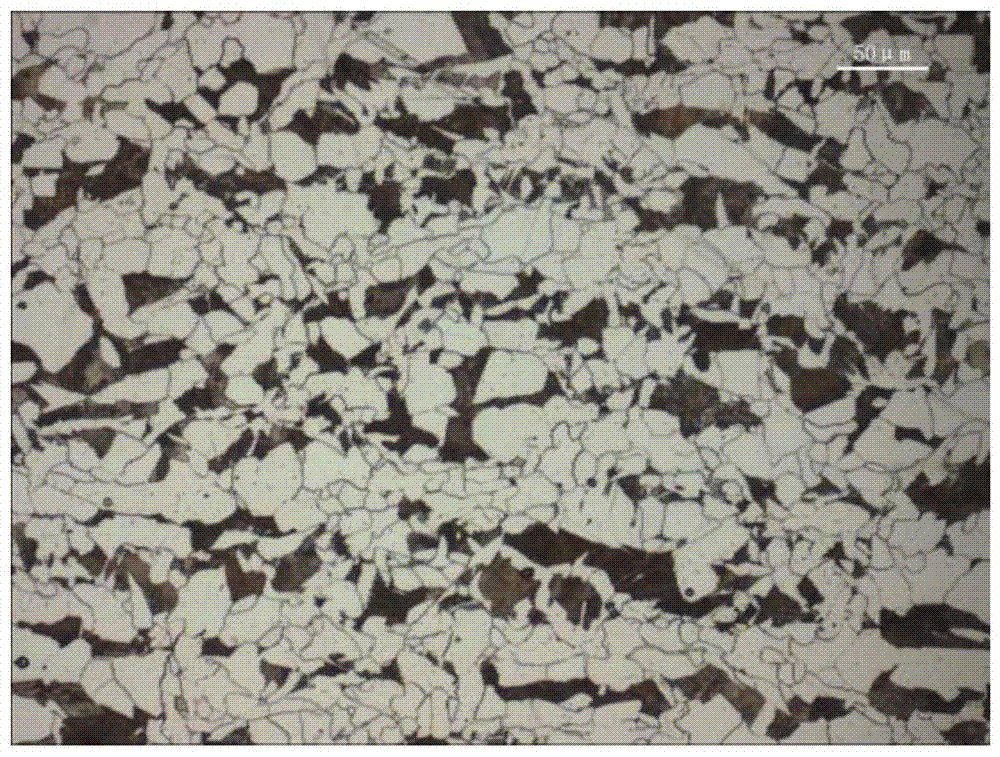

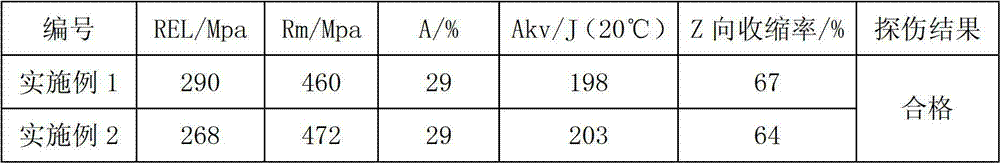

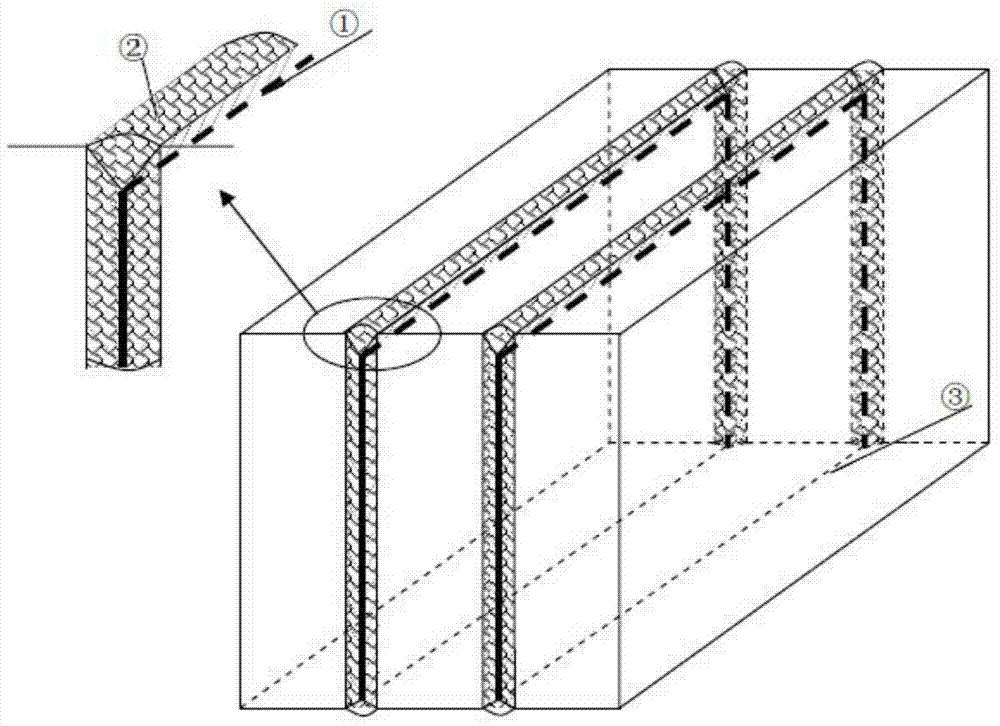

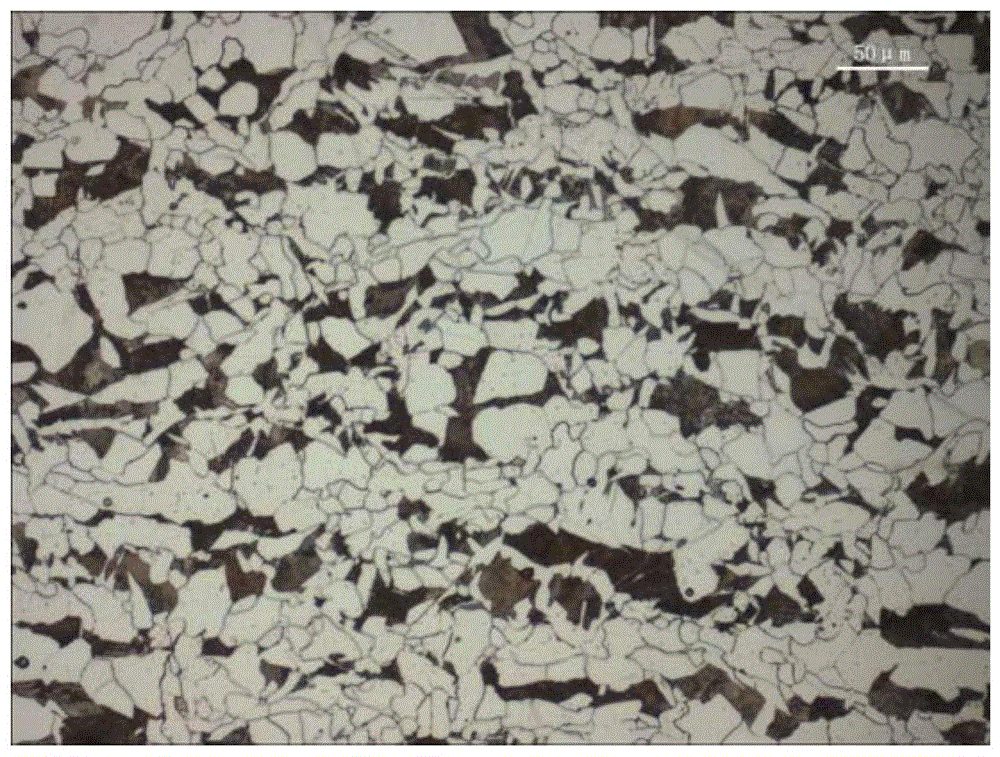

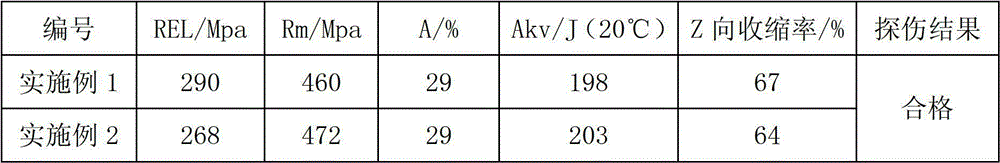

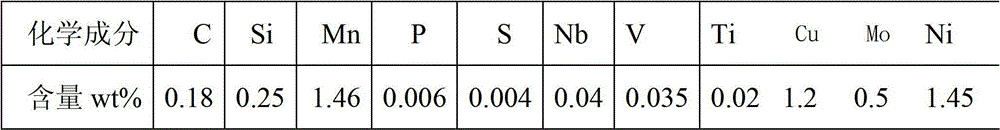

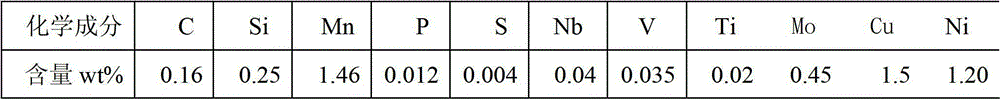

Technique for manufacturing 150-400mm thick carbon constructional steel plate by using continuous casting slabs

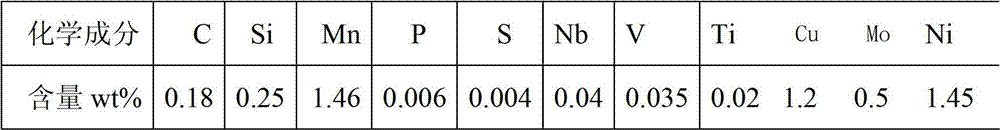

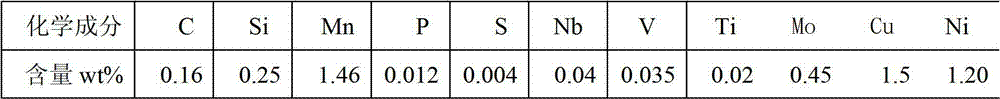

InactiveCN102764961AReduce organizational performance varianceAvoid growing upSteelmakingChemical composition

The invention discloses a technique for manufacturing a 150-400mm thick carbon constructional steel plate by using continuous casting slabs, belonging to the field of metal materials. The continuous casting slabs subjected to converter steelmaking and secondary refining are used in the technique; and the chemical components of the slabs include 0.14-0.20wt% of C, 0.20-0.50wt% of Si, 0.08-1.40wt% of Mn and less than or equal to 0.010wt% of S; at least two continuous casting slabs subjected to surface machining and cleaning are overlapped, four sides of the continuous casting slabs are combined and welded to form a big-thickness blank, the blank is arranged in a bogie-type furnace or a soaking pit furnace for heating, and then is rolled, water-cooled and subjected to heat treatment after being discharged from the furnace so as to produce the 120-400mm thick carbon constructional steel plate. The technique has the following characteristics of simple production process, high yield, high ultrasonic flaw detection rate of more than 98% and excellent performance.

Owner:JIGANG GRP

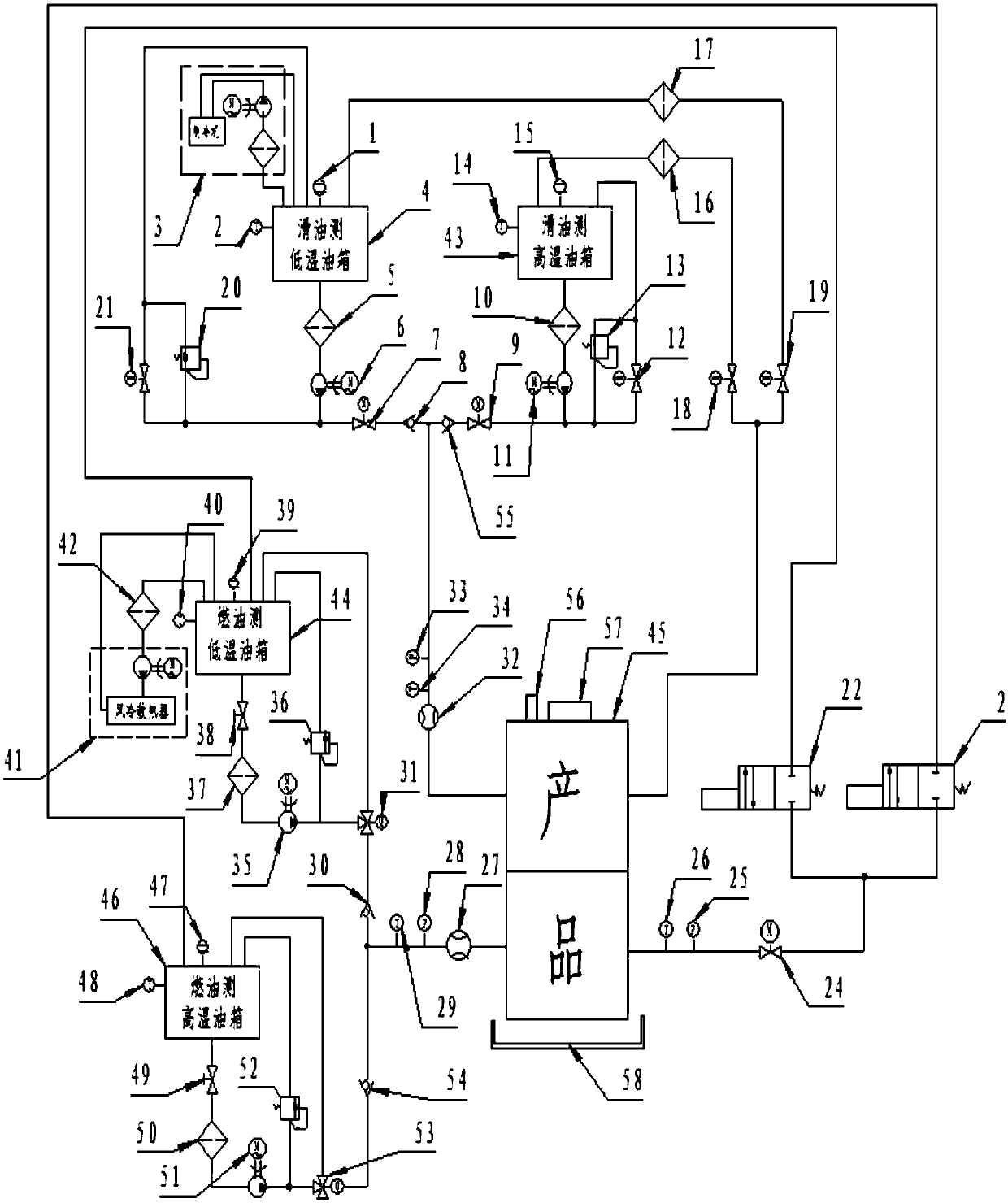

Test device for service life of aircraft alternating current generator fuel oil and slide oil radiator

ActiveCN109580209AHeating fastStable temperatureMachine part testingAutomatic controlAutomotive engineering

The invention discloses a test device for the service life of an aircraft alternating current generator fuel oil and slide oil radiator. The test device for the service life of the aircraft alternating current generator fuel oil and slide oil radiator comprises a slide oil side normal temperature system, a slide oil side high temperature system, a fuel oil side normal temperature system, a fuel oil side high temperature system, a refrigeration system, an automatic control system and an environment cabin. According to the technical scheme, a plurality of fuel oil and slide oil radiator bodies can be subjected to cyclic fatigue tests of flow rate, pressure, temperature and ambient temperature; under the test system, high-temperature, high-pressure and large-flow slide oil is introduced intoa product; after test conditions are stable, the automatic control system is used for automatically switching, and low-temperature, low-pressure and small-flow slide oil is introduced into the product, therefore, the impact of oil flow rate, pressure and temperature can be verified to simulate the influence of oil flow rate, pressure, temperature and environment temperature of an aircraft on the service life of the product. The test flow rate, pressure and temperature are automatically detected, adjusted, collected and recorded by the automatic control system for each detection point on a pipeline, and feedback control and data recording are carried out through the collection parameters of each detection point.

