Patents

Literature

4891results about "Abrasive blasting machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

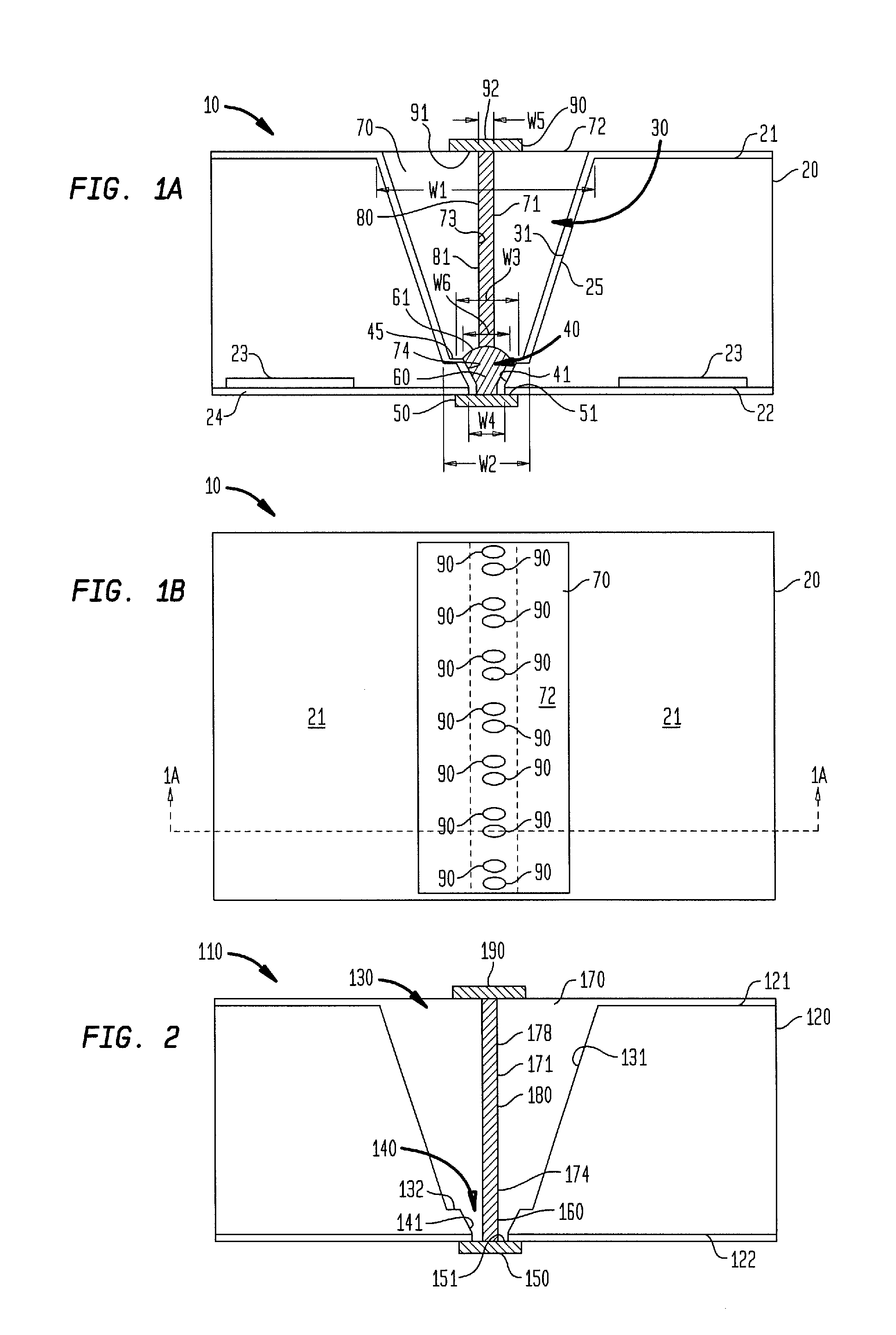

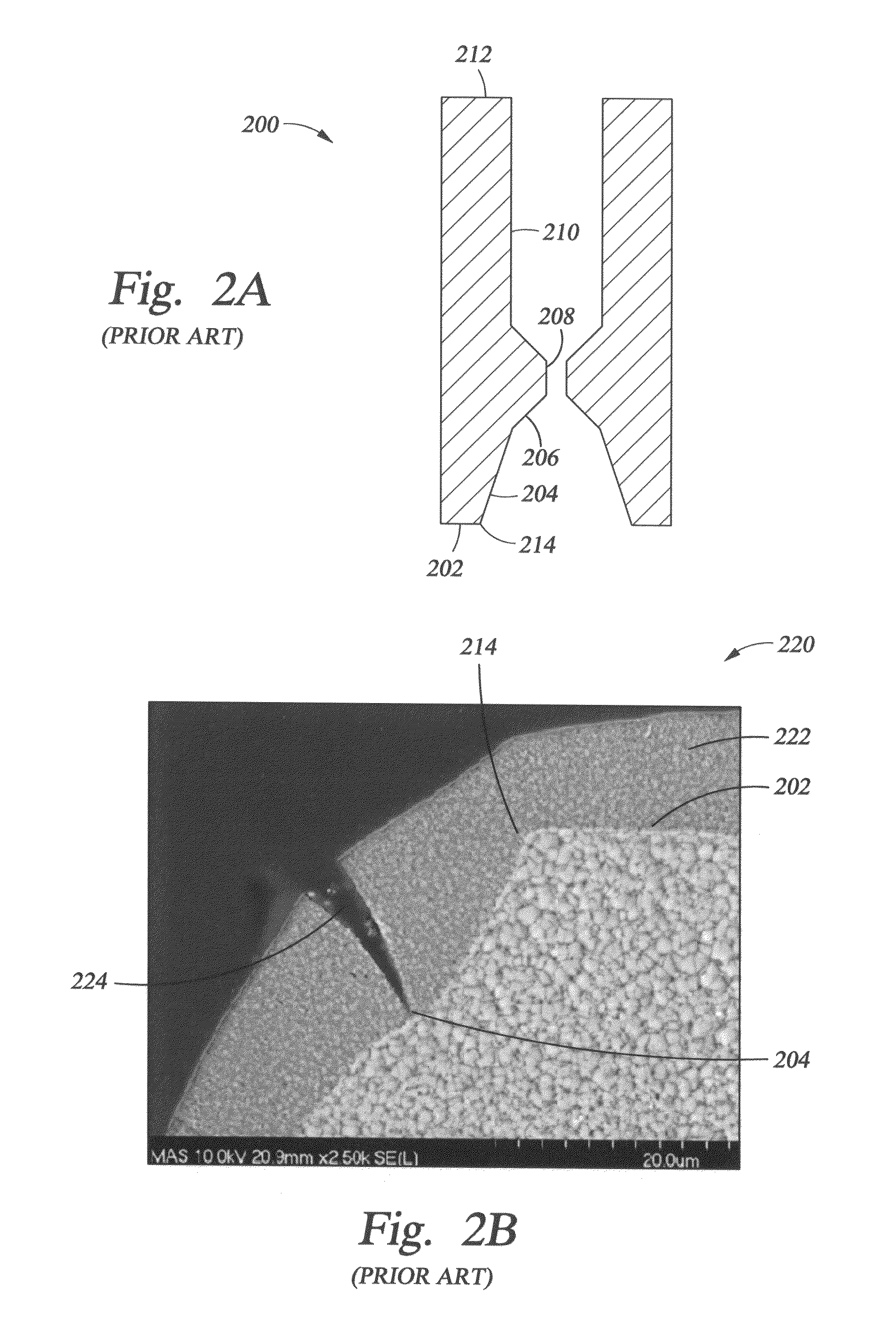

Methods of forming semiconductor elements using micro-abrasive particle stream

ActiveUS20120018893A1Semiconductor/solid-state device detailsSolid-state devicesDevice materialElectrical connection

A method of fabricating a microelectronic unit includes providing a semiconductor element having a front surface and a rear surface remote from the front surface, forming at least one first opening extending from the rear surface partially through the semiconductor element towards the front surface by directing a jet of fine abrasive particles towards the semiconductor element, and forming at least one conductive contact and at least one conductive interconnect coupled thereto. The semiconductor element can include a plurality of active semiconductor devices therein. The semiconductor element can include a plurality of conductive pads exposed at the front surface. Each conductive interconnect can extend within one or more of the first openings and can be coupled directly or indirectly to at least one of the conductive pads. Each of the conductive contacts can be exposed at the rear surface of the semiconductor element for electrical connection to an external device.

Owner:TESSERA INC

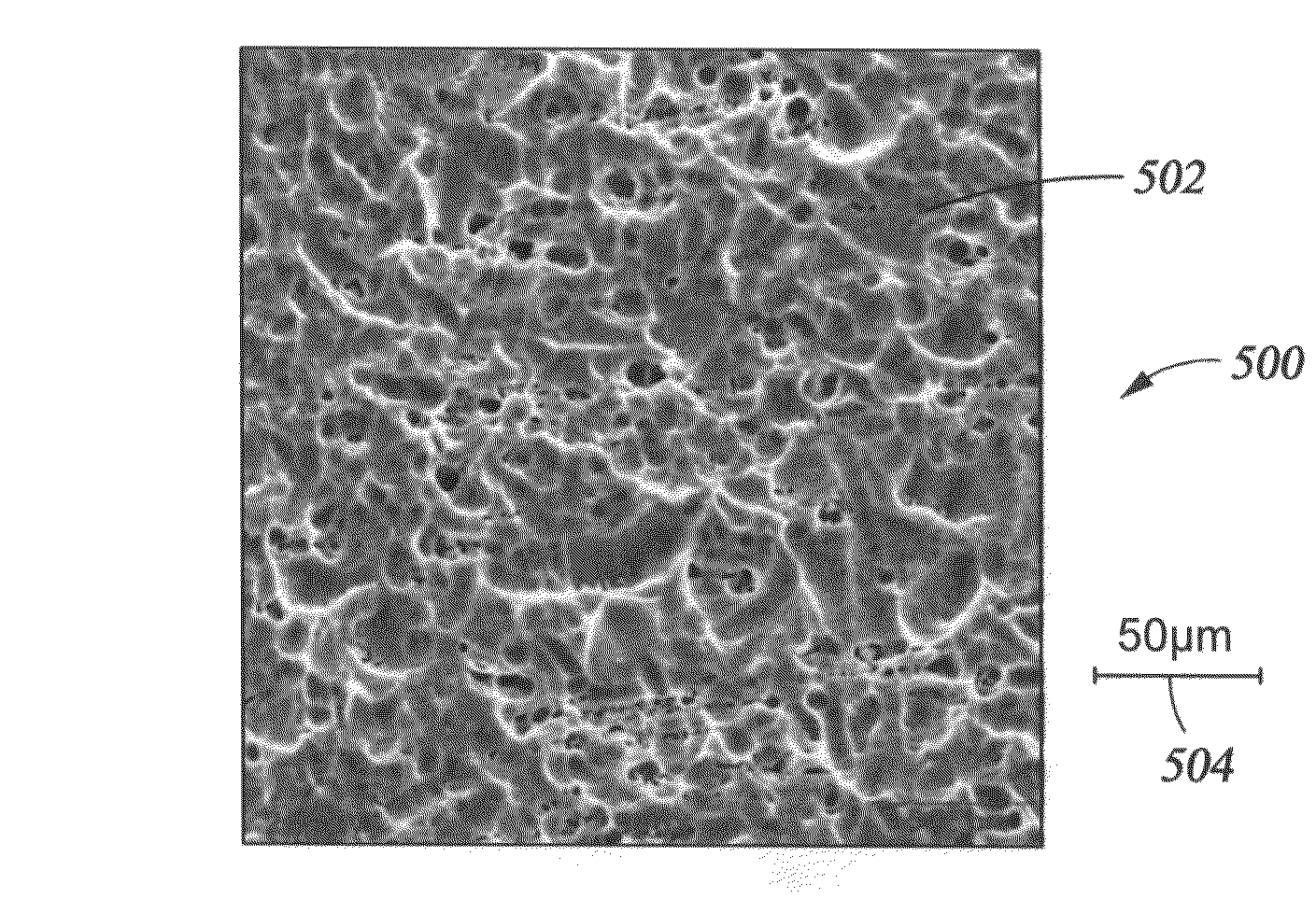

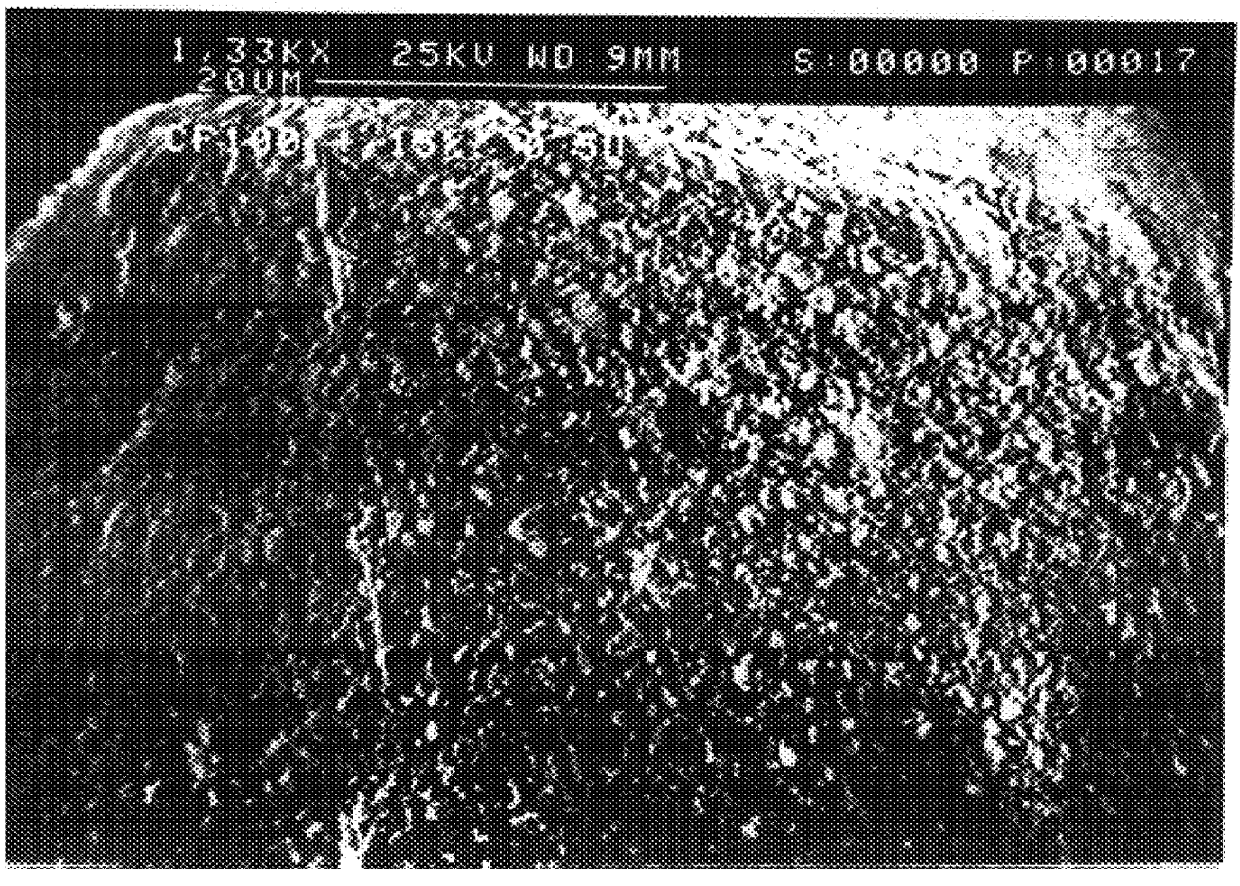

Particle reduction on surfaces of chemical vapor deposition processing apparatus

A method of reducing the amount of particulates generated from the surface of a processing component used during plasma enhanced chemical vapor deposition of thin films. The body of the processing component comprises an aluminum alloy, and an exterior surface of said processing component is texturized to increase the amount of surface area present on the exterior surface. The texturizing process includes at least one step in which the surface to be texturized is bead blasted or chemically grained, so that the surface roughness of the texturized surface ranges from about 50 μ-inch Ra to about 1,000 μ-inch Ra.

Owner:APPLIED MATERIALS INC

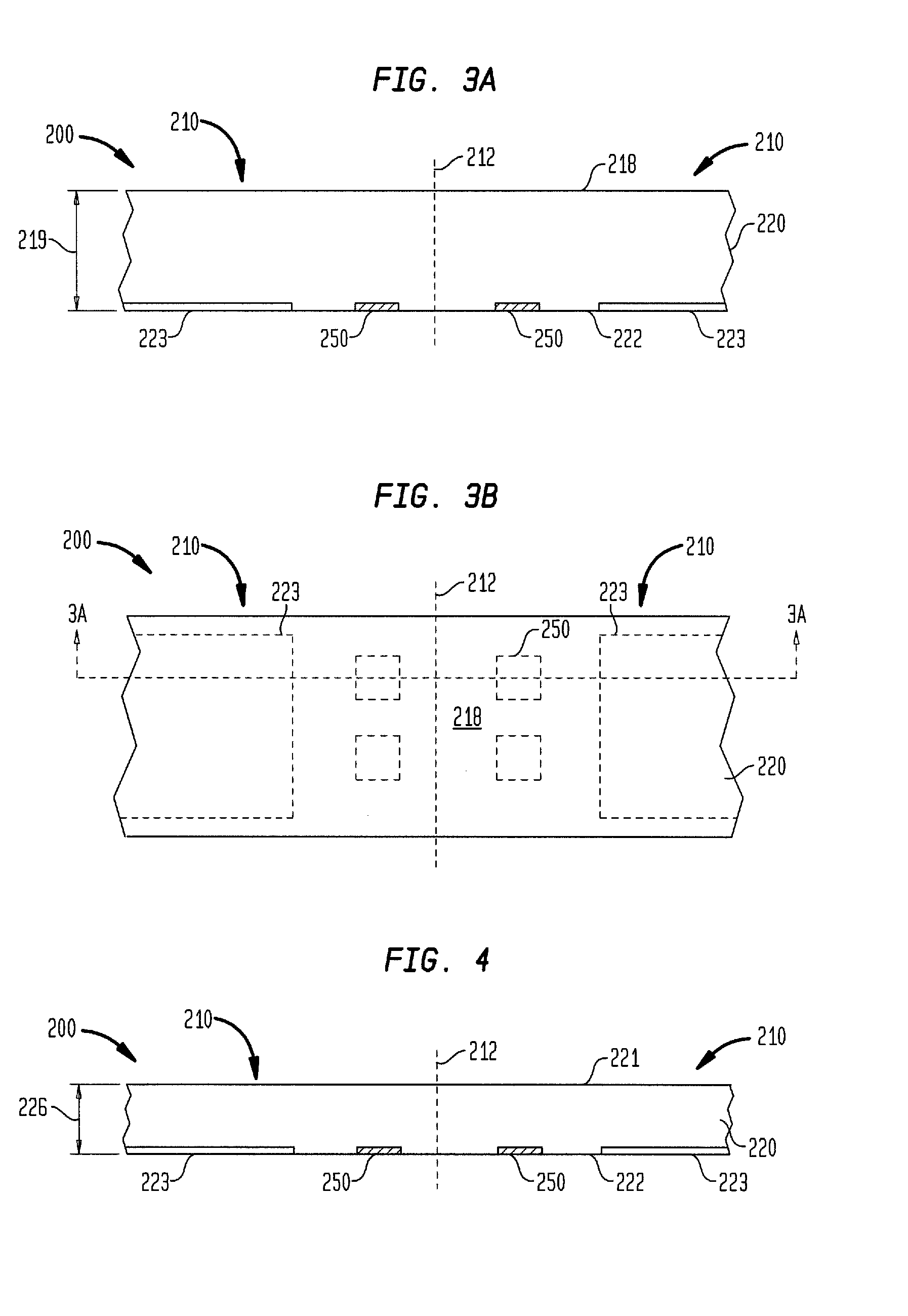

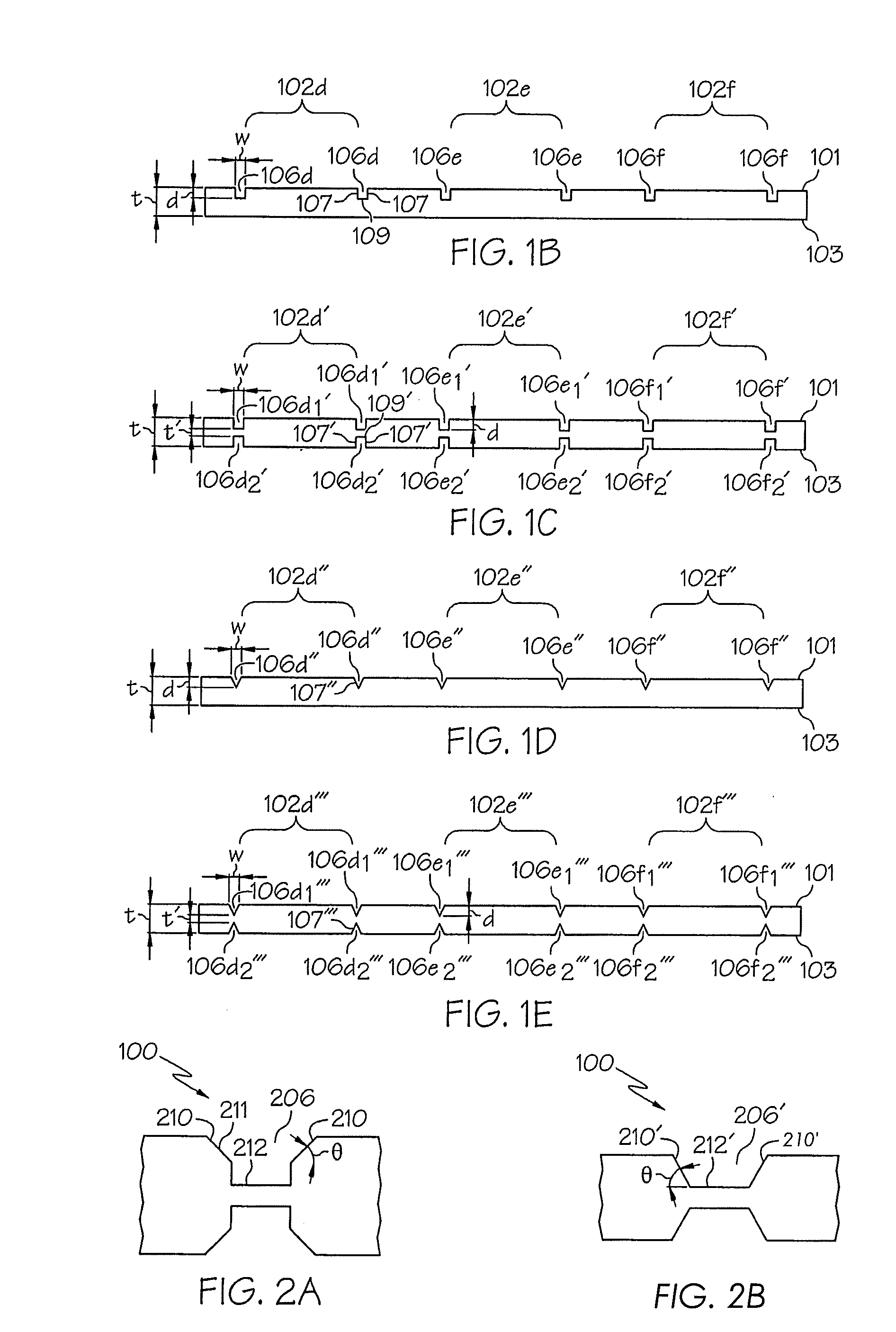

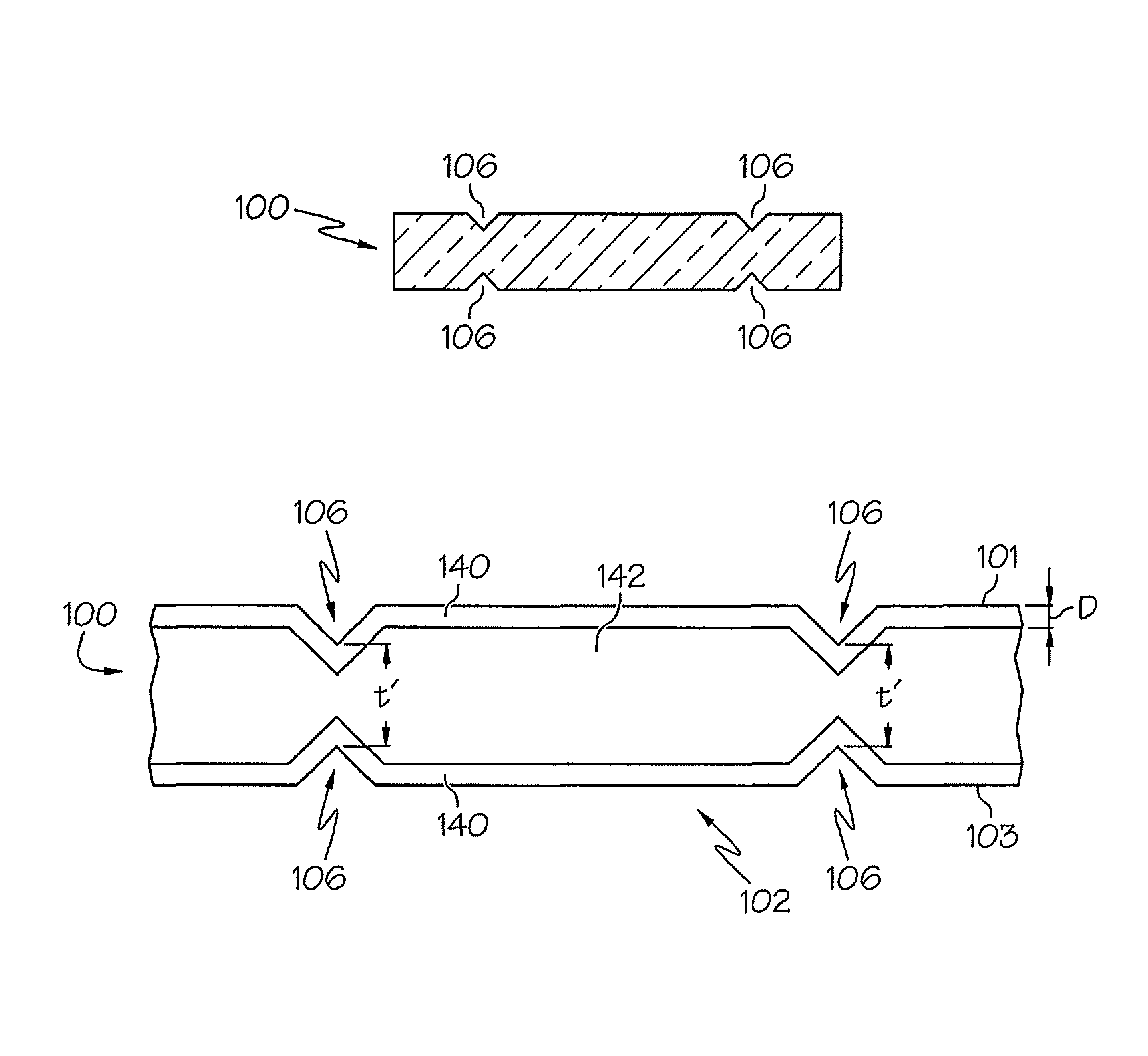

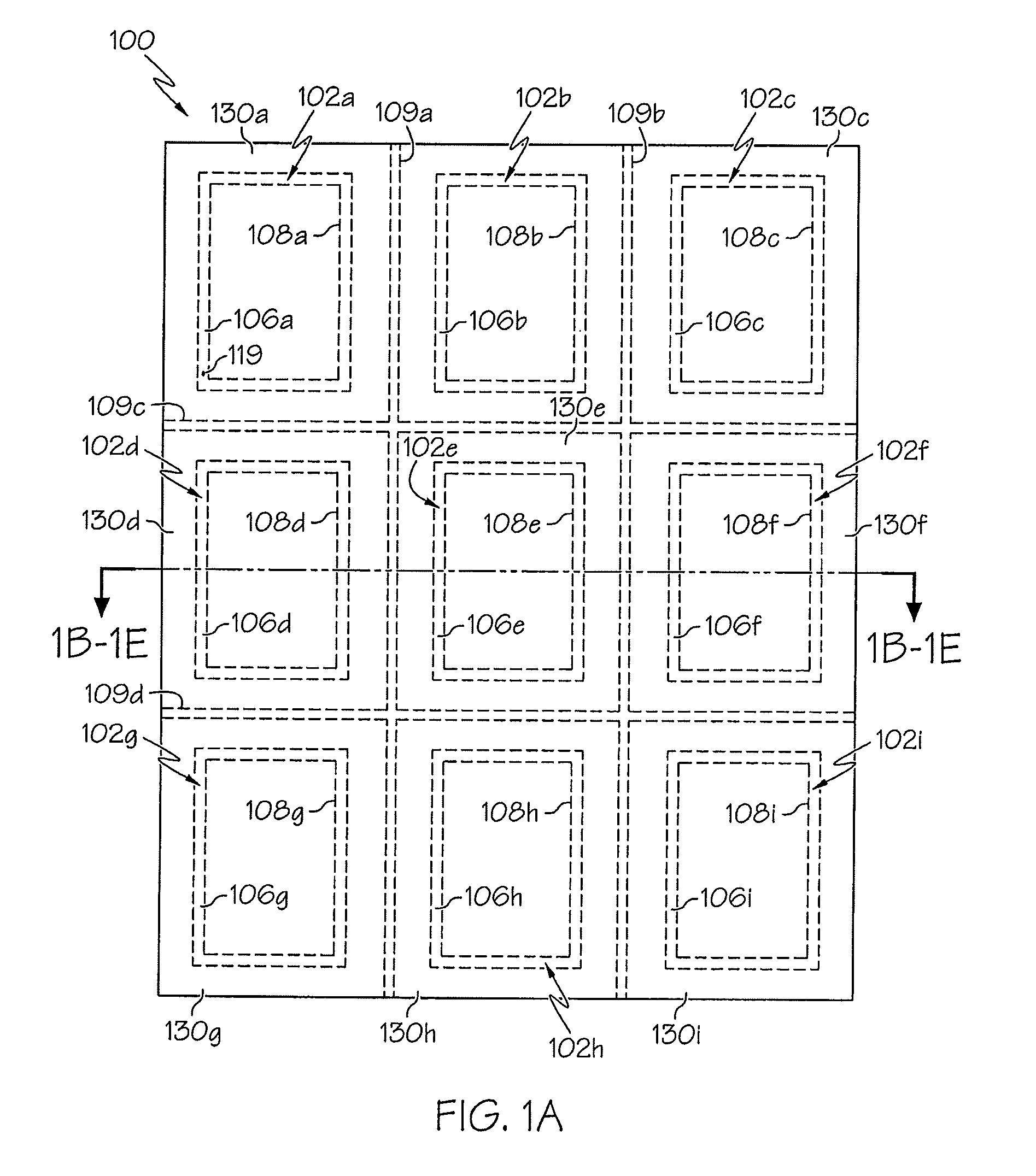

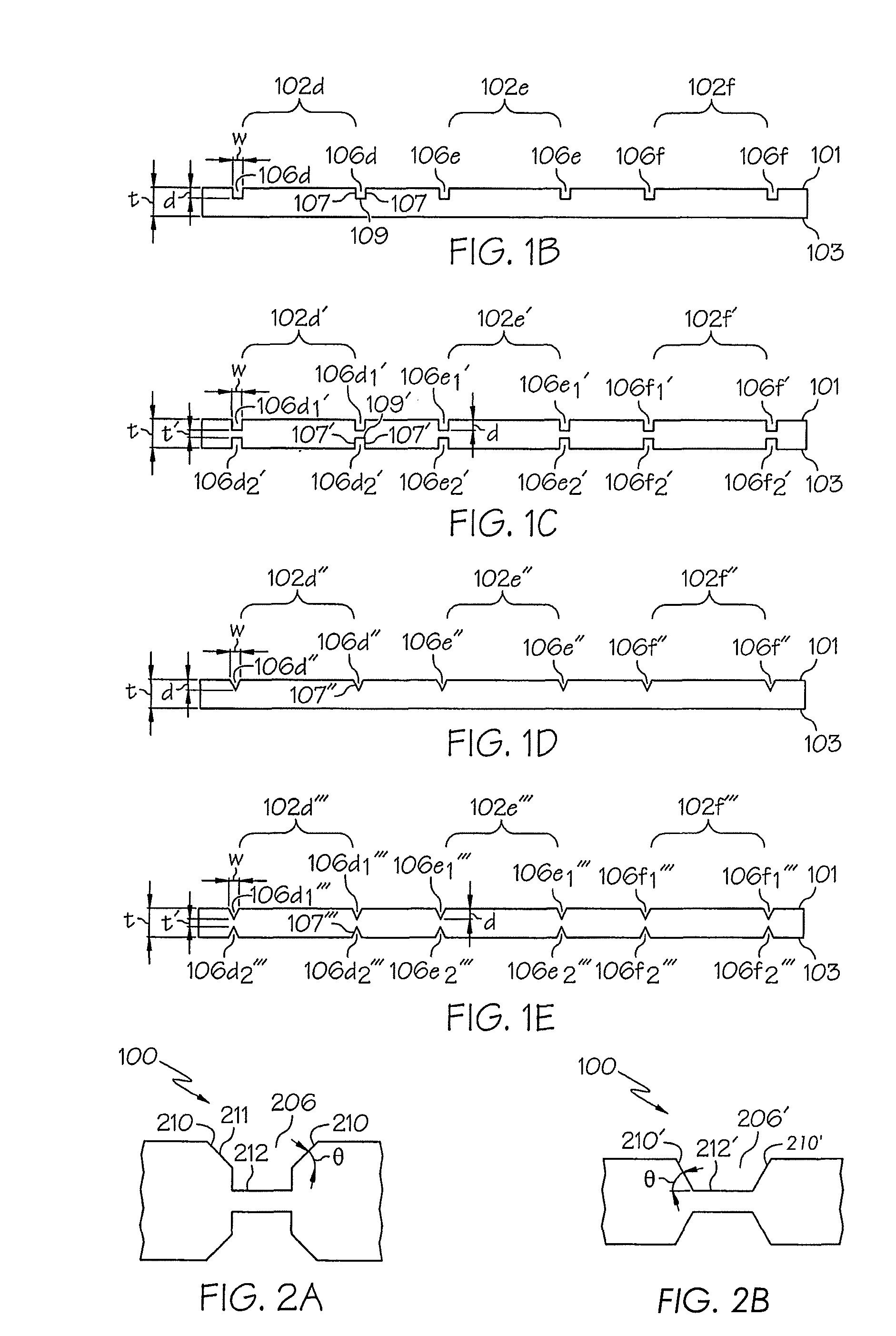

Methods for forming grooves and separating strengthened glass substrate sheets

Methods for separating strengthened glass articles from glass substrate sheets and strengthened glass substrate sheets are described herein. In one embodiment, a method of separating a glass article from a glass substrate sheet includes forming at least one groove on at least one surface of the glass substrate sheet. The at least one groove continuously extends around a perimeter of the glass article and extends partially through a thickness of the glass substrate sheet. The method further includes strengthening the glass substrate sheet by a strengthening process and separating the glass article from the glass substrate sheet along the at least one groove such that one or more edges of the glass article are under compressive stress. In another embodiment, a strengthened glass substrate sheet includes an ion exchanged glass having one or more grooves in one or more strengthened surface layers, the one or more grooves defining glass articles.

