Patents

Literature

100 results about "Silicon nanotube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon nanotubes are nanoparticles which create a tube-like structure from silicon atoms. The nanotubes' discovery has many significant implications for electronics development, as silicon is already a vastly important material in the semiconductor industry. Only recently has it been possible to prepare these nanotubes which are similar to carbon nanotubes. Nano-materials are complex, and understanding how the behaviour of silicon materials differs from their carbon-based cousins is still under research.

Method for preparing one-dimensional nanostructure in anode alumina template

InactiveCN1669920AImprove qualitySynthesis temperature is lowAnodisationPolycrystalline material growthSilanesHoneycomb structure

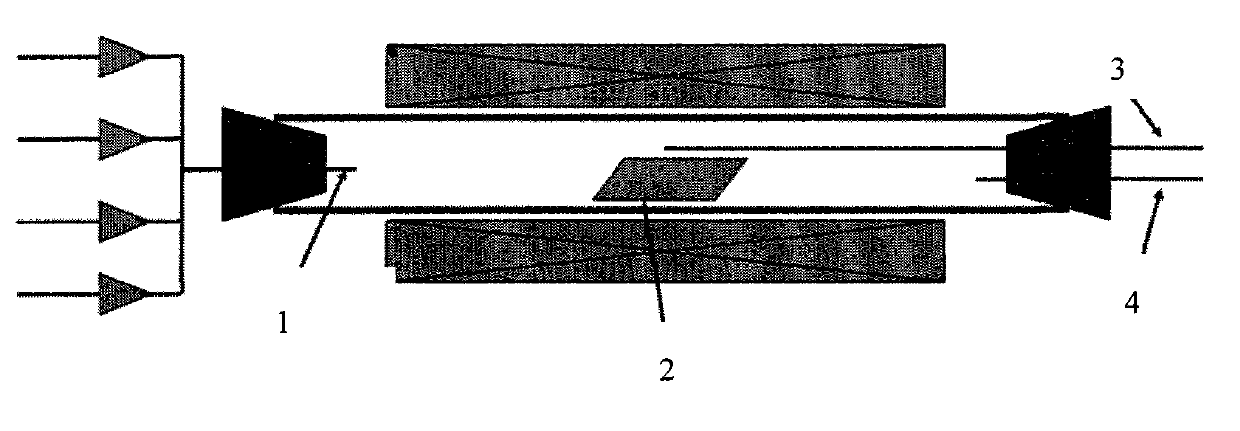

The invention discloses a method for preparing a one-dimensional silicon nanostructure in a anodic aluminum oxide mold, which comprises the following steps: growing the one-dimensional silicon nanostructure in low-temperature by the method of plasma chemical depositing with the spacing limited function of porous aluminium oxide, including the silicon nanowire and silicon nanotube, preparing a porous aluminum oxide mold with honeycomb structure by anodic oxidation process, wherein openings arrange ordered, apertures are coherent and vertical the surfaces of the mold, imbedding the mold into a plasma enhanced chemical depositing reaction chamber, growing the silicon nanowire or silicon nanotube at a temperature of 300 Deg. C by controlling the gas flow with the perhydrous diluting silane as the growth air supply.

Owner:ZHEJIANG UNIV

Method for preparing one or more of silicon nano power, silicon nanowires and silicon nanotubes by electrochemical method

ActiveCN101736354ARich sourcesNo pollution in the processPolycrystalline material growthNanotechMolten saltSilicon nanowires

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

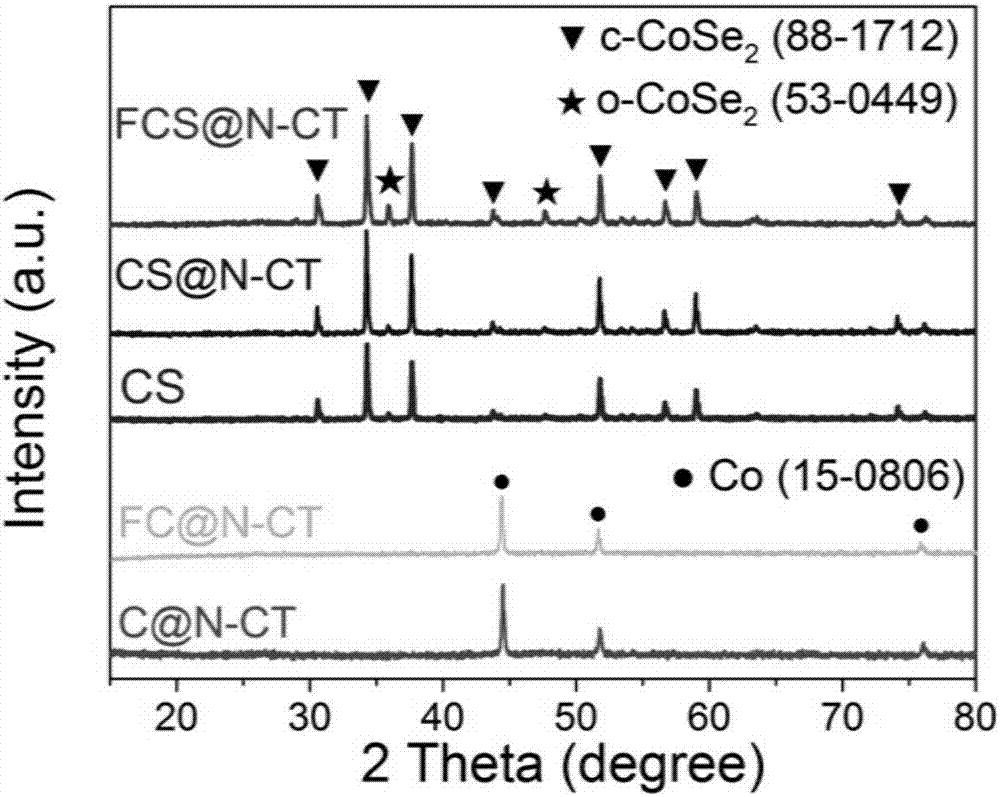

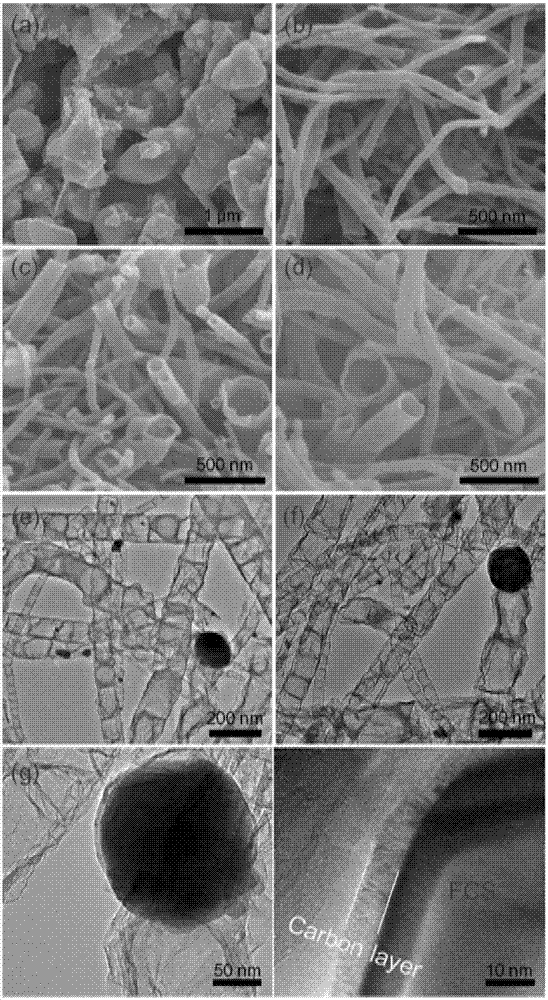

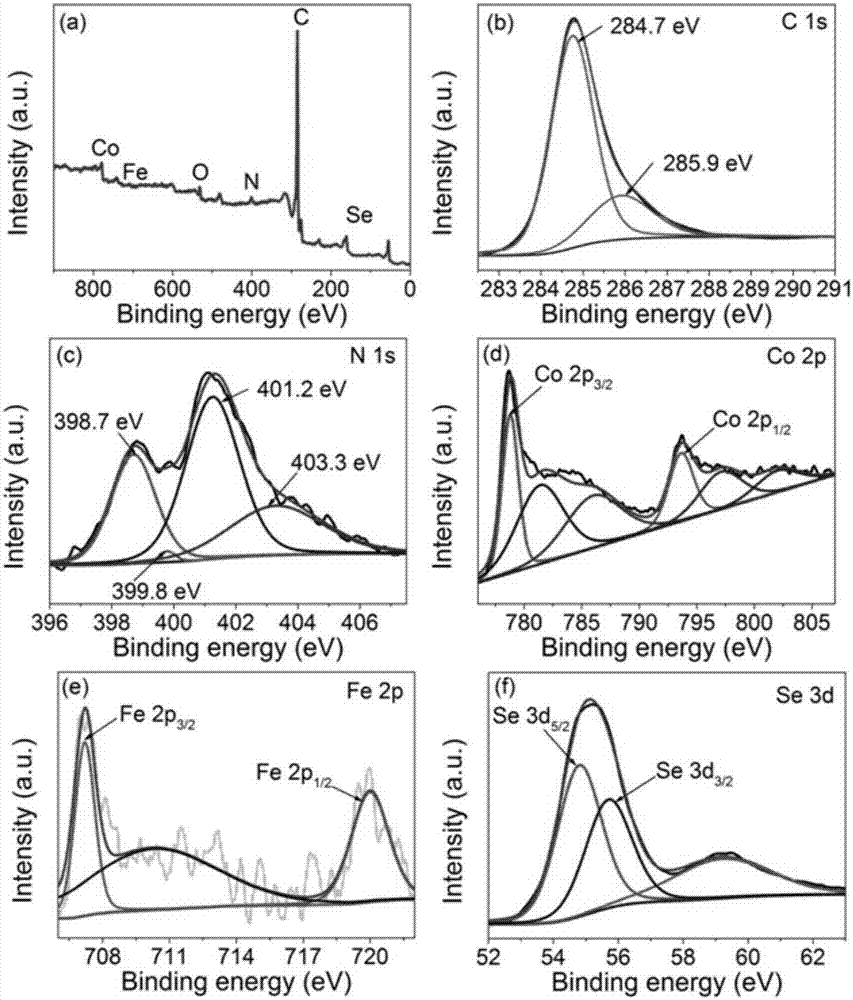

Oxygen evolution Fe-doped cobalt diselenide@N-CT compound catalyst and preparation method and application thereof

ActiveCN107051568AHigh catalytic activityHigh OER catalytic performanceOrganic-compounds/hydrides/coordination-complexes catalystsElectrodesDecompositionOxygen evolution

The invention discloses an oxygen evolution Fe-doped cobalt diselenide@N-CT compound catalyst and a preparation method and application thereof. The compound catalyst comprises Fe-doped CoSe2 nano particles coated by an N-doped carbon nanotube. The preparation method includes: evaporating and drying the solution of cobalt acetate, iron nitrate and urea, and performing high-temperature treatment to obtain the Fe-doped CoSe2 nano particles coated by the N-doped carbon nanotube; mixing the Fe-doped CoSe2 nano particles coated by the N-doped carbon nanotube with Se powder to obtain a mixture, and performing selenylation on the mixture under protective atmosphere to obtain the compound catalyst. The preparation method has the advantages that the method is simple, low in cost and beneficial to industrial production; the prepared Fe-doped CoSe2@N-CT (recorded as FCS@N-CT) compound catalyst is applicable to electrocatalytic water decomposition, and the compound catalyst is good in comprehensive performance as compared with a commercial RuO2 catalyst and is promising in application prospect.

Owner:CENT SOUTH UNIV

Phosphorus-doped graphene quantum dot and electrochemistry preparing method thereof

ActiveCN105862057AThe operation process is simple and convenientThe preparation process is easy to coordinateElectrolysis componentsElectrochemistryOxygen

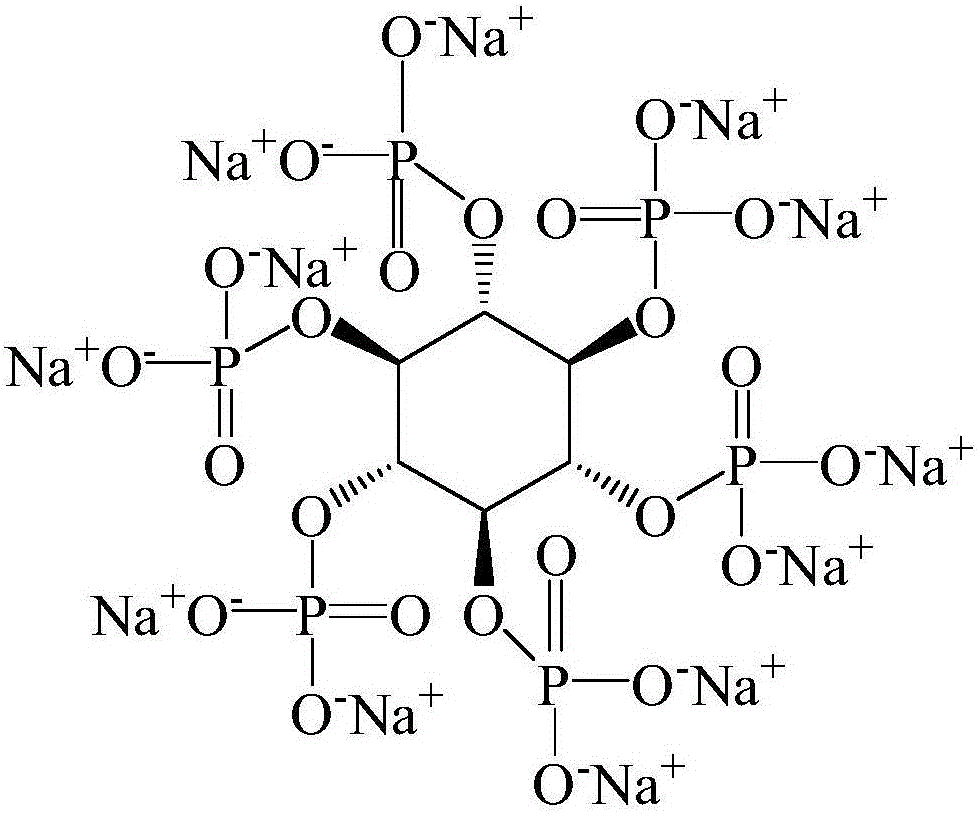

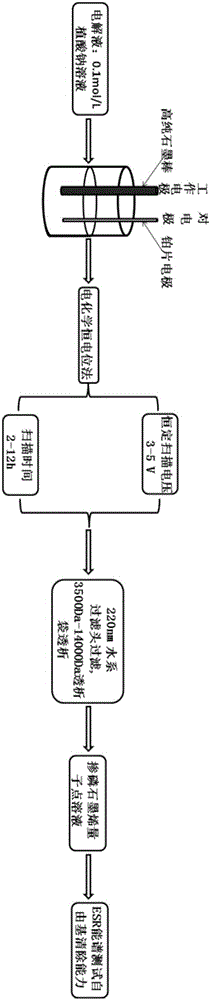

The invention provides a phosphorus-doped graphene quantum dot and an electrochemistry preparing method thereof. According to the preparing method, phosphorus-contained macromolecular organic compounds soluble in water are selected to serve as electrolytes, through controlled potential electrolyzing, phosphorus oxygen bonds are broken, phosphorus atoms are separated from the macromolecular organic compounds to enter the interior of the graphene quantum dot, carbon phosphorus bonds and the phosphorus oxygen bonds are formed, doping is completed, and the phosphorus-doped graphene quantum dot with the higher doping concentration content is prepared; the quantum dot has the good cleaning-up effect on hydroxyl radicals, and through ESR energy spectrum test, the clearing-up rate of the hydroxyl radicals can reach 78.49%; the method is easy and convenient in the operation process, the whole preparing process is conveniently planed as a whole, strong oxidizing acid or strong reducing agents are not used, and certain commercial feasibility is achieved; and graphene precursor which is rich in reserving and friendly to environment is adopted to replace expensive materials of graphite oxide, carbon nano-tubes and the like, and the method is hopefully and widely applied in the biomedical field.

Owner:UNIV OF SCI & TECH BEIJING

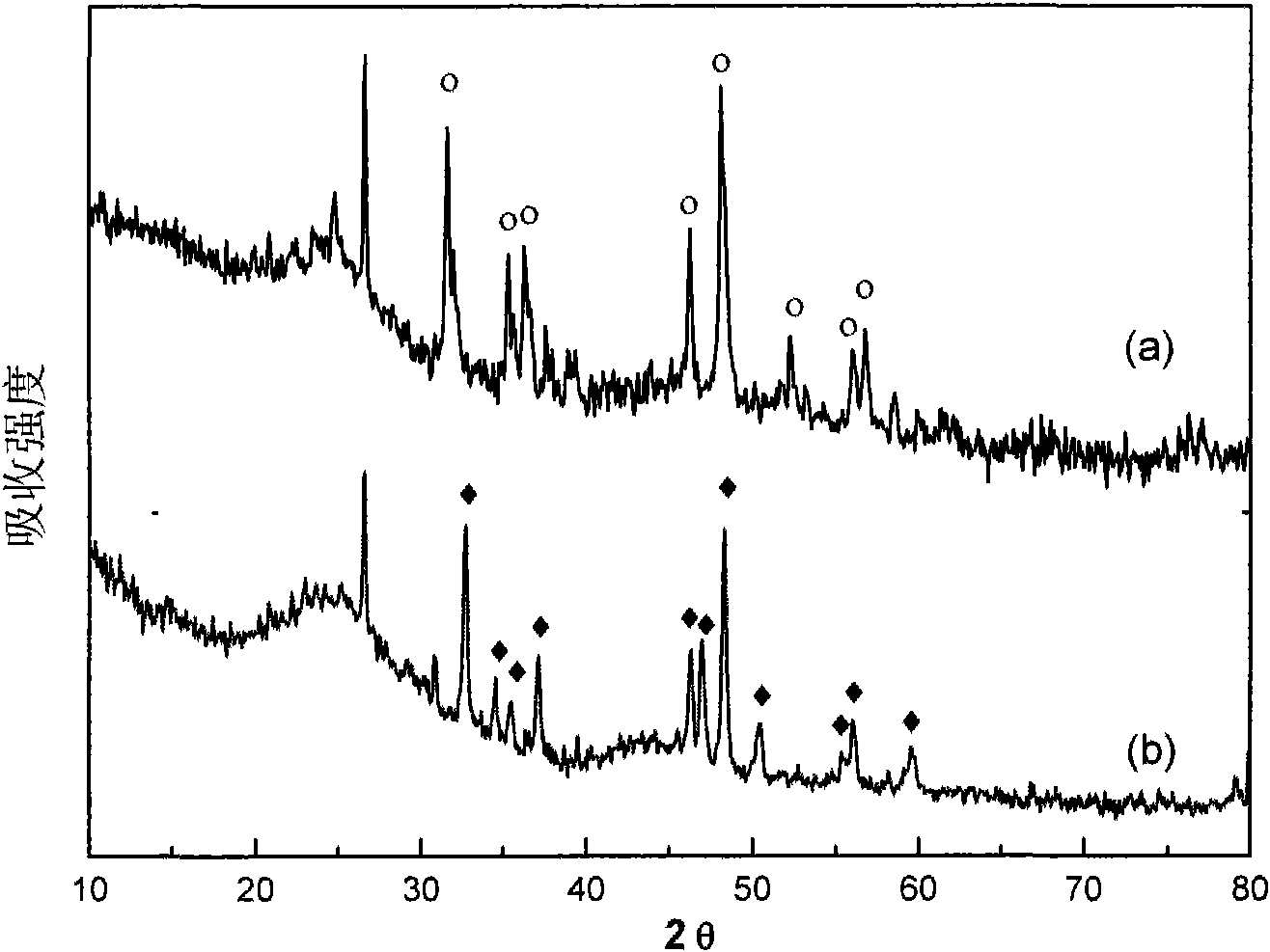

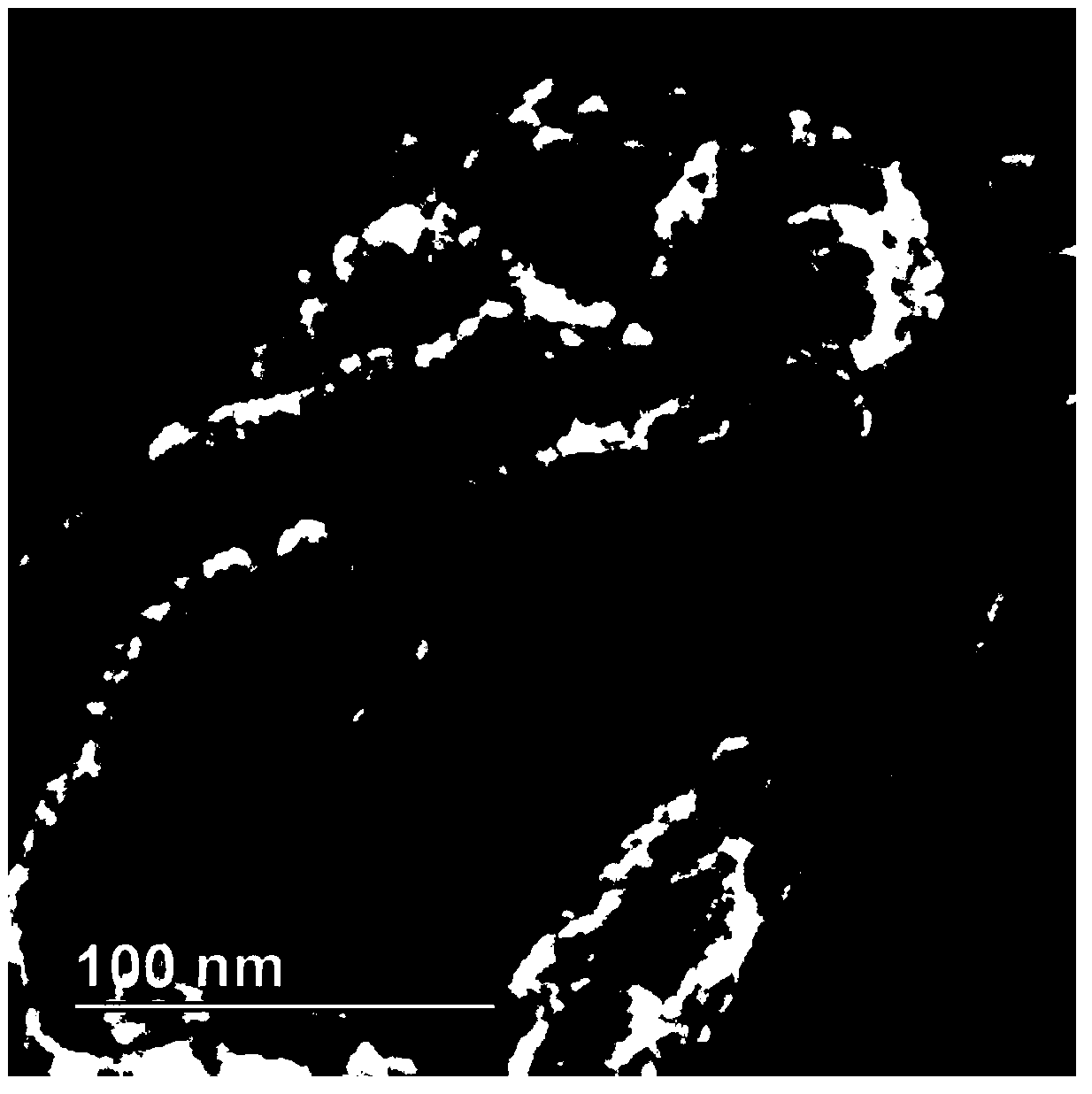

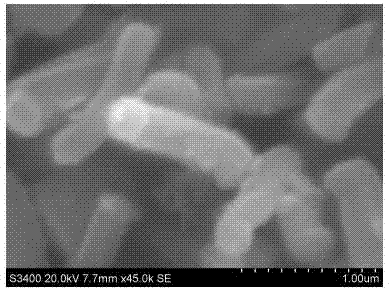

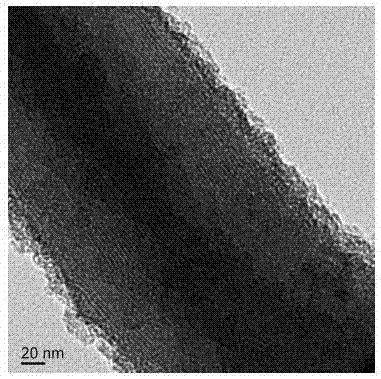

Preparation of self-assembled silicon nanotubes by hydrothermal method

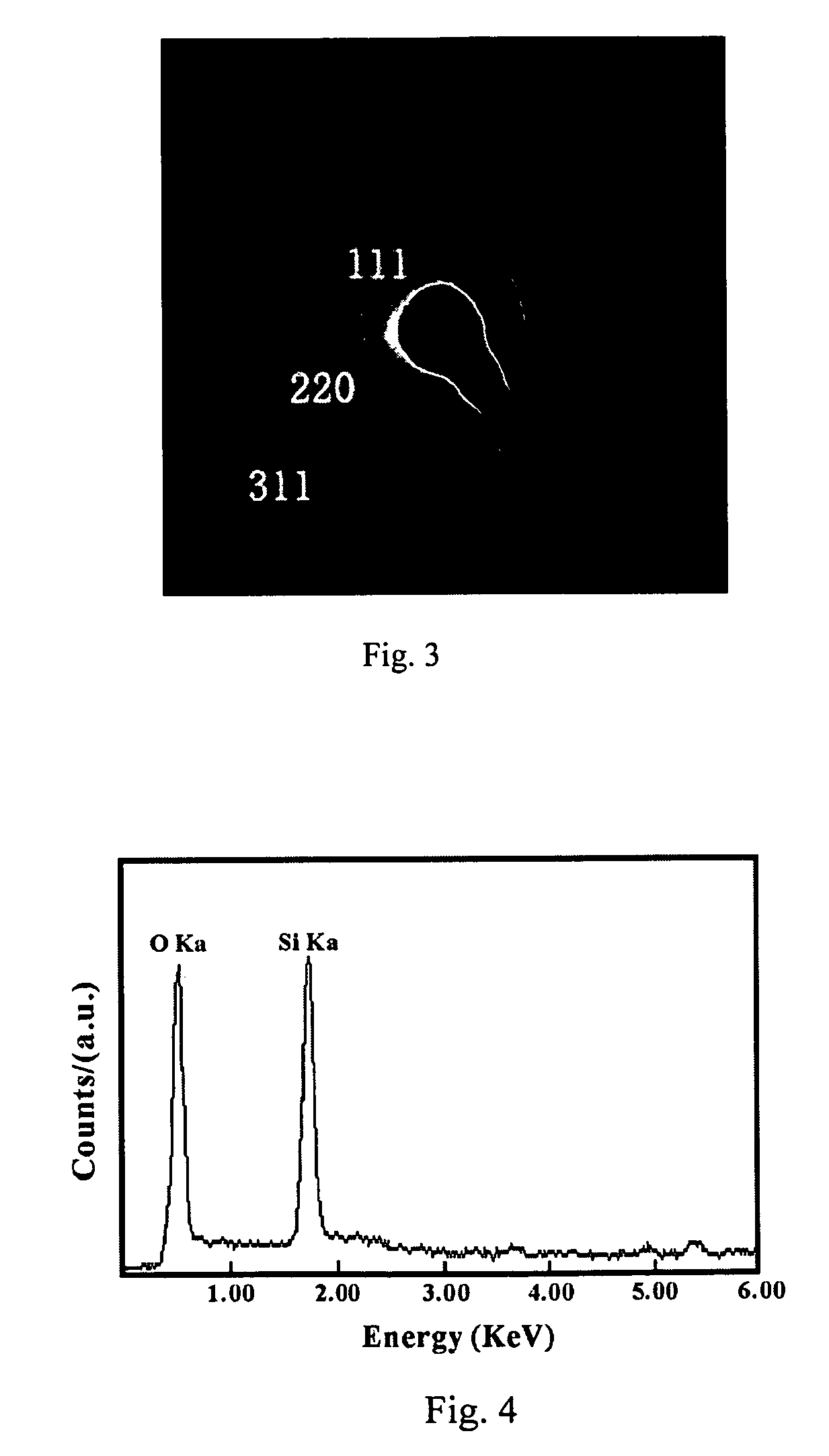

InactiveUS7544626B2Easy to operateEasy to controlMaterial nanotechnologyNanostructure manufactureSilicon oxideMaterials science

