Patents

Literature

655results about "Protective fabrics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

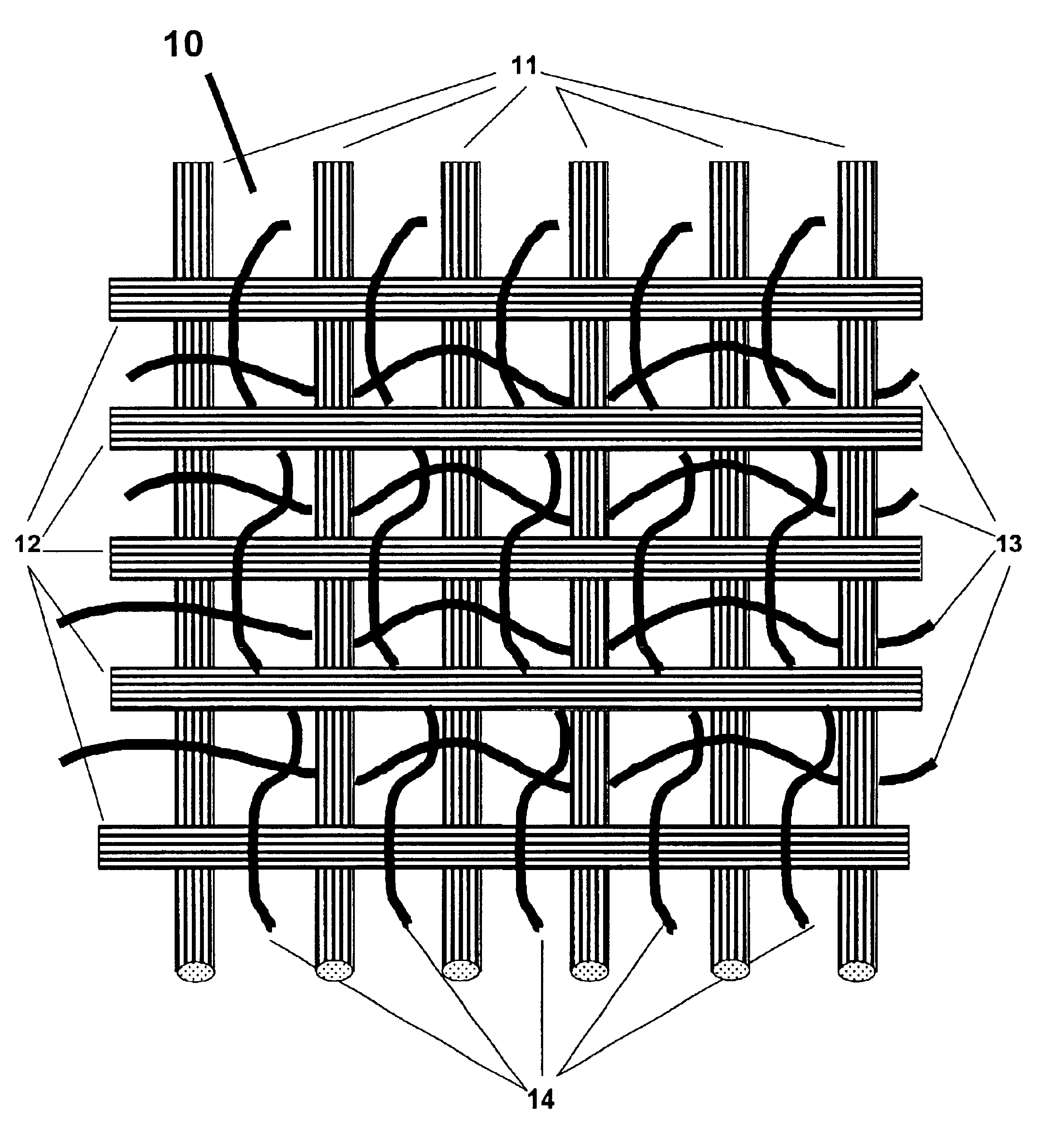

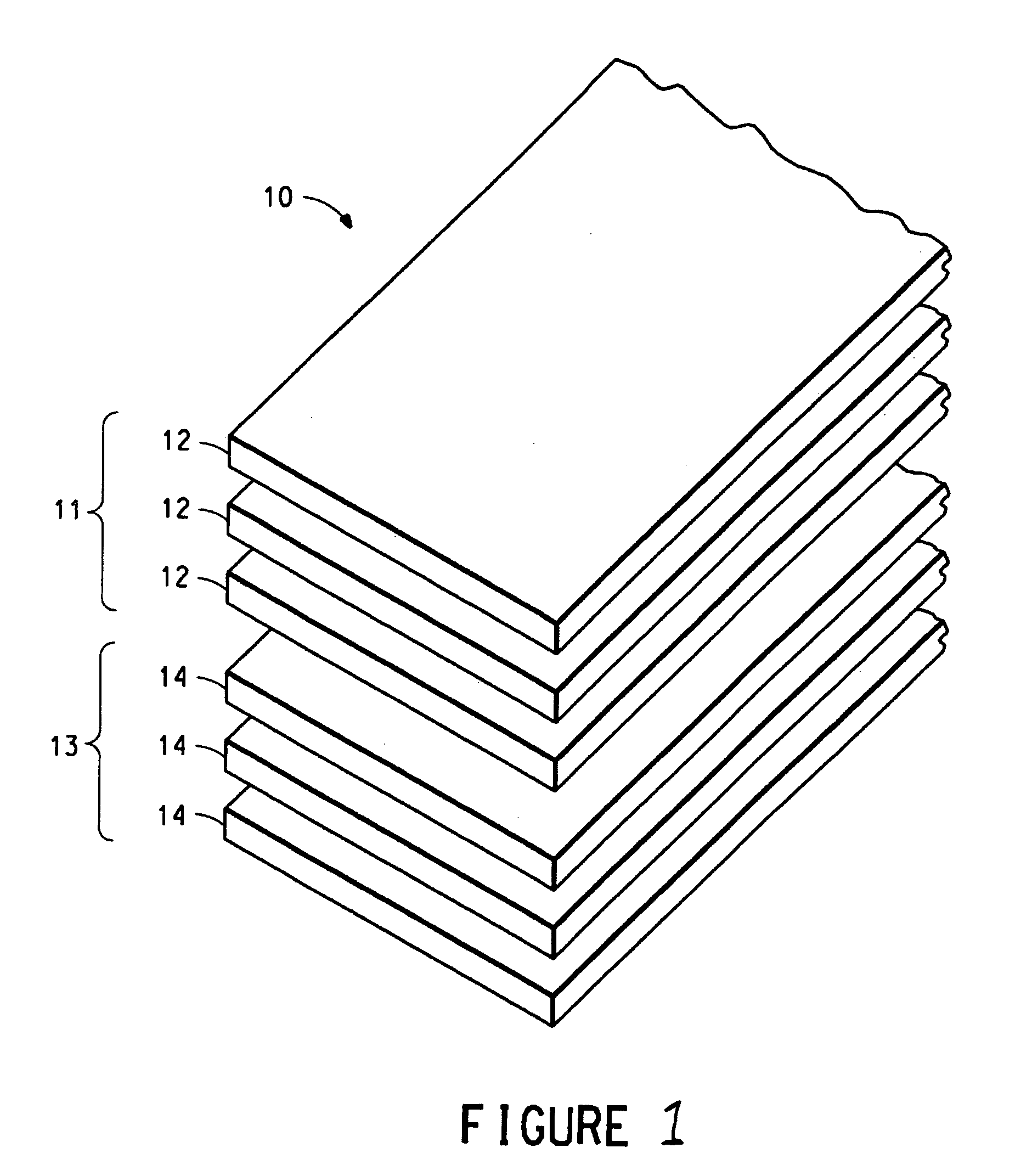

Carbon nanotube fabrics

The present invention provides fabrics that have unique chemical, electrical, and thermal properties. The fabrics comprise layers of yarns woven together wherein the yarns further comprise carbon nanotube fibers. These carbon nanotube fibers may be either single-walled or multi-walled carbon nanotubes. The use of carbon nanotube fibers allows the fabrics to insulate, semi-conduct or super-conduct electrical charges. Additionally, the thermal properties of carbon nanotubes allow thermal energy to flow efficiently between the fabric and a heat sink or source. Additional yarns of materials other than carbon nanotubes can be integrated or woven into the fabric to provide other unique properties for the fabric. These fabrics can be layered to form unique garments or structures.