Owner:CORNING INC

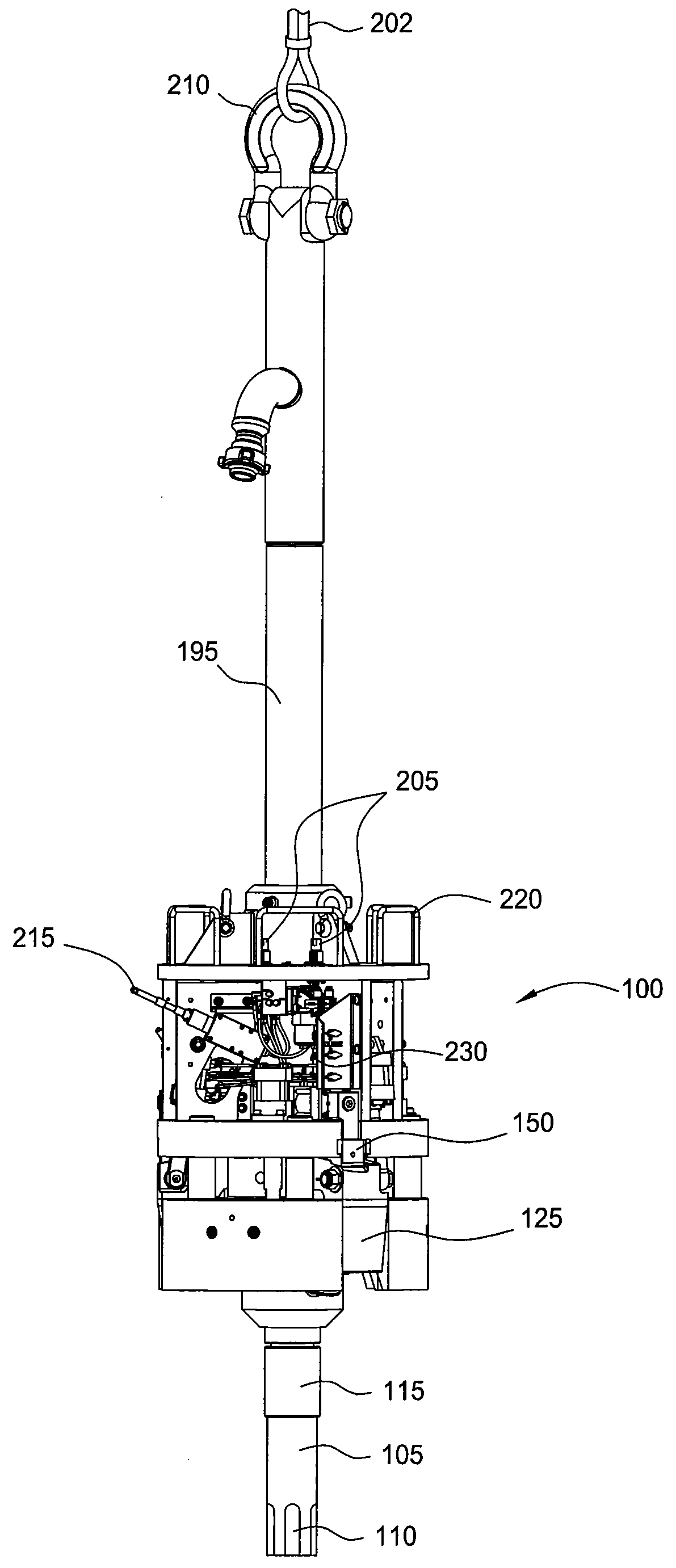

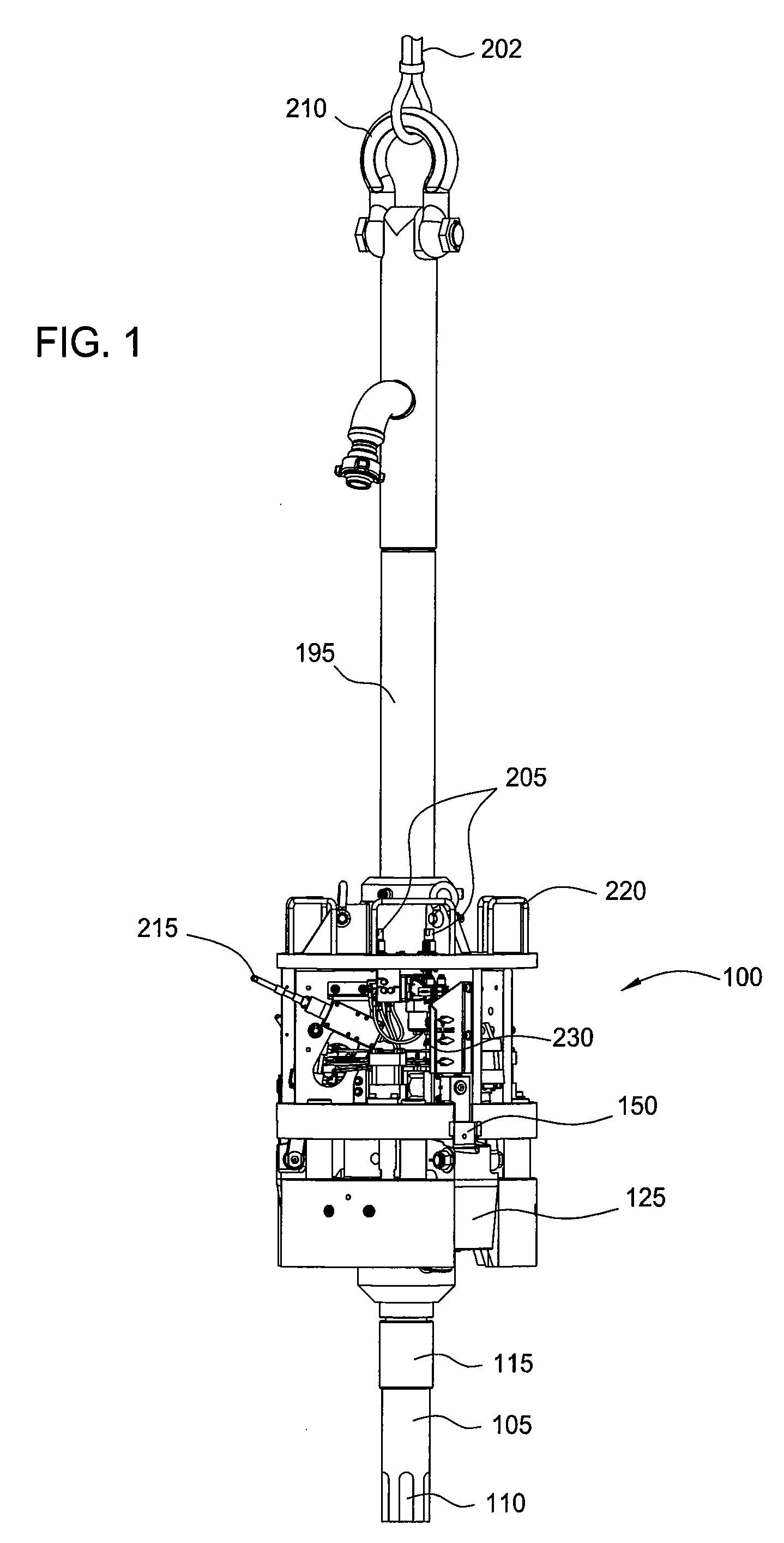

Methods and apparatus for subsea well intervention and subsea wellhead retrieval

The present invention generally relates to methods and apparatus for subsea well intervention operations, including retrieval of a wellhead from a subsea well. In one aspect, a method of performing an operation in a subsea well is provided. The method comprising the step of positioning a tool proximate a subsea wellhead. The tool has at least one grip member and the tool is attached to a downhole assembly. The method also comprising the step of clamping the tool to the subsea wellhead by moving the at least one grip member into engagement with a profile on the subsea wellhead. The method further comprising the step of applying an upward force to the tool thereby enhancing the grip between the grip member and the profile on the subsea wellhead. Additionally, the method comprising the step of performing the operation in the subsea well by utilizing the downhole assembly. In another aspect, an apparatus for use in a subsea well is provided. In a further aspect, a method of cutting a casing string in a subsea well is provided.

Owner:WEATHERFORD TECH HLDG LLC

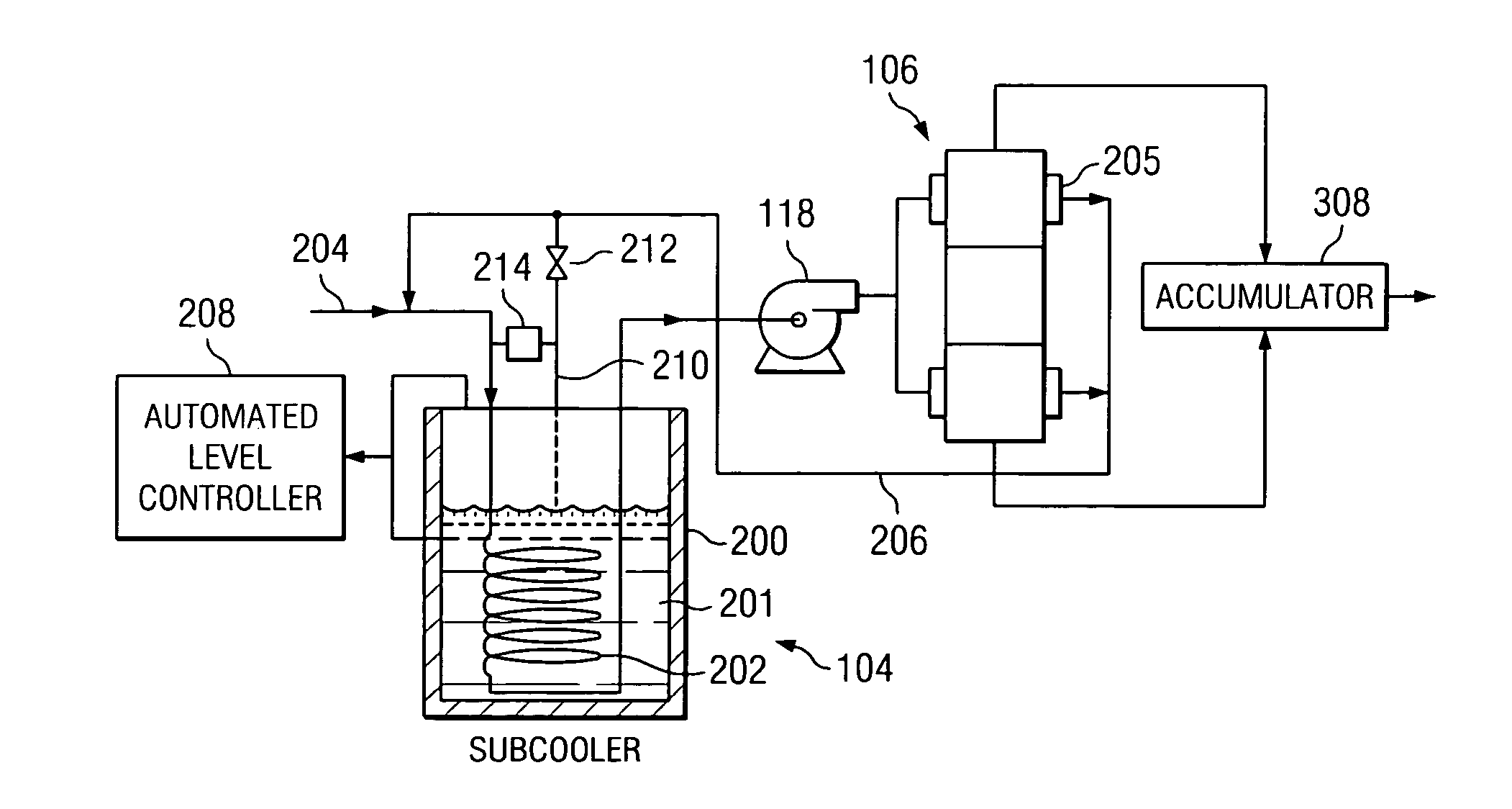

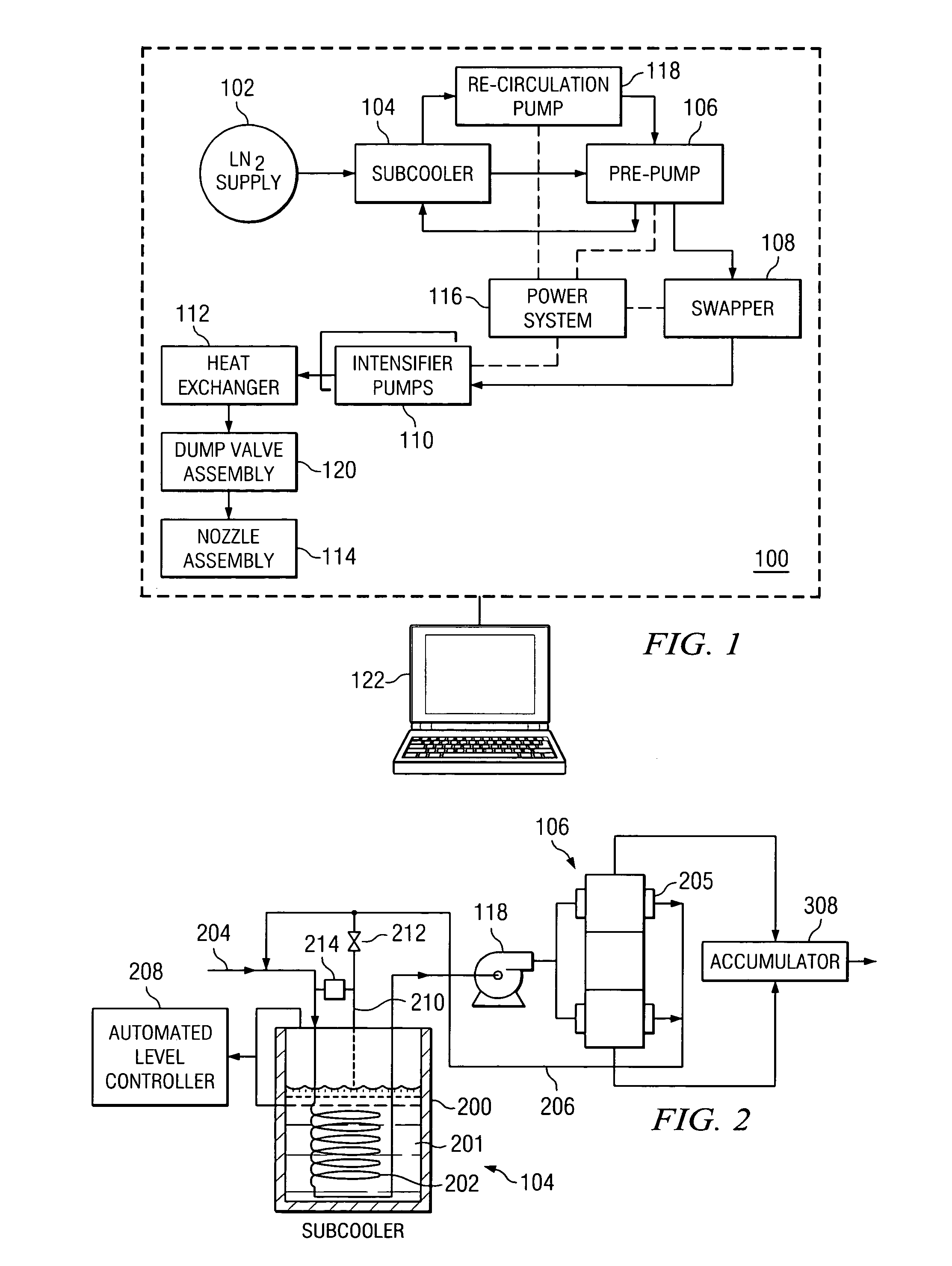

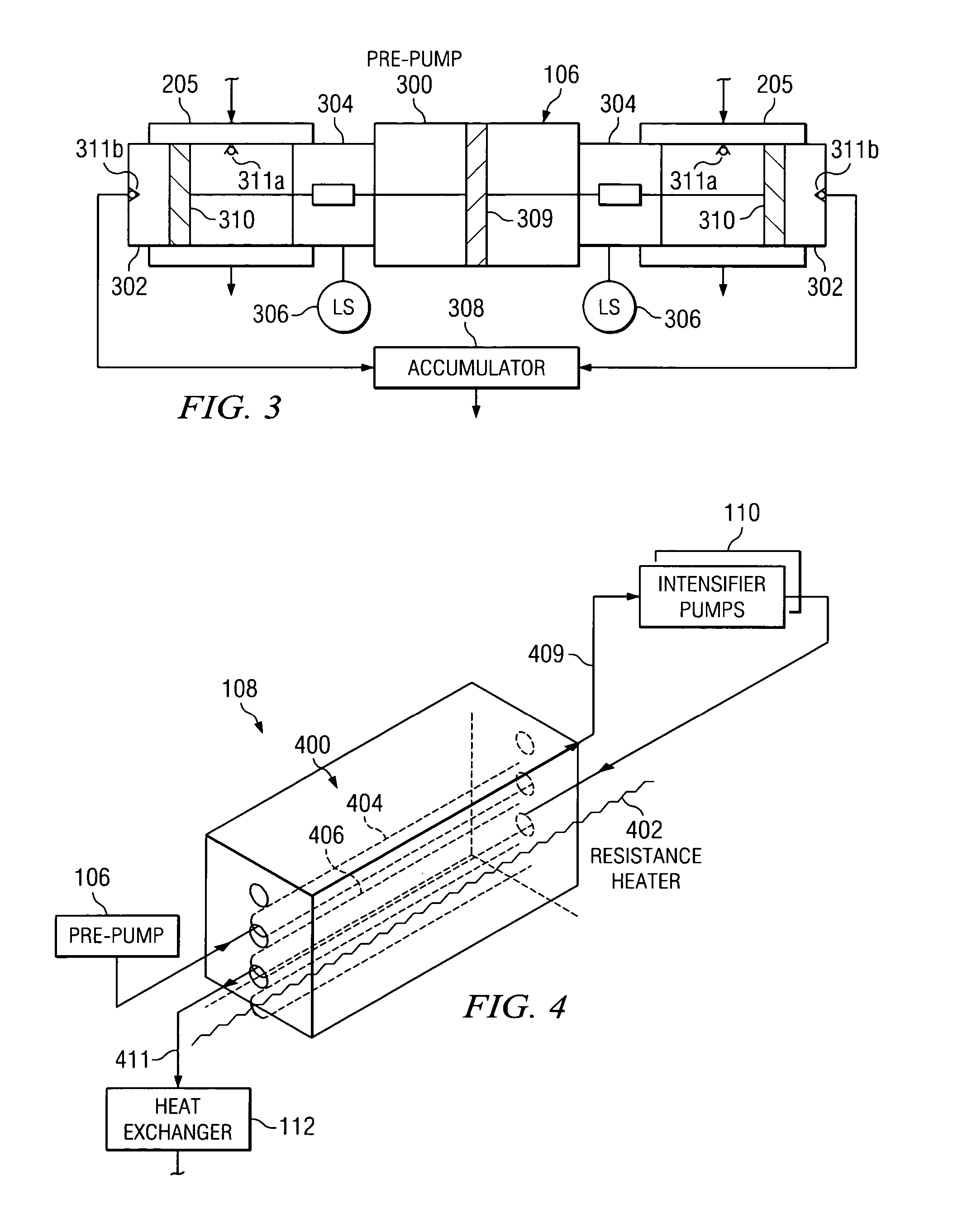

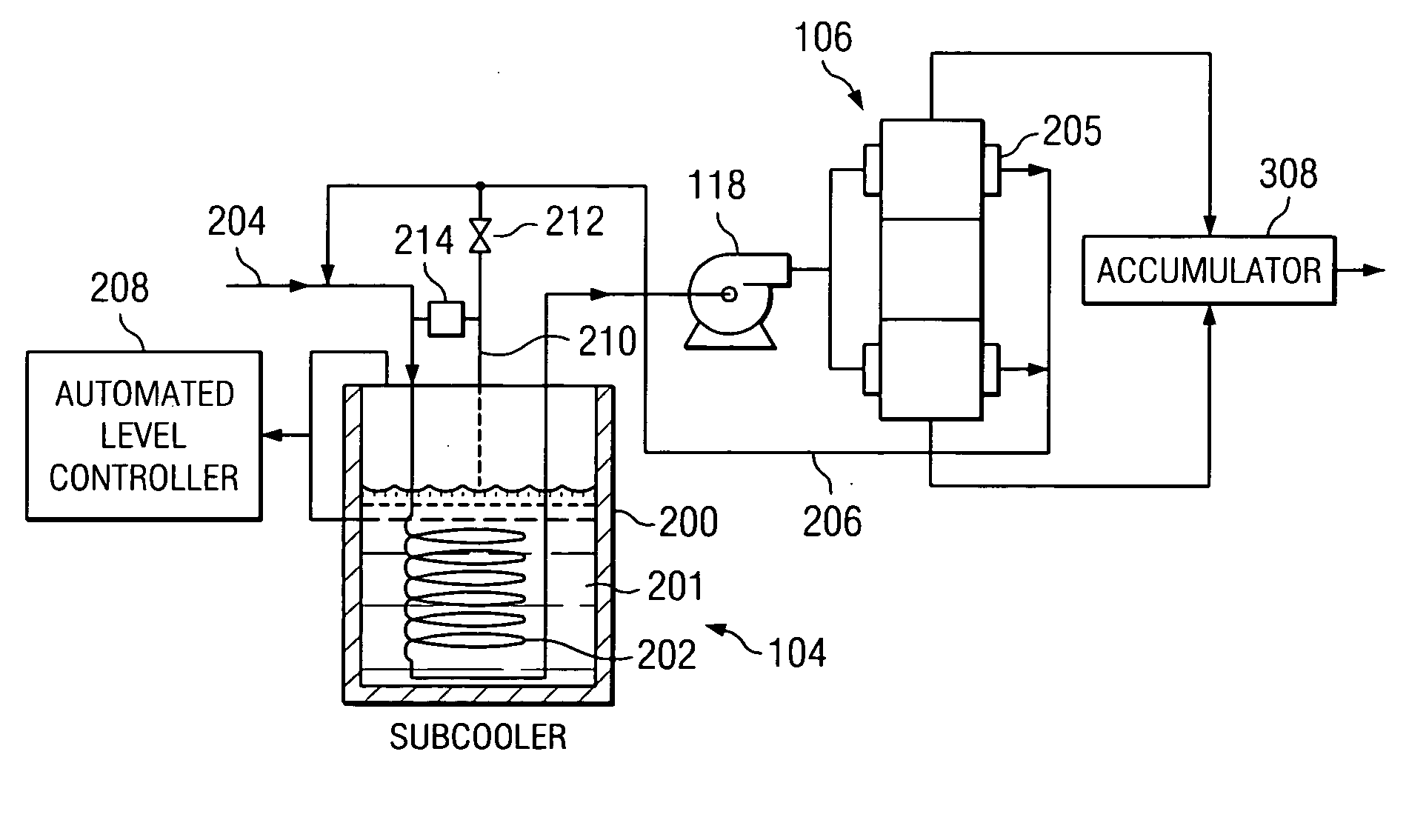

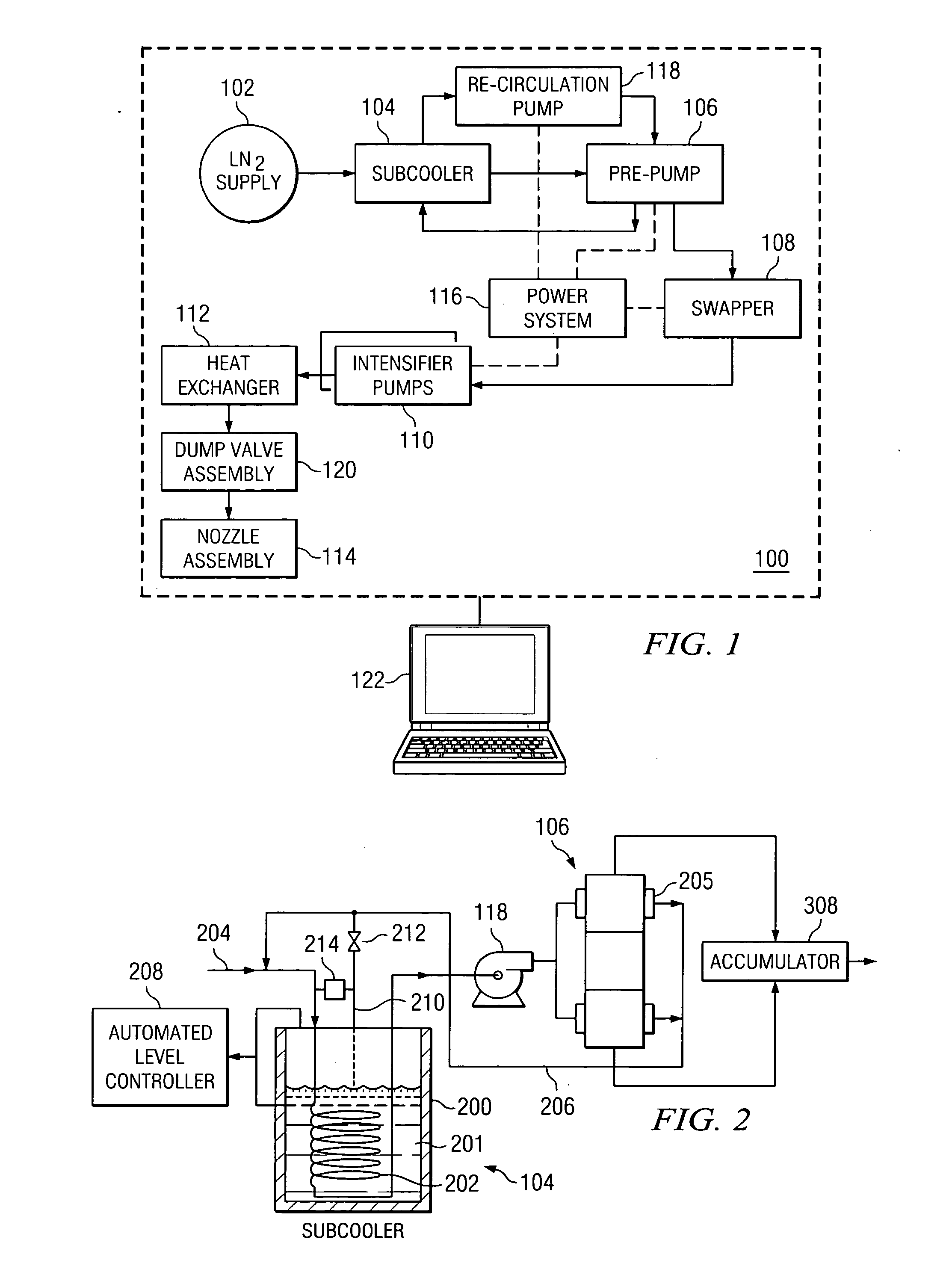

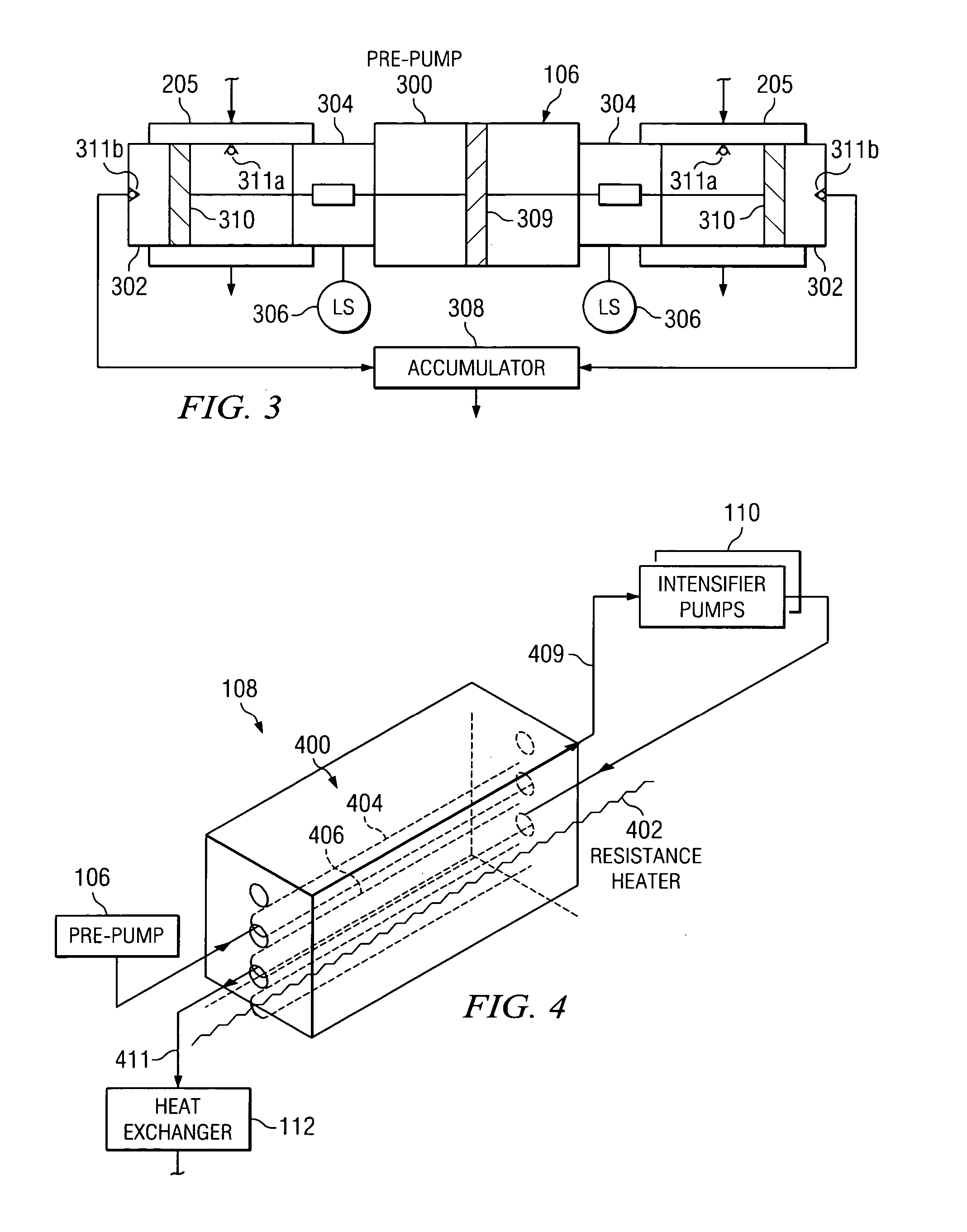

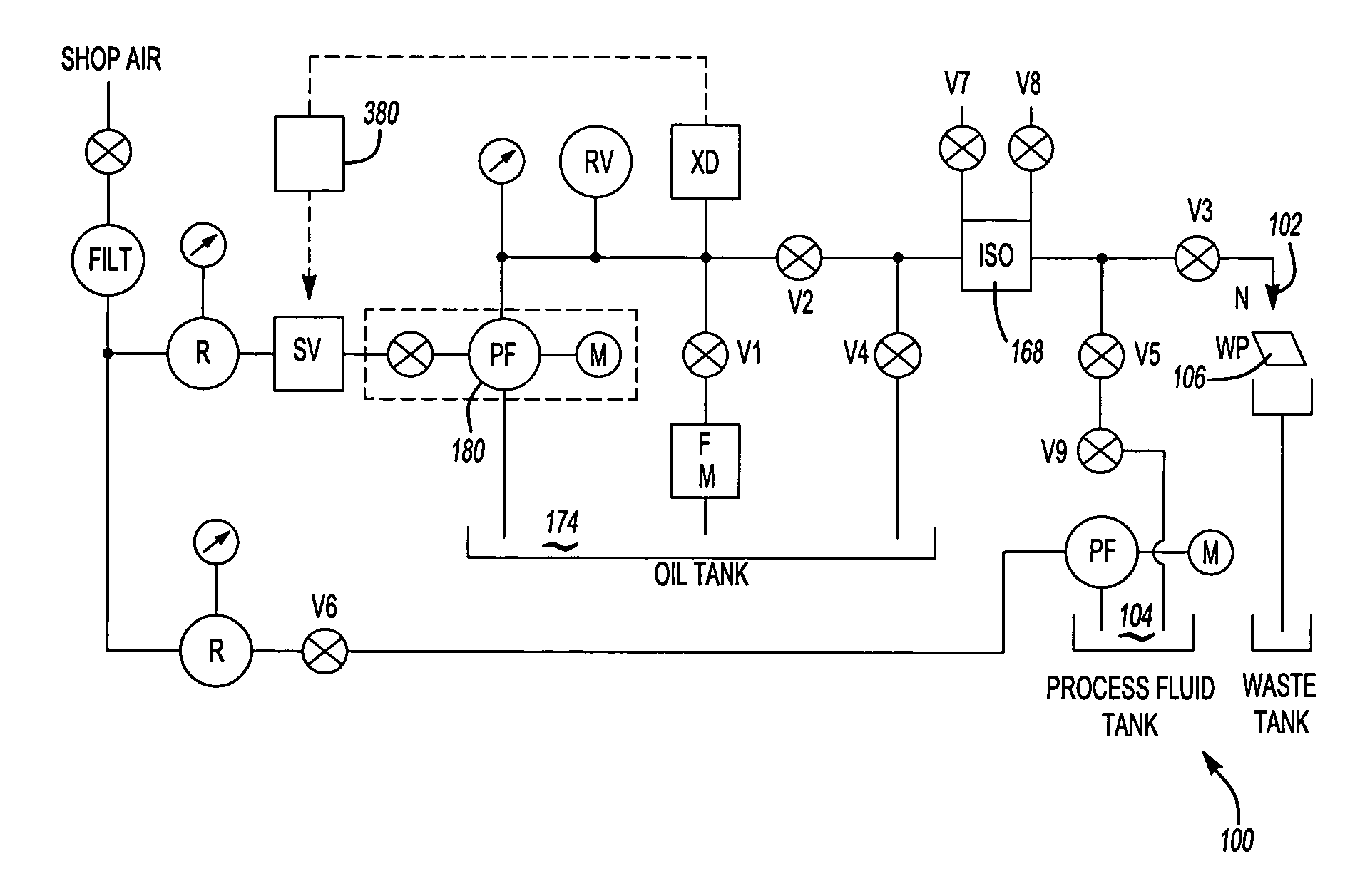

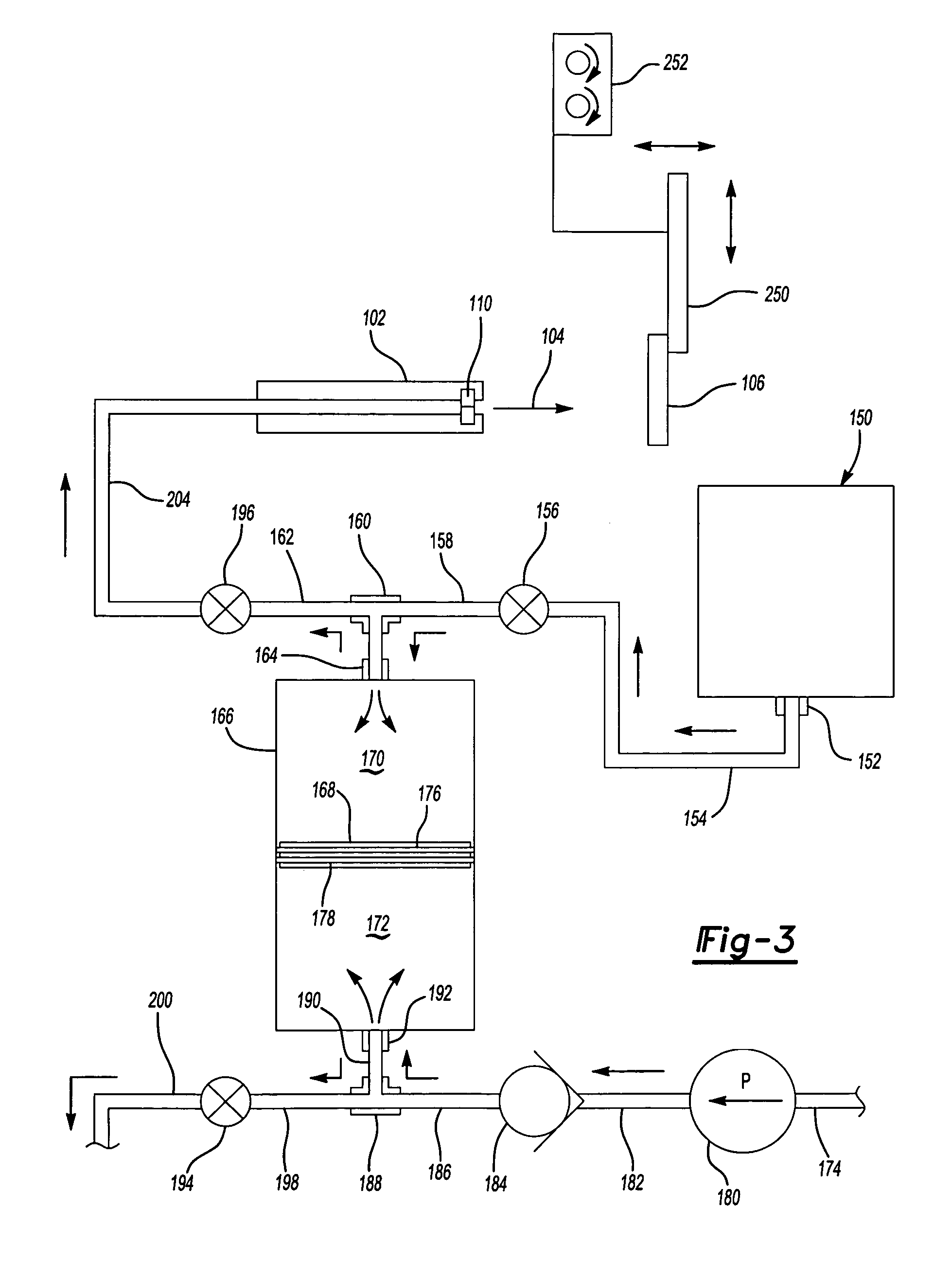

System and method for delivering cryogenic fluid

ActiveUS7310955B2Increase pressureIncrease speedContainer filling methodsGas handling applicationsProcess engineeringDelivery system

According to an embodiment of the present invention, a cryogenic fluid delivery system includes a vessel containing a cryogenic fluid at a first pressure and a first temperature, a first heat exchanger coupled to the vessel for receiving the cryogenic fluid and cooling the cryogenic fluid to a second temperature, a first pump coupled to the first heat exchanger for pressurizing the cryogenic fluid to a second pressure, a second pump for pressurizing the cryogenic fluid to a third pressure, a second heat exchanger coupled to the second pump for cooling the cryogenic fluid to a third temperature, and a nozzle coupled to the second heat exchanger for delivering a jet of the cryogenic fluid toward a target.

Owner:IHI CORP

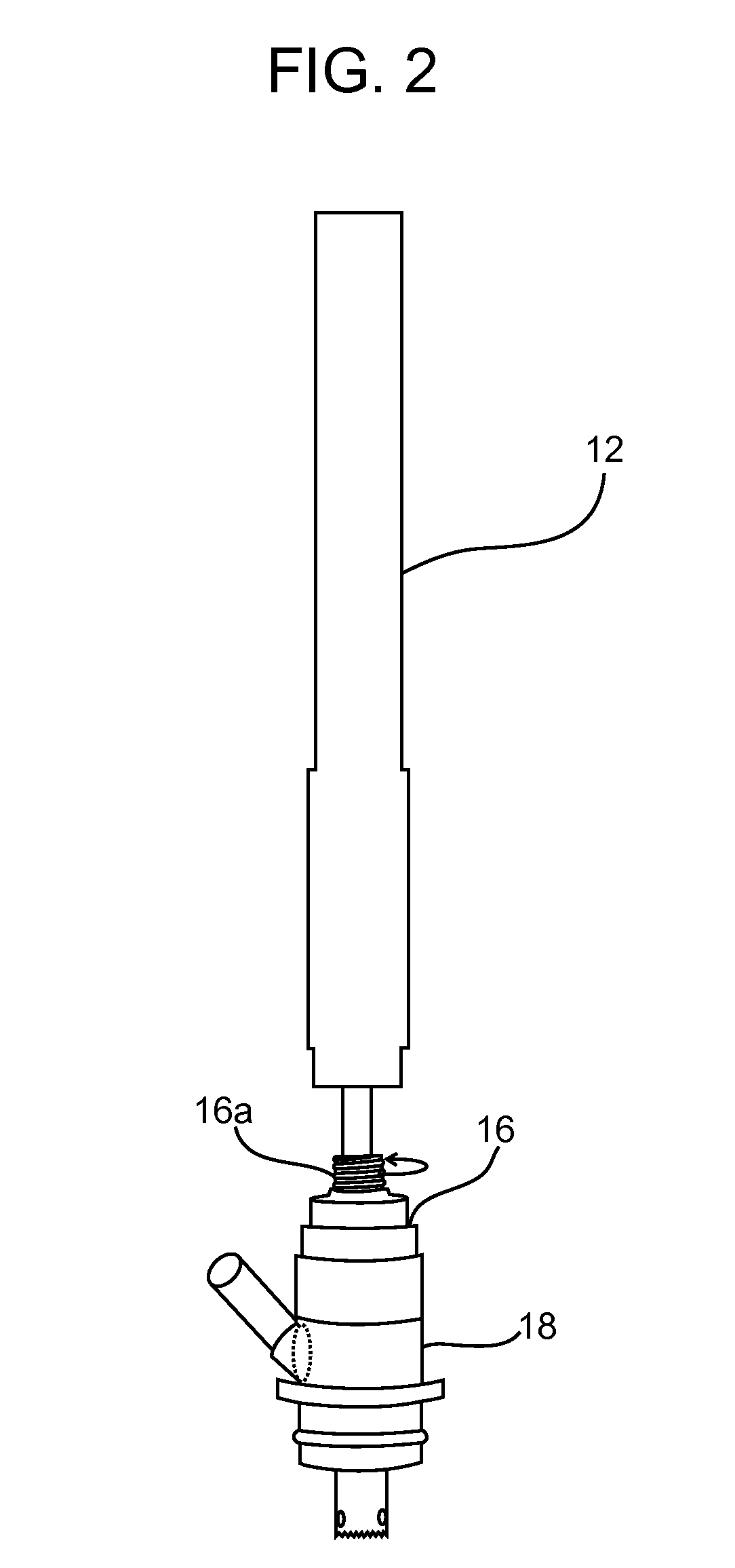

Dry ice blasting cleaning apparatus

The invention is an apparatus used for cleaning equipment including extremely high voltage energized electrical equipment using a dry ice blasting stream as the cleaning agent. The apparatus comprises a cleaning wand and a heating mechanism for impeding the formation of condensation and / or frost on the outer surface of the wand, thereby enabling the wand to operate for prolonged periods of time.

