Patents

Literature

35results about How to "Improved abrasion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

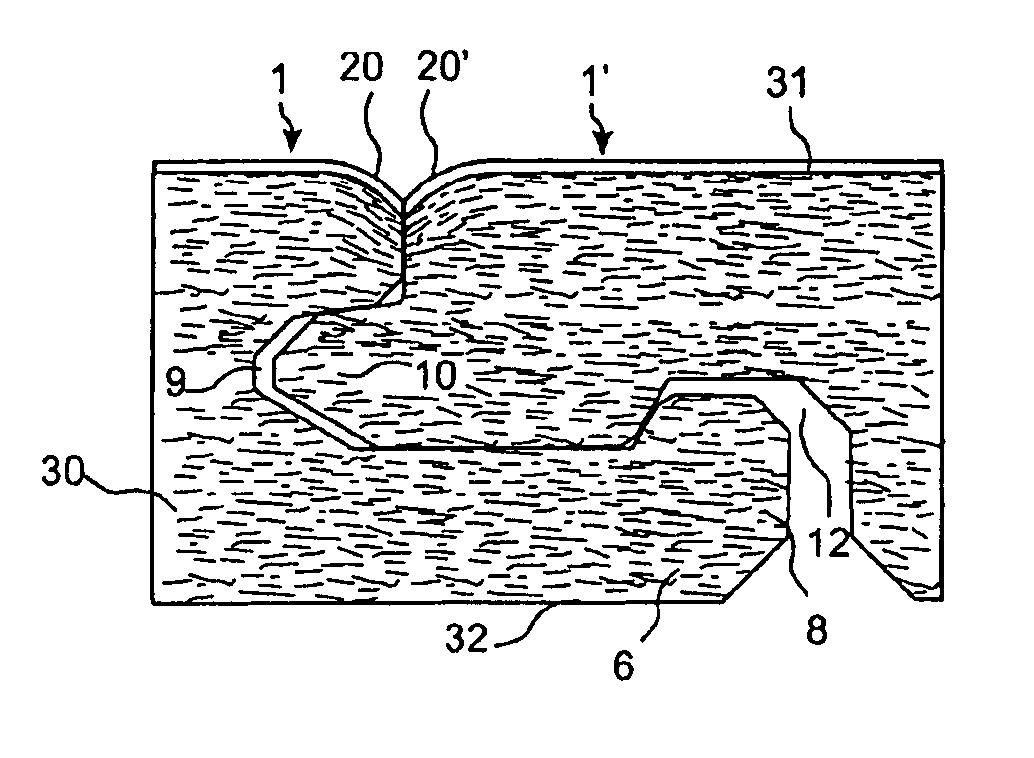

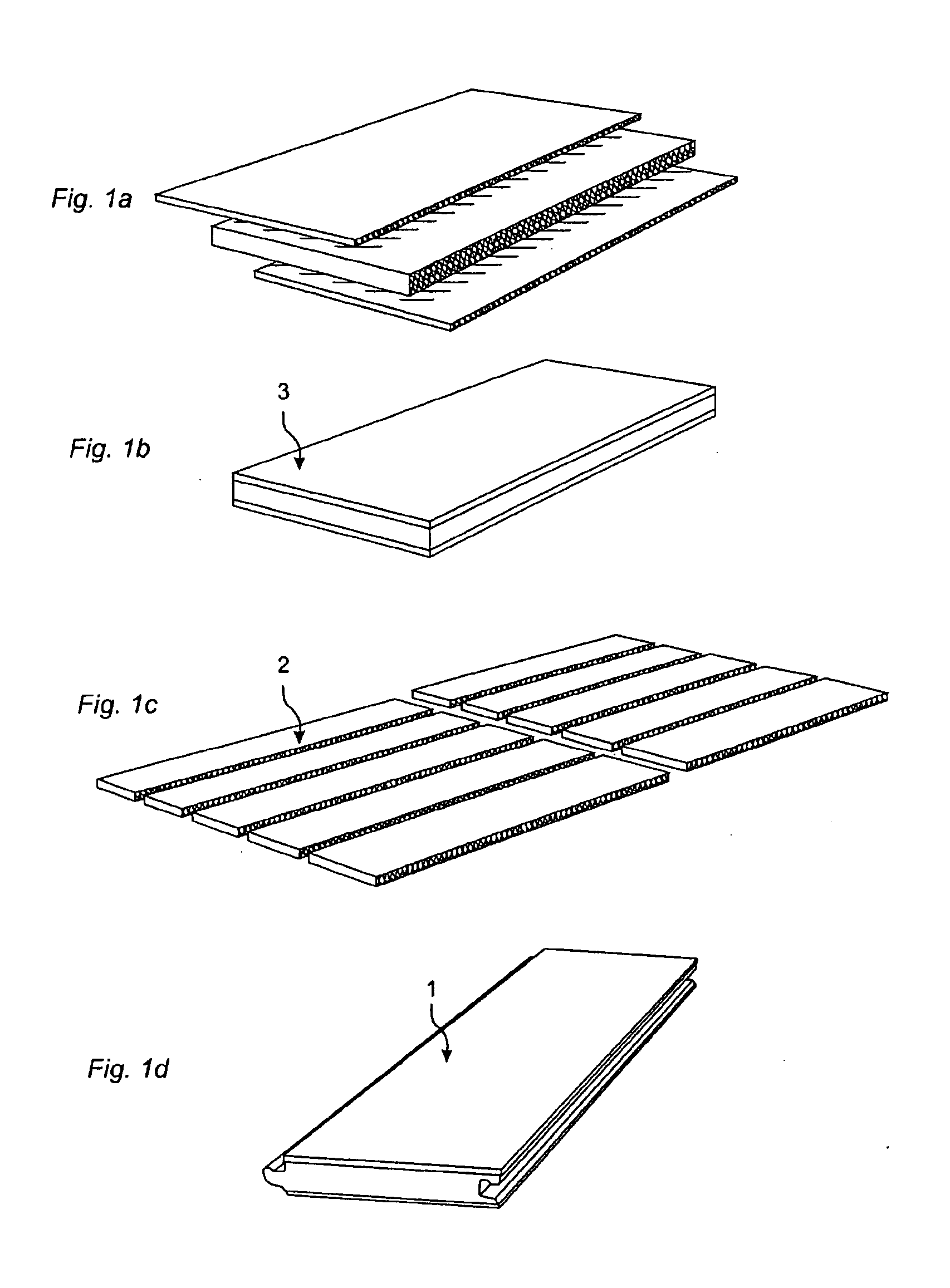

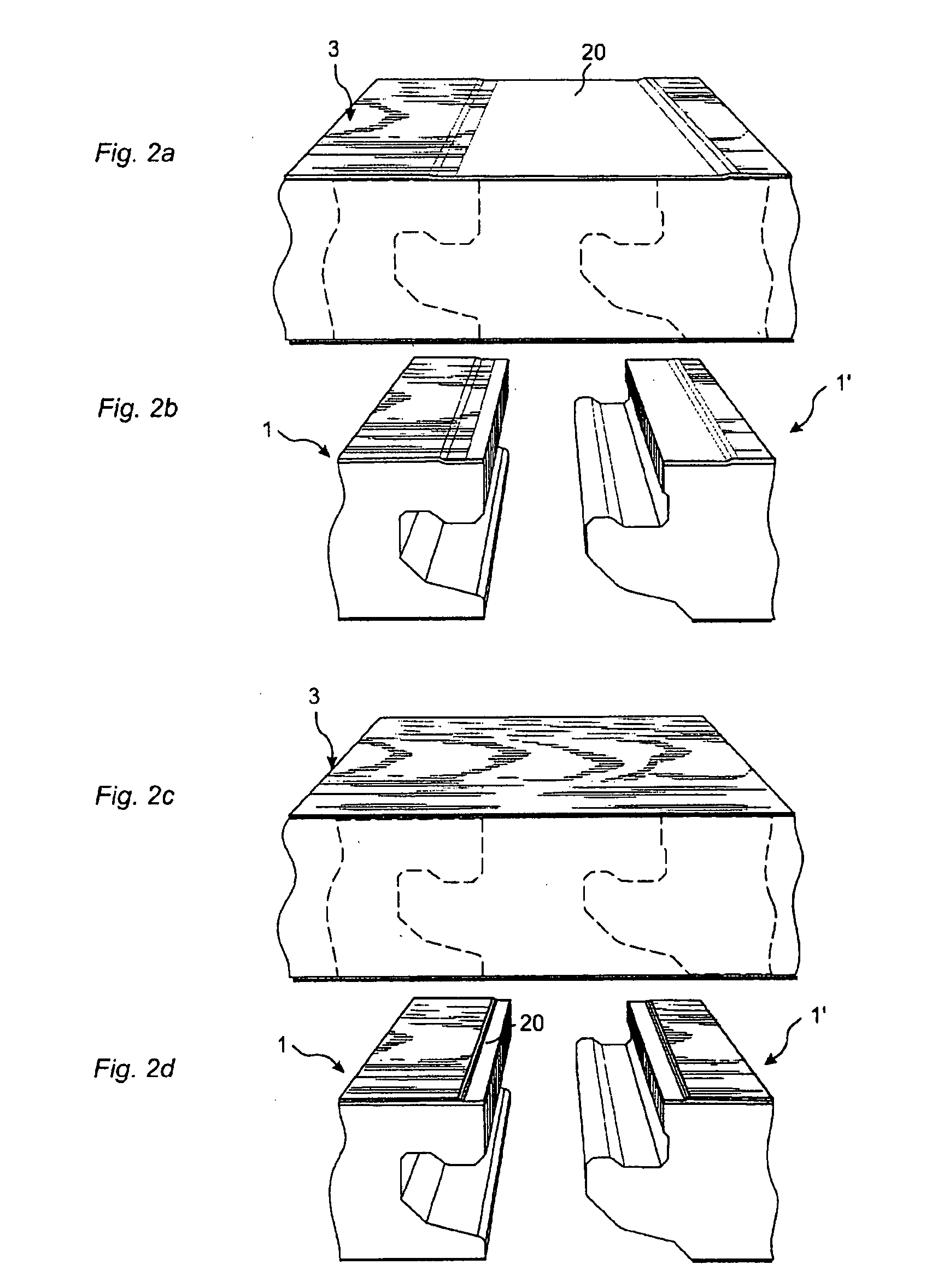

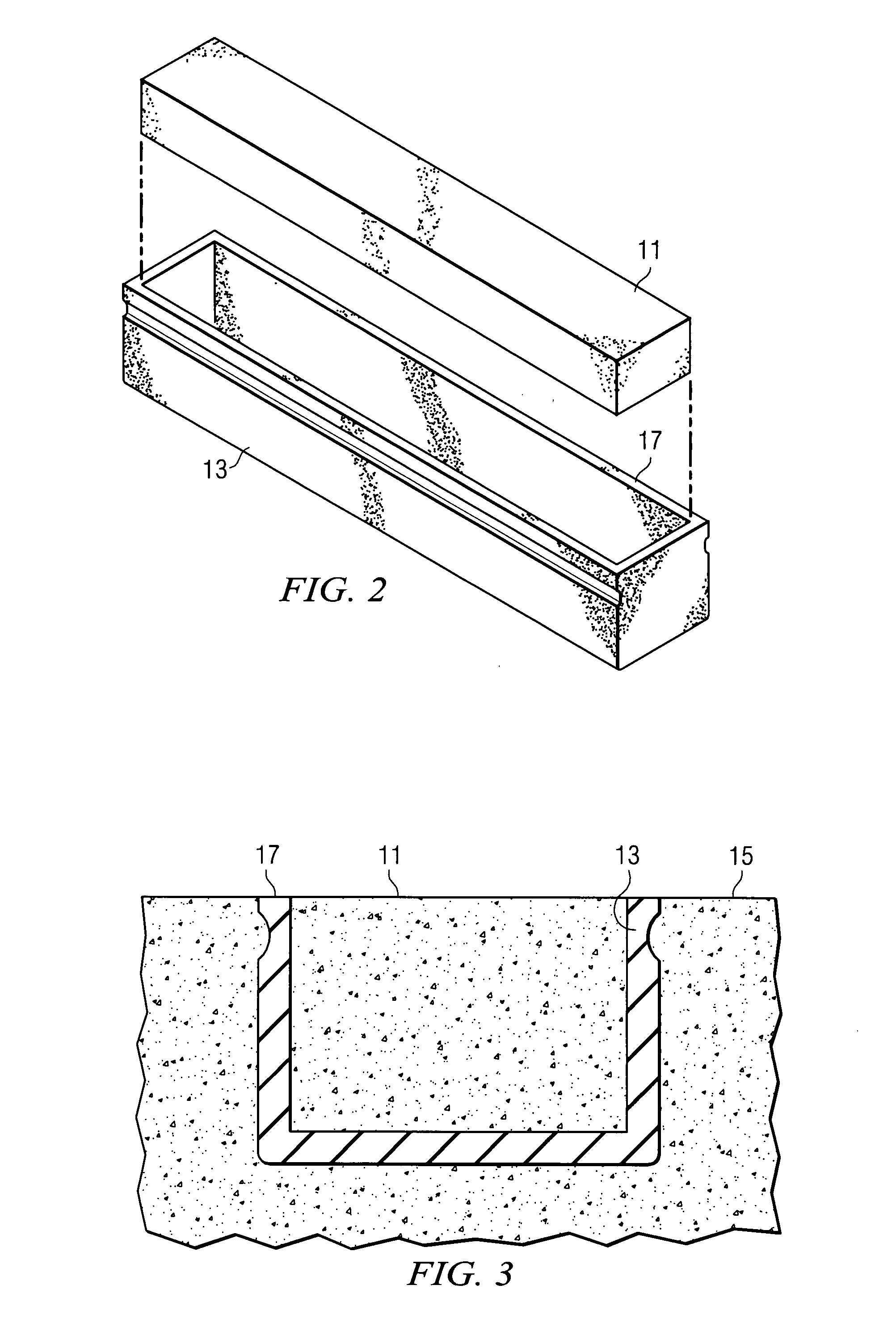

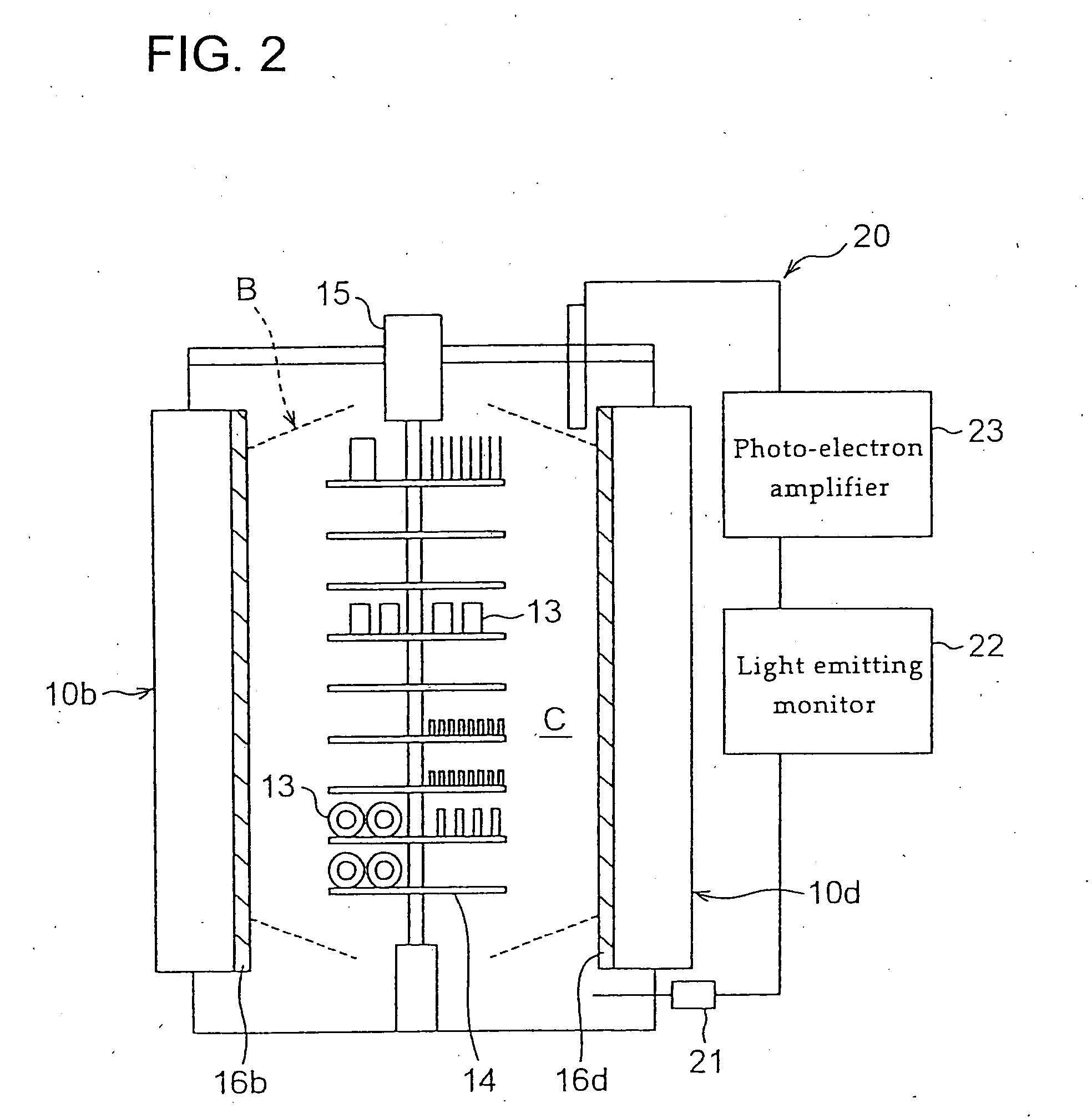

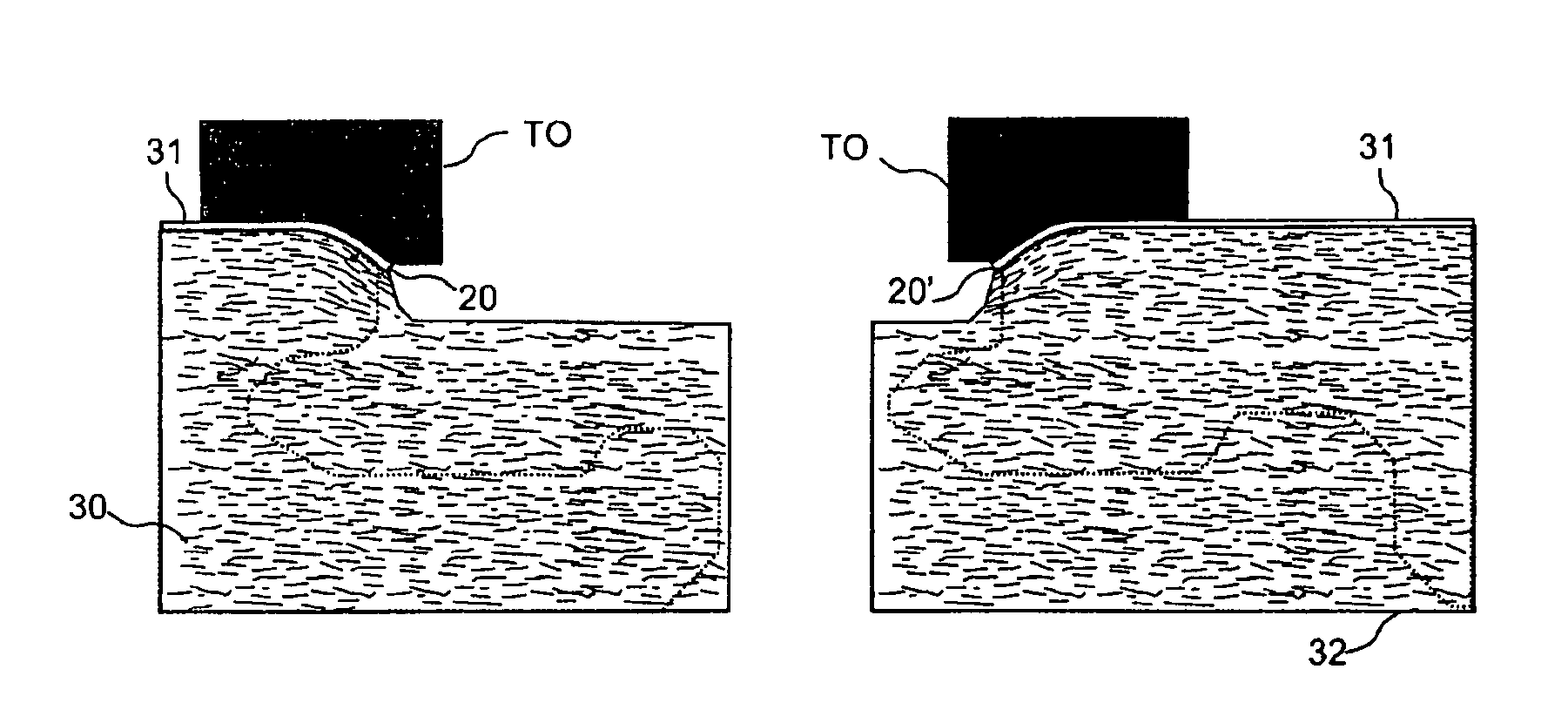

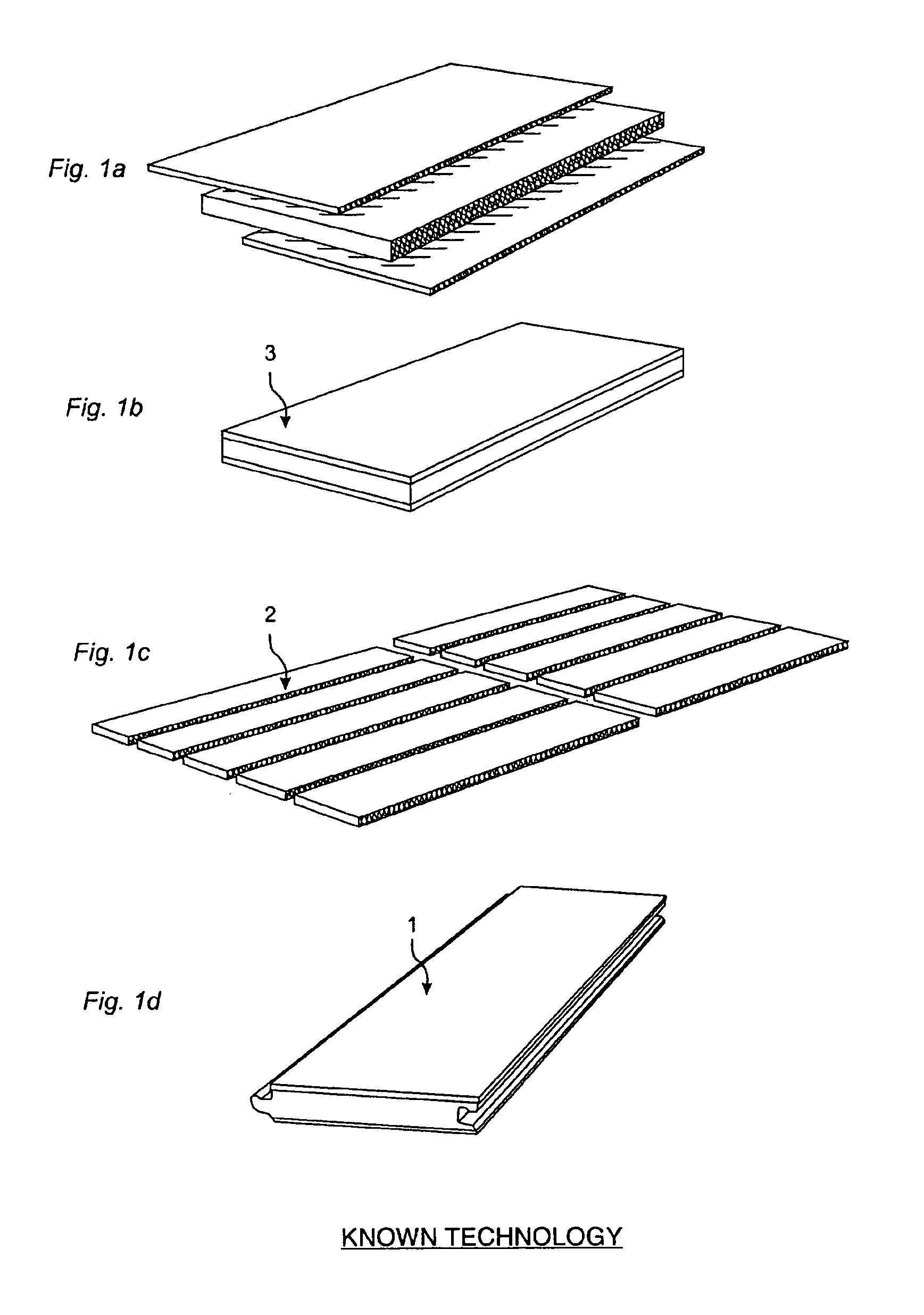

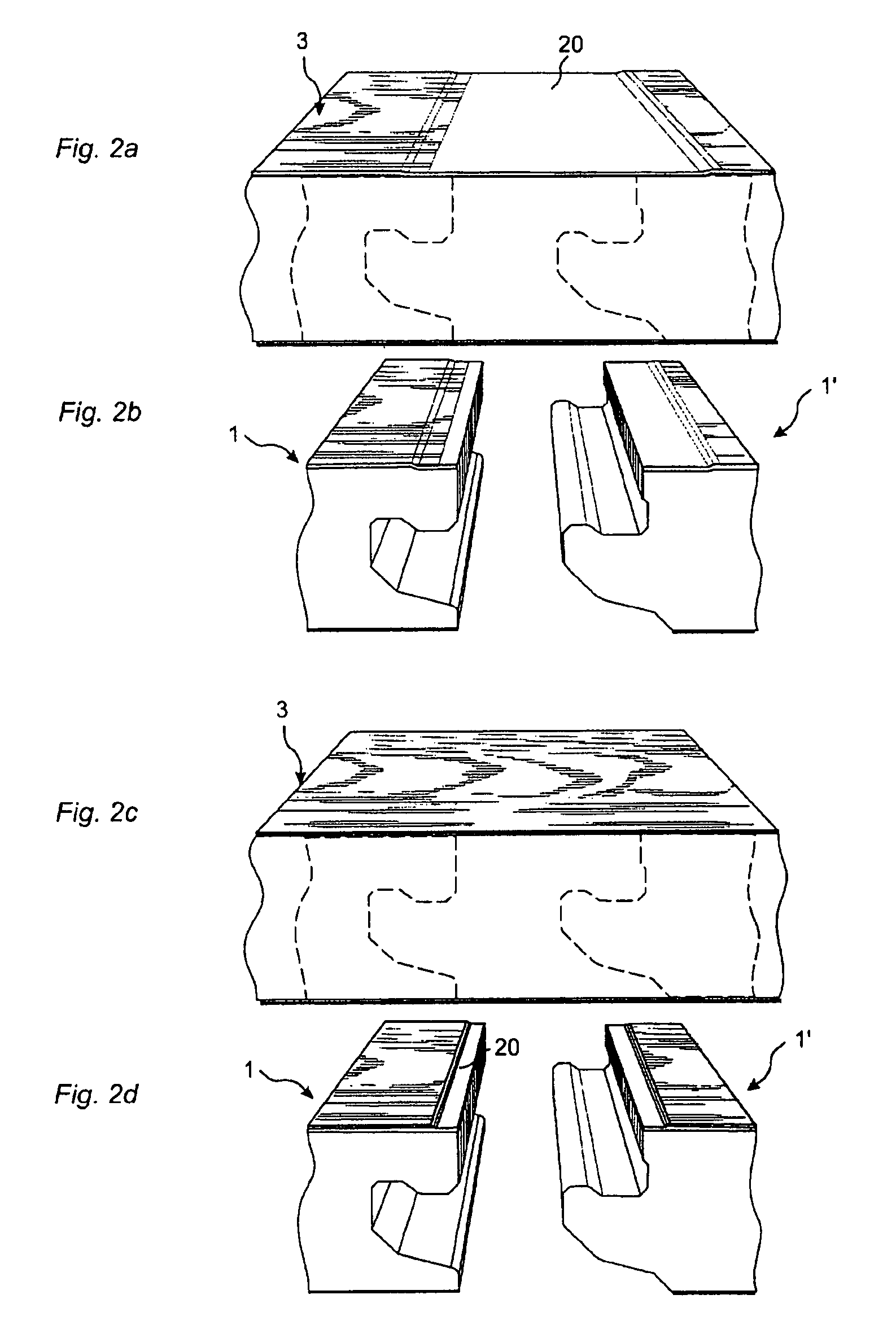

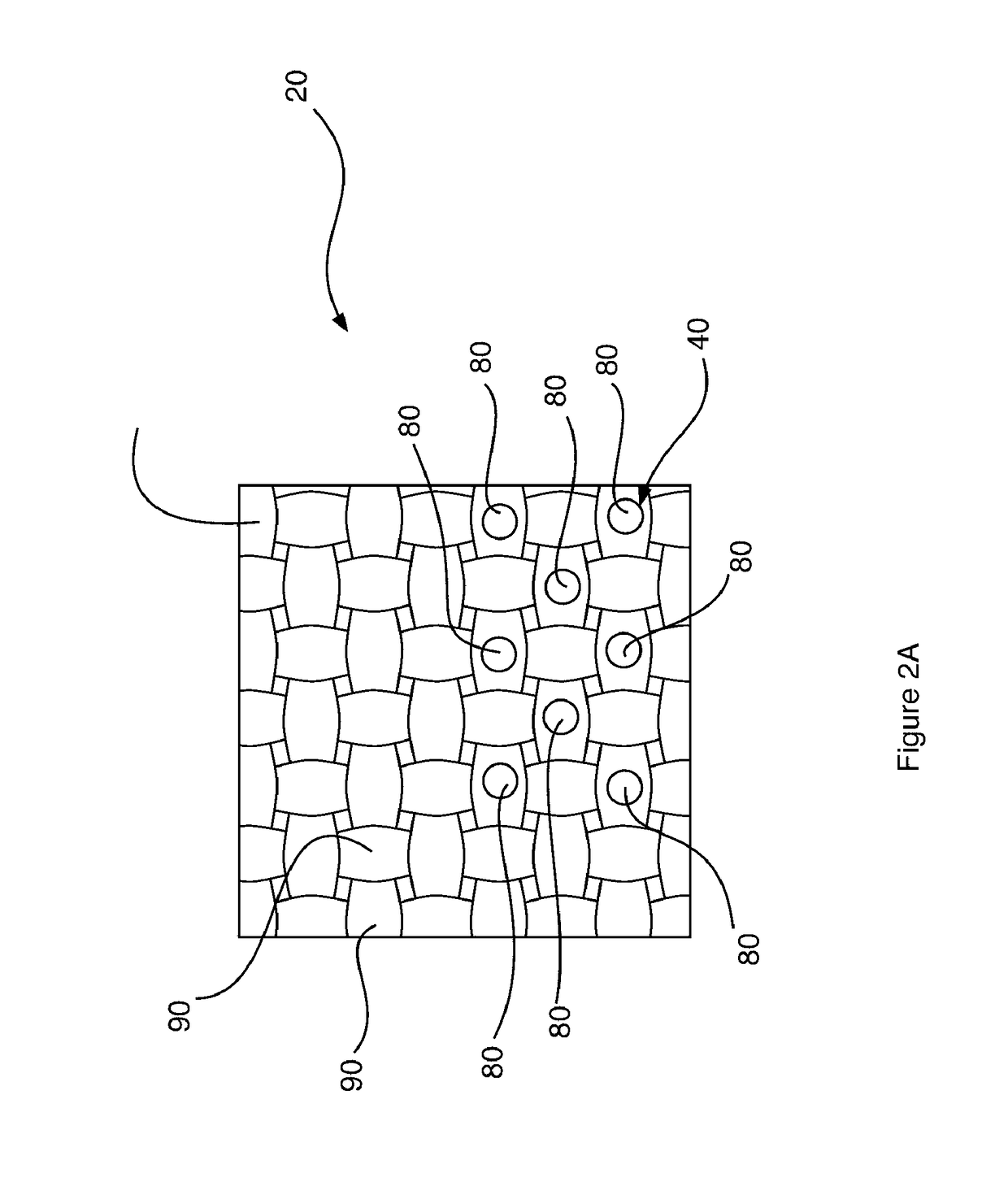

Building panel with compressed edges and method of making same

ActiveUS20080034701A1Efficient productionImproved abrasionWallsSpecial ornamental structuresSurface layerEngineering