Owner:LOCKHEED MARTIN CORP

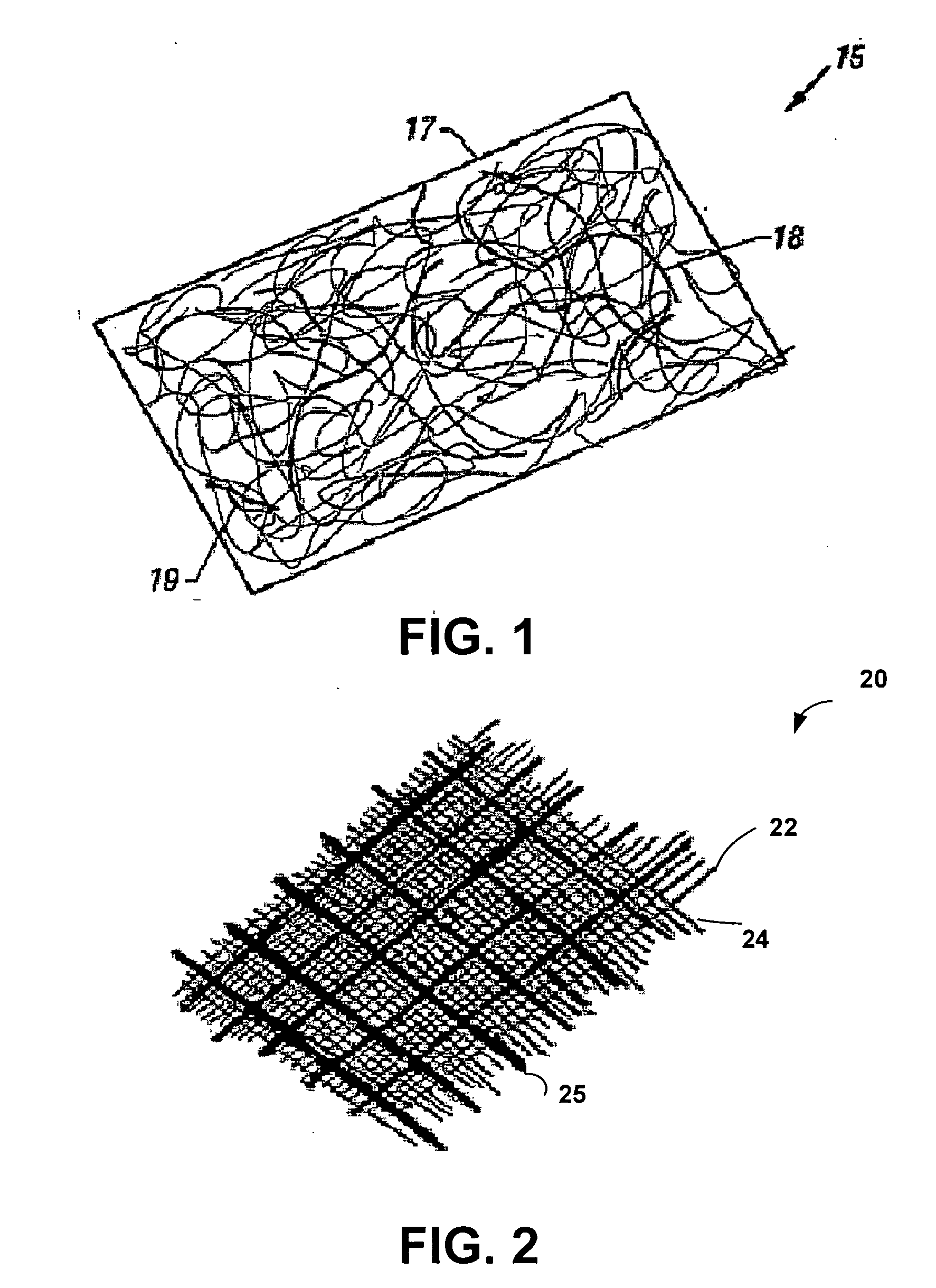

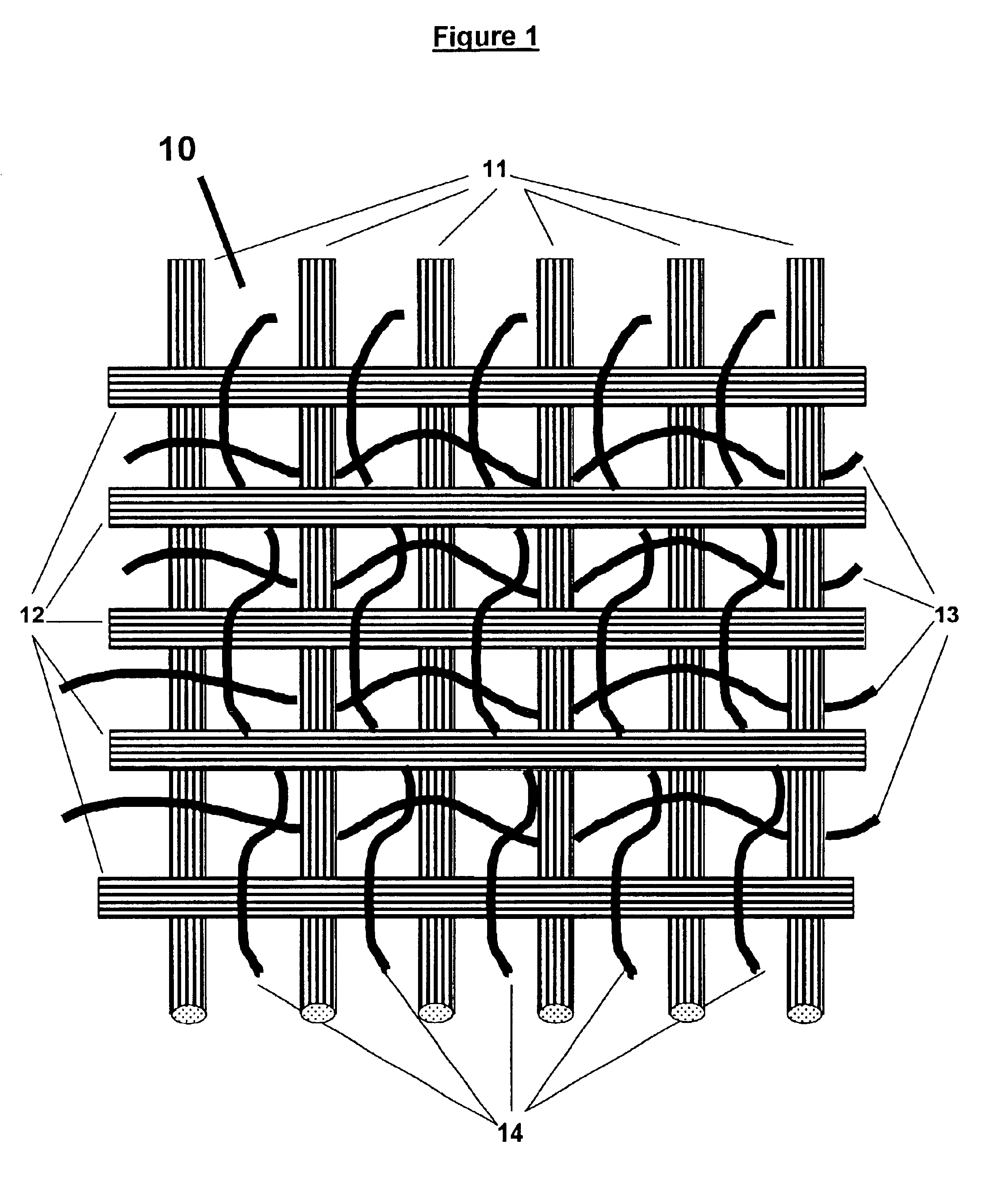

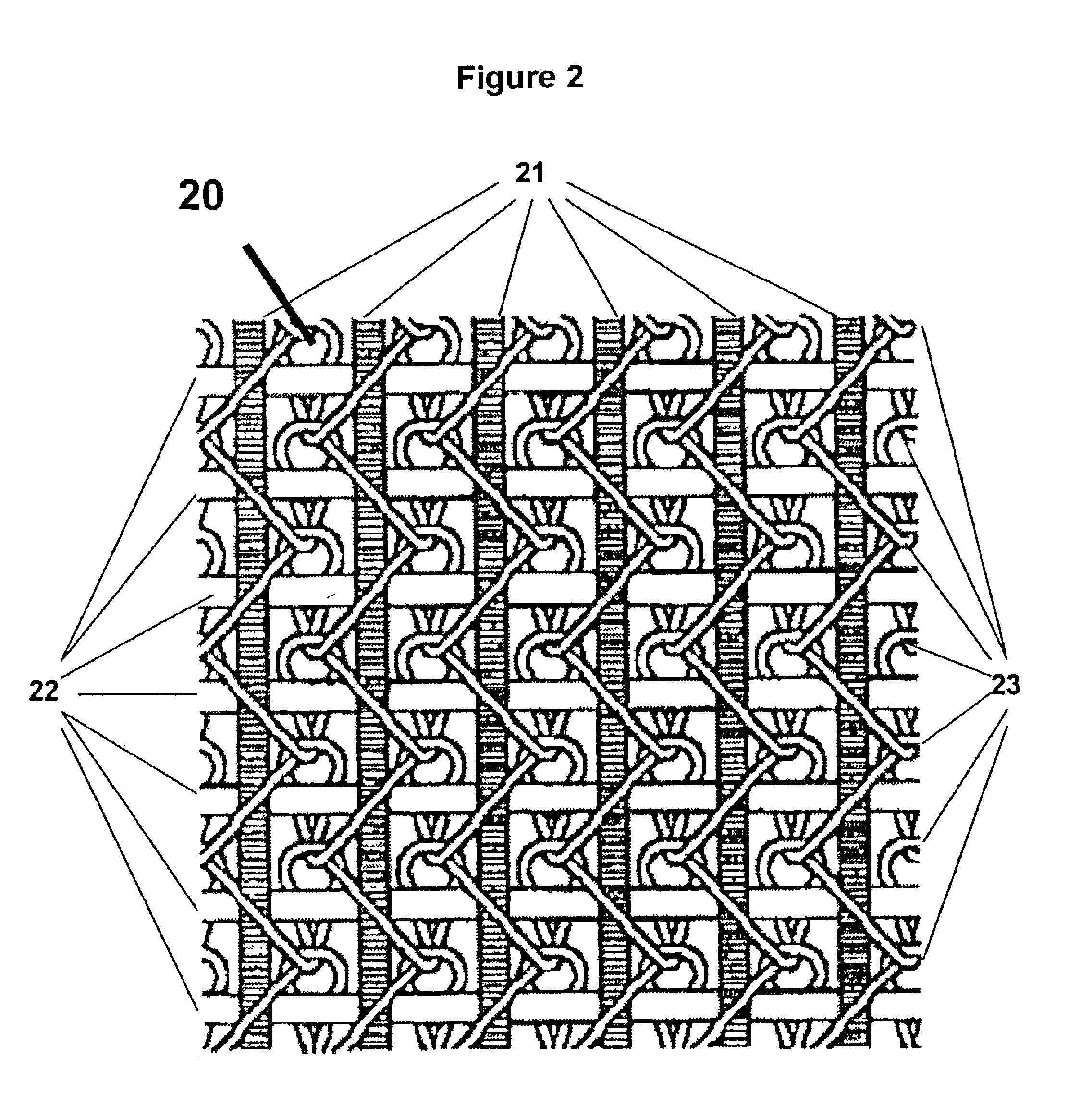

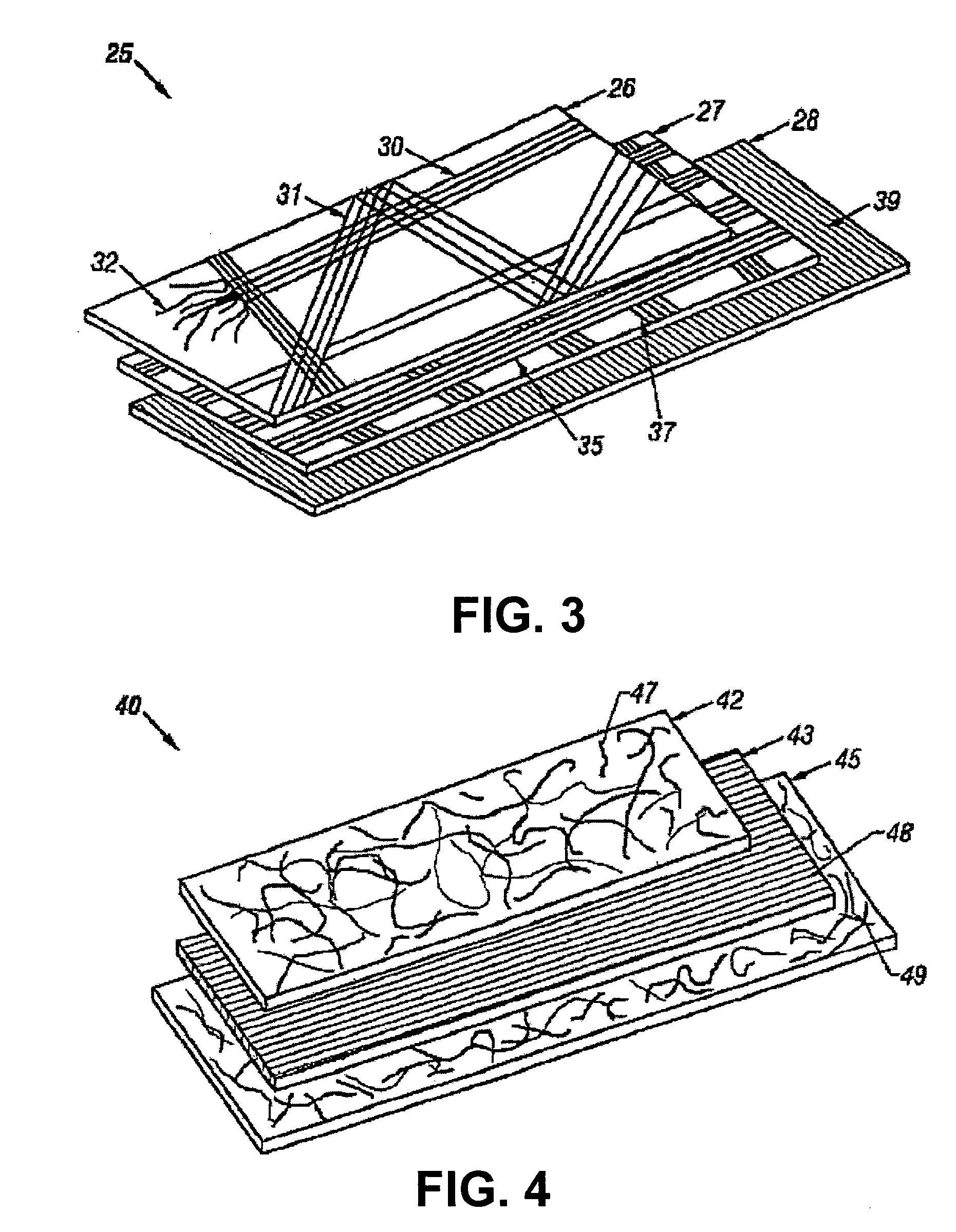

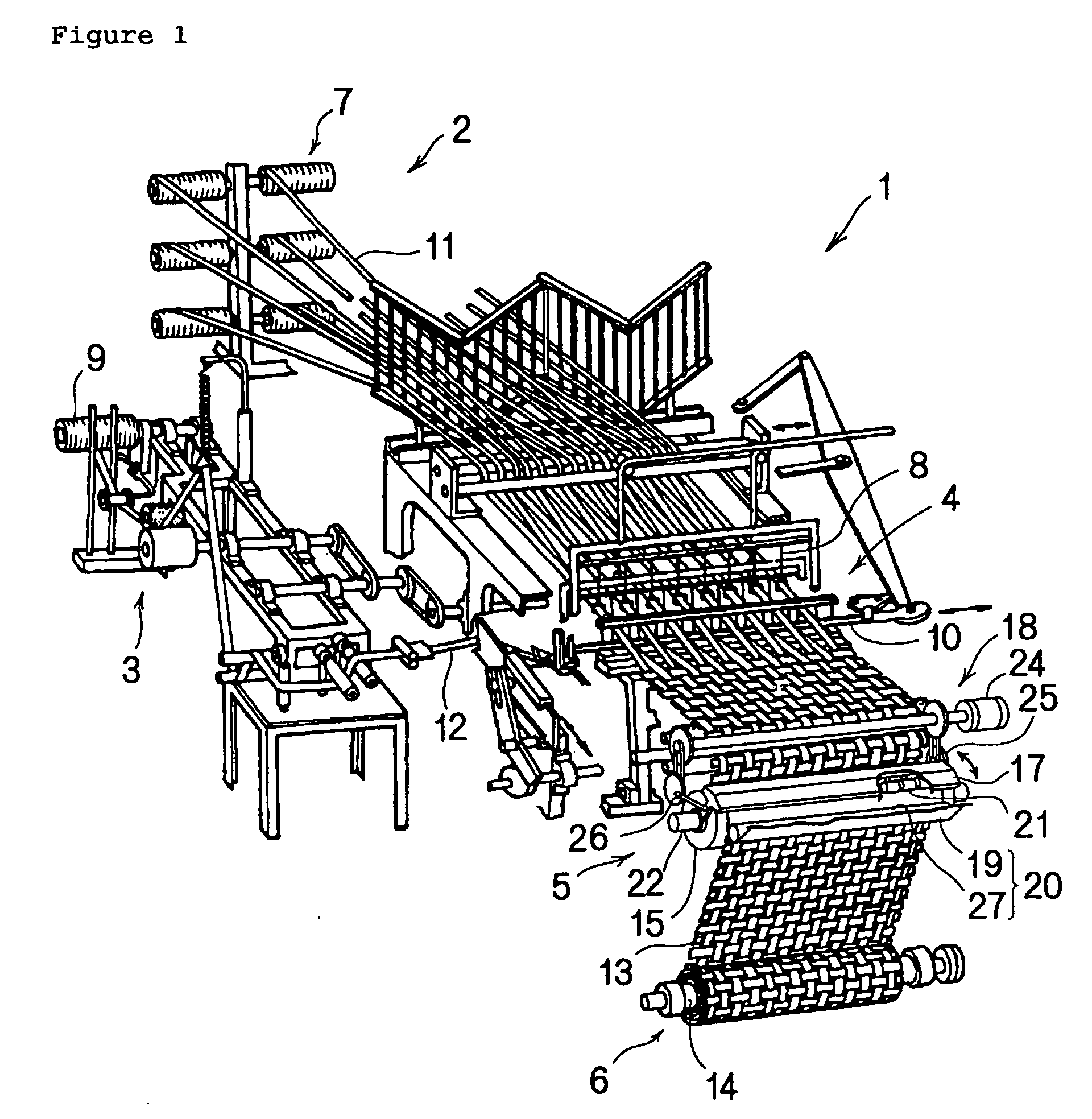

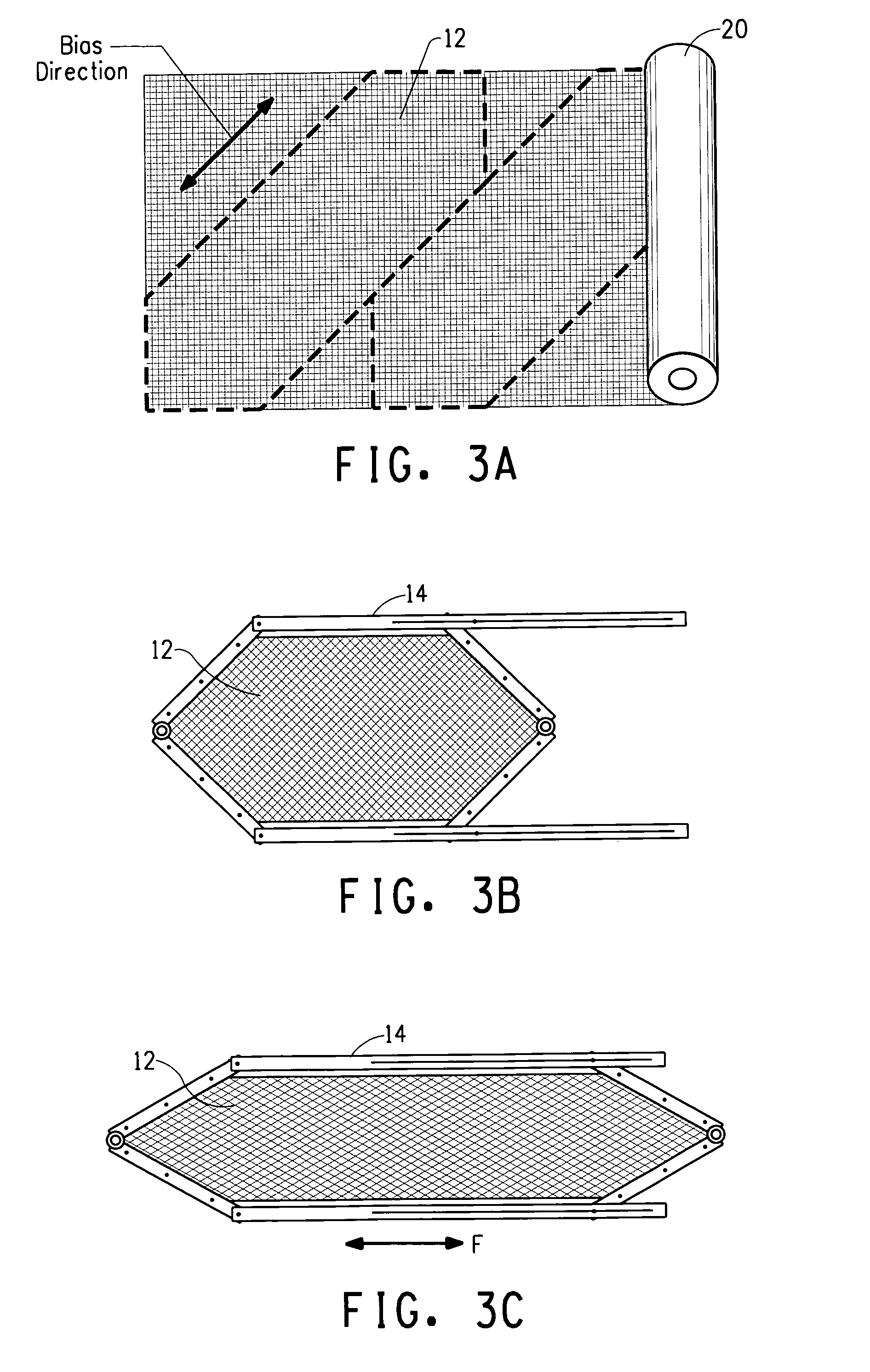

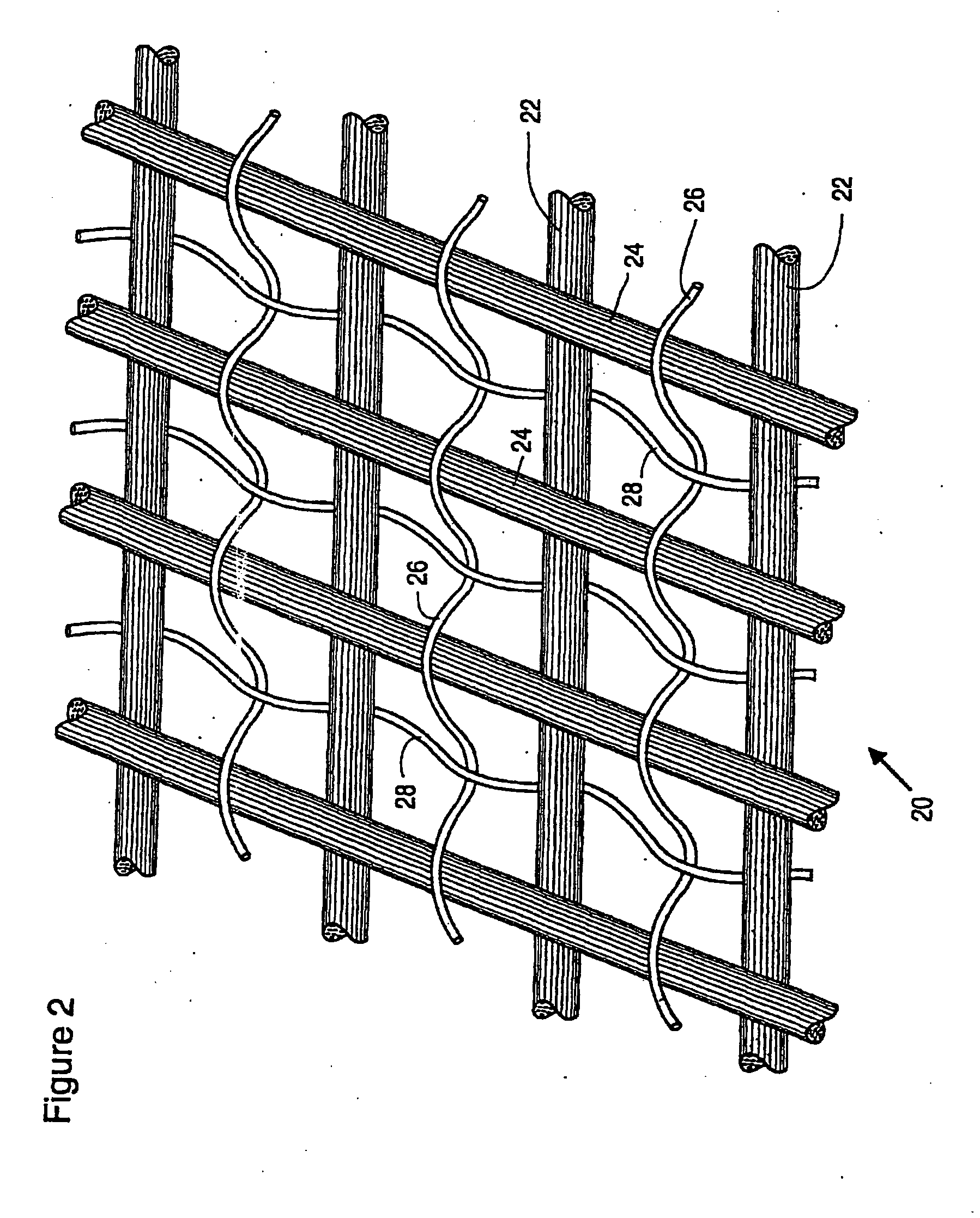

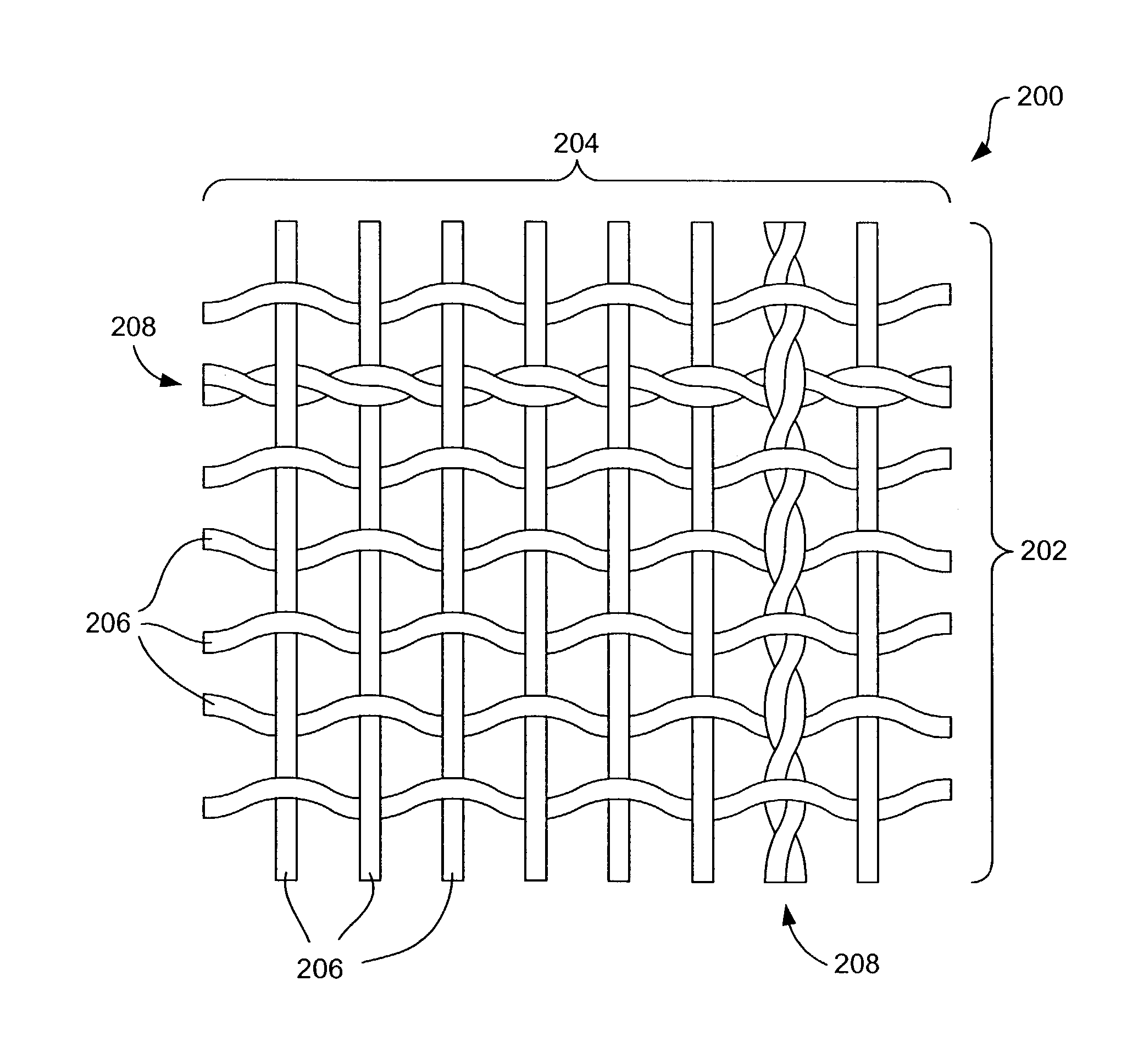

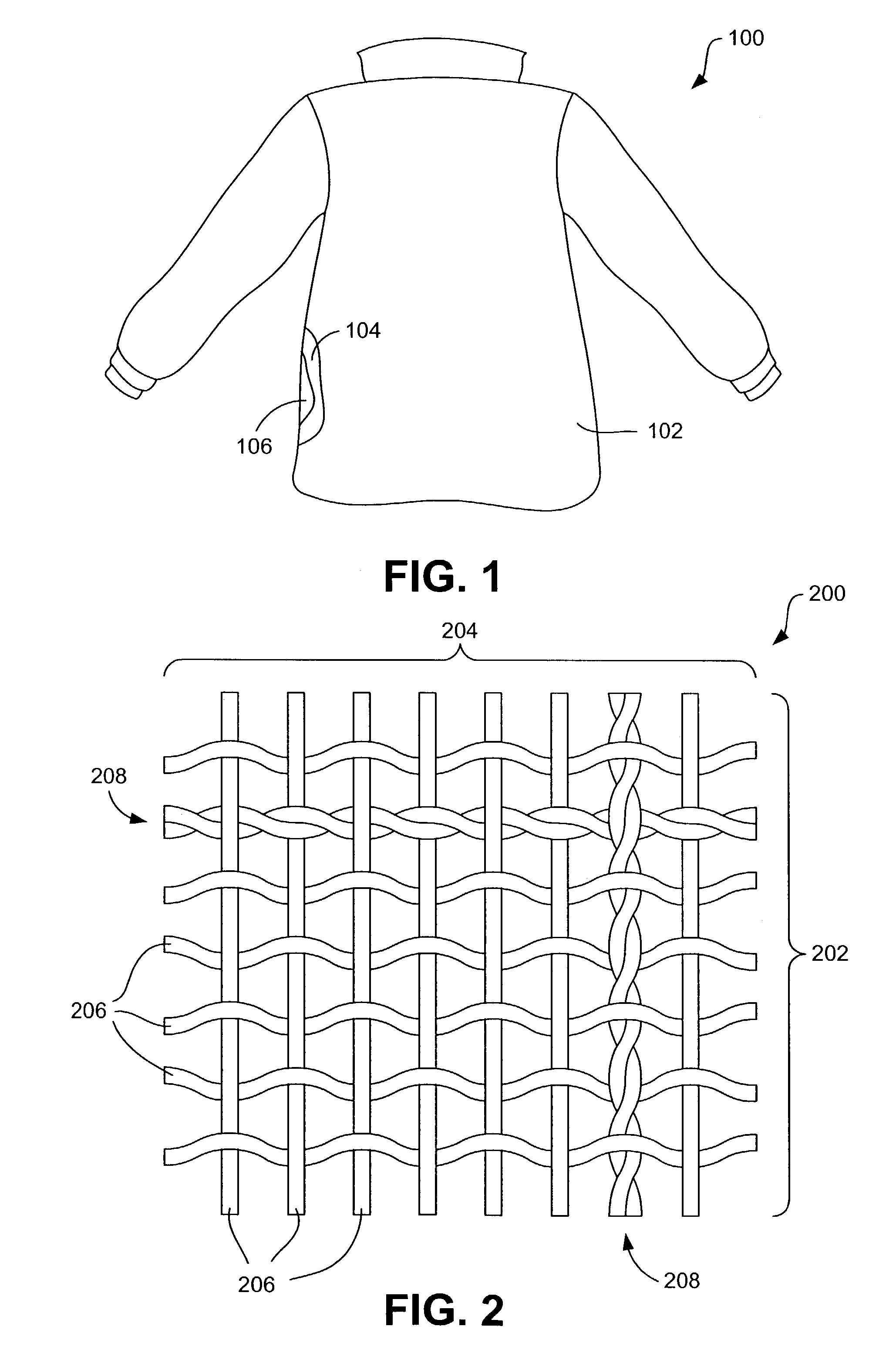

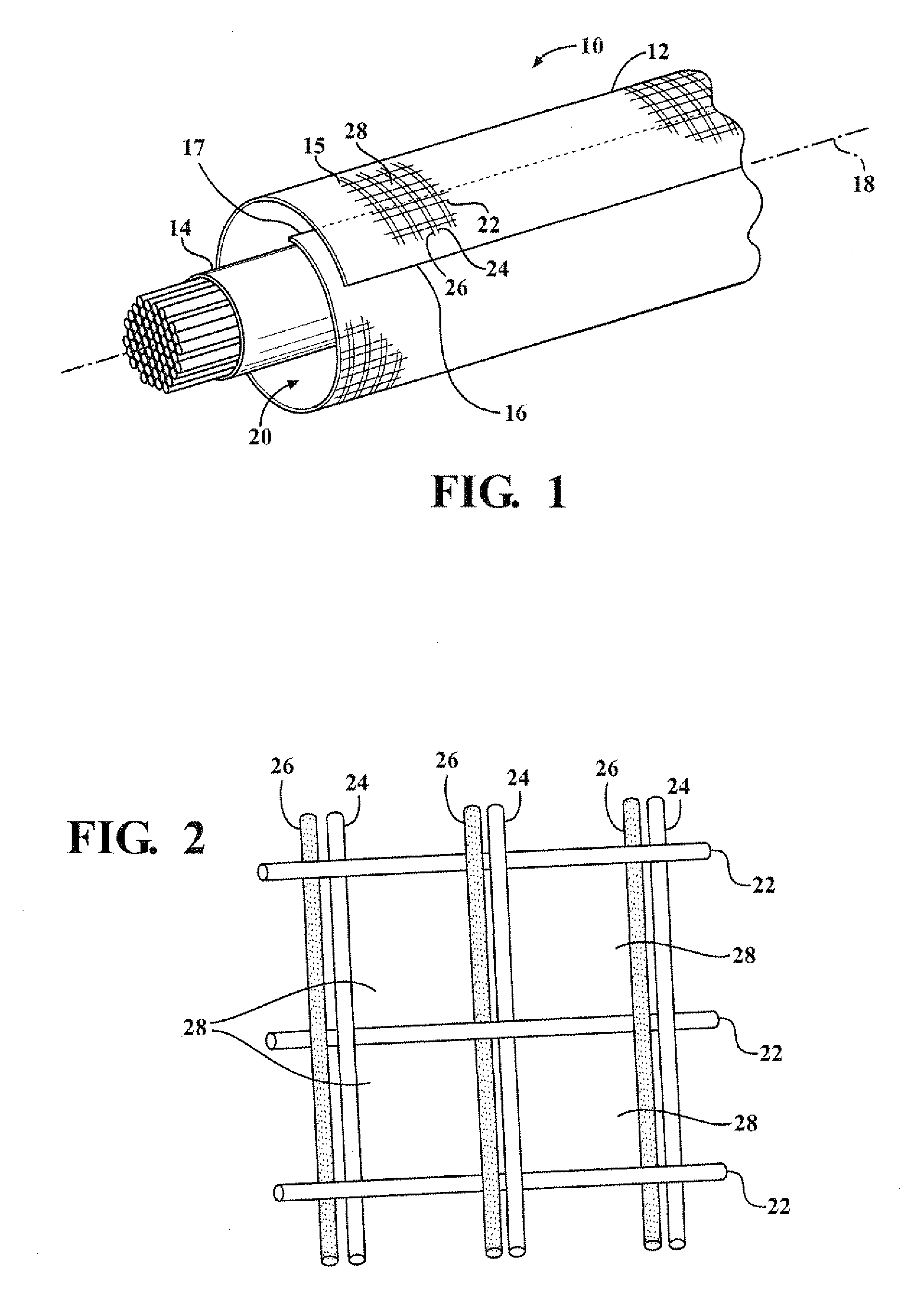

Bi-directional and multi-axial fabrics and fabric composites

InactiveUS6841492B2Increase resistanceImprove effectivenessOrnamental textile articlesProtective fabricsYarnEngineering