Owner:GUIZHOU YONGHONG AVIATION MACHINERY

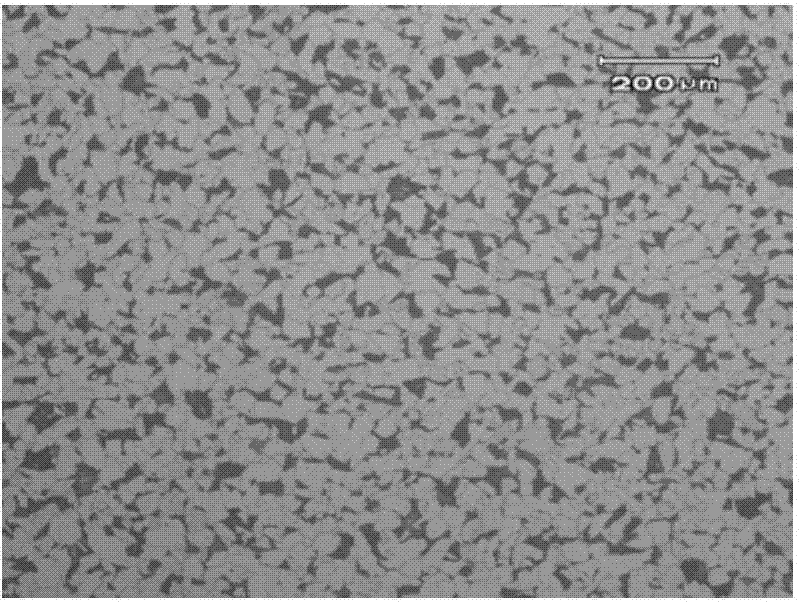

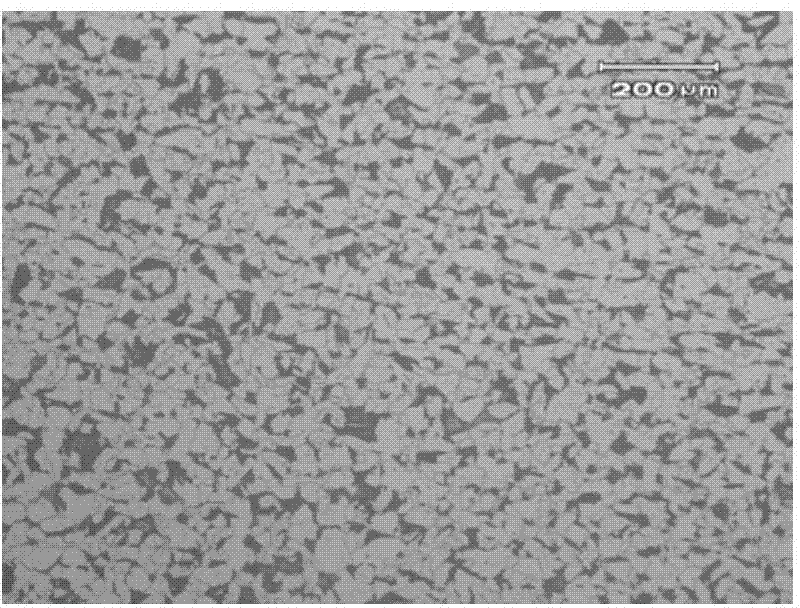

Medium-carbon alloy cast steel shots and manufacturing method thereof

The invention relates to medium-carbon alloy cast steel shots and a manufacturing method thereof. Each medium-carbon alloy cast steel shot comprises the following chemical components in percentage by mass: 0.35 to 0.45 percent of carbon, 0 to 0.2 silicon, 0.45 to 0.5 percent of manganese, 0.8 to 1.2 percent of chrome, 0 to 0.015 percent of sulfur, 0 to 0.020 percent of phosphor and the balance of iron and inevitable impurities. The manufacturing process comprises the following steps of: mixing and smelting, namely, smelting the raw material composition mixed proportionally into liquid steel, pouring the liquid steel into a tundish and performing deoxygenation by adopting an deoxidant; preparing shots by a centrifugally forming method, namely, pouring deoxygenized liquid steel into a centrifugal disc which rotates at a high speed, throwing out the liquid steel under the action of a centrifugal force to make the liquid steel fall into a cooling water pool, and taking the liquid steel out and drying the cooled steel to obtain formed cast steel shots; and performing heat treatment, namely, heating the formed cast steel shots until the temperature reaches 860 to 880 DEG C, performing cold quenching after keeping the temperature for 20 to 40 minutes, tempering for 40 to 80 minutes at the temperature of between 350 and 500 DEG C, and after tempering, cooling rapidly by a steel plate vibrating screen water cooling method to produce the medium-carbon alloy cast steel shots. The medium-carbon alloy cast steel shots and the manufacturing method thereof have the advantages of guaranteeing the high rigidity of the steel shots, avoiding crack generated in the centrifugally forming process and the heating tempering process, improving the toughness and the like.

Owner:淄博大亚金属科技股份有限公司

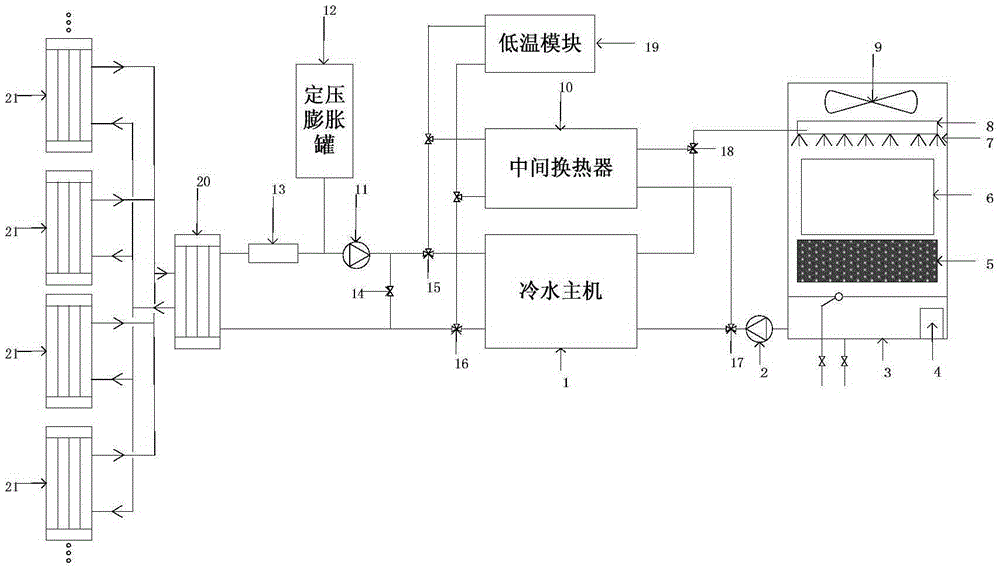

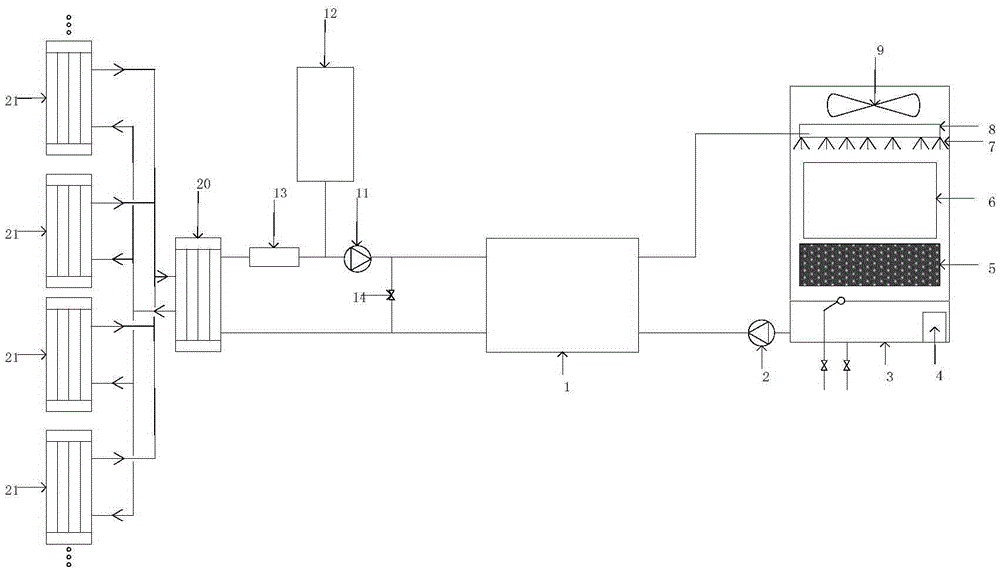

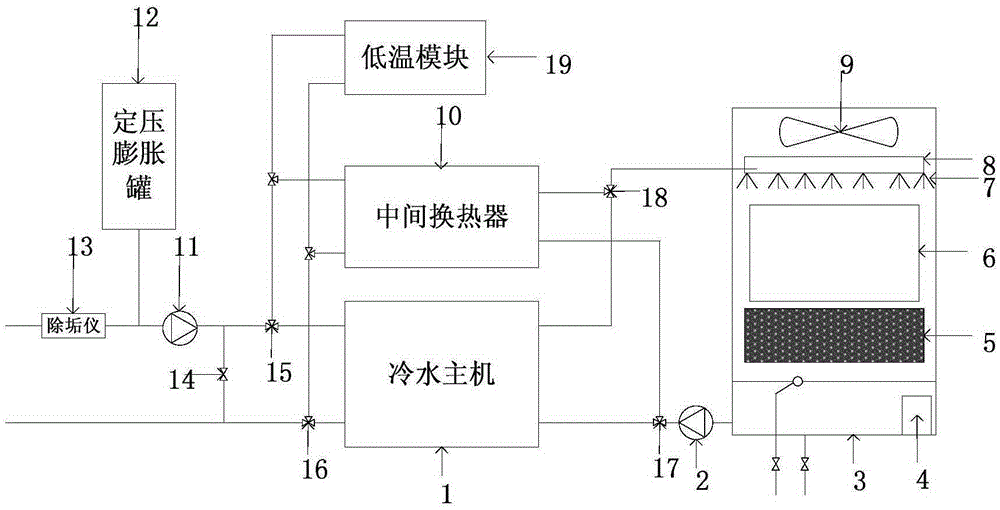

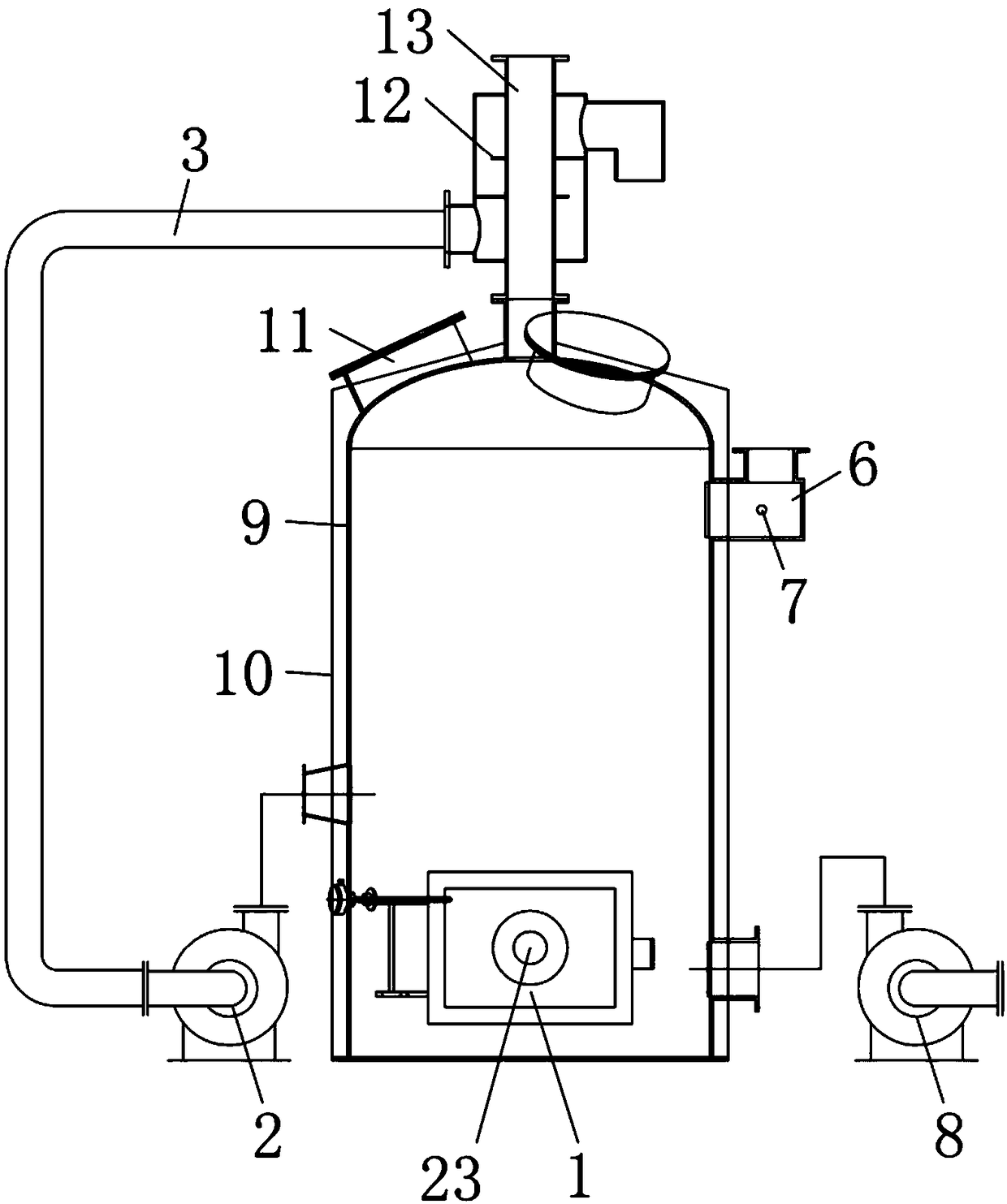

Multi-source heat-tube energy-saving system and refrigerating method based on multi-source heat tube