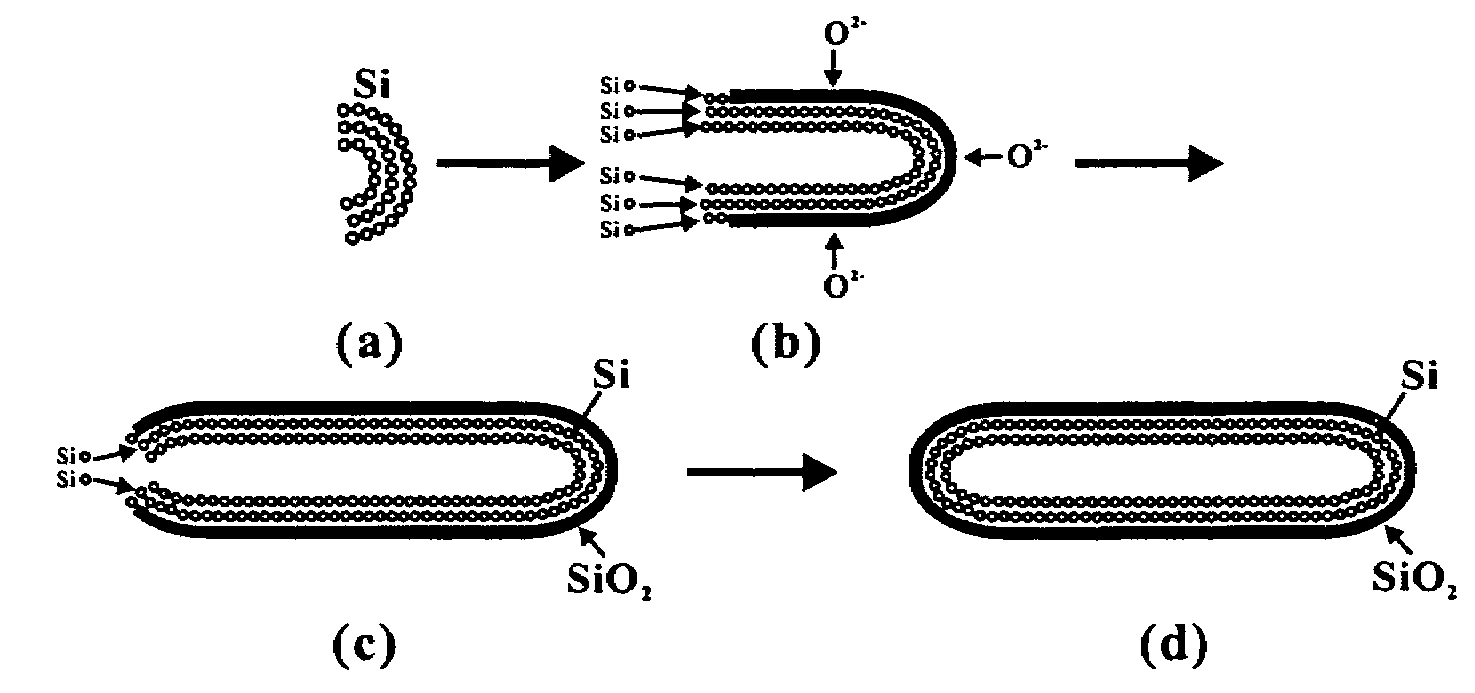

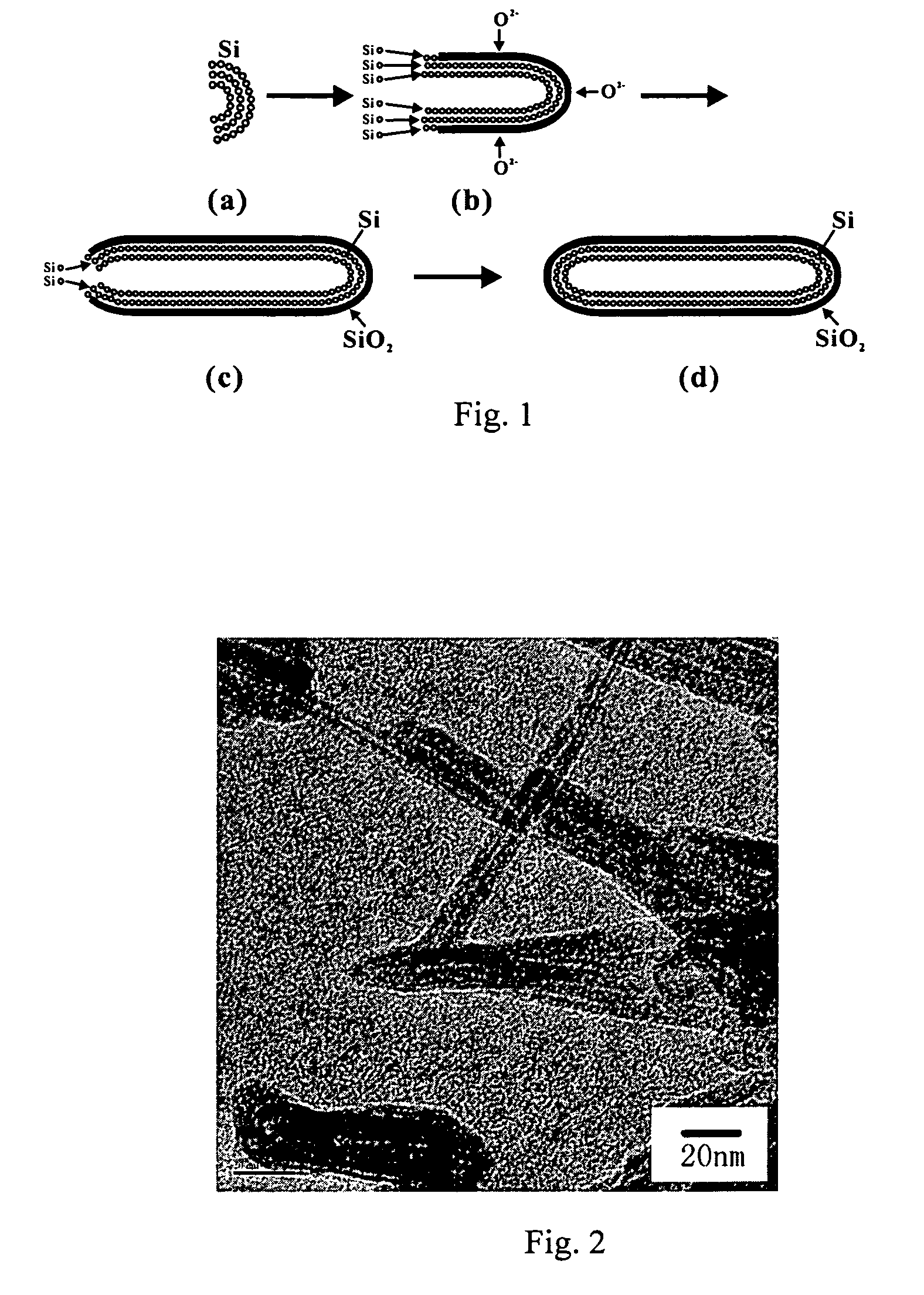

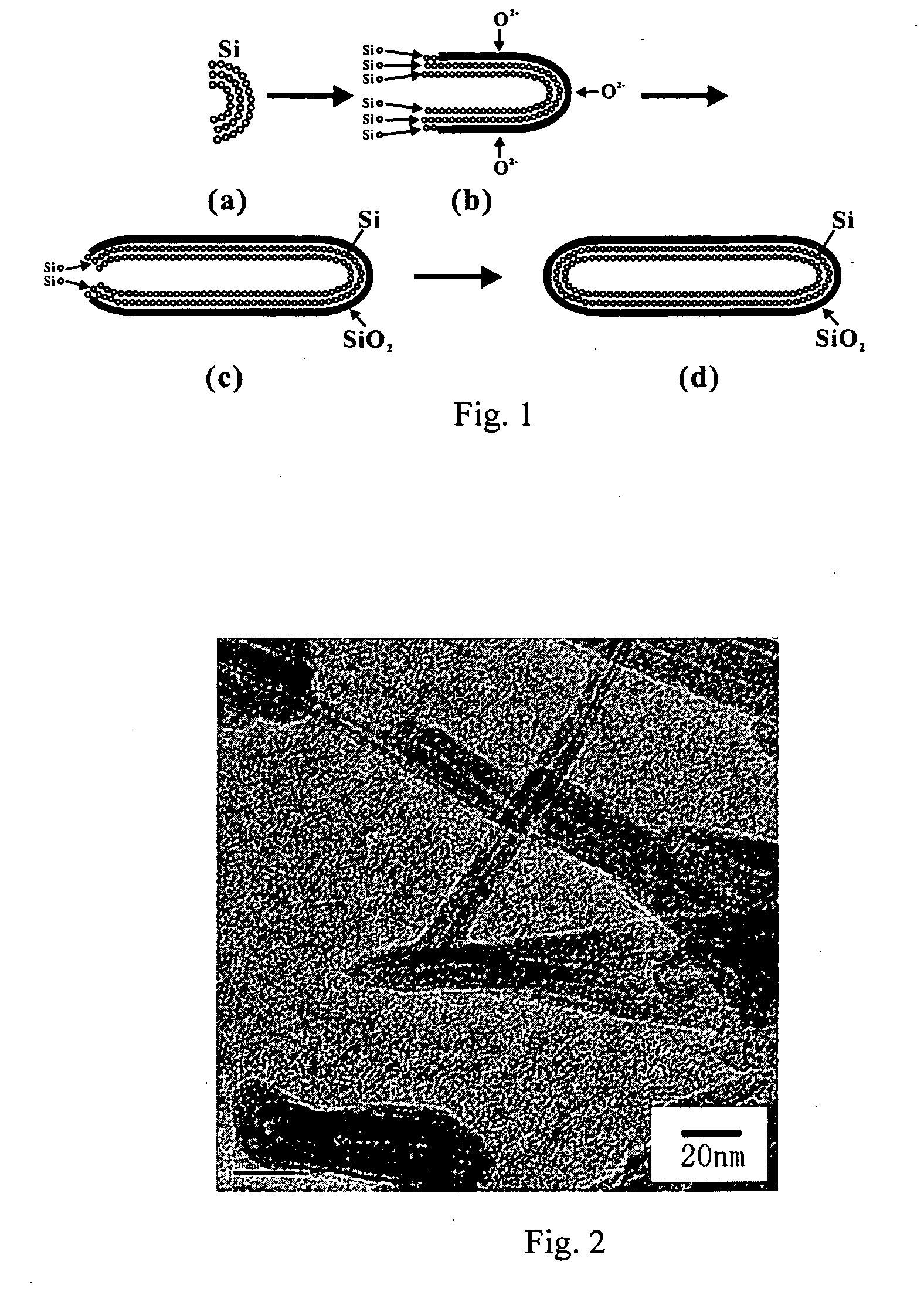

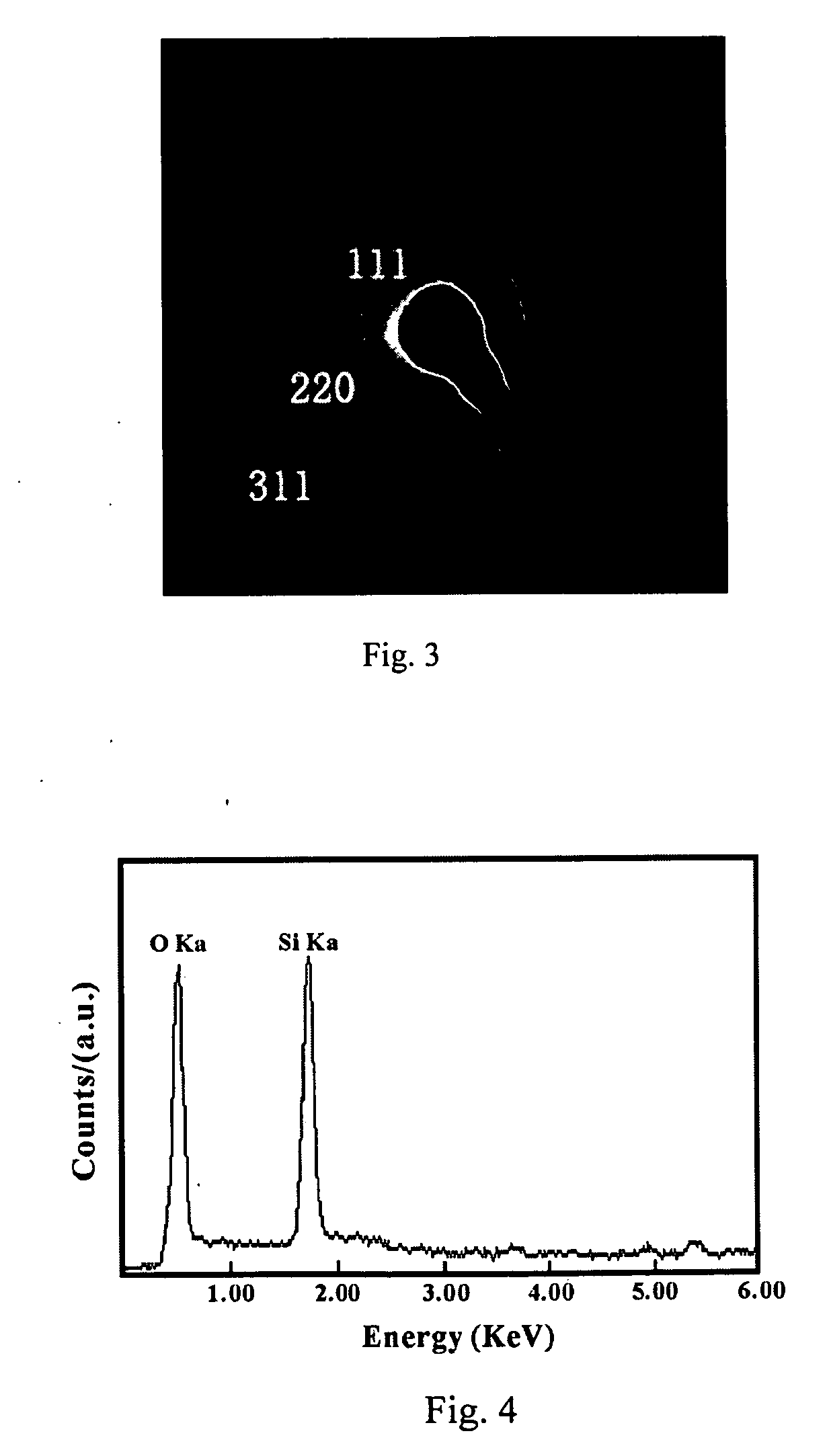

The present invention relates to a method for preparing self-assembled silicon nanotubes (SiNTs) by a hydrothermal method. A method for preparing self-assembled SiNTs comprises forming a mixture of silicon oxide and water in a sealed container, wherein the mixture has a silicon oxide to water ratio of no more than 10% by weight. The mixture is maintained at a constant temperature and a constant pressure, and the mixture is stirred for a period of time. Self-assembled SiNTs may be formed with an average inner diameter of less than 5 nm and an average outer diameter of around 15 nm. The present invention completely utilizes non-toxic raw materials, and the materials and process do not pollute the environment, so the method satisfies the development trends of the modern industry.

Owner:HUNAN UNIV

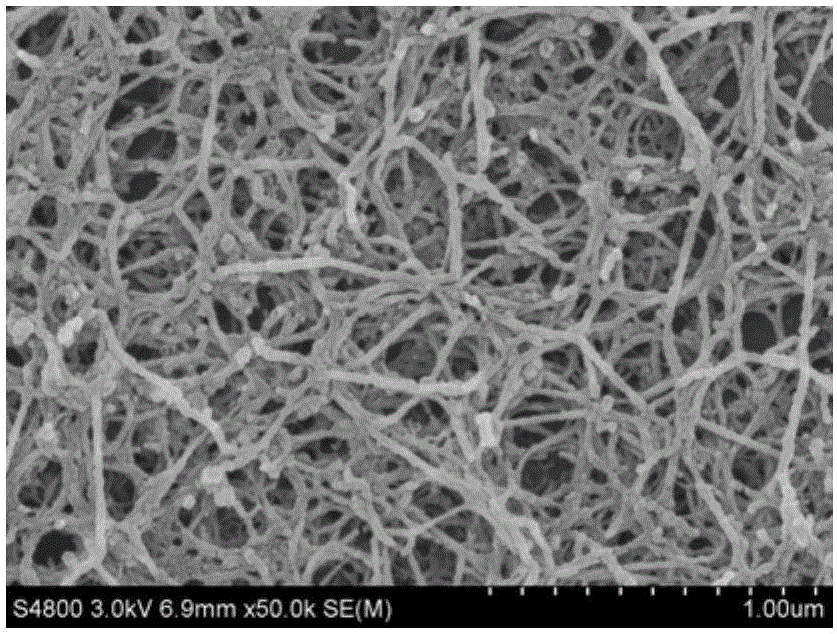

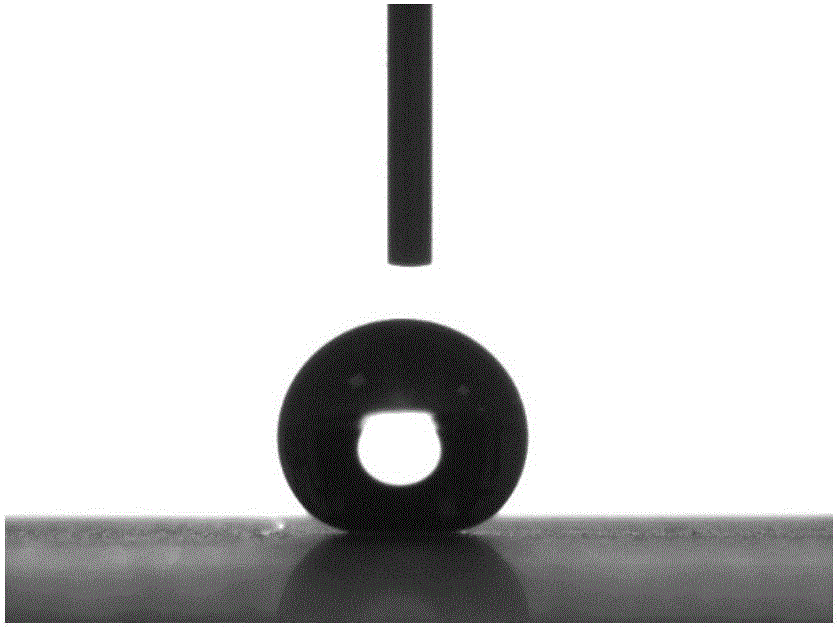

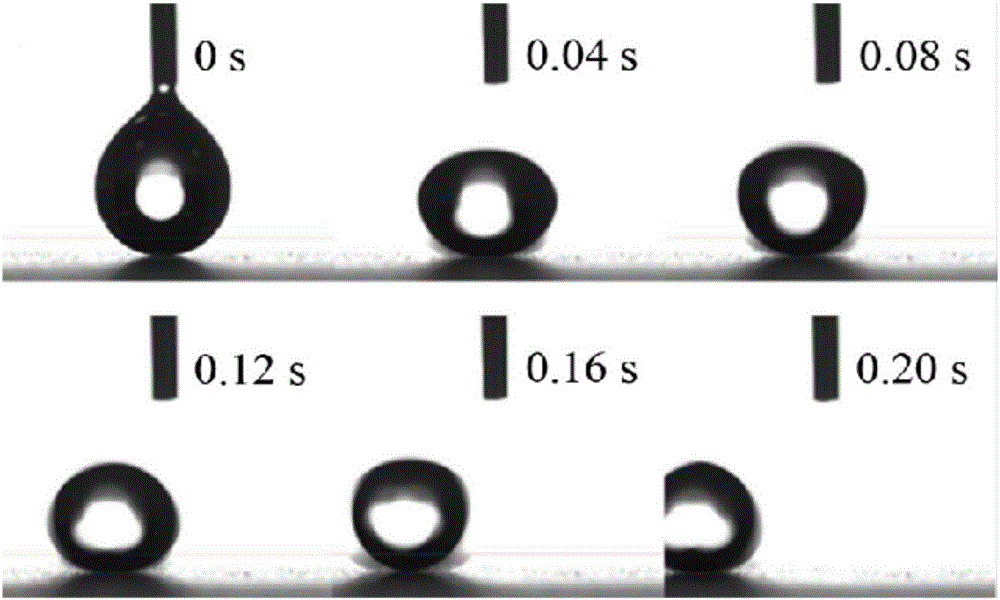

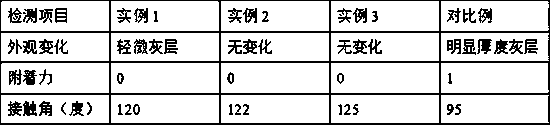

Transparent super-hydrophobic coating and preparation method thereof

The invention relates to a super-hydrophobic coating having automatical cleaning performance, which is used for protecting the outdoor optical devices. According to the invention, PDMS is taken as a silicon source, multi-walled carbon nanotube is taken as a template, a silicon nanotube coating is constructed on the surface of the glass, then PDMS solidified through chemical vapor deposition performs hydrophobization treatment on the coating, and the transparent super-hydrophobic coating is finally obtained. The super-hydrophobic coating has the advantages of low cost of the raw materials, easy purchase of the raw materials, no involved fluorine-containing pollutant. The super-hydrophobic coating has good transmittance, in a visible light scope, the average light transmittance is greater than 83%. surface water contact angle is greater than 165 DEG, the roll angle is less than 3 DEG, the drops are easily rolled on the surface, the dust on the surface can be taken away, so that the super-hydrophobic coating has good automatical cleaning function. The super-hydrophobic coating can be used for solar cell panel, automobile wind screen glass, contact lens, transparent electrode, camera lens, and building exterior wall.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing loaded transitional metal phosphide catalyst

ActiveCN102029169AEfficient synthesisSynthesis fastHydrocarbon by hydrogenationCatalyst activation/preparationFiberCarbon fibers

The invention relates to a method for preparing a loaded transitional metal phosphide catalyst. Red phosphorus is taken as a phosphorus source, chlorides, nitrates and acetates of one or more of metallic elements in a VIB family and / or a VIII family are taken as metal precursors, and wave-absorbing materials such as activated carbon, carbon nanotubes, carbon fibers, carbon molecular sieves, mesoporous carbon, silicon carbide and the like are taken as carriers, the loaded transitional metal phosphide catalyst is efficiently and rapidly synthesized by a microwave heating method in an argon or hydrogen flow atmosphere. The catalyst prepared by the method has high activity and selectivity in a catalytic reaction.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