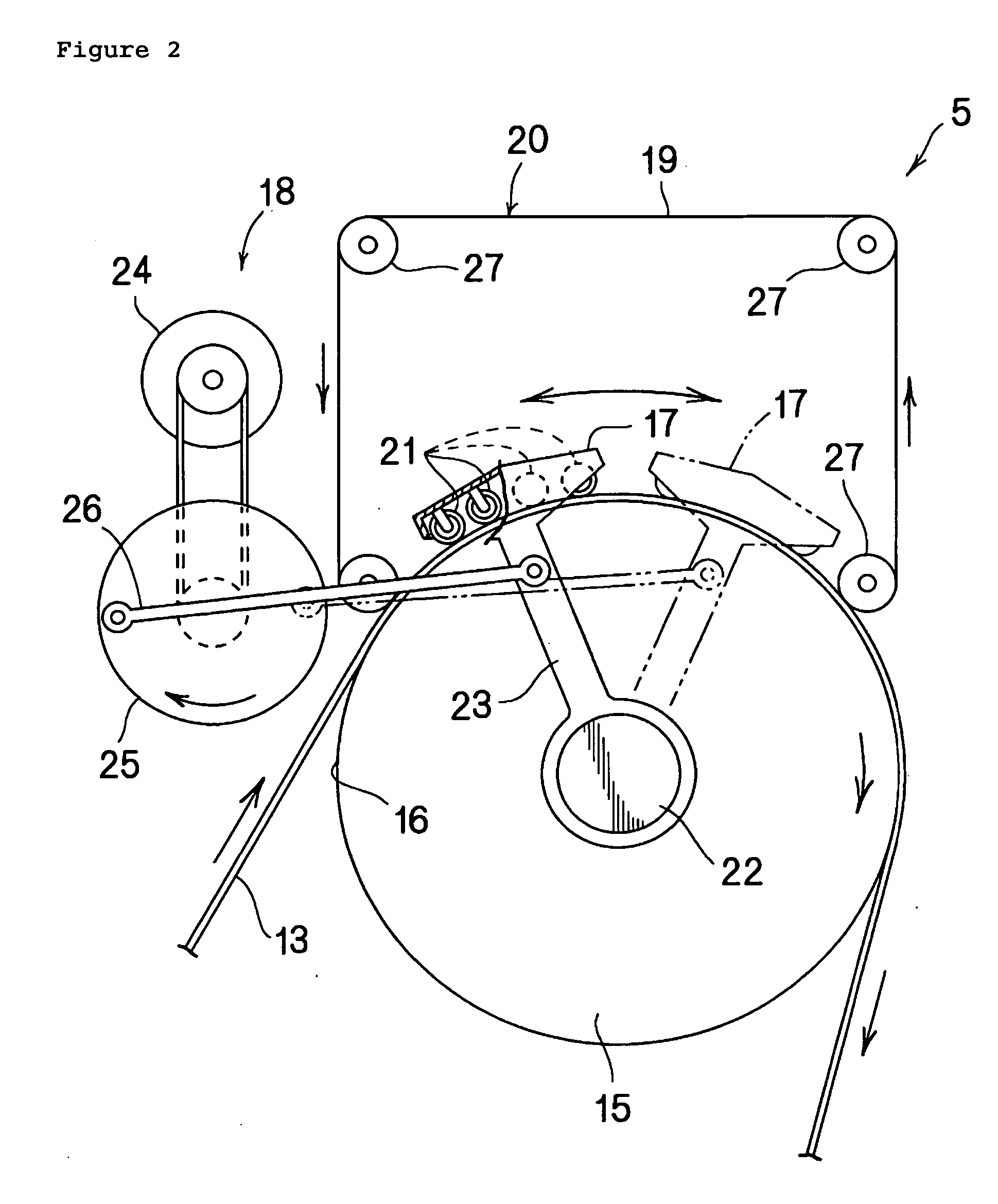

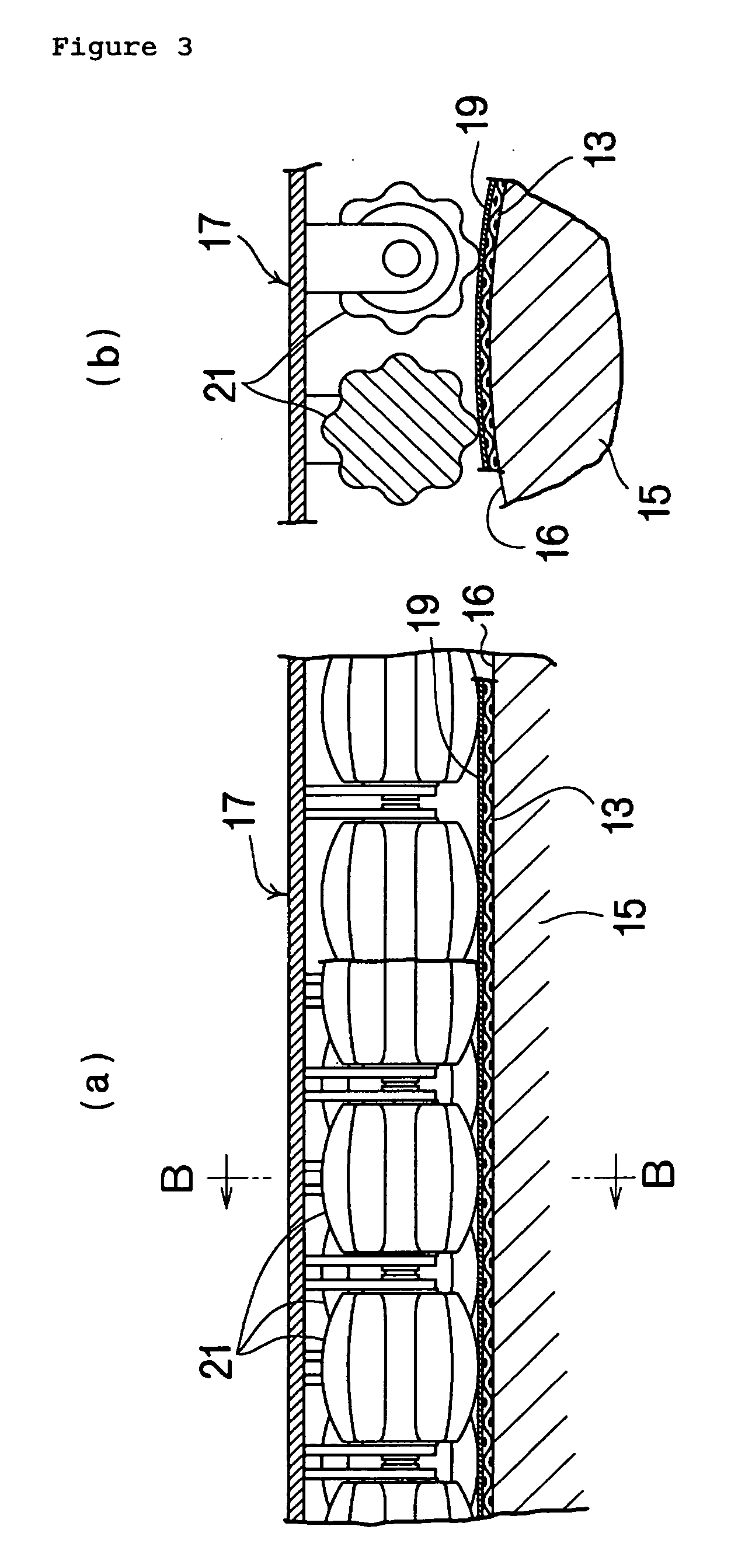

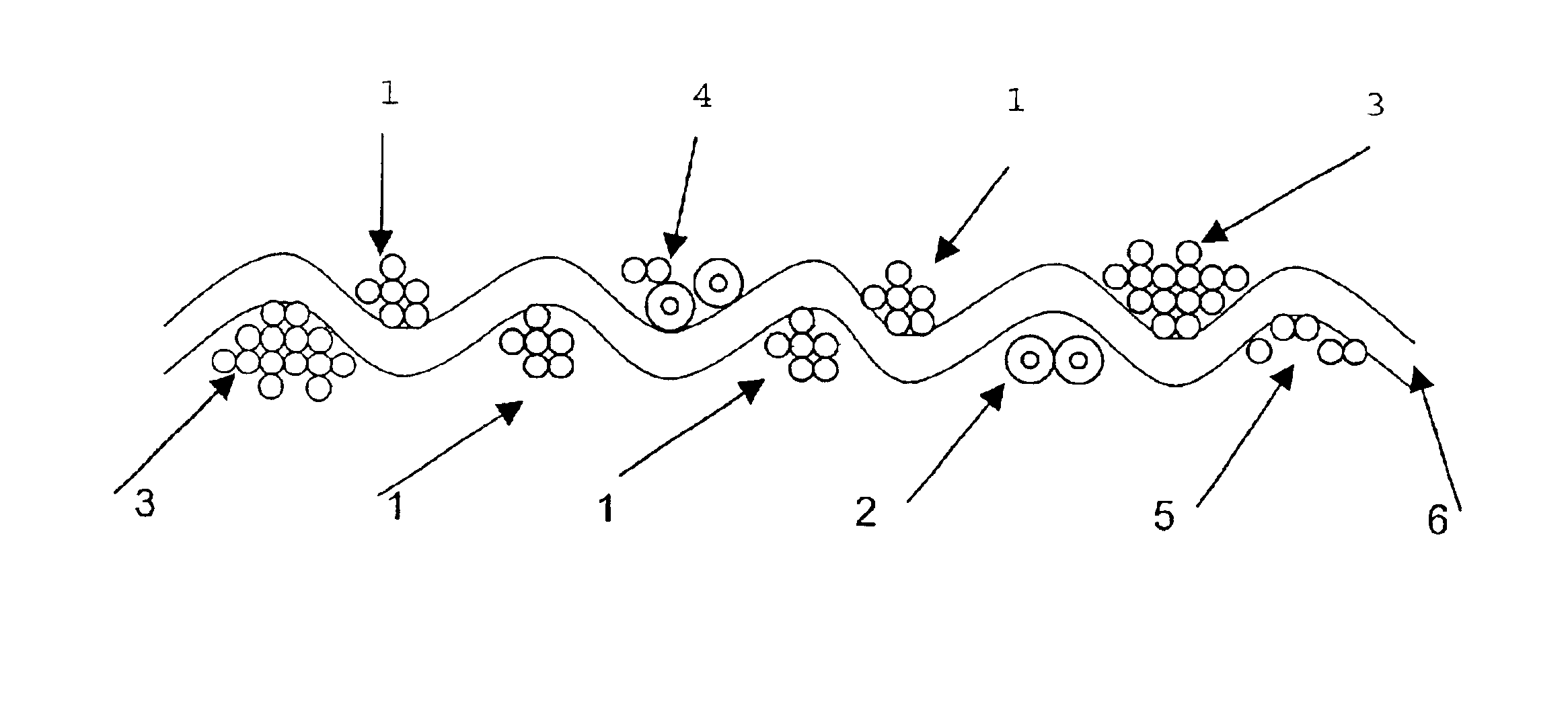

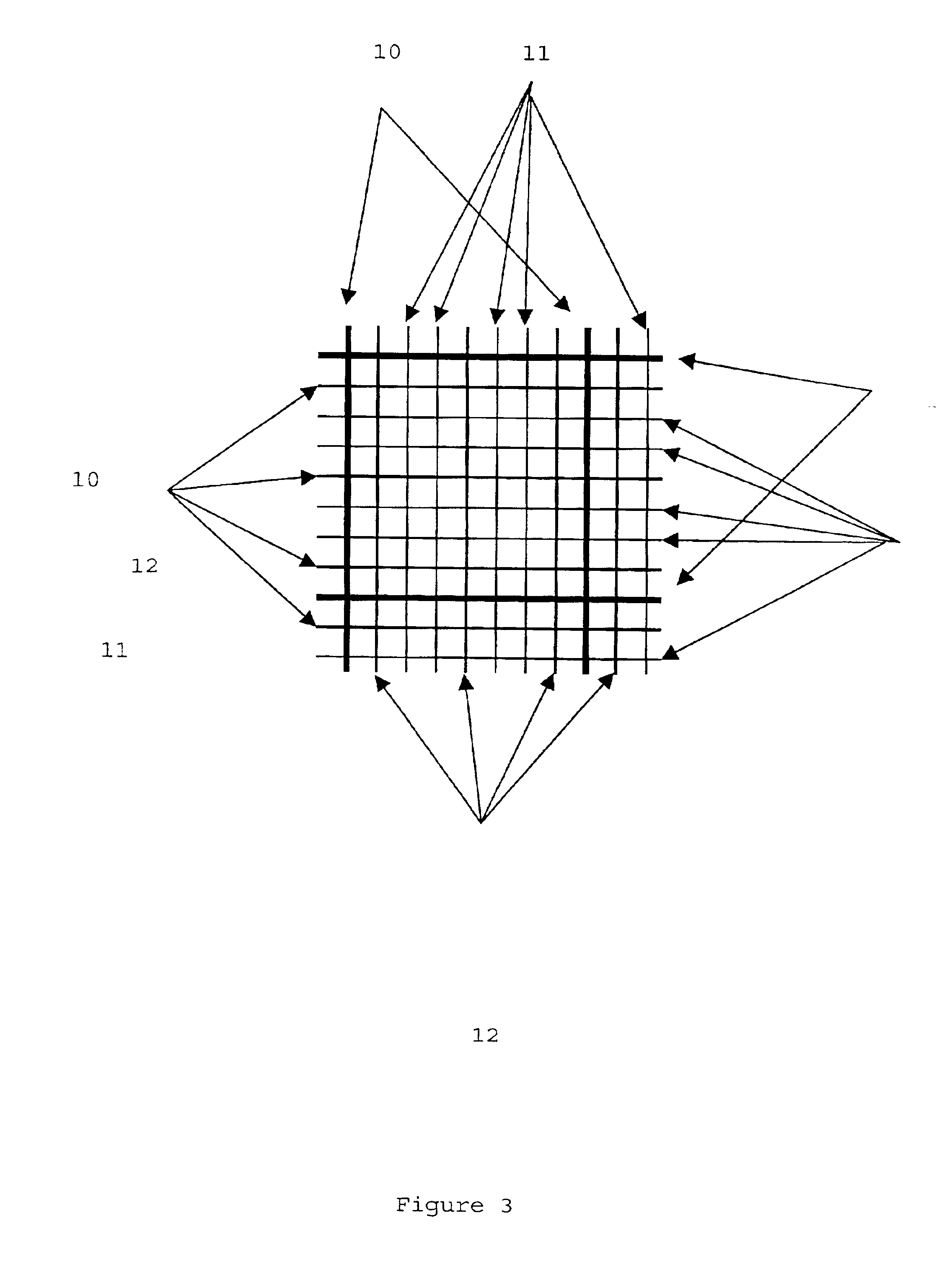

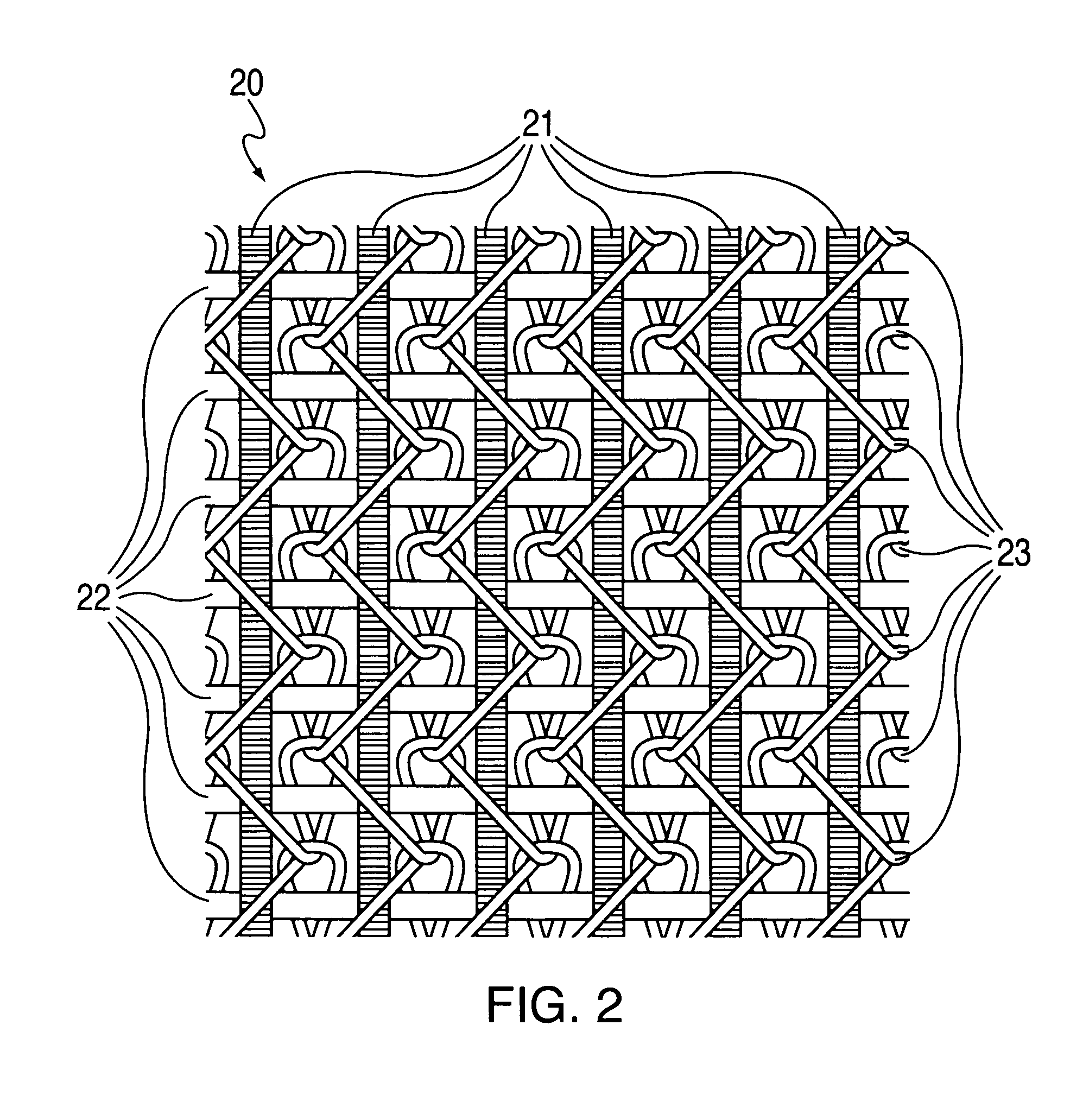

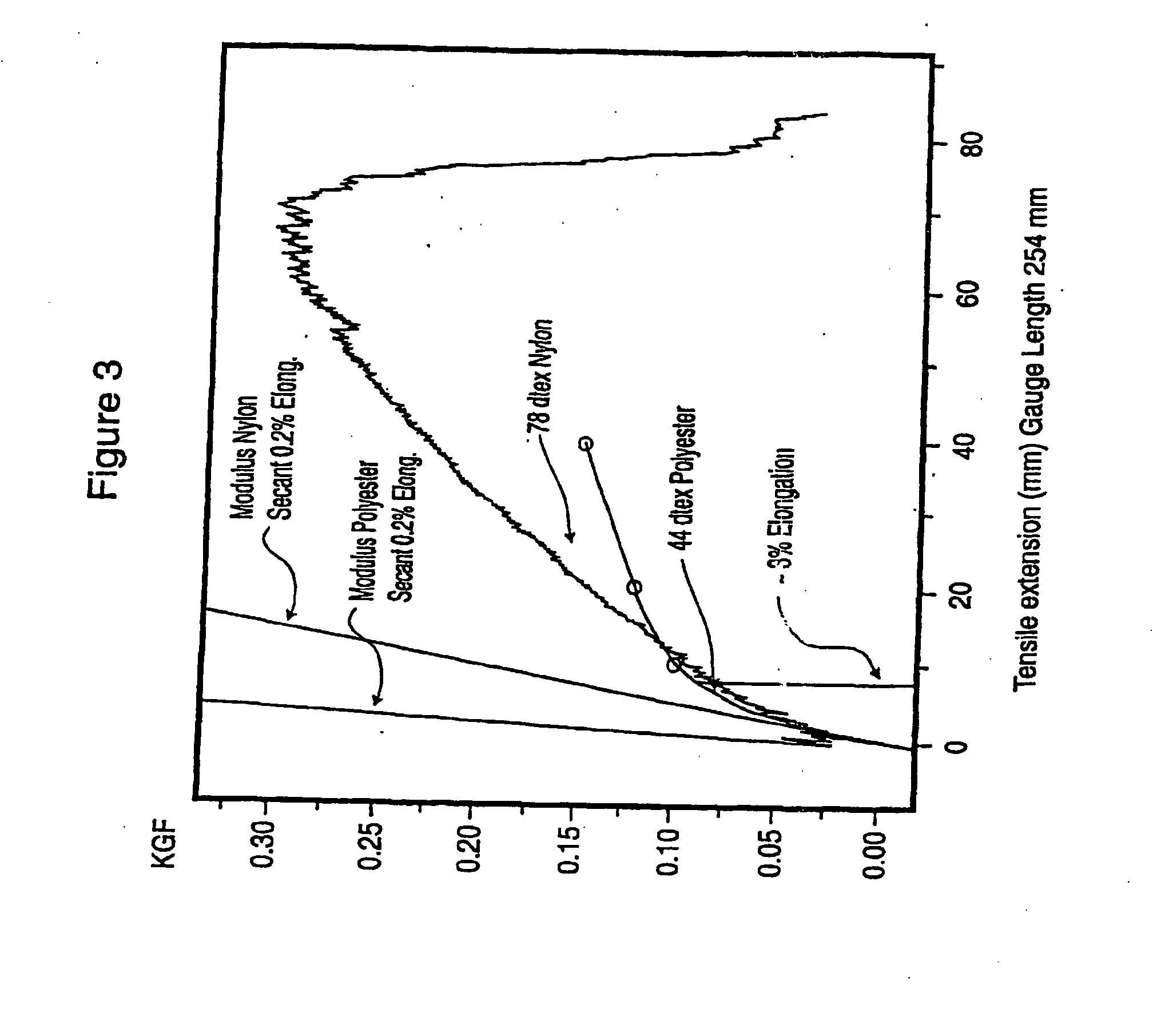

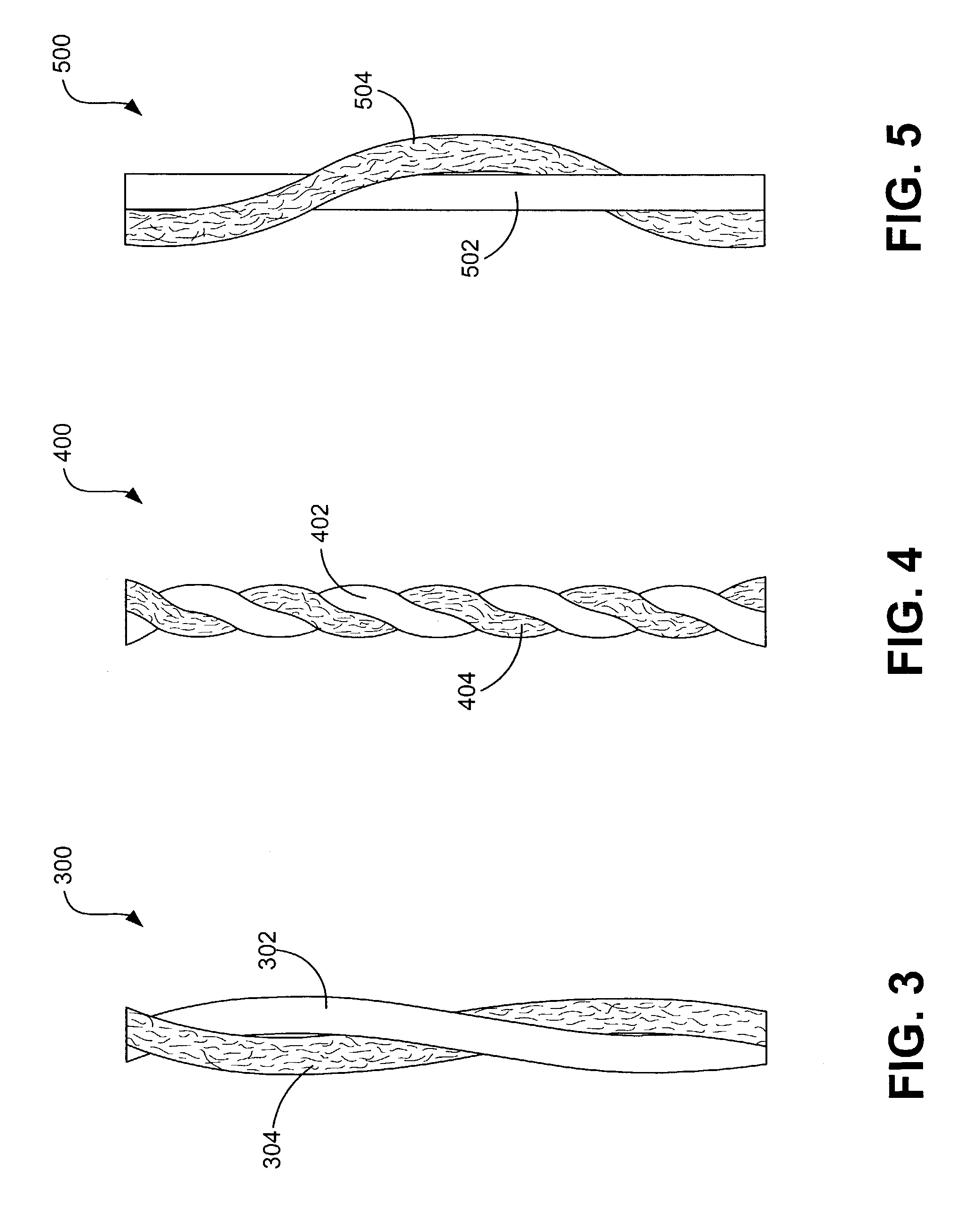

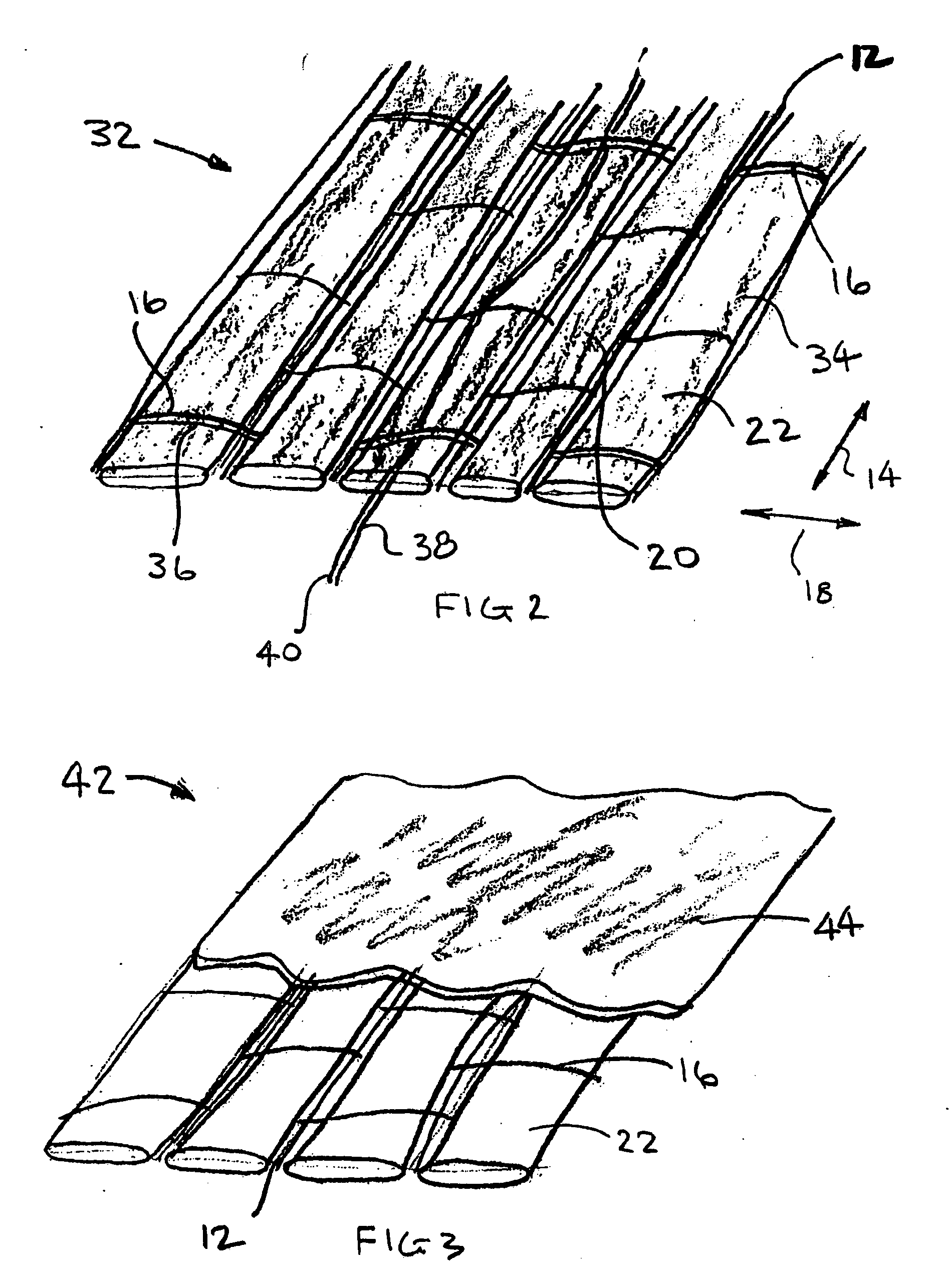

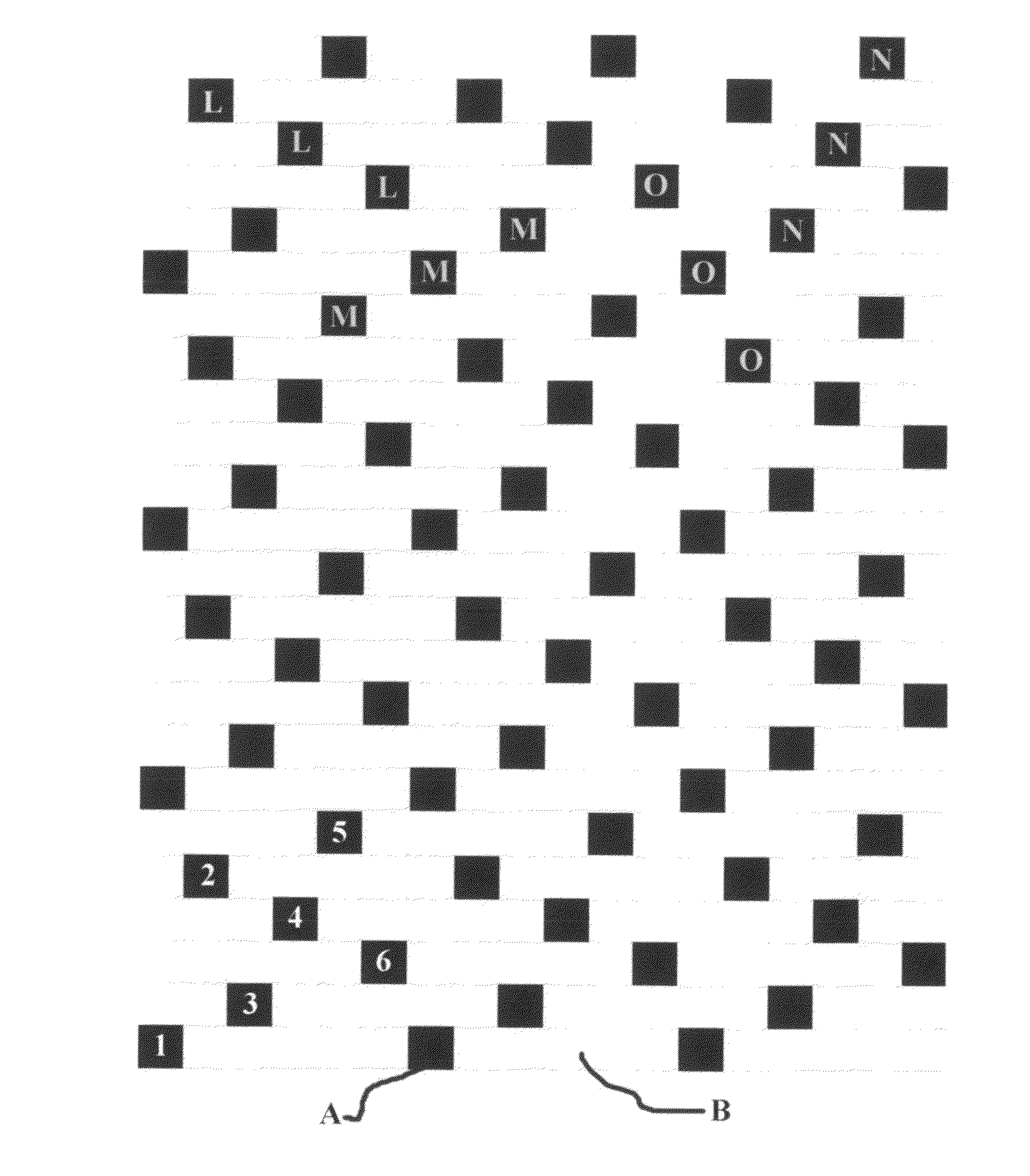

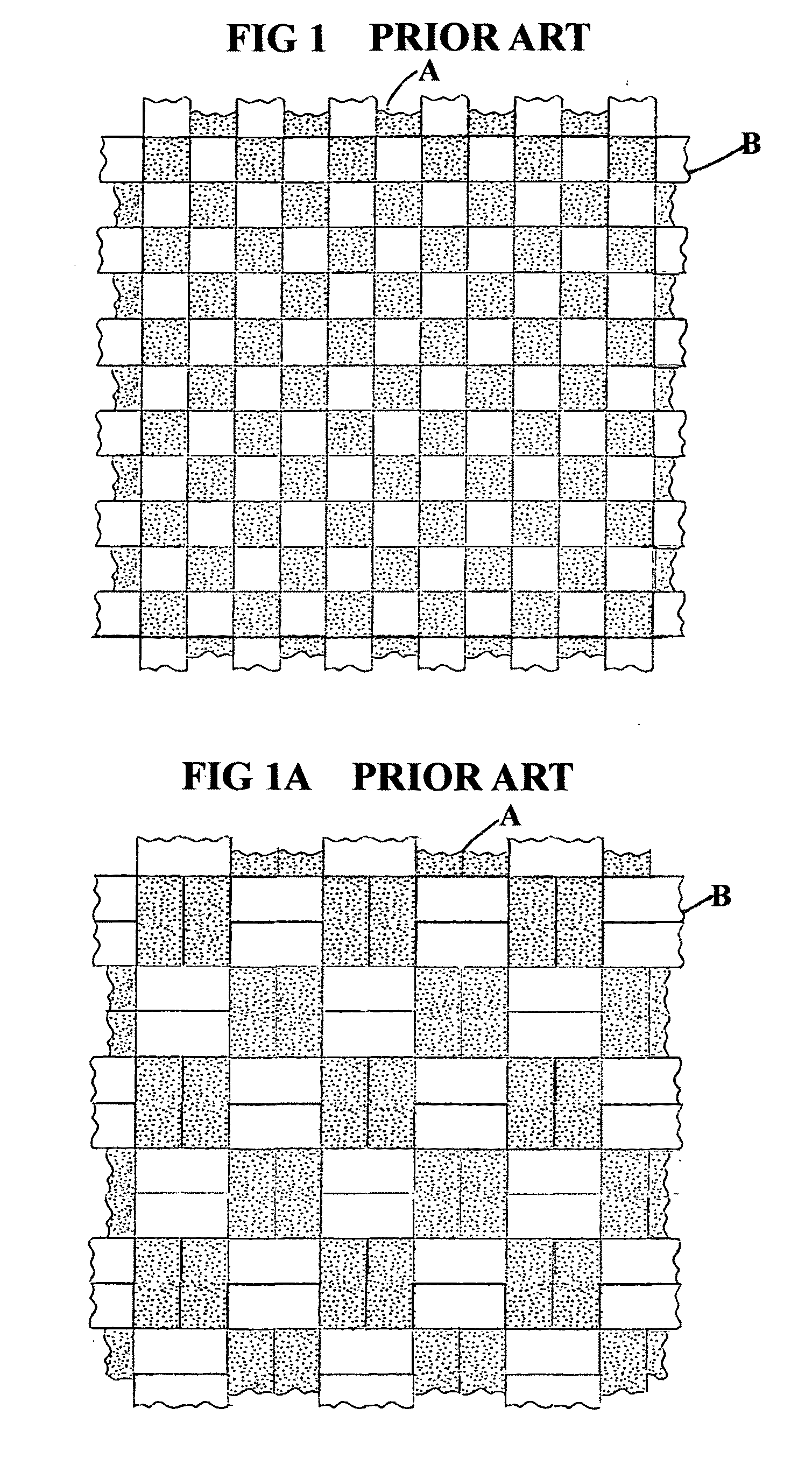

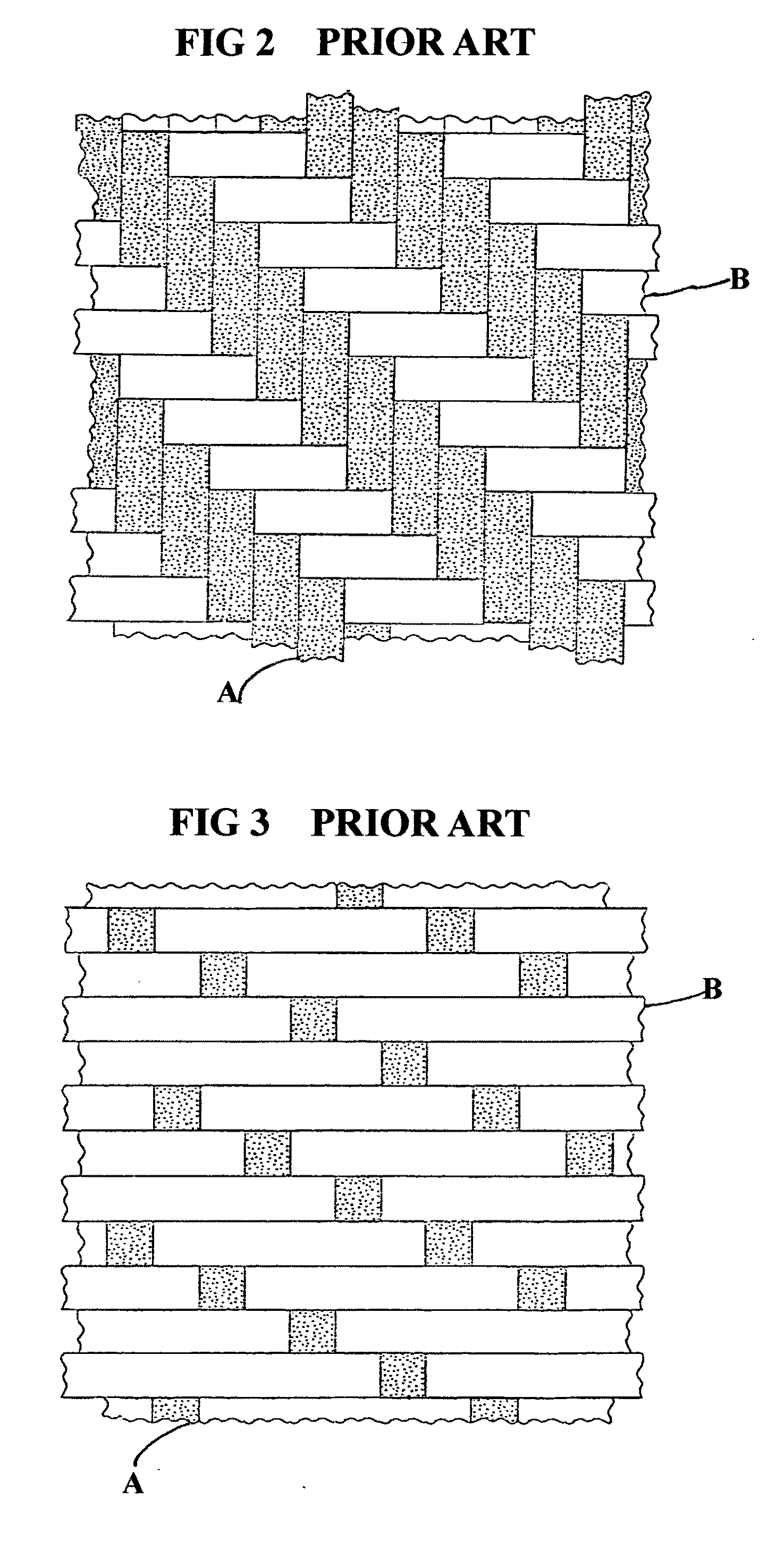

Bi-directional and multi-axial fabrics, fabric composites, ballistically resistant assemblies thereof, and the methods by which they are made. The fabrics are comprised of sets of strong, substantially parallel, unidirectional yarns lying in parallel planes, one above the other, with the direction of the yarns in a given plane rotated at an angle to the direction of the yarns in adjacent planes; and one or more sets of yarns having lower strength and higher elongation interleaved with the strong yarns. The fabrics of the invention provide superior ballistic effectiveness compared to ordinary woven and knitted fabrics but retain the ease of manufacture on conventional looms and knitting machines.