ActiveCN105387547AReduce running timeReduce energy consumptionMechanical apparatusSpace heating and ventilation safety systemsExpansion tankCooling tower

The invention discloses a multi-source heat-tube energy-saving system and a refrigerating method based on a multi-source heat tube. The multi-source heat-tube energy-saving system comprises a water cooling unit (1), an intermediate heat exchanger (10), a cooling water system, a freezing water system and a control system, wherein the water cooling unit is arranged between the cooling water system and the freeing water system; the intermediate heat exchanger and the water cooling unit share water supplying and returning pipelines of the cooling water system and the freeing water system; the water cooling unit, the intermediate heat exchanger, the cooling water system, the freezing water system and a three-way valve are controlled by the control system; the cooling water system comprises a cooling tower (3), and a cooling water pump (2) which is arranged on a water outlet pipeline of the cooling tower; the freeing water system comprises a refrigerating terminal (21), a refrigerant distributor (20), a freezing water pump (11), a constant-pressure expansion tank (12) and an incrustation cleaner (13); the refrigerating terminal is connected to the refrigerant distributor. The multi-source heat-tube energy-saving system and the refrigerating method based on the multi-source heat tube are easy to implement, and obvious in energy-saving effect.

Owner:CHANGSHA MAXXOM HIGH TECH CO LTD

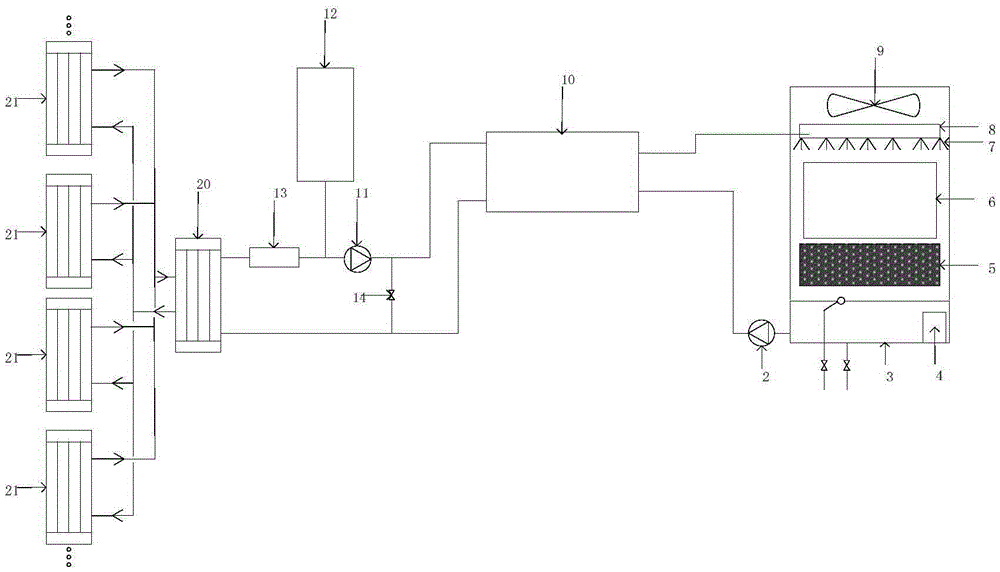

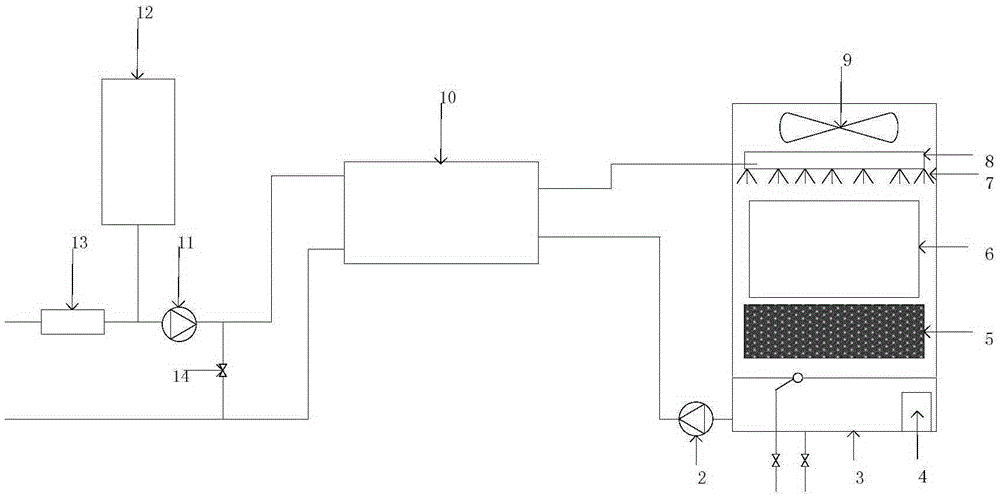

Multi-cold source cooling energy-saving system of data center and control method of system

ActiveCN109475067AImprove security levelGuaranteed cleanliness requirementsEnergy efficient computingCooling/ventilation/heating modificationsControl systemData center

The invention relates to a multi-cold source cooling energy-saving system of a data center and a control method of the system. The system comprises an air return system, an air sending system and a cooling system. Non-contact cooling between the system the an outdoor environment is achieved by water evaporation, an asymmetric hot pipe heat exchanging system and a compression heat exchange system,an outdoor natural cold source is efficiently utilized, and the running time of a compressor refrigerating system is reduced; under a condition that a fault occurs in an emergency water supply system,cooling running of the system in three running modes also can be achieved, and the safety level of the data center is improved; and automatic running of the system is controlled according to the change of an outdoor temperature, the system is high in intelligence and is more accurate, and the safety of the data center is improved.

Owner:XIANGJIANG TECH

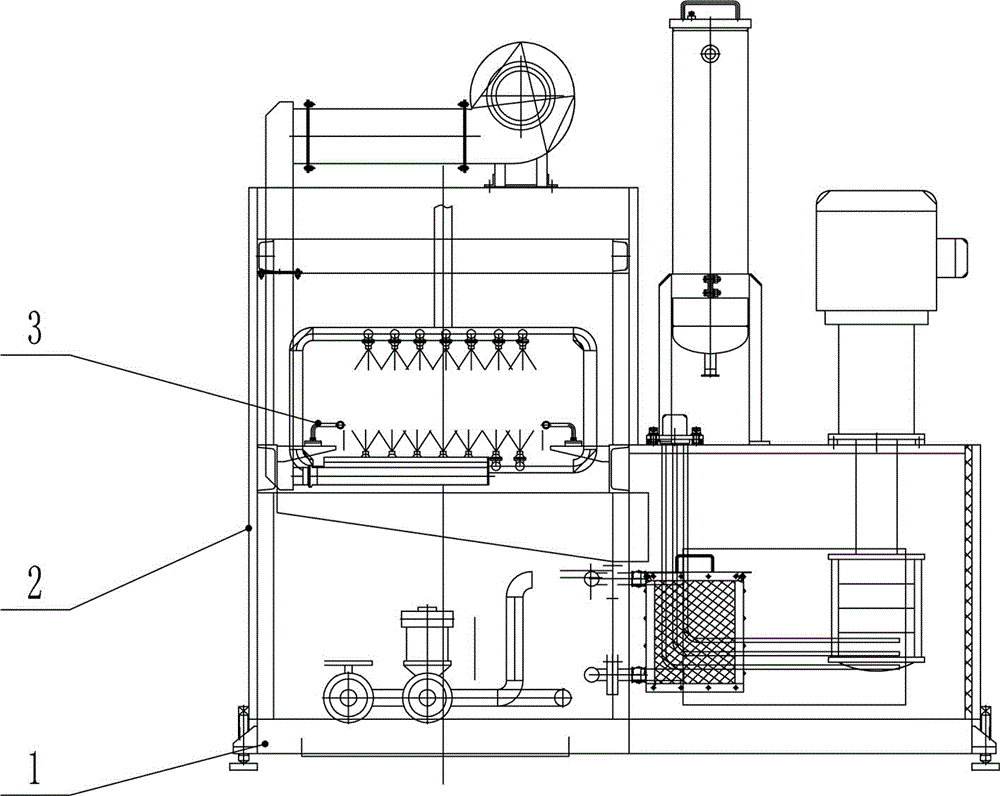

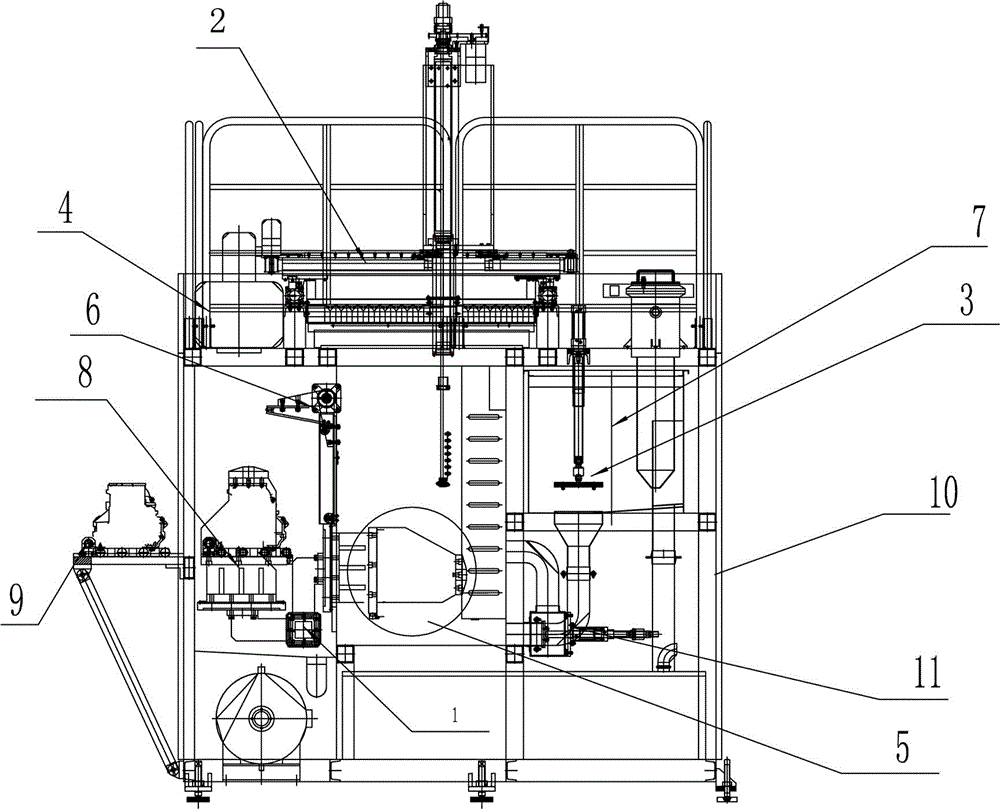

Intelligent efficient high-pressure cleaning machine

InactiveCN104646376APrevent escapeGuaranteed cleanliness requirementsHollow article cleaningCleaning using liquidsAutomatic controlWater storage tank

An intelligent efficient high-pressure cleaning machine comprises a framework and an electric control system. A workpiece pallet is arranged on the upper outside of the framework, a manipulator system is arranged at the upper end of the framework, a cleaning chamber is arranged below the manipulator system, an overturn mechanism and a cleaning chamber water retaining door are arranged between the workpiece pallet and the cleaning chamber, an overturn cage and a workpiece fixture are arranged on the overturn mechanism, the overturn mechanism overturns a workpiece to pass the cleaning chamber water retaining door and then enter the cleaning chamber, a water storage tank is arranged on the outer side of the cleaning chamber, a surging control mechanism is arranged in the water storage tank, a cleaning chamber water outlet device is arranged on the outer side at the bottom of the cleaning chamber, an inlet mist exhausting system is arranged above the cleaning chamber, and an electric control system is used for automatic control of the cleaning machine. The intelligent efficient high-pressure cleaning machine is flexible and safe, has an interlocking function, cannot start when a door cannot be closed and is provided with an excellent extraction and exhaust system, mist is prevented from overflowing the outside of the cleaning machine, a circulating and filtering system provides constant clean cleaning fluid for liquid tanks, cleanliness requirements of parts can be met, and the reuse rate of solution is increased.