Floorboards comprising a core and a surface layer with curved edge portions, which are formed by a compression of the core.

Owner:VÄLINGE INNOVATION AB

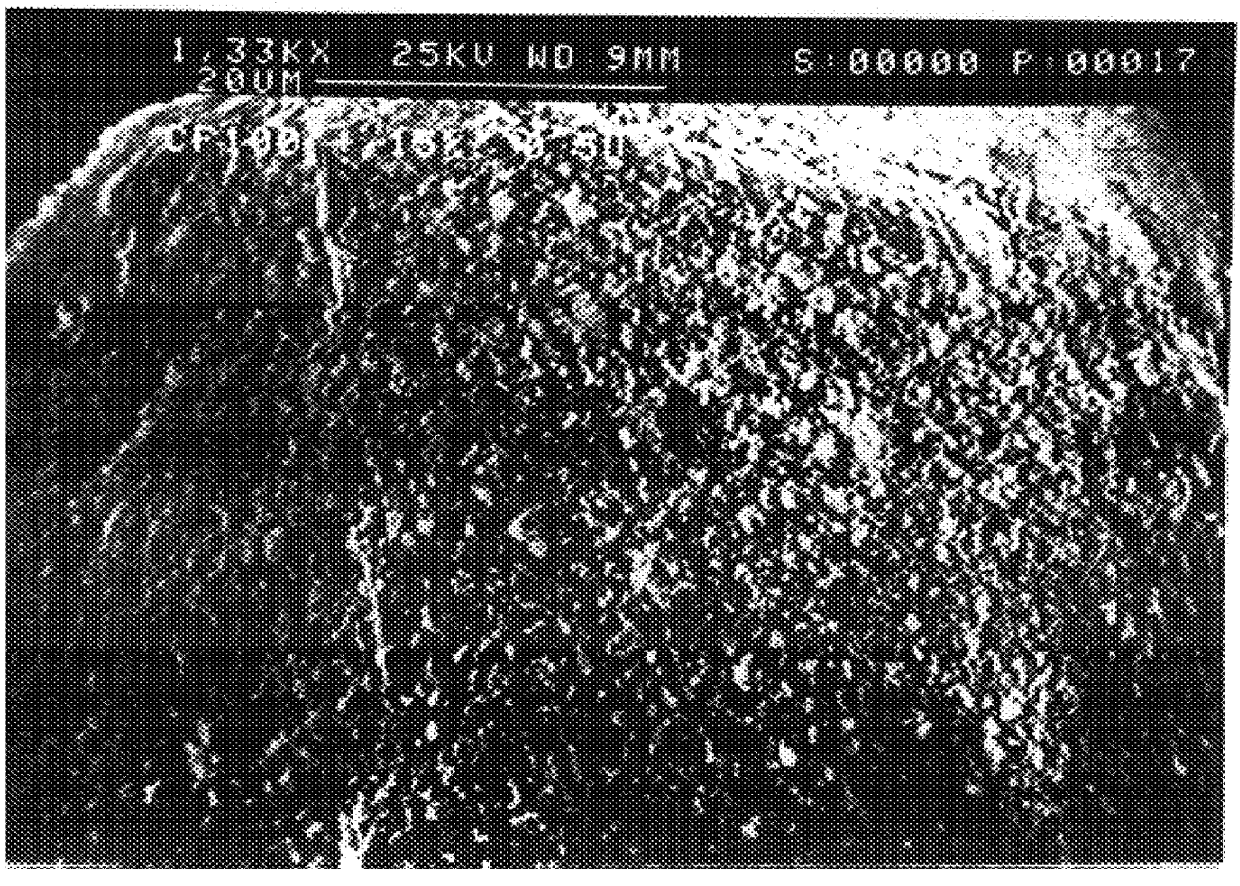

Method for producing abrasive compact with improved properties

InactiveUS6132675AImproved abrasionImprove stabilityUltra-high pressure processesCeramic shaping apparatusPolycrystalline diamondCarbide

Metal carbide supported polycrystalline diamond (PCD) compacts having improved abrasion / impact resistance properties and a method for making the same under high temperature / high pressure (HT / HP) processing conditions. The PCD compact is characterized as having a mixture of submicron sized diamond particles and large sized diamond particles.