Owner:HONEYWELL INT INC

Carbon nanotube fabrics

Owner:LOCKHEED MARTIN CORP

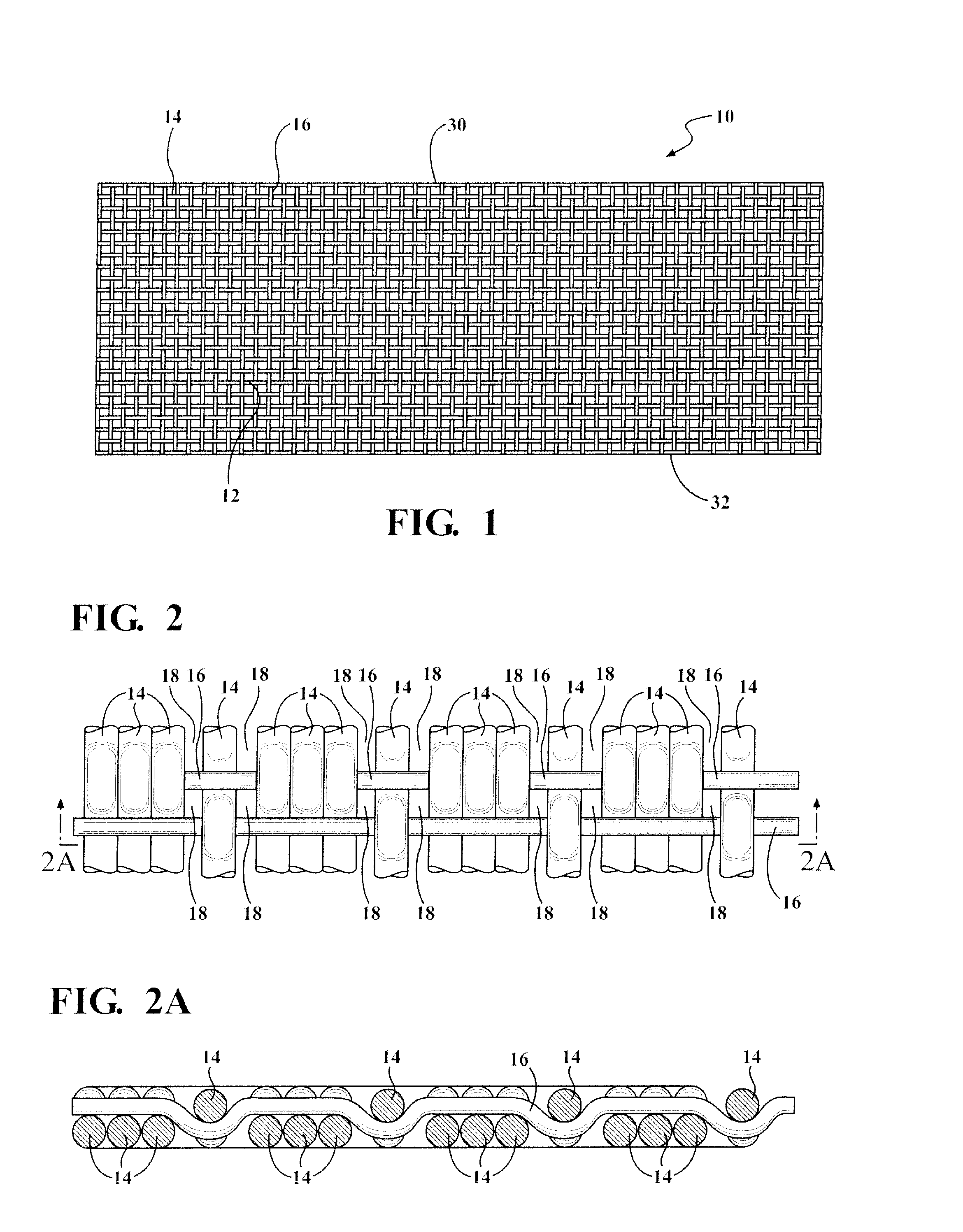

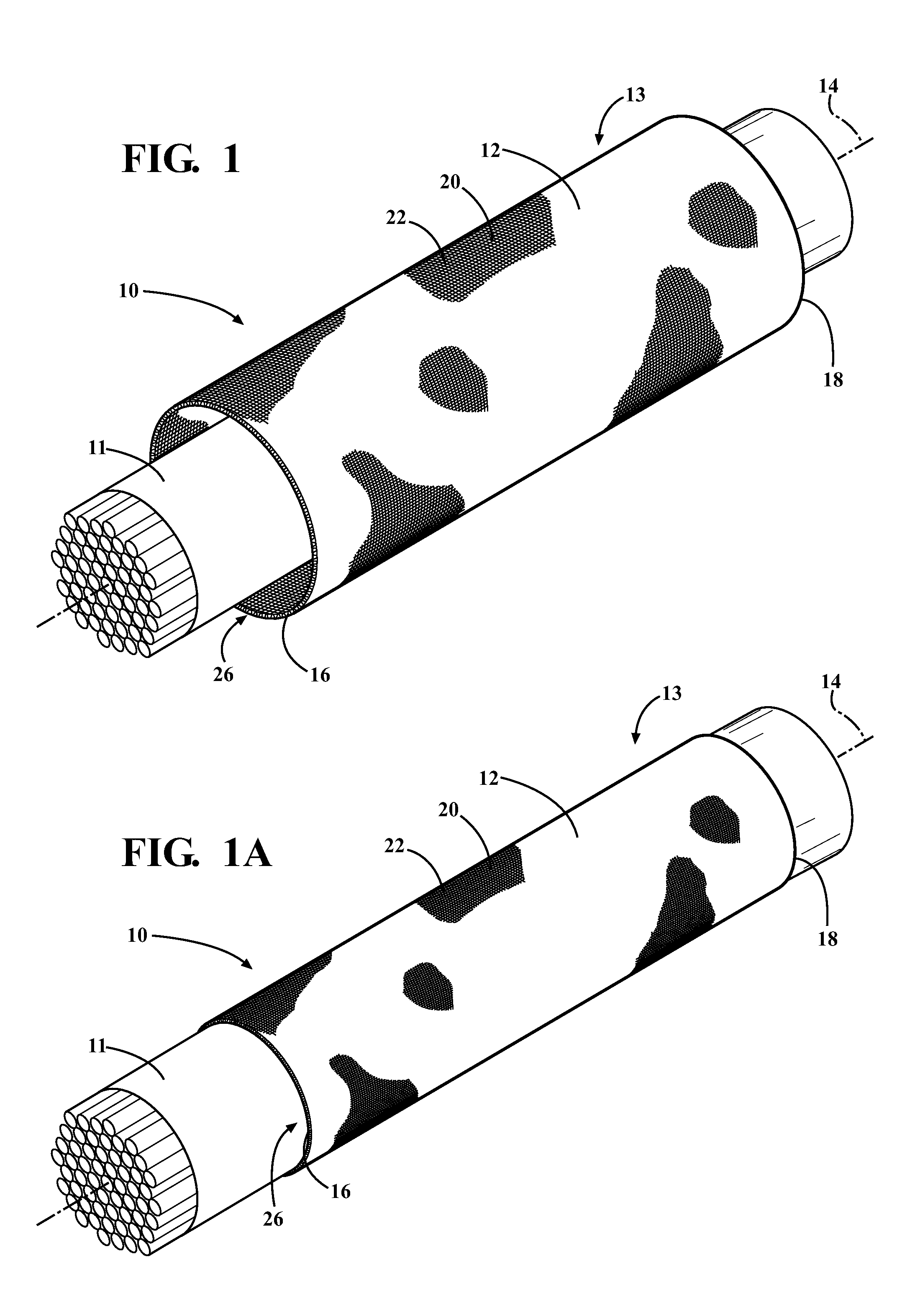

EMI Shielding Textile Fabric, Wrappable Sleeve Constructed Therefrom and Method of Construction Thereof

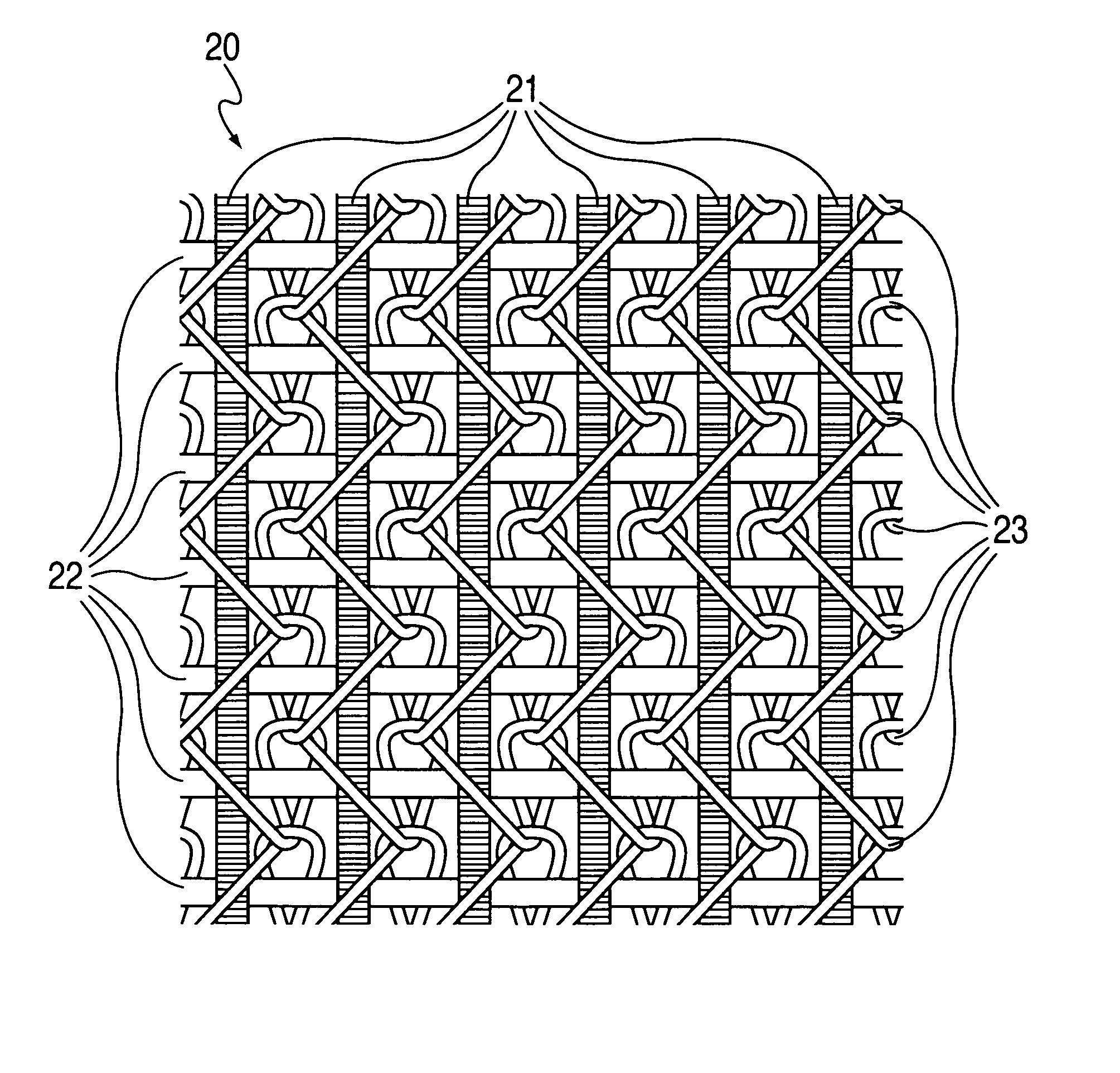

ActiveUS20140262478A1Improve abilitiesClose proximityShielding materialsLoomsArchitectural engineeringWeft yarn

A textile fabric, sleeve formed therefrom, and methods of construction thereof are provided. The fabric forms an elongate wall constructed from lengthwise extending warp yarns woven with widthwise extending weft yarns. At least some of the warp yarns are electrically conductive and have a first diameter. The weft yarns have a second diameter that is at least 25 percent less than the first diameter of the warp yarns. As such, the conductive warp yarns are brought into closer proximity with one another than if the weft yarns were the same diameter as the warp yarns. Accordingly, the ability of the fabric and sleeve formed therewith to provide shielding protection against EMI is enhanced.

Owner:FEDERAL MOGUL POWERTAIN LLC

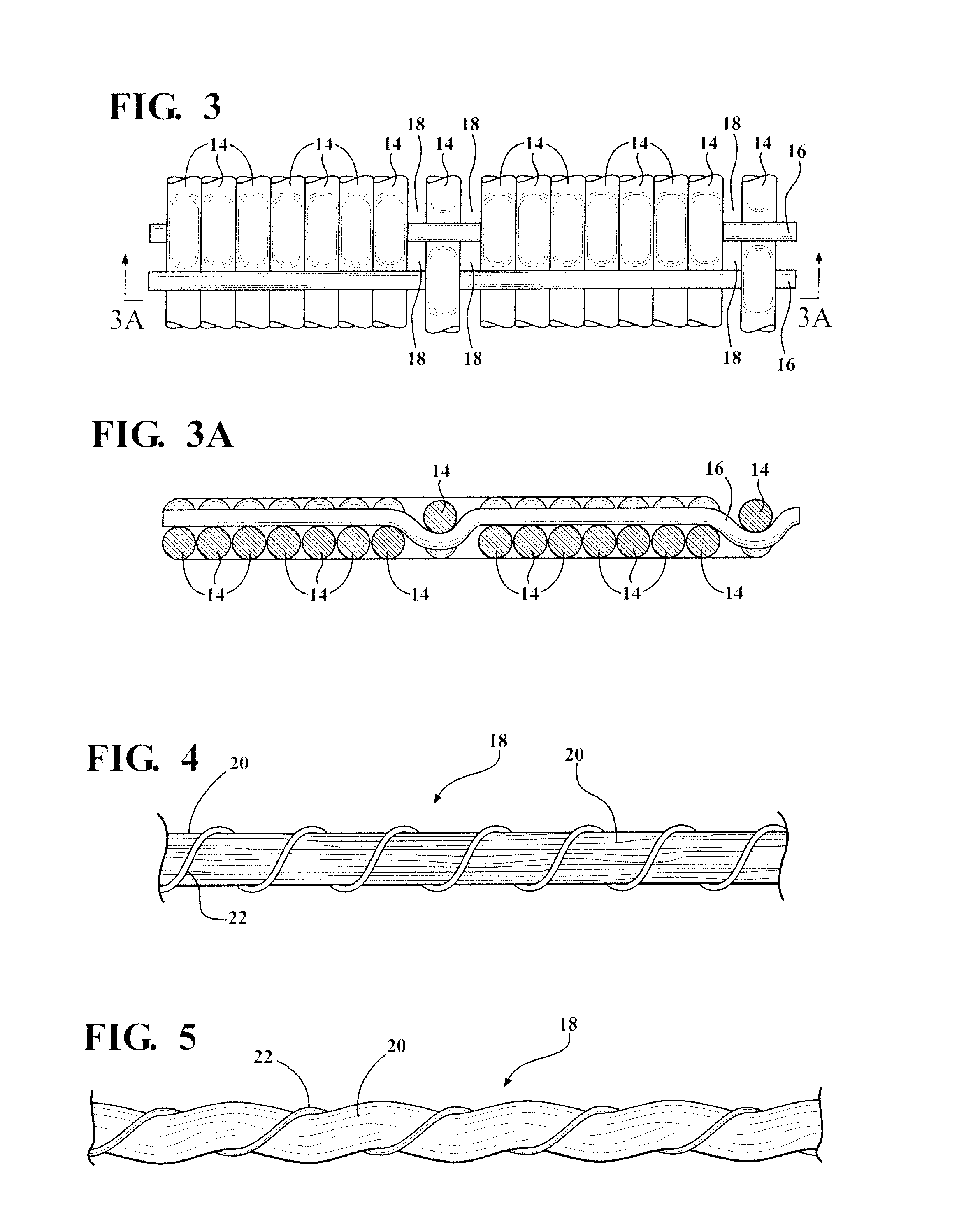

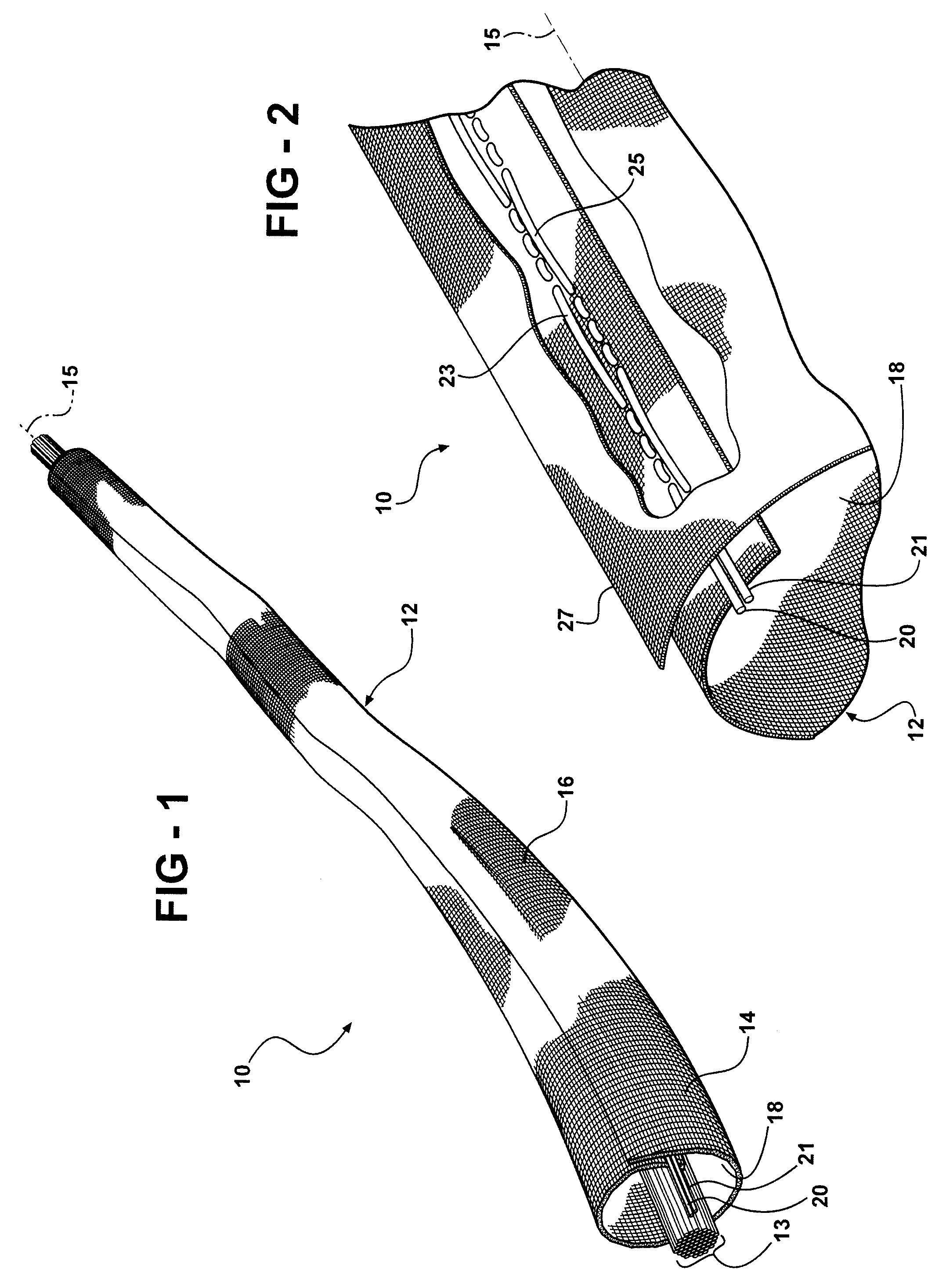

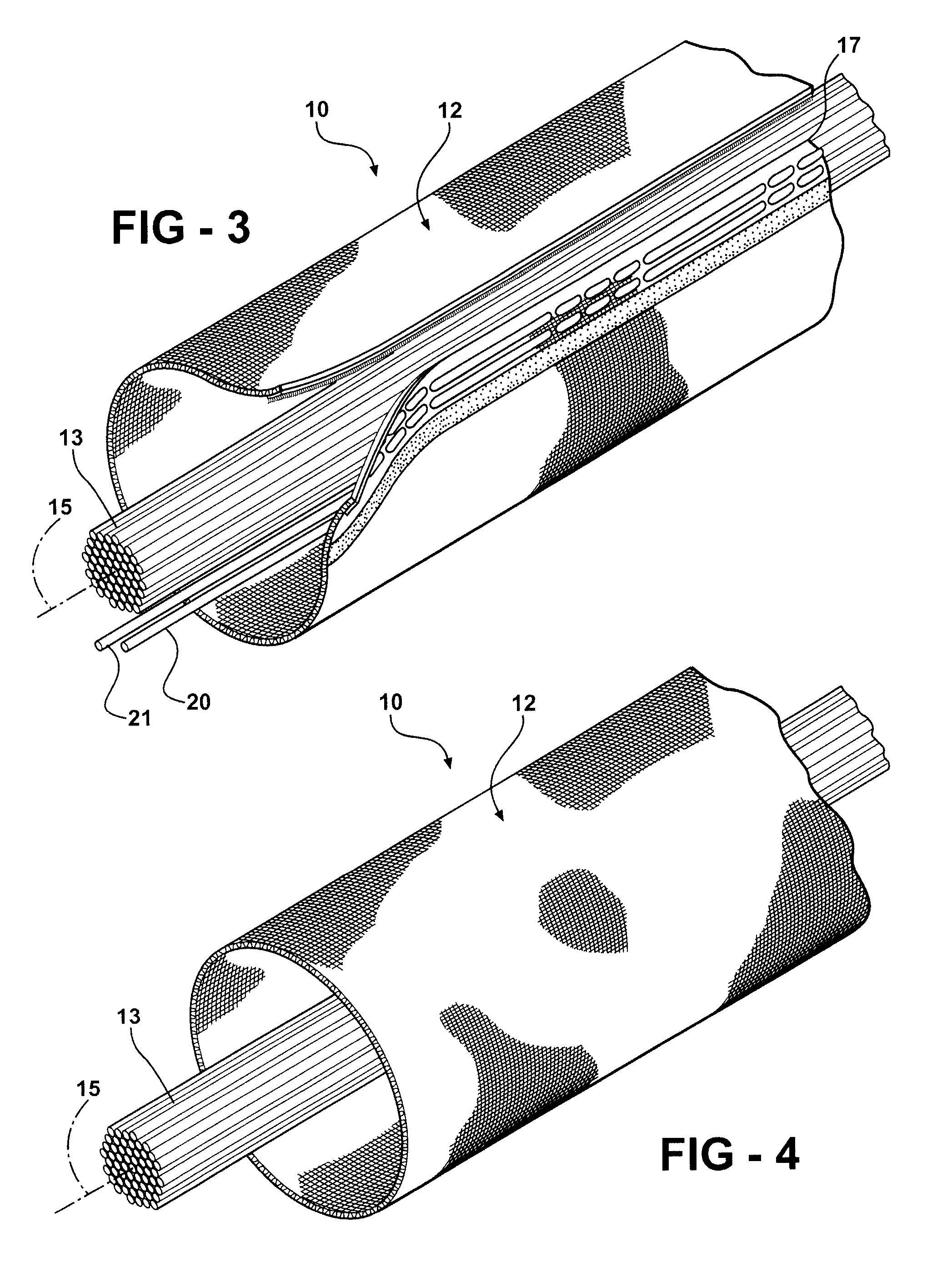

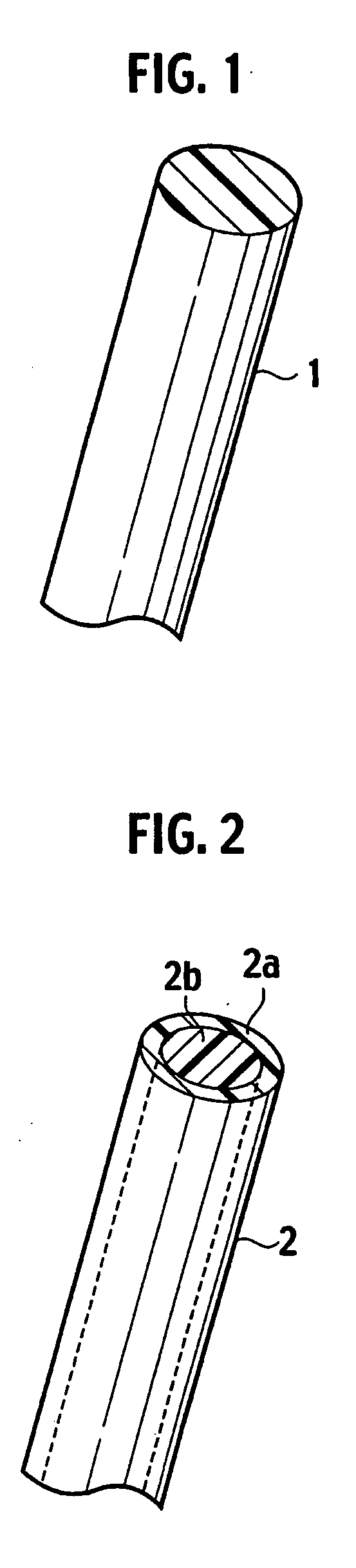

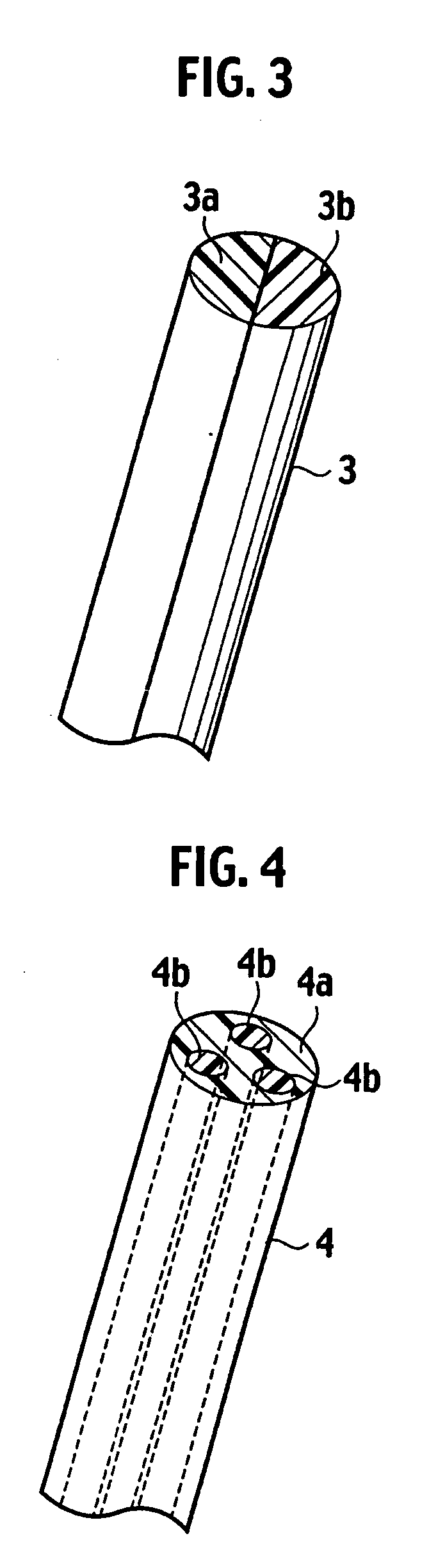

Protective sleeve fabricated with hybrid yard, hybrid yarn, and methods of construction thereof

ActiveUS20100084179A1Improve conductivityNon-insulated conductorsMagnetic/electric field screeningYarnArchitectural engineering

A hybrid yarn filament and sleeve constructed therefrom for protecting elongate members against at least one of EMI, RFI or ESD is provided, along with methods of constructing the hybrid yarn filament and sleeves. The hybrid yarn filament has a nonconductive filament and at least one conductive wire filament overlying an outer surface of the nonconductive filament. The hybrid yarn filament is arranged in electrical communication with itself or other hybrid yarn filaments during construction of the sleeve to provide uniform shielding against EMI, RFI, and and / or ESD.

Owner:FEDERAL MOGUL POWERTAIN LLC

Protection product

A protection product made of (i) a woven fabric woven with a high-performance fiber, in which the opening rate of thread-opening treatment is 0 to 5%, and the width of a thread constituting the woven fabric is 10-fold or more relative to the thread thickness, (ii) a woven fabric in which the cross-sectional shape of a thread constituting the woven fabric is thinner on an edge side of both ends as compared with an intermediate part in the width direction, or (iii) a woven fabric woven with a twistless high-performance fiber having a fineness of 200 to 15,000 dtex, in which the ratio of the thread width to the thread thickness of at least one of a warp and a weft is 10 to 100, and the opening rate is 0 to 5%.

Owner:SOWA TEXTILE +2

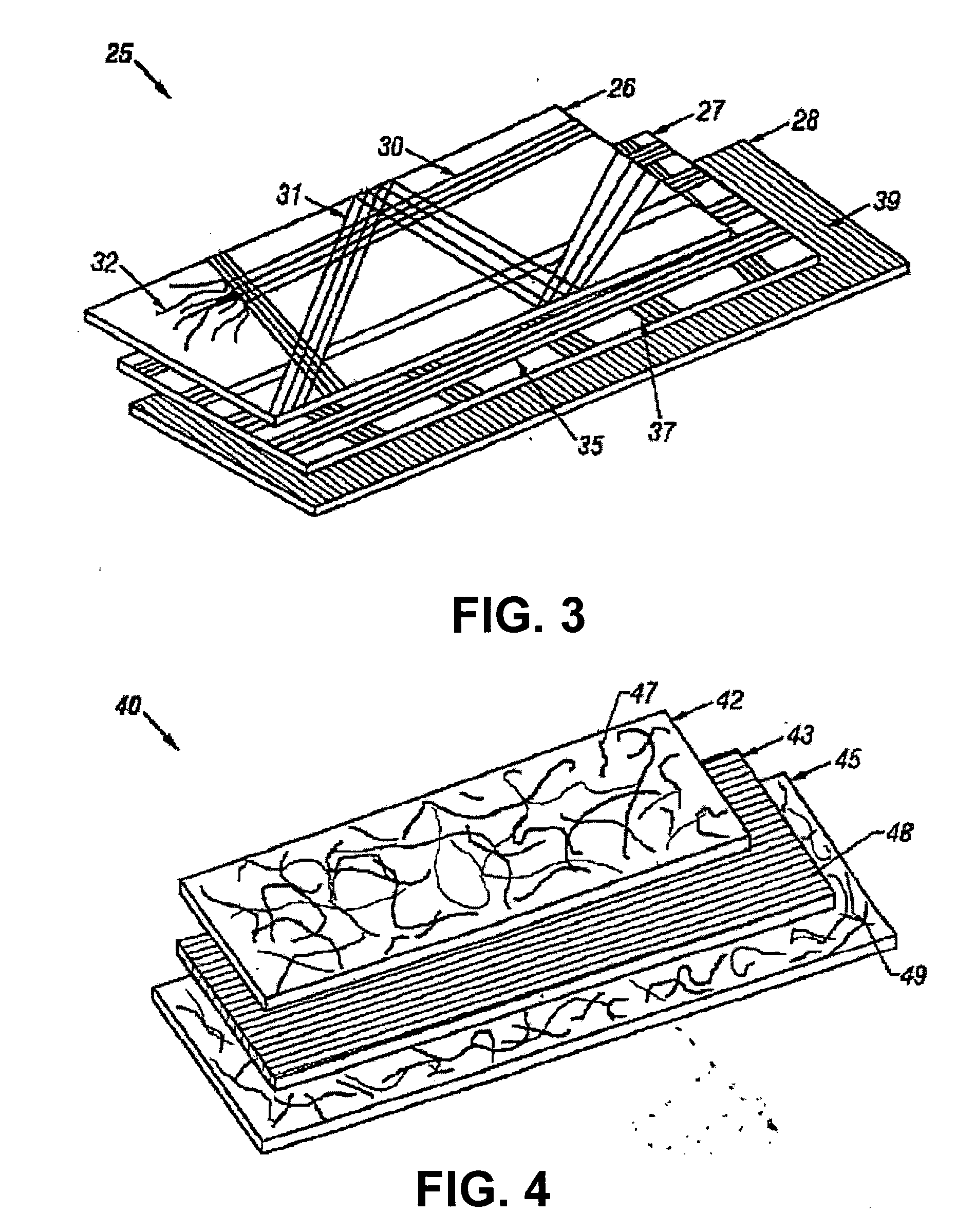

Flexible spike/ballistic penetration-resistant articles

ActiveUS20050003727A1Improve performanceImprove ballistic performanceProtective equipmentProtective fabricsYarnEngineering

An article is disclosed to protect a wearer from spike and ballistic threats that is made from a spike resistant panel and a ballistic resistant panel. Each panel is made from flexible fabric layers. The fabrics in the spike resistant panel are made from first yarns having a linear density of from 50 to 600, with a plurality of filaments. There are 40 to 100 first yarns per inch in both the warp and fill directions. The fabrics in the ballistic resistant panel are made from second yarns having a linear density of from 100 to no more than 840 denier with a plurality of filaments, which provide from 20,000,000 to no more than 90,000,000 filament crossovers per square inch. There are 5 to less than 40 second yarns per inch in both the warp and fill directions

Owner:DUPONT SAFETY & CONSTR INC

Fire-retardant fabric with improved tear, cut, and abrasion resistance

A woven fabric useful in protective apparel made from yarn components comprising a body fabric yarn component, a synthetic ripstop yarn component having at least 20% greater tensile strength than the body fabric yarn component, and a cut resistant yarn component comprising a yarn having a synthetic staple-fiber sheath and inorganic core, the body fabric yarn component, the ripstop yarn component, and cut-resistant yarn components all being comprised of at least one yarn and each yarn component distinguished from the adjacent yarn component by interweaving orthogonal yarn components.