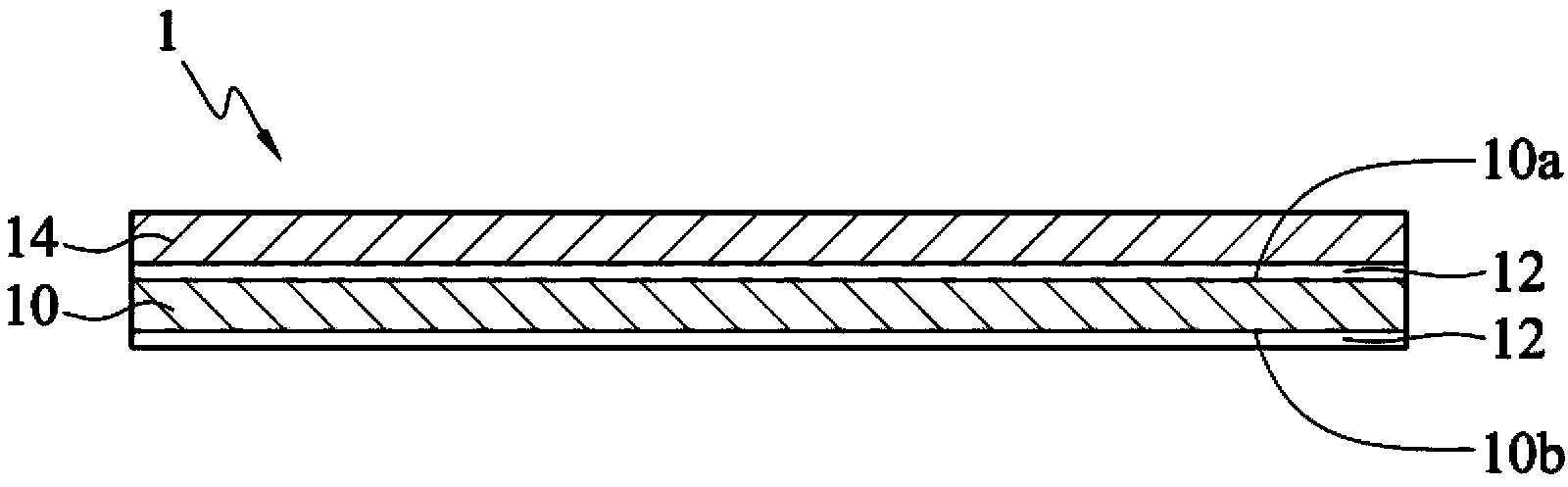

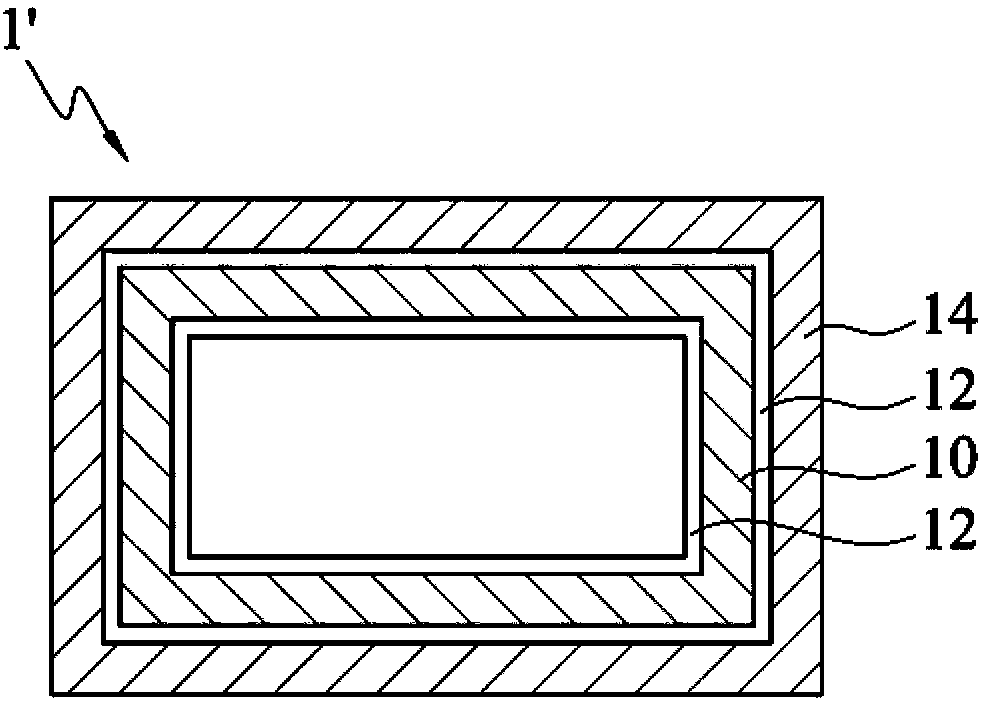

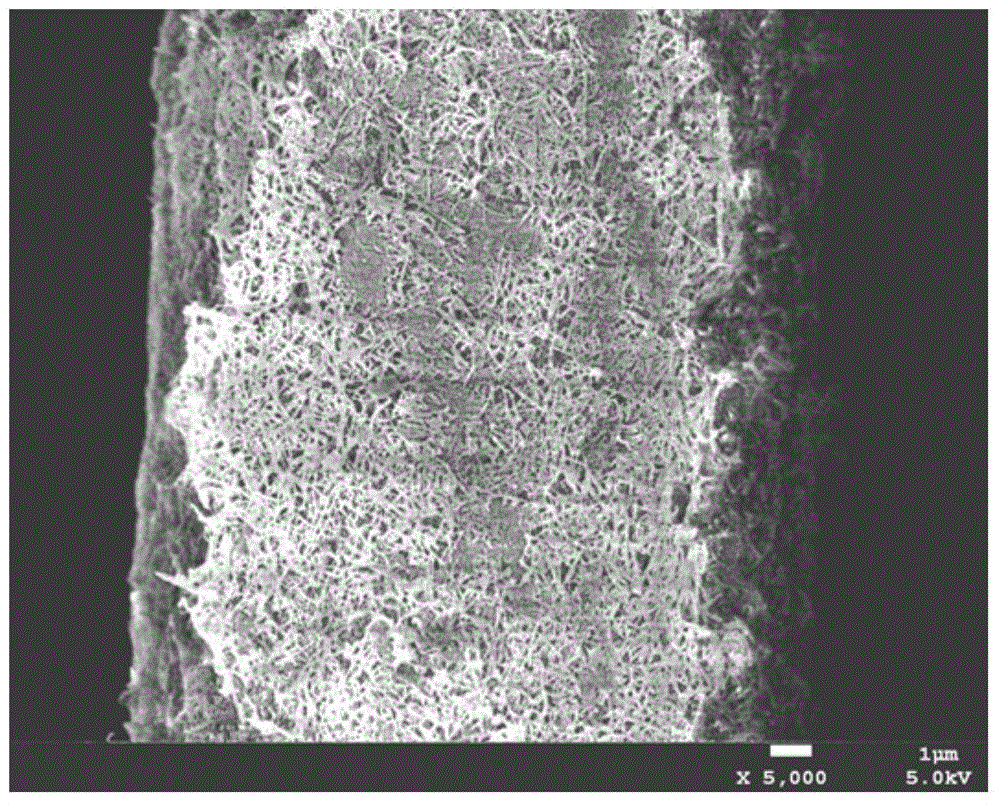

Carbon fiber composite material and method for preparing the same

ActiveCN103847206AWith reactive functional groupsSynthetic resin layered productsLaminationCarbon nanotubeSilicon nanotube

A carbon fiber composite material and a method for preparing the same are provided. The method includes binding a first surface of a first carbon fiber layer with a second carbon fiber layer to obtain a laminated article, wherein a resin containing carbon nanotubes is formed on the first surface or a second surface of the first carbon fiber layer and the carbon nanotubes have functional groups on the surfaces thereof; and shaping the laminated article.

Owner:IND TECH RES INST

Method for preparing carbon nano tube supported nano photocatalysis material capable of degrading nitrogen oxides

InactiveCN102101051AExcellent photocatalytic functionImprove photocatalytic functionDispersed particle separationCatalyst activation/preparationCarbon nanotubeNitrogen oxide

The invention discloses a method for preparing a carbon nano tube supported modified nano photocatalysis material capable of degrading nitrogen oxides, which comprises the following steps of: ultrasonically dispersing nano titanium dioxide mixed crystal in water for 20 to 30 minutes, then putting the dispersion into 0.3 to 0.5mol / L AgNO3 solution, adding partial ethanol and then stirring for 30 to 40 minutes; putting the solution under an ultraviolet lamp, continuously stirring the solution for 90 minutes, filtering, and calcining the filter residue for 2 to 3 hours at the temperature of between 400 and 450 DEG C to obtain modified nano titanium dioxide mixed crystal; and mixing the modified nano titanium dioxide mixed crystal and carbon nano tube for 2 to 4 hours in a ratio of 1:0.01-0.015 to obtain the carbon nano tube supported modified nano photocatalysis material capable of degrading the nitrogen oxides. The preparation process is simple; the prepared carbon nano tube supported modified nano photocatalysis material has better nitrogen oxide photocatalysis effect because of silver ion modification and nano carbon tube support, particularly the effect under visible light is obviously improved, and meanwhile, the long-term effectiveness of the photocatalysis effect is remarkably improved.

Owner:ZHEJIANG UNIV

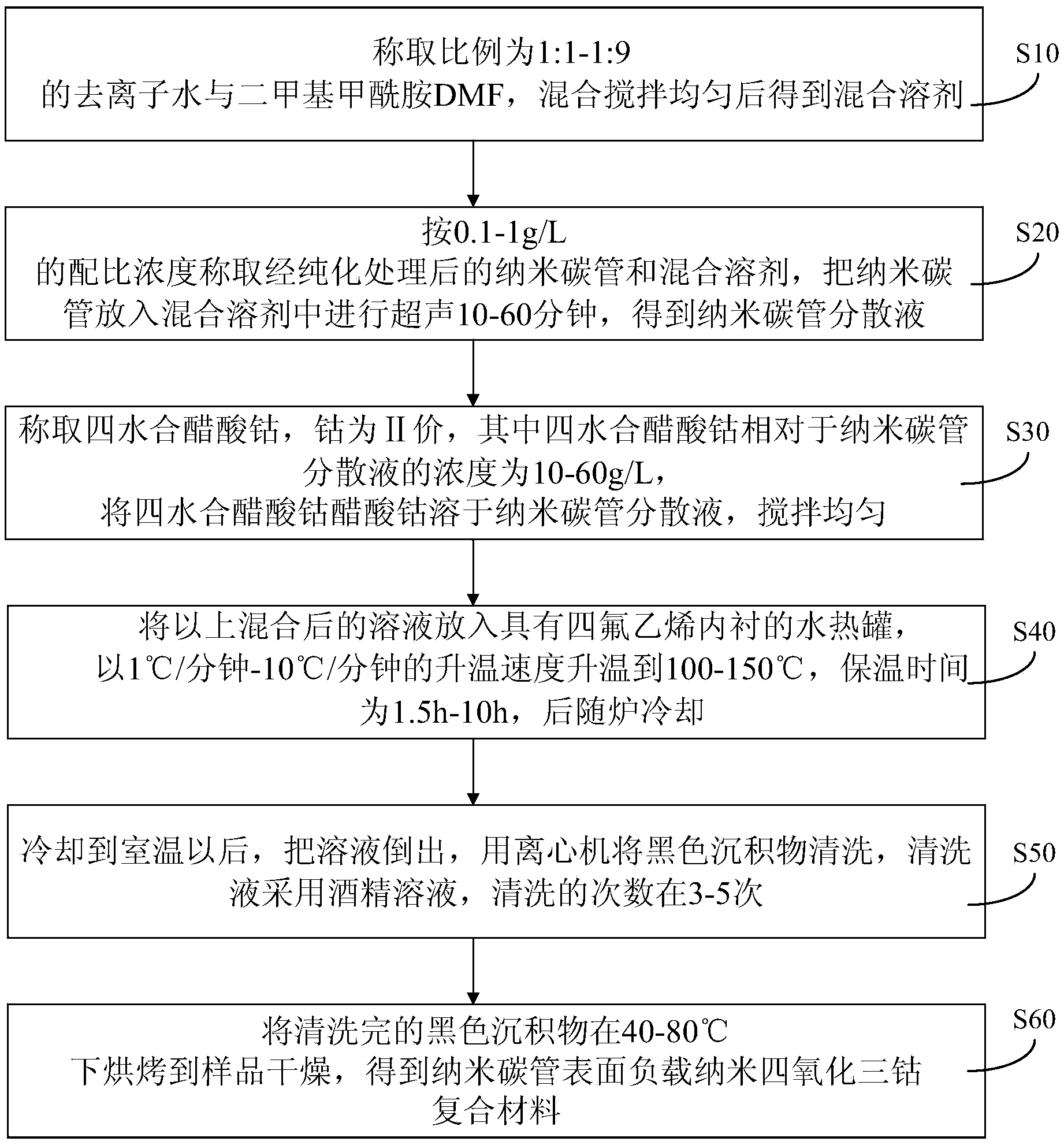

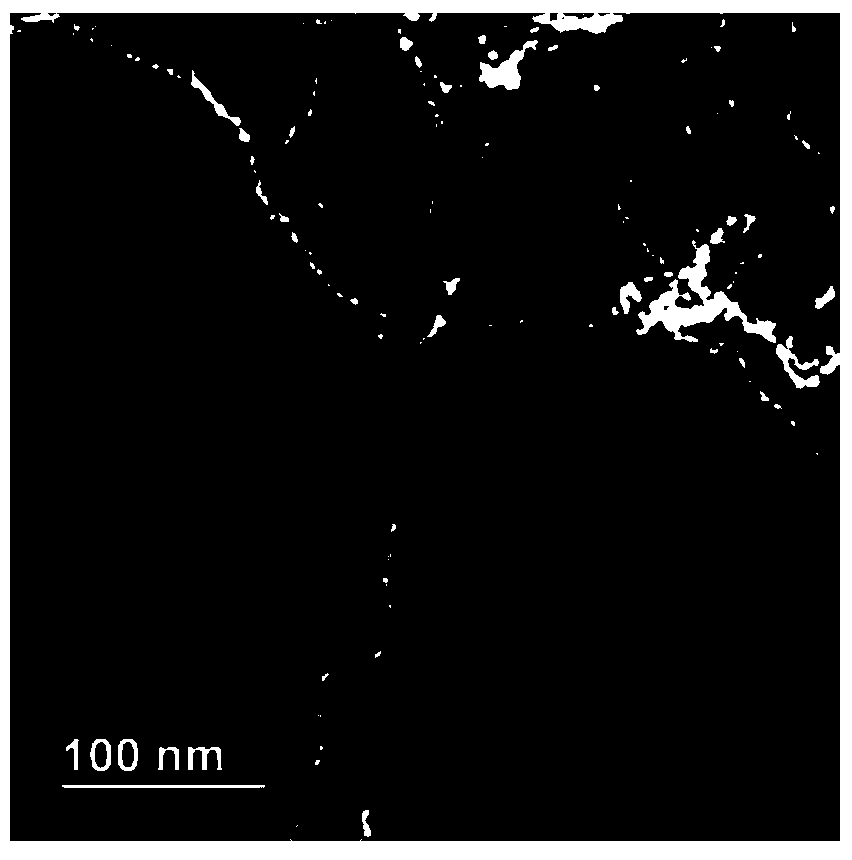

Carbon nano tube surface loaded nano cobaltosic oxide composite material and preparation method thereof

ActiveCN104167295ALarge specific surface areaImprove conductivityMaterial nanotechnologyHybrid capacitor electrodesCooking & bakingOxide composite

The embodiment of the invention discloses a carbon nano tube surface loaded nano cobaltosic oxide composite material and a preparation method thereof. The preparation method comprises the following steps: deionized water and DMF are weighed according to a ratio of 1:1 to 1:9 to obtain a mixed solvent; purified carbon nano tube and the mixed solvent are weighed according to the compounding concentration of 0.1-1g / L, and ultrasonic processing is performed for 10-60min; cobalt(II) acetate tetrahydrate of which the concentration is 10-60g / L relative to carbon nano tube dispersion liquid is weighed, and cobalt(II) acetate tetrahydrate is dispersed in the carbon nano tube dispersion liquid and stirred evenly; the obtained mixed solution is put in a hydrothermal tank with a tetrafluoroethylene liner and then cooled along with a furnace; after the solution is cooled to room temperature, black deposits are cleaned by a centrifuge; and baking is performed until a sample is dried. Co3O4 particles of the carbon nano tube surface loaded nano cobaltosic oxide composite material prepared by the method are cubic and uniform in size, have a side length smaller than 7nm, and are uniformly distributed on the surface of the carbon nano tube.

Owner:杭州中盟智控科技集团有限公司

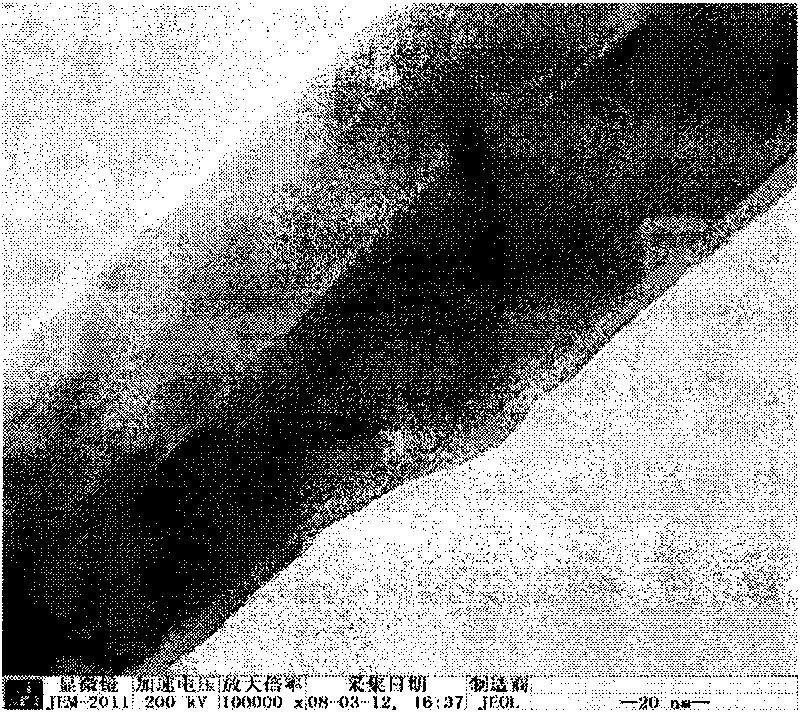

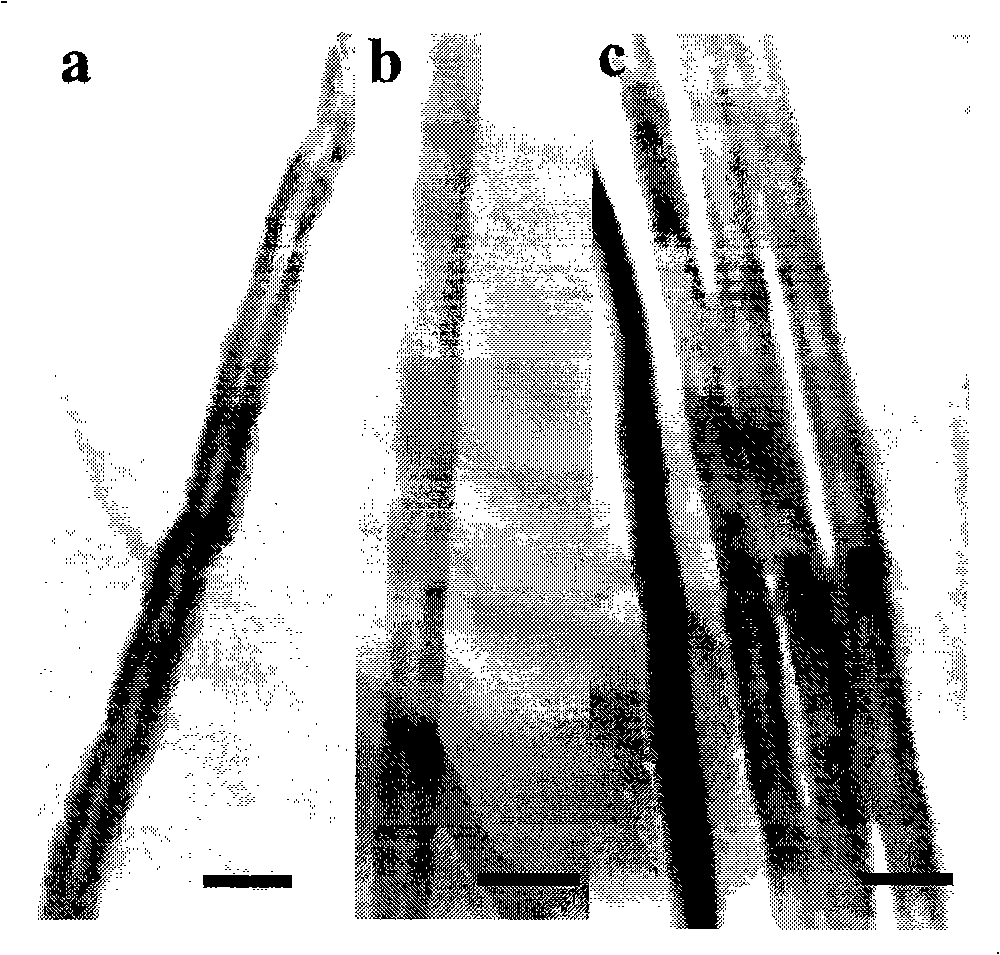

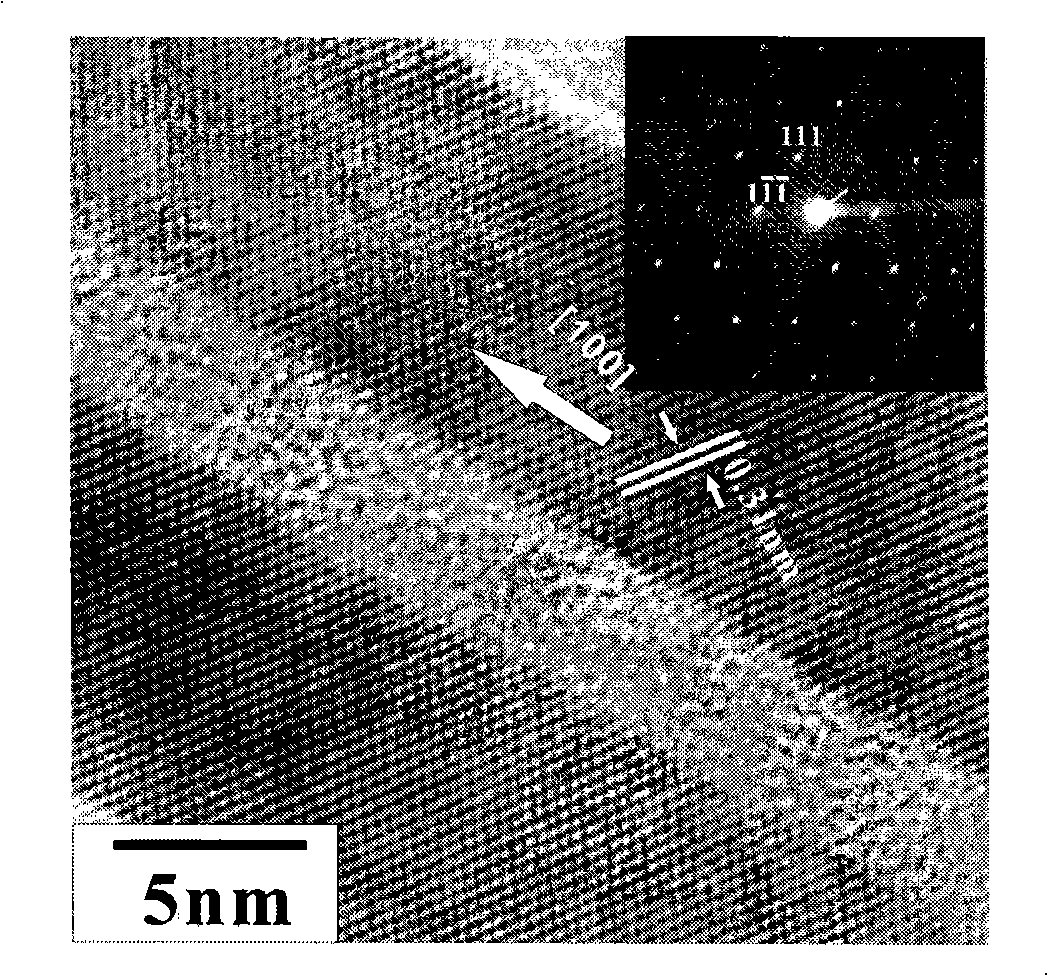

Preparation method for nano-tube

InactiveCN101284667ASimple processCrystal structure intactSilicon compoundsDeposition temperatureRare-earth element

The invention is a method for preparing a silicon nanotube, which takes the mixed powder of SiO, Si, etc. as the starting material and a small amount of rare earth elements as an indirect catalyst, evaporates the material under the conditions of high temperature and low air pressure, and causes the silicon atoms to accumulate and nucleate at a proper deposition temperature, thereby preparing the hollow-structured silicon nanotube. The method for preparing the silicon nanotube has the advantages of simple process, low-cost equipment, complete crystal structure of the nanotube, and capability for meeting the industrial requirements. The successful preparation of the nanotube provides a practicality foundation for the nanuotube to be widely applied in nanoelectronic devices in the future, and the theoretical research of the nanotube is verified from the experiment.

