Method for preparing electric vacuum suction element molded by powder injection

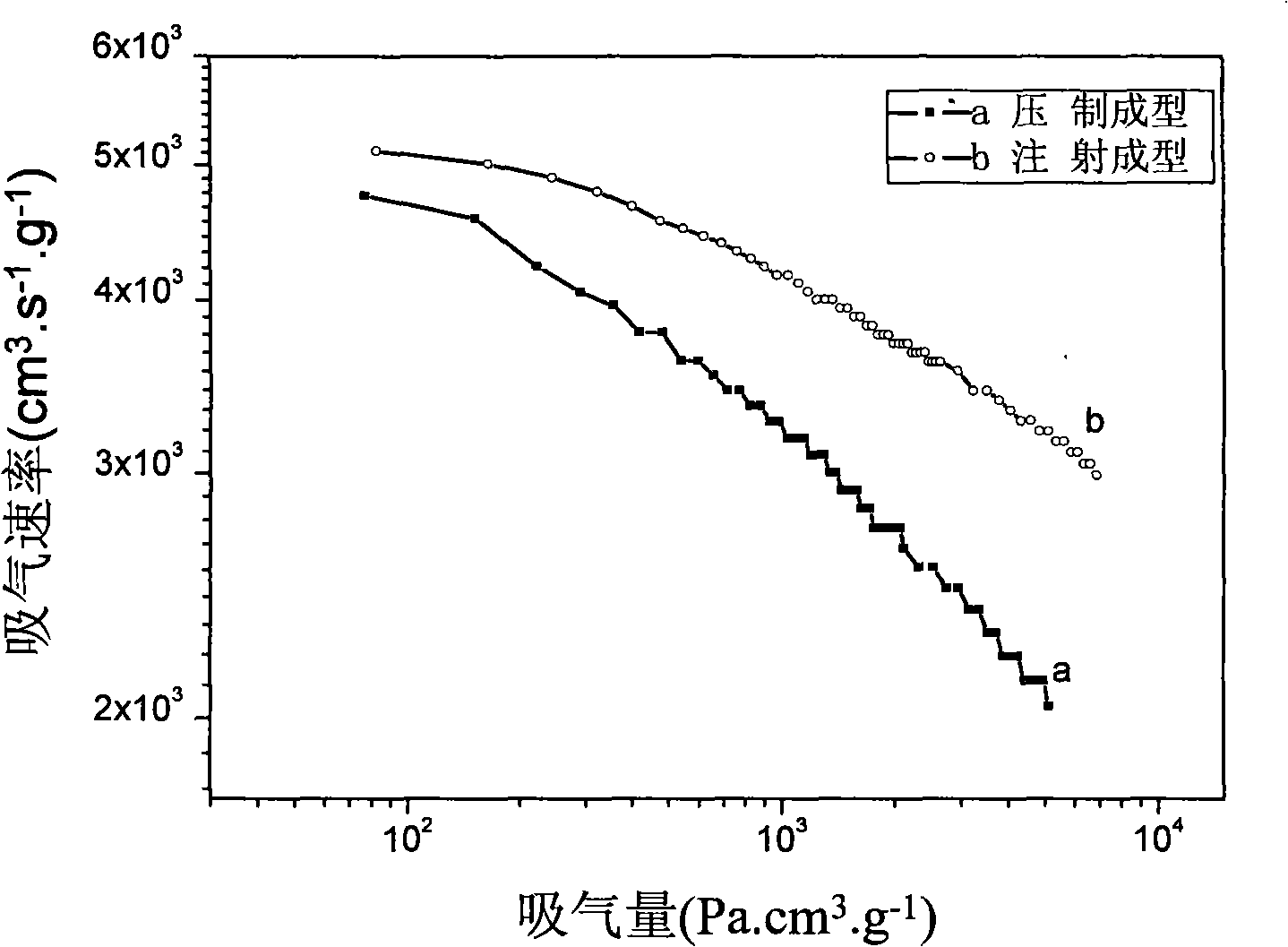

A technology of powder injection molding and injection molding, which is applied in the direction of electrical components, electric tube/lamp degassing, circuits, etc. It can solve the problems of high porosity, inability to prepare, and easy powder drop of components, etc., and achieve uniform porosity and uniform control , the effect of high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