Owner:EI DU PONT DE NEMOURS & CO

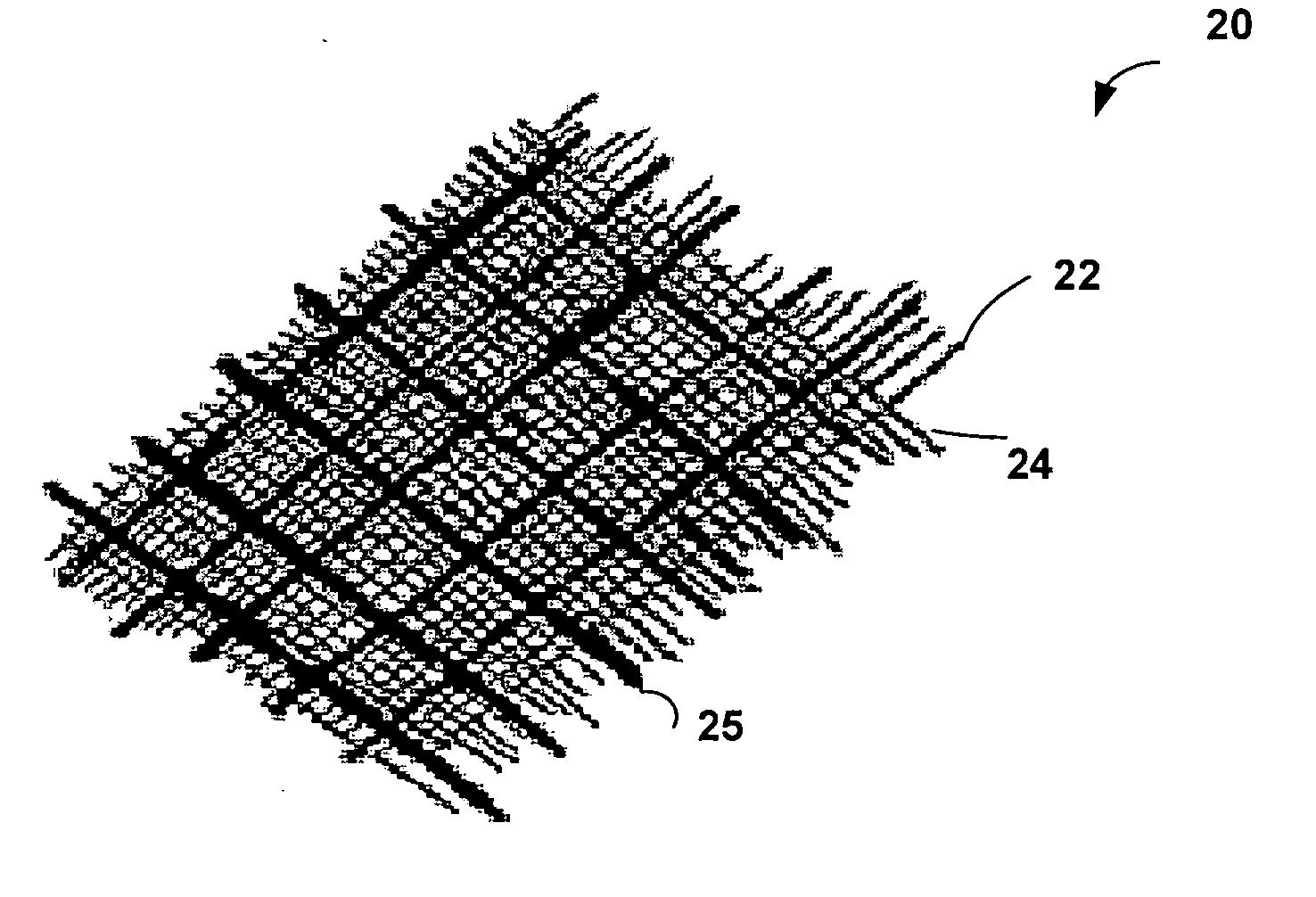

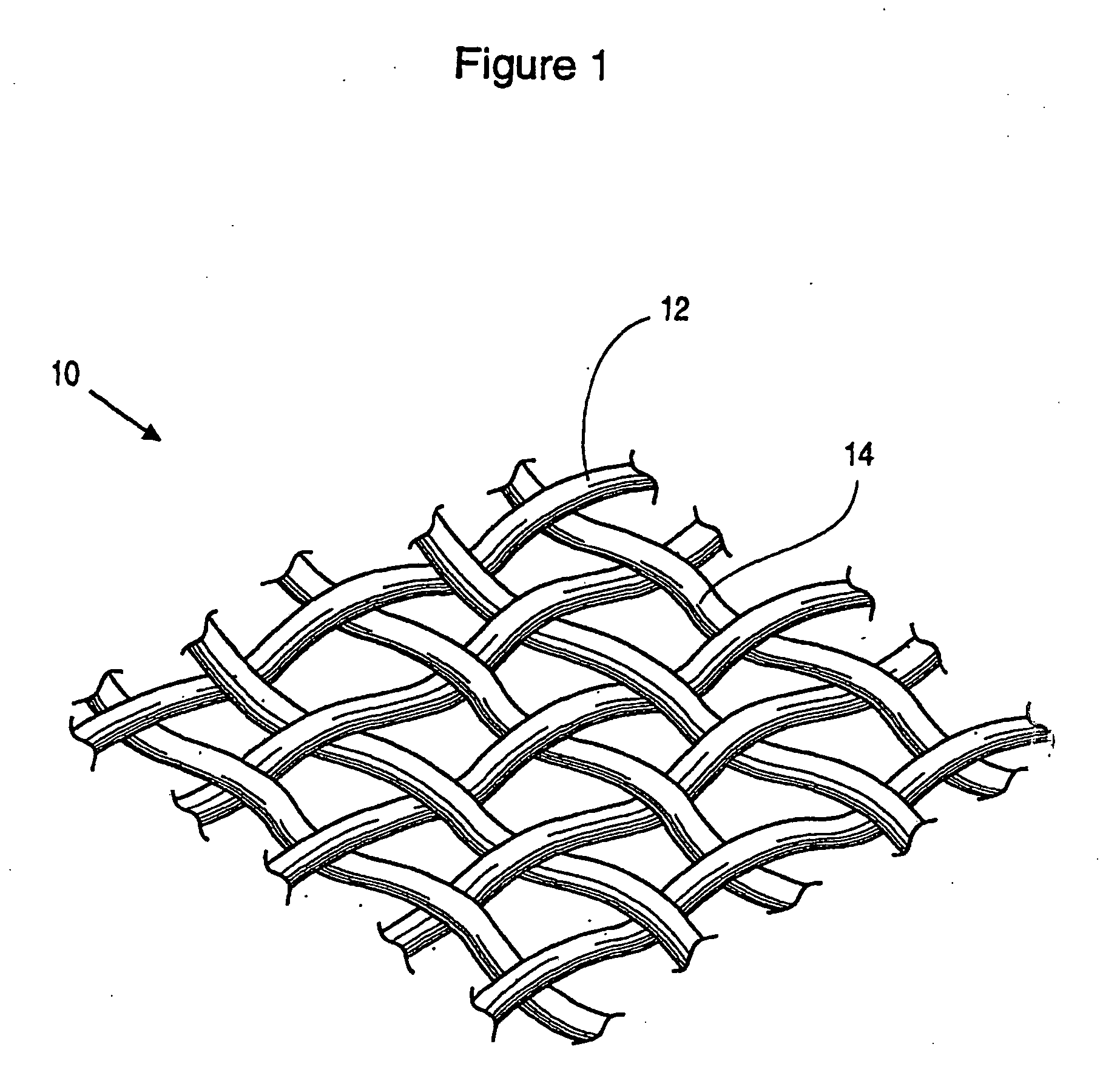

Bi-directional fabric and fabric composites

InactiveUS20050081571A1Increase resistanceSuperior ballistic effectivenessOrnamental textile articlesProtective fabricsYarnEngineering

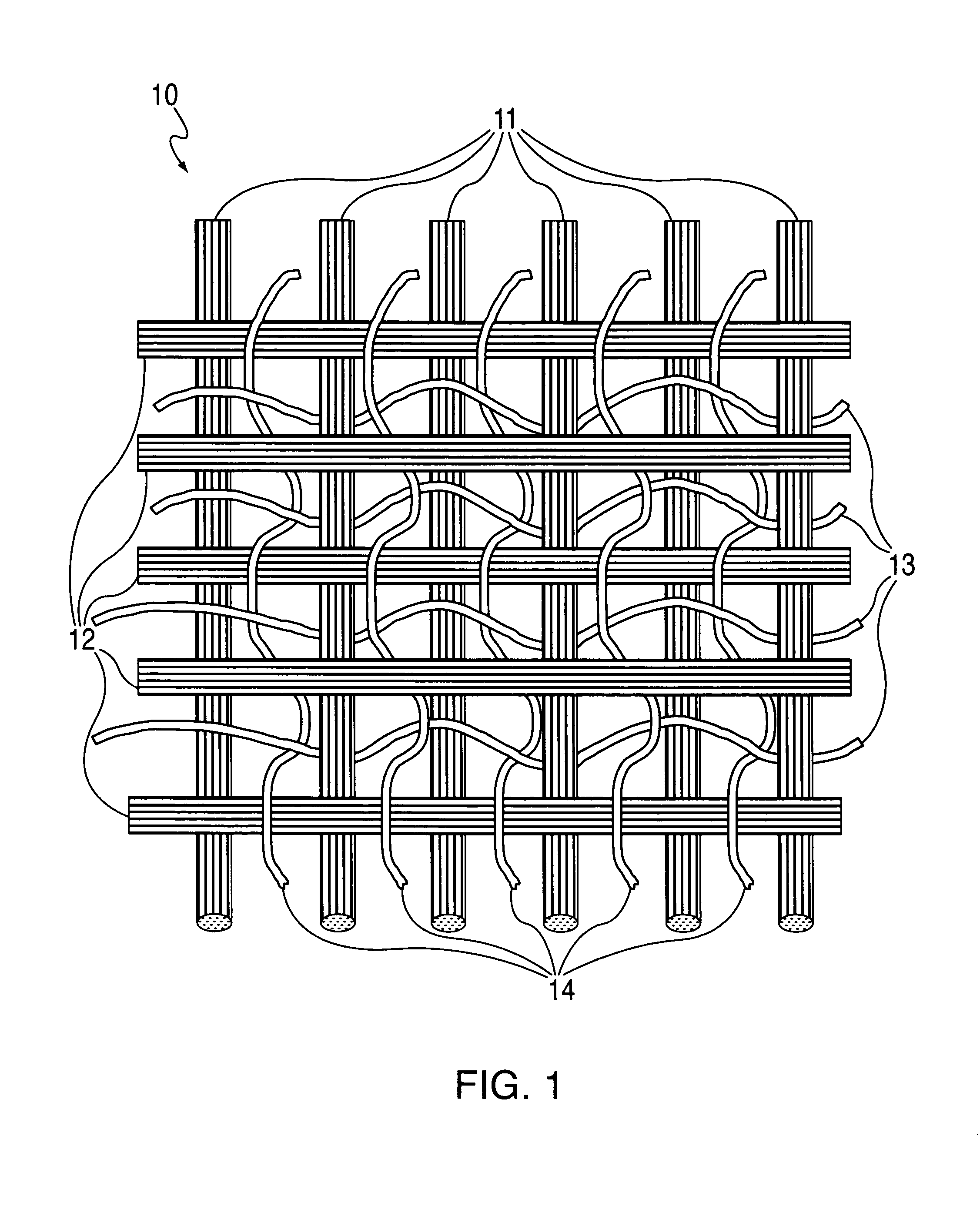

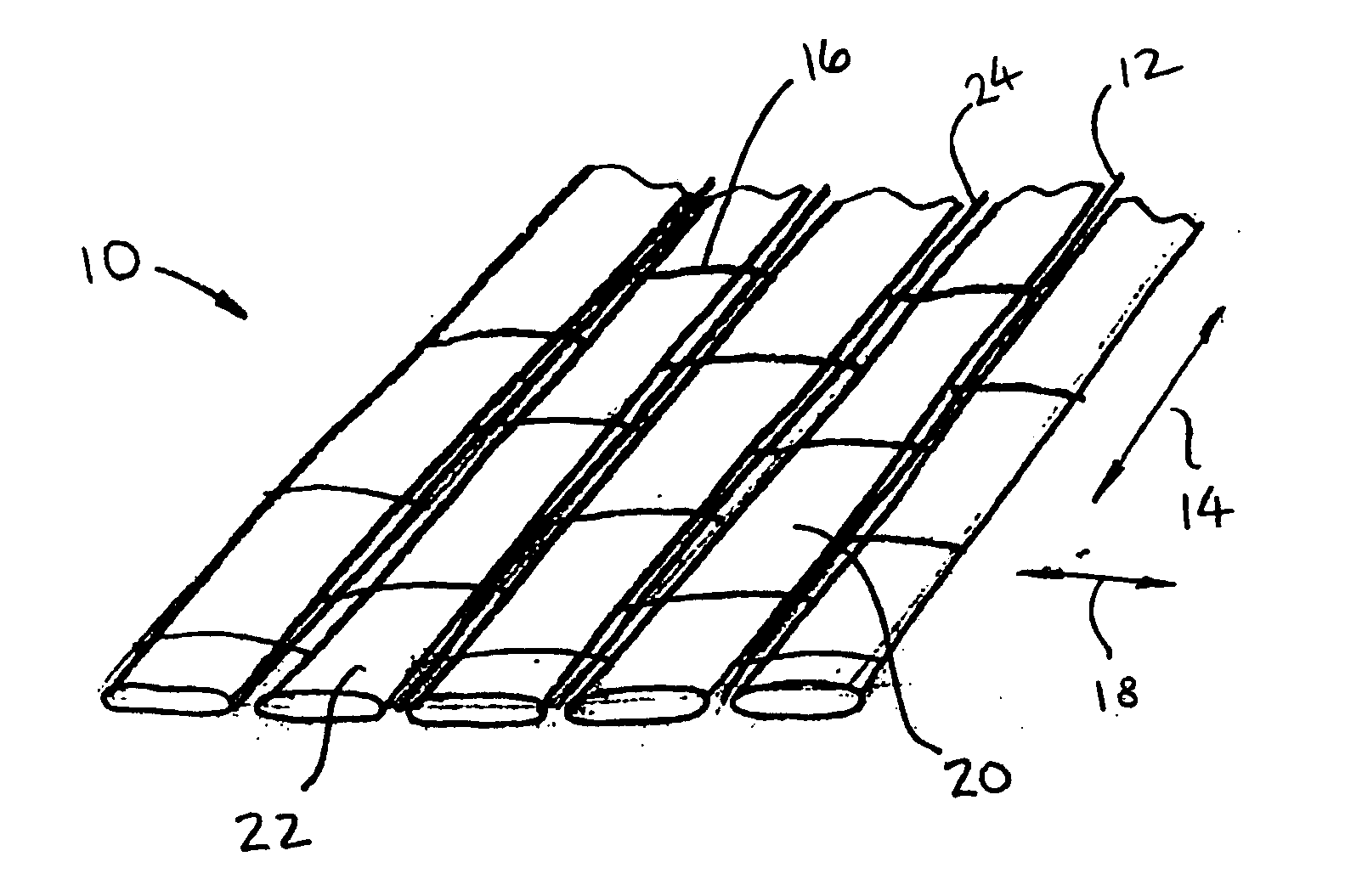

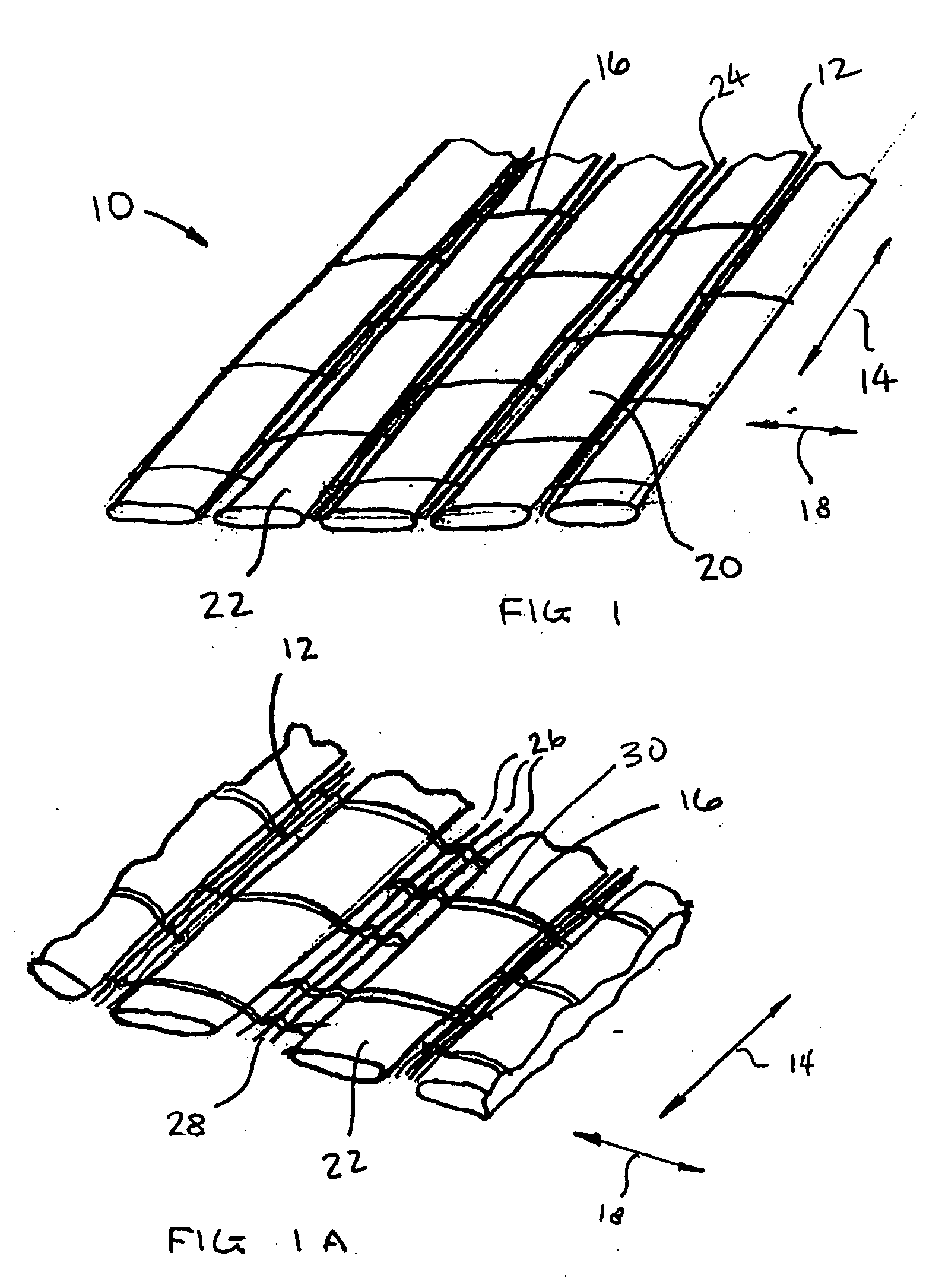

Bi-directional fabrics, fabric composites, ballistically resistant assemblies thereof, and the methods by which they are made. The bi-directional fabrics are comprised of a first set of strong, substantially parallel, unidirectional yarns lying in a first plane; a second set of strong, substantially parallel, unidirectional yarns lying in a second plane above the first plane and arranged transversely to the first set of yarns; and one or more sets of yarns having lower strength and higher elongation interleaved with the strong yarns. The bi-directional articles of the invention provide superior ballistic effectiveness compared to ordinary woven and knitted fabrics but retain the ease of manufacture on conventional looms and knitting machines.

Owner:HONEYWELL INT INC

Fabric architectures for improved ballistic impact performance

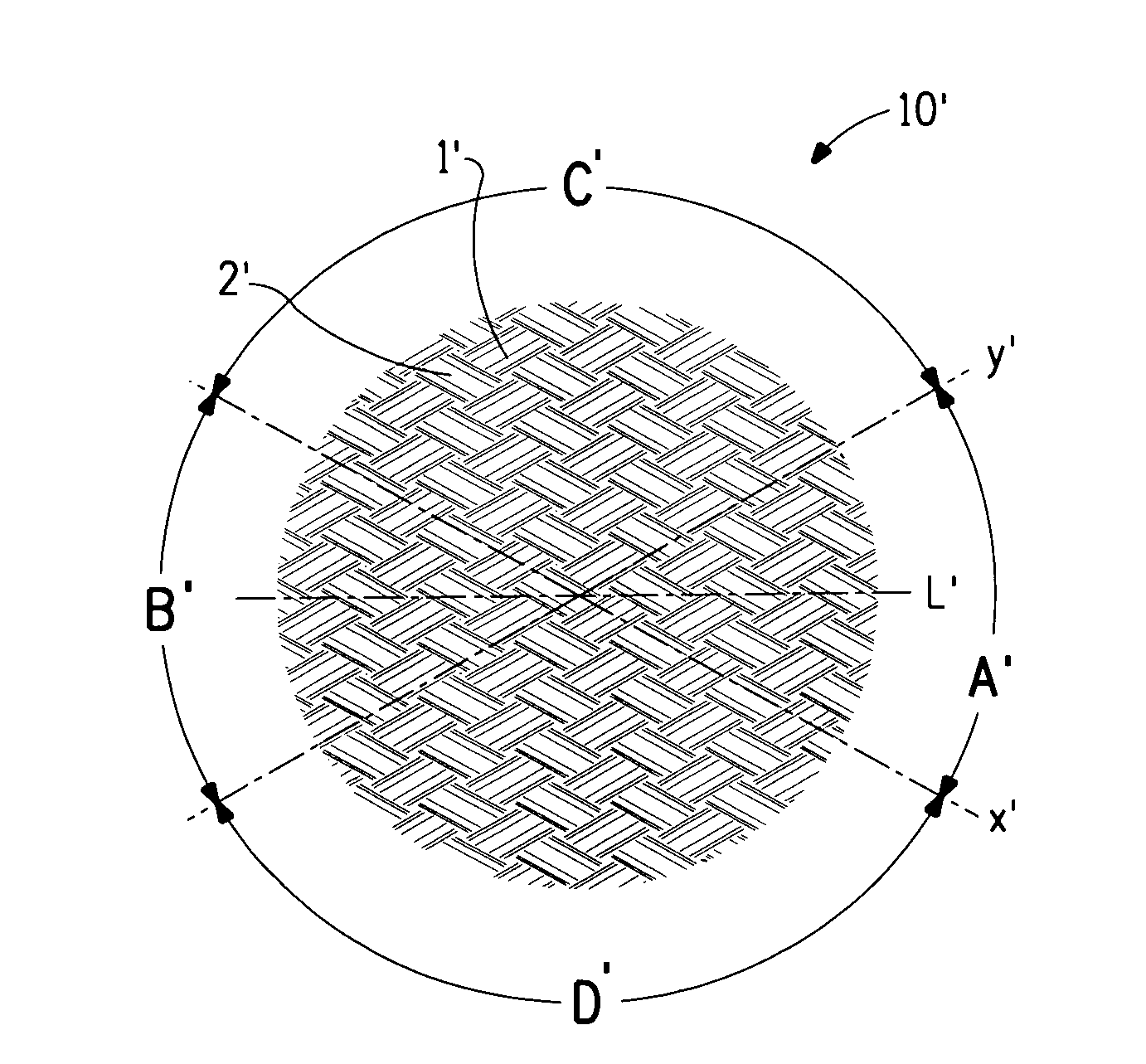

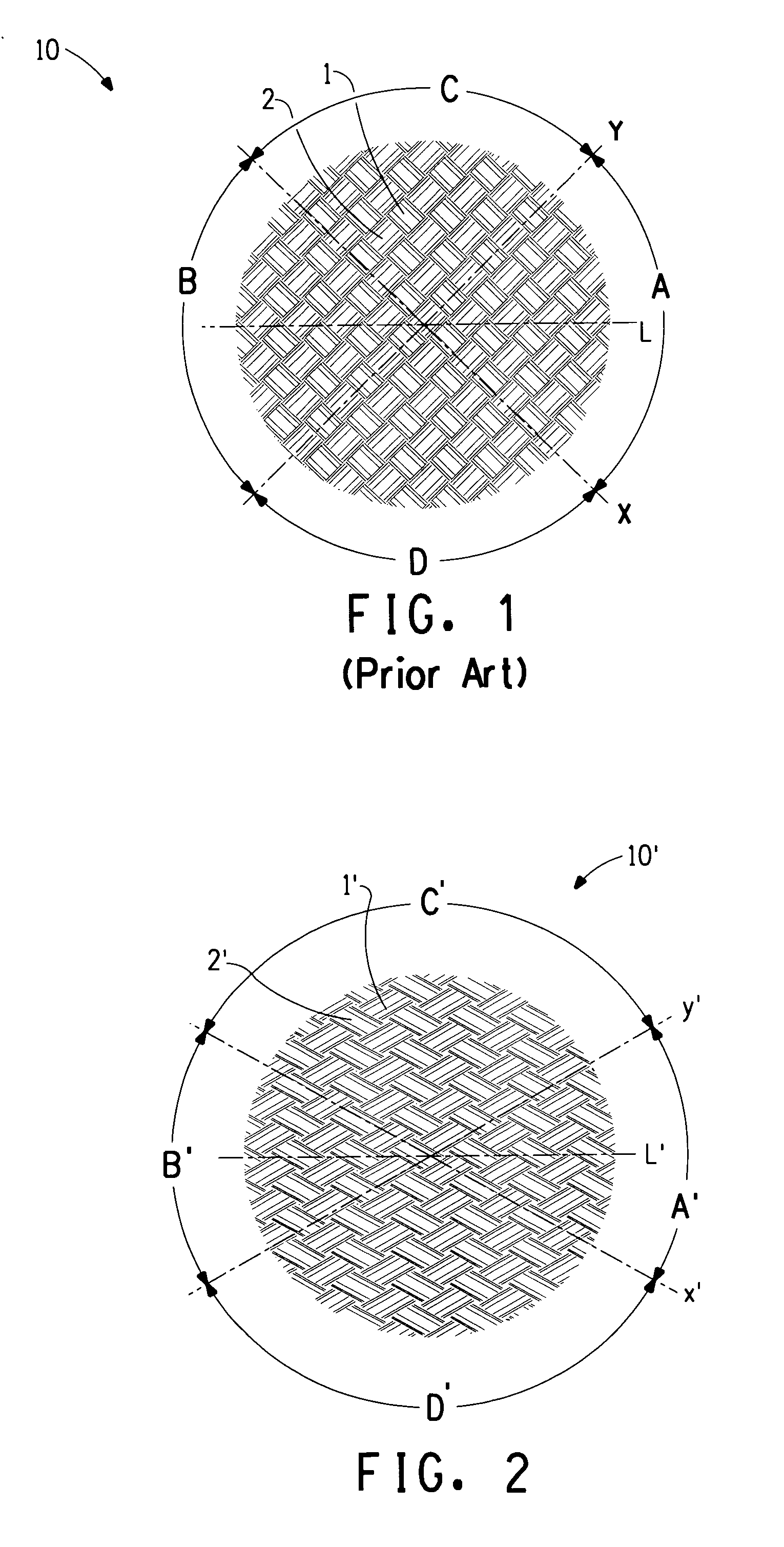

A woven fabric from yarn for use in the manufacture of ballistic projectile or puncture resistant articles where the fabric has a first plurality of parallel oriented yarns within the plane of the fabric interwoven with a second plurality of parallel oriented yarns within the plane of the fabric having a direction / orientation within the plane of the fabric different from that of the first plurality and where the crossing of any fiber yarn from the first plurality with a fiber yarn from the second plurality forms a pair of acute vertical angles having an angular measurement less than 90 degrees.

Owner:EGRES JR RONALD G

Stab resistant and anti-ballistic material and method of making the same

The invention relates to a fabric having both stab resistant and anti-ballistic properties. The fabric is made of yarn of a weight greater than about 500 dtex, and the fabric has a minimum shrinkage factor of at least about 1% achieved through a densification treatment. The invention further relates to a method of producing a such a fabric having the steps of agitating a fabric made of a yarn of a weight greater than about 500 dtex, substantially removing a spin finish from the fabric before, during or after the agitating step, and drying the fabric.

