Patents

Literature

185results about "Tube/lamp vessel degassing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

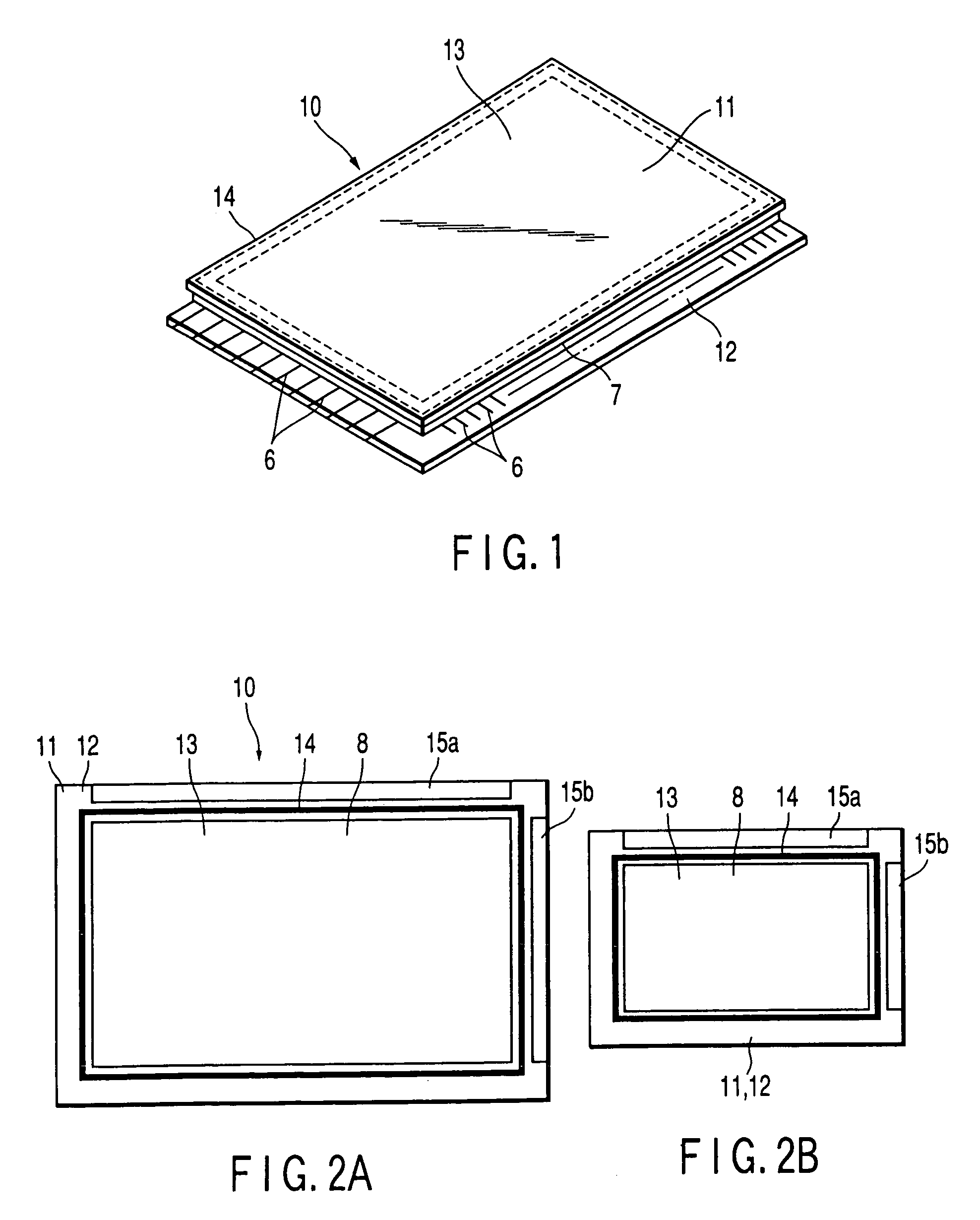

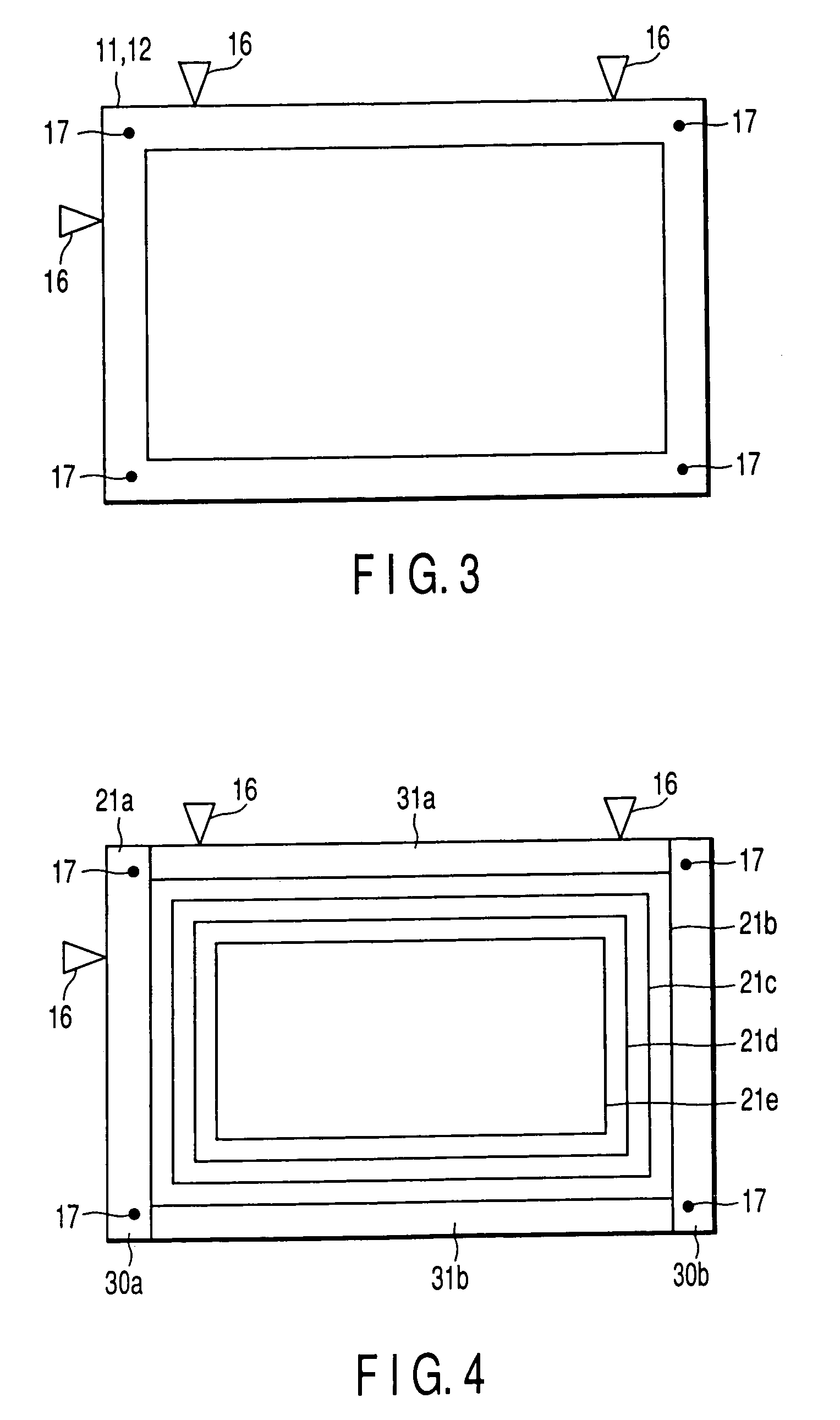

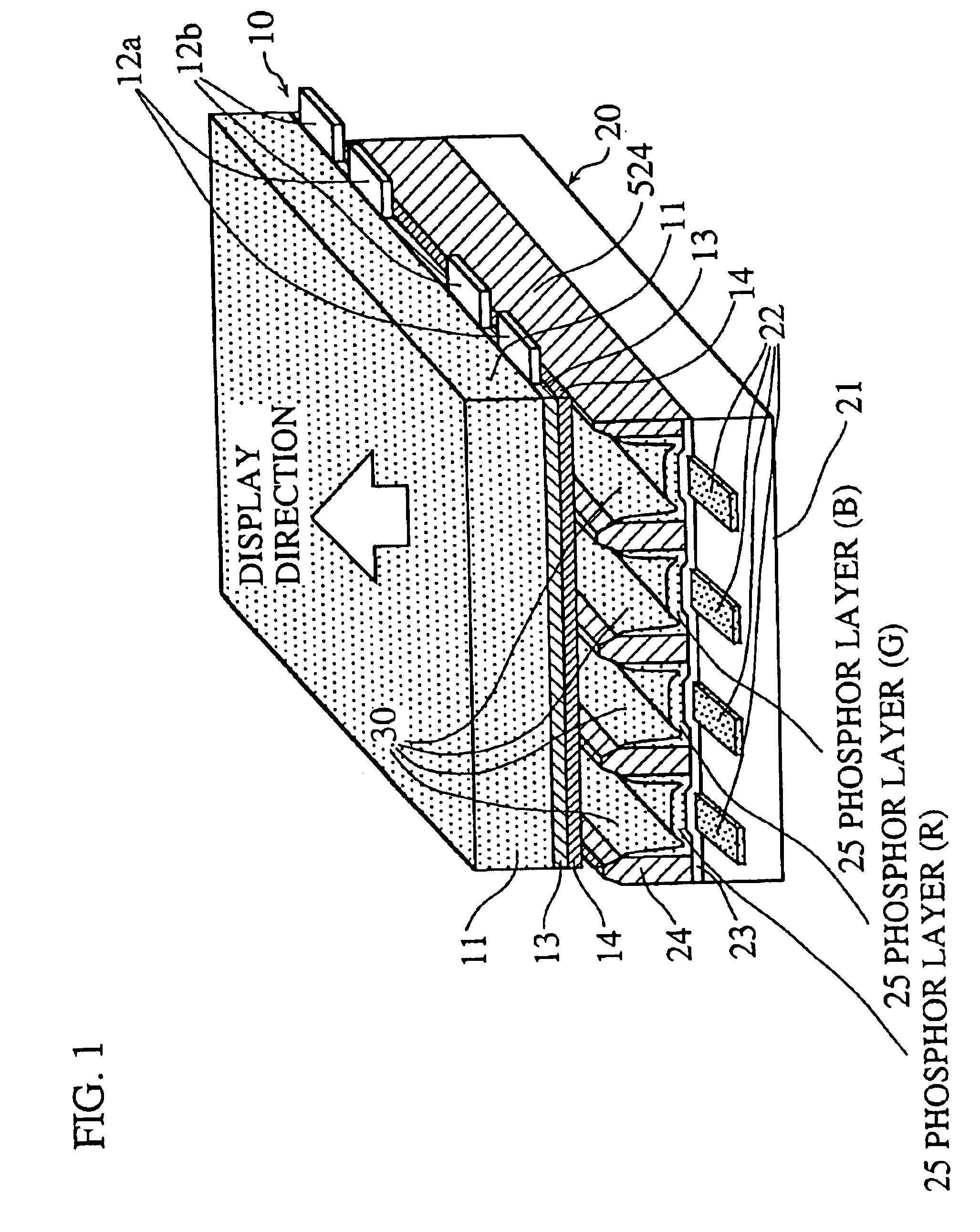

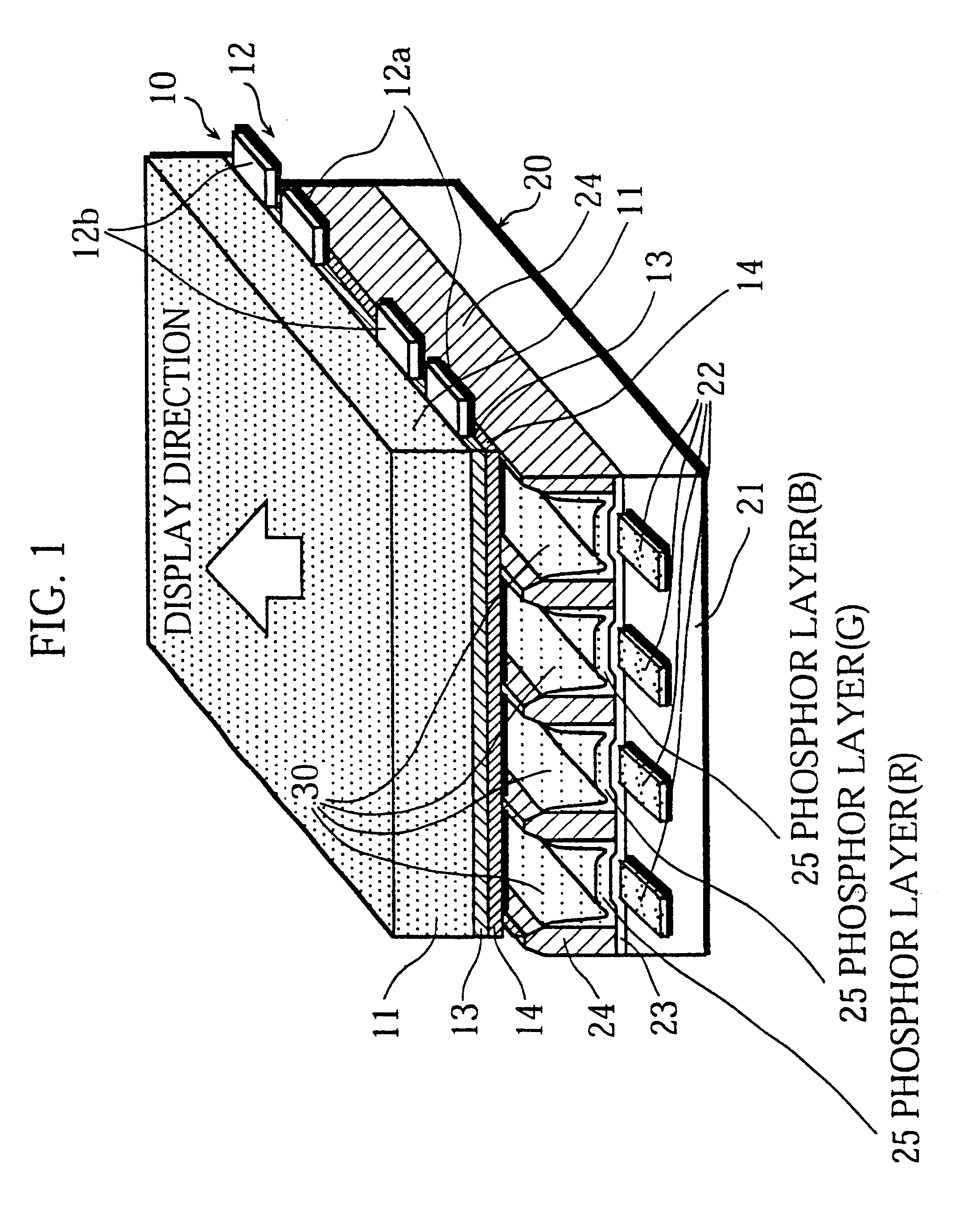

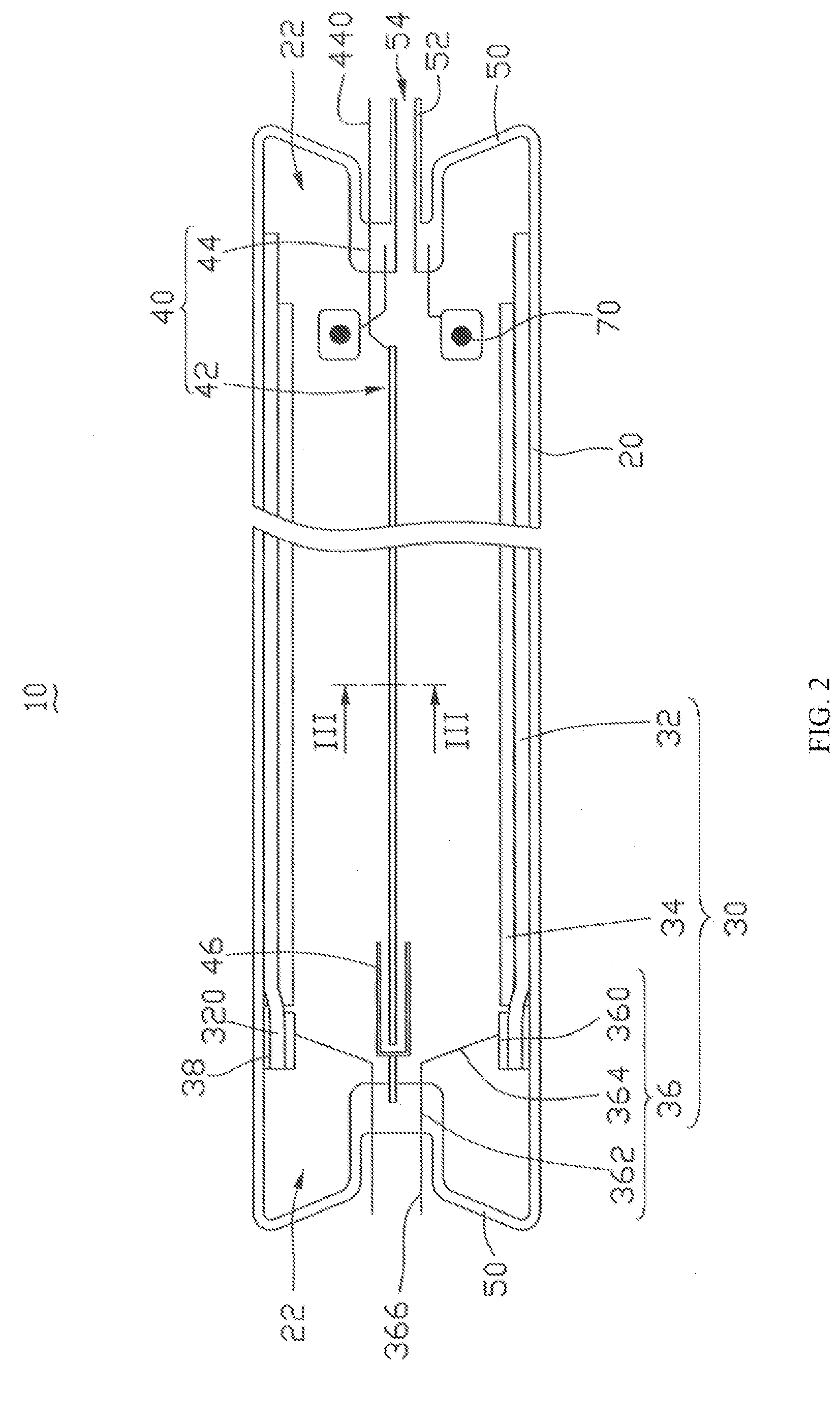

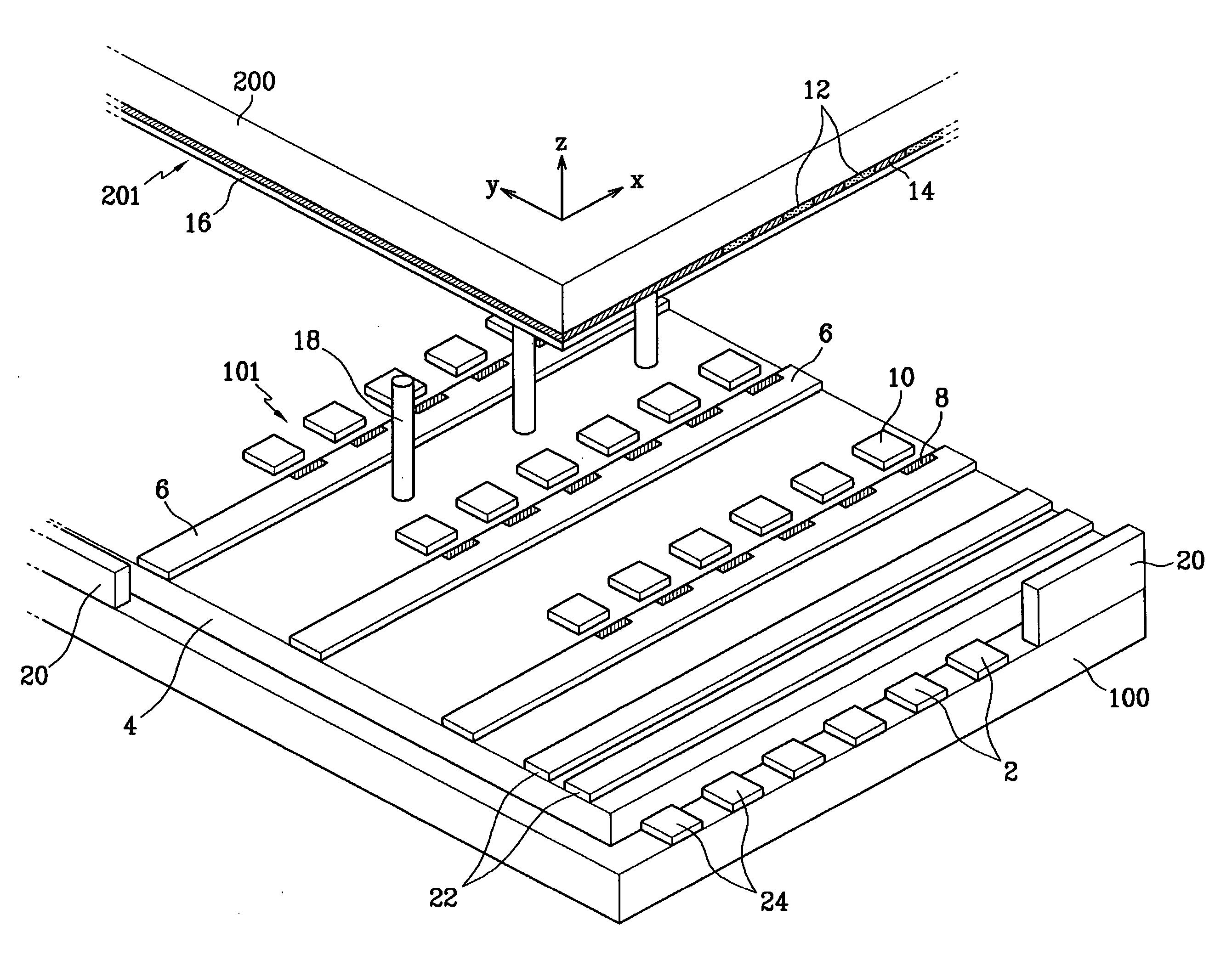

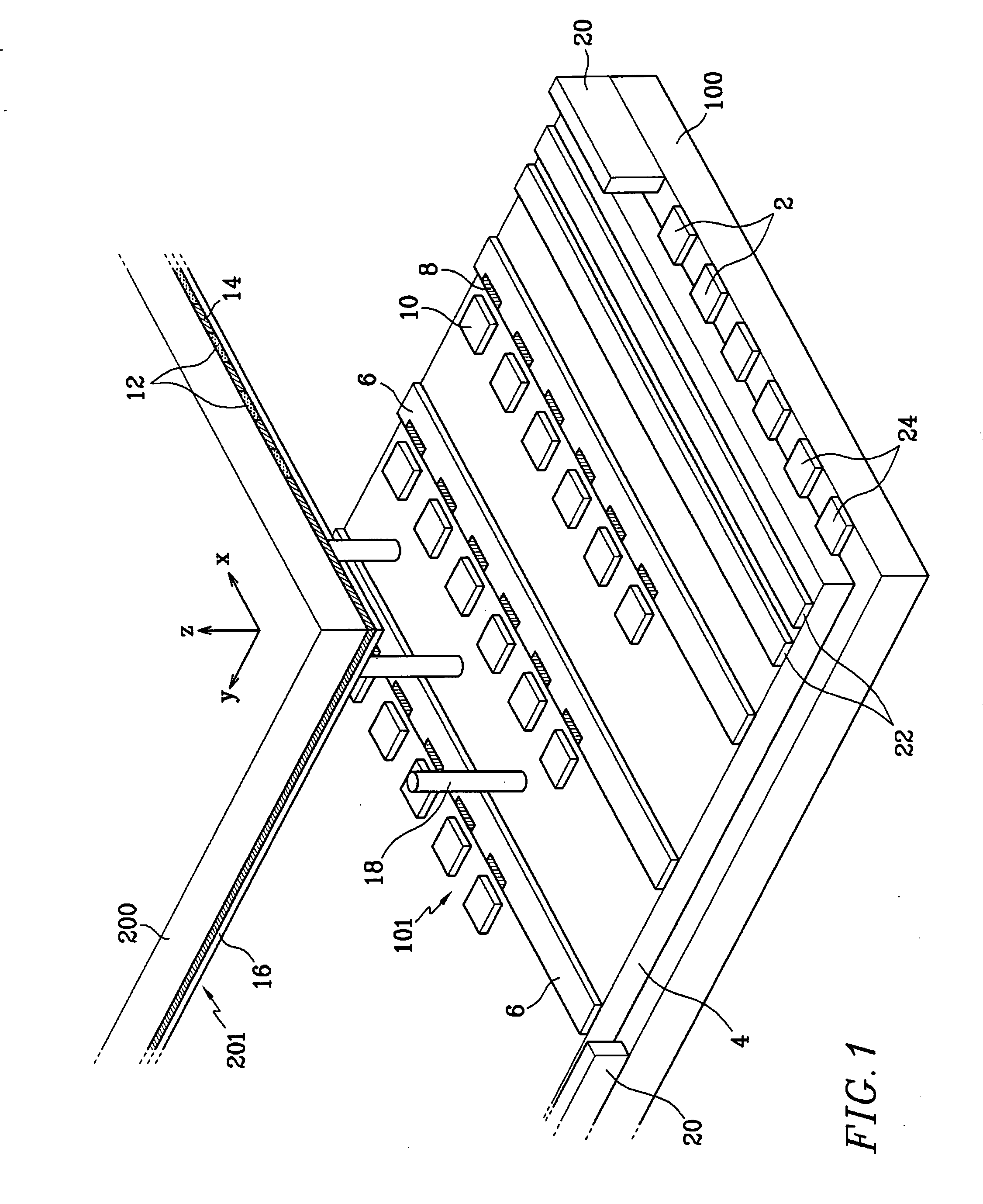

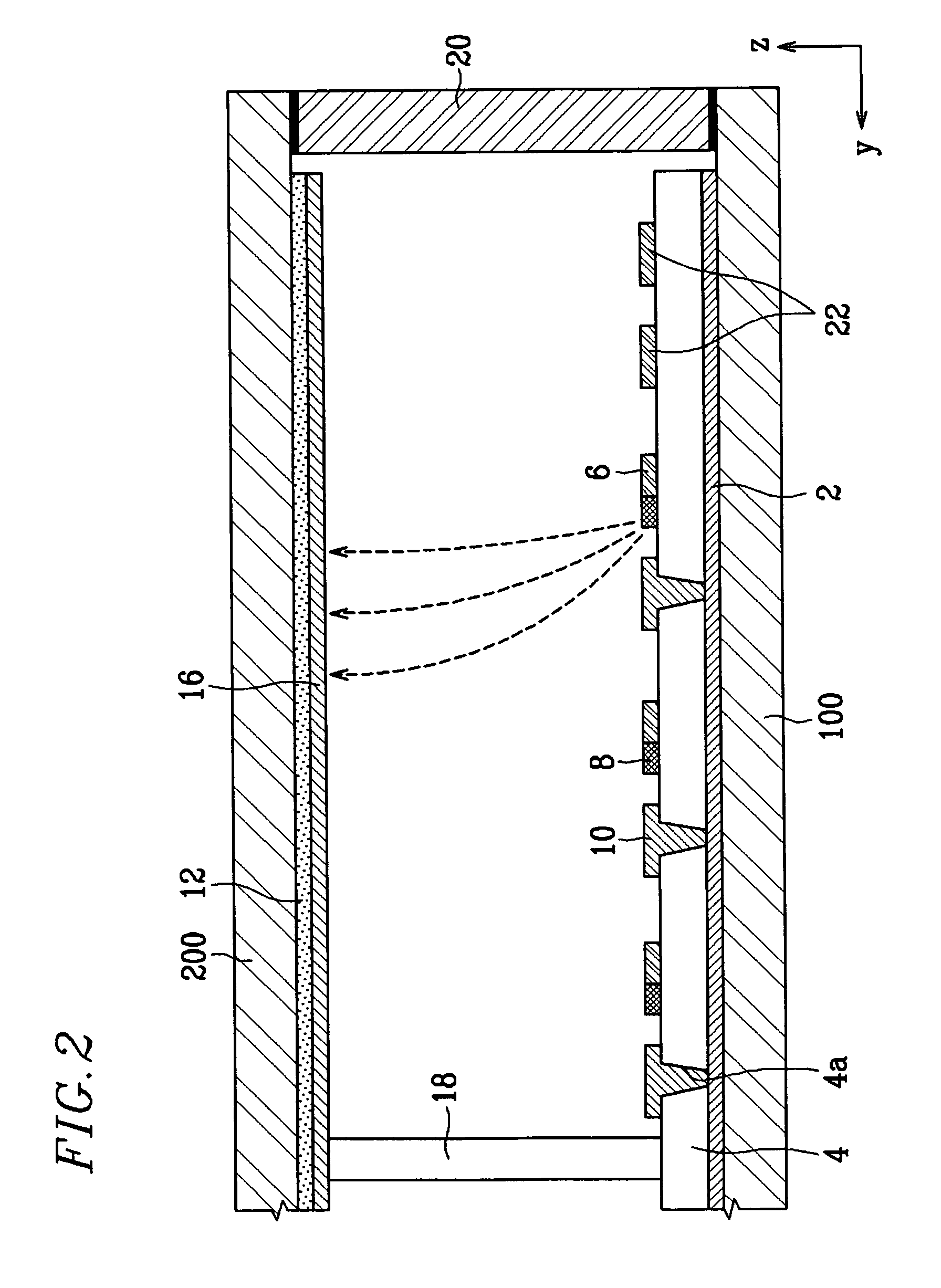

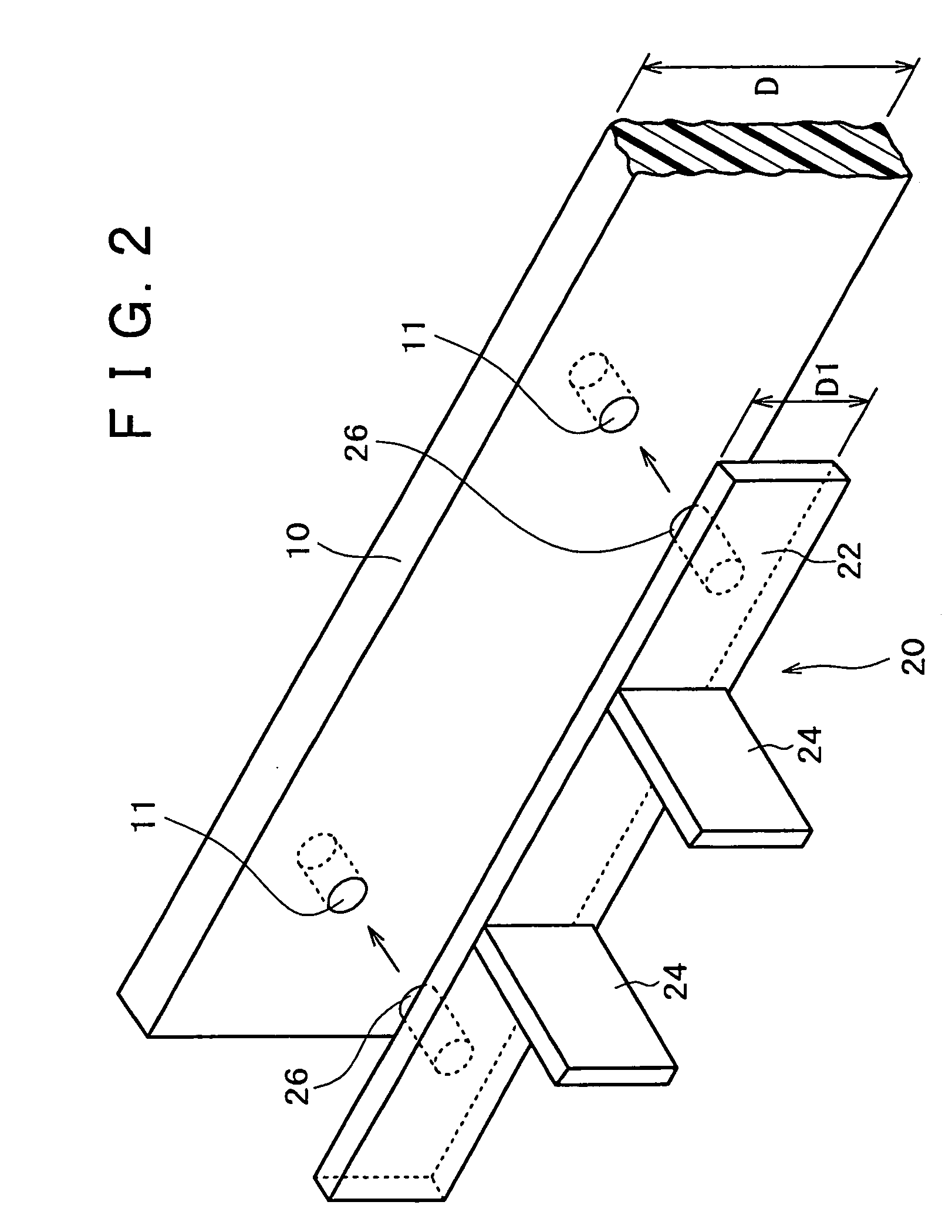

Method of manufacturing flat display panels of different sizes from a common base substrate

InactiveUS7273403B2Lower manufacturing requirementsNarrow widthSparking plugsStatic indicating devicesCommon baseDisplay device

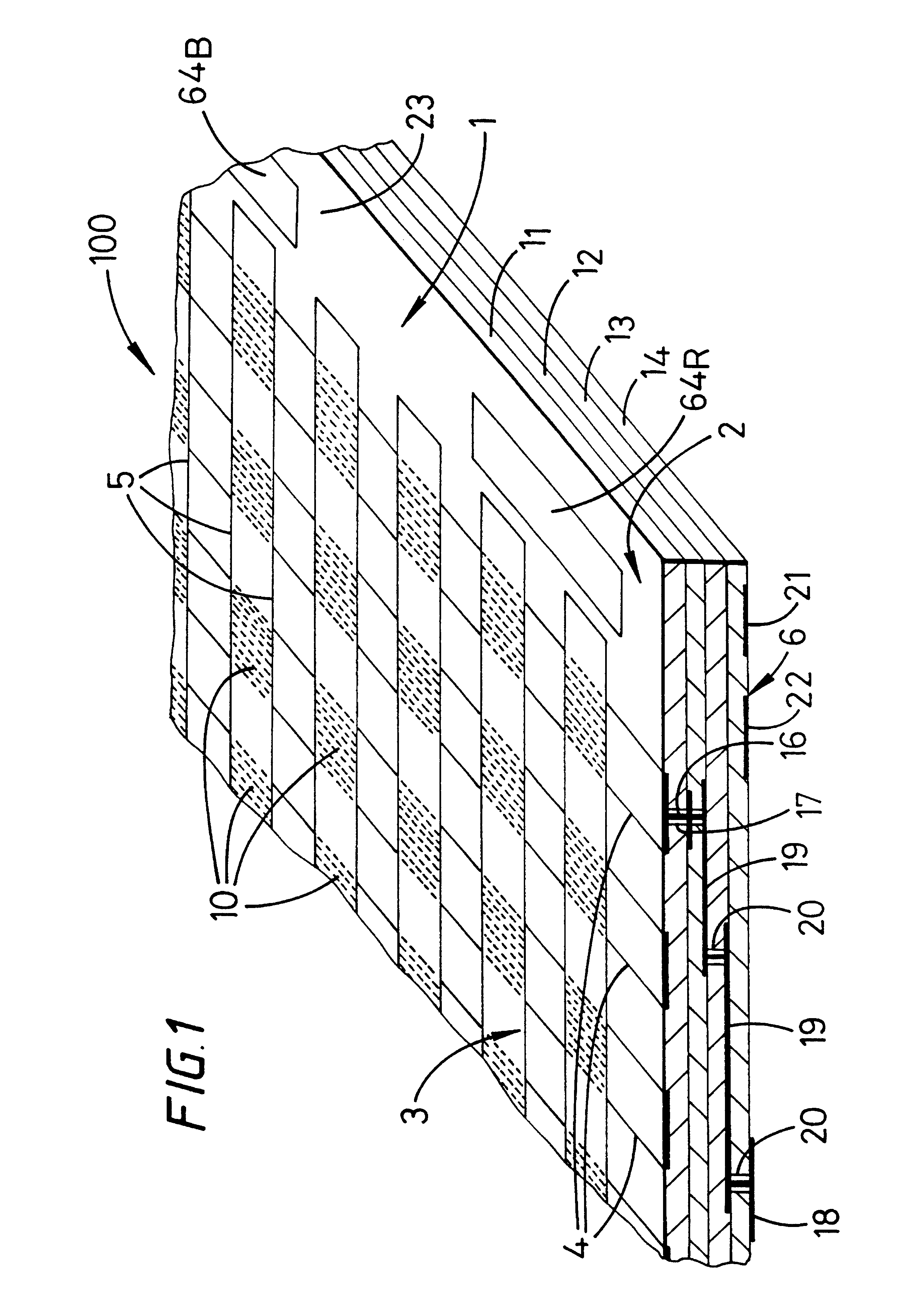

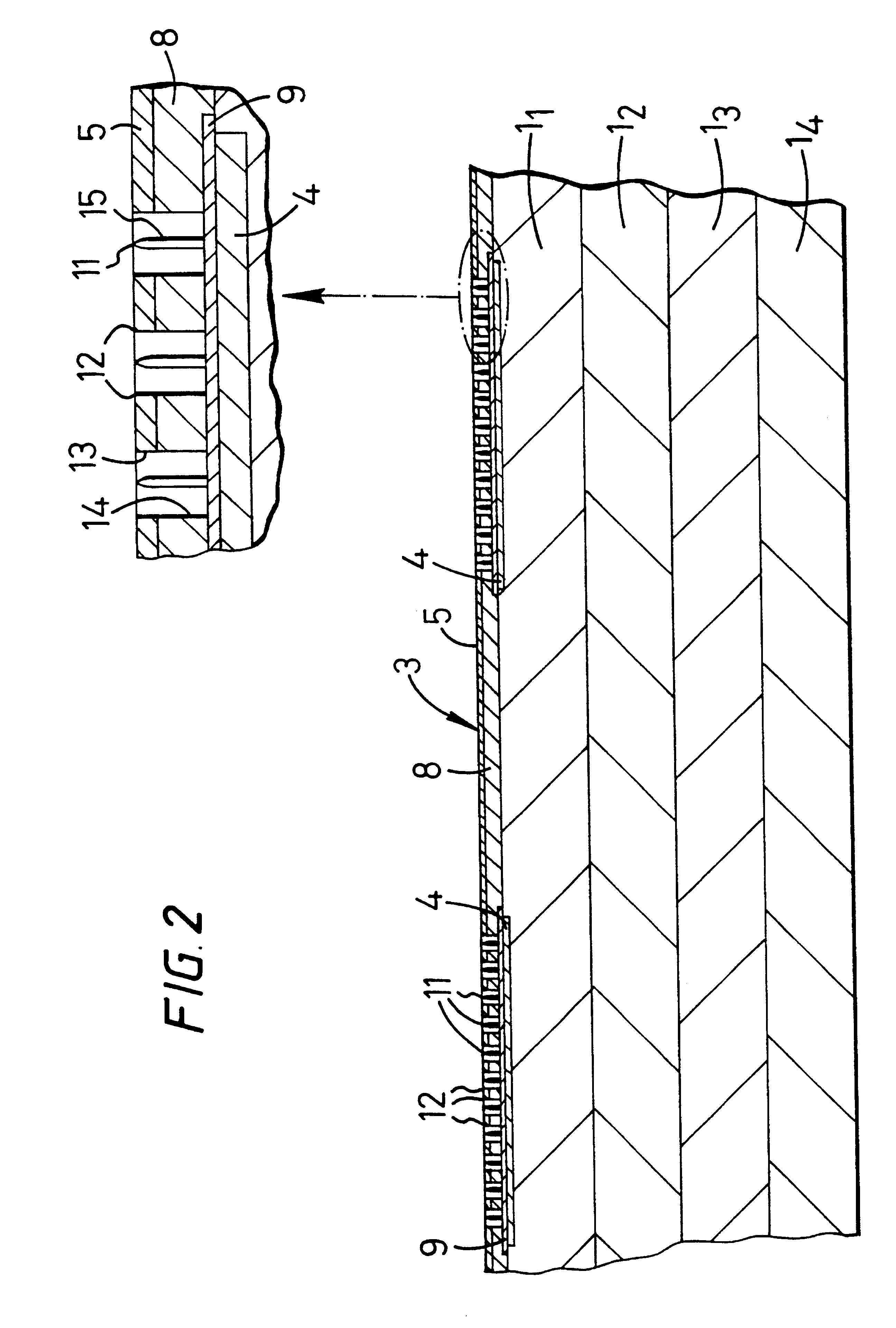

In a method of a manufacturing flat display apparatuses by working flat substrates, a flat substrate is prepared having a first region which is used as a flat display apparatus and a second region outside the first region. After the first region is worked as desired, the second region is cut and separated from the flat substrate.

