Patents

Literature

222 results about "Electron bombardment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

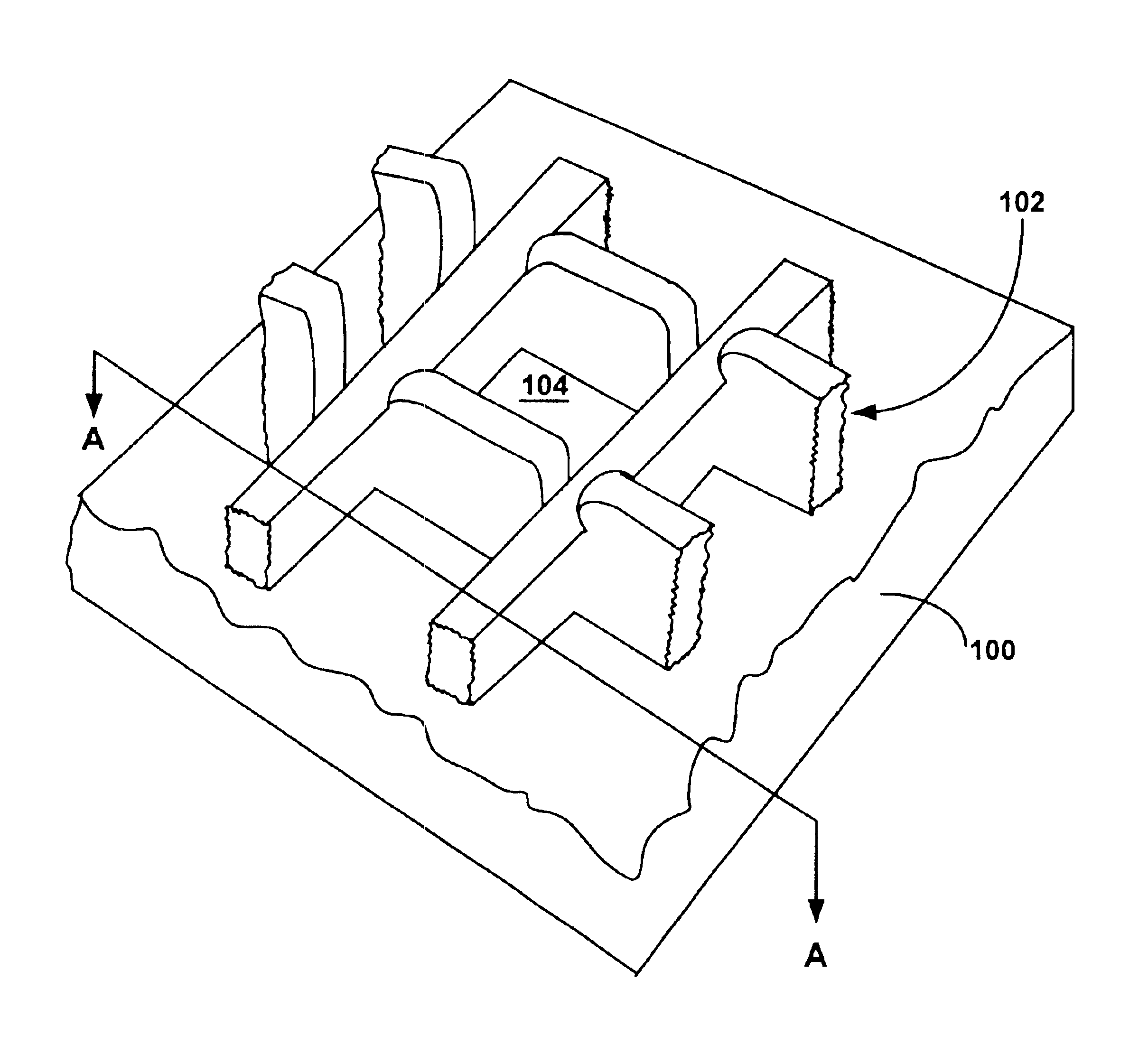

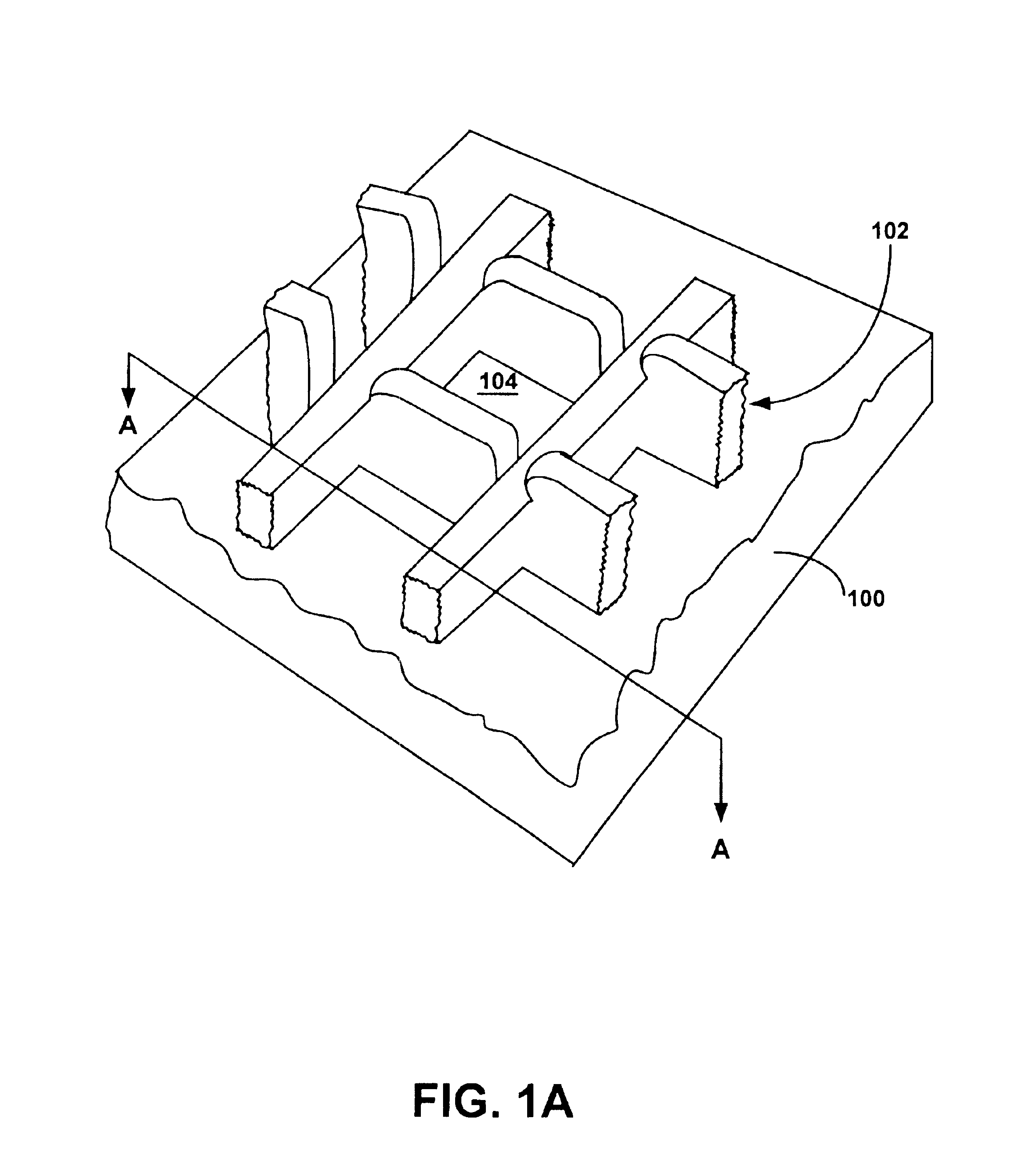

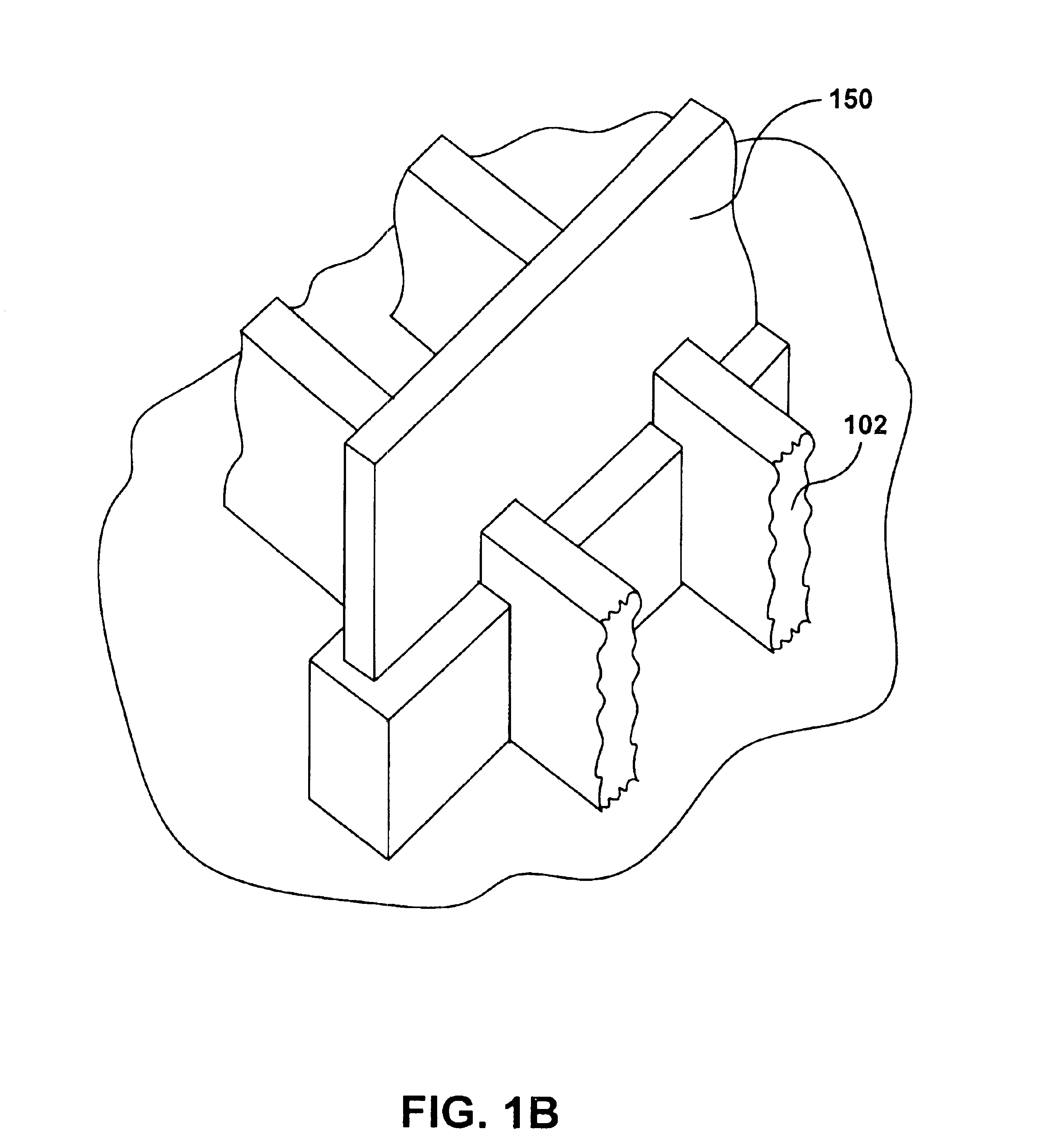

Protected substrate structure for a field emission display device

InactiveUS6853129B1Preventing electron bombardmentInhibit migrationElectrode assembly support/mounting/spacing/insulationIncadescent body mountings/supportSurface plateElectron bombardment

A protected faceplate structure of a field emission display device is disclosed in one embodiment. Specifically, in one embodiment, the present invention recites a faceplate of a field emission display device wherein the faceplate of the field emission display device is adapted to have phosphor containing areas disposed above one side thereof. The present embodiment is further comprised of a barrier layer which is disposed over the one side of said faceplate which is adapted to have phosphor containing areas disposed thereabove. The barrier layer of the present embodiment is adapted to prevent degradation of the faceplate. Specifically, the barrier layer of the present embodiment is adapted to prevent degradation of the faceplate due to electron bombardment by electrons directed towards the phosphor containing areas.

Owner:CANON KK

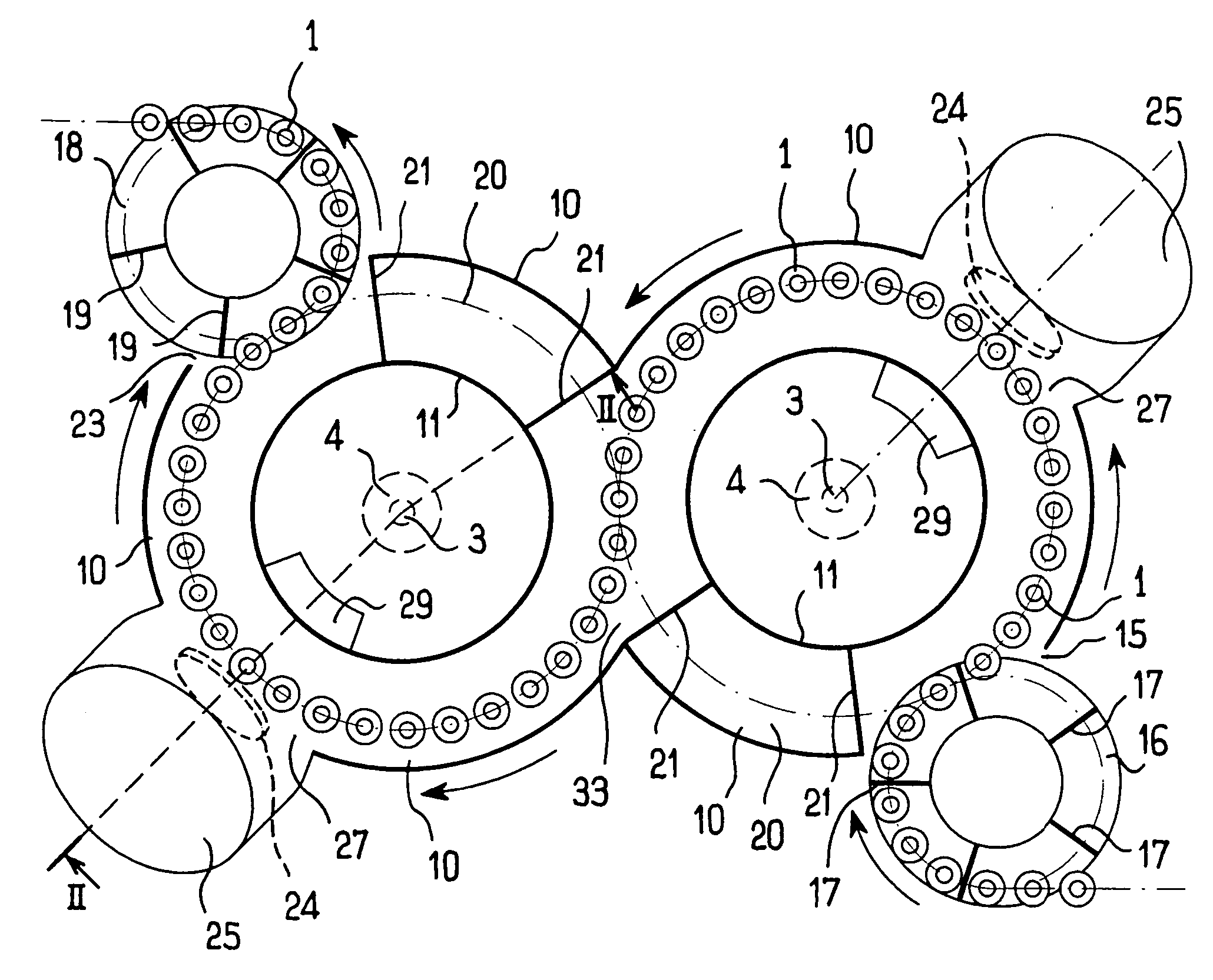

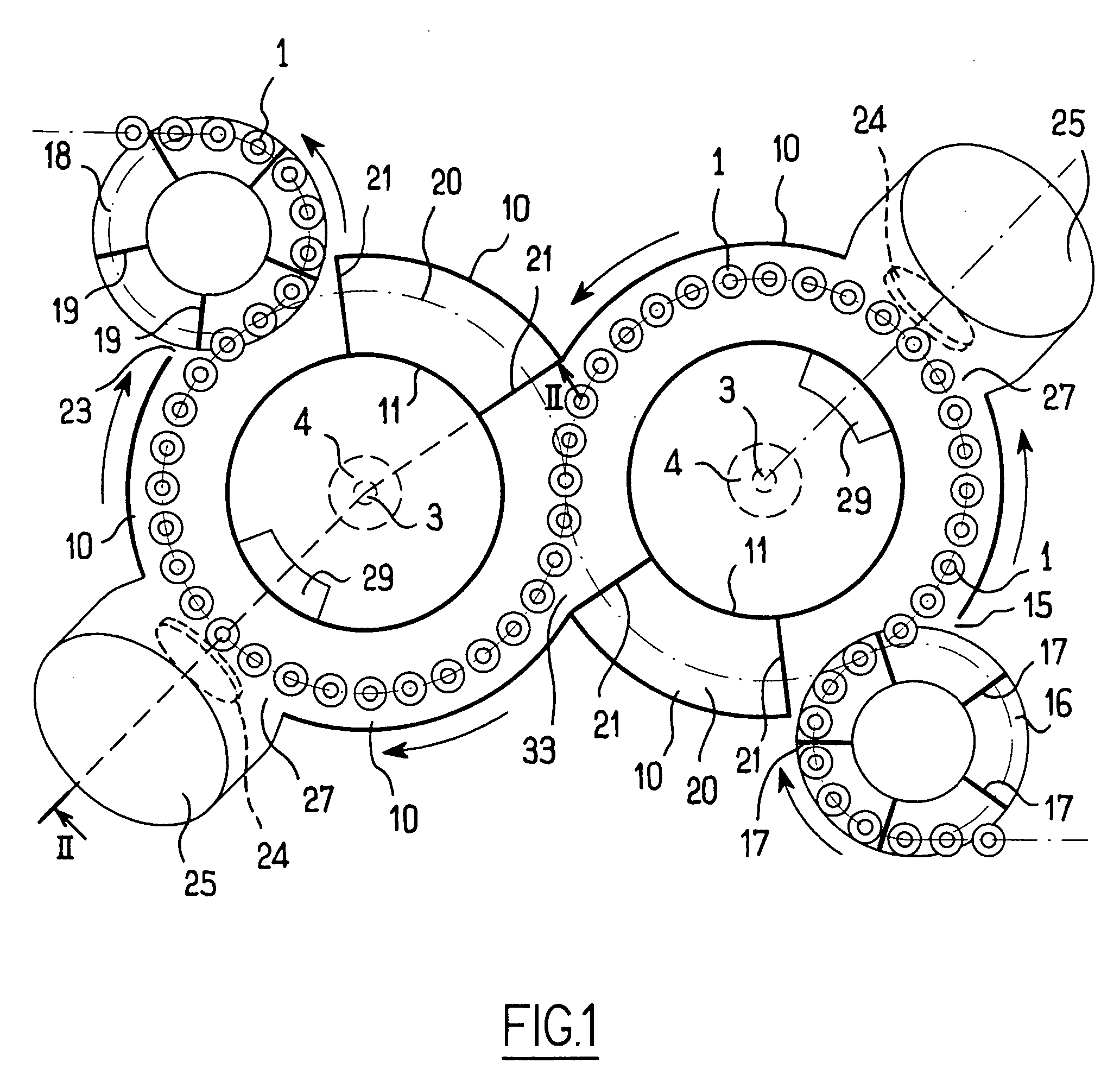

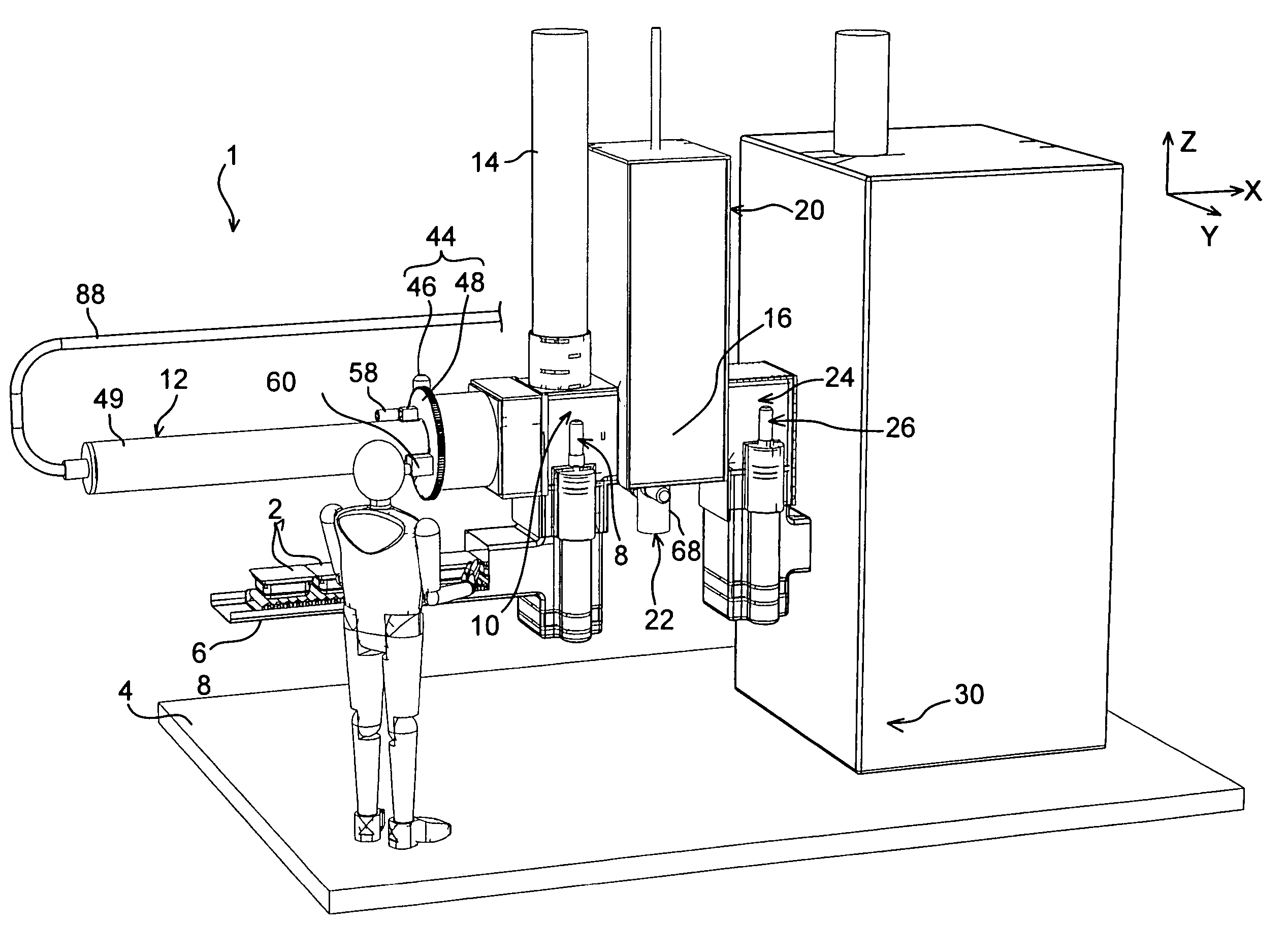

Installation for sterilizing articles by electron bombardment

InactiveUS20050158218A1Minimizing deteriorationFully sterilizedMaterial analysis using wave/particle radiationElectric discharge tubesElectron bombardmentMechanical engineering

An installation for sterilizing articles comprises an enclosure having an inlet opening and an outlet opening, a support device for moving the articles inside the enclosure, and two electron bombardment members disposed on different orientations relative to the articles to be sterilized and inclined relative to the longitudinal axis of the articles.