Owner:YICHANG WASHING MACHINE

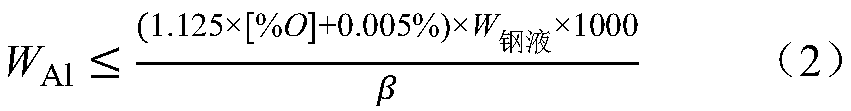

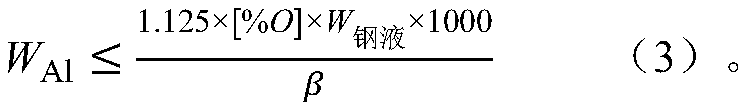

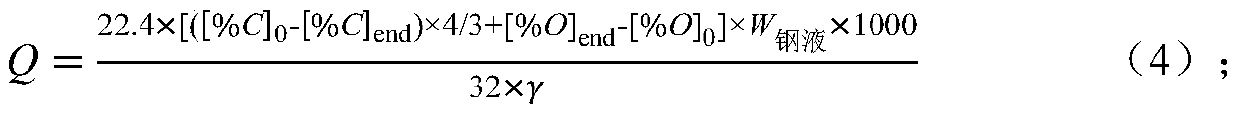

Temperature and cleanliness controlling method for production of steel liquid of low-carbon steel and ultra-low carbon steel

The invention discloses a temperature and cleanliness controlling method for production of steel liquid of low-carbon steel and ultra-low carbon steel, and belongs to the field of steel and iron metallurgy. The method disclosed by the invention comprises the following steps: adding aluminum products such as aluminum granules, aluminum ingots and aluminum alloys into the steel liquid in a steel ladle or in a tapping process before tapping of a converter so as to ensure that the aluminum products react with oxygen in the steel liquid and heat is released, and thus the temperature of molten steelis increased; simultaneously reducing oxidizability of furnace residues; controlling the added aluminum to ensure that the total aluminum products react with the oxygen in the tapping steel liquid and the aluminum content in the tapping steel liquid is less than 50*10<-6>; and basically floating and removing generated Al2O3 before entering into RH refining. When RH refining is performed and the vacuum degree of a vacuum tank is less than 20-50kPa, forced oxygen blowing and decarbonization can be carried out by adopting a top lance, so that the RH decarbonization efficiency is ensured; and meanwhile, after control of the decarbonization is finished, the oxygen content is less than 400x10<-6>, so that the phenomenon that the molten steel is higher in cleanliness after RH refining is performed is ensured. According to the method disclosed by the invention, the temperature of the steel liquid can be increased, the problem of insufficient temperature in RH decarbonization and refining processes in steel plants is solved, and meanwhile, the oxygen blowing amount for RH refining forced decarbonization can be controlled more accurately, the terminal oxygen content for RH decarbonization is controlled and reduced, and the cleanliness of the steel liquid is improved.

Owner:UNIV OF SCI & TECH BEIJING

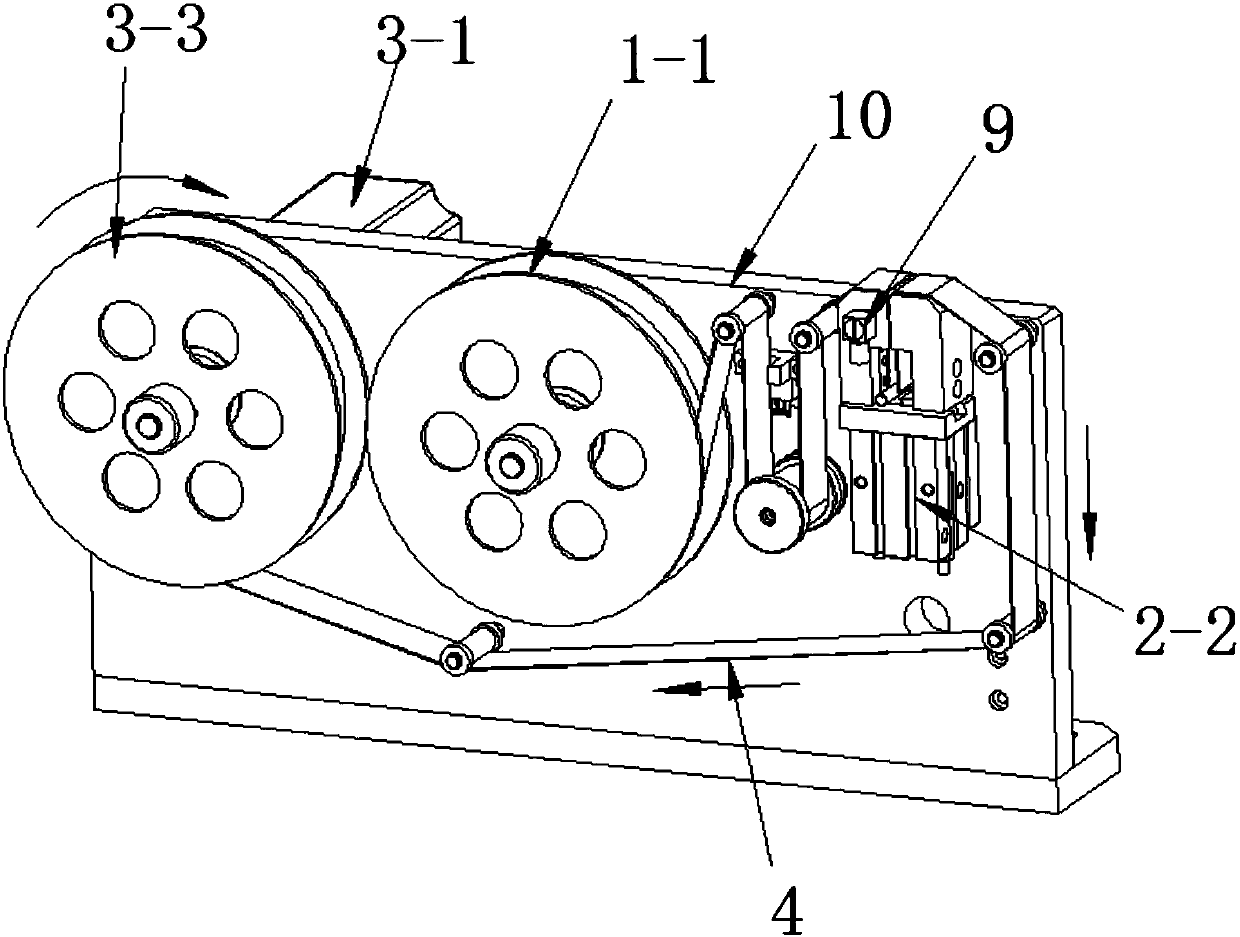

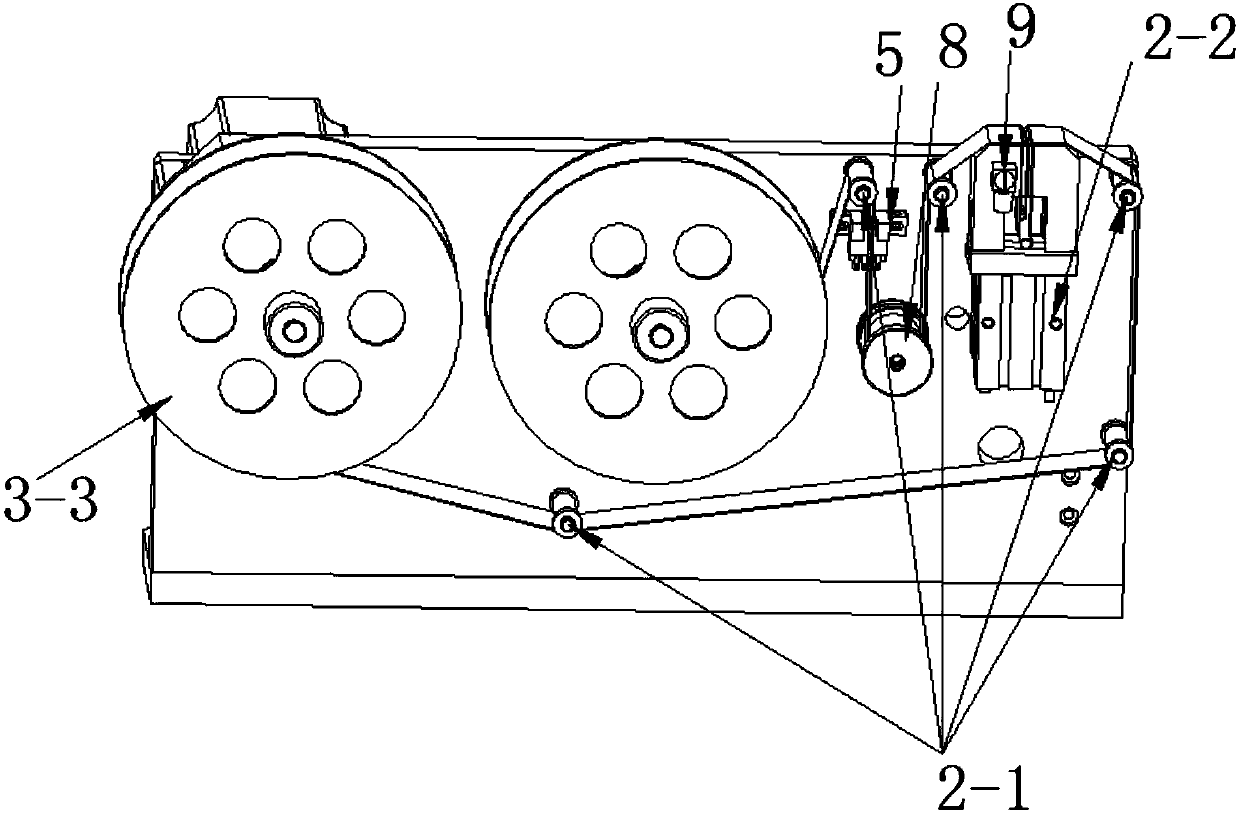

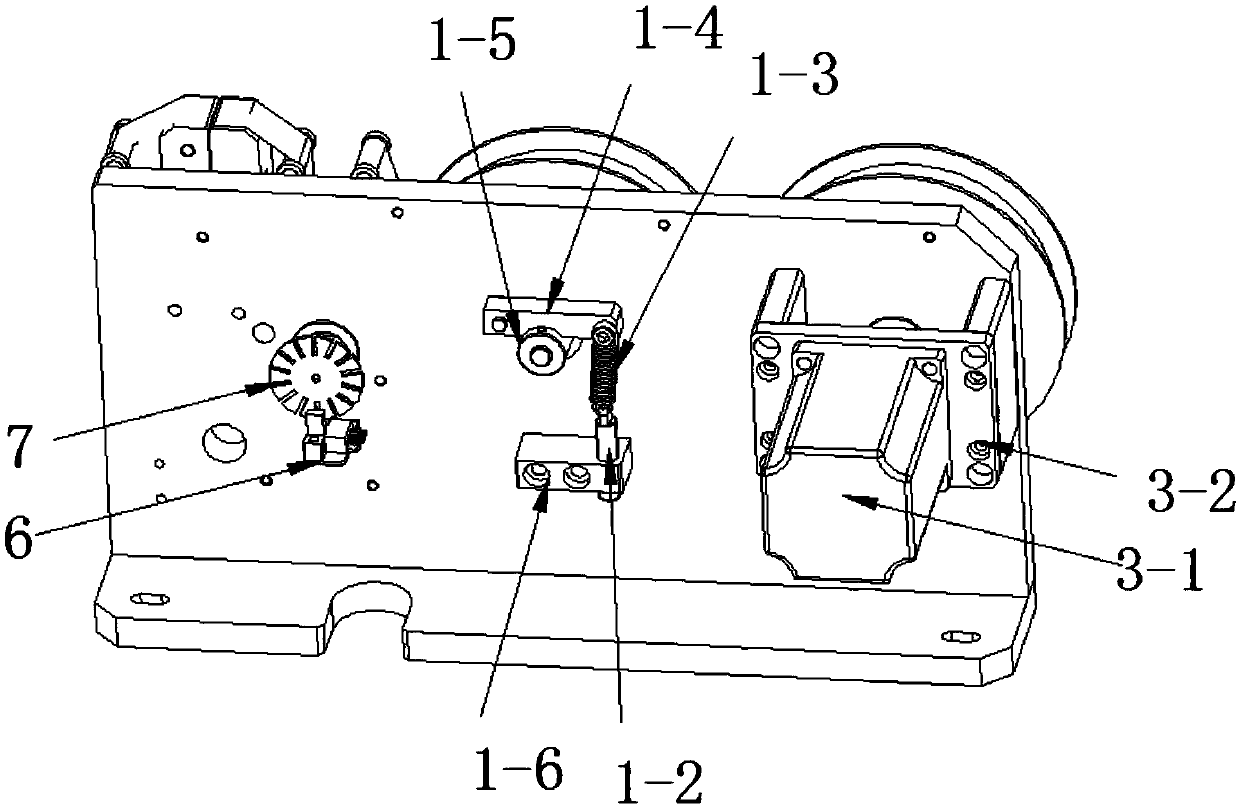

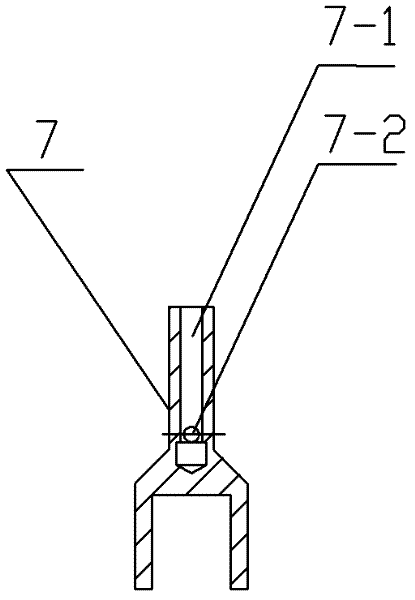

Horizontal glue valve glue wiping mechanism

PendingCN109530152AAvoid secondary pollutionEnsure needle cleanliness requirementsLiquid surface applicatorsSpraying apparatusEngineeringContact mode

The invention discloses a horizontal glue valve glue wiping mechanism, and relates to the technical field of mechanical equipment. A discharge installation plate is connected to the front side of a machine frame through a discharge installation plate shaft on the back part of the discharge installation plate in a screwed mode, and a pressing block is arranged on the upper part of the discharge installation plate shaft in a contact mode. An arc-shaped groove which is formed to be matched with the discharge installation plate shaft is formed in the lower part of the pressing block. One end of the pressing block is connected to the machine frame through a hinge pin in a screwed mode, and the other end of the pressing block is connected with an adjusting screw through a spring. The adjusting screw is fixed to an adjusting screw bracket, and the adjusting screw bracket is fixed to the back face of the machine frame. A plurality of guide wheels are arranged on the front side of the machine frame. A finger clamp cylinder is arranged on the front side of the machine frame, and is located on the right side of the discharge installation plate. The horizontal glue valve glue wiping mechanismadopts a motor to drive the feed of a non-dust cloth, can realize automatic glue wiping of a dispensing needle, and simultaneously uses the non-dust reel cloth to avoid secondary pollution during theglue wiping of the needle, so that high cleanness of the needle after glue wiping is effectively ensured, and higher practicability is achieved.

