Patents

Literature

598 results about "Plasma chemistry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasma - (physical chemistry) a fourth state of matter distinct from solid or liquid or gas and present in stars and fusion reactors; a gas becomes a plasma when it is heated until the atoms lose all their electrons, leaving a highly electrified collection of nuclei and free electrons; "particles in space exist in the form of a plasma".

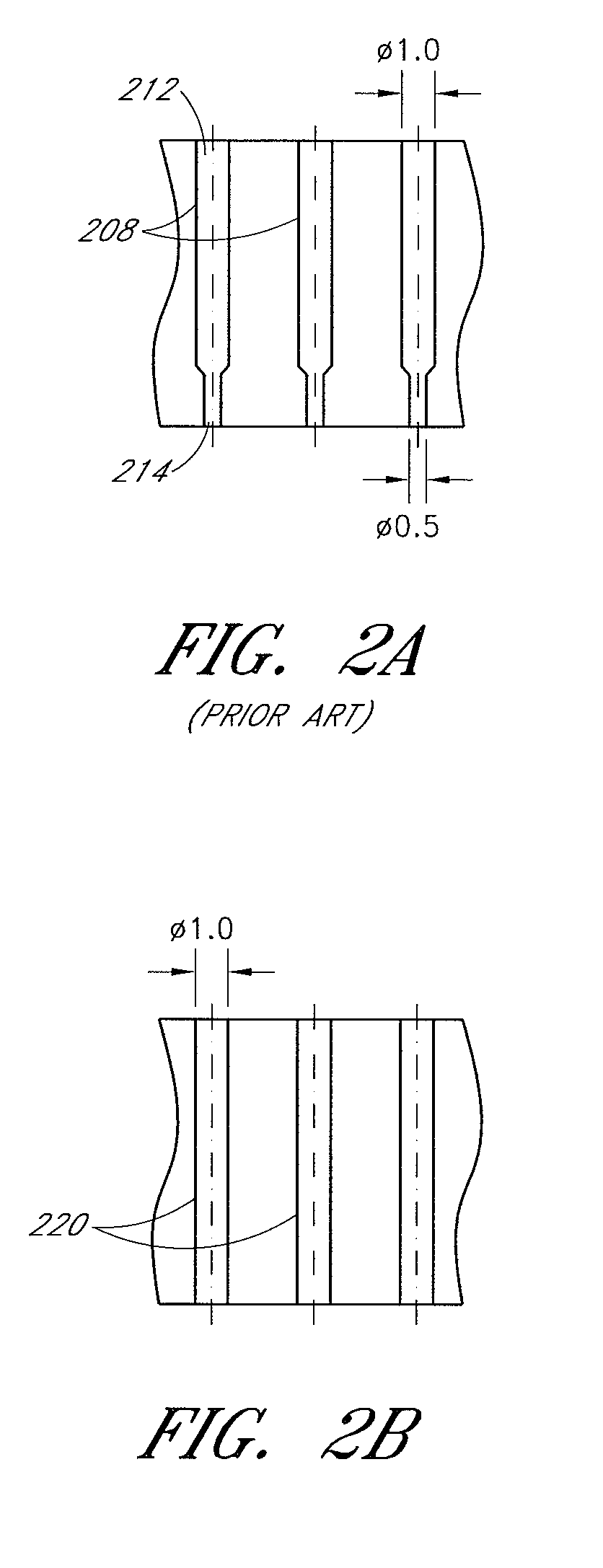

Shower plate electrode for plasma CVD reactor

InactiveUS20090155488A1Uniform cross-sectional areaElectrostatic cleaningChemical vapor deposition coatingMachined surfaceEngineering

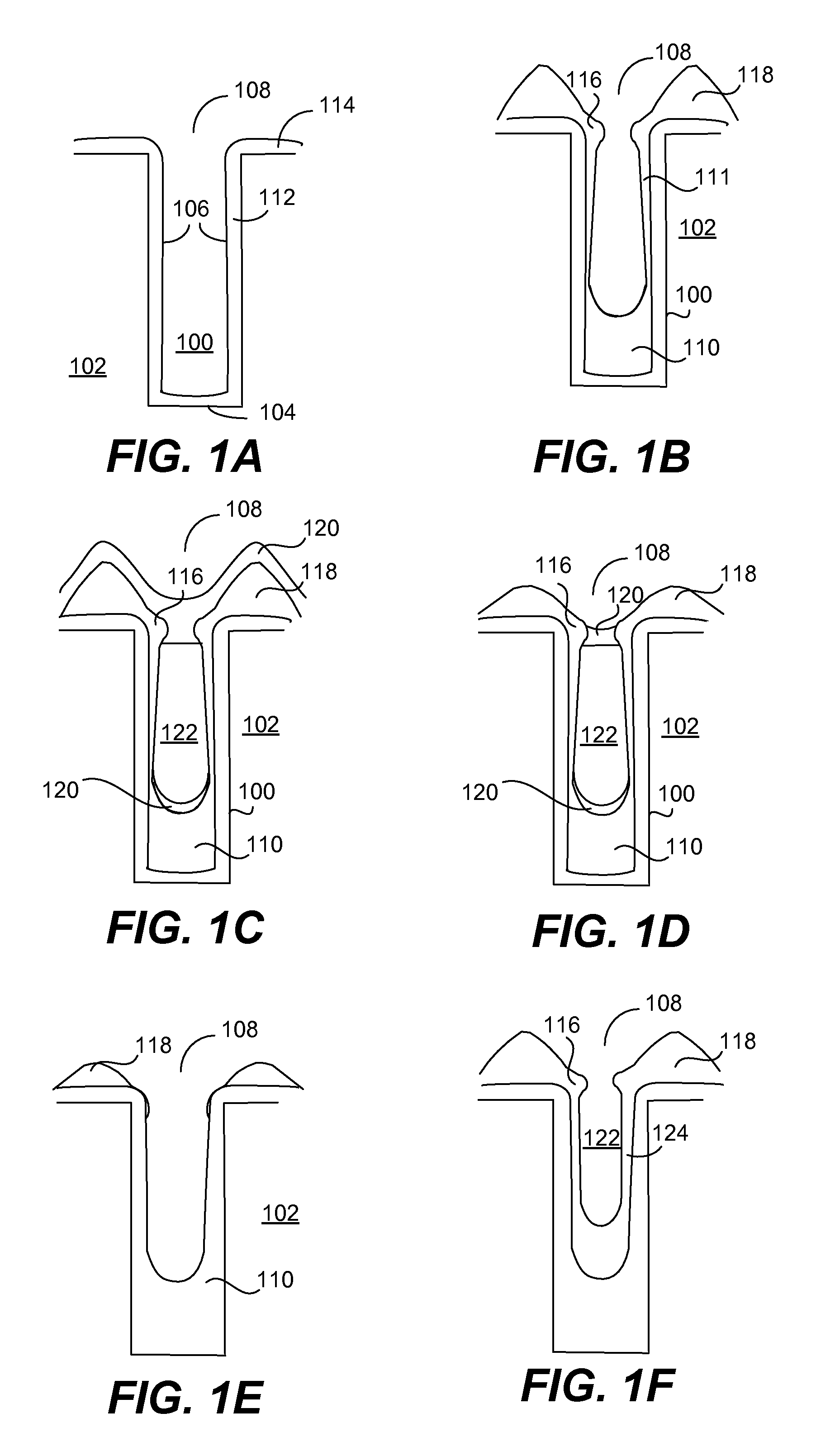

Methods and apparatuses for plasma chemical vapor deposition (CVD). In particular, a plasma CVD apparatus having a cleaning function, has an improved shower plate with holes having a uniform cross-sectional area to yield a high cleaning rate. The shower plate may serve as an electrode, and may have an electrically conductive extension connected to a power source. The shower plate, through which both cleaning gases and reaction source gases flow, may include a hole machined surface area with a size different than conventionally used to ensure a good film thickness uniformity during a deposition process. The size of the hole machined surface area may vary based on the size of a substrate to be processed, or the size of the entire surface of the shower plate.

Owner:ASM JAPAN

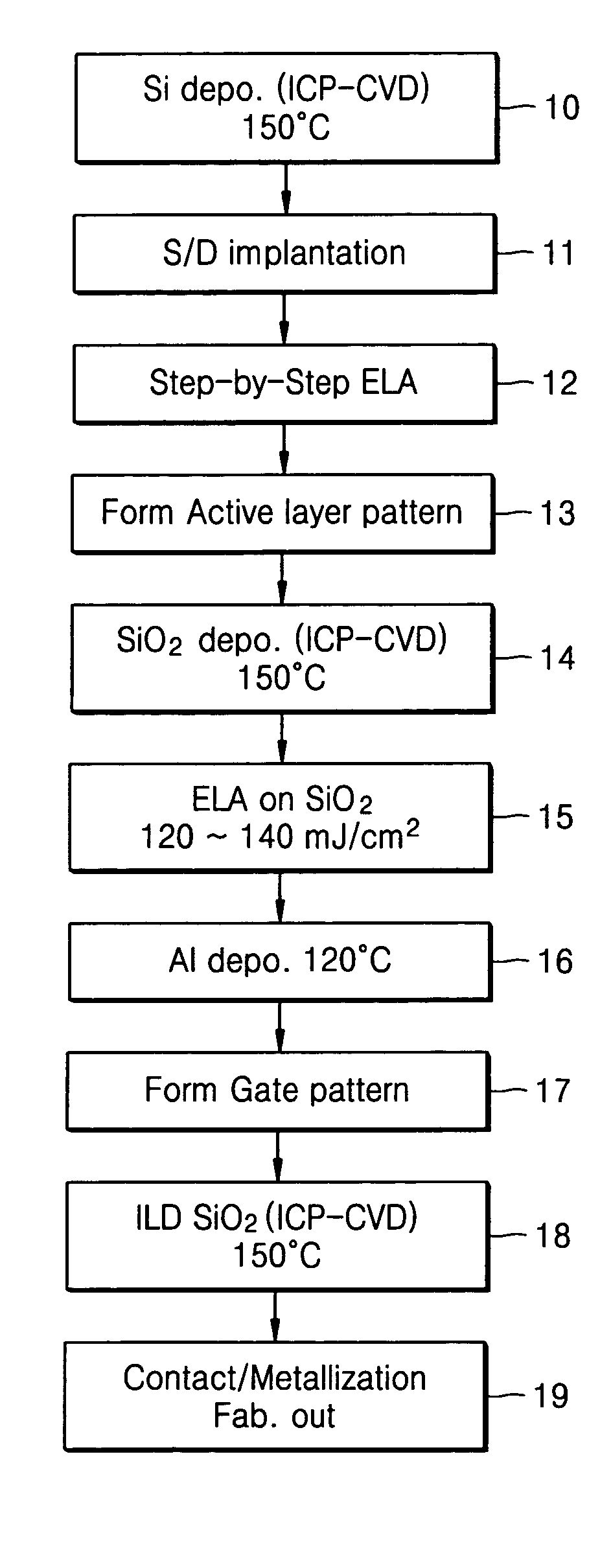

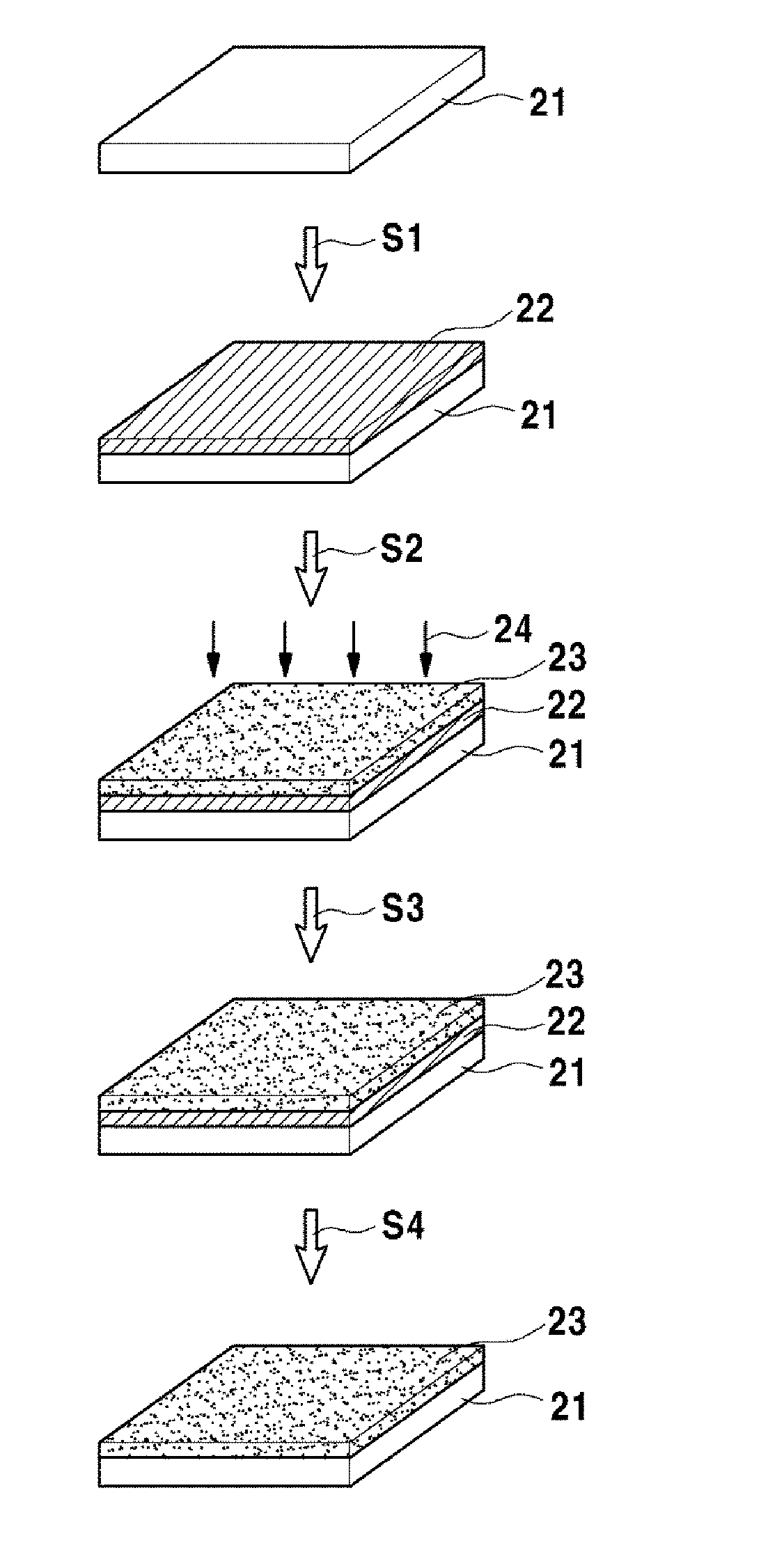

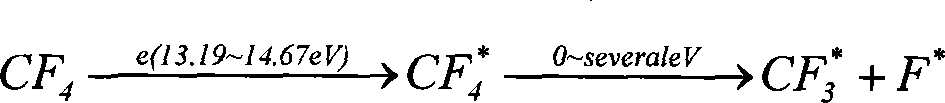

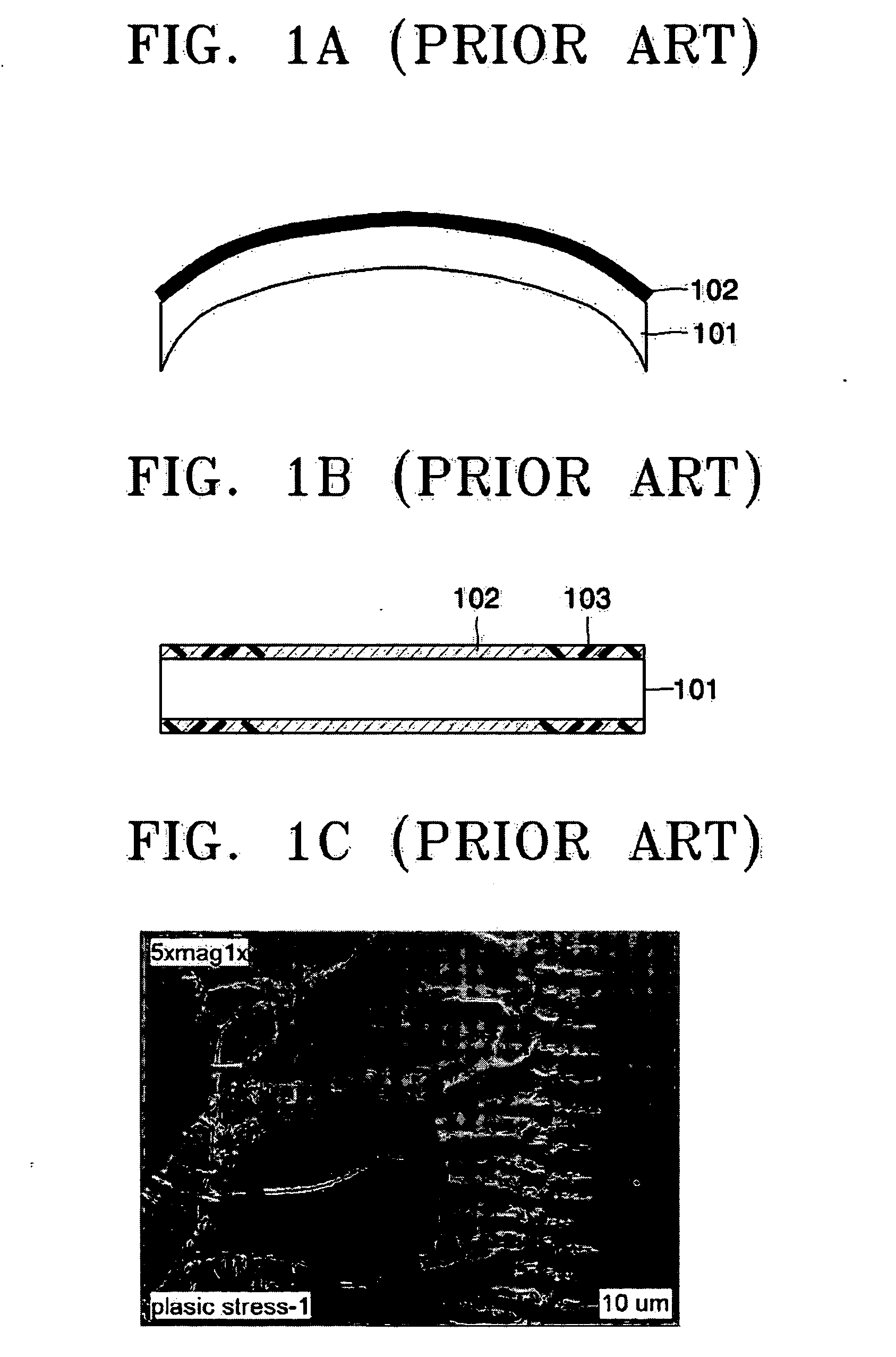

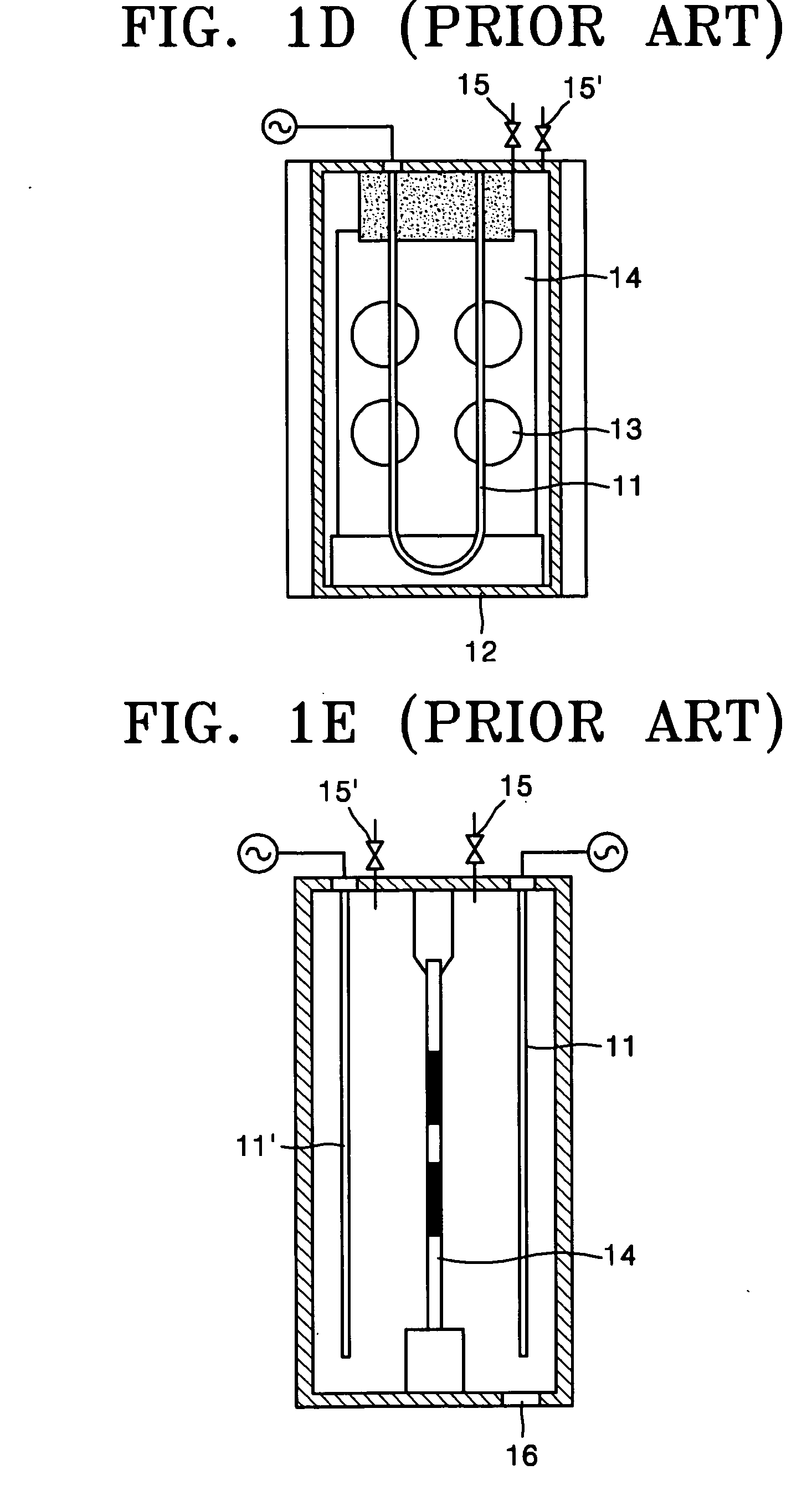

Method of fabricating poly-crystalline silicon thin film and method of fabricating transistor using the same

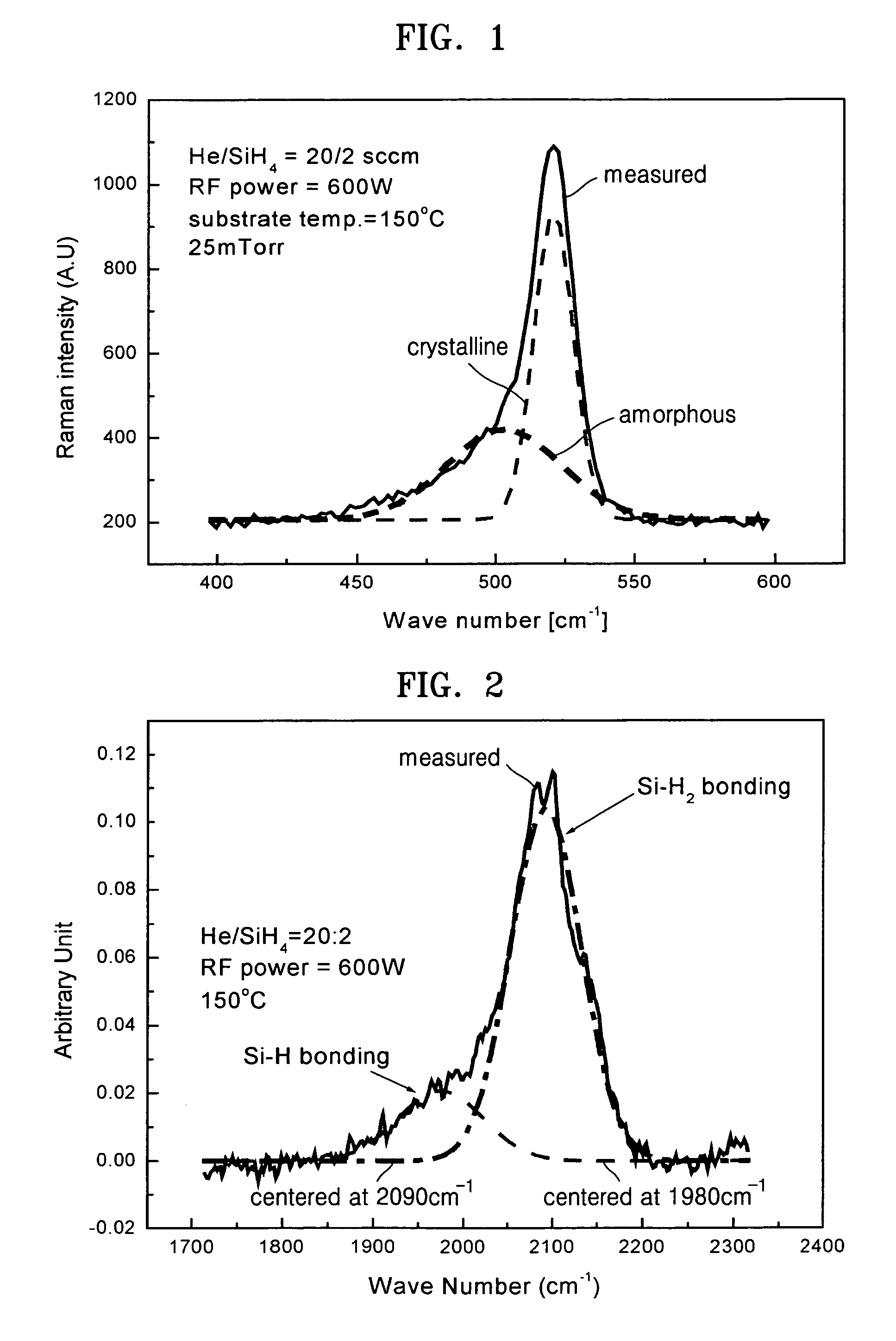

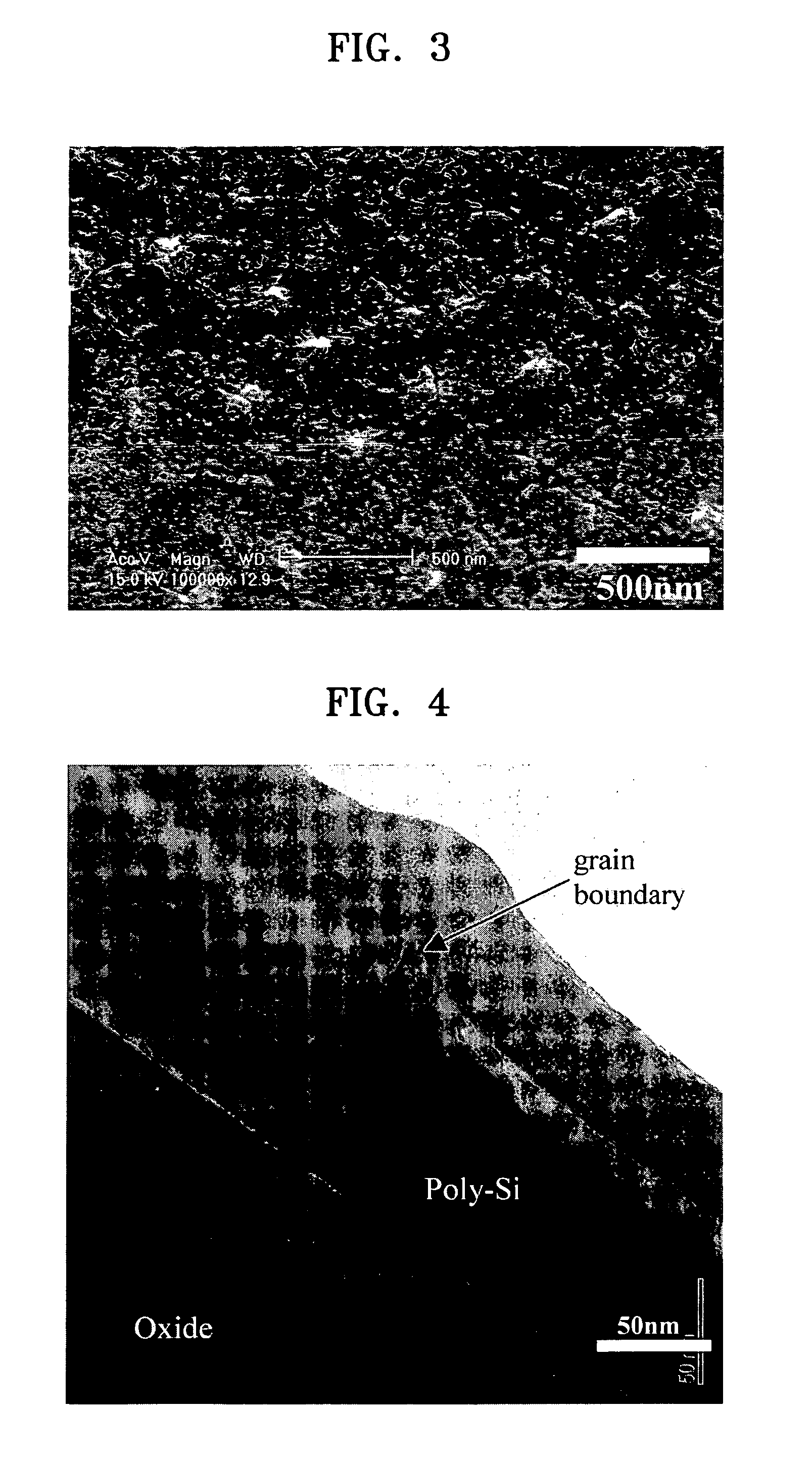

InactiveUS7563659B2Refined grain sizeHigh energyTransistorSemiconductor/solid-state device manufacturingInductively coupled plasmaSilicon thin film

A method of fabricating a poly-Si thin film and a method of fabricating a poly-Si TFT using the same are provided. The poly-Si thin film is formed at a low temperature using inductively coupled plasma chemical vapor deposition (ICP-CVD). After the ICP-CVD, excimer laser annealing (ELA) is performed while increasing energy by predetermined steps. A poly-Si active layer and a SiO2 gate insulating layer are deposited at a temperature of about 150° C. using ICP-CVD. The poly-Si has a large grain size of about 3000 Å or more. An interface trap density of the SiO2 can be as high as 1011 / cm2. A transistor having good electrical characteristics can be fabricated at a low temperature and thus can be formed on a heat tolerant plastic substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

Low temperature silicon nitride films using remote plasma CVD technology

ActiveUS9583333B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingCelsius DegreeRemote plasma

Embodiments of the present invention generally provide methods for forming a silicon nitride layer on a substrate. In one embodiment, a method of forming a silicon nitride layer using remote plasma chemical vapor deposition (CVD) at a temperature that is less than 300 degrees Celsius is disclosed. The precursors for the remote plasma CVD process include tris(dimethylamino)silane (TRIS), dichlorosilane (DCS), trisilylamine (TSA), bis-t-butylaminosilane (BTBAS), hexachlorodisilane (HCDS) or hexamethylcyclotrisilazane (HMCTZ).