Owner:SERAC GROUP

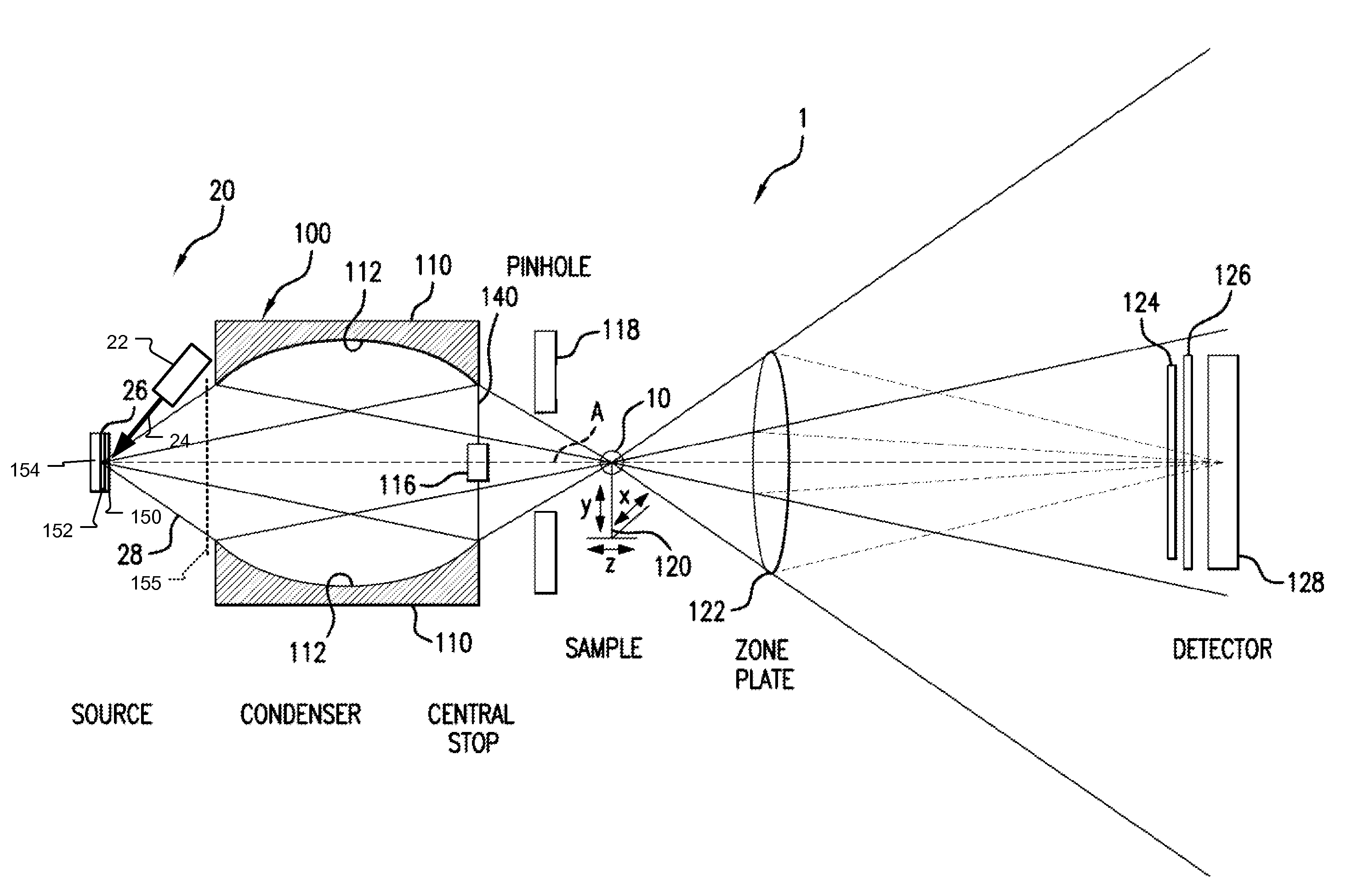

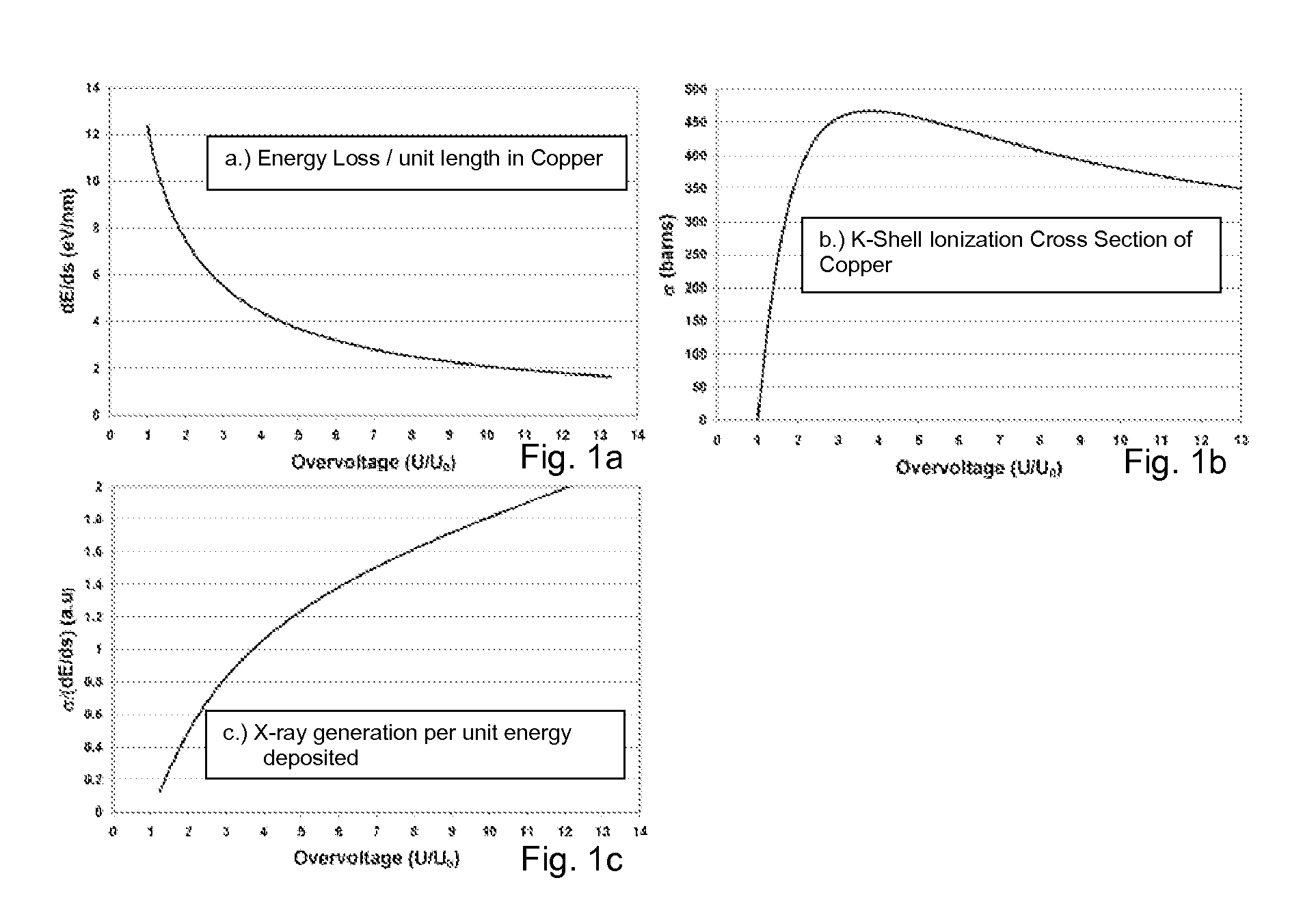

Structured anode X-ray source for X-ray microscopy

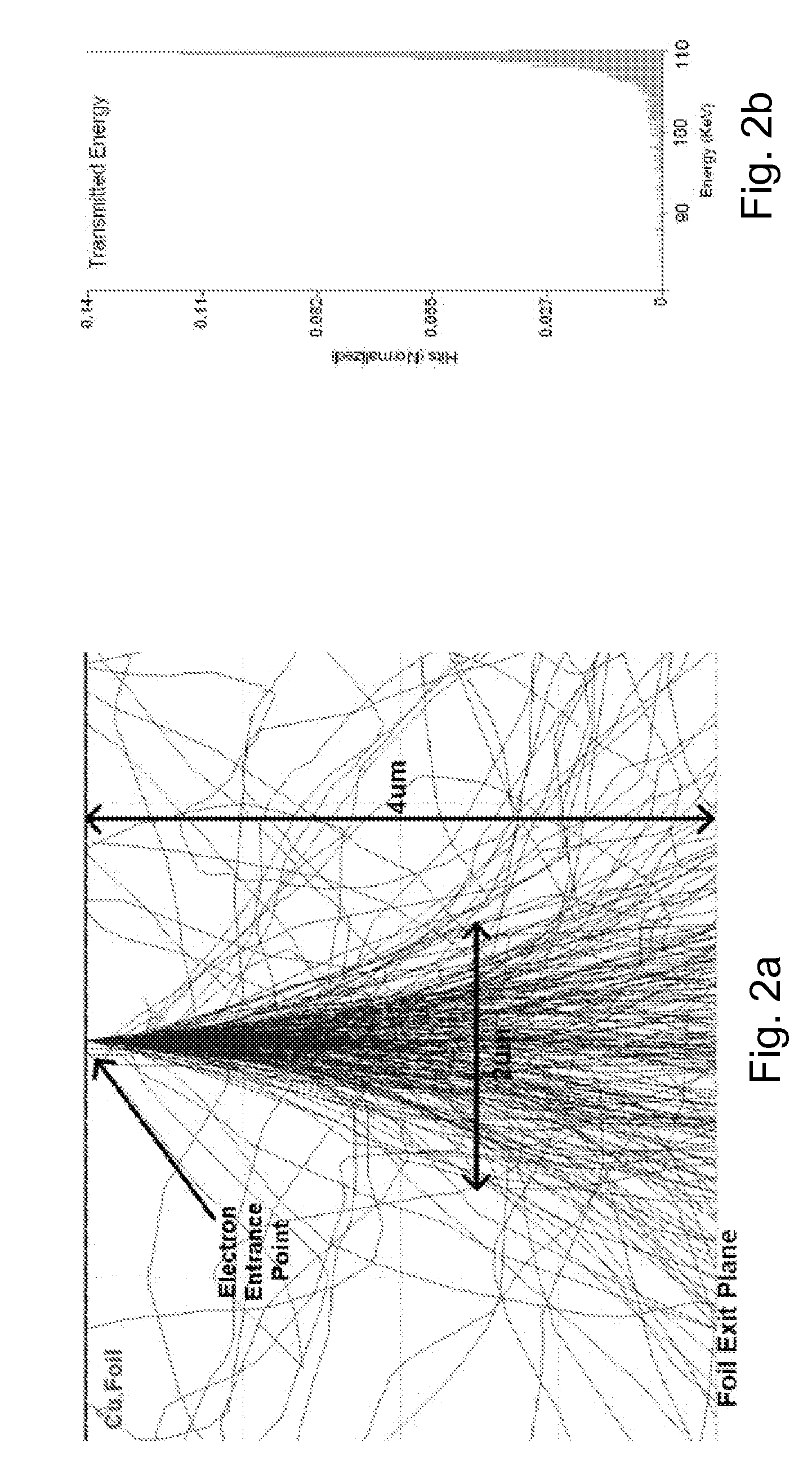

ActiveUS7443953B1Improve performanceImprove thermal performanceX-ray tube laminated targetsX-ray tube electrodesHigh energyX-ray

An x-ray source comprises a structured anode that has a thin top layer made of the desired target material and a thick bottom layer made of low atomic number and low density materials with good thermal properties. In one example, the anode comprises a layer of copper with an optimal thickness deposited on a layer of beryllium or diamond substrate. This structured target design allows for the use of efficient high energy electrons for generation of characteristic x-rays per unit energy deposited in the top layer and the use of the bottom layer as a thermal sink. This anode design can be applied to substantially increase the brightness of stationary, rotating anode or other electron bombardment-based sources where brightness is defined as number of x-rays per unit area and unit solid angle emitted by a source and is a key figure of merit parameter for a source.

Owner:CARL ZEISS X RAY MICROSCOPY

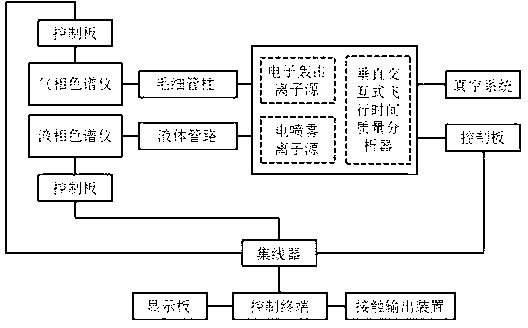

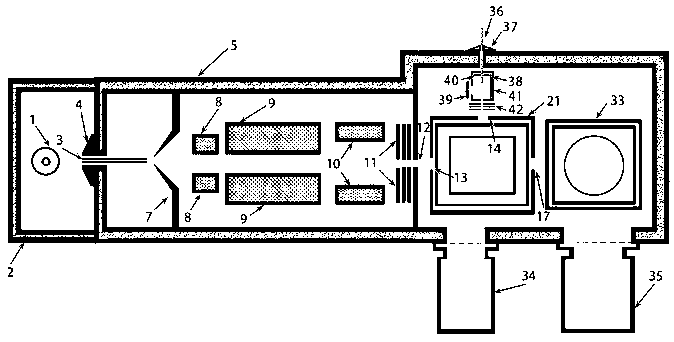

Gas/liquid chromatogram-electron bombardment electrospray dual-ion-source flight time mass spectrum system

InactiveCN102800553AImprove applicabilityComponent separationSamples introduction/extractionGas phaseMass analyzer

The invention provides a gas / liquid tandem mass spectrum system with a multimode ionization ion source. The gas / liquid tandem mass spectrum system is characterized by being formed by connecting a multimode ionization ion source, a gas chromatography, a Liquid Chromatography, a mass analyzer with purification and enrichment functions, and a flight time mass spectrometry in series. According to the invention, the applicability of a single-ion-source mass spectrometry specific to analysis of polymorphic samples is broadened, meanwhile, the high resolution performance of fragment ions on mass selection and analysis is enhanced, and the researches on an ionic reaction mechanism are realized.

Owner:王利兵

Apparatus and method for polishing gemstones and the like

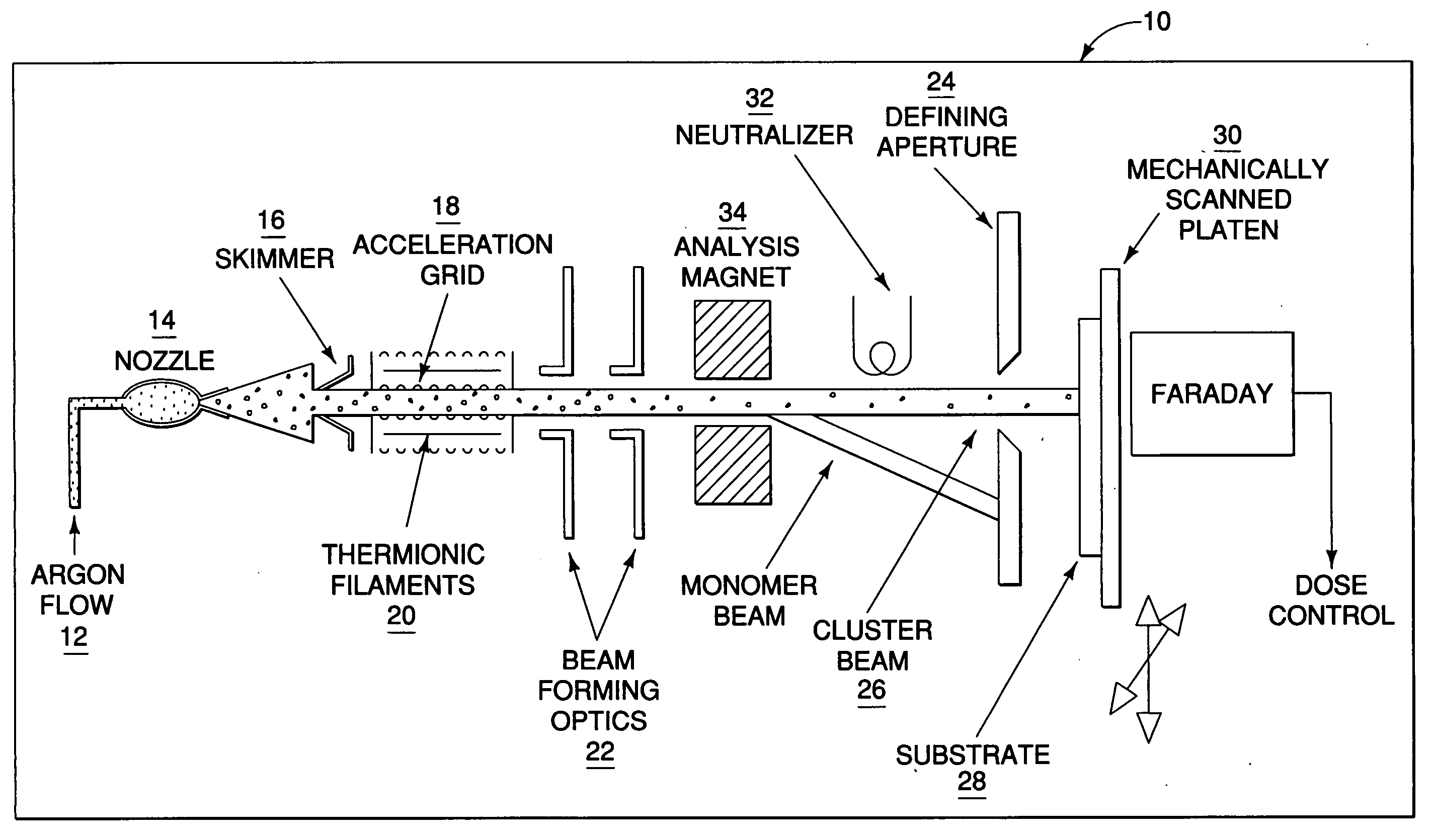

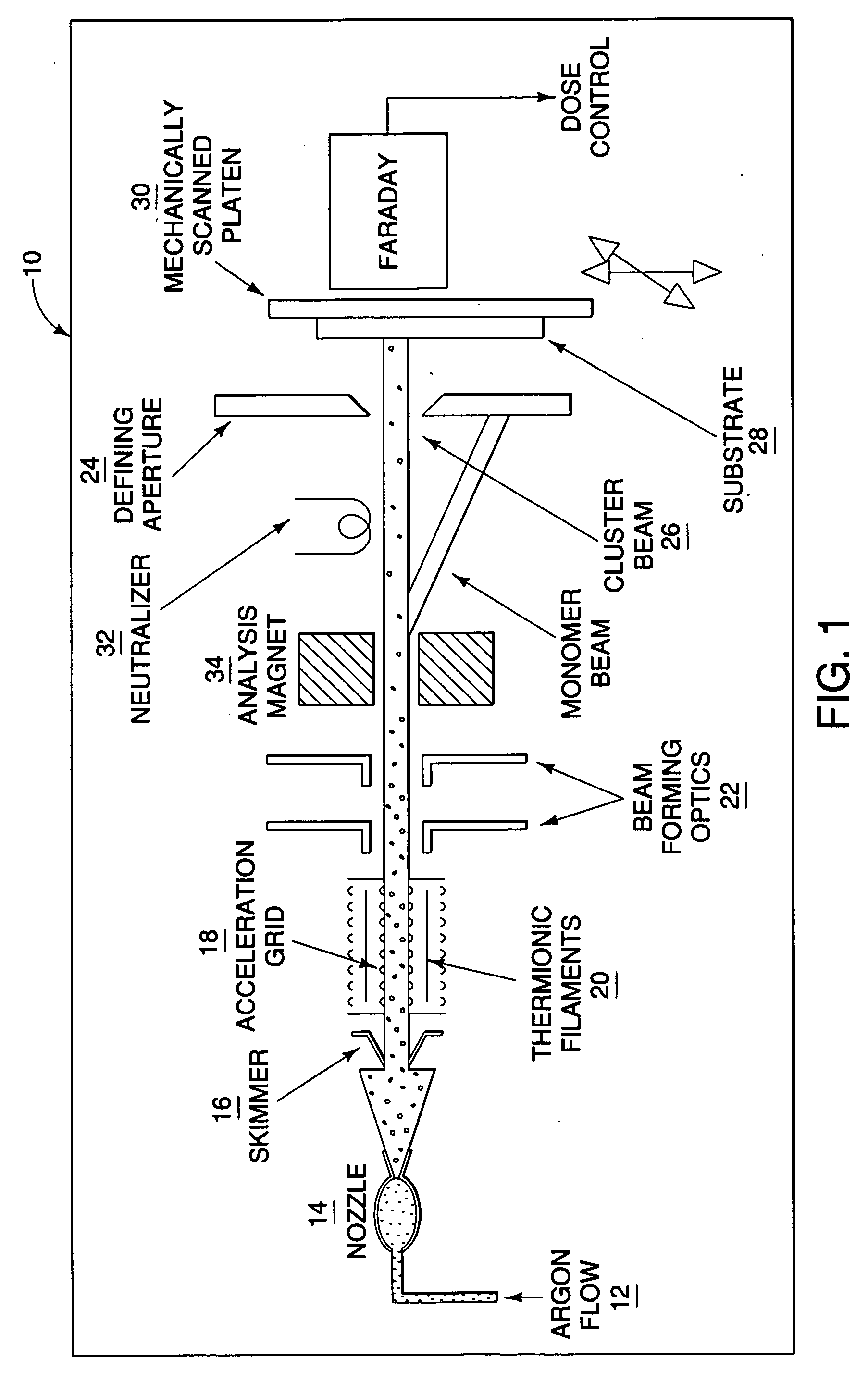

InactiveUS20060102854A1Increase throughput timeReduce errorsEdge grinding machinesRadiation/particle handlingGas cluster ion beamElectron bombardment

The invention comprises a two-step process for achieving an ultra-polish finish on materials such as gemstones and the like by first performing a chemical-mechanical polishing of the material using an intermetallic material as the grinding medium followed by a gas cluster ion beam (GCIB) treatment. The intermetallic grinding wheel is formed of carbide-forming metals in the form of intermetallics consisting of one kind or more of elements selected from the group of Al, Cr, Mn, Fe, Co, Ni, Cu, Ru, Rh, Pd, Os, Ir and Pt, and one kind or more of elements selected from the group of Ti, V, Zr, Nb, Mo, Hf, Ta and W. The gas cluster ion beams are comprised of gas clusters having nano-sized aggregates of materials that are gaseous under conditions of standard temperature and pressure. Such clusters can be ionized by electron bombardment or other means, permitting the gas clusters to be formed into directed beams of known and controllable energy. The larger sized gas clusters are the most useful because the larger sized gas clusters are able to carry substantial energy per cluster ion, while yet having only modest energy per atom or molecule.

Owner:NEOGI JAYANT +1

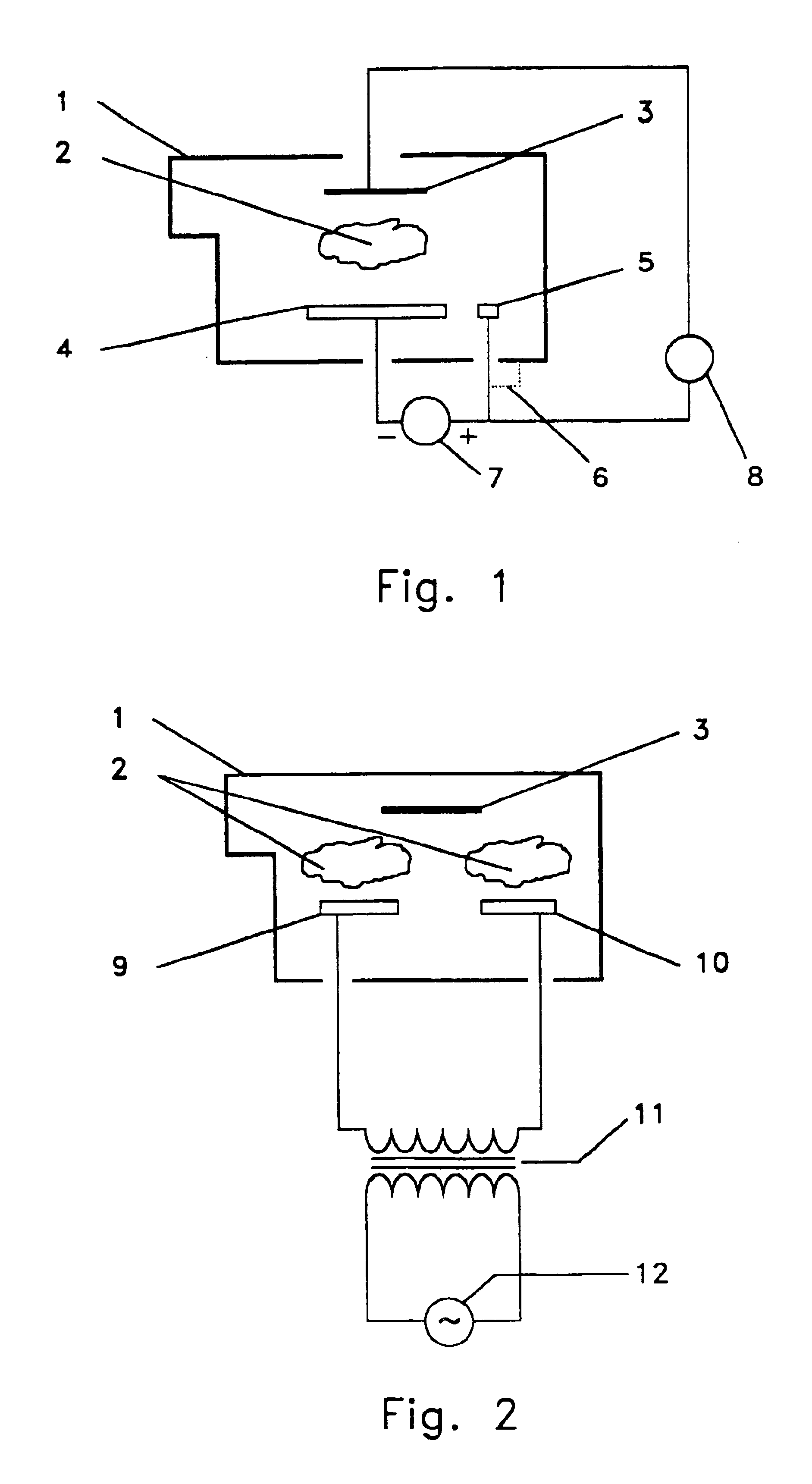

Method and apparatus for substrate biasing in multiple electrode sputtering systems

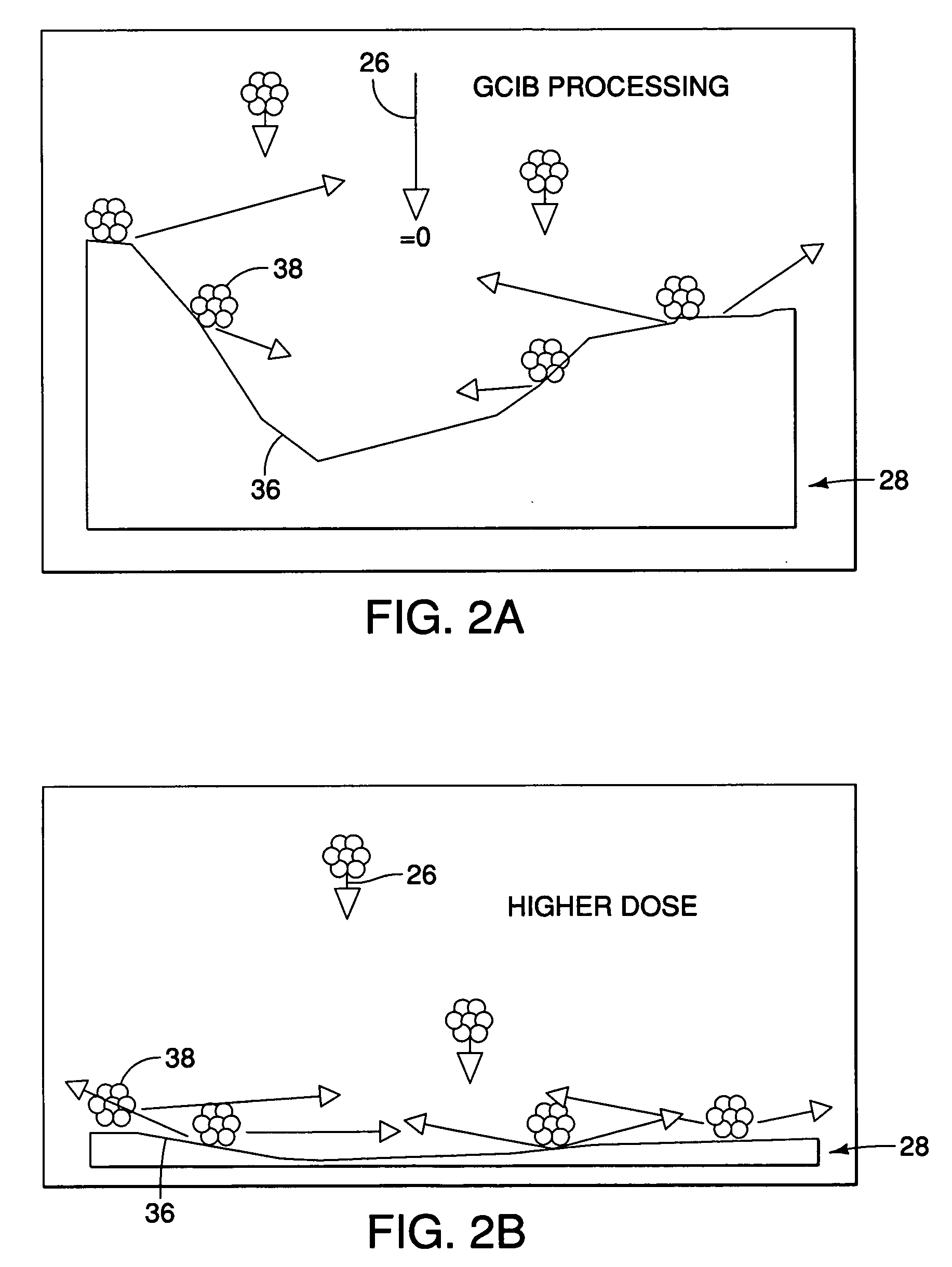

InactiveUS6818103B1The method is simple and reliableCellsVacuum evaporation coatingIon bombardmentElectron bombardment

A method and an apparatus are disclosed for causing ion bombardment of the substrate during sputter deposition of an insulating or conducting material on a substrate (3) when using dual cathode or dual anode sputtering approaches. A novel electrical circuit including a center-tapped transformer is disclosed to permit a controllable potential to be applied to the substrate relative to the plasma potential, without the necessity of an additional power supply. Also disclosed are approaches which permit the use of an auxiliary biasing supply (8), either dc or high frequency ac, and which can permit continuous discharging of the surface through alternate ion and electron bombardment.

Owner:ADVANCED ENERGY INDS

Steam turbine bulkhead electron-beam welding method

The electron beam welding method of the steam turbine clapboard refers to a kind of welding technique. The invention is realized in the following way: a. clean the surface of the clapboard; b. assemble and fix the clapboard on the frock in accordance with the requirement of mounting technology of the electron beam's clapboard; c. move the fixed clapboard to the electronic welding vacuum chamber to vacuumize it; d. when the vacuum degree reaches predetermined value, heat the clapboard for between 15min and 30min with electron beam stream; e. weld the clapboard with the electron bombardment welding machine; f. after finishing the welding, heat the clapboard for over 30min with electron beam stream; g. after postheat treatment, isolate the clapboard in the vacuum chamber for between 15min and 30min; h. move the welded clapboard out of the vacuum chamber and put it into the temper furnace for heat treatment. The invention is featured by short production cycle, high welding precision, simple technique and low cost.