Owner:FUDAN UNIV

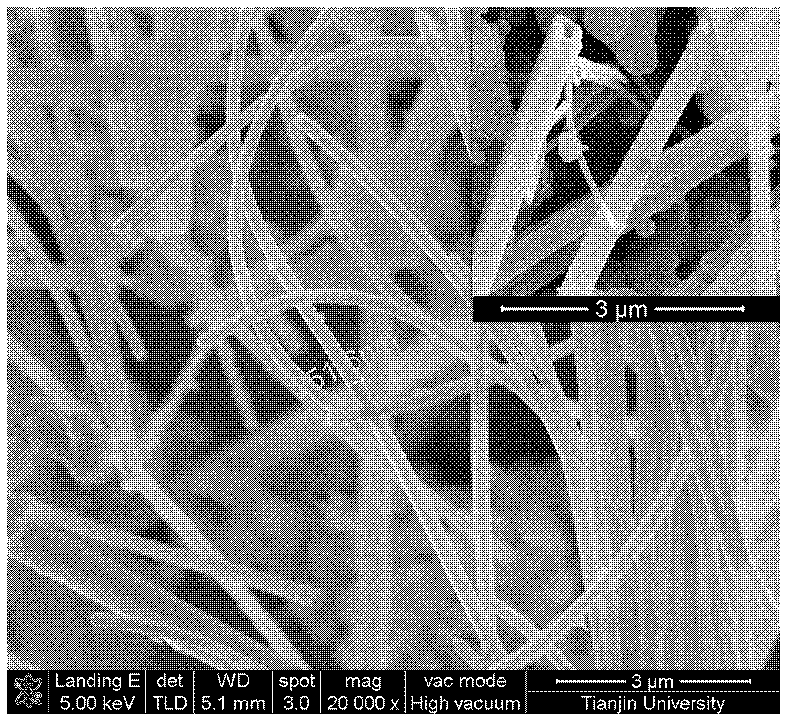

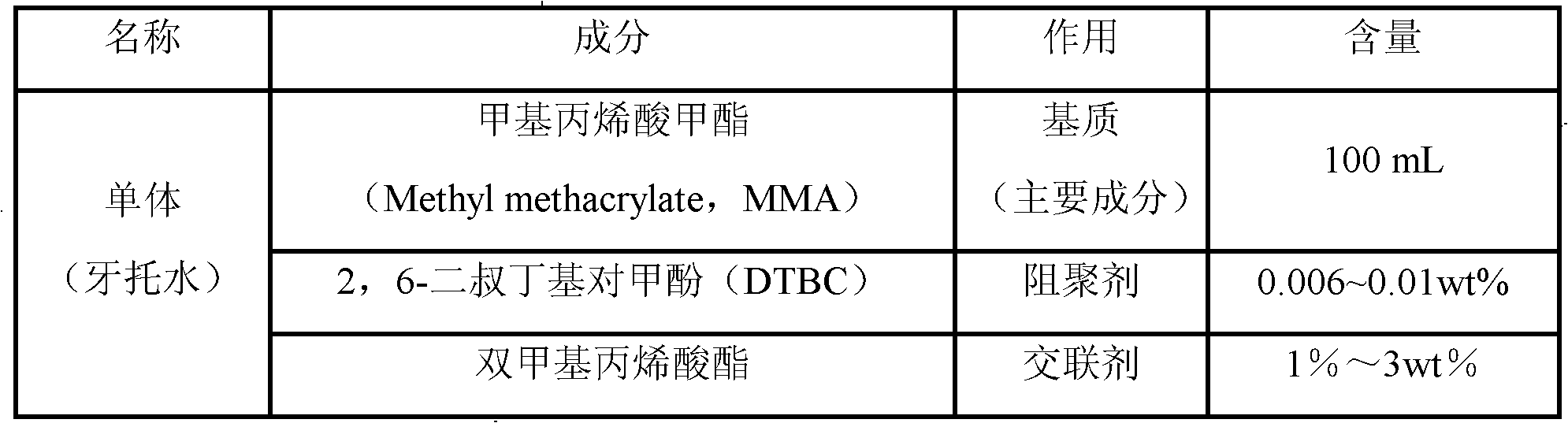

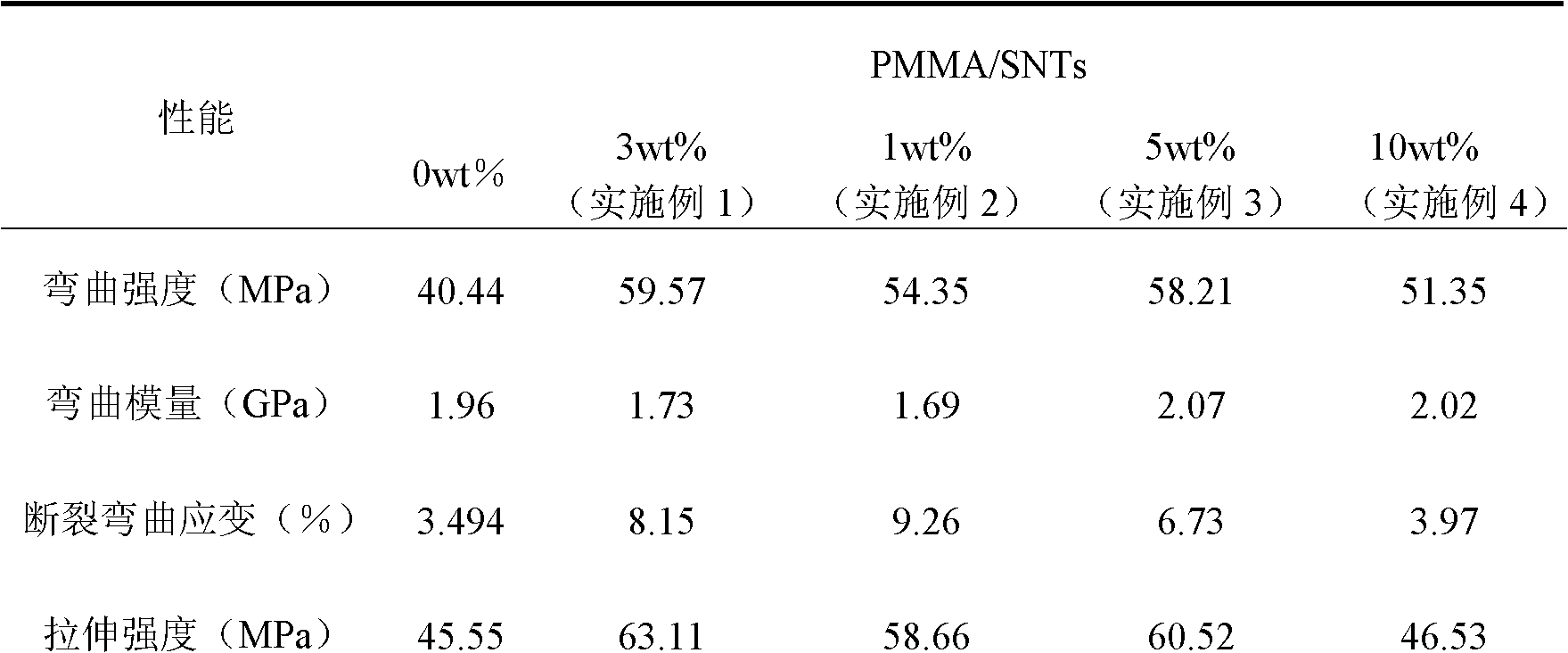

Polymethyl methacrylate (PMMA)-silicon nanotube (SNT) composite denture base material and preparation method and application thereof

InactiveCN102488623AImprove bending strengthHigh tensile strengthImpression capsDentistry preparationsFlexural strengthThermal coagulation

The invention discloses a polymethyl methacrylate (PMMA)-silicon nanotube (SNT) composite denture base material and a preparation method and an application thereof. The preparation method comprises the following steps of: suspending and polymerizing 100 parts by weight of methyl methacrylate monomers and 1-10 parts by weight of silicon nanotubes, uniformly mixing a product with a thermal coagulation dental base acrylic resin liquid; and heating and curing. In the invention, a PMMA / SNTs nano-composite material is prepared by adopting an in-situ suspension polymerization method, SNTs are taken as fillers, the performance of the PMMA is improved by performing SNTs in-situ filling, so that bending strength and tensile strength are improved greatly in comparison to pure PMMA resin, problems existing on the aspect of mechanical strength, in particular on the aspect of tensile strength of the PMMA denture base material are solved, and an oral rehabilitation material with excellent performance is obtained.

Owner:TIANJIN UNIV

Allophane silicon nanotube hybridized forward osmosis membrane

ActiveCN106492657AReduce internal concentration polarizationHigh permeation fluxSemi-permeable membranesAllophaneConcentration polarization

The invention discloses an allophane silicon nanotube hybridized forward osmosis membrane. An allophane silicon nanotube serves as a modifying agent, is pre-dispersed in membrane casting liquid and is converted into a membrane through a phase, and then allophane silicon nanotube hybridized forward osmosis membrane is obtained through interfacial polymerization. The inner concentration polarization of the forward osmosis membrane is effectively reduced, and water flux of the forward osmosis membrane is improved. The forward osmosis membrane has high permeation flux and efficient selectivity.

Owner:NINGBO UNIV

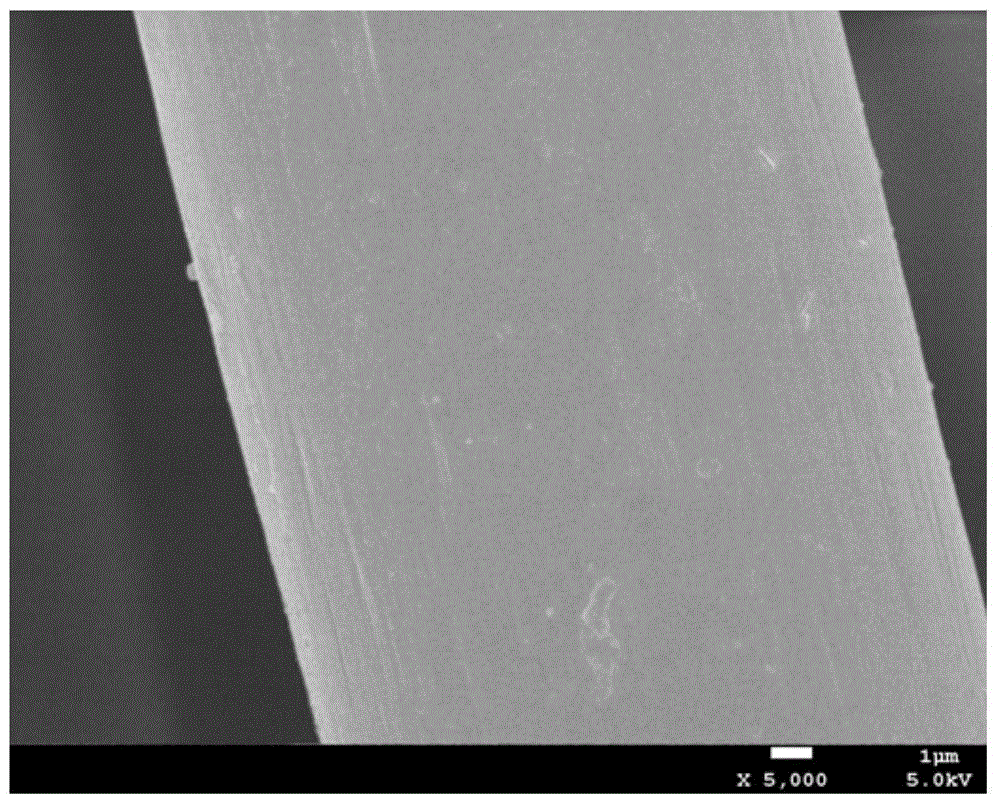

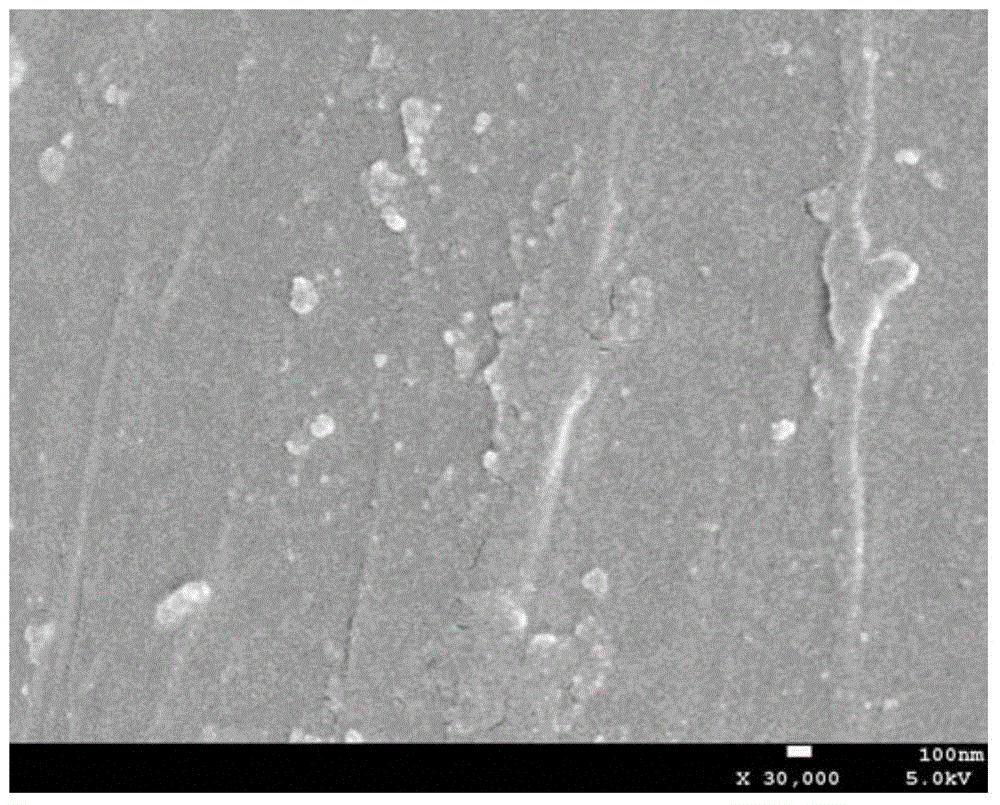

New method of silicon nanotube/ wire modified fiber surface

InactiveCN104878588AImprove hydrophobicityImprove hydrolysis resistancePhysical treatmentFiberOrganic solvent

The invention relates to a new method of a silicon nanotube / wire modified fiber surface. The new method of the silicon nanotube / wire modified fiber surface belongs to the technical field of fiber surface modification, and comprises the following steps of heating and refluxing fiber in organic solvent and deionized water sequentially, and vacuum drying for 1-12h at the temperature of 60-120 DEG C; putting the processed fiber into a plasma generation device, and processing for 10s-20min in gas atmosphere under the condition with the power being 50-400W; preparing silane, the organic solvent and protonic acid into acid-stage silane organic solvent with the volume fraction being 0.1-20 percent, putting the processed fiber into the solvent, and stirring for 0.1-36h under the conditions with the temperature being 0-80 DEG C and the rotary speed being 50-1000rpm; cleaning up the modified fiber through the organic solvent and the deionized water sequentially, and vacuum drying for 1-12h at the temperature of 60-120 DEG C. The roughness of the fiber surface modified by the method is obviously increased, the hydrophobicity of the fiber is improved, and the hydrolytic resistant capacity of the fiber is efficiently improved.

Owner:四川天策聚材科技有限公司

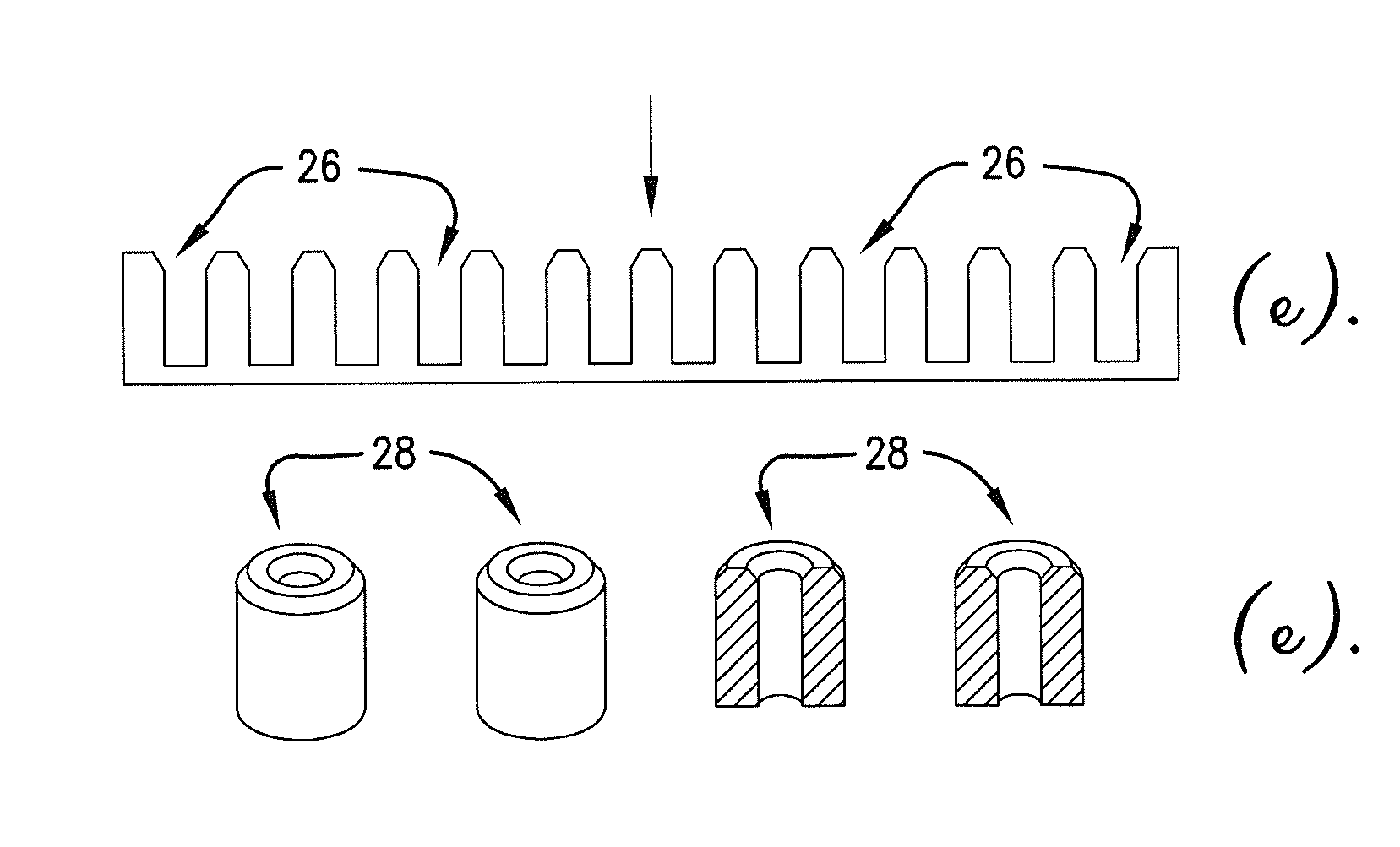

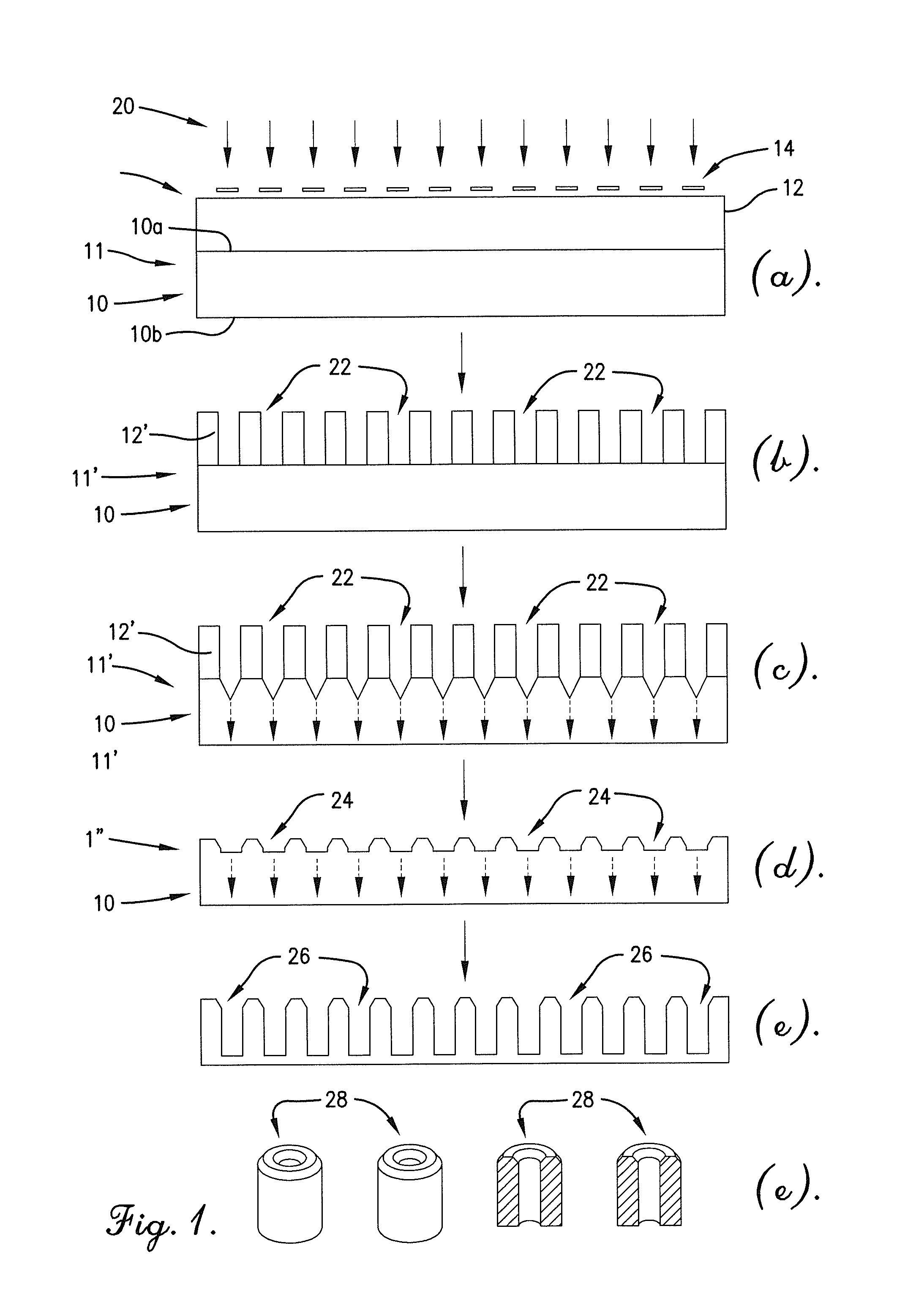

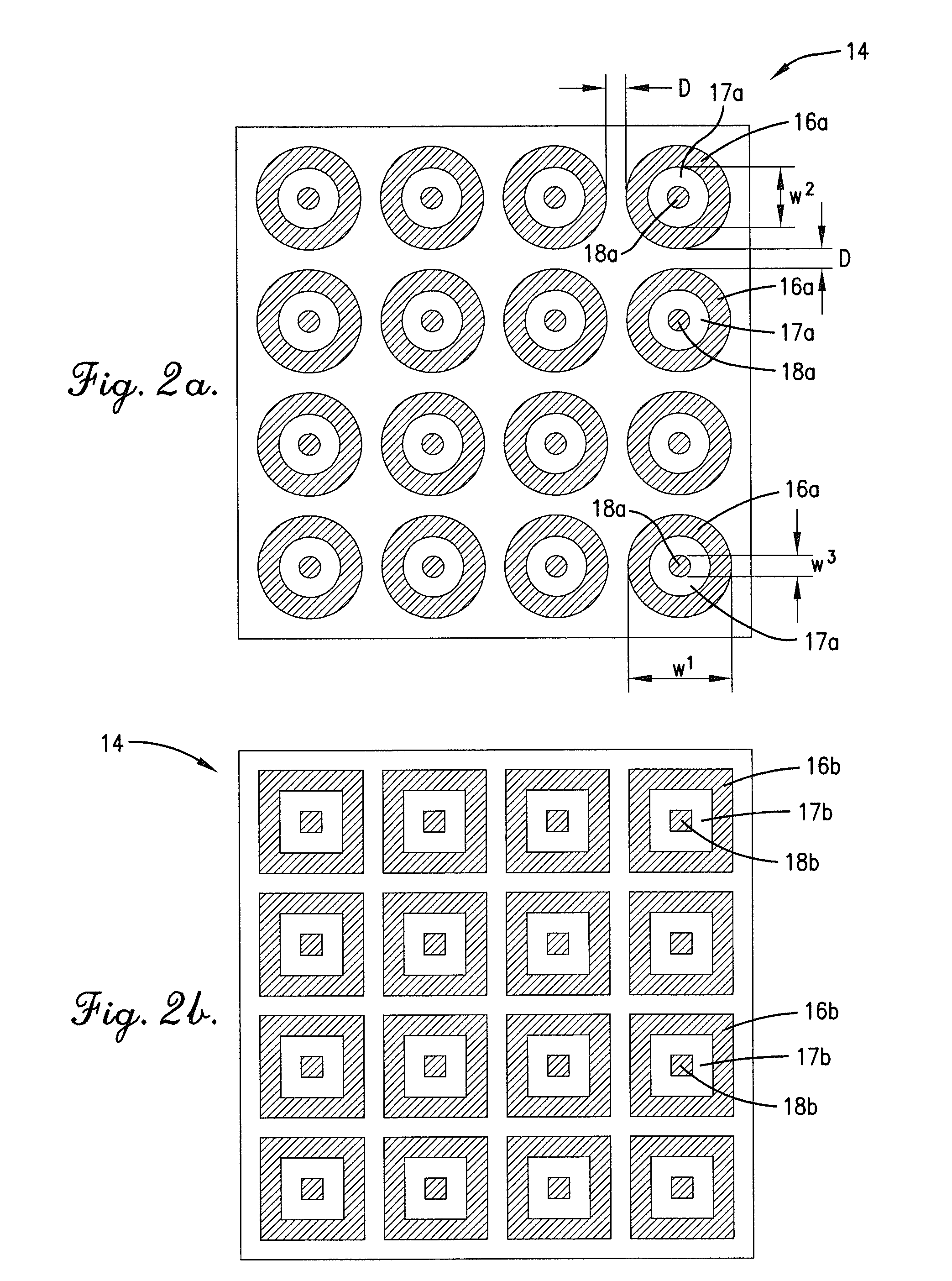

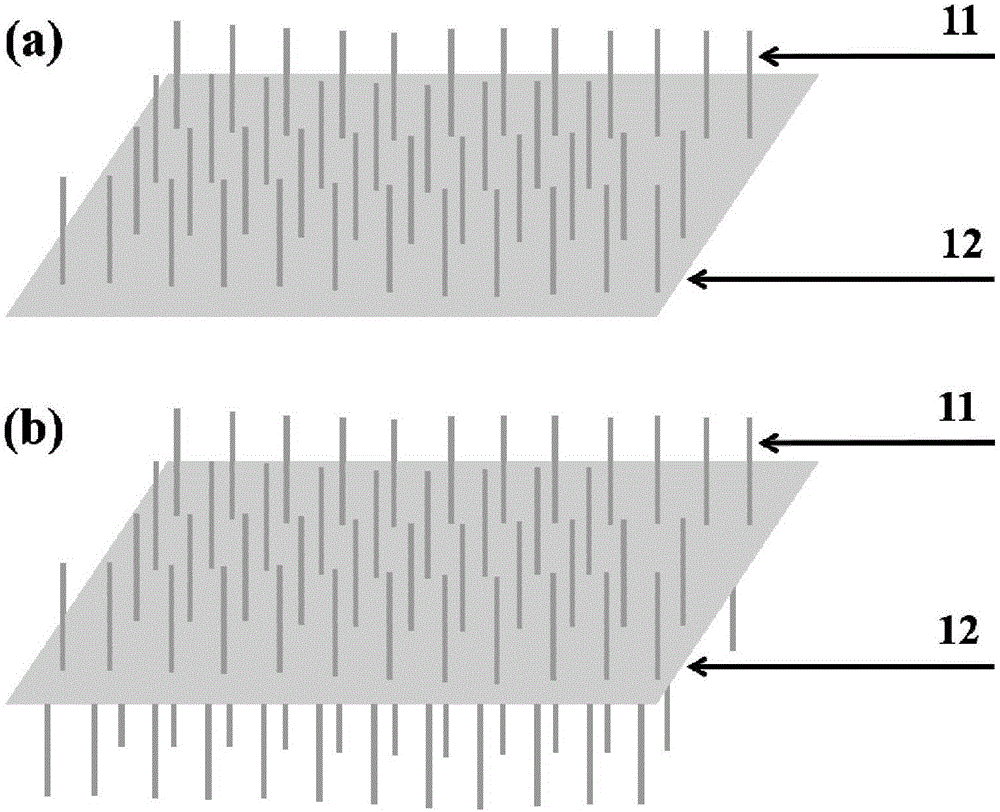

Cvd-free, scalable processes for the production of silicon micro- and nanostructures

Manufacturing-friendly and scalable methods for the production of silicon micro- and nanostructures, including silicon nanotubes, are described. The inventive methods utilize conventional integrated circuit and MEMS manufacturing processes, including spin-coating, photolithography, wet and dry silicon etching, and photoassisted electrochemical etch processes. The invention also provides a novel mask, for maximizing the number of tubes obtained per surface area unit of the silicon substrate on which the tubes are built. The resulting tubes have thick and straight outer walls, as well as high aspect ratios.