Owner:KK TOSHIBA

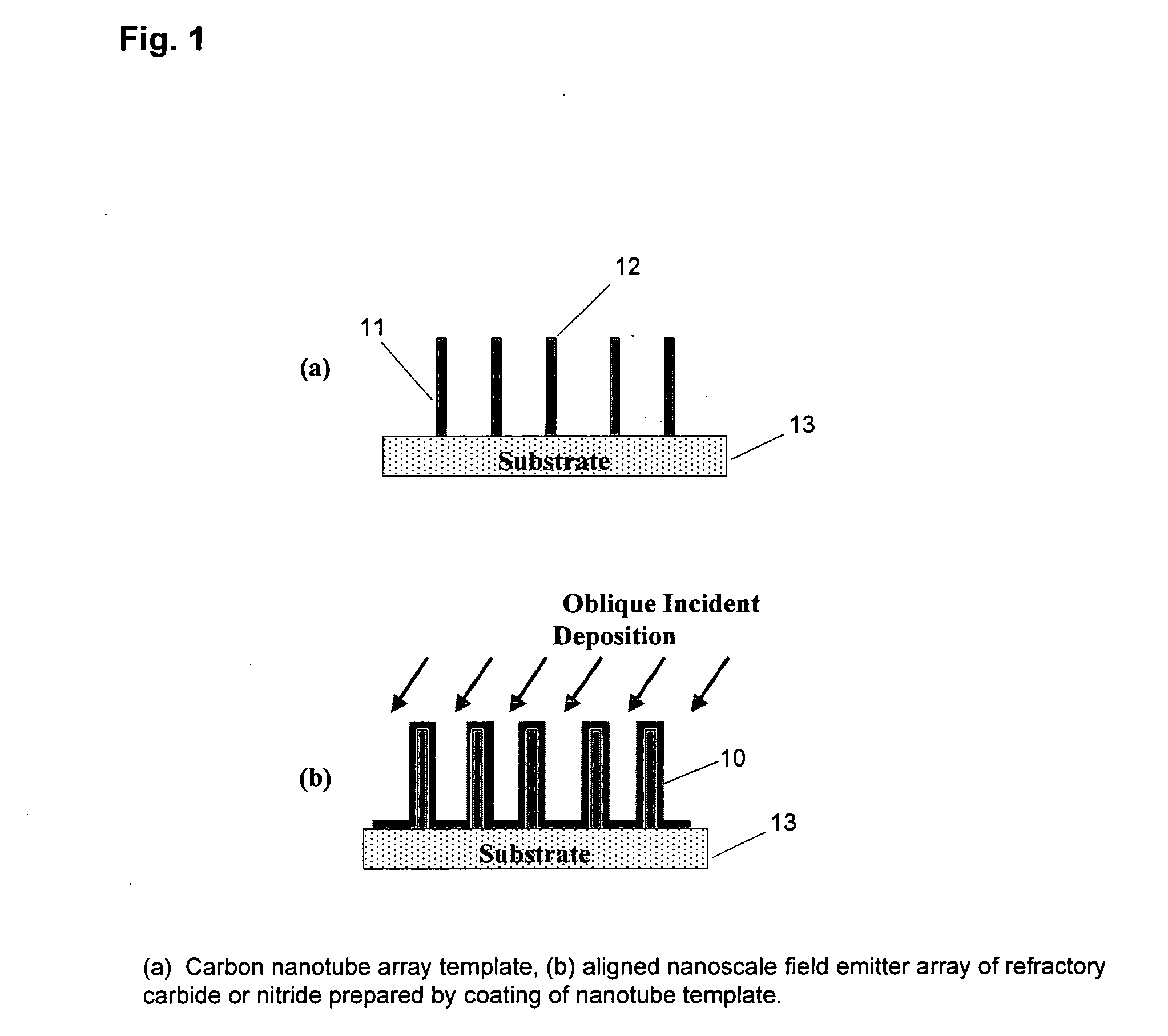

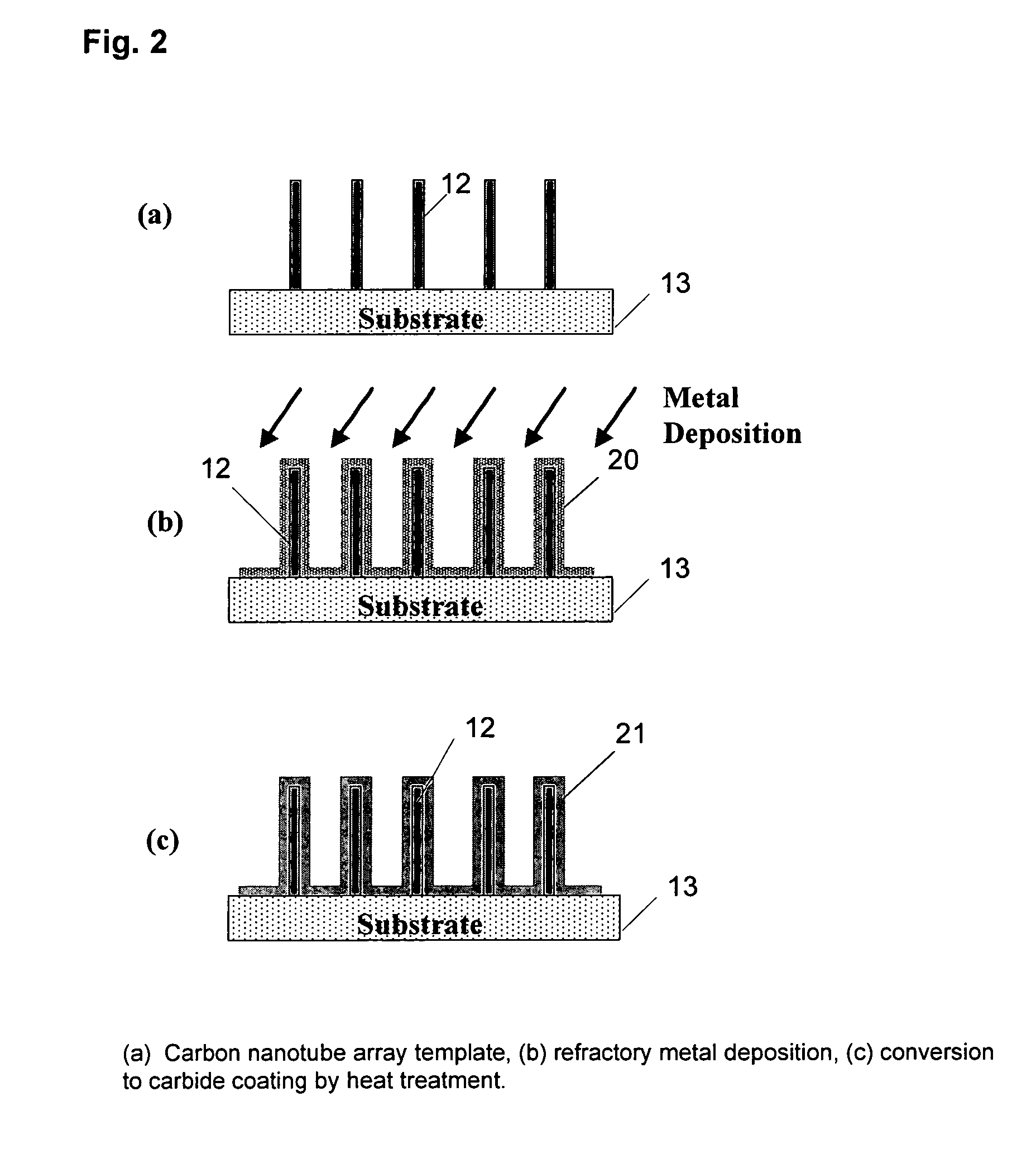

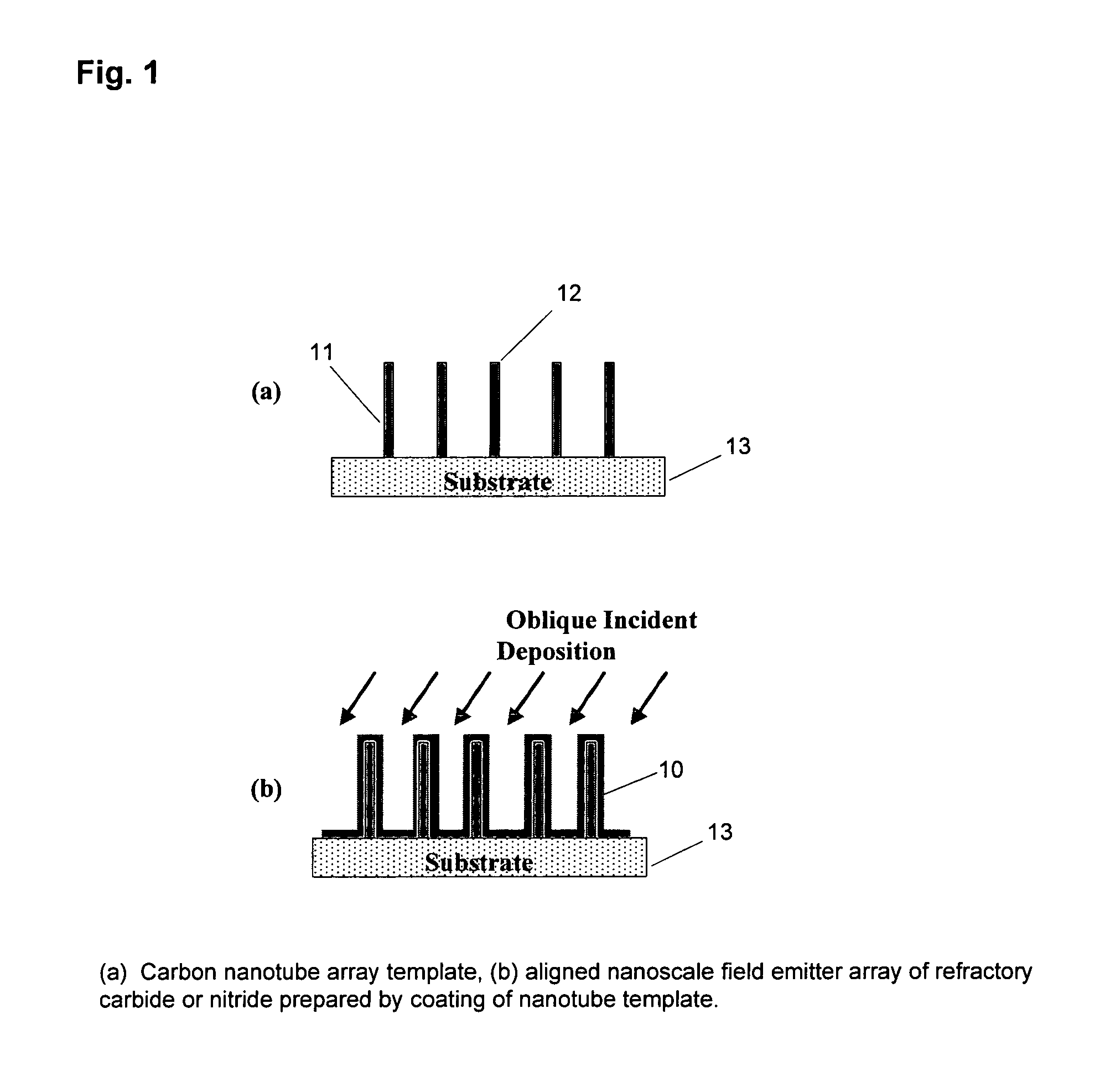

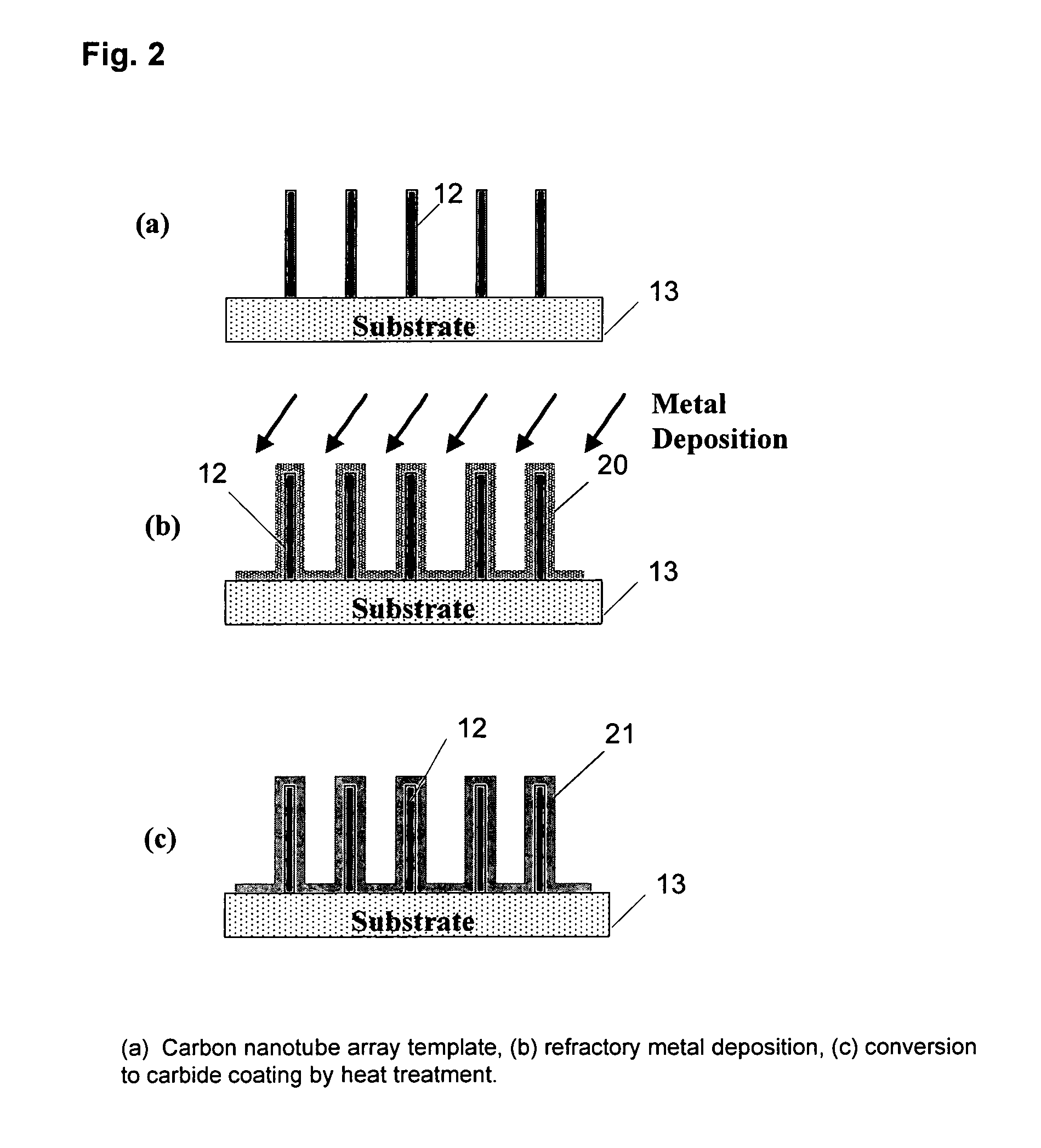

Method of fabricating carbide and nitride NANO electron emitters

InactiveUS20080287030A1Improve featuresImprove stabilityCathode ray tubes/electron beam tubesTube/lamp vessel degassingCarbideNitride

Owner:RGT UNIV OF CALIFORNIA +1

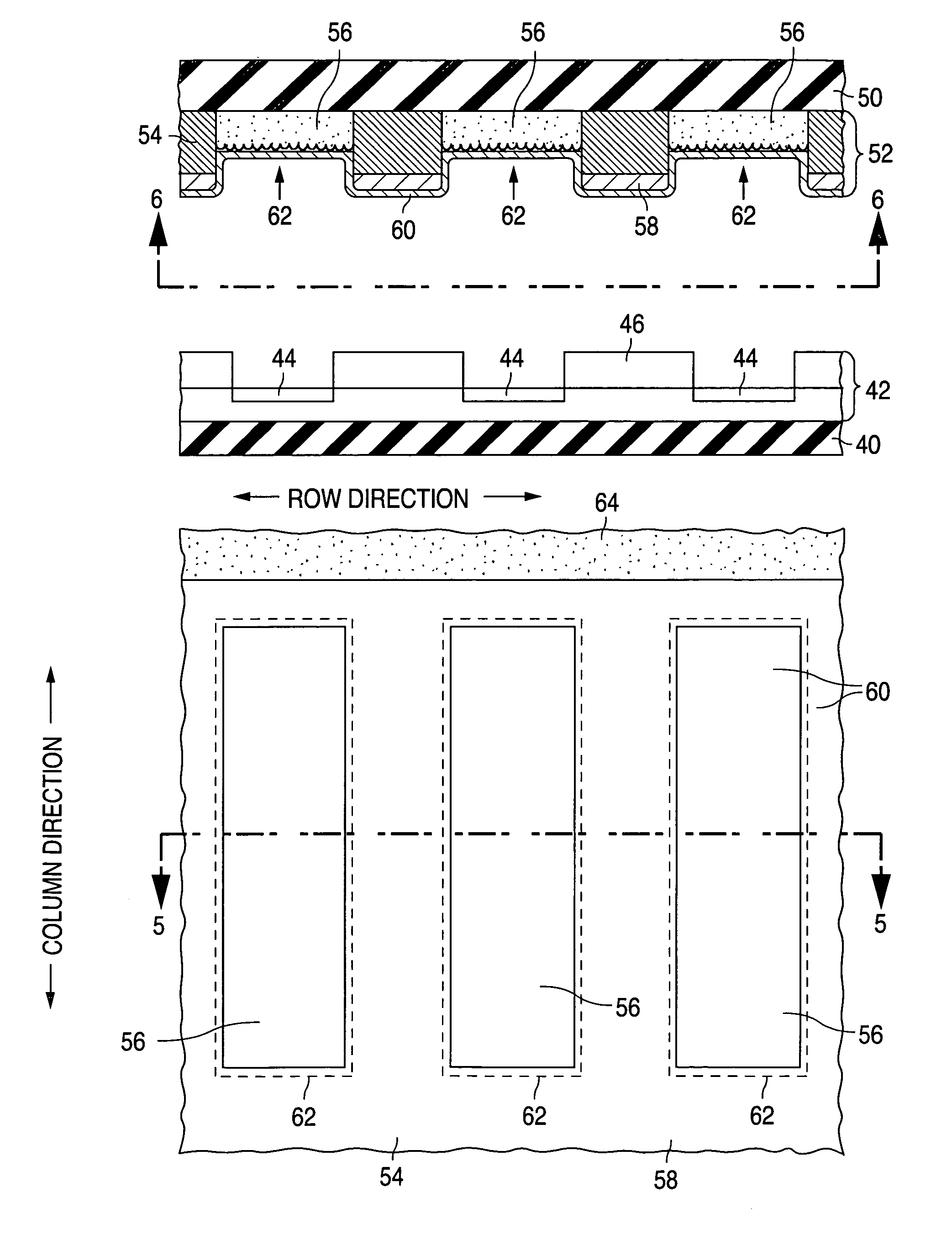

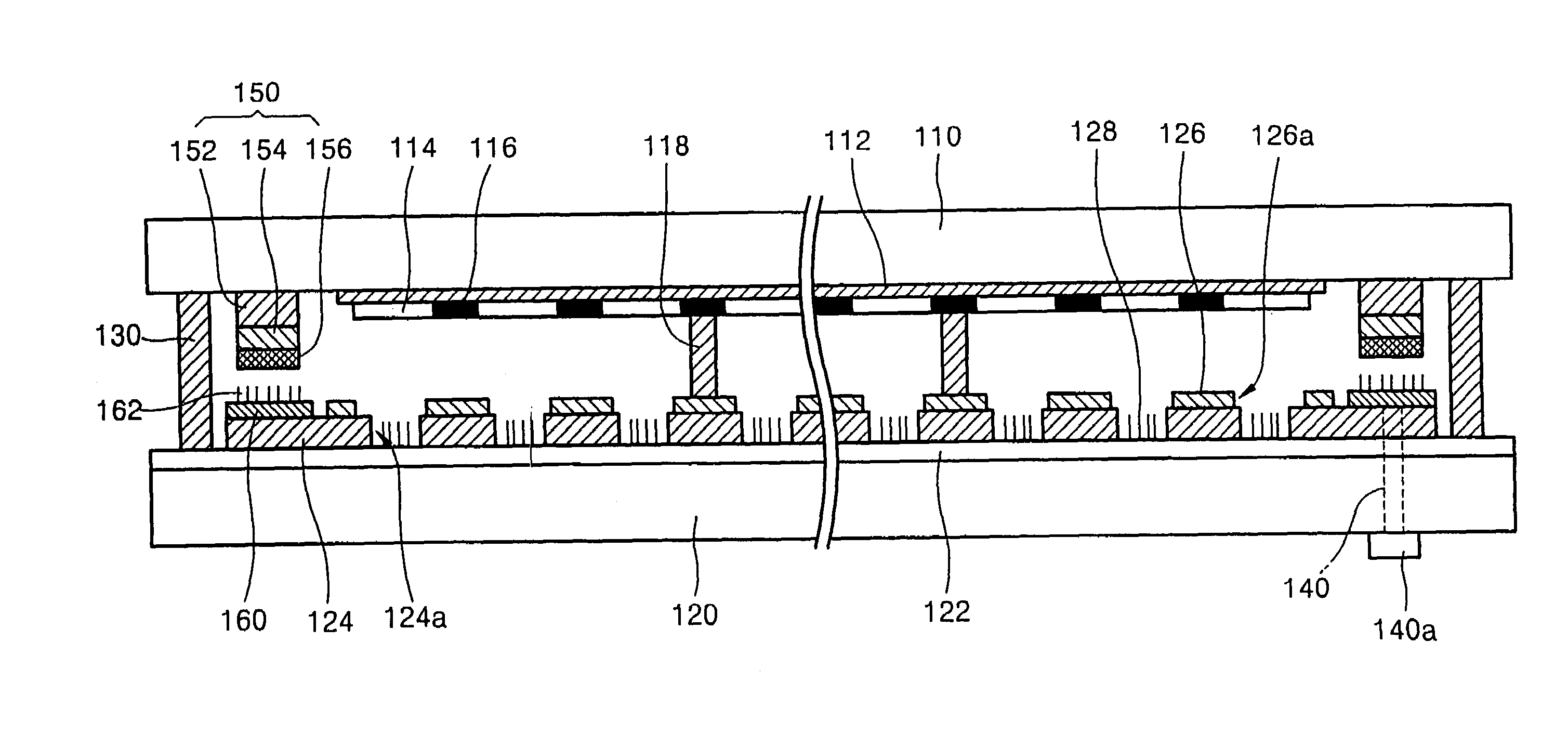

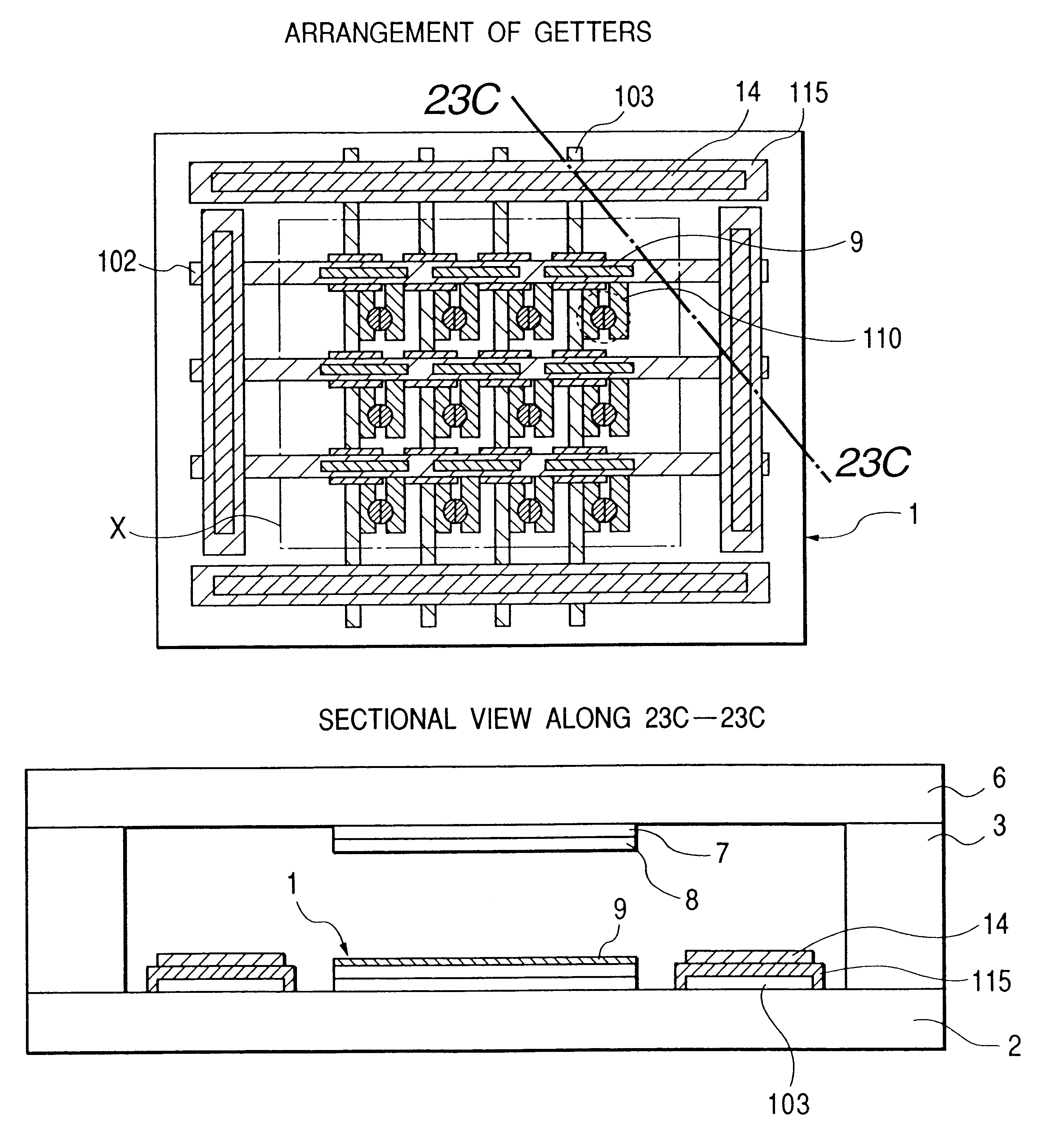

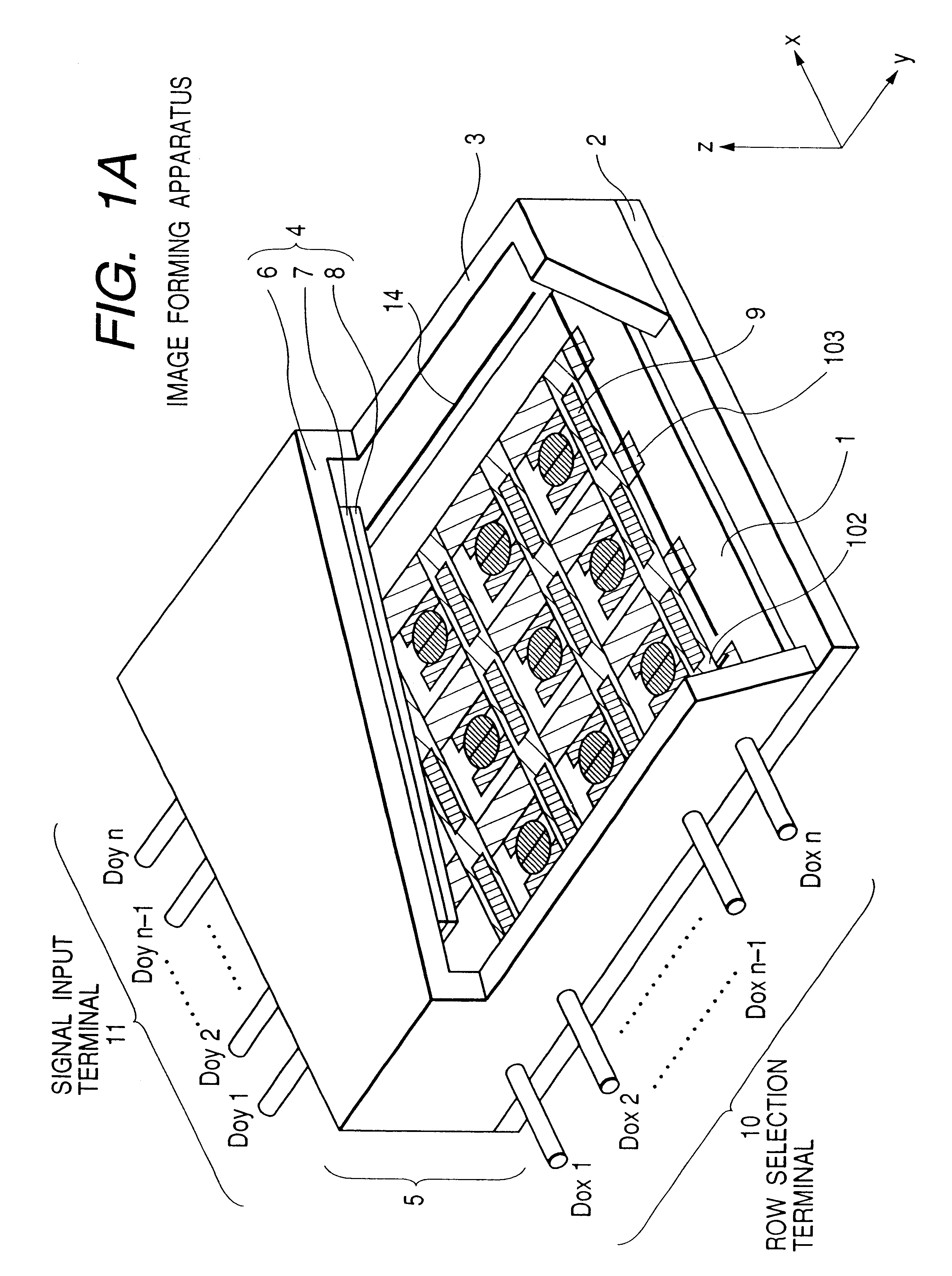

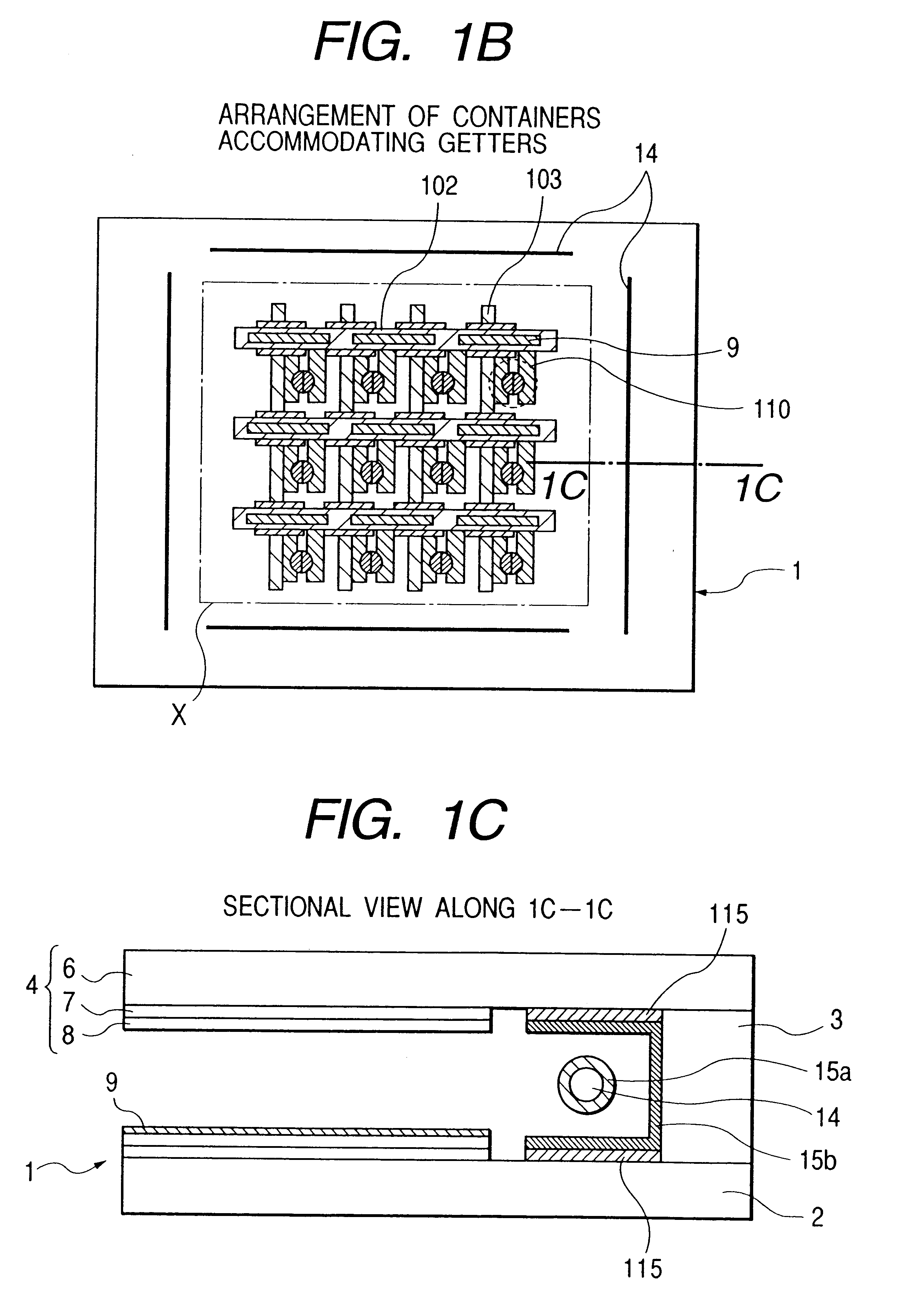

Light-emitting and electron-emitting devices having getter regions

InactiveUS7315115B1Improve performanceEasy to manufactureTube/lamp screens manufactureGetteringLight emitting deviceElectron

A light-emitting device contains getter material (58) typically distributed in a relatively uniform manner across the device's active light-emitting portion. An electron-emitting device similarly contains getter material (112, 110 / 112, 128, 132, and 142) typically distributed relatively uniformly across the active electron-emitting portion of the device.