Owner:HARBIN TURBINE

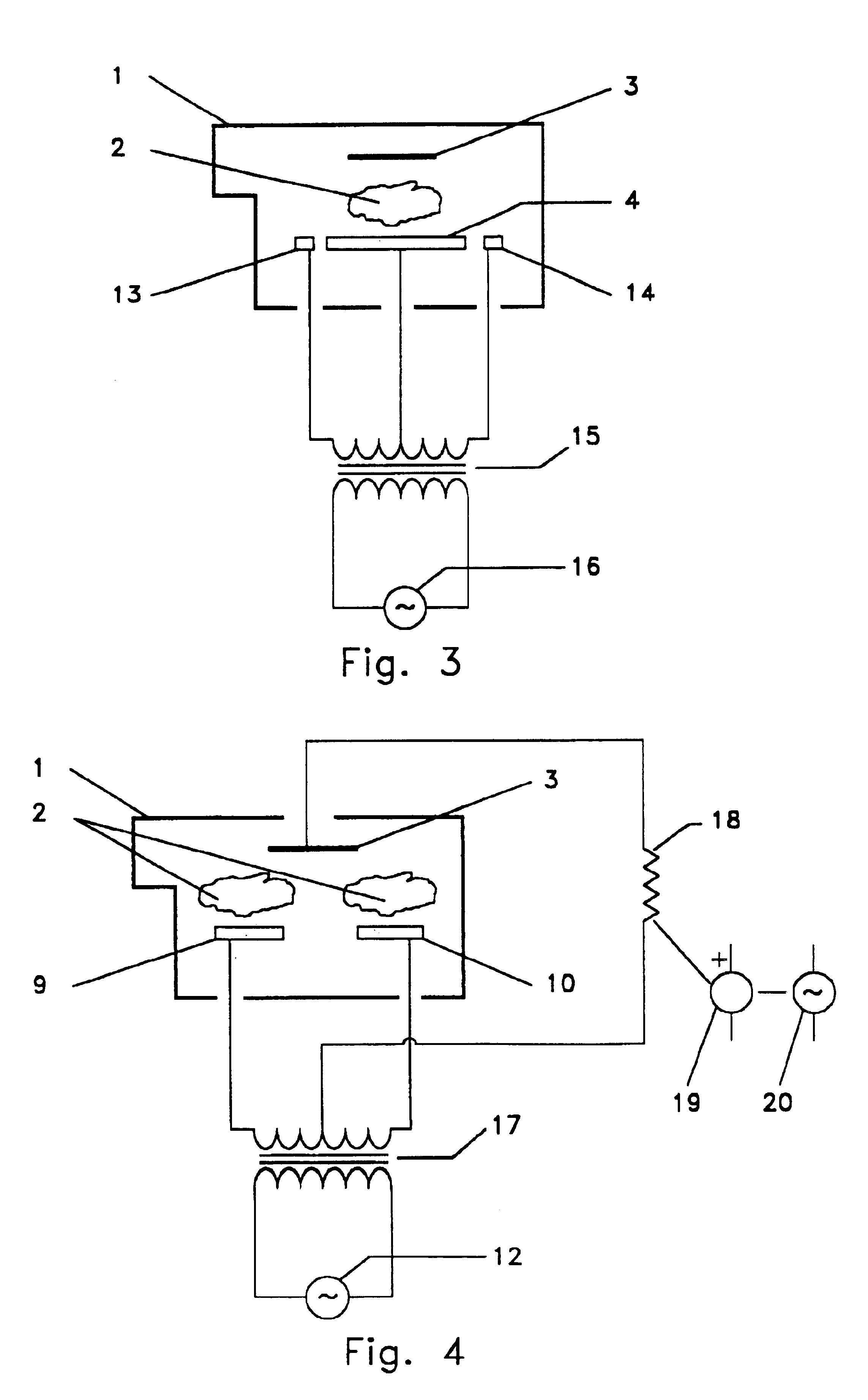

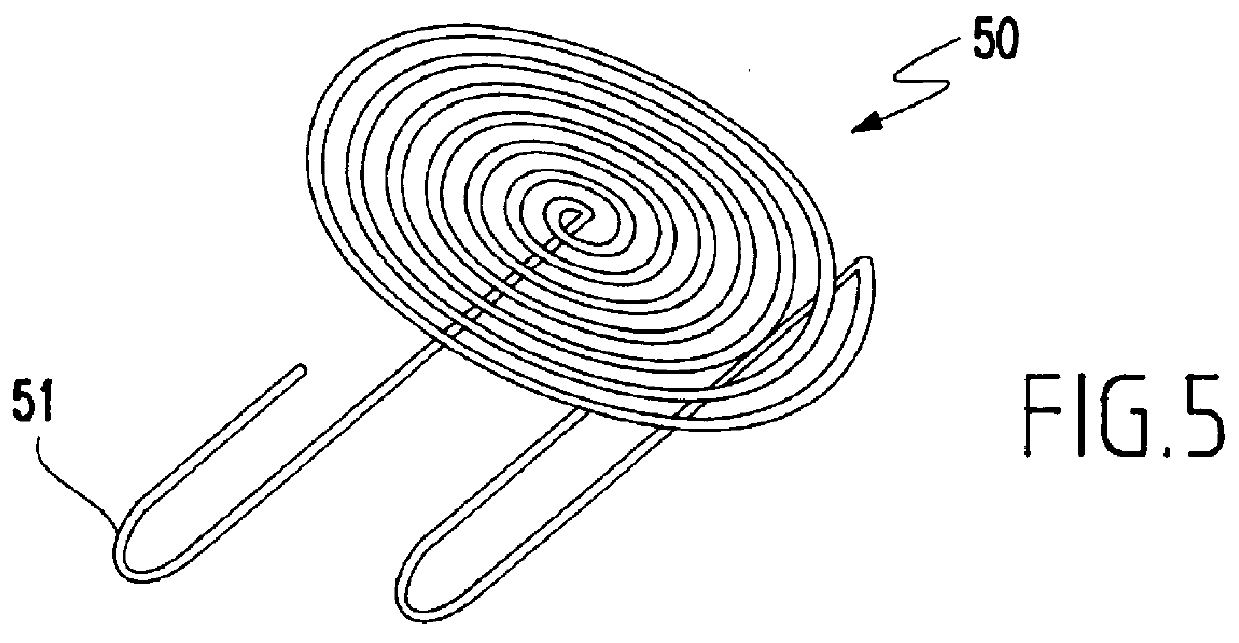

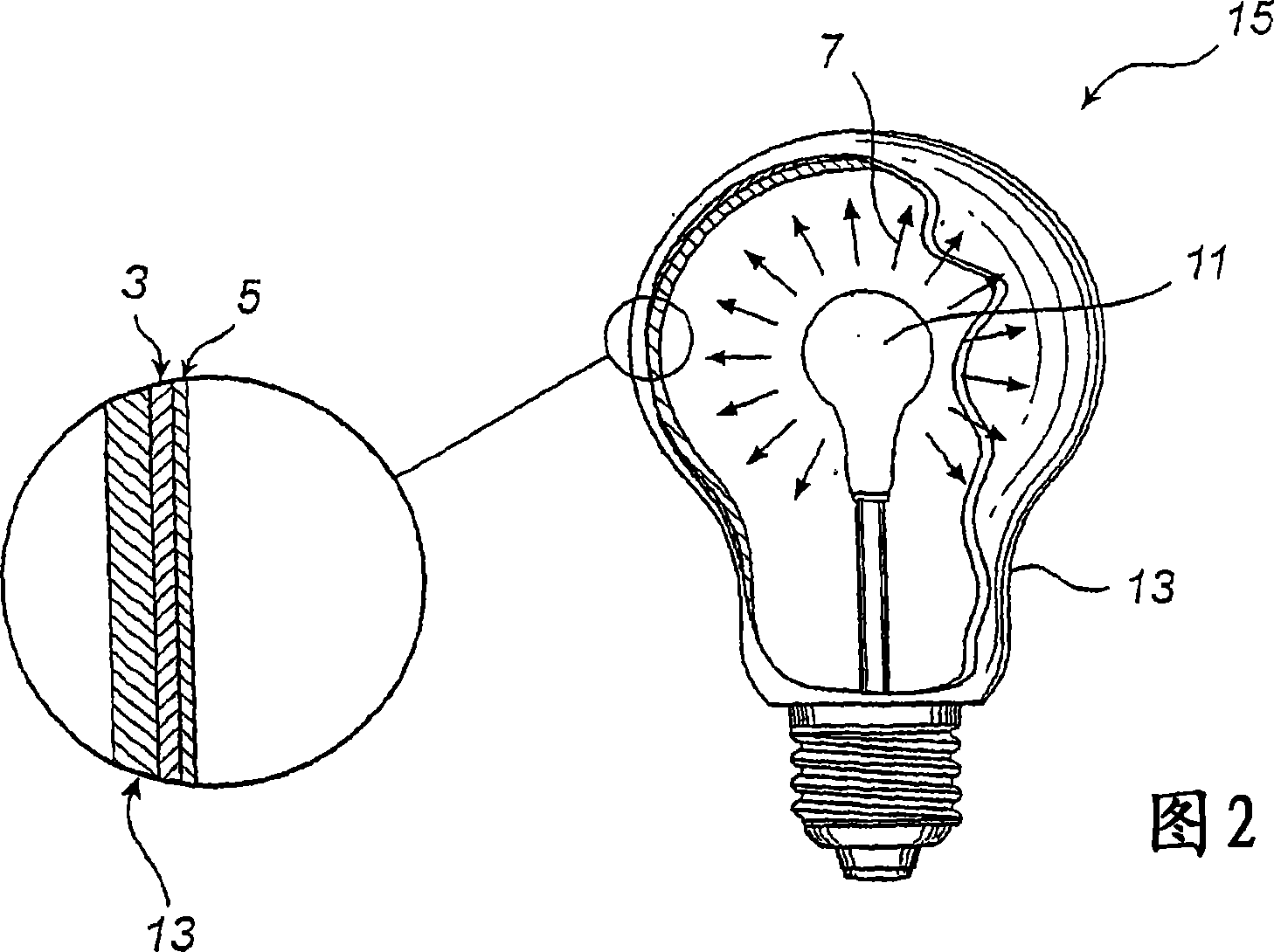

Light source, and a field emission cathode

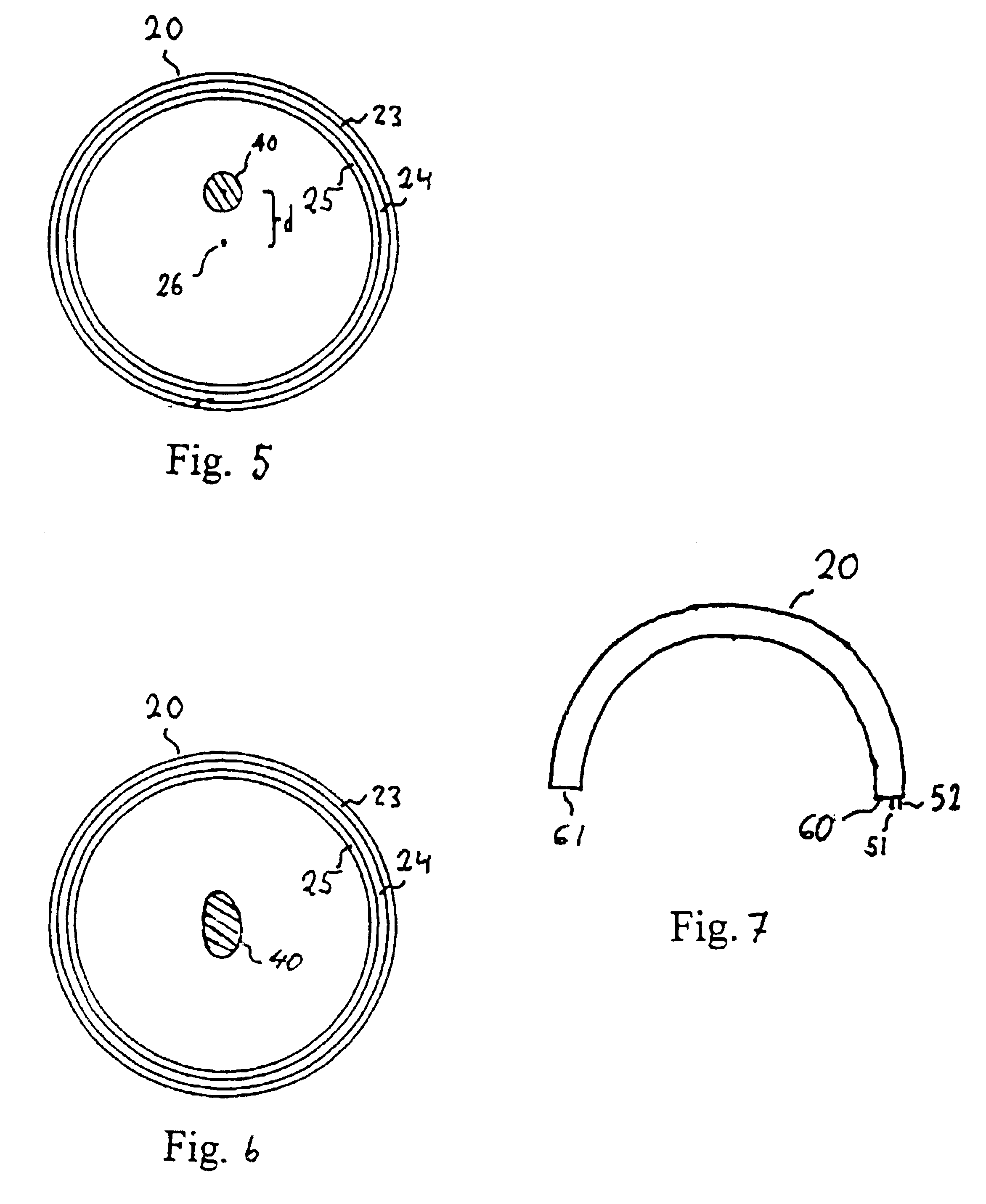

InactiveUS6873095B1Simple and robust constructionLarge luminous surfaceLamp incadescent bodiesNanoinformaticsEVACUATED CONTAINERPhosphor

The light source, comprises an evacuated container having walls, including an outer glass layer (23) which on at least part thereof is coated on the inside with a layer of phosphor (24) forming a luminescent layer and a conductive layer (25) forming an anode. The phosphor (24) is excited to luminescence by electron bombardment from a field emission cathode (40) located in the interior of the container. The field emission cathode (40) comprises a carrier having a diameter in the mm range. At least a portion of the surface of the carrier is provided with a conductive layer having surface irregularities in the form of tips, having a radial extension being less than about 10 μm. Due to the geometry and the tips, the electric field is concentrated and amplified at the field emission surface.

Owner:NANOLIGHT INT

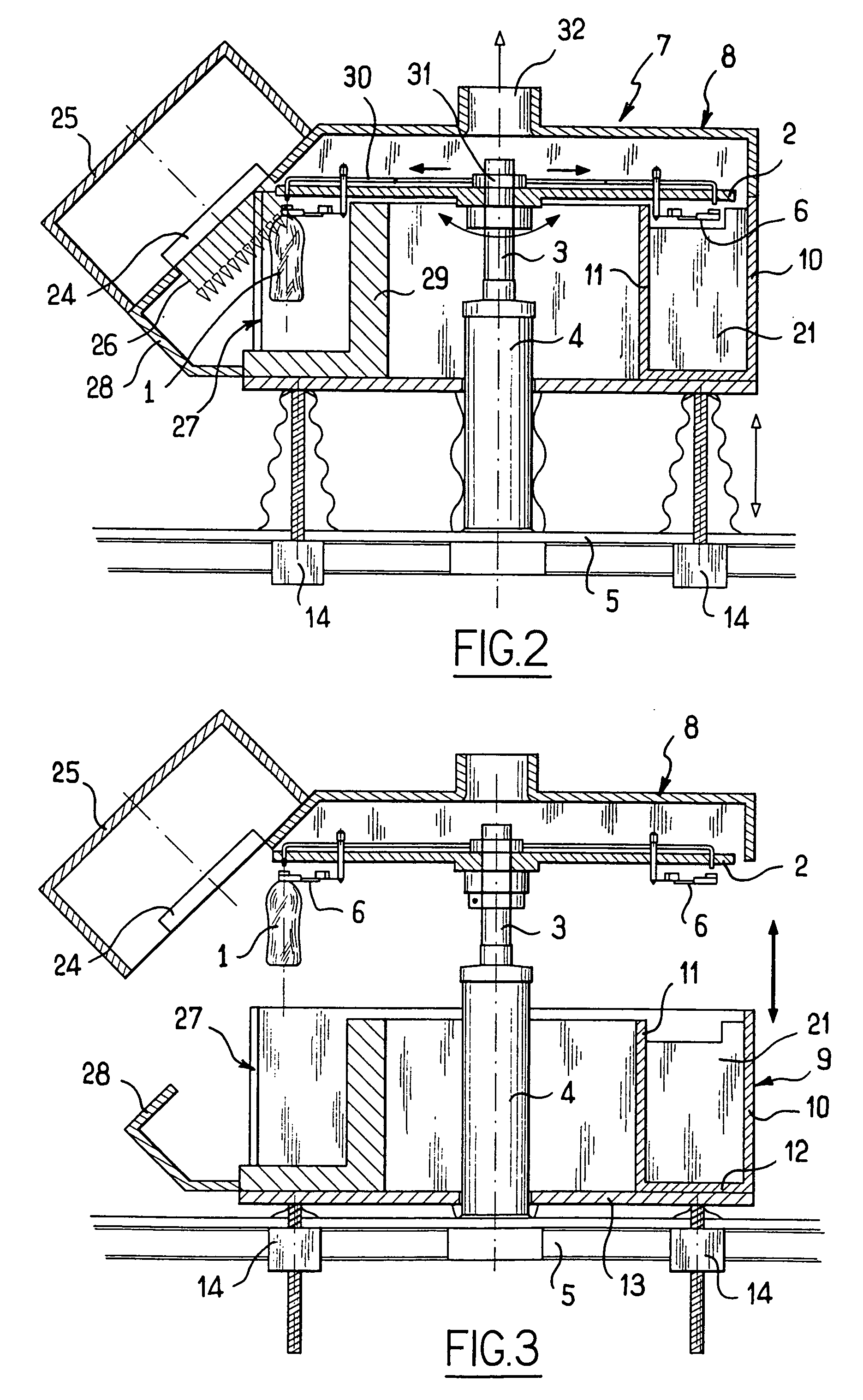

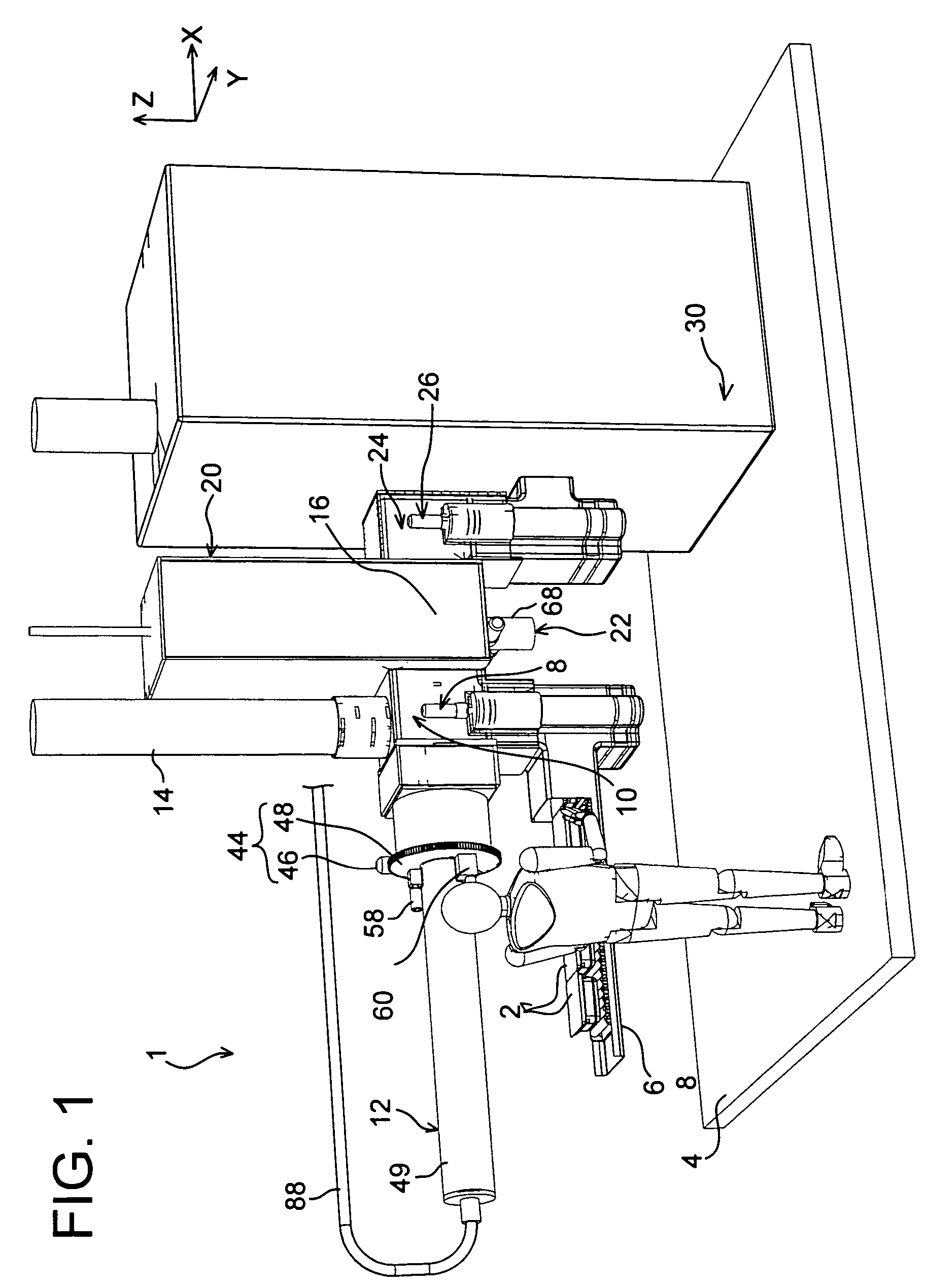

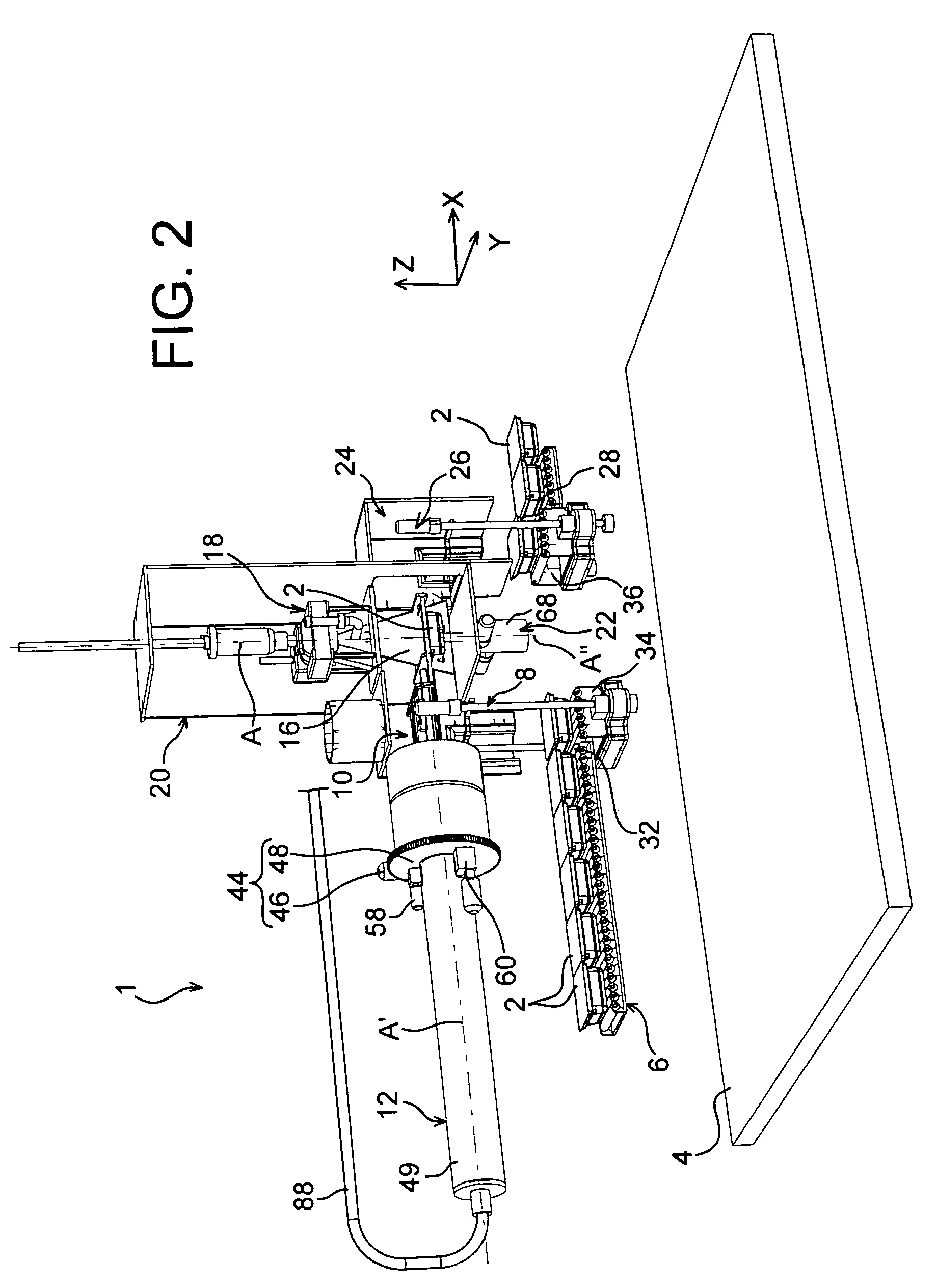

Installation and method for sterilising objects by low-energy electron bombardment