Owner:BREWER SCI

Method for preparing self-cleaning fluorocarbon paint

InactiveCN107629571AImprove stain resistanceHigh electronegativityAntifouling/underwater paintsPaints with biocidesSilanesCarbon chain

The invention discloses a method for preparing self-cleaning fluorocarbon paint, belonging to the technical field of coatings. The method disclosed by the invention comprises the following steps: mixing hydrolytic fluorosilane and titanium dioxide, and dispersing at high speed to obtain surface-modified titanium dioxide nano-particles; and mixing varnish and carbon nano-tube dispersion, and micro-curing, thereby obtaining the self-cleaning fluorocarbon paint. The binding effect between the titanium dioxide particles and fluorocarbon resins is increased by the fluorosilane, fluorosilane molecules are hydrolyzed under acidic conditions, the hydrolyzed fluorosilane molecules are adsorbed onto the surfaces of the titanium dioxide nano-particles due to hydrogen-bond interactions, and since carbon chains in the fluorosilane molecules are protected by a fluorine atom space barrier effect, other atoms difficultly intrude. Therefore, the fluorosilane has excellent chemical stability and low surface free energy. Due to a coating layer on the fluorosilane surface, Vander Wale force of the TiO2 nano-particles to water and the hydrogen-bond interaction are reduced, and the contact angle on thecoating surface is greatly enlarged, so that super-hydrophobicity is achieved, the stain resistance can be obviously improved, and the application prospects are wide.

Owner:袁玲燕

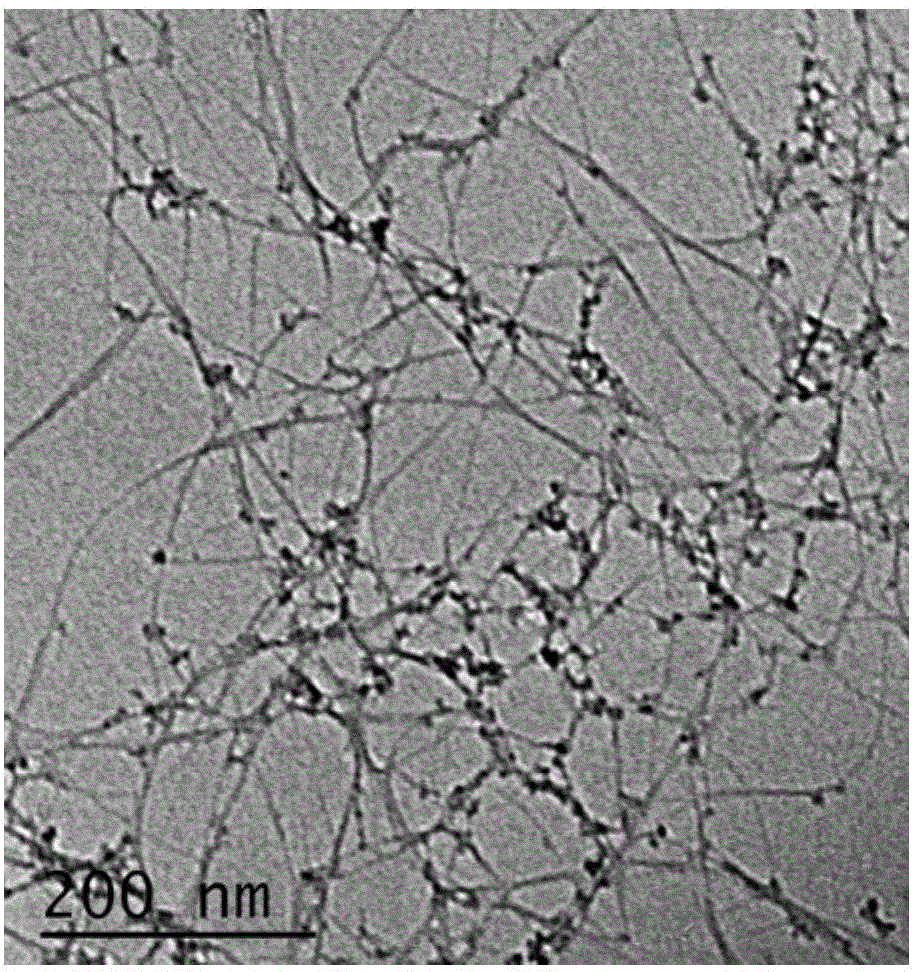

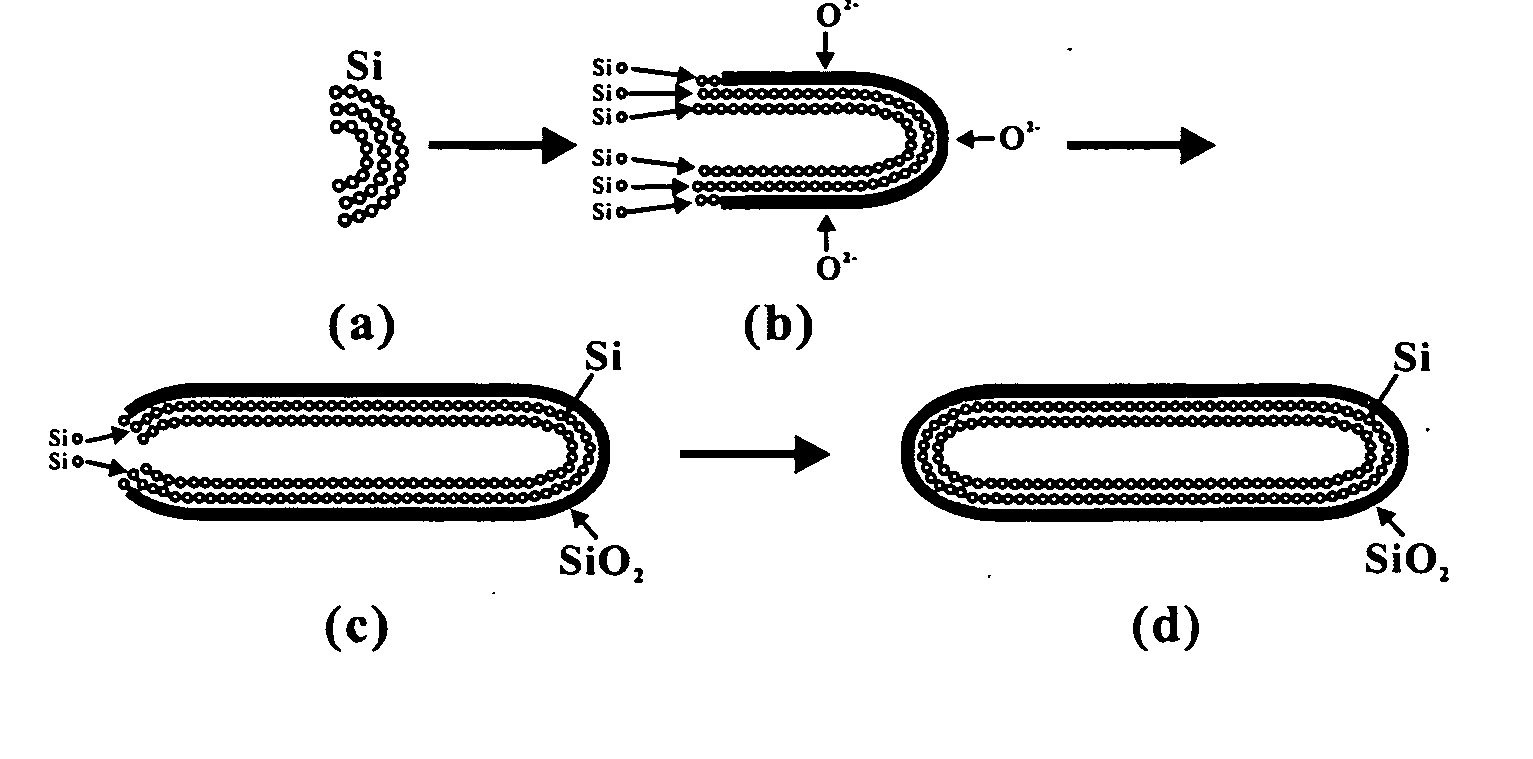

Preparation of self-assembled silicon nanotubes by hydrothermal method

InactiveUS20070077680A1Simple processEasy to operateMaterial nanotechnologyNanostructure manufactureSelf assembleSilicon oxide

The present invention relates to a method for preparing self-assembled silicon nanotubes (SiNTs) by a hydrothermal method. A method for preparing self-assembled SiNTs comprises forming a mixture of silicon oxide and water in a sealed container, wherein the mixture has a silicon oxide to water ratio of no more than 10% by weight. The mixture is maintained at a constant temperature and a constant pressure, and the mixture is stirred for a period of time. Self-assembled SiNTs may be formed with an average inner diameter of less than 5 nm and an average outer diameter of around 15 nm. The present invention completely utilizes non-toxic raw materials, and the materials and process do not pollute the environment, so the method satisfies the development trends of the modern industry.

Owner:HUNAN UNIV

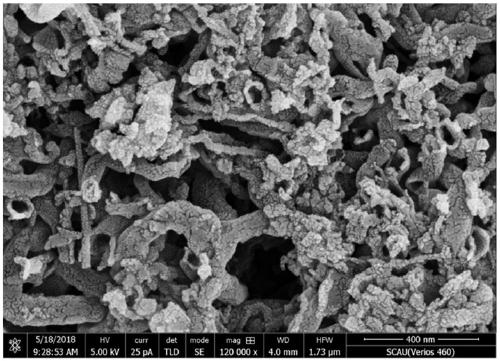

Silicon carbide nano tube as well as preparation method and application thereof

InactiveCN109110763AAchieving controllable synthesisUnique shapePhysical/chemical process catalystsCarbon compoundsCarbon nanotubeSilicon carbide nanotubes

The invention belongs to the technical field of nano material preparation and discloses a silicon carbide nano tube as well as a preparation method and application thereof. The method comprises the following steps: (1) dispersing carbon nano tubes into mixed acid of concentrated nitric acid and concentrated sulfuric acid, performing ultrasonic treatment, then stirring under room temperature, centrifuging, using water to clean obtained precipitate and drying to obtain pretreated carbon nano tubes; (2) evenly grinding silicon powder and the pretreated carbon nano tubes, putting into a tube furnace to perform warming reaction and purifying a reaction product to obtain a target product silicon carbide nano tube after reaction is finished. According to the silicon carbide nano tube disclosed bythe invention, the carbon nano tubes are treated by mixed acid to remove metal impurities and amorphous carbon in the carbon nano tubes; thus, the silicon carbide nano tube disclosed by the inventioncan be generated according to the V-S reaction mechanism; the SiC nano tube is of a one-dimensional conductive network structure, can promote separation of light induced electrons and cavities and can improve the photoelectrocatalysis efficiency; the SiC nano tube material has excellent photoelectrocatalysis performance.

Owner:SOUTH CHINA AGRI UNIV

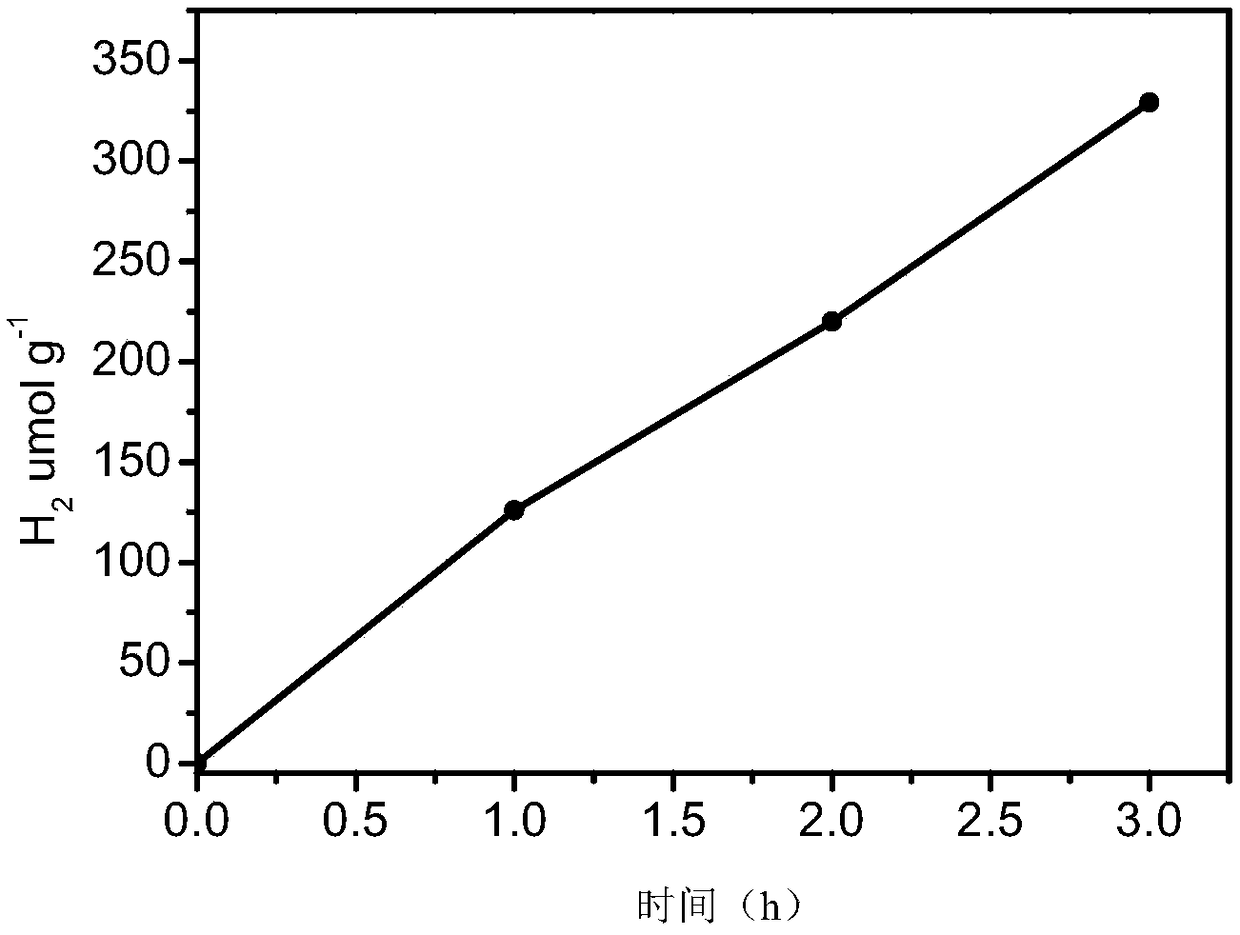

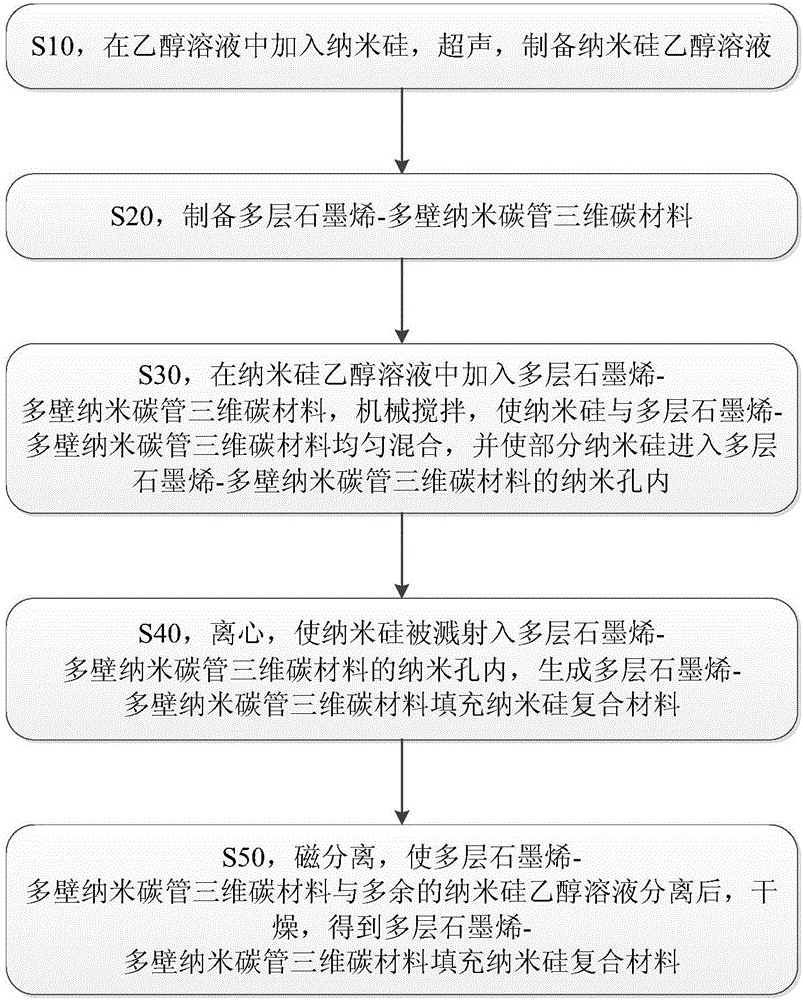

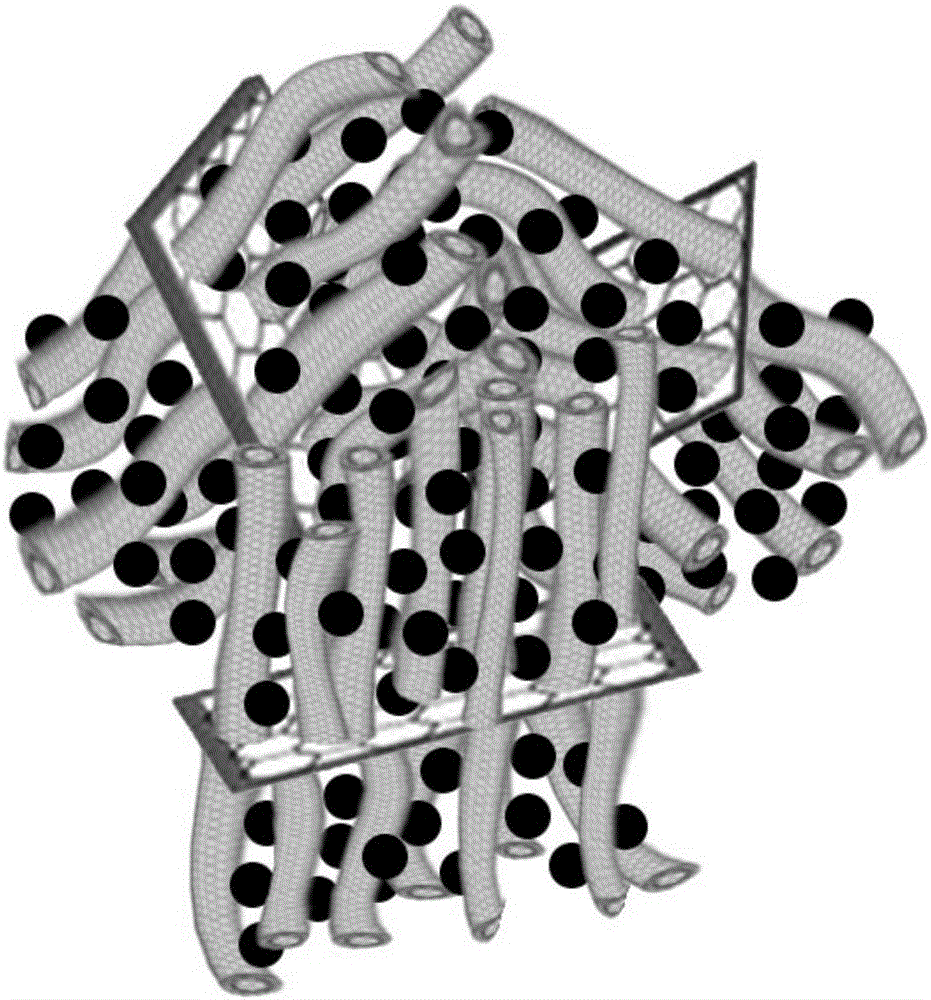

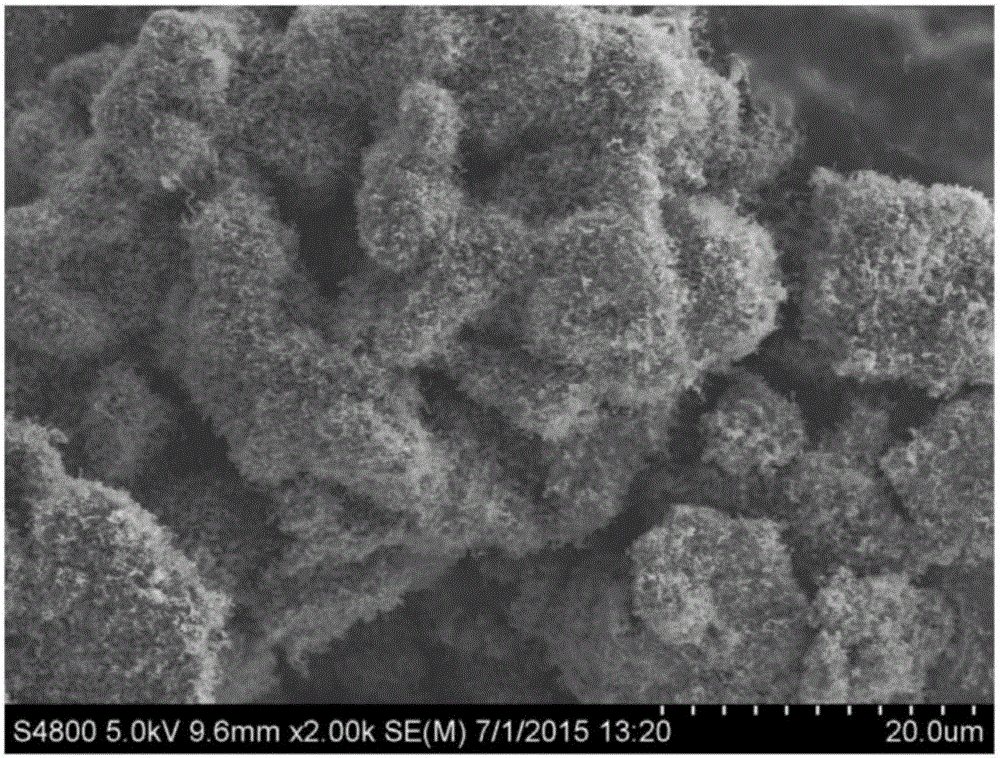

Multi-layer graphene carbon nanotube three-dimensional carbon material-filled nanometer silicon composite material and preparation method thereof

ActiveCN106410167AEffective isolationReduce reunionCell electrodesSecondary cellsNano siliconCarbon nanotube

The invention belongs to a material technique, and particularly relates to a multi-layer graphene carbon nanotube three-dimensional carbon material-filled nanometer silicon composite material and a preparation method thereof. The preparation method comprises the following steps of preparing a nanometer silicon ethanol solution; preparing a multi-layer graphene-multi-wall carbon nanotube three-dimensional carbon material; mechanically stirring, thus uniformly mixing nanometer silicon and the multi-layer graphene-multi-wall carbon nanotube three-dimensional carbon material, and enabling one part of the nanometer silicon to enter nanometer holes of the multi-layer graphene-multi-wall carbon nanotube three-dimensional carbon material; centrifuging, spattering the nanometer silicon into the nanometer holes of the multi-layer graphene-multi-wall carbon nanotube three-dimensional carbon material, and generating a multi-layer graphene-multi-wall carbon nanotube three-dimensional carbon material-filled nanometer silicon composite material; magnetically separating the multi-layer graphene-multi-wall carbon nanotube three-dimensional carbon material from the excessive nanometer silicon ethanol solution. The prepared multi-layer graphene carbon nanotube three-dimensional carbon material-filled nanometer silicon composite material has good application value on electrode materials and energy-storage materials.