Owner:CANON KK +1

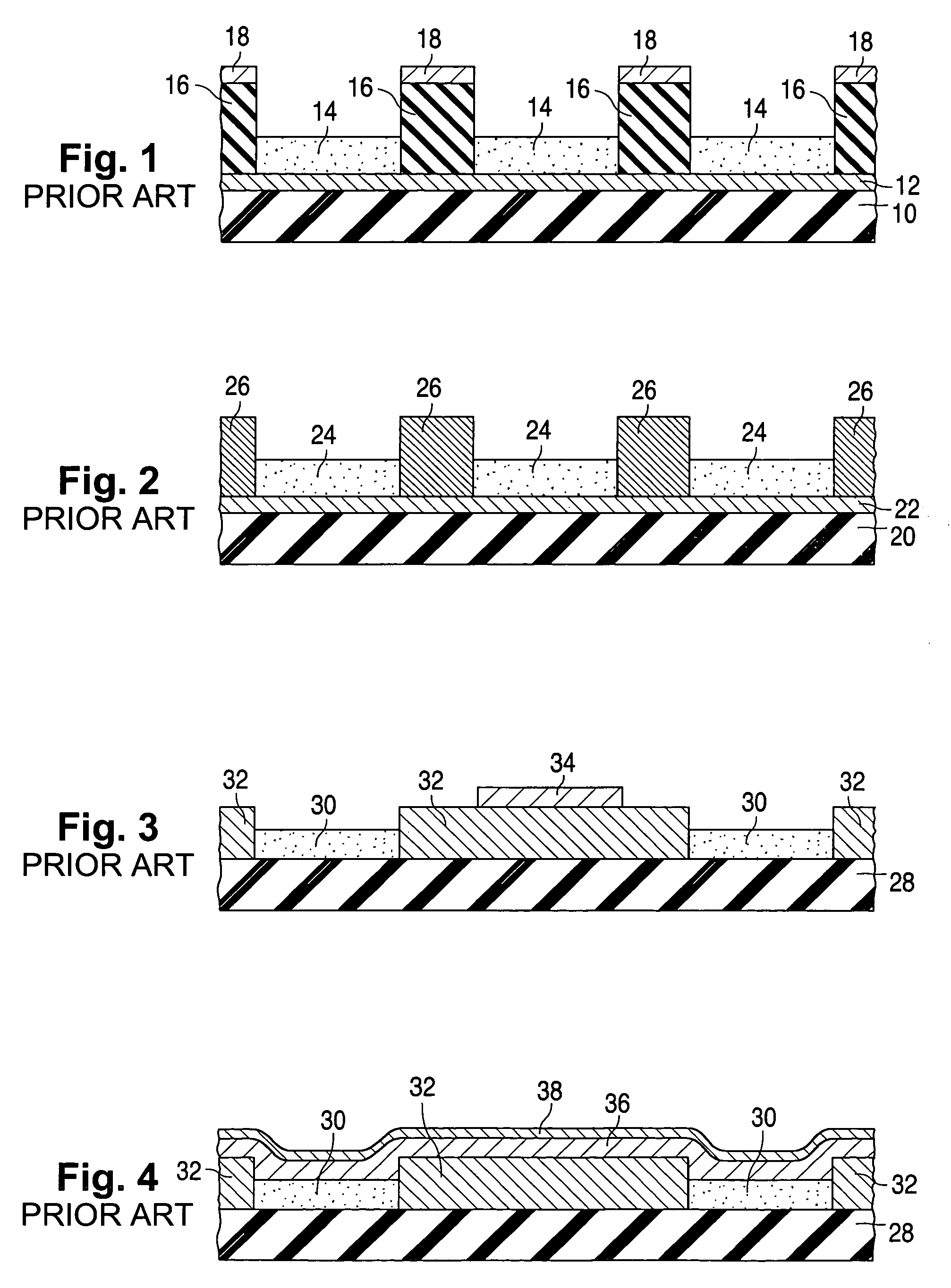

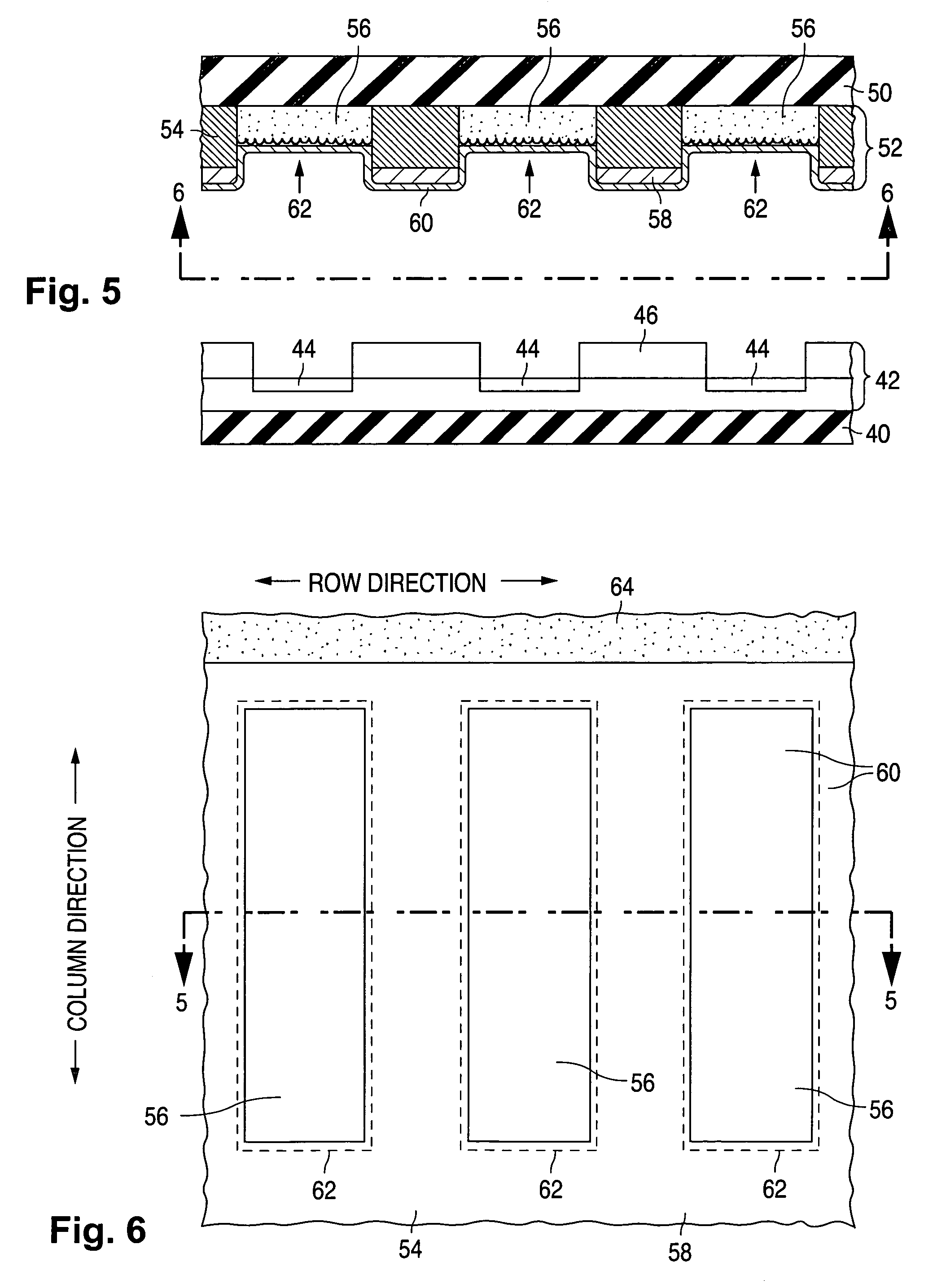

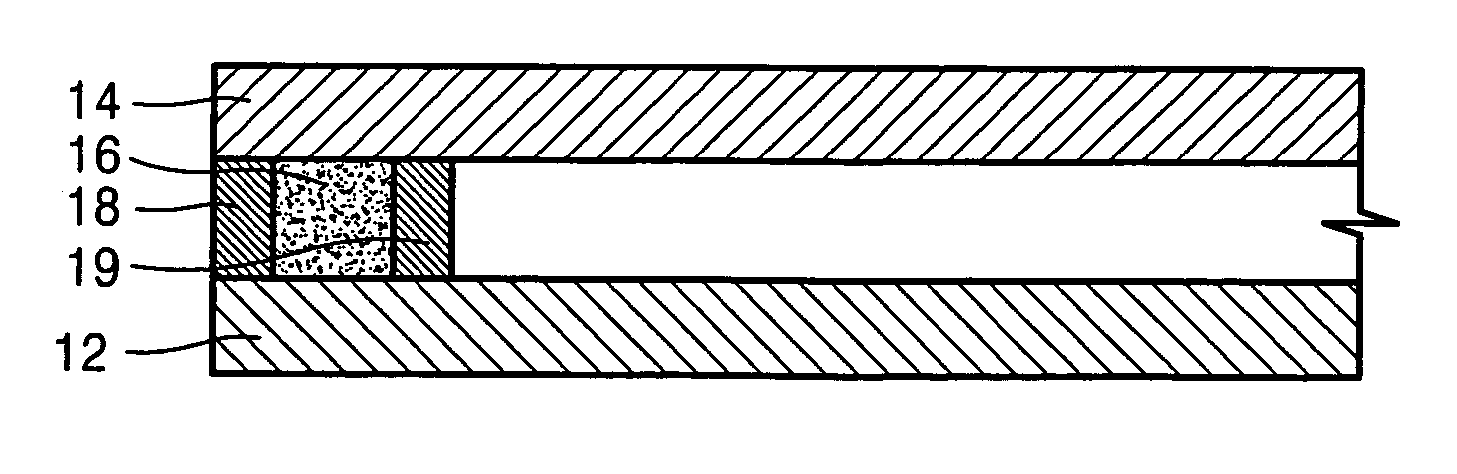

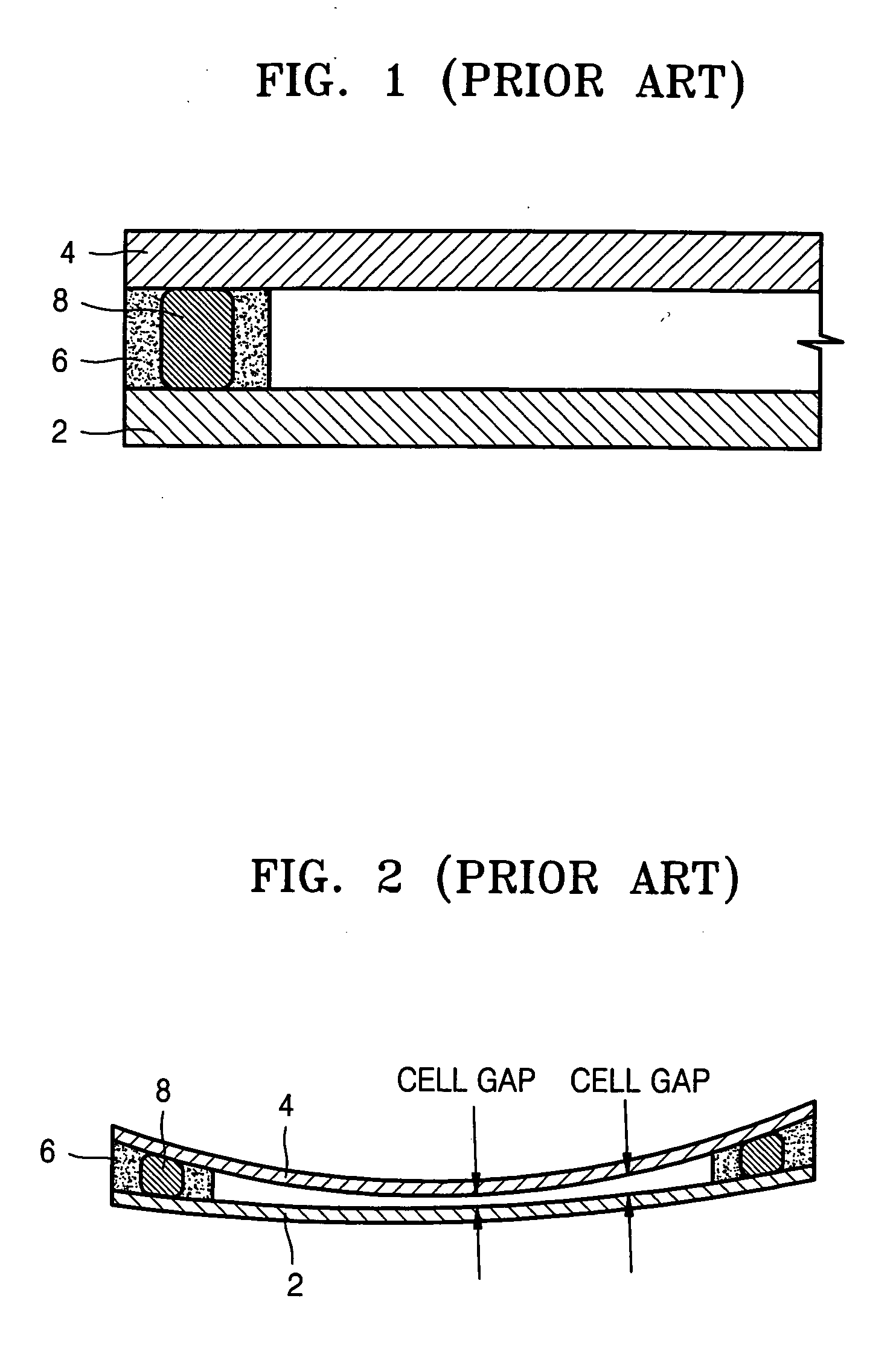

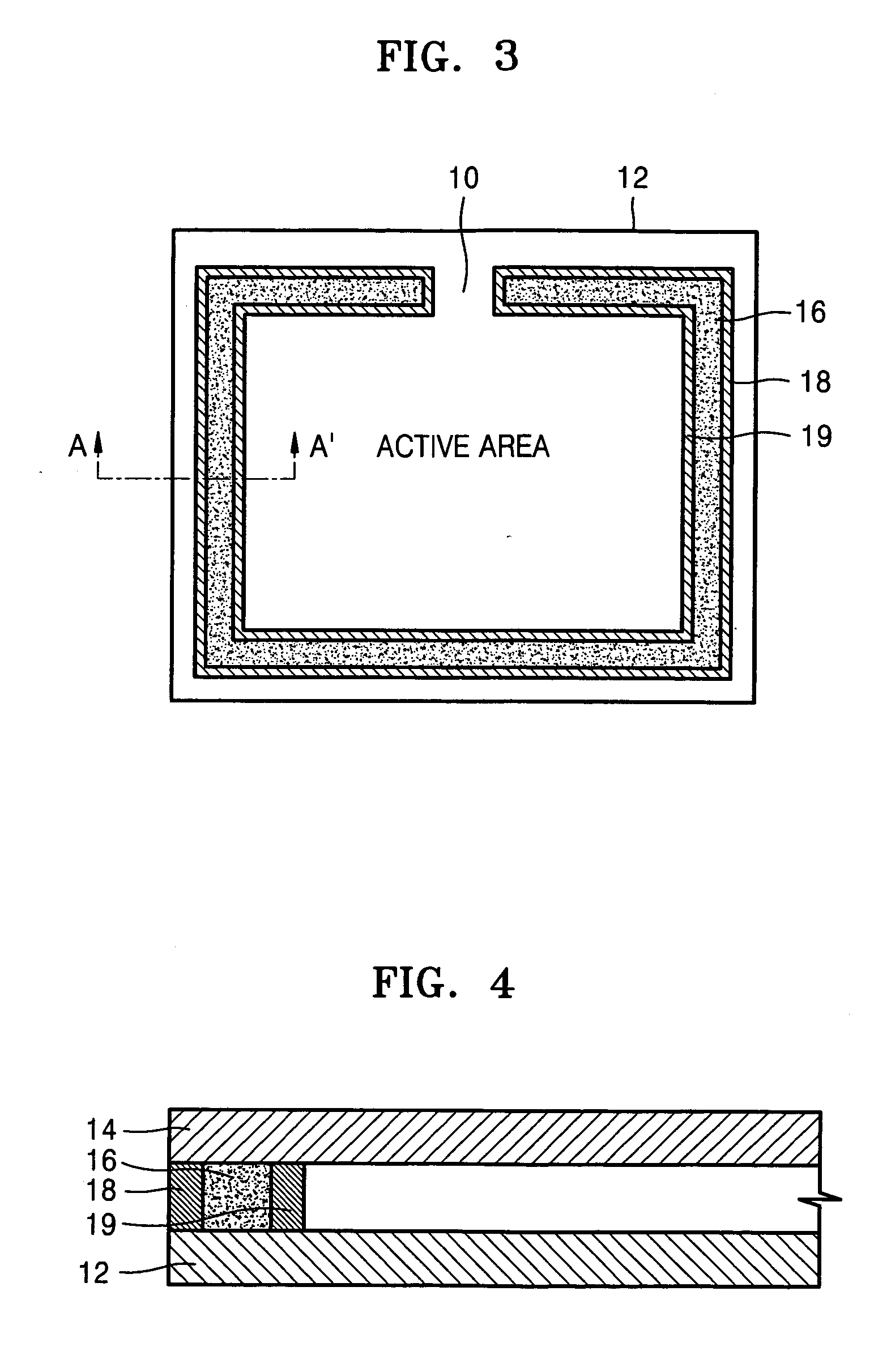

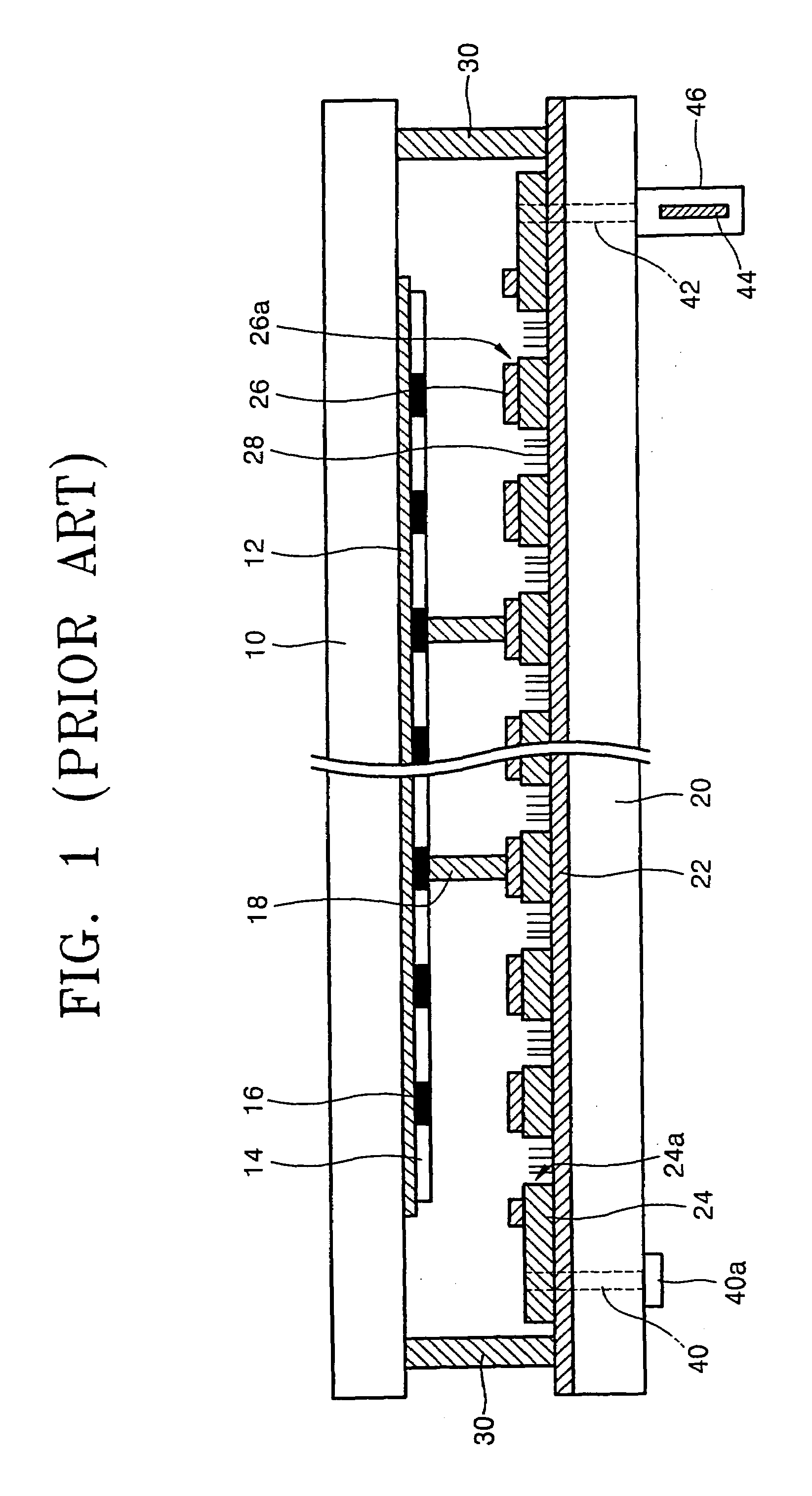

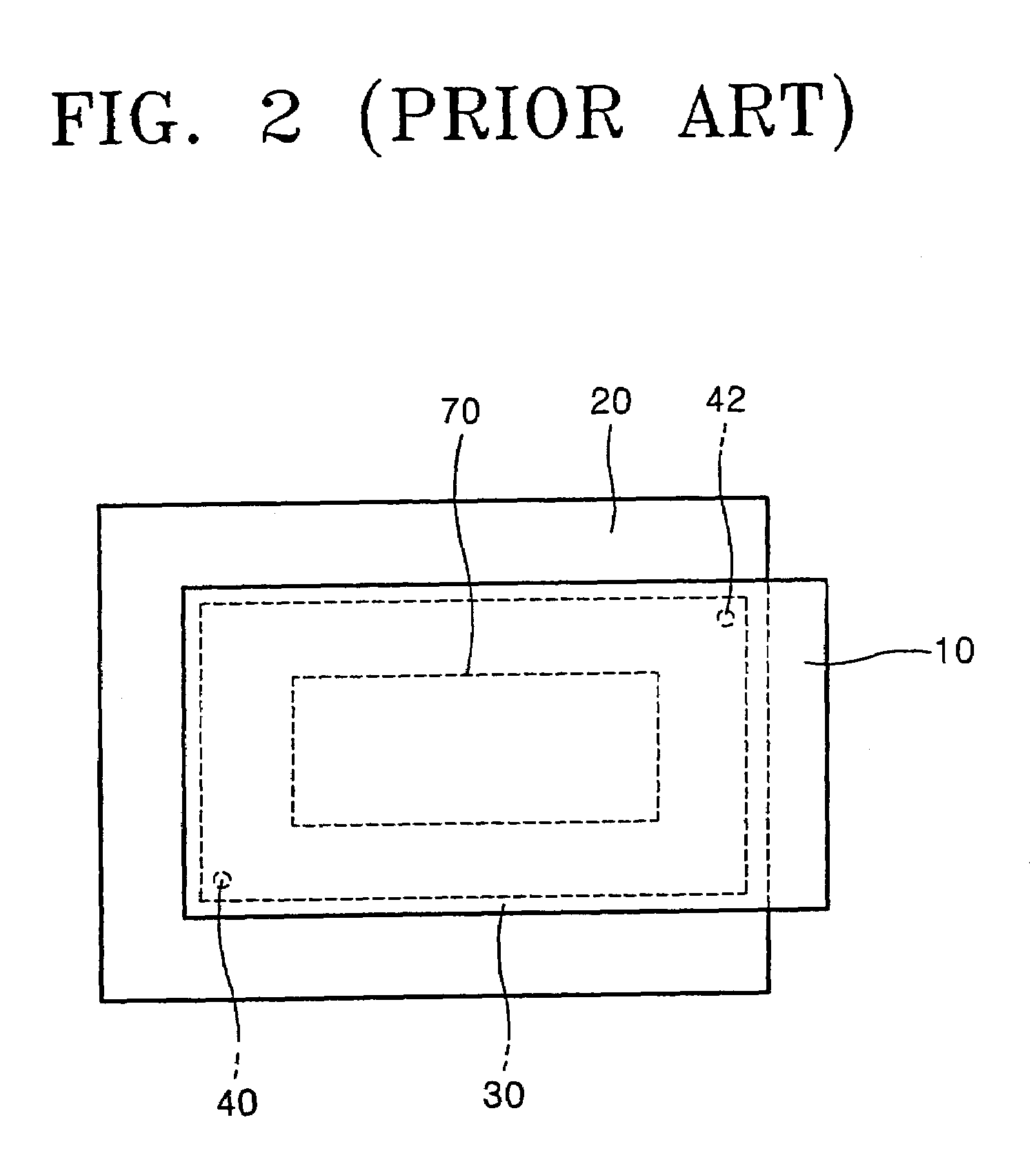

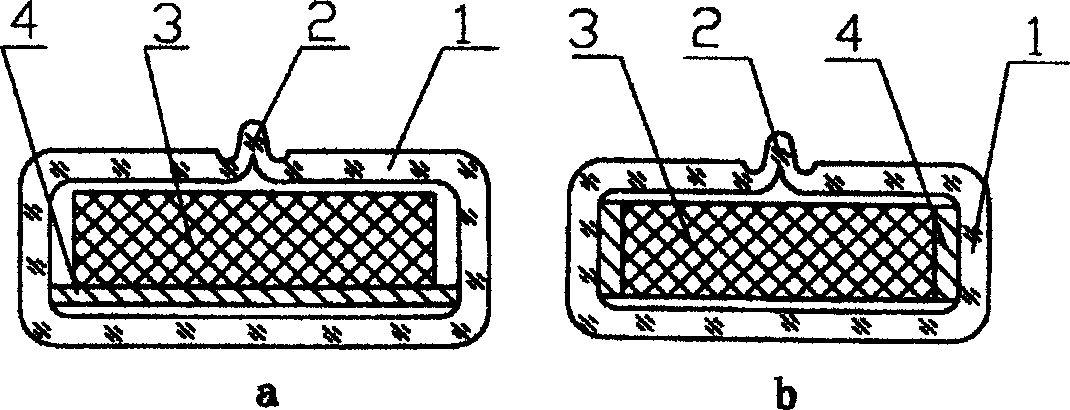

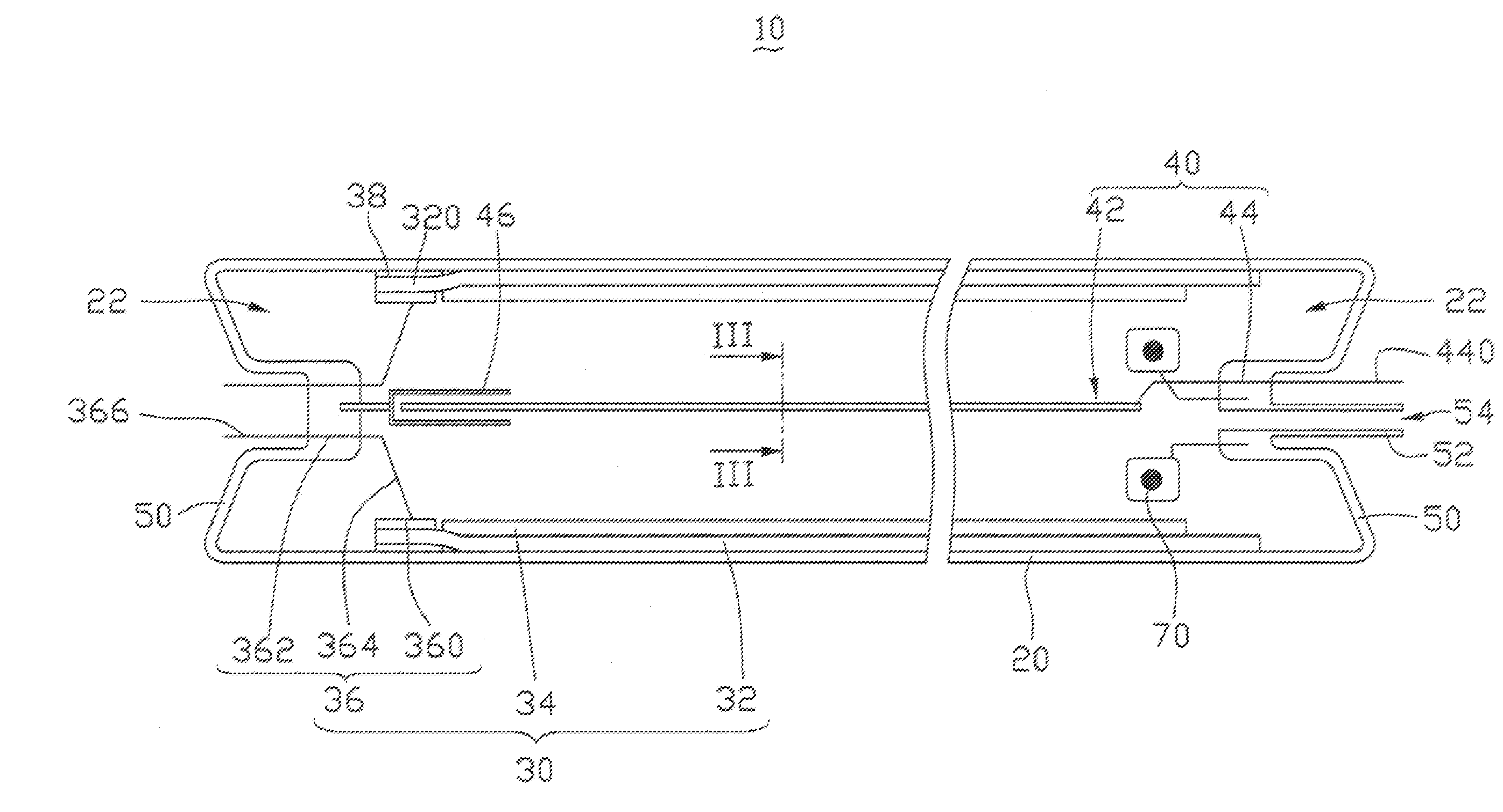

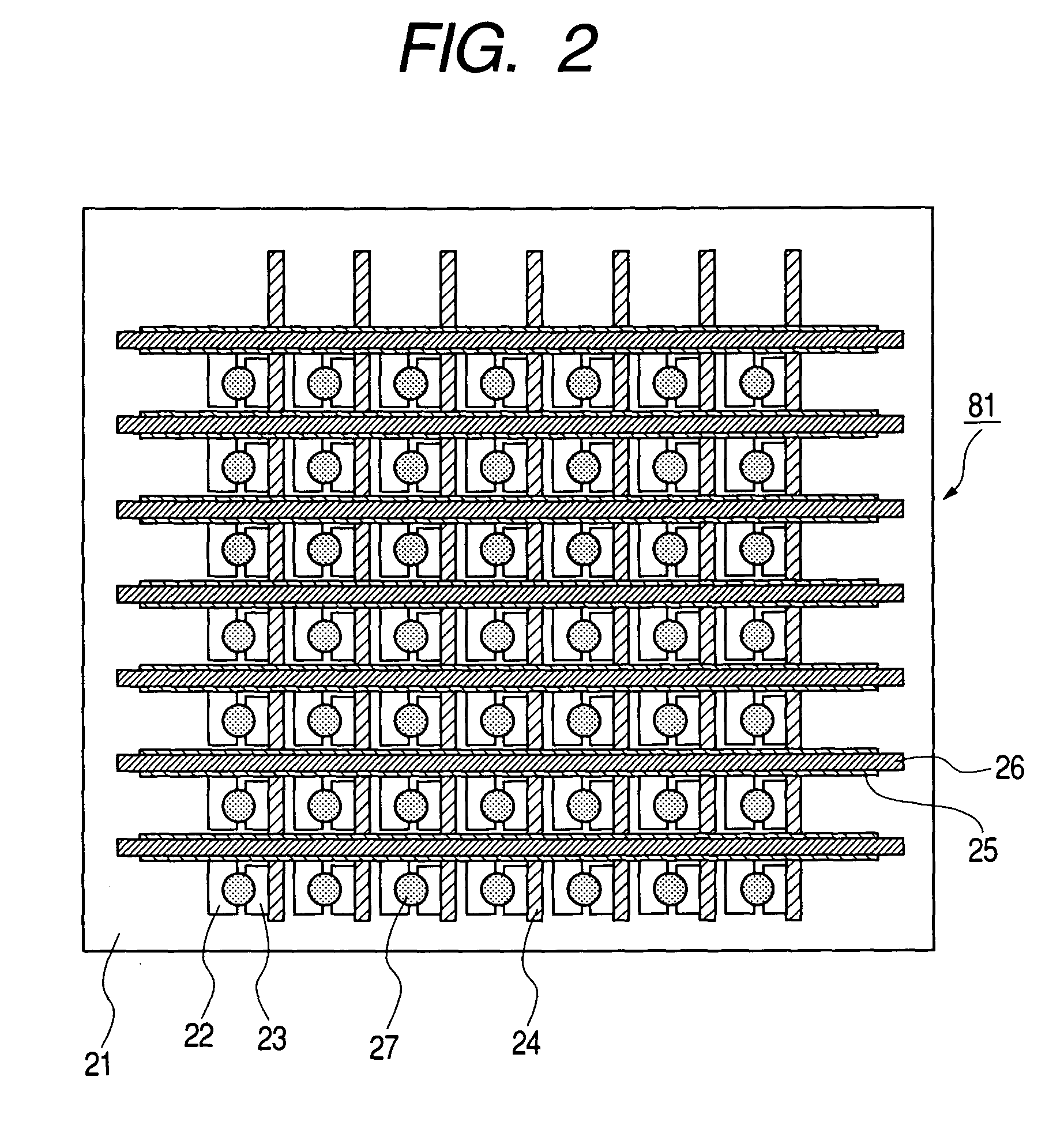

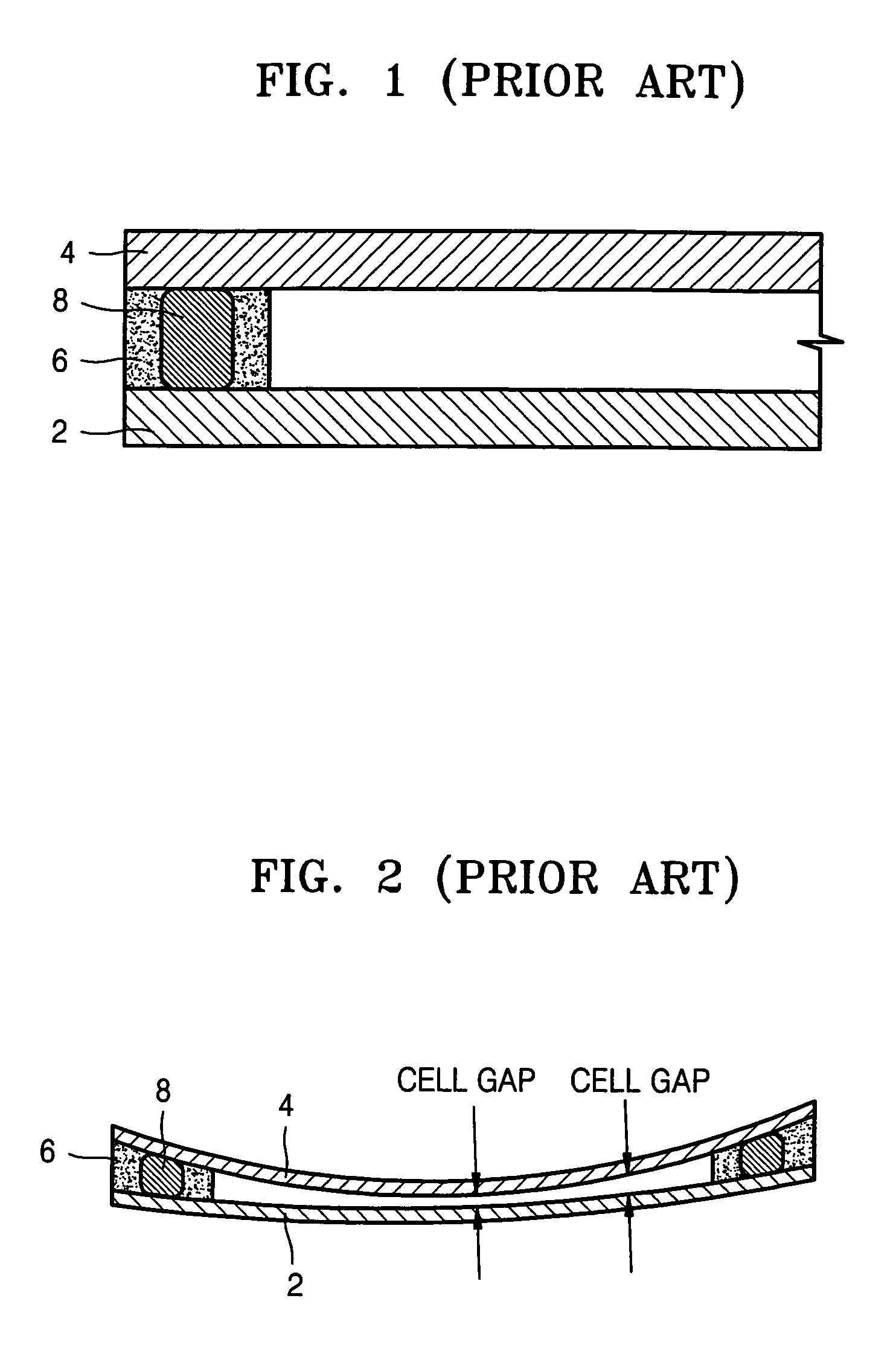

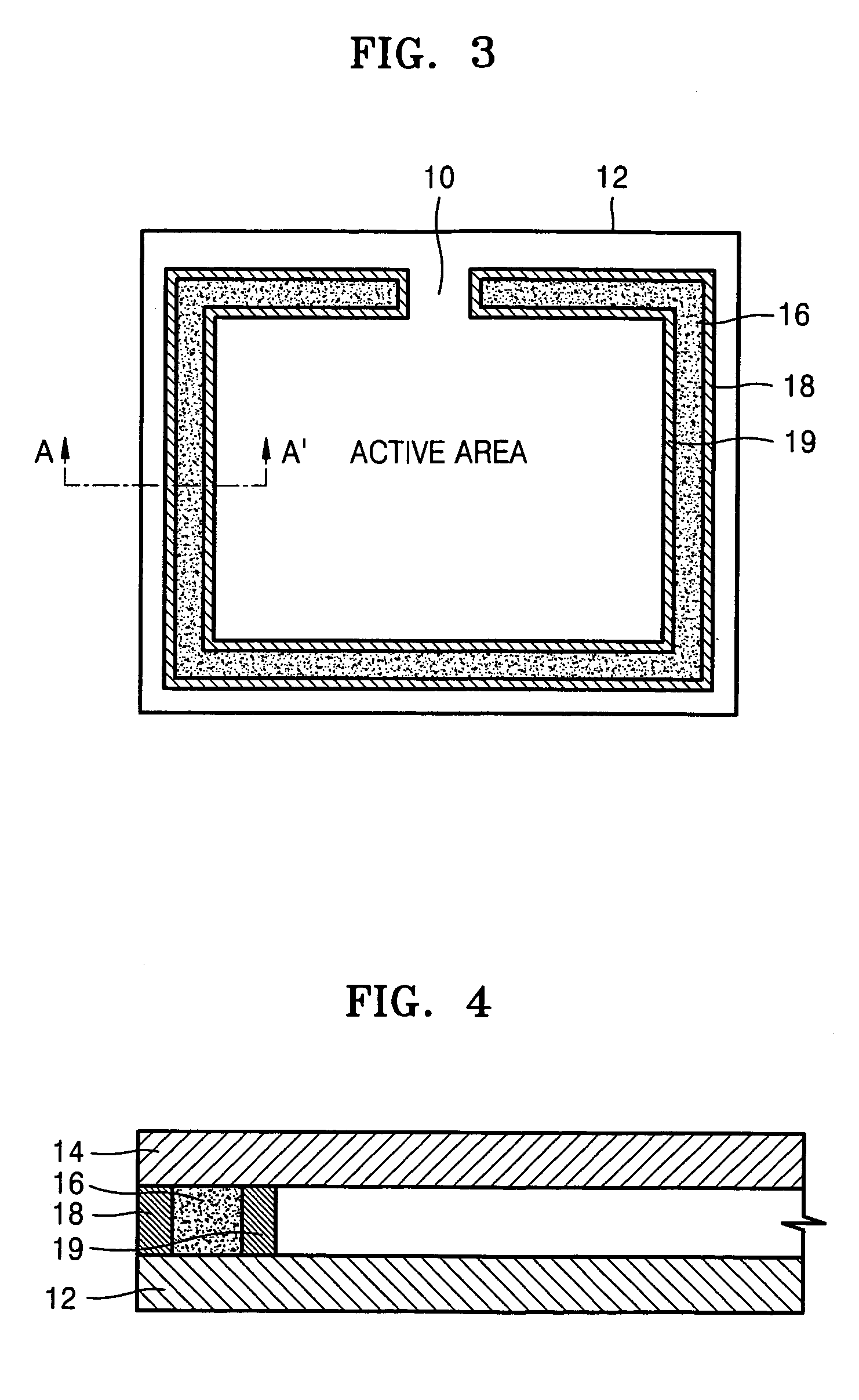

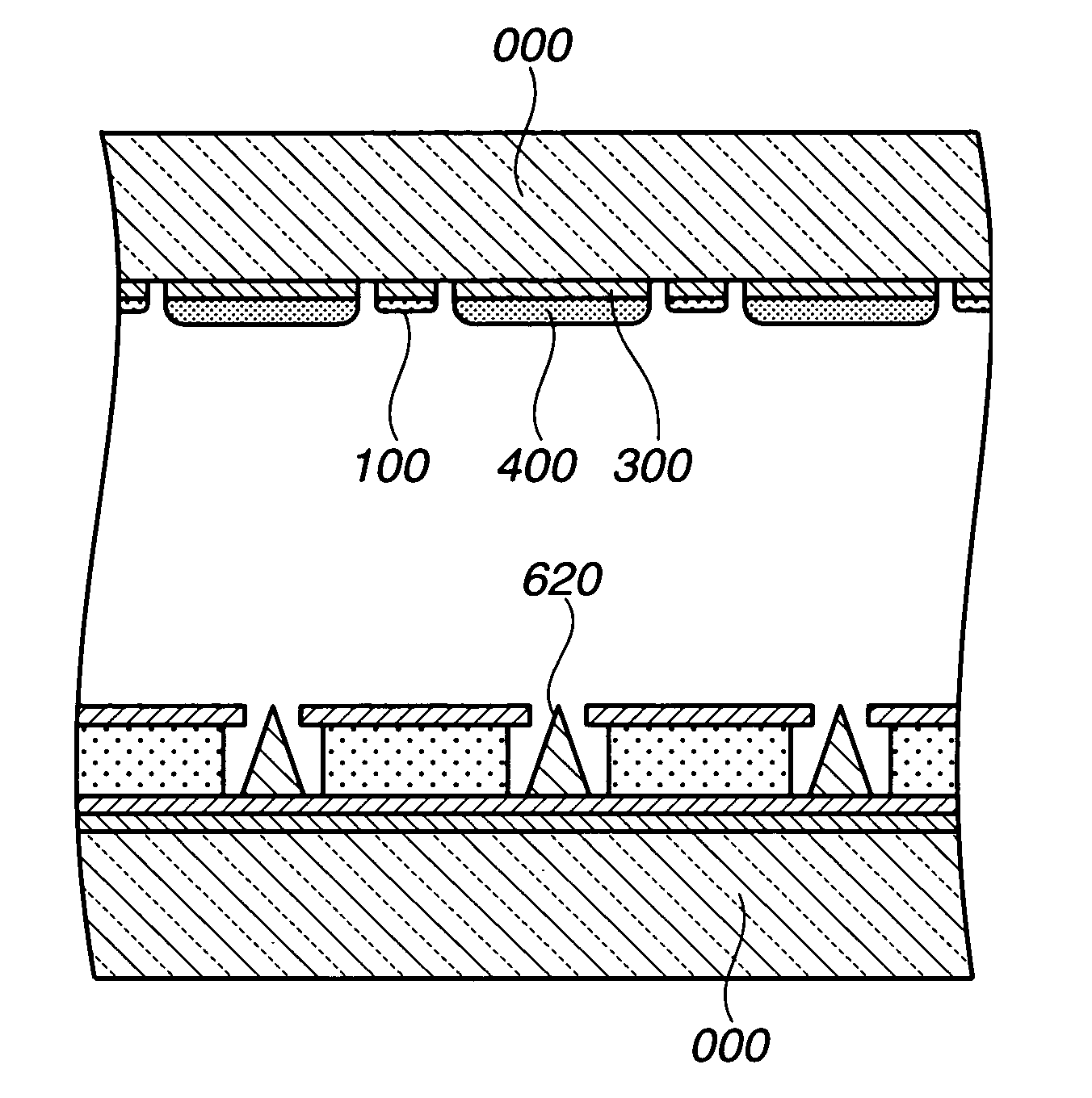

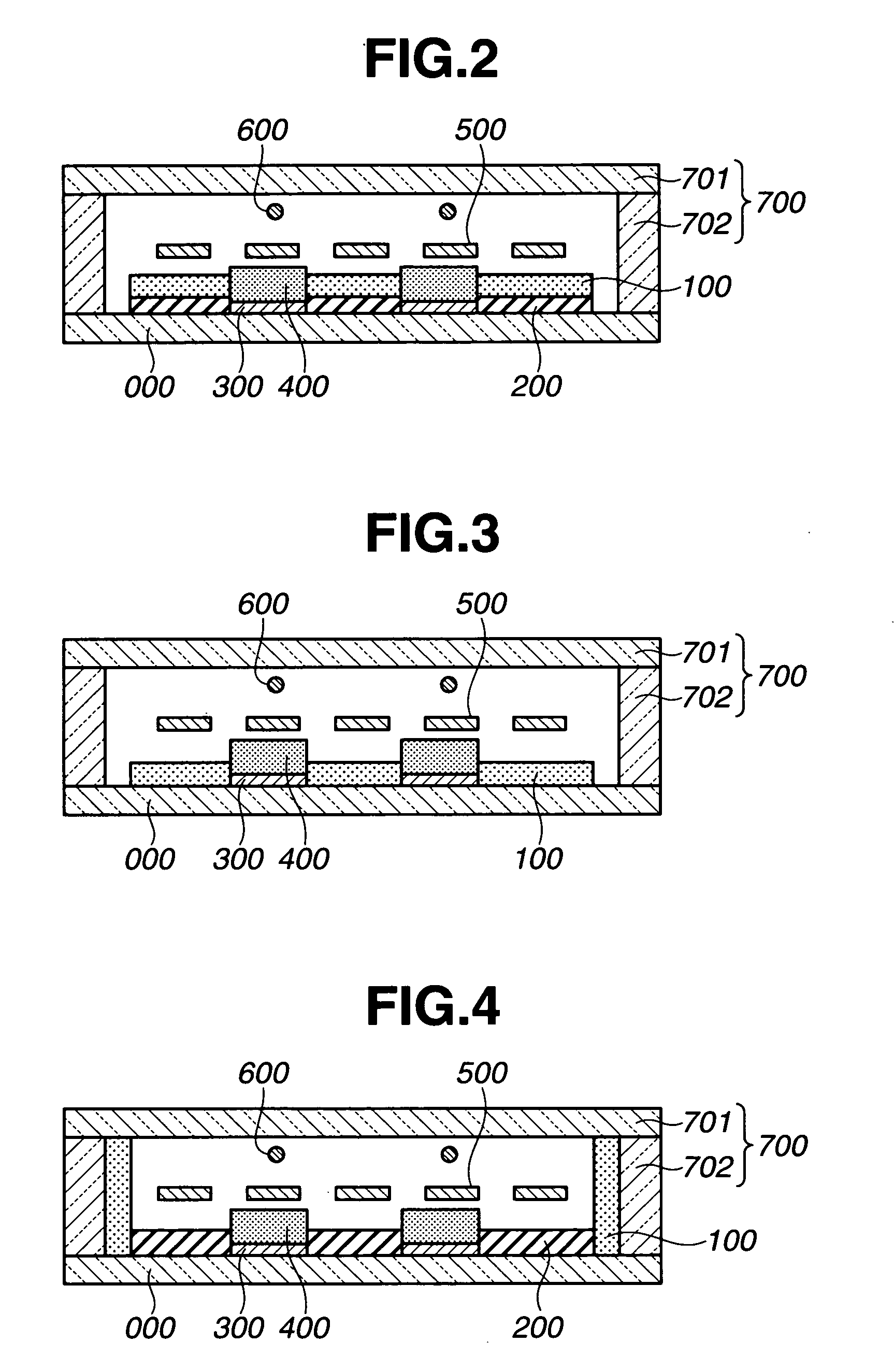

Bonding structure for flat panel display, method of forming the same, and flat panel display including bonding structure

ActiveUS20050238853A1Prevent penetrationMaintaining cell gapStatic indicating devicesTube/lamp vessel degassingDisplay deviceEngineering

Provided are a bonding structure for a flat panel display and a method of forming the same, and a flat panel display, including the bonding structure. The bonding structure of a flat panel display device, which is formed between an upper substrate and a lower substrate to seal and bond the two substrates of the flat panel display device, and the bonding structure includes an outer separation wall and an inner separation wall of same heights being arranged along edges of the upper substrate and the lower substrate with a predetermined interval, and a sealant being applied between the outer separation wall and tn wall.