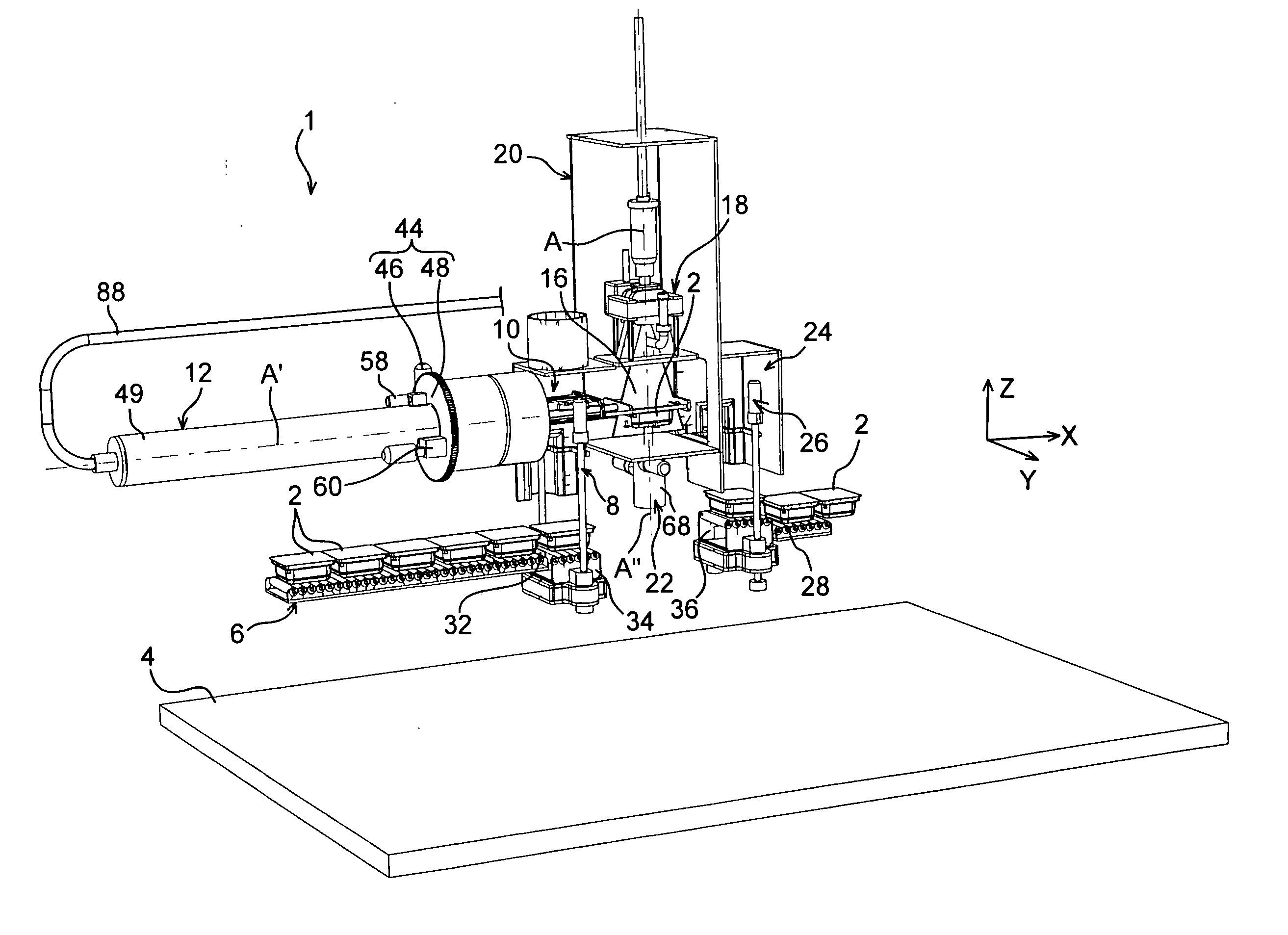

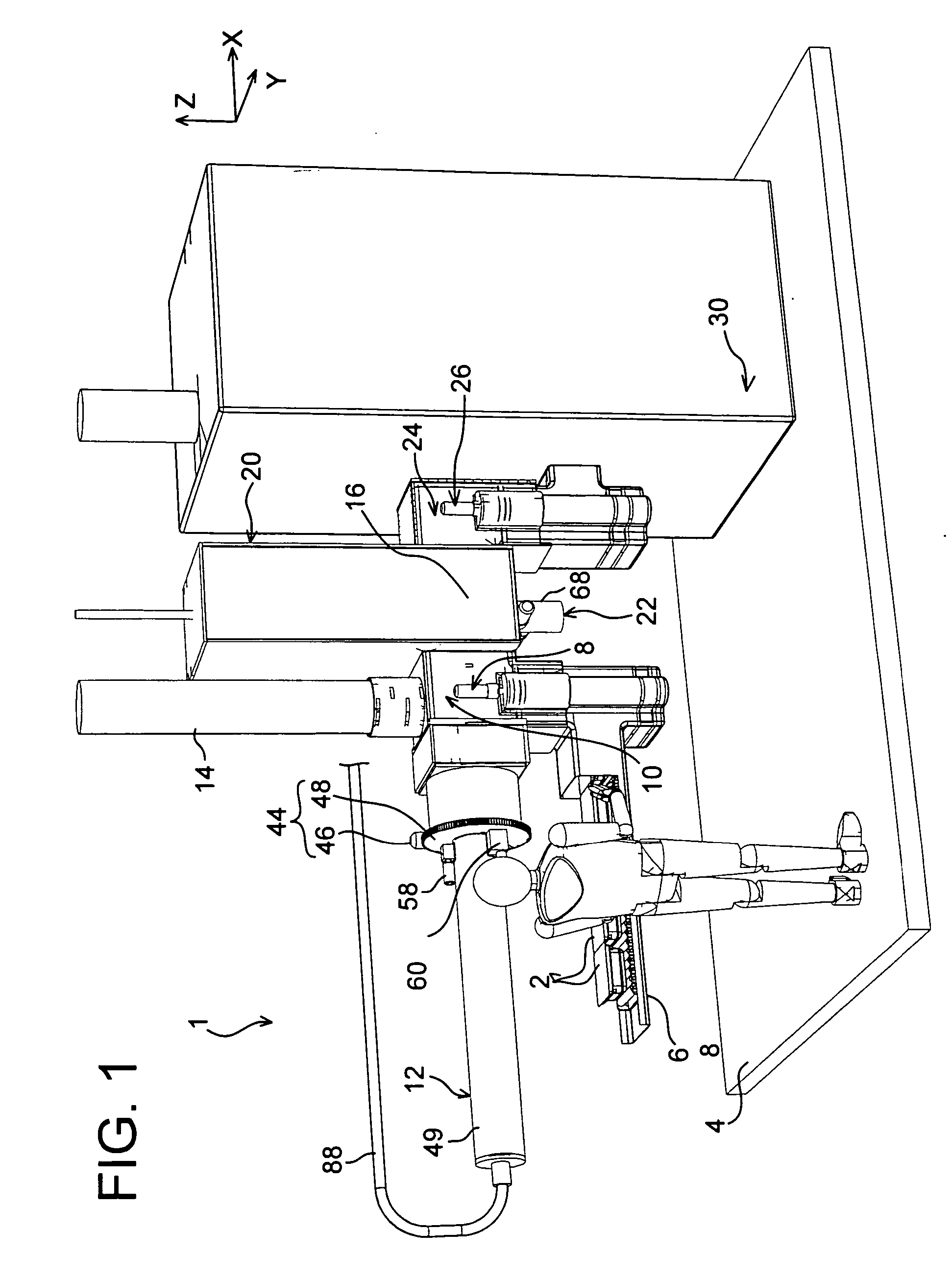

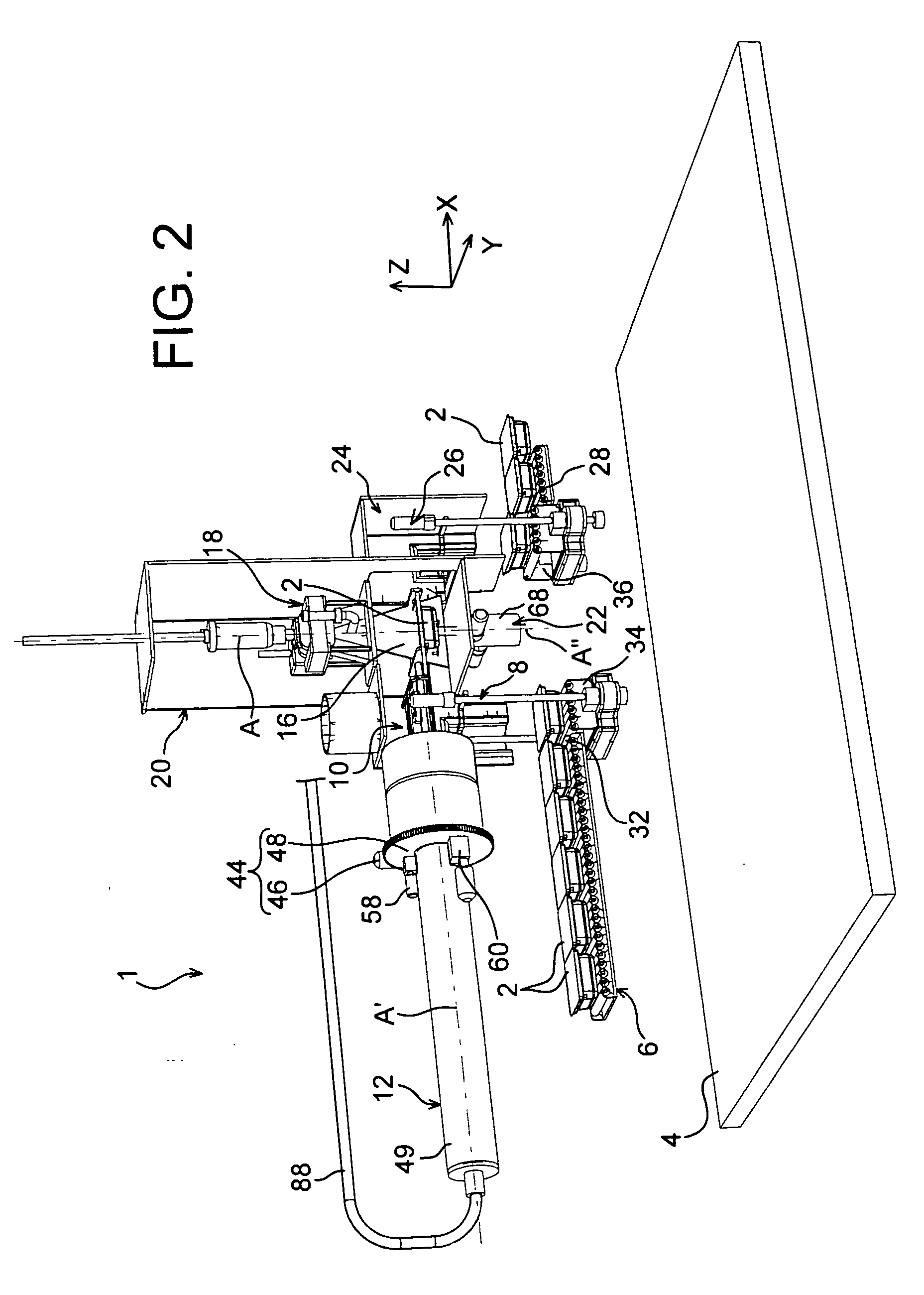

InactiveUS20060186350A1Reduced space requirementsLow costMaterial analysis using wave/particle radiationElectric discharge tubesClassical mechanicsElectron bombardment

The invention relates to an installation (1) for sterilising objects (2) by low-energy electron bombardment, including sterilisation means (18) capable of generating an electron beam along an axis (A) passing through a treatment chamber (16). According to the invention, the installation includes a mechanical module (12) designed so as to be capable of generating a relative rotation movement, between the object and said sterilisation means, about an axis (A′) chosen so that axis (A) of the electron beam generated by said sterilisation means continuously passes through the external surface of the object during the relative rotation movement about said axis (A′). In addition, it comprises mechanical module (22) enabling the object to be rotated about an axis (A″) oriented orthogonally with respect to axis (A′).

Owner:LINAC TECH

Focusing type cold cathode X-ray tube

InactiveCN102427015AAdjustment areaAdjust heating powerX-ray tube electrodesCathode ray concentrating/focusing/directingSoft x rayX-ray

The invention discloses a focusing type cold cathode X-ray tube which comprises a field emission cold cathode, a lamp filament gate electrode formed by lamp filaments, an anode, an X-ray tube case and a ray emergence window, wherein the field emission cold cathode and the anode are respectively arranged at two ends inside the X-ray tube case and are respectively extracted to the outside of the X-ray tube case through a cathode extraction electrode and an anode extraction electrode; the lamp filament gate electrode is arranged between the field emission cold cathode and the anode; two side surfaces of the lamp filament gate electrode are extracted to the outside of the X-ray tube case through the two extraction electrodes; the anode is provided with a slope surface for generating an X-ray by electron bombardment; and the ray emergence window is arranged at the position on the side surface of the e X-ray tube case, which is just opposite to the slope surface. Compared with the general field emission cold cathode X-ray tube, the focusing type cold cathode X-ray tube can be used for effectively carrying out electron bombardment on the anode to degass, improving the vacuum degree in the X-ray tube, simultaneously focusing electron beams, improving the performance of the X-ray tube and prolonging the service life of the X-ray tube.

Owner:SOUTHEAST UNIV

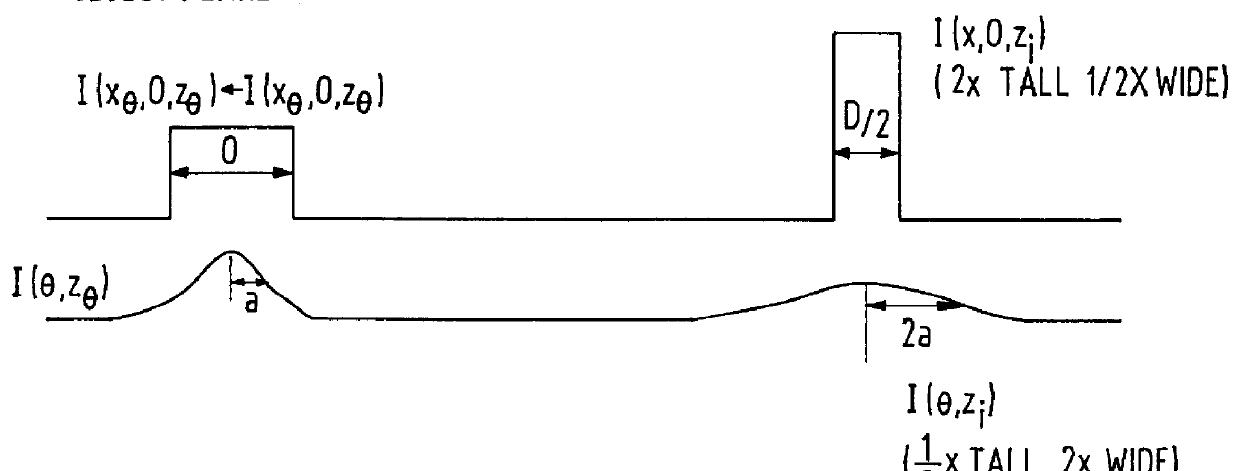

High emittance electron source having high illumination uniformity

InactiveUS6091187AImprove emission uniformityIncrease the areaElectric lighting sourcesThermionic cathodesField uniformityElectron source

Direct and indirect electron bombardment provide a sufficiently high degree of temperature uniformity across the emitting surface of a large-area electron source for an electron beam projection system such that a broad beam having illumination uniformity within 1% can be achieved. A diode gun is used to obtain extraction field uniformity and maintain uniformity of illumination. Power requirements and power dissipation in beam periphery truncating apertures is reduced by roughening the surface of a monocrystalline cathode or depositing materials having a higher work function thereon.

Owner:IBM CORP

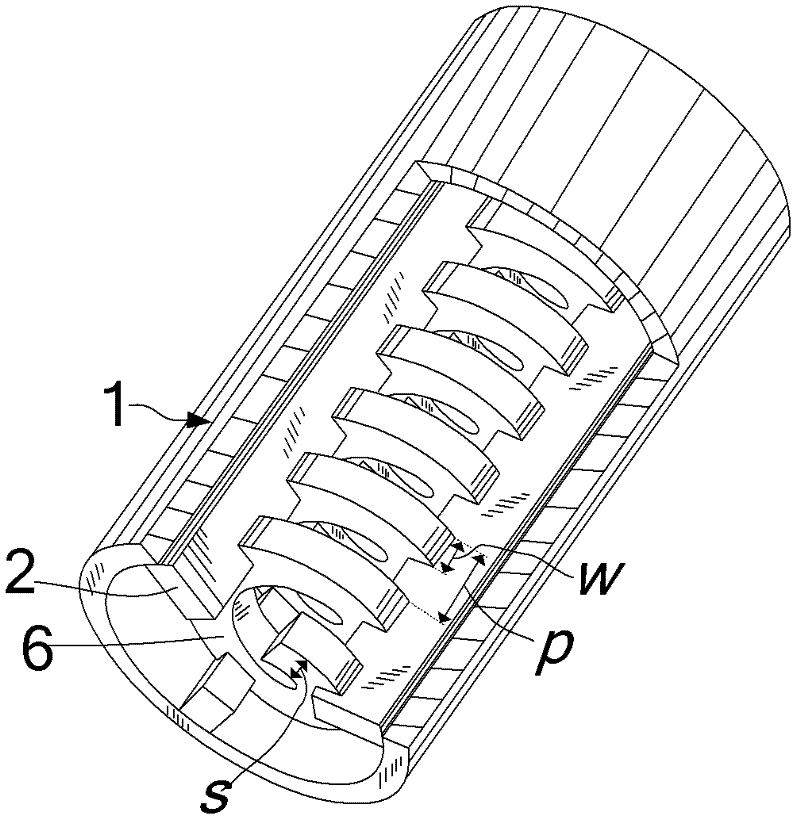

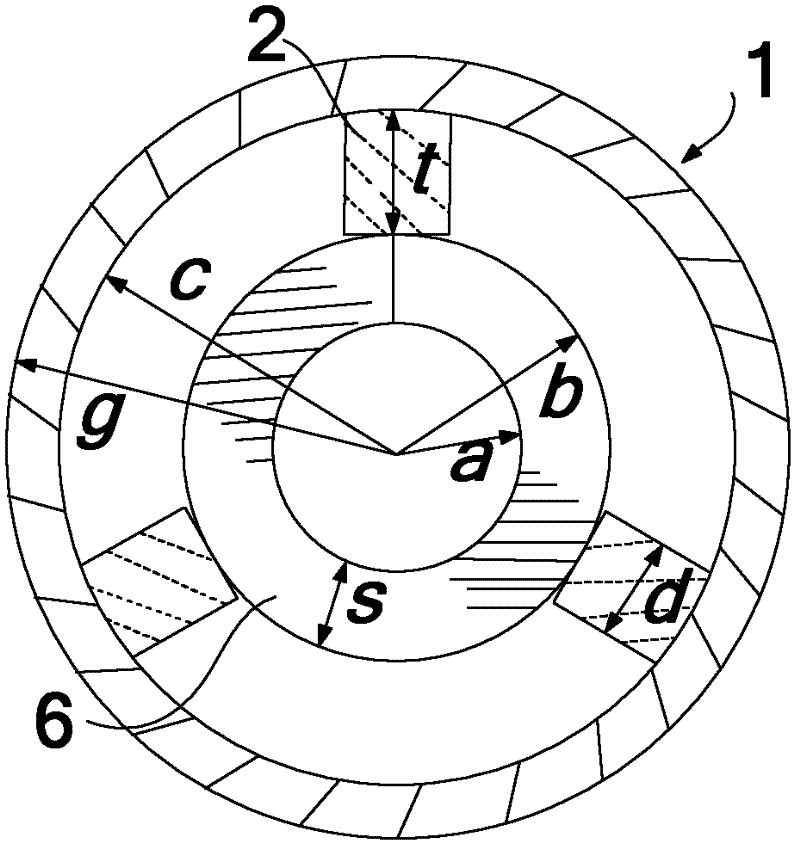

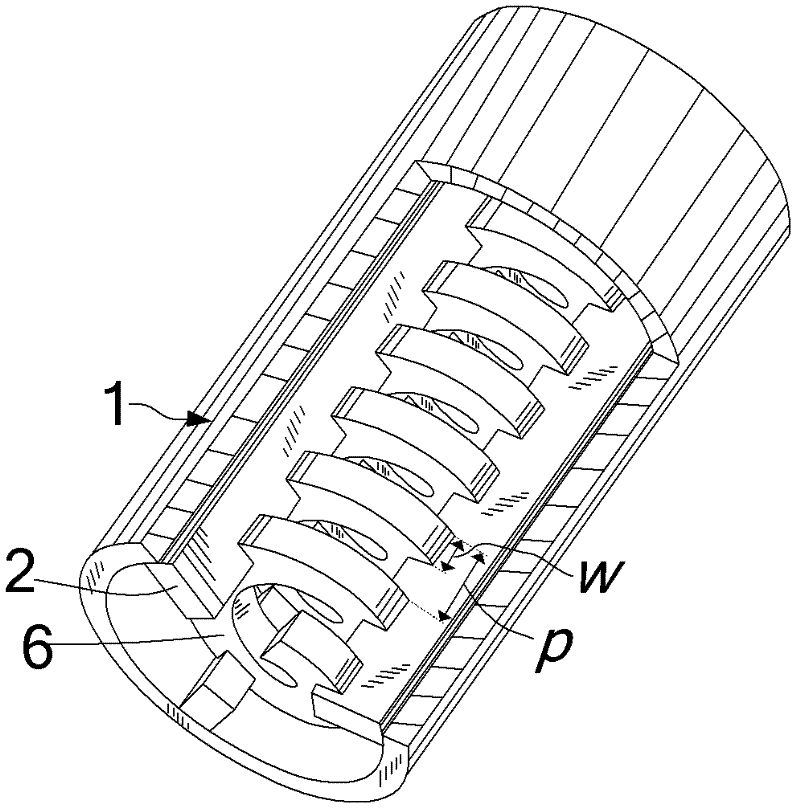

Helix slow wave structure

InactiveCN102446676AIncrease contact areaImprove cooling effectTransit-tube circuit elementsWave structureMicrowave

The invention relates to a helix slow wave structure, which belongs to the field of microwave vacuum electronic techniques. The helix slow wave structure comprises a helix, a tube shell and n (n is larger than or equal to 2) dielectric clamping rods. The inner diameter of the helix is a, the outer diameter of the helix is b, the pitch of the helix is p and the helix is formed by a belt-shaped metal wire with a rectangular cross section in a winding way, wherein the length s of the rectangular cross section is equal to b minus a, the width of the rectangular cross section is w and s / w is larger than or equal to 1; n grooves which are in parallel with the central axis of the helix and are evenly distributed on the external surface of the helix; and the shape of the side surface of the dielectric clamping rods in contact with the tube shell is adaptive to the shape of the internal surface of the tube shell, the shape of the side surface of the dielectric clamping rods in contact with the helix is adaptive to the shape of the grooves arranged on the external surface of the helix and therefore the dielectric clamping rods can fix the helix in the tube shell to keep the central axes of the helix and the tube shell to be consistent with each other. By adopting the thicker helix, the helix slow wave structure provided by the invention has the advantages that the electron bombardment resisting capacity of the slow-wave structure is improved, the structure is firmer and the reliability is improved; and moreover, since the contact area between the dielectric clamping rods and the external surface of the helix is larger, the heat dissipating capacity of the slow-wave structure is further improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

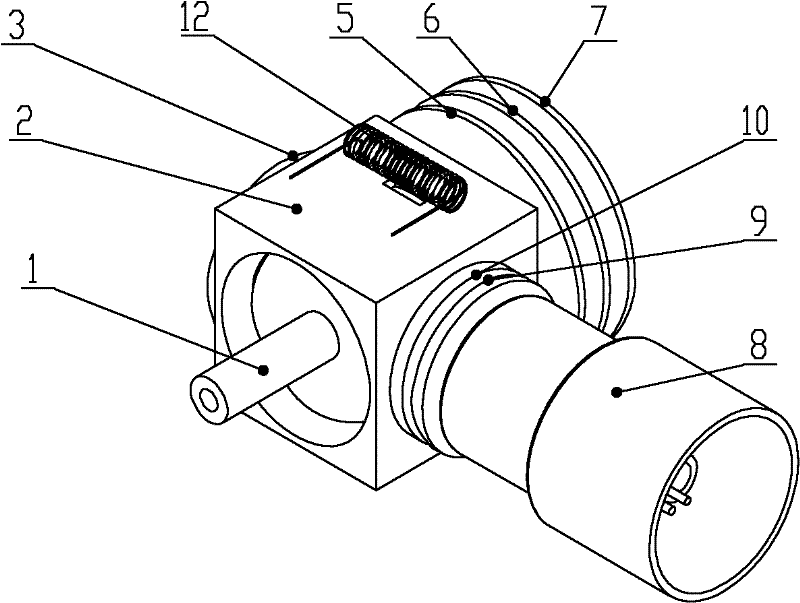

A compound ion source

ActiveCN102299038AIncrease profitImprove ionization efficiencyIon sources/gunsPhoton emissionIonization chamber

The invention provides a compound ion source, relating to a mass spectrometer. The compound ion source is applied to the mass spectrometer and has the advantage of combining the advantages of an electron bombardment source and a photoionization source, not only acquiring the fragment information of samples and the integral molecular ion peaks simultaneously, and reducing the difficulty in spectrogram analysis, but also improving the use ratio and IE (ionization efficiency) of the samples obviously to further improve the flexibility of the mass spectrometer, and being suitable for ionizing gaseous samples. The compound ion source comprises an ionization chamber, a sample import conduit, a repulsion electrode, an ion export pole piece, a focusing pole piece, an emitting pole piece, an uppergrid mesh, a reflecting mirror, a lower grid mesh, a glass window, a collecting mirror, a photon emission tube and lamp filaments.

