Preparation method of graphite/carbon nano-tube array composite heat conducting film

A carbon nanotube and thermally conductive film technology, applied in nanotechnology and other directions, can solve the problems of large changes, reduced specific surface area, easy agglomeration, etc., to reduce the interface thermal resistance, increase the radiation area, and improve the heat transfer effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

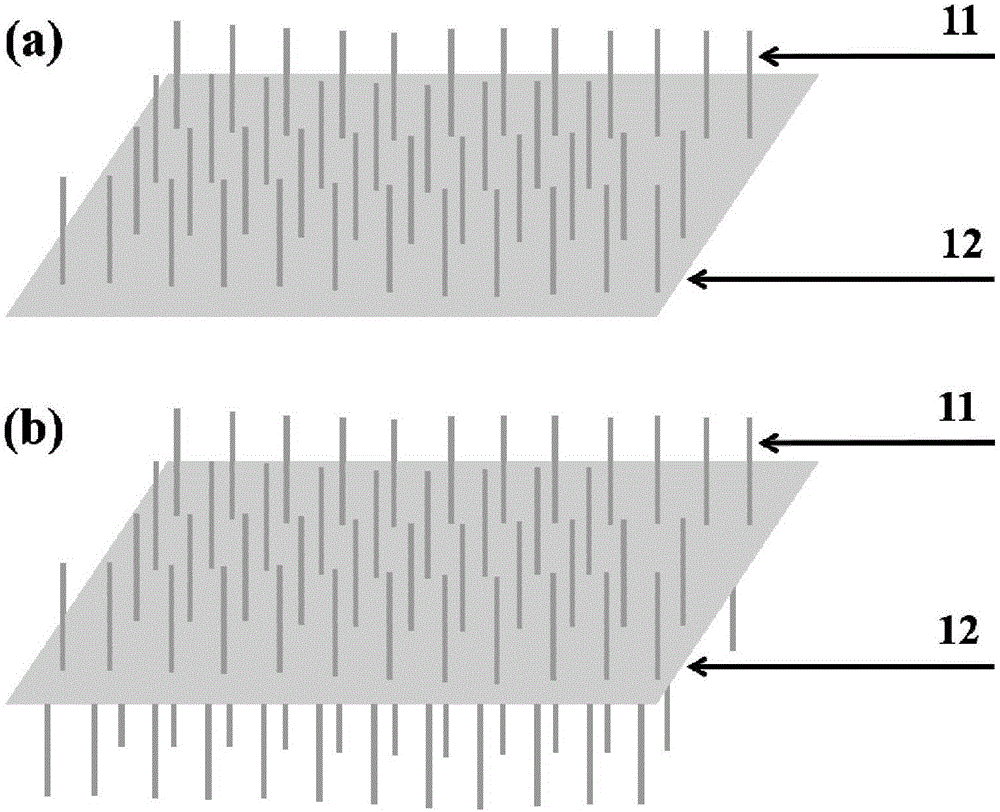

[0028] Such as figure 1 As shown in (a), a graphite / carbon nanotube array composite heat-conducting film includes: a graphite film 12 and a carbon nanotube array vertically grown on the upper surface of the graphite film, wherein the thickness of the graphite film can be 10-100 μm, and the nanocarbon The thickness of the tube array can be 1-200 μm. In this specific embodiment, the thickness of the graphite film is 100 μm, and the thickness of the carbon nanotube array is 200 μm.

Embodiment II

[0030] Such as figure 1 As shown, a graphite / carbon nanotube array composite heat-conducting film includes: graphite film 12 and carbon nanotube arrays grown vertically on the upper surface and the lower surface of the graphite film, wherein the thickness of the graphite film can be 10-100 μm, and the nanocarbon The thickness of the tube array can be 1-200 μm. In this specific embodiment, the thickness of the graphite film is 10 μm, and the thickness of the carbon nanotube array is 1 μm.

[0031] Preferably, the graphite film and the carbon nanotube array are produced by a one-step method.

[0032] A specific implementation of a method for preparing a carbon nanotube array / graphite composite thermally conductive film is as follows:

Embodiment 1

[0034] In this example, iron is used as a catalyst, and its loading implementation process is as follows:

[0035] One of the surfaces of the graphite film is loaded with an iron catalyst layer by magnetron sputtering technology; the graphite film is placed in the constant temperature zone of the vapor deposition furnace, and the graphite film is placed in the reducing atmosphere Ar / H 2 Under the program, the temperature was raised to 400 ° C and kept for 2 hours, and the reduction treatment of the catalyst was carried out, wherein Ar / H 2 The flow rate is 900mL / min, H 2 The volume fraction is 20%.

[0036] After the temperature is programmed to 800°C, switch the gas to carbon source gas C 2 h 4 / Ar / H 2 Keep for 2h, deposit the carbon nanotube array, switch to the reducing atmosphere Ar / H after the end 2 and down to room temperature, where C 2 h 4 / Ar / H2 The flow rate is 900mL / min, C 2 h 4 and H 2 The volume fraction is 25%.

[0037] Then, graphitization treatment i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com