Owner:SAMSUNG ELECTRONICS CO LTD

Visual display

InactiveUS6517403B1Cathode-ray/electron-beam tube electrical connectionGas filling substance selectionRadiant heaterIrradiation

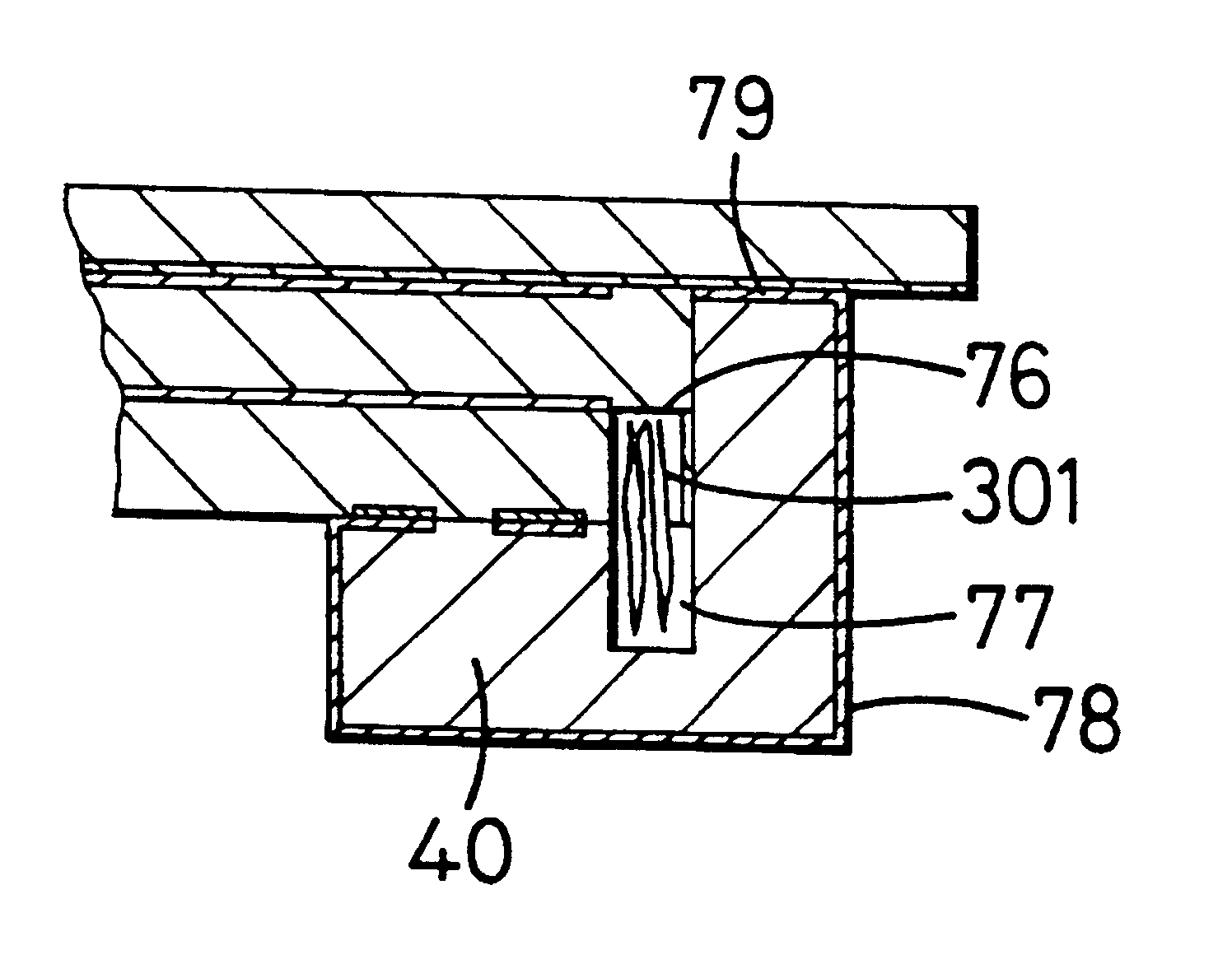

The apparatus for sealing face plates (753) and cathodes (754) has three stations (701, 702, 703). The first (701) is a preheater, the second (702) is an alignment and irradiation station and the third (703) is a controlled cooling station. Beneath each station, a vacuum pump (710) capable of drawing ultralow pressures is provided. The preheater is equipped with upper and lower banks of radiant heaters and reflectors (712). The upper heaters are Provided above a quartz: window (713) of a chamber (714) constituting the station. The pressure in the preheater is pumped down to that in the alignment and irradiation station prior to opening of the gate valve between them and transfer of the face plate and cathode. At the alignment and irradiation station, further heaters (716) are provided. Those above the face plate and cathode, the face plate being uppermost, are mounted on frames (717) about hinges (718), whereby they can be swung up to clear this station's top quartz window, exposing the face plate to the view of an optical system (719) and a laser (720). Manipulation controls (722) are provided for manipulating the position of the face plate to be pixel alignment, as measured by the optical system (719), with the cathode. The laser is traversed around further. The cooling station (703) has meanwhile been pumped down and the sealed device is transferred to it. The temperature of the device is allowed to rise very slowly, in order to reduce the risk of thermal cracking to as great an extent as possible. As the temperature slowly falls, air is slowly introduced, so that the finished device can be removed to the ambient surroundings.

Owner:COMPLETE MULTILAYER SOLUTIONS +1

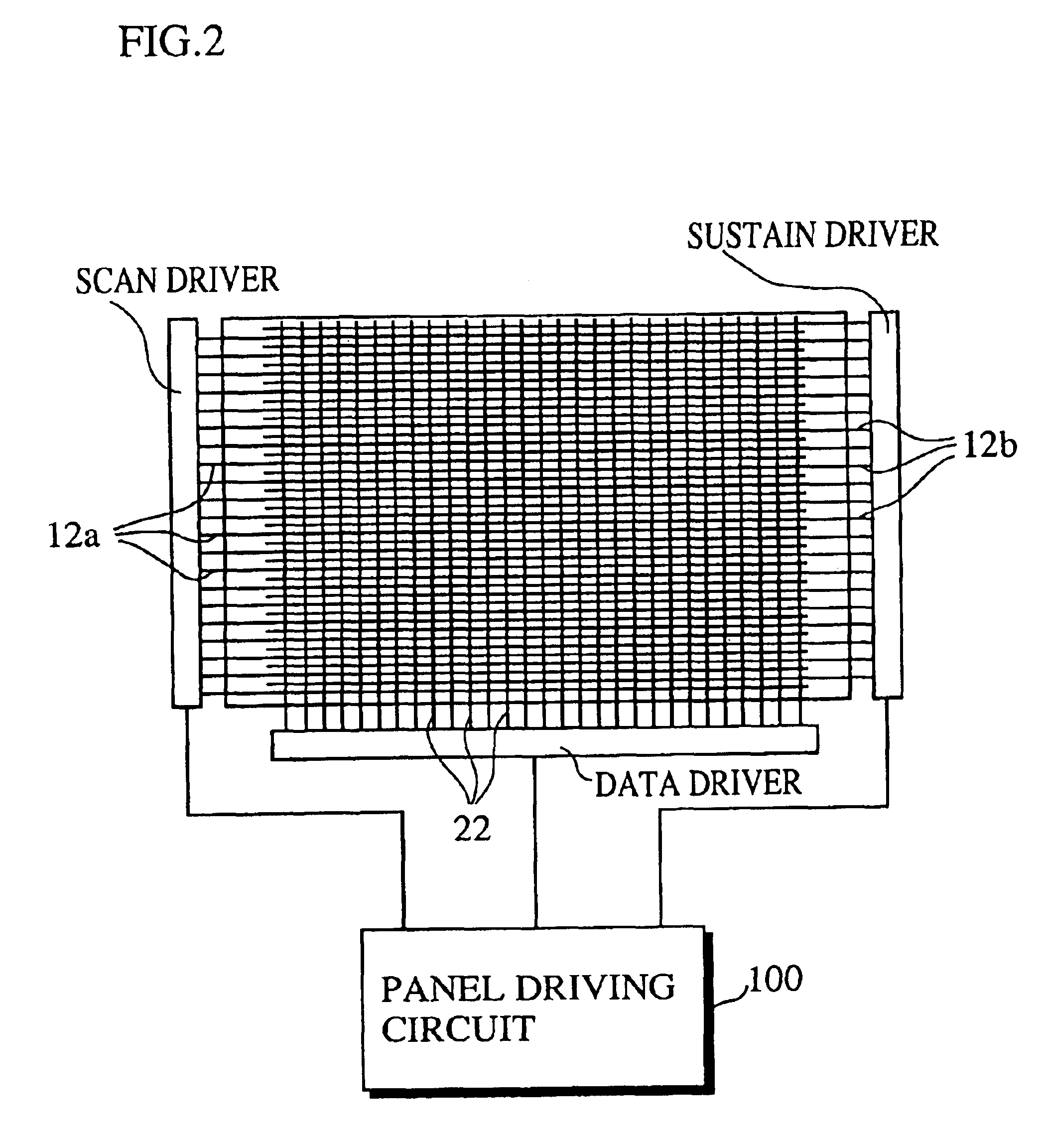

Highly productive method of producing plasma display panel

InactiveUS6860780B2Inhibit deteriorationHigh light-emitting efficiency and color purityAddress electrodesSustain/scan electrodesPhosphorEngineering

A method for producing a plasma display panel that has a front substrate and a back substrate disposed to face each other. A pre-baking phosphor layer containing a phosphor and an organic binder is formed on at least one of surfaces of the front substrate and the back substrate that are to face each other. A sealing material that softens with heat is applied to the peripheral region of at least one of the surfaces of the front and back substrates that are to face each other. The front and back substrates are disposed to face each other in a stack. The front and back substrates are heated to burn out the organic binder while supplying a dry gas containing oxygen to an internal space that is formed between the front and back substrates.

Owner:PANASONIC CORP

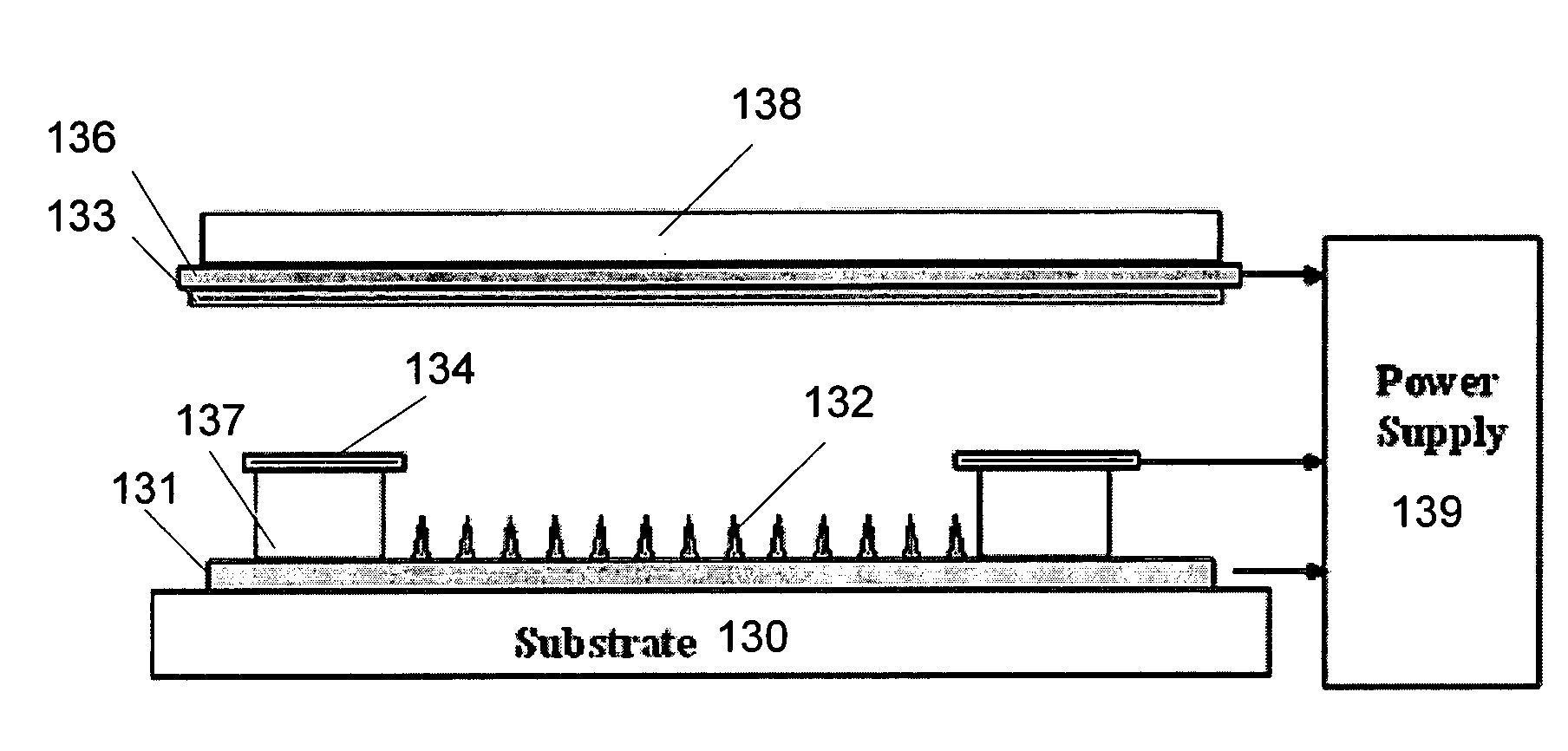

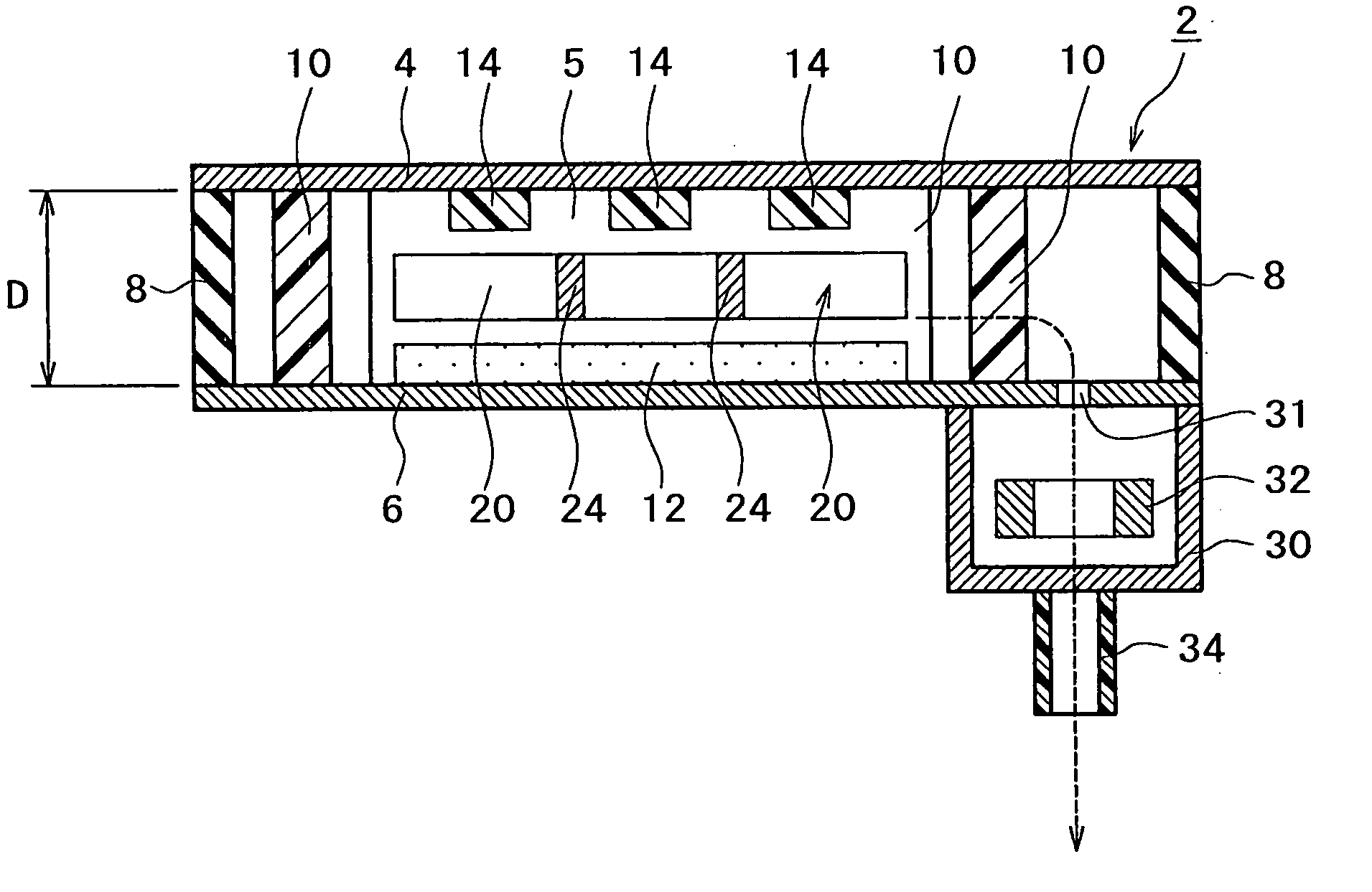

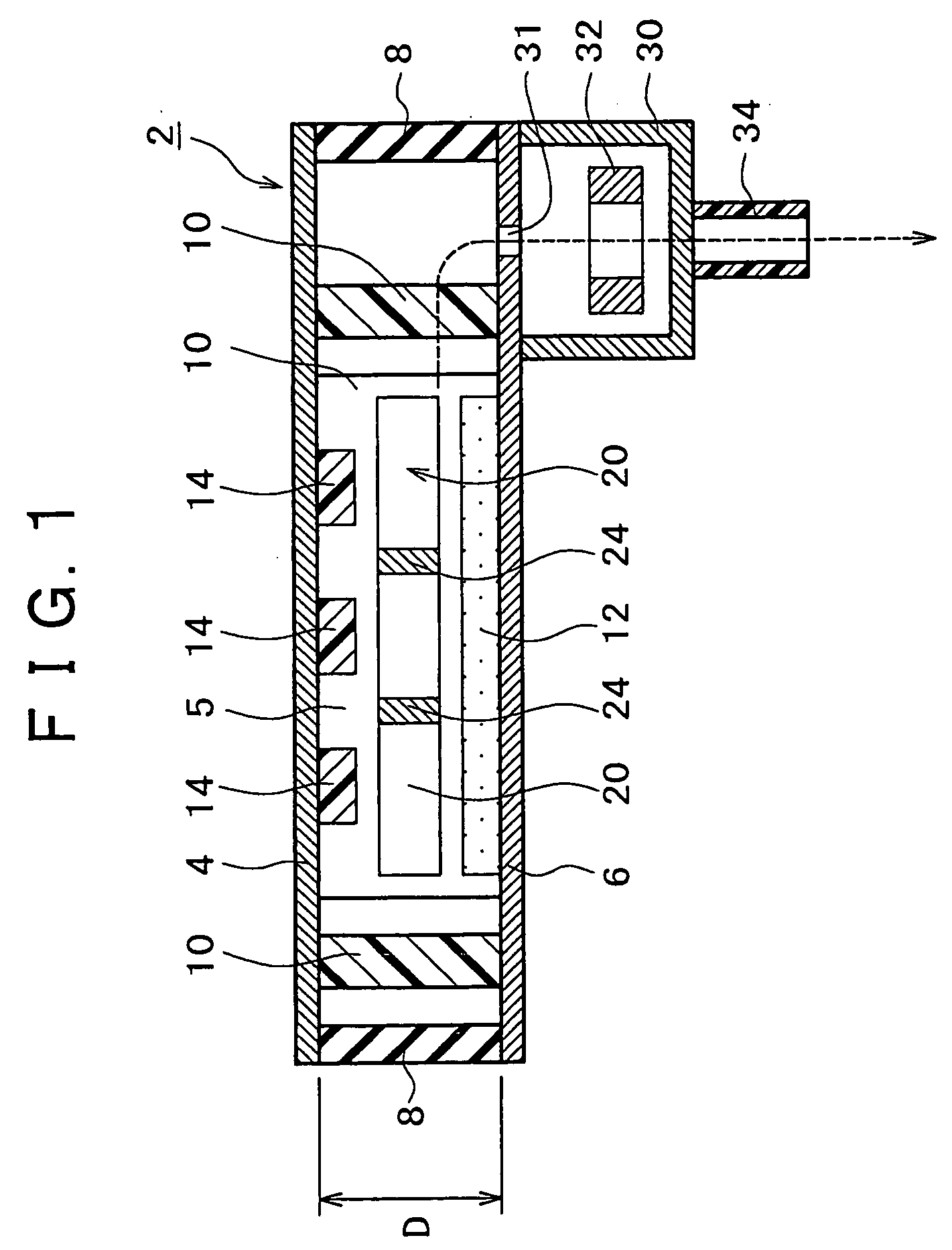

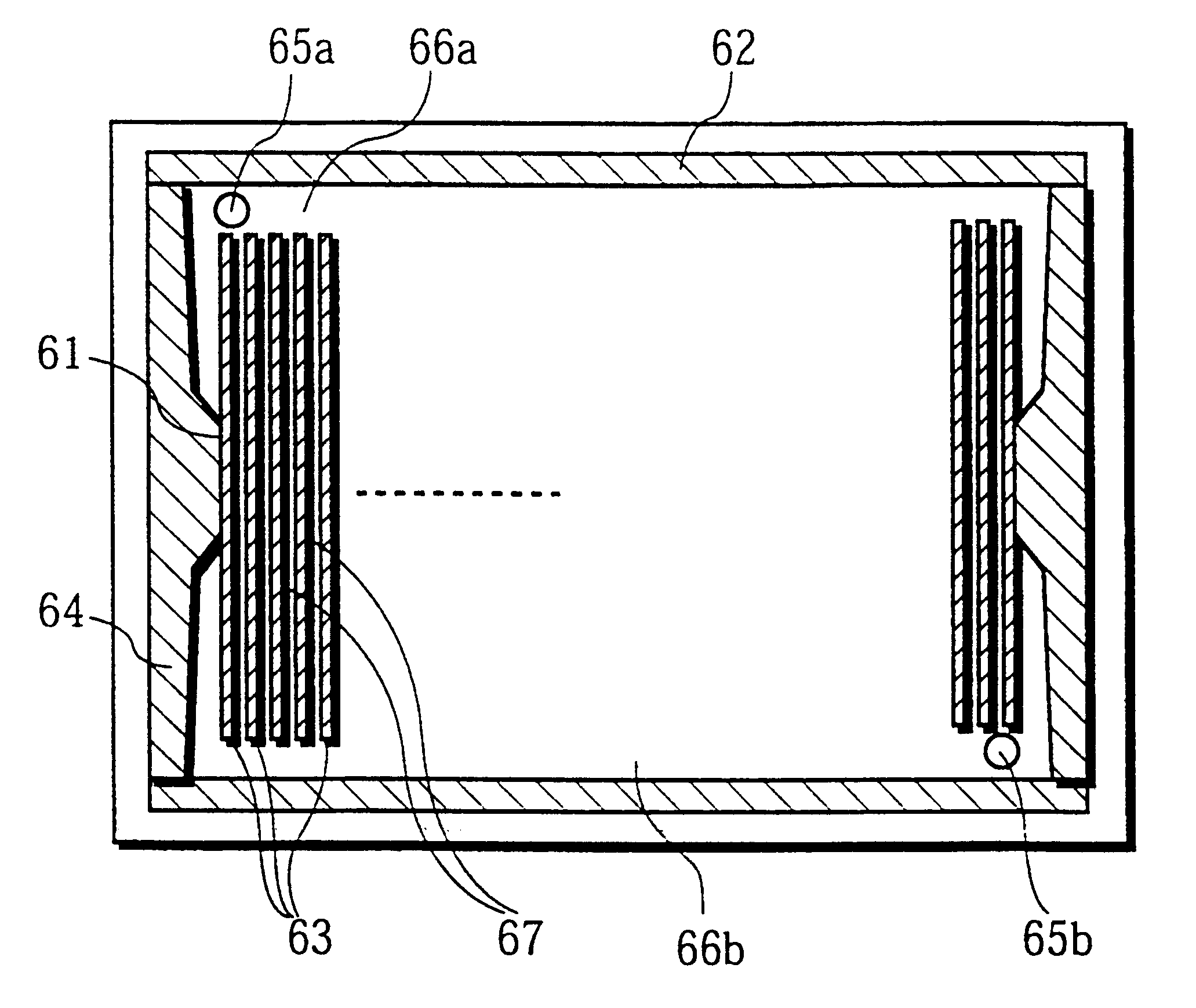

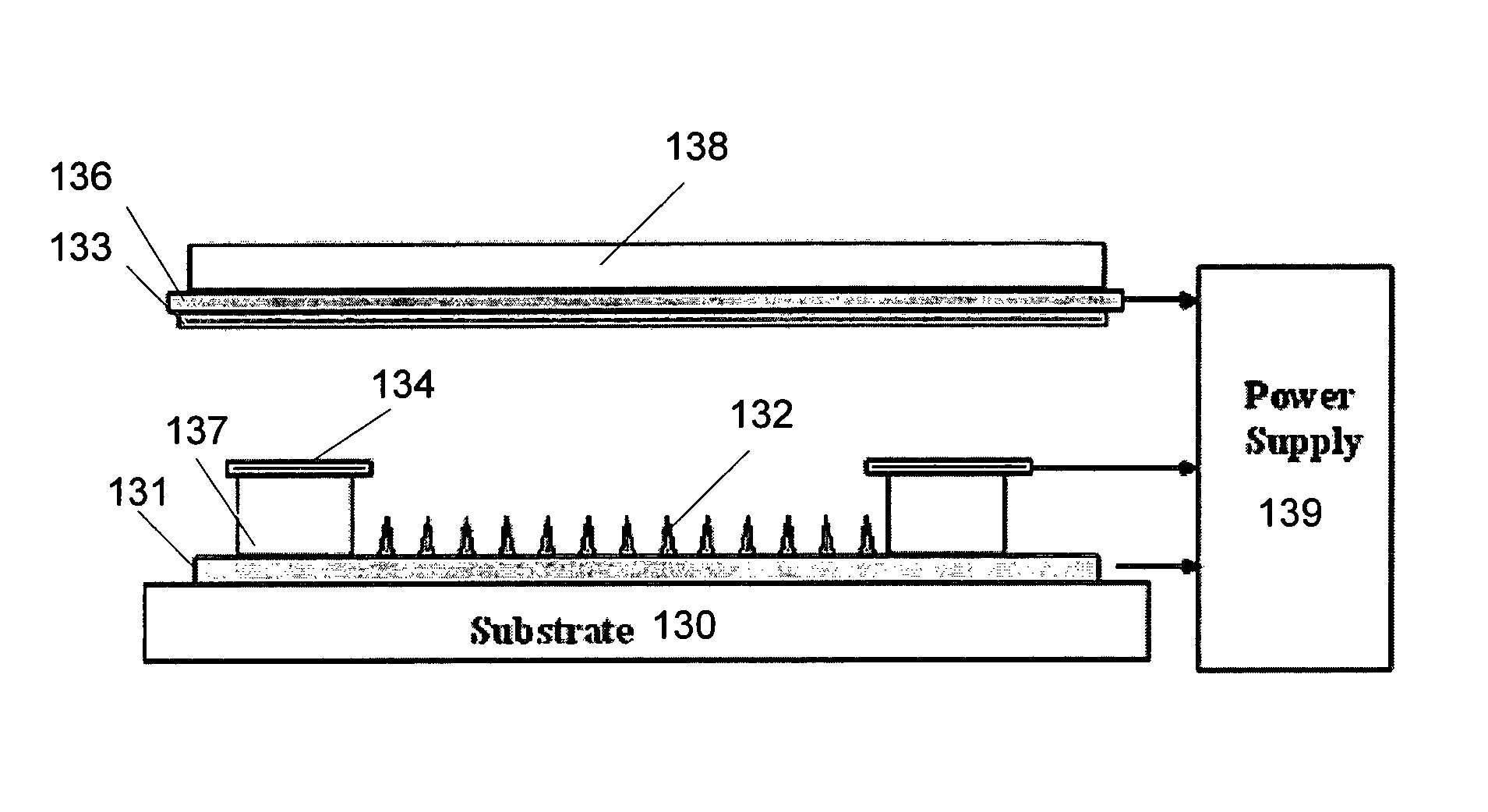

Field emission display manufacturing method having integrated getter arrangement

InactiveUS7131883B2Efficient removalGas filling substance selectionDischarge tube luminescnet screensField emission displayElectron

A field emission display (FED) and a manufacturing method thereof are provided. The FED includes a getter portion isolated outwardly from an active display region. This getter portion includes a non-evaporable getter layer for absorbing gas and an electron emission source for activating the getter layer. Accordingly, by activating the non-evaporable getter, the gas generated in the display is easily absorbed, and the FED is maintained in a high vacuum state.

Owner:SAMSUNG SDI CO LTD

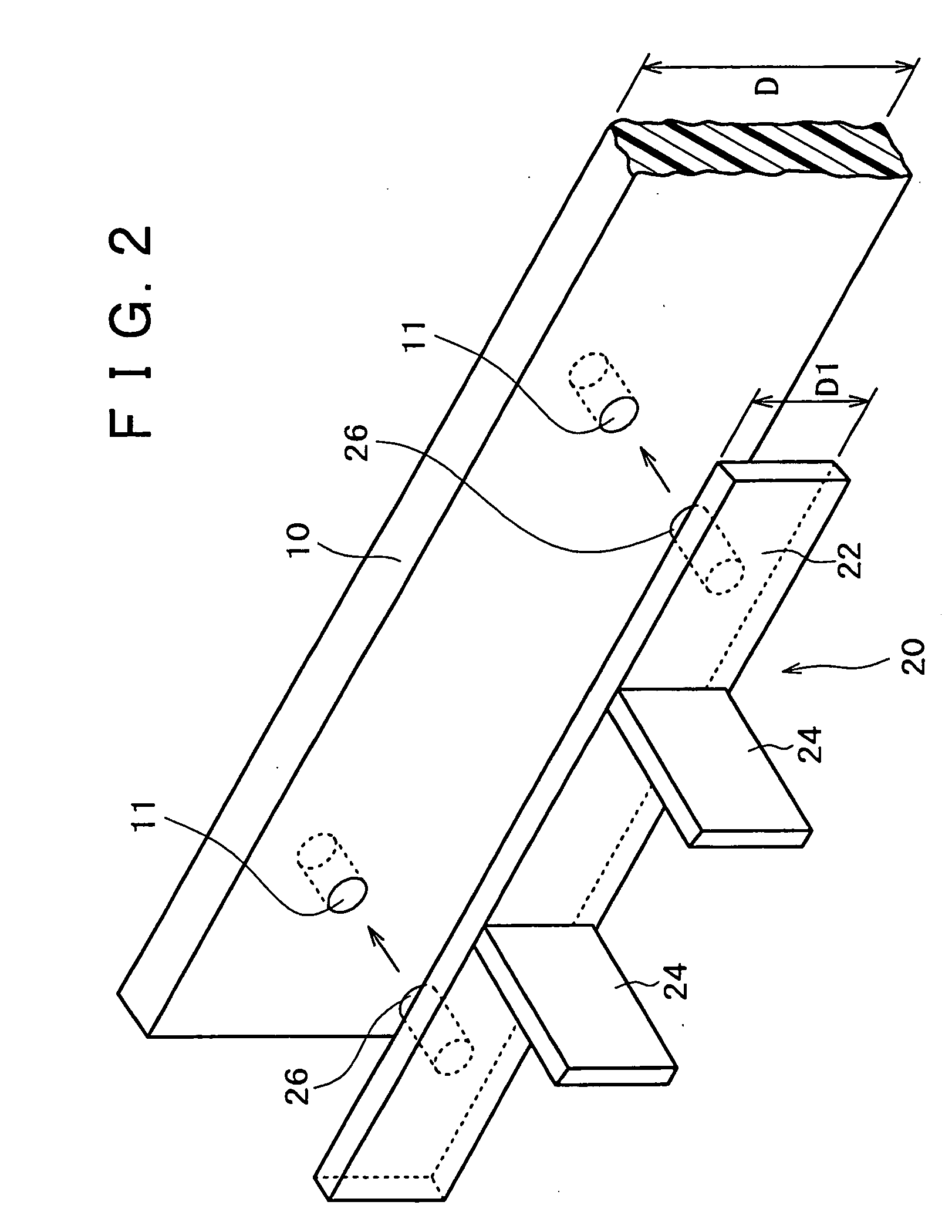

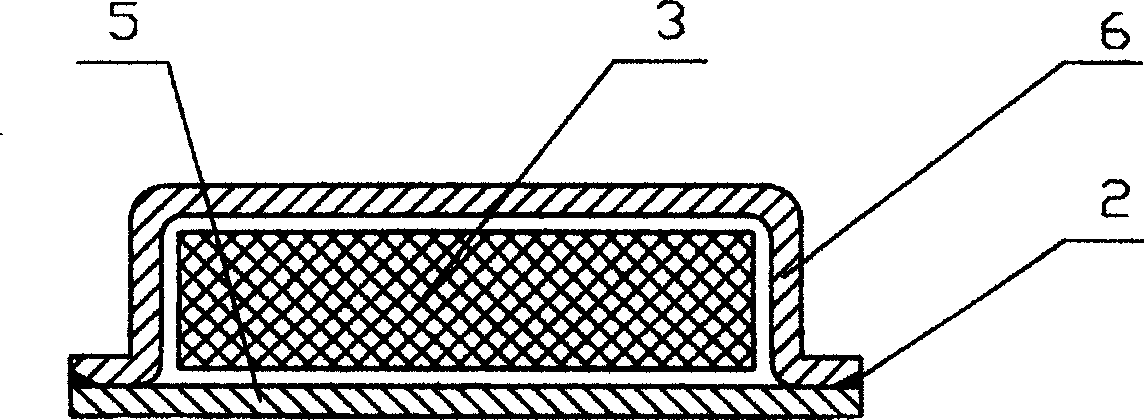

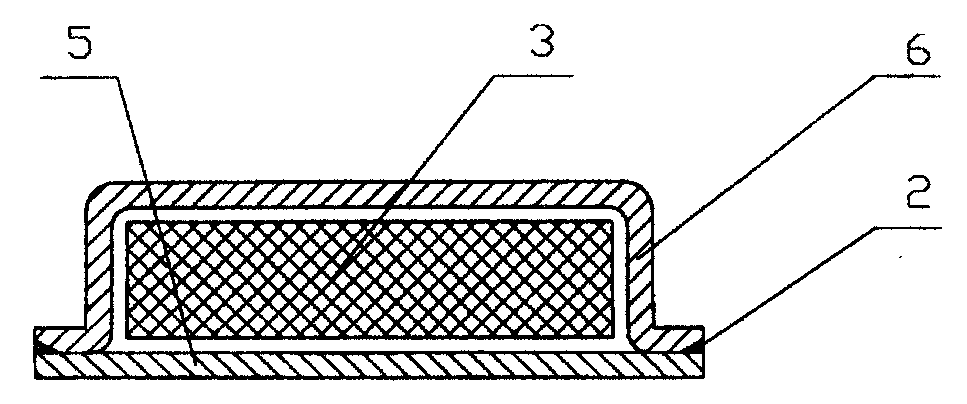

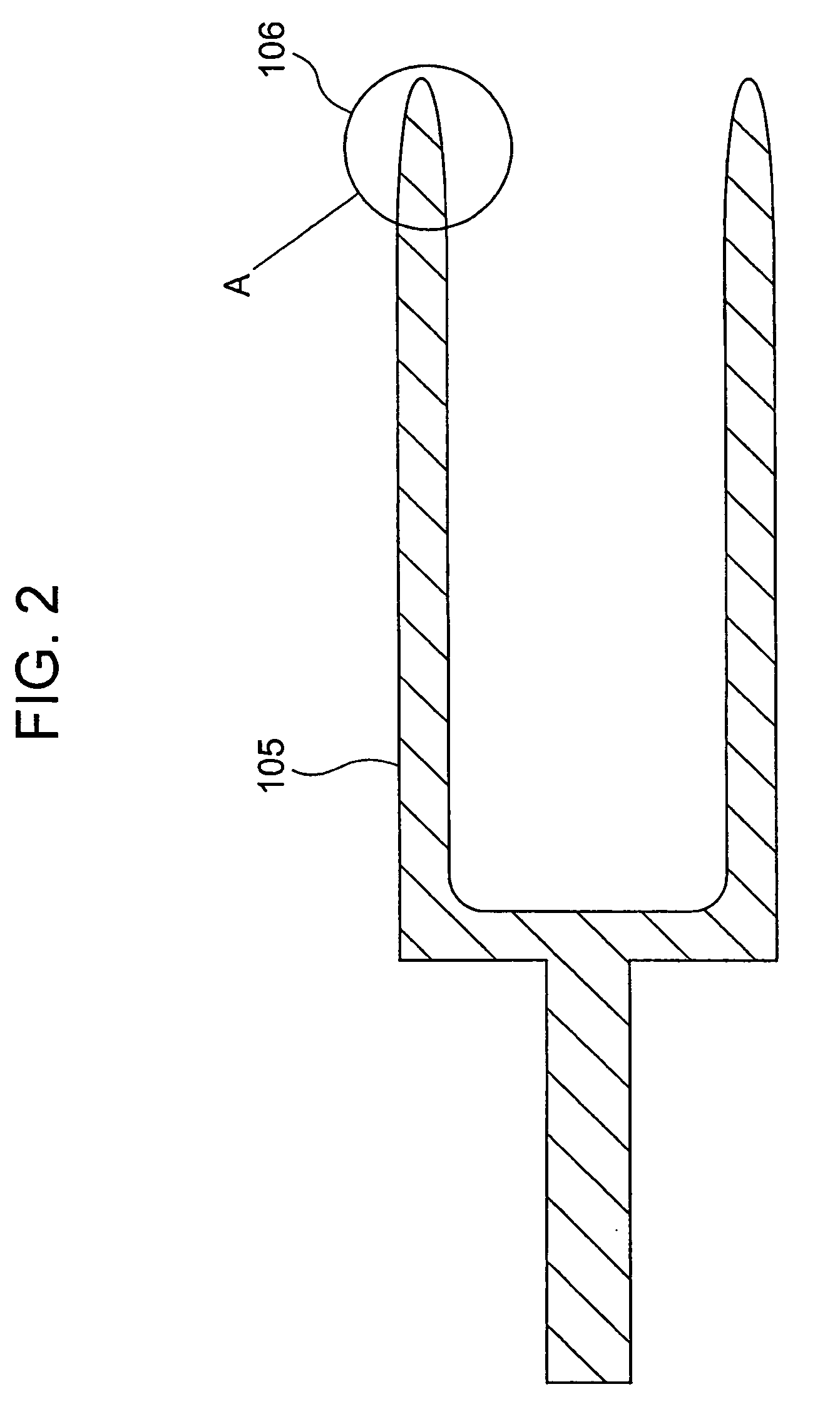

Non-evaporation type getter, display unit and production method for them

InactiveUS20040169469A1Complex shapeHigh mechanical strengthGas filling substance selectionCathode-ray/electron-beam tube vessels/containersPorosityEvaporation

Disclosed are a non-evaporation type getter excellent in gettering effect, capable of maintaining the inside of a gas-tight container in a display apparatus, particularly a flat panel display apparatus or the like, in a high vacuum condition, easy to mount and less liable to contaminate the inside of the gas-tight container, a display apparatus including the getter, and methods of manufacturing the same. The non-evaporation type getter (20) includes a molded body including at least one element selected from the group consisting of Ti, Zr, Al, V, and Fe as a principal constituent thereof, the molded body formed by powder injection molding. The molded body is composed of a porous body having a porosity of 10 to 30%.