Owner:TEIJIN TWARON GMBH

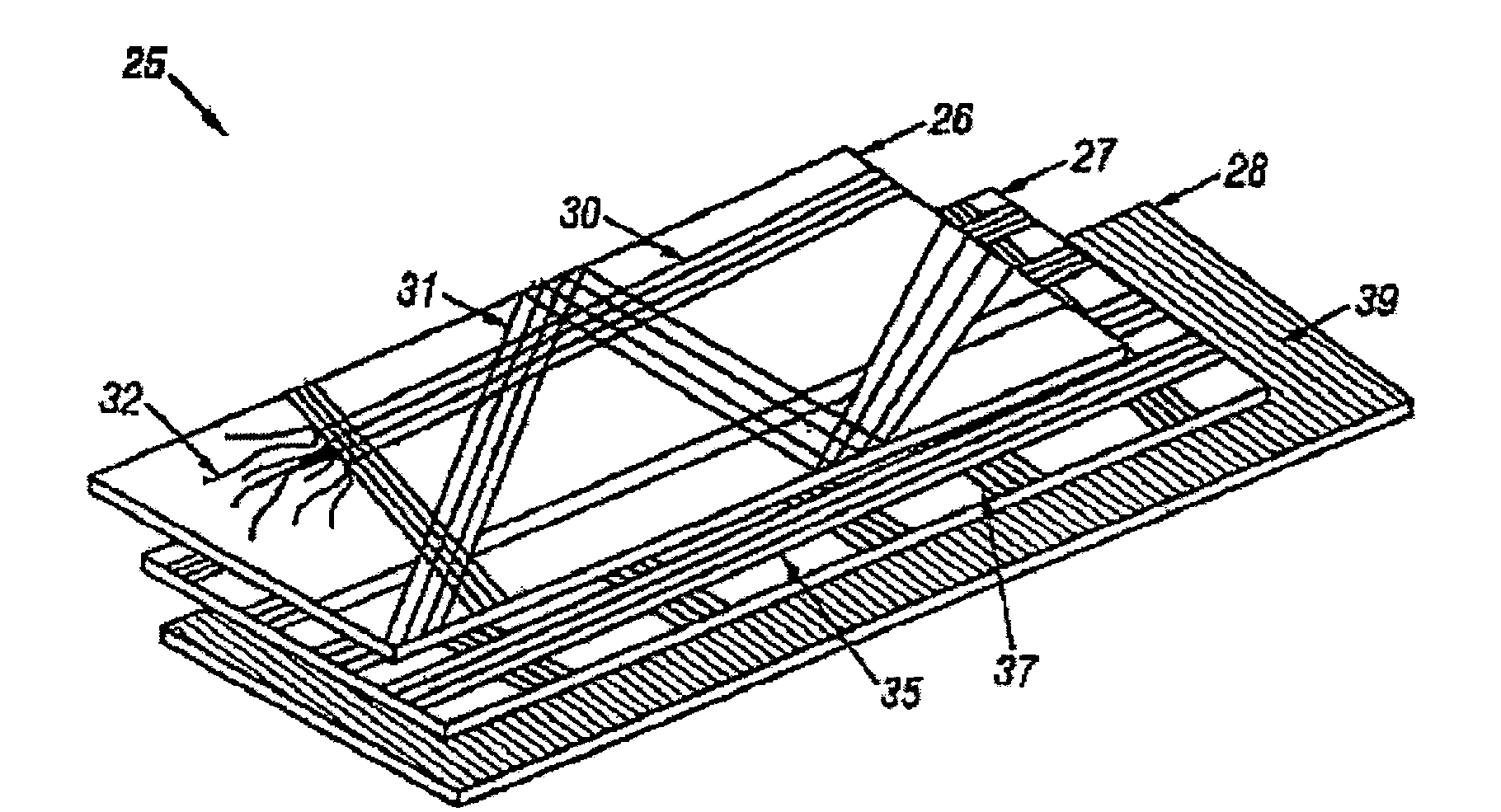

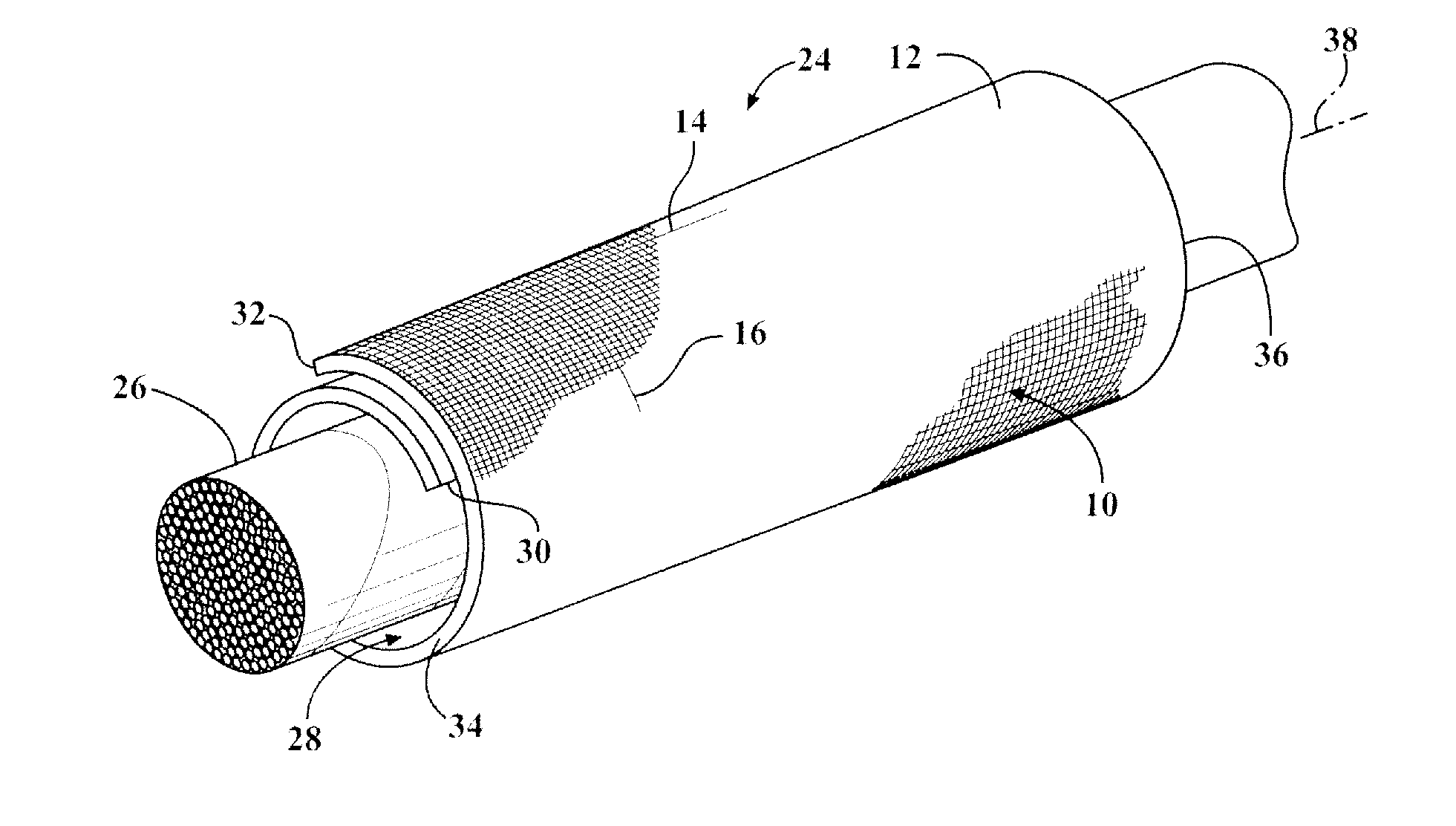

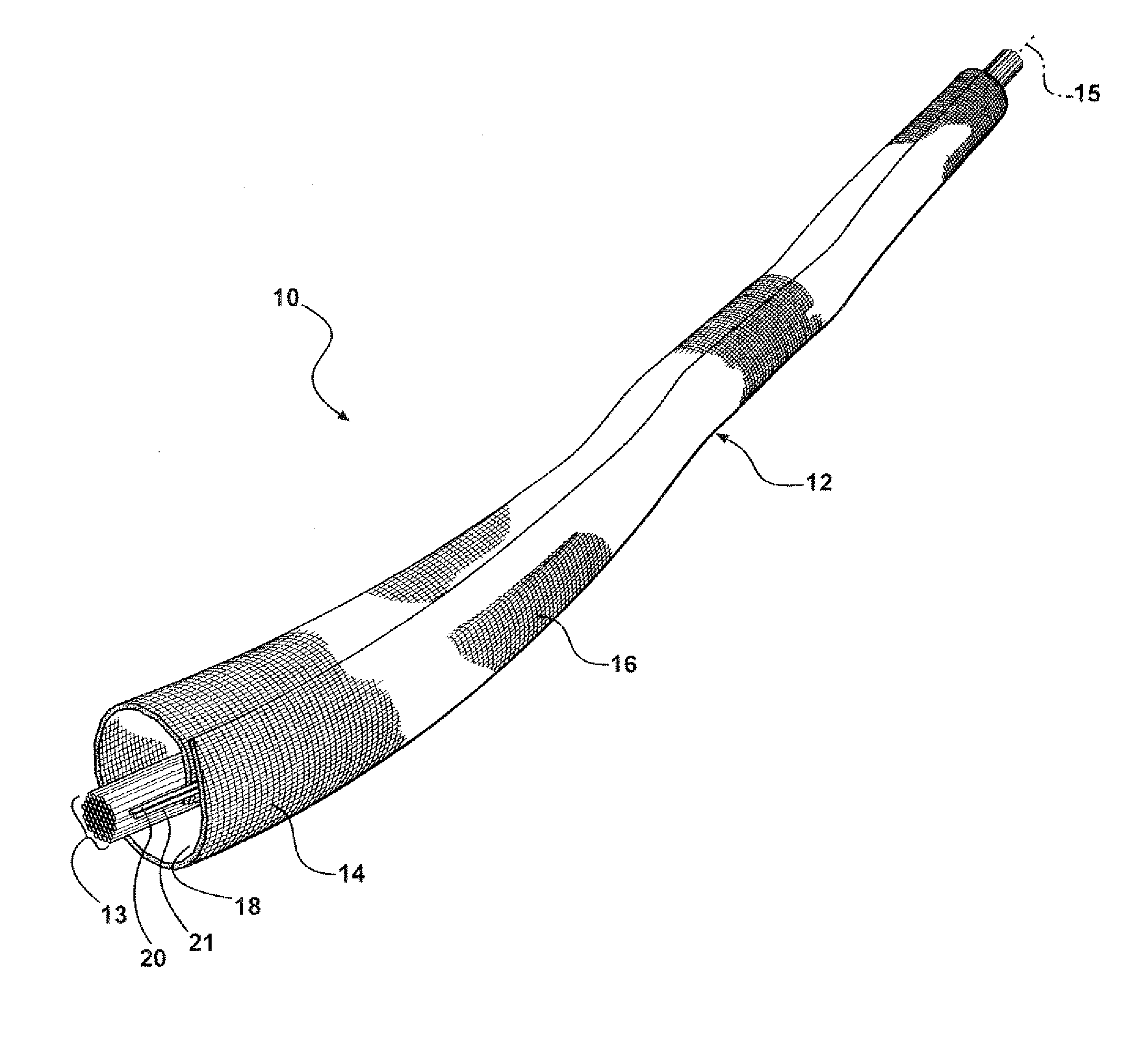

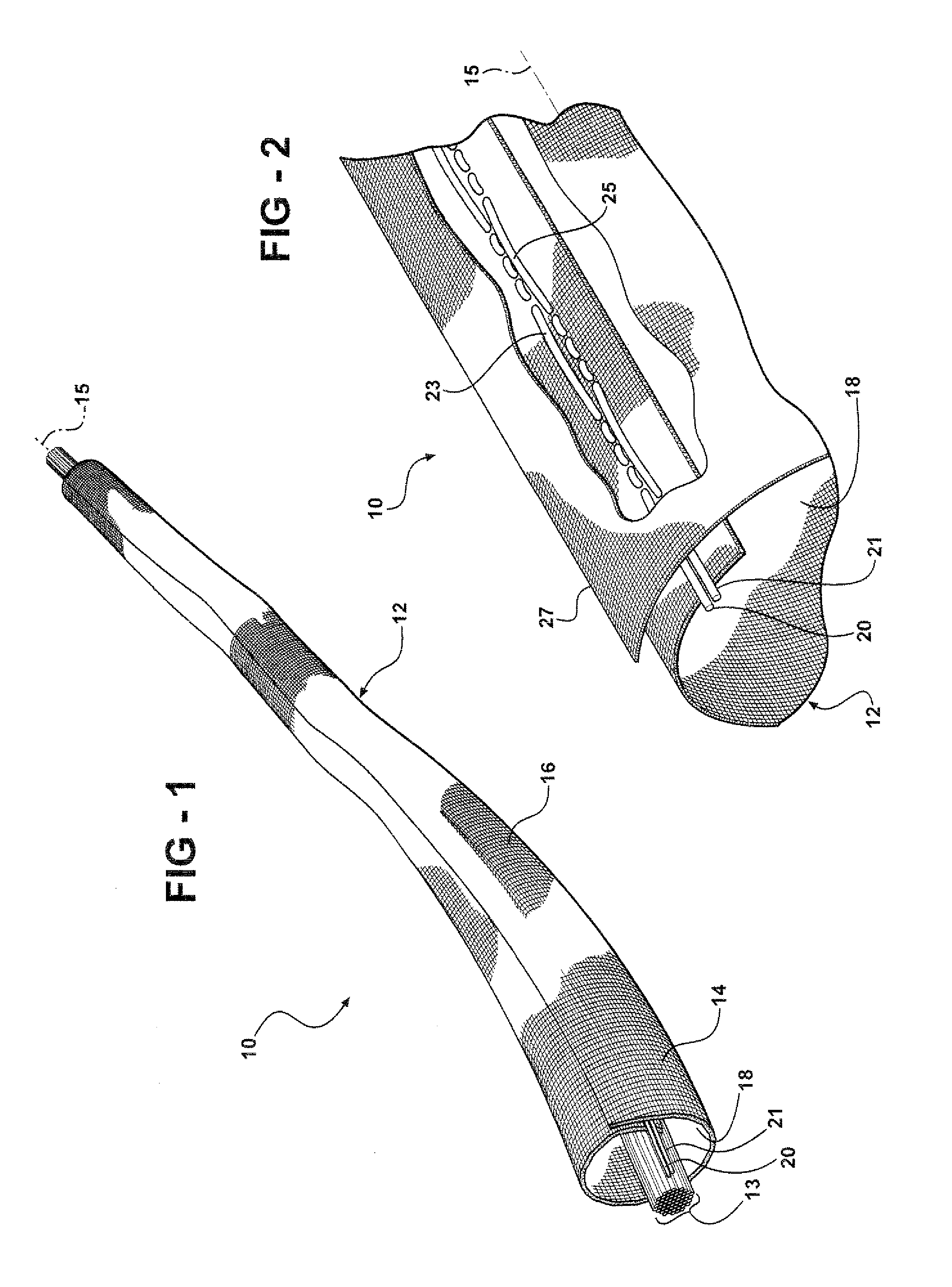

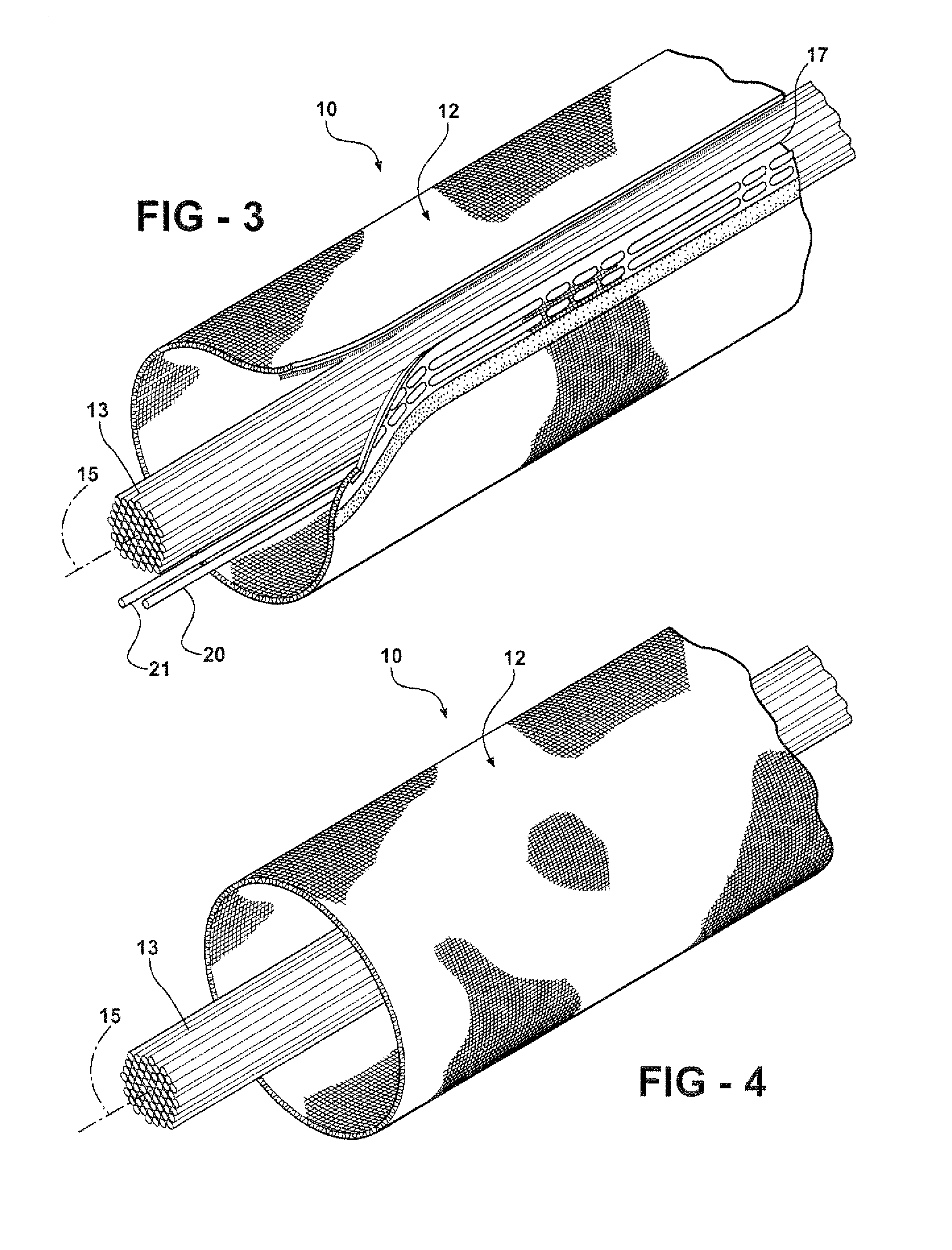

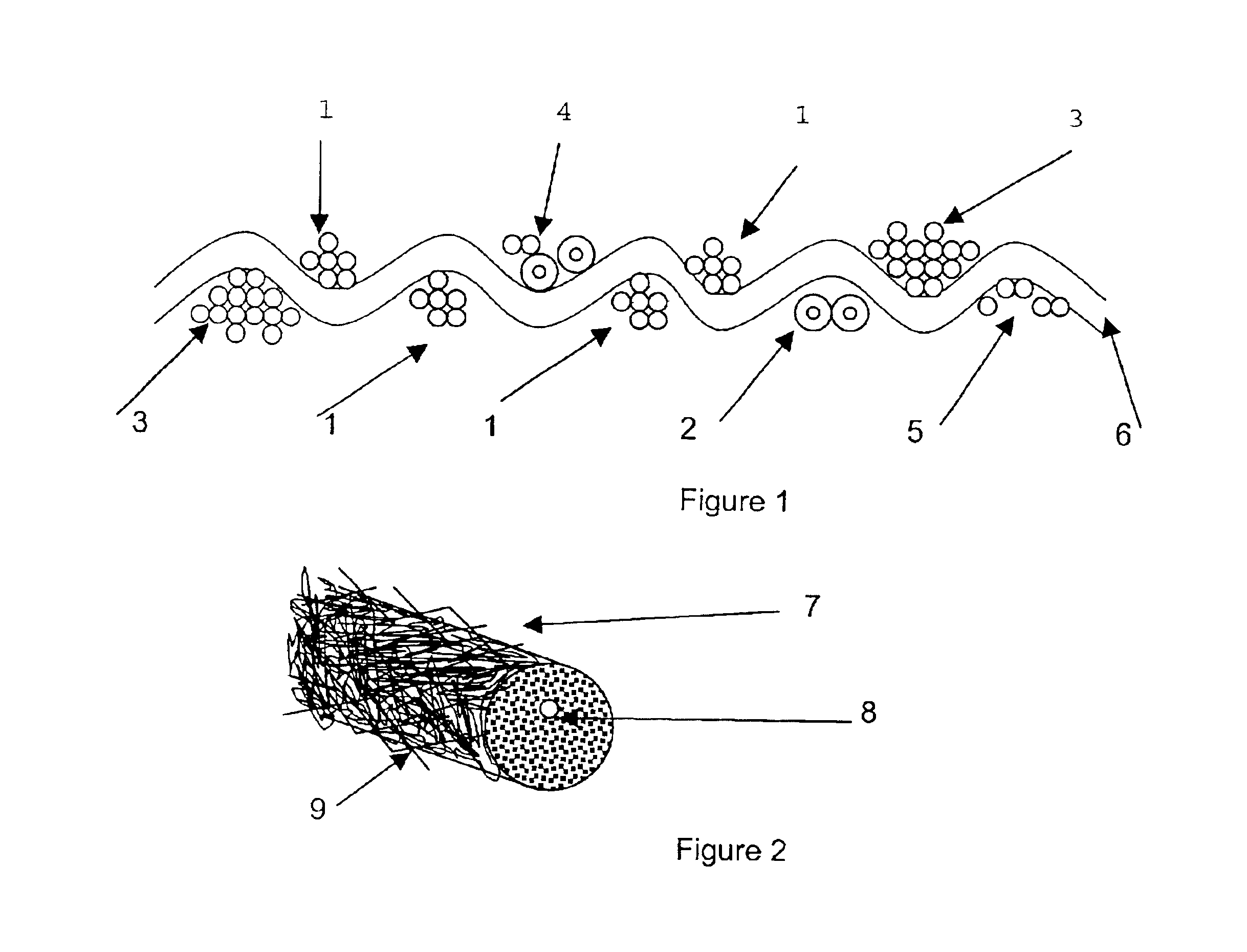

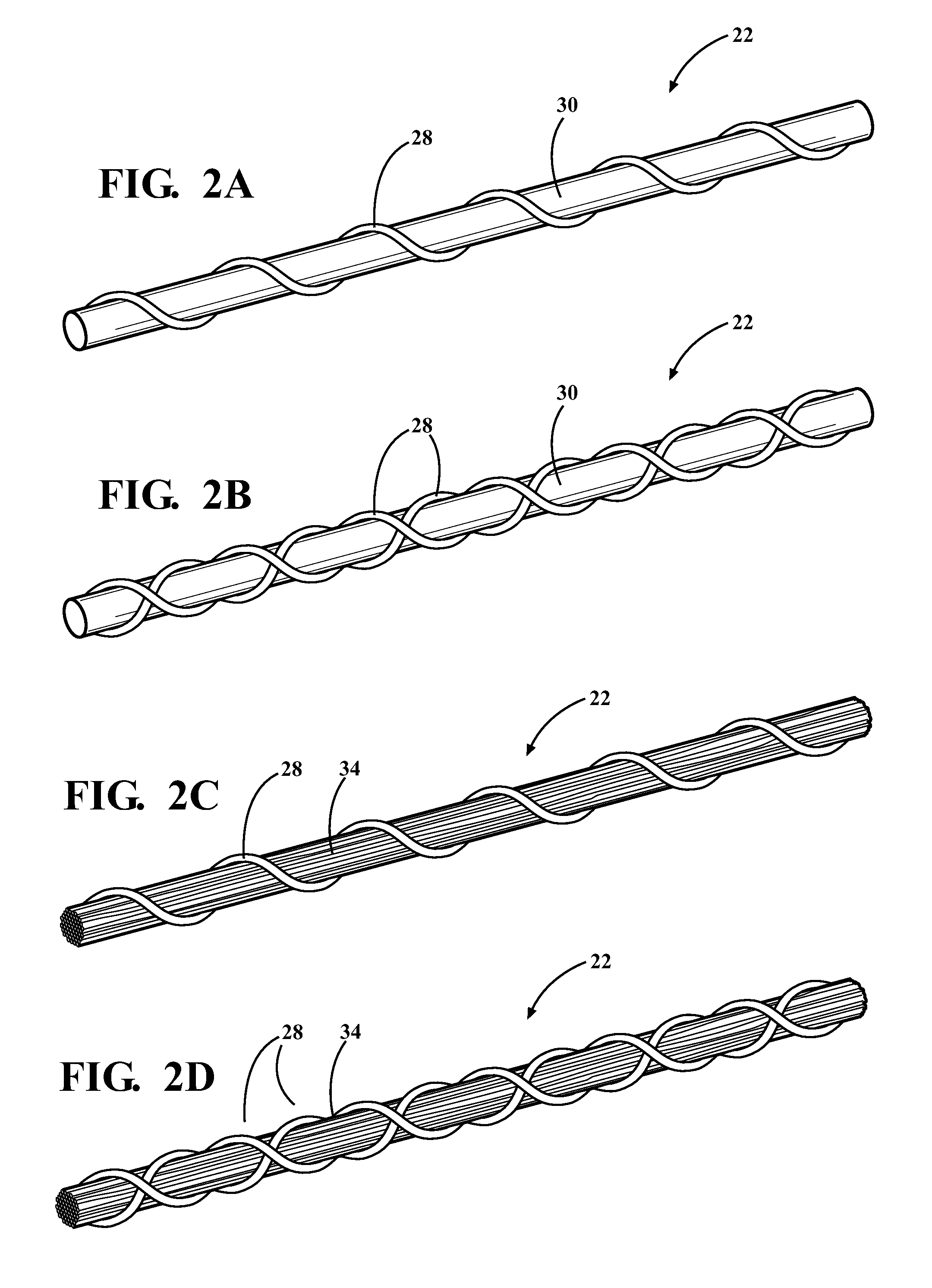

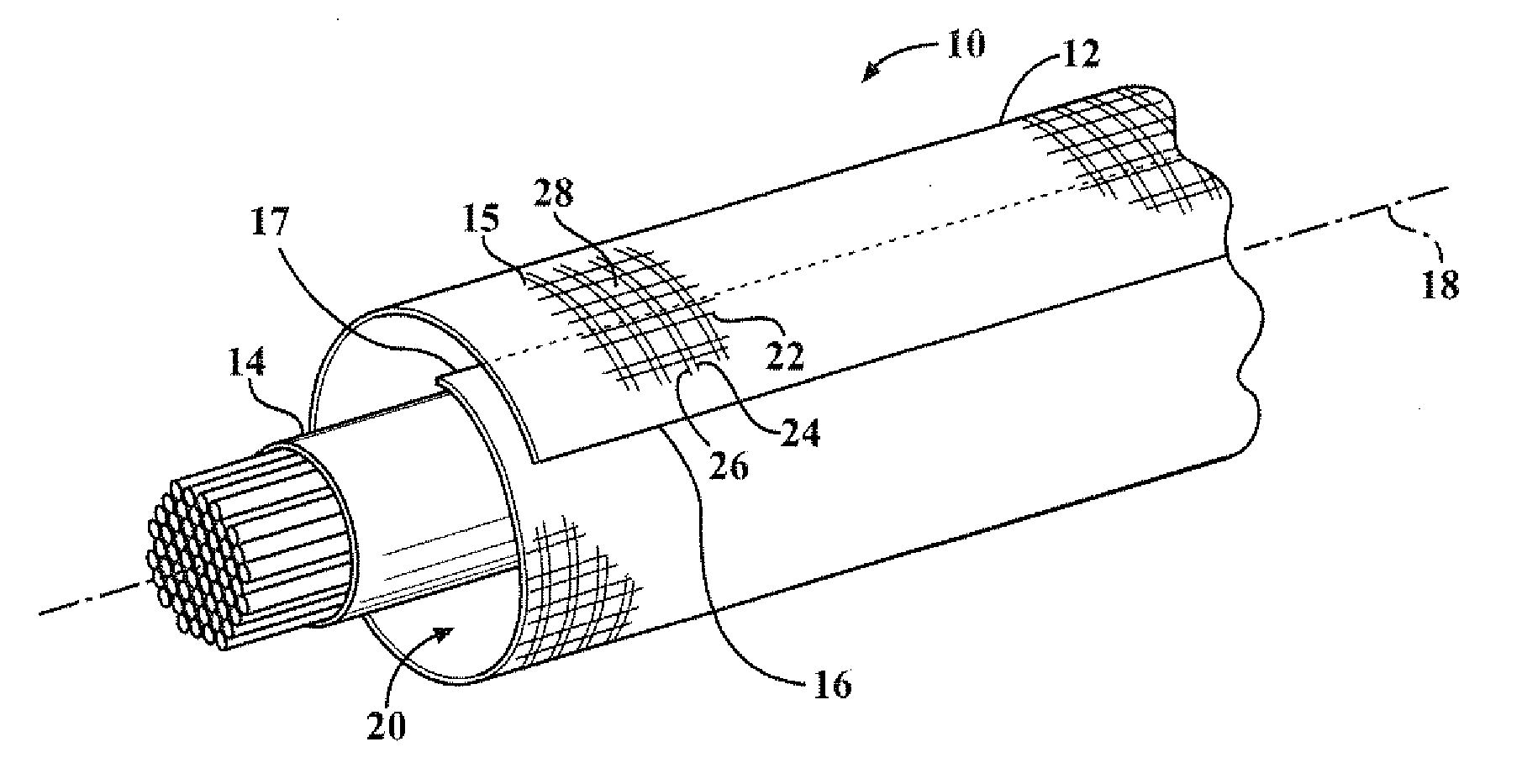

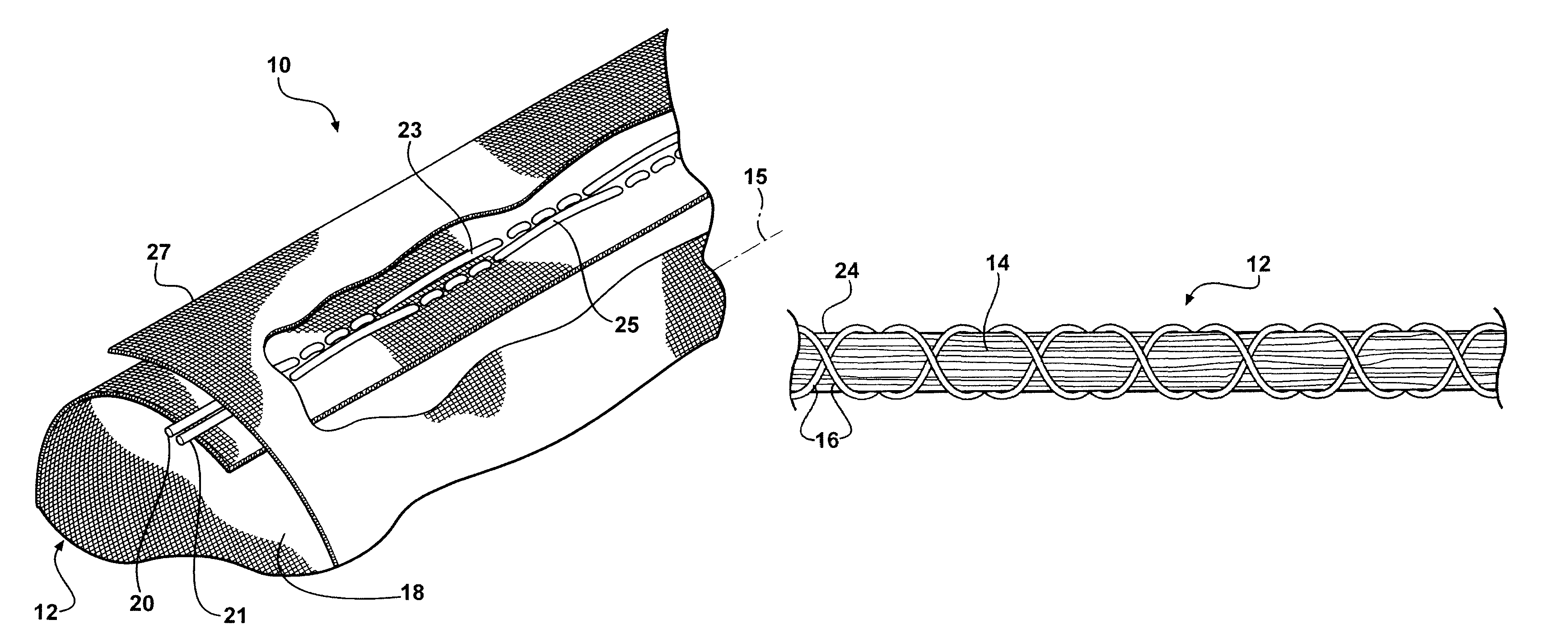

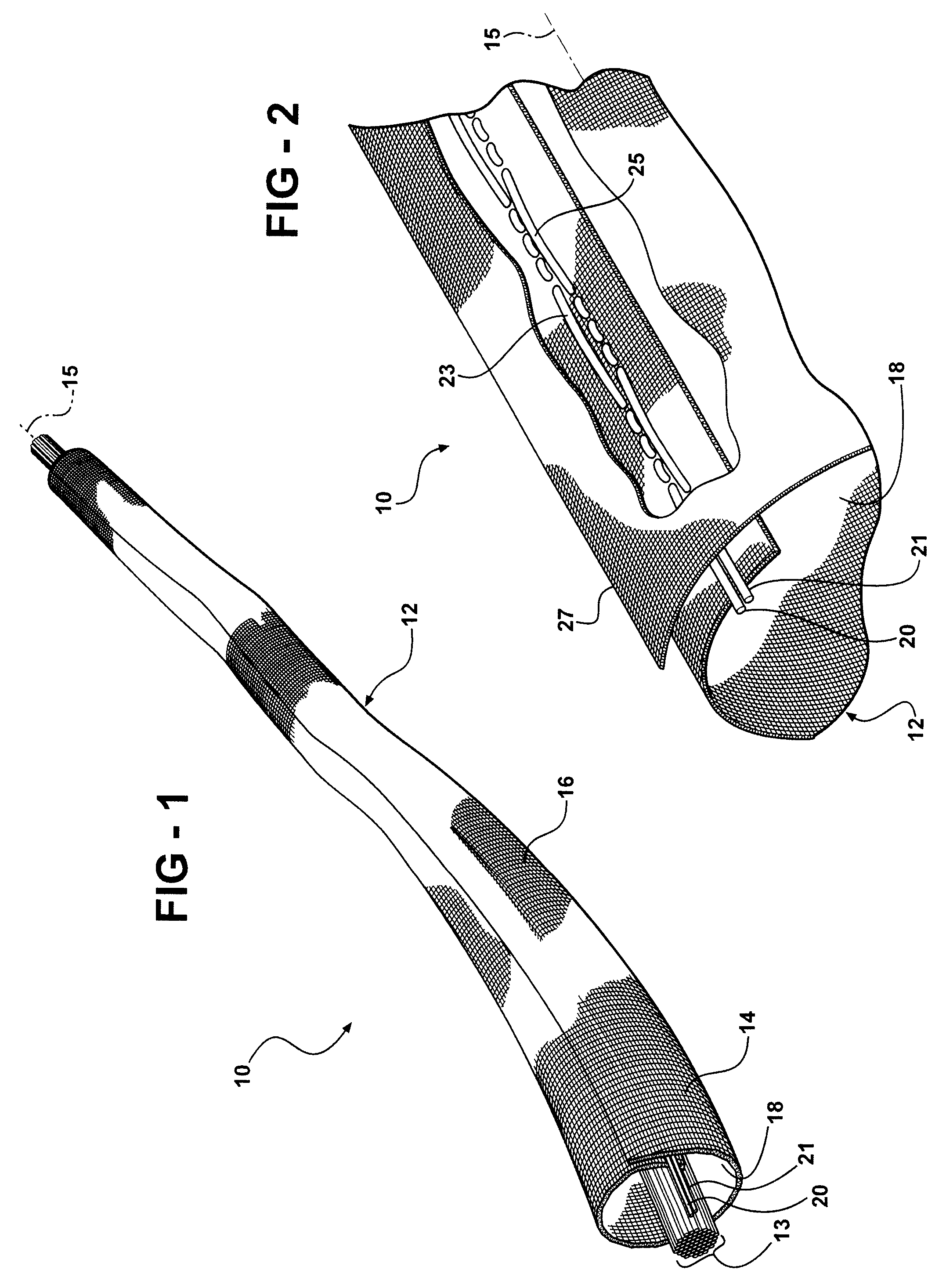

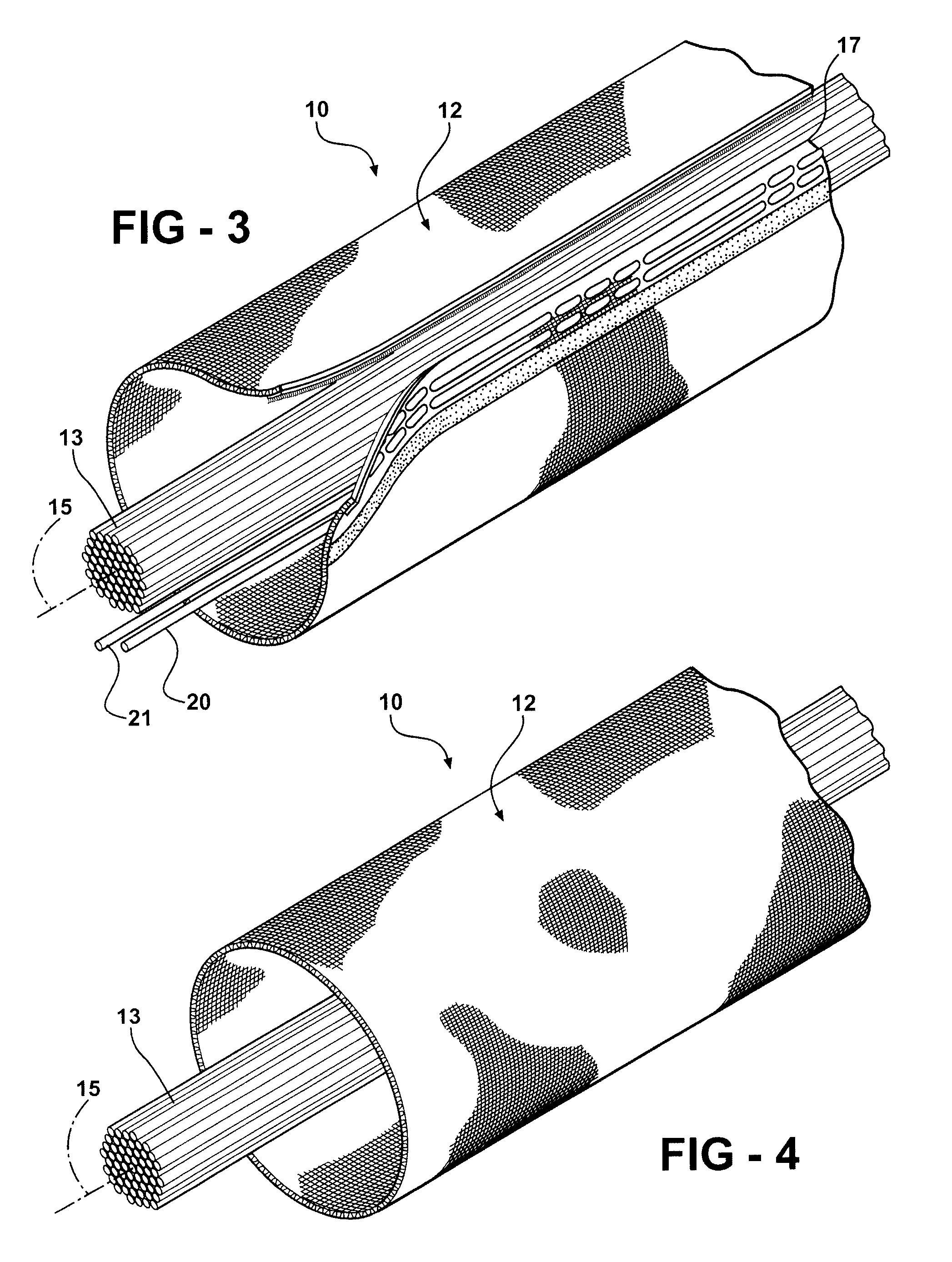

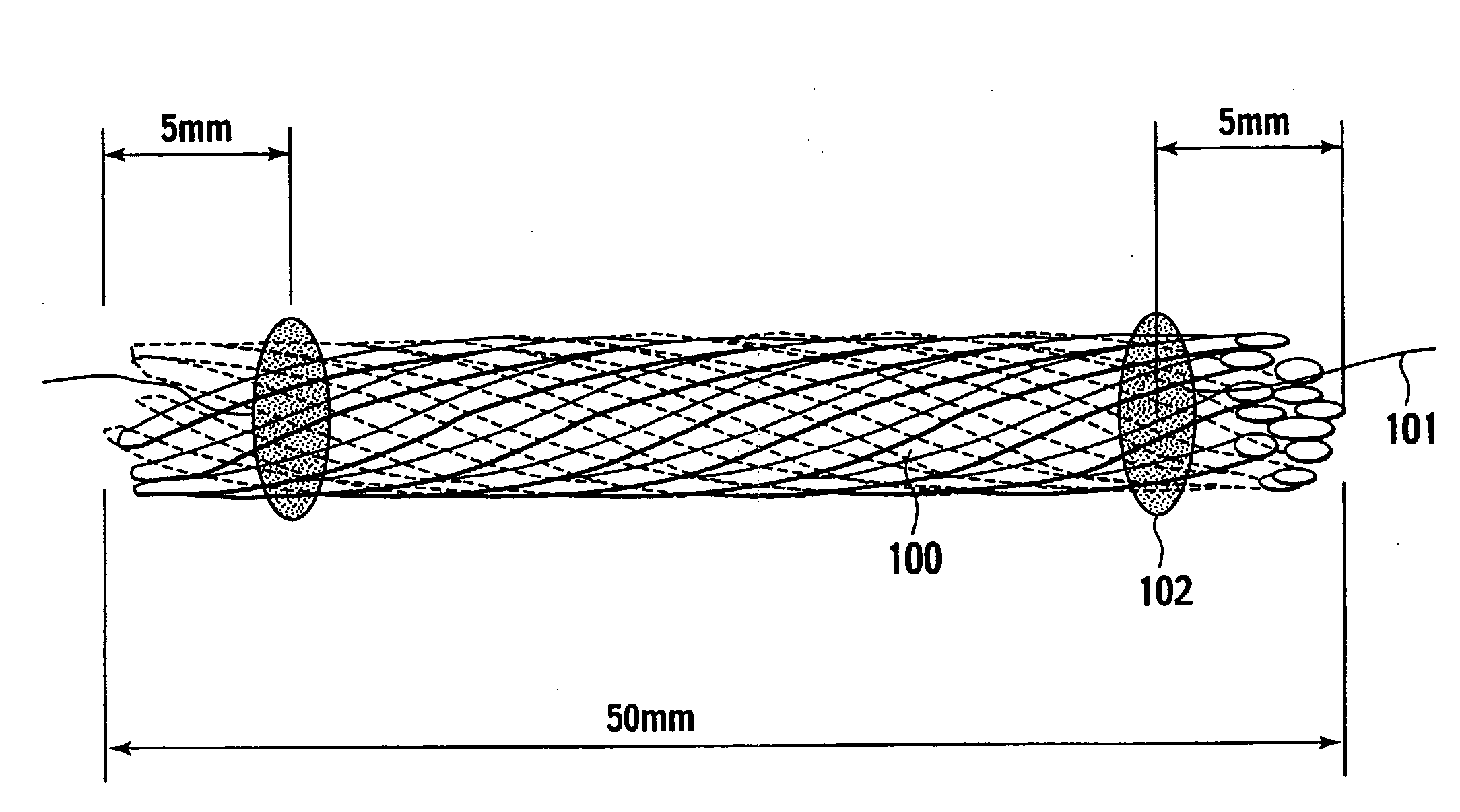

Protective sleeve fabricated with hybrid yarn having wire filaments and methods of construction

ActiveUS20070275199A1Provide protectionImprove conductivityLayered productsPedestrian/occupant safety arrangementYarnArchitectural engineering

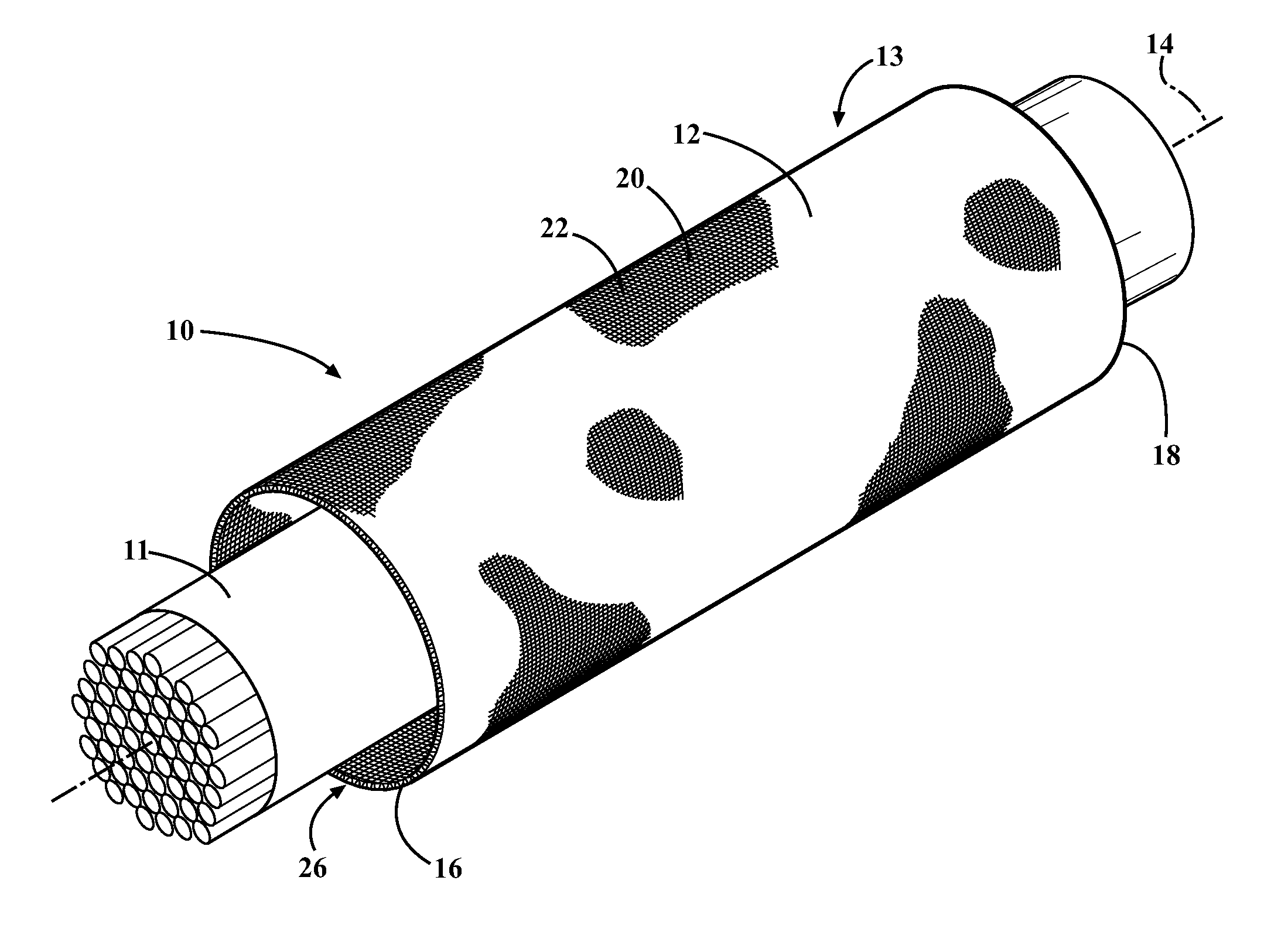

A fabric sleeve and hybrid yarn filament used in construction of the sleeve for protecting elongate members against at least one of EMI, RFI or ESD, and methods of construction of the sleeve and hybrid yarn filament. The sleeve includes at least one interlaced hybrid yarn filament having a non-conductive filament and at least one conductive wire filament overlying an outer surface of the non-conductive filament. The hybrid yarn filament is arranged in electrical communication with itself or other hybrid yarn filaments to provide uniform shielding against EMI, RFI, and / or ESD.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Flame resistant fabrics having increased strength and abrasion resistance

Flame resistant fabrics are disclosed. In one embodiment, a flame resistant fabric includes a plurality of flame resistant body yarns that form a body of the fabric, and a plurality of relatively tough yarns provided in discrete positions within the fabric body, wherein the relatively tough yarns do not protrude beyond an outer surface of the fabric body so as to reduce the susceptibility of the relatively tough yarns to abrasion.

Owner:SOUTHERN MILLS

Flame, Heat and Electric Arc Protective Yarn and Fabric

This invention relates to flame, heat and electric arc protective yarn that can be used for knitting and weaving a single layer fabric. Both knitted and woven fabrics are for use as a single layer flame, heat and electric arc protective fabric garment or as an outer layer of a flame, heat and electric arc protective multiple layer garment or accessory for a wearer.