Owner:DIAMOND INNOVATIONS INC

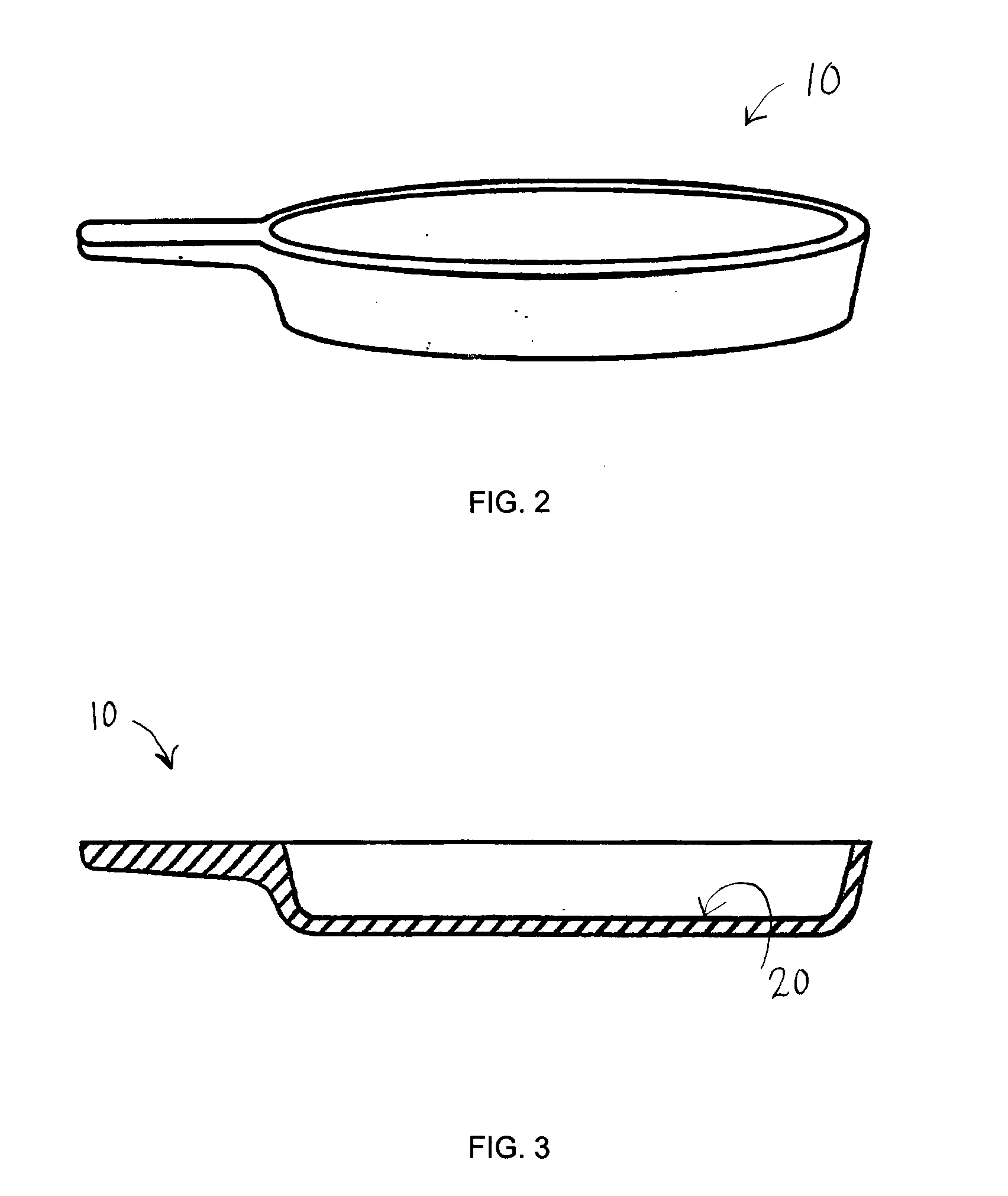

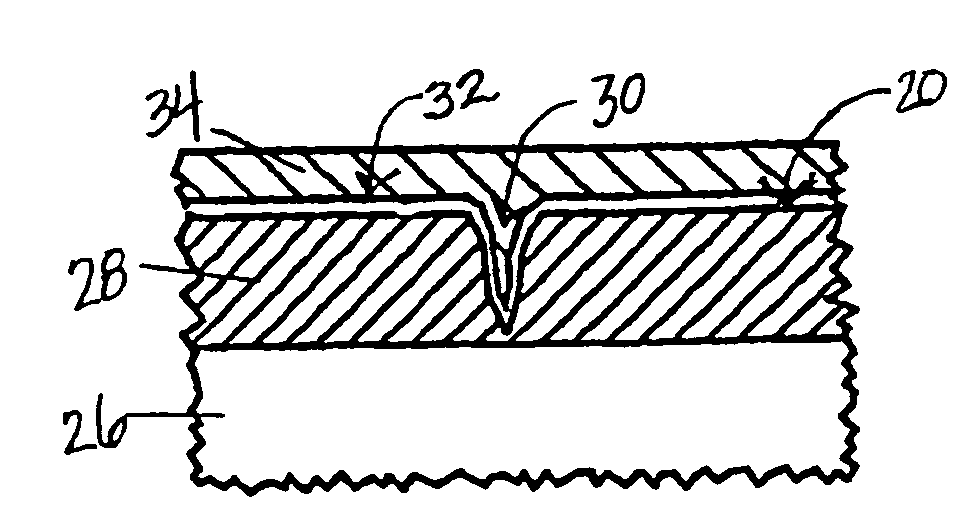

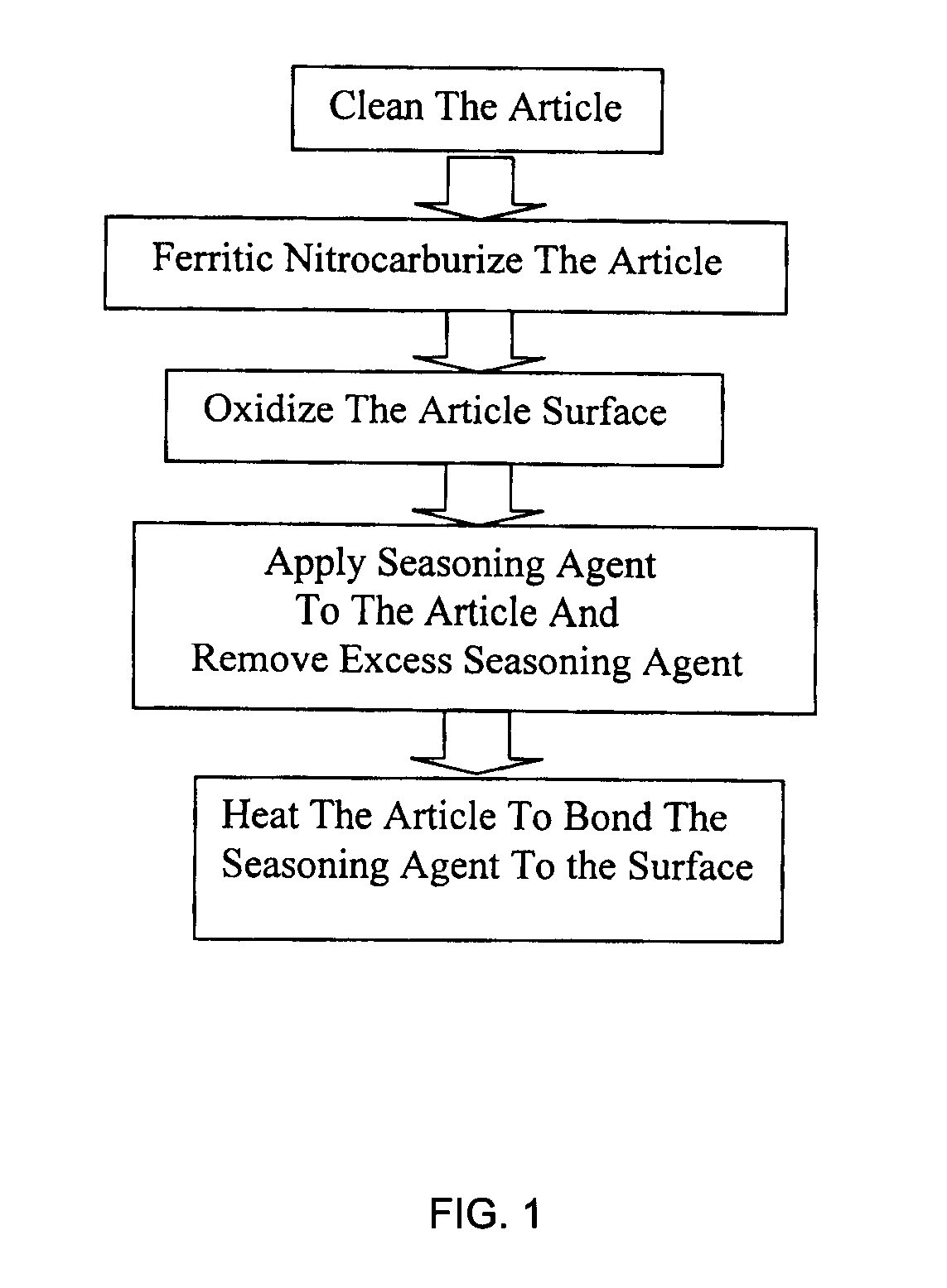

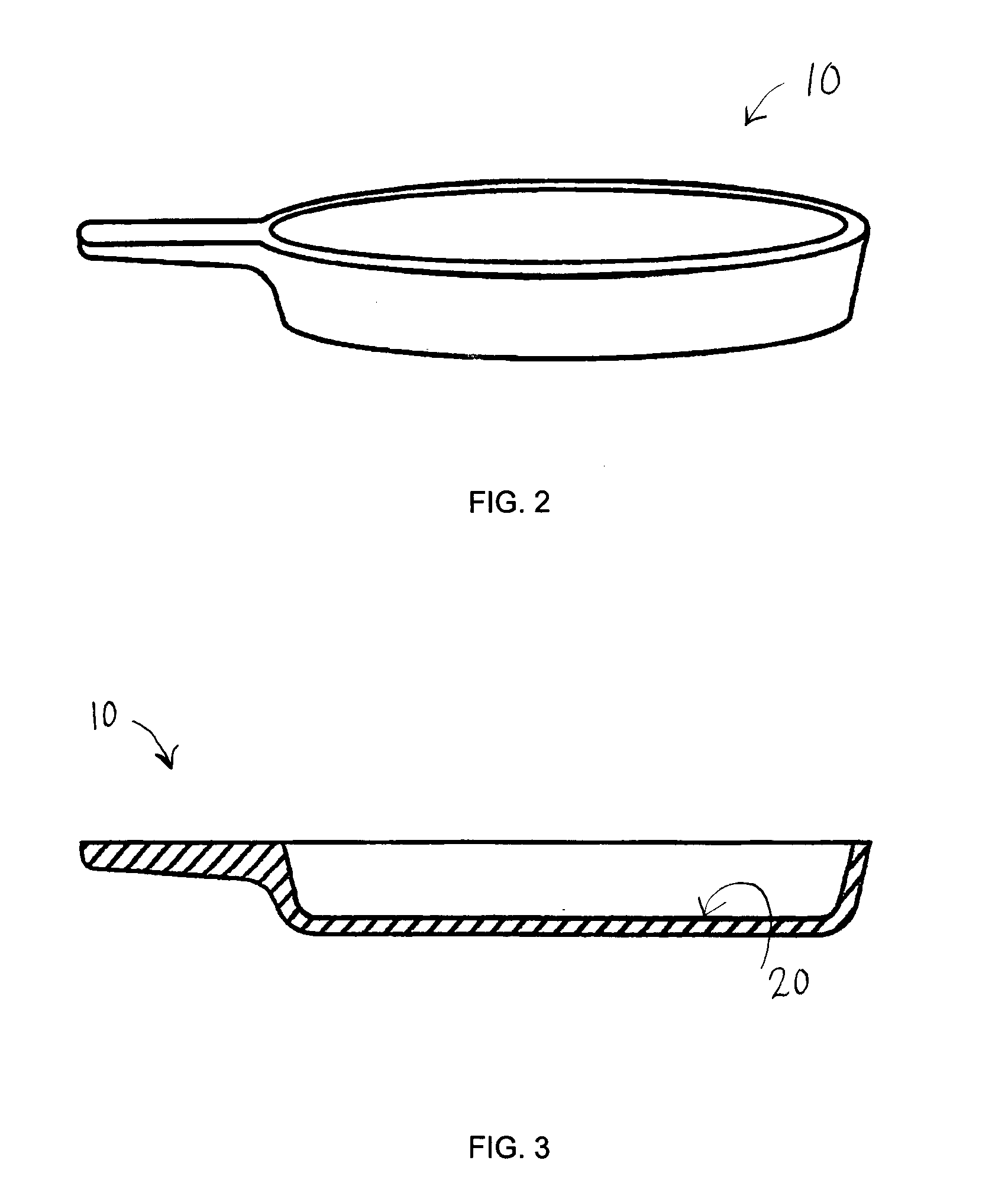

Seasoned Ferrous Cookware

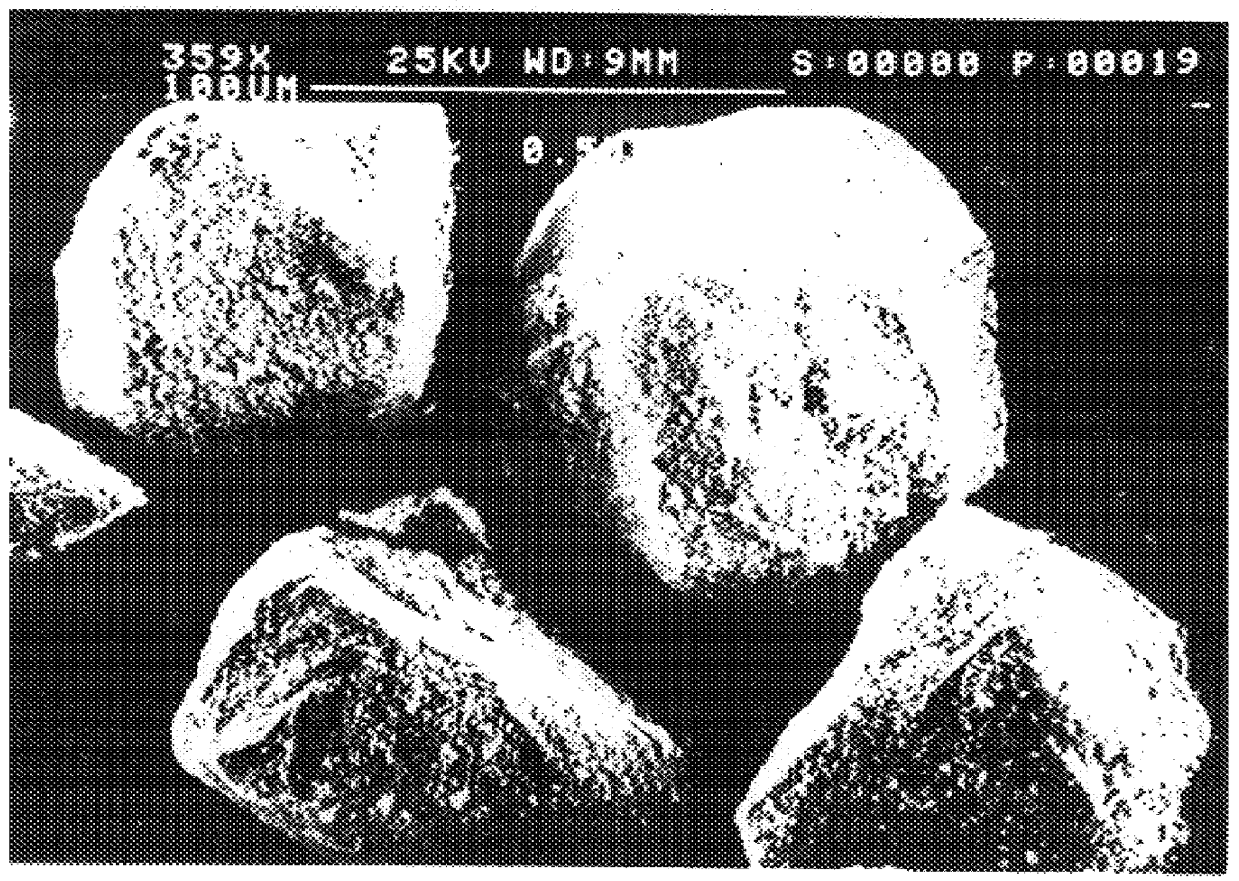

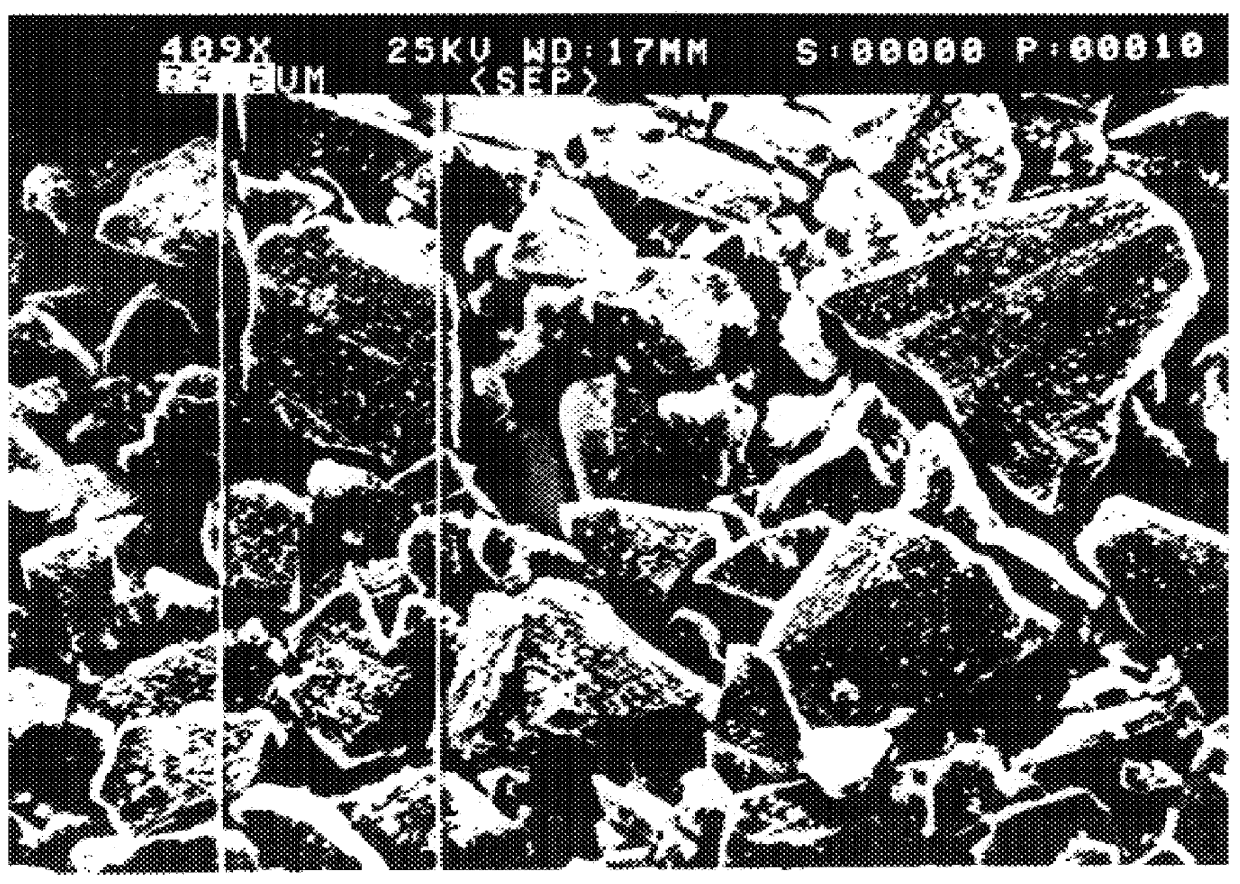

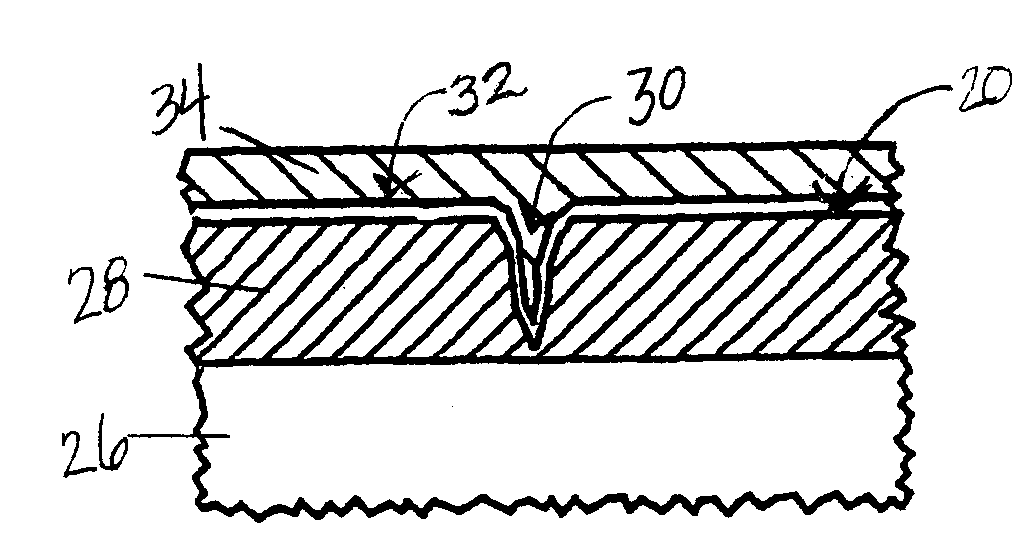

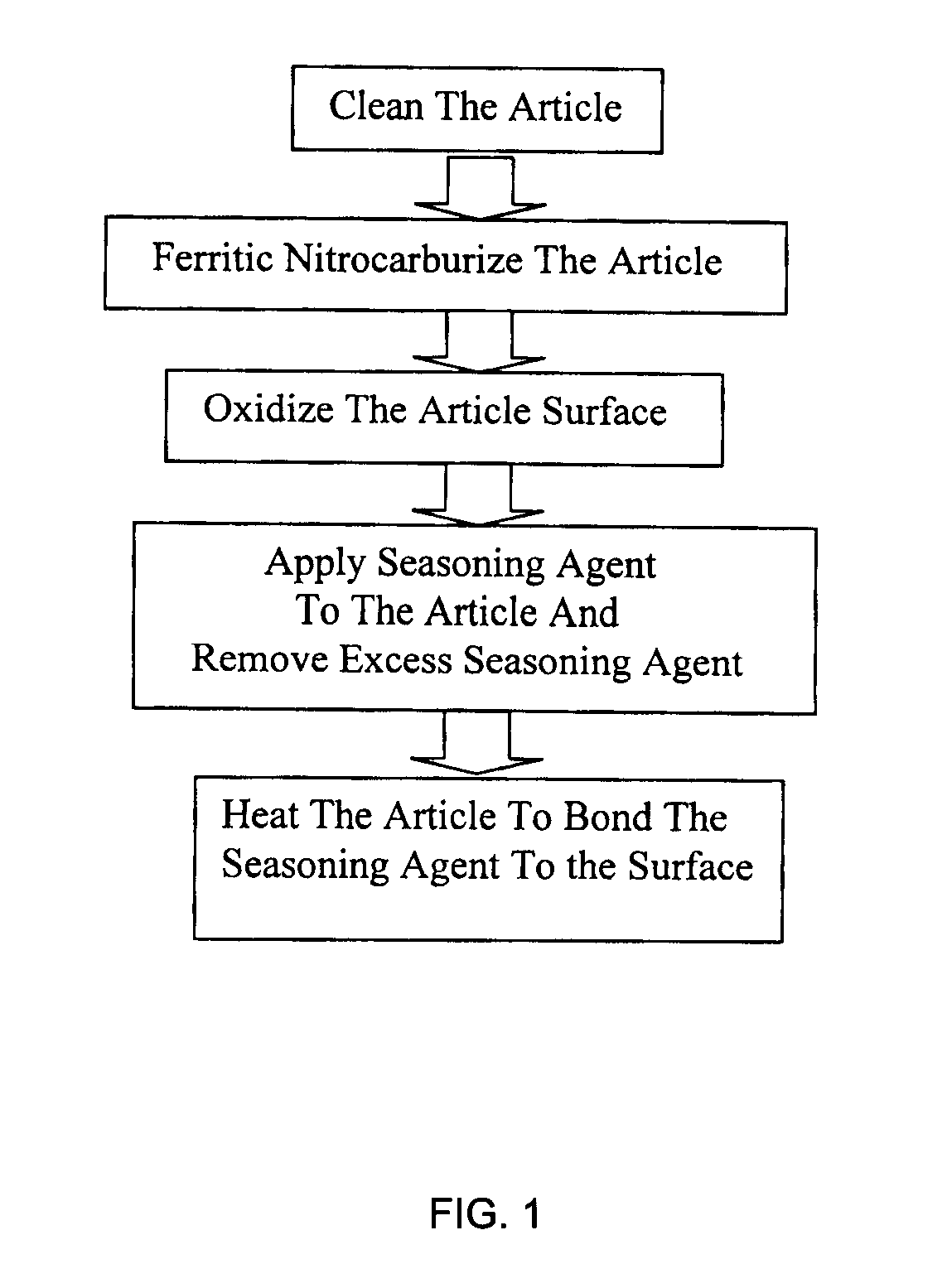

ActiveUS20080118763A1Excellent abrasion resistanceImprove corrosion resistanceCooking-vessel materialsPretreated surfacesNitrogenAmmonia

A method, and an article produced thereby, of providing a corroson-resistant, scratch-resistant, and stick-resistant, surface on a ferrous-metal-containing article, including forming microcavities in a ferrous-metal-containing article surface by ferritic nitrocarburization and seasoning the surface, including a non-stick agent deposited thereon. In preferred embodiments, the surface of the article including the exposed microcavities is oxidized before seasoning. The article includes cookware. Certain preferred embodiments include forming microcavities by ferritic nitrocarburization wherein the article is heated in an atmosphere including ammonia, nitrogen, and carbon-containing gas to a nitriding temperature of between about 800° F. and about 1300° F. for a time of about 0.5 hours to about 10 hours.

Owner:LODGE MFG CO

Polyvinyl chloride or polyolefin melt processable compositions containing polytetrafluoroethylene micropowder

Owner:TEKNOR APEX

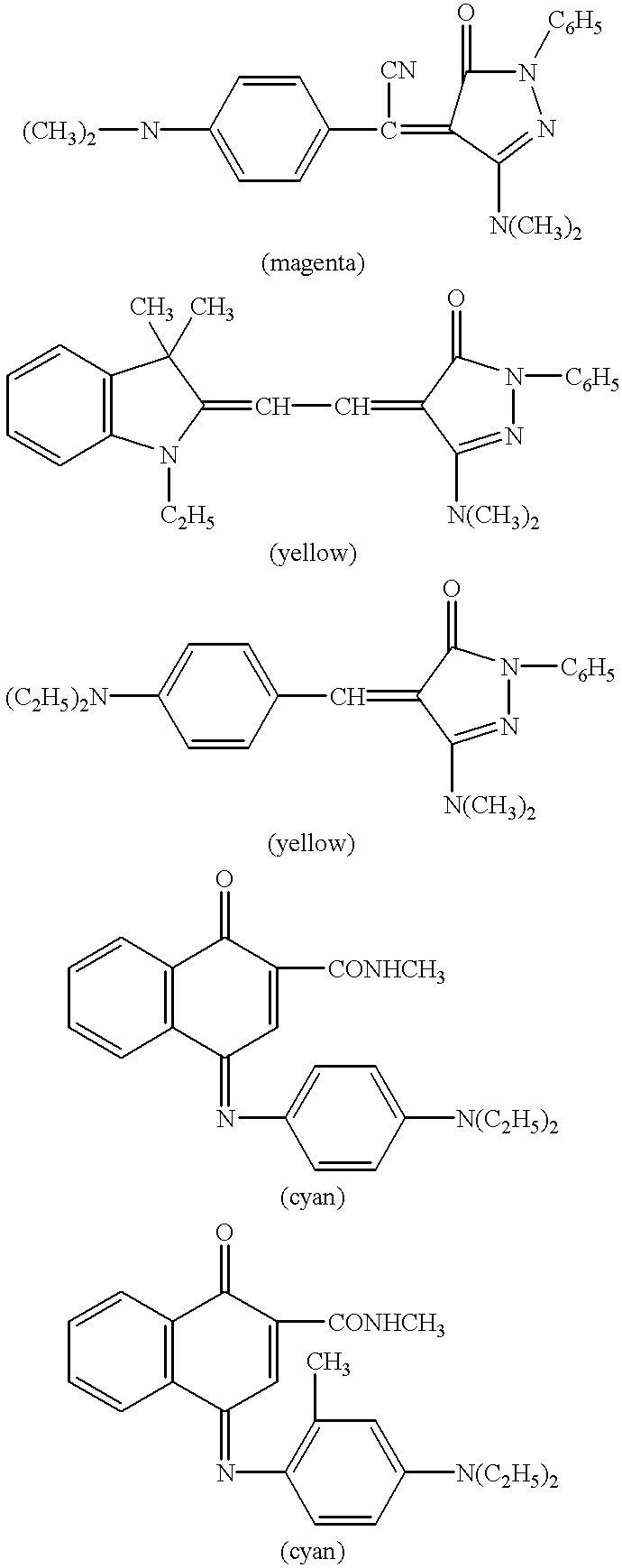

Laser thermal media with improved abrasion resistance

InactiveUS6259465B1Improved abrasionIncrease resistanceRecording apparatusAblative recordingNear infrared absorptionEngineering

A laser ablative recording element with a support having a certain Young's modulus and having thereon an image layer comprising an image dye or pigment dispersed in a polymeric binder, the image layer having a near infrared-absorbing material associated therewith to absorb at a given wavelength of the laser used to expose the element, the image dye or pigment absorbing in the region of from about 250 to about 700 nm, the element having a compliant layer between the support and the image layer, the compliant layer having a Young's modulus lower than that of the support, and the compliant layer having a thickness of between about 2 mum and about 200 mum.