Owner:SONY CORP

Plasma display panel manufacturing method for achieving luminescence characteristics

InactiveUS6666738B1Avoid flowInhibit deteriorationTube/lamp vessel degassingAlternating current plasma display panelsFluorescenceEngineering

The object of this invention is to provide a plasma display panel in which an aging process essential to the manufacturing process generates minimal phosphor deterioration, enabling a relatively high luminous efficiency and high quality color production to be produced. To achieve this object, the aging process takes place while gas generated inside the panel is evacuated. Alternatively, after completion of the aging process, the phosphor of the whole panel is heated to restore heat deterioration.

Owner:PANASONIC CORP

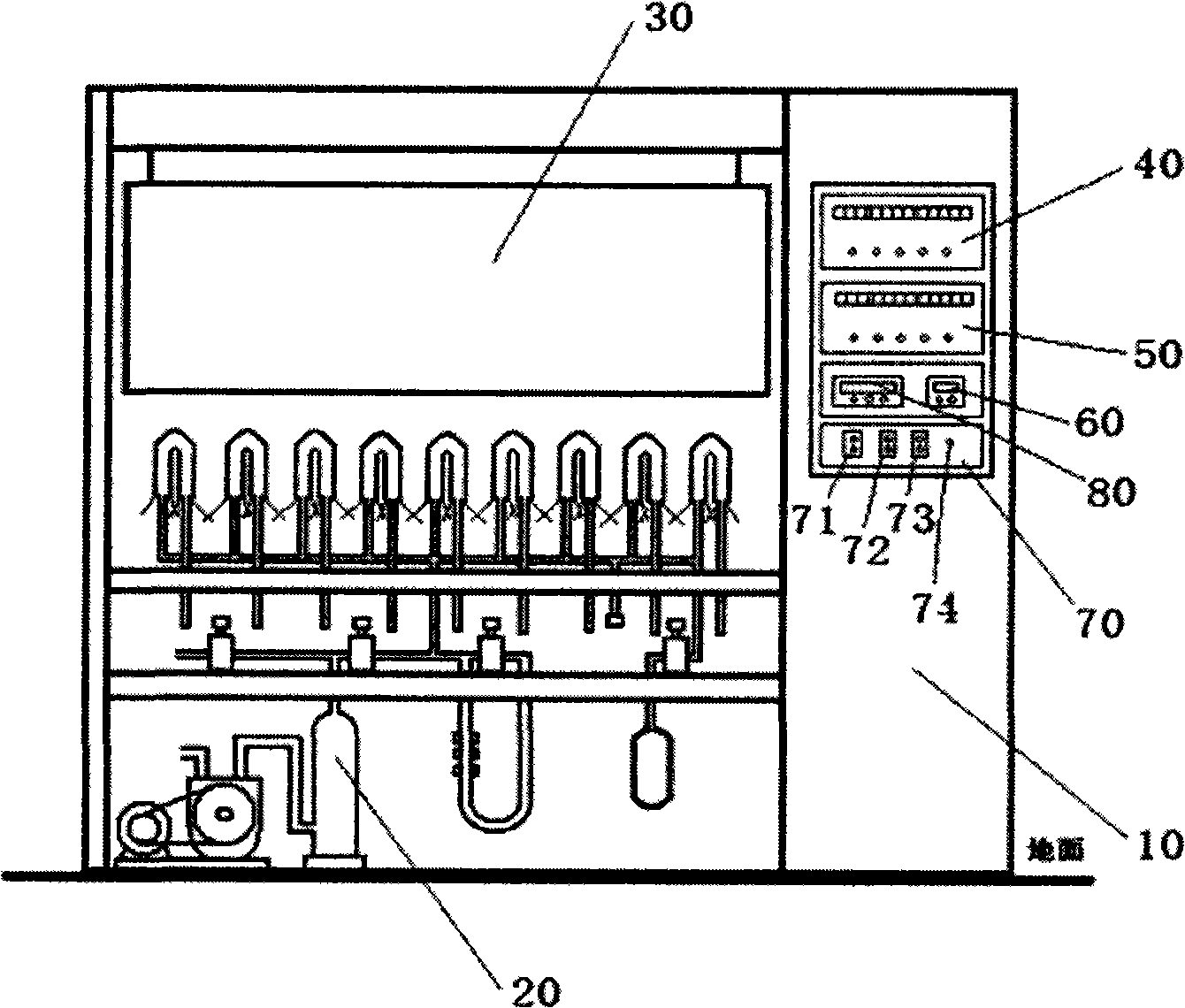

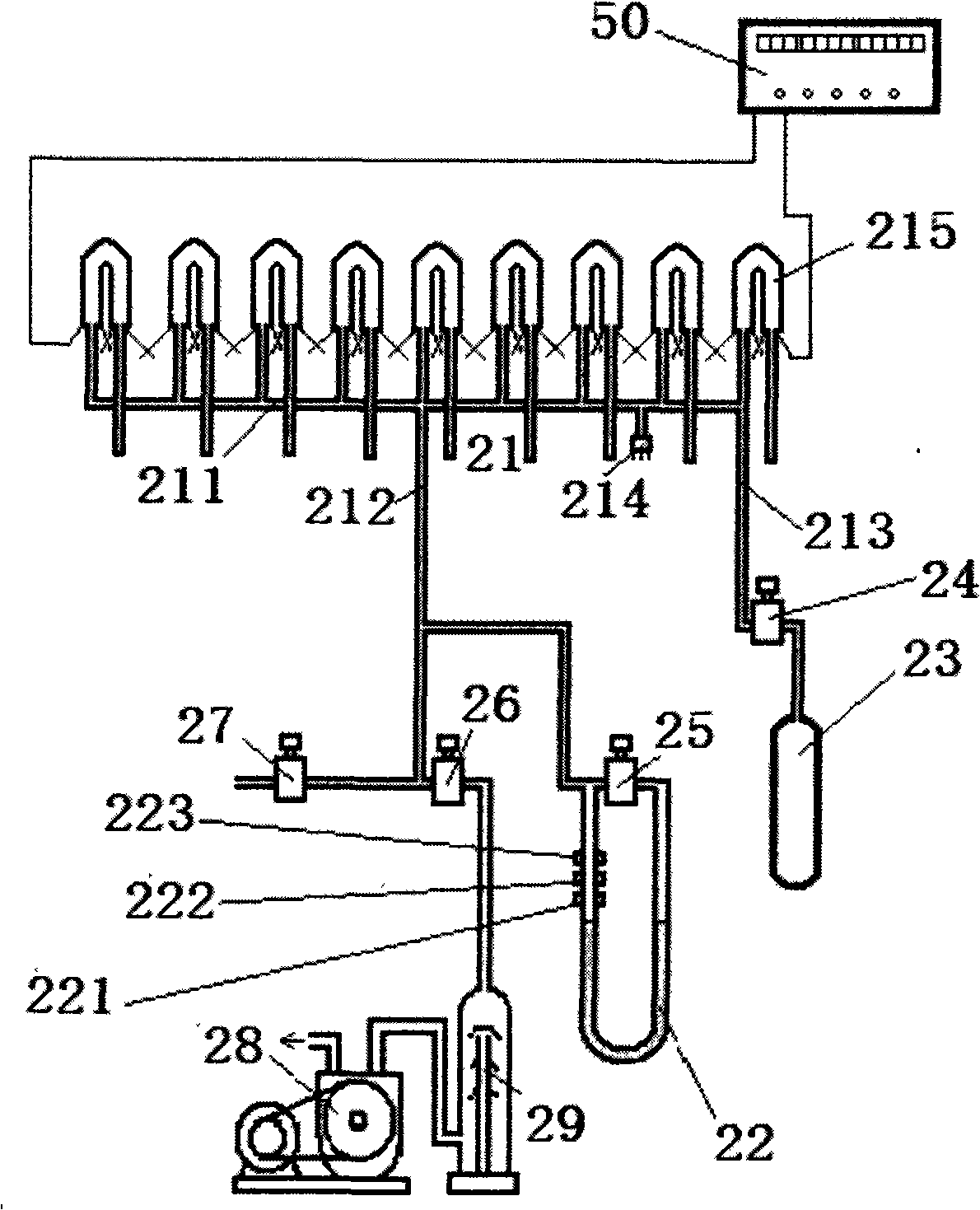

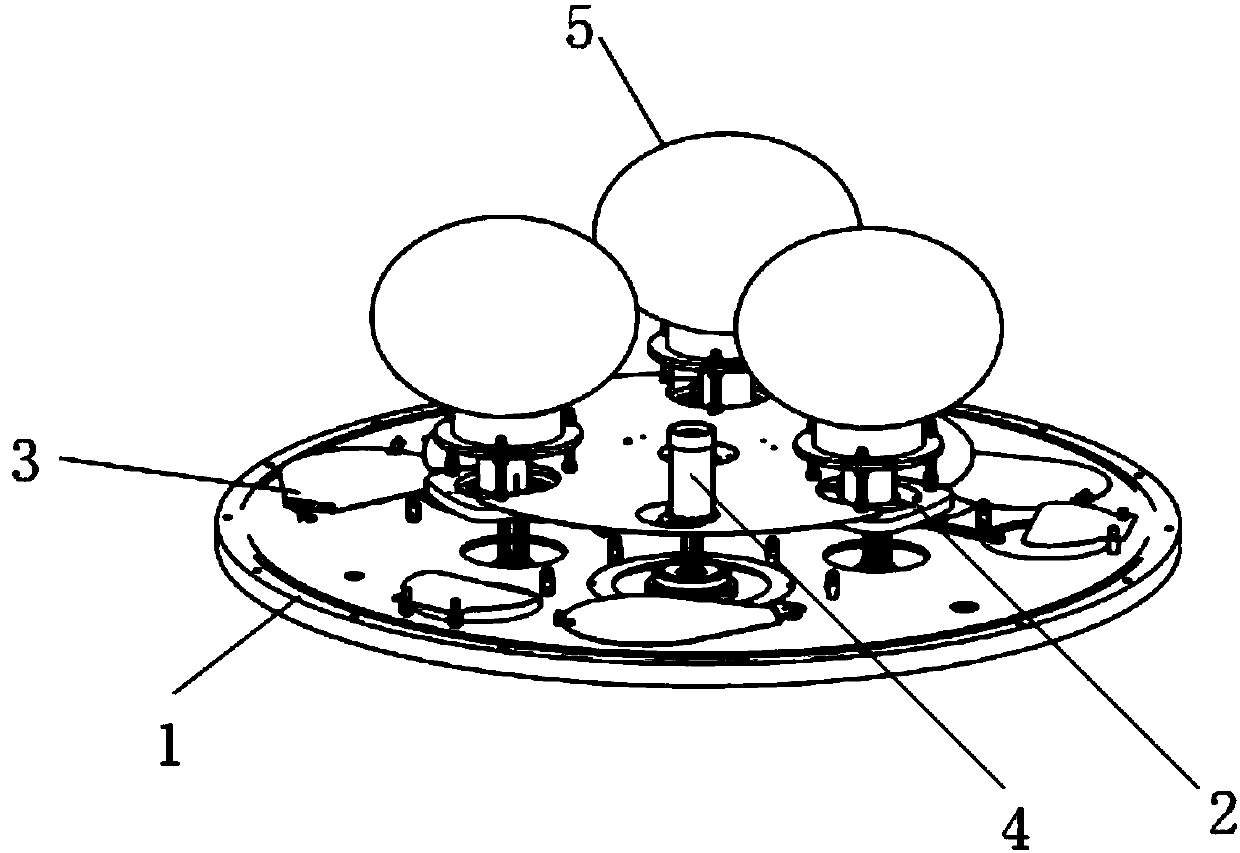

Exhaustion bench for full-automatic glass vacuum system

InactiveCN101276717ASimple structureLow priceTube/lamp vessel degassingTube/lamp vessels exhaustionAutomatic controlControl system

A full-automatic glass vacuum system exhausting table is disclosed, comprising a full glass vacuum pipeline, a glass target connected with a lamp to be exhausted, four electric control glass valves, a glass argon gas bottle and a photoelectric reading U-shaped glass pressure gauge. The vacuumization system is composed by a glass dispersing pump and a mechanical vacuum pump, and installed with an oven whose temperature is automatically controlled, an oven temperature preservation door and a control system for controlling the oven to automatic ascend and descend. The invention realize the automatization of the glass vacuum system by using above technical proposal. The full-automatic glass vacuum system exhausting table not only has good airproof performance and the advantage that preservation time of the glass vacuum system is far longer than that of common metal vacuum system, but also has low cost and convenient maintenance, thus completely eliminating the influence by human factors to the quality of products, reducing the waste product rate and enhancing production efficiency.

Owner:匡正芳

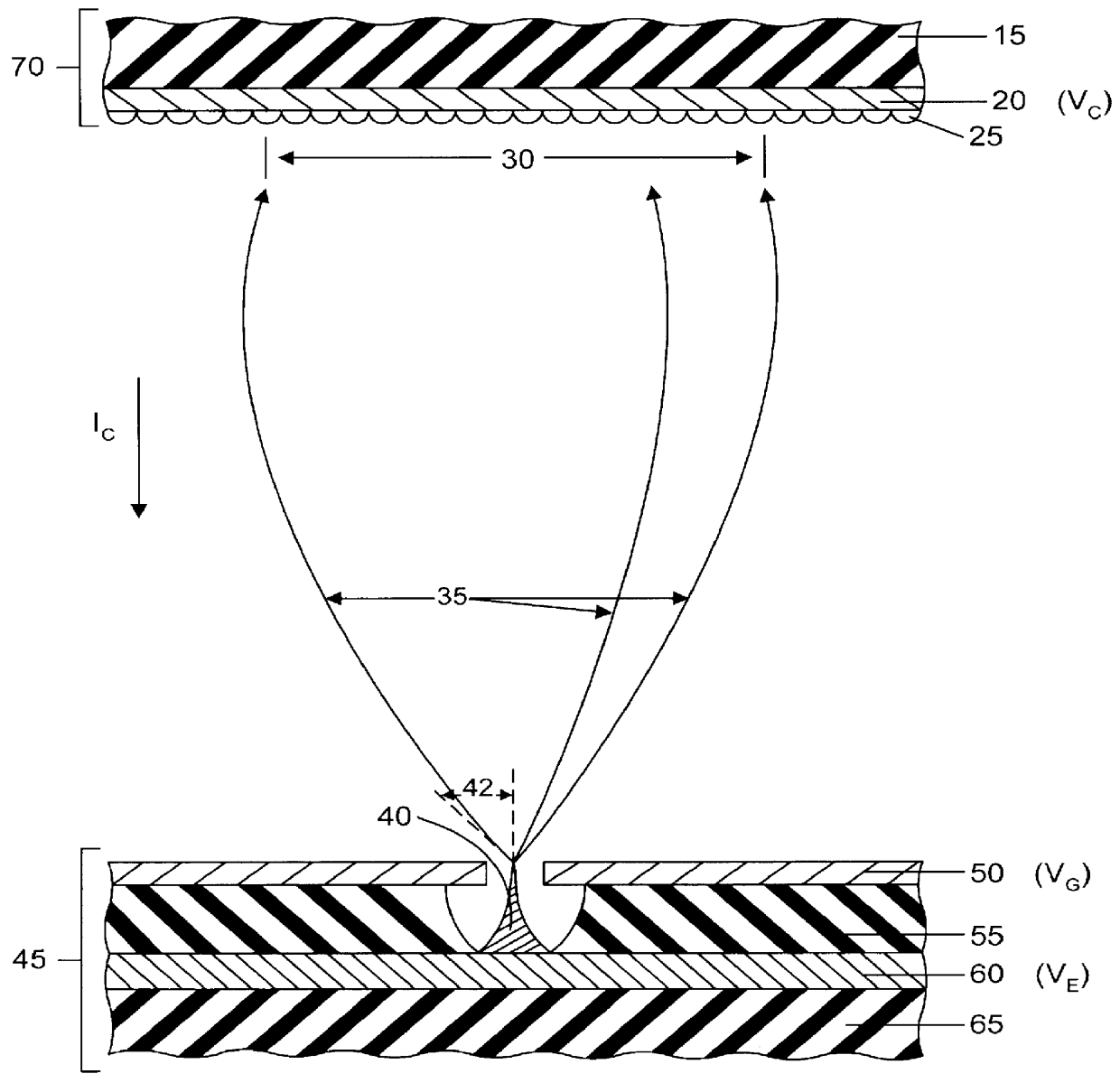

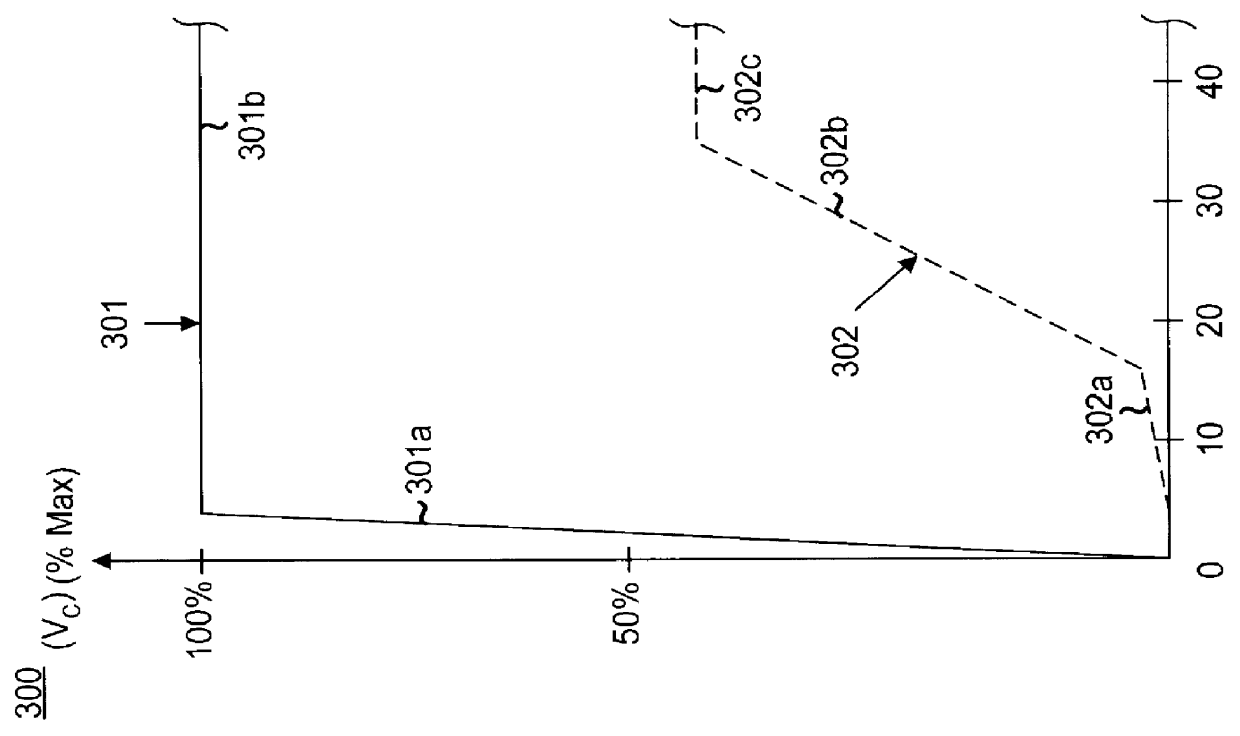

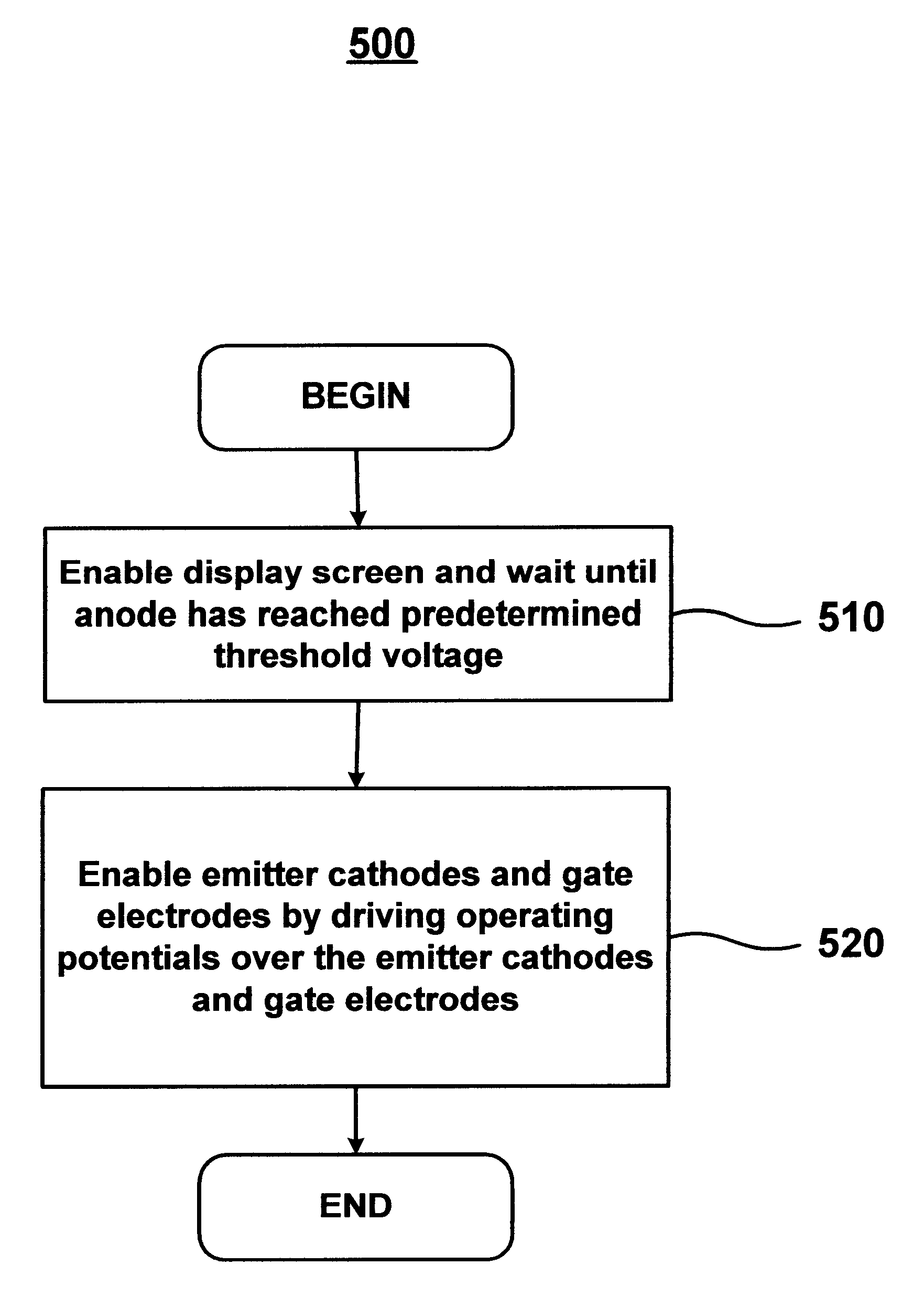

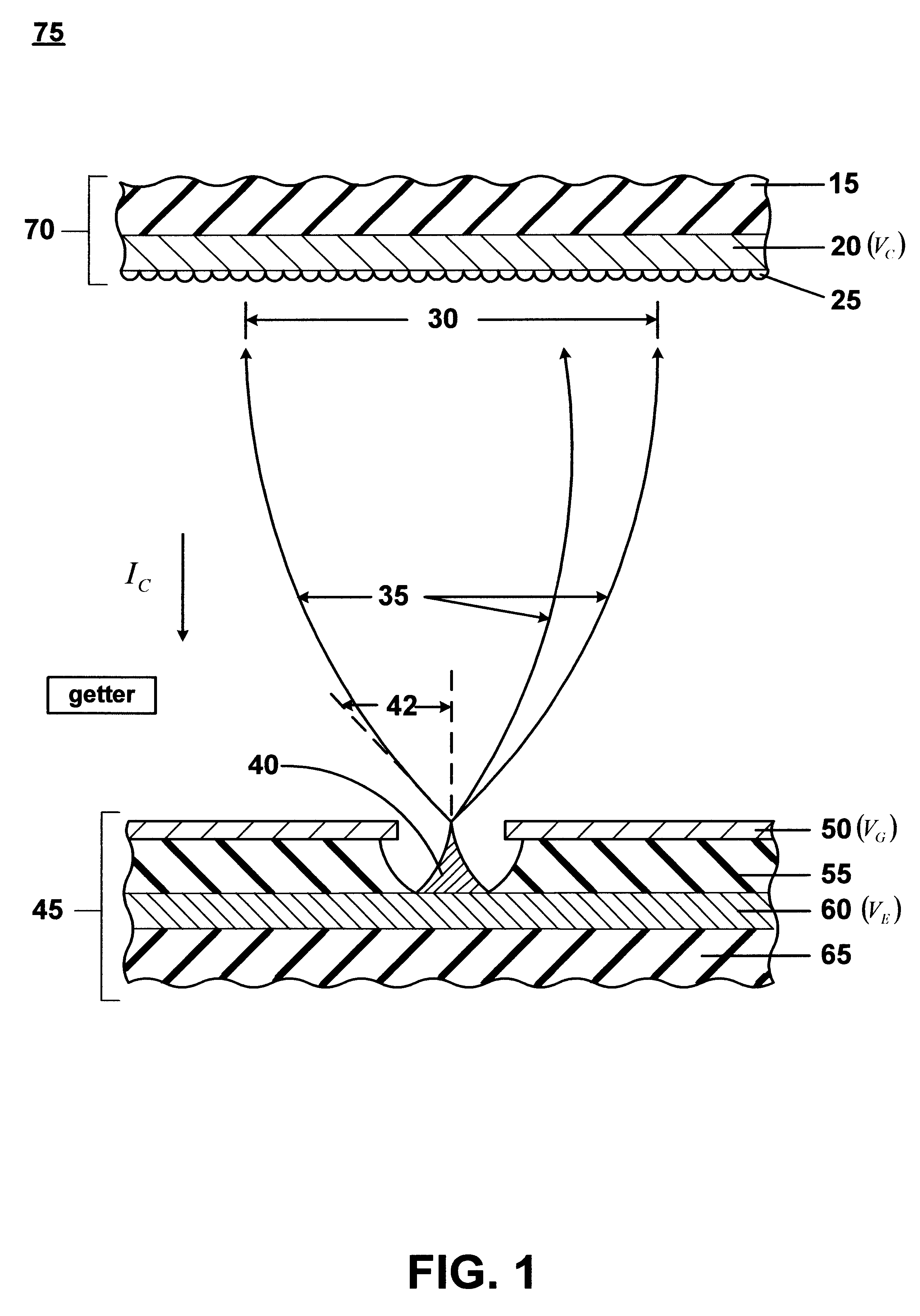

Procedures and apparatus for turning-on and turning-off elements within a field emission display device

InactiveUS6104139AIncrease currentEfficient removalDischarge tube luminescnet screensStatic indicating devicesSufficient timeField emission display

A method of removing contaminant particles in newly fabricated field emission displays. According to one embodiment of the present invention, contaminant particles are removed by a conditioning process which includes the steps of: a) driving a anode of a field emission display (FED) to a predetermined voltage; b) slowly increasing an emission current of the FED after the anode has reached the predetermined voltage; and c) providing an ion-trapping device for catching the ions and particles knocked off, or otherwise released, by emitted electrons. In this embodiment, by driving the anode to the predetermined voltage and by slowly increasing the emission current of the FED, contaminant particles are effectively removed without damaging the FED. The present invention also provides a method of operating FEDs to prevent gate-to-emitter current during turn-on and turn-off. In this embodiment, the method comprises the steps of: a) enabling the anode display screen; and, b) enabling the electron-emitters after the anode display screen is enabled. In this embodiment, by allowing sufficient time for the anode display screen to reach a predetermined voltage before the emitter is enabled, the emitted electrons will be attracted to the anode.

Owner:CANON KK

Method for gettering an image display apparatus

InactiveUS6652343B2Little changeLittle unevennessGas filling substance selectionDischarge tube luminescnet screensElectron sourceFluorescence

An image display apparatus is provided with an external housing constituted by members including first and second substrates positioned with a gap therebetween, an electron source positioned on the first substrate in the external housing, and a fluorescent film and an accelerating electrode provided on the second substrate. A first getter is positioned in the image display area in the external housing. A second getter is provided, so that it is insulated from the electron source and the accelerating electrode, which surrounds the first getter.

Owner:CANON KK

Sealed getter

InactiveCN1359127AFor long-term storageEasy to openLiving organism packagingTube/lamp vessel degassingAtmospheric airMetal sheet

The present invention discloses an encapsulated getter belongs to the field of vacuum getter techonlogy, and is characterized by that metal sheet or ring and getter component are placed in glass thin-wall pipe and tightly encapsulated or the getter is placed in metal thin-wall container or glass thin-wall container, said container is evacuated or charged by inert gas, then sealed and stored. Said invention is applicable to various vacuum devices, said getter can be stored for a long period, and can provide convenience for next procedure.

Owner:新立基节能玻璃(天津)有限公司

Procedures and apparatus for turning-on and turning-off elements within a field emission display device

InactiveUS6459209B1Increase currentEfficient removalDischarge tube luminescnet screensStatic indicating devicesSufficient timeField emission display

Owner:CANON KK

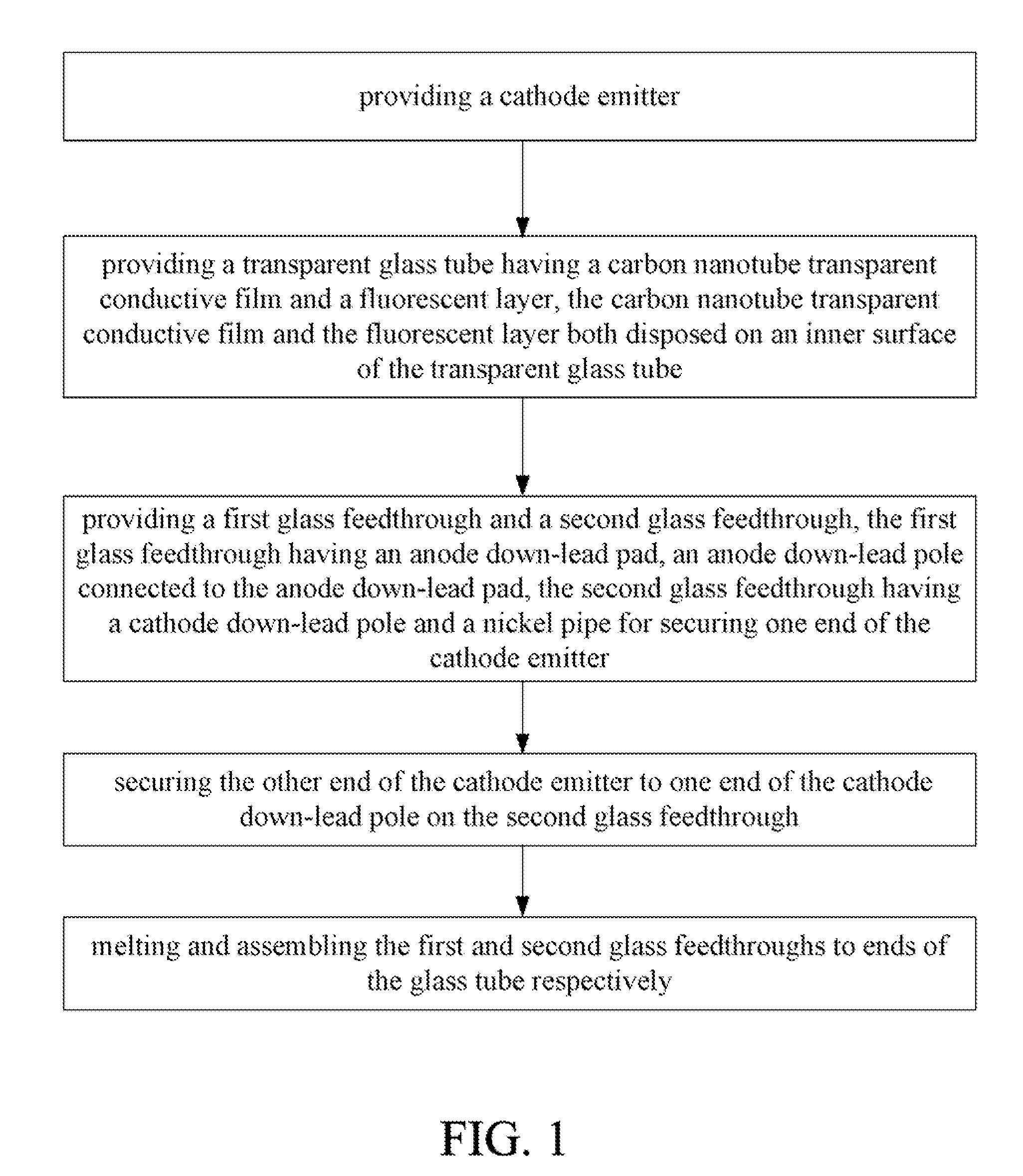

Method for making field emission lamp

ActiveUS20080160865A1Affects performance lifeLow costTube/lamp vessel degassingThermionic cathodesCarbon nanotubeNickel

A method for making a field emission lamp generally includes the steps of: (a) providing a cathode emitter; (b) providing a transparent glass tube having a carbon nanotube transparent conductive film and a fluorescent layer, the carbon nanotube transparent conductive film and the fluorescent layer both disposed on an inner surface of the transparent glass tube; (c) providing a first glass feedthrough and a second glass feedthrough, the first glass feedthrough having an anode down-lead pad, an anode down-lead pole connected to the anode down-lead pad, the second glass feedthrough having a cathode down-lead pole and a nickel pipe for securing one end of the cathode emitter; (d) securing the other end of the cathode emitter to one end of the cathode down-lead pole on the second glass feedthrough; (e) melting and assembling the first and second glass feedthroughs to ends of the glass tube respectively.

