Woven bullet resistant fabric

a fabric and fabric technology, applied in the direction of protective fabrics, weaving, looms, etc., can solve the problems of limited vest capability to stop low-energy handgun bullets, increased blunt trauma, high cost, etc., and achieve the effect of improving pound-for-pound ballistic penetration resistance, superior ability to entrap and entrap, and dispersing energy more laterally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

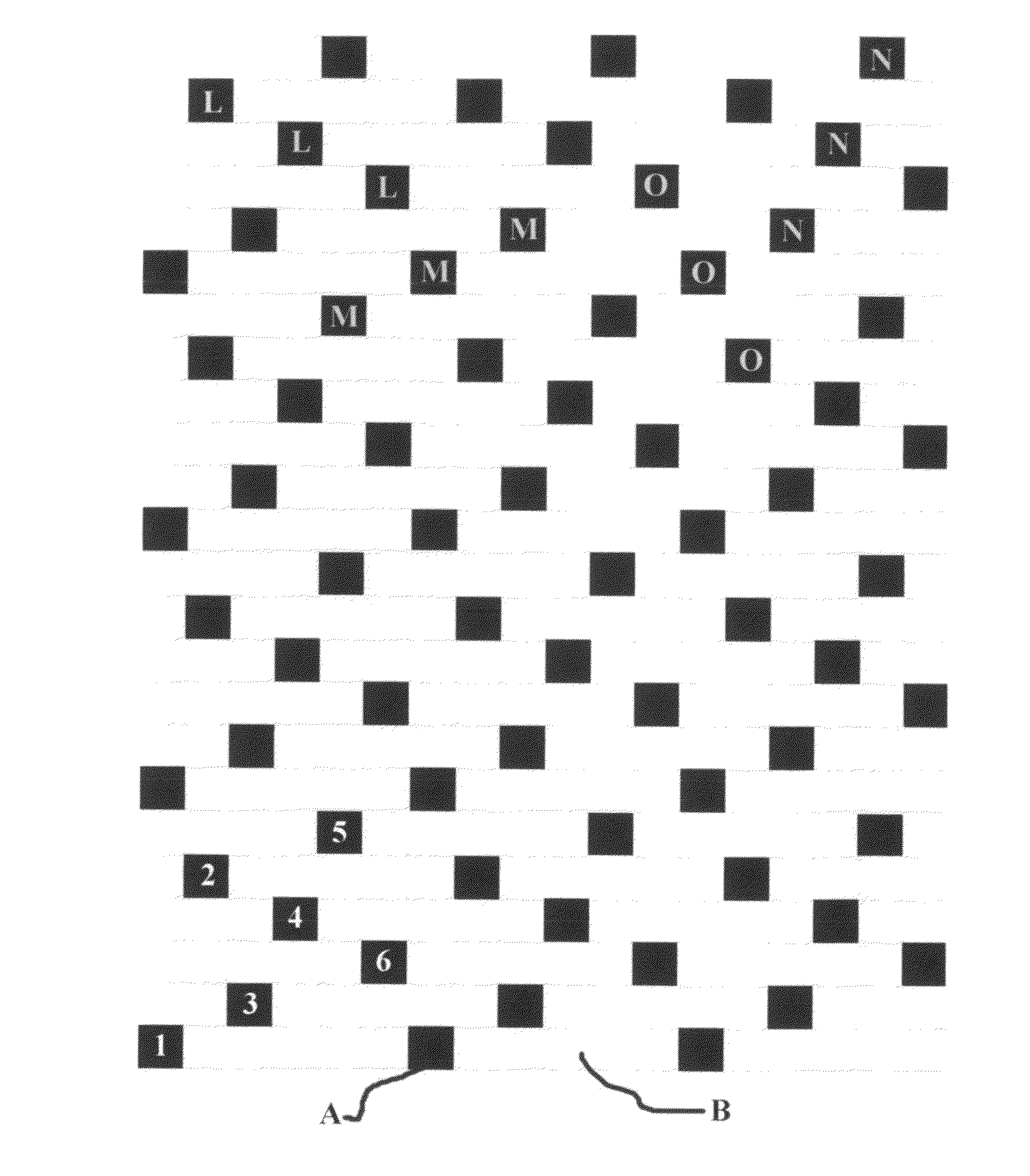

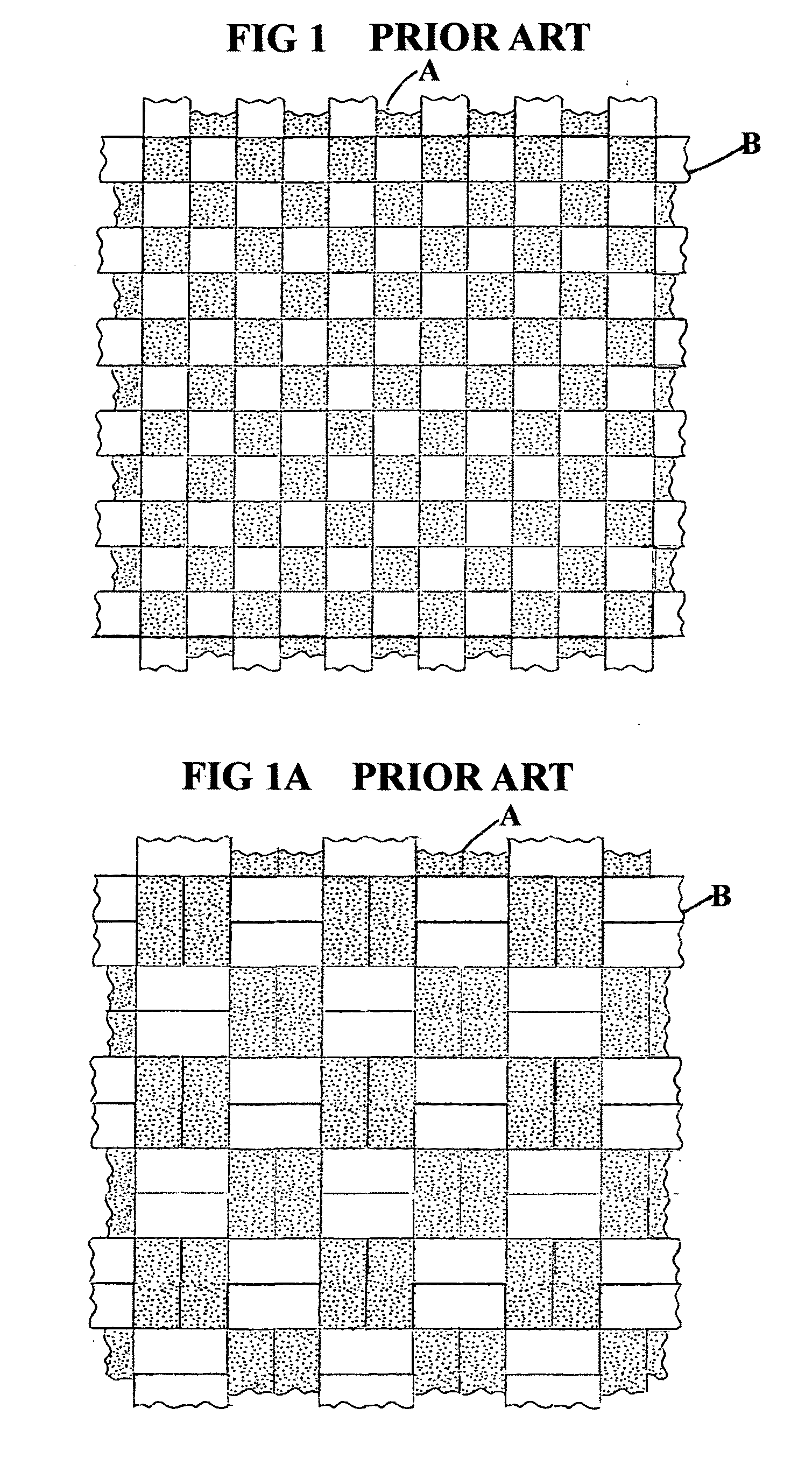

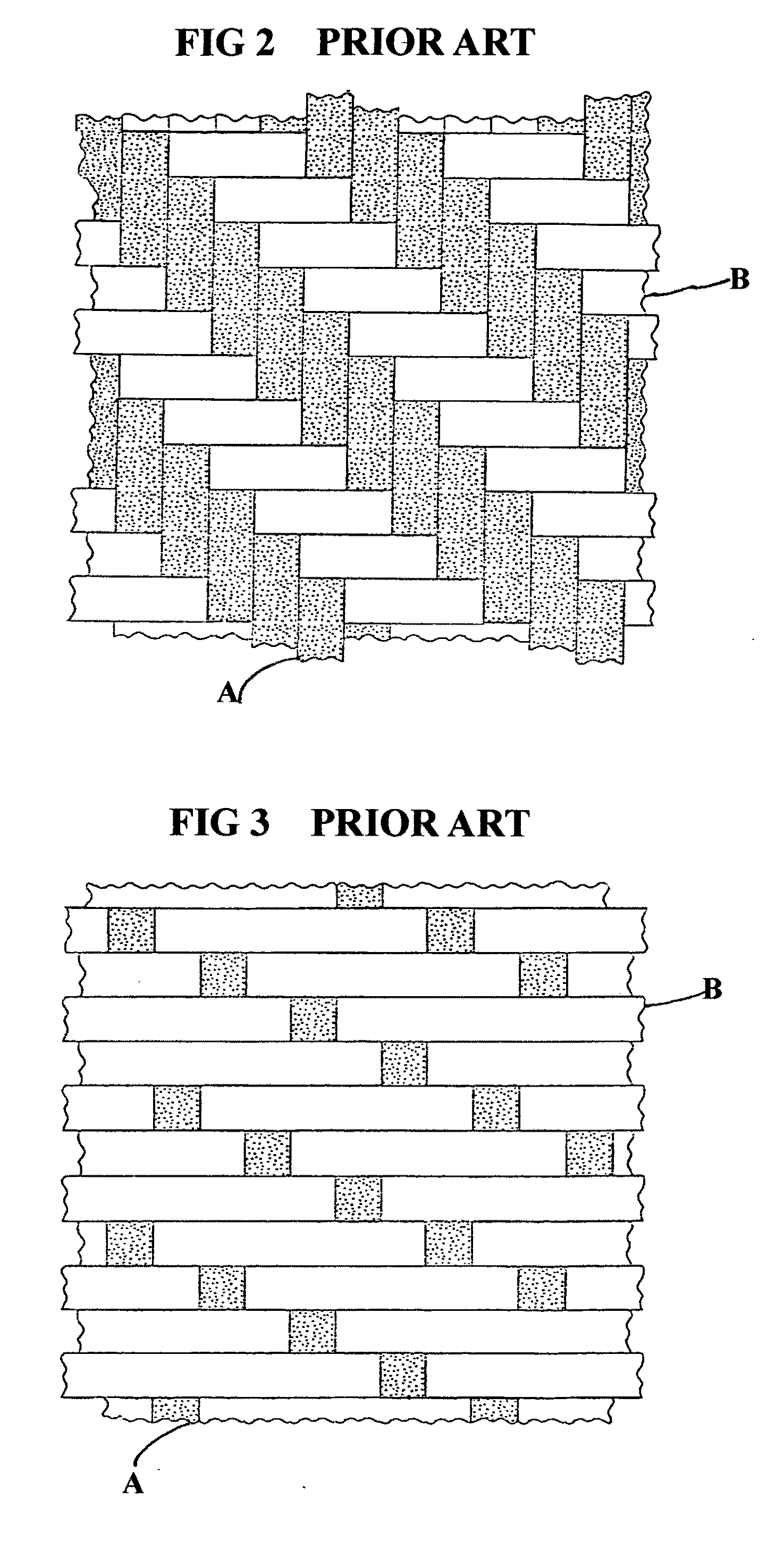

[0038]As previously discussed, plain woven ballistic fabrics have been used since the modern soft body armor industry was founded in the early 70's. Plain weaves continue to be considered the best balance of properties for penetration and blunt trauma resistance vs. other weaves, and are overwhelmingly utilized wherever wovens appear in soft body armor. When properly designed and optimized their advantages are high pound-for-pound ballistic penetration resistance, good flexibility and wearability, good consistency, and acceptable blunt trauma. Their primary disadvantage is that “all-woven” vest designs tend to require at least some additional fabrication steps such as stitching and / or laminating through either ballistic pacs or sub-pacs. More importantly, optimizing plain woven fabric ballistic penetration resistance and wearability is generally accomplished with finer yarns and looser weaves, at the expense of blunt trauma resistance.

[0039]Since the early 1990's UD ballistic materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angles | aaaaa | aaaaa |

| angles | aaaaa | aaaaa |

| break elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com