Owner:APPLIED MATERIALS INC

Method for controlling etch process repeatability

ActiveUS7078312B1Reducing and eliminating chamber loadingReducing and eliminating and redepositionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh densityHydrogen

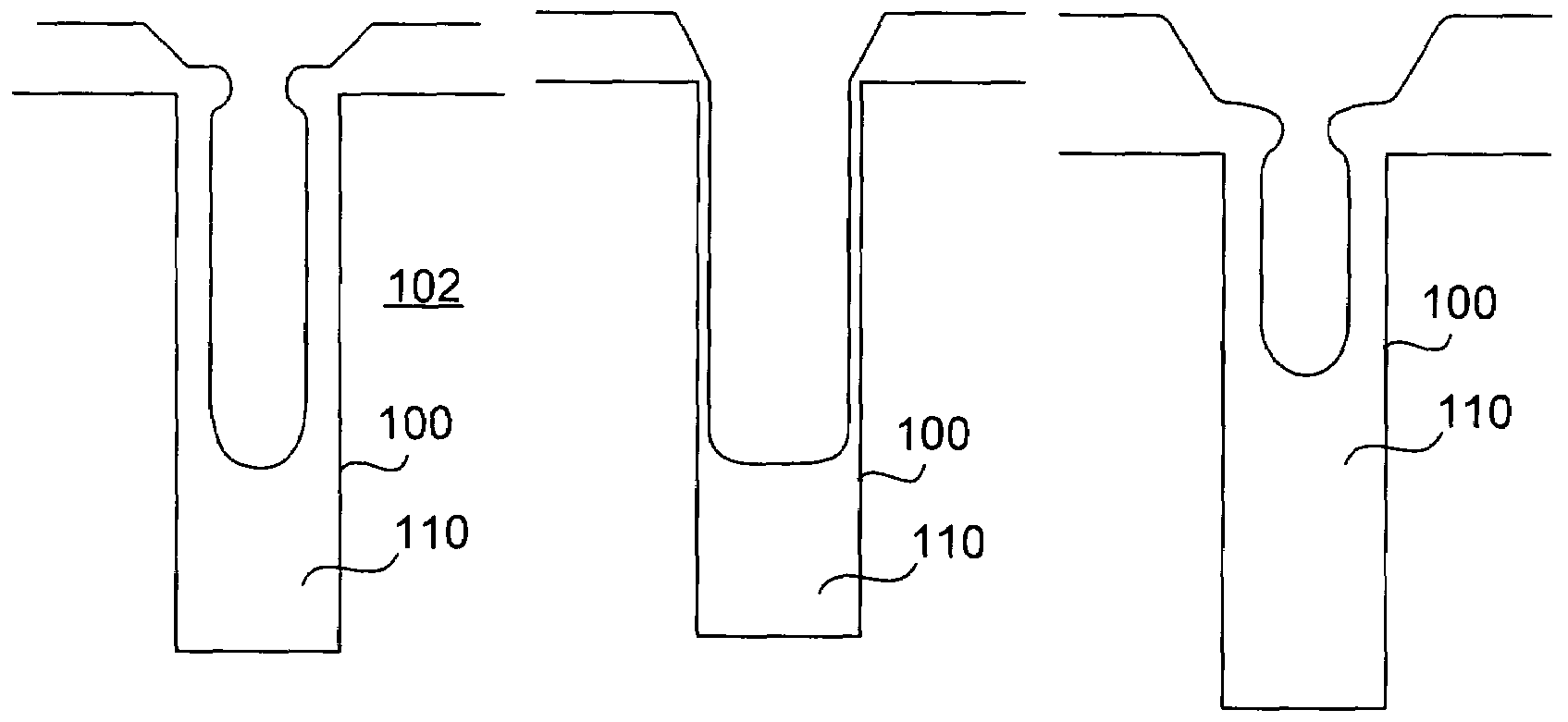

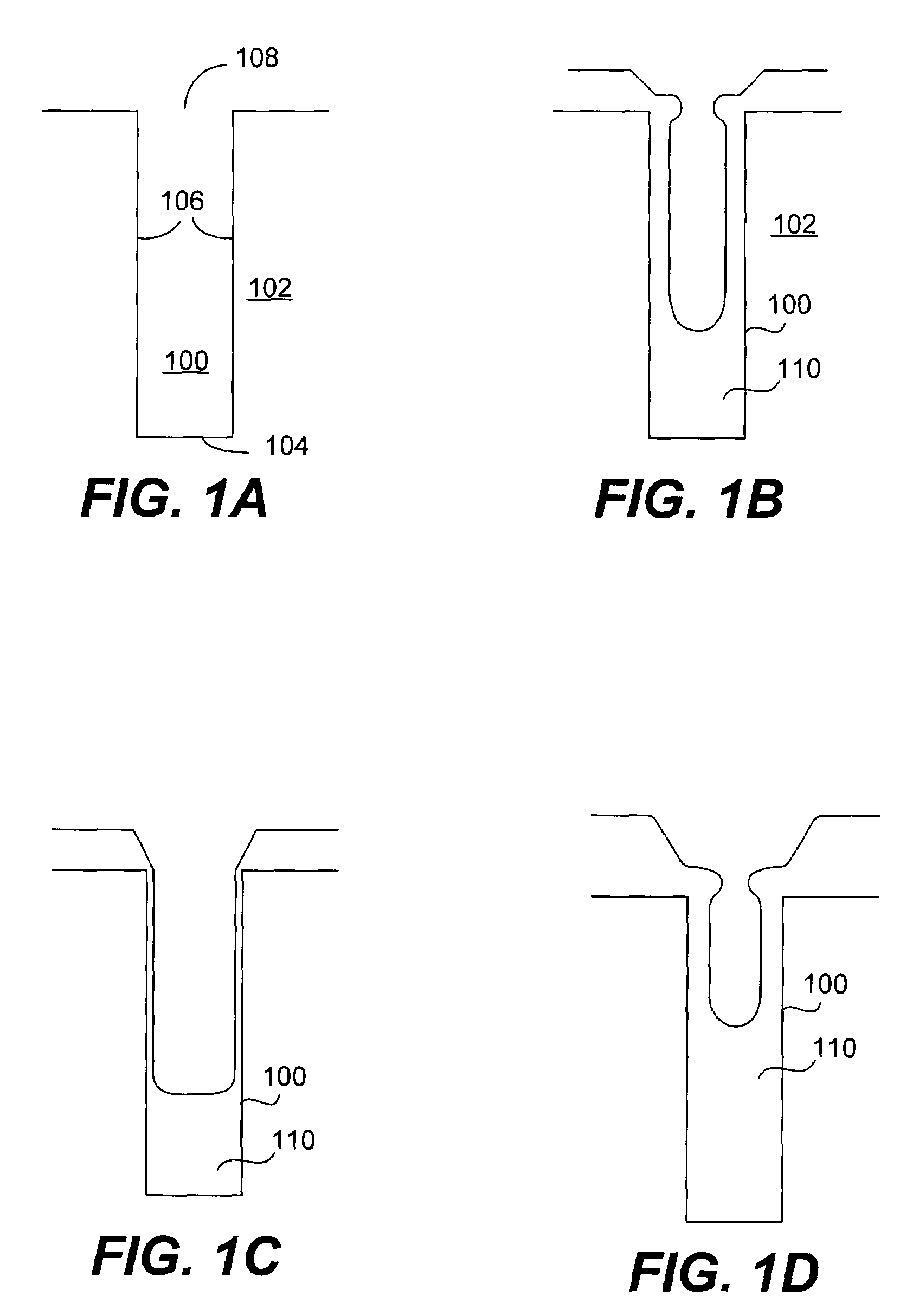

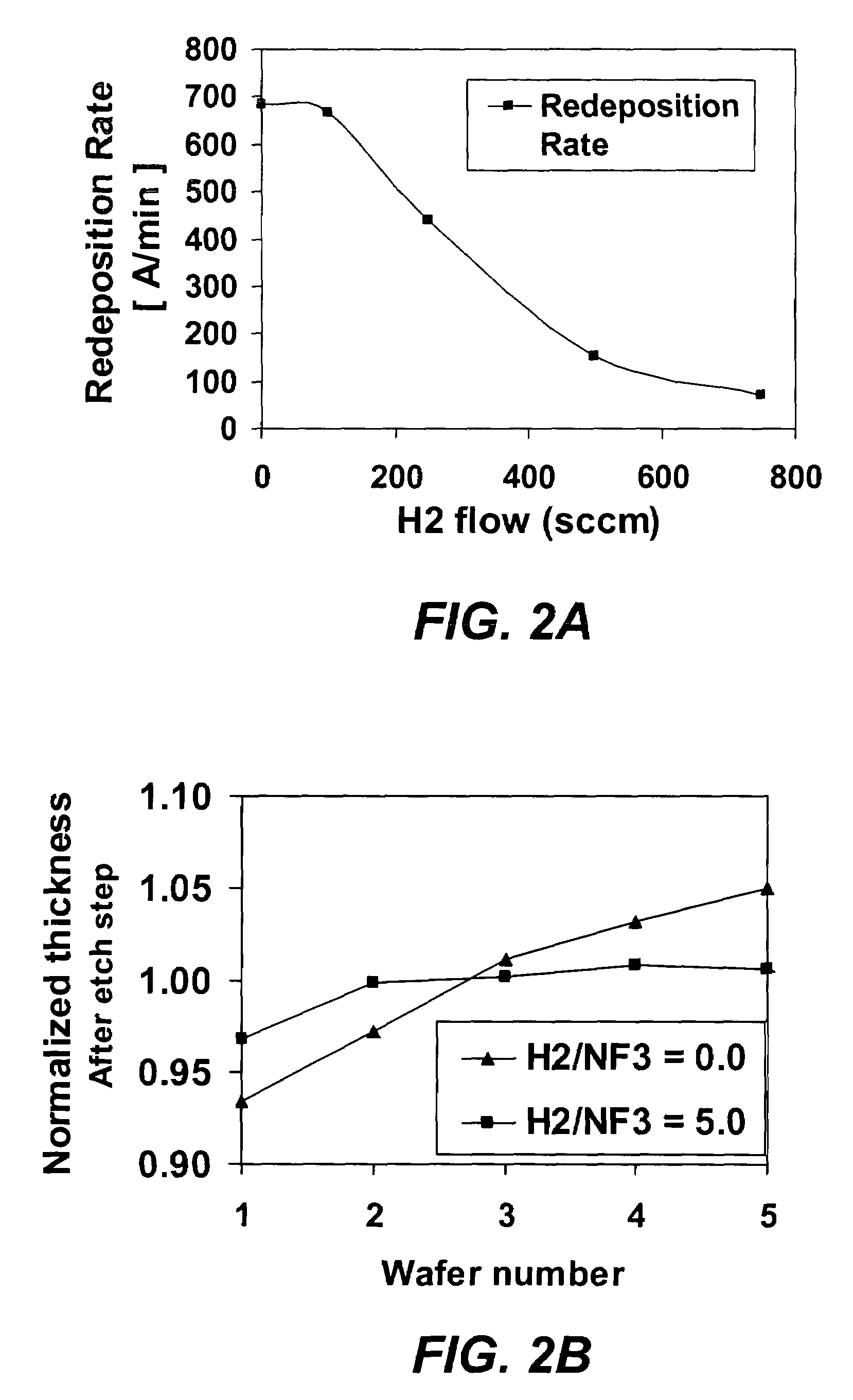

Plasma etch processes incorporating etch chemistries which include hydrogen. In particular, high density plasma chemical vapor deposition-etch-deposition processes incorporating etch chemistries which include hydrogen that can effectively fill high aspect ratio (typically at least 3:1, for example 6:1, and up to 10:1 or higher), narrow width (typically sub 0.13 micron, for example 0.1 micron or less) gaps while reducing or eliminating chamber loading and redeposition and improving wafer-to-wafer uniformity relative to conventional deposition-etch-deposition processes which do not incorporate hydrogen in their etch chemistries.

Owner:NOVELLUS SYSTEMS

Method for fabricating microelectronic fabrication electrical test apparatus electrical probe tip having pointed tips

InactiveUS6909300B2Improve accuracyHigh precisionElectrical measurement instrument detailsManufacture of electrical instrumentsElectrical conductorHigh density

A method for fabricating an electrical test apparatus electrical probe tip first provides a probe tip substrate having a topographic surface. A high density plasma chemical vapor deposition (HDP-CVD) deposited mandrel layer is then formed upon the topographic surface. It has a series of pointed tips formed over a series of topographic features within the topographic surface. Finally, a conductor probe tip layer is formed conformally upon the high density plasma chemical vapor deposition (HDP-CVD) deposited mandrel layer and replicating the series of pointed tips. Due to the series of pointed tips and the series of replicated pointed tips, a microelectronic fabrication when tested with the electrical test apparatus electrical probe tip is tested with enhanced accuracy.

Owner:TAIWAN SEMICON MFG CO LTD

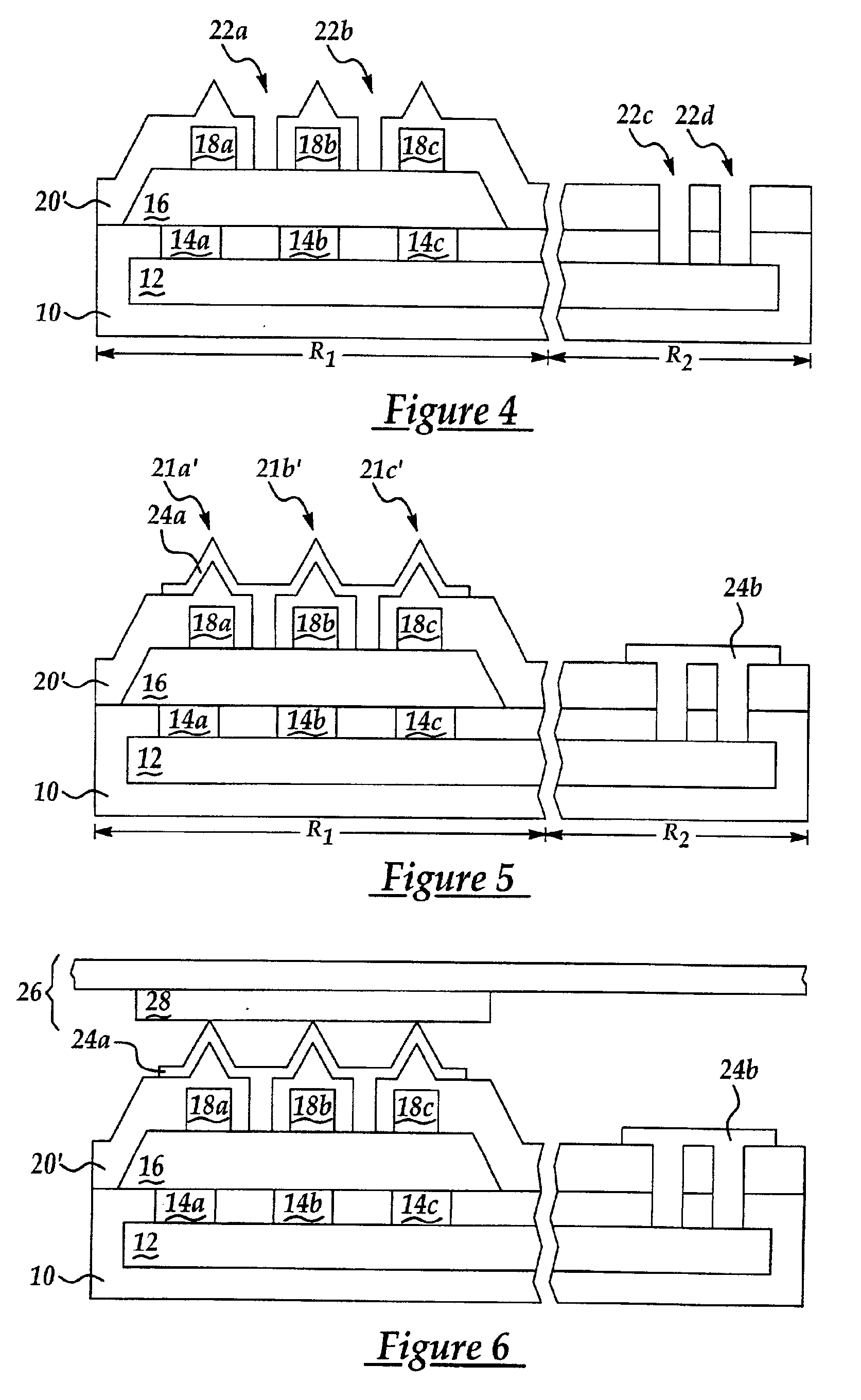

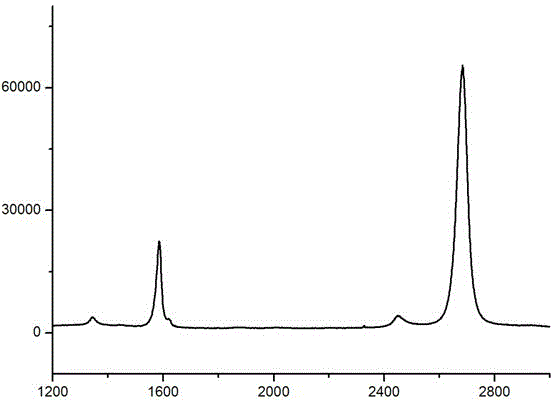

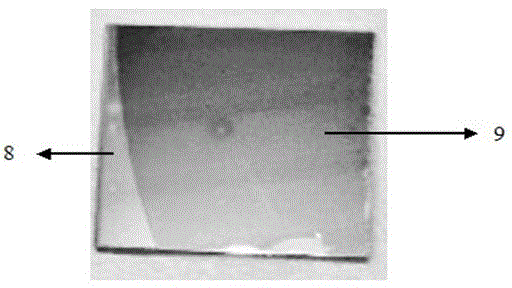

Method for producing graphene at a low temperature, method for direct transfer of graphene using same, and graphene sheet

ActiveUS20130187097A1Easy to produceEasy to useMaterial nanotechnologyNon-metal conductorsMetal catalystInductively coupled plasma

The present invention relates to a method for forming graphene at a low temperature, to a method for direct transfer of graphene using same, and to a graphene sheet. The method for forming graphene at a low temperature comprises supplying a carbon-source-containing gas to a metal catalyst layer for graphene growth formed on a substrate, and forming graphene at a low temperature of 500° C. or less by means of inductively coupled plasma-chemical vapor deposition (ICP-CVD).

Owner:GRAPHENE SQUARE +1

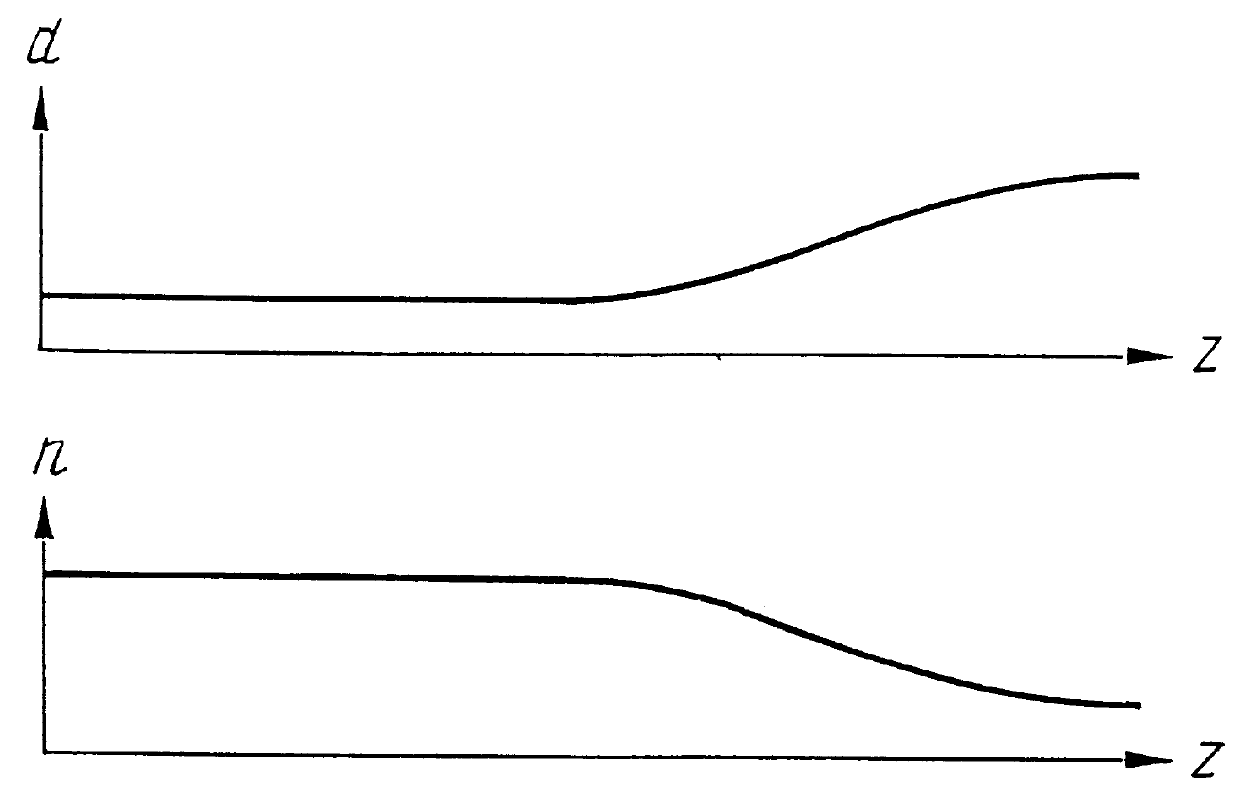

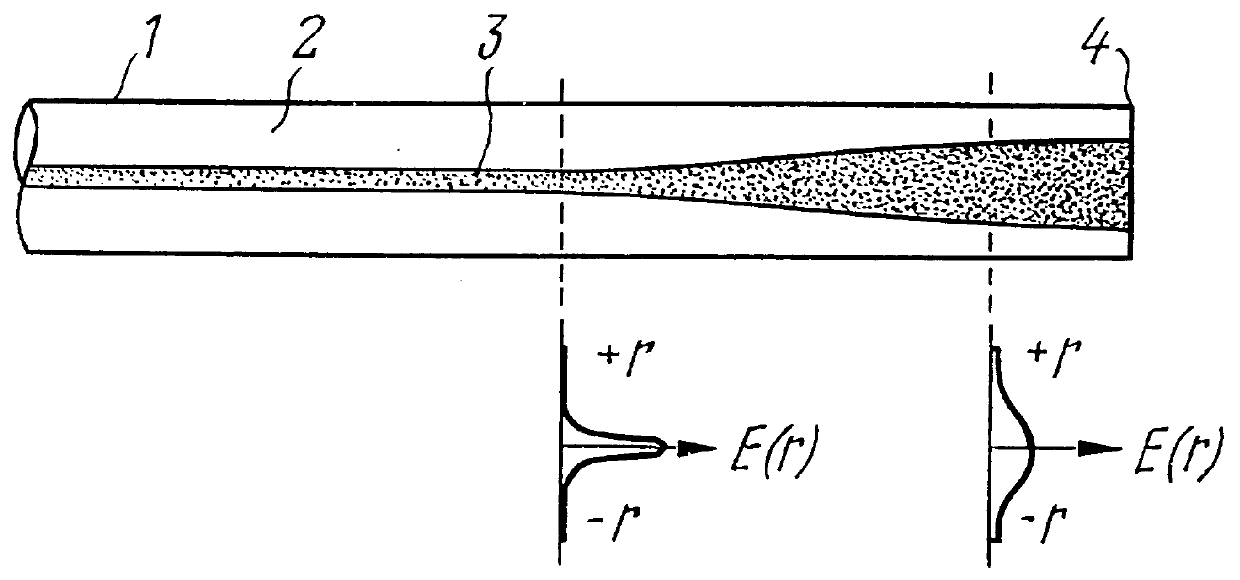

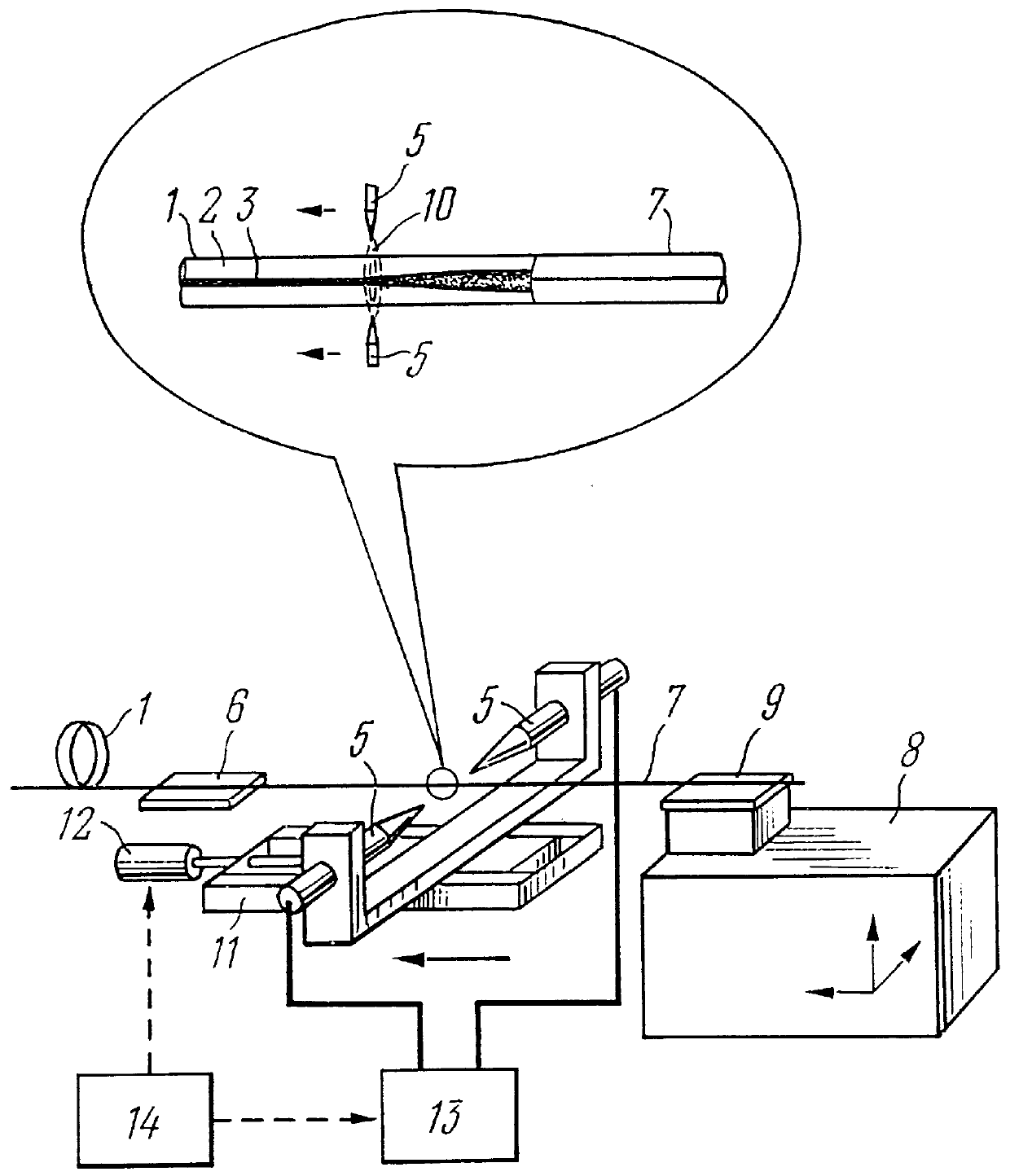

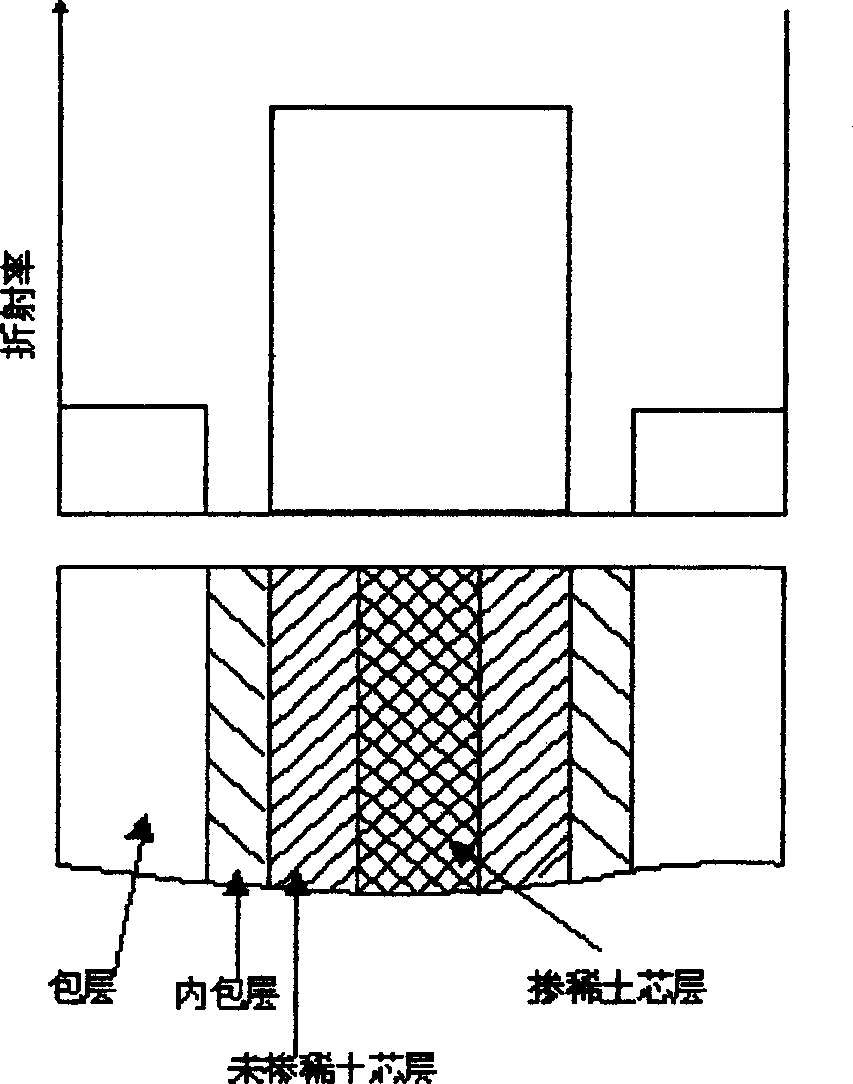

Mode field diameter conversion fiber, method for locally changing a refractive index of optical waveguides and method for fabricating optical waveguide preforms

InactiveUS6125225AAvoid mechanical stressGlass making apparatusOptical fibre with graded refractive index core/claddingGratingRefractive index

PCT No. PCT / RU97 / 00278 Sec. 371 Date Jul. 9, 1998 Sec. 102(e) Date Jul. 9, 1998 PCT Filed Sep. 3, 1997 PCT Pub. No. WO98 / 28643 PCT Pub. Date Jul. 2, 1998The invention relates to fiber optics and can be employed in fiber radiation collimators, optical waveguide couplers, spectral filters, optical isolators, long-period gratings, dispersion compensators, cascade mode field diameter conversion fibers on simulated Raman effect, physical value sensors, radiation suppression units for predetermined wavelengths, and for smoothing the gain spectrum in erbium fiber amplifiers. The invention facilitates fabrication of optical waveguides and apparatuses based on them. To produce preforms for optical waveguides (1) by a plasma chemical vapor deposition method, molecular gaseous agents, fed to a substrate tube (24), are mixed so that less than five atoms of oxygen fall on every atom of silicon and more than one atom of nitrogen falls on every 1000 atoms of oxygen. The refractive index is locally changed by heating a length of an optical waveguide (1). This causes a local thermal diffusion of elements contained in a core (3) into a cladding (2), or vice versa. The length of the optical waveguide (1) is heated by current of an electric arc (10) or by radiation (16) of an infrared laser (15). The core (3) is doped with nitrogen at concentration from 0.01 at. % to 5 at. %. In the mode field diameter conversion fiber, a diameter of the core (3) changes along the length of the optical waveguide (1), increasing towards its end (4).

Owner:VOLOKONNO OPTICHESKAYA TEKHNIKA KAPITAL +2

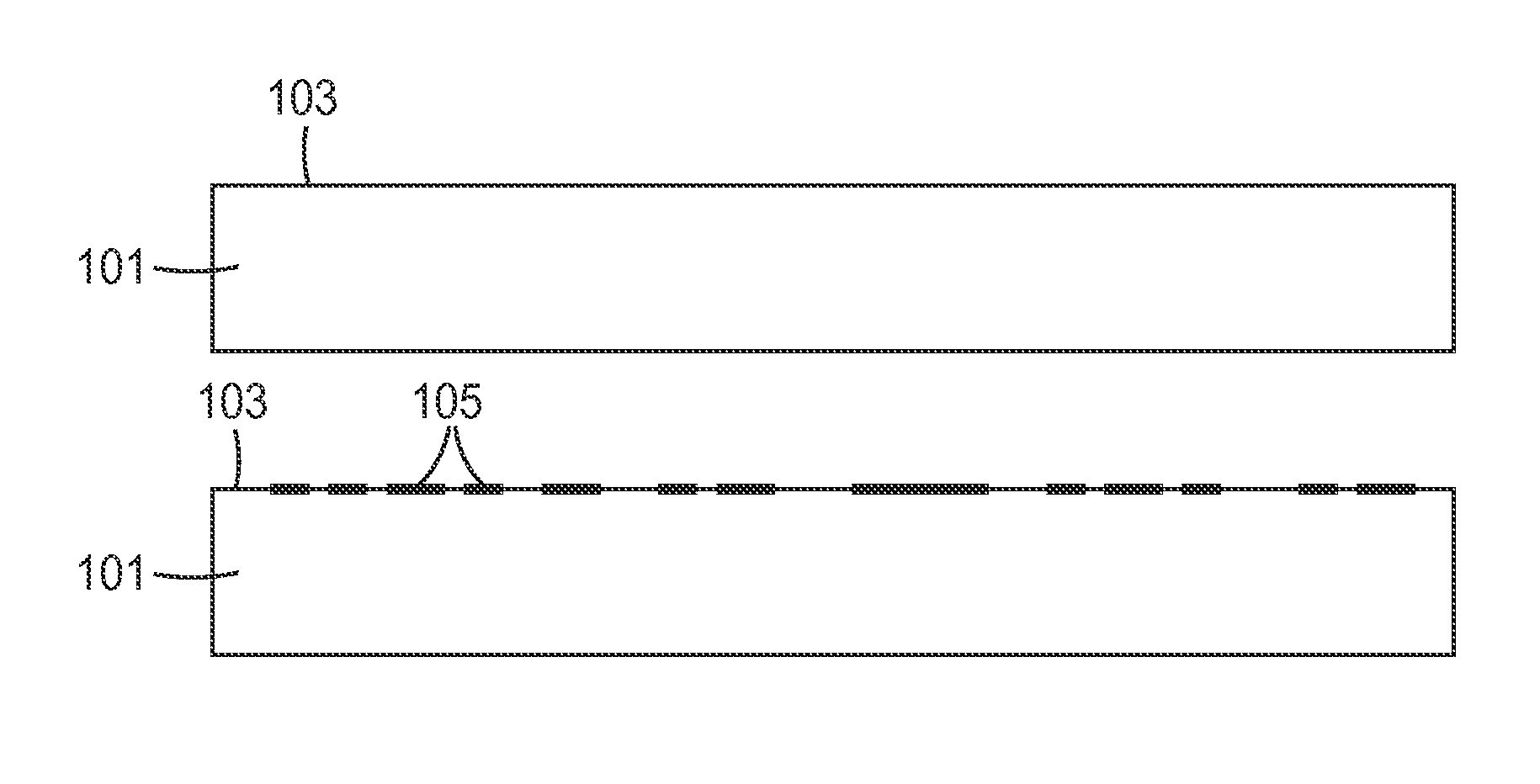

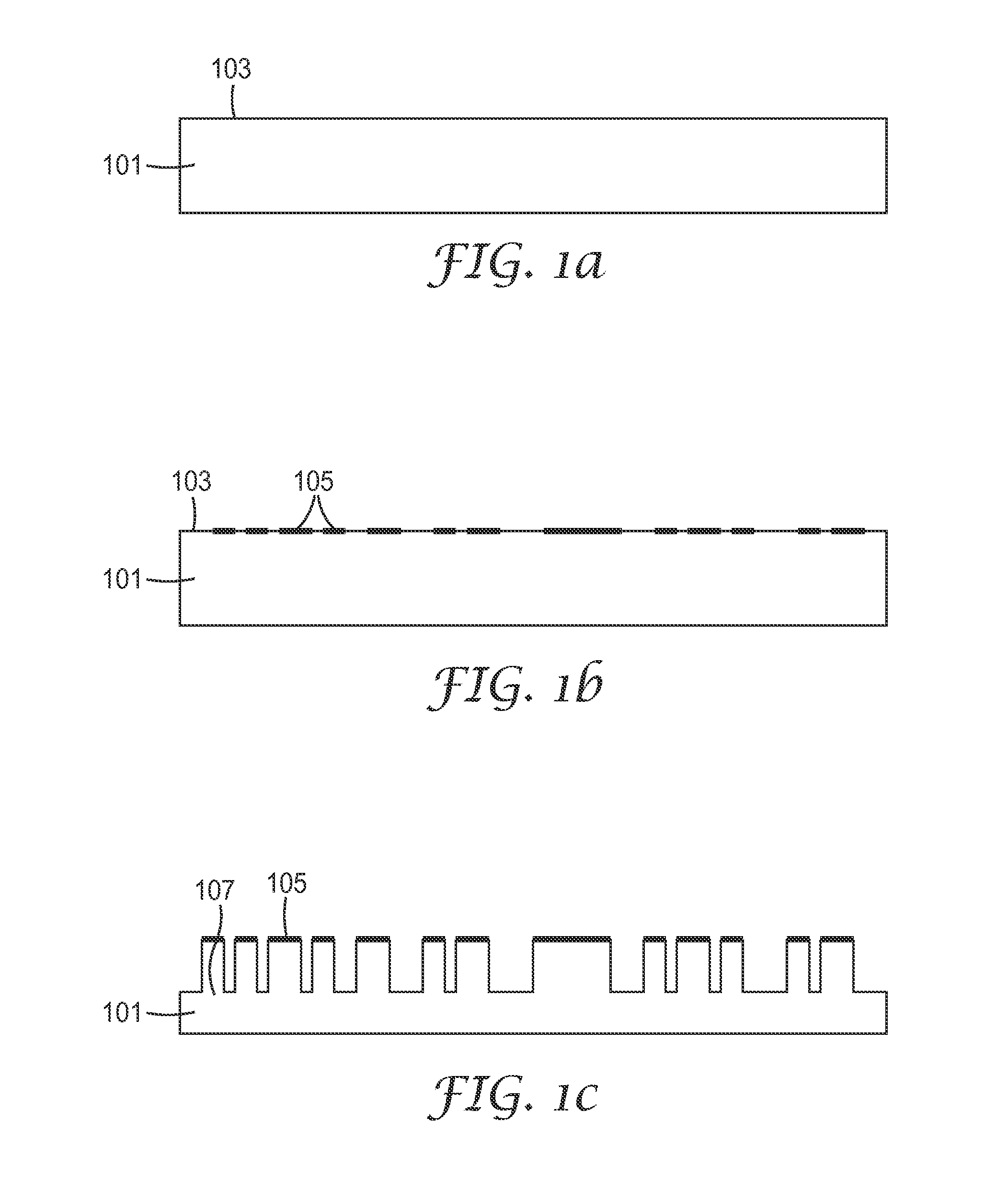

Method of making a nanostructure

ActiveUS8634146B2Reduce reflectivityScratch resistantMaterial nanotechnologyLayered productsMetal acetylacetonatesAlloy

A method of making a nanostructure is provided that includes applying a thin, random discontinuous masking layer (105) to a major surface (103) of a substrate (101) by plasma chemical vapor deposition. The substrate (101) can be a polymer, an inorganic material, an alloy, or a solid solution. The masking layer (105) can include the reaction product of plasma chemical vapor deposition using a reactant gas comprising a compound selected from the group consisting of organosilicon compounds, metal alkyls, metal isopropoxides, metal acetylacetonates, and metal halides. Portions (107) of the substrate (101) not protected by the masking layer (105) are then etched away by reactive ion etching to make the nanostructures.