Owner:TSINGHUA UNIV +1

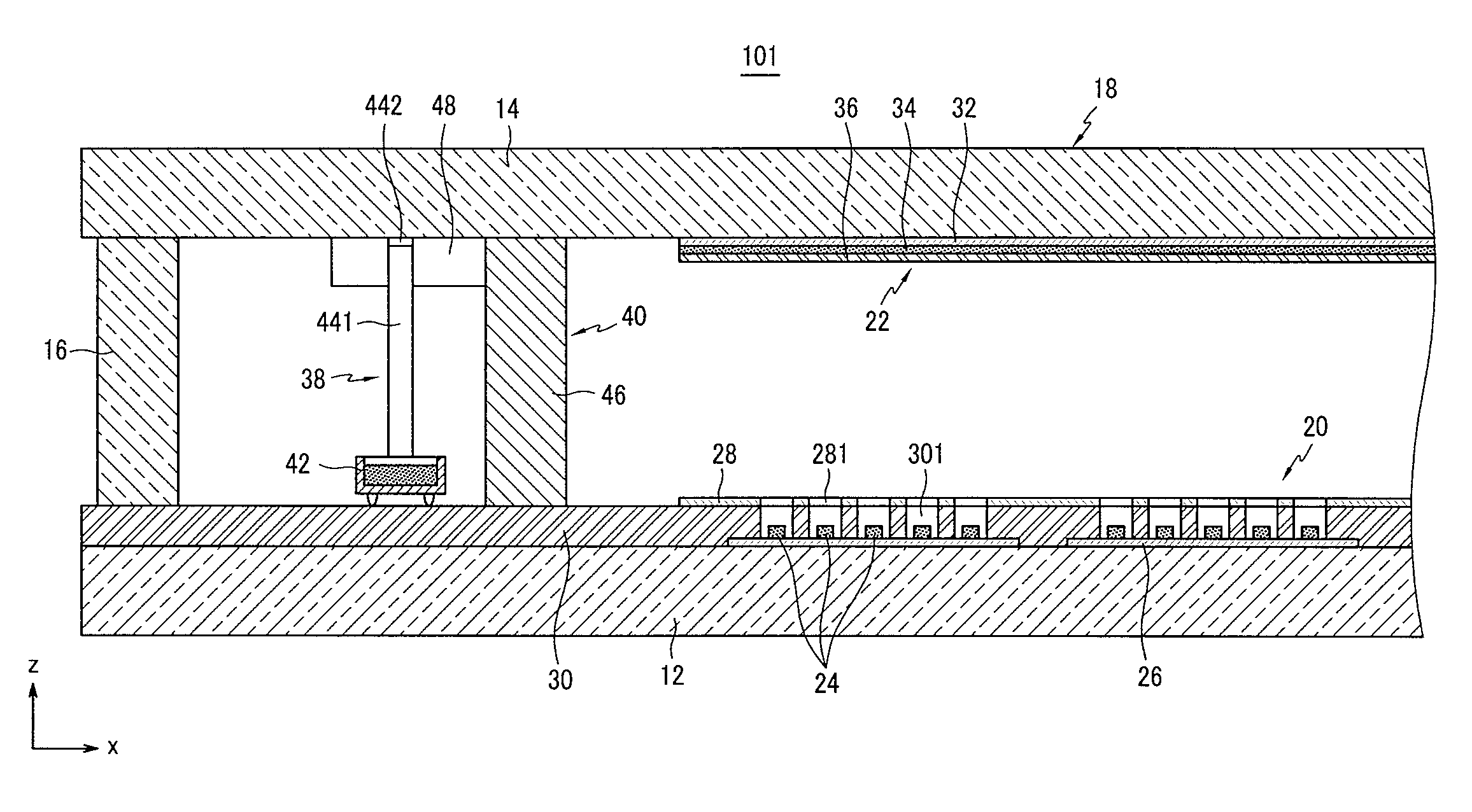

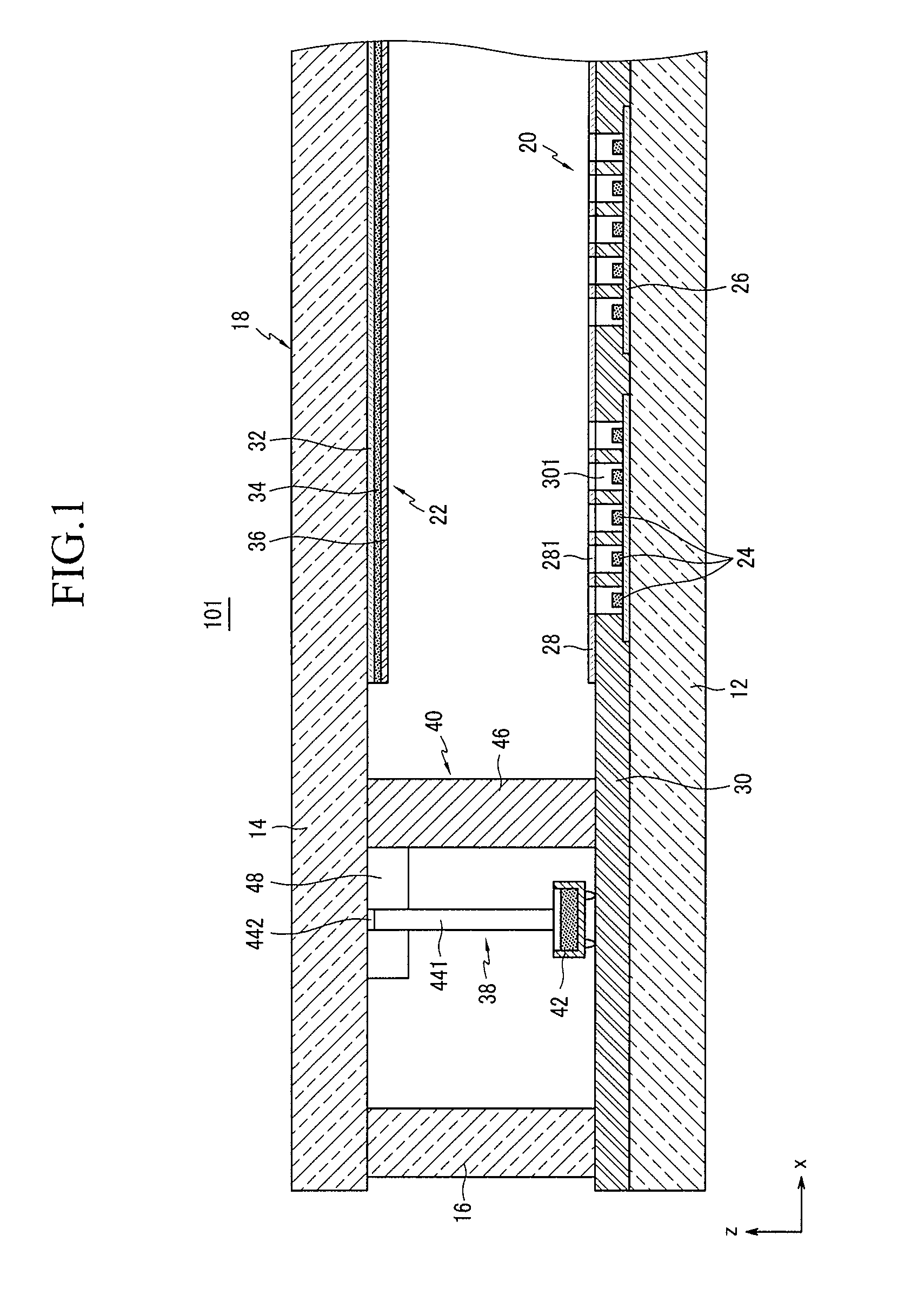

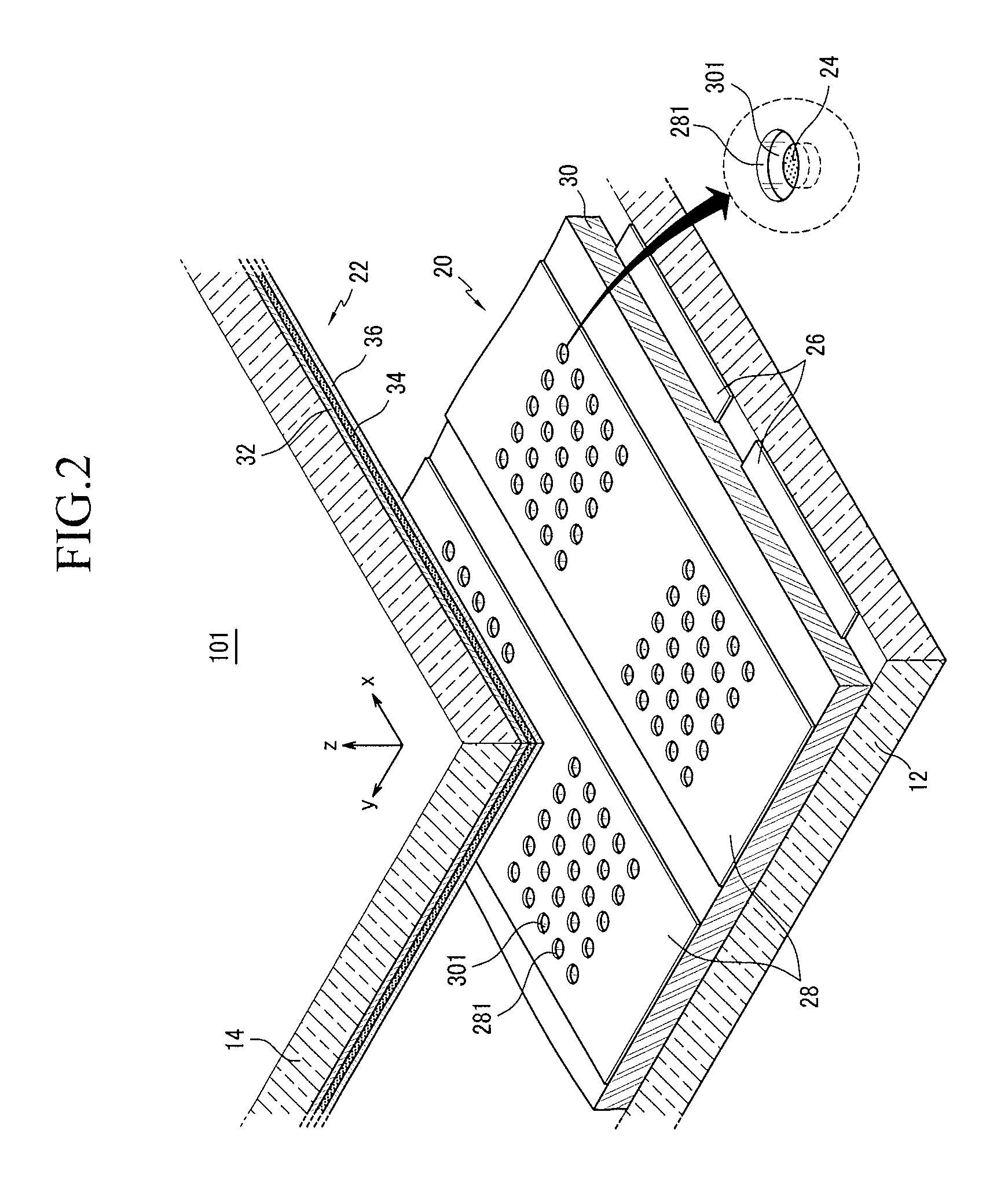

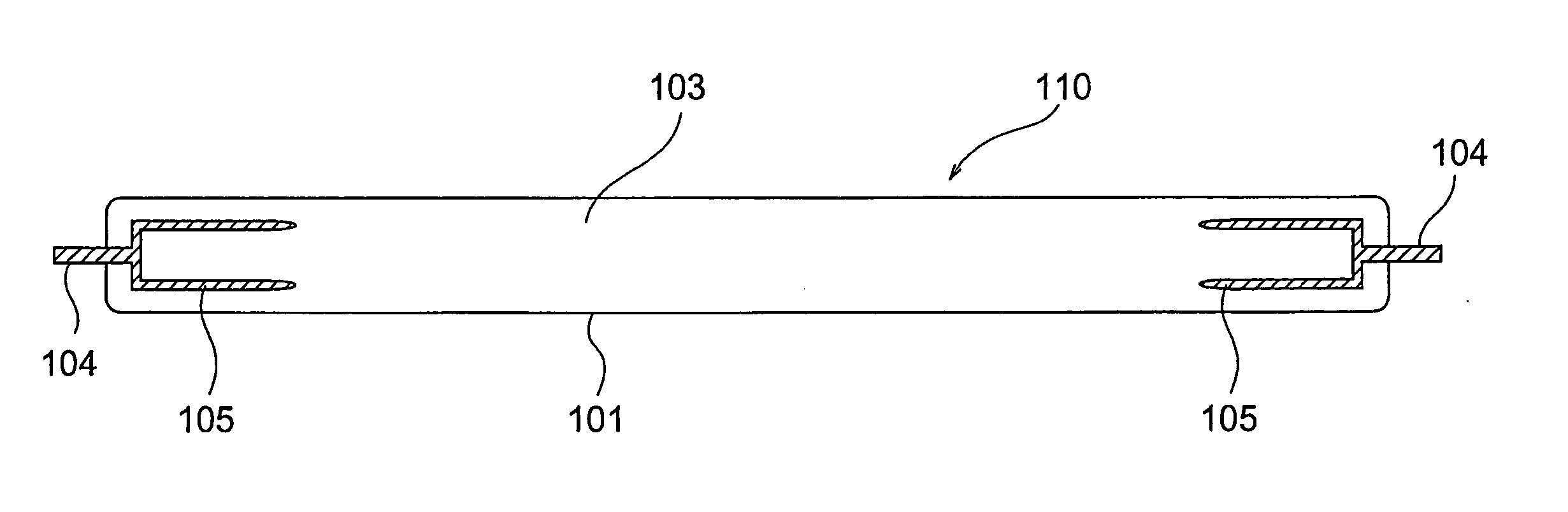

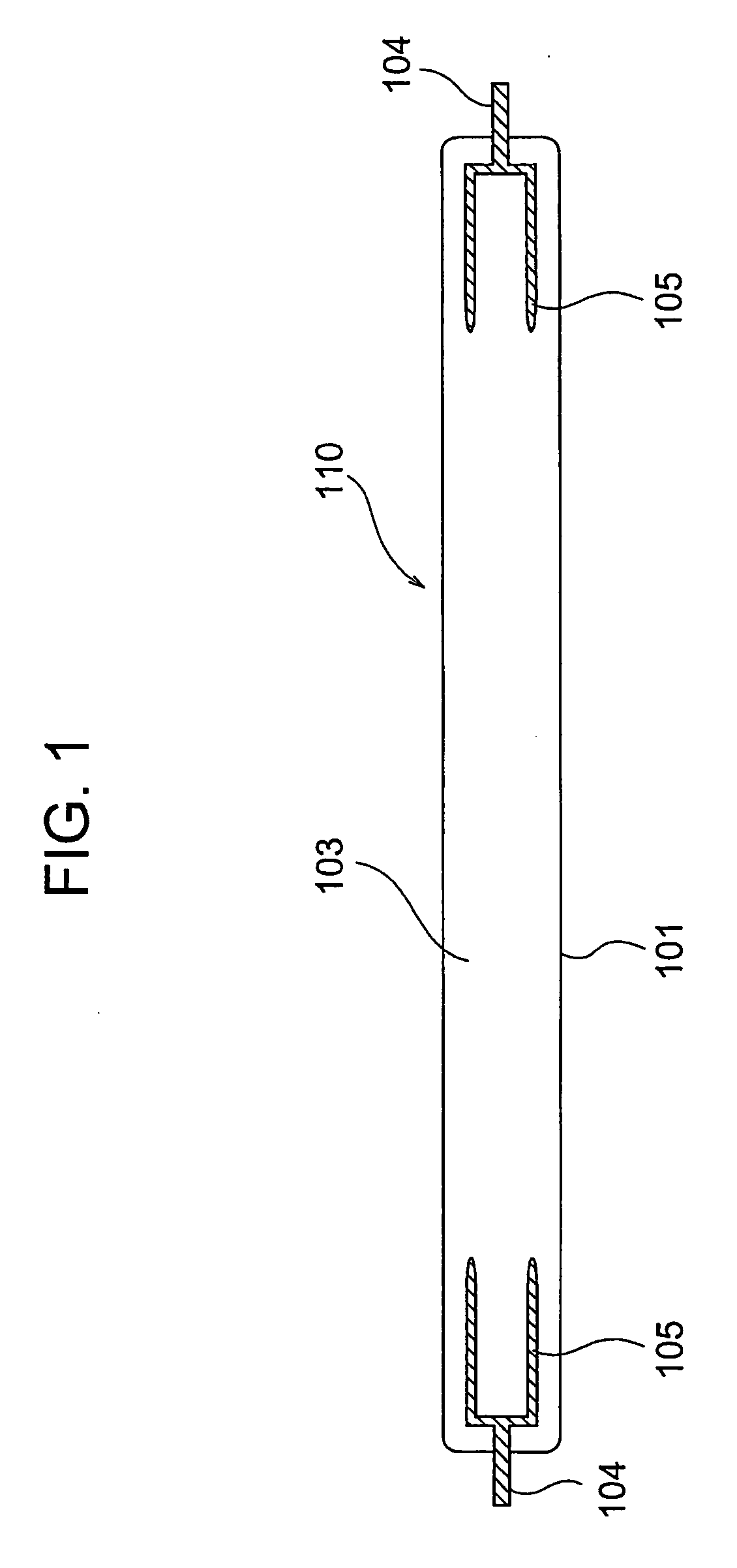

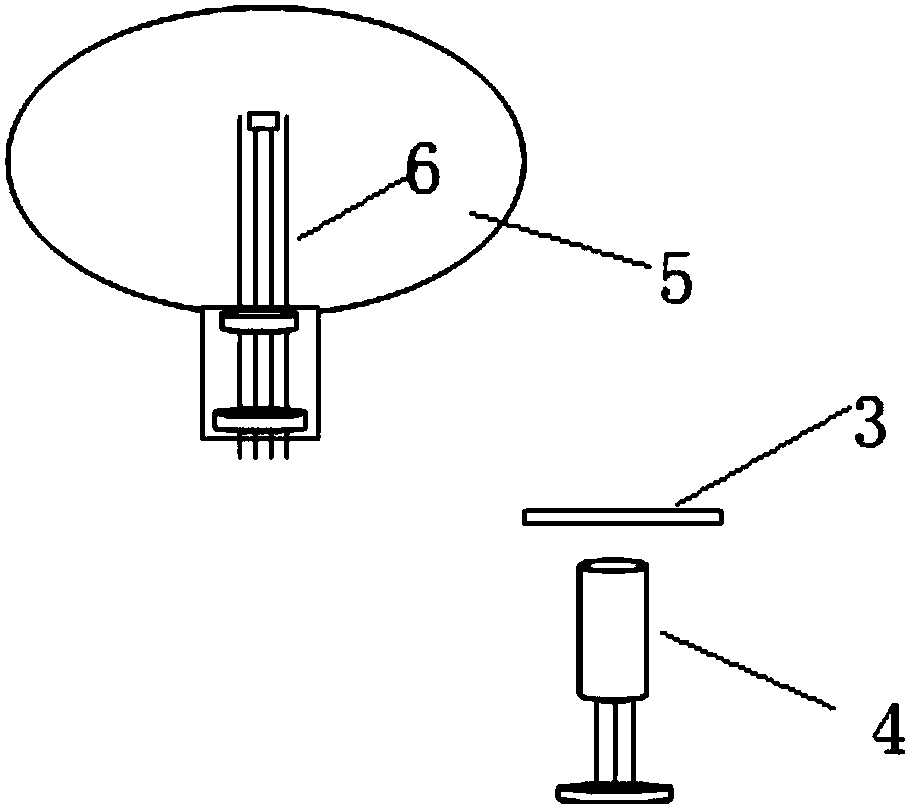

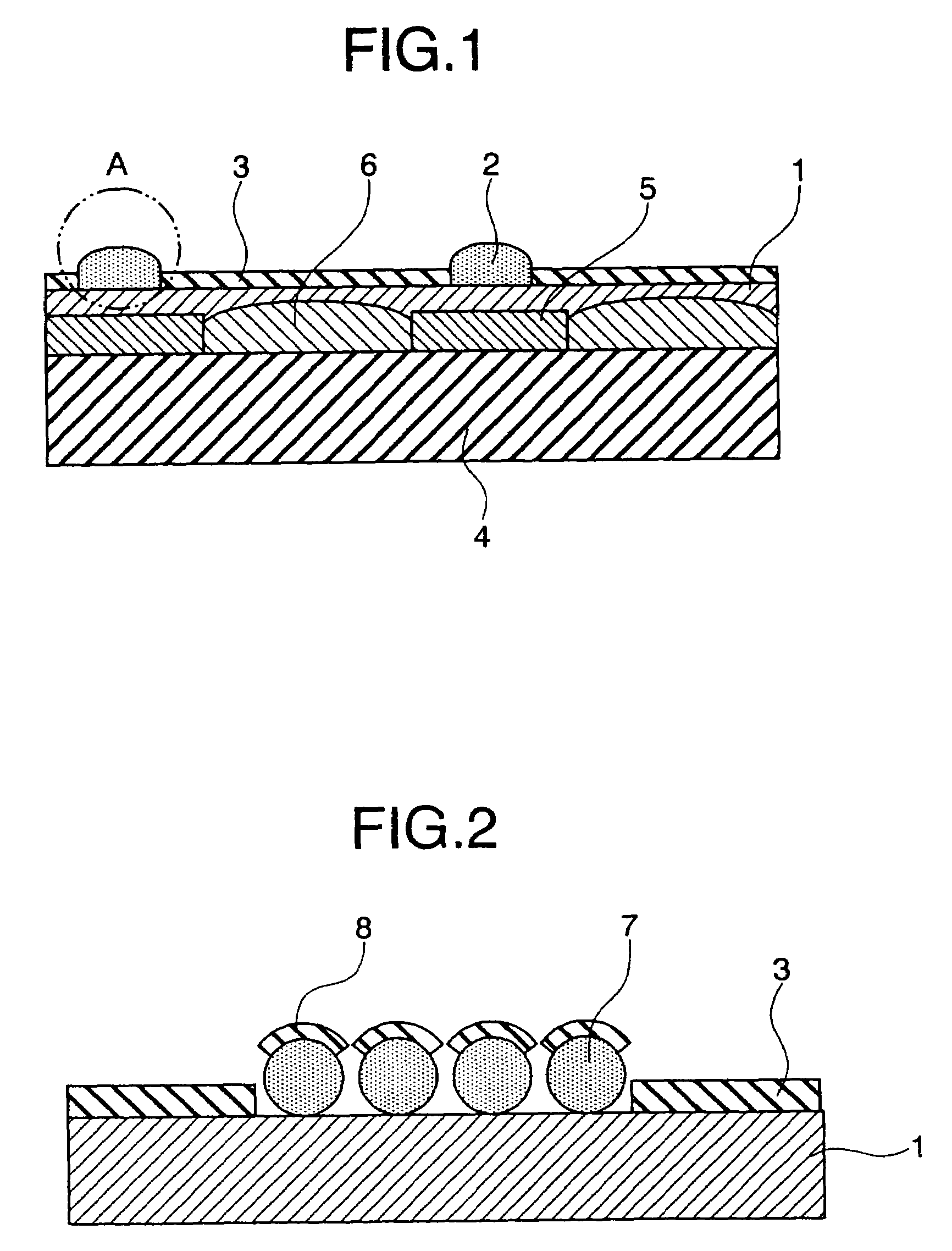

Light emission device and display device using the light emission device as a light source

InactiveUS20080265770A1Gas filling substance selectionDischarge tube luminescnet screensDisplay deviceLight emission

A light emission device having an evaporating getter unit and a display device utilizing the light emission device as a light source. The light emission device includes a vacuum vessel having first and second substrates facing each other and a sealing member, the first and second substrates having an active area and a non-active area, an electron emission unit located on the first substrate at the active area, a light emission unit located on the second substrate at the active area, a getter unit provided between the first and second substrates at the non-active area, and a barrier disposed between the getter unit and the active area. The barrier blocks diffusion of getter material toward the active area during the getter activating process and prevents (or reduces) a slip or a movement of the getter unit.

Owner:SAMSUNG SDI CO LTD

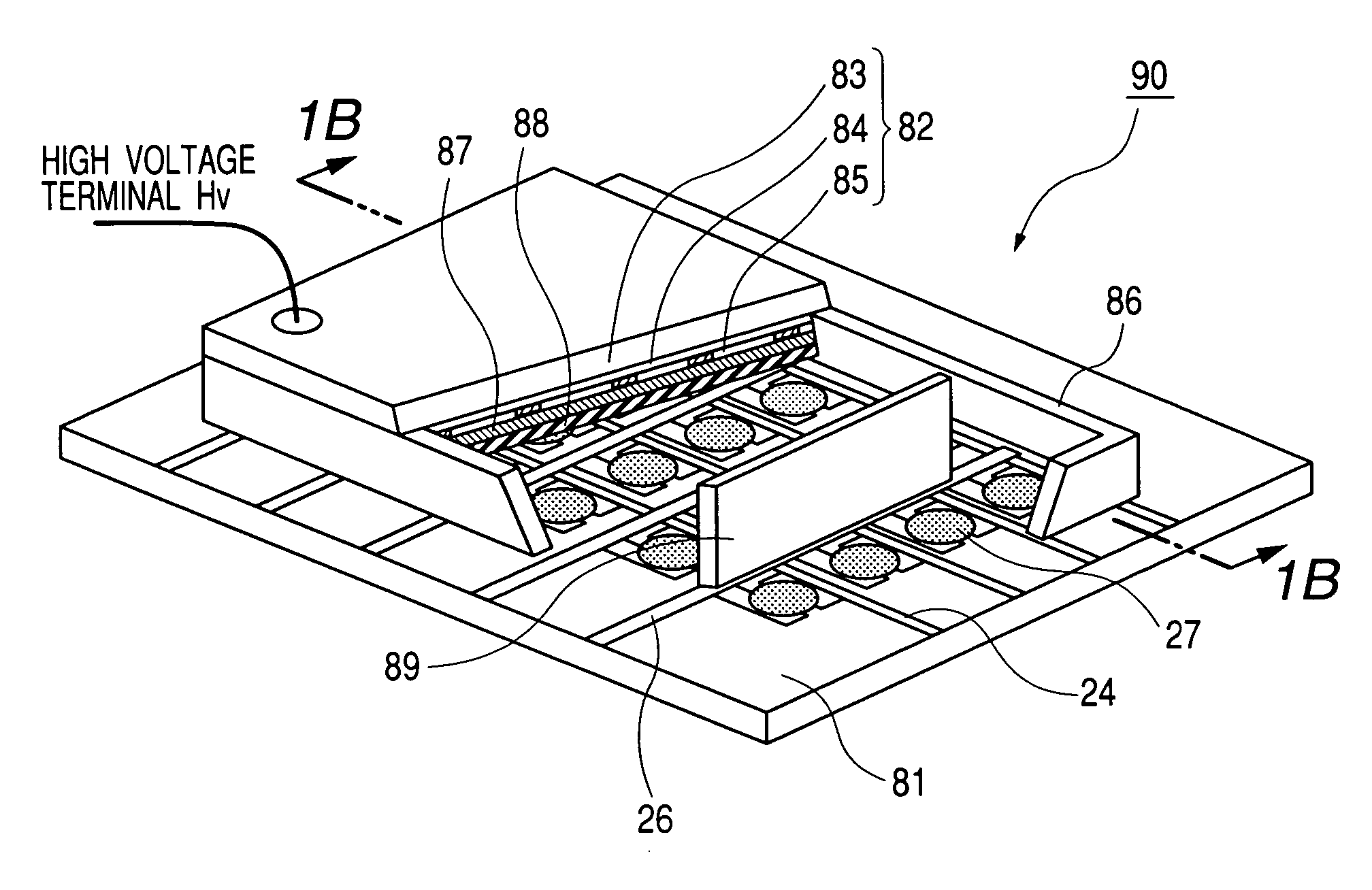

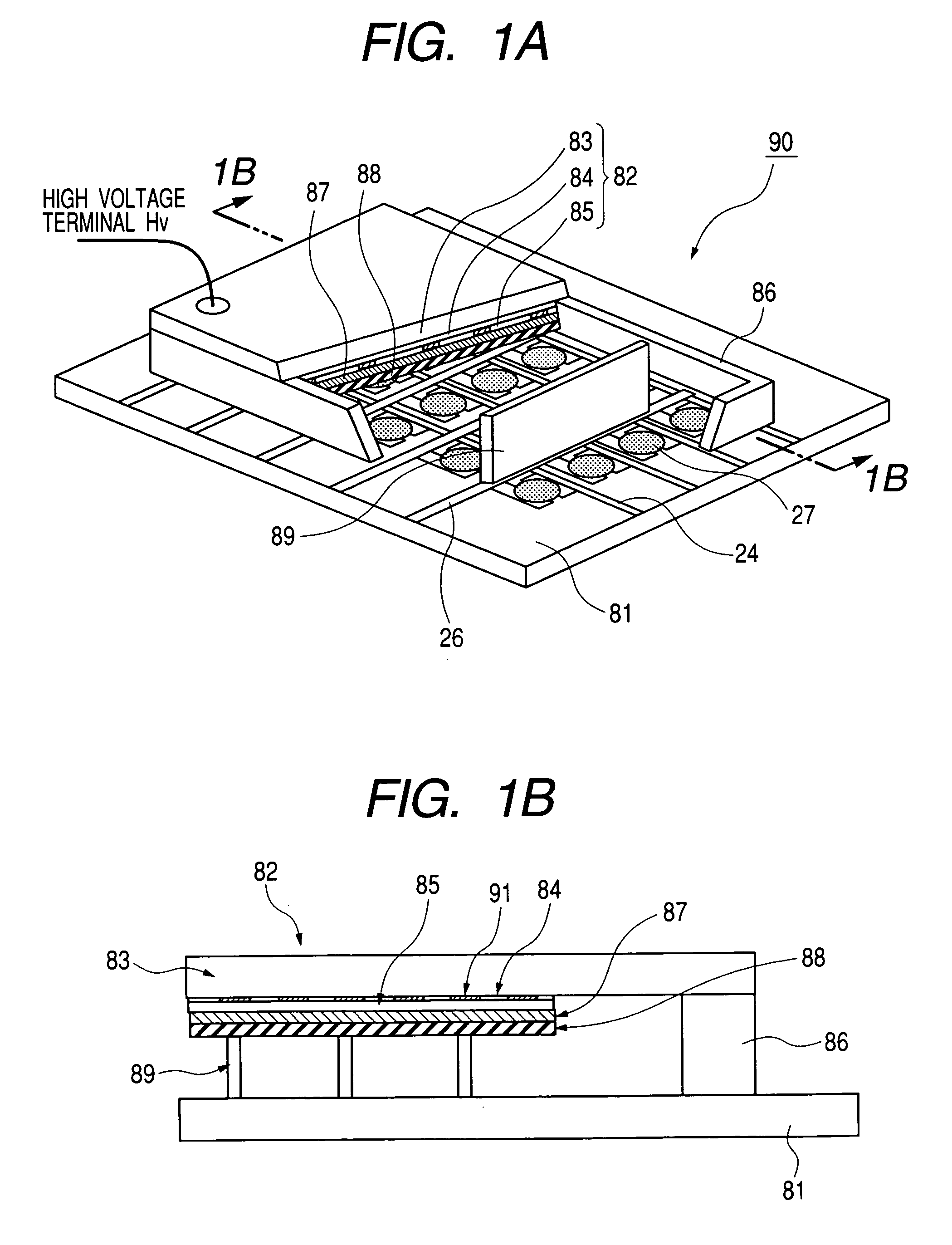

Image display device and method of manufacturing the same

InactiveUS7091662B2Less luminanceLess deteriorationGetteringGas filling substance selectionElectron sourceVacuum level

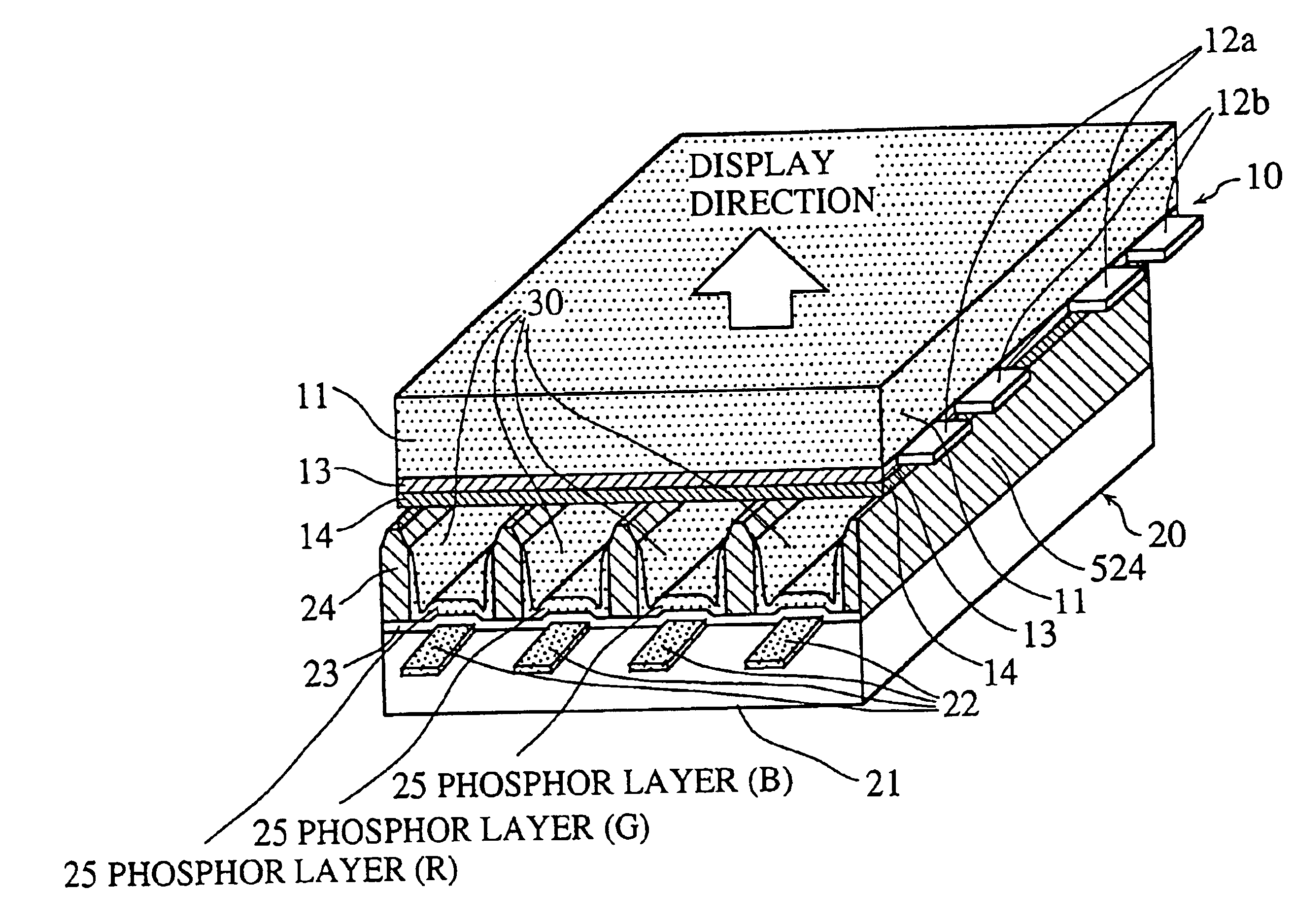

In an image display device having in an airtight container an electron source and an image display member that receives electrons from the electron source, an evaporating getter and a non-evaporating getter are stacked in the airtight container. This makes it possible to maintain the vacuum level in the airtight container. The image display device thus obtains a prolonged life and a stable display operation.

Owner:CANON KK

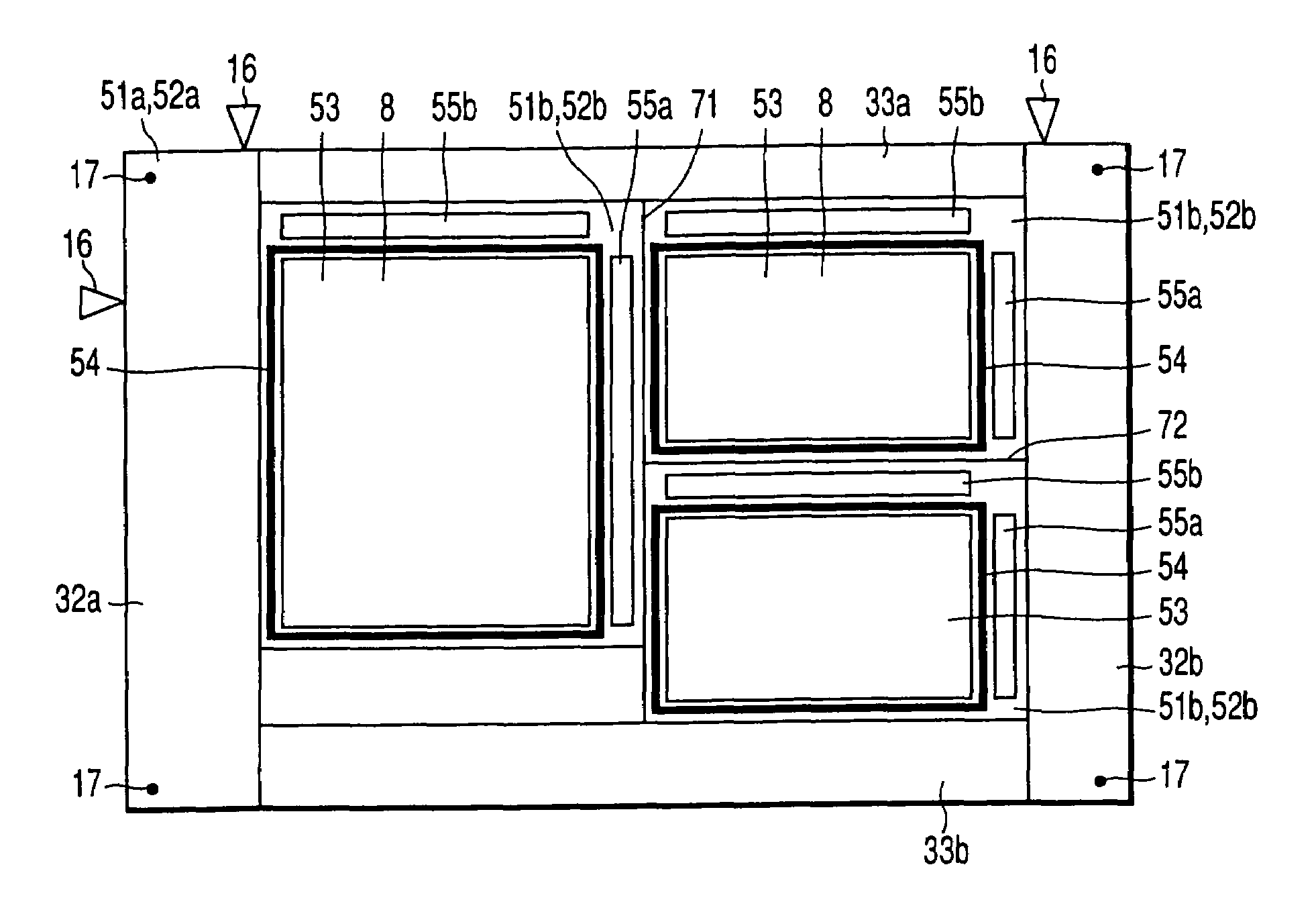

Bonding structure for flat panel display and method having outer and inner walls of a predetermined interval having sealant and bonded to upper and lower substrates for unimpeded cell gap between the substrates and the inner separation wall

ActiveUS7515241B2Prevent penetrationConstant cell gapStatic indicating devicesTube/lamp vessel degassingDisplay deviceEngineering

Provided are a bonding structure for a flat panel display and a method of forming the same, and a flat panel display, including the bonding structure. The bonding structure of a flat panel display device, which is formed between an upper substrate and a lower substrate to seal and bond the two substrates of the flat panel display device, and the bonding structure includes an outer separation wall and an inner separation wall of same heights being arranged along edges of the upper substrate and the lower substrate with a predetermined interval, and a sealant being applied between the outer separation wall and the inner separation wall.

Owner:SAMSUNG ELECTRONICS CO LTD

Fluorescent lamp and method of manufacturing same

InactiveUS20060097641A1Lower resistanceHigh melting pointDischarge tube luminescnet screensTube/lamp vessel degassingCold cathodeHelium

A cold cathode fluorescent tube where an electron emitting electrode is sealed in shows much deterioration in the luminance with time, thereby being not adequate for a long time use. The electrode emitting electrode is formed in such a shape that an electric field is not locally concentrated. By mixing a material of high heat conductivity, such as tungsten, as the material for the electron emitting electrode or using helium of high heat conductivity as the sealing gas, a long life of the cold cathode fluorescent tube is achieved.