Owner:浙江波仕科技有限公司

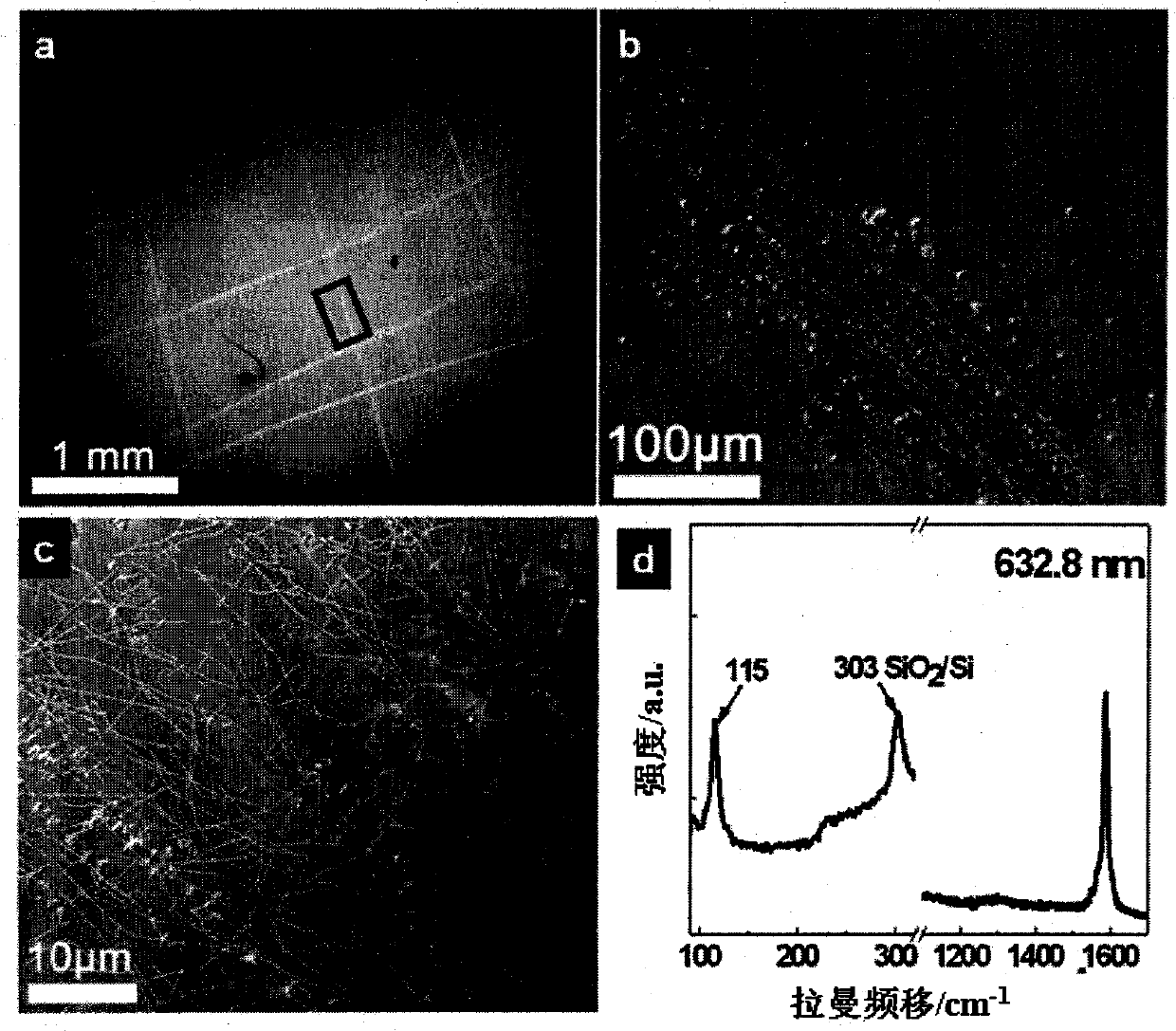

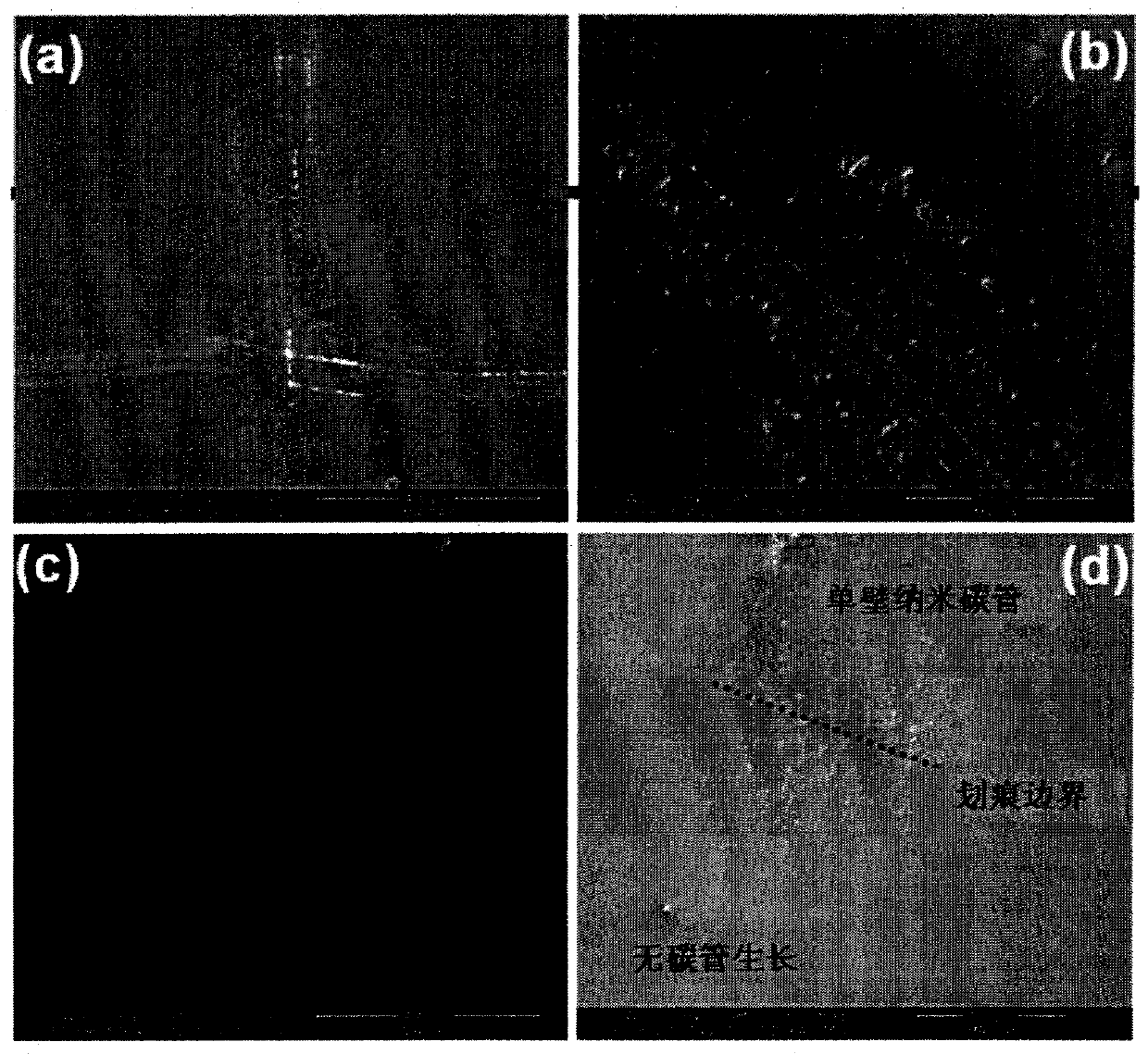

Patterning growth method of single-walled carbon nanotubes by surface ruling method

InactiveCN102020239APatterned growthDoes not existNanostructure manufactureReactive siteMetal impurities

The invention relates to a patterning preparation technology of single-walled carbon nanotubes, in particular to a patterning growth method of single-walled carbon nanotubes through the surface ruling of a silicon substrate with silicon oxide, which is suitable for the height localizability and the patterning growth of high-quality single-walled carbon nanotubes without impurity residue. The method comprises the following steps of: firstly, ruling the surface of the substrate which is a silicon chip with a thermal oxide layer with a sharp object into a certain pattern to generate a plurality of catalytic active sites in substrate surface localization; then, forming nucleating points of the single-walled carbon nanotubes through high-wetting oxidation treatment; and preparing the single-walled carbon nanotubes through the schizolysis of a carbon source at 600-1,100 DEG C. The invention realizes the location and the patterning growth of the high-quality single-walled carbon nanotubes without any metal impurities in a simple silicon substrate ruling mode, has the advantages of simple and convenient operation, low cost, good localizability and easy patterning and lays a foundation for the application of the single-walled carbon nanotubes in the fields of nano electronic devices, sensors, and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of graphite/carbon nano-tube array composite heat conducting film

ActiveCN106219531ARadiation area is largeLower interface thermal resistanceNanotechnologyReduction treatmentHeat conducting

The invention relates to a preparation method of a graphite / carbon nano-tube array composite heat conducting film. The preparation method comprises the following steps: (1) supporting a catalyst layer or a catalyst precursor layer on the surface of a graphite film; (2) placing the graphite film in chemical vapor deposition equipment, depositing carbon nano-tube arrays after carrying out reduction treatment to obtain a heat conducting graphite film of which the surface is deposited with the carbon nano-tube arrays; (3) carrying out graphitization on the heat conducting graphite film of which the surface is deposited with the carbon nano-tube arrays to obtain the graphite / carbon nano-tube array composite heat conducting film. According to the invention, a special method of depositing the highly oriented carbon nano-tube arrays on the surface is adopted, so that the effective radiation area of the heat conducting graphite film is obviously increased, and the interfacial thermal resistance between the conducting film and air is reduced to obviously improve the heat transfer rates of the heat conducting film with surrounding environments such as the air per unit area to rapidly diffuse heat from the heat conducting film to the surrounding environments such as air.

Owner:SHANGHAI JIEYUAN ENVIRONMENTAL SCI & TECH

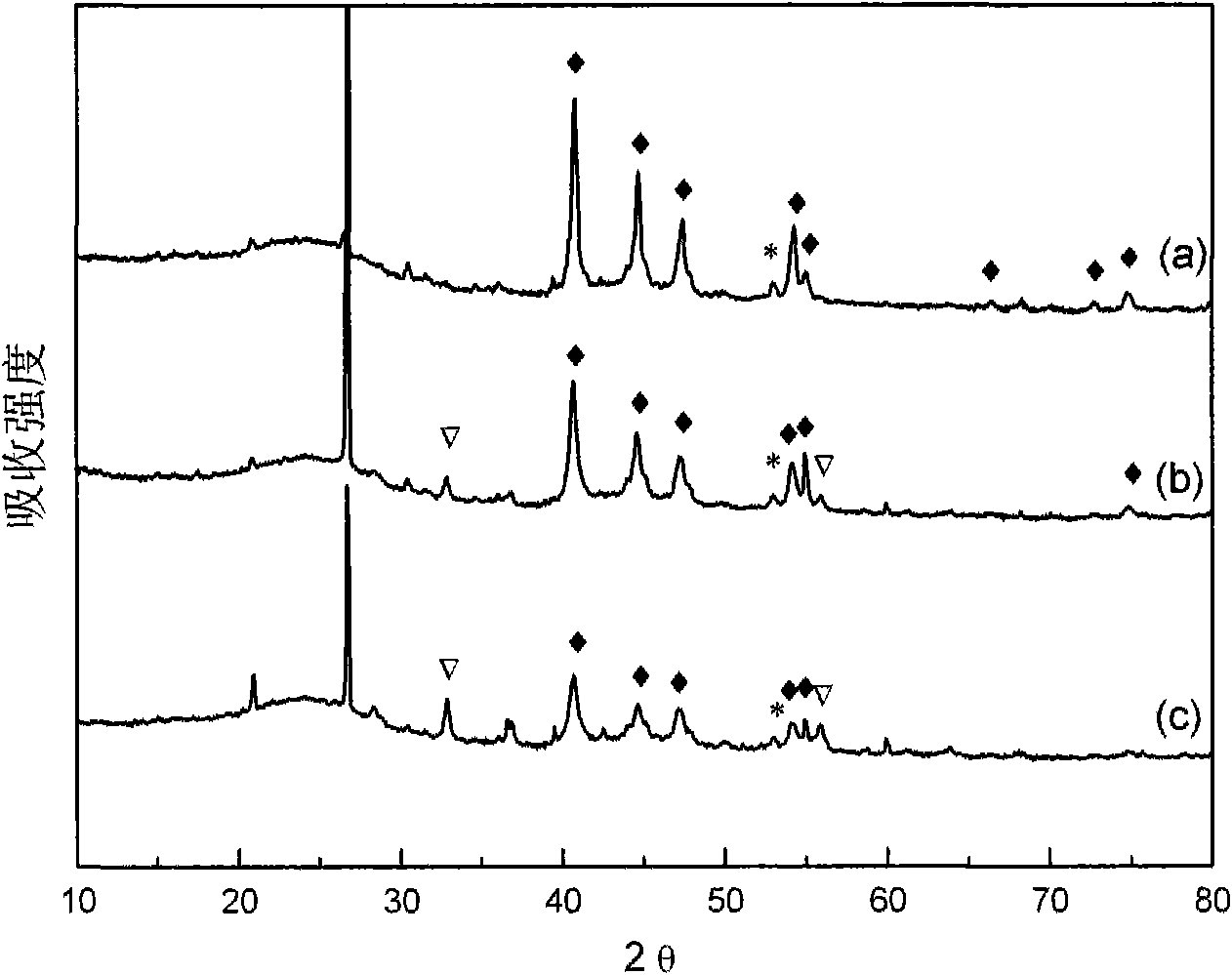

Method for preparing silicon nanotube by taking porous silicon as substrate

InactiveCN102942184ATake advantage of chemistryEasy to makeSilicaNanotechnologyChemical reactionNitrogen gas

The invention provides a method for preparing silicon a nanotube by taking porous silicon as a substrate, belonging to the field of new material preparation technologies. The preparation method comprises the steps of: immersing a cleaned planar silicon wafer into mixed aqueous solution of hydrofluoric acid and silver nitrate to carry out chemical reaction so as to convert the silicon wafer into a porous silicon wafer; immersing the porous silicon wafer into mixed aqueous solution containing fluorinated compounds and metal ions to carry out chemical reaction; taking out after reacting for a certain time; soaking by hydrochloric acid; and then washing by a large number of deionized water and drying by nitrogen so as to finally obtain the silicon nanotube in practical. Compared with the existing technologies of preparing silicon nanotubes, the method provided by the invention takes porous silicon as a silicon source and the chemical properties of the silicon element are fully utilized, so that the silicon nanotube can be prepared at relatively low temperature and normal pressure without the rigor conditions such as high temperature, high pressure, high vacuum and the like, and the preparation process is simple.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