Owner:EASTMAN KODAK CO

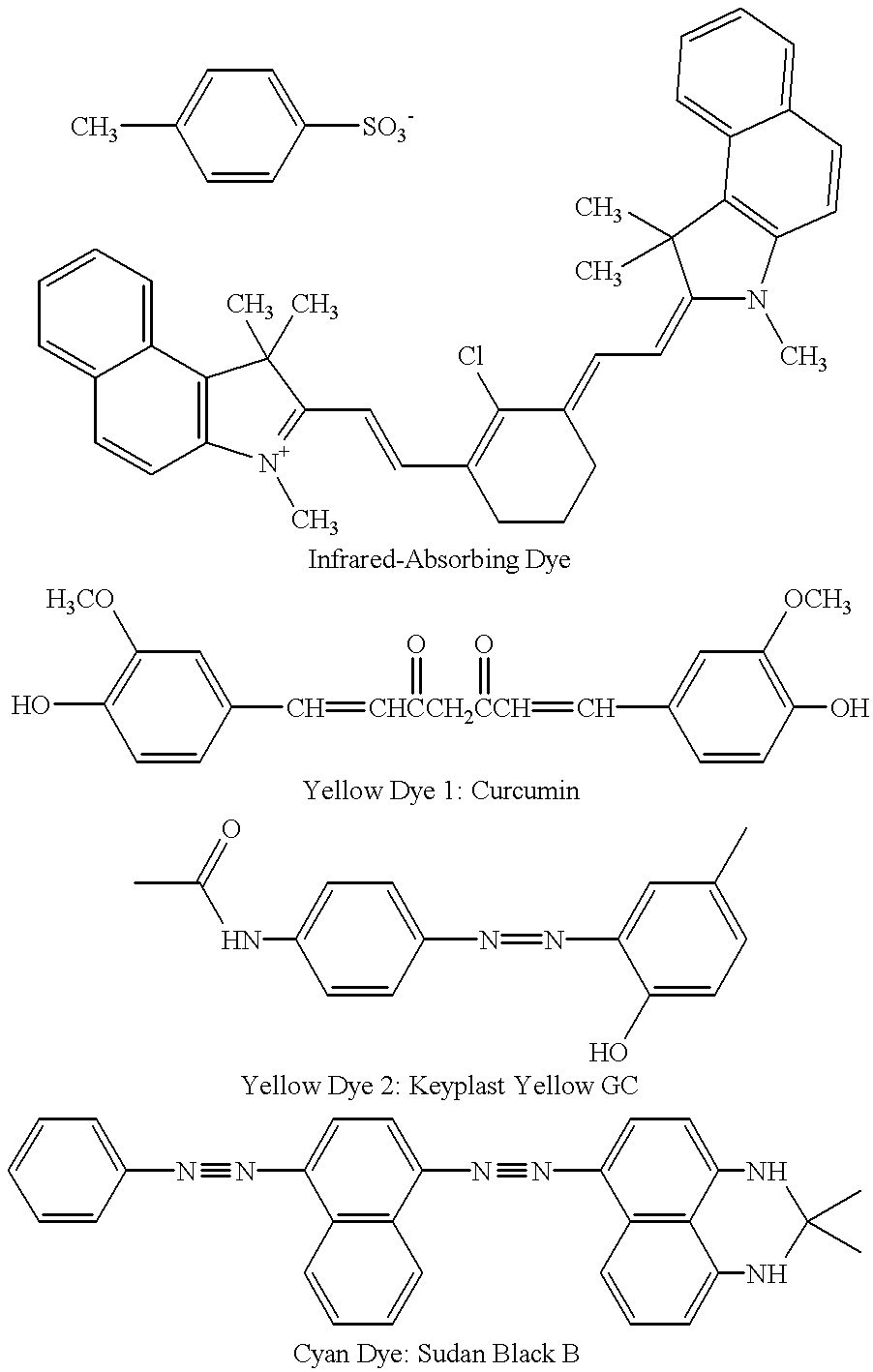

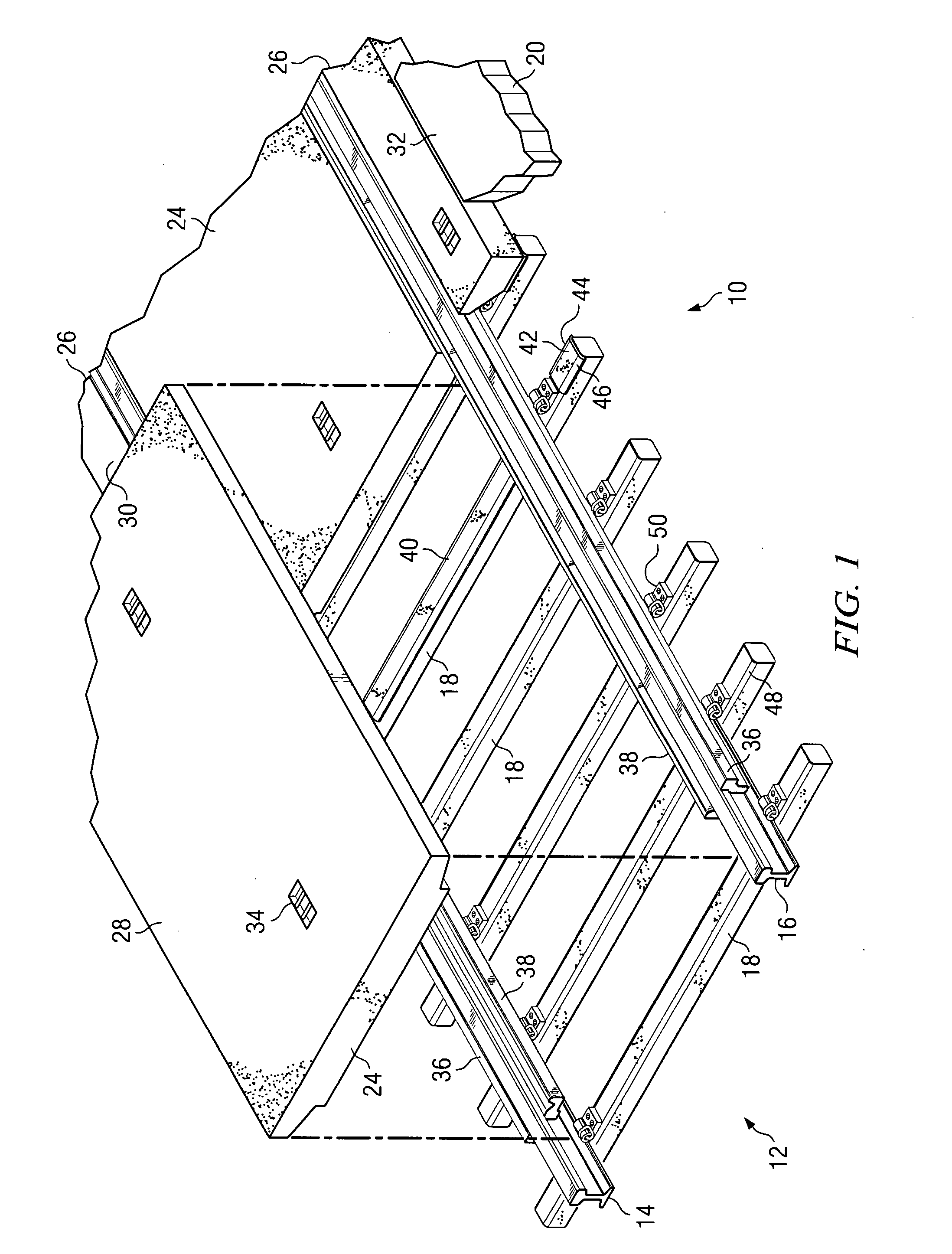

Ozone and Chemical Resistant Coating for Railway Line Elastomeric Components

InactiveUS20070200005A1Good weather resistanceIncrease impactBallastwayTemporary pavingsElastomerCompound (substance)

Elastomeric pads are shown for positioning on top of railroad ties. Pre-cast concrete panels that are commonly provided at railway grade crossings between and alongside the rails rest on the pads. The pads may be extruded from a variety of natural or synthetic elastomeric materials. The pads include a panel or body formed of the elastomeric material with an exterior surface. A synthetic, polymeric coating is applied to at least selected portions of the exterior surface of the elastomeric body. The coating provides improved properties which allow more standard elastomers to be utilized for the main body of the component. The coatings can also be applied to railroad tie boots to provide increased ozone resistance.

Owner:S & B TECHN PRODS

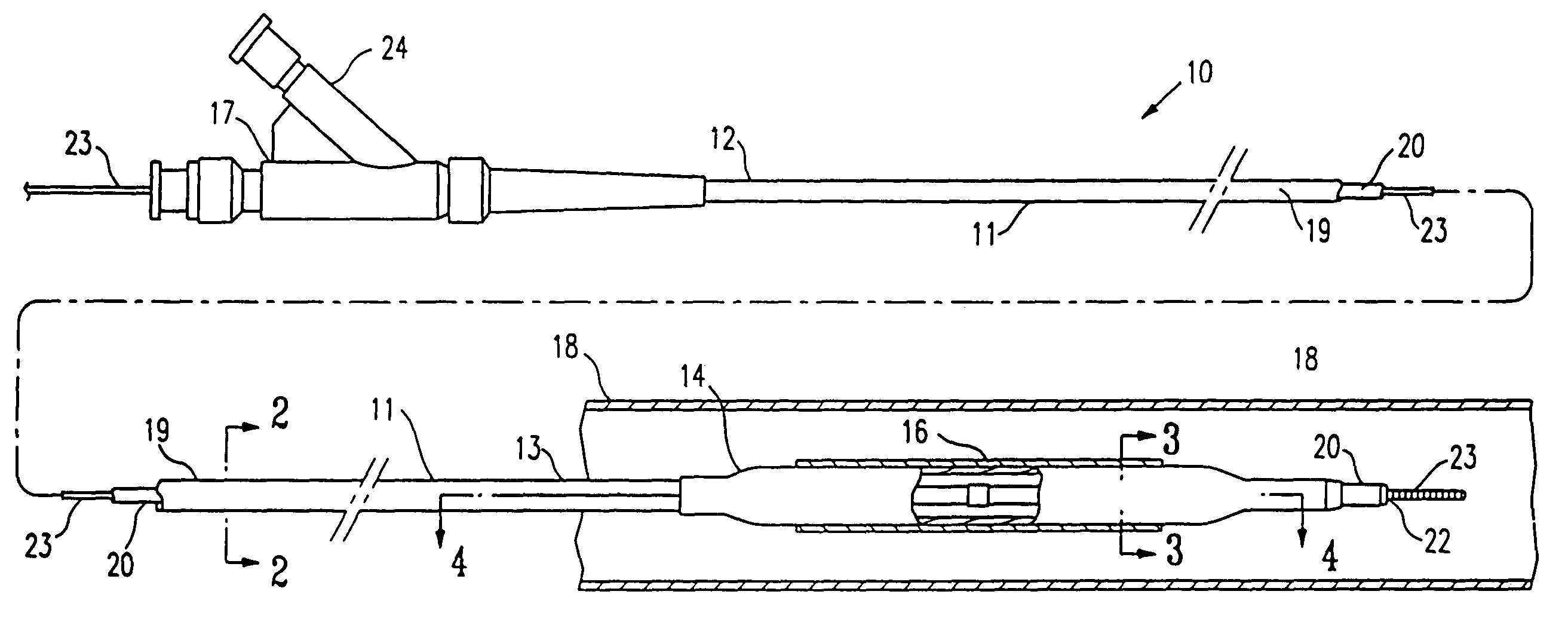

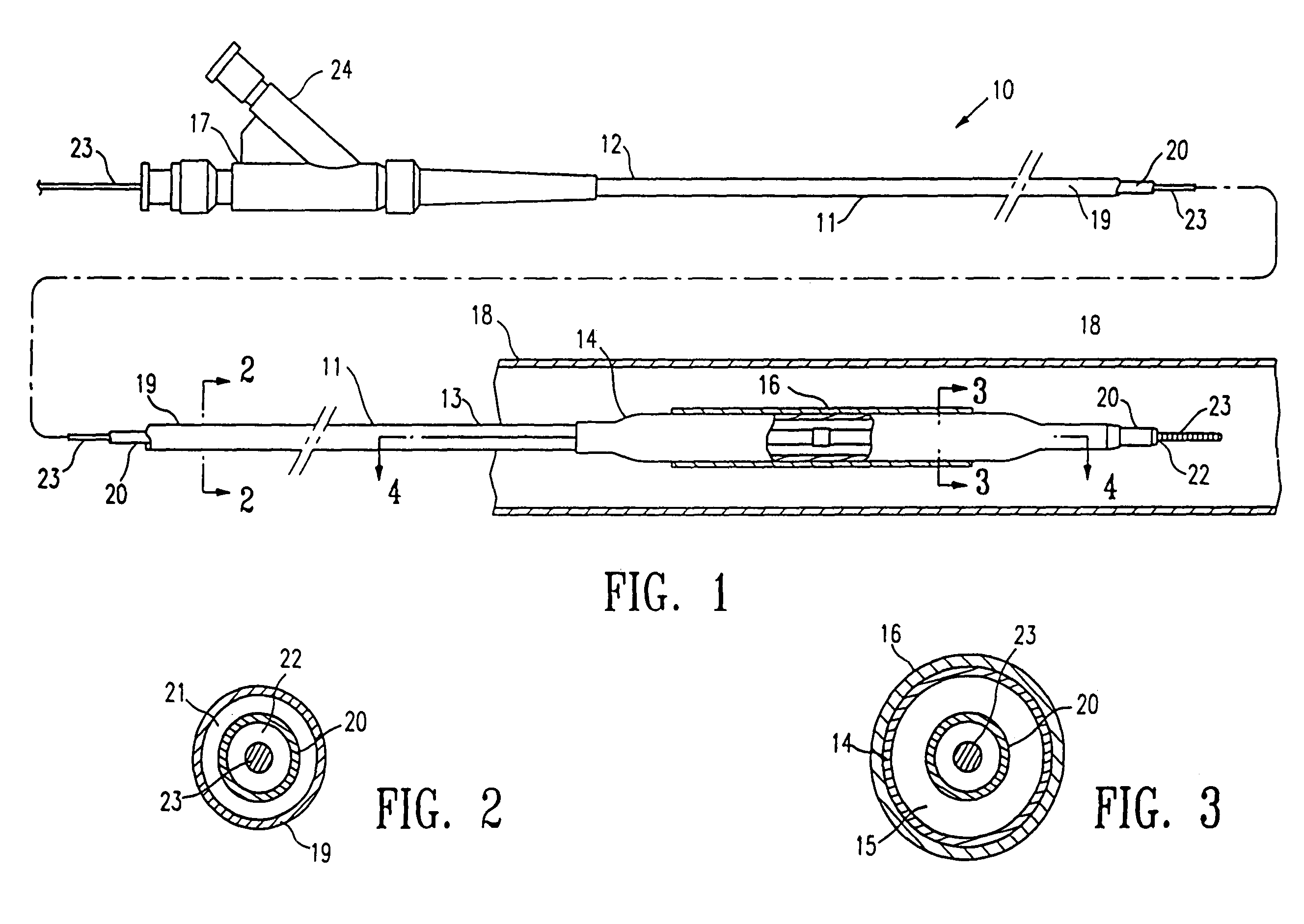

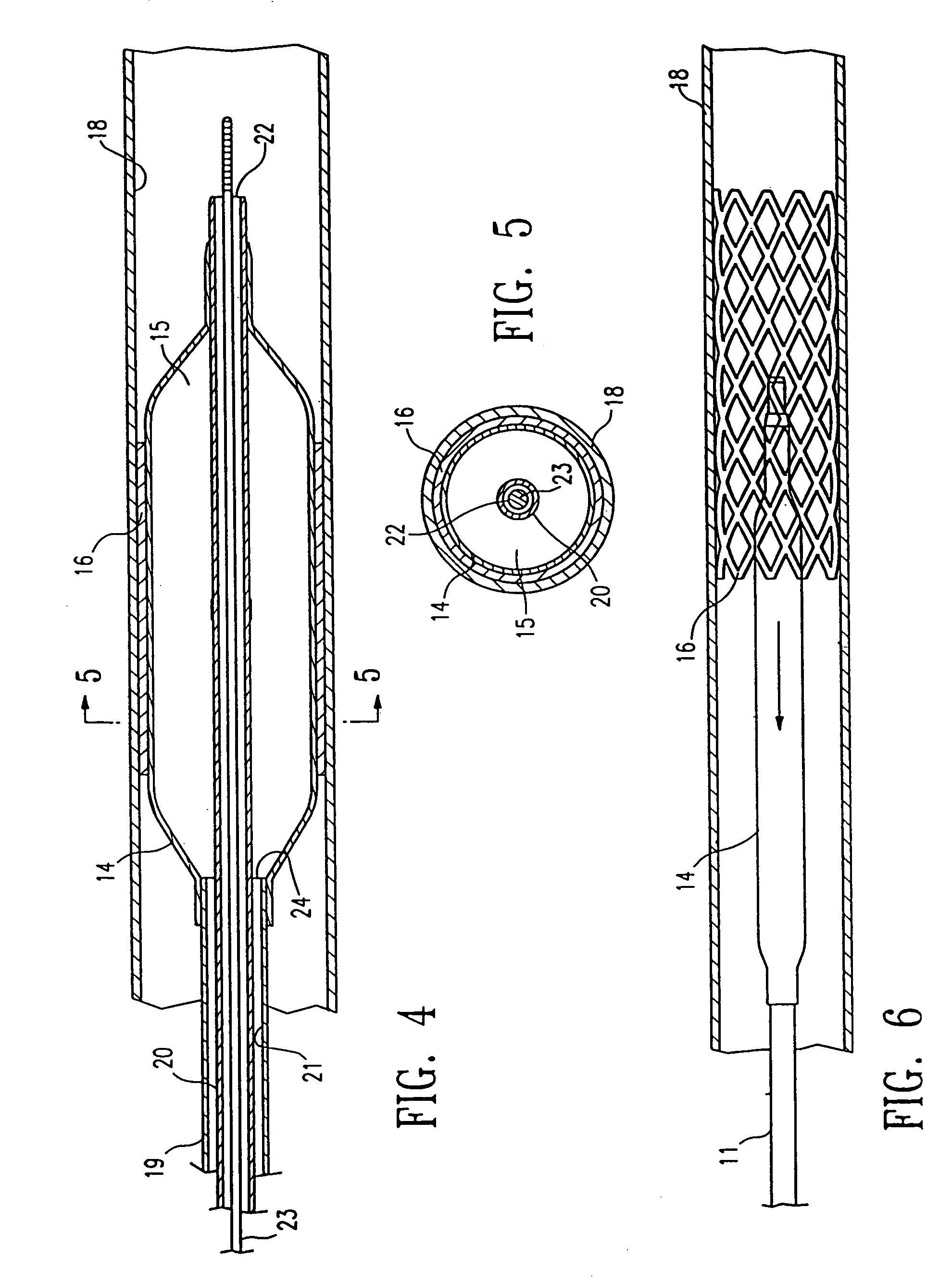

Method of making a non-compliant balloon for a catheter

InactiveUS7892469B2Improve performanceResist dilatationStentsHollow filament manufactureInsertion stentBalloon catheter

An intravascular catheter system for properly implanting a stent in a body lumen generally comprising a catheter having an elongated shaft with an inflatable balloon formed of compliant material and a stent mounted on the working length of the balloon. The balloon material is compliant within the working range of the balloon to provide substantial radial expansion. The wingless radially expansive balloon expands in a uniform manner, thereby producing uniform expansion and implantation of the stent. Another embodiment is directed to a balloon catheter, having a semi-compliant balloon or a noncompliant balloon formed at least in part of a block copolymer.

Owner:ABBOTT CARDIOVASCULAR

Seasoned ferrous cookware

ActiveUS7622197B2Improved abrasionIncrease resistanceCooking-vessel materialsPretreated surfacesNitrogenAmmonia