Owner:3M INNOVATIVE PROPERTIES CO

Electroconductive woven and non-woven fabric and method of manufacturing thereof

ActiveUS20070054577A1Improve adhesionUniform and stableNanotechPhysical treatmentEngineeringBiological activation

The invention relates to an electroconductive textile material and method of preparation thereof. The method consists mainly of two stages: 1) special pretreatment of the fabric substrate for activation and making it suitable for subsequent application and strong attachment of a conductive coating with the use of a layer-by-layer technique (LBL); 2) subsequent application and strong attachment of a conductive coating by means of a layer-by-layer technique. The first stage may be carried out thermally, thermochemically, by treating in hot solutions, or plasma-chemically by plasma treatment. The pre-treatment may be performed, e.g., for swelling and / or for the formation of unsaturated chemical bonds or uncompensated charges in the fabric material. The pretreatment is needed to ensure more efficient penetration of chemical components into the fabric structure during subsequent LBL applications of treatment solutions that contain nano-particles and that determine the density of the molecular layer. The types and amounts of the nano-particles determine their charge density (solution pH is very important for charge density) in the sublayer. Such a pretreatment increases bonds of the applied layers with the substrate material.

Owner:EEONYX CORP

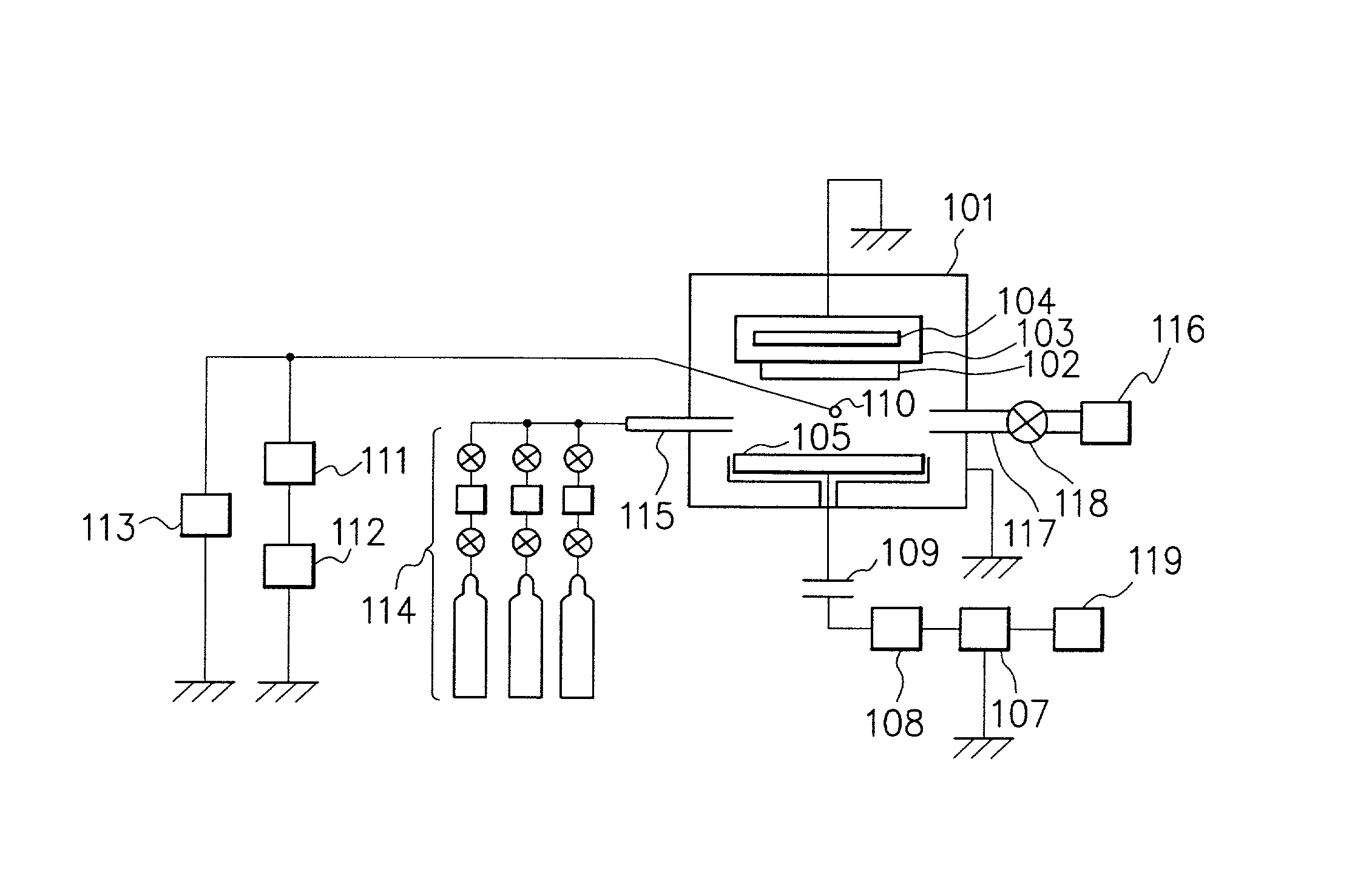

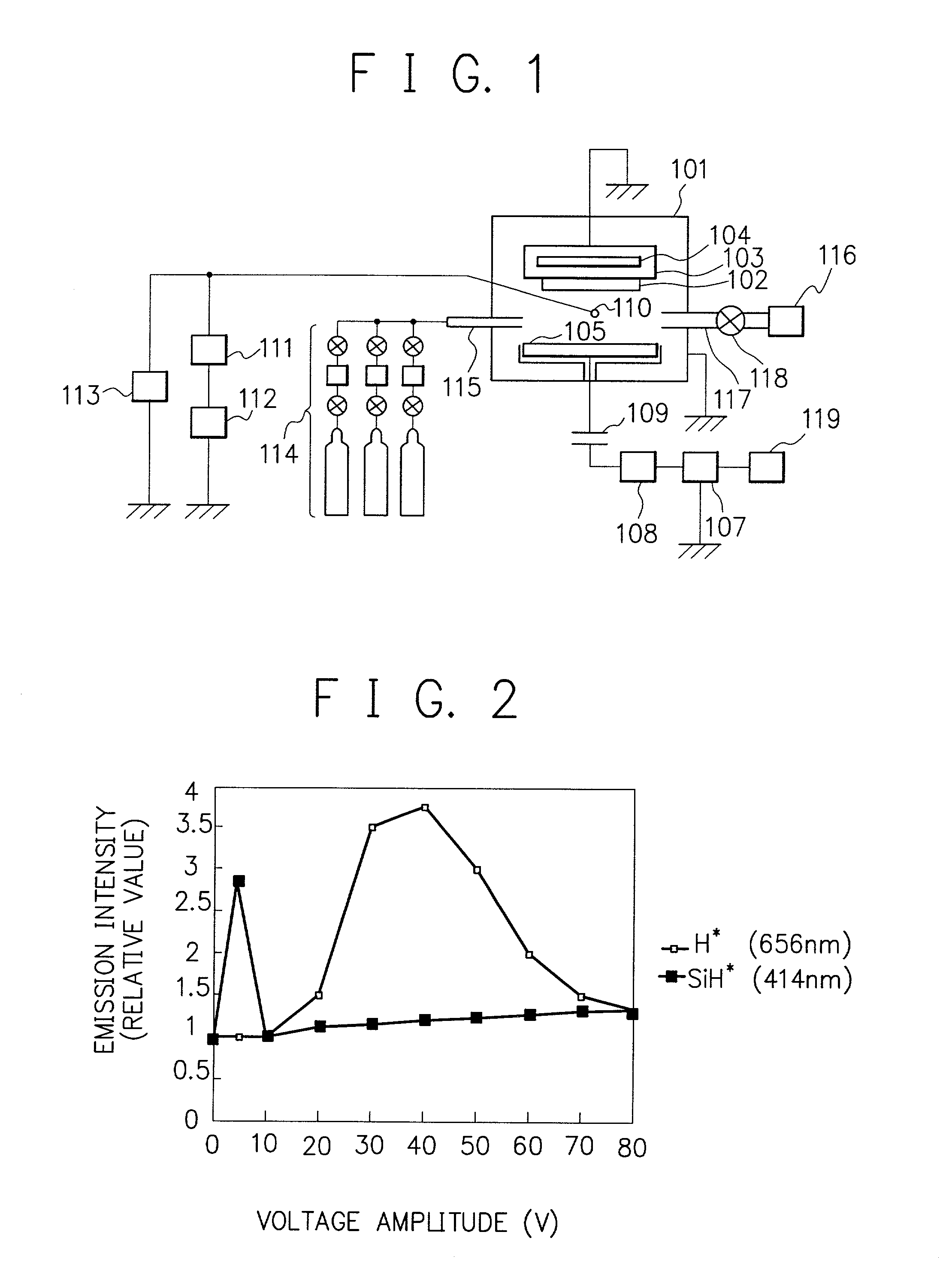

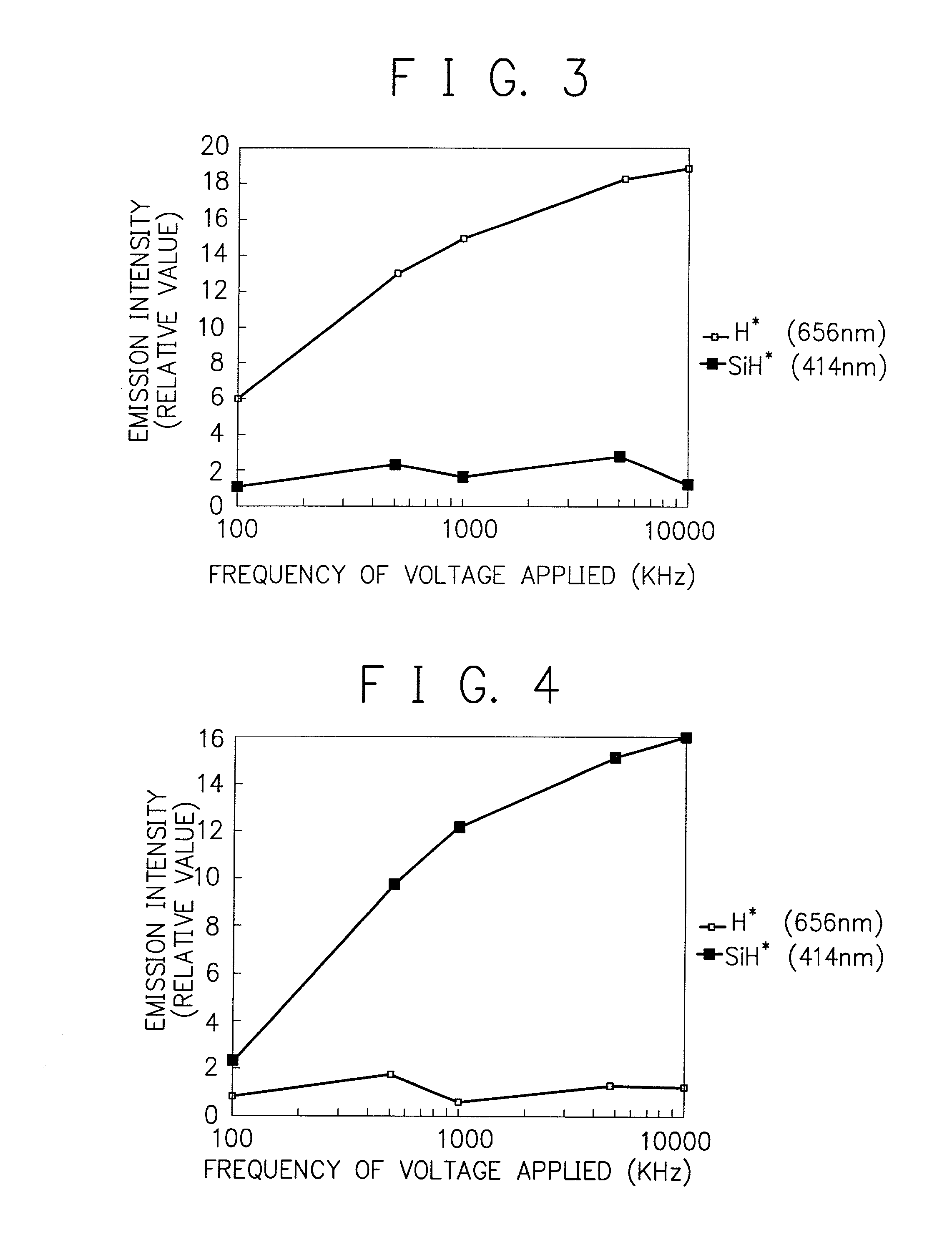

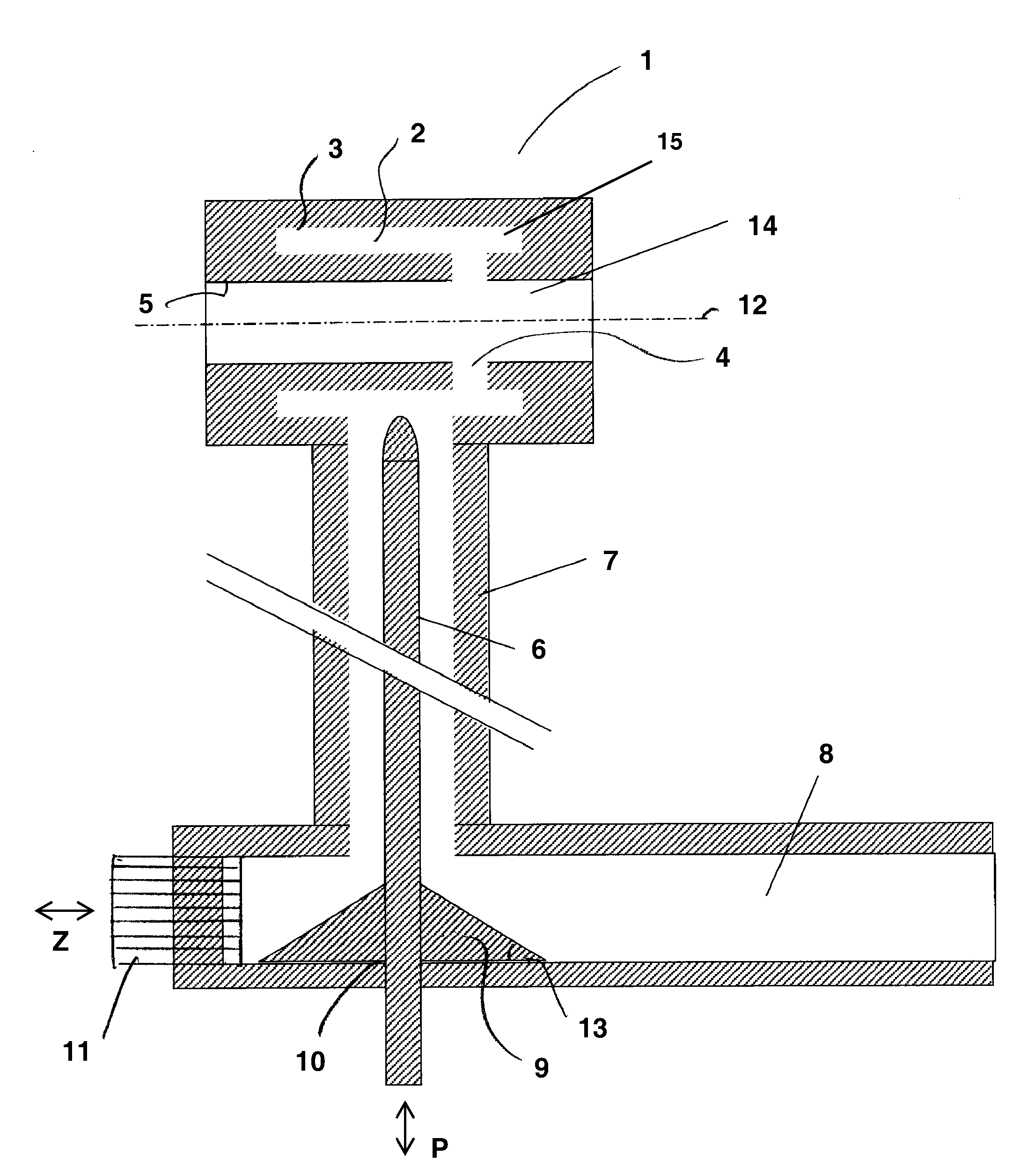

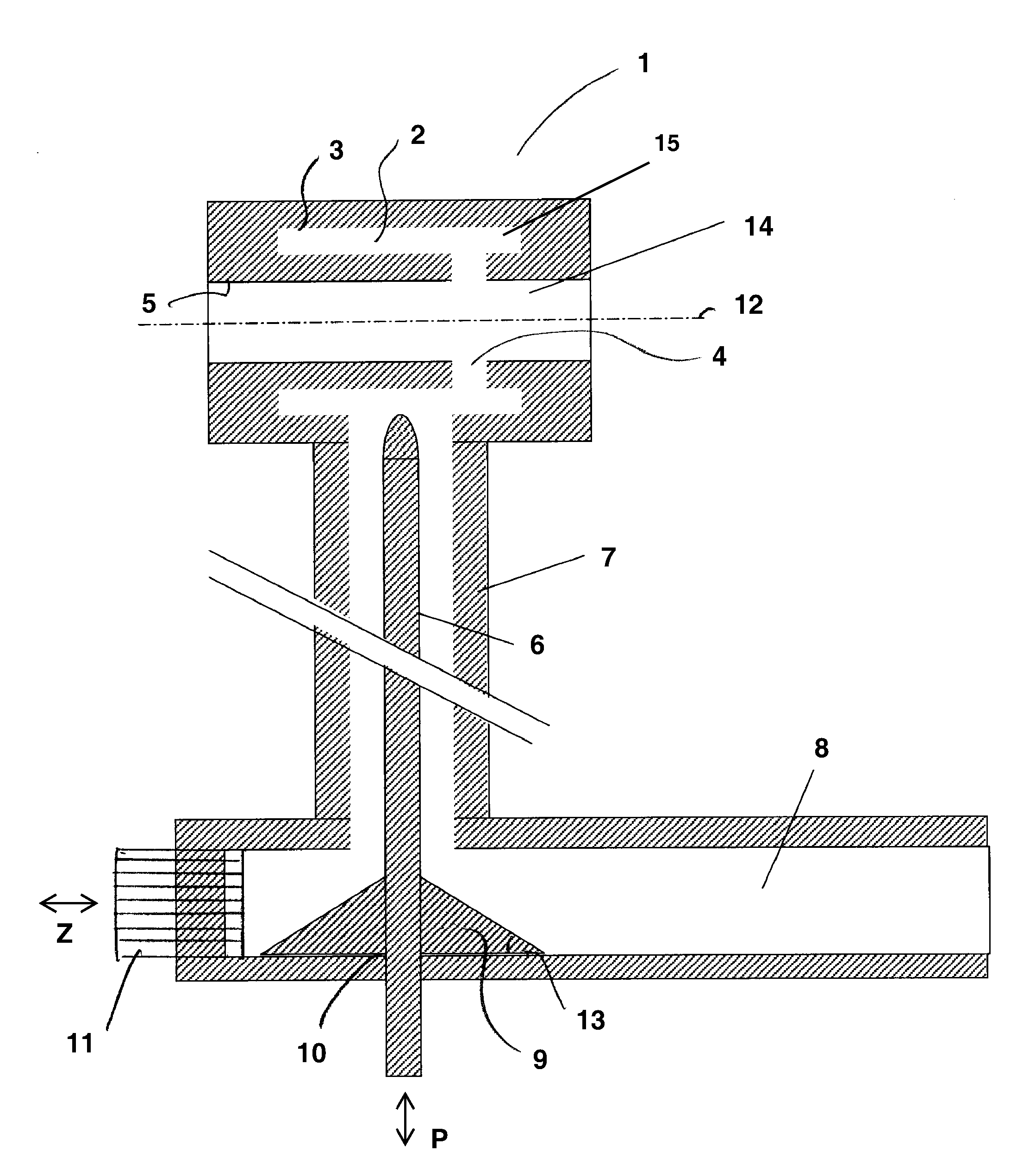

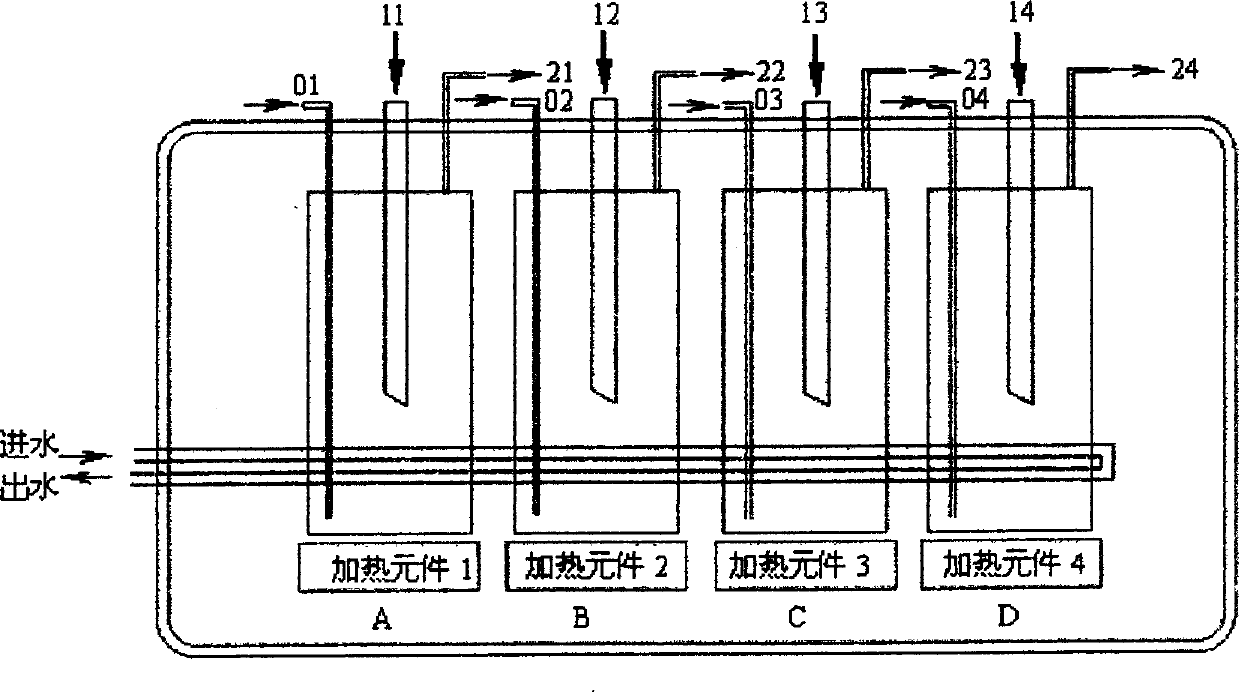

Method for forming a deposited film by plasma chemical vapor deposition

InactiveUS20020090815A1Efficiently formedQuality improvementElectric discharge tubesSemiconductor/solid-state device manufacturingHigh frequency powerHydrogen

A film-forming method for forming a deposited film on a substrate arranged in a substantially enclosed film-forming vessel by means of plasma CVD by introducing a raw material gas comprising at least a hydrogen gas and a silicon-containing raw material gas into said film-forming vessel and introducing a high frequency power into said film-forming vessel through a discharge electrode provided in said film-forming vessel to generate a plasma in a plasma generation region between said substrate and said discharge electrode in said film-forming vessel whereby forming said deposited film on said substrate, wherein the formation of said deposited film on said substrate is performed while applying a periodicity voltage having at least two different waveform components having a different amplitude to an auxiliary electrode arranged at a position in said plasma generation region of said film-forming vessel or an auxiliary electrode provided on the rear side of said substrate and outside said plasma generation region.

Owner:CANON KK

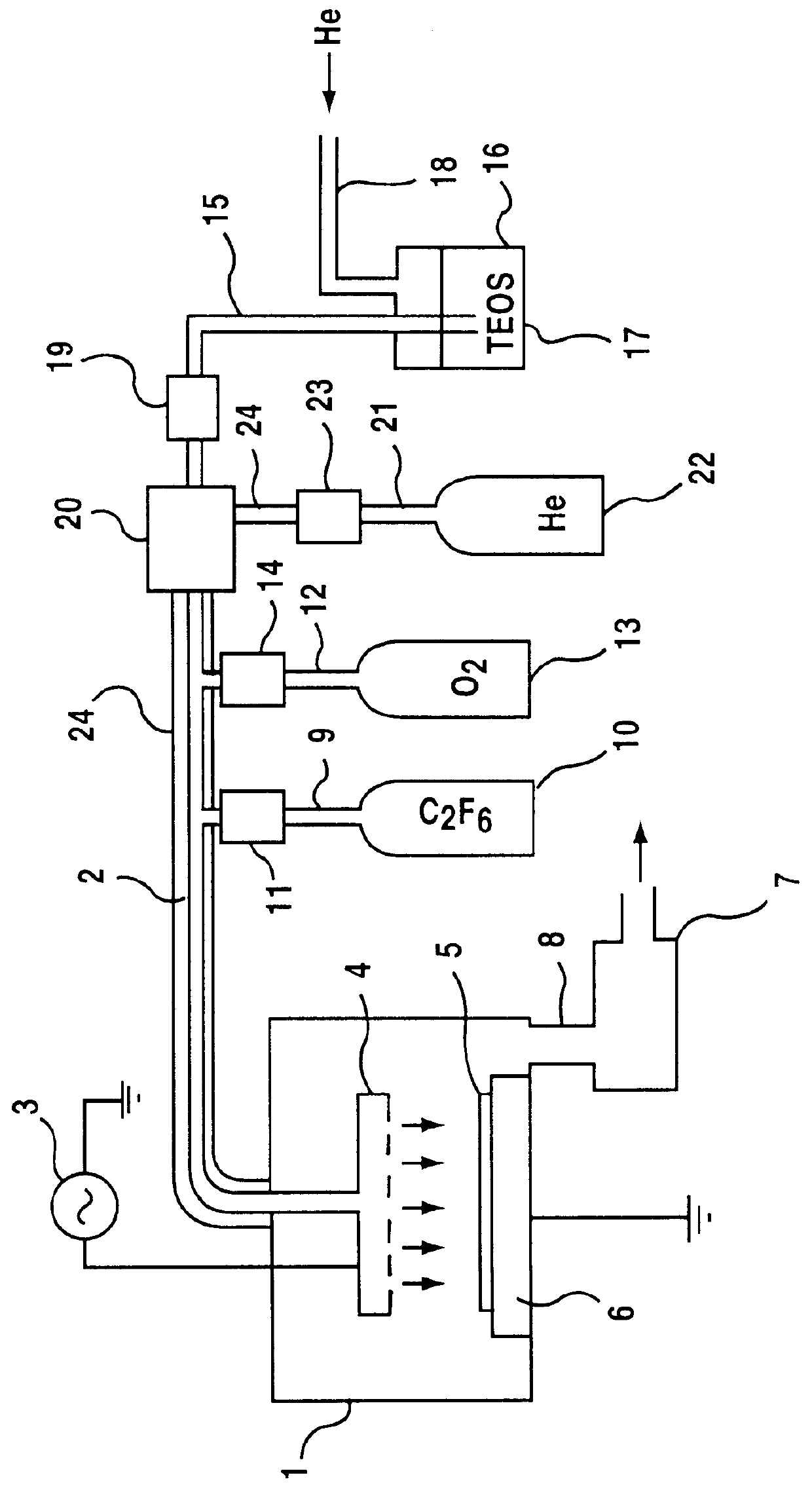

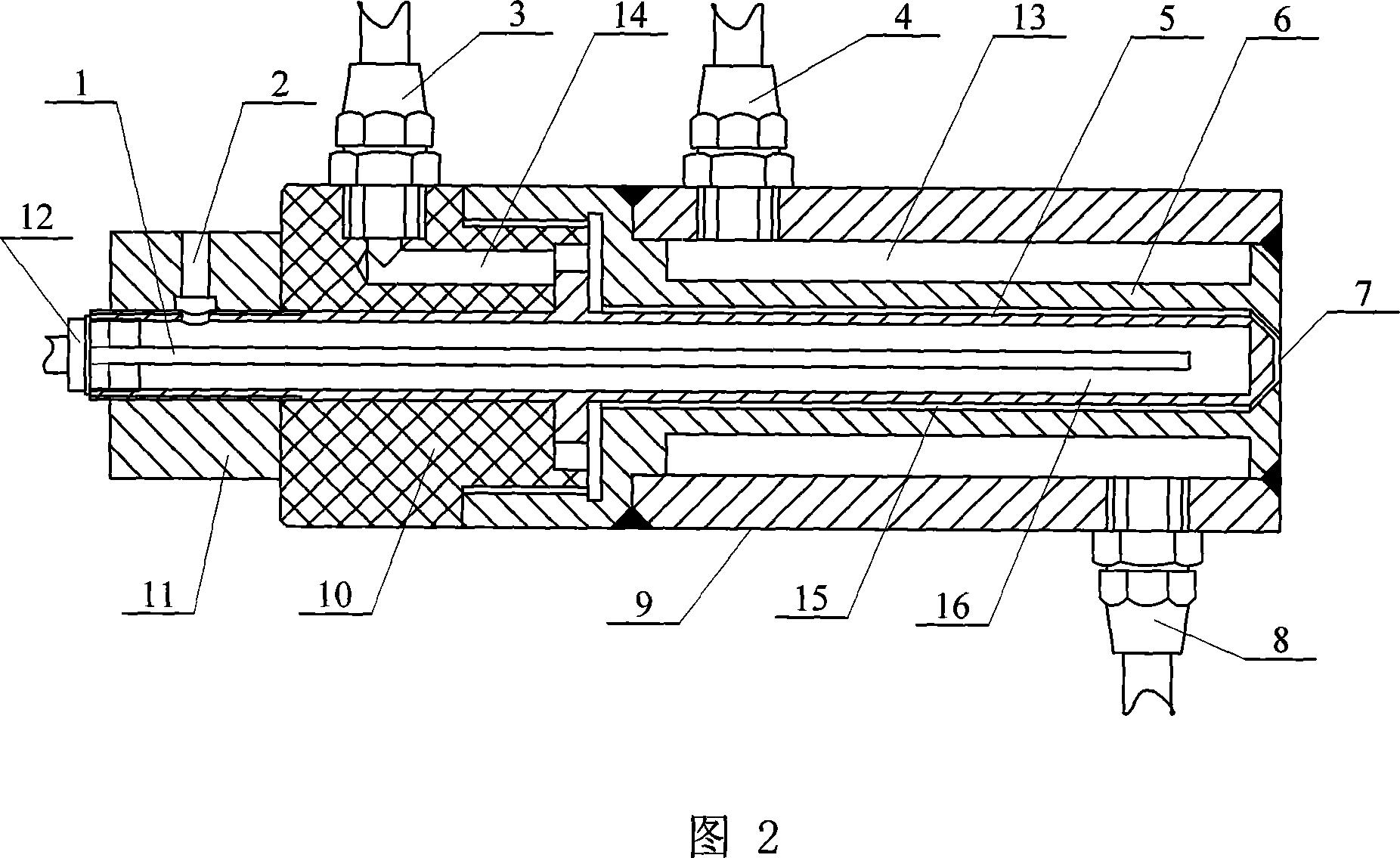

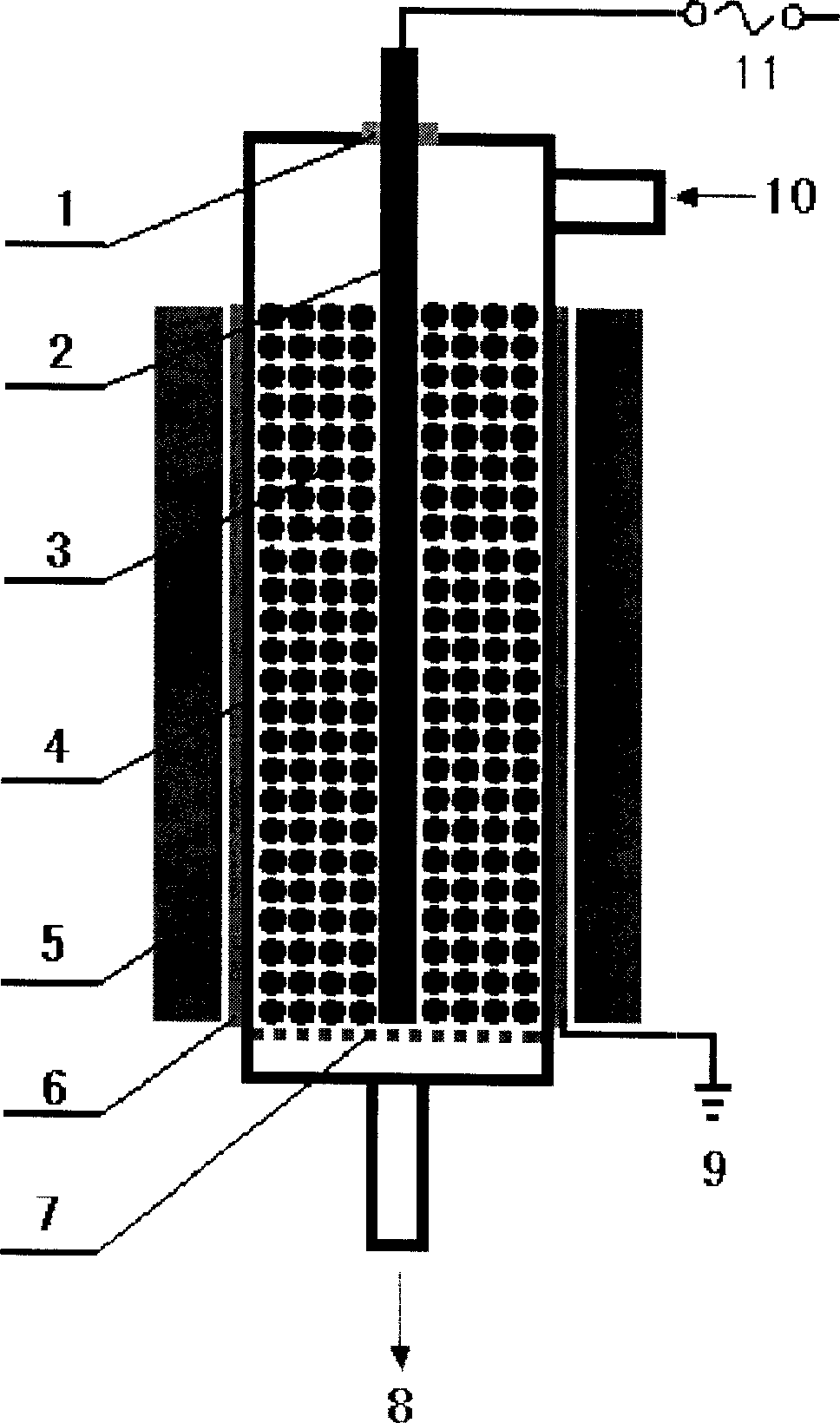

Apparatus for Effecting Plasma Chemical Vapor Deposition (PCVD)