Owner:BRITISH COLUMBIA HYDRO & POWER AUTHORITY

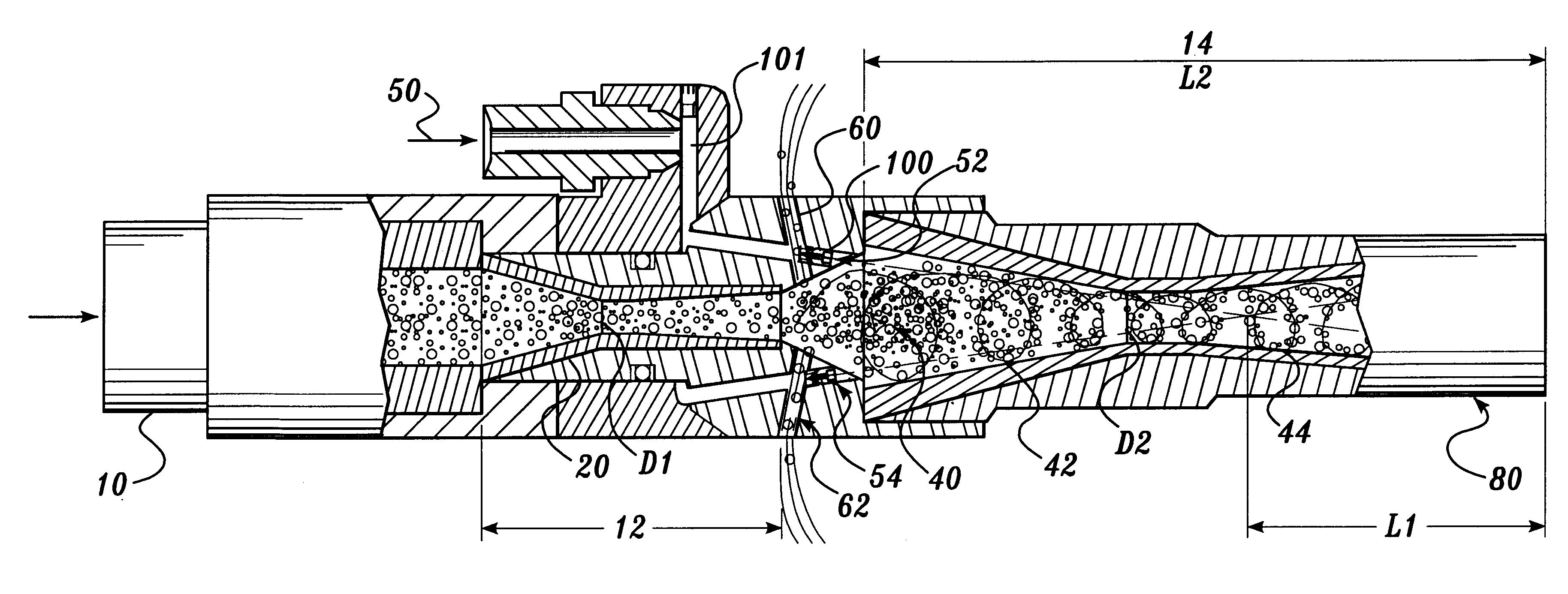

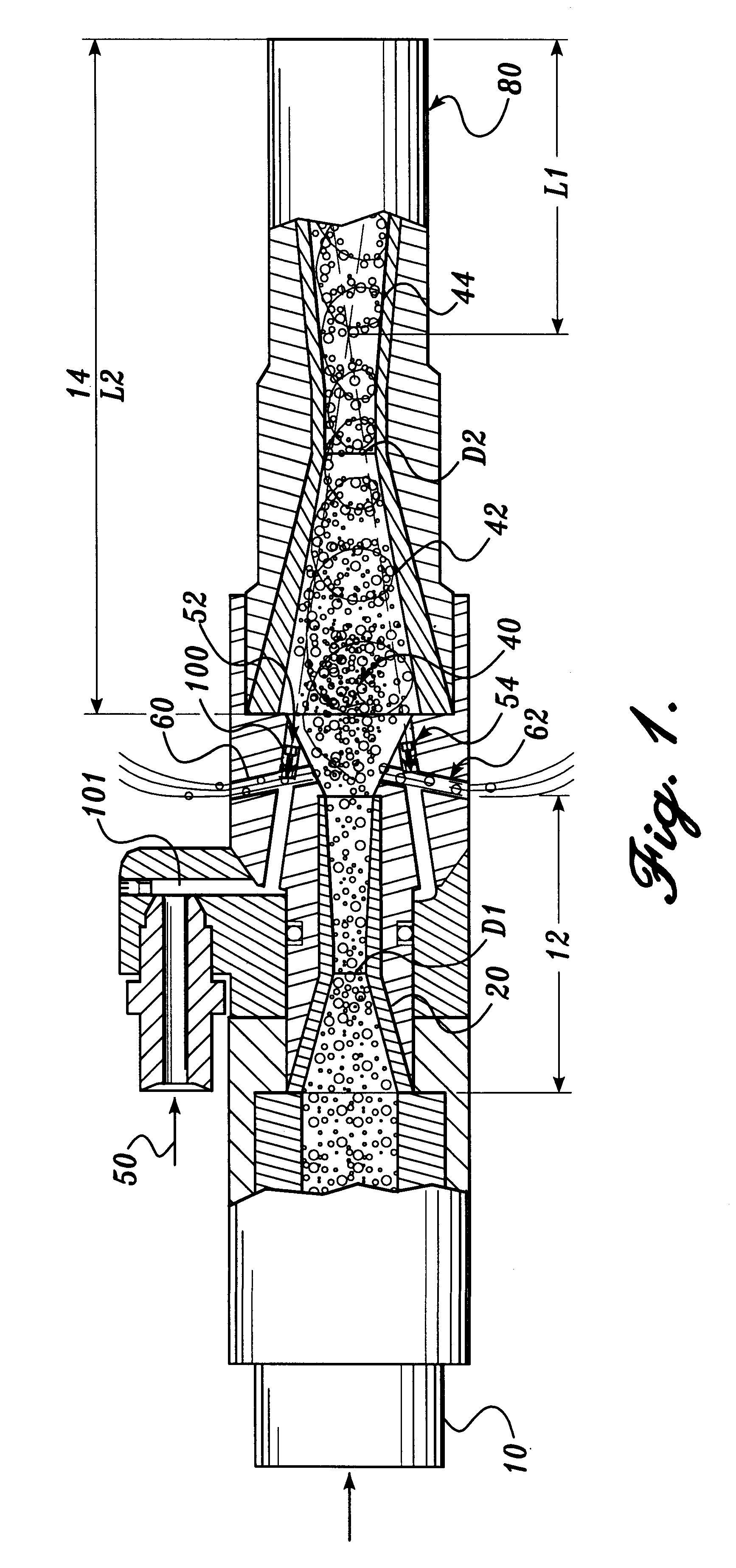

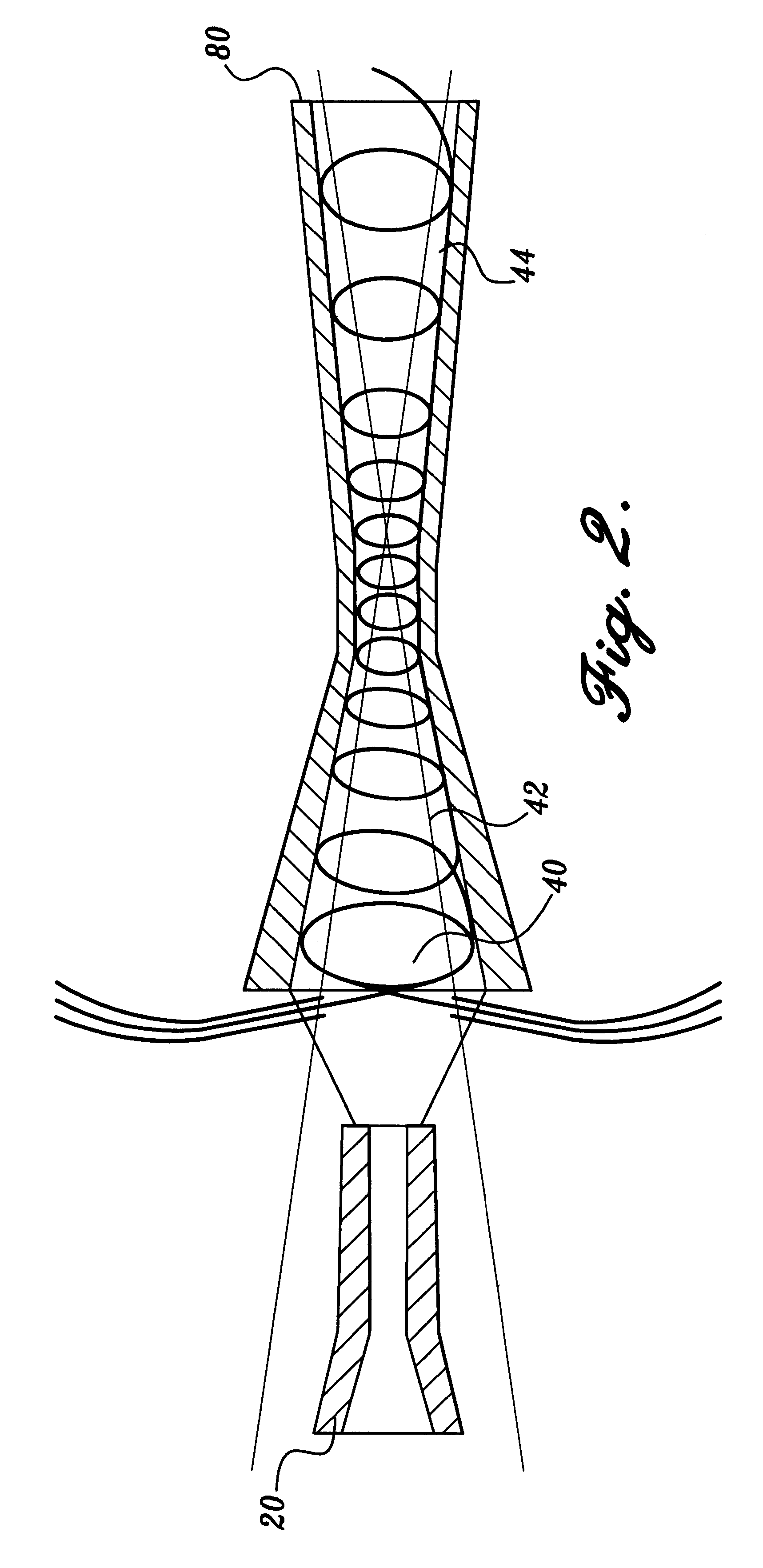

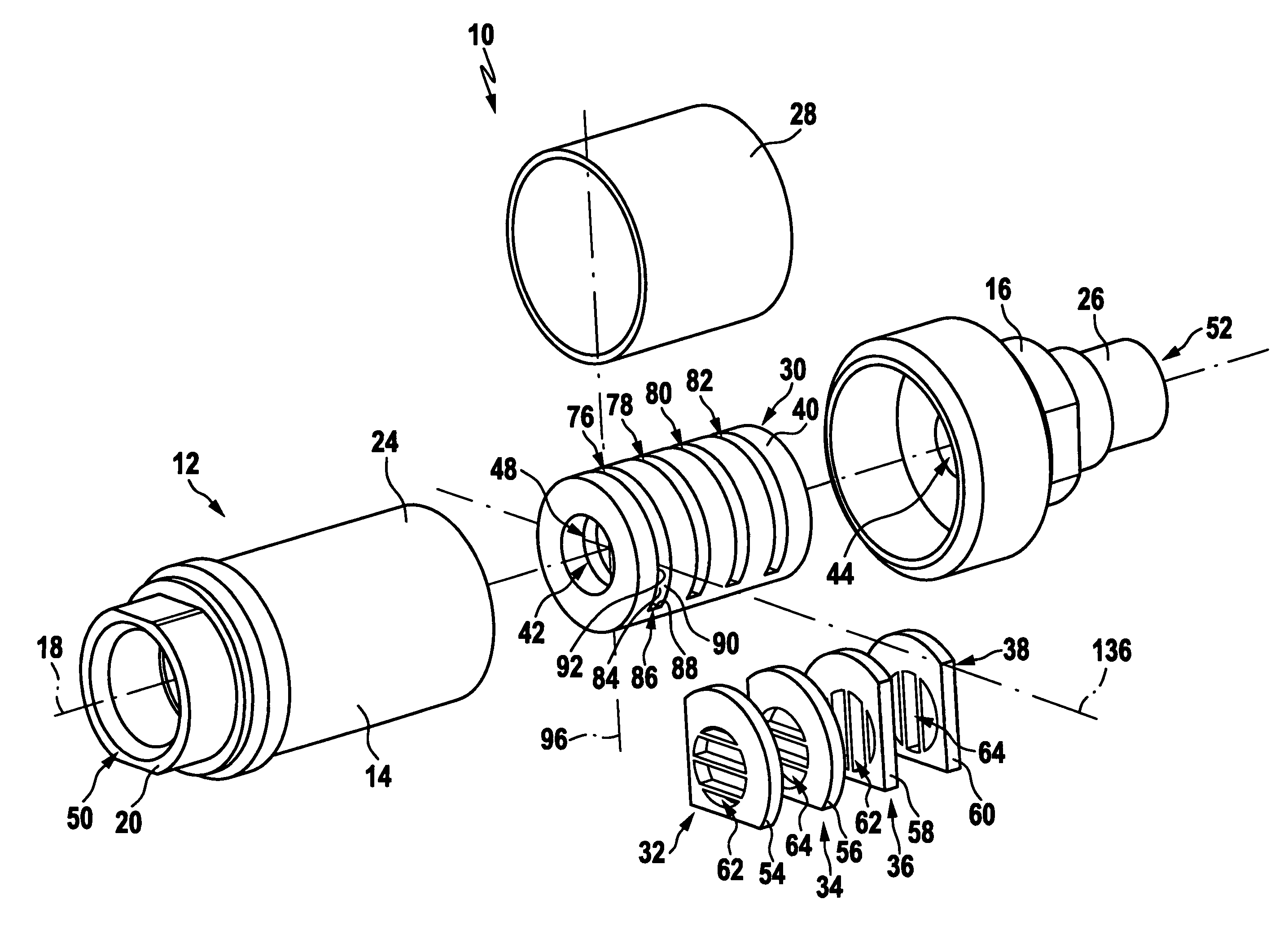

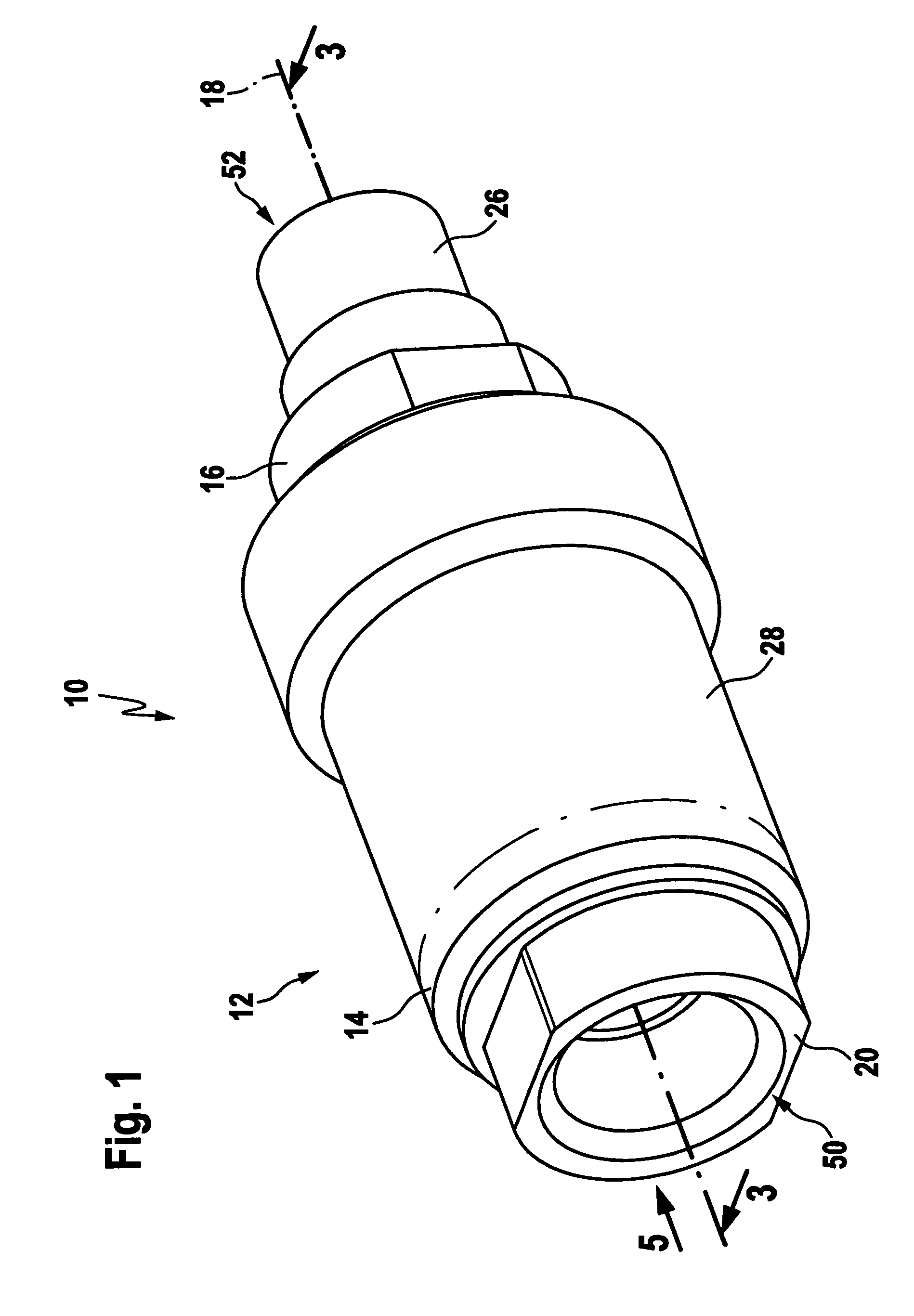

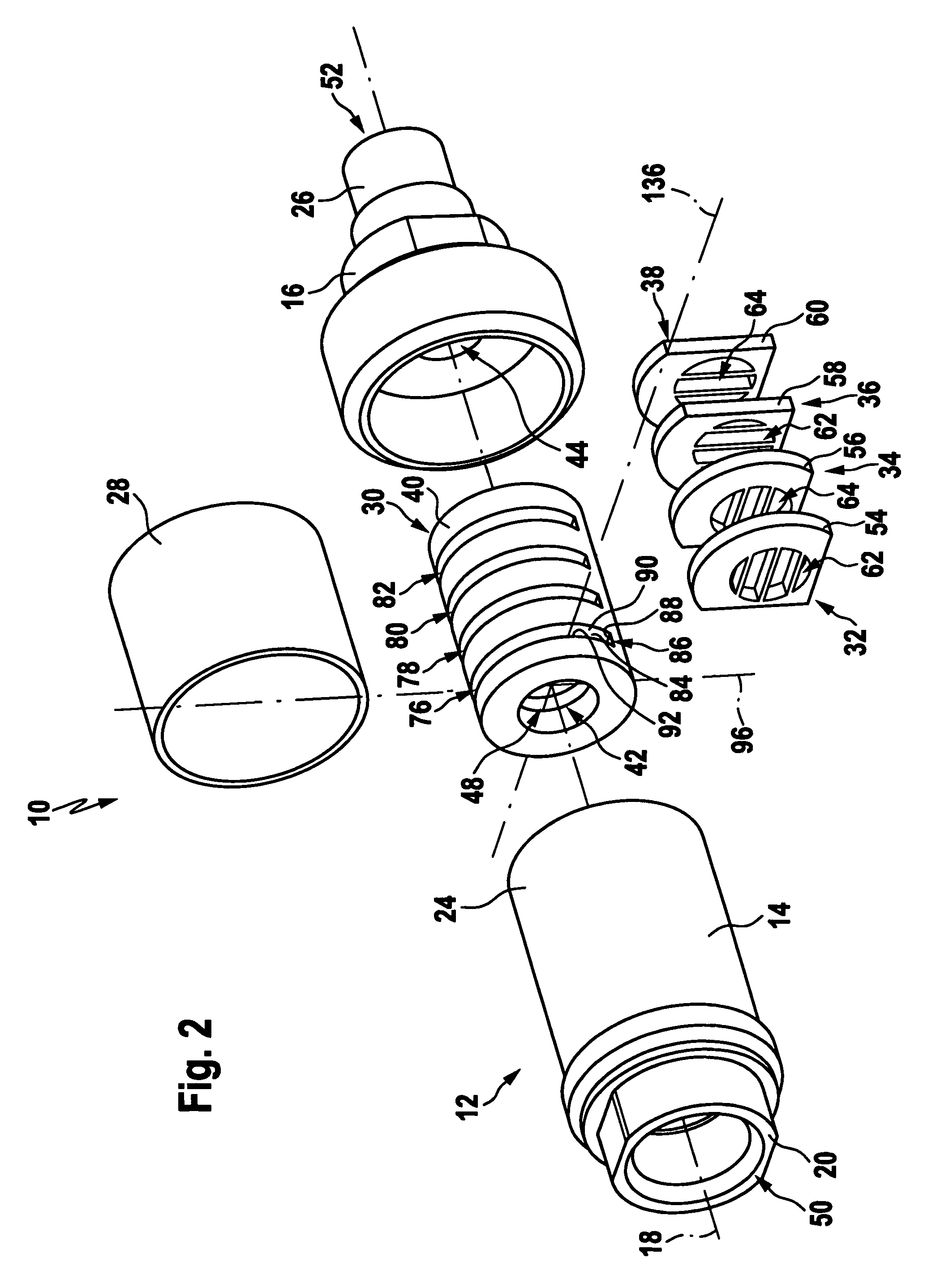

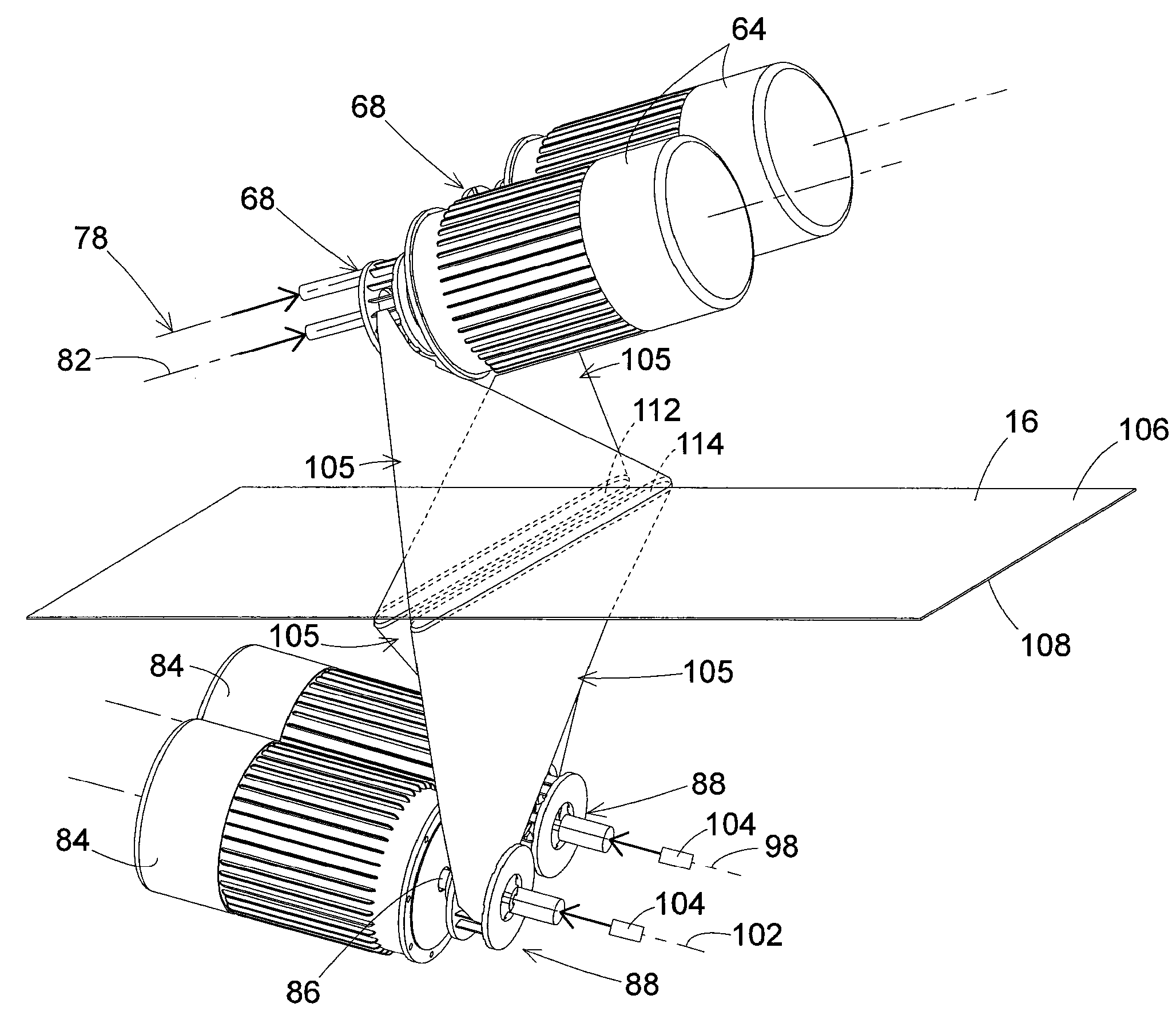

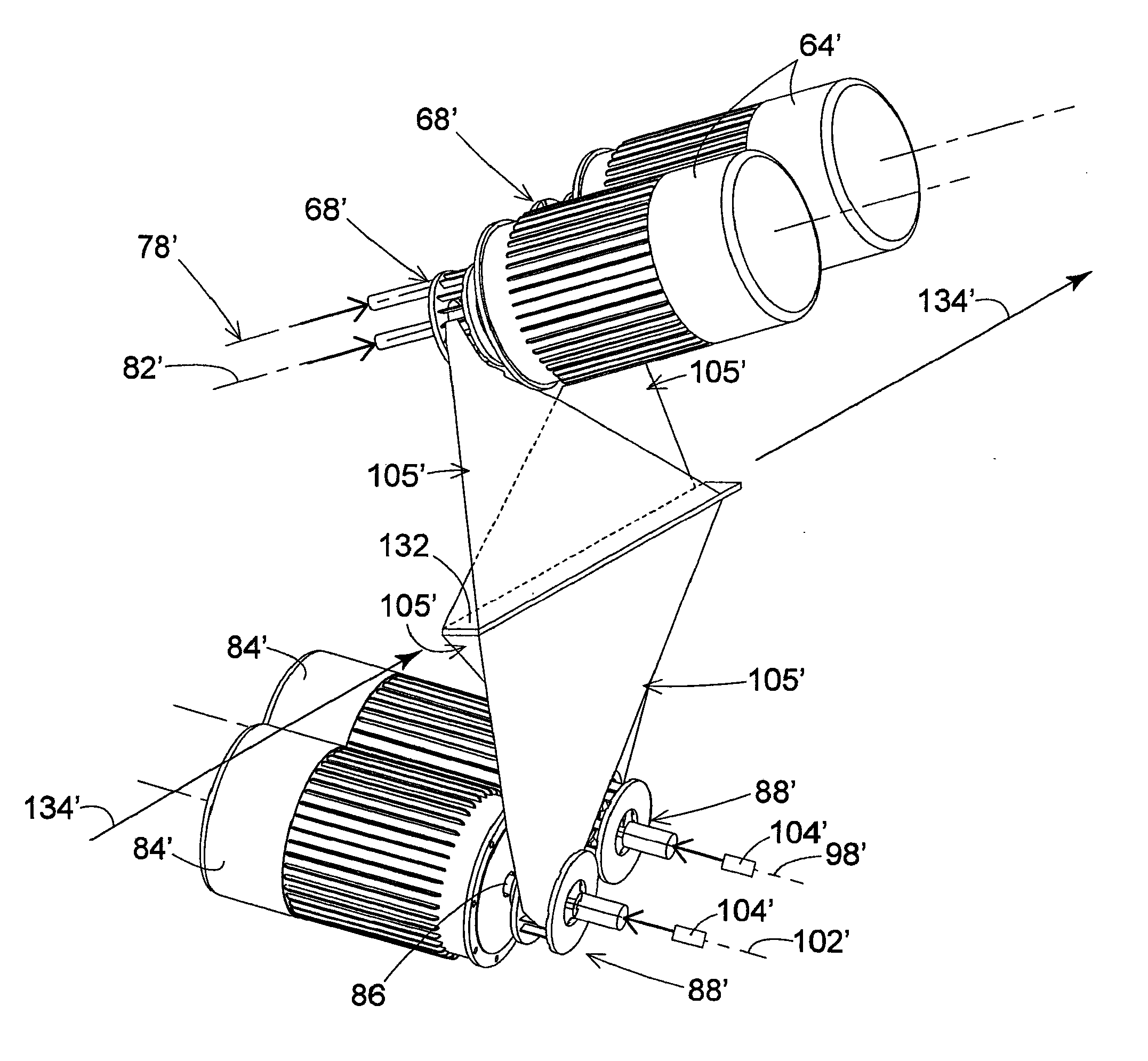

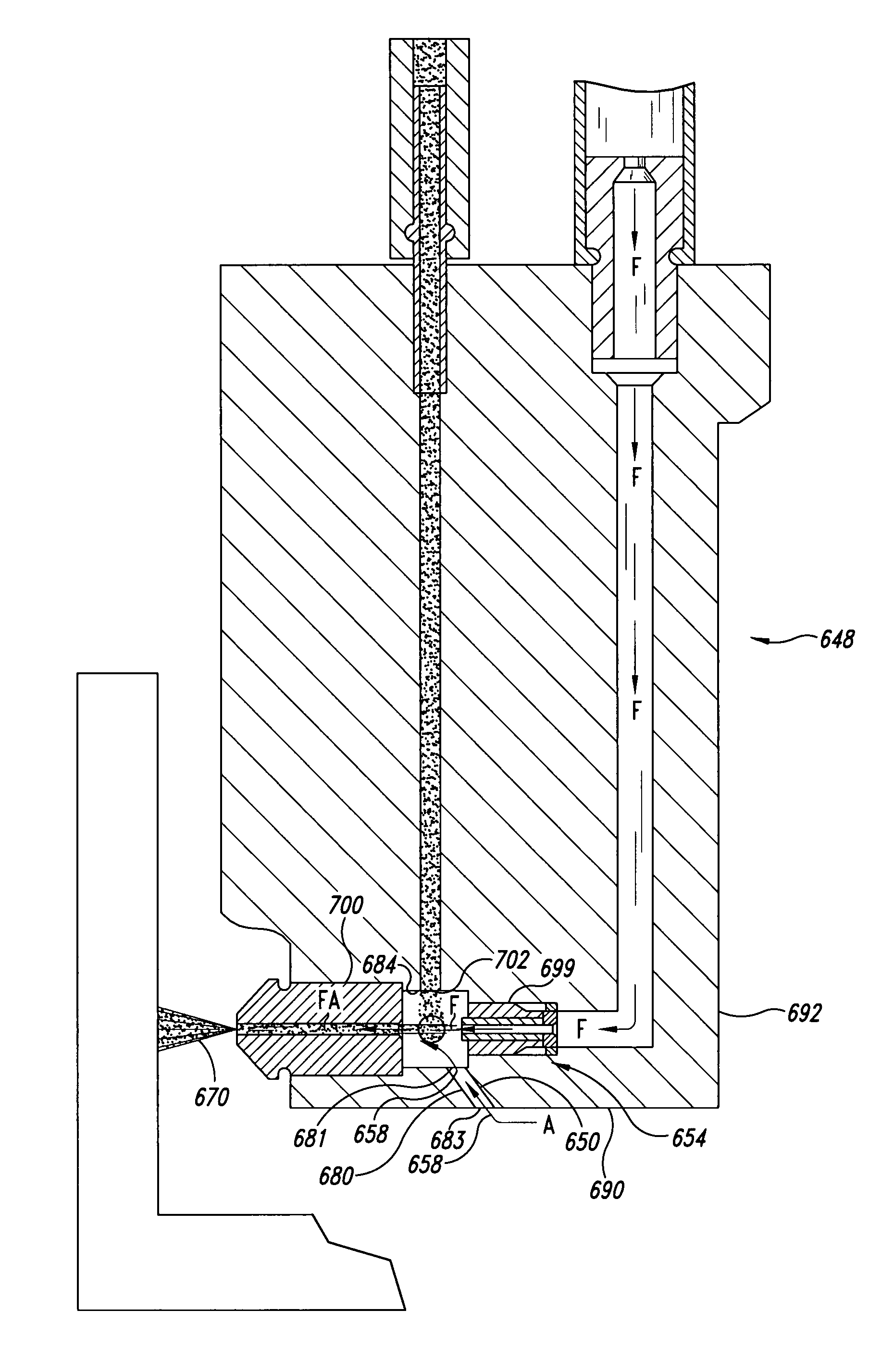

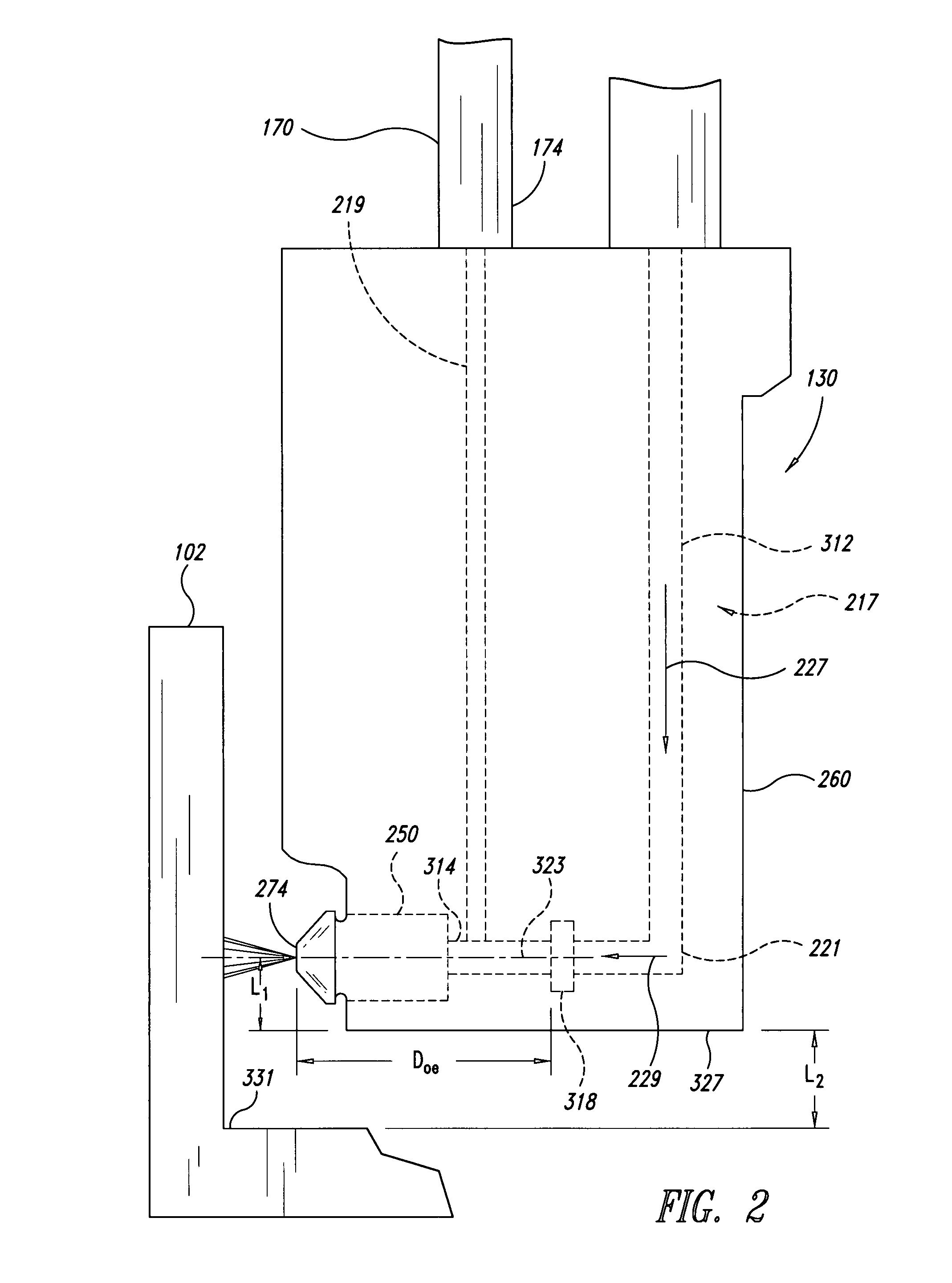

Method and apparatus for producing a high-velocity particle stream

InactiveUS6283833B1Uniform particle spreadingImprove productivityBlast gunsLiquid spraying apparatusJet flowClassical mechanics

A method and apparatus for producing a high-velocity particle stream at low cost through multi-staged acceleration using different media in each stage. The particles are accelerated to a subsonic velocity (with respect to the velocity of sound in air) using one or more jets of gas at low cost, then further accelerated to a higher velocity using jets of water. Additionally, to enhance particle acceleration, a vortex motion is created, and the particles introduced into the fluid having vortex motion, thereby enhancing the delivery of particles to the target.

