Automatic bothway sand-blasting machine

A sandblasting machine and automatic technology, applied in the field of sandblasting machines, can solve the problems of quartz sand waste, difficulty in collection, dust explosion, etc., achieve the effect of large sandblasting radiation area, improve processing efficiency, and reduce processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

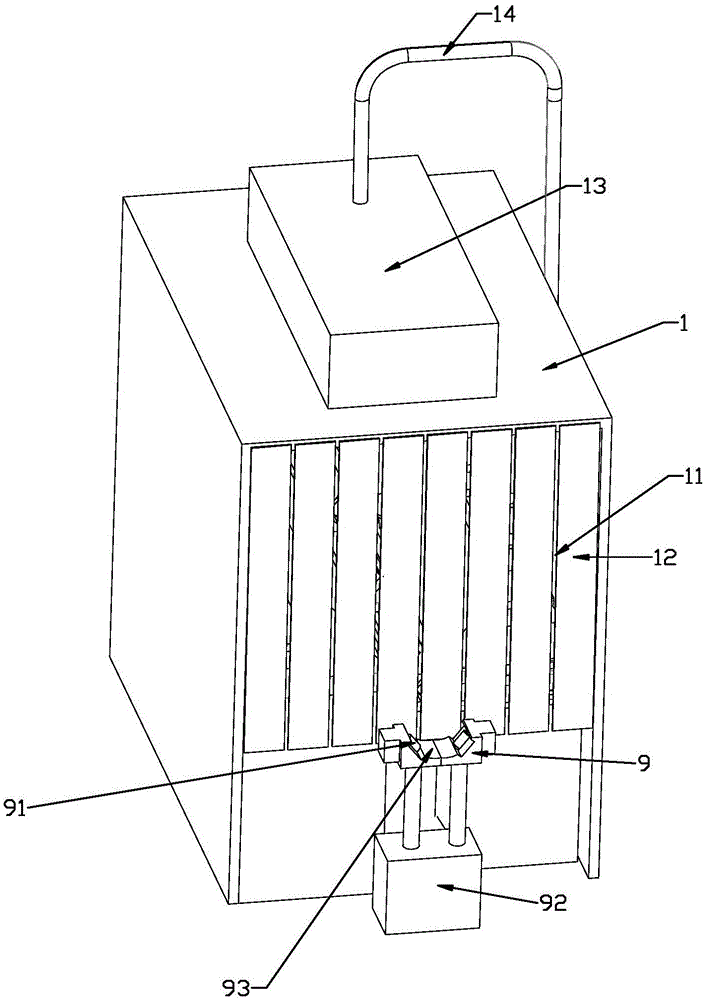

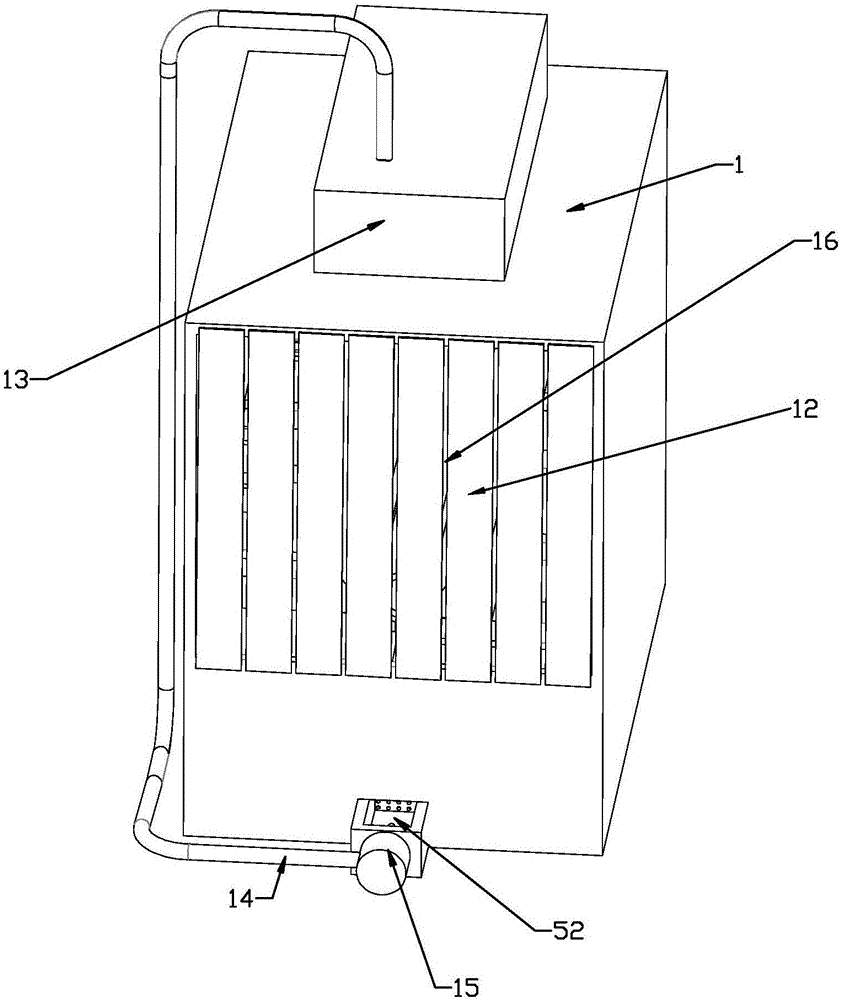

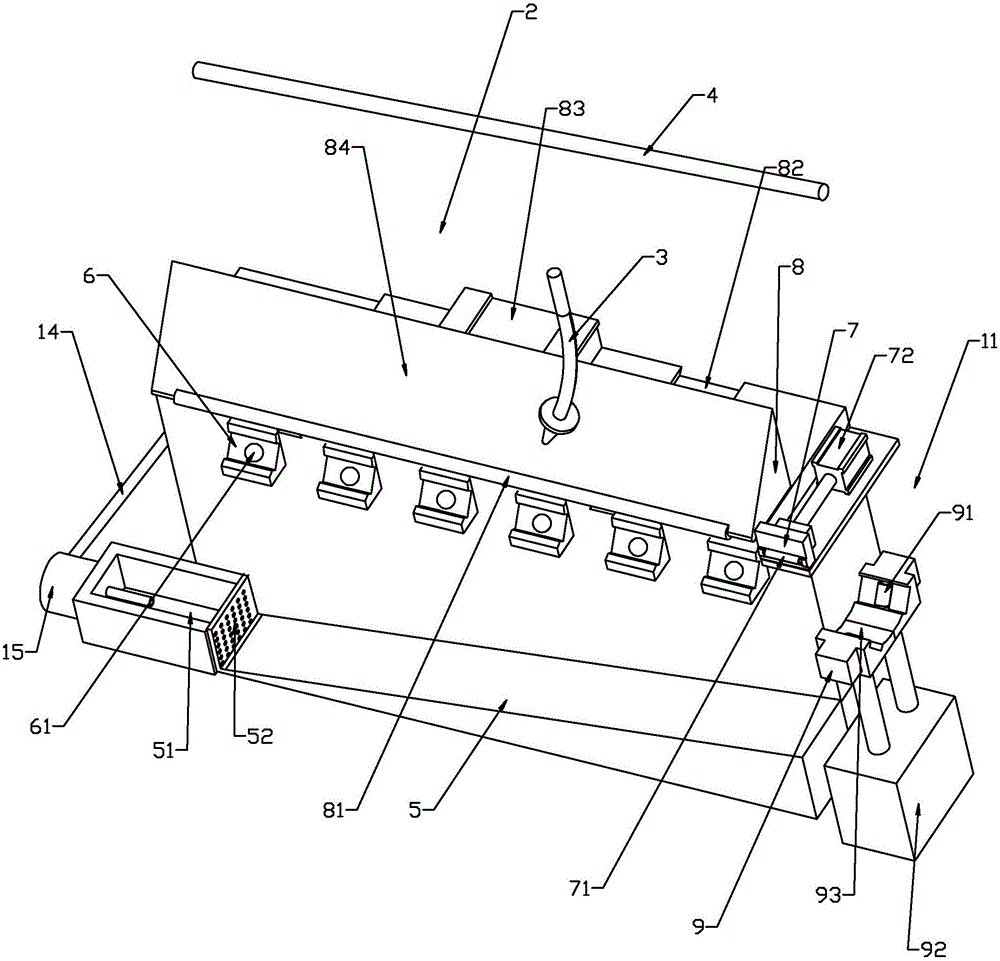

[0018] Such as figure 1 — Figure 4 As shown, the present invention discloses a two-way automatic sandblasting machine, comprising a housing 1, figure 2 The sandblasting chamber 2 is only located on one side of the pipeline, and the other side is symmetrically arranged with respect to the pipe body. The shell 1 is provided with a sandblasting chamber 2, and sandblasting heads 3 are arranged in the sandblasting chamber 2. The casing 1 is provided with a push port 11 for pushing pipe fittings into the sandblasting chamber 2 and a delivery port 16 for sending out of the sandblasting chamber. The casing 1 is located at the push port 11 and the delivery port 16 and is respectively provided with a dust-proof part covering the push port 11. , the dust-proof part is composed of several dust-proof units 12 arranged in sequence along the transverse direction of the push-in port 11. The dust-proof units 12 are made of soft materials and hang down naturally. The circulation device incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com