Owner:INT GLOBAL TRADING USA

Flame Resistant Fabric With Anisotropic Properties

Flame resistant fabrics are formed by warp and fill yarns having different fiber contents. The fabrics are constructed, for example, by selection of a suitable weaving pattern, such that the body side of the fabric and the face side of the fabric have different properties. The fabrics described herein can be printable and dyeable on both sides of the fabric and are suitable for use in military and industrial garments. Methods of forming flame resistant fabrics, and methods for forming garments from the fabrics, are also described.

Owner:SOUTHERN MILLS

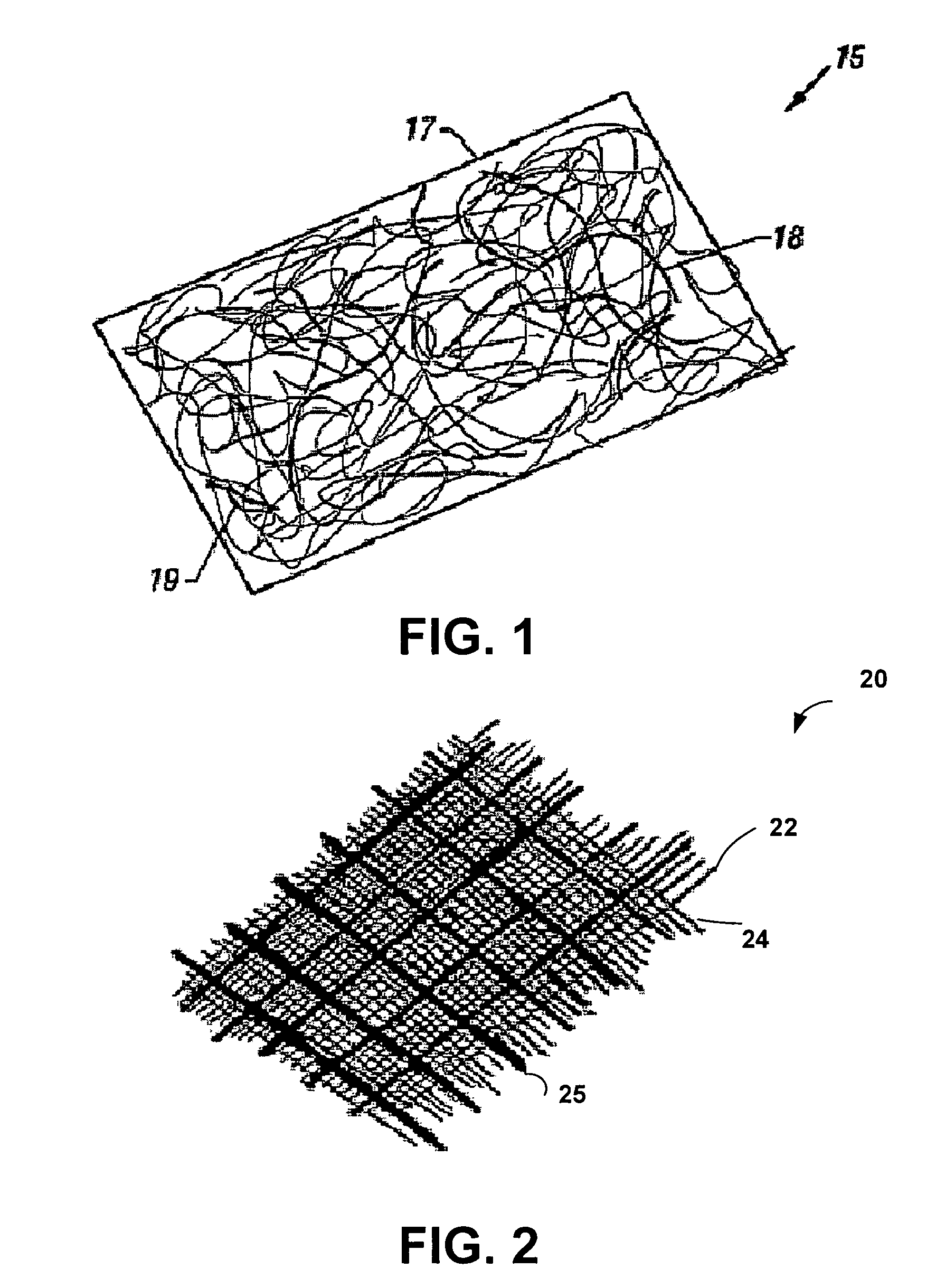

Substrate incorporating non-woven elements

InactiveUS20060213234A1Ornamental textile articlesProtective fabricsEngineeringElectrical and Electronics engineering

Owner:FEDERAL MOGUL WORLD WIDE

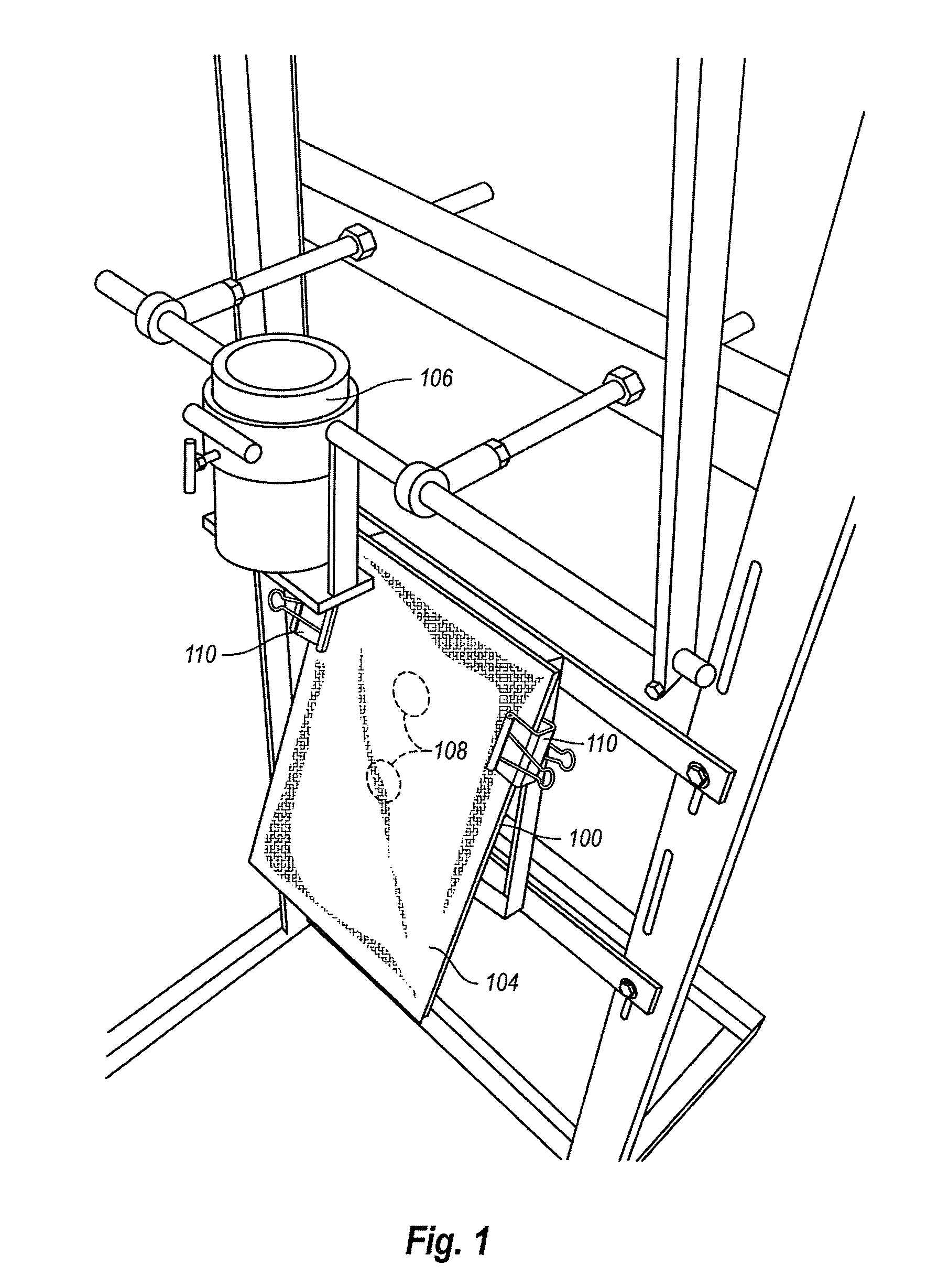

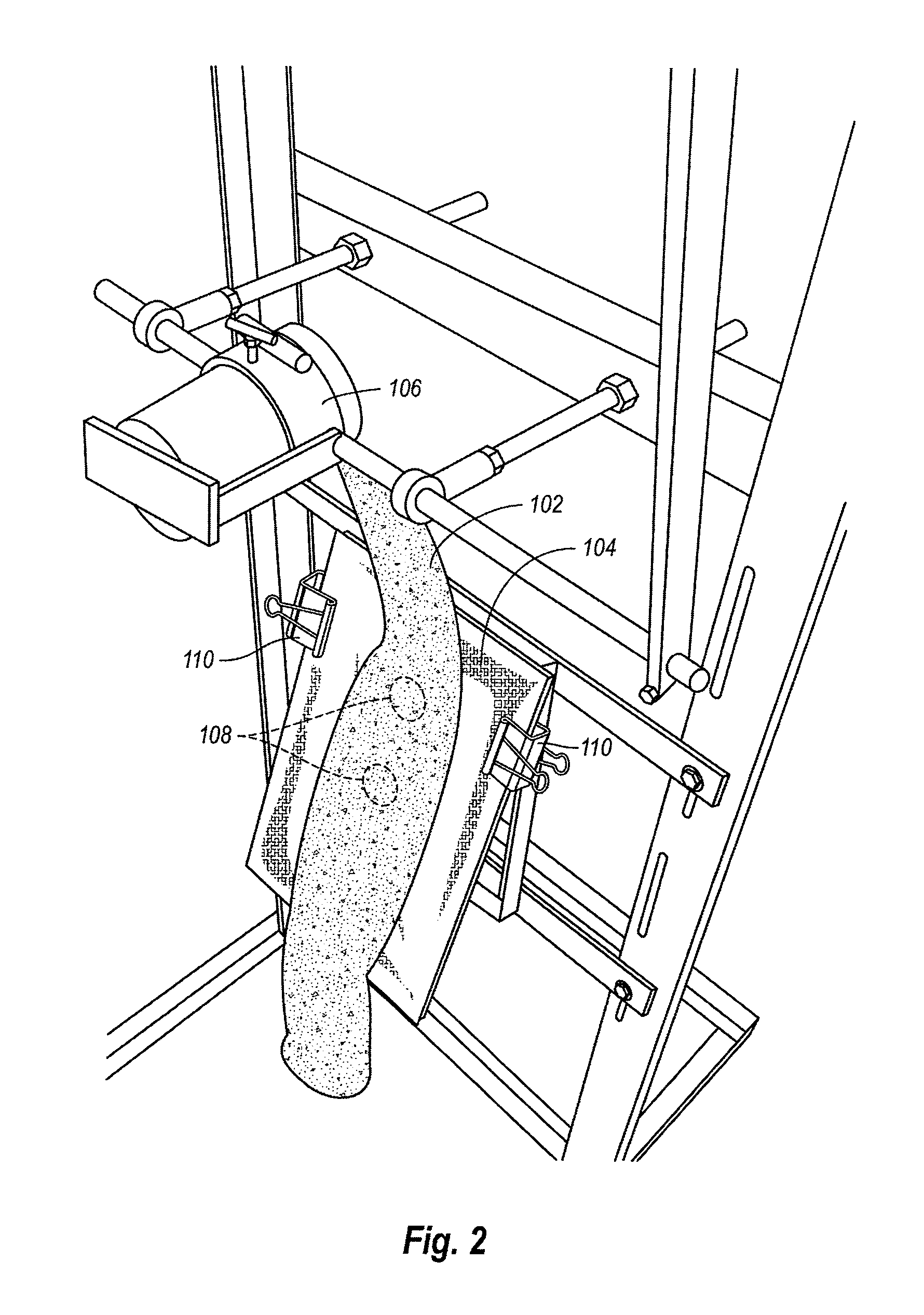

End-Fray Resistant Heat-Shrinkable Woven Sleeve, Assembly Therewith and Methods of Construction Thereof

ActiveUS20140272218A1Excellent abrasion resistanceIncreased crush strengthWrappers shrinkageProtective fabricsPliabilityArchitectural engineering

A woven sleeve, sleeve assembly and methods of construction thereof are provided. The sleeve has a flexible, abrasion resistant, circumferentially closed and continuous elongate wall extending lengthwise along a central axis between opposite ends. The wall is woven with warp yarns extending generally parallel to the central axis and at least one heat-shrinkable weft yarn extending generally transversely to the warp yarns. The warp yarns provide the sleeve with coverage, abrasion resistance and flexibility and the weft yarn provides the ability to shrink the wall about an elongate member being protected within a cavity of the sleeve, as well as providing enhanced crush strength and abrasion resistance. At least one of the warp yarns and / or weft yarn includes at least one low melt, heat-fusible yarn served therewith to enhance resistance to end-fray during a cutting operation.