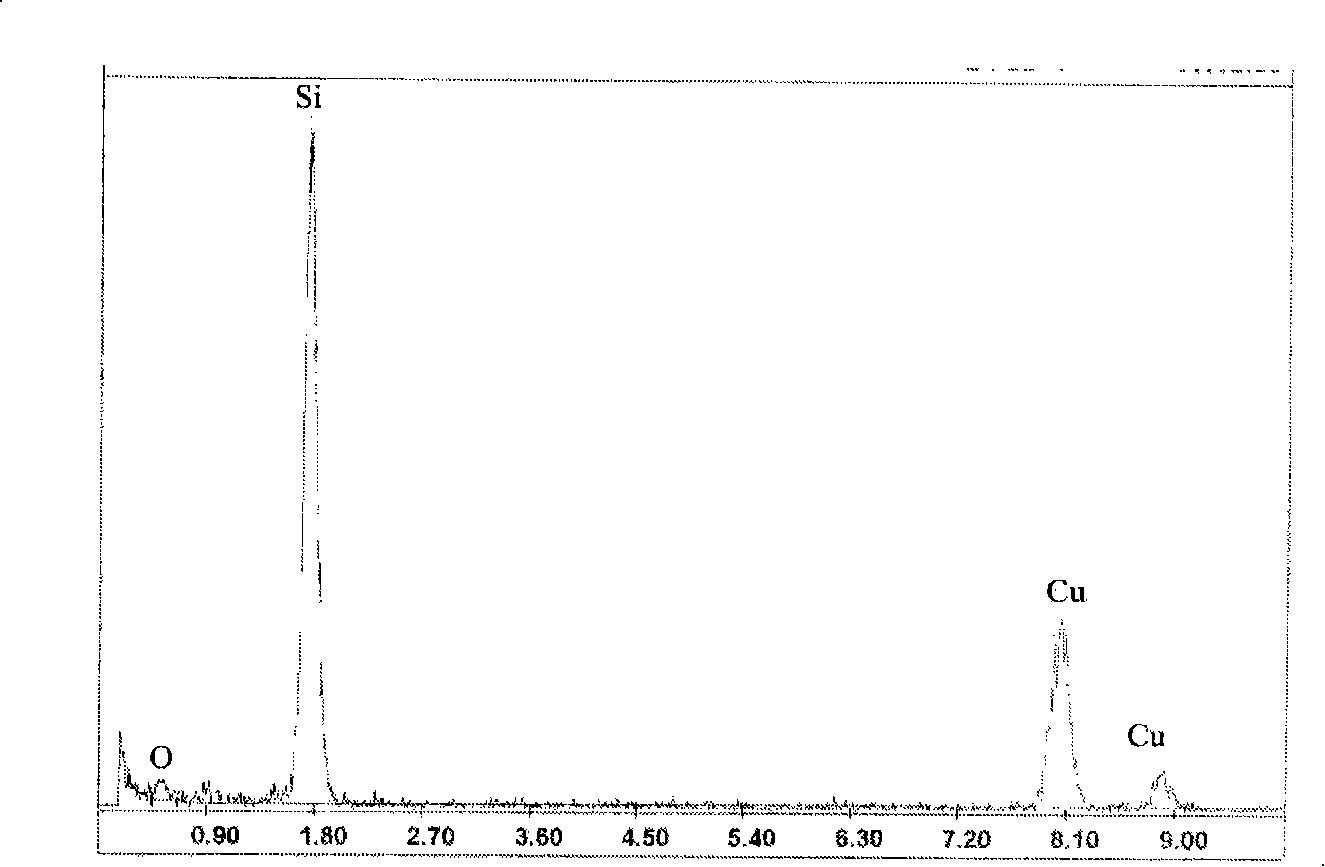

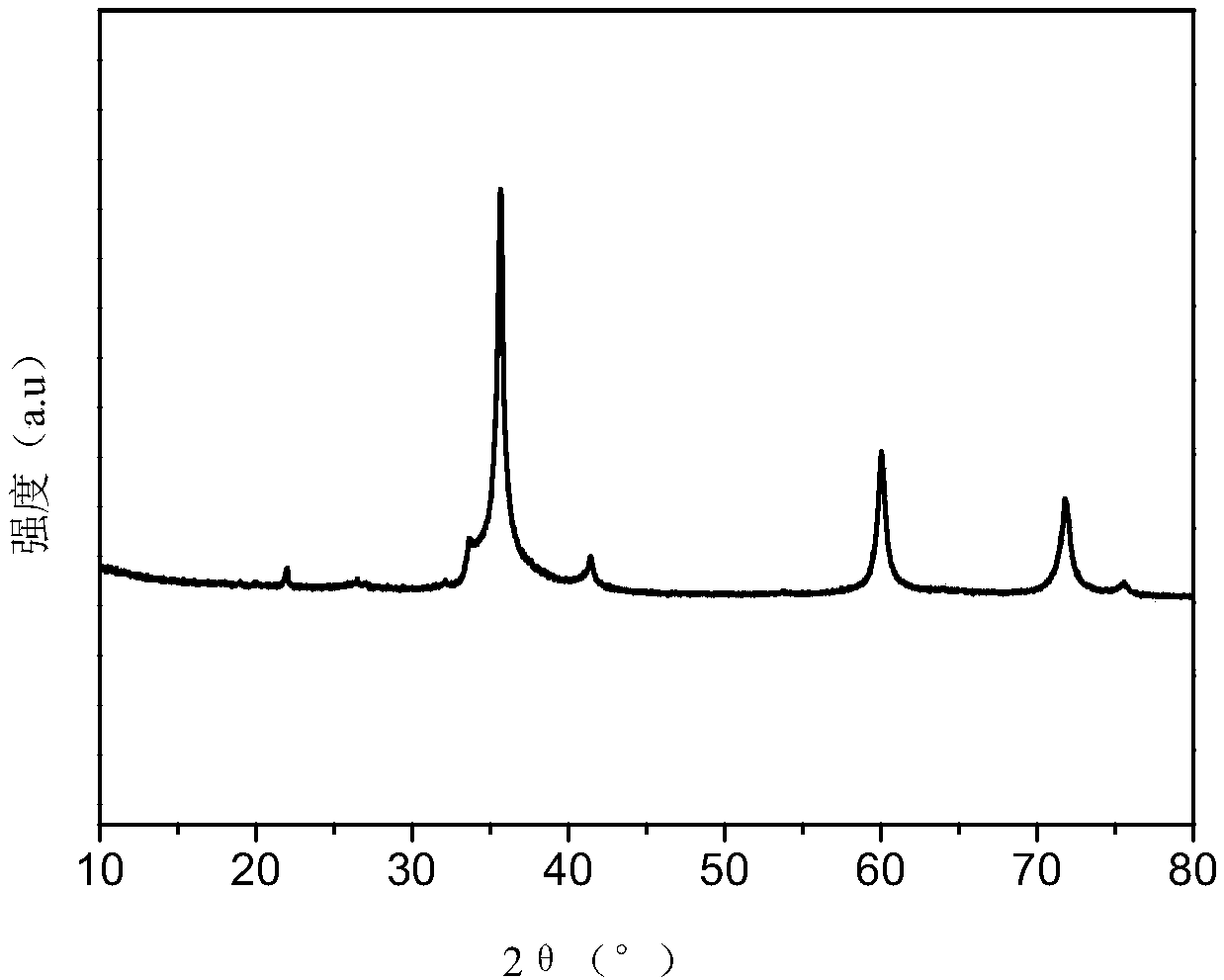

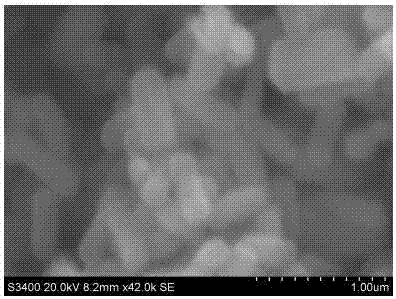

Method for preparing silicon nanotube

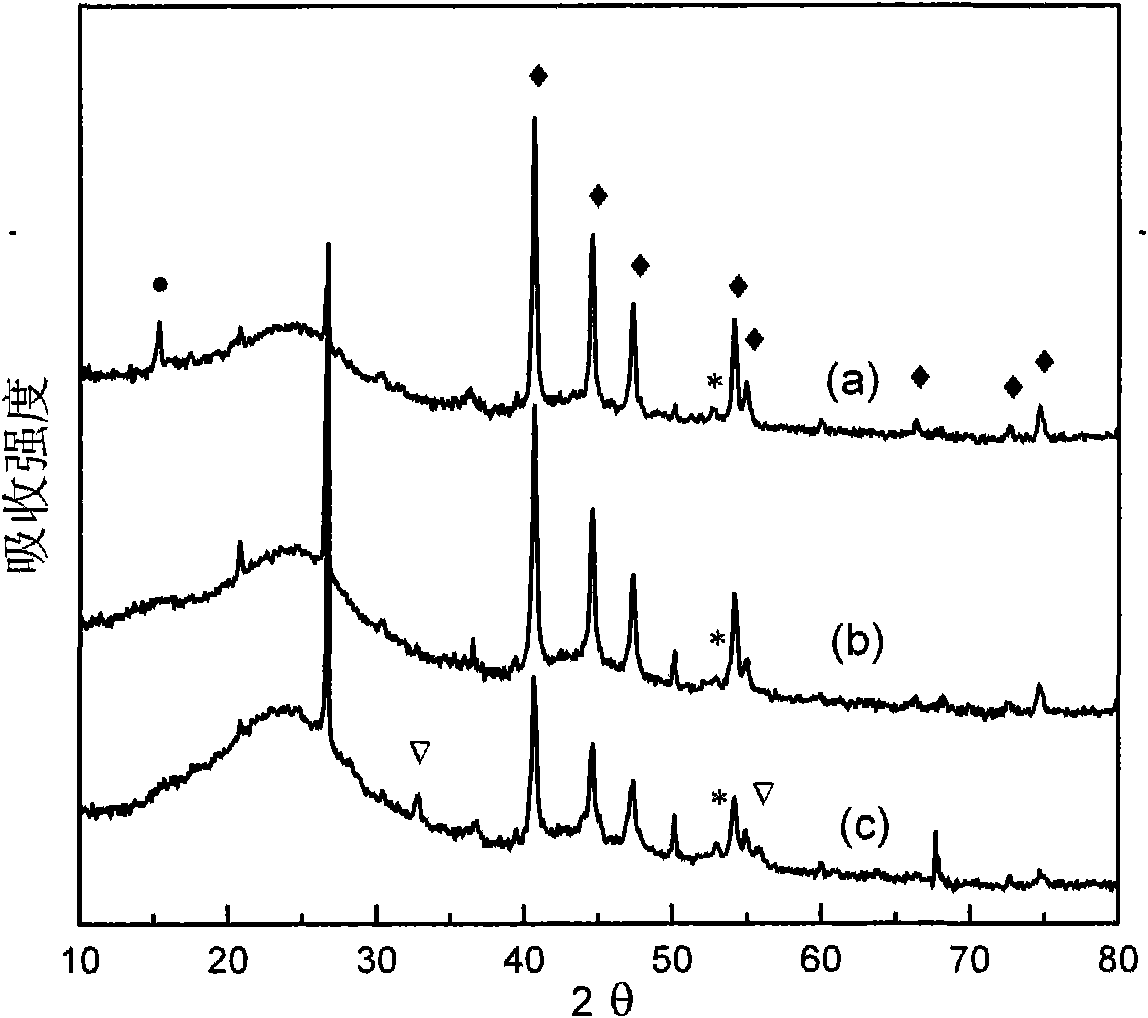

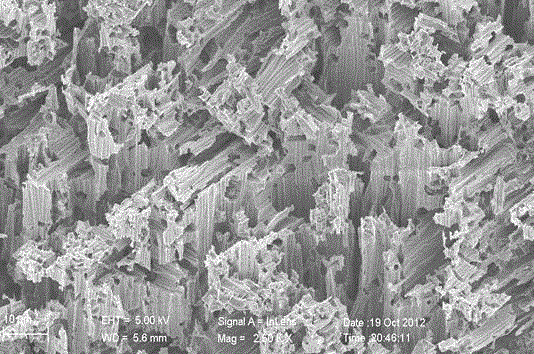

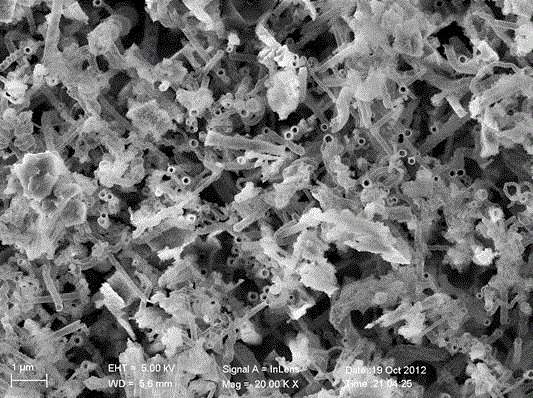

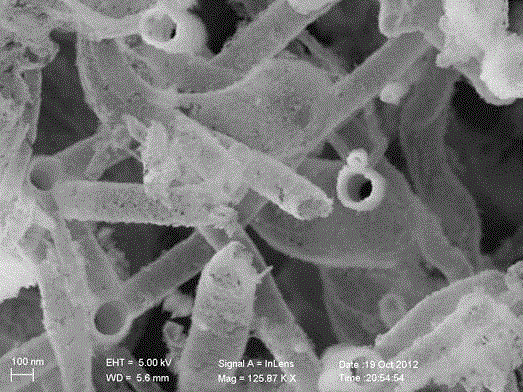

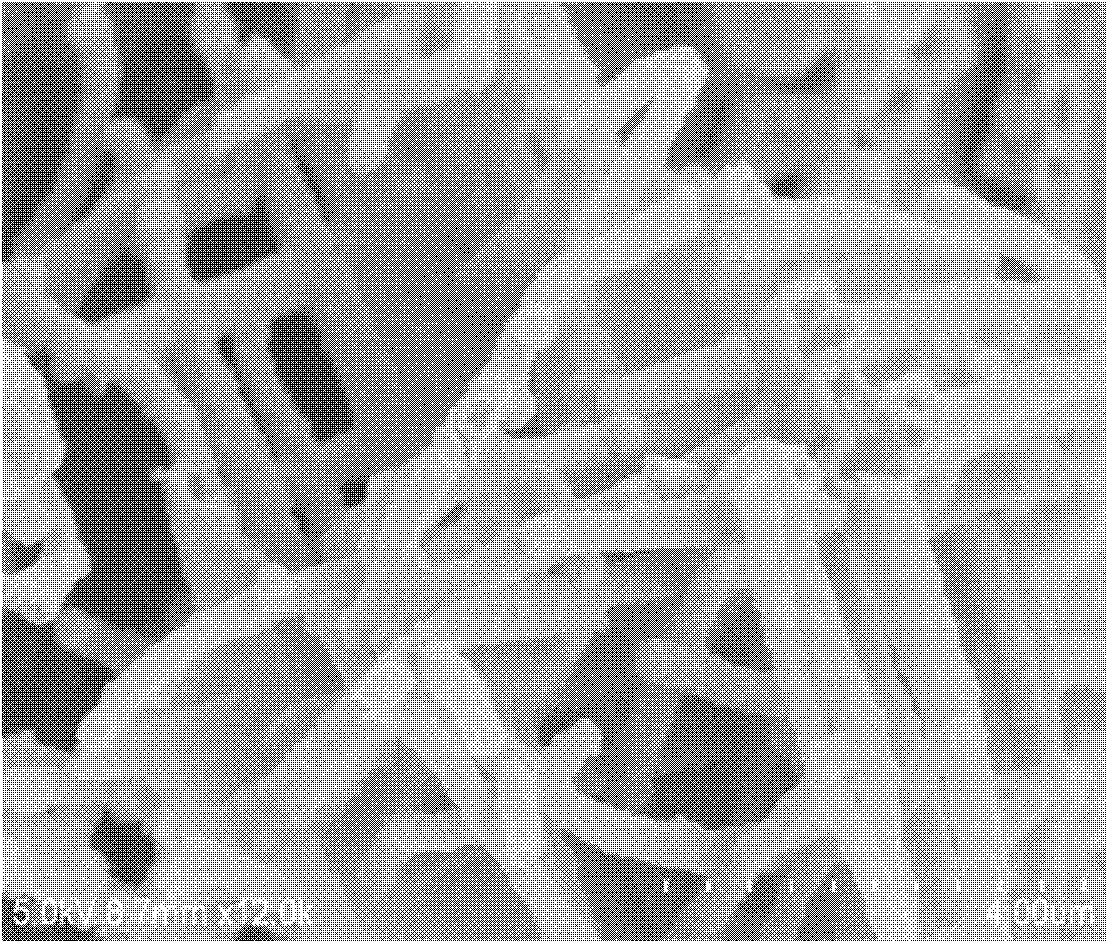

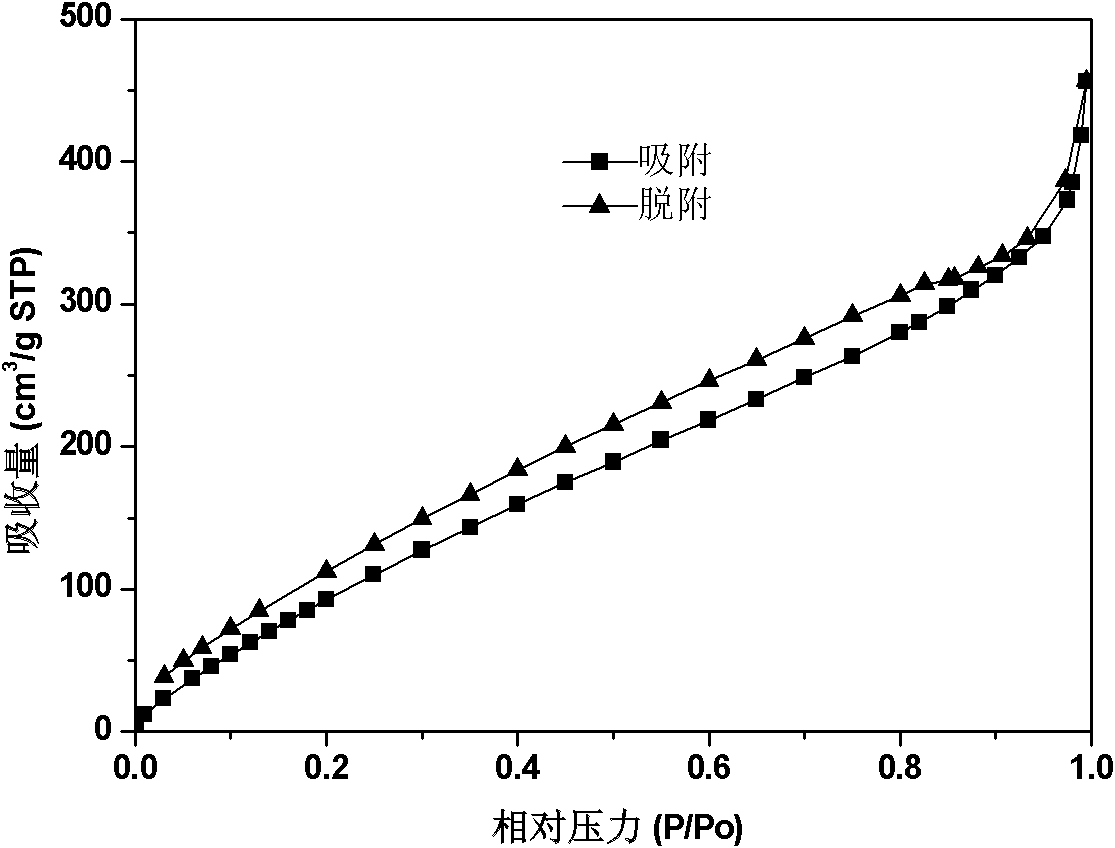

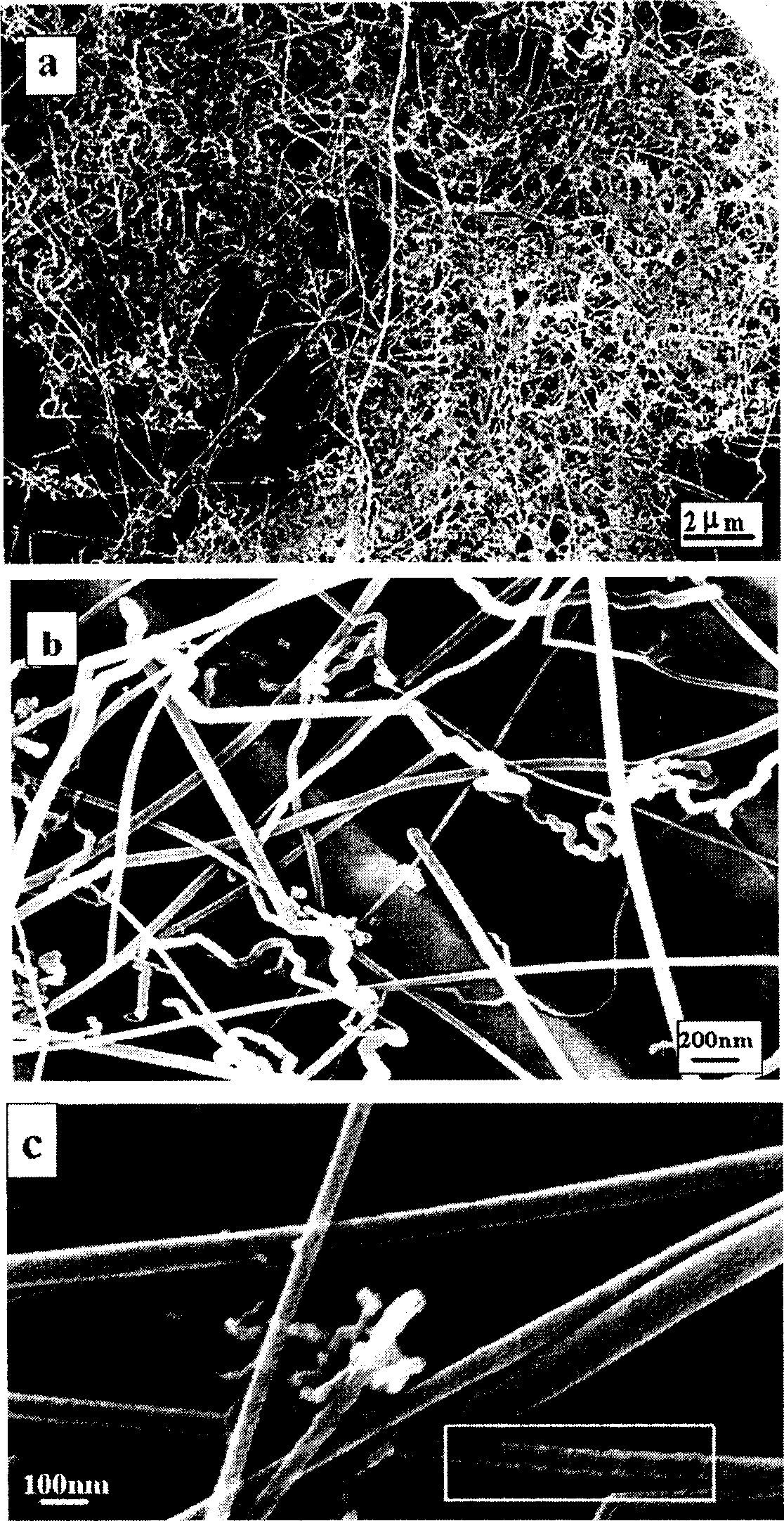

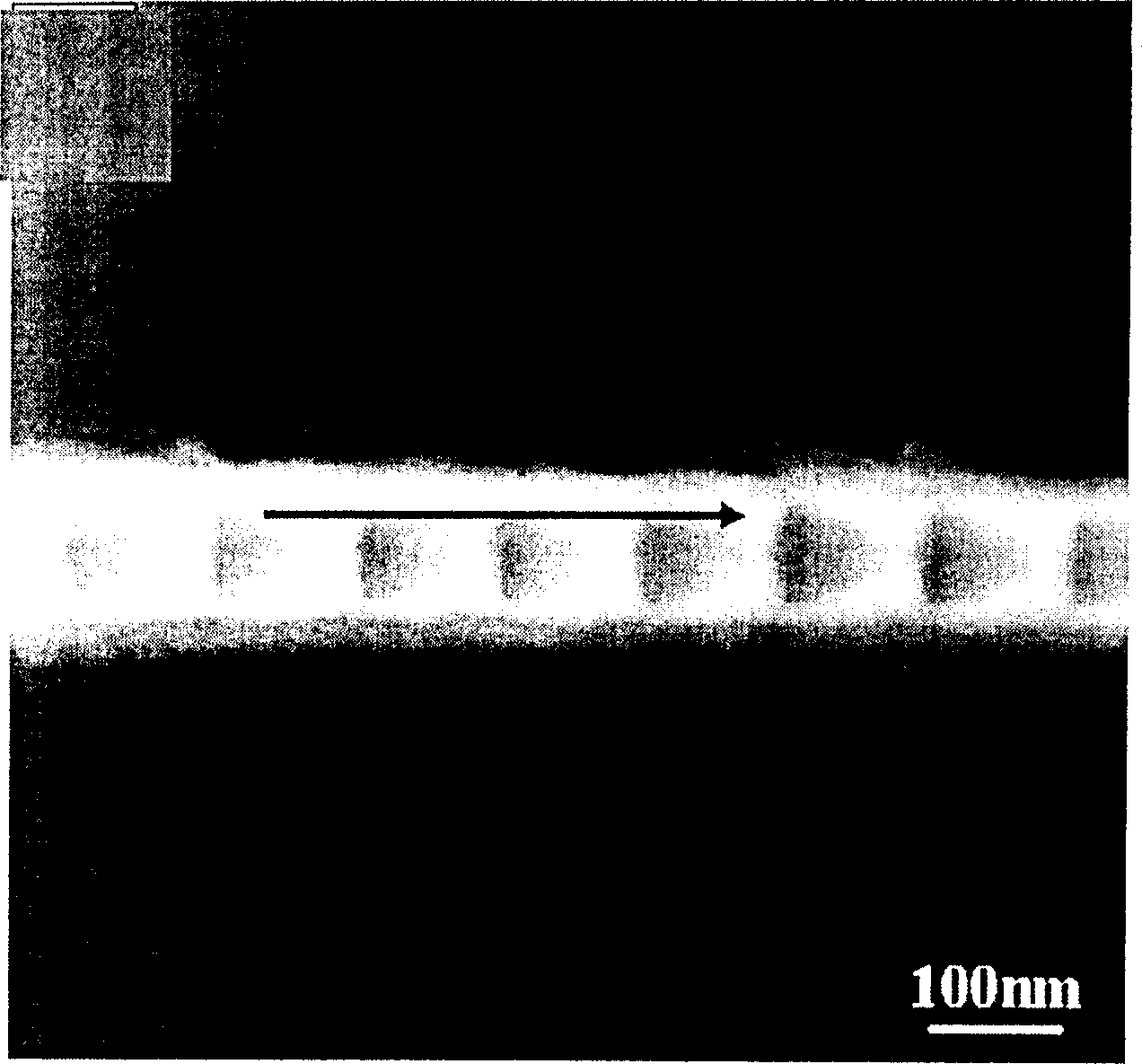

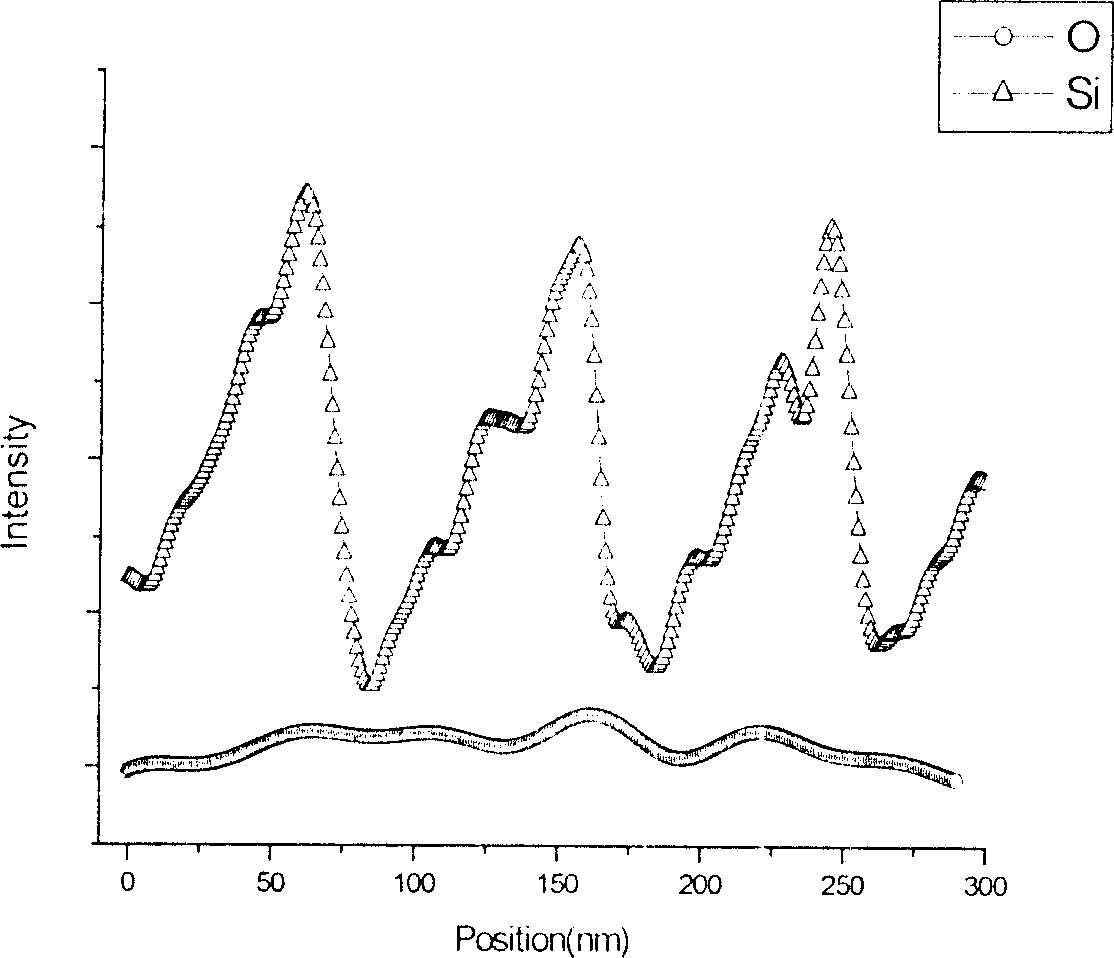

ActiveCN102139876ALarge specific surface areaNanotechnologySilicon compoundsNanowireScanning electron microscope

The invention relates to a method for preparing a silicon nanotube. SiO2 nano balls are reduced into the silicon nanotube under the action of a catalyst by using the reducing action of Mg on SiO2. The prepared silicon nanotube is gray black powder and the inner diameter of the tube is in a range of 120 to 170nm. The silicon nanotube is synthesized by the following two steps of: (1) synthesizing a SiO2 nano ball precursor by using a surfactant through the hydrothermal synthesis method; and (2) synthesizing the silicon nanotube under the action of the catalyst, such as Fe or Ni or Cu or Zn or Nb or Al or Sn or C and the like by solid-phase magnesiothermy. The silicon nanotube prepared by the method has the common characteristics of a nanowire and a hollow nano material. A scanning electron microscope test shows that the obtained material is the hollow silicon nanotube and the inner diameter of the hollow tube is in the range of 120 to 170nm. A nitrogen adsorption test at the absolute temperature of 77K shows that the specific surface area (BET) of the material is 531m<2> / g.

Owner:NANJING UNIV +1

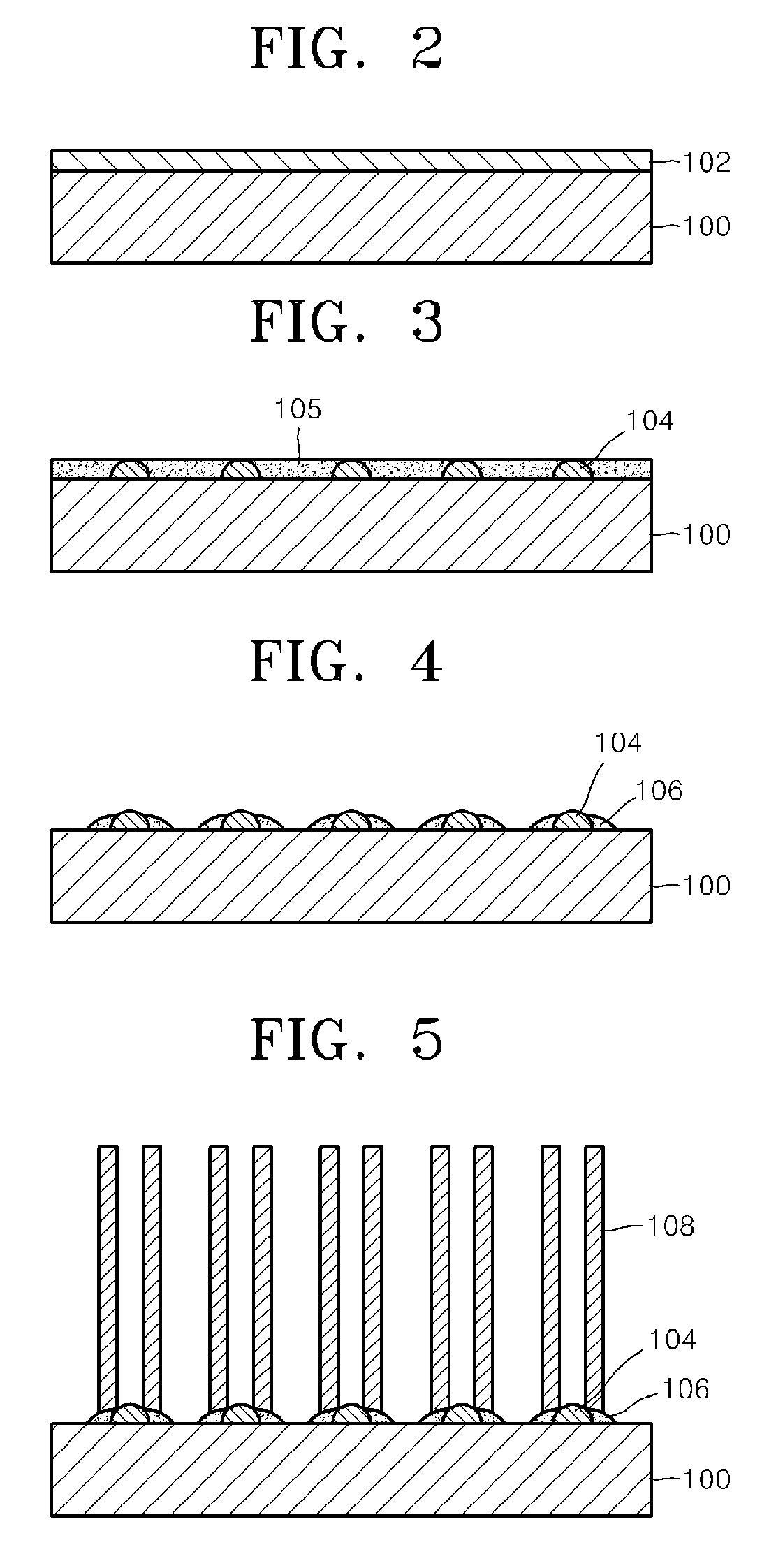

Method of manufacturing silicon nanotubes using doughnut-shaped catalytic metal layer

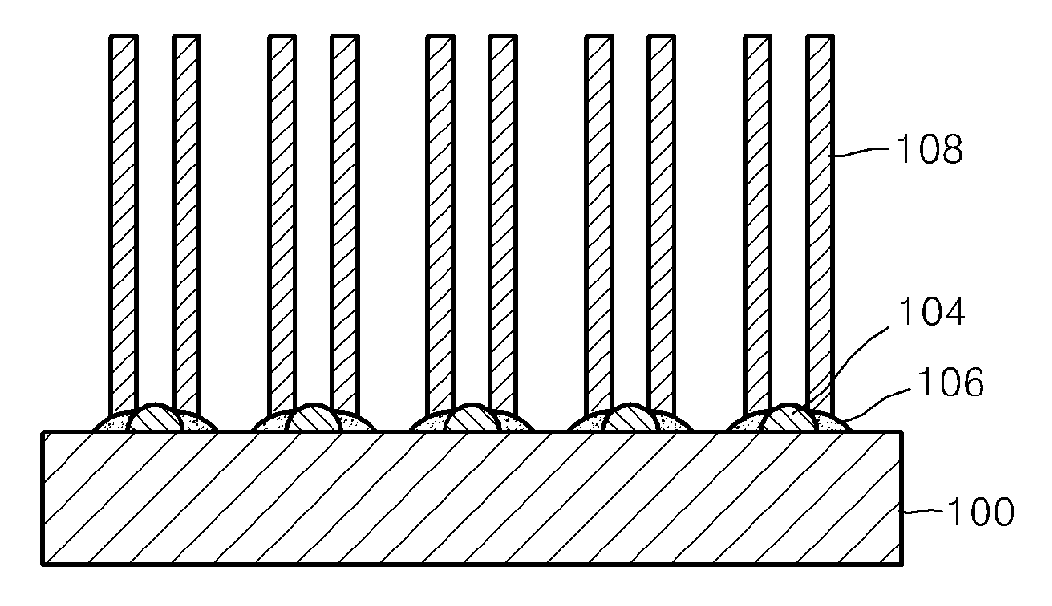

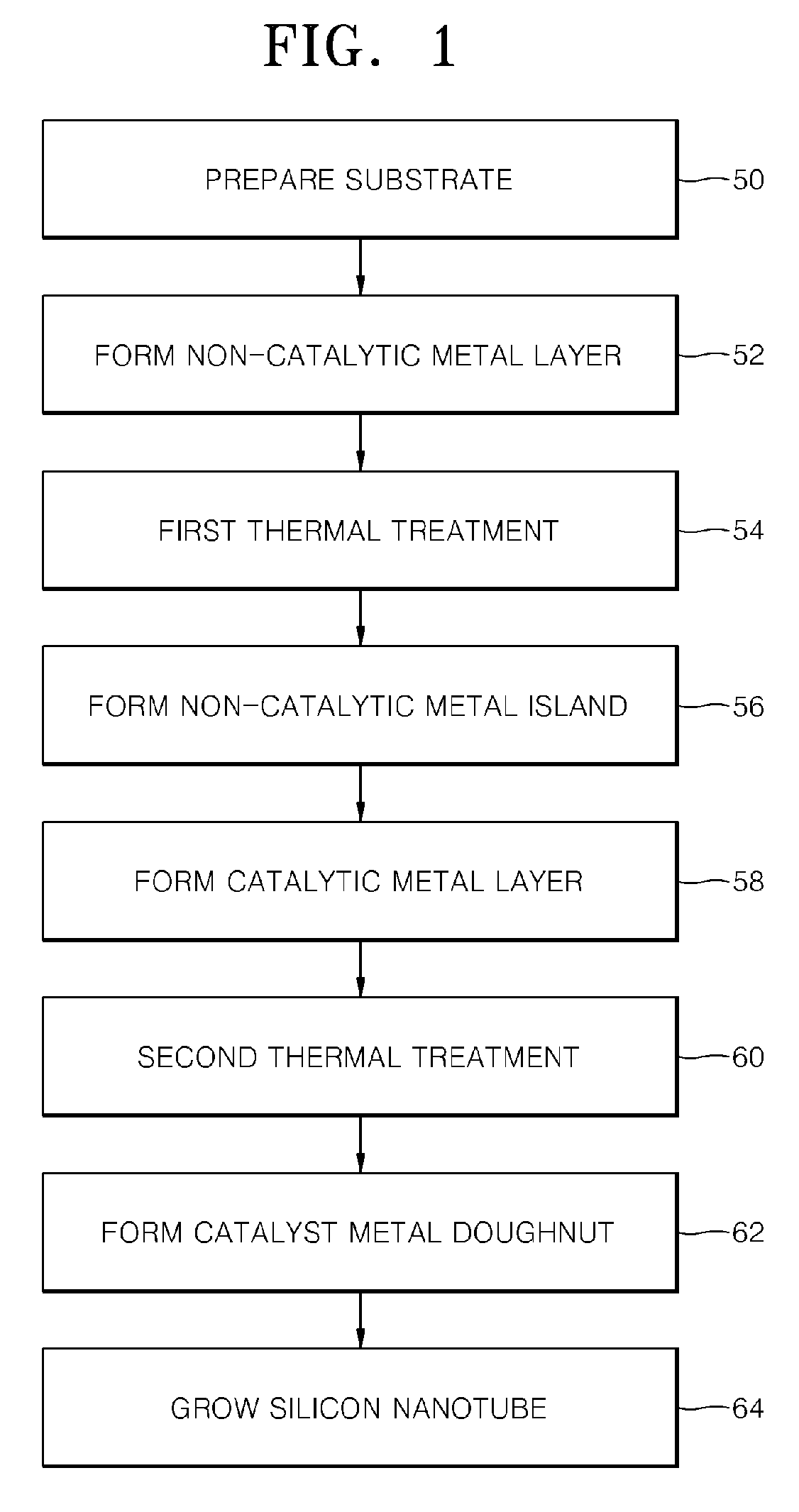

InactiveUS20090123649A1Efficient preparationMaterial nanotechnologyPolycrystalline material growthCatalytic metalSilicon

Provided is a method of manufacturing silicon nanotubes including forming non-catalytic metal islands on a substrate; forming catalyst metal doughnuts to surround the non-catalytic metal islands; and growing silicon nanotubes on the catalyst metal doughnuts. The silicon nanotubes are efficiently grown using the catalyst metal doughnuts.