ActiveUS20070289532A1Increase power levelIncrease deposition rateGlass making apparatusElectric discharge tubesChemical vapor depositionSilicon dioxide

The present invention relates to an apparatus for carrying out a plasma chemical vapor deposition process by which one or more layers of doped or undoped silica can be deposited on the interior of an elongated glass substrate tube. The present invention further relates to a method for manufacturing an optical fiber using such an apparatus.

Owner:DRAKA COMTEQ BV

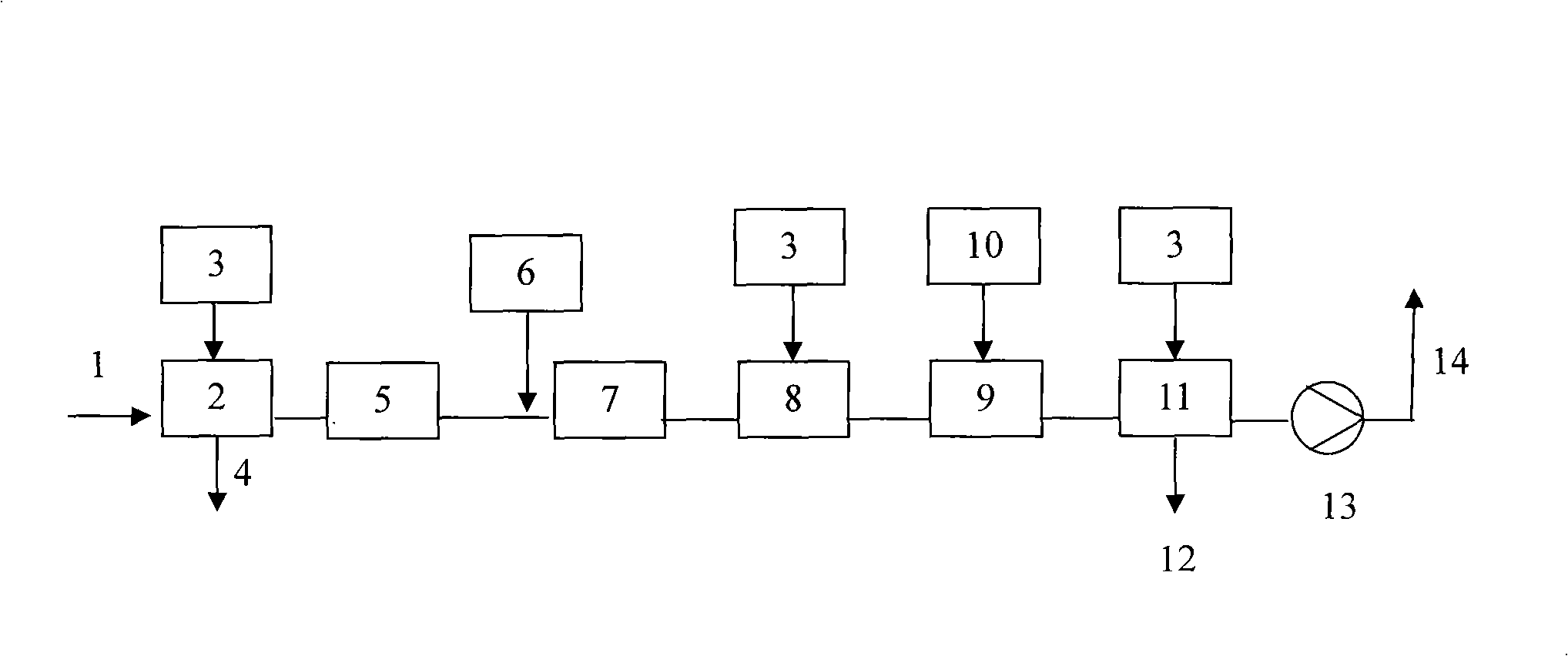

Resource ozone oxidation dry method capable of removing sulfur dioxide and nitrogen oxides in flue gas

InactiveCN101337152ASolve the problem of high energy consumptionNo governance issuesDispersed particle separationAir quality improvementPlasma chemistrySulfur dioxide

The invention belongs to the application technical field, such as gas ionization discharge, plasma chemistry and environment engineering, and relates to a method for reutilizing fume while removing sulfur dioxide and nitrogen oxides by adopting the ozone oxidation method. The method comprises the following steps: ozone gas with a concentration of 40 to 240 g / Nm<3> is fed into a reactor or a flue together with fume at 65 DEG C to 250 DEG C with a smoke dust concentration lower than 40 mg / Nm<3>; the ozone simultaneously oxidizes sulfur dioxide, nitrogen oxides and water in the fume and generates micro-fog drops which are collected into a mixed acid solution after being electrically coagulated; and the mixed acid solution is separated and purified into the sulfuric acid and the nitric acid by adopting a chemical method. The method has the advantages that during the process for simultaneously removing the sulfur dioxide and the nitrogen oxides in the fume, no catalyst is used, no absorbent is added, no byproduct is generated, and no any adverse effect on the environment is generated, and provides a reutilization method for the desulfurization and the denitrification of the fume from coal burning.