Owner:FEDERAL MOGUL POWERTAIN LLC

Low bfs composite and process of making the same

InactiveUS20130059496A1Improve adhesionProtective equipmentLayered productsBallistic resistanceFibrous composites

Methods for producing composites useful for the formation of both soft and hard armor. More particularly, methods for the production of ballistic resistant fibrous composites having improved ballistic resistance properties, including low backface signature. The methods employ fiber surface treatments to improve the anchorage of substances applied onto fiber surfaces, achieving a low delamination tendency and corresponding benefits.

Owner:HONEYWELL INT INC

Woven or knit fabric and process for producing the same

InactiveUS20050202741A1Increases interlacement degreeTextureWeft knittingProtective fabricsPolyesterYarn

A woven or knit fabric comprising air-jet interlacing spun yarns comprising polyester fibers of low titanium oxide content; a woven or knit fabric comprising air-jet interlacing spun yarns comprising polyester staple fibers obtained by graft polymerization of a hydrophilic compound; a woven or knit fabric comprising air-jet interlacing spun yarns comprising side by side crimped staple fibers; a woven or knit fabric comprising air-jet interlacing spun yarns comprising low-shrinkage staple fibers and copolymerized polyester staple fibers; and a process for producing these. A woven or knit fabric of polyester staple fibers that is bulky, excelling in moisture retention, lightweightness, water absorptivity, quick dryability, etc. and exhibits excellent anti-pilling properties can be obtained.

Owner:TOYOBO CO LTD

Sun protective fabric

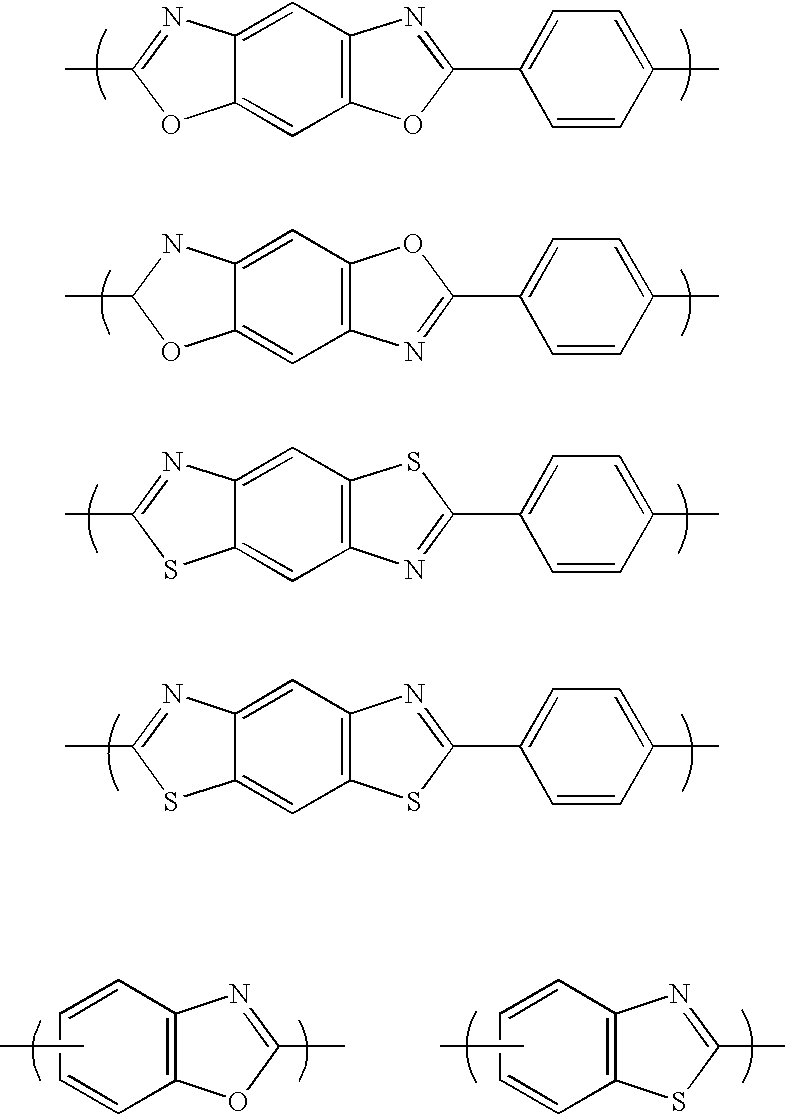

InactiveUS6025284AReduce ultraviolet radiation transmissionLow production costGarment special featuresSynthetic fibresWrinkle skinPolyester

Wrinkled fabrics comprising ultraviolet absorbers are disclosed which provide improvements in ultraviolet transmission, wearer comfort, and cost over those of the prior art. The preferred fabric is polyester and the preferred UV absorbers are chlorobenzotriazoles. The polyester is wrinkled permanently so as to provide an extra barrier to ultraviolet radiation from solely utilizing UV absorbers alone. This wrinkled product is also more comfortable to a wearer, particularly in warm weather or hotter climates. Other non-apparel uses are also contemplated including tents, awnings, and crowd covers. A method of making such a fabric is also disclosed comprising stuffing a jet dyeing machine with a more than normal load amount of fabric and eventually heat setting such resultant wrinkles into the finished product.

Owner:MILLIKEN & CO +1

Flexible, abrasion resistant textile sleeve and method of construction thereof

InactiveUS20100313989A1Improve protectionReduce manufacturing costElectrical apparatusLoomsYarnArchitectural engineering

A textile sleeve for routing and protecting elongate members and method of construction thereof is provided. The sleeve includes an elongate wall having opposite edges extending parallel to a central axis of the sleeve. The wall is woven with warp yams extending parallel to the axis and fill yarns extending transverse to the warp yams. The warp yarns are provided as monofilament yarns to provide abrasion resistance and the fill yams are provided as both monofilament yams to provide further abrasion resistance and multifilament yams to provide increased coverage, maintain flexibility, and to maintain the warp monofilaments in their intended position.

Owner:FEDERAL MOGUL POWERTAIN LLC

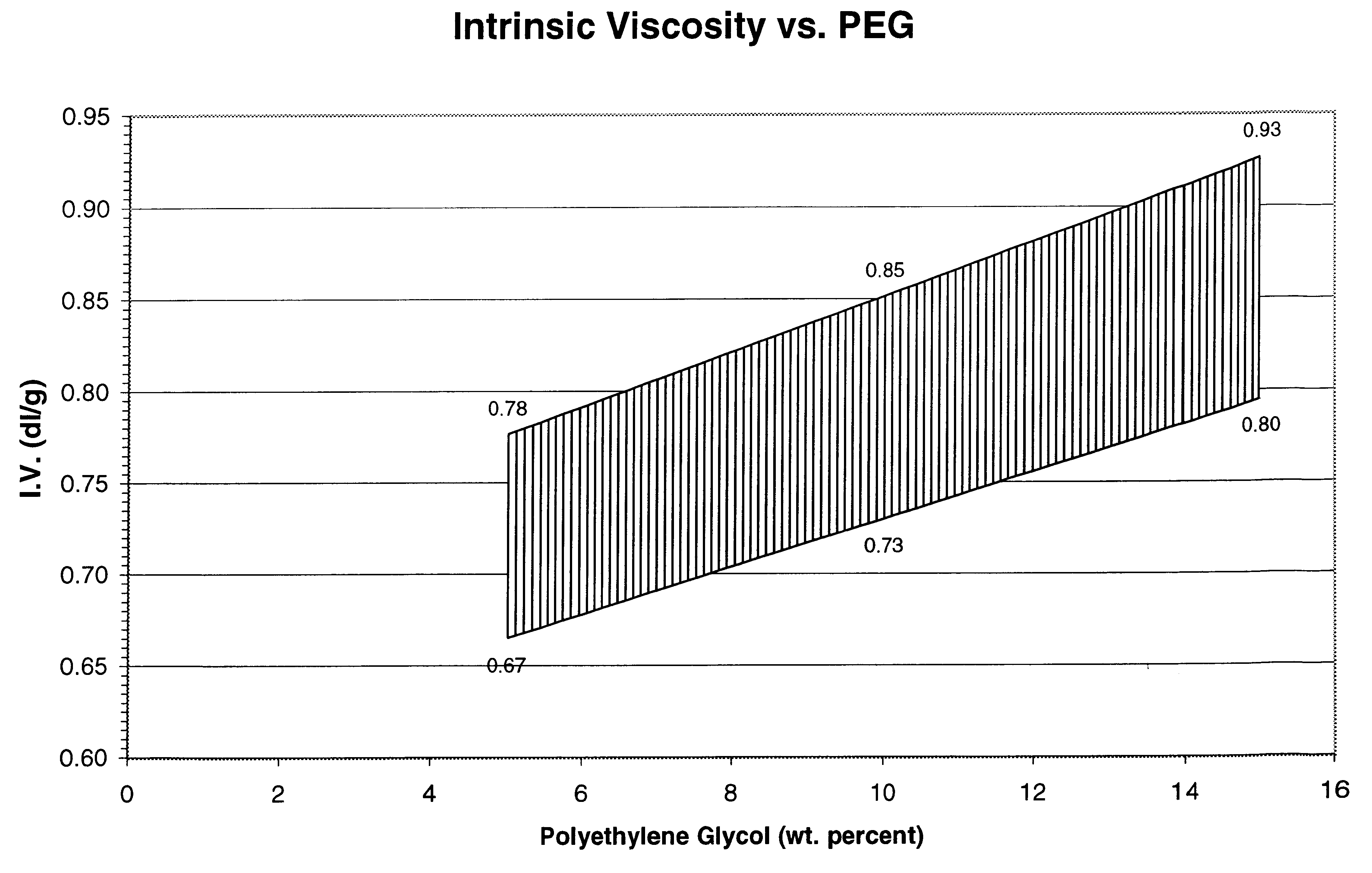

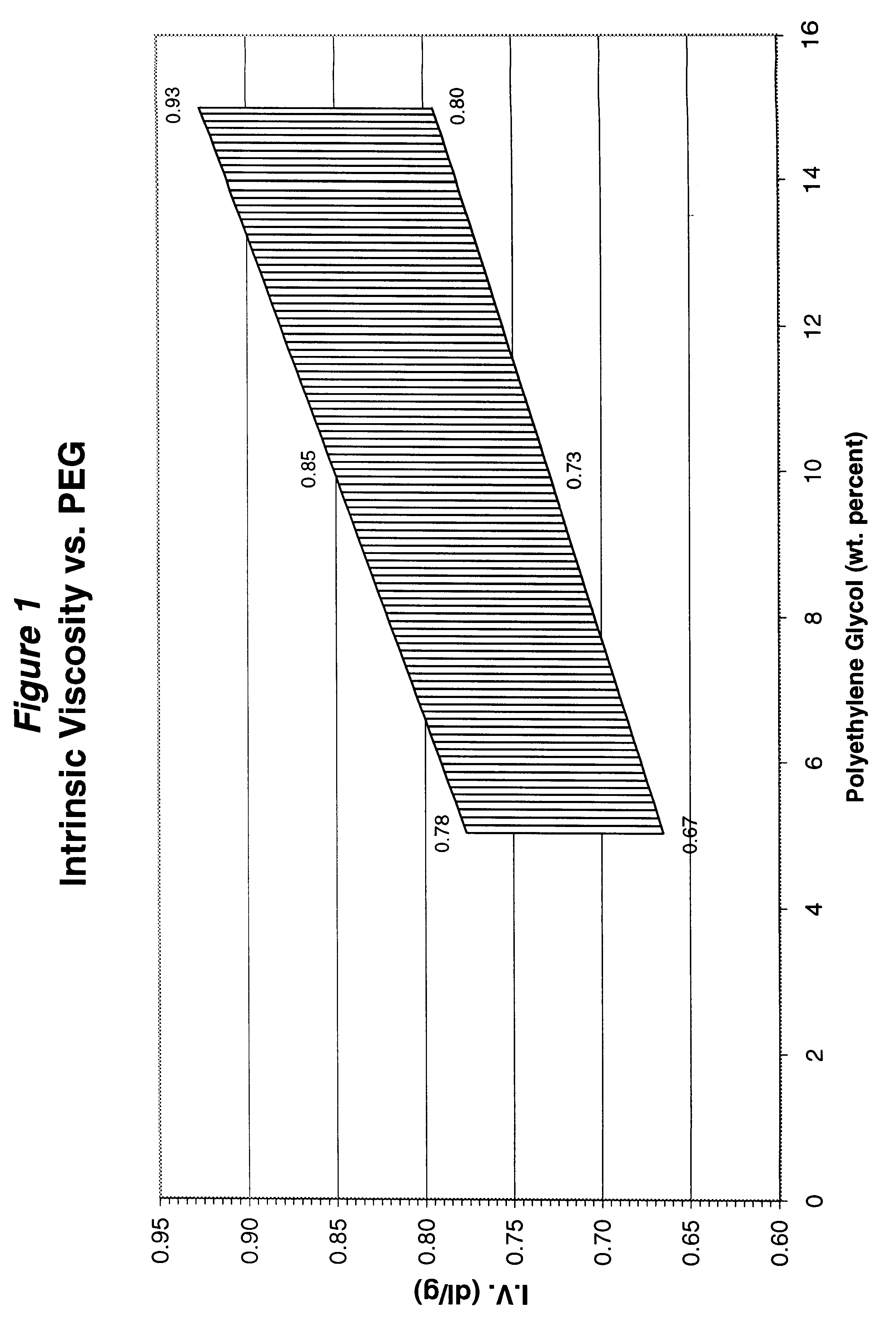

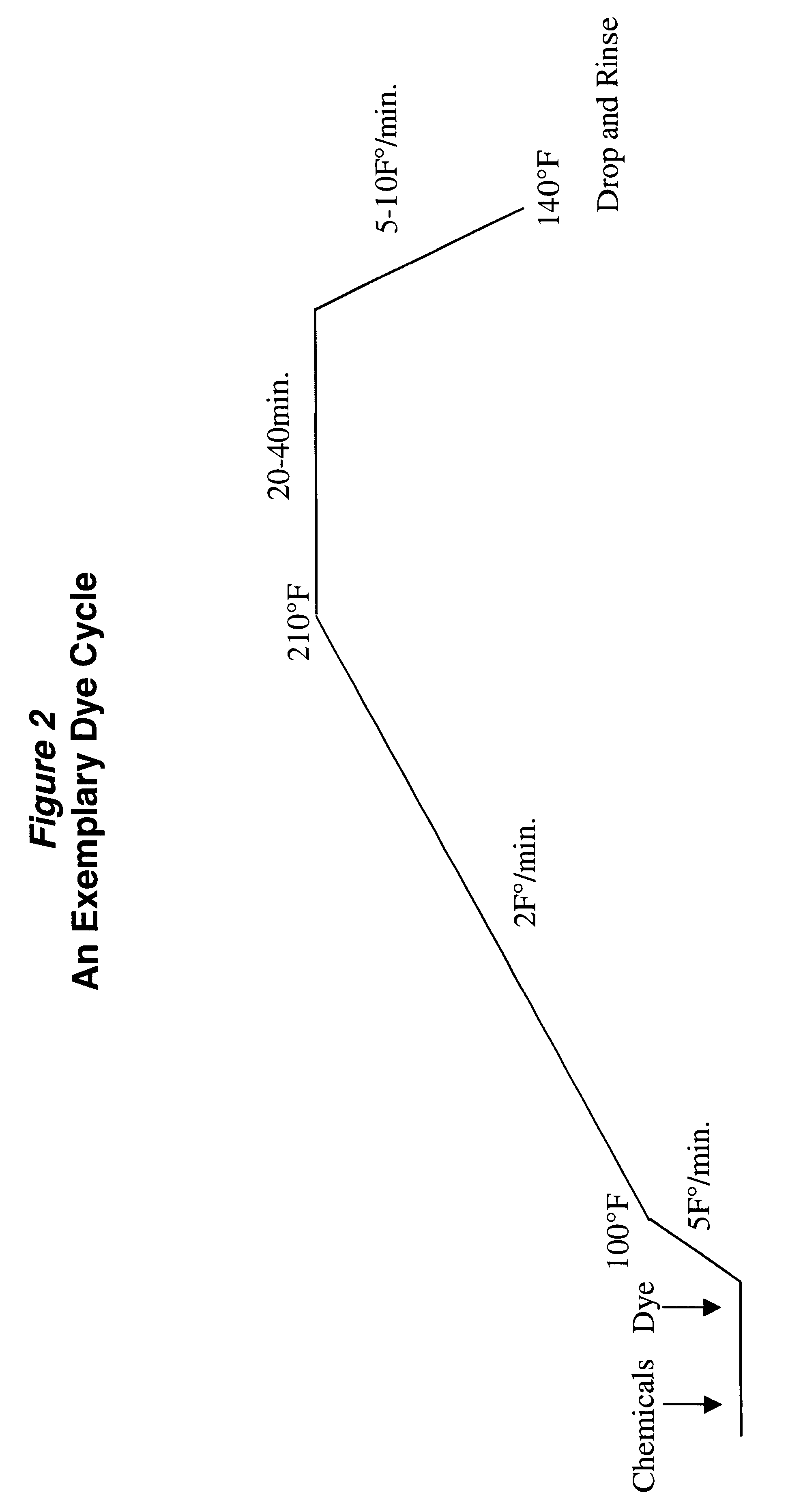

Polyethylene glycol modified polyester fibers and method for making the same

InactiveUS6291066B1Easy to dyeImprove dyeing effectProtective fabricsMonocomponent polyetheresters artificial filamentFiberYarn

Disclosed is a method of copolymerizing polyethylene glycol (PEG) and branching agent into polyethylene terephthalate (PET) to achieve a polyethylene glycol-modified polyester composition that can be spun into filaments. Fabrics made from fibers formed from the copolyester composition possess wicking, drying, stretching, abrasion-resistance, flame-retardancy, static-dissipation, dyeability, and tactility properties that are superior to those of fabrics formed from conventional polyethylene terephthalate fibers of the same yarn and fabric construction. Also disclosed are polyethylene glycol modified copolyester compositions, fibers, yarns, and fabrics.

Owner:FIBER IND INC

Protective sleeve fabricated with hybrid yarn having wire filaments and methods of construction

ActiveUS7576286B2Provide protectionImprove conductivityLayered productsProtective fabricsYarnArchitectural engineering

A fabric sleeve and hybrid yarn filament used in construction of the sleeve for protecting elongate members against at least one of EMI, RFI or ESD, and methods of construction of the sleeve and hybrid yarn filament. The sleeve includes at least one interlaced hybrid yarn filament having a non-conductive filament and at least one conductive wire filament overlying an outer surface of the non-conductive filament. The hybrid yarn filament is arranged in electrical communication with itself or other hybrid yarn filaments to provide uniform shielding against EMI, RFI, and / or ESD.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Yarns and fabrics that shed liquids, gels, sparks and molten metals and methods of manufacture and use

Fire retardant and heat resistant yarns and fabrics include a fabric or yarn comprised of oxidized polyacrylonitrile at least partially coated or encapsulated by a strengthening polymer material that helps the fabric or yarn shed liquids, gels, sparks, and molten metals. The polymer material includes one or more types of cured silicone polymer resin. A fluorochemical may be at least partially impregnated into the fabric or yarn prior to applying the strengthening polymer material in order to further enhance the shedding properties of the yarns or fabric. In one embodiment, the silicone polymer resin only coats or encapsulates the yarn, but does not form a continuous coating over the whole fabric, so that the treated fabric is still able to breath through pores and spaces between individual yarn strands that make up the fabric. The polymer material increases the strength, abrasion resistance, durability and shedding capability of the fire retardant heat resistant yarn or fabric.

Owner:CHAPMAN THERMAL PRODS

Penetration resistant fabric

A laminated fabric for penetration resistant e.g. ballistic applications. The fabric comprising a fabric of penetration resistant yarns having a linear density in the range from 100 to 700 dtex, said yarns being woven in a satin weave. The woven fabric is coated on at least one-side with a polymeric material in a micro-lamination process, the coating material being from 0.5 to 20%

Owner:TEIJIN TWARON GMBH

Fire retardant and heat resistant yarns and fabrics treated for increased strength and liquid shedding

InactiveUS20070231573A1High tensile strengthExcellent abrasion resistanceProtective fabricsBed linenYarnFire retardant

Fire retardant and heat resistant yarns and fabrics include an inner core comprised of oxidized polyacrylonitrile encapsulated by an outer shell comprised of a liquid-resistant and strengthening polymer material. The liquid-resistant and strengthening polymer material includes one or more types of cured silicone polymer resin. A fluorchemical may be at least partially impregnated into the inner core prior to applying the liquid-resistant and strengthening polymer material in order to further enhance the liquid shedding properties of the yarns or fabric. Because the silicone polymer resin only encapsulates the yarn, but does not form a continuous coating over the whole fabric, the treated fabric is still able to breath through pores and spaces between individual yarn strands that make up the fabric. The liquid-resistant and strengthening polymer material increases the strength, abrasion resistance, durability and liquid and gel shedding capability of the fire retardant heat resistant yarn or fabric.

Owner:CHAPMAN THERMAL PRODS

Woven bullet resistant fabric

InactiveUS20100124862A1Improve abilitiesImprove manufacturabilityLoomsProtective fabricsBallistic resistanceEngineering

A unique new group of “Faux-Sateen, Quasi-Unidirectional(UD)” woven anti-ballistic fabrics is disclosed. Novel and unexpected improvements in ballistic penetration resistance result. After appropriate lamination of at least two layers, ballistic resistance is either maintained or further enhanced, while blunt trauma resistance is improved. Fabric handling during vest fabrication is also greatly improved and significantly less stitching is required. Wearability is also improved.

Owner:BLS TEXTILES

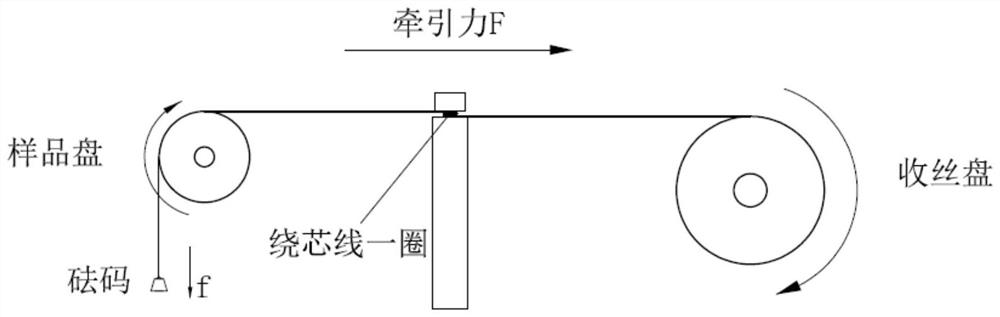

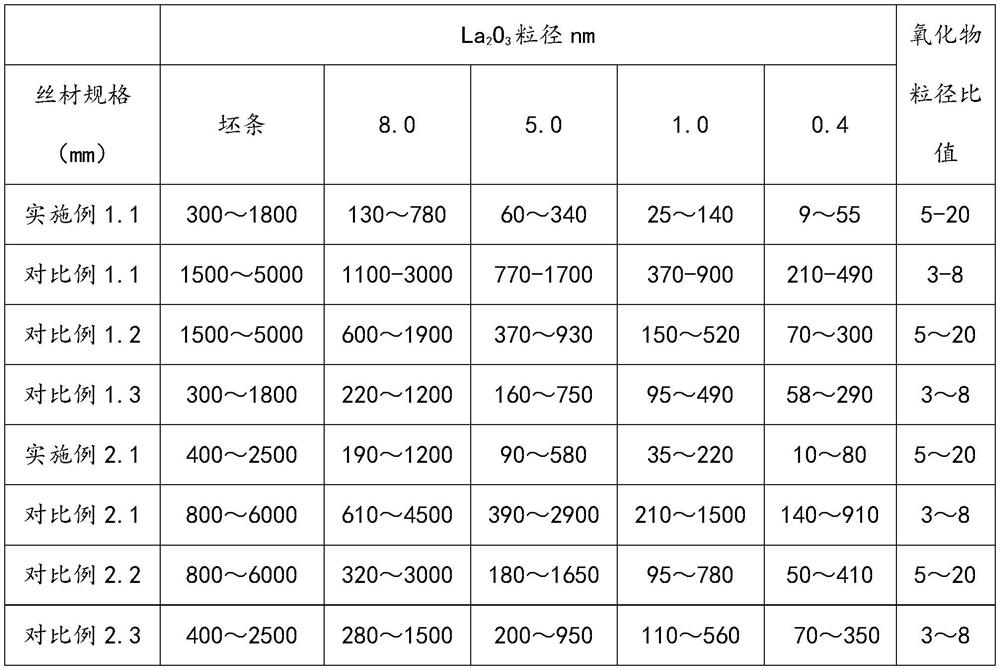

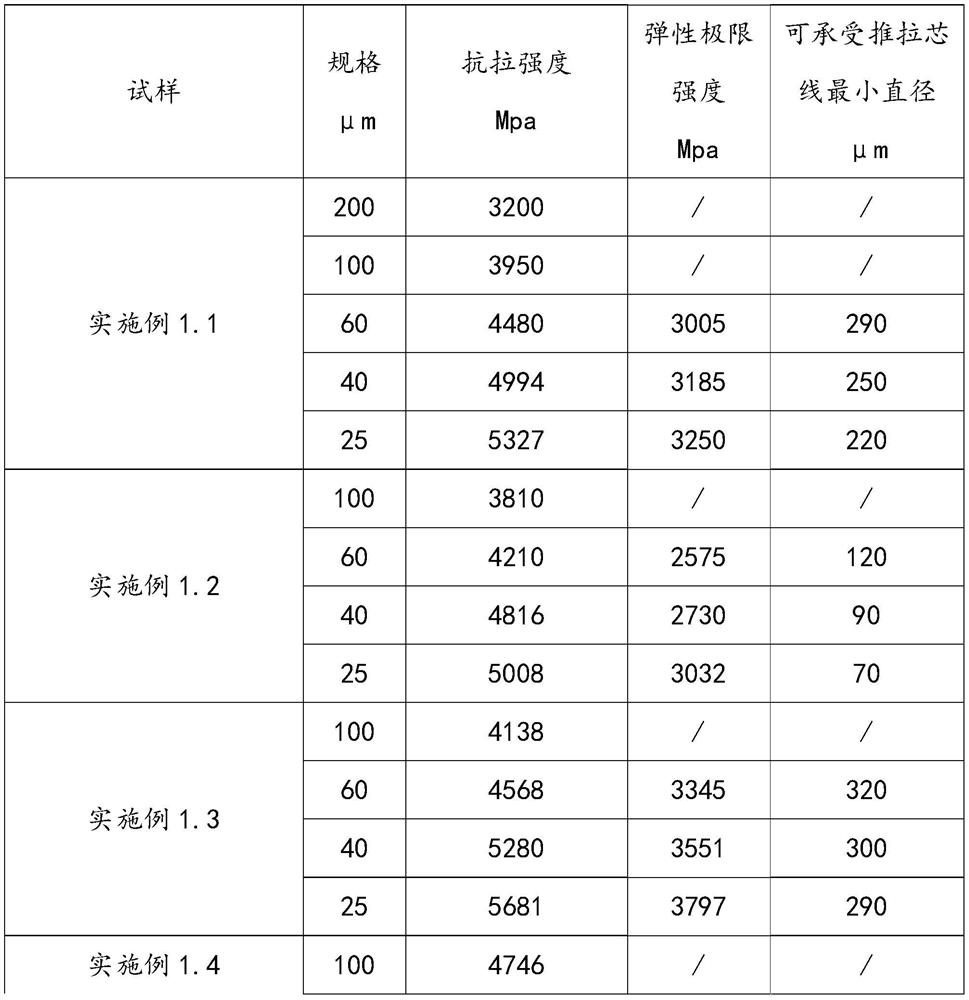

Alloy wire and preparation method and application thereof

The invention relates to the technical field of tungsten alloy materials, in particular to an alloy wire and a preparation method and application thereof.The alloy wire is made of tungsten alloy, the tungsten alloy comprises tungsten and lanthanum oxides, and the wire diameter of the alloy wire is 100 [mu] m or below. The tensile strength of the alloy wire is 3800 MPa or above. The wire diameter of the alloy wire is 60 [mu] m or below. The diameter of a push-pull core wire of the alloy wire is less than 350 [mu] m. The ultimate elastic strength of the alloy wire is 2500 MPa or above. The tensile strength of the alloy wire is 4200 MPa or above. According to the alloy wire, the alloy wire with ultrahigh strength and good toughness is obtained by doping the lanthanum oxide.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

Variable-airflow cloth, sound absorbing material, and vehicular part

ActiveUS20090029620A1Reduce weightSave spaceGarment special featuresProtective fabricsFiberPolymer science

Cloth, in which air permeability is variable by energization, includes: a fibrous object composed of composite fibers, each of the composite fibers including: an electrical-conductive polymeric material; and a material different from the electrical-conductive polymeric material, the different material being directly stacked on the electrical-conductive polymeric material; and electrodes which are attached to the fibrous object, and energize the electrical-conductive polymeric material. Each of the composite fibers has a structure in which the material different from the electrical-conductive polymeric material is stacked on at least a part of a surface of the electrical-conductive polymeric material, or a structure in which either one of the electrical-conductive polymeric material and the material different from the electrical-conductive polymeric material penetrates the other material in a longitudinal direction. The cloth is capable of controlling the air permeability by a control factor enabling weight reduction and space saving.

Owner:NISSAN MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com