Owner:LODGE MFG CO

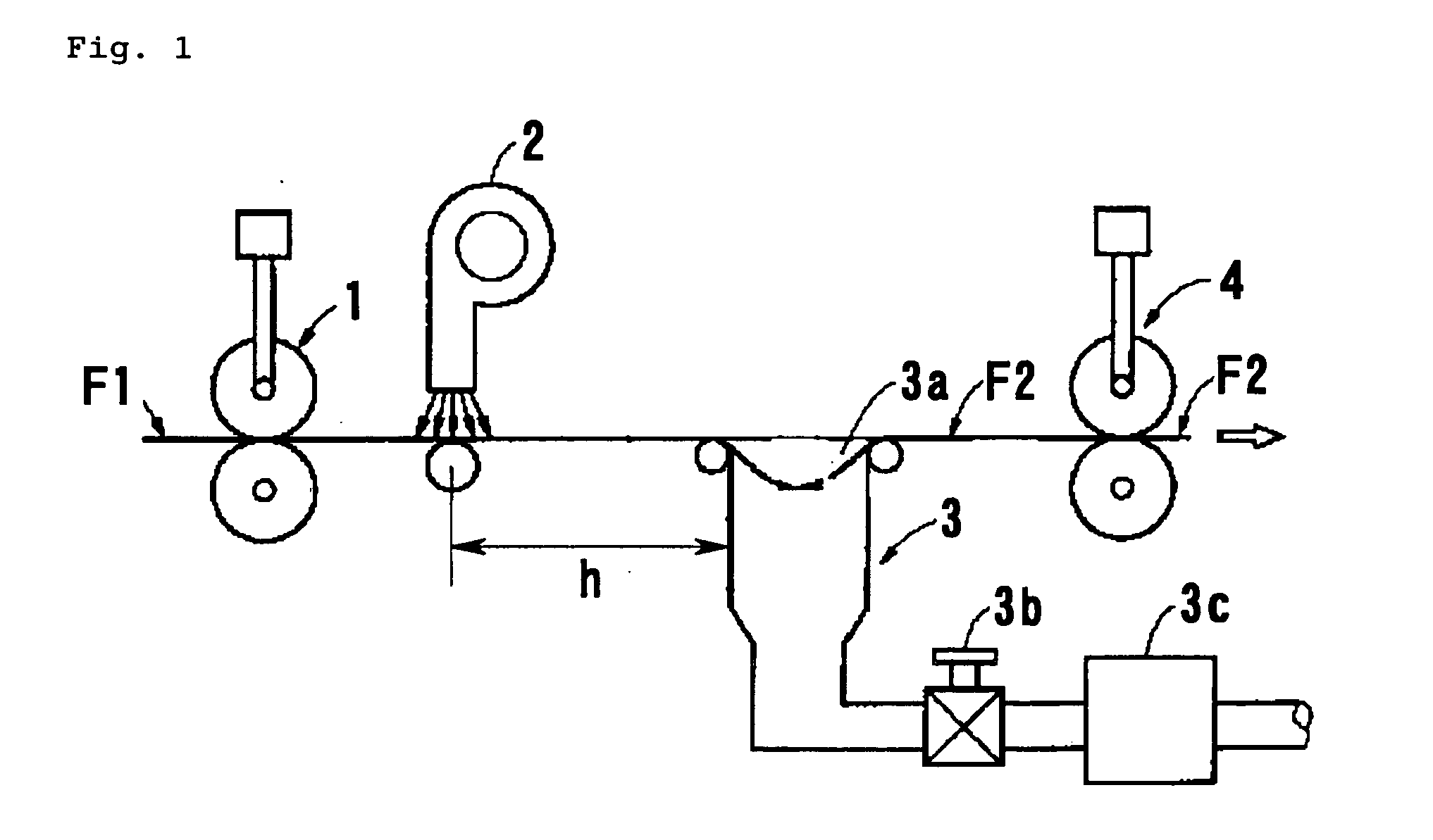

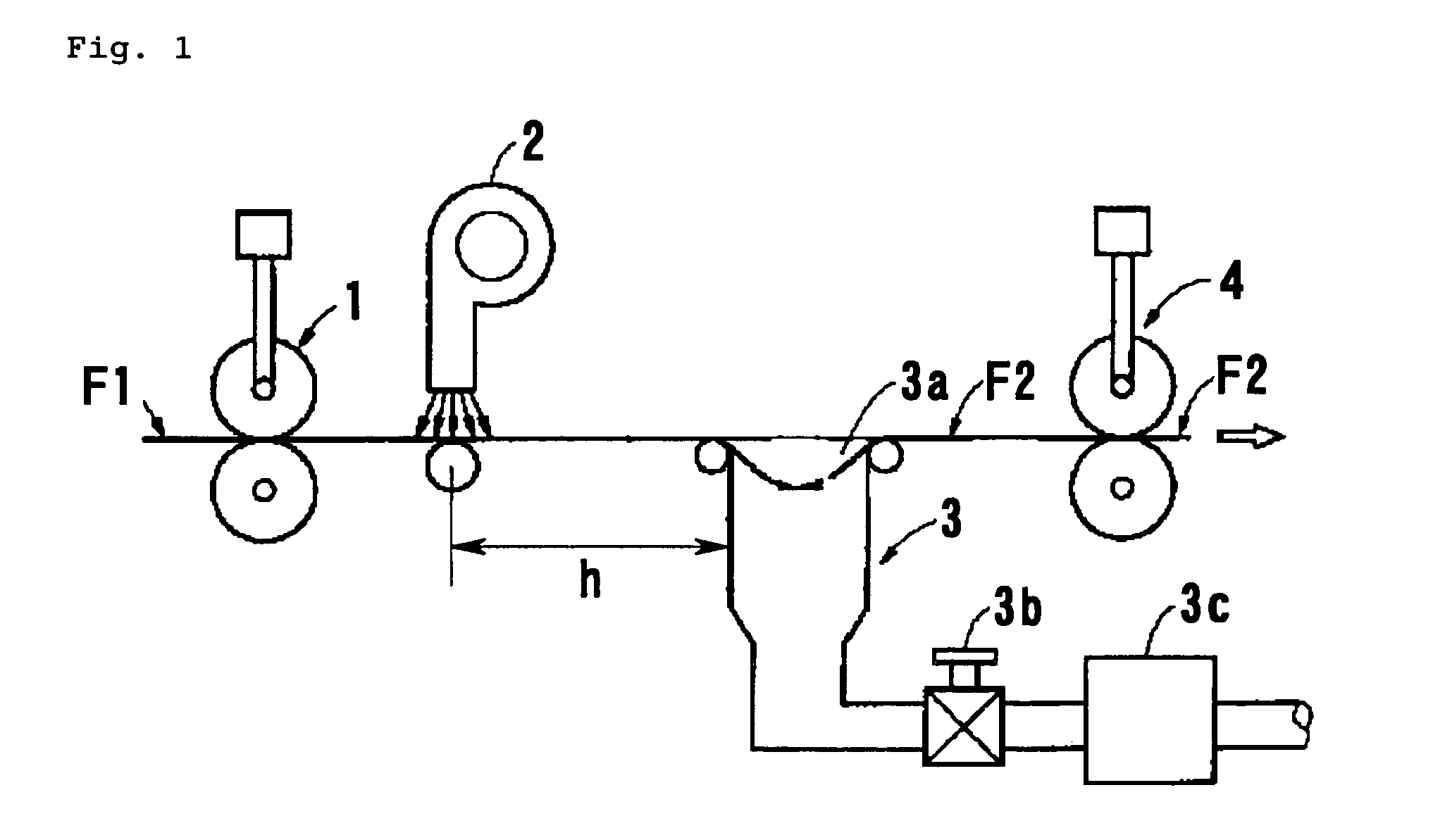

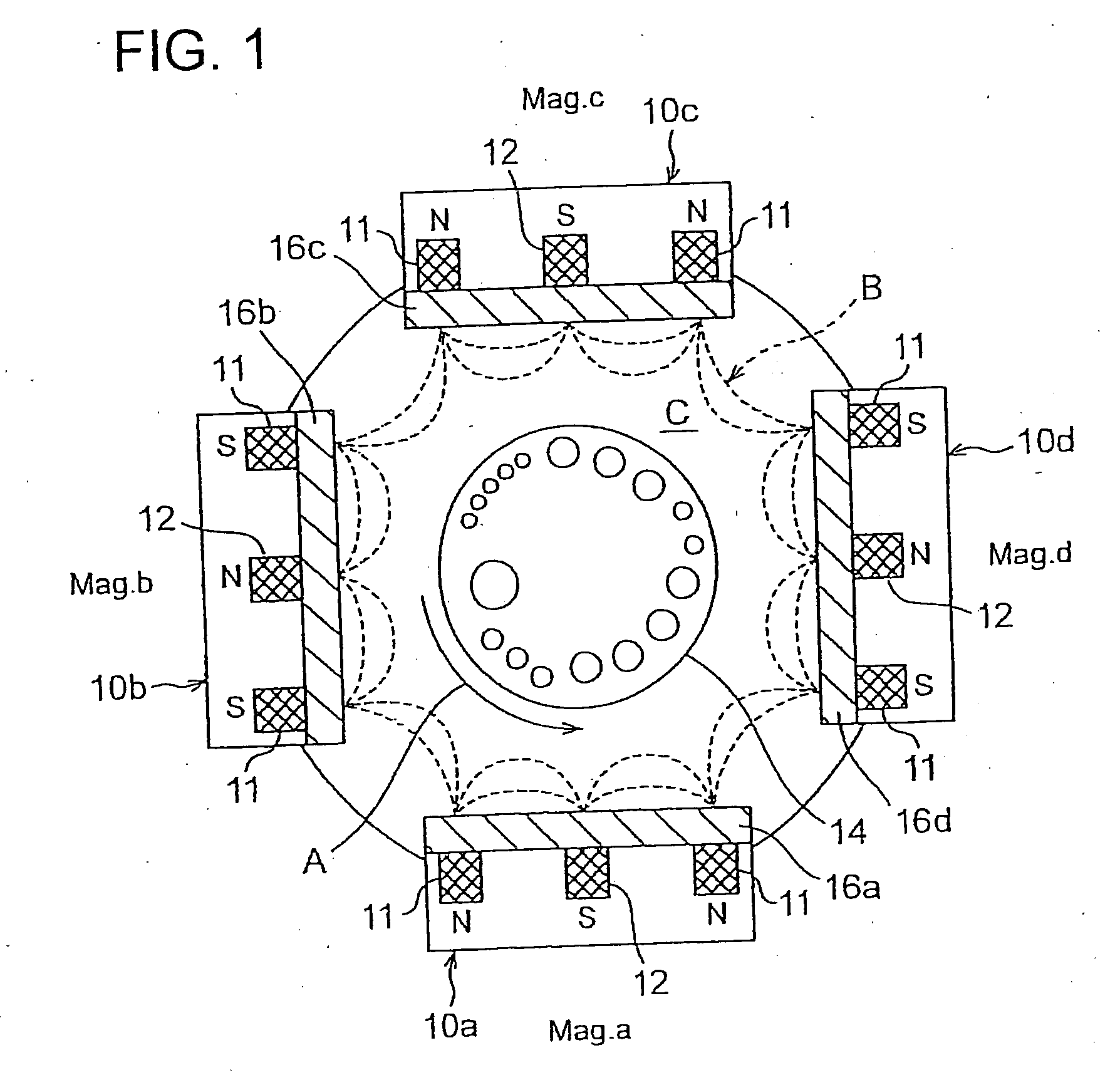

Composite comprising heat-resistant fiber and siloxane polymer

InactiveUS20050165154A1Improve heat resistanceImprove toughnessEngine sealsSynthetic resin layered productsPolymer scienceHeat resistance

The present invention provides a fiber-reinforced glass having excellent heat resistance and toughness, or a composite comprising a heat-resistant fiber and a siloxane polymer, which has a modified surface structure and is useful as a heat-resistant fiber.

Owner:IWAMIYA YOKO

Composite comprising heat-resistant fiber and siloxane polymer

InactiveUS7332196B2Increase resistanceImprove toughnessEngine sealsSynthetic resin layered productsPolymer scienceHeat resistance

The present invention provides a fiber-reinforced glass having excellent heat resistance and toughness, or a composite comprising a heat-resistant fiber and a siloxane polymer, which has a modified surface structure and is useful as a heat-resistant fiber.

Owner:IWAMIYA YOKO

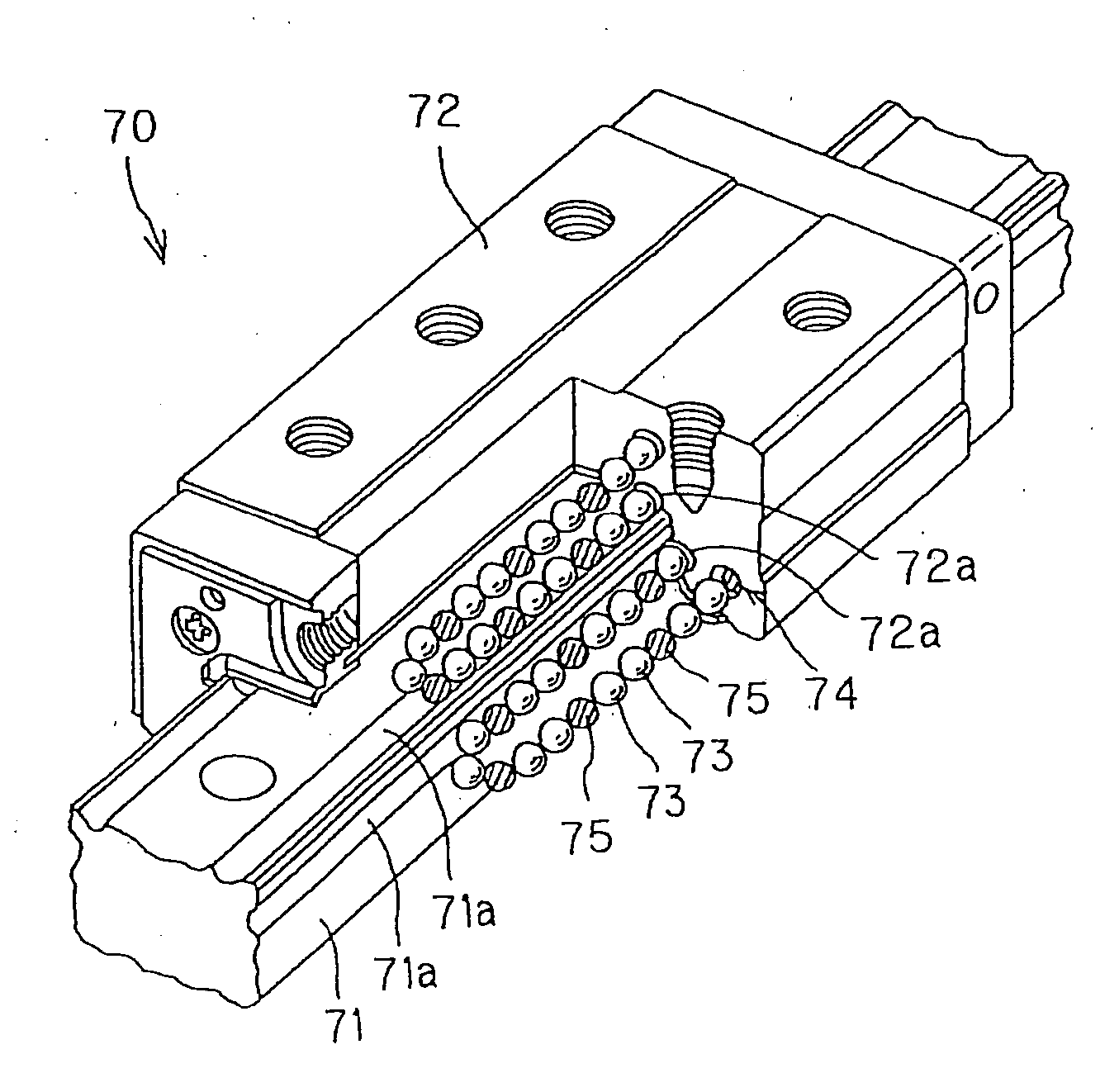

Rolling Guide Device

InactiveUS20080031557A1Excellent abrasion resistanceImprove fatigue strengthRolling contact bearingsLinear bearingsOil freeEngineering

A rolling guide device 160 is provided with a track rail 161 as a track member and a movable member 163 mounted to the track rail 161 to be movable through balls 162. A solid lubricant film is formed to the ball 162 by using a closed magnetic field unbalanced magnetron spattering apparatus (CUMS apparatus). The solid lubricant film has a low friction coefficient at the outermost surface of the film, withstands an inner repeated stress, and has a high adhesion performance. Such solid lubricant film has never been from its inside or boundary portion and wears at the minimum speed from the film surface, so that a reliable and highly ideal solid lubricating function can be attained, and by applying the solid lubricant film having improved adhesion performance and abrasion resistance to the rolling guide device, there can be provided a rolling guide device usable in a specific environmental condition such as an undesirable lubricating environment, high temperature vacuum condition, or an oil-free condition.

Owner:THK CO LTD

Polyvinyl chloride or polyolefin melt processable compositions containing polytetrafluoroethylene micropowder

InactiveUS20050192389A1Low flame retardancyLow smoke generationAbsorbent padsBandagesPolyolefinPolyvinyl chloride

The use of polytetrafluoroethylene micropowders having a particle size of generally less than about 20 microns as an additive for polyvinyl chloride or polyolefin unexpectedly produces compositions which are melt processable. Other unexpected properties include that the micropowder is deformable under shear and acts as a flame retardant.

Owner:TEKNOR APEX

Articles Including High Modulus Fibrous Material

InactiveUS20080233825A1High strengthImprove stabilityRoof covering using flexible materialsSynthetic resin layered productsFiberPolymer science

A composite sheet material including substantially randomly oriented high modulus fibrous material and a nonwoven web of thermoplastic fibrous material is disclosed. The composite sheet material can further include a substantially fluid impervious layer. The resultant composite sheet material can exhibit isotropic physical properties. The isotropic nature of the product can in turn improve the dimensional stability of the product, which can be useful for applications subject to multidirectional stresses, such as roofing membranes exposed to temperature variances.

Owner:GAMALELDIN MOHAMED WALID

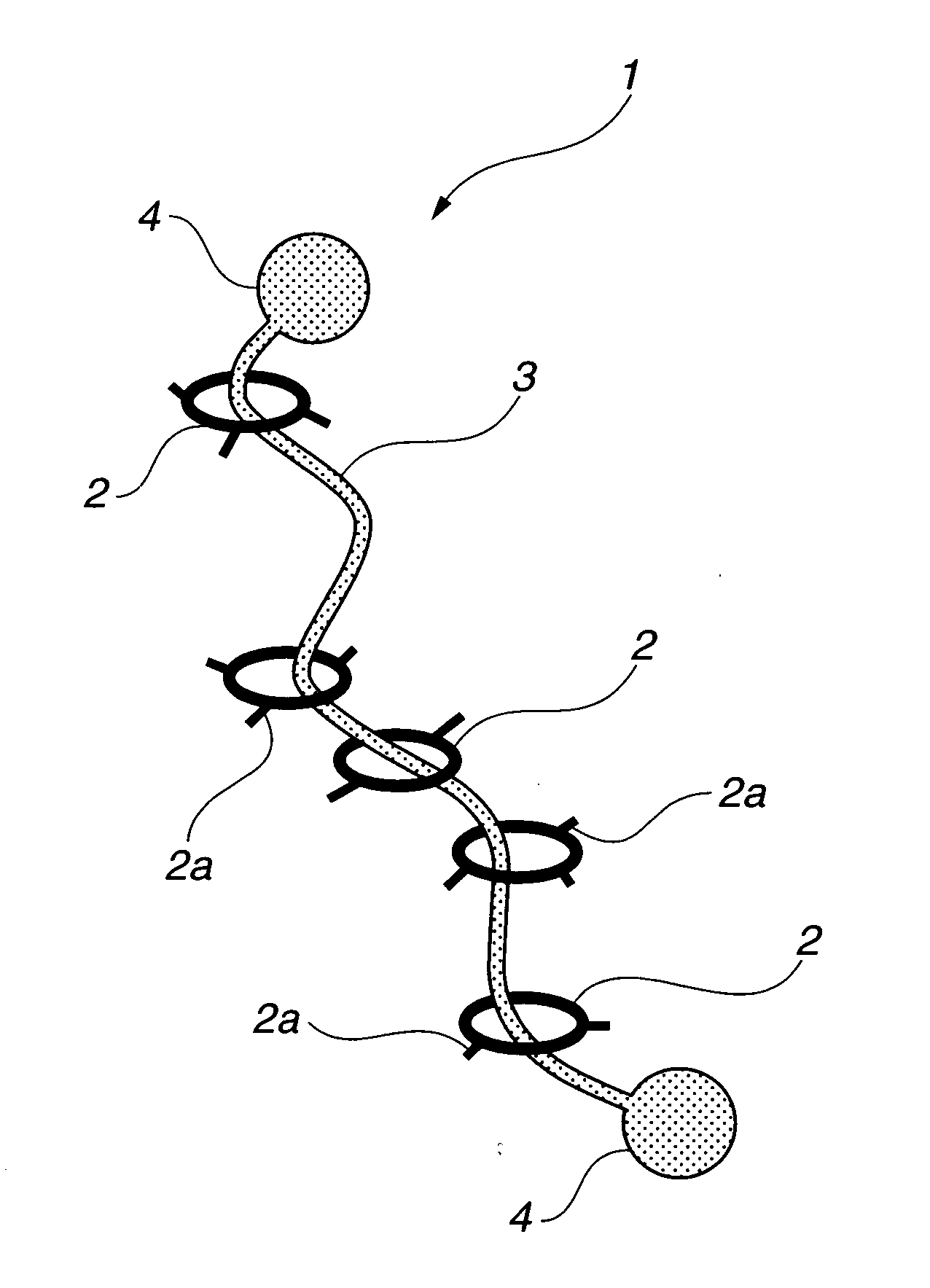

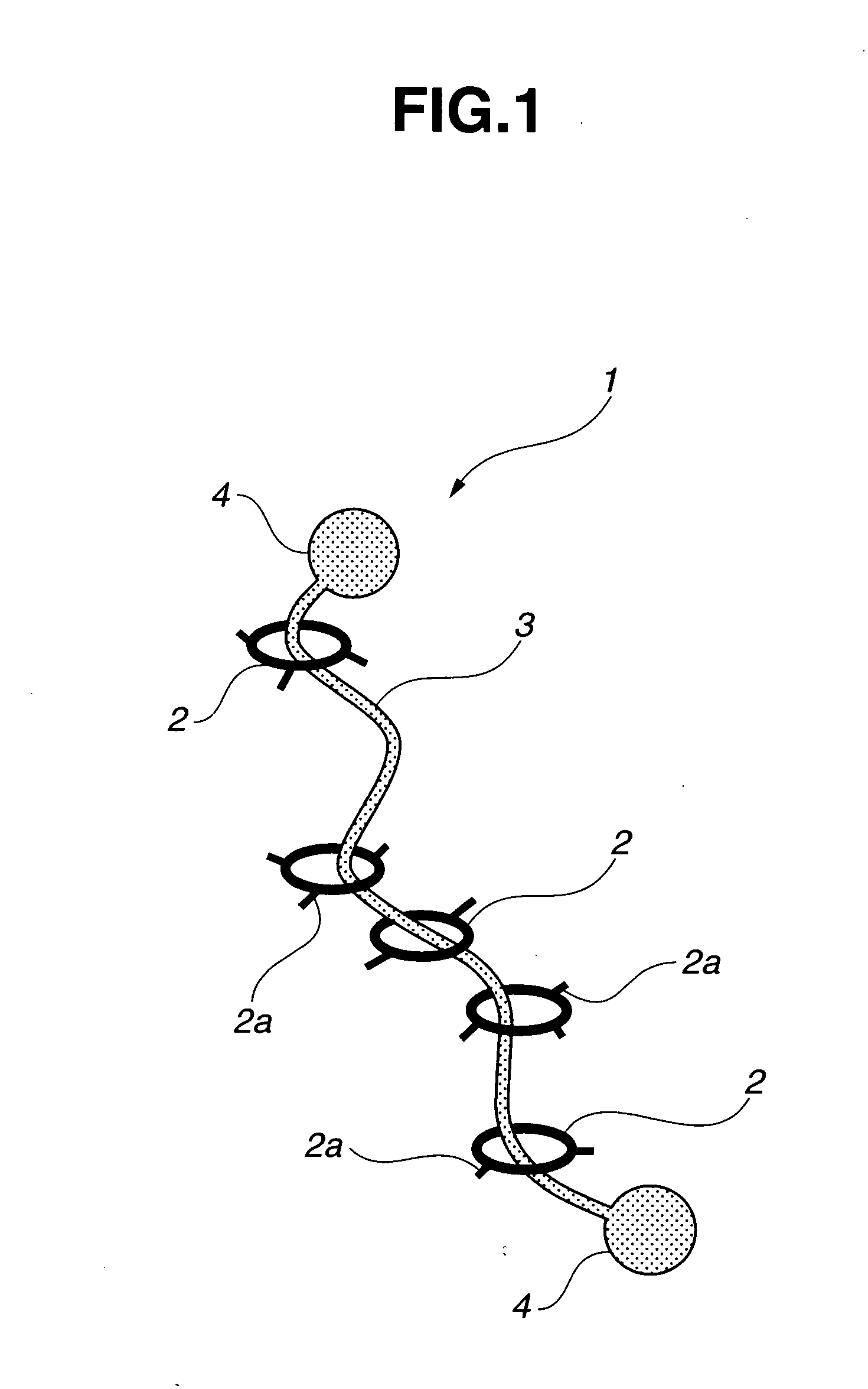

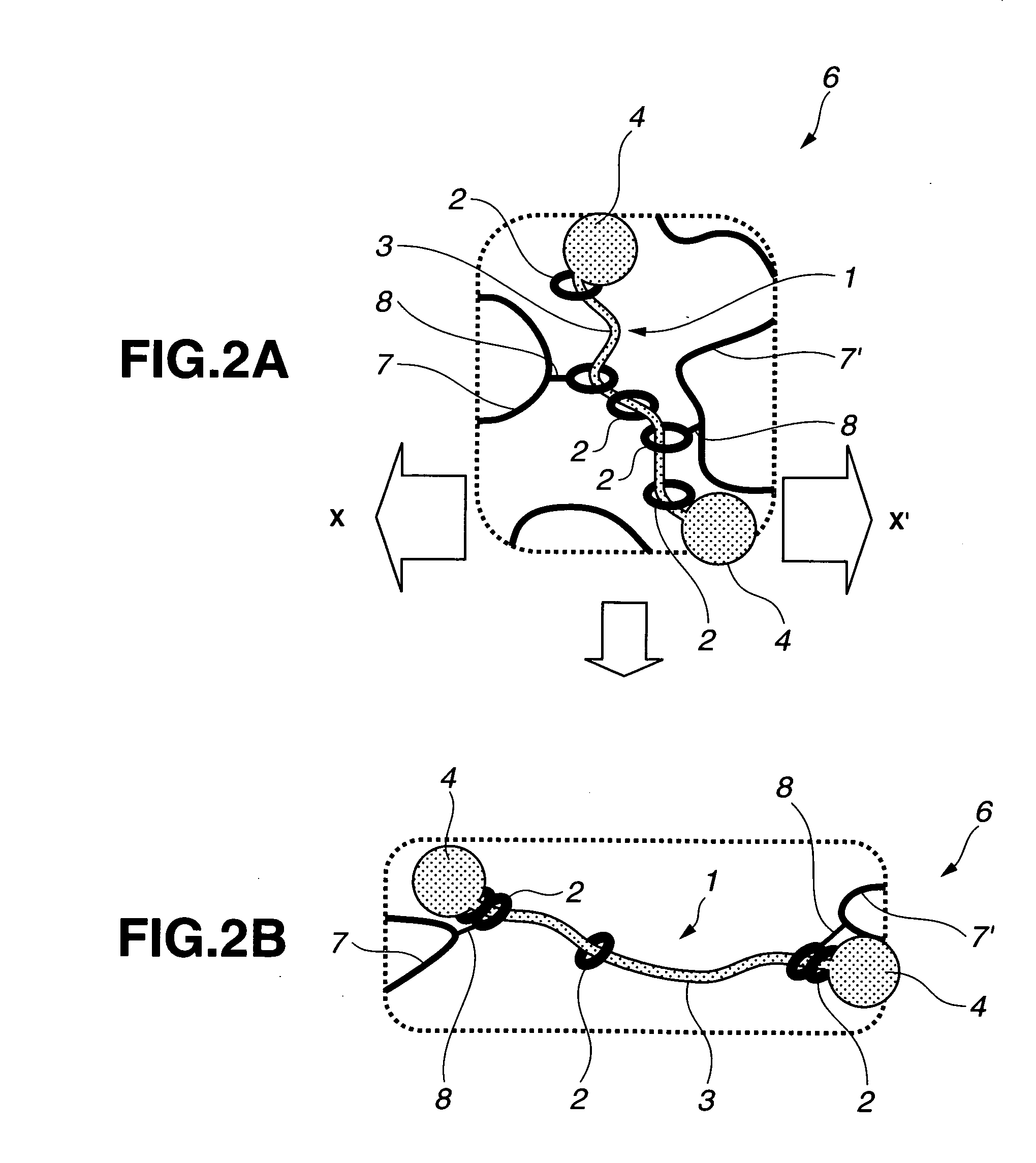

Material for Curable Aqueous Overcoating Material and Coating Material Using Same