Owner:DALIAN MARITIME UNIVERSITY

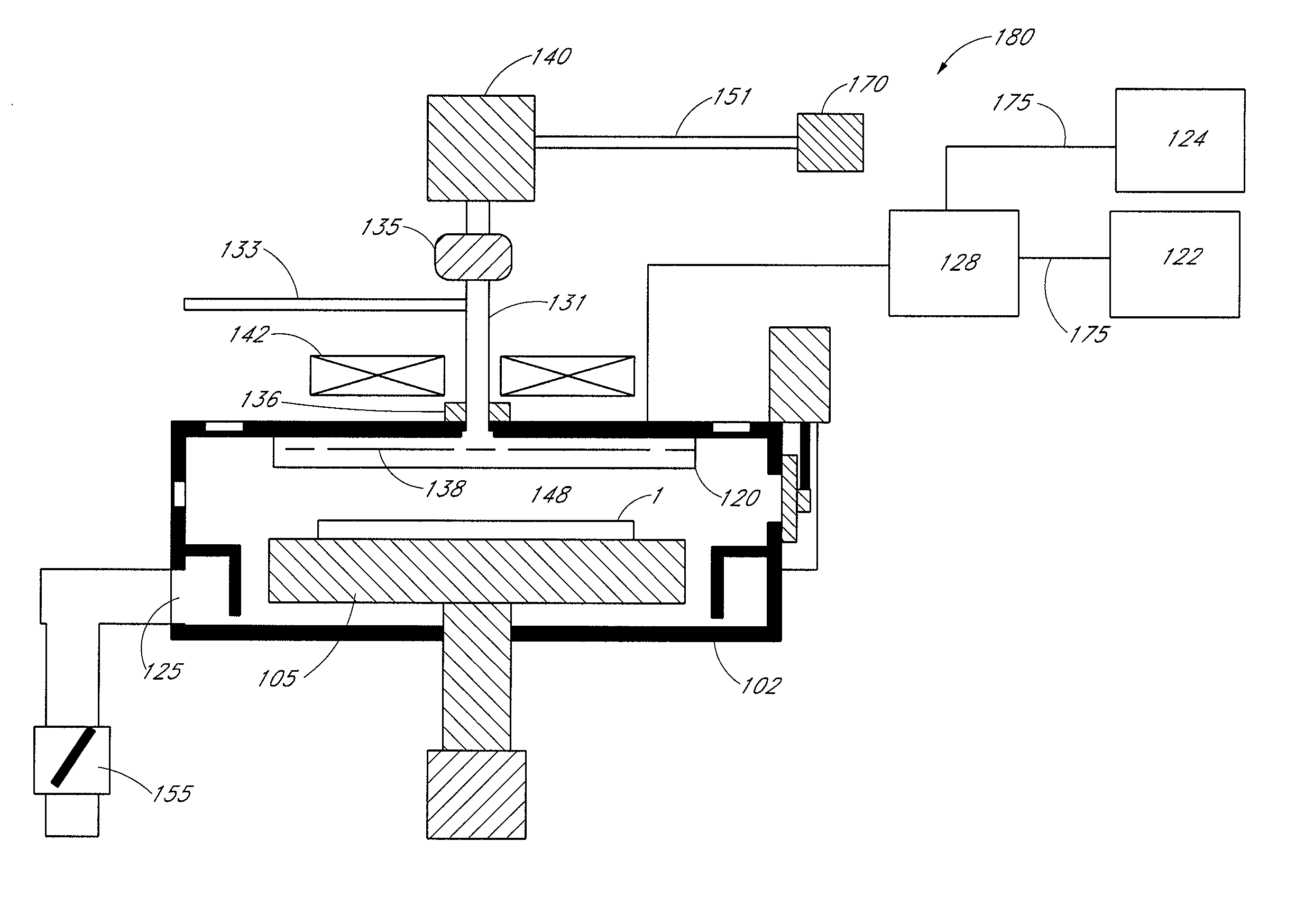

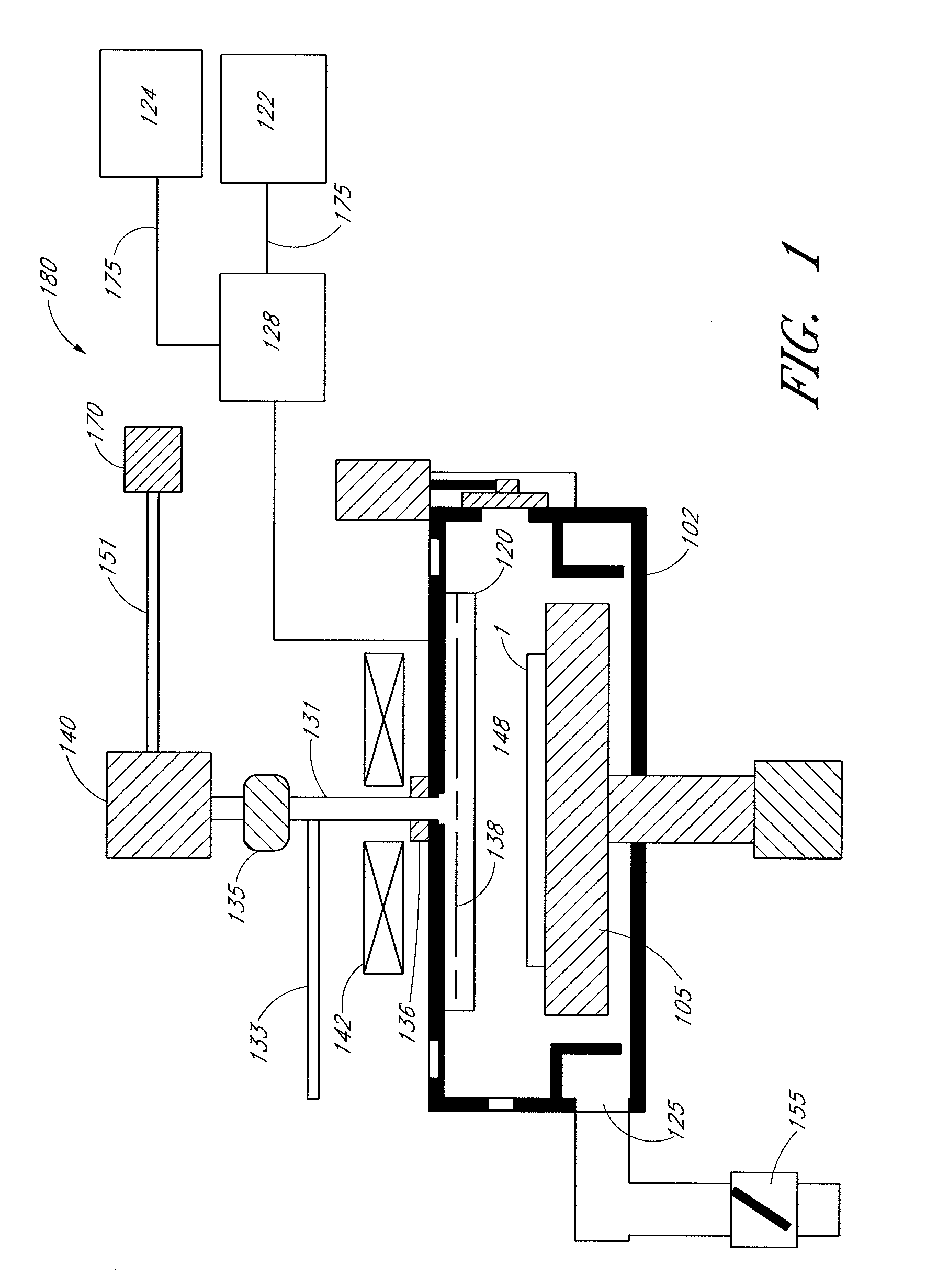

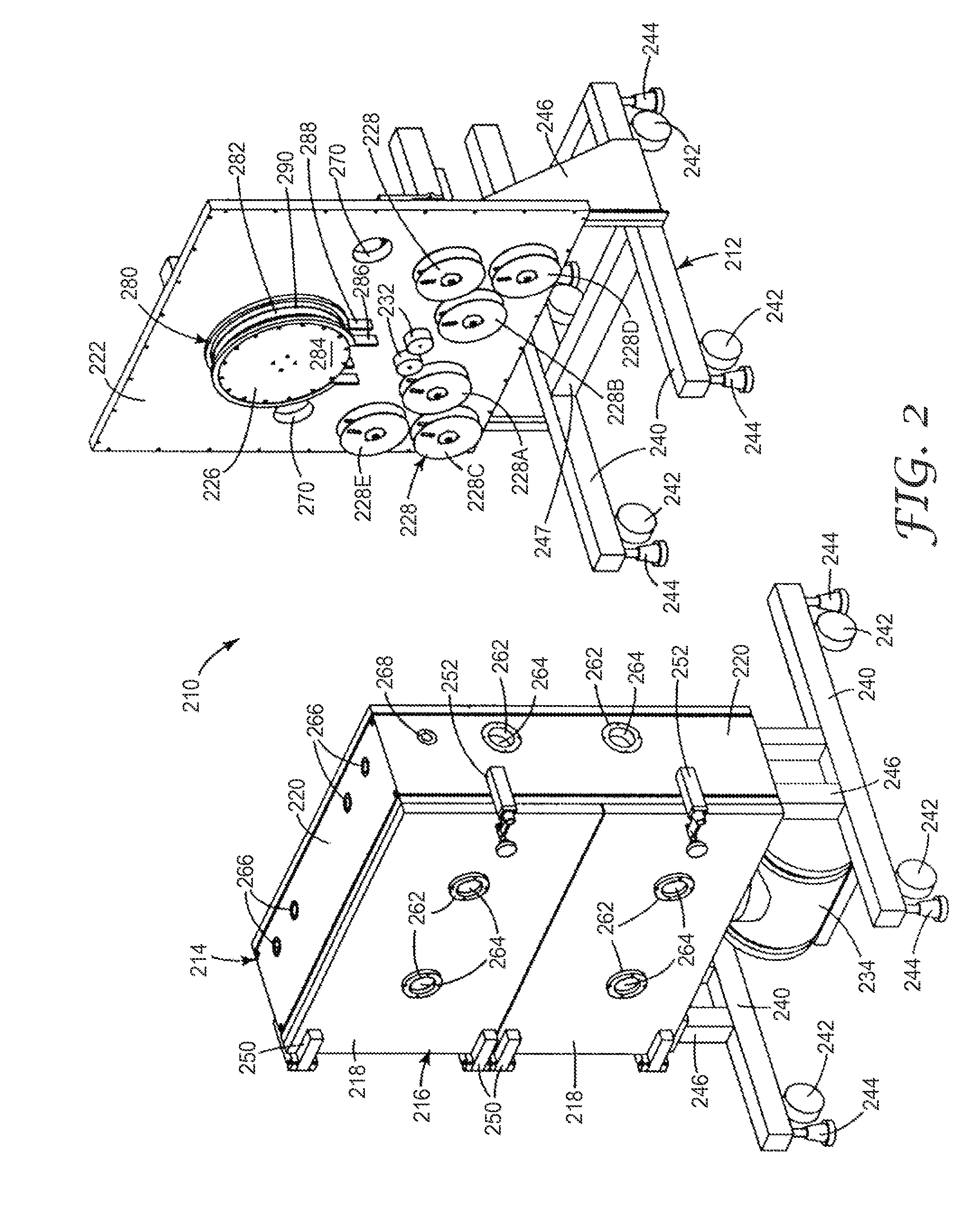

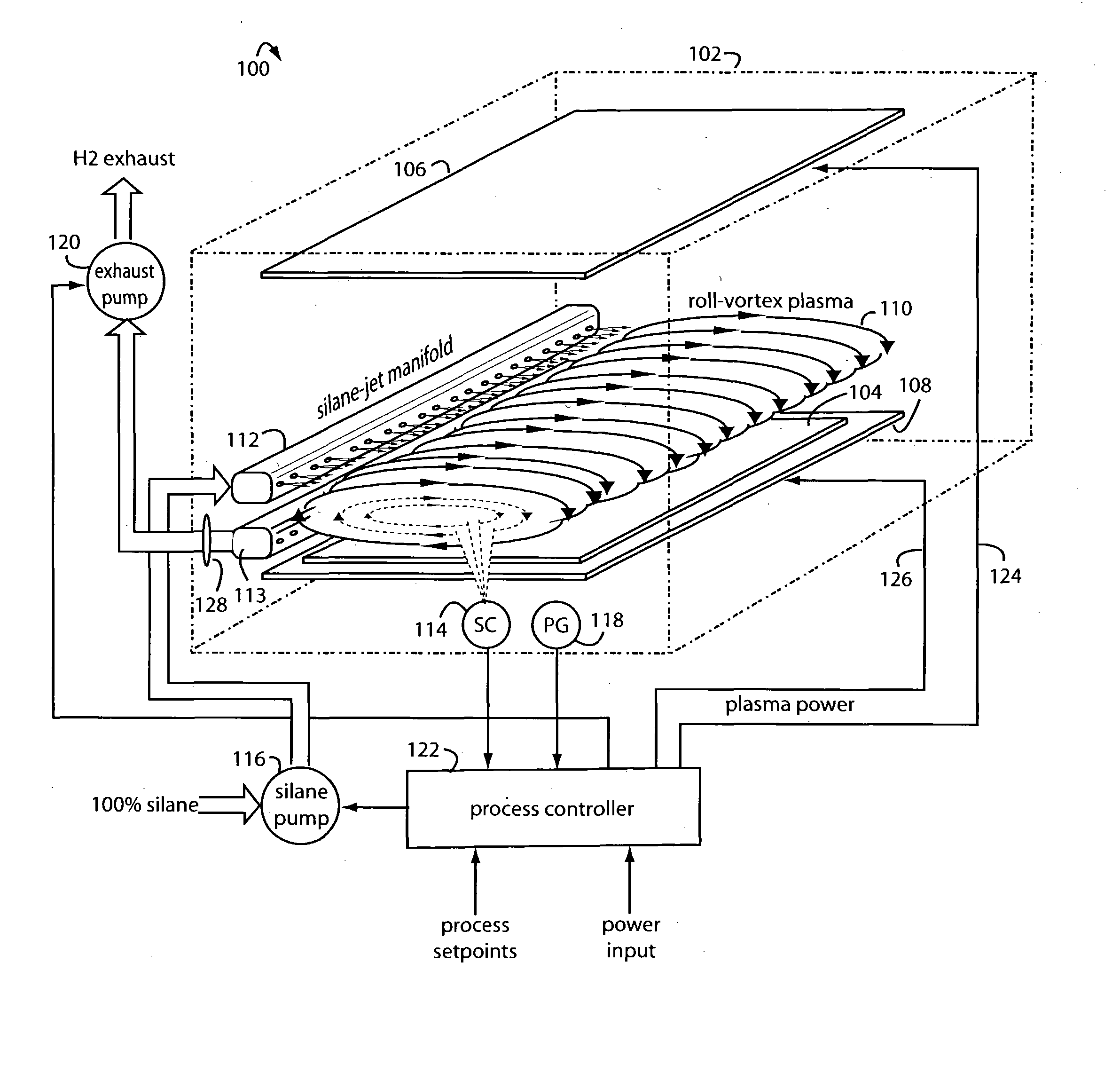

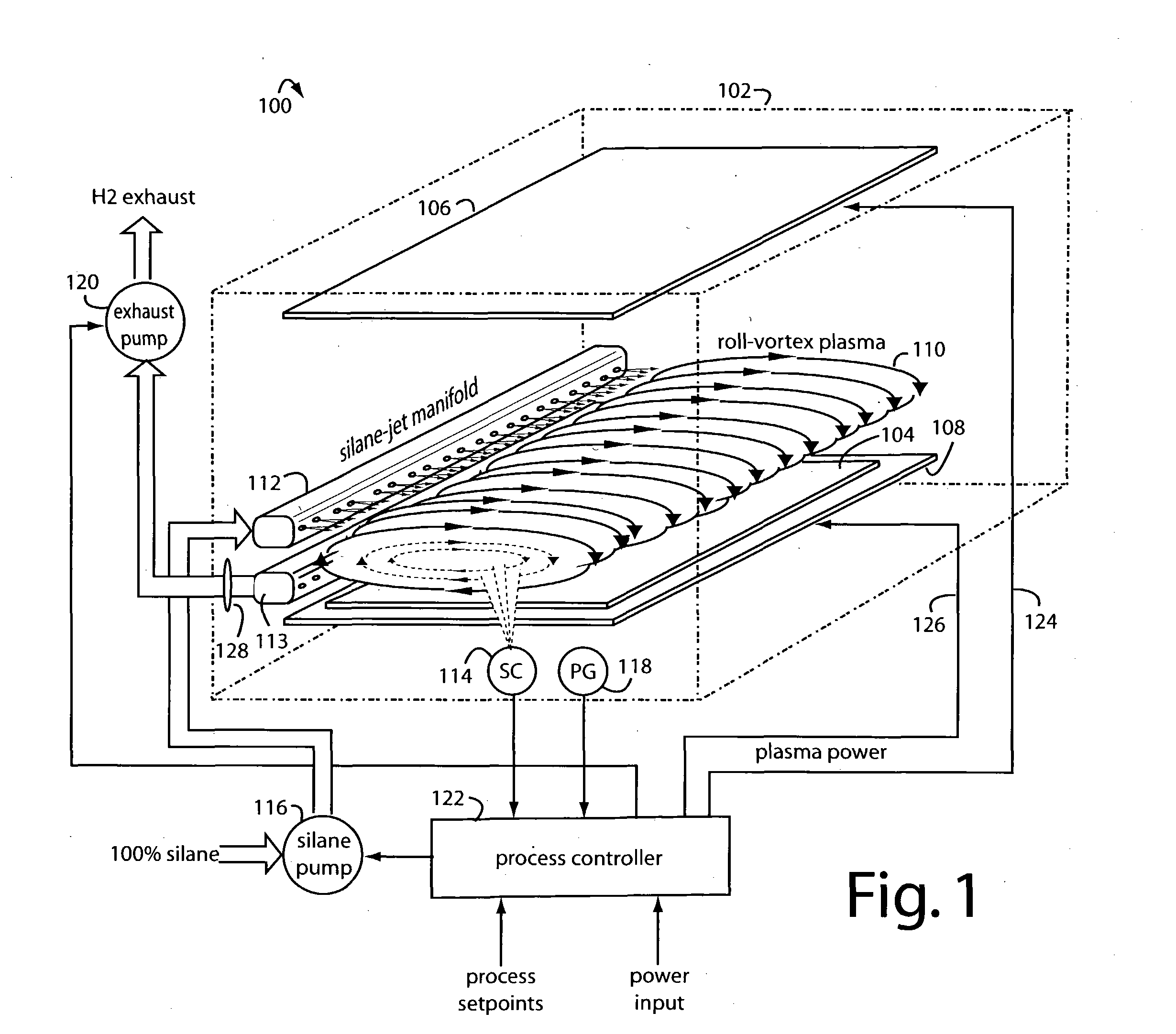

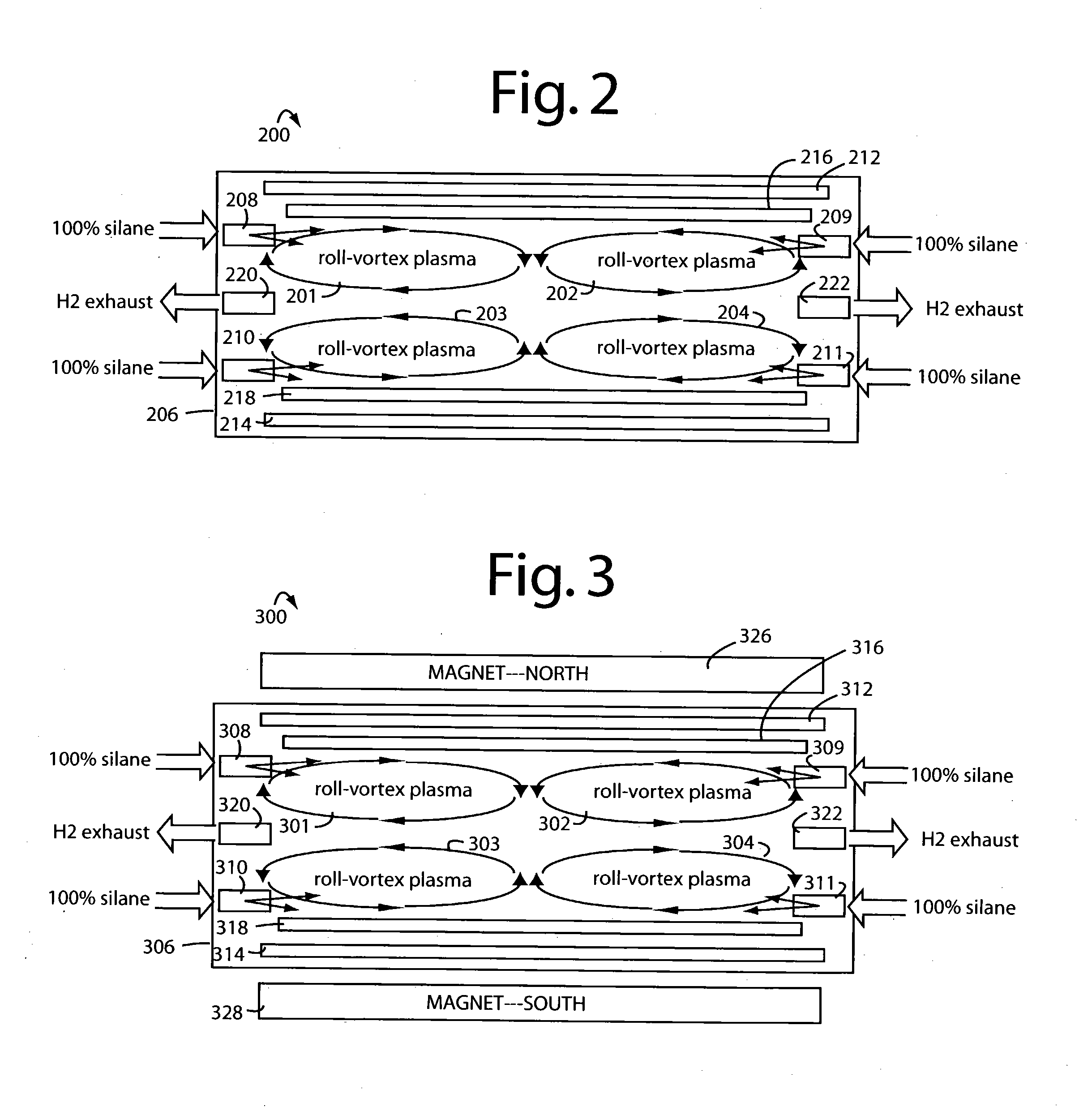

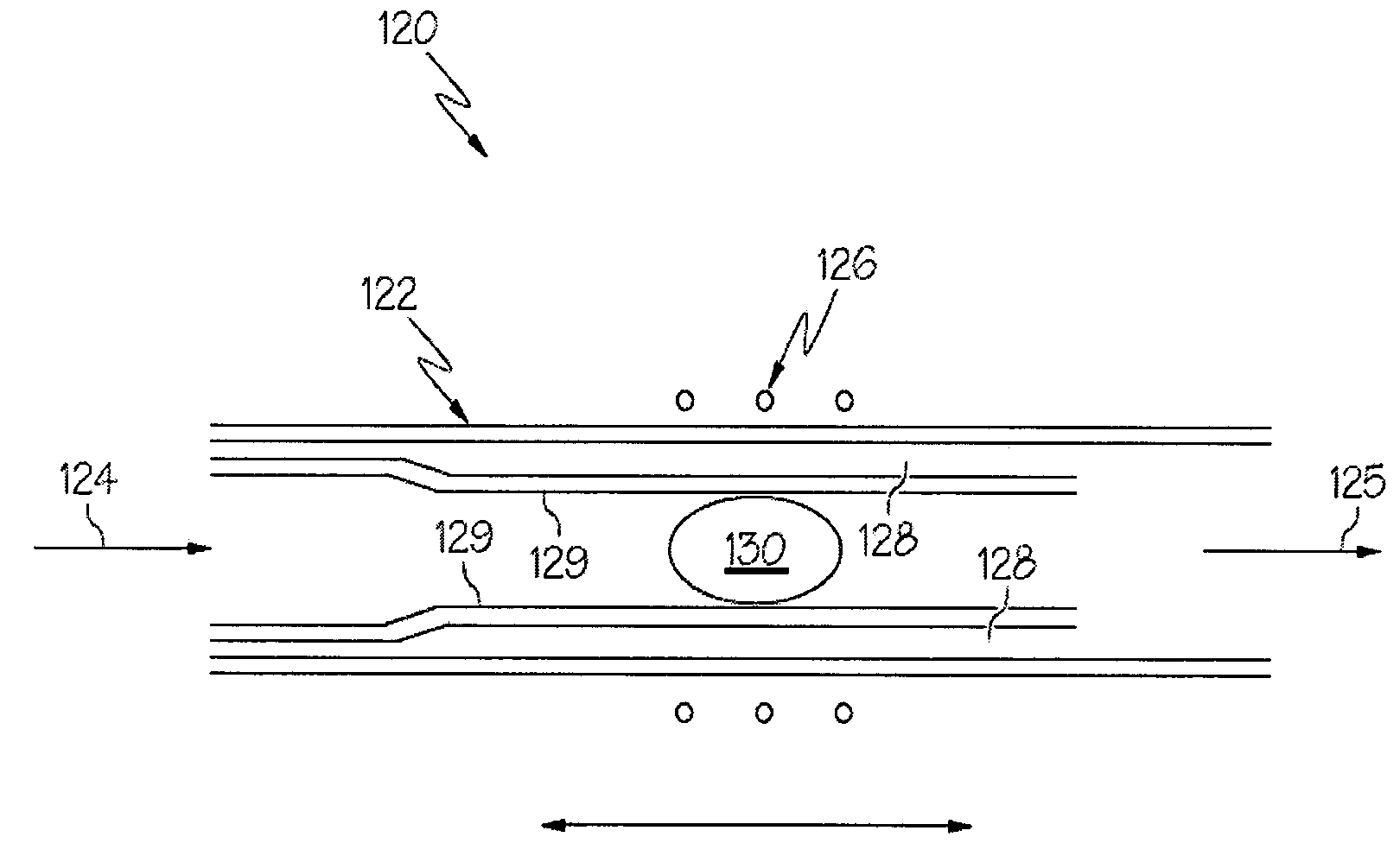

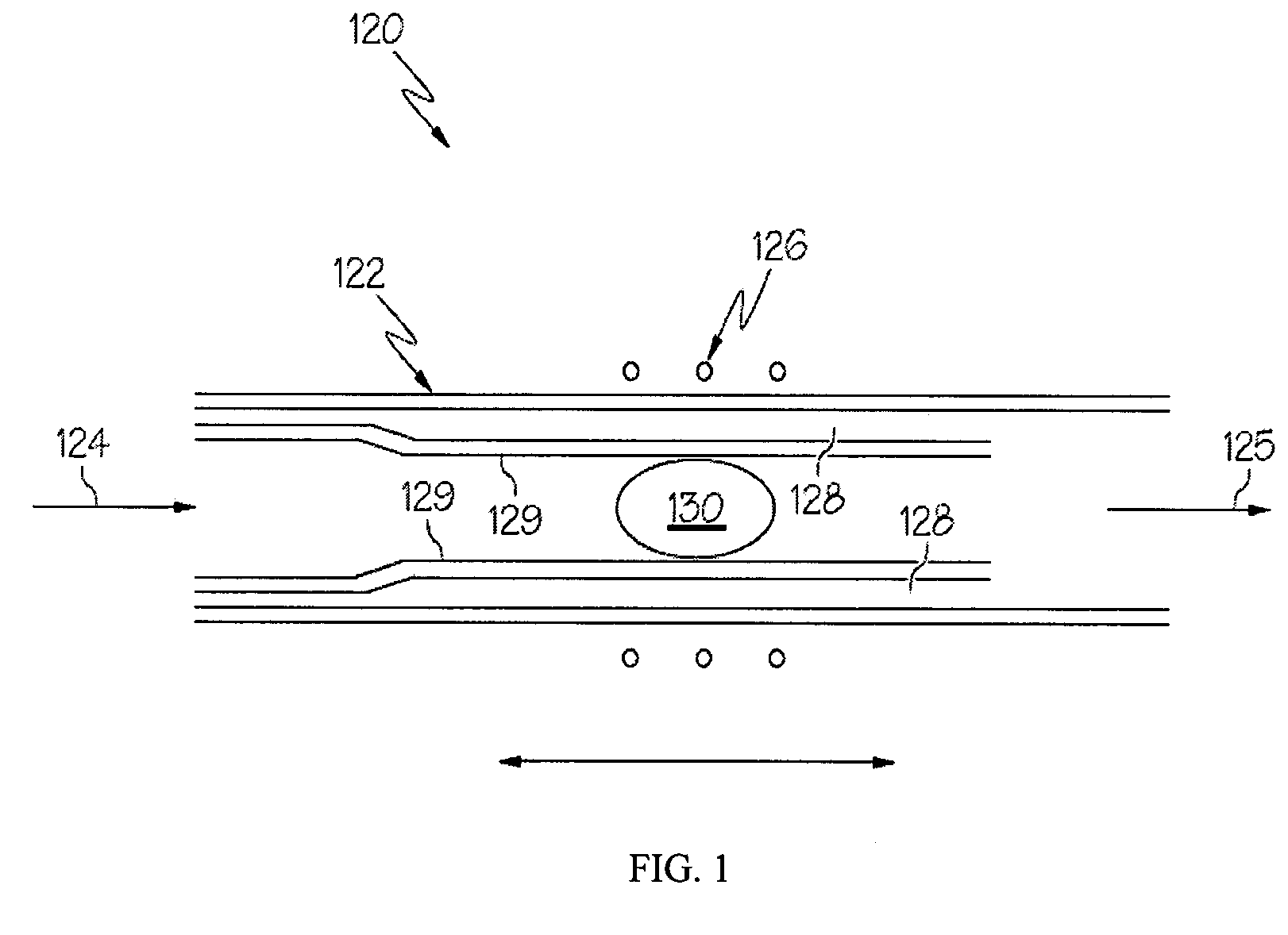

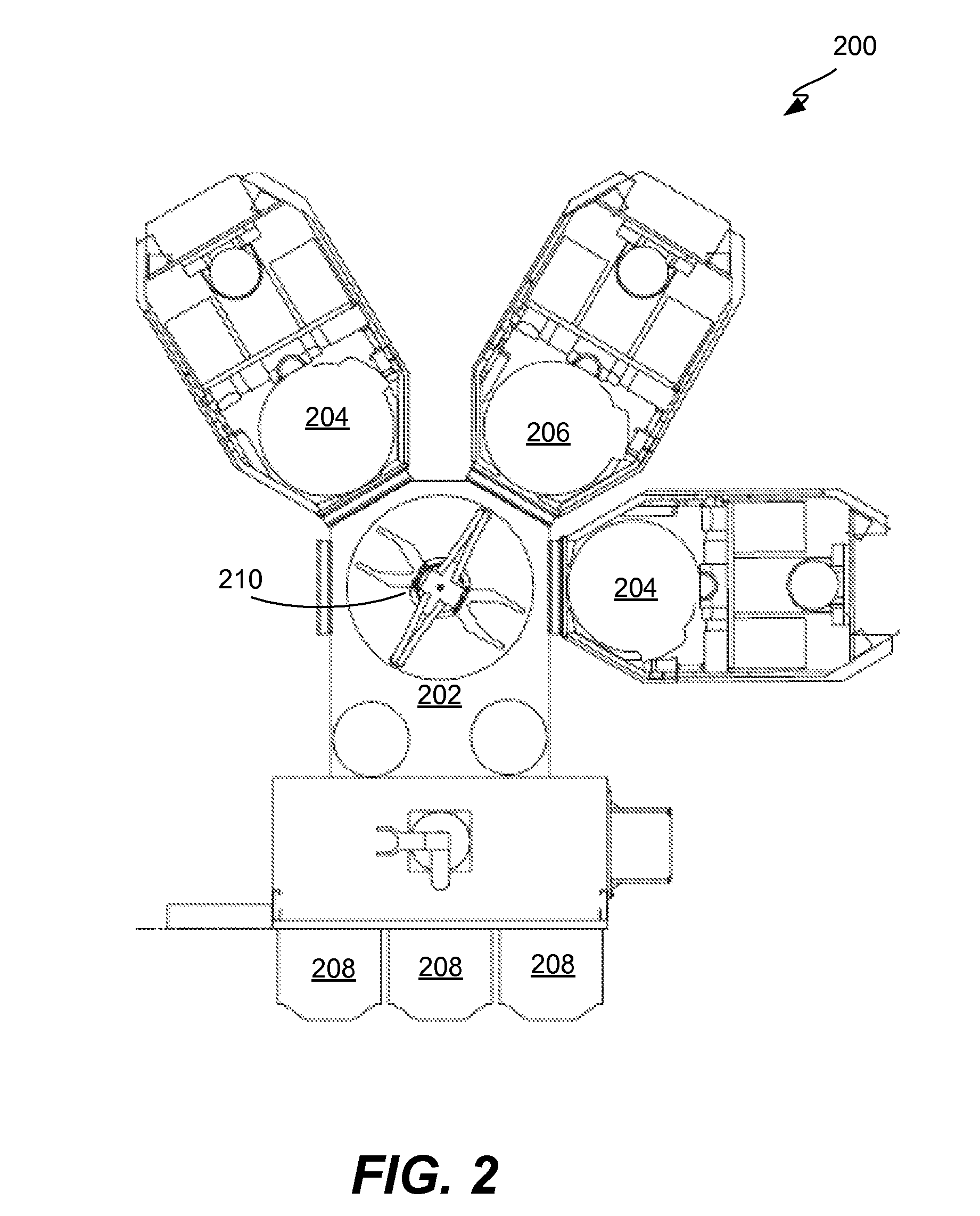

Roll-vortex plasma chemical vapor deposition system

InactiveUS20050005851A1Conserve useReduce manufacturing costElectric discharge tubesChemical vapor deposition coatingSilanesEngineering

A system comprises a processing chamber for maintaining a hydrogen plasma at low pressure. The processing chamber has a long, wide, thin geometry to favor deposition of thin-film silicon on sheet substrates over the chamber walls. The sheet substrates are moved through between ends. A pair of opposing radio frequency electrodes above and below the workpieces are electrically driven hard to generate a flat, pancaked plasma cloud in the middle spaces of the processing chamber. A collinear series of gas injector jets pointed slightly up on a silane-jet manifold introduce 100% silane gas at high velocity from the side in order to roll the plasma cloud in a coaxial vortex. A second such silane-jet manifold is placed on the opposite side and pointed slightly down to further help roll the plasma and maintain a narrow band of silane concentration. A silane-concentration monitor observes the relative amplitudes of the spectral signatures of the silane and the hydrogen constituents in the roll-vortex plasma and outputs a process control feedback signal that is used to keep the silane in hydrogen concentration at about 6-7%.

Owner:GEN 3 SOLAR +2

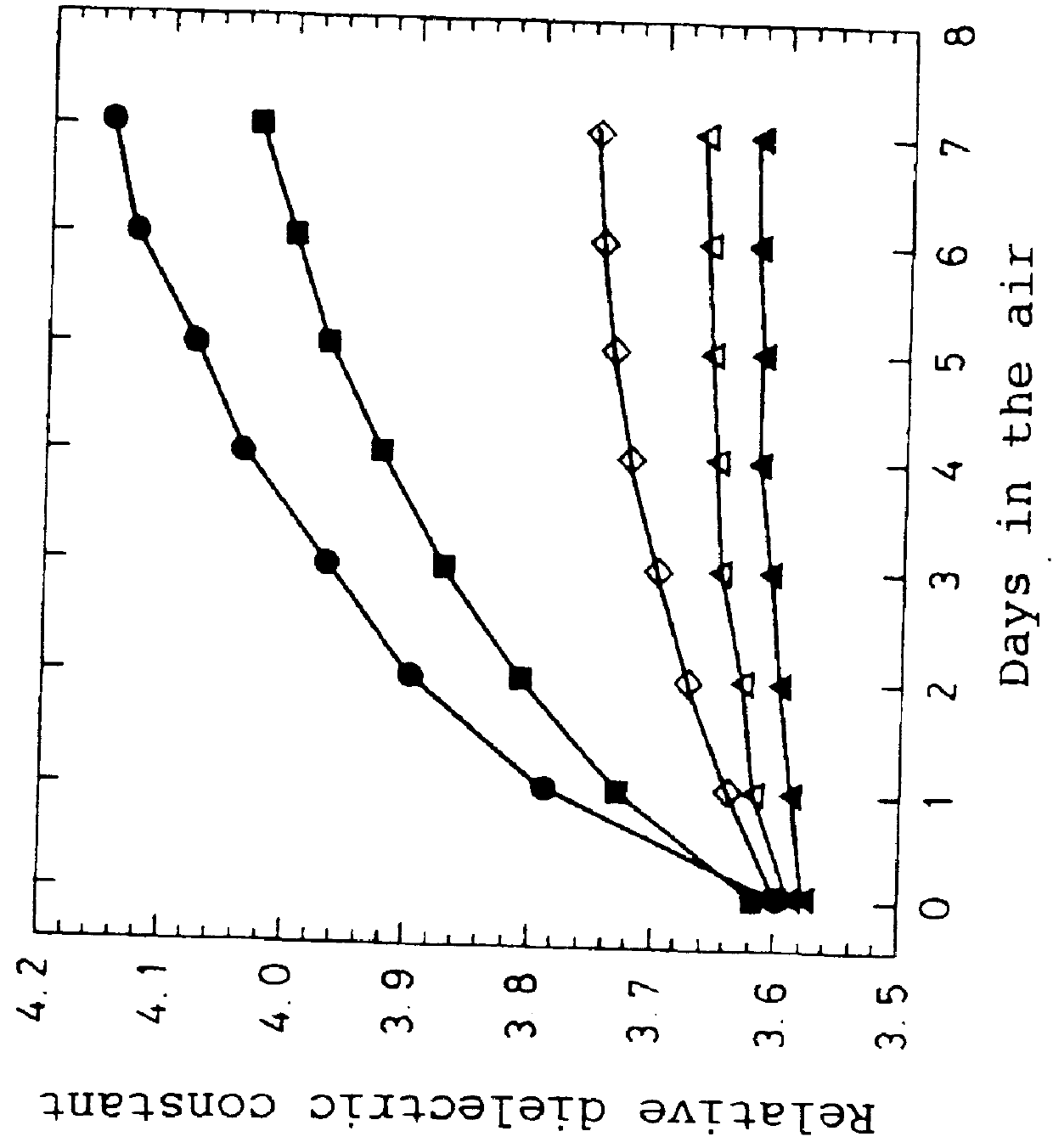

Method for forming insulating film

InactiveUS6037274AImprove featuresGood reproducibilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseChemical vapor deposition

The present invention relates to a method for forming an insulating film with a low relative dielectric constant. A method for forming an insulating film in terms of a plasma chemical vapor deposition, characterized in that a Si supply gas, an oxygen supply gas, and a fluorine supply gas are used a material gas to form said insulating film, and said insulating film is formed under a film forming condition that a density of said insulating film to be formed is equal to or more than 2.25 g / cm3.

Owner:FUJITSU SEMICON LTD

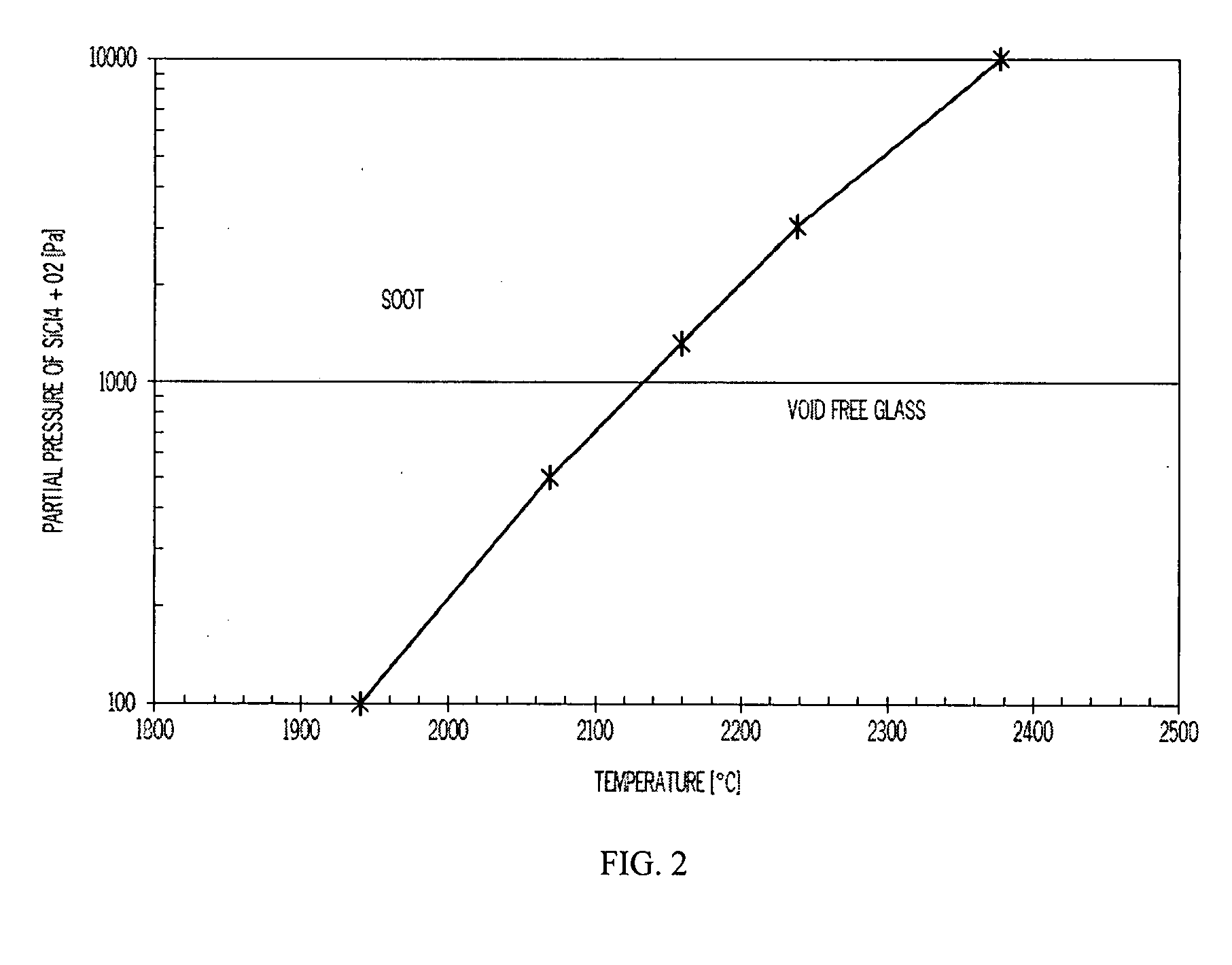

Methods for making optical fiber preforms and microstructured optical fibers

InactiveUS20090126407A1Glass deposition burnersGlass fibre productsRefractive indexChemical vapor deposition

A method of making an optical fiber preform includes depositing silica glass on the inside of a tube substrate via a plasma chemical vapor deposition (PCVD) operation. The parameters of the PCVD operation are controlled such that the silica glass deposited on the interior of the tube substrate contains a non-periodic array of voids in a cladding region of the optical fiber preform. The optical fiber preform may be used to produce an optical fiber having a core and a void containing cladding. The core of the optical fiber has a first index of refraction and the cladding has a second index of refraction less than that of the core.

Owner:CORNING INC

Method of polishing normal pressure plasma

The normal pressure plasma polishing method is provided. The normal pressure plasma polishing method includes providing plasma gas and reaction gas in the volume ratio of 4-1000; and starting RF power source and increasing power gradually while controlling the reflected power to zero, with the initial effective power being 180-240 W, normal power being 400-1200 W, and maximum power being 1500 W. The present invention realizes super smooth surface machining by means of plasma chemical reaction at normal pressure, and has no need of vacuum chamber, low cost, wide application range, high machining efficiency, no surface damage and contamination, and high surface smoothness up to 1nm Ra.

Owner:HARBIN INST OF TECH

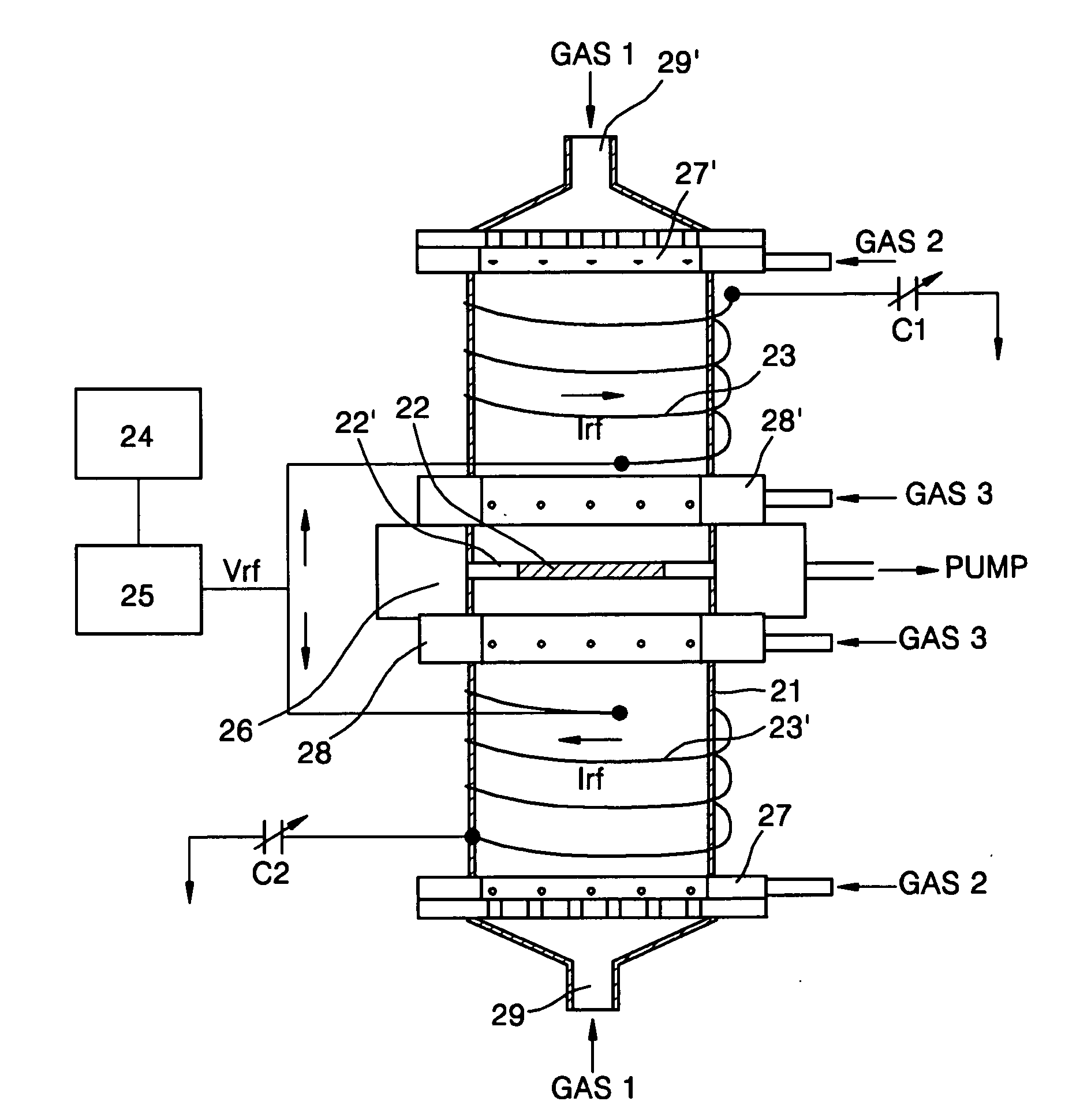

Plasma chemical vapor deposition system and method for coating both sides of substrate

InactiveUS20050170668A1Dispensing apparatusSemiconductor/solid-state device manufacturingEngineeringChemical vapor deposition

A plasma chemical vapor deposition system includes a chamber provided with gas injection holes, a gas exhaust unit mounted on the chamber, a substrate holder disposed on a central area of the chamber to support a substrate in a state where both sides of the substrate are exposed, and first and second coils generating induced magnetic fields. The first and second coils are disposed around upper and lower outer circumferences of the chamber, respectively.

Owner:SAMSUNG ELECTRONICS CO LTD

Plasma catalyzing process of preparing hydrogen by ammonia decomposition

InactiveCN1861519ALower decomposition temperatureLow costHydrogen productionMetal/metal-oxides/metal-hydroxide catalystsDecompositionManganese

A plasma catalysis process for preparing H2 by decomposing ammonia at lower temp to obtain the H2-N2 mixture used for the proton exchange membrane type fuel battery of car features that the non-noble-metal carried catalyst, whose active component is chosen from Fe, Co, Ni, Cr, Mo, Mn, Cu and W, is loaded in the discharge region in a plasma catalytic reactor.

Owner:DALIAN UNIV OF TECH

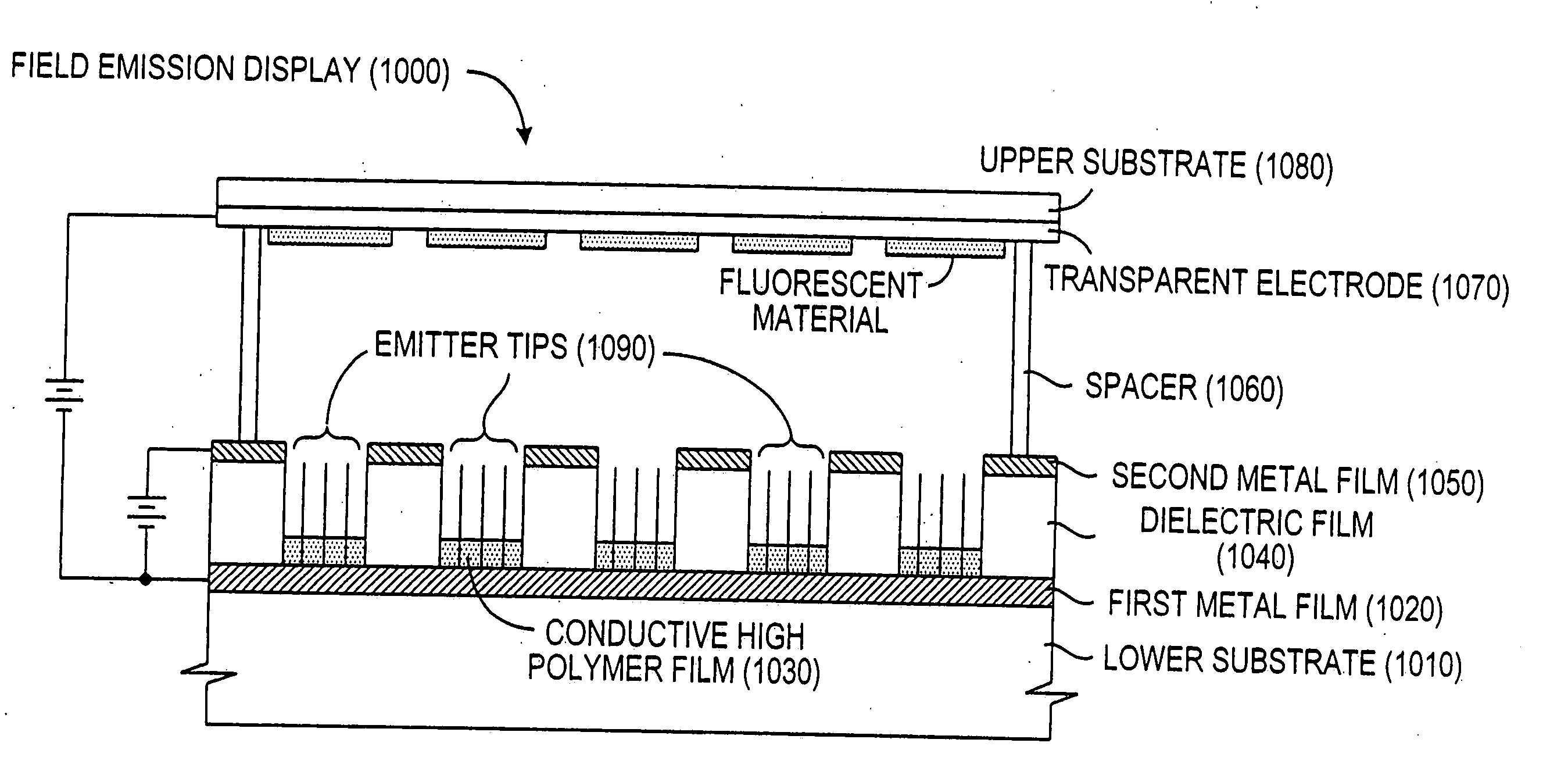

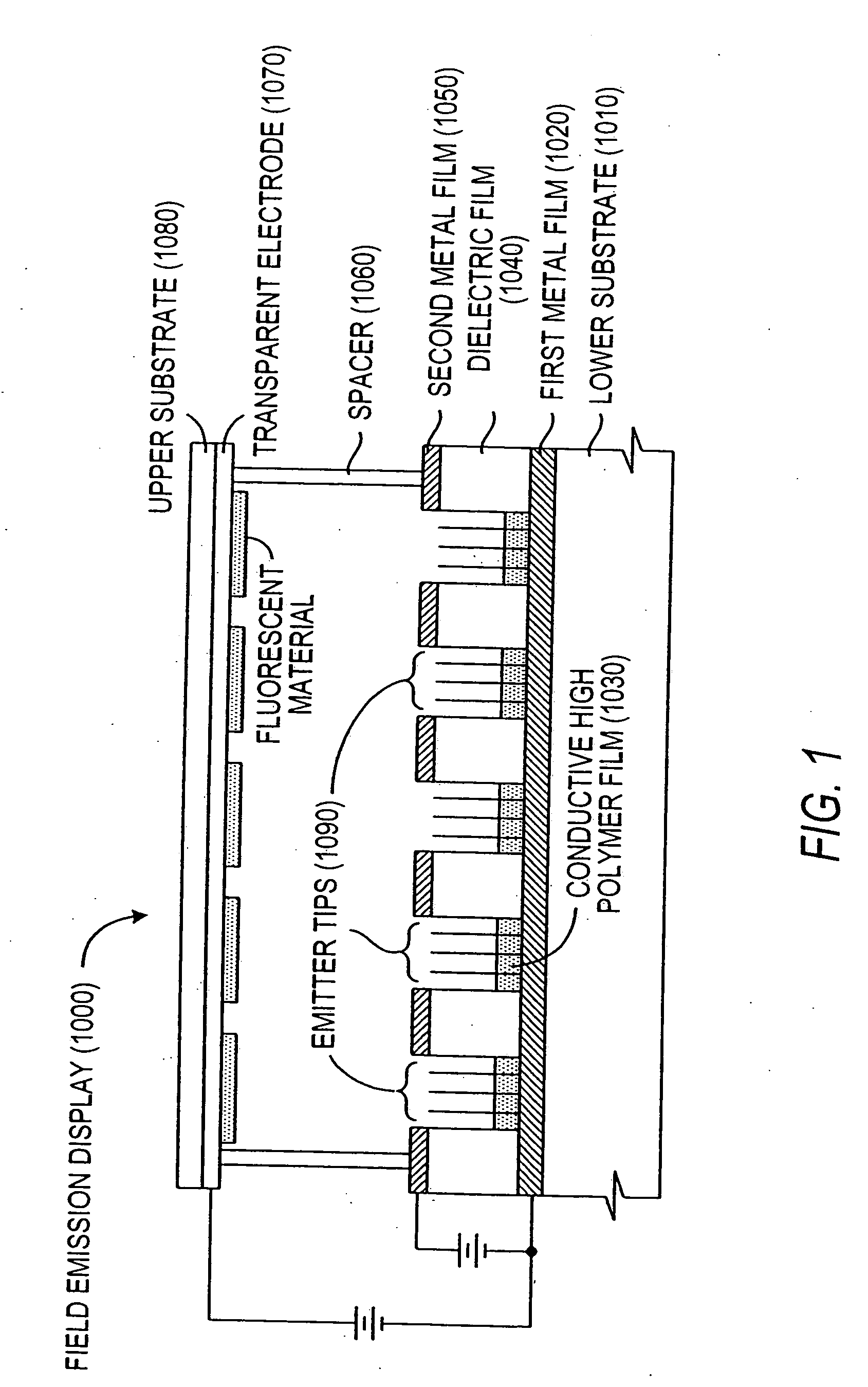

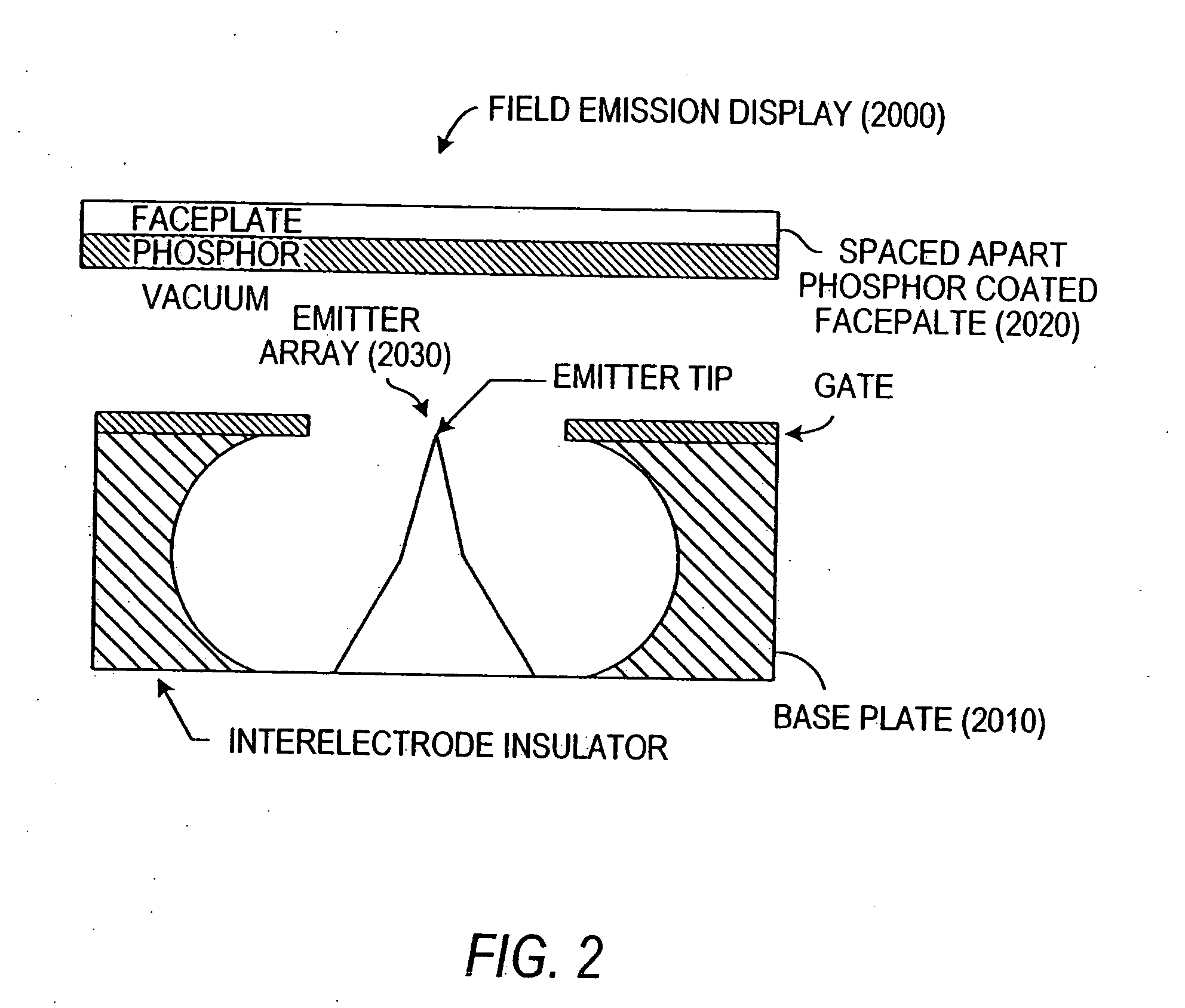

Field emission devices using modified carbon nanotubes

InactiveUS20050275331A1Reduce voltageAccelerate emissionsNanostructure manufactureNanoinformaticsField emission deviceModified carbon

The present invention relates to a field emission device comprising an anode and a cathode, wherein said cathode includes carbon nanotubes nanotubes which have been subjected to energy, plasma, chemical, or mechanical treatment. The present invention also relates to a field emission cathode comprising carbon nanotubes which have been subject to such treatment. A method for treating the carbon nanotubes and for creating a field emission cathode is also disclosed. A field emission display device containing carbon nanotube which have been subject to such treatment is further disclosed.