Owner:FLOW INT

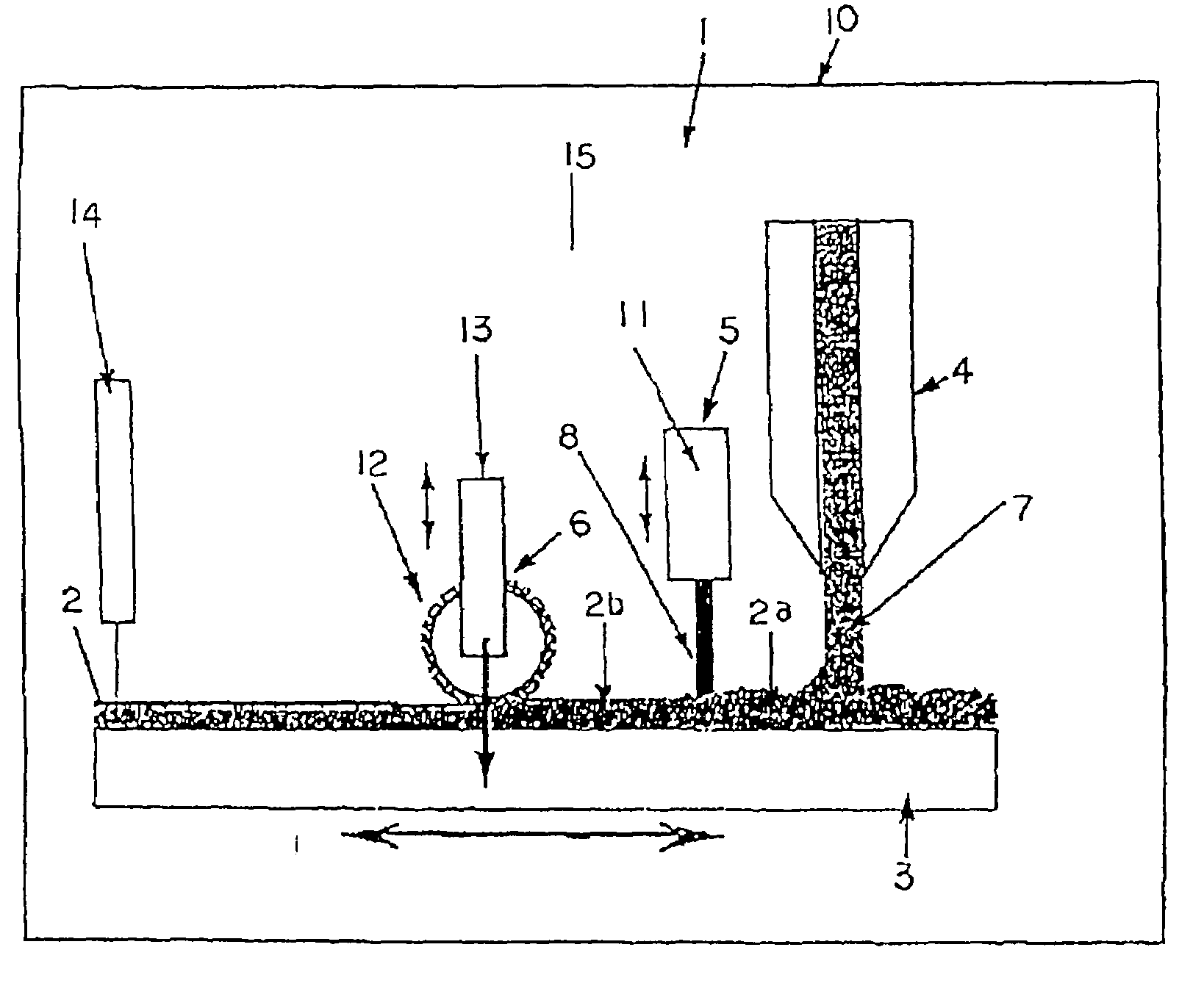

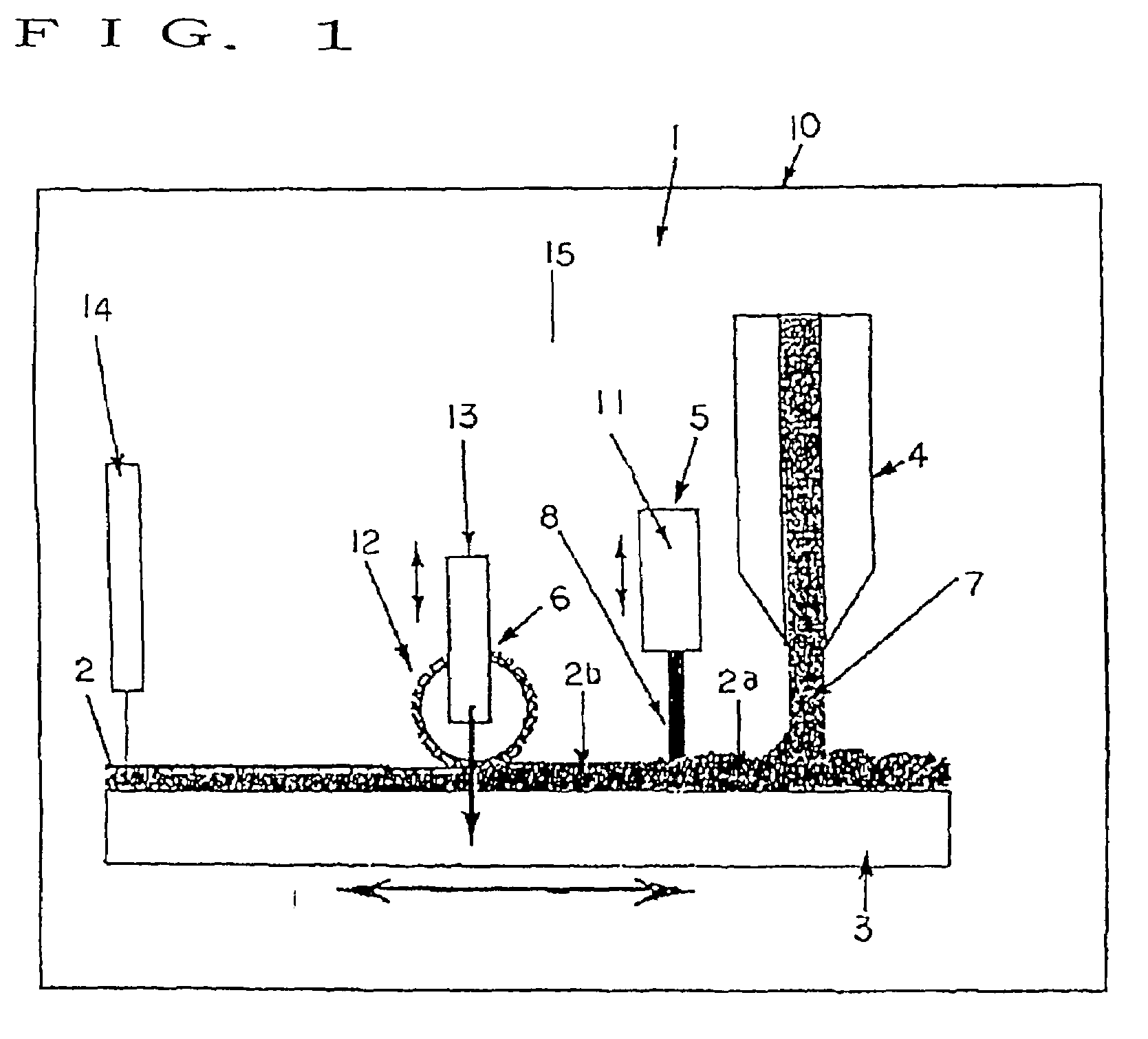

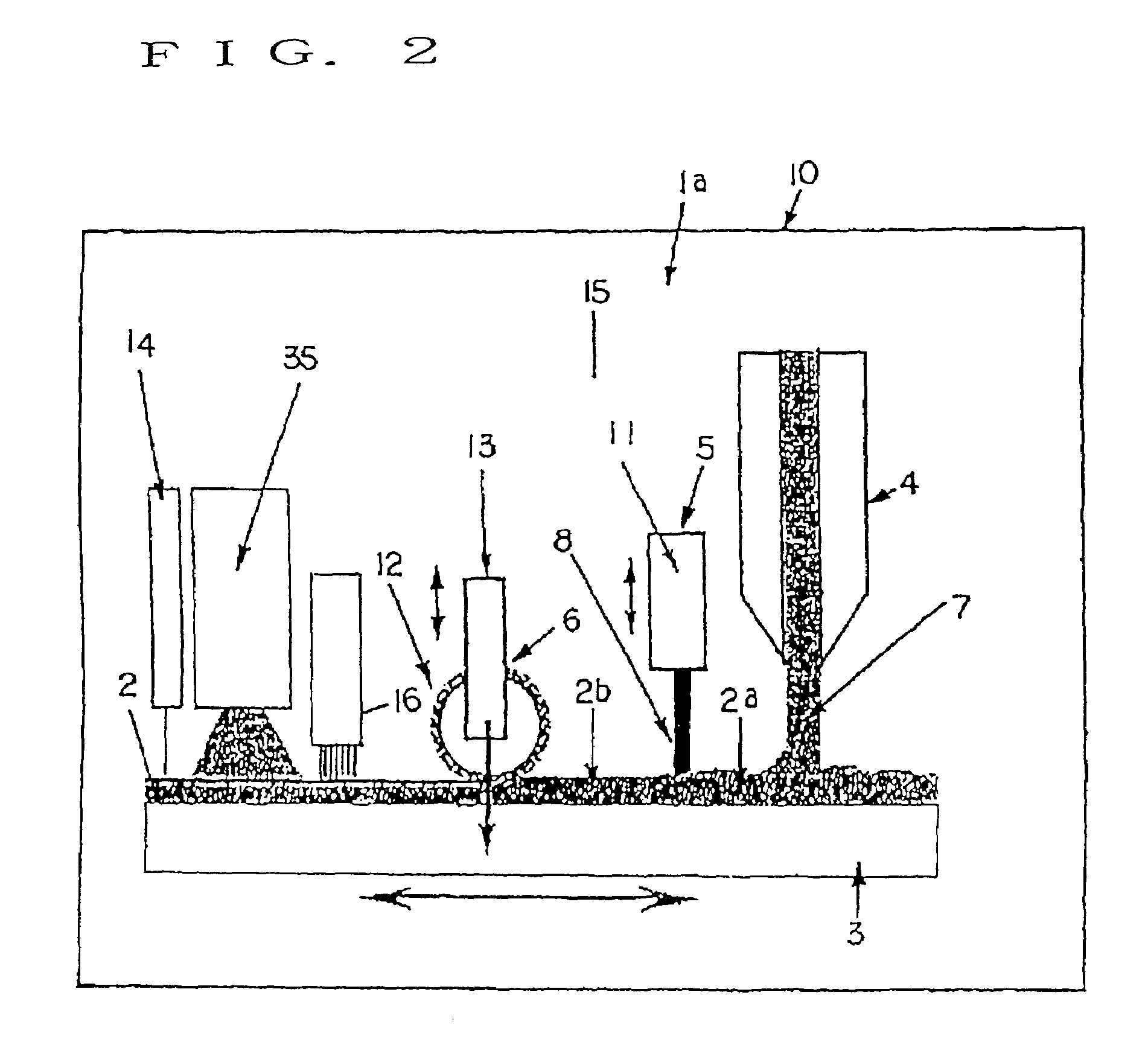

Ultra fine particle film forming method and apparatus

A ultra fine particle film forming apparatus is provided which is capable of forming a ultra fine particle film which has ultra fine particles sufficiently bonded together, sufficient density, flat surface and uniform density. A planarized ultra fine particle film forming method for forming a planarized ultra fine particle film from a deposited film of ultra fine particles formed by supplying the ultra fine particles to a substrate, the method comprising one or more of a planarizing step of planarizing a surface of the deposited film of the ultra fine particles supplied to the substrate.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Device for comminuting dry ice granules, and dry ice dispensing arrangement having such a device

The invention relates to a device for comminuting dry ice granules, comprising a housing having a flow channel for dry ice granules which can be applied, by means of compressed gas, to a surface to be cleaned, and also comprising a first comminution member for comminuting the dry ice granules which are to be dispensed. In order to provide a device of this kind with which different degrees of comminution of dry ice granules can be achieved in a simple manner, it is proposed according to the invention that the device has at least one second comminution member which can be disposed in the housing in a position in which a total degree of comminution, which is greater than the individual degree of comminution which can be achieved solely by the first comminution member, can be achieved in combination with the first comminution member. A dry ice dispensing arrangement for dispensing a mixture of compressed gas and dry ice granules is also proposed, having a device of the above kind.

Owner:ALFRED KARCHER GMBH & CO KG

Method for producing abrasive compact with improved properties

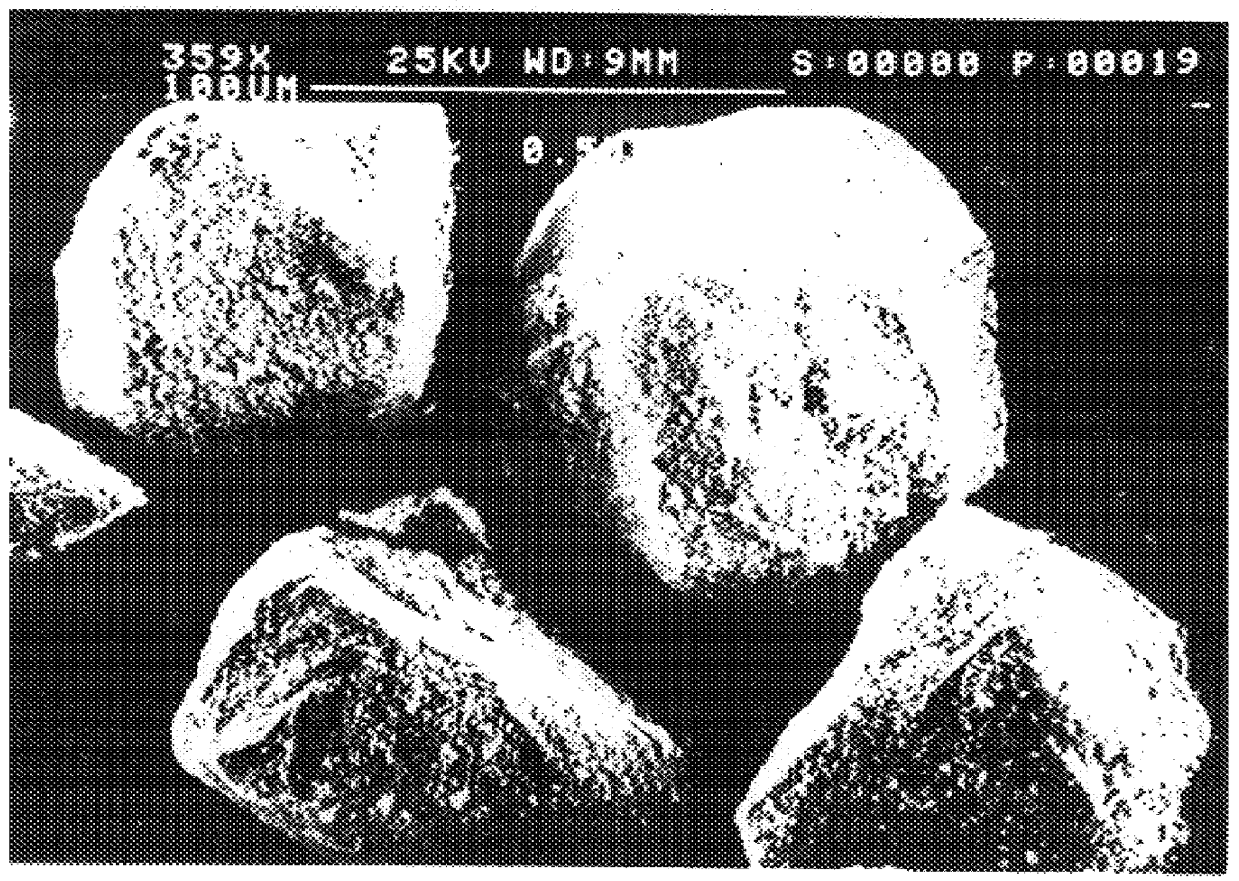

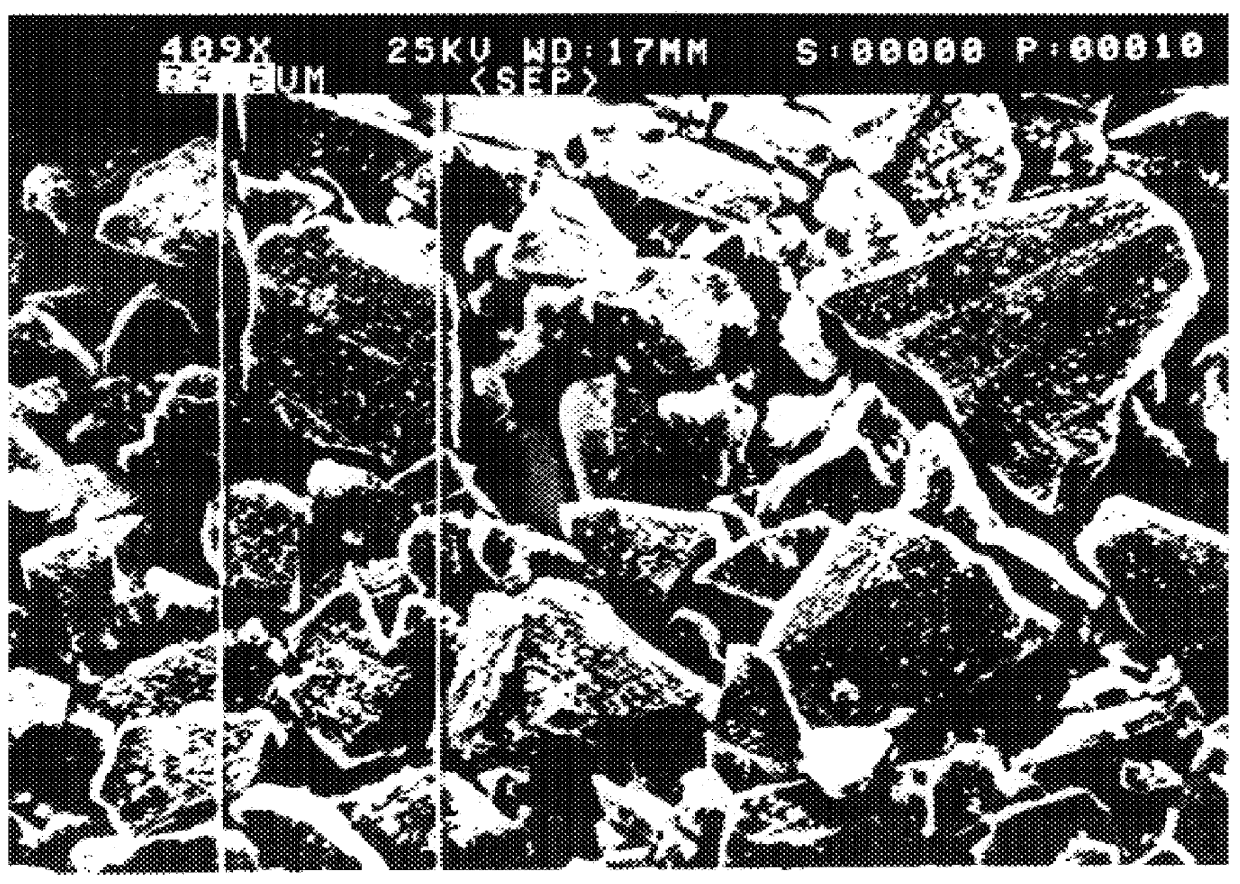

InactiveUS6132675AImproved abrasionImprove stabilityUltra-high pressure processesCeramic shaping apparatusPolycrystalline diamondCarbide

Metal carbide supported polycrystalline diamond (PCD) compacts having improved abrasion / impact resistance properties and a method for making the same under high temperature / high pressure (HT / HP) processing conditions. The PCD compact is characterized as having a mixture of submicron sized diamond particles and large sized diamond particles.

Owner:DIAMOND INNOVATIONS INC

System and method for delivering cryogenic fluid

ActiveUS20060053165A1Readily apparentIncrease pressureContainer filling methodsGas handling applicationsProcess engineeringDelivery system

According to an embodiment of the present invention, a cryogenic fluid delivery system includes a vessel containing a cryogenic fluid at a first pressure and a first temperature, a first heat exchanger coupled to the vessel for receiving the cryogenic fluid and cooling the cryogenic fluid to a second temperature, a first pump coupled to the first heat exchanger for pressurizing the cryogenic fluid to a second pressure, a second pump for pressurizing the cryogenic fluid to a third pressure, a second heat exchanger coupled to the second pump for cooling the cryogenic fluid to a third temperature, and a nozzle coupled to the second heat exchanger for delivering a jet of the cryogenic fluid toward a target.

Owner:IHI CORP

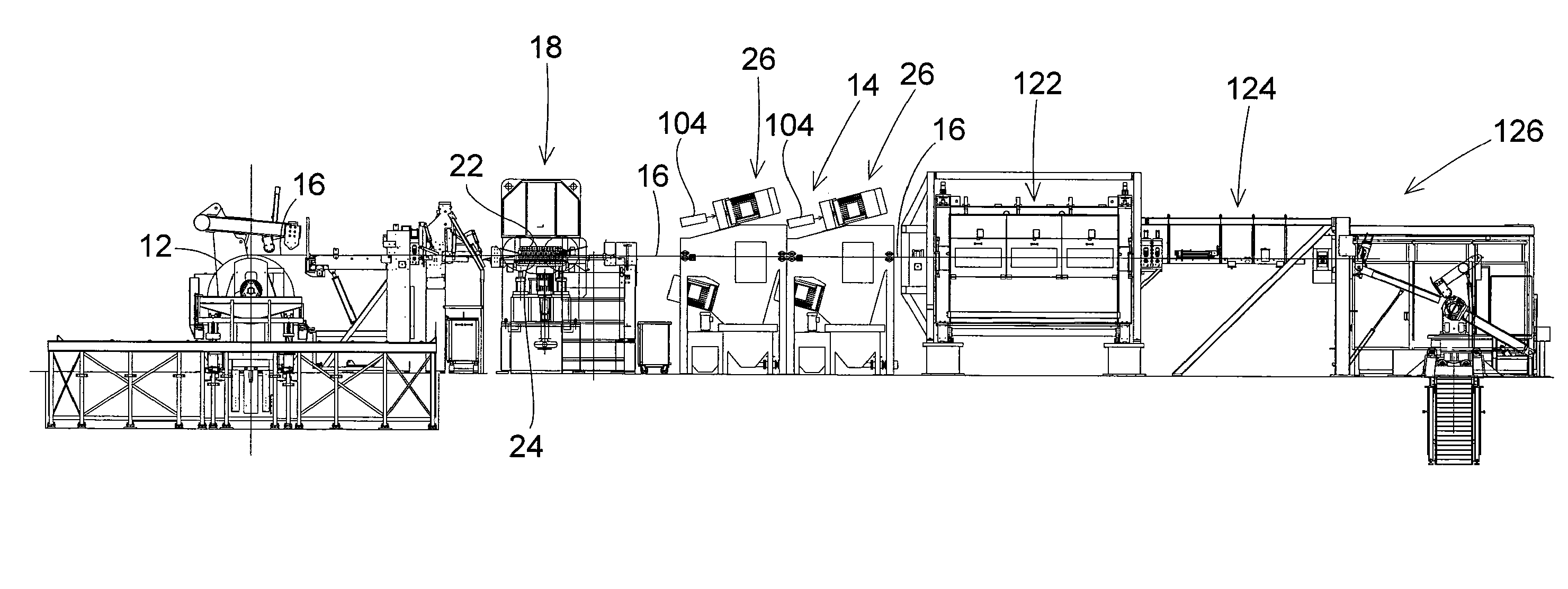

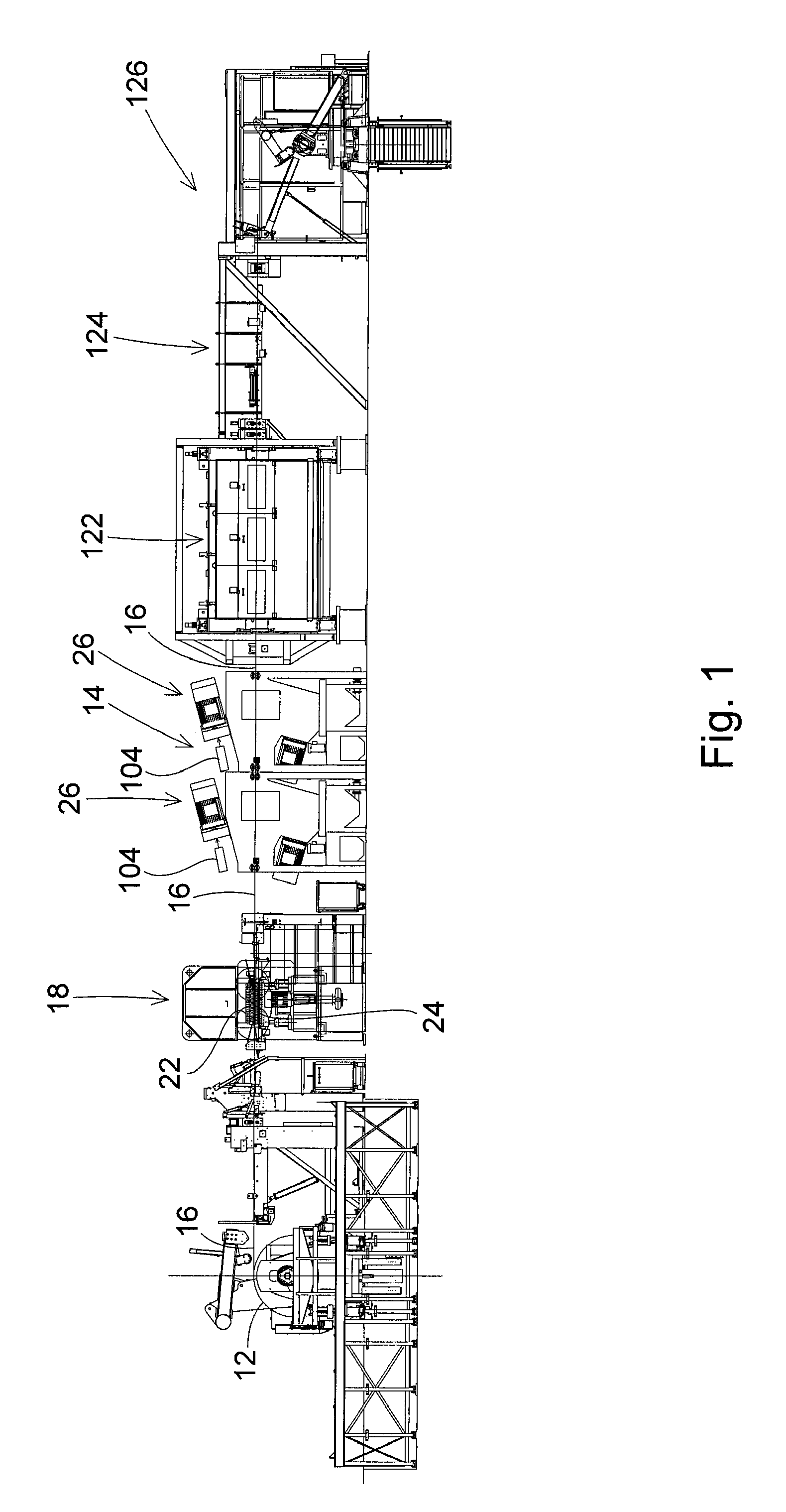

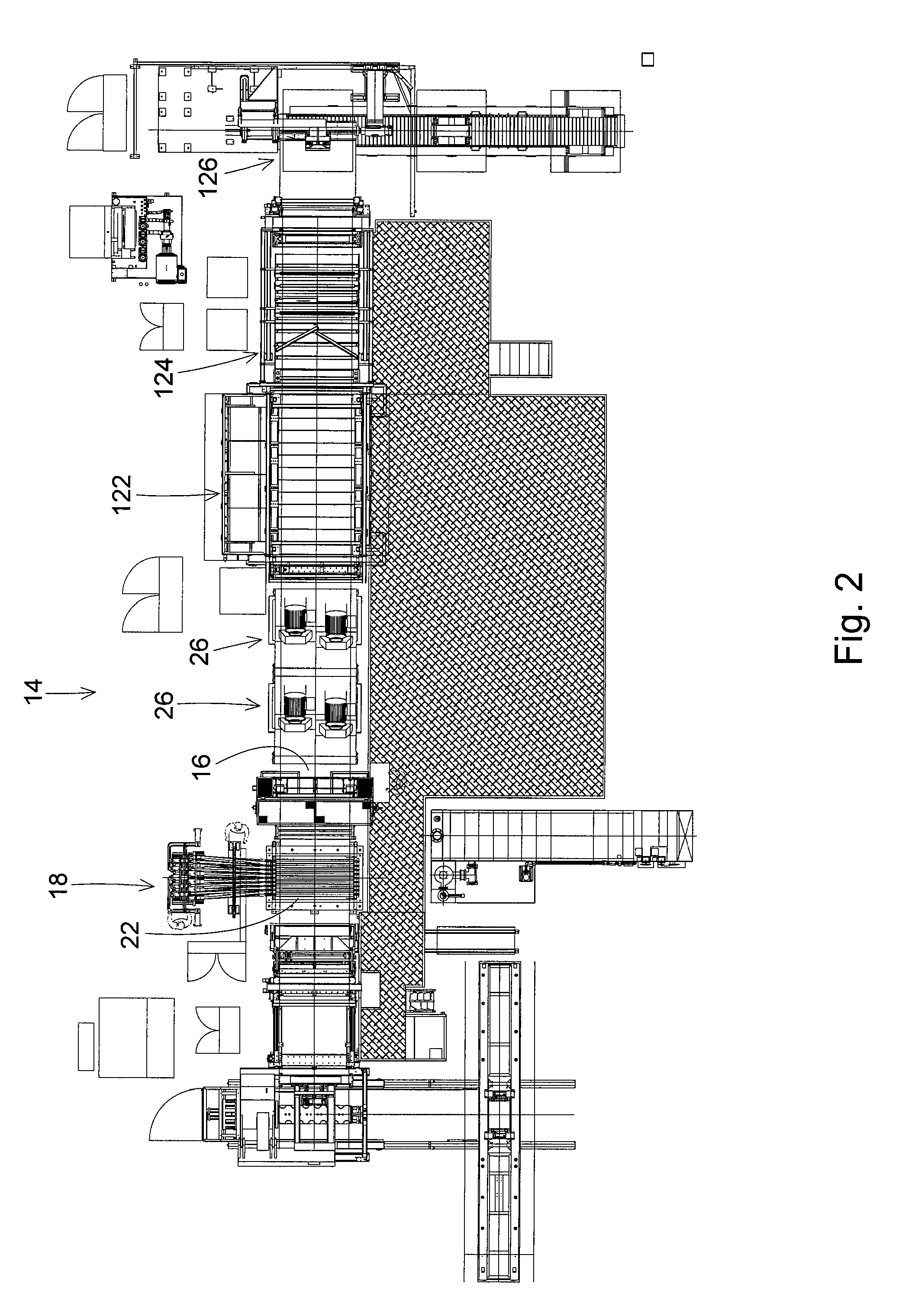

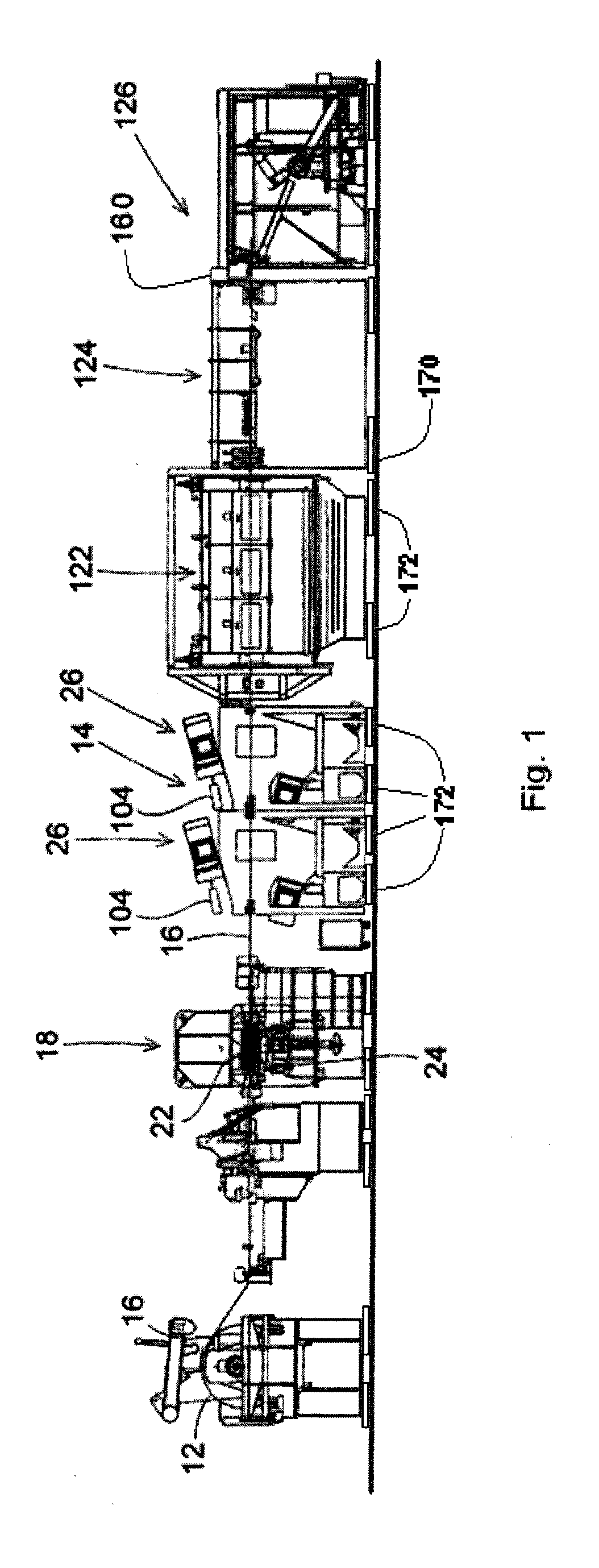

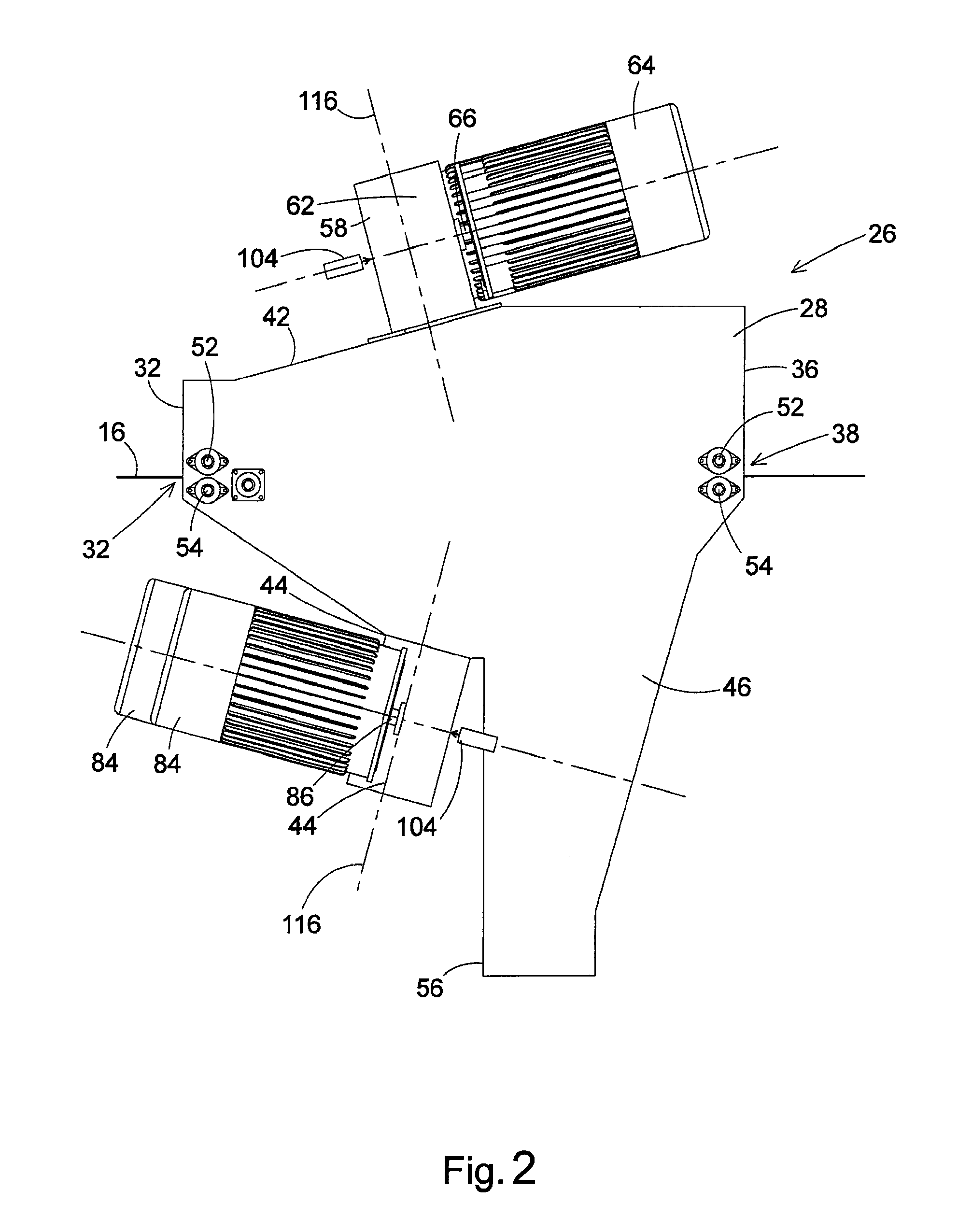

Slurry Blasting Apparatus for Removing Scale From Sheet Metal

ActiveUS20080182486A1Prevent reoxidationAvoid contact damageImpeller wheelsRotor bladesEngineeringMetal

Owner:THE MATERIAL WORKS

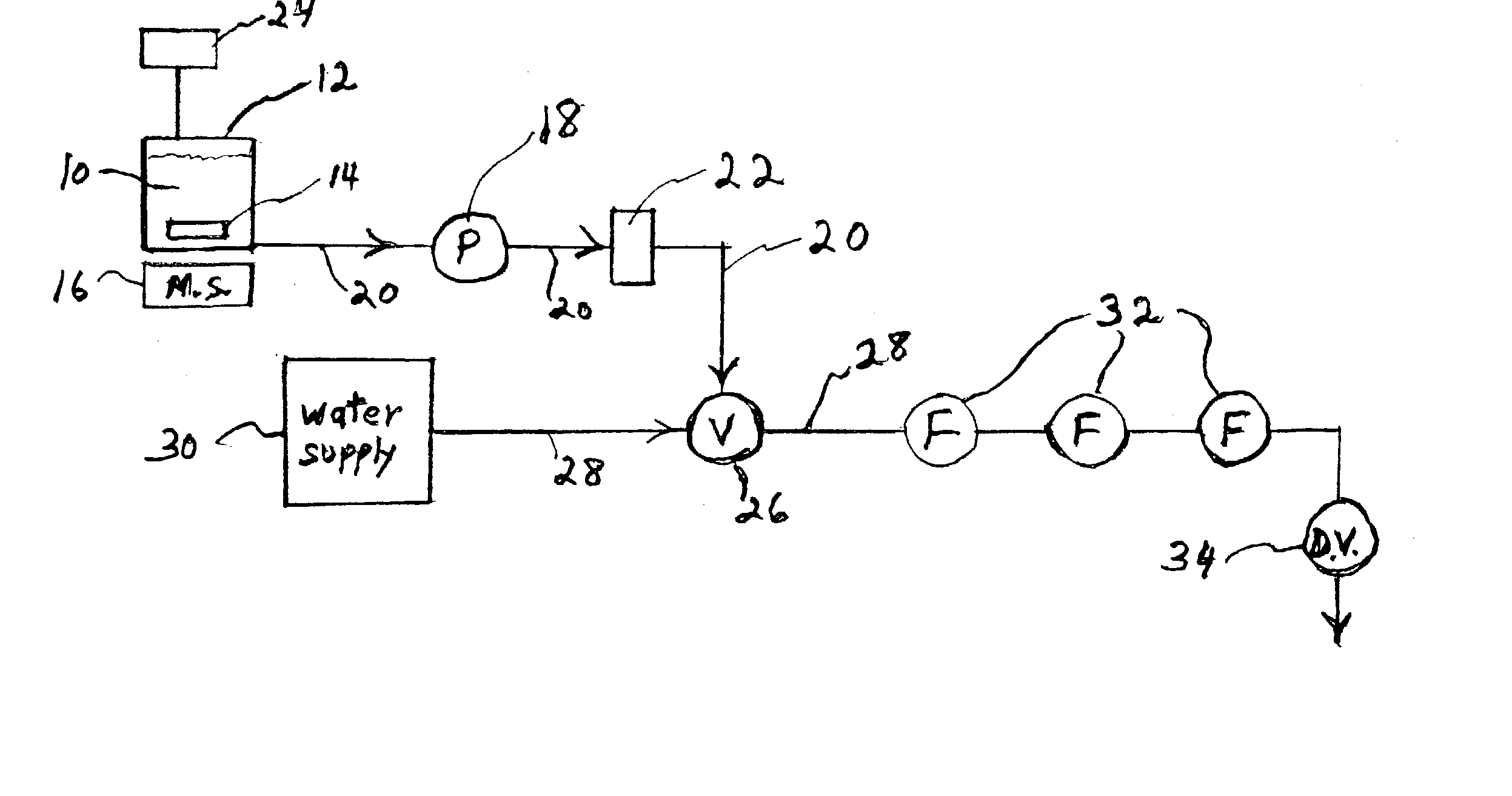

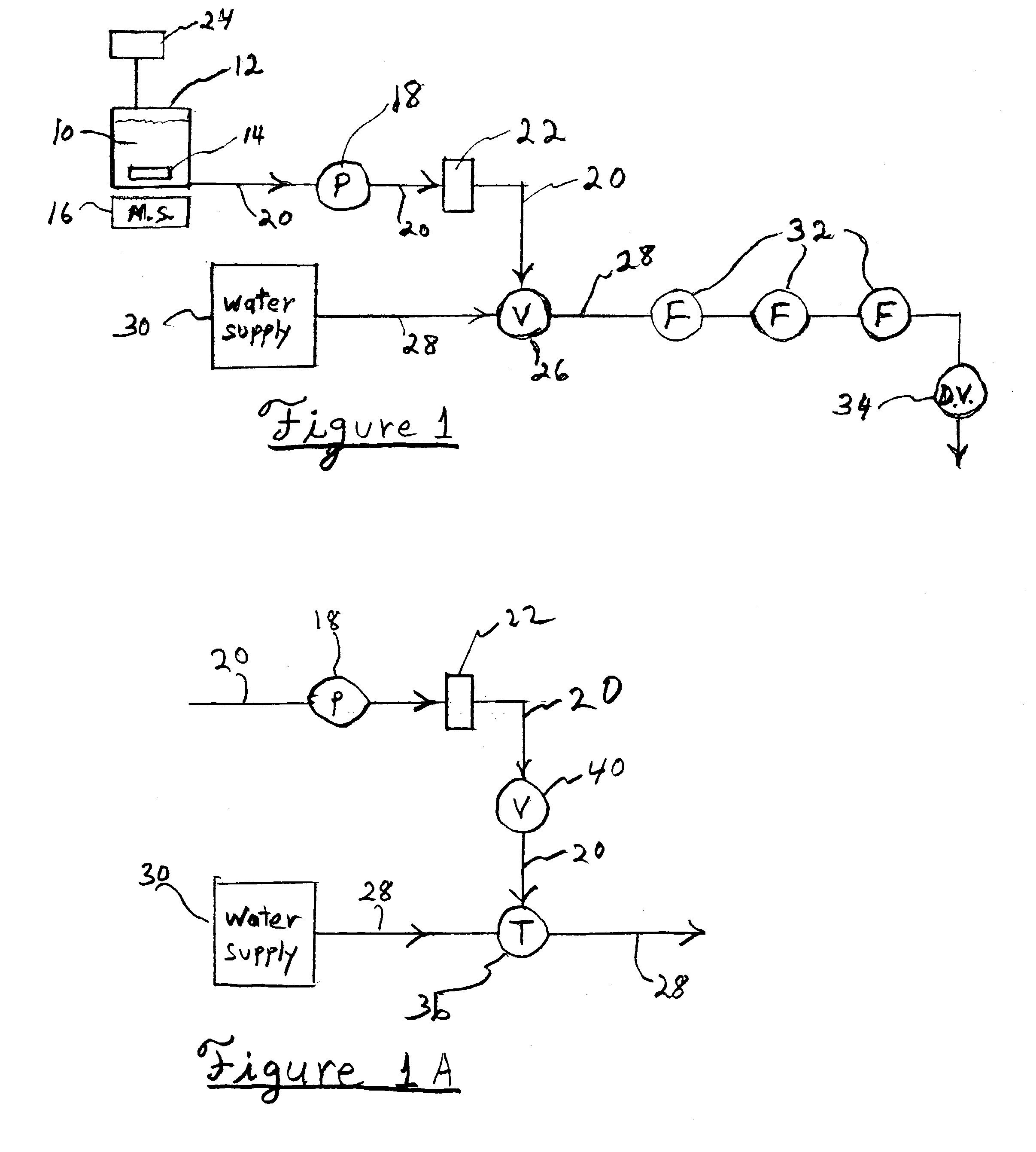

Removal of biofilm from surfaces

InactiveUS20030121532A1The process is simple and effectiveLess complexInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBiofilmPharmaceutical manufacturing

The disclosure encompasses composition, method and apparatus that provide improved and convenient removal of biofilm from surfaces. Surfaces cleaned according to the invention comprise the inner wall of conduits such as those employed in dental clinics, food and pharmaceutical manufacturing.