Owner:FOUND FOR ADVANCEMENT OF INT SCI

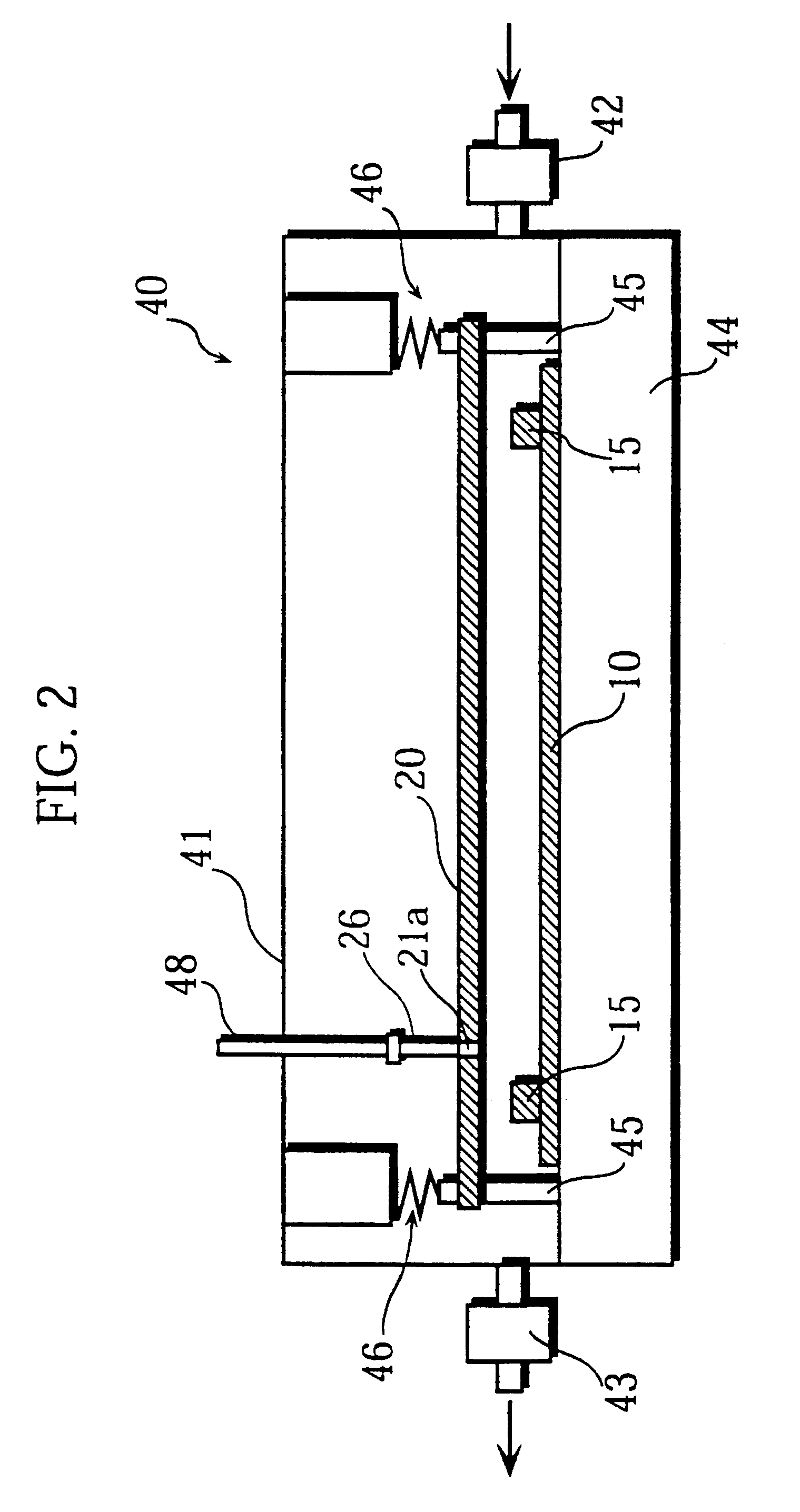

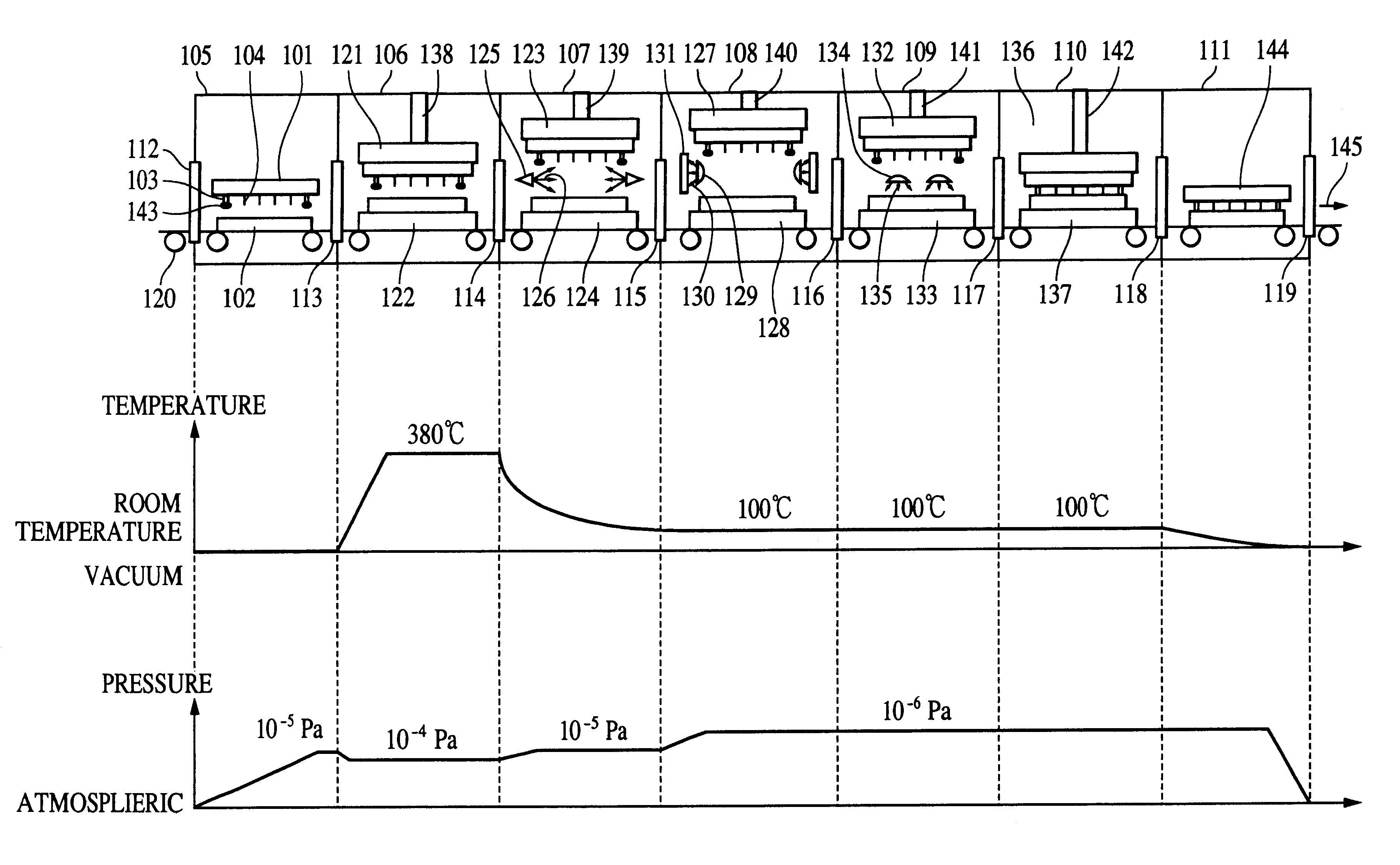

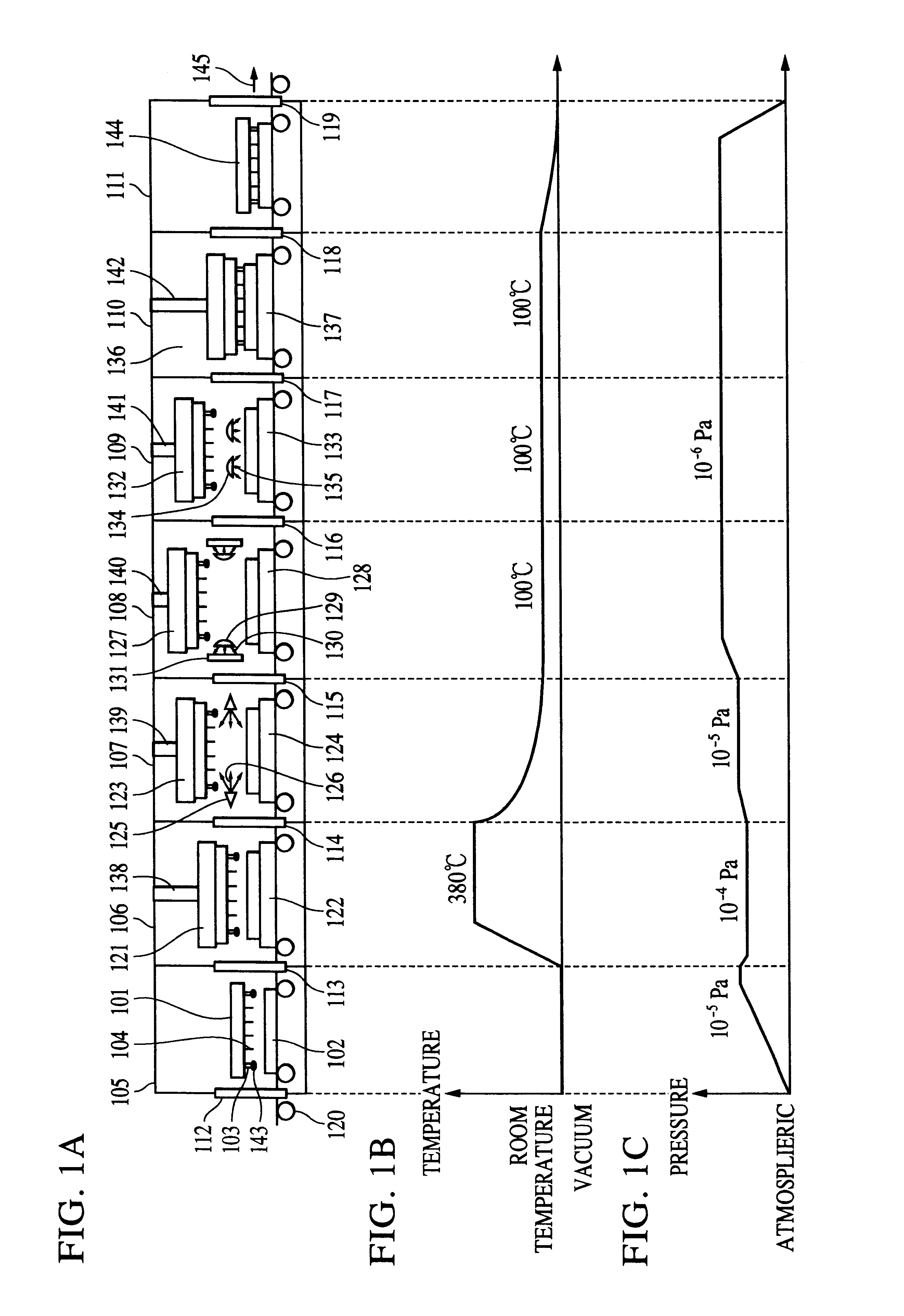

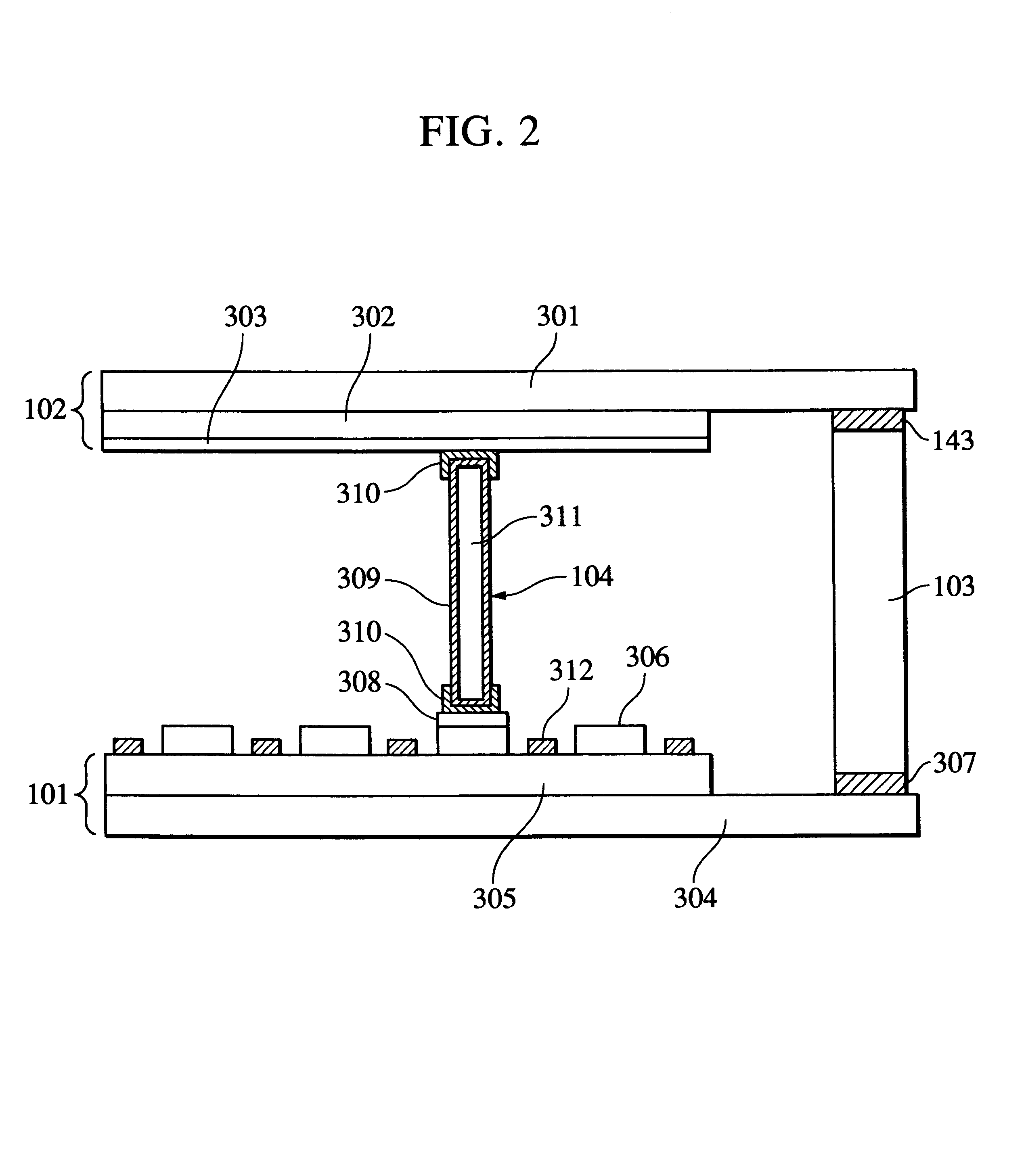

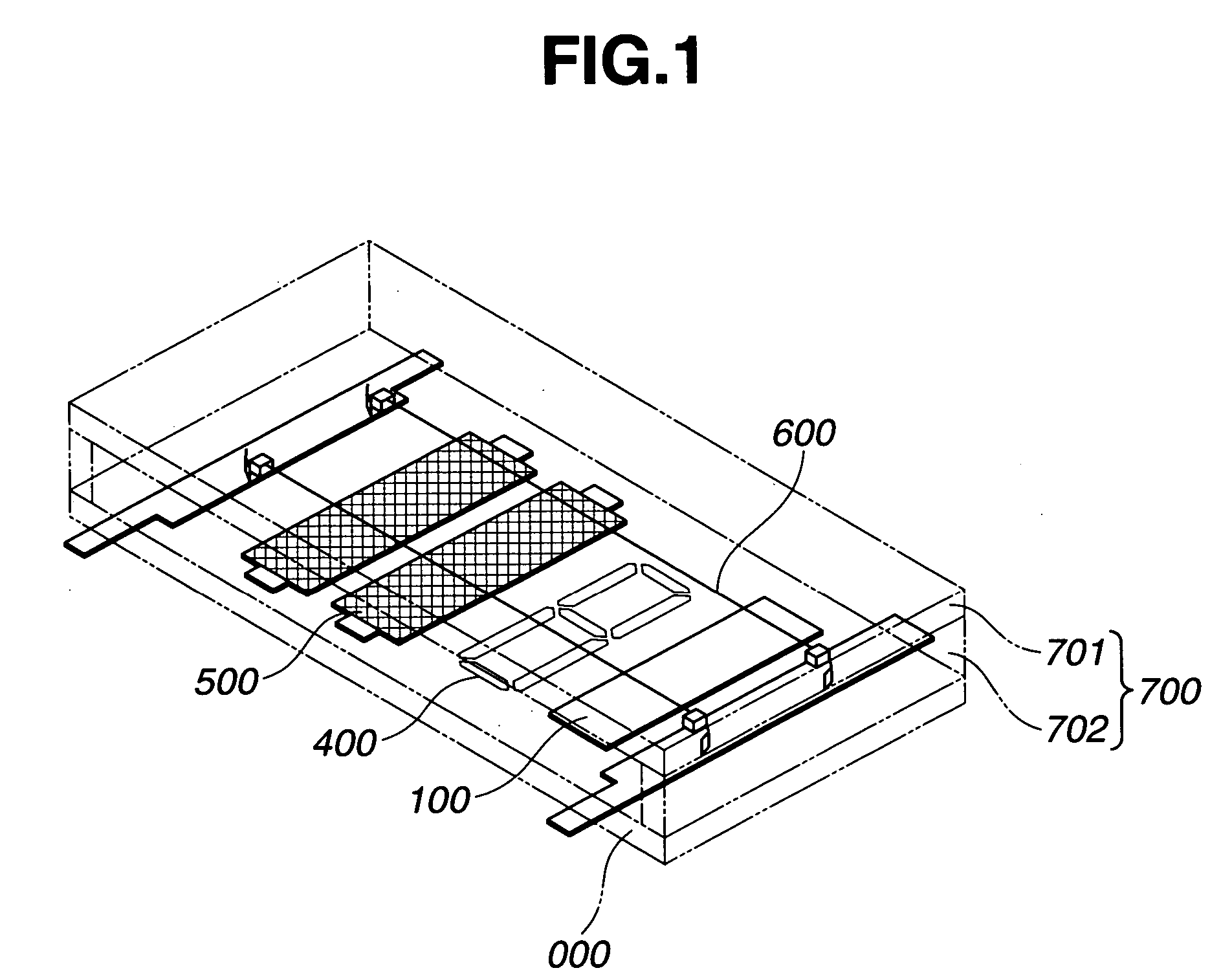

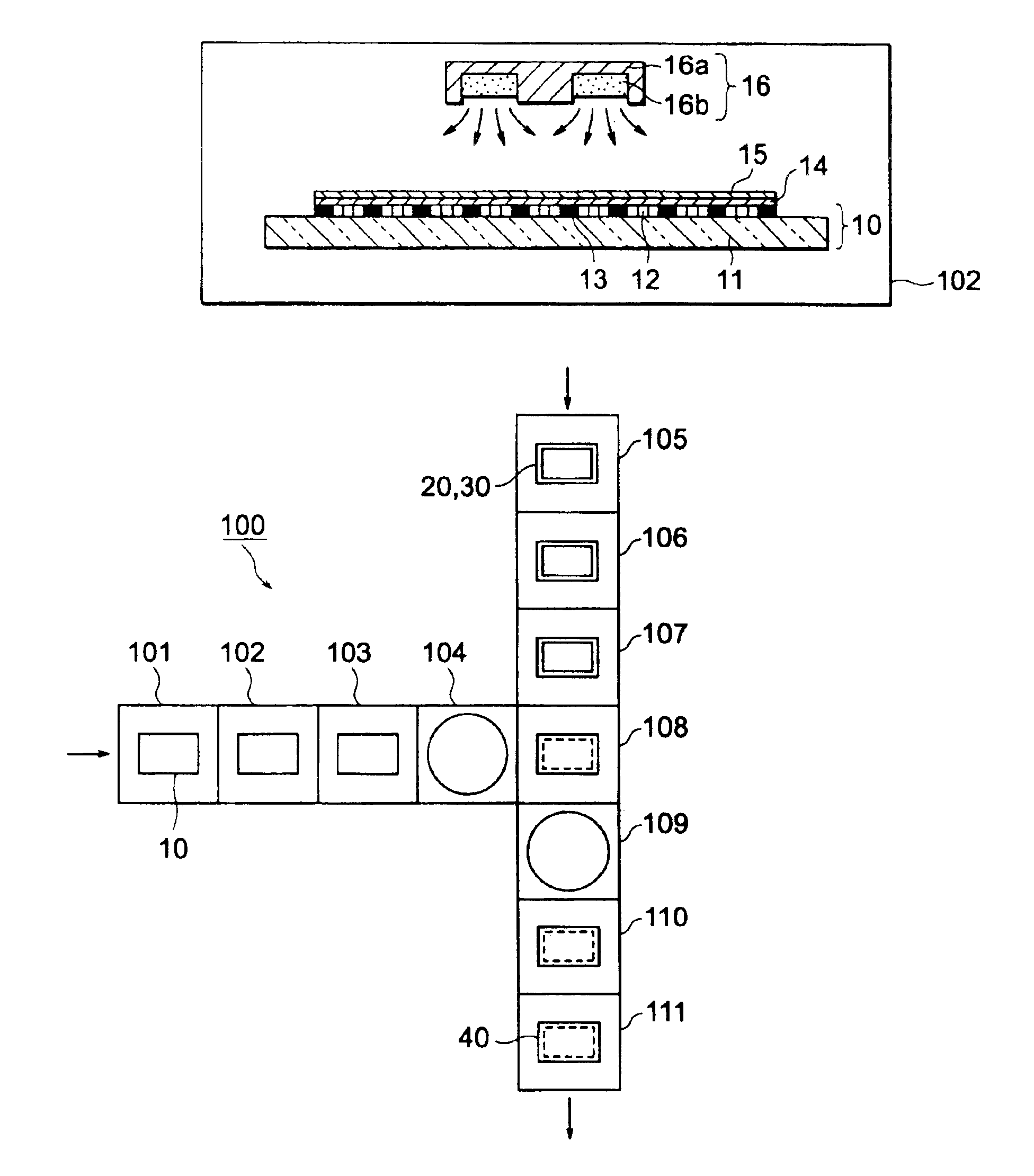

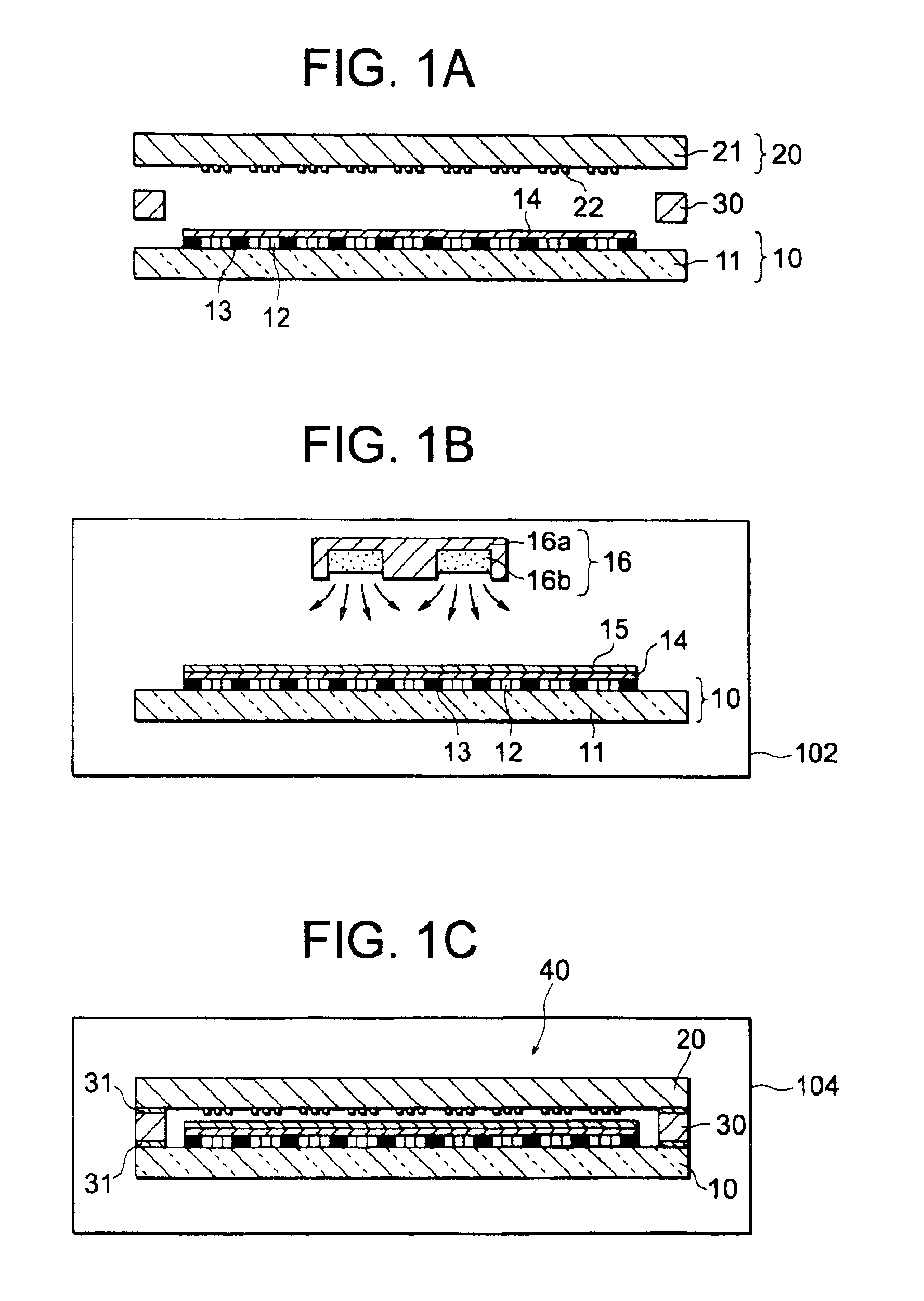

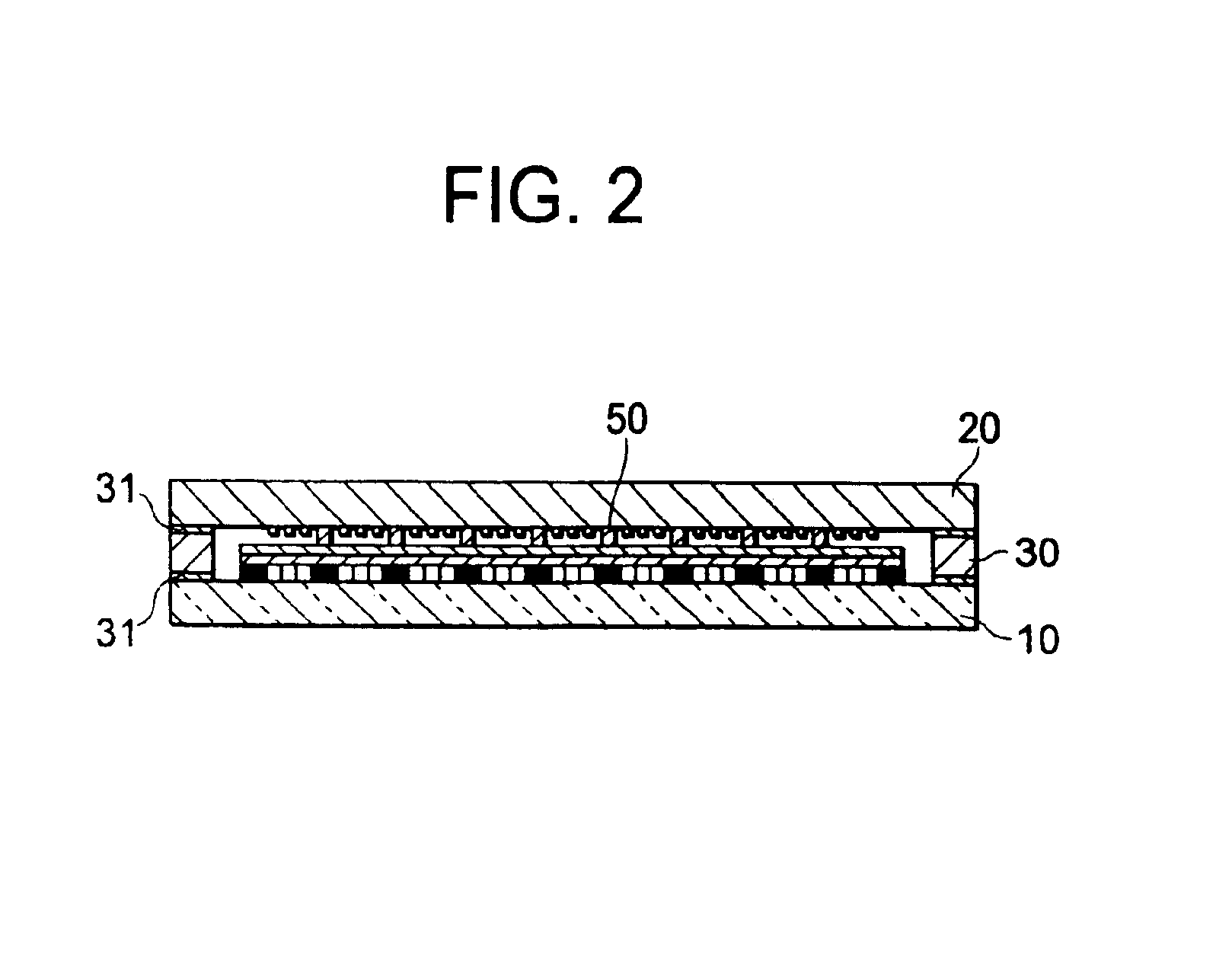

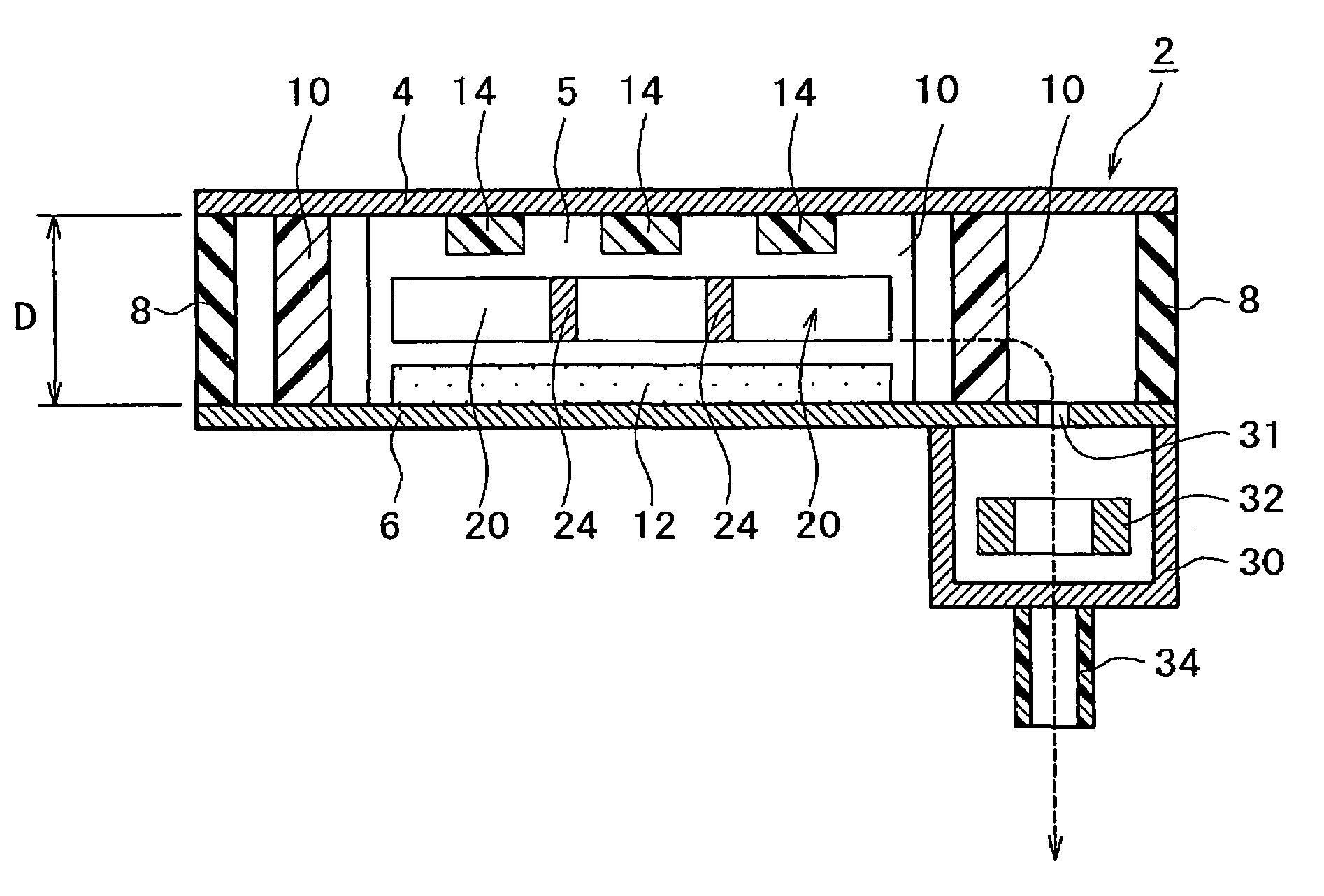

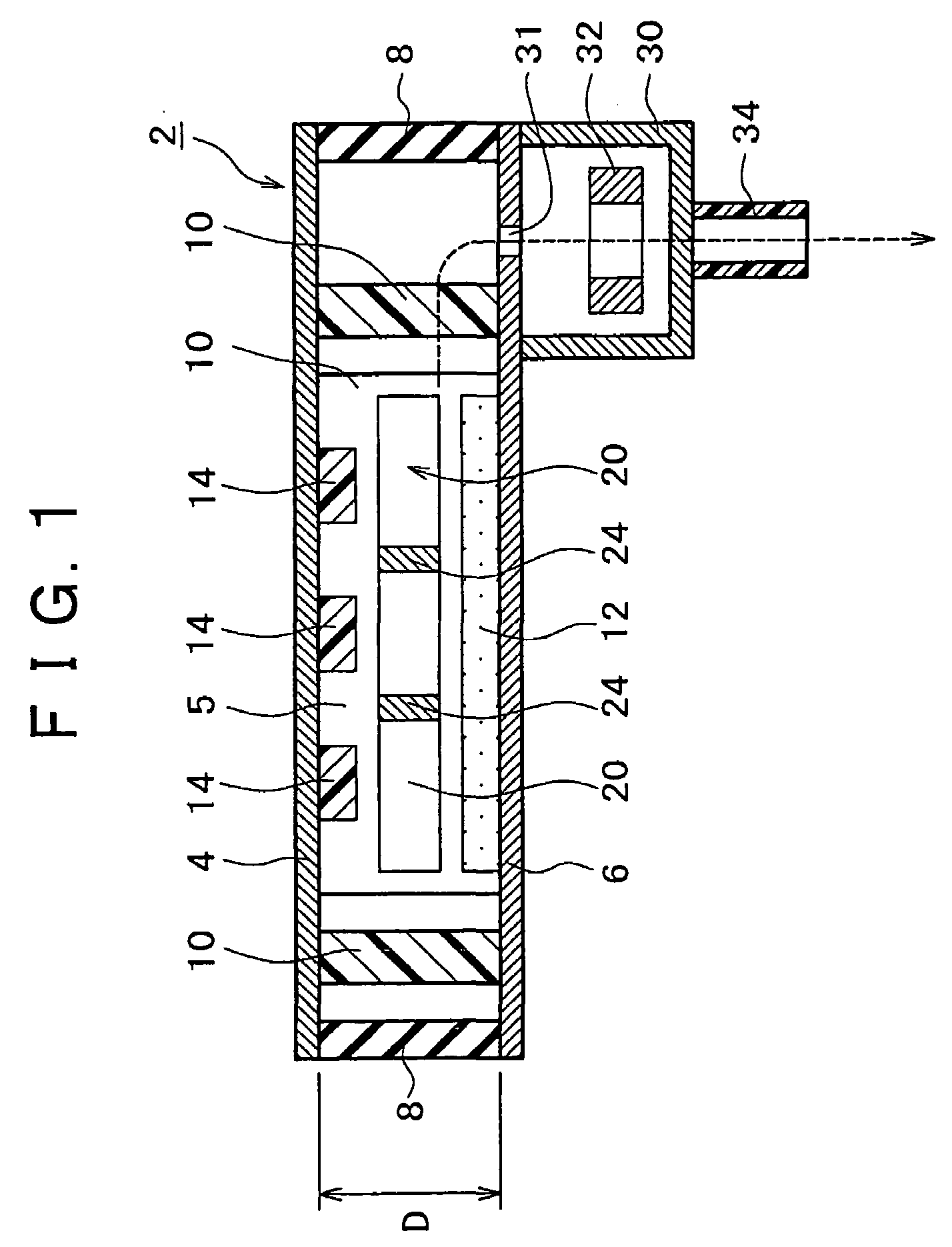

Method and apparatus for manufacturing image display device

InactiveUS6702636B2Glass furnace apparatusTube/lamp vessel degassingTemperature controlDisplay device

The present invention provides a method of manufacturing an image display device in which a panel member constituting a panel of an image display device is transferred to a plurality of processing chambers each having a temperature control unit, and subjected to a plurality of processing steps under temperature control. The temperature of the panel member in each of the processing chambers is set to be not more than the set temperature of the panel member in the previous processing chamber by the temperature control unit.

Owner:CANON KK

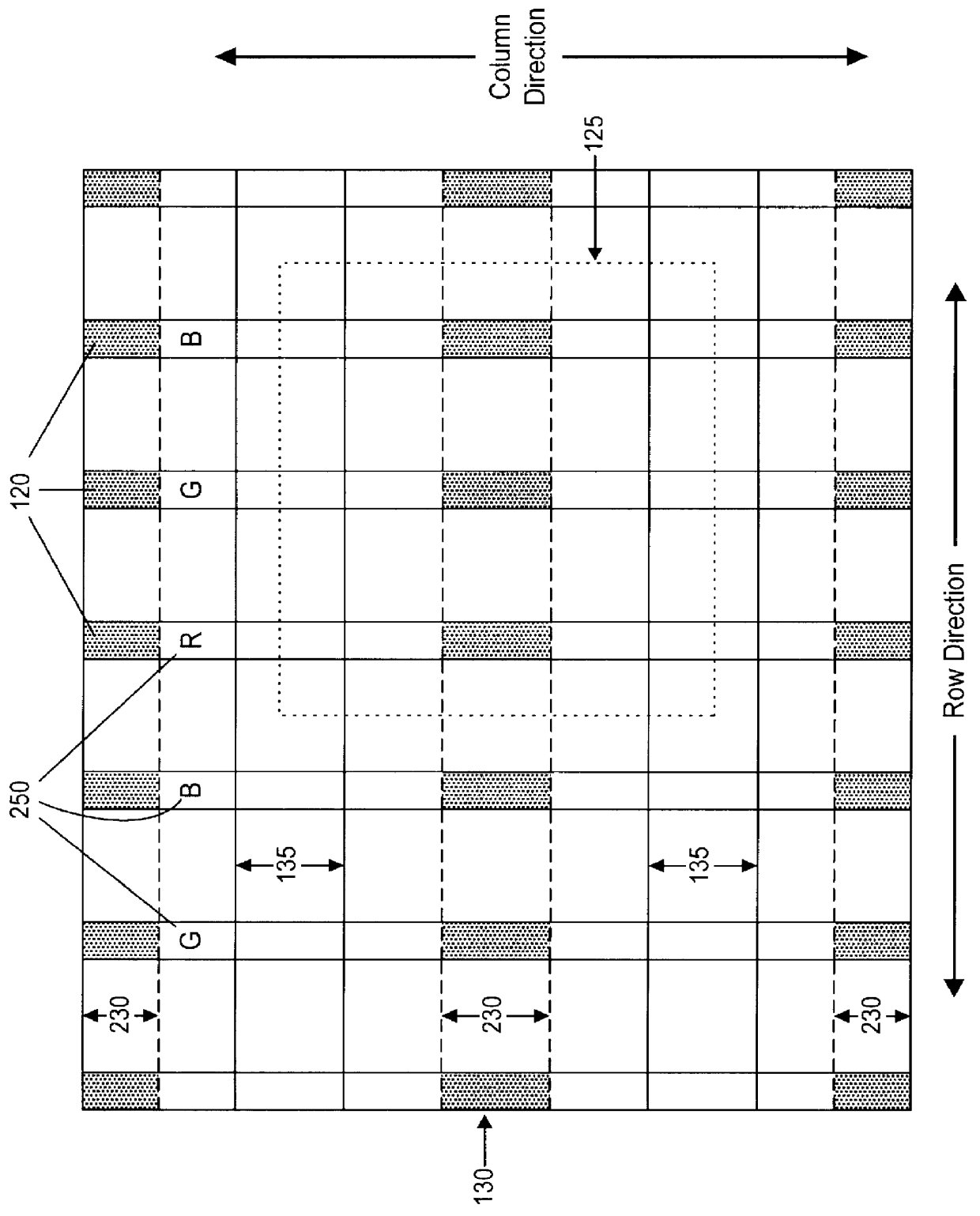

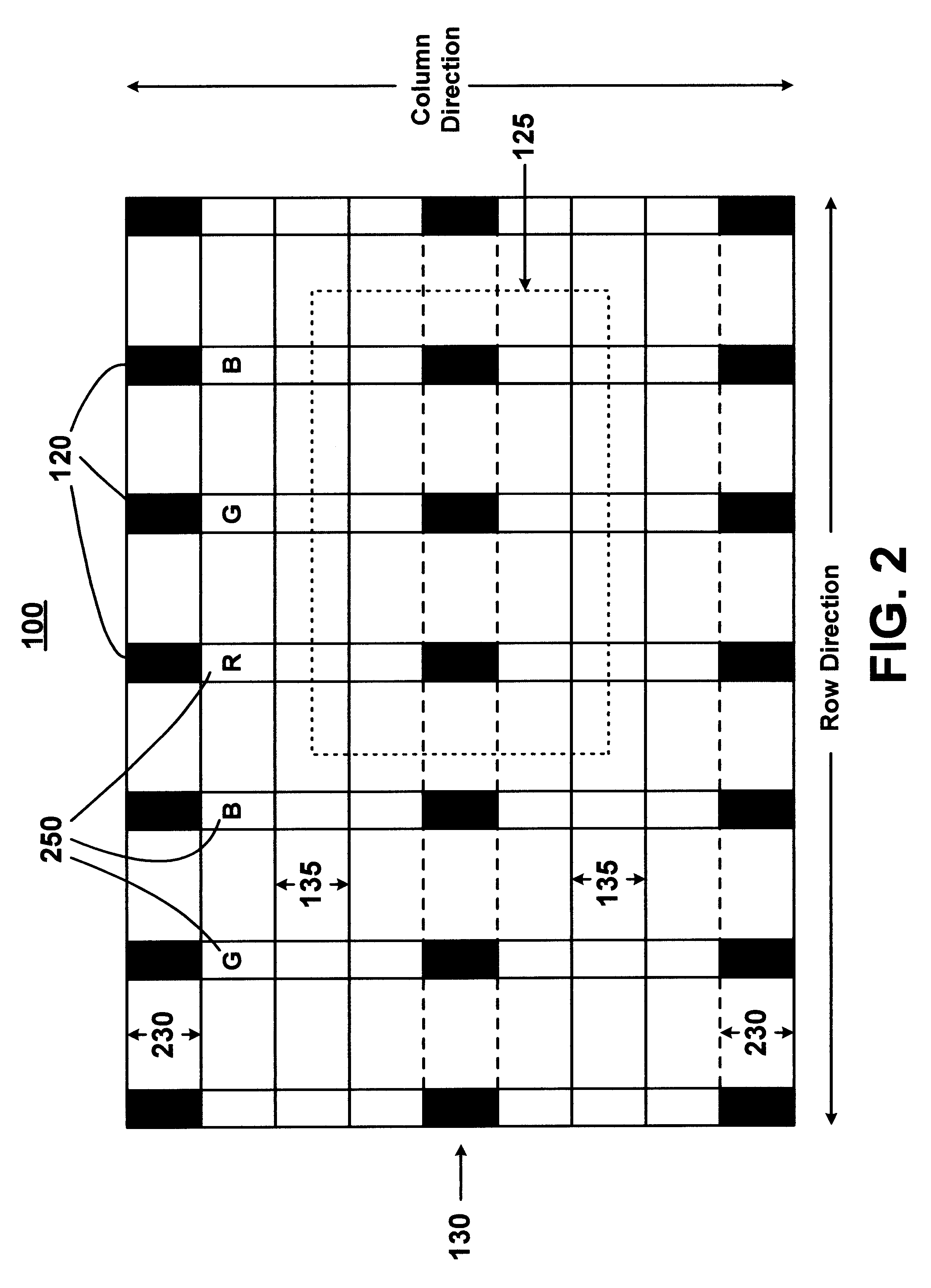

Electron emission device including dummy electrodes

InactiveUS20050140269A1Avoid signal distortionScreen quality is deterioratedGas filling substance selectionDischarge tube luminescnet screensPhosphorElectron

An electron emission device having various functional electrodes in addition to the electrodes serving to emit electrons includes: first and second substrates facing each other, and cathode and gate electrodes arranged on the first substrate within an effective electron emission area and including an insulating layer interposed therebetween. The electron emission regions are electrically connected to the cathode electrodes. At least one dummy electrode is arranged external to the effective electron emission area. At least one anode electrode is arranged on the second substrate. Phosphor layers are arranged on one surface of the anode electrode.

Owner:SAMSUNG SDI CO LTD

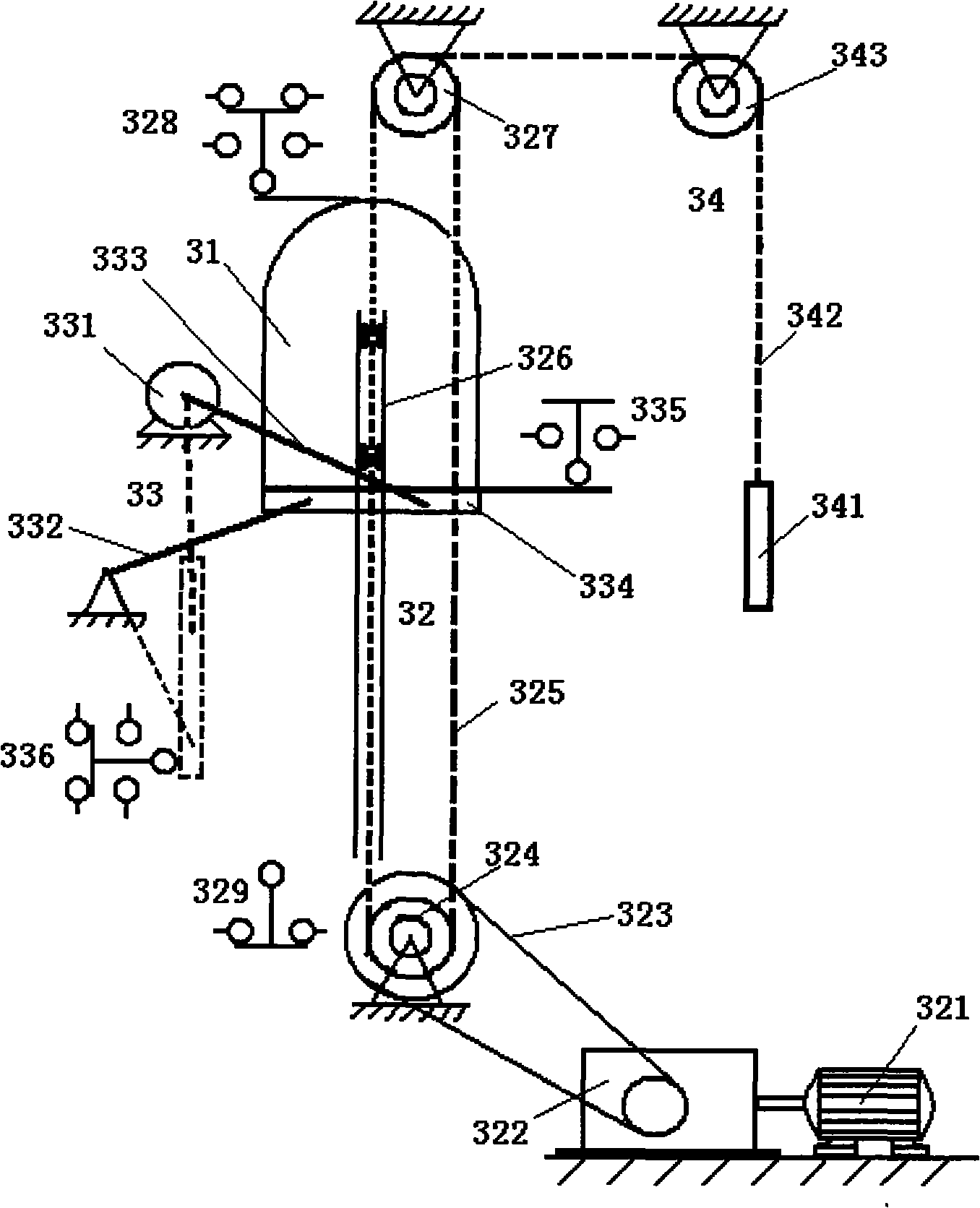

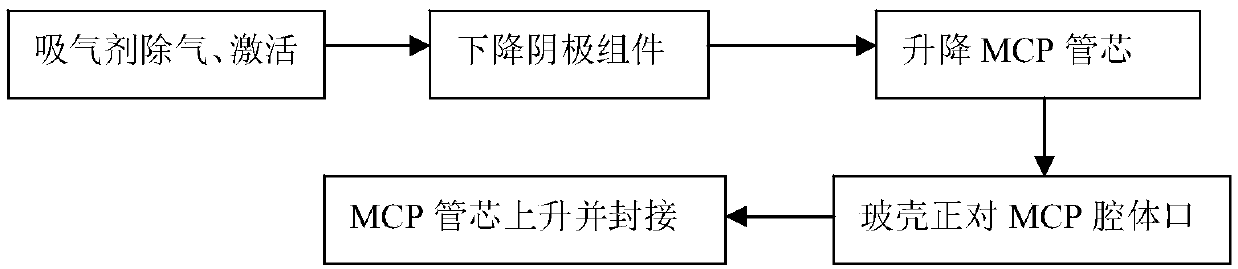

Negative electrode transfer equipment-based indium sealing method of photomultiplier and fabricated photomultiplier

ActiveCN107706072AIndium sealing process is clearImprove performanceTube/lamp vessel degassingTube/lamp vessels exhaustionIndiumPhotomultiplier

The invention discloses a negative electrode transfer equipment-based indium sealing method of a photomultiplier. After fabrication of a negative electrode, the sequence of an air absorption agent toremoval gas, simulation time, a switch multi-chip packaging (MCP) baffle plate and a lifting MCP pipe core is reasonably arranged, so that the indium sealing process has definite operation standard, favorable vacuum degree is obtained, and the performance of the photomultiplier is improved.