Owner:HYPERION CATALYSIS INT

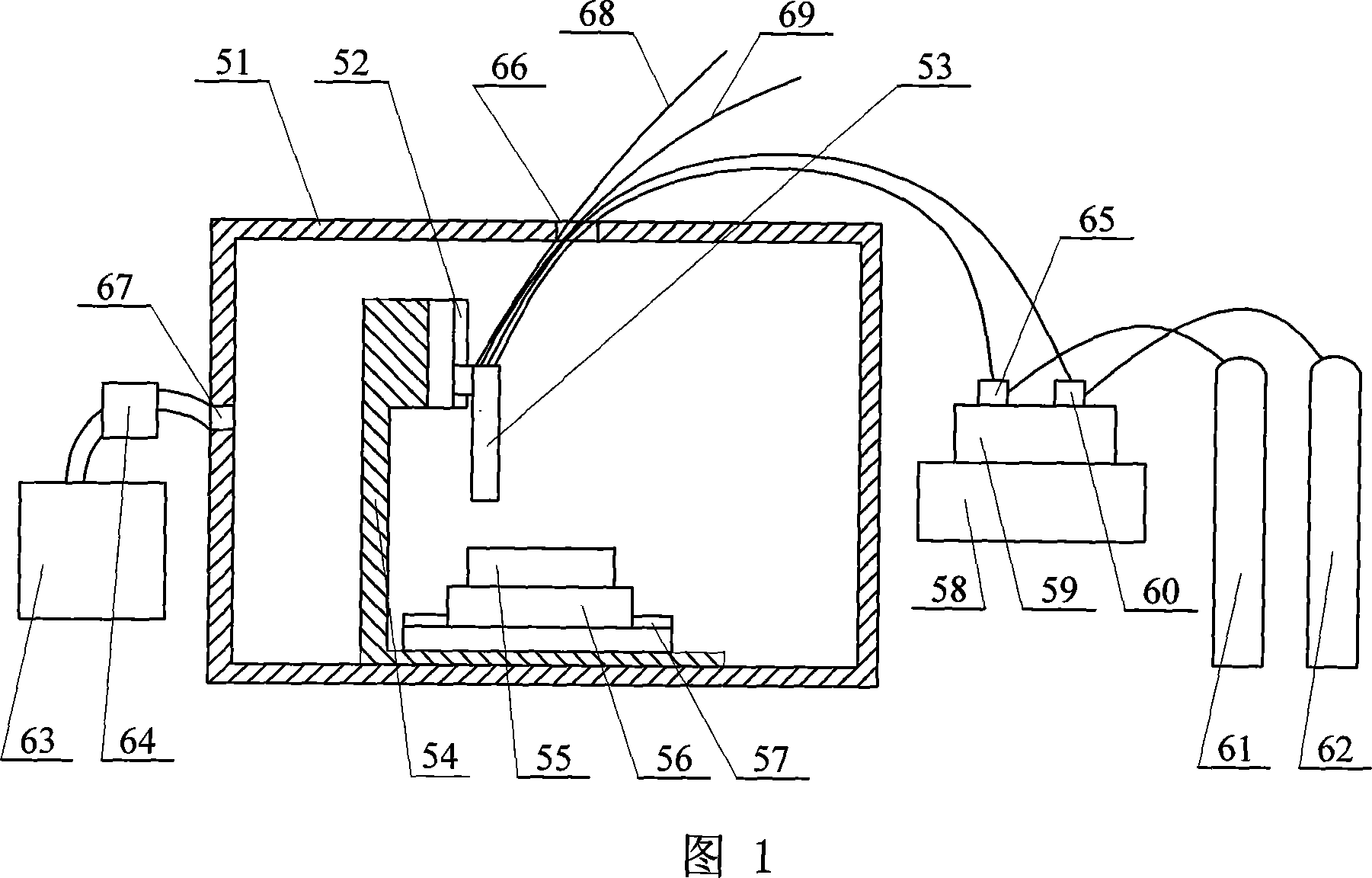

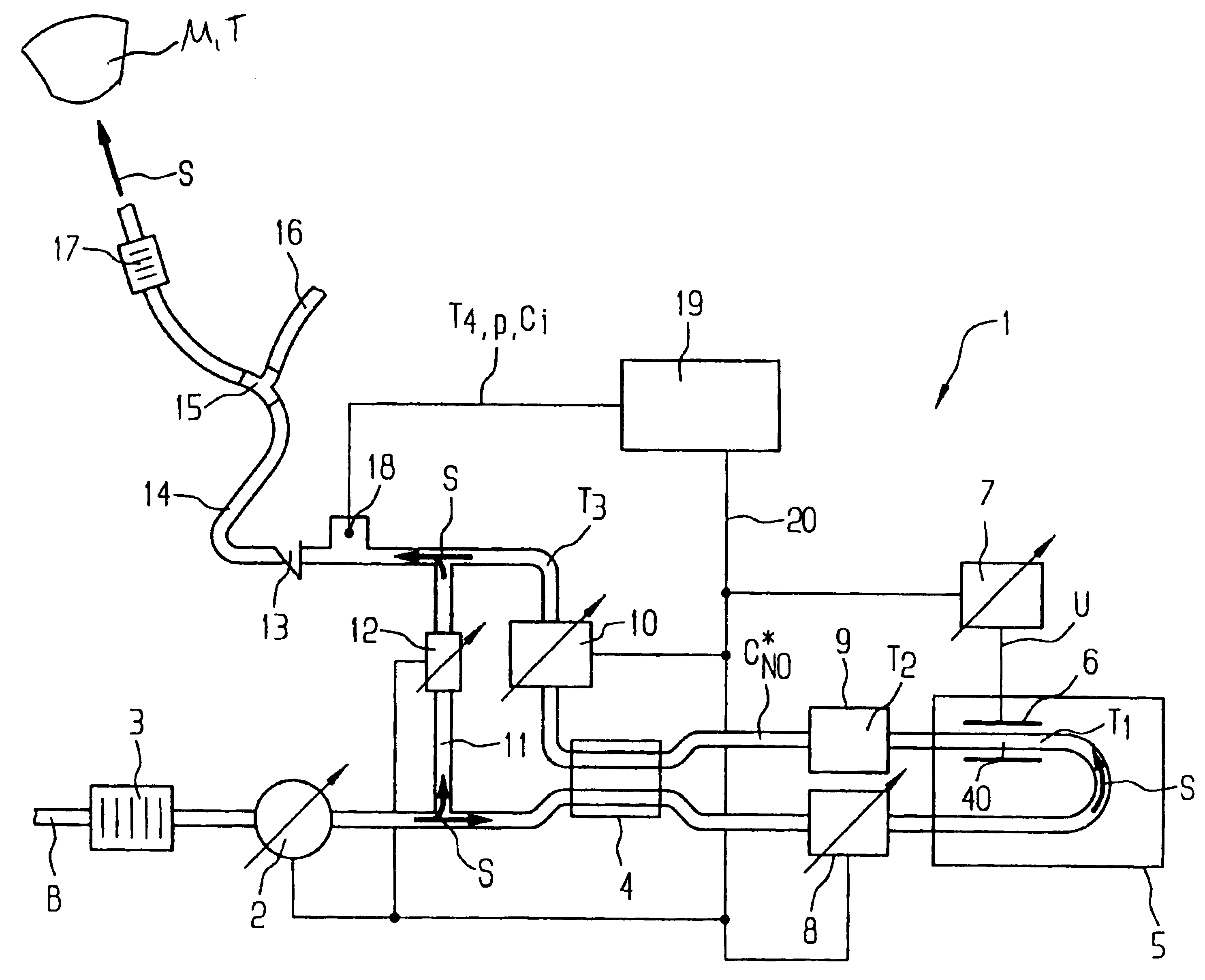

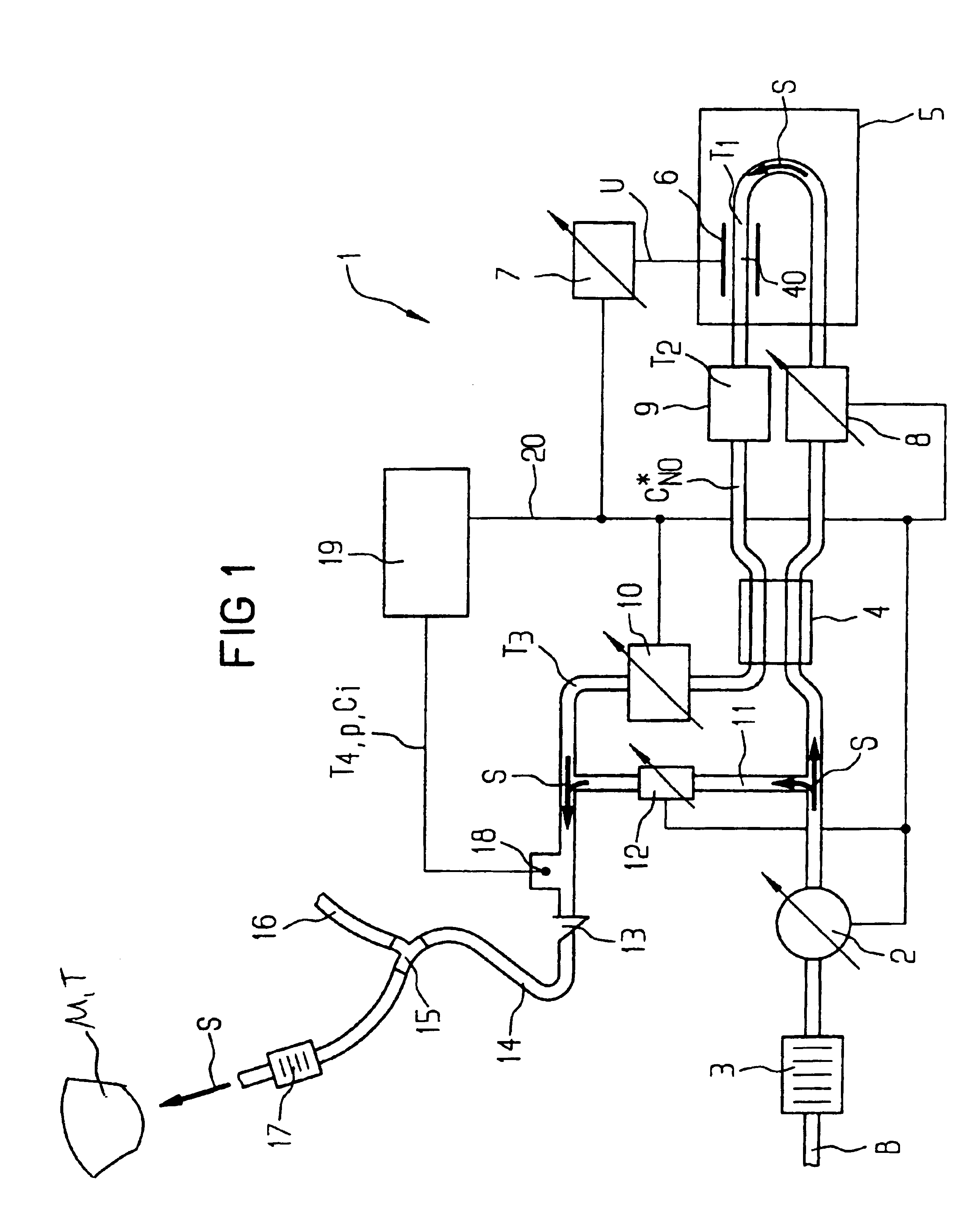

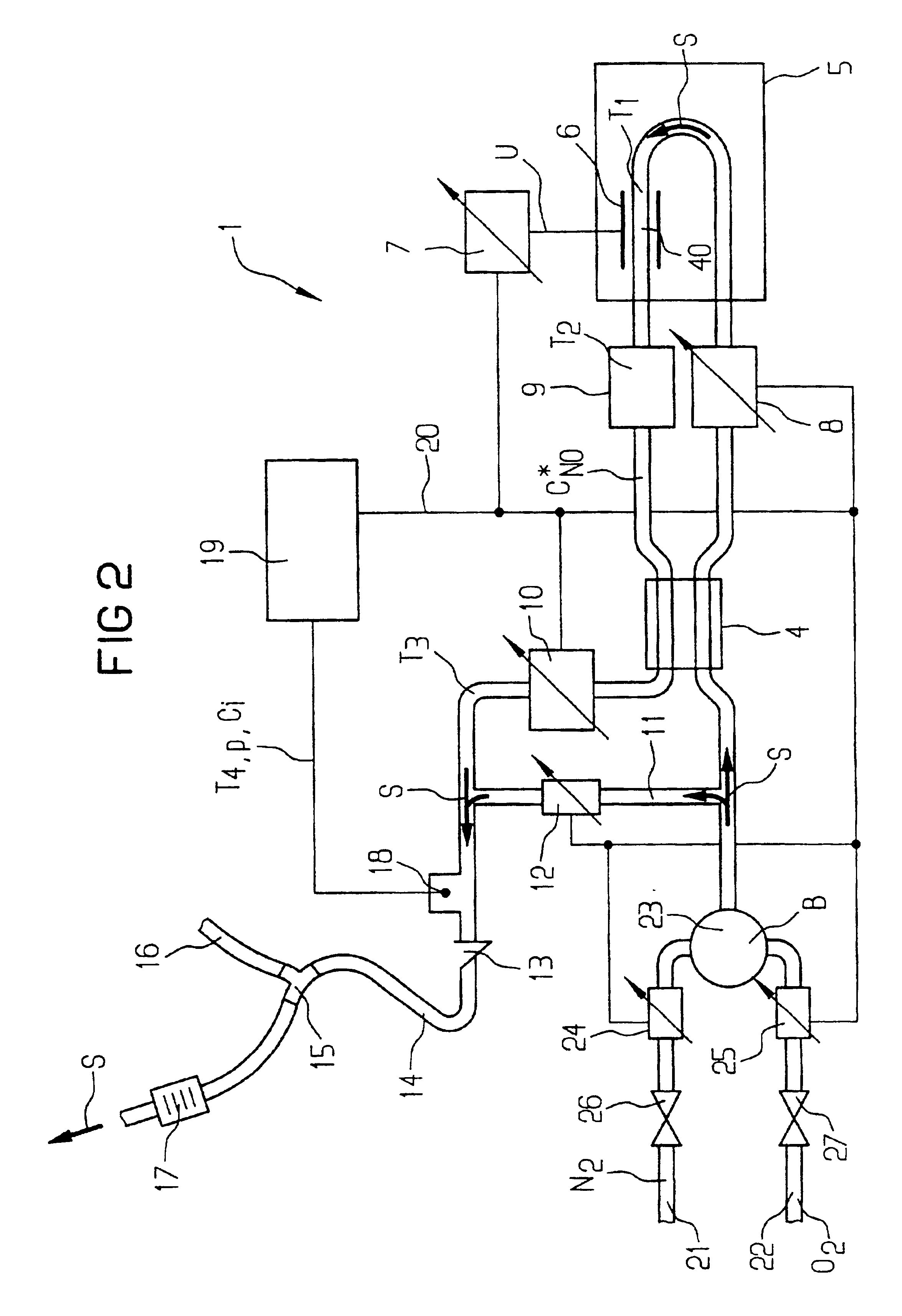

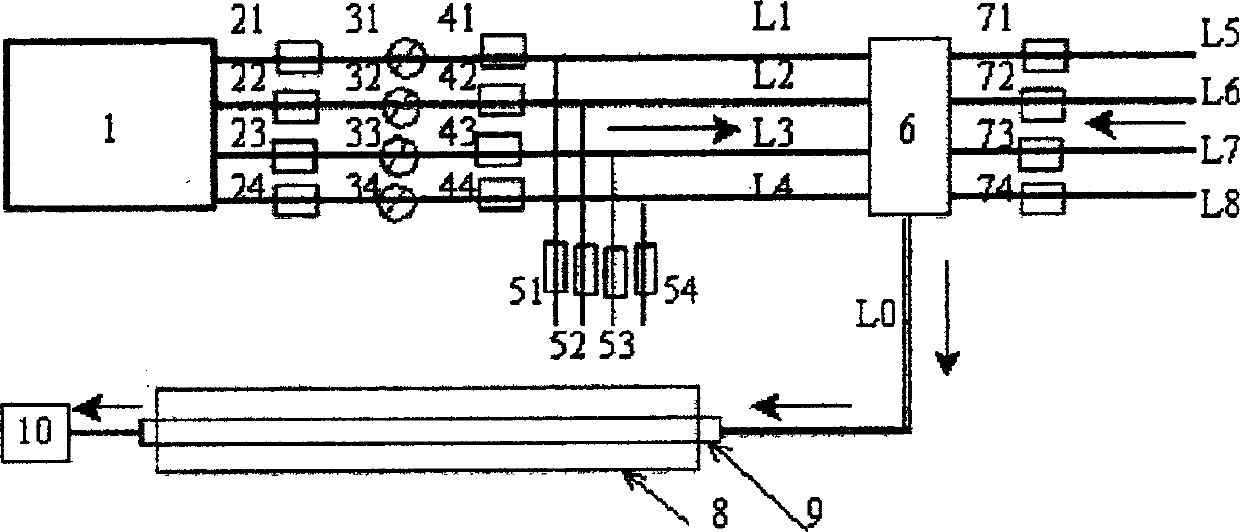

Apparatus for plasma-chemical production of nitrogen monoxide

InactiveUS6955790B2Overcome disadvantagesGas-gas reaction as plasma stateMedical devicesNitrogen monooxideNitrogen

A method and an apparatus for plasma-chemical production of nitrogen monoxide is used to produce inhalation gas enriched with nitrogen monoxide for medical purposes. The nitrogen-monoxide production is achieved through the use of a dielectric barrier discharge created in a process gas containing nitrogen and oxygen.