Owner:XIAMEN UNIV

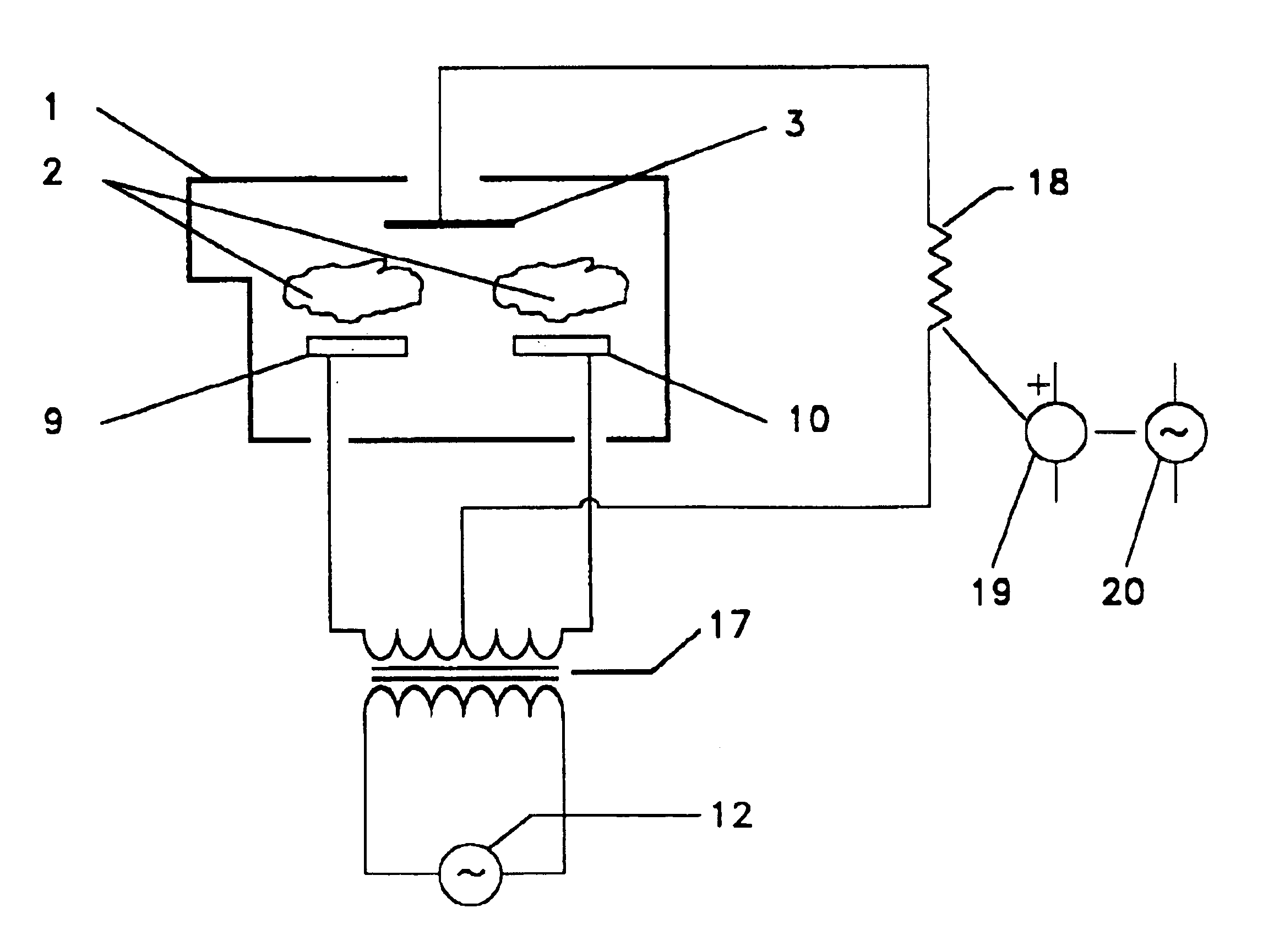

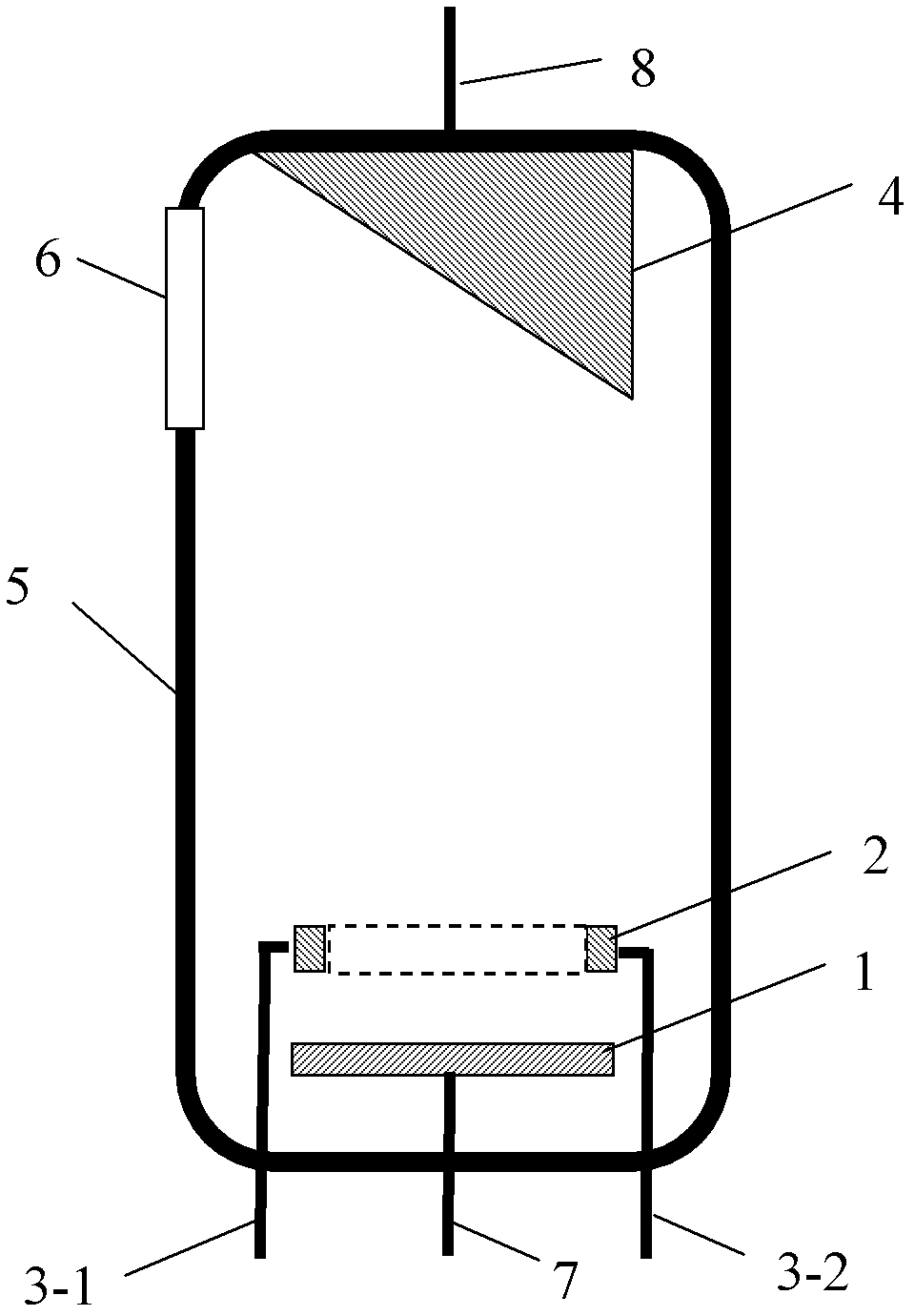

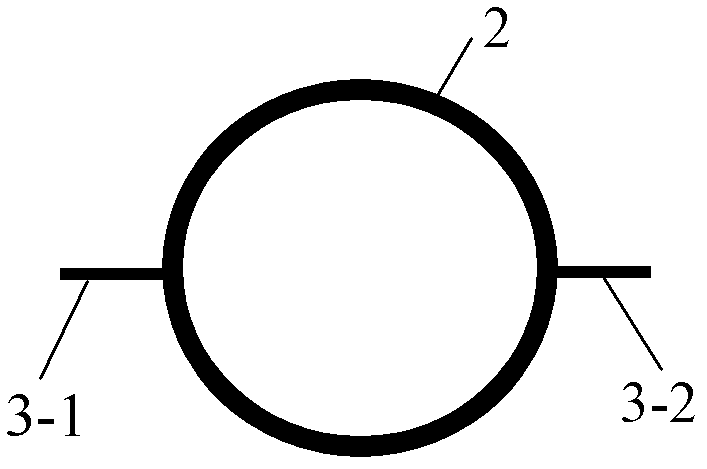

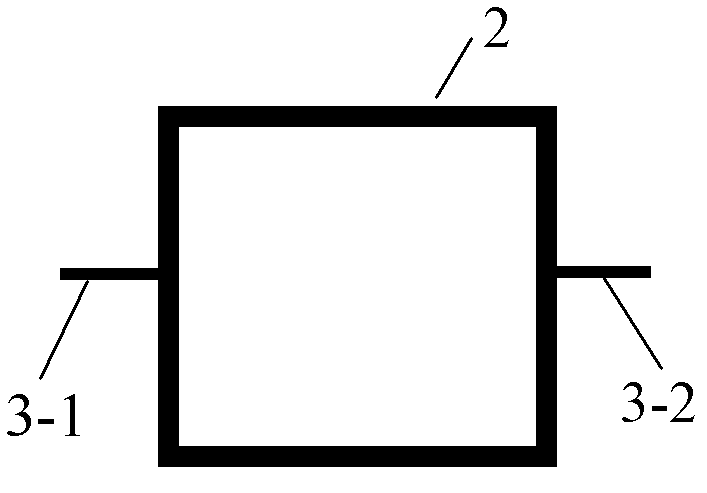

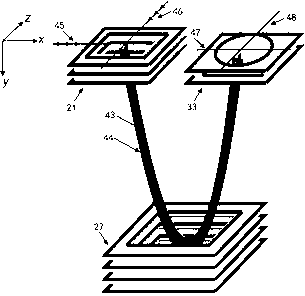

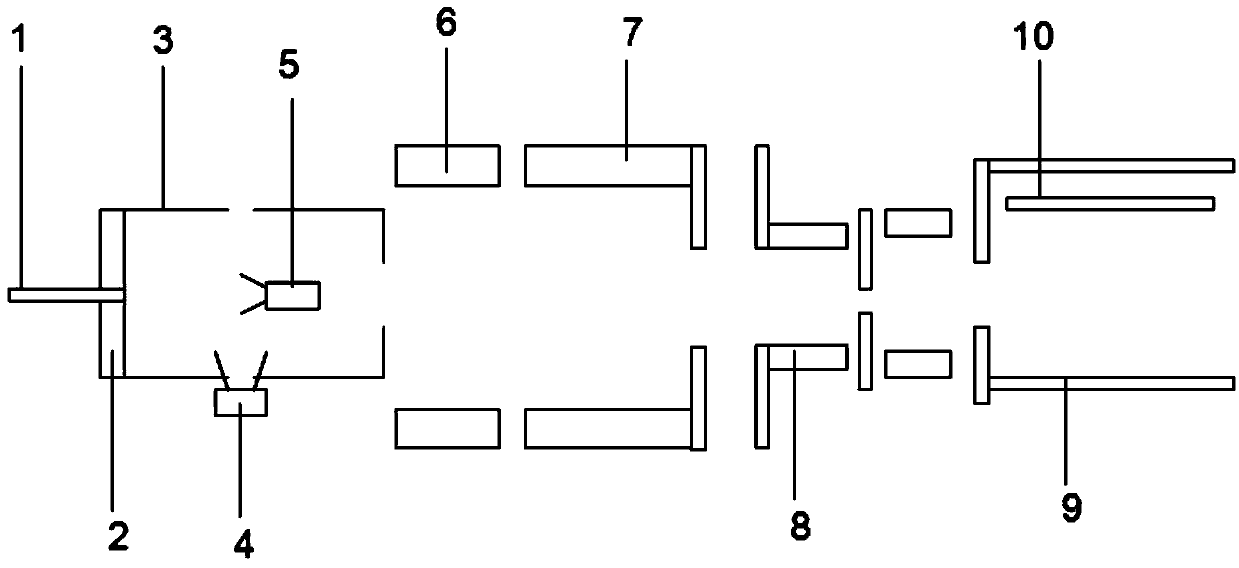

Dual ion sources matrix ion trap mass spectrograph

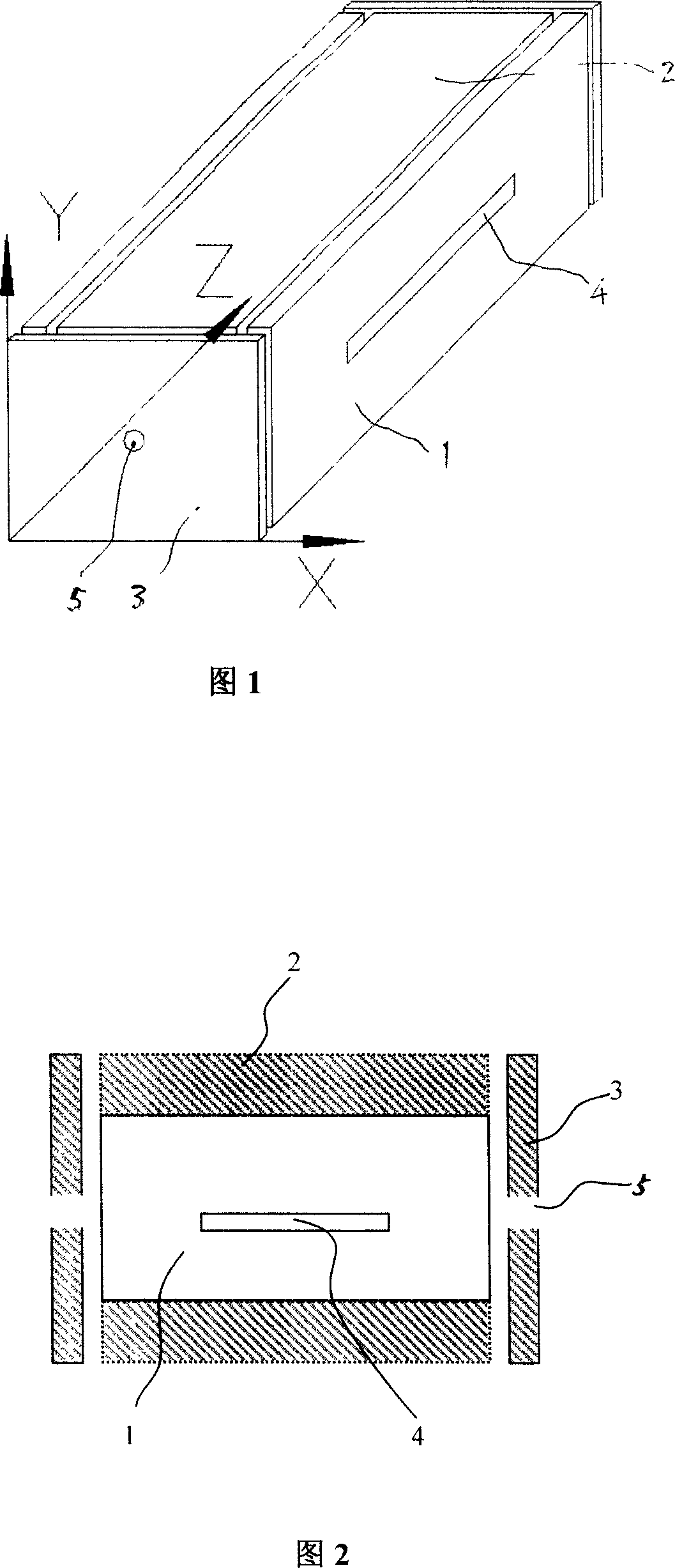

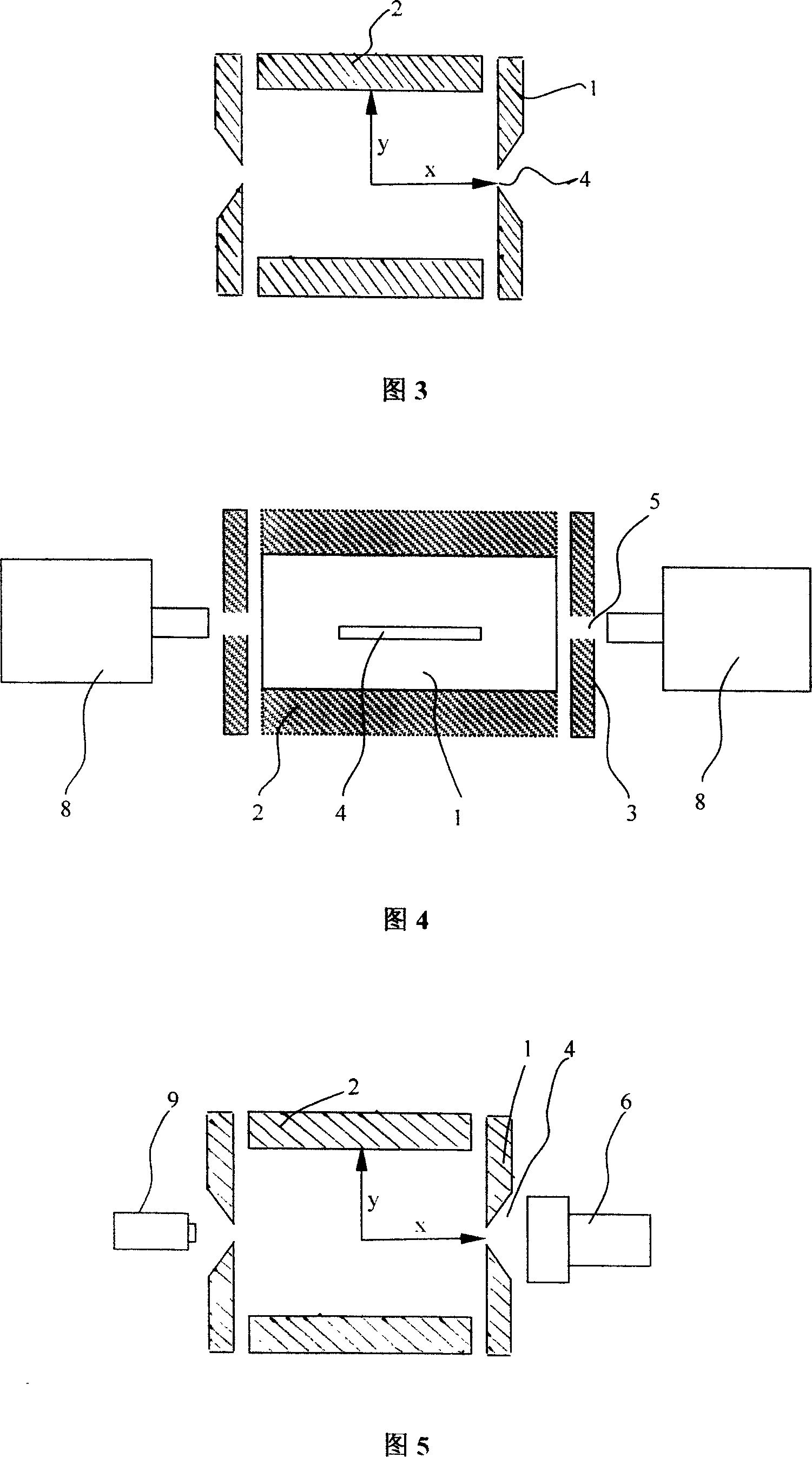

InactiveCN101017762ABroaden the field of applicationMaximize UtilizationIon sources/gunsStatic spectrometersElectric fieldIon trap mass spectrometry

The bi-ionic-source rectangular ion trap mass spectrometer comprises: an electric field of rectangular ion trap enclosed by x electrode (1), y electrode (2) and z electrode (3), a rectangular hole on x electrode, a circular hole (5) on z electrode center to inject ion, two ion sources (8) on end covers of mass analyzer; or when bombarding ion source (9) by inner-ionized electron, injecting electron and ion through hole (4) and (5) respectively. This invention increases device capability-price ratio, and benefit to deep research on molecular ion reaction mechanism.

Owner:JILIN UNIV

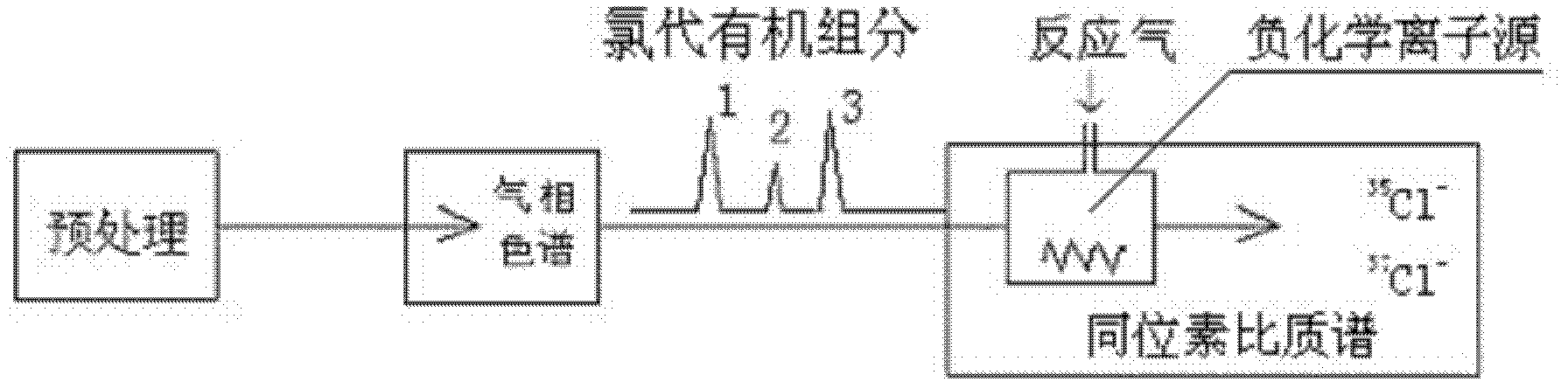

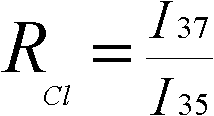

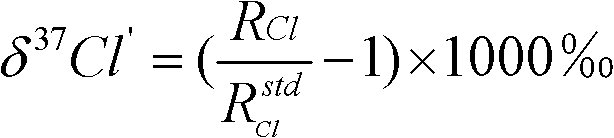

Method for online-analyzing organic monomer chlorine or bromine isotope and based on chemical ionization

InactiveCN102590379AAvoid separationSimplify the process of online analysisComponent separationMass numberGas phase

The invention aims at providing a method for online-analyzing organic monomer chlorine or bromine isotope, which adopts a direct negative chemical ionization to replace an original complex organic monomer conversion process. The method is characterized by including the steps: A. gathering chlorine or bromine substitute; B. separating gas chromatography: placing the gathered chlorine or bromine substitute into the gas chromatography to be separated; C. conducting negative chemical ionization: components analyzed through chromatography directly flow into a negative chemical ion source through acapillary column, the negative chemical ion source replaces an original electron bombardment source configured on an isotope ratio mass spectrum to conduct the negative chemical ionization; D. mass spectrometric detecting: on a gas isotope ratio mass spectrum, selecting a faraday receiving cup corresponding to mass number of chlorine or bromine substitute directly, and receiving electronegative isotope fragment ions generated by the negative chemical ionization. The process is conducted under high vacuum state, and degree of vacuum is higher than 1.0*10<-3> Pa. The method greatly simplifies aprocess of online-analyzing organic monomer chlorine or bromine isotope and can form various special devices for detecting organic monomer isotope ratio.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

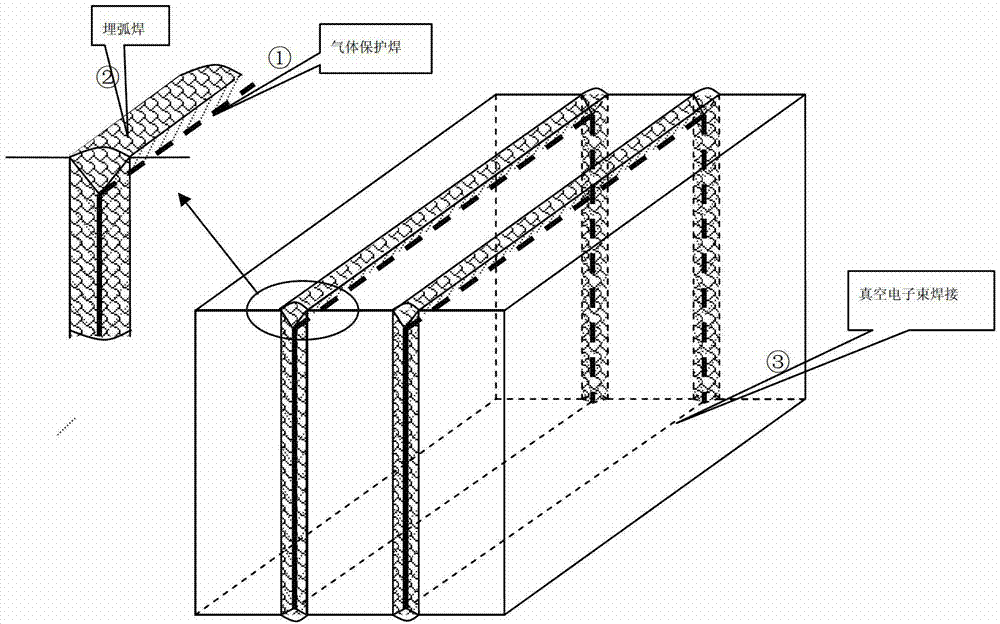

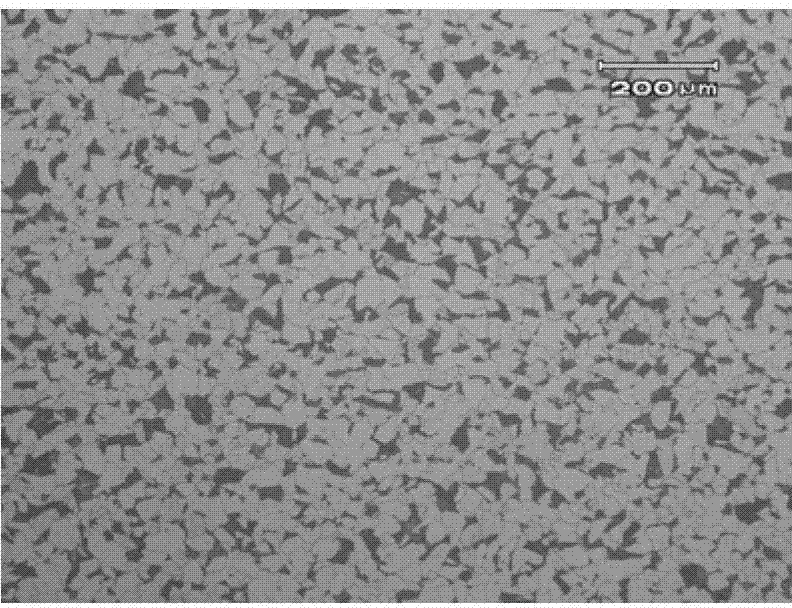

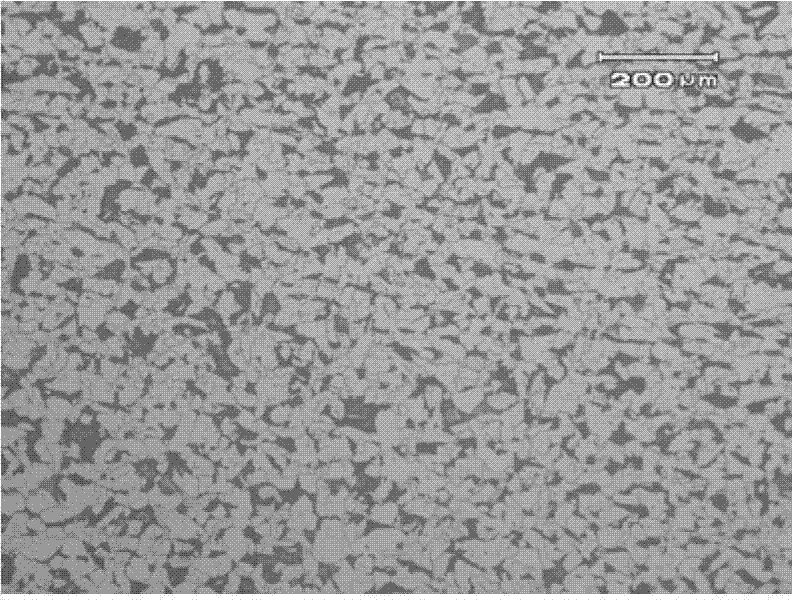

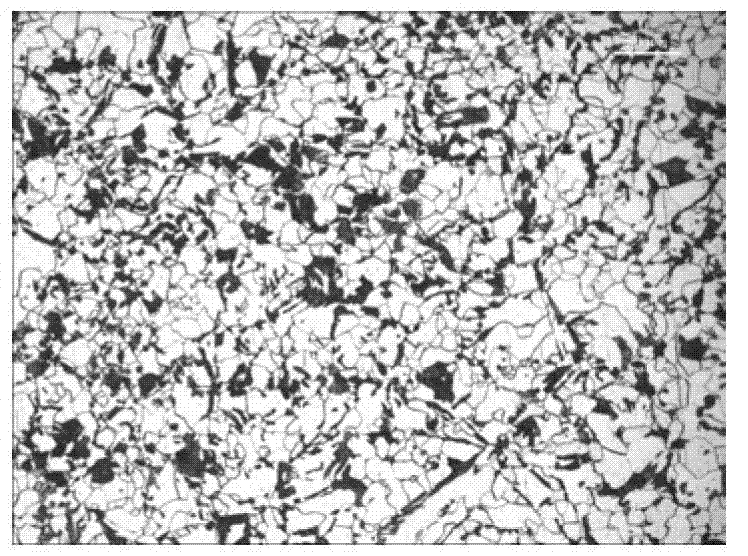

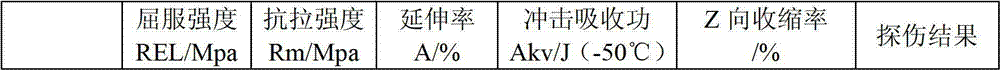

Big-thickness slab manufacturing technique

InactiveCN102764936AGuarantee the quality of joint surfaceOvercome costsWorkpiece edge portionsWelding apparatusEngineeringElectron bombardment

Owner:JIGANG GRP

Manufacturing technique of heavy piece-weight thick steel plate used for offshore wind turbine tower tube

InactiveCN102764962AHigh thermal insulation coefficientHeating evenlyWorkpiece edge portionsWelding apparatusElectricityThick plate

The invention discloses a manufacturing technique of a heavy piece-weight thick steel plate used for an offshore wind turbine tower tube. The chemical components of the used continuous casting slabs are as follows: 0.08-0.16% of C, 0.20-0.50% of Si, 1.10-1.60% of Mn, less than or equal to 0.010% of S, less than or equal to 0.010% of P and less than or equal to 0.50% of micro-alloyed elements; and at least two continuous casting slabs are provided with grooves, overlapped and welded into a big-thickness continuous casting blank by using a combined welding technique of gas shielded welding, submerged-arc welding and electron-bombardment welding, and then, the blank is arranged in a bogie-type furnace or a soaking pit furnace for heating, rolled by a thick plate rolling machine after being discharged from the furnace, cooled under control and subjected to heat treatment so as to obtain the heavy piece-weight thick steel plate used for the offshore wind turbine tower tube. The technique has the following characteristics that the maximum piece weight of the steel plate used for the offshore wind turbine tower tube is 40t, the requirement of reducing welding lines in the tower tube manufacturing process is satisfied, the manufacturing technique is simple in production process, high in yield, high in ultrasonic flaw detection rate of more than 98% and excellent in each factor such as low-temperature roughness, Z-direction performance and the like.