Owner:COUGHLIN ROBERT W +3

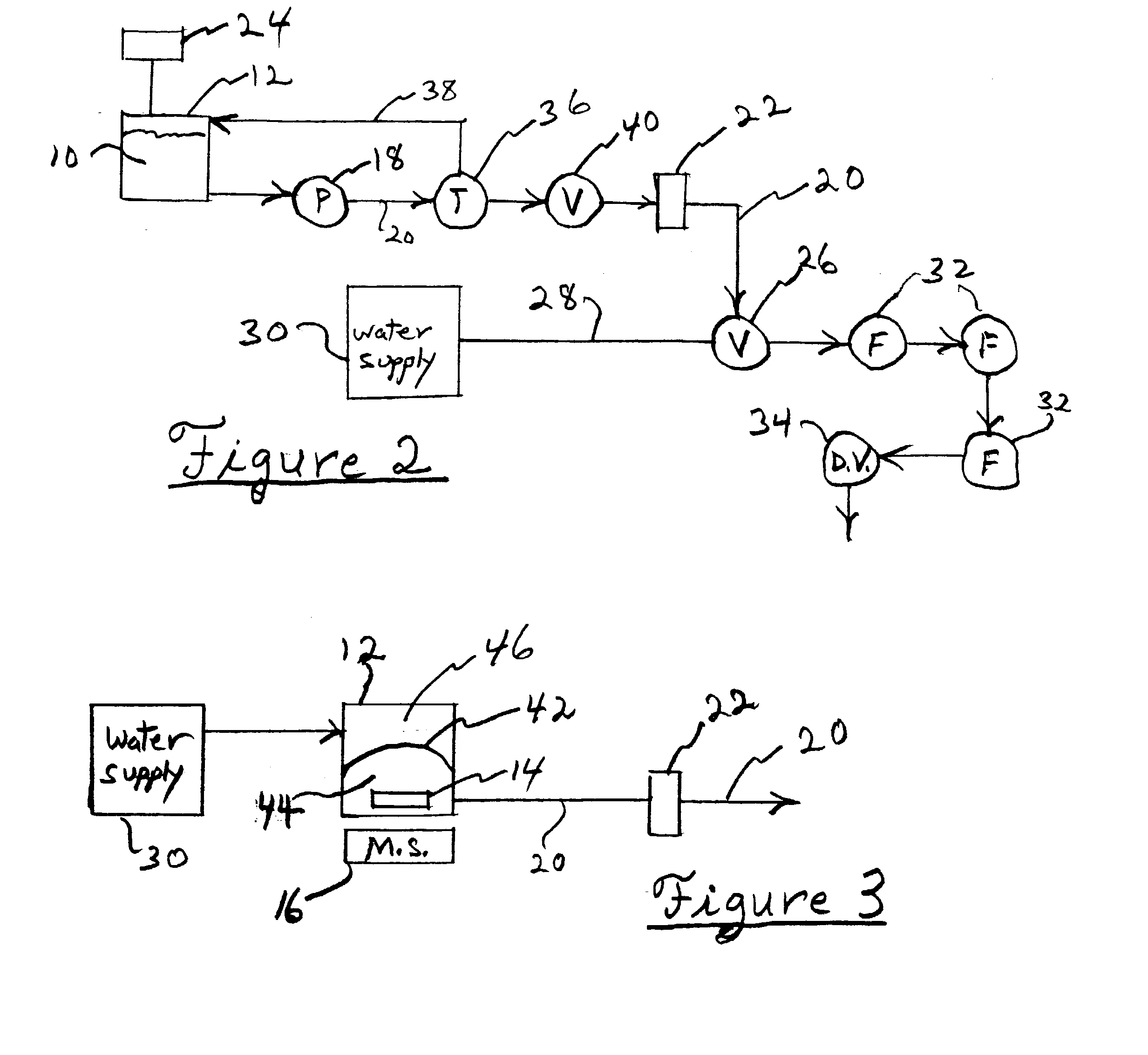

Novel method and special device for precisely processing titanium alloy joint prosthesis by curved-surface turbulence

InactiveCN102152240AIncrease profitImprove processing efficiencyAbrasive blasting machinesTitanium alloySacroiliac joint

The invention relates to a novel method for precisely processing a titanium alloy joint prosthesis by curved-surface turbulence. The novel method comprises the steps of: structuring a constraint runner on an outer surface of the titanium alloy joint prosthesis, introducing an abrasive grain flow into the constraint runner, and grinding and polishing the outer surface of the titanium alloy joint prosthesis in a turbulence state. A special device for the method provided by the invention comprises the titanium alloy joint prosthesis, a die arrangement model of the titanium alloy joint prosthesis covers the outer surface of the titanium alloy joint prosthesis, the constraint runner is formed between the outer surface of the titanium alloy joint prosthesis and the inner surface of the die arrangement model of the titanium alloy joint prosthesis, an inlet of the constraint runner is connected with an abrasive grain flow inlet pipeline, and an outlet of the constraint runner is connected with an abrasive grain flow outlet pipeline. The special device in the invention has the beneficial effects of simple structure, easiness for design and manufacture, high processing efficiency and processing precision and uniformity in processing.

Owner:ZHEJIANG UNIV OF TECH

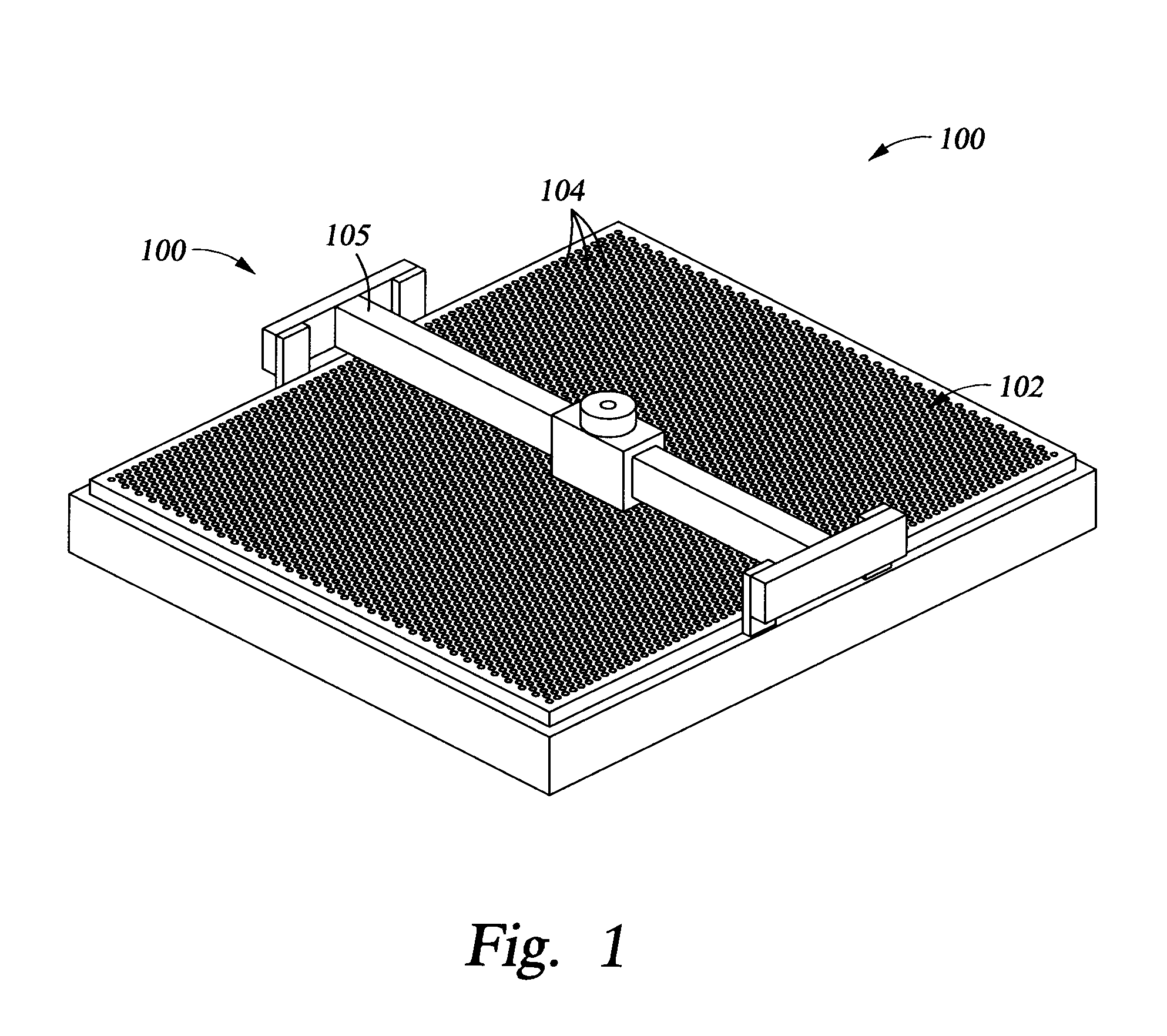

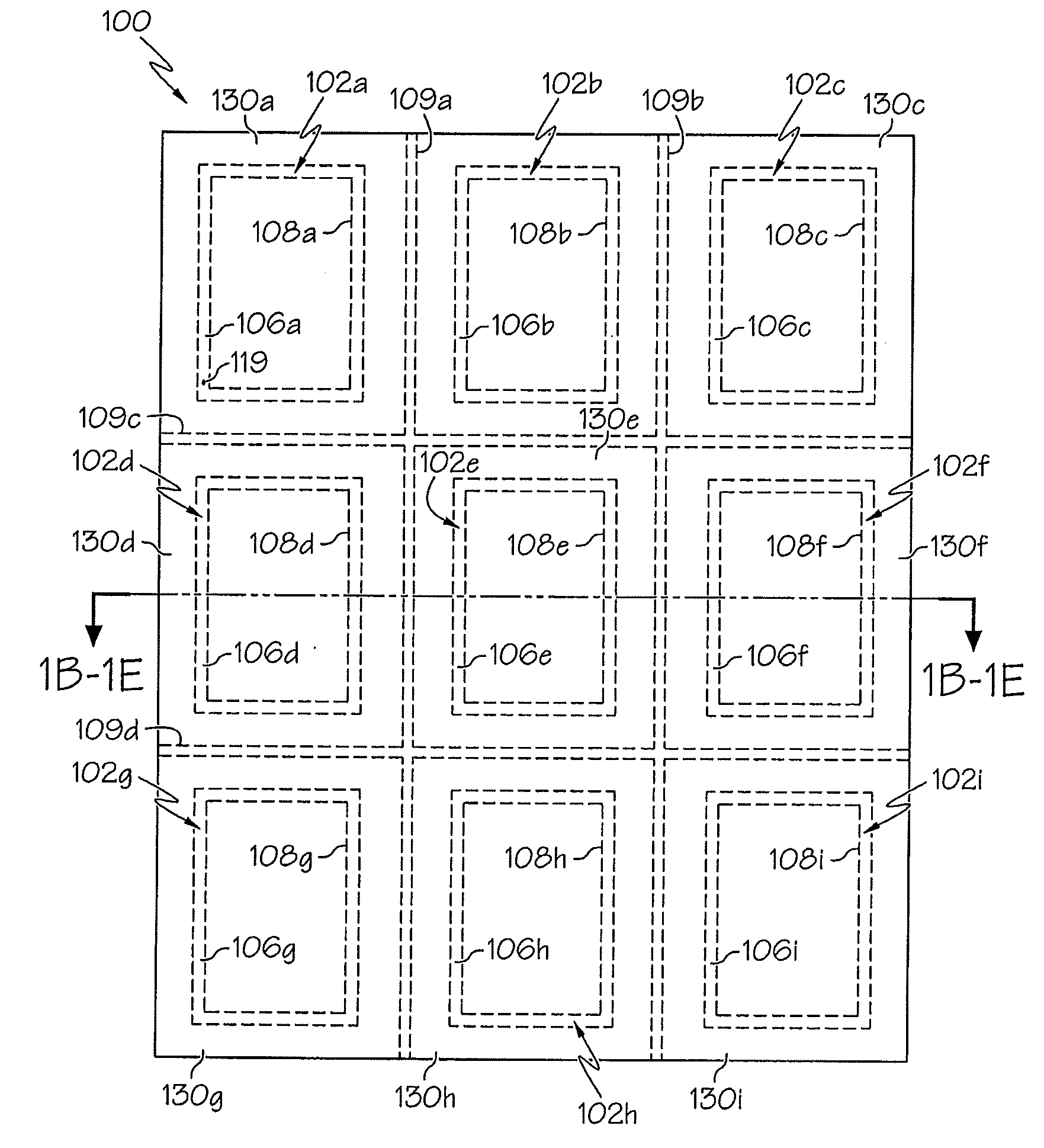

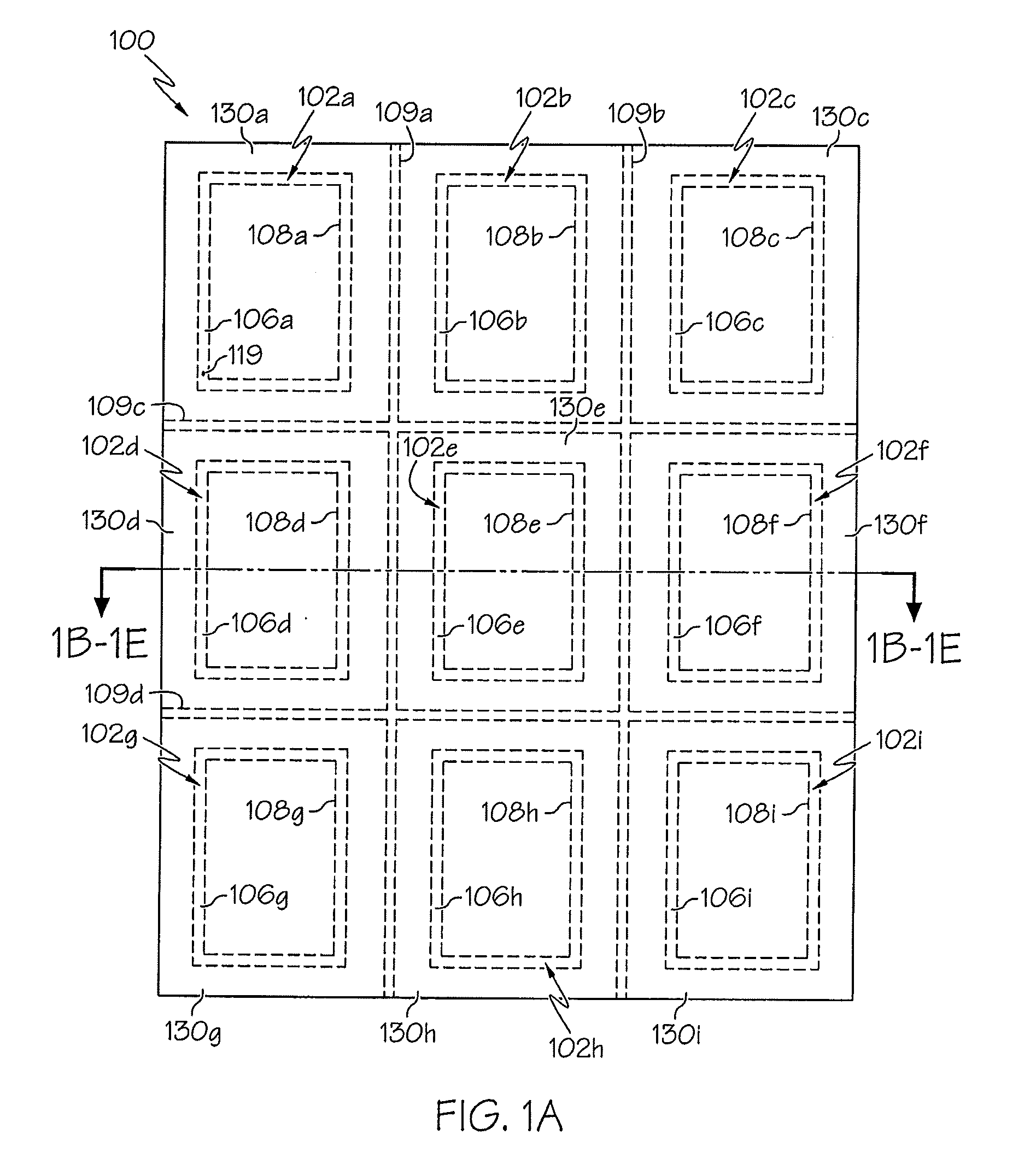

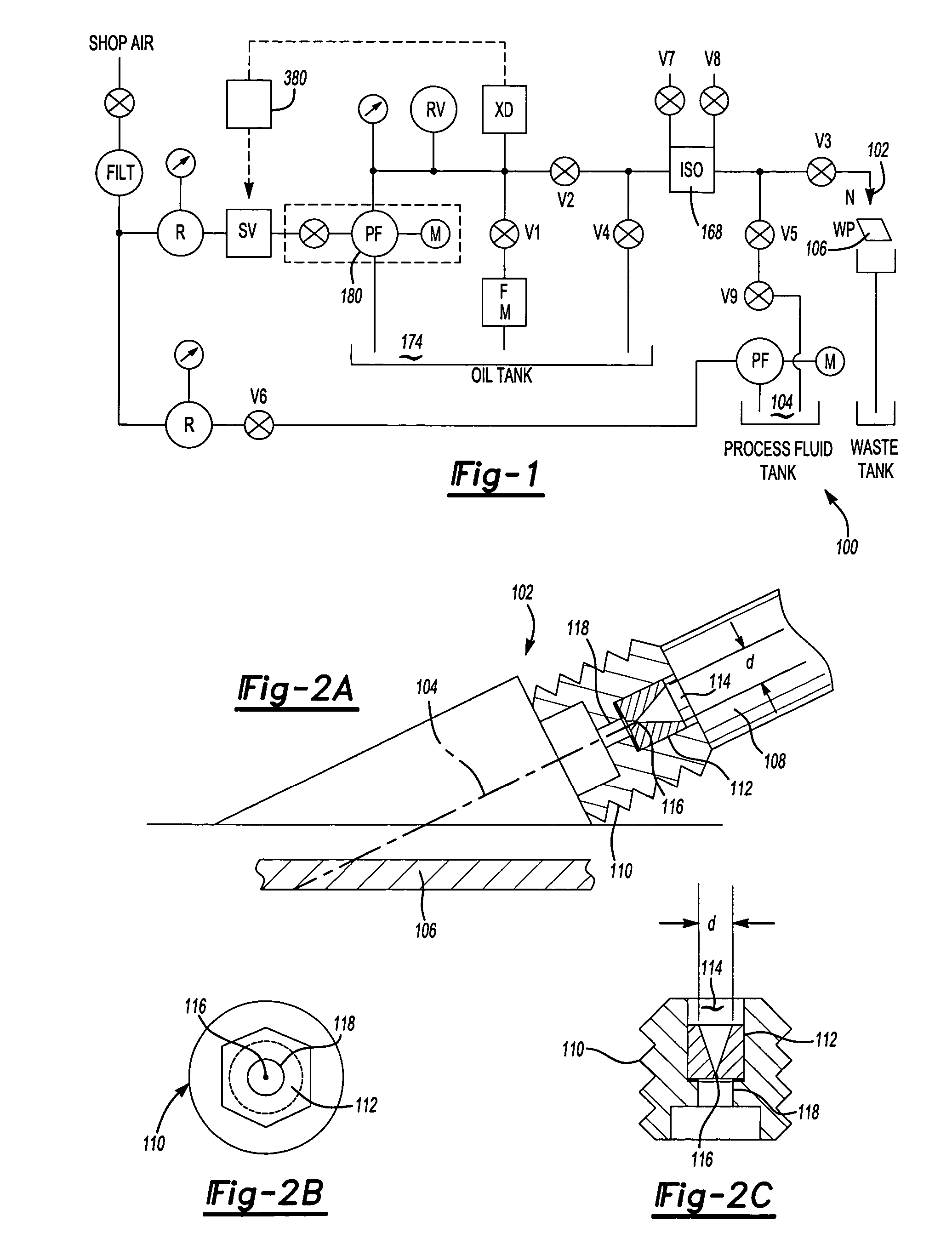

Suspended abrasive waterjet hole drilling system and method

ActiveUS7186167B2High viscosityVelocity increasesBlast gunsLiquid/gas jet drillingEngineeringDrilling system

A suspended abrasive waterjet narrow kerf cutting method is reconfigured to simultaneously drill multiple, closely-spaced holes in a target, including holes in confined non line-of-sight locations. Working fluid nozzles can be located on a flat or non-flat tool surface and arranged in uniform or non-uniform patterns, in an angled or perpendicular orientation, and in parallel or non-parallel arrangements. Individual nozzles or nozzle groups can be easily changed to provide increased or diminished working diameters, allowing control over the hole sizes and resultant airflow thru the drilled workpiece.

Owner:RTX CORP

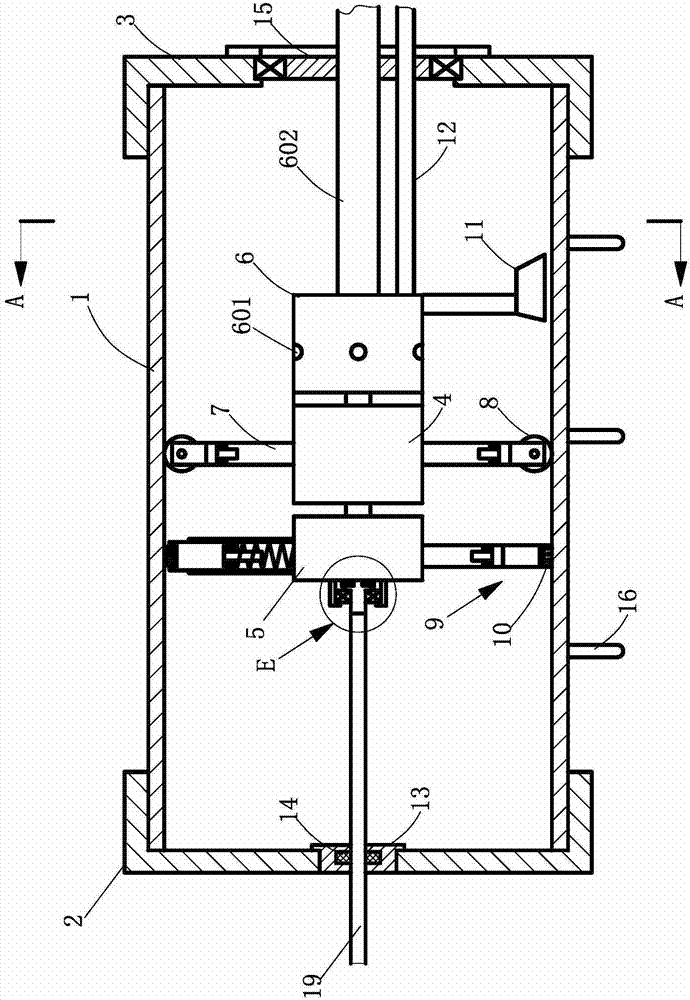

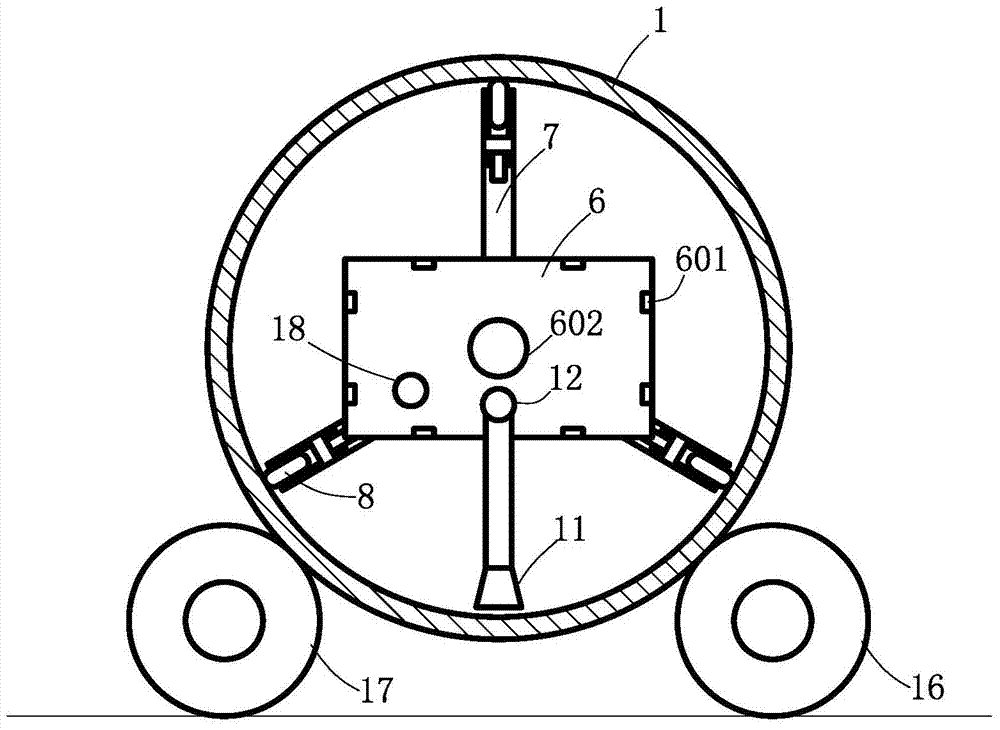

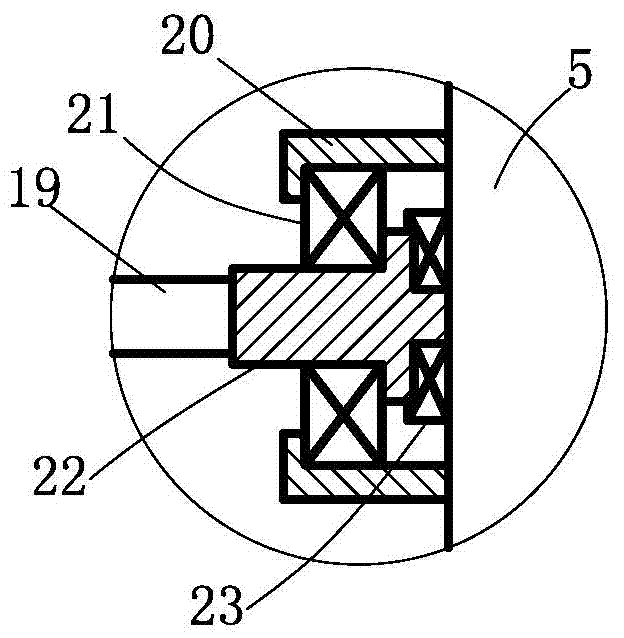

Pipeline inner wall rust removal device

ActiveCN104723223AAvoid pollutionReduce direct damageGrinding machinesAbrasive machine appurtenancesPneumatic motorPollution

The invention discloses a pipeline inner wall rust removal device, belonging to the technical field of polishing units. The device comprises a first end cover and a second end cover which are hermetically installed at two ends of the pipeline, a rust removal trolley is arranged in the pipeline, the dust removal trolley comprises a pneumatic motor with dual output shafts, a shell of the pneumatic motor is provided with a plurality of support shafts, the end part of each support shaft is provided with a roller wheel, a grinding disc is fixedly installed on the output shaft of the pneumatic motor, close to the first end cover, and is provided with a plurality of support rods in the radial direction, the end part of each support rod is provided with an abrasive disc, the output shaft of the pneumatic motor, close to the second end cover, is connected with a shot-blasting machine in a transmission manner; the end part of the grinding disc is connected with a traction rope, the traction rope extends out of the first end cover, one end of the shot-blasting machine, close to the second end cover, is connected with a shot feeding pipe, the pneumatic motor is connected with a gas inlet pipe, the shot feeding pipe and the gas inlet pipe extend out of the second end cover. The pipeline inner wall rust removal device can be used for solving the technical problems that the pipeline inner wall is serious in rust removal pollution and the rust removal effect is poor, and can be widely applied to pipeline cleaning.

Owner:SHANGHAI HONGPU STEEL STRUCTURE ENG

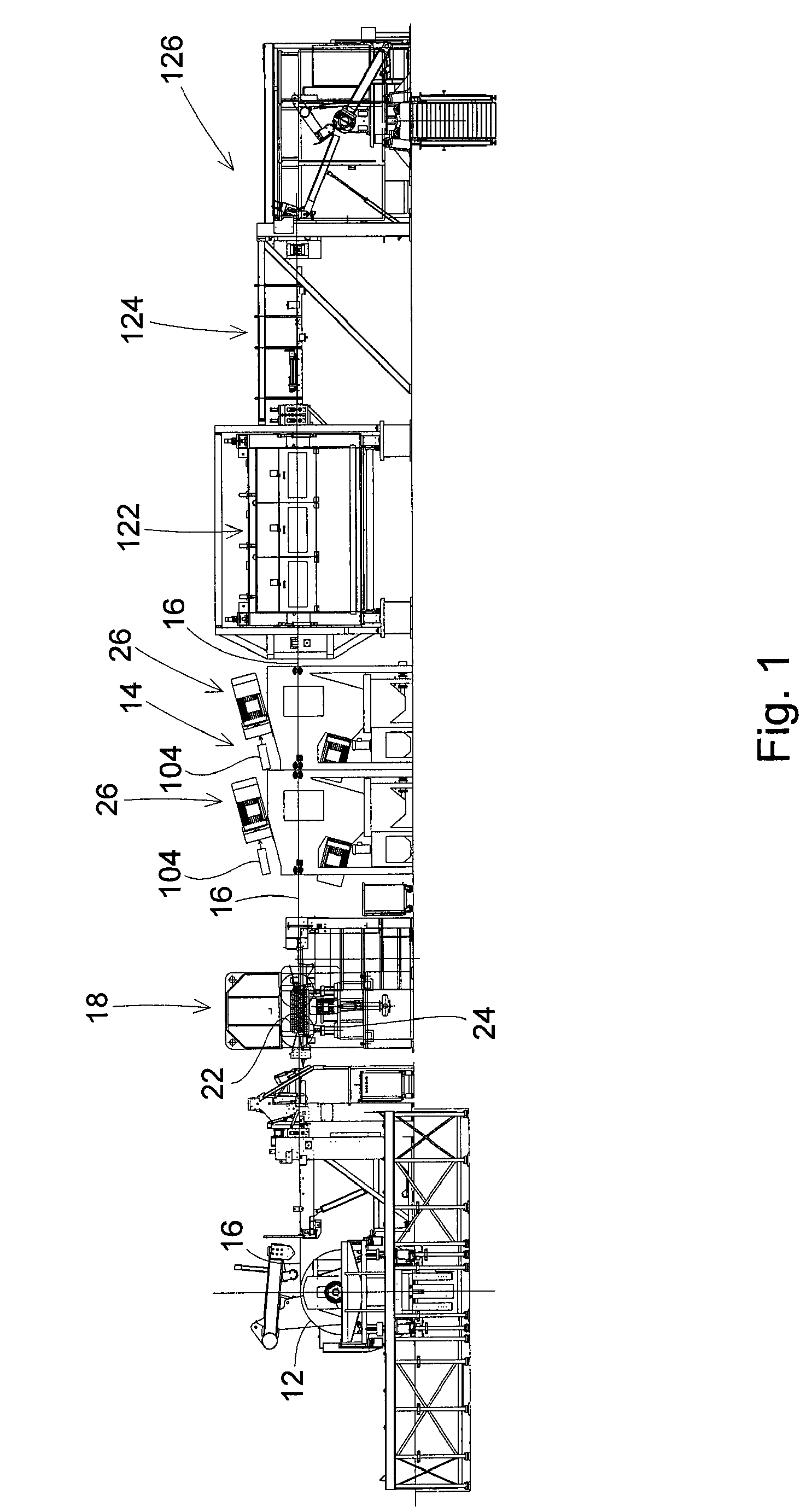

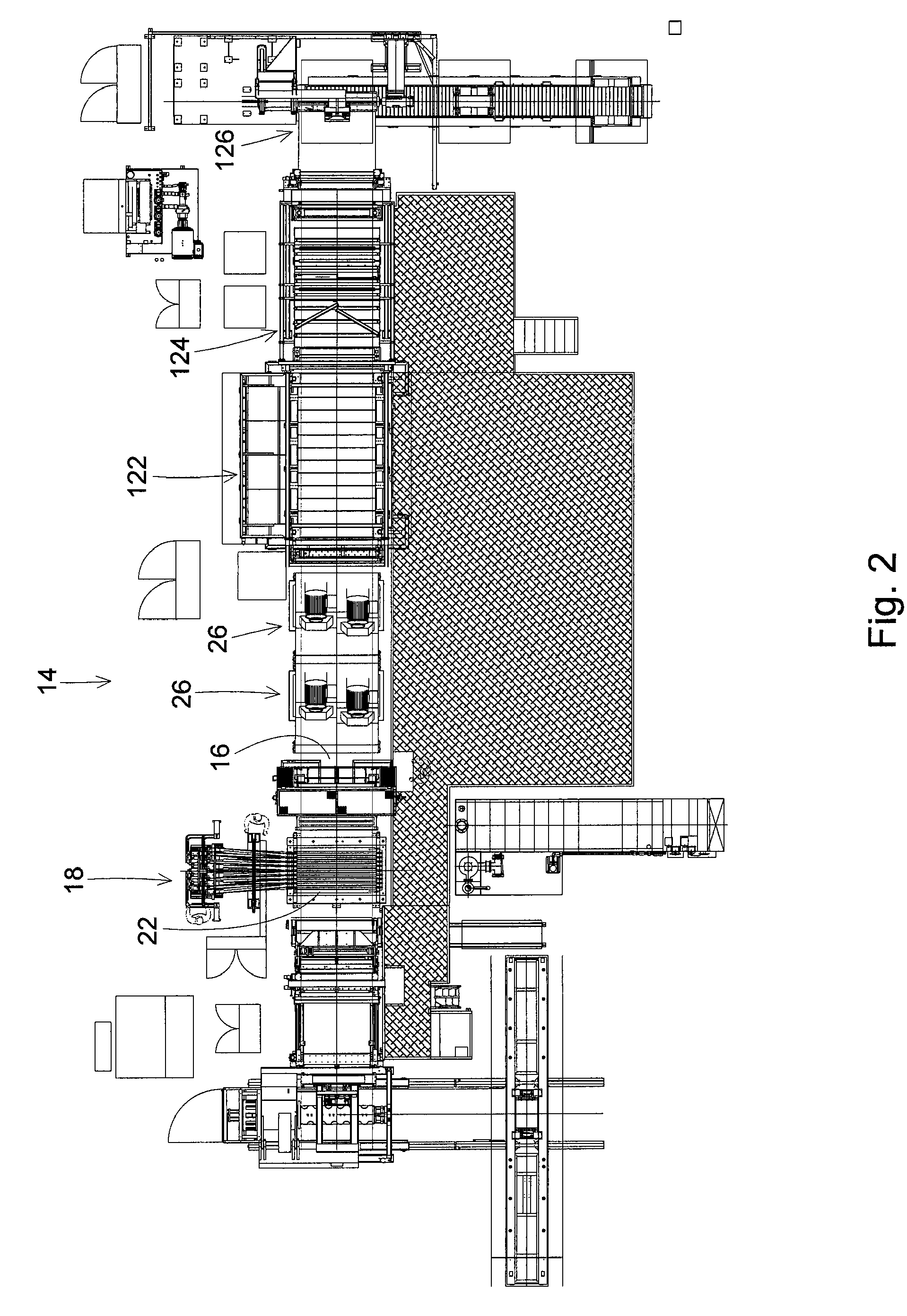

Slurry Blasting Apparatus for Removing Scale from Sheet Metal

ActiveUS20080108281A1Prevent reoxidationAvoid contact damageEdge grinding machinesImpeller wheelsEngineeringMetal