Owner:ELECTRONICS & TELECOMM RES INST

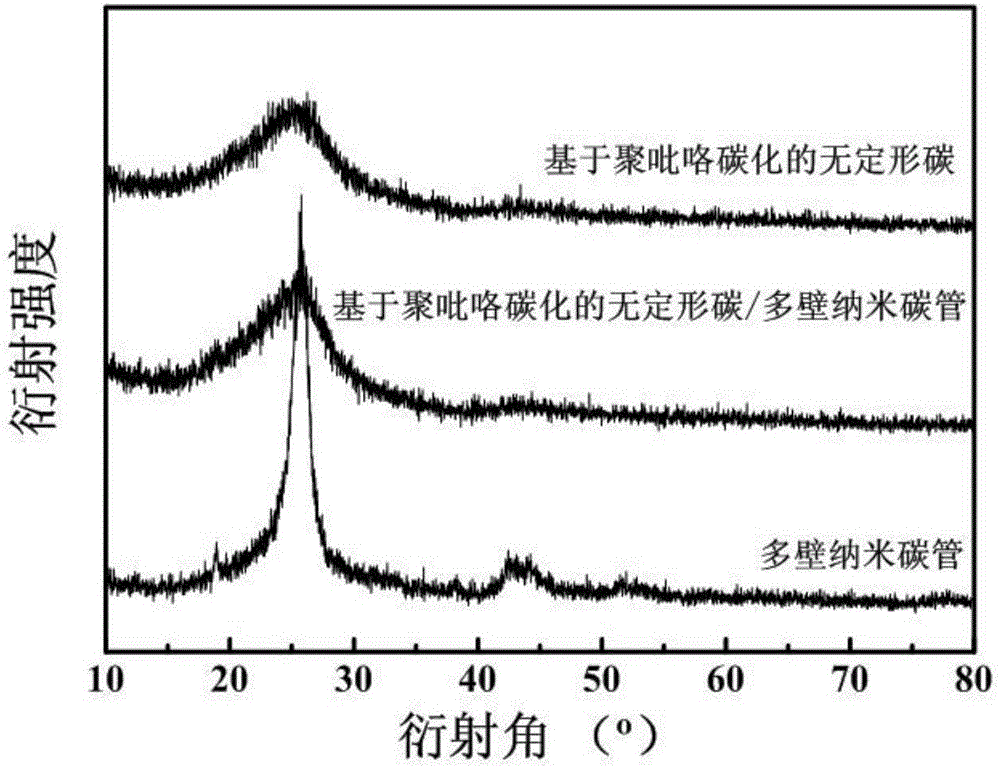

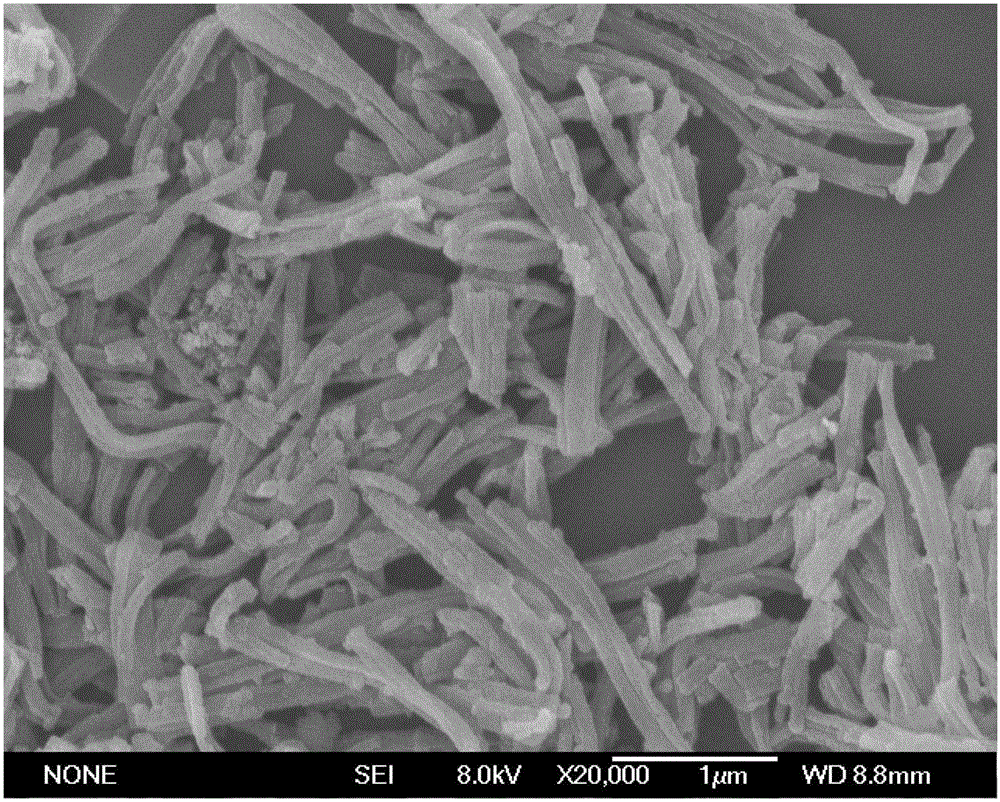

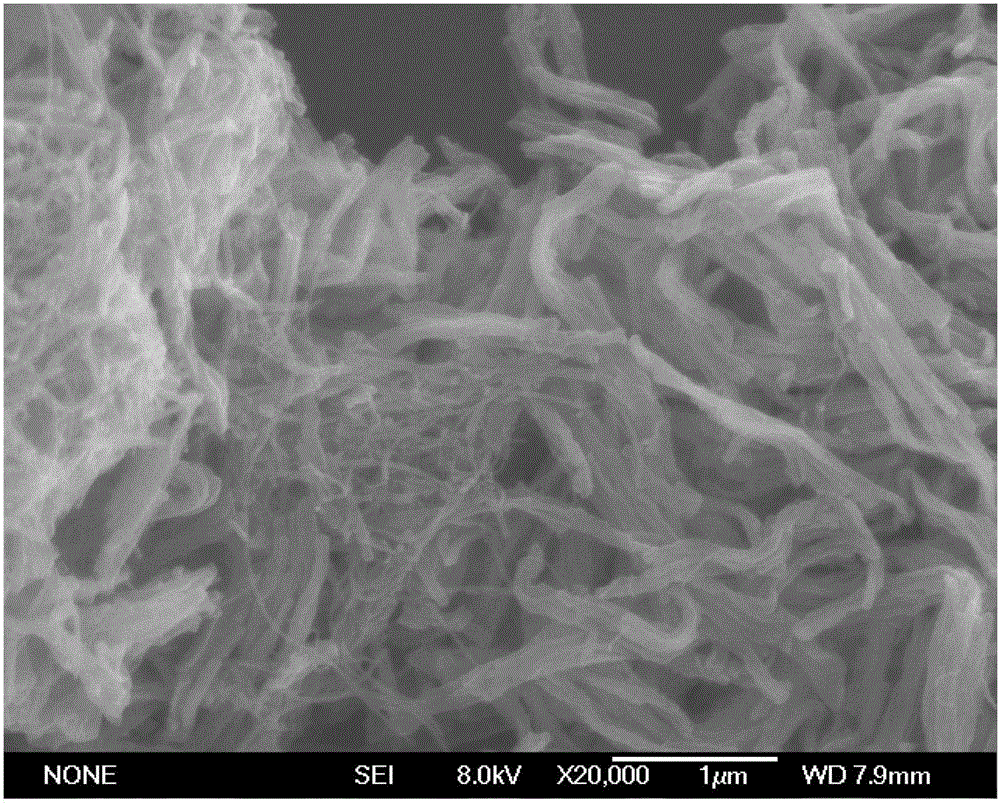

Method for manufacturing amorphous carbon and multi-walled carbon nano-tube composite electrode materials on basis of polypyrrole carbonization

InactiveCN105118997AImprove cycle performanceImprove discharge specific capacityCell electrodesSecondary cellsPolypyrroleCarbonization

The invention provides a method for manufacturing amorphous carbon and multi-walled carbon nano-tube composite electrode materials on the basis of polypyrrole carbonization, and belongs to the technical field of processes for manufacturing composite nano-materials. The method includes particular preparation steps of a, sequentially adding iron trichloride and pyrrole into methyl orange aqueous solution and stirring the iron trichloride and the pyrrole at the room temperature to obtain polypyrrole; b, washing the polypyrrole until the polypyrrole is neutral, drying the polypyrrole under a vacuum condition and carbonizing the polypyrrole in a tube furnace at the temperature of 700-970 DEG C for 1-4 hours to obtain amorphous carbon; c, magnetically stirring the amorphous carbon and multi-walled carbon nano-tubes in ethyl alcohol for 4-9 hours, and drying the amorphous carbon and the multi-walled carbon nano-tubes at the temperature of 50-70 DEG C under a vacuum condition for 10-30 hours to obtain the amorphous carbon and multi-walled carbon nano-tube composite electrode materials on the basis of polypyrrole carbonization. The method has the advantages that the amorphous carbon and multi-walled carbon nano-tube composite electrode materials on the basis of polypyrrole carbonization can be used as negative electrode materials for lithium batteries and electrode materials for super-capacitors, are excellent in electrochemical performance, free of memory effects or pollution and low in self-discharge rate, and the method is low in cost and simple in process.

Owner:JILIN UNIV

One-dimensional ring shaped Nano silicon material and preparation

A process for preparing the one-dimensional silicon nanotubes with bamboo shape includes preparing multi-pore aluminium oxide template by anodizing method, depositing Au in the pores of template by AC deposition method, dissolving the template in NaOH solution to obtain Au nanoparticles, dispersing them in absolute alcohol, loading it as catalyst in ceramic utensil as the substrate to grow silicon, putting it in the center of tubular furnace, filling the mixture of SiH4 and H2, growing said silicon nanotubes on the inner surface of ceramic utencil, closing SiH4 gas, and natural cooling.

Owner:XIAMEN UNIV

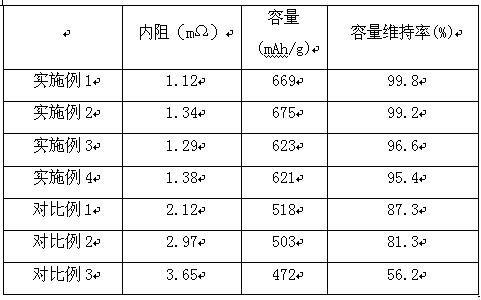

Silicon nanotube composite negative electrode material used for lithium battery and preparation method

ActiveCN107863517AGood effectSmall volume changeMaterial nanotechnologyCell electrodesCarbon layerGram

The invention relates to the technical field of a lithium battery, and particularly relates to a silicon nanotube composite negative electrode material used for a lithium battery and a preparation method. The silicon nanotube composite negative electrode material used for the lithium battery consists of a substrate and composite nanotubes vertically arranged on the substrate; and the composite nanotubes consist of silicon nanotubes, a titanium dioxide thin film and an amorphous form carbon layer from inside to outside in sequence. According to the silicon nanotube composite negative electrodematerial used for the lithium battery provided by the invention, in a charging-discharging process, the lateral volume effect in the Li de-intercalation process is relatively low, Li de-intercalationcan be quicker and more complete, the reversible specific capacity can be higher, a more stable SEI film can be formed, and the material coulombic efficiency can be improved; by virtue of a titanium oxide coating layer, volume change can be further suppressed, the service life and safety of the material can be prolonged and improved; and by virtue of C coating layer, the gram volume and electricalconductivity of the material can be improved.

Owner:湖北冠毓新材料科技有限公司

Silicon anode of lithium ion battery

InactiveCN106531970AGood flexibilityGood chemical stabilityCell electrodesSecondary cellsCyclic processSilicon dioxide

The invention discloses a silicon anode of a lithium ion battery. The silicon anode is formed by bonding a conductive agent and an anode material, the anode material comprises anode active matter and a binding material, the anode active matter comprises graphite and silicon dioxide, and the binding material is an organic solvent type binding agent. A conductive agent is of a silicon nanotube ball structure and comprises a plurality of evenly distributed silicon nanotubes, and the anode material is attached to the surfaces of the silicon nanotubes. A carbon material has high electronic conductivity and ionic conductivity, the rate capacity of the silicon material can be improved, and the volume effect of silicone in the circulating process can be inhibited. The silicon anode has high battery capacity and circulating stability.

Owner:SUZHOU GREEN POWER TECH CO LTD

Synthetic method for size-controllable silicon nanotubes for lithium ion batteries

InactiveCN107352544AImprove volume expansion effectSolve the volume expansion effectMaterial nanotechnologySilicon compoundsSynthesis methodsMesoporous silica

The invention discloses a synthesis method of size-controllable silicon nanotubes for lithium ion batteries. The method comprises the steps as follows: firstly, magnetically stirring a silicon source, a template agent, a dispersant, a catalyst and a solvent at a temperature of 20-35 DEG C for 12-24 hours, and performing centrifugation and drying to obtain mesoporous silica nanorods; then dispersing the mesoporous silica nanorods in a solvent, adding a surfactant with a surface protection effect and an etching effect, heating the mixed solution to 90-150 DEG C, performing magnetic stirring for 2-12 hours, allowing the mixed solution to stand for 2-8 hours, and performing centrifugation, cleaning and vacuum drying to constant weight to obtain silica nanotubes; finally, calcining the silica nanotubes with a reducing agent in a tube furnace at 640-670 DEG C under the protection of argon for 2-4 h to obtain the silicon nanotubes. The synthesis method has the characteristics that the volume expansion effect in the processes of charge and discharge of silicon lithium ion battery anode materials can be well solved, and the length / diameter ratio and the thickness dimension of the silicon nanotubes can be effectively controlled.

Owner:GUIZHOU UNIV

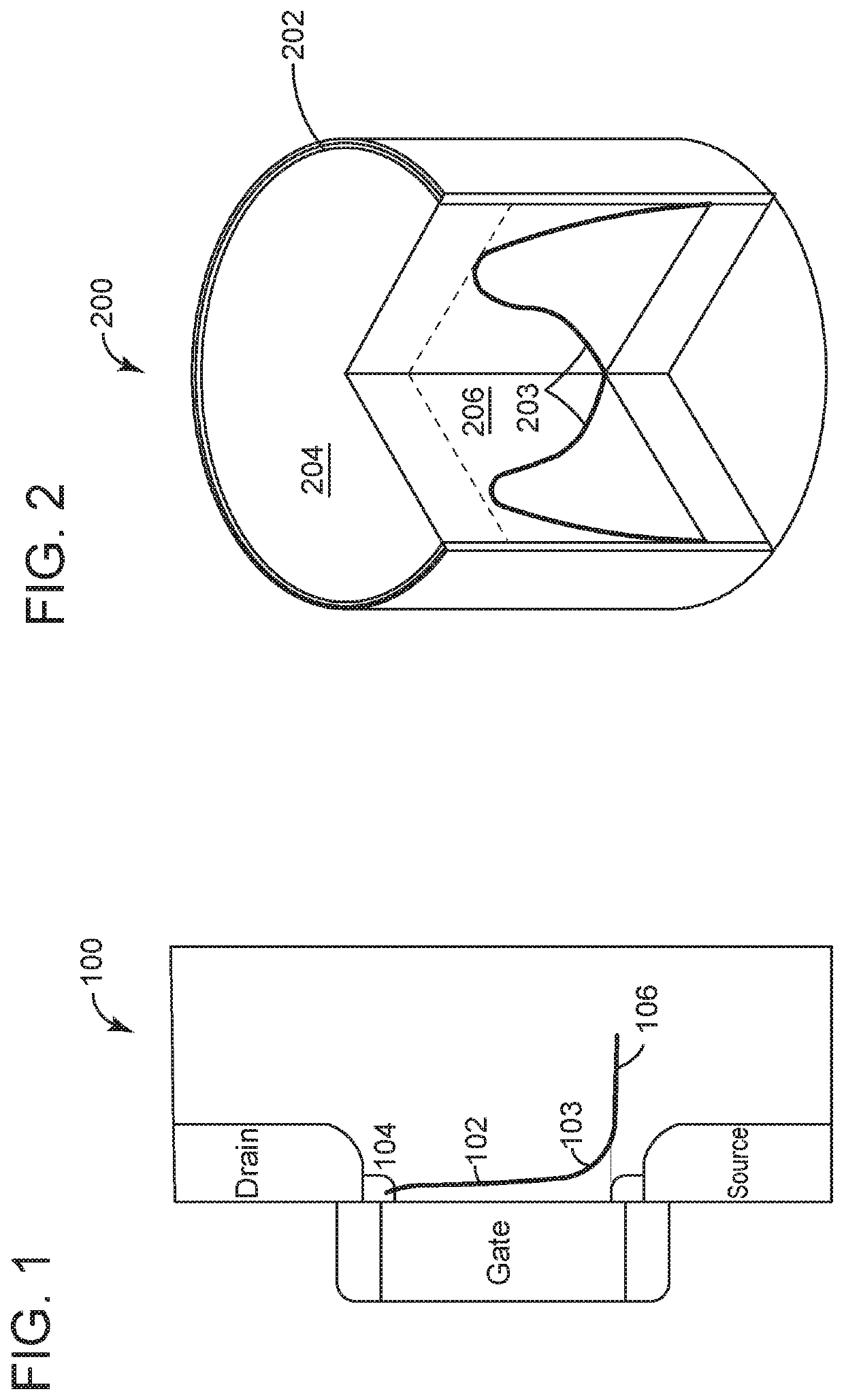

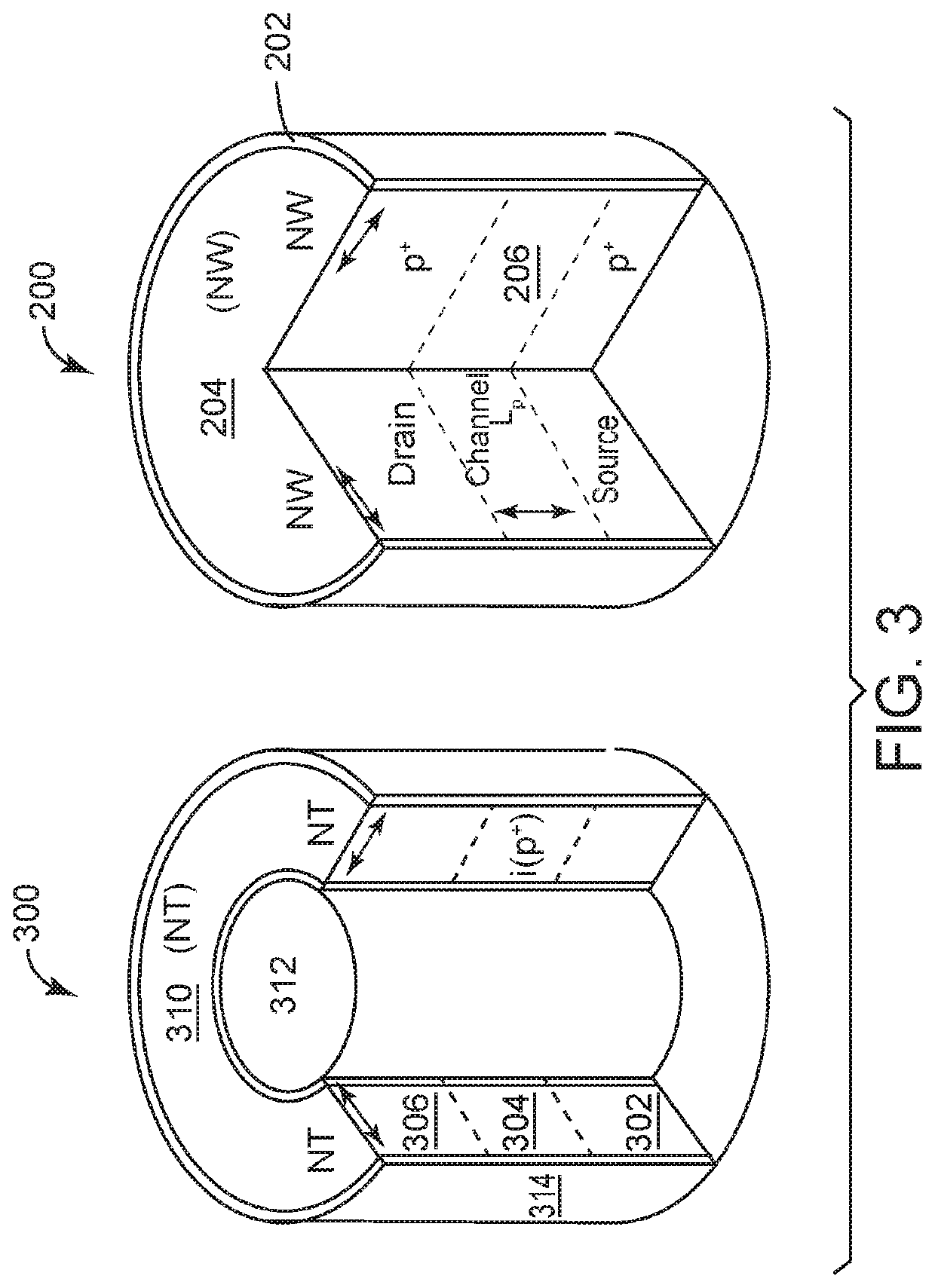

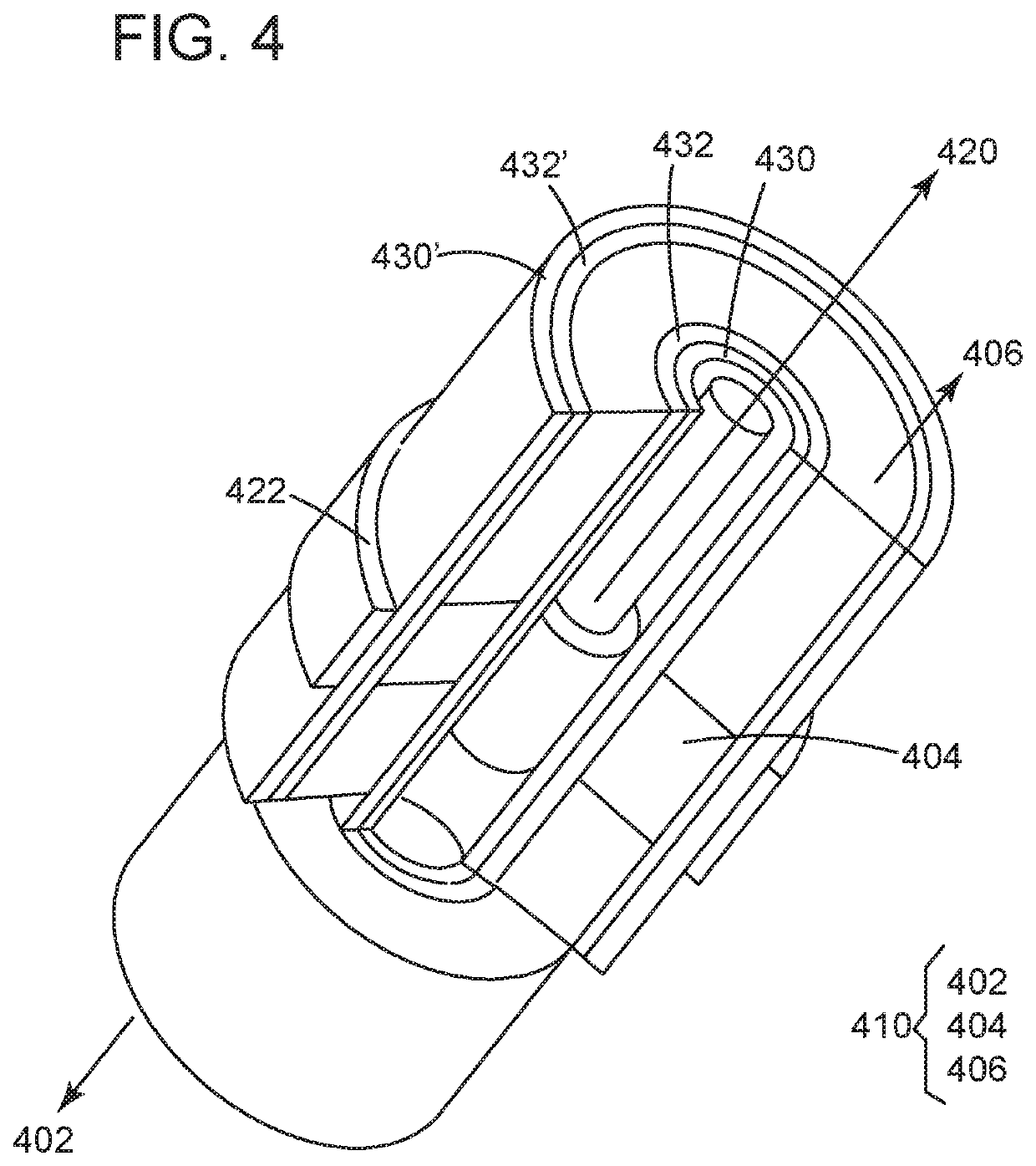

Silicon nanotube, negative-capacitance transistor with ferroelectric layer and method of making

There is a an electronic device that includes a substrate; a body including plural layers, the body being formed on top of the substrate; a nanotube trench formed vertically in the body and extending to the substrate; and a nanotube structure formed in the nanotube trench. The nanotube structure is mechanically separated from the body by a gate dielectric layer and a ferroelectric layer.

Owner:KING ABDULLAH UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com