Owner:SHENZHEN YUANSHUO AUTOMATION TECH

Production method of rack steel for self-elevating oil extraction platform

The invention discloses a production method of rack steel for a self-elevating oil extraction platform, and belongs to the field of metal materials. At least two continuous casting sheet billets are used as raw material. The continuous casting sheet billets are welded into billets with large thickness by combining gas shielded welding, submerged arc welding, and vacuum electron beam welding or full-vacuum electron beam welding. The billets with large thickness are heated in a bogie-type furnace or a soaking furnace. The heated billets are rolled through a heavy plate mill, water-cooled, and heat treated to obtain the rack steel for the self-elevating oil extraction platform. The rack steel produced by the method is fine in steel plate comprehensive mechanical performance, high in operability, low in cost, and high in production efficiency.

Owner:JIGANG GRP

Cast steel shot and manufacture method thereof

InactiveCN104451392AHigh hardnessImprove toughnessAbrasion apparatusManufacturing technologyQuenching

The invention relates to a cast steel shot and a manufacture thereof. The cast steel shot comprises the chemical compositions in percent by mass: 0.30-0.40% of C, 0.1-0.2% of Si, 0.5-0.65% of Mn, 1.0-1.2% of Cr, 0-0.01% of S, 0-0.01% of P, and the balance iron and unavoidable impurity. The manufacture technology comprises: preparing materials and melting, namely melting the prepared raw material compositions to form molten steel, pouring into a tundish, and employing a deoxidizer for deoxidization; forming a shot, namely, pouring deoxidized molten steel into a centrifugation disk rotating at a high speed, tossing out the pill under the centrifugal effect, dropping into a cooling pool, fishing out and baking to dry, so as to obtain a formed as-cast steel shot; and performing heat treatment, namely, heating the formed as-cast steel shot to 870-880 DEG C, keeping for 30-40 min, performing water-cooling quenching, performing tempering processing at 400-500 DEG C for 50-80 min, after tempering, employing a steel-plate vibrating-screen water cooling process to perform rapid cooling, so as to prepare the cast steel shot. The method guarantees the steel shot to have high hardness and also prevents the steel shot from generating cracks in the process of centrifugation forming and heating quenching, thereby increasing the toughness and other advantages of the steel shot.

Owner:李玉清

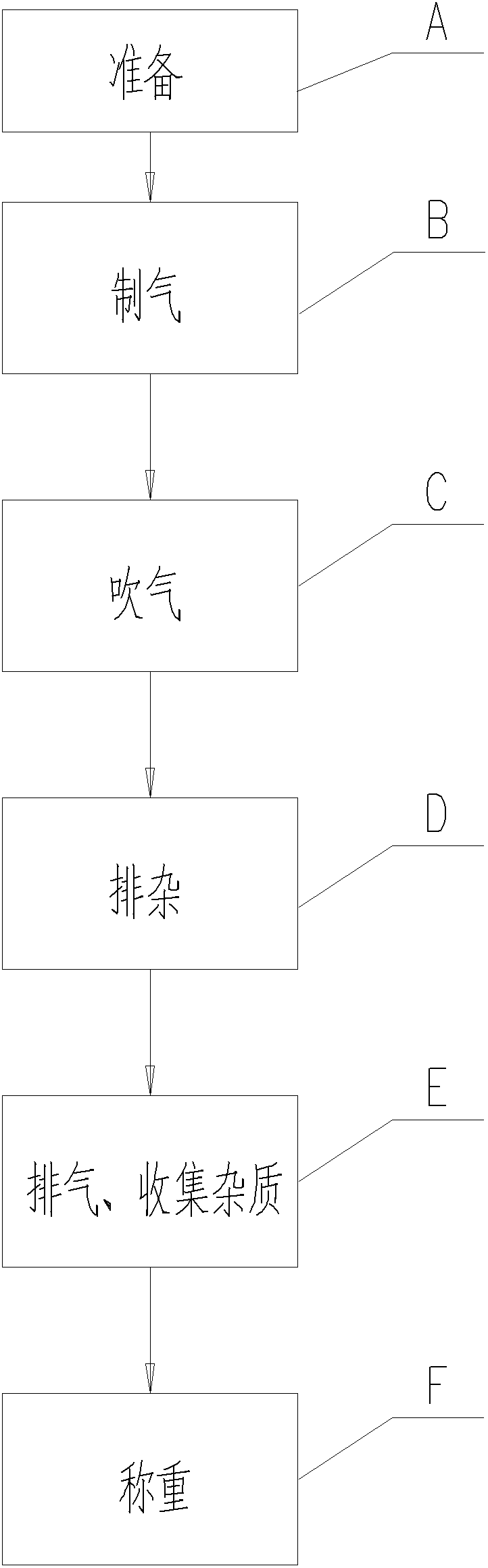

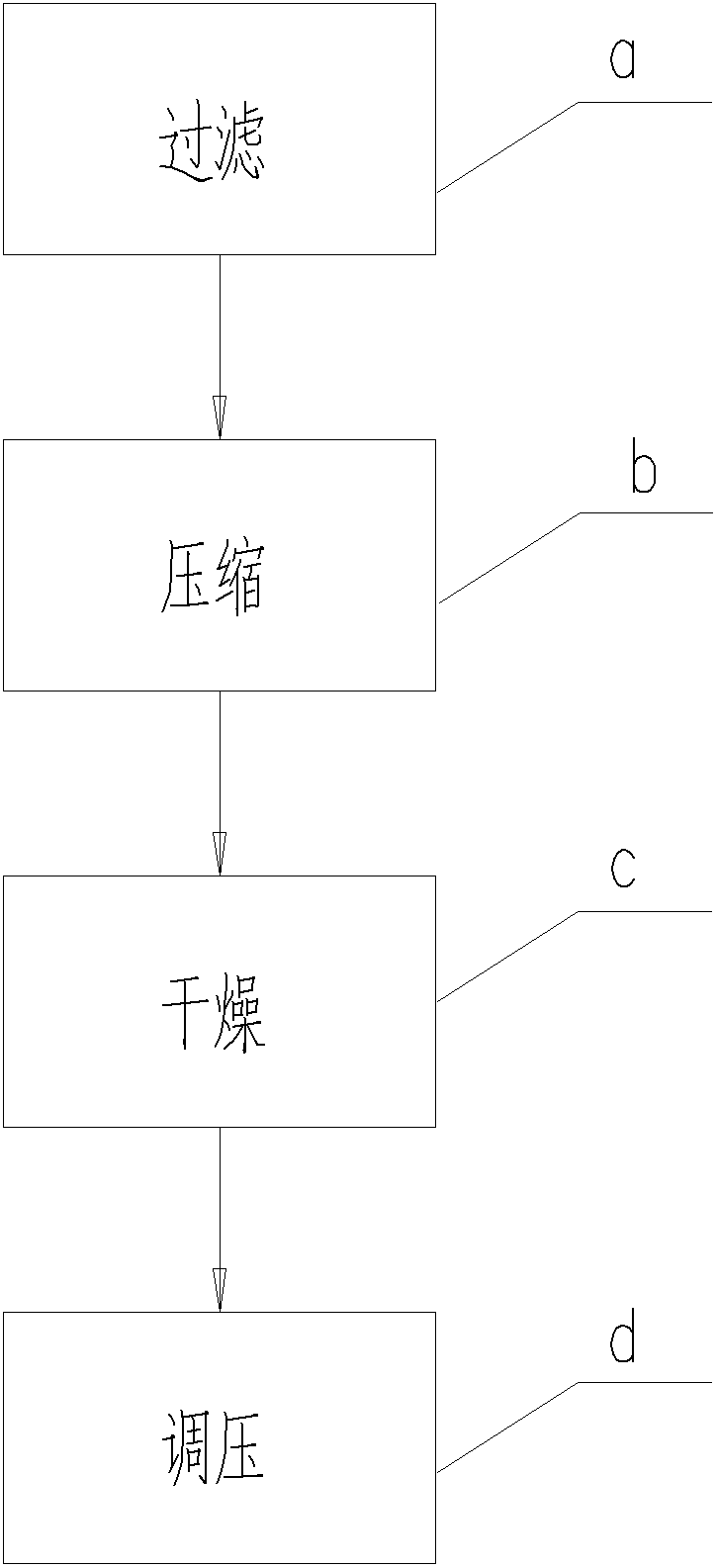

Detection method for impurities in receiver drier

ActiveCN102435526AEfficient detectionAccurate detectionMaterial weighingAutomobile air conditioningImpurity

The invention provides a detection method for impurities in a receiver drier and relates to a detection method for a receiver drier of an automobile air-conditioning system. The method comprises the following steps: A, preparation work; B, preparation of gas, wherein, clean compressed dry gas with a pressure of 1.0 MPa is prepared; C, air blowing, wherein, the clean compressed dry gas with a pressure of 1.0 MPa is continuously blown into the receiver drier; D, removal of impurities, wherein, impurities in the receiver drier enter into an impurity collector through a pipeline B as the compressed dry gas flows; E, discharge of the gas and collection of the impurities, wherein, the compressed dry gas is discharged through a pipeline C, and the impurities are obstructed by a filter layer of the impurity collector and retain in the impurity collector; F, weighing, wherein, the weight of the impurity collector that contains the impurities is measured by using a weighing means, and the content of the impurities can be obtained. According to the invention, the content of the impurities in the receiver drier can be accurately and effectively detected; the method is simple and convenient to operate; high cleanliness of components of an automobile air conditioner can be guaranteed, and therefore, faults like obstruction of the air-conditioning system can be avoided.

Owner:LIUZHOU WULING MOTORS

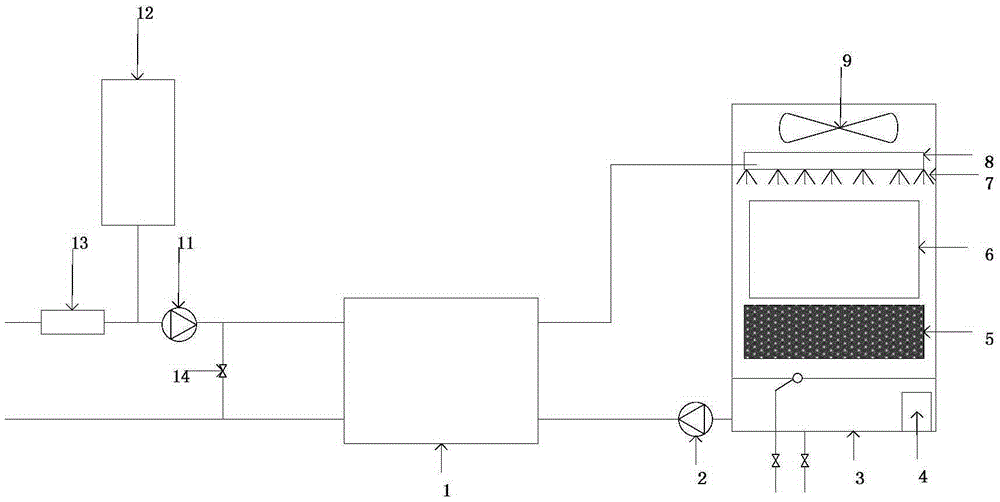

Integrated double-source freezing station and refrigerating method

ActiveCN105387546AReduce energy consumptionReduce running timeLighting and heating apparatusAir conditioning systemsExpansion tankCooling tower

The invention discloses an integrated double-source freezing station and a refrigerating method. The integrated double-source freezing station comprises a water cooling unit (1), an intermediate heat exchanger (10), a cooling water system, a freezing water system and a control system, wherein the water cooling unit is arranged between the cooling water system and the freezing water system; the intermediate heat exchanger and the water cooling unit share water supplying and returning pipelines of the cooling water system and the freezing water system; the water cooling unit, the intermediate heat exchanger, the cooling water system, the freezing water system and a three-way valve are controlled by the control system; the cooling water system comprises a cooling tower (3), and a cooling water pump (2) which is arranged on a water outlet pipeline of the cooling tower; the freezing water system comprises a freezing water pump (11), a constant-pressure expansion tank (13) and an incrustation cleaner (13) which are sequentially arranged on a water supplying pipeline of the freezing water system along the water supplying direction. The integrated double-source freezing station and the refrigerating method are easy to implement, and obvious in energy saving effect.

Owner:CHANGSHA MAXXOM HIGH TECH CO LTD

Manufacturing method of medium-carbon alloy cast steel shots

The invention relates to medium-carbon alloy cast steel shots and a manufacturing method thereof, which is characterized in that, each medium-carbon alloy cast steel shot comprises the following chemical components in percentage by mass: 0.35 percent of carbon, 0.11 percent of silicon, 0.45 percent of manganese, 1.2 percent of chrome, 0.015 percent of sulfur, 0.020 percent of phosphor and the balance of iron and inevitable impurities. The manufacturing process comprises the following steps of: mixing and smelting, namely, smelting the raw material composition mixed proportionally into liquid steel, pouring the liquid steel into a tundish and performing deoxygenation by adopting an deoxidant; preparing shots by a centrifugally forming method, namely, pouring deoxygenized liquid steel into a centrifugal disc which rotates at a high speed, throwing out the liquid steel under the action of a centrifugal force to make the liquid steel fall into a cooling water pool, and taking the liquid steel out and drying the cooled steel to obtain formed cast steel shots; and performing heat treatment, namely, heating the formed cast steel shots until the temperature reaches 860 to 880 DEG C, performing cold quenching after keeping the temperature for 20 to 40 minutes, tempering for 40 to 80 minutes at the temperature of between 350 and 500 DEG C, and after tempering, cooling rapidly by a steel plate vibrating screen water cooling method to produce the medium-carbon alloy cast steel shots. The medium-carbon alloy cast steel shots and the manufacturing method thereof have the advantages of guaranteeing the high rigidity of the steel shots, avoiding crack generated in the centrifugally forming process and the heating tempering process, improving the toughness and the like.