Owner:JIGANG GRP

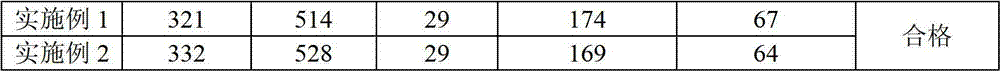

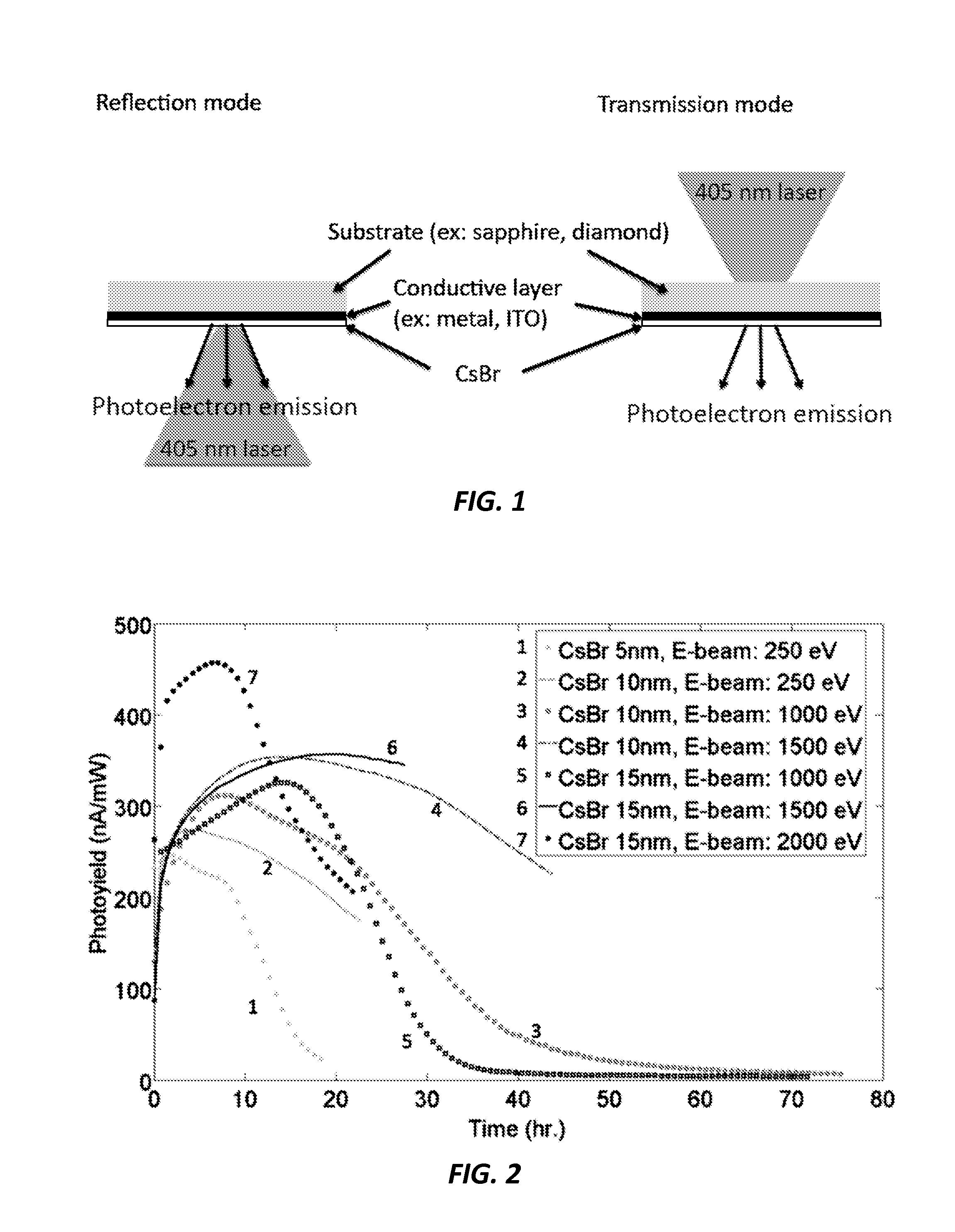

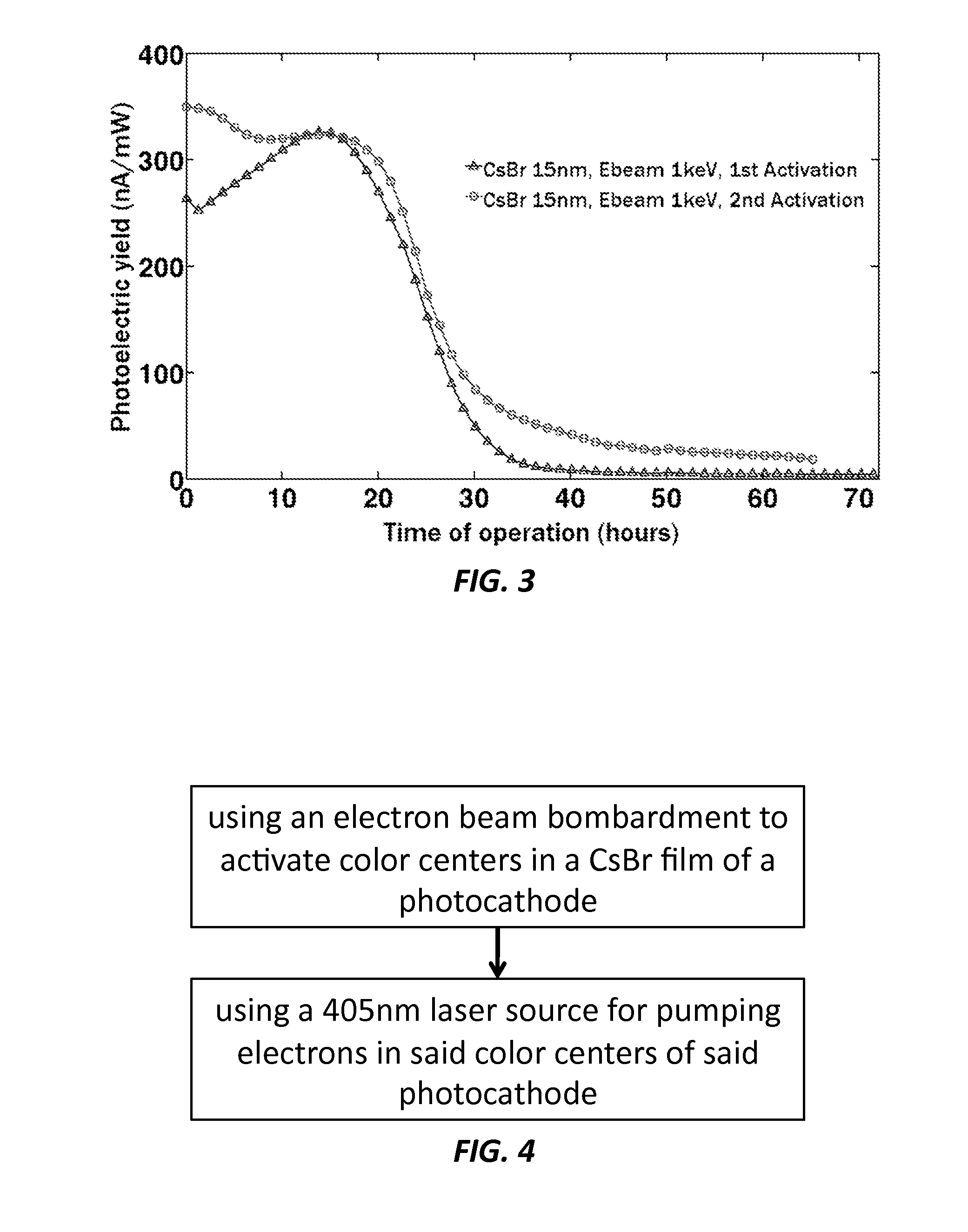

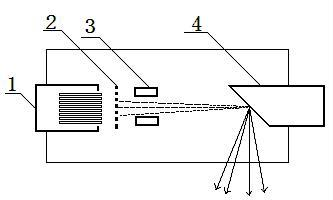

Enhanced photoelectron sources using electron bombardment

ActiveUS20140265828A1Improve quantum efficiencyExtended photocathode lifetimeElectrode and associated part arrangementsPhotoelectric discharge tubesQuantum efficiencyElectron source

A method of achieving heightened quantum efficiencies and extended photocathode lifetimes is provided that includes using an electron beam bombardment to activate color centers in a CsBr film of a photocathode, and using a laser source for pumping electrons in the color centers of the photocathode.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Multi-focal fixed anode X-ray tube based on field emission cathode

InactiveCN102543635AIncrease the number of projection anglesEasy to implementX-ray tube electrodesCathode ray concentrating/focusing/directingCt scannersX-ray

The invention discloses a multi-focal fixed anode X-ray tube based on a field emission cathode. The multi-focal fixed anode X-ray tube comprises the field emission cathode based on a nano-tube material, a gate for controlling the X-ray tube to work, a focusing electrode for controlling an electron beam to focus and an anode for receiving X photons generated by electron bombardment, as well as a pair of deflection electrodes for loading voltage to form a deflecting electric field, wherein the pair of the deflection electrodes is arranged between the field emission cathode and the anode, and the gate works in a pulse way. The multi-focal fixed anode X-ray tube based on the field emission cathode, disclosed by the invention, can possess more than one focal point, so that the number of projection angles, which can be provided by the single X-ray tube, can be significantly increased, the demand of a static CT (computerized tomography) scanner on the number of the X-ray tubes of the field emission cathode can be further reduced, and the static CT scanner is easier for engineering implementation.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH

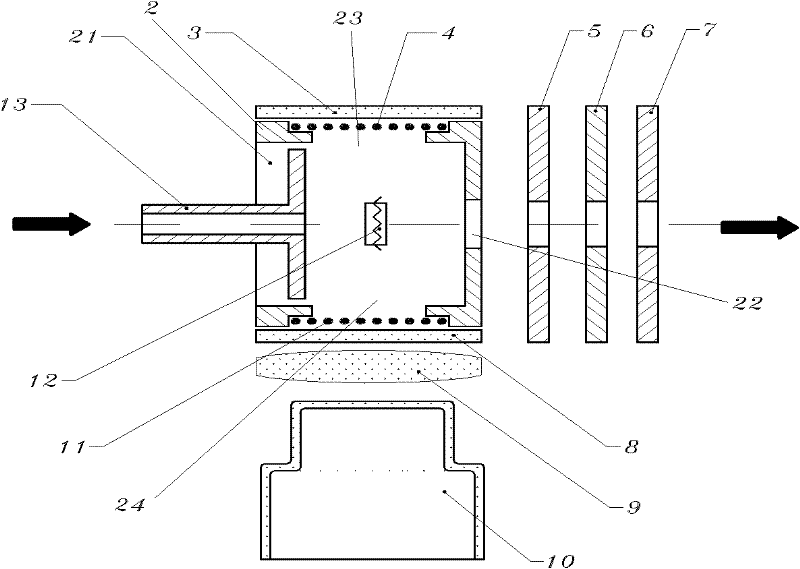

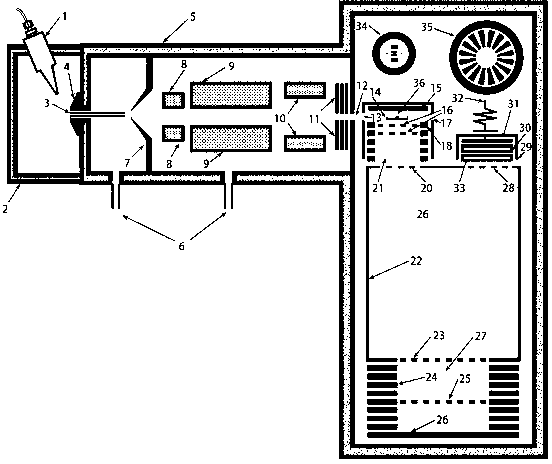

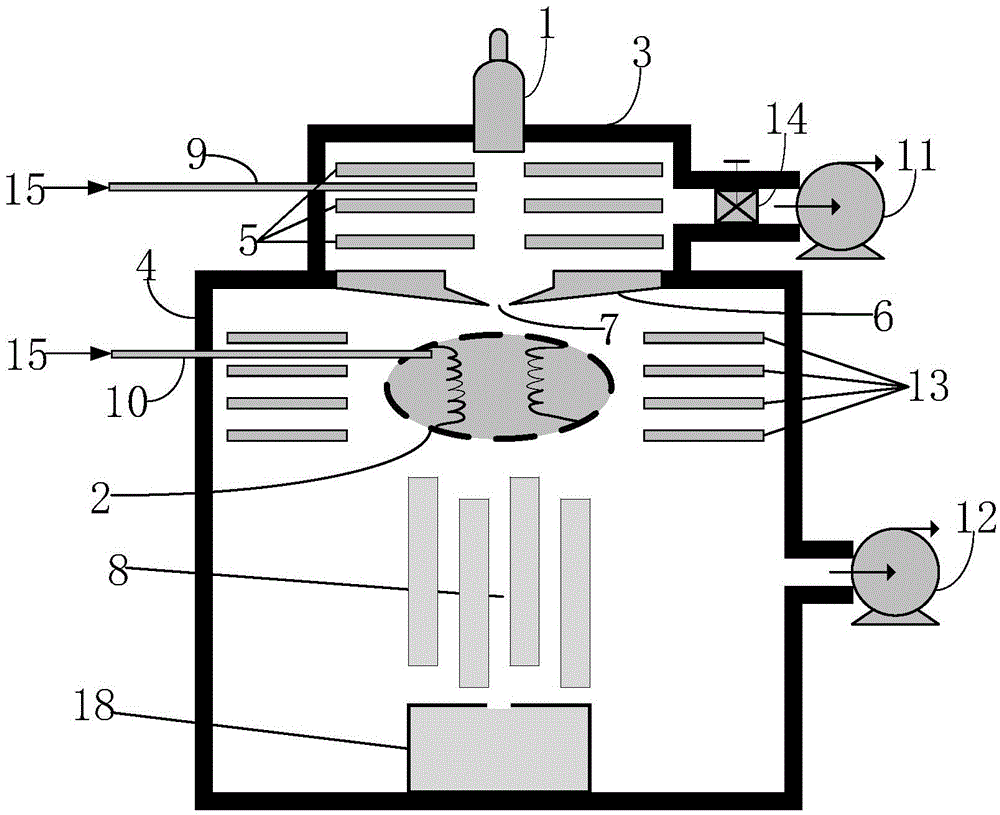

Vertical interactive electron bombardment electron spray ion source-flight time mass spectrograph

InactiveCN102800555AImprove utilization efficiencyImprove practicalityTime-of-flight spectrometersParticle separator tube detailsSpectrographElectron bombardment

A vertical interactive electron bombardment electron spray ion source-flight time mass spectrograph is characterized in that the vertical interactive electron bombardment electron spray ion source-flight time mass spectrograph comprises an electron bombardment ion source, an electron spray ion source and a two-way vertical lead-in type flight time mass analyzer; and the electron bombardment ion source, the electron spray ion source and the two-way vertical lead-in type flight time mass analyzer are perpendicular to each other. The vertical interactive electron bombardment electron spray ion source-flight time mass spectrograph can achieve automatic switching between three working modes of an electron bombardment-flight time mode, an electron spray-flight time mode and an electron bombardment electron spray-flight time mode. Vacuum accessories such as multi-stage vacuum cavities, preceding stage mechanical pumps and turbo-molecular pumps and the like are arranged on the vertical interactive electron bombardment electron spray ion source-flight time mass spectrograph, so as to ensure the high vacuum degree that is needed when relevant parts of the electron bombardment ion source operate normally. The vertical interactive electron bombardment electron spray ion source-flight time mass spectrograph combines the electron bombardment ion source capable of ionizing gaseous samples, the electron spray ion source capable of ionizing liquid samples and vertical lead-in type flight time mass analyzer in an extension manner, and improves the utilization efficiency and the practical performance of the flight time mass analyzer.

Owner:王利兵

Installation and method for sterilising objects by low-energy electron bombardment

InactiveUS7459706B2Low costReduced space requirementsMaterial analysis using wave/particle radiationElectric discharge tubesElectron bombardmentAtomic physics

Owner:LINAC TECH

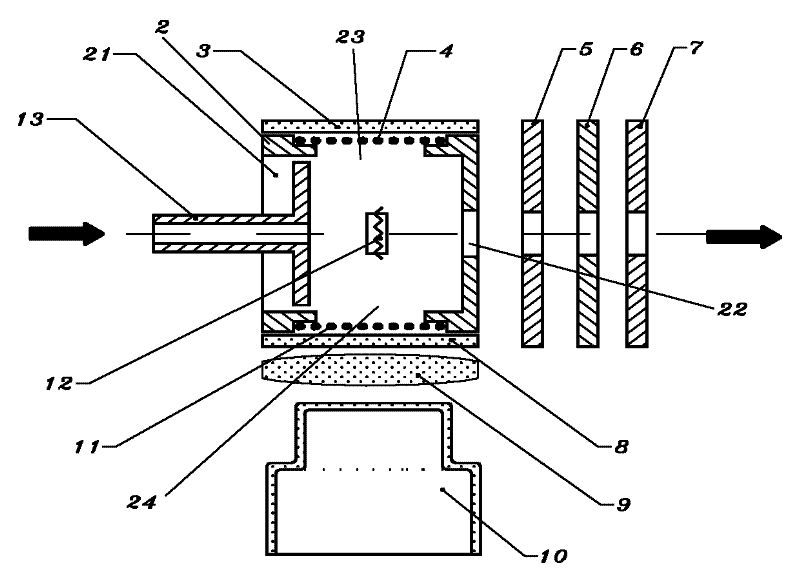

Double-ionization ion source

InactiveCN103594326AImprove applicabilityImprove quality optionsIon sources/gunsGrounding gridIonization chamber

The invention provides a double-ionization ion source which is composed of electron bombardment ionization (an EI source) and vacuum ultraviolet lamp ionization (a PI source). According to the structure, the double-ionization ion source comprises a sample feeding tube, a repelling electrode, an ionization chamber, a filament, an ultraviolet lamp, a lead-out electrode, a focusing electrode, an emitting electrode, a repelling board and a grounding grid board. According to the double-ionization ion source, the applicability is broadened when polymorphic samples are analyzed by a single ion source, quality selection of fragment ions is improved, and the ion composition and a sample structure can be effectively analyzed.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

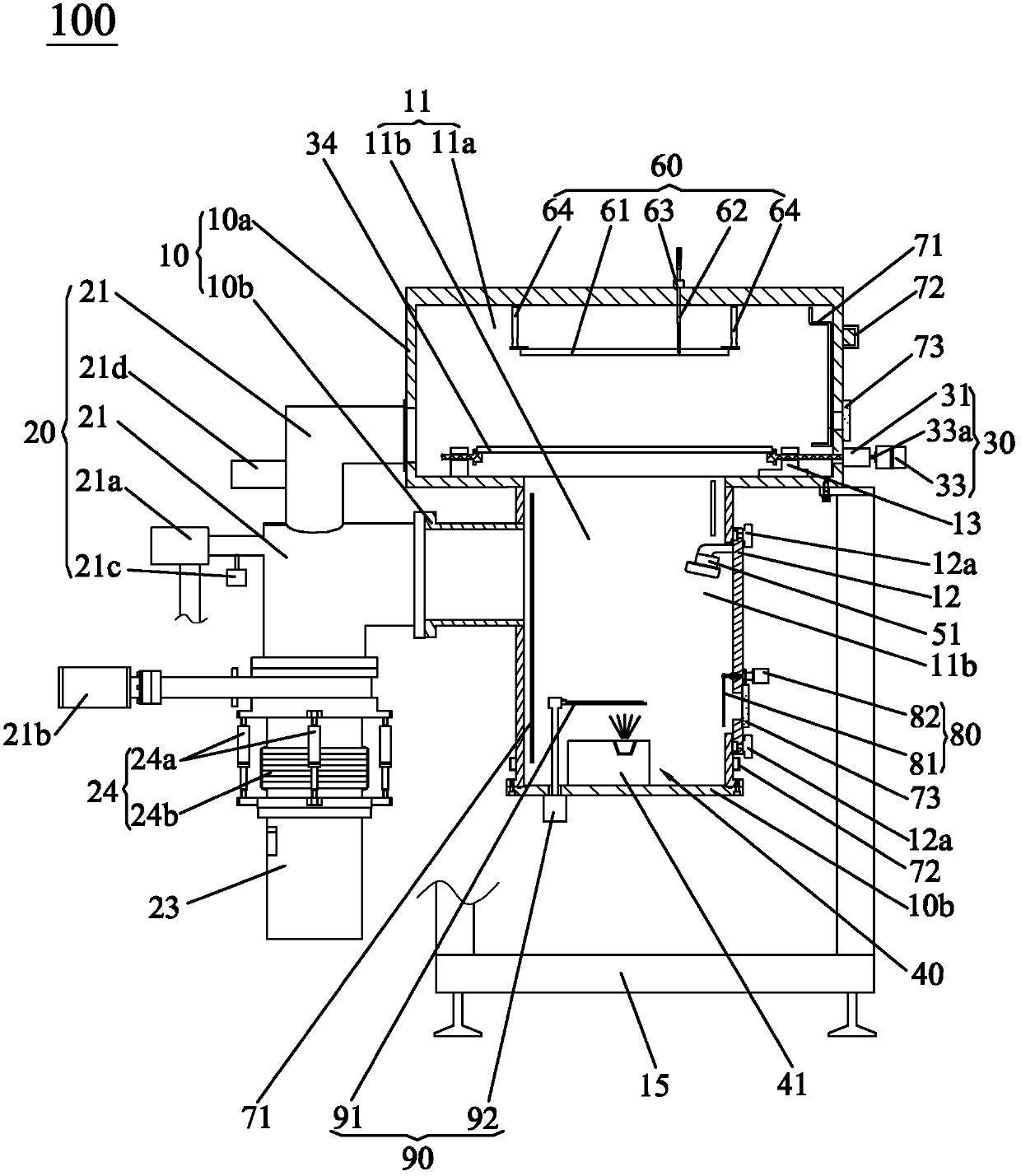

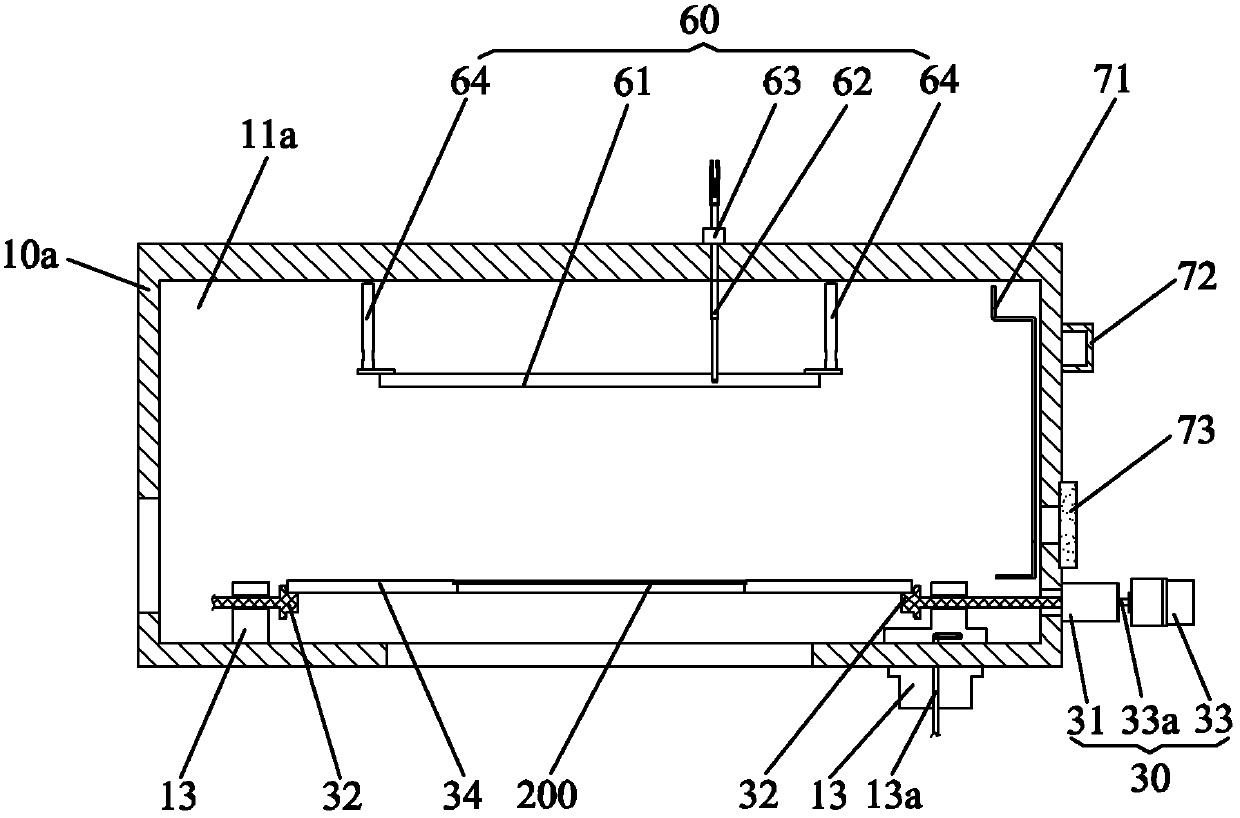

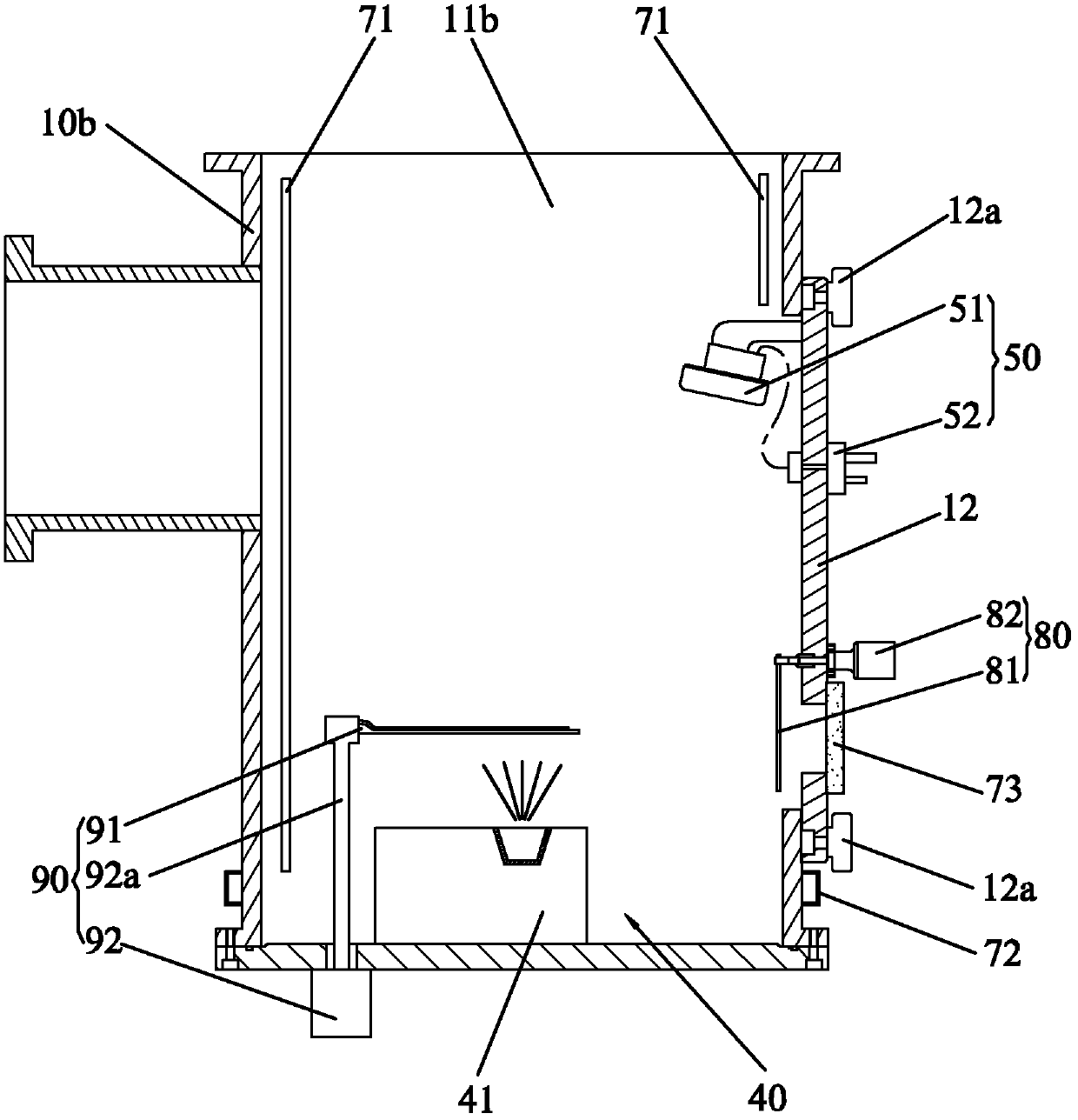

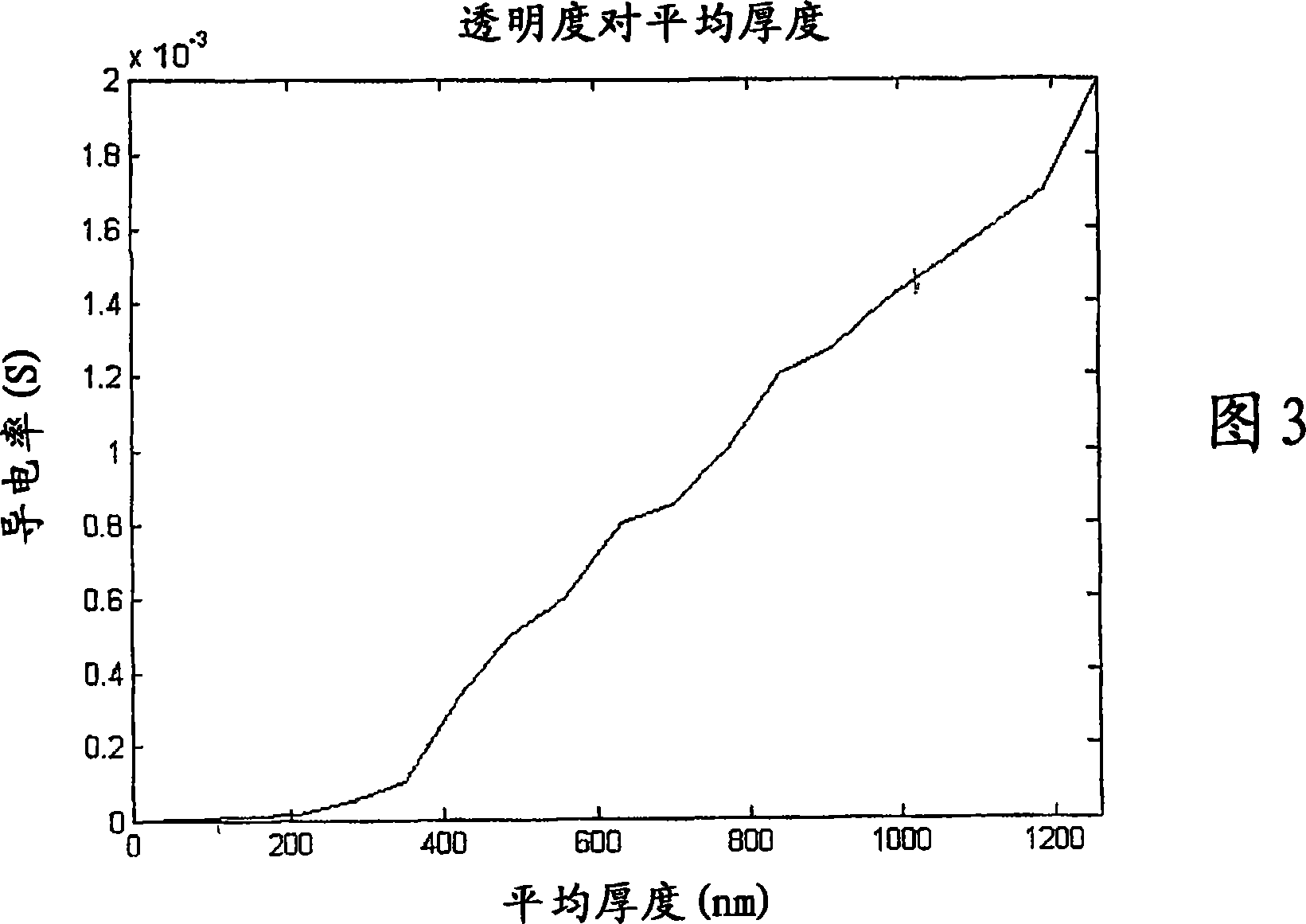

Electron bombardment coating machine

InactiveCN102703867AImprove thermal efficiencyLow thermal conductivityVacuum evaporation coatingSputtering coatingEvaporationElectron bombardment

The invention discloses an electron bombardment coating machine which comprises a cavity, an evacuating device, a substrate conveying device, an evaporation source device, a coating thickness monitoring unit and a controller. The cavity is provided with a vacuum cavity communicated with the evacuating device. The substrate conveying device is used for conveying substrates between the outside and the vacuum cavity. The evaporation source device located inside the vacuum cavity below the substrate inside the vacuum cavity comprises a body, an electron gun, deflecting electrodes and an evaporation source carrier. The electron gun and the evaporation source carrier are respectively arranged in the body of the evaporation source device. The deflecting electrodes are located between the electron gun and the evaporation source carrier. The top of the body is provided with an electron gun ejection outlet and a sputtering opening. The coating thickness monitoring unit comprises a coating thickness monitor which is located inside the vacuum cavity and between the evaporation source device and one substrate. The controller is respectively electrically connected with the evacuating device, the electron gun, the deflecting electrodes, the substrate conveying device and the coating thickness monitor. By the electron bombardment coating machine, evaporating efficiency and material utilization rate can be improved to meet the requirement for automation.