Owner:MAQUET CRITICAL CARE

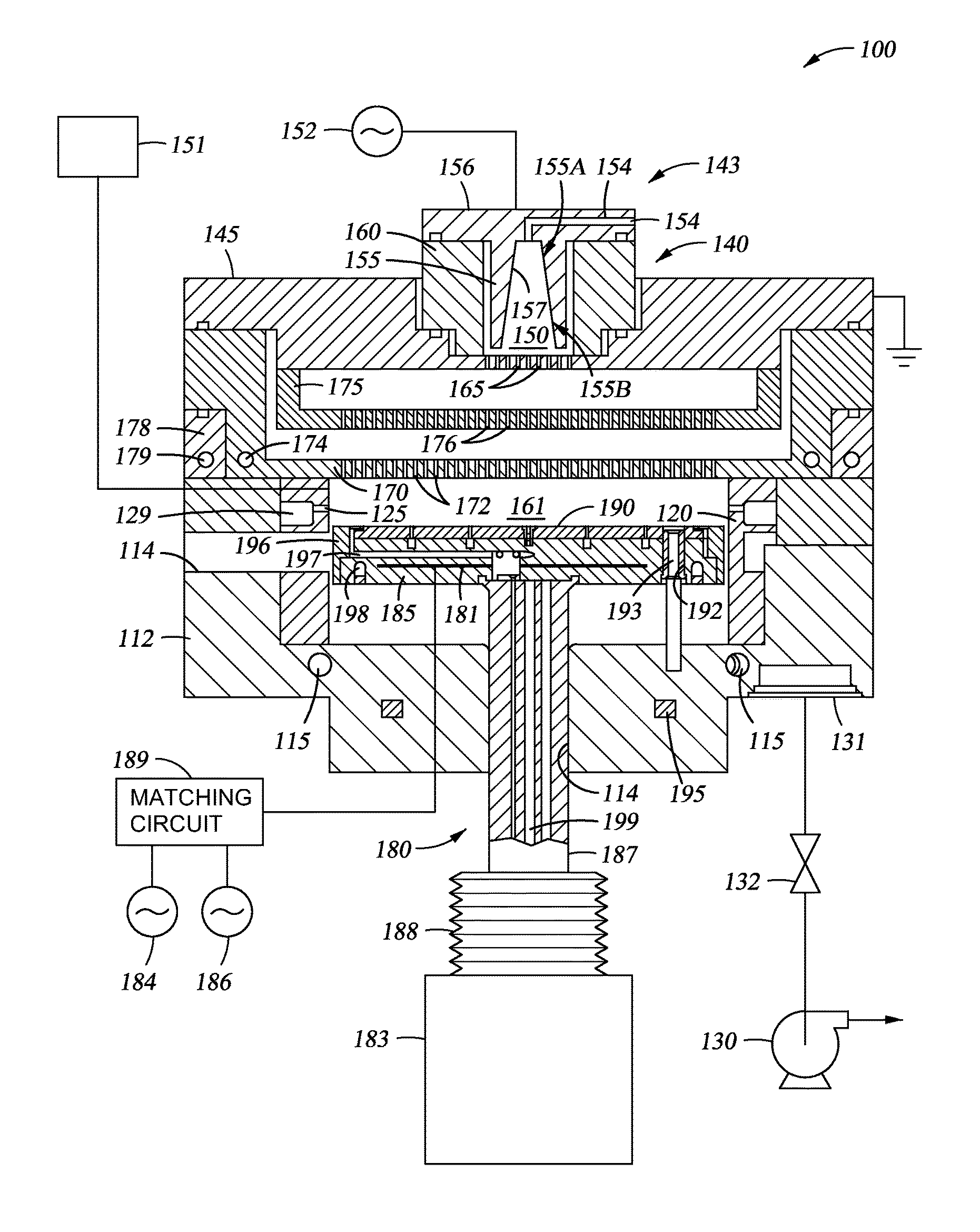

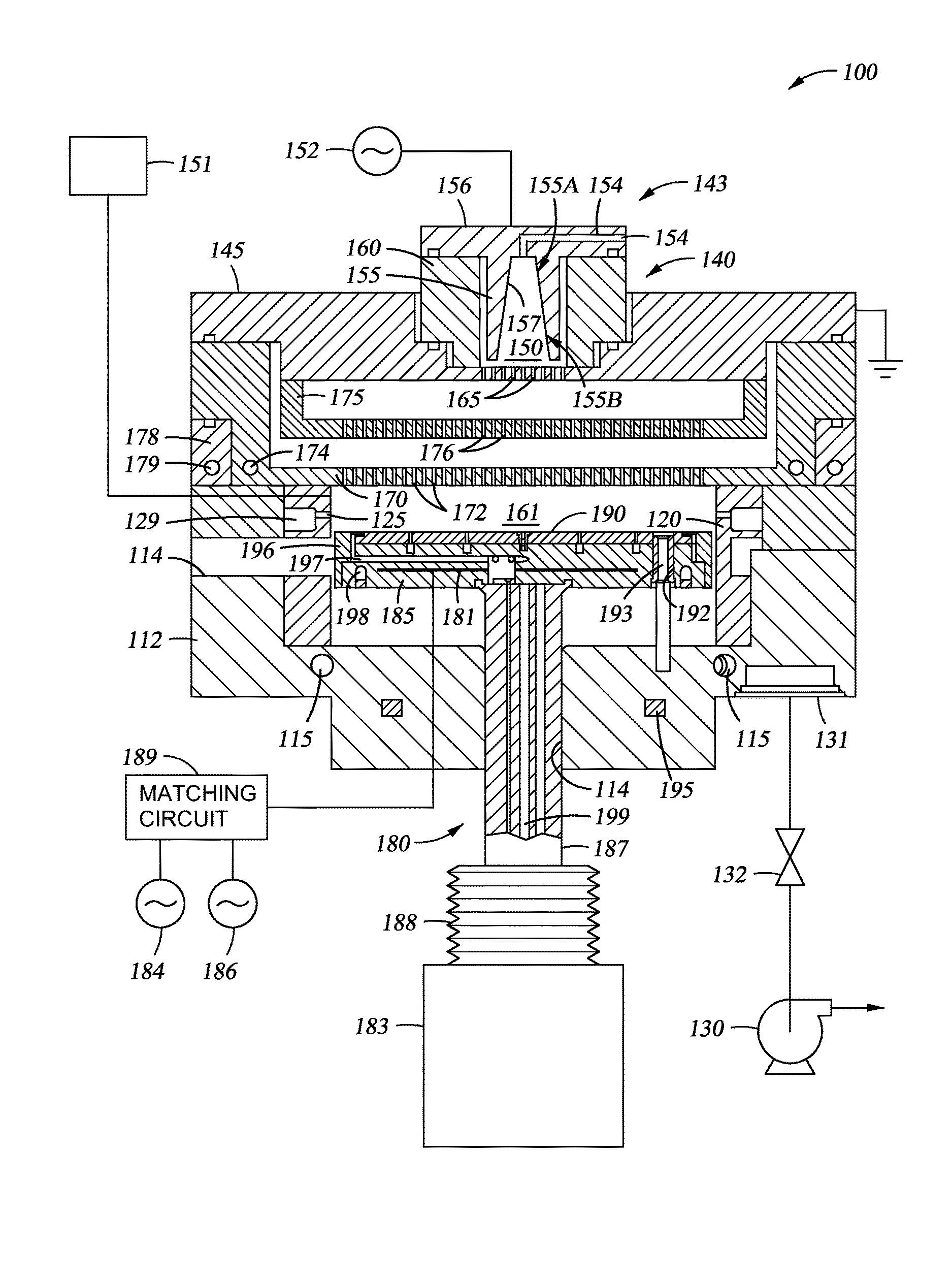

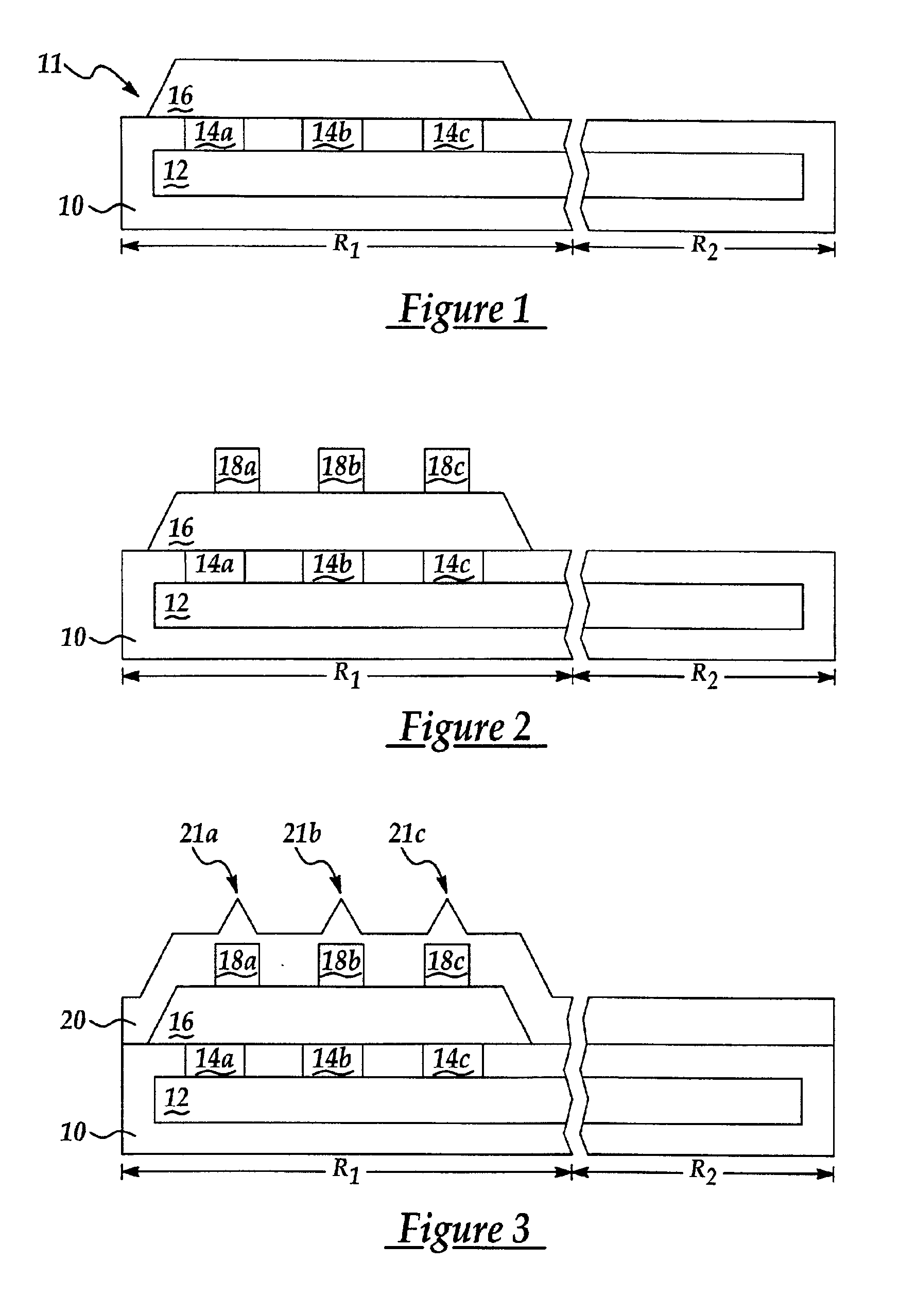

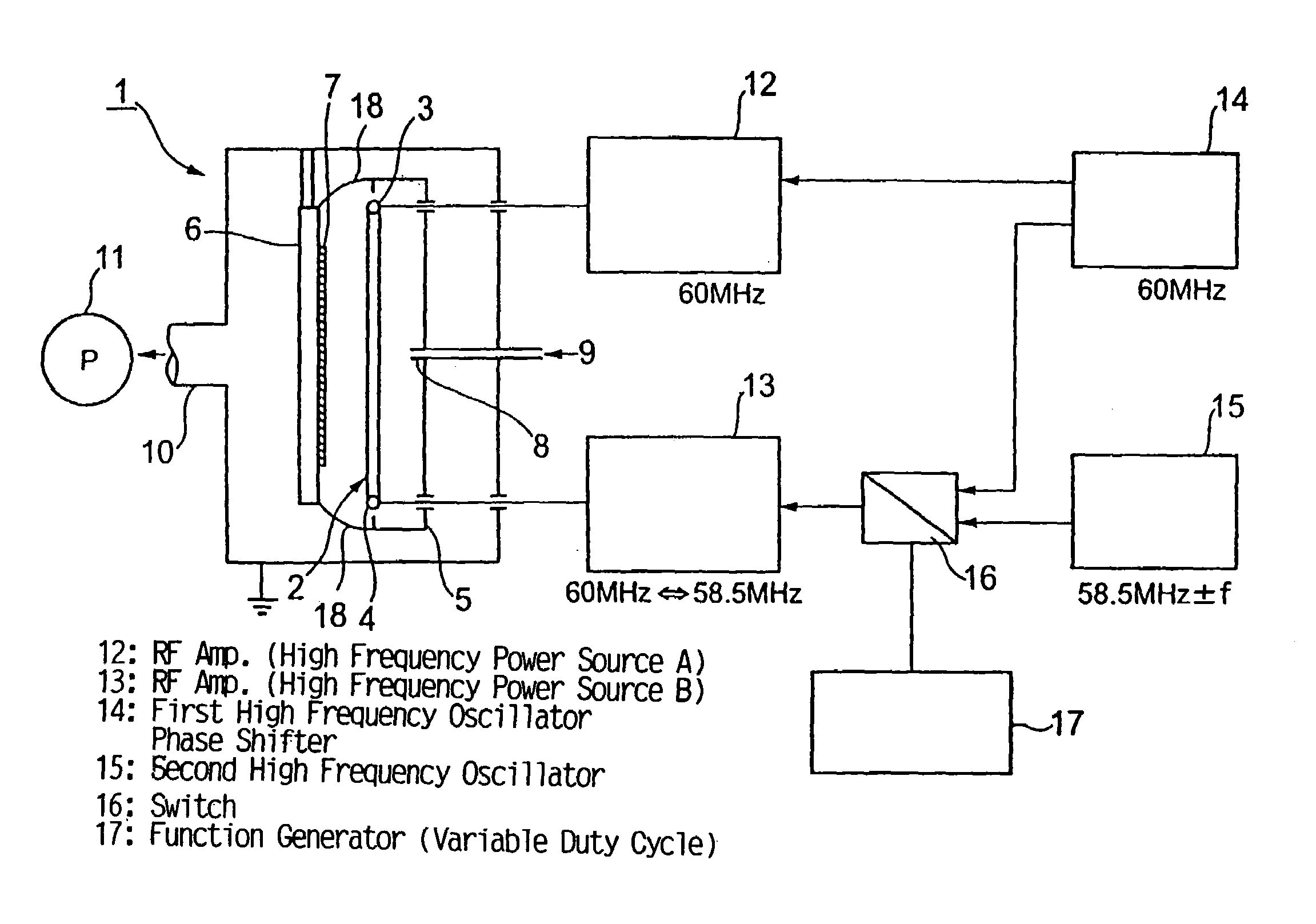

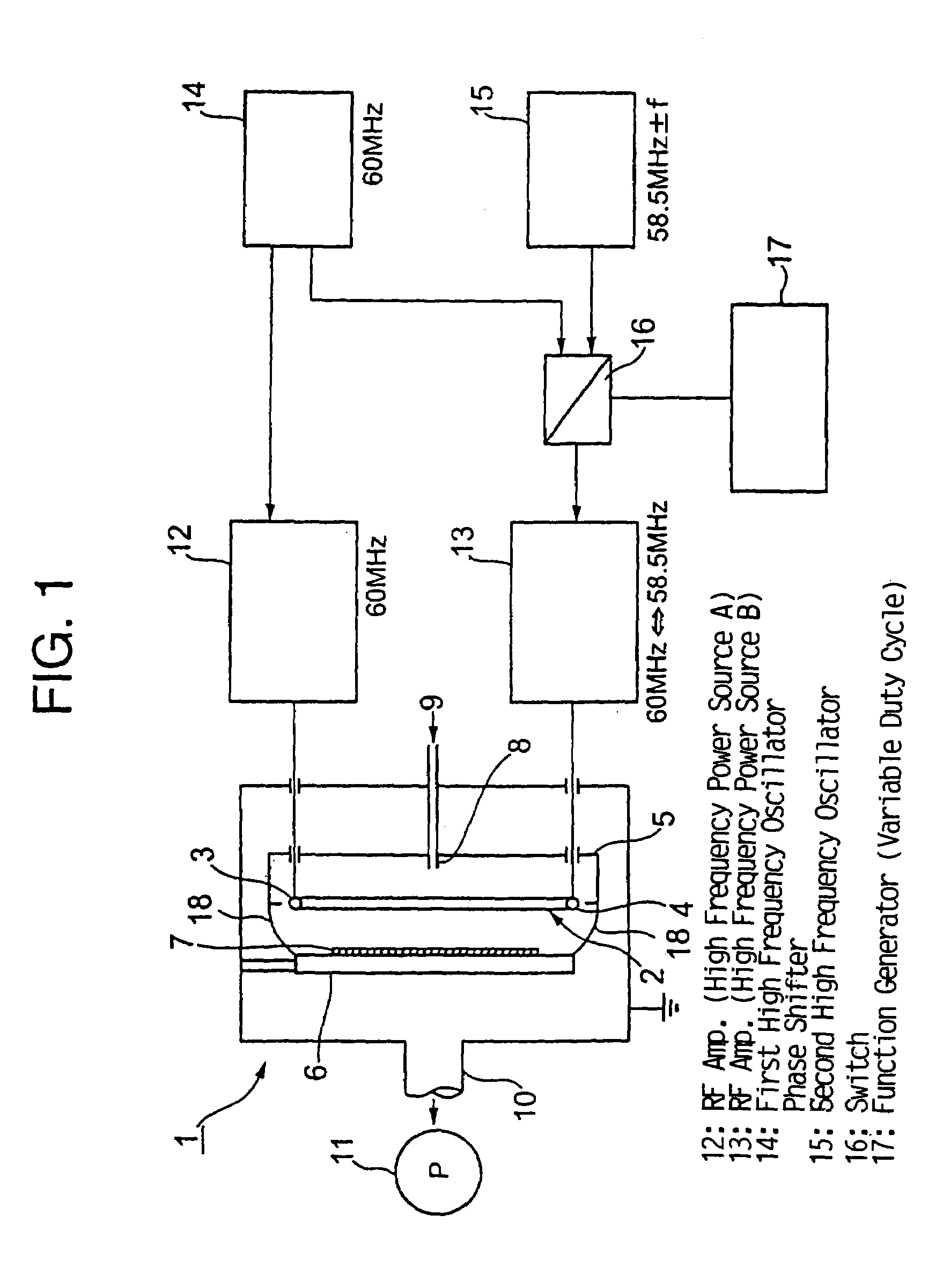

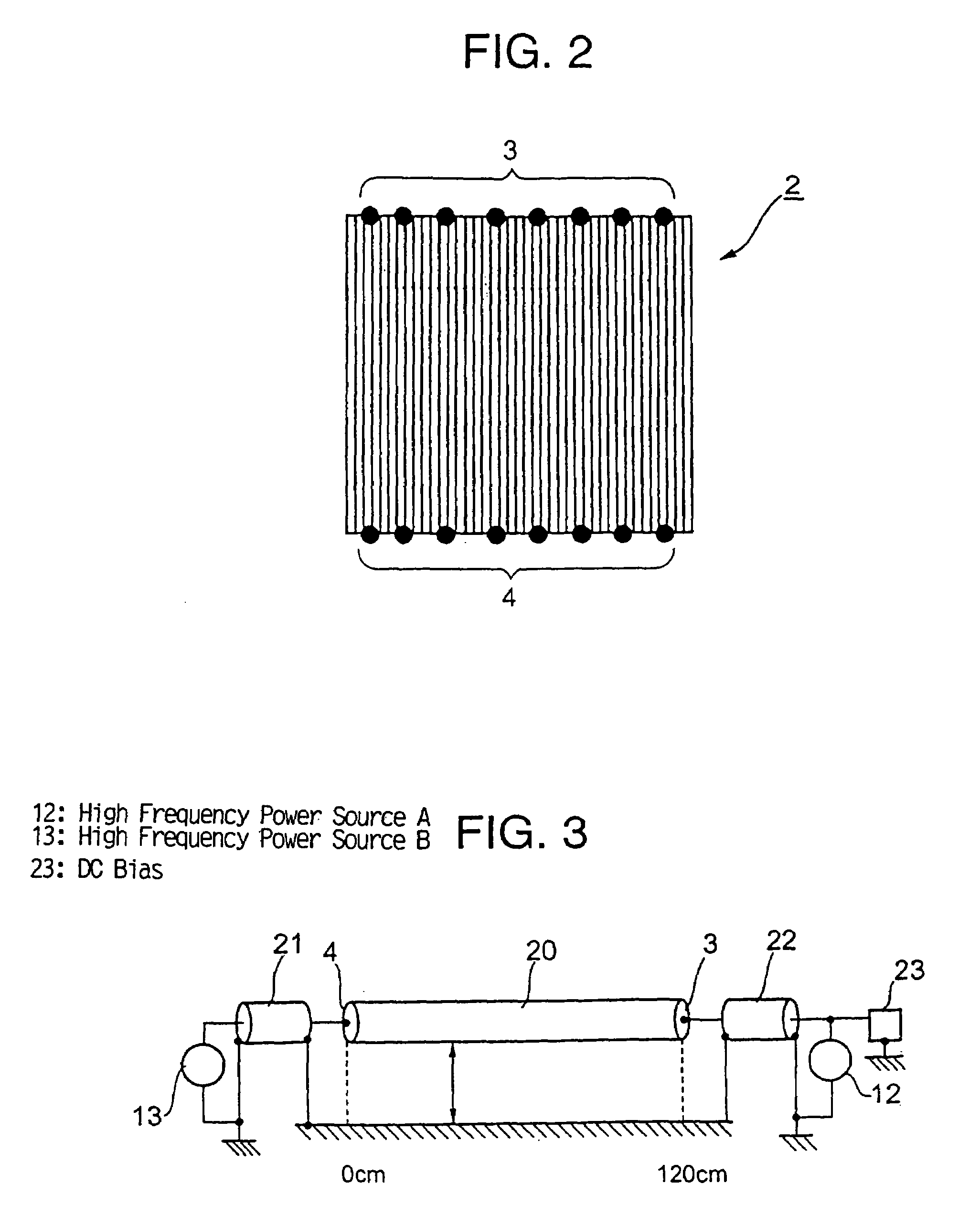

Method and device for generating uniform high-frequency plasma over large surface area used for plasma chemical vapor deposition apparatus

InactiveUS7205034B2Increase plasma densityLow densityElectric discharge tubesChemical vapor deposition coatingEngineeringChemical vapor deposition

A plasma generation device for generating plasma uniformly over a large surface area by very high frequency (VHF), which is installed in a plasma chemical vapor deposition apparatus. A first and a second power supply section are installed on both ends of the discharge electrode installed in a plasma chemical vapor deposition apparatus, and are supplied with alternate cycles: the first cycle wherein the first and second power supply sections receive high frequency waves at the same frequency, and a second cycle wherein different high frequency waves are received. In this manner, the state of plasma generation may be varied in each cycle, and when averaged over time, it makes possible uniform plasma generation over a large surface area.

Owner:MITSUBISHI HEAVY IND LTD

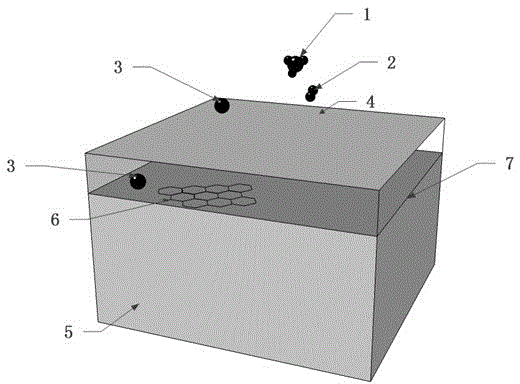

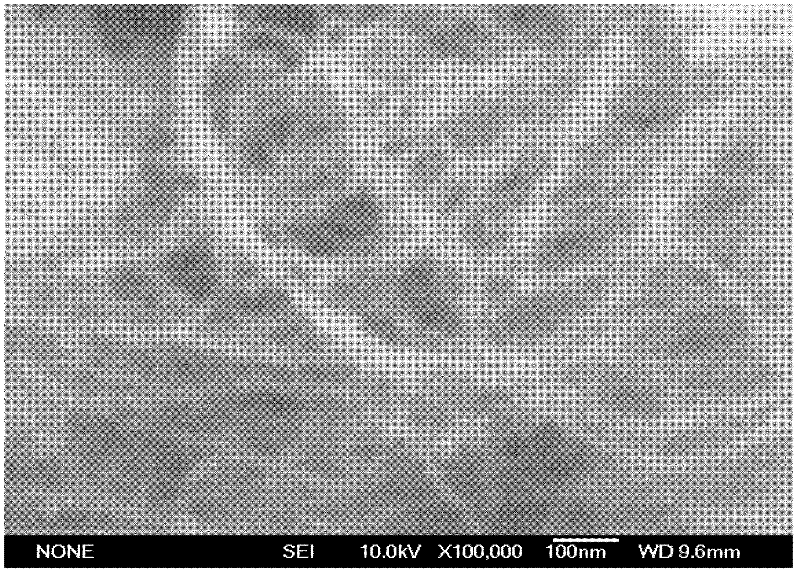

Method for preparing one-dimensional nanostructure in anode alumina template

InactiveCN1669920AImprove qualitySynthesis temperature is lowAnodisationPolycrystalline material growthSilanesHoneycomb structure

The invention discloses a method for preparing a one-dimensional silicon nanostructure in a anodic aluminum oxide mold, which comprises the following steps: growing the one-dimensional silicon nanostructure in low-temperature by the method of plasma chemical depositing with the spacing limited function of porous aluminium oxide, including the silicon nanowire and silicon nanotube, preparing a porous aluminum oxide mold with honeycomb structure by anodic oxidation process, wherein openings arrange ordered, apertures are coherent and vertical the surfaces of the mold, imbedding the mold into a plasma enhanced chemical depositing reaction chamber, growing the silicon nanowire or silicon nanotube at a temperature of 300 Deg. C by controlling the gas flow with the perhydrous diluting silane as the growth air supply.

Owner:ZHEJIANG UNIV

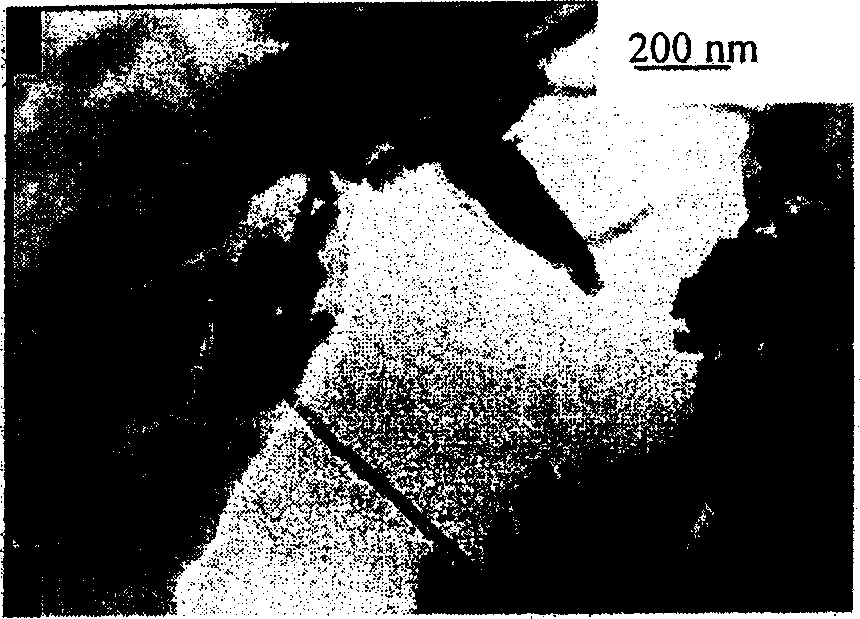

Method for forming carbon nanotubes with intermediate purification steps

InactiveUS6841003B2Promote growthSolve the small densityMaterial nanotechnologyPolycrystalline material growthHydrogenPlasma deposition

Carbon nanotubes are formed on a surface of a substrate using a plasma chemical deposition process. After the nanotubes have been grown, a purification step is performed on the newly formed nanotube structures. The purification removes graphite and other carbon particles from the walls of the grown nanotubes and controls the thickness of the nanotube layer. The purification is performed with the plasma at the same substrate temperature. For the purification, the hydrogen containing gas added as an additive to the source gas for the plasma chemical deposition is used as the plasma source gas. Because the source gas for the purification plasma is added as an additive to the source gas for the chemical plasma deposition, the grown carbon nanotubes are purified by reacting with the continuous plasma which is sustained in the plasma process chamber. This eliminates the need to purge and evacuate the plasma process chamber as well as to stabilize the pressure with the purification plasma source gas. Accordingly, the growth and the purification may be performed without shutting off the plasma in the plasma process chamber.

Owner:CDREAM DISPLAY CORP

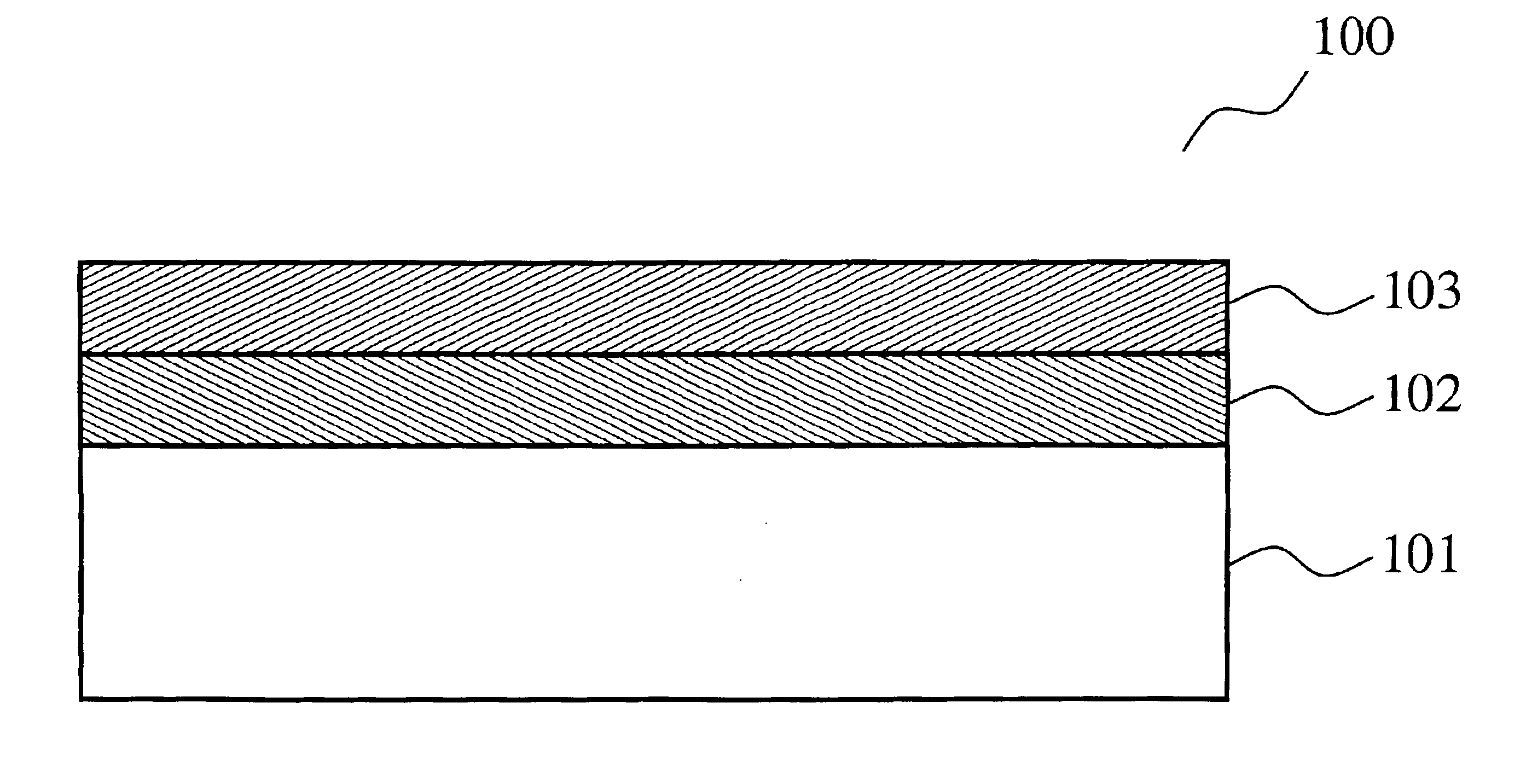

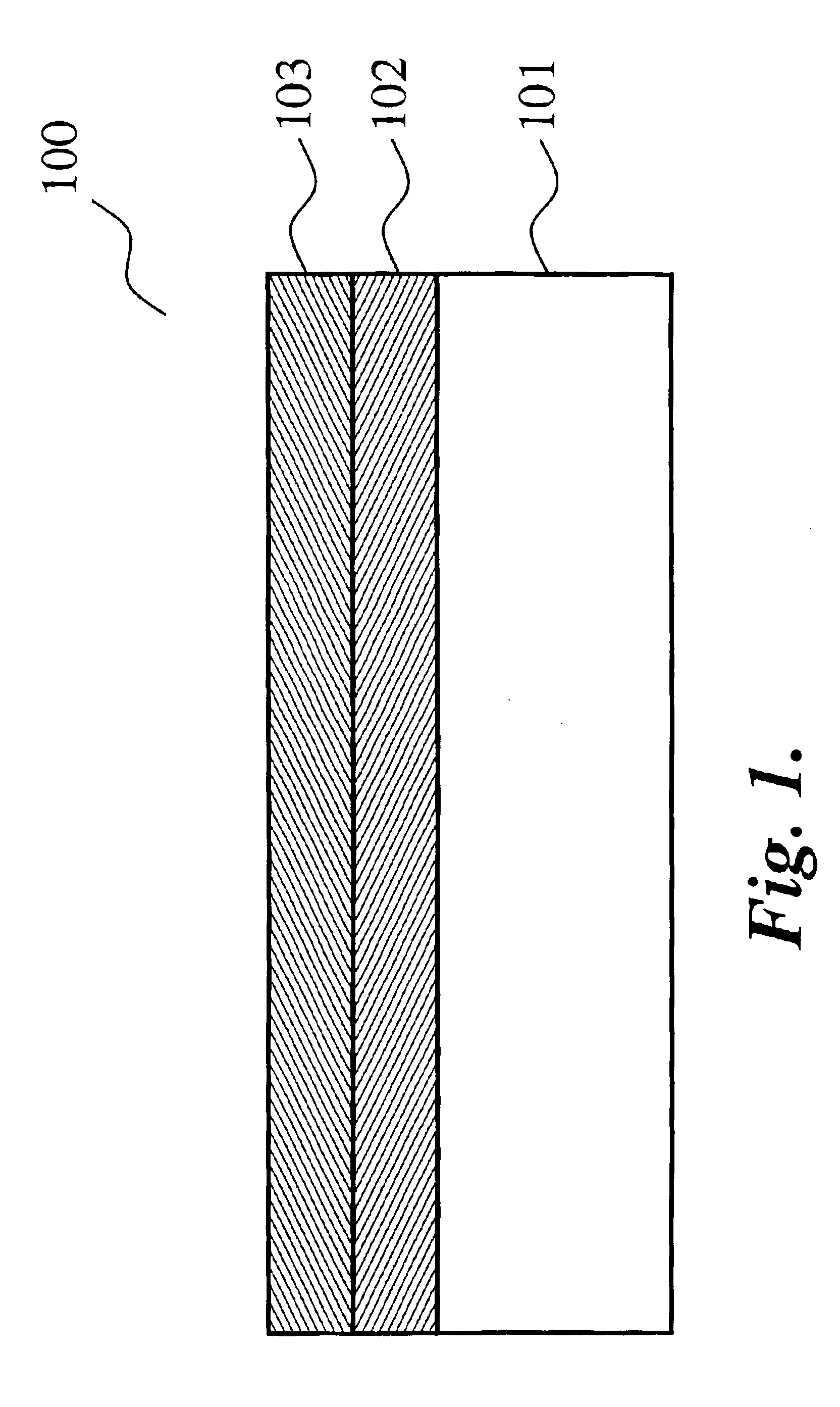

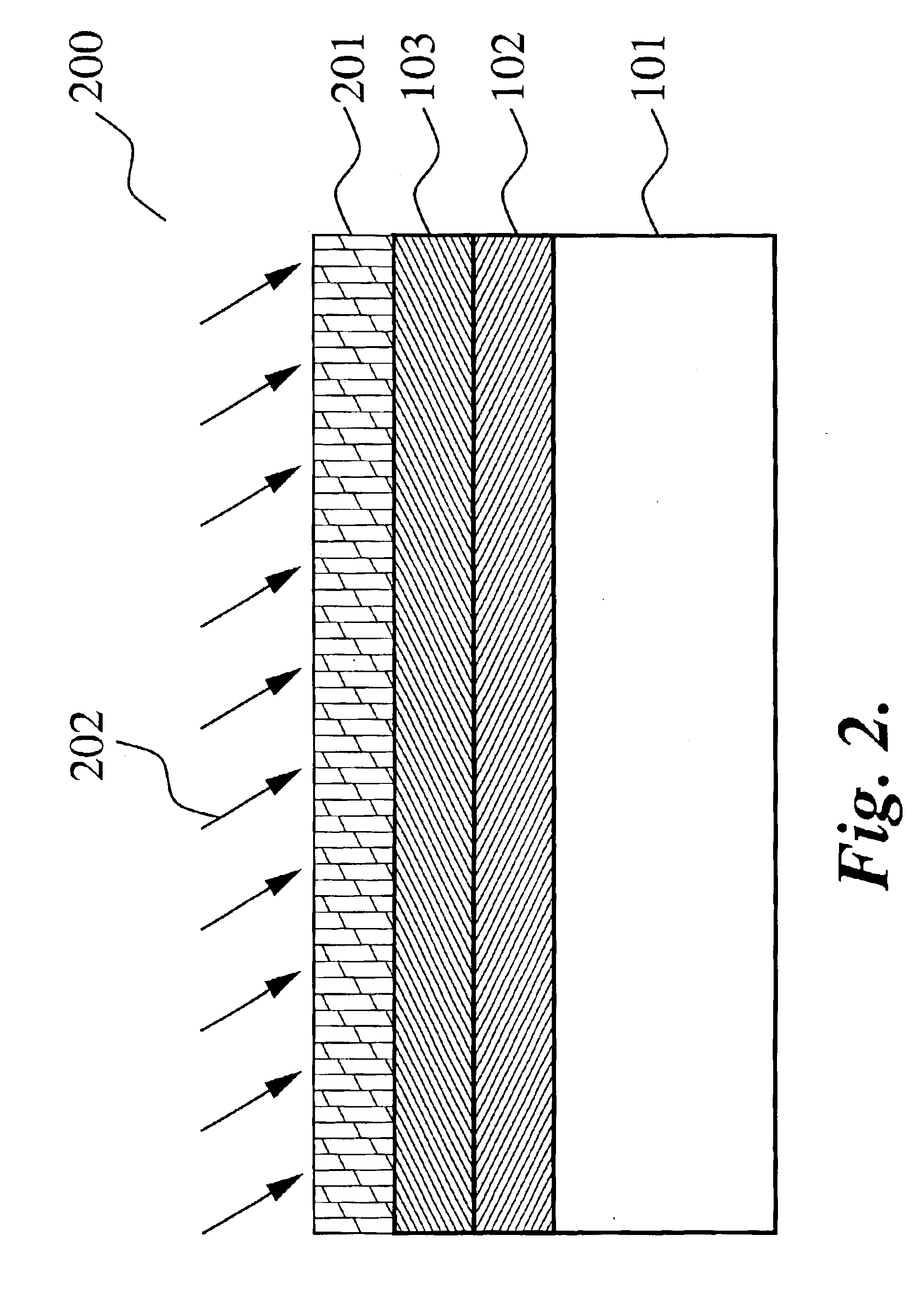

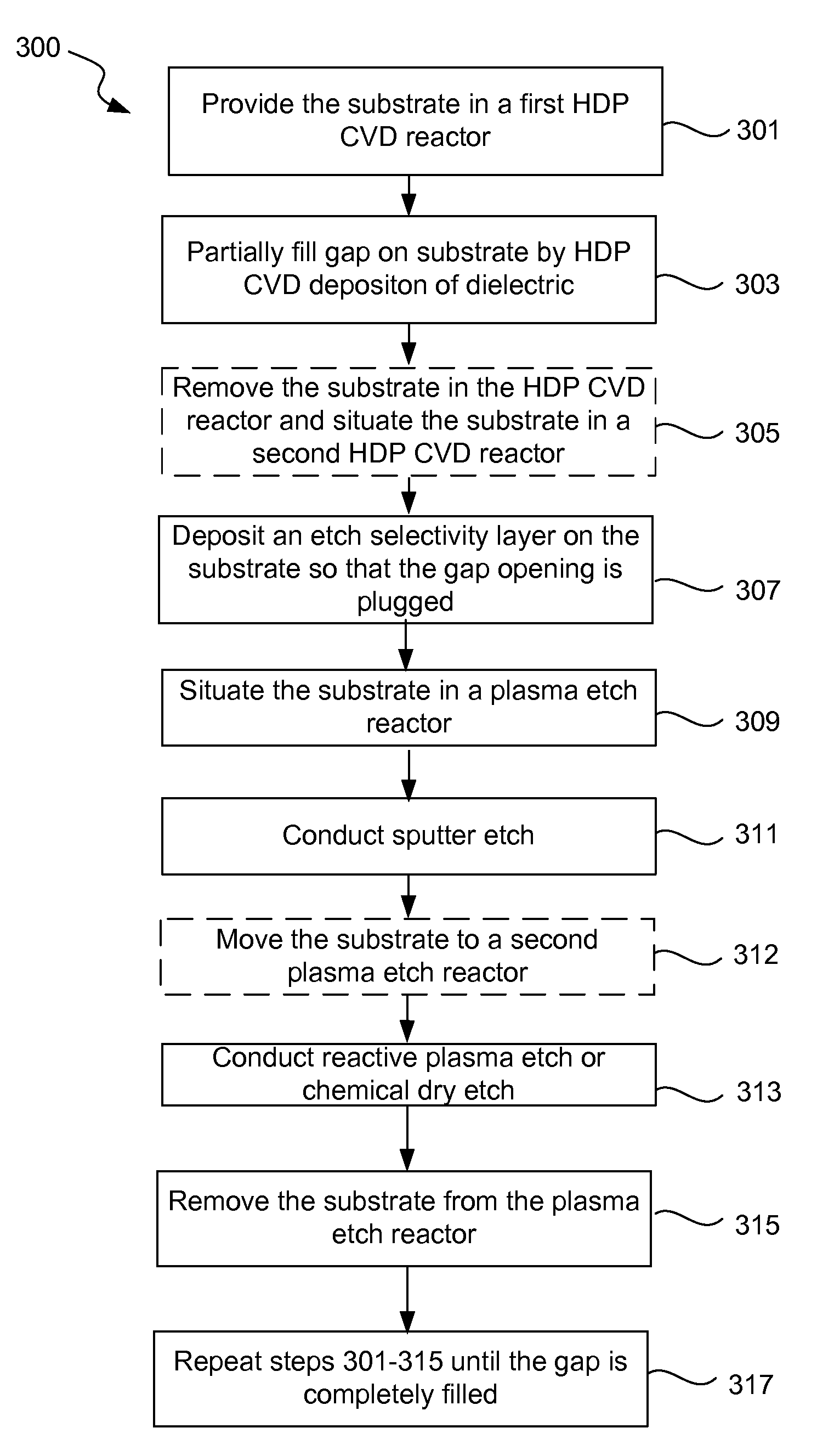

In-situ process layer using silicon-rich-oxide for etch selectivity in high AR gapfill

ActiveUS7951683B1Reduce morbiditySmall sizeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh densityReactive plasma

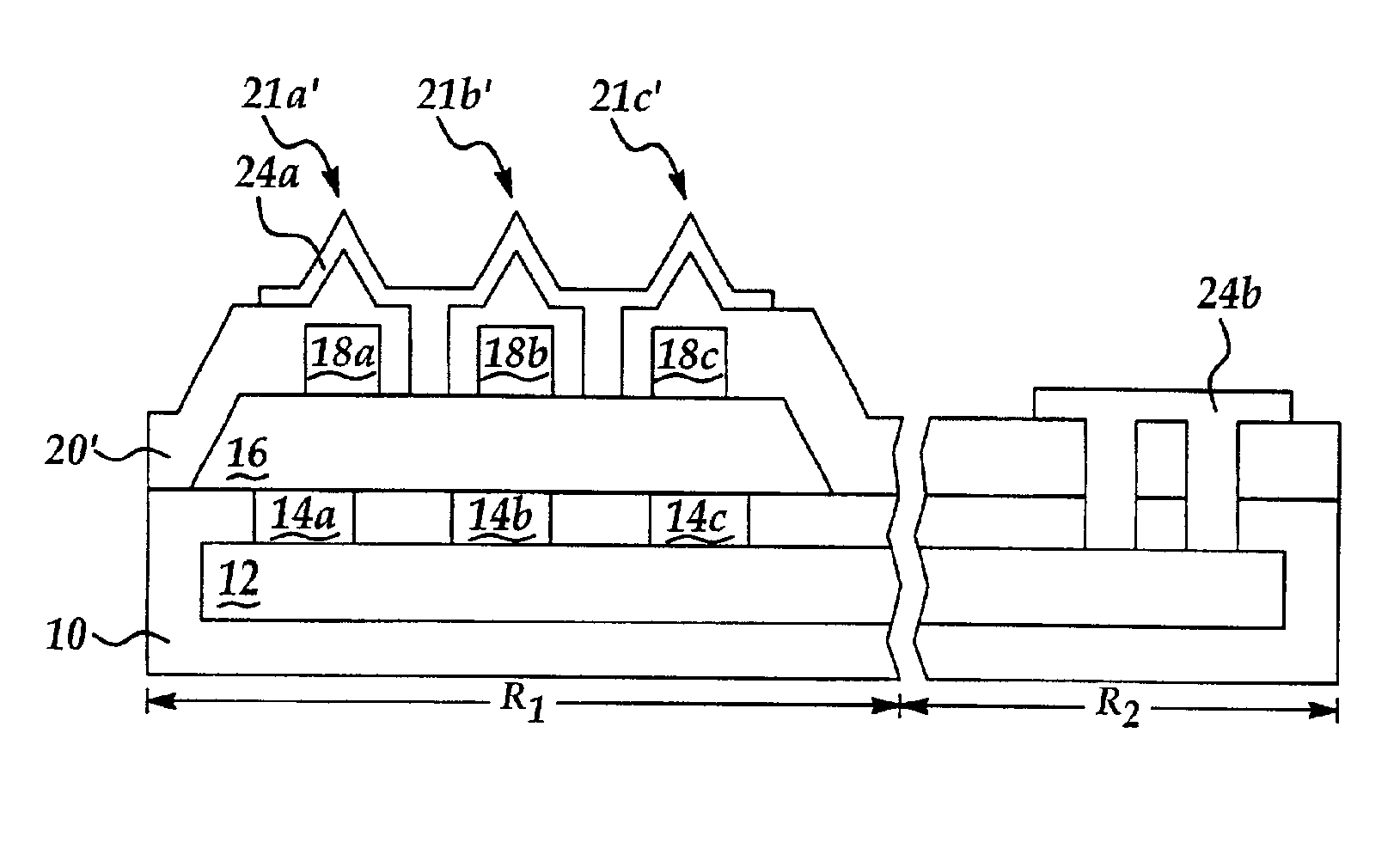

In-situ semiconductor process that can fill high aspect ratio (typically at least 6:1, for example 7:1 or higher), narrow width (typically sub 0.13 micron, for example 0.1 micron or less) gaps with significantly reduced incidence of voids or weak spots is provided. This deposition part of the process may involve the use of any suitable high density plasma chemical vapor deposition (HDP CVD) chemistry. Prior to etch back, the feature gap is plugged with an etch selectivity layer. The etch back part of the process involves multiple steps including a sputter etch to reduce the top hat formations followed by a reactive plasma etch to open the gap. This method improves gapfill, reduces the use of high cost fluorine-based etching and produces interim gaps with better sidewall profiles and aspect ratios.