InactiveUS20100129677A1Improved abrasionImprove chip resistanceLiquid surface applicatorsSynthetic resin layered productsPolyrotaxaneHydrophile

There is provided a curable aqueous overcoating composition containing 1 to 90 mass % of hydrophilic polyrotaxane with respect to the coating film forming component, where the hydrophilic polyrotaxane has a cyclic molecule, a linear molecule included in the cyclic molecule in a skewered manner and blocking groups arranged on opposite ends of the linear molecule to prevent elimination of the cyclic molecule from the linear molecule and at least one of the linear molecule and the cyclic molecule has a hydrophilic modifying group.

Owner:NISSAN MOTOR CO LTD +1

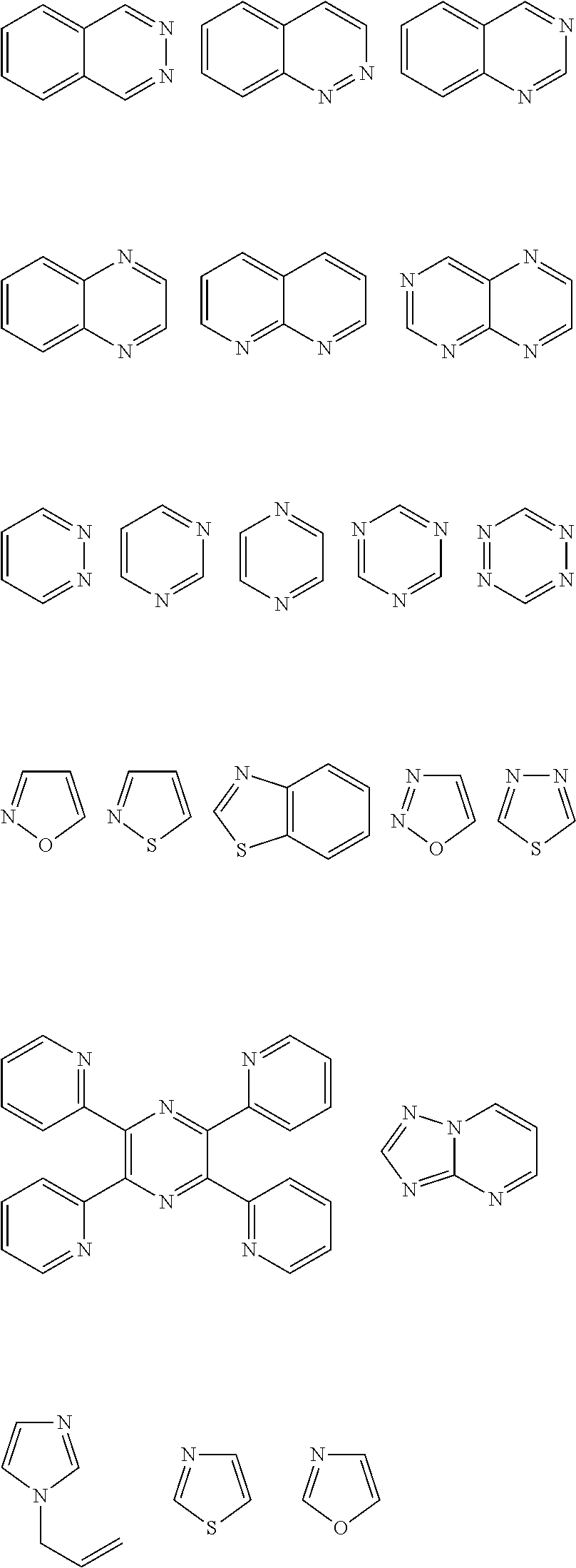

Functionalized polymers and processes for making same

A macromolecule includes at least one polymer chain with at least one functionality. The polymer can include unsaturated mer units and can be provided via anionic and pseudo-living polymerization techniques. In either technique, the functionality can include at least one 5- or 6-membered ring which includes a secondary amine group and at least one additional heteroatom; in the latter technique, the functionality can include a hydrazone radical. Such polymers can be used to provide compositions that also include particulate fillers, such compositions being useful for the production of vulcanizates.

Owner:BRIDGESTONE CORP

Durable overcoat material

InactiveUS6869675B2Excellent abrasion resistanceImprove stain resistanceX-ray/infra-red processesSynthetic resin layered productsWear resistantUrethane acrylate

This invention provides an element comprising a wear-resistant coating wherein said coating comprises radiation-cured urethane acrylate polymers and micronized polytetrafluoroethylene particles.

Owner:CARESTREAM HEALTH INC

Building panel with compressed edges and method of making same

ActiveUS8429872B2Efficient productionImproved abrasionWallsSpecial ornamental structuresSurface layerEngineering

Owner:VÄLINGE INNOVATION AB

Optical article having a reflective coating with high abrasion-resistance

PendingUS20220066079A1Improve abrasion and scratch resistanceWithout decrease optical performance and other mechanical performanceOptical partsOptical elementsRefractive indexHigh index

Disclosed is an optical article including a substrate having at least one main face coated with a reflective coating including a stack of at least one high refractive index layer having a refractive index higher than 1.55 and at least one low refractive index layer having a refractive index of 1.55 or less, in which the thicknesses of the layers in the reflective coating have been optimized according to specific design rules in order to boost the abrasion resistance of the optical article.

Owner:ESSILOR INT CIE GEN DOPTIQUE

High performance thermoplastic hose and method for manufacturing such hose from a thermoplastic vulcanizate

InactiveUS6524673B1Low costImprove performanceLayered productsFlexible pipesThermoplasticPolymer science

A high performance thermoplastic hose useful as a power steering hose, the high performance thermoplastic hose comprising a high performance engineering thermoplastic such as polyurethane and a chlorine-containing polyolefin such as chlorinated polyethylene, chlorinated polypropylene, chlorinated copolymers containing ethylene and propylene, chlorosulfonated polyethylene, chlorosulfonated polypropylene, chlorosulfonated copolymers of ethylene and propylene or mixture thereof, is disclosed. Also disclosed are a method for manufacturing the high performance thermoplastic hose, and a thermoplastic vulcanizate capable of resisting chemical attack and withstanding temperatures up to about 300° F.

Owner:FLUID ROUTING SOLUTIONS

Coating composition

ActiveUS20060167175A1Uniform propertyProlong lifeSynthetic resin layered productsCoatingsElastomerPolyolefin

The coating agent composition comprises an emulsion containing (A) polydiorganosiloxane having a viscosity of 50 to 10,000,000 mPa·s at 25° C. and having both terminal ends blocked by hydroxyl groups, (B) polyorganohydrogensiloxane having at least three hydrogen atoms bonded to silicon atoms in one molecule, (C) a curing catalyst, and (D) chlorinated polyolefine and / or acryl-modified polyolefine, with which (E) fine spherical particles comprised of a rubber-like elastomer having hardness of less than 90 are mixed to disperse into it. The coating agent composition having good uniform applying property, non tackness, water repellency and lubricating properties and outstanding adhesiveness to a rubber or plastic substrate can be obtained.