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD

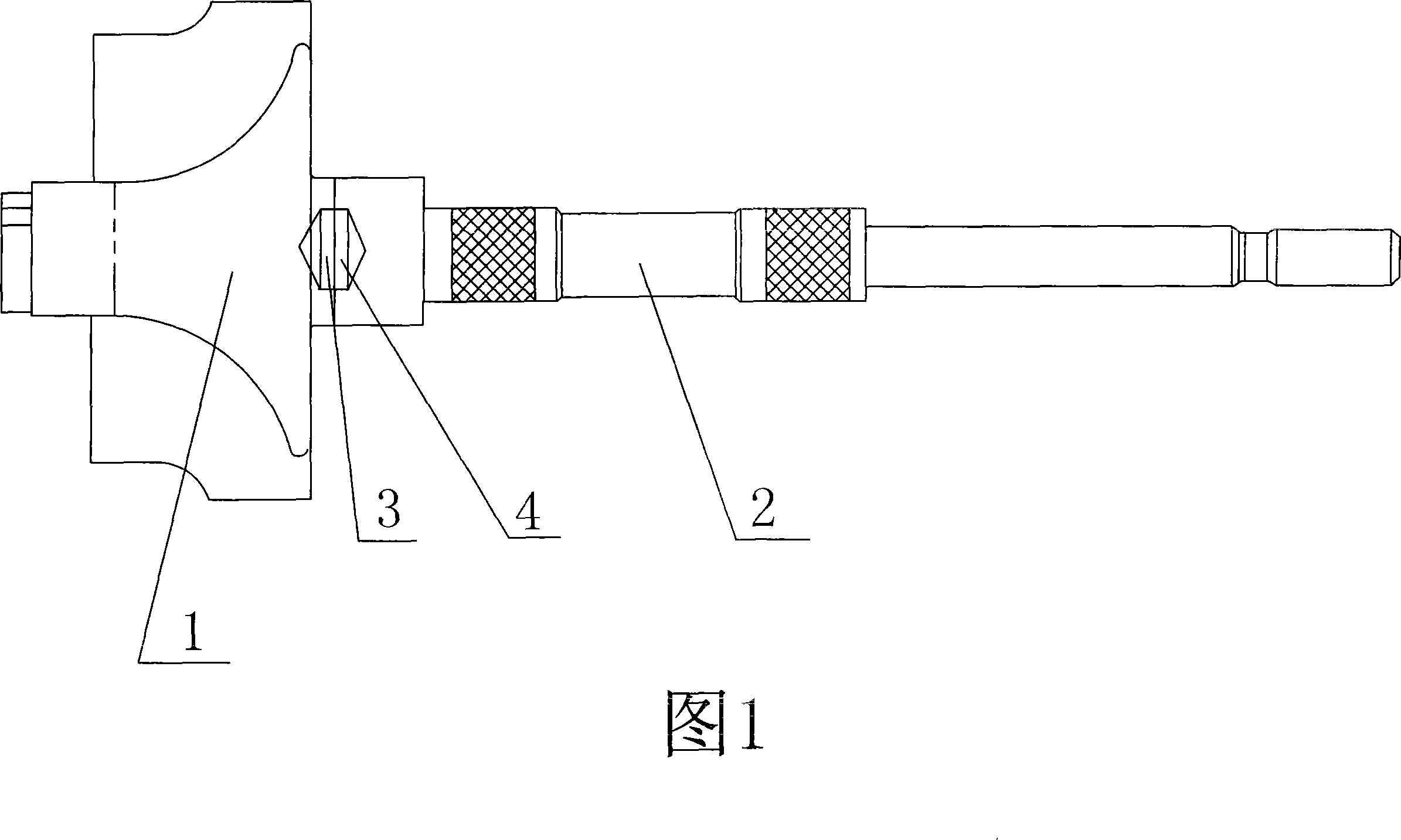

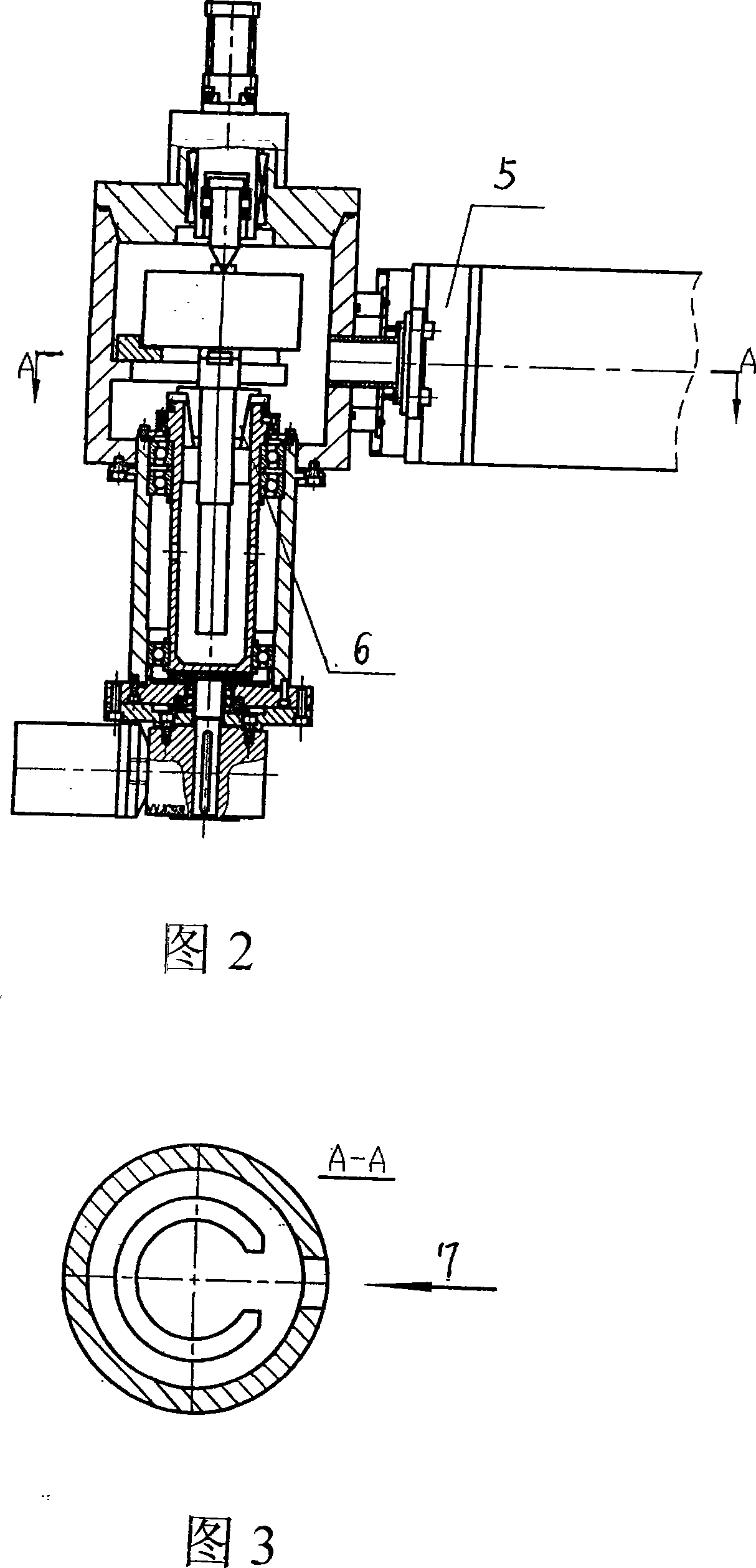

Electron bombardment welding turbine shaft, and producing technique

InactiveCN101092882AImprove stabilityIncrease profitBlade accessoriesMachines/enginesTurbine bladeEngineering

This invention relates to a technology for welding turbine shafts with vacuum electronic beams, in which a hole of 1-2mm deep is set at the center of a turbine welding end face and a hole of 1-2mm deep is set correspondingly at the center of a turbine shaft end face and concentricity of the two is kept by a special tool to keep the welding end faces parallel and connected fixedly by vacuum electronic beam welding. The method includes: processing a turbine welding end face and setting a hole of 1-2mm deep at the center, processing a shaft welding end face and setting a hole of 1-2mm deep correspondingly at the center to fixedly connect them by vacuum electronic beam welding. Advantages: tensile strength of the welding is greater than original material, high usability of materials, mechanical process stress is small and shaft stability is good.

Owner:刘天成

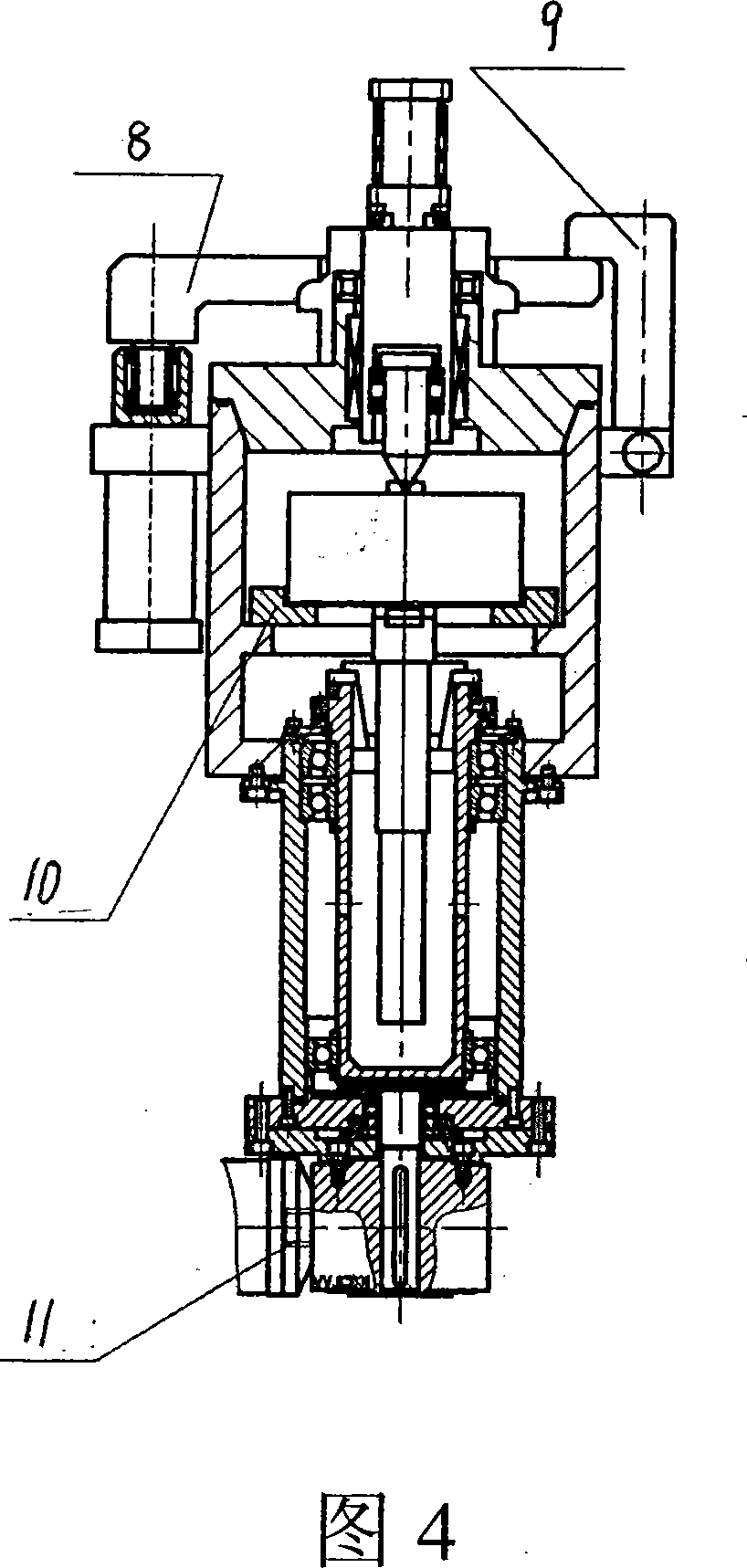

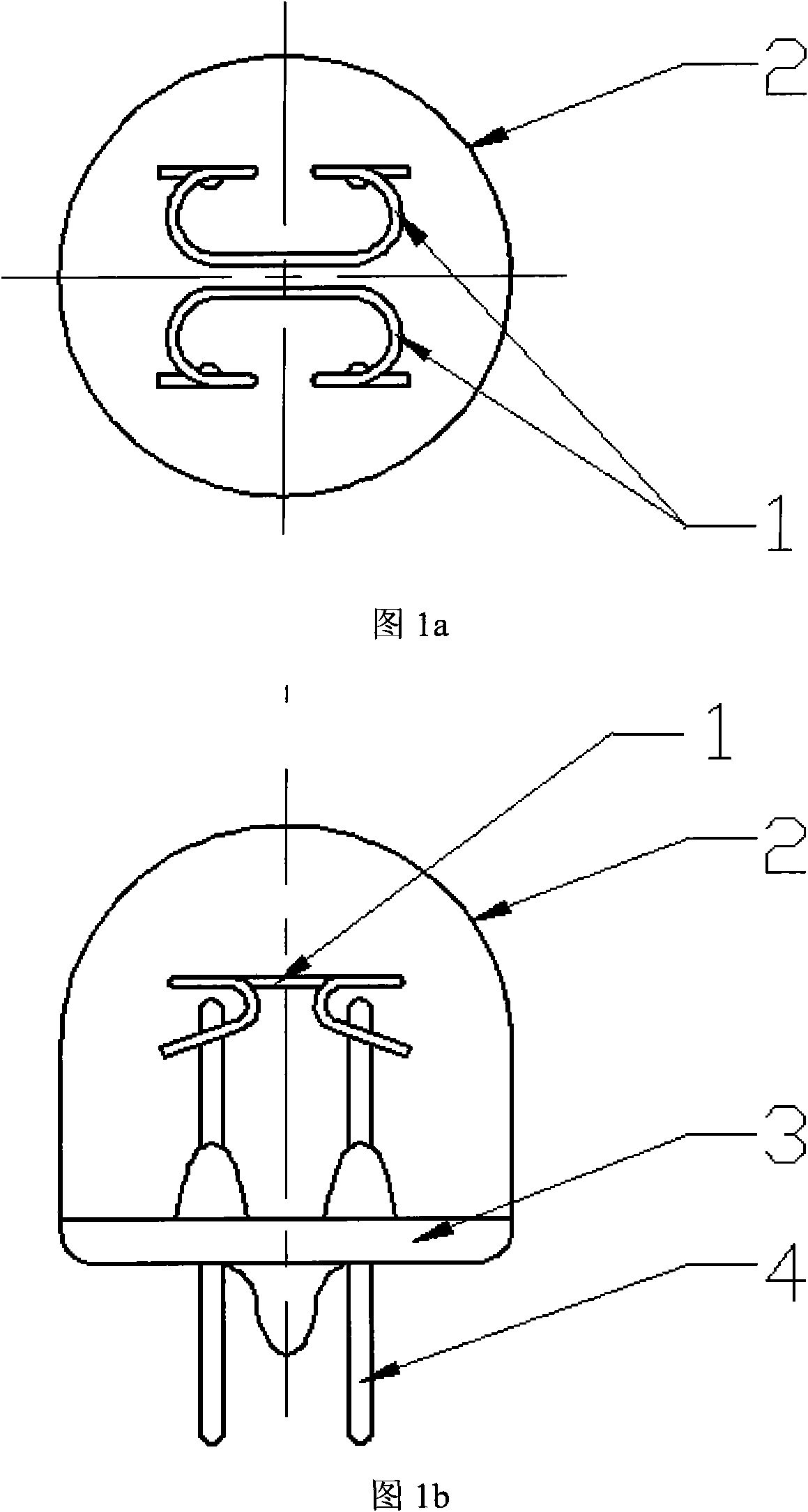

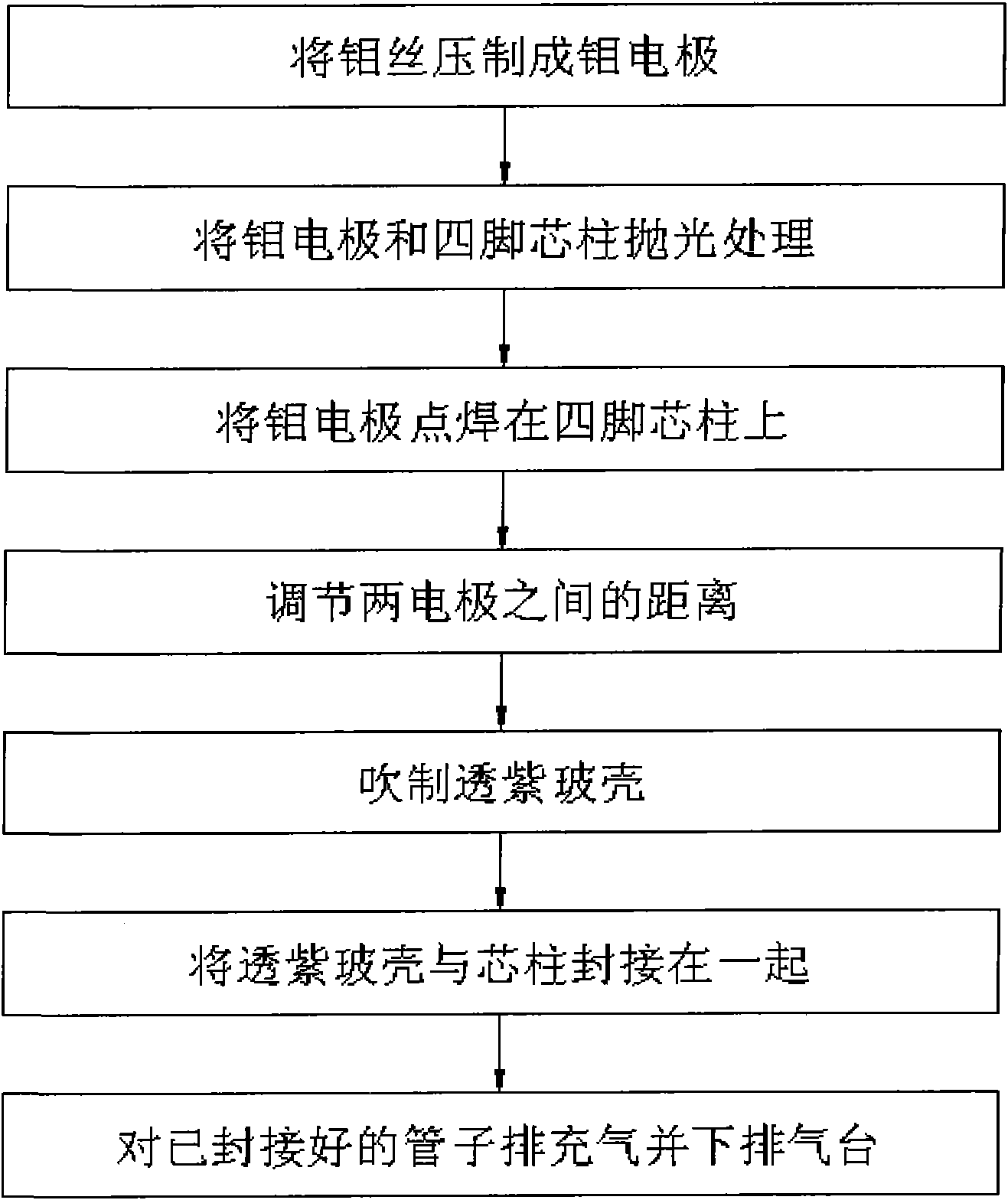

High-temperature solar blind ultraviolet photoelectric tube and manufacturing method thereof

InactiveCN102034667AHigh sensitivitySolution to short lifeTube/lamp vessel degassingPhotoelectric discharge tubesInfraredUltraviolet

The invention discloses a high-temperature solar blind ultraviolet photoelectric tube and a manufacturing method thereof. The photoelectric tube comprises a core column, a molybdenum group purple glass permeable shell, a metal straight rod and a molybdenum electrode, wherein the molybdenum group purple glass permeable shell is encapsulated on the core column; the metal straight rod is arranged in the core column; and the molybdenum electrode is connected to the metal straight rod. When the high-temperature solar blind ultraviolet photoelectric tube exhausts air, the molybdenum group purple glass permeable shell is baked at high temperature for a long time and the molybdenum electrode is treated by an electron bombardment method. The photoelectric tube has the advantages of high sensitivity, high reliability, long service life, high response speed, high temperature resistance, no response to visible light and infrared light, light weight and the like.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

Method for analyzing short-chain chlorinated paraffin in environment sample by comprehensive two-dimensional gas chromatography-flight time mass spectrometry

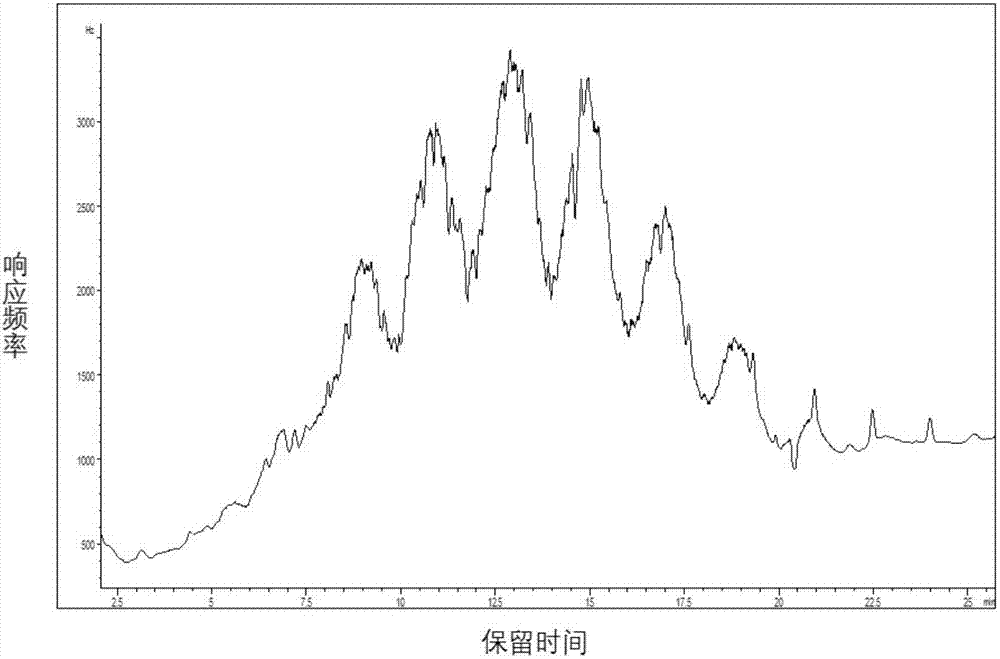

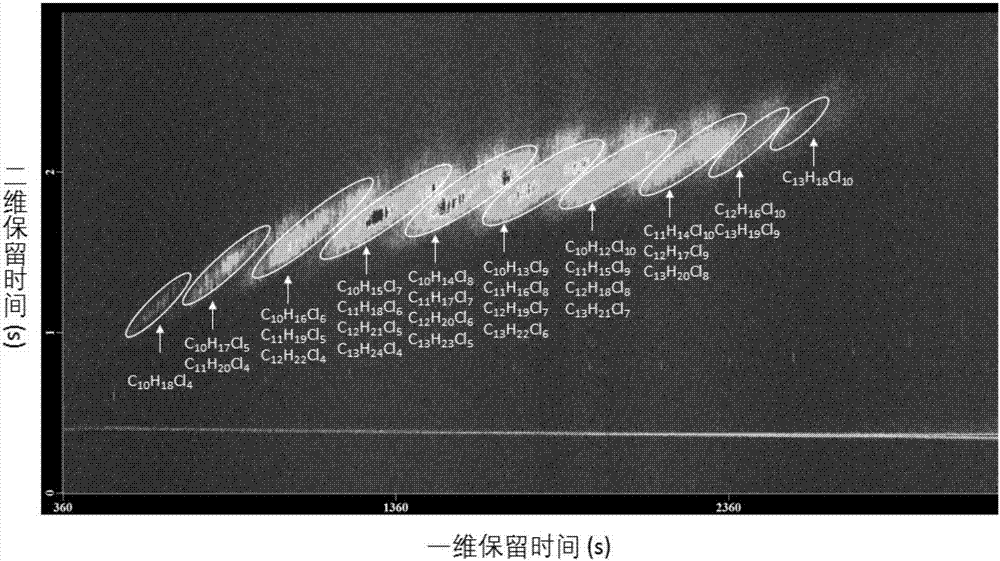

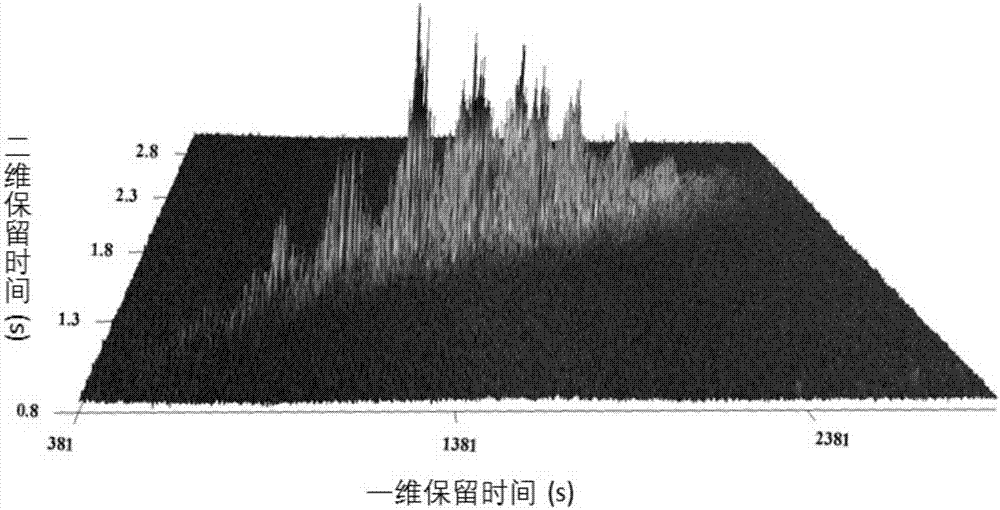

ActiveCN107884493AImprove stabilityImprove purification effectComponent separationApplicability domainRetention time

The invention discloses a method for analyzing short-chain chlorinated paraffin in an environment sample by a comprehensive two-dimensional gas chromatography-flight time mass spectrometry, which belongs to the technical field of analytical testing. The method comprises the following steps: 1) performing enrichment extraction on SCCPs in the environment sample; 2) employing a comprehensive two-dimensional gas chromatography-electron bombardment ionization source-low resolution time-of-flight mass spectrometer for detection; 3) employing library searching and a retention time index for determining the nature of the SCCPs component in the sample; and 4) employing an internal standard curve method for determining total amount of SCCPs. The pre-treatment method has the advantages of high extraction efficiency, good purifying effect, and wide application scope; the used apparatus has the advantages of high analysis efficiency, good separating effect, and strong anti-interference capability;the qualitative method is fast and accurate, and does not depend on a standard substance; the quantification method has the advantages of low detecting limit, low sensitivity, wide linearity range, and good repeatability, and the analysis requirement of SCCPs in the practical environment sample can be satisfied.