Owner:NOVELLUS SYSTEMS

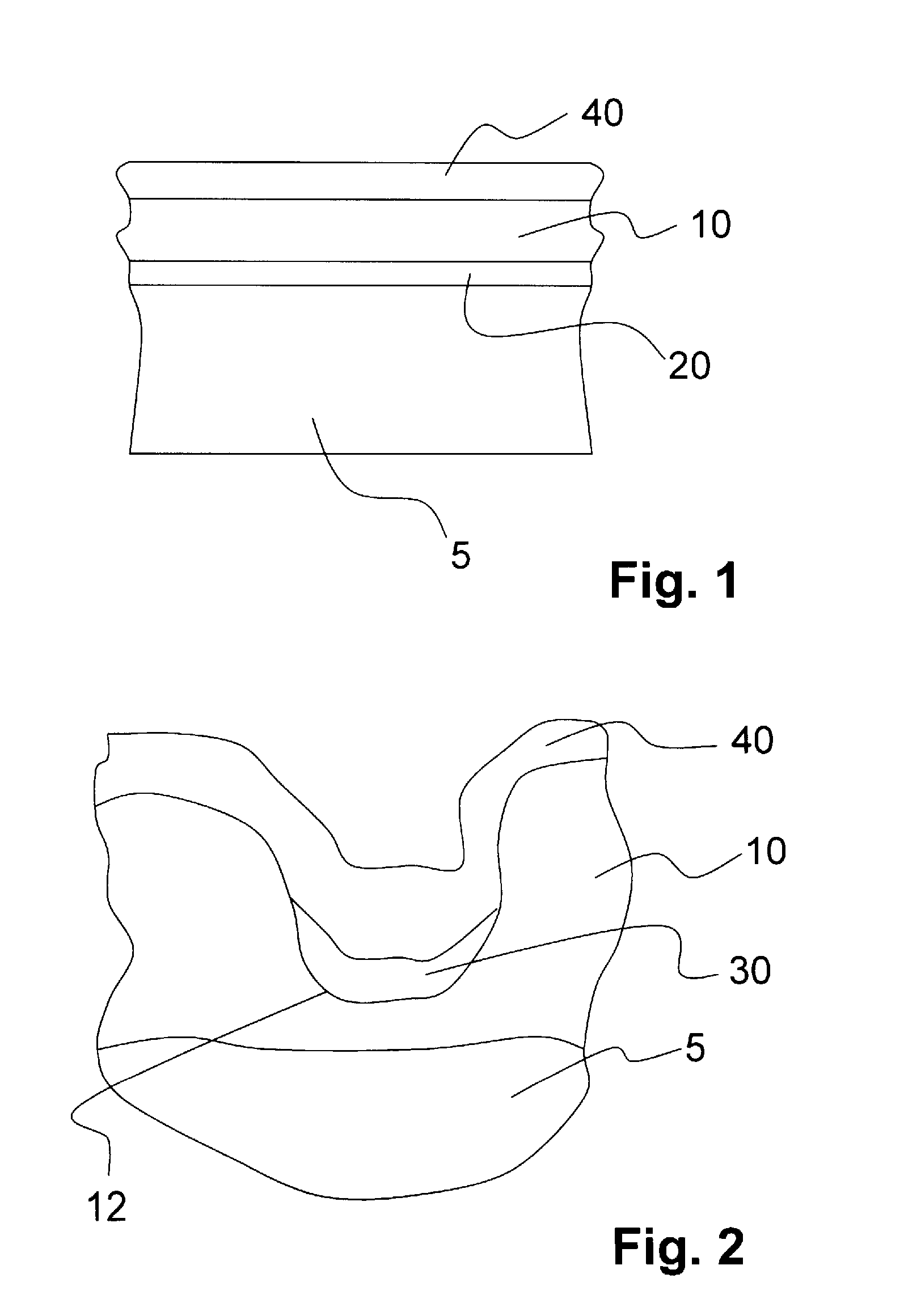

Method for manufacturing rare earth extended fibre-optical prefabricated bar

InactiveCN1490267APrecise control of doping amountImprove performanceGlass shaping apparatusGlass deposition burnersGas phaseRare earth

A process for preparing the prefabricated RE-doped optical-fibre rod features that the chemical gas-phase deposition of plasma is used to deposit the doped SiO2 layer on the inner surface of liner quartz tube and the evaporator is used to directly deliver the RE compound and other codoping agent into reaction tube for direct deposition without pollution.

Owner:FENGHUO COMM SCI & TECH CO LTD

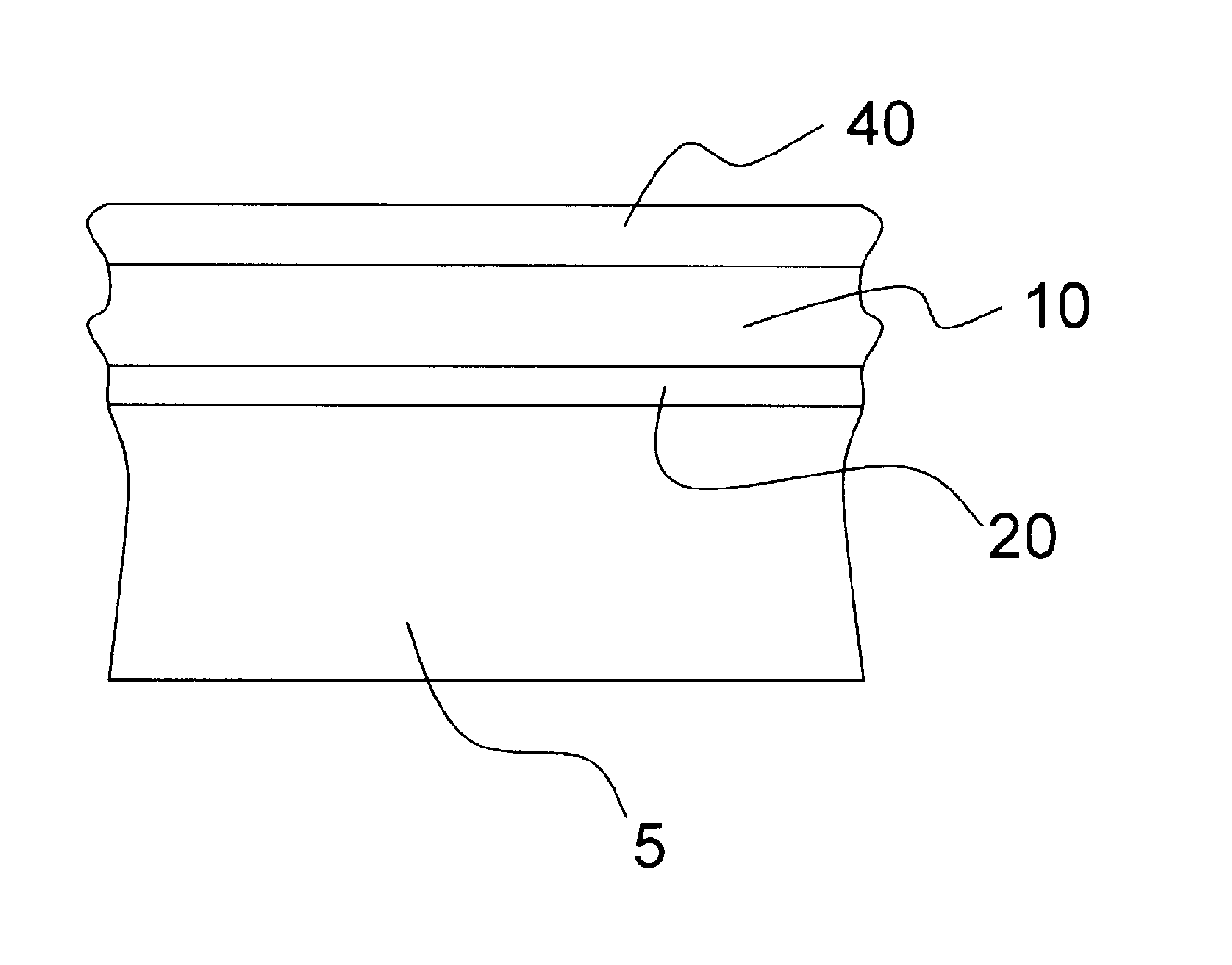

Implant and Method for Manufacturing Same

The present invention proposes a method for manufacturing an implant, in particular an intraluminal endoprosthesis, having a body such that the body has metallic material. To control the degradation in a desired time window, e.g., between four weeks and six months, the following production method is performed: a) preparing the body of the implant, and b) plasma-chemical treatment of at least a portion of the surface of the body in an aqueous solution by applying a plasma-generating electric alternating voltage to the body (5) of the implant, said voltage having a frequency of at least approximately 1 kHz, to create a first layer. The invention also relates to an implant obtainable by such a method.

Owner:BIOTRONIK AG

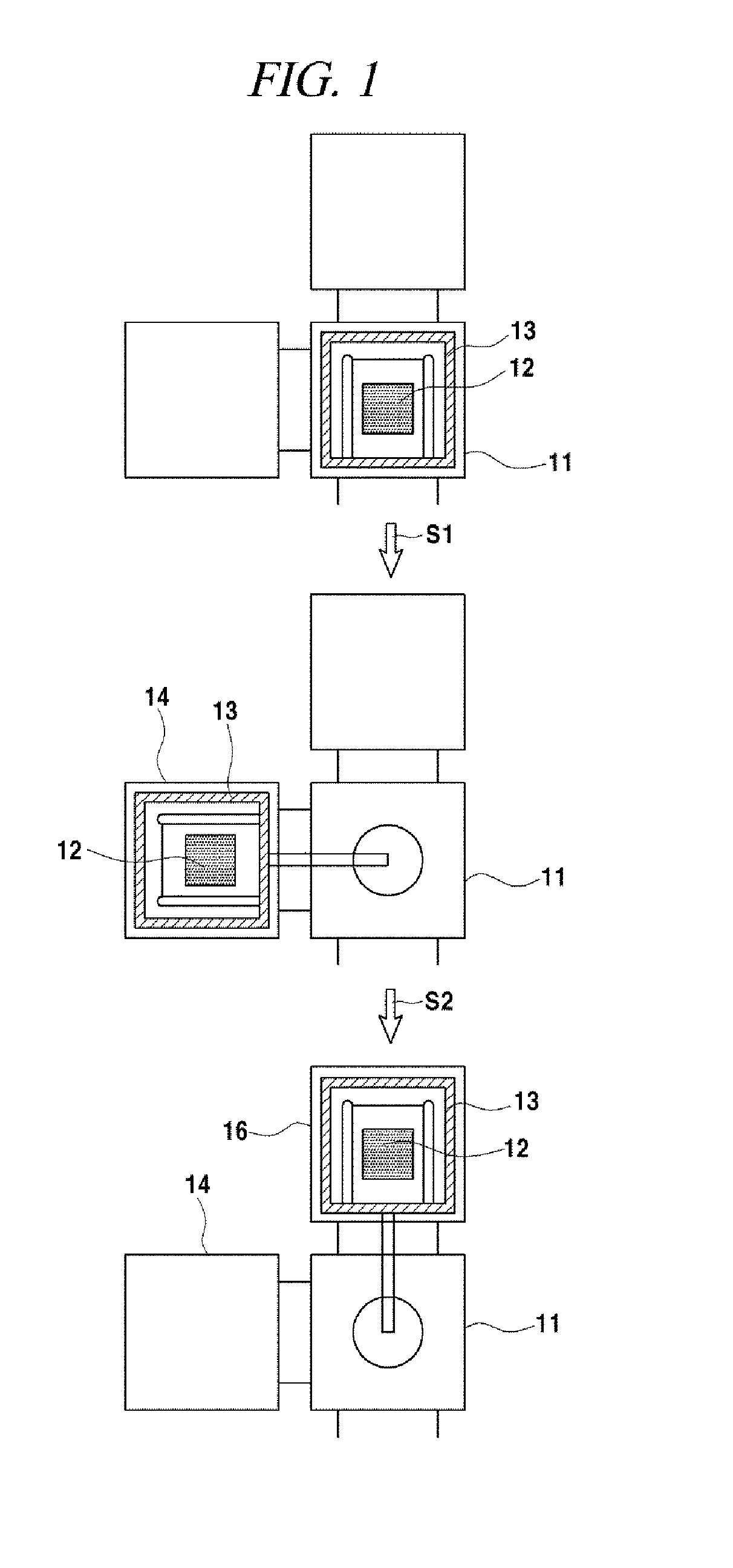

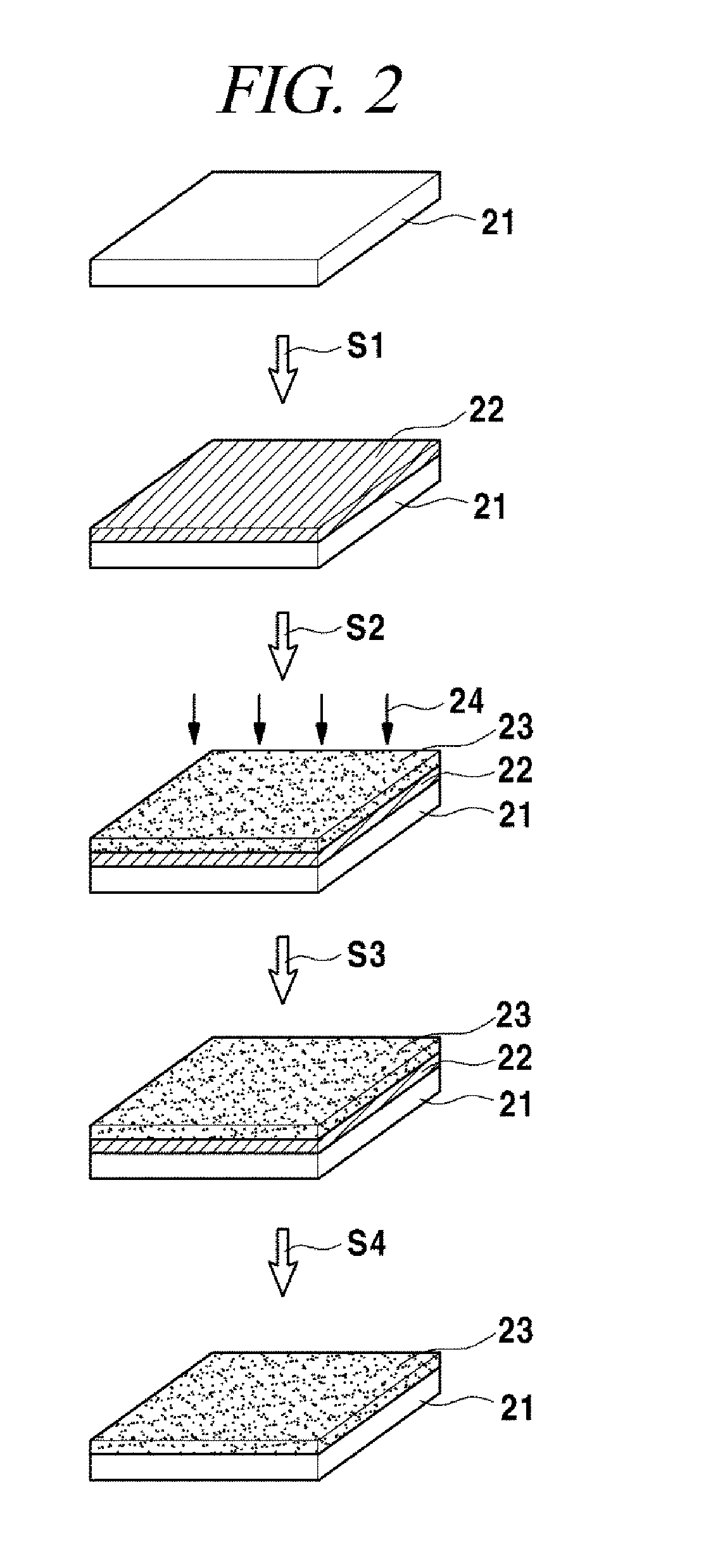

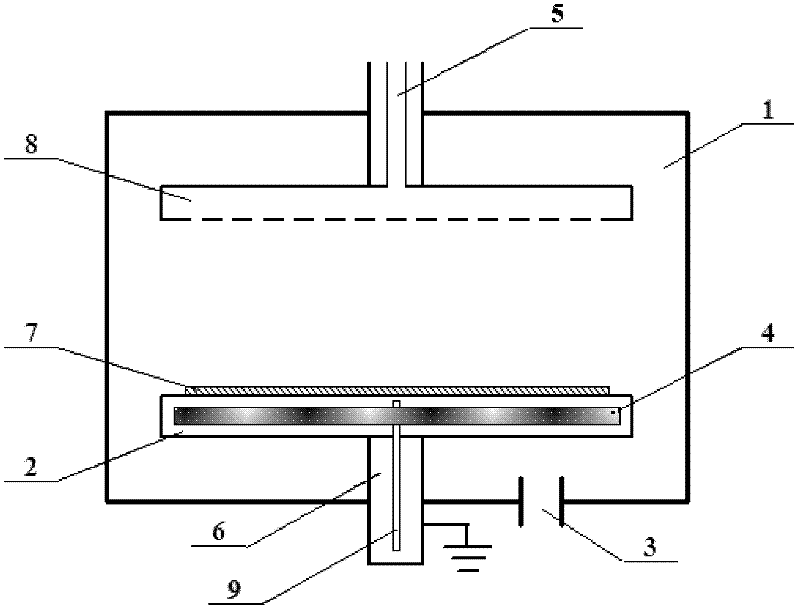

Graphene preparation method

ActiveCN103981507AImprove mobilityStrong adhesionChemical vapor deposition coatingHydrogenMetal catalyst

The invention discloses a graphene preparation method, belongs to the technical field of information materials, and aims at providing a novel method for preparing graphene by using plasma chemical vapor deposition. According to the technical scheme, the graphene preparation method comprises the following steps: cleaning a polished substrate; plating a metallic catalyst membrane on the substrate; putting the substrate plated with the metallic catalyst membrane in a reaction cavity of chemical vapor deposition equipment; feeding hydrogen into the reaction cavity; starting a plasma ball and a heating power supply; preheating to 500-900 DEG C, and feeding a carbon source gas, so graphene begins to grow; after completing the growth of the graphene, closing the heating power supply and a plasma power supply, and cooling the substrate; and after cooling to a room temperature, taking out the substrate, and removing the metal catalyst membrane by adopting an etching method, thus obtaining the graphene. The graphene preparation method is mainly used for manufacturing of graphene and graphene-based devices.

Owner:四川英能基科技有限公司

A low-temperature preparation method of carbon nanotubes

A low-temperature preparation method of carbon nanotubes by a chemical vapor deposition method with Ni / MgO as a catalyst comprises the following steps: dissolving nicdel nitrate hexahydrate and magnesium nitrate hexahydrate in ethanol according to different ratios and concentrations to obtain a mixed solution of nicdel nitrate and magnesium nitrate which is used as a catalyst precursor for carbonnanotube growth; spraying the catalyst precursor solution on a substrate such as silicon, glass, and the like, placing the substrate on a sample stage of a chemical vapor deposition system, heating and decomposing to generate nickel oxide and magnesium oxide, introducing hydrogen, performing reduction in hydrogen plasma of the plasma chemical vapor deposition system to generate nickel nanometer metal particles and to obtain a Ni / MgO catalyst system; introducing hydrocarbons, preparing carbon nanotubes for various demands under different process conditions. The advantages of the invention are that the carbon nanotube preparation process is simple, high in yield, and low in synthetic temperature, and the obtained carbon nanotubes have good quality, high purity, uniform tube diameter distribution, and microelectronic process compatibility.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Oxygen evolution electrode material containing FeOOH and preparation method thereof

The present invention provides an oxygen evolution electrode material containing FeOOH and a preparation method thereof. The oxygen evolution electrode material containing FeOOH is composed of metal nickel and FeOOH. The preparation method comprises the following steps of: preparing FeOOH by using a chemical precipitation method, a hydrothermal method, an electrodeposition method, a plasma chemical deposition method, a ferrous oxidation method or a forced hydrolysis method; and compounding metal nickel and FeOOH to obtain the oxygen evolution electrode. The invention has the advantages that: FeOOH is used as an oxygen evolution electrode and has excellent performance; FeOOH is inexpensive and widely available; the electrode is easy to prepare, can be prepared by a method for industrial preparation of DSA (dimensionally stable anode), and has strong practicality; and Fe is environmentally-friendly, thus reducing the environmental pollution caused by cobalt oxides.

Owner:HARBIN ENG UNIV

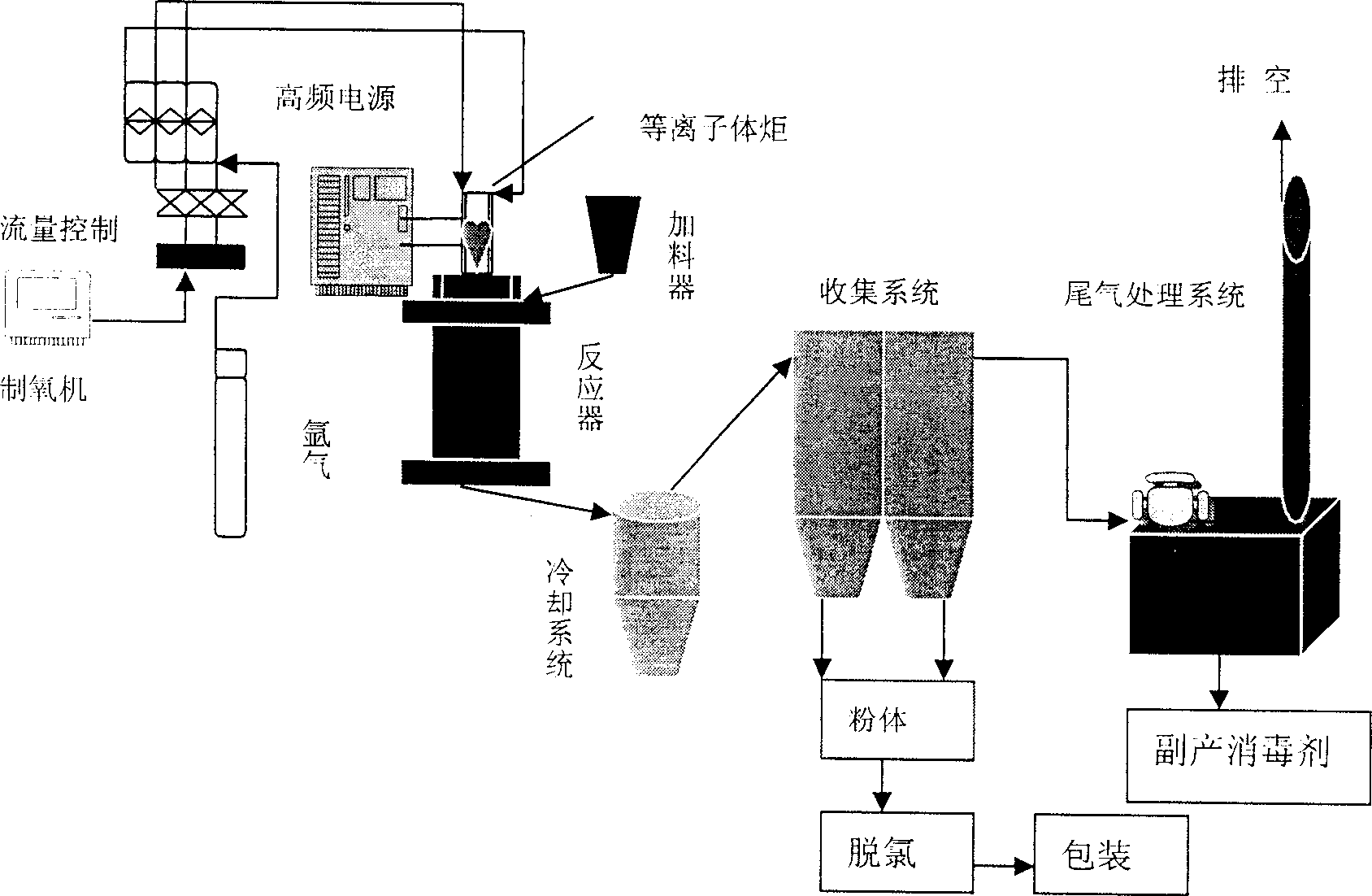

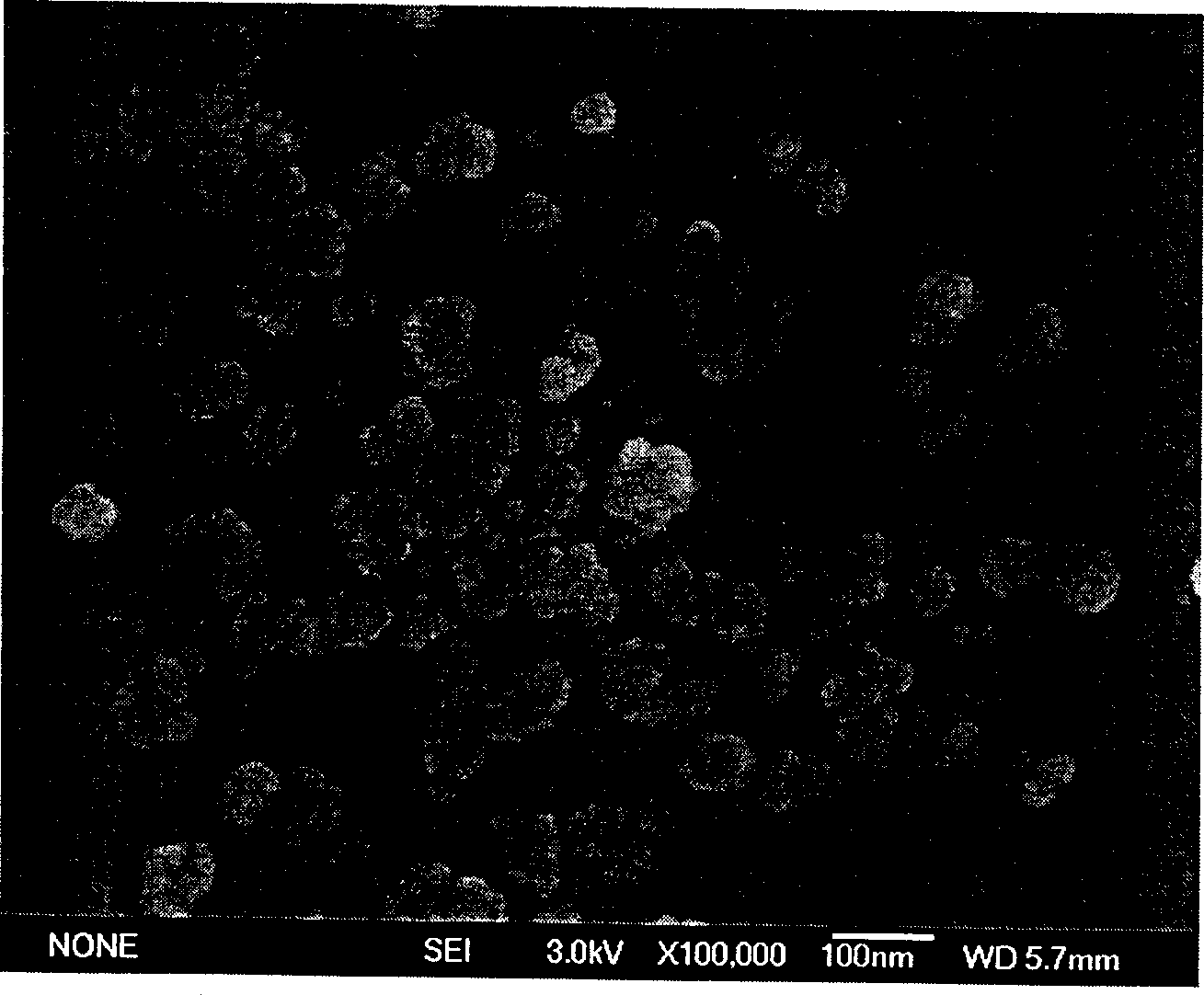

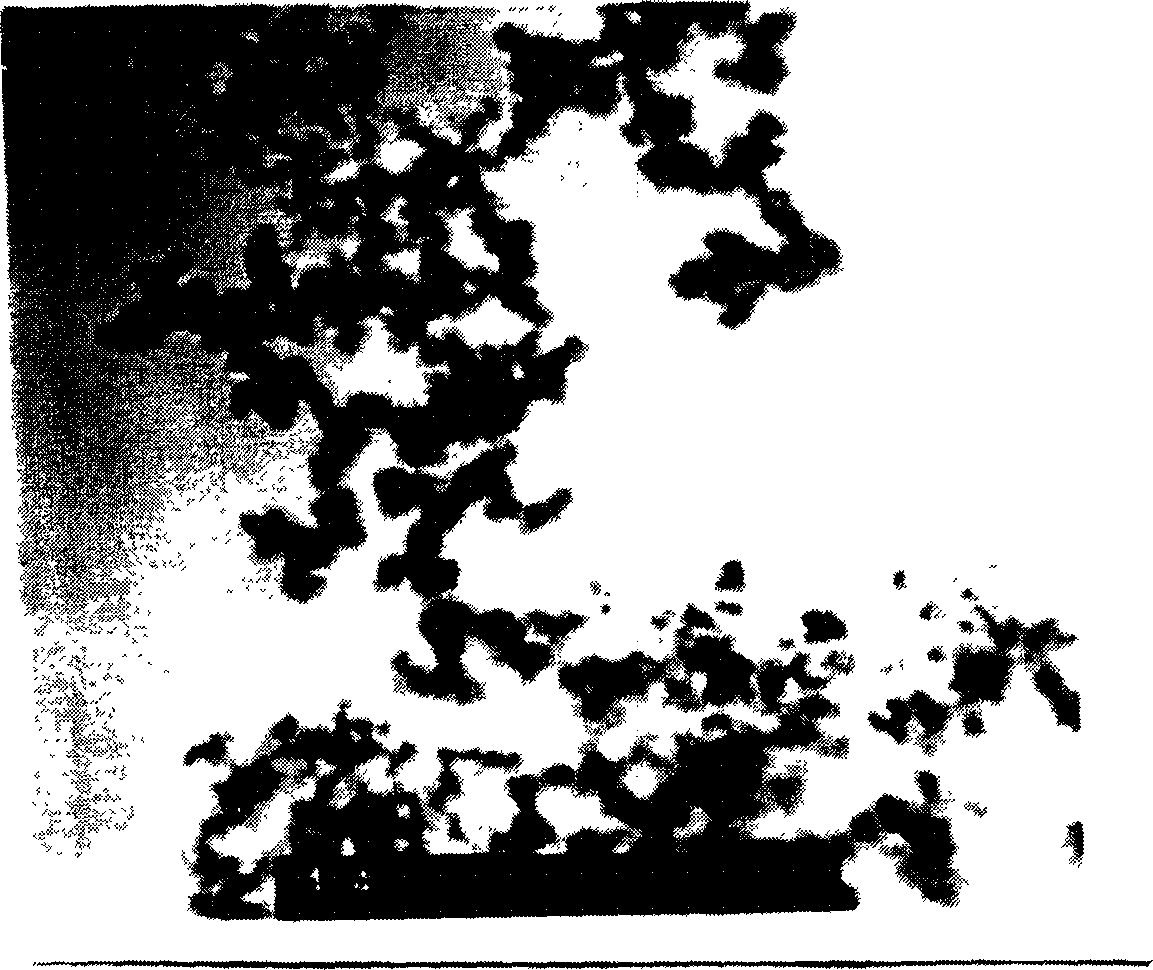

Preparation of high-purity nanometer silicon dioxide

Production of nanometer high-purity silicon dioxide in high-frequency plasma gas-phase oxidizing reactor is carried out by purifying air of oxygen and feeding it into high-frequency plasma generator, generating plasma oxygen at oscillating power 30KW and frequency 3í½4MHz, gasifying SiCl4 at 200í½300íÒC and delivering it plasma chemical reactor, reacting it with oxygen plasma at 1200í½1800íÒC, keeping the reactant in reactor for 0.15í½1s, removing scar with mol ratio of SiCl4 and oxygen: 1:1.2í½2, inducing dried air or N2 gas, quenching silicon dioxide crystal below 300íÒC, collecting powder, removing chlorine, and obtaining nanometer high-purity silicon dioxide. It achieves good dispersity, high output and simple process.

Owner:优美特(北京)环境材料科技股份公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com