Surface anti-impact abrasion-resisting lubricating composite coating for hydraulic valve rod and preparation method thereof

A technology of impact and wear resistance and composite coating, which is applied in the direction of coating, metal material coating process, superimposed layer plating, etc. Scratch performance and other issues, achieve good anti-wear lubrication effect and adaptability to variable working conditions, save manpower and material resources, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

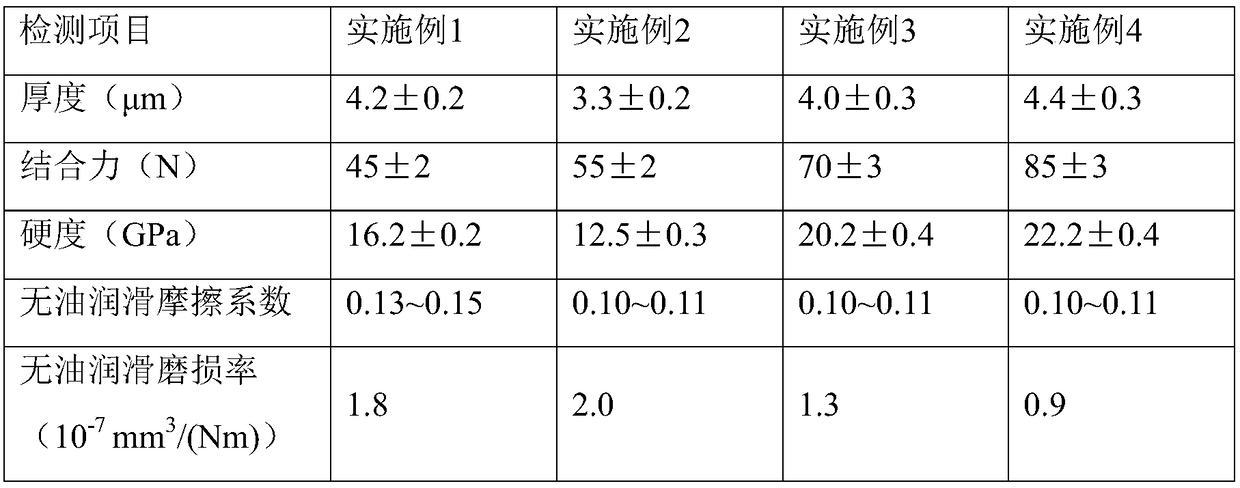

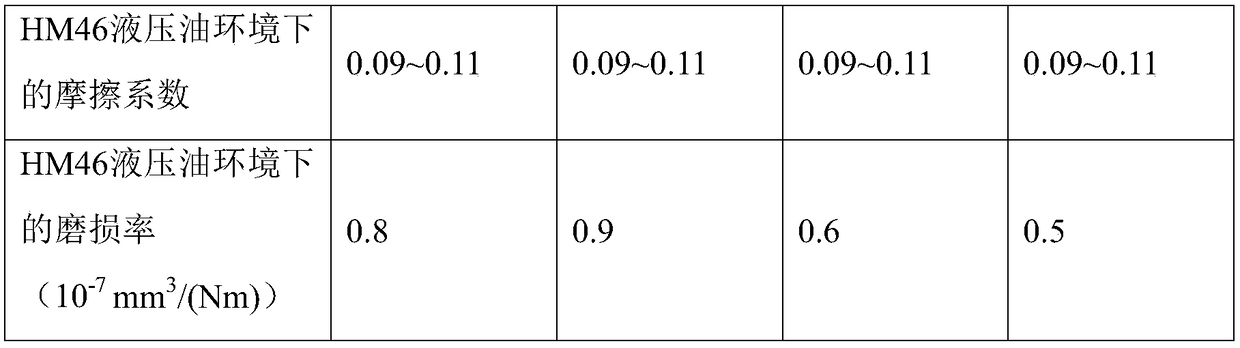

Embodiment 1

[0030] In this embodiment, the substrate is a Y15Pb Yiche iron hydraulic valve stem, and the hardness after aging treatment is ≥22HRC. The total thickness of the impact-resistant and wear-resistant lubricating composite coating on the surface of the hydraulic valve stem is controlled at 4.0-4.5 μm, and the composition is: Ti / TiC deposited by magnetron sputtering with a thickness of 0.6 μm from bottom to top on the surface of the substrate x / WTiC x / WC x Gradient transition layer, magnetron sputtering deposition of WC and amorphous carbon nano-multilayer composite functional layer with a thickness of 3.0-3.5 μm, and magnetron sputtering amorphous carbon top layer with a thickness of 0.5-1.0 μm.

[0031] The equipment used is a magnetron sputtering vacuum vapor deposition system in which high-purity graphite targets with a purity of 99.99%, high-purity titanium targets with a purity of 99.99%, graphite targets with a purity of 99.99%, and tungsten carbide targets are installed...

Embodiment 2

[0045] In this embodiment, the substrate is a 0Cr17Ni4Cu4N stainless steel hydraulic valve stem, and the hardness after aging treatment is ≥40HRC. The total thickness of the impact-resistant and wear-resistant lubricating composite coating on the surface of the hydraulic valve stem is controlled at 3.0-3.5 μm, and the composition is: Cr / CrC deposited by magnetron sputtering with a thickness of 0.5 μm from bottom to top on the surface of the substrate x A gradient transition layer, a Cr-doped amorphous carbon composite functional layer deposited by magnetron sputtering with a thickness of 1.8-2.5 μm, and a magnetron sputtered amorphous carbon top layer with a thickness of 0.5-1.0 μm.

[0046] The equipment used is magnetron sputtering with 99.99% pure graphite target, 99.99% pure chromium target, 99.99% pure graphite target, and 99.99% pure chromium target installed in sequence around the vacuum chamber. Sputtering vacuum vapor deposition system, the size of the sputtering targ...

Embodiment 3

[0060] In this embodiment, the substrate is a GCr15 bearing steel hydraulic valve stem, and the hardness after heat treatment is ≥56HRC. The total thickness of the impact-resistant and wear-resistant lubricating composite coating on the surface of the hydraulic valve stem is controlled at 3.5-4.5 μm, and the composition is: from bottom to top on the surface of the substrate, a Cr / CrN gradient transition layer deposited by magnetron sputtering with a thickness of 0.5-0.8 μm , a WC-doped amorphous carbon composite functional layer deposited by magnetron sputtering with a thickness of 1.5-2.0 μm, and an amorphous carbon top layer deposited by plasma chemical vapor technology with a thickness of 1.5-2.0 μm.

[0061] The equipment used is the magnetron-plasma of high-purity chromium target with a purity of 99.99%, tungsten carbide magnetron sputtering target, high-purity chromium target with a purity of 99.99%, and tungsten carbide magnetron sputtering target. Chemical vapor deposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com