Owner:THE MATERIAL WORKS

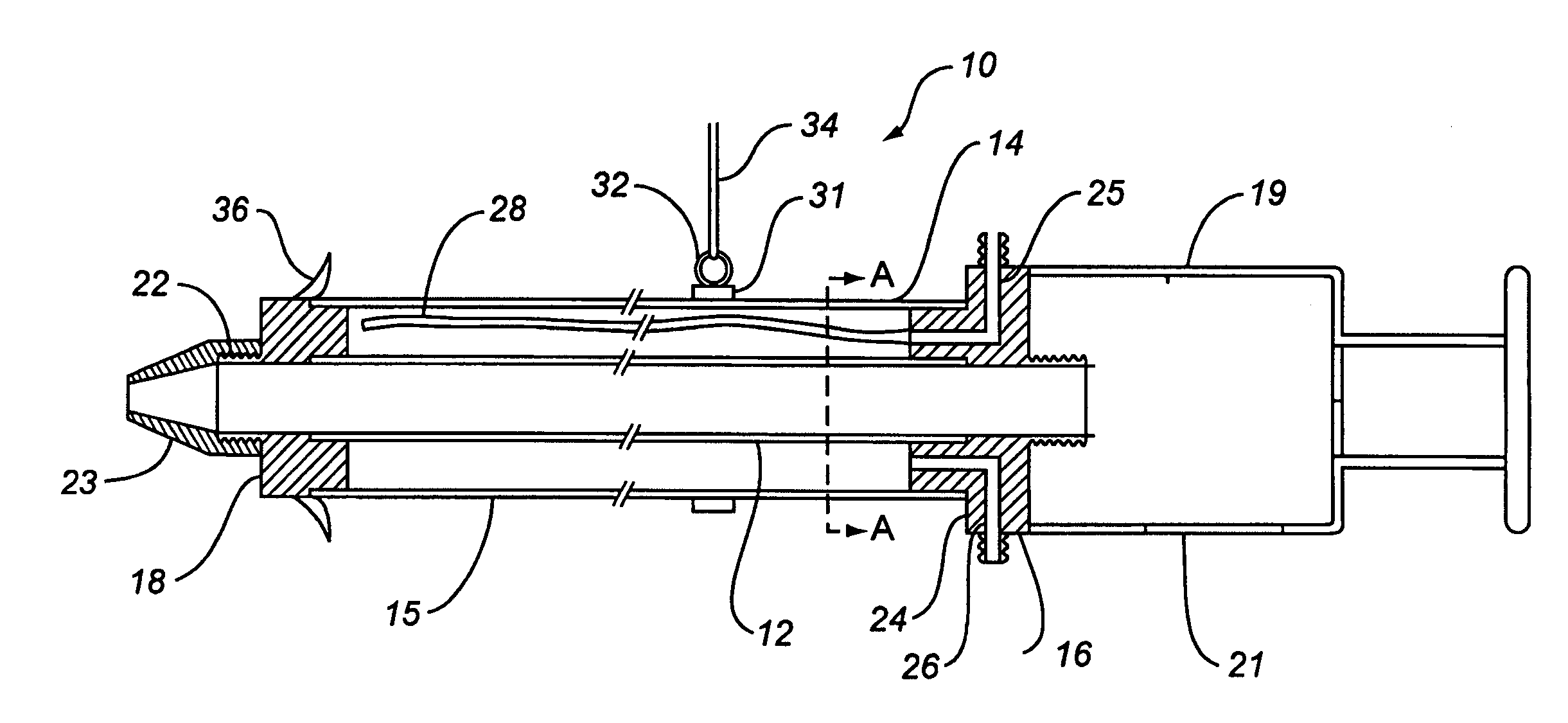

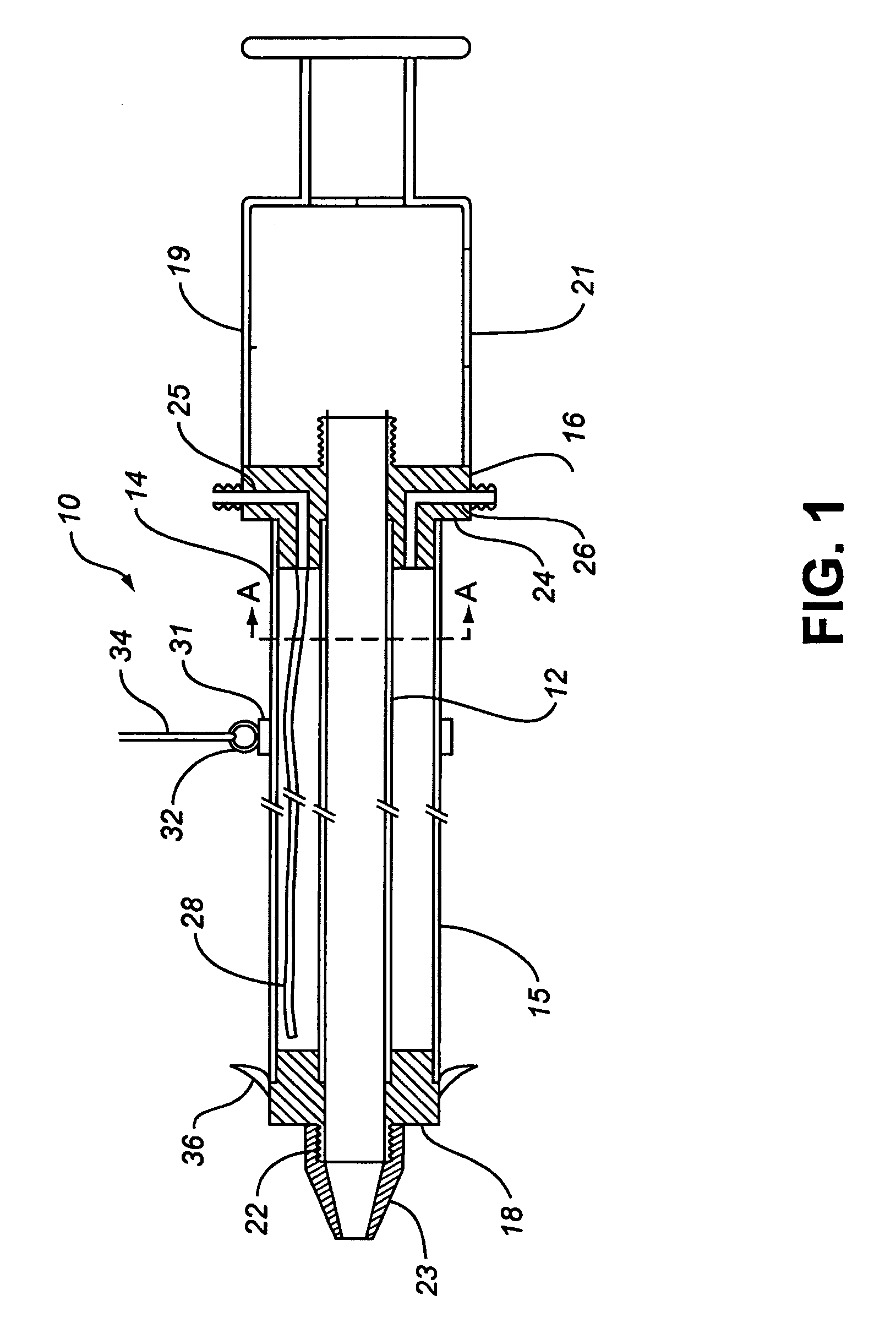

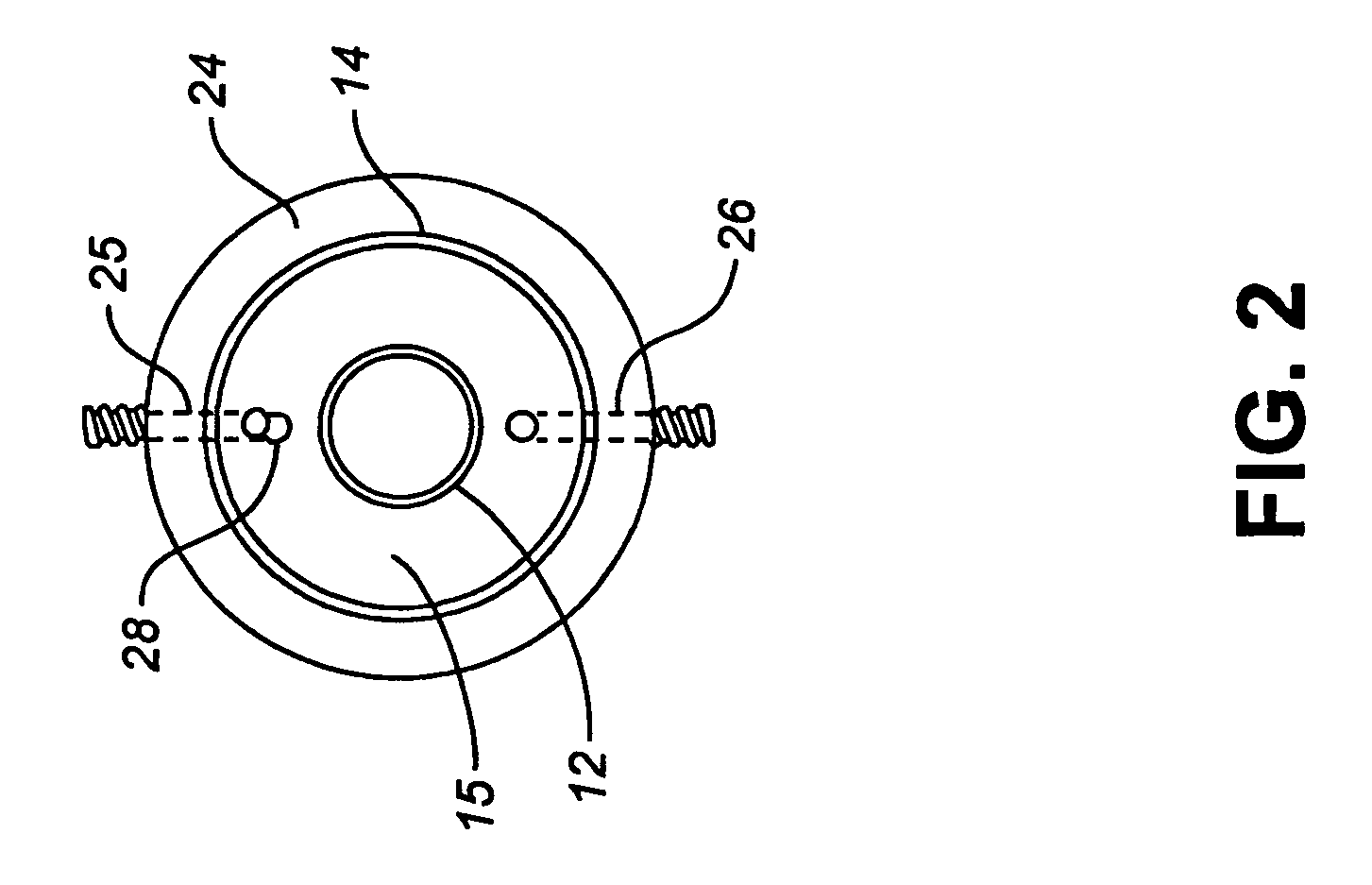

Microdermabrasion System and Method of Use

InactiveUS20070088371A1Avoid the needMaximize utilizationAbrasive feedersAbrasive surgical cuttersSkin treatmentsSkin cell

A device, a system employing the device, and method of performing skin treatment are provided for skin treatment. The device includes a vacuum head base defining a chamber therein and having a substantially smooth treatment tip attached and extending from an end thereof or integral therewith. The tip has at least one central opening that is open to the chamber, and is adapted to contact the skin and traverse the skin in a substantially nonabrasive manner. A vacuum access opening is provided through a side wall of the vacuum head base and adapted to connect with a source of vacuum. A tissue stop member is located within the chamber. It may have an abrasive surface for exfoliating skin cells, or a smoother surface for traversing the skin without substantial abrasion.

Owner:ENVY MEDICAL

Slurry blasting apparatus for removing scale from sheet metal

ActiveUS7601226B2Prevent reoxidationAvoid contact damageEdge grinding machinesImpeller wheelsEngineeringMetal

Owner:THE MATERIAL WORKS

Methods for forming grooves and separating strengthened glass substrate sheets

ActiveUS8616024B2Glass drawing apparatusSemiconductor/solid-state device manufacturingSurface layerIon exchange

Methods for separating strengthened glass articles from glass substrate sheets and strengthened glass substrate sheets are described herein. In one embodiment, a method of separating a glass article from a glass substrate sheet includes forming at least one groove on at least one surface of the glass substrate sheet. The at least one groove continuously extends around a perimeter of the glass article and extends partially through a thickness of the glass substrate sheet. The method further includes strengthening the glass substrate sheet by a strengthening process and separating the glass article from the glass substrate sheet along the at least one groove such that one or more edges of the glass article are under compressive stress. In another embodiment, a strengthened glass substrate sheet includes an ion exchanged glass having one or more grooves in one or more strengthened surface layers, the one or more grooves defining glass articles.

Owner:CORNING INC

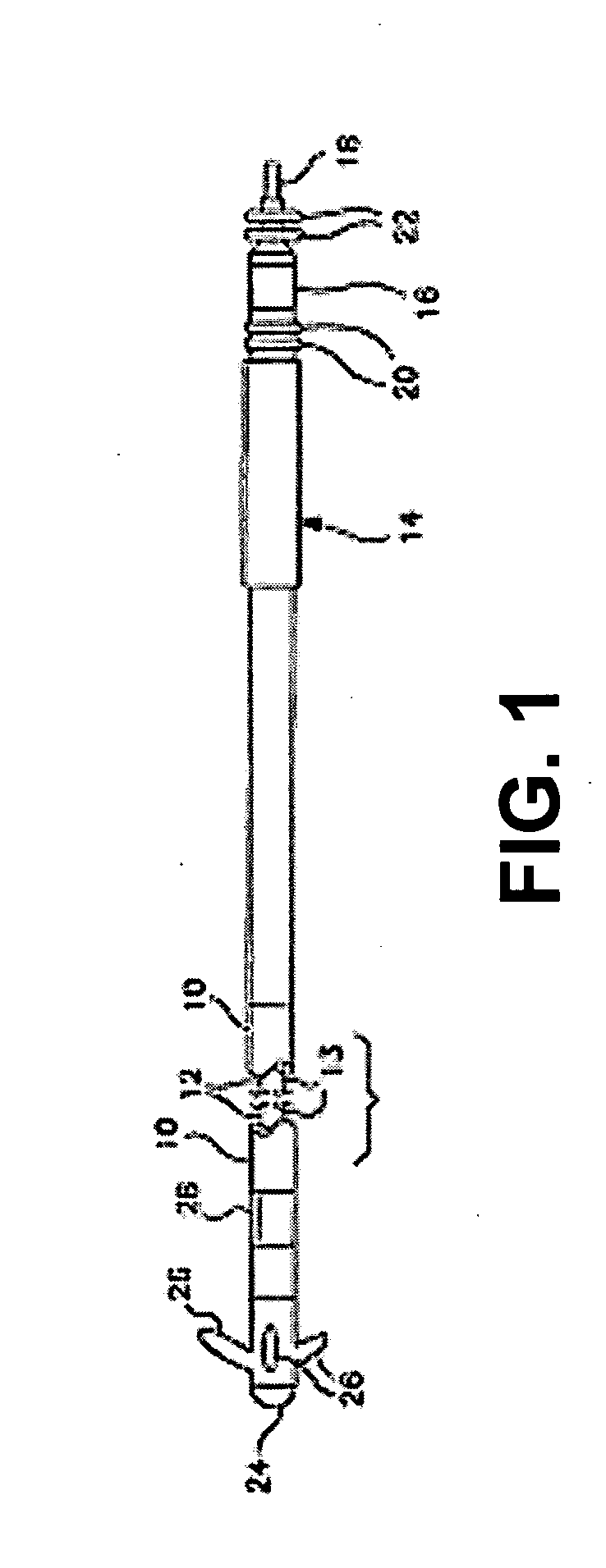

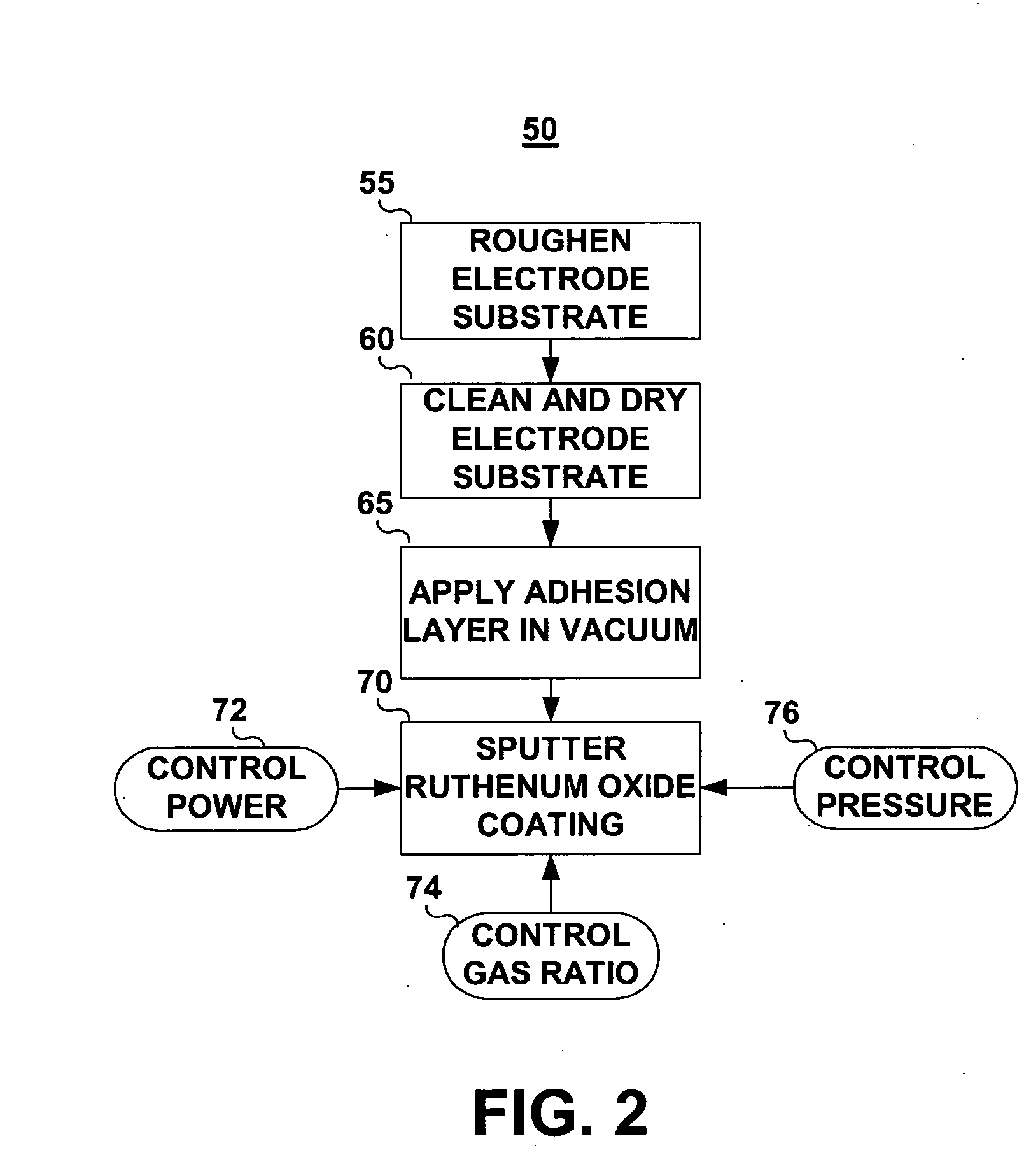

Method for fabrication of low-polarization implantable stimulation electrode

InactiveUS20060167536A1Avoid layeringPrevent oxidationInternal electrodesExternal electrodesIridiumImplantable Stimulation Electrodes

A method for fabricating an implantable medical electrode includes roughening the electrode substrate, applying an adhesion layer, and depositing a valve metal oxide coating over the adhesion layer under conditions optimized to minimize electrode impedance and post-pulse polarization. The electrode substrate may be a variety of electrode metals or alloys including titanium, platinum, platinum-iridium, or niobium. The adhesion layer may be formed of titanium or zirconium. The valve metal oxide coating is a ruthenium oxide coating sputtered onto the adhesion layer under controlled target power, sputtering pressure, and sputter gas ratio setting optimized to minimize electrode impedance and post-pulse polarization.

Owner:MEDTRONIC INC

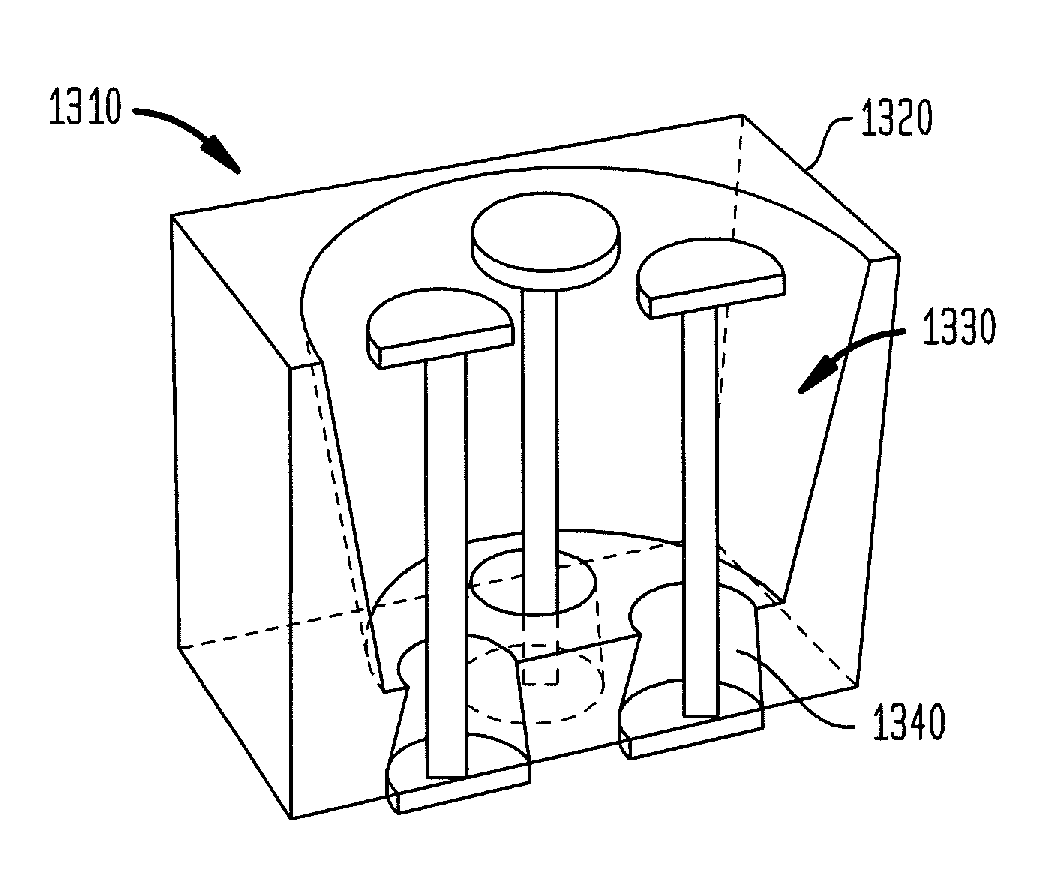

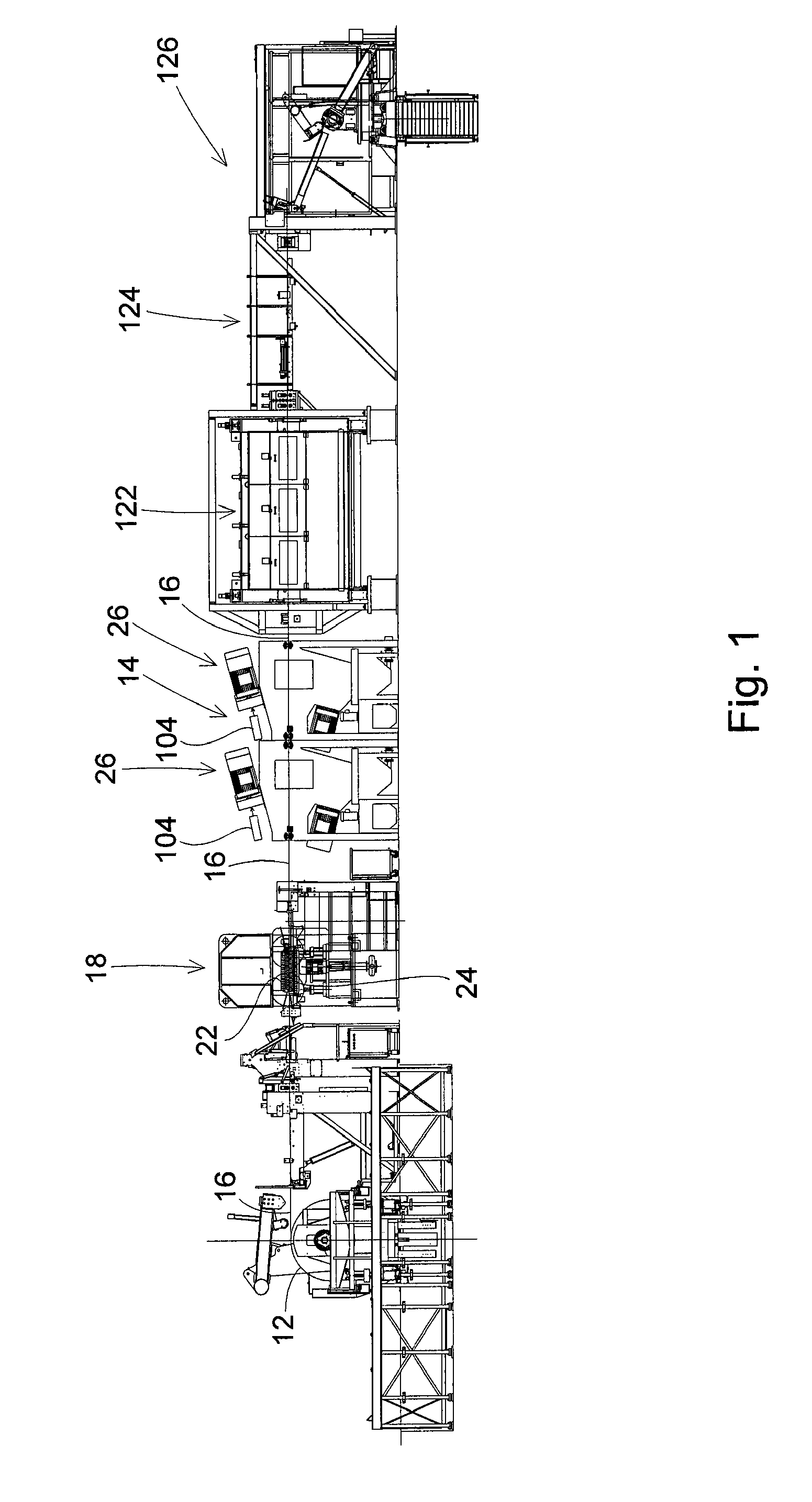

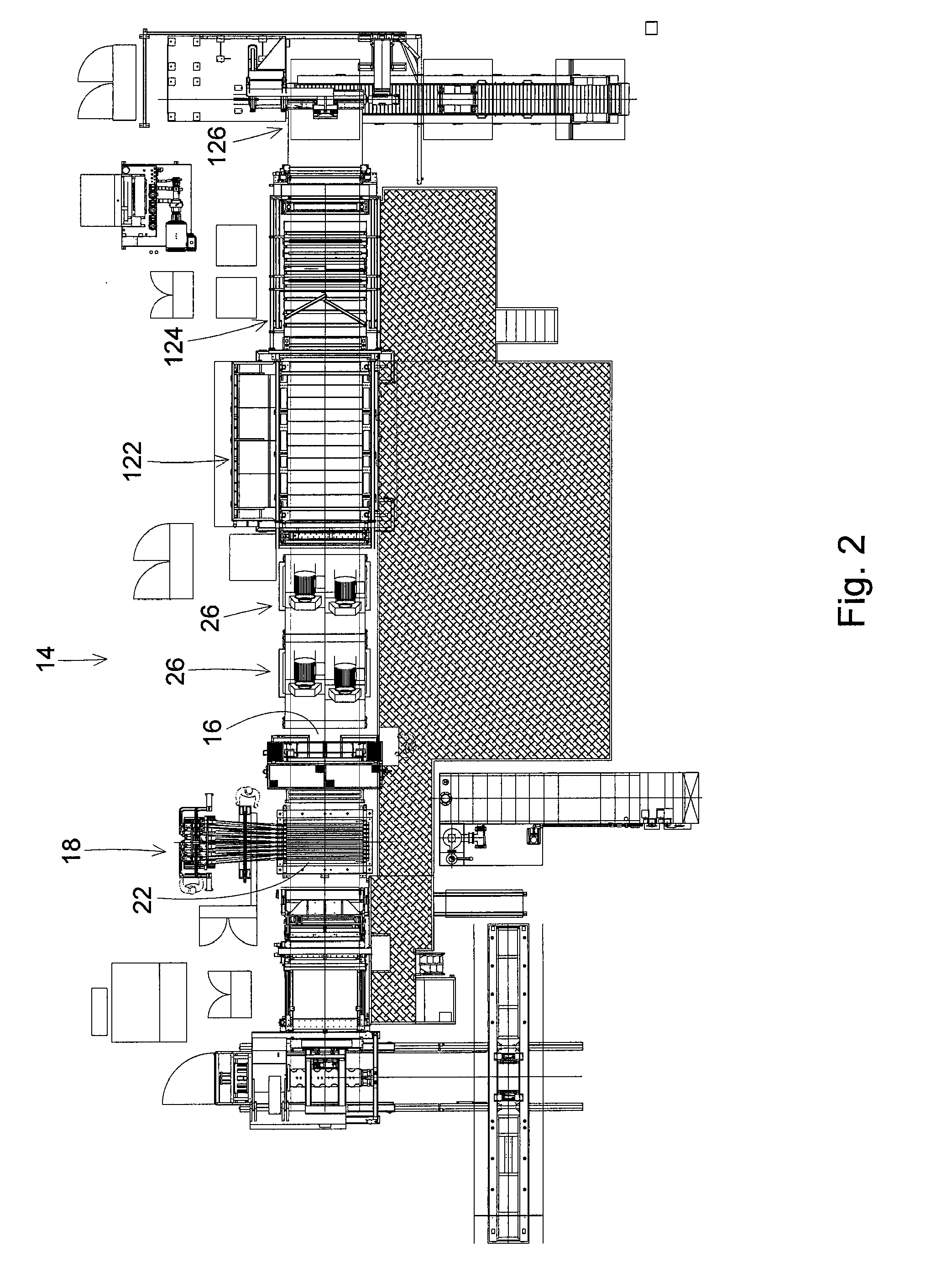

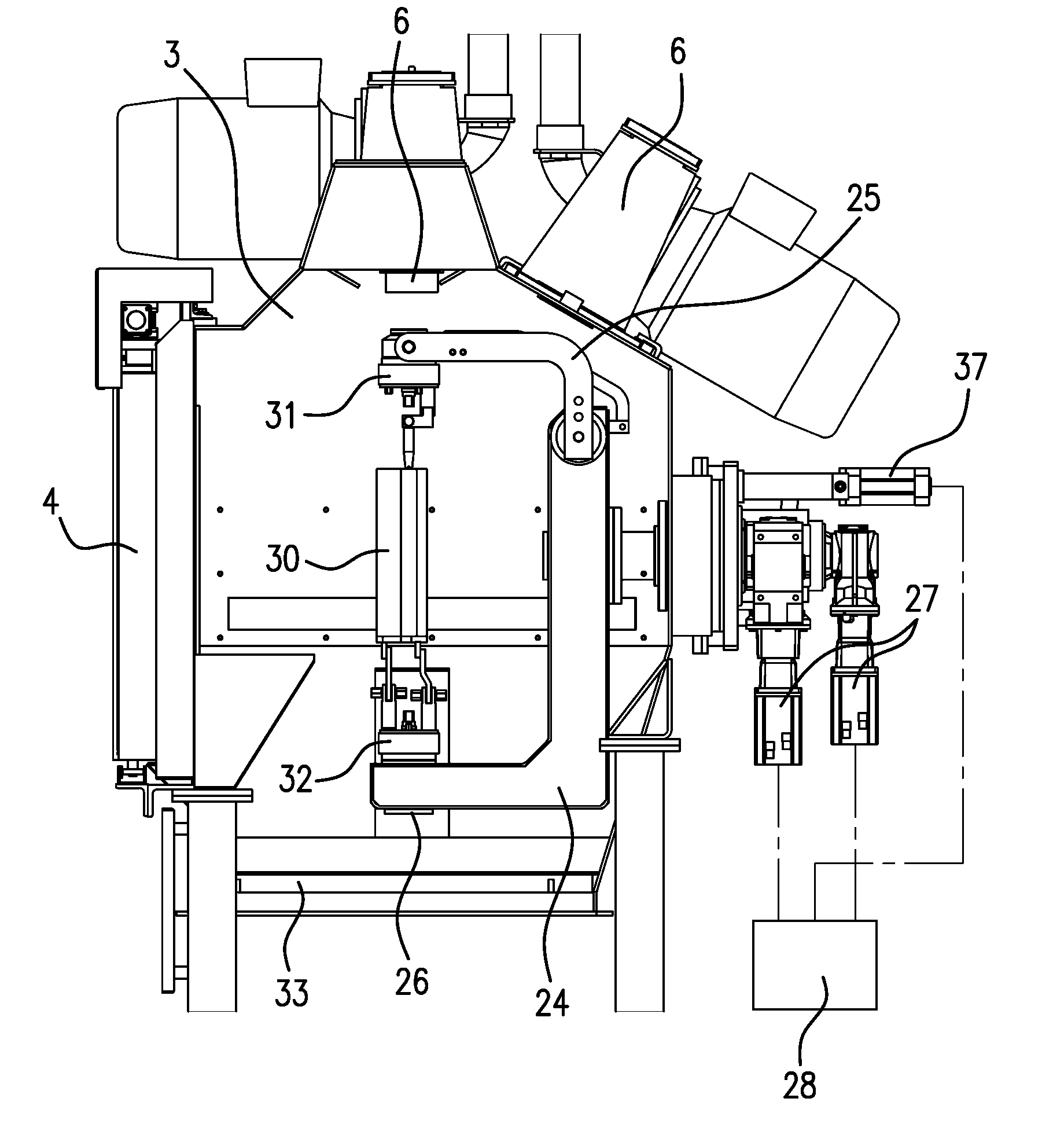

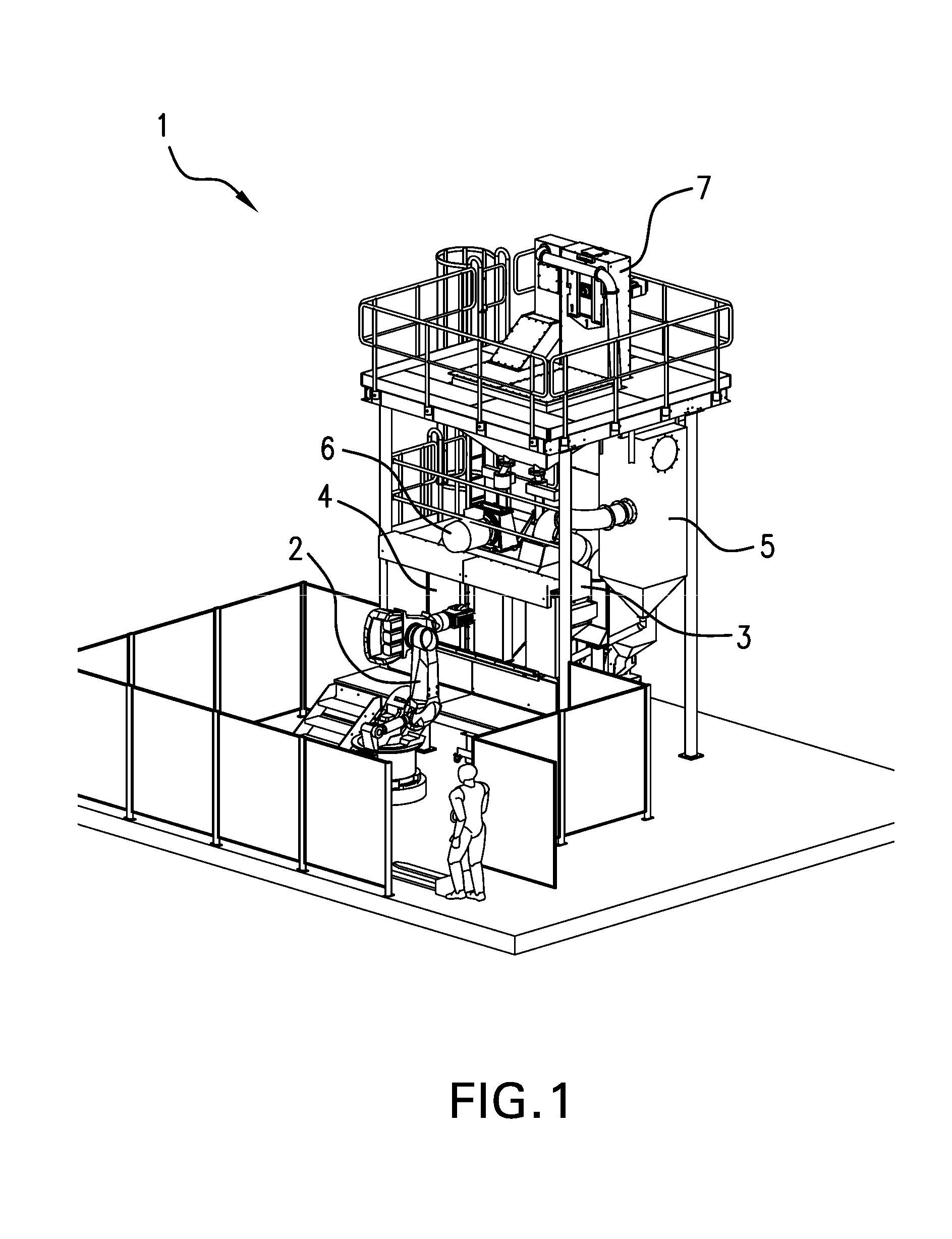

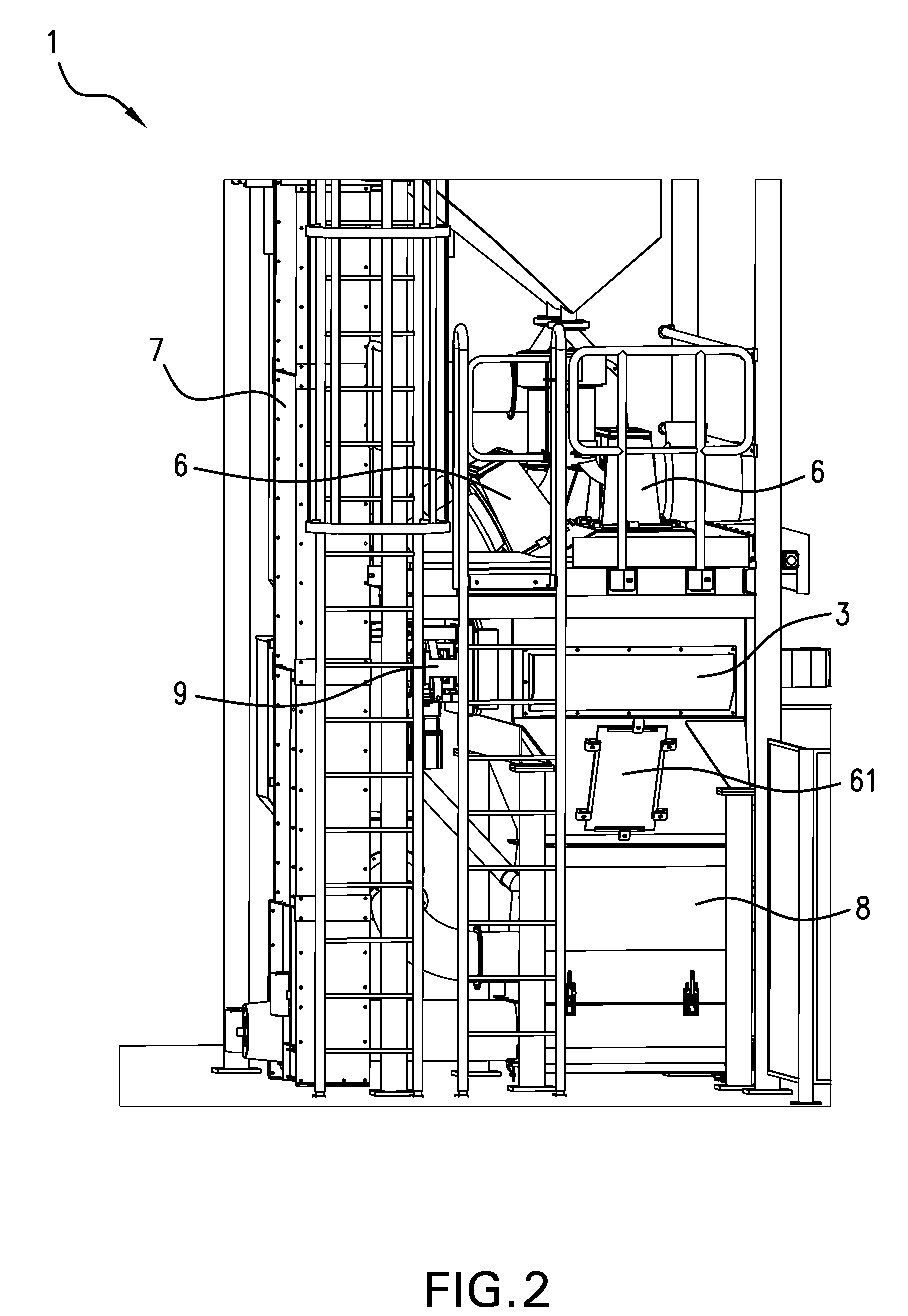

Shot-blasting installation for blasting work pieces made from light metal alloys

InactiveUS7421872B2Promote accumulationValve arrangementsFluid-tightness measurementAbrasive blastingEngineering

A shot-blasting installation (1) for blasting work pieces (30) made from light metal alloys, comprising at least one blasting chamber (3) for receiving the work pieces that are to be blasted, at least two blasting wheels (6) arranged in walls of the blasting chamber for introducing a blasting agent into the blasting chamber, and a separator (8) for separating the mixture of blasting agent and material that has been removed by blasting, wherein the separator (8) is arranged directly beneath the blasting chamber (3), and wherein a manipulator (10) for handling the cast work piece (30) during blasting is arranged in the blasting chamber (3).