Owner:NAT RESERACH CENT OF GEOANALYSIS

Double-ion-source quadrupole mass spectrometer based on single-photon ionization and electron bombardment ionization

InactiveCN105632877AEnhanced ability to analyze substancesStability-of-path spectrometersIon sources/gunsElectron bombardmentQuadrupole

The invention discloses a double-ion-source quadrupole mass spectrometer based on single-photon ionization and electron bombardment ionization, and particularly relates to a quadrupole mass spectrometer which can flexibly switch ionization modes according to physical and chemical properties of an analyzed sample. The quadrupole mass spectrometer comprises the components of a single-photon ionization source, an electron bombardment ionization source, an ionization transmission region chamber, a quadrupole mass analyzer chamber, a focusing lens set A, a focusing lens set B, a differential interface pole plate, a differential interface small hole, a sample inlet capillary A, a sample inlet capillary B, a quadrupole mass analyzer, a detector, a side suction valve, a vacuum pump A and a vacuum pump B.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

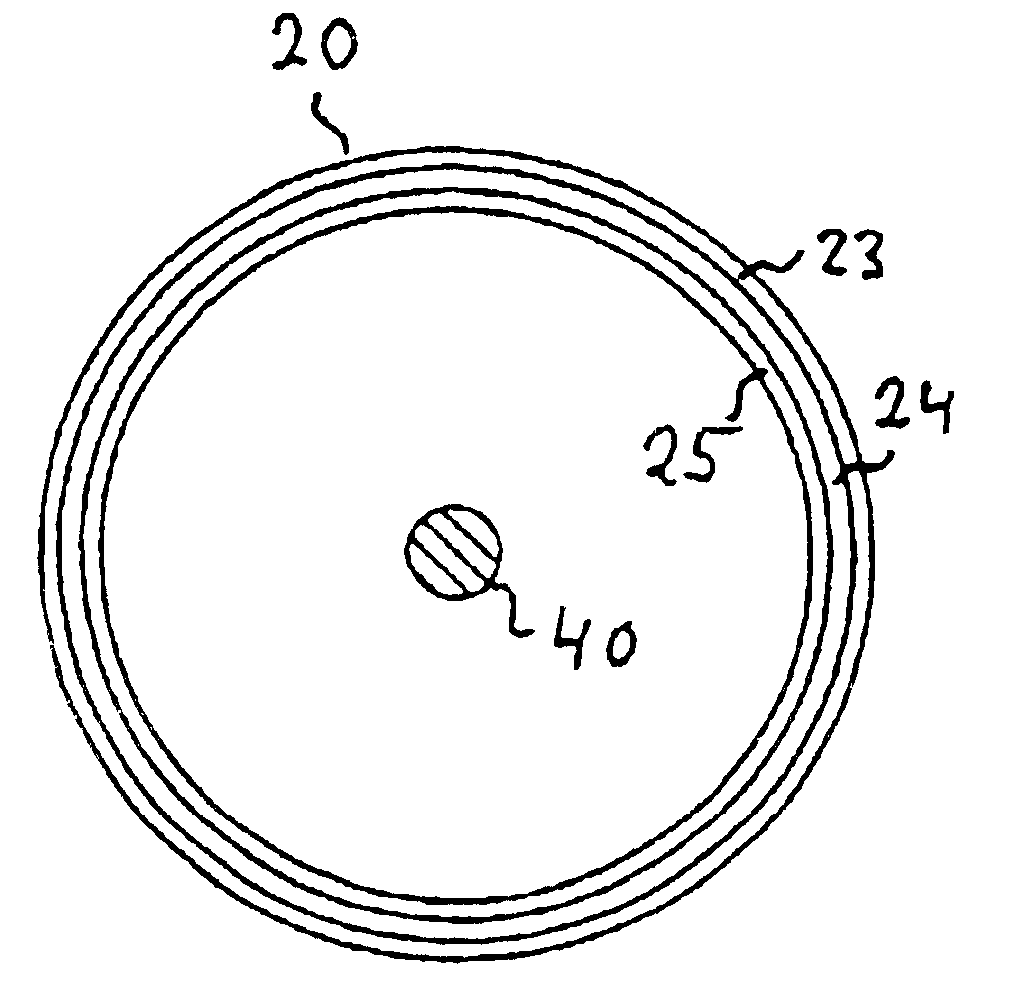

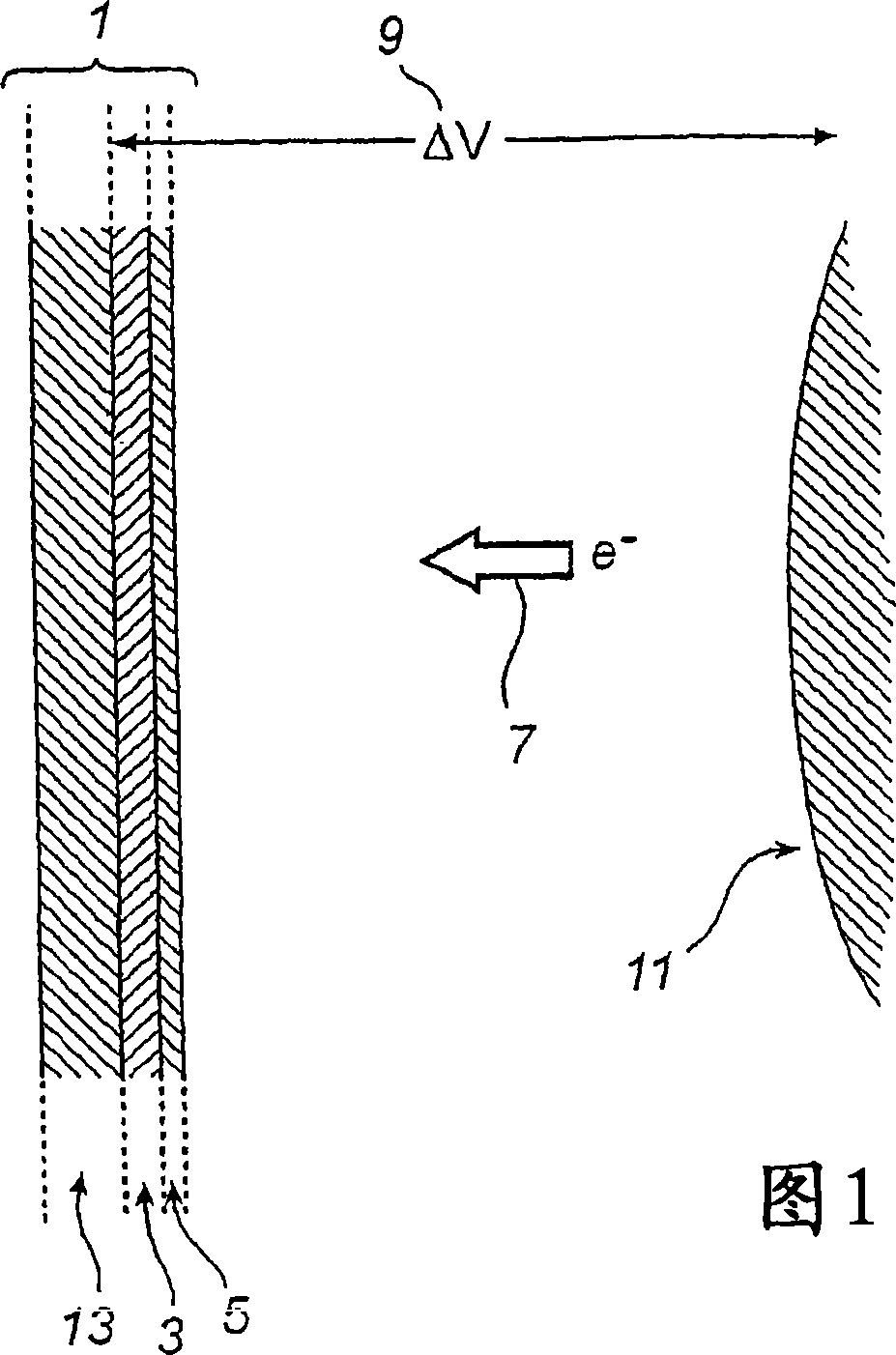

An anode in a field emission light source and a field emission light source comprising the anode

An anode (1) in a field emission light source (15) is disclosed. The anode (1) comprises an electrically conductive layer (3) and a luminescent layer (5) that is luminescent when excited by electron bombardment (7) caused by a potential difference (9) between the electrically conductive layer (3) and a cathode (11). Key features are that the luminescent layer (5) is arranged between the electrically conductive layer (3) and the cathode (11) and that the electrically conductive layer (3) is a transparent electrically conducting layer (3). Further, a field emission light source (15) comprising the anode (1) is also disclosed.

Owner:LIGHTLAB SWEDEN AB

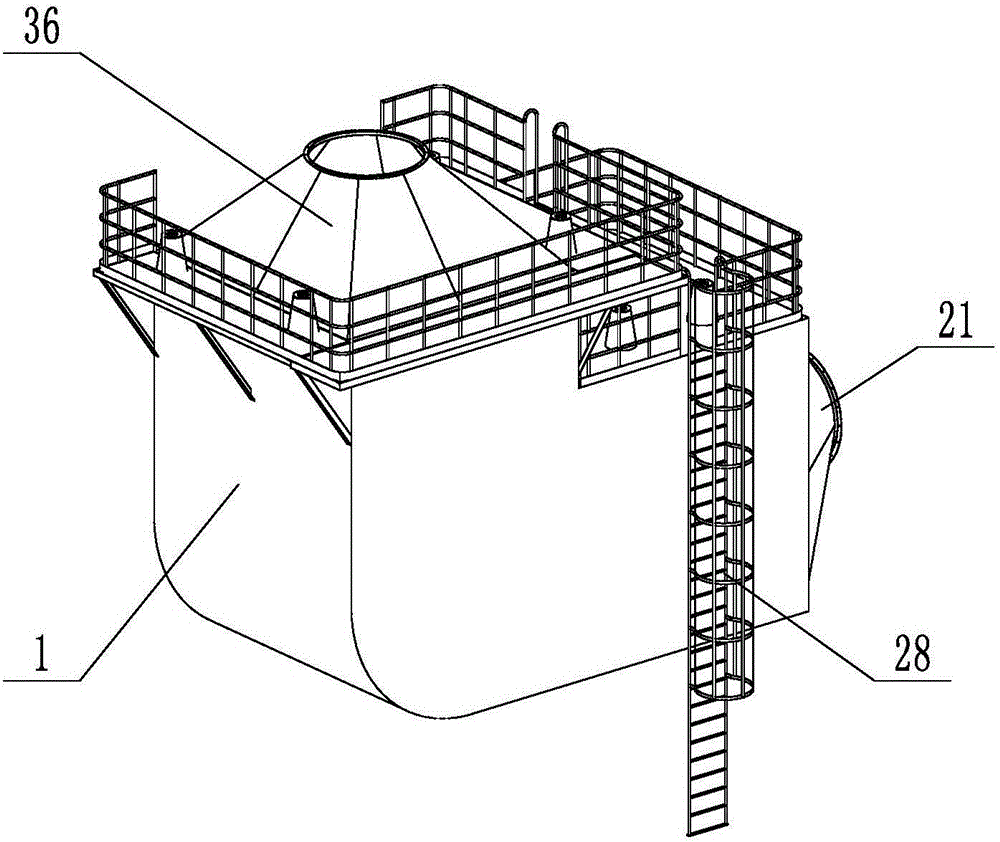

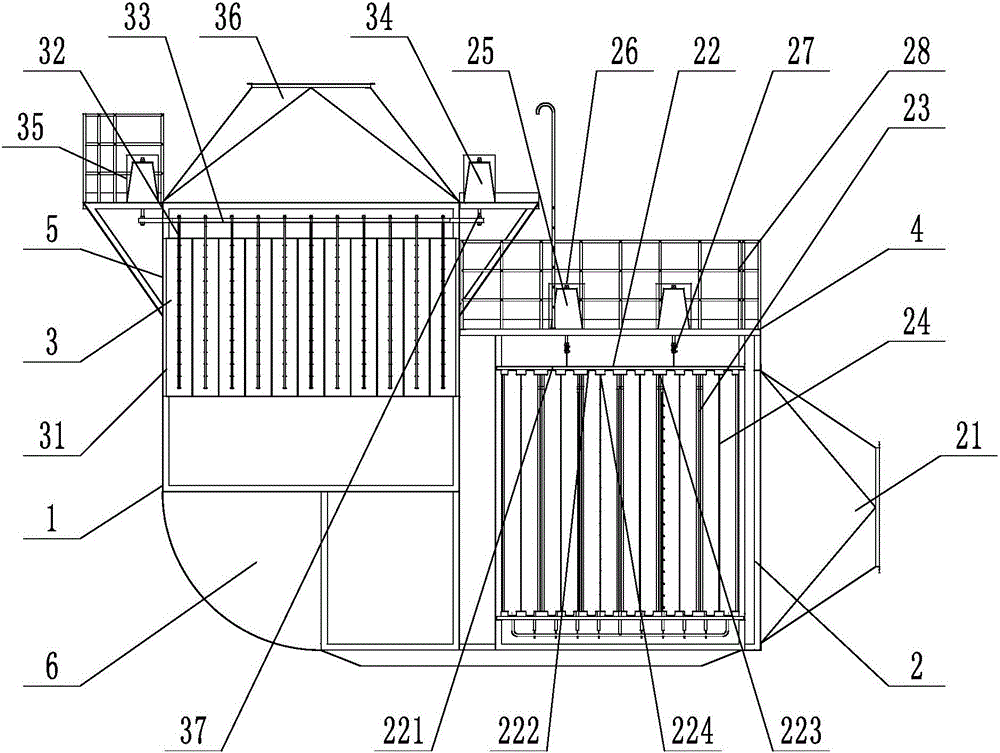

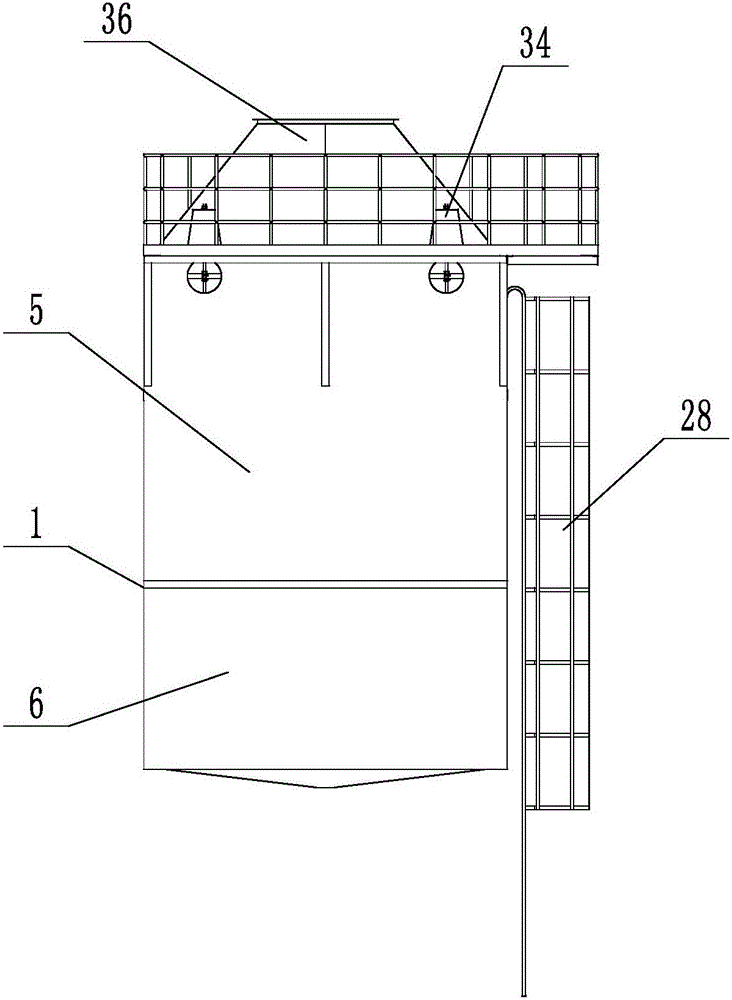

Low-temperature plasma waste gas purification device

PendingCN106582221AMeet processing needsLarge air volumeGas treatmentDispersed particle separationHigh concentrationDielectric

The invention discloses a low-temperature plasma waste gas purification device. The device comprises a shell, a dust removal system and an odor removal system. The device is characterized in that the shell is divided into a transverse shell and a longitudinal shell; the transverse shell is connected with the longitudinal shell through an arc-shaped shell; the dust removal system is mounted in the transverse shell; and the odor removal system is mounted in the longitudinal shell. Due to the adoption of the technical scheme, under the effect of an external electric field, a large amount of electron bombardment pollutant molecules generated by dielectric discharge are ionized, dissociated and excited, then a series of complex physical and chemical reactions are caused, and complex macromolecular pollutants are transformed into simple micromolecular safe substances, or toxic and harmful substances are transformed into nontoxic harmless or low-toxic low-harm substances, so that the pollutants are degraded and removed; and treatment demands of large-air-volume and high-concentration waste gas generated by large industrial production can be met.

Owner:山东艾派仕环境科技有限公司

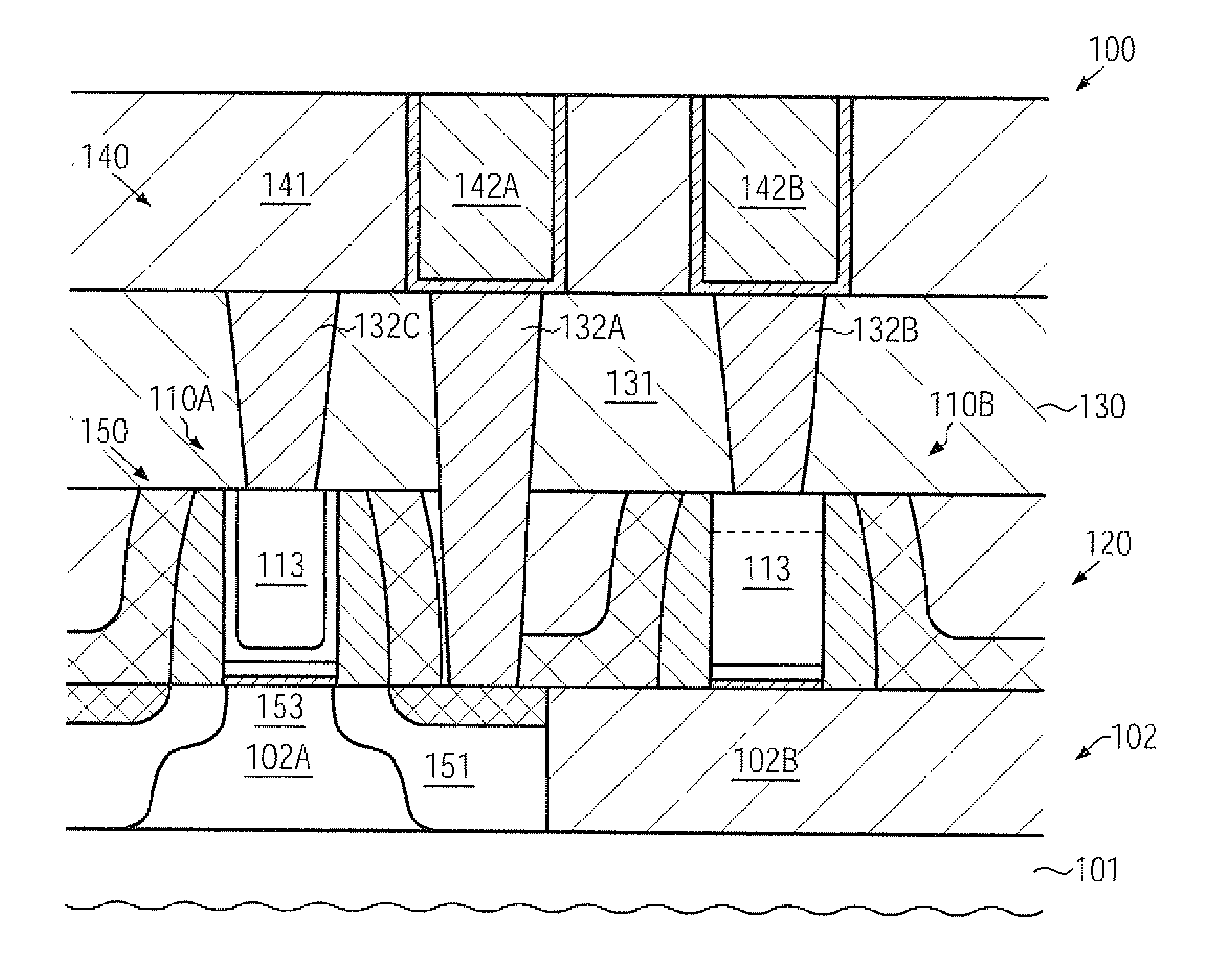

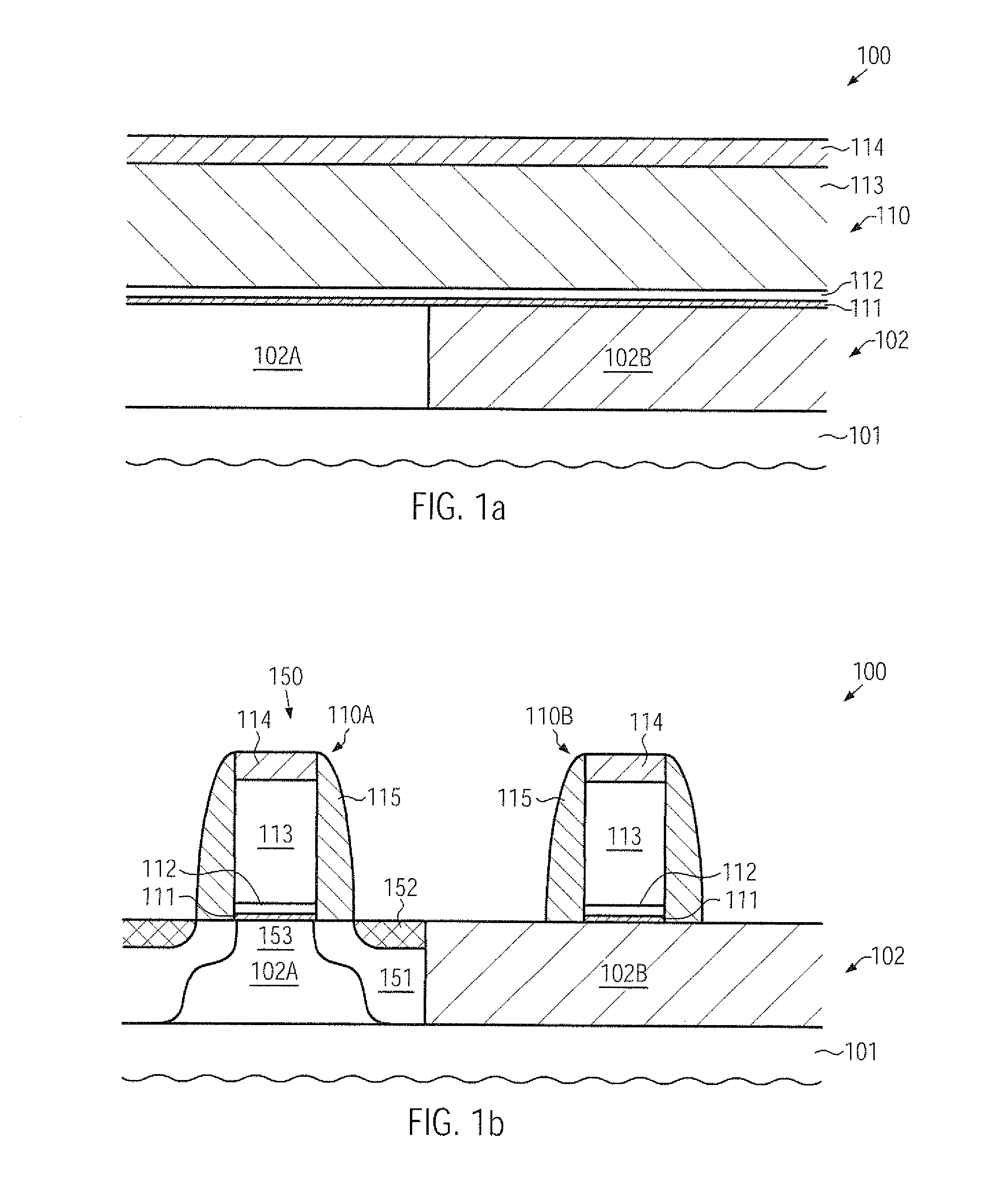

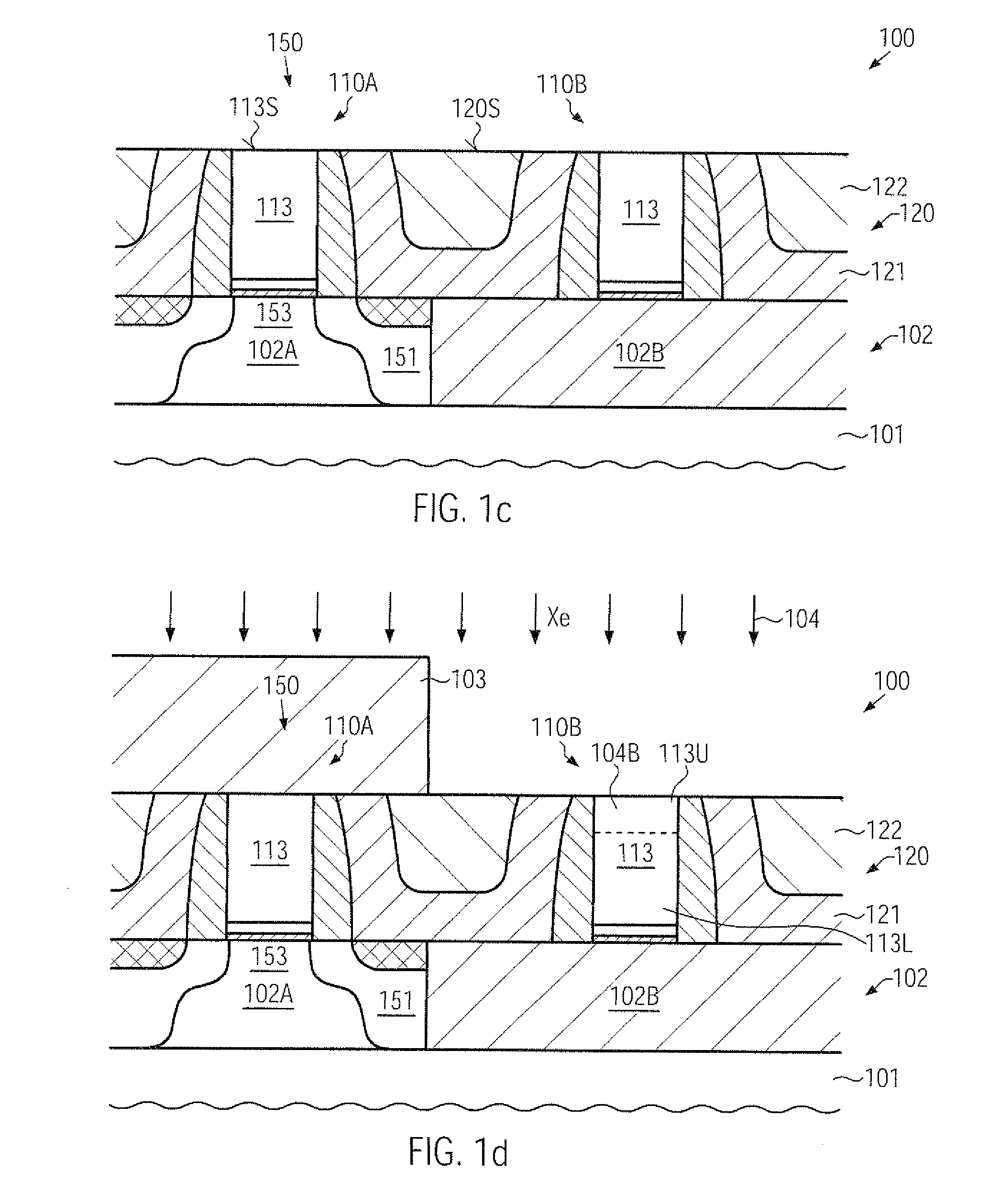

Semiconductor fuses in a semiconductor device comprising metal gates

InactiveUS20110101460A1Increased etch resistivityEfficient modificationSemiconductor/solid-state device detailsSolid-state devicesSemiconductor materialsElectron bombardment

In a replacement gate approach, the semiconductor material of the gate electrode structures may be efficiently removed during a wet chemical etch process, while this material may be substantially preserved in electronic fuses. Consequently, well-established semiconductor-based electronic fuses may be used instead of requiring sophisticated metal-based fuse structures. The etch selectivity of the semiconductor material may be modified on the basis of ion implantation or electron bombardment.

Owner:ALSEPHINA INNOVATIONS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com