Owner:淄博大亚金属科技股份有限公司

Bidirectional automatic dust removal and intelligent ventilation system and bidirectional dust removing method

InactiveCN101896057BGuaranteed cleanliness requirementsRealize self-cleaningCooling/ventilation/heating modificationsFailure rateCold air

The invention relates to the field of ventilation systems, in particular to a bidirectional automatic dust removal and intelligent ventilation system and a bidirectional dust removing method. The bidirectional automatic dust removal and intelligent ventilation system is arranged in a communication computer room and is provided with a dust removing outlet and an air supply outlet. The bidirectional automatic dust removal and intelligent ventilation system comprises an air supply unit, a dust removing unit, a control system, an air conditioner, a mixed air supply duct, an air exhaust duct and an air hood. The air supply unit brings a micro positive pressure environment for the computer room during air supply so as to automatically exhaust hot air of the communication computer room and remove dust of a strainer at the same time; and the air supply unit brings a micro negative pressure environment for the communication computer room during air exhaust and dust removal so as to pump outdoor cold air into the communication computer room. The bidirectional automatic dust removal and intelligent ventilation system has the advantages of reducing the hardware cost of the system, and reducing the use cost and maintenance cost of the system. The air exhaust unit is not provided with an air blower, so that the failure rate of the air exhaust unit due to the damage of the air blower is reduced, the energy efficiency ratio of the whole system is improved, and the energy consumption of the whole system in normal use is reduced.

Owner:SHENZHEN ZHONGXING SINDI TECH CO LTD

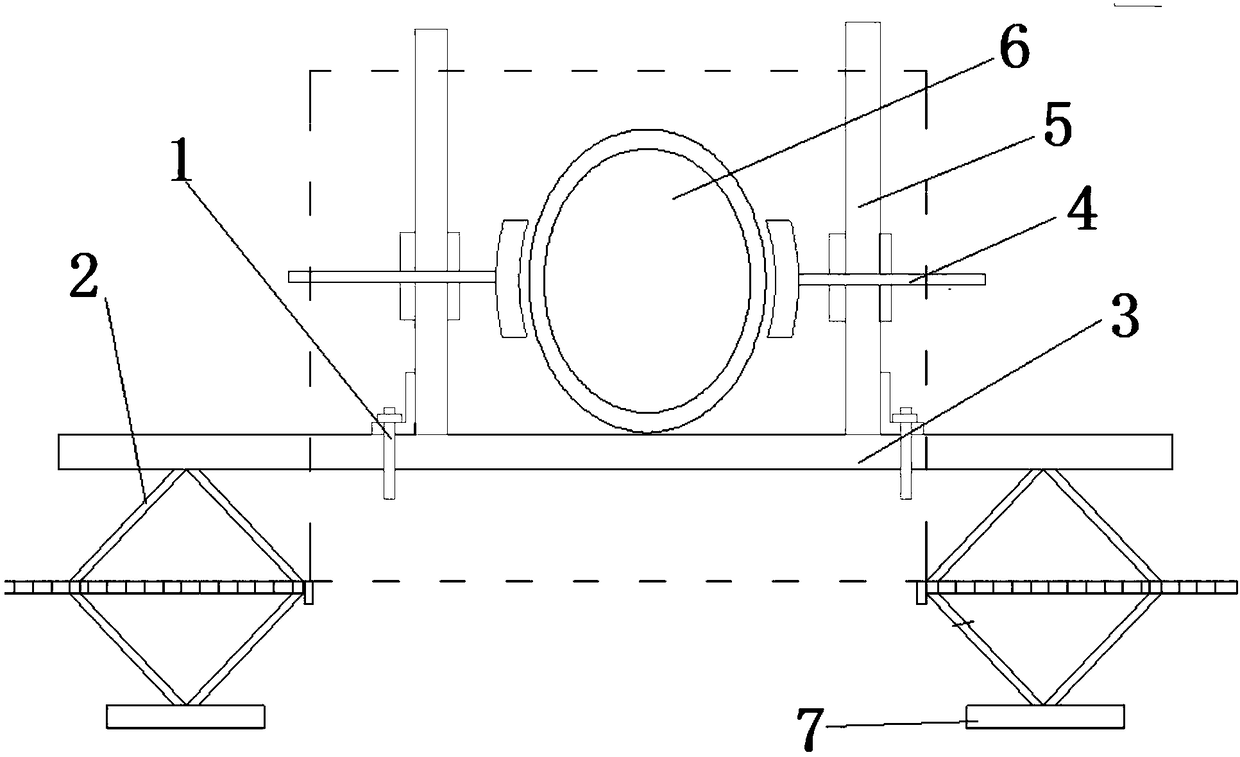

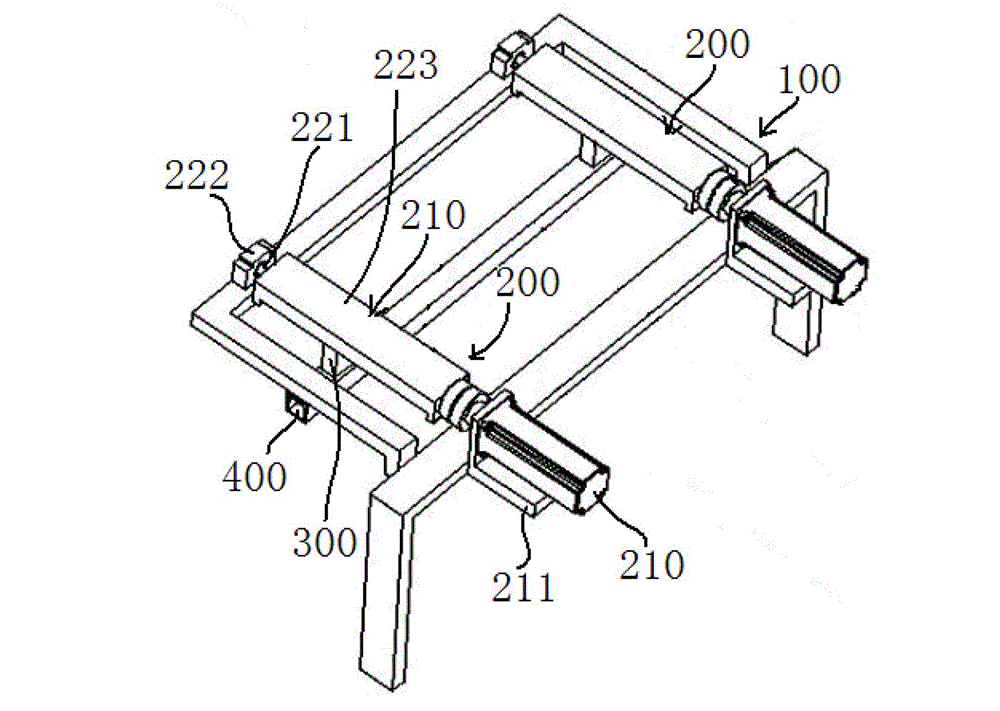

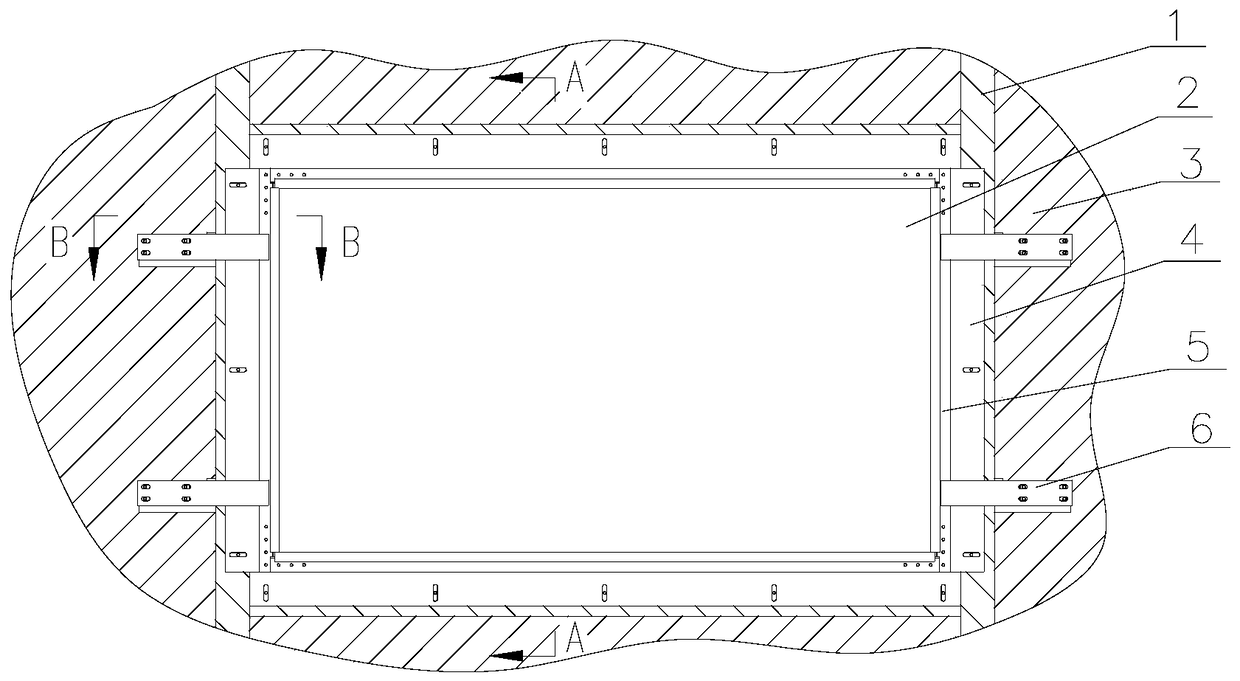

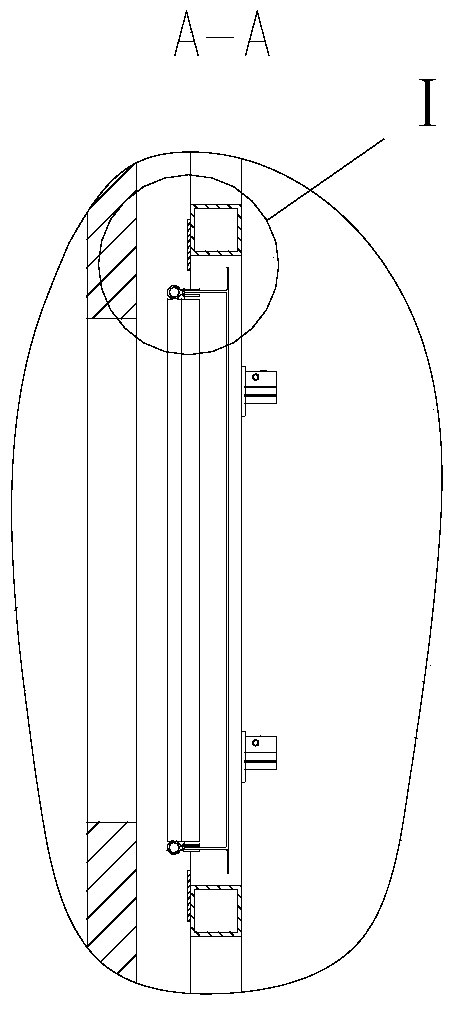

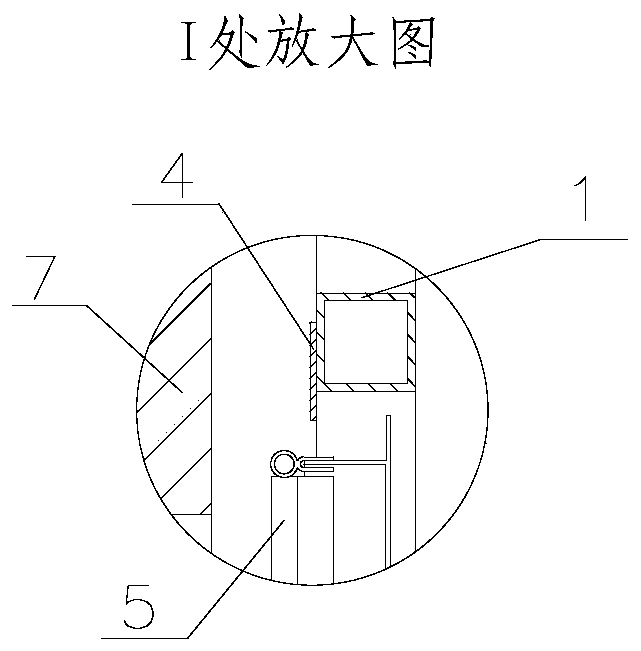

Channel cooling section platinum body installation positioning device

ActiveCN108383357AEasy to fixDoes not affect the displacement phenomenonForehearthsMechanical engineering

The invention discloses a channel cooling section platinum body installation positioning device. A lower jacking device is arranged on a channel guide rail; through puller screws which are arranged insymmetrical and disposed on an upper split frock clamp device, a platinum body which is to be fixed is clamped and left and right adjustment of the platinum body is achieved; the upper split frock clamp device is provided with screw mechanism at two sides; with application of the lower jacking device, fine adjustment of height of the platinum body in vertical direction can be achieved. Therefore,when the refractory material is mounted onto the platinum body, direction of the platinum body can be adjusted effectively by means of the upper split frock clamp device and the lower jacking device;under action of locking, the platinum body is prevented from shifting and is fixed stably in the process of installing other refractory material in the later period. The channel cooling section platinum body installation positioning device is simple in structure, convenient and rapid to use, can adjust installation angel of the platinum body in one step, and accordingly can guarantee installationprecision and speed of the platinum body.