Owner:MOMENTIVE PERFORMANCE MATERIALS JAPAN LLC

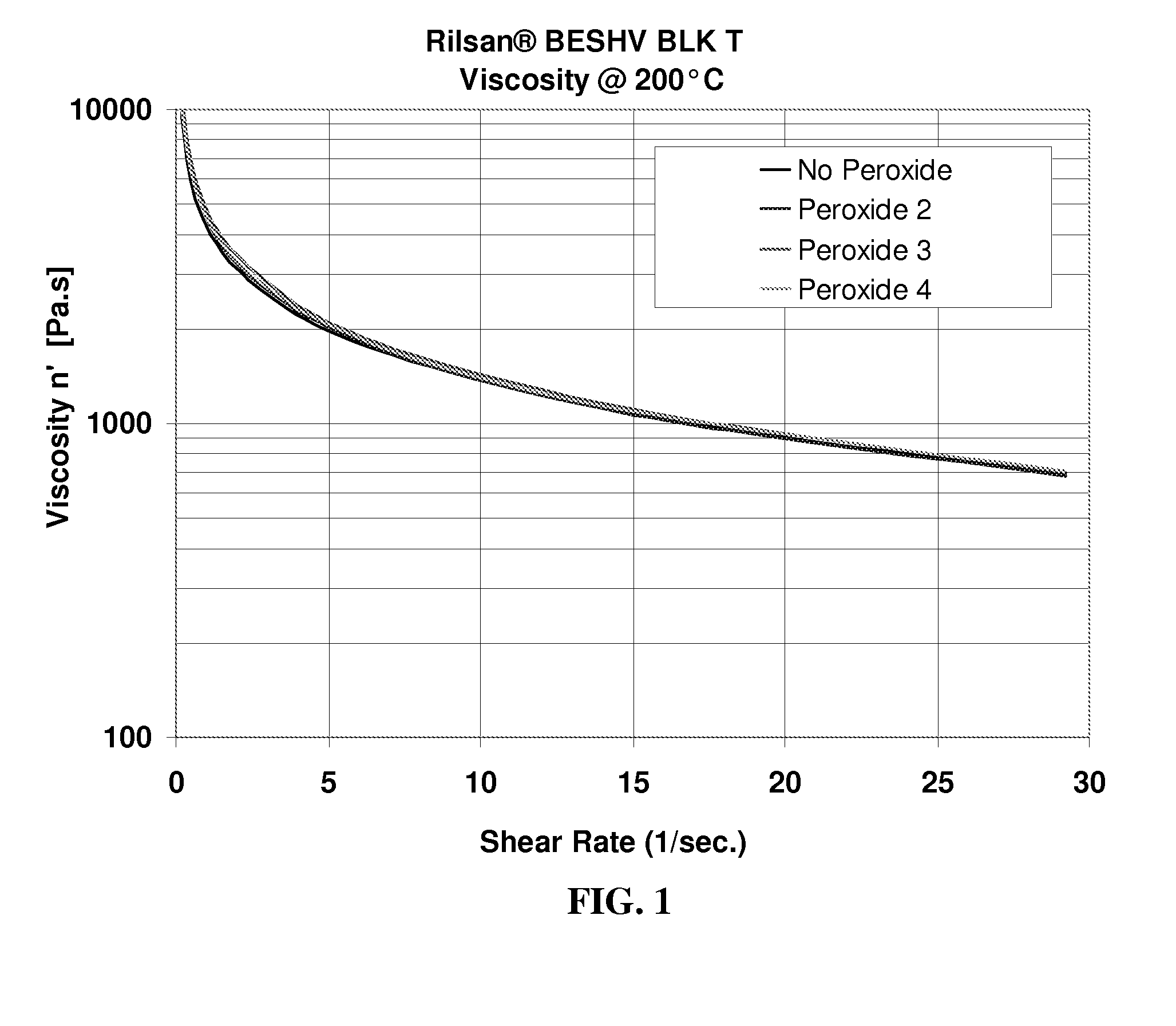

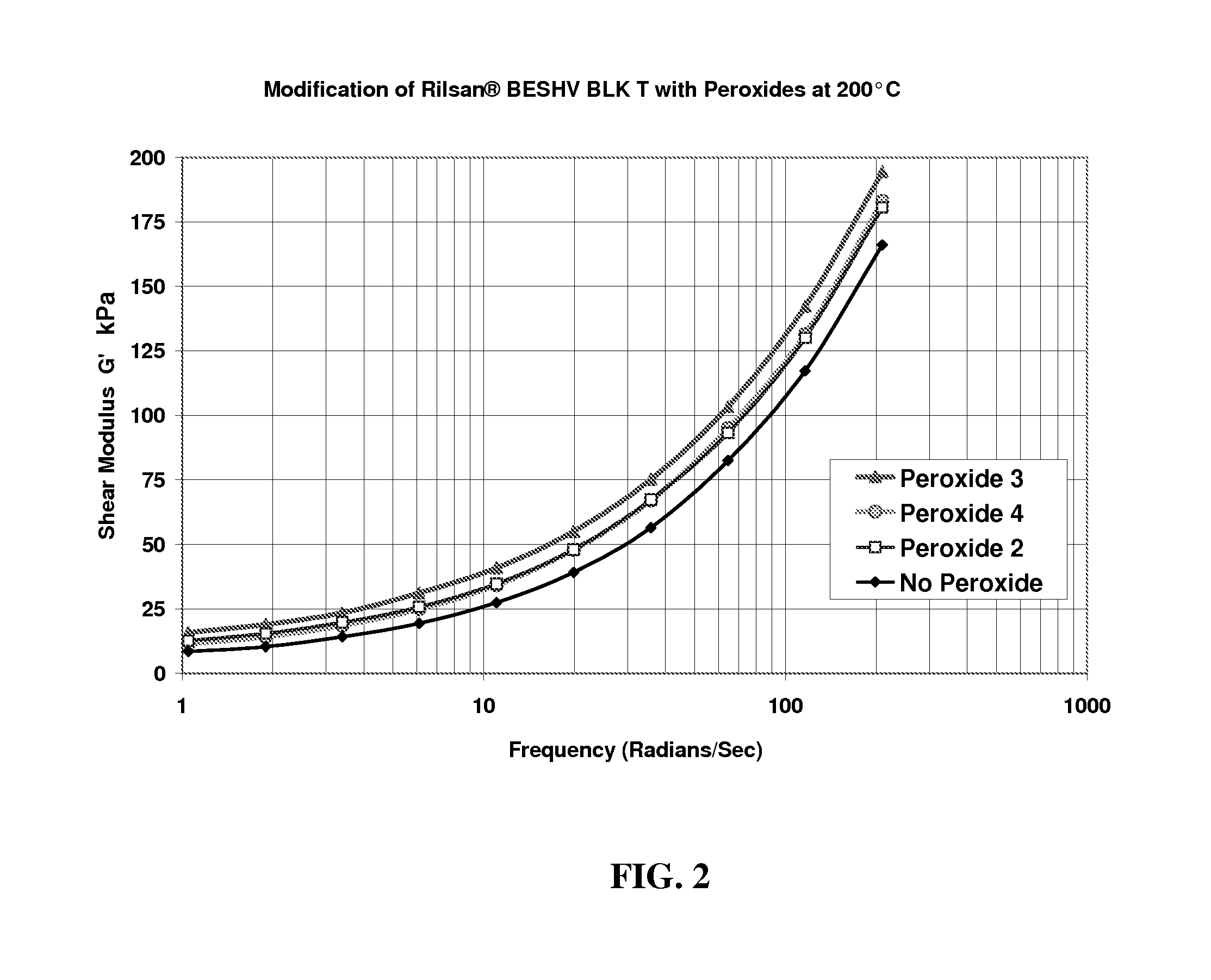

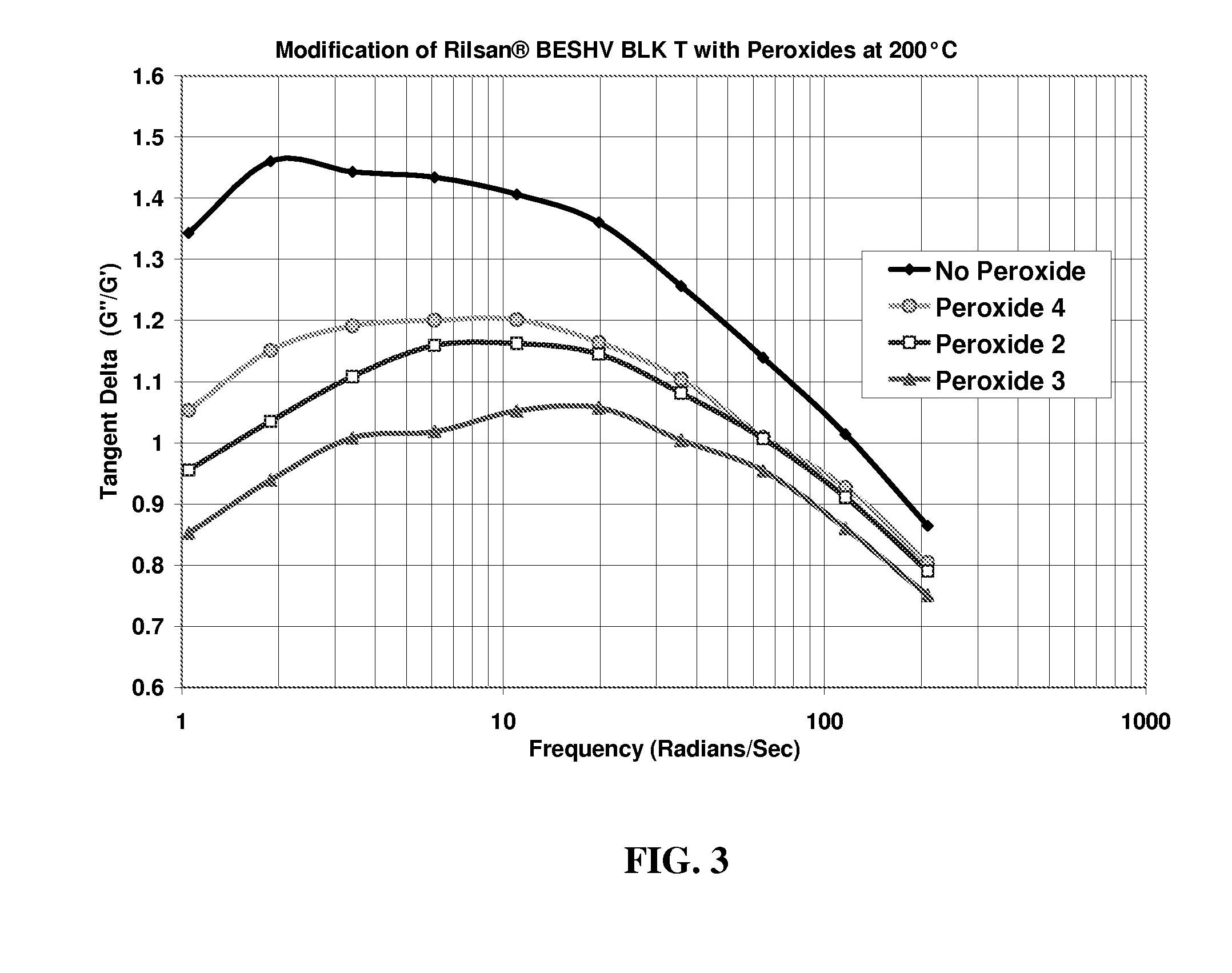

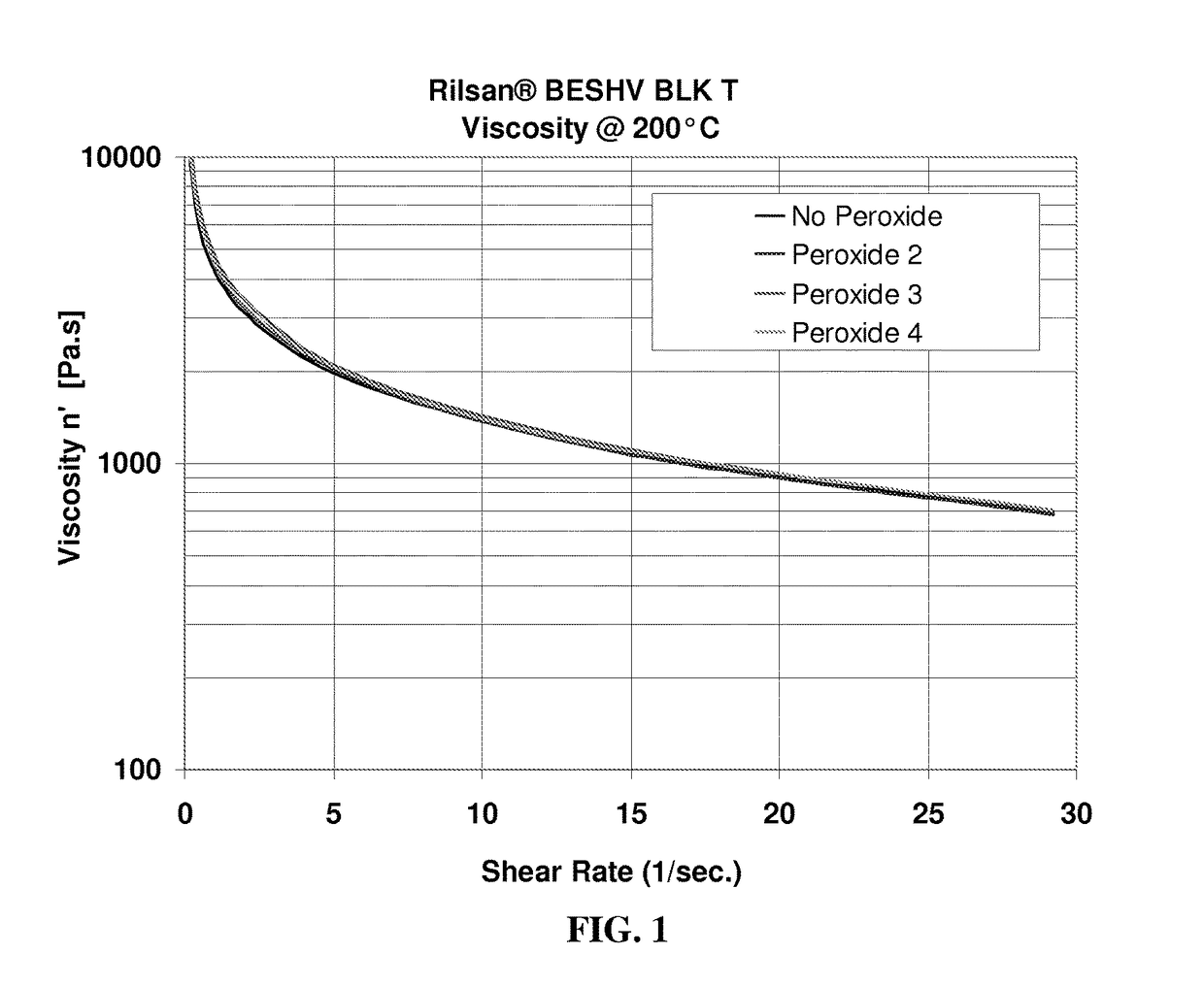

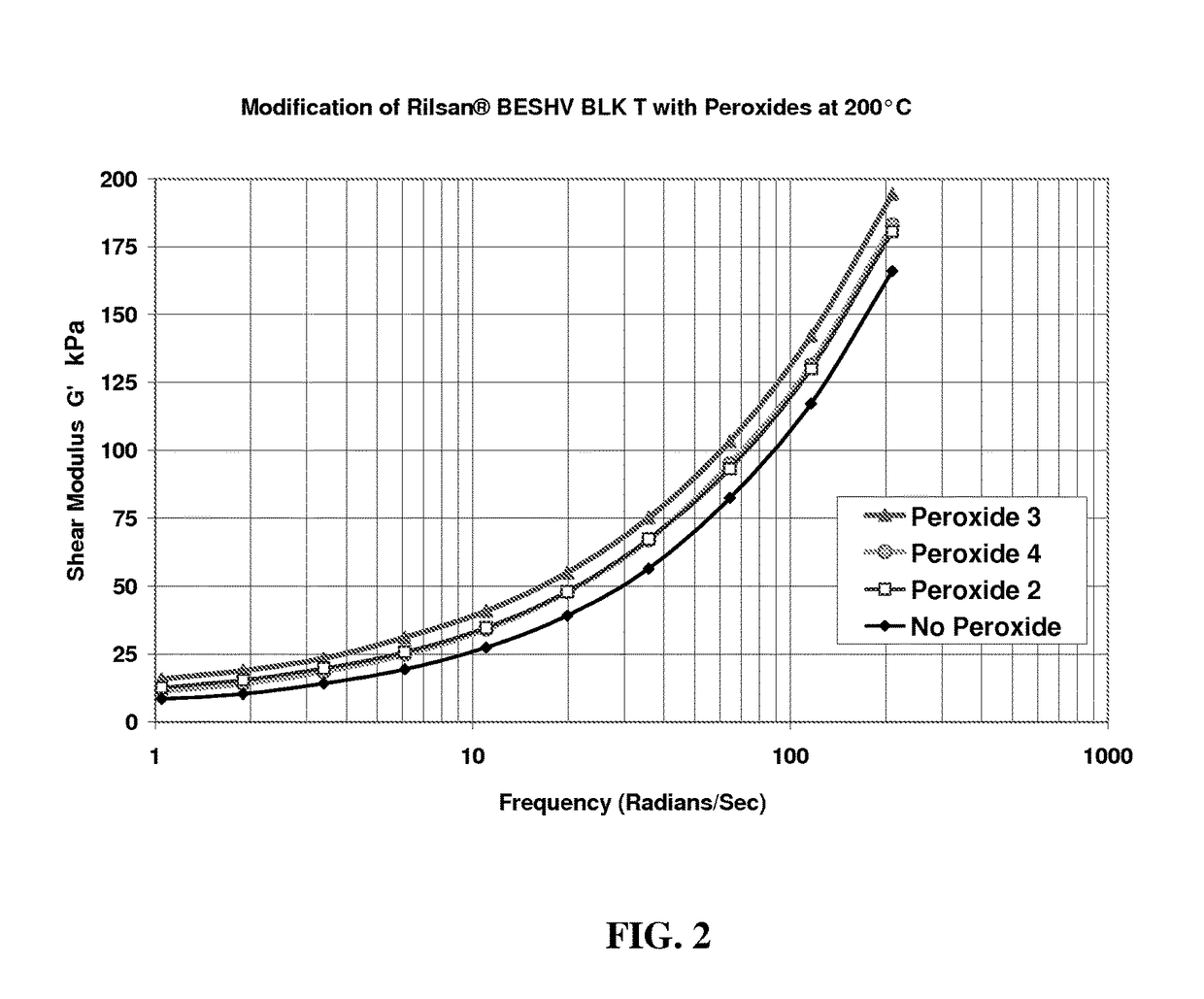

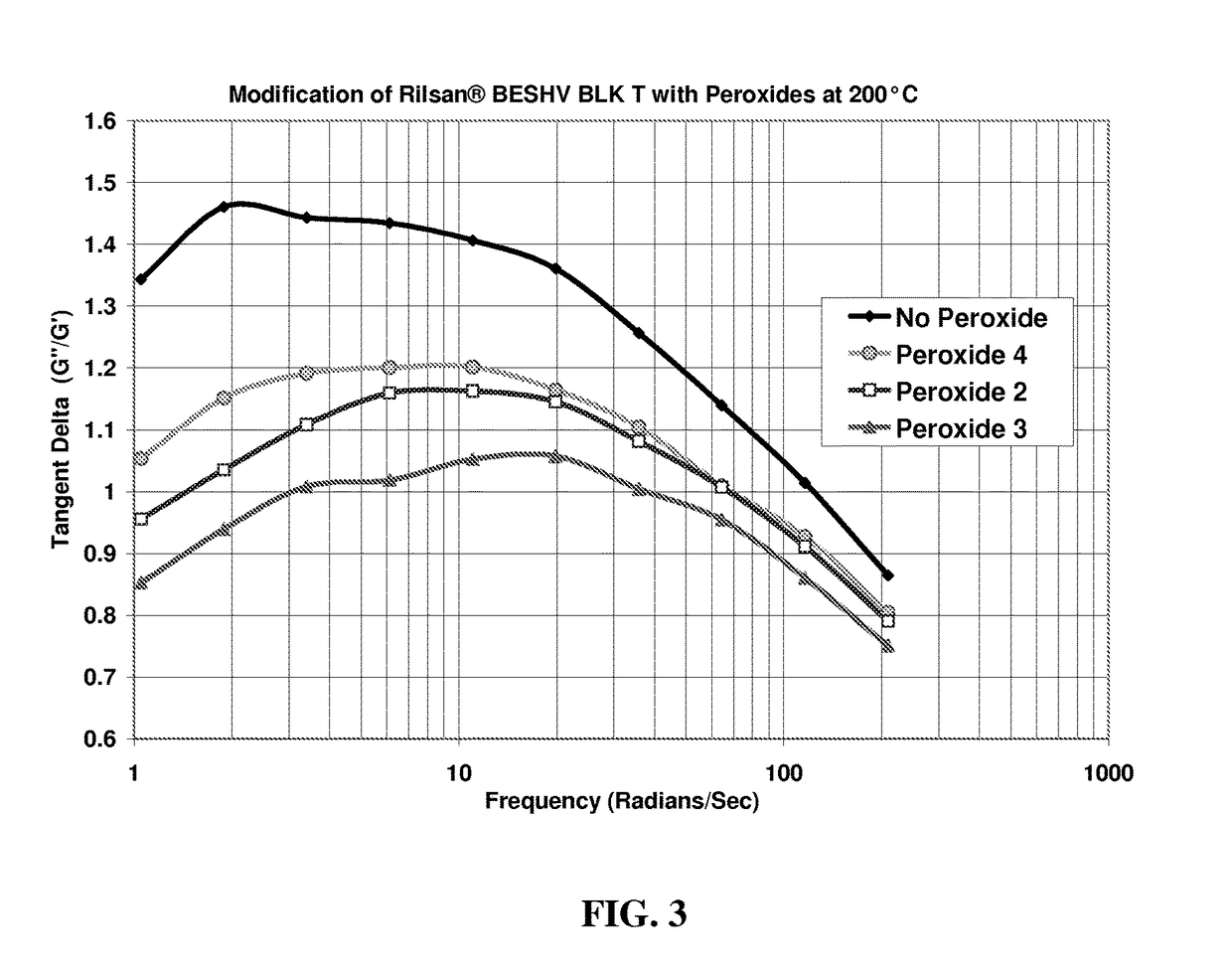

Modification of polyamides

The present invention relates to an improved modified polyamide having increased molecular weight and substantially the same or marginally increased viscosity versus shear weight as the unmodified polyamide. A method for modifying polyamides to provide these improved properties also is disclosed wherein a polyamide having an initial molecular weight is contacted with at least one organic peroxide, at least one coagent and / or one free-radical trap to form an improved polyamide having an increased molecular weight and substantially the same viscosity versus shear rate. The present disclosure also relates to polyamide compositions comprising organic peroxides and articles made from the modified polyamide.

Owner:ARKEMA INC

High performance thermoplastic hose and method for manufacturing such hose from a thermoplastic vulcanizate

InactiveUS20030026931A1Low costImprove performanceHollow filament manufactureLayered productsThermoplasticPolymer science

A high performance thermoplastic hose useful as a power steering hose, the high performance thermoplastic hose comprising a high performance engineering thermoplastic such as polyurethane and a chlorine-containing polyolefin such as chlorinated polyethylene, chlorinated polypropylene, chlorinated copolymers containing ethylene and propylene, chlorosulfonated polyethylene, chlorosulfonated polypropylene, chlorosulfonated copolymers of ethylene and propylene or mixture thereof, is disclosed. Also disclosed are a method for manufacturing the high performance thermoplastic hose, and a thermoplastic vulcanizate capable of resisting chemical attack and withstanding temperatures up to about 300° F.

Owner:FLUID ROUTING SOLUTIONS

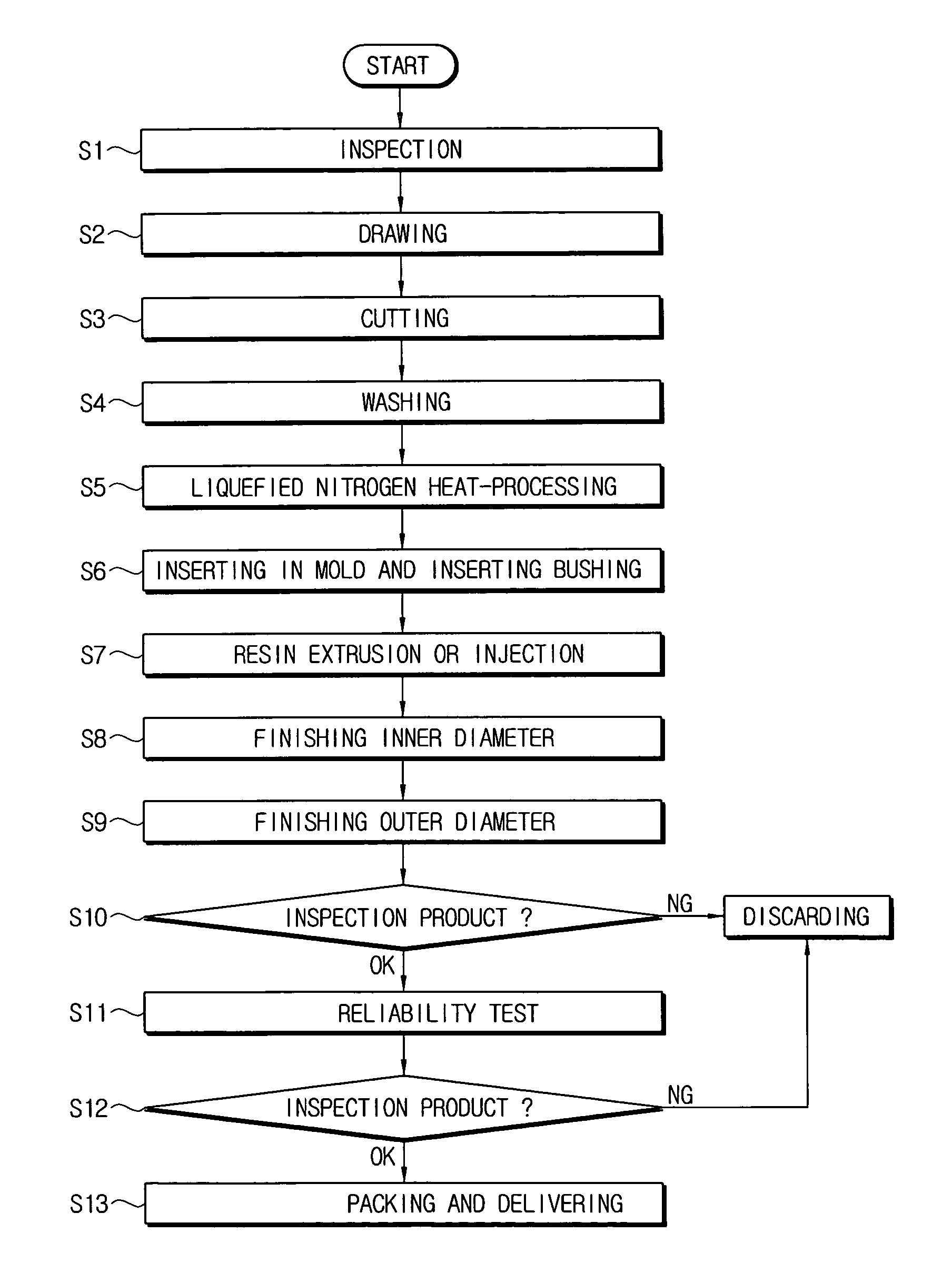

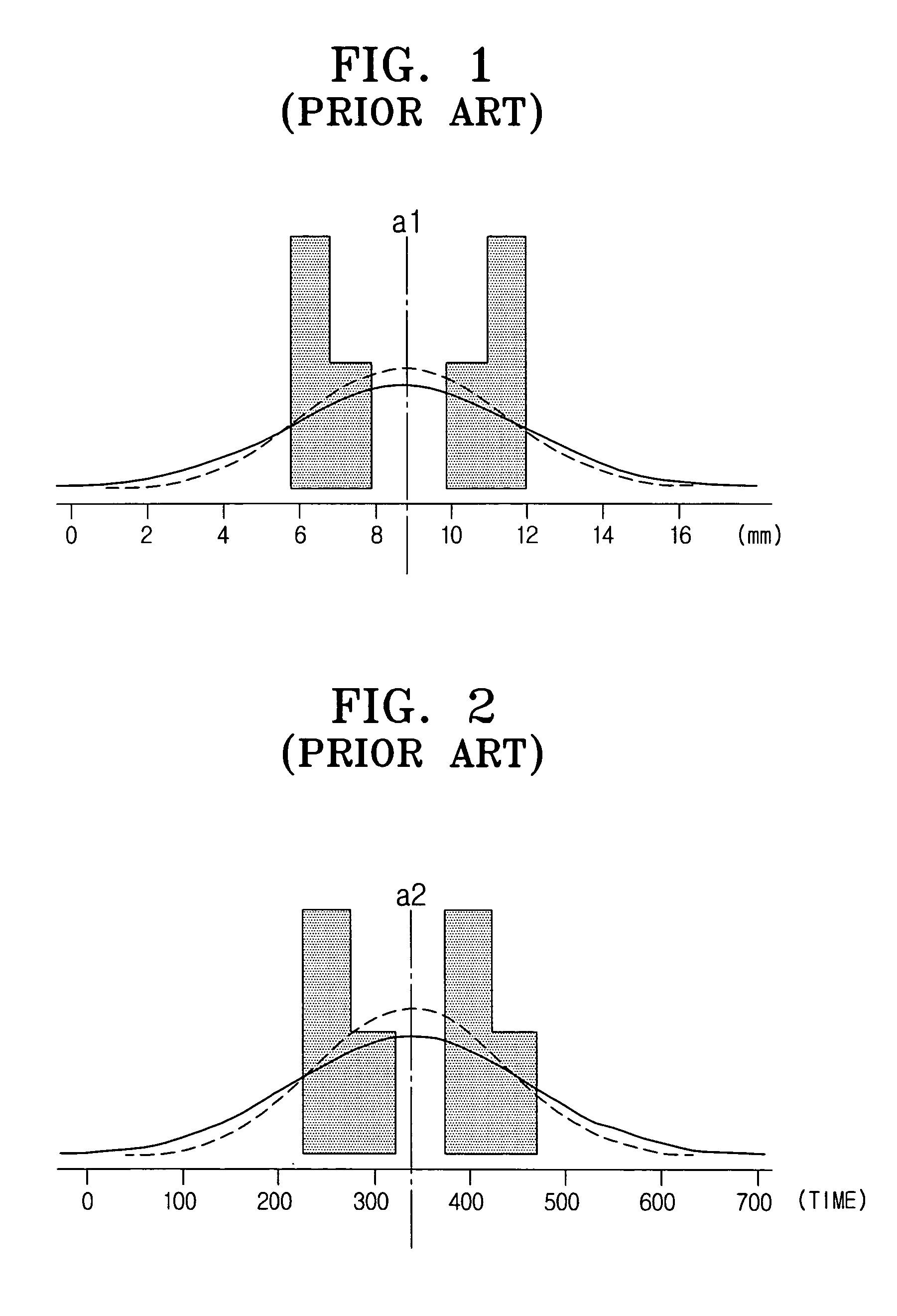

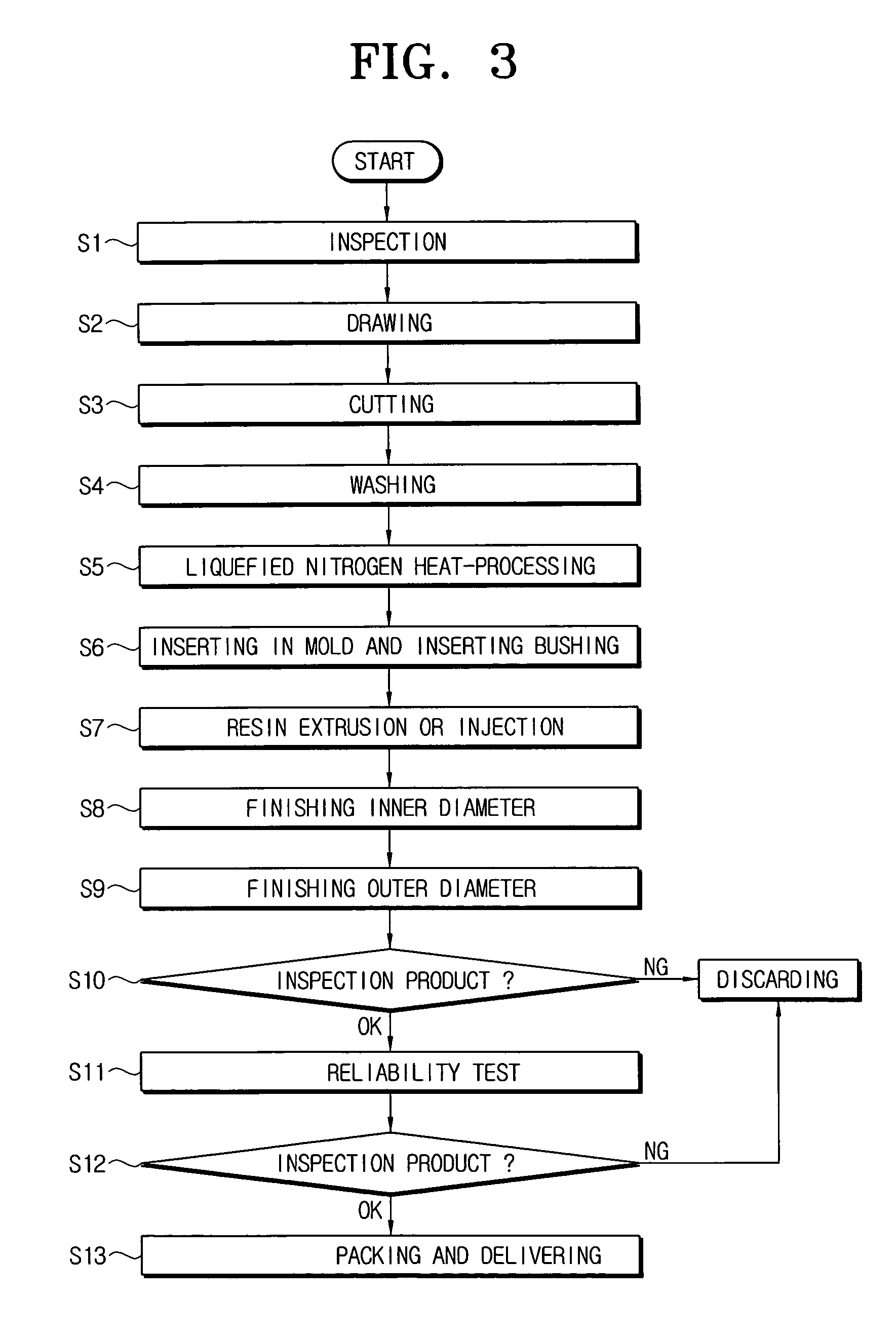

Method of fabricating a commutator for a motor

InactiveUS20050022367A1Reduces possibility of occurrenceImprove durability and abrasion resistanceLaminationLamination apparatusEngineeringNitrogen

