Gas spring with plurality of spiral columns

A gas spring and helical column technology, which is applied in the field of spring manufacturing, can solve problems such as complex structure, impact on health, and high requirements for parts matching, and achieve good horizontal and vertical ventilation, eliminate the impact on human health, and overcome the effect of complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

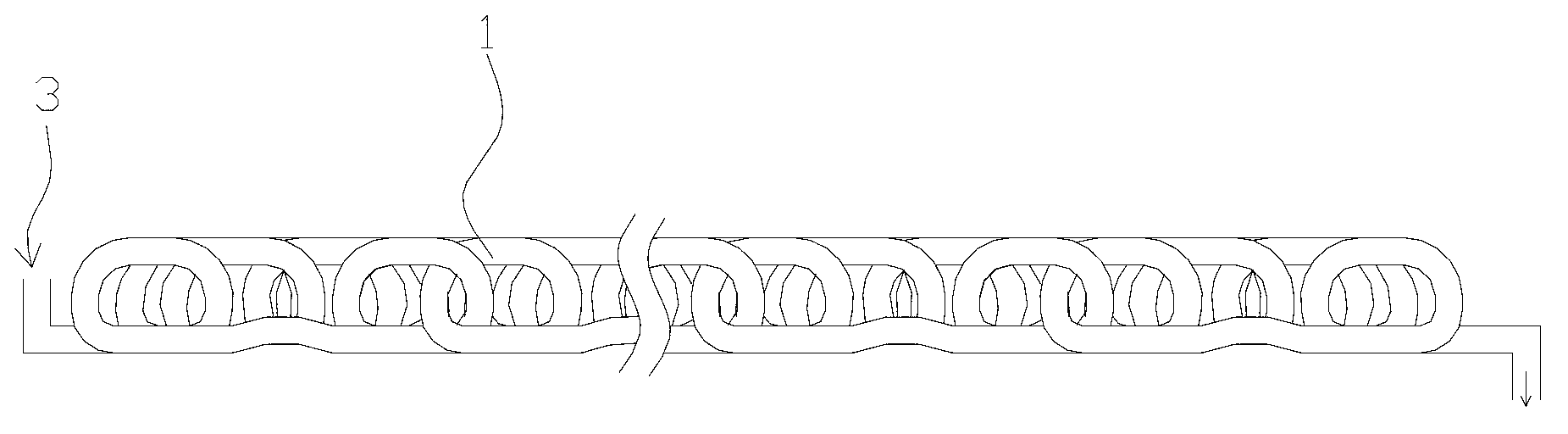

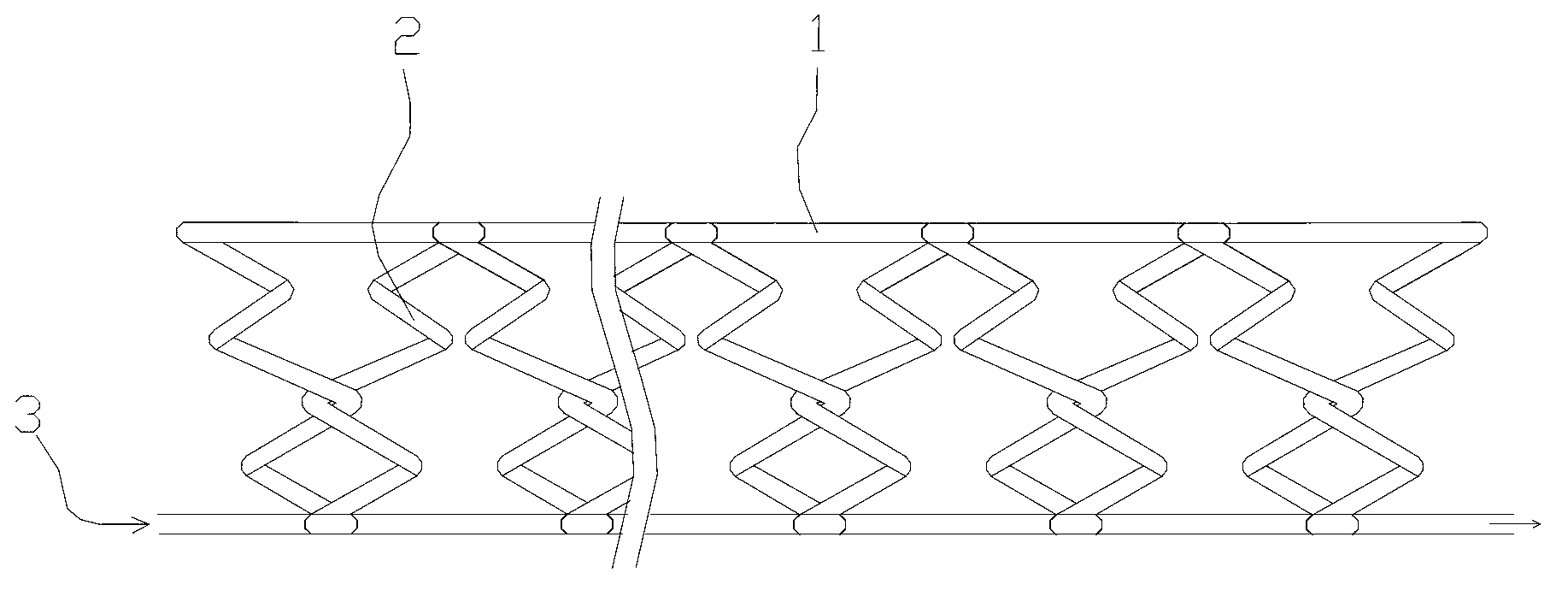

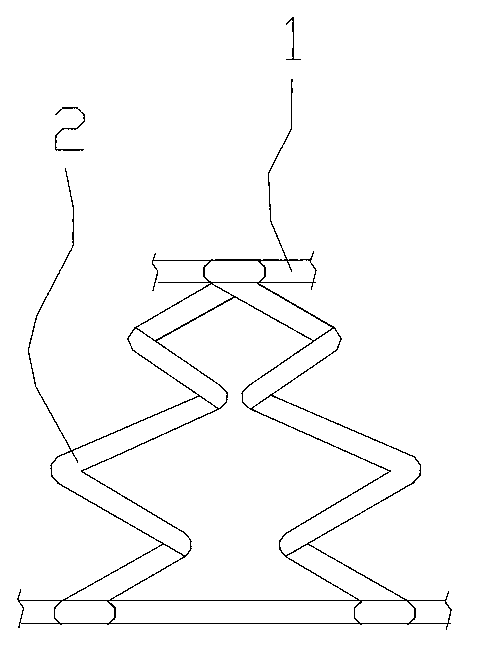

[0022] Such as Figure 1-Figure 4 As shown, a gas spring with a plurality of helical columns described in this embodiment includes a spring body, and the spring body is composed of a bar-shaped gas column 1 with a pressure gas containing chamber, and the gas column 1 A plurality of side-by-side and inclined spiral columns 2 are formed through repeated alternating spirals from top to bottom or bottom to top. The two adjacent spiral columns 2 form a figure-eight spiral unit, and the adjacent spiral units are connected with each other. , the air column 1 is provided with at least one vent hole 3 communicating with the containing chamber, and two vent holes 3 can be provided at both ends of the air column 1, one for inflation and one for exhaust.

[0023] The two adjacent helical columns 2 are arranged symmetrically, the inclination directions of the two separated helical columns 2 are consistent, and the heights of each helical column 2 are consistent, which is convenient for for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com