Owner:IRICO

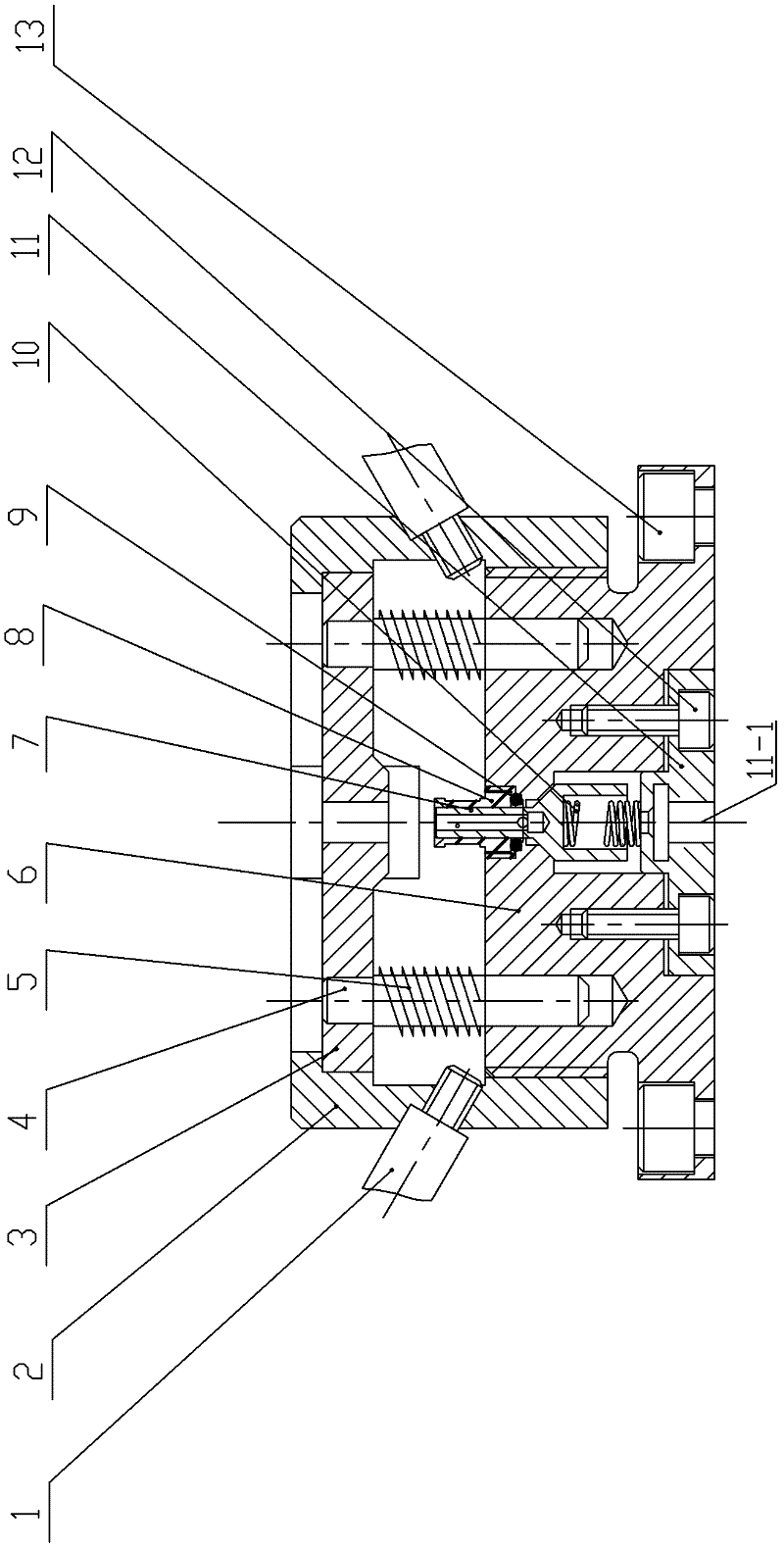

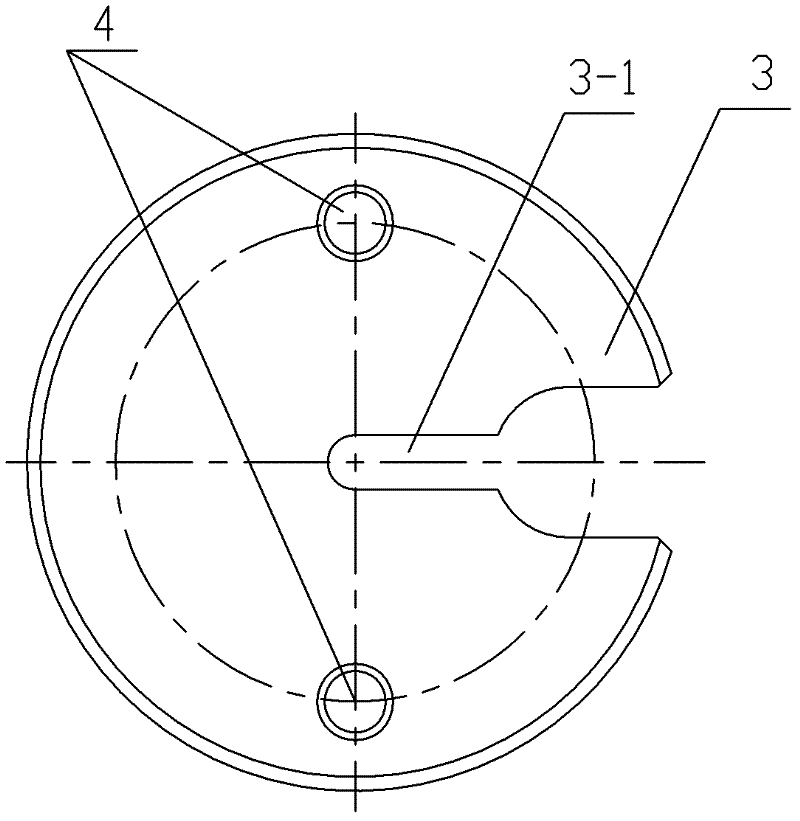

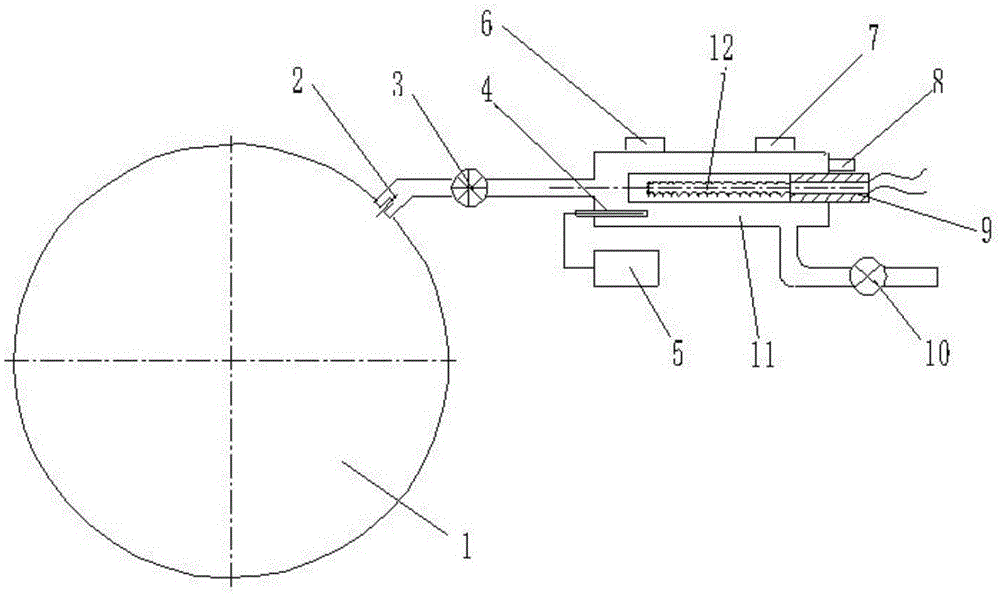

Inner cavity cleaning clamp for high-pressure oil pipe

InactiveCN102343346AGuaranteed cleanliness requirementsEasy loading and unloadingHollow article cleaningEngineeringHigh pressure

The invention relates to an inner cavity cleaning clamp for a high-pressure oil pipe. A valve core is positioned in the center of a clamp body; a joint is sleeved at the upper end of the valve core; the lower part of the joint is in threaded connection with the clamp body; a sealing ring is sleeved on the waist part of valve core, and is positioned in a crack between the lower part of the joint and clamp body; a gap is formed between the lower part of the valve core and the clamp body; a bottom plate is arranged below the valve core, and is fixed with the clamp body; one end of a first compression spring is fixed on the bottom plate; the other end of the spring is pressed against the lower end of the valve core; a cavity is formed in the upper part of the valve core; the side wall of the valve core is provided with a valve core through hole for communicating cavities outside and inside the valve core; the valve core through hole is sealed with the sealing ring when valve core is jacked up by the first compression spring; the clamp body is provided with a pressure plate; two guide posts are arranged below the pressure plate; the lower ends of the guide posts are inserted into the clamp body; second compression springs are sleeved on the guide posts; and the upper end of the pressure plate is pressed by a compression cap. The inner cavity cleaning clamp has the advantages of capability of meeting the requirement of inner cavity cleaning of the high-pressure oil pipe, simple structure, easiness and convenience for assembling and disassembling a mold, safety and reliability.

Owner:JIANGSU HONGFENG AOKAI ELECTROMECHANICAL

Air transportation device for small rodent experimental animals

InactiveCN106628676AGuaranteed normal exchangePrevent overcoolingLiving organism packagingInternal fittingsAviationTemperature control

The invention discloses an air transportation device for small rodent experimental animals. The air transportation device comprises an inner box and an outer box. A transparent observation window is arranged on the inner box. The inner box comprises a box cover and a box body. Each of the box cover and the box body is provided with a gas-permeable area. Each gas-permeable area is composed of small holes densely formed and is covered with a filtering film. The vertex angles of the box body are configured to be in a circular arc shape. A separation groove is formed in the box body. A plastic partition can be clamped into the separation groove. Both the box cover and the box body are provided with cylindrical supporting feet. The interior of the outer box is molded at a time by a lightweight thermal insulation material. Handles, exhaust flow diversion holes, exhaust flow diversion channels, a temperature sensor and a temperature control module with a pull hand are arranged on the outer box. The air transportation device for the small rodent experimental animals effectively solves the problems about air circulation of transportation boxes during transportation, meets the requirement on the cleanliness and solves the problem about temperature regulation, so that the comfort and safety of the animals during long-distance transportation, especially during the air transportation are guaranteed.

Owner:傅江南

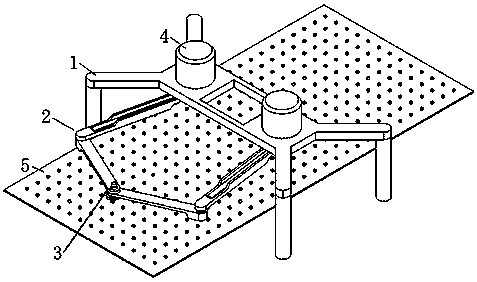

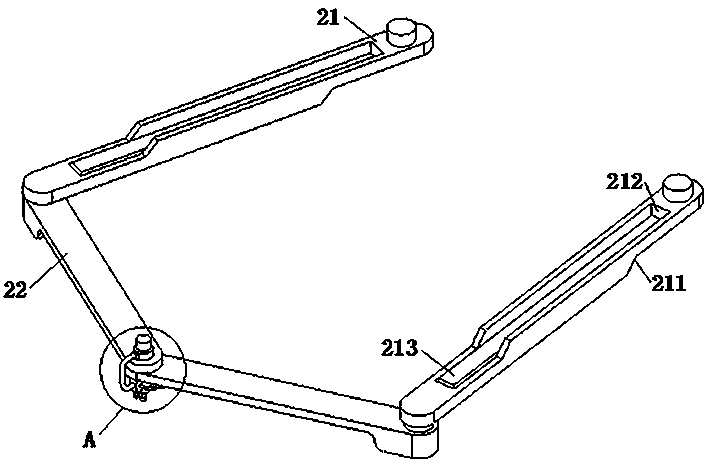

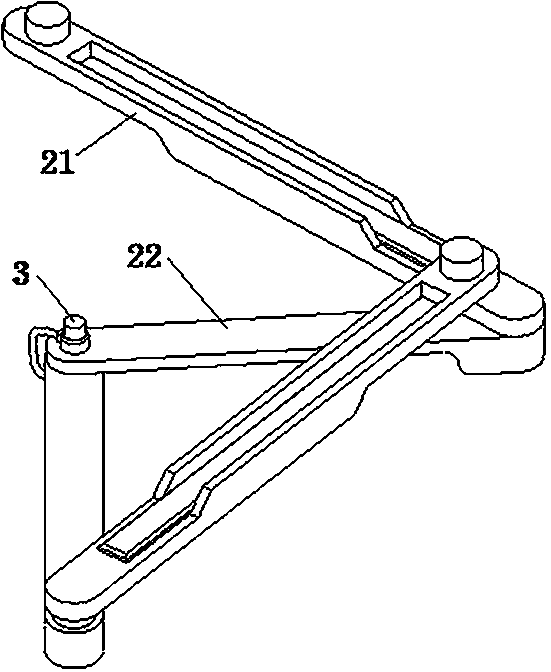

SCARA type high-speed parallel manipulator

ActiveCN111251282AFast assemblyImprove product qualityProgramme-controlled manipulatorGripping headsVertical planeMedicine

The invention relates to the technical field of manipulator equipment, in particular to an SCARA type high-speed parallel manipulator. The SCARA type high-speed parallel manipulator comprises a machine frame, a rotating joint, a moving joint, a servo motor and a controller, wherein the rotating joint comprises a pair of main connecting rods and a pair of auxiliary connecting rods; and the moving joint comprises a column body, a suction head and an electromagnetic valve. In the process that an existing SCARA type manipulator assembles child parts to a parent part, the child parts need to be collected and placed through the contraction and stretching actions of the mechanical claw, the child parts with the unconformable postures can be damaged through the fixing action of the mechanical claw, and then the assembly effect of the child parts is influenced, therefore, in the case of the SCARA type high-speed parallel manipulator, the suction head arranged on the moving joint is used for carrying out adsorption and release operation on the child parts to be assembled, contraction and stretching actions of the mechanical claw in the process of clamping the child parts for assembly are replaced, the assembly speed of the child parts on the vertical plane is increased, high-speed movement of the SCARA horizontal plane is used in cooperation, so that the assembly effect of the SCARA typehigh-speed parallel manipulator is improved.