Owner:DISA IND

Skin treatment system and method of use

InactiveUS7658742B2Maximize utilizationAvoid the needAbrasive feedersAbrasive surgical cuttersSkin treatmentsSkin cell

A device, a system employing the device and method of performing skin treatment are provided for skin treatment. The device includes a vacuum head base defining a chamber therein and having a substantially smooth treatment tip attached and extending from an end thereof or integral therewith. The tip has at least one central opening that is open to the chamber, and is adapted to contact the skin and traverse the skin in a substantially non-abrasive manner. A vacuum access opening is provided through a side wall of the vacuum head base and adapted to connect with a source of vacuum. A tissue stop member is located within the chamber. It may have an abrasive surface for exfoliating skin cells, or a smoother surface for traversing the skin without substantial abrasion.

Owner:ENVY MEDICAL

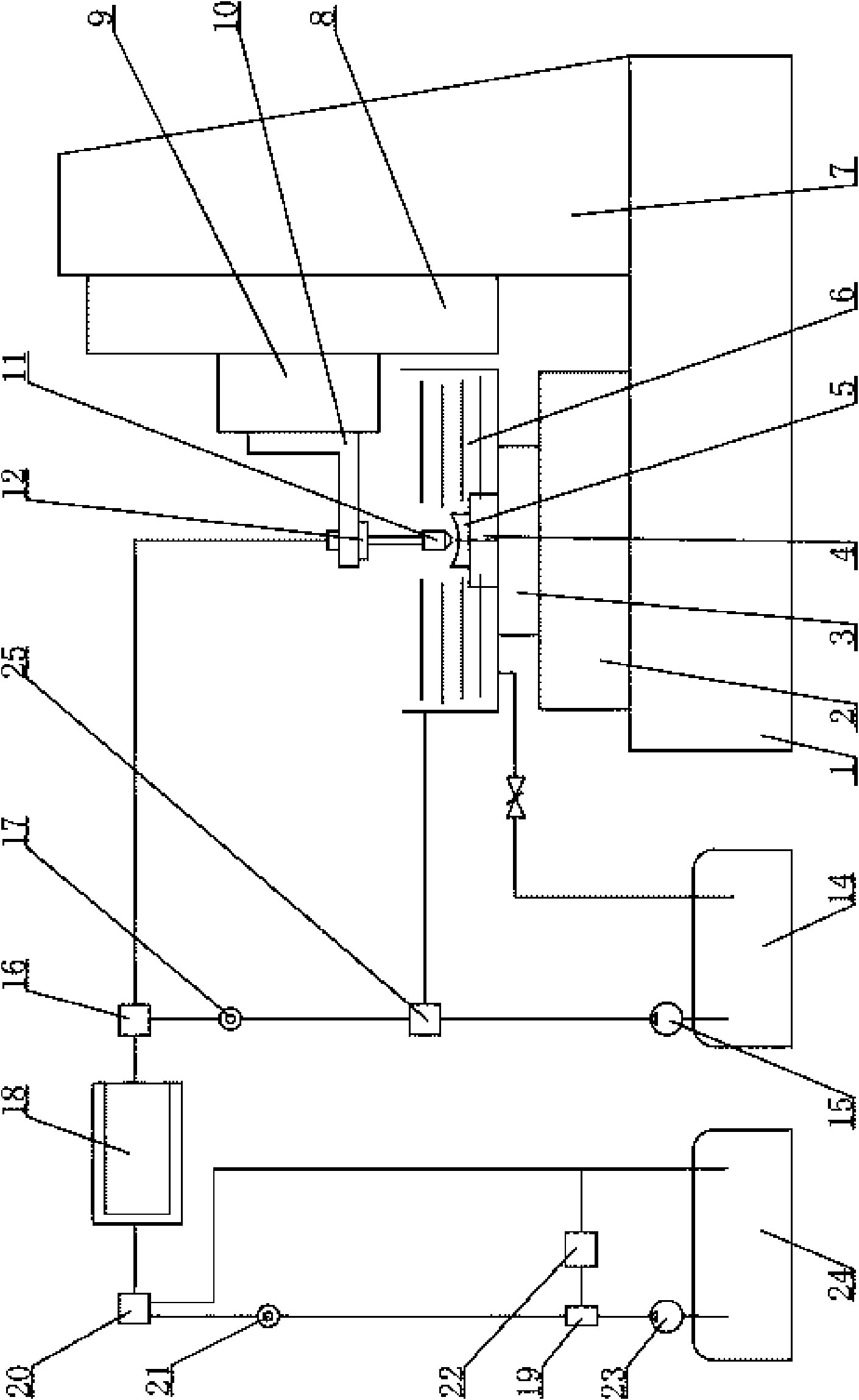

Dynamic pressure cavitation jet polishing device of colloidal flow and method

InactiveCN101670556AImprove quality and efficiencyImprove processing efficiencyBlast gunsAbrasive feedersCavitationSemiconductor materials

The invention discloses a dynamic pressure cavitation jet polishing device of colloidal flow and a method, relating to a polishing device and a method and aiming at solving the problems that the existing polishing method of the ultrasmooth surface has low processing efficiency and high cost, the adaptability of the work piece material is limited and the existing polishing device of the ultrasmoothsurface has complex equipment and high maintenance cost. The device is characterized in that a cavitation jet device is fixed on a bracket; the input end of the cavitation jet device is connected with an outlet of a first flow reversing valve by a pipeline. The method comprises the following steps: (1) the polished work piece is immersed with 10 to 200mm by the colloidal polished liquid level; (2) the oil pressure of the cavitation jet device is 0.5 to 15MPa; (3) the cavitation jet pressure is 0.5 to 15MPa; and (4) the cavitation jet device is arranged in colloidal polishing liquid, the cavitation jet device sprays to the work piece at the speed of 15 to 250m / s, and after polishing, the work piece is taken out, namely the polished work piece. The invention is used for ultraprecise and ultrasmooth polishing of optical glass, microcrystal glass, semiconductor materials and monocrystal materials.

Owner:HARBIN INST OF TECH

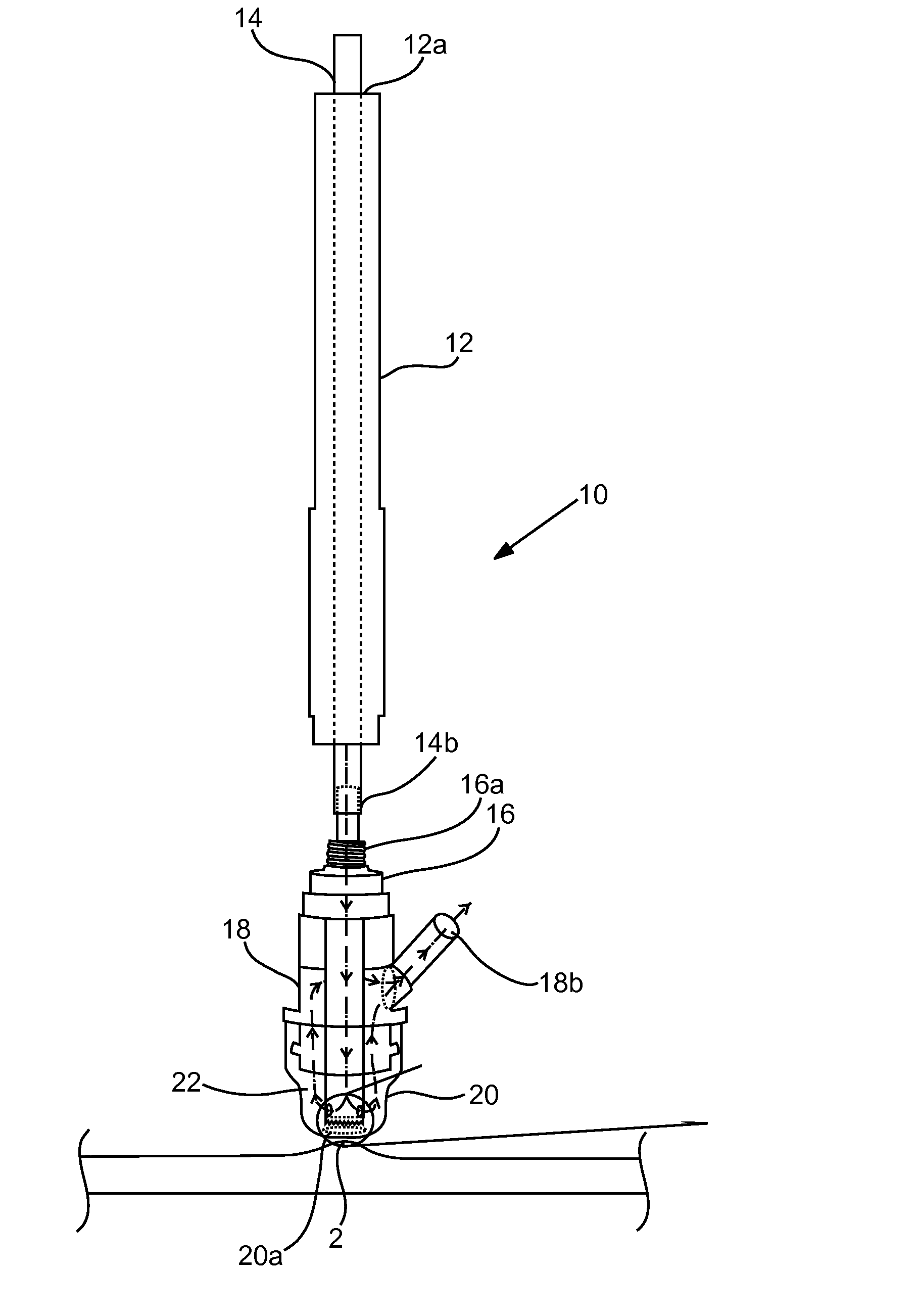

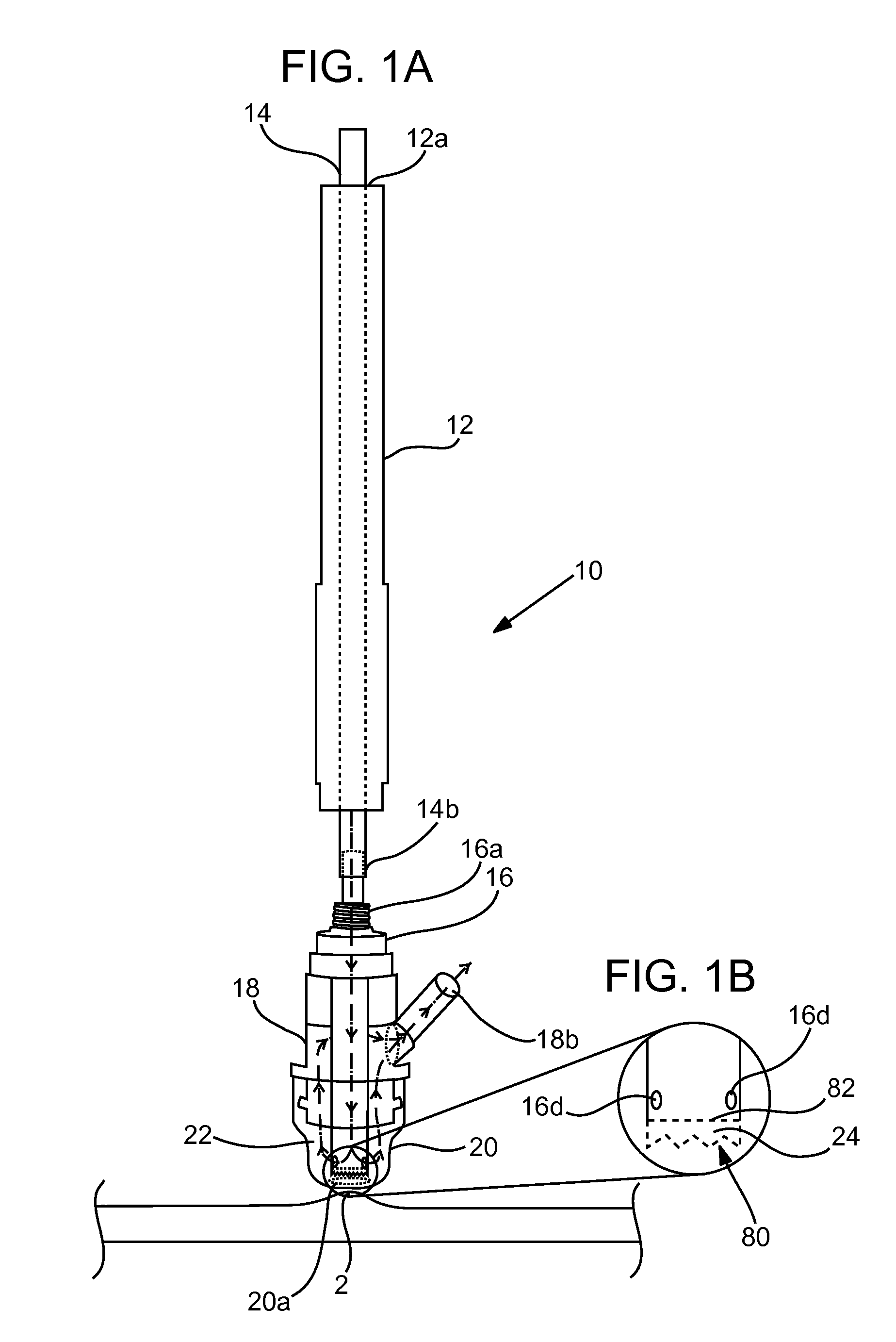

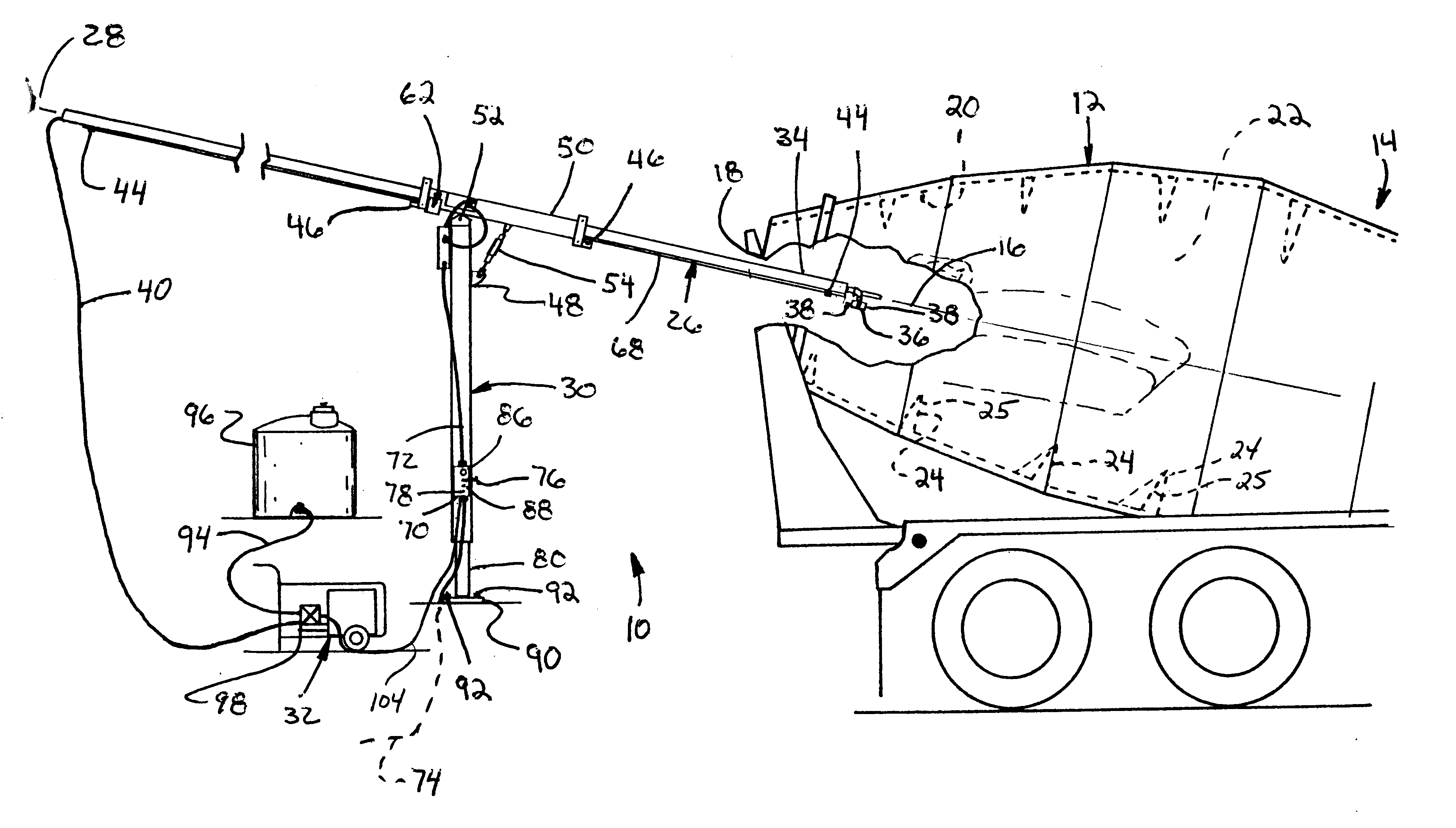

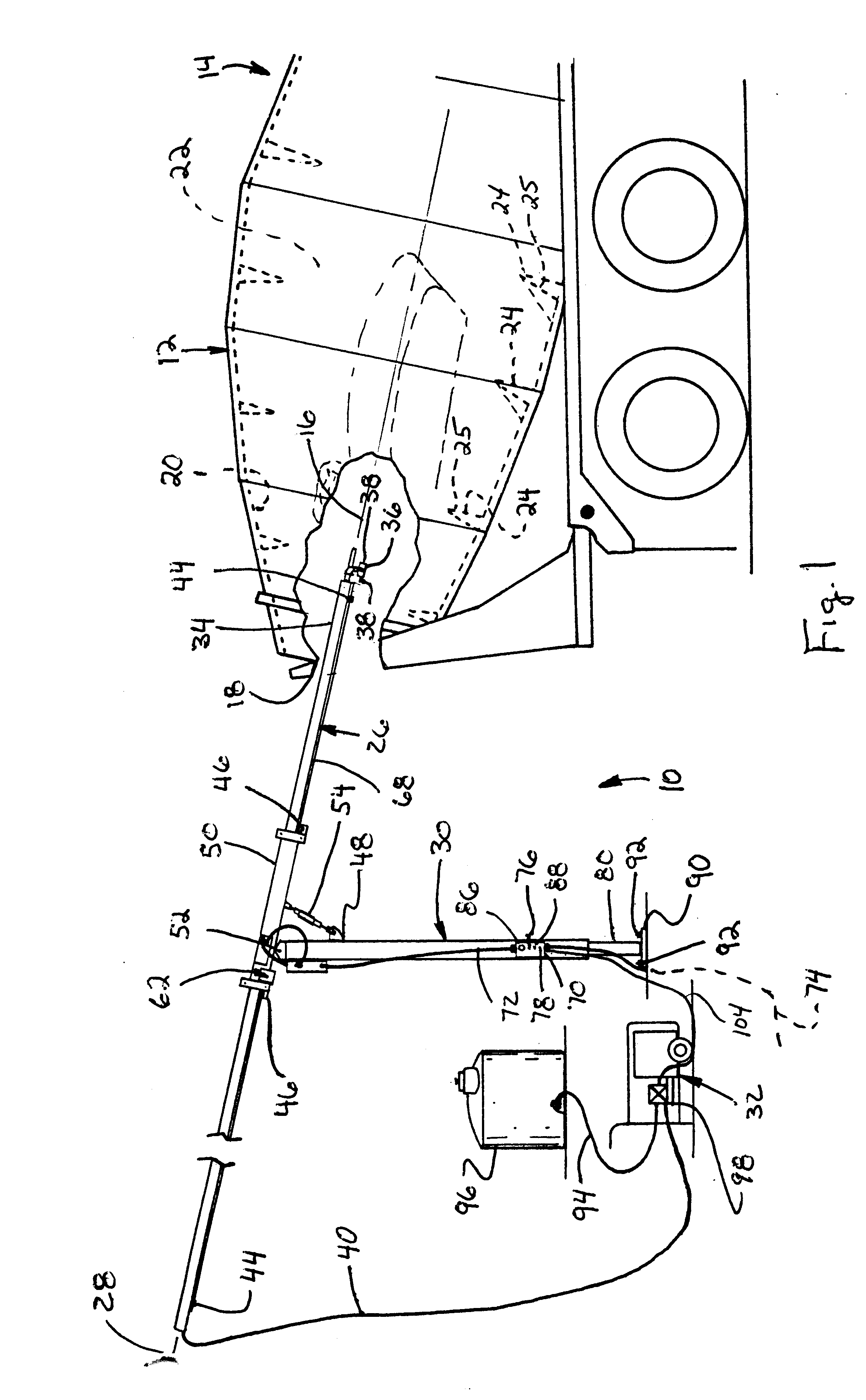

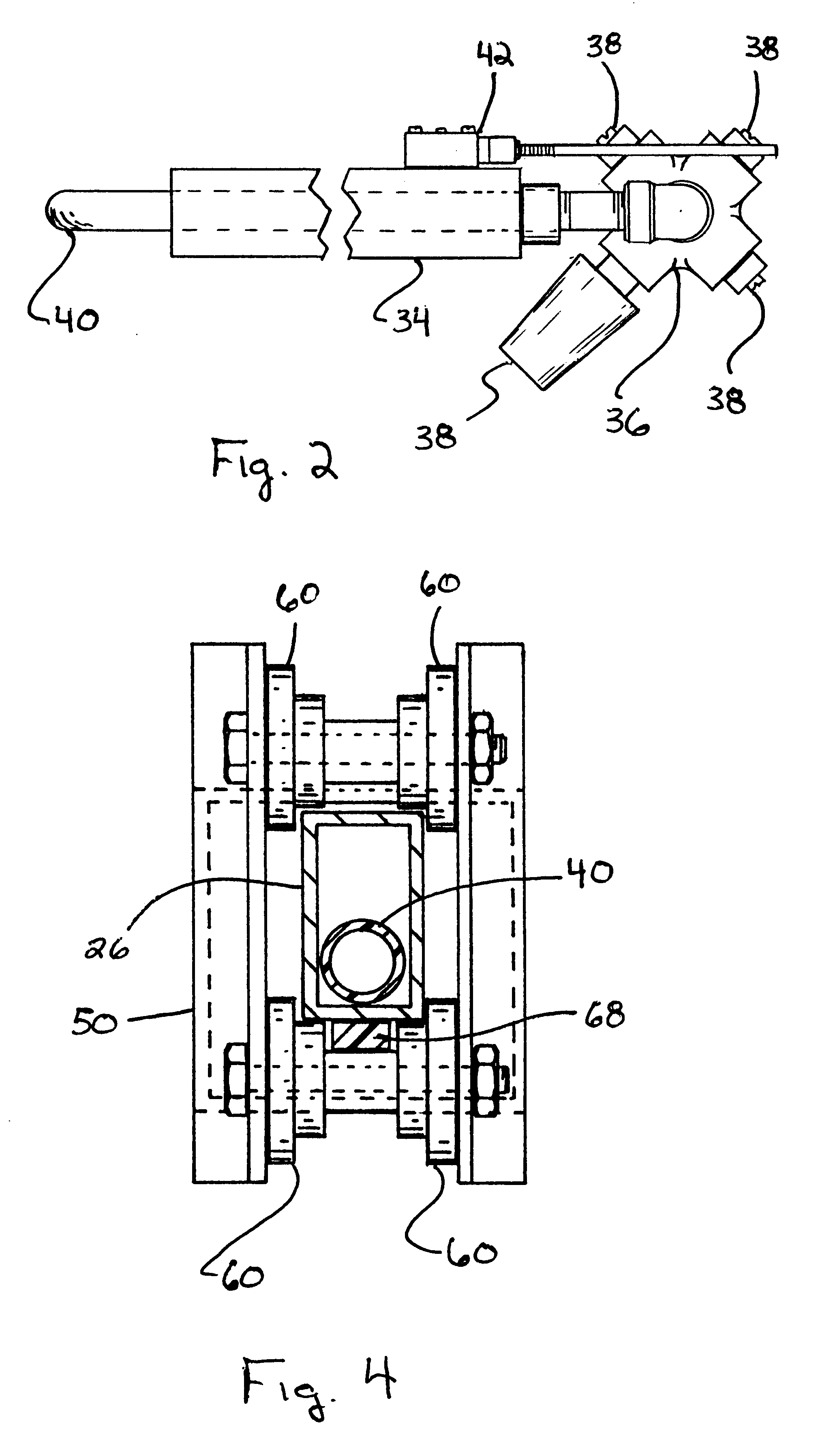

Apparatus and method for removing concrete from interior surfaces of a concrete mixing drum

Apparatus for removing concrete from the interior surfaces of a concrete mixing drum, the drum including an open end and at least one interior surface facing away from or opposite the open end, the apparatus including an elongate probe having a longitudinal axis and an axially extending forward end adapted for insertion into the drum through the open end thereof; a vertically adjustable support structure supporting a guideway support, the guideway support including at least one bearing adapted for supporting the probe for movement of the forward end thereof into and out of the drum through the open end thereof; and at least one fluid nozzle mounted to the probe in position for discharging a stream of fluid against the at least one interior surface facing opposite the open end under sufficient pressure to dislodge accumulated concrete therefrom as the probe is moved in the drum.

Owner:HARMON THOMAS G

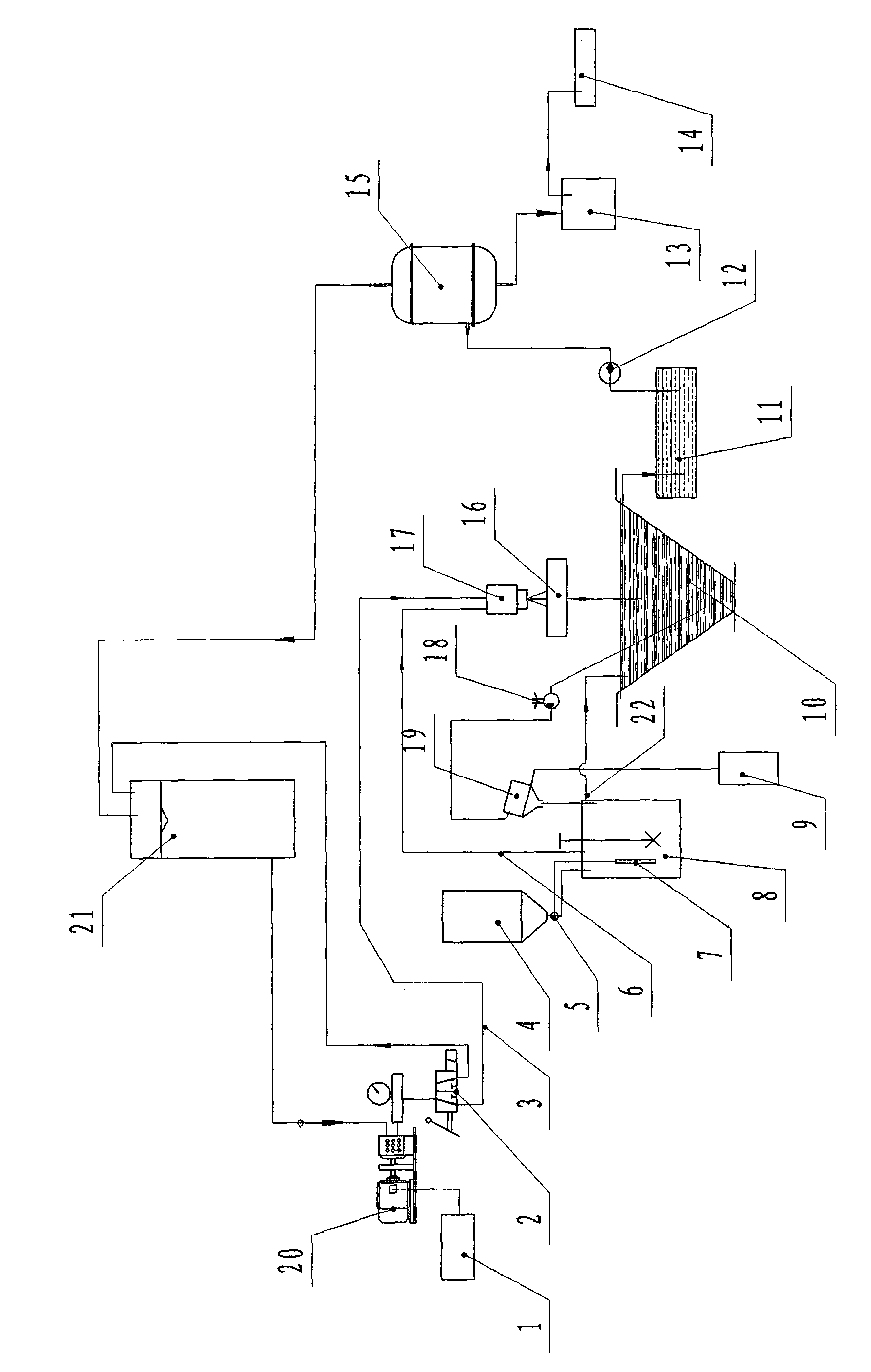

Online high-pressure water-jet blasting surface cleaning system

ActiveCN101633154AUniform supplyGuaranteed uptimeAbrasive feedersAbrasive machine appurtenancesSlagSurface cleaning

An online high-pressure water-jet blasting surface cleaning system comprises a high pressure water feed mechanism, an abrasive material feed mechanism and a spray nozzle. The high pressure water feed mechanism and the abrasive material feed mechanism are communicated with an input end of the spray nozzle, an abrasive material collecting pit is arranged below the spray nozzle, an output end of the abrasive material collecting pit is divided into two paths, one path is connected with an input end of an abrasive material sorting device by an abrasive material cyclical feeding device and a pipeline, and the other path is connected with an input end of a waste water treatment circulating mechanism by a pipeline, an output end of the waste water treatment circulating mechanism is connected with the high pressure water feed mechanism by a pipeline, an output end of the abrasive material sorting device is divided into two paths, one path is connected with the abrasive material feed mechanism, and the other path is connected with a slag collection barrel by a pipeline. The online high-pressure water-jet blasting surface cleaning system has the advantages of simple and compact structure, low energy consumption, good environmental protection, good operational reliability and stability, and recycled water and abrasive materials.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