A method of fabricating a commutator for a motor comprises the steps of: drawing a bar into the shape of a plate; forming plural commutator segments having a predetermined size by cutting the plate at appropriate intervals; heat-processing the commutator segments with liquefied nitrogen; inserting the heat-processed commutator segments, and setting the commutator segments in a mold in a circular pattern having a predetermined gap from one another for receiving insulating resin, and inserting a bushing in a central position of the circular pattern of commutator segments; forming an insulating resin layer in the gaps between the commutator segments by extruding or injecting an insulating resin into the mold; and finishing an inner diameter and an outer diameter of the fabricated commutator.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

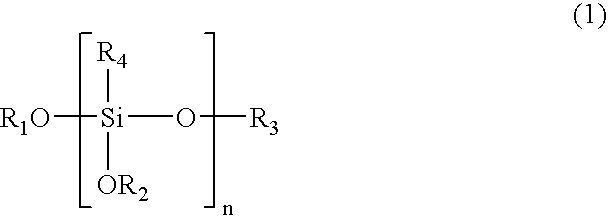

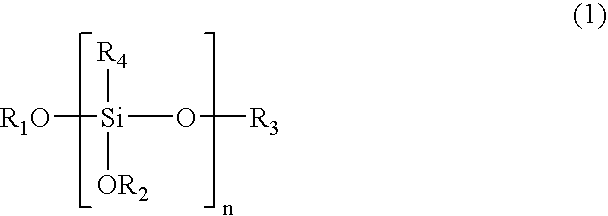

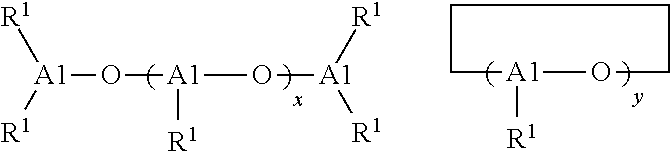

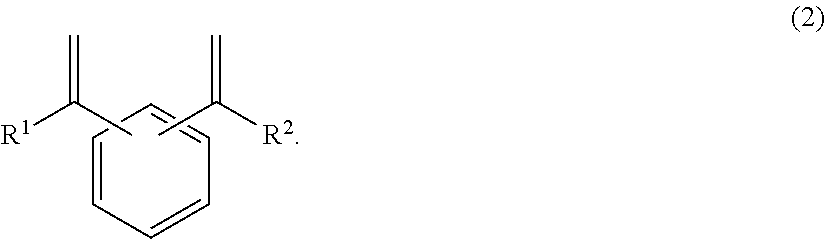

Tire rubber composition and pneumatic tire

InactiveUS9102816B2Improved abrasionImprove economySpecial tyresTyre tread bands/patternsPolymer scienceOrganic base

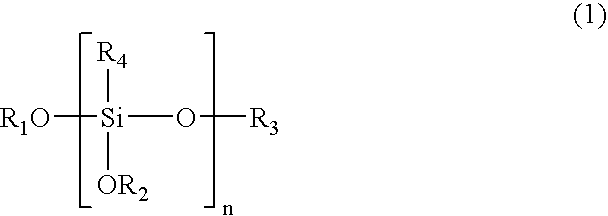

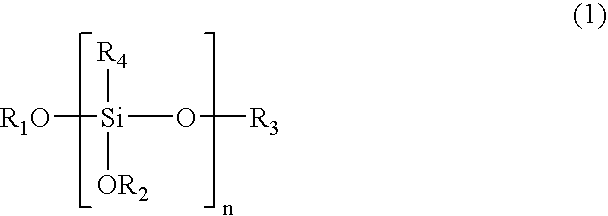

Provided are: a tire rubber composition improving fuel economy and abrasion resistance while maintaining good wet-grip performance or improving it; and a pneumatic tire including the same. The composition contains: a rubber component including a diene polymer (1); silica; and a diene polymer (2), the polymers (1) and (2) being modified diene polymers obtained by reacting components (A)-(B), the polymer (1) having a Mn of 110000-1500000, the polymer (2) having a Mn of 1000-100000, the amount of polymer (2) being 2-25 parts by mass per 100 parts by mass of the rubber component, wherein (A): an active alkali metal-terminated conjugated diene polymer obtained by polymerizing a conjugated diene monomer alone or with an aromatic vinyl monomer, in the presence of a component (C); (B): a modifying agent containing a functional group; (C): a chemical species obtained by reacting an organic alkali metal compound with a compound of formula (1):

Owner:SUMITOMO RUBBER IND LTD

Water-based 2-component composition with chemical curing

InactiveUS20210221748A1Improve mechanical propertiesHigh Shore A hardnessHydrocarbon polymer adhesivesPolymer sciencePlasticizer

A two-component composition including: a) a first component A, including: an aqueous dispersion of at least one polymer P1; b) a second component B, including: at least one hydraulic binder H, and at least one functional compound P2; wherein both components A and B are liquid or pasty and both are prepared and stored separately and mixed directly before application; and with the proviso that the functional compound P2 includes functional groups that chemically react with the aqueous dispersion of the first polymer P1 to form cross-linked and / or chain-extended polymers. The composition is highly suitable cementitious adhesive, joint sealant, casting composition, or coating and shows improved mechanical properties, adhesion properties, and resistance as well as minimized plasticizer migration problems.

Owner:SIKA TECH AG

Rubber composition for tire and pneumatic tire using same

InactiveUS20200055963A1Maintain machinabilityImproved abrasionSpecial tyresRolling resistance optimizationPolymer scienceOrganic chemistry

A rubber composition for a tire is disclosed having improved rupture strength and abrasion resistance while maintaining processability that is a property of a liquid rubber. The rubber component contains (A) a hydrogenated copolymer obtained by hydrogenating an aromatic vinyl-conjugated diene copolymer, the hydrogenated copolymer having a weight average molecular weight measured by gel permeation chromatography of 300,000 or more and having a hydrogenation ratio of a conjugated diene moiety of 80 mol % or more, and (B) a liquid rubber, and sulfur, wherein the content of the hydrogenated copolymer (A) is 80 to 95 parts by mass and the content of the liquid rubber (B) is 5 to 20 parts by mass, per 100 parts by mass of the rubber component, and the content of the sulfur is 15 to 30 parts by mass per 100 parts by mass of the liquid rubber (B).

Owner:TOYO TIRE & RUBBER CO LTD

Coating agent composition

ActiveUS7425372B2Prolong lifeMaintain good propertiesSynthetic resin layered productsCoatingsElastomerPolyolefin

The coating agent composition comprises an emulsion containing (A) polydiorganosiloxane having a viscosity of 50 to 10,000,000 mPa·s at 25° C. and having both terminal ends blocked by hydroxyl groups, (B) polyorganohydrogensiloxane having at least three hydrogen atoms bonded to silicon atoms in one molecule, (C) a curing catalyst, and (D) chlorinated polyolefine and / or acryl-modified polyolefine, with which (E) fine spherical particles comprised of a rubber-like elastomer having hardness of less than 90 are mixed to disperse into it. The coating agent composition having good uniform applying property, non tackness, water repellency and lubricating properties and outstanding adhesiveness to a rubber or plastic substrate can be obtained.

Owner:MOMENTIVE PERFORMANCE MATERIALS JAPAN LLC

Modification of polyamides

The present invention relates to an improved modified polyamide having increased molecular weight and substantially the same or marginally increased viscosity versus shear weight as the unmodified polyamide. A method for modifying polyamides to provide these improved properties also is disclosed wherein a polyamide having an initial molecular weight is contacted with at least one organic peroxide, at least one coagent and / or one free-radical trap to form an improved polyamide having an increased molecular weight and substantially the same viscosity versus shear rate. The present disclosure also relates to polyamide compositions comprising organic peroxides and articles made from the modified polyamide.

Owner:ARKEMA INC

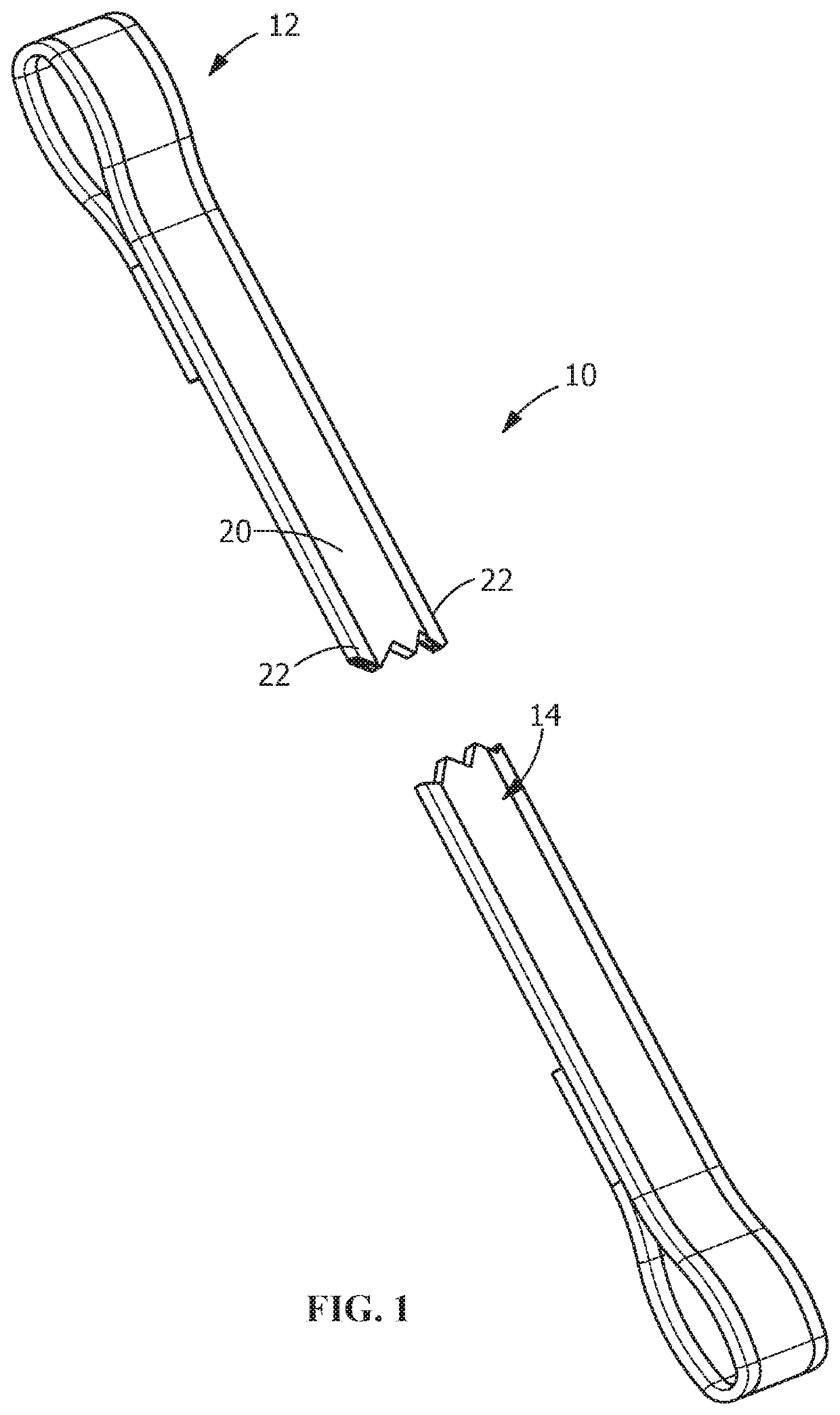

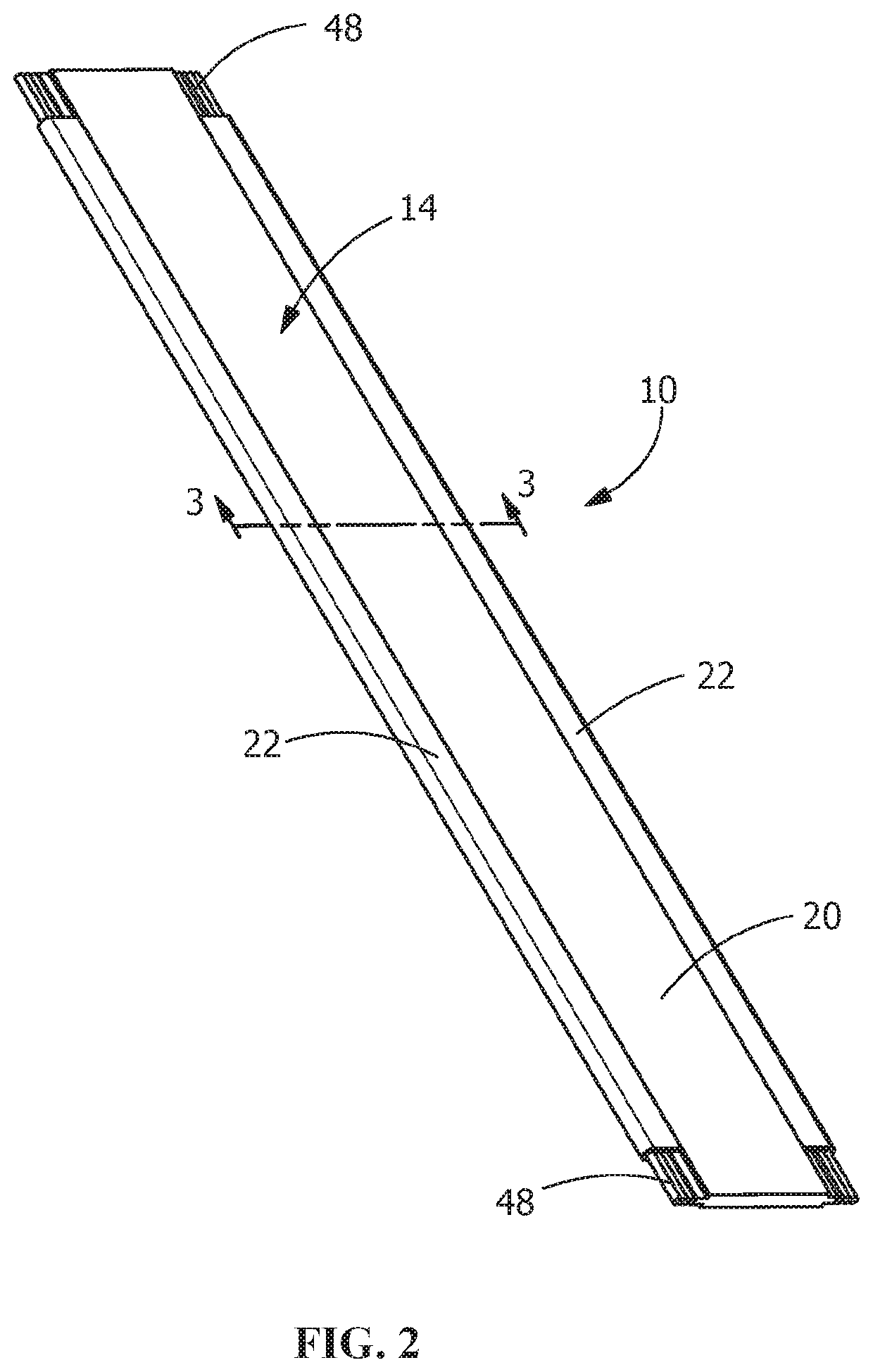

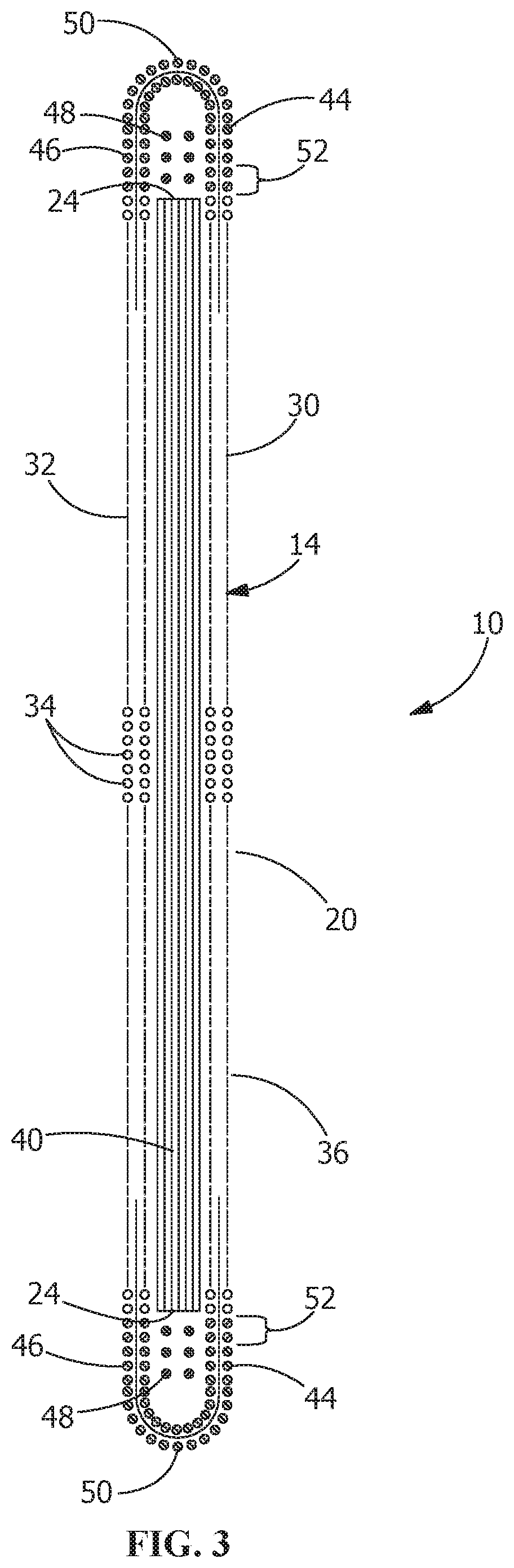

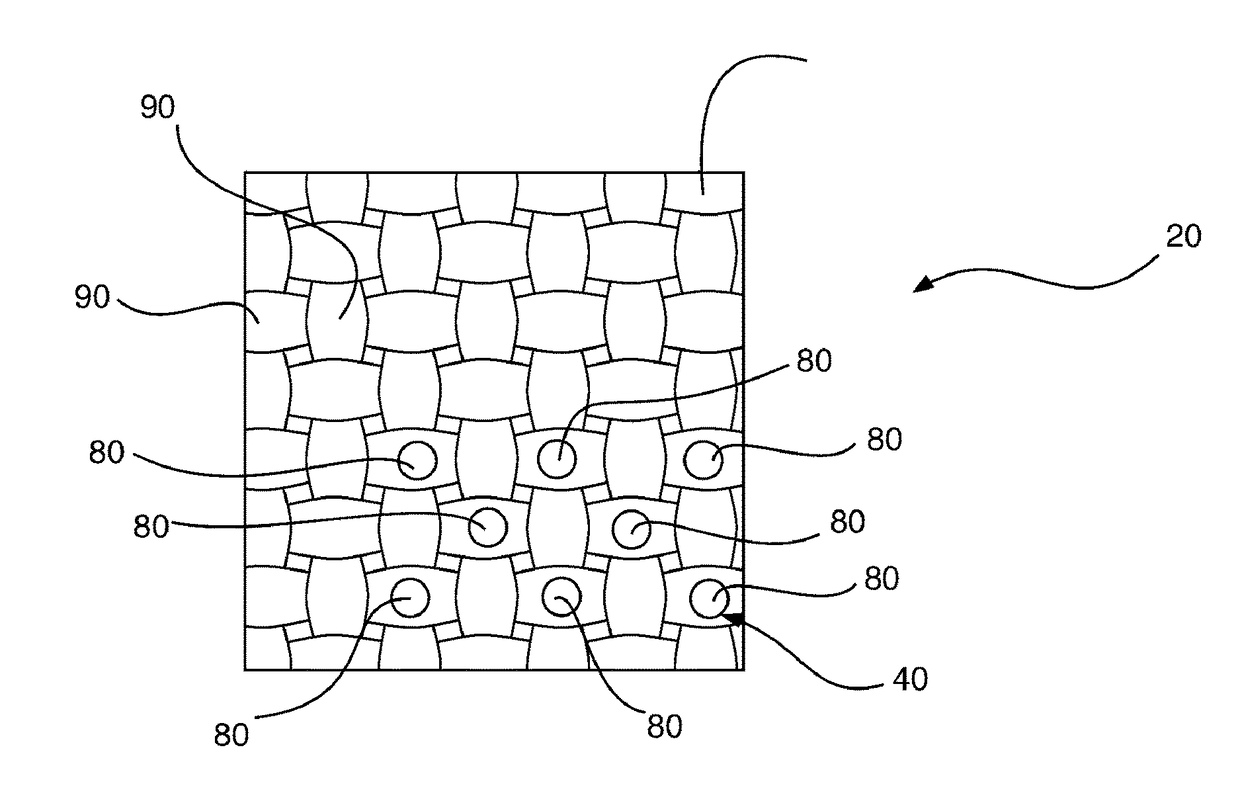

Woven webbing combining edge and body weave design features for improved overall durability in lifting and restraint applications

ActiveUS11021346B2Improved abrasionIncrease resistanceProtective fabricsMulti-ply fabricsYarnEngineering

A woven webbing for use in a tiedown or sling for lifting, restraint or other material handling functions. The woven webbing includes a central portion and tubular edges. The central portion has a top surface and an oppositely facing bottom surface. The top surface and bottom surface may be woven in a first pattern for strength and abrasion resistance while remaining flexible. The tubular edges extend from either side of the central portion. The tubular edges may be woven in a second pattern to improve the cut resistance of the tubular edges. The tubular edges have interior cavities which may include twisted floating yarn extending therethrough to enhance the cut resistance of the tubular edges. The tubular edges may include a high modulus yarn material which changes the orientation of the yarn material away from the axial direction of tension when a load is applied to the webbing.

Owner:ELEVATOR ALL

An abrasion resistant material and method of construction

InactiveUS20170251734A1Improved abrasionAccelerate burstArmourProtective equipmentSecondary layerBursting strength

An abrasion resistant material for use in the fabrication of protective garments that has at least two layers, a first layer and a second layer, wherein the first layer is the layer that is exposed to and engages with the abrasive surface, such as a road surface. The second layer comprises of substantially high tensile and burst strength so as to act as a protective layer which covers or is at least located closest to the skin of the wearer. The first layer has a plurality of abrasion resistant members dispersed throughout the first layer that act to absorb the bulk of any abrasion force and reduce the exposure and degradation of the second layer

Owner:BECON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com