Owner:浙江谱麦科技有限公司

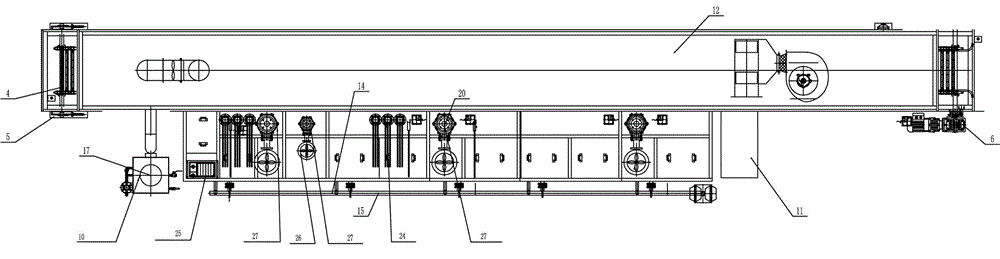

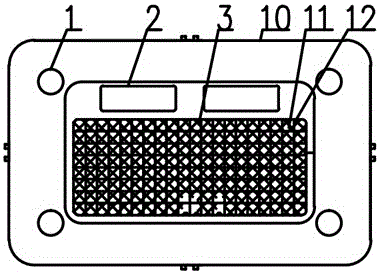

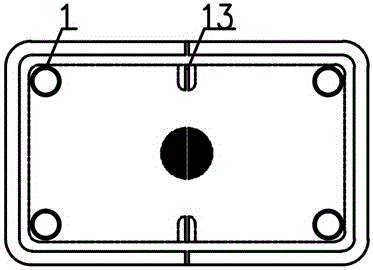

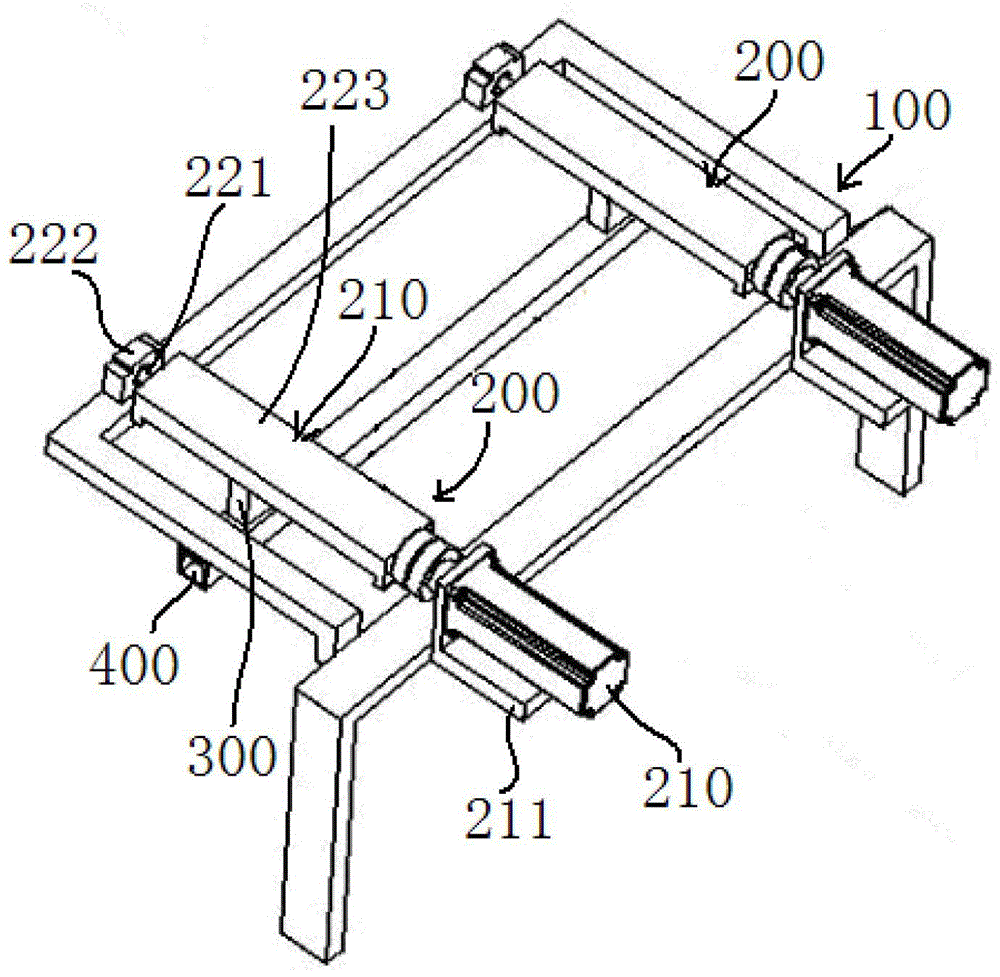

Conveying device conveying remaining glass bottles in bottle outlet opening of sterilizing dryer to filling machine

InactiveCN103332484AGuaranteed cleanliness requirementsAvoid pollutionConveyor partsReciprocating motionElectric machinery

The invention discloses a conveying device conveying remaining glass bottles in a bottle outlet opening of a sterilizing dryer to a filling machine. The conveying device comprises a rack, at least one linear driving mechanism installed on the rack, at least one elevator mechanism and at least one bottle-pushing block, wherein the elevator mechanism is driven by the linear driving mechanism to perform linear reciprocating motion, and the bottle-pushing block is connected with the elevator mechanism and driven by the linear driving mechanism and the elevator mechanism to go up and down and carry out linear bottle-pushing motion. A sliding block in a screw rod sliding block mechanism is driven through a motor to perform the linear reciprocating motion, and a lifting air cylinder is also driven to perform the linear reciprocating motion. The lifting air cylinder drives the bottle-pushing block to perform linear lifting motion and convey the glass bottles into the filling machine smoothly. Not only is unnecessary manpower reduced, but also contamination to the bottles is avoided, and requirements for cleanliness of the glass bottles are ensured.

Owner:上海千山远东制药机械有限公司

A kind of large-thickness slab manufacturing process method

InactiveCN102764936BImprove welding efficiencyFully automatedWorkpiece edge portionsWelding apparatusEngineeringElectron bombardment

Owner:JIGANG GRP

Technique for manufacturing 150-400mm thick carbon constructional steel plate by using continuous casting slabs

InactiveCN102764961BReduce organizational performance varianceAvoid growing upSteelmakingChemical composition

The invention discloses a technique for manufacturing a 150-400mm thick carbon constructional steel plate by using continuous casting slabs, belonging to the field of metal materials. The continuous casting slabs subjected to converter steelmaking and secondary refining are used in the technique; and the chemical components of the slabs include 0.14-0.20wt% of C, 0.20-0.50wt% of Si, 0.08-1.40wt% of Mn and less than or equal to 0.010wt% of S; at least two continuous casting slabs subjected to surface machining and cleaning are overlapped, four sides of the continuous casting slabs are combined and welded to form a big-thickness blank, the blank is arranged in a bogie-type furnace or a soaking pit furnace for heating, and then is rolled, water-cooled and subjected to heat treatment after being discharged from the furnace so as to produce the 120-400mm thick carbon constructional steel plate. The technique has the following characteristics of simple production process, high yield, high ultrasonic flaw detection rate of more than 98% and excellent performance.

Owner:JIGANG GRP

Interface sealing device for semiconductor interface unit

ActiveCN106298602BSimple structureEasy to implementSemiconductor/solid-state device manufacturingConveyor partsEngineeringClean environment

The invention belongs to the field of wafer photoresist-coating and developing production technology in a semiconductor industry, and particularly relates to an interface sealing device of a semiconductor interface unit. The interface sealing device is arranged at two side interface parts of an interface unit which is connected with a TRACK and a photoetching machine. The interface sealing device comprises sealing baffle plates, a sealing rack and a driving device, wherein the sealing baffle plates are arranged at the edge of the interface parts of the interface unit. The driving device is arranged on the frame of the interface unit. The sealing rack is arranged in the interface part of the interface unit and is connected with the driving device. The sealing rack extends out of or retreats from the two side interface parts of the interface unit. On the condition that the sealing rack extends out of the interface part and the inside end of the sealing rack abuts against the sealing baffle plate, the outside end of the sealing rack abuts against the TRACK and the photoetching machine, thereby sealing slits between the two side interface parts of the interface unit and the TRACK and the photoetching machine. The interface sealing device has advantages of preventing entry of outer air into inner part of equipment, keeping a clean environment in the equipment, and ensuring a fact that the wafer processing process is performed in the environment which satisfies a cleanness requirement.

Owner:SHENYANG KINGSEMI CO LTD

Production method of rack steel for self-elevating oil extraction platform

InactiveCN102766810BReduce organizational performance varianceAvoid growing upThick plateMetallic materials

The invention discloses a production method of rack steel for a self-elevating oil extraction platform, and belongs to the field of metal materials. At least two continuous casting sheet billets are used as raw material. The continuous casting sheet billets are welded into billets with large thickness by combining gas shielded welding, submerged arc welding, and vacuum electron beam welding or full-vacuum electron beam welding. The billets with large thickness are heated in a bogie-type furnace or a soaking furnace. The heated billets are rolled through a heavy plate mill, water-cooled, and heat treated to obtain the rack steel for the self-elevating oil extraction platform. The rack steel produced by the method is fine in steel plate comprehensive mechanical performance, high in operability, low in cost, and high in production efficiency.

Owner:JIGANG GRP

Air conditioning monitoring system

ActiveCN103008312BGuaranteed cleanliness requirementsImprove yieldSpace heating and ventilation safety systemsLighting and heating apparatusMonitoring systemEngineering

The invention discloses an air conditioning monitoring system which is applied to semiconductor cleaning equipment. The system comprises a main frame, a fan unit, a fan fixed support, a wind uniformizing device, an adjustable laminar flow device, a gas pressure sensor, a static impedance device, a static monitor and an air cleanliness test device. The air conditioning monitoring system is mainly used for eliminating various pollution sources in the internal environment of a semiconductor cleaning machine to cause the internal part of the semiconductor cleaning machine to be always in a steady laminar flow environment with a constant pressure value, effectively prevents and removes particles and dust in the air, conveniently knows the internal cleanliness of equipment, and effectively eliminates static electricity generated in the internal part of the equipment, therefore the possibility that silicon wafers are polluted by critical defects is reduced, finally, the rate of finished products of chips is increased, and the production cost of electron parts and components is reduced.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

A conveying device for sending the remaining glass bottles at the bottle outlet of the sterilizing dryer to the filling machine

InactiveCN103332484BGuaranteed cleanliness requirementsAvoid pollutionConveyor partsReciprocating motionEngineering

The invention discloses a conveying device conveying remaining glass bottles in a bottle outlet opening of a sterilizing dryer to a filling machine. The conveying device comprises a rack, at least one linear driving mechanism installed on the rack, at least one elevator mechanism and at least one bottle-pushing block, wherein the elevator mechanism is driven by the linear driving mechanism to perform linear reciprocating motion, and the bottle-pushing block is connected with the elevator mechanism and driven by the linear driving mechanism and the elevator mechanism to go up and down and carry out linear bottle-pushing motion. A sliding block in a screw rod sliding block mechanism is driven through a motor to perform the linear reciprocating motion, and a lifting air cylinder is also driven to perform the linear reciprocating motion. The lifting air cylinder drives the bottle-pushing block to perform linear lifting motion and convey the glass bottles into the filling machine smoothly. Not only is unnecessary manpower reduced, but also contamination to the bottles is avoided, and requirements for cleanliness of the glass bottles are ensured.

Owner:上海千山远东制药机械有限公司

Desorption regeneration device suitable for organic exhaust gas treatment

InactiveCN109174069ABurn fullyImprove combustion efficiencyGas treatmentDispersed particle separationAir volumeCombustion chamber

The invention discloses a desorption regeneration device suitable for organic exhaust gas treatment. The desorption regeneration device suitable for organic exhaust gas treatment comprises an outlet heat exchanger, a desorption blower fan, a combustion blower fan, and a cylinder; a tubular heat exchanger is arranged on the internal wall of the cylinder through welding; limit plates are fixedly arranged on the tubular heat exchanger; the top end of the tubular heat exchanger is provided with a heat exchanger free terminal, and the bottom end surface of the tubular heat exchanger is provided with a heat exchanger fixed terminal; the bottom end of the internal part of the cylinder is fixedly provided with a combustion chamber; a windproof insulation wall is arranged in the combustion chamber;the tubular heat exchanger is fixedly embedded into the top end surface of the combustion chamber, and the other end of the tubular heat exchanger is designed to penetrate through the cylinder, and is arranged at the top end surface of the cylinder; tail gas from the combustion chamber is discharged to the outside through a heat exchange pipe of the tubular heat exchanger; a wind outlet of the combustion blower fan is communicated with an exhaust gas inlet of the combustion chamber. The desorption regeneration device is simple in structure, convenient in operation and maintenance, is economical and practical; and the amount of exhaust gas introduced into the combustion chamber can be adjusted based on working conditions.

Owner:中科伟通智能科技(江西)有限公司

A New Type of Dryer Filter Heating System

ActiveCN103822458BGuaranteed cleanliness requirementsExistenceDispersed particle filtrationDrying gas arrangementsEconomic benefitsNitrogen

The invention provides a novel spin dryer filter heating system, which comprises a heated cavity, a heating nozzle, a temperature controller, a heater and a heating cavity, wherein the heating nozzle is arranged on one side of the heated cavity; the heating nozzle is connected to the heating cavity; a high-temperature gas filter is arranged between the heating nozzle and the heating cavity; the heater is arranged at the rear end of the heating cavity; one end of the downside of the heating cavity is connected with a gas intake pipe; the gas intake pipe is provided with a low-temperature gas filter; the other end is provided with an outlet gas temperature detecting probe; the outlet gas temperature detecting probe is connected with the temperature controller. The novel spin dryer filter heating system disclosed by the invention can ensure that the cleanliness of nitrogen blown into the cavity can meet requirements, and no contamination exists in the cavity; the probability of bad products occurring in the cleaning and drying links is reduced, and the yield of products is improved by 1%; the production cost is reduced, the yield is reduced, and the economic benefits are improved.

Owner:宁波安芯美半导体有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com