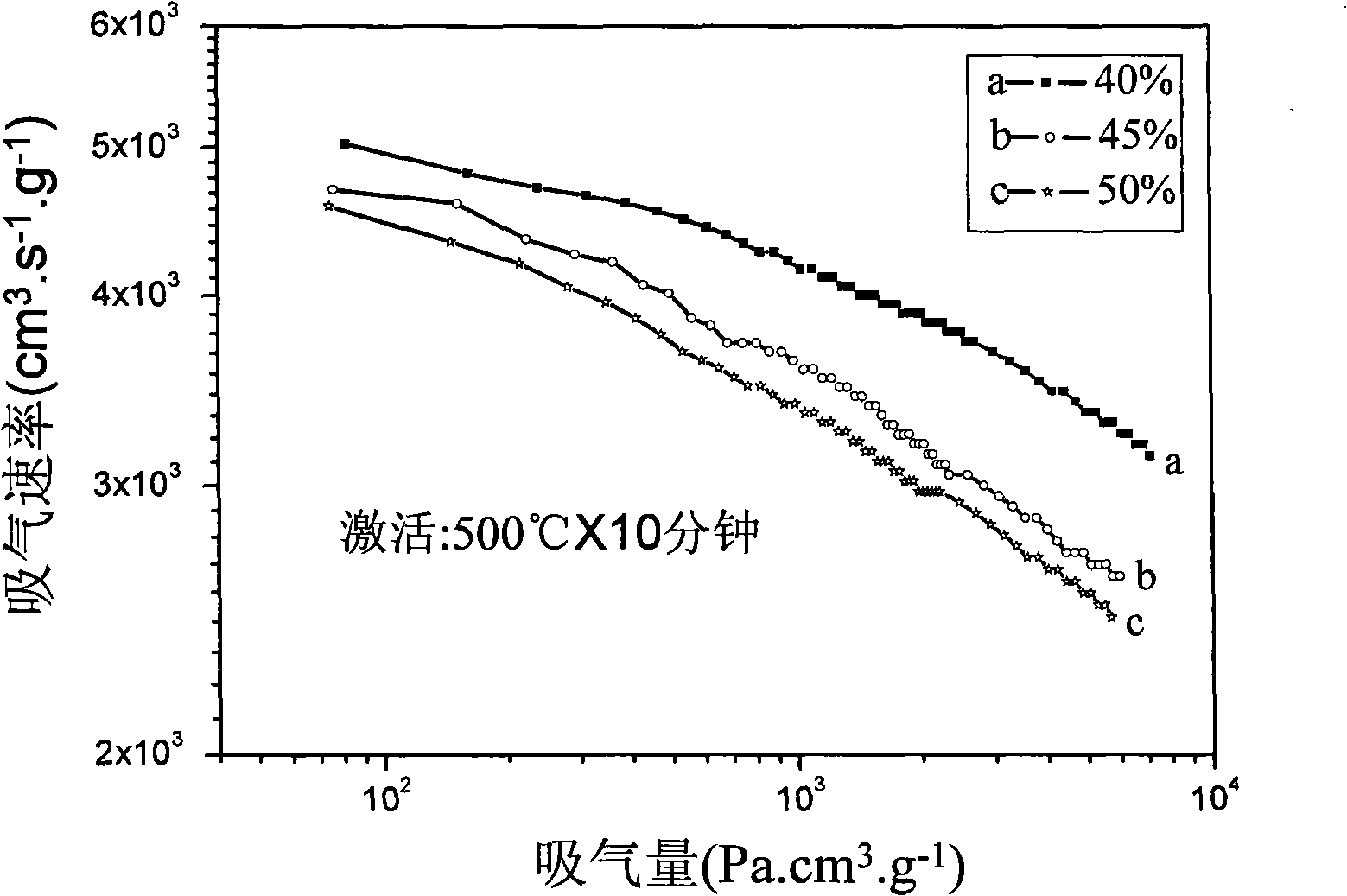

Embodiment 1

[0021] Put Ti powder with an average particle size of 35 μm and Mo powder with an average particle size of 35 μm in a weight ratio of 9:1 and put them into a mixer, and mix them for 20 hours under the protection of Ar gas to make a raw material powder. 60% of paraffin, 14% of high-density polyethylene, 14% of polypropylene and 12% of hard acid are uniformly mixed according to the weight percentage to prepare the binder. The mixed raw material powder and binder are mixed on a mixer at a volume ratio of 40:60, and the mixing temperature is 150°C. After mixing for 3 hours, it is cooled to room temperature and crushed into injection feed. The feed material is injection-molded on an injection molding machine, the injection temperature is 175° C., and the injection pressure is 70 MPa. Degrease the injection blank in trichlorethylene for 8 hours, then take out the blank and dry it in a vacuum oven at a temperature of 80°C for 3 hours, then heat and degrease the dried blank in a vacuu...

Embodiment 2

[0023] The operating method and process conditions are basically the same as in Example 1, the only difference being that the volume ratio of the raw material powder loading to the binder is 45:55. The air-absorbing element prepared by this process has a porosity of 55%, and the ten-minute hydrogen absorption rate S 10分钟 3728.73cm 3 .s -1 .g -1 , 60-minute inspiratory capacity Q 60分钟 3299.64Pa.cm 3 .g -1 .

Embodiment 3

[0025] The operation method and process conditions are basically the same as in Example 1, the only difference being that the volume ratio of the raw material powder loading to the binder is 50:50. The getter element prepared by this process has a porosity of 51%, and the tenth-minute hydrogen uptake rate S 10分钟 3587.65cm 3 .s -1 .g -1 , 60-minute inspiratory capacity Q 60分钟 3141.37Pa.cm 3 .g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com