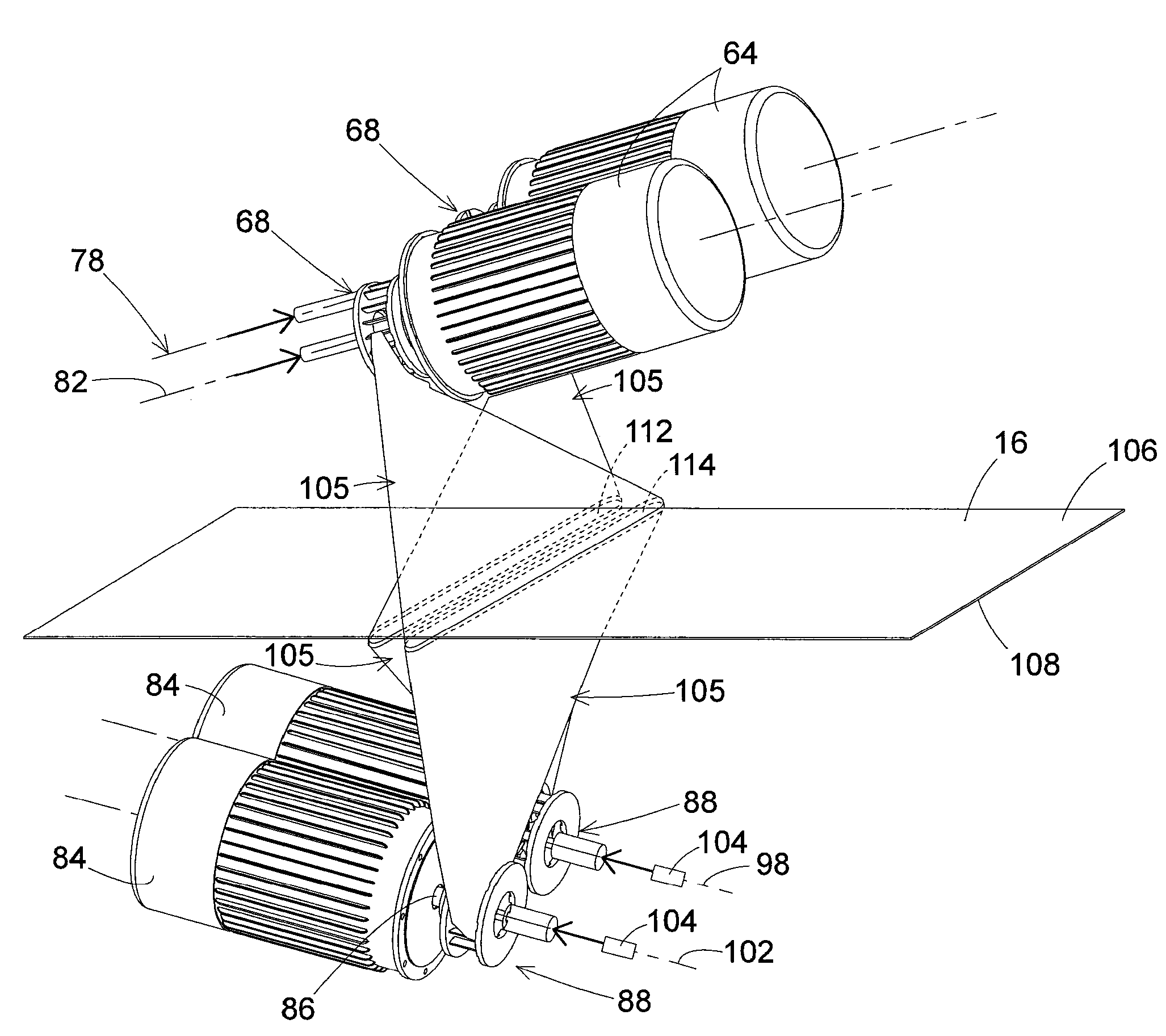

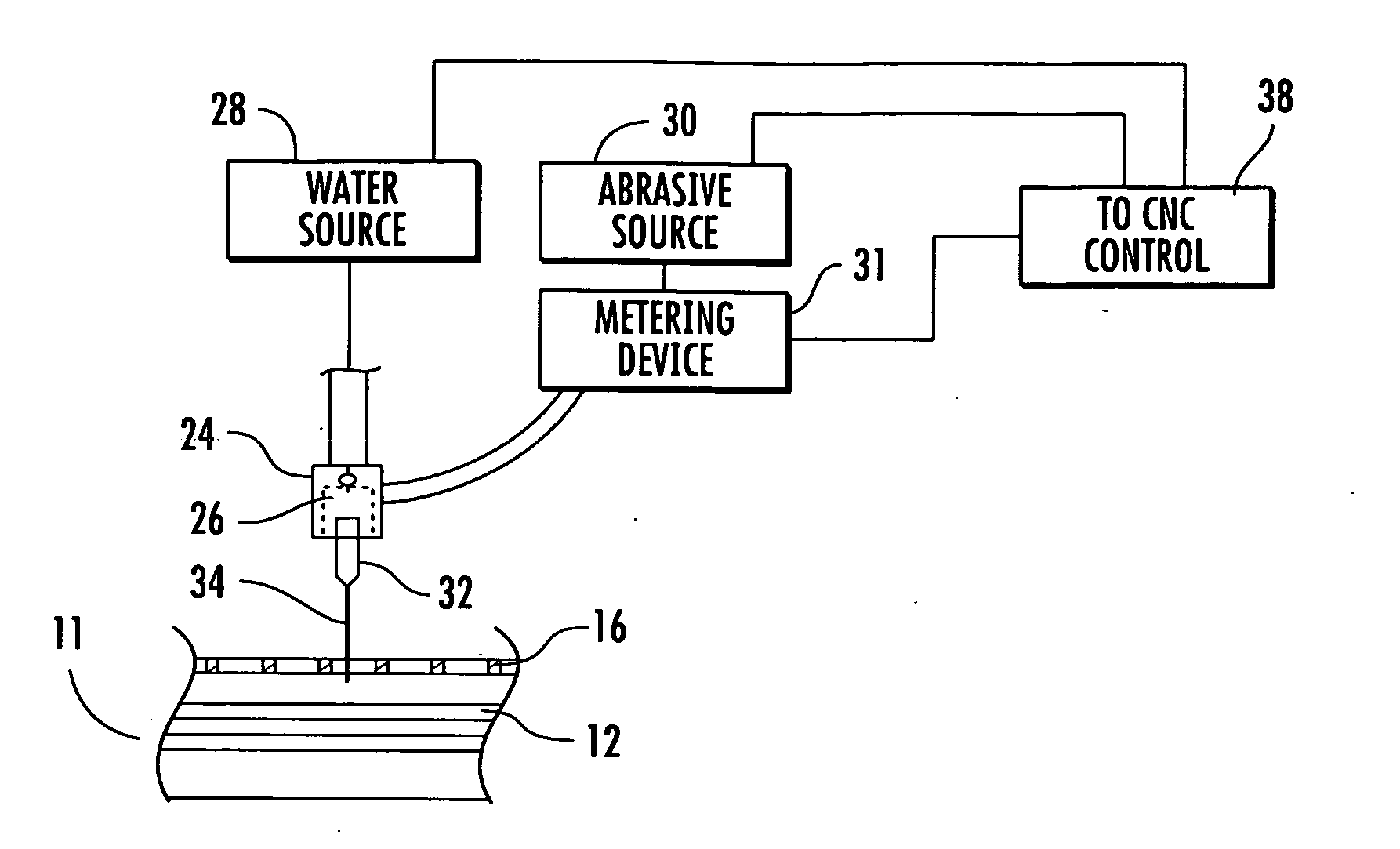

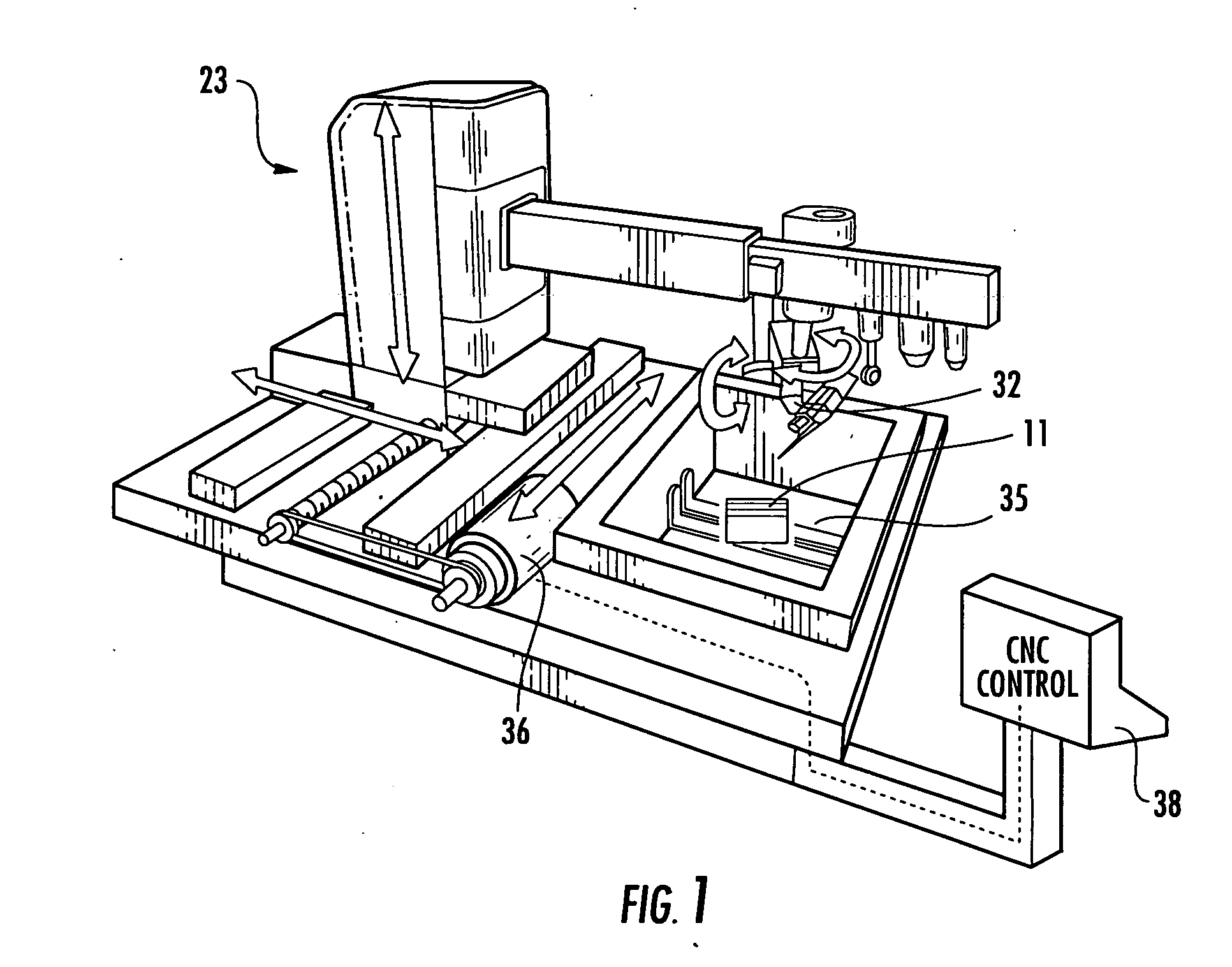

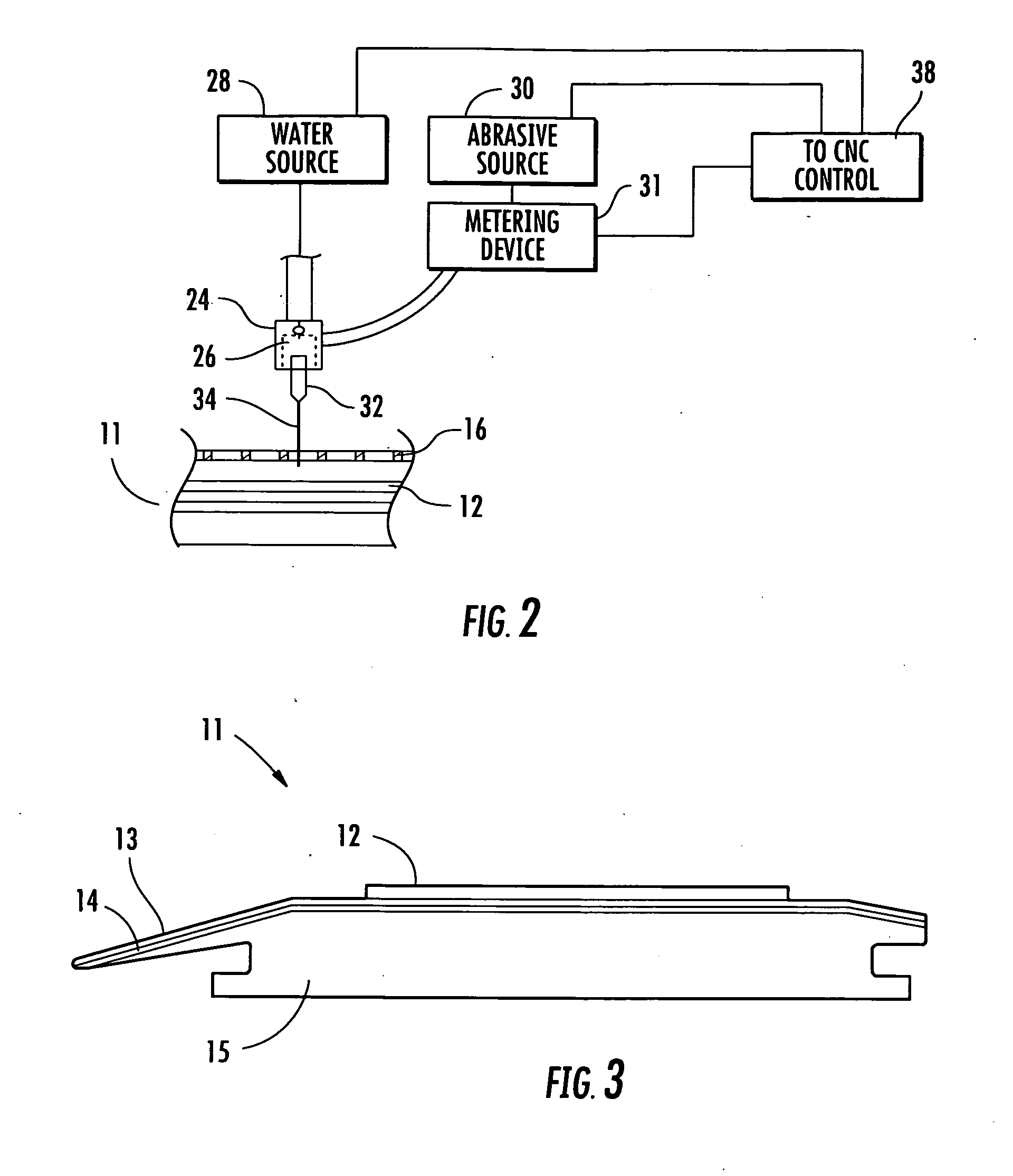

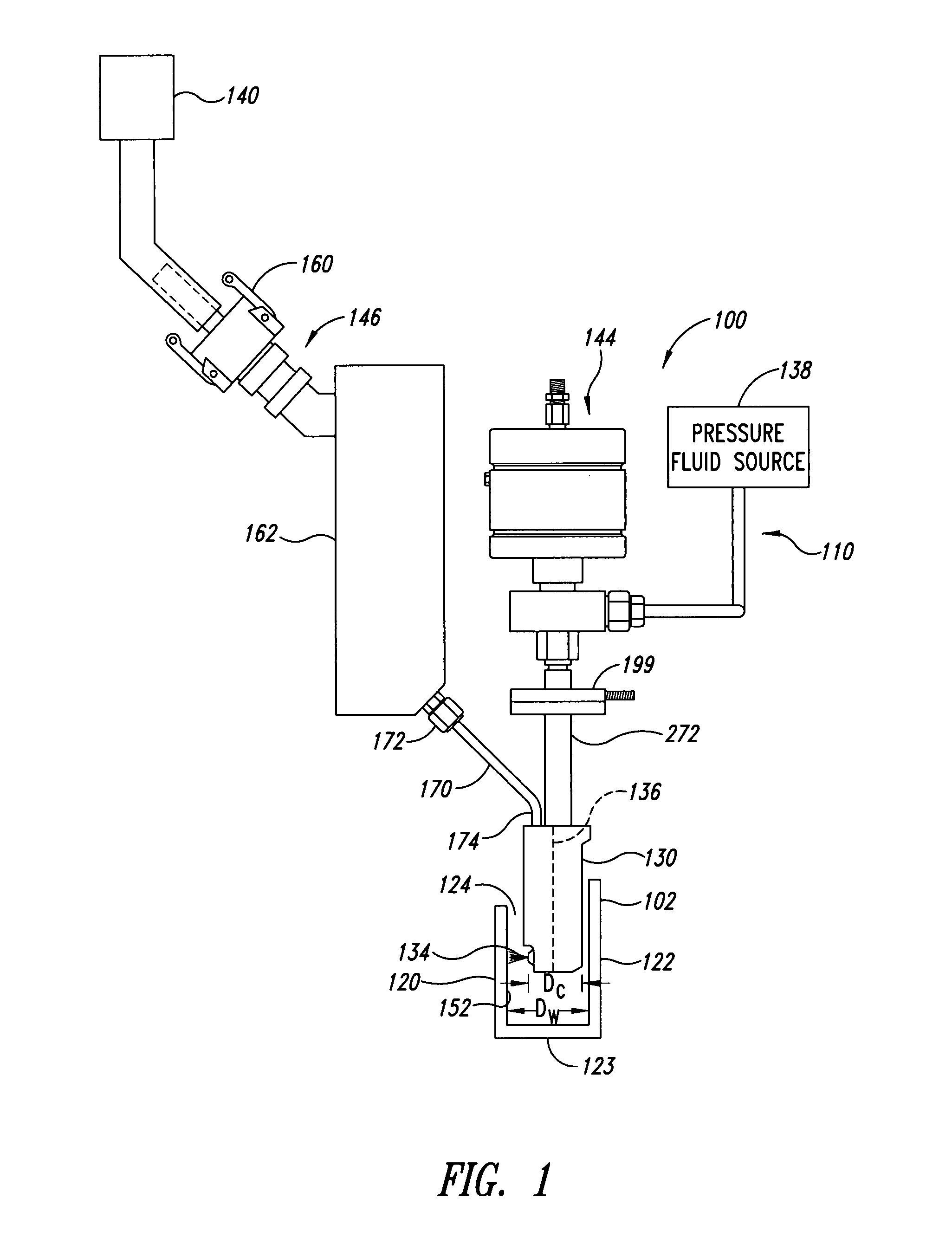

Method and apparatus for selectively removing portions of an abradable coating using a water jet

A method and apparatus for forming raised ridges on the surface of a turbine component having an abradable coating formed on an outer surface thereof which includes a mask having a predetermined pattern of openings therein adjacent the abradable coating on a surface of the turbine component; and a high pressure water jet that has movement relative to the mask so that the high pressure water jet passes along the extent of the openings in the mask and passes through the openings in the mask to remove portions of the abradable coating on the turbine component located beneath the openings in the mask.

Owner:OPTOMEC INC

Method of Producing Rust Inhibitive Sheet Metal Through Scale Removal with a Slurry Blasting Descaling Cell

A method is provided for removing iron oxide scale from sheet metal and producing a sheet metal surface with rust inhibitive properties. The sheet metal is advanced through the descaling cell and a slurry mixture is propelled against at least one of the top surface and bottom surface of the sheet metal across the sheet metal width as the material is advanced through the descaling cell. The rate of slurry impact against the at least one of the top surface and bottom surface of the sheet metal is controlled in a manner to remove substantially all of the scale from a surface of the sheet metal, and in a manner to create a passivation layer on the descaled surface of the sheet metal. The passivation layer comprises at least one of silicon, aluminum, manganese and chromium and inhibits oxidation of the descaled surface of the processed sheet metal.

Owner:THE MATERIAL WORKS

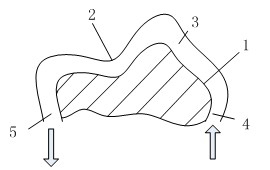

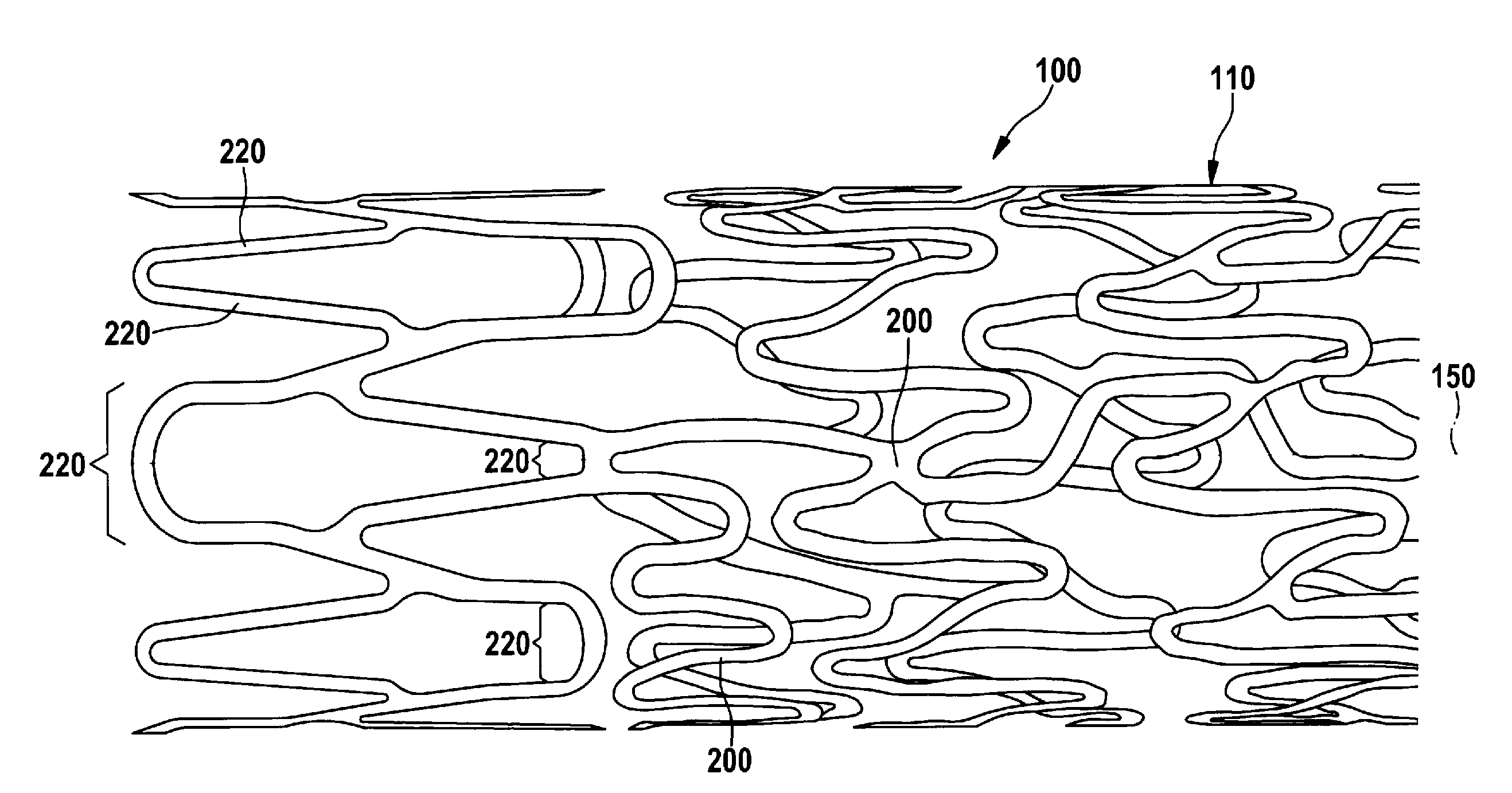

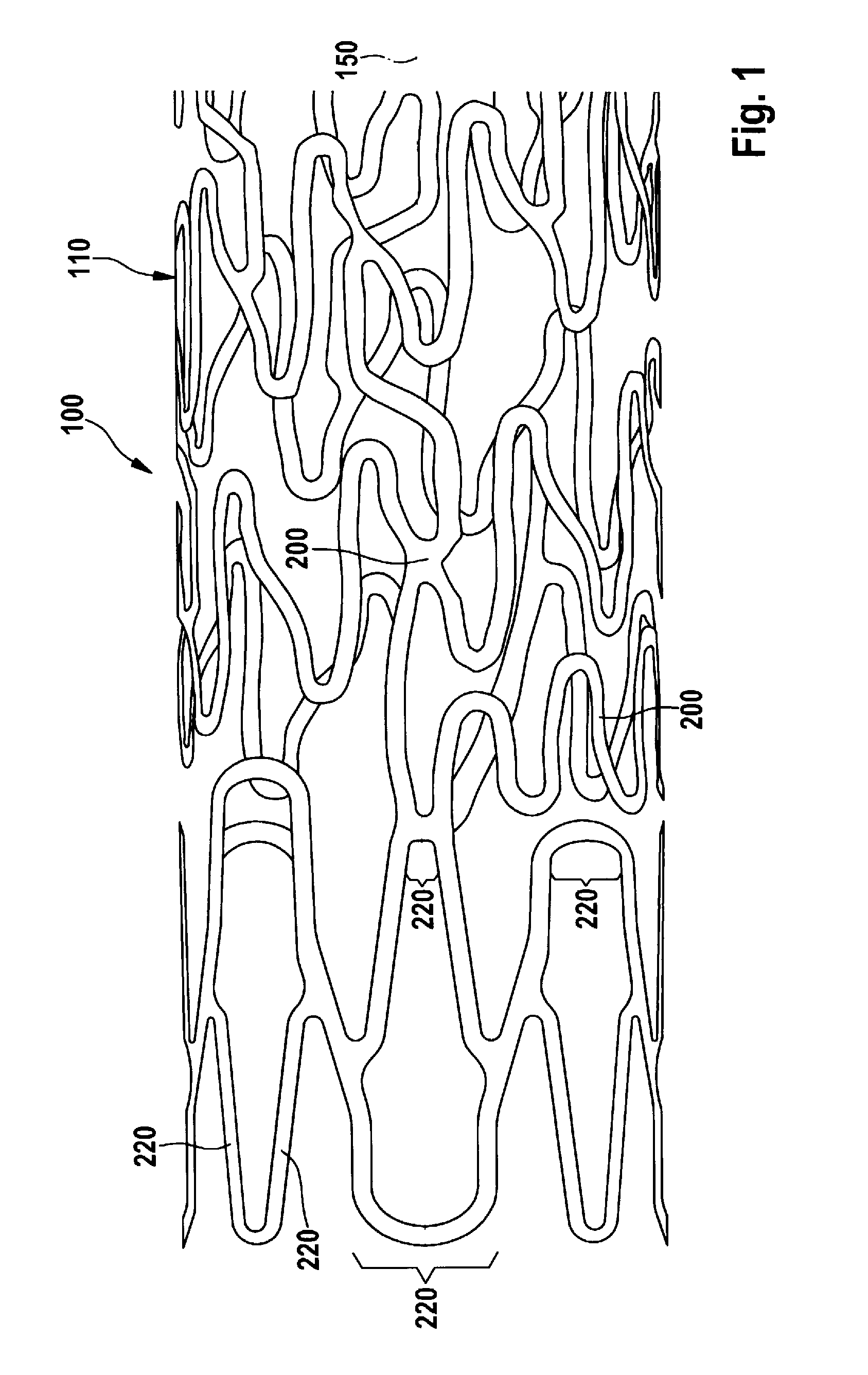

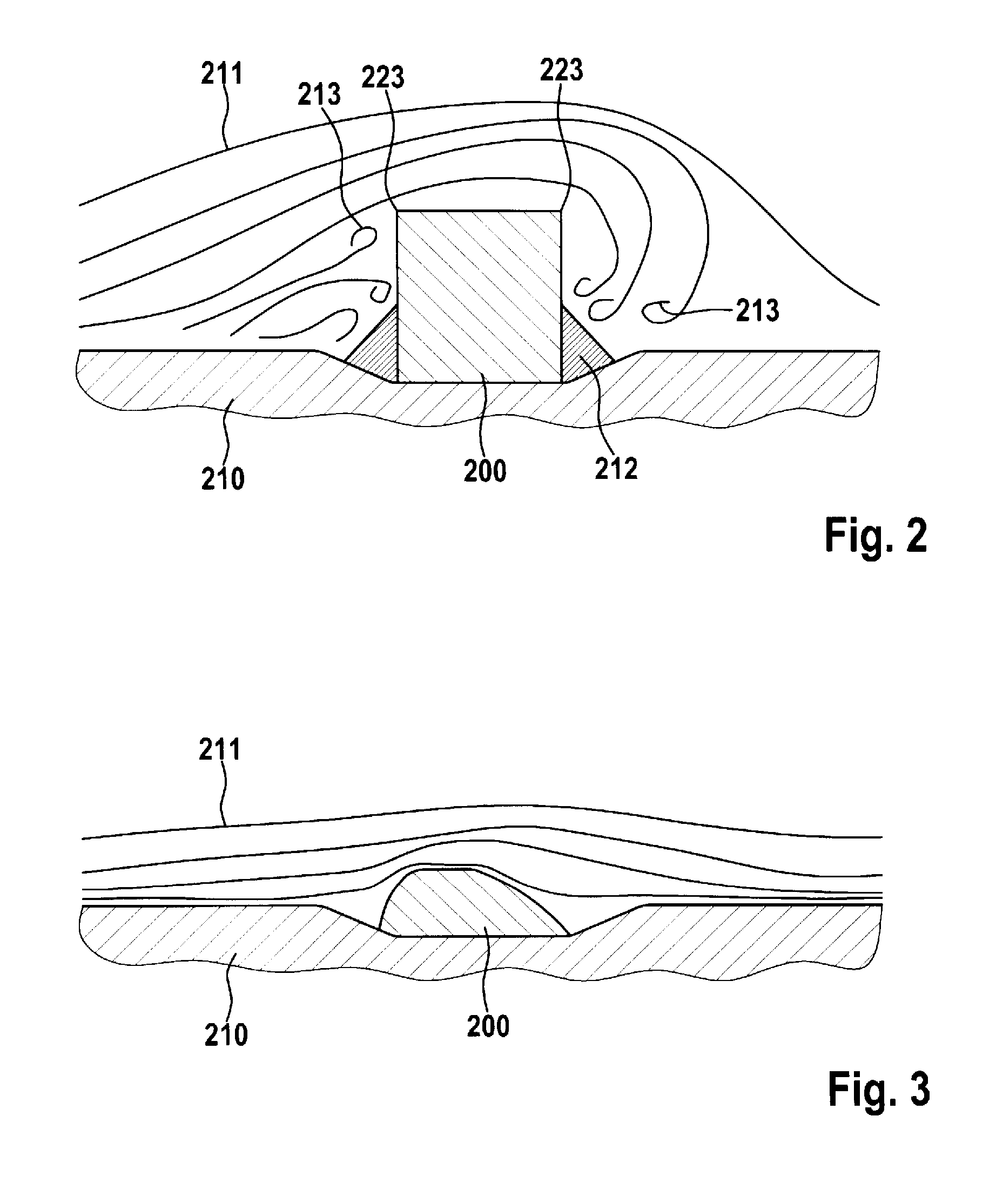

Stent and Method and Device for Fabricating the Stent

ActiveUS20100049300A1Stress minimizationAvoid injuryStentsElectrolysis componentsInsertion stentBiomedical engineering

Stent, as well as a method and device for fabricating the stent, wherein the stent has a tubular lattice structure comprising individual struts and at least one strut of which at least one longitudinal section runs with at least one directional component in the radial circumferential direction of the stent, wherein the surface of the longitudinal section facing the outside of the stent is curved only about the longitudinal axis of the stent. According to the invention, the surface of longitudinal section of the strut, which surface faces the inside of the stent, has such a curvature that the strut cross section is fluidically optimized.

Owner:BIOTRONIK AG

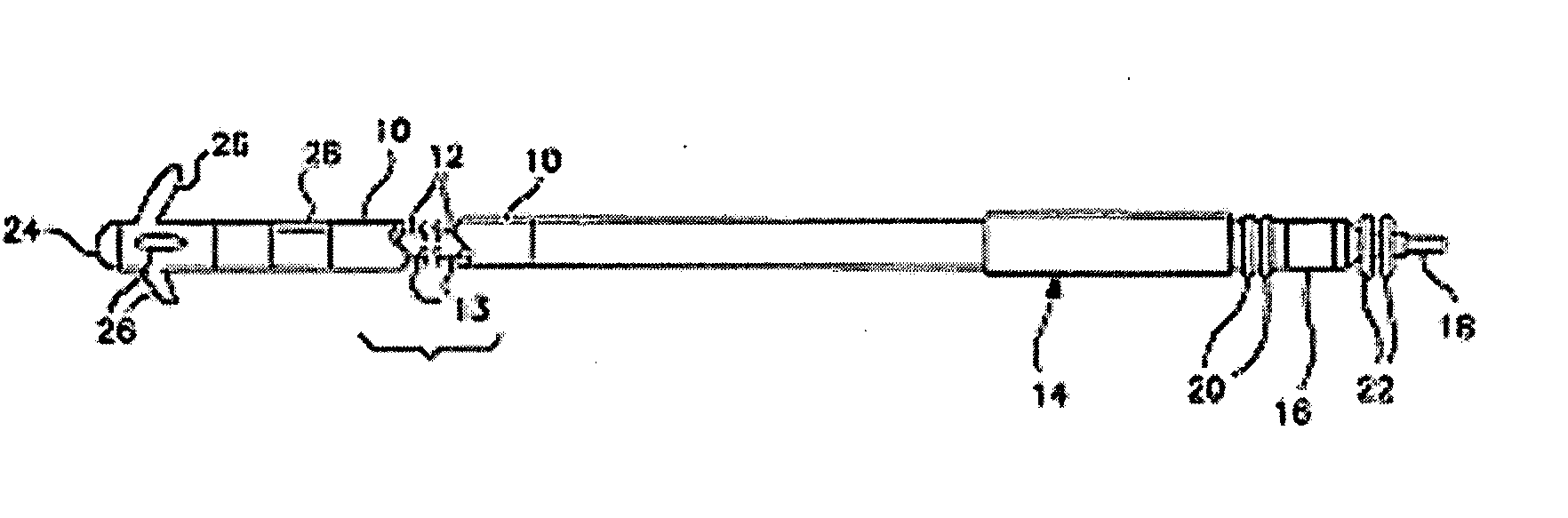

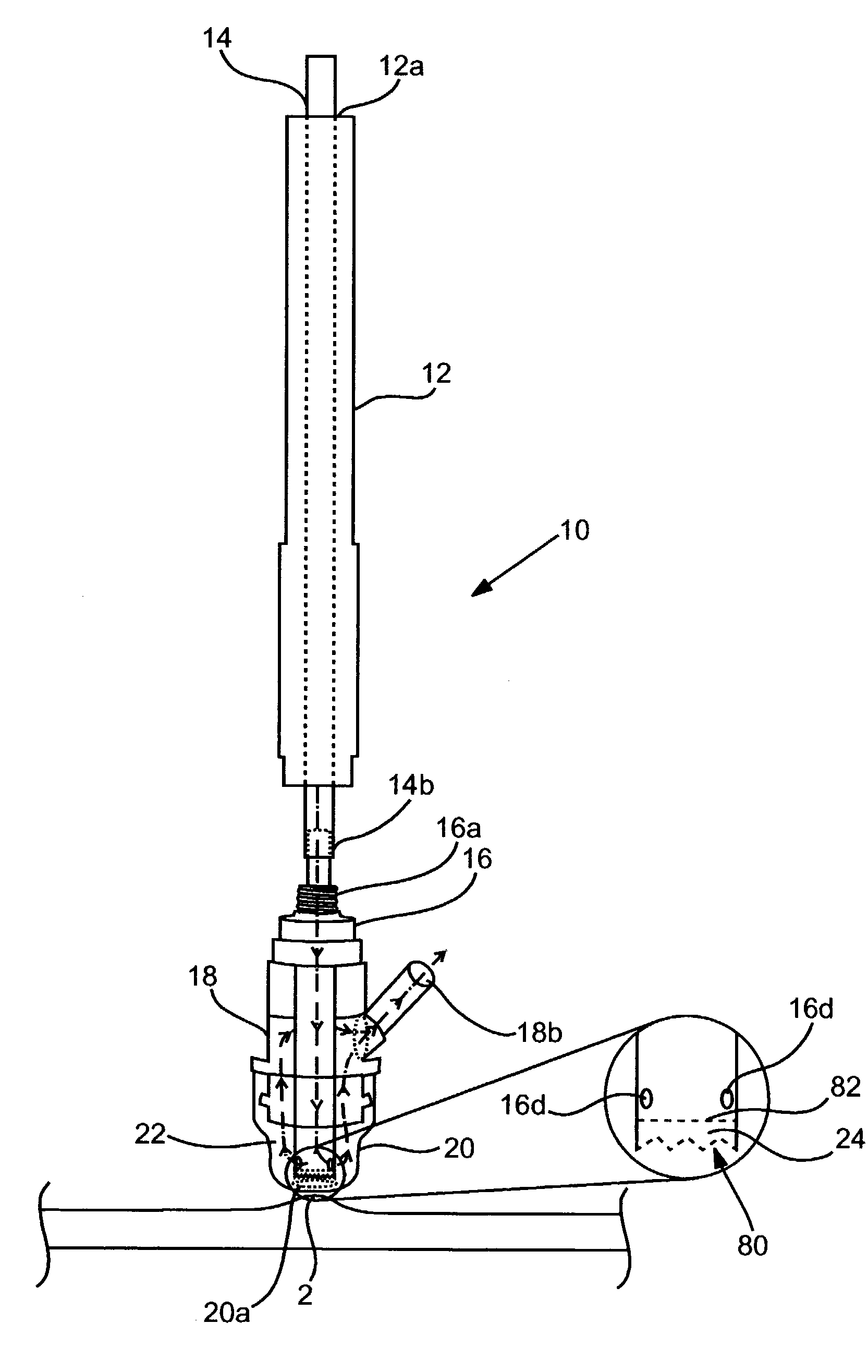

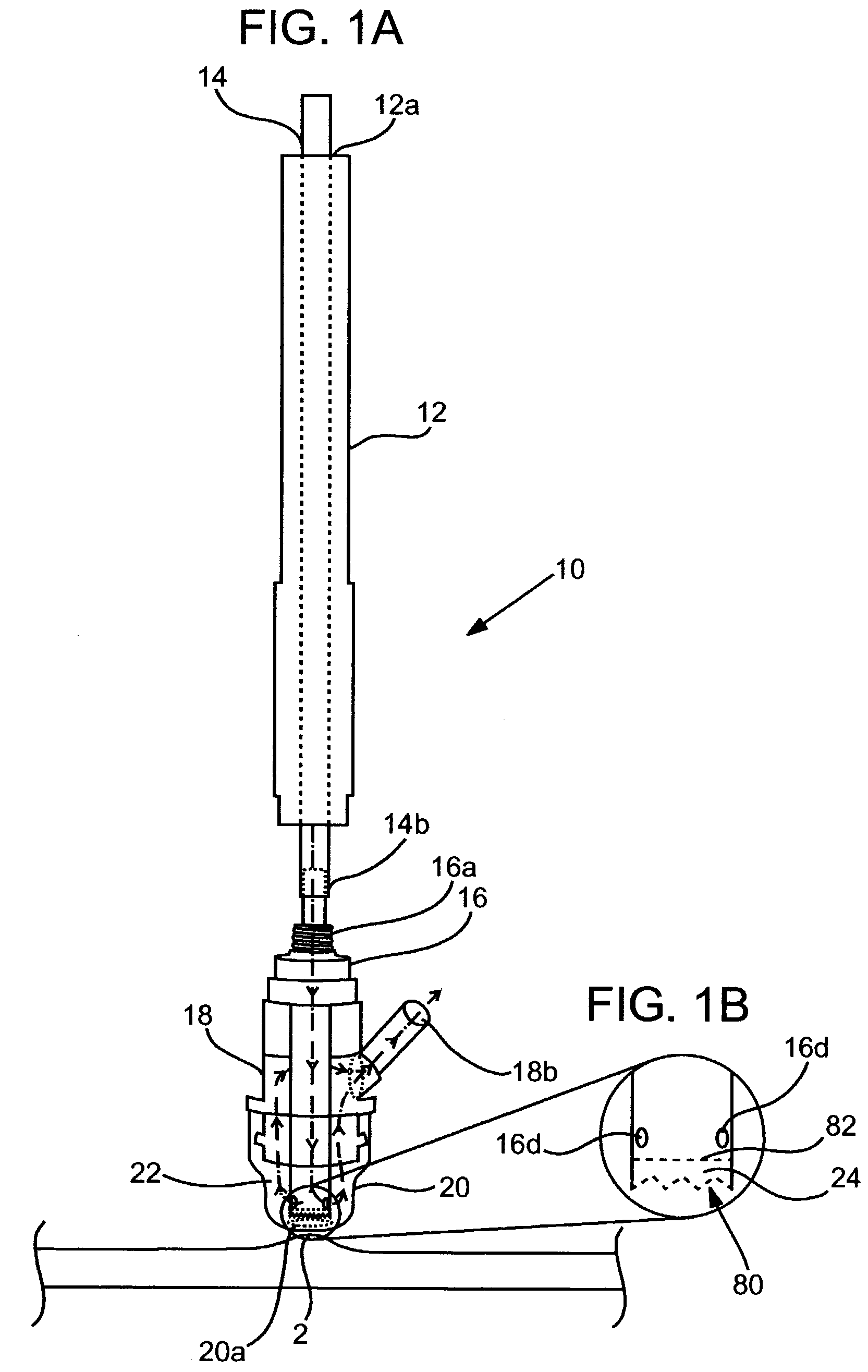

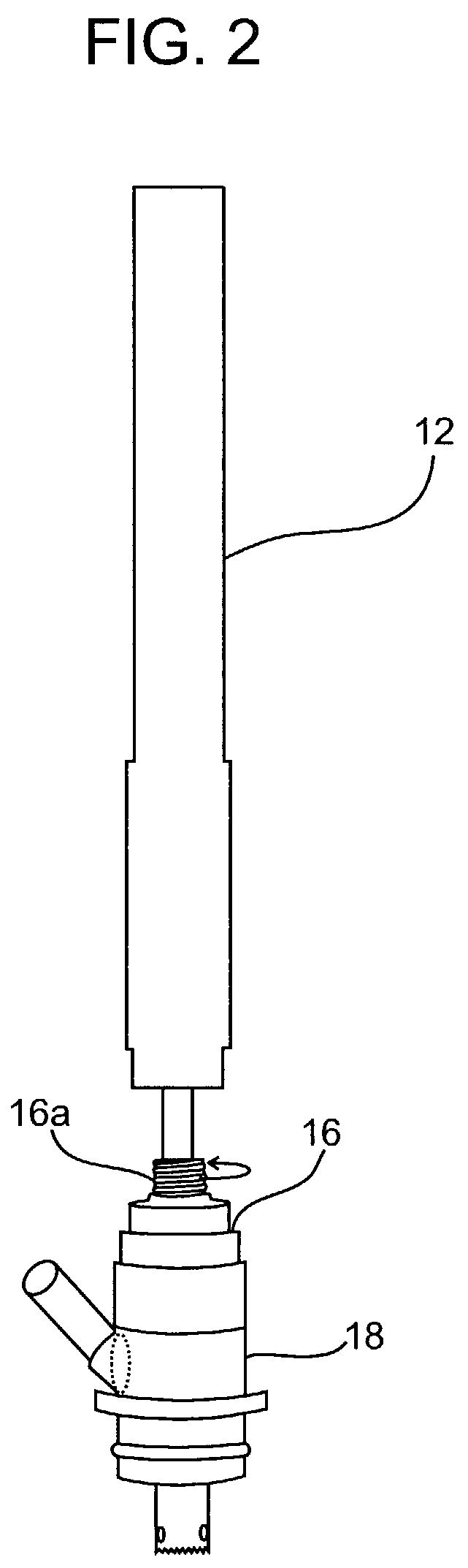

Apparatus and process for formation of laterally directed fluid jets

ActiveUS20090071303A1Liquid surface applicatorsGrinding machine componentsSpray nozzleMechanical engineering

A processing apparatus is provided to process a workpiece. The processing apparatus can have a low-profile nozzle system capable of navigating through spaces in order to process target regions with relatively small clearances. A fluid jet outputted from the nozzle system is used to cut, mill, or otherwise process the target region of the workpiece.

Owner:FLOW INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com