Owner:NORTH NIGHT VISION TECH +1

Self-luminous elements and method for producing the same

InactiveUS20050162067A1Effective maintenanceSave spaceGas filling substance selectionCathode-ray/electron-beam tube vessels/containersDisplay deviceZirconium dioxide

A vacuum retention agent, which is safe, easy to handle, saves space, and absorbs residual gases inside a hermetic envelope to maintain the hermetic envelope in a high degree of vacuum is provided in place of the conventional metal getter. A display device including the vacuum retention agent is provided. A gas occlusion material containing ZrOx (where 1≦×≦2) is disposed in a hermetic envelope forming a self-luminous element. ZrOx is formed in pattern from a paste of zirconium dioxide, which can be generally obtained as a reagent. In a production step, the patterned self-luminous element is hermetically sealed in vacuum in an atmosphere at 120° C. to 500° C., so that the vacuum retention effect is more improved.

Owner:FUTABA CORPORATION

Image display unit and production method therefor

InactiveUS7075220B2InhibitionAvoid destructionGas filling substance selectionDischarge tube luminescnet screensGas phasePhosphor

An image display unit having a structure in which a heat-resisting fine particle layer is formed on a metal back layer disposed on a phosphor layer, and a getter layer is deposited / formed on the heat-resisting fine particle layer by vapor-depositing. The fine particle layer is desirably formed in a specified pattern, and a filmy getter layer is formed in a pattern complementary to the former pattern. The average particle size of heat-resisting fine particles which may use SiO2, TiO2, Al2O3, Fe2O3 is 5 nm to 30 μm. Since abnormal discharging is restricted, the destruction and deterioration of an electron emitting element and a phosphor screen are prevented to provide a high-brightness, high-grade display.

Owner:KK TOSHIBA

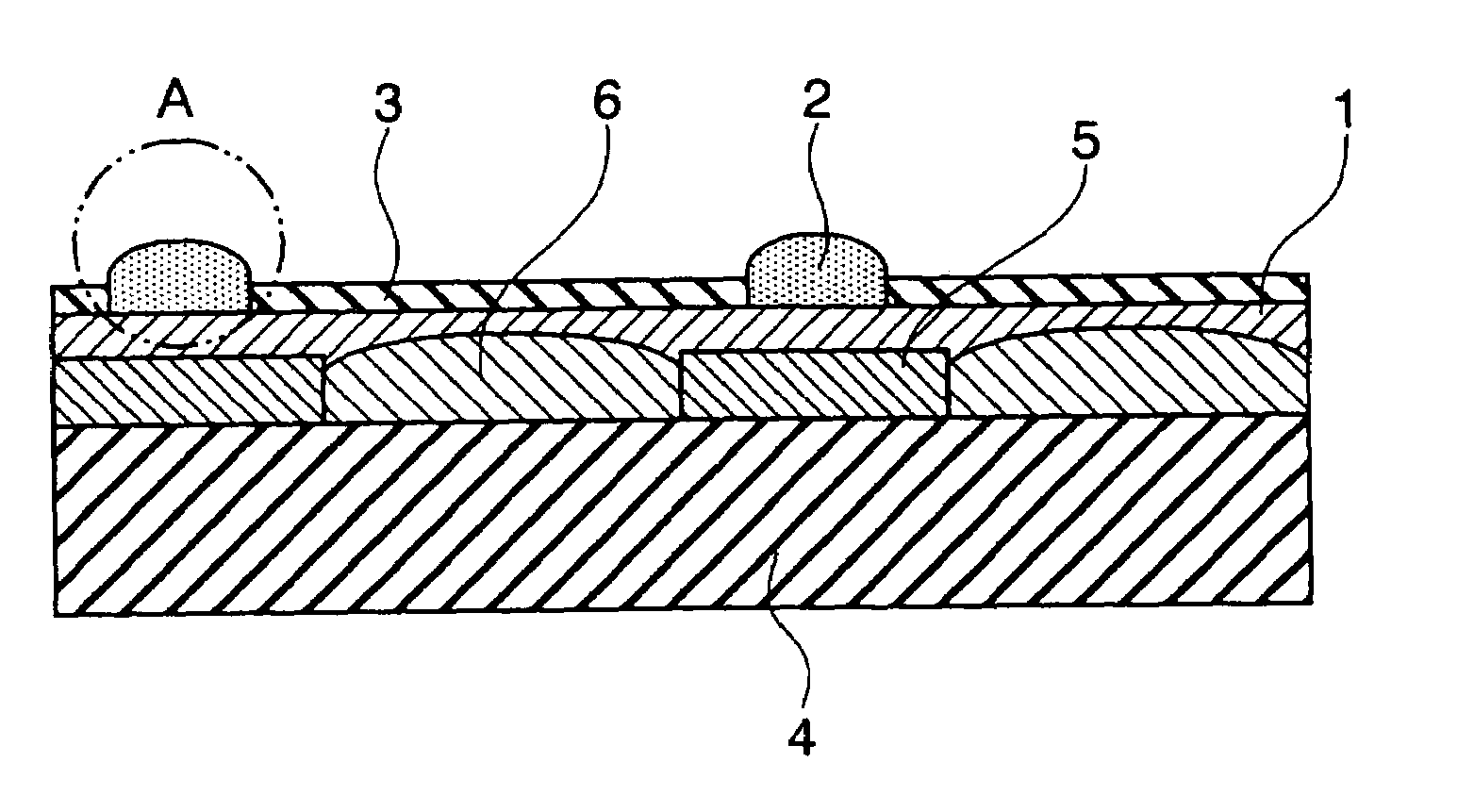

Method for manufacturing flat image display and flat image display

InactiveUS6926575B1Easy to displayEasy to reachGetteringGas filling substance selectionFluorescenceDisplay device

On a faceplate having a phosphor layer and a metal back that are formed on a substrate, in a vacuum atmosphere, for instance an active Ba film is deposited as a getter film. Following this, while maintaining the vacuum atmosphere, the faceplate thereon the getter film is deposited and a rear plate having a plurality of electron emitters formed on a substrate are oppositely disposed to form a gap therebetween through a support frame, the gap being hermetically sealed. A flat panel display comprises the active Ba film formed on for instance the metal back as a getter film. Such getter film, while maintaining an activity, is disposed on an image display region in a vacuum vessel, having an excellent getter function.

Owner:KK TOSHIBA

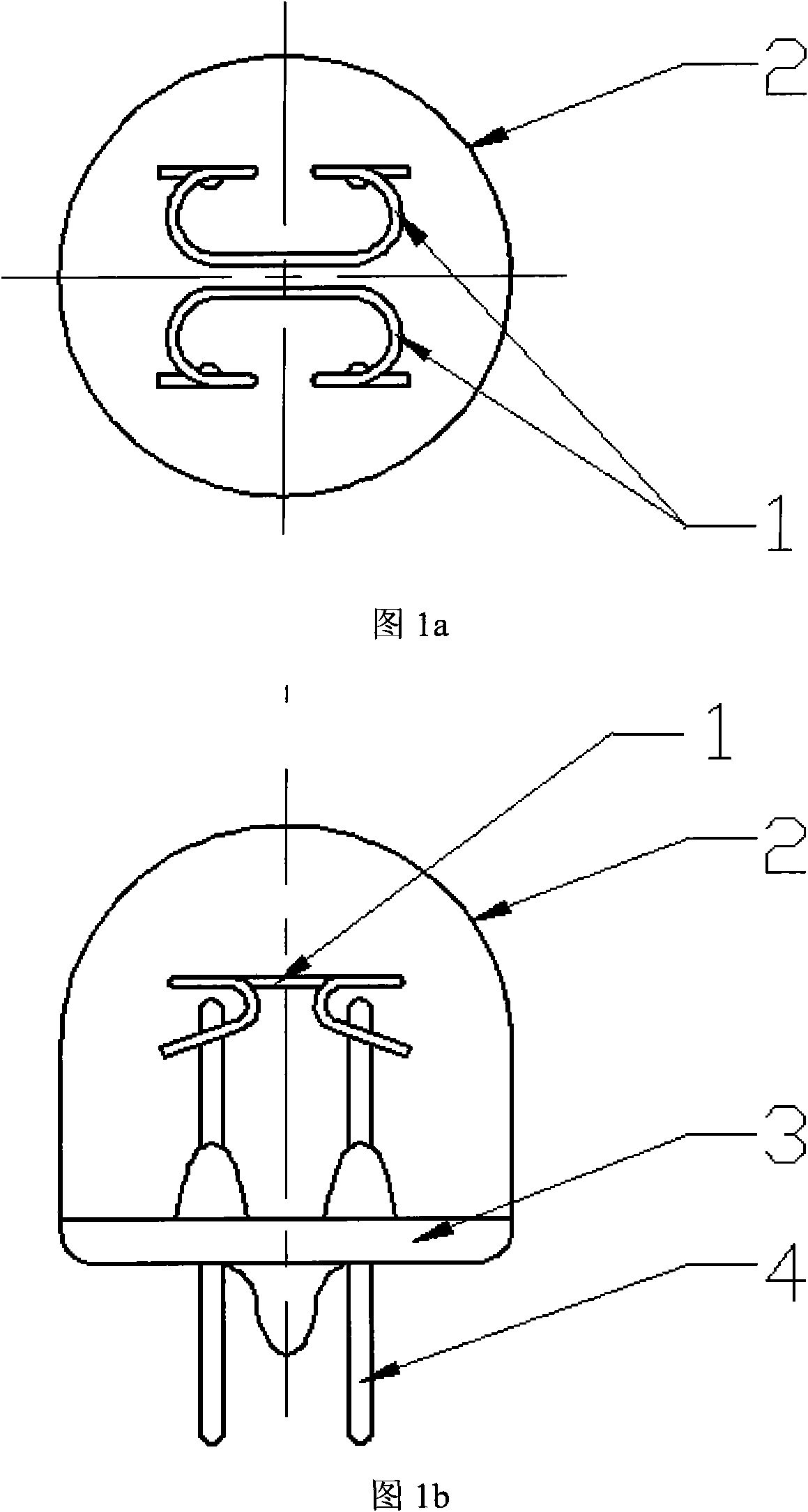

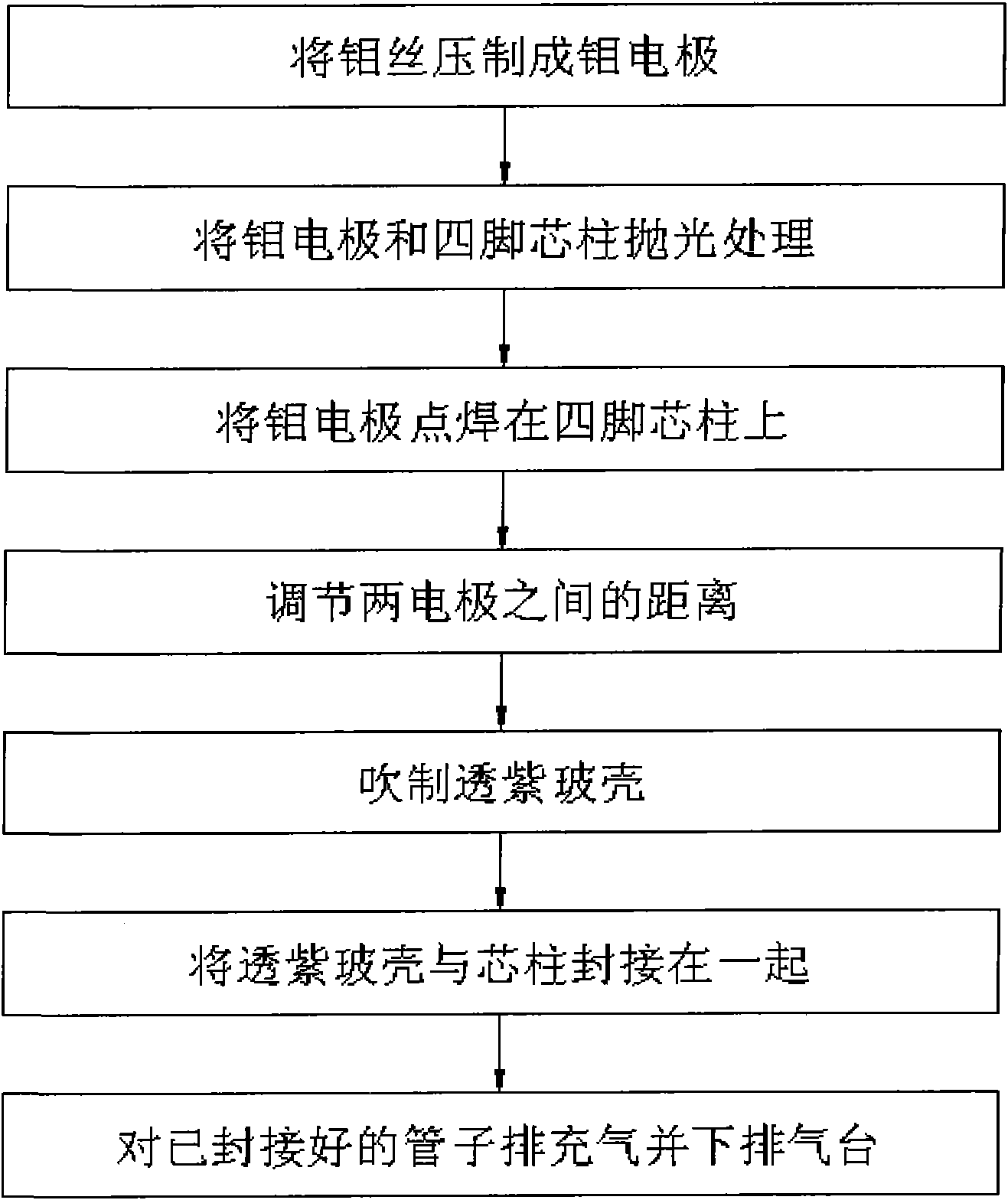

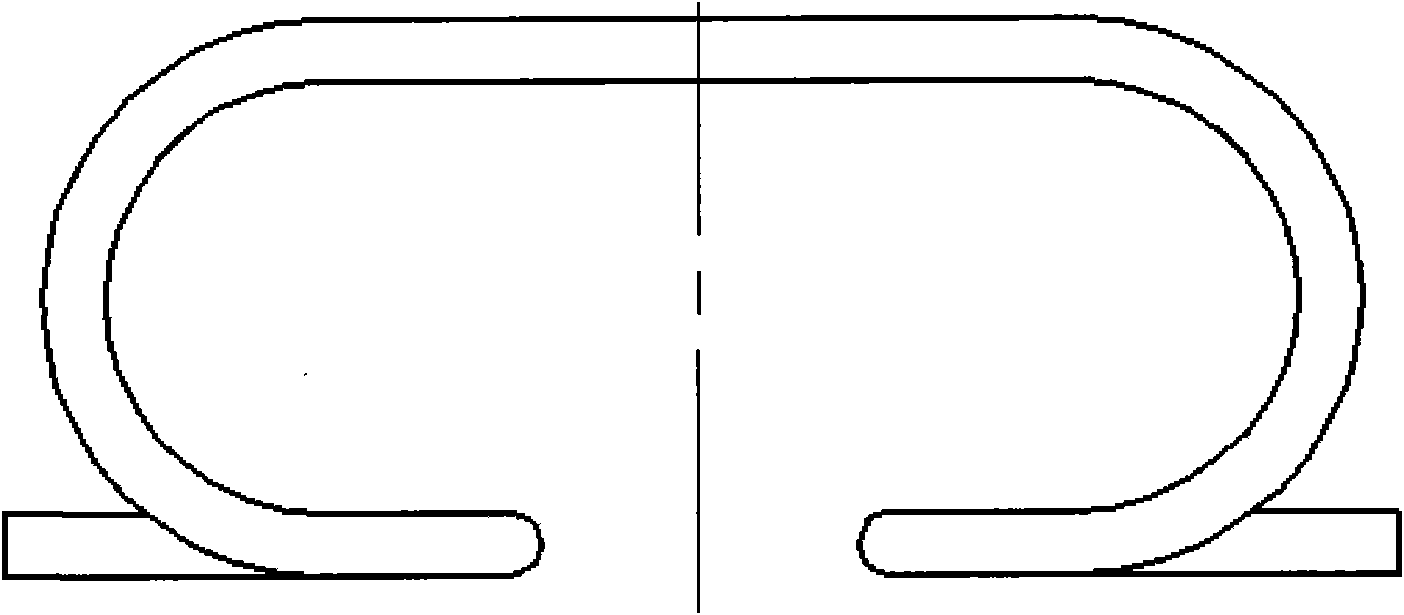

High-temperature solar blind ultraviolet photoelectric tube and manufacturing method thereof

InactiveCN102034667AHigh sensitivitySolution to short lifeTube/lamp vessel degassingPhotoelectric discharge tubesInfraredUltraviolet

The invention discloses a high-temperature solar blind ultraviolet photoelectric tube and a manufacturing method thereof. The photoelectric tube comprises a core column, a molybdenum group purple glass permeable shell, a metal straight rod and a molybdenum electrode, wherein the molybdenum group purple glass permeable shell is encapsulated on the core column; the metal straight rod is arranged in the core column; and the molybdenum electrode is connected to the metal straight rod. When the high-temperature solar blind ultraviolet photoelectric tube exhausts air, the molybdenum group purple glass permeable shell is baked at high temperature for a long time and the molybdenum electrode is treated by an electron bombardment method. The photoelectric tube has the advantages of high sensitivity, high reliability, long service life, high response speed, high temperature resistance, no response to visible light and infrared light, light weight and the like.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

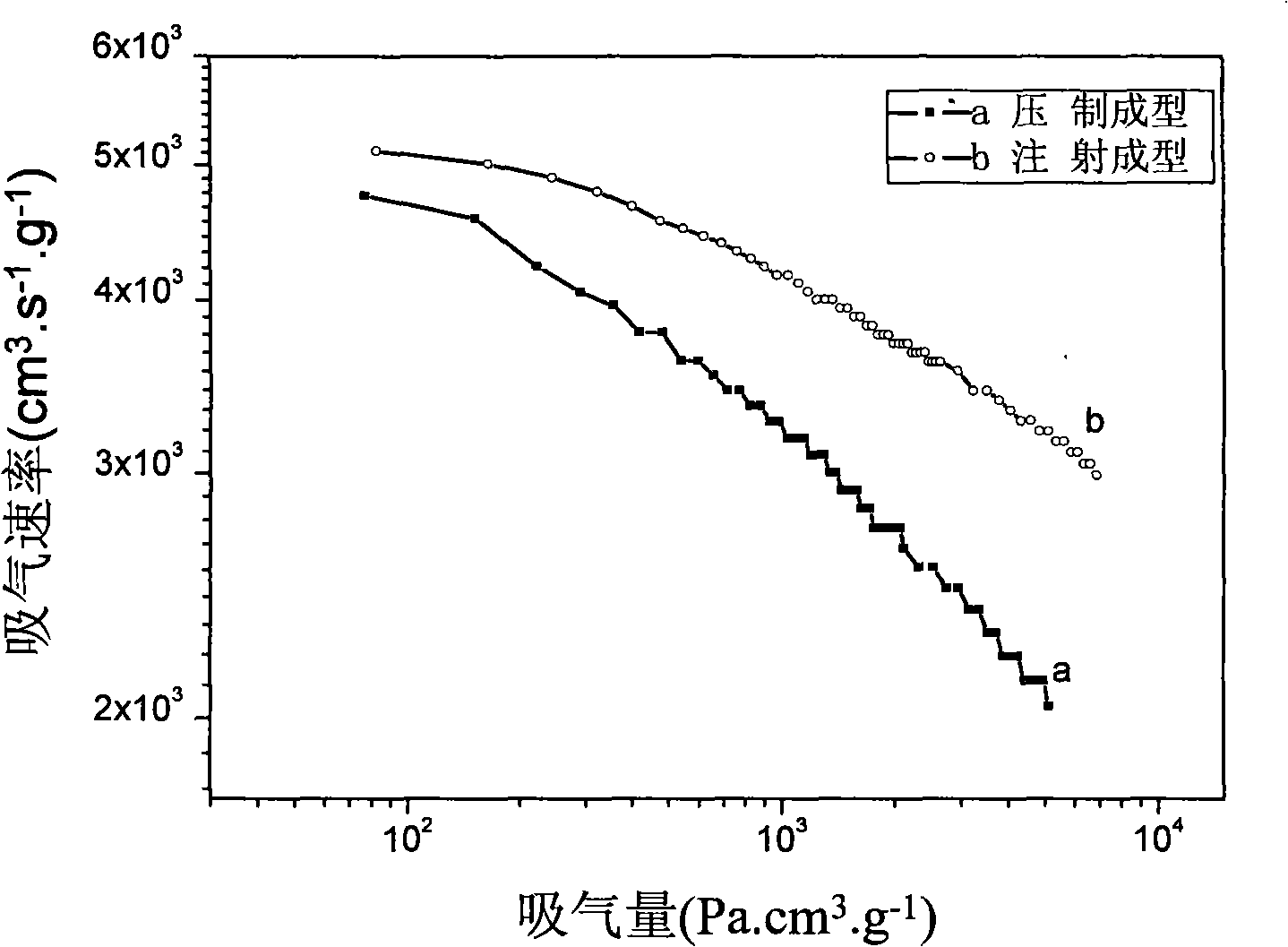

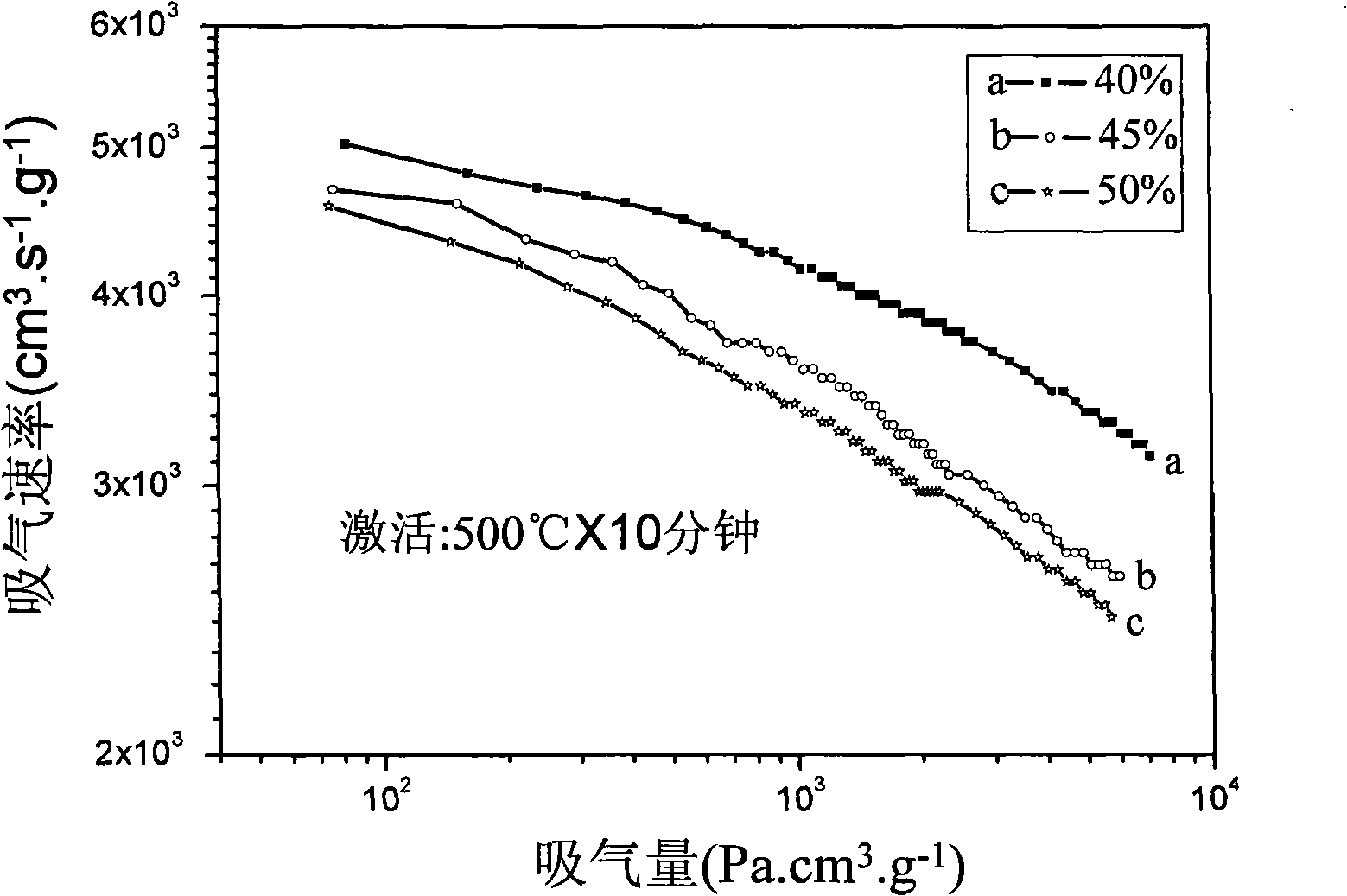

Method for preparing electric vacuum suction element molded by powder injection

ActiveCN101290851AMeet shape requirementsMeet the dimensional accuracy requirementsElectric discharge tubesTube/lamp vessel degassingElectricityPorosity

The invention provides a method for preparing an electric vacuum inspiration element by using powder injection molding, which belongs to the electric vacuum inspiration element manufacturing technical field. The preparation technology is as follows: Ti powder and Mo powder taken as raw materials are mixed in a mixer, the evenly-mixed raw material powder and adhesive are mixed according to the volume ratio, mixed in a mixing roll, cooled, then crushed into injection feedstock, and subject to the injection molding, two-step debinding process treatment is adopted to a blank formed by the injection molding, the blank formed by the injection molding undergoes solvent debinding and vacuum thermal debinding then, and finally vacuum sintering is carried out to the debound blank to prepare the vacuum inspiration element. The method has the advantages that: the method can prepare the inspiration elements with complicated shape and high dimension accuracy to meet the requirement of spaces with various shapes of various electric vacuum devices to the complicated shape and the dimension accuracy of the inspiration elements. The aperture and the degree of porosity of the product are evenly controlled, and the degree of porosity of the inspiration element can reach more than 50 percent.

Owner:GRIMAT ENG INST CO LTD

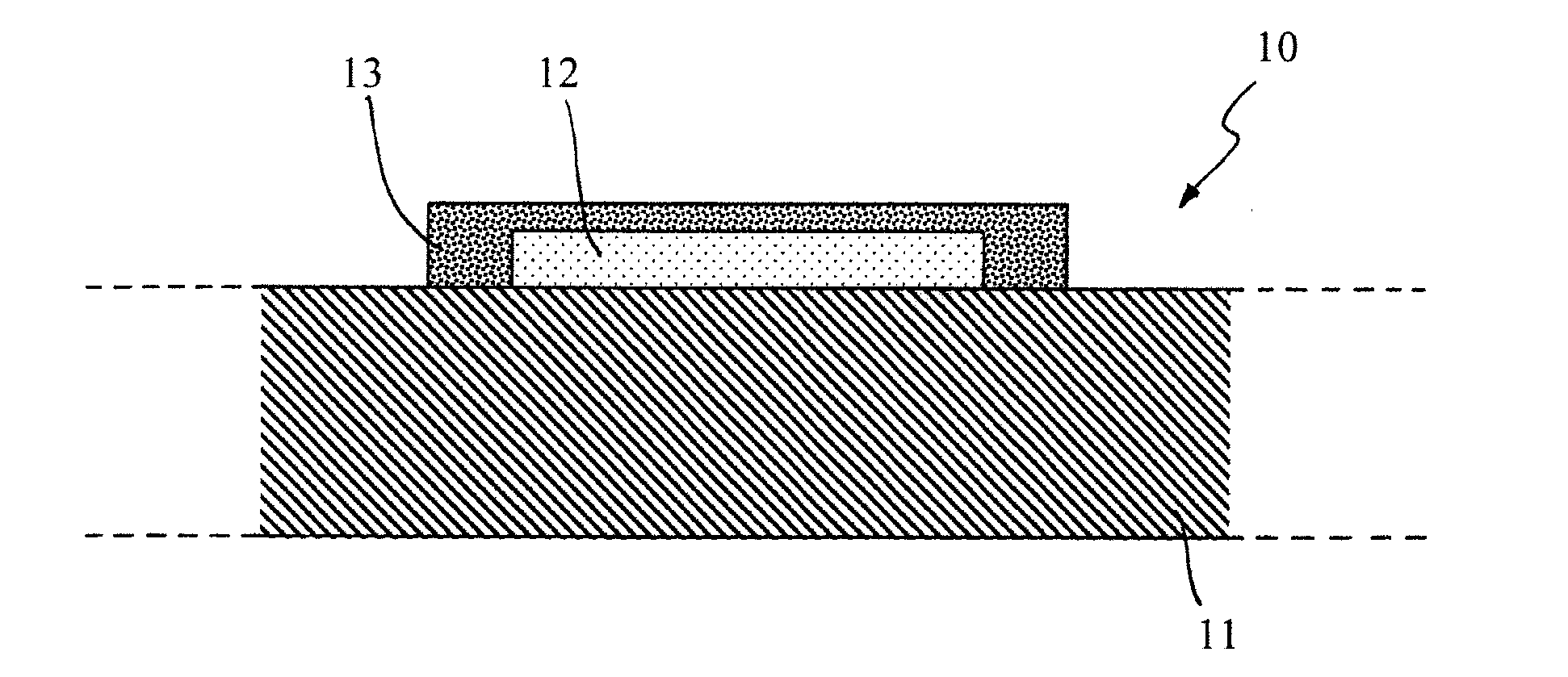

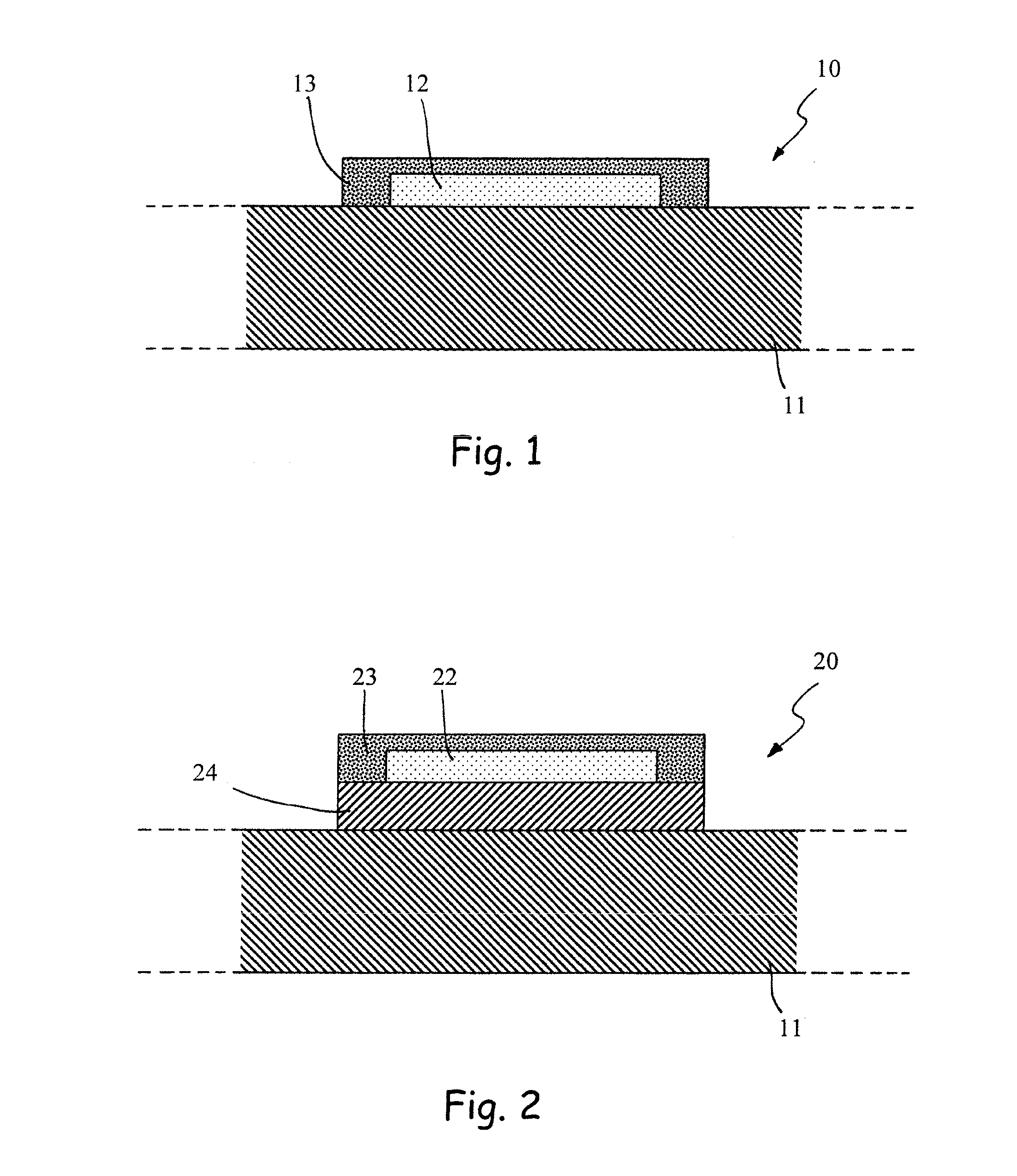

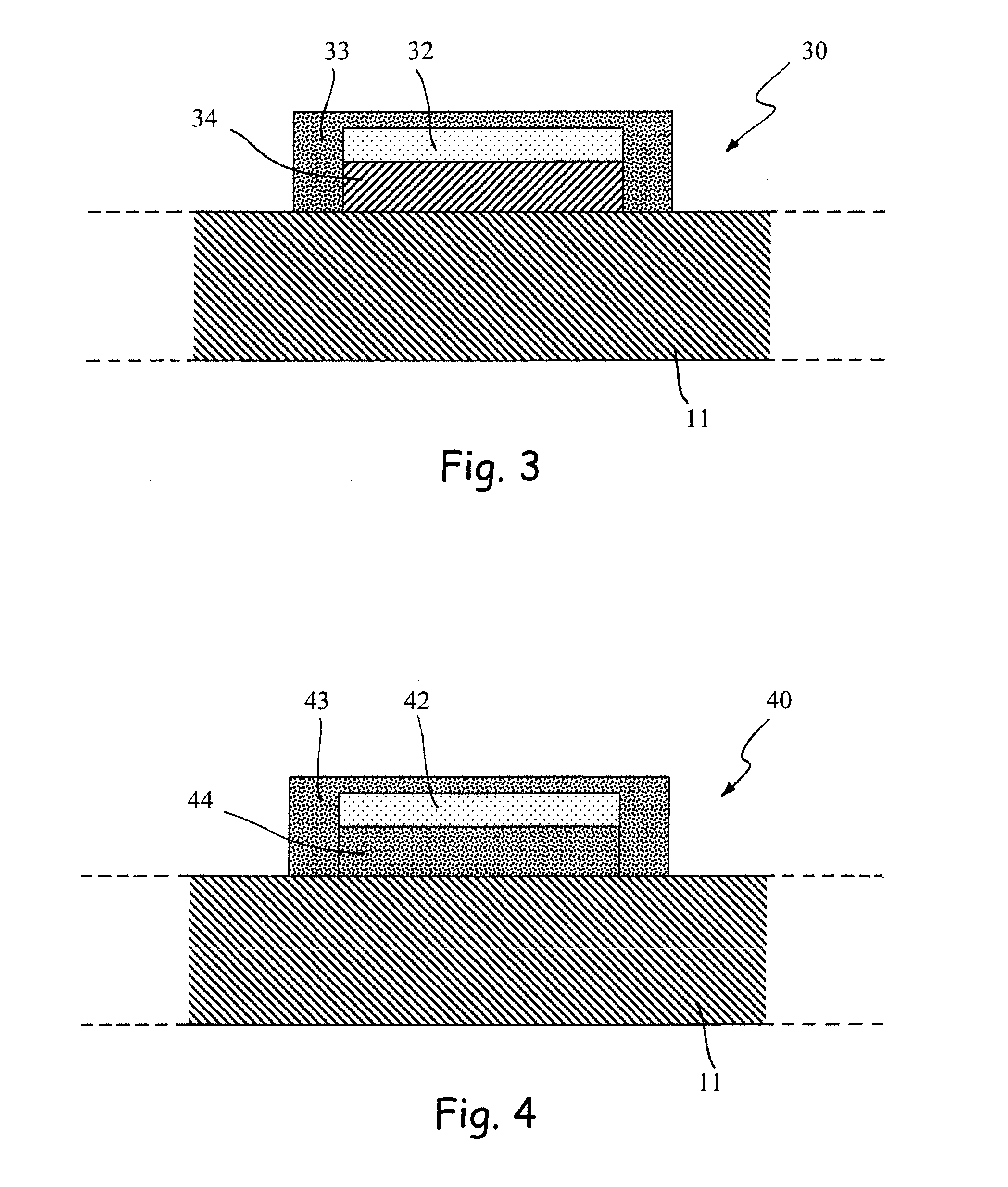

Air-stable alkali or alkaline-earth metal dispensers

ActiveUS20100104450A1Gas filling substance selectionPump componentsAlkaline earth metalNuclear chemistry

There are described dispensers (10; 20; 30; 40; 50; 60) of alkali or alkaline-earth metals, comprising deposits of getter materials (13; 23; 33; 43; 53; 63) and alkali or alkaline-earth metal sources (12, 22; 32; 42; 53; 63), in which the sources of alkali or alkaline-earth metal are protected from environmental gases by said deposits of getter materials.

Owner:SAES GETTERS SPA

Non-evaporation type getter, display unit and production method for them

InactiveUS7126276B2Complex shapeHigh mechanical strengthGas filling substance selectionCathode-ray/electron-beam tube vessels/containersPorosityEvaporation

Disclosed are a non-evaporation type getter excellent in gettering effect, capable of maintaining the inside of a gas-tight container in a display apparatus, particularly a flat panel display apparatus or the like, in a high vacuum condition, easy to mount and less liable to contaminate the inside of the gas-tight container, a display apparatus including the getter, and methods of manufacturing the same. The non-evaporation type getter (20) includes a molded body including at least one element selected from the group consisting of Ti, Zr, Al, V, and Fe as a principal constituent thereof, the molded body formed by powder injection molding. The molded body is composed of a porous body having a porosity of 10 to 30%.

Owner:SONY CORP

Popular searches

Vessels or leading-in conductors manufacture Spark gaps adjustment Manufacture testing/measurements Combustion ignition Non-linear optics Input/output processes for data processing Identification means Defective tube/lamp repair/regeneration Cold cathode manufacture Photo-emissive cathodes manufacture

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com